Page 1

Quick Reference Guide

Guía de referencia rápida

Guia de referência rápida

EPSON® SureColor® S-Series

Page 2

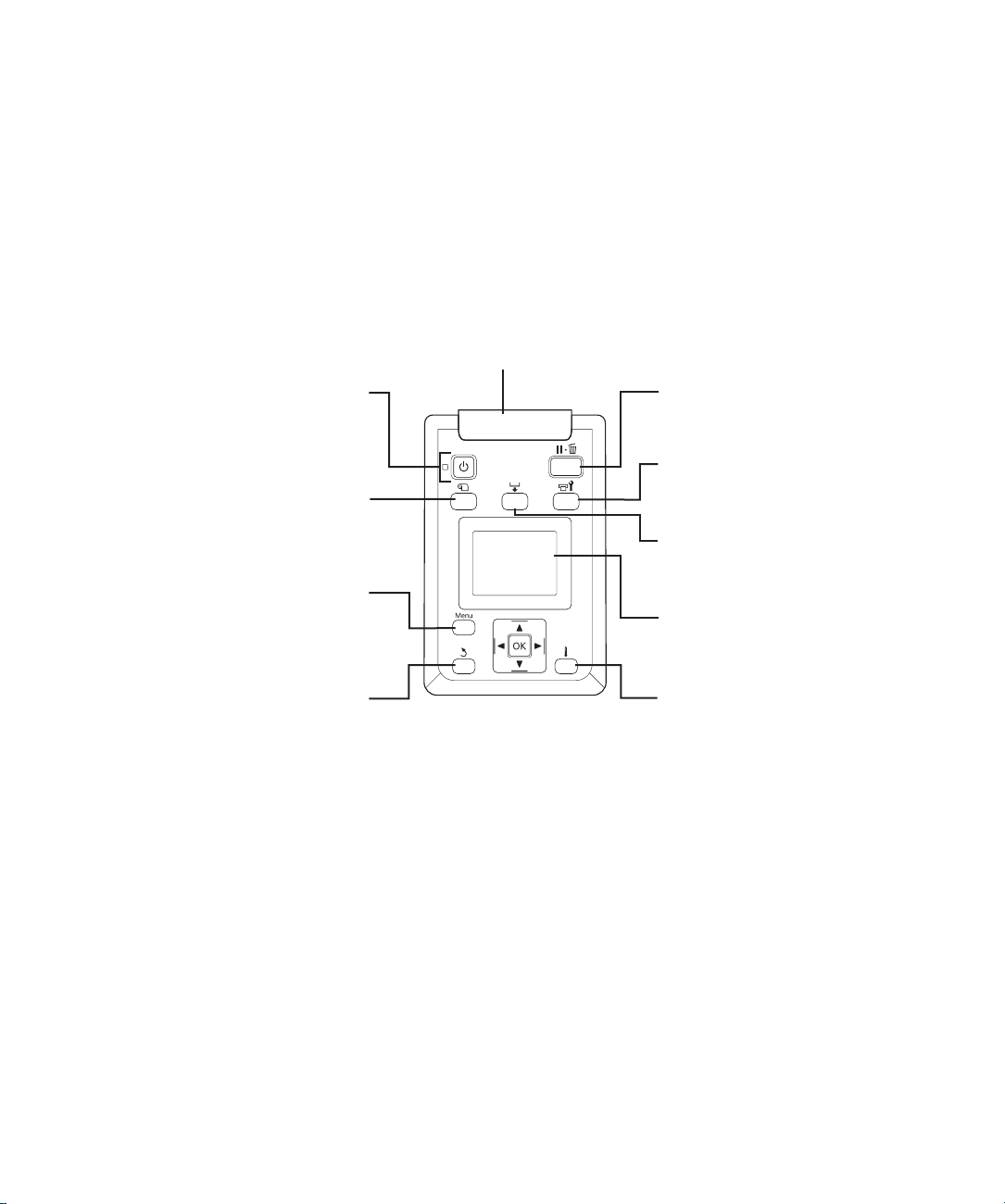

Control Panel

Panel de control

Painel de controle

Alert light

Indicador de alerta

Luz de alerta

Power button and light

Botón e indicador de encendido

Botão e luz de energia

Media setup button

Botón de configuración del papel

Botão de configuração de mídia

Menu button

Botón Menu

Botão menu

Back button

Botón de volver

Botão voltar

Pause/cancel button

Botón de pausa/cancelar

Botão Pausar/Cancelar

Maintenance button

Botón de mantenimiento

Botão de manutenção

Media feed button

Botón de alimentación del papel

Botão de alimentação de mídia

LCD display

Pantalla LCD

Visor LCD

Heating and drying button

Botón de calentamiento y secado

Botão de aquecimento e secagem

Page 3

Contents

Printer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Front - S30670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Inside - S30670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Front - S50670 and S70670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inside - S50670 and S70670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Using the Auto Take-up Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cutting Off and Removing Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuring Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pre-Printing Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Creating Media Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Performing Auto Feed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Performing Auto Head Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning the Media System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Checking and Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Maintaining the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Checking Ink Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replacing Ink Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Washing the Ink System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cleaning the Print Head, Wiper, Caps, and Wiper Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Disposing of Waste Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Replacing the Wiper, Wiper Cleaner, and Flushing Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Ordering Supplies and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Where to Get Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

English

Page 4

2 | Printer Parts

Flushi

d

Printer Parts

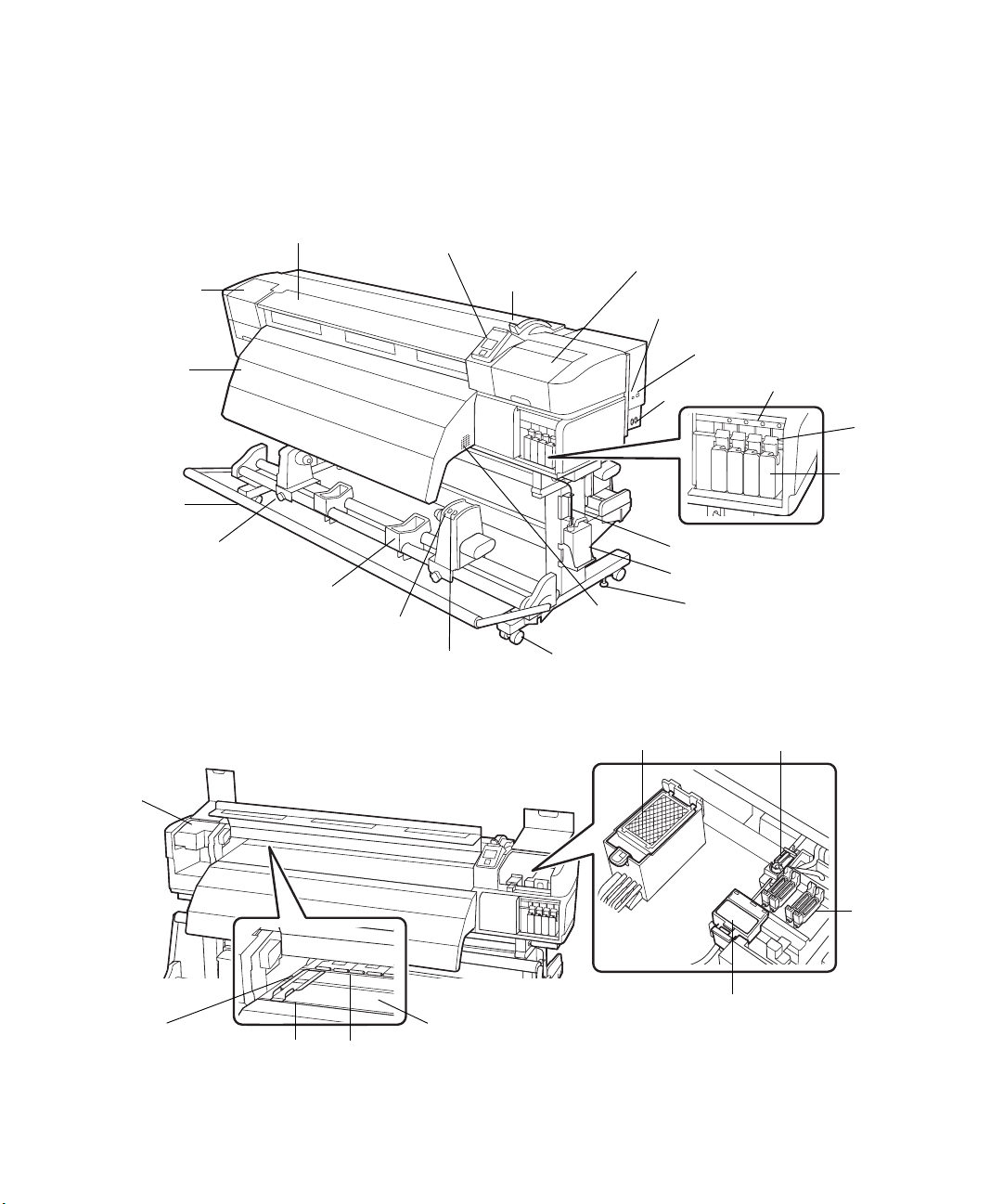

Front - S30670

Left maintenance

cover

After heater

Tensioner

Roll locking screw

Inside - S30670

Print head in

maintenance

position

Front cover

Roll support

Control panel

Auto switch

Manual switch

Media

loading lever

Caster

Right maintenance

cover

USB port

LAN port

AC inlets

Waste ink tube

Waste ink tank

Vent

Adjuster

ng pa

Cartridge

check lights

Lock

levers

Ink

cartridges

Wiper

Media

holding plate

Cutter

groove

Pressure

rollers

Platen heater

Nozzle

caps

Wiper cleaner

Page 5

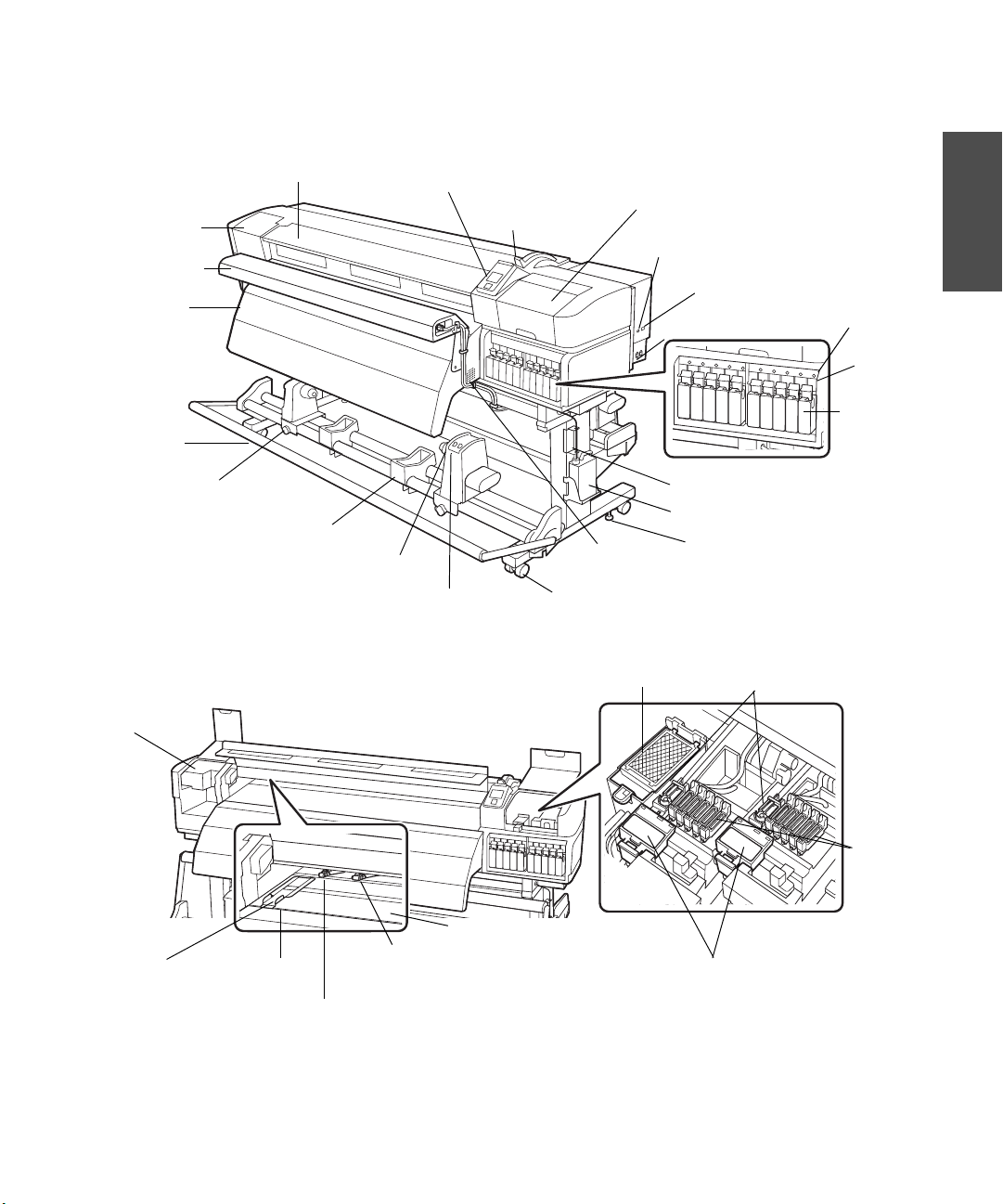

Front - S50670 and S70670

Flushi

d

Left maintenance

cover

High speed dryer

After heater

Tensioner

Front cover

Control panel

Media

loading lever

Front - S50670 and S70670 | 3

Right maintenance

cover

USB port

LAN port

AC inlets

Cartridge

check lights

English

Lock

levers

Ink

cartridges

Roll locking screw

Roll support

Auto switch

Inside - S50670 and S70670

Print head in

maintenance

position

Media

holding plate

Cutter

groove

High pressure

rollers (green)

Manual switch

Platen heater

Low pressure

rollers (white)

Caster

Vent

Waste ink tube

Waste ink tank

Adjuster

ng pa

Wiper cleaners

Wipers

Nozzle

caps

Page 6

4 | Back

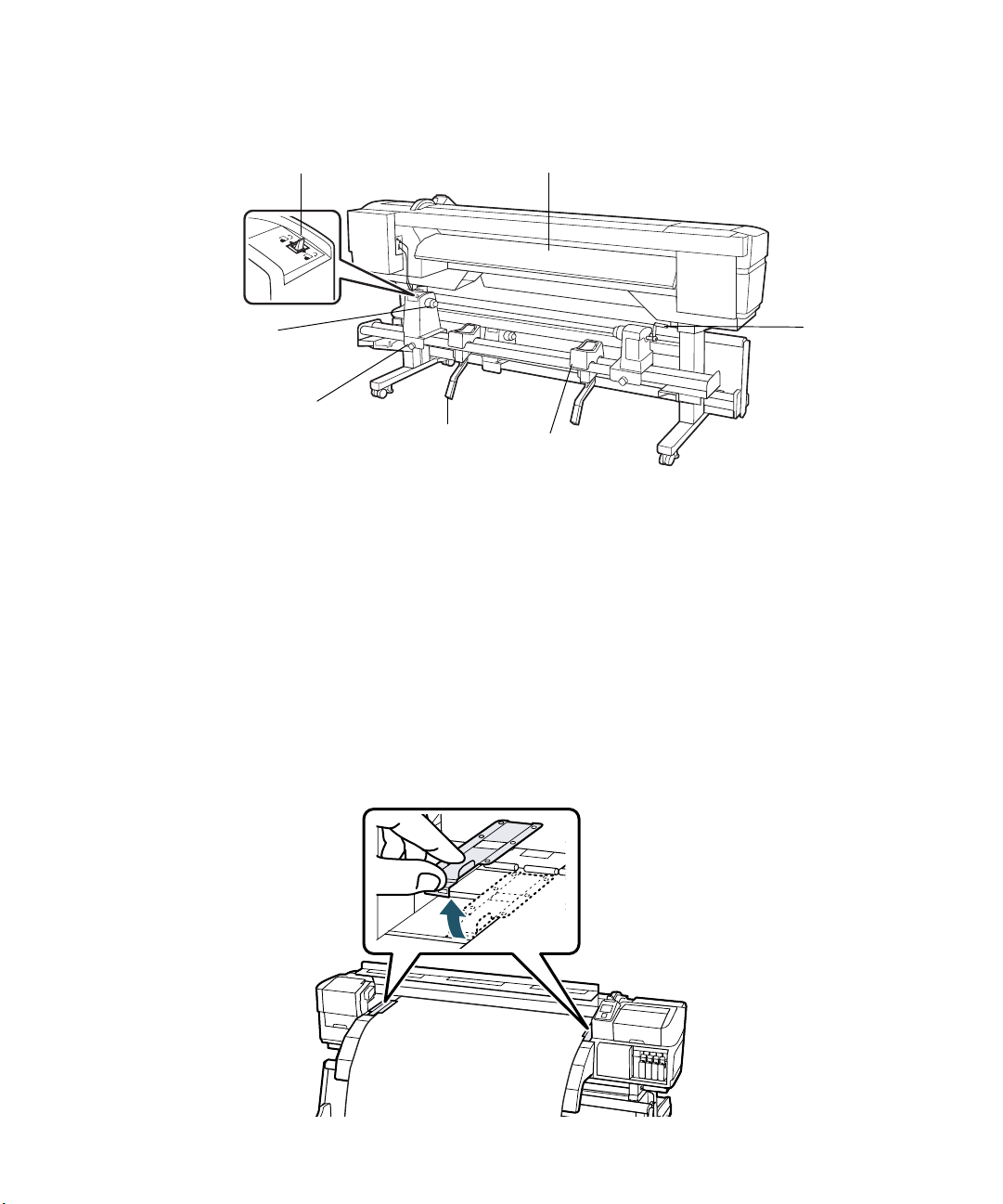

Back

Drive switch

Pre-heater

Roll holder

Roll locking

screw

Lift lever

Roll support

Handle

Loading Media

Before you start, make sure the printer is turned on. Follow these steps to use the built-in media feeding

unit. If you are using the optional heavy roll media system, see the on-screen User’s Guide for instructions.

Unless otherwise noted, the illustrations show the S30670, but the instructions in this manual apply to all

three models.

WARNING: The heaters and media holding plates may be hot; be careful to avoid burns. Heavy media rolls may

require two people for loading and removing.

Caution: Load media immediately before printing to avoid creases and curling.

Open the front cover and remove the media holding plates.

1.

