Page 1

USN 52R / USN 52L

Technical Reference and Operating Manual

Ident No. 28 642

Page 2

Krautkramer USN 52R/USN 52L Issue 05, 02/00 0-1

Index

1. Introduction ....................................... 1-1

1.1 Safety information ................................... 1-2

Storage batteries ....................................... 1-2

Defects/errors and exceptional stresses .... 1-2

Software .................................................... 1-3

1.2 Important notes........................................ 1-3

Preconditions for testing with ultrasonic

flaw detectors ............................................ 1-3

Operator training ........................................ 1-4

Technical test requirements ....................... 1-4

Limits of testing ......................................... 1-5

Wall thickness measurements

with ultrasonics .......................................... 1-5

Effect of the material of the test object ...... 1-5

Effect of temperature variations ................. 1-6

Measurement of remaining wall thickness .. 1-6

Flaw boundary scanning method ................ 1-6

Echo display comparison method .............. 1-7

1.3 USN 52R/USN 52L .................................... 1-8

Special features of the two versions: ......... 1-8

1.4 Remarks on this manual......................... 1-10

Before starting for the first time ................ 1-10

Getting to know the adjustment functions .1-10

Service ..................................................... 1-10

Specifications and basic settings..............1-10

Layout of this manual ...............................1-11

2. Standard package

and accessories ................................ 2-1

2.1 Standard package .................................... 2-3

2.2 Required accessories .............................. 2-4

2.3 Recommended accessories .................... 2-4

2.4 Recommended outside products ............ 2-5

3. Setting into operation ....................... 3-1

3.1 Positioning the USN 52R/USN 52L .......... 3-2

3.2 Power supply ........................................... 3-2

Battery operation ....................................... 3-3

Inserting the batteries ................................ 3-3

Using the battery charger ........................... 3-4

Page 3

0-2 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Index

3.3 Probe connection..................................... 3-5

3.4 Starting the USN 52 R .............................. 3-5

Switching on .............................................. 3-5

Reset ......................................................... 3-6

3.5 Screen saver ............................................. 3-6

4. Basics of operation ........................... 4-1

4.1 USN 52R and USN 52L ............................. 4-2

4.2 Display ...................................................... 4-4

A-scan display ........................................... 4-4

Functions on the display ............................ 4-5

Indications beneath the A-scan .................. 4-6

4.2 Keypad ...................................................... 4-8

Function keys ............................................ 4-8

Special keys .............................................. 4-8

Special keys of the USN 52L for

setting the display...................................... 4-9

4.3 Operational concept ...............................4-10

Changing the operating levels ...................4-10

Selection of function groups and functions 4-10

Setting the function ................................... 4-10

Accelerated adjustment ............................4-10

Selection of measured value for enlarged

display ......................................................4-11

4.4 Function keys ..........................................4-11

4.5 Keys for special functions ......................4-12

Only USN 52L ...........................................4-12

4.6 Important basic settings .........................4-13

Set language .............................................4-13

Setting the measurement units ................. 4-13

5. Operation ........................................... 5-1

5.1 Function overview

(first operating level) ................................ 5-2

5.2 Adjustment of the USN 52R/USN 52L ...... 5-3

GAIN Gain adjustment........................... 5-3

Selection of basic data .............................. 5-4

Setting the receiver .................................... 5-6

Setting the pulser....................................... 5-8

Gate adjustment .......................................5-10

Calibration functions .................................5-12

Page 4

Krautkramer USN 52R/USN 52L Issue 05, 02/00 0-3

Index

Storing data ..............................................5-14

Clearing the instrument setting..................5-15

Clearing all data ........................................ 5-16

Displaying stored A-Scans (preview) .........5-16

5.3 USN 52R/USN 52L calibration ................ 5-17

Calibration of display range .......................5-17

Calibration with a straight-beam probe .......5-18

Calibration with angle-beam probes ........... 5-20

Calibration with a dual (T/R) probe ............5-21

Automatic calibration ................................5-22

Preparing the instrument for

digital measurement ..................................5-23

Calibrating the sensitivity ..........................5-24

5.4 DAC/TCG ..................................................5-25

Function group TCG ..................................5-26

5.5 Recording a Distance-Amplitude

Curve .......................................................5-28

5.6 Echo evaluation with DAC/TCG .............. 5-31

DAC mode ................................................ 5-32

TCG mode ................................................ 5-33

5.7 Measuring thickness ...............................5-34

5.8 Storing measured values - Data Logger 5-35

Determining the number of FILES ............. 5-35

Selecting a FILE .......................................5-36

Clearing FILES ......................................... 5-37

Storing measured values .......................... 5-37

Viewing stored readings ............................ 5-38

Clearing the measured values ................... 5-38

5.9 Configuring the USN 52R/USN 52L ........ 5-39

5.10Data set names ........................................5-50

5.11Setting the RS232 interface .................... 5-57

5.12Setting the flaw location calculation......5-59

Displaying the measured values ...............5-61

Automatic calibration ................................ 5-62

5.13Setting the measurement methods ........ 5-62

5.14Locking set values .................................. 5-64

5.15Function check ........................................5-64

Page 5

0-4 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Index

6. Documentation .................................. 6-1

6.1 Printing instrument settings and

display contents ....................................... 6-2

Preparing the printer................................... 6-2

6.2 Documentation with the PC program

UltraDOC ................................................... 6-5

7. Servicing and maintenance .............. 7-1

7.1 Cleaning the USN 52R/USN 52L .............. 7-2

7.2 Maintenance of NiCd cells ....................... 7-2

Charging NiCd cells ................................... 7-2

Handling NiCd cells .................................... 7-3

Handling AlMn batteries ............................. 7-3

8. Interfaces, Peripherals 8 .................. 8-1

8.1 Interfaces .................................................. 8-2

Serial interface RS 232 .............................. 8-2

Layout of 7 pin Lemo socket (RS 232) ....... 8-3

Layout of 4 pin Lemo socket (charger

socket, switching output) ........................... 8-4

8.2 Connection of a peripheral ...................... 8-5

8.3 Transferring the display contents ........... 8-6

8.4 Printing Data Logger report .................... 8-6

Data Logger report format .......................... 8-7

8.5 Transferring measurement values........... 8-9

Transferring measurements values in

the Data Logger to a PC ............................ 8-9

Printing display contents and instrument

settings.....................................................8-10

Transfer formats ........................................8-10

8.6 USN 52R/USN 52L remote operation ......8-12

8.7 Configuring the MEMO function ............ 8-17

Defining data header ................................. 8-17

8.8 Analog outputs........................................8-20

Analog voltage for the echo amplitude

(echo in the monitor gate) ......................... 8-21

Analog voltage for the sound path of

an echo.....................................................8-21

TTL switching output.................................8-22

Page 6

Krautkramer USN 52R/USN 52L Issue 05, 02/00 0-5

Index

9. Specifications .................................... 9-1

10.Appendix.......................................... 10-1

10.1 Function directory ..................................10-2

10.2 EC Certificate of Conformity...................10-7

10.3 Service addresses...................................10-8

11.Changes........................................... 11-1

12.Index ................................................. 12-1

Page 7

0-6 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Page 8

Krautkramer USN 52R/USN 52L Issue 05, 02/00 1-1

Introduction 1

Page 9

1-2 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

1.1 Safety information

USN 52R and USN 52L have been designed and tested

according to DIN EN 61 010 Part 1, March 1994, Safety

requirements for electrical measuring, control and lab

equipment, and was technically in perfectly safe and

faultless condition when leaving the manufacturing

works.

In order to maintain this condition and to ensure a safe

operation, you should urgently read the following safety

information before putting the instrument into operation.

A Attention:

USN 52R and USN 52L are instruments for materials

testing. Any use for medical applications or other

purposes is not allowed!

The instruments may only be used in industrial environments!

Storage batteries

USN 52R/USN 52L can be operated with storage batteries. Please only use the power supply/battery charger

unit UN 655 for storage battery charge.

Defects/errors and exceptional stresses

If you have reason to believe that a safe operation of

your instrument is no longer possible, you have to disconnect the instrument and secure it against unintentional reconnection. Remove the batteries if necessary.

