Page 1

SERVICE MANUAL

Business Projector

EB-E01/X06/W06/E10

EB-X51/W51/E20/W52

Electric shock may result if you operate carelessly because there is electric charge remaining to reduce

power consumption in the Power Supply.

Make sure to follow the procedure below.

" 3.3.14 PS Ballast Assy (p122) "

INTERNAL USE ONLY

Page 2

EB-E01 series

INTERNAL USE ONLY

NOTICE

All rights reserved. No part of this manual may be reproduced, stored in retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual should be handled with sufficient consideration for confidentiality reasons.

After publication of this manual, the parts and mechanism may be subject to change for improvement of their performance. Therefore, note that the descriptions

given in this manual may not coincide with the actual machine.

Other company or product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners.

EPSON disclaims any and all rights in those marks.

EPSON is a registered trademark of Seiko Epson Corporation.

Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners.

Copyright 2020 SEIKO EPSON CORPORATION.

SEIKO EPSON 2 Revision A

Page 3

EB-E01 series

INTERNAL USE ONLY

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the product.

The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview of the features and specifications of the product.

CHAPTER 2. TROUBLESHOOTING

Explains basic confirmation items for identifying the location of obstacle based on defects and abnormal symptoms.

CHAPTER 3. DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the main component units and parts of the product.

CHAPTER 4. APPENDIX

Provides preventive maintenance procedures for servicing the product.

SEIKO EPSON 3 Revision A

Page 4

EB-E01 series

INTERNAL USE ONLY

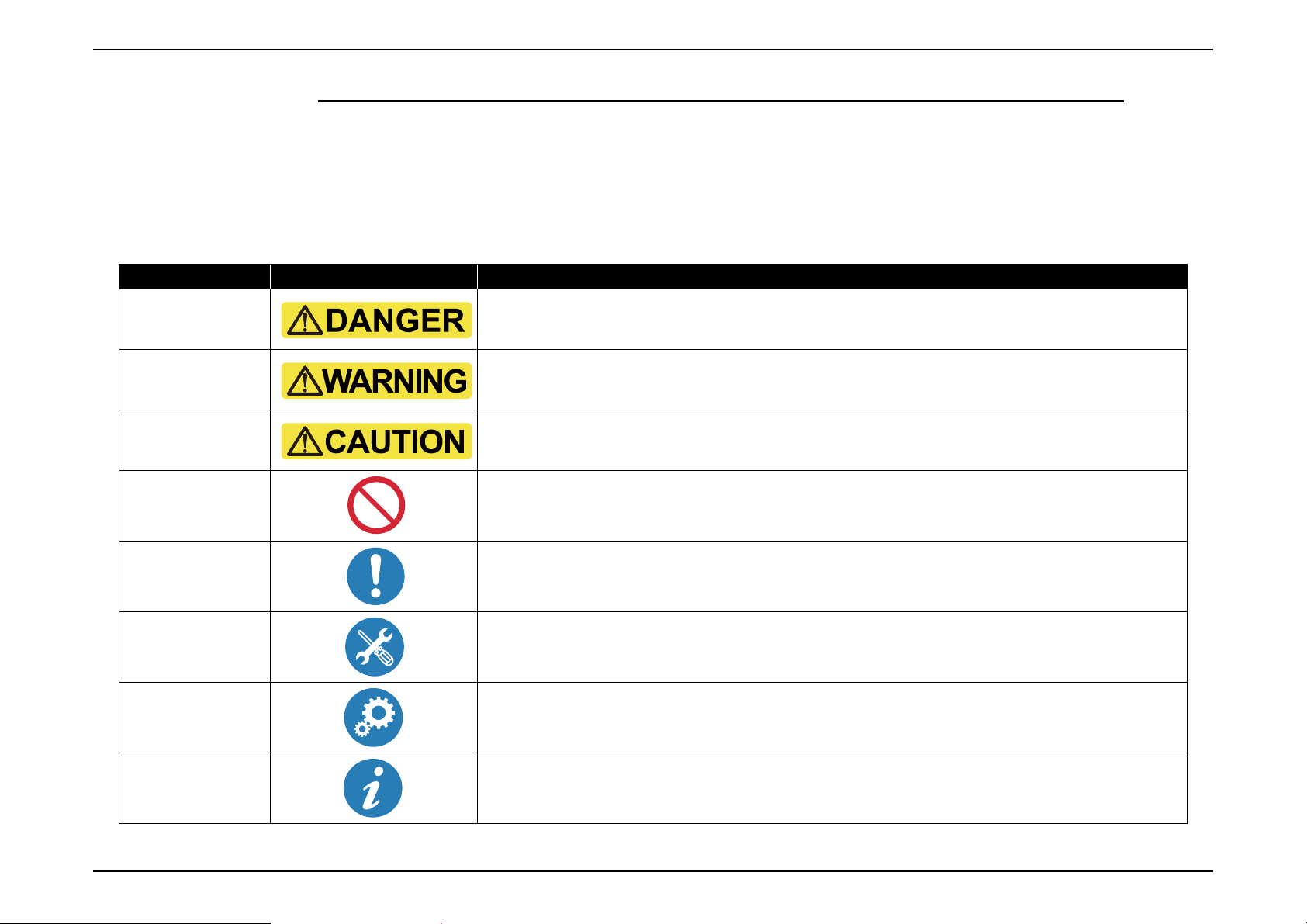

IMPORTANT PRECAUTIONS IN SAFETY AND MAINTENANCE PERFORMANCE

Here describes the important points to keep in mind in repair and maintenance performance.

SYMBOLS

To prevent injury to the repair technicians and to protect the devices, the categorized safety instructions are provided in this manual with the symbols below. Be sure to read and

understand their meanings before proceeding to the next section.

Category Symbol Meaning

Danger

Warning

Caution

Prohibited

Matter

Instruction

Reassembly

Setting/

Maintenance

Indicates an extremely hazardous operation which, if ignored or operated incorrectly, could result in serious or

fatal personal injury.

Indicates a potentially hazardous operation which, if ignored or operated incorrectly, could result in serious or

fatal personal injury.

Indicates a potentially hazardous operation which, if ignored or operated incorrectly, could result in minor injury

or damage to equipment.

Indicates a prohibited action or operation in repair and maintenance performance.

Indicates a compulsory action or operation that must be carried out in repair and/or maintenance.

Indicates a compulsory action or operation for reassembly of disassembled parts that must be carried out in repair

and/or maintenance.

Indicates a compulsory action or operation for settings or maintenance that must be carried out in repair and/or

maintenance.

Point

Indicates reference information in repair and/or maintenance.

SEIKO EPSON 4 Revision A

Page 5

EB-E01 series

INTERNAL USE ONLY

SAFETY INSTRUCTIONS

The precautionary measures itemized below should be fully understood when

performing repair and maintenance procedures.

When disassembling/assembling, be sure to turn off the power

switch and pull out the power cable from the projector beforehand.

Be extremely careful about the current-carrying part during a test

operation, signal measurement or any other situations that is

necessary to perform the repair/maintenance work with the power

turned on and the cover removed.

Take off the things made of metal (such as a wrist watch, cuff

buttons, rings, tie pin, etc.) which may come in contact with the

parts inside the projector.

Do not touch the lamp assy. or the parts around it. They are

extremely hot even after completing the cooling down operation,

and may cause a burn injury. Therefore, leave the unit until it

becomes cool enough before performing maintenance work.

Never let the safety devices mounted in this product inactivated,

modify the safety devices or replace them with the ones that are not

designated for any reason whatsoever. (Such actions may endanger

the projector's safety operation and may result in a fire or serious

injury.)

Never peer through the projection lens during repair/maintenance

work when the power is on. (Such an action may cause a visual

disability because of a very strong light emission.)

Never use a deformed plug or a damaged power cable to this

product. If any deformations or damages are found on the power

cable or plug section, replace it with a new specified power cable.

Never use the air blowers that contain flammable gas in repair/

maintenance work.

Never use or replace with any service parts that is not specified by

EPSON.

Do not disassemble any parts or components not specified in this

manual.

Do not apply any shock or vibration. (Otherwise, misalignment of

the optical parts inside the engine may cause irregular reflection of

the light and may result in burn (smoke) or damage to the internal

parts.)

Do not touch any parts such as inorganic polarizers that are

instructed not to.

Never modify the product for any reason whatsoever. (Except for a

case that is under the instructions to do so. In such a case,

understand the instructions thoroughly in advance and perform

modification appropriately.)

SEIKO EPSON 5 Revision A

Page 6

EB-E01 series

Be sure to perform the repair/maintenance work on the even and

stable work bench to prevent the product from dropping down or

mal-operation due to the improper setting of the product.

Be sure to take off the metal products such as wrist watch, cuff

buttons, rings, tie pin etc. in repair and/or maintenance to avoid

unsafe situations.

Be sure to wear the gloves during the repair/maintenance work to

avoid injuries by the parts with sharp edges such as metal plate or

the like.

INTERNAL USE ONLY

Be careful not to drop a metal part such as a screw, a washer, or a

clip into the inside of the product. If such cases should occur

accidentally, never turn on the power supply until all the dropped

parts are found and removed.

After reassembling the product, check the followings before

turning the power on.

All the parts and screws are installed and secured to the proper

positions.

No cables are caught in the metal frames.

If there are accumulated dust or foreign objects inside the product,

make sure to remove them before disassembling/reassembling the

product.

OTHER CAUTION

To protect sensitive circuitry, follow the instructions below.

When disassembling or reassembling, be sure to wear static

discharge equipment such as an anti-static wrist strap and a mat.

Since the lamp of this product contains mercury, be sure to dispose the used lamp

pursuant to the government’s law and regulations.

When replacing the circuit component such as a board or the

optical engine, be sure to contact the anti-static case containing

the new one to the metal part of this product before taking it out.

When performing the repair/maintenance work, be sure to use the

specified tools and follow the instructions that are specified in the

documents (service manual etc.) concerning to this product.

When carrying out the test operation, do not block the intake and

exhaust ducts.

(Such an action raises the internal temperature and may cause a

fire or a damages to the internal parts of this product.)

SEIKO EPSON 6 Revision A

Page 7

EB-E01 series

INTERNAL USE ONLY

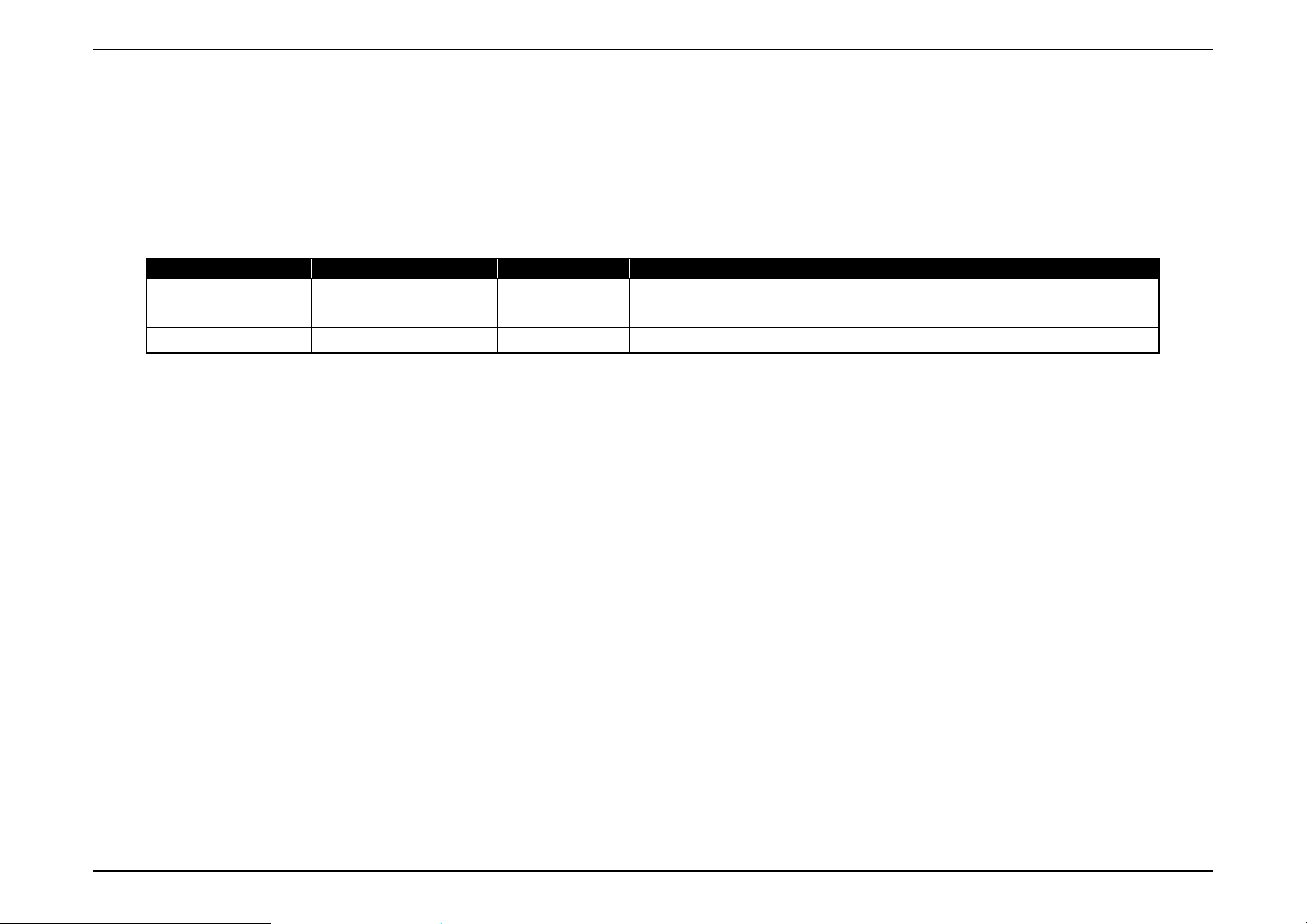

REVISION HISTORY

After first release of this manual, the parts and mechanism may be subject to change for improvement of their performance and the manual may be revised. Be sure to always keep

this manual up to date.

Revision Date Page of change Detail of change

A 2020.1.21 all

First Release

SEIKO EPSON 7 Revision A

Page 8

EB-E01 series

INTERNAL USE ONLY

Contents

Chapter 1 Product Description

1.1 Product Description .............................................................................................. 11

1.2 Specifications ....................................................................................................... 12

1.3 Dimensions ........................................................................................................... 20

1.4 Ceiling Mount....................................................................................................... 24

Chapter 2 Troubleshooting

2.1 Required Tools ..................................................................................................... 33

2.2 Troubleshooting Procedure .................................................................................. 34

2.3 Exterior Check...................................................................................................... 36

2.4 Troubleshooting from the Device Names............................................................. 37

2.5 Error Indication and Problem diagnosis ............................................................... 39

2.5.1 Troubleshooting based on LED Indications ................................................ 39

2.5.2 Troubleshooting by Error Names ................................................................ 43

2.5.3 Troubleshooting without Error Indications ................................................. 47

2.5.4 Troubleshooting on image abnormality ....................................................... 51

2.5.5 Cable connection on the MA Board and error symptoms .......................... 53

2.6 Parts Layout Diagrams ......................................................................................... 58

Chapter 3 Disassembly and Assembly

3.1 Precautions ........................................................................................................... 64

3.1.1 General Cautions in operation ..................................................................... 64

3.1.2 Precautions................................................................................................... 65

3.1.3 Workflow..................................................................................................... 65

3.1.4 Tools ............................................................................................................ 66

3.1.4.1 Tool List.............................................................................................. 66

3.1.4.2 Recommended Tool List..................................................................... 66

3.1.5 How to unlock connectors for FFC/FPC ..................................................... 67

3.2 Flowchart.............................................................................................................. 70

3.2.1 Standard operation time............................................................................... 70

3.3 Disassembly and Assembly.................................................................................. 73

3.3.1 Air Filter ...................................................................................................... 73

3.3.2 Lamp............................................................................................................ 74

3.3.3 Front Foot .................................................................................................... 75

3.3.4 Rear Foot ..................................................................................................... 76

3.3.5 Rear Case..................................................................................................... 77

3.3.6 Upper Case (Assy)....................................................................................... 80

3.3.6.1 SW Board............................................................................................ 84

3.3.6.2 H Key Assy/Upper Case..................................................................... 86

3.3.6.3 Shutter................................................................................................. 87

3.3.6.4 Upper Case.......................................................................................... 89

3.3.7 WFD Board.................................................................................................. 94

3.3.8 P3dash Module ............................................................................................ 96

3.3.9 RTC Board................................................................................................... 97

3.3.10 MA Board Assy....................................................................................... 100

3.3.10.1 Speaker 16W................................................................................... 105

3.3.10.2 IF Board .......................................................................................... 106

3.3.11 Optical Engine (Assy) ............................................................................. 113

3.3.11.1 Auto Iris Assy ................................................................................. 115

3.3.11.2 Focus Ring/Zoom Ring................................................................... 116

3.3.12 EX Duct (Assy) ....................................................................................... 118

3.3.12.1 EX Fan/TH Board........................................................................... 119

3.3.13 Lamp Fan (Assy) ..................................................................................... 120

3.3.13.1 Lamp Fan/Speaker 5W ................................................................... 121

3.3.14 PS Ballast Assy........................................................................................ 122

3.3.15 P4combo Module..................................................................................... 128

3.3.16 INT Duct (Assy) ...................................................................................... 129

3.3.16.1 IR Board.......................................................................................... 131

3.3.16.2 INT Fan/TH Board.......................................................................... 132

3.3.17 Filter Boards ............................................................................................ 135

3.3.18 Lower Case/IR Board .............................................................................. 136

3.4 Shortest removal procedures of identified failed parts....................................... 137

3.4.1 Speaker ...................................................................................................... 137

3.4.2 IR Board .................................................................................................... 138

3.4.3 LMP Thermistor ........................................................................................ 139

3.4.4 EX Fan....................................................................................................... 140

3.5 Individual Function Check After Repair ............................................................ 141

3.5.1 Safety Check after Servicing ..................................................................... 142

SEIKO EPSON 8 Revision A

Page 9

EB-E01 series

INTERNAL USE ONLY

3.5.1.1 Insulation resistance test ................................................................... 143

3.5.1.2 Ground continuity check................................................................... 144

3.5.1.3 Illumination check ............................................................................ 144

3.5.2 Initialization............................................................................................... 145

3.5.3 Operation Check for control panel ............................................................ 145

3.5.4 Operation Check for remote controller...................................................... 145

3.5.5 Operation Check for video input/output .................................................... 146

3.5.6 Operation Check for audio input/output .................................................... 146

3.5.7 Communication Check .............................................................................. 147

3.5.8 Internal Cable Connection Check.............................................................. 147

3.5.9 The service tools and the adjustment tasks list which required before

and after parts replacement.................................................................................. 148