Page 7

Loading Media | 5

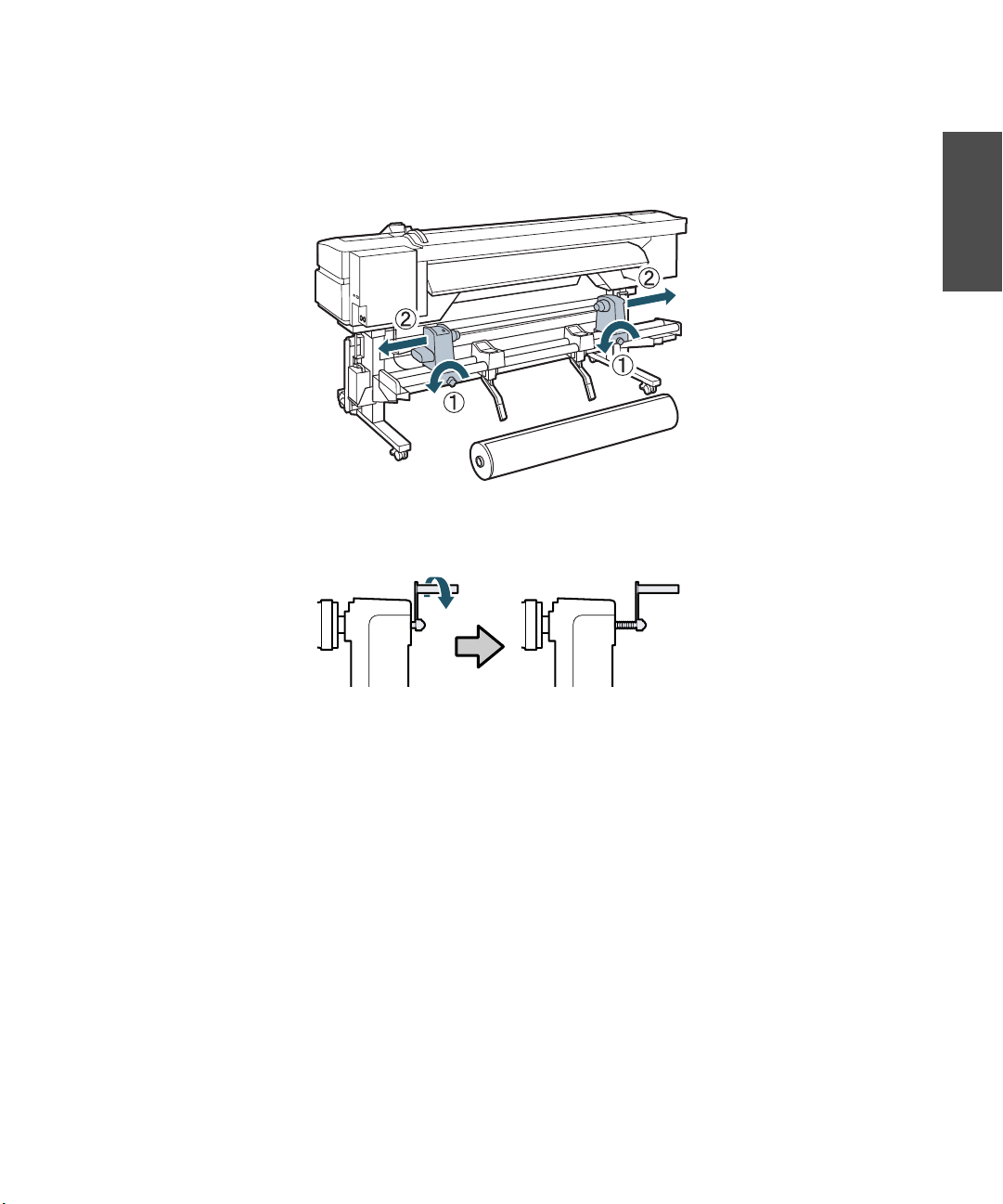

2. At the back of the printer, loosen the roll locking screws and slide the roll holders apart. Center the roll

supports between the holders.

Note: If you don’t see the right holder handle shaft, rotate the holder forward until it stops.

English

Page 8

6 | Loading Media

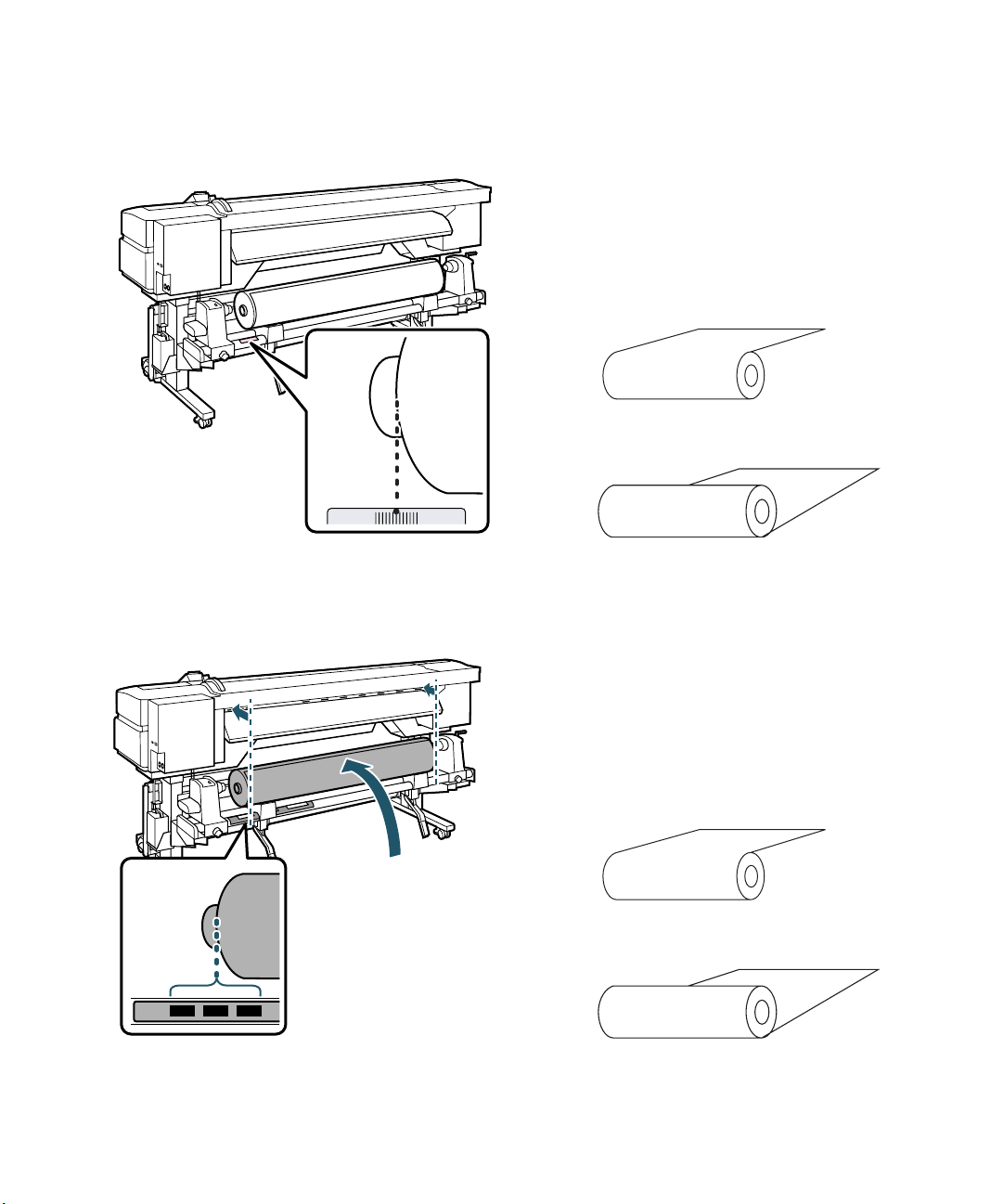

3. For the S30670, place the media on the roll supports and make sure the left edge is aligned as shown.

Orient the roll based on the printable side

Printable side out

Printable side in

For the S50670/S70670, place the left edge of the media in any of the black squares on the bar in back

of the printer and the right edge on any of the holes on the back of the printer. If the label with black

squares is not in place, attach it as described in the Setup Guide.

Orient the roll based on the printable side

Printable side out

Printable side in

Page 9

Loading Media | 7

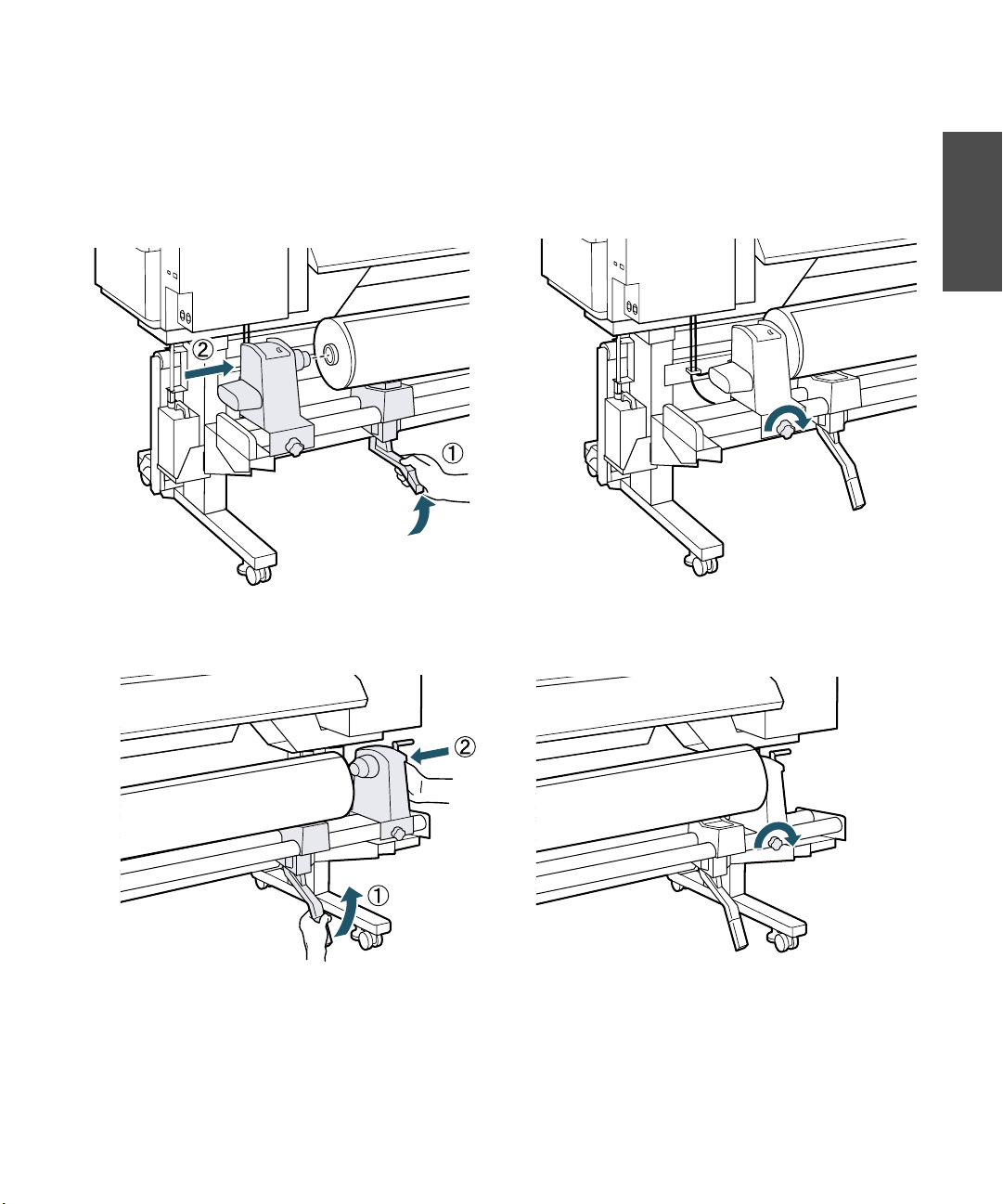

4. Raise the left lift lever to position the roll, then firmly insert the left roll holder. If the roll diameter is

less than 5.5 inches (140 mm), lift it manually to reach the roll holder.

Then tighten the roll holder screw.

English

5. Raise the right lift lever and insert the right roll holder, then tighten the right roll holder screw.

Page 10

8 | Loading Media

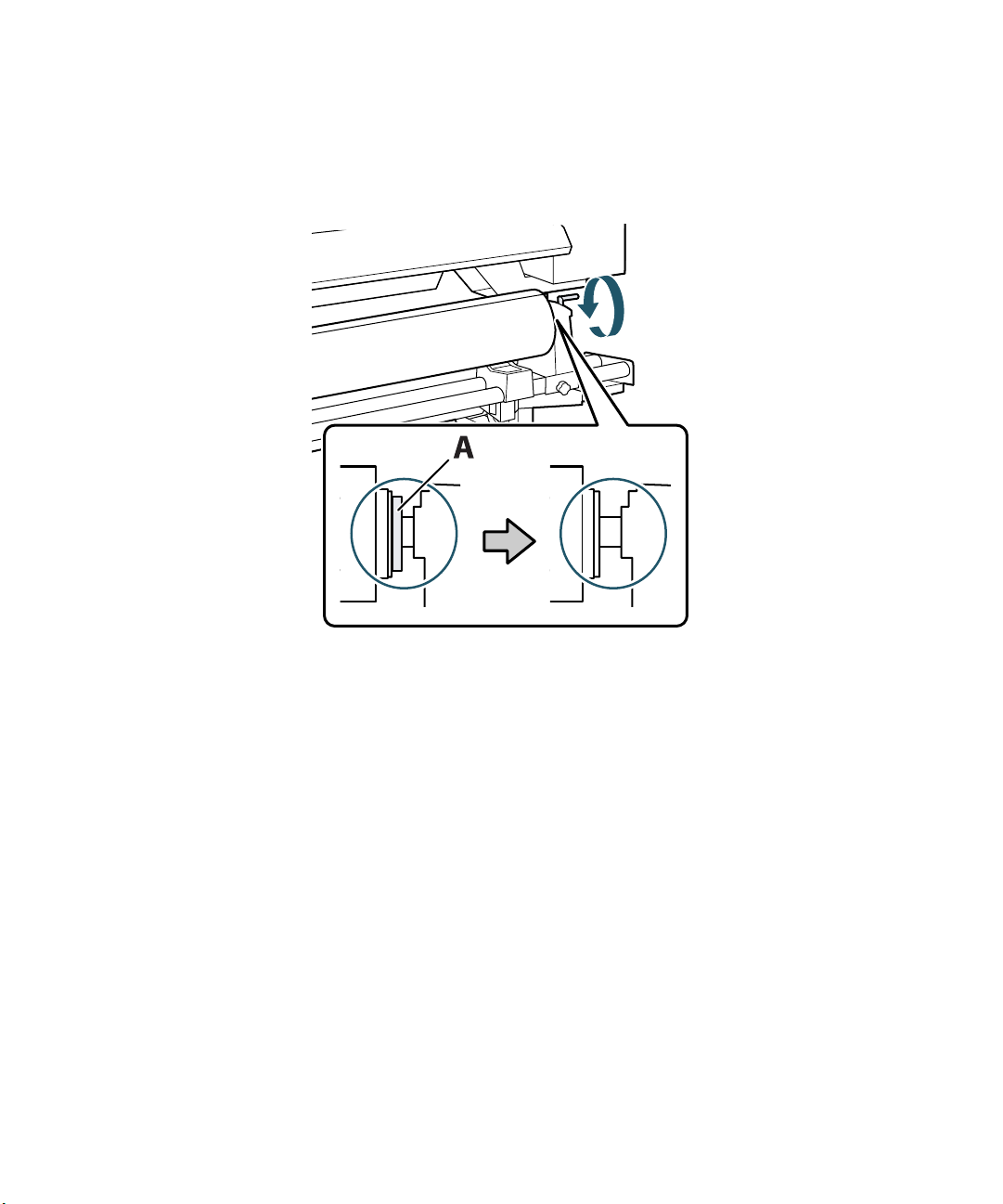

6. Rotate the handle until part A in the illustration below (the purple section) is fully inserted.

Caution: To avoid damaging the roll holder, do not continue turning the handle after part A is fully inserted.

Page 11

Loading Media | 9

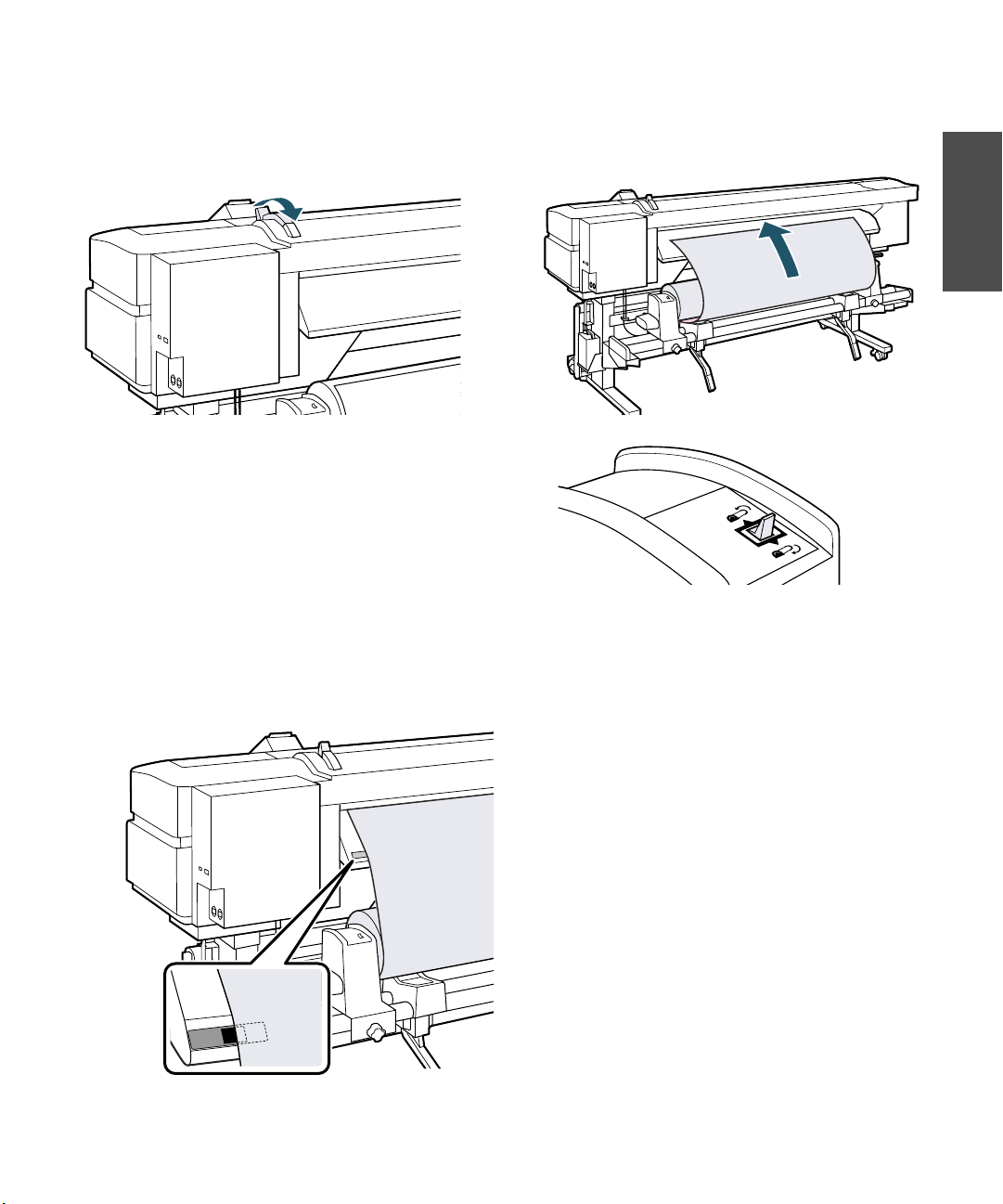

7. Raise the media loading lever, then pull out the media by hand and insert it into the printer.

English

Note: If the media is heavy and difficult to unroll, press the

drive switch on the left roll holder. Press the switch up or

down based on the orientation of the paper on the roll. You

can also pull out the media manually.

