Epson Stylus Color Service manual

EPSON TERMINAL PRINTER

.

n

As

tyhs

COLOR

TN

SERVICE MANUAL

-.

EPSON

4003353

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever without

SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

c’

-. -

All efforts have been made

any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for any errors in this

manual or the consequence thereof.

Epson and Epson

General Notice: Other product names used herein are for

trademarks of their respective

EsC/l?

@Copyright 7994 by SEIKO EPSON CORPORATION

toensurethe

are registered trademark of Seiko Epson Corporation.

campanies.

accuracy of the contents of this manual. However, should

identication

-i-

purposes only and may be

Nagano,

Japan

. .

“1

C

3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/

maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

2.

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

UNITTOA

POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

WARNING

1.

REPAIRS ON EPSON PRODUCT SHOULD BE

CERTIFIED REPAIR TECHNICIAN.

2.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO

NOT CONNECT IT TO THE POWER SOURCE.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM

3.

THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL

4.

IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

5.

BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

CHIPS.

PERFORMED ONLY BY AN EPSON

ICS

OR OTHER

- ii -

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of Stylus Color.

The instructions and procedures included herein are intended for the experience repair technician, and

attention should be given to the precautions on the preceding page. The chapters are organized as

follows:

CHAPTER 1. PRODUCT DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for

adjustmen~

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to

seMce

the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

-

iv -

REVISION SHEET

Revision Issue Date

April

Rev.-A

Rev.-B

Rev.-C

Rev.-D

27, 1994

October 4, 1994

November 30, 1994

January 11, 1995

3-1

3-3

4-7 to 4-17

Page /Contents

1 st issue

Change the WARNING contents

Change the explanation for the

upper case removal

Incorporate the simple adjust

method.

-v-

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

PRODUCT DESCRIPTION

OPERATING PRINCIPLES

DISASSEMBLY AND ASSEMBLY

ADJUSTMENTS

TROUBLESHOOTING

MAINTENANCE

-

vi -

Chapter 1

Product Description

Table of Contents

1.1

FEATURES

1.2 SPECIFICATIONS

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.2.6

1.2.7

1.2.8

1.2.9

1.3 INTERFACE SPECIFICATIONS

Printing Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Handling Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ink Cartridge Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-2

1-2

1-4

1-4

1-6

1-7

1-7

1-8

1-8

1-8

1-9

1.3.1 Serial Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.3.2 Parallel Interface Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.4 OPERATIONS

1.4.1

1.4.2

1.4.3

Control Panel... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Panel Operation atPowerOn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.1 Default Setting Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.2 Changing the Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.4

1.4.5

ErrorConditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5.1 Hardware lnitiaiization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5.2 Software Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5.3 Panel initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-12

1-12

1-13

1-14

1-14

1-15

1-17

1-17

1-17

1“17

1-17

1.5 MAIN COMPONENTS

1.5.1

1.5.2

1.5.3

1.5.4

1.5.5

Rev.A

Main Control Board

Power Supply Board

Control Panel

(C137

Printer Mechanism

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1-18

(C137

MAIN Board). . . . . . . . . . . . . . . . . . . . . . . . 1-18

(C137

PSB/PSE Board). . . . . . . . . . . . . . . . . . . . 1-19

PNL Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

(M-4AIO).

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

l-i

List of Figures

Rev. A

Figure 1-1. Exterior View of the Stylus Color. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Figure 1-2. Nozzle Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

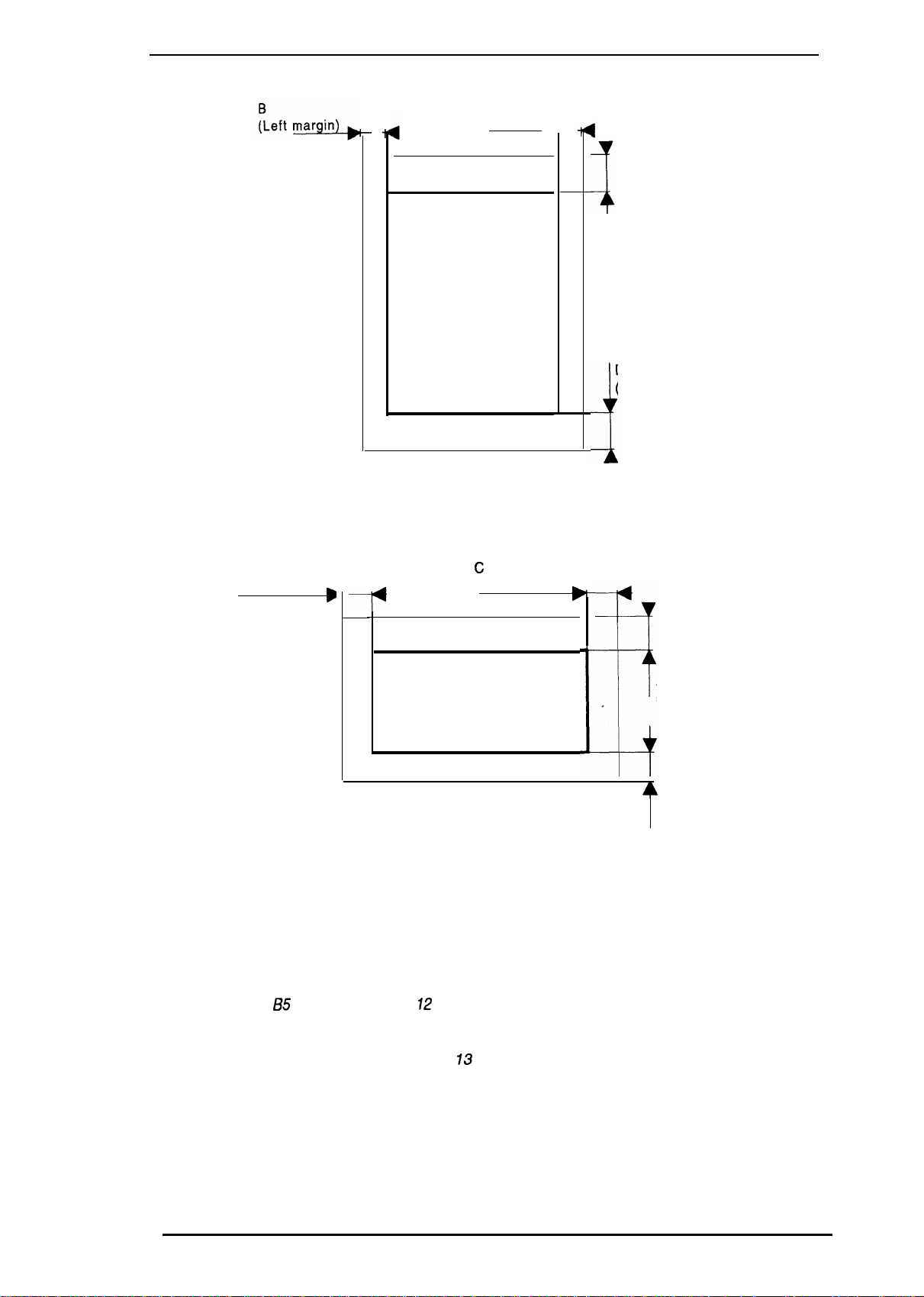

Figure 1-3. Printable Area for Cut Sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-4. Printable Area for Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-5. Adjust Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-6. Temperature/Humidity Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

●

Figure 1-7. Data Transmission Timing . . . .

Figure 1-8. Control Panel Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Figure 1-9.

Figure 1-10.

Figure 1-11.

Figure 1-12. Printer Mechanism (M-4A1O) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Figure 1-13. Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

C137

MAIN Board Component Layout . . . . . . . . . . . . . . . . . . . . . . 1-18

C137 PSB/PSE

C137

PNL Board Component Layout . . . . . . . . . . . . . . . . . . . . . 1-19

Component Layout . . . . . . . . . . . . . . . . . . . . . . 1-19

**9* **89 am8*, *s8, *a8ame 1,,

1-9

List of Tables

Table 1-1. Interface Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-2. Print Speed and Printable Columns. . . . . . . . . . . . . . . . . . . . . . . . . 1-2

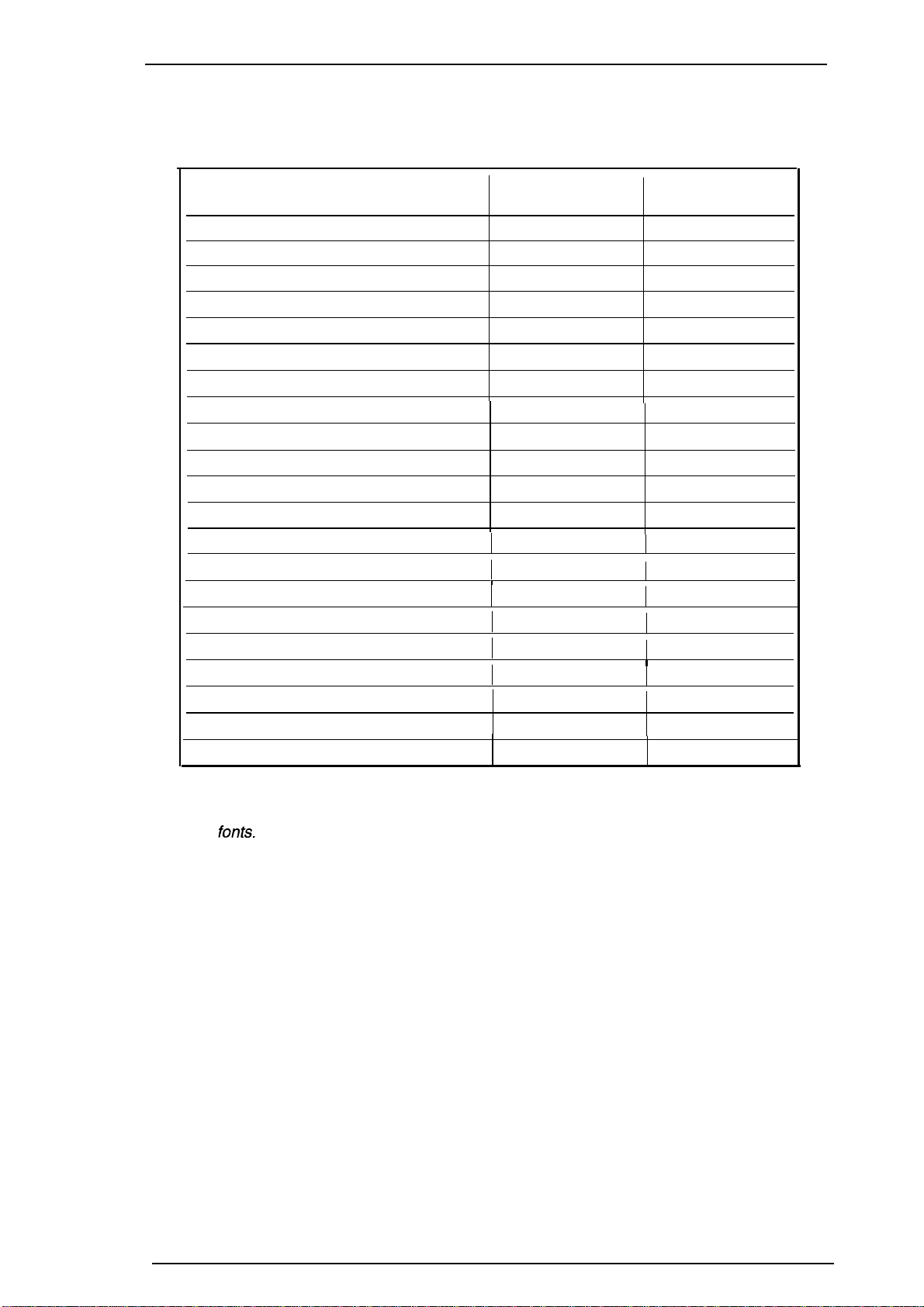

Table 1-3. Character Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-4. Cut Sheet Paper Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-5. Envelope Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

