Page 1

Confidential

developer’s guide

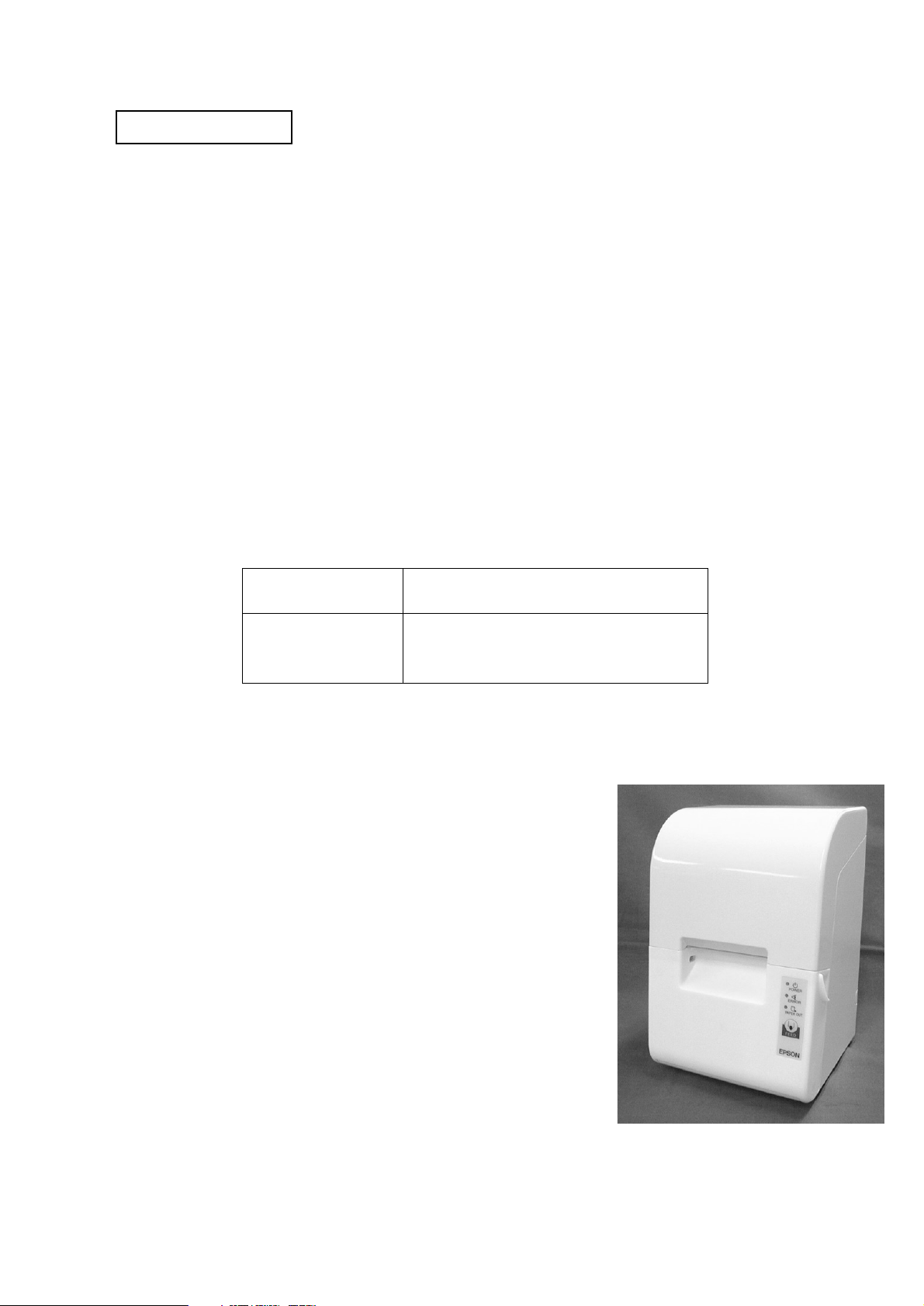

TM-U230

Copied Date , ,

Copied by

EPSON

English

401347601

Page 2

Confidential

CONFIDENTIALITY AGREEMENT

BY USING THIS DOCUMENT, YOU AGREE TO ABIDE BY THE TERMS OF THIS AGREEMENT. PLEASE RETURN

THIS DOCUMENT IMMEDIATELY IF YOU DO NOT AGREE TO THESE TERMS.

1. This document contains confidential, proprietary information of Seiko Epson Corporation or its affiliates. You

must keep such information confidential. If the user is a business entity or organization, you must limit disclosure

to those of your employees, agents and contractors who have a need to know and who are also bound by

obligations of confidentiality.

2. On the earlier of (a) termination of your relationship with Seiko Epson, or (b) Seiko Epson's request, you must stop

using the confidential information. You must then return or destroy the information, as directed by Seiko Epson.

3. If a court, arbitrator, government agency or the like orders you to disclose any confidential information, you must

immediately notify Seiko Epson. You agree to give Seiko Epson reasonable cooperation and assistance in resisting

disclosure.

4. You may use confidential information only for the purpose of facilitating authorized sales and service of, or

developing software and similar products for authorized use with, EPSON products. Any other use requires the

prior written consent of Seiko Epson.

5. THE INFORMATION IN THIS DOCUMENT IS PROVIDED “AS IS,” WITHOUT WARRANTY OF ANY KIND,

INCLUDING ANY WARRANTY OF TITLE OR NON-INFRINGEMENT. Seiko Epson has no liability for loss or

damage arising from or relating to your use of or reliance on the information in the document.

6. You may not reproduce, store or transmit the confidential information in any form or by any means (electronic,

mechanical, photocopying, recording, or otherwise) without the prior written permission of Seiko Epson.

7. Your obligations under this Agreement are in addition to any other legal obligations. Seiko Epson does not waive

any right under this Agreement by failing to exercise it. The laws of Japan apply to this Agreement.

CAUTIONS

❏ This document shall apply only to the product(s) identified herein.

❏ No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation.

❏ The contents of this document are subject to change without notice. Please contact us for the latest information.

❏ While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties

for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or

abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.)

failure to strictly comply with Seiko Epson Corporation's operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options

or any consumable products other than those designated as Original EPSON Products or EPSON Approved

Products by Seiko Epson Corporation.

TRADEMARKS

EPSON® and ESC/POS® are registered trademarks of Seiko Epson Corporation.

General Notice: Other product and company names used herein are for identification purposes only and may be

trademarks of their respective companies.

Page 3

Confidential

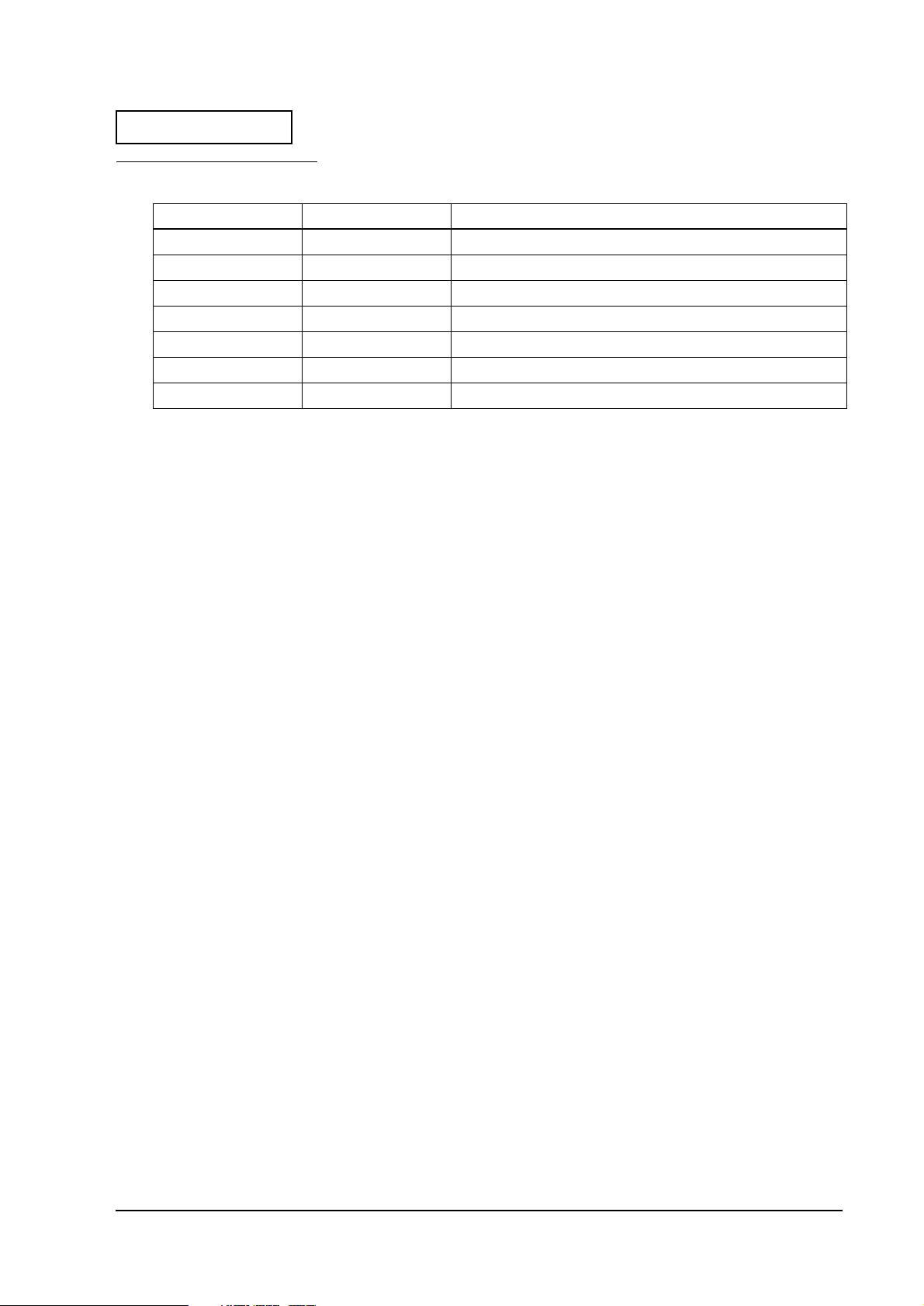

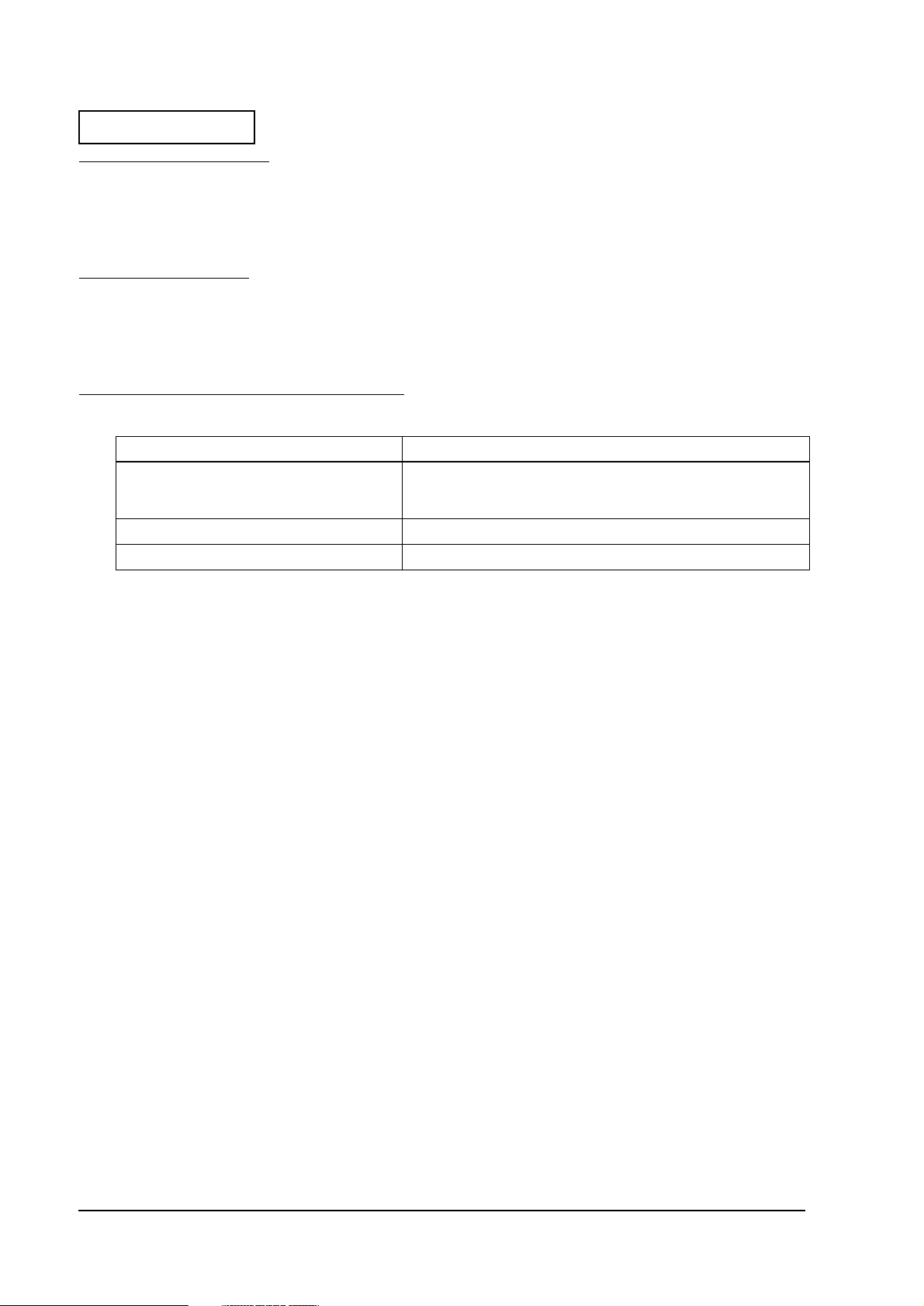

Revision Information

Revision Page Altered Items and Contents

Rev. A All

Rev. B 1-6 Ethernet interface specification is added .

