Page 1

™

Unison Foundry

Mini Panel

Installation and

User Operation Manual

Version 1.0.0

Part Number: 7179M1200-1.0.0 Rev: B

Released: 2017-12

Page 2

ETC®, Unison®, and Unison Foundry™ are either registered trademarks or trademarks of Electronic

Theatre Controls, Inc. in the United States and other countries.

All other trademarks, both marked and not marked, are the property of their respective owners.

ETC intends this document, whether printed or electronic, to be provided in its entirety.This

product is intended for professional use only. Read this entire document before using this product.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features and Specification . . . . . . . . . . . . . . . . . . . . . . .2

Codes and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Important Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warnings and Notice Conventions . . . . . . . . . . . . . . . .2

Help from ETC Technical Services . . . . . . . . . . . . . . . . .3

Contact ETC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Chapter 1

Chapter 2

Prepare for Installation . . . . . . . . . . . . . . . . 4

Inspect the Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Main Circuit Breaker Protection . . . . . . . . . . . . . . . . . .4

Installation Environment . . . . . . . . . . . . . . . . . . . . . . . .4

Tools and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Conduit Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Input Wiring Requirements . . . . . . . . . . . . . .6

Control Wiring Requirements . . . . . . . . . . . . . . . . . . . .7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mount the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rough-In and Terminate Cable . . . . . . . . . . . . . . . . . . .9

High Voltage Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Low Voltage Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Configure the Mini Panel. . . . . . . . . . . . . . . . . . . . . . .16

Set the Emergency UL 924 Configuration Switch. . . . . . . . . .16

Set the Emergency UL 924 Load Shed Switch . . . . . . . . . . . . .16

Set the Emergency UL 924 Inclusion Switches . . . . . . . . . . . .17

Set the Demand Response Levels . . . . . . . . . . . . . . . . . . . . . .17

Set the Data Loss Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Update the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Restore Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table of Contents i

Page 4

Chapter 3

Power Up and Set DMX Address . . . . . . .18

Before Applying Power to the Mini Panel . . . . . . . . .18

Power Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Set the DMX Address . . . . . . . . . . . . . . . . . . . . . . . . . .19

Manually Set the DMX Address . . . . . . . . . . . . . . . . . . . . . . . .19

Check Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Demand Response . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Appendix A

RDM Parameters . . . . . . . . . . . . . . . . . . . . 23

ii Unison Foundry Mini Panel Installation and User Operation Manual

Page 5

Introduction

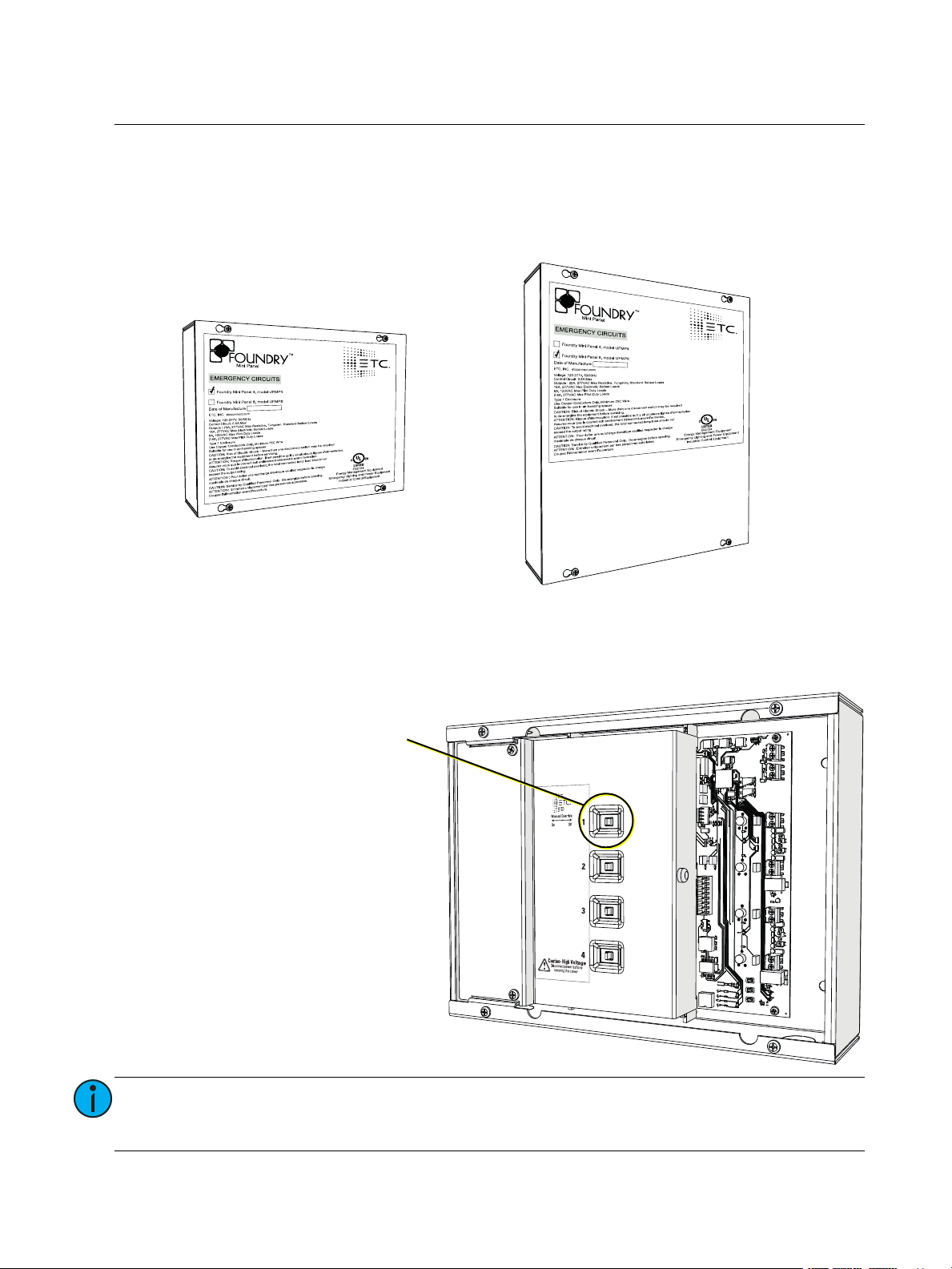

4-Relay Mini Panel

8-Relay Mini Panel

Welcome to the installation and user operation manual for the Unison Foundry Mini Panel.

