Page 1

INSTALLATION INSTRUCTION

Prepared

SEA/EBMP Stangelberger

Doc respons/Approved Checked

Subject responsible

SEA/EBAX/F

SEA/EBMP ASB 150 02

Documentnumber

1531-BDV BS 101 01 Uen

Date

Rev

1998-05-29 L

Database reference

Reference

1531-BDVBS10101Uen-1-L.emf

INSTALLATION INSTRUCTION

EXCHANGE CABINET

BDV BS 101 01

1(46)

businessphone

Page 2

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

3(46)

Contents Page

1 GENERAL . . . . . . . . . . . . . . . . . . . . 4

1.1 Supplementary documents. . . . . . . . 4

1.2 Tools . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 DECLARATION OF

CONFORMITY . . . . . . . . . . . . . . . . . 5

3 HOW TO OPEN THE CABINET. . . . 7

4 INSTALLATION . . . . . . . . . . . . . . . . 7

4.1 Mounting of the cabinet . . . . . . . . . . 7

4.2 Safety and EMC . . . . . . . . . . . . . . . . 8

4.3 Access to the boards . . . . . . . . . . . . 8

5 POWER SUPPLY UNIT . . . . . . . . . . 9

5.1 Replacement of the power

supply unit . . . . . . . . . . . . . . . . . . . . 9

5.2 Power feeding with an external

DC supply. . . . . . . . . . . . . . . . . . . . 10

6 ALLOCATION . . . . . . . . . . . . . . . . 10

Contents Page

7 INTEGRATED CORDLESS. . . . . . 28

7.1 Board Descriptions . . . . . . . . . . . . 28

7.2 Traffic capacity. . . . . . . . . . . . . . . . 28

7.3 IC-CU2 (GAP-Protocol) . . . . . . . . . 30

7.4 Base Station (KRCNB 201 03/_

and KRCNB 301 01/_). . . . . . . . . . 31

8 LINE NETWORK. . . . . . . . . . . . . . 39

8.1 Cables for BDV 113 08 . . . . . . . . . 40

9 MARKING OF CABLES . . . . . . . . 44

10 INTERNAL MDF

(Main Distribution Frame) . . . . . . 44

11 Door Interface Unit

(BFY BS 10101/1) . . . . . . . . . . . . . 45

12 INSTALLATION OF ALARM

INTERFACE UNIT . . . . . . . . . . . . . 46

6.1 Power supervision of ELU-A. . . . . . 10

6.2 Connection of CM-Boards . . . . . . . 11

6.3 System Power Consumption. . . . . . 11

6.4 BTU-A and BTU-A2 13

6.5 Power failure circuit (PFC) . . . . . . . 13

6.6 BTU-C. . . . . . . . . . . . . . . . . . . . . . . 14

6.7 BTU-B. . . . . . . . . . . . . . . . . . . . . . . 15

6.8 BTU-B2. . . . . . . . . . . . . . . . . . . . . . 15

6.9 BTU-D and REG). . . . . . . . . . . . . . 17

6.10 BTU-E. . . . . . . . . . . . . . . . . . . . . . . 19

6.11 CPU-D_ and AUX_ . . . . . . . . . . . . 23

6.12 CPU-D4 . . . . . . . . . . . . . . . . . . . . . 24

6.13 ELU-A and ELU-D . . . . . . . . . . . . . 26

6.14 VMU-HD . . . . . . . . . . . . . . . . . . . . . 27

6.15 VMU-D . . . . . . . . . . . . . . . . . . . . . . 27

Page 3

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

4(46)

1 GENERAL

Exchange cabinet BDV BS 101 01 is designed to be

furnished with Printed Board Assemblies (hereafter =

boards or PBAs) belonging to ERICSSON’s PBXsystem ASB 150 02. System functions, desired by the

customer, are realised with appropriate boards and

system programming.

The PBX is powered by an internally mounted power

supply that is available in two versions. The standard

version is an AC/DC converter and the version with

battery charger offers the same facility but additionally

provides battery back-up or can be supplied from an

external DC-source.

The installed PBX shall be made operational in

accordance with the stipulations that apply for system

ASB 150 02. See document START OF OPERATION

(1537-ASB 150 02).

NOTE: Boards may only be inserted or re-

moved from the cabinet when the power

supply in the cabinet is switched off.

The new cabinet is adapted for boards with brackets

containing screws to provide a ground connection and

should only be equipped with these boards.These

screws must always be fastened to ensure proper operation.

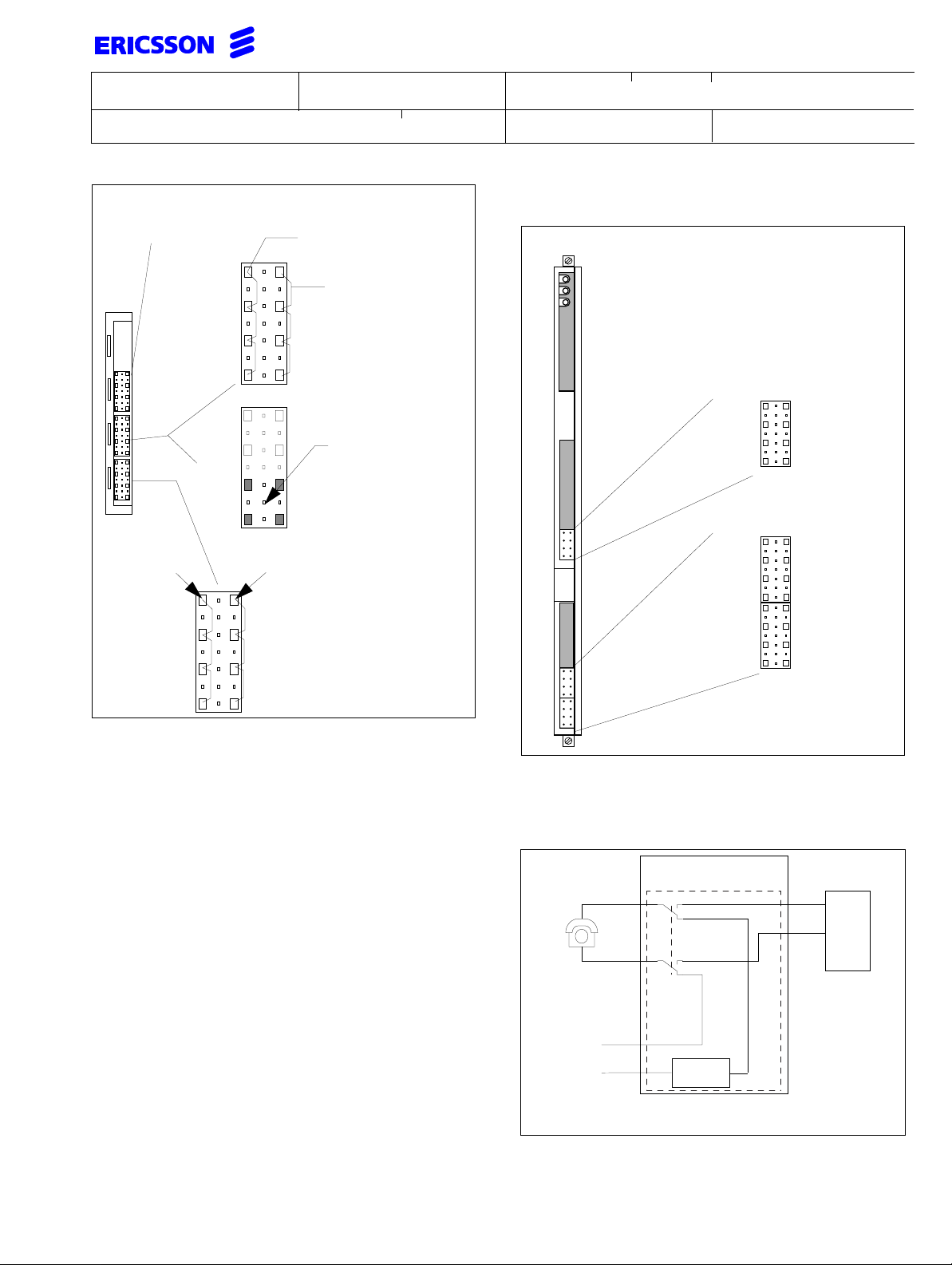

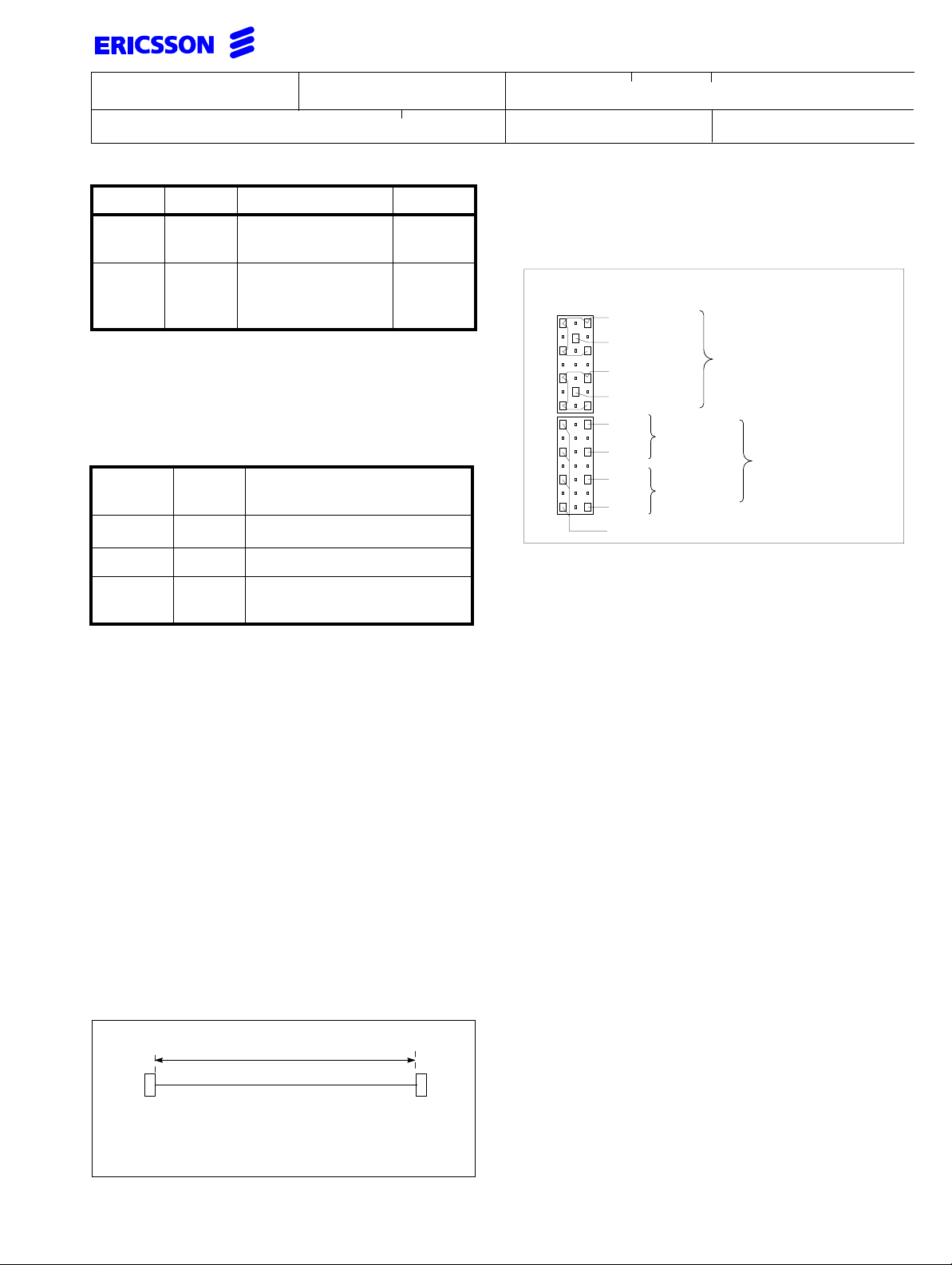

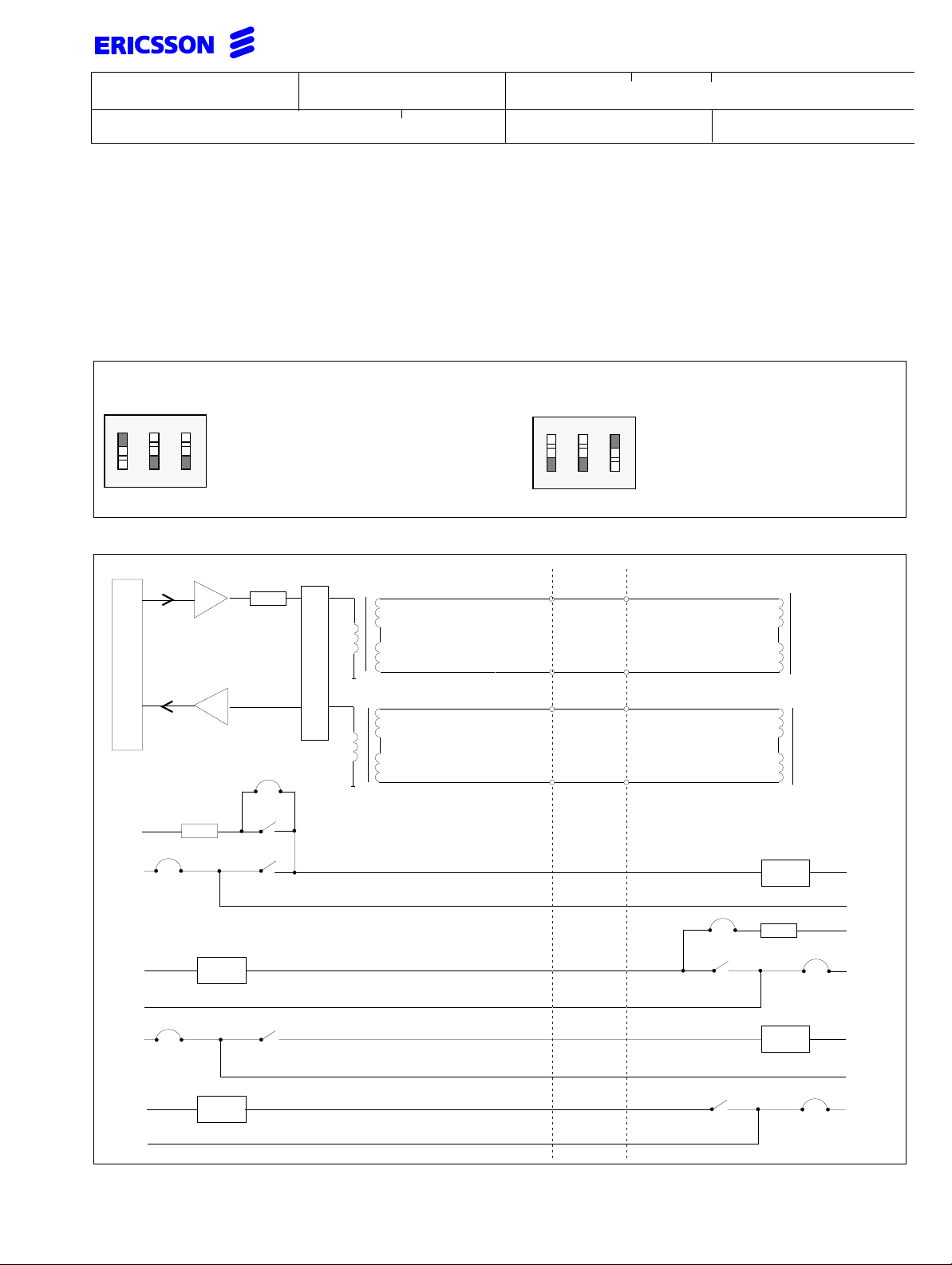

Each branch on the extension line must have:

1 A protective resistor of 10 Ω/1W

(REN 195 42/1) connected in series

between cabinet and MDF

2 An overvoltage arrester (gas discharge

tube) for quenching surges to protective

ground shouldbe installed onthe network

side of the protective resistor.

MDF

Overvoltage arresters

Protective

resistors 10 Ω/1W

(REN 195 42/1)

Protective

ground

(NGC 402 01)

Housed in:

overvoltage protection

cassette (769 027/3)

Note: Make sure the MDF is really connected

to protective ground.

Principal circuit drawing.

Don’t use older board revision states in the new

cabinet.

In principle, a cabinet’s board position can be used for

arbitrary furnishing with boards belonging to PBX

system ASB150 02 butthefirst position isreserved for

the CPU-D_.

Due to the limited load of the cabinet’s power supply

units, the definitive board configuration in a cabinet

must follow the prerequisites in section 6.3.

However, it isadvisable to protect trunk lines withextra

overvoltage protectors especially in geographical

areas highly exposed to lightning.

Any lines connected to the PBX that are subjected to

excess voltage (transients) in conjunction with e.g.

lightning discharges must be equipped with excess

voltage protection.

Special considerations must be taken to analogue

extension lines that are placed outdoors. In order to

prevent the analogue extension boards secondary

protection device from blowing in case of lightning.

1.1 Supplementary documents

• Document collection EN/LZB 103 1233

• INSTALLATION INSTRUCTION

(1531-BML BS 101 01) for the power supply,

equipped with battery charger

1.2 Tools

In addition tocustomaryinstallation tools, the following

are recommended:

• Use theappropriate connectiontool 769027/2 to

connect the cables in the internal MDF.

• Use the appropriate slotting tool LSY138 252 to

connect the cables to the external

MDF SXK 106 4139/1.

• Board extractor for PBAs (handle LTD 117 02

and bottom LTD 117 12)

Page 4

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

2 DECLARATION OF CONFORMITY

5(46)

This page is left blank for the CE-document. Use the link to read the document.

Page 5

Prepared

Doc respons/Approved Checked

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

1531-BDV BS 101 01 Uen

Date

Rev

Reference

1998-05-29 L

6(46)

This page is left blank for the CE-document. Use the link to read the document.

