Page 1

ETC Installation Guide

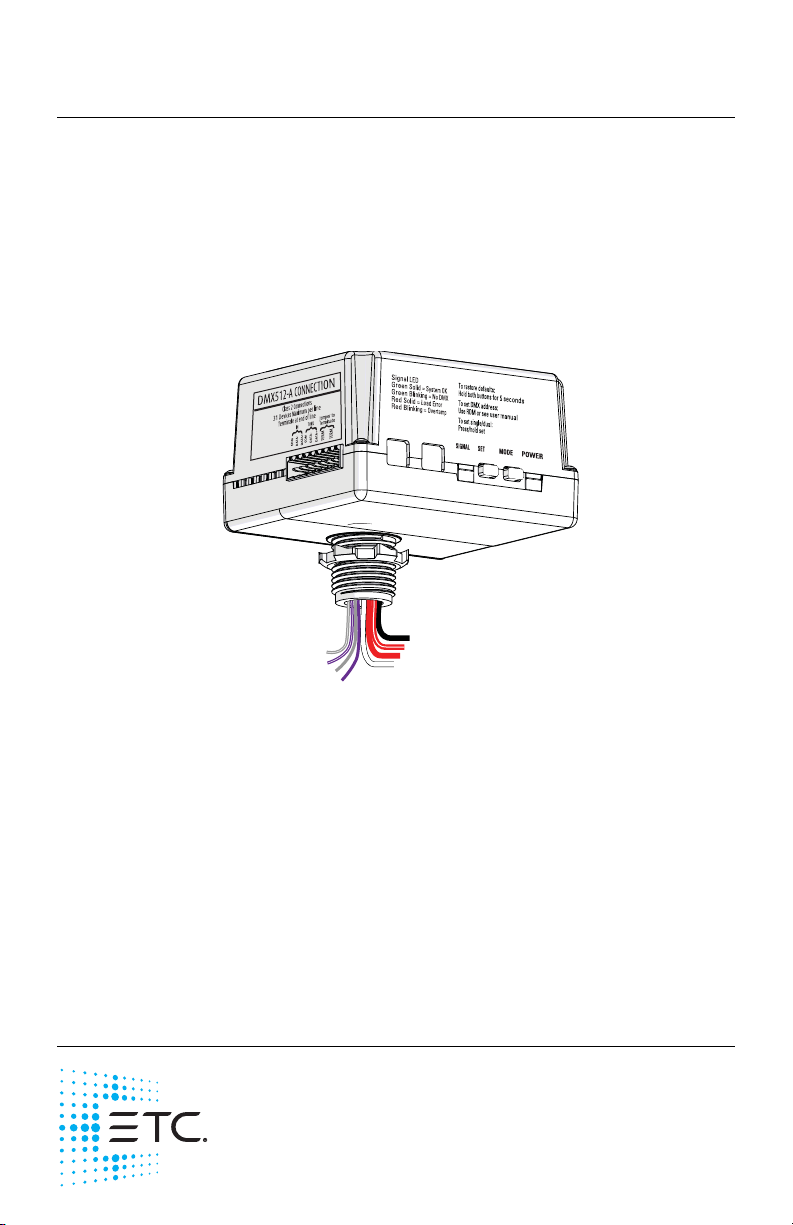

Unison Foundry™ 0–10V Controller

Overview

The Unison Foundry 0–10V Controller provides fully-rated 20A relays for

switched power control with 0–10V dimming for compatible fluorescent

ballasts and LED drivers. The 0–10V Controller provides two outputs of

control that can be wired to individual fixtures or used for zone control. Each

output can be configured to a separate DMX address, or both outputs can be

controlled in unison by setting the 0–10V Controller to single-channel mode

Channel Mode

(see

on

page 8

).

Control connected loads from any DMX control device. Configure the 0–10V

Controller either remotely via RDM (using a tool like ETC Net3 Concert) or

locally on the controller. See

Configure the 0–10V Controller

on

page 8

Specifications

Ambient Environment

For indoor use only. Rated for plenum use.

• 32°F to 104°F (0°C to 40°C) operating temperatures in 5–95% noncondensing humidity.