3.5.10 Service tool list ........................................................................................ 150

3.6 Writing the DR Data........................................................................................... 152

3.6.1 Overview.................................................................................................... 152

3.6.2 Preparation................................................................................................. 153

3.6.3 Operating Procedure .................................................................................. 153

3.6.3.1 Workflow .......................................................................................... 153

3.6.3.2 Check in advance .............................................................................. 154

3.6.3.3 Replacing the Optical Engine ........................................................... 156

3.6.3.4 Replacing the MA Board .................................................................. 158

3.7 G Sensor Calibration .......................................................................................... 161

3.7.1 Overview.................................................................................................... 161

3.7.2 Preparation................................................................................................. 161

3.7.3 Procedure ................................................................................................... 161

3.8 LCD Alignment .................................................................................................. 162

3.8.1 Overview.................................................................................................... 162

3.8.2 Pixel color shift confirmation method ....................................................... 162

3.8.3 LCD alignment activation method............................................................. 162

3.8.3.1 Adjustment method........................................................................... 164

3.9 Part Names List .................................................................................................. 166

4.1.2.2 Confirmation method which connects PC with projector................. 184

4.1.2.3 Confirmation method using a USB memory .................................... 188

4.1.3 Initializing (Resetting)............................................................................... 190

Chapter 4 Appendix

4.1 AS (After Service) Menu.................................................................................... 171

4.1.1 How To Display the AS (After Service) Menu ......................................... 171

4.1.1.1 How to enter the AS menu................................................................ 171

4.1.1.2 Menu Contents .................................................................................. 171

4.1.2 Confirmation method using IPS tool ......................................................... 184

4.1.2.1 Preparation ........................................................................................ 184

SEIKO EPSON 9 Revision A

Page 10

PRODUCT DESCRIPTION

CHAPTER

1

INTERNAL USE ONLY

Page 11

EB-E01 series Product Description INTERNAL USE ONLY

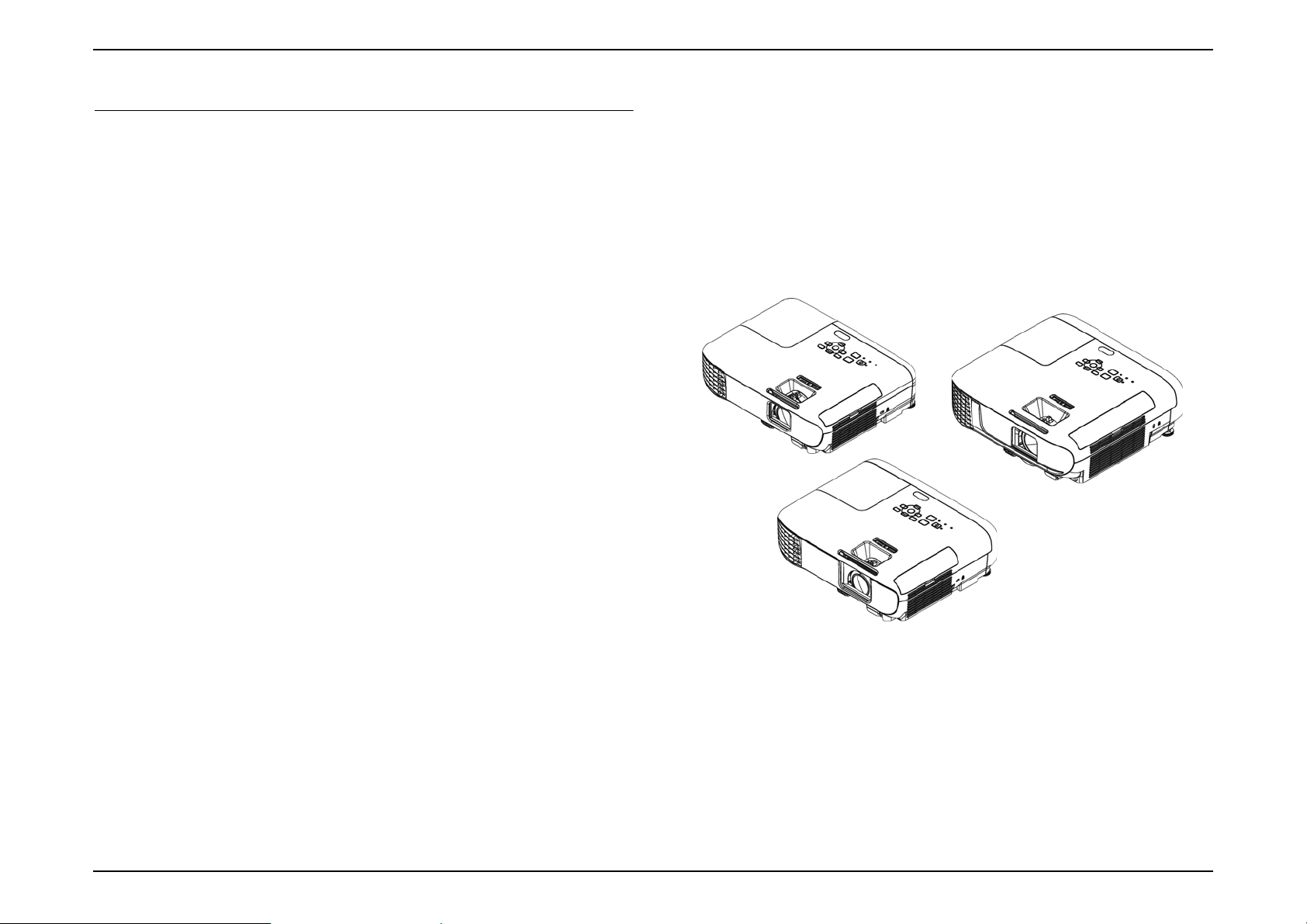

1.1 Product Description

This projector comes with this special features. Refer to these sections for more

details.

Quick and Easy Setup

Direct Power On feature to turn on the projector as soon as you plug it

in.

Auto Power On feature to turn on the projector when the projector

detects an image signal from the port you specified as the Auto Power

On source.

Home screen feature to easily select an input source and useful

functions.

Automatic vertical keystone correction always displays a rectangular

screen (Auto V-Keystone).

Horizontal correction slider to quickly correct the lateral strain of the

projected image. Sliding horizontal correction is convenient when the

projector cannot be parallel to the screen.

(Except EB-E01/E10)

Easy Wireless Projection (EB-FH52/992F EH-TW750 only)

Screen Mirroring allows a wireless connection between the projector

and a mobile device compatible with Miracast.

Epson iProjection (Windows/Mac) to project up to four images at the

same time by splitting the projected screen. You can project images

from computers on the network, or from smartphones or tablet devices.

Flexible Connectivity

Enhanced security functions

Operation button lock function

Security cable installation

Remote password

Sliding Lens Cover for Easy Projection And Storage

(other than EB-E01/E10)

No cool-down period is needed.

Auto Iris

External View

This projector can be connected to computers, video equipment,

smartphones, tablet terminals, and other devices.

Slide Show Function (except EB-E01/E10)

The images in a USB storage can be projected without using a

computer

Equipped with USB terminal (Type A)

SEIKO EPSON 11 Revision A

Page 12

EB-E01 series Product Description INTERNAL USE ONLY

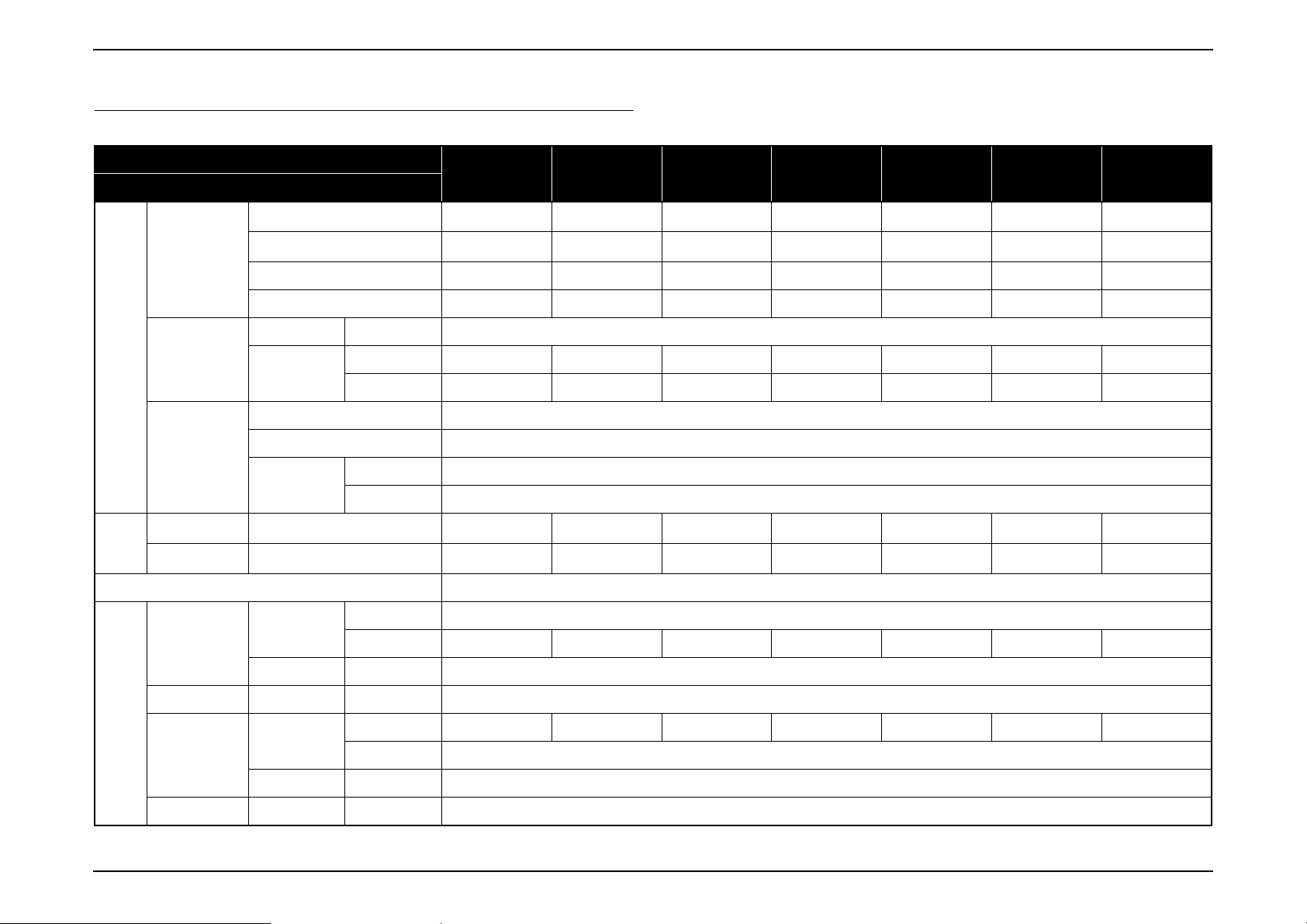

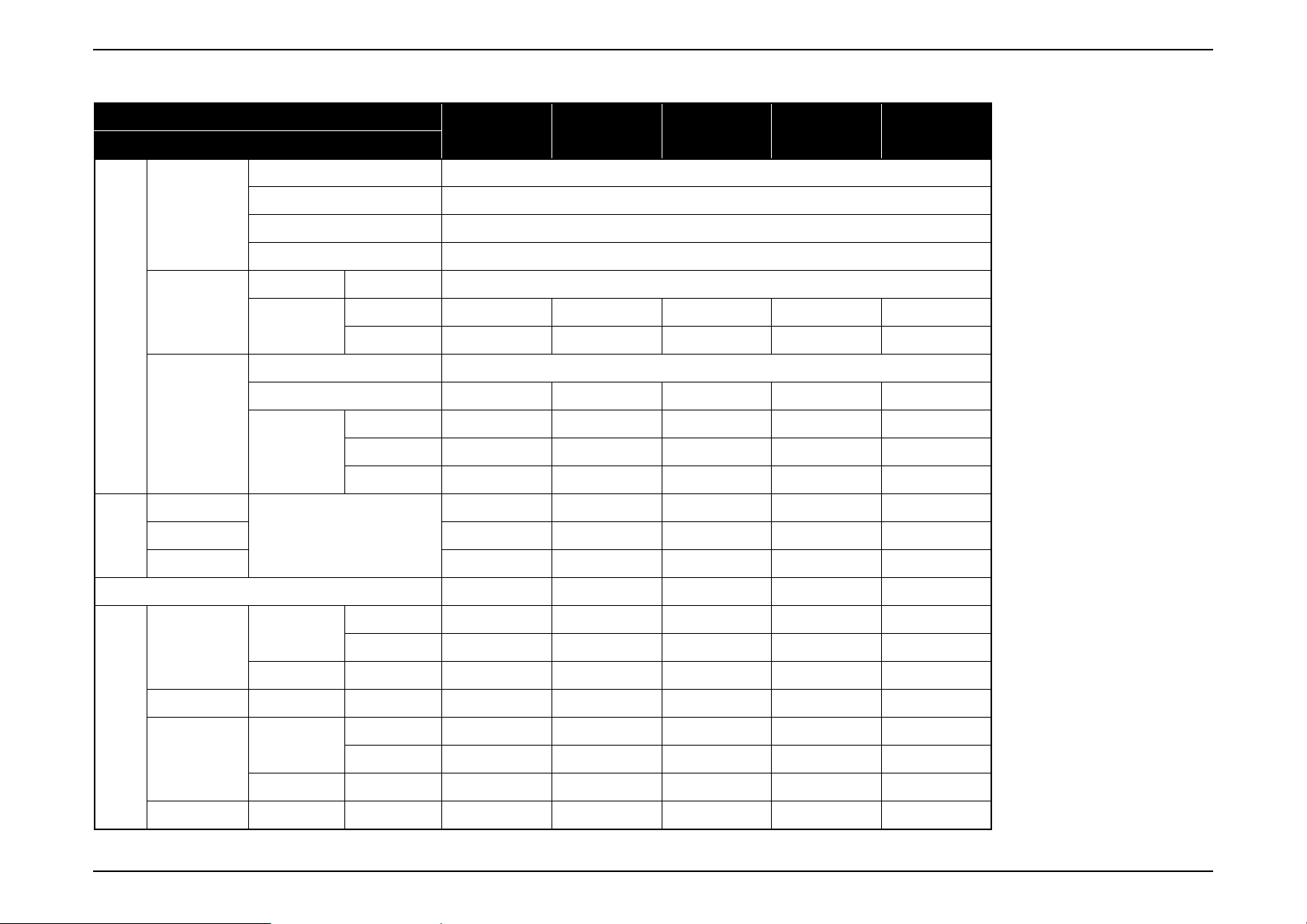

1.2 Specifications

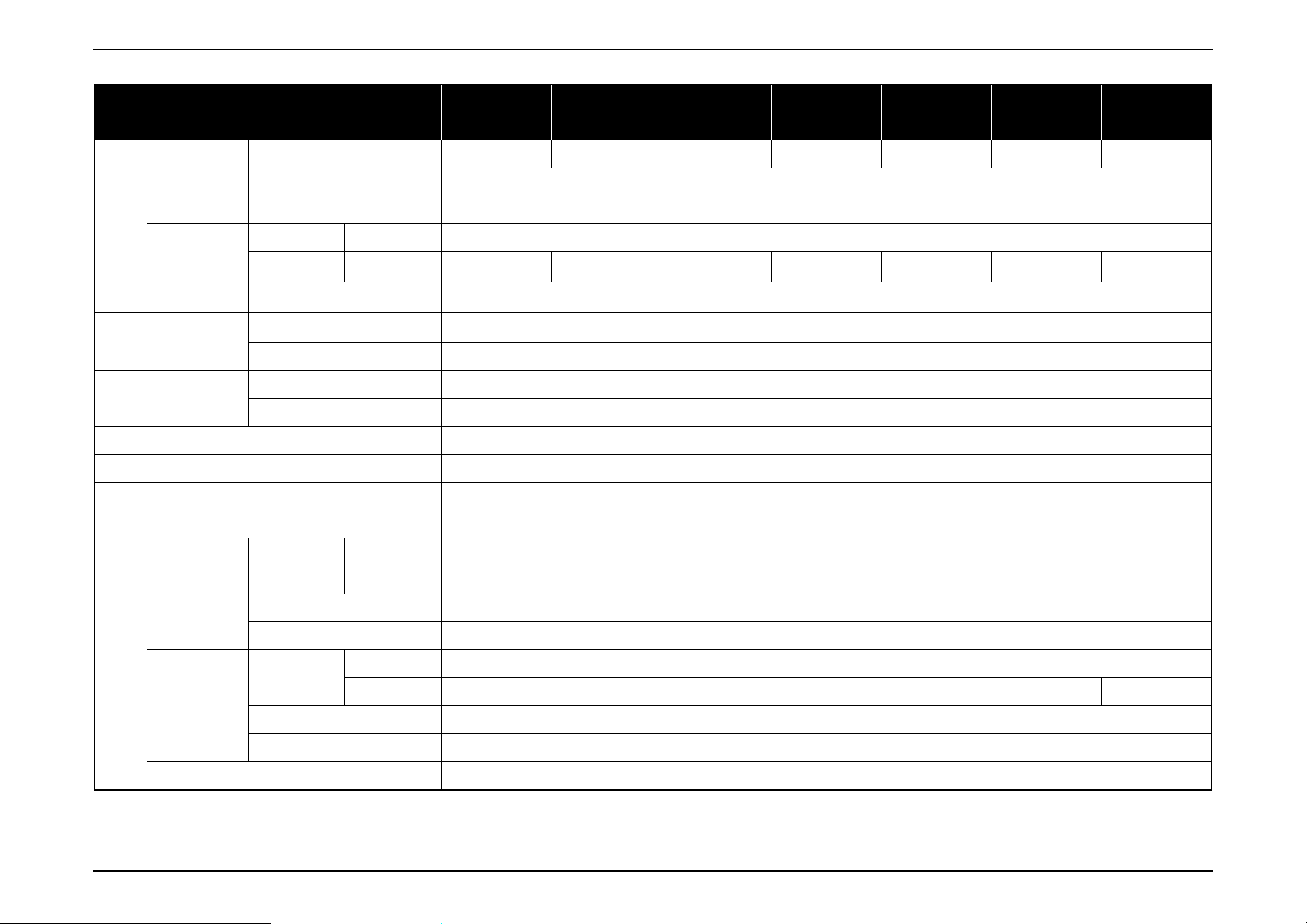

EB-E01/X06/W06/E10/X51/W51/W52

Model

Item

Size

Pixel number

LCD

Native resolution XGA XGA WXGA XGA XGA WXGA WXGA

Aspect ratio 4:3 4:3 16:10 4:3 4:3 16:10 16:10

EB-E01 EB-X06 EB-W06 EB-E10 EB-X51 EB-W51 EB-W52

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

0.59 inch

(C2fine)

1,024,000 pixels

(1280 x 800) x 3

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

0.59 inch

(C2fine)

1,024,000 pixels

(1280 x 800) x 3

1,024,000 pixels

(1280 x 800) x 3

0.59 inch

(C2fine)

Specific

ation

of main

part

Brightn

ess

Sound output Monaural: 2W x 1

I/O

Projection Lens

Lamp

Normal mode

Eco mode

Video input

Video output Analog D-sub 15pin —

Audio

Focus Type Manual

Zoom

Type UHE

Power consumption 210W

Life

Color mode: Dynamic,

Zoom: Wide

Color mode: Dynamic,

Zoom: Wide

Analog

Digital HDMI 1

Input

Type Digital Manual Manual Digital Manual Manual Manual

Ratio 1-1.35 1-1.2 1-1.2 1-1.35 1-1.2 1-1.2 1-1.2

Normal 6,000 hours

Eco 12,000 hours

3,300lm 3,600lm 3,700lm 3,600lm 3,800lm 4,000lm 4,000lm

2,200lm 2,400lm 2,400lm 2,200lm 2,500lm 2,600lm 2,600lm

D-sub 15pin 1 (Blue molding)

RCA — 1 (Yellow) 1 (Yellow) — 1 (Yellow) 1 (Yellow) 1 (Yellow)

RCA (L/R)—11—111

Stereo mini —

Output Stereo mini —

Mic Input Stereo mini —

SEIKO EPSON 12 Revision A

Page 13

EB-E01 series Product Description INTERNAL USE ONLY

Model

Item

USB

I/O

I/O

Operating Temperature

Operating Altitude

Start-up period Less than 6 seconds

Warm-up period 30 seconds

Cool-down period Instant off

Power on was possible/impossible 100 - 240 V AC +/- 10%, 50/60 Hz

RS232C D-sub 9pin —

Network

Wireless

connection

Type A —11—111

Type B 1

Cable LAN RJ45 —

Wireless LAN

Screen Mirroring —

Temperature

Humidity 20% - 80% humidity

Normal 0 m to 3,048 m <0 ft to 10000 ft>

High altitude mode 1500 m <4921 ft> or more

USB Type A

(ELPAP11)

EB-E01 EB-X06 EB-W06 EB-E10 EB-X51 EB-W51 EB-W52

— Optional Optional — Optional Optional —

5°C to 40°C [41°F to 104°F] (Elevation 0 to 2,286 m)

5°C to 35°C [41°F to 95°F] (Elevation 2,287 m or more)

ON (Normal) 345W

ON (Eco) 235W

ON (Normal) 327W

ON (Eco) 235W 225W

Power

consum

ption

100-120V Area

(JAPAN, USA,

etc.)