• A safe operation is e.g. no longer possible

• if the instrument shows visible damages,

• if the instrument no longer operates perfectly,

• after prolonged storage under adverse conditions

(e.g. exceptional temperatures and/or especially high

air humidity, or corrosive environmental conditions),

• after being subjected to heavy stresses during

transportation.

Introduction

Safety information

Page 10

Krautkramer USN 52R/USN 52L Issue 05, 02/00 1-3

Software

Based on the present state of the art software can

never be completely error-free.

That is why software-controlled instruments should be

checked before use to see if the necessary functions

operate perfectly in the provided combination.

Therefore, please check the functions of the instrument

according to the information given in Chapter 5.

Should you have any questions with regard to the application of your USN 52R/USN 52L, please contact your

local “Krautkrämer” or “Krautkramer-Branson” agent.

1.2 Important notes

Please read the following notes before using your

USN 52R/USN 52L. It is important that you understand

and observe this information to avoid making any mistakes in operating the instrument. These could lead to

false test results which can finally result in injury to

persons or damage to property.

Preconditions for testing with ultrasonic flaw

detectors

This Operating Manual contains all the necessary information on how to operate the USN 52R/USN 52L. There

are, however, a number of factors which affect the test

results obtained. In the following, please find a detailed

description of the three most important conditions for

reliable testing with ultrasonic flaw detection equipment:

• a properly trained operator,

• knowledge of the specialized test requirements and

limits of testing

• selection of the appropriate test equipment.

Important notes

Introduction

Page 11

1-4 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Operator training

The operator of an ultrasonic flaw detector must be

adequately trained in the field of ultrasonic test methods. This includes, among other things, sufficient

knowledge of:

– sound propagation theory,

– the effects of the velocity of sound in the material,

– what happens to the sound wave at the interface

between two different materials under test,

– the propagation of the sound beam,

– the effect of the sound attenuation in the object

under test,

– the effect of the surface condition of the object under

test.

Lack of knowledge here can lead to false test results

with unforeseeable consequences.

Information concerning existing possibilities for the

qualification of ultrasonic operators as well as the question of achieving these qualifications can be obtained

from the corresponding NDT societies in your country

(DGZfP in Germany, ASNT in the USA etc.), or also

from Krautkramer-Branson.

Technical test requirements

Every ultrasonic test is subject to specific technical

test requirements. The most important of these are:

• definition of the scope of the test;

• selection of the appropriate technical test method;

• taking into account the properties of the material;

• laying down the test limits for “recording and evaluation purposes“.

It is the task of those with overall responsibility for testing to ensure that the test operator is fully informed

about these requirements. The best basis for such information is experience with identical test objects. It is

also essential that the relevant test specifications be

clearly and completely understood by the test operator.

Krautkrämer GmbH & Co regularly hold specialized

training courses for qualified persons in the field of ultrasonic testing.

Scheduled dates of such courses will be given on request.

Introduction

Important notes

Page 12

Krautkramer USN 52R/USN 52L Issue 05, 02/00 1-5

Limits of testing

Ultrasonic tests can only provide information about

those parts of the test object which the sound beam

from the probe used has actually passed through.

Extreme caution is advised in making any conclusions

from the tested areas of the test object as to the condition of those parts of the test object which have not

actually been tested.

Such conclusions are usually only possible where a

large amount of previous data is available and proven

methods of statistical evaluation are used.

Boundary surfaces within the test object can completely reflect the sound beam so that flaws or reflection points lying deeper remain undetected. Care must

therefore be taken to ensure that the sound beam does

in fact penetrate all those parts of the test object which

are to be tested.

Wall thickness measurements with ultrasonics

All wall thickness measurements with ultrasonics are

based on a time-of-flight measurement. Accurate measurement results require a constant sound velocity

within the material. In test objects of steel, even with

varying alloying constituents, this condition is usually

fulfilled: the variation of the sound velocity within the

material is so slight that it is only of importance for

high-precision measurements. In other materials, however, e.g. nonferrous metals and plastics, the sound

velocity can vary substantially within the material and

cause inaccurate measurement results.

Effect of the material of the test object

If the test object is not of a single, homogeneous material, then the sound may propagate at different velocities in different parts of the object. In this case, the test

range adjustment should be chosen for the average of

the different velocities in the different parts of the object. This is done by using a calibration block in which

the velocity of sound is the same as the average within

the test object.

If substantial variations in the velocity of sound within

the objects are anticipated, then the instrument should

be readjusted at frequent short intervals to the actual

sound velocity values present. If this is not done, false

results may be obtained for the wall thickness.

Important notes

Introduction

Page 13

1-6 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Effect of temperature variations

The velocity of sound within the test object also varies

as a function of the temperature of the material. This

can cause appreciable errors if the instrument has been

calibrated on a cold calibration block and is then used

on a warm or hot test object. Such errors can be

avoided either by warming the calibration block to the

same temperature before calibrating, or by using a correction factor obtained from tables.

Measurement of remaining wall thickness

The measurement of the remaining wall thickness on

plant components such as pipes, tanks and reaction

vessels of all types which have been corroded or

eroded from the inside requires a suitable test instrument and special care in handling the probe.

The test operator must be told the nominal wall thicknesses and the likely amount of the loss due to erosion

or corrosion.

Assessing flaws using ultrasonics

In present-day test practice there are basically two

methods of assessing flaws.

If the diameter of the sound beam is smaller than the

extent of the flaw, then the beam can be used to scan

the boundaries of the flaw and thus determine its area.

If, however, the diameter of the sound beam is greater

than the size of the flaw, the maximum echo response

from the flaw must be compared with the maximum

echo response from an artificial flaw at the same depth

provided for comparison purposes.

Flaw boundary scanning method

The smaller the diameter of the sound beam from the

probe, the more accurately the determined flaw area

corresponds to the actual flaw area when scanning the

flaw boundaries with the sound beam from a probe.

If, however, the sound beam is relatively broad, the

determined flaw area can substantially differ from the

actual flaw area. Care should therefore be taken to select a probe which will give a sufficiently narrow beam

at the position of the flaw.

Introduction

Important notes

Page 14

Krautkramer USN 52R/USN 52L Issue 05, 02/00 1-7

Echo display comparison method

The echo from a small natural flaw is usually smaller

than the echo from an artificial comparison flaw (e.g.

circular disc reflector) of the same size. This is due, for

instance, to the roughness of the surface of a natural

flaw, or to the fact that the beam does not impinge on it

at right angles.

If this fact is not taken into account when assessing

natural flaws, there is a danger of underestimating their

magnitude.

In the case of very jagged or fissured flaws (e.g. shrink

holes in castings) it may be that so much scattering of

the sound occurs at the surface of the flaw that no flaw

echo is produced. In such cases, a different assessment method should be chosen, e.g. backwall echo

attenuation method.

When testing large components, the distance sensitiveness of the flaw echoes plays an important role. Care

should be taken here to choose artificial comparison

flaws whose distance sensitivity laws come as close

as possible to those of the natural flaws being assessed.

Ultrasound is subject to attenuation as it passes

through any material. This attenuation is very small in,

for instance, fine grained steel, and also in many small

components made of other materials.

If, however, the sound travels a large distance into the

medium, then even at low attenuation coefficients a

large cumulative attenuation can result. There is then a

danger that echoes from natural flaws appear too small.

For this reason, the effects of sound attenuation on the

evaluation results must always be estimated and, if

necessary, taken into account.

If the test object has a rough surface, part of the incident sound energy will be scattered at its surface and

is lost to the test instrument. The larger this initial scattering, the smaller the echoes appear, and the more

incorrect also the results of the evaluation.

It is therefore important to make an allowance for the

surface roughness of the test object and apply a correction to the observed height of the echoes (transfer

correction).

Important notes

Introduction

Page 15

1-8 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

1.3 USN 52R/USN 52L

USN 52R/USN 52L are lightweight, compact ultrasonic

flaw detectors which is especially well suited for

• locating and evaluating material flaws,

• measuring wall thicknesses.

• documenting all test results and readings.

