Page 1

SPIRAL MIXER WITH REMOVABLE BOWL

PETRIN A SPIRALE A CUVE FIXE

IMPASTATRICE A SPIRALE A VASCA ESTRAIBILE

SPI 160-300 A

HYBRID

Code/codice N° 876577 rev. 02

February/Février/Febbraio 2014

Instruction for use and maintenance

Notice d’utilisation et de maintenance

Istruzioni uso e manutenzione

Page 2

Page 3

CAREFULLY READ THIS INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE.

OBSERVE ALL SAFETY REGULATIONS AND INSTRUCTIONS

DURING OPERATION OF THE MACHINE.

LIRE ATTENTIVEMENT CE MANUEL D’INSTRUCTIONS

AVANT DE METTRE EN ROUTE LA MACHINE.

OBSERVER LES CONDITIONS ET LES INSTRUCTIONS DE SECURITE PENDANT

LE FONCTIONNEMENT DE LA MACHINE

LEGGERE ATTENTAMENTE IL PRESENTE MANUALE D’ISTRUZIONI

PRIMA DI FAR FUNZIONARE LA MACCHINA.

OSSERVARE LE NORME E LE ISTRUZIONI DI SICUREZZA

DURANTE IL FUNZIONAMENTO DELLA MACCHINA

GENERAL INDEX/INDICE GENERAL/INDICE GENERALE

ENGLISH P. 5

FRANÇAIS P. 57

ITALIANO P. 107

Tables with spare parts

Planches avec des pièces de rechange

P. 159

Tavole con ricambi

Page 4

Page 5

English

English

5

Page 6

Page 7

English

TABLE OF CONTENTS

Page

Introduction, general warnings and warranty rules 9

1. Machine identification 10

2. Technical specifications 11

3. Application 13

SECTION A 4. Machine description 13

5. Preventive measures against health and safety hazards 13

6. Safety signs - symbols 16

1. Transport, handling and storage 20

2. Preparing the room - Installing the machine 22

3. Start-up, use and adjustments 24

SECTION B 4. Troubleshooting 45

5. Food hygiene and cleaning 47

6. Maintenance and checks 48

7. Replacing worn parts 53

SECTION C 1. Emergency situations 53

2. Decommissioning - scrapping 53

ALPHABETICAL INDEX

application 13

decommissioning, scrapping 53

emergency situations 53

food hygiene and cleaning 47

general warnings 9

introduction 9

machine controls 25

machine description 13

machine identification 10

machine installation 22

maintenance and checks 48

maintenance to be performed by the manufacturer's authorised service department 48

maintenance to be performed by the operator 48

preparing the room 22

preventive measures against electrical hazards 15

preventive measures against health and safety hazards 13

preventive measures against mechanical hazards 14

preventive measures against noise hazards 16

preventive measures to guarantee hygiene 15

replace of worn out parts 53

Routine maintenance sheet 52

safety signs - symbols 16

start-up, use and adjustments 24

technical specifications 11

transport, handling and storage 20

troubleshouting 44

warranty rules 10

7

Page 8

Page 9

English

INTRODUCTION, GENERAL WARNINGS AND WARRANTY RULES

INTRODUCTION

This instruction manual has been designed and organised for quick easy reference. For this purpose, in addition to the INTRODUCTION and GENERAL WARNINGS, it contains a TABLE OF CONTENTS and an INDEX.

For each topic discussed, illustrations and tables are provided beside the corresponding text to

facilitate understanding.

The instruction manual is divided into SECTIONS.

For the topics discussed in each SECTION, refer to the detailed TABLE OF CONTENTS.

GENERAL WARNINGS

This instruction manual is intended for the owner/user of the machine, the personnel employed

by the latter in positions of responsibility within the company and personnel assigned to handling, installation, use, supervision, maintenance and scrapping of the machine etc.

This manual provides information on the technical specifications and scheduled use of the machine, instructions/indications/information on handling, installation, assembly, adjustment and

use in addition to information on personnel training in order to facilitate maintenance work, troubleshooting, ordering of spare parts, residual risk assessment etc.

This manual forms an integral part of the MACHINE which is DESIGNED FOR PROFESSIONAL

USE but the manual should never be considered a substitute for adequate user training and experience. Operations requiring personnel with specific skills are highlighted in the manual.

The manufacturer reminds its customers, i.e. users of the machine, that they are also required

to observe the specific legislation concerning places of work and that adequacy and conformity

of the work place with current regulations are essential conditions for correct installation and use

of the machine.

This manual should be considered part of the machine and must be kept for future reference until the machine is scrapped.

This manual must be kept in a dry easily accessible place, preferably within easy reach of the

machine.

The manufacturer reserves the right to update the machine and instruction manuals without being obliged to update machines and/or manuals produced previously, barring exceptional circumstances. On request, however, the manufacturer will provide customers with any further information they may require.

If the machine is sold, customers (users) are kindly requested to notify the manufacturer of the

address of the new owner for the above-mentioned purpose.

The manufacturer accepts no liability in the event of the following:

a. inappropriate use of the machine or use by personnel not trained to operate professional

machines

b. use not in compliance with specific national regulations

c. incorrect installation

d. power supply faults

e. lack of maintenance

f. unauthorised modifications or work

9

Page 10

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

g. use of non-original spare parts or parts not specifically intended for the model

h. total or partial failure to observe the instructions

i. exceptional events etc.

WARRANTY RULES

The machine is guaranteed for 12 (twelve) consecutive months from the date of purchase on

condition that it is used according to the instructions contained in this manual. The warranty

lapses if the machine has been used without following the directions contained in the manual or

if the machine has been repaired, disassembled or modified by unauthorised workshops or aftersales centres. All electrical parts are excluded from the warranty if the damage has been caused

by incorrect use of the machine.

SECTION A - POINT 1

MACHINE IDENTIFICATION

Figure n° 1 shows the plate affixed to the machine in the position indicated by the arrow in figure n° 2. The plate contains all the information necessary for identifying the machine.

Figure n° 1

Figure n° 1

10

Figure n° 2

Page 11

English

SECTION A - POINT 2

TECHNICAL SPECIFICATIONS

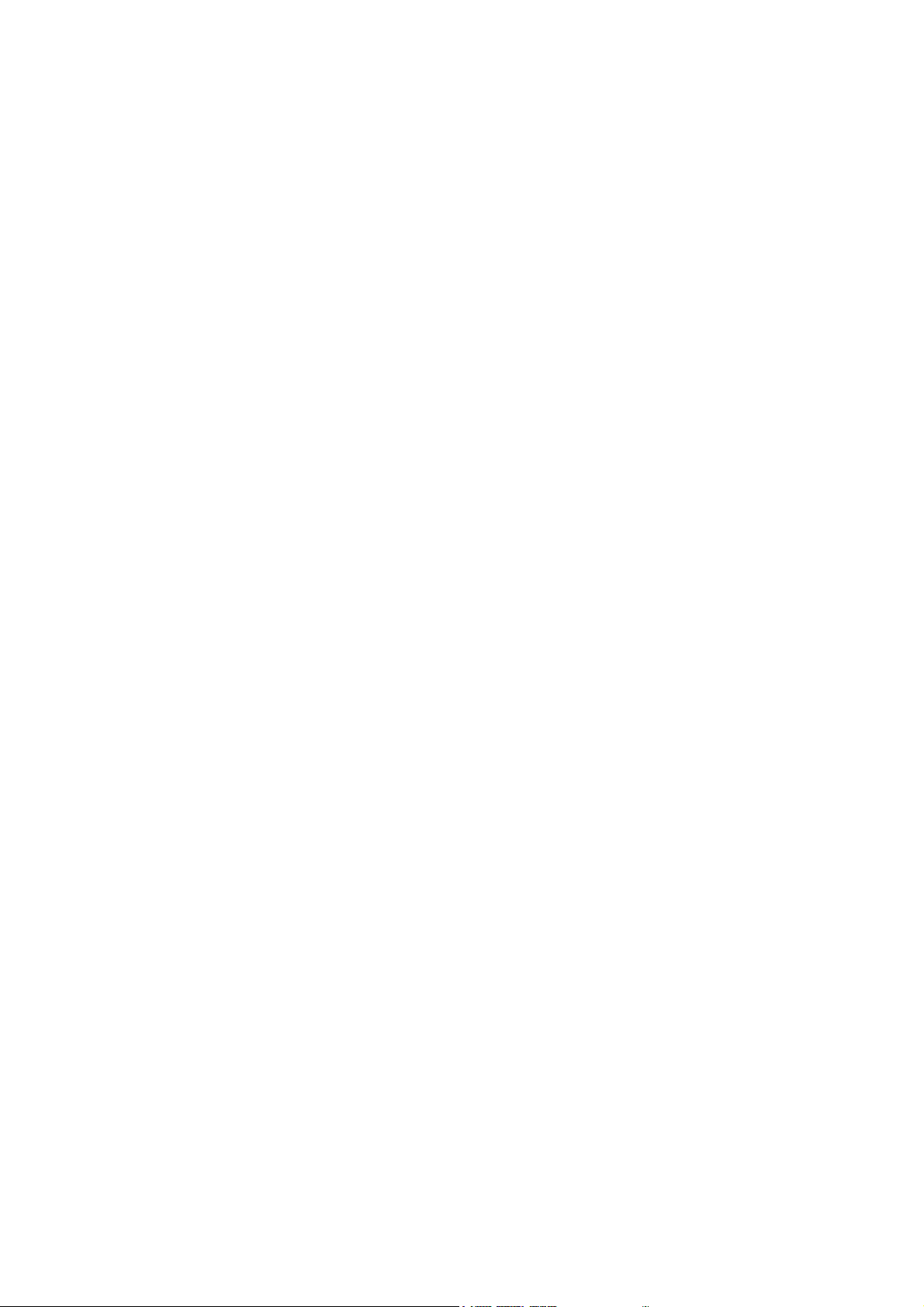

The main technical specifications of the machine are illustrated and indicated in figure n° 3 and in

tables on the following page.

Figure n° 3

Bowl rotation direction

(overhead view): anticlockwise

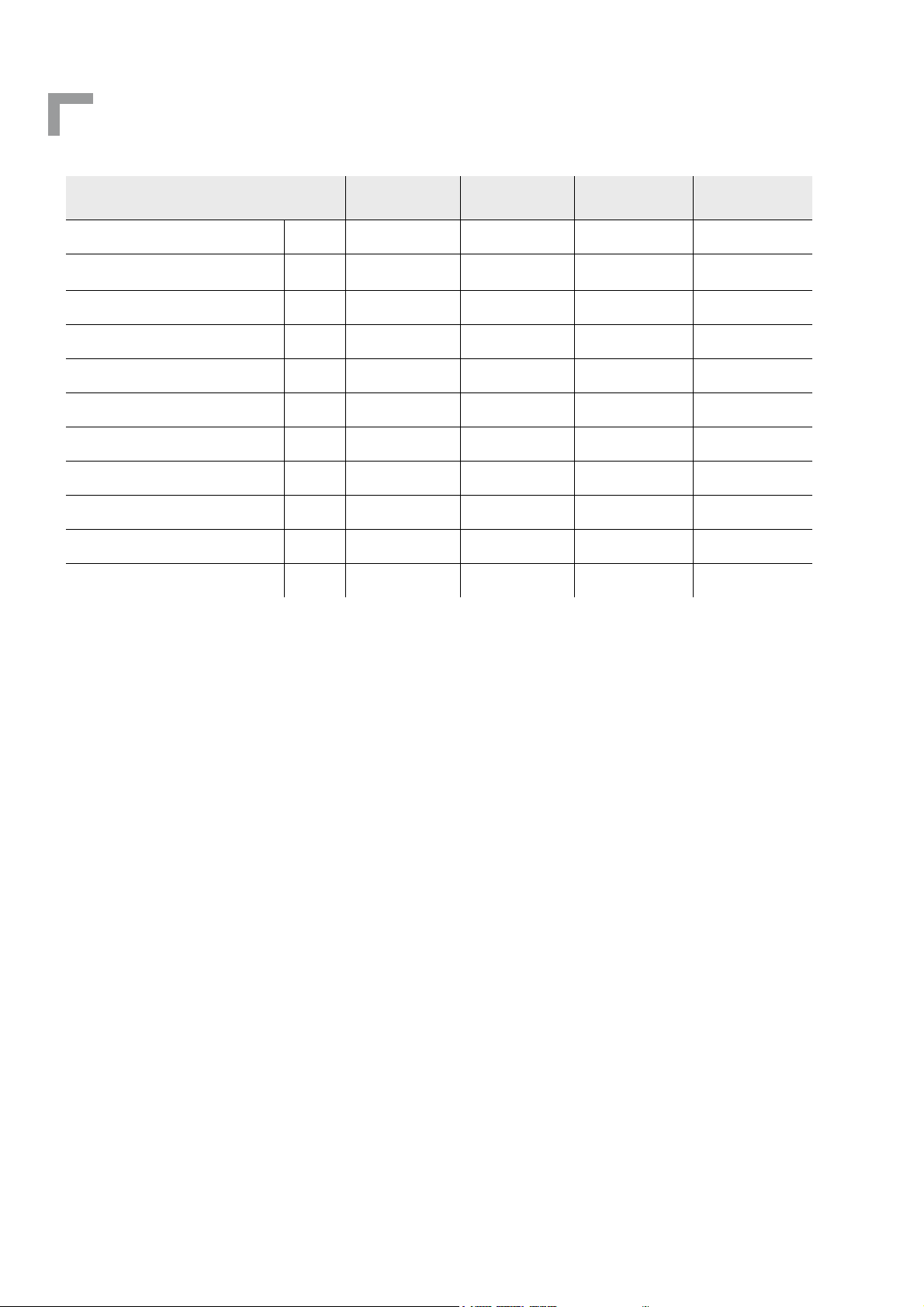

SPI A Hybrid 160 200 250 300

A mm 1656 1656 1654 1654

B mm 832 892 857 937

C mm 900 900 1045 1045

D mm 1862 1833 1954 1913

E mm 1127 1127 1200 1200

F mm 1860 1860 1983 1983

11

Page 12

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

TECHNICAL DATA 160 200 250 300

Maximum mixture capacity kg 160 200 250 300

Maximum flour capacity kg 100 125 150 185

Total capacity litres 250 300 360 430

Spiral arm speed 50 Hz (*) r.p.m. 86-172 86-172 86-172 86-172

Bowl speed 50 Hz (*) r.p.m. 9-18 9-18 10-20 10-20

Spiral arm speed 60 Hz (*) r.p.m. 103-206 103-206 103-206 103-206

Bowl speed 60 Hz (*) r.p.m. 10.8-21.6 10.8-21.6 12-24 12-24

Power with 50 Hz kW 10,1 10,1 12,9 12,9

Power with 60 Hz kW 12,9 12,9 15,1 15,1

Packaging volume m3 4,4 4,4 4,4 4,4

Net weight of machine kg 1210 1220 1370 1380

(*) indicative value

12

Page 13

English

SECTION A - POINT 3

APPLICATION

The spiral mixer, also called “machine” in this manual, is designed exclusively for blending flour

for bread, cakes and other baked products with ingredients such as sugar, fat, salt, water, yeast

etc. in bakeries and food shops. A very wide variety of ingredients can be mixed. The complete

operation normally consists of a number of cycles of varying duration.