Page 6

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

7(46)

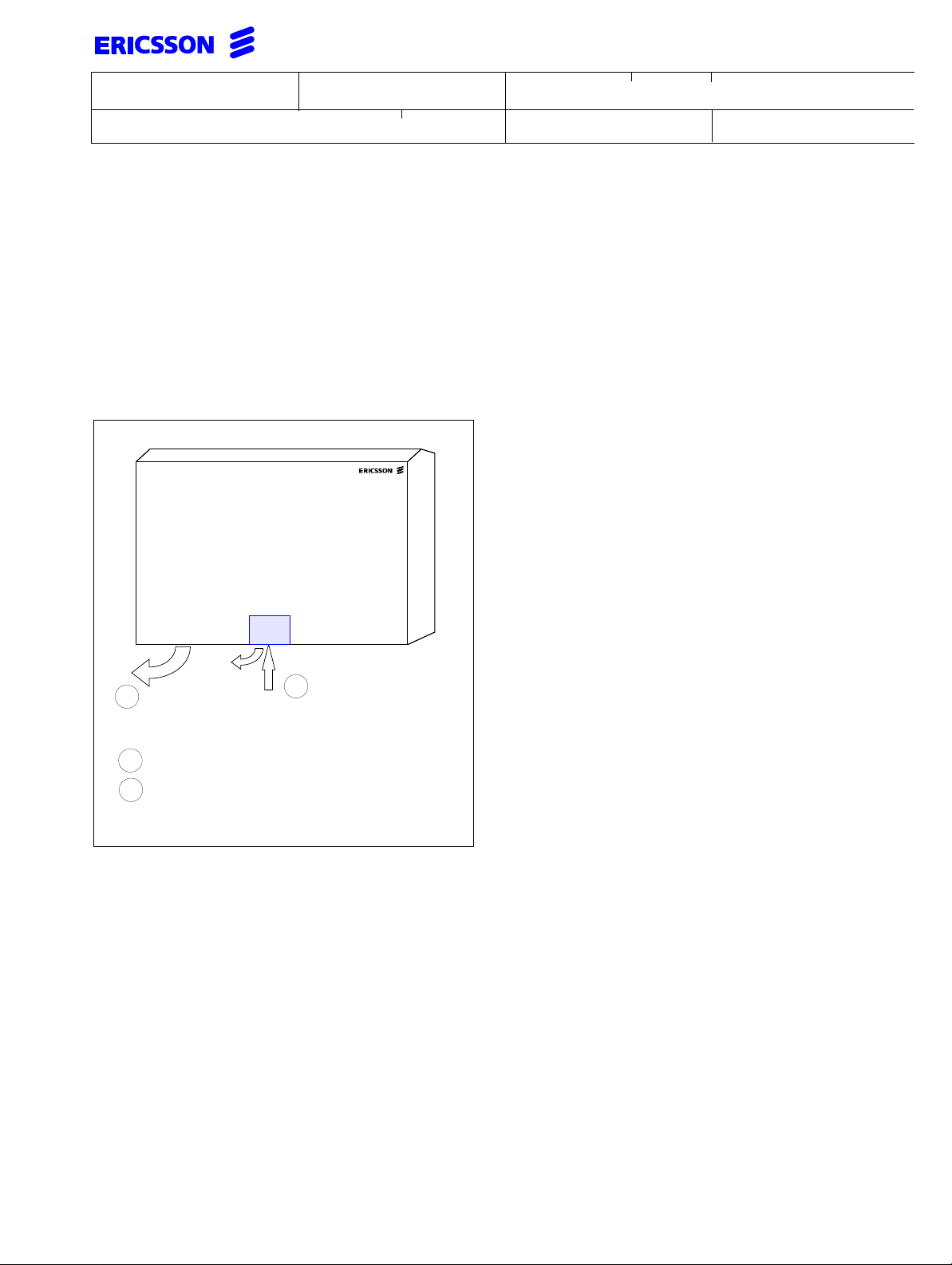

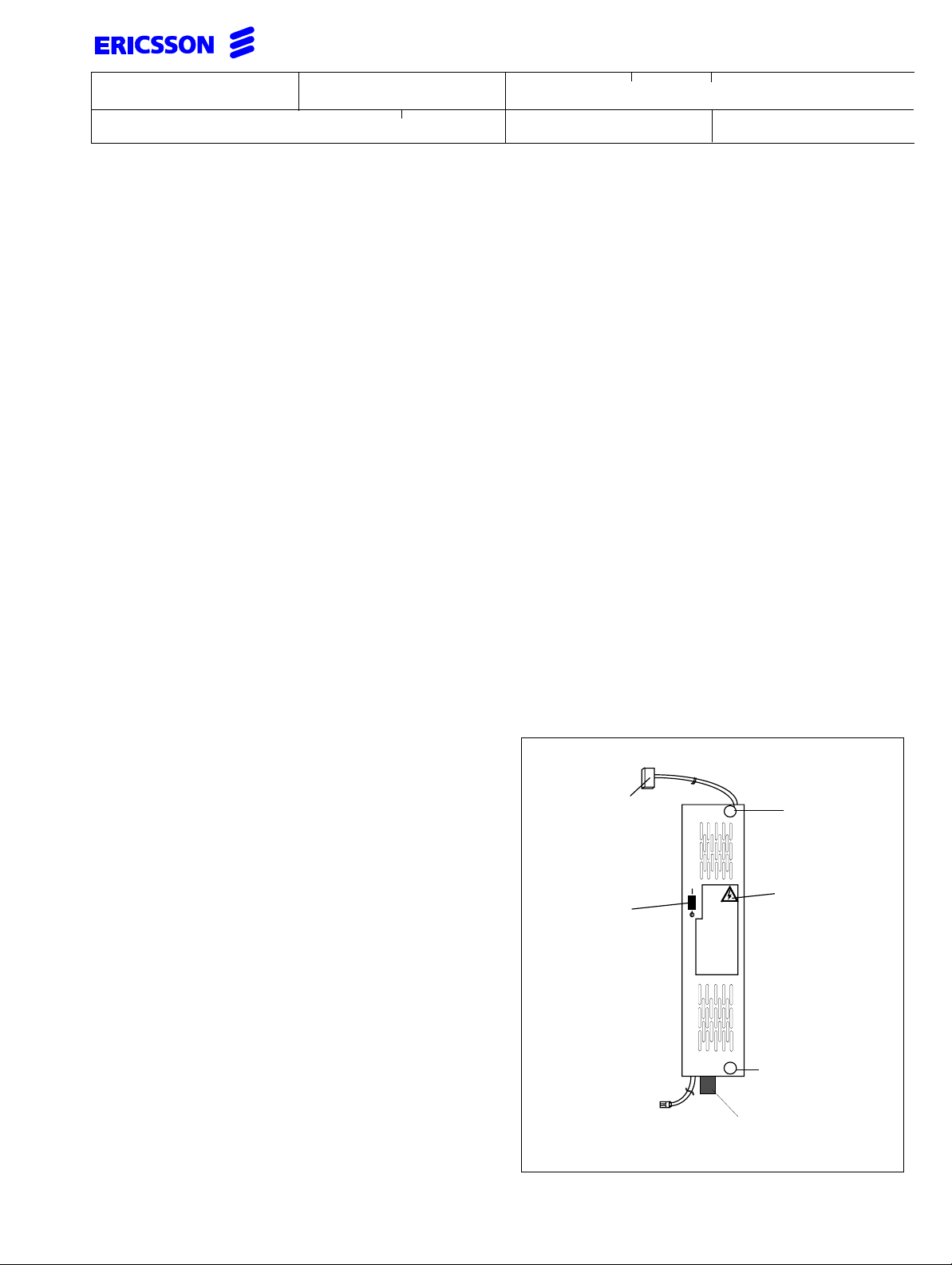

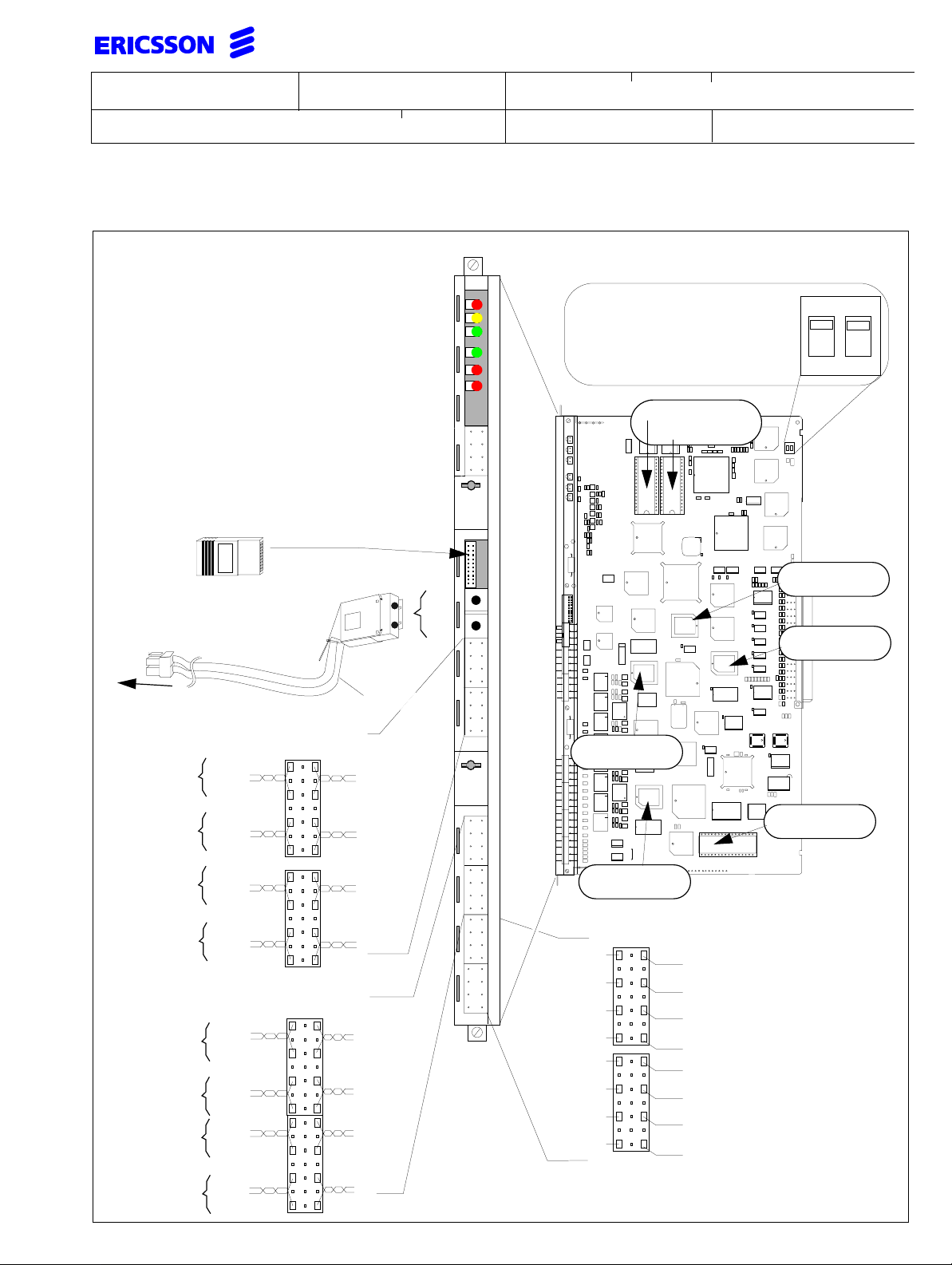

3 HOW TO OPEN THE

CABINET

Unpack the exchange cabinet.

Using ascrew driverliftthe bluelid. Unscrew thescrew

below and remove the cabinets front cover. Check that

everything hasbeen received accordingto the delivery

note and that nothing has been damaged during the

transport.

businessphone

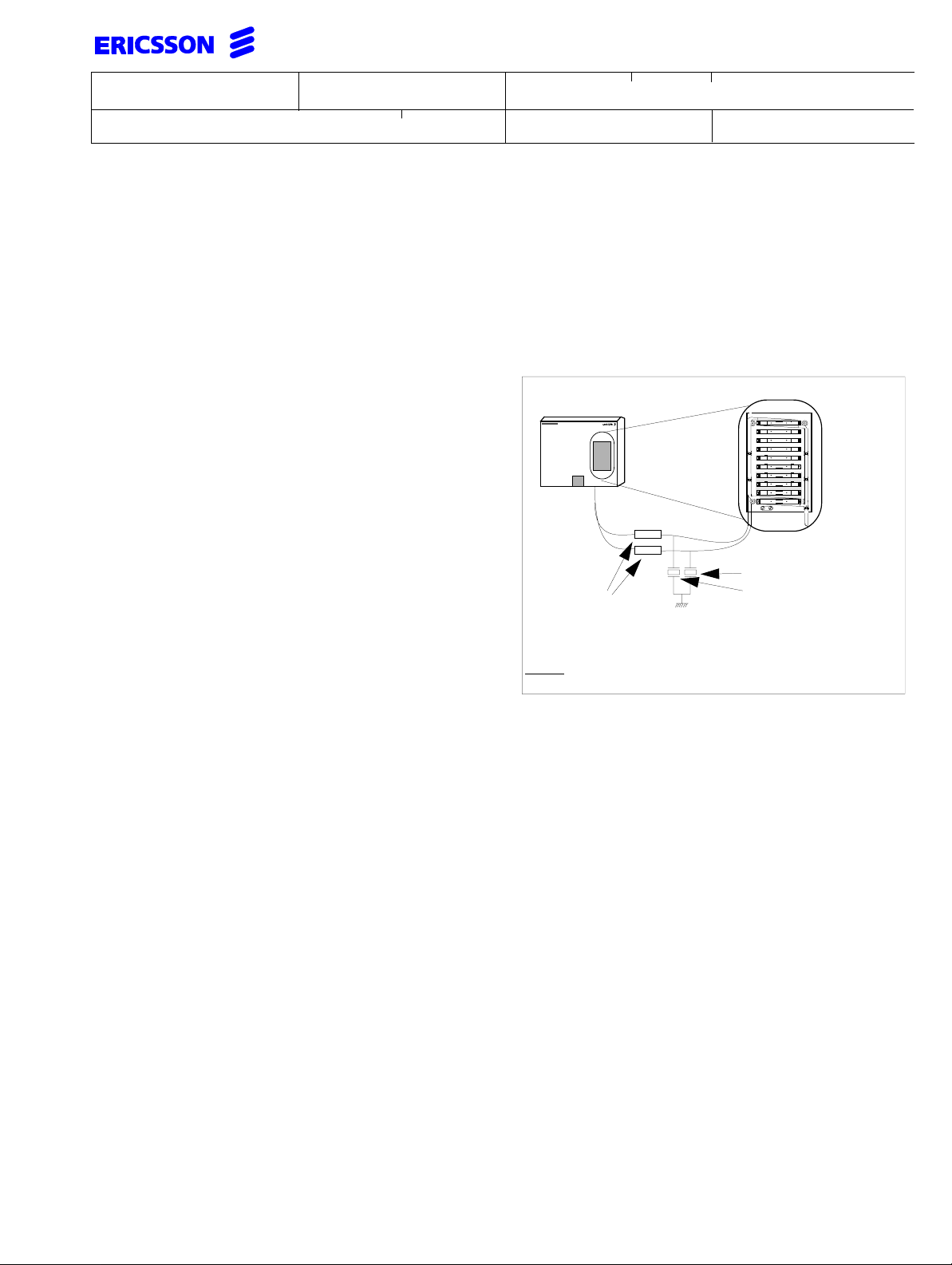

4 INSTALLATION

The PBX can be delivered as a customer configured

unit or the add-in boards are delivered separately. The

cabinet is always equipped with a power supply,

suitable for the local mains. Please check the label

stating the permitted mains voltage. The cabinet is to

be mounted on an indoor wall. A mains outlet must be

provided near the equipment and shall be easily

accessible. The premises shall comply with the

following prerequisites:

• The air shall be free from dust and smoke

• Environmental conditions according to

ETS 300 019 (1-4) (Temperature shall be

between + 5°C and +40°C and relative humidity

may vary between 15% and 80%)

• The PBX shall not be exposed to direct sunlight

• The cable shall preferablyrun into the PBX from

below the cabinet to ensure sufficient air flow.

4.1 Mounting of the cabinet

2

1

Lift blue lid to access the screw below.

2

Then turn the screw to loosen the cabinet

1

cover and take off the cabinet cover.

Use the enclosed drilling plan and drill four 8 mm

holes. Mountthe cabinet byusingthe enclosed screws

and plugs. Take into consideration the normal working

height above the floor (about 1.30 m to thelower edge

of the cabinet) and leave enough room for access on

both sides of the cabinet.

Overall dimensions of the cabinet:

• 485 x 600 x 134 (H x W x D in mm).

