Page 1

DRd Enclosure

Installation Manual

Revision D

Copyright © 2014 Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

7183M2100

Released: 2014-07

Rev D

Page 2

ETC®, Unison Paradigm®, Echo™, and SmartLink® are either registered trademarks or trademarks of Electronic

Theatre Controls, Inc. in the United States and other countries. All other trademarks, both marked and not

marked, are the property of their respective owners.

ETC intends this document, whether printed or electronic, to be provided in its entirety.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warnings and Notice Conventions . . . . . . . . . . . . . . . . . . . . . . .2

Contacting ETC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chapter 1

Chapter 2

Prepare for Installation . . . . . . . . . . . . . . . . . 5

Unpack and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Main Circuit Breaker Protection . . . . . . . . . . . . . . . . . . . . . . . . . .5

Using 90° Copper Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Maximum Current Draw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Short Circuit Current Rating (SCCR) . . . . . . . . . . . . . . . . . . .6

Where to Install the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation Environment Requirements . . . . . . . . . . . . . . . . . . . .8

Wire Routing and Specification . . . . . . . . . . . . . . . . . . . . . . . . . .8

Control Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Control Wire Specification . . . . . . . . . . . . . . . . . . . . . . . . . .10

Install Enclosures . . . . . . . . . . . . . . . . . . . . 12

Mounting Individual DRd Enclosures . . . . . . . . . . . . . . . . . . . . . . . .13

Mounting Individual Enclosures on a Wall . . . . . . . . . . . . . . . . .13

Mounting a DRd Enclosure on a Pedestal . . . . . . . . . . . . . . . . . . . .14

Mounting Auxiliary and DRd Enclosures Together. . . . . . . . . . . . . .15

Chapter 3

Chapter 4

Table of Contents i

Rough-in Conduit and Wiring . . . . . . . . . . . 17

Prepare the DRd Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Remove the DRd Power Supply/Dimming Engine Access Panel .

18

Modify Phase Bus for 120V AC Split Phase Operation . . . . . . .19

Rough-in Conduit to the DRd Enclosure . . . . . . . . . . . . . . . . . . . . .21

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Terminate Wiring. . . . . . . . . . . . . . . . . . . . . 24

Connect Line Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Connect Line Feed in an Individual DRd Installation . . . . . . . . .25

100, 120, 127 V AC, 3Ø DRd Enclosures. . . . . . . . . . . . . . .26

230V AC Neutral Disconnect DRd Enclosures . . . . . . . . . . .27

Page 4

240, 277V AC DRd Enclosures . . . . . . . . . . . . . . . . . . . . . .27

Connect Load Wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Fluorescent Load Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3-wire Fluorescent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2-wire Fluorescent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Connect Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

DRd Right I/O Data Terminations . . . . . . . . . . . . . . . . . . . . . . .34

Auxiliary Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

LinkConnect and EchoConnect Control Wiring . . . . . . . . . .35

UL 924 Listed Panic Input. . . . . . . . . . . . . . . . . . . . . . . . . . .35

DMX Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

AX12X Cross-bussed Interconnection . . . . . . . . . . . . . . . . .36

Terminate the Unison Options (URTO and UBPO) . . . . . . .37

Terminate DMX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

DRd Left I/O Data Termination . . . . . . . . . . . . . . . . . . . . . . . . .38

Connect to Serial RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Connect to Ethernet RJ-45 . . . . . . . . . . . . . . . . . . . . . . . . . .38

Connect to Contact Inputs and Contact Outputs . . . . . . . . .39

Chapter 5

Chapter 6

Appendix A

Install Option Kits . . . . . . . . . . . . . . . . . . . . 40

Installation of Option Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

DALI Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Install the DALI Option kit . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Connect DALI Option Wiring. . . . . . . . . . . . . . . . . . . . . . . . .43

0-10V Control Option Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Connect 0-10V Control Option Wiring . . . . . . . . . . . . . . . . .45

RideThru Option Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Install the RideThru Option Kit . . . . . . . . . . . . . . . . . . . . . . .46

Connect RideThru Option Wiring . . . . . . . . . . . . . . . . . . . . .47

BatteryPack Option Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Install the BatteryPack Option Kit . . . . . . . . . . . . . . . . . . . . .47

Final Installation and Power Up . . . . . . . . . 50

Checking the Installation before Installing Modules . . . . . . . . . . . . .51

Sealing Air Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Final Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Control Bypass (Test Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Reengage Module Retention Bar . . . . . . . . . . . . . . . . . . . . . . .55

Modules Specification. . . . . . . . . . . . . . . . . 57

Appendix B

ii DRd Enclosure Installation Manual

CE 230V Emergency Modules . . . . . . . . . . 61

About Emergency Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Wire Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Non Neutral Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Neutral Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Page 5

Introduction

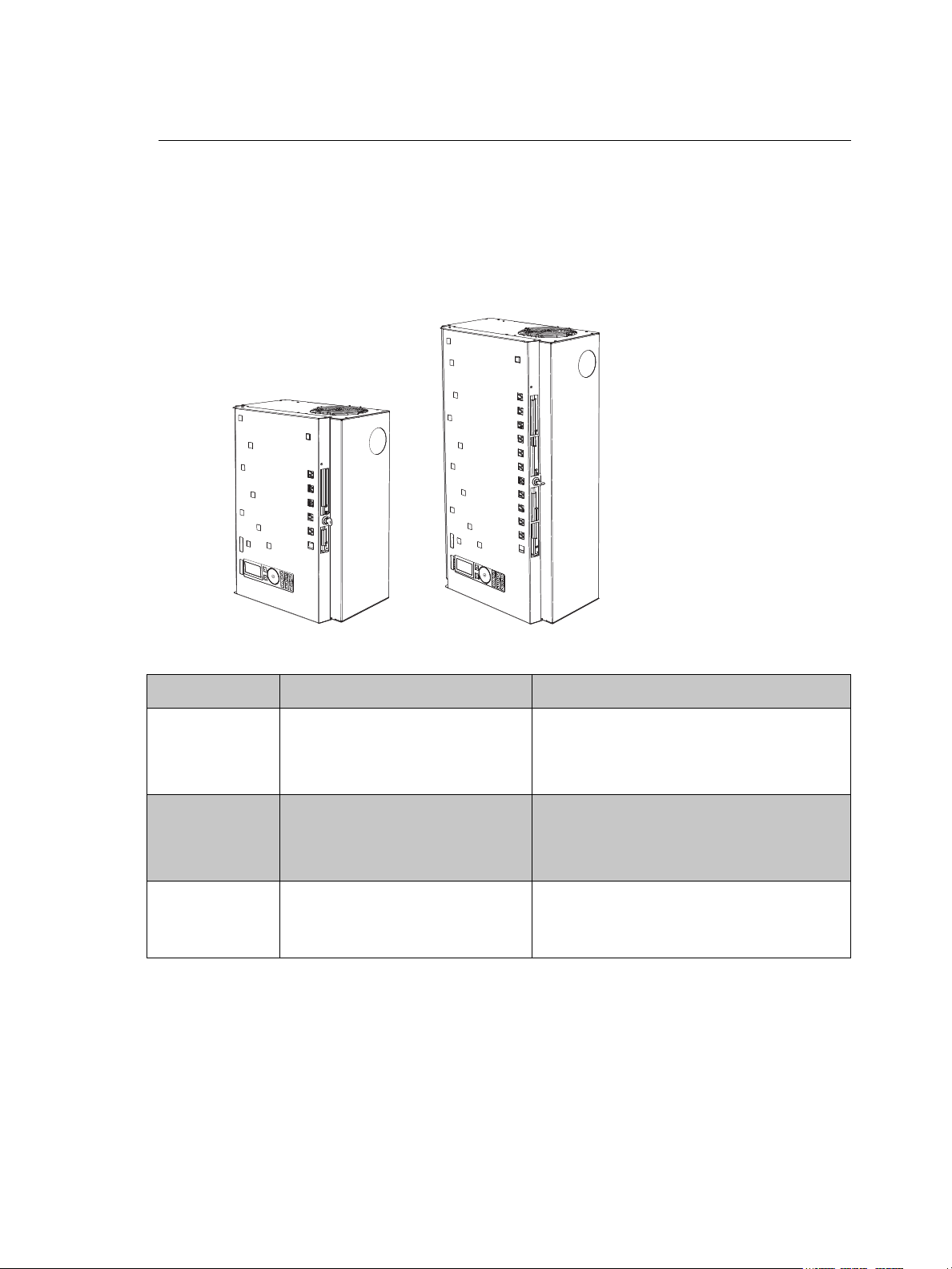

DRd6

DRd12

Welcome to the installation manual for Unison® DRd enclosures. This manual contains the

procedures for safe and efficient installation of your DRd enclosure and related

terminations.

Use this manual in conjunction with the Unison Auxiliary Enclosure Installation Manual

when your DRd is to be installed with an adjoining auxiliary enclosure.

DRd Series Enclosures

Series Voltage Notes

DRd6-12-120

DRd6-12-240

DRd6-12-230

DRd6-12-277

DRd12-24-120

DRd12-24-240

DRd12-24-230

DRd12-24-277

DRd12-48-120

DRd12-48-240

DRd12-48-277

120/208 V AC

240/415 V AC

230/400 V AC CE Neutral Disconnect

277/480 V AC

120/208 V AC

240/415 V AC

230/400 V AC CE Neutral Disconnect

277/480 V AC

120/208 V AC

240/415 V AC

277/480 V AC

6 module enclosure for up to 12 circuits.

12 module enclosure for up to 24 circuits.

Two 12 module enclosures for up to 48 circuits.

DRd12-48 enclosures are cross-bussed using

the AX12X series main lug or main breaker

enclosure.

Introduction 1

Page 6

Warnings and Notice Conventions

These symbols are used throughout this installation manual to alert you to danger or

important information:

Note:

CAUTION:

Notes are helpful hints or information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss, or an equipment

problem.

WARNING:

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an

action.

WARNING:

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of death by electric shock.

Contacting ETC

For questions about Unison system delivery, contact ETC Systems Group. For general

information, your most convenient resources are the references provided in this manual. To

search more widely try the ETC web site at www.etcconnect.com.

For technical questions about Unison systems, contact ETC Technical Services directly at

one of the offices listed below. Emergency service is available from all ETC offices outside

of normal business hours. When calling for assistance, please have the following

information handy:

• Your location and job name.

• A complete list of ETC equipment.

• A complete list of other installed products and components connected to the system

you are troubleshooting.

• DMX control source, if any.

Americas

ETC International

Technical Services Department

3031 Pleasant View Road

Middleton, WI 53562

800-775-4382 (USA, toll-free)

+1-608 831-4116

service@etcconnect.com

Asia

ETC Asia, Ltd.

Technical Services Department

Room 1801, 18/F, Tower 1, Phase 1

Enterprise Square

9 Sheung Yuet Road

Kowloon Bay, Kowloon, Hong Kong

+852 2799 1220

service@etcasia.com

United Kingdom

Electronic Theatre Controls, Ltd.