1-18~1-20 Ethernet interface specification is added.

2-2~2-4 Description of Waterproof is added.

3-1,3-3 The internal buzzer specification is added.

4-7~4-10 Description of DirectIO in OPOS is aded

AppendixC Newly added.

TM-U230 Developer’s Guide

i

Page 4

Confidential

Key to Symbols

The following symbols are used in the documentation for this product. See the specific warnings

and cautions at appropriate points throughout this guide.

WARNING:

Warnings must be followed carefully to avoid serious bodily injury.

CAUTION:

Cautions must be observed to avoid minor injury to yourself, damage to your

equipment, or loss of data.

Note:

Notes have important information and useful tips on the operation of the product.

Safety Precautions

This section presents important information to ensure safe and effective use of this product.

Please read this section carefully and store it in an accessible location.

WARNING:

❏ Turn off the power switch immediately and unplug the power cord from the electrical outlet

if the TM-U230 produces smoke, a strange odor, or unusual noise. Continued use may lead

to fire or electric shock.

❏ Do not modify the printer or perform any disassembly operation not described in this

manual. Doing so could result in a fire or shock hazard.

❏ Use only the designated power supply. Use of a different power supply could cause a fire or

shock hazard.

❏ Never insert or disconnect plugs with wet hands. Doing so may cause a serious shock.

❏ Never drop or push objects into the product through openings. This could cause a fire or

shock.

❏ If the printer is exposed to water or other liquid, turn off the POWER button and disconnect

the power cord immediately. Continued use under these conditions could cause a fire or

shock hazard.

❏ Do not connect the power cord to an overloaded wall outlet. This may cause a fire hazard.

Connect the printer directly to a wall outlet.

❏ Handle the power cord with care. Incorrect handling may lead to fire or shock.

ii

Page 5

Confidential

• Do not modify the power cord.

• Do not place heavy objects on the power cord.

• Do not bend, twist, or pull the power cord excessively.

• Do not route the power cord near heaters.

• Remove any dirt or dust from the power plug before plugging it in.

• Be sure to fully insert the power plug.

TM-U230 Developer’s Guide

CAUTION:

❏ All cables are to be connected only as described in the manual. Incorrect connection could

cause damage or a fire hazard.

❏ Be sure to set this product on a firm, stable, horizontal surface. The product may break or

cause injury if it falls.

❏ Do not install the printer in extremely humid or dusty locations. Operation under such

conditions could damage the printer or cause a fire or shock hazard.

❏ Do not stand on the printer or place heavy objects on it. The printer could fall or collapse,

causing breakage and possible injury.

❏ For added protection of the printer, disconnect the power plug from the wall outlet when

the printer is not to be used for an extended period of time.

❏ Be sure not to touch the print head or motors when you remove paper jammed in the

printer. Wait until the print head and motors have cooled down before removing jammed

paper. When the printer has been used for an extended period, the print head and the

motors are very hot and could cause burns.

Precautions in handling the fine coating of the case (only for fine coating case model)

A fine coating is used for the external surface of the plastic case of the printer, which makes

wiping and removing kitchen stains easy; however, you should note the following when

cleaning the surface in order to preserve the quality of the coating (the metal plate and the inside

of the case do not have the fine coating):

❏ Do not scrub the surface with a hard object. Otherwise, the case will be scratched and harder

to clean.

❏ Do not use a cleanser that includes polishing materials such as grains of glass, metal, or

ceramics. Otherwise, the case will be scratched and harder to clean.

❏ Never use disinfectant, bleach, alcohol, benzine, thinner, chlorine solvent, or ketone solvent.

Otherwise, the case will be harder to clean, and the case may be seriously harmed or even

deformed and its color may be changed.

❏ The label may come off of the fine coating of the case if harsh cleaning methods are used.

iii

Page 6

Confidential

Moduler Connector

Use the moduler connector specifically designed for the cash drawer for this product. Do not

connect a telephone line to the drawer kick-out connector.

About This Guide

This guide is intended to provide all information necessary for system planning, design,

installation and application of the TM-U230 for designers and developers of POS systems.

Related Software and Documents

Software/document name Description

TM-U230 User’s Manual Provides instructions for operators of POS systems in which the TM-

TM-U230 Service Manual Provides the information on printer maintenance and repair.

ESC/POS Application Programming Guide Provides ESC/POS commands descriptions

U230 is installed so that the operators can use the TM-U230 safely

and correctly.

iv

Page 7

Confidential

developer’s guide

TM-U230

Revision Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Key to Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Precautions in handling the fine coating of the case

(only for fine coating case model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Moduler Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Related Software and Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Chapter 1 Installation

Installation and Positioning of TM-U230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Precautions in Handling the Fine Coating Case

(only for Fine Coating Case model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Selecting a Place of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Environment Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Settings for Horizontal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Changing the Location of the Rubber Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Changing the Orientation of Near End Sensor . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Attaching Switch Panel for Horizontal Installation . . . . . . . . . . . . . . . . . . . . . 1-9

Attaching the Power Supply Box

(only for models with exclusive power supply unit) . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Assembling the Power Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Vertical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Horizontal Installation and Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Notes on Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Connecting a Host PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Drawer Kick-Out Connector (Marked DK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Developer’s Guide

Chapter 2 Handling

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Precautions in handling the fine coating of the case

(only for Fine Coating Case model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Waterproof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Replacing roll paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Replacing the ribbon cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Removing paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Installing the power button cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Chapter 3 Compatibility

Internal Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Receive Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Page 254, 255 (Space Page) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4 Programming Samples

Saving Space for Receipt Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

GS V (Function B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

v

Page 8

Confidential

GS V (Function C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Notes on Using GS V Function C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

The usage of DirectIO in OPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Contorol of The Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Appendix A Specifications

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Character Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Autocutter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Printing Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

External Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Drawer Kick-out Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Drawer Kick-out Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Drawer Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

vi

Page 9

Confidential

TM-U230 Developer’s Guide

Chapter 1

Installation

Installation and Positioning of TM-U230

Precautions in Handling the Fine Coating Case (only for Fine Coating Case model)

This printer is housed in a plastic case (*) with a fine coating; simple cleaning is enough to enable

dirt to come off easily so that the exterior of the printer remains in good condition. Like plastic

cases, handle the fine coating with care as described below.

(*)Fine coating is not applied to the installation surface of the metal plate, the power supply box

and the inside of the case.

• Do not scratch the surface with hard objects; otherwise the case may become damaged

and dirt may become difficult to remove.

• Do not use any type of abrasive agent (glass, metal, ceramic, etc.) to clean the case;

otherwise the surface of the case may become damaged and dirt may become difficult to

remove.

• Never clean the case with disinfectant, bleach, alcohol, benzene, thinner, chlorine, or

ketone; otherwise the dirt may become difficult to remove. Also, they may cause the case

to become discolored, dissolved, or deformed.

• Label may come off of the fine coating of the case.

Selecting a Place of Installation

This printer can be installed vertically (standard installation) so that the paper exit faces the

front or horizontally so that the paper exit faces upwards. With the optional wall mounting

bracket (Model No: WH-10) the printer can be wall-mounted.

Note:

Since vibrations are generated during paper cutting, take suitable measures to secure the printer.

❏ Installation on a table (vertical or horizontal installation)

• Regardless of installation method chosen, the tilt of surface selected must be 15° or less.

• Attach the supplied switch panel sheet for horizontal installation when the printer is to

be installed horizontally.

• Adjust the N.E detector and attach the rubber feet as required by the chosen method of

installation.

Environment Specifications

See the Environment Specifications section in Appendix A.

Installation 1-1

Page 10

Confidential

External Dimensions

See the External Appearance section in Appendix A.

Vertical installation

Desk installation

❏ Wall mounting

• Use the optional wall mounting bracket (Model Name: WH-10) when the printer is to be

wall mounted.

• When the printer is wall mounted, adjust the N.E. detector in the same way as for

vertical installation.

• The power supply box can be attached below the printer if necessary.

Horizontal installation

1-2 Installation

Wall-mounted installation

Page 11

Confidential

Dip Switch Settings

Make DIP switch settings according to the following procedures.

