Page 1

EPSON SureColor®

S30670

S50670

.

S70670

User’s Guide

Page 2

Copyrights and Trademarks

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Seiko Epson Corporation. The information contained herein is designed only for use with this

EPSON printer. Epson is not responsible for any use of this information as applied to other printers.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of accident, misuse, or

abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.)

failure to strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

Seiko Epson Corporation shall not be liable for any damages or problems arising from the use of any options or

any consumable products other than those designated as Original EPSON Products or Epson Approved Products

by Seiko Epson Corporation.

Seiko Epson Corporation shall not be held liable for any damage resulting from electromagnetic interference that

occurs from the use of any interface cables other than those designated as Epson Approved Products by Seiko

Epson Corporation.

EPSON is registered trademark, and EPSON Exceed Your Vision is a registered logomark of Seiko Epson

Corporation.

General Notice: Other product names used herein are for identification purposes only and may be trademarks of

their respective owners. Epson disclaims any and all rights in those marks.

This information is subject to change without notice.

© 2012 Epson America, Inc. 7/12

CPD-36618R1

Copyrights and Trademarks 2

Page 3

Contents

Chapter 1 Introduction

Important Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

When choosing a place for this product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

When setting up this product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

When using this product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

When handling the ink cartridges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warnings, Cautions, Important and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Illustrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Printer Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Front section - S50670 and S70670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Front section - S30670. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Inside - S70670, S50670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inside - S30670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LAN port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Understanding the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Realizing High Productivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

High Print Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Superior Ease of Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Notes on Usage and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Notes when using the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Notes when not using the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Notes on handling ink cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Handling Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Specialty Inks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Using the Supplied Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Contents of the Software CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Starting EPSON LFP Remote Panel 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Exiting EPSON LFP Remote Panel 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Uninstalling Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contents 3

Page 4

Chapter 2 Basic Operations

Loading and Exchanging Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Loading Media - S70670/S50670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Loading Media - S30670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Viewing and Changing Media Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Exchanging Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Using the Auto Take-up Reel Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Media Loading and Take Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Removing the Take-up Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Before Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Saving Optimal Settings for the Current Media (Print Media Settings) . . . . . . . . . . . . . . . . . 92

Parameters Stored in Media Setting Banks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Saving Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Changing Heater and Fan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Correcting Print Misalignment (Head Alignment). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Feed Adjustment (Manual Feed Adjustment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Using a Test Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Performing Feed Adjustment During Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Printable area - S70670/S50670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Positioning Media of Different Widths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Using the High Pressure Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Using the Low Pressure Rollers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Printable Area - S30670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Chapter 3 Maintenance

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Cleaning the Platen Heater, Pressure Rollers, and Media Holding Plates . . . . . . . . . 112

Checking for clogged nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Maintenance Procedures for Specialty Inks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Head Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Regular Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Regular Part Cleaning: Preparation and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Regular Part Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Cleaning the Wiper Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Disposing of Waste Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Replacing the Wiper and Wiper Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Replacing the Flushing Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Cleaning Check Sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Regular Replacement Check Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Replacing Ink Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

How to replace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Parts That Are Periodically Replaced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Contents 4

Page 5

Chapter 4 Using the Control Panel Menu

Menu Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Menu List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Details of the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

The Media Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Printer Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

The Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

The Ink Level Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

The Print Logs Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

The Printer Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

The Network Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

The Preference Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

The Reset All Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Chapter 5 Problem Solver

When a Message is Displayed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

When a Maintenance Call/Service Call Occurs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

You cannot print (because the printer does not work) . . . . . . . . . . . . . . . . . . . . . . . . . 167

The printer sounds like it is printing, but nothing prints . . . . . . . . . . . . . . . . . . . . . . . . 168

The prints are not what you expected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Chapter 6 Appendix

Options and Consumable Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Supported Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Moving and Transporting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Moving the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Specifications Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Standards and Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Contents 5

Page 6

Appendix A Where To Get Help

Contacting Epson Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Chapter B Software License Terms

Open Source Software Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Bonjour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Other Software Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Info-ZIP copyright and license . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Contents 6

Page 7

Chapter 1

Introduction

Important Safety Instructions

Read all of these instructions before using the printer. Also be sure to follow all warnings

and instructions marked on the printer.

When choosing a place for this product

❏ Place this product on a flat, stable surface that is larger than this product. This product

will not operate properly if it is tilted or at an angle.

❏ Avoid places subject to rapid changes in temperature and humidity. Also keep it away

from direct sunlight, strong light, or heat sources.

❏ Avoid places subject to shocks and vibrations.

❏ Keep this product away from dusty areas.

❏ Place this product near a wall outlet where the plug can be easily unplugged.

When setting up this product

❏ This product’s power cord is for use with this product only. Use with other equipment

may result in fire or electric shock.

❏ Connect all equipment to properly grounded power outlets. Avoid using outlets on the

same circuit as copiers or air control systems that regularly switch on and off.

❏ Avoid electrical outlets controlled by wall switches or automatic timers.

❏ Keep the entire computer system away from potential sources of electromagnetic

interference, such as loudspeakers or the base units of cordless telephones.

❏ Use only the type of power source indicated on the product’s label.

❏ Use only the power cord that comes with this product. Use of another cord may result

in fire or electric shock.

❏ Do not use a damaged or frayed power cord.

Introduction 7

Page 8

❏ The printer requires two power cables with a combined capacity of 20 A at 100 V or 10

A at 240 V. If the combined capacity can not be supplied by a single outlet, connect the

cables to different outlets with independent power sources.

❏ If you plan to use the printer in Germany, observe the following:

To provide adequate short-circuit protection and over-current protection for this printer,

the building installation must be protected by a 10 or 16 amp circuit breaker.

❏ If damage occurs to the plug, replace the cord set or consult a qualified electrician. If

there are fuses in the plug, make sure you replace them with fuses of the correct size

and rating.

When using this product

❏ Do not block or cover the openings in this product’s cabinet.

❏ Do not insert objects through the slots. Take care not to spill liquid on this product.

❏ Do not attempt to service this product yourself.

❏ Unplug this product and refer servicing to qualified service personnel under the

following conditions: The power cord or plug is damaged; liquid has entered the

product; the product has been dropped or the cabinet damaged; the product does not

operate normally or exhibits a distinct change in performance.

❏ Always turn the product off using the Power button on the control panel. When this

button is pressed, the Power light flashes briefly then goes off. Do not unplug the power

cord or turn off the product until the Power light stops flashing.

❏ This device has two power systems. There is a risk of electric shock unless the two

power cables are unplugged during maintenance.

When handling the ink cartridges

❏ Keep ink cartridges out of the reach of children and do not drink.

❏ Do not touch the green IC chip on the side of the cartridge. This may affect normal

operation and printing.

❏ The IC chip on this ink cartridge retains a variety of cartridge-related information, such

as the ink cartridge status, so that the cartridge may be removed and reinserted freely.

Introduction 8

Page 9

❏ If you remove an ink cartridge for later use, protect the ink supply area from dirt and

dust, and store it in the same environment as this product. Note that there is a valve in

the ink supply port, making covers or plugs unnecessary, but care is needed to prevent

the ink from staining items that the cartridge touches. Do not touch the ink supply port

or surrounding area.

Warnings, Cautions, Important and Notes

Warning:

Warnings must be followed to avoid serious bodily injury.

w

Caution:

Cautions must be followed to avoid bodily injury.

c

Important:

Note:

Illustrations

Unless otherwise noted, the illustrations show the S30670, but the instructions in this

manual apply to all three models.

Important must be followed to avoid damage to this product.

Notes contain useful or additional information on the operation of this

product.