220-240V Area

(Europe, etc.)

Rated Voltage & Current (Except Japan) 100 - 240 V AC 50/60 Hz 3.5A - 1.6A

Lamp

Standby (Network On) 2.0W

Energy Saving 0.3W

Lamp

Standby (Network On) 2.0W

Energy Saving 0.3W

SEIKO EPSON 13 Revision A

Page 14

EB-E01 series Product Description INTERNAL USE ONLY

Model

Item

Size

Weight

Fan

noise

Excluding feet

Unit: mm

Maximum Dimension

Normal mode 37 dB

Eco mode 28 dB

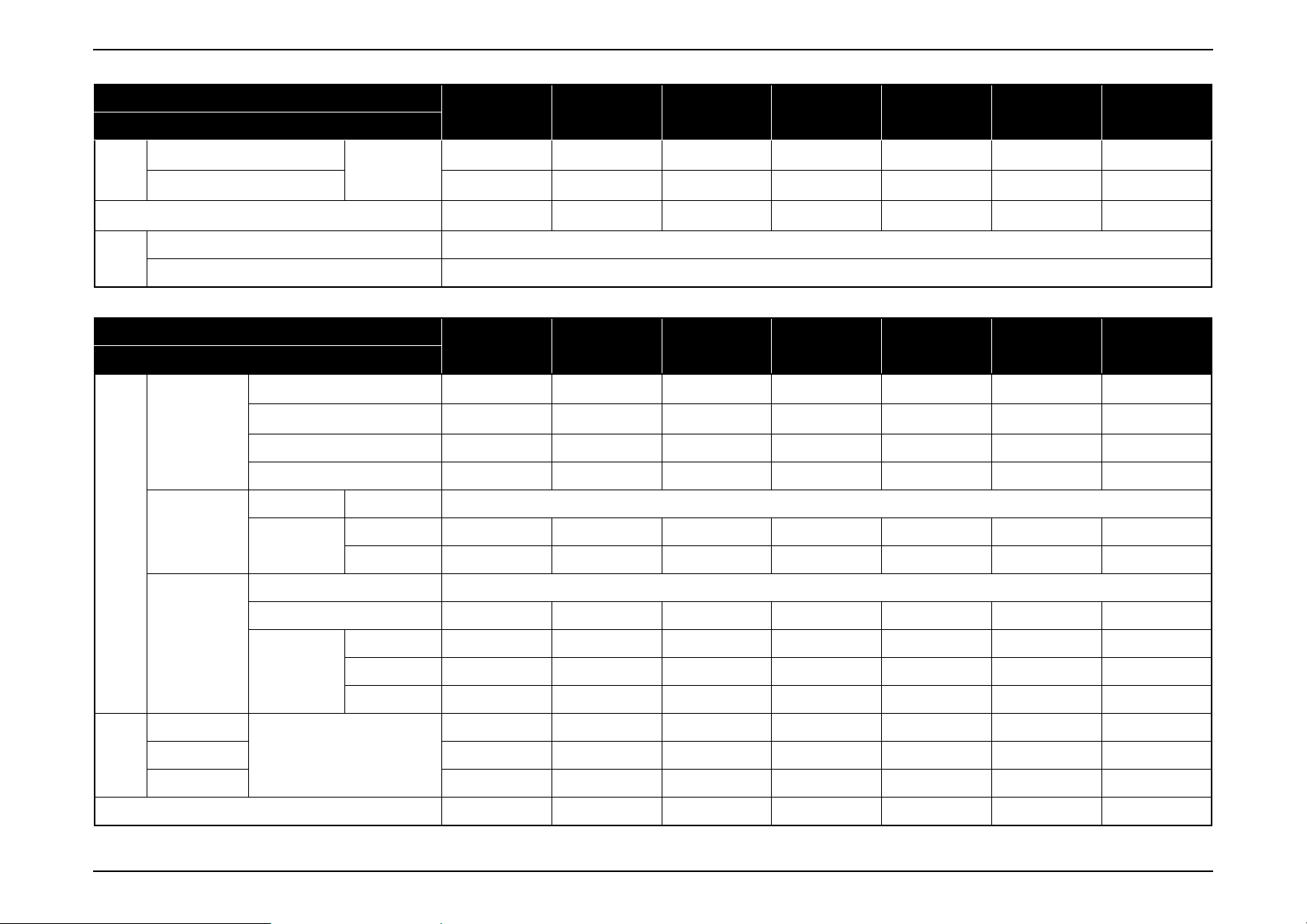

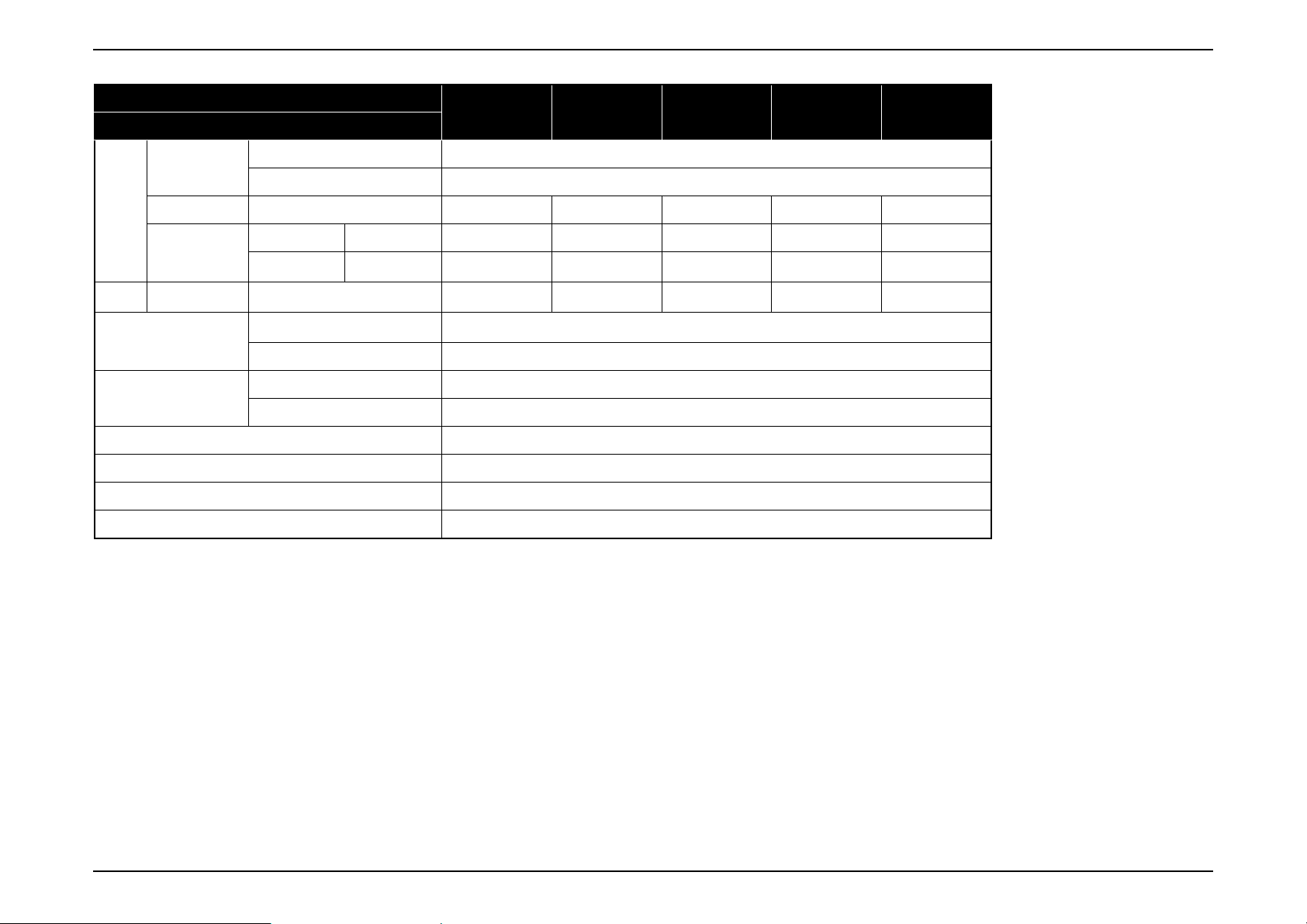

EB-E20/X49/W49/972/982W/118, PL 119W

Model

Item

Size

Pixel number

Native resolution XGA XGA WXGA XGA WXGA XGA WXGA

Aspect ratio 4:3 4:3 16:10 4:3 16:10 4:3 16:10

Focus Type Manual

Type Digital Manual Manual Manual Manual Manual Manual

Zoom

Ratio 1-1.35 1-1.2 1-1.2 1-1.6 1-1.6 1-1.2 1-1.2

Type UHE

Specific

ation

of main

part

LCD

Projection Lens

EB-E01 EB-X06 EB-W06 EB-E10 EB-X51 EB-W51 EB-W52

302(W) x 77 (H) x

234 (D)

302(W) x 82 (H) x

237 (D)

Approx. 5.29 lbs./

2.4 kg

EB-E20 EB-X49 EB-W49 EB-972 EB-982W EB-118 PL 119W

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

302(W) x 77 (H) x

234 (D)

302(W) x 82 (H) x

237 (D)

Approx. 5.51 lbs./

2.5 kg

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

302(W) x 77 (H) x

234 (D)

302(W) x 82 (H) x

237 (D)

Approx. 5.51 lbs./

2.5 kg

0.55 inch

(C2fine)

1,024,000 pixels

(1280 x 800) x 3

302(W) x 77 (H) x

234 (D)

302(W) x 82 (H) x

237 (D)

Approx. 5.29 lbs./

2.4 kg

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

302(W) x 77 (H) x

234 (D)

302(W) x 82 (H) x

237 (D)

Approx. 5.51 lbs./

2.5 kg

0.59 inch

(C2fine)

1,024,000 pixels

(1280 x 800) x 3

302(W) x 77 (H) x

234 (D)

302(W) x 82 (H) x

237 (D)

Approx. 5.51 lbs./

2.5 kg

0.55 inch

(C2fine)

786,432 pixels

(1024 x 768) x 3

302 (W) x 87 (H) x

302 (W) x 92 (H) x

Approx. 5.73lbs./

1,024,000 pixels

(1280 x 800) x 3

234 (D)

237 (D)

2.6 kg

0.59 inch

(C2fine)

Power consumption 210W 210W 210W 230W 230W 210W 210W

Lamp

Life

Normal mode

Brightn

ess

Sound output Monaural: 5W x 1 Monaural: 5W x 1 Monaural: 5W x 1

Medium mode — — 3,700lm 3,500lm 3,600lm 3,600lm 3,700lm

Eco mode 2,200lm 2,400lm 2,600lm 2,500lm 2,600lm 2,500lm 2,600lm

Color mode: Dynamic,

Zoom: Wide

Normal 6,000 hours 6,000 hours 8,000 hours 6,500 hours 6,500 hours 8,000 hours 8,000 hours

Medium — — 10,000 hours 10,000 hours 10,000 hours 10,000 hours 10,000 hours

Eco 12,000 hours 12,000 hours 17,000 hours 17,000 hours 17,000 hours 17,000 hours 17,000 hours

3,400lm 3,600lm 3,800lm 4,100lm 4,200lm 3,800lm 4,000lm

Monaural: 16W x 1 Monaural: 16W x 1 Monaural: 16W x 1 Monaural: 16W x 1

SEIKO EPSON 14 Revision A

Page 15

EB-E01 series Product Description INTERNAL USE ONLY

Video input

I/O

I/O

I/O

Operating Temperature

Video output Analog D-sub 15pin 1

Audio

Mic Input Stereo mini — — — 1 1 1 1

USB

RS232C D-sub 9pin 1 (for servicing only)

Network

Wireless

connection

Model

Item

Analog

DigitalHDMI1122222

Input

OutputStereo mini1111112

Type A —111111

Type B 1

Cable LANRJ45 —111111

Wireless LAN

Screen Mirroring —

Temperature

Humidity 20% - 80% humidity

D-sub 15pin 2 (Blue molding)

RCA 1 (Yellow)

RCA (L/R) 1

Stereo mini 2

USB TypeA

(ELPAP11)

EB-E20 EB-X49 EB-W49 EB-972 EB-982W EB-118 PL 119W

— 1 1 Optional Optional Optional 1

5°C to 40°C [41°F to 104°F] (Elevation 0 to 2,286 m)

5°C to 35°C [41°F to 95°F] (Elevation 2,287 m or more)

Operating Altitude

Start-up period Less than 6 seconds

Warm-up period 30 seconds

Cool-down period Instant off

Power on was possible/impossible 100 - 240 V AC +/- 10%, 50/60 Hz

Normal 0 m to 3,048 m <0 ft to 10000 ft>

High altitude mode 1500 m <4921 ft> or more

SEIKO EPSON 15 Revision A

Page 16

EB-E01 series Product Description INTERNAL USE ONLY

Power

consum

ption

Size

Weight

Fan

noise

Model

Item

ON (Normal) 345W

100-120V Area

Lamp

(JAPAN, USA,

etc.)

Standby (Network On) 2.0W

Energy Saving 0.3W

Lamp

220-240V Area

(Europe, etc.)

Standby (Network On) 2.0W

Energy Saving 0.3W

Rated Voltage & Current (Except Japan) 100 - 240 V AC 50/60 Hz 3.5A - 1.6A

Excluding feet

Maximum Dimension

Normal mode 37 dB

Eco mode 28 dB

ON (Medium) — — 303W 303W 303W 303W 303W

ON (Eco) 235W

ON (Normal) 327W

ON (Medium) — — 290W 290W 290W 290W 290W

ON (Eco) 225

Unit: mm

EB-E20 EB-X49 EB-W49 EB-972 EB-982W EB-118 PL 119W

302(W) x 87 (H) x

249 (D)

302(W) x 92 (H) x

249 (D)

Approx. 5.95 lbs./

2.7 kg

302(W) x 87 (H) x

249 (D)

302(W) x 92 (H) x

249 (D)

Approx. 5.95 lbs./

2.7 kg

302(W) x 87 (H) x

249 (D)

302(W) x 92 (H) x

249 (D)

Approx. 5.95 lbs./

2.7 kg

309 (W) x 90 (H) x

282 (D)

309 (W) x 105 (H)

x 293 (D)

Approx. 6.83 lbs./

3.1 kg

309 (W) x 90 (H) x

309 (W) x 105 (H)

x 293 (D)

Approx. 6.83 lbs./

282 (D)

3.1 kg

302 (W) x 87 (H) x

249 (D)

302 (W) x 92 (H) x

260 (D)

Approx. 6.17 lbs./

2.8 kg

302(W) x 87 (H) x

249 (D)

302(W) x 92 (H) x

260 (D)