Technical Services Department

26 - 28 Victoria Industrial Estate

Victoria Road,

London W3 6UU, UK

+44 (0)20 8896 1000

service@etceurope.com

Germany

Electronic Theatre Controls, GmbH

Technical Services Department

Ohmstrasse 3

93607, Holzkirchen, Germany

+49 (80 24) 47 00-0

techserv-hoki@etcconnect.com

Please email comments about this manual to: TechComm@etcconnect.com

2 DRd Enclosure Installation Manual

Page 7

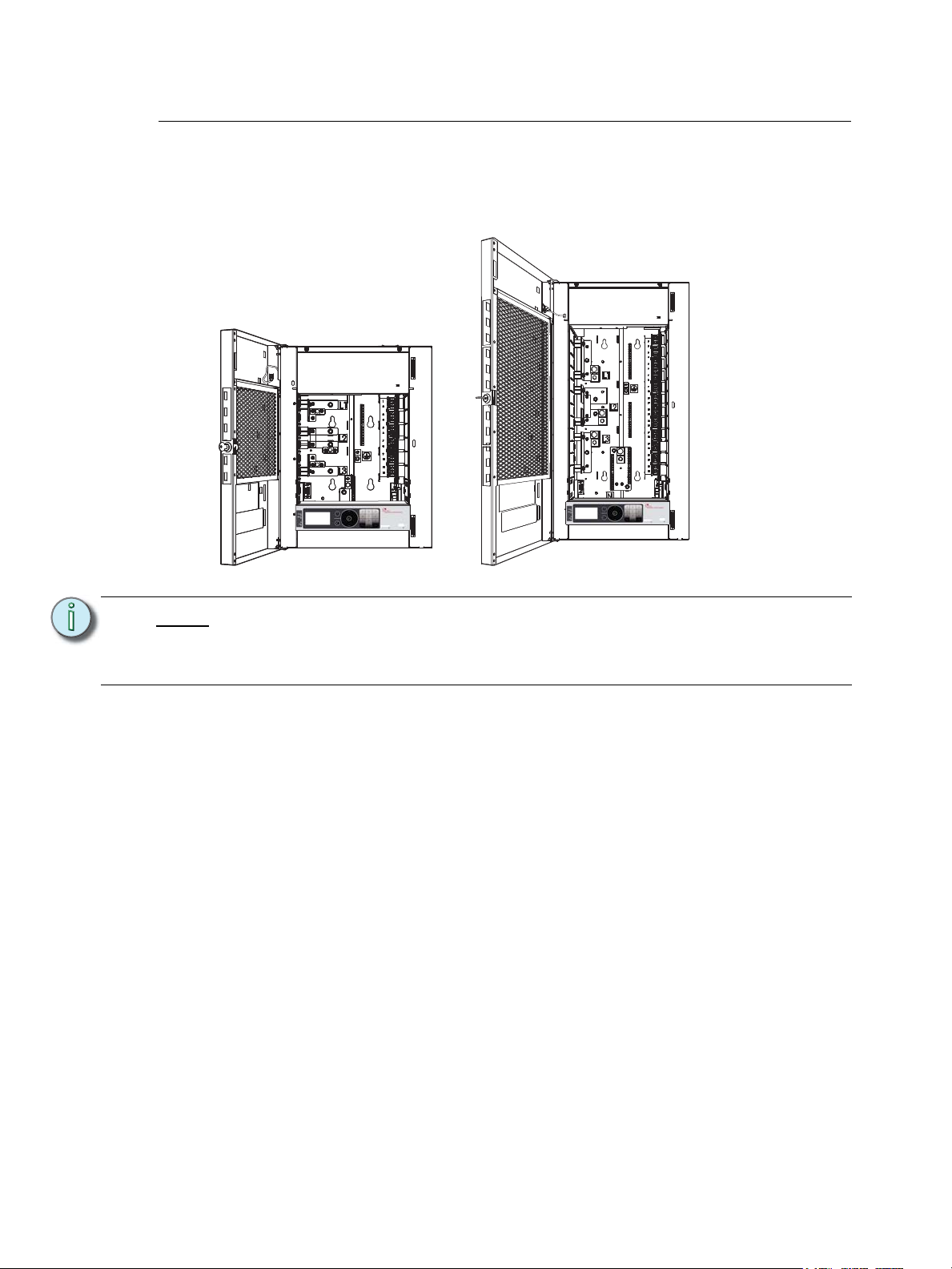

Overview

DRd6

DRd12

Unison DRd enclosures are available in 6 or 12 module enclosures and are available for an

input voltage range of 85-300 V AC, 47-63 Hz. Enclosures are pre-wired and supplied with

three phase, 4 wire and ground, main lugs which are easily converted for split phase, 3 wire

and ground, operation without the need for additional materials.

Note:

DRd enclosures are available in 12, 24 and 48 circuit configurations.

In 48-circuit configurations, two DRd12-24 enclosures are cross-bussed to an

AX12X series main lug or main circuit breaker auxiliary enclosure. A single

Architectural Control Processor (Echo, Paradigm, or SmartLink ACP) provides

control for both enclosures.

DRd enclosures are supplied pre-wired for the specified voltage for your installation. All

enclosures operate at specified voltages within a frequency range of 47-63 Hz. Phases

within the enclosure may be bused together provided the maximum supplied current does

not exceed that of a three phase connection.

• 100 / 200 V AC, 47-63 Hz, 1Ø

• 100 / 173 V AC, 47-63 Hz, 3Ø

• 120 / 208 V AC, 47-63 Hz, 3Ø

• 120 / 240 V AC, 47-63 Hz, 1Ø

• 127 / 220 V AC, 47-63 Hz, 3Ø

• 230 / 400 V AC, 47-63 Hz, 3Ø CE with Neutral Disconnect

• 240 / 415 V AC, 47-63 Hz, 3Ø

• 277 / 480 V AC, 47-63 Hz, 3Ø

• Supports universal dimmer modules, fluorescent dimmer modules, constant circuit

breaker modules, relay modules, and reverse phase dimmer modules. Reference

“Modules Specification” , page 57 for a complete list of compatible modules.

• The DRd is controlled from either the Echo

(E-ACP), SmartLink

Architectural Control Processor (P-ACP).

®

Architectural Control Processor (S-ACP) or the Paradigm™

®

Architectural Control Processor

Introduction 3

Page 8

• The use of a station power module provides power and control for architectural control

stations.

• Use an Echo Station Power Module (E-SPM) to provide power for up to 16 Echo

control stations when used with the Echo ACP.

• Use a SmartLink Station Power Module (S-SPM) to provide power for up to 16

SmartLink control stations when used with the SmartLink ACP.

• Use a Paradigm Station Power Module (P-SPM) to provide power for up to 32

Paradigm control stations when used with the Paradigm ACP.

• The 0-10V control option (DRd-FLO) provides up to 24 outputs for control of 0-10V

(4-wire) LED drivers or fluorescent ballasts (up to 12 on a DRd6).

• The Digital Addressable Lighting Interface (DALI) option controls up to 24 loops of 64

DALI compatible ballasts or drivers in a broadcast mode (up to 12 on a DRd6).

• The Unison BatteryPack option provides power back-up to the Architectural Control

Processor in the DRd for a period up to 90 minutes.

• The Unison RideThru option provides power to the Architectural Control Processor in

the DRd for at least 10 seconds during brief power outages or drop outs.

• All empty module spaces in a DRd enclosure must be filled with airflow module or blank

modules (DRd-BM) for proper cooling.

• The DRd pedestal (DRd-PED) is a floor mounting stand for the DRd enclosure.

4 DRd Enclosure Installation Manual

Page 9

Chapter 1

Prepare for Installation

Unpack and Inspect

Before you begin installation, check your shipment and confirm it arrived complete and

undamaged.

Step 1: Check the shipping container for physical damage.

Step 2: If you find damage, document it to help with a claim against your shipper.

Step 3: Unpack your order and check the contents against the packing list to be sure

your order is complete.

Step 4: If you discover a problem, call the ETC Systems Group the closest office of

purchase. See “Contacting ETC” on page 2.

Main Circuit Breaker Protection

Before you begin installing the DRd enclosure, make sure you have installed a main circuit

breaker cabinet or other readily accessible input power disconnect device. In certain

bussed and cross-bussed systems, this disconnect device may be the Unison AX series

auxiliary enclosure with a main circuit breaker.

WARNING:

DRd enclosures installed without an accessible power disconnect device

cannot be serviced or operated safely. Follow all local codes and

restrictions.

Before removing dimmer or control modules for service, de-energize main

feed to DRd and follow appropriate Lockout/Tagout procedures as

described in NFPA Standard 70E. It is important to note that electrical

equipment such as dimmer enclosures can present an arc flash safety

hazard if improperly serviced. This is due to available large short circuit

currents on the feeders of the equipment. Any work on energized equipment

must comply with OSHA Electrical Safe Working Practices.

Using 90° Copper Wire

To comply with UL requirements:

Use Copper Conductors Only, the torque rating for each Non-Class 2 field-wire

connector, and “Use 90°C conductors at the 75°C Ampacities”, where readily visible in

the field wiring compartment; Class 2 adjacent to each Class 2, field-wiring connector.

Use only 90°C-rated copper wiring installed in accordance with all applicable local electrical

codes.

CAUTION:

A two-wire circuit with separate hot and neutral conductors is required for every

branch circuit that will be connected to the DRd enclosure. Shared neutral (multiwire) branch circuit arrangements are not recommended for phase control

dimming systems due to harmonics and potentially elevated neutral currents in a

shared neutral arrangement.

For retrofit installations where shared neutral circuits are already installed, or

enclosure lighting installations where the enclosure has a shared neutral, consult

ETC Technical Services for installation guidelines.

1 Prepare for Installation 5

Page 10

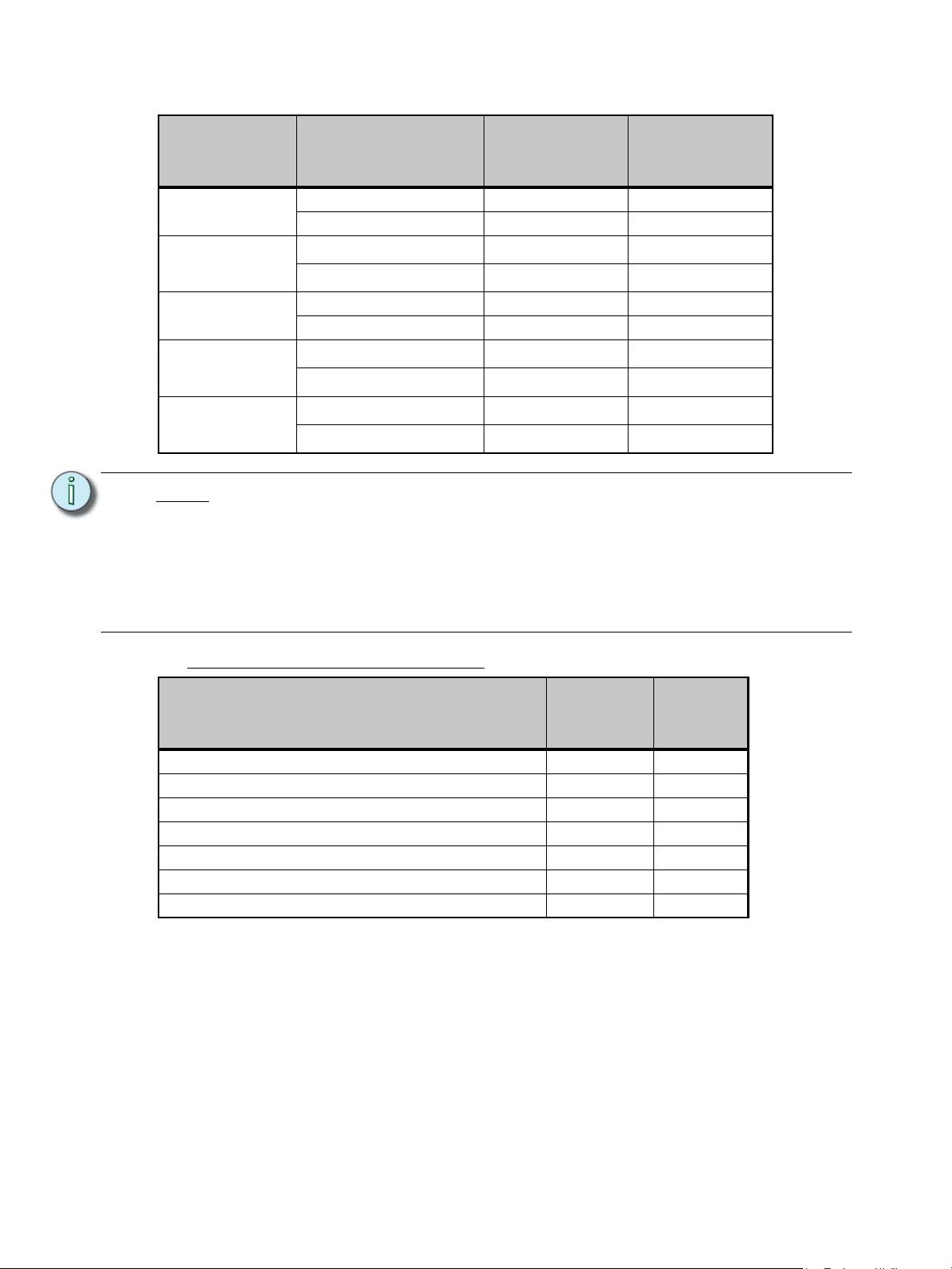

Maximum Current Draw

Type Phase Type

DRd6

AX6

DRd12

AX12

AX12X

Note:

Single Phase (1Ø) 120A 150A

Three Phase (3Ø) 80A 100A

Single Phase (1Ø)

Three Phase (3Ø)

Single Phase (1Ø) 240A 300A

Three Phase (3Ø) 160A 200A

Single Phase (1Ø)

Three Phase (3Ø)

Single Phase (1Ø)

Three Phase (3Ø)

1

Connected to DRd enclosure with a full complement of 20A modules.

2

Connected to two DRd enclosures with a full complement of 20A modules.

3

Installed in a main circuit breaker model auxiliary enclosure.

4

Wire bending space limits the feed to the AX12X-MCB to 400A maximum. ETC

installs a 100% rated two pole breaker (or two poles from a three pole breaker) in

the AX12X-MCB, for a total deliverable current of 400A in a single phase (split

phase) configuration.