Introduction 9

Page 10

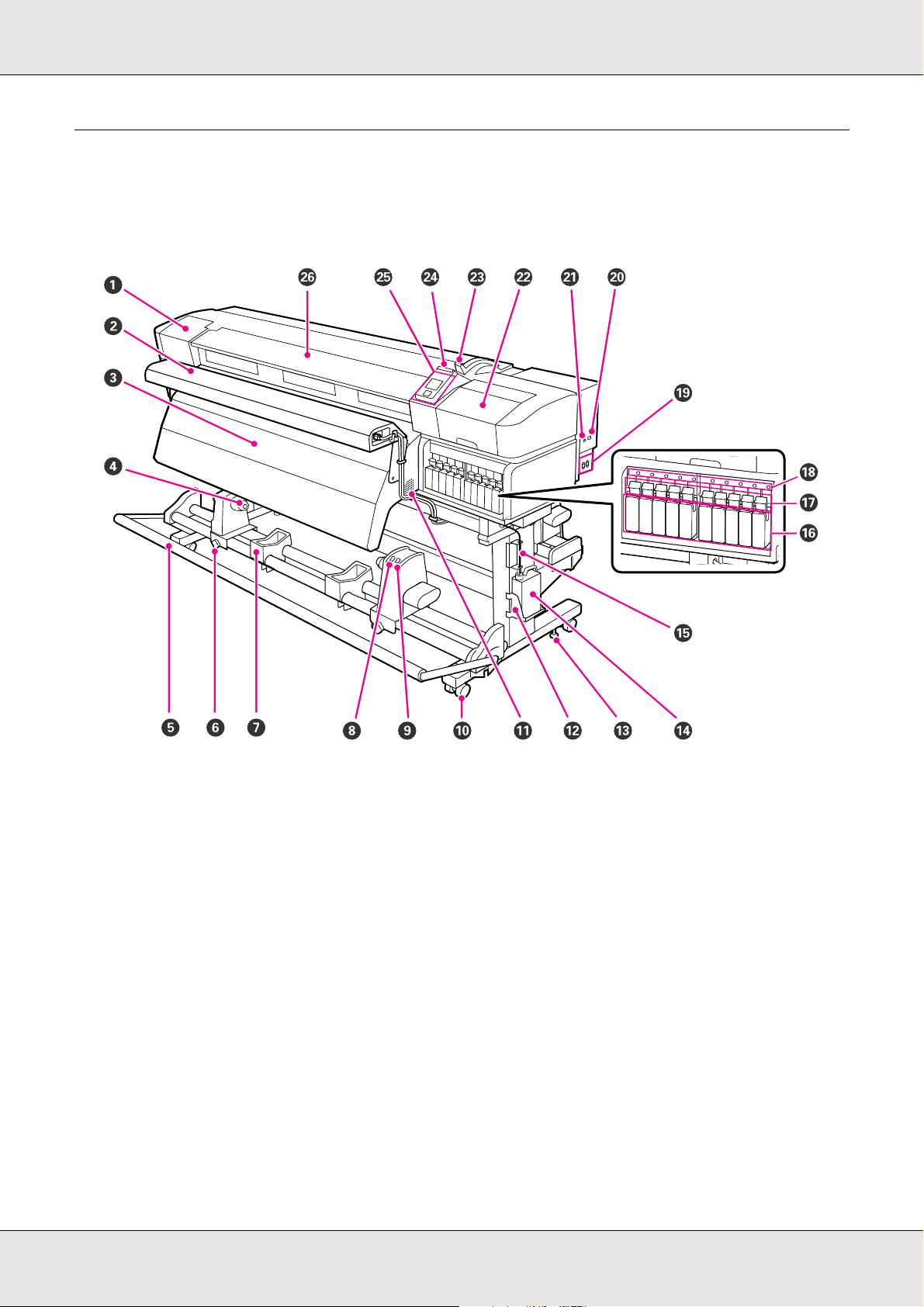

Printer Parts

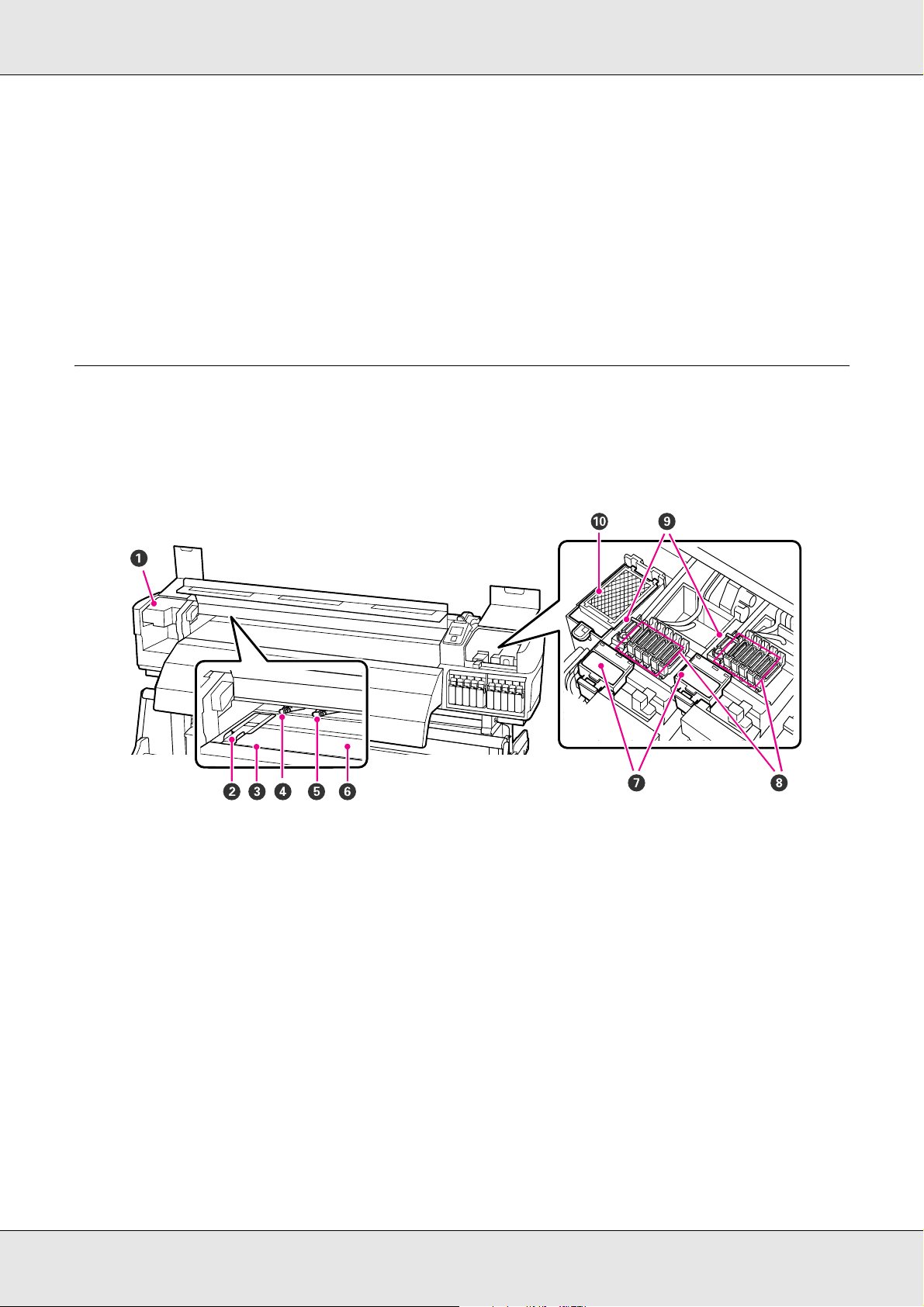

Front section - S50670 and S70670

1 Maintenance cover (left)

Open this cover to clean the area around the print head. Normally closed when using the printer.

See “Cleaning Around the Print Head” on page 126.

2 Additional print drying system

The additional print drying system can be used to rapidly dry ink after printing. Available separately for the S70670.

See the Additional Print Drying System Setup Guide.

3 After heater

The heater can be used to rapidly dry ink after printing.

See “Heating & Drying” on page 97.

4 Roll support

Rest media temporarily on these supports when removing the take-up roll. There are two supports: one on the left and one on

the right.

See “Media Loading and Take Up” on page 82.

5 Tensioner

The tensioner maintains tension to prevent the media sagging as it is taken up.

Introduction 10

Page 11

6 Roll core holder locking screw

The locking screws keep the roll core holders in place once they have been attached to the roll core. There are two lift levers:

one on the left and one on the right.

7 Roll support

Place the used roll core for media take-up on these holders. There are two supports: one on the left and one on the right.

8Auto switch

Use this switch to select the auto take-up direction. Choose Off to disable auto take-up.

9Manual switch

Use this switch to select the manual take-up direction.AutoThe selected option takes effect when the Auto switch is in the Off

position.

10 Casters

There are two casters on each leg. Once installation is complete, the front casters should be kept locked while the printer is in

use.

11 Airflow vents

These vents vent air from inside the printer. Do not obstruct these vents.

12 Waste ink bottle holder

Place the waste ink bottle in this holder.

13 Adjuster

The adjusters keep the printer in place. After installing the printer, keep it securely in place during use.

14 Waste ink bottle

Waste ink collects in this bottle.

Replace with a new waste ink bottle when the level approaches the line.

15 Waste ink tube

Waste ink is discharged from this tube. Be sure the end of this tube is in the waste ink bottle while the printer is in use.

16 Ink cartridge/replacement cartridge

The number of each type of cartridge installed varies with the option selected for color mode.

S70670: 8 colors/10 colors

S50670: 4 colors/5 colors

In 8 or 4 color mode, you need to use “replacement cartridges” to fill all slots. These are included with your printer.

17 Lock levers

Raise the levers to unlock the ink cartridges prior to removal. Lower the levers to lock the cartridges in place after insertion.

18 Cartridge check lamp

This lamp lights when an ink cartridge error occurs.

On : An error occurred. Check the contents of the error on the control panel's screen.

Off : No error.

19 AC inlet #1/AC inlet #2

Connects the power cable. Be sure to connect both cables.

20 LAN port

See “LAN port” on page 19.

Introduction 11

Page 12

21 USB port

Connects the USB cable.

22 Maintenance cover (right)

Open this cover when performing regular maintenance. Normally closed when using the printer.

See “Regular Maintenance” on page 121.

23 Media loading lever

After loading media, lower the media loading lever to keep the media in place. Raise the lever to release the media prior to

removal.

24 Alert lamp

This lamp lights or flashes when an error occurs.

On/Flashing : An error occurred; the type of error is indicated by how the lamp lights or flashes. Check the contents of the

error on the control panel's screen.

Off : No error.

25 Control panel

See “Control panel” on page 20.

26 Front cover

Open when loading media, cleaning the inside of the printer, or removing jammed media. Normally closed when using the

printer.

