Page 1

ETC® Installation Guide

Unison® Heritage Contact and Fader Interface

Overview

This guide includes instruction for installation of the Unison Heritage Contact Interface and Unison

Heritage Fader Interface.

The Unison Heritage Contact Interface (model# UHCI) provides

convenient interface and integration to external devices by sending

and receiving contact closures. The interface enclosure provides

up to eight switch input and relay output connections. Closures are

configurable for either maintained or momentary operation.

The Unison Heritage Fader Interface (model# UHFI) provides

interface to external devices, such as faders or sensors, through a

variable 0-3.3 Vdc analog signal. The interface enclosure consists

of eight fader input connections and eight output lamp-driver

connections.

Product Specification

Installation Requirements

• Surface mount using the mounting keyholes provided.

• Thermal requirements

• Ambient room temperature of 0-40°C (32-104°F) with an ambient humidity of 30-90%, noncondensing.

• Wiring requirements:

• Connect to the Echelon

Class II wiring. Wiring is topology free and polarity independent over Belden 8471 (or

approved equal).

• Connect two 16 AWG (1.5mm

• Connect one 18-10 AWG (0.75-6mm

• Switch terminals accept 18-10 AWG (0.75-6mm

®

LinkPower® (LinkConnect) control network utilizing low voltage

2

) wires for 24 Vdc Auxiliary Power.

2

) ESD drain (ground) wire.

2

).

Contact Interface

• Dry contact inputs with no voltage applied.

• Dry contact outputs consist of Normally-Open (NO) 2 pole contact closure outputs, rated up to 1

amp at 28 Vdc, .5A at 120 VAC.

• Relay outputs are capable of switching up to eight resistive or inductive loads.

• Inputs and outputs are configurable in the Paradigm configuration using LightDesigner software.

• Contact inputs support up to 1,000 feet (305m) of 16 AWG (1.5mm

2

) wire between input and

common.

Fader Interface

• Enclosure provides eight fader input connections and to eight lamp-driver outputs.

• Fader supply voltage is +3.3 Vdc. Each fader input requires signal between 3.3 Vdc and 0 Vdc.

• Each lamp driver output provides 100mA at 24 Vdc.

• Lamp outputs support 1,000 feet (305m) of 16 AWG (1.5mm

Corporate Headquarters

London, UK

Rome, IT

Holzkirchen, DE

Hong Kong Rm 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

Web:

7181M2110

Unison® Heritage Contact and Fader Interface Page 1 of 4 Electronic Theatre Controls, Inc.

Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Ennio Quirino Visconti, 11, 00193 Rome, Italy Tel +39 (06) 32 111 683 Fax +44 (0) 20 8752 8486

(Americas) service@etcconnect.com

www.etcconnect.com

Rev A Released 10/2008

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Copyright © 2008 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

2

) wire.

(Asia) service@etcasia.com

Page 2

ETC Installation Guide

2”

(5.08cm)

14” (35.5 cm)

10.5”

(27cm)

12”

(30.5cm)

9.1”

(23.2cm)

1.25”

