Page 1

Base Station F800

Field Service Manual

COPYRIGHT 1996 Ericsson Mobile Communications AB

EN/LZB 115 681 R1

Page 2

RUBRIKFÖRTECKNING

LIST OF HEADINGS

Dokumentnr - Document No

EN/LZB 115 681

Document maintenance

1

Safety instructions

Datum -Date

96-06-06

Rev

A

FIELD SERVICE MANUAL

F800

2

Overview

3

Technical specifications

4

Installation

5

Operations instructions

6

This manual is provided by Ericsson Mobile

Communications without any kind of warranty.

Improvements and changes in this manual due to

typographical errors, inaccuracies in current information, or

improvements to programs and/or equipment may be

made by Ericsson Mobile Communications at any

time and without notice. These changes will, however, be

incorporated into new editions of this manual.

Spare parts list

7

Service tools

8

Service information

9

Cabinet

10

Transceiver unit

All right reserved.

COPYRIGHT 1996

Ericsson Mobile Communications AB

11

Applications

12

Page 3

Page 4

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ESE Rune Tapper ECS/S/LT-96:1036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ESE (Rune Tapper) 1999-05-25 D

DOCUMENT LIST

1 (3)

F800 Field Service Manual

Document list

Chapt Document name Document number Rev

1. Document maintenance

Distribution list 031 51-LZB 115 681 B

Revision journal 109 21-LZB 115 681 A

Document list (this document) ECS/S/LT-96:1036 D

2. Safety instructions

Warning, health risk! ECS/S/LT-96:5031 A

Warning, health risk! ECS/S/LT-96:5032 A

Handling MOS devices ECS/S/LT-96:5033 A

Warning, high voltage! ECS/S/LT-96:5034 A

Information about ESD LZT 109 170 Ue -

3. Overview

Product structure 1315-KRD 103 10 Ux B

Mechanical structure ECS/S/LT-96:5035 A

Manufacturing instruction 1510-KRD 103 10 ux A

Coding scheme 1518-KRD 102 01 usv C

4. Technical specifications

Ericsson F800 Technical data EN/LZT 123 593 R3

F800 Product sheet EN/LZT 123 841 A

5. Installation

Installation ECS/S/LT-96:5036 A

Installation instruction 1531-SXK 107 2274/1 UX B

Installation instruction 1531-SXK 107 2274/4 UX A

Lightning protection for masts ECS/S/LT-96:5037 A

F800 Commissioning ECS/S/LT-96:1042 A

6. Operating Instructions

Operating Instructions F800 ECSTAP 97:1055 A

Page 5

DOCUMENT LIST

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

2 (3)

KL/ESE Rune Tapper ECS/S/LT-96:1036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ESE (Rune Tapper) 1999-05-25 D

7. Spare parts list

Spare parts list ECS/S/LT-96:5042 A

8. Service tools

LPC 102 213 F800 Test Handset KTR97:2444 A

Fault tracing F800 KTR97:2486 A

Special service tools for F800 15/EN/LZB 115 681 R1 Uen A

Service unit F800 15188-LPC 102 81 UX A

F800 personality programming ECS/S/LT:96-1014 A

9. Service information

Service information SI95-011 A

Service information SI96-003 A

Service information SI96-004 A

10. Cabinet

F800 Radio base station concept 109 21-KRD 103 10 - 1 Uen A

Cable 151 88-RPM 113 669 Ux B

Cable 151 88-RPM 113 671 Ux A

Cable 151 88-RPM 113 670 Ux A

Cable terminal info F800 193 12-SXK 107 2274/4 Uen A

Cable terminal info F800 193 12-SXK 107 2274/4 Uen B

Connection cable 151 88-RPM 113 1511 Ux A

Connection cable 151 88-RPM 113 1511 Ux B

Connection cable 151 88-RPM 113 1512 Ux A

Connection cable 151 88-RPM 113 1512 Ux B

Connection cable 151 88-RPM 113 1513Ux A

Fan kit 151 88-BKV 301 203 Ux A

Connection cable 151 88-RPM 113 1703 Ux A

Wiring diagram F800 MRS3000 107 31-SXK 107 2274/1 Ux E

Wiring diagram F800 MRS5000 107 31-SXK 107 2274/2 Ux D

Circuit board 1911-ROA 117 2010 Ux A

Printed board 1078-ROA 117 2010 Ux A

Station unit C700 151 88-NTM 201 57 Ux E

Assembly drawing F800 151 88-SXK 107 2274/1 Ux C

Wiring diagram transceiver unit F800 107 31-KRD 103 10 Ux A

Assembly drawing F800 151 88-SXK 107 2274/4 Ux C

11. Transceiver unit

Logic unit 3/EN/LZB 115 681 R1 Uen A

F800 Circuit description ECS/S/LT-96:5044 A

Logic board F800, circuit diagram 1911-ROA 119 8736 UEN C

Logic board F800, mounting drawing 1078-ROA 119 8736 Ux B

Page 6

DOCUMENT LIST

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

3 (3)

KL/ESE Rune Tapper ECS/S/LT-96:1036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ESE (Rune Tapper) 1999-05-25 D

12. Applications

F800 as radio link S/XT 95:7049 A

F800 as repeater station ECS/S/LT-96:1013 A

F800 as OEM station ECS/S/LT-96:1018 A

Enclosure

F800 Personality Programming Tool EN/LZY 213 633 1.47

Page 7

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ESE Magnus Lindahl ESE-9902150

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KL/ESE (Rune Tapper) 1999-10-27 A

Öppen Open

INFORMATION

1 (1)

This manual is an

unregistered copy

and will not be

updated!

This manual is provided by Ericsson Sverige AB without any kind of

warranty. Improvements and changes in this manual due to typographical

errors, inaccuracies in current information, or improvements to programs

and/or equipment may be made by Ericsson Sverige AB at any time and

without notice. These changes will, however, be incorporated into new

editions of this manual.

COPYRIGHT1999 Ericsson Sverige AB

All rights reserved.

Page 8

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5031

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

SAFETY PRECAUTIONS

1 (4)

WARNING, HEALTH RISK!

Beryllium oxide

The transistors in the power amplifier’s driver stage and in the power amplifier contain

beryllium oxide ceramics (BeO). Dust particles of this substance may be dangerous to

your health if you inhale or get them on your skin.

Therefore, DO NOT IN ANY WAY INTERFERE WITH THE TRANSISTORS. It is, vital

that you comply with the directions given in the appended “Beryllia safety precautions”.

BERYLLIA SAFETY PRECAUTIONS

Introduction

This appendix details the safety precautions when handling components containing

Beryllium oxide. Dust from this material can present a health hazard unless adequate

precautions are taken.

The hazard

The material is highly dangerous in a dust form when it might be inhaled or enter a cut

or skin irritation area.

If dust is caused as a result of chafing, filing or breakage and is inhaled, a single

exposure lasting minutes or seconds can cause injury to skin or mucous membranes

severe enough to endanger life or cause permanent injury. Particles penetrating the

skin through wounds or abrasions are liable to cause chronic ulceration’s.

Symptoms of poisoning indicated by respiratory troubles or cyanosis (grey blue

discoloration of the skin), may develop within a week, or after a period extending to

several years.

965031.doc

Page 9

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5031

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

SAFETY PRECAUTIONS

2 (4)

COMPONENTS

Power transistors, diodes and thyristors

Power transistors, diodes and thyristors, as received in the manufacturers packing, are

clearly identified by attached information. They should be stored in the original packing

and not mixed with other items. The Beryllia is encapsulated and components are safe

to handle for replacement purposes. Care should be exercised in removing defective

items to ensure that they do not become physically damaged.

They MUST NOT:

be carried loosely in a pocket, bag or container with other components where they

may rub together or break and disintegrate into dust

be heated excessively (normal soldering is quite safe)

be broken open for inspection or in any way abrased by tools.

Heat sink washers

Some of the heat sink washers contain Beryllia. When new these are packed

individually.

They MUST NOT:

be stored loosely

be filed, drilled or any way tooled

heated other than when clamped in heat sink application.

They are best handled with gloves or cloth when being removed from equipment.

Cathode ray tubes and ceramic applications

965031.doc

Some products of cathode ray tube are coated on the inside with a ceramic beryllium

oxide mixture. The tube is safe unless the glass is broken but should this occur.

DO NOT:

handle the broken glass with bare fingers

blow on the exposed surface (because of the danger of inhalation).

