Epson Stylus C63, Stylus C84 Service Manual

®

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus C63/C64/C83/C84

Notice

o All rights reserved. No p art of t his manual may be reprod uced, stored i n a ret rieval sy stem, or t ransmit ted in any form or by a ny means el ectroni c,

mechanical, photocopying, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

o The contents of this manual are subject to change witho ut notice.

o All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

greatly appreciate being informed of them.

o The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice:Other product names used herein are for identif ic ation purp ose only and may be trademarks or regi stered tr ademarks of thei r respec-

tive owners. EPSON disclaims any and all rights in those marks.

Copyright © 2000 SEIKO EPSON CORPORATION.

TPCS Quality Assurance Dept.

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCO NNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS

WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

EPSON WARRANTY.

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the

product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the

troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures fo r disassembling

and assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicing the product.

CHAPTER 7.APPENDIX

Provides the following additional information for

reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

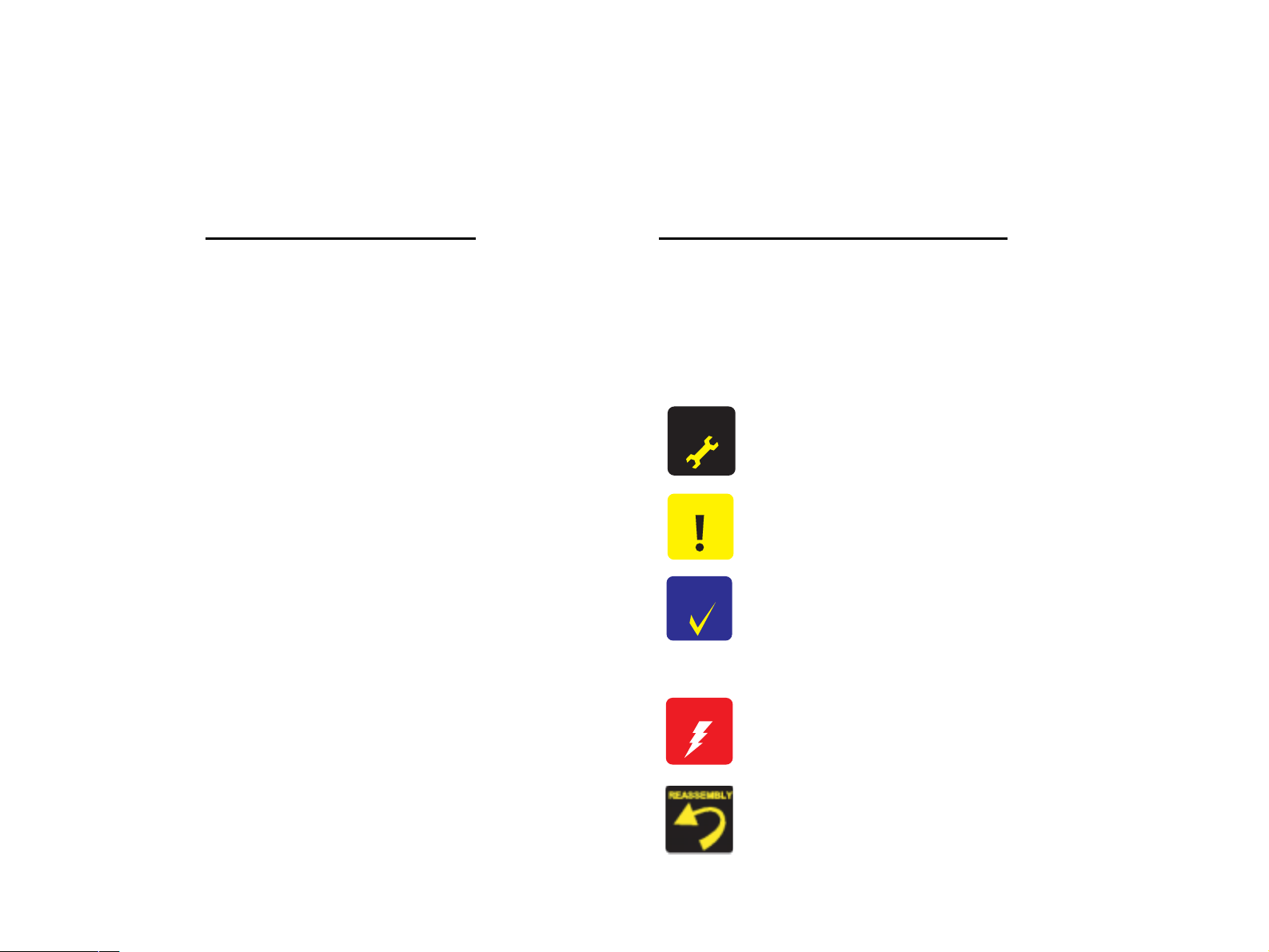

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide

additional information on a specific topic or to warn of possible danger

present during a procedure or an action. Be aware of all symbols when

they are used, and always read NOTE, CAUTION, or WARNING

messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice

or condition that, if not strictly observed, could result in

injury or loss of life.

Indicates an operating or maintenan ce pr ocedure, practi ce,

or condition that, if not strictly observed, could result in

damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure,

practice or condition that is necessar y to accomplish a task

efficiently. It may also provid e additional information that is

related to a specific subject, or comment on the results

achieved through a previous action.

I.ndicates an operating or maintenance procedure, practice

or condition that, if not strictly obser ved, could result i n injury

or loss of life.

Indicates that a particular task must be carried out

according to a certain standard after disassembly and

before re-assembly, otherwise the quality of the

components in question may be adversely affected.