Approx. 6.17 lbs./

2.8 kg

SEIKO EPSON 16 Revision A

Page 17

EB-E01 series Product Description INTERNAL USE ONLY

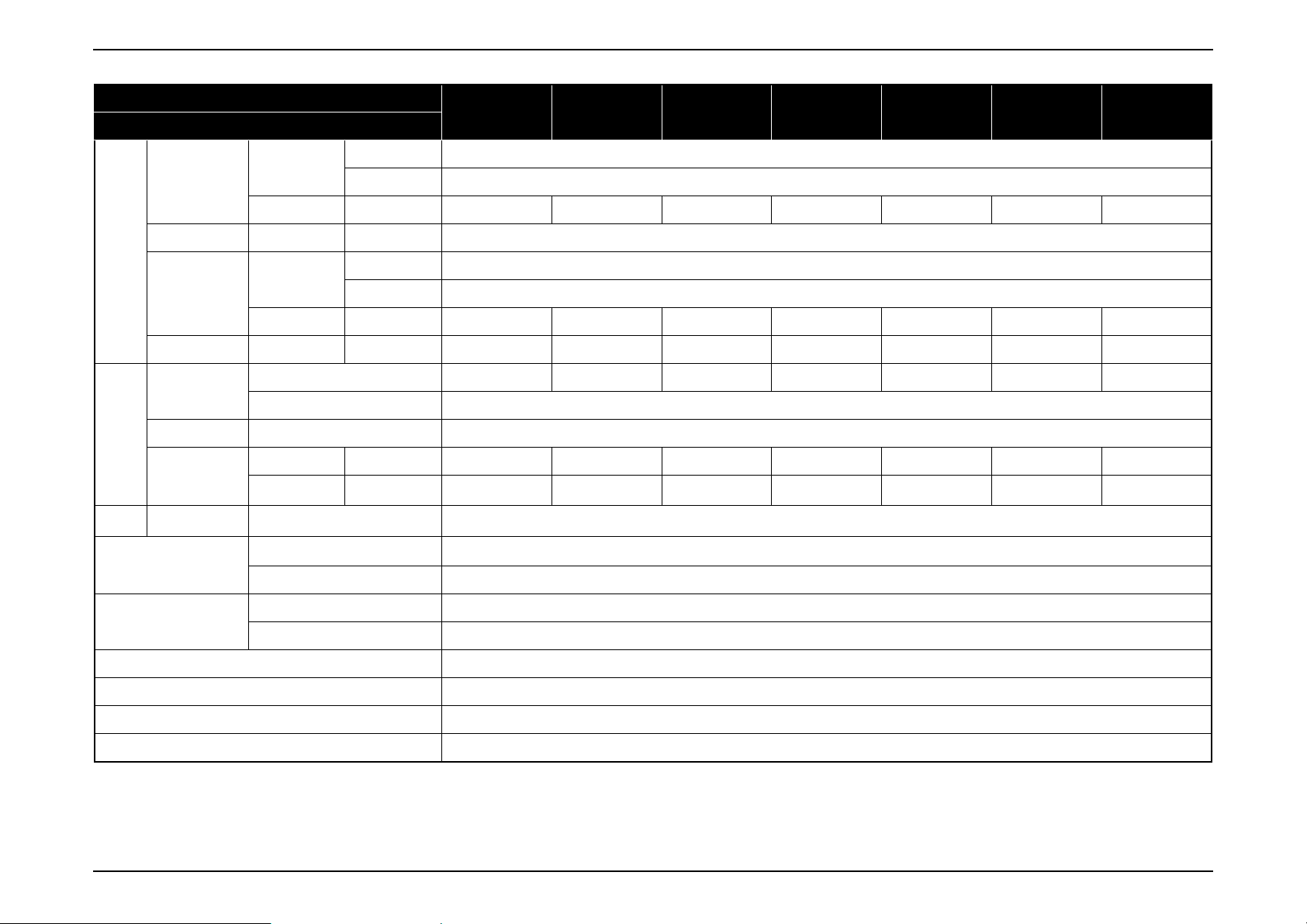

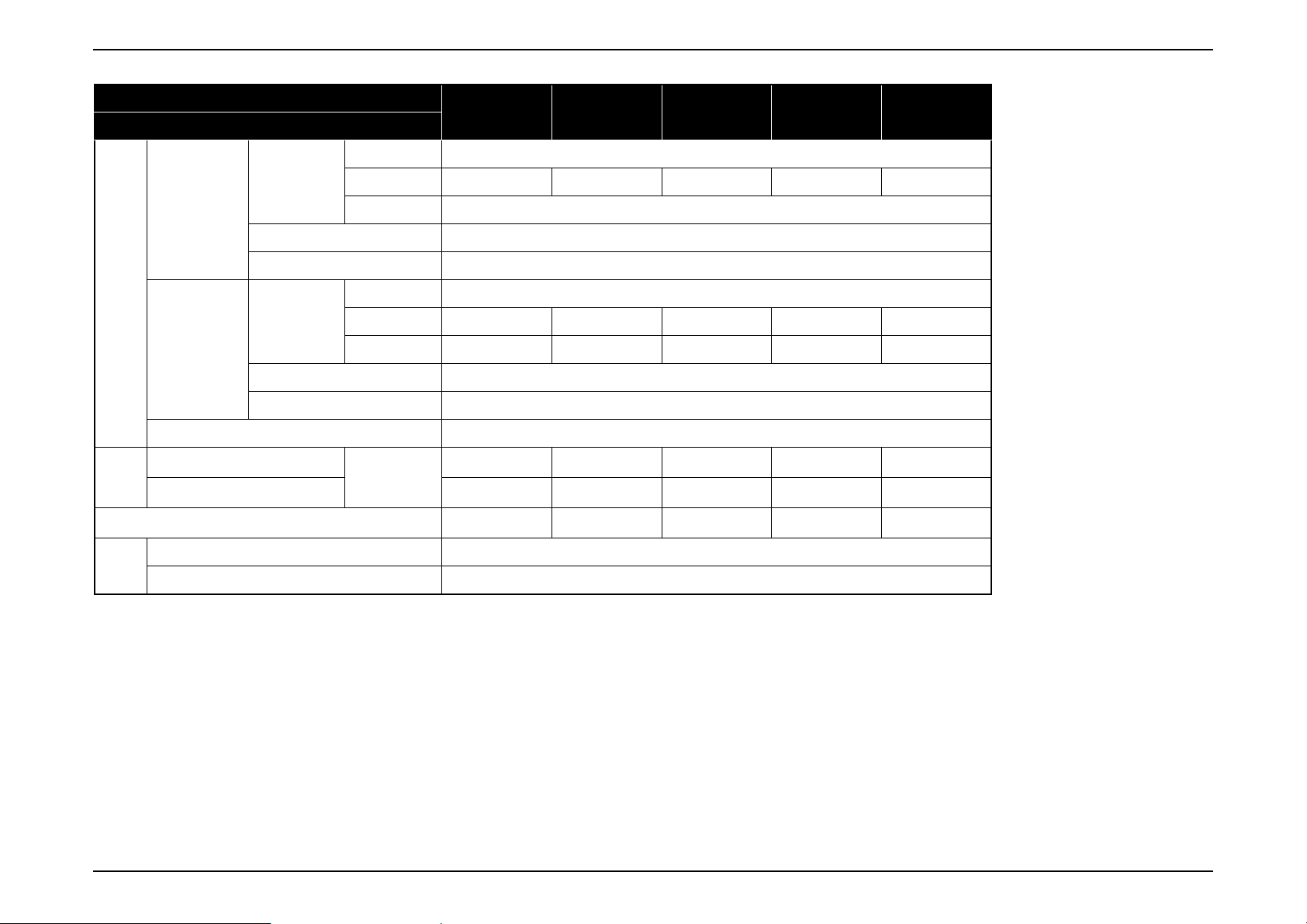

EB-FH06/FH52/992F, EH-TW740/TW750

Model

Item

Size 0.61 inch (C2fine)

EB-FH06 EB-FH52 EB-992F EH-TW740 EH-TW750

LCD

Specific

ation

of main

part

Brightn

ess

Sound output Monaural: 2W x 1

Projection Lens

Lamp

Normal mode

Medium mode — — 3,400lm — —

Eco mode 2,300lm 2,400lm 2,400lm 2,200lm 2,200lm

Video input

Pixel number 2,073,600 pixels (1920 x 1080) x 3

Native resolution Full HD

Aspect ratio 16:9

Focus Type Manual

Zoom

Type UHE

Power consumption 210W 230W 230W 210W 210W

Life

Color mode: Dynamic,

Zoom: Wide

Analog

Type Manual Manual Manual Digital Manual

Ratio 1-1.2 1-1.6 1-1.6 1-1.35 1-1.2

Normal 6,000 hours 5,500 hours 6,500 hours 6,000 hours 6,000 hours

Medium — — 10,000 hours — —

Eco 12,000 hours 12,000 hours 17,000 hours 12,000 hours 12,000 hours

3,500lm 4,000lm 4,000lm 3,300lm 3,400lm

D-sub 15pin 1 (Blue molding) 1 (Blue molding) 2 (Blue molding) — 1 (Blue molding)

RCA 1 (Yellow) 1 (Yellow) 1 (Yellow) — 1 (Yellow)

Monaural: 16W x 1 Monaural: 16W x 1

Monaural: 2W x 1 Monaural: 2W x 1

DigitalHDMI2 2212

I/O

Video output Analog D-sub 15pin — — 1 — —

Audio

Input

Output Stereo mini — — 1 1 1

Mic Input Stereo mini — — 1 — —

RCA (L/R)111—1

Stereo mini — — 2 — —

SEIKO EPSON 17 Revision A

Page 18

EB-E01 series Product Description INTERNAL USE ONLY

Model

Item

USB

I/O

I/O

Operating Temperature

Operating Altitude

Start-up period Less than 6 seconds

Warm-up period 30 seconds

Cool-down period Instant off

Power on was possible/impossible 100 - 240 V AC +/- 10%, 50/60 Hz

RS232C D-sub 9pin — —

Network

Wireless

connection

Type A 1

Type B 1

Cable LAN RJ45 — — 1 — —

Wireless LAN

Screen Mirroring — 1 1 — 1

Temperature

Humidity 20% - 80% humidity

Normal 0 m to 3,048 m <0 ft to 10000 ft>

High altitude mode 1500 m <4921 ft> or more

USB TypeA

(ELPAP10)

EB-FH06 EB-FH52 EB-992F EH-TW740 EH-TW750

1 (for servicing only)

Optional — 1 Optional —

5°C to 40°C [41°F to 104°F] (Elevation 0 to 2,286 m)

5°C to 35°C [41°F to 95°F] (Elevation 2,287 m or more)

——

SEIKO EPSON 18 Revision A

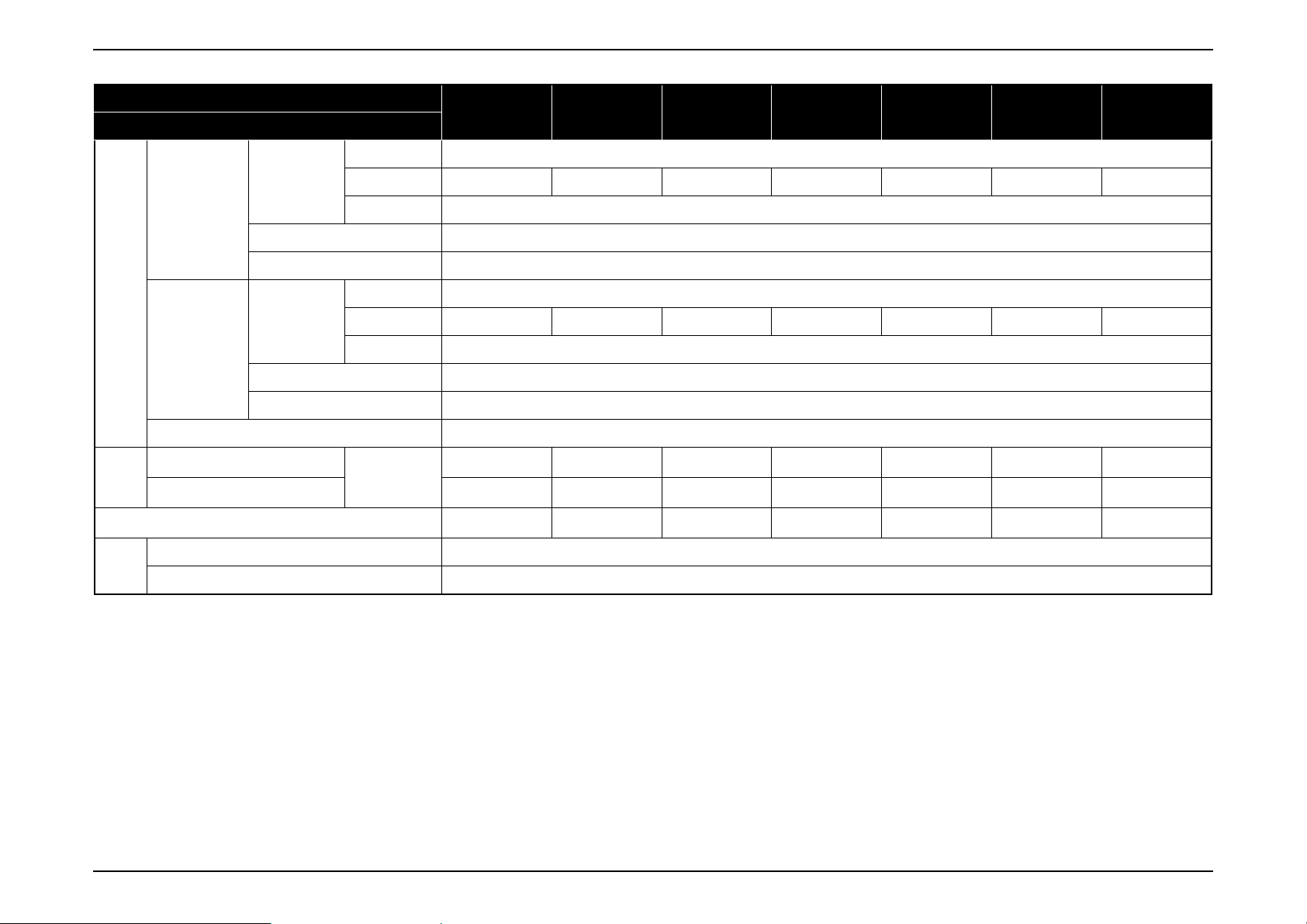

Page 19

EB-E01 series Product Description INTERNAL USE ONLY

Power

consum

ption

Size

Weight

Fan

noise

Model

Item

ON (Normal) 345W

100-120V Area

Lamp

(JAPAN, USA,

etc.)

Standby (Network On) 2.0W

Energy Saving 0.3W

Lamp

220-240V Area

(Europe, etc.)

Standby (Network On) 2.0W

Energy Saving 0.3W

Rated Voltage & Current (Except Japan) 100 - 240 V AC 50/60 Hz 3.5A - 1.6A

Excluding feet

Maximum Dimension

Normal mode 37 dB

Eco mode 28 dB

ON (Medium) — — 303W — —

ON (Eco) 235W

ON (Normal) 327

ON (Medium) — — 290W — —

ON (Eco) 235W 225W 225W 225W 225W

Unit: mm

EB-FH06 EB-FH52 EB-992F EH-TW740 EH-TW750

302(W) x 87 (H) x

249 (D)

302(W) x 92 (H) x

252 (D)

Approx. 5.95 lbs./

2.7 kg

309(W) x 90 (H) x

282 (D)

309(W) x 105 (H)

x 293 (D)

Approx. 6.83 lbs./

3.1 kg

309 (W) x 90 (H) x

282 (D)

309 (W) x 105 (H)

x 293 (D)

Approx. 6.83 lbs./

3.1 kg

302(W) x 87 (H) x

302(W) x 92 (H) x

Approx. 5.95 lbs./

249 (D)

252 (D)

2.7 kg

302(W) x 87 (H) x

249 (D)

302(W) x 92 (H) x

252 (D)