Ceramic cylinders or formers, identified by blue coloration or black lines, are safe to

handle provided they are not damaged. In the latter event take precautions as with

other components.

Page 10

SAFETY PRECAUTIONS

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

3 (4)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5031

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

Disposal

Defective and broken components MUST NOT be disposed of in containers used for

general refuse.

Defective components should be individually wrapped, clearly identified as

“DEFECTIVE BERYLLIA COMPONENTS” and returned for subsequent disposal. Such

components securely packed and with inside identification, may also be returned

directly to the manufacturer.

Broken components should be individually wrapped and identified as “BROKEN

BERYLLIA COMPONENTS”. They MUST NOT be sent through the post and should

be returned to a depot by hand.

Medical precautions

If Beryllia is believed to be on, or have entered the skin through cuts or abrasions, the

area should be thoroughly washed and treated by normal first aid methods followed by

subsequent medical inspection.

Suspected inhalation should be treated as soon as possible by a doctor, preferably at

a hospital.

965031.doc

Page 11

SAFETY PRECAUTIONS

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

4 (4)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5031

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

HANDLING THE BERYLLIUM OXIDE COMPONENT

In the radio station one or more components contains beryllium oxide. Dust from this

material is highly toxic and can present a health hazard.

These components must not be incinerated or damaged in any way. Exercise care

when removing or installing this component to prevent physical damage.

The component which contains beryllium oxide is

the RF-amplifier. It is located on the radio board

inside the radio station.

The components have the beryllium oxide encapsulated and the component is safe to

handle for replacement purpose.

Defective components or complete radio stations must not be disposed in containers

used for general refuse.

965031.doc

Therefore, return defective components or radio stations that contain beryllium

oxide, individually wrapped, clearly identified as “Defective beryllia

components” to your local Ericsson dealer or service facility.

Page 12

SAFETY PRECAUTIONS

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

1 (1)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5032

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

WARNING, HEALTH RISK!

Radio frequency radiation

Exposure to the antenna RF field may be dangerous to your health. Therefore,

SWITCH OFF THE TRANSMITTERS if you work with or near the antennas.

965032.doc

Page 13

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5033

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

SAFETY PRECAUTIONS

1 (2)

HANDLING MOS DEVICES

Though all MOS integrated circuits incorporate some protection against electrostatic

discharge, they can nevertheless be damaged by accidental over-voltages. In storing

and handling them, the following precautions are recommended.

Caution

Handling and mounting call for special attention to personal safety. Personnel

handling MOS devices should normally be connected to ground via a 1 M resistor.

Storage and transport

Store and transport the circuits in their original packing. Alternatively, use a

conductive material or special IC carrier that either short-circuits all leads or insulates

them from external contact.

Testing or handling

Work on a conductive surface (e.g. metal table top) when testing the circuits or

transferring them from one carrier to another. Electrically connect the person doing

the testing or handling to the conductive surface, for example by a metal bracelet and

a conductive cord or chain. Connect all testing and handling equipment to the same

surface. Signals should not be applied to the inputs while the device power supply is

off. All unused input leads should be connected to either the supply voltage or

ground.

OBSERVE: USE ONLY SPECIAL DESIGNED, ORIGINAL SAFETY DEVICES!

Mounting

Mount MOS integrated circuits on printed circuit boards after all other components

has been mounted. Take care that the circuits themselves, metal parts of the board,

mounting tools, and the person doing the mounting are kept at the same electric

(ground) potential. If it is impossible to ground the printed-circuit board the person

mounting the circuits should touch the board before bringing MOS circuits into

contact with it.

965033.doc

Soldering

Soldering iron tips, including those of low-voltage irons, or soldering baths should

also be kept at the same potential as the MOS circuits and the board.

Page 14

SAFETY PRECAUTIONS

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

2 (2)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5033

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

Static charges

Clothing of non-electrostatic material should be worn. Clothes made of material like

wool, silk or synthetic fibres can give very high static voltages and should therefore

NOT be worn.

After the MOS circuits have been mounted on the board proper handling precautions

should still be observed. Until the sub-assemblies are inserted into a complete

system in which the proper voltages are supplied, the board is no more than an

extension of the leads of the devices mounted on the board. To prevent static

charges from being transmitted through the board wiring to the device it is

recommended that conductive clip or conductive tape is put on the circuit board

terminals.

Transient voltages

To prevent permanent damage due to transient voltages, do not insert or remove

MOS devices, or printed-circuit boards with MOS devices, from test sockets or

systems with power on.

Voltage surges

Beware of voltage surges due to switching electrical equipment on or off, relays and

D.C. lines.

965033.doc

Page 15

SAFETY PRECAUTIONS

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

1 (1)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5034

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC (Ulf Brömster) 1996-06-03 A

WARNING, HIGH VOLTAGE!

High voltage warning (over 200 v)

Is used in the operation of this equipment.

Death on contact

May result if personnel fail to observe safety precautions.

Never work on electronic equipment unless there is another person nearby who is

familiar with the operation and the hazards of the equipment, and who is competent

in administering first aid. When the technician is aided by operators, he must warn

them about dangerous areas.

Whenever possible, the power supply to the equipment must be shut off before

beginning work on the equipment. Be careful not to contact high-voltage connections

when installing or operating this equipment.

Whenever the nature of the maintenance permits, keep one hand away from the

equipment to reduce the hazard of current flowing through vital organs of the body.

OBSERVE! Do not be misled by the term “low voltage”. Potentials as low as 50 volts

may cause death under adverse conditions.

965034.doc

Page 16

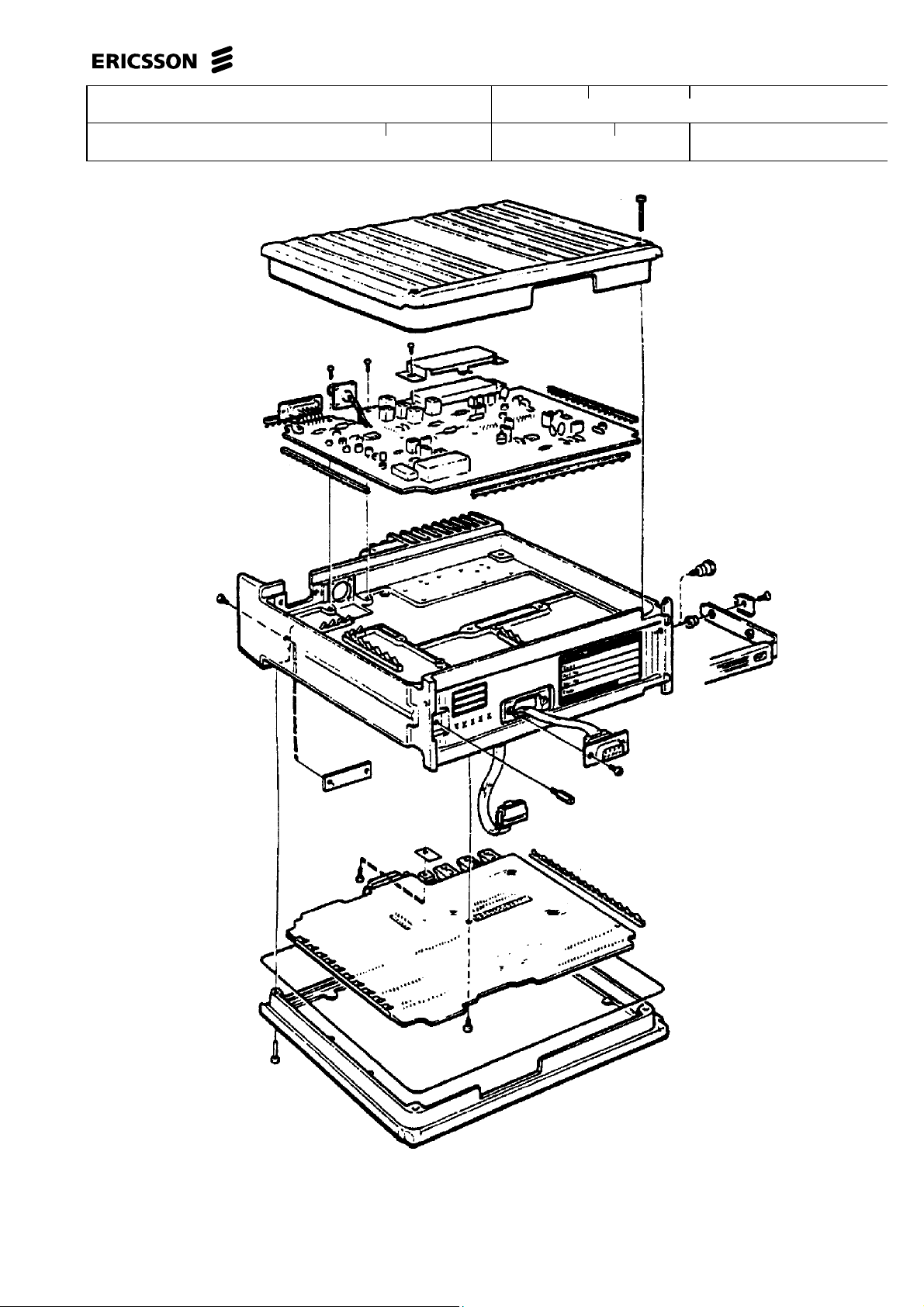

MECHANICAL STRUCTURE

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

1 (1)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5035

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-05 A

Error! Unknown switch argument.