1. Remove the circuit board plate.

2. Set the DIP switches.

TM-U230 Developer’s Guide

circuit board plate

Installation 1-3

Page 12

Confidential

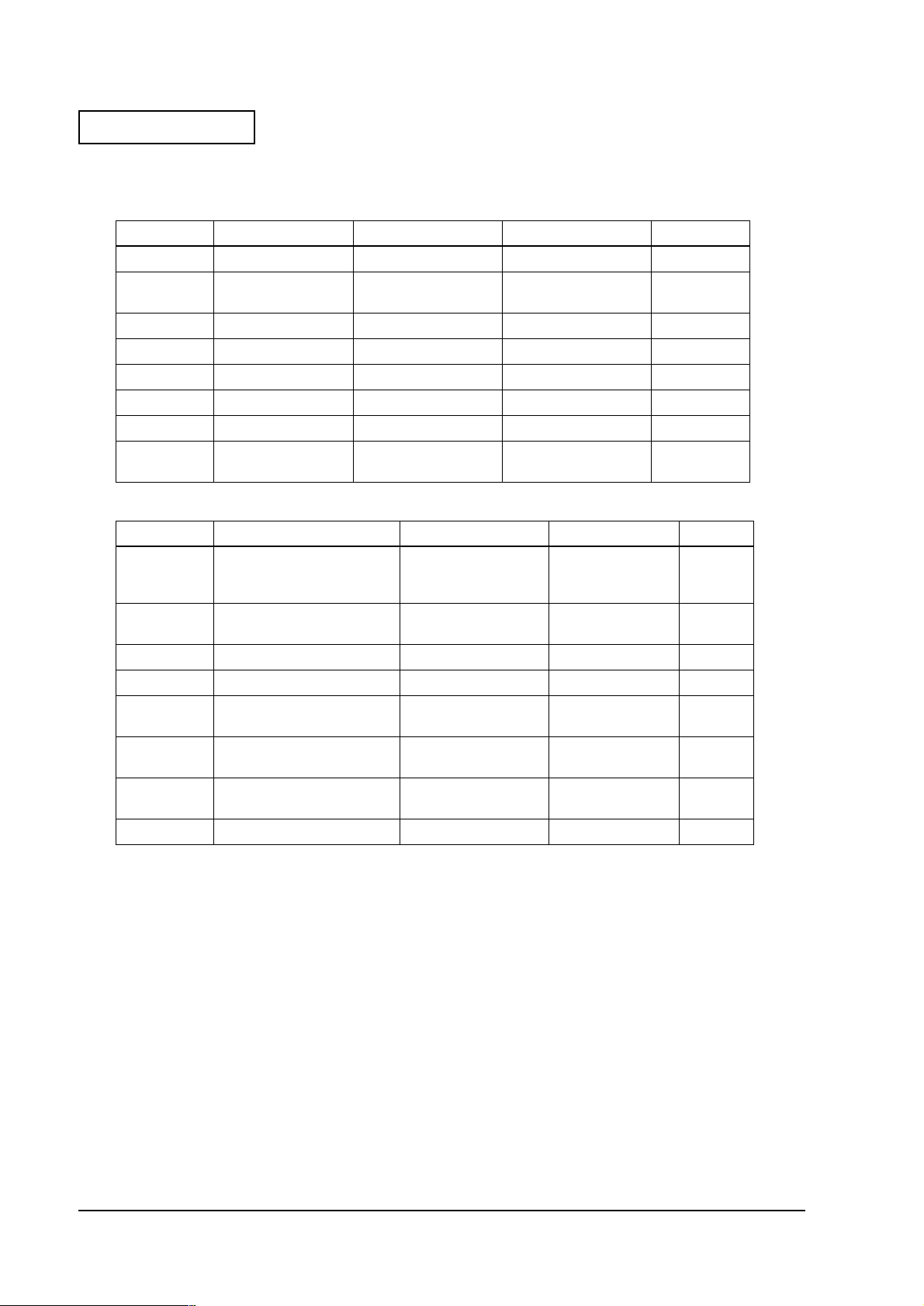

Serial Interface

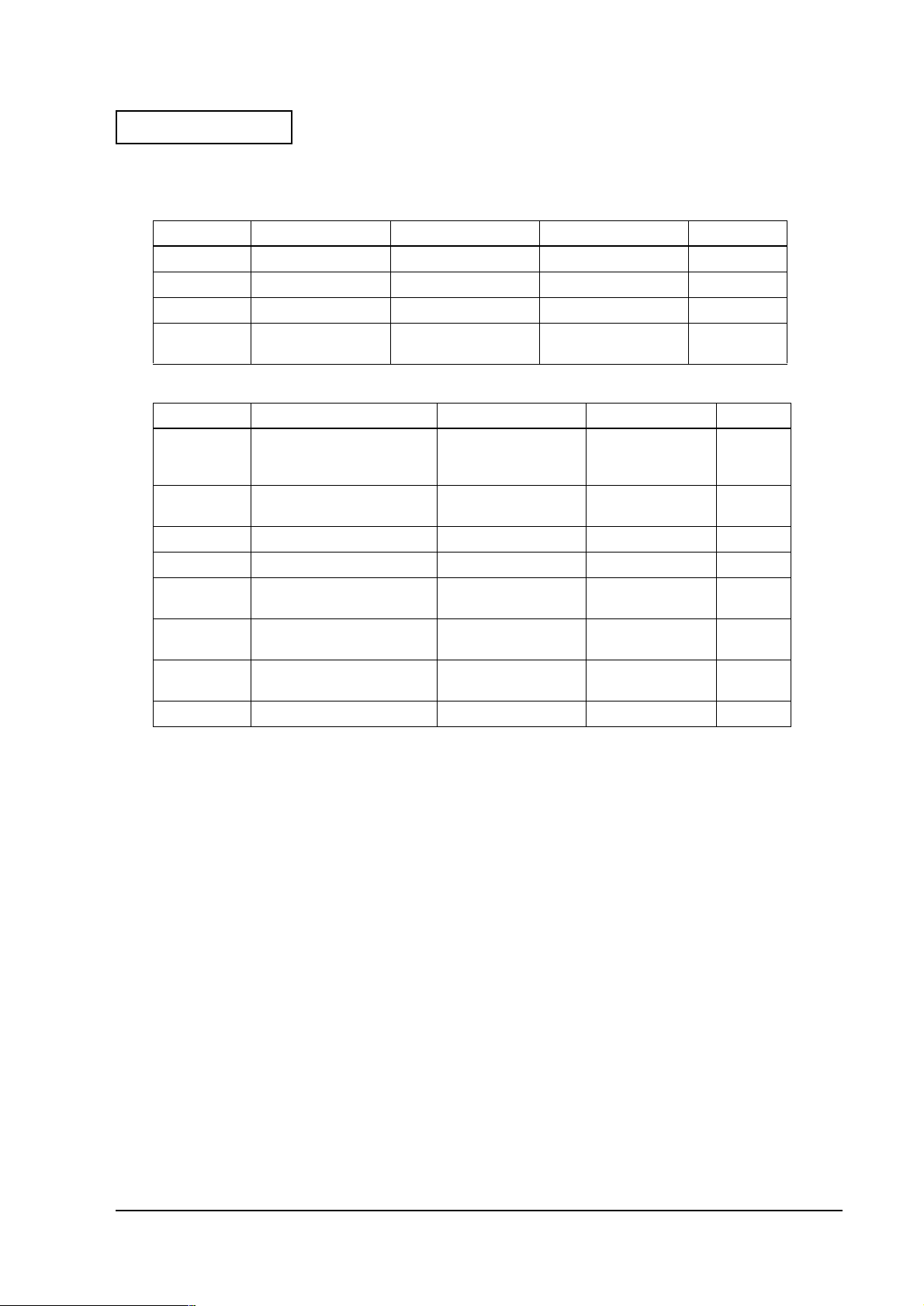

DIP Switch 1

Switch No. Function On Off Default

1 Data receive error

2 Receive buffer

capacity

3 Handshaking XON/XOFF DTR/DSR Off

4 Word length 7 bit 8 bit Off

5 Parity check Yes No Off

6 Parity selection Even Odd Off

7 Baud rate selection 4800 bps 9600 bps Off

8 BUSY condition Receive buffer-full Offline

Ignored

1KB 16KB Off

DIP Switch 2

Switch No. Function On Off Default

1 Selects number of

characters per line (cpl)

(7 × 9 font/9 × 9 font)

2 For internal use only (*1)

(autocutter)

3 Pin 6 reset signal Used Not used Off

4 Pin 25 reset signal Used Not used Off

5PAPER OUT LED blinking

pattern

6 For internal use only (*1)

(Flash memory rewriting)

7 For internal use only (*1)

(Interface synchronization)

8 internal buzzer Disabled Enabled Off

42 cpl//35 cpl 40 cpl/33 cpl Off

Enabled Disabled On

Blinks Lights on On

Enabled Disabled off

Asynchronous Synchronous with

Print "?" Off

Receive buffer-full

clock

Off

Off

*1: Do not change the settings of DIP switches 2-2, 2-6, and 2-7.

1-4 Installation

Page 13

Confidential

TM-U230 Developer’s Guide

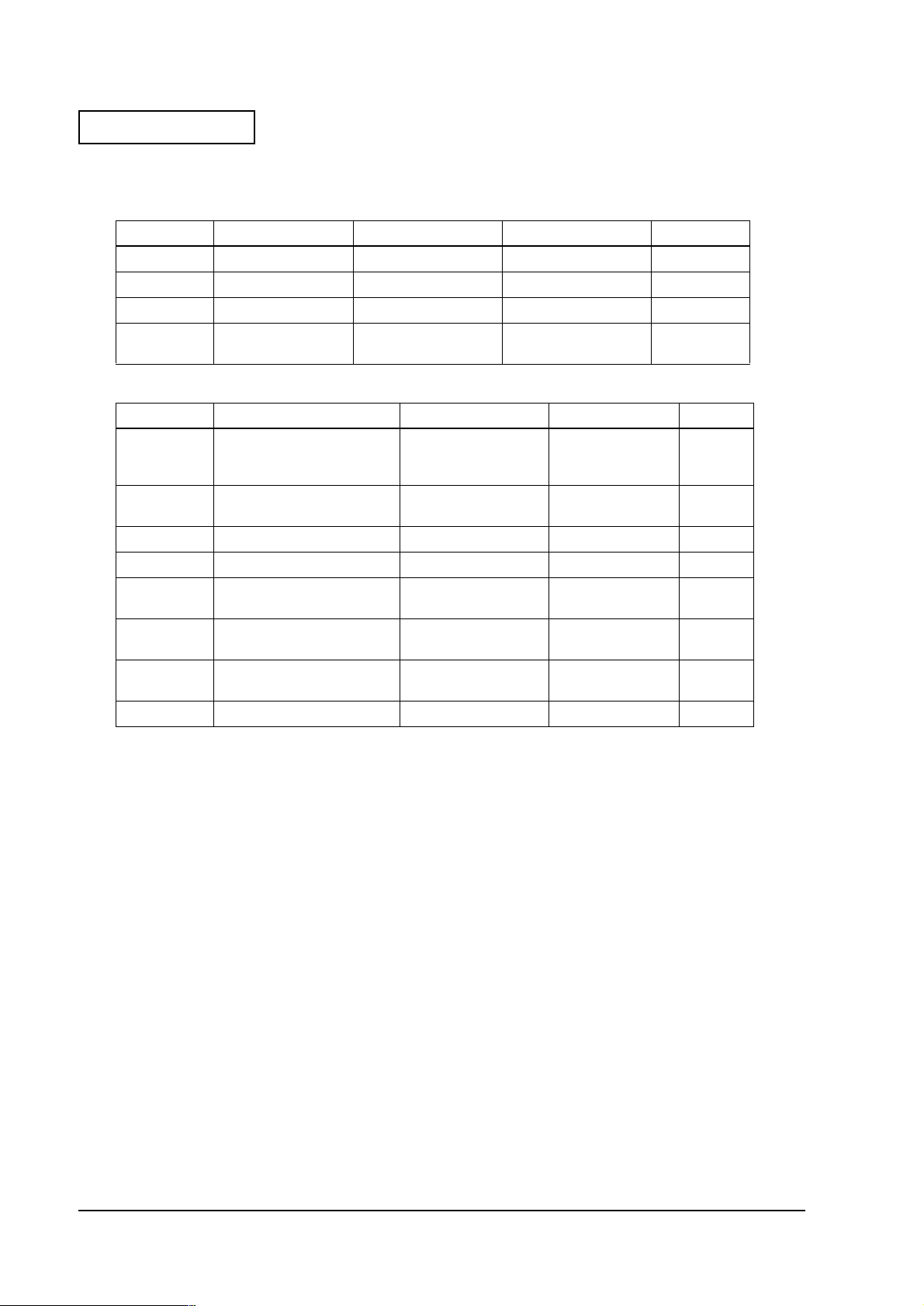

Parallel Interface

DIP Switch 1

Switch No. Function On Off Default

1 Auto line feed

2 Receive buffer 1KB 16KB Off

3 - 7 Undefined -- -- Off

8 Busy condition Receive buffer-full Offline

Enabled

DIP Switch 2

Switch No. Function On Off Default

1 Selects number of

characters per line (cpl)

(7 × 9 font/9 × 9 font)

2 For internal use only (*1)

(autocutter)

3 Undefined -- -- Off

4 Pin 31 reset signal Used Not used On

5PAPER OUT LED blinking

pattern

6 For internal use only (*1)

(Flash memory rewriting)

7 For internal use only (*1)

(Interface synchronization)

8 Undefined -- -- Off

42 cpl//35 cpl 40 cpl/33 cpl Off

Enabled Disabled On

Blinks Lights on On

Enabled Disabled off

Asynchronous Synchronous with

Disabled Off

Receive buffer-full

clock

Off

Off

*1: Do not change the settings of DIP switches 2-2, 2-6, and 2-7.

Installation 1-5

Page 14

Confidential

Ethernet Interface

DIP Switch 1

Switch No. Function On Off Default

1 Auto line feed

2 Receive buffer 1KB 16KB Off

3 - 7 Undefined -- -- Off

8 Busy condition Receive buffer-full Offline

Enabled

DIP Switch 2

Switch No. Function On Off Default

1 Selects number of

characters per line (cpl)

(7 × 9 font/9 × 9 font)

2 For internal use only (*1)

(autocutter)

3 Undefined -- -- Off

4 Pin 31 reset signal Used Not used On

5PAPER OUT LED blinking

pattern

6 For internal use only (*1)

(Flash memory rewriting)

7 For internal use only (*1)

(Interface synchronization)

8 Undefined -- -- Off

42 cpl//35 cpl 40 cpl/33 cpl Off

Enabled Disabled On

Blinks Lights on On

Enabled Disabled off

-- Synchronous with

Disabled Off

Receive buffer-full

clock

Off

Off

*1: Do not change the settings of DIP switches 2-2, 2-6, and 2-7.

1-6 Installation

Page 15

Confidential

TM-U230 Developer’s Guide

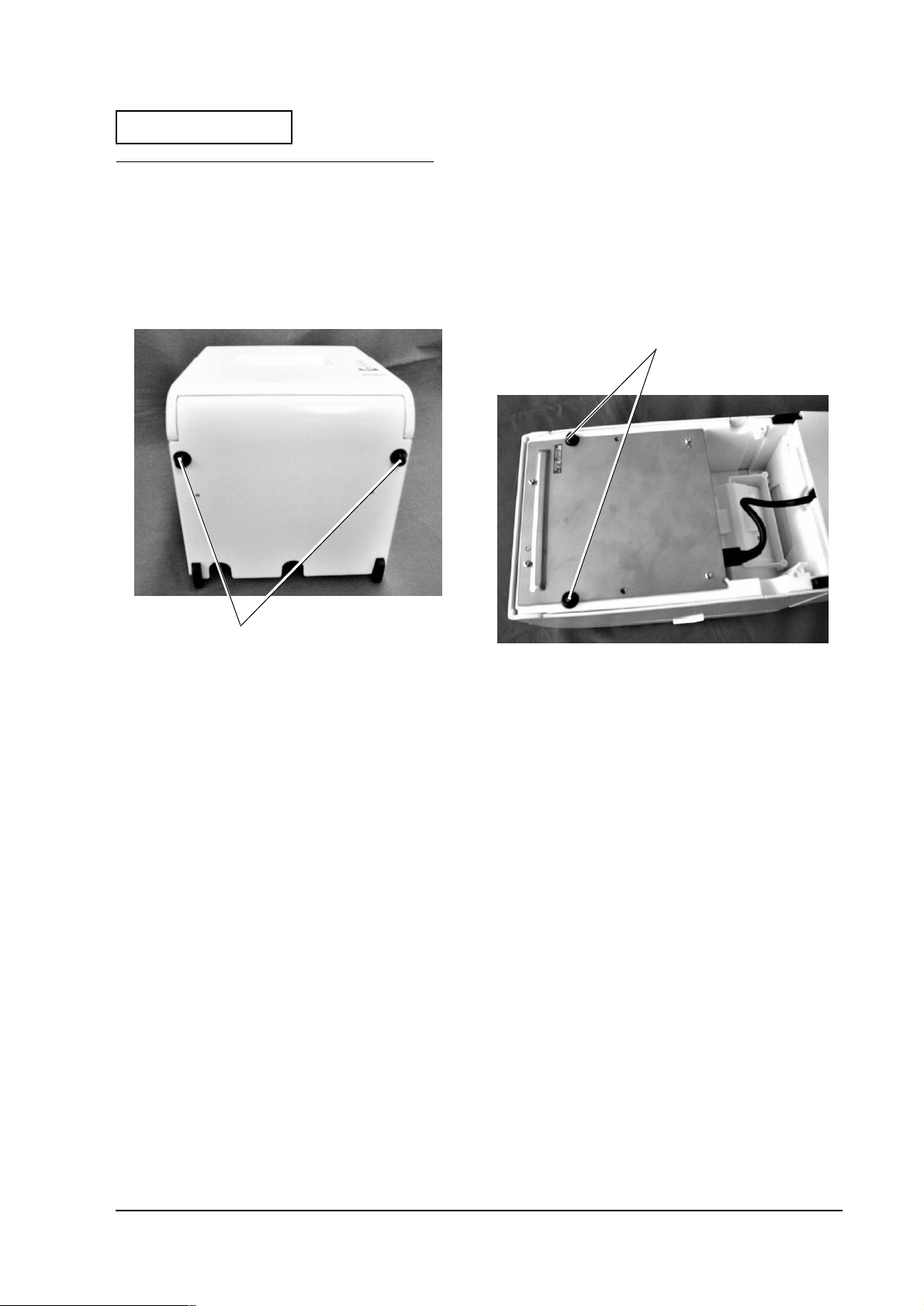

Settings for Horizontal Installation

Perform the following procedures when the printer is to be used in a horizontal installation.