USN 52R:

• high-resolution EL display, 146 mm x 67 mm

(5.75“ x 2.65“), 552 x 256 pixels

USN 52L:

• transflective LCD screen, 114 mm x 75 mm

(4.5“ x 3.0“), 480 x 320 pixels

Special features of the two versions:

• lightness in weight (2.7 kg including batteries) and

small in size,

• an easy-to-clean keypad,

Introduction

USN 52R/USN 52L

USN 52R

USN 52L

Page 16

Krautkramer USN 52R/USN 52L Issue 05, 02/00 1-9

• 2-stage adjustment of pulse repetition rate in order to

avoid phantom echoes,

• indication of amplitude and sound path for flaw

testing and thickness measurement,

• DAC for convenient display evaluation according to

the reference block method (e.g. ASME code, etc.),

• analog outputs for external control purposes: proportional voltage for amplitude and sound path of the

echo in the monitor gate,

• A-scan storage, peak freeze and zoom function,

• preview of all stored A-Scans,

• locking function to avoid unintentional alteration of

set values,

• magnified display of measured values for easy

reading even from longer distances,

• rapid switching between programmable sound

velocities, e.g. for longitudinal and transverse waves

in steel.

• 60 Hz A-scan refresh rate,

• mains power or battery operation (max. 5 hours of

operation),

• on-board Data Logger for storage of up to 2,500

thickness readings in a maximum of 99 freely

configurable files,

• RS232 interface for data transfer, A-scan displays

and reports, or for remote control of the USN 52 R,

• storage of 140 (USN 52R) / 100 (USN 52L) control

data sets enabling quick calibration and reproducibility of the test,

• alphanumeric entry of data set names and display of

a directory of all data sets,

• frequency ranges from 0.25 - 11 MHz wide band

• echo representation: RF signal, full-wave, positive

and negative half-wave,

• optimized probe matching by means of 4 adjustable

damping values between 50 and 1000 ohms,

• automatic calibration of the sound velocity and probe

delay according to data from 2 calibration echoes

(with plausibility check),

USN 52R/USN 52L

Introduction

Page 17

1-10 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

1.4 Remarks on this manual

H Note:

This manual applies to the two USN 52 versions

USN 52R and USN 52L. The examples shown refer to

the USN 52R; however, since function groups and functions of the two instruments are basically the same, the

examples also apply to the USN 52L. Only the display

size and type are different. For more details on the differences between the two versions, please refer to

pages 1-8 and 4-2 to 4-3.

Before starting for the first time

Before operating your USN 52 R for the first time, read

Chapters 1 and 3 in this manual. There you will find a

description of the necessary preparations for starting.

In addition to this, you will be informed about the most

important adjustment possibilities available on the front

panel of the instrument.

By doing this, you will avoid interferences or failures

and you will be in a position to use the instruments’s

function range to the full.

Getting to know the adjustment functions

Chapters 4 and 5 describe the most important adjustment functions using the corresponding menus. In

Chapter 10 you will find a list and a brief description of

all functions together with adjustment criteria.

Service

Chapter 10 also contains a list of After-Sales Service

Centers which can be contacted in case of defects.

Specifications and basic settings

The USN 52 R specifications are contained in

Chapter 9.

There is a basic setting for each adjustment function,

this can be seen in the function tables in Chapter 8:

default values are shown in bold-face type.

Introduction

Remarks on this manual

Page 18

Krautkramer USN 52R/USN 52L Issue 05, 02/00 1-11

Layout of this manual

In order to simplify use of this manual, the operating

steps are always presented in the same way. This enables you to find information quickly.

Descriptions of functions

Chapter 5 shows the functions that you require for various operating procedures in the same way as they are

displayed by the USN 52 R, e.g.:

a-START

Operating steps

The operating steps are presented in the same way as

in the following example:

With U mark the second function group in the righthand table.

With NO set the function PARITY to ON.

Keys

– JC / NO / U mean:

Press the right or left key.

– J / N / T mean:

Only press the left key.

– C / O / V mean:

Only press the right key.

H Note:

Under Note you will find, for example, references to

other chapters or special recommendations.

A Attention:

The Attention symbol warns you about wrong operation

when the correctness of the results is endangered.

Remarks on this manual

Introduction

Page 19

1-12 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Page 20

Krautkramer USN 52R/USN 52L Issue 05, 02/00 2-1

Standard package and accessories 2

Page 21

2-2 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

This chapter gives information about all parts and

options supplied for the USN 52R/USN 52L.

Among others, it describes:

• Accessories in the Standard Package

• Accessories required for operation of the instrument

• Recommended accessories

• Outside products configured for operation with the

USN 52R/USN 52L which have been successfully

proven and were tested in connection with the

instruments at our company.

Standard package and accessories

Page 22

Krautkramer USN 52R/USN 52L Issue 05, 02/00 2-3

2.1 Standard package

Product type Description Order no.

USN 52R Portable ultrasonic flaw detector

with high-resolution EL display,

with probe connector LEMO 00 34 900

with probe connector BNC 34 901

USN 52R DGS Portable ultrasonic flaw detector

with high-resolution EL display, including DGS function

with probe connector LEMO 00 34 911

with probe connector BNC 35 022

USN 52L Portable ultrasonic flaw detector

with transflective LCD screen

with probe connector LEMO 00 35 062

USN 52L DGS Portable ultrasonic flaw detector

with transflective LCD screen, including DGS function 35 063

including:

Operating manual (English) or 28 641

Operating manual (German) 28 642

Standard package Standard package and accessories

Page 23

2-4 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

2.2 Required accessories

Product type Description Order no.

UN 655 Power supply/battery charger unit 34 941

NCA 2-6 Set of six NiCd batteries 25 812

2.3 Recommended accessories

UN 777 Case with light shield and strap 34 094

UN 762 Light shield 34 093

UN 685 Charging frame for NiCd batteries 33 763

UNRCH External charging adapter cable (connects UN 655

with UN 685) 18 840

UNCO Remote copy switch 05 301

TGDL/PC Cable for transfer of data 13 647

to the PC. LEMO 00 7-pin to DB 25S.

Incl. adaptor DB 25P to DB 9S for AT

Standard package and accessories Standard package

Page 24

Krautkramer USN 52R/USN 52L Issue 05, 02/00 2-5

Product type Description Order no.

GCH1 Adaptor DB 25P (gender changer) to connect 13 648

the USN 52/PC cable to a printer

with serial interface (EPSON)

GCH3 Adapter (gender changer) to connect the 34 797

USN 52/PC cable to a Seiko printer (DPU 414)

UNAN Connecting cable for analog output (one end open) 17 337

UN 100 W UltraDOC for USN 50/52 33 827

2.4 Recommended outside products

Printer EPSON LX-300 17 995

Printer Seiko DPU 414 17 993

Recommended outside products Standard package and accessories

Page 25

2-6 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Page 26

Krautkramer USN 52R/USN 52L Issue 05, 02/00 3-1

Setting into operation 3

Page 27

3-2 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

It is imperative that you observe the instructions given

in this chapter before setting the instrument into operation.

Here you will be informed about the necessary preparations before startig the instrument for the first time in

order to avoid any damages or wrong measurement

results.

3.1 Positioning the USN 52R/

USN 52L

Refer to Chapter 9 concerning the permitted ambient

conditions, such as temperature and humidity. Position

the instrument on a smooth surface so that the display

can be easily read.

If the instrument is taken from a cold area into a warm

area, you should wait until it has adjusted to the temperature before switching on (avoids condensation).

3.2 Power supply

There must be sufficient power in order to guarantee

operation.

The instrument can be operated with batteries or on

mains power via a special instrument charger.

Setting into operation

Positioning the USN 52R/USN 52L

Page 28

Krautkramer USN 52R/USN 52L Issue 05, 02/00 3-3

Battery operation

For battery operation, you will either require 6 NiCd or

alkaline batteries (D-cells). The current battery voltage

is indicated on the display by a symbol:

H Note:

The batteries should be exchanged as soon as possible

when the charge indication is at about 25%. The instrument automatically switches off when reliable operation

can no longer be ensured. We recommend that a spare

set of fully charged batteries be available when using

the instrument for longer periods outside.

When the batteries are exchanged, all settings will remain stored and are instantly available when switching

on again.

H Note:

Used or defective batteries are special refuse and shall

be disposed of according to legal regulations.