Page 17

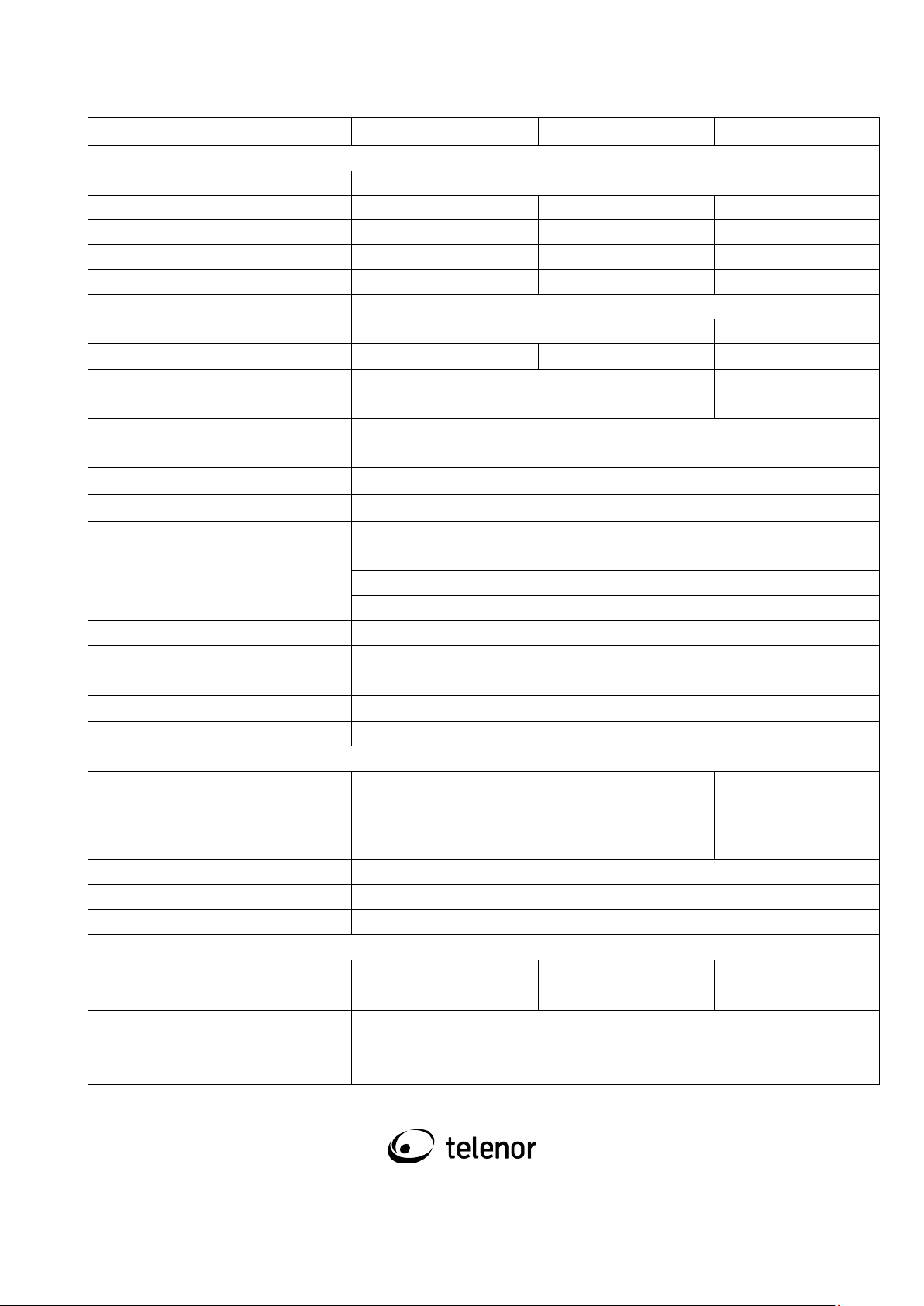

Base Station F800 - Technical Data

TYPE OF STATION

F802

F804

F805

GENERAL

TRANSMITTER

RECEIVER

Operating mode Simplex or Duplex

Frequency range 68 - 88 MHz 146 - 174 MHz 370 - 415 MHz

378 - 415 MHz

400 - 443 MHz

430 - 470 MHz

No of channels 15 (255 as option)

Channel separation 25 kHz 25 or 12.5 kHz

Frequency stability

Signal/noise ratio, SINAD CCITT >40 dB 25 kHz >40dB

AF in and output level -10dBm at 600 ohm

Antenna impedance 50 ohm

Supply voltage

Voltage to interface

Power consumption

-transmission <7 A at 13.8 V DC and 20 W incl. Interface

-reception <0.8A at 13.8 V DC (<1.5A incl. Interface)

-stand by <0.8A at 13.8 V DC (<1.5A incl. Interface)

Weight < 15 kg

Dimensions (WxHxD) Approx. 439 x 177 x 325 mm, equipped with brackets for 19” rack mount, 3HE

Operating temperature range

Storage temperature range

Standards Meets or exceeds ETS 300 086, ETS 300279

13.8 V

13.2 V

-25°C to +55°C

-40°C to +85°C

± 1.35 kHz ± 2 kHz ± 2.5 kHz

12.5 kHz >37 dB

(10.8-15.6 V)

DC

max. 1 A

DC

Output power, High

Output power, Low

Adjacent channel power

Spurious emissions at operation < -36 dBm ( 9 kHz - 1 GHz )

Spurious emissions at standby < -57 dBm ( 9 kHz - 1 GHz )

Sensitivity 20 dB SINAD CCITT

Adjacent channel selectivity >70 dB

Intermodulation attenuation >70 dB

Spurious response rejection >70 dB

Telenor products are under continuos development. We therefore reserve the right to change technical data or to modify the equipment without prior notice.

> 70 dBc or 0.2µW

≤ -116 dBm ≤ -116 dBm 25 kHz = ≤ -115 dBm

20 W ±1 dB 6 W ±1 dB for 370 -

2 W ±1 dB 0.6 W ±1 dB for 370 -

Telenor Radio Systems AB

P.O. Box 903

SE-692 29 KUMLA, Sweden

Tel +46 19 586 400. Fax +46 19 584 510

EN/LZT 123 593 R7

415 MHz

415 MHz

12.5 kHz = ≤-113 dBm

Page 18

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

Error! Unknown switch argument. Error! Unknown switch argument.

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC

Error! Unknown switch argument.

Error!

Error!

1 (4)

F800 Commissioning

Contents:

INTRODUCTION 1

SITE INFORMATION FORM 2

F800 BASE STATION INFORMATION 3

INSTALLATION CHECK 4

SITE COMPLETED 4

Introduction

The intent of this form is to make sure that the installation is performed and

tested in such way, that the customers and our requirements will be fulfilled.

Error! Unknown switch argument.

Page 19

Datum - Date Rev Nr - No.

Error! Unknown switch argument.

Error!

Error!

Error! Unknown

2 (4)

Site Information Form

On completion of installation of a station unit, please place a completed form

of this information including F800 Base Station Information and Installation

Check in the Site Documentation that is prepared for the site (customer). One

copy must be filed at the local workshop.

Site identification: .....................................................................................

..................................................................................................................

Owner: ......................................................................................................

..................................................................................................................

The key is available at: ..............................................................................

Telephone no, main operator: ..................................................................

Telephone no at site: ................................................................................

Number or name for the control line: ........................................................

Servicing organised by: ............................................................................