This manual contains the procedures for safe and efficient installation of the Mini Panel.

The Mini Panel is designed for 120–277VAC, 47–63 Hz installations and provides switching

with fully isolated 0–10V dimming of four or eight zones with integrated 0–10V dimming

control per output, all in a compact, surface-mount enclosure.

Two models are available:

• 4 relays with Demand Response input, UL 924 control bypass contact input and sense feed

• 8 relays with Demand Response input, UL 924 control bypass contact input and sense feed

You can manually override

each relay on or off.

• Slide the relay switch left to

turn on

• Slide the relay switch right

to turn off

Note:

Introduction 1

If you manually override a relay when DMX is present, the relay will remain in its

overridden state until DMX control is reasserted (when the DMX control level crosses

the control threshold again).

Page 6

Features and Specification

Mini Panels are designed for indoor use only!

The Mini Panel features:

• Either four or eight mechanically latching relays. Relays are rated for the following load types:

- 100,000 cycles of 20A resistive load

- 30,000 cycles of 20A tungsten load at 277 VAC

- 30,000 cycles of standard ballast at 20A, 120 or 277 VAC

- 30,000 cycles of electronic ballast at 16A, 120 or 277 VAC

• Either four or eight 0–10V outputs with current sink of 100 mA

• Dry contact closures for UL 924 control bypass and Demand Response control input

• Integrated sense feed for UL 924 control bypass

Codes and Standards

The Mini Panel meets or exceeds the following regulatory standards:

• UL 916 for energy management equipment

• UL 924 for emergency lighting and power equipment

• UL 2043 for installation in air-handling (plenum) spaces

Important Safeguards

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

When using electrical equipment, basic safety precautions should always be followed

including the following:

• Do not use outdoors.

• Do not mount near gas or electric heaters.

• Equipment should be mounted in locations and at heights where it will not readily be subjected

to tampering by unauthorized personnel.

• The use of accessory equipment not recommended by the manufacturer may cause an unsafe

condition.

• Do not use this equipment for anything other than its intended use.

• Operation and servicing by qualified personnel only!

SAVE THESE INSTRUCTIONS

Warnings and Notice Conventions

These symbols are used in this document to alert you to danger or important information.

Note:

CAUTION:

WARNING:

WARNING:

2 Unison Foundry Mini Panel Installation and User Operation Manual

Notes are helpful hints and information that is supplemental to the main text.

A Caution statement indicates situations where there may be undefined or unwanted

consequences of an action, potential for data loss or an equipment problem.

A Warning statement indicates situations where damage may occur, people

may be harmed, or there are serious or dangerous consequences of an action.

RISK OF ELECTRIC SHOCK! This warning statement indicates situations where

there is a risk of electric shock.

Page 7

Help from ETC Technical Services

If you are having difficulties, your most convenient resources are the references given in this

manual. To search more widely, try the ETC Web site at etcconnect.com. If none of these

resources is sufficient, contact ETC Technical Services directly at one of the offices identified

below. Emergency service is available from all ETC offices outside of normal business hours.

When calling for help, please have the following information handy:

• Product model and serial number (located on the product label)

• List of connected load types

• Connected devices, if any

Contact ETC

Americas United Kingdom

ETC, Inc. ETC Ltd

Technical Services Department Technical Services Department

3031 Pleasant View Road 26-28 Victoria Industrial Estate

Middleton, WI 53562 Victoria Road,

800-775-4382 (USA, toll-free) London W3 6UU England

+1-608 831-4116 +44 (0)20 8896 1000

service@etcconnect.com service@etceurope.com

Asia Germany

ETC Asia ETC GmbH

Technical Services Department Technical Services Department

Room 1801, 18/F Ohmstrasse 3

Tower 1, Phase 1 Enterprise Square 83607 Holzkirchen, Germany

9 Sheung Yuet Road +49 (80 24) 47 00-0

Kowloon Bay, Kowloon, Hong Kong techserv-hoki@etcconnect.com

+852 2799 1220

service@etcasia.com

Please email comments about this manual to: TechComm@etcconnect.com.

Introduction 3

Page 8

Chapter 1

Prepare for Installation

Inspect the Shipment

Before you begin installation, check your shipment and confirm that it arrived complete and

undamaged.

1: Check the shipping box for physical damage.

• If you find damage, document it to help with a claim against your shipper.

2: Inspect the order for completeness.

• Check the box contents received against the packing list to ensure that your order received is

complete.

• If you discover a problem with the contents of the shipment, contact ETC Technical Services

at the location nearest you. See

Main Circuit Breaker Protection

Before beginning installation of your Mini Panel, make sure you have installed a main circuit breaker

cabinet or other readily accessible input power disconnect device.

When more than one power source is supplying the Mini Panel, a voltage separator may be required by

local code. This voltage divider is an accessory option, sold separately, and available for use when local

code requires. Order ETC part number 7187A4021.

Help from ETC Technical Services

on

page 3

.

WARNING:

Mini Panel circuits installed without an accessible power disconnect device

cannot be serviced or operated safely.

Installation Environment

Follow these guidelines for the installation environment:

• Intended for surface wall mounting. The installation location and the mounting hardware must

support at least 20 lb (9 kg).

• Install the enclosure in a location where it will not be subject to tampering or vandalism.

• For indoor use only! Operates at ambient temperature between 0°C–40°C (32°F–104°F), dry

room 5–90% non-condensing relative humidity.

• The Mini Panel is rated for installation in a plenum space.

Note:

Always follow applicable building and local electrical code requirements when

installing this equipment.