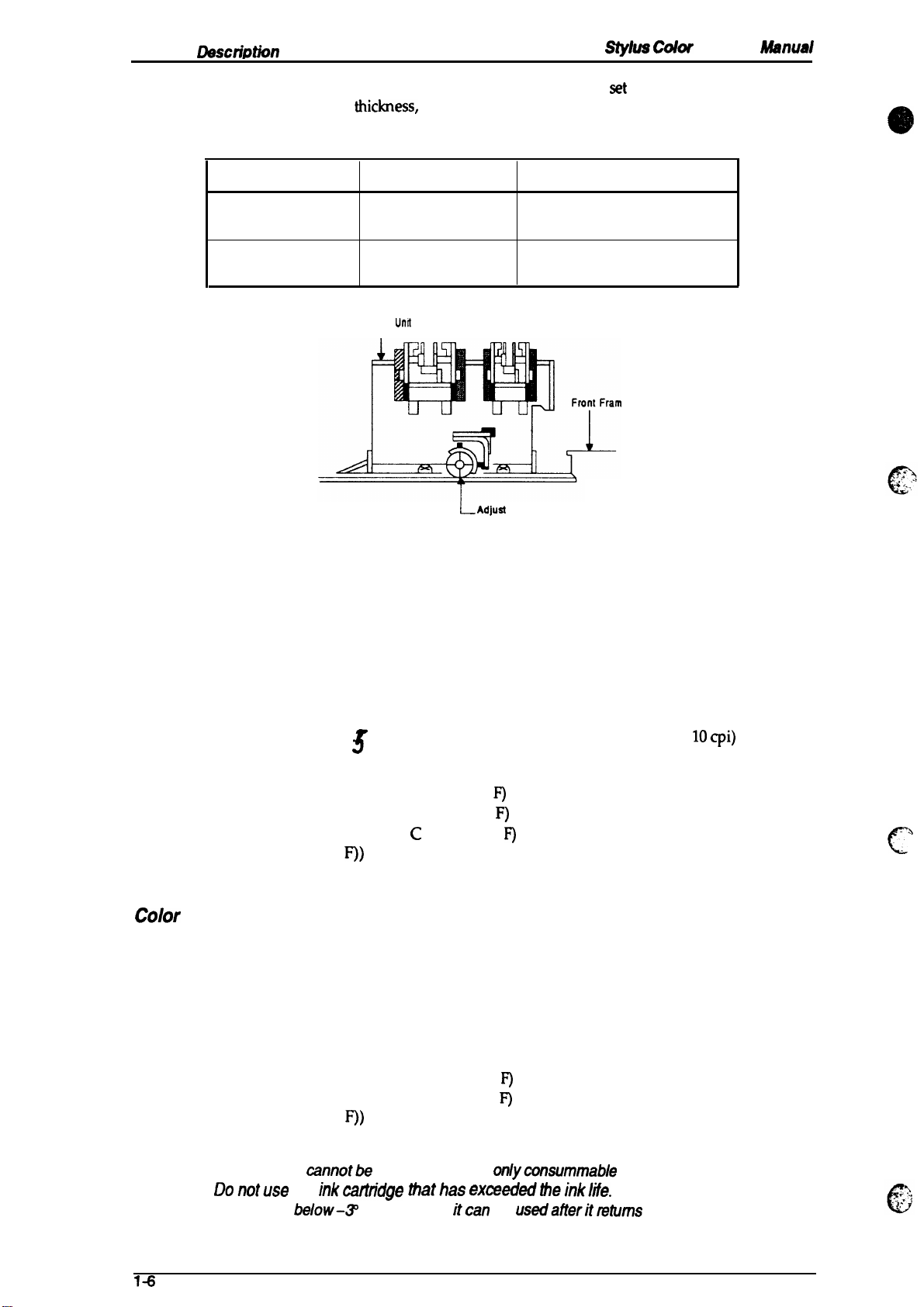

Table 1-6. Adjust Lever Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

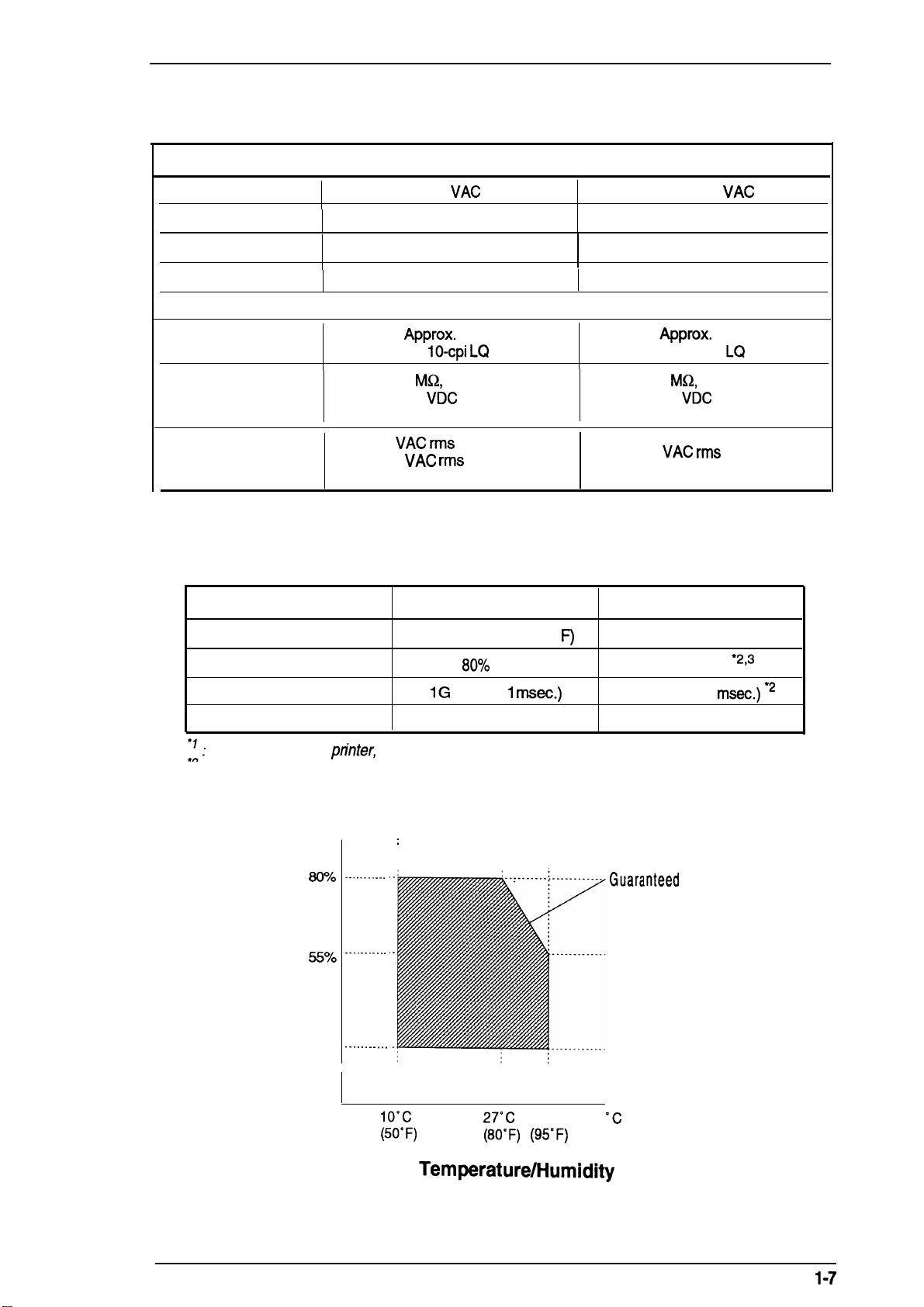

Table 1-7. Rated Electrical Ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-8. Acceptable Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-9. Signal and Connector Pin Assignments for Parallel Interface . . . . 1-10

Table 1-10. DTR and X-ON/X-OFF Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Table 1-11. Signal and Connector Pin Assignments for Serial Interface. . . . . 1-11

Table 1-12. Default Setting Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Table 1-13. Characteristics of Print Direction Mode . . . . . . . . . . . . . . . . . . . . 1-14

Table 1-14. Printing Direction and ESC U Command. . . . . . . . . . . . . . . . . . . 1-14

Table 1-15. Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Table 1-16. Feature Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Table 1-17. Character Table Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Table 1-18. Error Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

c

-.,

l-ii

Stylus Color Service Manual

Product Description

1.1 FEATURES

The Stylus Color is a 64- + 48-nozzle (monochrome and CMY) color ink jet dot matrix printer that

uses new ink jet technology to achieve high-quality, high-speed printing. The major features of this

printer are:

Q

Highquality color printing as a result of new inkjet technology.

Cl

Fast print speeds, capable of printing LQ characters at 200

D

Compact design to save precious work space.

Built-in auto sheet feeder with a maximum capacity of 100 cut sheets, 50 transparencies,

c1

70 heavy or special papers, or 10 envelopes.

8-bit parallel interface and

tl

Easy setup.

c1

Four scalable fonts and five LQ fonts standard.

L1

c1

Support for 9 character tables in the standard version and 15 character tables in the NLSP

(Na~ional

Inexpensive to run and maintain.

L1

figure below shows the Stylus Color.

The

Language Support Printer) version.

Macintosh@

serial interface standard.

cps.

\

paper

feeder,

cover

paper

separators

/h

~

paper

\“

supporl

Figure 1-1. Exterior View of the

Table 1-1. Interface Cards

knob

parollel

interface

k

Stylus Color

\(A~i.,et)

I

I serial

interface card

I 32KB

serial interface card

I 32KB

parallel interface card

I 32KB

IEEE-488 interface card

I

LocalTalk@ interface card

IT

winax interface card

I Coax interface card

*

The asterisk is a substitute for the

Rev. A

Interface Card

I

I C823051/C823061

I

C823071/C823081

I

C82310*

\

C82313*

I

C82312*

I

C82315*

I

C82314*

Iastdigit,

which varies

Model Number

bycountty.