Use of the machine for purposes other than those specified above is dangerous for the operator

and for the machine itself. In the same way, machine installation and/or operation procedures

other than those specified in Section B points 2 and 3 can injure the operator and damage the

machine.

.

SEZIONE A - PUNTO 4

MACHINE DESCRIPTION

The machine consists basically of:

▪ one fixed structure with

- on the side the switchboard and the operating devices

- inside are the mechanical transmission parts:

-for the head upstroke

-for trolley coupling

-for bowl transmission

▪ a mobile head bound to the fixed structure equipped with:

- a tool for mixing the ingredients

- a central bar that guarantees a better dough oxygenation

- an electronic panel placed in the machine front part.

▪ a removable trolley

- a bowl for containing the ingredients to be mixed

- all the organs that allows the coupling to the central structure

Main features:

-the machine emits a weighted equivalent continuous acoustic pressure level ≤ of 70 dB (A).

-The machine as a whole is protected to IP 44.

Note:

Further details of the machine with illustrations are given in Section B point 3.

SECTION A - POINT 5

PREVENTIVE MEASURES AGAINST HEALTH AND SAFETY HAZARDS

In design and construction of the machine, the manufacturer has taken into account the results

of a previous assessment of SAFETY AND HEALTH hazards relating to use of the machine.

The protections and safety devices fitted on the machine are therefore the result of the company’s considerable efforts to achieve state-of-the-art safety levels as indicated in the specific

EEC directives.

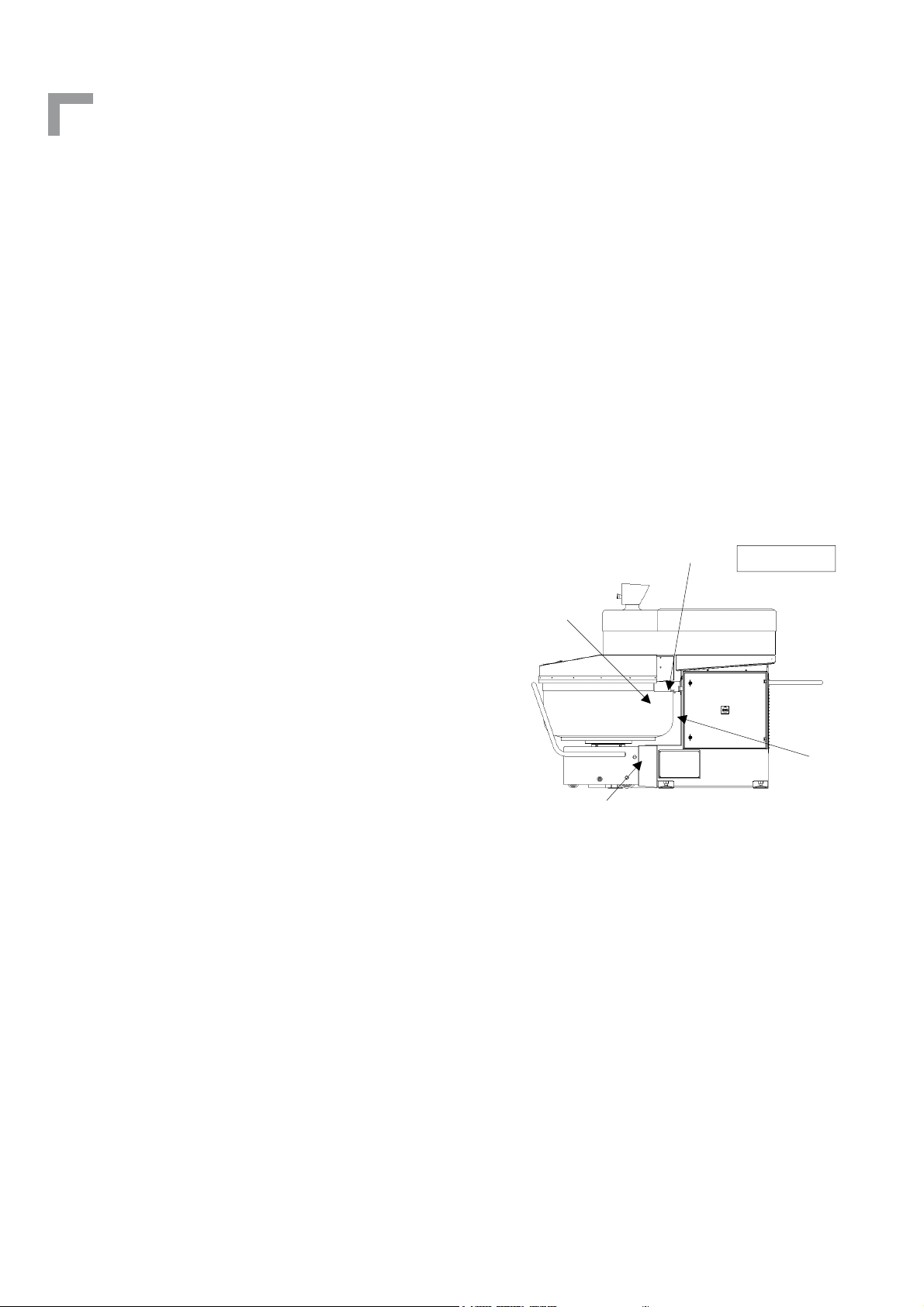

Figure n° 4

13

Page 14

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

The machine conforms to:

▪ the Directive 98/37 CEE

▪ the Directive CEM 89/336 CEE

▪ the Directive BT 73/23 CEE

▪ the specific product standard EN 453 dated August 1999 where the major apllicable stan-

dard are listed.

The machine complies with the laws in effet when it was delivered.

To adapt the equipment to any subsequent modification of standards is under the responsability

of the user. In this case, he has to ask the manufacturer whether a modification is necessary.

PREVENTIVE MEASURES AGAINST MECHANICAL HAZARDS

TOOL (SPIRAL ARM) OPERATING AREA

(Figure n° 5 zone 1)

The bowl is protected in the front part with a stainless steel closed protection and in the rear

part with a flour protection sheet.

The head and its protection opening is temporized as per EN 453 to let the toll stops in 4 seconds from the opening of the machine head.

5

Figura n° 5

SPACE BETWEEN BOWL AND STRUCTURE (Figure n° 5

zone 2)

It conforms to the specific product standard EN 453.

1

4

MECHANISM OF BOWL MOVEMENT (Figure n° 5 zone 3)

Parts in movement advised by warning stickers in order

to maintain the safety.

POSITIONING AND ADJUSTING MECHANISMS

2

(Figure n° 5 zone 4)

All motions of the machine are essentially made by hold-to-run control devices (double

3

push buttons) and doesn’t present risks for the operator.

Note: the operator must be sure there is no person near the machine.

Remove the guards with the specific tools, to accede to the moving elements of the transmission

for inspection, cleaning and maintenance purpose.

BOWL GUIDE DEVICE (figure n° 5 zone 5)

The zone is protected by fixed guards as per EN 453.

In any case we suggest to not insert the fingers in that zone to avoid possible crushing

14

Page 15

English

MACHINE STABILITY

The mixer is provided with adjustable feet with anti-slide rubber.

After having correctly positioned the feet (as explained in SECTION B POINT 2), the machine becomes automatically stable and does not require anchoring to the floor

PREVENTIVE MEASURES AGAINST ELECTRICAL HAZARDS

The preventive measures provided for by the EN 60204-1 standard have been adopted against

the danger of direct and indirect contact and all the tests provided for by the above standard

have been performed as certified in the attachment to the EC declaration of conformity. All the

tests provided for by the current technical regulations have also been carried out for implementation of the EEC directive on EMC.

PREVENTIVE MEASURES TO GUARANTEE HYGIENE

The following should be noted in particular:

A. The elements or parts of the machine (bowl, tool, dividing blade and bowl protection) that are

meant to come in contact with the dough ingredients or are in the so-called FOOD AREA are

made of STAINLESS STEEL (the bowl protection can be made of Transparent thermoformed

suitable for contact with food).

B. The elements or parts of the machine that may come into contact with the above food

products or are in the so-called DIRTYING OR SPLASH AREA are made of STAINLESS STEEL

or OVEN PAINTED STEEL.

C. The machine is in conformity with the principles of design to ensure the cleanability of the

machine as per EN 453.

Measures to protect against flour dust

MEASURES FOR THE REDUCTION OF FLOUR DUST EMISSIONS.

The flour is a powdery agent that can impair the operator health (respiratory illnesses), and

therefore it must be handled in such way to limit to a minimum the presence of flour dust within

the premises.

As concern the machine, if it is equipped with s/s grille, its operating time in the first speed cannot be set up to a value lower than 120 seconds (ref. EN 453) in order to limit the production of

flour dust.

Other warnings useful for operators who regularly handle flour are provided below.

15

Page 16

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

PREVENTIVE MEASURES AGAINST NOISE HAZARDS

When the machine is operating empty, which is considered the most unfavourable condition, it

emits a weighted equivalent continuous acoustic pressure level of ≤ 70 dB (A).

It can be affirmed that the machine does not produce harmful noise or noise requiring the use

of headsets or earplugs.

SECTION A - POINT 6

SAFETY SIGNS - SYMBOLS

The safety signs are affixed to the machine by

means of stickers designed to draw the operator’s attention to possible hazards and to ensure his safety.

Make sure that the colours and wording of the

signs and symbols are always in perfect condition. At the first signs of deterioration, immediately request replacements from your supplier or the manufacturer.