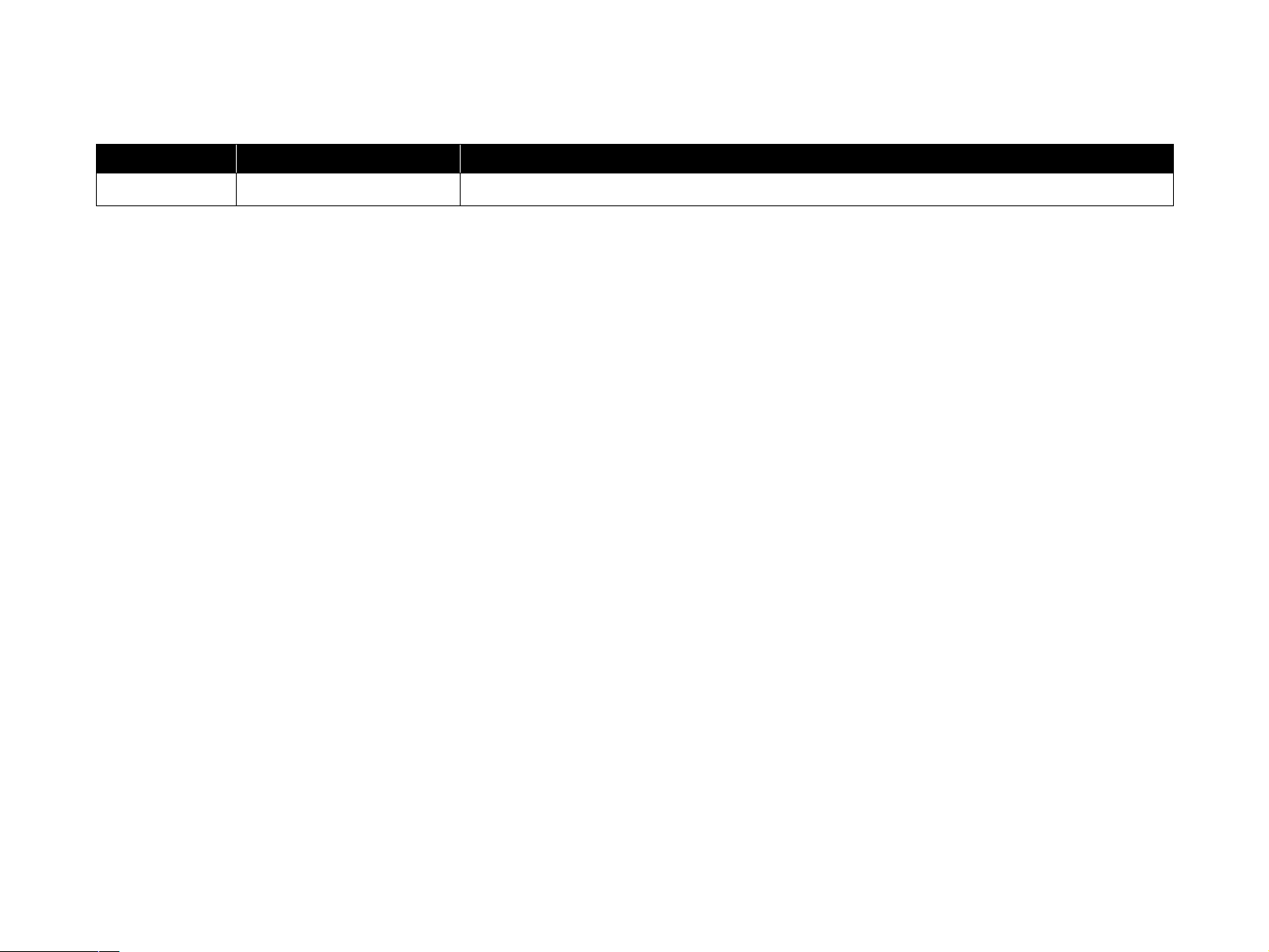

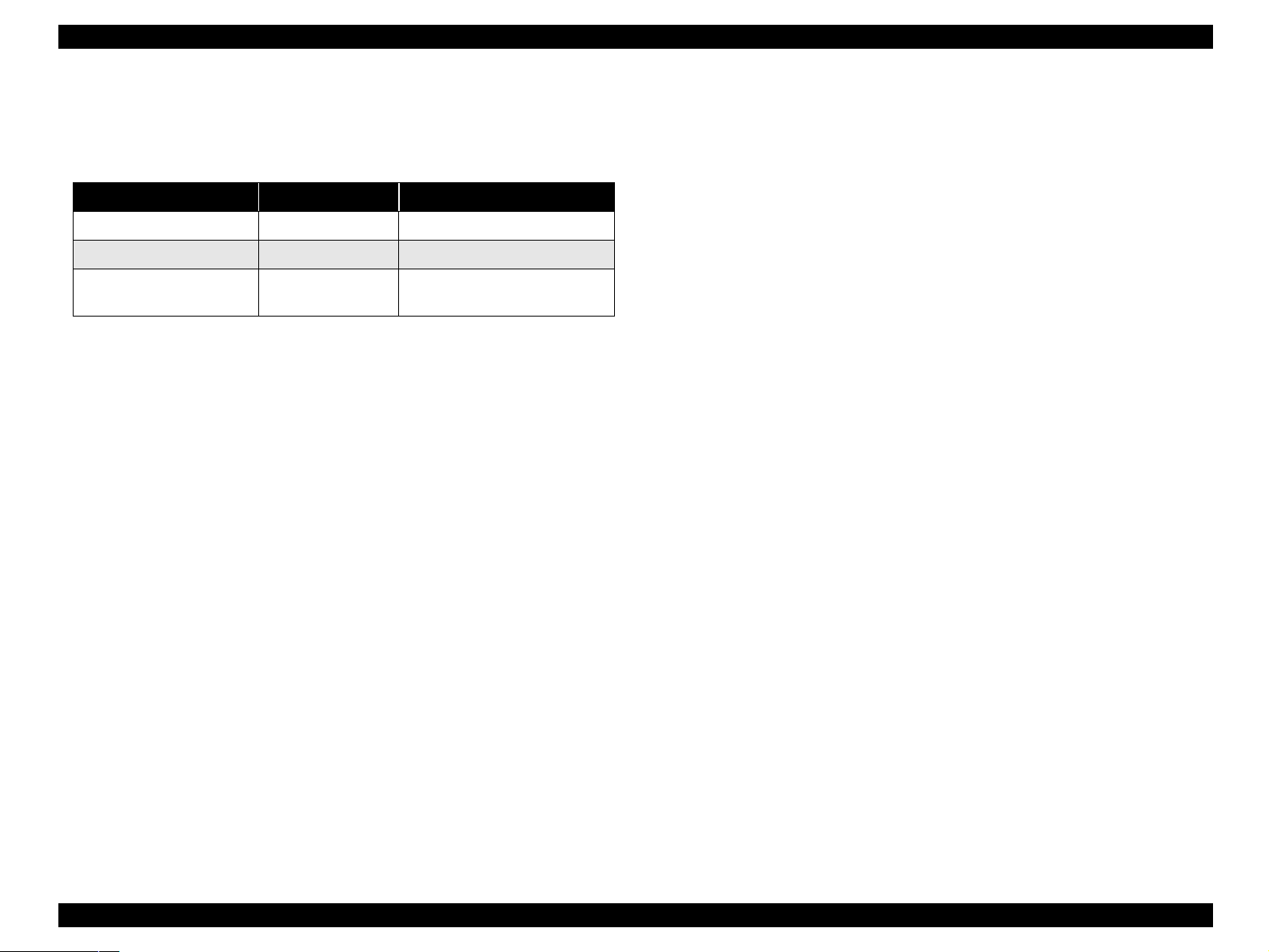

Revision Status

Revision Issued Date Description

A 2003/7/31 First Release

CONTENTS

Disassembly and Assembly

Overview................................................ ....... ...... ....... ...... ....... ...... ....... ...... ..... 8