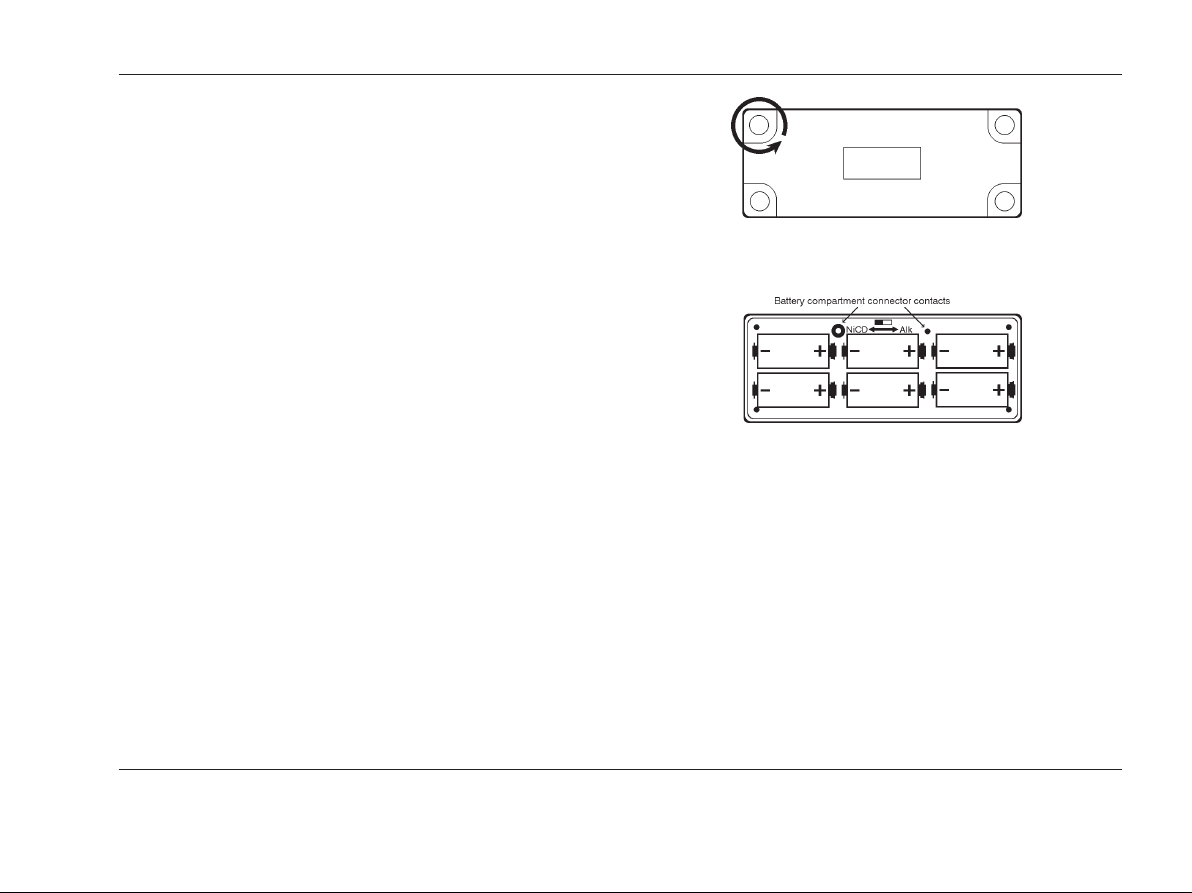

Inserting the batteries

To insert new batteries, you must first loosen the four

screws at the bottom of the instrument (see following

figure) and then remove the battery compartment lid.

Each battery in the battery pack is secured with a

separate holder.

AAttention:

When inserting the batteries, make sure that the polarities are correct and that the switch in the battery compartment is set to the type of battery being used!

Nickel Cadmium (NiCd): left

Alkaline (Alk): right

This ensures that only rechargeable batteries are

charged.

Positioning the USN 52 R

Setting into operation

Page 29

3-4 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

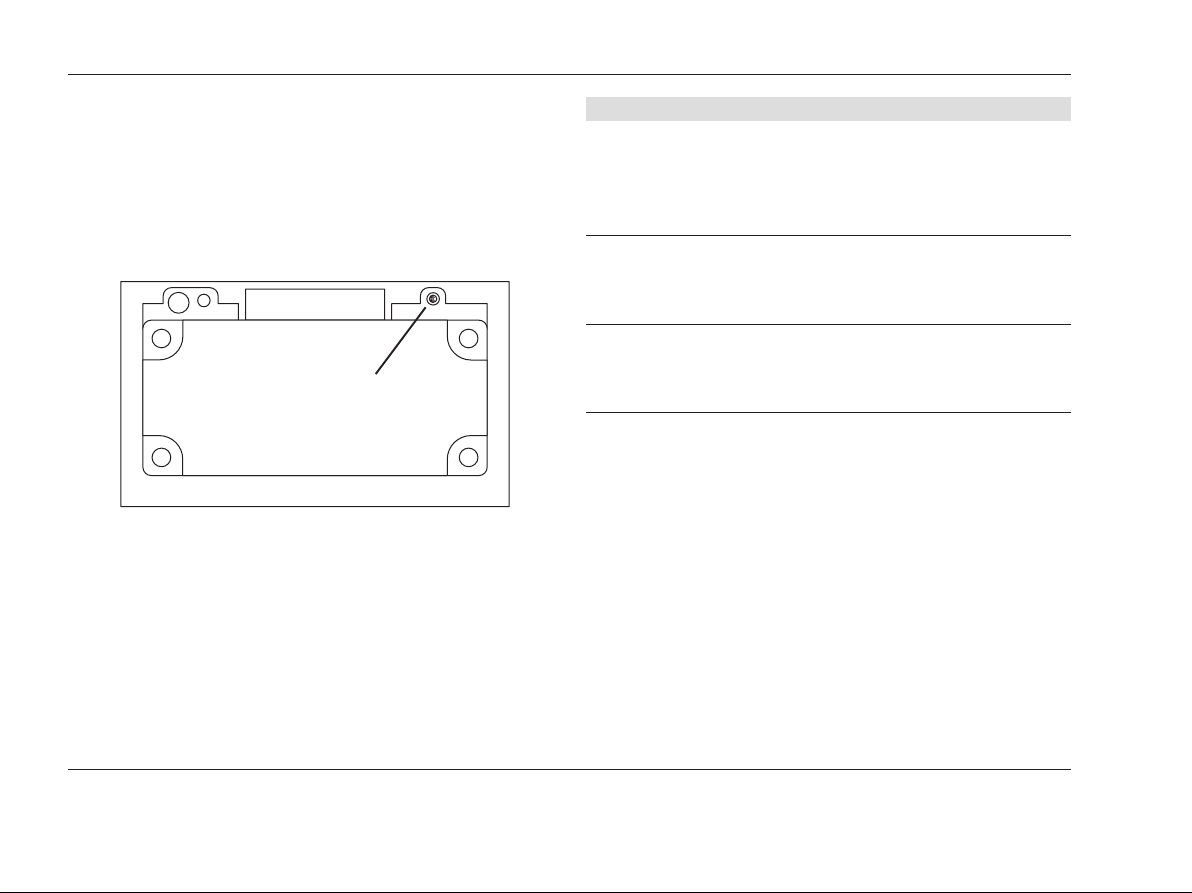

Using the battery charger

The power supply/charger unit for USN 52R/USN 52L

automatically adjusts itself fo the existing supply voltage in the range from 80 to 250 V.

The connection for the combined power supply/charger

unit is at the rear of the instrument (see following figure).

LED Status

LED off - instrument is switched off

- no NiCd batteries in the

insturment

- instrument is set to AlMn

LED on - instrument is switched on

- NiCd batteries are being

charged

LED flashes - instrument is switched off

- NiCd batteries are fully

charged (trickle charge)

A Attention:

If you have inserted AlMn cells and the switch is set to

NiCd, the internal charge of the cells will be isolated. In

this case, the AlMn cells will become quickly hot and

the pressure in the cells will cause a leakage of electrolyte after a short period of time. This strongly caustic

fluid can damage the instrument!

Only use the batteries that we recommend. There is a

danger of explosion if the charger and the batteries are

incorrectly used.