Insert the media past the pressure rollers.

8.

Printable

side out

Make sure the left edge of the media passes over the center of the square in the label on the pre-heater

(the media sensor). To avoid media skew, feed extra media, then use the motor to wind it back on the

roll.

Caution: If the left edge of the media is not in the

right position, perform steps 7 to 2 in reverse

order and restart the loading process. Do not

attempt to reposition the roll holders while they

are inserted in the media roll.

Printable

side in

Page 12

10 | Loading Media

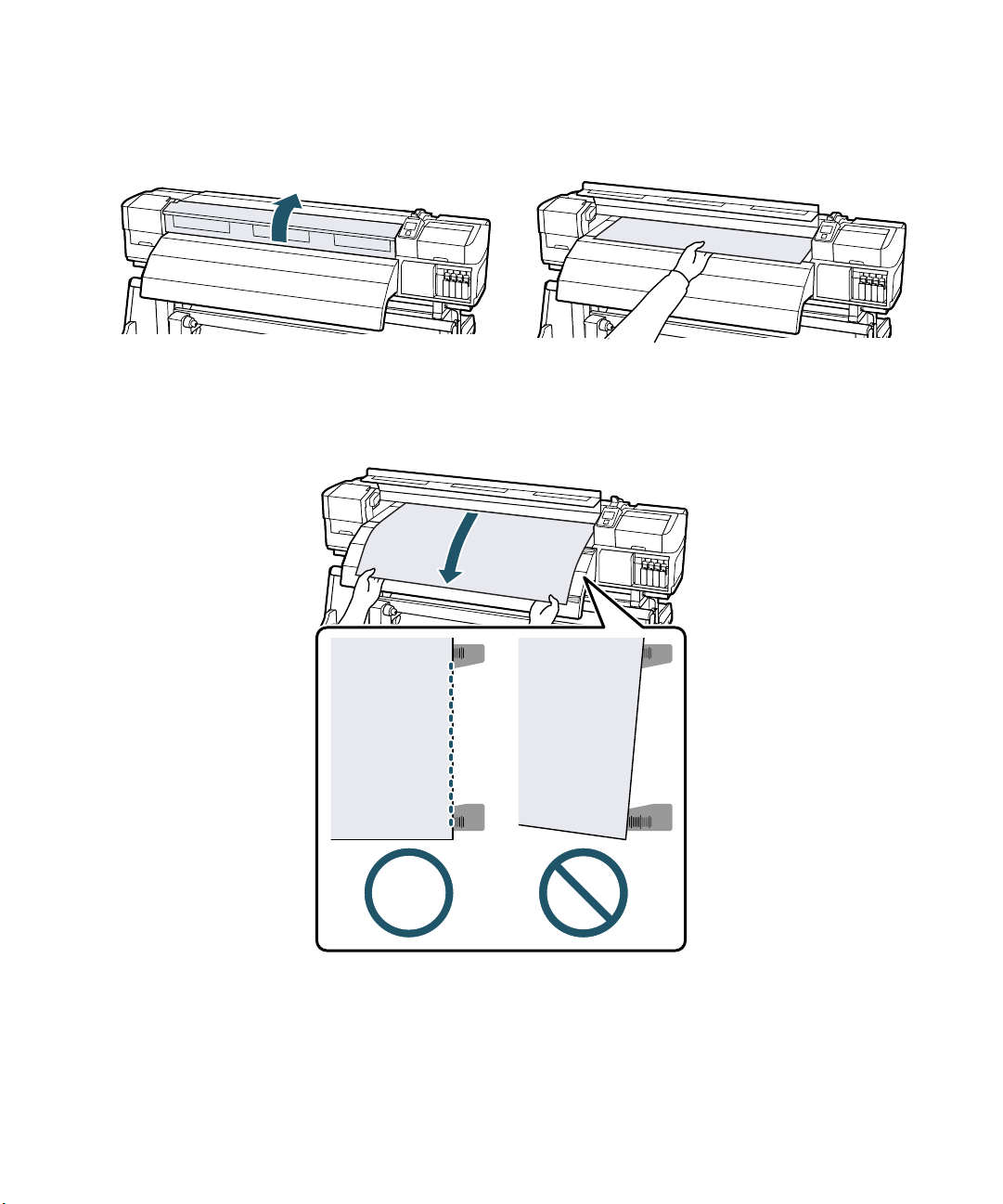

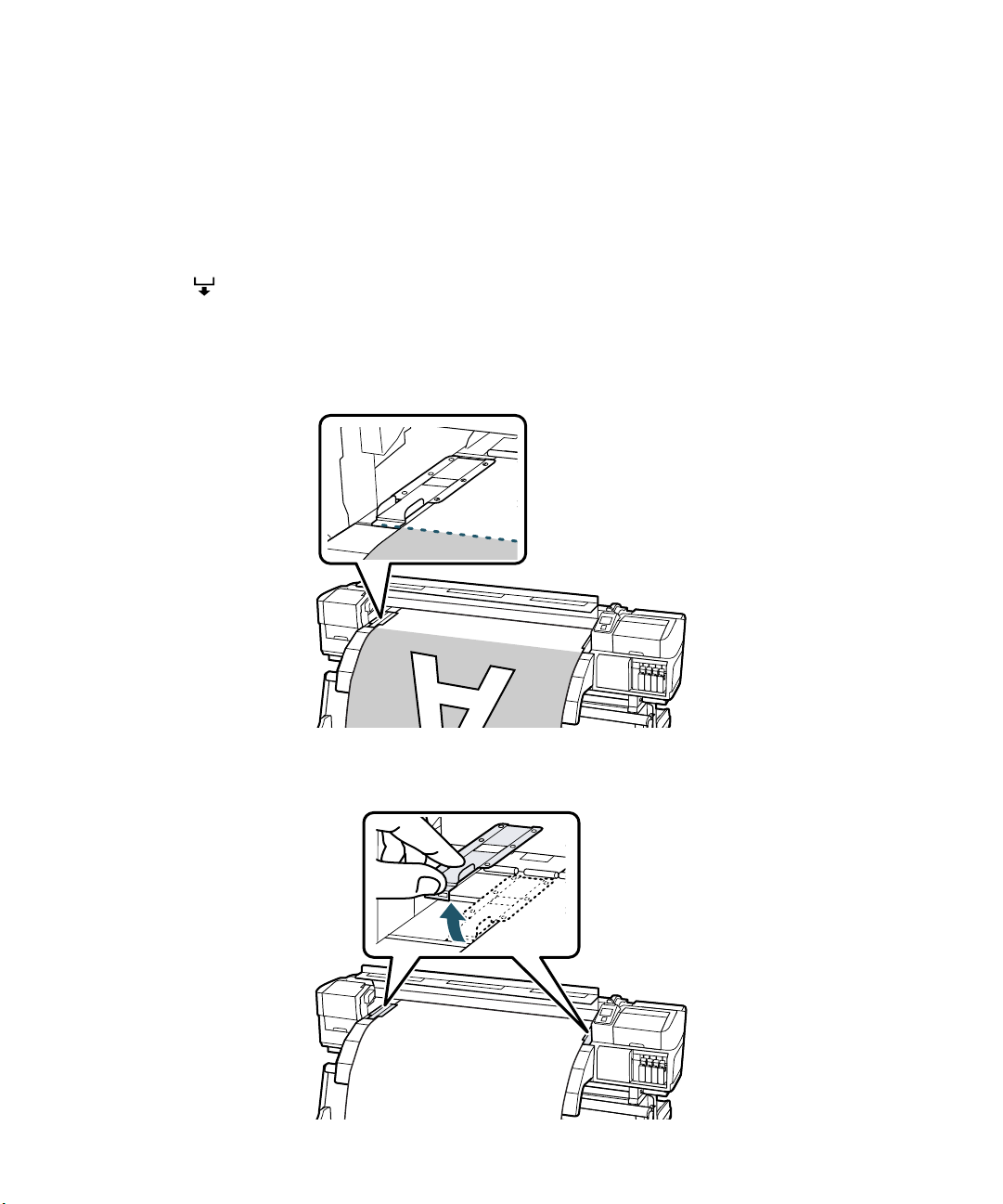

9. Move to the front of the printer, make sure the front cover is open, and grasp the media as shown.

10. Pull the media straight forward past the label on the left side of the after heater.

Keep the right edge of the media parallel to the scale markings on the right side of the after heater.

Page 13

Loading Media | 11

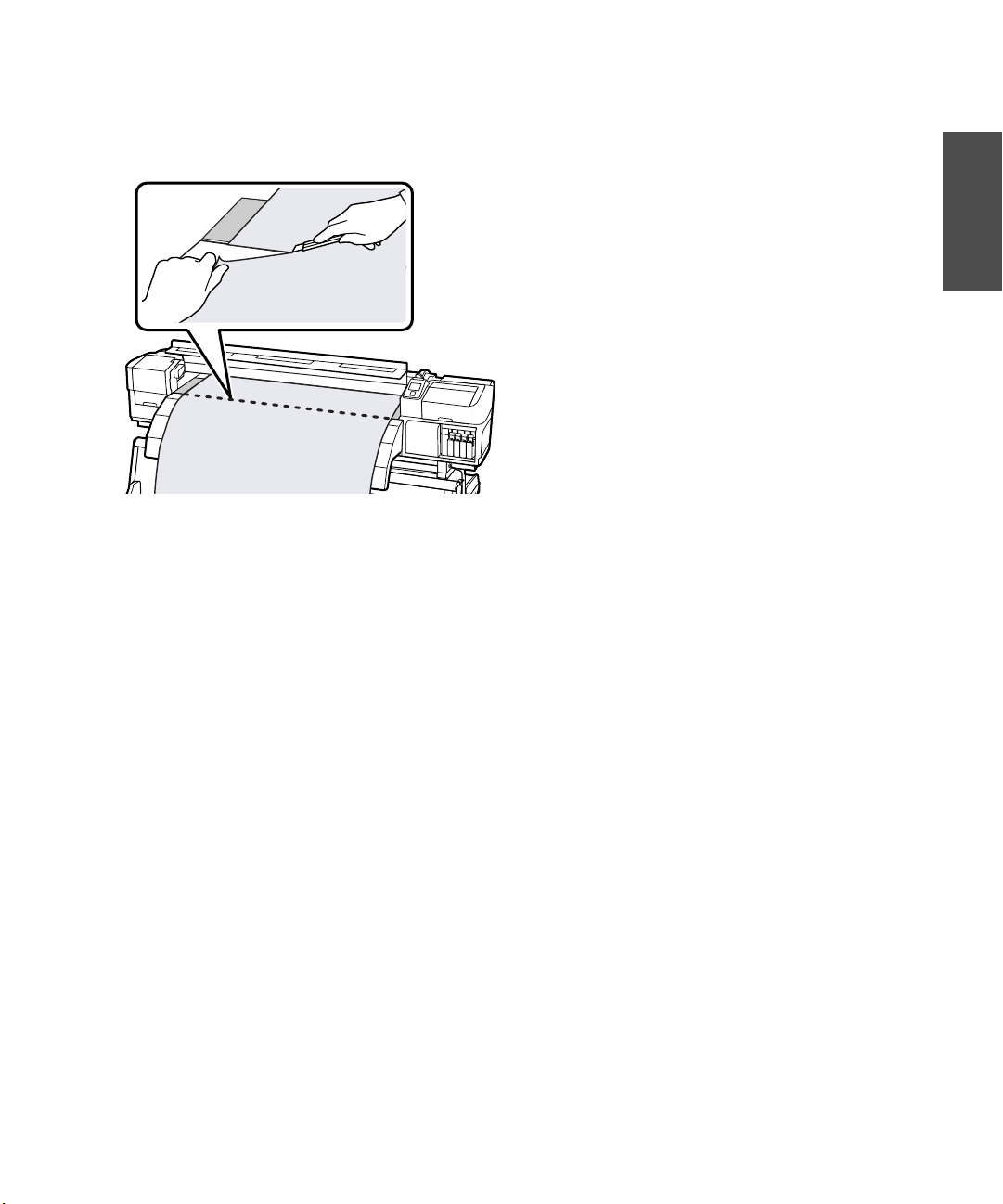

11. For the S50670/S70670, adjust the position of the pressure rollers.

The white low pressure rollers are used for normal printing, and the green high pressure rollers for ink

layering. Their positions vary with the width of the media and the rollers used.

• For normal printing, position the white rollers over the media and under the black rectangles.

Make sure each rectangle has a white roller under it. Rollers that are beyond the width of the

media should be positioned between the black rectangles. Place as many white rollers on the media

as possible.

• For ink layering (printing with white/metallic silver), position the two green rollers under the

black rectangles at the left and right sides of the media as close to the edge as possible. Move the

white rollers between the black rectangles.

• You may need to shift the media slightly to the left or adjust its position to optimize media use.

You will only be able to print between the green rollers when they are in use. When they are not in

use, place the green rollers at the far left and right of the outside black rectangles.

Note: If the rollers are not placed correctly, you will see a warning message on the printer’s LCD screen.

English

Page 14

12 | Loading Media

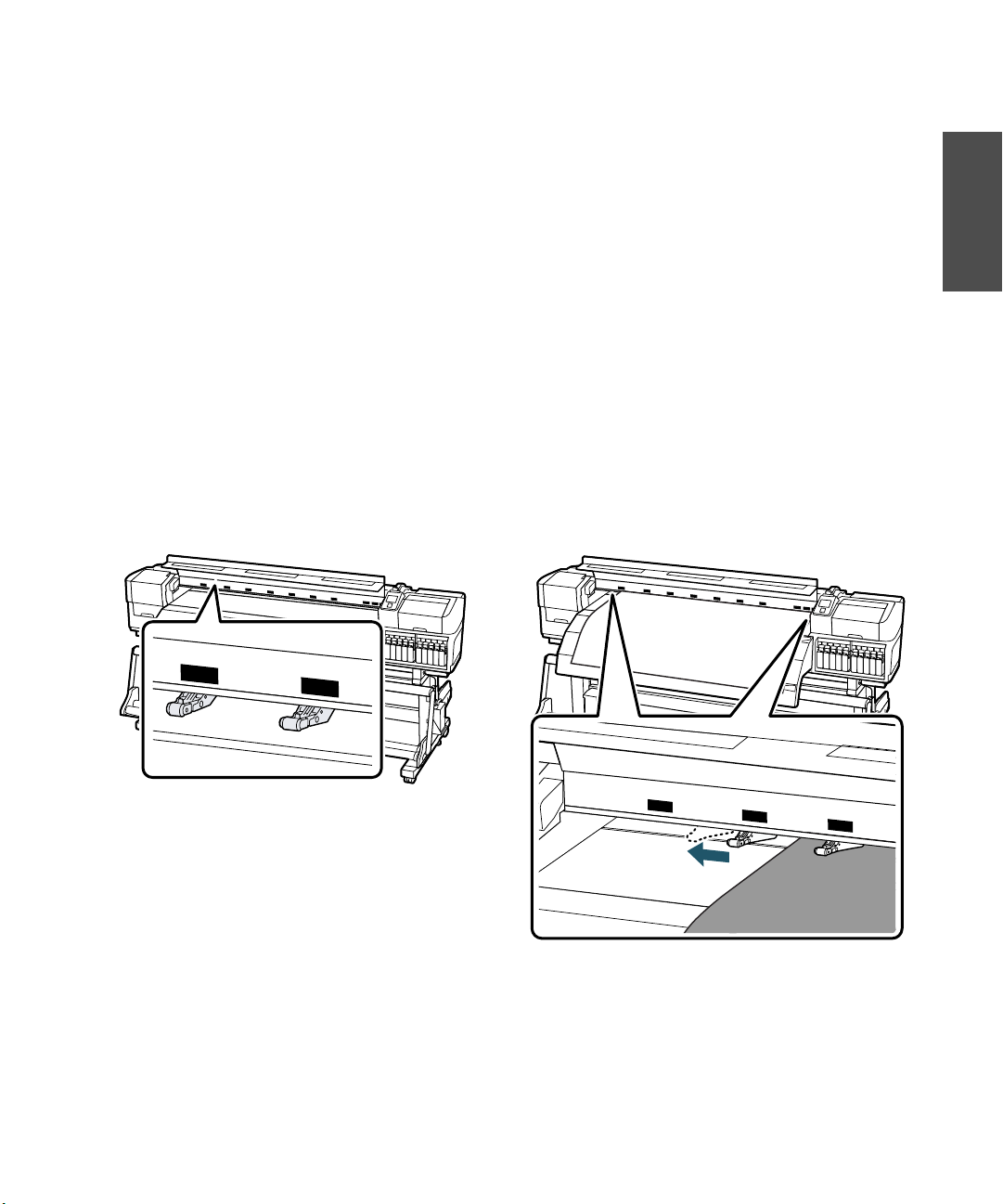

12. Lower the media loading lever to hold the media in place.

Note: Media that is left in the feed path with the heater activated may buckle. If this happens, raise and

lower the media loading lever to allow the media to flatten.

13.

When you are ready to print, attach the media holding plates at either side of the media.

First, position the plates so that the edges of the media are in the centers of the round holes. Adjust the

position so that the white line is visible in the square window, then push the plates down to lock them

in place.

Caution: To avoid damaging the print head, do not use the media holding plates with media that is more than

0.02 inch (0.4 mm) thick. To avoid printing over the plates, make sure the side margins of your print are at

least 0.39 inch (10 mm, unless you are using ink layering). Remove the media holding plates when they are

not in use.

14. Close the front cover.

Page 15

Using the Auto Take-up Reel | 13

Using the Auto Take-up Reel

Note that the auto take-up reel may not function as expected when you use ink layering on the

S50670/S70670.

