Page 1

Auxiliary Enclosure Series

Installation Manual

Revision A

Copyright © 2008 Electronic Theatre Controls, Inc.

All Rights reserved.

Product information and specifications subject to change.

Part Number:

7183M2110

Released: 08/2008

Rev A

Page 2

ETC®, Unison®, EDMX™ are either registered tr ademarks or trademarks of Electronic Theatre Controls, Inc. in

the United States and other countries.

All other trademarks, both marked and not marked, are the property of their respective owners.

ETC permits the reproduction o f materials in this manual only for non-commercial pur pose s. All other rights are

reserved by ETC.

ETC int en ds this documen t, whet her printe d or electronic, to b e provided in i ts entirety.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warnings and Notice Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Contacting ETC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Unison Auxiliary Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Prepare for Installation . . . . . . . . . . . . . . . . .4

Unpack and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Main Circuit Breaker Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Using 90°C Wire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Maximum Current Draw of Enclosures . . . . . . . . . . . . . . . . . . . . . . .5

Short Circuit Current Rating (SCCR) . . . . . . . . . . . . . . . . . . . . . . . . .5

Where to Install the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Enclosure Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . .6

Installation Environment Requirements . . . . . . . . . . . . . . . . . . . .7

Wire Routing and Specification . . . . . . . . . . . . . . . . . . . . . . . . . .7

Install Enclosures . . . . . . . . . . . . . . . . . . . . .9

Mounting Auxiliary and DRd Enclosures Together. . . . . . . . . . . . . . .9

Rough-in Conduit and Wiring . . . . . . . . . . .11

Rough-in Line Conduit to the Auxiliary Enclosure . . . . . . . . . . . . . .12

Connect Line Power . . . . . . . . . . . . . . . . . .14

Final Installation and Power Up . . . . . . . . . 18

Check Main Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Sealing Enclosure Air Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Table of Contents i

Page 4

Introduction

Welcome to the installation manual for Unison® AX series auxiliary enclosures. This

manual contains the procedures for safe and efficient installation of an AX main breaker or

AX main lug auxiliary enclosure, and the cross-bussed AX12X auxiliary enclosure.

AX Series Auxiliary Enclosures

Series Voltage Notes

AX6-MCB-1-150 100-120 VAC 150A main breaker for DRd6 – 1Ø, 3-wire

AX6-MCB-3-100 100-277 VAC 100A main breaker for DRd6 – 3Ø, 4-wire

AX12-MCB-1-300 100-120 VAC 300A main breaker for DRd12 – 1Ø, 3-wire

AX12-MCB-3-200 100-277 VAC 200A main breaker for DRd12 – 3Ø, 4-wire

AX12X Series Cross-bussed Auxiliary Enclosures

Series Voltage Notes

AX12X-MCB-1-400 100-120 VAC 400A main breaker for (2) DRd12 – 1Ø, 3-wire

AX12X-MCB-3-400 100-277 VAC 400A main breaker for (2) DRd12 – 3Ø, 4-wire

AX12X-ML-1-600 100-120 VAC

AX12X-ML-3-400 100-277 VAC

Main Lug with cross-bussing for (2) DRd12 enclosures – 1Ø,

3-wire

Main lug with cross-bussing for (2) DRd12 enclosures – 3Ø,

4-wire

Warnings and Notice Conventions

These symbols are used in ETC documentation to alert you to danger or important

information:

Note:

CAUTION:

WARNING:

WARNING:

Notes are helpful hints and information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or

unwanted consequences of an action, potential for data loss or an equipment

problem.

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an

action.

RISK OF ELECTRIC SHOCK! This warning statement indicates situations

where there is a risk of death by electric shock.

1 Unison Enclosure Installation

Page 5

Contacting ETC

For questions about Unison enclosure system delivery, contact ETC Systems Group. For

general information, your most convenient resources are the references provided in this

manual. To search more widely try the ETC web site at www.etcconnect.com.

For technical questions about Unison enclosure systems, contact ETC Technical Services

directly at one of the offices listed below. Emergency service is available from all ETC

offices outside of normal business hours. When calling for assistance, please have the

following information handy:

• Your location and job name.

• A complete list of ETC equipment.

• A complete list of other installed products and components connected to the system

you are troubleshooting.

• DMX control source, if any.

Americas

ETC International

Technical Services Department

3031 Pleasant View Road

Middleton, WI 53562

800-775-4382 (USA, toll-free)

+1-608 831-4116

service@etcconnect.com

Asia

ETC Asia, Ltd.

Technical Services Department

Room 1801, 18/F, Tower 1, Phase 1

Enterprise Square

9 Sheung Yuet Road

Kowloon Bay, Kowloon, Hong Kong

+852 2799 1220

service@etcasia.com

United Kingdom

Electronic Theatre Controls, Ltd.