Introduction 12

Page 13

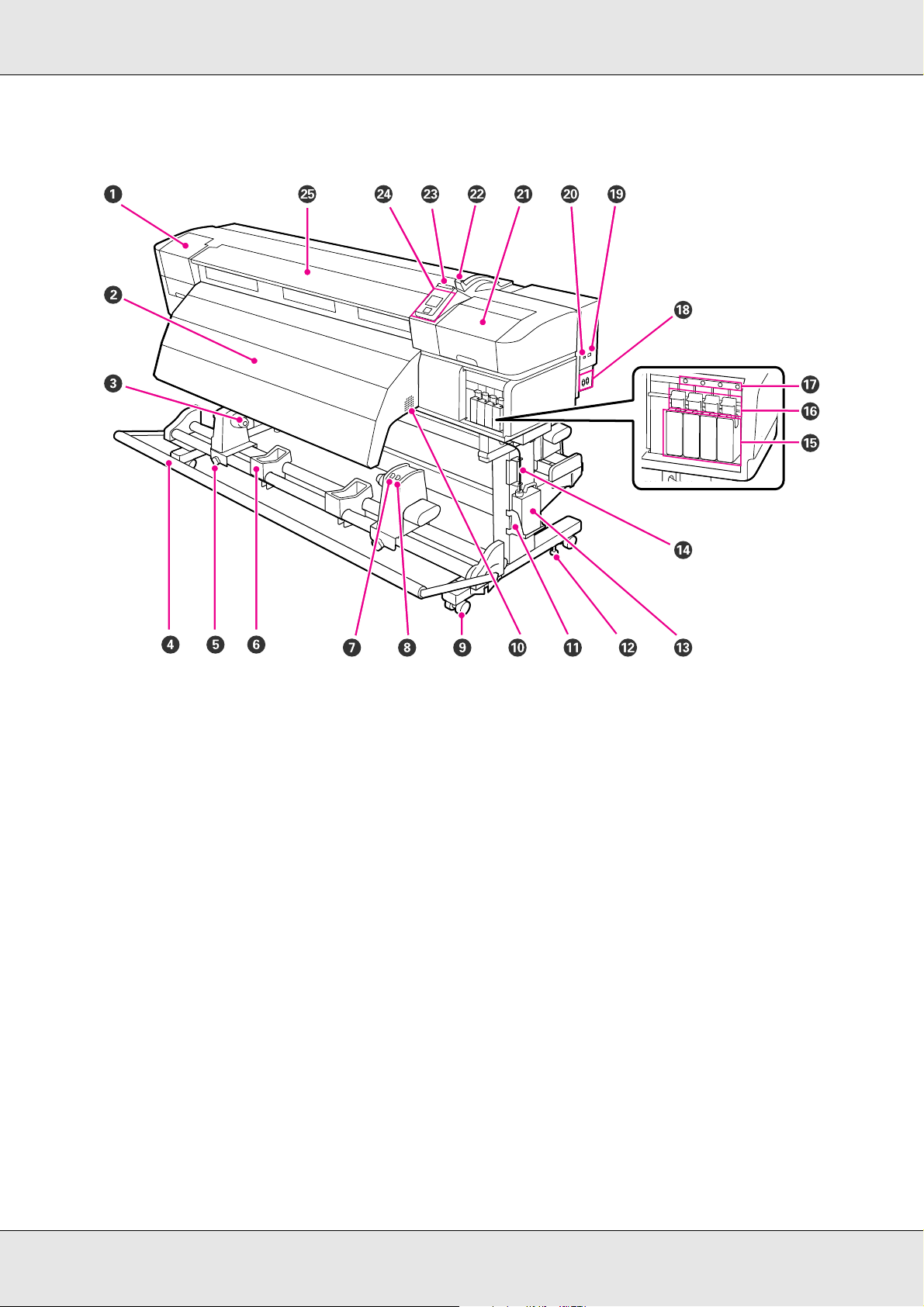

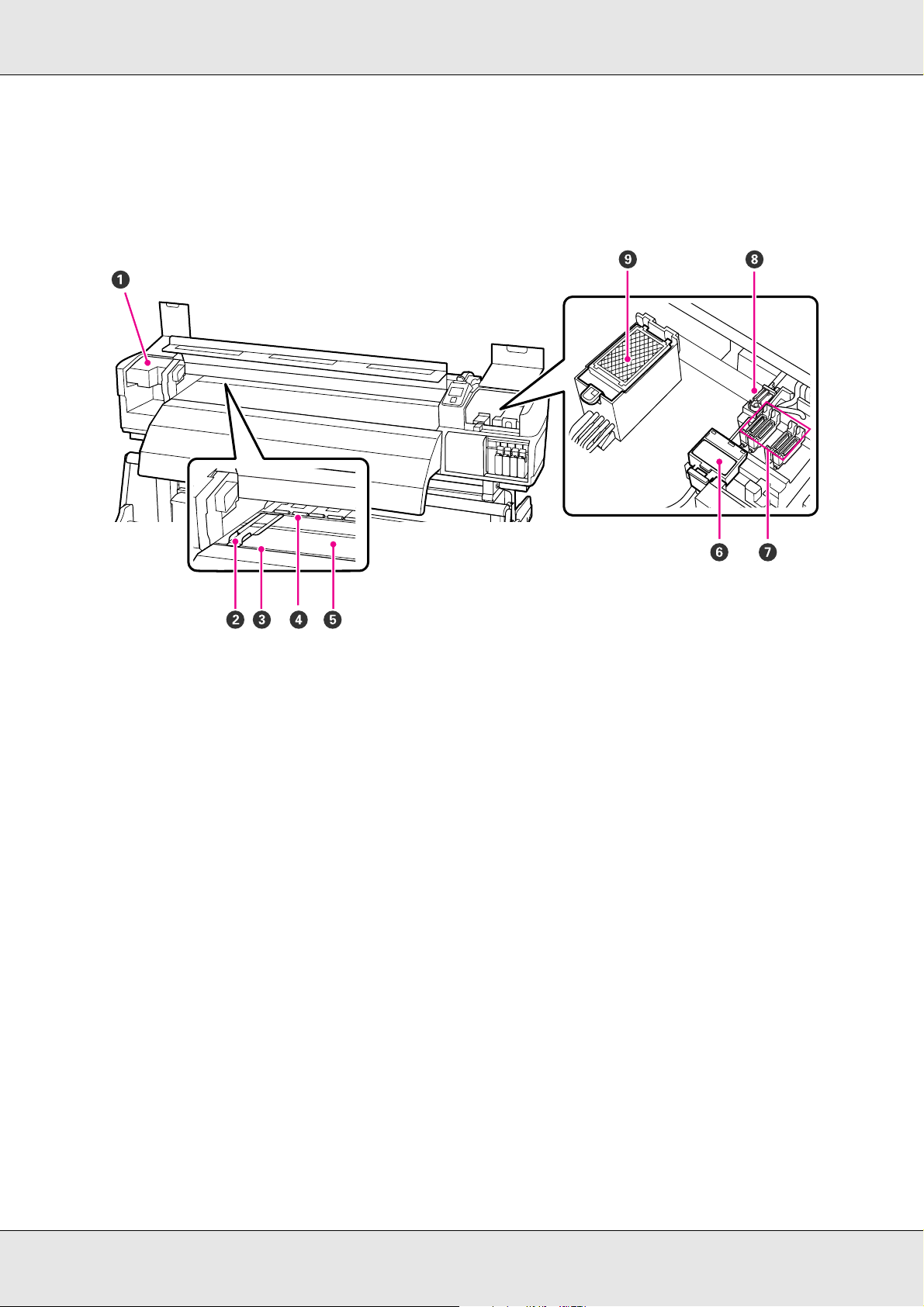

Front section - S30670

1 Maintenance cover (left)

Open this cover to clean the area around the print head. Normally closed when using the printer.

See “Cleaning Around the Print Head” on page 126.

2 After heater

The heater can be used to rapidly dry ink after printing.

See “Heating & Drying” on page 97.

3 Roll core holder

Place the used roll core for media take-up on these holders. There are two holders: one on the left and one on the right.

See“Media Loading and Take Up” on page 82.

4Tensioner

The tensioner maintains tension to prevent the media sagging as it is taken up.

5 Roll core holder locking screw

The locking screws keep the roll core holders in place once they have been attached to the roll core. There are two locking

screws: one on the left and one on the right.

6 Roll support

Rest media temporarily on these supports when removing the take-up roll. There are two supports: one on the left and one on

the right.

7Auto switch

Use this switch to select the auto take-up direction. Choose Off to disable auto take-up.

Introduction 13

Page 14

8Manual switch

Use this switch to select the manual take-up direction. The selected option takes effect when the Auto switch is in the Off

position.

9Casters

There are two casters on each leg. Once installation is complete, the front casters should be kept locked while the printer is in

use.

10 Airflow vents

These vents vent air from inside the printer. Do not obstruct these vents.

11 Waste ink bottle (tank) holder

Place the waste ink bottle in this holder.

12 Adjuster

The adjusters keep the printer in place. After installing the printer, keep it securely in place during use.

13 Waste ink bottle (tank)

Waste ink collects in this bottle.

Replace with a new waste ink bottle when the level approaches the line.

14 Waste ink tube

Waste ink is discharged from this tube. Be sure the end of this tube is in the waste ink bottle while the printer is in use.

15 Ink cartridges

Install all ink cartridges into each slot.

16 Lock levers

Raise the levers to unlock the ink cartridges prior to removal. Lower the levers to lock the cartridges in place after insertion.

17 Cartridge check lamp

This lamp lights when an ink cartridge error occurs.

On : An error occurred. Check the message on the control panel’s screen.

Off : No error.

18 AC inlet #1/AC inlet #2

Connects the power cable. Be sure to connect both cables.

19 LAN port

Connects the LAN cable.

20 USB port

Connects the USB cable.

21 Maintenance cover (right)

Open this cover when performing regular maintenance. Normally closed when using the printer.

See “Regular Maintenance” on page 121.

22 Media loading lever

After loading media, lower the media loading lever to keep the media in place. Raise the lever to release the media prior to

removal.

23 Alert lamp

This lamp lights or flashes when an error occurs.

Introduction 14

Page 15

On/flashing : An error has occurred; the type of error is indicated by how the lamp lights or flashes. Check the message on

the control panel’s screen.

Off : No error.

24 Control panel

See “Control panel” on page 20.

25 Front cover

Open when loading media, cleaning the inside of the printer, or removing jammed media. Normally closed when using the

printer.

Inside - S70670, S50670

Dirt on any of the following parts may reduce print quality. Regularly clean or exchange

these parts as described in the chapters listed in the reference sections below. The

illustration shows the S70670.

1 Print head

The print head prints by moving left and right while emitting ink. The print head on the left is Head 1, the print head on the

right Head 2. We recommend that you clean the area around this unit once a week.

See “Cleaning Around the Print Head” on page 126.

2 Media holding plate

The media holding plates prevent the media riding up and keeps fuzz on the cut edge of the media from touching the print

head. Position the plates at either side of the media before printing.

See “Loading Media - S70670/S50670” on page 39 and “Loading Media - S30670” on page 58.

3 Cutter groove

Pass the blade of a cutter (not included) down this groove to cut media.

Introduction 15

Page 16

4 Pressure rollers (high)

There are ten rollers in total; the high pressure rollers are the two on the outside edges. They press down on the edges of the

media during ink layering.

See “Cleaning the Platen Heater, Pressure Rollers, and Media Holding Plates” on page 112.

See “High Print Quality” on page 27.

5 Pressure rollers (low)

There are ten rollers in total; all of which are low pressure rollers apart from the two on the outside edges. They press down

on the media during normal (non-layer) printing. The number used varies with the width of the media.

See “Cleaning the Platen Heater, Pressure Rollers, and Media Holding Plates” on page 112.

6 Platen heater

The platen heater ensures that the ink adheres evenly.

See “Heating & Drying” on page 97.

See “Cleaning the Platen Heater, Pressure Rollers, and Media Holding Plates” on page 112.

7 Wiper cleaner

The wiper cleaner removes ink from the wiper. It is included in the maintenance kit and needs to be replaced about once

every six months.

See “Replacing the Wiper and Wiper Cleaner” on page 135.

8Caps

Except during printing, these caps cover the print head nozzles to prevent them drying out. We recommend that this unit be

cleaned once a week.

See “Regular Part Cleaning” on page 124.

9Wiper

The wiper removes ink from the print head nozzles. We recommend that this unit be cleaned once a week. It is included in the

maintenance kit and needs to be replaced about once every six months.

See “Regular Part Cleaning” on page 124.

See “Replacing the Wiper and Wiper Cleaner” on page 135.

10 Flushing pad

Ink is discharged onto this pad during flushing. It is It is included in the maintenance kit and needs to be replaced about once

every six months.

See “Replacing the Flushing Pad” on page 138.

Introduction 16

Page 17

Inside - S30670

Dirt on any of the following parts may reduce print quality. Regularly clean or exchange

these parts as described in the chapters listed in the reference sections below.

1 Print head

The print head prints by moving left and right while emitting ink. We recommend that you clean the area around this unit once

a week. Make sure the print head is at the far left side of the printer before cleaning.

See “Cleaning Around the Print Head” on page 126.

2 Media holding plate

The media holding plates prevent the media riding up and keeps fuzz on the cut edge of the media from touching the print

head. Position the plates at either side of the media before printing.

See “Loading Media - S30670” on page 58.

3Cutter groove

Pass the blade of a cutter (not included) down this groove to cut media.

4 Pressure rollers

These rollers press down on the media during printing.

See “Cleaning the Platen Heater, Pressure Rollers, and Media Holding Plates” on page 112.

5 Platen heater

The platen heater ensures that the ink adheres evenly.

See “Heating & Drying” on page 97

See “Cleaning the Platen Heater, Pressure Rollers, and Media Holding Plates” on page 112.

6 Wiper cleaner

The wiper cleaner removes ink from the wiper. It is included in the maintenance kit and needs to be replaced about once every

six months (or more often, depending on usage).

See “Replacing the Wiper and Wiper Cleaner” on page 135.

Introduction 17

Page 18

7Caps

Except during printing, these caps cover the print head nozzles to prevent them from drying out. We recommend that the caps

be cleaned once a week.

See “Regular Part Cleaning” on page 124.

8Wiper

The wiper removes ink from the print head nozzles. We recommend that this unit be cleaned once a week. It is included in the

maintenance kit and needs to be replaced about once every six months (or more often, depending on usage).

See “Regular Part Cleaning” on page 124

See “Replacing the Wiper and Wiper Cleaner” on page 135.

9Flushing pad

Ink is discharged onto this pad during flushing. It is included in the maintenance kit and needs to be replaced about once every

six months (or more often, depending on usage).

See “Replacing the Flushing Pad” on page 138.

