Page 1

ERn Wall Mount Enclosure

Installation Manual

Revision B

Copyright © Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

7180M2100

Released: 2012-10

Rev B

Page 2

ETC®, Unison®, EDMX™ are either registered trademarks or trademarks of Electronic Theatre Controls, Inc. in

the United States and other countries.

Echelon®, LON®, LONW

ORKS

®

are registered trademarks of Echelon Corporation in the United States and

other countries.

All other trademarks, both marked and not marked, are the property of their respective owners.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ERn External Processing Rack . . . . . . . . . . . . . . . . . . . . . . . . . .1

ERn Modules and Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warnings and Notice Conventions . . . . . . . . . . . . . . . . . . . . . . .4

Contacting ETC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Prepare for Installation . . . . . . . . . . . . . . . . .5

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Unpack and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Main Circuit Breaker Protection . . . . . . . . . . . . . . . . . . . . . . . . . .6

Lockout / Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General Lockout/Tagout Procedures: . . . . . . . . . . . . . . . . . . . .7

Maximum Current Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Where to Install the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rack Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installation Environment Requirements . . . . . . . . . . . . . . . . . . . .8

Wire Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Wire Routing and Specification . . . . . . . . . . . . . . . . . . . . . . . . . .9

Control Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Data Types and Topologies . . . . . . . . . . . . . . . . . . . . . . . . .10

DMX (Digital Multiplex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Auxiliary 24 Vdc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Install Rack Enclosures. . . . . . . . . . . . . . . . 11

Install the Rack Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Rough-in Conduit and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Remove Option Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Rough-in Line and Control Conduit and Wiring . . . . . . . . . . . . .14

Terminate Wiring. . . . . . . . . . . . . . . . . . . . . 15

Connect Line Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Connect Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Connect ERn Right I/O Data Terminations . . . . . . . . . . . . . . . .18

Terminate DMX Control Wiring . . . . . . . . . . . . . . . . . . . . . . .18

DMX Input Termination: Screw Terminals Connector. . . . . . .18

DMX Input/Output Termination: Insulation Displacement Con-

nectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Terminate LinkConnect Control Wiring . . . . . . . . . . . . . . . . .19

Terminate Auxiliary Power . . . . . . . . . . . . . . . . . . . . . . . . . .20

DMX Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Connect ERn Left I/O Data Terminations . . . . . . . . . . . . . . . . .21

Connect to Serial RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Connect to Ethernet RJ-45 . . . . . . . . . . . . . . . . . . . . . . . . . .22

Connect to Contact Inputs and Contact Outputs . . . . . . . . .22

Terminate Contact Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Table of Contents i

Page 4

Terminate Contact Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Final Installation and Power Up . . . . . . . . . 23

Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Check Main Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Check Line Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Final Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Install Rack Options . . . . . . . . . . . . . . . . . . 26

Rack Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Install the RideThru Option (URTO) Kit . . . . . . . . . . . . . . . . . . .27

Connect RideThru Option Wiring . . . . . . . . . . . . . . . . . . . . .28

Install the BatteryPack Option (UBPO) Kit. . . . . . . . . . . . . . . . .29

Install a Paradigm Repeater or Dual Repeater Module. . . . . . .31

Terminate LinkConnect Control Wiring . . . . . . . . . . . . . . . . .32

Terminate Auxiliary Power . . . . . . . . . . . . . . . . . . . . . . . . . .33

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Install Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . . . .35

Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Install the Ethernet Switch Module . . . . . . . . . . . . . . . . . . . . . .36

Connect CAT5e Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

ii Unison® ERn Wall Mount Enclosure Installation Manual

Page 5

Introduction

Welcome to the installation manual for the Unison® ERn Enclosure. This manual contains

the procedures for safe and efficient installation of wall-mount ERn series control

enclosures, including wire termination and option kit installation.

ERn series enclosures provide Unison architectural control to distributed Unison, Sensor+,

or other DMX512 systems. Used stand alone or in multi-processor network systems, the

Wall Mount ERn series offers elegant low-profile surface mounting, modular back-lit control

electronics, and the ultimate in architectural lighting control versatility.

The ERn enclosure is available in two sizes, ERn2 (single processor) and ERn4 (dual

processor), The ERn is available in three single phase voltage options, 100-120, 230 CE,

and 240 VAC to meet your installation requirements.

ERn External Processing Rack

Model Voltage / Frequency Notes

ERn2-W-120 85-120 VAC, 47-63 Hz (single phase) External processing rack configured for wall

ERn2-W-230CE 180-265 VAC, 47-63Hz (single phase)

ERn2-W-240 180-265 VAC, 47-63 Hz (single phase)

ERn4-W-120 85-120 VAC, 47-63 Hz (single phase) External processing rack configured for wall

ERn4-W-230CE 180-265 VAC, 47-63Hz (single phase)

Wall Mount

ERn4-W-240 180-265 VAC, 47-63 Hz (single phase)

The ERn2 enclosure supports a single Paradigm Architectural Control Processor (P-ACP)

and one Paradigm Station Power Module (P-SPM) or a blank module (ERn-BM). The

accessory tray in the bottom of the enclosure can be used for an additional accessory

option including a 5-port Ethernet Switch (ERn-NET) or a Redundant Rack Power Supply

(ERn-RPS).

The ERn4 enclosure supports up to two Paradigm Architectural Control Processors (PACP) and two Paradigm Station Power Modules (P-SPM) or a Paradigm Repeater Module

(P-REP). Alternatively, the top two slots in the enclosure may be used for a Paradigm Dual

Repeater Module (P-DREP). The accessory tray in the bottom of the enclosure can be used

for an additional accessory option including a 5-port Ethernet Switch (ERn-NET) or a

Redundant Rack Power Supply (ERn-RPS).

mounting. Use with one Paradigm

Architectural Control Processor (ACP) and

one option module.

mounting. Use with up to two Paradigm

Architectural Control Processors (ACP) and

up to two option modules.

Introduction 1

Page 6

ERn Modules and Options

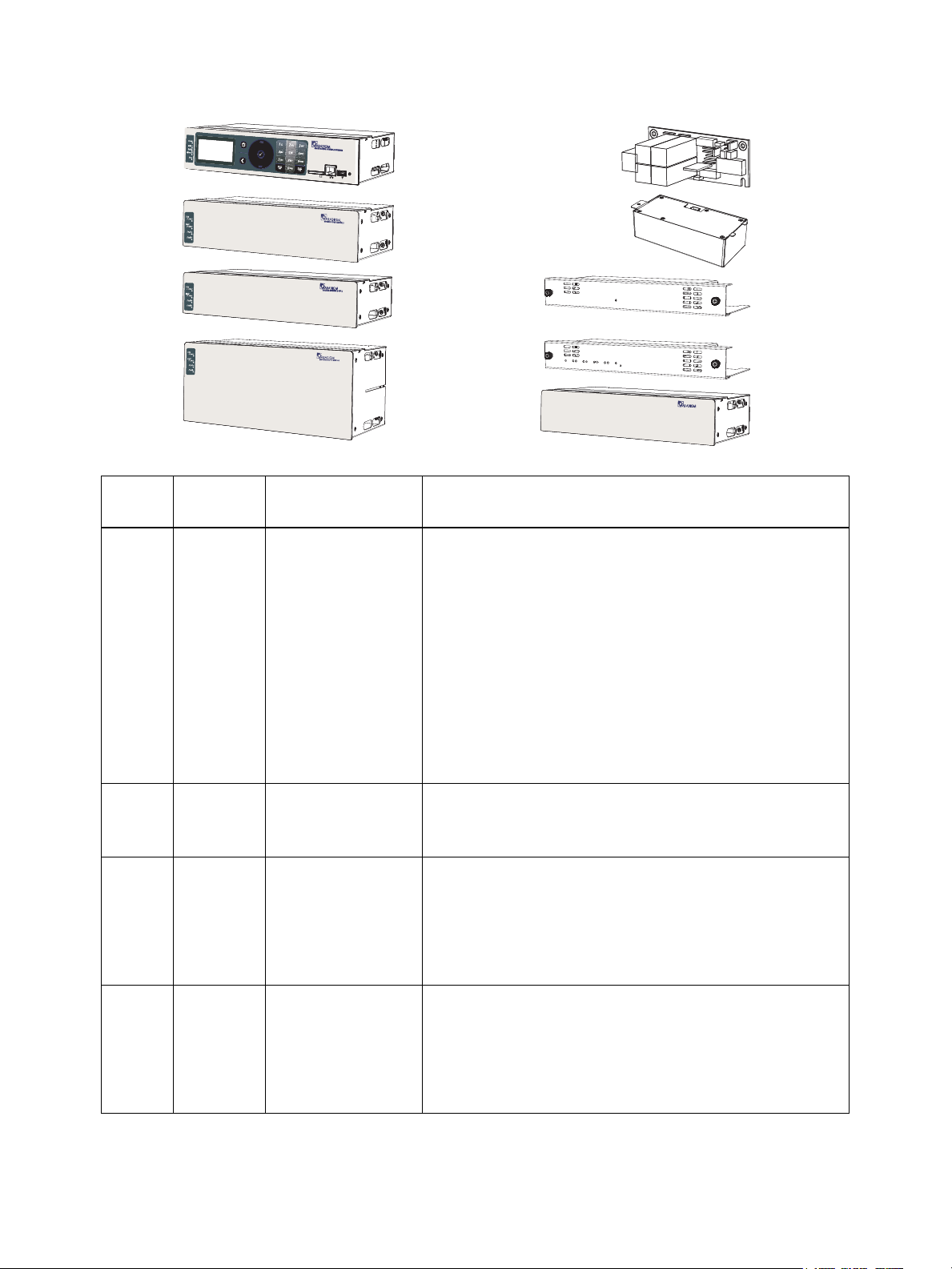

P-ACP

P-SPM

P-REP

P-DREP

ERn-NET

ERn-RPS

UBPO

URTO

ERn-BM

Model

P-ACP 7180A1001 Paradigm Architectural

P-SPM 7182A1001 Paradigm Station

P-REP 7182A1003 Paradigm Station

P-DREP 7182A1004 Paradigm Dual Station

Part

Number

Description Notes

Control Processor

Power Module

Repeater Module

Repeater Module

The Paradigm ACP provides powerful and flexible control for

architectural and theatrical applications with integrated

networking for both NetConnect and LinkConnect networks.

• Supports up to 1024 control channels using industry standard

protocols.

• User interface remains accessible with the enclosure door

closed.

• Supports up to 62 Unison control stations over the

LinkConnect network with the use of Paradigm Station Power

and Repeater Modules.

• Supports up to 12 Paradigm Touchscreen Stations using

LinkConnect or NetConnect protocols.

• Provides two ports of one DMX universe each (512 addresses

each), individually switchable between input and output.

The Paradigm Station Power Module (P-SPM) provides power for

Unison control stations over the LinkConnect network and

supports the station data bus length up to 1,640 feet (500m).

• Supports up to 32 Unison control stations over LinkConnect.

The Paradigm Station Repeater (P-REP) module extends the

system station bus length by 1,640 feet (500m) and increases the

possible station count by an additional 30 stations. For use only in

an ERn4 enclosure.

• For use in an ERn4 enclosure only.

• Supports up to 30 additional Unison control stations over

LinkConnect.

The Paradigm Dual Station Repeater (P-DREP) module extends

the system station bus length by 3,280 feet (1,000m) through two

separate topology-free segments, each supporting 1,640 feet

(500m).

• The dual repeater supports up to 30 additional Unison control

stations.

• For use in an ERn4 enclosure only.

2 Unison® ERn Wall Mount Enclosure Installation Manual

Page 7

Model

ERn-NET 7180A1400 ERn Ethernet Switch

UBPO 7180A1411 Unison Battery Pack

URTO 7180A1410 Unison Ride Thru

ERn-BM 7180A1402 Airflow Option Module Required for any empty module space in the ERn enclosure.

ERn-RPS 7180A1401 ERn Redundant Power

Part

Number

Description Notes

The ERn Ethernet Switch (ERn-NET) provides four ports of

Module

Option Kit

Option Kit

Supply

802.3af compliant Power over Ethernet (PoE) and one port for the

Paradigm Architectural Control Processor.