Technical Services Department

26 - 28 Victoria Industrial Estate

Victoria Road,

London W3 6UU, UK

+44 (0)20 8896 1000

service@etceurope.com

Germany

Electronic Theatre Controls, GmbH

Technical Services Department

Ohmstrasse 3

93607, Holzkirchen, Germany

+49 (80 24) 47 00-0

techserv-hoki@etcconnect.com

Please email comments about this manual to: TechComm@etcconnect.com

Introduction 2

Page 6

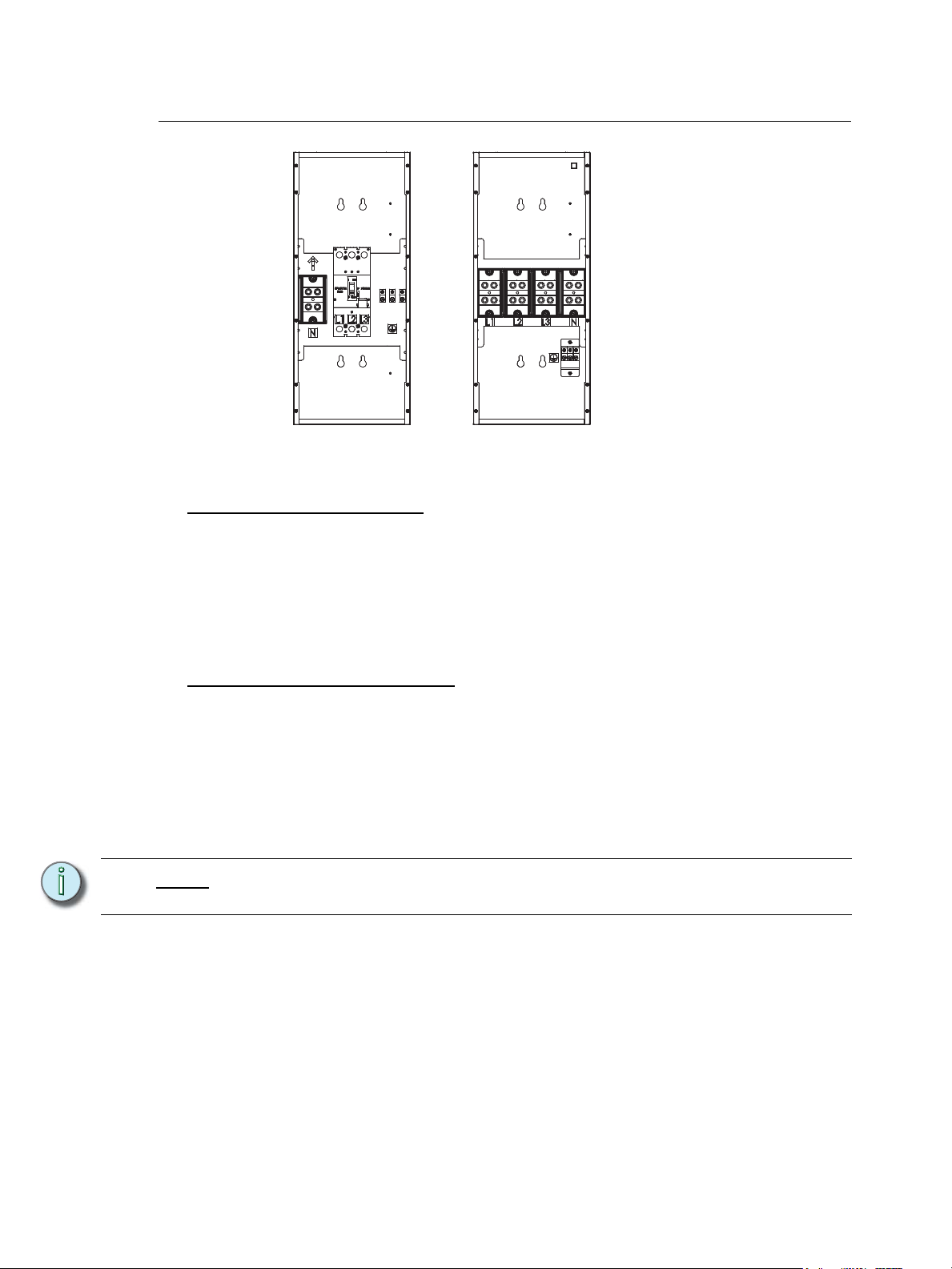

Unison Auxiliary Enclosure

Main LugMain Circuit

Breaker

A main circuit breaker auxiliary enclosure is equipped with breakers that are sized for

maximum load capacity for the DRd configuration.

AX Series Enclosure Options

Unison AX series enclosures are designed to provide main lug or main circuit breaker input

feed provisions for single DRd6 or DRd12 applications.

• AX6-MCB-1-150 – includes main breaker for DRd6, 150A/1Ø, 3-wire

• AX6-MCB-3-100 – includes main breaker for DRd6, 100A/3Ø, 4-wire

• AX12-MCB-1-300 – includes main breaker for DRd12, 300A/1Ø, 3-wire

• AX12-MCB-3-200 – includes main breaker for DRd12, 200A/3Ø, 4-wire

AX12X Series Enclosure Options

Unison AX12X cross-bussing enclosures are designed to provide main lug or main breaker

input feed termination for cross-bussed DRd12 applications.