B

Figure n° 6

H

D

C

16

F

E

G

A

Page 17

English

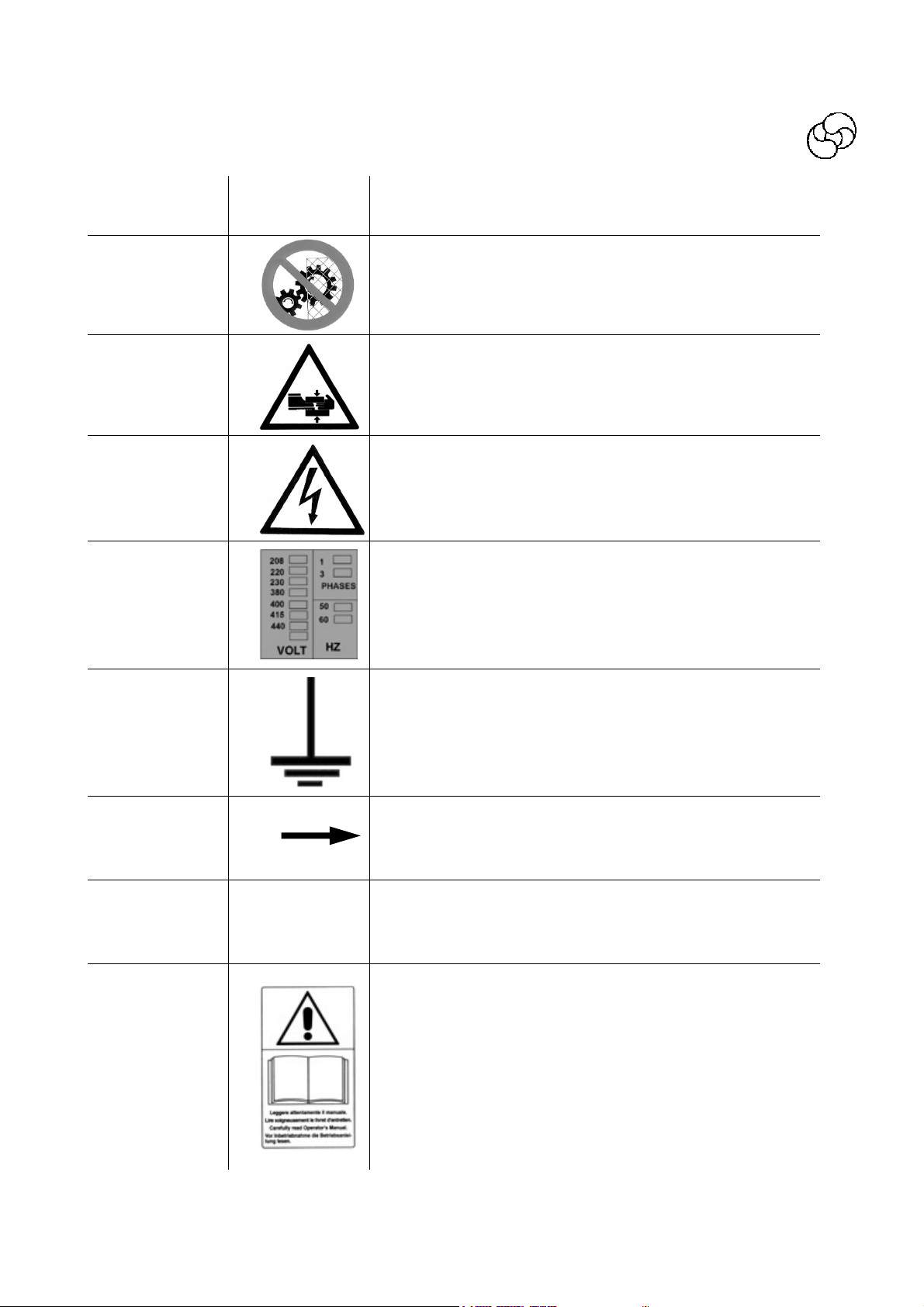

References

A

B

C

D

SYMBOL DESCRIPTION

DO NOT REMOVE THE SAFETY DEVICES

CAUTION – DANGER OF CRUSHING

DANGER – LIVE PARTS

VOLTAGE

E

F

G

H

PE

EARTH

BOWL AND TOOL ROTATION DIRECTION

OUTER PROTECTION WIRE TERMINAL

CAUTION – READ THE INSTRUCTION MANUAL

17

Page 18

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

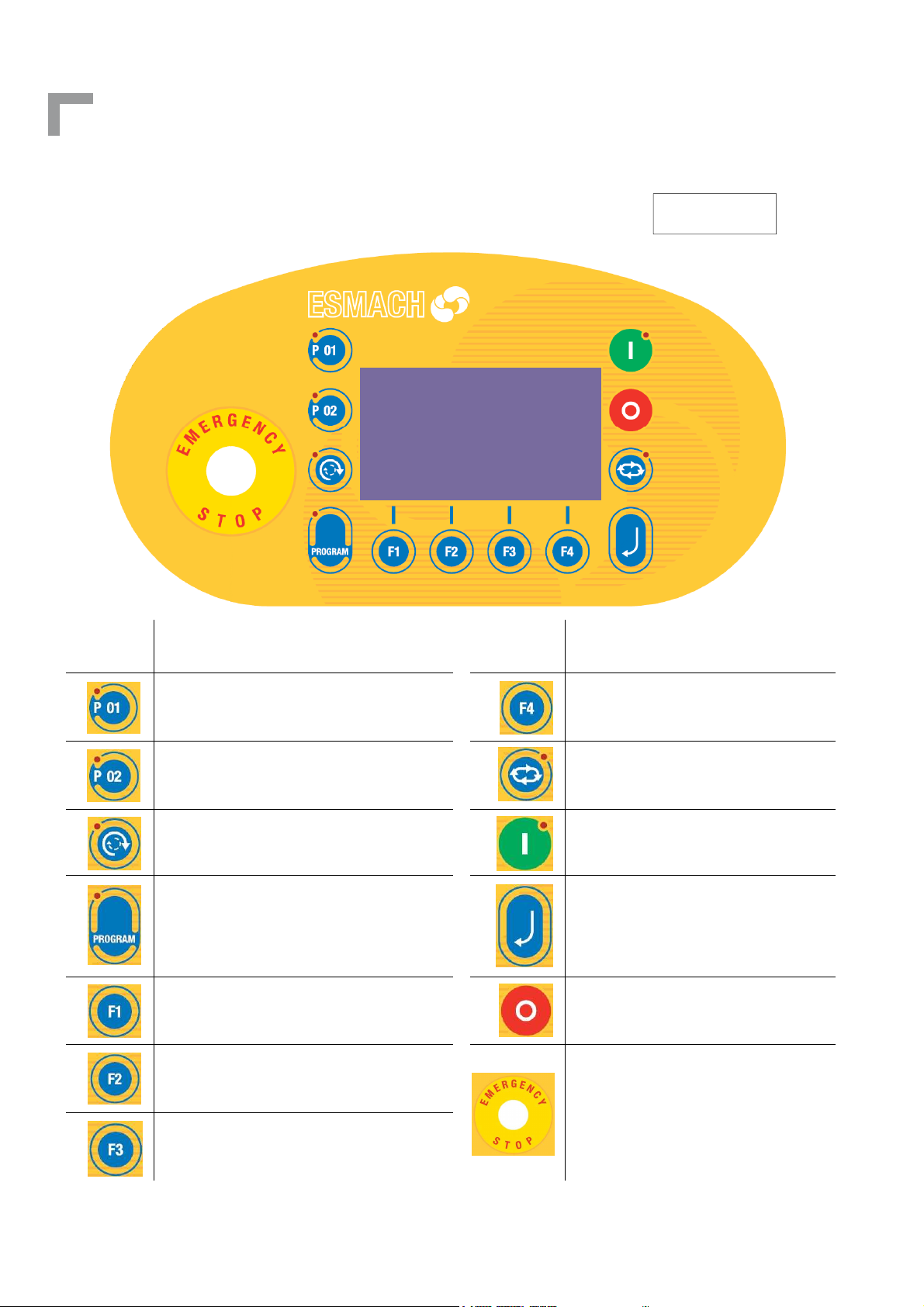

SYMBOLS ON CONTROL PANEL

“Advanced control panel”

Figure n° 7

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

PROGRAMME QUICK RECALL KEY

PROGRAMME QUICK RECALL KEY

BOWL INVERSION

PROGRAMME KEY

FUNCTION KEY

AUTOMATIC/MANUAL CYCLE KEY

CYCLE START KEY

ENTER KEY

FUNCTION KEY

FUNCTION KEY

CYCLE STOP KEY

18

EMERGENCY BUTTON

FUNCTION KEY

Page 19

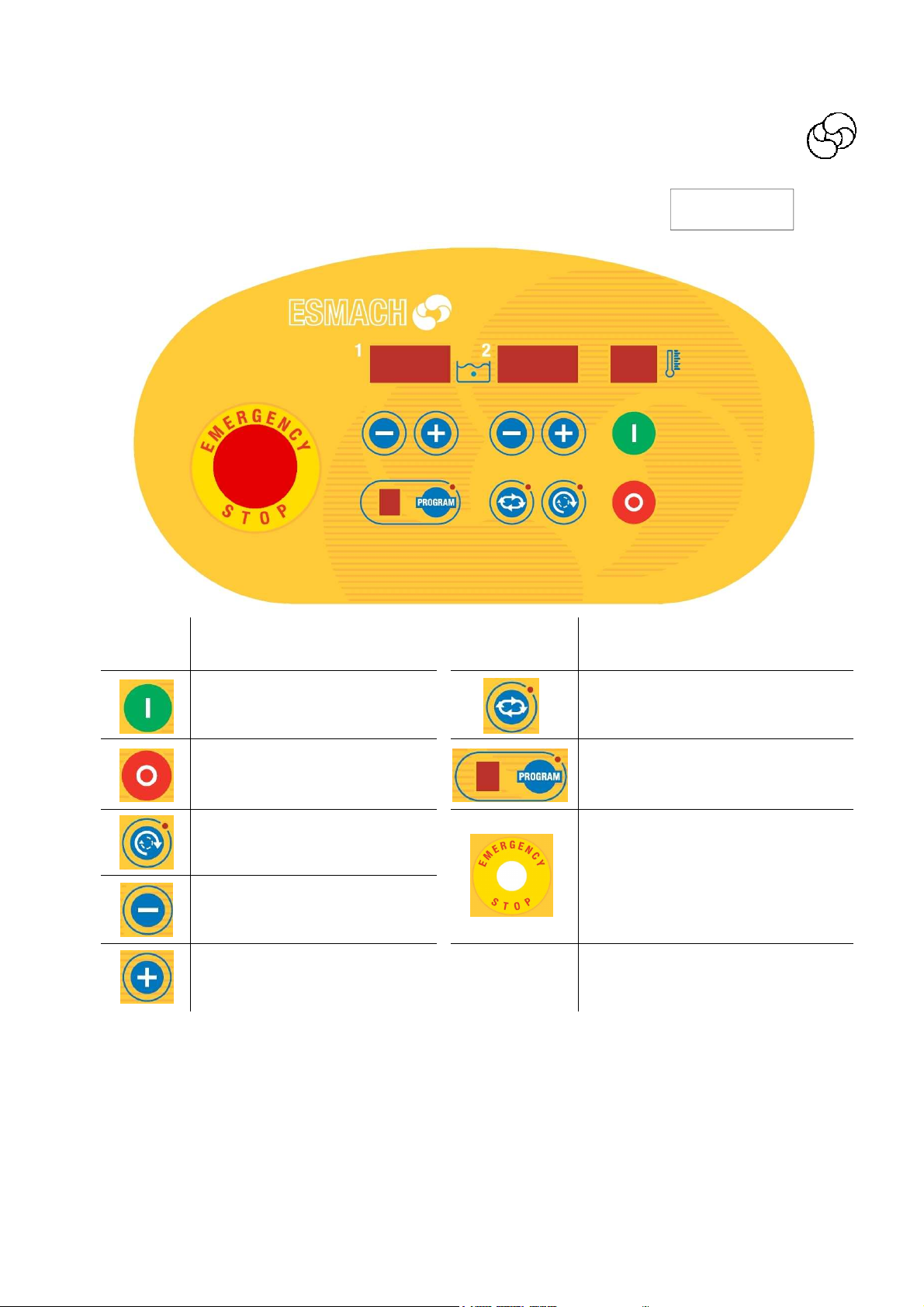

SYMBOLS ON CONTROL PANEL

“Simplified control panel”

Figure n° 8

English

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

START CYCLE KEY

STOPO CYCLE KEY

BOWL INVERSION KEY

DECREASING KEY “DOWN”

INCREASING KEY “UP”

AUTOMATIC/MANUAL CYCLE KEY

PROGRAM SELECTION/PROGRAM

CONFIRMATION KEY

EMERGENCY PUSH BUTTON

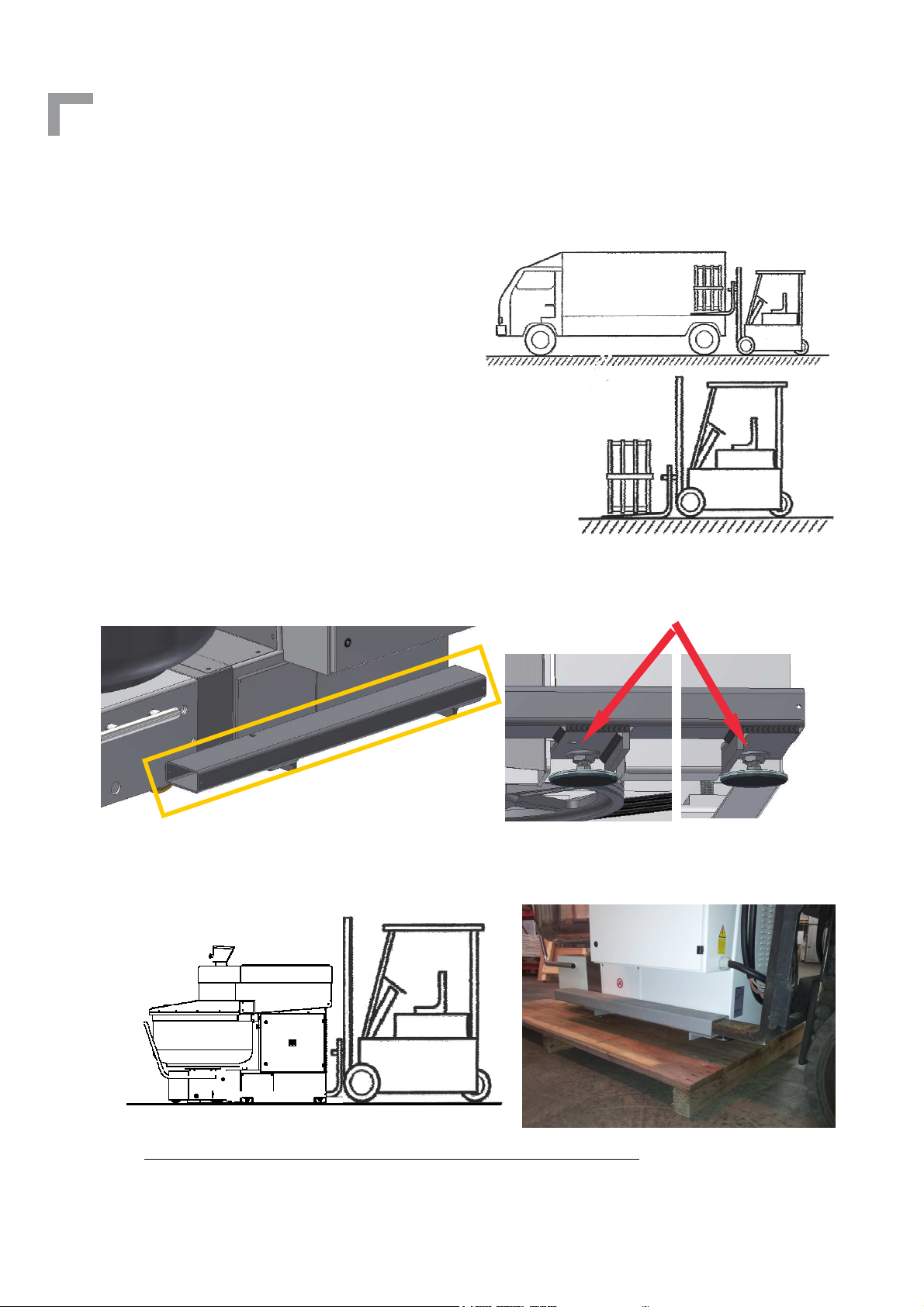

SECTION B - POINT 1

TRANSPORT, HANDLING AND STORAGE

The weight and overall dimensions of the machine are given in Section A point 2. The machine is

shipped assembled and packed in a case/crate/pallet made of nailed wooden boards provided

with the symbols and indications for handling. The operators in charge of handling the load must

be qualified and adequately trained. Store the machine in a dry ventilated room and cover it

with a protective sheet.

will stabilize the machine.

19

Page 20

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

EXAMPLE OF MACHINE UNLOADING WITH FORKLIFT TRUCK

Stage 1: Unload the machine from the lorry in its

packaging;

Stage 2: Rest the machine on the ground;

Stage 3: Unpack the machine;

Stage 4: Make sure that the machine in its complex is in equilibrium .

Stage 5: Make sure that the brackets for lifting are properly inserted on the feet of the machine

and fixed with nuts of the same feet.

FIXING NUTS

BRACKET FOR

LIFTING

Stage 6: Lift the machine avoiding sudden movements.