• Not compatible with a rack mounted ERn enclosures.

• Not compatible with an ERn4 230 VAC enclosures.

The BatteryPack Option (UBPO) provides back-up power during

power outages for the Paradigm Architectural Control Processor

for up to 90 minutes for an ERn enclosure with one P-ACP or up

to 45 minutes for an ERn4 with two P-ACPs installed.

• Not compatible with rack mounted ERn enclosures.

The Unison Ride Through Option (URTO) kit provides power for

one Paradigm Architectural Control Processor in the host

enclosure for a limited time (minimum of 12 seconds) during brief

power outages or drop outs.

• If installed in an ERn4 enclosure, one URTO is required per

installed Paradigm ACP.

• Installs into the accessory option module slot of an ERn

enclosure.

The ERn Redundant Power Supply (ERn-RPS) provides an

additional rack power Supply that powers the ERn enclosure if the

primary rack power supply is removed or fails.

• Tool-free installation into the accessory option slot of an ERn

enclosure.

• Not supported in ERn4 230 VAC enclosures. The ERn4

230 VAC enclosure requires two rack power supplies as

standard.

Introduction 3

Page 8

Warnings and Notice Conventions

These symbols are used throughout this installation manual to alert you to danger or

important information:

Note:

CAUTION:

Notes are helpful hints and information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss or an equipment

problem.

WARNING:

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an

action.

WARNING:

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of death by electric shock.

Contacting ETC

For questions about Unison rack system delivery, contact ETC Systems Group. For general

information, your most convenient resources are the references provided in this manual. To

search more widely try the ETC web site at www.etcconnect.com.

For technical questions about Unison rack systems, contact ETC Technical Services

directly at one of the offices listed below. Emergency service is available from all ETC

offices outside of normal business hours. When calling for assistance, please have the

following information handy:

• Your location and job name.

• A complete list of ETC equipment.

• A complete list of other installed products and components connected to the system

you are troubleshooting.

• DMX control source, if any.

Americas

ETC International

Technical Services Department

3031 Pleasant View Road

Middleton, WI 53562

800-775-4382 (USA, toll-free)

+1-608 831-4116

service@etcconnect.com

Asia

ETC Asia, Ltd.

Technical Services Department

Room 1801, 18/F, Tower 1, Phase 1

Enterprise Square

9 Sheung Yuet Road

Kowloon Bay, Kowloon, Hong Kong

+852 2799 1220

service@etcasia.com

United Kingdom

Electronic Theatre Controls, Ltd.

Technical Services Department

26 - 28 Victoria Industrial Estate

Victoria Road,

London W3 6UU, UK

+44 (0)20 8896 1000

service@etceurope.com

Germany

Electronic Theatre Controls, GmbH

Technical Services Department

Ohmstrasse 3

93607, Holzkirchen, Germany

+49 (80 24) 47 00-0

techserv-hoki@etcconnect.com

Please email comments about this manual to: TechComm@etcconnect.com

4 Unison® ERn Wall Mount Enclosure Installation Manual

Page 9

Chapter 1

Prepare for Installation

This chapter contains the following sections:

• Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

• Where to Install the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . .8

• Wire Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1 Prepare for Installation 5

Page 10

Preparations

Unpack and Inspect

Before you begin installation, check your shipment and confirm it arrived complete and

undamaged.

Step 1: Check the shipping container for physical damage.

Step 2: If you find damage, document it to help with a claim against your shipper.

Step 3: Unpack your order and check the contents against the packing list to be sure

your order is complete.

Step 4: If you discover a problem, call ETC Systems Group at (608) 831-4116.

Main Circuit Breaker Protection

Before you begin installing the Unison® external processing rack enclosure, make sure you

have installed a main circuit breaker cabinet or other readily accessible input power

disconnect device in the same, room or in close proximity to the installed ERn enclosure.

WARNING:

Lockout / Tagout

Note:

Equipment should have power disconnected and be locked out while being repaired.

Accidents which occur because equipment that is being repaired and not locked out can

result in serious injuries like amputations, fractures, and even death. Locking out and

tagging power at its source is important while repairing or adjusting equipment because it

ensures that power does not reach the equipment being serviced.

•To lockout means to place a lock on a device that prevents the release of energy.

Locking out is intended to prevent the unexpected startup or energizing of machinery

and equipment during service and maintenance operations.

•To tagout means to place a tag on a switch or other shut off device which warns others

not to start the piece of equipment. Tagout should only be used with lockout, unless

locking out the equipment is impossible.

Rack enclosures installed without an accessible power disconnect device

cannot be serviced or operated safely. Follow all local codes and

restrictions.

When the disconnect device is not located near the installed rack enclosure,

the disconnect must allow for proper lockout and tagout.

While ETC does not intend to qualify your facility Lockout/Tagout procedures, we

have provided a generic guide below for your reference as needed.

6 Unison® ERn Wall Mount Enclosure Installation Manual

Page 11

General Lockout/Tagout Procedures:

• Notify all affected employees that a lockout/tagout procedure is ready to begin.

• Turn off the equipment at the control panel.

• Turn off or pull the main disconnect. Be sure all stored energy is released or restrained.

• Check all locks and tags for defects.

• Attach your safety lock or tag on the energy isolating device.

• Try to restart the equipment at the control panel to ensure that it is secured.

• Check the machine for possible residual pressures, particularly for hydraulic systems.

• Complete the repair or servicing work.

• Remove the safety lock and adapter.

• Let others know that the equipment is back in service.

Maximum Current Input

The ERn enclosure draws a maximum current of 3 amps when fully populated. the

maximum allowable protection device rating is:

• 20A at 120 VAC

• 15A at 230/240 VAC

1 Prepare for Installation 7

Page 12

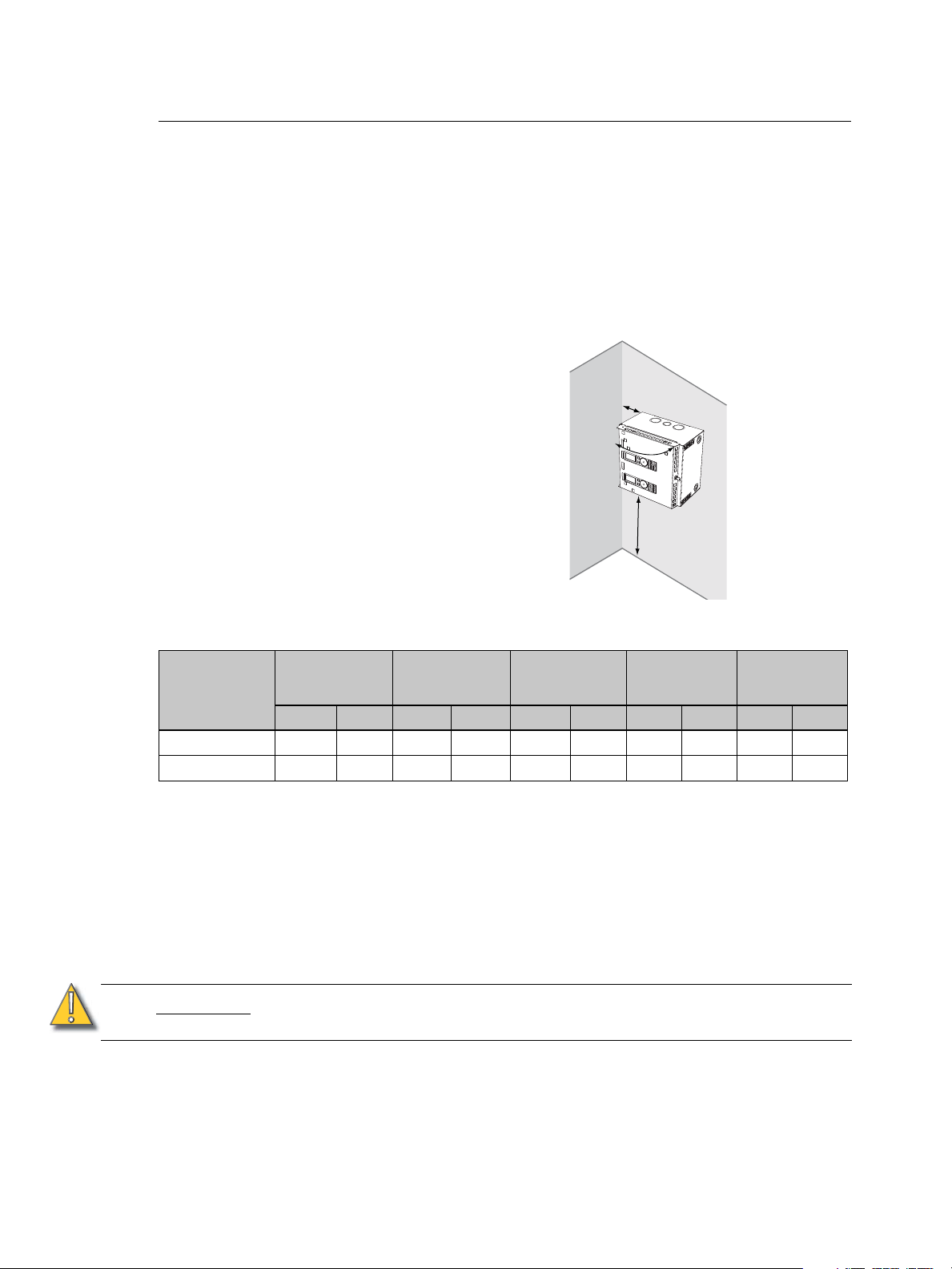

Where to Install the Enclosure

152 mm

(6”)

394 mm

(15.5”)

914.4 mm

(36”)

Surface mount the ERn enclosure with:

• a minimum of 15.5” (394mm) front

clearance for proper door operation.

• a minimum of 6” (152mm) clearance

from the left and right sides from walls

or other equipment to allow proper

convection airflow in the enclosure.

The Unison External Processing Enclosure (ERn) can be wall (surface) mounted or rack

mounted depending on the rack mounting type ordered. For rack mounted installation

instructions reference the “ERn Rack Mount Enclosure Installation Manual”.

Surface mount the ERn enclosure on a load bearing wall, in an electrical closet or a room

with restricted public access. It is recommended that you install the rack at least 36”

(914.4mm) off the floor surface to ensure clear view of the Paradigm Architectural Control

Processor (P-ACP) for programming and general operation.