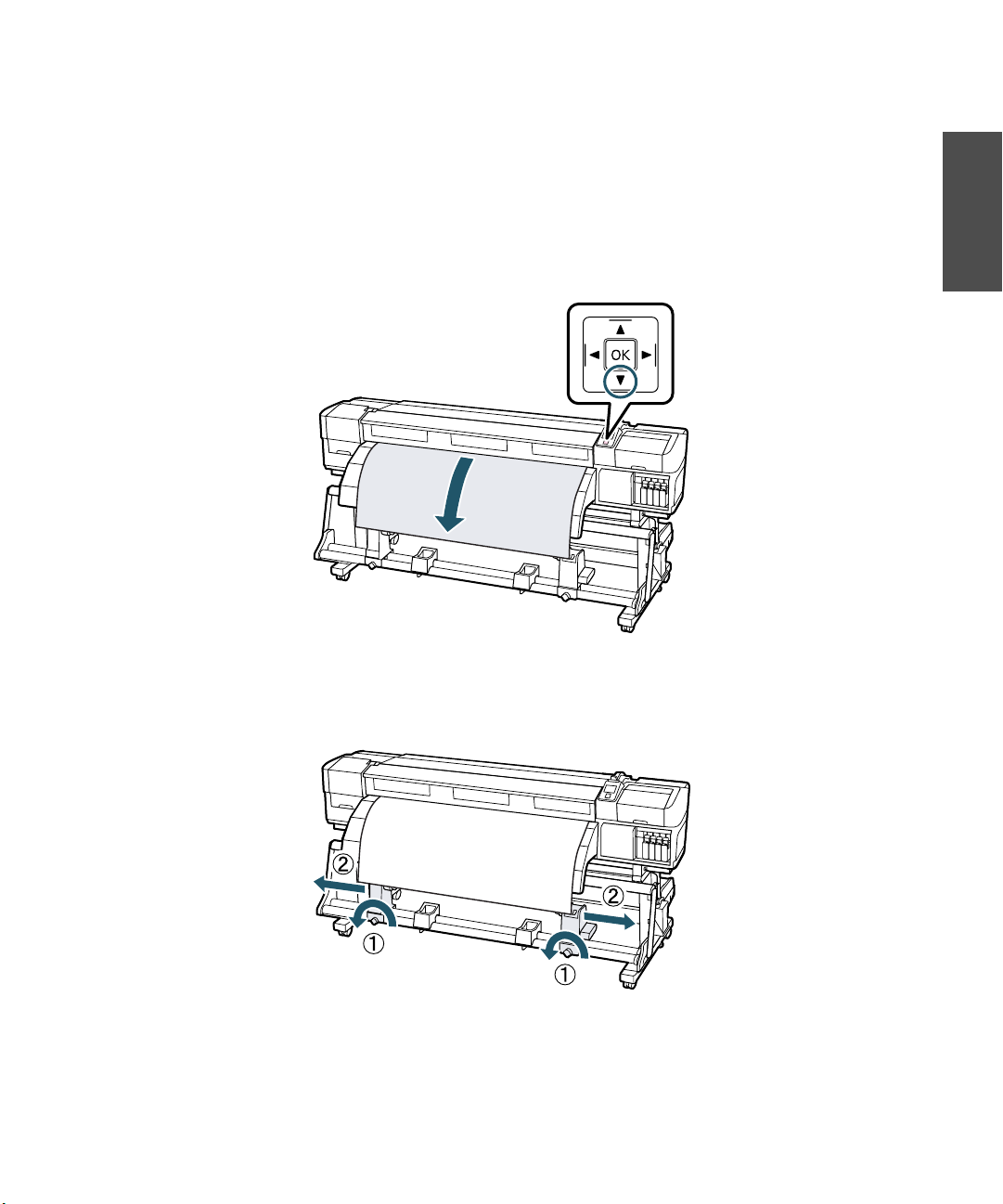

1. Press the d button to feed the media down to the auto take-up reel core holder.

English

2. Loosen the core holder screws and slide the core holders apart. Center the roll supports between the

roll holders.

Page 16

14 | Using the Auto Take-up Reel

3. Align the right roll core holder with the right edge of the media and tighten the screw.

4. Insert the roll core onto the right holder.

Note: The take-up core must be wider than the core of the media you are using.

Page 17

Using the Auto Take-up Reel | 15

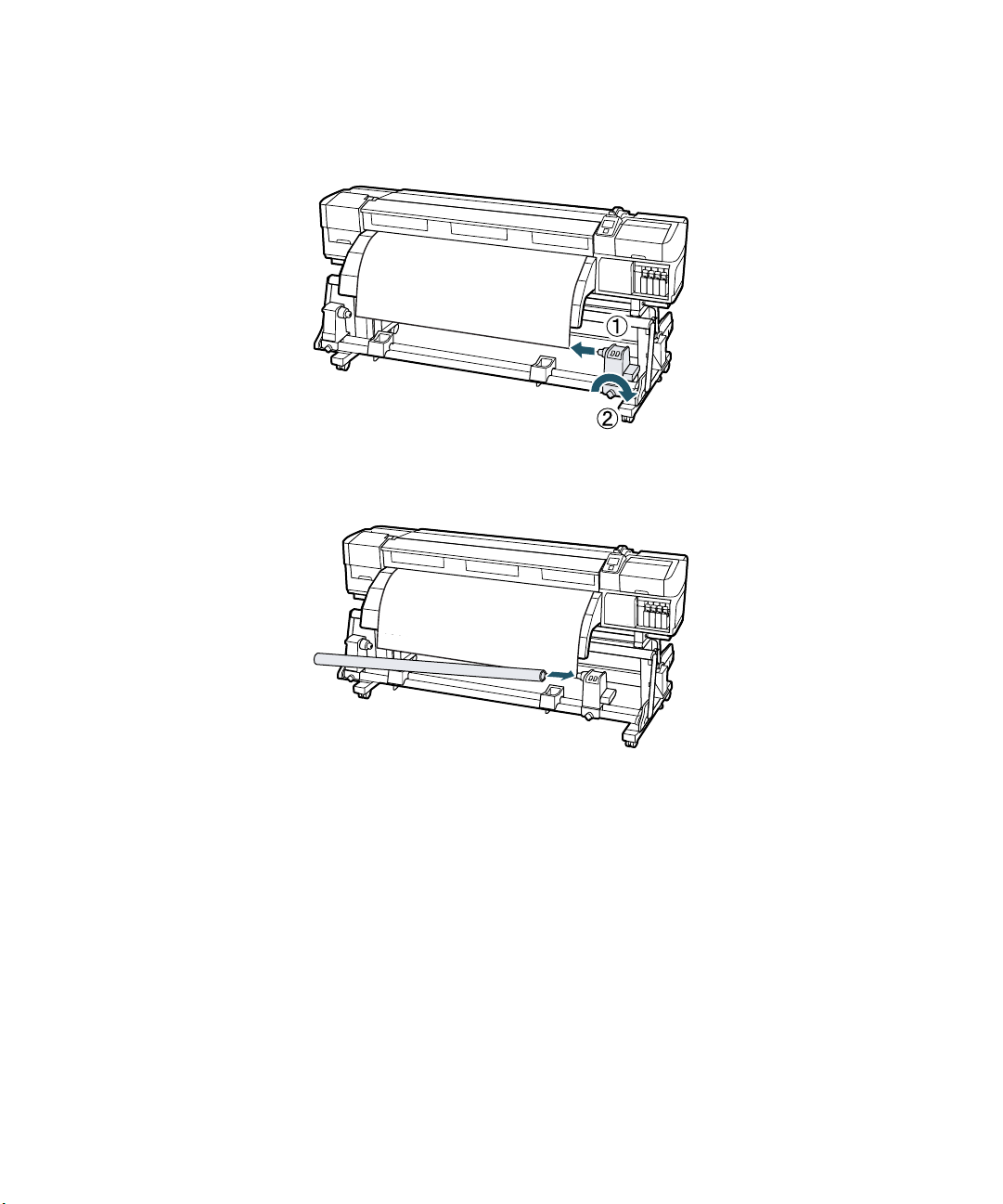

5. Insert the left holder into the roll core. Slide the holder in until part A in the illustration is fully

inserted.

Caution: Stop when part A is no

longer visible. Do not push the

holder too far in.

English

6. Tighten the roll core holder screw.

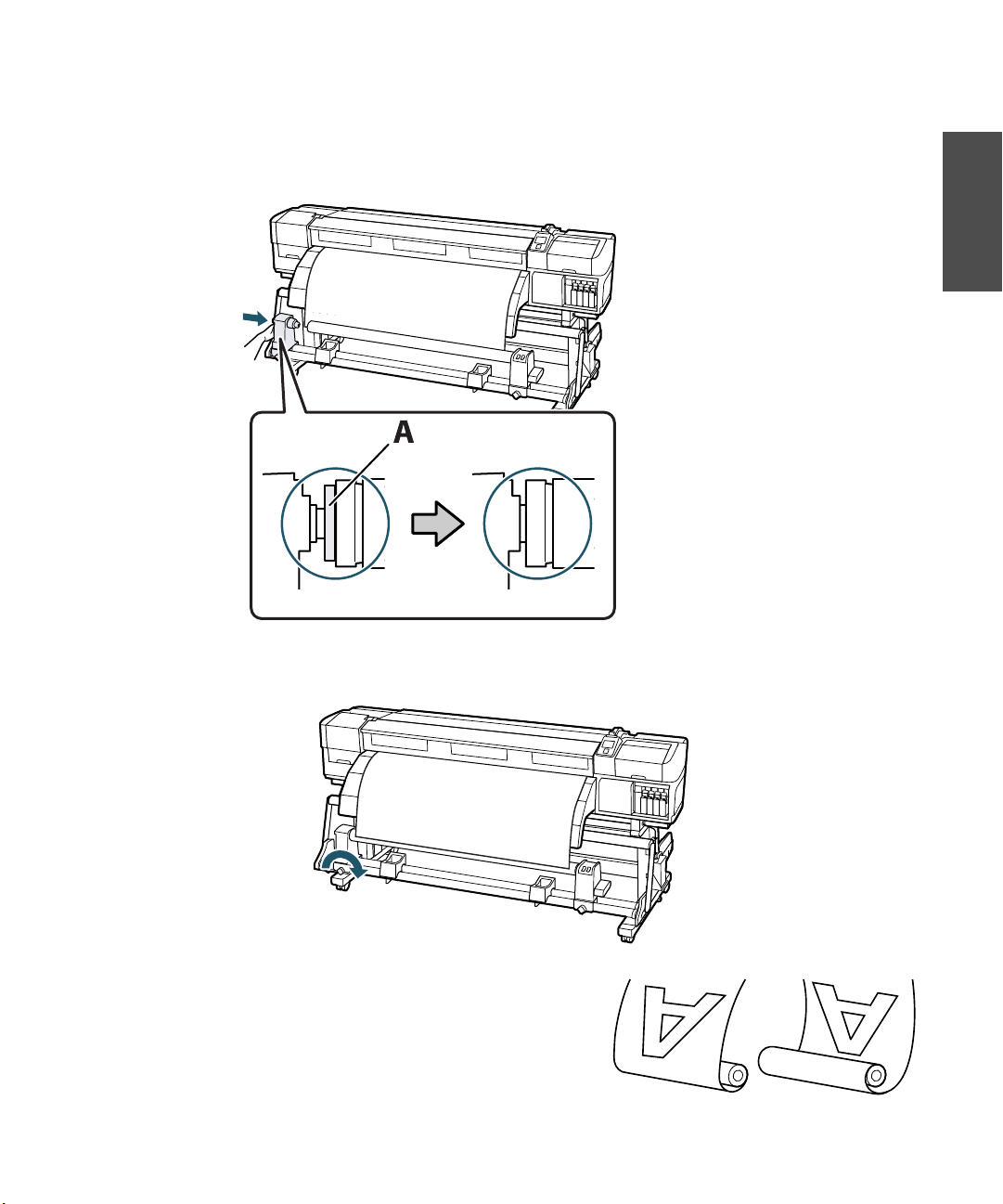

7. Attach the media to the take-up roll core.

You can take up the media either counterclockwise (printed

side out) or clockwise (printed side in).

Printed side out

Printed side in

Page 18

16 | Using the Auto Take-up Reel

Tape the media to the take-up roll core in the center and on both sides as shown below:

Printed side out

Printed side in

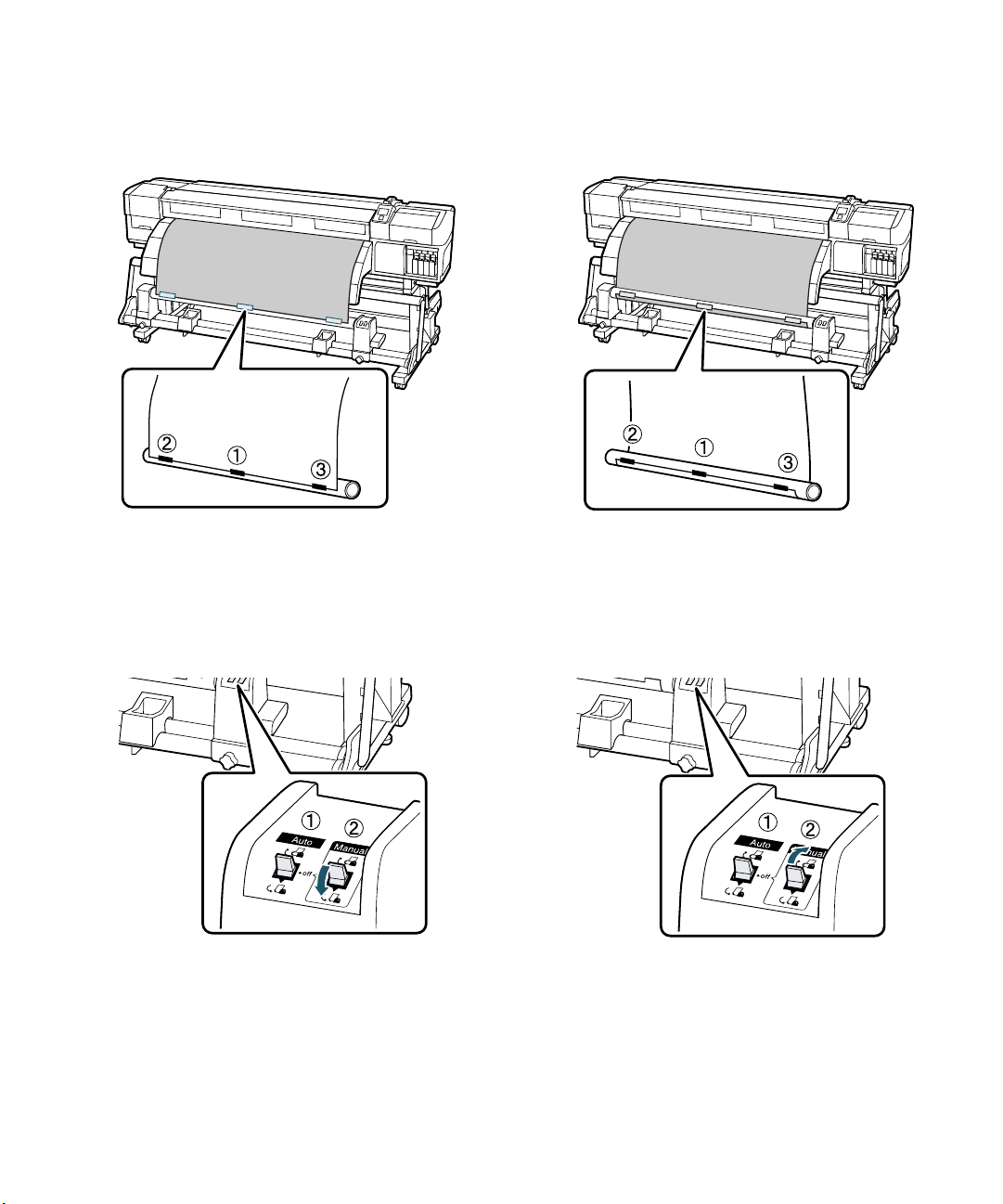

8. Press the d button on the control panel to feed enough media for a single wrap around the roll core.

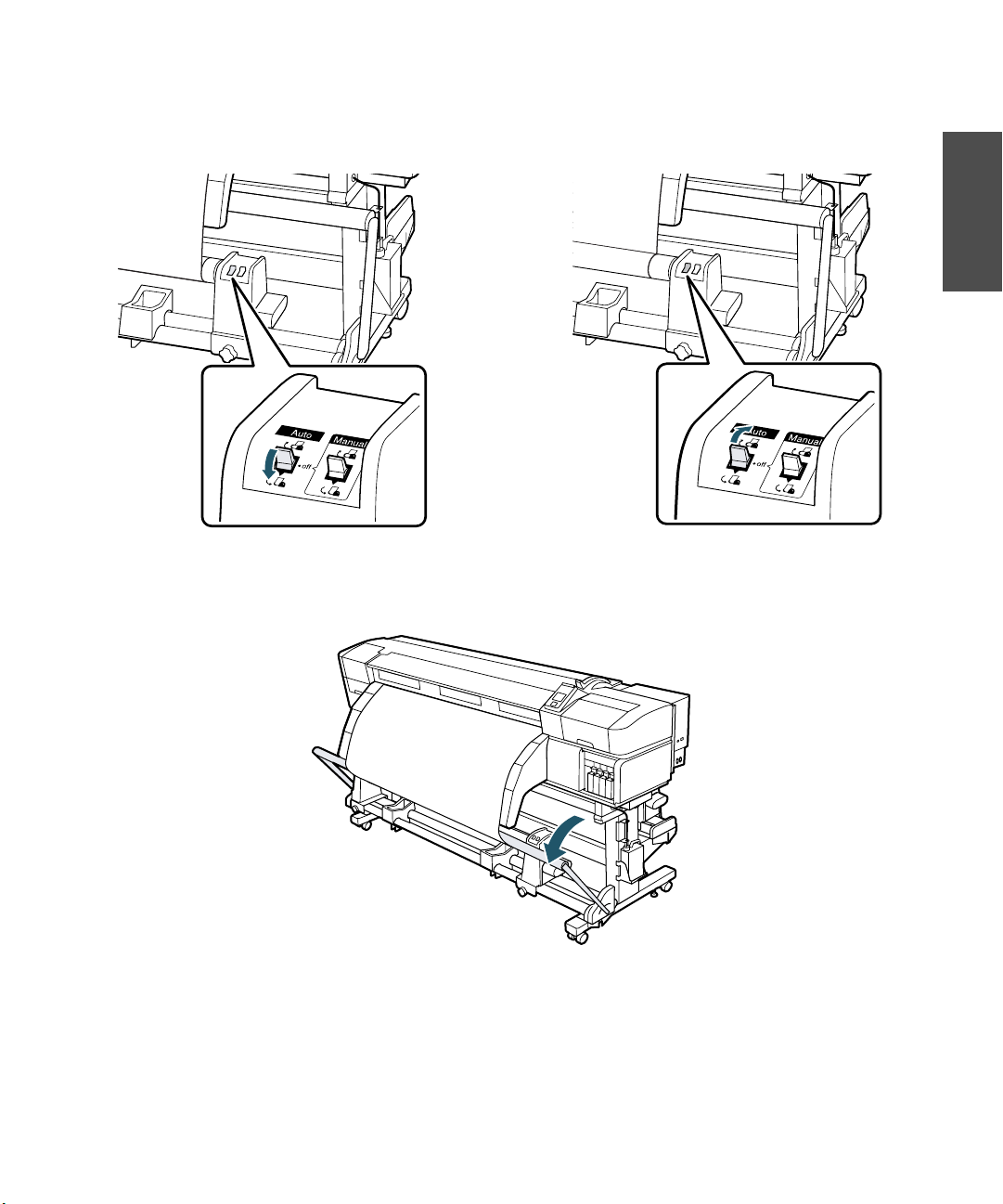

9. Flip the Auto switch to Off and set the Manual switch as shown to wind the media once around the

roll core.