Precautions ...... ....... ...... ...... ....... ...... ....... ...... ....................................... ..... 8

Tools................. ....... ...... ...... ....... ...... ....................................... ....... ...... ..... 9

Work Completion Check.......................................................................... 10

Caution regarding assembling/disassembling

of the printer mechanism, and how to ensure

of quality on re-assembled product ...................................................... 11

Disassembly ................................................................................................. 12

Housing (Right/Left/Frame), Stacker Assy. removal ............................... 13

ASF unit removal..................................................................................... 14

Circuit board removal .............................................................................. 15

Holder shaft unit removal ........................................................................ 17

PS board unit removal............................................................................. 19

CR motor removal ................................................................................... 20

Paper guide upper removal..................................................................... 21

Front frame removal................................................................................ 22

CR unit removal....................................................................................... 23

Paper eject roller removal ....................................................................... 27

Paper guide front removal....................................................................... 28

Printer mechanism/Housing (Lower) removal ......................................... 29

Ink system removal ................................................................................. 32

PF motor removal.................................................................................... 33

First Dot Adjustment................................................................................ 39

Top Margin Adjustment........................................................................... 39

CR Motor Drive Torque Dispersion Measurement.................................. 39

A4 Normal Print and A4 SF Paper Print.................................................. 39

Maintenance

Overview ...................................................................................................... 41

Cleaning.................................................................................................. 41

Service Maintenance............................................................................... 41

Lubrication............................................................................................... 43

Appendix

Electrical Circuits.......................................................................................... 48

Parts List ...................................................................................................... 48

Adjustment

Overview....................................................................................................... 35

Required Adjustment............................................................................... 35

Head Angular Adjustment ....................................................................... 37

Bi-D Adjustment ...................................................................................... 37

PF Adjustment......................................................................................... 38

PW Adjustment........................................................................................ 38

DISASSEMBLY AND ASSEMBLY

CHAPTER

EPSON Stylus C63/64/83/84 Revision A

1.1 Overview

This section describes p rocedures for disassembling the main components of the Stylus

C63/64/83/84. Unless otherwise specified, disassembly units or components can be

reassembled by reversi ng the disassembly procedure. Things, if not strictly observed,

that could result in injury or loss of life are described under the heading “Warning”.

Precautions for any disassembly or assembly procedures are described under the

heading “CAUTION”. Chips for disassembling procedures are described under the

heading “CHECK POINT”.

If the assembling procedure is different from the reversed procedure of the

disassembling, the procedure is described under the heading “REASSEMBLY”.

Any adjustments required after reassembling the units are described under the heading

“ADJUSTMENT REQUIRED”. When you have to remove any units or parts that are

not described in this chapter, refer to the exploded diagrams in the appendix.

Read precautions described in the next section before starting.

1.1.1 Precautions

See the precautions given under the handling “WARNING” and “CAUTION” in the

following column when disassembling or assembling EPSON Stylus PC63/64/83/84..

W A R N I N G

n Disconnect the power cable before disassembling or assembling

the printer.

n If you need to work on the printer with power applied, strictly

follow the instructions in this manual.

n Wear protective goggles to protect your eyes from ink. If ink gets

in your eye, flush the eye with fresh water and see a doctor

immediately.

n Always wear gloves for disassembly and reassembly to avoid

iujury from sharp metal edges.

n To protect sensitive microprocessors and circuitry, use static

discharge equipment, such as anti-static wrist straps, when

accessing internal components.

n Never touch the ink or wasted ink with bare hands. If in k comes

into contact with your skin, wash it off with soap and water

immediately. If irritation occurs, contact a physician.

W A R N I N G

C A U T I O N

C A U T I O N

n Avant de commencer, assure vous que l’imprimante soit eteinte

et que le cordon d’alimentation soit debranche.

n Veillez a jeter les piles usagees selon le reglement local.

Risque d’explosion si la pile est remplacée incorrectment. Ne

remplacer que par une pile du même type ou d’un type équivalent

recommandé par le fabricant. Eliminer les piles déchargées selon

les lois et les règles de sécurité en vigueur.

n When transporting the printer after installing the ink cartridge,

be sure to pack the printer for transportation without removing

the ink cartridge.

n Use only recommended tools for disassembling, assembling or

adjusting the printer.

n Observe the specified torque when tightening screws.

n Apply lubricants and adhesives as specified. (See Chapter 3 for

details.)

n Make the specified adjustments when you disassemble the

printer.

(See Chapter 5 for details.)

n Make sure the tip of the waste ink tube is located at correct

position when reassembling the waste ink tube. Otherwise it will

cause ink leakage.

Disassembly and Assembly Overview 8

EPSON Stylus C63/64/83/84 Revision A

1.1.2 Tools

Use only specified tools to avoid damaging of the printer.

Table 1-1. Tools

Name Supplier Parts No.

Phillips Screw Driver (No.2) EPSON B743800200

Tweezer EPSON B741000100

Hexagon Box Driver

(Opposite side : 5.5 mm)

EPSON B741700100

Disassembly and Assembly Overview 9

EPSON Stylus C63/64/83/84 Revision A

1.1.3 Work Completion Check

If any service is made to the printer, use the checklist shown below to confirm all

works are completed properly and the printer is ready to be returned to the user.