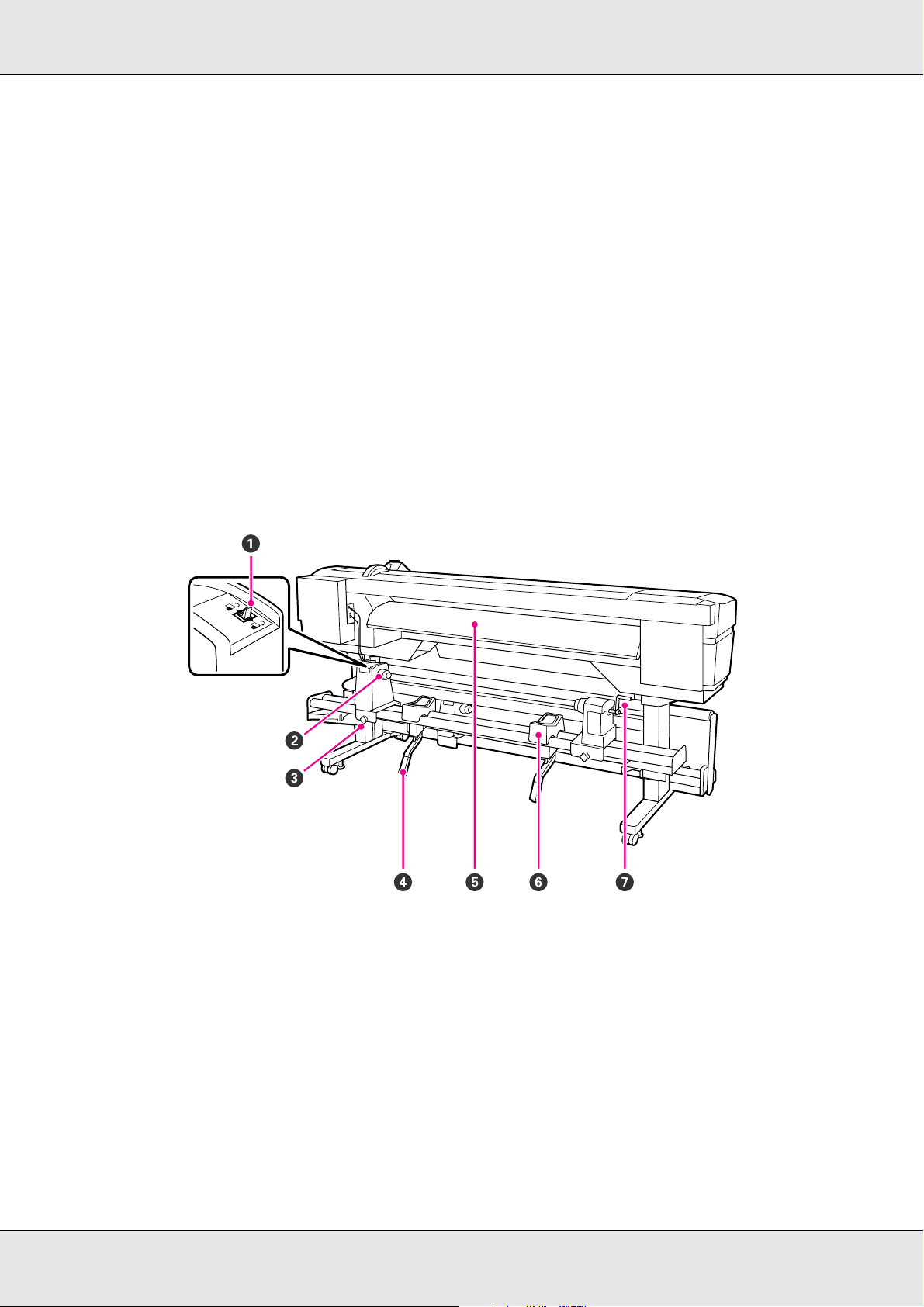

Back

1Drive switch

The drive switch is used to feed the media during loading and to rewind the media for replacement.

2 Roll holder

Place media on these holders. There are two holders: one on the left and one on the right.

3 Roll holder fixing screw

These screws fix the roll holders in place once the media has been installed. There are two screws: one on the left and one on

the right.

4 EPSON LiftAssist lever

If the media to be mounted on the roll holders seems heavy, use these levers to raise the media effortlessly to the level of the

roll holders. There are two LiftAssist levers: one on the left and one on the right.

Introduction 18

Page 19

5Pre-heater

Heats the media before printing so that the print area is not subject to sudden changes in temperature.

6 Roll support

Rest media on these supports before placing it on the roll holders. There are two supports: one on the left and one on the right.

7Handle

After placing media on the right roll holder, rotate the handle to press the holder and apply pressure to the roll core.

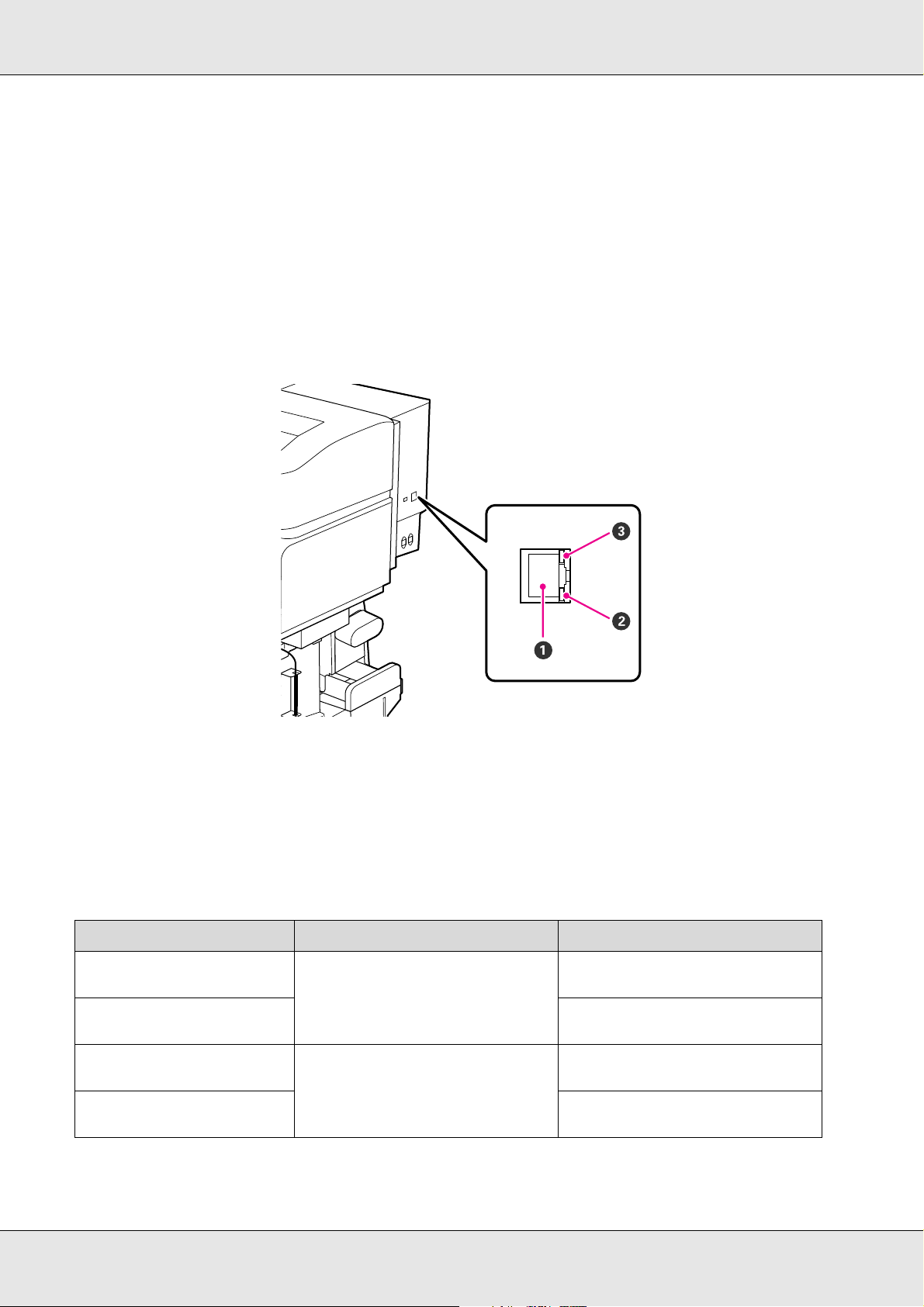

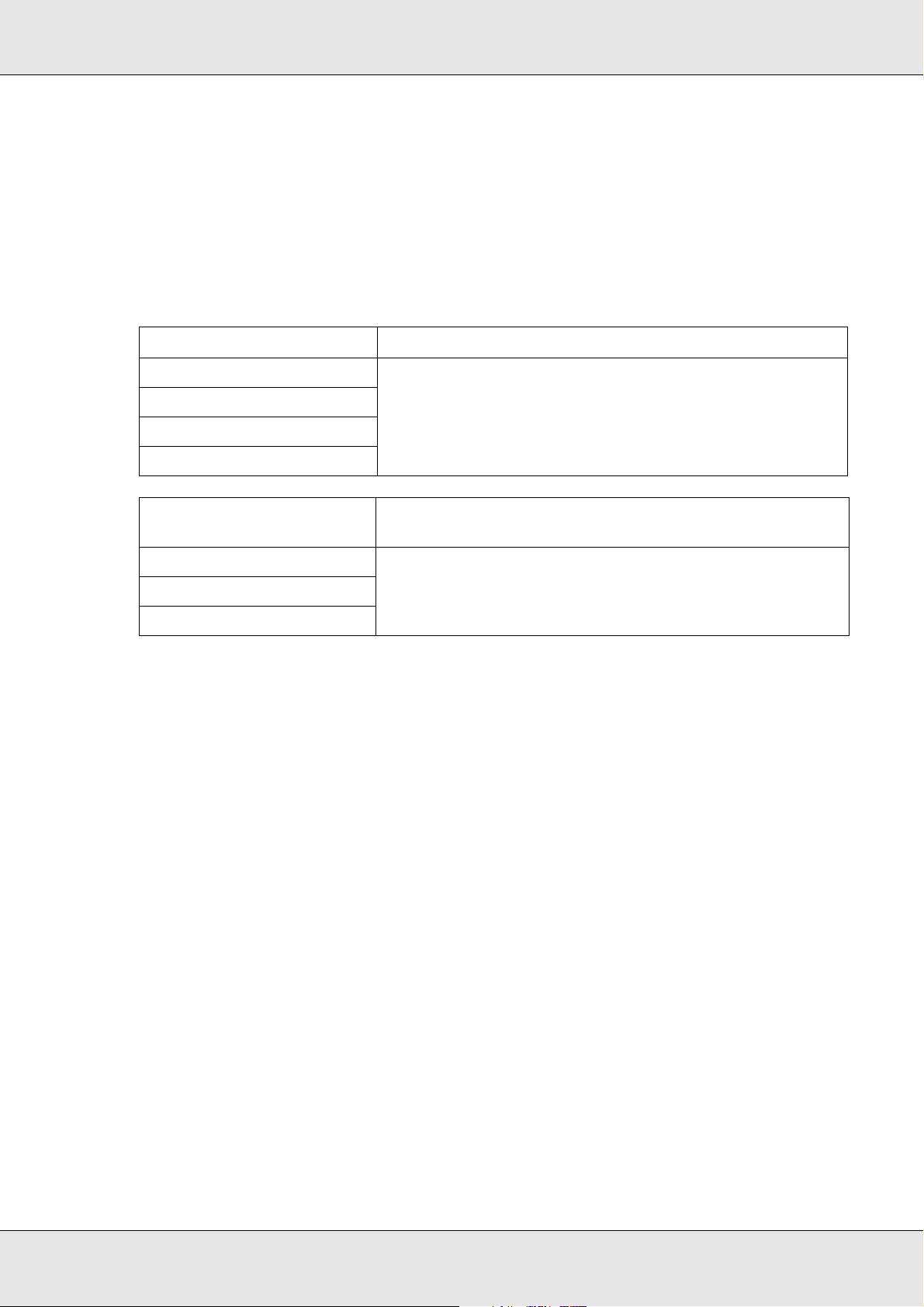

LAN port

1RJ-45 connector

Connects the LAN cable. Use a shielded twisted pair cable (category 5 or higher).

2 Data lamp

The data lamp shows connection status and indicates whether the printer is receiving data.

3 Status lamp (green/red)

The status lamp indicates network connection speed.

Data lamp Status lamp (green/red) Status

On On (green) The printer is connected using a

1000base-T connection.

Flashing The printer is receiving data over a

1000base-T connection.

On On (red) The printer is connected using a

100base-TX connection.

Flashing The printer is receiving data over a

100base-TX connection.

