Page 1

®

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus Color C70/C80

SEIJ01-004

Page 2

Notice

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic,

mechanical, photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2000 SEIKO EPSON CORPORATION.

Imaging & Information Product Division

TPCS Quality Assurance Center

TPCS Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO.

WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED

CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS,

WHEN ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC

OR OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. TROUBLESHOOTING

Describes the step-by-step procedures for the

troubleshooting.

CHAPTER 4. DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling

and assembling the product.

CHAPTER 5. ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

APPENDIX Provides the following additional information for

reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

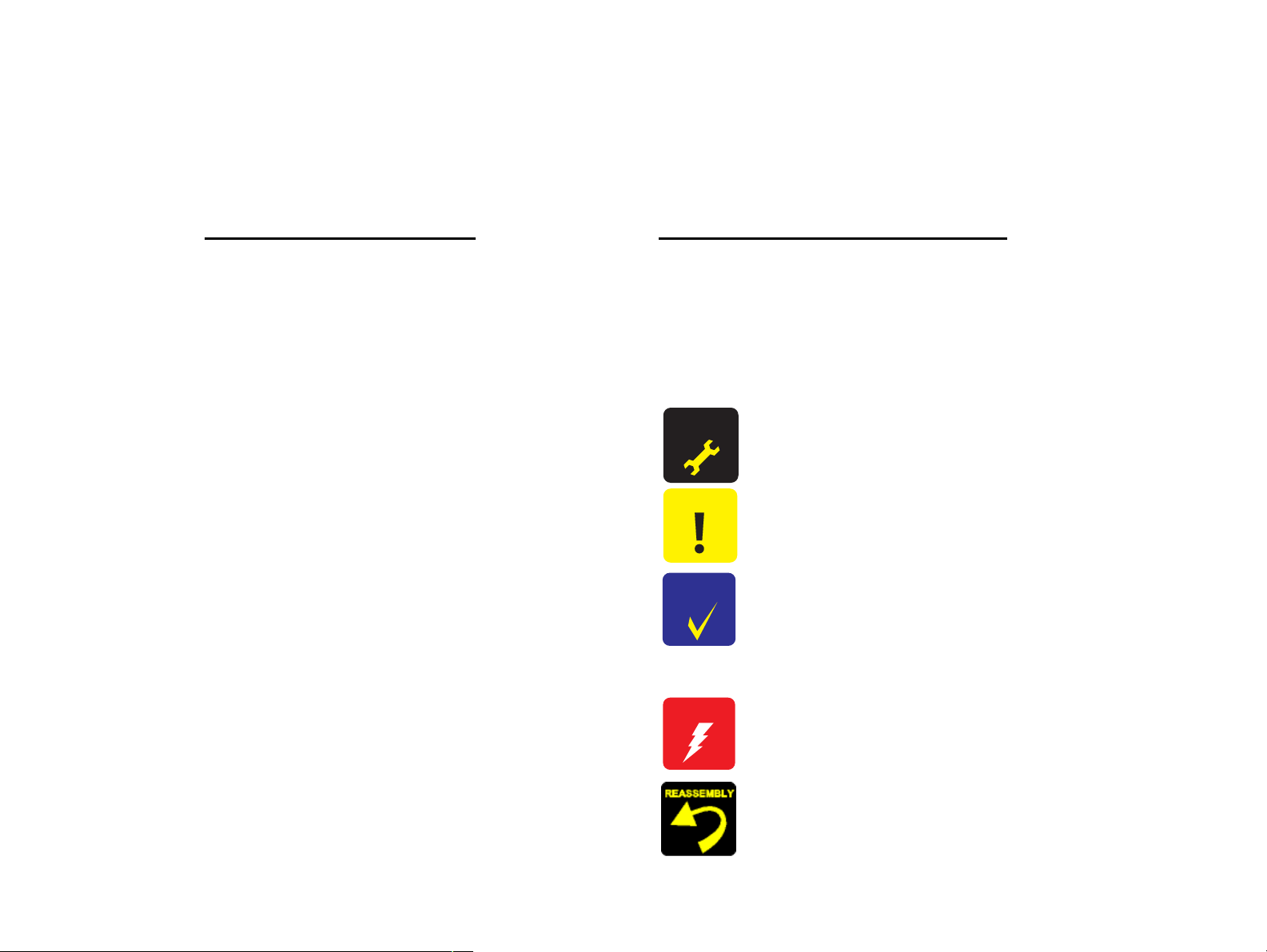

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide

additional information on a specific topic or to warn of possible danger

present during a procedure or an action. Be aware of all symbols when

they are used, and always read NOTE, CAUTION, or WARNING

messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice

or condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice,

or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure,

practice or condition that is necessary to accomplish a task

efficiently. It may also provide additional information that is

related to a specific subject, or comment on the results

achieved through a previous action.

Indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, could result in injury

or loss of life.

Indicates that a particular task must be carried out

according to a certain standard after disassembly and

before re-assembly, otherwise the quality of the

components in question may be adversely affected.

Page 5

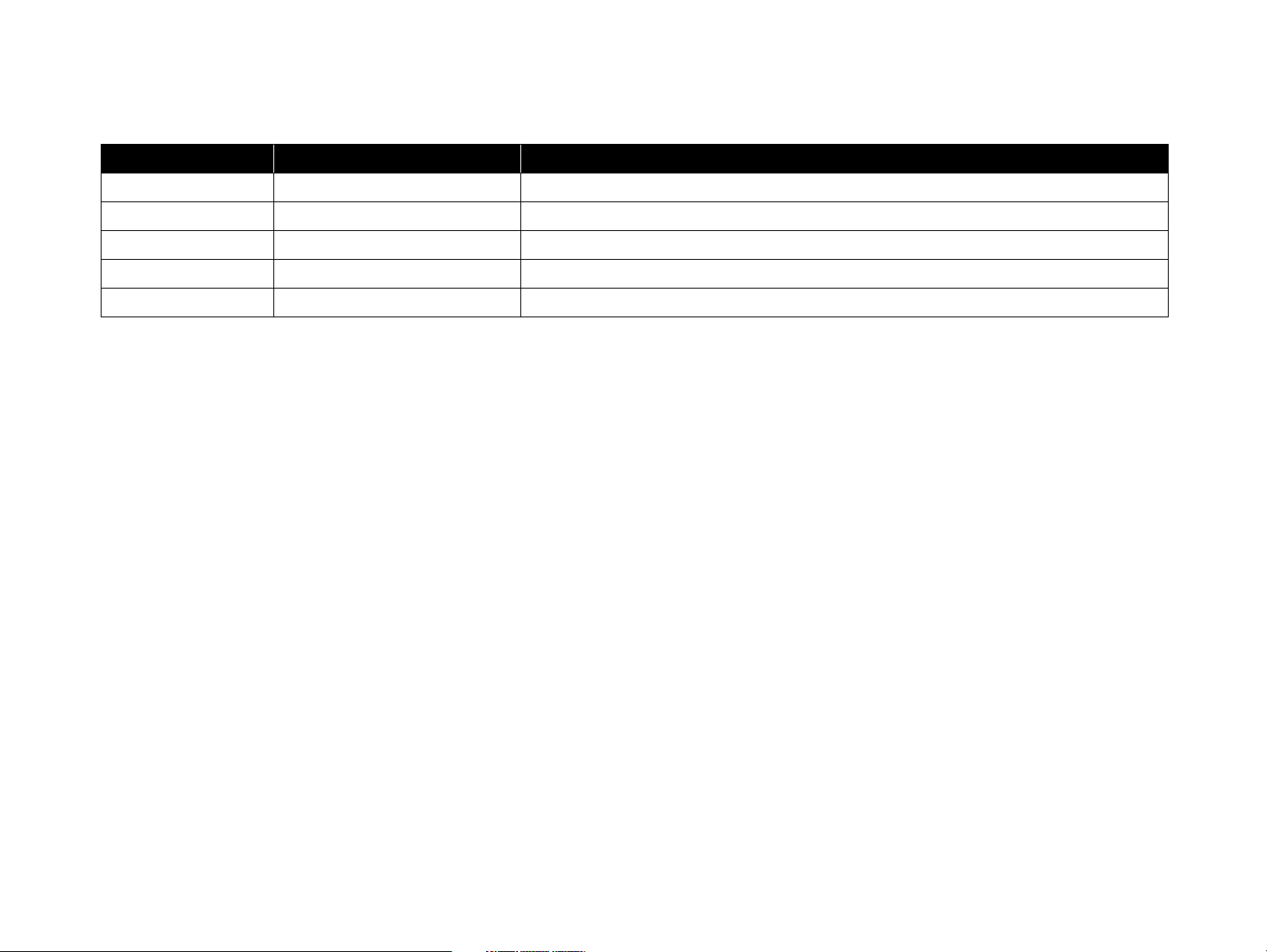

Revision Status

Revision Issued Date Description

A July 31, 2001 First Release

Page 6

CONTENTS

Chapter 1 PRODUCT DESCRIPTION

1.1 FEATURES ....................................................................................................... 10

1.2 SPECIFICATIONS .......................................................................................... 11

1.2.1 Physical Specification ................................................................................ 11

1.2.2 Printing Specification ................................................................................ 11

1.2.3 Paper Feeding ............................................................................................ 13

1.2.4 Input Data Buffer ....................................................................................... 13

1.2.5 Electric Specification ................................................................................. 13

1.2.6 Environmental Condition ........................................................................... 14

1.2.7 Reliability .................................................................................................. 14

1.2.8 Safety Approvals ....................................................................................... 14

1.2.9 Acoustic Noise ........................................................................................... 14

1.2.10 CE Marking ............................................................................................. 14

1.3 INTERFACE ..................................................................................................... 15

1.3.1 Parallel Interface ........................................................................................ 15

1.3.2 Parallel Interface (Reserve Channel) ......................................................... 17

1.3.3 USB Interface ............................................................................................ 18

1.3.4 Prevention Hosts of Data Transfer Time-out ............................................. 19

1.3.5 Interface Selection ..................................................................................... 19

1.3.6 IEEE1284.4 Protocol ................................................................................. 19

1.3.7 Printer Language and Emulation ............................................................... 20

1.3.7.1 Control codes ..................................................................................... 20

1.3.7.2 EPSON D4 control channel commands ............................................ 21

1.4 OPERATOR CONTROLS .............................................................................. 24

1.4.1 Operate Switch ........................................................................................... 24

1.4.2 Control Panel ............................................................................................. 24

1.4.2.1 Switches ............................................................................................. 24

1.4.2.2 Indicators ........................................................................................... 24

1.4.3 Panel Functions .......................................................................................... 25

1.4.4 Printer Condition and Panel Status ............................................................ 26

1.4.5 Printer setting mode (Stylus COLOR C80 only) ....................................... 27

1.4.5.1 Default setting mode ......................................................................... 27

1.4.5.2 Print head alignment mode ................................................................ 28

1.4.6 Printer Initialization ................................................................................... 28

1.4.7 Errors ......................................................................................................... 29

1.5 PAPER ............................................................................................................... 30

1.5.1 Paper Handling .......................................................................................... 30

1.5.2 Paper Specification .................................................................................... 30

1.5.2.1 Cut Sheet ........................................................................................... 30

1.5.2.2 Envelope ............................................................................................ 30

1.5.2.3 Index Card ......................................................................................... 30

1.5.2.4 EPSON special media ....................................................................... 31

1.5.3 Printing Area .............................................................................................. 32

1.5.3.1 Cut Sheet ........................................................................................... 32

1.5.3.2 Envelopes .......................................................................................... 33

1.6 INK CARTRIDGE ........................................................................................... 34

1.6.1 Black Ink Cartridge ................................................................................... 34

1.6.2 Color Ink Cartridge .................................................................................... 34

Chapter 2 Operating Principles

2.1 Overview ............................................................................................................ 36

2.1.1 Printer Mechanism ..................................................................................... 36

2.1.2 Printhead .................................................................................................... 37

2.1.2.1 Printing Process ................................................................................. 37

2.1.2.2 Printing Method ................................................................................. 38

2.1.3 Carriage Mechanism .................................................................................. 39

2.1.4 Paper Feeding Mechanism ......................................................................... 40

2.1.5 Paper Loading Mechanism (ASF Unit) ..................................................... 41

2.1.6 Ink System Mechanism ............................................................................. 49

2.1.6.1 Pump Unit & Wiper mechanism ....................................................... 49

2.1.6.2 Capping Mechanism .......................................................................... 50

2.2 Electrical Circuit Operating Principles .......................................................... 51

Page 7

2.2.1 C424 PSB/PSE board ................................................................................ 51

2.2.2 C424 MAIN-B Board ................................................................................ 54

2.2.2.1 Main elements ................................................................................... 55

2.2.2.2 Printhead Driver Circuit .................................................................... 56

2.2.2.3 CR / PF Motor (PF/ PUMP/ ASF Motor) Driver Circuit .................. 57

2.2.2.4 Reset Circuit ...................................................................................... 57

2.2.2.5 EEPROM Control Circuit ................................................................. 58

2.2.2.6 Sensor Circuit .................................................................................... 58

Chapter 3 Troubleshooting

3.1 Overview ............................................................................................................ 61

3.1.1 Communication Error ................................................................................ 62

3.1.2 Too Late Throughput ................................................................................. 62

3.1.3 Status Monitor does not operate ................................................................ 63

3.1.4 Troubleshooting with LED Error Indications ............................................ 64

3.1.4.1 Remedy when a paper out, double feed or paper jam error

occurs ................................................................................................. 66

3.1.4.2 Remedies for No I/C and Ink Out Errors .......................................... 71

3.1.4.3 Countermeasures when an Ink Low indication appears. ................... 75

3.1.4.4 Remedies for the Maintenance Error ................................................. 75

3.1.4.5 Remedies for Fatal Error ................................................................... 76

3.1.5 Isolating the Faulty Part on the Power Supply Board ................................ 79

3.1.6 Isolating the Faulty Part according to the Phenomenon ............................ 82

3.1.6.1 PF Motor Driver Abnormal 1 ............................................................ 83

3.1.6.2 ASF Driver Abnormal 1 .................................................................... 84

3.1.6.3 Unexpected Ink Out Error 1 (During Print Operation) ..................... 85

3.1.6.4 PF Motor Driver Abnormal 2 ............................................................ 86

3.1.6.5 Carriage Operation Abnormal ........................................................... 87

3.1.6.6 Dot Missing 1 .................................................................................... 89

3.1.6.7 Dot Missing 2 .................................................................................... 90

3.1.6.8 Dot Missing 3 .................................................................................... 92

3.1.6.9 Repair Handling Failure .................................................................... 93

3.1.6.10 ASF Driver Abnormal 2 .................................................................. 93

3.1.6.11 CR Motor Operation Abnormal ...................................................... 95

Chapter 4 Disassembly and Assembly

4.1 Overview ............................................................................................................ 97

4.1.1 Precautions ................................................................................................. 97

4.1.2 Tools .......................................................................................................... 98

4.1.3 Work Completion Check ........................................................................... 99

4.1.4 Screws ...................................................................................................... 100

4.2 Disassembly ..................................................................................................... 101

4.2.1 Housing Removal .................................................................................... 102

4.2.1.1 Printer Cover Removal .................................................................... 102

4.2.1.2 Stacker Assembly Removal ............................................................ 102

4.2.1.3 Upper Case Removal ....................................................................... 103

4.2.1.4 Rear Cover Removal ....................................................................... 104

4.2.1.5 Middle Housing Removal ............................................................... 104

4.2.1.6 Printer Mechanism Unit Removal ................................................... 105

4.2.1.7 Waste Ink Pad Removal .................................................................. 108

4.2.2 ASF Unit Removal .................................................................................. 108

4.2.3 Main Board Assembly Removal .............................................................. 110

4.2.4 Power Supply Board Assembly Removal ............................................... 111

4.2.5 Print Head / Ink System Unit Removal ................................................... 113

4.2.6 Carriage Unit / CR Guide Shaft Removal ............................................... 116

4.2.7 Front Paper Guide Removal .................................................................... 121

4.2.8 EJ Roller Unit Removal ........................................................................... 122

4.2.9 Motor Removal ........................................................................................ 123

4.2.9.1 PF Motor Removal .......................................................................... 123

4.2.9.2 CR Motor Removal ......................................................................... 124

4.2.10 PE Actuator Removal ............................................................................ 125

4.2.10.1 Encoder Unit Board Removal ....................................................... 125

4.2.11 PF Roller Unit Removal ........................................................................ 126

4.2.12 ASF Unit Disassembly .......................................................................... 127

4.2.12.1 ASF Assembly Points .................................................................... 132

4.2.13 Rotary Encoder Removal ....................................................................... 134

Chapter 5 Adjustment

5.1 Overview .......................................................................................................... 138