1-1

Product Description

stylus

color

sdwvk

1.2 SPECIFICATIONS

This section provides statistical facts and other detailed intonation for the printer.

1.2.1 Printing Specifications

Msnual

Print system:

On demand inkjet system

Nozzle configuration: 64 nozzles

4$ nozzles

Yellow

i

#2

Q“-”--”-”””-

*#16

0

Cyan

’“0 ~’

-“”o”#-2-”””---e---e

“0:3 “““o

v

#16

o

Magenta

..() #l . .

64/360”

V

0

#16

t

1/90”

#2

4

. . . . . . . .

#3

.

,,36(J*

-- .-..

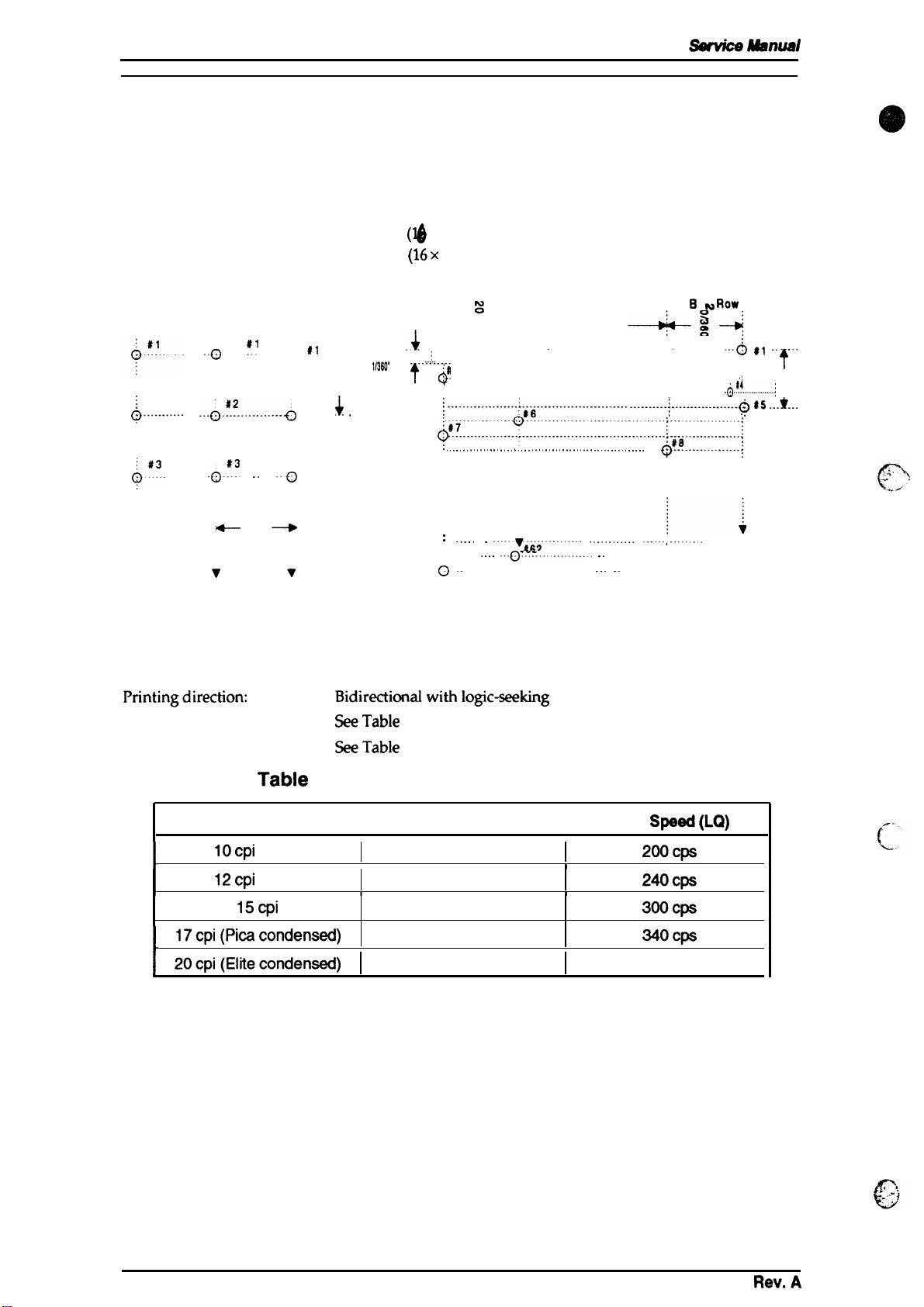

Figure 1-2. Nozzle Configuration

($

x

4 staggered): Monochrome

(16x

3

staggered): Color

Row D

+g-

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

.$

--;..

----------------& 2-------------- .................. +...... -------------

:il

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

tQ

i---------. ---"" ----i--" ----.. --"-. ----" ----------------6

:--.------;--------------

J87----::---""---------------"----------------.--.--!#8--------.-.----i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

: ----- .

‘#63”

o -

Row C

:

.

-6;6

““””’viii”””-”””-

‘- -“0---=’------”” -

‘“ ’ --------- ‘- - --0864-- - --

721360”

.

. . . . . . . . . . . . . . . . . . . . . . . . . .

-------

“-”’”--”’-”

-------+ --------”

Row 8

-.4

.

. . .

__-+___..~#5

--”:--- --- -:

Q-.-......-:

“--””;-”””””-”

~

f?ow

A

s

0

.

.

--6 *I ‘- ““”

-;4--------------;

-.....0861

t

. :

1/90’

I

..*_.

Printingdirection: Bidirectionalwithlogic-seeking

Printspeed:

Printable columns:

SeeTable

SeeTable

l-2.

l-2.

TabIe l-2. Print Speed and Printable Columns

CharacterPitch

IOcpi

I

I

(Pica)

12cpi (Elite)

15cpi

17cpi (Picacondensed)

L

20cpi(Eiitecondensed)

I

PrintableColumns

I

I I

1

60

96

120

137

160

Print

I

1

Speed(LQ)

2oocps

240cps

3oocps

340cps

4oocps

1-2

Rev.A

Sty/us Co/or Service Manual

Product Description

Character sets:

Character tables:

Character Tables

Italic

PC437 (U.S./Standard

PC850 (Multilingual)

PC860 (Portuguese)

PC861 (Iceland)

PC863 (Canadian-French)

PC865 (Nordic)

PC437 (Greek)

PC852 (East Europe)

PC853 (Turkish)

PC855 (Cyrillic)

PC857 (Turkish)

PC866 (Russian)

PC869 (Greek)

MAZOWIA (Poland)

Code MJK (Czechoslovakia)

ISO 8859-7 (Greek)

ISO Latin IT (Turkish)

Bulgaria (Bulgaria)

Abicomp

BRASCII

Legal and 14 international character sets.

See Table 1-3.

Table 1-3. Character Tables

Standard

Version

o 0

Europe)

0 o

o

o

o

o

o

x

x

x

x

x

I

1

x

x

x O

I

I

x

x

x

x

o

o

NLSP* Version

0

x

O

(Note)

O (Note)

O

(Note)

O

(Note)

O

(Note)

O

I

1

(Note)

O (Note)

(Note)

O

I

I

I

(Note)

O

(Note)

O

(Note)

O (Note)

x

x

x

x

x

o supported

Note:

These fonts are not supported for EPSON Roman Tand EPSON Saris Serif H of scalable

Fonts:

Control code:

Input data buffer:

X Not SUpported

Bitmap LQ fonts

-

EPSON Roman

- EPSON Saris Serif

- EPSON Courier

- EPSON Prestige

- EPSON Script

National Language Support Printer

*

(10 cpi/12 cpi/15 cpi/Proportional)

(10/12/15/Proportional)

(10/12/15)

(10/12/15)

(10/12/15)

Scalable fonts

-

EPSON Roman

- EPSON Saris Serif

- EPSON Roman T

10.5 points, 8

10.5 points, 8

-32

points (in

units of 2 points)

-32 points (in units of 2 points)

10.5 points, 8-32 points (in units of 2 points)

- EPSON Saris Serif H 10.5 points, 8-32 points (in units of 2 points)

ESC/P 2 and expanded raster graphics code

64K bytes

Rev.

A

1-3

Ptvduct

Rev. A

1.2.2

&SCf@th

Paper Handling Specifications

!wJdus

color

Sefvkw

Mmu8/

Feeding method:

Notes: The

following

1. Reverse feeding within 3 mm (O. 12in.) from the top edge of the paper or 16mm

(0.63 in.) from the bottom edge of the paper.

2. Reverse feeding beyond 7.9mm (0.3in.).

Line spacing:

Paper path:

Feeding speed:

1.2.3

Paper Specifications

Size (W x

L)

Thickness

Weight

Qualitv

Friction feed paper is fed from the built-in auto sheet feeder (ASF).

operations are

not allowed.

1/6 inch feed, 1/8 inch feed, or programmable with a 1/360 inch minimum

increment.

Cut sheet: Built-in auto sheet feeder (ASF) (front entry)

89 msec. (at l/6-inch feed pitch)

Table 1-4. Cut Sheet Paper Specifications

A4:

Letter:

B5:

I

Legal:

I

0.08 mm (0.003

55 g/m2 (17

Bond paper. PPC

210 mm

216 mm

(8.3

(8.5

in.)

in.) x

x 297

279

182 mm (7.2 in.) x 257

216

mm

(8.5

in.) x

356

in.) -0.11 mm (0.004 in.)

lb) -90 g/m2 (24

lb)

mm (1 1.7 in.)

mm (1 1.0 in.)

mm (10.1 in.)

mm (14.0 in.)

Size (W x

Thickness

Weight

Qualitv

Note:

Table 1-5. Envelope Specifications

I

I

No. 6:

L)

No. 10:

I

DL: 220 mm

]

Less than

75 g/m2 (20 lb) -90 g/m2 (24 lb)

Bond Paper

Envelope printing is supported onfy at room temperature.

When inserting envelopes, keep the longer side honzontal.

166

mm(6½ in.) x 92

mm (3 % in.)

240 mm(91A in.) x 104mm(41A in.)

(8.7

in.) x 110 mm (4.3 in.)

0.52

mm

(0.020

in.)

1-4

Stylus Color Service Manual

Product Description

Printable area:

Cut sheet

c

(Right margin~

A

(Top margin)

Printable area

D

(Bottom margin)

i

Figure 1-3. Printable Area for Cut Sheet

Note:

Envelope

B

(Left margin)

A: The minimum top margin= 3 mm (0. 12 in.)

B: The minimum left margin= 3 mm (O. ?2 in.)