Setting into operation

Positioning the USN 52R/USN 52L

Connection supply/battery charger

When using the power supply/charger unit you are able

to simultaneously charge NiCd cells in the USN 52 R

and operate the instrument. The power supply/charger

unit requires 4 to 7 hours in order to fully charge the

NiCd cells.

The green LED indicates that the power supply/charger

unit is connected to mains.

The yellow LED of the power supply/charger unit indicates the operational status:

Page 30

Krautkramer USN 52R/USN 52L Issue 05, 02/00 3-5

3.3 Probe connection

The probe connections are on the lower right of the

front panel.

Connect straight-beam probes to the red socket (Receive - right). With T/R probes, connect the pulser cable

to the green socket (left) and the receiver cable to the

red socket (right).

– Set the pulser power as follows:

– Switch the USN 52 R on with K.

– Select the function group RCVR by pressing C.

– Using N or O, set the damping resistor in function

DAMPING There are 4 settings available: 50, 75, 150

and 1000 ohms.

3.4 Starting the USN 52 R

Switching on

This is the normal way of switching on the USN 52 R.

– Press the switch-on key K in the operator’s control

panel.

After a short time, the start display appears with information about the applied software version and about

the instrument configuration.

The settings for all function values and default settings

are the same as before switching off.

Probe connection

Setting into operation

Page 31

3-6 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Reset

If you are not able to operate the functions after a warm

start, you must carry out a cold start:

– Press A and K together.

– Keep A pressed until the A-scan appears.

A Attention:

The instrument has now the factory-preset default setting. The dialog language is English.

Refer to Chapter 4 for changing the default settings

according to your own requirements.

3.5 Screen saver

USN 52R/USN 52L are equipped with a screen saver in

order to extend the life of the display screen and the

operating time of the batteries. If your instrument is on,

and you have not pressed a key, and no positive gate

violation has occurred for 30 minutes the text/graphics

portion of the display will be erased and only a live Ascan trace will be displayed. If a frozen image is being

displayed when the unit goes into screen saver mode,

the frozen image will be lost. To exit the screen saver

mode, you must press a key or have a positive gate

violation. The keypress to exit screen saver mode will

not change any instrument settings. When screen saver

mode is exited, the screen will return to the display

which was present before.

Setting into operation

Screen saver

Page 32

Krautkramer USN 52R/USN 52L Issue 05, 02/00 4-1

Basics of operation 4

Page 33

4-2 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

4.1 USN 52R and USN 52L

The present operating manual applies to both instrument versions. Operating concept, operating levels,

function groups and functions of the two instruments

are basically the same.

The only difference is the type and size of the display

screen or its setting.

Basics of operation

USN 52R and USN 52L

USN 52R

USN 52R: The screen brightness of the EL display is

set in the function INTENSITY (Please refer to page

5-45).

USN 52L: The LCD screen is set using special keys

(please refer to page 4-3).

Page 34

Krautkramer USN 52R/USN 52L Issue 05, 02/00 4-3

USN 52R and USN 52L Basics of operation

The USN 52L is provided with the following special

keys for the LCD screen:

l

switches the display backlight directly on

and off.

u

varies the brightness / the contrast of the

LCD screen.

USN 52L

Page 35

4-4 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

4.2 Display

A-scan display

The digital display shows the A-scan either

• in the normal mode

with measured-value overlay - the value highlighted

in the measurement line is overlaid on the display.

Basics of operation Display

• in the enlarged mode

display mode with overlaid measured value.

– Press L for switching over.

Page 36

Krautkramer USN 52R/USN 52L Issue 05, 02/00 4-5

Functions on the display

Selected function groups are shown on the display:

• In the first operating level one selected function

group is displayed in addition to the A-scan.

• In the second operating level there are 3 groups

compiled into one function table (refer to fold-out

page).

– Press X for switching between the two operating

levels.

Display Basics of operation

Page 37

4-6 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Indications beneath the A-scan

Measurement line

The current measurement results are displayed here.

The contents of this line depend on the settings of the

functions MEASURE, TOF, AMPLITUDE, FILE MODE,

ANGLE and X-VALUE.

Basics of operation

Display

Status line

Symbols appear here which indicate certain settings,

e.g. battery charge status (please refer to fold-out

page).

Page 38

Krautkramer USN 52R/USN 52L Issue 05, 02/00 4-7

Menu line

The function groups in the first operating level are displayed here. The selected group is inverted.

Display

Basics of operation

Page 39

4-8 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

4.2 Keypad

Function keys

– Below: for function group selection and for switching

over between operating levels.

– To the right: for changing instrument settings and

values.

Basics of operation Keypad

Special keys

– for special instrument functions

Page 40

Krautkramer USN 52R/USN 52L Issue 05, 02/00 4-9

Special keys of the USN 52L for setting the

display

For switching the backlight on and off, and for setting

the contrast/brightness.

Keypad Basics of operation

Page 41

4-10 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

4.3 Operational concept

The functions are divided into two operating levels.

– In the first operating level you will find the most

frequently used functions divided into seven function

groups. You can toggle between the function groups

as you like.

– The second operating level contains seven groups of

functions which do not influence the A-scan. That is

why the A-scan is removed here and the whole

screen used for display of the function tables

between which you are able to switch back and forth

as you like.

Changing the operating levels

Press X in order to toggle between the first and the

second operating level.

Selection of function groups and functions

– With J or C you can select a function group.

– With T or V you can change between the function

tables in the second operating level.

Setting the function

To the right of each function you will find a pair of keys

M. With N you will decrease the displayed value and

with O you will increase it.

Accelerated adjustment

You are able to accelerate the adjustment of all functions having a certain adjustment range in order to

quickly bridge large differences between the values.

Press N or O and keep it pressed. The accelerated

adjustment is completed as soon as the key is released.

Example: Adjustment of sound velocity

– Select the function group BASIC.

– In MTL VEL press N or O in order to change the

sound velocity.

Basics of operation Operational concept

Page 42

Krautkramer USN 52R/USN 52L Issue 05, 02/00 4-11

Selection of measured value for enlarged

display

Using U in the measurement line select the value

which is to be enlarged on the display.

With U you also can toggle between graticule scaling

in scale divisions (Div.) and display of the RANGE/

DELAY in the measurement line. For this, either the

function GATE LOGIC or MEASURE must be set to

OFF (both functions: lower operating level).

4.4 Function keys

With the function keys you select functions and change

the indicated settings:

Ke y Function

K Switches the USN 52 R on and off

F Returns to the first operating level and to

the BASIC function group

U Selects measured values or function tables

I Selects function group.

M Changes active setting

X Change of operating level

Operational concept Basics of operation

Page 43

4-12 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

4.5 Keys for special functions

Important functions and special functions can be selected via special keys on the right-hand side of the

operating field:

Ke y Function

D dB-Step – Changes step size for the gain

setting

B dB-REF – Stores reference echo

E Display freeze – Freezes display

A Copy – Transmits data to the RS232

interface

L Zoom – Expands the echo display over the

whole screen

H Magnify – Expands the gate over the whole

display width

G Lock on/off – Locks function values

Basics of operation Keys for special functions

Only USN 52L

The USN 52L is provided with two additional special

keys on the left-hand side of the display. They are used

for setting the LCD screen.

Ke y Function

l Backlight - Switches the display backlight

on and off.

u

Contrast - varies the brightness / contrast

of the LCD screen.

Page 44

Krautkramer USN 52R/USN 52L Issue 05, 02/00 4-13

4.6 Important basic settings

Set language

In the LANGUAGE function in the second operating

level you can select the language in which the names

of the functions are to be displayed.

The following languages are available:

• German • Swedish

• English • Danish

• Italian • Norwegian

• French • Finnish

• Spanish • Dutch

• Portuguese • Russian

Operation:

– Change to the second level with X.

– Select the left-hand function table with T V.

– Highlight the left function group with C.

Important basic settings Basics of operation

– Set the required language in the LANGUAGE

function with N or O.

– You will return to the first operating level with X

or F.

Setting the measurement units

In the function MEAS. UNITS in the second operating

level you can determine the measurement units in

which you wish to operate the instrument (mm or

inches).