• AX12X-ML-1-600 – includes cross-bussed main lugs for (2) DRd12, 600A/1Ø, 3-wire

• AX12X-ML-3-400 – includes cross-bussed main lugs for (2) DRd12, 400A/3Ø, 4-wire

• AX12X-MCB-1-400 – includes main breaker for (2) DRd12, 400A/1Ø, 3-wire

• AX12X-MCB-3-400 – includes main breaker for (2) DRd12, 400A/3Ø, 4-wire

Note:

A 600A single phase main circuit breaker is not available due to NEC wire bending

space limitations.

3 Unison Enclosure Installation

Page 7

Chapter 1

Prepare for Installation

Unpack and Inspect

Before you begin installation, check your shipment and confirm it arrived complete and

undamaged.

Step 1: Check the shipping container for physical damage.

Step 2: If you find damage, document it to help with a claim against your shipper.

Step 3: Unpack your order and check the contents against the packing list to be sure

your order is complete.

Step 4: If you discover a problem, call ETC Systems Group at (608) 831-4116.

Main Circuit Breaker Protection

Before you begin installing the Unison auxiliary enclosure, make sure you have installed a

main circuit breaker cabinet or other readily accessible input power disconnect device. In

certain bussed and cross-bussed systems, this disconnect device may be the Unison AX

series auxiliary enclosure with a main circuit breaker.

WARNING:

Note:

Auxiliary enclosures installed without an accessible power disconnect

device cannot be serviced or operated safely. Follow all local codes and

restrictions.

Before removing dimmer or control modules for service, de-energize the main

feed to the dimmer rack and follow appropriate Lockout and Tagout procedures

as described in NFPA Standard 70E. It is important to note that electrical

equipment such as dimmer enclosures can present an arc flash safety hazard if

improperly serviced. This is due to available large Short Circuit Currents on the

feeders of the equipment. Any work on energized equipment must comply with

OSHA Electrical Safe Working Practices.

Using 90°C Wire

The AX MCB cabinets are listed for both copper and aluminum feed wiring, while the ML

cabinets are listed for Copper wire only. Bus cabling to DRd enclosures must use the

included copper cable to satisfy the requirement that the DRd is fed by copper wire only and

to meet UL bend radius limitations. All terminations in the AX and DRd cabinets are listed

for 75°C.

Note:

The terminals may be marked AL9CU indicating a 90°C rating; this is the lug

manufacturer’s rating - not the tested UL listing for the AX enclosure.