Maximum

Current Draw

1

120A

1

80A

1

240A

1

160A

2

480A

2

320A

Suggested

Breaker

Rating

3

150A

3

100A

3

300A

3

200A

4

400A

3

400A

Short Circuit Current Rating (SCCR)

SCCR at

Configuration

100-120v

Ac

DRd6 22,000A 22,000A

DRd6 with AX6 (MCB) 100,000A 65,000A

DRd12 22,000A 22,000A

DRd12 with AX12 Main Lug 22,000A 22,000A

DRd12 with AX12X (cross-bussed) Main Lug 22,000A 22,000A

DRd12 with AX12 Main Circuit breaker 100,000A 65,000A

DRd12 with AX12X Main Circuit breaker 100,000A 65,000A

SCCR at

240 &

277v Ac

6 DRd Enclosure Installation Manual

Page 11

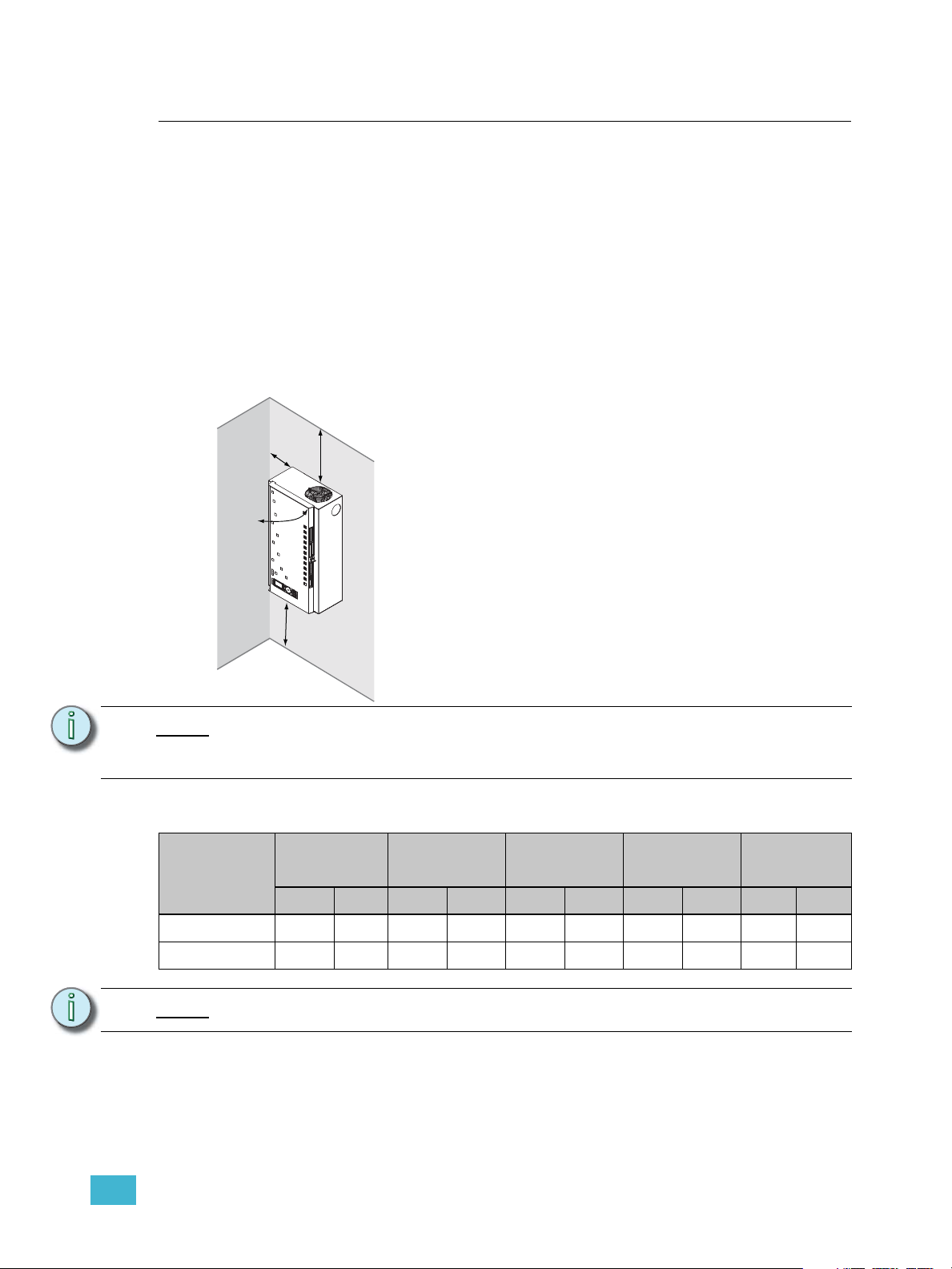

Where to Install the Enclosure

Unison DRd enclosures are designed to be surface mounted on load bearing walls in an

electrical closet or a room with restricted public access. When required, an optional

semi-recessed installation kit is also available. It is recommended that you install the

enclosure at least 36” (915mm) above the finished floor to ensure clear view of the control

processor (E-ACP, S-ACP, or P-ACP) for programming and operation. Alternatively, DRd

enclosures may install to a floor standing pedestal (model DRd-Ped).

Clearance Requirements

DRd enclosures require 12” (305mm) top clearance for proper airflow through the cabinet.

For sufficient door clearance, install the enclosure with at least 17” (432mm) of front

clearance and a 6” (152mm) clearance to the left of the door hinge from walls or other

equipment.

152 mm

(6”)

432 mm

(17”)

305 mm

(12”)

914.4 mm

(36”)

Note:

Additional Unison dimming and auxiliary enclosures of the same size are the

exception to the 6” (152mm) hinge side clearance rule. Unison enclosures are

designed for side by side installation.

Dimensions and Weights

Type

DRd6 21.8 553 17 431 10 254 37.8 17.2 42 19.0

DRd12 31 787 17 431 10 254 51 23.1 55 25

Note:

Height Width Depth

inches mm inches mm inches mm lbs kgs lbs kgs

For module weight please reference “Modules Specification,” page 57.

Product

Weight

Shipping

Weight

1 Prepare for Installation 7

Page 12

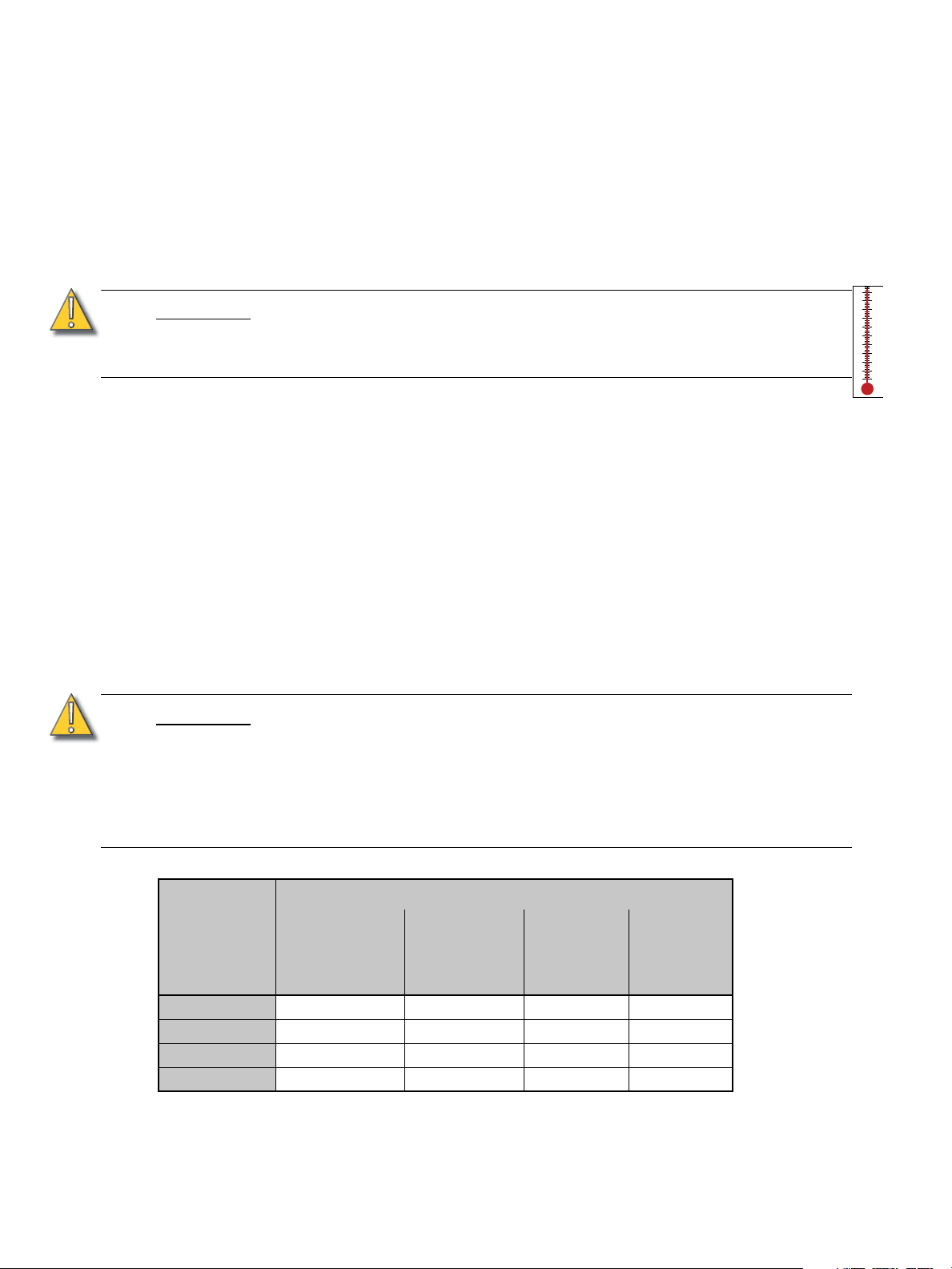

Installation Environment Requirements

0°

10°

20°

30°

40°

50°

60°

70°

80°

90°

100°

-18°

-10°

0°

10°

20°

30°

40°

• For your own safety, install a main circuit breaker cabinet or other readily accessible

power disconnect in the same area as the DRd enclosure. For cross-bussed

installations, this device may be the auxiliary enclosure. Main breakers not in the same

room must have a physical means to be locked off. ETC recommends adopting lockout

/ tagout procedures for your facility and following appropriate Lockout/Tagout

procedures as described in NFPA Standard 70E.

• A clean (not dusty) temperature-controlled environment with an ambient temperature

of 32-104°F / 0-40°C and ambient humidity of 10-90%, non-condensing.

CAUTION:

HVAC systems must at all times maintain the specified ambient temperature at the

enclosure. Dimming systems operating within 10°F (5°C) of the upper or lower

temperature limits must strictly follow installation and operation guidelines to

operate reliably.

• Restricted public access to prevent tampering.

• Soundproofing or performance area separation to muffle ventilation fan noise is

recommended.

• All CE equipment is tested to EMC category B environment.

Wire Routing and Specification

When planning wire entry into the enclosure, notice that conduit knockouts are provided

only on the sides of the unit. These knockouts are primarily used for bussing to an auxiliary

enclosure but may also be used for load or control wiring. Signal and power wiring must be

run in separate conduit per local code.

Due to the bend radii of certain size line feed wires and the location of terminations, special

attention is required for line feed wire entry. Reference the wiring guidelines below for

recommendations.

CAUTION:

Do not route line (input feed) wires through the back panel. Doing so requires bend

radii that violate NEC code, UL standards and because of undue stress at the wire

joint is likely to create a poor connection.

Line and load wire used with Unison DRd enclosures must be copper. Load wires

may either be stranded (preferred) or solid core. The use of aluminum wire is not

allowed in DRd enclosures.

Aluminum feed wires are supported only in the auxiliary (AX Series) enclosures.

Wire Size

Wire Access

Location

DRd12 Feed

(max)

350 Kcmil

185mm

Top

Bottom

Left side

Right side

8 DRd Enclosure Installation Manual

acceptable acceptable acceptable acceptable

acceptable acceptable acceptable preferred

Do Not Use Do Not Use acceptable acceptable

Do Not Use Do Not Use acceptable acceptable

2

DRd6 Feed

(max)

2/0-3

2

70mm

Load Wires

12 - 6AWG

2.5 - 16mm

2

Control

Wires

Page 13

Note:

To a ddi t i ona l

DRd rack

enclosures

EchoConnect

& DMX

power

feed

power

feed

power

feed

To l o ad c i rc u i ts

DMX input

to DRd rack

ETC Console

(for optional stage lighting)

EchoConnect

Preset 4

Unison DRd12

rack enclosure

Echo

Relay Panel

Unison DRd12

rack enclosure

Echo Inspire Stations

Element

console

Split phase applications require a simple field adjustment to the phase bussing.

See “Modify Phase Bus for 120V AC Split Phase Operation” on page 19.