Approx. 6.17 lbs./

2.8 kg

SEIKO EPSON 19 Revision A

Page 20

EB-E01 series Product Description INTERNAL USE ONLY

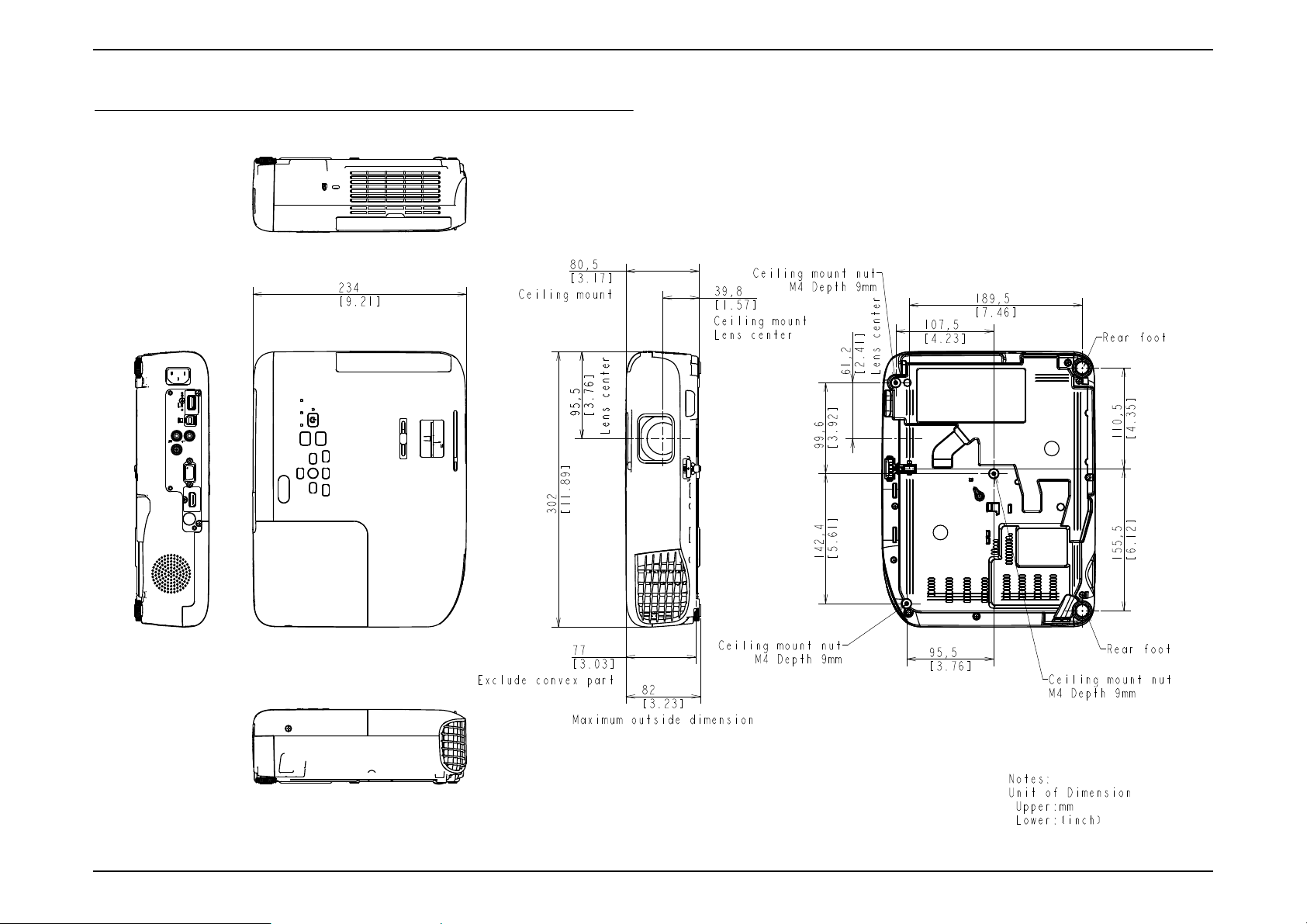

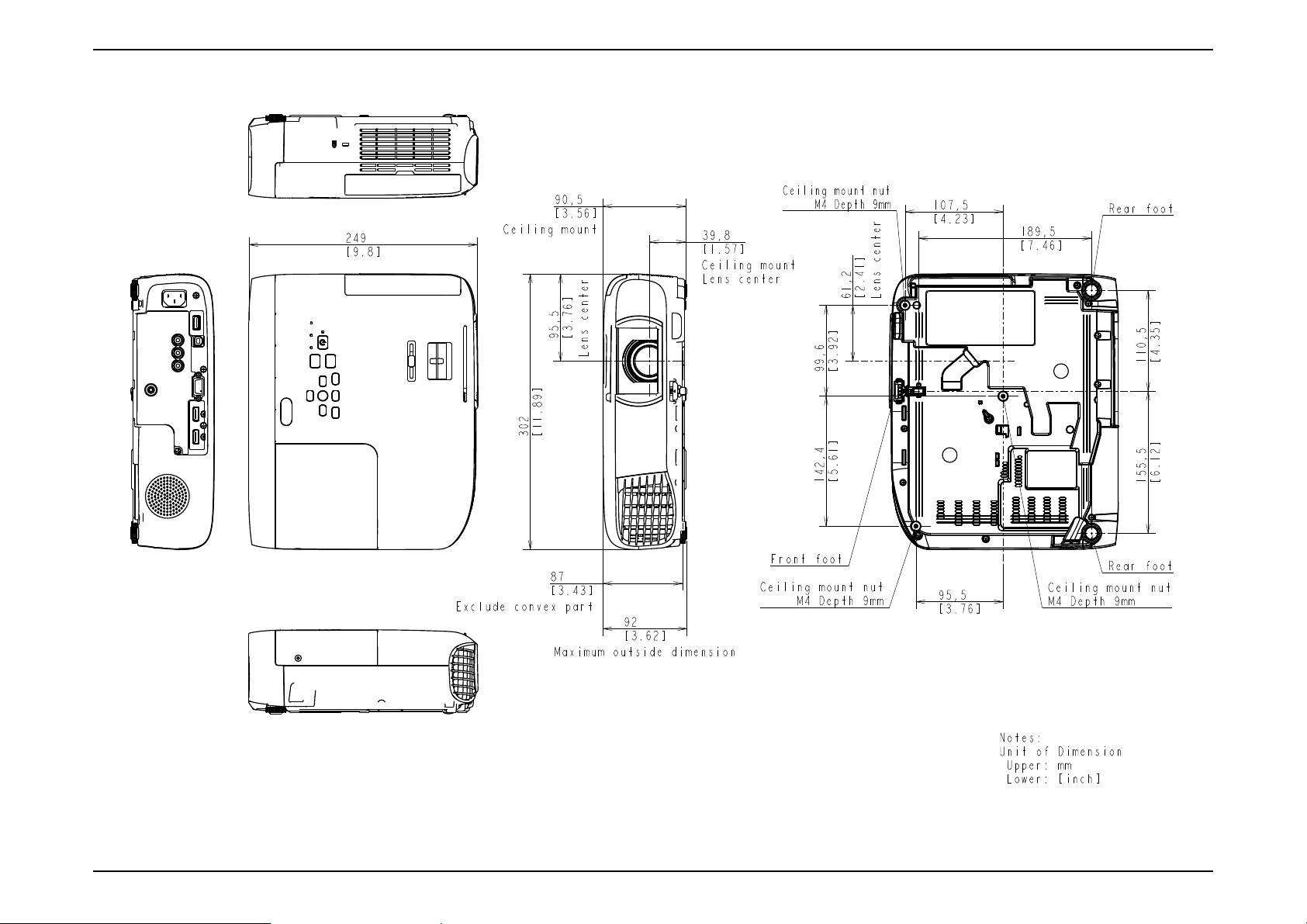

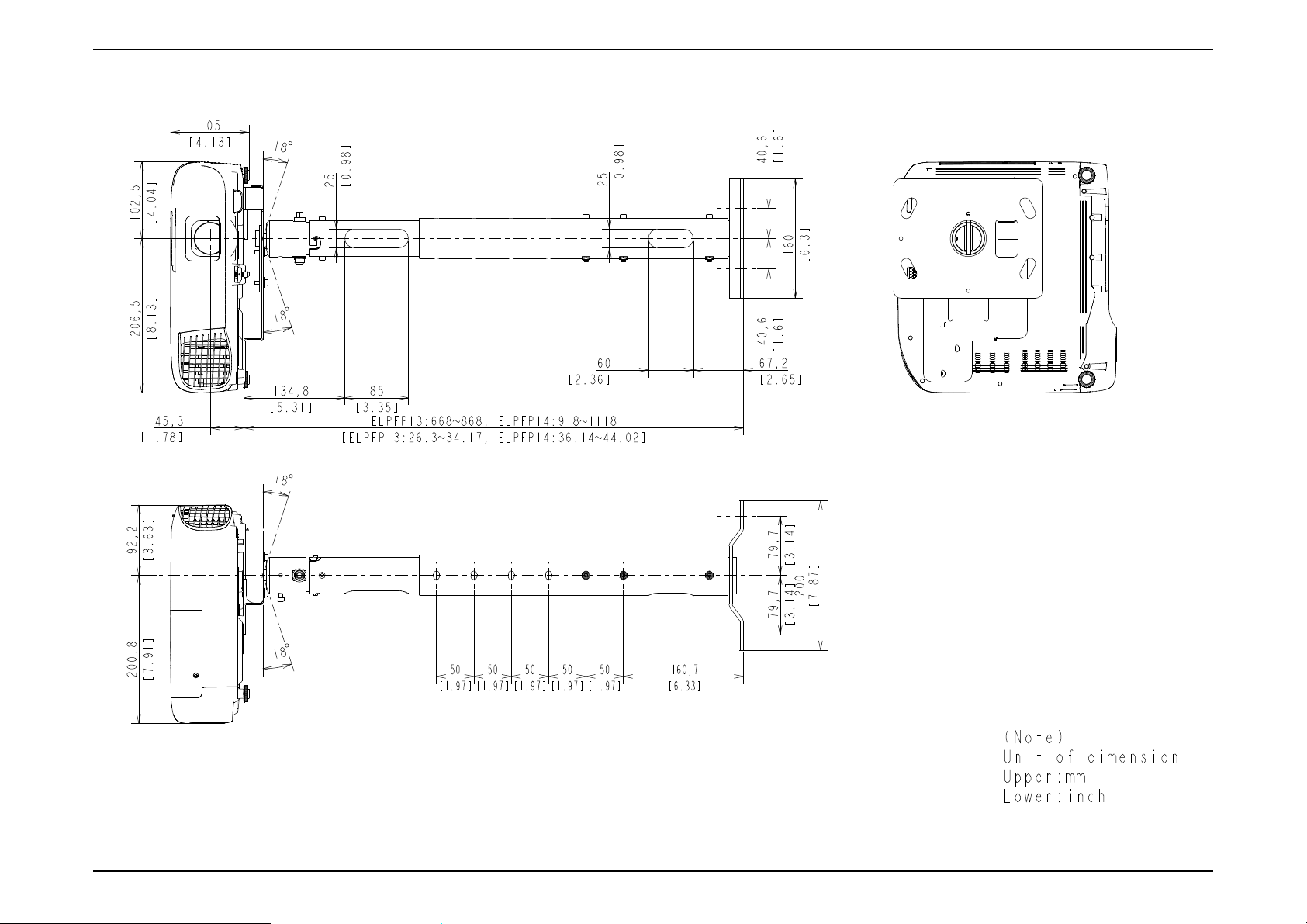

1.3 Dimensions

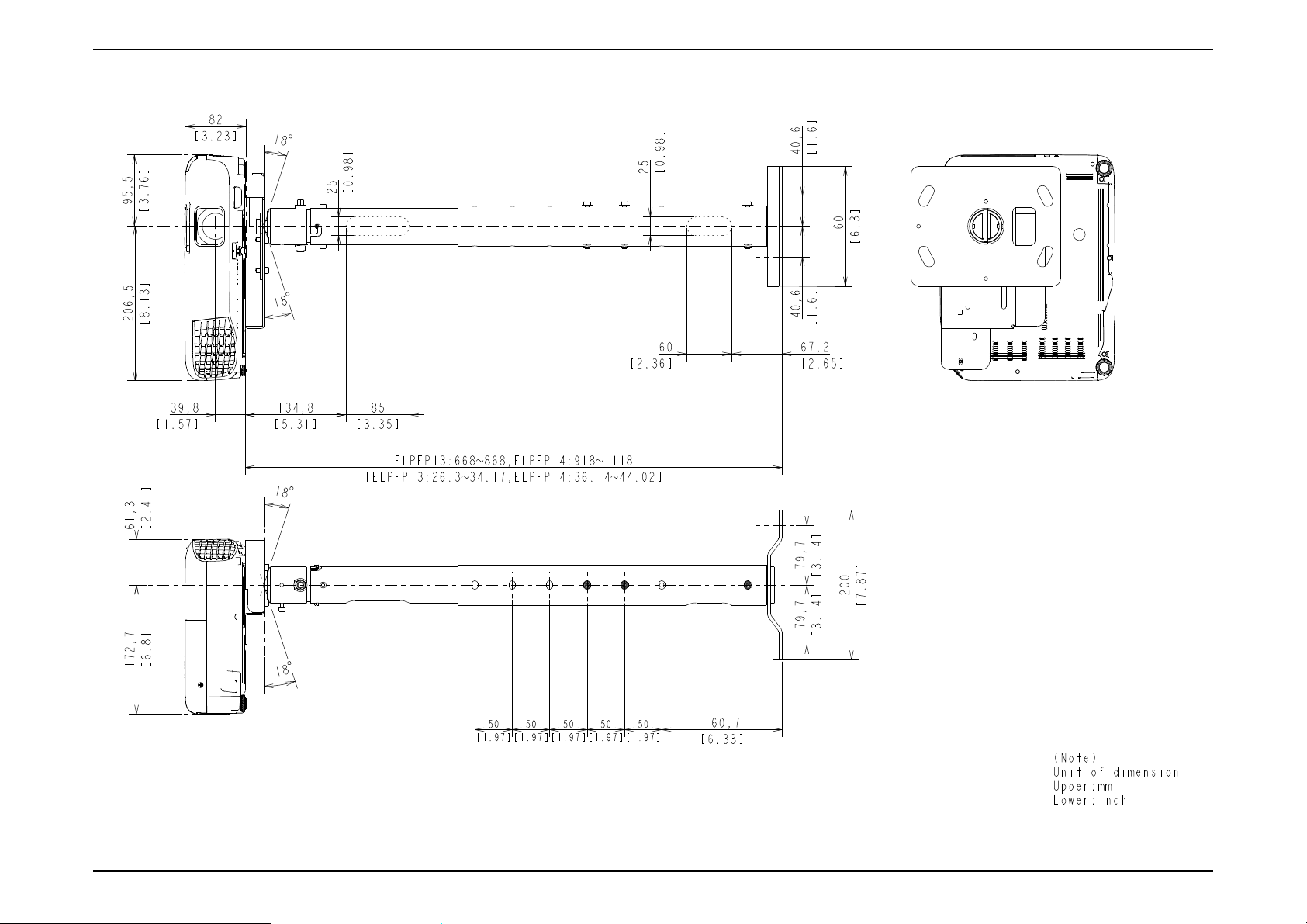

EB-EB-E01/X06/W06/E10/X51/W51

SEIKO EPSON 20 Revision A

Page 21

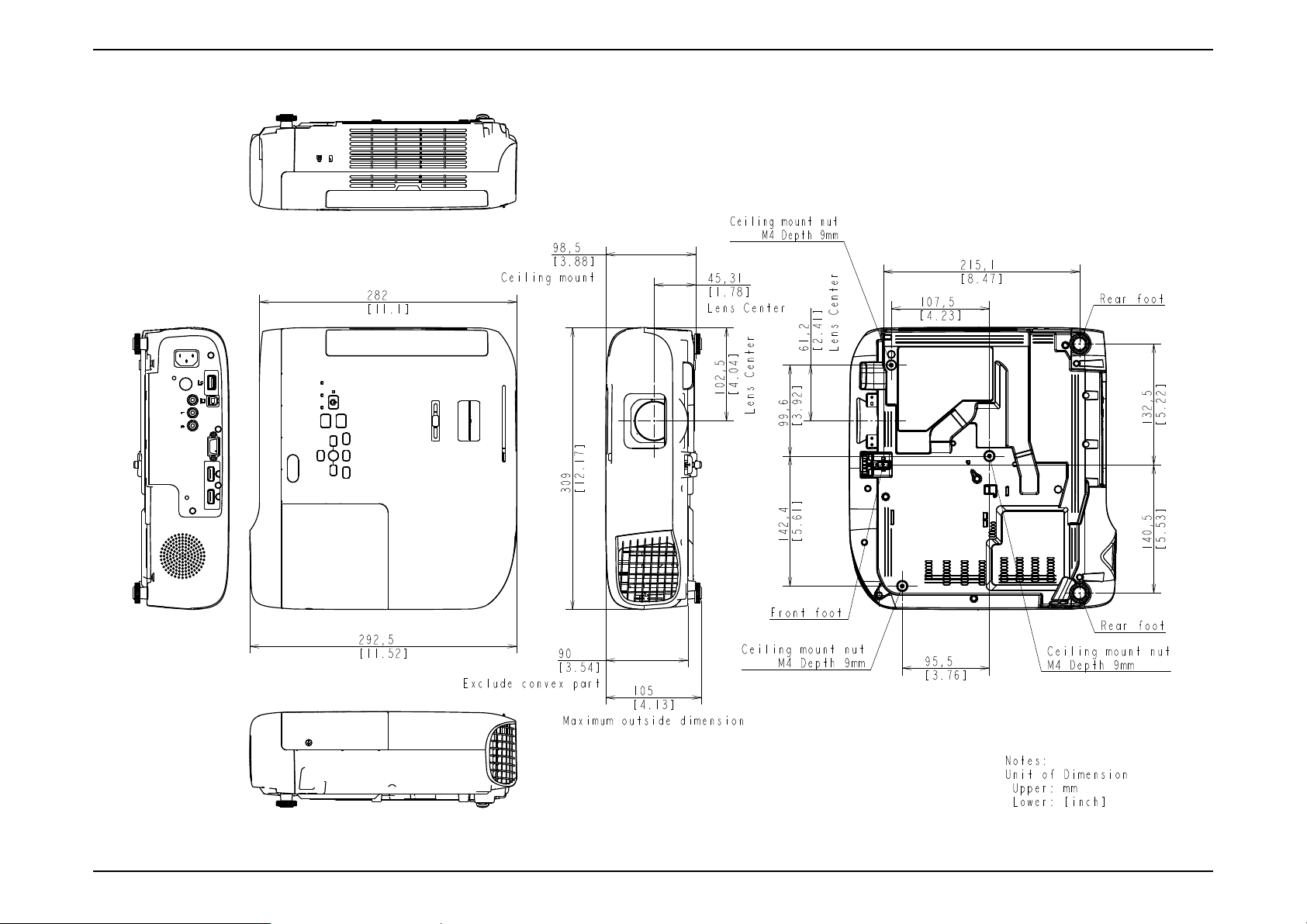

EB-E01 series Product Description INTERNAL USE ONLY

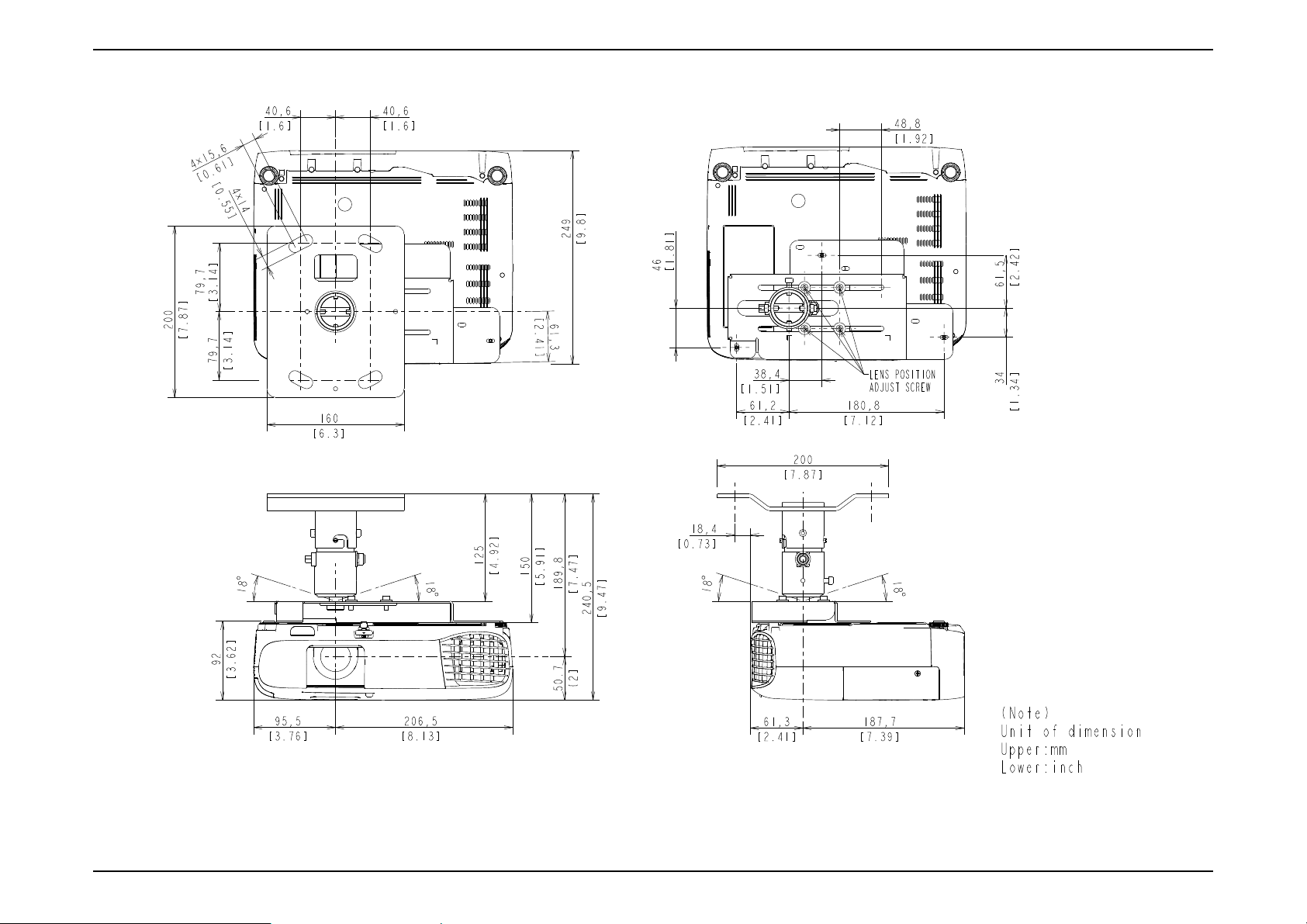

EB-FH06/E20/X49/W49/118, PL 119W, EH-TW740/TW750

SEIKO EPSON 21 Revision A

Page 22

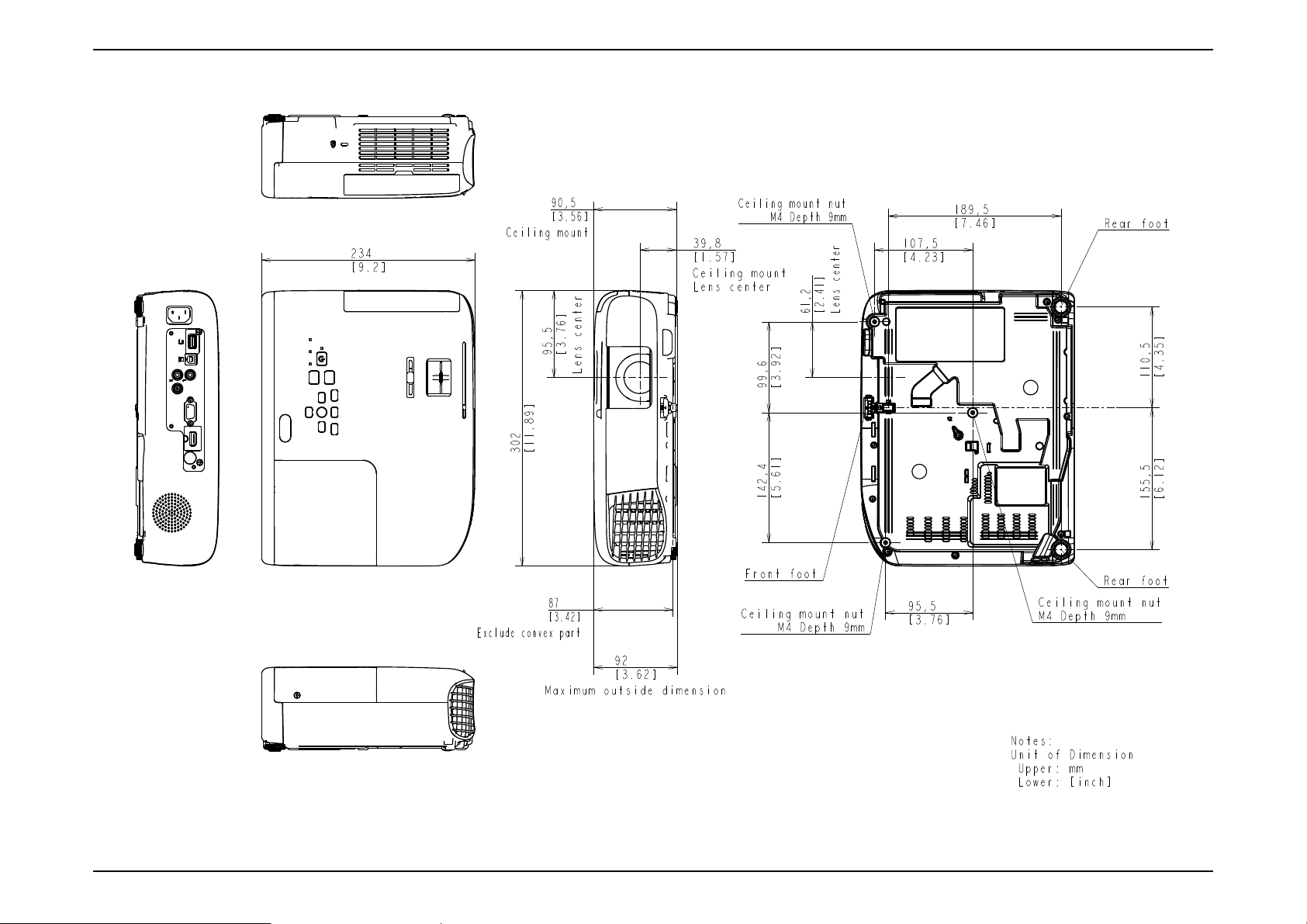

EB-E01 series Product Description INTERNAL USE ONLY

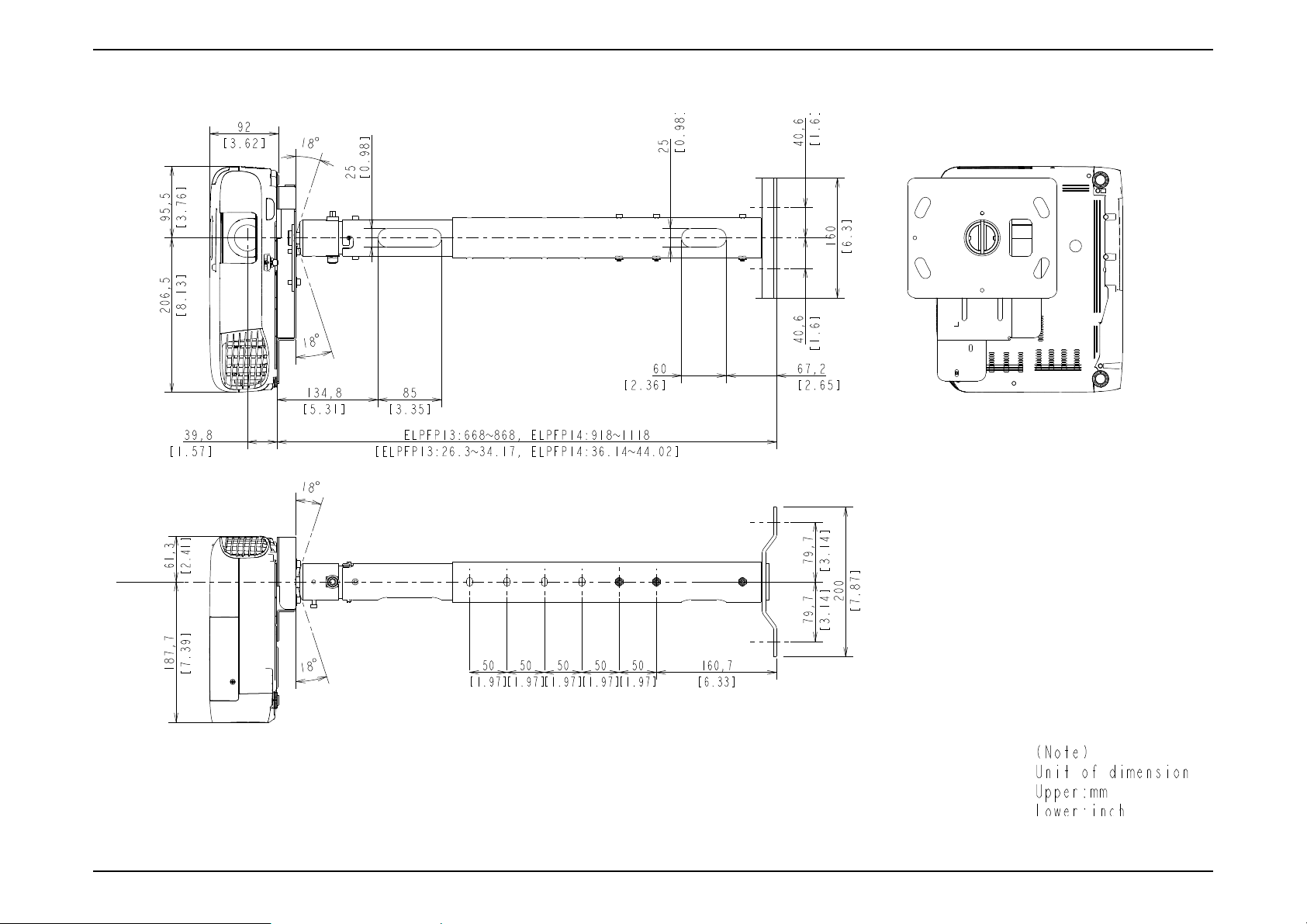

EB-FH52/972/982W/992F

SEIKO EPSON 22 Revision A

Page 23

EB-E01 series Product Description INTERNAL USE ONLY

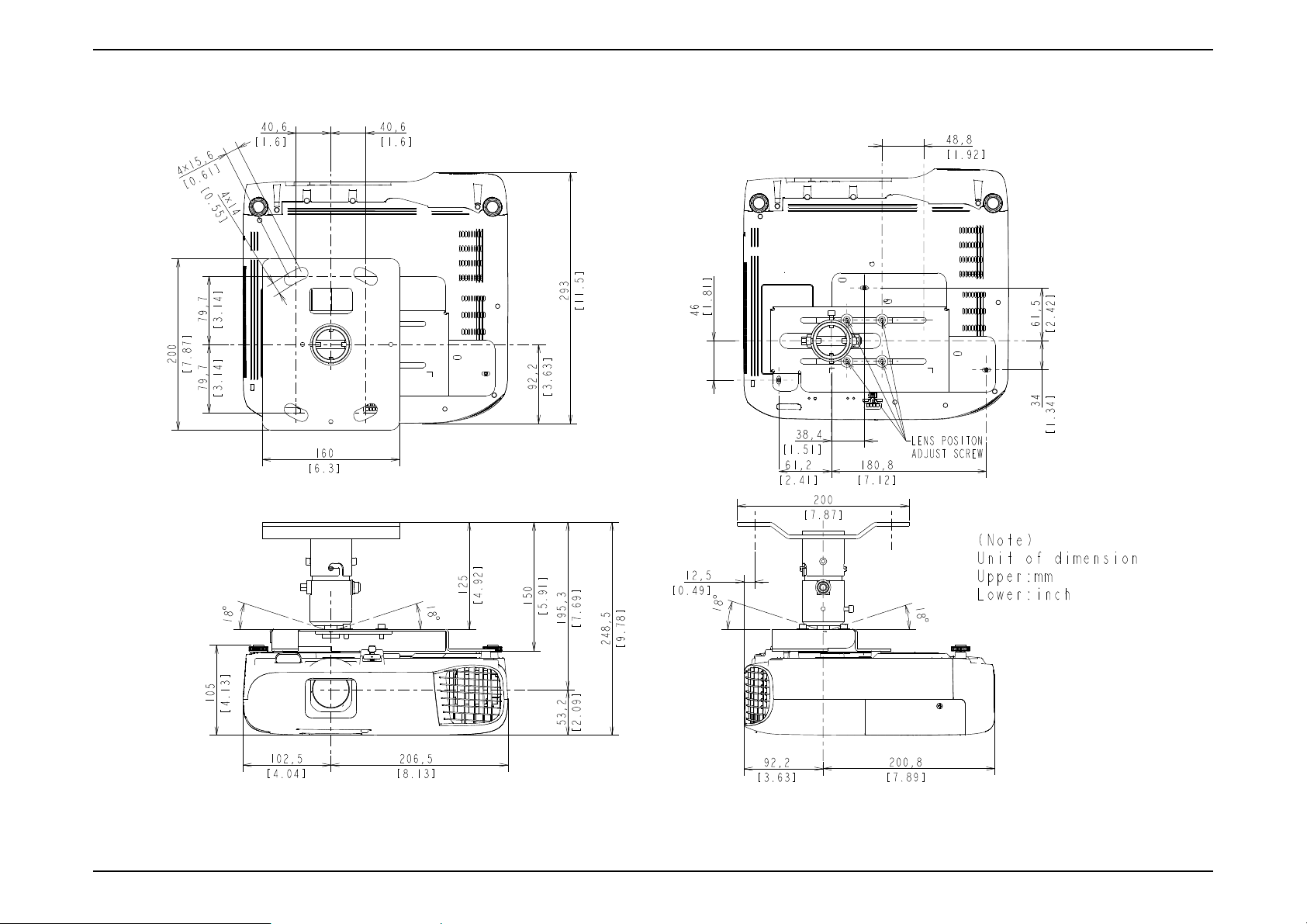

EB-W52

SEIKO EPSON 23 Revision A

Page 24

EB-E01 series Product Description INTERNAL USE ONLY

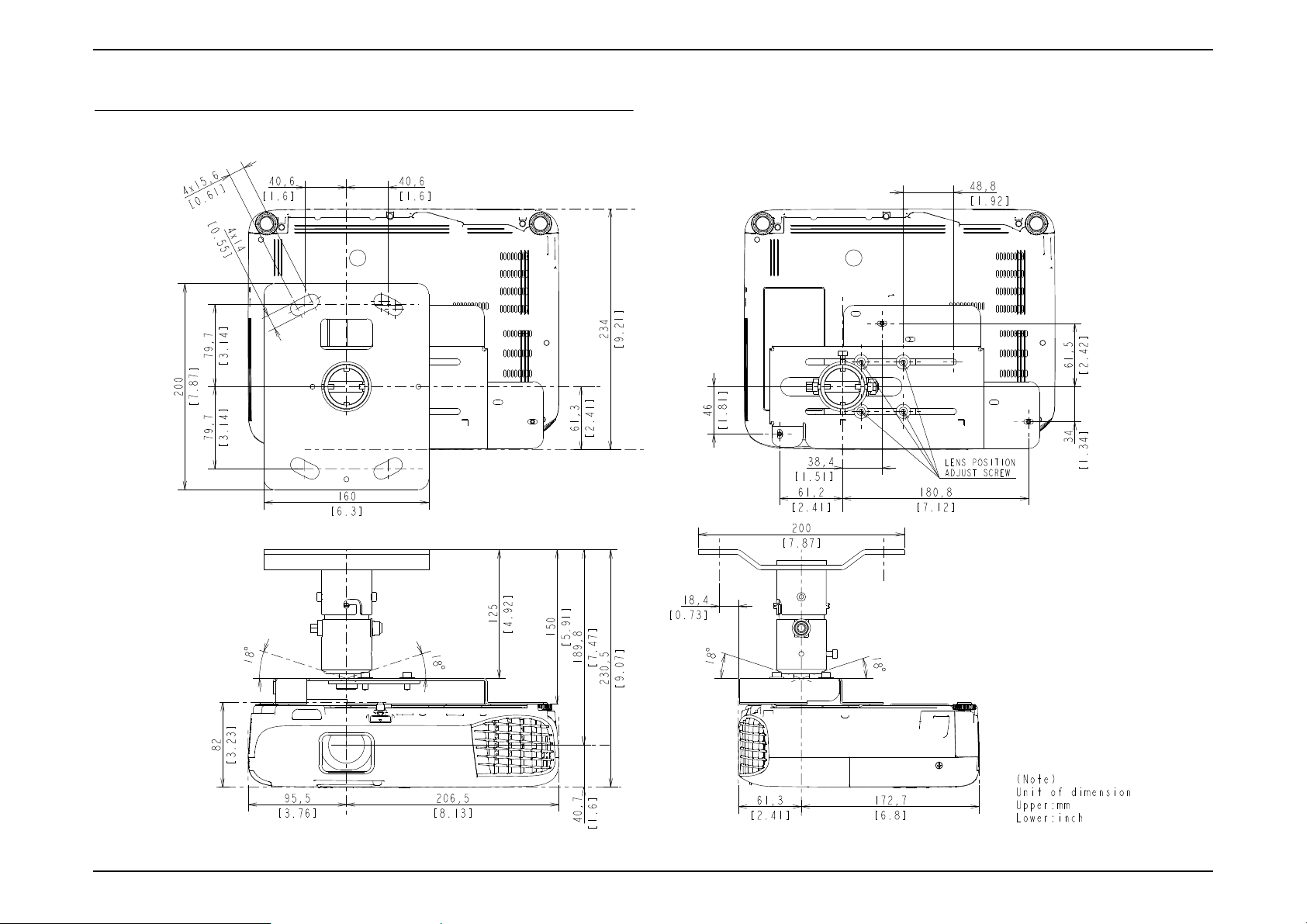

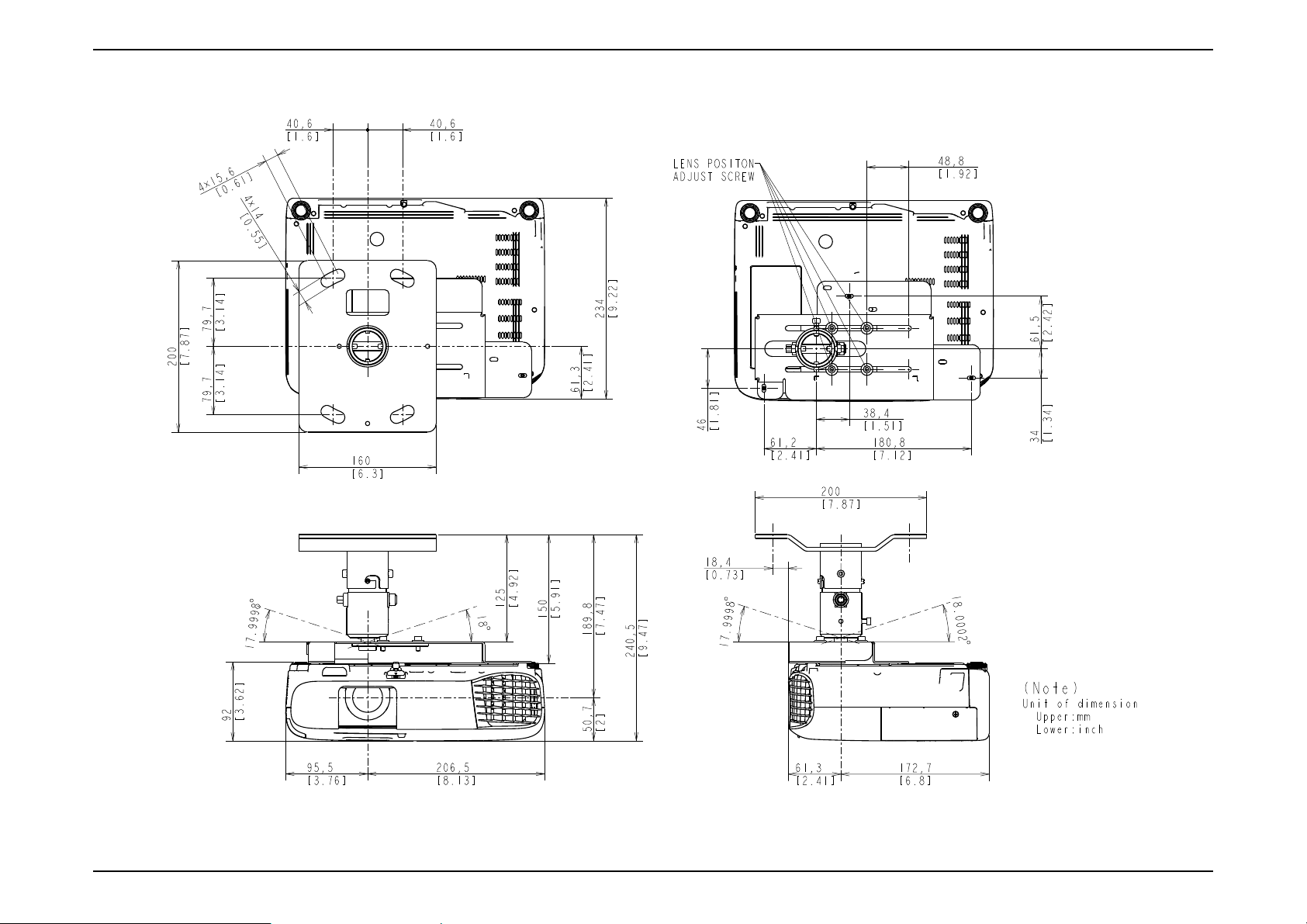

1.4 Ceiling Mount

EB-E01/X06/W06/E10/X51/W51 (ELPMB23)

SEIKO EPSON 24 Revision A

Page 25