Stage 7: Only after standing the machine DOWN in the desired position

, loosen the nuts on the

feet and remove the brackets from the side. The nuts will be fixed later when it will stabilize the

machine.

20

Page 21

English

PROCEDURES FOR UNLOADING THE MACHINE USING A CRANE OR HOIST

Unloading personnel must be equipped with chains or ropes compatible with the weight and dimensions of the machine to be moved and in compliance with current safety regulations.

IMPORTANT WARNINGS !

- The slings must comply with ISO 4878 - ISO 9351 standards.

- Use the sling only if the label containing all the manufacturer information is affixed to it and

the capacity is clearly visible.

- Inspect the slings before all lifting operations. Do not use them if they are damaged, cut or

worn.

- Follow the load factors indicated for the various standardised configurations.

- Use adequate protection for lifting loads with sharp edges.

- Do not twist or knot the sling.

- Insert the other ends of the slings in the lifting equipment hook.

- Before moving the machine, ensure that there are no persons nearby.

- Carefully follow the unloading procedures described below.

1. remove the cover screws as per figure n°10

Figure n° 10

2. lift the rear cover

3. lean with care the cover

4. lift the machine:

- machine with jointed trolley : pass the belt in the front part of the central tube (Figure n°

11).

- pass the belts in the two eyebolts on the side of the head attached to the top of the col-

umn (Figures n ° 12 - 13).

Figure n° 11 Figure n° 12 Figure n° 13

21

Page 22

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

SECTION B – POINT 2

PREPARING THE ROOM - INSTALLING THE MACHINE

PREPARING THE ROOM

The room where the machine is installed and any existing equipment already installed in the

room must comply with the directives, regulations, standards and technical specifications etc. in

force in the user’s country (E.U. or EFTA).

INSTALLING THE MACHINE

The purchaser/user or his representative must check the condition of the machine upon unpacking, immediately notifying the manufacturer of any damage or defects encountered.

For installation of the machine, the specifications on the identification label illustrated in Section

A point 1 and the overall dimensions given in Section A point 2 should be taken into account. To

guarantee an optimal use of the machine it is necessary to follow the present installing procedure:

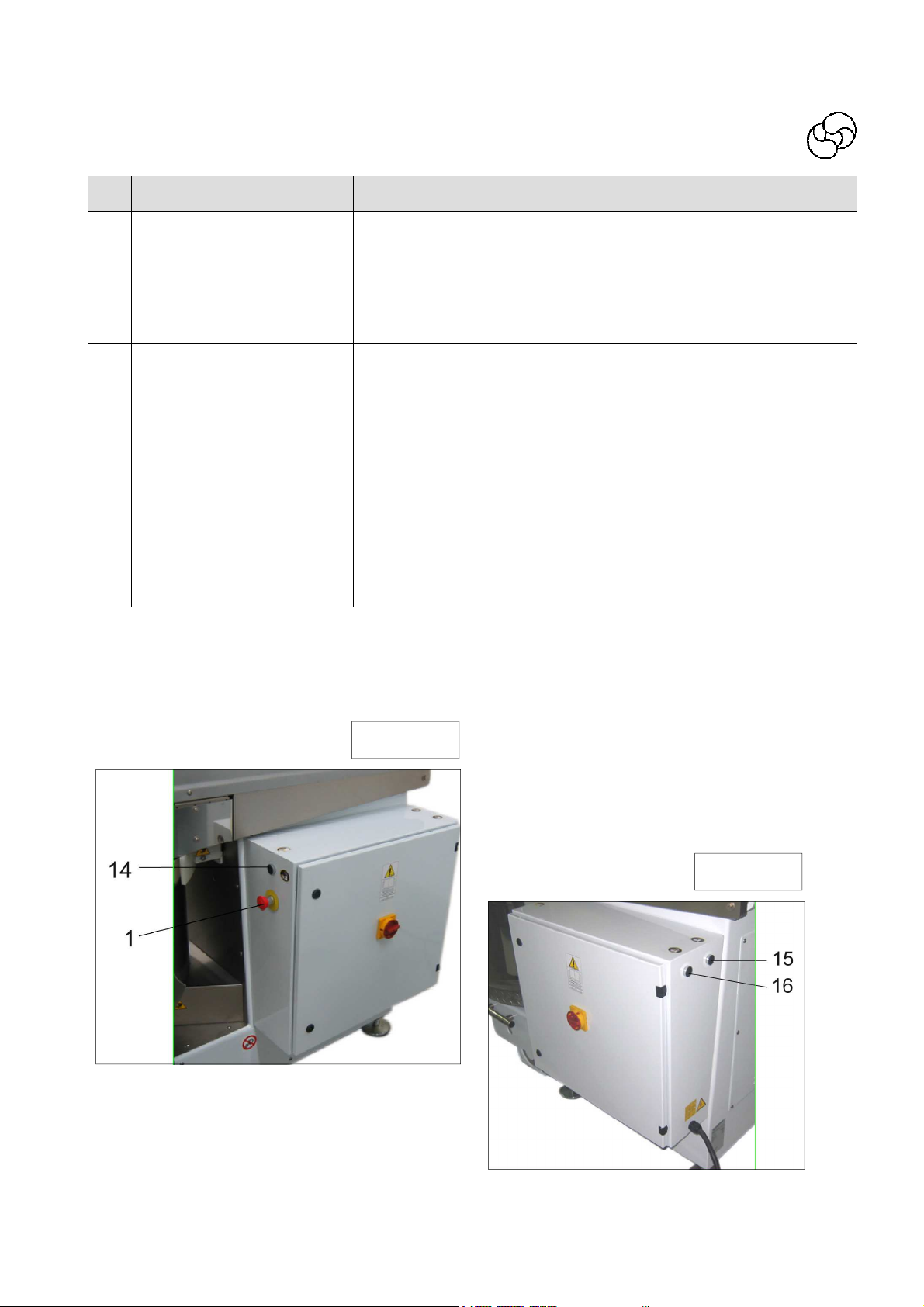

1. clean accurately the floor zone on which will be placed the machine so that the feet with anti-slide rubber have a better adhesion to the floor (figure n° 14)

2. Put the machine on the floor making sure there is an area of approximately 50 cm all around the machine for use and maintenance

3. fix the safety spacer tube (figure n°15) of the machine in the rear

zone in order to let the head raise automatically and avoid accidental crushing of the operators between the cover and the wall

under the machine

4. at this point switch on the machine (figure n° 16) following the

instructions as per Section B—Point 3

5. after having verified that all runs in the correct way, push contemporarily the common button and the button to lift the head

and unhook the trolley (figure n° 17)

Figure n° 15

Figure n° 16

Figure n° 17

Figure n° 14

22

Page 23

English

6. By means of the spacer (which is in the machine equipments) act on the feet in order to

carry the two chutes of the frontal rostrum at a right height from the floor (figure n°18-

19),

figure n° 18 figure n° 19

NB: it is indispensable that all feet are well fitted on the floor.

figure n°20

7. Put the trolley in the machine and hook it (figure n° 20)

8. Verify that the distance from the floor and the wheels under the trolley in the hooking

position is at least the thickness of a sheet of paper.

9. if the wheel touch the floor it must lift again the feet so that the wheels became free.

10.Now it must block the feet tightening nut with the key (equipment).

The machine is designed to operate in the normal temperature and humidity conditions found in

EU and EFTA countries.

The machine must not under any circumstances be used in places where there is the

danger of explosion or fire due to the presence or generation of dust, gas or explosive

or flammable mixtures.

For connection of the machine to the electrical power source, see points 4 and 5 of Section B.

NOTE: For connections in the US/Canada:

An electrician licensed under the jurisdiction (city, municipality, county, state, etc.) in which the

mixer will be installed must install the plug that meets requirements in sub-clauses 4.5.2.2 of

C22.2 No. 195 and 6.2.1, 11.1.1, 15.1.6 of UL 763.

23

Page 24

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

SECTION B – POINT 3

START-UP, USE AND ADJUSTMENTS

START-UP

One single trained and instructed operator is sufficient for use of the machine according to this

handbook.

IMPORTANT WARNINGS

Before starting the machine, follow the instructions below:

1. Check that the machine voltage, indicated in the identification label illustrated in Section

A, point 1, corresponds to the line voltage at the socket. If not, suspend the connection

operations and call the supplier or the manufacturer.

2. Turn the master switch to position 1. The display must be on. Make sure that the emergency buttons on the card and on the side of the electric box are not pressed. If the trolley is hooked and the head is lowered, press at the same time the common and upstroke

buttons (keys 3 and 6 as shown by the machine controls). When these two buttons are

pressed, the head lifts. This means that the pump turns correctly. If not, invert the

phases on the electrical plug.

24

Page 25

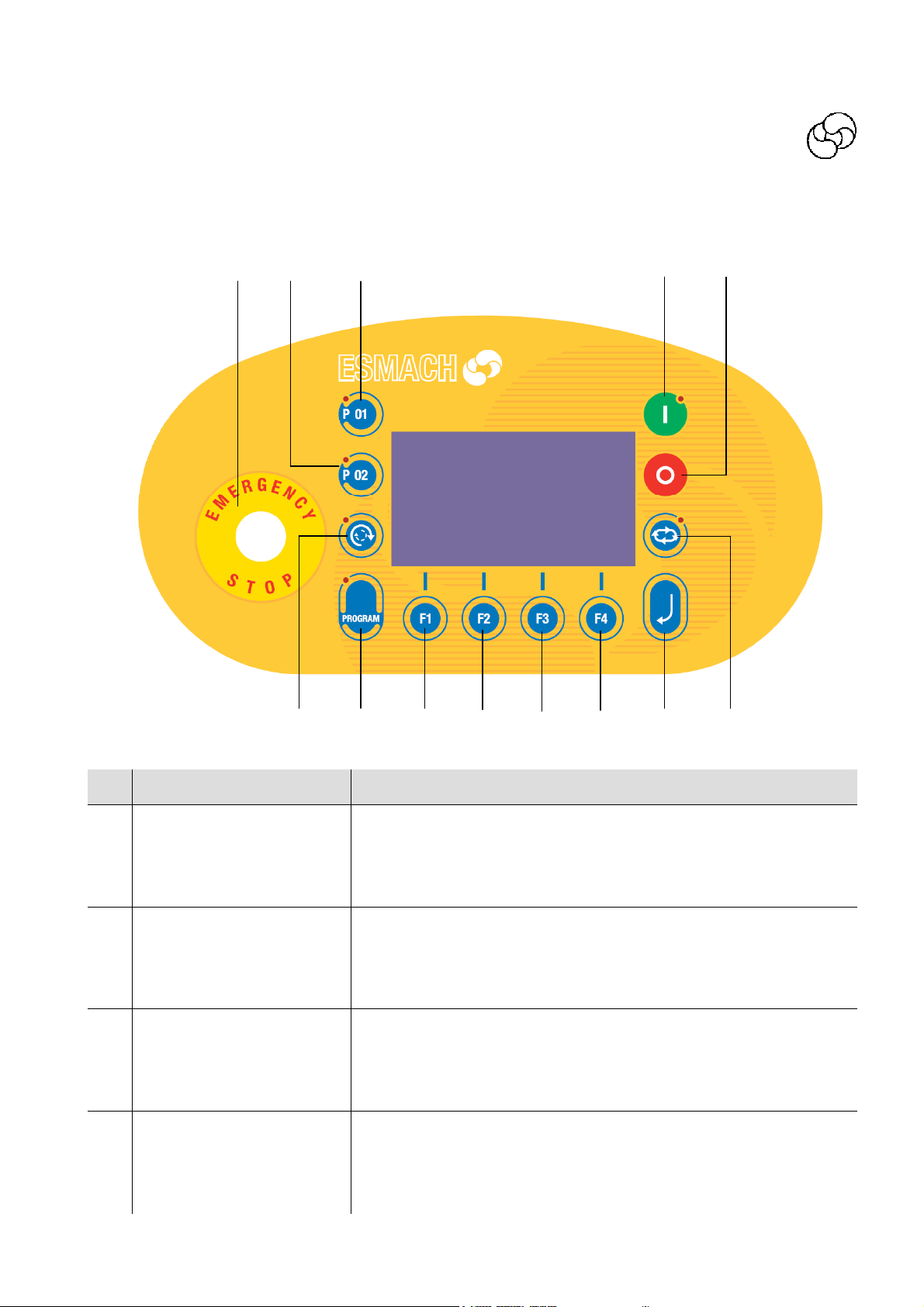

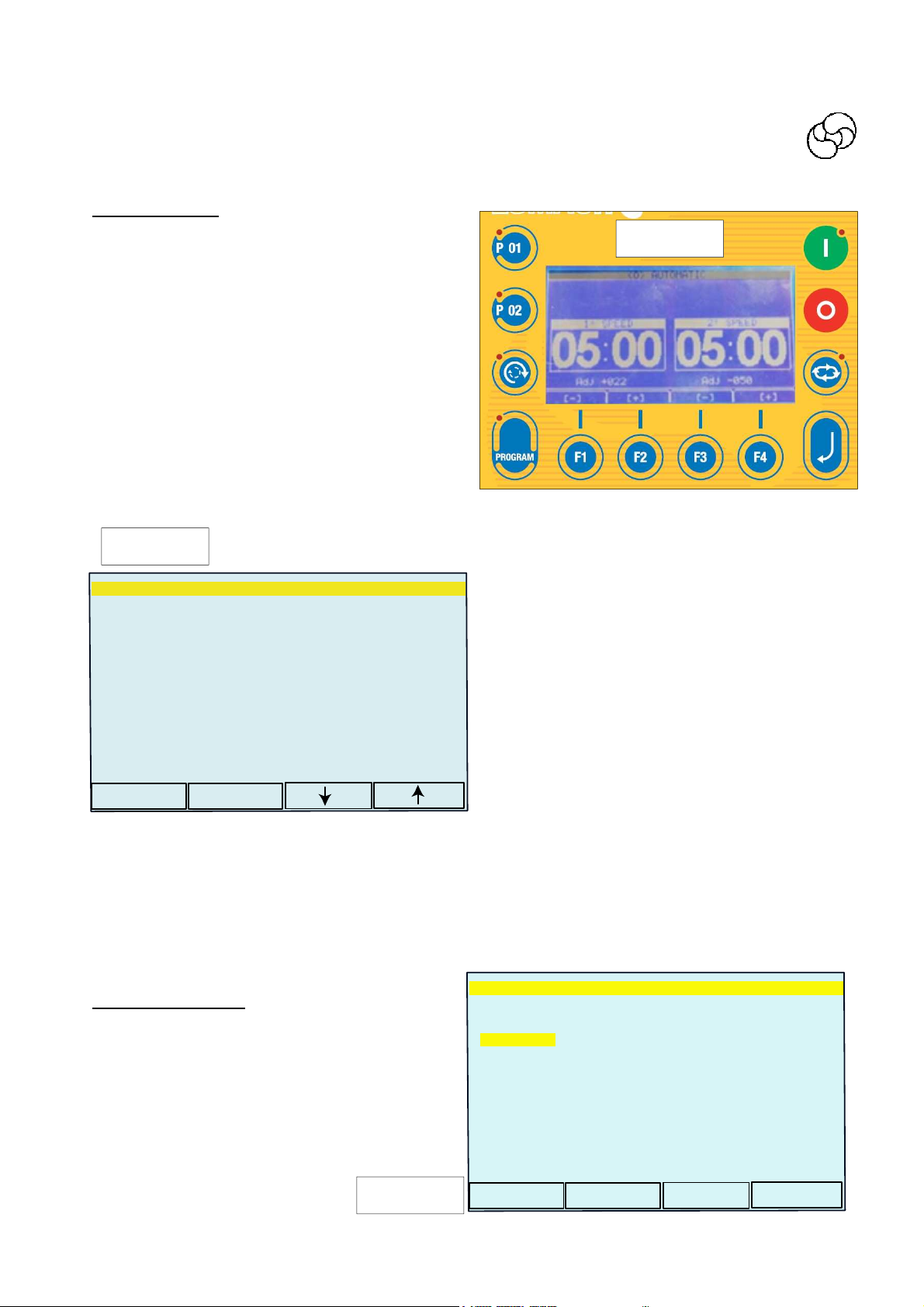

MACHINE CONTROLS:

“Advanced control panel”

English

Figure n°21

1 3 2

12 13

legend:

DESCRIPTION FUNCTION

1 EMERGENCY BUTTON

PROGRAMME QUICK RE-

2

PROGRAMME QUICK RE-

3

4 BOWL INVERSION

CALL KEY

CALL KEY

4 5 6

When it is pressed, it stops the machine and locks all possible

movements. Turn it clockwise to unlock the button.

Note: there are two emergency push buttons (ref. 17)

When it is pressed, it recalls the main programme n° 1

(without access to programming).

When it is pressed, it recalls the main programme n° 2

(without access to programming).

When it is pressed, it inverts the bowl motion (led on). Inversion is possible only when the spiral turns at low speed and not

in programming mode. (programs from10 to 99)

When it is pressed during recipe programming it insert the inversion phase

7

8

9

10 11

25

Page 26

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

DESCRIPTION FUNCTION

Pressing it one time you can recall the last program you set

up.

When it is pressed twice, it displays the list of all 99 recipes.

5 PROGRAMME KEY

After having selected the recipe, it is possible to start the

working cycle pressing the START key (if the situation allows

starting). During programming the led on the left of the key is

on.

6

7

8

9

FUNCTION KEY

F1

FUNCTION KEY

F2

FUNCTION KEY

F3

FUNCTION KEY

F4

10 ENTER KEY

The key can have different functions according to what the display shows.

The key function is displayed in the down line

The key can have different functions according to what the display shows.

The key function is displayed in the down line

The key can have different functions according to what the display shows.

The key function is displayed in the down line

The key can have different functions according to what the display shows.

The key function is displayed in the down line

It allows entering or exiting from recipe programming. For

these operations, the key has to be kept pressed for 3 seconds

until is displayed “insert code”.

AUTOMATIC/MANUAL

11

CYCLE KEY

12 CYCLE STOP KEY

13 CYCLE START KEY

26

It allows changing from manual cycle to automatic cycle. During the automatic cycle the led on the right of the key is on.

1-When it is pressed, it stops the machine. If pressed during

the machine running it allows the cycle stopping and times

memorization.

2-if pressed twice during the machine running, it allows the

machine stopping and the working times restoring.

When it is pressed, it starts the mixing cycle. The cycle can

starts only if the head is in work position and there is no emergency.

Page 27

DESCRIPTION FUNCTION

Common button for trolley hooking/unhooking and head upstroke/downstroke. This button has to be pressed at the same

14

MACHINE HANDLING

COMMON BUTTON

time of the buttons 15-16.

When it is pressed alone for at least 0,5 sec. at upstroke head

without trolley, it allows the hook lowering to make easier the

trolley connection in case of not levelled floor.

English

HEAD UPSTROKE /

15

TROLLEY UNHOOKING

BUTTON

HEAD DOWNSTROKE /

16

TROLLEY HOOKING BUT-

TON

When it is pressed together with button 14, it allows to lift the

head and, once the head is lifted, to unhook the trolley.

If pressed together with the button 14, it hooks the trolley

and, at hooked trolley pressing the same buttons it allows the

head lower

Figure n°22

Figure n°23

27

Page 28

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

WORKING CYCLE START – AUTOMATIC WORKING

Trolley hooking / Head downstroke / Head upstroke / Trolley unhooking

To hook the trolley, place the trolley near the machine and follow the instructions below:

Press at the same time the buttons on the two sides of the box (common button “14” and downstroke button “16”)

When the trolley is hooked, the head begins to lower. Keep buttons pressed until the head has

gained the work position (head down). The trolley unhook is automatic only when the head is

completely upstroke.

All controls are of hands-on type.

If the floor has a slope opposite to the unit and the trolley into position goes away from the machine, it is possible to pre-hook the trolley by pressing the common key. “14” for at least 3 seconds.

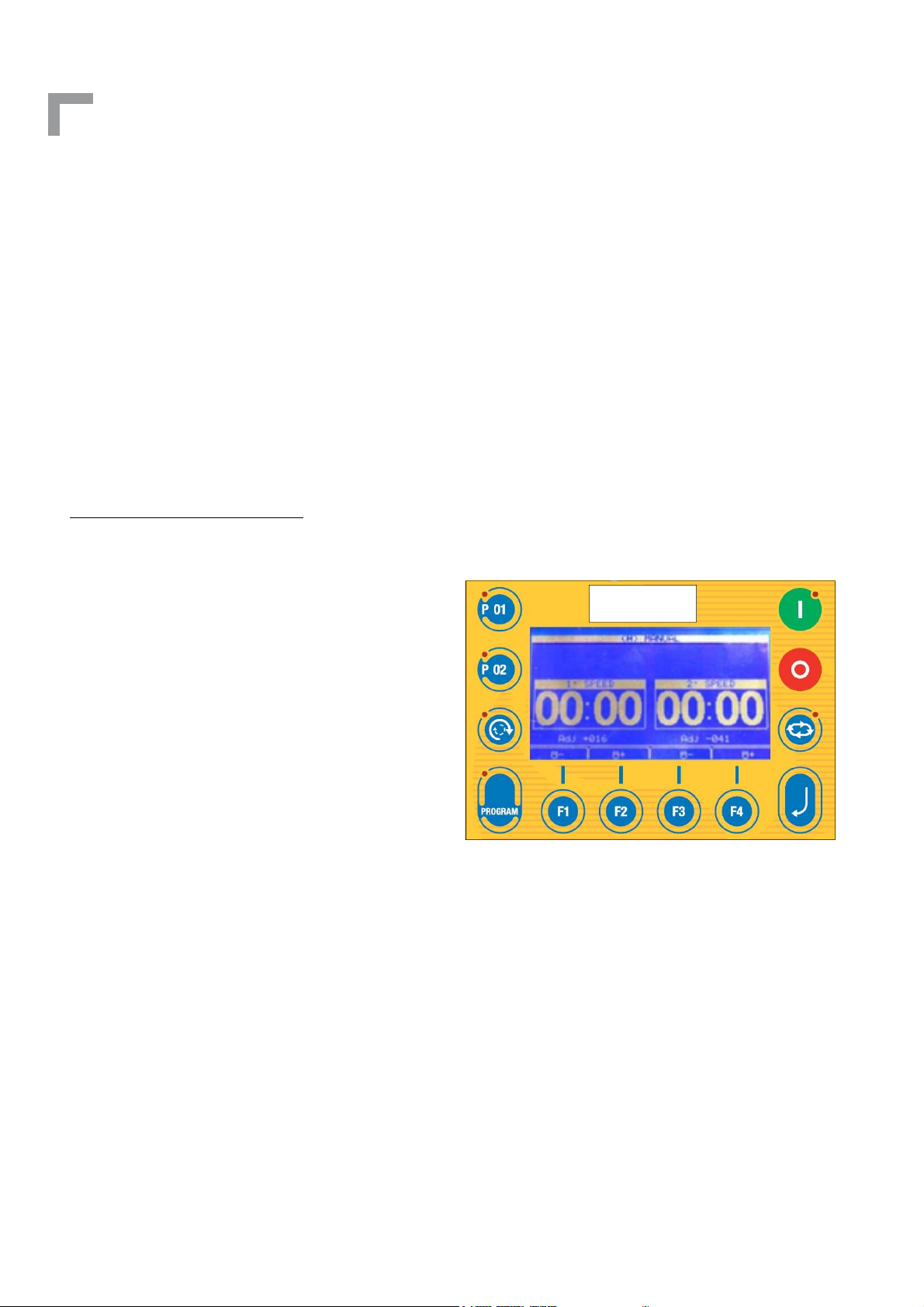

MANUAL CYCLE WORKING H (figure n° 24)

The manual cycle is available if key leds n°5 and 10 are off. Contrarily, touch over and over on

key “11” utill “MANUAL (H) “ appears.

When the START key 13 is pressed, the machine begins to work at the 1

The time on the 1

st

speed left timer increases.

During this phase it is possible to invert the bowl

direction by pressing the key 4.

The machine works at the 2

again the START key.

The machine can work at 2

minimum time in 1

utes) has been spent.

The time on the 2

st

speed (minimum 2 min-

nd

speed right timer increases.

The machine works at the 1

again the START key,

You can change the bowl speed at the 1

with the function keys F1-F2 (ADJ from +50-50).

You can change the bowl speed at the 2

nd

speed by pressing

nd

speed only if the

st

speed by pressing

st

speed

nd

speed

st

speed.

Figure n°24

with the function keys F3-F4 (ADJ from + 50-

50).

The machine stops by pressing the STOP key 12. The timer count is reset by pressing again the

STOP key.

AUTOMATIC CYCLE WORKING “0”

Press the key 11 to change from the programme MANUAL H to the programme AUTOMATIC 0.

The led must light on (figure n°30).

Set the working time at the 1

Set the working time at the 2

st

speed with the function keys F1-F2.

nd

speed with the function keys F3-F4.

Press the START key 13 to start the cycle.

If you press the ENTER key, the last line of the display shows the bowl speed variation at first

and second speed as already explained for THE MANUAL CYCLE.

If you do not press one of the keys F1-F2-F3-F4 within 3 seconds, with these buttons you do not

change the bowl speed but times are increased.

28

Page 29

RECIPES - LIST

It is possible to memory two kinds of recipes:

simple recipes: numbered from 1 to 9 in which

Figura n°25

it is possible to recorder the dough times, the

bowl speed and in case the automatic upstroke

recipes with variations: from n° 10 to n° 99,

in addition to the functions described in

point a), the following can be programmed and

stored: addition of salt, improver, temperature

control and raising of the head at the end of the

cycle (only if the machine is provided

with the relevant optionals).

Figure n°26

-05-

RECIPE N. 05

The names of the recipes are shown by pressing

the key PROG. With the keys F4-F3 you can select a new recipe.

SELECT RECIPE

05:RECIPE N.05

06:RECIPE N.06

07:RECIPE N.07

08:RECIPE N.08

09:RECIPE N.09

10:RECIPE N.10

11:RECIPE N.11

12:RECIPE N.12

Confirm by pressing the key F2.

Exit from the list of the recipes by using the key

F1. You go back to the previous recipe if you do

not confirm by pressing the key F2.

Start the work cycle by pressing the key START.

To recorder the automatic up-stroke at the end

of cycle in the simple recipes you must:

▪ push ENTER key

ESC

OK

▪ digit the programming access code “250”

confirming it with ENTER key.

▪ move in the proper box with F1/F2 keys

▪ select “yes” or “not” with key F3/F4 confirming than with ENTER.

▪ With “P01” and “P02” you can recall possible priority programs.

▪ To relate the program to the recipe see “list of parameter modifiable by the user”

RECIPES WORKING

-11 -

RECIPE N. 11

Press twice STOP key.

Press the key PROG: the led is on.

The last selected recipe is shown (figure n°

RECIPE

PHASES

PHASE NUMBER:04 TOTAL TIME : 05.30

27).

Figure n°27

NAME :RECIPE N.11

MAX TEMP. °C :25.2

TEMP. CONTROL :No

INSERT THE CODE : 255

TAB

EDIT

English

29

Page 30

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

Only if present on the machine,

the display shows the accessory

salt, improver, temperature

To enter in programming or modify a recipe press the key Enter “10” for 3 seconds.

The enter code is required. (figure n° 28).

Figure n°29

-11 -

PHSE NUMBER : 00 22°C

TOTAL TIME : 00.00

NAME : RICETTA N. 11

UP-STROKE : yes

T. SALT : 00.10

T. IMPROVER : 00.10

MAX. TEMP. °C : 25.2

TEMP. CONTROL : Si

F01 STOP :

INSERT THE CODE : 250

Now the cursor is on the first letter of recipe

name.

The keys F3-F4 let run through the character

The keys F1-F2 let move to the right or to the

left.

The F2 key lets go to the next phase (salt distribution, improver , upstroke ...):the distribution

time must be counted from the cycle end

(example: total kneading time =10 minutes;

salt distribution time: 3 minutes; the salt will be

distributed at the 7th minutes form the beginning of the cycle)

UP-STROKE

By setting “yes”, 10 seconds after the end of mixing, the head moves up automatically until

it reaches the raised position. The trolley is manually released. To release the trolley, simply

press the common buttons “18” and up button “19” for 0.5 seconds.