Wire Size

Wire Access

Location

Top

Bottom

Left side

Right side

Wire Access

Location

Top

Bottom

Left side

Right side

Feed (max)

350 Kcmil

185mm

2

acceptable acceptable acceptable acceptable

acceptable acceptable acceptable preferred

Do Not Use Do Not Use acceptable acceptable

Do Not Use Do Not Use acceptable acceptable

DRd12 Feed

(max) 250 Kcmil

120mm

2

acceptable acceptable acceptable acceptable

acceptable acceptable acceptable preferred

Do Not Use Do Not Use acceptable acceptable

Do Not Use Do Not Use acceptable acceptable

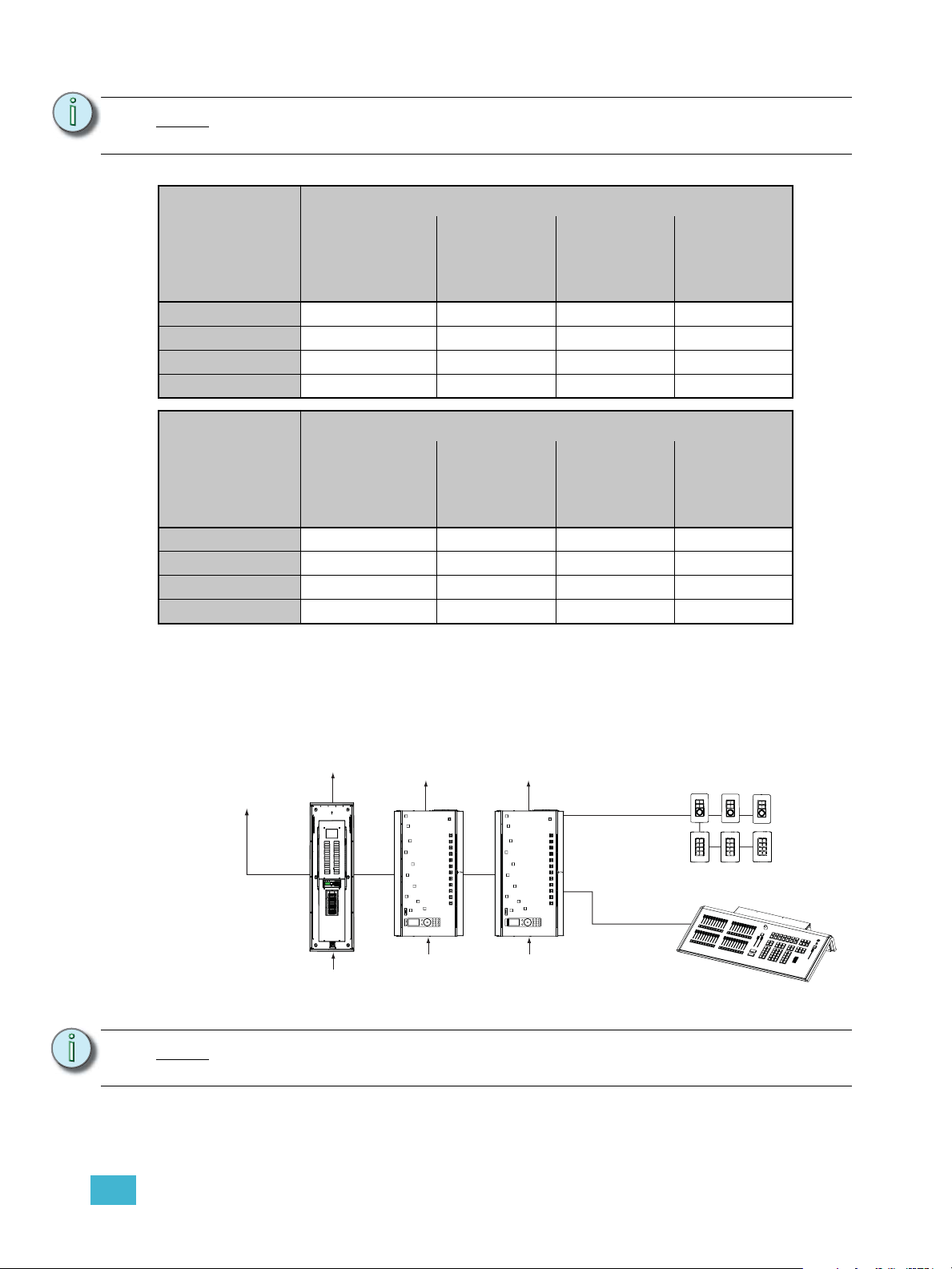

Control Specifications

The riser below is typical of a small Unison system utilizing Echo Architectural Control

Processors (E-ACP) for control and Unison Echo

activation. DMX input to the DRd enclosures provide an additional level of system control

and integrates the architectural and theatrical lighting control systems.

DRd6 Feed

(max)

250 KCmil

120mm

2

Wire Size

DRd6 Feed

(max)

2/0-3

2

70mm

Load Wires

12 - 6AWG

2.5 - 16mm

Control Wires

2

Load Wires

12 - 6AWG

2.5 - 16mm

®

Inspire™ control stations for control

Control Wires

2

1 Prepare for Installation 9

Note:

DRd enclosures are shipped with the lugs installed in a top feed orientation by

default. You can change the lug orientation to a bottom feed if required.

Page 14

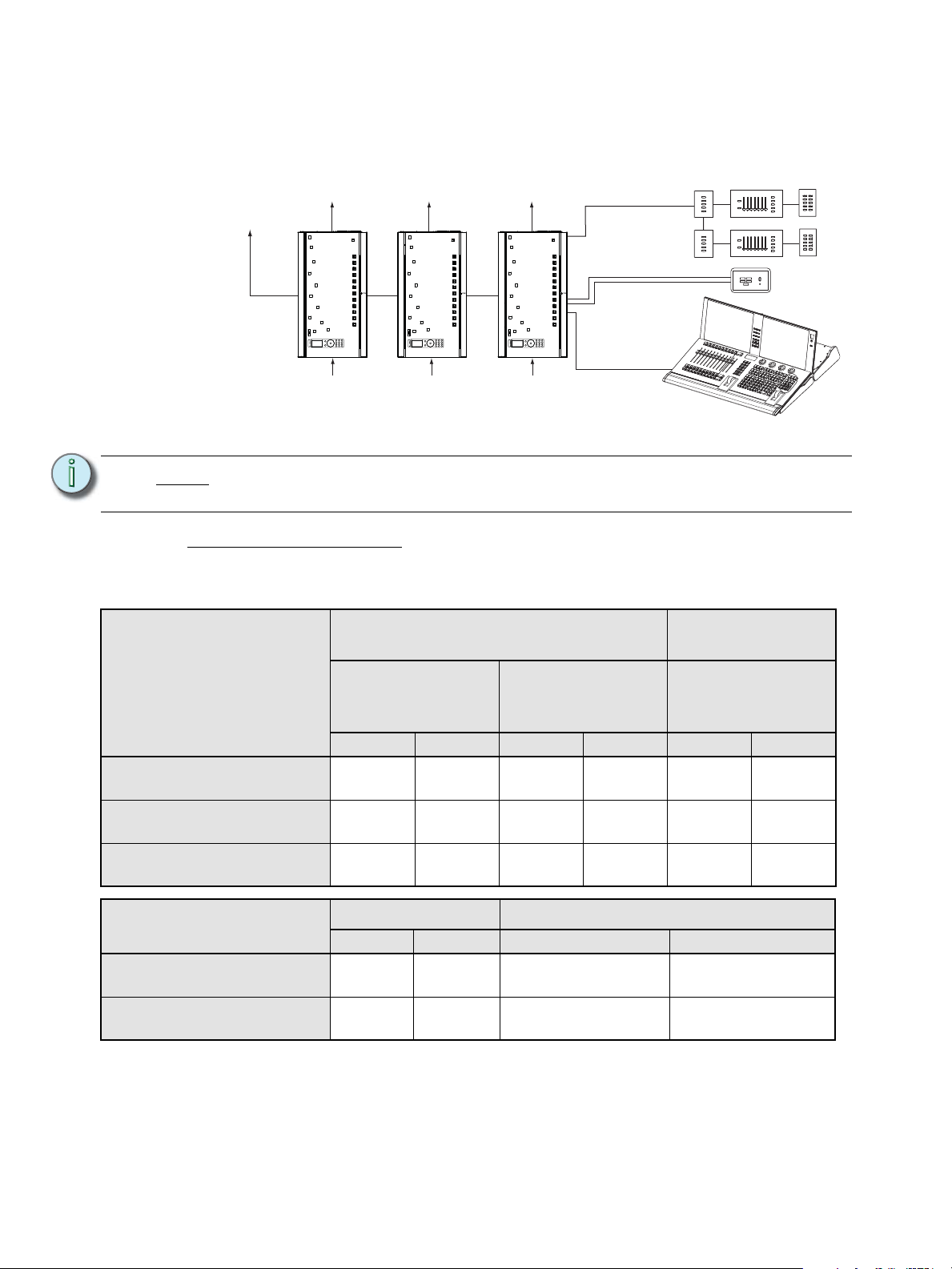

The riser below is typical of a Unison system utilizing Paradigm Architectural Control

Processors (P-ACP) for control and Unison control stations for control activation. Paradigm

systems provide a DMX input into the system for larger system integration and control. A

Paradigm system also utilizes Net3 networking for an additional level of system-wide

control.

Preset 1

Preset 6

To a ddi t i ona l

DRd rack

enclosures

DMX

thru

Unison DRd12

rack enclosure

power

feed

To l o ad c i rc u i ts

Unison DRd12

rack enclosure

power

feed

Unison DRd12

rack enclosure

power

feed

Unison

LinkConnect

LinkConnect

Aux Power 24 vdc

DMX input

to DRd rack

Preset 1

Preset 2

Preset 3

Preset 4

Preset 5

Preset 1

Preset 2

Preset 3

Preset 4

Preset 5

Gio

console

ETC Console

(for optional stage lighting)

Sequence

Macro Record

Heritage stations

Sequence

Macro Record

Preset 1

Preset 2

Preset 7

Preset 2

Preset 8

Preset 3

Preset 3

Preset 9

Preset 4

Preset 4

Preset 5

Preset 10

Preset 5

Preset 1

Preset 6

Preset 1

Preset 2

Preset 7

Preset 2

Preset 8

Preset 3

Preset 3

Preset 9

Preset 4

Preset 4

Preset 5

Preset 10

Preset 5

Paradigm Touchscreen

station

Note:

DRd enclosures are shipped with the lugs installed in a top feed orientation by

default. You may change the lug orientation to a bottom feed if required.

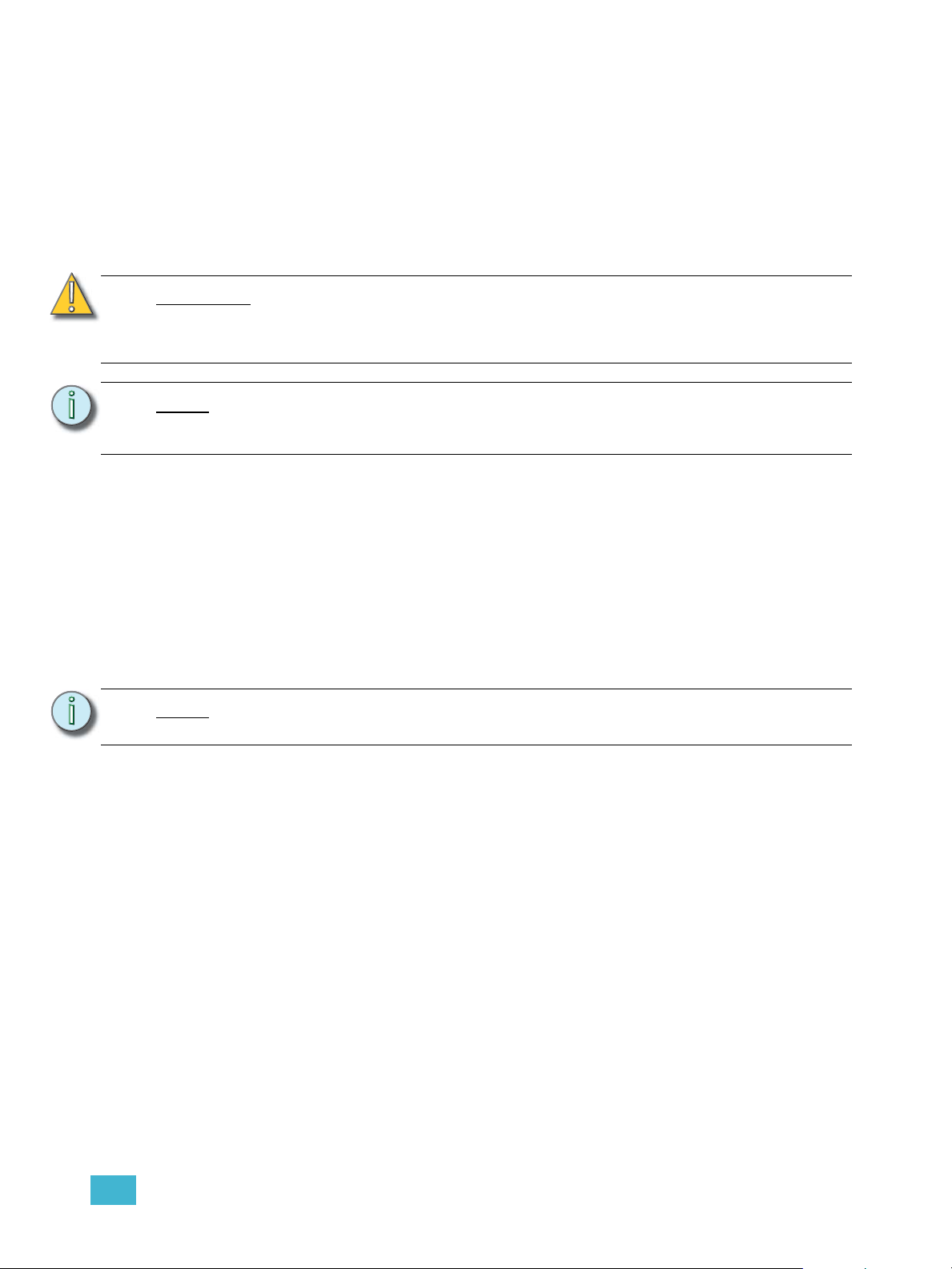

Control Wire Specification

The following tables lists the recommended control wire types used in a DRd installation

and the maximum length (aggregate) of wire runs allowed for each type.