Local workshop: .......................................................................................

Telephone no: ..........................................................................................

Other important names, telephone numbers etc.: ....................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

Error! Unknown switch argument.

..................................................................................................................

..................................................................................................................

Prepared by Place Date

..................................... .................................. ...............................

Page 20

Datum - Date Rev Nr - No.

Error! Unknown switch argument.

Error!

Error!

Error! Unknown

3 (4)

F800 Base Station Information

Station unit number: .................................................................................

F80X transceiver unit type: KRD 103 10/ ..................................................

Serial number: .....................................................................................

Line panel type: ........................................................................................

Serial number: .....................................................................................

Frequencies: TX= ................................... RX= .......................................

Traffic mode simplex/duplex: ....................................................................

Power supply:

Mains power unit type: .........................................................................

Type of batteries: .................................................................................

Others: .................................................................................................

..............................................................................................................

Antenna installation etc.: ..........................................................................

Error! Unknown switch argument.

..................................................................................................................

..................................................................................................................

..................................................................................................................

..................................................................................................................

If necessary please make up separate sketches and/or drawings.

Page 21

Datum - Date Rev Nr - No.

Error! Unknown switch argument.

Error!

Error!

Error! Unknown

4 (4)

Installation Check

Customer: ..........................................................................................................

Installation site: ..................................................................................................

Yes No Date and sign

Hardware installation checked

Main power installation, checked and tested

Backup power installation, checked and tested

Antenna installation, checked and tested

Constant load

Antenna

Reflected

Equipment alarm system, checked and tested

Control lines installed, checked and tested

Earthing installed and checked

Lightning protection installation checked

..............W

..............W

..............W

...........................

...........................

...........................

...........................

...........................

...........................

...........................

...........................

Error! Unknown switch argument.

Radio test to mobile units, function OK

Control unit(-s) installed, checked and tested

...........................

...........................

Site completed

Customer Technician

Date: ............................................... ...............................................

Signature: ............................................... ...............................................

Page 22

INSTALLATION

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

1 (6)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

INSTALLATION

Contents

Introduction .................................................................................... 2

Station unit ................................................................................ 2

Base station .............................................................................. 2

Preparation of installation site ....................................................... 3

Installation ..................................................................................... 3

Packaging ................................................................................. 3

Unpacking ................................................................................. 3

Wall mounting ........................................................................... 4

Rack mounting .......................................................................... 4

Safeguards for installation of lead-acid accumulators .............. 4

Connection instructions ................................................................. 5

Connection of power supply ..................................................... 5

Connection of antenna .............................................................. 5

Connection of signal cables ...................................................... 5

Installation documentation ............................................................. 6

Error! Unknown switch argument.

Page 23

INSTALLATION

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

2 (6)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

INTRODUCTION

Incorrectly planned or badly equipped station sites generally result in higher

maintenance costs, malfunction of the radio equipment and may even create the

breakdown of the radio equipment.

To facilitate servicing and to create reasonable working conditions and a safe

working environment for service personnel, the following points should be observed

when planning a new station site:

The service workshop should be consulted. Local problems may arise which make

it more difficult, or even prevent, service personnel visiting the proposed station

site under certain conditions or certain periods of the year.

In the event of planned extension or modification of radio equipment at an existing

station site, the service workshop concerned should be consulted. Modification of

a station site which is already fully utilized may interfere with rational servicing of

the existing radio equipment.

Station unit

The F800 station consists of up to four separate sub-systems:

Transceiver unit

Line panel

Duplex filter/isolators

Power supply unit

The transceiver unit, line panel , duplex filter and isolator are normally mounted

together in the F800 enclosure, see installation drawing at the end of this chapter.

Other alternatives may arise due to the final configuration of the actual radio system.

The Power supply unit is a sub-unit which is separated from the station unit.

Base station

When the station unit, power supply and antenna system have been installed and put

into service, together with the other accessories, a functional Base station is

obtained.

Error! Unknown switch argument.

Page 24

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

INSTALLATION

3 (6)

PREPARATION OF INSTALLATION SITE

The installation site should meet the requirements for station units:

Normal temperature range +15°C to +35°C.

Extreme temperature -25°C to +15°C and +35°C to +55°C. (During operation in

extreme temperatures reduced radio data is accepted).

Atmospheric humidity 93%, non condensing.

The proposed installation site is prepared as follows:

Check that the wall is sufficiently strong to carry the load of the station unit.

Install the antenna and lay the antenna cable to the proposed installation site.

For lightning protection of antenna masts, see the recommendations given in chapter

5.

Arrange for an authorized electrician to lay the mains power cables or battery

power supply to the installation site.

Arrange with the Telecommunications Administration for installation of telephone

lines to the installation site and the lightning protection kit(s).

INSTALLATION

Packaging

When delivered, the station unit is packed in a special carton with shock-absorbent

material.

Check if the package is undamaged before opening it.

Examine the contents carefully, if the package has been damaged.

If there is any damage to the contents, contact the transport/forwarding company

shown on the Delivery Note.

Unpacking

Check that the accessories shown on the Packing Note are complete. If not, notify

The station unit is basically supplied without accessories. Note that this also applies

to all external connection cables. Accessories must be ordered from a separate list.

Error! Unknown switch argument.

our shipping department in Kumla, Sweden at once. Telephone international +46

19 584100. (national 019-584100.) or FAX No. +46 19 584510.

Page 25

INSTALLATION

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

4 (6)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

Wall mounting

Refer to Installation instruction 1531-SXK 107 2274/1 UX or 1531-SXK 107 2274/4

UX in the Appendix of this chapter, which shows an example of wall mounting.

Drill holes as shown in the hole-drilling instruction in the Installation instruction.

Mount the wall consoles, in position on the wall. Note that the consoles are only

enclosed if specially ordered.

Turn the front panel 180° before installation. This will give you the possibility of

folding out the lid and making the service more convenient.

Please note the space required for service, Installation instruction 1531-SXK 107

2274/1 UX or 1531-SXK 107 2274/4 UX.

The station unit is now ready for connection.

Rack mounting

It is also possible to install the F800 Base Station in a 19 inch rack.

Refer to Installation instruction 1531-SXK 107 2274/1 UX or 1531-SXK 107 2274/4

UX in the Appendix of this chapter, which shows an example of rackl mounting.

Safeguards for installation of lead-acid accumulators

When installing lead-acid accumulators for standby power supply, it must be kept in

mind that hydrogen is produced during charging and this may cause an explosion. It

is, therefore, of the greatest importance to ensure that the room is well ventilated.

The best position for installation of accumulators is in a separate room or in a battery

box - in both cases well ventilated.

Error! Unknown switch argument.

Page 26

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

INSTALLATION

5 (6)

CONNECTION INSTRUCTIONS

Connection of power supply

The operating voltages for the station unit are obtained by:

supplying the Power supply unit with 110/220 V AC 50/60 Hz. The power required

is approx. 100 W. External gas-tight accumulators can be maintenance-charged.

external supply of 13.8 V DC. Power required approx. 100 W.

When connecting to a mains power supply:

before connection check that the rating plate on the Power supply unit indicates

that the correct unit has been supplied

connect the mains cable that has been laid to the site, to the connector marked

13-15 V DC on the rear of the station unit.

When connecting to a battery power supply:

Prepare the cable for the battery supply as shown in chapter 8.

Connect to the connector marked 13-15 V DC on the rear of the station unit.

Cable area required: The voltage drop from the battery must be less than 0.1 V at 20

A.

Connection of antenna

Connect the antenna cable to the connector marked ANT(Tx) on the rear of the

station unit.

Please note that other alternatives are available, depending on the final configuration

of the antenna and filter system.

Connection of signal cables

Connect the telephone line from the “control unit” to the connector marked LINES

OUT, on the rear of the station unit.

Make sure that the lightning protection kits are installed properly.

Control the connections of “Alarm unit” if applicable.

Error! Unknown switch argument.

Page 27

INSTALLATION

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

6 (6)

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5036

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

INSTALLATION DOCUMENTATION

On completion of installation, the technician should prepare installation

documentation which should include specific instructions and documents to facilitate

servicing of the installation. The installation documentation should be available at the

installation site and at the local workshop.

The installation documentation may include, for example:

How access is obtained to the site (keys, etc.)

General information on the power supply (location of fuses and switches)

Information on control and maintenance of the air-conditioning equipment, if

provided, etc.

Further, copies of the forms in chapter 5, Commissioning, must be filled in and

included with the documentation.