Clearance Requirements

Rack Dimensions and Weights

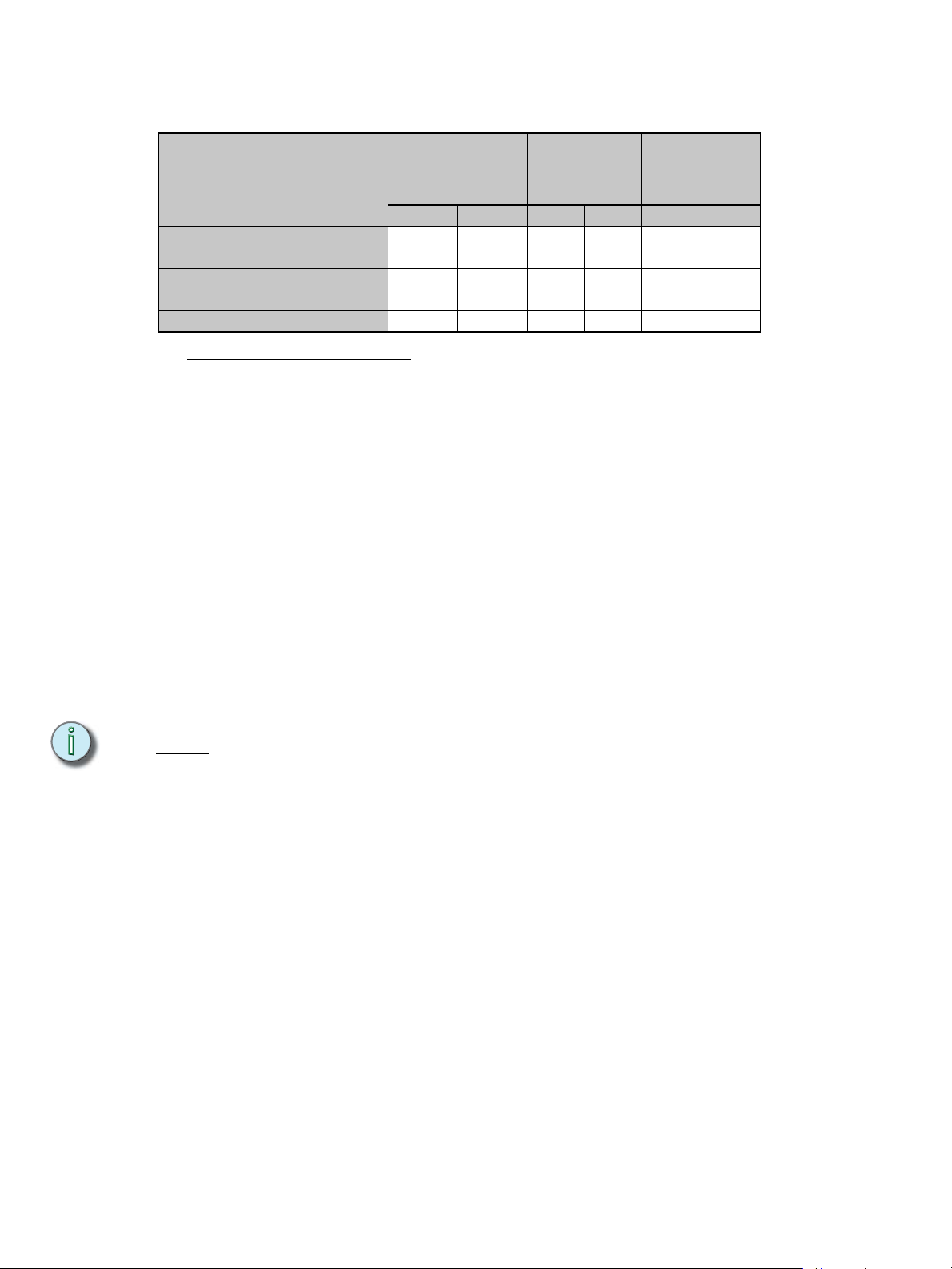

Rack Type

ERn2 - W

ERn4 - W

Height Width Depth

inches mm inches mm inches mm lbs kgs lbs kgs

8.8 223 15.5 394 9.6 244 15 6.8 20 9.1

14.1 358 15.5 394 9.6 244 20 9.1 25 11.3

Product

Weight

Shipping

Weight

Installation Environment Requirements

• For your safety, you should install a circuit breaker cabinet or other readily accessible

input power disconnect device in the same area as the Unison External Processing

Enclosure. Breakers not in the same room must have a physical means to be locked off.

• A clean (not dusty), temperature controlled environment with the following conditions:

• ambient temperature of 32-104°F / 0-40°C

• ambient humidity of 10-90%, non-condensing

CAUTION:

8 Unison® ERn Wall Mount Enclosure Installation Manual

• Restricted public access to prevent tampering is recommended.

• All CE equipment is tested to EMC category B environment.

HVAC systems must at all times maintain the specified ambient temperature at the

Unison ERn enclosure.

Page 13

Wire Requirements

Wire Access

Location

Wire Size

Single Phase, 20A

2 - wire + gnd

Control Wires

Top of rack

preferred acceptable

Bottom of rack

preferred acceptable

Left side

acceptable acceptable

Right side

acceptable acceptable

Wire Routing and Specification

Unison ERn enclosures have conduit knockouts on the top and bottom for incoming power

and control wiring. Alternatively, conduit knockouts are located on both sides of the rack for

control signal wiring as needed. Signal and power wiring must be run in separate conduit

in accordance with local codes.

Control and power must be run in separate conduit.

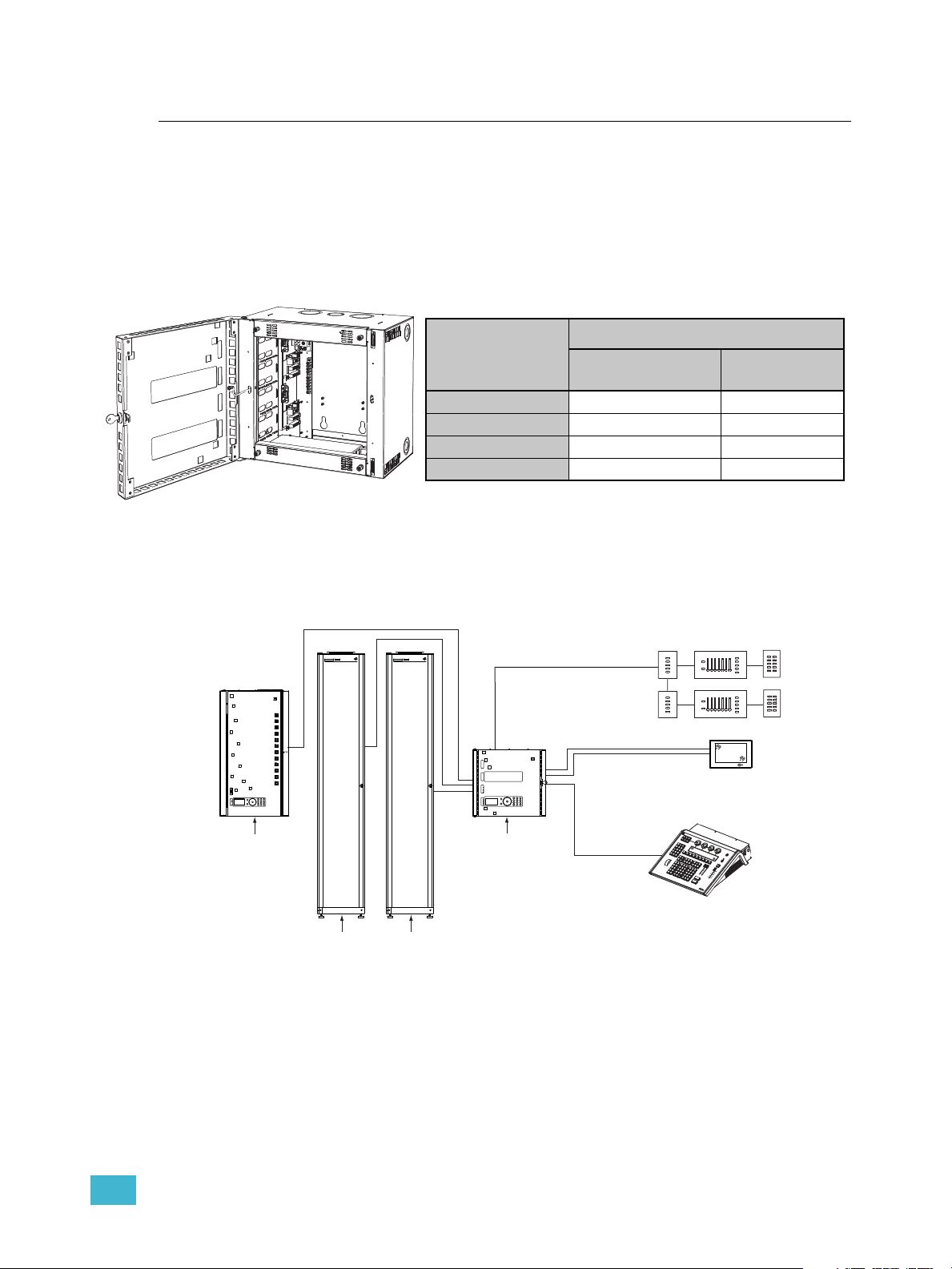

Control Specifications

The riser below is typical of a system utilizing the ERn enclosure with the Paradigm

Architectural Control Processor (P-ACP). Paradigm systems provide up to two DMX inputs

for control of more advanced systems. A Paradigm system also utilizes Net3 networking for

system wide control.

Sequence

Macro Record

Unison Heritage

Stations

Sequence

Macro Record

Unison Paradigm

Touchscreen LCD

Preset 1

Preset 2

Preset 7

Preset 2

Preset 8

Preset 3

Preset 3

Preset 9

Preset 4

Preset 4

Preset 5

Preset 10

Preset 5

Preset 1

Preset 6

Preset 1

Preset 2

Preset 7

Preset 2

Preset 8

Preset 3

Preset 3

Preset 9

Preset 4

Preset 4

Preset 5

Preset 10

Preset 5

Unison DRd12

rack enclosure

power

feed

SYSTEMLORTNOCGNIHGIL T SYSTEMLORTNOCGNIHGIL T

SENSOR+

SR48+

dimmer rack

SENSOR+

SR48+

dimmer rack

Unison ERn4

processing rack

power

feed

Unison

LinkPower

LinkPower

Aux Power 24 Vdc

DMX input

to ERn rack

Preset 1

Preset 2

Preset 3

Preset 4

Preset 5

Preset 1

Preset 2

Preset 3

Preset 4

Preset 5

Preset 1

Preset 6

ETC Console

(for optional stage lighting)

power

feed

1 Prepare for Installation 9

power

feed

Page 14

The following table lists the recommended control wire types used in a typical Unison

installation and the maximum wire runs allowed.

Purpose

Total length of control wire

(without repeater module)

Maximum wire length

(device to device)

Maximum repeater distance

Data Types and Topologies

LinkConnect

LinkConnect is the station communication bus from the Architectural Control Processor to

the stations. LinkConnect is based on Echelon

protocol, and uses one pair of wires (data +, data -). An additional 14 AWG (2.5mm

for grounding is required when not installed in grounded metal conduit.

ETC uses two types of LinkConnect networks, for SmartLink and Paradigm systems. While

the wiring for LinkConnect in SmartLink and Paradigm systems are the same, the two

communication and control types are not interchangeable. SmartLink products are

compatible only with the SmartLink ACP, SmartLink Station Power Module, and SmartLink

Architectural Control Stations. Paradigm products are compatible only with the Paradigm

ACP, Paradigm Station Power Modules, Unison Heritage Control Stations, and Paradigm

Touchscreens.

LinkConnect is topology-free and polarity independent, you can install your LinkPower data

runs in any desired combination of bus, loop, star, and home run. ETC recommends the

use of Belden 8471 (or approved equal) wire. The total combined length of a LinkPower

wire run cannot exceed 1,640 feet (500m) with a maximum distance of 1,312 feet (400m)

between any two devices.

Stations

(Belden 8471)

Feet Meter Feet Meter Feet Meter

1640 500 1600 487 328 100

1313 400 1600 487 N/A N/A

1640 500 N/A N/A N/A N/A

DMX (Belden

9729)

®

LonWorks™ with LinkPower bidirectional

Ethernet

(Cat5 /Belden

1583a)

2

) wire

Note:

DMX (Digital Multiplex)

DMX can address up to 512 channels of control. DMX is installed in a daisy chain topology

and includes one pair of wires (data+ and data-) plus ground. ETC recommends the use of

Belden 9729 (or approved equal) wire with a single end of line termination (90-150 For

best DMX performance, twist the wires together as close to the pluggable connector as

possible. DMX devices manufactured by ETC are compliant with the USITT DMX512A

standard.

Auxiliary 24 Vdc

Auxiliary power is required when you are installing powered Unison control stations. ETC

recommends using two 16 AWG (1.5mm

control station(s). Auxiliary power is topology-free. Maximum auxiliary voltage runs are

dependant by the wire gauge and the distribution of auxiliary load determined by

installation. The auxiliary supply is capable is of 36W (1.5A at 24Vdc).

10 Unison® ERn Wall Mount Enclosure Installation Manual

Repeater modules may be used to extend the Unison LinkPower station data bus

an additional 1,640 feet (500m) total wire, with a maximum distance of 1,313 feet

(400m) between the repeater and any station or Station Power Module.

2

) stranded wires for 24 Vdc auxiliary power to the

Page 15

Chapter 2

Install Rack Enclosures

This chapter contains instructions for installation of the ERn enclosure and rough-in of

conduit and wiring.