Operation:

– Change to the second operating level with X.

– Select the left-hand function table with T V.

– Highlight the left function group with C.

– Using N or O in MEAS. UNITS set the required

units.

– You will return to the first operating level with X

or F.

Page 45

4-14 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Page 46

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-1

Operation 5

Page 47

5-2 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

5.1 Function overview

(first operating level)

In the first operating level you will find all functions

required for basic adjustment of the USN 52R/USN 52L.

They are compiled into function groups allocated to

certain operation tasks.

In order to change between the function groups, press

J or C.

Function group Contents

BASIC Here you can enter the basic settings

for the measurement

RCVR Here you can set the functions of the

receiver.

PULS In this group you will find the functions

for DUAL/SINGLE changeover

GATE Contains all functions for adjusting the

positions of both gates.

S-CAL Contains all functions for the calibration

of the digital sound path measurement.

MEM Contains functions for storing your data

into the memory.

TCG You can use these functions to operate

the DAC/TCG.

Operation

Function overview

Page 48

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-3

5.2 Adjustment of the USN 52R/

USN 52L

GAIN Gain adjustment

With this function the echoes of the reflectors to be

detected are amplified so that they appear on the display at the required height.

In order that you are able to change the gain at any

time, you will find this function in all function groups of

the first operating level.

Operation:

– Change the setting of GAIN with M.

D

-Setting the dB STEP

You set the gain with a certain step size which you can

select with D. There are five steps available:

• 6.5 to 24 dB

(variable via dB STEP in the second operating level,

refer to Chapter 5.6)

• 6.0 dB

• 2.0 dB

• 1.0 dB

• 0.5 dB

• 0.1 dB

Operation:

• Press D in order to change between the five steps.

The set step is displayed as a value in the GAIN

function.

Adjustment of the USN 52 R

Operation

Page 49

5-4 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Selection of basic data

In this function you set the different values which serve

as a measurement basis and for the display indication.

– With JC go to the BASIC function group.

RANGE Calibration range

In this function you set the display range for the A-Scan.

In doing this, you can select between two settings:

• coarse: in steps

-5 mm

- 10 mm

- 25 mm

- 50 mm

- 100 mm

- 125 mm

- 200 mm

- 250 mm

- 500 mm

- 1000 mm

- 5000 mm

• fine: continuous from 5.0 mm bis 5000 mm. The

function name appears in small letters (“Range”).

Operation:

– Press N or O in order to change between the steps

or to continuously select the required value.

– Coarse/Fine change-over: Simultaneously press N

and O in RANGE.

Operation Adjustment of the USN 52R/USN 52L

Page 50

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-5

H Note:

The setting is limited by the set sound velocity.

The measurement units for all settings – mm or inches

– can be selected in the second operating level.

MTL VEL Setting the sound velocity

In this function you enter the test object’s sound velocity as a reference value. You have two possibilities:

Coarse: switch between the two preset values, e.g.

3353 m/s or 5918 m/s.

Fine: set a value between 1000 m/s and 9999 m/s. The

name of the function appears in small letters (mtl vel)

H Note:

You can select the two values for the coarse setting in

the second operating level.

Operation:

– Press M to change the displayed value. The set

value is displayed in the MTL VEL function.

– Coarse/Fine change-over: Simultaneously press N

and O in MTL VEL.

DELAY Setting the delay

In this function the timing of the sweep start is adjusted.

Operation:

– Set a value between -20 µs and 999 µs (range

dependent) in steps of 0.008 µs with M.

– Reset delay to 0.000 µs: simultaneously press N

and O in DELAY.

H Note:

In order to take the probe delay into account, you must

calibrate the probe zero point with ZERO in the function

group S-CAL.

Adjustment of the USN 52R/USN 52L Operation

Page 51

5-6 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Setting the receiver

All functions for adjustment of the receiver can be

found in the function group RCVR.

– With JC go to the function group RCVR.

FREQ. Frequency

With this function you can set the operating frequency.

You can choose between four settings:

• 0.4 - 10 MHz = broadband amplifier

• 2 - 8 MHz = 4MHz according to DIN 25 450

• 3 - 10 MHz = high frequency range

• 0.3 - 4 MHz = low frequency range

Operation:

– Select the required setting in FREQ. using M.

Operation Adjustment of the USN 52R/USN 52L

Page 52

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-7

DAMPING Electrical damping of the probe

You can use the function DAMPING to connect various

resistors in parallel to the probe in order to achieve an

optimum matching of the probe’s electrical impedance

to the instrument.

– Select a low value with broadband probes, or if you

wish to improve the near resolution.

– Select a high value if you are using narrow-band

probes, or if you need a high sound intensity.

Operation:

Set the required value in DAMPING using M.

RECTIF. Setting the rectification mode

In the RECTIF. function you select the rectification

mode of the echo pulses according to the application.

You have the following possibilities:

• FULL (full-wave): All half-waves above the base line

are displayed

•RF (radio-frequency display): All signals are

displayed in their original form.

H Note:

The RF display mode is only adjustable if the function

INTENSITY (display brightness) is set to LOW and the

range does not exceed 196 mm (with 5920 mm).

• NEG HALF (negative half-wave): Only negative halfwaves are displayed.

• POS HALF (positive half-wave): Only positive halfwaves are displayed.

Operation:

– Select the required setting in RECTIF. with M.

Adjustment of the USN 52R/USN 52L Operation

Page 53

5-8 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Setting the pulser

In the function group PULS you can change the operating mode and the pulse repetition rate of the pulser as

well as operate the reject function.

– Use JC to go to the function group PULS.

PULSER Changeover of initial pulse

You can use this function to change between the singleelement or dual (T/R) mode for the instrument operation:

• SINGLE: single-element operation mode; the probe

connector sockets are connected in parallel.

• DUAL: dual (T/R) operation mode; the initial pulse is

available at the green socket - the red socket is

connected to the amplifier input.

Select this setting if you are using a dual (T/R) probe

or the through-transmission mode.

Operation:

– Select the required setting in PULSER using M.

H Note:

The corresponding symbol will be displayed in the status line:

Single Dual

Operation Adjustment of the USN 52R/USN 52L

Page 54

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-9

REJECT Suppression of spurious echoes

With the REJECT function you are able to suppress

unwanted signals, e.g. material noise.

The setting, given in percent, indicates the height that

echoes have to reach in order to be displayed in the

first place.

Operation:

In REJECT set the required percentage value with M.

A Attention:

Be careful with this function because flaw echoes can

also be suppressed.

REP-RATE Repetition rate

The number of the ultrasonic signals emitted per second is varied using this function. This enables selective

suppression of spurious or interference echoes and

especially phantom echoes which may occur when

testing larger test objects. The function enables two

settings:

•HIGH: Maximum pulse repetition rate

(113 to 905 Hz, depending on the range setting);

default setting.

•LOW: Reduced pulse repetition rate

(56 to 452 Hz, depending on the range setting);

for testing larger test objects or in case any

statistical noise signals occur.

Operation:

In REP-RATE set the required percentage value with

M.

Adjustment of the USN 52R/USN 52L Operation

Page 55

5-10 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Gate adjustment

All functions for adjustment of Gates a and b are contained in the function group GATE.

– With JC go to function group GATE.

USN 52R/USN 52L make the two gates a and b available. Gate b is only required for the measurement or

calibration of multi-echo sequences and enables the

measurement of the distance between two echoes. The

flaw Gate b is dependent of Gate a and is correspondingly adjusted:

• b-START: at 10% to 90% of a-WIDTH (after a-

START)

• b-THRESH: 10% to 90% screen height

A Attention:

When both gates are superimposed on each other, the

wrong values can be indicated with a wrongly selected

Gate b.

Both gates evaluate only within the visible area of the

display. If there are gates or parts of gates outside this

area, an evaluation will not be made.

The gates have two tasks:

• They monitor the area of the test object in which a

flaw is expected. When an echo exceeds or falls

below the gate, a warning signal can be activated.

• They select the echoes for the digital time-of-flight or

amplitude measurement.

Operation Adjustment of the USN 52R/USN 52L

Page 56

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-11

Operation:

The MULTECHO setting of the function MEASURE

(lower operating level) is a prerequisite for operation.