Page 7

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

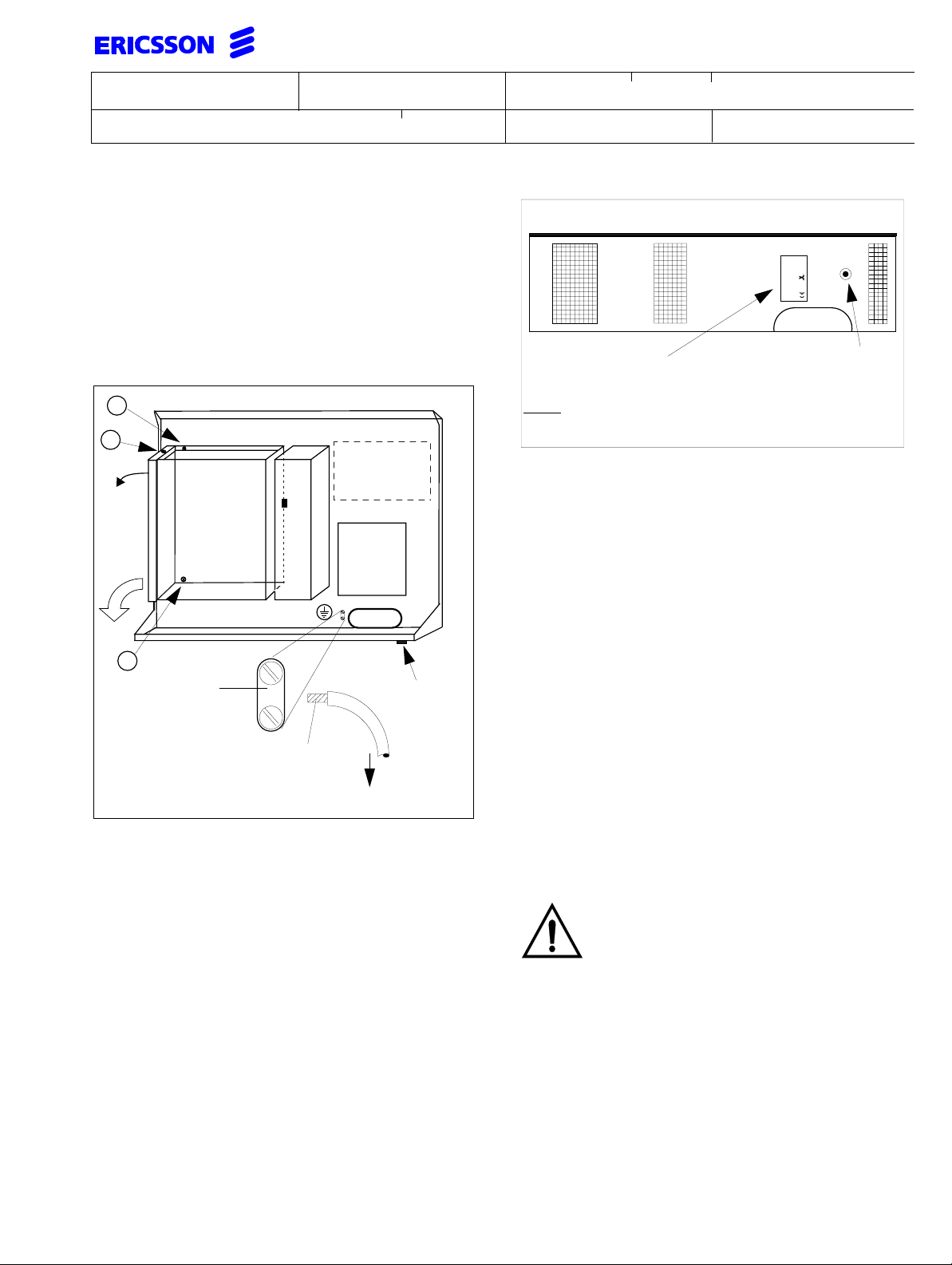

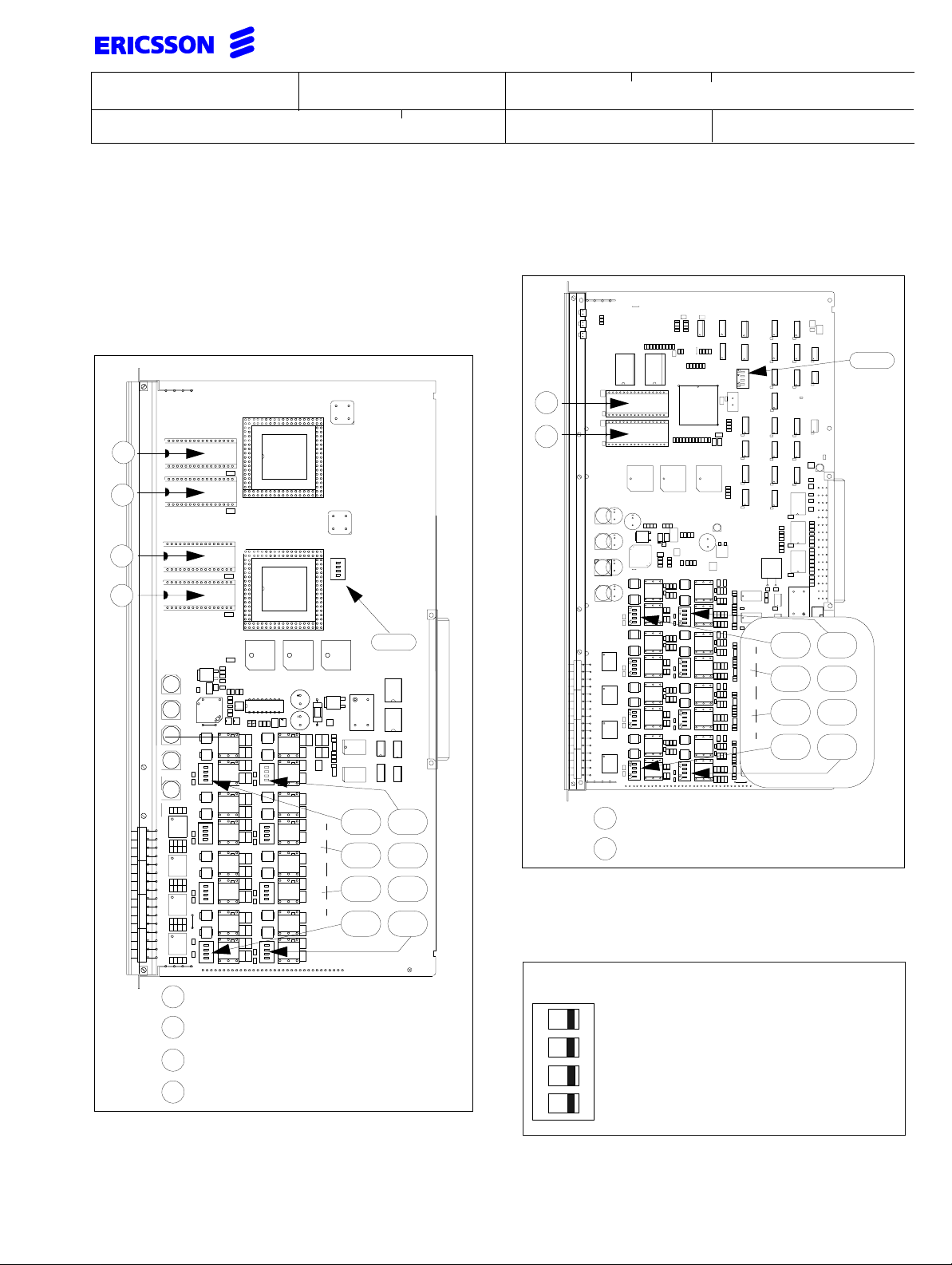

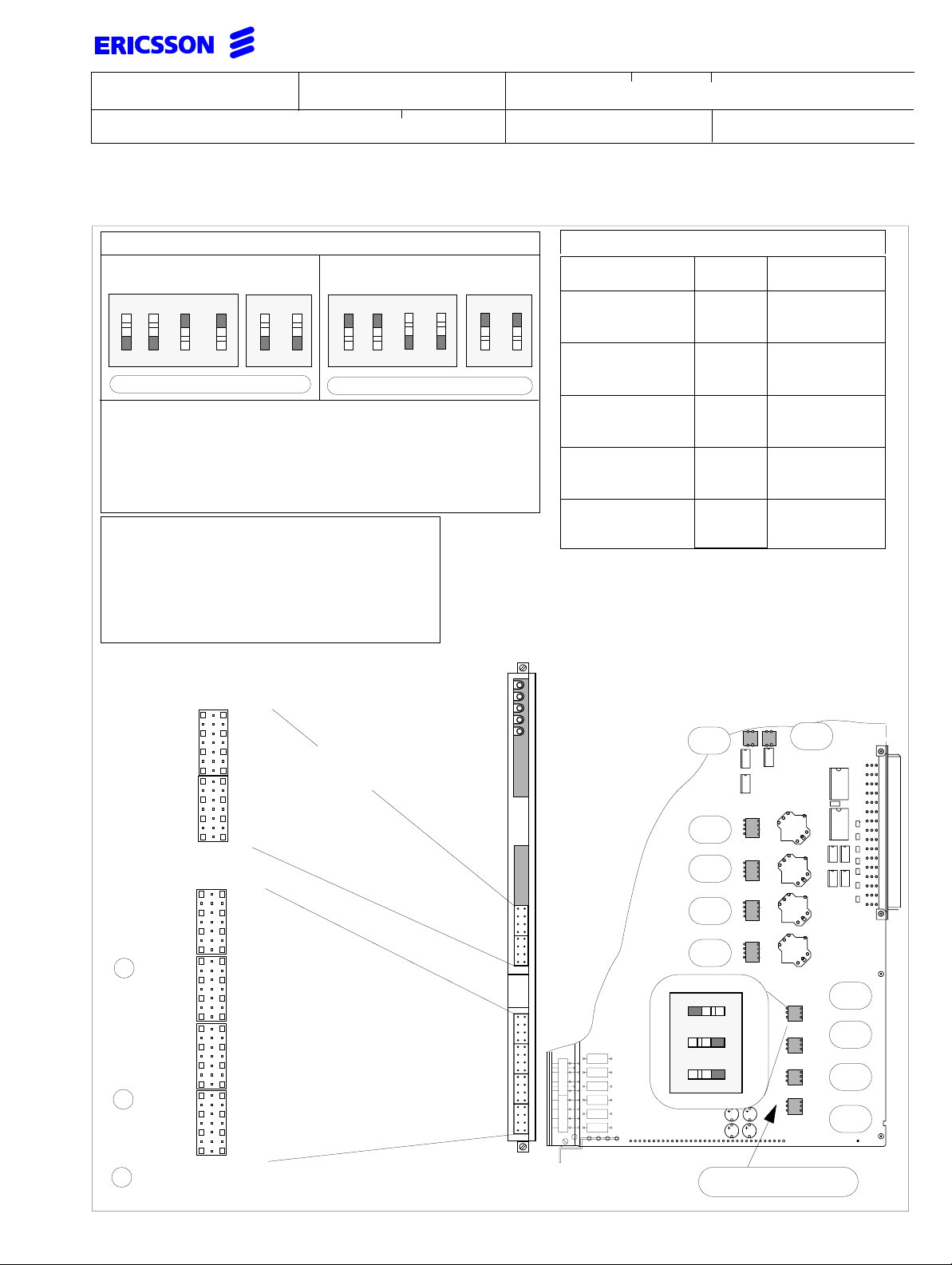

4.2 Safety and EMC

8(46)

To fulfil electrical safety requirements IEC 950 and

EN 60950 respectively EN 41003, the exchange must

be connected toprotective earth via a flexible wire with

a cross sectional area of at least 6 mm2.

Local requirements shall be adhered to.

The connection must be carried out by authorised

personnel.

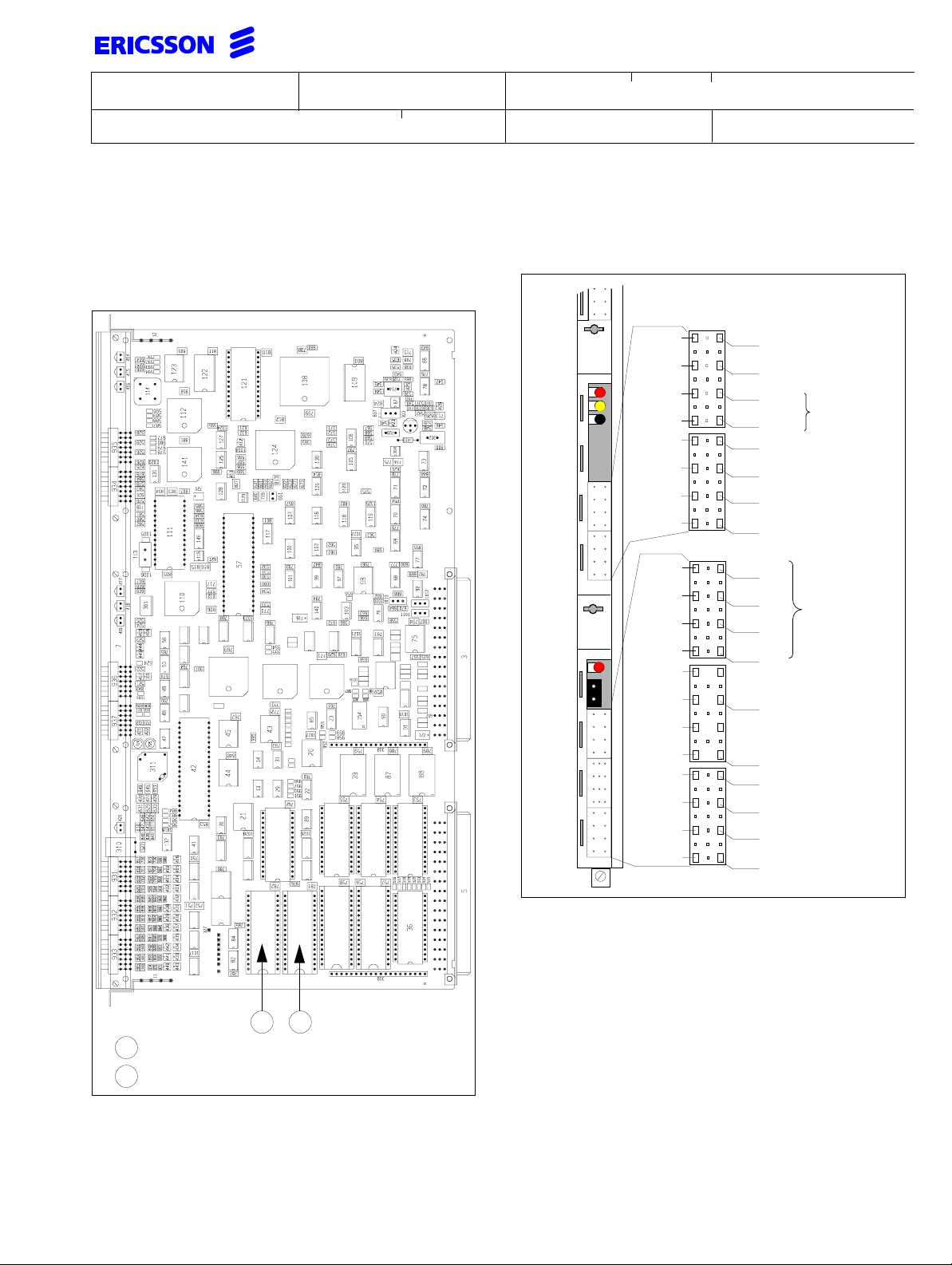

A

B

BATT.

Shelf

cover

SWIVELSHELF

Turn

out

PSU

MDF

A

Connection

for protective

earth

cross sectional area >6 mm

2

Wrist strap

connector

(only for

AUSTRIA)

Front edge

168

Label

SVB BS 101 02/_

Note: The mains current rating stated on the label

is the maximum current of the charger version.

Bottom view of cabinet BDV BS 101 01

All line interfaces in the PBX are protected in

accordance with K.21 (voltage transients up to 1.5kV).

BTU-A, BTU-A2, BTU-B, BTU-C, BTU-D and BTU-E

are working with interface TNV.

All other boards and the V.24 port work with interface

SELV.

4.2.1 EMC

The ferrites, with the ERICSSON ordering number

STF 82 601, should be situatedclose to the slot where

the cablesare led outof the cabinet.Twoturnsthrough

the ferrite core are sufficient to comply with EN 55022

Class B and to avoid disturbances in non-industrial,

residential (home) usage.

snap-on

wrist strap

connector

Protective earth

Before operating,ensure that the chassis isconnected

to a hard wired protective earth.

4.3 Access to the boards

NOTE:

Turn out the transport screws (A)about 1 cm at thetop

and bottom of the swivel shelf. See figure in section

4.2. Hold the bottom of the shelf, lift the shelf slightly

and turn the swivel shelf counter clockwise(ccw). Turn

the screw (B) two turns at the top of the shelf cover

and remove the cover.

Makesure thatasound groundconnection to

the exchange has been established. Otherwise this can be hazardous in case of lightning. Use a grounding wrist strap when

handling PBAs sensitive to electrostatic discharges.

Page 8

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

9(46)

5 POWER SUPPLY UNIT

The power supply units (PSU) for the cabinet are

AC/DCswitching powersupplieswith two inputvoltage

ranges. Please check if the label states the proper

mains voltage as required. For mains supplies with

230V to 250V AC, two versions are available:

• BML BS 101 02/1 (PSU 230V standard)

• BML BS 101 01/1 (PSU 230V equipped with

battery charger).

Formainssupplies with 115V to127V AC twoversions

are available:

• BML BS 101 02/2 (PSU 115V standard)

• BML BS 101 01/2 (PSU 115V equipped with

battery charger).

The PSUs deliver 25 W on the PBA supply voltages

and 80 W on the 48 V supply voltage. After switching

on, the power supply has a start-up delay of 8

seconds.

Warning: The power switch does not disconnect

from mains. The mains cord must be unplugged to

disconnect the mains.

The PSU is equipped with a mains fuse rated

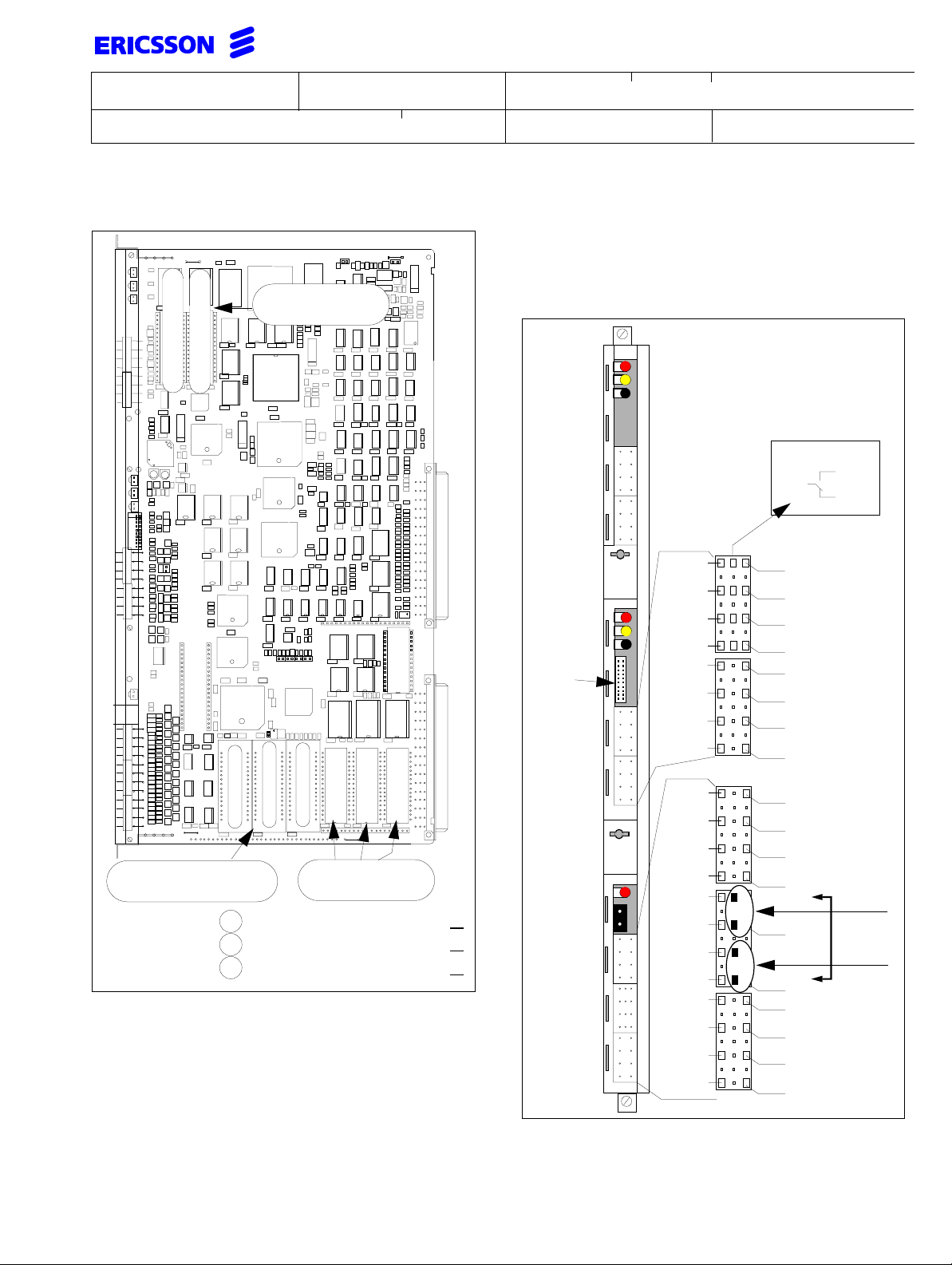

5.1 Replacement of the power supply unit

The cabinet is delivered with a PSU already installed.

The procedure how to dismount the unit is described

below.

a Switch off the PSU (A) and unplug the mains

from the wall outlet. If the unit is a PSU with

battery charger, disconnecttheDC supplyline to

the batteriesand plugoff the alarmconnector on

the unit.

b Disconnect the DC supply cord (D) to the swivel

shelf.

c Unscrew the transport screw(B) completely and

make 3 turns on screw (C) counter clock wise.

d Push the PSU from the bottom and turn out the

PSU clock wise, unhinge and take it out. Then

pull off the mains plug at the bottom of the PSU

and disconnect the ground wire.

e Install the PSU in the reverse manner.

When installing a power supply unit with battery

charger and battery backup please refer to the

INSTALLATION INSTRUCTION

(1531-BML BS 101 01).

250VAC 6,3 A T.

NOTE: This fuse NGH 243 01/6300 can be ordered

from Ericsson but is a non-accessible and non-user

serviceable part. Only authorised personnel is

allowed to change the fuse. Contact the local

supplier in this matter.

Battery backup time

The batteries in the integrated battery pack have a

capacity of 2Ah. The power consumption on the 48 V

should be less than 1.7A. Using fresh batteries a

backup time of 20 minutes is guaranteed and

depending on the system configuration longer backup

times could be achieved.

(D)

Power switch

does not

disconnect

unit from

mains.