EB-E01 series Product Description INTERNAL USE ONLY

EB-E01/X06/W06/E10/X51/W51 (ELPMB23 + ELPFP13/ELPFP14)

SEIKO EPSON 25 Revision A

Page 26

EB-E01 series Product Description INTERNAL USE ONLY

EB-FH06/E20/X49/W49/118, PL 119W, EH-TW740/TW750 (ELPMB23)

SEIKO EPSON 26 Revision A

Page 27

EB-E01 series Product Description INTERNAL USE ONLY

EB-FH06/E20/X49/W49/118, PL 119W, EH-TW740/TW750 (ELPMB23 + ELPFP13/ELPFP14)

SEIKO EPSON 27 Revision A

Page 28

EB-E01 series Product Description INTERNAL USE ONLY

EB-FH52/972/982W/992F (ELPMB23)

SEIKO EPSON 28 Revision A

Page 29

EB-E01 series Product Description INTERNAL USE ONLY

EB-FH52/972/982W/992F (ELPMB23 + ELPFP13/ELPFP14)

SEIKO EPSON 29 Revision A

Page 30

EB-E01 series Product Description INTERNAL USE ONLY

EB-W52 (ELPMB23)

SEIKO EPSON 30 Revision A

Page 31

EB-E01 series Product Description INTERNAL USE ONLY

EB-W52 (ELPMB23 + ELPFP13/ELPFP14)

SEIKO EPSON 31 Revision A

Page 32

TROUBLESHOOTING

CHAPTER

2

INTERNAL USE ONLY

Page 33

EB-E01 series Troubleshooting INTERNAL USE ONLY

2.1 Required Tools

The following tools are required in order to carry out troubleshooting of this

projector.