1 Prepare for Installation 4

Page 8

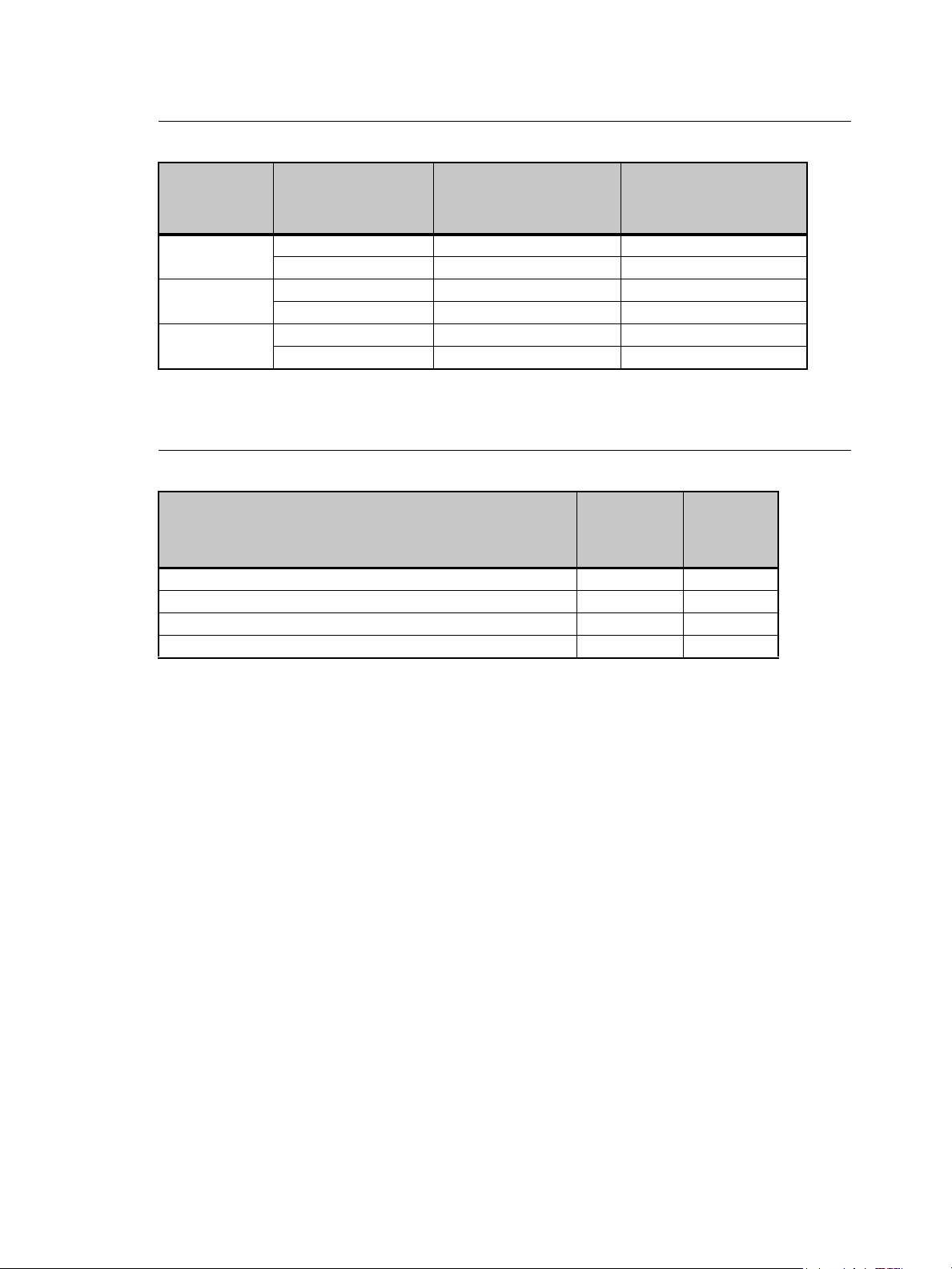

Maximum Current Draw of Enclosures

Enclosure

Type

AX6

AX12

AX12X

a)With 15A modules.

Phase Type

Single phase (1Ø)

Three phase (3Ø)

Single phase (1Ø)

Three phase (3Ø)

Single phase (1Ø)

Three phase (3Ø)

UL Market

Maximum Current

Draw

120A –

80A 60A

240A –

160A 120A

480A –

320A 240A

240V Maximum

Current Draw

Short Circuit Current Rating (SCCR)

SCCR at

Enclosure Configuration

DRd6 with AX6 main circuit breaker enclosure 100,000A 65,000A

DRd12 with AX12X (cross-bussed) main lug enclosure 22,000A 22,000A

DRd12 with AX12 main circuit breaker enclosure 100,000A 65,000A

DRd12 with AX12X main circuit breaker enclosure 100,000A 65,000A

a)Ratings are for three phase systems.

100-120

a

VAC

a

SCCR at

240-277

a

VAC

5 Unison Enclosure Installation

Page 9

Where to Install the Enclosure

Unison DRd enclosures require 12" (305mm) top clearance for proper

airflow through the cabinet. For sufficient door clearance, install the DRd

enclosure with at least 17" (432mm) of front clearance and 6" (152mm)

of clearance to the left of the door hinge from walls or other equipment.

Unison auxiliary enclosures are designed to be surface mounted on load bearing walls in

an electrical closet or a room with restricted public access. It is recommended that you

install the enclosure at least 36" (914.4mm) off the floor surface.

Clearance Requirements

6”

(152 mm)

17”

(432 mm)

12”

(305 mm)

36”

(914.4 mm)

Note:

Additional Unison DRd and auxiliary enclosures of the same size are the

exception to the 6" hinge side clearance rule. Unison enclosures are designed for

side by side use without issue.

Enclosure Dimensions and Weights

Enclosure

Type

AX6 MCB

enclosure

AX12 MCB

enclosure

AX12X ML

enclosure

AX12X MCB

enclosure

a)Note: All weights are approximate.

Height Width Depth

inches mm inches mm inches mm lbs kgs lbs kgs

21.8 553.7 13 330 8 203 27.6 12.5 35 16

31 787 13 330 8 203 33 15 40 20

31 787 13 330 8 203 28 12.7 35 16

31 787 13 330 8 20 33 15 40 20

Product

Weight

a

Shipping

Weight

a

1 Prepare for Installation 6

Page 10

Installation Environment Requirements

• For your safety, you should install a main circuit breaker cabinet or other readily

accessible input power disconnect device in the same area as the Unison auxiliary

enclosure. For bussed enclosure installations, this device may be the auxiliary

enclosure. Main breakers not in the same room must have a physical means to be

locked off.

Note:

Before removing dimmer or control modules for service, de-energize the main

feed to the dimmer rack and follow appropriate Lockout and Tagout procedures

as described in NFPA Standard 70E. It is important to note that electrical

equipment such as dimmer enclosures can present an arc flash safety hazard if

improperly serviced. This is due to available large Short Circuit Currents on the

feeders of the equipment. Any work on energized equipment must comply with

OSHA Electrical Safe Working Practices.

• A clean (not dusty) temperature-controlled environment with an ambient temperature

of 32 to 104°F (0 to 40°C) and ambient humidity of 10 to 90%, non-condensing.

CAUTION:

HVAC systems must at all times maintain the specified ambient temperature at the

enclosure. Unison systems operating within 10°F (5°C) of the upper or lower

temperature limits must strictly follow installation and operation guidelines to

operate reliably.

• Restricted public access to prevent tampering.

• Soundproofing or performance area separation to muffle ventilation fan noise.

Wire Routing and Specification

Unison AX series enclosures have conduit knockouts on both sides of the cabinet for feed

through to the adjacent DRd enclosure(s). The top and bottom are intentionally left blank to

allow holes to be punched to match the incoming conduit.

40°

100°

90°

30°

80°

70°

20°

60°

10°

50°

40°

0°

30°

20°

-10°

10°

0°

-18°

CAUTION:

Do not route line (input feed) wires through the back panel. Doing so requires bend

radii that place undue stress on the input lugs, may damage insulation, and will

violate the UL listing of this enclosure.