Purpose

Total length of control wire

(without repeater module)

Maximum wire length

(station to station)

Maximum repeater distance

(P-SPM only)

Purpose

Total length of control wire

(without repeater module)

Maximum wire length

(station to station)

LinkConnect (P-SPM and S-SPM)

Aux 24 vDC

(Belden 8471)

(P-SPM only)

(2) #16 AWG

EchoConnect

(E-SPM)

Belden 8471 or

Belden 1583a

Feet Meter Feet Meter Feet Meter

1640 500 1500 457 1640 500

1312 400 1312 400 1640 500

1640 500 1500 457 N/A N/A

DMX (Belden 9729) Category 5 /Belden 1583a

Feet Meter Feet Meter

1600 487 328 100

1600 487 N/A N/A

10 DRd Enclosure Installation Manual

Page 15

Data Types and Topologies

LinkConnect and EchoConnect Control Wiring

Control stations communicate with the control processor using the LinkConnect or

EchoConnect station communication bus.

Termination is available for up to six home runs of LinkConnect / EchoConnect data runs

utilizing Belden 8471 cable (or approved equal) plus one 14 AWG (2.5mm2) ESD drain

wire. This wiring is topology-free and can be installed in any combination of bus, star, loop,

and home run. The total combined length of all wire runs cannot exceed 1,640 feet (500m).

CAUTION:

Note:

Auxiliary 24 vDC

Auxiliary power is required when you are installing certain Unison control stations. ETC

recommends using two 16 AWG stranded wires for 24 vDC auxiliary power to the control

station(s). Auxiliary power is topology-free.

DMX (Digital Multiplex)

DMX can address up to 512 channels of control. DMX is installed in a daisy chain topology

and includes one pair of wires (data +, data -) plus an ISO ground. ETC recommends the

use of Belden 9729 (or approved equal) wire with a single end of line termination (90150). For best DMX performance, twist the wires together as close to the pluggable

connector as possible.

Note:

While the wiring terminations for LinkConnect, used in SmartLink and Paradigm

systems, and EchoConnect used in Echo systems, are similar, the communication

and control types are not interchangeable. Each product family requires a

dedicated station infrastructure that cannot be shared.

It is required that you terminate LinkConnect / EchoConnect station wiring and the

auxiliary power wiring in the same enclosure the station power module and

architectural control processor will be installed.

It is required that you terminate DMX control wiring in the same enclosure (rack 1)

where the architectural control processor will be installed.

1 Prepare for Installation 11

Page 16

Chapter 2

Install Enclosures

This chapter contains instructions for installation of the DRd enclosure.

This chapter contains the following sections:

• Mounting Individual DRd Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

• Mounting a DRd Enclosure on a Pedestal. . . . . . . . . . . . . . . . . . . . . . . . 14

• Mounting Auxiliary and DRd Enclosures Together . . . . . . . . . . . . . . . . 15

12 DRd Enclosure Installation Manual

Page 17

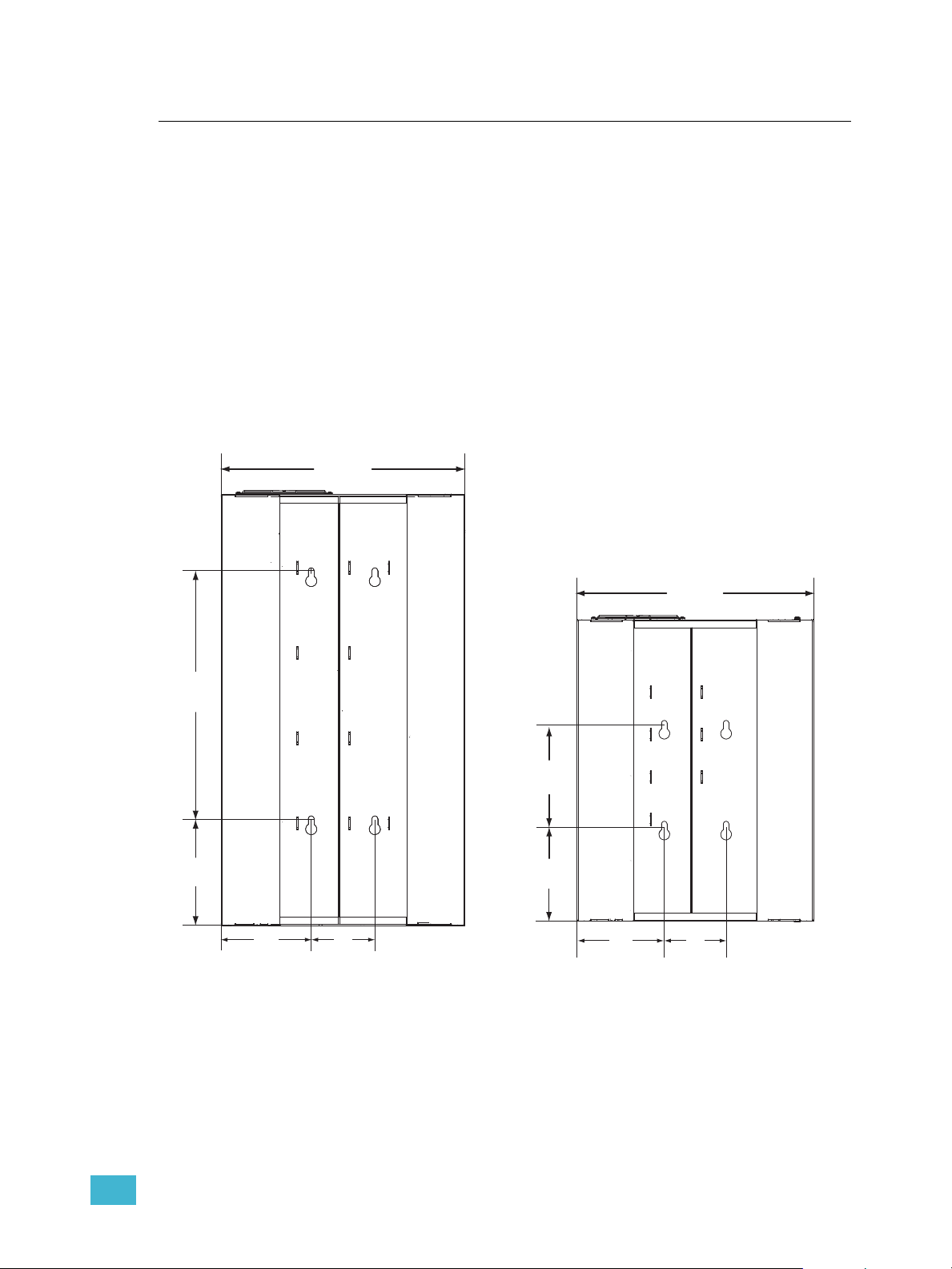

Mounting Individual DRd Enclosures

432 mm

17”

451 mm

17.75”

194mm

7.64”

113mm

4.45”

160mm

6.3”

DRd12 rear panel

DRd6 rear panel

Unison DRd enclosures are designed to be surface mounted on load bearing walls in an

electrical closet or a room with restricted public access. Alternatively the DRd enclosure

may be mounted on a pedestal (DRd-Ped). It is recommended that enclosures installed on

the pedestal floor stand also be secured to the wall for greater stability.

Mounting Individual Enclosures on a Wall

The wall must be strong enough to hold the enclosure fully populated with modules, conduit

and wire. See “Dimensions and Weights,” on page 7 and

“Modules Specification,” page 57.

Step 1: Determine where your enclosure will be installed using the weight and dimension

requirements detailed in “Where to Install the Enclosure,” page 7.

Step 2: Use the measured slot dimensions located in the graphic below to mark the hole

locations for the mounting hardware.

Step 3: Drill the holes and install the mounting hardware for each enclosure.

Step 4: Attach the enclosure to the wall.

Step 5: Check that the enclosure is level and plumb and tighten the mounting hardware.

432 mm

17”

184mm

7.25

194mm

7.64”

160mm

6.3”

113mm

4.45”

• Four 3/8” (M8-M10) bolts or screws 2-4” (50-100mm) long, and suitable

wall plugs are suggested mounting hardware (lag bolts recommended).

• Both the surface and the mounting hardware must support the weight of

the enclosure unit fully populated with modules.

• Expose at least 1” (25mm) of threads for mounting the enclosure.

2 Install Enclosures 13

Page 18

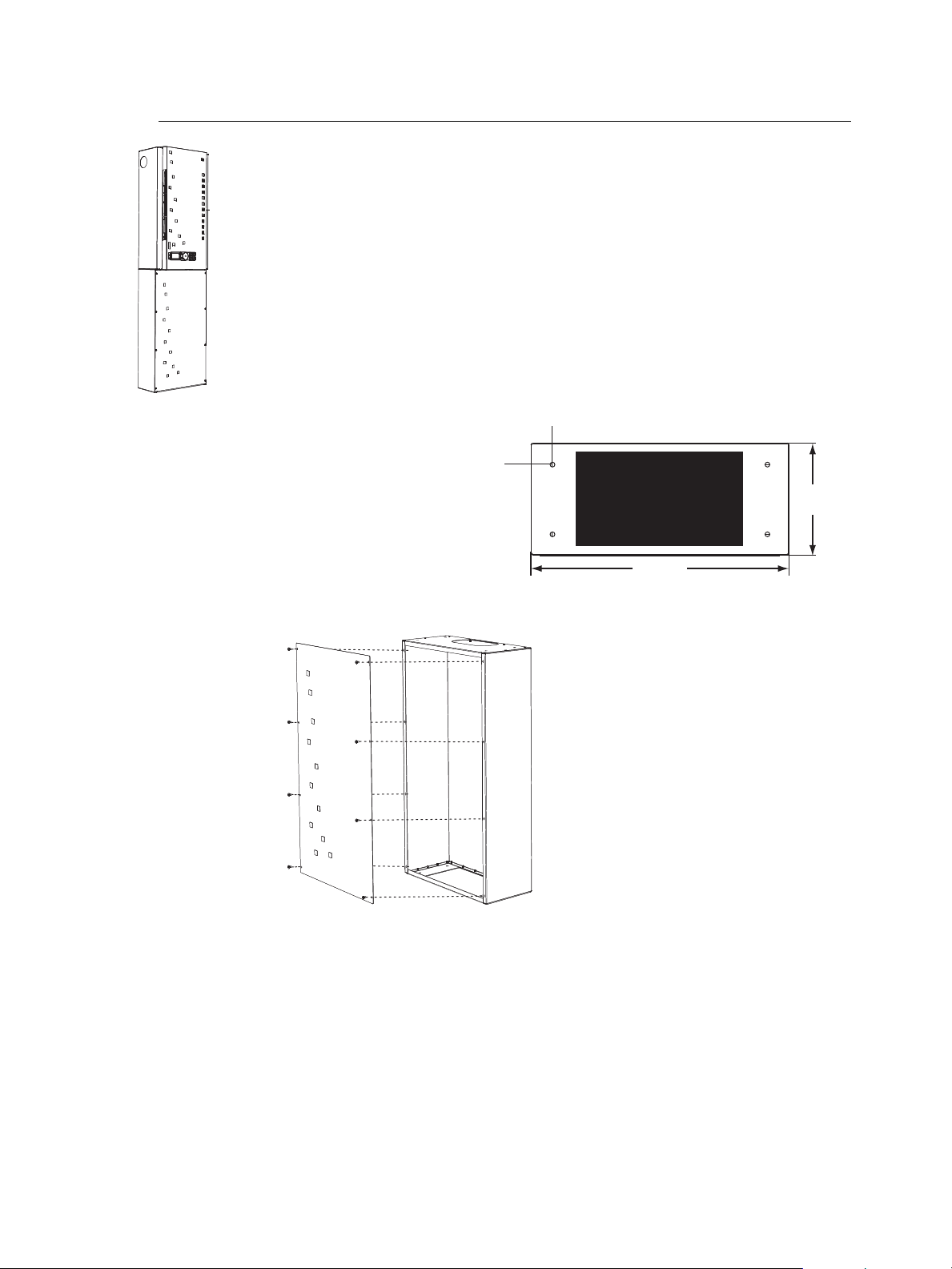

Mounting a DRd Enclosure on a Pedestal

The Unison DRd pedestal is designed with the same footprint as the DRd enclosure.

The acceptable conduit access in the bottom of the DRd overlaps the floor stand access

panel for contractor wiring and installation convenience. It is recommended to secure a

DRd enclosure installed on a pedestal to a wall for greater stability.

432mm

17”

186.7mm

7.35”

35.5mm

1.4”

35.5mm

1.4”

Step 1: Use the measured

dimensions in the

graphic (right) to mark

the hole locations for the

floor mounting hardware.

Step 2: Drill holes for floor

mounting hardware.

Step 3: Remove the eight screws and washers that secure the front panel to the unit.

Step 4: Position the floor stand on floor hardware previously placed for marking the

holes.

Step 5: Secure the pedestal base to the floor.

Step 6: Create conduit access in the bottom of the DRd enclosure. Notice the label inside

the bottom of the enclosure indicating the recommended locations for conduit

access. Do not create conduit access outside of the recommended locations.

Step 7: Position the DRd on the floor stand pedestal and align with the mounting holes

Step 8: Bolt the enclosure into place.

Step 9: Reinstall the front panel to the pedestal unit, replacing all hardware removed in

14 DRd Enclosure Installation Manual

provided.

step 3.