Changing the Location of the Rubber Feet

Remove the rubber feet from the bottom of the printer and attach them to the back of the printer.

attach

Remove

Installation 1-7

Page 16

Confidential

Changing the Orientation of Near End Sensor

Perform the following procedures to change the orientation of the near end sensor.

1. Place the printer horizontally and open the roll paper cover.

2. Use a coin to loosen the near end adjustment screw.

3. Turn the protrusion on the near end holder to change the position of the near end lever.

4. Tighten the near end adjustment screw, check that the near end sensor lever operates

normally and close roll paper cover.

near end sensor

holder protrusion

near end sensor

adjustment screw

near end sensor lever

Roll paper cover

Changing the orientation of Near end sensor

1-8 Installation

Page 17

Confidential

TM-U230 Developer’s Guide

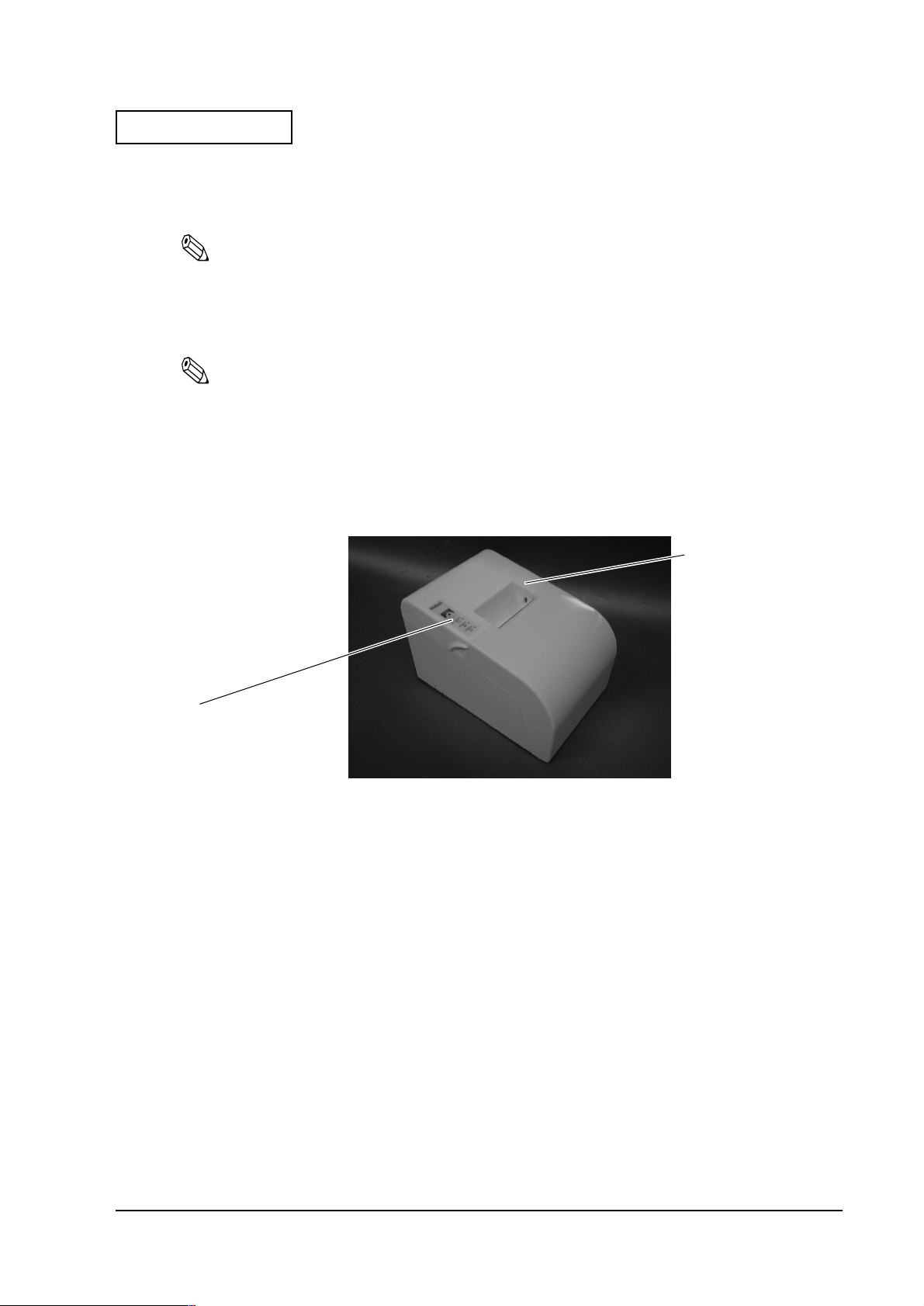

Attaching Switch Panel for Horizontal Installation

1. Clean the switch panel attached to roll paper cover.

Note:

Do not touch the switch panel surface after cleaning. Touching this surface may lower the strength of

the adhesive.

2. Remove the seal covering the adhesive surface of the switch panel for horizontal installation.

Note:

Do not touch the adhesive surface of the switch panel for horizontal installation. Touching this surface

may lower the strength of the adhesive.

3. Attach the switch panel for horizontal installation on top of the switch panel attached to the

roll paper cover. Press down the switch panel with sufficient force equally across the surface

of the panel.

Roll paper cover

Attach the switch panel for

horizontal installation on top of

the existing switch panel.

Switch panel attachment

Installation 1-9

Page 18

Confidential

Attaching the Power Supply Box (only for models with exclusive power supply unit)

The location of the power supply box varies with the method of installation.

WARNING:

Use only AC adapter designated by EPSON. Using a non-standard power supply may

cause a fire or shock hazard.

When you are using an EPSON AC power supply or the equivalent, immediately turn off

the printer and disconnect the power plug when you notice an abnormality.

CAUTION:

Always disconnect the power plug from the wall outlet when connecting or

disconnecting the AC adapter. Otherwise you may damage the AC adapter or the

printer.

Make sure that the rated voltage of the AC adapter matches the voltage of the wall

outlet before connecting the AC adapter. Do not plug in the AC adapter if the voltages

do not match. Otherwise you may damage the AC adapter or the printer.

Note:

To remove the DC cable connector, make sure the power supply power cord is unplugged; then grasp the

connector at the arrow and pull it straight out.

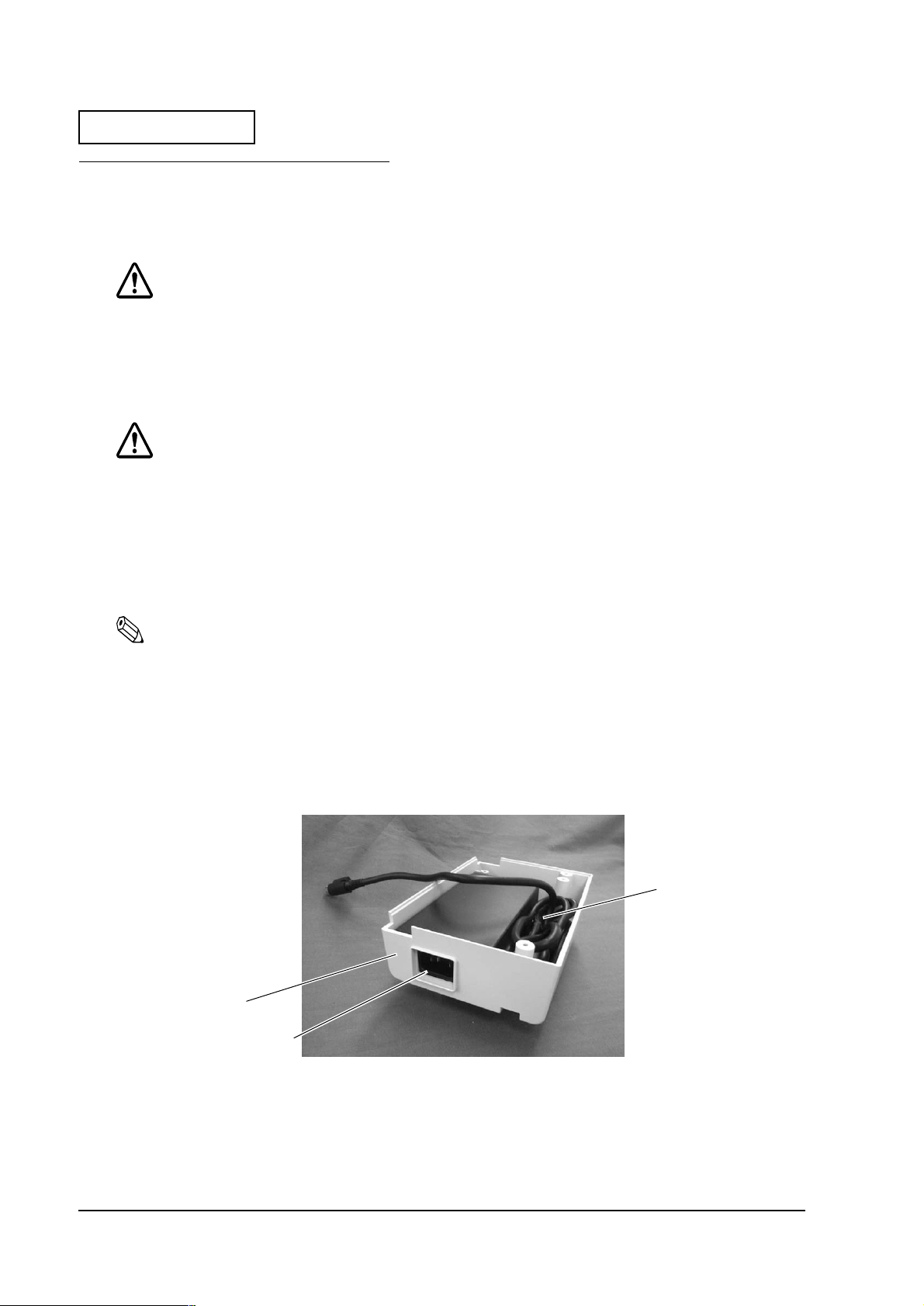

Assembling the Power Box

1. Place the AC adapter in the upper adapter cover. Bundle up the DC power supply cable. Be

sure that the power receptacle is against the rectangular hole in the power supply box.