Standby only

Ground

(A)

(B)

Label

(C)

Mains power cord plug

IEC 320 C17

Page 9

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

10(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

5.2 Power feeding with an external DC supply

When the PBX is supplied with power by an external battery with 48V nom. (44 - 56V), the installation of a power

supply equipped with a battery charger (BML BS 101 01/_) is required. The DC supply is connected directly to the

PSU.

An externally accessible fuse 250VAC 6,3 A T isprovided on the PSU,but additionally a fuse must be installed in the

supply line with DC current switching capability greater than 160 A.

Note: To prevent arcing never connect the DC source when the PSU has not started-up.

Use the mains to power up or use an external switch to connect the DC source. This is a precaution to minimise the

contact loads on the plug.

For further details see INSTALLATION INSTRUCTION (1531-BML BS 101 01).

Battery operation often requires different preconditions consequently, only an overview can be provided with regard

to battery capacity/charging capacity. The batteries should be supplied locally. The type is described in detail in

INSTALLATION INSTRUCTION (1531-BML BS 101 01).

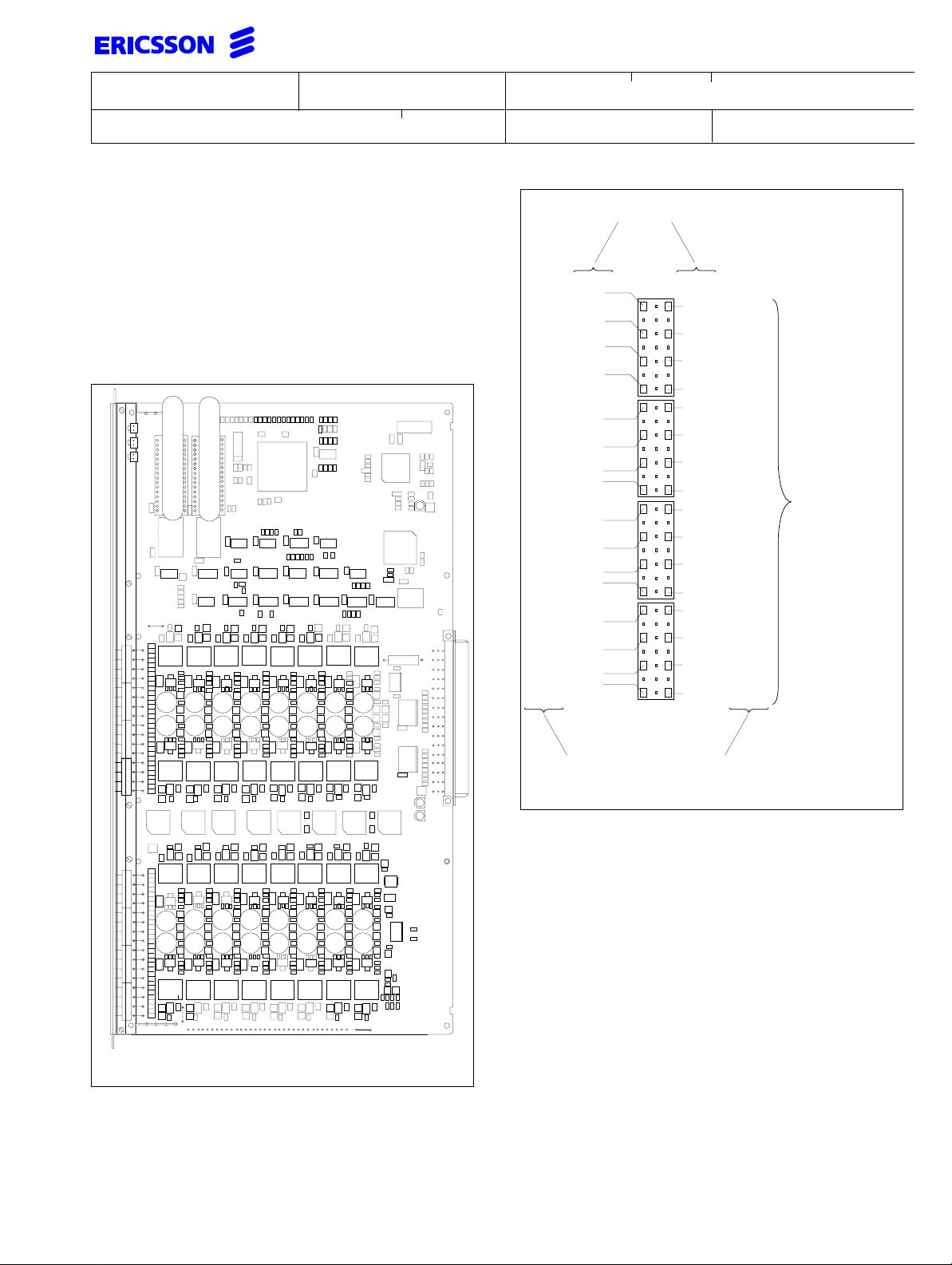

6 ALLOCATION

In principle, all board positions in cabinet BDV BS 101 01 can be used for arbitrary configurations with PBAs

belonging to PBX-system ASB 150 02.

The boards are equipped with ground brackets on the top and bottom. When installing make sure to fasten the

boards with the supplied screws.

There arerecommendations for configurationsin order to simplifyoperation and maintenance.For further information

see document collection EN/LZB 103 1233.

Sub-equipped boards:

Install sub-equipped boards in the last position after the standard boards to enable easy upgrading without having to

re-number trunks and extensions.

6.1 Power supervision of ELU-A

The board is equipped with an automatic traffic limiter restricting the internal power dissipation on the board to a

maximum of 12W. This depends on both the line length and the number of lines busy.

When the power consumption exceeds the limit, no more lines have access for use and at least two lines have to go

on hook for all lines to work normally again.

When connecting external voice systems a maximum of 8 lines are recommended on each board. The remaining

lines on the board are to be connected to low-traffic extensions.

Page 10

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

11(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

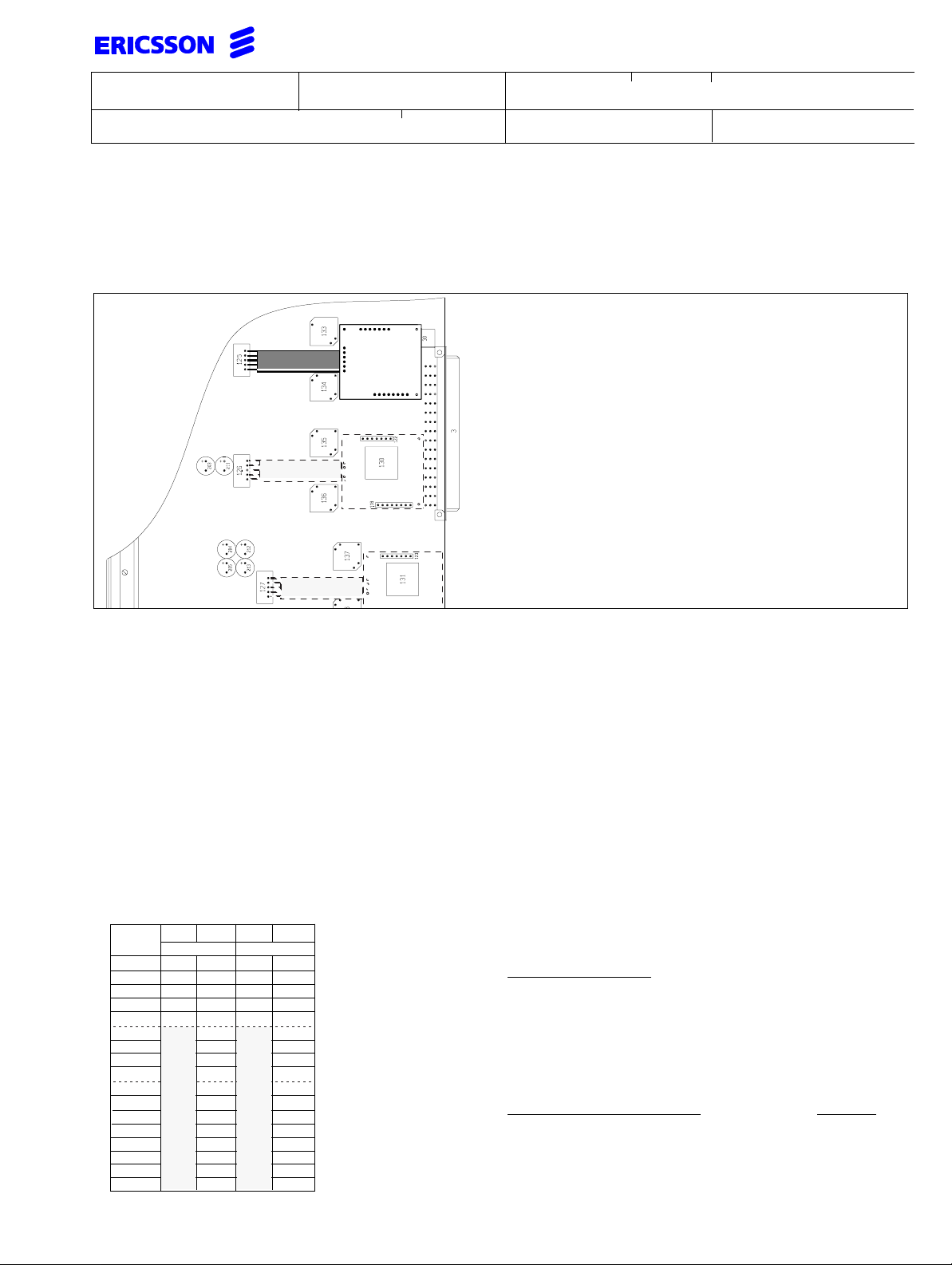

6.2 Connection of CM-Boards

Connect the correct type of call metering board, according to the figure below, on BTU-A board ROF 157 5110/_ or

ROF 157 5127/_ and in the same fashion on the BTU-C board ROF 157 5111/_. The BTU-C cannot be equipped

with a CM50 board as the flat ribbon cable cannot be connected and CM12/16 (ROA 219 5135/1).

Line 0 - 1

CMboard

Line 2 - 3

Note: When installing a CM50-board connect the

cable before mounting the CM50-board. The

BTU-A board must also be connected to

Line 4 - 5

earth.

The following boards are available CM50 ROA 219 5064/1, with flat ribbon cable and CM12/16 ROA 219 5135/1 or

ROA 219 5062/1 without cable.

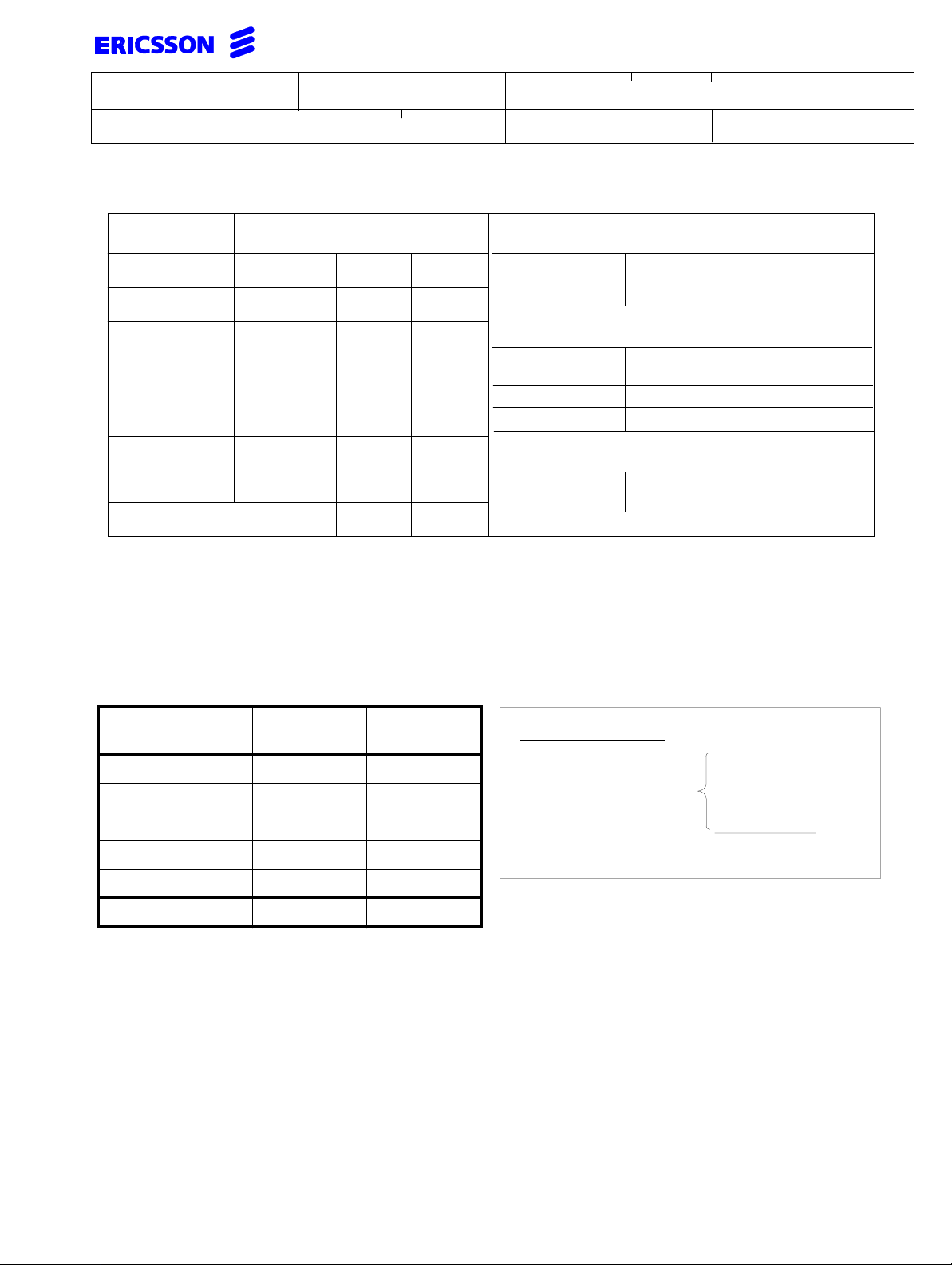

6.3 System Power Consumption

The power demand of the system comprises the sum of the current demands of all extensions, base stations etc.

This total current hastobe delivered by the power supply. Choose the one delivering therated current with a suitable

margin for add on equipment depending on the installation site.

Base Station Power Demand

To minimise the power dissipation on the serial communication wires EPP should be used extensively. Up to 60 BS

can be installed in a cabinet. Short power peaks can be covered by installing a battery cabinet.

The total current for all BS must be less than the power supply(s) capacity. The total 48 VDC load on the power supply has to be calculated as follows:

Cable

length

0m

100m

200m

300m

400m

500m

600m

700m

800m

900m

1,0km

1,1km

1,2km

1,3km

1,4km

1,5km

1,6km

STD EPP

0,5 mm

104

104

110

106

114

110

112

121

115

129

119

121

125

129

133

139

146

152

160

171

183

204

∅

STD EPP

0,6 mm ∅

104

104

108

106

110

108

114

109

118

110

112

114

117

118

121

123

125

127

129

131

135

137

STD EPP

0,5 mm

77

104

83

106

87

110

112

94

115

103

119

121

125

129

133

139

146

152

160

171

183

204

∅

STD EPP

0,6 mm ∅

104

104

108

106

110

108

114

109

118

110

112

114

117

118

121

123

125

127

129

131

135

137

This table states the current demand in mA for a Base Station depending on the cable length and cable diameter.

Calculation example:

Line length to Base Station:

Resistance of loop:

Cable diameter (

φ):

200m

0.18 Ω/m

0,6 mm

Assuming 4 Base Stations are already

connected they consume a current of:

440 mA

Power demand taken from Power Calculations below, for telephones:

984 mA

Total load on power supply: 1424 mA

This total load for the exchange can be

suppliedby thepowersupply asitis less

than 1.7A.

Page 11

Prepared

Doc respons/Approved Checked

Subject responsible

Extension Power Demand

INSTALLATION INSTRUCTION

Documentnumber

1531-BDV BS 101 01 Uen

Date

Rev

Reference

1998-05-29 L

12(46)

TELEPHONES

BASIC

ECONOMY

ECONOMY

plus

STANDARD

EXECUTIVE

DBC 213 with 2 DBY 409 01

DBC 213 with 4 DBY 409 02*)

1

) provides current on trunk lines in active state to public exchange.

CURRENT CONSUMPTION

Typ (mA)Max (mA)

DBC 210

DBC 199

DBC 601

DBC 751

DBC 211

DBC 201

DBC 212

DBC 202

DBC 631

DBC 755

DBC 752

DBC 213

DBC 203

DBC 662

DBC 753

14

25

27

38

14

30

14

30

65

50

50

35

35

70

75

42

35 70

35

35

32

35

50

35

50

70

73

73

70

70

73

70

TELEPHONES

OPERATOR

CONSOLE

DBC 214 with 2 DBY 409 01

DBC 214 with 4 DBY 409 02*)

ANALOGUE

(in active state)

TAU 2610

Desktop Adapter

BTU-B (S-interface

per physical link)

BTU-C

index (/1,/2)1)

Radio base station:

CURRENT CONSUMPTION

Typ (mA)Max (mA)

DBC 214

DBC 663

DBC 754

40

67

75

35

35

40

4

(per trunk)

refer to table above

14

50

120

110

70

70

4

23

50

35

The maximum values for telephones result when all LEDs are lit and if available, loudspeaking is on at max. volume.

*) with connected external power supply.

Power calculation example

LINE

EQUIPMENT

QUANTITY

DBC 210 3 54

DBC 201 5 150

DBC 202 13 390

DBC 203 10 350

CURRENT

(mA)

Calculation example:

selected

line equipment

3 x DBC 210

5 x DBC 201

13 x DBC 202

10 x DBC 203

1 x DBC 663

Total: 32 system telephones

DBC 214 1 40

TOTAL 32 984

The calculation above shows howto calculate the current demand fora given installation. This amount of currenthas

to be supplied by the installed power supply.

Page 12

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

13(46)

6.4 BTU-A (ROF 157 5110/-) and BTU-A2 (ROF 157 5120/_)

On delivery from the factory both contacts are in the OFF

position, and the line is a normal trunk.

When both contacts on a DIP-switch are set to position

ON, the line is to be regarded as a music source input.

Different contact positions are not allowed.

Note: Only lines4-7canbeused as a music source

input. Not available on BTU-A subequipped ROF

157 5127/_.

.