4 Unison Foundry Mini Panel Installation and User Operation Manual

Page 9

Tools and Supplies

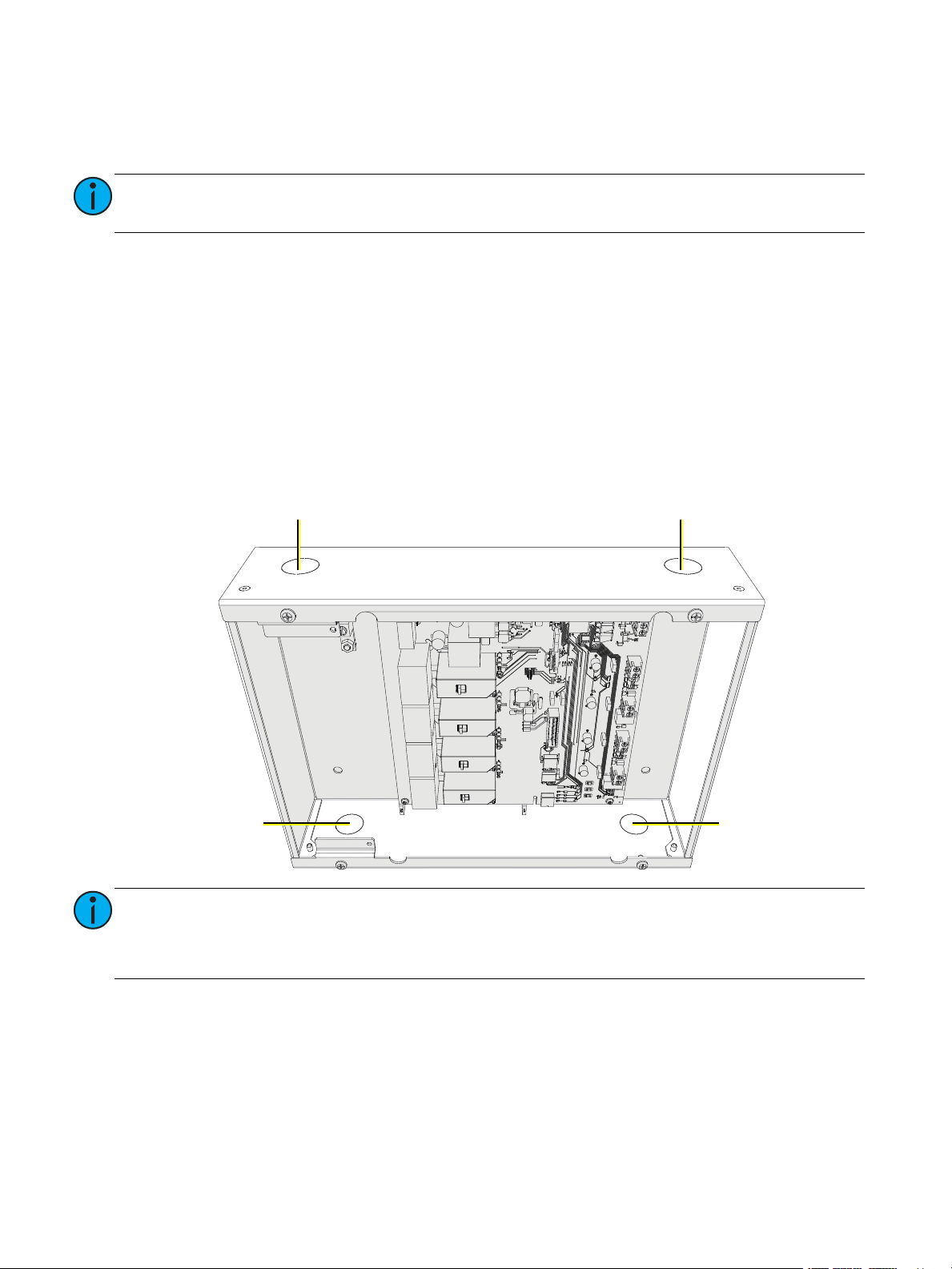

High voltage Low voltage

Low voltageHigh voltage

The following tools and supplies are required for installation but are not included with the Mini Panel.

• Mounting hardware: four mounting bolts or screws

Note:

Both the installation location and the mounting hardware must support a fully

installed unit (including conduit and cable), which weighs approximately 20 lb (9 kg).

• Set of screwdrivers, including both flat-blade and Phillips-head types

• Conduit and supporting hardware

• Insulation stripping tool

• Appropriately sized wire nuts or WAGO

• Small 4–6” (10–15 cm) cable ties

®

installation connectors

Conduit Access

Take care to separate high voltage power from low voltage (Class 2) control wiring. Use the knockouts

on the top and bottom of the enclosure for conduit access into the unit. You can create additional

conduit access using a knockout punch as needed.

• High voltage wires: Left side (top or bottom) of the enclosure

• Low voltage wires: Right side (top or bottom) of the enclosure

Note:

All low voltage (Class 2) control cables must run in separate conduit from high

voltage power wires. To maintain the integrity of the voltage separation, use the

provided voltage barrier inside the enclosure to separate all low voltage components

from the high voltage power.

Prepare for Installation 5

Page 10

Electrical Input Wiring Requirements

IN1

THRU1

OUT1

IN2

THRU2

OUT2

IN3

THRU3

OUT3

IN4

THRU4

OUT4

L

SENSE

N

Control power and

optional sense feed input

Output terminal blocks

(4 or 8, depending on

the model)

Voltage separator

(optional)

Remove the main cover and the high voltage cover to access the high voltage electrical terminations,

including control power input and relay inputs/outputs, which are located on the left side of the

enclosure.

Power Input

UL 924

Emergency Sense

Feed Input

Relay Output

6 Unison Foundry Mini Panel Installation and User Operation Manual

Purpose

Note:

CAUTION:

12–20 AWG

(4–0.5 mm

12–20 AWG

(4–0.5 mm

6–20 AWG

(16–0.5 mm

Note:

Always follow applicable US National Electrical Code (NEC) and local electrical code

requirements when installing and powering this equipment.

For your own safety, do not supply power to the enclosure until all

installation is complete, connected circuits have been tested and found free

of electrical shorts, and covers have been replaced. Follow appropriate

Lockout/Tagout procedures as described in National Fire Protection

Association (NFPA) Standard 70E.

Electrical Terminations

Terminal

Accepts

Supports a 20A input

2

)

breaker (maximum)

Optional sense feed

2

)

with a 20A maximum

input breaker

Each relay supports a

maximum current of

2

20A in discrete feed

)

configuration

When bridging input power (hot) across relays in the enclosure, the total loading of

all bridged relays is limited to 20A.