5.1.1 Conditions for Each Adjustment ............................................................. 138

5.2 Adjustment ...................................................................................................... 140

5.2.1 Setup the Adjustment Program ................................................................ 140

5.2.2 Head ID Input .......................................................................................... 141

5.2.3 Ink Charge ............................................................................................... 143

5.2.4 Head Angle Adjustment. ......................................................................... 144

5.2.5 Bi-D Adjustment ...................................................................................... 149

5.2.6 PF Adjustment ......................................................................................... 152

Page 8

5.2.7 USB ID Readout (Checking) ................................................................... 155

5.2.7.1 Possible to Readout the Original USB ID (CASE 1) ...................... 155

5.2.7.2 Impossible to Readout the Original USB ID (CASE 2) .................. 157

5.2.8 EEPROM Initialization ............................................................................ 157

5.2.9 Platen Gap Adjustment (Mechanism Adjustment) .................................. 159

5.2.10 Head Cleaning Operation ...................................................................... 162

5.2.11 Protection Counter Clear (and Check) ................................................... 163

5.2.12 Top Margin Adjustment ........................................................................ 164

5.2.13 First Dot Position Adjustment ............................................................... 166

Chapter 6 Maintenance

6.1 Overview .......................................................................................................... 170

6.1.1 Cleaning ................................................................................................... 170

6.1.2 Service Maintenance ................................................................................ 171

6.1.3 Lubrication and Adhesion ........................................................................ 172

6.1.4 Lubrication the Carriage Guide Shaft ...................................................... 173

Chapter 7 Appendix

7.1 Connector Summary ...................................................................................... 183

7.1.1 Major Component Unit ............................................................................ 183

7.1.2 EEPROM Address Map ........................................................................... 187

7.1.3 CSIC Address Map .................................................................................. 193

7.2 Component Layout ......................................................................................... 196

7.3 Exploded Diagram .......................................................................................... 198

7.4 Parts List ......................................................................................................... 208

7.5 Electrical Circuits ........................................................................................... 213

Page 9

PRODUCT DESCRIPTION

CHAPTER

1

Page 10

EPSON Stylus COLOR C70/C80 Revision A

1.1 FEATURES

The major features of EPSON color inkjet printers EPSON Stylus COLOR C70 / C80

are:

High Color Print Quality

2880 (H) X 720 (V) dpi printing

4 Color Printing (YMCK)

Built-in Auto Sheet Feeder

Holds 150 cut-sheets (64g/m

Holds 15 envelopes

Built-in 2 I/F

Bi-directional parallel I/F (IEEE-1284 level 1 device)

USB

Windows/Macintosh exclusive (Stylus COLOR C70 only )

1 scalable fonts, 2 LQ fonts (Stylus COLOR C80 only )

Roman (scalable)

2

)

Roman, Courier (LQ)

Accessory

Figure 1-1. Product’s external view

Enclosed parts

User’s manual: 1

Driver disk: 1

Black ink cartridge: 1

Cyan ink cartridge: 1

Magenta ink cartridge: 1

Yellow ink cartridge: 1

Power cord: 1 (220-240 version)

PRODUCT DESCRIPTION FEATURES 10

Page 11

EPSON Stylus COLOR C70/C80 Revision A

1.2 SPECIFICATIONS

This section covers specifications of the printers.

1.2.1 Physical Specification

Weight: 5.8kg (without the ink cartridges)

Dimension: 452 mm (W) x 562 mm (D) x 295 mm (H)

1.2.2 Printing Specification

Print Method

On demand ink jet

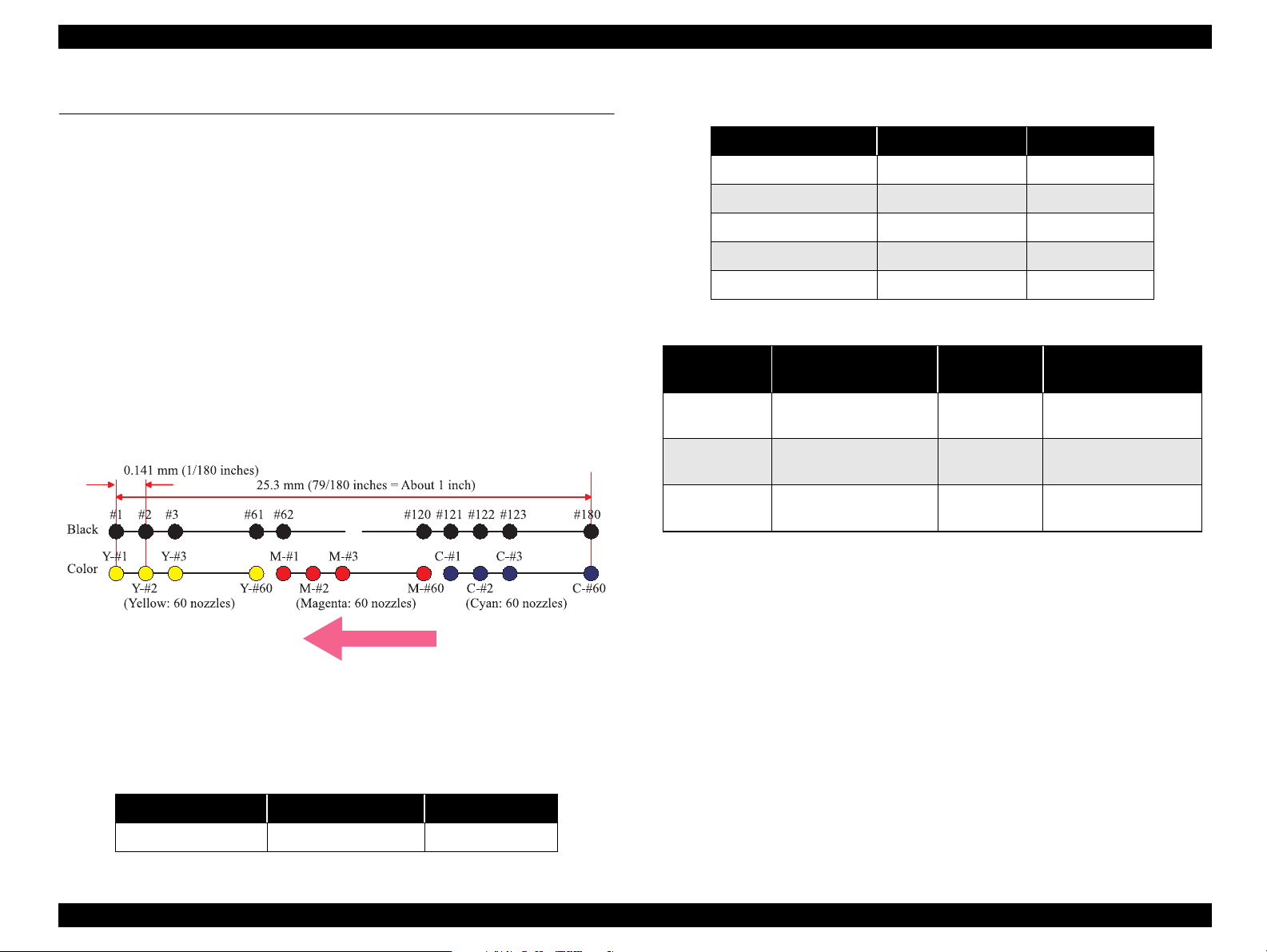

Nozzle Configuration

Monochrome 180 nozzles

Color 60 nozzles x 3 (Cyan, Magenta, Yellow)

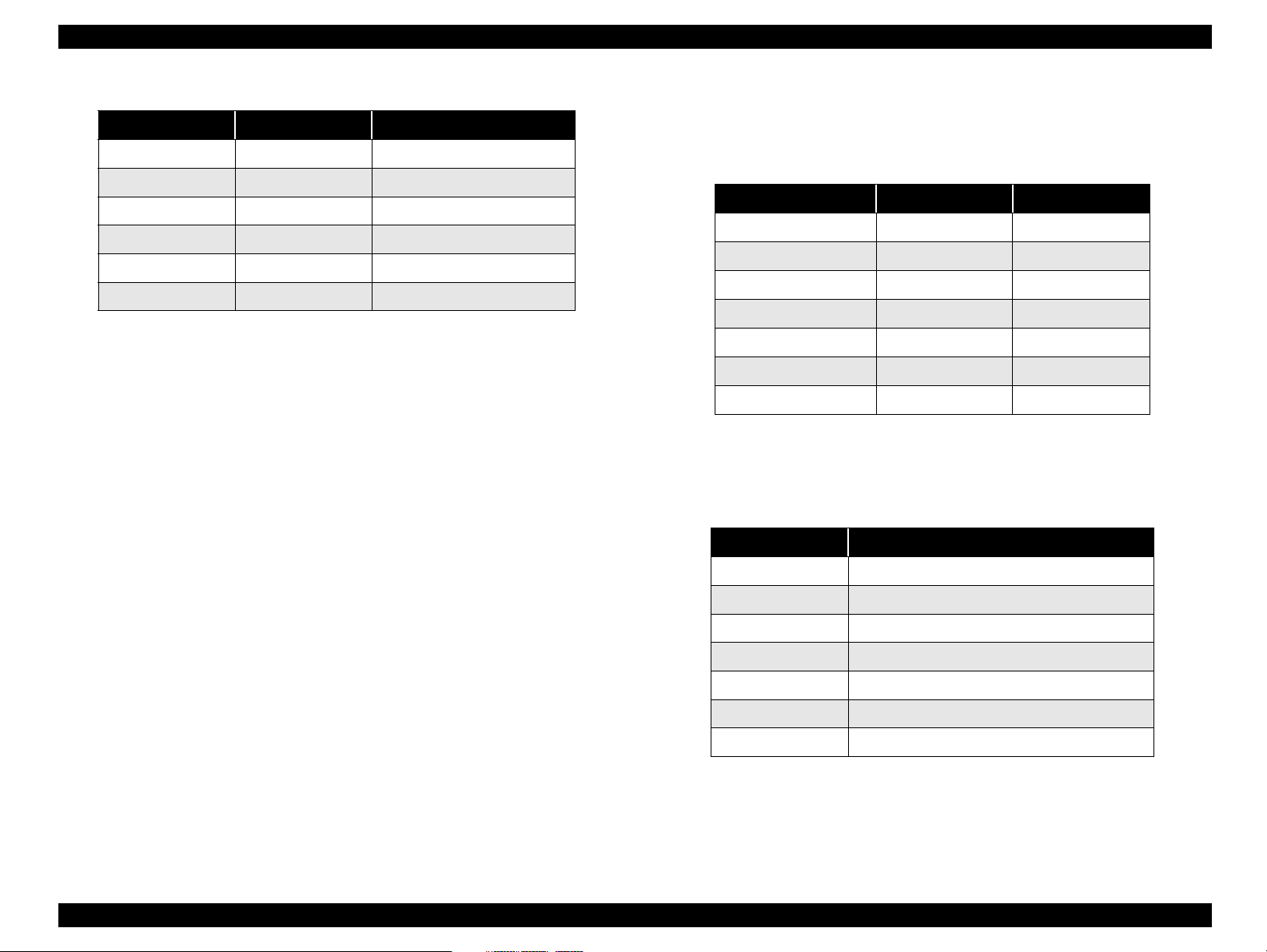

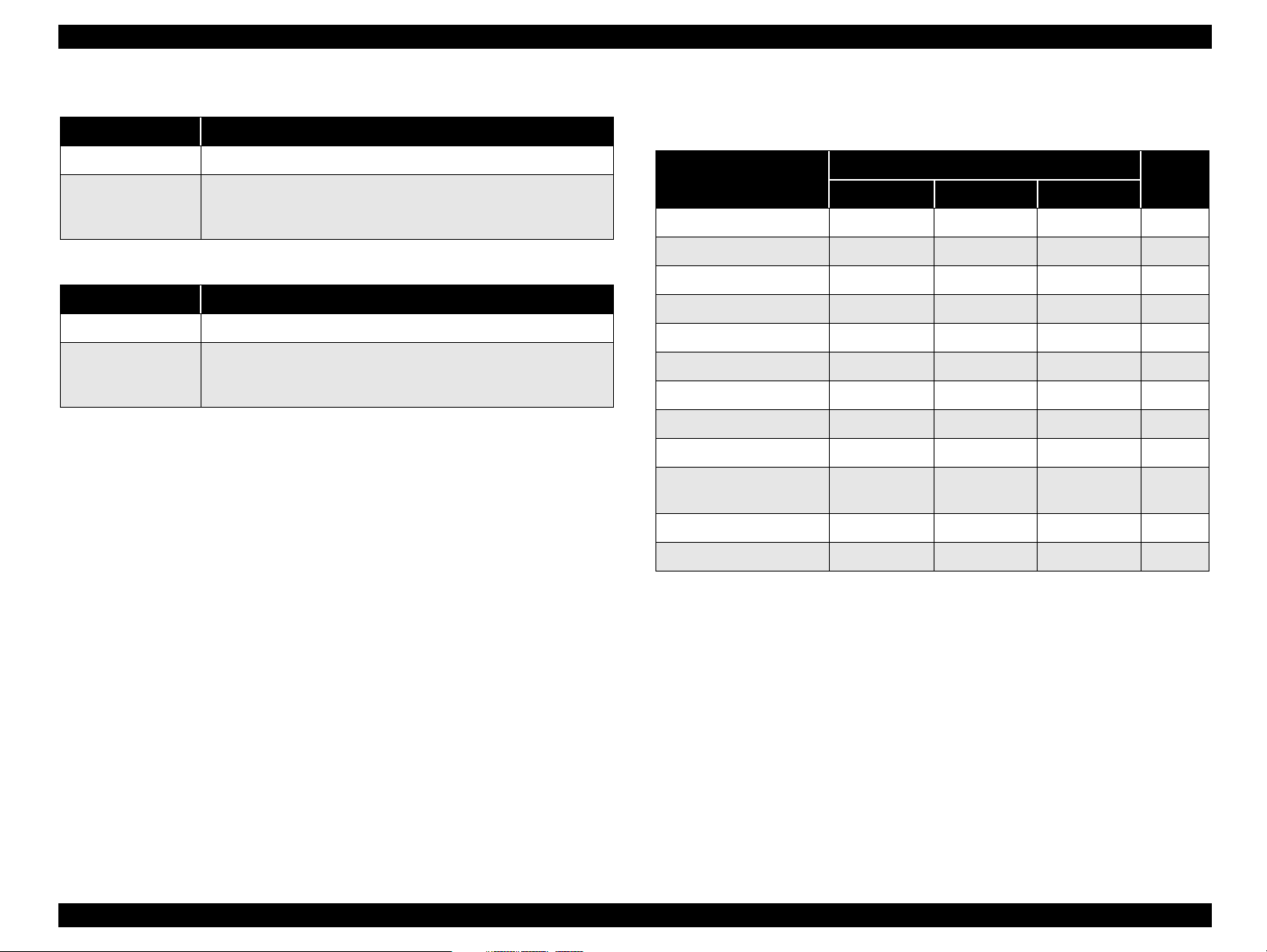

Table 1-2. Character Mode (Stylus COLOR C80)

Character Pitch Printable Column LQ Speed

10 CPI (Pica) 80 238 CPS

12 CPI (Elite) 96 285 CPS

15 CPI 120 357 CPS

17 CPI (Pica condensed) 137 406 CPS

20 CPI (Elite condensed) 160 476 CPS

Table 1-3. Raster Graphics Mode

Horizontal

Resolution

180 dpi 209.8mm(8.26 inch) 1488

360 dpi 209.8mm(8.26 inch) 2976

720 dpi 209.8mm(8.26 inch) 5952

Printable Area Available Dot CR Speed

Control Code*

762/482.6 mm/s

30/19 IPS

571.5/482.6 mm/s

22.5/19 IPS

482.6 mm/s

19 IPS

ESC/P2 expanded raster graphics code

EPSON Remote command

Paper Ejecting Direction

Print Direction

Bi-direction with logic seeking

Print Speed & Printable Columns*

Table 1-1. Character Mode (Stylus COLOR C70)

Character Pitch Printable Columns LQ Speed

10 CPI (Pica) 80 238 CPS

Character Tables*

(Stylus COLOR C70)

2 international character sets:

- PC 437 (US Standard Europe)

- PC 850 (Multilingual)

NOTE: But user cannot selsct.