Page 19

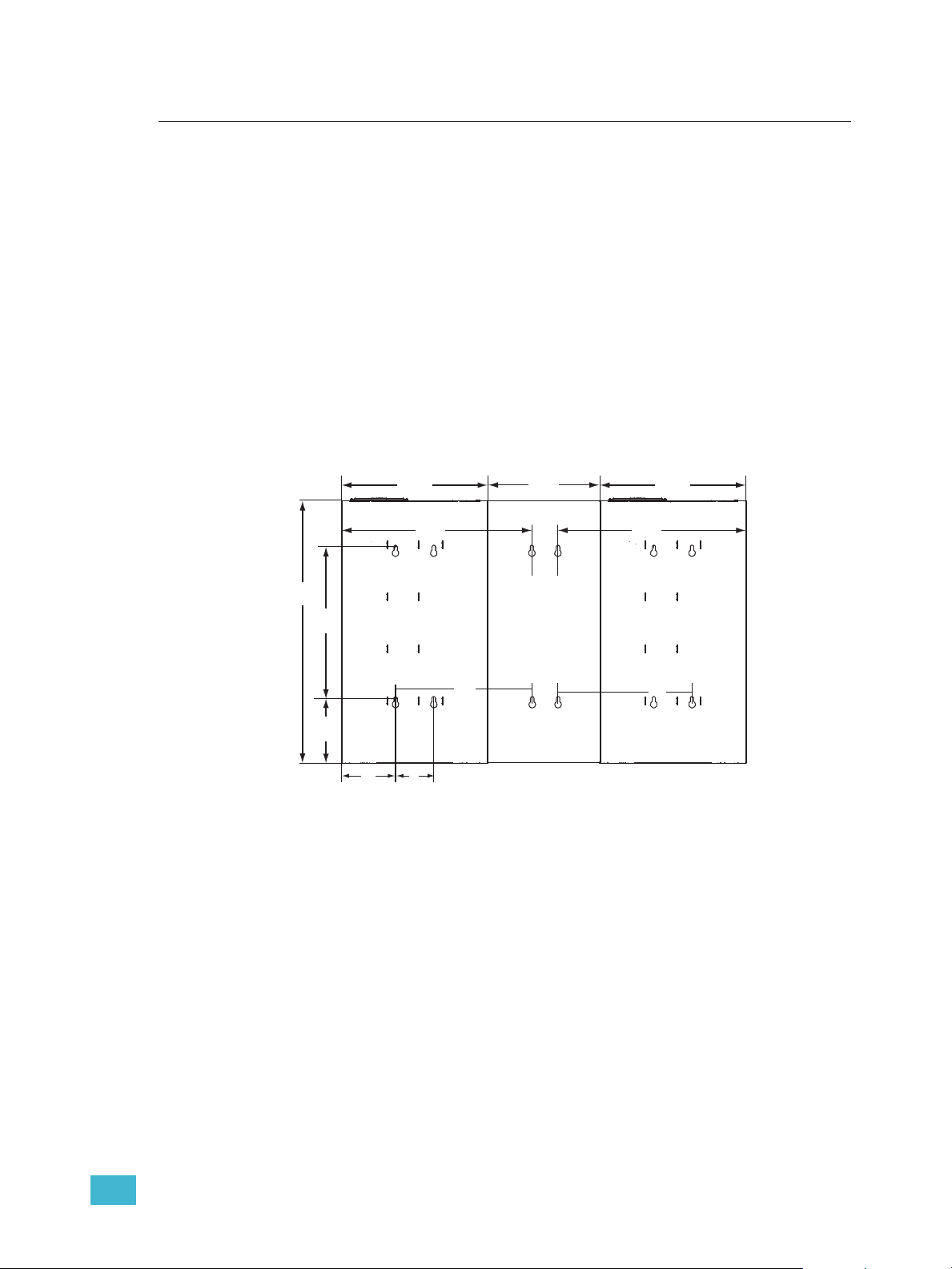

Mounting Auxiliary and DRd Enclosures Together

432mm

17”

451mm

17.75”

194mm

7.64”

113mm

4.45”

160mm

6.3”

432mm

17”

62mm

2.44”

787mm

31”

406mm

16”

406mm

16”

330mm

13”

559mm

22”

559mm

22”

DRd12-48 rear panel view

Unison DRd and AX auxiliary enclosures are designed to be surface mounted on load

bearing walls in an electrical closet or a room with restricted public access. One DRd

enclosure may be bussed to the AX series auxiliary enclosure, which may contain a main

circuit breaker or a main lug for power distribution to the adjacent DRd12 enclosure. Two

DRd12 enclosures may be cross-bussed to an AX12X auxiliary enclosure which is

designed to provide main lug or main breaker input feed termination to the adjacent DRd12

enclosures.

The wall must be strong enough to hold all enclosures fully populated with modules, conduit

and wire. Reference “Where to Install the Enclosure,” page 7 for weight, dimension and

clearance requirements.

Step 1: Determine where the enclosures will be installed using the weight and dimension

requirements detailed in “Where to Install the Enclosure,” page 7.

Step 2: Use the measured slot dimensions located in the graphics below to mark the hole

locations for the mounting hardware.

Step 3: Drill the holes and install the mounting hardware for each enclosure.

• Four 3/8” (M8-M10) bolts or screws 2-4” (50-100mm) long, and suitable

wall plugs are suggested mounting hardware per enclosure (lag bolts

recommended).

• Both the surface and the mounting hardware must support the weight of

Step 4: Remove the conduit knockouts from the mating side conduit plugs on the DRd

the enclosures fully populated with modules.

• Expose at least 1” (25mm) of threads for mounting the enclosure.

and auxiliary enclosures before installation. Only remove the knockouts that are

adjacent to another enclosure.

Step 5: Install one DRd enclosure first (follow instructions as outlined in “Mounting

Individual Enclosures on a Wall,” on page 13. Remember to install the DRd

enclosure to either side of the auxiliary enclosure in cross-bussed applications.

Step 6: Align the auxiliary enclosure against the DRd enclosure and mount it to the

previously installed hardware. Keyholes in the DRd and auxiliary enclosures are

aligned with each other for mounting to Unistrut or Kindorf. With conduit holes

mated, the bolt spacings are on 16” (406mm) centers (top left DRd and top left

2 Install Enclosures 15

Page 20

Ax) for installation convenience.

Step 7: Install the ETC supplied 2 1/2” (64mm) nylon insulated chase nipple and 2 1/2”

(64mm) locknut between the auxiliary and DRd enclosures.

Step 8: For cross-bussed DRd12-24 installations, install the second DRd12-24 by

following steps 4 through 7 above.

Step 9: Check that each enclosure is level and plumb then tighten the mounting

hardware for a secure installation.

Note:

Reference the related Auxiliary Enclosure Installation Manual to complete the

auxiliary enclosure installation and for DRd12-24 and DRd 12-48 enclosure input

power bus wiring termination.

Follow the instructions in this manual for all other DRd enclosure installation

procedures.

16 DRd Enclosure Installation Manual

Page 21

Chapter 3

Rough-in Conduit and Wiring

This chapter contains instructions for conduit and wiring installation of the DRd enclosure.

This chapter contains the following sections:

• Prepare the DRd Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

• Remove the DRd Power Supply/Dimming Engine Access Panel . . . . . 18

• Modify Phase Bus for 120V AC Split Phase Operation . . . . . . . . . . . . . 19

• Rough-in Conduit to the DRd Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . 21

3 Rough-in Conduit and Wiring 17

Page 22

Prepare the DRd Enclosure

Step 1

Step 4.a

Step 4.b

Step 4.c

The enclosure door

has been removed

from this graphic for

clarity of this

procedure.

All terminations are accessible from the front of the enclosure. Reference “Wire Routing

and Specification”, page 8 for conduit access specifications.

Prior to conduit installation you should remove the power supply access panel for clear

access to the top of the DRd enclosure. Reference “Remove the DRd Power Supply/

Dimming Engine Access Panel” below.

Take the opportunity before roughing in your conduit to change your DRd for split phase

operation (100/120V AC enclosures only) if required. Reference “Modify Phase Bus for

120V AC Split Phase Operation”, page 19.

Remove the DRd Power Supply/Dimming Engine Access Panel

Remove the power supply/dimming engine access panel to allow for better access in the

top of the DRd enclosure while roughing in conduit and cable.

18 DRd Enclosure Installation Manual

Step 1: Loosen the two captive screws that secure the access panel.

Step 2: Gently pull the panel straight down until the top of the access panel is clear of the

enclosure.

Step 3: Tilt the supply access panel away from the enclosure.

Step 4: Disconnect the three cables that are attached to the unit.

a: For the cable bundle on the left side, squeeze the tabs on either side of the

connector and gently pull the cable until it is free from the unit.

Page 23

b: For the ribbon cable connected on the right rear side, release the tabs on

L1

L2

L3

N

L1

L2

L3

Step 1:

Step 2a:

Step 2b:

The enclosure door

has been removed

from this graphic for

clarity of this

procedure.

either side of the connector by sliding them opposite the connector then

gently pull the cable free. Temporarily secure this cable out of the way while

pulling conductors into the enclosure.

c: For the two-wire cable on the right side, gently pull the connector straight out.

Step 5: Remove the power supply access panel.

a: Align the panel perpendicular to the enclosure.

b: Slide the panel up approximately one inch to align the guide pins on the top

of the guided slots.

c: Then pull the panel straight out.

Note:

Store this access panel in a safe place until you are finished roughing in conduit

and terminations. You will need to reinstall this panel when then enclosure is

installed and all wires have been terminated.

Modify Phase Bus for 120V AC Split Phase Operation

The DRd can be simply field modified from a three phase operation to a split phase (3 wire

plus ground) operation.

3 Rough-in Conduit and Wiring 19

Step 1: Notice the two copper straps (stacked) on phase L2.

Step 2: Change the DRd operation from 3Ø to split phase by moving the copper straps,

strapping the phase bars together, (reference the graphic above to follow along).

a: Move one of the copper straps to connect between phase 1 (L1) and phase

2 (L2). The screws required are installed to the phase bars in the location the

copper strap will be mounted.

Page 24

b: Remove the red sense wire from phase 2 (L2) and reroute it to the neutral

L1

L2

L3

N

N

L1

L2 L3

L1 L2 L3

L1

L2

L3

N

The enclosure

doors have

been removed

from this

graphic for

clarity of this

procedure.

bar.

c: Move the second copper strap to connect between phase 2 (L2) and phase

3 (L3).

Step 3: For cross-bussed DRd12-48 installations, complete step 2 for both enclosures.

20 DRd Enclosure Installation Manual

Page 25

Rough-in Conduit to the DRd Enclosure

L1

L2

L3

N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Top Feed DRd Bottom Feed DRd

Line feed wires terminate on the main lugs provided.

The DRd12 enclosure is shipped from the factory with the main lugs in a top feed

orientation. The lugs can be changed to a bottom feed orientation by removing the lug

mounting bolt, rotating the lug 180°, and re-mounting the lug in the opposite lug mounting

PEM. This is true for all DRd12 models.

The DRd6 enclosure phase lugs are both top and bottom feed by default and don’t require

any change, but the neutral and ground lugs will require re-orientation for bottom feed.

1

2

3

4

5

6

L1

L2

L3

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

When utilizing an auxiliary enclosure with the DRd enclosure, line feed wires from the

auxiliary enclosure enter the DRd enclosure through the top side conduit knockout. For

cross-bussed installations the line feed wires will be fed to the DRd through the conduit

knockout on the adjoining side of the auxiliary enclosure.

Enclosure

Type

Lug Mounting

Bolt Torque

Wire Range

Lug Wire

Tightening

Torque

350kcmil -

185mm

375 in-lbs 200 in-lbs 375 in-lbs 275 in-lbs 50 in-lbs 45 in-lbs

DRd12

120 and 230V AC

DRd12

240 and 277V AC

6 Ft-lbs 8 Nm 11 Ft-lbs 15 Nm 6 Ft-lbs 8 Nm

2

250kcmil -

1 AWG

120mm2 -

2

50mm

2-6 AWG 2/0-3 AWG 4-6 AWG

35mm2 -

2

16mm

1 AWG

50mm

2-6 AWG

2

-

35mm2 -

2

16mm

42.4 Nm 22.6 Nm 42.4 Nm 31 Nm 5.65 Nm 5.1 Nm

N

(all models)

70mm2 -

2

25mm

DRd6

25mm2 -

2

16mm

3 Rough-in Conduit and Wiring 21

Page 26

Load circuits terminate to the right side the enclosure.

L1

L2

L3

N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Load Hot / Live

Load Neutral

Load Ground /

Earth

The enclosure door

has been removed

from this graphic for

clarity of this

procedure.

Load wires terminate to the load lugs on the

right side of the enclosure.

Load neutral and load ground wires terminate

on the neutral and ground bus bars located on

the back panel of the enclosure. An exception

to this is made for the DRd with CE neutral

disconnect. Neutrals are terminated to the

neutral disconnect on the left side of the

enclosure. See “230V AC Neutral Disconnect

DRd Enclosures” on page 27.

Control wires terminate to the right and left I/O boards in

the DRd enclosure.

Control wires can enter the enclosure from the top, bottom, or

either side, although ETC recommends that you pull control

wires into the enclosure from the bottom since all control

AUX POWER

LON LINK / ECHO BUS

SIGNAL DISTRO

LPS

terminations are located near the bottom.