The introduction contains the following sections:

• Install the Rack Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

• Rough-in Conduit and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2 Install Rack Enclosures 11

Page 16

Install the Rack Enclosure

ERn2 - 8.9” / 226mm

ERn4 - 14.2” / 360.7mm

5.5”

139.7mm

5.5”

139.7mm

4.5”

114.3mm

15.5”

393.7mm

ERn2 - 6.8” / 172.7mm

ERn4 - 12” / 304.8mm

3.4”

86.4mm

ERn enclosure rear panel

The wall must be strong enough to hold the rack fully populated with modules, conduit and

wire. The maximum weight of an ERn enclosure is approximately 45 lbs (20.4 kg).

Step 1: Determine where your rack will be installed using the weight and dimension

requirements detailed in “Where to Install the Enclosure,” page 8.

Step 2: Use the measured slot dimensions located in the graphic below to mark the hole

locations for the mounting hardware.

Step 3: Drill the holes and install the mounting hardware for each rack.

• Four 3/8” (8-10mm) bolts or screws 2-4” (50-100mm) long, and suitable

wall plugs are suggested mounting hardware (lag bolts recommended).

• All hardware must support the weight of the rack unit fully populated with

modules.

• Expose at least 1” (25mm) of threads for mounting the rack.

Step 4: Attach the rack enclosure to the mounting hardware using the mounting

keyholes.

Step 5: Check that the rack is level and plumb then tighten the mounting hardware for a

secure installation.

12 Unison® ERn Wall Mount Enclosure Installation Manual

Page 17

Rough-in Conduit and Wiring

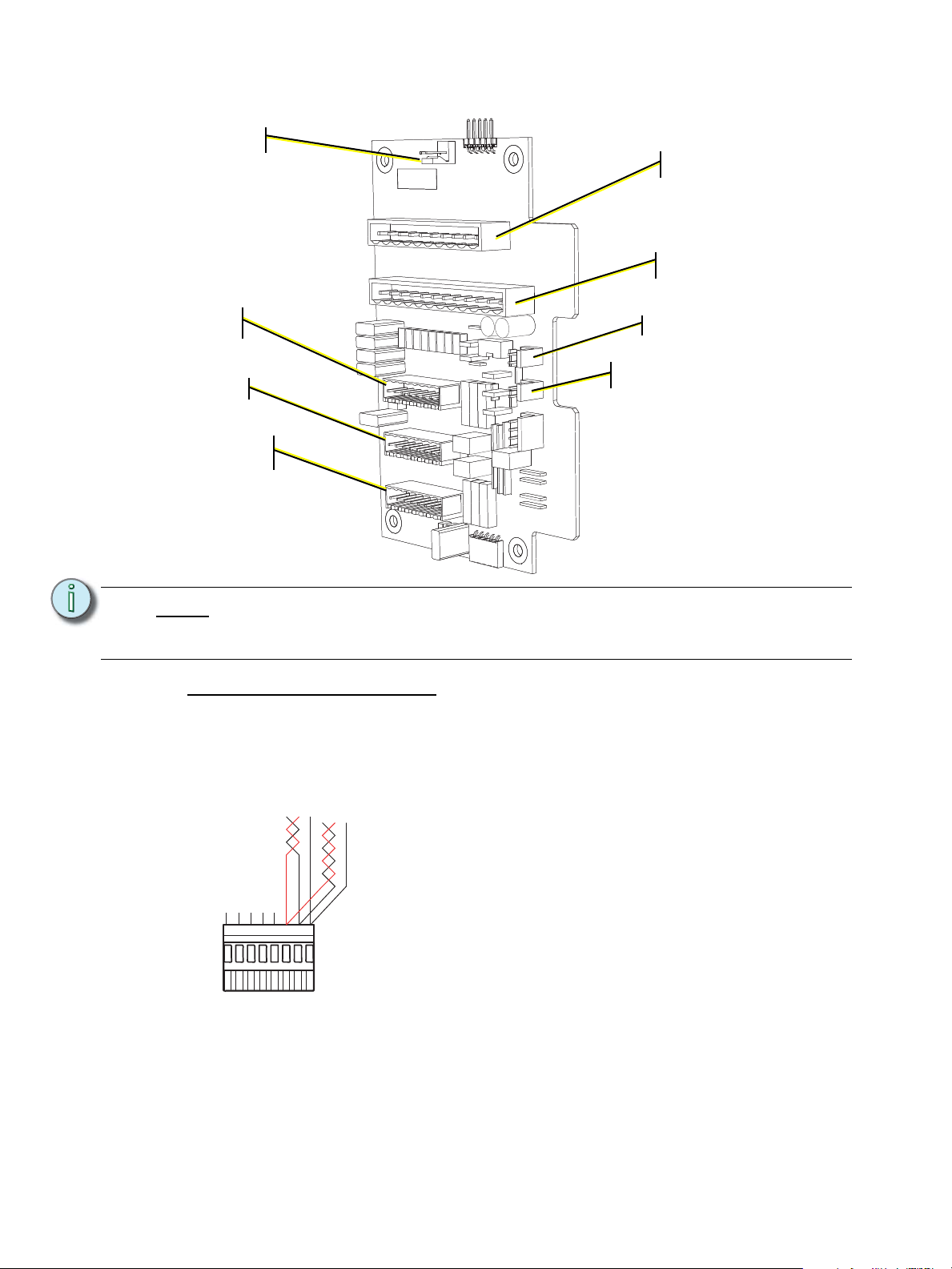

Rack power supply (ERn-PS)

The blank option module installed

at shipment can be replaced with

either the Ethernet Switch Module

(ERn-NET) or the Redundant

Power Supply (ERn-RPS).

WARNING:

All rack terminations must be done with the power off. Racks installed

without an accessible power disconnect device cannot be serviced or

operated safely. Follow all local codes and restrictions.

When the disconnect device is not located near the installed rack enclosure,

the disconnect should allow for proper lockout / tagout. See “Lockout /

Tagout” on page 6.

Remove Option Modules

Prior to installing conduit and pulling wires into the ERn enclosure, remove the rack power

Supply (top of enclosure) and blank option module (bottom of enclosure) from the ERn

enclosure to provide a clear access to the conduit access openings and connections.

Note:

For 230 VAC CE enclosures, before removing any modules, loosen the hardware

and slide the module retention bar to the left.

Note:

Step 1: Loosen the two captured thumbscrews that secure the Rack Power Supply to the

Step 2: Pull the power supply straight out of the rack.

Step 3: Repeat for the blank option module, Ethernet Switch or secondary power supply.

Step 4: Place these modules in a safe place until the conduit rough-in and wiring

2 Install Rack Enclosures 13

An ERn4 at 230 VAC does not support the Redundant Rack Power Supply (ERnRPS) nor the Ethernet Switch Option Module (ERn-NET). Instead an ERn4 at 230

VAC is shipped from the factory with a Rack Power Supply installed in the top

(normal) position and in the lower option module slot.

ERn enclosure.

terminations are complete.

Page 18

Rough-in Line and Control Conduit and Wiring

The ERn enclosure requires line power and control wire terminations. For installation

convenience all terminations are accessible from the front of the rack. A single phase line

power and all required control wires may be pulled through any of the conduit knockouts

provided, or other labeled locations.

Note:

Step 1: Plan wire entry to the rack. See “Wire Routing and Specification” on page 9.

Step 2: Remove the required conduit knockouts from the rack or punch new conduit

Step 3: Install conduit fittings or insert lining materials in the new opening.

CAUTION:

Control (signal) wiring and power wiring must be run in separate conduit in

accordance with local code.

holes. Pay special attention to the rack design so that you do not punch conduit

access in a place that will prevent components from being installed.

Wire openings must have fittings, bushings, grommets or fish paper lining material

to protect wire and cable insulation from damage by sharp metal edges.

14 Unison® ERn Wall Mount Enclosure Installation Manual

Page 19

Chapter 3

Terminate Wiring

This chapter contains the following sections:

• Connect Line Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

• Connect Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3 Terminate Wiring 15

Page 20

Connect Line Power Wiring

WARNING:

ERn enclosures are available in 100-120, 230 CE, and 240 VAC single phase

configurations. The ERn enclosure requires a single phase, 20 amp (maximum) at 120 VAC

input feed or a 15 amp (maximum) at 230 and 240 VAC. The two-wire hot and neutral

terminates to the power input terminal block (top left) and a ground wire terminates to the

ground bar.

Step 1: Pull the line, neutral, and ground cables to the enclosure through the conduit

Step 2: Insert the ground wire into a screw terminal on the ground terminal block and

Step 3: Insert the neutral wire into the neutral screw terminal on the power input terminal

Step 4: Insert the line (input feed) into the line screw terminal on the power input terminal

All rack terminations must be done with the power off. Racks installed

without an accessible power disconnect device cannot be serviced or

operated safely.

openings previously prepared.

secure.

block and secure.

block and secure.

16 Unison® ERn Wall Mount Enclosure Installation Manual

Page 21

Connect Control Wiring

Right I/O boards

Left I/O board(s)

Wire tie down locations

are provided on the rear

panel.

Note:

All low voltage control cables must be run in separate conduit from power wires in

accordance with local codes.

Low voltage data connects to pluggable connectors on the left and right input/output boards

of the ERn enclosure. The ERn2 includes only one each left and right I/O board while the

ERn4 includes two of each.

WARNING:

• The left I/O provides termination for contact inputs and outputs, RS-232 serial, and

• The right I/O provides termination for LinkPower, auxiliary power, DMX in, DMX Out,

RISK OF DEATH BY ELECTRIC SHOCK! Failure to disconnect all power to

the rack before working in the enclosure could result in serious injury or

even death.

Ethernet control.

DMX through, and all enclosure option kits. The right I/O also provides termination for

option modules installed on the bottom module slot of the rack enclosure for enhanced

control and operation.

3 Terminate Wiring 17

Page 22

Connect ERn Right I/O Data Terminations

Auxiliary Power - 24Vdc

LinkPower control

DMX A

Input/Output

DMX Pass-Thru

DMX B

Input/Output

ERn-RPS In

Ride Thru / Batt

24Vdc In

12345678

COM

n/c

n/c

n/c

n/c

n/c

Data + (Red)

Data - (Black)

From source

DMX A

If daisy-chaining to

another rack or

DMX device...

This graphic illustrates DMX termination layout for the

screw-terminal connectors that are intended for use

with Belden 9729 cable (or approved equal) cable type.

Screw terminal connectors are supplied as standard in

the DMX Preparation Kit w/ Screw Connector, part

number 4100A1012.

Be aware that cable other than Belden 9729 may have

a different color code for its wire pairs.

In

V

4

2

Note:

- + - + -

B

A B

D

DM

+

-

+

-

+

Aux Power

A B

A

B

A

B

A B A

LO

N

n

I

M

X

A

X

Pas

s-

T

hru

DM

DMX

DM

B

RPS

t

t

Ba

/

u

r

h

T

e

d

i

R

I

D

C

A

X

B

X

N

O

L

The 24 Vdc connection is the power Supply (ERn-PS) connection and is

connected for you at the factory. The ERn-RPS and Ride Thru / Batt terminations

are detailed in “Rack Options” on page 27.

Terminate DMX Control Wiring

DMX wire preparation and termination will vary with the type of wire and termination kit

being utilized. Please refer to the instructions supplied with the DMX termination kit for

specifics on the wire preparation.