Printed side out

Printed side in

Page 19

10. Flip the Auto switch as shown:

Using the Auto Take-up Reel | 17

English

Printed side out

11. Lower the tension bar.

12. Press the d button on the control panel to feed the media until the take-up roll core begins to turn.

Printed side in

Page 20

18 | Cutting Off and Removing Prints

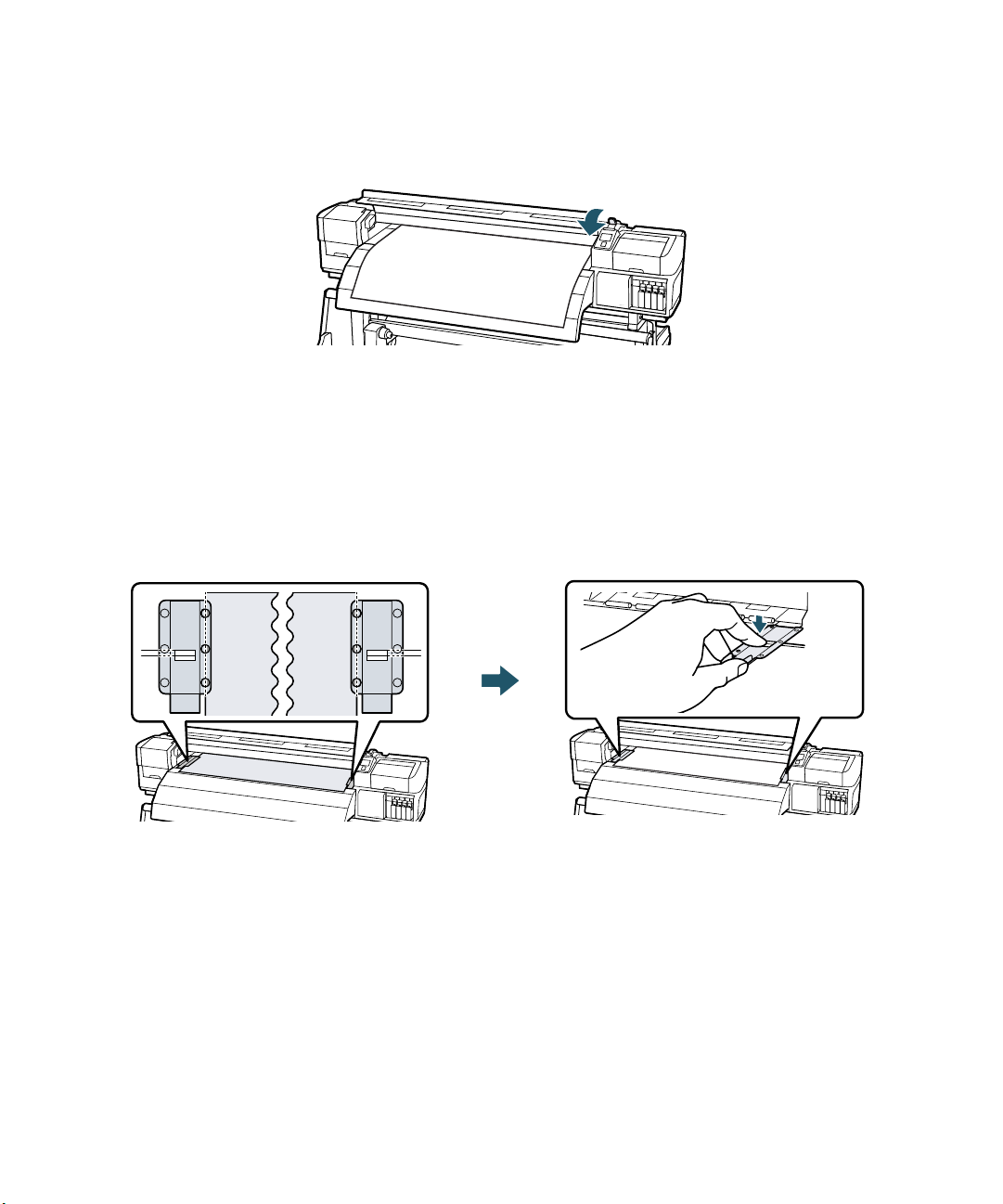

Cutting Off and Removing Prints

1. Make sure Ready appears on the LCD display.

Note: If you are using the auto take-up reel, set the Auto switch to OFF before using the manual switch to

position the media over the cutting groove.

2. Press the Media feed button and the OK button. The printer feeds the media to the cutting

position.

Note: If you have printed the amount of media remaining, press the u button to rewind the media so this

information is not cut off.

3.

Remove the media holding plates.

Page 21

Configuring Media | 19

4. Using a razor blade or other cutting tool, cut off your print along the cutting groove.

WARNING: Do not place your fingers in the path of

the cutting tool to avoid injuring yourself.

5. If you are finished using the media, remove it from the roll holders, reversing the steps you followed to

load it.

English

Configuring Media

Before printing on your loaded media, create a configuration or settings bank (a group of print settings) for

the media. Create a configuration for each media type you use (up to 30 types) and select the desired

configuration whenever you print on that media. This ensures that the printer uses the optimum print

quality settings, and is the most effective way to avoid banding problems.

You can save configuration settings for as many as 30 different media types.

Pre-Printing Checklist

Whenever you print on a new media type, follow these guidelines to configure the media and print:

• Check the media packaging for print requirements.

• Select a media bank number (1 to 30) and assign an alphanumeric name that your users will recognize.

Page 22

20 | Creating Media Configurations

• Select these settings using the information supplied with your media:

Setting Name Feed Adjustment

Platen Gap Head Alignment

Heating & Drying Media Suction

Head Movement Multi-Strike Printing

Roll Type Tension Measurement

Media Tension Feed Speed

Note: The Heating & Drying setting is especially important, and includes several sub-settings.

• Print a nozzle check pattern and clean the print head, if necessary. See page 23.

• Perform an Auto Feed Adjustment. See page 21.

• Perform an Auto Head Alignment. See page 21.

• Select the Setting Name for the media and print.

Creating Media Configurations

1. Press the Menu button.

2. Select Media Setup and press OK.

3. Select Customize Settings and press OK.

4. Select the media bank setting number (1 to 30) you want to use for this media type and press OK.

5. Select the settings for your media.

Page 23

Performing Auto Feed Adjustment | 21

Performing Auto Feed Adjustment

Feed Adjustment corrects banding problems, and can be performed manually (as described in the

on-screen User’s Guide) or automatically (as described below).

1. Press the Menu button.

2. Select Media Setup and press OK.

3. Select Customize Settings and press OK.

4. Select the media bank setting number and name for the loaded media and press OK.

5. Select Feed Adjustment and press OK.

6. Select Auto and press OK.

7. Press OK again to print a test pattern and perform auto feed adjustment.

Performing Auto Head Alignment

English

Head Alignment corrects grainy or misaligned prints, and can be performed manually (as described in the

on-screen User’s Guide) or automatically (as described below).

1. Press the Menu button.

2. Select Media Setup and press OK.

3. Select Customize Settings and press OK.

4. Select the media bank setting number and name for the loaded media and press OK.

5. Select Head Alignment and press OK.

6. Select Auto(Uni-D) first, then Auto(BI-D).

7. Press OK again to print a test pattern and perform auto head alignment.

Note: If the automatic adjustments do not work, use manual adjustments. Some media types will not work with

automatic adjustments.

Page 24

22 | Cleaning the Media System

Cleaning the Media System

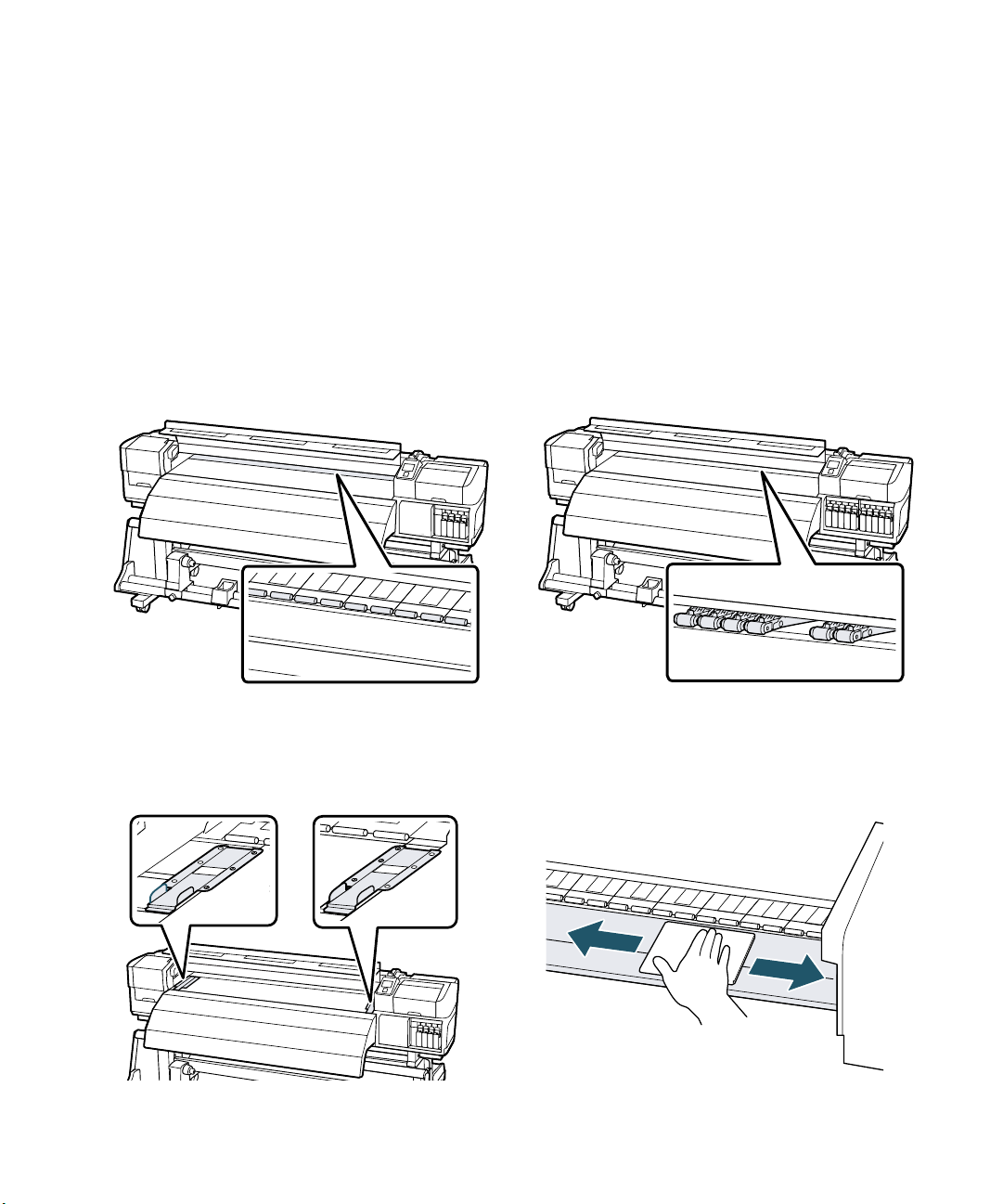

To remove ink and particles of paper, clean the platen heater, pressure rollers, and media holding plates

before starting work each day.

1. Make sure the printer is turned off.

2. Wait a minute, then open the front cover.

3. Remove particles of paper and dust from the pressure rollers using a soft-bristled brush.

S30670

S50670/S70670

4. Dampen a soft cloth in water, wring it out thoroughly, and use it to remove lint and dust from the

media holding plates on both the left and right sides and from the platen.

Page 25

Checking and Cleaning the Print Head | 23

Checking and Cleaning the Print Head

If your prints show a color shift or horizontal lines, check the print head nozzles for clogs or deflections. If

necessary, run a cleaning cycle.

Note: You can set the printer to automatically check the nozzles periodically using Auto Nozzle Check or before

each print job using Print Nozzle Pattern. You can also run different head cleaning levels and set up automatic

cleaning cycles.

1. Press the # Maintenance button.

2. Select Nozzle Check and press OK.

3. Examine the printed pattern to determine if the print head needs cleaning.

English

Cleaning not needed

4. If you need to clean the print head, select one of the following:

• All Nozzles (if all numbered patterns have faint or missing segments)

• Selected Nozzles (if only some of the numbered patterns have faint or missing segments)

5. Choose the nozzle arrays (corresponding to the numbered patterns) to be cleaned.

6. Select Proceed and press OK.

7. Select a cleaning level and press OK.

8. Print a nozzle pattern and check the results to determine whether the head cleaning was successful.

Clean the print head

If you cannot recover all nozzles by running the heaviest cleaning cycle, you need to wash the ink system,

as described on page 27.

Maintaining the Printer

You should regularly check the ink status and replace cartridges (see page 25) as necessary. For the

S50670/S70670, the printer performs automatic maintenance to prevent ink accumulating and causing

clogs. Do not turn the printer off, or this maintenance will not be performed.

Page 26

24 | Checking Ink Status

S30670

S50670

Periodically, you also must perform the following maintenance procedures:

Procedure Frequency Instructions

Clean print head, wiper, caps, and wiper rail Weekly or more often if needed page 27

Remove and shake ink cartridges

Remove and shake white and metallic silver cartridges

Every 3 weeks

Every 24 hours

page 26

Dispose of waste ink As needed page 32

Wash ink system As needed page 27

Replace wiper, wiper cleaner, and ink flushing pad Every 6 months or as needed page 34

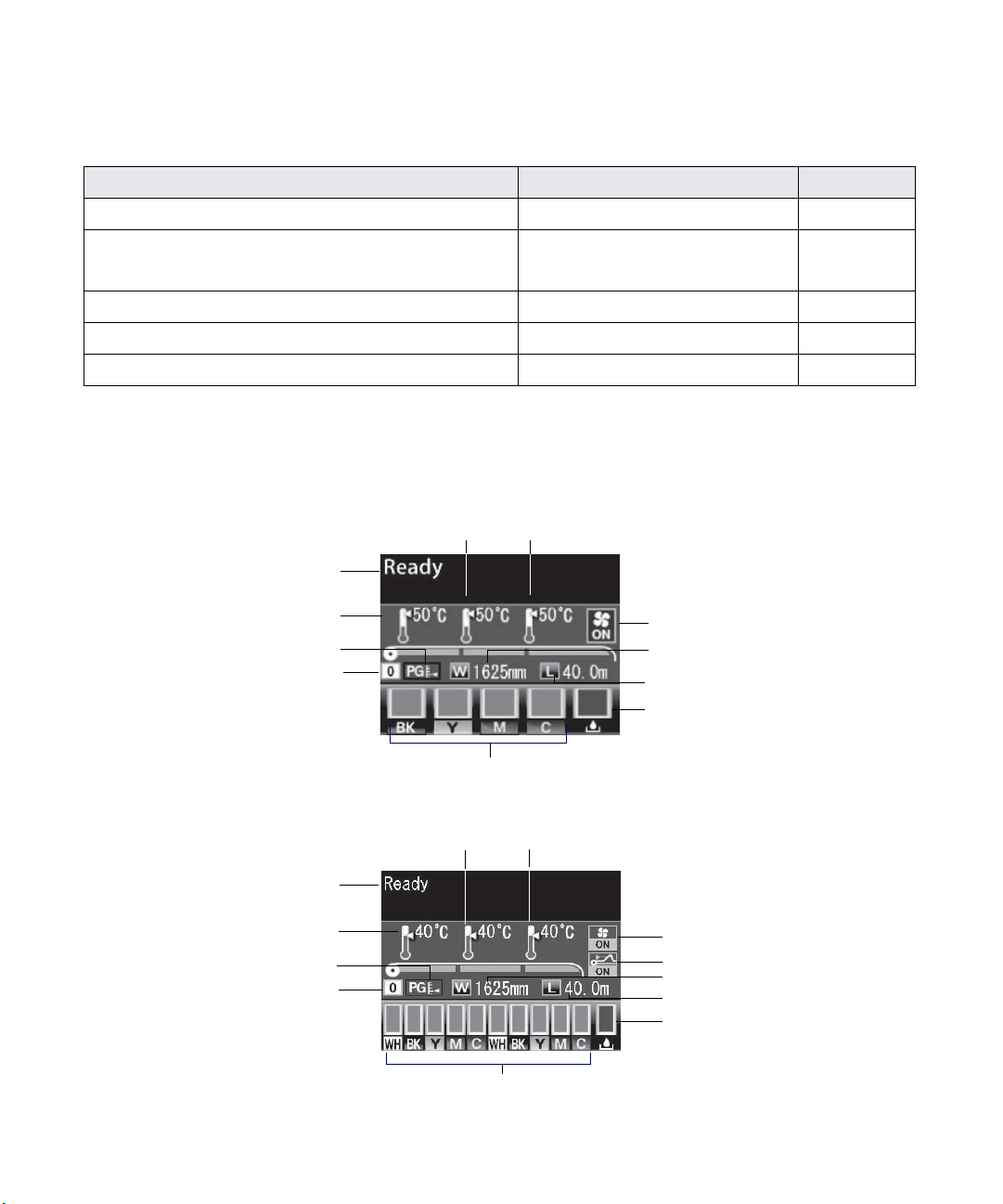

Checking Ink Status

The easiest way to check ink levels is from the control panel LCD display.

Printer status messages

Pre-heater temperature

Platen gap

Selected media

Printer status messages

Pre-heater temperature

Platen gap

Selected media

Platen heater

temperature

Ink cartridge status

Platen heater

temperature

After heater

temperature

Optional drying fan indicator

Media width

Media remaining

Waste ink tank status

After heater

temperature

High-speed drying fan status

Media lift detection status

Media width

Media remaining

Waste ink tank status

Ink cartridge status

Page 27

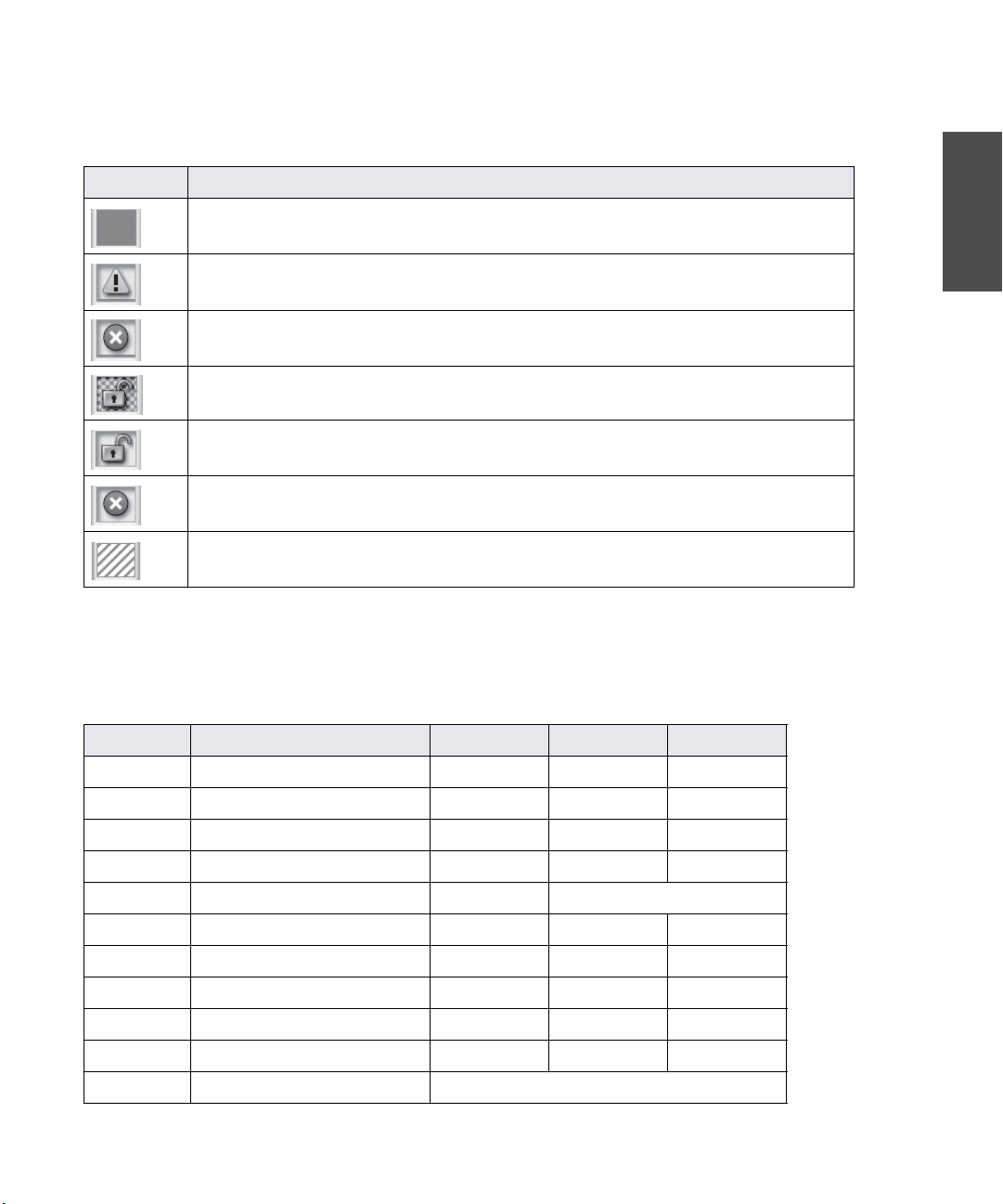

The icons indicate the ink status as follows:

Icon Description

Ready to print. The height of the indicator shows the approximate level of ink remaining.