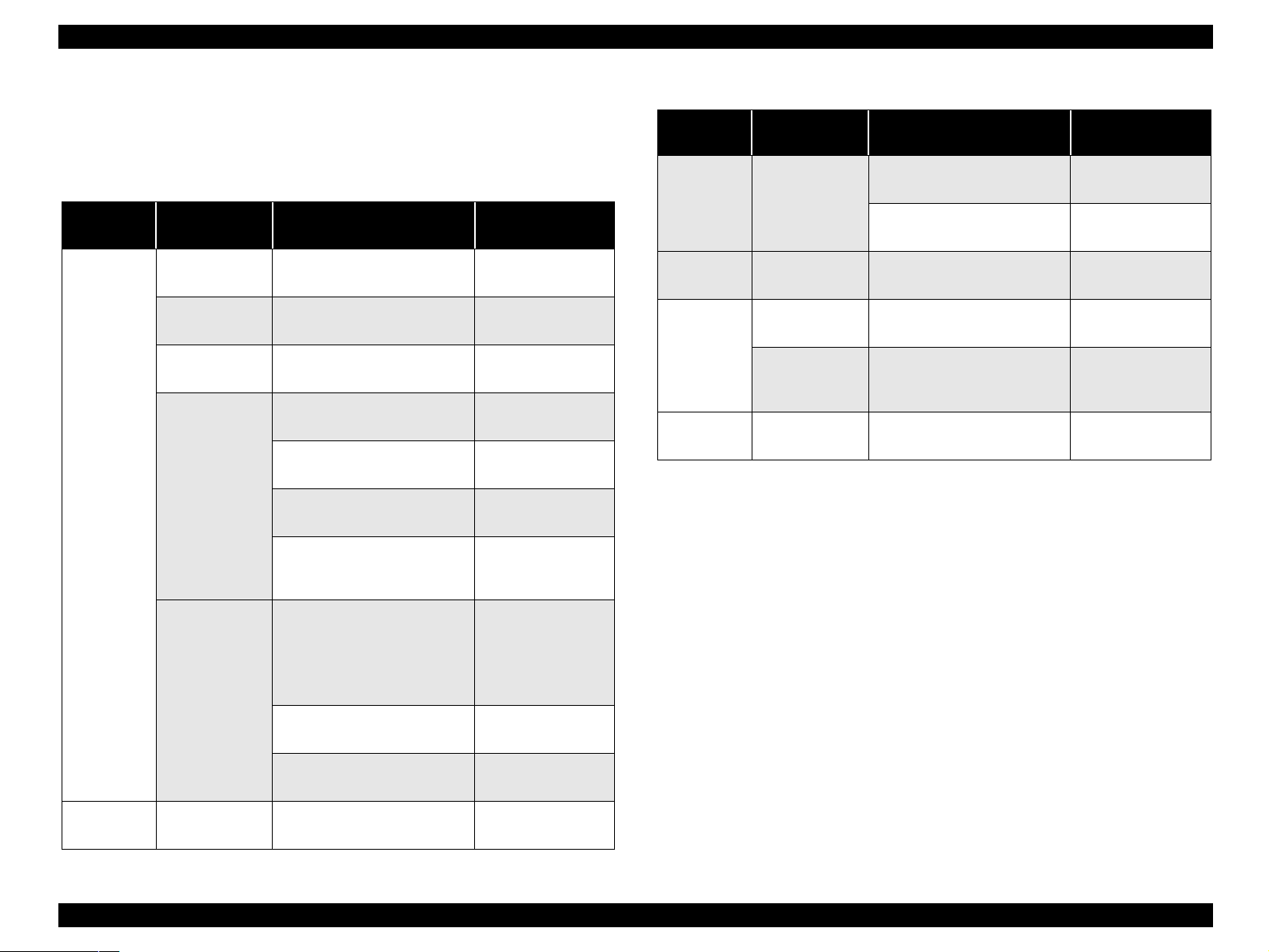

Table 1-2. Work Completion Check

Classifi-

cation

Main Unit

Adjustment

Item Check Point Status

Self-test Is the op eration normal?

On-line Test Is the printing successful?

Printhead

Carriage

Mechanism

Paper Feeding

Mechanism

Specified

Adjustment

Is ink discharged normally from

all the nozzles?

Does it move smoothly?

Is there any abnormal noise

during its operation?

Is there any dirt or foreign

objects on the CR Guide Shaft?

Is the CR Motor at the correct

temperature?

(Not too heated?)

• Is paper advanced smoothly?

• No paper jamm ing?

• No paper skew?

• No multiple feeding?

• No abnormal noise?

Is the PF Motor at correct

temperature?

Is the paper path free of any

obstructions?

Are all the adjustment done

correctly?

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

Table 1-2. Work Completion Check

Classifi-

cation

Lubrication

Function ROM Version Version:

Packing

Others

Item Check Point Status

Are all the lubrication made at

Specified

Lubrication

Ink Cartridge

Protective

Materials

Attachments,

Accessories

the specified points?

Is the amount of lubrication

correct?

Are the ink cartridges installed

correctly?

Have all relevant protec tive

materials been attached to the

printer?

Have all the relevant items been

included in the package?

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

o Checked

o Not necessary

Disassembly and Assembly Overview 10

EPSON Stylus C63/64/83/84 Revision A

1.2 Caution regarding assembling/disassembling

of the printer mechanism, and how to ensure

of quality on re-assembled product

On current low end models, we basically forbided to remove Housing (Lower) from

Printer mechanism in your repair. This is because there is a possibility of main frame

deformation when a part (such as Ink system) is removed from Printer mechanism

without Housing (Lower).

Therefore, if you want to replace Ink system/PF motor, we reco mmend to replace with

new Printer mechanism with Housing (Lower).

On these models, you have to remove Housing (Lower) from printer mechanism when

replacing [Porous Pad] with new one.

Therefore, we clarify caution regarding assembling/disassembling of the printer

mechanism without Housing (Lower), and how to ensure of quality on repaired

productsin this section.

[Caution regarding assembling/disassembling of the printer mechanism]

1) Main frame

(a) Control of assembled standard position.

[Reason]

The assembed accuracy of each part composed of Printer mechanism is

based on Housing (Lower).

[Service treatment]

Confirm that there is no gap between main f rame and Housing (Lower).

[Reference]

To ensure the assembled accuracy, you have to control the assembled

standard position of main frame against X/Y/Z-axis direction.

[X-axis direction]

- Make sure that main frame is correctly placed on the groove of Housing

(Lower).

- Make sure that there is no gap between main frame and Housing (Lower).

[Y-axis direction]

Make sure that cut-out portion of main frame is correctly placed on the

square protrusion of Housing (Lower).