Name Qt. Application/Other

Projection screen 1 To project images on.

Genuine power cable 1

Genuine remote controller 1

Host computer 1 To output audio and video data to the projector*

PC cable 1

Video equipment 1

Audio and Video cables

(HDMI/Composite/USB, and

each audio)

Multi tester 1

Double-sided tape q.s.*

General tools 1 set Tools given in " 3.1.4 Tools (p66)".

RS-232C cable 1 For writing DR data

USB memory or USB cable 1 For USB Updater

IPS tool 1

CAT 1

Intra-mart 1

RESCUE 1

USB firmware for updater 1

EasyMP Network firmware for

updater

Microsoft .Net Framework 3.5

or later

USB COM Driver 1

*1: When repairing a wide panel (16:10) model, prepare the video source and devices

considering the full screen display of 16:10 aspect.

1 each

(To check the component video input)

To control service tools

To output audio and video data to the projector*

(To check the HDMI and composite video input)

To measure resistance values and voltages (AC/

DC).

2

To secure parts

See " 3.5.10 Service tool list (p150)".

1

1

1

1

*2: q.s.: Sufficient quantity

SEIKO EPSON 33 Revision A

Page 34

EB-E01 series Troubleshooting INTERNAL USE ONLY

Start

Is the projector

able to project the

Check the error name.

" 4.1.1 How To Display the AS (After

Service) Menu (p171)"

No

Yes

>> To the next page

Yes

Troubleshoot referring to

" 2.4 Troubleshooting from the Device

Names (p37)"

Does the LED Indicator flash

or turn on?

Has any error

occurred?

Check the error name.

" 4.1.2.3 Confirmation method using a USB

memory (p188)"

" 2.5.3 Troubleshooting without Error Indications (p47)"

Troubleshoot according to Troubleshooting at the time of

Power-ON.

No

Yes

No

Yes

Troubleshoot referring to " 2.5.2 Troubleshooting by

Error Names (p43)"

No

Device Name can be

checked?

Is the projector

able to project the image?

2.2 Troubleshooting Procedure

This chapter describes troubleshooting procedure starting from error messages/status to diagnose problems. Refer to the descriptions and remedies below to specify

the troubled part, and carry out the necessary repair or replacement.

SEIKO EPSON 34 Revision A

Page 35

EB-E01 series Troubleshooting INTERNAL USE ONLY

Are there any errors listed in

2.5.3 Troubleshooting without

Error Indications?

Troubleshoot

referring to " 2.5.3 Troubleshooting without Error Indications

(p47)".

No

Yes

Troubleshoot

referring to " 2.5.4 Troubleshooting on image abnormality

(p51)".

From the previous page >>

No

Yes

Are there any errors listed in

2.5.4 Troubleshooting on

Image Abnormality?

Finish

SEIKO EPSON 35 Revision A

Page 36

EB-E01 series Troubleshooting INTERNAL USE ONLY

2.3 Exterior Check

When repairing this product, carry out exterior check of the target parts/units as

necessary.

Target part Check items

Any damage/deformation/cracking due to external forces?

Upper Case

Rear Case

Control panel

Lamp Cover Unit

Projection Lens

Lower Case

Foot

AC Inlet

Interface

(Connector part)

Air Filter

Is it fixed to Lower Case correctly?

Any foreign object/dirt on IR receiver?

Any damage/deformation/cracking due to external forces?

Is it fixed to Lower Case and in the frame correctly?

Is it fixed to Upper Case correctly?

Are there any stuck buttons?

Do buttons work smoothly?

Is it fixed to Upper Case correctly?

Any damage on the latch to operate the Interlock SW? (Remove the

lamp cover unit and check it.)

Does FOCUS RING work smoothly?

Does Zoom Ring work smoothly?

Any dirt/scratches on the projection lens?

Any damage/deformation/cracking due to external forces?

Any foreign object/dirt on it?

Does Front Foot work smoothly to adjust height?

Does Rear Foot work smoothly to adjust height?

Any Foot Rubber detached?

Any deformation/discoloration on the connector/terminals?

Any damage on the socket?

Any deformation/discoloration on the connector/terminals?

Any foreign objects on the connectors/terminals?

Is it fixed correctly?

Is there any dirt or foreign substance on the filter?

(Remove the air filter and check it.)

Is there any dirt/foreign substance on the fan inside the filter?

Target part Check items

Any deformation/discoloration on it?

Lens Shutter

Lamp

Is it fixed to Upper Case correctly?

Does it work smoothly?

Any deformation/discoloration on the frame?

Any deformation/discoloration on the connector?

Any dirt on the glass surface?

SEIKO EPSON 36 Revision A

Page 37

EB-E01 series Troubleshooting INTERNAL USE ONLY

2.4 Troubleshooting from the Device Names

To display the device names, see " o Error Name/Warning Name/Device ID/Source Name List (p179)".

This section explains the troubleshooting mainly for the troubling parts identified using the error names and device codes displayed on the AS (after service) Menu

and the IPS tool to carry out their necessary repair. If a device code can be identified through the AS Menu or IPS tool, find the specific troubling part from the table

below.

When the troubling part can be identified, the blue-lettered parts with reference pages in the following table can be replaced in shorter ways than the ordinary

disassembling procedures.

COOLING SYSTEM COMPONENTS (FAN) P.58

Error Name (Error Code)

Device Name IPS tool Name used in the manual SPI Parts Name

Fan (FN)

(P.40)

Device Code

LV1 LV1 Fan CN1602 INT Fan FAN;SR7039-THT-H838

LMP LMP Fan CN1604 Lamp Fan FAN,LAMP

EX EX Fan CN1603 EX Fan(P.140) FAN;TB6035-NMB-H838

COOLING SYSTEM/SWITCH COMPONENTS (SENSOR) P.59

Error Name (Error Code)

Device Name IPS tool Name used in the manual SPI Parts Name

Thermistor (SE)

(P.40)

Cover Open (LC) --- ---

Device Code

LMP LMP TH CN1601 Lamp Thermistor(P.139)

AIR AIR TH CN1600 AIR thermistor

CN

CN

CN4

(SW Board)

Part Name

Part Name

PCB ASSY;H980TH-MP;PH

Lamp Switch SWITCH,LID LAMP;PH;2

SEIKO EPSON 37 Revision A

Page 38

EB-E01 series Troubleshooting INTERNAL USE ONLY

POWER SUPPLY P.61

Error Name (Error Code)

Thermistor (SE)

(P.40)

CIRCUIT BOARDS P.62

Error Name (Error Code)

Thermistor (SE)

(P.40)

Device Code

CN

Device Name IPS tool Name used in the manual SPI Parts Name

PS (1) PS TH ---

PS Ballast Assy PS BALLAST UNIT ASSY;H838;EP;PH2;5PB BA TH ---

PFC (1) PFC TH ---

Device Code

CN

Device Name IPS tool Name used in the manual SPI Parts Name

LV LV TH --- MA Board MA Board Assy;H9**;PH;AS

Part Name

Part Name

SEIKO EPSON 38 Revision A

Page 39

EB-E01 series Troubleshooting INTERNAL USE ONLY

1. Power indicator

2. Status indicator

3. Wireless LAN indicator

4. Lamp indicator

5. Temp indicator

2.5 Error Indication and Problem diagnosis

2.5.1 Troubleshooting based on LED Indications

This section describes the LED error indications and corresponding error

names and their remedies.

ON Blink OFF

INTERNAL ERROR

LED Status

Power Status Lamp

Temp

Wireless LAN

Corresponding error name Remedy Reference

I2C: I2C H/W Error

DR: DR Status H/W Error

RAM: RAM H/W Error

ROM: ROM H/W Error

IV: Inner Error (Video sub-processor

error)

Disconnect the AC cable once and reconnect it and turn the

power back on.

P.45

If the same error occurs after trying the remedy above, check the

error name and carry out the remedy referring to the reference on

the right column.

SEIKO EPSON 39 Revision A

Page 40

EB-E01 series Troubleshooting INTERNAL USE ONLY

FAN ERROR/SENSOR ERROR

LED Status

Power Status Lamp

Temp

Wireless LAN

Corresponding error name Remedy Reference

Fan: Fan Error

Thermistor: Sensor Error

HIGH TEMPERATURE ERROR/AIR FILTER FLOW REDUCTION ERROR

LED Status

Power Status Lamp

Temp

Wireless LAN

Corresponding error name Remedy Reference

Temp: High Temp Error

Check the connections between each fan/sensor and MA Board.

If any connection failure is found, correct it.

If the same error occurs when turning the power back on after

trying the remedy above, check the error name and carry out the

remedy referring to the reference on the right column.

1. Check the Air Filter's condition (dirt accumulation,

clogging). When clogging or similar is found, clean/

replace the filter.

2. If the same error occurs when turning the power

back on after trying the remedy above, check the

error name and carry out the remedy referring to the

reference on the right column.

P.44

P.44

SEIKO EPSON 40 Revision A

Page 41

EB-E01 series Troubleshooting INTERNAL USE ONLY

AUTO IRIS ERROR/POWER SUPPLY (BALLAST) ERROR

Power Status Lamp

LAMP ERROR

Power Status Lamp

LED Status

LED Status

Temp

Temp

Wireless LAN

Wireless LAN

Corresponding error name Remedy Reference

Auto Iris: Auto Iris Error

If the same error occurs after turning the power back on, check

the error name and carry out the remedy referring to the reference

on the right column.

Ballast: Power Supply (Ballast) Error

Corresponding error name Remedy Reference

Check if the Lamp Cover is

installed correctly.

If not, reinstall the Lamp Cover

correctly.

Cover Open: Lamp Cover open Error

Lamp: Lamp Error

Lamp On: Lamp Lit Error

Check if the Lamp is installed

correctly.

If not, reinstall the Lamp Cover

correctly.

Lamp Off: Lamp Failure

If the Lamp is not broken,

Take out the lamp and check if

the Lamp is cracked or

damaged.

reinstall it and turn the power

back on. If the error recurs,

replace the Lamp with a new

one.

P.45

P.43

SEIKO EPSON 41 Revision A

Page 42

EB-E01 series Troubleshooting INTERNAL USE ONLY

LED Status

Power Status Lamp

Temp

Wireless LAN

Corresponding error name Remedy Reference

Take out the lamp and check if

the Lamp is cracked or

damaged.

Air Filter condition

(dirt accumulation, clogging)

If the Lamp is cracked/

damaged,

replace it with a new one.

If clogging is found, clean or

replace the Air Filter.

Lamp: Lamp Error

Lamp On: Lamp Lit Error

Lamp Off: Lamp Failure

If the projector has been used at

a place where is 1500 meters or

higher above sea level:

After trying above remedies:

If the High altitude mode is

ON, set it to OFF.

If the same error occurs after

turning the power back on,

check the error name and carry

out the remedy referring to the

references on the right column.

P.43

SEIKO EPSON 42 Revision A

Page 43

EB-E01 series Troubleshooting INTERNAL USE ONLY

2.5.2 Troubleshooting by Error Names

To display the error names, see " o Error Name/Warning Name/Device ID/Source Name List (p179)".

This section explains the troubleshooting mainly for the troubling parts identified using the error names and device codes displayed on the AS (after service) Menu

and the IPS tool to carry out their necessary repair. If a device code can be identified through the AS Menu or IPS tool, find the specific troubling part from the table

below.

TROUBLESHOOTING FROM THE ERROR NAME ON LAMP ERRORS

Error name Description Faulty part/part name Cause Remedy

Lamp Lamp is broken. Replace Lamp. P.74

Lamp Lamp Burnt Out Error

Lamp On

Lamp Off

Lamp lit error

Lamp Failure

Air Filter Air Filter is clogging. Clean Air Filter. Replace it if not improved. P.73

Lamp Switch Lamp Switch is broken. Replace Lamp Switch. P.86

PS Ballast Assy PS Ballast Assy is broken. Replace PS Ballast Assy. P.122

Lamp is broken due to the following

reasons:

Lamp

Cracks on the arc tube

Replace Lamp. P.74

Blackening/whitening of the arc tube

Swelled arc tube

PS Ballast Assy PS Ballast Assy is broken. Replace PS Ballast Assy. P.122

Reference

SEIKO EPSON 43 Revision A

Page 44

EB-E01 series Troubleshooting INTERNAL USE ONLY

TROUBLESHOOTING FROM THE ERROR NAME ON COOLING SYSTEM ERRORS

*: You can identify the broken fan or sensor by checking the device names in the "AS Menu" or IPS tool. For details, see AS Menu: 5TH Page (p176). For the positions of each fan

and sensor, see COOLING SYSTEM COMPONENTS (FAN) (p58) and COOLING SYSTEM/ SWITCH COMPONENTS (SENSOR) (p59).

Error name Description Faulty part/part name Cause Remedy

Air Filter is clogging. Clean Air Filter. Replace it if not improved. P.73

Thermistor is broken. Replace the broken Thermistor.

TH Cable is not connected properly. Connect TH Cable correctly to MA Board.

TH Cable is broken. Replace the broken TH Cable.

Vent is deformed or blocked by foreign

bodies.

Intake or exhaust opening is blocked by

something

Elements for temperature control on MA

Board are broken.

TH Cable is not connected properly. Connect TH Cable correctly to MA Board. P.53

TH Cable is broken.

Blades are broken.

Revolutions of the fan has become

abnormal.

Dust is accumulated on the fan. Clean the foreign material off of the fan. ---

Elements for fan control on MA Board are

broken. (Circuit error)

Clean the vent to remove the foreign material. ---

Replace the parts with deformed vent.

Improve the installation status. (Place it away from the

wall or obstacles)

Remove the obstacle from the opening area. ---

If the error continues after carrying out the remedies

above, the related circuit on MA Board is broken, replace

MA Board Assy.

Replace Fan.

If the error continues after carrying out the remedies

above, the related circuit on MA Board is broken, replace

MA Board Assy.

Temp Overheat Error

Fan Fan Error

Air Filter

Thermistor

Thermistor Cable

Exterior Parts

Installation Not installed correctly.

Environment of usage

MA Board

LV1

LMP

MA Board

Fan

EX

Reference

P.119

P.132

P.53

P.89

P.136

---

P.100

P.119

P.121

P.132

P.100

SEIKO EPSON 44 Revision A

Page 45

EB-E01 series Troubleshooting INTERNAL USE ONLY

Error name Description Faulty part/part name Cause Remedy

FPC is not connected properly. Connect FPC correctly to MA Board. P.53

FPC is broken.

The thermistor mounted on the circuit

board is broken.

Thermistor is broken. Replace Thermistor.

TH Cable is not connected properly. Connect TH Cable correctly to MA Board.

TH Cable is broken. Replace the broken TH Cable.

The thermistor mounted on the main

circuit board is broken.

The thermistor mounted on the BA Unit is

broken.

Replace MA Board. P.100

Replace PS Ballast Assy. P.122

Thermistor Sensor Error

LV

LMP

LWR

PS(1)

PFC(1)

PB

Optical engine

Thermistor

PS Ballast Assy

TROUBLESHOOTING FROM THE ERROR NAME ON ELECTRIC CIRCUIT ERRORS

Error name Description Faulty part/part name Cause Remedy

RAM

Inner

I2C Internal error I2C

DR Internal error DR

IV Video sub-processor error

Auto Iris Auto Iris Error

Internal error

(RAM)

Internal error

(ROM)

RAM has become abnormal.

MA Board

Input AC power supply

Environment (Temperature of the

customer’s operating

environment)

MA Board MA Board is broken. Replace MA Board. P.100

Auto Iris Assy

Moving parts (Gears) of Auto Iris

Assy

Flash ROM is broken.

(The number of data rewrite times has

exceeded its limit)

MA Board is broken.

Instability of the input AC Power

Supply. (caused by an external factor)

Access timing error (occurs in a low

temperature environment (Y43series))

TH Cable is not connected properly. Connect TH Cable correctly to MA Board. P.39

TH Cable is broken.

Auto Iris Assy is broken.

Foreign material sticks on the part and

causes operation failure.

Replace MA Board. P.100

If not appropriate, request the customer to improve the usage

environment. (Refer to “Safety precautions” in the projector’s User's

Guide)

Replace the Auto Iris Assy. P.115

Remove the foreign material in between the gears. ---

Reference

P.119

P.132

Reference

SEIKO EPSON 45 Revision A

Page 46

EB-E01 series Troubleshooting INTERNAL USE ONLY

Error name Description Faulty part/part name Cause Remedy

PS Ballast Assy BA Unit is broken. Replace PS Ballast Assy. P.122

Ballast Power Supply (Ballast) Error

PS Cable

TH Cable is not connected properly. Connect TH Cable correctly to MA Board. P.53

TH Cable is broken. Replace the broken TH Cable. P.122

Reference

SEIKO EPSON 46 Revision A

Page 47

EB-E01 series Troubleshooting INTERNAL USE ONLY

2.5.3 Troubleshooting without Error Indications

This section provides troubleshooting procedures based on observed faults.