CAUTION:

Line (feed) lugs for the Unison AX main circuit breaker enclosures are UL/cUL

listed for use with both copper and aluminum wire, while the main lug enclosures

are listed for copper wire only. Load side terminations used to feed the DRd

enclosures must be the included extra flexible copper wire.

7 Unison Enclosure Installation

Page 11

AX and AX12X Auxiliary Enclosure

It is required that line feed enters from the top or bottom panels of the enclosure. The side

knockouts are provided for cross-bussing and data interconnect feed through to the

adjacent DRd dimming enclosure(s). The corresponding number of chase nipples with

integral bushings are included.

Wire Access

Location

Top of enclosure

Bottom of

enclosure

Left side

Right side

Wire

Feed wire Interconnect wiring to

DRd enclosure

Acceptable Not recommended

Preferred Not recommended

Not recommended Preferred

Not recommended Preferred

1 Prepare for Installation 8

Page 12

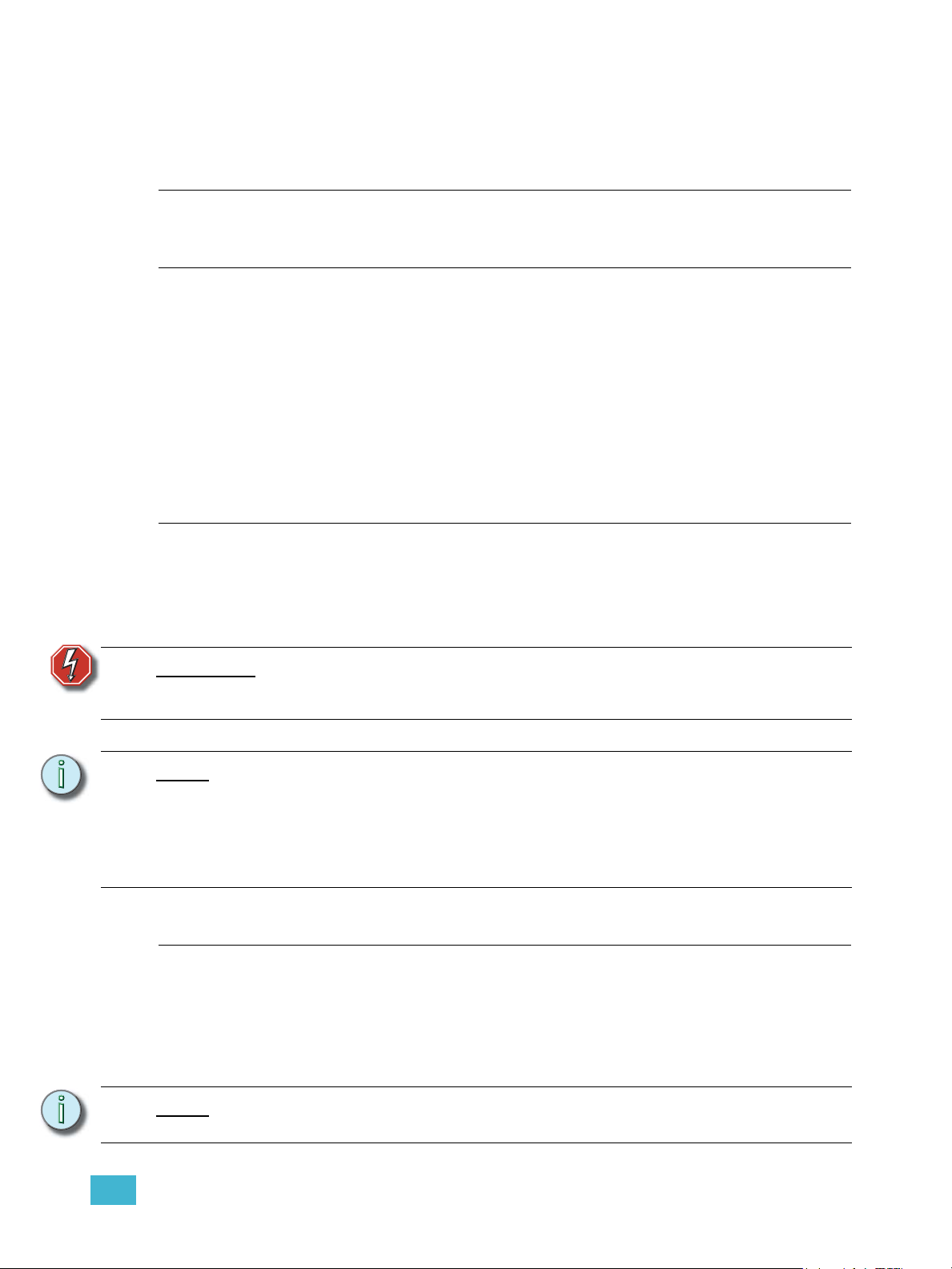

Chapter 2

AX6 / DR6 - 16.3”

AX12 / DR12 - 19.9”

16” 11”

AX6 / DR6 - 5.7”

AX12 / DR12 - 7.7”

22”

AX6 / DR6 - 21.9”

AX12 / DR12 - 31”

10.7”

6.3”

AX6 / DR6 - 10.6”

AX12 / DR12 - 7.7”

17” 17”13”

DRd DRdAX

Install Enclosures

Mounting Auxiliary and DRd Enclosures Together

One DRd may be bussed to the AX series auxiliary enclosure, which contains a main circuit

breaker (MCB) for power distribution to the adjacent DRd enclosure.