Introduction 19

Page 20

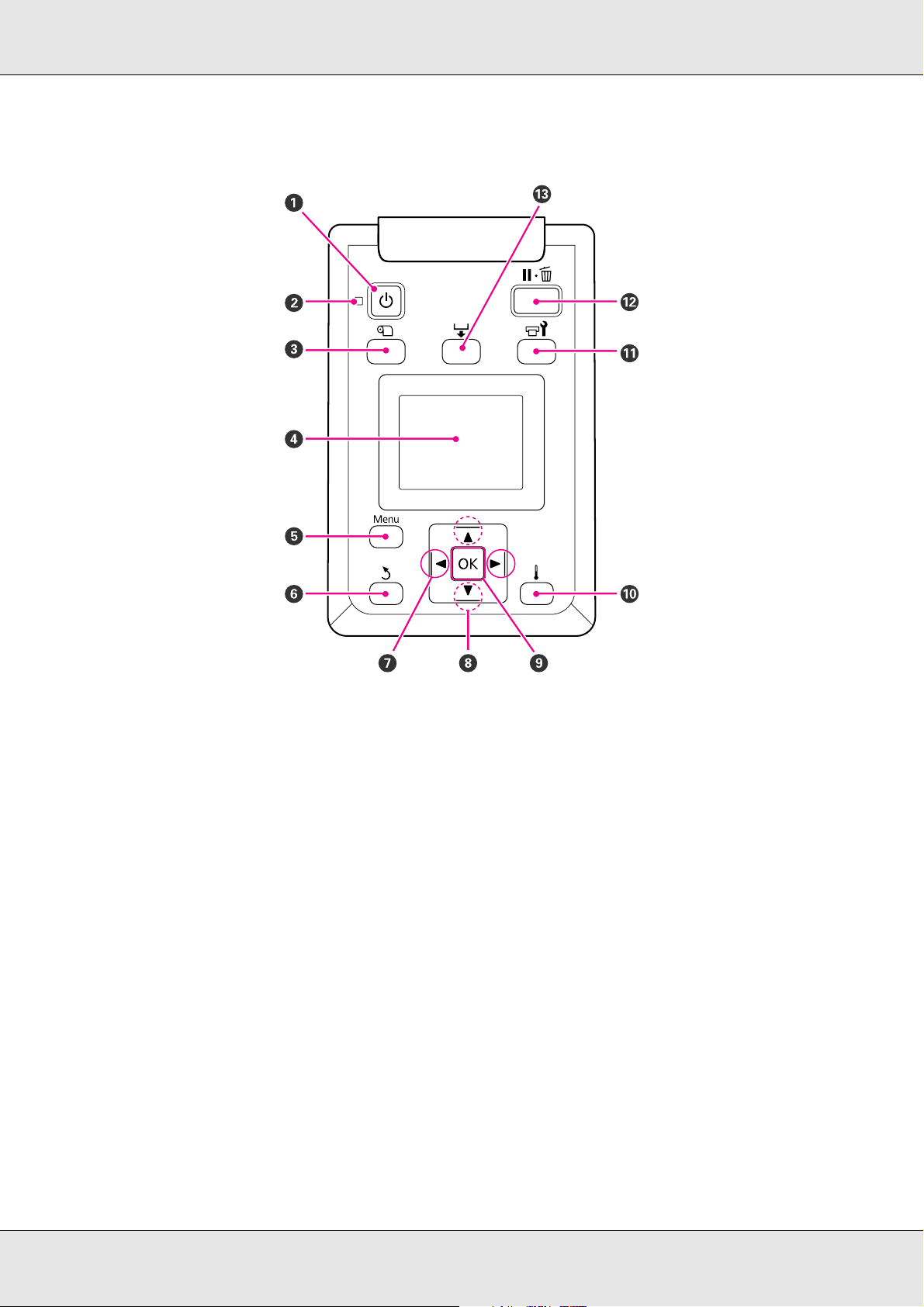

Control panel

1 P button (power button)

Turns the power on and off.

2 P light (power light)

The printer's operational status is indicated by a lit or flashing light.

On : The power is on.

Flashing : The printer is receiving data or performing head cleaning or other operations during shut-down.

Off : The power is off.

3 M button (media setup button)

Press this button to display the Media Setup menu, which contains such items as Media Remaining, Select Media,

Customize Settings, and Print Media List. This button is disabled during printing.

See “The Media Setup Menu” on page 152.

Introduction 20

Page 21

4 Display

Displays the printer's status, menus, error messages, and so on. See “Understanding the Display” on page 22.

5 Menu button

Press this button to display menus. See “Using the Control Panel Menu” on page 147.

6 y button (back button)

Press this button to exit to the previous menu when options are displayed. See “Menu Operations” on page 147.

7 l/r buttons (left and right arrow buttons)

Use to position the cursor when performing such tasks as entering a Setting Name or IP Address in the setup menu.

8 u/d buttons (media feed buttons)

When media is loaded, you can press the d to feed the media and u to rewind. Keep the d button pressed to feed the media.

Keep the u button pressed to rewind the media. Note that when the u button is used to rewind, the media will stop when its

edge reaches the starting print position. Rewind can be resumed by releasing the button and then pressing it again.

When the menus are displayed, these buttons can be used to select menu items and options. See “Menu Operations” on page

147.

9OK button

Pressing this button when a menu item is highlighted displays options for the selected item.

Pressing this button when an option is highlighted selects the highlighted item or performs the selected operation.

10 button (heating and drying button)

Pressing this button displays the Heating & Drying menu, where you can adjust the Heater Temperature. If the optional

additional print drying system is attached, you can also adjust Additional Dryer settings. These options can be adjusted

during printing.

See “The Media Setup Menu” on page 152.

11 # button (maintenance button)

Pressing this button displays the Maintenance menu, which contains such items as Nozzle Check, Cleaning, Head Washing,

Head Maintenance, and Waste Ink Counter. This button is disabled during printing.

See “The Maintenance Menu” on page 159.

Introduction 21

Page 22

12 W button (pause/cancel button)

The printer enters pause status if this is pressed while printing. To release the pause status, press the W button again, or

select Pause Cancel on the screen and then press the Z button. To cancel print jobs being processed, select Job Cancel on

the screen and then press the Z button.

Pressing this button when menus are displayed closes the menus and returns the printer to ready status.

13 button (media feed button)

When the printer is in the ready state, you can feed the media to the cut position by pressing this button and then Z.

See “Cutting Media” on page 80.

When printing is in progress, you can use this button to adjust media feed.

See “Feed Adjustment (Manual Feed Adjustment)” on page 103.

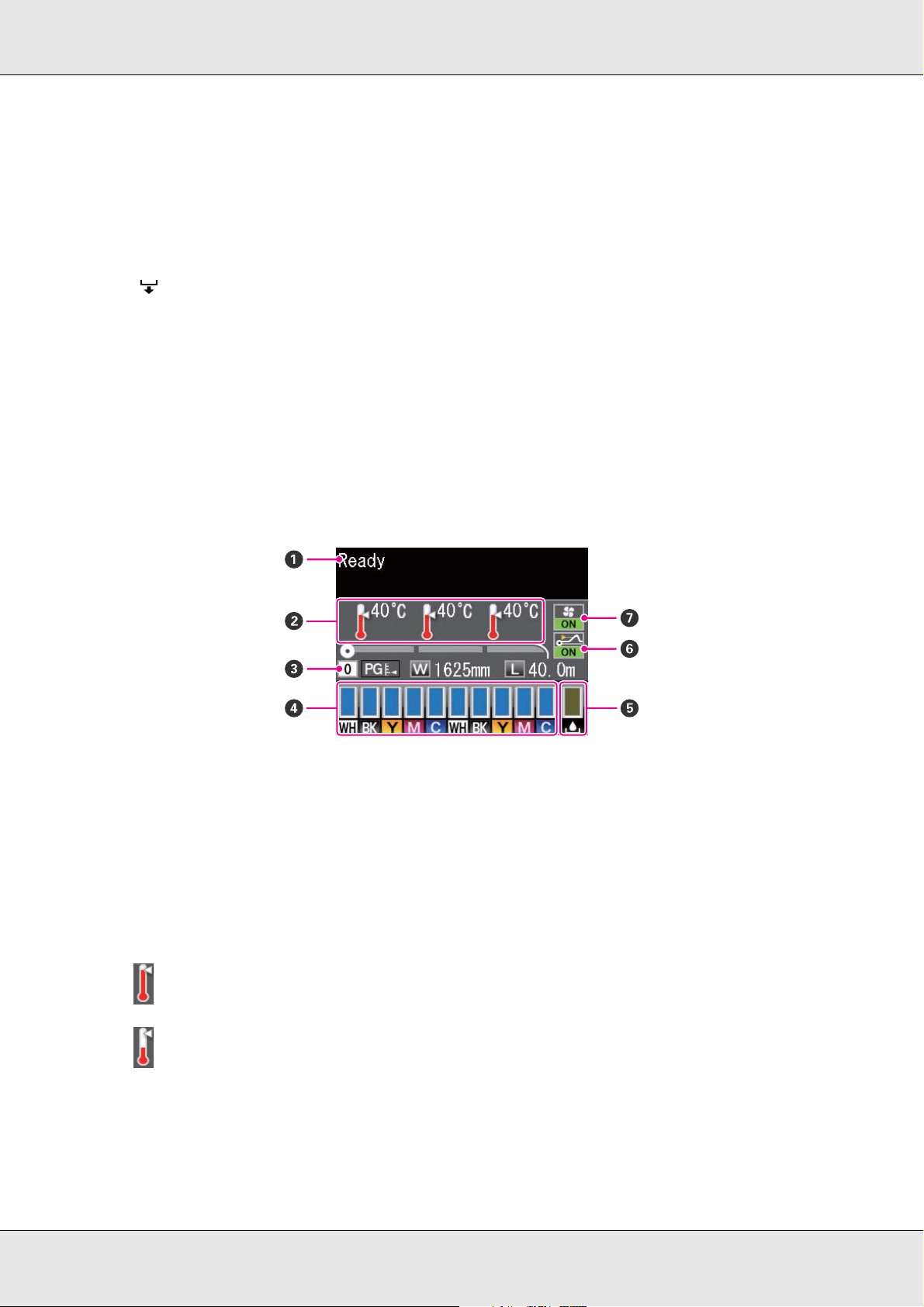

Understanding the Display

The following illustration shows the display for the S50670.

1Messages

Displays the printer's status, operation, and error messages.

See “When a Message is Displayed” on page 164.

2 Heater temperature

From left to right, this display shows the temperature settings for the pre-heater, platen heater, and after heater. The

thermometer icons give a rough indication of the current temperatures of the heaters.

: The heater has reached the selected temperature.

: The heater has not reached the selected temperature.

Introduction 22

Page 23

3Media info

From left to right, this display shows the selected media, platen gap, media width, and media remaining.

If a media setting bank number created with this printer is selected as the print media, the number (from 1 to 30) will be

displayed. When RIP Settings is selected, 0 will be displayed.

The selected platen gap is shown as follows.

:1.5

:2.0

:2.5

The media remaining is not displayed if Off is selected for Remaining Setup in the Media Remaining menu.

See “The Media Setup Menu” on page 152.