Type Notes

20A maximum, 120–277 VAC, 47–63 Hz

Upon loss of sense feed power, activates

Mini Panel emergency state, driving

configured loads On, and others Off.

Each relay in the enclosure can be

discretely fed, and configured for bridging

from the input power connection or

bridging between the relays.

Page 11

Control Wiring Requirements

Demand Response Contact

UL 924 Emergency Contact

0–10V out 100 mA

(one per channel)

All control wires are terminated to the low voltage (right) side of the enclosure, accessible with the

main cover removed.

Purpose

UL 924

Emergency

Contact Input

Demand

Response

Contact Input

0–10V Outputs

Terminals

Accept

16–22 AWG

(1.5–0.5 mm

Control Terminations

Type Notes

Dry: Normally Open

(default) or Normally

Closed Closure

2

)

Dry: Maintained Closure

Capable of sinking

100 mA of current

Activates Mini Panel emergency state,

driving configured loads On, and others

Off. See

page 14

About Contact Inputs

.

on

Limits the maximum level of each output

to the configured level set at the

configuration potentiometers. See

Contact Inputs

on

page 14

.

Allows for 0–10V dimming control of

connected compatible loads. See

Terminate 0–10V Outputs

on

page 15

About

.

Prepare for Installation 7

Page 12

Chapter 2

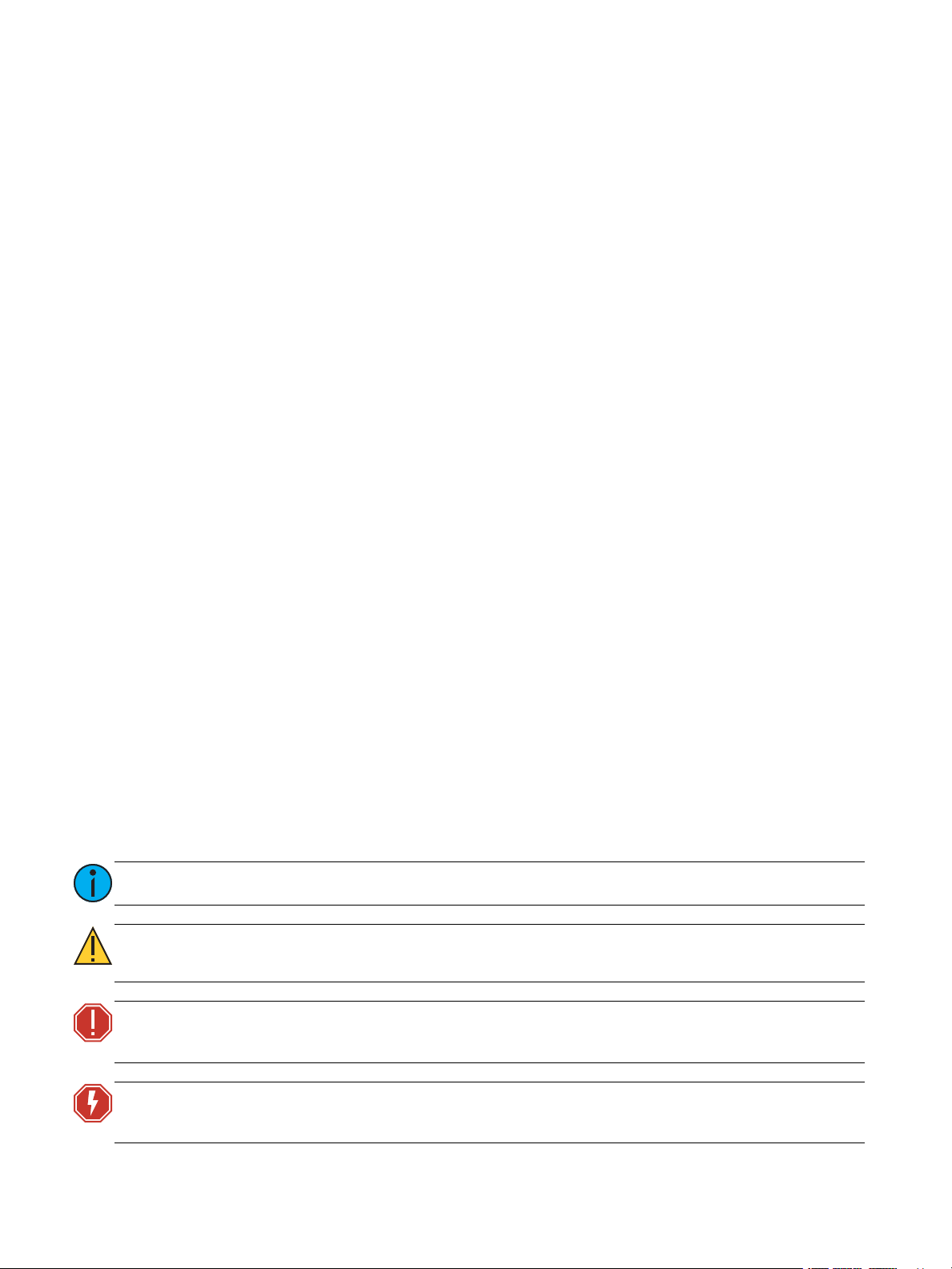

Step 4:

Lift cover using lift pin

Step 3:

Remove screws

Step 2:

Loosen screws,

remove cover

Step 2:

Loosen screws,

remove cover

Installation

Mount the Controller

1: Determine where the Mini Panel will be installed using the details outlined in

Environment

2: Remove the front cover from the controller.

a: Loosen,

b: Slide the cover sideways, aligning the keyholes with screws, and then lift the cover off the

enclosure.

3: Remove the two screws securing the high voltage cover.

4: Lift the high voltage cover off the enclosure using the provided lift pin.

on

page 4

.

but do not remove

, the four screws securing the front cover.

Installation

5: Align the enclosure in the installation location and mark the mounting holes.

8 Unison Foundry Mini Panel Installation and User Operation Manual

6: Remove the enclosure from the installation location and pre-drill the mounting holes.

7: Remove conduit knockouts or use knockout punch as required to accommodate control wiring.

See

Conduit Access

8: Re-align the enclosure in the mounting location and install the mounting hardware. Tighten the

mounting hardware securely.