DC power supply

cable

Upper adapter cover

Power receptacle

Power supply box assembly (1)

1-10 Installation

Page 19

Confidential

TM-U230 Developer’s Guide

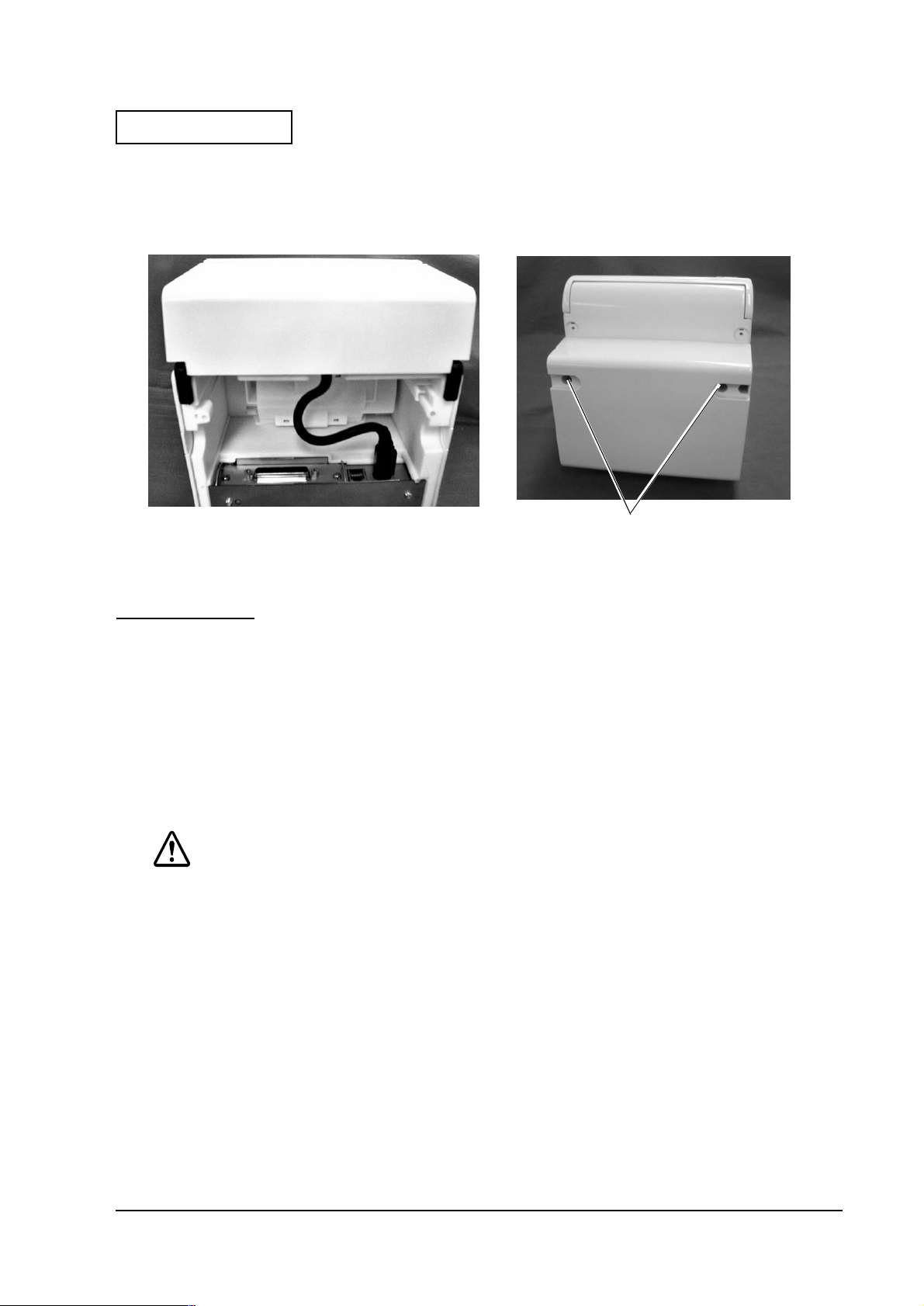

2. Put on the lower adapter cover with the cable through the notch in the lid and tighten the

screws. In doing so, pull out the DC power supply cable from the DC power supply cable

exit in the lower adapter cover so that around 15 cm of the cable protrudes from the cover.

3. Secure the covers with the screws packed with the printer (C.P.T-B Screw, 3 × 12, F/Zn).

Pull out around 15 cm

of the power cable

Screws

Lower adapter

cover

notch

Power supply box assembly (2)

Vertical Installation

1. Check that the printer POWER switch is off and that the power supply cord of the AC

adapter is not plugged into the wall outlet.

2. Connect DC power supply cable of the AC adapter to the DC connector on the printer.

Note:

Place the cables so that they go through the holes numbered 1 in the illlustration below. If

there are many cables used, use the other holes numbered 2 (you need to break that parts).

Installation 1-11

Page 20

Confidential

3. Attach the power supply box to the rear of the printer, aligning the box inside the rubber

pads and secure with two screws packed with the printer (C.P.T-B Screw, 3 × 14, F/Ni).

Holes 2

Holes 1

Rubber pads

Screws

Horizontal Installation and Wall Mounting

1. Check that the printer POWER switch is off and that the power supply cord of the AC

adapter is not plugged into the wall outlet.

2. Connect DC power supply cable of the AC adapter to the DC connector on the printer.

1-12 Installation

Page 21

Confidential

3. Attach the power supply box to the bottom of the printer and secure with two screws

packed with the printer(C.P.T-B Screw, 3 × 14, F/Ni).

Attaching the power supply box for horizontal installation and wall mounting

TM-U230 Developer’s Guide

Screws

Wall Mounting

An optional wall mounting bracket (Model Name: WH-10) is required to wall mount the printer.

Notes on Wall Mounting

❏ Cut printing paper may stick to the case due to static electricity (however, this does not

affect printer operation).

Installation

CAUTION:

Before starting any installation work, turn off the printer and all accessories connected to

the printer, and connect all cables connected to the printer.

Installation 1-13

Page 22

Confidential

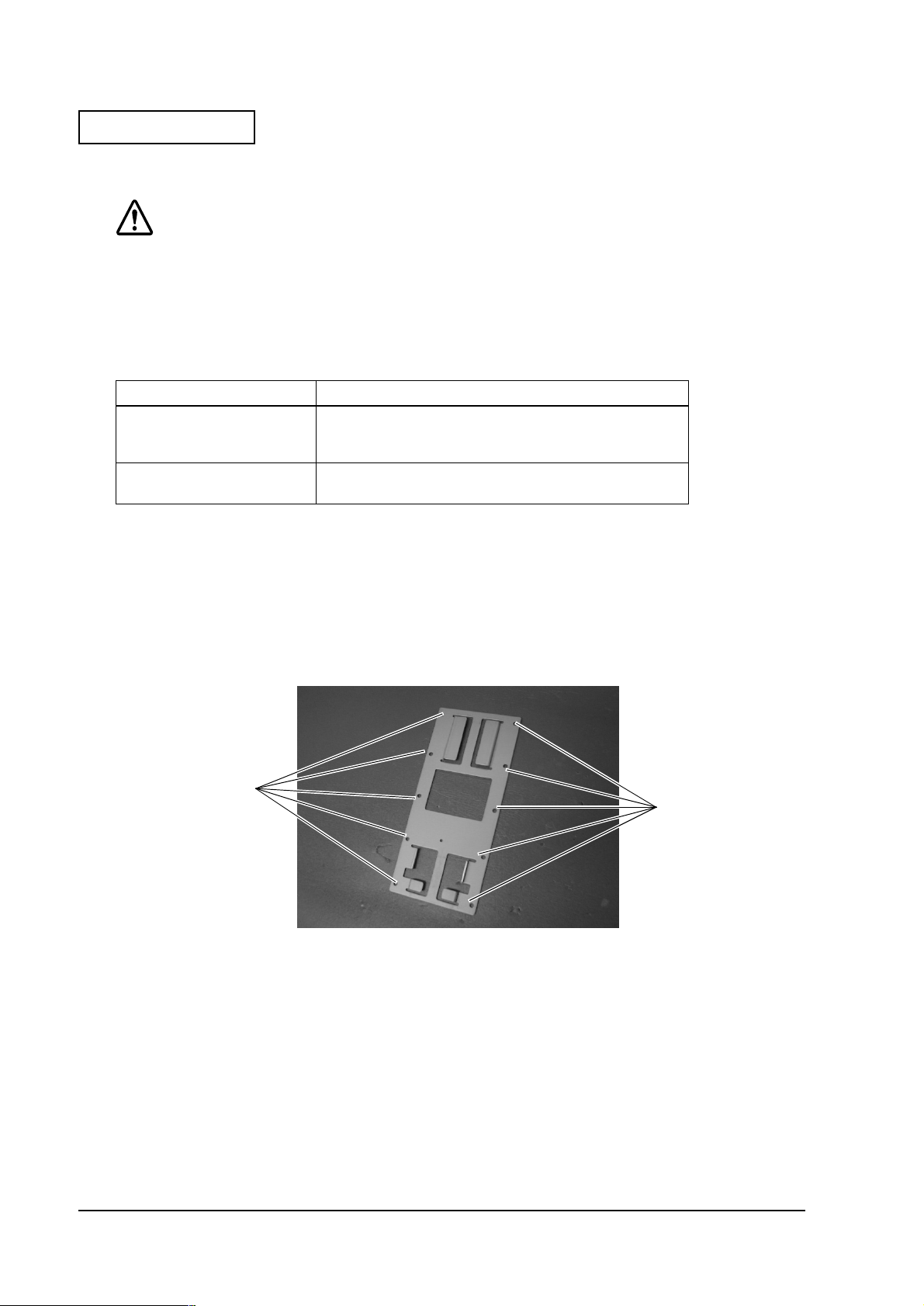

Installing the wall mount

CAUTION:

The weight of the printer is listed in the table below. Use screws that are long enough to

properly support the weight of the printer and that suit the type of wall you attach the

mount to. It is recommended that you use screws with a 4 mm diameter.

Secure the mount to the wall using all the 10 screw holes.

Table 1-1 Weight of printer and accessories

Weight

TM-U230 printer

AC adapter

Power supply box

TM-U230 printer Approx. 2,8 kg

❏ Select a location for wall mounting that will provide sufficient space around the printer

when the roll paper cover and cutter cover are open.

Approx. 3.5 kg

❏ Attach the wall mounting bracket using all the 10 screw holes.

❏ Since no screws have been supplied with the wall mounting bracket, select screws that suit

the wall where the bracket is to be attached.

Holes for screws in the

wall mounting bracket

Holes for screws in the

wall mounting bracket

Screw holes in the wall mounting bracket

1-14 Installation

Page 23

Confidential

TM-U230 Developer’s Guide

Attaching the hangers

Note:

❏ There are holes for 4 screws in the hangers (The number of the type of screw to be used is

stamped on the hanger). Use the correct screw holes.

❏ In attaching the hangers to the printer, use the 4 screws supplied with the WH-10 wall

mounting bracket.

1. Place the hangers on the printer (one at the center and the other at the bottom of the printer).

2. Use the screw holes in the printer marked "2" for the top hanger. Secure the hanger using

two of the supplied screws.

3. Use the screw holes in the printer marked "1" for the bottom hanger. Secure the hanger using

two of the supplied screws.

The two screw holes

labeled "2"

Hanger

The two screw holes

labeled "1"

Attaching the hanger

CAUTION:

Make sure that all 4 screws are properly secured.

Hanger

Installation 1-15

Page 24

Confidential

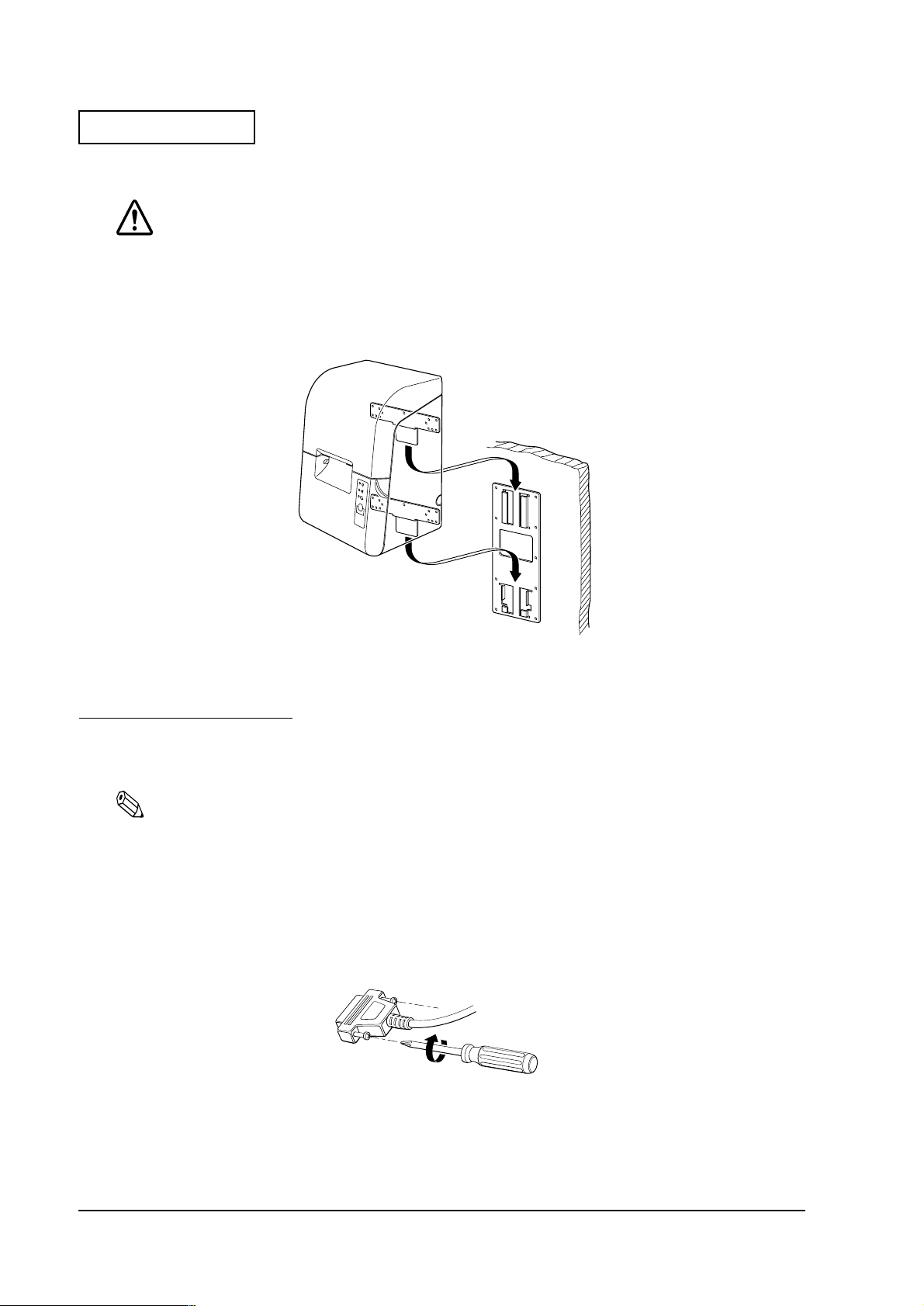

Attaching the printer to the wall

CAUTION:

Check again that the wall mounting bracket is properly secured to the wall before

attaching the printer.