RIDE THRU/BATT

A+ A- COM

B+ B- COM A+ A- COM

B+ B- COM

COM PANIC

SRC OFF END

CDI

J9

DUAL RACKS

APM

DMXB DMXA

The right I/O board is shipped standard with all DRd

enclosures and includes terminations for:

• 24 vDC Auxiliary Power output connector.

• LinkConnect/EchoConnect connector.

• UL 924 emergency contact input for control bypass.

• Auxiliary enclosure (Dual Enclosure) cross-bussed

interconnection.

• (2) DMX connections and a DMX pass-through

connection.

DMXA

DMX PASS-THRU

7183B4606 REV F © 2013 ETC, INC. MADE IN THE U.S.A.

DMXB

• All option kit connections including DALI, 0-10V, Unison

RideThru option / Unison BatteryPack option.

22 DRd Enclosure Installation Manual

Page 27

A Left I/O card is available for use with Echo

ACP and is required for use with Paradigm ACP

systems.

Optional Echo Left I/O

The Echo Left I/O board is available as an option

for use with the Echo Architectural Control

Processor and includes Ethernet connection.

Required Paradigm Left I/O

The Paradigm left I/O board is included with the

Paradigm ACP system and include terminations

for:

• Ethernet

• RS232 bi-directional serial

• 4 dry contact inputs

• 4 relay contact outputs

Procedure

Step 1: Plan wire entry to the enclosure. See “Wire Routing and Specification” on page 8.

Step 2: Make the desired conduit access (top, bottom, left or right) from the enclosure.

Read and comply with the label inside the enclosure which details the

recommended access locations for conduit entry.

Note:

Step 3: Punch holes and install conduit fittings or insert lining materials in conduit

Step 4: Be sure there are minimal air gaps. See “Sealing Air Leaks” on page 52.

CAUTION:

Do not run power and control cable in the same conduit.

opening.

Wire openings must have fittings, bushings, grommets or fiche paper lining

material to protect the wire and cable insulation from damage by sharp metal

edges, and to prevent air leaks.

3 Rough-in Conduit and Wiring 23

Page 28

Chapter 4

Terminate Wiring

This chapter contains the following sections:

• Connect Line Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

• Connect Load Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

• Fluorescent Load Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

• Connect Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

24 DRd Enclosure Installation Manual

Page 29

Connect Line Power Wiring

WARNING:

CAUTION:

All terminations must be done with the power off. DRd enclosures installed

without an accessible power disconnect device cannot be serviced or

operated safely. In some instances, this device may be an auxiliary

enclosure with a main circuit breaker. Follow all local codes and

restrictions.

Before servicing, de-energize main feed to DRd and follow appropriate

Lockout/Tagout procedures as described in NFPA Standard 70E. It is

important to note that electrical equipment such as dimmer enclosures can

present an arc flash safety hazard if improperly serviced. This is due to

available large short circuit currents on the feeders of the equipment. Any

work on energized equipment must comply with OSHA Electrical Safe

Working Practices.

Line and load wires used with the Unison DRd must be copper. Do not use

aluminum wire.

Connect Line Feed in an Individual DRd Installation

Line feed cables are terminated on the main phase lugs. It is best to route line (feeder)

cables first, load neutral and ground/earth wires next, load phase and control wires last. In

multiple enclosure installations, load neutral and ground/earth wires must terminate in the

same enclosure as the matching load phase wires.

Note:

For DRd6 and DRd12 main lug, main breaker, and cross-bussed applications,

reference the Unison Auxiliary Series Enclosure Installation Manual.

The bus bars are different for each enclosure type (DRd6 or DRd12) and each voltage (120,

230 or 240-277). Graphics are provided on the following page for reference.

Step 1: Pull the line phase, neutral and ground cables to the enclosure through the

openings (conduit or other fittings) previously prepared.

Step 2: Strip the insulation from the end of each cable and terminate them to the lugs.

Reference the table below for wire stripping lengths.

Model

DRd6 120, 240, 277V AC

DRd6 230V AC

DRd12 240, 277V AC

DRd12 120, 230V AC

• Line and neutral connections are labeled L1, L2, L3 and N. The equipment

grounding/earthing lug is labeled with the universal grounding symbol for

easy identification.

Hex Key Size / Wire Strip Length

Phase

3/16” /

5mm

5/16” /

8mm

5/16” /

8mm

3/8” /

10mm

Strip

Length

5/8” /

16mm

1” / 25mm

1” / 25mm

1” / 25mm

Neutral

3/16” /

5mm

5/16” /

8mm

3/8” /

10mm

3/8” /

10mm

Strip

Length

5/8” /

16mm

1” / 25mm

1” / 25mm

1” / 25mm

Ground/

Earth

3/16” /

5mm

3/16” /

5mm

3/16” /

5mm

3/16” /

5mm

Strip

Length

5/8” /

16mm

5/8” /

16mm

5/8” /

16mm

5/8” /

16mm

4 Terminate Wiring 25

Page 30

Note:

CE enclosures are supplied with ANSI hex wrenches for line feed terminations.

Step 3: Tighten the lugs to the correct torque based on cable size. Torque ratings are

also labeled in the DRd enclosure for your convenience.

Type

Lug Mounting

Bolt Torque

Wire Range

Lug Wire

Tightening

Torque

CAUTION:

350kcmil -

185mm2 -

375 in-lbs 200 in-lbs 375 in-lbs 275 in-lbs 50 in-lbs 45 in-lbs

DRd12

120 and 230V AC

6 Ft-lbs 8 Nm 11 Ft-lbs 15 Nm 6 Ft-lbs 8 Nm

2

2-6 AWG

35mm2 -

2

16mm

1 AWG

50mm

42.4 Nm 22.6 Nm 42.4 Nm 31 Nm 5.65 Nm 5.1 Nm

Dress wires neatly and avoid leaving extra wire inside the enclosure. Too much

clutter can restrict airflow and cause overtemp errors.

100, 120, 127 V AC, 3Ø DRd Enclosures

1

2

3

4

5

6

L1

L2

L3

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

N

23

24

DRd12

240 and 277V AC

250kcmil -

1 AWG

120mm2 -

50mm

2-6 AWG 2/0-3 AWG 4-6 AWG

35mm2 -

2

16mm

DRd6

(all models)

2

25mm

L1

2

L2

L3

N

70mm2 -

1

2

3

4

5

6

7

8

9

10

11

12

25mm2 -

2

16mm

Note:

For 120V AC single phase installation you must modify the phase bus before

connecting wiring. See “Modify Phase Bus for 120V AC Split Phase Operation” on

page 19.

26 DRd Enclosure Installation Manual

Page 31

230V AC Neutral Disconnect DRd Enclosures

L1

L2

L3

N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

L1

L2

L3

N

1

2

3

4

5

6

7

8

9

10

11

12

L1

L2

L3

N

1

2

3

4

5

6

7

8

9

10

11

12

240, 277V AC DRd Enclosures

1

2

3

4

5

L1

L2

L3

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

N

4 Terminate Wiring 27

Page 32

Connect Load Wires

Load wire phase

Load wire

ground bus

Load wire

neutral bus

120, 240, and 277V AC DRd

enclosures share similar load

lugs.

L1

L2

L3

N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Load wire phase

Load wire

ground bus

Load wire

neutral bus

230V AC DRd enclosures have a

neutral disconnect bus structure.

This design places neutral lugs

on the same side of the enclosure

as the main feeds. Neutral output

lugs are numbered on the filter

PCB. It is important to wire hot

and neutral from each load to the

corresponding numbered

outputs.

Load wires are terminated to the load lugs on the right side of the enclosure. In 120V AC

and 240/277V AC DRd enclosures, load neutral and load ground wires are terminated to

the terminal strips on the back panel. In 230V AC enclosure types, load neutrals are

connected to the left side of the enclosure, stacked on top of the input feeds to maintain a

true neutral disconnect.

Phase balancing of the loads is set from within the Architectural Control Processor “Dimmer

Setup” menu. Reference the related Architectural Control Processor configuration manual

for details.

1

2

3

4

5

6

L1

L3

7

8

9

10

11

12

13

L2

14

15

16

17

18

19

20

21

22

N

23

24

WARNING:

Use of emergency modules (ED15AFE or ER15AFE) in CE 230V DRd

enclosures require the neutral (N) lug in place of the neutral jumper per

module.

CAUTION:

A two-wire circuit with separate hot/live and neutral conductors is required for

every branch circuit that will be connected to the DRd. Shared neutral (multi wire)

branch circuit arrangements are not recommended for phase-control dimming

systems due to harmonics and potentially elevated neutral currents in a shared

28 DRd Enclosure Installation Manual

neutral arrangement.

For retrofit installations where shared neutral circuits are already installed, or

enclosure lighting installations where the enclosure has a shared neutral, consult

ETC Technical Services for installation guidelines.

Page 33

Note:

a: Insert the wire on the back side of the lugs.

b: Torque the lug screw to the recommended

value indicated in the table below.

Plan load wiring appropriately to avoid splicing wiring. Only one load wire per load

terminal.

Step 1: Route the load wires to the DRd enclosure(s) through the conduit previously

installed.

Step 2: Prepare the load wires for termination:

a: Label each wire in the set with circuit designation.

b: Separate load circuit wires into ground, neutral and hot/live wire bundles.

CAUTION:

Step 3: Strip 5/8” (16mm) of insulation from the end of each load wire.

Step 4: Route each load hot/live wire to its individual load output connection.

Connection

15 - 20 amp

Ground bus

Neutral bus

(excluding

Dress and terminate wires neatly and avoid leaving extra wire inside the

enclosure. Too much clutter (especially along the right side of the enclosure) can

restrict air circulation and reduce cooling efficiency. If cabling interferes with

airflow during operation, the DRd may be forced to shut down due to overheating.

Load wires should not cross between DRd enclosures. Instead, they should enter

the enclosure in which they will be terminated. Hot/Live and neutral load wiring

must follow the same conduit/path for each circuit.

load lugs

230V AC)

Cable Size Torque

AWG

14 - 10 2.5 - 6 35 2.9 4.0

6 - 4 16 45 3.8 5.1

14 - 8 2.5 - 6 75 6.3 8.5

6 - 4 16 110 9.2 12.4

14 - 8 2.5 - 6 75 6.3 8.5

6 - 4 16 110 9.2 12.4

mm

2

lbf-in lbf-ft N - m

Wire Strip

Length

5/8” - 16mm8 10 40 3.3 4.5

5/16” - 8mm

5/16” - 8mm

Neutral

Disconnect

(230V AC only)

4 Terminate Wiring 29

14 - 10 2.5 - 6 35 2.9 4.0

5/8” - 16mm8 10 40 3.3 4.5

6 - 4 16 45 3.8 5.1

Page 34

Step 5: Strip the neutral wire to the length indicated in the table above and terminate to

the neutral terminal assembly. Torque to the recommended value also indicated

in the table above. For 230V AC DRd enclosures, the neutral bus is located on

the line input feed side of the enclosure.

Step 6: Strip the ground/earth wires to the length indicated in the table above and

terminate to the ground bus terminal. Torque to the recommended value also

indicated in the table above.

Note:

Ground connections must use all metal nuts and lock washers.

30 DRd Enclosure Installation Manual

Page 35

Fluorescent Load Wiring

a: Insert the wire on the back side of the lugs.

b: Torque the lug screw to the recommended

value indicated in the table below.

Note:

When using D20FB modules, connected to dimmable fluorescent 2-wire ballasts

with integral battery backup, use the same terminations as listed in the 3-wire

Fluorescent instructions.

3-wire Fluorescent

To control 3-wire fluorescent ballasts, the power circuit in the enclosure must be configured

as a fluorescent module type (D15F, D20F, AD15F, AD20F,HD25F), which is a single

density module, with a 2/3 wire fluorescent dimmer mode assignment. Reference the

related Architectural Control Processor Configuration Manual for instructions on changing

the dimmer mode.

Note:

Step 1: Pull the three wire fluorescent ballast wiring into the DRd enclosure per the wire

Step 2: Strip 5/8” (16mm) of insulation from the end of each load wire.

Step 3: Terminate the black switched hot/live wire to the top terminal in its assigned

Even though two lugs are used, the configuration (as found in the Dimmer Setup

menu of the ACP) refers only to the top (odd) number lug.

entry plan.

dimmer lug pair. Insert the wire between the back of the lug and the pressure

plate as shown.

Cable Size Torque

Connection

AWG

14 - 10 2.5 - 6 35 2.9 4.0

mm

2

lbf-in lbf-ft N - m

15 - 20 amp

load lugs

6 - 4 16 45 3.8 5.1

Ground bus

Neutral bus

(excluding

230V AC)

Neutral

14 - 8 2.5 -6 75 6.3 8.5

6 - 4 10 110 9.2 12.4

14 - 8 2.5 -6 75 6.3 8.5

6 - 4 10 110 9.2 12.4

14 - 10 2.5 - 6 35 2.9 4.0

Disconnect

(230V AC only)

Step 4: Terminate the dimmed hot/live wire to the bottom terminal in its assigned dimmer

lug pair. Insert the wire between the back of the lug and the pressure plate as

4 Terminate Wiring 31

6 - 4 16 45 3.8 5.1

Wire Strip

Length

5/8” - 16mm8 10 40 3.3 4.5

5/16” - 8mm

5/16” - 8mm

5/8” - 16mm8 10 40 3.3 4.5

Page 36

shown in the graphic above. Torque the wire to the recommended value in the

torque table above.