C: The minimum right margin is:

A4 size:

Letter size: 9 mm (0.35 in.)

i35

Legal size: 9mm (0.35 in.)

Envelope: 3 mm (0.12 in.)

D: The minimum bottom margin= 13 mm (0.51 in.)

B

-P

Figure 1-4. Printable Area for

3 mm (O. 12 in.)

size:

3 mm (0. 12 in.)

c

(Right margin)

Printable area

B

A

(Top

&

D

(Bottom margin)

Envelope

margin)

Rev. A

1-5

Product

Rev. A

Descfhtion

Stylus Color

Service

Ahnual

Adjust lever setting:

The adjust lever on the carriage unit must be

the paper

Lever Position

LEFT

(Vertical)

RIGHT

(Horizontal)

set

thiclmess,

as shown m Table 1-6.

Table 1-6. Adjust Lever Setting

Paper Thickness

0.08-0.11 mm

(0.003 -0.004 in.)

Less than 0.5 mm (0.020 in.)

Carriage

I

Paper

Cut Sheet

Envelope

Umt

~ Adjual

Lever

to the proper position for

e

Figure 1-5. Adjust Lever

1.2.4 Ink Cartridge Specifications

Black

Type:

Color:

Print capacity:

Life:

Storage temperature:

Dimension (W x D x H):

color

Type:

Color:

Exclusive cartridge

Black

1 million characters (315 dots/character, Roman

3

The effective life from the indicated production date is 2 years.

-30- 40° C (–22 - 104° F) (Storage, within a month at 40° C (104° F))

-30- 60° C (-22 –30 - 60° C (–22 -

F))

26.9 x67.4 X 41.8 mm (1.06 x2.65 X 1.65 in.)

Exclusive cartridge

Cyan, Magenta, Yellow

IOcpi)

140° F) (Transit, within a month at 40° C (104° F))

140” F) (Transit, within 120 hours at 60° C (140°

-%

c

Print capacity:

Life:

Storage Temperature:

Dimension (W x D x H):

Notes:- Ink cartridge

cannotbe

- Donotuse an inkcarlndge thathas exceededtheink/ife.

-

Ink freezes

below-~

1-6

28 sheets/color (A4, Full image printing at 360 dpi)

The effective life from the indicated production date is 2 years.

-30- 40° C (–22 - 104° F) (Storage, within a month at 40° C (104° F))

-30- 60° C (–22 - 140°

–30 - 60° C (–22 - 140”

F)

(Transit, within a month at 40° C (104° F))

F)

(Transit, within 120 hours at 60° C (140°

F))

54.0 X 67.4X

re-tiled; it is the

41.8 mm (2.13

onlywnsummable

X

2.65X

1.65 in.)

article.

C; however, itcan be usedafieritmfums to room temperature.

Stylus Color Service Manual

1.2.5 Electrical Specifications

Table 1-7. Rated Electrical Ranges

Product Description

Item

I

Rated voltage

Input voltage range

Rated frequency range

Input frequency range

Rated current

I

Power consumption

Insulation resistance

(self-test with

(applying 500

120 V Version

120

103.5-132 V

50-60 Hz

49.5 -60.5 Hz

0.6 A

Approx.

10-cpi LQ

10

Mf2,

minimum 10

VDC

and chassis)

1000

VAC rms

1200

Dielectric strength

VAC rms

(between AC line and chassis)

1.2.6 Environmental Conditions

Table 1-8. Acceptable Environmental Conditions

Description

VAC

20 W

characters)

between AC line

-1 minute or

-1 second

Operating

I

220-240 V Version

220-240

VAC

198-264 V

50-60 Hz

49.5 -60.5 Hz

I

0.4 A

Approx.

20 w

(self-test with 10-cpi LQ characters)

MQ,

minimum

(applying 500

VDC

between AC line

and chassis)

1500

VAC rms

-1 minute

(between AC line and chassis)

Non Operating

Temperature

Humidity

Shock resistance

Vibration resistance

:1:

For operating the

2

,

: These conditions are acceptable when the printer is in its shipping container.

3

: Without condensation.

Humidity

(% RH)

pn”nter,

80!!0

55?40

20?40

I

. . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . .

10-

35° c (50 - 95° F) “

20-

80!%0

RH ● ’73

IG (within 1

rnsec.)

0.15 G

–20 - 60° C (-4 - 122° F) ● 2

5- 85% RH

2G (within 2

0.50 G

“2’3

msec.)

2

conditions must be in the range shown in the figure below.

:

Guara,nleed

range

Rev. A

Io”c

(50”F)

Figure 1-6.

27°C

35°C

(80°F) (95°F)

Temperature/l=lumidity

‘c

(“F)

Range

1-7

Product

Llsscriptkm

1.2.7 Reliability

MTBF:

Total print volume:

Printhead life:

1.2.8 Safety Approvals

4JIO0

power on hour

75,0(X) pages

1$00 million

(pOH)

(A4,

Letter)

dots/nozzIe

stylus Colar

&wvke Msnusl

Safety

Radio frequency interference

standanis:

(RFI):

1.2.9 Physical Specifications

Dimension (W x D x H):

Weight

120V

version:

22@240V

120V

version:

220-240V

470

X

525X

7.4 Kg

(163 lb)

UL1950

CSA22.2

version:

version:

192 (mm) (18.5X 20.7X 7.56 (in.))

EN 60950

NEMKO,

FCC part 15 subpart B class B

Vfg.243 (VDE0878

EN55022

with D3,

#950 with D3

~, SEMKO, DEMKO,

SETI)

(CEPR

part 3, part 30)

PUB. 22) class B

.-

\

(

1-8

Rev. A

Stylus

Color

Service Manual

Product Description

1.3 INTERFACE SPECIFICATIONS

The Stylus Color is standard-equipped with an 8-bit parallel and serial interface.

1.3.1 Serial interface Specifications

Data format:

Synchronization:

Handshaking:

Signal level:

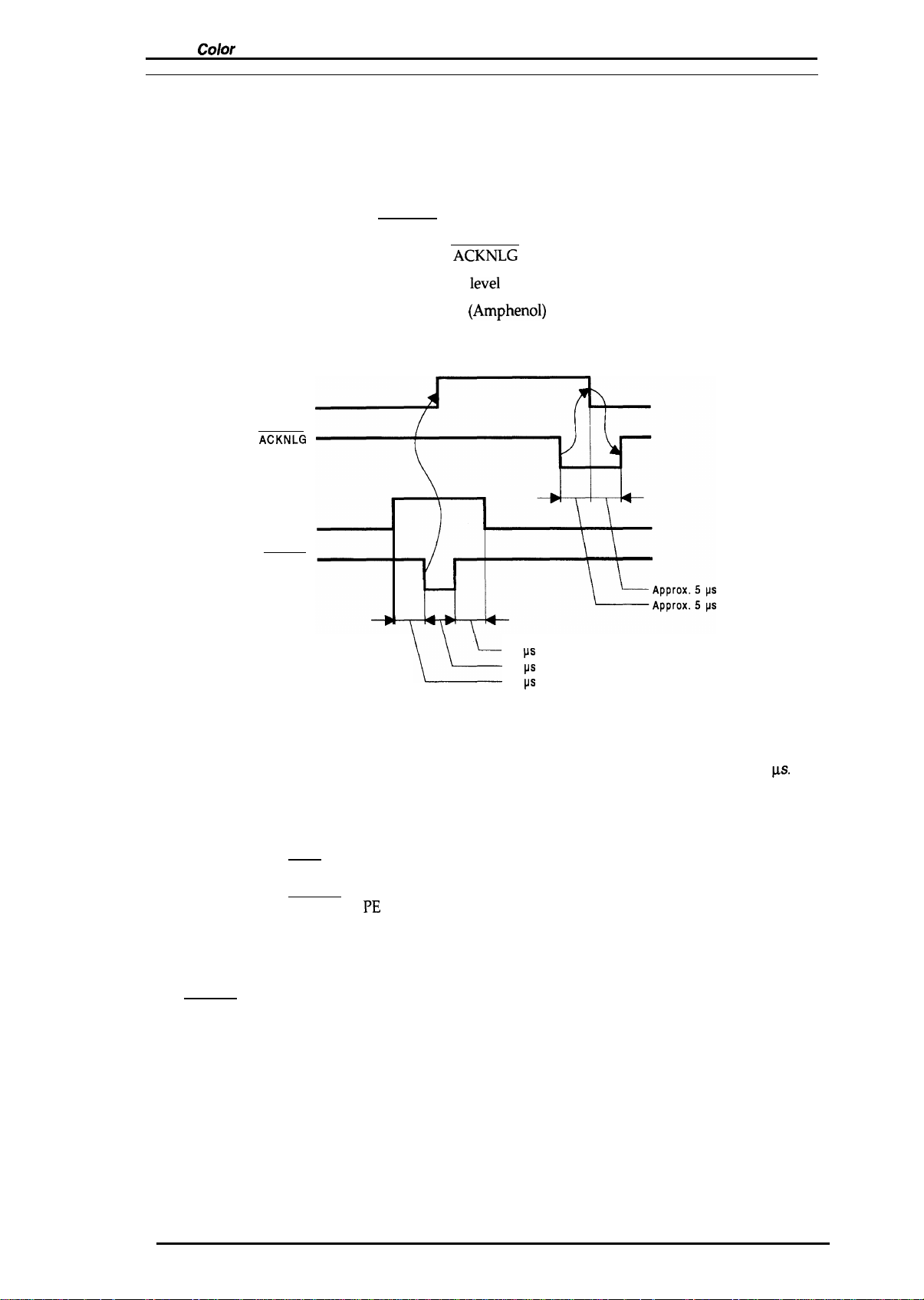

8-bit parallel

By STROBE pulse synchronization

By BUSY and

TTL compatible

ACKNLG

level

signals

Adaptable connector:

Data transmission timing:

BUSY

ACKNLG

DATA

STROBE

Figure 1-7. Data Transmission Timing

36 pin 57-30360

See Figure 1-7.

L.&

(Amphenol)

L_-

or equivalent

0.5 ps (minimum)

0.5

IJS

(minimum)

0.5

ps

(minimum)

Note:

The Busy signal is active (HIGH) under the following conditions:

The ERROR signal is active (LOW) under the following conditions:

The PE signal is active (HIGH) under the following conditions:

Transition time (rise time and fall time) of every input signal must be less than 0.2

- During data reception (See Figure 1-7.)

- When the input buffer is full

- When the INIT input signal is active

- During initialization

- When the ERROR or PE signal is active

- During the self-test mode

- During the demonstration mode

- During the default setting mode

- When a fatal error occurs

- When a paper-out error occurs

- When a no ink cartridge error occurs

- When a fatal error occurs

- When a paper-out error occurs

- When a fatal error occurs

ps.

Rev. A

1-9

Table 1-9 shows the

Rev. A

co

nm@or

pin assignments and signal functions

of the

8-bit parallel interface.