Ink is low. Make sure you have a new cartridge.

Ink is expended. Replace with a new cartridge.

Cartridge is not locked. Lower the lock lever.

No cartridge.

Cartridge error. Check the message and clear the error.

Cleaning cartridge installed. The height of the indicator shows the approximate level of

cleaning liquid remaining.

Replacing Ink Cartridges | 25

English

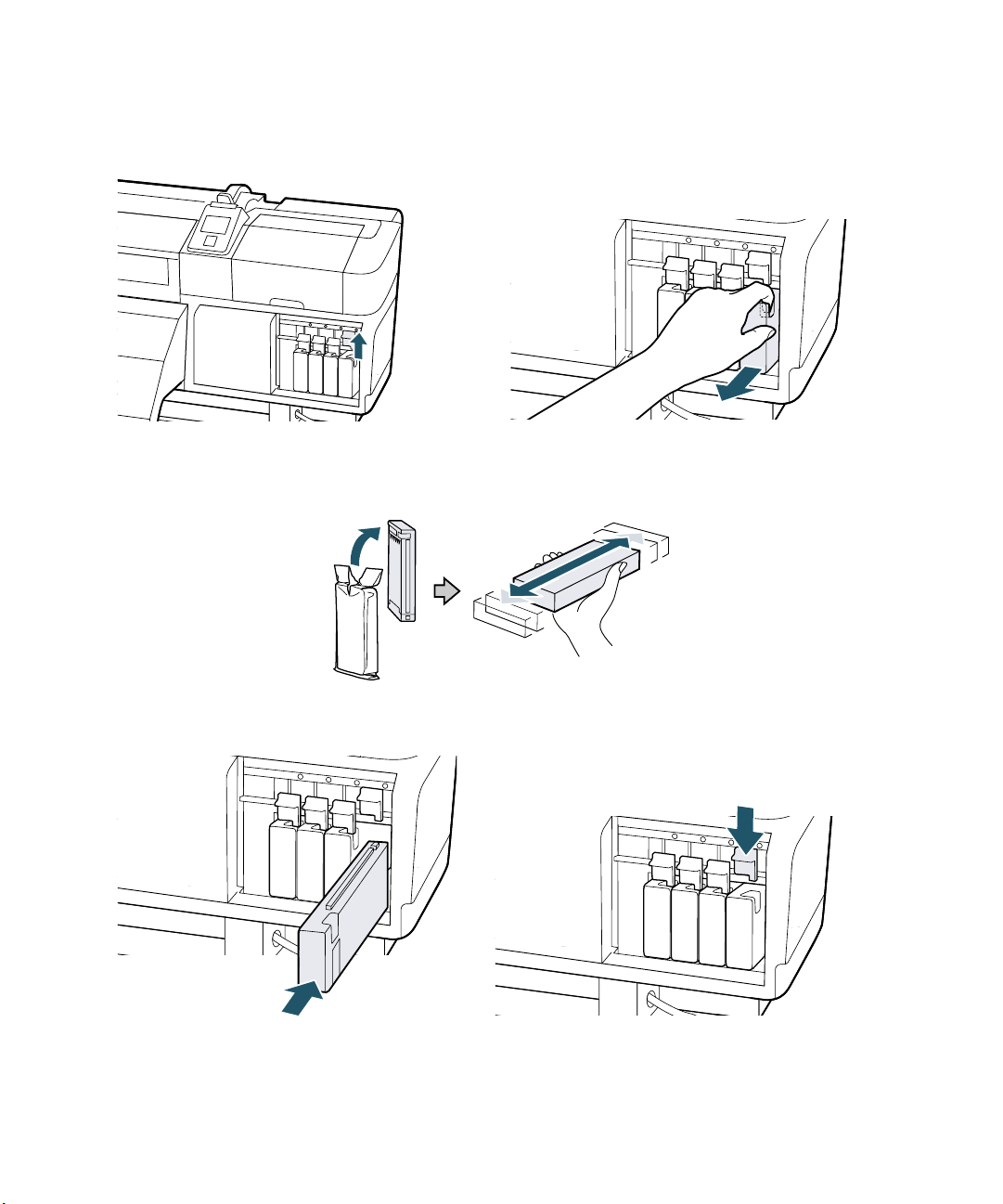

Replacing Ink Cartridges

Use the following EPSON UltraChrome® GSX or GS2 ink cartridges (see page 37 for ordering

information)

Slot Cartridge S30670 S50670 S70670

BK Black T689100 T689100 T715100

Y Yellow T689400 T689400 T715400

M Magenta T689300 T689300 T715300

C Cyan T689200 T689200 T715200

WH White — T715A00

MS Metallic silver — — T715B00

LK Light black — — T715700

OR Orange — — T715800

LC Light cyan — — T715500

LM Light magenta — — T715600

All Cleaning cartridge T699000

:

Page 28

26 | Replacing Ink Cartridges

1. Lift the lock lever for the cartridge that needs replacing, then pull out the cartridge.

2. Unpack the new cartridge and shake it for 5 seconds or 15 seconds for the white, metallic silver, and

orange inks.

3. Hold the cartridge with the label facing out and insert it into the slot. Then lower the lock lever.

Note: Approximately every three weeks (or every 24 hours for white and metallic silver) you need to remove the

ink cartridges and shake them as described in step 2 (5 seconds for all colors).

Page 29

Washing the Ink System | 27

Washing the Ink System

If you cannot recover nozzles by running the heaviest cleaning cycle, you need to wash the print head. This

involves removing ink cartridges, installing cleaning cartridges, and then reinstalling ink cartridges. The

washing process also requires you to empty the waste ink tank several times.

Because of the amount of ink consumed, you should not perform head washing unless you cannot recover

nozzles through normal head cleaning.

1. Press the # Maintenance button.

2. Select Head Washing and press OK.

3. Select individual nozzle arrays or All Nozzles.

4. Follow all instructions on the LCD display. For detailed instructions, see these sections:

• Removing and inserting ink cartridges and cleaning cartridges (see page 25)

• Emptying the waste ink tank (see page 32)

English

Cleaning the Print Head, Wiper, Caps, and Wiper Rail

Clean the print head, wiper, caps, and wiper rail at least once a week. You may need to clean them more

often if you notice blurred ink or gaps in your prints after cleaning the print head. In addition to the

maintenance kit that came with the printer, you will need protective eyewear, ink cleaner, a clean room

wipe (lint-free disposable cleaning cloth), and a metal or plastic tray (to hold parts that have been removed

for cleaning or replacement).

Note: If you need more maintenance kit supplies, you can order an Additional Printer Maintenance Kit. See

page 37 for ordering information.

Caution: To clean ink stains that cannot be removed with cleaning swabs alone, apply ink cleaner to a swab. Ink

cleaner should be used only to clean the area around the wiper, caps, and print head. Used ink cleaner should be

disposed of in the same way as used ink.

Caution: You must complete this cleaning process within 10 minutes to prevent the print head from drying out.

Page 30

28 | Cleaning the Print Head, Wiper, Caps, and Wiper Rail

1. Press the # Maintenance button, then select Head Maintenance and press OK.

2. Press OK again to move the print head to the cleaning position.

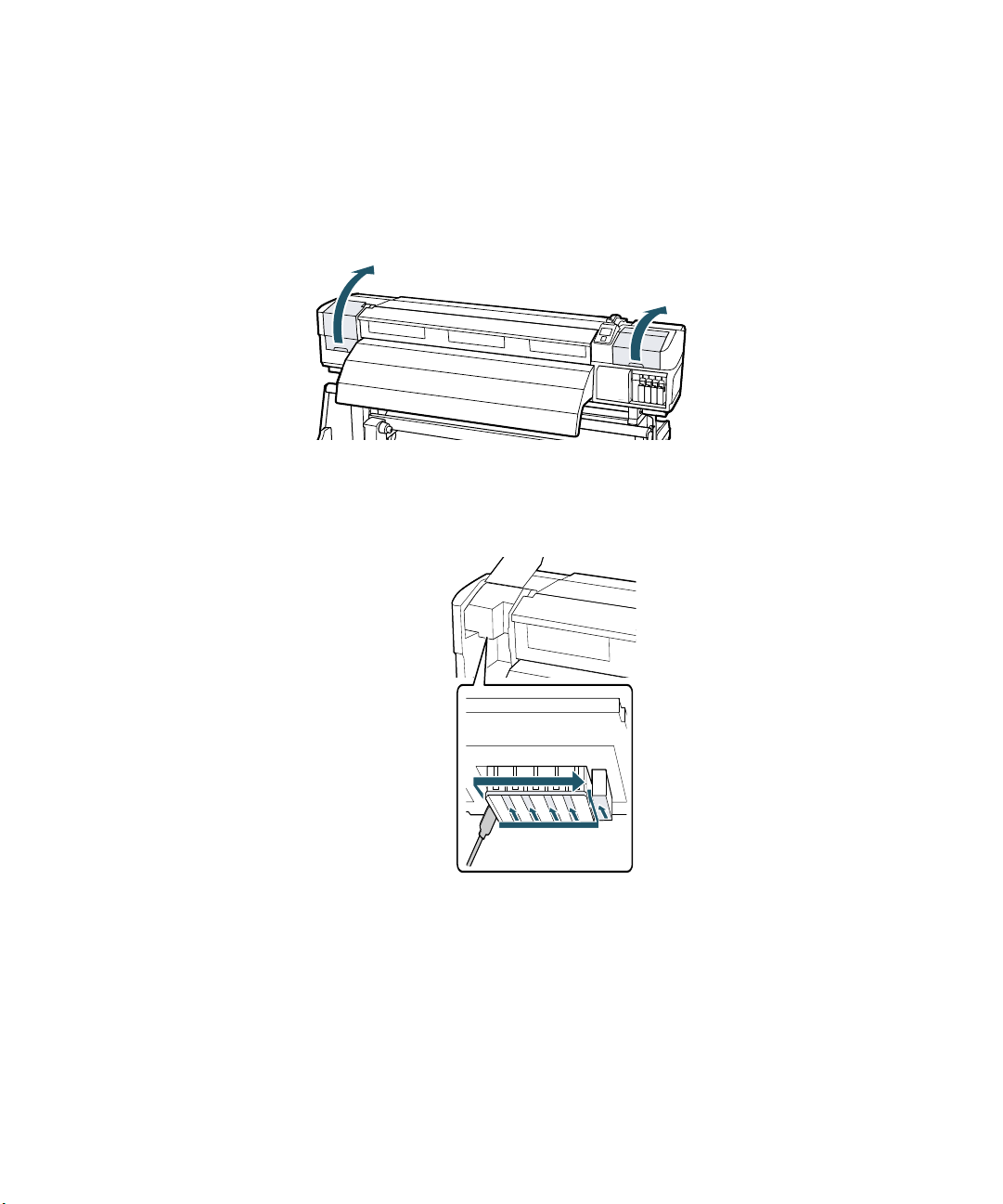

3. Open the maintenance covers at each end of the printer.

4. Put on plastic gloves, then use the large and small cleaning swabs to wipe areas of the print head shown

below. You may need to dampen the swabs with ink cleaner to remove all the ink residue.

Page 31

Cleaning the Print Head, Wiper, Caps, and Wiper Rail | 29

Ink spatters or paper dust on the base of the print head (shown below) can be removed using an

extremely small amount of ink cleaner applied to a clean room wipe.

English

S30670

Sensors

Caution: Do not touch the nozzle surface or any other internal part with your hands to prevent oil from your

skin interfering with head cleaning operations. Do not touch the sensors with your hands or swab. Do not

moisten the cleaning swab with water or it may damage the print head. Do not let the cleaning swab touch

any other part of the printer or it may stain it with ink. Do not reuse a cleaning swab; dirt or ink from the swab

may damage the print head.

5. Clean the front and back of the wiper (or wipers for the S50670/S70670) with a cleaning swab, as

S50670/S70670

Sensors

Head 1

Head 2

shown below. You may need to dampen the swab with ink cleaner to remove all the ink residue.

Page 32

30 | Cleaning the Print Head, Wiper, Caps, and Wiper Rail

6. Tilt the wiper to the left and lift it out.

7. Clean the front, back, and bottom of the wiper as shown below.

Page 33

Cleaning the Print Head, Wiper, Caps, and Wiper Rail | 31

8. Clean the attachment points, then place the wiper on the points and press it down until it clicks into

place.

9. Clean the area around the outside of the four caps (S30670) or 10 caps (S50670/S70670) with a

cleaning swab, as shown below.

Caution: Do not touch the insides of the caps, or they might become deformed.

English

10.

Press the OK button to move the wiper to the rear. Make sure you see this message on the display:

Clean wiper rail.

After cleaning, close

maintenance covers and

press OK.

Page 34

32 | Disposing of Waste Ink

11. Grasp the wiper cleaner as shown below and lift it out of the printer. Then dampen a cleaning swab

with ink cleaner and use it to clean the area shown. For the S50670/S70670, make sure you clean both

rails.

Caution: Be careful not to dislodge any springs or other parts.

Replace the wiper cleaner, pressing it in until it clicks into place.

12.

13. Close the left and right maintenance covers and press the OK button.

14. Dispose of the used gloves, swabs, and ink cleaner in compliance with industrial waste disposal laws

and local government ordinances as required in your area.

Disposing of Waste Ink

You need to dispose of waste ink that collects in the waste ink tank beneath the printer when you see the

following message:

Prepare empty waste ink bottle.

Replace waste ink bottle and press OK.

Before you dispose of waste ink, make sure you have a replacement tank or an appropriate waste disposal

drum.

Page 35

Caution: Before handling the waste ink, read the Material

Safety Data Sheet (MSDS) for your printer. You can download it

from Epson’s support website at epson.com/support (U.S.) or

epson.ca/support (Canada).

The waste ink from the printer is industrial waste. Proper waste

ink disposal in compliance with the industrial waste disposal

laws and ordinances of your local government is required.

Consign disposal of waste inks to an industrial waste disposer.

Please provide the Waste Ink Data Sheet to the industrial waste

disposer. You can download it from Epson’s support website at

epson.com/support (U.S.) or epson.ca/support (Canada).

WARNING: Wear protective eyewear and gloves. If waste ink

contacts your skin or enters your eyes or mouth, immediately

take the following actions:

If fluid adheres to your skin, immediately wash it off using large

volumes of soapy water. Consult a physician if the skin appears

irritated or is discolored.

If fluid enters your eyes, rinse immediately with water. Failure

to observe this precaution could result in bloodshot eyes or

mild inflammation.

Disposing of Waste Ink | 33

English

If fluid is swallowed, consult a physician immediately; do not

induce vomiting.

After replacing waste ink tank, wash your hands thoroughly.

Put on plastic gloves, then remove the waste ink tank

1.

from its holder, as shown on the right.

2. Insert the waste ink tube into the mouth of the new

tank and place the tank in the holder.

Caution: Make sure you keep the lid from the waste ink tank so you can use it when disposing of waste ink.

3.

Tightly seal the lid on the used waste ink tank.

4. Press the OK button, then make sure the new tank is installed correctly, and press OK again to reset

the waste ink counter.

5. Dispose of the waste ink in compliance with industrial waste disposal laws and local government

ordinances as required in your area.

Page 36

34 | Replacing the Wiper, Wiper Cleaner, and Flushing Pad

Replacing the Wiper, Wiper Cleaner, and Flushing Pad

Replace the wiper and wiper cleaner every six months, or when the front of the wiper cleaner starts to get

stained with ink. For the S50670/S70670, make sure you replace both wipers and wiper cleaners.

Replace the printer’s flushing pad every six months. You may need to replace it sooner if you notice ink

smears on your media or if you see dust from the media on the front of the pad. Use the replacement

flushing pad and plastic gloves that came in the Maintenance Kit.

Note: If you need more flushing pads, purchase an Additional Printer Maintenance Kit. See page 37 for ordering

information.

Press the # Maintenance button, then select Head Maintenance and press OK.

1.

2. Press OK again to move the print head to the cleaning position.

3. Open the right maintenance cover.

Page 37

Replacing the Wiper, Wiper Cleaner, and Flushing Pad | 35

4. Put on plastic gloves, then grasp the wiper cleaner as shown and lift it out of the printer. Insert a new

wiper cleaner and press it down until it clicks into place.

English

5. Tilt the wiper to the left and lift it out of the printer. Then insert a new wiper and press it down until

it clicks into place.

Page 38

36 | Replacing the Wiper, Wiper Cleaner, and Flushing Pad

6. Remove the flushing pad by grasping its tab.

Caution: Hold the flushing pad upright and level as you remove it to prevent ink from spilling. Be careful not

to let ink spill onto any part of the printer.

7. Place the used flushing pad on a tray.

8. Insert the two hooks on the new flushing pad into the slots as shown, and press the tab down until the

pad clicks into place.

9. Close the right maintenance cover.

10. Press OK, then press OK again.

Page 39

Ordering Supplies and Accessories | 37

Ordering Supplies and Accessories

Part Part number

Ink cartridges See page 25 for a complete list

Additional printer maintenance kit (six-month supply) T724100

Cleaning cartridge T699000

Ink cleaner T699300

Additional waste ink tank T724000

Media holding plate C12C890891

Heavy roll media system C12C890761

High speed dryer C890751

Note: Cleaning cartridges can be used more than once, but make sure you order as many cartridges as needed.