By setting “no”, at the end of mixing, the head must be raised manually by simultaneously

pressing the common buttons “18” and up button “19”.

RECIPE N. 11

Figure n°28

[-]

[+]

-11 -

PHASE NUMBER : 00 22°C

TOTAL TIME: 00.00

NAME : RICETTA N. 11

UP-STROKE : yes

T. SALT : 00.10

T. IMPROVER : 00,10

MAX. TEMP °C : 25.2

TEMP. CONTROL : si

F01 STOP :

Set the value 250 with the keys F3-F4

(figure n° 29) and confirm with Enter key.

-11-

PHASE NUMBER : 00 22°C

TOTAL TIME : 00.00

NAME : RICETTA N. 11

UPSTROKE : yes

T. SALT : 03.00

T. IMPROVER : 00.10

MAX. TEMP. °C : 25.20

TEMP. CONTROL : si

F01 STOP :

RECIPE MODIFICATION >Stop<TO EXIT

RECIPE N. 11

RECIPE N. 11

Figure n°30

[-]

[+]

30

Page 31

English

V-V1 adj + 037

Mixing TEMPERATURE (OPTIONAL)

The temperature value can be set only from recipe 10 to recipe 99.

To set the temperature, follow the procedure

below:

▪ press the ENTER key

▪ type in the code for “250” programming access and confirm via the

“ENTER” key

▪ move to the required field via keys F1/F2

▪ set the temperature value via keys F3/F4

▪ go to the next parameter via key F2

▪ use key F4 to enable the temperature control

during mixing (phase F01 is ignored)

▪ use key F3 to disable the control. In this case

the temperature value is displayed all the same.

If the operator activates the mixing temperature control, the machine stops when the set temperature is reached.

The operator can then decide whether to suspend or resume the work cycle by pressing the

STOP or START key.

WORKING PHASES: F01

The keys F1-F2 let move to the right or to the left.

Press the key F3-F4 to select the requested function.

Under the phase F01 it is possible to set:

-1

st

speed (bowl rotation in the same sense of

the spiral arm)

-bowl inversion (bowl rotation sense contrarily

to the spiral arm)

After function selection, press F2 key. The cursor goes to value area of the relative phase.

With F3-F4 keys set the time. To go to the next

phase press F2 key. To return to the previous

phase press F1 key.

Under the phase F02 it is possible to set:

▪ 1

st

speed

▪ bowl inversion

▪ 2

nd

speed

▪ stand-by

▪ stop

Press ENTER to confirm all recipe parameters.

The stop key let exit to the recipe programming without saving the datas.

If the machine is in working position press start key. Display will show the programm as per

figure n° 33

USER MODIFYABLE PARAMETERS: access code 111

To accede to user parameters, press PROG key for at least 3 seconds untill “insert the code” is

displaied.

Insert the code 111 by F3-F4 keys.

Conferm with F2 key.

Select the parameter by F3-F4 keys.

Set up the value with F1-F2 keys.

-11-

PHASE NUMBER : 04 22°C

TOTAL TIME : 11.45

MAX. TEMP. °C : 25.20

TEMP. CONTROL : si

F01 1° SPEED : 00.45

F02 BOWL INVERSION : 00.30

F03 1° SPEED : 02.15

F04 2° SPEED : 06.15

F05 STOP

-15-

Total : 02.30 Remaning : 02.28

TEMP. MAX. °C : 25.20

F01: 1st speed : 02.30

F02: STOP

02.26

RECIPE N. 11

RECIPE N. 15

RUN

Figure n°31

Figure n°32

-

+

31

Page 32

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

P01 Inversion exclusion P06 Recipe connected to P01 key

P02 Horne activated P07 Recipe connected to P02 key

P03 Bowl rotation sense P08 language

P04 Display contrast adjustment P09

P05 Display brightness adjustment

Press STOP key to exit programming.

PROGRAMS DISPLAY

The display shows the 1st and 2nd speed incremental time.

Switching from the 1st to the 2nd speed is performed by

(H) MANUAL

pressing the START key. To return to the 1st speed, press the

START key again.

Possibility of modifying the bowl speed.

The display shows the 1st and 2nd speed decremental time.

Switching from the 1st to the 2nd speed occurs when the 1st

bowl speed time expires.

(O) AUTOMATIC

Possibility of raising the head in automatic mode at the end of

the cycle.

Any modifications to the work times remain stored without

entering programming.

The display shows the 1st and 2nd speed incremental time.

Switching from the 1st to the 2nd speed occurs when the 1st

bowl speed time expires.

1÷9 RECIPES

Possibility of raising the head in automatic mode at the end of

the cycle.

Any modifications to the work times do not remain stored. To

store the times, enter programming.

The display shows:

▪ Work cycle total time

▪ Remaining time

▪ Phase in progress time

10÷99 RECIPES

▪ Phase in progress remaining time

▪ Head up at end of cycle

▪ Bowl speed /adj)

▪ Mixture temperature (*)

▪ Salt distribution time (*)

▪ Improver distribution time (*)

(*) only if provided on the machine (optionals)

32

Page 33

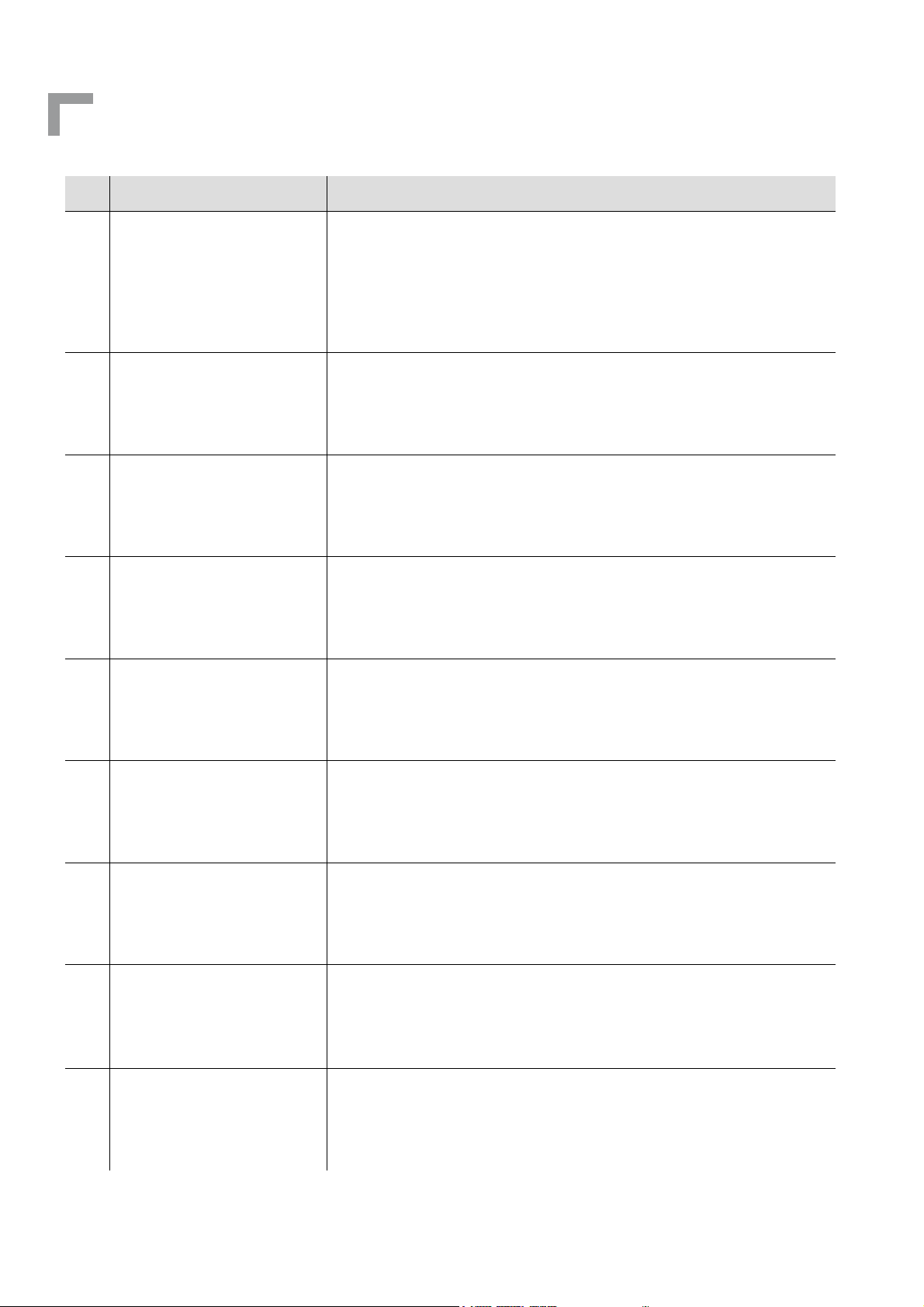

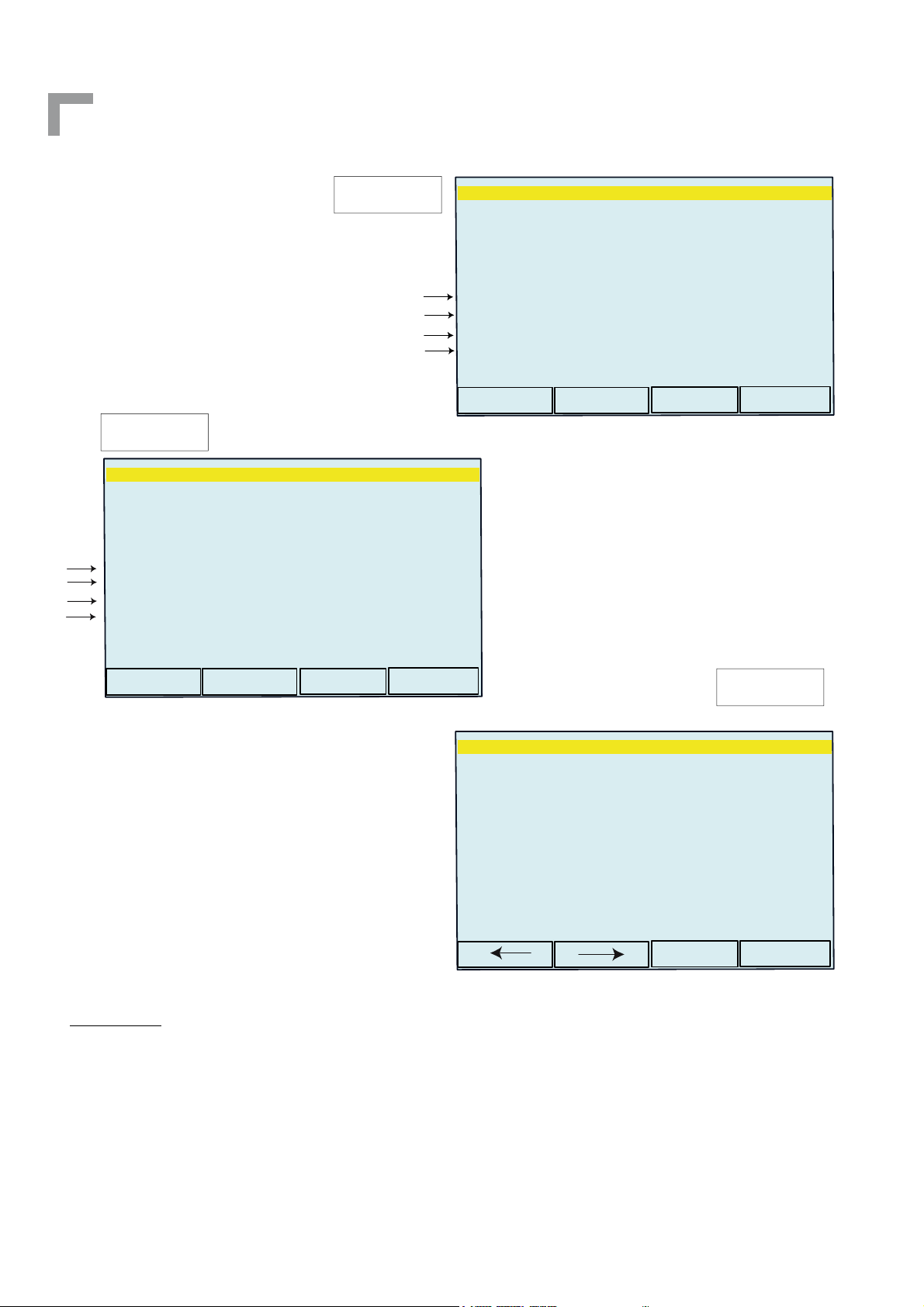

MACHINE CONTROLS:

“Symplified control panel EB”

English

Figure n°33

1 3 2

4

18

7

6 5

17

8 9

11 12 13 1 4

10

16

15

legend:

DESCRIPTION DESCRIPTION

1 EMERGENCY BUTTON 10 PROGRAMMING LED

2 1

ST

SPEED TIME DISPLAY 11 AUTOMATIC/MANUAL CYCLE KEY

3 1

st

SPEED TIME “UP” KEY 12 AUTOMATIC OPERATION LED

4 1

st

SPEED TIME “DOWN” KEY 13 13 BOWL INVERSION KEY (*)

5 2

nd

SPEED TIME DISPLAY 14 BOWL INVERSION LED

6 2

nd

SPEED TIME “UP” KEY 15 CYCLE START

7 2

nd

SPEED TIME “UP” KEY 16 CYCLE STOP

8 PROGRAM NUMBER. DISPLAY 17 TEMPERATURE PROBE DISPLAY

9 PROGRAM SELECTION/ 18

WATER DISPENSER LED

(only for spiral mixers SPI F)

33

Page 34

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

DESCRIPTION FUNCTION

Common button for trolley hooking/unhooking and head

upstroke/

downstroke. This button has to be pressed at the same

19 MACHINE HANDLING

HEAD UPSTROKE /

TROLLEY UNHOOKING

20

BUTTON

time of the buttons 19-20..