Corporate Headquarters Middleton, Wisconsin, USA Tel +608 831 4116

Service (Americas) service@etcconnect.com

London, UK Tel +44 (0)20 8896 1000 Service: (UK) service@etceurope.com

Rome, IT Tel +39 (06) 32 111 683 Service: (UK) service@etceurope.com

Holzkirchen, DE Tel +49 (80 24) 47 00-0 Service: (DE) techserv-hoki@etcconnect.com

Hong Kong Tel +852 2799 1220 Service: (Asia) service@etcasia.com

Web: etcconnect.com

specifications subject to change.

7179M2120 Rev B Released 2017-12

© 2017 Electronic Theatre Controls, Inc.

ETC intends this document to be provided in its entirety.

Product information and

.

Page 2

ETC Installation Guide

0–10V Controller

Electrical Specification

The 0–10V Controller Supports:

• Power input 120–277VAC, 60 Hz

• Maximum load rating is 20A (total connected load)

Note:

• Independent control for 0–10V fluorescent ballasts and/or LED drivers,

each is capable of sinking 100mA

Supported Load Types (all voltages):

• 20A fully-rated relay for use with general purpose, tungsten,

fluorescent, and LED lighting loads.

The maximum load on the 0–10V Controller can be split

between the two relay outputs in any combination

required for the installation, but cannot exceed 20A

total connected load for the controller.

Compliance

• UL and cUL listed

• Conforms to UL 916 (Energy Management Equipment) and UL 2043

(Plenum rated)

0–10V Controller Page 2 of 16 ETC

Page 3

ETC Installation Guide

0–10V Controller

Prepare for Installation

The 0–10V Controller is designed for mounting directly to an electrical

junction box or panel (provided by others) at the electrical lighting load,

upstream of the load in the circuit.

Note:

If your installation requires Class 2 wiring to be installed

in separate conduit, a voltage barrier installation box is

available from ETC. Order ETC part number 7187A1000.