The DIP-switch is shown

with both contacts in

OFF position

ON

1 2

86

85

Line 4

Line 5

Line 6

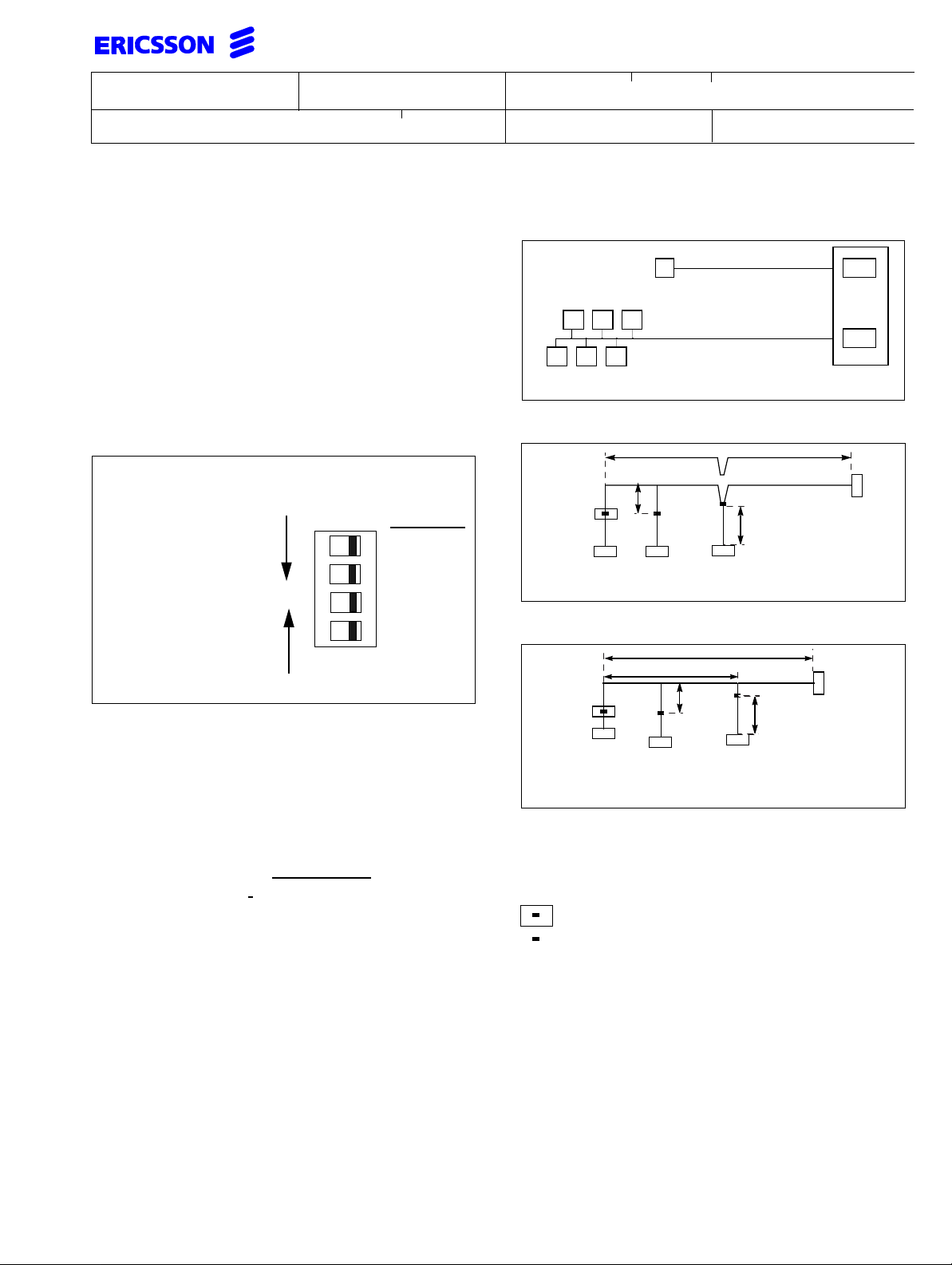

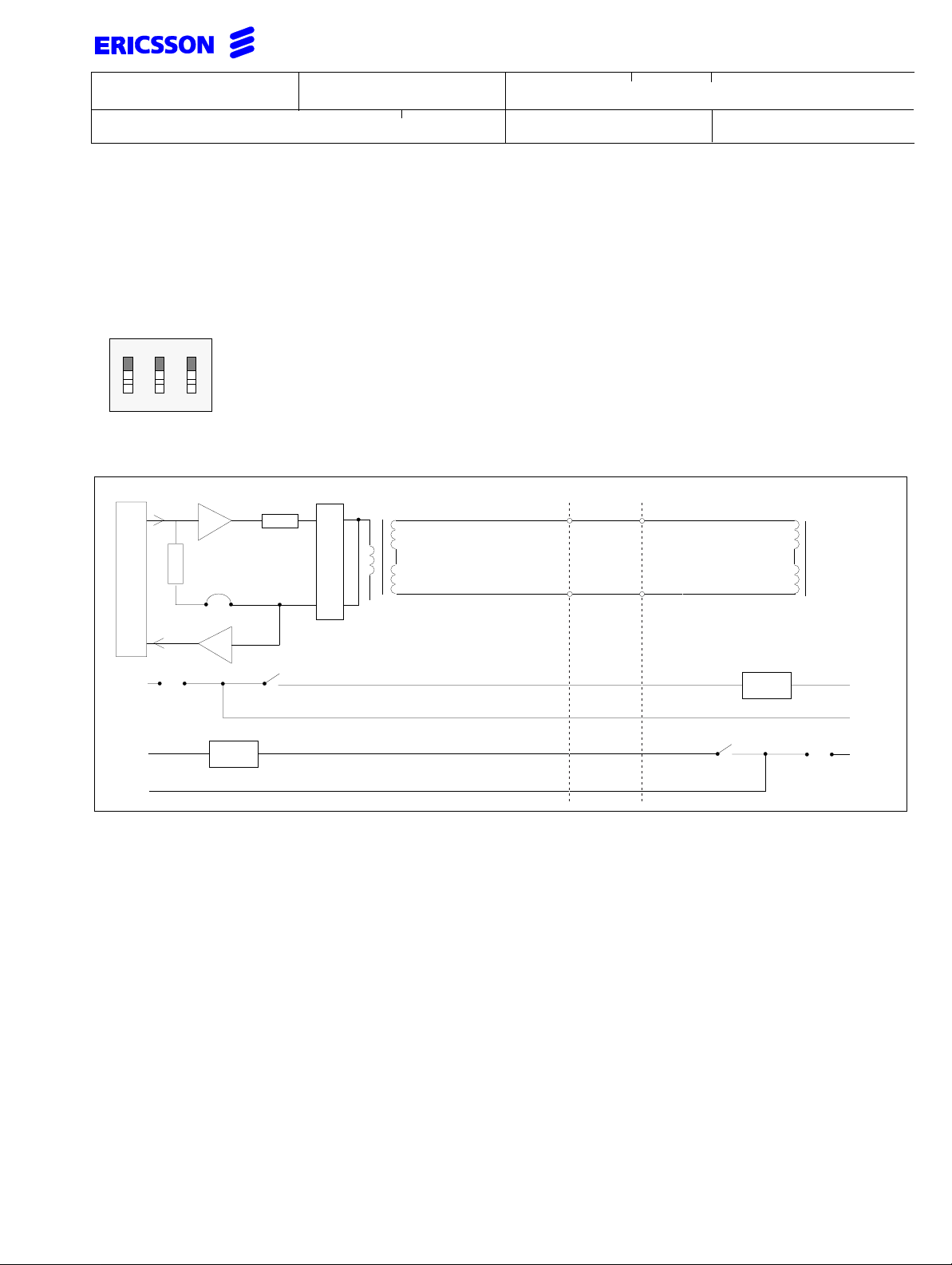

6.5 Power failure circuit (PFC)

In the event of mains failure and if no battery back up

is available for the PBX, there are normally 2 lines on

the BTU-A and BTU-C (see under BTU-C on next

page) board which automatically switch the trunk lines

to analogue telephones connected to this board.

On power failure, these telephones will automatically

be connected to the public exchange.

It is also possible to use the power failure telephones

during normal operation, if an ELU-A board is installed.

BTU-A & BTU-C1

bPFb

ELUA

a

PFa

Power failure set

La

Trunk

Lb

BTC

Indicator

87

88

Line 7

Connection field 6

C

LA0

LB0

LA2

LB2

LA4

LB4

LA6

LB6

*)

A

18

20

22

24

26

28

30

32

LA1

LB1

LA3

LB3

LA5

LB5

LA7

LB7

Line wires for

connection to

Public Exchange

*)

Not available on sub-equipped board see below

Relay shown in power fail position

Page 13

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

14(46)

Connection field 4

Not always mounted

(market-dependent)

18

PFa0

4

PFb0

PFa1

PFb1

20

22

24

18

20

22

24

Connection

to analogue

telephone(s)

PFa2

PFb2

PFa3

PFb3

A

26

28

30

32

A

C

analogue telephone

a0

Connection to

ELU-A board

b0

a1

b1

On the BTU-A2 the

bottom half of this

connector is used

to connect to PTT

signalling ground

Connection to

ELU-A board

C

Connection of

a0

Only mounted if the BTU-A

has 4 PFC circuits (market

b0

dependent).

This connector is used

a1

for PFC circuits on the

BTU-A2

b1

6.6 BTU-C (ROF 157 5111/-)

Connection field 4 and 6

RED

YELLOW

GREEN

The index number

refers to the individual

on the board

power failure (field 4)

PFa0

PFb0

A C

a0

b0

trunk lines (field 6)

La_0

Lb_0

La_2

Lb_2

La_4

Lb_4

La_6

Lb_6

A C

La_1

Lb_1

La_3

Lb_3

La_5

Lb_5

La_7

Lb_7

Earth connection on BTU-A2 (Austria only)

Some markets require an earth connection of the incoming PTT earth (functional earth) to the exchange.

This is provided on the connector installed above the

PFC circuit connectoron pins A22, A24, C22and C24.

Use an extra Krone bar toconnect the PTT earth wires

to the wires going to the board connector.

The BTU-C (ROF 1575 111/1)features eight incoming

trunk lines with DID. The first four individuals can also

be used for outgoing traffic.

BTU-A & BTU-C1

BTC

PFa

Power failure set

bPFb

ELUA

a

La

Trunk

Lb

Indicator

Relay shown in power fail position

Page 14

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

15(46)

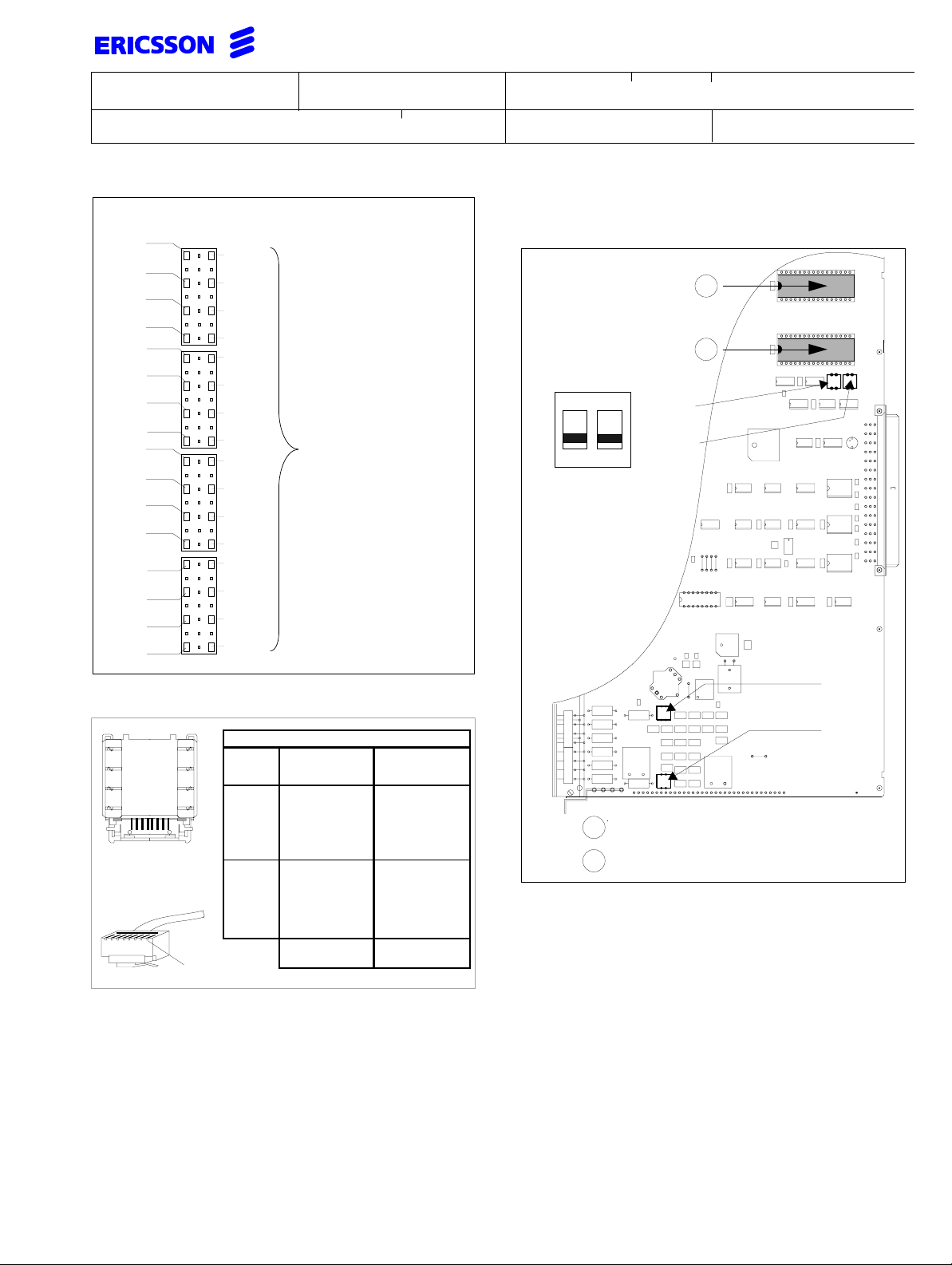

6.7 BTU-B (ROF 157 5121/_)

Applies for indices 1 and 3

The BTU-B provides connection for up to 8 physical

links and every physicallink can be configured as a Sor T-interface. On the S-interface every link provides

remote power feeding with 40V/50 mA = 2W and connection for up to 8 terminals.

A

B

C

ON

D

418

6.8 BTU-B2 (ROF 157 5121/_)

Applies for indices 4 and 5

418

A

B

410 411

ON

ON

ON

ON

Insert PROM "RYS 102 521/ 1

A

Insert PROM "RYS 102 521/ 2

B

Insert PROM "RYS 102 521/ 3

C

Insert PROM "RYS 102 521/4

D

ON

ON

ON

ON

410 411

412 413

414 415

416 417

412 413

414 415

416 417

Insert PROM "RYS 102 521/ 3

A

Insert PROM "RYS 102 521/ 4

B

DIP-switches position 410-417

These switches control S- and T-interface termination

and S-interface power feeding on the link 0...7.

On factory delivery all

switches are set to OFF

4

Connects power feeding ground

3

Connects -40V for power feeding

21

Connects 100 Ω receive side termination

ON

Connects 100 Ω send side termination

Page 15

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

16(46)

Note: at the end of each line a termination resistor

must be installed (e.g. in the last wall outlet).

The switch 1 selects the termination on the transmitter

interface and switch 2 selects the termination on the

receiver interface. Switches 3 and 4 enable remote

power feeding to ISDN terminals connected to a link.

When connected as S-interface switches 1...4 should

be set to ON.

Settings of the S-interface relevant on

board indices -3,-4,-5

DIP-switch position 418

When selecting which link is to be configured

as a S-/Q-/T-interfaces start with switch:

Line pairs:

Q/T-interface

OFF... Q/T-Interface

ON ...S-Interface

ON

4

3

21

0 + 1

2 + 3

4 + 5

6 + 7

S-interface

On factory delivery all switches are set to OFF

Note: When selecting S- or T-interfaces start by

setting the T-interfaces using switches 4, 3, 2

and 1 in consecutive order then set the Sinterfaces starting with switches 1, 2, 3 and 4.

Settings of the S-interface

Choose with RASC the configuration of the interface:

Extended passive bus default setting

and Short passive bus.

Ranges on the interface

The BTU-B is equipped with the S/T Bus Interface Circuit eXtended (SBCX). This circuit offers the advantage of covering a higher attenuation on cables.

(refer to documentation of the TE) is also equipped

with a SBCX or equivalent.

1 km (standard range)

TE TE

TE TE TE

Ranges on the extended passive bus

TE

and up to 2 km with

TEs equipped with SBCX

TE

up to 500 m (standard range)

and up to 1.5 km with

TEs equipped with SBCX

SBCX

SBCX

BTU-B

Short passive bus

d1

TE

d4

TE TE

d3

BTU-B

d4 - up to 1m

with TR

in outlet

d1 - 150m to 250m (standard range)

d3 - line to terminal up to 10m

Extended passive bus

d1

d2

TE

d4

TE

BTU-B

d3

25 to 50 meters

d4 - up to 1m

with TR

in outlet

TE

d1 - up to 500m (standard range), d2 - between terminals

1,5 km on 30 nF cables with

TEs equipped with SBCX

d3 - line to terminal up to 10m

Abbreviations:

TE Terminal Equipment

TR Termination Resistor (

installed at the end of the

interface line. Use outlets with resistor mounted

Outlet according to IEC 603-7 with termination

Outlet according to IEC 603-7 without termina-

tion

)

The standard S/T-interface specification considers cableswith 6,5 dBattenuation equivalent toabout 1000m

cable length in single terminal configuration.

Using the S/T Bus Interface Circuit eXtended (SBCX)

up to13 dB line attenuationcanbe covered. The figure

below shows the ranges using standard 0.6 mm diameter twisted pair unshielded cables with a capacitive

load of max. 30nF per km and the terminal equipment

Page 16

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

6.9 BTU-D (ROF 157 5112/1) and

Connection field 6

A

T0A

T0B

T1A

T1B

T2A

T2B

T3A

T3B

T4A

T4B

T5A

T5B

T6A

T6B

T7A

T7B

C

02

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

R0A

R0B

R1A

R1B

R2A

R2B

R3A

R3B

R4A

R4B

R5A

R5B

R6A

R6B

R7A

R7B

The DIP-switch is

shown with

both contacts in

OFF position

S/T-Interface for

connecting trunks

and S-terminals

REG (ROF 157 5112/2)

A

B

ON

1 2

197

200

17(46)

Wall outlet connection

4

5

6

3

8

1

7

2

Wiring side of 8-pole

wall outlet e.g.

KRONE RJ-K LN

Pin desig-

nation

optional

1

EIA/TIA 568 Wiring Schemes

NT function: TE function:

(polarity of remote

Transmit (-)

5

4

Transmit (-)

Receive (+)

3

6

Receive (+)

1

Power sink 3 (+)

2

Power sink 3 (-)

7

Power source 2(-)

8

Power source 2(+)

S-interface in

socket

(polarity of remote

power feeding)power feeding)

Receive (-)

Receive (-)

Transmit (+)

Transmit (+)

Power source 3(+)

Power source 3(-)

Power sink 2(-)

Power sink 2(+)

T-interface on

plug

199

198

Insert PROM "RYS 102 5xx/1

A

Insert PROM "RYS 102 5xx/2

B

6.9.1 DIP-switches in position 197 and 200

Depending on the firmware used, this board enables

either ISDN or CAS function. The PROM set is available for CAS (LZY203 2212/1) or ISDN PRA

(LZY203 2213/1). DIP-switch pos. 197 on BTU-D selects the register function of the board. The switch 200

is reserved for future use.

Page 17

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

18(46)

197/1 197/2 FUNCTION

OFF OFF

ON

ON OFF

ON

digital trunk MFC

digital trunk MFE

Register MFC

Register MFE

only

BTU-D

BTU-D

or

REG.

6.9.2 DIP-switches in positions 198 and 199

Selection of ground strapping for the coax 75 Ω or selection of the 120 Ω twisted pair interface.