When it is pressed alone for at least 0,5 sec. at upstroke head

without trolley, it allows the hook lowering to make easier the

trolley connection in case of not levelled floor.

When it is pressed together with button 18, it allows to lift the

head and, once the head is lifted, to unhook the trolley.

HEAD DOWNSTROKE /

21

TROLLEY HOOKING

BUTTON

19

If pressed together with the button 18, it hooks the trolley

and, at hooked trolley pressing the same buttons it allows the

head lower

Figure n°34

Figure n°35

20

21

34

Page 35

English

WORKING CYCLE START – SPI Awith simplified control panel EB

Completely down stroke the machine head. On the machine keft side, the led near the emergency

push button must be on.

After this operation it is possible to programm the cart and push START.

MANUAL OPERATION

If the emergency button is not pressed, the haed is downstroke, the automatic key led is not on

and the machine is not working, “ooo ooo” will be shown on the 1st-2nd speed time display. The

program display will show -.

In addition to the emergency button, only the following keys are active:

- “start”

- “stop”

- “bowl-inversion” (also during operation)

Keys 9 “PRG programming” and 11 “automatic cycle” are not enabled.

Time Keys 3-6 “up” and 4-7 “down” are neither active nor enabled.

Led 12 on the “automatic cycle” key and the led on the “PRG” key are off.

The two “display-timers” are set to zero (000 000).

When key 15 “start” is pressed, the machine starts at first speed.

The first speed display indicates the operating time (incremental): up to 9’ and 50” it shows 2

digits for the seconds and 1 for the minutes; beyond this, it shows three digits for the minutes

(blinking dot to mark the seconds).

The program display 8 shows H.

With the machine operating only at first speed the “bowl-inversion” command is enabled.

When key 13 “bowl-inversion” is pressed, both the spiral arm and the bowl stop. After 1.5s the

movement is inverted. This interval is not calculated by the timer. (The same thing happens

when the key is pressed again and the inversion is de-activated).

The first speed display shows the time in incremental mode.

Whenever key 13 “bowl-inversion” is pressed, the first speed timer is temporarily blocked for the

time indicated above (1.5s).

If the bowl inversion function is enabled and the start key 15 is pressed twice, the machine operates

at minimum time at first speed with the bowl in reverse direction; it then operates for

1.5s with the bowl in normal direction and then switches to the 2

inversion function is automatically disabled. While the machine operates in 1

speed display blinks; this means that the machine switches automatically to 2

minimum operating time in 1

st

speed.

nd

speed. In this case the bowl

st

speed, the second

nd

speed after the

If the machine is operating in 1

to 2

nd

speed. Reaching of the 1

st

speed and button 15 “start” is pressed, the machine switches

st

speed minimum time (2 seconds or 2 minutes) must always be

guaranteed.

The 1

st

speed display stops at the time reached; the 2

nd

speed display indicates the operating

time (incremental).

If the machine is operating in 2

st

return to 1

speed (intermediate pause time between 2

nd

speed and the start key 15 is pressed again, the machine will

nd

and 1

st

time: 1.5s).

If the start key 15 is pressed again, the machine operates at 2

nd

speed.

All this is possible if the grille is not lifted or the stop key 16 is not pressed.

35

Page 36

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

If the stop key is pressed, the machine stops and the display-timers lock at the time reached up

to that moment.

If the “emergency button” is pressed, the machine stops and the display-timers show a code

that corresponds to the message “emergency pressed” (e.g. “---“ “---“).

When the mushroom-headed button is released, the display-timers show the time reached up to

that moment.

Opening the machine protection, the machine will stop and the display-timers will show the time

reached up to that moment, in blinking mode.

When the protection is closed, the display-timers show the time reached up to that moment (in

continuous non-intermittent mode).

In these last three conditions, since the timer that measures the 1

st

speed minimum time has

set to zero, we can have the following situations:

If the stop has occurred with the machine in 1

At the next start-up, it will resume operation in 1

st

speed:

st

speed from the moment when it was interrupted

until it completes at least the minimum time (2 seconds or 2 minutes).

Once the minimum operating time in 1

st

speed has been completed, you can switch to 2

nd

speed

by pressing the START button.

When the “stop” key is pressed, the display-timers go to zero and it is possible to start a new

cycle;

The START button can be pressed also during operation of the machine in 1

if the minimum time in 1

st

speed has not yet elapsed, the 2

nd

speed display will blink.

st

speed. In this case,

If the stop has occurred with the machine in 2

by pressing the “start” key it is possible to continue operation: the machine restarts in 1

for the duration of the minimum 1

2

nd

speed (in this case the 1

until the 1

st

speed minimum time is reached). When the machine switches to 2

st

st

speed time (2 seconds) and then switches automatically to

speed display-timer increments while the 2

nd

speed:

st

nd

speed display blinks

nd

speed, the time

speed

increments and the display stops blinking.

If the “stop” key is pressed only once, the display-timers lock. If the stop key is pressed a second

time, the displays go to zero and it is possible to start a new cycle.

If the maximum time of 99’5(9)” is reached, the machine stops.

AUTOMATIC OPERATION

The “automatic cycle” key is enabled exclusively with the machine at a standstill, not in the work

cycle (i.e. at the end of an automatic cycle or after interrupting a manual cycle by pressing the

“stop” key twice).

When the “automatic cycle” key is pressed, the red led comes on and the two displays show the

operating times set in the last automatic work cycle (the first time the machine is used,

the following default values are set by Esmach: 5’ in first speed, 8’ in second speed).

These values can be modified via the “up” and “down” keys (the increment/decrement is 15” up

to 9’59” and 1’ over 9’59”; if pressed for longer than 3s the scroll speed increases).

If the machine is provided with stainless steel grille bowl-protection it will not be possible to set

an operating time in first speed below 2’ (minimum time in first speed = 2’).

If the machine is provided with bowl-protection with ABS closed cover, it will not be possible to

set an operating time in first speed below 15” (minimum time in first speed = 15”).

36

Page 37

English

When the “start” key is pressed, the automatic cycle starts: the machine starts in first speed

and the display indicates the remaining operating time (decremental).

With the machine operating in first speed the “bowl-inversion” command is enabled.

When the related key is pressed, the red led comes on, the bowl stops and after a pause of 1.5s

the machine inverts the movement of the bowl. This interval is not calculated by the timer. The

same thing happens when the key is pressed again and the inversion is de-activated).

The first speed display shows the remaining time.

Whenever the “bowl-inversion” key is pressed, the first speed timer is temporarily locked for the

time indicated above (1.5s).

Once the time in first speed has elapsed, the machine switches automatically to second speed:

the first speed display remains set to zero while the second speed display begins to decrement.

During operation of the machine it is possible to modify the 1

st

and 2

nd

speed times with the following limits:

minimum time in 1

st

speed, i.e. if the min. time has already elapsed, the 1

st

speed time can be

zero-set but not otherwise;

the 1

st

and 2

nd

speed time cannot be modified simultaneously.

The modifications made during operation are not stored.

When the “stop” key is pressed, the machine stops and the display-timers lock at the time remaining up to that point.

When the machine is stopped in 1

st

speed, when restarted, it will resume operation in 1

st

speed

from the moment when it was interrupted until it completes at least the minimum time (2 seconds or 2 minutes).

Once the minimum operating time in 1

the 1

st

speed display you can set the time up to zero and switch to 2

remaining time in 1

st

speed after which the machine automatically switches to 2nd speed.

st

speed has been completed, via the “down” key below

nd

speed, or complete the

If the “emergency button” is pressed, the machine stops and the display-timers show a code

that corresponds to the message “emergency pressed” (“---“ “---“).

When the emergency button is released, the display-timers show the time remaining up to that

moment.

When the bowl-protection is raised with the machine operating, the machine stops and the

display timers show the time remaining up to that moment in blinking mode. When the protection is closed, the display-timers show the time remaining up to that moment (in continuous nonintermittent mode).

In these last three conditions, since the timer that measures the 1

st

speed minimum time has

set to zero, we can have the following situations:

If the stop has occurred with the machine in 1

by pressing the “start” key it is possible to continue operation; the machine restarts in 1

st

speed:

st

speed

(in this case the display-timers do not set to zero but continue to decrement the time).

By pressing the “stop” key, the display-timers return to the initial values and it is possible to

start a new cycle.

If the stop has occurred with the machine in 2

by pressing the “start” button it is possible to continue operation: the machine restarts in 1

speed for the duration of the 1

st

speed minimum time (2 seconds) (in this case the 1

display-timer is updated to the minimum operating time) and then switches automatically to 2

speed (once the minimum time in 1

st

speed has elapsed, it resumes decreasing the 2

nd

speed:

nd

speed

st

st

speed

nd

37

Page 38

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

display time);

At the end of the cycle, the mixing times are reset on the displays.

If the START button is pressed within 60 seconds from the end of the cycle, the machine restarts

in 1

st

speed and the time can be modified (via the “down” button below the 1

to zero. If the 1

st

speed time is set to zero, it is possible to switch to 2

nd

st

speed.

speed display) up

The second speed time can be modified as required (up to zero).

When the “stop” key is pressed, the display-timers go to zero and it is possible to start a new

cycle.

During the last 60s of operation in second speed (the machine signals the beginning of this

phase by emitting an acoustic signal) the 2

nd

speed display-timer shows the time remaining in

blinking mode (0.5s “on”, 0.5s “off”).

Once the time in second speed has elapsed, the machine automatically stops and an acoustic

signal sounds for 5s.

After the end of cycle acoustic signal, the display-timers show the initial values.

By pressing the “stop” key or the emergency button before the end of the acoustic signal, the

acoustic signal stops and the display-timers show the initial values.

In this condition, by pressing the “start” button, a new automatic cycle is started.

PROGRAMMING

Key 9 “PRG programming” is enabled exclusively with the machine at a standstill, not in the

work cycle (i.e. at the end of an automatic cycle or after interrupting a manual cycle by pressing

the “stop” key twice).

To enter “program-mode”, press the “PRG programming” key for at least 3s: the related red led

will come on and the display will blink.

In this condition it is possible to set the 1st and 2nd speed times by pressing the UP – DOWN

keys. To store these times the PRG key must be pressed again for 3s; the led will go out and the

program display will stop blinking.

If you enter programming, modify the times and then do not press any key, after 30s the

program display will stop blinking, the PRG key led will go out and the times will not be stored.

It is possible to use 10 programs (from 0 to 9).

By pressing the “PRG programming” key several times, it is possible to scroll the 10 programs

on the related display (the display-timers will consequently show the related stored times).

When the number corresponding to the required program is displayed, it is possible to start the

automatic operation cycle by pressing the “start” key.

If key 9 “PRG programming” is pressed for less than 3s, you go on to the next program (if the

start, stop or automatic cycle keys are pressed in this phase or if the operator does not touch

any key for 30s); the modified times are not stored in memory (the program-display stops blinking) and you return to the “program-mode”.

To quit the “program-mode”, press the “PRG programming” key for at least 3s: the related red

led will go out.

PROGRAM “0”

Unlike the other programs, program “0” allows you to set the times and store them without having to press key 9 PRG for 3s. The times can be stored in program “0” with the same logic as

programs 1 to 9.

The times can be modified even when the machine is operating but those set before the START

remain stored.

38

Page 39

English

BOWL-IMPULSES” COMMAND

With the machine at a standstill, not in the work cycle (i.e. at the end of an automatic cycle or

after interrupting a manual cycle by pressing the “stop” key twice) and the bowl protection open,

impulse rotation of the bowl can be commanded by pressing key 13 “bowl inversionimpulses”.

MACHINE WITH “INFRA-RED” MEASUREMENT DEVICE

The temperature measurement does not require any direct operation of the operator ( the device is permanently installed under the head of the machine and executes its function without

interruption). According to the value assigned to parameter P07 the following alternatives are

possible:

P07 = 0 = check the mixture temperature without stopping the cycle; if the temperature value

measured exceeds the value set up, an acoustic alarm is activated through flashing

and the display (17) blinks showing the value of the temperature every 4 seconds.

P07 = 1 = if the temperature value measured exceeds the value set up, this is detected through

the activation of a flashing acoustic alarm; the system controls the stop of the ongoing cycle and the display (17) blinks showing the value of the temperature every 4

seconds. The operator can allow the cycle to proceed by pressing the button START

(15) or cancelling it by pressing the button STOP (16).

P07 = 2 = the value of the temperature measured is displayed only (flashing) without any fur-

ther effect.

IMPORTANT REMARK: the acoustic alarm is activated the first time only when the

temperature measured exceeds the value set up in the program; for later exceedings,

no acoustic alarm is activated.

In MANUAL operating mode, the temperature is shown on the display (17) only and no value can

be set up for it.

HOW TO SET UP THE TEMPERATURE VALUE IN A PROGRAM

For each program ( from 0 to 9) a different temperature value can be set, but in the range between 0 °C and 65 °C (32 °F and 149 °F). To set and store the temperature value in a program,

proceed as follows:

-press repeatedly the button (9) until the program required is shown on the display (8)

-press the key PROGRAM (9) for about 3 seconds and keep it pressed until the led (10)

switches on and the display (8) starts blinking.

-press again the key (9) ( the display (19) blinks); set the temperature through the keys (3),

(4),(6),(7)

-if the machine has no ingredient dispenser systems, by pressing the key (9) for 3 seconds, it is

possible to go out from PROGRAMMING (the led (10) switches off and the display (8)stops

blinking), and the data are saved; otherwise switch to the programming of the 1° dispenser

If the set up temperature value has been exceeded, this may depend on the following :

a)machine not in operation: the display (17) blinks, showing the value of the temperature every

4 seconds

b)machine in operation: the display (17) blinks, as in case a), and ( only the first time when the

temperature value set exceeds, then no more) the acoustic alarm is activated for a time of 10

seconds.

The warning time is set up through the parameter P05

39

Page 40

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

USER’S PARAMETERS PROGRAMMING – CODE NO. 111

To reach the configuration “parameters set up” mentioned here below, do not press the emergency button (17), the led (12) is to be off and the machine not in operation.

On displays (2) and (5) the following “ooo” and “ooo” are to be shown.