9: Attach and tighten the conduit fittings to the enclosure.

on

page 5

.

Page 13

Rough-In and Terminate Cable

IN1

THRU1

OUT1

IN2

THRU2

OUT2

IN3

THRU3

OUT3

IN4

THRU4

OUT4

L

SENSE

N

Voltage separator

(optional)

All terminations are accessible from the front of the enclosure with the covers removed. The left side

of the enclosure provides conduit entry for high voltage wires and the right side provides conduit entry

for low voltage wires.

Note:

Low voltage control cables must run in separate conduit from input power wires. To

maintain the integrity of the voltage separation inside the enclosure, a cover over the

high voltage terminations serves as a mechanical voltage barrier, separating the low

voltage power wiring from the high voltage power inside the enclosure.

WARNING:

RISK OF DEATH BY ELECTRIC SHOCK! Before installing input power to the

Mini Panel, make sure the upstream source of power is off or isolated. Follow

appropriate Lockout/Tagout procedures as described in NFPA Standard 70E.

CAUTION:

Connecting to and configuring the Mini Panel requires contact with the

printed circuit board inside the enclosure, which has electrostatic discharge

(ESD) sensitive components on it. To avoid risk of damage to the equipment,

ensure body static is discharged first by touching a grounded surface or

wearing suitable ESD grounding equipment while terminating cables.

High Voltage Wiring

High voltage wire terminations are located in the left side of the enclosure, separated from the low

voltage terminations with a high voltage cover. An additional voltage separator is available to separate

normal power and emergency power circuits within the high voltage wiring in the enclosure (as

needed).

Installation 9

The recommended cable for each termination is limited to the termination connectors provided in the

Mini Panel. See

Electrical Input Wiring Requirements

on

page 6

.

Page 14

Sample Power Input and Relay Output Terminations

IN1

THRU1

OUT1

IN2

THRU2

OUT2

IN3

THRU3

OUT3

IN4

THRU4

OUT4

L

SENSE

N

To load

From 120V normal/emergency breaker

To load

From 120V normal breaker

To load

From 277V normal breaker

To load

Ground

Neutral

Voltage separator

Voltage separator

From 120V normal breaker

Bridging Relays with

Normal/Emergency Power and

Discrete Fed Breakers

In this installation scenario, a single

Normal/Emergency input power

connection (line, neutral, and

ground) is bridged between the

control input and one or more relay

inputs. Additional relays can be

discretely fed from circuit breakers.

Because the input power is

Normal/Emergency, a Normal

sense feed has been added to drive

the Mini Panel to its emergency

control configuration on loss of

normal power. This circuit does not

feed a load from the Mini Panel.

Voltage separators are available

and sold separately for separating

between mixed voltage or normal

and emergency loads.

When bridging the input power,

the total load is limited to 20A

across all connected relays.

The following are sample termination scenarios for Mini Panel installations. Use these scenarios only as

a reference, and refer to your electrical and wiring plans for your specific installation requirements.

Note:

The In and Thru terminals are electrically connected on the circuit board.

10 Unison Foundry Mini Panel Installation and User Operation Manual

Note:

Note:

If any emergency circuits are fed or controlled from this panel, the panel must be

located electrically where fed from a UPS, generator, or other guaranteed source of

power during emergency and power outage situations.

Voltage barriers between normal circuits with different voltage inputs are only

required if the wiring used for 120V circuits is not rated for 277V.

Page 15

IN1

THRU1

OUT1

IN2

THRU2

OUT2

IN3

THRU3

OUT3

IN4

THRU4

OUT4

L

SENSE

N

To load

To load

To load

To load

Ground

Neutral

From breaker

Bridging a Single Input Power

Connection Across Relay Outputs

In this installation scenario, a single

input power connection (line,

neutral, and ground) is bridged

between the power input and all

relays or partial bridging.

When bridging the input power,

the total load is limited to 20A

across all connected relays.

IN1

THRU1

OUT1

IN2

THRU2

OUT2

IN3

THRU3

OUT3

IN4

THRU4

OUT4

L

SENSE

N

To load

To load

To load

To load

Ground

Neutral

From breaker

From breaker

From breaker

From breaker

Control power

Discrete Power for each Relay

Output

In this typical installation scenario,

power input would be provided

through an upstream breaker

panel, with one breaker for each

relay plus one control power feed.

Installation 11

Page 16

Terminate Input Power and Relay Outputs

Voltage separator

1: Terminate input power:

a: Pull input power (2 wires plus ground) to the left side of the enclosure.

b: Strip 1/2” (12 mm) of insulation from each wire.

c: Insert the ground wire into the ground terminal (labeled with a ground symbol), and torque

the terminal to 1.3 foot-pounds (1.76 N·m).

d: Insert the line (hot) wire into the L terminal and torque the terminal to 1.3 foot-pounds

(1.76 N·m).

e: Insert the optional sense feed wire into the SENSE terminal and torque the terminal to

1.3 foot-pounds (1.76 N·m).

f: Insert the neutral wire into the N terminal and torque the terminal to 1.3 foot-pounds

(1.76 N·m).

2: Terminate relay outputs (4 or 8 relays):

a: Pull relay output wires (2 to 3 wires for each relay, depending on the installation

requirements) to the left side of the enclosure.

b: Strip 1/2” (12 mm) of insulation from each wire.

c: Insert the line (hot) wire into the terminal marked IN* (IN2, IN3, etc.) and torque the terminal

to 1.3 foot-pounds (1.76 N·m).

d: When bridging relay outputs, insert a wire between the THRU* terminal and the next relay

IN* terminal. If you are not bridging outputs, do not terminate to the THRU terminal.

e: Connect the load wire to the terminal marked OUT* (OUT2, OUT3, etc.) and torque the

terminal to 1.3 foot-pounds (1.76 N·m).

3: Install a relay voltage separator between any normal power relays and emergency power relays

in the enclosure, or between relays with different voltage inputs. Additional relay voltage

separators are available for purchase from ETC. Order part number 7187A4021.