198/1

199/1

OFF OFF

198/2

199/2

FUNCTION

120 Ω connection

1)

OFF ON screen connected toground

ON OFF screenconnected toground

via 1nF capacitor

1) Factory setting

On factory delivery the switches are set to OFF-position = no ground thus enabling 120 Ω interface with a

twisted pair cable. These DIP-switches connect the

75 Ω interface coaxscreento ground, either directly to

0Vorviaa1nFcapacitor.DIP-switch 198 switches the

receiver and199the transmitter side. The screenshall

normally be grounded on the transmitter side. Normally, the screen on the reception side isnot connected to

ground. Refer to local market requirements

Ranges on the interface of the BTU-D

This interface coversthe short distance to the next NT

or Line Terminating Unit as the end point of a public or

private network. The range is only defined in terms of

the covered attenuation by the interface that is 6 dB. If

required choosecables with low attenuationto achieve

a maximum distance.

For ranges exceeding 6 dB attenuation additional digital data transmission equipment is required. Line Terminating Unit (LTU) ASB 501 04 is available for such

purposes.

Connection field 6

A

C

18

19

20

22

23

24

26

28

30

32

RING_OUT

TIP_OUT

RING_IN

TIP_IN

LA1

Outgoing

wires

LB1

LA2

Incoming

wires

LB2

Connection for 75 Ω

coaxial cable

Connection for

120 Ω twisted pairs

0 V

There are specificrequirements for thedigital interface

wiring to meet the demands of EMC.

If a twisted pair connection shouldbeinstalled and the

requirements of EN 55022, class Bhave to be fulfilled,

a ferrite is available with the ERICSSON ordering

number STF 82 601. Taking the cable and making

three turns around the ferrite core meets the demand

of sufficient noise reduction. The ferrite should be

situated close to the slot where the cables are led out

of the cabinet. In most cases this cable is supplied by

the PTT and should not be fed via the MDF.

Some markets (e.g. Austrian PTT) require the use ofa

double-shielded interface cable. The outer shield

should be connected to frame earth and the inner

shield shouldbe connected to0V on the board.A 20 m

long standard cable is available with the ERICSSON

ordering number TSR 901 0481/20000.

Coax 75 Ω and twisted pair 120 Ω interface

d1

Line terminating unit BTU-D

d1 - The line length depends on cable type used. The board

allows 6 dB cable attenuation at 1.024 MHz. Check cable

attenuation at 1,024 MHz per 100m.

Page 18

Prepared

Doc respons/Approved Checked

Subject responsible

6.10 BTU-E (ROF 157 5113/_)

INSTALLATION INSTRUCTION

Documentnumber

1531-BDV BS 101 01 Uen

Date

Rev

Reference

1998-05-29 L

19(46)

SPEECH CONNECTION SETTINGS

2-wire connection

106...406

on

1 2 3 4

S1 S2

S3 S4

108/308

on

1 2

S5

INDIVIDUAL 0

uses switches 106 and 108/1

INDIVIDUAL 2

uses switches 306 and 308/1

SPEECH CONNECTION SETTINGS

4-wire connection

106...406

on

1 2 3 4

S1 S2

S3 S4

INDIVIDUAL 1

uses switches 206 and 108/2

INDIVIDUAL 3

uses switches 406 and 308/2

Switches select between 2- or 4-wire speech

connection. Two individualsshare switches 108

and 308

On boardswith Rev. R2Athese switchesare replaced byrelays. These relays are setautomatically by programming the filter coefficients.

Connection field 4 and 6 at front of BTU-E_

Speech (field 4)

AC

18

LA_0

LB_0

LA_1

LB_1

LA_2

LB_2

LA_3

LB_3

M2_0

M20_0

M2_1

M20_1

M2_2

1

M20_2

M2_3

M20_3

M1_0

M0_0

M1_1

M0_1

M1_2

1

M0_2

M1_3

M0_3

20

22

24

26

28

30

32

Signalling (field 6)

AC

LC_0

LD_0

LC_1

LD_1

LC_2

LD_2

LC_3

LD_3

E2_0

E20_0

E2_1

E20_1

E2_2

E20_2

E2_3

E20_3

E1_0

E0_0

E1_1

E0_1

E1_2

E0_2

E1_3

E0_3

LA & LB - 2-wire send/receive or 4-wire send.

LC & LD - 4-wire receive.

108/308

on

1 2

RED

YELLOW

GREEN

YELLOW

GREEN

S5

M-WIRE CONNECTION SETTINGS

APPLICATION

PAGING

SPEECH M-WIRES

2-wire

S6..off

S7..off

S8..off

AMERICAN

E&M

SIGNALLING

DOUBLE

M-WIRE

SIGNALLING

CAILHO E&M

SIGNALLING

4-wire

4-wire

4-wire

S6, S7 and S8

see local

requirements

S6..on

S7..on

S8..off

S6..off

S7..off

S8..off

CEPT L1/SSAC 15

Only on /2 boards

4-wire

S6..off

S7..off

S8..off

S6 connects -48V to M1 terminal via 6.2 Kohm

S7 connects 0V to M0 wire locally.

S8 connects 0V to M20-wire.

108

106

206

306

406

308

0

1

2

INDIVIDUALS

3

109

209

10

2

on

1 2 3

S6 S7 S8

309

INDIVIDUALS

3

409

1

M20_ and M0_ can be switched by S7 and S8 to 0V on

the BTU-E_ locally.

M-WIRE SETTINGS

Page 19

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

20(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

6.10.1 Paging connection

The figure shows howto connect the paging equipment Ericall Contactor with 2 wire speech. The PBX sends paging

information to paging system (pin 6A18) using M1 contact, and information about ’paging in progress’ or ’paging

equipment not present’ is received on the E1-wire (pin 6C18) from the paging equipment.

Switch settings

on

This switch setting is used for

signalling on E1 and M1.

1 2 3

S6 S7 S8

Applies for switches 109, 209, 309 and 409.

Z

DSLAC

0V

-48V

0V

S7

S5

M1

Detector

autom. 2/4wire

0V

PBX

4A18

4A20

6A18

6A20

6C18

6C20

LA

LB

M1 E1

M0 E0

E1 M1

E0 M0

Paging equipment

Detector

-48V

0V

0V

Figure showing Paging equipment and 2-wire speech with ’loop connection’ of the E&M-wires.

Page 20

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

21(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

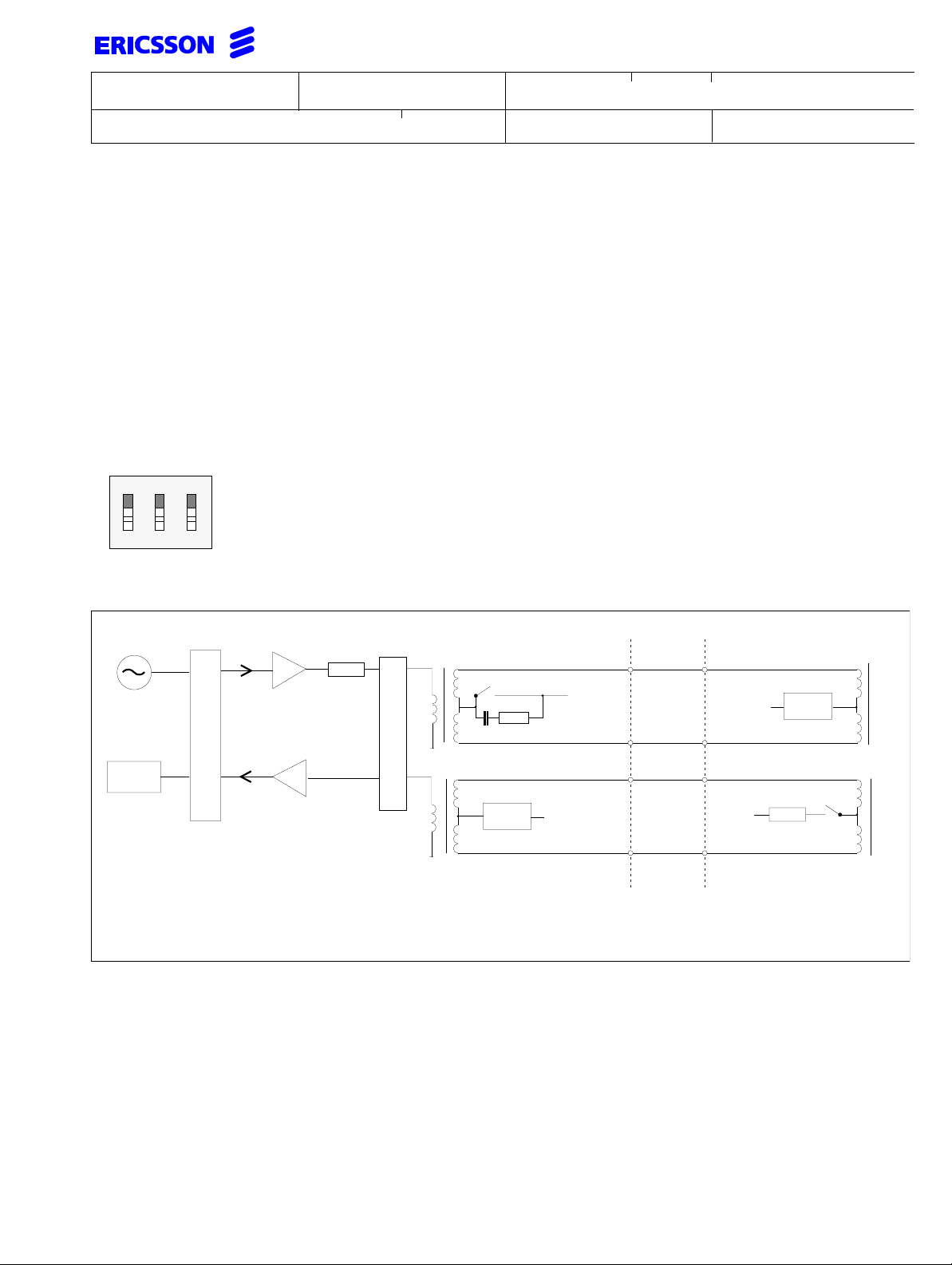

6.10.2 Four wire speech connection

The four wire speech and signalling connection has the benefit of not needing additional signalling wires. There are

two different types of signalling supported:

Cailho E&M-signalling (balanced battery). The two way signalling utilises common mode DC pulses via the centre

tap of the transformer. On one side a detector is connected between the -48 VDC and the centre tap of the

transformer.The other end uses opto relay M4 to switch the line to 0V (Ground). The detector reads the current flow

to ground every time M4 closes.

CEPT L1/SSAC 15 with 2280 Hz tones. In this case no DC signalling is used but instead signalling is performed by

switching on and off a 2280 Hz tone, which is detected by a tone receiver on the other side. This is only available on

index 2 boards.

Switch settings

on

This switch setting inhibits signalling on E1 and M1. Only AC or DC

signalling on the four wire speech connection is used.

1 2 3

S6 S7 S8

Applies for switches 109, 209, 309 and 409.

2280 Hz

DSLAC

2280 Hz

detector

R

0V

autom. 2/4wire

0V

M4

1uF

Detector

560

PBX

LA

4A18

0V

Ω

-48V

4A20

4C18

4C20

LB

LC

LD

PBX or channel equipment

Detector

-48V

0V

Figure showing Cailho E&M signalling and CEPT L1 or SSAC 15 with tone signalling

Page 21

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

22(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

6.10.3 E&M-signalling

Signalling on E & M wires is done either using one or two E&M pairs depending on what is required. Using just E1

and M1 is a very common practice. One case to mention is the American E&M signalling where the M1 wire toggles

between -48VDC and 0V.

Double E&M signalling requires the E1/M1 wires for the signalling of information and the E2/M2 wires indicate

blocking of the connection. The E1/M1-wires are used for signalling and E2/M2-wires are used for blocking. The

figure shows 0V connection to the M-wires in both ends.

Switch settings

Standard E & M signalling

on

This switch setting is used

forsignallingon E1and M1.

1 2 3

S6 S7 S8

Double E & M signalling

on

This is the switch setting when

E1, E2, M1 andM2are used for

signalling.

1 2 3

S6 S7 S8

Applies for switches 109, 209, 309 and 409.

R

DSLAC

0V

autom. 2/4wire

S8**

0V

-48V

0V

-48V

S7

M3**

M1

Detector

**application specific

toggles between 0 and -48VDC

(e.g. American signalling)

PBX

4A18

4A20

4C18

4C20

6A18

6A20

6C18

LA

LB

LC

LD

M1 E1

M0

E1 M1

E0

PBX or channel equipment

Detector

-48V

0V

-48V

0V

E0 M0

0V

0V

-48V

0V

S6

M2

Detector

6C20

6A02

6A04

6C02

6C04

M2 E2

M20

E2 M2

E20

Figure showing four wire speech and standard (double) E&M signalling.

E20

M20

Detector

-48V

0V

0V

Page 22

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

23(46)

6.11 CPU-D_ (ROF 157 5118/_) and

AUX_(ROF1575 119/_)

Before installing the board mount the system software

PROMs in the appropriate positions.

Connections on the CPU-D_

For connection of TEMPERATURE SENSOR KIT, see

INSTALLATION INSTRUCTION (1531-RPM 603 339).

CA

18

Factory test

20

-48 VDC

22

24

26

28

30

32

10

12

14

16

18

20

22

24

26

28

30

32

ALARM

ALARM

External

sensor 3

0 V

Not used

Not used

RTS

DTR

DCD

CTS

RTS

DTR

DCD

CTS

RTS

DTR

DCD

CTS

Polarity

independent

input

only this V.24

port is active

on the AUX3

board

red

yellow

green

red

Cold

start

strap

BS2 9727

CPU-D

R1A

ROF1575118

Audio

Audio

ALARM

(out)

0 V

External

sensor 1

0 V

External

sensor 2

0 V

TXD

0 V

RXD

DSR

TXD

0 V

RXD

DSR

TXD

0 V

RXD

DSR

A B

A

Insert PROM "RYS 102 1x9/ xx

Insert PROM "RYS 102 1x8/ xx

B

r additional CIL storage capacity up to two additional

battery backup RAMs can be added.

The ALARM input is optically isolated and the voltage

has to be between 20 - 60 VDC.

The ALARM output is equipped with an open collector

transistor with a capacity of 20 mA at 12 VDC

(Maximum 14 VDC).

Use the following prefabricated cables to connect the

peripheral data equipment to CPU-D_ and AUX_:

• PC is TSR 902 0448/1

• printer is TSR 902 0476/1

• modem is TSR 902 0466/1

Page 23

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

24(46)

6.12 CPU-D4 (ROF 157 5124/_)

FW PROMS

RYS 102 533/1

RYS 102 533/2

Connections on the CPU-D4

Similar tothe previous versionsthis board providesthe

V.24 interfacesbut additionallythe RS-485interface for

longer ranges. With the software key (FECU)

KDU BS 130 06/_ new functionalities can be accessed.

red

yellow

green

alarm relay

B18

B22

B20

CA

B

ROF1575130

BS2 9727

CPU

R1A

Audio

Audio

red

yellow

green

RTC

FECU

connector

ALARM

(out)

0 V

External

Temp1

0 V

External

Temp2

0 V

18

Factory test

20

-48 VDC

22

ALARM (in)

24

0 V

26

External

Temp3

28

0 V

30

Not used

32

Not used

Battery RAM

Battery RAM

st

1

Battery RAM

KDY BS 101 02/1

Insert PROM "RYS 102 xx1/ x"

A

Insert PROM "RYS 102 xx2/ x"

B

Insert PROM "RYS 102 xx3/ x"

C

Battery RAM

rd

nd

3

2

SW PROMS

C B A

To put the board in operation mount the system software PROMsin the appropriate positions.The number

of battery RAMs mounted on the CPU-D4 board is

functionality dependent.

red

Coldstart

strap

TXD

0 V

RXD

DSR

TXD

0 V

RXD

DSR

TXD

0 V

RXD

DSR

RTS

10

DTR

12

DCD

14

CTS

16

+

RTS

18

-

DTR

20

+

DCD

22

-

CTS

24

RTS

26

DTR

28

DCD

30

CTS

32

Transmit

RS 485

loop

Receive

RS 485

To connect the RS-485 data interface use plug

RNV 321 01 02 be sure to loop RTS with CTS other-

Page 24

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

wise data is lost if printer is OFF. The range of the interface is up to 1200m.

Several converters may be used but with the following

successful tests were accomplished:

IC-485SI from ARP DATACON and

232<->485/422 Converter Plus IC-109AE from Black

Box Corp.

6.12.1 Feature Enabling Control Unit (FECU)

Connecting this plug activates the appropriate applications and features asordered depending on the FECU

index number. If no plug is connected only a limited

Version 3.0 system functionality is available. The indices 2 to 10 always include the Basic Version 3 functionality (index 1).

25(46)

For detailed information of the featuresenabled by the

different FECUs refer to 15534-ASB 150 02 Uen

FACILITY DESCRIPTION GENERAL.