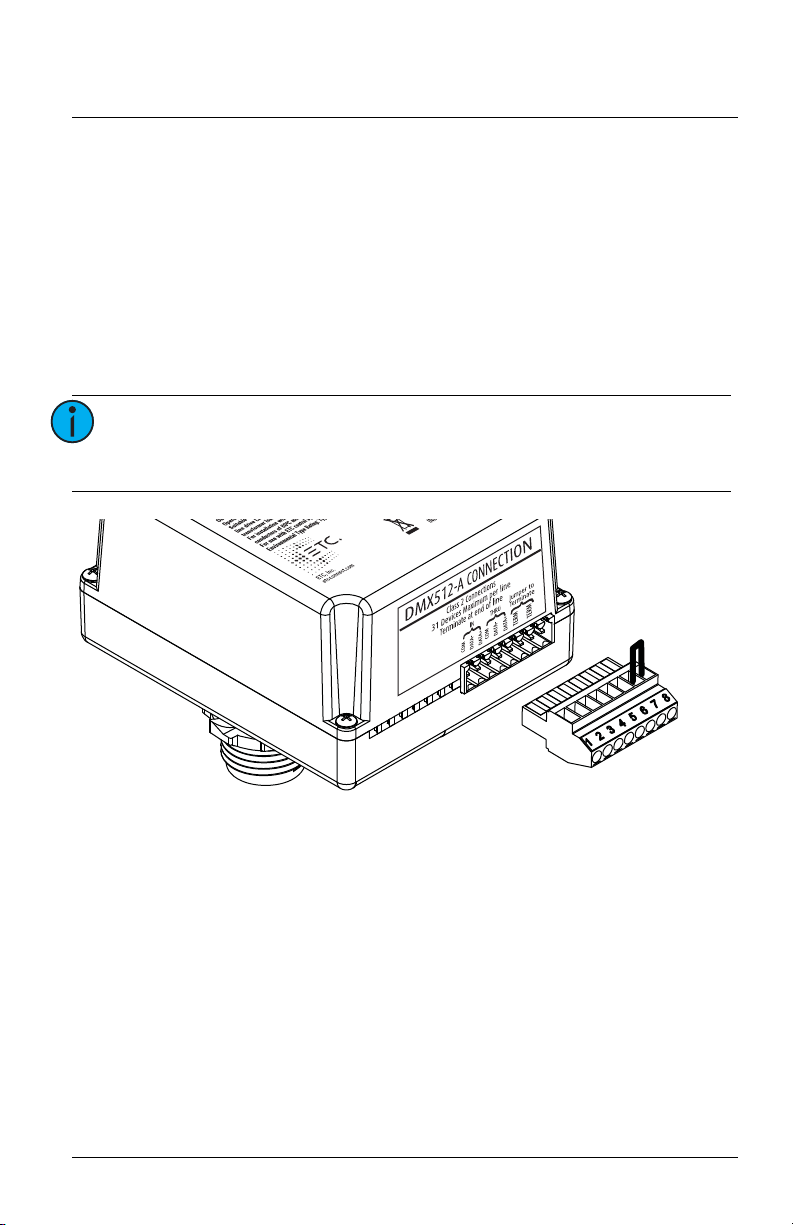

DMX Control Wiring

The 0–10V Controller connects to a DMX512-A source (provided by others)

for control.

DMX wiring runs can be daisy chains of up to 32 devices with no Y’s or loops.

Each DMX daisy chain must be terminated for proper control performance

(see

Terminate DMX

ETC recommends using Belden 9729 (or approved equivalent) Class 2 wire.

Belden 1583A or equivalent Cat5, Cat5e, or Cat 6 UTP wire is also acceptable

when properly shielded or installed in grounded metal conduit and

connected using the Cat5 IDC termination kit (ETC part number

4100A1013). This termination kit is not provided with the 0–10V Controller.

A voltage barrier installation box (part number 7187A1000) is available for

installations where DMX control wiring is installed in grounded metal

conduit. Contact ETC to purchase termination kits or voltage barrier

installation boxes if required.

The total combined length of a DMX wire run (using Belden 9729 or

equivalent) may not exceed 1,000 ft (300 m).

Note:

on

page 5

).

All control wiring should be installed and terminated by

a qualified installer and should follow standard wiring

installation practices.

Leave approximately 10 in (255 mm) of wiring available

for connection and to allow slack for future service

.

needs

Note:

0–10V Controller Page 3 of 16 ETC

For more information on DMX control wiring

requirements, see these and other Support Articles at

etcconnect.com:

• etcconnect.com/Support/Articles/DMX-512-Info.aspx

• etcconnect.com/Support/Articles/DMX-Over-Cat5.aspx

Page 4

ETC Installation Guide

0–10V Controller

Installation

Installation should follow all local codes and standard electrical practices.

Ensure that the junction box is clean and free of obstructions and that all

wiring is installed correctly.

WARNING:

WARNING:

1: Locate the circuit breaker panel and turn off the power to the lighting

circuit.

2: To gain access to the line voltage wiring, remove the cover plate and

other hardware from the junction box at the load.

3: Mount the 0–10V Controller to the exterior of the junction box or

panel using the 1/2” threaded nipple. Use the provided 1/2” conduit

locknut to secure the 0–10V Controller to the junction box or panel.

Note:

Risk of electric shock! This device utilizes high voltage

and should only be installed by a qualified installer or

electrician. Follow all local codes for installation. Before

terminating the AC power wiring verify that the main

breaker is in the off position and follow the proper

lockout/tag out procedures per NFPA Standard 70E.

For indoor use only! Must install to an electrical

junction box or wire way.

Follow all local code requirements for terminating wire.

• Notice that the harness wires on the controller are

pre-stripped for your installation convenience.

• Use appropriately sized wire nuts (not provided) to

secure each termination.

0–10V Controller Page 4 of 16 ETC

Page 5

ETC Installation Guide

Wire jumper

0–10V Controller

Connect DMX

1: Pull wiring to the junction box.

2: Terminate the DMX cable by following the steps in the termination kit

supplied with the unit.

Terminate DMX

Terminate the last device in the DMX data run for proper control

performance. To terminate the DMX data run at the 0–10V Controller,

connect the last two pins on the termination connector with a wire jumper

(not included) as shown below.

Note:

Because resistance is built into the 0–10V Controller, no

additional resistor is required to terminate the last

device in the DMX data run.