SENSE

THRU1

OUT1

THRU2

OUT2

THRU3

OUT3

THRU4

OUT4

L

N

IN1

IN2

IN3

IN4

12 Unison Foundry Mini Panel Installation and User Operation Manual

Page 17

Low Voltage Wiring

Demand Response Contact

UL 924 Emergency Contact

0–10V out 100 mA

(one per channel)

Low voltage wire terminations are located on the right side of the enclosure, visible with the front

cover removed.

Installation 13

Page 18

About Contact Inputs

Demand Response Input

UL 924 Emergency Contact

Input

UL 924 Emergency Contact

Configuration Switch

Contact inputs are available for:

• Demand Response Input: Accepts a remote trigger that allows the controller to reduce lighting

levels, thereby reducing power consumption.

• UL 924 Emergency Contact Input: Triggers emergency lighting control bypass from a system such

as a fire alarm.

The contact inputs can be configured as follows:

• Demand Response input requires a normally open dry contact closure.

• UL 924 Emergency Contact input is configurable to be a normally open or normally closed

contact, and requires a maintained dry contact closure.

A configuration switch is available for the UL 924 Emergency Contact to further define normally closed

(maintained) configuration as needed. Demand Response contacts are always open and are not

provided with additional configuration options.

MODE SET RESET

NO OFF NC

EMERGENCY DMND RESP

_

+

Terminate Contact Inputs

Dry contact input terminations are the same regardless of function.

1: Pull 2 wires to the right side of the enclosure.

2: Strip 1/4” (6 mm) of insulation from each wire.

3: Insert one wire into each terminal for the contact input, and torque the terminal to

4.4 inch-pounds (0.5 N·m).

14 Unison Foundry Mini Panel Installation and User Operation Manual

Page 19

Terminate 0–10V Outputs

EMERGENCY DMND RESP

_

+

MODE SET RESET

NO OFF NC

CH1 0–10V

_

+

CH2 0–10V

_

+

CH3 0–10V

_

+

CH4 0–10V

0 100

DMND RESP LEVEL

IN EMERG

0 100

DMND RESP LEVEL

IN EMERG

0 100

DMND RESP LEVEL

IN EMERG

0 100

DMND RESP LEVEL

IN EMERG

SHIELD

–

+

SHIELD

–

+

THRU IN

DMX TERM

OFF

ON

J8 DMX

SIGNAL

ERROR

POWER

DMND RESP

EMERG

DMX

0–10V

Outputs

WARNING:

RISK OF DEATH OR INJURY BY ELECTRIC SHOCK! 0–10V wiring may not be

fully isolated from high voltage AC power. Do not assume that 0–10V wiring

is safe to touch, even when run as an NEC Class 2 signal. Test for AC voltage

to ground before terminating any 0–10V control wiring to the Mini Panel.

CAUTION:

Only ballasts and drivers with

isolating transformers are

recommended for use with

the Mini Panel.

The Mini Panel offers fully isolated 0–10V output

control for each zone, allowing direct connection

to dimming ballasts and LED drivers. The 0–10V

outputs are capable of sinking a current of up to

100 mA.

1: Pull 0–10V wiring (typically a gray and violet

wire pair) to the right side of the enclosure.

2: Strip 1/4” (6 mm) of insulation from each

wire.

3: Insert the positive wire (typically gray) into

the terminal labeled “+” and torque the

terminal to 4.4 inch-pounds (0.5 N·m).

4: Insert the negative wire (typically violet) into

the terminal labeled “-” and torque the

terminal to 4.4 inch-pounds (0.5 N·m).

About DMX Control Wiring

The Mini Panel connects to a DMX512-A source (provided by others) for control.

DMX wiring runs can be daisy chains of up to 32 devices with no Y’s or loops. Each DMX daisy chain

must be terminated for proper control performance (see

ETC recommends using Belden 9729 (or approved equivalent) Class 2 wire. Belden 1583A or

equivalent Cat5, Cat5e, or Cat 6 UTP wire is also acceptable when properly shielded or installed in

grounded metal conduit and connected using the Cat5 IDC termination kit (ETC part number

4100A1013). This termination kit is not provided with the Mini Panel. Contact ETC to purchase

termination kits if required.

The total combined length of a DMX wire run (using Belden 9729 or equivalent) may not exceed

1,000 ft (305 m).

Note:

All control wiring should be installed and terminated by a qualified installer and

should follow standard wiring installation practices.

Installation 15

For more information on DMX control wiring requirements, see these and other

support articles at etcconnect.com:

• etcconnect.com/Support/Articles/DMX-512-Info.aspx

• etcconnect.com/Support/Articles/DMX-Over-Cat5.aspx

Terminate the Final DMX Device

on

page 16

).

Page 20

Terminate DMX

_

+

CH2 0–10V

_

+

CH3 0–10V

_

+

CH4 0–10V

IN EMERGIN EMERGIN EMERG

SHIELD

–

+

SHIELD

–

+

THRU IN

DMX TERM

OFF

ON

J8 DMX

SIGNAL

ERROR

POWER

DMND RESP

EMERG

0 100

DMND RESP LEVEL

0 100

DMND RESP LEVEL

0 100

DMND RESP LEVEL

DMX

DMX

Connection

DMX

Termination

Switch

EMERGENCY DMND RESP

MODE SET RESET

NO OFF NCLOAD

SHED

SENSE

ENABLE

UL 924

Configuration

Switch

UL 924 Load

Shed Switch

1: Pull DMX wiring to the right side of the

enclosure.

2: Terminate the DMX cable to the DMX

header by following the steps in the

termination kit supplied with the unit.

3: Insert the DMX header into the DMX

connection on the Mini Panel.

Terminate the Final DMX Device

You must terminate the final device (and only the

final device) in each DMX daisy chain for proper

control performance. To terminate the final device

in a chain, set the DMX termination switch to ON

(see image at right).

Configure the Mini Panel

Set the Emergency UL 924 Configuration Switch

To configure the UL 924 contact input, set

the Emergency UL 924 Configuration

switch to one of the following options:

• NO (normally open [default])

• NC (normally closed)

• Off (disabled).

Set the Emergency UL 924 Load Shed Switch

The Emergency UL 924 Load Shed switch provides configuration to enable or disable load shedding

when an Emergency Contact input is activated (opened or closed depending on the state of the

Emergency UL 924 Configuration switch). By factory default, this switch is set to On (enabled).