TROUBLESHOOTING AT POWER-ON

Error Status Faulty part/part name Cause Remedy

The projector cannot be turned on from

the Control Panel. (Power indicator lights

up blue, and power can be turned on

using the remote controller)

Projector is not turned on

(Power LED does not light blue)

Control panel cable (FFC)

Control panel Control panel is broken. Replace the control panel.

PS Ballast Assy

MA Board MA Board is broken. Replace MA Board. P.100

TROUBLESHOOTING ON IMAGE DISPLAY & QUALITY

Error Status Faulty part/part name Cause Remedy

No image is projected. (Lamp lights)

Focus cannot be adjusted.

Zoom cannot be adjusted.

Black part of image is reddish.

Black part of image is greenish.

Input video signal

MA Board Video Input terminal is broken. Replace MA Board. P.100

FOCUS RING FOCUS RING is broken. Replace FOCUS RING. P.116

Projection Lens (Optical Engine) Projection Lens is broken. Replace Optical Engine. P.113

Zoom Ring Zoom Ring is broken. Replace Zoom Ring. P.116

Projection Lens (Optical Engine) Projection Lens is broken. Replace Optical Engine. P.113

Optical engine

MA Board MA Board is broken. Replace MA Board. P.100

Optical engine

MA Board MA Board is broken. Replace MA Board. P.100

Reference

TH Cable is not connected properly. Connect TH Cable correctly to MA Board. P.39

TH Cable is broken. Replace the control panel.

TH Cable is not connected properly. Connect TH Cable correctly to MA Board. P.39

PS Ballast Assy is broken. Replace PS Ballast Assy. P.122

The selected input video cable is not

connected correctly.

FPC for L/V (R) is not connected

properly.

FPC for L/V (R) is broken. Replace Optical Engine. P.113

FPC for L/V (G) is not connected

properly.

FPC for L/V (G) is broken. Replace Optical Engine. P.113

Connect the selected input video cable correctly. ---

Connect FPC for L/V (R) to MA Board correctly. P.39

Connect FPC for L/V (G) to MA Board correctly. P.39

P.84

Reference

SEIKO EPSON 47 Revision A

Page 48

EB-E01 series Troubleshooting INTERNAL USE ONLY

Error Status Faulty part/part name Cause Remedy

Black part of image is bluish.

Abnormality can be seen on the projected

image.

Optical engine

MA Board MA Board is broken. Replace MA Board. P.100

Optical parts

TROUBLESHOOTING ON AUDIO INPUT/OUTPUT

Error Status Faulty part/part name Cause Remedy

Audio Input cables

Sound does not come out.

Speaker

IF Board

Reference

FPC for L/V (B) is not connected

properly.

FPC for L/V (B) is broken. Replace Optical Engine. P.113

Dirt or problems (deterioration,

misalignment, or looseness) of the optical

part(s)

TH Cable is not connected properly. Connect the audio input cable correctly.

TH Cable is broken. Replace the broken audio input cable.

TH Cable is not connected properly. Connect TH Cable correctly to MA Board. P.53

TH Cable is broken.

Speaker is broken.

Input terminal is broken.

Elements for audio control on IF Board

are broken. (Circuit error)

Connect FPC for L/V (B) to MA Board correctly. P.39

Replace Optical Engine. P.113

Reference

---

Replace Speaker.

If the error continues after carrying out the remedies

above, the related circuit on IF Board is broken, so

replace IF Board.

P.105

P.121

P.106

SEIKO EPSON 48 Revision A

Page 49

EB-E01 series Troubleshooting INTERNAL USE ONLY

TROUBLESHOOTING ON OPERATION ABNORMALITY

Error Status Faulty part/part name Cause Remedy

Operation using Remote Controller

cannot be made.

Projector cannot be operated from the

control panel.

LED does not light up

(Power can be turned on using remote

control.)

AV Mute does not function even if the

shutter is closed.

Remote Controller

Receiver (RC Filter)

Cable (IR Board)

IR Board

IF Board

Control panel cable (FFC)

SW Buttons SW Buttons are broken. Replace the SW Buttons.

SW Board SW Board is broken. Replace the SW Board.

MA Board

SW Board

MA Board

Lens Shutter Output Switch

Batteries ran out. Replace the batteries with new ones. ---

Remote Controller is broken. Replace Remote Controller. ---

The Lower Case or IF Case receiver is

dirty.

TH Cable is not connected properly.

TH Cable is broken. Replace the cables of the IR Board. P.136

Elements for remote control processing on

the IR Board are broken. (Circuit error)

Elements for remote control processing on

the IF Board are broken. (Circuit error)

TH Cable is not connected properly. Connect TH Cable correctly to MA Board.

TH Cable is broken. Replace the broken TH Cable.

Elements for operation processing on MA

Board are broken. (Circuit error)

TH Cable is not connected properly. Connect the cable to MA Board correctly. P.53

SW Board is broken. Replace the SW Board. P.84

Elements for LED display on MA Board

are broken. (Circuit error)

TH Cable is not connected properly. Connect the cable to SW Board correctly. P.87

Lens shutter output switch is broken. Replace the lens shutter output switch. P.87

Clean Lower Case or IF Case. Replace Lower Case or IF

Case if not improved.

Connect the cables of the IR Board to the MA Board

correctly.

If the error continues after carrying out the remedies

above, the circuit on the IR Board is broken, so replace

the IR Board.

If the error continues after carrying out the remedies

above, the related circuit on IF Board is broken, so

replace IF Board.

If the error continues after carrying out the remedies

above, the related circuit on MA Board is broken, so

replace MA Board Assy.

If the error continues after carrying out the remedies

above, the related circuit on MA Board is broken,

replace MA Board Assy.

Reference

P.77

P.136

P.53

P.136

P.106

P.84

P.100

P.100

SEIKO EPSON 49 Revision A

Page 50

EB-E01 series Troubleshooting INTERNAL USE ONLY

TROUBLESHOOTING ON OTHER ABNORMALITY

Error Status Faulty part/part name Cause Remedy

Smoke/Abnormal odor

Abnormal noises

Reference

Lamp Burn on foreign objects (dust) from heat.

Fan,Lamp Burn on cables from heat. Replace the burned cables or parts with new ones. P.122

PS Ballast Assy Burn on circuit board from heat. Replace PS Ballast Assy. P.122

PS Ballast Assy

Fan

Operating parts Screws are loose or fallen off. Tighten the screws or reassemble the parts. ---

Pulse transformer vibrates abnormally.

BA Unit vibrates abnormally.

Foreign material sticks on a fan. Clean the foreign material off of the fan.

Fan’s impeller is broken. Replace Fan.

Clean the area around Lamp to remove the foreign

objects.

Replace PS Ballast Assy. P.122

Check if one of the fans contacts with other parts. If so,

correct its installation.

P.74

P.37Fan is contacting other parts.

SEIKO EPSON 50 Revision A

Page 51

EB-E01 series Troubleshooting INTERNAL USE ONLY

2.5.4 Troubleshooting on image abnormality

The following tables present this projector’s possible troubles in image quality, and provides probable causes and troubleshooting procedures based on the observed

phenomena.

ILLUMINATION REDUCTION

Phenomenon Cause Remedy Reference

The projected image became darker.

Some optical parts might mist for some

reasons.

COLOR NON-UNIFORMITY

Phenomenon Cause Remedy Reference

Color non-uniformity can be seen partially in

the projected image.

Some optical parts may become

deteriorated.

Some optical parts may be broken.

Clean the parts with a cotton swab or

the like moistened with ethanol.

Replace the deteriorated or broken

parts with new ones.

Optical Engine Repair Service Manual

Optical Engine Repair Service Manual

SEIKO EPSON 51 Revision A

Page 52

EB-E01 series Troubleshooting INTERNAL USE ONLY

COLOR BANDING (SHADOW)

Phenomenon Cause Remedy Reference

There occur “shadows”* on the right and left

side.

* : * “Shadow” is a vertical color banding

appearing on the left or right side.

Some optical parts may be displaced due to

some shock or the like.

Re-assemble the defective parts.

If the phenomenon not improved,

replace the part with a new one. If

still not improved, replace the

Optical Engine.

Optical Engine Repair Service Manual

ABNORMAL IMAGE

Phenomenon Cause Remedy Reference

Some abnormality can be seen in the projected

image.

Some optical parts may be detached.

Re-assemble the defective parts. If

the phenomenon not improved,

replace the part with a new one.

Optical Engine Repair Service Manual

SEIKO EPSON 52 Revision A

Page 53

EB-E01 series Troubleshooting INTERNAL USE ONLY

CN1405

RTC Board

CN501

WFD Board 2

CN3000

PS Ballast Assy

CN8900

B L/V

CN8800

G L/V

CN8700

R L/V

CN1603

EX Fan

CN1604

Lamp Fan

CN701 (700/702)

Speaker

CN2200

Auto Iris Assy

CN1400

SW Board

CN1600

AIR-TH

CN1403

F-IR

CN1602

LV-FAN

CN500

WFD Board 1

CN1601

LMP-TH

Circuit Board Image

CN1800

W-LAN

2.5.5 Cable connection on the MA Board and error symptoms

This section describes the projector’s status when disconnection occurs somewhere between the parts/units and the MA Board. If any problem has occurred, refer to

the following table and check the doubted connectors are securely connected. If there is a disconnection or a loose connection, connect it correctly.

SEIKO EPSON 53 Revision A

Page 54

EB-E01 series Troubleshooting INTERNAL USE ONLY

MA

Board

Board-to-board

Air TH

RTC Board

SW Board

LMP TH

CN1600

CN1400

CN1405

CN1403

CN1602

CN501

CN3000

CN8800

CN701*

CN702*

CN8700 CN8900

CN2200

CN1603

CN500

CN1601

CN1604

IF Board

Speaker 5W*

EX Fan

WFD Board

PS Ballast Assy

WFD Board

P4Combo

Optical Engine

CN700*

Speaker 16W*

Lamp Fan

Auto Iris

Front IR

LV Fan

Indicates connector on the back side

* Speakers and connectors dif-

fer according to model.

CONNECTION DIAGRAM BETWEEN BOARDS

SEIKO EPSON 54 Revision A

Page 55

EB-E01 series Troubleshooting INTERNAL USE ONLY

Connector

No.

CN8700 Optical Engine (R L/V) --- ---

CN8800 Optical Engine (G L/V) --- ---

CN8900 Optical Engine (B L/V) --- ---

CN3000 PS Unit (P/S) --- ---

CN1600 AIR-TH Thermistor AIR

CN1601 LMP-TH Thermistor LMP

CN1602 LV-FAN Fan LV1

CN1603 EX-FAN Fan EX

CN1604 LMP-FAN Fan LMP

CN500*

CN501*

CN1405*

CN1800*

1

1

CN1400 SW Board Cover Open Lamp cover open error

CN1403 IR Board --- ---

1

2

Destination

WFD Module WFD WFD error

RTC Board I2C Internal error

P4Combo --- ---

Error Name/

Device Name

Name

Sensor Error

Fan Error

Error Information

Phenomenon

When pressing the power button, projection starts normally. But the black part of the

projected image is reddish.

When pressing the power button, projection starts normally. But the black part of the

projected image is greenish.

When pressing the power button, projection starts normally, then the projection starts.

But the black part of the projected image is bluish. (This phenomenon is not easily

recognized on Logo screen or No Signal screen; therefore try displaying the menu or

the like to check for it.)

When connecting the AC cable, the power LED does not light blue. The power button

does not work or power cannot turn on.

The power can turn on and after the status LED blinks in blue, temperature LED blinks

in orange. When pressing the power button, initialization starts normally but sensor

error occurs while initializing. Then LEDs indicate the error, and then the projector

turns into the abnormal stand-by status

The power can turn on and after the status LED blinks in blue, temperature LED blinks

in orange. When pressing the power button, initialization starts normally but sensor

error occurs while initializing. Then LEDs indicate the error, and then the projector

turns into the abnormal stand-by status

The power can turn on and Power LED lights blue. Projection starts normally when the

power button is pressed, but the WFD does not function.

The power cannot be turned on with the operation panel. However, the power can be

turned on with the remote controller. When the power is turned on, the fan rotates at

high speed and turns off after a short while. Then the machine goes into abnormal

stand-by mode after displaying Lamp Cover Open Error.

Operates normally after the power turns on. However, IR receiver at the front stops

working.

The power can turn on and Power LED lights blue. When pressing the power button,

initialization starts but instantly the projector changes to the Internal error mode. After

a certain period of cooling, the projector turns into the abnormal stand-by status. The

LED Indicator’s warning display continues until unplugging the AC cable.

The power can turn on and Power LED lights blue. Projection starts normally when the

power button is pressed, but the W-LAN does not function.

Reference

P.60

P.61

P.37

P.37

P.62

P.62

P.62

P.62

P.62

SEIKO EPSON 55 Revision A

Page 56

EB-E01 series Troubleshooting INTERNAL USE ONLY

Connector

No.

CN2200 Auto Iris Assy Auto Iris Auto Iris Error

CN700*

CN701*

CN702*

3

4

5

Destination

Speaker (2W)

Speaker (16W)

Speaker (5W)

Error Name/

Device Name

--- ---

Name

*1 EB-FH52/992F, EH-TW750

*2 EB-FH52/992F/W52, EH-TW750

*3 EB-E01/X06/W06/E10/X51/W51/W52

*4 EB-FH52/972/982W/992F/118, PL 119W

*5 EB-FH06/E20/X49/W49, EH-TW740/TW750

Error Information

Phenomenon

The power can turn on and Power LED lights blue. When pressing the power button,

initialization starts but instantly the projector changes to the Auto Iris Error mode. The

error message in Auto Iris is displayed on the screen, and it advises the user to turn off

the power and to contact the Epson Service. When pressing the power button, the LEDs

indicate the warning and after a certain period of cooling, the projector turns into the

abnormal stand-by status. The LED Indicator’s warning display continues until

unplugging the AC cable.

When pressing the power button, initialization starts normally and the projection starts.

However, no sound is output from the speaker even if the audio input is applied. Audio

controller on screen display appears, but no sound is output from the speaker even if

the audio input is applied.

Reference

P.60

P.62

SEIKO EPSON 56 Revision A

Page 57

EB-E01 series Troubleshooting INTERNAL USE ONLY

SW Board

Connector

No.

CN1 MA Board (CN1400) Cover Open Lamp cover open error

CN2* H Key ASSY --- ---

CN3* Lens Cover SW SH Shutter error

CN4 Lamp Cover SW Cover Open Lamp cover open error

Destination

Error Name/

Device Name

Name

* Not for EB-E01/E10

Error Information

Phenomenon

The power cannot be turned on with the operation panel. However, the power can be

turned on with the remote controller. When the power is turned on, the fan rotates at

high speed and turns off after a short while. Then the machine goes into abnormal

stand-by mode after displaying Lamp Cover Open Error.

Operates normally after the power turns on, but the lateral strain of the projected image

cannot be corrected.

The power can turn on and Power LED lights blue. When pressing the power button,

initialization starts normally and the projection starts. But the lamp does not turn off

even when the shutter is closed, and the AV mute does not function. (However, AV

mute on the remote controller works normally)

Note) Please note that this error may cause troubles such as deformation of the shutter

if it is kept closed.

When the power is turned on, the machine goes into abnormal stand-by mode after

displaying Lamp Cover Open Error.

Reference

P.62

P.62

P.59

P.59

SEIKO EPSON 57 Revision A

Page 58

EB-E01 series Troubleshooting INTERNAL USE ONLY

Lamp Fan (P.120)

INT Fan (P.132)

EX Fan (P.119)

2.6 Parts Layout Diagrams

COOLING SYSTEM COMPONENTS (FAN)

SEIKO EPSON 58 Revision A

Page 59

EB-E01 series Troubleshooting INTERNAL USE ONLY

LMP Thermistor (TH Board) (P.119)

Air Thermistor (TH Board) (P.132)

Lens Shutter Output Switch

(Switch Cable H721-A) (P.87)

Lamp Output Switch

(Lid Lamp Switch) (P.86)

COOLING SYSTEM/ SWITCH COMPONENTS (SENSOR)

SEIKO EPSON 59 Revision A

Page 60

EB-E01 series Troubleshooting INTERNAL USE ONLY

Auto Iris Assy (P.115)

Optical Engine (Assy) (P.113)

Lamp Assy (P.74)

OPTICAL PARTS

SEIKO EPSON 60 Revision A

Page 61

EB-E01 series Troubleshooting INTERNAL USE ONLY

PS Ballast Assy (P.122)

Filter Board (P.135)

POWER SUPPLY

SEIKO EPSON 61 Revision A

Page 62

EB-E01 series Troubleshooting INTERNAL USE ONLY

Speaker (P.105) (P.121)

MA Board (P.100)

Control Panel (P.84)

IF Board (P.106)

P3dash Module (P.96)

WFD Board (P.94)

IR Board (P.131) (P.136) P4combo Module (P.128)

RTC Board (P.97)

H KEY ASSY (P.86)

RTC Board (EH-TW750) (P.112)

CIRCUIT BOARDS

SEIKO EPSON 62 Revision A

Page 63

DISASSEMBLY AND ASSEMBLY

CHAPTER

3

INTERNAL USE ONLY

Page 64

EB-E01 series Disassembly and Assembly INTERNAL USE ONLY

3.1 Precautions

This section describes cautions before starting disassembling and

assembling this product. Make sure to read the precautions below before

starting.

3.1.1 General Cautions in operation

General cautions for disassembling and assembling this product are

provided below. Cautions for each procedure are provided in its

corresponding section. Make sure to refer to them before starting.

Do not touch the lamp or the parts around it. They are extremely hot

even after the cooling down operation completed. If any maintenance

work inside the projector is necessary soon after the projector is in

operation, leave the unit until it becomes cool enough before performing

maintenance work.

Never use the air blowers such as a lens cleaner that contains flammable

gas in repair/maintenance work.

Do not disassemble any components not as specified in this Service

Manual.

The Optical Engine, the circuit boards are very sensitive to static

electricity; therefore, be sure to take appropriate measures to prevent

static destruction such as to place them inside static-proof bags once they

have been removed from the projector.

The Optical Engine is very sensitive to vibration and shocks; therefore,

make sure to handle it with care.

The speaker unit contains a permanent magnet; therefore, make sure to

keep it away from any storage media such as floppy disks or magnetic

cards.

Be careful not to drop a metal part such as a screw, a washer, or a clip