[Z-axis direction]

- Make sure that there is no gap between main frame and Housing (Lower).

- Make sure that the left side of Printer mechanism is correctly fixed by

two hooks.

(b) Control of vertical level of guide rail (Guide rail means the portion latched by

hooks of IC holder & Print head assy..)

[Reason]

There is a possibility that printing failre/operation failure occurs by guide rail

deformation.

[Service treatment]

- Do not remove [Mounting Plate, M/B] from Printer mechanism.

- Hold up the specified position of main frame to avoid the deformation.

(c) How to assemble of ASF unit/Circuit board/Paper guide upper

[Reason]

There is a possibility that main frame deformation is caused extra force in

assembling. As the result, printing failre/operation failure occurs.

[Service treatment]

Hold the opposite side by by hand while you are installing the above parts.

2) Front frame

(a) Control of vertical level

[Reason]

There is a possibility that printing failre occurs by front frame deformation.

[Service treatment]

Handle Front frame in assembling/disassembling carefully.

3) IC holder

(a) Handling of IC holder

[Reason]

If IC holder is damaged in assembling/disassembling of your repair, there is a

possibility that vital problem occus in user’s futher operation.

[Service treatment]

Released two hooks of IC holder from the inside of IC holder by the tweezer.

[How to ensure of quality on re-assembled product]

We judge that the quality of re-assembled product is ensured if there is no problem

about the print result by adjustment program..

Disassembly and Assembly Caution regarding assembling/disassembling of the printer mechanism, and how to ensure of quality on re-assembled product

EPSON Stylus C63/64/83/84 Revision A

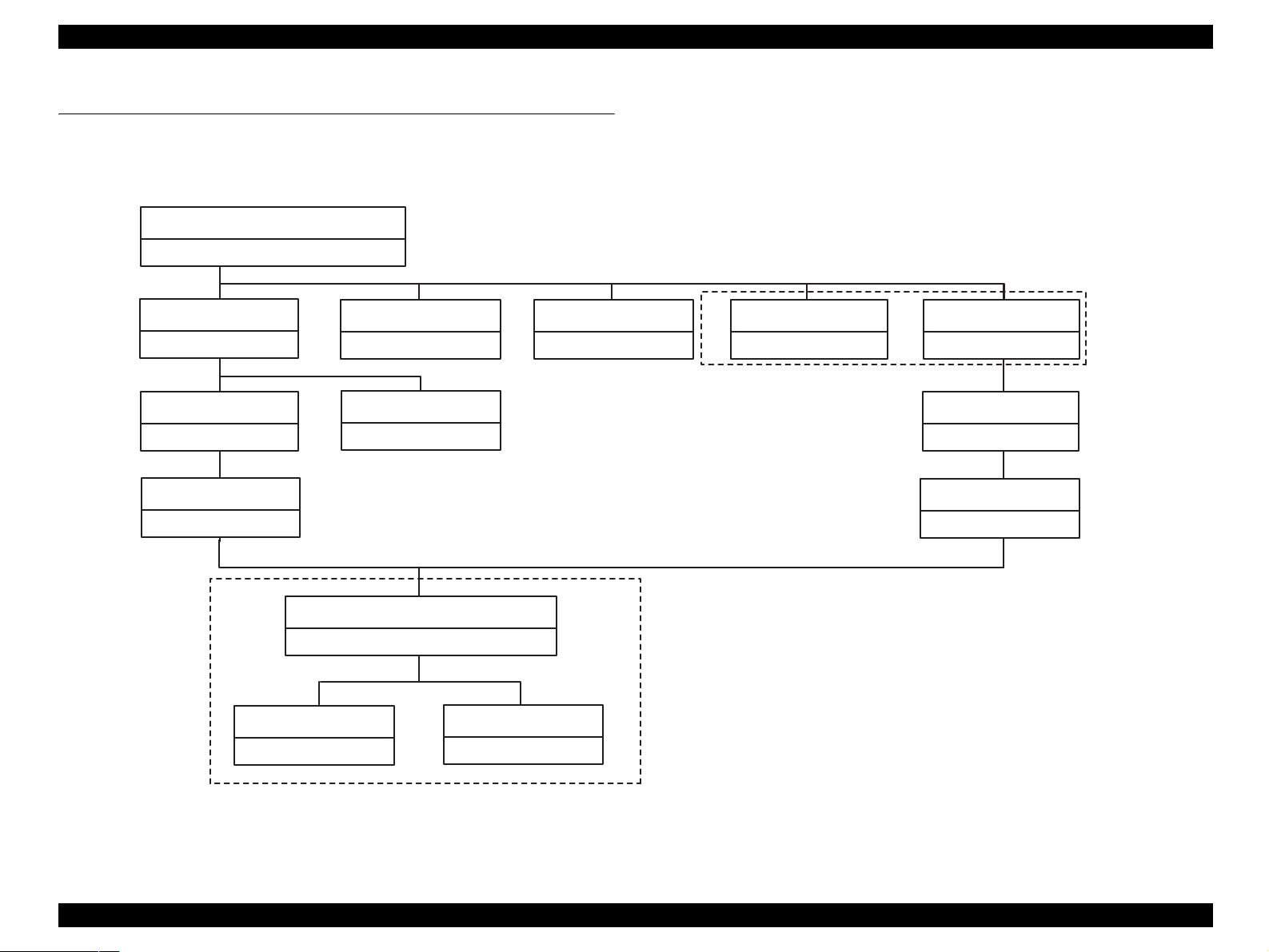

1.3 Disassembly

The flowchart below shows step-by-step disassemb ly procedures. When d isassembling

each unit, refer to the page number shown in the figure.

Housing (Right/Left/Frame), Stacker assy.

Page 13

ASF unit removal

Page 14

Circuit board removal

Page 15

PS board unit removal

Page 19

*2)

Ink system removal

CR motor removal

Page 20

Holder shaft unit removal

Page 17

Printer mechanis m/Housing (Lower) rem oval

Page 29

PF motor removal

Page 32

Page 33

Paper guide upper removal

Page 21

*1) In "Front frame removal", the procedure only for

*2) There is some cautions regarding repair of these parts.

*1)

Front frame removal

Page 22

CR unit removal

Page 23

Paper eject roller removal

Page 27

Paper guide front removal

Page 28

removing Front frame is mentioned.

In "CR unit removal, the sequencial procedure of all parts

composed of CR unit is mentioned.