Table 1-9. Signal and Connector Pin Assignments

Pin No.

1

2-9 DATA 1-8

10

11

12

13

Signal Name

STROBE

ACKNLG

BUSY

PE

SLCT

I/o’

The

STROBE pulse is used to read data from the host

computer. The pulse

I

it is

HIGH, and data is latched with the rising edge of this

signal.

DATA 1-8 are parallel data

HIGH, the data bit is 1; when LOW, the data bit is O. The most

significant bit

I

maintained

active edge.

ACKNLG

approximately 10 p.s. This signal goes LOW upon the

o

completion of data reception to indicate that the printer

ready to receive further

The BUSY signal informs the host computer of the printer’s

status. When this signal is HIGH, the printer cannot accept

o

any more data.

This signal indicates whether paper is available in the printer

o

or not. A HIGH level indicates no paper.

o

Pulled up to

(MSB)

for 0.5 ps on either side of the STROBE signal’s

is an acknowledge pulse with a width of

+5V

through a 1.0 KQ resistor in the printer.

Description

width must be 0.5 ~ or more.

bits. When one of these signals

is

DATA 8. The signal state must

data.

for

Parallel Interface

Normally,

is

be

is

14

31

32

35

17

16

19-30

33,36

15,18,34

—

*

7he //0

If this signal is set to LOW, the printer automatically performs

AFXT

m

ERROR

+5V

CHASSIS

GND

-

-

-

column indicates the direction of the

one line feed upon receipt of a CR (carriage return) code. The

I

status of this signal is checked onty at power on and

initialization.

If this signal goes LOW, the printer is initialized. The pulse

I

width of this signal must be 50

This signal goes LOW if the printer has a fatal error or runs

o

out of paper.

Pulled up to

-

Chassis ground.

-

Signal ground.

.

.

.

Not

USed.

-

+5V

signal

@ or more.

through 1.0 KQ resistor in the printer.

as viewed hm the

printe~

. .

,.

c

2

1-1o

Stvlus Color

Service

Manual

1.3.2 Parallel Interface Specifications

RS-422

Data format:

serial

Product Description

Synchronization:

Handshaking:

Table 1-10.

State

Busy

Ready

Word length

Start bit:

Data bit: 8 bit

Parity bit:

Stop bit:

Bit rate:

Adaptable connector:

Recommended I/F cable:

Asynchronous

By

DTR

signal and X-ON/X-OFF protocol

DTR

and

X-OIVX-OFF

Buffer Space

Less than 512 bytes

More than 1,024 bytes

1 bit

none

1 bit

57.6K bps

8-pin mini-circular connector

Apple@

System Peripheral-8 cable

Protocol

DTR

off

On

X-OWX-OFF

X-OFF

X-ON

Table 1-11. Signal and Connector Pin Assignments for Serial Interface

Pin No.

Signal Name

I/o’

Description

1

2 NC

3

4 SG

5

6

7

8

* The

1/0 column

DTR

TXD

RXD

TXD

NC

RXD

indicates the data flow as viewed from the

out

out

In

In

out

In

Data terminal ready

No connection

Transmit data

Signal ground

Receive data

Balanced transmit

No connection

Balanced receive

printer.

Rev. A

1-11

Product

Rev. A

LMscriptkw

1.4 OPERATIONS

This

section describes the basic operations of the printer.

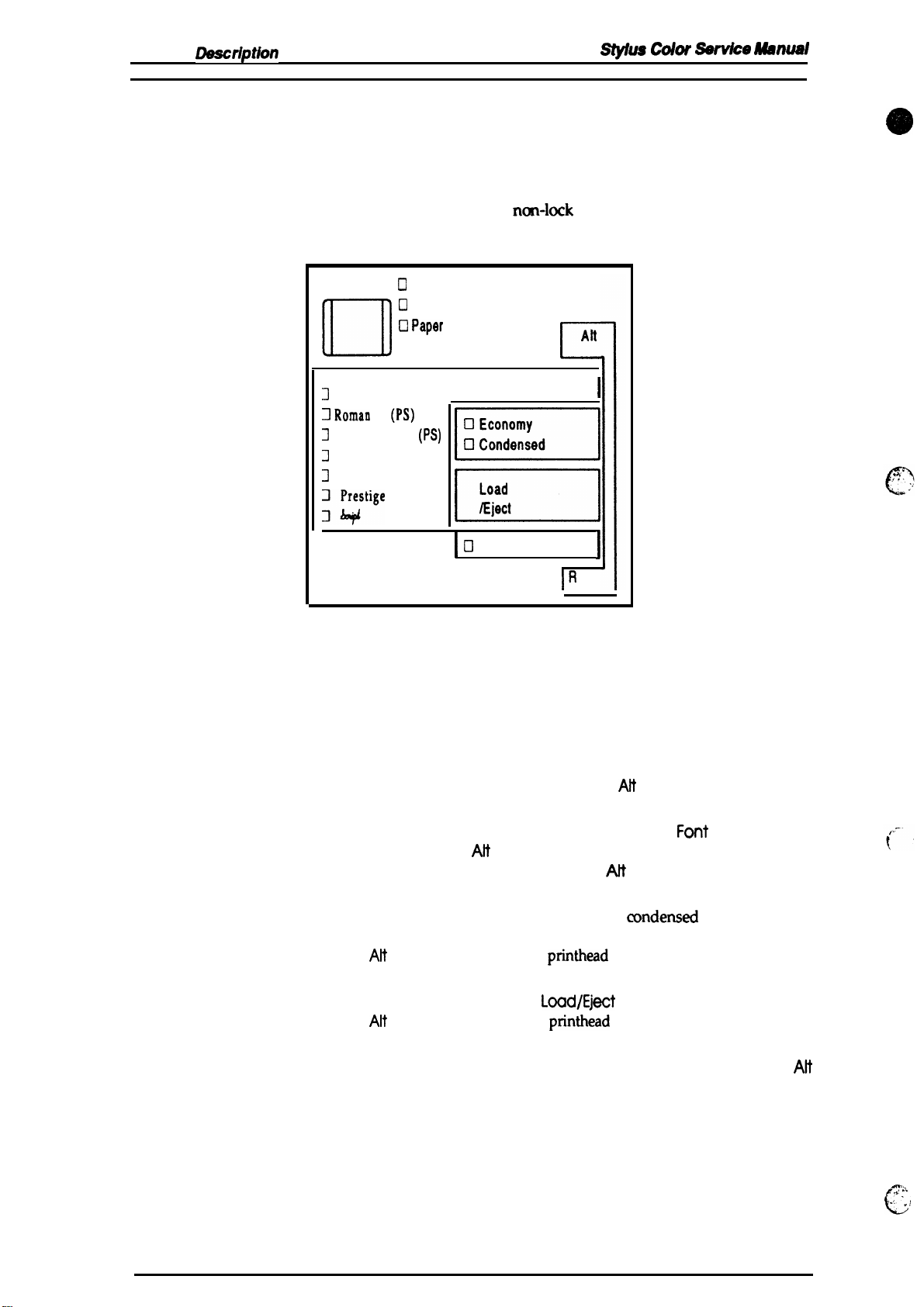

1.4.1 Control Panel

stylus COW

SerVke

Aww4d

The control panel for this printer has 1 lock type, 5

indicators for easy

operation

Un

J

3 Romau

3

Z

3

;$s’ige

of the various printer functions.

Cl

Operate

U

Data

O Pap9r

Out

No Ink Cartridge

Courier

T

(PS)

Saris Serif H

Roman

Saris Serif

Font

(PS)

m

m

Cl

ncm-lock

Pause

Figure 1-8. Control Panel Appearance

type push buttons, and 14 LED

Alt

c

I

I

IR

t

ese

Buttons

Operate

Att

Font

Economy/Condensed

Load/Eject

Pause Stops printing temporarily or resumes printing if it has been

Turns the printer on or off.

Modifies the function of other buttons. Holding down this button

for 3 seconds causes the printer to move the carriage to the ink

cartridge installation position. Pressing

to return to the home position.

Cycles through the font choices. pressing the

holding down the AH button causes the carriage to move to the gap

adjustment position. Pressing the AN button again causes the

carriage to return to the home position.

Selects either the economy printing or

Pressing the

the

Alt

button starts the color

Either loads a new sheet into the printer or ejects paper currently in

the paper path. Pressing the

the

Alt

button starts the black

stopped temporarily. Pressing

button resets the printer.

Economy/Condensed

printhead

L~d/E@t

printhead

Pause

Ait

again causes the carriage

F~t

button, while

mndensed

button while holding down

cleaning cycle.

button while holding down

cleaning cycle.

while holding down the

printing mode.

Alt

1-12

ma,.

L

~.

A

‘,

.;

Stvlus Color

Indicators

Operate

Se

fvice Manual

Product Description

On

when the printer is on. Blinks during power on and off sequence.

Data

On when print data is in the input buffer. Data and Pause lights

blink if an error occurs.

On

Paper Out

when the printer is out of paper. Blinks when a paper jam

occurs.

On

No Ink Cartridge

Economy

Condensed

Font

Pause

when the ink is exhausted.

On

when economy printing mode is selected.

On

when condensed printing mode is selected.

These

LEDs indicate the selected font.

On

when printing is paused.

1.4.2 Panel Operation at Power On

You can activate the following modes by doing the following:

Self-test mode

Hex dump mode

Demonstration mode

Default setting mode

Initialize EEPROM

Turn on the printer while holding down the

Turn on the printer while holding down the

buttons. Once this mode is selected, the printer prints all received

data in hexadecimal format.

Turn on the printer while holding down the

Turn on the printer while holding down the Economy/

Condensed

button. For more information about the mode, see

Section 1.4.3.

Turn on the printer while holding the Alt, Font, Load/Eject, and

Pause

buttons.

Load/Eject

Font

and

Alt

button.

button.

Load/Eject

Rev. A

1-13

Product

Oesct’iptkm

1.4.3 Default Settings

St’jms Cokw

SawicO

ManUd

The printer can save some printer setting parameters that define its functions at

can change these parameters by using the printer’s default setting mode.

initializatkn.