You can purchase optional equipment and genuine EPSON ink and media from an EPSON Professional

Imaging Authorized Reseller. To find the nearest reseller, visit www.proimaging.epson.com (U.S. sales),

www.epson.ca (Canadian sales), or call 800-GO-EPSON (800-463-7766). Or you can purchase online at

www.proimaging.epson.com (U.S. sales) or www.epson.ca (Canadian sales).

English

Where to Get Help

Epson provides technical support and information on the installation, configuration, and operation of

professional printing products through the EPSON Preferred Limited Warranty Plan.

Dial (888) 377-6611, 6

AM to 6 PM, Pacific Time, Monday through Friday. Days and hours of support

are subject to change without notice. Before you call, make sure you have your:

• Unit ID number: __________________________________

(included with the EPSON Preferred Limited Warranty Plan information that came with your

printer)

• Your printer serial number: ___________________________

• Proof of purchase and date: ___________________________

Tip: If you experience difficulty with the toll-free line or your Unit ID number, call (562) 276-1305.

Visit Epson’s support website at epson.com/support (U.S.) or epson.ca/support (Canada) and select your

product for solutions to common problems. You can download drivers, firmware, and documentation, get

FAQs and troubleshooting advice, or e-mail Epson with your questions.

SM

Page 40

38 | Where to Get Help

EPSON, EPSON UltraChrome, and SureColor are registered trademarks, and EPSON Exceed Your Vision is a registered

logomark, of Seiko Epson Corporation. EPSON Preferred is a service mark of Epson America, Inc.

General Notice: Other product names used herein are for identification purposes only and may be trademarks of their respective

owners. Epson disclaims any and all rights in those marks.

This information is subject to change without notice.

Page 41

Contenido

Contenido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Piezas de la impresora . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Parte frontal - S30670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Parte interior - S30670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Parte frontal - S50670 y S70670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Parte interior - S50670 y S70670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Parte posterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Carga del papel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Uso del rodillo de recogida automática . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Corte y retiro de impresiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Configuración del papel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Lista de verificación previa a la impresión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Creación de configuraciones de papel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Realización de un ajuste automático de la alimentación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Realización de una alineación automática del cabezal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Limpieza del sistema de papel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Comprobación y limpieza del cabezal de impresión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mantenimiento de la impresora . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Comprobación del nivel de tinta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Reemplazo de los cartuchos de tinta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Lavado del sistema de tinta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Limpieza del cabezal, del limpiacabezales, las tapas y el riel del limpiacabezales . . . . . . . . . . . . . . 66

Eliminación de la tinta de desecho . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Reemplazo del limpiacabezales, el dispositivo de limpieza y la almohadilla de aclarado . . . . . . . . . 74

Suministros y accesorios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

¿Dónde obtener ayuda? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Marcas comerciales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Español

Page 42

40 | Piezas de la impresora

Posición d

Almohadilla d

Piezas de la impresora

Parte frontal - S30670

Tapa frontal

Cubierta de

mantenimiento

izquierda

Cubierta de

mantenimiento derecha

Palanca de

carga del papel

Panel de control

Puerto USB

Post-calentador

Tensor

Seguro del topo

del rollo

Soporte

del rollo

Parte interior - S30670

e

mantenimiento

del cabezal de

impresión

Interruptor Auto

Interruptor Manual

Rueda

Entradas de CA

Salida de aire

Puerto LAN

Tubo de la tinta sobrante

Depósito de tinta de desecho

Regulador

e aclarado

Indicadores de

estado de los

cartuchos

Palancas

de bloqueo

Cartuchos

de tinta

Limpiacabezales

Placa de sujeción

del papel

Rodillos de

presión

Guía del

cortador

Calentador de

la platina

Dispositivo de

limpieza del

limpiacabezales

Tapas de los

inyectores

Page 43

Parte frontal - S50670 y S70670

Almohadill

Posición d

Tapa frontal

Cubierta de

mantenimiento

izquierda

Secador de alta

velocidad

Post-calentador

Tensor

Cubierta de

mantenimient

o derecha

Parte frontal - S50670 y S70670 | 41

Palanca de carga

del papel

Panel de control

Puerto USB

Puerto LAN

Entradas de

Indicadores

de estado de

los cartuchos

Palancas

de bloqueo

Cartuchos

de tinta

Español

Seguro del topo

del rollo

Soporte del

rollo

Parte interior - S50670 y S70670

mantenimiento

del cabezal de

impresión

Placa de

sujeción del

papel

e

Rodillos

de presión

Rodillos de

presión alta

(verde)

Interruptor Auto

Interruptor Manual

Rodillos de presión

baja (blanco)

Rueda

Calentador de la platina

Salida

de aire

de aclarado

Tubo de la tinta sobrante

Depósito de tinta de desecho

Regulador

a

Limpiacabezales

Tapas de los

inyectores

Dispositivo de

limpieza del

limpiacabezales

Page 44

42 | Parte posterior

Parte posterior

Interruptor de dirección

Pre-calentador

Tope del

rollo

Seguro del

tope del

rollo

Palanca

de alzado

Soporte del

rollo

Manivela

Carga del papel

Antes de comenzar, asegúrese de que la impresora esté encendida. Siga estos pasos para usar la unidad de

alimentación de papel integrada. Si va a usar el sistema opcional para rollos pesados de papel, consulte las

instrucciones en el Manual del usuario en formato electrónico. Las ilustraciones incluido en el presente

muestran la impresora S30670, a no ser indicado lo contrario, pero las instrucciones aplican a los tres

modelos.

ADVERTENCIA: Los calentadores y las placas de sujeción del papel podrían estar calientes; tome precauciones

para evitar quemaduras. Es posible que se requieran dos personas para cargar y retirar los rollos pesados.

Precaución: Cargue el papel antes de imprimir para evitar dobleces y ondulaciones.

Nota: En el presente, la palabra “papel” se utiliza para referirse a todos los materiales de impresión compatibles

con esta impresora.

Page 45

Carga del papel | 43

1. Abra la tapa frontal y retire las placas de sujeción del papel.

2. En la parte posterior de la impresora, afloje los seguros del rollo y deslice los soportes del rollo para

separarlos. Centre los soportes del rollo entre los topes.

Español

Nota: Si no ve el eje derecho de la manivela del tope, gire el tope hacia adelante lo máximo posible.

Page 46

44 | Carga del papel

3. S30670: Coloque el papel sobre los soportes del rollo y asegúrese de que el borde izquierdo esté

alineado, tal como se indica a continuación.

Oriente el rollo según el lado imprimible

Cara imprimible hacia afuera

Cara imprimible hacia adentro

S50670/S70670: Coloque la orilla izquierda del papel en cualquiera de los cuadros negros de la barra

posterior de la impresora y la orilla derecha en cualquiera de los agujeros de la parte posterior de la

impresora. Si la etiqueta con cuadros negros no ha sido adherida a la impresora, péguela según se

indica en la Guía de instalación.

Oriente el rollo según el lado imprimible

Cara imprimible hacia afuera

Cara imprimible hacia adentro

Page 47

Carga del papel | 45

4. Suba la palanca de alzado izquierda para colocar el rollo, luego introduzca con fuerza el tope izquierdo

del rollo. Si el diámetro del rollo es menor a 14 cm (5,5 pulg.), levántelo manualmente para alcanzar el

tope del rollo.

Luego apriete el seguro del rollo.

Español

5. Suba la palanca de alzado derecha e introduzca el tope del rollo derecho, luego apriete el seguro del

rollo derecho.

Page 48

46 | Carga del papel

6. Gire la manivela hasta que la parte A (la parte morada), que se muestra la siguiente ilustración, esté

completamente insertada.

Precaución: Para evitar dañar el tope del rollo, no continúe girando la manivela después de que la parte A

esté completamente insertada.

Page 49

Carga del papel | 47

7. Suba la palanca de carga del papel, luego retire el papel manualmente e introdúzcalo en la impresora.

Español

Nota: Si el papel es pesado y difícil de desenrollar,

desplace el interruptor de dirección del tope izquierdo

del rollo. Mueva el interruptor hacia arriba o hacia abajo

de acuerdo con la orientación del papel en el rollo.

También puede sacar el papel manualmente.

8. Introduzca el papel más allá de los rodillos de

Cara

imprimible

hacia afuera

Cara

imprimible

hacia

adentro

presión.

Asegúrese de que el extremo izquierdo del papel pase por encima del centro del cuadrado de la etiqueta

del pre-calentador (sensor de papel). Para evitar que el papel se tuerza, haga avanzar papel adicional,

luego utilice el motor para rebobinar el rollo.

Precaución: Si el extremo izquierdo del papel no

se encuentra en la posición correcta, siga los

pasos 7 a 2 en orden inverso y vuelva a iniciar el

proceso de carga. No trate de cambiar la posición

de los topes del rollo mientras estén instalados

en el rollo de papel.

Page 50

48 | Carga del papel

9. Párese enfrente de la impresora, asegure que la tapa frontal esté abierta y sujete el papel, tal como se

muestra a continuación.

10. Tire del papel hacia adelante hasta que haya pasado la etiqueta en el lado izquierdo del post-calentador.

Mantenga el extremo derecho del papel paralelo a la escala ubicada en el lado derecho del

post-calentador.

Page 51

Carga del papel | 49

11. S50670 y S70670: Ajuste la posición de los rodillos de presión.

Los rodillos de baja presión blancos se utilizan para imprimir, mientras que los rodillos de presión alta

verdes se utilizan para la separación por capas de tinta. Su posición varía según el ancho del papel y los

rodillos que se utilicen.

• Para la impresión normal, coloque los rodillos blancos sobre el papel y debajo de los rectángulos

negros. Confirme que cada rectángulo tenga un rodillo banco por debajo. Mueva los rodillos que

están más allá del ancho del papel de modo que estén entre los rectángulos negros. Coloque el

mayor número de rodillos blancos sobre el papel.

• Para la separación por capas de tinta (impresión con tinta blanca o plateada metálica), mueva los

dos rodillos verdes localizados debajo de los rectángulos negros lo más cerca posible a las orillas

izquierda y derecha del papel. Mueva los rodillos blancos de modo que queden entre los

rectángulos negros.

• Para optimizar el uso del papel, es posible que tenga que desplazarlo ligeramente a la izquierda o

que tenga que ajustar su posición. No podrá imprimir en la zona entre los rodillos verdes cuando

los esté utilizando. Cuando no los esté utilizando, muévalos a la extrema derecha o izquierda de los

rectángulos negros que estén fuera de los límites del papel.

Español

Nota: Si los rodillos no están colocados correctamente, verá un mensaje en la pantalla LCD de la impresora.

Page 52

50 | Carga del papel

12. Baje la palanca de carga del papel para fijarlo en su sitio.

Nota: El papel que quede en la vía de alimentación con el calentador activado se puede deformar. Si esto

ocurre, levante y baje la palanca de carga del papel para que el papel se aplane.

13.

Cuando esté listo para imprimir, coloque las placas de sujeción del papel en ambos lados del papel.

Primero, coloque las placas de forma que los bordes del papel queden en los centros de los orificios.

Ajuste la posición de modo que la línea blanca quede visible en la ventanita cuadrada, luego baje las

placas para que queden fijas en su sitio.

Precaución: Para no dañar el cabezal de impresión, no use las placas de sujeción del papel con papel de más

de 0,02 pulg. (0,4 mm) de grosor. Para evitar imprimir sobre las placas, deje márgenes laterales de más de

10 mm (0,39 pulg.) (a menos que esté imprimiendo por separación de capas de tinta). Retire las placas de

sujeción del papel cuando no las esté usando.

14. Cierre la tapa frontal.

Page 53

Uso del rodillo de recogida automática | 51

Uso del rodillo de recogida automática

Tenga en cuenta que es posible que el rodillo de recogida automática no funcione como se espera con la

separación por capas de tinta (S50670/S70670).

1. Pulse el botón d para alimentar el papel en el tope del eje del rodillo de recogida automática.

Español

2. Afloje los seguros del portarrollos y separe los topes del eje. Centre los soportes del rollo entre los topes

del rollo.

Page 54

52 | Uso del rodillo de recogida automática

3. Alinee el tope derecho del portarrollos con el borde derecho del papel y apriete el seguro.

4. Introduzca el portarrollos en el tope derecho.

Nota: El eje de recogida debe ser más ancho que el eje del papel que está usando.

Page 55

Uso del rodillo de recogida automática | 53

5. Introduzca el tope izquierdo en el portarrollos. Deslícelo hacia adentro hasta que la pieza A, que se

muestra en la ilustración, quede completamente insertada.

Precaución: Pare cuando la

pieza A quede oculta. No

introduzca demasiado el tope.

Español

6. Apriete el seguro del portarrollos.

7. Coloque el papel en el portarrollos de recogida.

Puede recoger el papel hacia la izquierda (cara impresa hacia

afuera) o hacia la derecha (cara impresa hacia adentro).

Cara impresa

hacia afuera

Cara impresa

hacia adentro

Page 56

54 | Uso del rodillo de recogida automática

Pegue con cita adhesiva el papel al portarrollos de recogida de papel en el centro y a ambos lados, como

se indica a continuación:

Cara impresa hacia afuera

8. Pulse el botón d sobre el panel de control para alimentar suficiente papel como para una vuelta en

Cara impresa hacia adentro

el portarrollos.

9. Coloque el interruptor Auto en la posición Off (Desactivado) y coloque el interruptor Manual tal

como se muestra a continuación para enrollar el papel alrededor del portarrollos.

Cara impresa hacia afuera

Cara impresa hacia adentro

Page 57

Uso del rodillo de recogida automática | 55

10. Coloque el interruptor Auto en la posición que se muestra a continuación:

Español

Cara impresa hacia afuera

11. Baje la barra tensora.

12. Pulse el botón d del panel de control para alimentar el papel hasta que el portarrollos de recogida

Cara impresa hacia adentro

comience a girar.

Page 58

56 | Corte y retiro de impresiones

Corte y retiro de impresiones

1. Asegúrese de que aparezca Preparada en la pantalla LCD.

Nota: Si va a usar el rodillo de recogida automática, coloque el interruptor Auto en la posición OFF antes

de usar el interruptor Manual para colocar el papel sobre la guía de corte.

2. Pulse el botón de alimentación del papel y el botón OK. La impresora lleva el papel a la posición de

corte.

Nota: Si imprimió la cantidad de papel restante, pulse el botón u para rebobinar el papel de manera que

esta información no se corte.

3.

Retire las placas de sujeción del papel.

Page 59

Configuración del papel | 57

4. Utilice una hoja de afeitar o una herramienta de corte para cortar la hoja impresa por la guía de corte.

ADVERTENCIA: No coloque los dedos en el

recorrido de la herramienta de corte para evitar

lesiones.

5. Si terminó de usar el papel, retírelo de los topes del rollo y siga en orden inverso los pasos que realizó

para cargarlo.

Español

Configuración del papel

Antes de imprimir en el papel que cargó, cree una configuración o un banco de memoria de

configuraciones (un grupo de ajustes de impresión) para el tipo de papel. Cree una configuración para cada

tipo de papel que use (hasta 30 tipos) y seleccione la configuración que desee cuando imprima en dicho

papel. Esto garantiza que la impresora use configuraciones de calidad de impresión óptima y es la forma

más efectiva de evitar problemas por la aparición de bandas.

Puede guardar configuraciones para un máximo de 30 tipos de papel distintos.

Lista de verificación previa a la impresión

Cuando imprima en un nuevo tipo de papel, siga estas pautas para configurar el papel e imprimir:

• Revise el paquete del papel para conocer los requisitos de impresión.

• Seleccione un numero del banco de memoria de configuraciones (del 1 al 30) y asígnele un nombre

alfanumérico que sus usuarios puedan reconocer.

Page 60

58 | Creación de configuraciones de papel

• Seleccione estas configuraciones en base a la información que se proporciona con el papel:

Nombre Soporte Ajuste Alimentación

Separción dl Cabezal Alineación Cabezales

Calentamiento y Secado Succión dl Soporte

Movimiento Cabezal Imprim Varias Capas

Tipo de Rollo Medición de la Tensión

Tensión Soporte Velocidad Alimentación

Nota: La configuración de calentamiento y secado es especialmente importante e incluye varias

subconfiguraciones.

• Imprima un patrón de prueba de inyectores y limpie los cabezales de impresión, si es necesario.

Consulte la página 61.

• Realice un ajuste automático de la alimentación. Consulte la página 59.

• Realice una alineación automática del cabezal. Consulte la página 59.

• Seleccionar el nombre de la configuración para el papel y la impresión.

Creación de configuraciones de papel

1. Pulse el botón Menu.

2. Seleccione Config. Soportes y pulse el botón OK.

3. Seleccione Personalizar Ajustes y pulse el botón OK.

4. Seleccione el número de configuración de bancos de memoria (1 al 30) que desee usar para este tipo de

papel y pulse el botón

5. Seleccione los ajustes para el papel.

OK.

Page 61

Realización de un ajuste automático de la alimentación | 59

Realización de un ajuste automático de la alimentación

El ajuste de la alimentación corrige los problemas por la aparición de bandas y se puede realizar

manualmente (como se describe en el Manual del usuario en formato electrónico) o automáticamente

(como se indica a continuación).

1. Pulse el botón Menu.

2. Seleccione Config. Soportes y pulse el botón OK.

3. Seleccione Personalizar Ajustes y pulse el botón OK.

4. Seleccione el número y el nombre de la configuración del banco de papel cargado y pulse el botón OK.

5. Seleccione Ajuste Alimentación y luego pulse el botón OK.

6. Seleccione Automática y luego pulse el botón OK.

7. Pulse el botón OK nuevamente para imprimir un patrón de prueba y realizar un ajuste automático

de alimentación.

Realización de una alineación automática del cabezal

La alineación del cabezal corrige los problemas de impresión granulosa o desalineada y se puede realizar

manualmente (como se describe en el Manual del usuario en formato electrónico) o automáticamente

(como se indica a continuación).

1. Pulse el botón Menu.

2. Seleccione Config. Soportes y pulse el botón OK.

3. Seleccione Personalizar Ajustes y pulse el botón OK.

Español

4. Seleccione el número y el nombre de la configuración del banco de papel cargado y pulse el botón OK.

5. Seleccione Alineación Cabezales y pulse el botón el botón OK.

6. Seleccione primero Auto (Uni-D), después seleccione Auto (BI-D).

7. Pulse el botón OK nuevamente para imprimir un patrón de prueba y realizar una alineación

automática de cabezales.

Nota: Si los ajuste automáticos no funcionan, utilice ajustes manuales. Algunos tipos de papel no son

compatibles con los ajustes automáticos.

Page 62

60 | Limpieza del sistema de papel

Limpieza del sistema de papel

Para quitar la tinta y las partículas de papel, limpie todos los días el calentador de la platina, los rodillos de

presión y las placas de sujeción del papel antes de comenzar el trabajo.

1. Asegúrese de que la impresora esté apagada.

2. Espere un minuto y luego abra la tapa frontal.

3. Limpie las partículas de papel y de polvo de los rodillos de presión con un cepillo de cerdas suaves.

S30670

S50670 y S70670

4. Humedezca un paño suave con agua, escúrralo por completo y úselo para eliminar las pelusas y el

polvo de las placas de sujeción del papel derecha e izquierda y del cabezal.