1. Insert the hangers in the groove of the wall mounting bracket.

Attaching the printer to a wall

Connecting a Host PC

Turn off both the printer and the computer before making any cable connections.

Note:

Be sure that cables go through the holes numbered 1 in the illlustration on page 1-10. If there are many

cables used, use the other holes numbered 2 (you need to break that parts).

Serial interface connections

1. Connect the interface cable connector to the interface connector on the connector panel.

2. Secure both screws of connectors equipped with screws.

Tightening connector screws

1-16 Installation

Page 25

Confidential

Note:

Your printer has inch-type hexagonal lock screws installed. If your interface cable requires

millimeter-type screws, replace the inch-type screws with the enclosed millimeter-type

screws using a hex screwdriver (5 mm).

TM-U230 Developer’s Guide

Inch-type screw is marked with a line

Inch screw

Inch screw and millimeter screw

3. If your interface connector has a grounding wire, attach it to the printer using the screw

labeled FG.

4. Connect the other end of the interface cable to the host PC.

Millimeter screw

Connecting to a parallel interface

1. Connect the interface cable connector to the interface connector on the connector panel.

2. Close the tabs on both sides of the connector to lock it.

3. If your interface cable has a grounding wire, attach it to the printer using the screw labeled

FG.

4. Connect the other end of the interface cable to the host PC.

Connecting to a USB interface

Be sure to use the same settings of the DIP switches as the parallel interface. Set DIP switch 2-4 (#

31 reset signal) On.

1. Attach a locking wire saddle as shown in the figure below.

2. Pass the USB cable through the locking wire saddle as shown in the figure.

Installation 1-17

Page 26

Confidential

Note:

Passing the USB cable through the wire locking saddle as shown in the figure will keep the connection

from coming loose.

USB upstream connector

UB-BOARD

Locking wire saddle

USB cable

USB downstream connector

(USB HUB: only for UB-U01)

Attaching the locking wire saddle

3. Connect the USB cable from the host PC to the USB upstream connector.

4. A total of 2 USB devices can be connected to the USB downstream connector to a printer

equipped with UB-U01.

DM connector

Note:

The UB-U01 hub is a power supply hub. Consequently, a bus power supply hub (including UB-U01)

or a bus power supply function with a current consumption exceeding 100 mA cannot be directly

connected to this connector. (A UB-U02 can be directly connected to a UB-U01 hub.)

5. Install a UB-U01/02 device driver on the host PC.

Note:

Please contact the dealer where you purchased the product for information on how to obtain device

drivers and instructions on how to install them.

Connecting to an Ethernet interface

Be sure to note the following when using the Ethernet interface.

❏ Use the same settings of the DIP switches as the parallel interface.

❏ When turning on the power, the Ethernet interface board transmits the GS I and GS a ffh

commands to acquire printer information.

❏ Refer to the DIP switch setting section on page 1- 6 for the settings when using the Ethernet

interface.

1-18 Installation

Page 27

Confidential

Names of parts

Ethernet interface terms are given below.

TM-U230 Developer’s Guide

10 BASE-T Ethernet

interface

connector

LED (green) LED (red) Switch

Do not press the

LEDs.

Holding down this switch

when the printer is powered

up returns all settings to

their default values.

Names of parts

Ethernet test switch

The Ethernet test switch has the following functions.

❏ Setting Initialization

Holding down this switch for 5 seconds or more when the printer is powered up returns all

settings to their factory default values.

❏ Status Sheet Test Printing

Holding down this switch for 3 seconds or more while the printer is online causes the printer

status sheet to be printed out.

Installation 1-19

Page 28

Confidential

Ethernet LEDs

The operating status of the Ethernet interface is indicated by the combined status of the two

Ethernet LEDs (redx1 and greenx1).

No. Green Red Status

1Off Off Power off

2 Off On Hardware error

3 Off 1 blink CPU test error

4 Off 6 blink Printer reset error

5 On Off Waiting

6 Slowblinking Off Data or status sheet printing

7 Slow blinking in unison Download mode

8 Blinking alternately Downloading

9 Fast blinking in unison Initializing

10 Fast blinking Off Sending and receiving packets

Interface cable connections

CAUTION:

Connecting devices directly to LAN cables that are installed outdoors will expose them

to damage from power surges caused by lightning and other inductive sources. It is best

to make sure that devices without proper surge protection are cushioned by being

connected through devices that do have surge protection. Otherwise, it is better not to

connect them to outdoors lines.

1. Make sure that both the printer and the host PC are turned off.

2. Press in the 10 BASE-T cable plug into the 10 BASE-T Ethernet connector until you hear a

clicking sound.

CAUTION:

Never connect a customer display connector cable, drawer kick-out connector or a public telephone

line to the 10 BASE-T Ethernet connector.

Note:

Refer to the UB-E01 Developer’s Guide for more details about the Ethernet Interface.

1-20 Installation

Page 29

Confidential

TM-U230 Developer’s Guide

Drawer Kick-Out Connector (Marked DK)

CAUTION:

Connect a drawer that matches the printer specifications. Using an improper drawer

may damage the printer as well as the drawer.

Do not connect a telephone line to the drawer kick-out connector (marked DK). Such a

connection may damage both the printer and the telephone lines.

Note:

Be sure that cables go through the holes numbered 1 in the illlustration on page 1-10. If there are many

cables used, use the other holes numbered 2 (you need to break that parts).

1. Connect the drawer cable to the drawer kick-out connector (marked DK) on the connector

panel.

Drawer kick-out connector

Drawer connection

Installation 1-21

Page 30

Confidential

1-22 Installation

Page 31

Confidential

TM-U230 Developer’s Guide

Chapter 2

Handling

Important Safety Information

WARNING:

❏ Turn off the power switch immediately and unplug the power cord from the electrical outlet

if the TM-U230 produces smoke, a strange odor, or unusual noise. Continued use may lead

to fire or electric shock.

❏ Do not modify the printer or perform any disassembly operation not described in this

manual. Doing so could result in a fire or shock hazard.

❏ Use only the designated power supply. Use of a different power supply could cause a fire or

shock hazard.

❏ Never insert or disconnect plugs with wet hands. Doing so may cause a serious shock.

❏ Never drop or push objects into the product through openings. This could cause a fire or

shock.

❏ If the printer is exposed to water or other liquid, turn off the

the power cord immediately. Continued use under these conditions could cause a fire or

shock hazard.

❏ Do not connect the power cord to an overloaded wall outlet. This may cause a fire hazard.

Connect the printer directly to a wall outlet.

❏ Handle the power cord with care. Incorrect handling may lead to fire or shock.

• Do not modify the power cord.

• Do not place heavy objects on the power cord.

• Do not bend, twist, or pull the power cord excessively.

• Do not route the power cord near heaters.

• Remove any dirt or dust from the power plug before plugging it in.

• Be sure to fully insert the power plug.

POWER

button and disconnect

Handling 2-1

Page 32

Confidential

CAUTION:

❏ All cables are to be connected only as described in the manual. Incorrect connection could

cause damage or a fire hazard.

❏ Be sure to set this product on a firm, stable, horizontal surface. The product may break or

cause injury if it falls.

❏ Do not install the printer in extremely humid or dusty locations. Operation under such

conditions could damage the printer or cause a fire or shock hazard.

❏ Do not stand on the printer or place heavy objects on it. The printer could fall or collapse,

causing breakage and possible injury.

❏ For added protection of the printer, disconnect the power plug from the wall outlet when

the printer is not to be used for an extended period of time.

❏ Be sure not to touch the print head or motors when you remove paper jammed in the

printer. Wait until the print head and motors have cooled down before removing jammed

paper. When the printer has been used for an extended period, the print head and the

motors are very hot and could cause burns.

Precautions in handling the fine coating of the case (only for Fine Coating Case model)

A fine coating is used for the external surface of the plastic case of the printer, which makes

wiping and removing kitchen stains easy; however, you should note the following when

cleaning the surface in order to preserve the quality of the coating (the metal plate and the inside

of the case do not have the fine coating):

❏ Do not scrub the surface with a hard object. Otherwise, the case will be scratched and harder

to clean.

❏ Do not use a cleanser that includes polishing materials such as grains of glass, metal, or

ceramics. Otherwise, the case will be scratched and harder to clean.

❏ Never use disinfectant, bleach, alcohol, benzine, thinner, chlorine solvent, or ketone solvent.

Otherwise, the case will be harder to clean, and the case may be seriously harmed or even

deformed and its color may be changed.

❏ The label may come off of the fine coating of the case if harsh cleaning methods are used

Waterproof

The TM-U230 is designed as a kitchen printer with protection from water. When it is installed

vertically or horizontally, the printer meets the European Standards IEC 529 for protection

against water of "keeps out water coming from an angle up to 15

level. (The TM-U230 also meets the IEC Standards for protection from tools and thin wires with

a diameter more than 2.5 mm and protection from solid foreign objects with a diameter greater

than 2.5 mm.) The IP code of the TM-U230 when it is installed vertically or horizontally is IP32.

The meaning of the "IP" numbers is described in the next section of this manual.

from vertical, evaluating IP

°

.

2-2 Handling

Page 33

Confidential

TM-U230 Developer’s Guide

IP

The ability of an enclosure to keep out dirt and water is defined in IEC 529. When an enclosure

protects the equipment from water and particles of dirt, it also protects people from any

potential hazard inside the equipment.

The degree of protection is designated by the letters "IP" followed by two digits such as "IP01" or

"IP34." The first digit indicates the degree that the equipment is protected from solid foreign

objects. The second digit indicates the degree that the equipment is protected from water. The

details are described in the tables below. The first digit, protection from solid foreign objects, is

divided into "protection from human contact" and "protection from foreign bodies."

First Digit Protection From Human Contact Protection From Foreign Bodies

0 No protection No protection

1 Protection from the palm of a hand Protection from foreign bodies with a

2 Protection from fingers Protection from foreign bodies with a

3 Protection from tools and thin wires, etc. with

a diameter more than 2.5 mm

4 Protection from tools and thin wires, etc. with

a diameter more than 1 mm

5 Complete protection Protection from grainy foreign bodies

6 Complete protection Complete protection from grainy foreign

diameter greater than 50 mm

diameter greater than 12.5 mm

Protection from foreign bodies with a

diameter greater than 2.5 mm

Foreign body with a diameter greater

than 1 mm

(only a certain amount is permitted)

bodies

Second Digit Ability to keep water out

0 No protection

1 Keeps out water coming from directly above

2 Keeps out water coming from an angle up to 15

3 Keeps out water sprayed at an angle of 60

4 Keeps out water sprayed from all directions (only a certain amount of water

penetrating the enclosure is permitted)(*)

5 Keeps out low pressure water jet sprayed from all directions (only a certain amount of

water penetrating the enclosure is permitted)(*)

6 Keeps out high pressure water jet sprayed from all directions (only a certain amount of

water penetrating the enclosure is permitted)(*)

7 Keeps out water during temporary immersion

8 Keeps out water during permanent immersion

(*) : Only a certain amount of water may enter though the printer can continue printing.

from vertical

°

from vertical

°

Handling 2-3

Page 34

Confidential

Example:

When the IP code of a product is IP32, the first digit means that the product has protection from

tools and thin wires with a diameter more than 2.5 mm and protection from solid foreign objects

with a diameter greater than 2.5 mm. The second digit means that the product is protected from

water coming from an angle up to 15

from vertical.

°

The test for keeping out water coming from an angle up to 15

from vertical is executed under

°

the following conditions.

Amount of water Angle Time

3mm/min 15° from each of front, rear, right and left 2.5 min. for each angle.

Waterproof mechanism

TM-U230 is especially designed to protect the printer from water. If the printer is installed

horizontally, when water enters the printer through the portions indicated in blue, that water

goes out of the printer through the portions indicated in red.

portions that water

portions that

water goes out

goes out

2-4 Handling

Figure 2-1

Page 35

Confidential

TM-U230 Developer’s Guide

Replacing roll paper

Use the designated type of roll paper. (See Appendix A for information on roll paper

specifications.)

1. Be sure that the power is turned on.

2. Open the roll paper cover.

3. Remove the roll paper and cut the paper along the dotted line in the figure below.

Cut

Roll paper cover

Figure 2-2 Cutting roll paper

4. Press the

PAPER FEED

button to remove the cut paper.

5. Use a pair of scissors to cut the front end of the paper off squarely.

PAPER FEED

button

Figure 2-3 Shape of roll paper front end

6. Load the roll paper in the printer. Be sure to note the correct direction that the paper should

come off the roll. (See Figure 2-4.)

7. Hold the front end of the roll paper with both hands and insert the roll paper into the paper

insertion slot as far as it will go. The roll paper is now automatically fed.

Handling 2-5

Page 36

Confidential

Note:

If the cutter cover is opened, the printer is offline and paper will not be fed automatically. Be sure to

close the cutter cover.

paper insert slot

Figure 2-4 Loading roll paper

8. Close the roll paper cover.

9. When the

when the

The printer is offline as long as the LED is flashing.