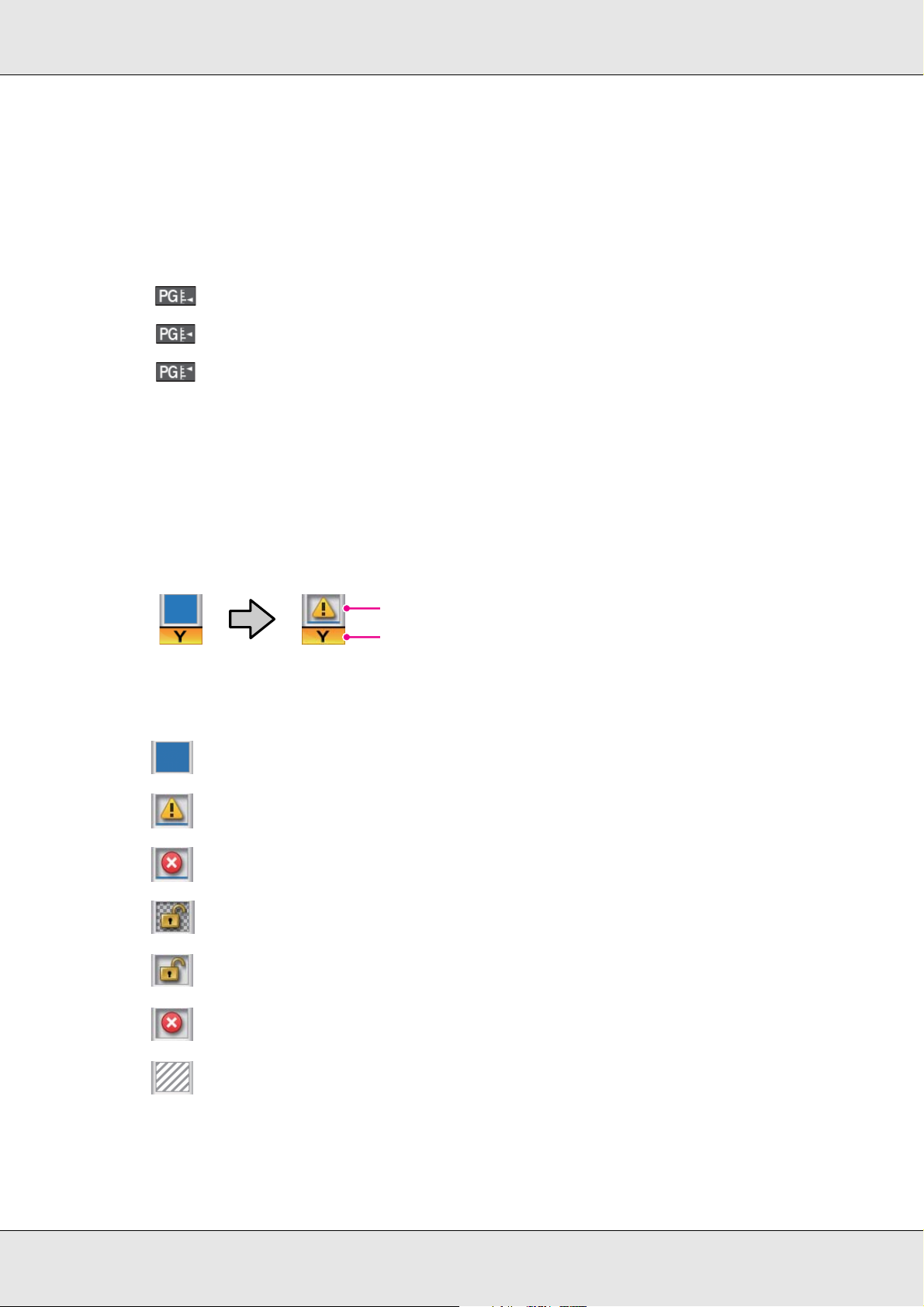

4Ink cartridge status

Displays the approximate level of remaining ink and the current status. When ink runs low or an error occurs, the display

changes as shown below.

Normal Warning or error

1 Status indicators

The ink cartridge status is indicated as follows.

Ready to print. The height of the indicator changes with the level of ink remaining.

:

Ink is low. You need to prepare a new ink cartridge.

:

The level of ink remaining has reached the limit; replace with a new cartridge.

:

The ink cartridge is not locked. Lower the lock lever to engage the lock.

:

No ink cartridge is inserted. Insert the ink cartridge and lower the lock lever to engage the lock.

:

An error occurred. Check the message on the screen, and clear the error.

:

1

2

A cleaning cartridge is installed. The height of the indicator shows the amount of cleaning liquid

:

remaining in the cartridge in three levels.

Introduction 23

Page 24

Note:

You can also check the level of ink remaining using the Ink Level option in the menus. See “The

Ink Level Menu” on page 160.

2 Ink color codes

BK : Black

Y : Yellow

M : Magenta

C : Cyan

MS Metallic Silver

LK Light Black

OR Orange

LC Light Cyan

LM Light Magenta

WH White

5 Waste ink bottle status

Displays the approximate amount of space available in the waste ink bottle. The display changes as shown below when the

waste ink bottle is nearly full or an error occurs .

Normal Warning or error

Status indicators

The status of the waste ink bottle is shown as follows.

No error. The indicator changes to show the amount of space available.

:

The waste ink bottle is almost full. Ready a new waste ink bottle.

:

The waste ink bottle is full. Replace with a new waste ink bottle.

:

Introduction 24

Page 25

6 Head strike detection status

This is displayed by the S50670 only.

: The printer checks whether the media lifts during printing.

: The printer does not check whether the media lifts during printing.

See the “The Maintenance Menu” on page 159.

7 Additional print drying system status (system included with the S50670 and optional for other

models)

This display shows settings for the optional additional print drying system.

No icon : Not installed, or it is not installed correctly.

The drying fan is enabled.

:

The drying fan is not enabled. To start the fan, select Additional Dryer for On in the setup menu.

:

See “The Media Setup Menu” on page 152.

Introduction 25

Page 26

Features

This wide-format color ink jet printer supports roll media up to 1626 mm (64 inches) in

width. The main features of this printer are described below.

Realizing High Productivity

Triple Heaters

The three heaters listed below support improved productivity and print quality.

The pre-heater: Warms media before printing to protect the print area from sudden

changes in temperature.

The platen heater: Ensures that the ink adheres evenly.

The after heater: Can be used to rapidly dry ink after printing.

Media Feeding Unit Accommodates High-Capacity Rolls

The standard media feeding unit can handle high-capacity rolls with external diameters of

up to 250 mm (9.8 inches) and weights of up to 40 kg (88.2 lb), ensuring that media require

less frequent replacement.

With the optional heavy roll media system, the printer can handle even larger 80 kg (176.4

lb) rolls with external diameters of 300 mm (11.8 inches).

Auto Take-up Reel Unit Comes Standard

The auto take-up reel unit automatically takes up printed media cleanly, with no wrinkles.

You’ll find it comes in handy for banner printing, high-volume print jobs, and continuous

overnight printing.

High-Capacity Ink Cartridges

The printer uses high-capacity, 700 ml ink cartridges (white cartridges 600 ml, metallic

silver cartridges 350 ml) to ensure productivity, reducing the nuisance of frequent ink

replacements.

High-Speed Printing

The S-Series printers all use the EPSON MicroPiezo® TFT print head(s) for extreme print

speeds.

Introduction 26

Page 27

Additional Print Drying System Available

The additional print drying system (included with the S50670; optional with other models)

can be used for increased drying performance and improved productivity. It is

recommended when using the S70670 in 10 color mode, as the white and metallic silver

inks are slow to dry.

High Print Quality

Smooth Tone Gradations, High-Fidelity Color Reproduction

The S70670 is equipped for light-colored inks (light black, light cyan and light magenta),

reducing grain for continuous tone gradation, while the use of orange ink increases the

color gamut for high-fidelity color reproduction. It is capable of print quality of a level

sufficient for car wraps and indoor display advertising that can be inspected at close range.

Support for White and Metallic Silver Inks

A variety of print effects are available when using the S70670 with white and metallic silver

inks or the S50670 with white ink. The white ink is high opacity, making it suitable for

masking on transparent media (window graphics). Other inks can be printed over white or

metallic silver inks (ink layering), preventing color inks showing through and allowing for a

variety of metallic colors.

Note:

Note the following when using ink layering.

❏ Use media at least 2% longer than specified in document print settings.

❏ Note that the auto take-up reel unit may not function as expected, causing a decline in print

quality.

❏ Some media types, such as banner and canvas, are not supported. Before buying media in

large quantities, try printing on a smaller sample and check the results.

Superior Ease of Use

Easy Media Installation and Take up

The roll and roll core holders require no spindles, eliminating the need to attach spindles

before installing media. Just bring the media to the printer and install it directly. Never

having to juggle long spindles makes installing media a snap even where space is limited.

Introduction 27

Page 28

In addition to roll supports that give you a place to rest media during installation, the printer

offers lift levers that allow heavy media to be effortlessly raised to the level of the roll

holders.

Virtually Odorless Solvent Ink

The distinctive odor of solvent-based inks has been reduced with our solvent inks. This not

only improves the work environment during printing but ensures that items intended for

indoor display can be exhibited in any venue.

Head Strike Detection

The S50670 is equipped with a system for detecting media lift during printing. If the media

lifts during printing, printing will stop to prevent the media coming into contact with the print

head. Stopping printing avoids printing errors and prevents waste of ink and media.

Ease of Maintenance

Print quality can only be ensured through daily maintenance, and the design of this printer

leaves plenty of space for maintenance.

E-Mail Error/Warning Notification

The EpsonNet Config with Web Browser system built into the printer’s network interface

offers e-mail notification. Once configured for e-mail notification, the printer will send errors

and warnings to selected e-mail addresses, ensuring peace of mind when the printer is left

unmanned during overnight operation and in other similar situations.

Lamp and Alarm Error Alerts

When an error occurs, a alarm will sound and the alert lamp will light. The large alert lamp

is highly visible, even at a distance.

A alarm sounds simultaneously to prevent time wasted while stoppages due to errors go

unnoticed.

High-Speed USB/Gigabit Ethernet

The printer comes equipped with high-speed USB and 100 Base-TX/1000 Base-T network

interfaces.

Introduction 28

Page 29

Notes on Usage and Storage

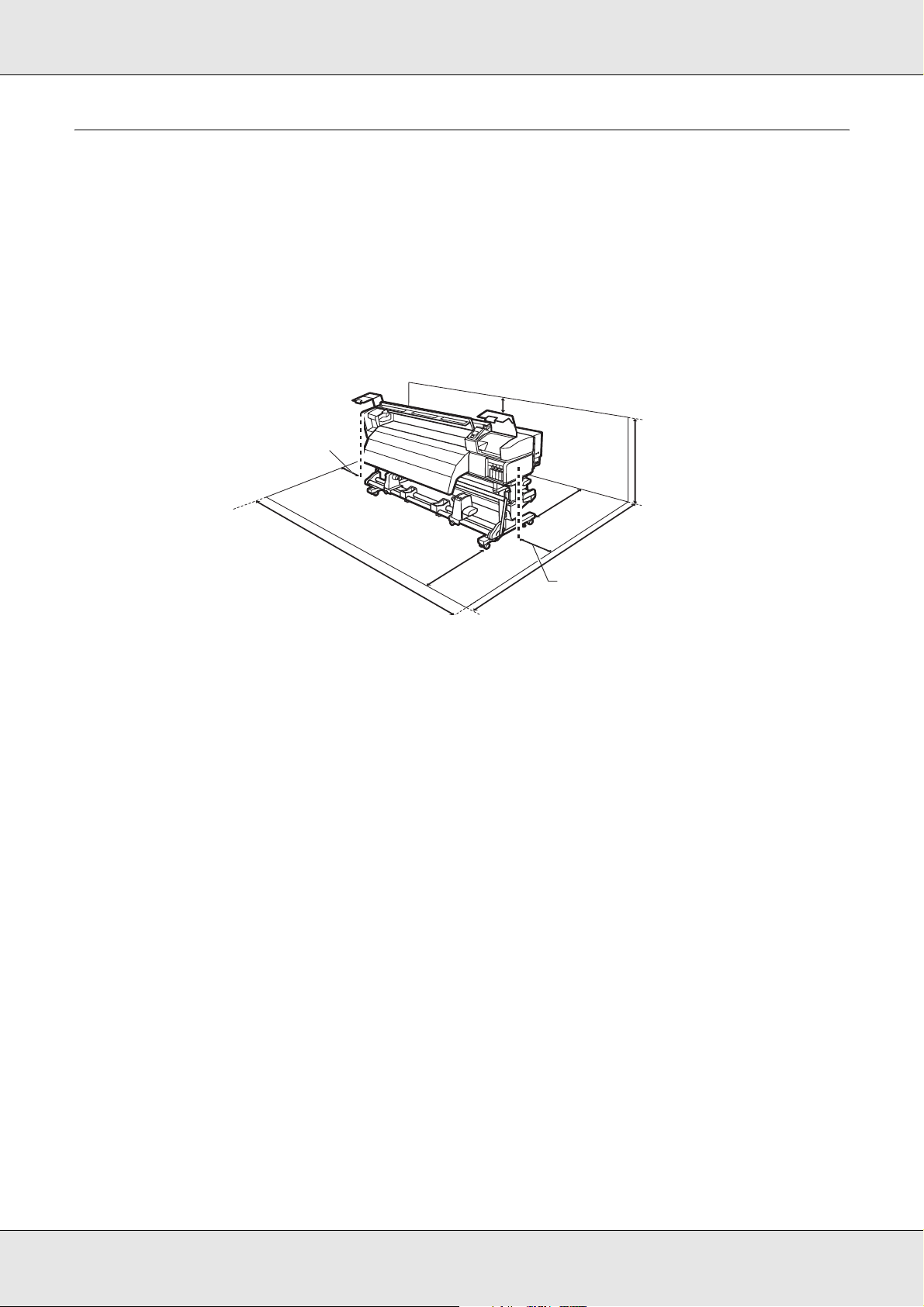

Installation space

Make sure that you secure the following space, clear of any other objects, so that paper

ejection and consumable replacement are not obstructed.