1.4.3.1 Default Setting Items

You can

default-setting mode by holding down the

printer.

use the

det%ult

setting mode to change the settings listed in the table below. Activate the

Economy/Condensed

button while turning on the

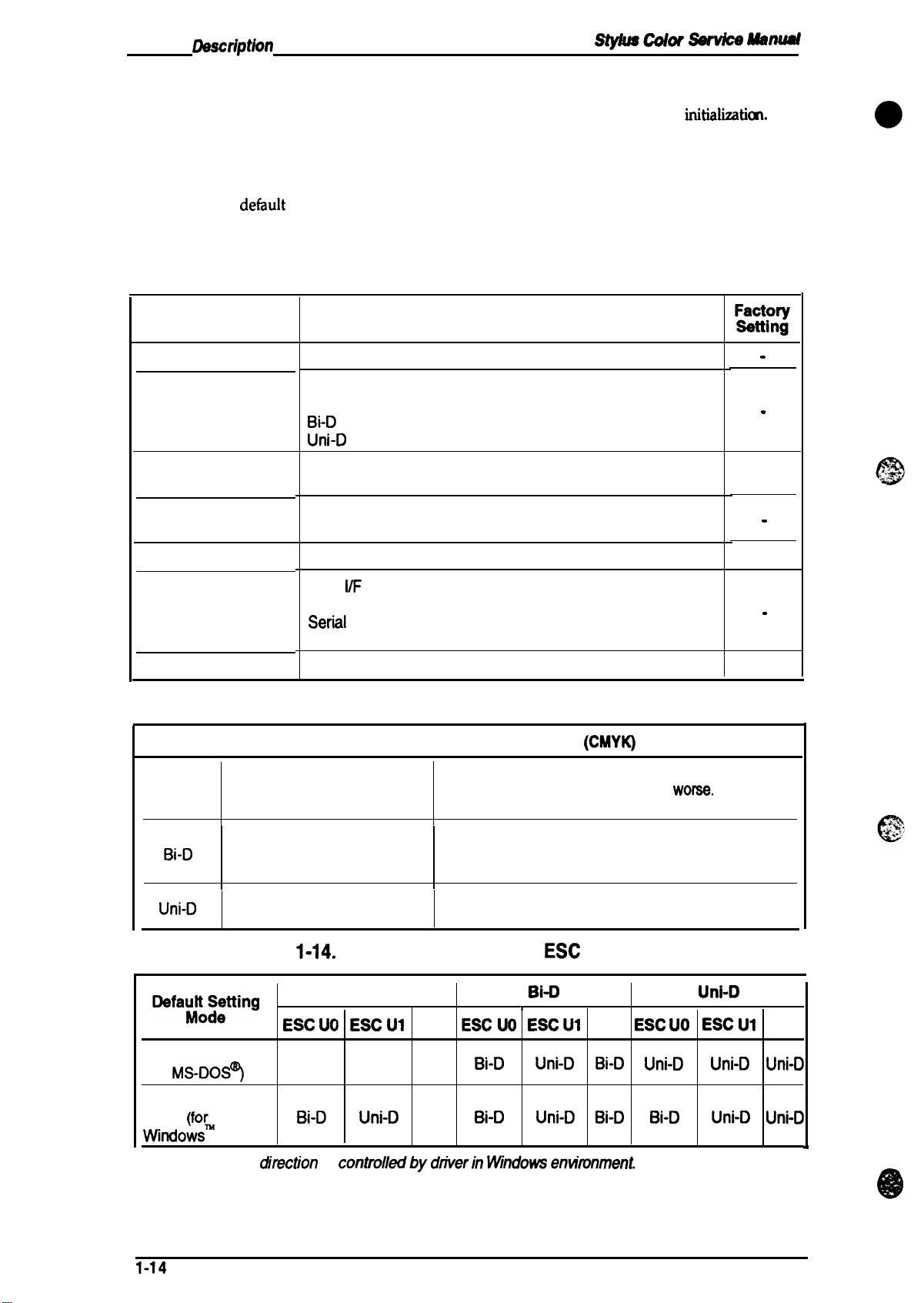

Table 1-12. Default Setting Items

Menu

Contents

Character table

Print direction

Network l/F mode

Auto line feed

Loading position

Selects the character table

Controls the print direction. (See Tables 1-12 and 1-13)

Auto

Bi-D

Uni-D

Off: For normal environments.

On: For network environments.

On: Valid

Off: Invalid

3.0/8.5

mm (0.12/0.33 in.)

Description

You

mct31111

.

.

off

.

3.0

mm

e

Interface mode

Auto l/F wait mode

Table 1-13. Characteristics of Print Direction Mode

ttem

Auto

Bi-D

Uni-D

Black and White Printing

I

Throughput and quality is

better.

Throughput is best.

Print quality may be down.

Throughput is worse.

Print quality is better.

Table

l)efaul:~~tting

Auto

I/F

mode

Parallel l/F mode

Seriil

l/F mode

Optional l/F mode

1 0/30 seconds

1-14.

Printing Direction and

Auto

ESC UO

ESC U1

.

10 sec.

Color

I

Throughput is better.

Color quality with special paper is

(Color correction depends on the printing direction.)

Throughput is better.

Color quality with special paper is worse.

(Color correction depends on the printing direction.)

Throughput is worse.

Color quality is best.

Bi-O

r

None

ESC UO

ESC UI

(CMYK)

ESC

U Command

Printing

WOW.

None ESC UO

Uni-D

ESC U1

None

Character mode

(for

MS-DOS?

Raster graphics

mode (fo~

Vvindows

Note:

1-14

)

Printing

Auto

Bi-D

ditection

Auto

Uni-D

is

controlkdby

Auto

Auto

dtiverin

Bi-D

Bi-D

IMndows entimnment

Uni-D

Uni-D

Bi-D

Bi-D

Uni-D Uni-D Uni-D

Bi-D Uni-D

Uni-D

Rev.

*

A

Stylus Color Service Manual

Product Description

1.4.3.2 Changing the Default Settings

To change the printer’s default settings:

a.

Hold down the

sheet that shows the firmware version and describes how to select the language used to print

messages.

b.

Press

the

Font

which language corresponds to which font LED.

Economy/Condensed

button until the appropriate font LED is selected. The following table shows

button and turn on the printer. The printer pMts a

Table 1-15. Language Selection

Language

English

Fran~is

Deutsch

Italiana Roman

Espafiol

c.

Press the

prints a table showing how to change the printer settings.

d.

Press

the

indicated by the Courier, Roman T

Font button, you adance to the next setting, and the three font

selection.

Alt

button. The printer prints the current settings using the selected language. It also

Font

button to advance through the setting menu. The current printer settings are

(PS)~and

Font LED

Courier

Roman T

Saris Serif H

Saris Serif

San Se;if H

(PS)

(PS)

Table 1-16. Feature Selection

Menu

Saris

Serif H

(ps)

LED

Setting

Feature/Menu

Courier

LED

Roman T

(PS)

LED

(PS) LEDs. Ead”time

LEDs

change according to the

Setting Value

I

O rate

r

ED

I i

Data Paper

LED

you

pr&s

the

Out LED

Character table

Print direction

Vetwork

Loading position

Auto l/F

e. Change the setting value by pressing

l/F mode

Auto line feed

interface mode

wait time

for the current menu. The status

On

On

off

On

off

On

off

On

off

On

On

off

off

On

Alt

of the

On

I

I

off

I

off

off

On

I

On

I

On

button. Pressing the

LEDs

I

Auto

I

Bi-D

Uni-D

off

On

off

On

3

mm

8.5 mm

Auto

Parallel

Serial

Option

I

10

sec.

30 sec.

will be changed as the button is pressed,

See Table 1-16

On

I

off

I

On

off

On

off

On

off

On

On

off

On On

I

Off

off

On

Alt

button changes the setting

off off

1

On

I

On

off

off

off

off off

off

off

off

On

off

1

off

off

+

I

r

off

1

off

off

off

off

off

off

off

off

off

On

1

off

off

-

Rev. A

1-15

Pfvduct

Rev.

Description

Sty#Us Cokw

Table 1-17. Character Table Selection

~

Mllnuul

Version

Common

Standard

NLSP

f. Repeat d and e to change other printer settings. The setting menu selection will return to the

first menu after the

g. Turn off the printer. The setting is stored intonon-volatile memory.

Settings

Italic U.S.A.

Italic France

Italic Germany

Italic U.K.

ttalic

Denmark 1

Italic Sweden

Italic Italy

Italic Spain 1

PC437

PC850

PC860

PC863

PC865

PC861

BRASCII Blinks

Abicomp

PC437

Greek

PC853 Blinks

PC855

PC852 On

PC857 Blinks

PC866

PC869

MAZOWIA

Code MJK

1s0

8859-7

ISO Latin IT

Bulgaria

lastmenu *l@ion

Operate LED

off off

On

Blinks

Off On

On On

Blinks

off

On

Blinks Blinks

off off

On

Blinks

off

On

off

off

off

off

On

Blinks

off

On

Blinks

off

is over.

Data LED

m

off off

On

Blinks

Blinks

off

off on

On

On

On

Blinks

off

Off

On

On

On

Blinks

Blinks

Blinks

off

off

off

On

Pa~hr)ut

Off

off

off

off

Off

Off

oft

Off

on

On

on

On

On

On

On

on

on

on

on

On

on

On

Blinks

Blinks

Blinks

Blinks

,

:-l.

.

t

,’

“

c.

. .

;