PAPER OUT LED

PAPER OUT LED

Note:

starts to flash, press the

stops flashing.

PAPER FEED

button. The printer is online

2-6 Handling

Page 37

Confidential

TM-U230 Developer’s Guide

Replacing the ribbon cassette

Use the EPSON ERC-38 ribbon cassette.

1. Open the roll paper cover.

2. Open the cutter cover.

3. Raise the autocutter lock lever and open the autocutter. Be sure that the autocutter is locked.

Lock lever

Figure 2-5 Autocutter lock lever

4. Take the ribbon cassette out of the printer.

5. Turn the knob on the new ribbon cassette in the direction indicted by the arrow on the

cassette to remove any slack.

CAUTION:

Do not turn the ribbon cassette knob in the opposite direction. Turning the knob in the

opposite direction may damage the ribbon cassette.

Figure 2-6 Removing ribbon slack

Handling 2-7

Page 38

Confidential

6. Insert the ribbon between the print head and the platen, as shown in the figure below, and

press it in until it clicks into place.

7. Turn the ribbon cassette knob 5 to 6 times in the direction of the arrow to remove any slack

in the ribbon.

Note:

Make sure that the ribbon is inserted between the print head and the platen and that there are no

creases or folds in the ribbon.

Figure 2-7 Installing the ribbon cassette and removing ribbon slack

2-8 Handling

Page 39

Confidential

TM-U230 Developer’s Guide

Removing paper jams

Paper jams in the vicinity of the print head

1. Turn off the power and open the roll paper cover.

2. Take out the roll paper and cut the paper along the dotted line in the figure below.

Roll paper cover

Cut

Figure 2-8 Cutting roll paper

3. Open the cutter cover.

4. Raise the autocutter lock lever and open the autocutter.

5. If possible, pull the jammed paper in the paper exit direction to remove it. If the paper

cannot be pulled out in the direction of the paper exit, try the following procedure.

Handling 2-9

Page 40

Confidential

CAUTION:

Do not remove jammed paper by pulling it against paper feed direction.

Figure 2-9 Removing jammed paper

6. Take the ribbon cassette out of the printer.

7. Loosen the screw that secures the print head cover. Loosen the screw until it tilts.

8. Remove the print head cover.

CAUTION:

The print head becomes hot during printing. Perform this procedure when the print

head has become cool.

2-10 Handling

Page 41

Confidential

TM-U230 Developer’s Guide

Figure 2-10 Removing the print head cover

9. Remove the jammed paper.

CAUTION:

Do not remove jammed paper by pulling it against paper feed direction.

10. Perform Steps 7 and 8 above in the opposite order to install the print head cover and secure

it with the screw.

CAUTION:

Be sure to properly secure the cover with the screw.

11. Install the ribbon cassette in the printer.

Handling 2-11

Page 42

Confidential

Paper jam in the auto cutter

When the autocutter blade is visible through the slit, a paper jam may have occurred in the auto

cutter. Insert a screwdriver in the hole on the side of the autocutter to turn the gear and return

the blade to a position where it cannot be seen from the slit (indicated by the bold dotted line in

Figure 2-11).

Slit

Figure 2-11 Normal auto cutter position

2-12 Handling

Page 43

Confidential

TM-U230 Developer’s Guide

Installing the power button cover

The power button cover is provided to prevent someone from pressing the power button

inadvertently. Install the cover over the printer POWER button as shown in the figure below.

When a power button cover has been installed, insert a ballpoint pen or the like in the holes

provided to turn the printer on and off.

Figure 2-12 Installing the power button cover

WARNING:

Should an emergency arise when the power button is installed, immediately disconnect

the AC cable of the AC adapter from the power outlet. Continued use under these

conditions could result in fire or shock hazard.

Handling 2-13

Page 44

Confidential

2-14 Handling

Page 45

Confidential

TM-U230 Developer’s Guide

Chapter 3

Compatibility

This Chapter describes features that are different between the TM-U230 and TM-U210 Series

printers.

Internal Buzzer

The TM-U230 have the internal buzzer and changing the DIP Switch 2-8 setting enables/

disables the internal buzzer.

Switch No. On Off Defaut

2-8 Internal buzzer Disabled Internal buzzer Enabled Off

Internal buzzer noise level: Approx. 75dB

(Environment temperature(Ta)=25

When the internal buzzer is enabled and a paper roll end or near-end is detected, the buzzer will

sound and the

be selected by DIP switch 2-5.)

PAPER OUT

LED will be on or blinking. (The pattern of the

C, measured at 100mm from the paper exit)

°

PAPER OUT

LED can

Paper roll end settings

❏ When the paper roll end sensor is disabled to stop printing and it detects a paper end

⇒ The

❏ When the paper roll end sensor is enabled to stop printing and it detects a paper end

⇒ Both the

will be offline.

Refer to the Figure 3-1 for detailed specification of the internal buzzer operation by DIP switch

and the LED indication.

PAPER OUT

PAPER OUT

LED will be on (or blinking) but the printer will not be offline.

LED and the

ERROR

LED will be on (or blinking) and the printer

Compatibility 3-1

Page 46

Confidential

DIP Switch 2-5

Condition

Paper end Off

(PAPER OUT LED)

(LED is On)

DIP Switch 2-8

(Internal buzzer)

Off

(Enabled)

On

(Disabled)

Blinking pattern of PAPER OUT LED and

buzzer pattern

LED is On

Buzzer sounds continuously

LED is On

No buzzer sound

On

(Blinking)

Off

(Enabled)

On

(Disabled)

LED blinking pattern

Approx. 640 ms

Buzzer sound pattern

Approx. 640 ms

LED blinking pattern

Approx. 640 ms

No buzzer sound

Figure 3-1 PAPER OUT LED and internal buzzer operation

3-2 Compatibility

Page 47

Confidential

TM-U230 Developer’s Guide

Replacing the paper roll stops the buzzer sound and turns off the

pressing the

Be sure that the

FEED

button stops the buzzer sound and turns off the

PAPER OUT

LED goes off when the buzzer sounds is stopped.

PAPER OUT

PAPER OUT

LED. Also

LED.

For details of the status of the LEDs when a paper end is detected, see the following table:

Stop printing

disabled/

enabled Sensor

Disabled Paper roll

Enabled Paper roll

near-end

sensor

(

ESC c 4 0

near-end

sensor

(

ESC c 4 1

Paper roll

end sensor

Status of panel LEDs and printer

Normal Paper end detected

POWER LED: On

ERROR LED: Off

PAPER OUT LED: Off

)

Printer status: Online

POWER LED: On

ERROR LED: Off

PAPER OUT LED: Off

)

Printer status: Online

(the first time)

POWER LED: On

ERROR LED: Off

PAPER OUT LED: On (blinking)

Printer status: Online

POWER LED: On

ERROR LED: On

PAPER OUT LED: On (blinking)

Printer status: Offline

After pressing the FEED

button

POWER LED: On

ERROR LED: Off

PAPER OUT LED: Off

Printer status: Online

POWER LED: On

ERROR LED: On

PAPER OUT LED: Off

Printer status: Offline

See Appendix B for more details.

TM-U230 has ESC(A command, which can control the internal buzzer. With this command, TMU230 can beep the internal buzzer at the specified interval or beeps when the specified event

(paper near end, cover open, paper end, stop printing, recoverable error or unrecoverable error)

occured.

Note:

• When the internal buzzer is disabled by ESC(A command, the

light or blink, because the internal buzzer corresponds to the

• The

PAPER OUT

LED blinks correspondingly when the internal buzzer is set to beep if

PAPER OUT

PAPER OUT

paper end is detected.

• ESC(A command setting is canceled when the power is turned off.

• Refer to the ESC(A command description in TM-U230 series specification for more

details.

The printer status can be checked by commands such as GS a.

Receive Buffer

The selectable receive buffer size differs depending on the setting of DIP switch 1-2.

Printer DIP switch On Off Default

TM-U230 1-2 1K bytes 16K bytes Off

TM-U210

series

1-2 40 bytes ANK: 1K bytes

Multilingual: 512 bytes

Off

LED does not

LED.

Compatibility 3-3

Page 48

Confidential

For the TM-U210 series printers, when DIP switch 1-2 is off, the following commands cannot be

used; however the TM-U230 can use them.

Printer Name

HT

ESC %

ESC &

ESC ?

ESC D

FS 2

FS ?

Receive buffer full conditions are different.

Printer Receive buffer-full conditions

TM-U230 When the remaining memory size becomes 128 bytes, the printer will be BUSY

TM-U210 series When the remaining memory size becomes 16 bytes, the printer will be BUSY

Horizontal tab

Select/cancel user-defined character set

Define user-defined characters

Cancel user-defined characters

Set horizontal tab positions

Define user-defined Kanji characters (only for Multilingual specification)

Cancel user-defined Kanji characters (only for Multilingual specification)

and when it returns to 256 bytes, the BUSY condition will be canceled.

and when it returns to 26 bytes, the BUSY condition will be canceled.

Mounted Mechanism

Printer Mounted Mechanism

TM-U230 Autocutter and near-end sensor are standard equipment

TM-U210 series Near-end sensor is an option

Has no paper roll take-up device

Available with or without an autocutter

Available with or without a paper roll take-up device

Page 254, 255 (Space Page)

There is difference in a memory mapping.

Printer Memory Mapping

TM-U230 Page 254 7 × 9 font First address ECBA0

9

9 font First address ED5A0

×

Page 255 7

TM-U210 series Page 254 7

Page 255 7

9 font First address EE1A0

×

9

9 font First address EEBA0

×

9 font First address 8CBA0

×

9

9 font First address 8D5A0

×

9 font First address 8E1A0

×

9

9 font First address 8EBA0

×

3-4 Compatibility

Page 49

Confidential

;

;

;

;

TM-U230 Developer’s Guide

Chapter 4

Programming Samples

Saving Space for Receipt Printing

TM-U230 has GS V function C, which can save space for receipt printing. Executes a paper cut

automatically when the current position reaches the autocutter position.

The details of this function are described below, comparing GS V function C with GS V

function B.

❏ GS V function C Executes a partial cut (one point left uncut)

❏ GS V

function B Feeds paper for cutting position + [n × 0.176 mm {1/144

"

executes a partial cut (one point left uncut)

GS V (Function B)

1. The application will start printing Receipt 1. (There is space at the top when executing GS V

function B.)

Program Example

111111111111111

222222222222222

333333333333333

444444444444444

Assumed A/C position

Assumed head position

PRINT #1, “111111111111111”; CHR$(&HA)

PRINT #1, “222222222222222”; CHR$(&HA)

PRINT #1, “333333333333333”; CHR$(&HA)

PRINT #1, “444444444444444”; CHR$(&HA)

}] and

Programming Samples 4-1

Page 50

Confidential

2. After printing Receipt 1, the application executes GS V function B. The printer feeds paper

so that the printing on Receipt 1 exceeds the autocutter position and cuts the paper. For the

next printing, there will be space between the positions of the autocutter and the print head.

Program Example

PRINT #1, “111111111111111”; CHR$(&HA);

PRINT #1, “222222222222222”; CHR$(&HA);

PRINT #1, “333333333333333”; CHR$(&HA);

PRINT #1, “444444444444444”; CHR$(&HA);

PRINT #1,CHR$(&H1D);”V”;CHR&(66);CHR&(0);

Assumed A/C position

Assumed head position

Executing a cut

111111111111111

222222222222222

333333333333333

444444444444444

GS V (Function C)

1. The application will start printing Receipt 1. (There is space at the top when executing GS V

function B.)

Program Example

PRINT #1, “111111111111111”; CHR$(&HA);

PRINT #1, “222222222222222”; CHR$(&HA);

111111111111111

222222222222222

Programming Samples 4-2

Page 51

Confidential

0

TM-U230 Developer’s Guide

2. After printing the last line of Receipt 1, the application executes GS V function C.

Assumed A/C position

111111111111111

222222222222222

333333333333333

444444444444444

(Execute GS V 98 0)

Assumed head position

The parameter “0” of GS V 98 0 indicates paper

feed amount executed right before the paper cut.

Program Example

Printing direction

PRINT #1, “333333333333333”; CHR$(&HA);

PRINT #1, “444444444444444”; CHR$(&HA);

PRINT #1,CHR$(&H1D);”V”;CHR&(98);CHR&(

When the printer processes GS V function C, feeds paper for 4 mm to secure space for the

cutting range.

3. The application starts printing Receipt 2.

111111111111111

222222222222222

333333333333333

444444444444444

Cutting range

55555555555555

66666666666666

77777777777777

88888888888888

Assumed A/C position

Printing direction

Assumed head position

Program Example

PRINT #1, “555555555555555”; CHR$(&HA);

PRINT #1, “666666666666666”; CHR$(&HA);

PRINT #1, “777777777777777”; CHR$(&HA);

PRINT #1, “88888888888888”; CHR$(&HA);

Programming Samples 4-3

Page 52

Confidential

4. When the cutting range of Receipt 1 reaches the autocutter position while printing Receipt 2,

the printer cuts the paper.