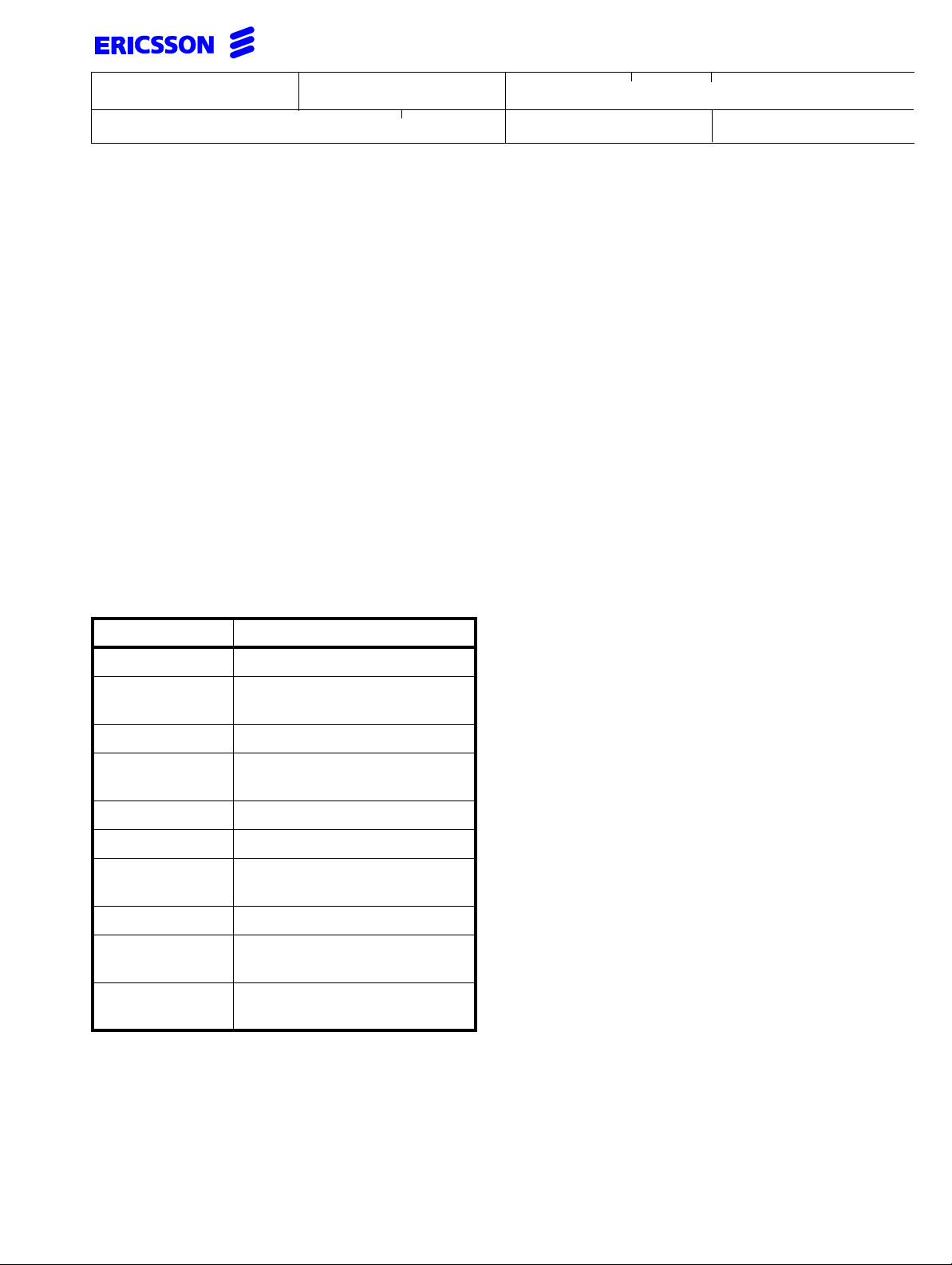

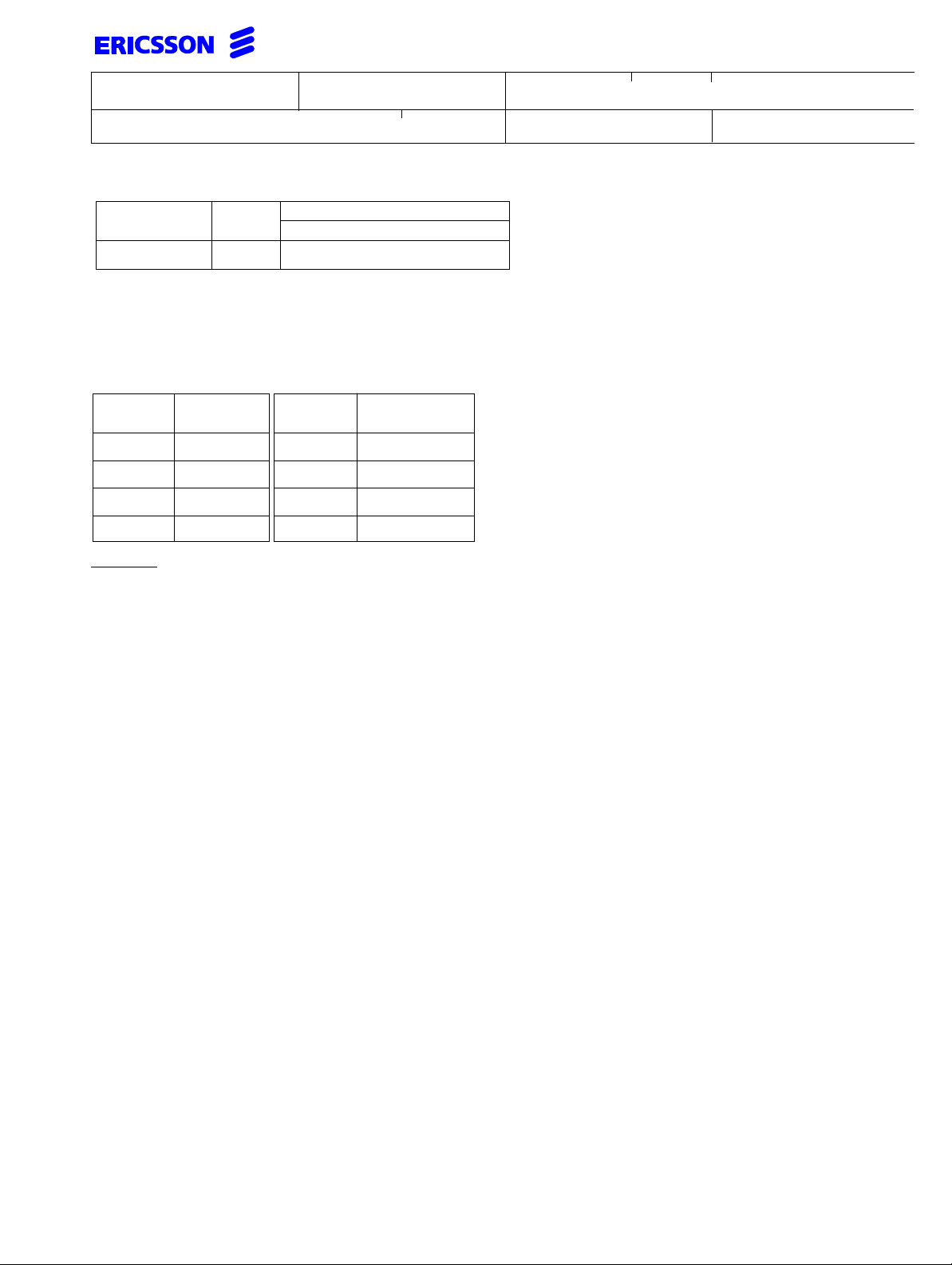

FECU number Functionality Version 3.1

KDU BS 130 06/1 Basic Version 3.0 functionality

KDU BS 130 06/2 + std. digital networking for max.

32 interfaces

KDU BS 130 06/3 + std. digital networking

KDU BS 130 06/4 + full. digital networking for max.

32 interfaces

KDU BS 130 06/5 + full. digital networking

KDU BS 130 06/6 + CTI

KDU BS 130 06/7 + CTI and std. digital networking

for max. 32 interfaces

KDU BS 130 06/8 + CTI and std. digital networking

KDU BS 130 06/9 + CTI + full. digital networking for

max. 32 interfaces

KDU BS 130 06/10 + CTI + full. digital networking for

unlimited number of interfaces

Page 25

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

6.13 ELU-A and ELU-D

Connection field6 at frontof ELU-D(3)and ELU-A

The relevant boards are:

• ELU-D (ROF 1575 116/_)

26(46)

• ELU-A (ROF 1575 114/1)

• ELU-A2 (ROF 1575 114/2)

• ELU-D3 (ROF 157 5130/_)

This switch is mount-

RYS 102 532/2

RYS 102 532/1

ON

3 4

ed for future use

1 2

(LA16)

(LB16)

(LA18)

(LB18)

(LA20)

(LB20)

(LA22)

(LB22)

(LA24)

(LB24)

(LA26)

(LB26)

(LA28)

(LB28)

(LA30)

(LB30)

LA0

LB0

LA2

LB2

LA4

LB4

LA6

LB6

LA8

LB8

LA10

LB10

LA12

LB12

LA14

LB14

02

04

06

08

10

12

14

16

18

20

22

24

26

28

30

32

C

A

LA1

LB1

LA3

LB3

LA3

LB5

LA7

LB7

LA9

LB9

LA11

LB11

LA13

LB13

LA15

LB15

(LA17)

(LB17)

(LA19)

(LB19)

(LA21)

(LB21)

(LA23)

(LB23)

(LA25)

(LB25)

(LA27)

(LB27)

(LA29)

(LB29)

(LA31)

(LB31)

Extension Line

connector to

terminal

equipment

View of the ELU-D3 board

The connections in field 4 are in brackets (only on

ELU-D3 for individuals 16 to 31)

On the first ELU-D_ board in the system the first three

extension positions should be used to connect the

OPERATOR telephones.

On sub-equipped ELU-A and ELU-D_ boards the connection for extensions 8...15 (32) are not mounted.

Page 26

INSTALLATION INSTRUCTION

Subject responsible

Doc respons/Approved Checked Reference

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Date Rev

1998-05-29

L

27(46)

6.14 VMU-HD (ROF 157 5126/1)

To install unpack the VMU-HDboard with the mounted

hard disk.The Flash disksare availablewith a capacity

of 60 MB. Removethe transport protection forthehard

disk and keep it in case of re-shipment e.g. factory repair. Install and configure the VMU-HD in the cabinet

according to the stipulations in 1537-ASB15002Uen

START OF OPERATION.

Note: The VMU-HD will not start up without internal

directories created on the hard disk.

The DIP-switch is shown with

both contacts in OFF position

(factory setting)

ON

1 2

990

990/2990/1 FUNCTION

OFF

ON

Structure of directories on hard disk or Flash card

\Info0 \message2 \anno0

\Info1 \message3 \anno1

Removal of hard disk or Flash card

To remove the hard disk take out the board from the

system. Disengagethehard disk with lever and pull

out the hard disk.

ON or

OFF

OFF

ON

\message4 \anno2

\message5 \anno3

16 channels, no register function

8 channels with MFC detection

and DTMF / Tone receiver

8 channels with MFE detection

and DTMF / Tone receiver

\annoF

A

6.15 VMU-D (ROF 157 5117/1)

PCMCIA Hard/

Flash disk

type III and II

A

Press button to disengage the hard disk and

Press button to disengage the hard

A

take it out.

disk and take it out.

DIP switch on VMU-HD

DIP switch 990 selects whether register function is enabled or not.

Limitations:

Only one VMU-HD can be mounted per cabinet and

just one type either VMU-HD or VMU-D can be installed in a system.

The VMU-D has no switches, but is equipped with a

back up battery, RNV 991 942/001 to prevent loss of

data in case of power failure. Install the battery to connection field4. beforethe exchange isstarted. Forsafe

operation, replace this battery periodically every five

years in accordance with document MAINTENANCE

INSTRUCTION (1541-ASB 150 02 Uen).

Installation of battery back-up on VMU-D

Connection

field 4

Battery RNV 991 942/001

Page 27

INSTALLATION INSTRUCTION

Subject responsible

DocumentnumberPrepared

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked Reference

Date Rev

1998-05-29

L

28(46)

7 INTEGRATED CORDLESS

The Integrated Cordless (IC) is a digital cordless telephone solution complying to the DECT standard providing wireless connection for up to 108portables with

the A-protocol and 210 portables in GAP-protocol applications. Several components comprise a complete

system.

After the system has been physically installed use

RASC and the Cordless System Manager (CSM) for

initialization, maintenance, updating, fault finding and

when possible to recover the PBX from errors. The

CSM is orderable under LZYNB 201 01 R6A or higher

forthe A-protocol and LZYNB201 05 R1B orhigher for

GAP applications.

7.1 Board Descriptions

7.1.1 IC-Control Unit2 (IC-CU2)

The IC-CU2 is the control board supporting the DECT

GAP-protocol. The IC-CU2 includes 8 voice channel

units and is equipped with 4 BSs interfaces.

The wiring distance with remote power feeding to the

BSs using only the serial communication wires SC0

and SC1 is limited to 400m. For line lengths up to

900m additional Express Power feeding Pairs (EPP)

need to be wired. The maximum wire length between

BS (fed locally) and IC-CU2 is only data limited and

may reach up to 900 meters.

The board offers the following connections:

• the Cordless System Manager (on a PC)

• a printer to log errors

• 4 Base Stations

• the Feature Enabling Control Unit (FECU).

7.1.2 Feature Enabling Control Unit (FECU)

plug is available for various numbers of cordless telephones. For up to 8 portables no plug is required.

FECU number Number of Portables

KDU 130 05/1 16

KDU 130 05/2 24

KDU 130 05/3 32

KDU 130 05/4 48

KDU 130 05/5 64

KDU 130 05/6 108

KDU 130 05/7 210 (only with IC-CU2)

7.2 Traffic capacity

The traffic capacity of the Cordless part of the PBX is

mainly determined by the IC-CU_ and in exceptional

cases also by the Base Stations. The IC-CU can handle a maximum of 56 simultaneous calls and the ICCU2 can handle up to 60 simultaneous calls. Each

Base Station has a capacity of 8 simultaneous calls.

The traffic capacity of the IC-CU_ is determined by:

• the Grade Of Service (GOS) required by the

customer

• the number of speech circuits available, with a

limit of 64.

The Grade Of Service is the probability that acall is rejected because of system congestion. The customer

has to indicate which Grade Of Service is acceptable.

A Grade Of Service of 1%, or 0.01, means an average

of 1 lost call in every 100 calls. The IC-CU2 is

equipped with a SPU providing 8 speech circuits.

The two parametersmentioned above (GOS and the8

speech circuits) and the totalamountof traffic (Erlang)

that is required, are related to each other. The table

below shows the capacity at a required GOS.

This plug determines which maximum number of portables are allowed to be connected to the system. This

Page 28

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

29(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

Practically, this table is used to calculate from a given GOS and Erlang value the number of portable users.

IC-CU2

1

Speech Grade of service (GOS)

circuits

2% 1% 0.5% 0.1%

8 3.6 3.2 2.7 2.1

For the calculation it is necessary to estimate the time the portables actually make calls. The table below shows the

Erlang value depending on the estimated mean call-minutes fora portable telephone. These values may be different

between departments depending on their activities. These values multiplied by the number of portables result in a

traffic capacity that has to be provided.

mErlangMinutes

25015

30018

50030

75045

per hour

mErlangMinutes

per hour

503

1006

1509

20012

Example:

A customer ordering a system with 24 portable telephones. He estimates that each portable generates 200 mE

each in average. These values requirea system with a traffic capacityof3,6 E (0,15x24). With an acceptedGOS of

2.0% the traffic capacity can be met.

7.2.1 Traffic Capacity of Base Stations

A Base Station, having 8 channels available, has an Erlang value of 2.7 with a GOS of 0.5%. This means that each

Base Station can serve 18 portables, assuming each portable generates 150 mE during busy hour or 13.5 portables

generating 200 mE each.

Example:

Assuming a full coverage in a building canbeachieved with 2 Base Stations means that 20portables generate

together 20 x 0.150 = 3 E. Every Base Station has a traffic capacity of 2.7 Erlang. To have a sufficient

coverage two Base Stations covering the area of the busiest part of the company are needed.

Practically, the total capacity offered by the cordless network is generally more than sufficient, but this is from an average point of view. In certain places, traffic demands may vary such that locally the network is often blocked, or has

a lower GOS than required. For instance a purchase department may easily generate 300 mE per Portable during

busy hour, thus, when e.g. with 6 persons giving a very high load on the Base Station close by. It may be necessary

to add aBase Station in this areatohave enough capacityfor others to callas well. Also think ofe.g. canteens during

lunch time etc.

Page 29

INSTALLATION INSTRUCTION

Prepared

Subject responsible

Documentnumber

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

1998-05-29 L

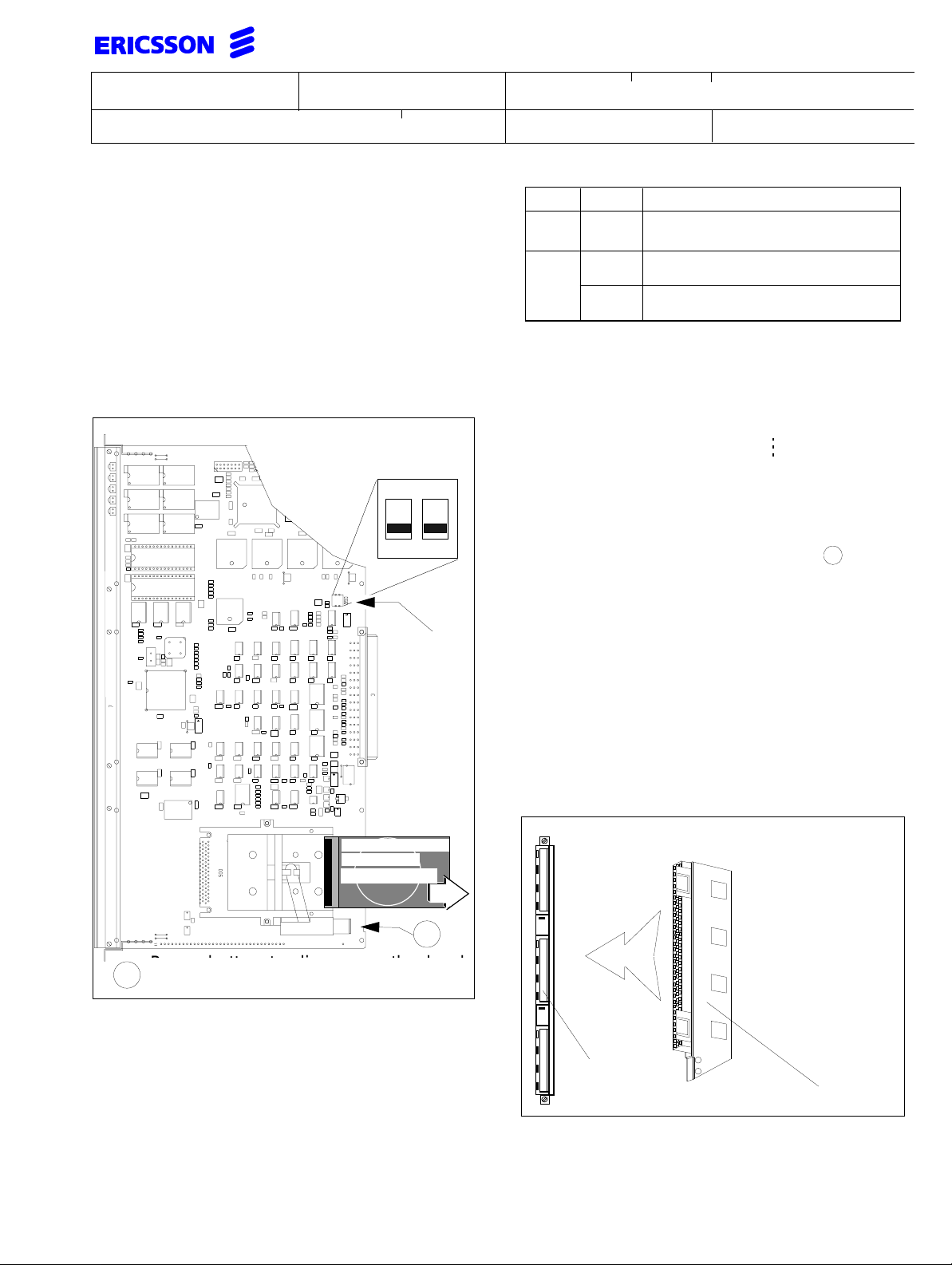

7.3 IC-CU2 (ROF 157 5131/_) (GAP-Protocol)

LEDs

Rev

30(46)

Reference

RP error

Individual blocked

Individual busy

CPU error/DCT error log

SPU error

DECT Sync port

SYNCH A IN

SYNCH B IN

SYNCH A OUT

SYNCH B OUT

CLU error

0 V

0 V

(KDU 130 05/__)

External power input

via front connector (to enable

set switch 1and 2 to OFF)

to power supply BML 351 048

Express Power feeding to base stations

(-)

To BS 4

EPP

TSR BS 101 12/1500

AC

18

20

22

(-)

To BS 3

EPP

EPP

EPP

(+)

(+)

red

yellow

green

green

red

red

V0

V1

(-)

(+)

BS2 9727

IC-CU2

R1A

ROF1575131/1

Switch 1 and 2 must have the

same position. ON (default)

48V from the backplane. OFF

activatesexternal DC inputand

disconnects the backplane.