(Added operations before Front frame removal + Front

frame removal + IC holder +Print head assy. / PW sensor

/ CR encoder sensor)

As for the details, please refer to 1.2 "Caution regarding

assembling/disassembling of the printer mechanism, and

how to ensure of quality on re-assembled product!.

Figure 1-1. Disassembling flowchart

Disassembly and Assembly Disassembly 12

EPSON Stylus C63/64/83/84 Revision A

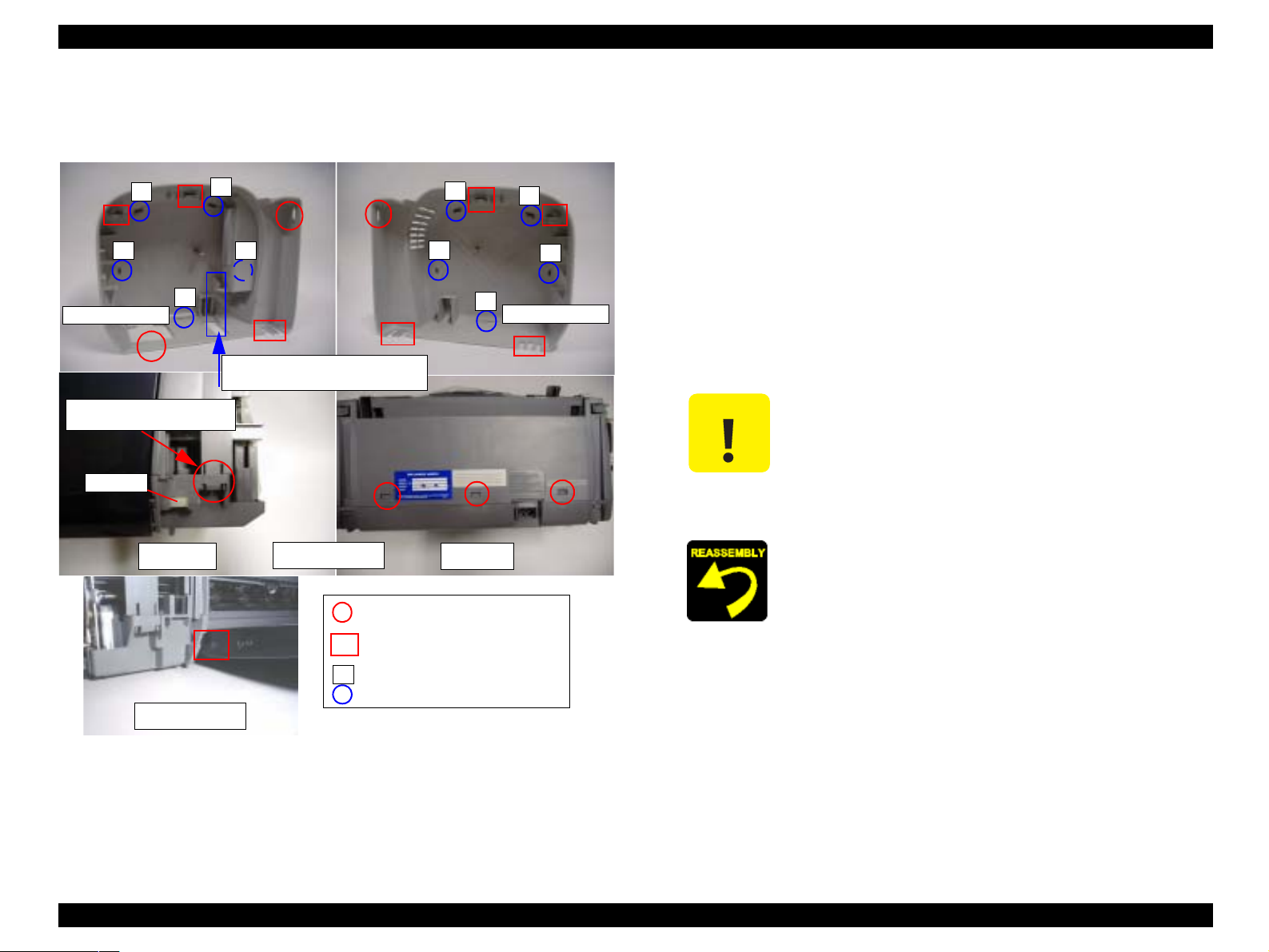

1.3.1 Housing (Right/Left/Frame), Stacker Assy. removal

o External view

1

3 4

Housing (Left)

This hook is not only the right

side but also the left side.

Damper

Front side Backside

2

5

Insert metal scale from this slit, and

release one hook of I/F cover.

Housing (Frame)

1

3

2

4

5

Housing (Right)

o Removal procedure

[Housing (Right/Left/Frame) removal]

1) Releasing five hooks by hand/precision screwdriver (-), and remove Housing

(Right).

2) Release one hook of I/F cover b y insert ing me tal scale verti cally fr om the sli t on

bottom of Housing (Left), and remove I/F cover.

3) Releasing five hooks by hand/precision screwdriver (-), and remove Housing

(Left)

4) Release five hooks by hand/precision screwdriver (-), and remove Housing

(Frame).

[Stacker assy. removal]

1) Push cut-out portion of Stacker Assy. (left side) by precision screwdriver (-),

and pull Stacker assy. to the front side of the printer.

C A U T I O N

o Do not damage hooks by hand/precision screwdriver (-) in

removing Housing (Right/Left) & Stacker assy..

o Do not tilt the printer too much when Housing (Right/Left/

Frame) is removed by hand/precision screwdriver (-). This is

because ink may possible flow if the cap is not covered by

the Print head. (CR is out of the home position)

o When assembling Housing (Right/Left/Frame) or Stacker

assy. to printer mechanism,

This marking is the hook that should

be removed/installed.

This marking is m ore careful hooks

in assembling/disassembling

This marking is the hook portion for

1

Housing cover (Right/Left) and the

order of assembling.

Stacker assy.

Figure 1-2. Housing (Right/Left/Frame) and Stacker assy. removal

n Hook five ribs for securing Housing cover (Right/Left)

to Housing (Right/Left) in the order indicated in the

figure.

n Make sure that hooks/protrusions of Housing (Right/

Left/Frame), Stacker assy., SW bottom and Panel board

is correctly fixed to Housing (Frame/Lower).

n Make sure that there is not the clearance between

Housing (Right/Left/Frame) and Housing (Lower).

n Make sure that damper for Stacker assy. is correctly

Part/Unit that should be removed before removing Housing (Right/Left/

o

installed to the Housing (Lower).