PC437 is the default setting.

PRODUCT DESCRIPTION SPECIFICATIONS 11

Page 12

EPSON Stylus COLOR C70/C80 Revision A

(Stylus COLOR C80)

legal and 14 international character sets

(38 character tables)

Typeface*

(Stylus COLOR C70)

Bit map LQ font:

-EPSON Courier 10 CPI

(Stylus COLOR C80)

Bit map LQ font:

-EPSON Roman 10 CPI, 12 CPI, 15 CPI, Proportional

-EPSON Courier 10 CPI, 12 CPI, 15 CPI

Scalable font

-EPSON Roman 0.5 pt., 8 pt. - 32pt.(every 2 pt.)

NOTE: Each Typeface has 4 variations as the following example of EPSON

Roman.

-EPSON Roman normal

-EPSON Roman bold

-EPSON Roman italic

-EPSON Roman bold italic

NOTE: (*)Do not mention to the user’s manual.

Character table and Typeface (Stylus COLOR C80 only )

Table 1-4. Character table and Typeface

Bit map font Scalable font

DOS version

Character table

Italic table

PC 437(US Standard

Europe)

PC 850 (Multilingual)

PC 860(Portuguese)

PC 861(Icelandic)

PC 865(Nordic)

BRASCII

Abicomp

Roman 8

ISO Latin 1

PC 858

ISO 8859-15

PC 437 Greek

PC 852(East Europe)

PC 853(Turkish)

PC 855(Cyrillic)

PC 857(Turkish)

PC 866(Russian)

PC 869(Greek)

MAZOWIA(Poland)

Code MJK(CSFR)

ISO 8859-7(Latin/Greek)

ISO Latin 1T(Turkish)

Bulgaria(Bulgaria)

PC 774

Estonia

ISO 8859-2(ISO Latin 2)

PC 866 LAT

PC 866 UKR

EPSON Roman

EPSON Courier

supported supported

supported supported

EPSON Roman

PC APTEC(Arabic)

PC 708(Arabic)

PC 720(Arabic)

PC AR864(Arabic)

Hebrew 7

Hebrew 8

PC 862(Hebrew)

*

*

*

EPSON Roman

not supported

EPSON Roman

NOTE: (*) Do not describe in manual. These character tables can’t select in the

Default setting mode.

PRODUCT DESCRIPTION SPECIFICATIONS 12

Page 13

EPSON Stylus COLOR C70/C80 Revision A

1.2.3 Paper Feeding

Feeding Method

Friction feed with ASF

Paper Path

Cut-sheet ASF (Top entry Front out)

Feed Speed

59.994 mm/sec (2.36 inch/sec) (Normal, continuous feed)

114.3 mm/sec (4.5 inch/sec) (Fast, continuous feed)

1.2.4 Input Data Buffer

(Stylus COLOR C70)

32KB

(Stylus COLOR C80)

256KB

1.2.5 Electric Specification

[120V Version]

Rated Voltage: AC120V

Input Voltage Range: AC99∼132V

Rated Frequency Range: 50∼ 60Hz

Input Frequency Range: 49.5∼ 60.5Hz

Rated Current: 0.6A (max. 1.2A)

Power Consumption: Approx. T.B.D (ISO 10561 Letter Pattern)

Approx. 5W in standby mode

Energy Star compliant

Insulation Resistance: 10 M ohms min.

(between AC line and chassis, DC 500V)

Dielectric Strength: AC 1000V rms. 1 minute or AC 1200V rms. 1second

(between AC line and chassis)

[220 ∼ 240V Version]

Rated Voltage: AC220V∼240V

Input Voltage Range: AC198∼264V

Rated Frequency Range: 50∼60Hz

Input Frequency Range: 49.5∼60.5Hz

Rated Current: 0.3A (max. 0.6A)

Power Consumption: Approx. T.B.D (ISO10561 Letter Pattern)

Approx. 5W in standby mode

Energy Star compliant

Insulation Resistance: 10 M ohms min.

(between AC line and chassis, DC 500V)

Dielectric Strength: AC 1500V rms. 1 minute

(between AC line and chassis)

PRODUCT DESCRIPTION SPECIFICATIONS 13

Page 14

EPSON Stylus COLOR C70/C80 Revision A

1.2.6 Environmental Condition

Temperature

Operating: 10 to 35°C (*

Non-operating: -20 to 40°C

1 month at 40°C and 120 hours at 60°C

Humidity

Operating: 20 to 80% RH

Non-operating: 5 to 85% RH

Resistance to Shock

Operating: 1G, within 1 ms

Non-operating: 2G, within 2 ms

Resistance to Vibration

Operating: 0.15G

Non-operating: 0.50G

NOTE: (*1) with shipment container

NOTE: (*2) without condensation

3)

(*1)

(*1)

(*2, *3)

(*1, *2)

(*1)

1.2.7 Reliability

Total Print Volume: 75,000 pages (A4, Letter)

Print Head Life: 3000 million dots/nozzle

1.2.8 Safety Approvals

[120V Version]

Safety Standards: UL1950

CSA 22.2 No.950

EMI: FCC part 15 subpart B Class B

CSA C108.8 Class B

[220∼240V Version]

Safety Standards: EN60950 (VDE)

EMI: EN55022 (CISPR Pub.22) Class B

AS/NZS 3548 Class B

1.2.9 Acoustic Noise

Level: Approx. 42dB(A) (According to ISO 7779)

NOTE: (*3) Condition is as following figure

90

80

70

60

Humidity (%)

50

40

30

20

10

27

20

35

30

40

1.2.10 CE Marking

[220∼240V Version]

Low Voltage Directive 73/23/EEC: EN60950

EMC Directive 89/336/EEC: EN55022 Class B

EN55024

EN61000-3-2

EN61000-3-3

Temperature (°C)

Figure 1-2. Temperature/Humidity Range

PRODUCT DESCRIPTION SPECIFICATIONS 14

Page 15

EPSON Stylus COLOR C70/C80 Revision A

1.3 INTERFACE

The EPSON Stylus COLOR C70 / C80 provide USB and parallel interface as standard.

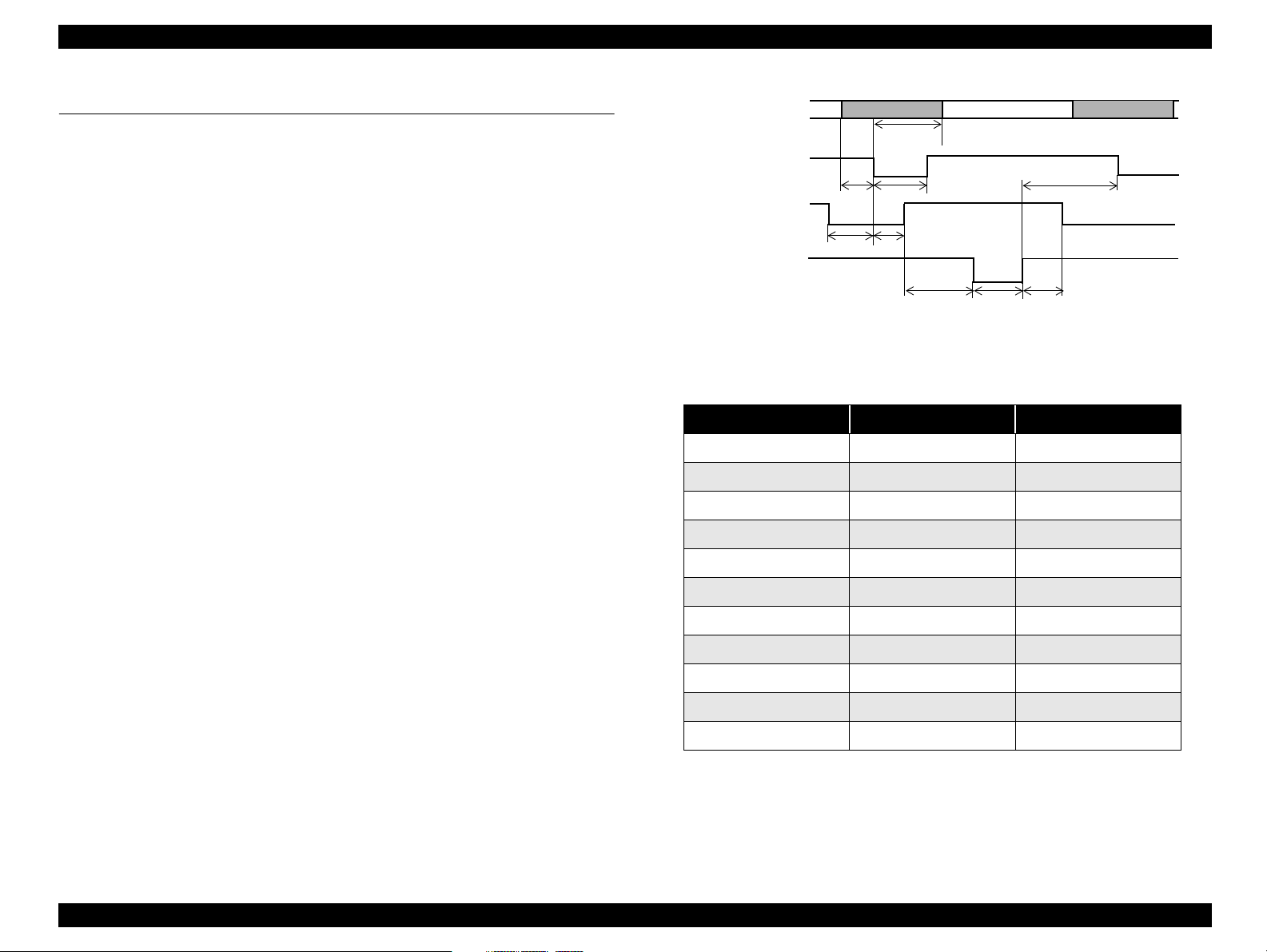

1.3.1 Parallel Interface

Transmission Mode: 8 bit parallel, IEEE-1284 compatibility mode

Synchronization: By STROBE pulse

Handshaking: By BUSY and ACKNLG signal

Signal Level: TTL compatible level

Adaptable Connector: 57-30360 (amphenol) or equivalent

BUSY signal is set high before setting either -ERROR low or PE high and held high

until all these signals return to their inactive state.

BUSY signal is at high level in the following cases.

During data entry (see Data transmission timing)

When input data buffer is full

During -INIT signal is at low level or during hardware initialization

During printer error (see -ERROR signal)

When the parallel interface is not selected

ERROR signal is at low level when the printer is in one of the following states.

Printer hardware error (fatal error)

Paper-out error

Paper-jam error

Ink-out error

Maintenance request

Double feed

DATA

data byte n

t

hold

-STROBE

t

t

setup

stb

BUSY

t

ready

t

busy

-ACKNLG

t

ack

t

t

reply

nbusy

Figure 1-3. Data Transmission Timing

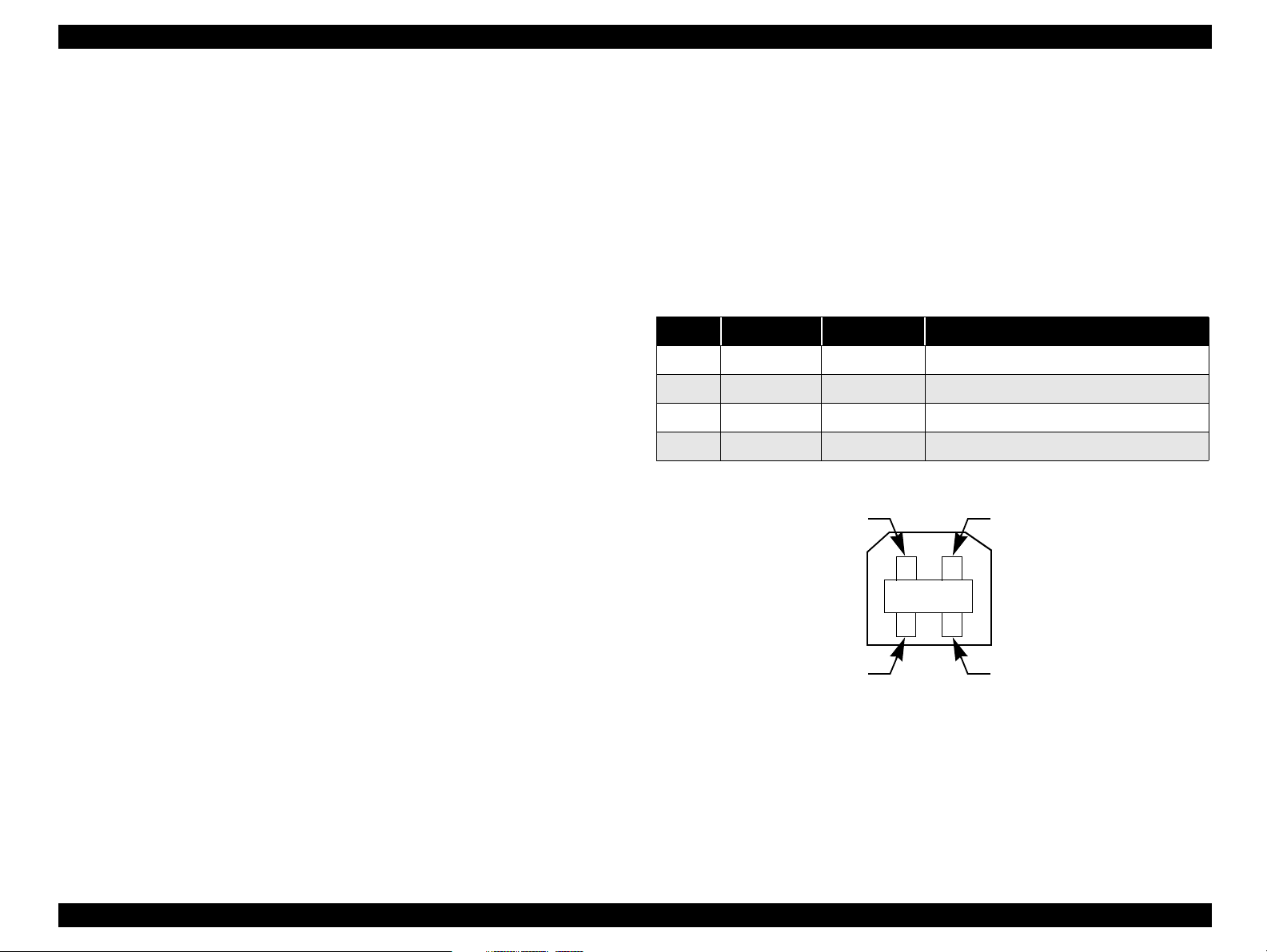

Table 1-5. Parameter

Parameter Minimum Maximum

tsetup 500ns -

thold 500ns -

tstb 500ns -

tready 0 -

tbusy - 500ns

1)

tt-out (*

2)

tt-in (*

treply 0 -

tack 500ns 10us

tnbusy 0 -

tnext 0 -

- 120ns

- 200ns

data byte n+1

t

next

PE signal is at high level during paper-out error.

NOTE: (*1) Rise and fall time of every output signal.

NOTE: (*2) Rise and fall time of every input signal.