0–10V Controller Page 5 of 16 ETC

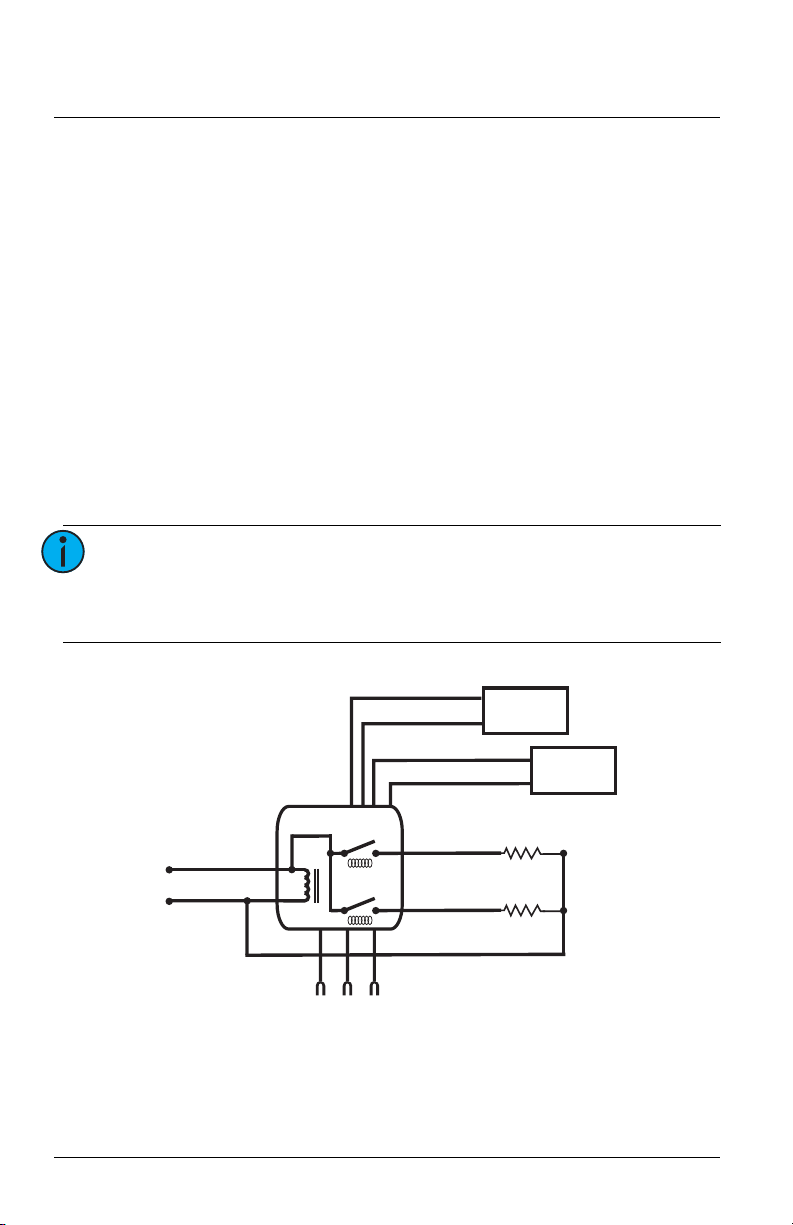

Page 6

ETC Installation Guide

DMX-512A

Black

Line In

White

Neutral

Load 1

Red

Load 2

Red/White

Dimming

Ballast 1

Dimming

Ballast 2

Gray

0–10V

Violet

Gray/White

0–10V

Violet/White

0–10V Controller

Connect Power Input and Relay Output

The power input and relay output wiring exits the 0–10V Controller through

the knockout mount on the enclosure.

1: Connect the power input wiring.

a: Connect the white wire (14 AWG) to the incoming neutral wire

from the breaker panel and the neutral wire of the lighting load.

b: Connect the power input wire (12 AWG) to the line input feed

wire (hot) from the breaker panel. Power input wire is black for

120VAC or brown for 277VAC.

2: Connect the relay output wiring. The 0–10V Controller has two relay

output wires (18 AWG): Zone 1 is red and Zone 2 is red/white.

a: Connect the Zone 1 relay output wire (red) to the hot input of the

first load.

b: Connect the Zone 2 relay output wire (red/white) to the hot input

of the second load.

Note:

When configured to single-channel mode, a single DMX

address controls both relays. If you are using only one

output, cap off the unused wires with wire nuts (not

included).

0–10V Controller Page 6 of 16 ETC

Page 7

ETC Installation Guide

0–10V Controller

Connect 0–10V Dimming Output

WARNING:

The 0–10V dimming output wiring exits the 0–10V Controller through the

top nipple of the enclosure with the power wiring.