DMX Input Termination: Screw Terminals Connector

18 Unison® ERn Wall Mount Enclosure Installation Manual

Page 23

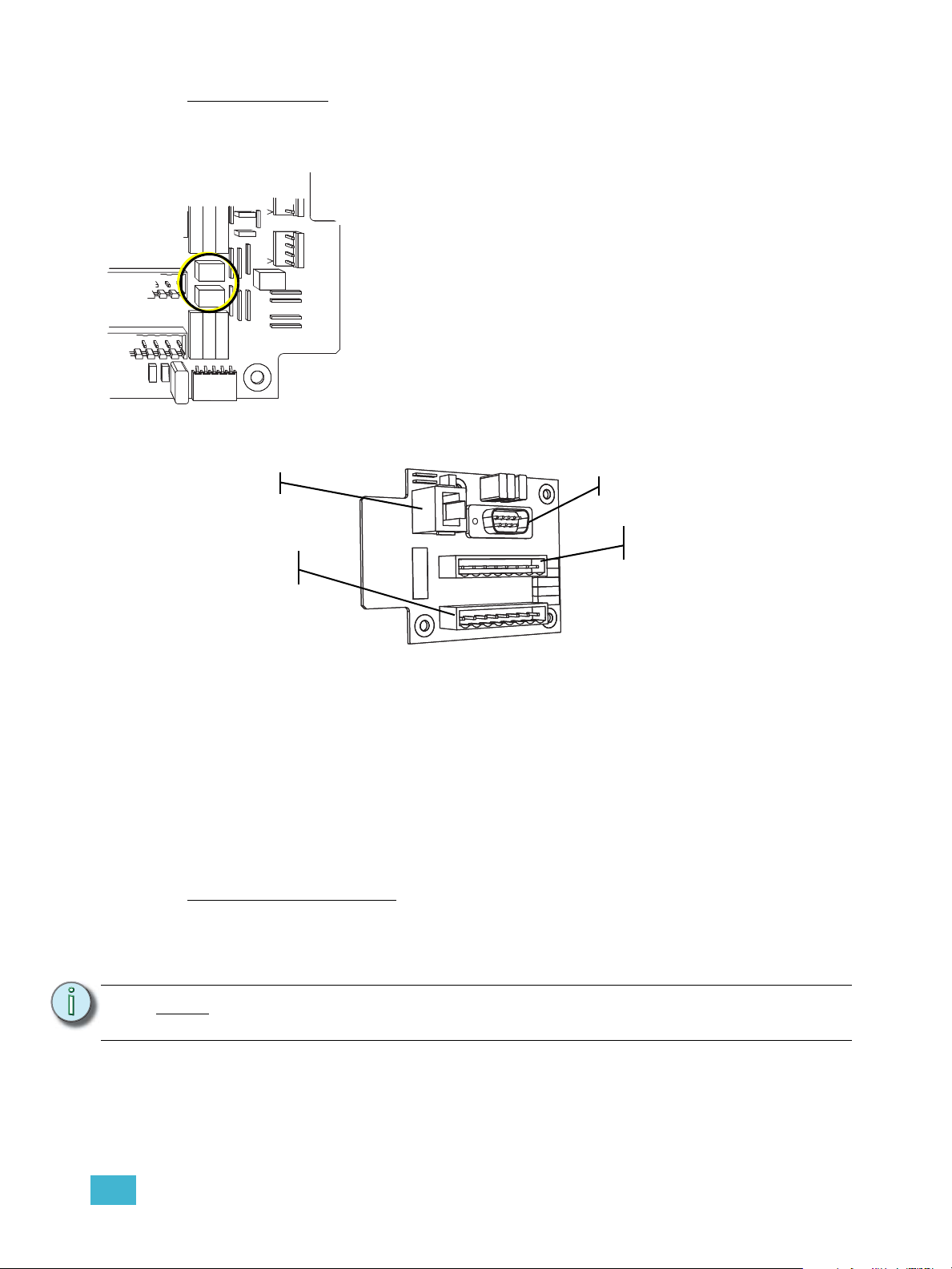

DMX Input/Output Termination: Insulation Displacement Connectors

The graphic below illustrates DMX termination layout for an insulation displacement

connector (IDC). This connector type is intended for use with belden 1583A (or approved

equal, such as Category 5, 5E, or 6) cable type.

The insulation displacement connector kit (IDC) may be requested from the factory but is

not supplied as standard. Request the IDC Pluggable Connector Termination kit, part

number 4100A1013. Be aware that cable other than Belden 1583A may have different color

code for its wire pairs.

BLU

W/GRN

From source

BRN

GRN

DMX A

ORG

W/ORG

Data +

Data -

W/BRN

COM

Use this DMX Pass-Thru

connector when

daisy-chaining to

another rack or

DMX device...

W/BLU

BLU

GRN

W/GRN

From source

DMX B

W/BLU

W/ORG

BRN

W/BRN

COM

Data +

Data - ORG

1234567812345678

DMX A

DMX B

Thru

Thru

W/ORG

Data - ORG

W/BRN

W/BRN

COM

Data +

Data - ORG

COM

12345678

W/ORG

n/c

n/c

Data +

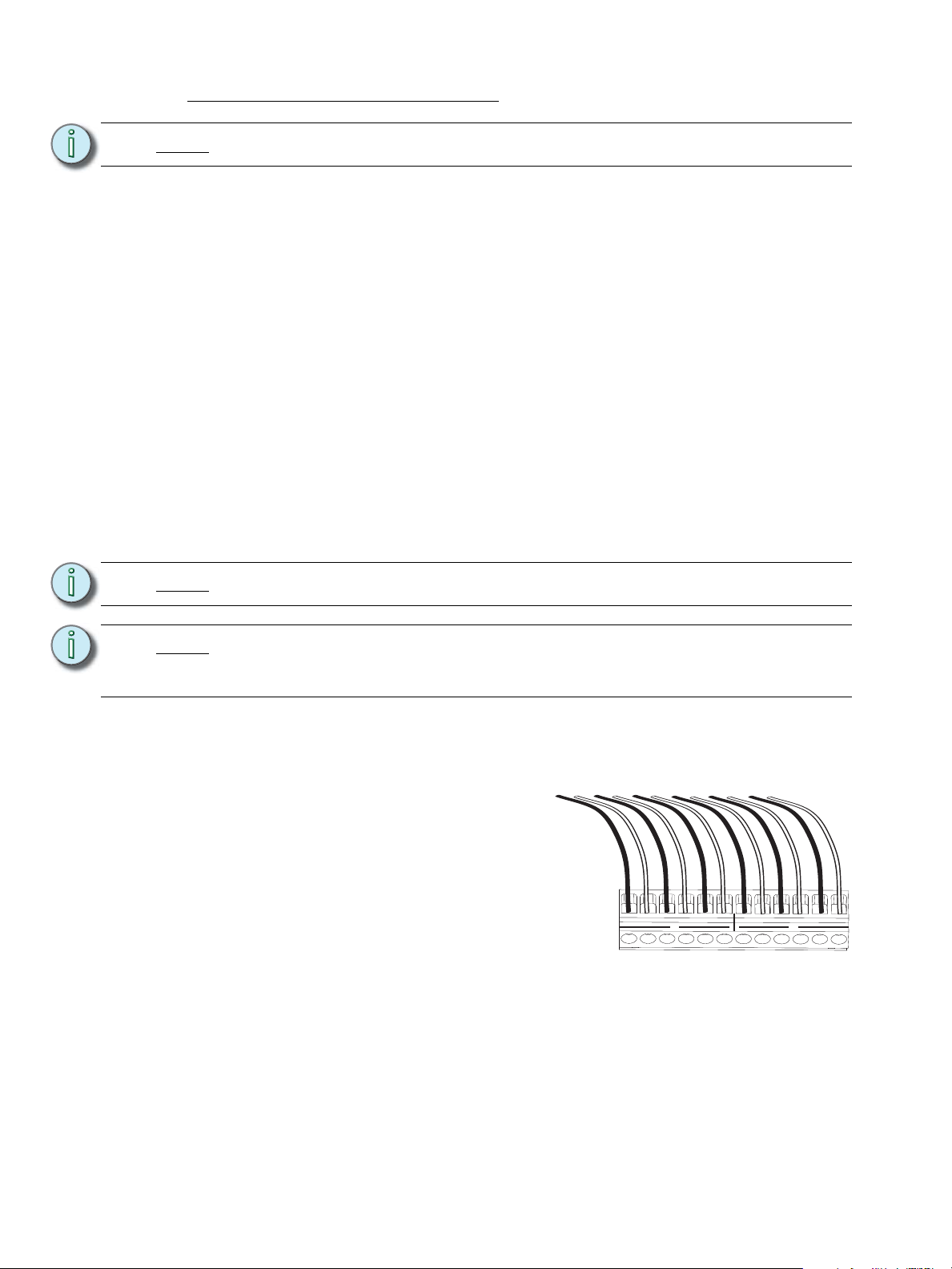

Terminate LinkConnect Control Wiring

Note:

All low voltage control cables must run in separate conduit from power wires in

accordance with local codes.

Unison control stations communicate with the Paradigm Architectural Control Processor

using the Echelon

twelve home runs of LinkPower data runs utilizing Belden 8471 cable (or its equivalent) plus

one 14 AWG (2.5mm

®

LinkPower network (LinkConnect). Termination is available for up to

2

) ESD drain wire when the data cable is not installed in grounded

metal conduit.

LinkPower wiring is topology-free and polarity independent utilizing a LinkPower network.

Wiring may be bus, star, loop, home run or any combination of these. Total combined length

of LinkPower data runs cannot exceed 1,640 feet (500m), with a maximum distance of

1,313 feet (400m) between any two communicating devices. Without a repeater, no device

may be more than 1,313 feet (400m) away from the Architectural Control Processor.

Standard interoperability requires that there should be a maximum of only one station

repeater between any two LinkConnect devices. This means that only one repeater

module, whether a Paradigm Repeater module (P-REP) or a Paradigm Dual Repeater

Module (P-DREP), may be used per Paradigm Architectural Control Processor (P-ACP).

B A B A B A B A B A B A

Note:

It is required that you terminate LinkPower station wiring and the auxiliary power

wiring to the ERn enclosure I/O board that will host the Paradigm Station Power

Module (P-SPM).

Step 1: Pull Belden 8471 (or an equal type) control wiring into the ERn enclosure through

the conduit opening previously prepared.

3 Terminate Wiring 19

Page 24

Step 2: Strip 3/16” (5mm) if insulation from the ends of each wire pair.

Step 3: Remove the LinkPower connector (labeled LON) from the right I/O board.

Step 4: Loosen the terminal screws for as many wire pairs you are terminating.

Step 5: Insert each white wire from the pairs into an “A” terminal on the connector and

tighten the screw firmly to secure the wire into the connector.

Step 6: Insert each black wire from the pairs into an “B” terminal on the connector and

tighten the screw firmly to secure the wire into the connector.

Step 7: The 14 AWG (2.5mm

2

) ground wire can terminate to the ground bus located

inside the ERn enclosure.

• If grounded metal conduit is installed a ground wire may not be required for

termination. Reference the related station installation manual for details.

Step 8: Replace the connector to the right I/O board.

Terminate Auxiliary Power

Note:

The auxiliary power connector (labeled Aux Power) provides termination for up to 20 wires

in the ten position pluggable connector. Each terminal allows up to two 16 AWG(1.5mm

2

wire and provides 24 Vdc power to Unison control stations when used with the Paradigm

ACP.

- + - + - + - + - +

It is required that you terminate LinkPower station wiring and the auxiliary power

wiring to the ERn enclosure I/O board that will host the Paradigm Station Power

Module (P-SPM).

Step 1: Pull auxiliary control power wiring (typically 16 AWG (1.5mm

2

) red / black wire

pair) into the ERn enclosure through the conduit opening previously prepared.

Step 2: Strip 3/16” (5mm) of insulation from the ends of each wire pair.

Step 3: Remove the auxiliary power connector from the right I/O board.

Step 4: Loosen the terminal screws for as many auxiliary wire pairs as you are

terminating.

Step 5: Insert the black auxiliary power wire from the pair into a “-” terminal on the

connector and tighten the screw to secure the wire into the connector.

Step 6: Insert the red auxiliary power wire from the pair into a “+” terminal on the

connectors and tighten the screw to secure the wire into the connector.

Step 7: Repeat steps 5 and 6 for all auxiliary power wires in the rack.

Step 8: Replace the connector on the right I/O board.

)

20 Unison® ERn Wall Mount Enclosure Installation Manual

Page 25

DMX Termination

B+ B- Com A+ A- Com

B+ B- Com

Ride Thru

/Batt

CDI port

LON

Full

Half

DMXADMXB

SRCOff

End

Notice the two termination switches labeled DMXA and DMXB.

Each switch has three termination positions:

• Source - reserved for RDM termination (future development).

• Off - no termination, DMX will pass through this device on to the

next DMX device in the data run.

• End - termination is on. Used if the ERn is the last DMX device

that is physically connected in the daisy chained DMX data run.