Two DRd12 enclosures may be cross-bussed to an AX12X which is designed to provide

main lug or main breaker input feed termination to the adjacent DRd12 enclosures.

The wall must be strong enough to hold all enclosures fully populated with modules, conduit

and wire. Reference “Where to Install the Enclosure,” page 6 for weight, dimension and

clearance requirements.

Note:

The AX series enclosure is best installed to the left of the DRd in main lug and

main breaker applications and must be installed between two DRd12 enclosures

in a cross-bussed application.

Step 1: Determine where your enclosures will be installed using the weight and

dimension requirements detailed in “Where to Install the Enclosure,” page 6.

Step 2: Use the measured slot dimensions located in the graphic below to mark the hole

locations for the mounting hardware.

Step 3: Drill the holes and install the mounting hardware for each enclosure.

• Four 3/8” (8mm) bolts or screws 2 to 4" (50-100mm) long, and suitable wall

9 Unison Enclosure Installation

plugs are suggested mounting hardware (lag bolts recommended).

• Both the surface and the mounting hardware must support the weight of

the enclosure unit fully populated with modules.

• Expose at least 1" (25mm) of threads for mounting.

Page 13

Step 4: Remove the knockouts from the side conduit plug on the DRd and auxiliary

enclosure before installation. Only remove the knockouts that are adjacent to

another enclosure.

Step 5: Install the DRd first, following the instructions as outlined in the DRd Enclosure

Installation Manual.

Step 6: Align the auxiliary enclosure against the left side of the DRd enclosure and mount

it to the previously installed mounting hardware. Notice, with conduit holes mated

the bolt spacings are on 16" centers (top left DRd and top left AX enclosure) for

installation convenience.

Step 7: For cross-bussed DRd12 enclosure installations, install the second DRd12 by

following steps 4 through 6 above.

Step 8: Check that each enclosure is level and plumb then tighten the mounting

hardware for a secure installation.

2 Install Enclosures 10

Page 14

Chapter 3

DRd enclosure with AX enclosure

Two DRd12 enclosures with AX12X enclosure

Rough-in Conduit and Wiring

See “Wire Routing and Specification” on page 7. Line or (input feed) wires for standard AX

series enclosures should enter through the top or bottom.

All terminations are accessible from the front of the enclosure.

11 Unison Enclosure Installation

Page 15

Rough-in Line Conduit to the Auxiliary Enclosure

Line input may enter the auxiliary enclosure from

the top or bottom.

The ETC supplied line feed interconnect cables

will feed through the side conduit knockouts to the

adjacent DRd. Reference “Route and Connect

Interconnect Cables to Adjacent DRd

Enclosure(s)”, page 17 for interconnect cable

termination instructions.

Line input wires in main lug, main breaker, or cross-bussed DRd enclosure applications

terminate first in the Auxiliary enclosure and then are fed through the side conduit

knockouts to the adjoining DRd enclosure(s).

The line feed-through (interconnect) cables for phase, neutral and ground lugs in the

auxiliary enclosure are connected for you at the factory. Your enclosure is supplied with one

or two sets of interconnect cables depending on the model ordered.

Step 1: Plan wire entry in to the enclosure. See “Wire Routing and Specification” on

Step 2: Remove the side conduit knockout from adjoining side of the auxiliary enclosure

Step 3: Install the ETC supplied nylon insulated chase nipple to the knockouts between

Step 4: Remove the auxiliary enclosure front cover, and if necessary, the top or bottom

Step 5: Punch conduit holes, top or bottom, as required by the wire entry plan.

Step 6: Install conduit fittings or insert fish paper lining material into the opening.

Step 7: Be sure there are minimal air gaps. See “Sealing Enclosure Air Leaks” on

CAUTION:

page 7.

and the DRd enclosure. When installing in a cross-bussed application, remove

both side knockouts.

the auxiliary and DRd enclosure(s).

front trim covers for complete access to the lugs.

page 18.

Wire openings must have fittings, grommets or fish paper lining material to protect

wire and cable insulation from damage by sharp metal edges and to prevent air

leaks.

When using the 400A breaker frame you must replace the plastic lug covers for

compliance and safe operation.

3 Rough-in Conduit and Wiring 12

Page 16

Main Lug Support Panel Breaker Position

The unit ships with the support panel in the top feed position (shifted to the bottom of the

AX). These positions are to comply with UL and NEC wire bending space requirements.

Step 1: If you are bottom feeding the AX, loosen the 4 nuts from the sides of the

enclosure.

Step 2: Reposition the support panel with the breaker on the main lugs to the top

position.

Step 3: Tighten the nuts.

13 Unison Enclosure Installation

Page 17

Chapter 4

Connect Line Power

WARNING:

CAUTION:

Note:

Line input wires in main breaker or cross-bussed DRd applications terminate in the Auxiliary

enclosure. Interconnect cables are fed through the side conduit knockouts of the auxiliary

enclosure and connect to the adjacent DRd enclosure(s).