Error! Unknown switch argument.

Page 28

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

LIGHTNING PROTECTION FOR MASTS 1 (8)

LIGHTNING PROTECTION FOR MASTS

Contents

Introduction .................................................................................... 2

Need for lightning protection ......................................................... 2

Explanation of terms ...................................................................... 3

Lightning frequency ....................................................................... 4

Properties of lightning strikes ........................................................ 4

Ground conditions ......................................................................... 4

Inspection of installations .............................................................. 4

Choice of materials ........................................................................ 5

Dimensions .................................................................................... 5

High voltage input .......................................................................... 7

Low voltage input .......................................................................... 8

Error! Unknown switch argument.

Page 29

LIGHTNING PROTECTION FOR MASTS 2 (8)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

Introduction

It is in the nature of the subject that no complete solutions suitable for all situations

can be given, but merely general recommendations. The possibilities that can be

utilized are described below, together with the rules that should be followed and

some information on materials.

Lightning protection should primarily be used to avoid the screening of the antenna

lead functioning as a conductor in the event of a lightning strike on the antenna mast.

The consequences of a strike may involve risks to service personnel. Effective

earthing of the mast should be carried out with an earth electrode and a connection

to a common earthing point, close to the incoming high-voltage earth. Before

connection to the high-voltage earth, permission must be obtained from the power

supply company. Any parts of the installation which are hidden (buried) must be

marked on the site drawing.

The purpose of these measures is to protect personnel and equipment from

transients caused by lightning. High voltages may arise through direct lightning strike

to the antenna or other metal objects such as support wires, roof fittings or power

lines. Other strikes in the surrounding area may also give rise to voltage transients

through induction in leads, masts and support wires. Free conductivity in power and

telephone lines may also transfer high voltages caused by distant lightning strikes.

Need for lightning protection

To prevent injury and damage to equipment, certain reasonable precautions must be

taken.

The degree of lightning protection that is required must be assessed in the light of the

consequences that may occur. Failure of a radio installation may cause users in

considerable difficulties. Lightning protection giving 100% protection cannot,

however, be installed. The cost of materials and labour must also be taken into

account.

Error! Unknown switch argument.

Page 30

LIGHTNING PROTECTION FOR MASTS 3 (8)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

Explanation of terms

Lightning conductor

A conductor dimensioned to withstand the direct action of lightning and capable of

conducting the lightning current without becoming damaged.

Earth electrode

A conductor laid in the ground, giving good contact with the surrounding soil.

Earth electrode system

A number of interconnected earth electrodes.

Deep earth electrode

A conductor driven vertically into the ground; also known as an earthing bar.

Down lead

The connection between the collector and the earth electrode system. Metal masts

with good conductivity may be used as down leads.

Ring leads

Conductors, usually buried in the ground, connecting one or more down leads with

one or more earth electrodes. Often placed in the form of a closed circuit around a

mast or building to give symmetrical current conduction.

Protection distance

The minimum air gap between two objects, over which a lightning discharge

cannot take place.

Surge voltage protection

Lightning frequency

Lightning - exposed object or conductor

Error! Unknown switch argument.

Spark gap with voltage - dependent components.

Number of days with lightning per year.

Object or conductor on which lightning strikes can be anticipated, for example,

antennas, masts, support wires and down leads.

Page 31

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

LIGHTNING PROTECTION FOR MASTS 4 (8)

Lightning frequency

The number of days with lightning in a year varies considerably with geographical

location. Local variations occur, depending on differing ground conditions.

Properties of lightning strikes

A lightning strike consists of a number of current pulses of varying strength and

duration. The following are mean values observed in Sweden:

Lightning current, peak value 25 KA

charge 25 AS

duration 0.25 s

Because of the high heating effect at the point of strike, conductors which are of too

low cross-section may burn off and roof sheet metal may burn through. A 10 mm

copper conductor may increase in temperature to around 100C.

Ground conditions

The ability of the ground to carry away and distribute lightning strikes varies

considerably between different places. Consequently, it may be difficult to provide

earth electrodes where conductivity is low.

Inspection of installations

Modifications to, or around, a building or mast fitted with lightning protection may

impair the functioning of the protection system. Such modifications may include, for

example:

sheet-metal work (window-sills, ventilation ducts)

pipework (water, heating systems)

electrical work (changes or additions to the power supply or telephone cables)

The owner of a lightning protection installation is responsible for ensuring that any

work carried out on, or around, the building or mast does not have an adverse effect

on the functioning of the lightning protection. If necessary, additional work should be

carried out in order to maintain the same degree of protection. Further, regular

inspections should be made; the visible parts should be inspected annually and the

buried parts should be checked every 3 - 6 years.

To assist in inspection of the buried part of the installation, there must be drawings

showing the layout. These should be placed in the building, preferably in the central

switchboard.

Choice of materials

Error! Unknown switch argument.

Page 32

LIGHTNING PROTECTION FOR MASTS 5 (8)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

Since an installation for lightning protection is a relatively major investment, it must

function for many years. Corrosion should be avoided, as far as possible, through

selection of the correct materials.

Above ground level, copper, aluminium and galvanized steel can be used, but these

should not be mixed in the same installation.

Earth electrodes and conductors buried in the ground may be of copper or galvanized

steel. Aluminium should not be used in soil.

Copper should be used if a non - insulated copper cable has previously been

installed at a distance of less than two metres. This may, for example be an earth line

associated with electrical installations or existing earth electrodes.

Galvanized steel should be used if there are objects in the ground, in direct contact

with the soil, which are not made of copper, for example lead - covered cable, steel or

cast - iron water pipes.

If it is not possible to guide the choice of materials, insulation must be created for one

or the other or both metals to ensure that the distance through the soil, in the

electrical sense, is more than two metres.

Connections or branches of the component of the installation above ground level

should be carried out so that moisture cannot collect at the connection point. This is

particularly important if differing materials must be joined. Attachment components

must also be selected with possible corrosion effects in mind.

Dimensions

Conductors used in lightning conductor systems must be sufficiently strong - both

mechanically and chemically.

The minimum recommended area for conductors and earth electrode leads laid in or

above the ground are: copper cable, 25 mm²; steel cable 50 mm²; aluminium cable

(not underground) 50 mm².

Conductors connecting surge voltage protectors with lightning conductors or mains

earths at common terminals must be at least 6 mm copper wire with insulation. The

wire should be laid by the shortest possible route, max. 10 m

The connection between the lightning earth electrode and the common mains neutral

terminals must be so dimensioned that any earth leakage currents do not cause heat

damage or high voltages loss through induction. The link between the radio rack and

the earth electrode must not be less than 10 mm² copper.

NOTE: All connections involving the mains power supply must be carried out by an

authorized electrician and with the approval of the power supply company.

Error! Unknown switch argument.

Page 33

LIGHTNING PROTECTION FOR MASTS 6 (8)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

Suggestions for installation sites: see figure 1.

Figure 1. Suggestion for installation

Error! Unknown switch argument.

Page 34

LIGHTNING PROTECTION FOR MASTS 7 (8)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

High voltage input

See Figure 2.

The lightning protection system must be linked to the incoming neutral lead of the

electrical system. A terminal or busbar for this purpose must be available in the fuse

box. This terminal must be marked ”Lightning conductor earth”. The terminal must be

so placed in the electrical system that the functioning of any earth leakage trip circuit

breaker is not affected.

Figure 2. Mains power supply input with common neutral terminal for lightning

Error! Unknown switch argument.

protection.

Page 35

LIGHTNING PROTECTION FOR MASTS 8 (8)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/LT Magnus Lindahl ECS/S/LT-96:5037

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KI/ECS/S/LTC 1996-06-04 A

Low voltage input

See Figure 3.

Incoming low-voltage inputs, usually telephone lines must, if not an earth cable, be

protected by lightning protection RR-192500. This is a surge and transient protection.

Assembly must be such that there is no obvious fire hazard.

The earth connection must be to the earth electrode system or common earth

terminal.

The connecting leads must be at least 6 mm copper and insulated.

Figure 3. Low voltage input

Error! Unknown switch argument.

Page 36

Open

DESCRIPTION

1 (1)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other)

Nr - No.