When used as a DMX output port, the termination switch should be

set to “OFF”.

Ethernet

RS-232

Contact

Outputs

Contact

Inputs

DMX requires 120 termination at the last DMX device in the control run. Since an ERn

enclosure with a Paradigm Architectural Control Processor installed can utilize up to two

DMX inputs (2 DMX runs) the right I/O board provides termination switches.

Connect ERn Left I/O Data Terminations

Ethernet

Com0

No0

Com1

No1

Outputs

In1

Gnd

In0

Gnd

RS-232

Com2

No2

Com3

No3

In3

Gnd

In2

Gnd

ts

pu

n

I

The left IO board supports the Paradigm Architectural Control Processor data terminations

including:

• RS-232 on a male 9 pin (D style) connector

• Ethernet on a RJ45 female connector

• Contact closure input terminations on a 8 pin pluggable connector.

• Terminations available for 4 inputs and 4 common wires.

• Contact closure output terminations on a 8 pin pluggable connector.

• Terminations available for 4 normally open outputs and 4 common wires.

Connect to Serial RS-232

Integrators and users of advanced systems can interface with the Unison system through

the RS-232 connection on the left I/O board. This connection provides an interface with

external devices capable of sending or receiving RS-232. This connection can also receive

serial commands from a transmitter and provide rack and system status when queried.

Note:

The RS-232 cable (not supplied) should follow common RS-232 pinout for a DB9 receptacle (pin 2 is RS-232 Rx, pin 3 is RS-232 Tx, and pin 5 is ground).

3 Terminate Wiring 21

Page 26

Connect to Ethernet RJ-45

Network interface to the ERn enclosure is made through the RJ-45 connector (labeled

Ethernet) located on the left I/O board. Use the included Network Termination Kit to

terminate the incoming building wire.

Note:

All Ethernet terminations must follow IEEE 802.3 and be terminated to the T568B

standard.

Connect to Contact Inputs and Contact Outputs

The left I/O provides interface with external devices via contact closure on removable

pluggable connectors. Up to four contact inputs are available and can be configured for

either maintained or momentary operation as set in the Paradigm Architectural Control

Processor. Up to four contact outputs are also available and are preset for normally open

operation. Reference the Paradigm Architectural Control Processor Configuration Manual

for details on configuration.

Note:

Terminate Contact Inputs

Step 1: Remove the contact inputs removable screw terminal connector located on the

Step 2: Strip 3/16” (5mm) of insulation from the ends of each wire pair.

Step 3: Loosen the desired number of contact input screw terminals and related ground

Step 4: Insert contact closure 1 into the terminal labeled “IN1” on the connector and

Step 5: Insert the related ground wire for contact closure 1 into the terminal labeled

Step 6: Repeat for each contact input and ground wire pair (up to four total).

Typical contact I/O wiring is color coded as follows: contact 1 - brown, contact 2 orange, contact 3 - yellow, contact 4 - green. All commons and ground voltages

are typically black or red.

left I/O board. Each connector is labeled for installation convenience.

screw terminals on the connector.

tighten the screw terminal.

“GND” on the connector and tighten the screw terminal.

Terminate Contact Outputs

Step 1: Remove the contact outputs removable screw terminal connector located on the

left I/O board. Each connector is labeled for installation convenience.

Step 2: Strip 3/16” (5mm) of insulation from the ends of each wire pair.

Step 3: Loosen the desired number of contact output (normal open) screw terminals and

related ground screw terminals on the connector.

Step 4: Insert contact output 1 into the terminal labeled “N.O.1” on the connector and

tighten the screw terminal.

Step 5: Insert the related common wire for contact output 1 into the terminal labeled

“COM1” on the connector and tighten the screw terminal.

Step 6: Repeat for each contact output and common wire (up to four total).

22 Unison® ERn Wall Mount Enclosure Installation Manual

Page 27

Chapter 4

Final Installation and Power Up

This chapter contains the following sections:

• Check Main Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

• Check Line Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

• Final Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4 Final Installation and Power Up 23

Page 28

Completing the Installation

ERn door removed from graphic for

clarity of rack power Supply

installation.

It’s a good idea to look over the entire installation before applying power to the enclosure.

WARNING:

• Clean out dust and debris from the enclosure interior.

• Check for loose connections, bare wires, and damaged insulation. Repair any damage

Power must be turned OFF when you perform this procedure. ETC

recommends that your facility adopts a lockout / tagout procedure to protect

your maintenance personnel during maintenance procedures.

that is discovered.

Check Main Power Wiring

Check resistance between line, neutral, and ground busses with a digital voltmeter (DVM).

• Line to ground resistance should be 10M Ohm or higher.

• Neutral to ground resistance should be 0 Ohm.

• Line to neutral resistance should be 10M Ohm or higher.

• Re-install the rack power supply into the top slot of the ERn enclosure.

Check Line Voltages

Check the voltage on your input terminals using a digital volt meter (DVM) before installing

modules.

WARNING:

• HIGH LEAKAGE CURRENT

• Ground connection is essential before connecting supply

• Disconnect power before removing modules

• Service by authorized persons only.

Step 1: Close the ERn door.

Step 2: Apply line power at the main circuit breaker for 90 seconds. Observe the

24 Unison® ERn Wall Mount Enclosure Installation Manual

Line voltages will be on the input terminals during this procedure. You must

be a qualified electrician familiar with the hazards of working with high

voltage electricity. Use extreme caution when performing this procedure.

enclosure for evidence of shorting, like arcing sounds or a burning smell. If you

detect evidence of shorting, shut off power and fix the wiring.

Page 29

Step 3: Open the ERn door and check voltage between phase, neutral, and ground. The

ERn supports input power ranging + / - 10% of the rated voltage.

• 100 VAC, (acceptable range 90-110 VAC)

• 120 VAC, (acceptable range 108-132 VAC)

• 230 VAC CE, (acceptable range 207-253 VAC)

• 240 VAC, (acceptable range 216-264 VAC)

Step 4: Turn off power at the main circuit breaker.

Final Installation

Step 1: Install the Paradigm Architectural Control Processor (P-ACP) in the appropriate

module slot.

Step 2: Install the Paradigm Station Power Module (P-SPM) in the module slot above the

Paradigm Architectural Control Processor.

Step 3: Install option modules if they are not installed. For an ERn4, you may install

either two blank modules, a Paradigm Dual Repeater Module (P-DREP) in the

top two module slots of the enclosure, or only a Paradigm Station Repeater

module (P-REP) in the top module slot with a blank module below.

Step 4: Install either the ERn blank option module, the ERn ethernet switch Module

(ERn-NET), or the Redundant Power Supply (ERn-RPS) in the lower option

module slot.

a: If installing the ERn ethernet switch Module (ERn-NET) or the Redundant

Rack Power Supply (ERn-RPS) module in the option module slot, be certain

you have completed the installation requirements. See “Install Rack Options”

on page 26.

Note:

Step 5: Install blank module (ERn-BM) in any unused module slot in the enclosure to

Neither the Redundant Power Supply (ERn-RPS) nor the Ethernet Switch module

(ERn-NET) are supported in an ERn4 enclosure at 230 VAC. Instead, an ERn4 at

230 VAC is shipped from the factory with a rack power supply installed in the top

(normal) position and in the lower option module slot as standard.

maintain the required convection cooling requirements.

4 Final Installation and Power Up 25

Page 30

Chapter 5

Install Rack Options

This chapter contains the following sections:

• Install the RideThru Option (URTO) Kit . . . . . . . . . . . . . . . . .27

• Install the BatteryPack Option (UBPO) Kit . . . . . . . . . . . . . .29

• Install a Paradigm Repeater or Dual Repeater Module . . . .31

• Install Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . .35

• Install the Ethernet Switch Module . . . . . . . . . . . . . . . . . . . .36

26 Unison® ERn Wall Mount Enclosure Installation Manual

Page 31

Rack Options

2008

Unison ERn options include the RideThru Option (URTO) kit, BatteryPack Option kit

(UBPO), Ethernet Switch Module (ERn-NET), and the Redundant Rack Power Supply

(ERn-RPS).

Additionally you may use a Station Repeater Module in the ERn4 enclosure top module slot

instead of a secondary Paradigm Station Power Module. See “Install a Paradigm Repeater

or Dual Repeater Module” on page 31.

Install the RideThru Option (URTO) Kit

WARNING:

Note:

The RideThru Option kit (URTO) provides power to the Paradigm Architectural Control

Processor for a minimum of 12 seconds during brief power outages or power drop outs. The

Ride Through option board fully charges and is ready for operation within ten minutes of the

ERn enclosure being powered.

Risk of Electric Shock! The Unison RideThru Option board retains an

electrical charge even when power to the ERn enclosure is off.

A single ERn enclosure supports the use of either the Unison RideThru Option

(URTO) or the Unison BatteryPack Option (UBPO), but not both in the same

enclosure.

Note:

One Unison RideThru Option board powers one Paradigm ACP. therefore an

ERn4 enclosure with two Paradigm ACPs installed requires two RideThru Option

boards.

5 Install Rack Options 27

Page 32

Step 1: Remove modules from the ERn enclosure for RideThru Option board installation

2008

Step 1:

access.

• For an ERn2, remove only the bottom option module from the rack

enclosure.

• For an ERn4 with two Paradigm ACPs, remove the bottom option module

and the rack power Supply from the rack enclosure.

Step 2: Align the RideThru Option board to the mounting studs in the right corner of the

ERn enclosure (see graphic on the previous page).

• Notice the mounting holes on the option board. Two are open ended slots

used to set the board in place and the remaining two standard mounting

holes are used to secure the board in place.

• Align the open ended slots to the studs located closest to the bottom of the

rack.

Step 3: Secure the board to the top two mounting pems with the screws provided.

Connect RideThru Option Wiring

The Unison RideThru Option board is provided with a wiring harness for connection to the

ERn enclosure right I/O board.

Step 1: Connect one end of the wiring harness to the two pin receptacle on the option

board.

Step 2: Connect the other end of the wiring harness to the two pin receptacle labeled

“RideThru / Batt” on the ERn enclosure right I/O board. When two RideThru

Option boards are installed (ERn4 only), the top RideThru Option wiring harness

terminates to the I/O board in the top and the bottom RideThru Option wiring

harness terminate to the I/O board in the bottom of the unit.

Step 3: Secure the wiring harness to the ERn enclosure using the cable tie and cable tie

mount provided in with the RideThru Option board. A loose or poorly routed

wiring harness could interfere with option module installation in the lower option

module slot. In the top module slot the wiring harness could interfere with the

rack power supply (ERn-PS).

28 Unison® ERn Wall Mount Enclosure Installation Manual

Page 33

Install the BatteryPack Option (UBPO) Kit

The BatteryPack Option (UBPO) kit provides battery

power during power outages to the Paradigm

Architectural Control Processor for up to 90 minutes (ERn

with a single P-ACP) or up to 45 minutes (ERn4 with two

Paradigm ACPs). The self-contained battery installs on

the bottom of the ERn enclosure.

ERn after UBPO cable and

connector installation

a: Insert the connector end through the opening in the

bottom of the ERn enclosure. The connector is designed

to snap into place without additional hardware, slight

force may be required to ensure the connector installs

properly.

b: Connect the two pin connector to the appropriate

receptacle labeled “Ride Thru / Batt” on the

ERn right I/O board. See “Connect ERn Right I/O Data

Terminations” on page 18.

Note:

Note:

An ERn enclosure supports the use of either the Unison RideThru Option (URTO)

or the Unison BatteryPack Option (UBPO), but not both in the same enclosure.

The BatteryPack Option kit is intended for use only in wall mount ERn enclosures

and is not compatible with rack mounted enclosures.

Step 1: The BatteryPack Option board is provided with a wiring harness for connection

between the BatteryPack and the right I/O board. Install the Unison BatteryPack

Option cable harness and connector into the ERn enclosure.

5 Install Rack Options 29

Page 34

Step 2: Install the Unison BatteryPack on to the bottom of the ERn enclosure as pictured

see note after 2a:

Step 2a:

Step 2b:

below.

a: Insert the tabs from the UBPO into the slots in the ERn enclosure.