PRODUCT DESCRIPTION INTERFACE 15

Page 16

EPSON Stylus COLOR C70/C80 Revision A

Table 1-6. Typical Time of tack

Parallel I/F Mode Typical Time of tack

High Speed 0.5us

Normal Speed 2us

Table 1-7. Signal Level: TTL Compatible (IEEE-1284 level 1 device)

Parameter Minimum Maximum Condition

VOH* - 5.5V

VOL* -0.5V -

IOH* - 0.32mA VOH = 2.4V

IOL* - 12mA VOL = 0.4V

CO - 50pF

VIH - 2.0V

VIL 0.8V -

IIH - 0.32mA VIH = 2.0V

IIL - 12mA VIL = 0.8V

CI - 50pF

NOTE: (*) A low logic level on the Logic H signal is 2.0V or less when the

printers powered off and this signal is equal or exceeding 3.0V when

the printer is powered on. The receiver shall provide an impedance

equivalent to 7.5K ohm to ground.

z

Table 1-8. Connector Pin Assignment and Signals

Pin No. Signal Name

1 -STROBE 19 In

2 DATA 0 20 In The DATA 0 through DATA 7 signals represent

3 DATA 1 21 In

Return

GND Pin

In/Out Functional Description

The strobe pulse. Read-in of data is performed at

the falling edge of this pulse.

data bits 0 to 7, respectively.

Each signal is at high level when data is logical

1 and low level when data is logical 0.

Table 1-8. Connector Pin Assignment and Signals (continued)

Pin No. Signal Name

4 DATA 2 22 In

5 DATA 3 23 In

6 DATA 4 24 In

7 DATA 5 25 In

8 DATA 6 26 In

9 DATA 7 27 In

10 -ACKNLG 28 Out

11 BUSY 29 Out

12 PE 28 Out A high signal indicates paper-out error.

13 SLCT 28 Out

14 -AFXT 30 In Not used.

31 -INIT 30 In

32 -ERROR 29 Out A low signal indicates printer error condition.

36 -SLIN 30 In Not used.

18 Logic H - Out Pulled up to +5V via 3.9 K ohm resistor.

35 +5V - Out Pulled up to +5V via 3.3K ohm resistor.

17 Chassis GND - - Chassis GND

16,33,

19-30

15,34 NC - - Not connected

GND - - Signal GND

NOTE: In/Out refers to the direction of signal flow from the printer’s point of

view.

Return

GND Pin

In/Out Functional Description

The DATA 0 through DATA 7 signals represent

data bits 0 to 7, respectively.

Each signal is at high level when data is logical

1 and low level when data is logical 0.

This signal is a negative pulse indicating that the

printer can accept data again.

A high signal indicates that the printer cannot

receive data.

Always at high level when the printer is

powered on.

The falling edge of a negative pulse or a low

signal on this line causes the printer to initialize.

Minimum 50 us pulse is necessary.

PRODUCT DESCRIPTION INTERFACE 16

Page 17

EPSON Stylus COLOR C70/C80 Revision A

1.3.2 Parallel Interface (Reserve Channel)

Transmission Mode: IEEE-1284 nibble mode

Adaptable Connector: See forward channel

Synchronization: Refer to the IEEE-1284 specification

Handshaking: Refer to the IEEE-1284 specification

Data Trans. Timing: Refer to the IEEE-1284 specification

Signal Level: IEEE-1284 level 1 device

See forward channel

Table 1-9. Connector Pin Assignment and Signals

Pin No. Signal Name

1 Host Clk 19 In Host clock signal.

2 DATA 0 20 In

3DATA 121 In

4 DATA 2 22 In

5DATA 323 In

6 DATA 4 24 In

7DATA 525 In

8 DATA 6 26 In

Return

GND Pin

In/Out Functional Description

The DATA 0 through DATA 7 signals

represent data bits 0 to 7, respectively.

Each signal is at high level when data is

logical 1 and low level when data is

logical 0.

These signals are used to transfer the

1284 extensibility request values to the

printer.

Table 1-9. Connector Pin Assignment and Signals (continued)

Pin No. Signal Name

32

36 1284-Active 30 In 1284 active signal.

18 Logic-H - Out Pulled up to +5V via 3.9K ohm resistor.

35 +5V - Out Pulled up to +5V via 3.3K ohm resistor.

17 Chassis GND - - Chassis GND

16,33,

19-30

15,34 NC - - Not connected

-DataAvail /

DataBit-0,4

GND - - Signal GND

NOTE: In/Out refers to the direction of signal flow from the printer’s point of

view.

Return

GND Pin

29 Out

In/Out Functional Description

Data available signal and reverse channel

transfer data bit 0 or 4.

9DATA 727 In

10 PtrClk 28 Out Printer clock signal.

11

12

13

14 Host Busy 30 In Host busy signal.

31 -INIT 30 In Not used.

PtrBusy /

DataBit-3,7

AckDataReq

/ DataBit-2,6

Xflag /

DataBit-1,5

29 Out

28 Out

28 Out

Printer busy signal and reverse channel

transfer data bit 3 or 7.

Acknowledge data request signal and

reverse channel transfer data bit 2 or 6.

X-flag signal and reverse channel

transfer data bit 1 or 5.

PRODUCT DESCRIPTION INTERFACE 17

Page 18

EPSON Stylus COLOR C70/C80 Revision A

Extensibility Request:

The printer responds affirmatively when the extensibility request values are 00H or

04H, that mean,

00H: Request Nibble Mode Reverse Channel Transfer.

04H: Request Device ID;

Return Data Using Nibble Mode Rev Channel Transfer.

Device ID:

The printer sends the following device ID string when it is requested.

When IEEE1284.4 is enabled,

[00H] [4EH]

MFG: EPSON;

CMD: ESCPL2, BDC, D4;

MDL: STYLUS[SP]COLOR[SP]C70/C80;

CLS: PRINTER;

DES: EPSON[SP]STYLUS[SP]COLOR[SP]C70/C80;

When IEEE1284.4 is disabled,

[00H] [4BH]

MFG: EPSON;

CMD: ESCPL2, BDC;

MDL: STYLUS[SP]COLOR[SP]C70/C80;

CLS: PRINTER;

DES: EPSON[SP]STYLUS[SP]COLOR[SP]C70/C80;

1.3.3 USB Interface

Standard: Based on

“Universal Serial Bus Specifications Revision 1.0”

“Universal Serial Bus Device Class Definition

for Printing Devices Version 1.0”

Bit Rate: 12 M bps (Full Speed Device)

Data Encoding: NRZI

Adaptable Connector: USB Series B

Recommended Cable Length: 2 meters

Table 1-10. Connector Pin Assignment and Signals

Pin No. Signal Name I/O Function Description

1 VCC - Cable power. Max. power consumption is 2mA

2 -Data Bi-Directional Data

3 +Data Bi-Directional Data, pull up to +3.3 V via 1.5K ohm resistor

4 Ground - Cable ground

Pin #2

Pin #1

Pin #3

Pin #4

Figure 1-4. USB Pin Assignment

PRODUCT DESCRIPTION INTERFACE 18

Page 19

EPSON Stylus COLOR C70/C80 Revision A

Automatic Selection

1.3.4 Prevention Hosts of Data Transfer Time-out

Generally, hosts abandon data transfer to peripherals when a peripheral is in the busy

state for dozens of seconds continuously. To prevent hosts from this kind of time-out,

the printer receives data very slowly, several bytes per minute, even if the printer is in

busy state. The slowdown is started when the rest of the input buffer becomes several

hundreds of bytes. Finally the printer is in the busy state continuously when the input

buffer is full.

USB and IEEE1284.4 on the parallel interface do not require this function.

1.3.5 Interface Selection

The printer has 2 built-in interfaces: the USB and parallel interface.

These interfaces are selected automatically.

An initial state is compatible interface and starts IEEE1284.4 communication

when magic strings (1284.4 synchronous commands) are received.

On

An initial state is IEEE1284.4 communication and data that received it by the time

it is able to take synchronization by magic string (1284.4 synchronous commands)

is discarded.

Off

An initial state is compatible interface and never starts IEEE1284.4

communication even if magic strings (1284.4 synchronous commands) are

received.

Automatic Selection

In this automatic interface selection mode, the printer is initialized to the idle state

scanning which interface receives data when it is powered on. Then the interface

that receives data first is selected. When the host stops data transfer and the printer

is in the stand-by state for the seconds, the printer is returned to the idle state. As

long as the host sends data or the printer interface is busy state, the selected

interface is let as it is.

The changes to other Interface are prohibited during Duplex printing.

Interface State and Interface Selection

When the parallel interface is not selected, the interface got into the busy state.

When the printer is initialized or returned to the idle state, the parallel interface got

into the ready state. Caution that the interrupt signal such as the -INIT signal on

the parallel interface is not effective while that interface is not selected.

1.3.6 IEEE1284.4 Protocol

The packet protocol described by IEEE1284.4 standard allows a device to carry on

multiple exchanges or conversations which contain data and/or control information

with another device at the same time across a single point-to-point link. The protocol is

not, however, a device control language. It does provide basic transport-level flow

control and multiplexing services. The multiplexed logical channels are independent of

each other and blocking of one has no effect on the others. The protocol operate over

IEEE1284.

PRODUCT DESCRIPTION INTERFACE 19

Page 20

EPSON Stylus COLOR C70/C80 Revision A

1.3.7 Printer Language and Emulation

Printer Language: (Stylus COLOR C70)

EPSON ESC/P2 expanded raster graphics

EPSON Remote

(Stylus COLOR C80)

ESC/P2 and expanded raster graphics code

EPSON Remote command

1.3.7.1 Control codes

ESC/P2 control codes

Table 1-11. ESC/P2 control codes (Stylus COLOR C70)

General operation Initialize Printer ESC @

Paper feeding

Table 1-12. ESP/P2 control codes (Stylus COLOR C80)

General operation

Paper feeding

Form Feed

Line Feed

Carriage Return

Initialize Printer

Unidirectional Printing

CSF Mode Control

Form Feed

Line Feed

Line Spacing

Carriage Return

FF

LF

CR

ESC @

ESC U

ESC EM

FF

LF

ESC 0, ESC 2, ESC 3, ESC +

CR

Table 1-12. ESP/P2 control codes (Stylus COLOR C80) (continued)

Typeface

Pitch and Point

Font selection

Font enhancement

Spacing

Character handling

Bit image Bit Image ESC

Color Printing Color ESC r (Black )

EEPROM control EEPROM control ESC |

Pitch

Italic font

Bold Font

Master Select

Double-Width

Condensed

Double-height

Double-Strike

Super / Subscript

Underline

Line / Score

Character Style

Intercharacter Space

HMI

Define Unit

Character Table

International Character

User-Defined Characters

Upper Control Codes

Print Data as characters

ESC k, ESC x

ESC X

ESC P, ESC M, ESC g, ESC p

ESC 4, ESC 5

ESC E, ESC F

ESC !

ESC W, DC4, SO

DC2, SI

ESC w

ESC G, ESC H

ESC T, ESC S

ESC ESC(ESC q

ESC Space

ESC c

ESC (U

ESC t, ESC (t

ESC R

ESC %, ESC &, ESC :

ESC 6, ESC 7

ESC (^

Page format

Print position

motion

Page Length

Left / Right Margin

Top / Bottom Margin

Horizontal Print Position

Vertical Print Position

Tab Horizontally

Tab Vertically

Advance paper

ESC (C, ESC C, ESC C0, ESC (S

ESC Q, ESC I

ESC (c, ESC N, ESC O

ESC $, ESC ¥

ESC (V, ESC (v

ESC D, HT

ESC B, VT

ESC J

PRODUCT DESCRIPTION INTERFACE 20

Page 21

EPSON Stylus COLOR C70/C80 Revision A

Control codes for graphics mode

1.3.7.2 EPSON D4 control channel commands

Table 1-13. Control codes for graphics mode

Initialize Printer

General operation

Paper feeding

Page format

Print position motion

Spacing Define Unit ESC (U

Graphics

Printing mode Printing mode ESC (K

Color Printing Color ESC r, ESC (r

Unidirectional Printing

CSF Mode Control

Form Feed

Line Feed

Line Spacing

Carriage Return

Page Length

Top / Bottom Margin

Paper size

Horizontal Print Position

Vertical Print Position

Graphics Mode

Raster Graphics

Dot size control

Print a Image

Microweave control

(Stylus COLOR C80 )

ESC @

ESC U

ESC EM

FF

LF

ESC +

CR

ESC (C

ESC (c

ESC (S

ESC $, ESC ¥, ESC ($, ESC (/

ESC (V, ESC (v

ESC (G

ESC ., ESC (D, ESC i

ESC (e

ESC ACK

ESC (i

The details of each command refer to 1284.4 control command specifications (DS-716).

Command List

Table 1-14. Command List

Contents Command m1

Reply Device ID di -

Reply Status string st -

Reply Cartridge

Position

Reply Ink Cartridge

condition

Exchange Ink

Cartridge

Execute Cleaning ch 0x01

Print Nozzle check

pattern

Terminate Ink-

exchange Sequence

Reply CSIC

Information

Set Printer timer

(Stylus COLOR C70 )

cx -

cs 0x00, 0x01

xi 0x01, 0x80

nc -

ei 0x00

ii 0x01, 0x02, 0x03, 0x04

ti m1

(*1)

Clear Paper Out

Error

Clear Paper Jam

Error

Reply Ink-exchange

flag

Initialize Printer rs 0x01

Reply number of

printable sheet

pe 0x01

pj 0x01

ex Com Num = 0x19

ir 0x80

PRODUCT DESCRIPTION INTERFACE 21

Page 22

EPSON Stylus COLOR C70/C80 Revision A

Status Codes

NOTE: (*1) parameters indicate a time (Stylus COLOR C70 only)

Parameter Mean Note

m1, m2, year year = m2 x 256 +m1

m3 month 1<= m3 <= 12

m4 day 1 <= m4 <= 31

m5 hour 0 <= m5 <= 24

m6 minute 0 <= m6 <= 60

m7 second 0 <= m7 <= 60

Reply Printer State

The printer sends one of six string shown below that indicates current printer state

periodically (set by a BDC-PS command. by default, 2 seconds.).

Format of reply strings:

@BDC [SP] ST [CR] [LF]

ST:<Status Code>;

ER:<Error Code>;

[WR:<Warning Code>[,<Warning Code>]...;]

IQ:<nn1><nn2><nn3><nn4>;

RV;<n>;

AI;CW:02<KK><CC><MM><YY>,MI:<mm>;

[TC:<TTTT>;]

INK:1101,3202,4304,5408;IG:0108NA;

[FF]

The parameter <Status Code>is two bytes of ASCII codes that indicates

printer status.