For the external dimensions of the printer, see “Specifications Table” on page 180.

100 mm (3.9 in.)

500 mm (19.7 in.)

3620 mm (142.5 in.)

1000 mm

(39.4 in.)

m

m

.

0

n

0

i

0

4

1

.

9

3

(

2903 mm

(114.3 in.)

500 mm (19.7 in.)

1750 mm

(68.9 in.)

)

Notes when using the printer

Note the following points when using this printer to avoid breakdowns, malfunctions, and

print quality decline.

Additional precautions are required for white and metallic silver inks. See “Specialty Inks”

on page 35.

❏ When using the printer, observe the operating temperature and humidity range

described in the “Specifications Table” on page 180.

Note, however, that the desired results may not be achieved if the temperature and

humidity are within the limits for the printer but not within those for the media. Be sure

the operating conditions suit the media. For more information, see the documentation

supplied with the media.

Also, when operating in dry areas, air conditioned environment, or under direct sunlight,

maintain the appropriate humidity.

❏ Avoid using the printer in locations with heat sources or locations that are exposed to

direct drafts from ventilators or air conditioners. The print head nozzles could dry out

and clog.

Introduction 29

Page 30

❏ Do not bend or tug the waste ink tube. Ink could spill inside or around the printer.

❏ The following components require regular maintenance at recommended intervals or

according to the frequency with which the printer is used. Failure to perform regular

maintenance could result in loss of print quality. In the absence of the appropriate

maintenance, continued use could damage the print head.

See “Regular Maintenance” on page 121.

Component to be cleaned Frequency

Print head Once a week

Wiper

Caps

Wiper rail

When colors in the printout are faint or missing even after head has been

cleaned.

Component requiring

replacement

Flushing pad Once every six months (or more often, depending on usage)

Wiper cleaner

Wiper

Frequency

❏ The print head may not be capped (the print head may not return to the right side) if the

printer is turned off when the media is jammed or an error has occurred. Capping is a

function for automatically covering the print head with a cap (lid) to prevent the print

head from drying out. In this case, turn on the power and wait until capping is performed

automatically.

❏ When the power is on, do not remove the power plug or cut the power at the breaker.

The print head may not be capped properly. In this case, turn on the power and wait

until capping is performed automatically.

❏ The print head is automatically cleaned at a fixed interval after printing to keep the

nozzle from clogging.

Be sure that the waste ink bottle is installed whenever the printer is on.

❏ As well as being expended during printing, ink is used during head cleaning and other

maintenance required to keep the print head in working order.

Introduction 30

Page 31

Notes when not using the printer

If you are not using it, note the following points when storing the printer. If it is not stored

correctly, you may not be able to print properly the next time it is used.

Additional precautions are required for white and metallic silver inks. See “Specialty Inks”

on page 35.

❏ The pressure rollers may crease media left in the printer. The media may also become

wavy or curled, causing jams or resulting in the media coming into contact with the print

head. Remove the media before putting the printer in storage.

❏ Store the printer after confirming that the print head has been capped (the print head is

positioned at the far right). If the print head is left uncapped for a long time, the print

quality may decline.

Note:

If the print head is not capped, turn the printer on, and then turn it off.

❏ Close all covers before placing the printer in storage. If you are not using the printer for

a long time, put an anti-static cloth or cover on the printer to prevent dust build-up. The

print head nozzles are very small, and they can become clogged easily if fine dust gets

on the print head, and you may not be able to print properly.

❏ If you have not used the printer for a long time, check the print head for clogging before

you start printing. Perform head cleaning if the print head is clogged.

See “Checking for clogged nozzles” on page 114.

❏ When storing the printer, be sure that it is level: do not store it on an angle, on end, or

upside down.

Using the S30670 or Printers Without Specialty Inks

Note:

The term “specialty inks” is used for white and metallic silver inks.

❏ If you do not print for a long time, the print head nozzles may become clogged. Turn the

printer on at least once every seven days to prevent the print head clogging. Head

cleaning will be performed automatically after the printer is turned on. Head cleaning

helps maintain print quality. Do not turn the printer off until cleaning is complete.

❏ If the printer will not be used for an extended period, use a cleaning cartridge (available

separately) to wash the heads. Leaving the heads unwashed causes permanent clogs.

Introduction 31

Page 32

Whether head washing is required depends on the length of time the printer will be left

unused.

❏ S70670 (8 color mode): 2 weeks or more

❏ S50670 (4 color mode): 3 weeks or more

❏ S30670: 1 month or more

See the “The Maintenance Menu” on page 159 for more information.

Notes on handling ink cartridges

Note the following points when handling ink cartridges to maintain good print quality.

Additional precautions are required for white and metallic silver inks. See “Specialty Inks”

on page 35.

❏ Extra ink is required to fully charge the print head nozzles the first time the printer is

used.

❏ Store ink cartridges at room temperature in a location that is not exposed to direct

sunlight.

❏ To ensure print quality, use all the ink in the cartridge before the earlier of the following

dates:

❏ The expiration date shown on the ink cartridge packaging

❏ Six months after opening the ink cartridge package

❏ If you move ink cartridges from a cold place to a warm place, leave it at room

temperature for more than four hours before using the ink cartridge.

❏ Do not touch the ink cartridge IC chip.

❏ Fill all slots using ink or replacement cartridges (replacement cartridges are required in

8 and 4 color modes). You cannot print if any of the slots are empty.

❏ Do not leave the printer without ink cartridges installed. The ink in the printer will dry out

and the printer will not function as expected. Leave ink cartridges or replacement

cartridges in all slots even while you are not using the printer.

❏ Because the green IC chip contains the cartridge’s own information such as the

remaining ink level, you can still reinstall and use the ink cartridge after removing it from

the printer.

Introduction 32

Page 33

❏ Use a cleaning stick from the supplied maintenance kit to wipe ink from the ink supply

port of cartridges that have been removed from the printer before all the ink is used.

Dried ink on the supply port may cause ink leaks when the cartridge is reinserted and

used.

While cartridges are in storage, keep the ink supply ports free of dust. The ink supply

port has a valve in it so it does not need to be capped.

❏ Removed ink cartridges may have ink around the ink supply port, so be careful not to

get any ink on the surrounding area when removing the cartridges.

❏ To maintain the quality of the print head, this printer stops printing before ink cartridges

are completely expended.

❏ Although the ink cartridges may contain recycled materials, this does not affect printer

function or performance.

❏ Do not dismantle or remodel ink cartridges. You may not be able to print properly.

❏ Do not drop or knock cartridges against hard objects; otherwise, the ink may leak.

❏ With the exception of white and metallic silver, ink cartridges must be removed and

shaken thoroughly once every three weeks.

See “How to replace” on page 143.

❏ Do not insert or remove replacement cartridges during printing.

Handling Media

Note the following when handling or storing media. Media that is in poor condition will not

produce good quality prints.

Be sure to read the documentation provided with each type of media.

Introduction 33

Page 34

Notes on Handling

❏ Do not fold the media or damage the printable surface.

❏ Do not touch the printable surface. Moisture and oils from your hands can affect print

quality.

❏ When handling media, hold it by both edges. We recommend wearing cotton gloves.

❏ Keep the media dry.

❏ Packaging materials can be used to store media and should not be thrown away.

❏ Avoid locations that are subject to direct sunlight, excessive heat, or humidity.

❏ When not in use, media should be removed from the printer, rewound, and inserted in

its original packaging for storage. Leaving media in the printer for extended periods

may cause it to deteriorate.

Handling Media After Printing

To maintain long lasting, high quality print results, note the following points.

❏ Do not rub or scratch the printed surface. If they are rubbed or scratched, the ink may

peel off.

❏ Do not touch the printed surface, as this may remove the ink.

❏ Make sure printouts are completely dry before folding or stacking, as otherwise

discoloration or other marks may appear where the prints touch. These marks will

disappear if the prints are immediately separated and dried but will become permanent

if the surfaces are not separated.

❏ Avoid direct sunlight.

❏ To prevent discoloration, display and store prints as instructed in the documentation

supplied with the media.

Introduction 34

Page 35

Specialty Inks

The term “specialty inks” is used for white and metallic silver inks. White and metallic silver

inks are prone to settling (components settling to the bottom of the liquid). Using the ink in

this state can cause a decline in print quality and printer malfunction. This section

describes precautions for handling white and metallic silver inks. The S30670 does not

support specialty inks.

Cautions

❏ When specialty inks are installed, maintenance will be performed automatically to

prevent ink accumulating in the printer and causing clogs. Because turning the printer

off prevents maintenance being performed, leading to printer malfunction, we

recommend that the printer not be turned off.

❏ White and metallic silver ink cartridges must be stored flat (i.e., laid on their sides). If the

cartridges are stored on end, agitating the cartridges before use may fail to dissolve the

materials that have precipitated from the ink (i.e., settled to the bottom of the liquid)

during storage.

❏ If the printer will not be used for seven days or more, use a cleaning cartridge (available

separately) to wash the heads. You will have to drain all channels, not just the white and

metallic silver. Leaving the heads unwashed causes permanent clogs. See “The

Maintenance Menu” on page 159 for more information.

Maintenance

The maintenance required to keep the printer in good working order can be divided into

routine maintenance and tasks that the printer performs automatically.

Auto Maintenance

To prevent malfunctions caused by settling of the white and metallic silver inks, the printer

automatically cycles the ink if no operations are performed for some time after printing or

after the printer is turned on.

Automatic maintenance is performed if the printer is on; no user intervention is required.

Daily Maintenance

❏ White and metallic silver ink cartridges must be removed and thoroughly shaken once

every 24 hours. See “How to replace” on page 143.

Introduction 35

Page 36

❏ If print results are uneven, circulate or refresh the ink. See “Maintenance Procedures

for Specialty Inks” on page 117.

Using the Supplied Software

Contents of the Software CD

The following applications are available on the supplied software CD. Install as required.

For information about these applications, see the on-line help for the application in

question.

Note:

❏ The supplied disk does not contain printer drivers. A software RIP is required for printing.

❏ The latest applications can be downloaded from the EPSON website.

Software Name Summary

EPSON LFP Remote Panel 2 EPSON LFP Remote Panel 2 is used to update firmware from a computer and copy the media

settings bank created in the printer’s setup menu to a computer.

See “Starting EPSON LFP Remote Panel 2” on page 36 and “Exiting EPSON LFP Remote Panel 2” on

page 37.

Drivers and utilities Install the EPSON communications driver (EPSON SC-S30600 Series Comm Driver).

The EPSON communications driver is required if the EPSON LFP Remote Panel 2 is to be used to

copy media settings. It is not a printer driver. In addition, the software RIP may not display printer

status if the EPSON communications driver is not installed when the printer is connected to a

computer via USB. See the software RIP documentation for more information on the status display.

Network utility Install and launch a wizard that will help you enter IP addresses for a simple network connection.

EPSONNet Config With this software, you can configure various network settings for the printer from your computer.

This is useful as it allows you to enter addresses and names using the keyboard.