RYS 102 531/1

DECT

synchronization

RYSNB 101 19

RYS 102 531/2

+

RYS 102 553/1

ON

1 2

ON

RYS 102 554/1

RYSNB 101 20

24

To BS 2

EPP

26

(-)

28

To BS 1

EPP

30

(-)

32

Serial communication to base stations

AC

To BS 4

SC0

02

04

06

To BS 3

SC0

08

To BS 2

SC0

10

12

14

To BS 1

SC0

16

EPP

EPP

(+)

(+)

SC1

SC1

SC1

SC1

RYSNB 101 23/2

Maintenance port

TXM

0 V

RCV

n.c.

TXM

0 V

RCV

DSR

18

20

22

24

26

28

30

32

RTS

DTR

PRINTER

DCD

PORT

CTS

RTS

DTR

MAINTENANCE

DCD

PORT

CTS

remove paper

insulation

Page 30

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

31(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

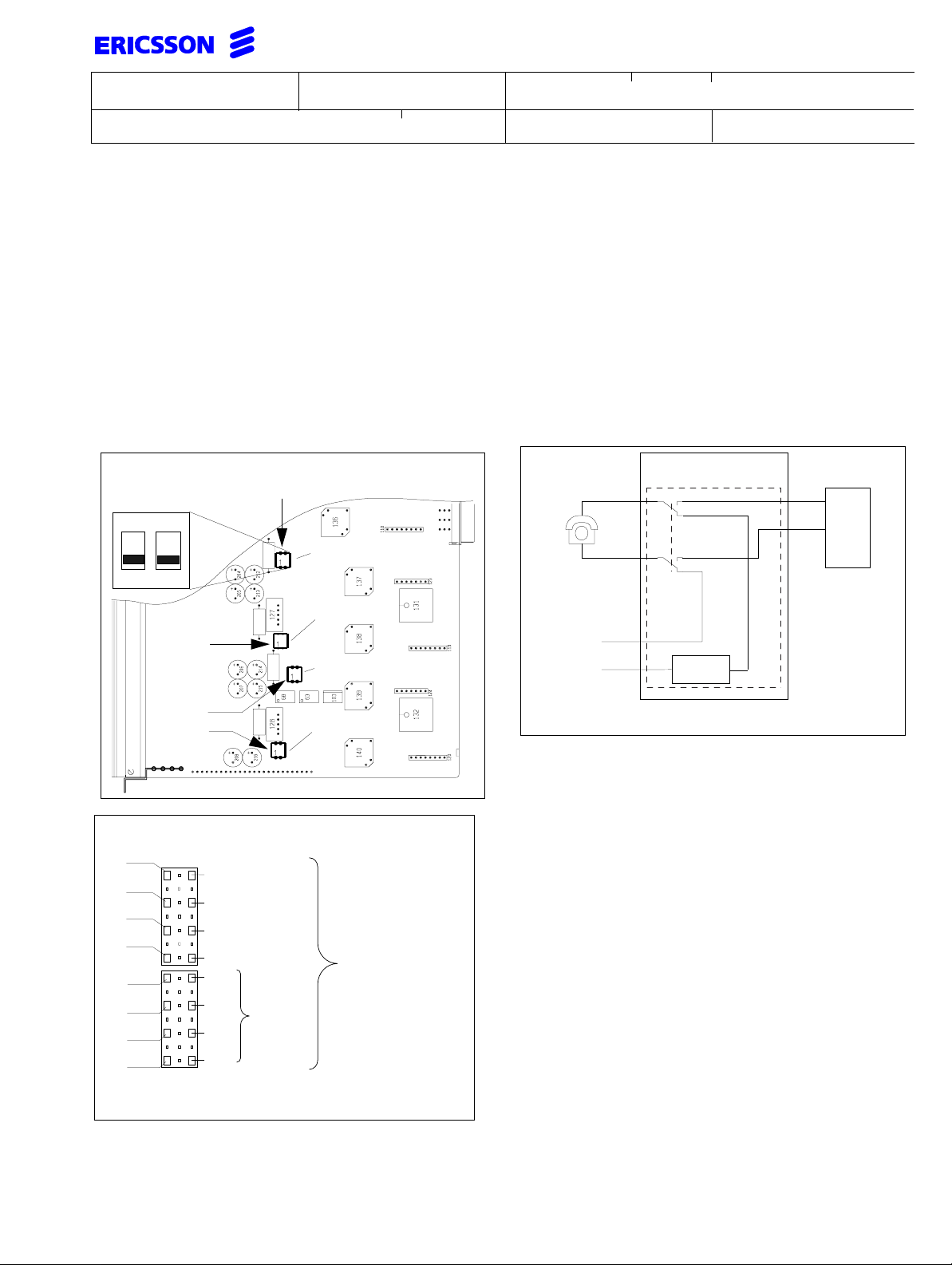

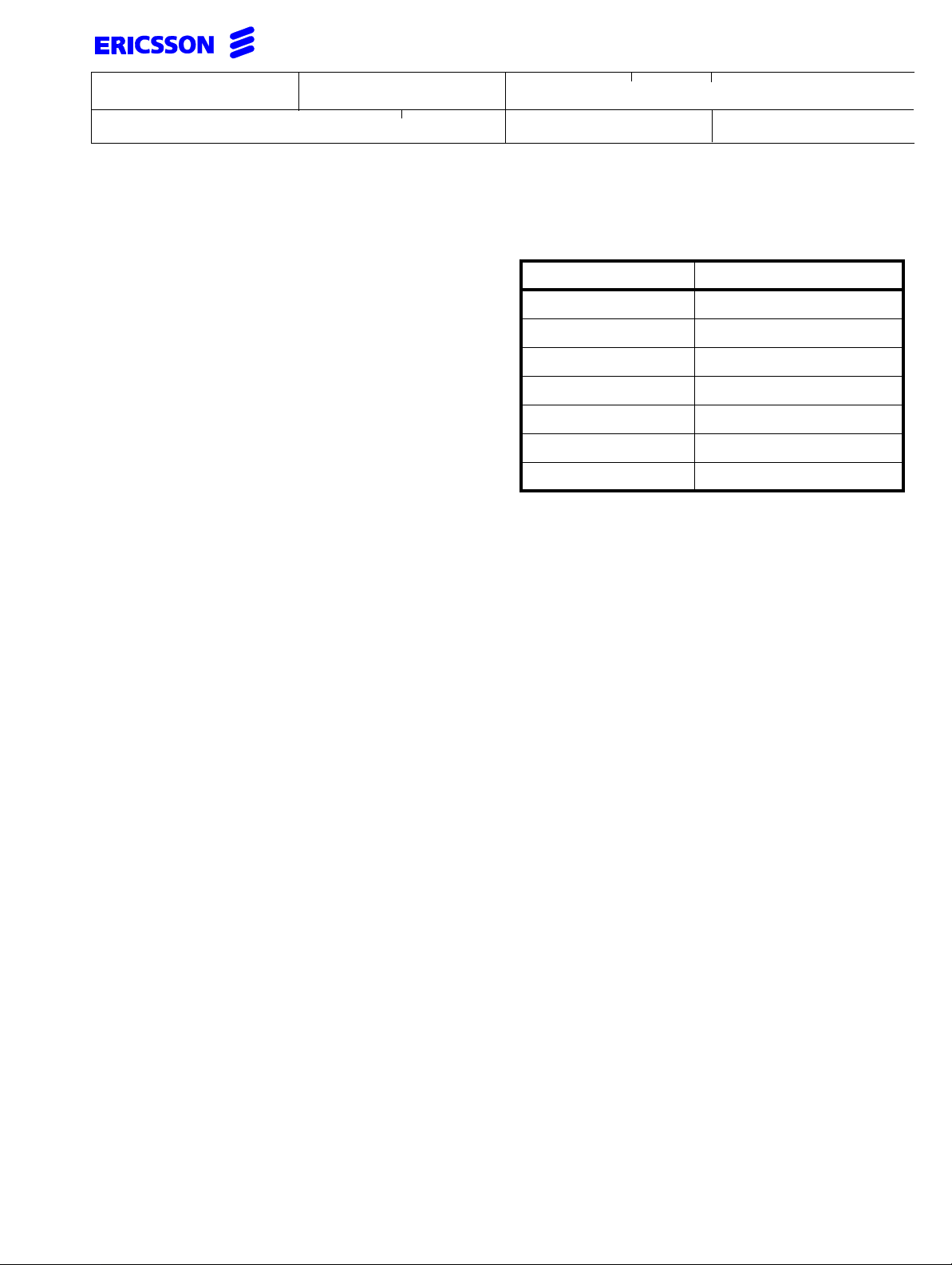

7.4 Base Station (KRCNB 201 03/_ and KRCNB 301 01/_)

The Base Station (BS) enables radio communication between the Integrated Cordless system and the portable

telephones. The communication via two2B+D interfaces, requires two twisted pair cables. Both interfaces provide in

total eight 32 kbit/s speech paths between a BS and IC-CU2, enabling a BS to handle eight simultaneous calls. The

BS is connected to the IC-CU2 via two wire pairs called serial communication wires (SC0 & SC1) carrying up to 8

simultaneousdigitalvoiceconnectionsandthecentralpowerfeeding.Apart fromdatacommunicationthesetwotwisted

pairs are alsobe used to distribute power to theBSs. Two additional pairs canbe wired to provide agreater powering

range. There are three methods to power BSs:

1. centrally via backplane (with or without EPP)

2. centrally via external input (with / w.o EPP)

3. via local power supply (optional).

With the first and second methods power is distributed via the IC-CU2 to the BS. The cable length between BS and

IC-CU2 depends on thenumber wires used for power feeding,the type of cable and environmentalnoise. In the third

case (local feeding),BSs are powered by anAC-adapter or another power source which isnot routed via the cabinet.

The number of BSs used in a system depends on the area to be covered and the traffic density. Typical in-house

coverageis upto 30meter radius.In practicethecell sizemayvary between10 metersindoorsin worstcasesituations,

up to 300 meters outdoor in free space.

The BS has two main functions:

• to modulate a carrier with the digital encoded information (TDMA frame directed to portable)

• to demodulate a modulated carrier (TDMA frame received from portable).

A special cover (KRY NB 101 01) is available to mount the BS (KRCNB 201 03) outdoors providing splash proof

housing and water tight sealings for the wiring.

7.4.1 Base Station Planning

The major task when providing a wireless service is to estimate the number of BSs and to find their most suitable

location. A number of factors tend to limit the range of a BS like the materials the wall is composed of or the location

and size of machines, furniture, air-conditioning systems, elevators etc. This results in unexpected reflections or

absorption of radio waves. Generally BSs should not be located on outer walls, except if the outdoor area has to be

covered as well, as this reduces the area actually covered. All of these unpredictable influencing factors makes it

extremely difficulttodefine rules for how to cover an areawith a suitable number of BSs.In difficult environments the

use of a site survey tool (LTT NB 101 01/_) is recommended.

Establish a Base Station plan for the installation site to determine the best location for the BSs.

Base Station aerial range

• Inan officeenvironment in asteel concretebuilding up to30 mindiameter canbe coveredand including,

under normal conditions, the neighbouring floors.

• Production halls up to 200 m in diameter are covered but ranges can be less if bulky machines, cranes

etc. are part of the interior.

• Outdoor ranges can be up to 300m.

When installing a BS, position it, then walk around to determine cell coverage area either by listening to the speech

quality- whethermutesor cracklingsounds areheardin theportable -or measuretheRQIindicator usingtheportables

Service Display facility (see FAULT TRACING 1545-ASB15002Uen).

Page 31

Prepared

Doc respons/Approved Checked

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

1531-BDV BS 101 01 Uen

Date

Rev

Reference

1998-05-29 L

32(46)

16m

intermediate

floor

Ground floor

3,5m

e.g. 40m

corridor

Base

Station 1

7.4.2 Base Stations Cabling

Usinga four-paircable ormore-pair cable,the freecablepairs canbeused asadditionalpower wires(EPP)to increase

the feeding distance andreduce overallpower consumption(by reducingthe ohmic resistance)to theBS. The BScan

also be powered by an on-site adapter (refer to section 7.4.7).

Connection of serial communication wires and EPP lines is polarity-independent. SC0-0 and SC0-1 may be

interchanged but SC0-xandSC1-x may not be interchanged. The diagrambelow shows the wiring principle to each

base station connected to the IC-CU2.

Power feeding of the Base Station

There are three alternatives to power feed (-48V) the Base Station:

• Thepower feeding canbe takenvia the IC-CU2from the backplane in thecabinet. TheDIP-switch on the

IC-CU2 is set to OFF.

• From an external power source via the front connector on the IC-CU2 (≤56V). Note the polarity on the

input (see drawing of IC-CU2 board). The switch on the IC-CU2 is set to ON.

• By an AC-adapter (see page 38). The switch on the IC-CU2 should be set to ON but

no power feeding from an external power source via the front connector on the IC-CU2.

Page 32

Prepared

Doc respons/Approved Checked

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

1531-BDV BS 101 01 Uen

Date

Rev

Reference

1998-05-29 L

33(46)

+

SC0-a

SC0-b

SC1-a

SC1-b

EPPa

EPPb

+

DC

DC

-

-48V from

backplane

CLC x

(one of 4

S1 & 2

+

T

-

48Vexternal

V0

source

+

V1

(optional)

SC0-a

SC0-b

SC1-a

Data/power

connector 1

up to 2 power pairs "EPP

carrying V0- and V1

or 8)

+

IC-CU2

T

SC1-b

EPPa

EPPb

Data/power

connector 2

available only on

Base Station

KRC NB 30101/_

SC0-a

SC0-b

SC1-a

SC1-b

EPPa

EPPb

Base Station KRC NB 201 03/_

and KRC NB 301 01/_

7.4.3 Base station cable delay measurement

After all base stations have been installed, the cable delays must be measured in order to program the base station

delaysinto thesystem atinitializationtime.OnIC-CU2s withtherevision R1Candhigherautomaticdelaymeasurement

is performed. In this caseno measurement is needed but using the cordless systemmanager (CSM) go to the menu

"add Base Station" and enter a "1" in the field "delay".

7.4.4 Ranges on cables

Thefollowingrangesare givenforbase stationsconnected toan IC-CU2.Dependingon thecable typerangesdepend

on noise levels imposed on the cables. The values stated are maximum achievable ranges:

Type Cable

Wire diameter (∅)

Twisted pair 0.4 mm 45 nF/km 1.2 km 1.0 km

Twisted pair 0.5 mm 45 nF/km 1.6 km 1.4 km

Twisted pair 0.5 mm 120 nF/km 0.9 km 0.8 km

Twisted pair 0.6 mm 45 nF/km 1.9 km 1.7 km

Twisted pair 0.6 mm 120 nF/km 1.1 km 1.0 km

Double twisted pair

(J-Y (St)Y 2×2×0.6)

0.6 mm 120 nF/km 1.0 km 0.9 km

Capacitance

Maximum cable length

Superimposed noise

8 mV/pHz 10 mV/pHz

Page 33

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

34(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

7.4.5 Base Station (KRC NB 203 01/_)

The Base Station (BS) is supplied with a drilling template to mount the unit and 2 antennas with TNC connectors.

Mount the unit in a suitable location to provide the best communication coverage.

Use the supplied drilling template and mount the BS with four screws (6 mm Φ). Complete the electrical connection

according to the above drawing. Do not connect to the Base station yet.

IF power is supplied by the adapter (BMLNB 101 04), the screw/slide connector must be used. The serial

communication wires can be connected via the modular jack or the screw/slide connector. A screw with a bundling

cord holder is provided for traction relief to the left of the connection field.The BS starts up if the supply lines deliver

more than 12 VDC.

LEDs

X52

RJ 45

modular jack

TNC connector

Power

Reset

(v0)

(v1)

EPP

EPP

SC1-a

1

SC0-a

SC0-b

X51

SC1-bncnc

Status of LEDs

Power LED on (green)

Reset LED on (red)

LED1 and LED2 on or

Mounting

holes (4x)

LED1 and LED2 flashing

LED1 and LED2 off

LED1 off and LED2 on

LED1 on and LED2 off

LED 2

LED 1

1

2345

or

SC1-a

SC0-a

SC0-b

67

8

(v0)

(v1)

EPP

EPP

SC1-bncnc

screw/slide

connector

Use connectors 5 & 6 for AC adapter

connection. This input is insensitive to

polarity reversal

Meaning

BS power on

Power Fail/Reset

BS in non

operational mode

BS operational (no traffic)

BS operational (traffic)

Fatal software error

Note: ) If theBase Station (KRCNB 201 03/_)is accessibleby persons otherthan trainedpersonnelmount thecover

(SDFNB 101101/_ or similar.

Page 34

Prepared

Doc respons/Approved Checked

Subject responsible

7.4.6 Base Station (KRCNB 301 01/_)

LED2

INSTALLATION INSTRUCTION

Documentnumber

1531-BDV BS 101 01 Uen

Date

Rev

Reference

1998-05-29 L

35(46)

Front view

SC = Serial Channel

EPP = Express Power Pair

NC = Not connected

LED1

RJ 45

modular jack

(v0)

EPP

(v1)

EPP

SC1-a

SC0-a

SC0-b

SC1-bncnc

Rear view

Factory testing

(RJ45)

Data/power

(RJ45)

Data/power

(RJ45)

The BS is connected to the radio exchange by means of a standard twisted pair cable. The BS is can be fixed to a

wall, a ceiling, a pole or a beam, by means of the mounting bracket included. When fixing the BS to a wall or ceiling

the included plugs and screws must be used. When fixing it to a pole or beam a (not included) strap a flexible metal

band must be used.

Connectors

• Two 8-pin RJ45 modular jacks for data and powering

• A 6-pin RJ45 modular jack for factory testing

The two data/powering connectors are interconnected on the board.

LEDs

LED 1: Green power LED

LED 2: Three colour LED, see table below

Status of LED2 Meaning

Off Base station operational and no traffic on the base station

Green Base station operational and traffic on the base station

Red Base station is malfunctioning

Amber Basestation is OK, but not available (self-test, notinitialized,

Flashing green All 8 channels are in use

Flashing amber Software is being downloaded to the base station

no communication with radio exchange)

Page 35

Prepared

Subject responsible

INSTALLATION INSTRUCTION

Documentnumber

36(46)

1531-BDV BS 101 01 Uen

Doc respons/Approved Checked

Date

Rev

Reference

1998-05-29 L

TheBSs canbemountedvertically orhorizontally. Mountthe BSsat placesand positionsas determinedin thesystem

configuration plan. The BS must be placed such that it is not facing large metal objects such as large heating pipes,

machines.

Fixing the mounting bracket to a wall

Fix the mounting bracket (see figure below) to the wall as follows:

1. Hold the mounting bracket with its flat side against the wallsuch that the text ‘TOP’ is the right way up,

and mark the two holes. The minimum distance between the upper hole and the ceiling or any object

above the BS must be as least 65 mm. If the distance is less than 65 mm, the BS cannot be slid onto

the bracket.

2. When using wall plugs, take a ∅ 6 mm drill and drill the two holes and insert the included wall plugs.

3. Position the mounting bracket with its flat side to the wall and fasten it with the two included ∅ 3.5 mm

screws.

Ceiling

≥ 65 mm

TOP

Fixing the mounting bracket to a pole or beam

The mounting bracket can befixed to a pole (diameter ≥ 45 mm) or a beam (wider than 50 mm) by means of a strap

or flexible metal band less than 30 mm wide. Fix the mounting bracket to a pole or beam such that the text ‘TOP’ is

right way up. The strap or flexible metal band must be purchased locally.

Tied wrongly