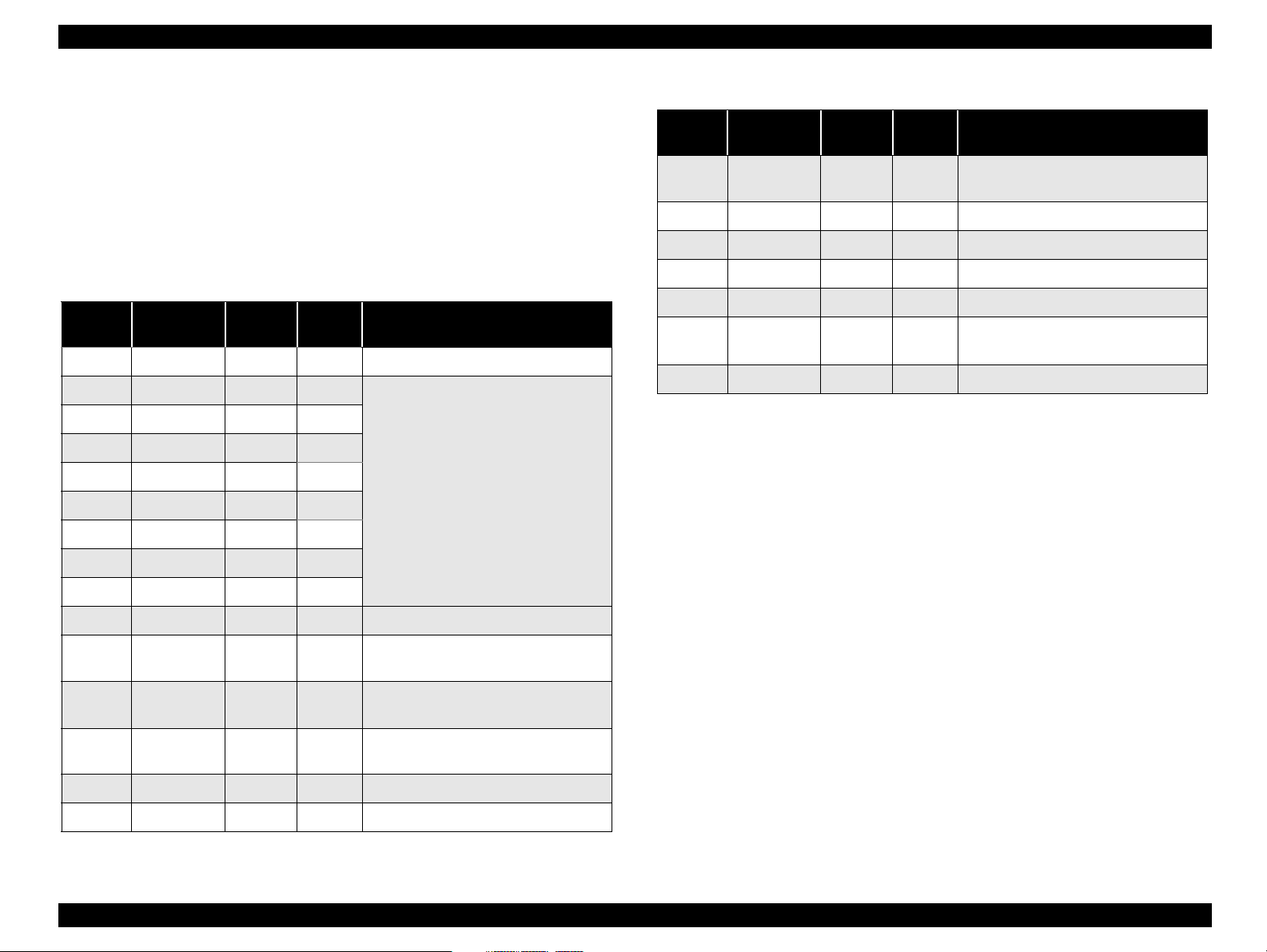

Table 1-15. Status Codes

Status Status code Priority

Error “00“ 1

Self-test “01“ 1

Busy (buffer full) “02“ 4

Wait (printing) “03“ 5

Idle “04“ 6

Cleaning/fill up “07“ 2

Before Initialize fill up “08“ 1

Error Codes

Theparameter <Error Code> is two bytes of ASCII codes that indicates

following errors of a printer.

Table 1-16. Error Codes

Error Code Printer State

“00“ Fatal Error

“01“ I/F not select Error

“04“ Paper jam Error

“05“ Ink Out Error

“06“ Paper Out Error

“10“ Maintenance request

“12“ Double Feed Error

PRODUCT DESCRIPTION INTERFACE 22

Page 23

EPSON Stylus COLOR C70/C80 Revision A

Quantity of ink

The parameter <nn1>, <nn2>, <nn3>, <nn4> are two bytes ASCII codes that

indicate quantity of black ink, cyan ink, magenta ink and yellow ink

respectively.

If the ink cartridge is not inserted, <nnx> indicates “NA”.

The unit of these parameters is percentage in hex-decimal.

Warning Codes

The parameter <Warning Code> is two bytes of ASCII codes that indicates

printer status

Table 1-17. Warning Codes

WR Ink state

“10“ Black ink low

“11“ Cyan ink low

“12“ Magenta ink low

“13“ Yellow ink low

Firmware revision

The parameter <n> is one bytes ASCII codes that indicate printer firmware

revision.

Actuator information

The parameter <KK>, <CC>, <MM>, <YY> are two bytes ASCII codes that

indicate ink weight rank ID of black ink, Cyan ink, magenta ink and yellow

ink respectively.

The parameter <mm> is two bytes ASCII codes that indicate SelectMicroweave ID to determine the feed length of Microweave printings.

Cleaning time information

The parameter <TTTT> is four bytes ASCII codes that indicate total time of

cleaning or charging sequences in second unit.

This character strings is displayed only during cleaning or charging. (Status

code of “07”)

MIB information

INK parameter shows the ink cartridge information for MIB.

IG parameter shows the auto sheet feeder information for MIB.

PRODUCT DESCRIPTION INTERFACE 23

Page 24

EPSON Stylus COLOR C70/C80 Revision A

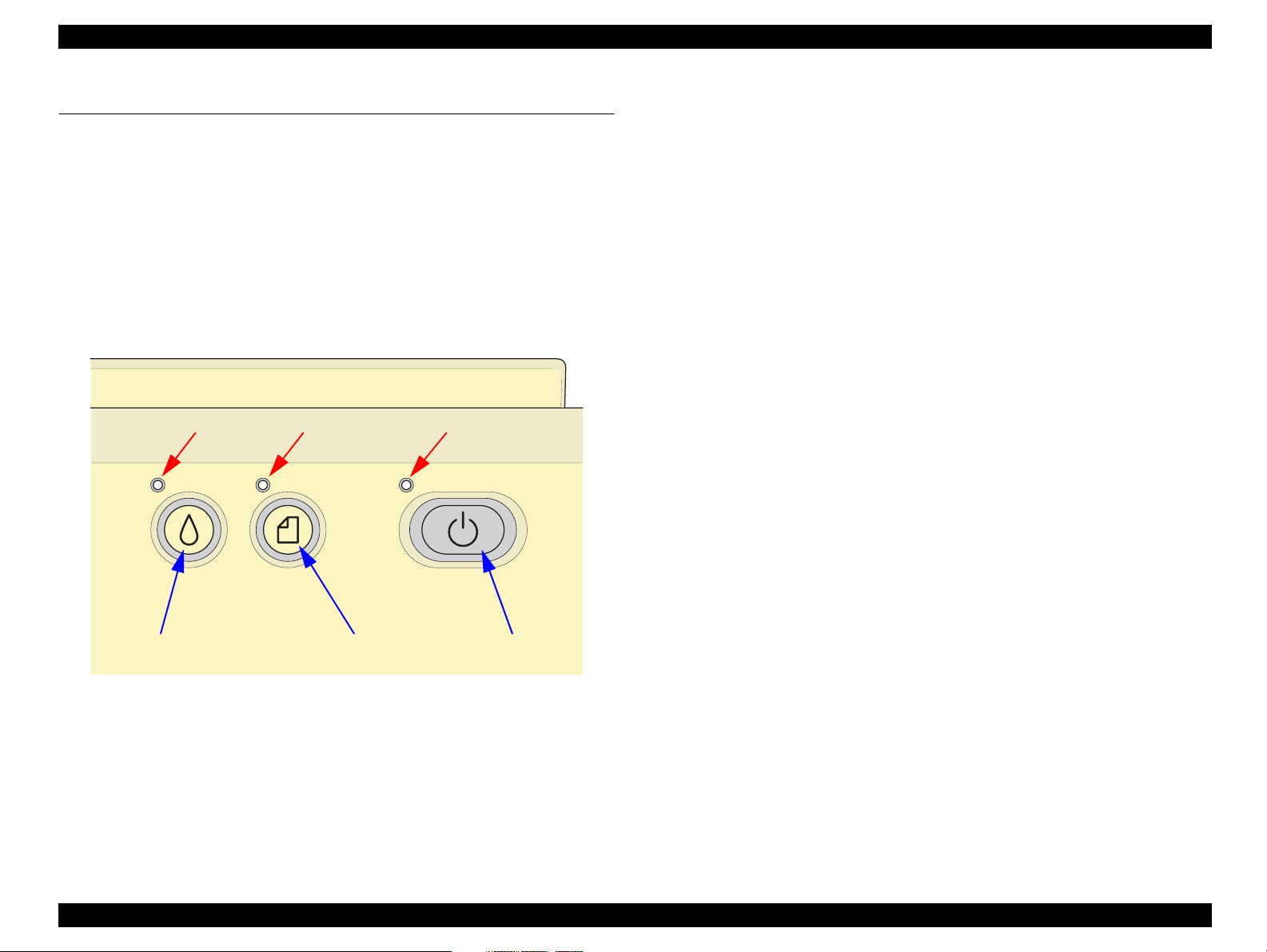

1.4 OPERATOR CONTROLS

1.4.1 Operate Switch

Operate switch is located on the control panel.

1.4.2 Control Panel

1.4.2.1 Switches

There are 2 non-lock type push switches, 1 lock type push switch and 3 LED.

123

1.4.2.2 Indicators

(1) Power

Lights when the operate switch is “ON” and AC power is supplied.

(2) Paper Out

Lights during the paper-out condition, and blinks during the paper-jam condition.

(3) Ink Out

Lights during no ink condition, and blinks during the ink low condition.

Ink Button Paper Button Power Button

Figure 1-5. Control Panel

PRODUCT DESCRIPTION OPERATOR CONTROLS 24

Page 25

EPSON Stylus COLOR C70/C80 Revision A

1.4.3 Panel Functions

Table 1-18. Panel Functions(Stylus COLOR C70)

Switch Function

Load/Eject

Cleaning

Cleaning

(Pushing for 2 seconds

NOTE: (*1) 3 seconds is required at the User’s manual.

NOTE: (*2) This function is not available in printing status.

Table 1-19. Panel Functions with Power On(Stylus COLOR C70)

• Loads or Ejects the Paper.

• When carriage is on the Ink check position, move carriage to

next ink check position or cartridge change position.

• When carriage is on the ink cartridge change position, return

carriage from Ink Cartridge change position.

• In the condition of ‘Double Feed Error’, Returning from error

condition printing is restarted.

• Starts the Ink Cartridge change sequence.

Move the carriage to cartridge change position.

• When carriage is on the ink change position, move carriage to

next ink check position or cartridge change position.

• When carriage is on the ink change position, return carriage from

ink cartridge change position.

• Starts the cleaning of head.

• In the condition of ‘Ink Low’ or ‘Ink Out’ or ‘No Ink Cartridge’,

*1)

starts the ink cartridge change sequence.

(*2)

(*2)

Table 1-20. Panel Functions with Power On(Stylus COLOR C80)

Switch Pressing with Power on Function

Paper

Ink

Paper

+

Ink

• Start status printings. *

• Enters the user setting mode.

• Enters the particular setting mode (Service use only).

To enter the particular settings mode, it is necessary to push

following switch while Paper Out LED is blinking.

(It blinks about 5 seconds.)

(*1)

(*3)

NOTE: (*) Status printings prints firmware version, ink counter and nozzle

check patterns.

NOTE: (*1) According to the content of 1 BH of EEPROM, one of following

actions is carried out.

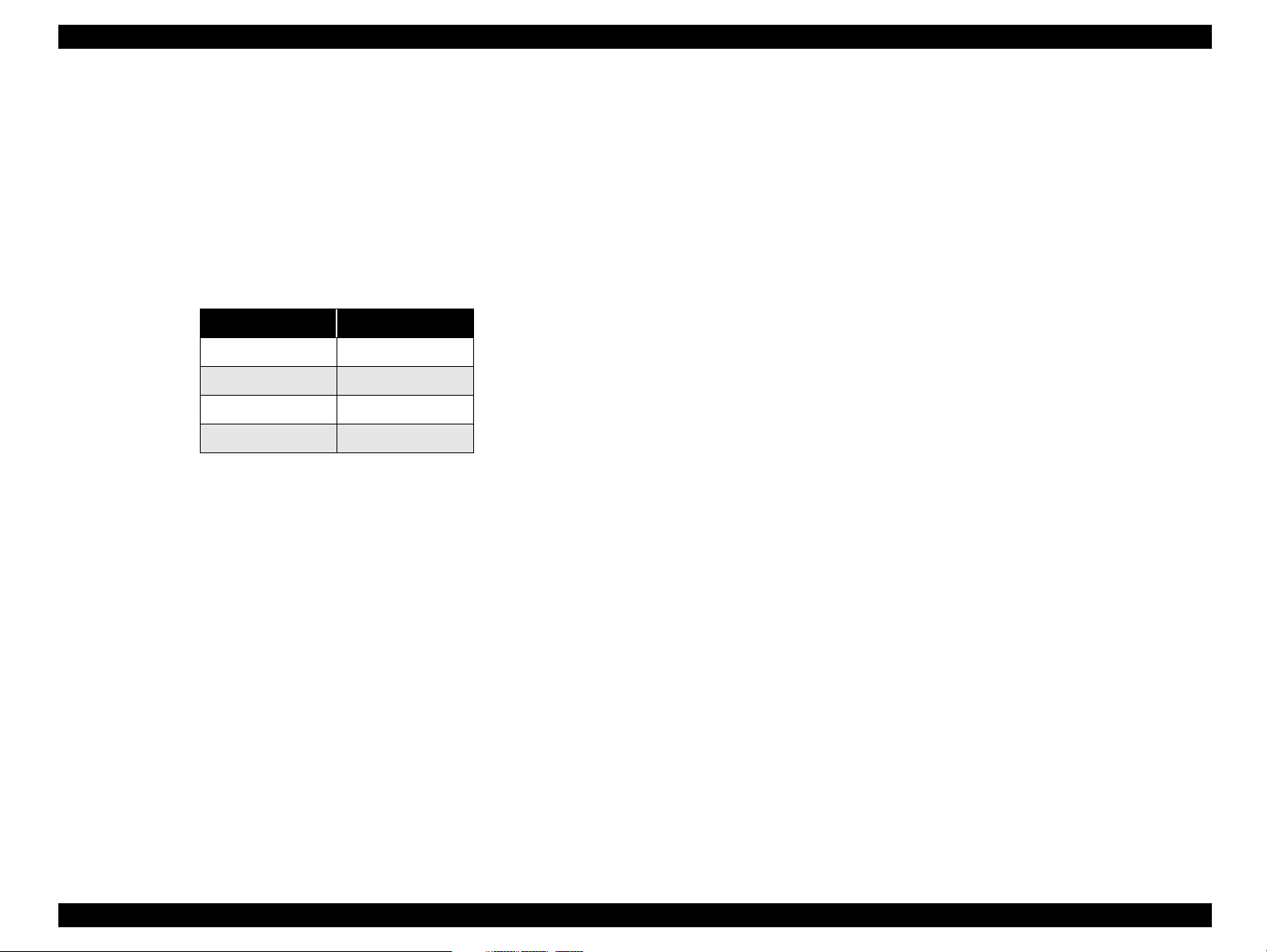

Table 1-21. The Content of 1 BH of EEPROM

Content of 1BH of EEPROM,

[bit 7][bit 6]

00

11

01

10

• Print firmware version, ink counter, selected code

page and nozzle check pattern

• Start hex-dump printing

• Start self test printing

Action

Switch Pressing with Power on Function

Load/Eject

Load/Eject

+

Cleaning

• Start status printings.*

• Enters the particular settings mode. (Service use only.)

To enter the particular settings mode, it is necessary to push

following switch while Paper Out LED is blinking. (It blinks about

5 seconds.)

(*3)

(*1)

Table 1-22. User settings mode (Stylus COLOR C80 only)

Switch Function

Paper

Ink

• Enters the default setting mode.

• Enters the print head alignment mode.

(*1)

(*2)

NOTE: (*1) Refer to 1.4.5.1 Default setting.

NOTE: (*2) Refer to 1.4.5.2 Print head alignment.

PRODUCT DESCRIPTION OPERATOR CONTROLS 25

Page 26

EPSON Stylus COLOR C70/C80 Revision A

Table 1-23. Particular settings mode (Stylus COLOR C70)

Switch Function

Load/Eject

Cleaning

(Pushing for 10

seconds )

• Initialize EEPROM.

• Reset the ink overflow counter in EEPROM.

(*3)

Table 1-24. Particular settings mode (Stylus COLOR C80)

Switch Function

Paper

Ink

(Pushing for 10

seconds )

• Initialize EEPROM

• Reset the ink overflow counter in EEPROM.

NOTE: (*3) Refer to Chapter 7 EEPROM map.

(*3)

and rest timer IC.