Main Breaker power input options include:

• AX6-MCB-1-150 – 1Ø, 3-wire, 150A

All enclosure terminations must be done with the power off. Enclosures

installed without an accessible power disconnect device cannot be serviced

or operated safely. In some instances, this device may be an auxiliary

enclosure with a main circuit breaker. Follow all local codes and

restrictions.

Load wires used with ETC dimming systems must be copper. Do not use wire

containing aluminum. Line wires must be copper for the AX Main Lug enclosures.

Main circuit breaker enclosures are listed for use with copper or aluminum wire.

Before removing dimmer or control modules for service, de-energize the main

feed to the dimmer rack and follow appropriate Lockout and Tagout procedures

as described in NFPA Standard 70E. It is important to note that electrical

equipment such as dimmer enclosures can present an arc flash safety hazard if

improperly serviced. This is due to available large Short Circuit Currents on the

feeders of the equipment. Any work on energized equipment must comply with

OSHA Electrical Safe Working Practices.

• AX6-MCB-3-100 – 3Ø, 4-wire, 100A

• AX12-MCB-1-300– 1Ø, 3-wire, 300A

• AX12-MCB-3-200 – 3Ø, 4-wire, 200A

• AX12X-MCB-1-400 - 1Ø, 4 wire, 400A (use with 2 DRd12 cross-bussed enclosures)

• AX12X-MCB-3-400 – 3Ø, 4-wire, 400A (use with 2 DRd12 cross-bussed enclosures)

Main Lug power input options include:

• AX12X-ML-1-600 – 1Ø, 3-wire, 600A Main lugs (use with 2 DRd12 cross-bussed

enclosures)

• AX12X-ML-3-400 – 3Ø, 4-wire, 400A Main lugs (use with 2 DRd12 cross-bussed

enclosures)

4 Connect Line Power 14

Page 18

Step 1: Pull the line phase, neutral, and ground cables to the enclosure through the

Phase lugs

Neutral lugs

Ground lugs

Neutral lugs

Phase lugs

Ground lugs

Main Lug

Main Circuit Breaker

conduit openings previously prepared.

Step 2: Strip one inch of insulation from the end of each cable and terminate them to the

lugs. Line connections are labeled L1, L2, L3 (for three phase) and N. The

equipment grounding lug is labeled with the universal grounding symbol for easy

identification.

Step 3: Tighten the lugs to the correct torque based on cable size. Refer to the following

table.

15 Unison Enclosure Installation

Page 19

AX

Enclosure

Wire

Lug Wire Range

(Qty.)

Wire Size for

Torque (Qty.)

Lug Wire

Torque

Wrench

Size

3-phase

AX-MCB

1-phase

AX-MCB

AX12X ML

8 AWG to 350 kcmil

Phase

(1)

(10 to 185mm

2

)

4 AWG to 500 kcmil

Neutral

(2)

(25 to 240mm

2

)

Ground 6 to 2/0 AWG

2/0 AWG to 400 kcmil

(2)

2

)

Phase

(70 - 185 mm

or

1 AWG to 600 kcmil

(1)

(50 to 300 mm

2

)

4 AWG to 500 kcmil

Neutral

(2)

(25 to 240mm

2

)

Ground 350 kcmil to 1 AWG

4 AWG to 500 kcmil

Phase

(2)

(25 to 240mm

2

)

4 AWG to 500 kcmil

Neutral

(2)

(25 to 240mm

2

)

Ground 6 to 2/0 AWG

3 to 1 AWG (1)

(25 to 35mm

2

)

1/0 AWG to 350

(50 to 185mm

2

)

4 AWG to 500 kcmil

(2)

(25 to 240mm2)

2/0 to 3 AWG (1)

4 to 6 AWG (1)

2/0 AWG to 400 kcmil

(2)

(70 - 185 mm

2

)

or

1 AWG to 600 kcmil

(1)

(50 to 300 mm

2

)

4 AWG to 500 kcmil

(2)

(25 to 240mm2)

6 to 2 AWG (1)

1 AWG to 350 kcmil

(1)

4 AWG to 500 kcmil

(2)

(25 to 240mm2)

4 AWG to 500 kcmil

(2)

(25 to 240mm2)

2/0 to 3 AWG (1)

4 to 6 AWG (1)

150 in-lb

(17 Nm)

275 in-lb

(31 Nm)

375 in-lb

(42.3 Nm)

50 in-lb

(5.65 Nm)

45 in-lb

(5.1 Nm)

375 in-lb

(42.3 Nm)

375 in-lb

(42.3 Nm)

375 in-lb

(42.3 Nm)

375 in-lb

(42.3 Nm)

375 in-lb

(42.3 Nm)

200 in-lb

(22.6 Nm)

375 in-lb

(42.4 Nm)

5/16”

3/8”

3/16”

5/16”

3/8”

3/8”

3/8”

3/8”

3/16”

4 Connect Line Power 16

Page 20

Route and Connect Interconnect Cables to Adjacent DRd Enclosure(s)

ETC has supplied extra flexible wire for phase, neutral, and ground lugs from the auxiliary

enclosure to the DRd enclosure(s). Once your auxiliary and DRd enclosures are installed,

feed the load wires through the side chase nipples to the adjacent DRd enclosure phase,

neutral, and ground lugs. Your AX6, AX12, or AX12X will be supplied with one or two sets

of cables, depending on the model ordered.