• Simultaneously press N and O in a-WIDTH or

a-THRESH in order to switch to the settings for

Gate b.

a-THRESH Determination of threshold

With this function you determine the threshold for the

selected gate. You can set a range from 10% to 90%

screen height in 1% steps.

Operation:

– Set the required threshold value in a-THRESH with

M.

The selected gate is displayed as a line.

If there is a violation of the set threshold (signals exceeding or falling below it), an alarm is activated.

The exact gate position is defined by two further

parameters:

• Gate start (a-START)

• Gate width (a-WIDTH)

a-START Start of the gate

In the function a-START you determine the start of

Gate a within a range from 0 to 5000 mm (continuous).

a-WIDTH Width of the gate

In the function a-WIDTH you determine the width within

a range from 1 to 5000 mm (continuous).

Operation:

– Set the gate position in a-START and a-WIDTH

with the assigned M keys.

Adjustment of the USN 52R/USN 52L Operation

Page 57

5-12 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Calibration functions

USN 52R/USN 52L are accurately calibrated using the

functions of the function group S-CAL.

– With I go the function group S-CAL.

H Note:

Read Chapter 5.3 first in order to exactly set the sound

velocity and the probe delay.

H Note:

Refer also to the AUTO CAL function in Chapter 5.3.

The function group S-CAL correspondingly changes

when this function is used.

a-START Gate start

The active value for the gate start, which you have

entered into the function group GATE, is displayed in

a-START. If necessary, you can make a subsequent

change to this value here.

H Note:

In order to obtain the correct setting, you must have

selected the display range, according to the test task,

in the function group BASIC beforehand.

Operation Adjustment of the USN 52R/USN 52L

Page 58

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-13

MTL VEL Sound velocity

In MTL VEL you set the value for the sound velocity in

the material under test. You can change between preset

fixed values or continuously adjust the value.

Operation:

– Set the sound velocity in MTL VEL with M, e.g.

5920 m/s (longitudinal wave velocity in steel).

H Note:

The default value for the sound velocity can be

changed in the second operating level (functions VE-

LOCITY # 1 and VELOCITY # 2) if you frequently operate with other materials (refer to Chapter 5.6).

Adjustment of the freely selected value:

– Simultaneously press NO in MTL VEL.

– Change the setting with M.

With free adjustment of the value, the function name

appears in small letters (mtl vel). In this way you are

able to recognize which mode of adjustment you have

selected.

A Attention:

Always make sure that the sound velocity in MTL VEL

is set correctly! The instrument calculates all interval

and distance indications using the values which have

been set here.

ZERO Probe delay

Each probe has a delay block (protective layer, delay

wedge with angle-beam probes) between the element

and the coupling surface. The initial pulse must be

transmitted through this delay block before the sound

can enter the test object. The ZERO function allows

you to take into account the loss of time caused by the

delay block in order to achieve the correct measurement of all sound paths in the test object.

Operation:

Set the value for the probe delay in ZERO using M.

H Note:

If the value for ZERO is not known, read Chapter 5.3

beforehand in order to determine this value.

Adjustment of the USN 52 R Operation

Page 59

5-14 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Storing data

This group contains functions for storage and recall of

your data.

– With I go the function group MEM.

Data set names and MEMO mode in chapter 5.10 on

this.

RECALL Loading of a stored setting

With this function you can load the instrument settings

(data set) which you have previously stored. If a data

set contains a stored setting, this will be indicated by

the symbol ■ in the RECALL function.

A Attention:

The active settings will be overwritten, therefore store

beforehand in order to save them.

Operation:

– With M switch to ON so that the settings can be

loaded. When the sequence is finished, the display

automatically changes to OFF.

– Acknowledge system safety prompt with F.

H Note:

To be able to find everything better, you can store a

name (max. 8 alphanumeric characters) with every data

set. If the MEMO function is activated, you have additional possibilities of data set description (free formulation of texts or filling-in of predetermined header fields)

to improve the documentation. Please read the sections

Operation Adjustment of the USN 52R/USN 52L

Page 60

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-15

SET# Selection of data set

You are able to select the required data set number with

this function. If necessary, an allocated data set name

will be displayed at the same time.

Additionally, you can give each data set a name with

which it is stored. Refer to Chapter 5.10

Entering and

displaying data set names

.

Operation:

– Select a number between 1 and 140 (USN 52R) / 1

and 100 (USN 52L) with M.

STORE Storing the instrument settings

With this function you store the active instrument settings and the active A-scan under the number indicated

in SET#.

If the data set is already allocated (symbol ■) you cannot overwrite it. You must firstly clear the old data set.

Operation:

– Switch to ON with M to store the setting. When the

process is completed, the display automatically

changes to OFF.

– Acknowledge system safety prompt with F.

– If required, enter the required additional information

in the displayed MEMO menu (please see chapter

5.10).

Clearing the instrument setting

An instrument setting which is stored can be overwritten after you have disabled the write protection.

You can reallocate the data set.

Operation:

– Simultaneously press N and O in the RECALL

function.

– Acknowledge system safety prompt with F.

Write protection is disabled. The symbol ■ is deleted.

The data set can now be reallocated.

Adjustment of the USN 52R/USN 52L Operation

Page 61

5-16 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Clearing all data

You can clear all data sets (data logger and active instrument settings).

Operation:

– Switch off the instrument.

– Keep keys F , E and K simultaneously for

approximately 10 seconds.

All data sets are now cleared.

Displaying stored A-Scans (preview)

In the function group MEM you have the possibility to

display all A-Scans belonging to the stored data sets

without having to load them simultaneously. In this way,

you obtain a quick overlook of your stored data.

Operation:

– Simultaneously press N and O in the function

SET#.

The selected data set’s A-Scan is displayed. At the

same time, the function GAIN is changed in DATA SET

PREVIEW as recognition of this preview function.

If additional information was stored for this data set by

means of the MEMO function, the first 46 characters of

this additional information are displayed in the menu bar

(please refer to chapter 5.10).

– You can scroll through all stored data sets

using M. The corresponding A-Scans are

displayed.

– If you require to load a displayed data set, set the

RECALL function to ON using M and acknowledge

system safety prompt with F. The preview function

will then be switched off.

– If you do not wish to load a data set: exit the preview

function by pressing N and O simultaneously in

SET#.

Operation Adjustment of the USN 52R/USN 52L

Page 62

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-17

5.3 USN 52R/USN 52L calibration

Calibration of display range

Before you operate the instrument, you must calibrate

it. Depending on the material and the dimensions of the

test object, the sound velocity and the calibration range

have to be set and the probe delay taken into consideration. In addition, the test sensitivity has to be adjusted

according to the specified requirements.

A Attention:

In order to reliably operate the instrument, adequate

training in ultrasonics is required.

Calibration guarantees that

– the total thickness of the test object is displayed,

– the distance to the flaw or to the backwall of the test

object can be determined using the horizontal

position of the echo, or it can be digitally displayed,

– all flaws are displayed which must be detected

according to test specifications,

– the size of the flaw can be determined by

comparison with a known reflector.

H Note:

For all calibration procedures, use a calibration block

which is made of the same material and has the same

temperature as your test object.

The following examples show three main methods of

ultrasonic testing:

• Testing with a straight-beam probe,

• Vertical testing with a dual (T/R) probe,

• Angle beaming with an angle-beam probe (transverse

waves).

With all calibrations you must

– set the pulser and receiver according to the test task

and

– decide whether you are going to use the FLANK or

PEAK mode for your measurements (MEASURE

function int the lower operating level) before

calibrating.

USN 52R/USN 52L calibration Operation

Page 63

5-18 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Recommendation:

As long as the echoes to be evaluated indicate a distinct maximum amplitude, select the PEAK mode of

measurement.

Basic adjustment:

Before calibrating the instrument, you must carry out

the following basic adjustment:

Group Function Setting

BASIC DELAY 0.000 ms

RANGE adjust

Calibration with a straight-beam probe

Known sound velocity, no delay block

– Set sound velocity MTL VEL

– Position Gate a over one of the echoes

– Adjust ZERO so that the correct “S=...”-value is

indicated in the measurement line.

Example:

Carry out the calibration on a flat calibration block V1

(thickness: 25 mm) for a calibration range of 100 mm.