Frame) or Stacker assy..

Non

Disassembly and Assembly Disassembly 13

EPSON Stylus C63/64/83/84 Revision A

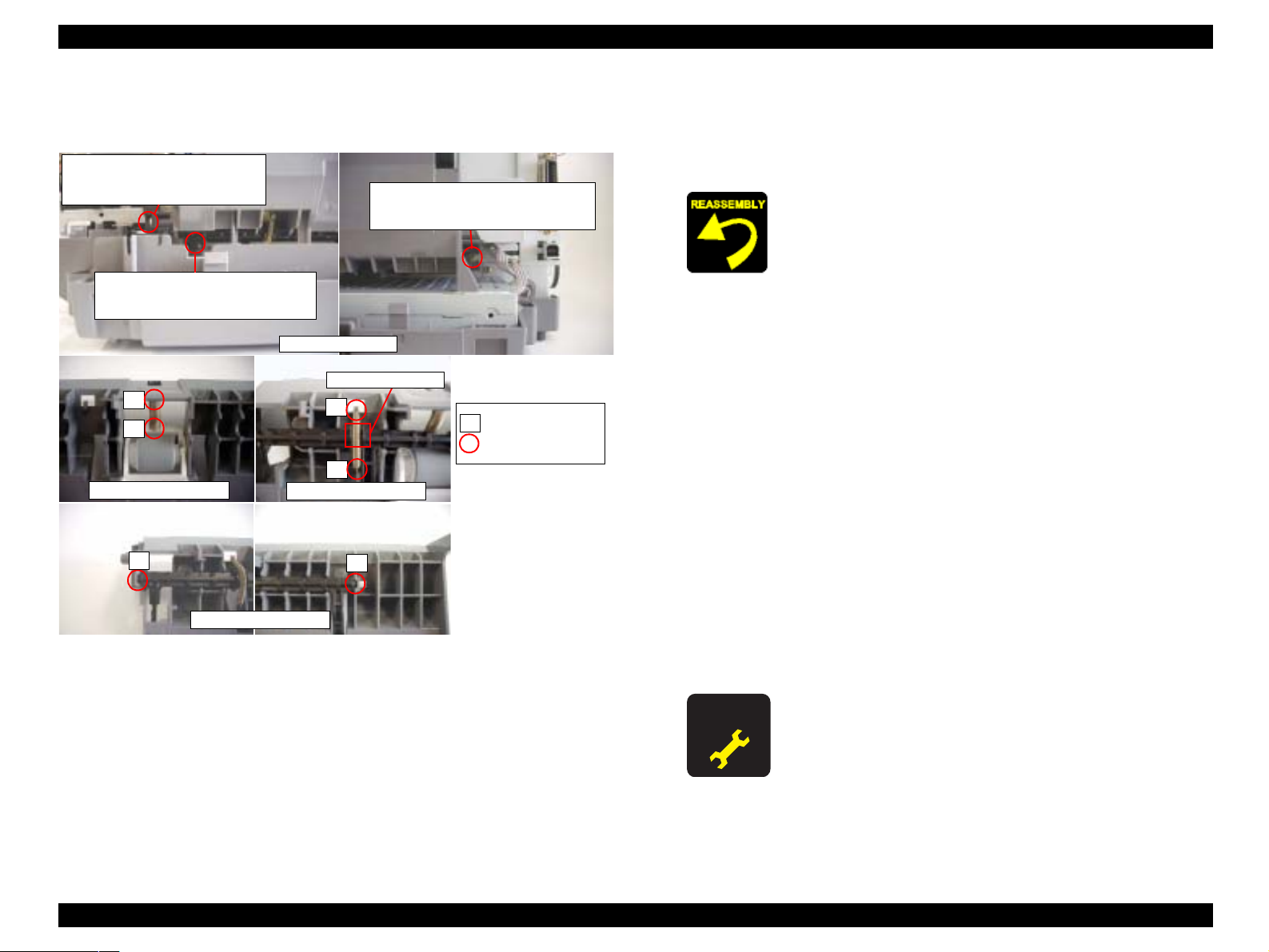

1.3.2 ASF unit removal

o External view

Screw type : C.B.P-TITE, 3x8, F/SN

Order of tightening : Third

Thghtening torque : 6

Screw type : C.B.S SCREW, 3x6, F/SN

Order of tightening : First

Thghtening torque : 8

2

1

Compression spring 1.88

1

±

1 kgf.cm

±

1 kgf.cm

Screw type : C.B.S-TITE (P4), 3x6, F/SN

ASF unit (Backside)

Ribs of ASF frame

1

2

Extension spring 0.585

2

Order of tightening : Second

Thghtening torque : 8

±

1 kgf.cm

This marki n g is

1

dowel/latched

position and the

order of asse mb ling.

3) Release Extension spring 0.585 for Paper return lever, and remove the lever

with releasing two protrusions.

4) Release Compression spring 1.88 for Returd roller unit, and turn the roller unit

until it is free.

o When assembling ASF unit,

n Make sure to latch Extension spring 0.585 for Paper

return lever & Compression spring 1.88 for Returd

roller unit in the order indicated in the figure, and to set

Expression spring 0.585 between ribs of ASF frame.

n Make sure that Paper return lever & Returd roller unit

move smoothly.

n Do not touch returd roller and cork on Hopper.

n Hook two dowels for securing Paper return lever to ASF

frame in the order incicated in the figure.

o When assembling ASF unit to main frame,

n Make sure to install Compression spring 2.53 for

Hopper correctly.

n Make sure that Hopper moves smoothly.

n Make sure to set ASF unit with the flat surface of LD

roller up.

n Fasten three screws for securing ASF unit in the order/

Paper return lever

Figure 1-3. ASF unit removal

Part/Unit that should be removed before removing ASF unit

o

Housing (Right/Left/Frame)

o Removal procedure

1) Remove three screws for securing ASF unit to main frame, and remove the unit

with pulling up slightly to the backside of the printer.

2) Release left protrusion of Hopper by pulling its bottom toward the front side,

and remove Hopper from ASF frame.