Step 1: Route the ETC supplied interconnect cabling through the conduit knockouts on

either side of the auxiliary enclosure to the adjacent DRd enclosure(s).

.

Note:

Tie wrap the interconnect cables to the back wall of the DRd immediately after

they are pulled through the conduit fitting. This prevents the cables from

unnecessarily restricting the air flow to the fan.

Step 2: Pull each cable to the appropriate lug. It is necessary to cut the cable to the

pre-marked length in DRd6 applications

Step 3: Attach each cable to its appropriate phase, neutral and ground lugs inside the

DRd enclosure using the supplied copper foil to avoid damaging the fine

stranding of the extra flex wire.

Note:

Step 4: Tighten the lugs to the correct torque based on cable size. Refer to the table on

CAUTION:

Step 5: Fill empty spaces of the conduit openings with UL/CE approved filler.

CAUTION:

17 Unison Enclosure Installation

When a single phase auxiliary enclosure is ordered from the factory, the

interconnect cables will be installed in a single-phase configuration. Reference the

DRd Enclosure Installation Manual for instructions to configuring the DRd

enclosure bus for single phase operation.

the previous page.

Failure to use the proper torque when tightening the set screws can cause

premature failure of the equipment.

Air leaks can cause DRd enclosures to shut down due to insufficient air flow.

Reference “Sealing Enclosure Air Leaks,” page 18.

Page 21

Chapter 5

Final Installation and Power Up

It’s a good idea to look over the entire installation before applying power to the system.

WARNING:

Note:

Step 1: Clean out dust and debris from the interior.

Step 2: Check for loose connections, bare wires and damaged insulation.

Step 3: Check for and stop air leaks left in conduit openings, empty screw holes or

Power must be turned OFF when you perform this procedure.

Before removing dimmer or control modules for service, de-energize the main

feed to the dimmer rack and follow appropriate Lockout and Tagout procedures

as described in NFPA Standard 70E. It is important to note that electrical

equipment such as dimmer enclosures can present an arc flash safety hazard if

improperly serviced. This is due to available large Short Circuit Currents on the

feeders of the equipment. Any work on energized equipment must comply with

OSHA Electrical Safe Working Practices.

misaligned panels. For complete instructions for this procedure reference

Sealing Enclosure Air Leaks below.

Check Main Power Wiring

With all modules removed and the power harness to all dimming engines unplugged, check

resistance between phases, neutral and ground busses with a digital voltmeter (DVM).

• Phase to phase resistance should be 10M Ohm or higher.

• Phase to ground resistance should be 10M Ohm or higher.

• Neutral to ground resistance should be 0 Ohm.

• Phase to neutral resistance should be 10M Ohm or higher.

Sealing Enclosure Air Leaks

After you have attached all the conduit to the enclosure(s) and connected all wiring, you

must seal any air leaks created during the installation process. Use UL/cUL approved filler.

Step 1: Seal all conduit access holes.

Step 2: Completely cover all conduit openings with fish paper and UL/cUL approved

filler.

Step 3: Seal any air gaps caused by bent access panels.

Step 4: Fill in any gaps inside partially filled wiring conduit.

Step 5: Fill in other gaps or holes in the cabinet created during installation.

5 Final Installation and Power Up 18

Page 22

Step 6: Any enclosures that are installed side-by-side (bolted together) should only have

minimal airflow between them.

CAUTION:

Air leaks can cause DRd enclosures to overheat during operation and shut down.

Air leaks can also cause a shut down to do an “Airflow Error”, meaning that too

little air is flowing through the front of the enclosure where it is needed to cool the

dimmers.

19 Unison Enclosure Installation

Page 23

5 Final Installation and Power Up 20

Page 24

Corporate Headquarters

London, UK

Rome, IT

Unit 26-28, Victoria Industrial Estate, Victoria Road, London W3 6UU, UK Tel +44 (0)20 8896 1000 Fax +44 (0)20 8896 2000

Via Ennio Quirino Visconti, 11, 00193 Rome, Italy Tel +39 (06) 32 111 683 Fax +44 (0)20 8896 2000

Holzkirchen, DE

3031 Pleasant View Road, P.O. Box 620979, Middleton, Wisconsin 53562-0979 USA Tel +608 831 4116 Fax +608 836 1736

Ohmstrasse 3, 83607 Holzkirchen, Germany Tel +49 (80 24) 47 00-0 Fax +49 (80 24) 47 00-3 00

Hong Kong Rm 1801, 18/F, Tower 1 Phase 1, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon, Hong Kong Tel +852 2799 1220 Fax +852 2799 9325

Service:

(Americas) service@etcconnect.com

Web:

www.etcconnect.com

7183M2110

Rev A Released 08/2008

Copyright © 2008 ETC. All Rights Reserved. Product information and specifications subject to change.

(UK) service@etceurope.com (DE) techserv-hoki@etcconnect.com

(Asia) service@etcasia.com

Loading...

Loading...