Step 5: Strip the neutral wire to the length indicated in the table above and terminate to

the neutral terminal assembly. Torque to the recommended value also indicated

in the table above.

Step 6: Strip the ground/earth wires to the length indicated in the table above and

terminate to the ground bus terminal. Torque to the recommended value also

indicated in the table above.

Note:

Ground connections must use all metal nuts and lock washers.

2-wire Fluorescent

To control 2-wire fluorescent ballasts, the power circuit in the enclosure must be configured

as a standard module type (D15, D20, AD15, AD20, ED15, ED25, HD15, HD25) with a 2/

3 wire fluorescent dimmer mode assignment. Reference the related Architectural Control

Processor Configuration Guide for instruction to change dimmer mode.

Step 1: Pull fluorescent ballast power wiring into the DRd enclosure per the wire entry

plan.

Step 2: Strip 5/8” (16mm) of insulation from the end of each load wire.

Step 3: Terminate the load wire (typically black) to the assigned dimmer lug by inserting

wire between the back of the lug and the pressure plate.

a: Insert the wire on the back side of the lugs.

b: Torque the lug screw to the recommended value indicated in the table below.

Connection

15 - 20 amp

load lugs

Ground bus

Neutral bus

(excluding

230V AC)

Cable Size Torque

AWG

14 - 10 2.5 - 6 35 2.9 4.0

6 - 4 16 45 3.8 5.1

14 - 8 2.5 -6 75 6.3 8.5

6 - 4 10 110 9.2 12.4

14 - 8 2.5 -6 75 6.3 8.5

6 - 4 10 110 9.2 12.4

mm

2

lbf-in lbf-ft N - m

Wire Strip

Length

5/8” - 16mm8 10 40 3.3 4.5

5/16” - 8mm

5/16” - 8mm

Neutral

Disconnect

(230V AC only)

Step 4: Strip the neutral wire to the length indicated in the table above and terminate to

the neutral terminal assembly. Torque to the recommended value also indicated

in the table above.

Step 5: Strip the ground/earth wires to the length indicated in the table above and

terminate to the ground bus terminal. Torque to the recommended value also

indicated in the table above.

Note:

32 DRd Enclosure Installation Manual

Ground connections must use all metal nuts and lock washers.

14 - 10 2.5 - 6 35 2.9 4.0

5/8” - 16mm8 10 40 3.3 4.5

6 - 4 16 45 3.8 5.1

Page 37

Connect Control Wiring

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

3

Right I/O board ships standard with

each DRd enclosure.

Left I/O board is

available as part of the

Paradigm Termination

Kit which ships with

the Paradigm ACP.

An optional Left I/O kit

is available for use

with Echo ACP when

DRd is being used in a

networked system.

The enclosure door has

been removed from these

graphics for clarity of the

procedure.

Note:

Overview

All low voltage data and option wiring connects to pluggable connectors on the left and right

I/O boards near the bottom of the DRd enclosure.

The DRd ships with a right side I/O board for low voltage control connections. Left side I/O

board is available in the optional Paradigm and Echo Termination Kits.

• The Paradigm Left I/O Kit supports contact inputs and outputs, serial RS232 and

• The Echo Network Kit supports an Ethernet connection for the Echo ACP. The Echo

All low voltage control cables must run in separate conduit from power wires.

Ethernet control. This Left I/O board is not compatible with the SmartLink or Echo

Architectural Control Processors.

Network Kit is not compatible with the SmartLink or Paradigm ACPs.

4 Terminate Wiring 33

Note:

• The right side I/O board is shipped installed with each DRd and provides termination

for SmartLink / LinkConnect / EchoConnect, auxiliary power, DMX, and a UL 924

emergency contact input. The DRd enclosure supports option kits which install in the

bottom of the DRd for extended control and operation and terminate to the right I/O

board. Option modules include:

• 0-10V Control Option (DRd-FLO) which provides 24 outputs for control of 0-10V

(4-wire) control for LED drivers and fluorescent ballasts. Each channel output is

linked one-to-one with a circuit for power control.

• Digital Addressable Lighting Interface (DRd-DALI) which provides 24 outputs for

control of DALI-compatible fluorescent ballasts. Each channel output of DALI

control is linked one-to-one with a circuit for power control (DALI Broadcast Mode).

A DRd enclosure supports the use of either a DALI option board (DRd-DALI) or

the FLO option board (DRd-FLO), but not both.

• Unison RideThru kit provides power to the ACP during brief power outages or drop

outs. The URTO sustains power to the ACP for at least 12 seconds.

• Unison BatteryPack kit sustains power to the ACP for up to 90 minutes during

power outages.

Page 38

.

Note:

A DRd enclosure supports the use of either the Unison RideThru option or the

Unison BatteryPack option, but not both.

DRd Right I/O Data Terminations

7183B4606 REV F © 2013 ETC, INC. MADE IN THE U.S.A.

DMXB

WARNING:

B+ B- COM

DMX PASS-THRU

DMXB DMXA

DMXA

B+ B- COM A+ A- COM

SRC OFF END

APM

RIDE THRU/BATT

A+ A- COM

J9

DUAL RACKS

CDI

LON LINK / ECHO BUS

COM PANIC

LPS

RISK OF DEATH BY ELECTRIC SHOCK! Failure to disconnect all power to

the enclosure before working inside the DRd could result in serious injury

or death.

De-energize main feed to DRd enclosure and follow appropriate Lockout/

Tagout procedures as described in NFPA Standard 70E. It is important to

note that electrical equipment such as dimmer enclosures can present an

arc flash safety hazard if improperly serviced. This is due to available large

short circuit currents on the feeders of the equipment. Any work on

energized equipment must comply with OSHA Electrical Safe Working

Practices.

AUX POWER

SIGNAL DISTRO

Note:

Auxiliary Power

The auxiliary power connector (labeled Aux Power) provides termination for up to 16 wires

in the eight position pluggable connector. Each terminal allows up to two 16 AWG (1.5mm

wires and provides 24vDC power to control stations when used with the Paradigm Station

Power Module. Auxiliary power is not compatible with the Echo or SmartLink Station Power

Module.

Note:

Step 1: Pull control auxiliary power wiring (typically 16 AWG (1.5mm

Step 2: Strip 3/16” (5mm) of insulation from the ends of each wire pair.

Step 3: Remove the auxiliary power connector from the right I/O board.

Step 4: Loosen the terminal screws for as many auxiliary wire pairs as you are

Step 5: Insert the black auxiliary power wire from the pair into a “-” terminal on the

Step 6: Insert the red auxiliary power wire from the pair into a “+” terminal on the

Step 7: Repeat steps 5 and 6 for each auxiliary power wire pair.

Step 8: Replace the connector on the right I/O board.

All low voltage control cables must run in separate conduit from power wires.

2

It is required that you terminate LinkConnect / EchoConnect station wiring and the

auxiliary power wiring in the same enclosure (rack 1) where the station power

module and architectural control processor will be installed.

2

) red / black wire

pair) into the enclosure through the conduit opening previously prepared.

terminating.

connector and tighten the screw to secure the wire into the connector.

connector and tighten the screw to secure the wire into the connector.

)

34 DRd Enclosure Installation Manual

Page 39

LinkConnect and EchoConnect Control Wiring

Control stations communicate with the Architectural Control Processor using the

LinkConnect or EchoConnect station communication bus from the Architectural Control

Processor to the stations.

Note:

Note:

Termination is available for up to six home runs of LinkConnect / EchoConnect data runs

utilizing Belden 8471 cable (or approved equal) plus one 14 AWG (2.5mm

2

) ESD drain

wire. This wiring is topology-free and can be installed in any combination of bus, star, loop,

and home run. The total combined length of all wire runs cannot exceed 1,640 feet (500m).

While the wiring for LinkConnect in SmartLink and Paradigm and EchoConnect for

Echo systems are similar, the communication and control types are not

interchangeable. Each product family requires a dedicated station infrastructure

that cannot be shared.

Step 1: Pull Belden 8471 (approved equal) control wiring and a 14 AWG ground into the

enclosure through the conduit opening previously prepared.

Step 2: Strip 3/16” (5mm) of insulation from the ends of each wire pair.

Step 3: Remove the EchoConnect/ LinkConnect (LON) connector from the right I/O

board.

Step 4: Loosen the terminal screws for as many wire pairs you are terminating.

Step 5: Insert each white wire (typical) from the pairs into a “B” terminal on the connector

and tighten the screws firmly to secure the wire into the connector.

Step 6: Insert each black wire (typical) from the pairs into an “A” terminal, next to the

previously installed “B” terminal on the connector and tighten the screws firmly to

secure the wire into the connector.

It is required that you terminate LinkConnect / EchoConnect station wiring and the

auxiliary power wiring in the same enclosure (rack 1) where the station power

module and architectural control processor will be installed.

Step 7: Terminate the 14 AWG (2.5mm

2

) ground wire to the DRd ground bus bar in the

rear of the enclosure.

Step 8: Replace the connector to the right I/O board.

UL 924 Listed Panic Input

Termination is available for a UL 924 Listed dry contact input for

control bypass. The two pin panic connector, labeled “PANIC”,

accepts 16 AWG (1.5mm

2

) wire. Reference the related

Architectural Control Processor Configuration Manual for panic

look setup.

Step 1: Pull panic wiring into the enclosure through the conduit

opening previously prepared.

Step 2: Strip 3/16” (5mm) of insulation from the ends of each

wire.

Step 3: Remove the 2 pin Panic connector from the right I/O board.

Step 4: Loosen the terminal screws.

Step 5: Insert each wire into the terminals on the connector and tighten the screws firmly

to secure the wires into the connector.

Step 6: Replace the connector to the right I/O board.

ER /

RU/BATT

COM PANI C

J9

DUAL RACKS

CDI

4 Terminate Wiring 35

Page 40

DMX Control Wiring

12345678

n/c

n/c

COM

Data +

Data - ORG

W/ORG

W/BRN

COM

Data +

Data - ORG

W/ORG

W/BRN

Use the DMX Pass-Thru

connector

If daisy-chaining to

another rack or

DMX device...

DMX A

Thru

DMX B

Thru

1234567812345678

COM

Data +

Data +

Data -

Data - ORG

W/ORG

BRN

GRN

W/GRN

BLU

W/BLU

W/BRN

ORG

W/ORG

BRN

GRN

W/GRN

BLU

W/BLU

W/BRN

COM

From source

DMX A

From source

DMX B

Note:

It is required that you terminate DMX wiring in the same enclosure (rack 1) where

the architectural control processor will be installed.

DMX wire preparation and termination will vary with the type of wire and termination kit

being used. Please refer to the instructions supplied with the DMX termination kit for

specific wire preparation.

DMX Input Wire Termination using the Screw Terminals Connector

The graphic to the left illustrates DMX termination layout for the

screw-terminal connectors that are intended for use with Belden

9729 cable (or approved equal) cable type.

Screw terminal connectors are supplied as standard in the DMX

Preparation Kit w/ Screw Connector, part number 4100A1012.

Be aware that cable other than Belden 9729 may have a different

color code for its wire pairs.

DMX Input Wire Termination using the Insulation Displacement Connector (IDC)

The graphic below illustrates DMX termination layout for an insulation displacement

connector. This connector type is intended for use with Belden 1583A (or approved equal,

such as Category 5, 5E, or 6) cable type. Be aware that cable other than Category 5 may

have a different color code for its wire pairs.

If daisy-chaining to

From source

another rack or

DMX A

DMX device...

COM

Data + (Red)

Data - (Black)

n/c

n/c

n/c

n/c

n/c

12345678

Reference and follow the DMX Cable Preparation for IDC Termination instruction sheet that

is shipped with the insulation displacement pluggable connector kit (part number

4100A1013).

AX12X Cross-bussed Interconnection

Termination is provided for connection of a second DRd enclosure when installed in a

cross-bussed application. This termination point is labeled “Dual Enclosures” on the right

I/O board.

An interconnect cable is provided which connects enclosure 1, which is the DRd with the

ACP installed, to enclosure 2, which is the secondary enclosure in the cross-bussed

system. This cable is labeled at both ends, one end indicating enclosure 1 and the other

end indicating enclosure 2. You must have installed this cable to the correct enclosure for

proper operation.

This interconnection of enclosures allows full control of both DRd enclosures from only one

Architectural Control Processor installed in rack 1. This may only be used in a cross-bussed

applications.

Reference the Unison Auxiliary Enclosure Installation Manual for instructions to accomplish

this termination.

36 DRd Enclosure Installation Manual

Page 41

Terminate the Unison Options (URTO and UBPO)

LO

Termination is available on the right I/O for the either the Unison

Ride Through Option or the Unison BatteryPack Option. You may

use only one of these option kits per enclosure.

Step 1: Notice the two pin connector labeled “RideThru / Batt” on

the right I/O board.

Step 2: Follow the instructions provided in the Setup Guide,

provided with the option kit, for appropriate termination.

APM

-THRU

B

+ B- COM

DMXB DMXA

SRC OFF END

Note:

Terminate DMX

DMX requires 120 termination at the last DMX

device in the control run. Since a DRd with a

Paradigm module installed can utilize up to two DMX

inputs (2 DMX runs) the right I/O board provides

convenient termination switches for use.

Notice the two termination switches labeled DMXA