c

G.-

1-16

A

Sty/us Color Service

Manual

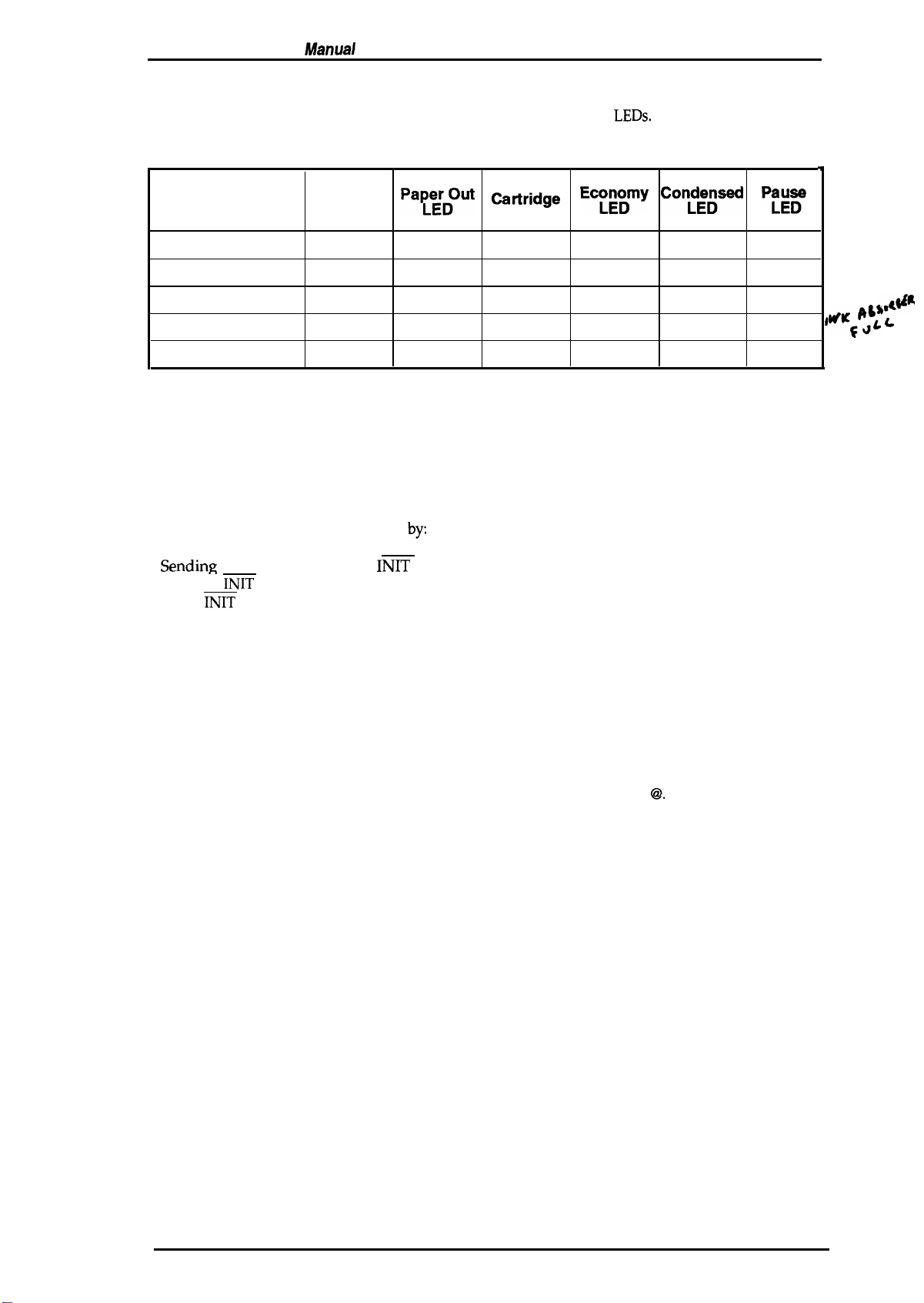

1.4.4 Error Conditions

Product Description

The printer can detect the various errors and indicate them with the

LEDs.

Table 1-18. Error Indications

f

Error

Paper out

No ink cartridge

Paper jam

Maintenance request

Carriage error

Data LED

off

off off

off

Blinks

Blinks

Pa~;rDOut

On

Blinks

Blinks

off off

No Ink

Catiridge

LED

off

On

off

Blinks Blinks

Ecm~my

off off

off off

off

off off

Con&sed

off off

Blinks

Pfg~

off

off

Blinks

Blinks

#KG@$4 L

1.4.5 Printer Initialization

There are three initialization methods: hardware initialization, software initialization, and panel

initialization.

1.4.5.1 Hardware

Hardware initialization is performed

Turning on the printer.

-

%mdin~

the parallel interface

(If the

INIT

the

INIT

signal becomes inactive.)

Initialization

by:

INIT

signal.

signal is active when the printer is turned on, hardware initialization is started when

,,4#R

When the hardware initialization is performed:

- The printer mechanism is initialized.

Input data buffer is cleared.

Downloaded character definitions are cleared.

Print buffer is cleared.

Default values are set.

1.4.5.2 Software Initialization

Software initialization is performed upon receipt of the control code ESC

When the software initialization is performed:

Print buffer is cleared.

Default values are set.

1.4.5.3 Panel Initialization

This printer is initialized by pressing the

When the panel initialization is performed:

Input data buffer is cleared.

Print buffer is cleared.

Default values are set.

Load/Eject

button while pressing the

@.

Alt

button.

Rev. A

1-17

Product

Rev. A

—

Descriptkm

1.5 MAIN COMPONENTS

- . — . - . --

-

Color Setvke

hfg@g##

.

The main components of the Stylus Color

Q

Printer mechanism

Q

Main control board

Cl

Power supply unit(C137PSB/PSE Board)

Q

Control panel board

Q

Housing

1.5.1 Main Control Board

The Main Control Board

array, a program ROM

and a lithium battery for powering the

equipped with both a logic system and a power system.

NJ.5P

(National Language Support Printer) specification.

z~

,

(M-4A10)

(C137

MAIN Board)

(C137PNL

(C137

(C137

MAIN Board) consists of an

(4M),

a dynamic

. . . . . . . . .

CN2

are:

Board)

MAIN Board)

RAM (4M),

protect counters.

IC14

a mask ROM

SLA7041

H8/3003

The

reset IC

The

8M program ROM is used only

1

1

m

l~bit CPU, E05A% gate

(4M

or

8M),

an

EEP-ROM

(M51955

~ ICl!i SI A7041

.-

,“ — .,

I

f-l

and ~ 592) is

“

—

c)

z

0

-

RM12

(lK),

fix

the

#——————

Figure 1-9.

/

Q14

CN1

K

BAT 1

C137

MAIN Board Component Layout

RM11

\@

i

I

(

“

.,

1-18

Stylus Color Service Manual

Product Description

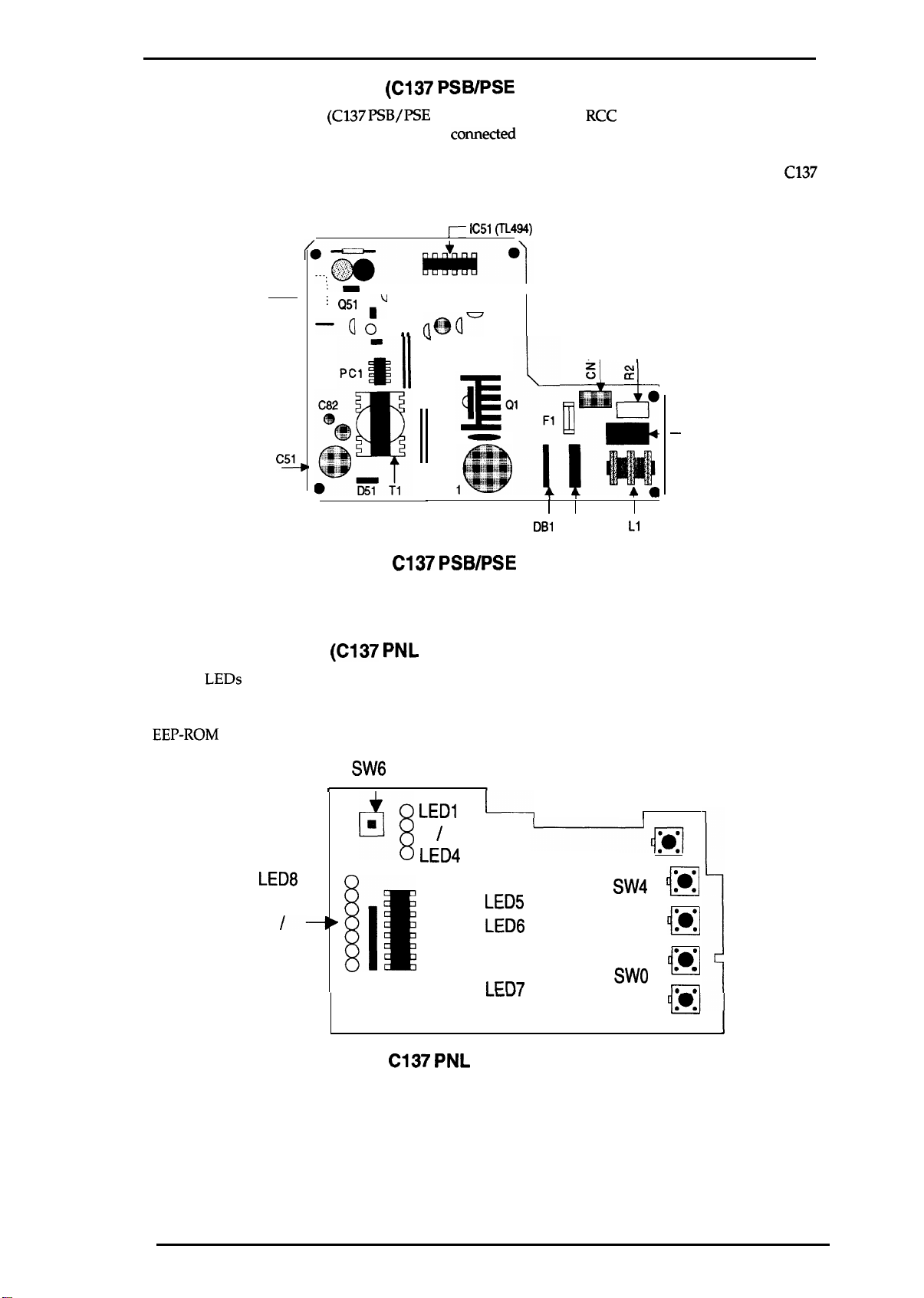

1.5.2 Power Supply Board

The

Power Supply Board

This board is equipped with a power switch

is turned off, it can continue to operate in order to eject the paper and perform the head capping

operation. The power on/off signal is always monitored by the E05A96 gate array on the

MAIN Board,

and the logic system

CN2 ,

(C137 PSB/PSE

:-

. .

; Q51

–Qo

c~

(C137 PSB/PSE

Board) consists of an

comected

recognizes the power switch status.

j-- IC51 (TL494)

n

Board)

RCC

switching regulator circuit.

to the secondary circuit. Thus, if the printer

I

J

(@r

aa

u

I

cl

1-

DB1

C3

1-

,

L1

C137

–

cl

—

Figure 1-10.

1.5.3 Control Panel

The 14

6 switches in combination with one another, the printer can operate in each protect operation (color

or black cleaning, cartridge exchanging self-test, default setting value exchanging, reset, and

EEP-ROM

LEDs

on this board indicate the error status (there is no buzzer system); by using the

clear operation).

LED8

/-

LED14

(C137 PNL

t

[It

C137 PSB/PSE

Board)

SW6

❑

q

LED1

LED4

Component Layout

t

1---1

/

LED5

0

LED6

0

I

m7

0

I

SW4 Ill

M

/

i-l

Swo

n

● 0

‘0

:0°

m

—

‘

I

Rev.

Figure 1-11.