(*3)

(*3)

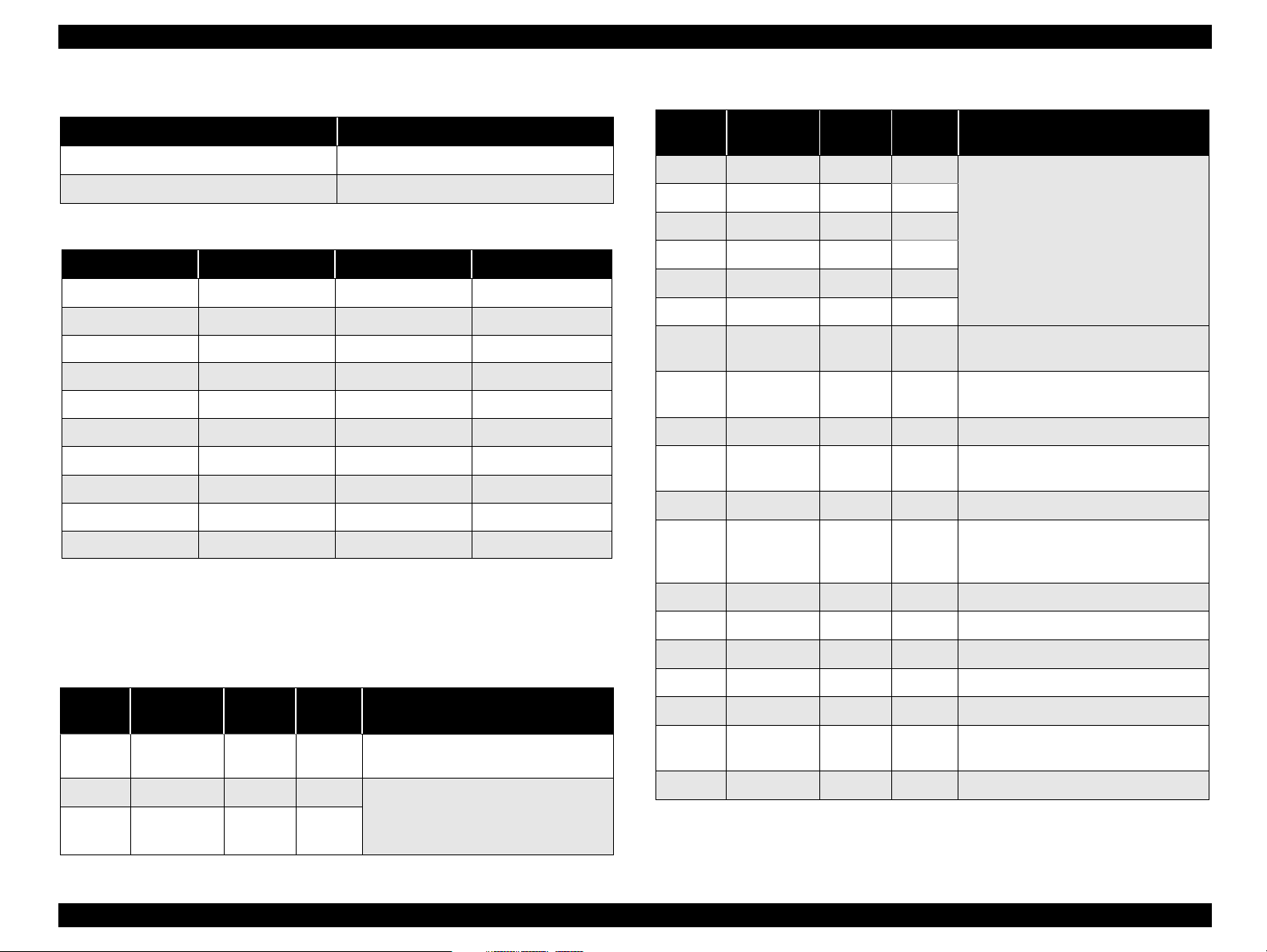

1.4.4 Printer Condition and Panel Status

Table 1-25. Printer Condition and LED Status

Printer Status

Power ON condition On - - 10

Ink sequence Blink - - 6

Ink Cartridge change mode Blink - - 5

Data processing Blink - - 8

Paper Out - - On 4

Double feed - - On 4

Paper jam condition - Off Blink 3

No ink cartridge or ink end - On - 7

Ink level low - Blink - 9

Enter EEPROM and Timer

IC reset

Maintenance request Blink Blink Blink 2

Fatal error Blink On Blink 1

Power Ink Out Paper Out

- On On -

Indicators

Priority

NOTE: (-) Don’t care.

The reason why possible causes of paper out and double feed errors are listed together

is because double feeding during duplex printing can cause problems with page

numbering and render the whole printing job useless, so that if it is judged that the

paper is longer than the normal length, the current page is fully ejected, and then a

paper out error is indicated straight away to prompt the customer to reset the paper.

Furthermore, it is also assumed that such double-feed errors will result in the paper

running out before the last page or the last few pages are printed, and so double feed

and paper out errors are handled in the same way. This is considered to be a refinement

of conventional paper jam detection.

PRODUCT DESCRIPTION OPERATOR CONTROLS 26

Page 27

EPSON Stylus COLOR C70/C80 Revision A

1.4.5 Printer setting mode (Stylus COLOR C80 only)

When turning the printer on with pushing the Cleaning switch, the Paper Out LED

starts blinking. Then, to pushing the Load /Eject switch again while the Paper Out LED

is blinking, or no switch pushing while the Paper Out LED is blinking, the printer

enters the Default setting mode.

To pushing the Cleaning switch while the Paper Out LED is blinking, the printer enters

the Print head alignment mode.

1.4.5.1 Default setting mode

There are some parameters that can be changed by users and will be referred at the time

of initialization of the printer.

Setting method

(a)Press Load/Eject button.

The method of selecting language for ‘Usage of this mode’ is printed.

(b)Select language for ‘Usage of this mode’ by Cleaning button.

Paper Out LED, Ink Out LED and Power LED show the language for ‘Usage of this

mode’ that is currently selected. The selection will be advanced one by one as the

button is pressed and the On/Off/Blink of those three LEDs will also be changed

according to the selection.

(c)Press Load/Eject button.

The current setting and the ‘Usage of this mode’ by selected language will be printed

on the paper set in the paper path at that time.

(d)Select menu by Cleaning button.

Paper Out LED, Ink Out LED and Power LED show the menu which is selected at

that time. The selection will be advanced one by one as the button is pressed and the

combination of those three LEDs status of On/Off/Blink/2-Blinks will be changed

according to the selection.

(e)When Load/Eject button is pressed, Printer changes the indication to the setting value

of the selected menu.

Paper Out LED , Ink Out LED and Power LED show the current setting value.

(f)Select setting value by Load/Eject button.

Paper Out LED, Ink Out LED and Power LED show that menu’s value by status of

On/Off/Blink/2-Blinks.

That value can be changed by pressing Load/Eject button and the LEDs status of On/

Off/Blink/2-Blinks will be changed as the button is pressed.

(g)When Cleaning button is pressed, Printer memorize the setting value, and changes

the indication to the main menu.

Paper Out LED, Ink Out LED and Power LED show the current menu setting.

(h)Repeat (d) to (g)

The menu selection will return to the first menu after the last menu selection is over.

(i)Turn the printer off

The setting is stored into non-volatile memory.

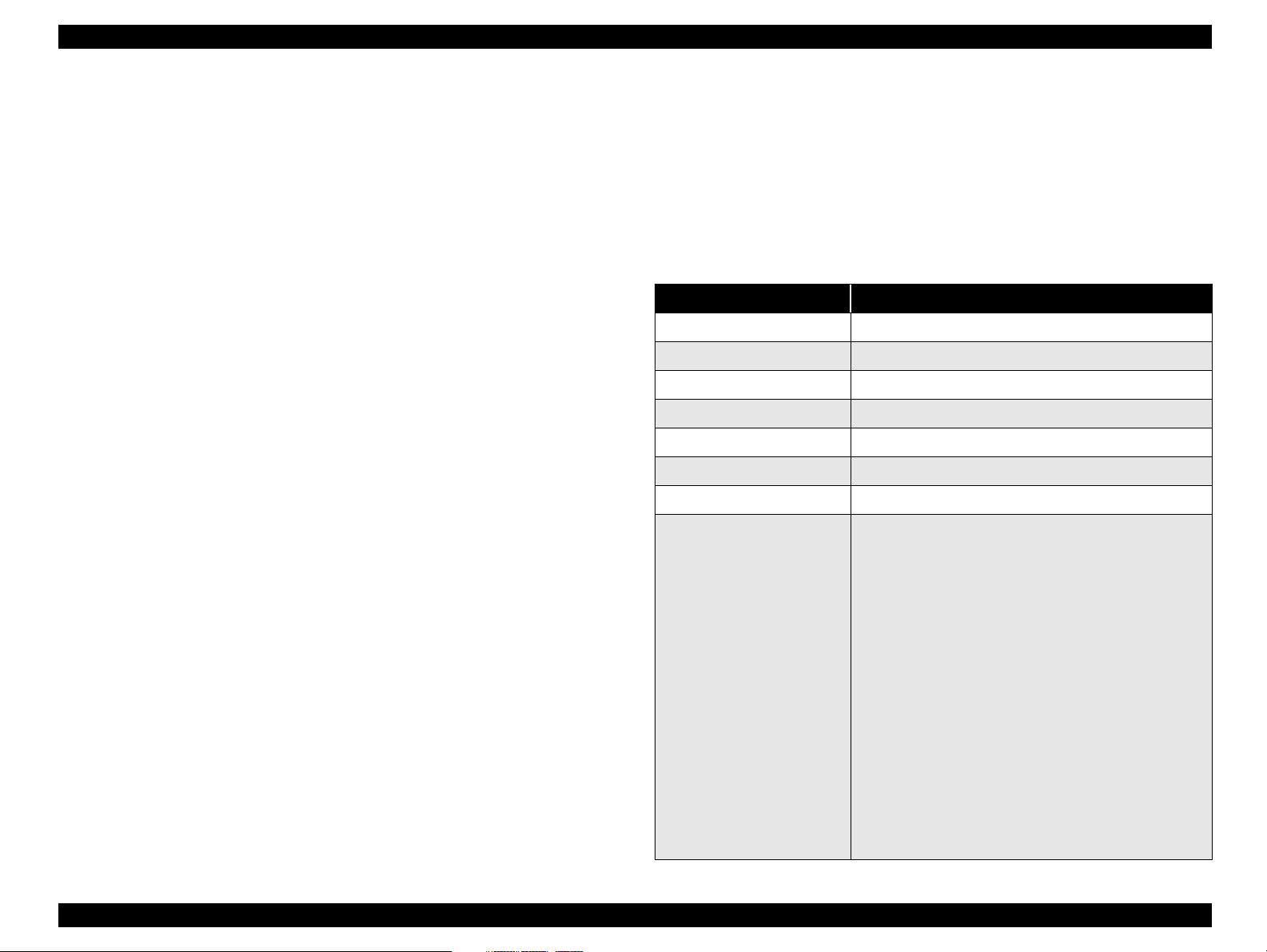

Table 1-26. Setting Menu

Menu Setting

Font Roman / Courier / Draft

Print direction Auto / Bi-D / Uni-D

Loading Position 3 mm / 8.5 mm / Others

Parallel I/F transfer rate Fast / Normal

Auto line feed Off / On

0 slash

Pitch 10 cpi, 12 cpi, 15 cpi, 17 cpi, 20 cpi, Proportional

Italic USA, Italic France, PC 858.

Italic Germany, Italic U.K, ISO 8859-15,

Italic Denmark, Italic Sweden, PC 863,

Italic Italy, Italic Spain, PC 861,

PC 437, PC 437 Greek, PC 771,

PC 850, PC 853,

PC 855, PC 852,

PC 857, PC 866,

PC 869, MAZOWIA,

Character tables

Code MJK. ISO 8859-7,

ISO Latin 1T, Bulgaria,

PC 774, Estonia,

ISO 8859-2, PC 866 LAT,

PC 860, PC 861,

PC 865, PC 866 UKR,

PC AR864, PC APTEC,

PC 708, PC 720,

BRASCII, Abicomp, Roman 8

ISO Latin1

0 / ø

PRODUCT DESCRIPTION OPERATOR CONTROLS 27

Page 28

EPSON Stylus COLOR C70/C80 Revision A

1.4.5.2 Print head alignment mode

Some alignment can be adjusted by users.

Alignment method

(a) Press Cleaning button.

The method of selecting language for ‘Usage of this mode’ is printed.

(b) Select language for ‘Usage of this mode’ by Cleaning button.

Paper Out LED, Ink Out LED and Power LED show the language for ‘Usage of this

mode’ that is currently selected. The selection will be advanced one by one as the

button is pressed and the On/Off/Blink of those three LEDs will also be changed

according to the selection.

(c) Press Load/Eject button.

Printer prints the instruction sheets on how to adjust the printer.

(d) Look at the tests printed along with the instruction and press the Cleaning button

until the panel lights indicate the appropriate test number.

(e) Press Load/Eject button. Then, printer prints the test pattern.

(f) Look at the test patterns on the new printout and press the Load/Eject button until

the panel lights indicate the test pattern that is most closely aligned.

(g) Press the Cleaning button.

(h) Follow step (d) to step (g) as many times as needed to properly align all the test

patterns on the printouts.

(i) Turn the printer off.

1.4.6 Printer Initialization

There are three kinds of initialization method.

1. Power-on Initialization

This printer is initialized when turning the printer power on, or printer recognized

the cold-reset command (remote RS command).

When printer is initialized, following action is performed:

(a) Initializes printer mechanism.

(b) Clears input data buffer.

(c) Clears print buffer.

(d) Sets default values.

2. Operator Initialization

This printer is initialized when turning the printer power on again within 10

seconds from last power off, or printer recognized the -INIT signal (negative

pulse) of parallel interface.

When printer is initialized, following action is performed:

(a) Cap the printer head.

(b) Eject a paper.

(c) Clears input data buffer.

(d) Clears print buffer.

(e) Sets default values.

3. Software Initialization

The ESC@ command also initialize the printer.

When printer is initialized, following action is performed:

(a) Clears print buffer.

(b) Sets default values.

4. Power-on initialization except I/F

The printer recognized the IEEE 1284.4 “rs” command.

When printer is initialized, following action is performed.

(a) Initializes printer mechanism.

(b) Clears input data buffer.

(c) Clears print buffer.

(d) Sets default values except I/F.

PRODUCT DESCRIPTION OPERATOR CONTROLS 28

Page 29

EPSON Stylus COLOR C70/C80 Revision A

1.4.7 Errors

Ink Out

When the printer runs out the most part of the ink of any color, it warns ink-low

and keeps printing. When the printer runs out the whole ink of any one color, it

stops printing and indicates ink-out error. User is requested to install a new inkcartridge in this state. An ink-cartridge once taken out should never be used again.

Re-installation of the cartridge not filled fully upsets the ink level detection and

may cause a serious problem in the print head as a result.

Paper Out

When printer fails to load a sheet, it goes paper out error.

Paper Jam

When printer fails to eject a sheet, it goes a paper jam error.

No Ink-Cartridge

When printer detects that ink-cartridge comes off, it goes this error mode.

Maintenance Request

When the total quantity of ink wasted through the cleanings and flushing is

reaches to the limit, printer indicates this error and stops. The absorber in the

printer enclosure is needed to be replaced with new one by service person.

Fatal Errors

Carriage control error or CG access error.

Double Feed

When printer fails to load a sheet, it goes Double feed error.

PRODUCT DESCRIPTION OPERATOR CONTROLS 29

Page 30

EPSON Stylus COLOR C70/C80 Revision A

1.5 PAPER

1.5.1 Paper Handling

Do not perform reverse feed more than 9.5 mm (0.38”).

1.5.2 Paper Specification

1.5.2.1 Cut Sheet

Table 1-27. Paper Specification (Cut Sheet)

A4: Width 210 mm x Length 297 mm)

Letter: Width 216 mm x Length 279 mm

B5: Width 182 mm x Length 257 mm

Size

Thickness 0.08mm - 0.11mm

Weight 64g/m2 (17 lb.) - 90g/m2 (24 lb.)