3.2 cm

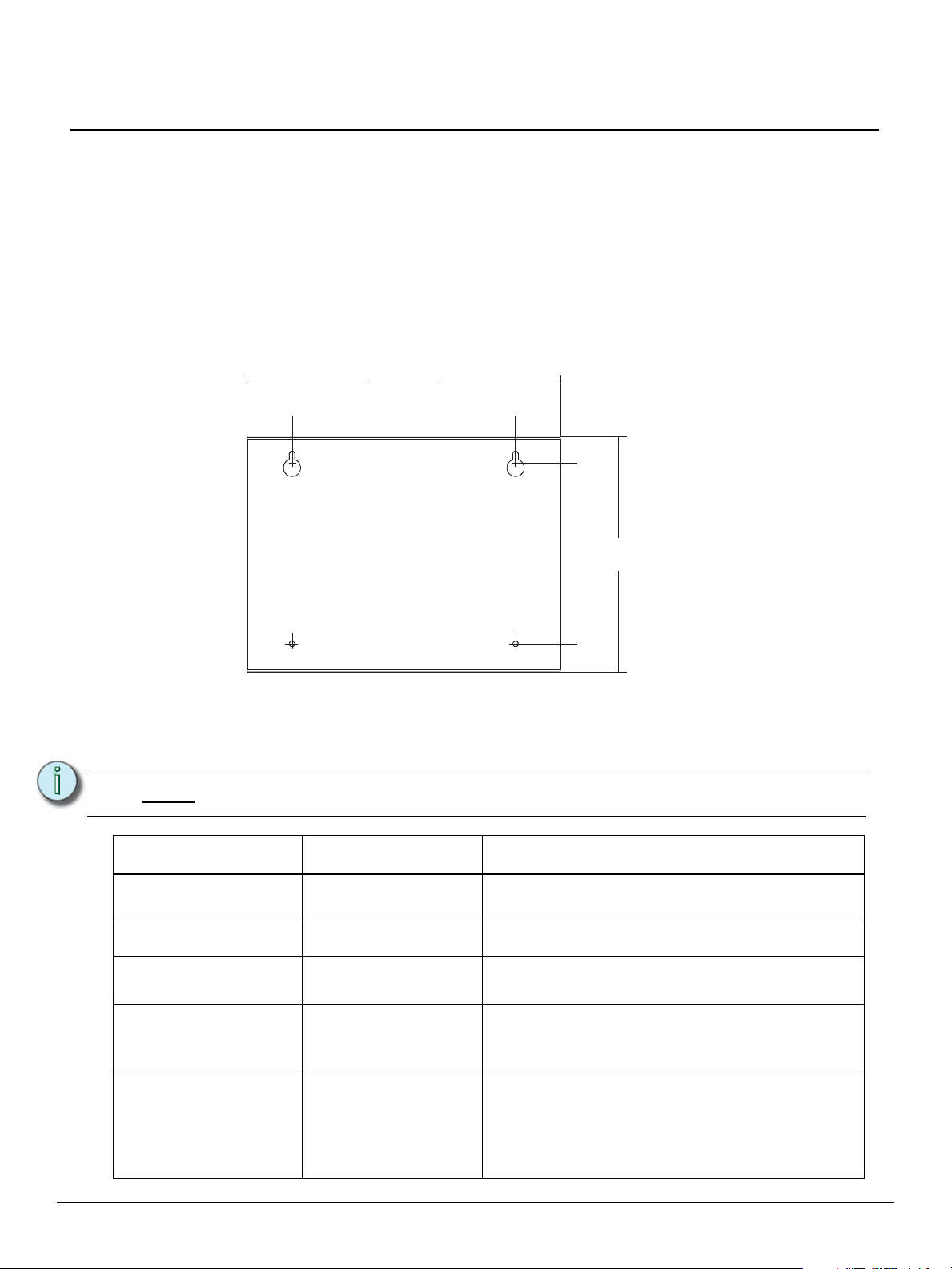

Installation

Install the Enclosure

Step 1: Remove both covers from the enclosure to reveal the mounting keyholes.

a: The left cover is secured with four screws.

b: The right cover is secured with two 3/4 turn fasteners.

Step 2: Using the keyhole measurements in the graphic below, predrill and install two 1/4” (6mm)

bolts (bolts not provided).

Step 3: Install the enclosure onto the mounting bolts and secure.

Step 4: Notice the two screw holes on the bottom right and left of the rear panel. Use two screws

(not provided) to secure the enclosure the wall.

Interface Series

Rough-in Conduit and Wire

Conduit knockouts are provided on the left and bottom sides of the enclosure for installation

convenience. Wiring and termination for each interface type, Heritage Contact Interface and Heritage

Fader Interface, are similar. Pull the required wiring into the enclosure.

Note:

Purpose Wire Type Notes

Link Power Belden 8471 (or

Auxiliary Power 24 Vdc

ESD drain (ground)

Contact Interface:

Switch In and Switch Out

terminals

Fader Interface:

Fader input and Lamp

output terminals

Low voltage control cables must be run in separate conduit from power wires.

Wiring is topology free, polarity independent with a

approved equal)

(2) 18 AWG (0.75mm2)

18-10 AWG (0.75-6mm

18-10 AWG (0.75-6mm

18-10 AWG (0.75-6mm

maximum total system length of 1,640 feet (500m).

2

Required when wiring is not installed in grounded metal

)

conduit.

2

Two wires are required per switch (switch in or switch out

)

and common). Supports up to 1,000 feet (305m) of 16

AWG (1.5mm

2

Three wires are required per fader input connection

)

(fader input, +3.3 Vdc and common). An additional two

wires are required for Lamp output (lamp output and V

out). Supports up to 1,000 feet (305m) of 16 AWG

(1.5mm

2

) between input and common.

2

).

Unison® Heritage Contact and Fader Interface Page 2 of 4 Electronic Theatre Controls, Inc.

Page 3

ETC Installation Guide

LinkPower

pigtail

Auxiliary

Power pigtail

WAGO

topology of a single

station installation

topology of multiple

stations installed in

series

installed control wire

installed control wire to next station

pigtail wire

installed control wire

pigtail wire

Terminate Wiring

Locate the termination kit shipped with the Interface packaging. This kit

includes a LinkPower pigtail, an Auxiliary Power pigtail and all required

connectors for use during installation.