111111111111111

222222222222222

333333333333333

444444444444444

Cutting range

55555555555555

66666666666666

77777777777777

88888888888888

99999999999999

11111111111111

Executing a cut

Assumed A/C position

Assumed head position

Printing direction

5. When printing the last line of Receipt 2, the application executes GS V function C.

111111111111111

222222222222222

333333333333333

444444444444444

Cutting range

55555555555555

66666666666666

77777777777777

Assumed A/C position

88888888888888

99999999999999

11111111111111

22222222222222

33333333333333

(Execute GS V 98 0)

Assumed head position

Printing direction

Programming Samples 4-4

Page 53

Confidential

TM-U230 Developer’s Guide

6. The application starts printing Receipt 3. When the cutting range of Receipt 2 reaches the

autocutter position while printing Receipt 3, the printer cuts the paper.

Receipt 1

111111111111111

222222222222222

333333333333333

444444444444444

Cutting range

55555555555555

Receipt 2

66666666666666

77777777777777

88888888888888

99999999999999

11111111111111

Executing a cut

22222222222222

33333333333333

Cutting range

Assumed A/C position

00000000000000

Receipt 3

11111111111111

22222222222222

33333333333333

44444444444444

55555555555555

Assumed head position

Printing direction

When you remove the assumed Receipt 2, you will have the result shown below. There will be

no space at top and bottom of the paper, which saves paper.

555555555555555

666666666666666

777777777777777

888888888888888

9999999999999999

111111111111111

222222222222222

3333333333333333

Notes on Using GS V Function C

When using GS V function C, there is a possibility of paper not being ejected (or not being cut),

depending on usage.

Programming Samples 4-5

Page 54

Confidential

Here is an example when executing the following steps.

1. Print receipt A

2. Execute GS V 98 0

3. Print receipt B

4. Execute GS V 98 0

5. Print receipt C

6. Execute GS V 98 0

If the cutting ranges designated in step 4 and 5 have not reached the autocutter position, Receipt

B and C will not be cut. Even if they have reached the autocutter position and have been cut, the

receipts do not reach the paper exit. With this condition, if the next printing is not performed,

Receipts B and C will not be ejected. Therefore, be sure to take the following into consideration.

Executing paper feed after a certain time has passed or executing a cut with GS V 66 0 for each

receipt.

See Figure A-2 Printing area for the relationship between the cutting position and the print head

position.

Programming Samples 4-6

Page 55

Confidential

TM-U230 Developer’s Guide

The usage of DirectIO in OPOS

This Chapter describes the programming samples of DirectIO in OPOS.

Executes a paper cut automatically when the current position reaches the autocutter position.

Executes a paper cut after feeding for 4 + pData ∗ 0.176 [mm]. The value of the pData is 0 in the

following example. (the available range of pData is 0 - 255)

button is pressed or a command that results printer

This function is canceled when the

reset is executed.

Command: PTR_DI_DELAYED_CUT Execute the delayed cut

pData : Specify feed lines to the autocutter position

pString : Not used

Dim RC As Long

Dim pString As Long

Dim pData As String

FEED

pString = PTR_DI_DUMMY

pData = 0

.....Printing process.....

RC = Coptr1.DirectIO(PTR_DI_DELAYED_CUT ,pData,pString)

Programming Samples 4-7

Page 56

Confidential

Contorol of The Buzzer

TM-U230 has ESC(A command, which can control the internal buzzer. ESC(A command is

supported by the Firmware version 1.02 and above. You can confirm the Firmware version by

the following procedure.

<Starting the self test>

1. Hold on the FEED button and turn on the printer with the paper roll cover opened.

2. Printer then prints the current printer status(Control ROM version, DIP switch settings)

on a roll paper.

This chapter describes the programming samples of DirectIO in OPOS.

Dim RC As Long

Dim pString As Long

Dim pData As String

pData = PTR_DI_DUMMY

pString = Chr(&H1B)+”=”+Chr(&H01)+Chr(&H1B)+"(" + "A" + Chr(&H5) + Chr(&H0)

+ Chr(&H61) + Chr(&H64) + Chr(&H5) + Chr(&H0A) + Chr(&H0A) `Stores the data

to be sent by DirectIO

.....Printing process.....

RC = Coptr1.DirectIO(PTR_DI_OUTPUT_NORMAL,

pData,

pString )`send the command data (ESC=1 and ESC (A 5 0 61 64 5 A A)

Chr(&H1B) + “=” + Chr(&H01) included at the start of the output data is the command

for selecting the printer. If the printer and customer display are connected by hydraconnection, it is necessary to branch the transmission to the printer and customer

display by commands.

ESC=1: Printer

ESC=2: Display

Programming Samples 4-8

Page 57

Confidential

Be sure to consider the BinaryConversion property when transmit the data over 80h.

Chr(&H1B)+"(" + "A" + Chr(&H5) + Chr(&H0) + Chr(&H61) + Chr(&H64) + Chr(&H5) +

Chr(&H0A) + Chr(&H0A) is the printer command that controls the internal buzzer. The internal

buzzer beeps five times at intervals of one second. Format of the ESC(A command is as follows.

[Format] ASCII ESC ( A pL pH fn n c t1 t2

Hex 1B 28 41 05 00 61 64 c t1 t2

c: specifies the number of times for beeps

t1: specifies the length of time to be ON

t2: specifies the length of time to be OFF

Refer to the TM-U230 series specification for more details of ESC(A command.

Refer to OPOS manuals for the programming using OPOS.

The following explanations are the details about programming samples using Control-A font in

EPSON Advanced Windows Driver.

TM-U230 Developer’s Guide

Edit the TMCTRLA.INI as follows so that the buzzer control command ESC(A is assigned to

“A”(code41) of control-A font.

[TM-U230]

41=1B284105006164050A0A

“41=1B284105006164050A0A” in the description above assigns the buzzer control command

ESC(A to “A”(code41) of control-A font. This data specifies the internal buzzer to beep five

times at intervals of one second.

Save the TMCTRLA.INI under the following system folder.

Windows 95/98 :\windows\system

Windows NT :\winnt\system32\spool\Prcpocs\W32x86

Then describe as follows in your program.

Printer.DeviceName = "EPSON TM-U230 Receipt"

Printer.font.Name = " FontA"

Printer.Print "TM-U230"

Printer.Print "Buzzer Test"

Programming Samples 4-9

Page 58

Confidential

Printer.font.Name = "ControlA"

Printer.Print "A"

Printer.EndDoc

This specifies the driver to transmit the buzzer control command ESC(A defined by Control-A

font to the printer subsequently to the print data “TM-U230” and “Buzzer Test”.

Refer to the TM-U230 series specification for more details of ESC(A command.

Refer to the manuals included in EPSON Advanced Windows Driver for more details of

Control-A function.

Programming Samples 4-10

Page 59

Confidential

Appendix A

Specifications

Printing Specifications

Item Specification

Printing method Serial impact dot-matrix

Head wire configuration 9-pin serial configuration

Printing direction Bi-directional printing (logical seeking)

Printing speed Approx. 3.5 lps (40 column, 16 cpi)

Approx. 6.4 lps (16 column, 16 cpi) (excludes data transfer and processing

time)

Character per line See table A-1

Character per inch See table A-1

Two-color printing Black and read colors selectable

Character Specifications

TM-U230 Developer’s Guide

Item Specification

Character types Alphanumerics (95 characters)

Character configuration 7

Character size See table A-1

Graphics (128

International characters (37 characters)

9, 9 × 9

×

8 character tables)

×

Table A-1 Character per line, character per inch, character size

Character

Character

configuration

W × H

7 × 9 (default) ANK 1.2 × 3.1 3 Half-dot 40 16

9

9 ANK 1.6 × 3.1 3 Half-dot 33 13.3

×

7

9 ANK 1.2 × 3.1 2 Half-dot 42 17.8

×

9 ANK 1.6 × 3.1 2 Half-dot 35 14.5

9

×

configuration

Character

types

Graphics 1.7

Graphics 2.0

Graphics 1.6

Graphics 1.9

Character

dimensions

W × H(mm)

Dot spacing between

characters

3.1 0 40 16

×

3.1 0 33 13.3

×

3.1 0 42 17.8

×

3.1 0 35 14.5

×

Characters

per line

Characters

per 25.4 mm

[cpi: characters per 25.4 mm (characters per inch)]

Specifications Appendix A-1

Page 60

Confidential

[cpl: characters per line]

[lps: lines per second]

Note:

The dot spacing between characters for 3-half dot and 2 half-dot can be set by changing the DIP

switch setting.

1.5871.24

0.353

2.4.

0.159

Figure A-1 7 × 9 font

Paper Specifications

Item Specification

Paper feed method Friction feed

Paper feed interval Initial setting: approximately 0.176 mm {1/6”}

Paper feed speed Approximately 4.17 inches/second (25 lps) (continuous printing)

Paper dimensions Paper roll Width: 76 ± 0.5 {3” ± 0.02”}

Can be set in units of approximately 0.176 mm {1/144”} by a command

(lps: lines per second)

Maximum diameter: 83 mm

Core: when there is no near end sensor, always be sure to use a

paper roll htat is not glued to the core

Normal paper:

Paper thickness: 1 sheet 0.06 to 0.085 mm

Mass: 52.3 to 64 g/m

1091

788 mm}

×

2

{14 to 17lb} (45 to 55 kg/1000 sheets/

3.1

[Units: mm]

Autocutter Specifications

Partial cut is executed by command.

Partial cut: cutting with one point left uncut

Appendix A-2 Specifications

Page 61

Confidential

Printing Area

TM-U230 Developer’s Guide

(NOTE)

Maximum of 200 dots, 400 positions

Figure A-2 Printing area

Note:

The values shown for the printing area are the values calculated (between dot centers) according to the

wire diameter (0.29 mm {0.0011”}).

Electrical Specifications

❏ Power supply operations: AC adapter PS-180

❏ Printer power consumption: operating: 38 W avg., standby: 3W avg.

Environmental Specifications

❏ Temperature

• During operation:

0 to 50°C {41° to 122°F} (At 34°C {93°F} or higher, there are humidity restrictions

• During storage: -10 to 50°C {14° to 122°F} (excludes paper and ribbon)

Specifications Appendix A-3

Page 62

Confidential

,

,

❏ Humidity

• During operation: 10 to 90% (no condensation)

During storage: 10 to 90% (no condensation; excludes paper and ribbon)

90

80

60

40

Relative humidity (RH%)

20

10

0

Operating environment range

0102030

Ambient temperature (°C)

Figure A-3 Ambient temperature (

34°C

40

90%

40°C

65%

50°C, 35%

50

C)

°

Appendix A-4 Specifications

Page 63

Confidential

External Appearance

TM-U230 Developer’s Guide

259.5mm

166mm 168mm

Figure A-4 Without the power supply cover

259.5mm

166mm 168mm

258.4mm

383.5mm

Figure A-5 When the cover is opened

Specifications Appendix A-5

Page 64

Confidential

114.5mm

259.5mm

166mm 168mm 41mm

Figure A-6 When placed on the desk with the power supply box

259.5mm41

166mm

168mm

114.5mm

Figure A-7 When hanging on the wall with the power supply box

Appendix A-6 Specifications

Page 65

Confidential

TM-U230 Developer’s Guide

168mm

114.5mm

259.5mm 41

166mm

Figure A-8 When placed horizontally with the power supply box

Specifications Appendix A-7

Page 66

Confidential

Drawer Kick-out Connector

The signal specified by the ESC p command is output to this connector. The host can check the

status of input signal by the following commands.

• DLE EOT

• GS r

• GS a (ASB)

Drawer Kick-out Specifications

Item Specifications

Pin assignment See “Drawer kick-out connector pin assignment”

table

Model Printer side Molex 52018-6615 (or equivalent)

User side 6-position 6-contact (RJ12 telephone jack)

Drawer kick drive signal Output voltage Approx. 24 V

Output current 1A or less

Output waveform

t1× 2 ms t2× 2 ms

Drawer open/close signal Input signal level

(connector pin )

Connector appearance

Outputs the waveforms in the figure “Drawer

circuitry”. (The

t1

and OFF time t2.)

time

"L"= 0 V

"H"= 2

Å`

5 V

command specifies ON

ESC p

1

6

Limitations

❏ The resistance of the drawer kick-out solenoid must not be less than that specified (24 Ω).

Otherwisee, an overcurrent could damage the solenoid.

❏ Drawer kick-out cable must be shielded.

Appendix A-8 Specifications

Page 67

Confidential

TM-U230 Developer’s Guide

❏ Two driver transistors cannot be driven simultaneously.

❏ Do not drive the drawer continuously.

❏ Be sure to use the printer power supply (conector pin 4) for the drawer power source.

❏ Do not connect a telephone line to the drawer kick-out connector.

Pin Assignment

Pin No. Signal name Direction

1Frame GND --

2 Drawer kick drive signal 1 Output

3 Drawer kick open/close signal Input

4 + 24V --

5 Drawer kick drive signal 2 Output

6Signal GND --

Drawer Circuitry

Specifications Appendix A-9

Page 68

Confidential

Appendix A-10 Specifications

Page 69

Appendix B:

t2

The table below shows the status when the parameter

status. (The PAPER OUT LED will be off.)

t2

When

≠ 0, the printer recovers from the offline status automatically after a defined time is passed and the PAPER OUT LED will be off automatically.

When selecting the paper near end sensor enabled to stop printing with ESC c 4