1: Connect the 0–10V dimming output wiring. The 0–10V Controller has

two pairs of 0–10V output wires (22 AWG): Zone 1 is gray and violet,

and Zone 2 is gray/white and violet/white.

a: Connect the Zone 1 output wires, gray (+) and violet (-), to the

b: Connect the Zone 2 output wires, gray/white (+) and

2: Reinstall the junction box cover plate.

CAUTION:

RISK OF DEATH OR INJURY BY ELECTRIC SHOCK!

0–10V wiring may not be fully isolated from high

voltage AC power. Do not assume that 0–10V wiring is

safe to touch, even when run as an NEC Class 2 signal.

Test for AC voltage to ground before terminating any

0–10V control wiring to the 0–10V Controller.

control input of the connected load.

violet/white (-), to the control input of the second connected load.

The 0–10V control outputs must be treated as

NEC Class 1 control signals, in the same manner as other

high voltage connections.

0–10V Controller Page 7 of 16 ETC

Page 8

ETC Installation Guide

0–10V Controller

Configure the 0–10V Controller

You can use RDM to set the DMX address and data loss behavior for the

0–10V Controller. You can set other parameters using RDM, too. See

Parameters

Channel Mode

You can configure the 0–10V Controller to single-channel or dual-channel

mode using Net3 Concert or another RDM controller. In dual-channel mode,

each relay is assigned a separate DMX address for control. In single-channel

mode, both relays are assigned to a single DMX address and function in

unison. The 0–10V Controller ships from the factory in dual-channel mode.

See

You can also switch between single-channel mode and dual-channel mode

using the SET button on the 0–10V Controller. Press and hold the SET button

to switch modes. The POWER LED will blink once for single-channel mode or

twice for dual-channel mode.

DMX Address

You can assign DMX addresses to an entire daisy chain of Unison Foundry

devices using Net3 Concert or another RDM controller. If you cannot assign

the DMX addresses using RDM, you can manually set the DMX start address

on the device. The default factory-set DMX address is 1, and the range of

available addresses is 1–512.

on

page 14

RDM Parameters

.

on

page 14

.