KL/ECS/S/MK Rune Tapper

ECSTAP 97:1055

Dokansv/Godk - Doc respons/Approved

Kontr - Checked

Datum - Date

Rev

File

KL/ECS/S/MK (Rune Tapper)

1997-10-30

A

Sign on back plane

Color

Comment

+12V

Green

Lights when 12VDC is connected

TX

Red

Lights when the transmitter is on

SQ

Yellow

Lights when the carrier is received

LIJ

+12V

TX

SQ

LIJ

MRS3000 Line Panel

MRS5000 Line Panel

Power LED

(Green)

TX LED

(Red)

Squelch LED

(Yellow)

Channel Selector

(Rotary switch)

F800

Transceiver

unit

Connection for

service tool F800

LPC 102 81

or

LPC 102 213

Operating Instructions F800

The F800 base station is normally not operated locally other than for maintenance and service by a radio technician.

The back plane of F800 is equipped with tree LED (Light Emitting Diodes) to indicate the following states:

See fig 1.

There is also a 16 positions channel switch that can be operated by a small

screw driver. The 16 positions are marked: 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C,

D, E, F. The channel number is selected by setting the switch to any position

between 1 and F. In systems where the line panel is controlling the channel

setting, the channel switch should be set to position 0.

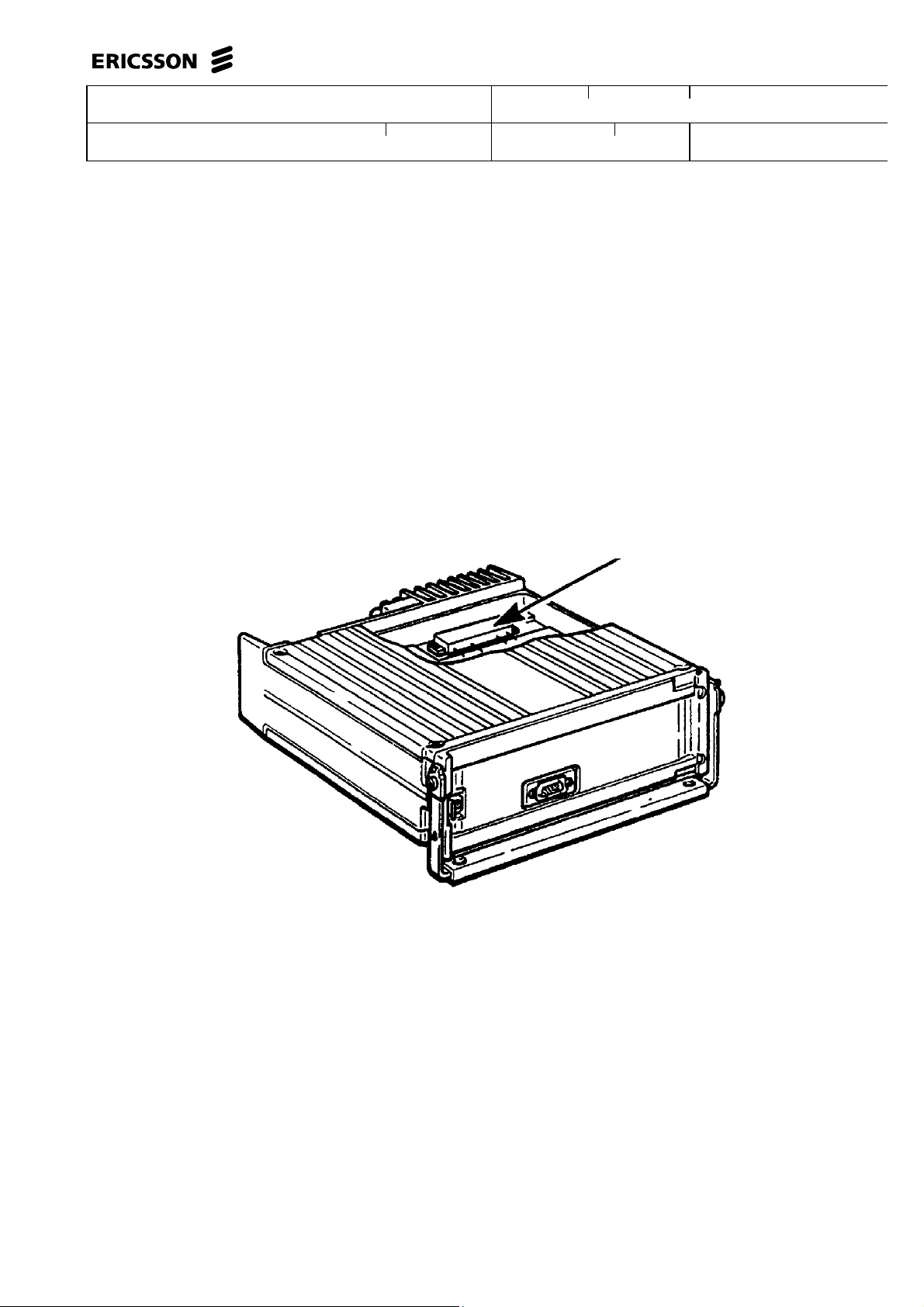

Fig 1, F800 seen from the front with the front cover removed

97-1055-Operating Instructions F800.doc

EN/FAD 109 116 R4

Page 37

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/MK Magnus Lindahl ECS/S/LT-96:5042

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KL/ECS/S/MK (Magnus Lindahl) 1997-11-04 A

SPARE PARTS CATALOGUE

1 (2)

STRUCTURE FOR SPARE PARTS & ACCCESSORIES

F800 BASE STATION

Title

Enclosures

Enclosures MRS2000 / MRS3000 SXK 107 2274/4

Enclosures MRS5000 SXK 107 2274/4

-Power supply 220 VAC/12 VDC

-Cable for DC input RPM113 669 Cable with connectors

-Cable for line input 860 7724/11 Cable with connectors

-Telephone jack HE 500011-0001 Swedish version

-Line unit ROA 119 7534/2 Only 4-wire

-Fan BKV 301 203 For SXK 107 2274/1, /2 and /4

Accessories

-Bracket for wall mounting SXA 105 9585 2 per F800

-Lightning protection kit RR-192500 2 per 4 wire line

-OEM kit NTM 201 1010

-MRS 5000 kit NTM 201 1009 Incl. Line unit and cables

-255 Channel kit NTM 201 1020 Incl. OEM kit

-Duplex kit NTZ 112 65 Filter plate, cables and connectors

Transceiver F80X

80 MHz Simplex KRD 103 10/8S

80 MHz Duplex KRD 103 10/8S

160 MHz Simplex KRD 103 10/16S

160 MHz Duplex KRD 103 10/16D

450 MHz low Simplex KRD 103 10/45LS

450 MHz low Duplex KRD 103 10/45LD

450 MHz low Duplex KRD 103 10/45LD2 Link

450 MHz mid Simplex KRD 103 10/45MS

450 MHz mid Duplex KRD 103 10/45MD

450 MHz high Simplex KRD 103 10/45HS

450 MHz high Duplex KRD 103 10/45HD

Product No.

BMJ 142 106/1

Notes

Page 38

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

KL/ECS/S/MK Magnus Lindahl ECS/S/LT-96:5042

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KL/ECS/S/MK (Magnus Lindahl) 1997-11-04 A

Title

Radio board

80 MHz Simplex ROA 119 7527/5

80 MHz Duplex ROA 119 7539/10

160 MHz Simplex ROA 119 7533/5

160 MHz Duplex ROA 119 7540

450 MHz low Simplex ROA 119 3004

450 MHz low Duplex ROA 119 3030

450 MHz low Duplex ROA 119 3030/2 Link ”LD2”

450 MHz mid Simplex ROA 119 8734

450 MHz mid Duplex ROA 119 3031

450 MHz high Simplex ROA 119 7553

450 MHz high Duplex ROA 119 7541

Power modules

80 MHz Simplex/Duplex XTE519003-0101

160 MHz Simplex/Duplex XTE519002-0101

450 MHz low Simplex/Duplex RYT 901 6024/1 incl. link ”LD2”

450 MHz mid Simplex/Duplex TE 519006-0001

450 MHz high Simplex/Duplex TE 519006-0002

Logic board

-Logic board ROA 119 8736

-Prom kit RYS 105 354 Latest version= R3A

Mechanical parts

-Distance SXA 105 0757 To avoid connection of regular

Product No.

SPARE PARTS CATALOGUE

Notes

and service CU C700 at the front

of F80X

2 (2)

Page 39

Fel! Okänt växelargument.

1 (5)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other)

Nr - No.

Fel! Okänt växelargument.

Fel! Okänt växelargument.