Page 63

Comprobación y limpieza del cabezal de impresión | 61

Comprobación y limpieza del cabezal de impresión

Si las impresiones muestran un cambio de color o líneas horizontales, revise los inyectores del cabezal de

impresión en busca de obstrucciones o desviaciones. Si es necesario, ejecute un ciclo de limpieza.

Nota: Puede configurar la impresora para revisar automáticamente los inyectores en forma periódica mediante la

opción Rev Autom Inyectores o antes de cada trabajo de impresión mediante la opción Impr Patrn Test Inyect.

También puede ejecutar distintos niveles de limpieza de cabezales y configurar ciclos de limpieza automática.

1. Pulse el botón # de mantenimiento.

2. Seleccione Test De Inyectores y pulse el botón OK.

3. Examine el patrón impreso para determinar si es necesario limpiar el cabezal de impresión.

No se necesita limpiar

4. Si necesita limpiar el cabezal de impresión, seleccione una de las siguientes opciones:

Se debe limpiar el cabezal

• Todos los inyectores (si a todos los patrones numerados les faltan segmentos o si los segmentos

se imprimen muy claros)

• Inyectores seleccionads (si solo a algunos de los patrones numerados les faltan segmentos o si se

imprimen muy claros)

5. Elija los grupos de inyectores (correspondientes a los patrones numerados) que desee limpiar.

6. Seleccione Continuar y pulse el botón OK.

7. Seleccione un nivel de limpieza y pulse el botón OK.

Español

8. Imprima un patrón de inyectores y revise los resultados para determinar si la limpieza de cabezales

fue exitosa.

Si no logra limpiar todos los inyectores ejecutando los ciclos de limpieza más intensos, debe lavar el sistema

de tinta según se describe en la página 66.

Page 64

62 | Mantenimiento de la impresora

Mantenimiento de la impresora

Debe revisar regularmente el nivel de tinta y reemplazar los cartuchos (consulte la página 64) según sea

necesario. S50670 y S70670: La impresora ejecuta ciclos de mantenimiento automáticos para evitar que se

acumule la tinta, lo cual puede ocasionar obstrucciones de tinta. No apague la impresora o el ciclo de

mantenimiento no se realizará.

También debe realizar periódicamente los siguientes procedimientos de mantenimiento:

Procedimiento Frecuencia Instrucciones

Limpiar el cabezal de impresión, el limpiacabezales, las

tapas y el riel del limpiacabezales

Semanalmente o con más

frecuencia si es necesario

página 66

Retirar y agitar los cartuchos de tinta

Saque y agite los cartuchos de tinta blanca y plateada

metálica

Eliminar la tinta de desecho Según sea necesario página 72

Lavar el sistema de tinta Según sea necesario página 66

Reemplazar el limpiacabezales, el dispositivo de limpieza

del limpiacabezales y la almohadilla de aclarado de tinta

Cada 3 semanas

Cada 24 horas

Casa 6 meses o según sea

necesario

página 65

página 74

Page 65

Comprobación del nivel de tinta | 63

S30670

S50670

Comprobación del nivel de tinta

La forma más fácil de comprobar los niveles de tinta es desde la pantalla LCD del panel de control.

Mensajes de estado

de la impresora

Temperatura del pre-calentador

Separación del cabezal

Papel seleccionado

Mensajes de estado

de la impresora

Temperatura del

pre-calentador

Separación del cabezal

Papel seleccionado

Temperatura del

calentador de la platina

Nivel de los

cartuchos de tinta

Temperatura del

calentador de la platina

Temperatura del

post-calentador

Temperatura del

post-calentador

Indicador del ventilador de

secado opcional

Ancho del papel

Papel restante

Nivel del depósito de

tinta de desecho

Estado del ventilador

de secado

Estado de detección

de golpe de cabezal

Ancho del papel

Papel restante

Nivel del depósito de

tinta de desecho

Español

Nivel de los

cartuchos de tinta

Page 66

64 | Reemplazo de los cartuchos de tinta

Los íconos indican la tinta que queda, tal como se explica a continuación:

Ícono Descripción

Preparada para imprimir. La altura del indicador muestra el nivel aproximado de

tinta restante.

Nivel de tinta bajo. Asegúrese de tener un cartucho de repuesto listo.

No queda tinta. Reemplace con un cartucho nuevo.

El cartucho no está fijo. Baje la palanca de bloqueo.

No hay cartucho.

Error de cartucho. Lea el mensaje y solucione el problema.

Hay un cartucho de limpieza instalado. La altura del indicador muestra aproximadamente

cuánto líquido limpiador queda en el cartucho.

Reemplazo de los cartuchos de tinta

Use los siguientes cartuchos de tinta EPSON UltraChrome® GSX o GS2 (consulte la página 77 para

obtener información de compra)

Ranura Cartucho S30670 S50670 S70670

BK Negro T689100 T689100 T715100

Y Amarillo T689400 T689400 T715400

M Magenta T689300 T689300 T715300

C Cian T689200 T689200 T715200

WH Blanco — T715A00

MS Plateado metálico — — T715B00

LK Negro claro — — T715700

OR Naranja — — T715800

LC Cian claro — — T715500

LM Magenta claro — — T715600

Todos Cartucho de limpieza T699000

:

Page 67

Reemplazo de los cartuchos de tinta | 65

1. Levante la palanca de bloqueo del cartucho que debe reemplazar, luego retire el cartucho.

2. Desembale el cartucho nuevo y sacúdalo durante 5 segundos o 15 segundos si es un cartucho de tinta

blanca, plateada metálica o naranja.

Español

3. Sujete el cartucho con la etiqueta hacia afuera e introdúzcalo en la ranura. Luego, baje la palanca

de bloqueo.

Nota: Aproximadamente cada tres semanas (o cada 24 horas si se trata de tinta blanca o plateada metálica),

tendrá que sacar los cartuchos de tinta y agitarlos como se describe en el paso 2 (5 segundos cada uno).

Page 68

66 | Lavado del sistema de tinta

Lavado del sistema de tinta

Si no puede recuperar todos los inyectores ejecutando los ciclos de limpieza más intensos, debe lavar el

cabezal de impresión. Esto significa sacar los cartuchos, instalar los cartuchos de limpieza y luego volver

a instalar los cartuchos. El proceso de lavado también requiere que vacíe varias veces el depósito de tinta

de desecho.

Debido a la cantidad de tinta que se consume, no es aconsejable realizar el lavado de cabezales, a menos

que no pueda recuperar los inyectores con la limpieza normal.

1. Pulse el botón # de mantenimiento.

2. Seleccione Lavado Del Cabezal y pulse el botón OK.

3. Seleccione los grupos de inyectores individuales o Todos los inyectores.

4. Siga las instrucciones de la pantalla LCD. Para obtener instrucciones detalladas, consulte estas

secciones:

• Retiro e inserción de cartuchos de tinta y cartuchos de limpieza (consulte la página 64)

• Vaciado del depósito de tinta de desecho (consulte la página 72)

Limpieza del cabezal, del limpiacabezales, las tapas y el riel del limpiacabezales

Limpie el cabezal de impresión, el limpiacabezales, las tapas y el riel del limpiacabezales al menos una vez a

la semana. Es posible que también necesite limpiarlos si nota espacios o tinta borrosa en sus impresiones

después de limpiar el cabezal de impresión. Además del kit de mantenimiento que viene con la impresora,

necesitará anteojos de seguridad, limpiador de tinta, un paño de limpieza (un paño de limpieza desechable

que no deje pelusas) y una bandeja de metal o plástico (para depositar las piezas que saque para limpieza o

reemplazo).

Nota: Si necesita más kits de mantenimiento, puede comprar un kit de mantenimiento adicional para la

impresora. Consulte la página 77 para obtener información de compra.

Precaución: Para quitar manchas de tinta que no salen con los bastoncillos de limpieza, use un bastoncillo

con limpiador de tinta. El limpiador de tinta solo se debe usar para limpiar el área alrededor del limpiacabezales,

las tapas y el cabezal de impresión. El limpiador de tinta usado se debe desechar de la misma forma que la

tinta usada.

Precaución: Debe realizar este proceso de limpieza en un período de 10 minutos para evitar que el cabezal

de impresión se reseque.

Page 69

Limpieza del cabezal, del limpiacabezales, las tapas y el riel del limpiacabezales | 67

1. Pulse el botón # de mantenimiento, luego seleccione Mantenimiento Cabezal y luego pulse el

botón

OK.

2. Pulse el botón OK nuevamente para desplazar el cabezal a la posición de limpieza.

3. Abra la cubierta de mantenimiento en cada extremo de la impresora.

4. Use guantes de plástico cuando proceda a limpiar las áreas del cabezal de impresión con los

bastoncillos de limpieza, tal como se indica a continuación. Tal vez tenga que humedecer los

bastoncillos de limpieza con limpiador de tinta para eliminar los residuos de tinta.

Español

Page 70

68 | Limpieza del cabezal, del limpiacabezales, las tapas y el riel del limpiacabezales

Para quitar las salpicaduras de tinta o las partículas de papel que pueda haber en la base del cabezal de

impresión (como se muestra a continuación), humedezca un bastoncillo con una cantidad mínima de

limpiador de tinta.

S30670

Sensores

Precaución: No toque las superficies de los inyectores o cualquier otra pieza interna con las manos, para

evitar que la grasa de la piel interfiera con las operaciones de limpieza del cabezal. No toque los sensores con

las manos o el bastoncillo. No humedezca el bastoncillo de limpieza con agua, ya que puede dañar el cabezal

de impresión. No deje que el bastoncillo de limpieza toque ninguna pieza de la impresora, ya que se puede

manchar de tinta. No reutilice un bastoncillo de limpieza, ya que la suciedad o tinta del mismo pueden dañar

el cabezal de impresión.

S50670 y S70670

Sensores

Cabezal 1

Cabezal 2

Page 71

Limpieza del cabezal, del limpiacabezales, las tapas y el riel del limpiacabezales | 69

5. Limpie la parte frontal y posterior del limpiacabezales (o de los limpiacabezales si se trata de las

impresoras S50670 y S70670) con un bastoncillo de limpieza, tal como se muestra a continuación. Tal

vez tenga que humedecer el bastoncillo de limpieza con limpiador de tinta para eliminar los residuos

de tinta.

Español

6. Incline el limpiacabezales hacia la izquierda y retírelo de la impresora.

Page 72

70 | Limpieza del cabezal, del limpiacabezales, las tapas y el riel del limpiacabezales

7. Limpie por el frente, por detrás y por debajo del limpiacabezales, tal como se muestra a continuación.

8. Limpie los puntos de sujeción, luego coloque el limpiacabezales sobre los puntos y presiónelo hasta que

quede trabado en su sitio.

Page 73

Limpieza del cabezal, del limpiacabezales, las tapas y el riel del limpiacabezales | 71

9. Limpie alrededor del área exterior de las cuatro tapas (S30670) o las 10 tapas (S50670/S70670) con un

bastoncillo de limpieza, tal como se muestra a continuación.

Precaución: No toque el interior de las tapas ya que se podrían deformar.

Español

10.

Pulse el botón OK para desplazar el limpiacabezales hacia atrás. Asegúrese de que aparezca un mensaje

parecido a este en la pantalla:

Limpie el riel del limpiacabezales.

Después de limpiar el cabezal, cierre

las tapas de mantenimiento y

pulse OK.

11. Sujete el dispositivo de limpieza del limpiacabezales, tal como se muestra a continuación, y levántelo

para sacarlo de la impresora. Luego, moje un bastoncillo de limpieza con limpiador de tinta y úselo

para limpiar el área que se muestra a continuación.

S50670/S70670: Debe limpiar los dos rieles.

Page 74

72 | Eliminación de la tinta de desecho

Precaución: Tenga cuidado de no dislocar ninguno de los resortes o ninguna otra pieza.

Para reemplazar el dispositivo de limpieza, presiónelo hacia abajo hasta que quede trabado en su sitio.

12.

13. Cierre las cubiertas de mantenimiento derecha e izquierda y luego pulse el botón OK.

14. Elimine los guantes usados, el bastoncillo y el limpiador de tinta, conforme a las leyes y ordenanzas de

eliminación de desechos industriales del gobierno local, como se requiera en su área.

Eliminación de la tinta de desecho

Debe eliminar la tinta de desecho que se acumula en el depósito de tinta de desecho debajo de la impresora

cuando observe el siguiente mensaje:

Prepare el bote de tinta desechada.

Cambie el bote de tinta desechada y pulse OK.

Antes de eliminar la tinta de desecho, asegúrese de tener un recipiente de reemplazo o un tambor para tinta

de desecho apropiado.

Page 75

Eliminación de la tinta de desecho | 73

Precaución: Antes de manipular la tinta de desecho, lea la hoja

de datos de seguridad de materiales (Material Safety Data

Sheet o MSDS) de la impresora. Puede descargarla desde el

sitio web de soporte técnico de Epson en epson.com/support

(solamente disponible en inglés).

La tinta de desecho de la impresora es un desecho industrial.

Deberá desecharla según lo estipulado en las leyes y normativa

sobre el desecho de residuos industriales vigentes en su

localidad. La tinta usada debe llevarse a un triturador de

residuos industriales. Proporcione la hoja de datos de tinta de

desecho (Waste Ink Data Sheet) a la empresa de eliminación de

desechos industriales. Puede descargarla desde el sitio web de

soporte técnico de Epson en epson.com/support (solamente

disponible en inglés).

ADVERTENCIA: Use lentes y guantes de protección. Si se

moja la piel con tinta de desecho o le entra tinta en los ojos o en

la boca, tome las siguientes medidas de inmediato:

Si el líquido se le adhiere a la piel, lávese inmediatamente con

abundante agua y jabón. Consulte a un médico si le irrita o

descolora la piel.

Español

Si el líquido le entra en los ojos, enjuágueselos inmediatamente

con agua. De lo contrario, los ojos se le pueden irritar o inflamar

ligeramente.

Si se traga el líquido, consulte a un médico de inmediato y no

provoque el vómito.

Después de reemplazar el depósito de tinta de desecho, lávese

bien las manos.

Use guantes de plástico para sacar el depósito de tinta

1.

de desecho del soporte, tal como se muestra a la derecha.

2. Introduzca el tubo de tinta de desecho en la boquilla del depósito nuevo y colóquelo en el soporte.

Precaución: Asegúrese de guardar la tapa del depósito de tinta de desecho para que la pueda usar cuando

descarte la tinta.

3.

Cierre herméticamente la tapa del depósito de tinta de desecho usado.

4. Pulse el botón OK, luego asegúrese de que el recipiente nuevo quede instalado correctamente y pulse

una vez más el botón

OK para poner a cero el contador de la tinta de desecho.

Page 76

74 | Reemplazo del limpiacabezales, el dispositivo de limpieza y la almohadilla de

5. Elimine la tinta de desecho conforme a las leyes y ordenanzas de eliminación de desechos industriales

del gobierno local, según se requiera en su área.

Reemplazo del limpiacabezales, el dispositivo de limpieza y la almohadilla de aclarado

Reemplace el limpiacabezales y el dispositivo de limpieza del limpiacabezales cada seis meses o cuando la

parte frontal del limpiacabezales comience a aparecer manchada con tinta. Con las impresoras

S50670/S70670, debe reemplazar los dos limpiacabezales y dispositivos de limpieza de los limpiacabezales.

Reemplace la almohadilla de aclarado de la impresora cada seis meses. Tal vez tenga que cambiarla antes si

observa salpicaduras de tinta en el papel o si aparece polvo del papel en la parte frontal de la almohadilla.

Use la almohadilla de aclarado y los guantes de reemplazo que vienen en el kit de mantenimiento.

Nota: Si necesita más almohadillas de aclarado, adquiera un kit de mantenimiento adicional de la impresora.

Consulte la página 77 para obtener información sobre pedidos.

Pulse el botón # de mantenimiento, luego seleccione Mantenimiento Cabezal y luego pulse el

1.

OK.

botón

2. Pulse el botón OK nuevamente para desplazar el cabezal a la posición de limpieza.

3. Abra la cubierta de mantenimiento derecha.

Page 77

Reemplazo del limpiacabezales, el dispositivo de limpieza y la almohadilla de

4. Use los guantes plásticos para sostener el dispositivo de limpieza del limpiacabezales, tal como se

muestra a continuación, y levántelo para sacarlo de la impresora. Introduzca un dispositivo de limpieza

del limpiacabezales nuevo y presiónelo hasta que encaje en su lugar.

Español

5. Incline el limpiacabezales hacia la izquierda y levántelo para sacarlo de la impresora. Luego introduzca

un limpiacabezales nuevo y empújelo hasta que encaje en su lugar.

Page 78

76 | Reemplazo del limpiacabezales, el dispositivo de limpieza y la almohadilla de

6. Retire la almohadilla de aclarado sujetándola por su lengüeta.

Precaución: Mantenga la almohadilla de aclarado recta y nivelada mientras la saca para evitar que se

derrame la tinta. Tenga cuidado de no dejar que se derrame tinta sobre ninguna pieza de la impresora.

7. Coloque la almohadilla de aclarado usada sobre una bandeja.

8. Introduzca los dos ganchos de la almohadilla de aclarado nueva en las ranuras, tal como se indica a

continuación, y presione la lengüeta hasta que la almohadilla encaje en su lugar.

9. Cierre la cubierta de mantenimiento derecha.

10. Pulse el botón OK y luego pulse el botón OK nuevamente.

Page 79

Suministros y accesorios | 77

Suministros y accesorios

Pieza Número de pieza

Cartuchos de tinta Consulte la página 64 para ver una lista

completa

Kit de mantenimiento adicional de la impresora (suministro para

seis meses)

Cartucho de limpieza T699000

Limpiador de tinta T699300

Depósito para tinta de desecho adicional T724000

Placa de sujeción del papel C12C890891

Sistema para rollos pesados de papel C12C890761

Secador de alta velocidad C890751

Nota: Los cartuchos de limpieza se pueden utilizar más de una vez, pero debe comprar tantos cartuchos como

sean necesarios.

T724100

Puede comprar equipos opcionales y cartuchos de tinta y papel EPSON originales de un distribuidor de

productos EPSON autorizado. Para encontrar el distribuidor más cercano, comuníquese con Epson como

se indica a continuación.

¿Dónde obtener ayuda?

Epson proporciona soporte técnico e información sobre la instalación, configuración y operación de los

productos de impresión profesional por medio de los servicios de soporte técnico de Epson.

Puede comunicarse con un especialista de soporte técnico marcando uno de estos números de teléfono

Español

País Número de teléfono País Número de teléfono

Argentina (54 11) 5167-0300 México

Bolivia* 800-100-116

Chile (56 2) 484-3400

Colombia (57 1) 523-5000 Nicaragua* 00-1-800-226-0368

Costa Rica 800-377-6627 Panamá* 00-800-052-1376

México, D.F.

Resto del país

(52 55) 1323-2052

01-800-087-1080

Page 80

78 | Marcas comerciales

País Número de teléfono País Número de teléfono

Ecuador* 1-800-000-044 Perú

El Salvador* 800-6570

Guatemala* 1-800-835-0358

Honduras** 800-0122

Código NIP: 8320