RDM

0–10V Controller Page 8 of 16 ETC

Page 9

ETC Installation Guide

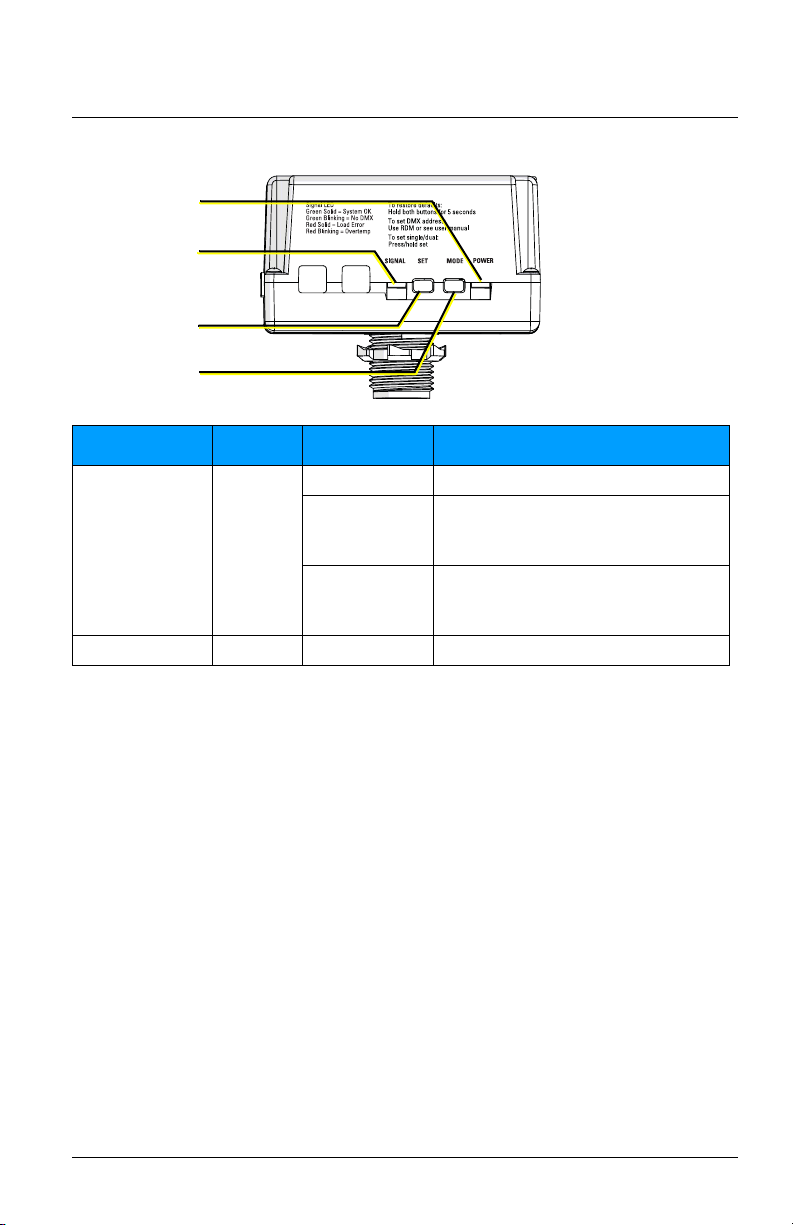

SIGNAL LED

POWER LED

MODE button

SET button

201

10s 1s100s

0–10V Controller

Manually Set the DMX Address

If you cannot assign the DMX addresses using RDM, use the MODE and SET

buttons to set the value of each digit in the three-digit DMX address in

sequence.

Task What to do What you will see

1: Put the controller

into DMX addressing

mode.

2: Set the 100s digit

of the DMX address.

0–10V Controller Page 9 of 16 ETC

Press and hold the MODE

button.

Press the SET button to

set the 100s digit. For

example, press the button

once for 1, twice for 2,

and so forth up to five

times for 5. Press and hold

the SET button for 0.

If the 100s digit in the

new DMX address is the

same as in the current

DMX address, you can

keep the digit by skipping

to step 3.

•The POWER LED indicator blinks 3 times

to indicate that you can set the 100s

digit of the DMX address.

•The SIGNAL LED indicator blinks the

100s digit in the current DMX address.

For example, if the current DMX address

is 201, the SIGNAL LED indicator blinks

2 times. (If the 100s digit is a 0, the

indicator remains lit and does not blink.)

•The POWER LED indicator continues to

blink 3 times to indicate that you are

setting the 100s digit of the DMX

address.

•The SIGNAL LED indicator blinks the

value that you set for the 100s digit in

the DMX address.

Page 10

ETC Installation Guide

201

10s 1s100s

0–10V Controller

Task What to do What you will see

3: Set the 10s digit of

the DMX address.

Press the MODE button to

advance to the 10s digit.

Press the SET button to

set the 10s digit. For

example, press the button

once for 1, twice for 2,

and so forth up to nine

times for 9. Press and hold

the SET button for 0.

If the 10s digit in the new

DMX address is the same

as in the current DMX

address, you can keep the

digit by skipping to step 4.

•The POWER LED indicator blinks 2 times

to indicate that you are setting the 10s

digit of the DMX address.

•The SIGNAL LED indicator blinks the 10s

digit in the current DMX address. For

example, if the current DMX address is

201, the SIGNAL LED indicator remains

lit and does not blink.

• If the SIGNAL LED indicator rapidly blinks

red, this means that you set the 100s

digit to an invalid value (for example, 6).

When this occurs, the 0–10V Controller

exits DMX addressing mode without

saving.

•The POWER LED indicator continues to

blink 2 times to indicate that you are

setting the 10s digit of the DMX address.

•The SIGNAL LED indicator blinks the

value that you set for the 10s digit in the

DMX address.

0–10V Controller Page 10 of 16 ETC

Page 11

ETC Installation Guide

10s

201

1s100s

0–10V Controller

Task What to do What you will see

4: Set the 1s digit of

the DMX address.

5: Save the new DMX

address.

Press the MODE button to

advance to the 1s digit.

Press the SET button to

set the 1s digit.

If the 1s digit in the new

DMX address is the same

as in the current DMX

address, you can keep the

digit by skipping to step 5.

Press the MODE button. • The POWER LED indicator and SIGNAL

•The POWER LED indicator blinks once to

indicate that you are setting the 1s digit

of the DMX address.

•The SIGNAL LED indicator blinks the 1s

digit in the current DMX address. For

example, if the current DMX address is

201, the SIGNAL LED indicator blinks

once.