Note:

As the BatteryPack is mated to the rack, the connector on the BatteryPack and the

connector receptacle installed in step 1a also mate.

b: Secure the UBPO to the ERn enclosure using the screw provided.

30 Unison® ERn Wall Mount Enclosure Installation Manual

Page 35

Install a Paradigm Repeater or Dual Repeater Module

Blank (Air flow) module (ERn-BM)

Paradigm Station Repeater module (P-REP)

Paradigm Station Power Module (P-SPM)

Paradigm Architectural Control

Processor (P-ACP)

Paradigm Dual Station Repeater module (P-DREP

Paradigm Station Power Module (P-SPM)

Paradigm Architectural Control Processor (PACP)

Both repeater module types may only be utilized in the top module slots of the ERn4 rack

enclosure.

The Paradigm Station Repeater (P-REP) module extends the system station bus length by

1,640 feet (500m) and adds support for up to 30 additional stations.

The Paradigm Dual Station Repeater (P-DREP) module extends the system station bus

length 3,280 feet (1,000m) through two separate topology-free Echelon segments (each

supporting 1,640 feet (500m) of additional LinkPower station wire each) and adds support

for up to 30 additional stations.

The following table lists the recommended control wire types used in a typical Unison

installation and the maximum wire runs allowed.

Ethernet

(Cat5 /Belden

1583a)

Purpose

Total length of control wire

(without repeater module)

Maximum wire length (ERn

to station)

Maximum repeater distance

Link Power

(Belden 8471)

Feet Meter Feet Meter Feet Meter

1640 500 1600 487 328 100

1313 400 1600 487 N/A N/A

1640 500 N/A N/A N/A N/A

DMX (Belden

9729)

5 Install Rack Options 31

Page 36

Terminate LinkConnect Control Wiring

B A B A B A B A B A B A

1 2

Note:

Note:

Wire tie down locations provided on rear panel.

Unison control stations communicate with the Paradigm Architectural Control Processor

using the Echelon LinkPower network (LinkConnect). LinkConnect is based on Echelon

LonWorks

®

with LinkPower bidirectional protocol, and uses one pair of wires (data+ and

®

data-).

Termination is available for up to twelve home runs of LinkPower data runs utilizing Belden

8471 cable (or approved equal) plus one 14 AWG ESD drain wire when the data cable is

not installed in grounded metal conduit.

LinkPower wiring is topology-free and polarity independent. Wiring may be any combination

of bus, star, loop, and home run. The total combined length of LinkPower wire run cannot

exceed 1,640 feet (500m), with a maximum distance of 1,313 feet (400m) between any two

communicating devices. Without a repeater, no device may be more than 1,313 feet (400m)

away from the Architectural Control Processor.

Standard interoperability requires that there should be a maximum of only one station

repeater between any two LinkConnect devices. This means that only one Repeater

Module, whether a Paradigm Station Repeater Module (P-REP) or a Paradigm Dual Station

Repeater Module (P-DREP), may be used per Paradigm Architectural Control Processor

(P-ACP). Each individual topology-free LonWorks network can have no more than 62 LON

stations with a repeater, Station Power Module,and Paradigm Architectural Control

Processor.

All low voltage control cables must run in separate conduit from power wires.

Note:

When utilizing a Paradigm Station Repeater module (P-REP) or Paradigm dual

station repeater module (P-DREP), terminate the affected LON segment(s) and

associated auxiliary power wiring to the top right I/O board in the ERn4 enclosure.

Step 1: Pull Belden 8471 (or approved equal) control wiring into the ERn4 enclosure

through the conduit opening previously prepared.

Step 2: Strip 3/16” (5mm) of insulation from the ends of each wire pair.

Step 3: Remove the LinkPower connector

(labeled LON) from the top right I/O

board.

• Notice the LinkPower connector

is labeled to indicate that the

connector is split between two

segments, allowing six station

wire home runs per segment.

This is effective only when a

Paradigm Dual Station Repeater

module (P-DREP) is used. With the standard Paradigm Station Repeater

module (P-REP) you may connect up to twelve station home runs connect to

the single control segment.

32 Unison® ERn Wall Mount Enclosure Installation Manual

Page 37

Step 4: Loosen the terminal screws for as many wire pairs you are terminating. Keep in

mind that the connector is split into two segments when used with a Dual

Repeater Module. Be sure to terminate each wire pair to the correct segment.

Step 5: Insert each white (typical) wire from the pairs into an “A” terminal on the

connector and tighten the screw firmly to secure the wire into the connector.

Step 6: Insert each black (typical) wire from the pairs into an “B” terminal on the

connector and tighten the screw firmly to secure the wire into the connector.

Step 7: The 14 AWG ground wire can terminate to the ground bus located inside the ERn

enclosure.

• If grounded metal conduit is installed a ground wire may not be required for

termination. Reference the related station installation manual for details.

Step 8: Replace the connector on the top right I/O board.

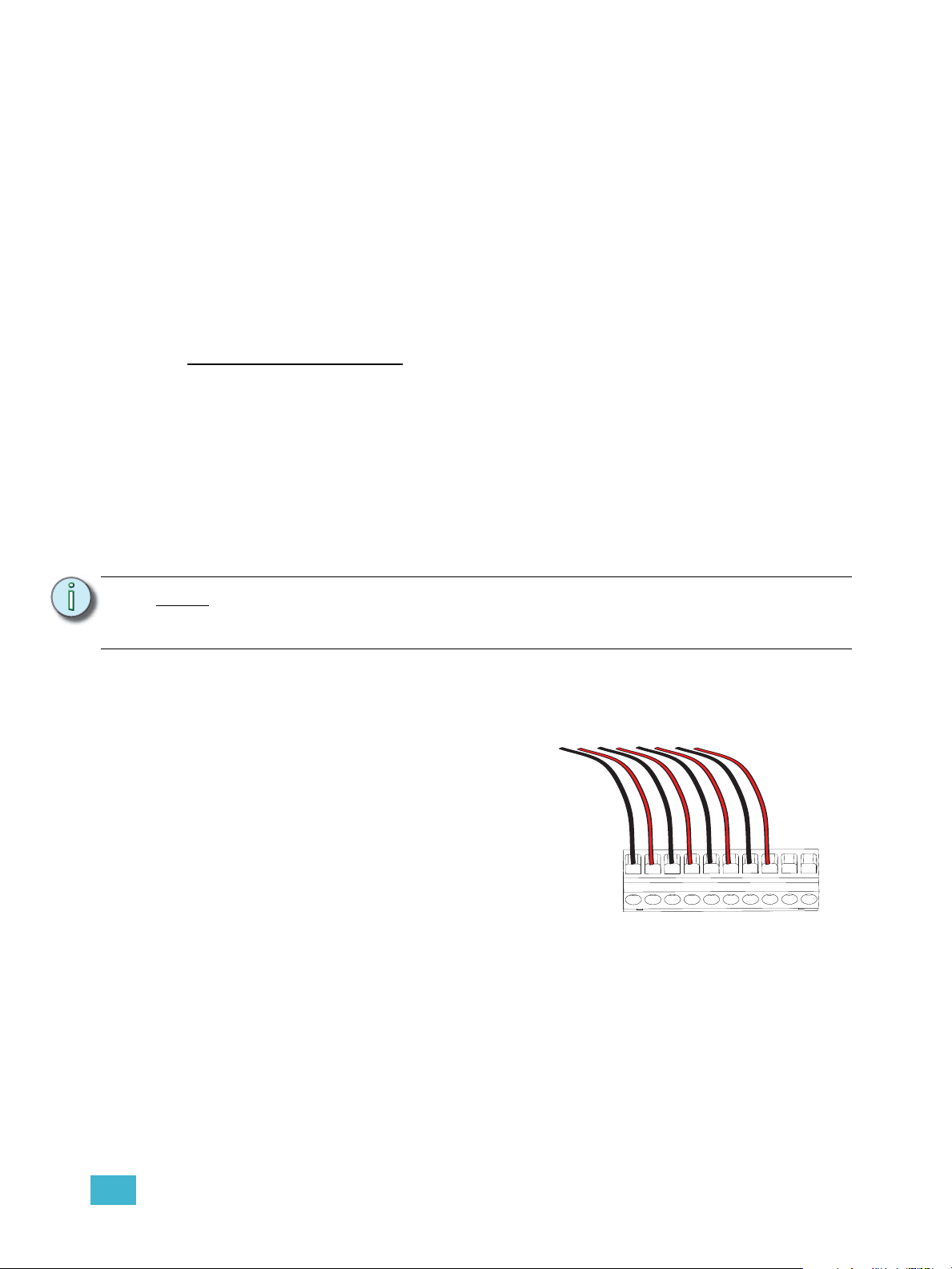

Terminate Auxiliary Power

Note:

Auxiliary power is required when you are installing powered Unison control stations. ETC

recommends using two 16 AWG (1.5mm

2

) stranded wires for 24 Vdc auxiliary power to the

control station(s). Auxiliary power is topology-free. Maximum auxiliary voltage runs are

dependant by the wire gauge and the distribution of auxiliary load determined by

installation. The auxiliary supply is capable is of powering up to four Paradigm Touchscreen

Stations and 28 interface stations.

The auxiliary power connector (labeled Aux Power) provides termination for up to 20 wires

in the ten position pluggable connector. Each terminal allows up to two 16 AWG(1.5mm

2

wire and provides 24 Vdc power to Unison control stations when used with the Paradigm

ACP.

When utilizing a Paradigm Station Repeater Module (P-REP) or Paradigm Dual

Station Repeater Module (P-DREP) in an ERn4 rack, terminate the repeated LON

segment(s) and auxiliary power wiring to the top right I/O board.

Step 1: Pull auxiliary control power wiring (typically 16 AWG (1.5mm

2

) red / black wire

pair) into the ERn enclosure through the conduit opening previously prepared.

Step 2: Strip 3/16” (5mm) of insulation from the ends of each wire pair.

Step 3: Remove the auxiliary power

connector from the right I/O board.

Step 4: Loosen the terminal screws for as

many auxiliary wire pairs as you are

terminating.

Step 5: Insert the black (typical) auxiliary

power wire from the pair into a “-”

terminal on the connector and

- + - + - + - + - +

tighten the screw to secure the wire

into the connector.

Step 6: Insert the red (typical) auxiliary power wire from the pair into a “+” terminal on the

connector and tighten the screw to secure the wire into the connector.

Step 7: Repeat steps 5 and 6 for each auxiliary power wire in the enclosure.

Step 8: Replace the connector on the right I/O board.