– Set RANGE to 100 mm

– Set known sound velocity MTL VEL (5920 m/s)

– Position the gate over the first calibration echo out of

25 mm

– Adjust ZERO so that “S=25.0" is displayed in the

measurement line

The display range is now calibrated for the described

task.

Sound velocity unknown, no delay block

– Set MEASURE to MULTECHO

– Set the gates so that the first echo is evaluated in

Gate a and the second echo in Gate b.

Attention: Be careful of node errors when adjusting

the threshold!

– Adjust the sound velocity MTL VEL until the

displayed reading (sound path between the two

backwall echoes) corresponds to the actual

thickness of the test object. If necessary, you have

to readjust the gate parameters.

– Set MEASURE to 0 TO 1st

Operation USN 52R/USN 52L calibration

Page 64

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-19

– Increase ZERO until the correct sound path value for

the echo is displayed.

Example:

– Carry out calibration on a 25 mm thick test piece for

a calibration range of 100 mm.

– Set RANGE to 100 mm

– Set ZERO to 0.000 s

– If possible, when in MTL VEL, set an approximate

value for the sound velocity

– Set MEASURE to MULTECHO

– Adjust the gates so that the first echo is evaluated in

Gate a and the second in Gate b.

Attention: Be careful of node errors when setting the

threshold!

– Adjust the sound velocity MTL VEL until the

displayed reading (sound path between the two

backwall echoes) corresponds to the actual

thickness of the test object. If necessary, you have

to readjust the gate parameters.

– Set MEASURE to 0 TO 1st

– Increase ZERO until the correct sound path for the

echo in the gate is displayed.

Straight-beam probe with delay

Calibration with straight-beam probes, which have a

greater delay path, mainly corresponds to the above

calibration for straight-beam probes which only have the

protection layer as a delay path.

Unlike the above procedure, you have to start by making the following adjustments:

– Set DELAY and ZERO to 0

– Preadjust ZERO so that the first interface echo is at

the zero point of the scale.

– Adjust RANGE so that, with a known sound

velocity, the first interface echo and at least the first

backwall echo appear, and, with an unknown sound

velocity, at least two backwall echoes appear before

the second interface echo.

– From this point, proceed the same as for both

previous cases.

USN 52R/USN 52L calibration Operation

Page 65

5-20 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Calibration with angle-beam probes

Known sound velocity

In this case, it is sufficient when there is an echo from

a known reflector with a known distance, e.g. the arc of

the calibration block V1, V2.

– Enter known sound velocity MTL VEL

– Set Gate a to the first echo

– Set ZERO so that the correct value is displayed in

the measurement line “S=...”.

Example:

Calibration of the 100 mm range for steel (trans) using

calibration block V2

– Enter sound velocity MTL VEL (3255 m/s)

– Set RANGE to 100 mm.

– Set DELAY and ZERO to 0.

– Couple the probe and peak the first echo from the

25 mm radius of V2.

– Set Gate a to the first arc echo.

– Adjust ZERO so that “S=25" is displayed in the

measurement line.

The display range is now calibrated. For the measurement you can now enter the values for ANGLE, X-

VALUE and THICKNESS.

Unknown sound velocity

In this case you will require a calibration block made of

the test material. A semicylinder is suitable for this

purpose.

Couple the probe to the plane of section of the

semicylinder with the radius R, and peak the first echo

from the semicircle. An echo sequence occurs with the

sound paths R, 3R, 5R, etc.

You apply these echoes for calibration the same as the

backwall echoes described above which come from a

plane-parallel calibration piece with vertical beaming.

Operation USN 52R/USN 52L calibration

Page 66

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-21

Example:

Calibration on a semicylinder having a radius of

R=50 mm at a test range of 200 mm.

– Set RANGE to 200 mm.

– Set DELAY and ZERO to 0.

– Set MEASURE to MULTECHO.

– Couple the probe and peak the echoes.

– Adjust the gate so that the first arc echo (® 50 mm

sound path) in Gate a and the second arc echo

(® 150 mm sound path) in Gate b are evaluated.

– Set the sound velocity MTL VEL so that

“S=100" is displayed in the measurement line

– Set MEASURE to 0 TO 1st

– Set Gate a to an echo

– Set ZERO so that “S=50" is displayed in the

measurement line

The calibration has now been completed.

Calibration with a dual (T/R) probe

Above all, dual (T/R) probes are mainly used for thickness measurement. When applying these probes observe the following characteristics:

The FLANK mode

Most dual (T/R) probes have a roof angle (an element

which is at an angle to the surface of the test object).

Due to this, mode conversions occur with sound entry

and at the reflection on the backwall which can cause

rugged, wide echoes. This is the reason why you should

always select FLANK in TOF.

In order to obtain steep increasing flanks, which enable

a higher measurement accuracy, you can use the Reject function if necessary. In this regard, refer to the

information on the DAMPING function.

V-path error

With dual (T/R) probes, there is a V-shaped sound path

from the pulser to the receiver element via the reflection from the backwall. This “V-path” influences the

measurement accuracy. Therefore, you should select

two thicknesses which include the expected thickness

range. The V-path error can be largely compensated in

this way.

USN 52 R calibration Operation

Page 67

5-22 Issue 05, 02/00 Krautkramer USN 52R/USN 52L

Higher sound velocity

Due to the V-path error, a higher sound velocity than

the test material is required when calibrating, especially

with smaller thicknesses. This is typical of dual (T/R)

probes and acts as compensation of the V-path error.

Owing to the described effect there is a drop in the

echo amplitude with smaller thicknesses which should

be carefully observed with values < 2 mm.

A calibration block having different thicknesses must be

used for calibration. The thicknesses are to be selected

so that they include the expected measurement value.

– Set PULSER in the function group PULS to DUAL.

– Set RANGE according to the test task and the probe

being used..

– Set TOF to FLANK.

– Couple the probe to the thinner part of the calibration

block and peak the echo.

– Set the flank as steeply as possible by adjusting the gain.

– Set Gate a on the first echo.

– Set ZERO in the function group S-CAL so that the

measurement line display the correct value at

“S=...”.

– Couple the probe to the thicker part of the calibration

block and peak the echo.

– Set the flank as steeply as possible by adjusting the

gain.

– Set Gate a on the first echo.

– Set the sound velocity “C” so that the correct value is

displayed in the measurement line at “S=...”.

Automatic calibration

The instrument has an automatic calibration capability

via the function AUTO CAL. Two calibration echoes

must be entered. The instrument then carries out a plausibility check and automatically sets the parameter.

– Set the function AUTO CAL in the second operation

level (right function table) to ON.

– Return to the first operation level with X and select

function group S-CAL with I.

The function group S-CAL changes in preparation for

the automatic calibration and now contains the CAL

function (calibration) as well as the function S-REF

(sound path for the reference echo).

Operation USN 52R/USN 52L calibration

Page 68

Krautkramer USN 52R/USN 52L Issue 05, 02/00 5-23

Operation:

– In the function CAL press N and O simultaneously.

The function is now enabled.

– REC 0 is displayed, indicating that no calibration

echo has been recordet yet.

– Set the gate onto the first calibration echo and enter

the sound path in S-REF using M.

– Save the first calibration echo using M in the CAL

function. On the display: REC 1.

– Set the gate onto the second calibration echo and

enter the sound path in S-REF using M.

– Save the second calibration echo using M in thte

CAL function. On the display: REC 2.

– Press O on CAL again to terminate the 2-step

calibration procedure.

Automatic calibration is carried out after the instrument

has calculated the entered parameters and made a

plausibility check.

H Note:

To verify a correct instrument calibration, always check

the setting using the echo of a known distance, other

than those used for calibration.

Preparing the instrument for

digital measurement

USN 52R/USN 52L must be calibrated to the material to

be tested in order to give the correct measurement

readings.

H Note:

For all calibration procedures, use a calibration block

with a known thickness, made of the same material and

having the same temperature as your test object.

Preconditions:

To start with, calibrate the A-scan display as described

in the preceding section. Carry out the following basic

settings:

GATE LOGIC:

POSITIVE, NEGATIVE or MEASURE

MEASURE: 0 TO 1st – for measurement to the first