Dokansv/Godk - Doc respons/Approved

Kontr - Checked

Datum - Date

Rev

File

KI/ECS/S/LTC

Fel! Okänt

Fel!

F800 Personality Programming

Contents

F800 PERSONALITY PROGRAMMING .................................................................. 1

CONTENTS .................................................................................................................... 1

INTRODUCTION .......................................................................................................... 2

WHAT DO I NEED? ..................................................................................................... 2

HOW TO INSTALL THE SOFTWARE ..................................................................... 3

ELECTRICAL CONNECTIONS ................................................................................. 4

HOW TO SET UP YOUR PROM PROGRAMMER EQUIPMENT ....................... 4

WHAT CAN BE PROGRAMMED? ............................................................................ 4

HOW TO USE THE PROGRAM ................................................................................ 5

Fel! Okänt växelargument.

Page 40

Fel! Okänt växelargument.

2 (5)

Datum - Date

Rev

Nr - No.

Fel! Okänt

Fel!

Fel! Okänt

IBM Compatible PC Printer (optional) F800 Personality

Programming Software

Cable

PROM programmer

equipment

Introduction

The F800 has a synthesised frequency generator, which means that the

operating frequency can be programmed without changing crystals or tuning

the radio. The freq uency data is st ored in a EEPROM which is 8 bits * 1FFFh

in size. The type is Xicor 28C64. The EEPROM must be removed from t he

radio to be programmed in a PROM programm er equipment and can not be

programmed in place in the radio. In a st andar d F800, 15 channels

(frequency pairs) can be prog r ammed. As an option the F800 can be

equipped with a 255 channel kit.

What do I need?

To be able to program the F800 radio you will need the following:

• IBM compatible PC with one serial port

• The F800 personality programm ing software

• A printer (optional)

• PROM programmer equipment

• Cable between PC and programming equipment

• A Xicor 28C64 EEPROM

Fel! Okänt växelargument.

You will probably be able to use any PC to do this work, just an ordinary

machine will do the job. No problems have been discovered on any PC:s. We

have also tested various types of programming equipment from Data I/O,

Stag, Elan, and Dataman without any problems.

You will also need the following knowledge:

• Basic knowledge about your PC, how to operate from the DOS prompt,

how to make directories, how to use the mode command, how to edit your

AUTOEXEC.BAT file etc.

Page 41

Fel! Okänt växelargument.

3 (5)

Datum - Date

Rev

Nr - No.

Fel! Okänt

Fel!

Fel! Okänt

• Knowledge of how to operate your PROM programmer equipment, how to

receive files from the PC etc.

• You also need information about thos e frequencies that will be

programmed in the radio.

How to install the software

Make a directory on your hard drive called \ERICSSON\FAST.

Copy all files from the distribution diskette to the \ERICSSON\FAST direct ory.

Use the MODE command on your PC to set the preferred speed, parity and

stop bit for the selected port . Usually it is 9600 baud, one st op bit , no par it y.

Example: C:\DOS\MODE COM1:96,N,8,1

To make this setting per manent, edit your AUTOEXEC.BAT file to include t he

MODE command. See your DOS manual for how to use the MODE

command.

Change directory with the CD command to the \ERICSSON\FAST directory.

Start the program by typing the pr ogram name and press enter.

Example: CD \ERICSSON\FAST [Enter]

F800 [Enter]

The program will now start. From the main m enu, choos e SET -UP. Make any

settings of programmer equipment, printer (ports), screen colors, direct or ies

etc. Save your settings while leaving the set-up menu.

If you want to be able to start your progr am s without changing to the

\ERICSSON\FAST directory, make the following two changes to your

AUTOEXEC.BAT file:

Add C:\ERICSSON\FAST to your PATH-statement

Add the statement SET FAST=C:\ERICSSON\FAST

See your DOS manual for how to edit your AUTOEXEC.BAT f ile.

Fel! Okänt växelargument.

Page 42

Fel! Okänt växelargument.

4 (5)

Datum - Date

Rev

Nr - No.

Fel! Okänt

Fel!

Fel! Okänt

IBM Compatible PC

PROM Programmer

Equipment

Serial cable

RS232 Port

RS232 Port

EEPROM

Xicor

28C64

Electrical connections

Connect your PROM programmer equipment to one of the serial, RS232,

ports on the PC. Usually it is COM1 or COM2. See your PROM programmer

equipment manual for how to make this connection.

How to set up your PROM programmer equipment

Set the prom programmer equipment to the preferr ed speed and file format.

Usually it is 9600 baud, no parity, 1 stop bit. The recommended file format is

"Motorola S-record". Set the progr am mer to receive a file from the PC. See

the user manual for your prom programmer equipment on how to do this

setting.

What can be programmed?

The F800 can be programmed with some basic radio data:

• Frequency band (depending on hardware)

• Traffic mode (usually simplex or duplex, depending on hardware)

• TX fr equency for each channel

• RX frequency for each channel

• RF output power for each channel, hig h or low (usually 20 or 2 Watt)

Fel! Okänt växelargument.

Page 43

Fel! Okänt växelargument.

5 (5)

Datum - Date

Rev

Nr - No.

Fel! Okänt

Fel!

Fel! Okänt

How to use the program

Change directory with the CD command to the \ERICSSON\FAST directory.

Start the program by typing the pr ogram name and press enter.

Example: CD \ERICSSON\FAST [Enter]

F800 [Enter].

Select PROGRAMMING from the main menu to start working on your code

prom. Choose frequency band and traffic mode. Enter the frequency menu

and enter the frequencies and t he out put power for each channel.

When you have finished f r equency programming, ret ur n t o the main menu

and save your work by selecting the ”file menu” and ”save as”. You will be

prompted for a file name and a c om m ent that will be saved together with the

file. Your file is now saved for later use. You can at any time r etrieve your file

for editing or printing . When your file is saved, the program will automatically

return to the main menu.

From the main menu you can select ”Printing” t o pr int the result of the

programming on any printer connect ed t o t he PC.

To make the prom, choose ” Make pr om ” from the main menu. Press ret ur n

once more to transfer t he PRO M contents t o the PROM programmer

equipment. When the transfer is ready the PROM checksum will be

presented on the screen. Verify that t he dat a in t he PRO M progr am m er

equipment has the same checksum . Bur n t he PRO M according to the

instruction manual for your PROM programm er equipment.

Do not forget to label your PROM with file name, date and checksum.

Fel! Okänt växelargument.

Page 44

1 (4)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2444

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-11-15 A

LPC 102 213 F800 TEST HANDSET

1 GENERAL

The test handset LPC 102 213 replaces test box LPC 102 81 and handset

RR-164870/5 and is used together with all versions of Ericsson F800. It has a

built-in earphone and microphone that allows the service engineer to listen to

ongoing radio traffic and talk to radio users over the F800.

The test handset connects to the service connector on the transceiver’s front

and provides access to audio signals and enables channel selection, PTT

etc.. The test unit is powered from the transceiver unit and a LED (12V)

indicates power on. With sliding switches located at the handset’s upper edge

allows enabling or disabling of the built-in microphone and earphone.. The

handset has a PTT switch on the lower edge that is used when talking into

the handset. The modulation signal is connected from the external line input

(TX line) to the transmitter when the built-in microphone is disabled. The

received audio signal is available at the RX line connectors when the

earphone is disabled. Channel is selected with a rotary dial on the handset’s

rear.

Antenna output

(J1: N-type located on

the cabinet's rear)

Service connector

(P401: DB9 located on the

transciver unit's front)

RADIO TEST SET

RF In/Out

AF in

AF out

RX line

TX line

Figure 1: Typical test set up

F800

F800

TEST

UNIT

97-2444-LPC 102 213 F800 TEST HANDSET.doc

Page 45

2 (4)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2444

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-11-15 A

2 CONNECTIONS

Connection Type Comment

RX line AF output

TX line AF input

600 , Nominal level -10 dBm

600 , Nominal level -10 dBm

The above listed connectors are located on the unit’s front.

The test unit is connected to the transceiver unit by connecting the DB9

connector on the spiraled cord to the transceiver’s service connector.

3 SWITCHES

Channel setting is made with the rotary dial on the test unit’s rear. The dial is

labelled 0 - 15 which corresponds to the channels of the F800. Set the

internal rotary switch on the F800 backplane to 0. If the line panel is

programmed to select channel, it should be removed.

The transmitter is keyed either by the built-in PTT switch on the unit’s side or

by the switch labelled PTT on the front.