Load shedding functions in conjunction with the Emergency UL 924 Inclusion switch for each output

(see

Set the Emergency UL 924 Inclusion Switches

when the Emergency Contact input is activated.

UL 924 Load Shedding

Load Shed

Switch State

On Yes

On No Load and its connected 0–10V output will be turned off.

Off Yes

Off No Load remains at its current level.

16 Unison Foundry Mini Panel Installation and User Operation Manual

Output

Included in

Emergency?

Relay will close and the 0–10V output will be driven to its

maximum output level.

Relay will close and the 0–10V output will be driven to its

maximum output level.

on

page 17

). The table below describes what occurs

Result

Page 21

Set the Emergency UL 924 Inclusion

_

+

CH1 0–10V

_

+

CH2 0–10V

_

+

CH3 0–10V

_

+

CH4 0–10V

IN EMERGIN EMERGIN EMERGIN EMERG

GNAL

D RESP

0 100

DMND RESP LEVEL

0 100

DMND RESP LEVEL

0 100

DMND RESP LEVEL

0 100

DMND RESP LEVEL

DMX

UL 924

Inclusion

Switches

Demand

Response

Levels

Switches

Each output in the Mini Panel has an Emergency

UL 924 Inclusion Switch, which configures the

circuit to be included or excluded from the

Emergency UL 924 configuration. By factory

default, all outputs are set to On (included) in

Emergency.

• An output that is included in Emergency

(switch is set to On) will turn the load on to

full when the Emergency Contact input is

activated.

• An output that is excluded from Emergency

(switch is set to Off) will behave according to

the UL 924 Load Shed switch. See

Emergency UL 924 Load Shed Switch

page 16

.

Set the

on

Set the Demand Response Levels

When closed, the Demand Response contact input limits the maximum 0–10V level of each output to

the configured level that was determined by the Demand Response rotary fader corresponding to each

zone.

Use a precision screwdriver to change the rotary fader level to any value between 0–100%. A Demand

Response rotary fader setting of 0 turns the relay off when Demand Response is triggered. The

Demand Response rotary faders are set to 50% as a default.

Set the Data Loss Behavior

Use RDM to set the behavior of the Mini Panel when DMX is lost. The Mini Panel has three options for

data loss behavior:

• Hold last look

• Wait and fade

• Go to full (default data loss behavior)

Update the Software

You can update the software for the Mini Panel using ETC UpdaterAtor software and an ETC Gadget II

or Gateway. The SIGNAL/ERROR and POWER LED indicators, located on the low voltage side of the

enclosure, blink rapidly during software updates. See

about the LED indicators.

Check Features

on

page 22

for information

Restore Defaults

Return the Mini Panel to factory defaults by pressing and holding both the MODE and SET buttons

simultaneously for 5 seconds. The SIGNAL/ERROR and POWER LED indicators, located on the low

voltage side of the enclosure, blink rapidly to indicate that the factory defaults have been restored. See

Check Features

on

page 22

for information about the LED indicators.

Installation 17

Page 22

Chapter 3

Replace

screws

Power Up and Set DMX Address

Before Applying Power to the Mini Panel

WARNING:

CAUTION:

1: Clean out dust, metal scraps,

or other debris from the

enclosure.

2: Check for loose connections,

bare wires, or damaged

insulation on both the low

voltage and high voltage sides

of the enclosure.

3: Replace the high voltage cover

on the unit and secure with

screws.

4: Check that all configuration

switches are set according to

the installation requirement.

See

on

page 16

RISK OF ELECTRIC SHOCK! Power must be off when you perform this

procedure.

Checking the Mini Panel installation requires contact with the printed circuit

board inside the enclosure, which has electrostatic discharge (ESD) sensitive

components on it. To avoid risk of damage to the equipment, ensure that

body static is discharged first by touching a grounded surface or wearing

suitable ESD grounding equipment while terminating cables.

Configure the Mini Panel

.

Power Up

Apply power at the breaker that supplies power to the electronics.

WARNING:

18 Unison Foundry Mini Panel Installation and User Operation Manual

RISK OF ELECTRIC SHOCK! Mains voltage is present inside the high voltage

compartment of the enclosure. Do not remove the high voltage cover when

power is applied.

Page 23

Set the DMX Address

MODE button

SET button

SIGNAL/ERROR

POWER

You can assign each Mini Panel a unique DMX start address from 1–512. You can assign DMX

addresses to an entire daisy chain of Unison Foundry devices using Net3 Concert or another RDM

controller (see

can manually set the DMX start address on the device.

RDM Parameters

on

page 23

). If you cannot assign the DMX addresses using RDM, you

Note:

Consider the number of outputs in the Mini Panel when you assign the DMX start

address. If any outputs are assigned an address above 512 they will have no DMX

control. For example, if you set a DMX start address of 511 for a 4-Relay Mini Panel

the last two outputs will have no DMX control.

Manually Set the DMX Address

If you cannot assign the DMX addresses using RDM, use the MODE and SET buttons to set the value of

each digit in the three-digit DMX address in sequence.

MODE SET RESET

NO OFF NCLOAD

SHED

SENSE

ENABLE

EMERGENCY DMND RESP

_

DMND RESP LEVEL

SIGNAL

ERROR

POWER

DMND RESP

EMERG

0 100

IN EMERG

Tas k What to do What you will see

1: Put the controller

into DMX addressing

Press and hold the MODE

button.

mode.

Power Up and Set DMX Address 19

CH4 0–10V

+

•The POWER LED indicator blinks 3 times to indicate

that you can set the 100s digit of the DMX address.

•The SIGNAL/ERROR LED indicator blinks the 100s

digit in the current DMX address. For example, if the

current DMX address is 201, the SIGNAL/ERROR LED

indicator blinks 2 times. (If the 100s digit is a 0, the

indicator remains lit and does not blink.)

Page 24

Tas k What to do What you will see

2: Set the 100s digit of

the DMX address.

10s 1s100s

201

3: Set the 10s digit of

the DMX address.

10s 1s100s

201

Press the SET button to set

the 100s digit. For example,

press the button once for 1,

twice for 2, and so forth up

to five times for 5. Press

and hold the SET button for

0.