Quality Exclusive paper, Bond paper, PPC

Legal: Width 216 mm x Length 356 mm

Statement: Width 139.7 mm x Length 215.9 mm

Executive: Width 184.2 mm x Length 266.7 mm

Photo Paper: Width 101.6 mm x Length 152.4 mm

1.5.2.2 Envelope

Table 1-28. Paper Specification (Envelope)

No.10: Width 241 mm x Length 104.8 mm

Size

Thickness 0.16mm - 0.52mm

Weight 45g/m2 (12 lb.) - 75g/m2 (20 lb.)

Quality Bond paper, Plain paper, Air mail

NOTE: Envelope printing is only available at normal temperature.

NOTE: Keep the longer side of the envelope horizontally at setting.

DL: Width 220 mm x Length 110 mm

C6: Width 162 mm x Length 114 mm

1.5.2.3 Index Card

Table 1-29. Paper Specification (Envelope)

A6 Index Card: Width 105 mm x Length 148 mm

Size

Thickness Less than 0.23 mm

A5 Index Card: Width 148 mm x Length 210 mm

5 x 8” Index Card: Width 127 mm x Length 203 mm

10 x 8” Index Card: Width 254 mm x Length 203 mm

PRODUCT DESCRIPTION PAPER 30

Page 31

EPSON Stylus COLOR C70/C80 Revision A

1.5.2.4 EPSON special media

EPSON specifically designed media for ink jet printers

(1) Bright White ink Jet Paper

Table 1-30. Bright White ink Jet Paper

Size A4: Width 210 mm x Length 297 mm

Thickness 0.13 mm

Weight 92.5 g/m2(25 lb)

(2) 360 dpi Ink Jet Paper

Table 1-31. 360 dpi Ink Jet Paper

Size

Thickness 0.11 mm

Weight 89 g/m2 (24 lb)

(3) Matte Paper-Heavyweight

Table 1-32. Matte Paper-Heavyweight

Size

Thickness 0.23 mm

A4: Width 210 mm x Length 297 mm

Letter: Width 215.9 mm x Length 279.4 mm

A4: Width 210 mm x Length 297 mm

Letter: Width 215.9 mm x Length 279.4 mm

(5) Premium Glossy Photo Paper

Table 1-34. Premium Glossy Photo Paper

Size

Thickness

Weight

(6) Premium Semigloss Photo Paper

A4: Width 210 mm x Length 297 mm

Letter: Width 215.9 mm x Length 279.4 mm

0.27 mm

255 g/m2 (68 lb)

Table 1-35. Premium Semigloss Photo Paper

Size

Thickness

Weight

(7) Ink Jet Transparencies

A4: Width 210 mm x Length 297 mm

Letter: Width 215.9 mm x Length 279.4 mm

0.27 mm

250 g/m2 (66 lb)

Table 1-36. Bright White ink Jet Paper

Size

Thickness 0.13 mm

(8) Photo Stickers 4/16

A4: Width 210 mm x Length 297 mm

Letter: Width 215.9 mm x Length 279.4 mm

Weight 167 g/m2 (44 lb)

(4) Archival Matte Paper

Size

Thickness

Table 1-37. Photo Stickers 4/16

A6: Width 105 mm x Length 148 mm

0.19 mm

Table 1-33. Archival Matte Paper

Size

A4: Width 210 mm x Length 297 mm

Letter: Width 215.9 mm x Length 279.4 mm

(9) Iron-On Cool Peel Transfer Paper

Table 1-38. Iron-On Cool Peel Transfer Paper

Thickness 0.25 mm

Weight 189 g/m2 (50 lb)