The sliding switches on the unit’s upper edge is used to select either internal

signal sources microphone and earphone) or external signal sources (line

connectors).

Test TestRx-line Tx-line

Figure 2: Part of test handset showing line connections and sliding switches.

The table show the appropriate setting for the different signals. The unit is

seen from front.

Rx-line Test

(left most switch)

Tx-line Test

(right most switch)

Internal signals Right Left

External signals Left Right

4 INDICATORS

97-2444-LPC 102 213 F800 TEST HANDSET.doc

Power on is indicated by a green LED labelled 12V. This indicates that the

transceiver provides 12VDC to the test unit.

Transmission is indicated by the LED labelled PTT. This LED is on when the

transceiver is in transmit mode.

Selected channel is shown by LED:s labelled CH1 to CH8. They represent the

binary value of the selected channel.

Page 46

3 (4)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2444

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-11-15 A

CH8 CH4 CH2 CH1 Selected channel

Channel 0*

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Channel 7

Channel 8

Channel 9

Channel 10

Channel 11

Channel 12

Channel 13

Channel 14

Channel 15

LED On, LED Off

When channel selector is set to 0, the LED:s indicate the transceiver’s

internal channel setting.

5 RECEIVER TESTING WITH LPC 102 213

1. Set the sliding switches for external signal sources.

2. Connect the Radio test set’s AF input to the test unit’s RX line out and set

up the radio test set for AF measurements (AF voltmeter). Select CCITT or

Psofometric filter.

3. Apply a RF signal from the radio test set to the antenna input of the F800.

Use antenna jack for simplex stations and stations with built-in duplex filter,

use the RX jack for duplex stations with external filters.

4. Set the RF generator’s frequency to the channel frequency and set the RF

level to -80 dBm. Modulate the RF signal with 1 kHz test tone and 3.0 kHz

deviation.

5. Measure line output and distortion with the radio test set.

6. Reduce the RF level until the SINAD meter shows 20 dB. Note the RF

level.

97-2444-LPC 102 213 F800 TEST HANDSET.doc

7. Reduce the RF level until the AF voltmeter indicates 0, the squelch circuit

mutes the AF output. Note the value.

Increase the RF level until the AF voltmeter shows -10 dBm, the squelch

circuit un-mutes the AF output. Note the value.

The squelch circuits hysterisis is the difference between the two values.

Page 47

4 (4)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2444

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-11-15 A

6 TRANSMITTER TESTING WITH LPC 102 213

1. Set the sliding switches for external signal sources.

2. Connect the Radio test set’s AF output to the test unit’s TX line in and set

up the radio test set for TX measurements.

3. Connect the antenna output from F800 to the radio test set’s RF input.

4. Set the AF generator’s frequency to 1 kHz and the level to -10 dBm.

5. Start the transmitter by setting the PTT switch in PTT position.

6. Measure TX output power and modulation with the radio test set.

7. Switch of the transmitter.

8. Set up the radio test set for signal to noise measurements.

9. Start the transmitter and measure the S/N ratio.

7 LPC 102 213 AS SERVICE HANDSET

The test unit can be used as a service handset when connected to F800. This

enables the service engineer to monitor ongoing traffic and key and modulate

the transmitter.

1. Set the sliding switches in position for internal signal sources.

2. Connect the RF input of the radio test set to the antenna connector of

F800.

3. Set up the test set for duplex testing.

4. Set the RF generator to the channel frequency and set the level to -100

dBm. Modulate the RF signal with 1 kHz tone and 3.0 kHz deviation.

5. Check that the test tone is heard in the earphone.

6. Press the PTT button and talk normally in the microphone. Check that the

radio test set indicate output power and modulation.

97-2444-LPC 102 213 F800 TEST HANDSET.doc

Page 48

1 (5)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2486

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-12-07 A

FAULT TRACING F800

1 GENERAL

This document provides fault tracing guide lines for field or first line

maintenance of all F800 versions. Maintenance instructions for the various

control and line panels used in F800 are not covered by this document.

This document applies to F800 stations with cabinet SXK 107 2274/4

2 TOOLS AND INSTRUMENTS

To perform first line maintenance of F800 requires a minimum of tools and

instruments. The list below serves as a recommendation only.

Type

Radio test set Marconi 2945 or equivalent.

Wattmeter Bird 43 or equivalent

Test hand set Ericsson LPC 102 213

Voltmeter Fluke 77 or equivalent.

RF cable RG224 or equivalent Connections to F800

Test leads Connections to the

Torx screwdrivers TX8, TX10 and TX15

In addition to this, normal hand tools are required.

3 FAULT TRACING

Model Comment

require N male

connector.

test hand set require

3.5 mm plugs.

3.1 NORMAL SETTINGS

97-2486-FAULT TRACING F800.doc

As with all fault tracing, start with a visual inception and make sure that all

cables are connected, the boards are inserted, etc.. To gain access to the

various indicators and test points in F800, you have to remove the front cover.

The interconnection board located in the cabinet has three (3) jumpers and

one rotary switch.

Page 49

2 (5)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2486

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-12-07 A

SQ LED

Yellow

TX LED

Red

+12V LED

Green

Channel selector

Jumpers

Service connector

Figure 1: F800 front view with front cover removed.

All jumpers are normally open when the station is configured as a base or

repeater station. Closing all jumpers will configure the station as a link.

The rotary switch selects the working channel for the station. It is normally set

to the 0 position. To set the channel manually, i.e., with the rotary switch, it

requires that the line panel is either removed or programmed not to select

channel.

3.2 NO OUTPUT POWER

Step

Check Likely fault(s)

1 Check that the green led

indicating 12VDC on the

interconnection board is lit.

2 Connect the test handset

and check that the line

panel selects a valid

channel number.

3 Key the unit from the test

handset. Check that the red

led indicating transmission

is lit and that the fan is

working.

1. Power supply

2. Transceiver unit

1. Line panel

2. Transceiver unit

3. Interconnection board

1. Transceiver unit

97-2486-FAULT TRACING F800.doc

4 Connect the watt-meter in

the antenna feeder line. Key

the unit and measure the

RF output power and SWR.

Low output power:

1. Transceiver unit

2. Power supply

Low output power and high SWR:

1. Antenna system

2. Transceiver unit

Page 50

3 (5)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2486

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-12-07 A

3.3 NO MODULATION OR LOW MODULATION

Step

Check Likely fault(s)

1 Connect the test handset to

the transceiver unit and

No or low modulation:

1. Transceiver unit

connect the RF test set to

the station’s antenna

output. Set up the test set

for transmitter testing. Set

Normal modulation:

1. Line panel

2. Interconnection board

the switches on the test

handset for internal audio

sources. Key the unit and

talk into the microphone.

2 Check audio level on the

incoming line. Refer to

No or low line level:

1. Line problem

service manual for line

panel used.

Normal line level:

1. Line panel

2. Interconnection board

3.4 NO OR LOW AUDIO SIGNAL FROM STATION

Step

Check Likely fault(s)

1 Connect the test handset to

the transceiver unit and

connect the RF test set to

the station’s antenna

output. Set up the test set

for receiver testing. Set the

switches on the test

handset for internal audio

sources. Apply an onfrequency signal to the

station and listen in the test

handset..

2 Check audio level on the

incoming line. Refer to

service manual for line

panel used.

No or low audio level:

1. Transceiver unit

2. Line panel

3. Interconnection board

Normal audio level:

1. Line panel

2. Interconnection board

No or low line level:

1. Line panel

2. Interconnection board

Normal line level:

1. Line problem

97-2486-FAULT TRACING F800.doc

Page 51

4 (5)

Uppgjord (även faktaansvarig om annan) - Prepared (also subject responsible if other) Nr - No.

SES/KTR Mats Andersson KTR97:2486

Dokansv/Godk - Doc respons/Approved Kontr - Checked Datum - Date Rev File

KTR M. Andersson 1997-12-07 A

3.5 LOW SENSITIVITY OR POOR AUDIO QUALITY

Step

Check Likely fault(s)

1 Connect the test handset to

the transceiver unit and

connect the RF test set to

the station’s antenna

Low sensitivity:

1. Transceiver unit

2. Internal RF cabling

3. Built-in filters, if any.

output. Set up the test set

for receiver testing. Set the

switches on the test

handset for external audio

Normal sensitivity:

1. Line panel

2. Interconnection board

sources and connect the

RX line signal from the

handset to the RF test set.

Apply an on-frequency

signal to the station and

measure the sensitivity