Step 1: Terminate and connect LinkPower. LinkPower is topology

free and polarity independent. You may install LinkPower

in any combination of bus, loop, star or home-run.

a: Locate the LinkPower pigtail and two WAGO cage

clamp connectors from the termination kit.

b: Strip 3/8” (9-10mm) from the ends of each LinkPower

wire (both the provided pigtail and installed LinkPower

wire).

c: Use the WAGO cage clamp connector to connect the installed control wire to the

connectorized pigtail wires provided. Open the terminal levers on the WAGO

connector and insert the installed (typically black) Belden 8471 LinkPower wire and

the black lead from the LinkPower pigtail into the terminals.

d: Close the levers onto the wires.

e: Repeat for the installed (typically white) Belden 8471 LinkPower wire and remaining

pigtail wire using a new WAGO connector.

f: Install the LinkPower connector to J2 (NET) on the control board.

Interface Series

Unison® Heritage Contact and Fader Interface Page 3 of 4 Electronic Theatre Controls, Inc.

Step 2: Terminate and connect Auxiliary Power (24 Vdc) wiring.

a: Locate the Auxiliary Power pigtail and two WAGO cage clamp connectors from the

termination kit.

b: Strip 3/8” (9-10mm) from the ends of each Auxiliary wire (both the provided pigtail and

installed wire).

c: Use the WAGO cage clamp connector to connect the installed power wire to the

connectorized pigtail wires provided. Open the terminal levers on the WAGO

connector and insert the installed (typically black) 16 AWG (1.5mm

wire and the black lead from the pigtail into the terminals.

d: Close the levers onto the wires.

e: Repeat for the installed (typically red) 16 AWG (1.5mm

remaining pigtail wire using a new WAGO connector.

f: Install the Auxiliary connector, labeled “Power” (location J5 for Contact Interface and

J7 for the Fader Interface) on the control board.

Step 3: Terminate the ESD drain (ground) wire.

a: Strip 7/16” (11mm) from the end of the ground wire.

b: Loosen the terminal screw on a green/yellow terminal block. The green/yellow

terminal blocks are located at either end of the terminal strip. All field terminations

should be made to the right side of the terminal strip.

c: Insert the ground wire and tighten the screw onto the wire.

2

) Auxiliary Power

2

) Auxiliary power wire and

Page 4

ETC Installation Guide

COM2

SWITCH OUT

COM5

SW6 OUT

COM4

SW5 OUT

COM3

SW4 OUT

SW3 OUT

SW1 OUT

SW2 OUT

SWITCH IN

COM

SW8 IN

SW7 IN

SW6 IN

SW5 IN

SW4 IN

SW3 IN

SW2 IN

SW1 IN

COM

COM

COM

COM1

COM6

SW7 OUT

COM7

SW8 OUT

COM8

LAMPS FADER

+3.3 VDC

PT8

PT7

PT6

PT5

PT4

PT3

PT2

PT1

COM

V out

LP1

LP2

LP3

LP4

LP5

LP6

LP8

LP7

Contact

Interface

Fader

Interface

Step 4: Terminate contact / fader interface wires. All field terminations are made to the right side

of the terminal strip.

Interface Series

• When terminating a switch to a Contact Interface, each pair of terminations, either

Switch In or Switch Out, requires one switch and one common connection.

• When terminating a fader input to a Fader Interface, three wires are terminated

including a “PT” connection, “+3.3 Vdc” connection and a “Com” connection.

Note:

There is only one +3.3 Vdc terminal and one common (COM) terminal for fader inputs.

When multiple fader inputs are required, each terminal allows up to eight wires in the

single terminal. Additional connections can be bussed together to share the line using

WAGO connectors as required.

• When a lamp indication is required for the fader input (Fader Interface only), two

additional wires are required including an “LP” and a common (COM) connection.

Each lamp output terminal is functionally connected to a fader input terminal

(example: PT1 is factory wired and functionally connected to LP1).

Note:

The lamp voltage conducts from “V out” to the lamp outputs. When using polarity

sensitive indicators such as an LED, connect the anode to “V out” and the cathode to

the lamp “LP” connection.

a: Strip 7/16” (11mm) from the ends of each wire.

b: Loosen the terminal screw for each required termination.

c: Insert the wires into the corresponding terminal block number and tighten the screws

Unison® Heritage Contact and Fader Interface Page 4 of 4 Electronic Theatre Controls, Inc.

firmly onto the wires.

Loading...

Loading...