If the 100s digit in the new

DMX address is the same as

in the current DMX address,

you can keep the digit by

skipping to step 3.

Press the MODE button to

advance to the 10s digit.

Press the SET button to set

the 10s digit. For example,

press the button once for 1,

twice for 2, and so forth up

to nine times for 9. Press

and hold the SET button for

0.

•The POWER LED indicator continues to blink 3 times

to indicate that you are setting the 100s digit of the

DMX address.

•The SIGNAL/ERROR LED indicator blinks the value

that you set for the 100s digit in the DMX address.

•The POWER LED indicator blinks 2 times to indicate

that you are setting the 10s digit of the DMX

address.

•The SIGNAL/ERROR LED indicator blinks the 10s digit

in the current DMX address. For example, if the

current DMX address is 201, the SIGNAL/ERROR LED

indicator remains lit and does not blink.

•If the SIGNAL/ERROR LED indicator rapidly blinks red,

this means that you set the 100s digit to an invalid

value (for example, 6). When this occurs, the Mini

Panel exits DMX addressing mode without saving.

•The POWER LED indicator continues to blink 2 times

to indicate that you are setting the 10s digit of the

DMX address.

•The SIGNAL/ERROR LED indicator blinks the value

that you set for the 10s digit in the DMX address.

If the 10s digit in the new

DMX address is the same as

in the current DMX address,

you can keep the digit by

skipping to step 4.

20 Unison Foundry Mini Panel Installation and User Operation Manual

Page 25

Tas k What to do What you will see

4: Set the 1s digit of the

DMX address.

10s

1s100s

201

5: Save the new DMX

address.

Press the MODE button to

advance to the 1s digit.

Press the SET button to set

the 1s digit.

If the 1s digit in the new

DMX address is the same as

in the current DMX address,

you can keep the digit by

skipping to step 5.

Press the MODE button. • The POWER LED indicator and SIGNAL/ERROR LED

•The POWER LED indicator blinks once to indicate

that you are setting the 1s digit of the DMX address.

•The SIGNAL/ERROR LED indicator blinks the 1s digit

in the current DMX address. For example, if the

current DMX address is 201, the SIGNAL/ERROR LED

indicator blinks once.

•If the SIGNAL/ERROR LED indicator rapidly blinks red,

this means that you set the 10s digit to an invalid

value. When this occurs, the Mini Panel exits DMX

addressing mode without saving.

•The POWER LED indicator continues to blink once to

indicate that you are setting the 1s digit of the DMX

address.

•The SIGNAL/ERROR LED indicator blinks the value

that you set for the 1s digit in the DMX address.

indicator return to their normal functions (see

Features

•If the SIGNAL/ERROR LED indicator rapidly blinks red,

this means that you set the 1s digit to an invalid

value. When this occurs, the Mini Panel exits DMX

addressing mode without saving.

on

page 22

).

Check

Note:

The Mini Panel will exit DMX addressing mode after 1 minute of inactivity. When this

occurs, the Mini Panel retains the current DMX address.

Power Up and Set DMX Address 21

Page 26

Check Features

_

+

CH4 0–10V

IN EMERG

SIGNAL

ERROR

POWER

DMND RESP

EMERG

0 100

DMND RESP LEVEL

SIGNAL/ERROR

POWER

DMND RESP

EMERG

1: Locate the status LEDs on the low voltage side of the enclosure.

LED Indicator Color State Description

Solid DMX present, system OK

Slow blinking

SIGNAL/ERROR Green

DMX absent. Verify that the DMX

wiring is correct, and verify that the

DMX source is functioning correctly.

DMX errors. Verify that the DMX

Rapid blinking

wiring is correct, and verify that the

DMX source is functioning correctly.

POWER Blue Solid Power is OK.

DMND RESP

(Demand Response)

EMERG (UL 924)

Green

Red

Solid Demand Response input is closed.

Solid UL 924 is active.

2: Test each contact input to ensure that it functions as expected. With contact activity, the

configured relays should respond and the status LEDs should indicate. See

Panel

on

page 16

as needed for further configuration.

Configure the Mini

3: Replace the main cover on the unit and secure the screws firmly.

Demand Response

When Demand Response is active, check that the outputs are at the expected level.

If the observed output level is different than expected, check the Demand Response LED for indication

of activation. See

The outputs generated with an active Demand Response will not exceed the level set by each of the

corresponding Demand Response rotary faders. See

22 Unison Foundry Mini Panel Installation and User Operation Manual

Check Features

above for LED indications.

Set the Demand Response Levels

on

page 17

.

Page 27

Appendix A

RDM Parameters

You can set the following RDM parameters on the Mini Panel using Net3 Concert or another RDM

controller.

Parameter ID and Number Description Default Value

Device Label

DMX Start

Address

DMX Fail Mode

(Data Loss)

Packet Delay

E120_DEVICE_LABEL

0x0082

E120_DMX_START_ADDRESS

0x00F0

E137_1_DMX_FAIL_MODE

0x0141

ETC_E120_PACKET_DELAY

0xB000

User-configurable name for the

device

DMX address, range = 1–512. See

Set the DMX Address

Configures the behavior when

DMX is lost:

• Hold last look

• Wait and fade

•Go to full

Requires any change of level to be

present for at least this number of

packets before action is taken

(open/close the relay or change

0–10V output)

on

page 19

ETC DMX 4 Ch. Mini Panel or

ETC DMX 8 Ch. Mini Panel

1

.

Go to full

0

RDM Parameters 23

Page 28

Corporate Headquarters Middleton, WI, USA Tel +608 831 4116 Service: (Americas) service@etcconnect.com

London, UK

Rome, IT

Holzkirchen, DE

Hong Kong

Web: etcconnect.com

Product information and specifications subject to change. ETC intends this document to be provided in its entirety.

7179M1200-1.0.0

Tel +44 (0)20 8896 1000 Service: (UK) service@etceurope.com

Tel +39 (06) 32 111 683 Service: (UK) service@etceurope.com

Tel +49 (80 24) 47 00-0 Service: (DE) techserv-hoki@etcconnect.com

Tel +852 2799 1220 Service: (Asia) service@etcasia.com

© 2017 Electronic Theatre Controls, Inc.

Rev B Released 2017-12

Loading...

Loading...