Press and keep pressed at the same time the keys -/+ (3) - (4) - (6) - (7) for 4 seconds.

The display (2) shows “Cod” and the display (5) shows “000”

Through the keys +/- (3) and (4) set up on (5) the number 111; confirm it through the keys

(15) (see picture by side).

The display (2) shows the number of the parameter P01.

Through the keys +/- (6) e (7), the parameter is activated (ON) or deactivated (OFF) or the

value it to set up.

Through the keys +/- (3) and (4) the number of the parameter is changed progressively from

P01 to P19.

After the parameter set up, press the keys (16) to store the set up carried out and go out.

Descrizione parametro Opzioni

P01

Bowl reverse exclusion

OFF

Min

ON

ON

Max

Default Note

P02

Alarm activated

Bowl rotation direction for

P03

unload ( through lift only)

Activate sign from to 1st to

P04

nd

2

speed

Acoustic alarm operating

time to signalize:

-

switching from 1a to 2

speed (only if P04 = ON)

P05

-

exceeding of temperature

set up (for infra-red probe

machine only)

Temperature scale °C or °F

P06

Infra-red temperature measurement probe usage mo-

P07

de

ON

LH nor-

OFF

a

2 20 10

C F C

mal

direction

If this type of probe is present, the options are:

0 = mixture temperature control without stopping the cycle. Intermittent acoustic alarm if the temperature set up

exceeds.

0 2 2

1 = cycle stop through intermittent acoustic alarm while

exceeding the temperature set up. The operator proceeds

with the cycle by pressing the key (15) or terminates the

cycle by pressing the key (16).

2 = Display of the measured temperature only.

D1 dispenser time (seconds)

P08

40

2 120 30

Page 41

Descrizione parametro Opzioni

OFF

Min

ON

Max

Default Note

English

Default value “delay from the initial START ” (see Remark)

Default value “delay from the initial START ” (see Remark)

Set the value according to the mixture capacity of the

machine

If = 0 loads the values of P08 or P10

If > 0 loads the value set on P13 for both D1 and D2.

Advan-

Advan-

Delay Delay

ce

2 120 30

Delay Delay

ce

1 999 150

D1 dispenser mode

P09

D2 dispenser time (seconds)

P10

D2 dispenser mode

P11

Litre dispenser max. limit

P12

Acoustic alarm activation

P13

time (seconds) for D1 or D2

dispenser

P14 - - -

0 sec 30 sec 5 sec

Remark.

Delay = the distribution begins once the dispenser time set up has elapsed after the start

Advance = the distribution begins when the dispenser time set up is missing to reach the end of the cycle

41

Page 42

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

ADDITIONAL MANUAL CONTROLS

Only for special version mixers with additional manual controls.

Figure n°36

1

3

4

2

Figure n°37

3

4

2

42

Page 43

DESCRIPTION FUNCTION

When the selector is in position AUTO, the electronic card can

AUTOMATIC WORKING

1

operate. When the selector is in MANUAL position, working is

possible in manual mode. Attention: the selector can be

moved to the right (MANUAL) only when the card fails.

English

TROLLEY HOOKING/

UNHOOKING

2

HEAD UPSTROKE/

DOWNSTROKE

MANUAL WORKING AT

3

ST

1

SPEED

When the selector is turned DOWN BELOW (fig. A), it hooks or

unhooks the trolley.

When the selector is turned UP ABOVE (fig. B), it lifts or lowers

the head.

Attention: before making the head lower, the trolley has to be

hooked correctly

When the selector 1 is in HAND position and the 1st SPEED

button is pressed, the machine works at the 1

st

speed for an

indeterminate time. If you want to change the speed, press

both the emergency button near the box and the speed button

you prefer.

Attention: make sure the trolley is hooked correctly and the

head is in work position.

nd

SPEED

speed for an

MANUAL WORKING AT

4

2

ND

SPEED

When the selector 1 is in HAND position and the 2

button is pressed, the machine works at the 2

nd

indeterminate time. If you want to change the speed, press

both the emergency button near the box and the speed button

you prefer.

WORKING CYCLE START – MANUAL WORKING

If the electronic card fails, the machine can work in manual mode “HAND”.

Cut off the electrical power supply to the machine in order to open the electric box. Move the

selector 1 to the MANUAL position. Close the electric box and give electrical power supply to the

machine by turning the master switch.

If the trolley is unhooked, put the selector 2 turned DOWN BELOW in position A and hook the

trolley by pressing at the same time the buttons on the two sides of the box (common button

and downstroke button). When the trolley is hooked, keep buttons pressed for 3 seconds to

guarantee the tightness.

To lower the head, put the selector 2 turned UP ABOVE in position B and hook the trolley by

pressing at the same time the buttons on the two sides of the box (common button and downstroke button). When the head is lowered, keep buttons pressed for 3 seconds to guarantee the

tightness.

Attention: before lowering the head, hook the trolley correctly.

To make the machine work at the 1st speed, press the button 3 1st SPEED. The machine works at

the 1st speed for an indeterminate time. If you want to make the machine work at the 2nd speed,

press the emergency button near the box and press the button 4 2nd SPEED.

To open the head, put the selector 2 turned UP ABOVE in position B and press at the same time

the buttons on the two sides of the box (common button and upstroke button). When the head

is up, to unhook the trolley, put the selector 2 turned DOWN BELOW in position A and press at

the same time the buttons on the two sides of the box (common button and upstroke button).

43

Page 44

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

SECTION B – POINT 4

TROUBLESHOOTING

For troubleshooting and ordinary repairs, refer to the table below:

PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION

The bowl has an irregular operation during work.

The bowl wobbles badly during

operation.

The spiral arm slows down during mixing.

By pushing the upstroke and

down stroke keys the machine

doesn’t run but the hydraulic

unit motor is operating.

There is voltage on the power

board but the panel display

does not come on.

Drive belts loose. Tension the belt correctly.

Check that the play between

bowl and sliding block is 2-3

mm.

Adjust the distance between

rollers and replace them if

necessary.

Drive belts loose. Tension the belt correctly.

Motor turns in the opposite

direction.

Uncoupled solenoid connector.

Oil lack in the circuit.

No tension to the solenoid connector.

Solenoid failed.

Inverse the phases.

Check that all solenoid connectors are correctly connected.

Verify that the oil level on the

circuit tank is at list to ¾.

Replace the connector or its

the solenoid.

Check that the 5-pole green

connector is correctly inserted

in the board.

Check that the 9-pole connec-

Check the connectors.

tor between board and panel

and base board is correctly

inserted.

This connector is near the

head up/down microswitches.

The machine does not perform

some functions (carriage connection-release, head updown).

After trolley hooking, the head

downstroke but stop before

completing the stroke (complete

closure).

The oil unit motor stops.

If the trolley is not released after the ascent of the head.

If pressing start the machine

does not move after the descent

of the head.

44

Board.

Microswitch SQ4.

Microswitch SQ3.

Microswitch SQ4.

Turn the machine master

switch to the zero position

(OFF) and after five seconds

re-set to position one (ON).

Check if microswitch SQ4 is

pressed ( machine rear under

head cover).

Micro must be free only when

head is completely downstroke

(closed) and in working

position.

Verify if the microswitch SQ3

working properly.

Verify if the microswitch SQ4

working properly.

Page 45

PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION

When the buttons common

“14” and ascent “15” are

pressed, the head does not

move up.

When the buttons common

“14” and descent “16” are

pressed, the head does not

move down and the display

shows “EXTRACT THE TROLLEY

AND REPEAT THE COUPLING

ERR:17”.

When the buttons common

“14” and descent “16” are

pressed, the head does not

move down and the display

shows “EXTRACT THE TROLLEY

AND REPEAT THE COUPLING

ERR:18”.

Switch for up head.

Solenoid valve connectors engine control unit.

The input of the microswitch

SQ1 is not present.

The input of the microswitch

SQ2 is not present.

English

Verify the functionality of the

switch SQ3.

Make sure the connectors are

properly inserted and solenoid

valves that work.

Check the contact unit motor.

Verify the mounting and operation of the microswitch SQ1.

The micro must be pressed

when there is the trolley.

Verify the mounting and operation of the microswitch SQ2.

The micro mustn’t be pressed

when there is the trolley.

The display shows “CHECK

GRID LIMIT SWITCH”.

The machine stops during work

and display shows “VERIFY INVERTER”.

The machine stops during work

and the display shows “ERRORLINK”.

If the display shows “EXTRACT

THE TROLLEY AND REPEAT THE

COUPLING ERR:19”.

Bowl protection grid microswitch.

Inverter overcharged Inverter

failing.

Connector.

Sheath.

Motherboards.

Pressing the

“common”+“descent” buttons

when the trolley is not present

or is not resting on the hook.

The inputs of the microswitches SQ1-SQ2 are not

present.

Check the grid microswitches.

Switch off the machine.

After 15 s switch it on again: if

the problem still exist, call the

AFTER SALE SERVICE.

Verify on yhe inverter the last

alarm message.

Verify connection between

panel card and display.:

-1

st

connector CN6 on card to

relay

-2

nd

connector on panel card

-3

rd

intermediate connector under the head cover.

Switch off and than switch on

the machine.

If the problem still exit call the

after sale service.

Check that the sheath and conductors within it are not damaged.

Verify the microswitches.

45

Page 46

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION

The display shows the message

“ACTIVE EMERGENCY PUSH

BUTTON”.

If the display shows “VERIFY

THE MAGNETOTHERMAL INTERVENTION”.

If the display shows “HEAD

OUT OF POSITION - LOWER

THE HEAD”.

If the display shows “HEAD

OUT OF POSITION”.

If the display shows “VERIFY

SQ1-SQ2 END STROKE”.

If the display shows “VERIFY

THE TEMPERATURE PROBE”.

Emergency button pressed.

When a circuit breaker trips

inside the electrical panel.

When the head is completely

closed and the power supply

is interrupted.

When pressing START button

in an intermediate position of

the head.

Working time at "0".

Pressing START when the trolley is not completely hooked.

When the temperature probe

is present and the mixture

exceeds the set temperature

set.

Check and turn to the right to

release the button.

Check which breaker is tripped

and reset it.

Move up the head a few inches

and then proceed with the descent.

Complete closure of the head

before pressing start.

Verify that the time is not at

"0" (excluding program H)

Press the related buttons and

move down the head.

Complete the coupling of the

trolley and the closure of the

head before press START.

Check the temperature of the

dough and the set value. Check

the probe.

46

Figure n°38 Figure n°39

SQ1 SQ2

SQ3

SQ4

Page 47

English

SECTION B – POINT 5

FOOD HYGIENE AND CLEANING

The machine has been designed and built according to the specifications of the EEC machinery

directive 89/392 (point 2.1).

The following machine cleaning instructions are provided for the user.

CAUTION: DO NOT USE HIGH PRESSURE WATER JETS

Once a day:

Clean the bowl, column, tool, dough guard and bowl protection. These are the stainless steel

elements (or thermoformed in the case of the transparent cover) in the food area. Use the tool

provided (plastic spatula) and clean with a cloth soaked in water. Never use metal tools and/or

abrasive products.

Once a week:

Clean the painted parts with lukewarm water (max 40°C). Never use metal tools and/or abrasive

products.

Once a year:

General cleaning of the machine according to the above instructions.

SECTION B – POINT 6

MAINTENANCE AND CHECKS

FOR CORRECT OPERATION AND LONG LIFE OF YOUR MIXER, FOLLOW THE ORDINARY AND SPECIAL MAINTENANCE PROGRAMME BELOW.

IMPORTANT WARNINGS!

All maintenance work must be performed after setting the master switch to 0 (zero) and removing the plug from the electrical power supply socket interlocked with switch.

This means:

- Do not clean, oil or grease by hand the moving parts and elements of the machine.

- Do not carry out any operation, repair or adjustment on moving parts.

The manufacturer accepts no liability for injury to persons or damage to things resulting from

failure to observe these instructions, tampering with the protections and safety devices fitted on

the machine and/or inappropriate use of the machine.

47

Page 48

Instruction for use and maintenance

Spiral mixer with removable bowl SPI 160-300 A HYBRID

MAINTENANCE TO BE PERFORMED BY THE OPERATOR

These operations and checks are very simple and can therefore be performed by the user, following the instructions below.

Once a day:

Check the efficiency of the protections and safety devices by operating and inspecting them.

MAINTENANCE TO BE PERFORMED BY SERVICE PERSONNEL AUTHORISED BY THE

MANUFACTURER

Due to their delicate and complex nature, these operations and checks must be performed by

the manufacturer or qualified/specialist personnel.

Once a month:

Check the efficiency of the safety devices

Check the condition and positioning of the bowl guide rollers (instructions follow)

Once every six months:

Adjust the spiral arm drive belt tension (instructions follows)

Adjust the bowl drive belt tension (instructions follows)

Check the electrical equipment

Check that the tool is correctly fixed

Check possible sliding of the moving wheel (corrective instructions follow)

check the hydraulic unit oil level (it must be at least ¾ of the tank)

It is good to periodically lubricate the mechanisms of movement of the trolley through the grease nipples. Two grease nipples are located in the front of the trolley close to the two front rollers

and two are accessing from the two holes in the side of the trolley and lubricate the two rear rollers (Figure 40).

48

Figure n°40

Page 49

English

It is a good idea to grease the pinion referral using the spe-

Figura n°41

cial grease gun indicated by the arrow (Figure 41).

Once a year

Perform general checks on the condition and efficiency of the machine, the protections and

safety devices.

Replace worn parts and/or broken elements if necessary.

Perform electrical tests to check the electrical insulation and continuity tests on the protection

circuit.

When necessary

Replace worn parts and/or broken elements, check and adjust the protections and safety devices. The power supply cable must be replaced if the outer insulation is damaged.

Caution: original parts must be used when replacing components.

CAUTION!

Cut off the electrical power supply before carrying out work

on any electrical component

or on the control panel.

ADJUSTING THE BOWL GUIDE ROLLERS/SLIDING BLOCKS

problem: the bowl wobbles badly

solution: adjust the bowl guide rollers in order to have a distance of mm 2-3 between the bowl

and the rollers (figure n° 42, 43)

Figure n° 42