Starting EPSON LFP Remote Panel 2

Launch EPSON LFP Remote Panel 2 after confirming that the printer displays Ready.

1. The application can be launched using either of the following two methods.

❏ Double-click the EPSON LFP Remote Panel 2 icon on the desktop. The EPSON LFP Remote

Panel 2 icon is created when the application is installed.

❏ Click Start > All Programs (or Programs) > EPSON LFP Remote Panel 2 > EPSON LFP Remote

Panel 2.

Introduction 36

Page 37

2. Click the desired item in the EPSON LFP Remote Panel 2 main window.

See EPSON LFP Remote Panel 2 help for more information.

Exiting EPSON LFP Remote Panel 2

Click Finish in the EPSON LFP Remote Panel 2 main window.

Uninstalling Software

Important:

❏ Log in to an “Computer administrator” account (an account with Administrators group

privileges).

❏ Enter the administrator password when prompted and then proceed with the remainder of the

operation.

❏ Exit any other applications that may be running.

This section describes how to uninstall EPSON LFP Remote Panel 2 and the EPSON

communications driver.

1. Turn off the printer, and unplug the interface cable.

2. Go to the Control Panel and click Uninstall a program from the Programs category.

In Windows XP, go to the Control Panel and click Add or Remove Programs.

3. Select the software you want to remove and then click Uninstall/Change (or

Change/Remove).

Selecting the following deletes the Epson communications drivers:

❏ EPSON SC-S70670 Series Comm Driver Printer Uninstall

❏ EPSON SC-S50670 Series Comm Driver Printer Uninstall

❏ EPSON SC-S30670 Series Comm Driver Printer Uninstall

To uninstall EPSON LFP Remote Panel 2, select EPSON LFP Remote Panel 2.

Introduction 37

Page 38

4. Select the target printer icon, and then click OK.

5. Follow the on-screen instructions to continue.

When the delete confirmation message appears, click Yes.

If you are reinstalling the EPSON communications driver, restart the computer.

Introduction 38

Page 39

Chapter 2

Basic Operations

Loading and Exchanging Media

The process for loading media varies with the model of printer or type of media feeding unit

used. Choose the method suited to your particular setup.

Caution:

❏ The heaters and media holding plates may be hot; observe all necessary precautions.

c

Failure to observe the necessary precautions could result in burns.

❏ Be careful not to trap your hands or fingers when opening or closing the front cover.

Failure to observe this precaution could result in injury.

❏ Do not rub your hands along the edges of the media. The edges of the media are sharp

and can cause injury.

Important:

Load media immediately before printing. The pressure rollers may crease media left in the

printer. The media may also become wavy or curled, causing jams or resulting in the media

coming into contact with the print head.

Note:

For information on the media that can be used in the printer, see “Supported Media” on page

177.

Loading Media - S70670/S50670

The procedure for loading media varies depending on whether you are using the installed

media feeding unit or the optional heavy roll media system.

Follow the steps below when using the supplied media feeding unit.

When the Heavy Roll Media Feeding Unit is installed, see “Using the Optional Heavy Roll

Media Feeding Unit” on page 68.

Basic Operations 39

Page 40

When the Standard Media Feeding Unit Is Installed

This section uses the S70670 to illustrate the process of loading media when the supplied

media feeding unit is installed.

Caution:

Because the media is heavy, it should not be carried by one person. When loading or

c

removing the media, use at least two persons.

1. Turn on the printer by pressing the P button.

Important:

When white and metallic silver inks are installed, maintenance will be performed

automatically to prevent ink accumulating in the printer and causing clogs. Because turning

the printer off prevents maintenance being performed, leading to printer malfunction, we

recommend that the printer not be turned off.

2. Loosen the roll holder fixing screws and adjust the roll holders so that the gap between

the two is wider than the media.

Center the roll supports between the roll holders.

Important:

If the right holder handle shaft is not visible, rotate the holder forward until it stops. The

media can not be properly loaded if the handle shaft is not visible.

3. Place media on the roll supports oriented according to how it is rolled (see below) and

position it as indicated by the mark on the label.

Basic Operations 40

Page 41

Printable side out

Printable side in

Note:

Be sure the option selected for Roll Type in the Customize Settings menu matches how

the media is rolled. Roll Type defaults to Printable Side Out. Be sure to select Printable

Side In after loading media rolled printable side in. For more information see “Roll Type”

on page 98.

4. Place the left edge of the media in any of the black squares on the bar in back of the

printer and the right edge on any of the holes on the back of the printer.

The recommended positions for media of different widths are shown below.

See “Positioning Media of Different Widths” on page 107.

Basic Operations 41

Page 42

Note:

If the label with black squares is not in place, affix the label as described in the Setup

Guide.

5. Raise the lift lever on the left side of the printer to lift the media into position, then firmly

insert the roll holder.

If the roll of media has an outer diameter which is less than 140mm (5.5 inches), lift it

up by your hands, and set it to the roll holder. The roll core will not reach the holder

when raised using the lift lever.

6. Tighten the roll holder screw to fix the roll holder in place.

7. Raise the lift lever on the right side of the printer to lift the media into position, then firmly

insert the roll holder.

Basic Operations 42

Page 43

If the roll of media has the outer diameter which is less than 140mm (5.5 inches), lift it

up by your hands, and set it to the roll holder as described in Step 5.

8. Tighten the roll holder screw to fix the roll holder in place.

Basic Operations 43

Page 44

9. Rotate the handle until part A in the illustration below is fully inserted.

Important:

Once part A is hidden, do not turn the handle any further. Failure to observe this precaution

could damage the roll holder.

10.Raise the media loading lever.

Basic Operations 44

Page 45

11.Pull out the media and insert it into the printer.

Note:

Media that is heavy and difficult to unroll can be fed by pressing the drive switch on the left

roll holder.

Printable Side Out

Printable Side In

12.Insert the media past the pressure rollers and lower the media loading lever to hold it in

place.

13.Go to the front of the printer and open the front cover.

Basic Operations 45

Page 46

14.Hold the center of the media and raise the media loading lever.

15.Pull the media straight forward until the edge is past the label on the left side of the after

heater.

Keep the right edge of the media parallel with the scale markings on the two labels on

the right side of the after heater.

Important:

Perform Steps 14 to 3 in reverse order and repeat the loading process if the right edge of

the media is not within the scale markings. Do not attempt to reposition the roll holders

while they are inserted in the media.

16.Adjust the position of the pressure rollers.

The low pressure rollers are used for normal printing, the high pressure rollers for ink

layering. Their positions vary with the width of the media and the rollers used.

Basic Operations 46

Page 47

Position the low pressure rollers 5 mm (0.20 inch) and the high pressure rollers 10 mm

(0.39 inch) from the edges of the media, keeping them in the bounds shown by the

black labels (see “Printable area - S70670/S50670” on page 107, “Printable Area S30670” on page 110, and “High Print Quality” on page 27).

17.Move unused rollers and rollers that can not be positioned over the media to the sides

of the black labels.

18.Lower the media loading lever to hold the media in place.

To print immediately, proceed to Step 19.

For information on loading the media into the auto take-up reel unit, see “Using the Auto

Take-up Reel Unit” on page 82.

Basic Operations 47

Page 48

Note:

If you would prefer to print from the very start of the roll, press the u button in the control

panel to rewind the media slightly.

Be sure, however, to stop rewinding before the leading edge of the media is over the cutter

groove (on the pressure roller side).

19.Attach the media holding plates at either side of the media.

First, position the plates so that the edges of the media are in the centers of the round

holes. Next, adjust the position until the white line is visible in the square window and

push the plates down to lock them in place and keep them from lifting.

Basic Operations 48

Page 49

Important:

❏ Do not use the media holding plates with media that is more than 0.4 mm (0.02 inch)

thick. The media holding plates could touch and damage the print head.

❏ Move the media holding plates to the left and right edges of the platen when they are

not in use.

❏ Do not use the media holding plates if the sides of the printed media are smudged or

torn.

❏ Leave left and right margins of over 10 mm (0.39 inch) when using the media holding

plates. Narrower margins could result in printer printing over the plates (this does not

apply when ink layering is used).

20.Close the front cover.

Using the Optional Heavy Roll Media Feeding Unit

This section uses the S70670 to illustrate how to load media when the optional heavy roll

media feeding unit is installed.

We recommend using a lifter for media over 40 kg (88.2 lb).

The explanation that follows assumes that a lifter is used.

The following types of lifter can be used.

❏ Fork or platform thickness: 28 mm (1.10 inches) or less

❏ The fork or platform can be lowered to approx. 190 mm (7.5 inches) from the floor.

Caution:

Because the media is heavy, it should not be carried by one person. When loading or

c

removing the media, use at least two persons. Using a lifter is recommended when

handling a media that is 40 kg (88.3 lb) or heavier.

1. Turn on the printer by pressing the P button.

Basic Operations 49

Page 50

Important:

When white and metallic silver inks are installed, maintenance will be performed

automatically to prevent ink accumulating in the printer and causing clogs. Because turning

the printer off prevents maintenance being performed, leading to printer malfunction, we

recommend that the printer not be turned off.

2. Loosen the roll holder fixing screws and adjust the roll holders so that the gap between

the two is wider than the media.

Important:

If the right holder handle shaft is not visible, rotate the holder forward until it stops. The

media can not be properly loaded if the handle shaft is not visible.

3. Temporarily place media on the lifter oriented according to how it is rolled (see below)

Printable side out

Basic Operations 50

Page 51

Printable side in

Note:

Be sure the option selected for Roll Type in the Customize Settings menu matches how

the media is rolled. Roll Type defaults to Printable Side Out. Be sure to select Printable

Side In after loading media rolled printable side in.

For more information, see “Roll Type” on page 98.

4. Place the left edge of the media in any of the black squares on the bar in back of the

printer and the right edge on any of the holes on the back of the printer.

The recommended positions for media of different widths are shown below.

See “Positioning Media of Different Widths” on page 107.

Note:

If the label with black squares is not in place, affix the label as described in the Setup

Guide.

Basic Operations 51

Page 52

5. Align the media and the roll holders.

Raise or lower the lifter until the media roll core is level with the roll holders.

6. Fully insert the left roll holder. Next, tighten the roll holder screw to fix the roll holder in

place.

7. Fully insert the right roll holder. Next, tighten the roll holder screw to fix the roll holder in

place.

Basic Operations 52

Page 53

8. Remove the lifter.

9. Rotate the handle until part A in the illustration below is fully inserted.

Important:

Once part A is hidden, do not turn the handle any further. Failure to observe this precaution

could damage the roll holder.

If part A is not hidden even after turning the handle until it can no longer be turned, return

to step 7 and fully press the right unit into the roll core.

10.Raise the media loading lever.

Basic Operations 53

Page 54

11.Pull out the media and insert it into the printer.

Note:

Media that is heavy and difficult to unroll can be fed by pressing the drive switch on the left

roll holder.

Printable Side Out

Printable Side In

12.Insert the media past the pressure rollers and lower the media loading lever to hold it in

place.

13.Go to the front of the printer and open the front cover.

Basic Operations 54

Page 55

14.Hold the center of the media and raise the media loading lever.

15.Pull the media straight forward until the edge has past the label on the left side of the

after heater.

Keep the right edge of the media parallel with the scale markings on the two labels on

the right side of the after heater.

Important:

Perform Steps 14 to 3 in reverse order and repeat the loading process if the right edge of

the media is not within the scale markings. Do not attempt to reposition the roll holders

while they are inserted in the media.

16.Adjust the position of the pressure rollers.

The low pressure rollers are used for normal printing, the high pressure rollers for ink

layering. Their positions vary with the width of the media and the rollers used.

Basic Operations 55

Page 56

Position the low pressure rollers 5 mm (0.20 inch) and the high pressure rollers 10 mm