Size

Thickness

A4: Width 210 mm x Length 297 mm

Letter: Width 215.9 mm x Length 279.4 mm

0.18 mm

PRODUCT DESCRIPTION PAPER 31

Page 32

EPSON Stylus COLOR C70/C80 Revision A

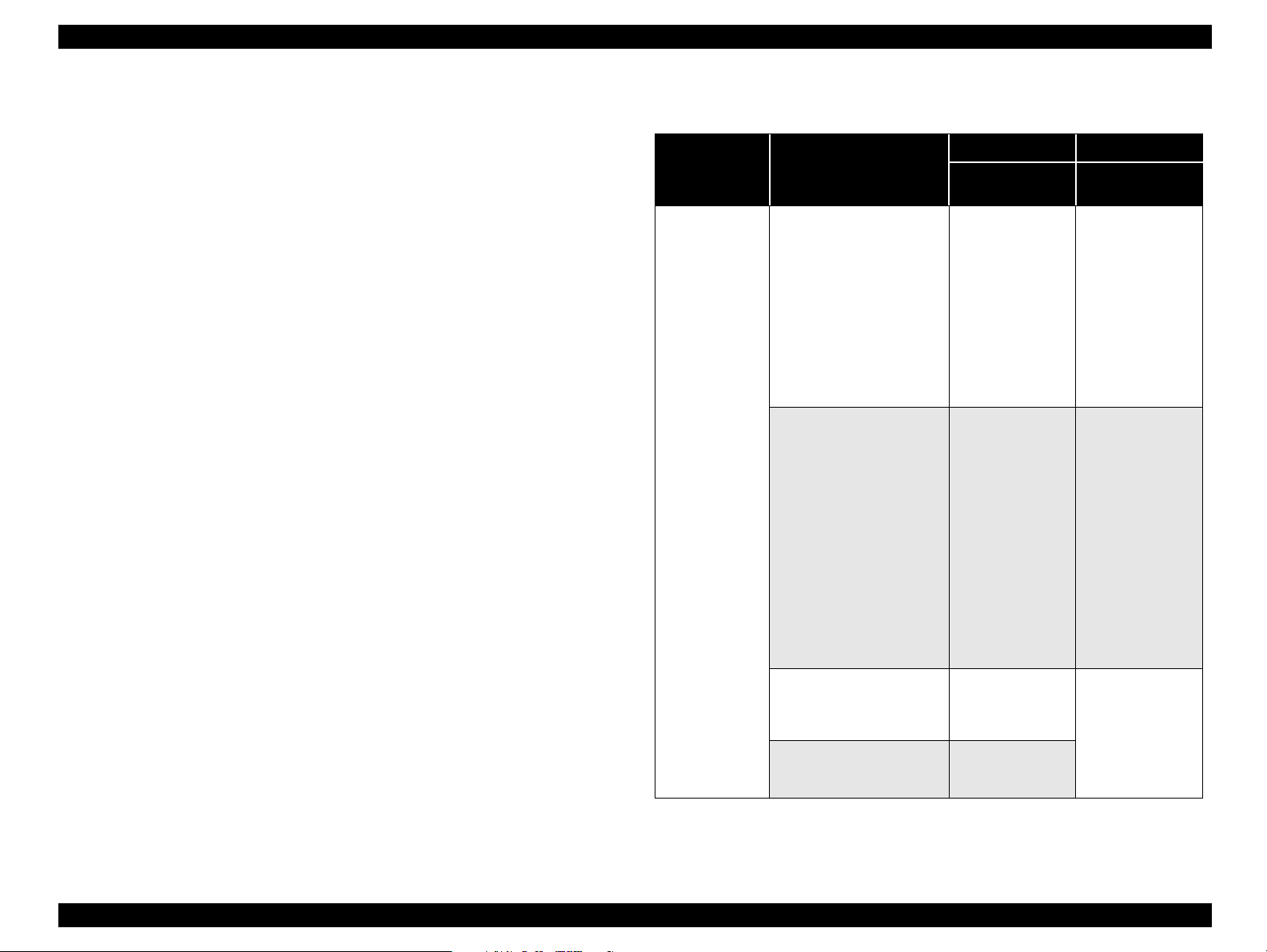

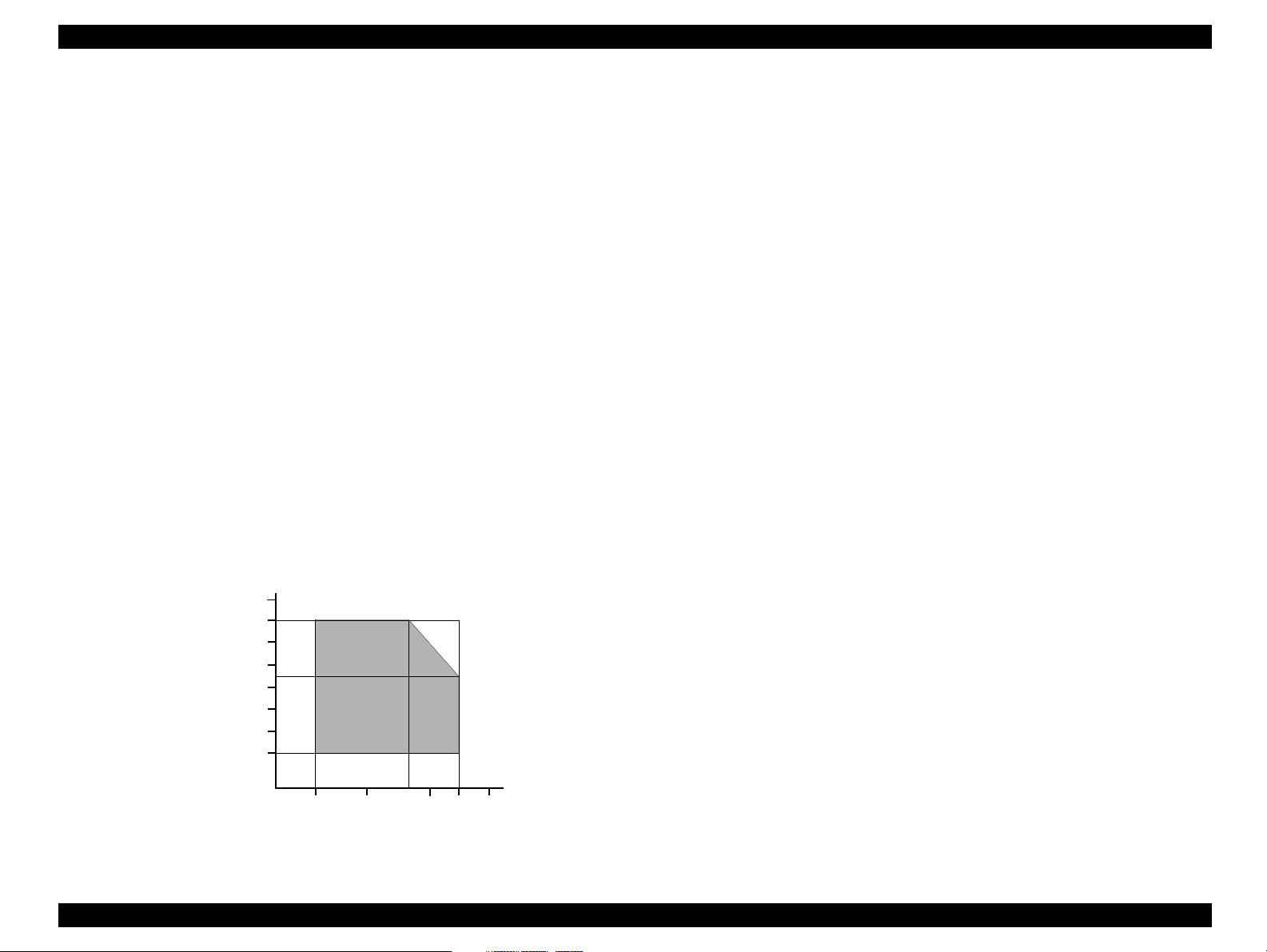

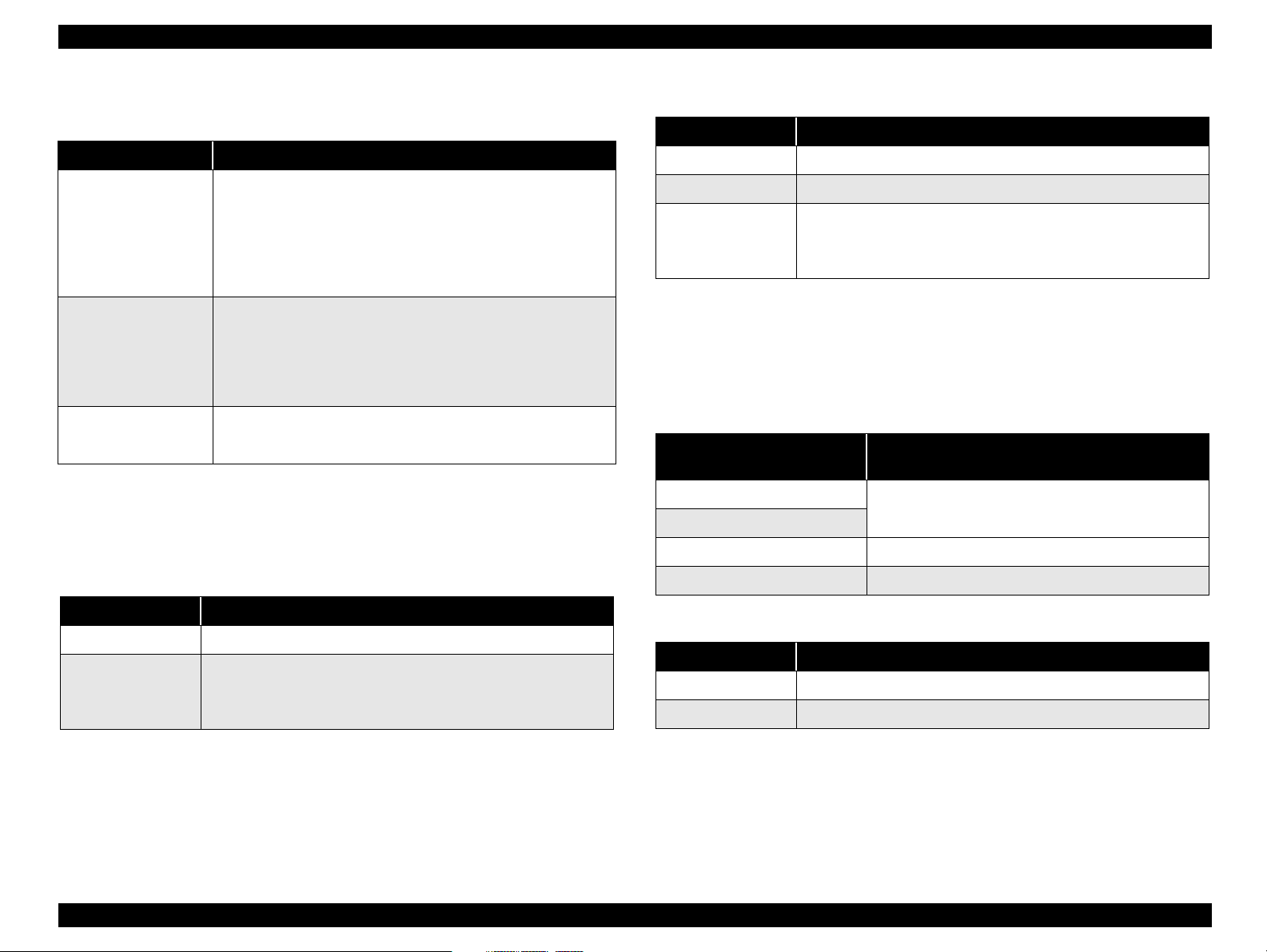

1.5.3 Printing Area

1.5.3.1 Cut Sheet

LM

PW

Printable Area

RM

TM

BM

PL

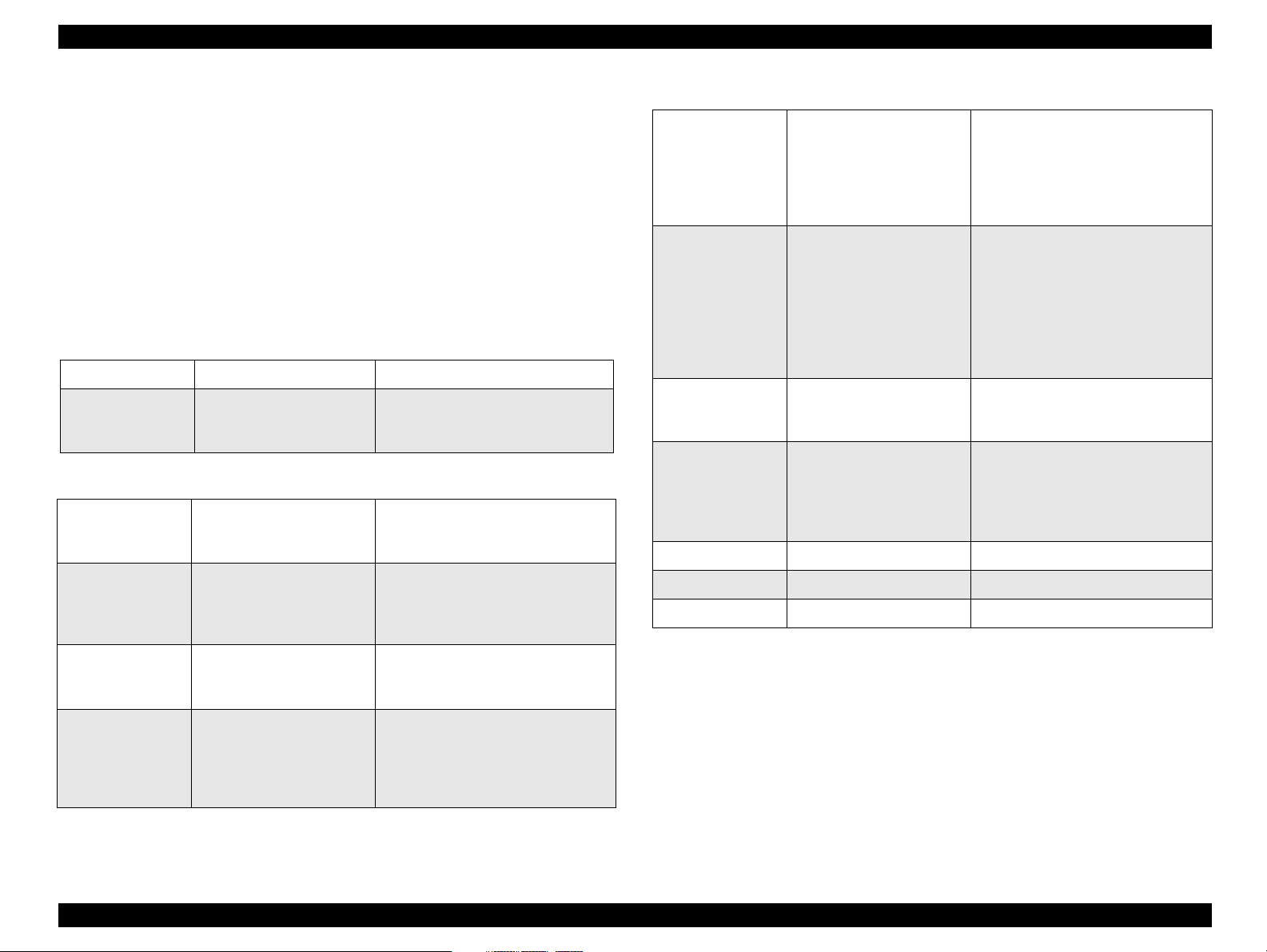

Table 1-39. Character mode

Paper Size

A4 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Letter 3 mm (0.12”) 9 mm (0.35”) 3 mm (0.12”)

B5 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Legal 3 mm (0.12”) 9 mm (0.35”) 3 mm (0.12”)

Statement 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Exclusive 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Left margin

(min.)

Right Margin

(min.)

Top Margin

(min.)

Table 1-40. Raster Graphics mode

Paper Size

A4 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Letter 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

B5 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Legal 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Statement 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Executive 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”)

Left margin

(min.)

Right Margin

(min.)

Top Margin

(min.)

Bottom Margin

(min.)

14 mm (0.54”)

14 mm (0.54”)

14 mm (0.54”)

14 mm (0.54”)

14 mm (0.54”)

14 mm (0.54”)

Bottom Margin

(min.)

14 mm (0.54”) / 3mm

(0.12”) *

14 mm (0.54”) / 3mm

(0.12”) *

14 mm (0.54”) / 3mm

(0.12”) *

14 mm (0.54”) / 3mm

(0.12”) *

14 mm (0.54”) / 3mm

(0.12”) *

14 mm (0.54”) / 3mm

(0.12”) *

NOTE: (*)Bottom margin is expanded to 3mm when paper dimension is

defined by using command, otherwise it is not expanded (14mm).

Figure 1-6. Printable Area for Cut Sheet

NOTE: From a form lower end 3 mm as for 14 mm area a printing may scramble.

NOTE: Refer to 1.5.2 PW (paper width) and PL (paper length)

PRODUCT DESCRIPTION PAPER 32

Page 33

EPSON Stylus COLOR C70/C80 Revision A

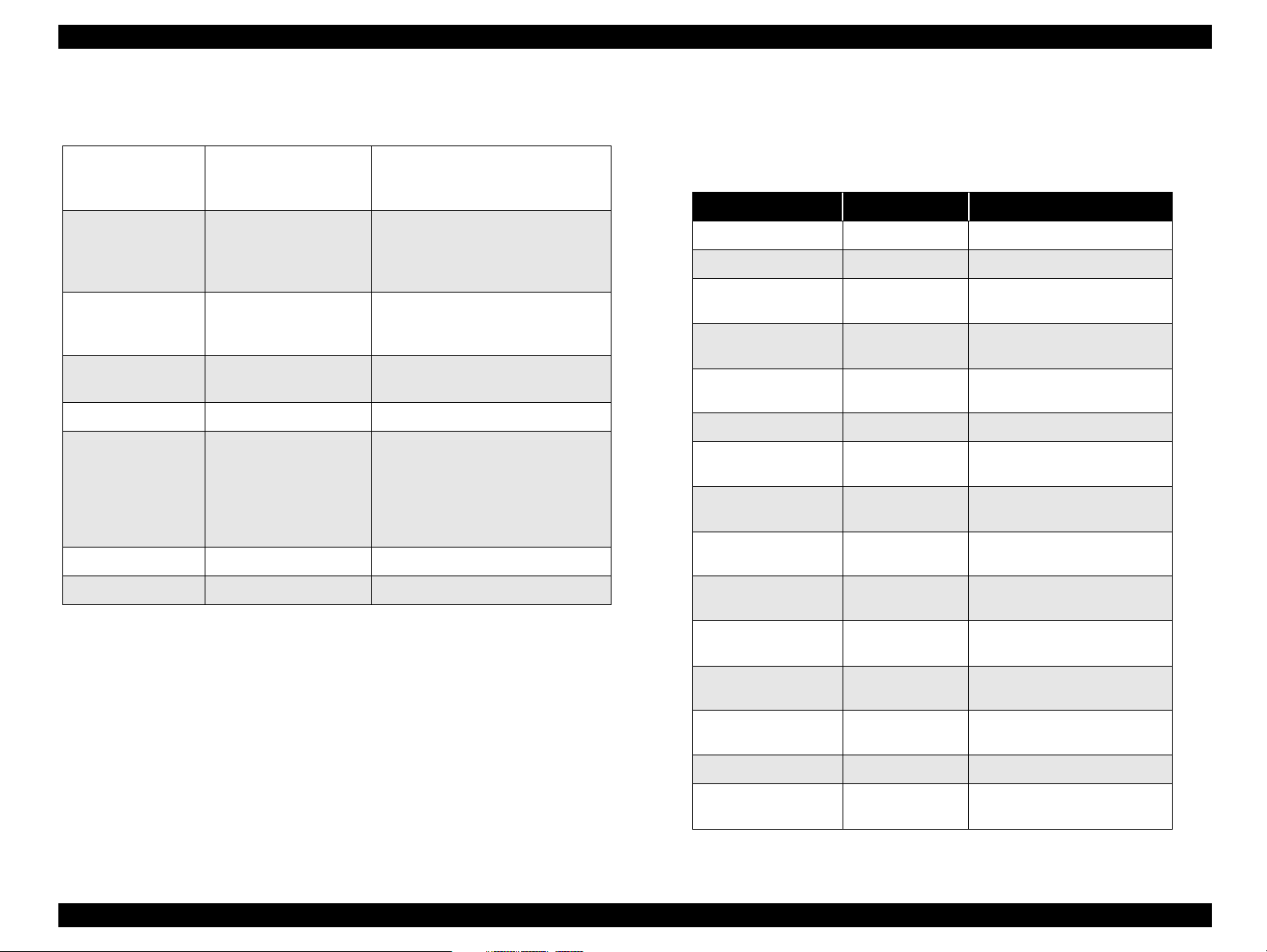

1.5.3.2 Envelopes

LM

Printable Area

Figure 1-7. Printable Area for Envelopes

Table 1-41. Envelope Margin

Paper Size

#10 3 mm (0.12”) 28 mm (1.10”) 3 mm (0.12”) 14 mm (0.55”)

Left Margin

(min.)

Right Margin

(min.)

Top Margin

(min.)

Bottom Margin

(min.)

RM

TM

BM

DL 3 mm (0.12”) 7 mm (0.28”) 3 mm (0.12”) 14 mm (0.55”)

C6 3 mm (0.12”) 3 mm (0.12”) 3 mm (0.12”) 14 mm (0.55”)

PRODUCT DESCRIPTION PAPER 33

Page 34

EPSON Stylus COLOR C70/C80 Revision A

1.6 INK CARTRIDGE

1.6.1 Black Ink Cartridge

Type: Exclusive Cartridge

Color: Black

Print Capacity: 1240 pages/A4

(ISO/IEC 10561 Letter Pattern at 360 dpi)

Ink Life: 2 years from production data.

Storage Temperature: -20

Dimension: 22.0 mm (W) x 71.2 mm (D) x 66.5 mm (H)

o

C to 40 oC (Storage, within a month at 40 oC)

o

-30

C to 40 oC (Packing storage, within a month at 40 oC)

o

-30

C to 60 oC (Transit, within 120 hours at 60 oC

and within a month at 40

o

C)

1.6.2 Color Ink Cartridge

Type: Exclusive Cartridge

Color: Magenta, Cyan, Yellow

Print Capacity: 420 pages / A4 (360 dpi, 5% duty each color)

Ink Life: 2 years from production date

Storage Temperature: -20

Dimension: 12.7 mm (W) x 71.2 mm (D) x 66.5 mm (H)

o

C to 40 oC (Storage, within a month at 40 oC)

o

-30

C to 40 oC (Packing storage, within a month at 40 oC)

o

-30

C to 60 oC (Transit, within 120 hours at 60 oC

and within a month at 40

o

C)

Figure 1-9. Color Ink Cartridge

NOTE: Ink cartridge can not re-fill, only ink cartridge is prepared for article of

consumption.

NOTE: Do not use the ink cartridge which was passed away the ink life.

o

Figure 1-8. Black Ink Cartridge

NOTE: Ink will be frozen under -4

C environment however, it will be usable

after placing it more than 3 hours at room temperature.

PRODUCT DESCRIPTION INK CARTRIDGE 34

Page 35

OPERATING PRINCIPLES

CHAPTER

2

Page 36

EPSON Stylus COLOR C70/C80 Revision A

2.1 Overview

PF Roller

CR Motor

Rotary Scale

Clutch mechanism

This section describes the operating principles of the printer mechanism and electrical

circuit boards. The Stylus COLOR C70/C80 has the following boards:

Main board: C424 MAIN-B

NOTE: There is no part with the name C424 Main in current products. The C424

Main-B board in the Stylus C70 and C80 has a different name, and so is

not exactly the same part. The parts code for ordering is also different.

PF Timing Belt

PF Encoder

PF Motor

Power supply board: C424 PSB/PSE

2.1.1 Printer Mechanism

The printer mechanism for Stylus COLOR C70/C80 is designed newly. But, the basic

component of the printer mechanism is same as previous product.

This printer consists of Print Head, Carriage Mechanism, Paper Feeding Mechanism,

Paper Loading Mechanism, Ink System (Pump Mechanism, Cap Mechanism, and

Carriage Lock Mechanism).

Like other EPSON ink jet printers, the Stylus COLOR C70/C80 is equipped with two

DC motors; one for ASF, Paper feeding/ Pump mechanism, and one for CR

mechanism. ASF unit uses rear entry front eject system. This ASF unit is also designed

newly and LD roller loads the paper to the printer mechanism.

For cap assembly, Stylus COLOR C70/C80 uses valveless mechanism; new design for

this model.

CR unit

CR lock Lever

Paper Eject Roller

Pump Assembly

CR Timing belt

Cap Assembly

Linear Scale

CR Encoder

LD Roller

P a p e r B a c k L e v e r

Paper separation pad

ASF Hopper Spring

PE Actuator

Silence Cam

Figure 2-1. Printer Mechanism block diagram

Operating Principles Overview 36

Page 37

EPSON Stylus COLOR C70/C80 Revision A

2.1.2 Printhead

The printhead uses a new developed P-MACH head and Stylus COLOR C70/C80 can

perform variable dot printing.

The CSIC-chip is mounted on the ink cartridge. By storing ink life data, this IC makes

it possible to control the ink in ink cartridge unit.

The basic operating principles of the printhead, which plays a major role in printing,

are the same as previous models; on-demand method which uses PZT (Piezo Electric

Element). In order to uniform the amount of ejecting ink, the printhead has its own

head ID (13 digits for this printhead) which adjust PZT voltage drive features.

The printhead stores the head ID to EEPROM and generates appropriate PZT drive

voltage to prevent amount of ink from varying by printheads.

Following explains printhead basic components.

PZT

PZT is an abbreviation of Piezo Electric Element. Certain amount of voltage

expands and contracts PTZ. The drive wave generated on MAIN board drives PZT

and PZT pushes the top cavity which has ink stored to discharge the ink from each

nozzle on the nozzle plate.

Ink Cavity

The ink absorbed from the ink cartridge goes through the filter and then is stored

temporarily in this tank called “cavity” until PZT is driven.

Nozzle Plate

The board with nozzle holes on the printhead surface is called Nozzle Plate.

Electrodes for CSIC-chip

The communication between CSIC-chip and main unit is performing via the

electrodes on the carriage.

Filter

When the ink cartridge is installed, if any dirt or dust around the cartridge needle is

absorbed into the head, there is a great possibility of causing nozzle clog and

disturbance of ink flow, and finally causing alignment failure and dot missing. To

prevent this problem, a filter is set below the cartridge needle, where ink is filtered.

Nozzle Plate

Ink Cartridge

PZT

CSIC-chip

Needle

Cavity

Nozzle Selector Board

Electrodes for CSIC-chip

Filter

Figure 2-2. Printhead Sectional Drawing (Image)

2.1.2.1 Printing Process

This section explains the process in which the printheads of On-Demand inkjet printers

eject ink from each nozzle.

1.

Normal State:

When no printing signal is sent from PC, or no PZT drive voltage is applied, PZT

does not change shape, therefore PZT does not squeeze the cavity. Ink pressure

inside the cavity is kept normal. (Refer to Figure 2-3.)

2)

Ejecting State:

When the print signal is output from the C424 MAIN-B board, IC (Nozzle

Selector) located on the printhead unit latches data once by 1-byte unit.

Operating Principles Overview 37

Page 38

EPSON Stylus COLOR C70/C80 Revision A

An appropriate PZT latched by the nozzle selector is pushed into the cavity by the

common voltage applied from the main board. By this operation, ink stored in the

cavity spurts out from nozzles.(Refer to Figure 2.1.2.2.)

Ink Path

Nozzle

PZT drive voltage

PZT

Ink Cavity

Nozzle plate

Normal dot printing

With this printer, Economy dot printing is basically used only during Economy

mode printing. The reason is that the resolution is low during Economy mode

printing, so that the dot size needs to be bigger. Economy printing consists of 2

shots.

Variable dot printing

This printing mode is developed to improve the power of graduation-expression.

This mode is basically the same as variable dot printing mode used on other

products /; small dot, middle dot, and large dot compose this mode. Print dot size

varies according to print data and this mode enables even sharper image output on

almost all the papers.