A D J U S T M E N T

R E Q U I R E D

o When you replace ASF unit with new one, lubricate it with

o When ASF unit is removed or replaced with new one, the

tightening torque indicated in the figure.

n Make sure that there is no gap between ASF unit and

Shield plate (upper) of PS board unit.

the suitable amount of G-26 grea se by the specified position.

following adjustment must be performed in the order below.

1) Top margin adjust ment

2) 1st dot adjustment

Disassembly and Assembly Disassembly 14

EPSON Stylus C63/64/83/84 Revision A

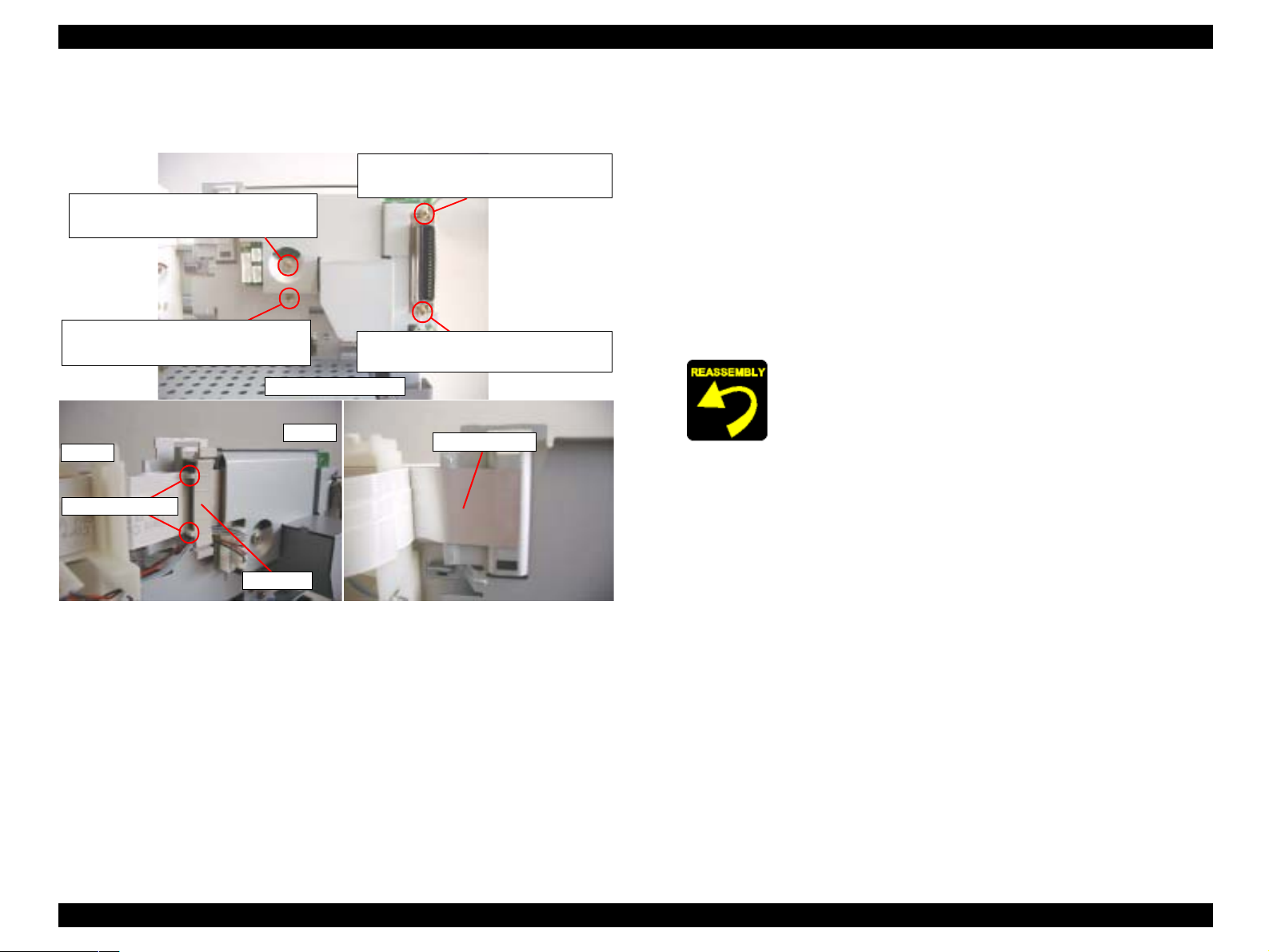

1.3.3 Circuit board removal

o External view

Screw type : C.B.S TITE SCREW, 3x14, F/SN

Screw type : C.B.S TITE SCREW, 3x10, F/SN

Screw type : C.B.S TITE SCREW, 3x6, F/SN

HP side

Dowel of cramp core

Order of tightening : Third

Thghtening torque : 8

Order of tightening : 4th

Thghtening torque : 8

±

1 kgf.cm

±

1 kgf.cm

Screw type : C.B.S TITE SCREW , 3x14, F/SN

Main board (Backside)

Far side

Cramp core

Figure 1-4. Circuit board

Part/Unit that should be removed before removing Circuit board

o

Housing (Right/Left/Frame) / ASF unit

Order of tightening : First

Thghtening torque : 8

Order of tightening : Second

Thghtening torque : 8

Shield Plate FFC

±

1 kgf.cm

±

1 kgf.cm

o Removal procedure

1) Remove Clamp core from [Mounting Plat e, M/B], and disconnect the follo win g

seven cables from the corresponding connectors on main board.

- CR motor connector cable : CN5

- PF motor connector cable : CN6

- Head FFC : CN7, CN8

- PE sensor cable : CN9

- Power supply connect cable : CN2

- Panel board connector cable : CN4

2) Remove four screws for securing Circuit board to main frame, and remove

the board.

3) Remove [Shield Plate, M/B] from main board.

o When assembling Circuit board,

n Make sure that the metal fittings for locking the Parallel

interface is on its shield plate.

o When assembling Circuit board to main frame,

n Make sure to connect all cables to the connectors (CN2,

CN4, CN5, CN6, CN7, CN8, CN9) on main board in the

correct direction.

n Fasten four screws for securing Circuit board in the

order/tightening torque indicated in the figure.

n Make sure that Shield plate FFC on Head FFC is

securely pasted on [Mounting Plate, M/B].

n Make sure that two dowels of Clamp core is set in home

position direction.

n Make sure that PE sensor cable & CR motor connector

cable are set on Holder shaft unit, and in Clamp core.

Disassembly and Assembly Disassembly 15

Loading...

Loading...