A

C137 PNL

Board Component Layout

1-19

Product

Rev. A

D9sctiptk3n

Stylus

Color *vim Manual

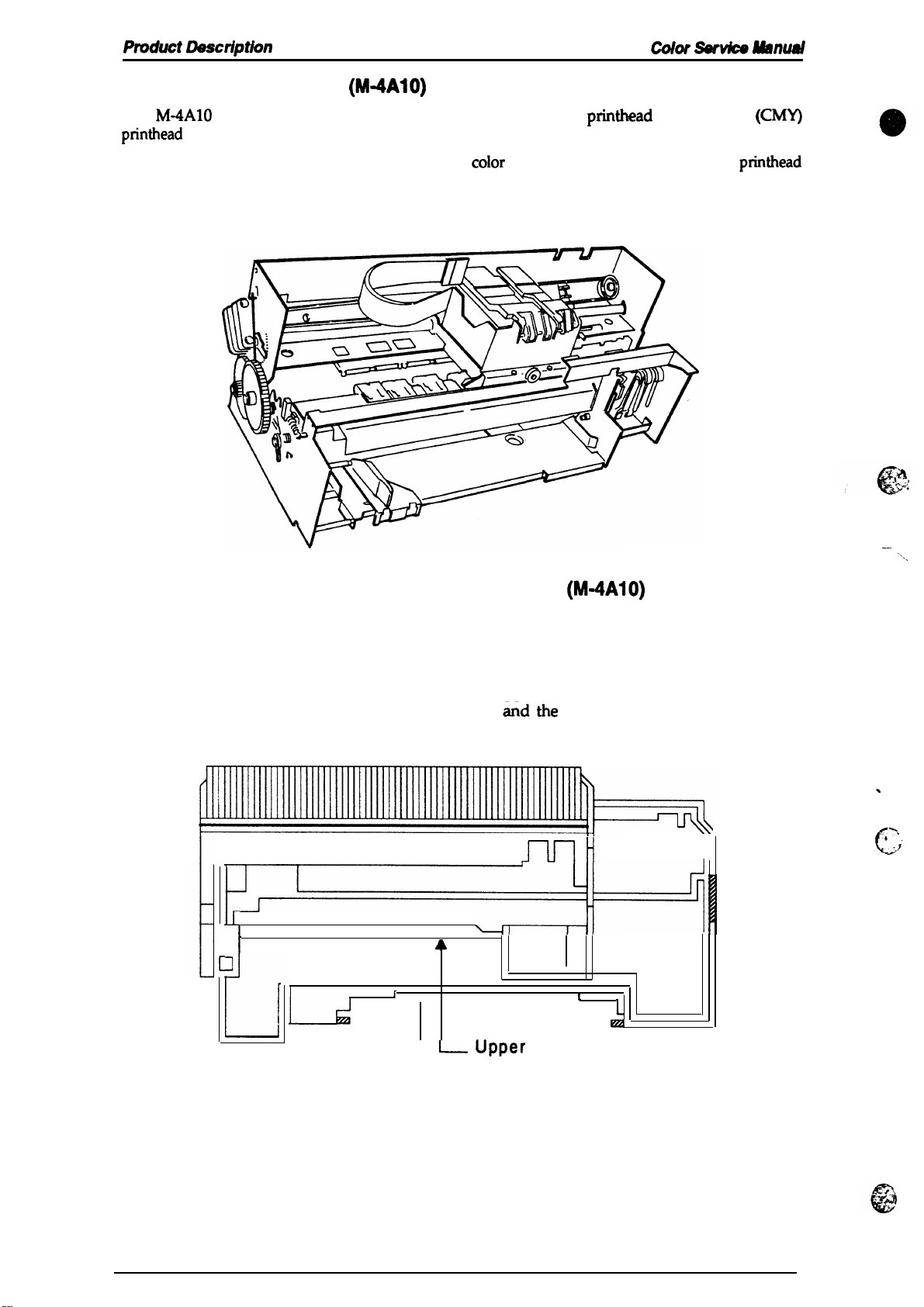

1.5.4 Printer Mechanism

The

M-4A1O

printhead

The ink system has both a black pump unit and a

is made to flow into the individual caps. Power for the pump system and paper feed system is

supplied from the paper feed motor.

printer mechanism is equipped with a 64-black

on the carnage unit. Resolution of 720 dpi is possible with special (non-absorbent) paper.

(M-4A1O)

printhead

coIor

pump unit. Waste ink from each

and M-color

(CMY)

printhead

Figure 1-12. Printer Mechanism

1.5.5 Housing

The Stylus Color housing consists of the printer cover, uppercase, and the lowercase.

Attached to the housing

separator.

1

I

are the front paper

r

A

L

support

4

L- upper

Lower Case

ejected paper support

mH

1

L

km

Case

with paper

II

-—

4

-.

c

‘.,

‘,

-7

1-20

Figure 1-13. Housing

Chapter 2 Operating Principles

Table of Contents

2.1 OVERVIEW

2.2

OPERATING PRINCIPLES OF THE PRINTER MECHANISM

2.2.1

2.2.2

Printer Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Carriage Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.2.1 Platen GapAdjust Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.3

2.3.1 Operating Principles

2.3.2 Operating

Paper Feed Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

InkSystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Pump Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Cap Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Wiping Mechanism

..~ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

OPERATING PRINCIPLES OF THE ELECTRICAL CIRCUITS

ofthe

Power Supply Circuit . . . . . . . . . . . . . . . . .

2.3.2.1

2.3.2.2

2.3.2.3

2.3.2.4

2.3.2.5

2.3.2.6

2.3.2.7

Principlesofthe

Reset Circuits.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SensorCircuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage MotorDriveCircuit . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper Feed Motor Drive Circuit. . . . . . . . . . . . . . . . . . . . . . . . .

Printhead

Drive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DMAControlier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-RAM Refreshment Controller. . . . . . . . . . . . . . . . . . . . . . . . .

Main Control Circuit . . . . . . . . . . . . . . . . . .

2-1

2“1

2-13

2-13

2-15

2-16

2-16

2-17

2-19

2-20

2“21

2-22

2.4

INK SYSTEM MANAGEMENT

2.4.1

InkOperations. . . . . . . . . . . . . . .

2.4.1.1

2.4.1.2

2.4.1.3

2.4.1.4

2.4.1.5

2.4.1.6

2.4.1.7

2.4.1.8

2.4.1.9

2.4.1.10

2.1.4.11

2.4.1.12

2.4.1.13

2.4.1.14

2.4.1.15

2.4.1.16

2.4.1.17

2.4.1.18

PowerOnOperation. . . .

Cleaning Selection Mode

Micro Absorbing Cleaning

PowerOffOperation . . .

Print Start Operation . . .

Refresh Operation . . . . .

Standby Operation . . . . .

Fail Absorbing Operation

Ink Cartridge Replacement Operation . . . . . . . . . . . . . . . . . . . .

Wiping Operation 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WipingOperation2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rubbing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disengage ON Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disengage OFFOperation . . . . . . . . . . . . . . . . . . . . . . . . . . .

Micro Absorbing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage Lock Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage Lock Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refresh Operation (Performed when loading or

ejecting paper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Lever Operate Position Moving Sequence. . . . . . . . . .

2.4.2

2.4.1.19

TimerandCounter. . . . . . . . . . . . . . . . .

2.4.2.1 Refresh Timer (Monochrome and

2.4.2.2 Timer (Monochrome and

2.4.2.3 Flushing Counter (Black,

Rev. A

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . ,..,.,

. . . . . . . . . . . . . . . . . . . . . . . ,.,,..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .m.,m, ,,..,.

....._...;..

CMY

CMY

Head). . . . . . .

CMY

Head). . . . . . .

Head)

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . ,.

. . . . . . . . . . . . .

2-23

2-24

2-24

2-25

2-26

2-26

2-26

2-27

2-27

2-27

2-28

2-29

2-29

2-29

2-29

2-29

2-30

2-30

2-30

2-30

2-30

2-30

2-30

2-31

2-31

2-i

2.4.2.4 Fail Absorbing Timer (Black,

2.4.2.5

2.4.2.6

Ink Level Counter R (On the RAM)

CMY

(Monochrome = Rb,

= Ry) . . . . . . . . . . . . . . . . . . . . .. ..2-31

CL Counter K (Monochrome = Kb,

2.4.2.7 CL2 Counter KK (Monochrome = KKb,

2.4.2.8

Protect Counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

CMy

Head) . . . . . . . . . . . . .....2-31

CMY

= Ky) . . . . . . . . . . . . . 2-32

CMY

= KKy). . . . . . . . . 2-32

@

List of Figures

Figure 2-1. Printer Mechanism Block . . . . . . . . . . . . . . . . . . . . . ...........2-1

Figure 2-2. Structure of

Figure 2-3. Principles of the Printing Operation. . . . . . . . . . . . . . . . . . . . . .. ..2-3

Figure 2-4. Microwave Mode Operation . . . . . . . . . . . . . . . . . . . . . ........2-4

Figure 2-5. Carriage Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-6. Platen Gap Lever Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-7. Paper Feed Mechanism . . . . . . . . . . . . . . . . . . . . . ............2-7

Figure 2-8. Ink System Block . . . . . . . . . . . . . . . . . . . . . .................2-8

Figure 2-9. Pump Mechanism Block. . . . . . . . . . . . . . . . . . . . . . ...........2-9

Figure 2-10. Switch Lever Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-11. Paper Feed Mechanism Block . . . . . . . . . . . . . . . . . . . . . . . . . . 2-IO ‘-=

Figure 2-12. Switch Lever Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-13. Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Figure 2-14. Cap Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-15. Wiping Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-16. Block Diagram of the Electrical Circuit . . . . . . . . . . . . . . . . . . . .

Figure 2-17. Power Supply Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . .

Figure 2-18. Main Control Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-19. Reset Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-20. Sensor Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-21. Carriage Motor Circuit Block Diagram. . . . . . . . . . . . . . . . . . . . .

Figure 2-22. Serial Data Transfer Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-23. Paper Feed Motor Drive Circuit Diagram . . . . . . . . . . . . . . . . . . 2-19

Figure 2-24. Trapezoidal Drive Wave Form. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Figure 2-25.

Printhead

Figure 2-26. DMA Controller Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-27. D-RAM Cycle Timings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Figure 2-28. Junction Method (CPU-DRAM). . . . . . . . . . . . . . . . . . . . . .. ...2-22

Figure 2-29. Relation of Ink System & Carriage Operation. . . . . . . . . . . . . . . 2-23

Figure 2-30. Power On Operation Classification. . . . . . . . . . . . . . . . . . . . . . . 2-24

Figure 2-31. Power Off Operation Classification. . . . . . . . . . . . . . . . . . . . . . . 2-26

Figure 2-32. Ink Cartridge Replacement Classification . . . . . . . . . . . . . . . . . . 2-28

Printhead.

. . . . . . . . . . . . . . . . . . . . . .............2-2

2-13

2-14

2-17

Drive Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . 2-20

f~l

f

k.

-.

~.-

List of Tables

Table 2-1. Carriage Drive Motor Specifications. . . . . . . . . . . . . . . . . . . . . .. ..2-5

2-2.

Table

Table

Table 2-4. Paper Feed Drive Motor Specification . . . . . . . . . . . . . . . . . . . . .. .2-6

Table 2-5. Drive Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 2-7

Table 2-6. Pump Mechanism Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table 2-7. DC Voltage Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Table 2-8. Serial Data contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-17

Table 2-9. Paper

Table 2-10. Junction Method

2-ii

Drive Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .2-5

2-3.

Platen Gap Adjust Lever Position. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Feed Motor Drive Modes. . . . . . . . . . . . . . . . . . . . . . .....2-19

(CPU-2CAS

DRAM) . . . . . . . . . . . . . . . . . . . . .2-22

Rev. A

C,?,

*U)

Loading...

Loading...