• If the SIGNAL LED indicator rapidly blinks

red, this means that you set the 10s digit

to an invalid value. When this occurs, the

0–10V Controller exits DMX addressing

mode without saving.

•The POWER LED indicator continues to

blink once to indicate that you are

setting the 1s digit of the DMX address.

•The SIGNAL LED indicator blinks the

value that you set for the 1s digit in the

DMX address.

LED indicator return to their normal

functions (see

Interface

• If the SIGNAL LED indicator rapidly blinks

red, this means that you set the 1s digit

to an invalid value. When this occurs, the

0–10V Controller exits DMX addressing

mode without saving.

LED Indicators and User

on

page 13

).

0–10V Controller Page 11 of 16 ETC

Note:

The 0–10V Controller will exit DMX addressing mode

after 1 minute of inactivity. When this occurs, the

controller retains the DMX address that was saved

before you entered DMX addressing mode.

Page 12

ETC Installation Guide

0–10V Controller

Data Loss Behavior

Use RDM to set the behavior of the 0–10V Controller when DMX is lost. The

0–10V Controller has three options for data loss behavior:

• Hold last look

• Wait and fade

• Go to full

Note:

The “Go to full” data loss behavior does not meet the

requirements of UL924 for emergency lighting control.

Power Up and Test

1: Restore power to the circuit. The 0–10V Controller will power up and

turn on all connected loads to full output.

2: Verify that DMX input is present. The green signal LED on the unit

should be lit steadily. If it is blinking, check the DMX wiring.

3: Configure the controller. If additional configuration is required, use an

RDM controller such as ETC Net3 Concert software to configure the

appropriate properties. For more detailed information, see the Net3

Concert integrated help system.

4: Test the controller response. Use the DMX control system to alter the

control level, and make sure the 0–10V Controller responds.

Power-Up Behavior

In the event of a power loss to the 0–10V Controller, the controller will return

to its last output level when power is restored.

0–10V Controller Page 12 of 16 ETC

Page 13

ETC Installation Guide

SIGNAL LED

POWER LED

MODE button

SET button

0–10V Controller

LED Indicators and User Interface

LED Indicator Color State Description

Solid DMX present, system OK.

DMX absent. Verify that the DMX wiring is

SIGNAL Green

Slow blinking

Rapid blinking

POWER Blue Solid Power is OK.

correct, and verify that the DMX source is

functioning correctly.

DMX errors. Verify that the DMX wiring is

correct, and verify that the DMX source is

functioning correctly.

Update the Software

You can update the software for the 0–10V Controller using ETC

UpdaterAtor software and an ETC Gadget II or Gateway. Both LED indicators

on the 0–10V Controller blink during software updates.

Restore Defaults

Return the 0–10V Controller to factory defaults by pressing and holding both

the MODE and SET buttons simultaneously for 5 seconds. Both LEDs will blink

rapidly to indicate that the factory defaults have been restored. For factory

default values, see

0–10V Controller Page 13 of 16 ETC

RDM Parameters

on

page 14

.

Page 14

ETC Installation Guide

0–10V Controller

RDM Parameters

You can set the following RDM parameters on the 0–10V Controller using

Net3 Concert or another RDM controller.

Parameter ID and Number Description Default Value

Device Label

DMX Start

Address

DMX

Personality

DMX Fail

Mode

(Data Loss)

Packet Delay

E120_DEVICE_LABEL

0x0082

E120_DMX_START_ADDRESS

0x00F0

E120_DMX_PERSONALITY

0x00E0

E137_1_DMX_FAIL_MODE

0x0141

ETC_E120_PACKET_DELAY

0xB000

User-configurable name

for the device

DMX address,

range = 1–512

Sets the channel mode:

• Dual-channel mode

• Single-channel mode

Configures the behavior

when DMX is lost:

• Hold last look

• Wait and fade

• Go to full

Requires any change of

level to be present for at

least this number of

packets before action is

taken (open/close the

relay or change 0–10V

output). Range = 0–50.

ETC DMX Dual Relay

0–10V

1

Dual-channel mode

Go to full

0

0–10V Controller Page 14 of 16 ETC

Page 15

ETC Installation Guide

0–10V Controller

0–10V Controller Page 15 of 16 ETC

Page 16

ETC Installation Guide

0–10V Controller

0–10V Controller Page 16 of 16 ETC

Loading...

Loading...