)

5 Install Rack Options 33

Page 38

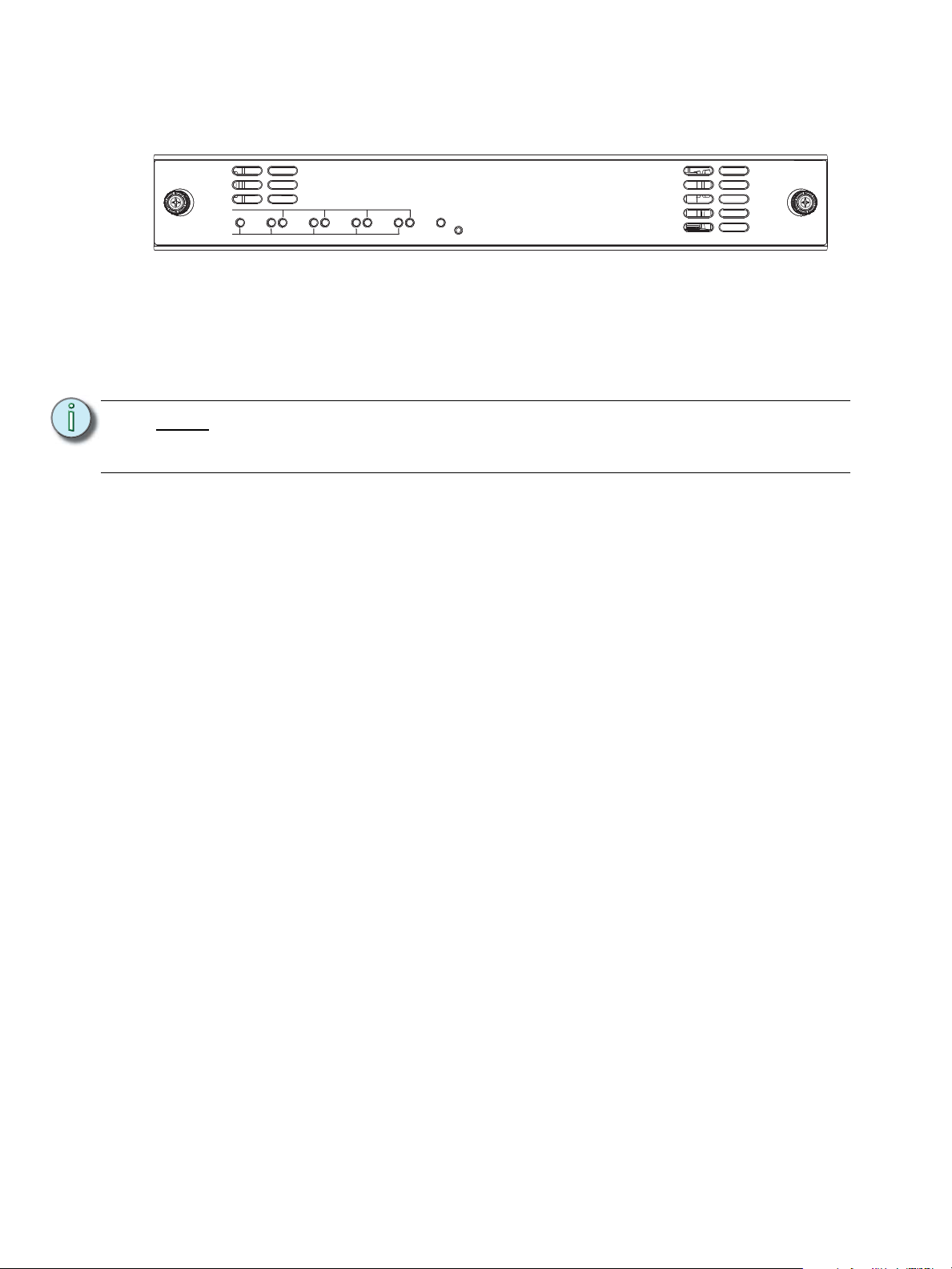

Status Indicators

When power is applied to the ERn enclosure, the Paradigm Station Repeater Module LEDs

located on the front panel illuminate, indicating the status of the auxiliary power, LinkPower

control network, and connected stations.

The Aux Power and LinkPower LEDs indicate in green when the Paradigm Station Power

Module is connected properly and auxiliary power and LinkPower are present. When there

is an unbalance in LinkPower the fault indicators illuminate. This condition typically means

that the station wiring has a fault, however it could mean a connected device is having an

issue. A qualified technician should inspect the system wire and terminations first, then

proceed to disconnecting devices to pinpoint the fault and correct it. The power supply will

update the fault indicators automatically when the fault condition is cleared.

• If the NET A line has a fault (is shorted or has leakage to ground), the Fault + LED

lights.

• If the NET B line has a fault (is shorted or has leakage to ground), the Fault - LED lights.

• If neither fault LED is illuminated the data connections are properly installed and the

stations are receiving the data and power required for operation.

34 Unison® ERn Wall Mount Enclosure Installation Manual

Page 39

Install Redundant Power Supply

Install the Redundant Rack Power Supply in the bottom

option slot of the ERn enclosure and secure it in place

with the two captured screws.

The ERn Redundant Power Supply (ERn-RPS) is an additional rack power supply that

powers the ERn enclosure if the primary rack power supply is removed or fails.

Note:

The Redundant Power Supply (ERn-RPS) is not supported in an ERn4 rack

enclosure at 230 VAC. Instead, the ERn4 rack at 230 VAC requires two rack

power supplies installed in the top (normal) position and in the lower rack option

module slot as standard.

Status Indicator

When the Redundant Power Supply is installed properly, and power is applied to the ERn

enclosure, the LED will indicate in green if the supply is powered. If the LED is off but the

primary rack supply status indicator is on, the Redundant Power Supply requires servicing.

Alternatively, if the primary rack supply status LED is off, but the Redundant Power Supply

is on, the primary rack supply requires service. Contact ETC Technical Services for

assistance. See “Contacting ETC” on page 4.

5 Install Rack Options 35

Page 40

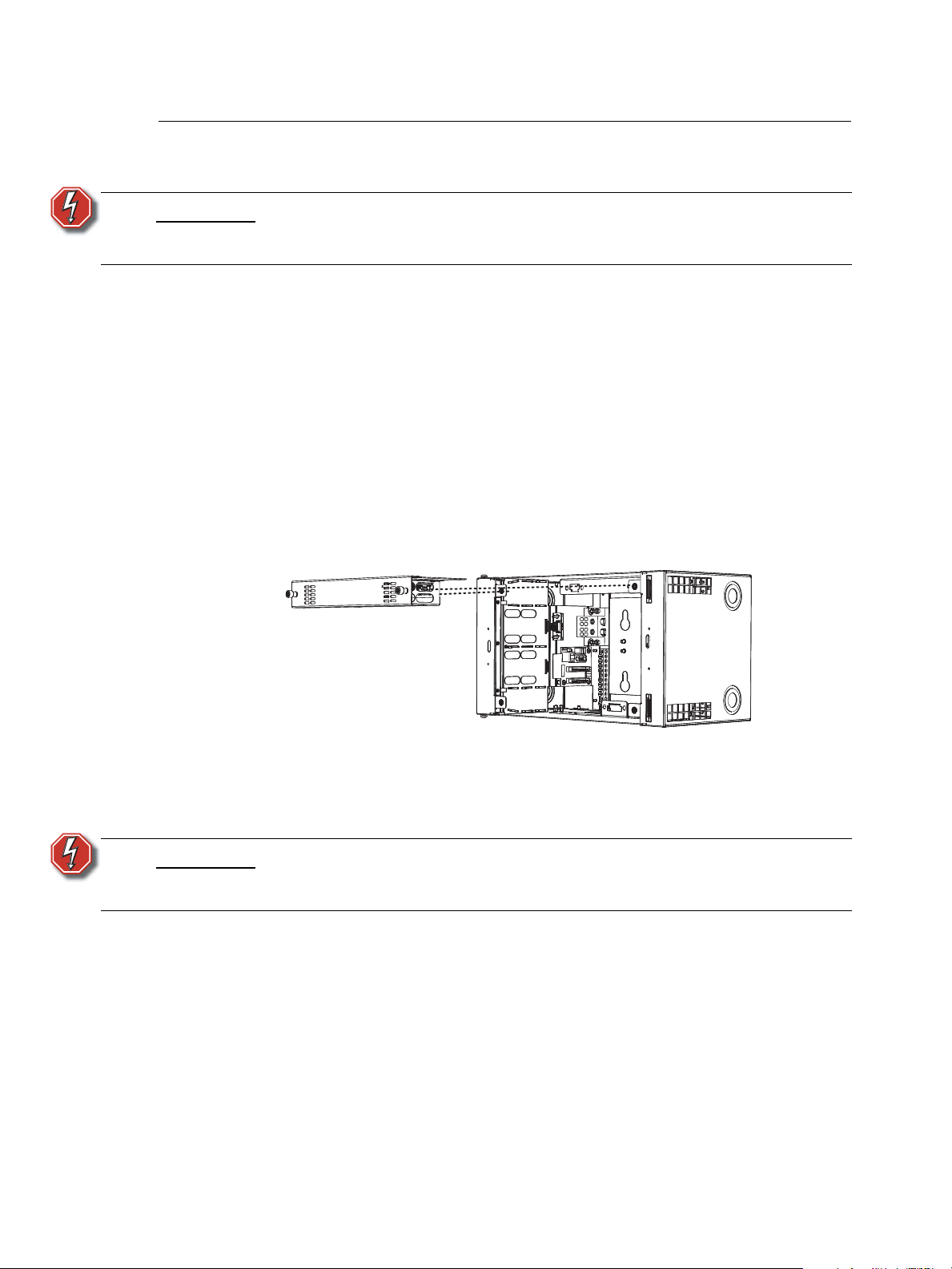

Install the Ethernet Switch Module

Switch

module

patch panel

Ethernet Switch

panel

Step 1:

Step 2:

The ERn Ethernet Switch Module installs in the bottom option module tray of the ERn

enclsoure, replacing the blank module that ships with the rack from the factory. The bottom

option slot is the only position for the Ethernet Switch Module.

Note:

Note:

The ERn Ethernet Switch module (ERn-NET) is not supported in an ERn4

enclosure at 230 VAC, nor is it compatible with a rack mounted ERn enclosure.

An ERn Ethernet Switch (ERn-NET) provides five ports of Power over Ethernet (PoE). The

kit includes , a Switch module patch panel, Ethernet Switch panel, and five patch cables.

The ERn-NET option is intended for use only in wall mount ERn enclosures and

is not compatible with rack mounted enclosures.

The Ethernet patch panel includes four punch down terminal blocks that accept CAT5e

wire. Building wire enters the ERn enclosure and terminates to this patch panel. For each

Ethernet data run, an Ethernet patch cable is provided to connect between the Ethernet

patch panel and the Ethernet Switch panel.

Step 1: Install the Ethernet patch panel to the mounting studs on the rear panel of the

ERn enclosure using the hardware provided.

Step 2: Install the Ethernet Switch panel to the mounting studs on the bottom panel of

the ERn enclosure using the hardware provided. Be sure to install the panel with

the card edge receptacle facing the front of the ERn enclosure.

36 Unison® ERn Wall Mount Enclosure Installation Manual

Page 41

Connect CAT5e Wiring

As needed, press here gently

with screwdriver to release

connector from panel.

Note:

All Ethernet terminations must follow IEEE 802.3 and be terminated to the T568B

standard.

Step 1: Pull your CAT5e building wire through the conduit access previously prepared.

Step 2: The punch down connector provides insulation displacement therefore stripping

of wire is not required. Reference the connector label for the color code for Cat5e

wire using the 568B standard.

Note:

Use a 110 punch down tool to complete the wire termination.

Step 3: Install the protective covers over the wire terminals.

Step 4: Install the punch down connector on the patch panel.

Step 5: Connect Ethernet patch cables.

a: Connect a patch cable from the left I/O to the first RJ-45 input on the Ethernet

Switch panel.

b: Connect a patch cable from the punch down connector to an RJ-45 input on

the switch panel. Repeat for each building service connection (up to four).

Step 6: Install the Ethernet Switch Module into the enclosure and secure it in place using

the captured screws provided.

5 Install Rack Options 37

Page 42

Status Indicators

PoE

Power

LINK/ACT

1

234

5

When power is applied to the ERn enclosure, the Paradigm Ethernet Switch Module LEDs, located

on the front panel, indicate main power, data, and PoE power status.

• The power LED is blue and will illuminate when the Ethernet Switch is powered.

• The LINK/ACT and PoE power LEDs are typical of an Ethernet Switch.

• The Link/Act indicator is green and is on if there is a device connected to that port. A

blinking LED indicates data activity on the port.

• The PoE indicator is yellow and will be on if the Ethernet Switch is supplying power to

the device connected to that port. A blinking PoE LED indicates a powering error on

that port.

Note:

Port one does not have a port power indicator as it does not supply power. Port

one is always connected to the Paradigm Architectural Control Processor which

is powered by the ERn enclosure power supply.

38 Unison® ERn Wall Mount Enclosure Installation Manual

Page 43

5 Install Rack Options 39

Page 44

Corporate Headquarters

London, UK

Rome, IT

Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Pieve Torina, 48, 00156 Rome, Italy Tel +39 (06) 32 111 683 Fax +44 (0) 20 8752 8486

Holzkirchen, DE

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Hong Kong Rm 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

(Americas) service@etcconnect.com

Web:

www.etcconnect.com

7180M2100

Rev B Released 2012-10 ETC intends this document, whether printed or electronic, to be provided in its entirety.

Copyright © 2012 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

(Asia) service@etcasia.com

Loading...

Loading...