Epson S1D15G00D00*100, S1D15G00D01*100, S1D15G00D03*100, S1D15G00D05*100, S1D15G00D06*100 Schematic [ru]

...

MF1387-04

S1D15G00 Series

Rev. 1.0

“Seiko Epson is neither licensed nor authorized to license its customers under one or more patents held by

Motif Corporation to use this integrated circuit in the manufacture of liquid crystal display modules. Such

license, however, may be obtained directly from MOTIF by writing to: Motif, Inc., c/o In Focus Systems, Inc.,

27700A SW Parkway Avenue, Wilsonville, OR 97070-9215, Attention: Vice President Corporate

Development.”

Seiko Epson Corporation 2001, All rights reserved.

Rev. 1.0

Contents

1. DESCRIPTION .................................................................................................................................................. 1

2. FEATURES........................................................................................................................................................ 1

3. BLOCK DIAGRAM............................................................................................................................................. 2

4. PIN LAYOUT ..................................................................................................................................................... 3

5. LIST OF DEVICE MODELS............................................................................................................................... 3

6. PIN COORDINATE............................................................................................................................................ 4

7. PIN DESCRIPTION ........................................................................................................................................... 6

8. FUNCTIONAL DESCRIPTION ........................................................................................................................ 11

9. COMMANDS ................................................................................................................................................... 30

10. ABSOLUTE MAXIMUM RATING..................................................................................................................... 42

11. ELECTRIC CHARACTERISTICS.................................................................................................................... 43

12. MPU INTERFACES (EXAMPLES FOR YOUR REFERENCE)....................................................................... 53

13. PERIPHERAL CONNECTION EXAMPLES .................................................................................................... 58

14. EEPROM INTERFACE.................................................................................................................................... 60

15. CAUTIONS ...................................................................................................................................................... 61

– i – Rev. 1.0

S1D15G00 Series

1. DESCRIPTION

S1D15G00 series are the LCD drivers equipped with

the liquid crystal drive power circuit to realize color

display with one chip.

S1D15G00 can be directly connected to the MPU bus to

store parallel or serial gray-scale display data from

MPU on the built-in RAM and to generate liquid crystal

drive signals independent from MPU. S1D15G00

generates 396 segment outputs and 160

outputs for driving liquid crystal. It incorporates the

display RAM with capacity of 396 × 168 × 4 (16 grayscale). A single dot of pixel on the liquid crystal panel

corresponds to 4 bits of the built-in RAM, enabling to

display 132 (RGB) × 160 pixels with one chip.

Read or write operations from MPU to the display RAM

can be performed without resorting to external actuating

clock signals. S1D15G00 allows you to run the display

system of high performance and handy equipment at the

minimum power consumption thanks to its low-power

liquid crystal drive power circuit and oscillation circuit.

*1

:The S1D15G00D10*100 generates 300 segment

outputs and 120 common outputs. It incorporates

the display RAM with 300 × 168 × 4 capacity and

displays 100 (RGB) × 120 pixels.

*1

common

2. FEATURES

• Number of liquid crystal-drive outputs:

396 segment outputs and 160 common outputs.

• Low cross talk by frame rate modulation.

• 256 color from 4096-color display or full 4096-color

display.

When 256 color from 4096-color display is selected:

8 gray-scale for red and green and 4 gray-scale for

blue (intermediate tone is selected with the command).

When 4096-color display is selected: 16 gray-scale

for red, green and blue.

• Direct data display with display RAM

(When the LCD is set to normally black)

RAM bit Data “0000” ... OFF (Black)

“1111” ...ON (Maximum RGB display)

(Normally black LCD, using "inverse display" command)

• Partial display function: You can save power by

limiting the display space. This function is most

suited for handy equipment in the standby mode.

• Display RAM : 396 × 168 × 4 = 266,112 bits.*1

*1: The S1D15G00D10

× 4 = 144,000 bits.

• MPU interface: S1D15G00 can be directly connected

to both of the 8/16-bit parallel 80 and 68 series MPU.

Two type serial interface are also available.

• 3 pins serial : CS, SCL and SI (D/C + 8-bit data)

• 4 pins serial : CS, SCL, SI and A0

• Abundant command functions: Area scroll function,

automatic page & column increment function, display

direction switching function and power circuit control

function.

• Built-in liquid crystal drive power circuit: S1D15G00

is equipped the charge pump booster circuit, voltage

follower circuit and electric volume control circuit.

• Oscillation circuit with built-in high precision CR

(external clock signals acceptable)

• EEPROM interface functions

• Low current consumption

500µA (Conditions: S1D15G00D01B100, V

VDDI = 3.0V, frame frequency 130Hz, V2 = 6.0V, all

display RAM data is “0”)

• Supply voltage

Power for input/output system power:

VDDI–GND=1.7V to 3.6V

Power for internal circuit operation:

VDD–GND=2.6V to 3.6V

Reference power for booster circuit:

VDD2–GND=2.6V to 3.6V

Power for liquid crystal drive:

V3–MV3=12.0V to 21.0V

• Wider operational range: –40°C to 85°C.

• Shipping from: Chip with gold bump. COF.

• Note that the radiation resistant design or light

resistance design in strict sense is not employed for

S1D15G00.

000 has RAM of 300 × 120

*

DD =

Rev. 1.0 EPSON 1

S1D15G00 Series

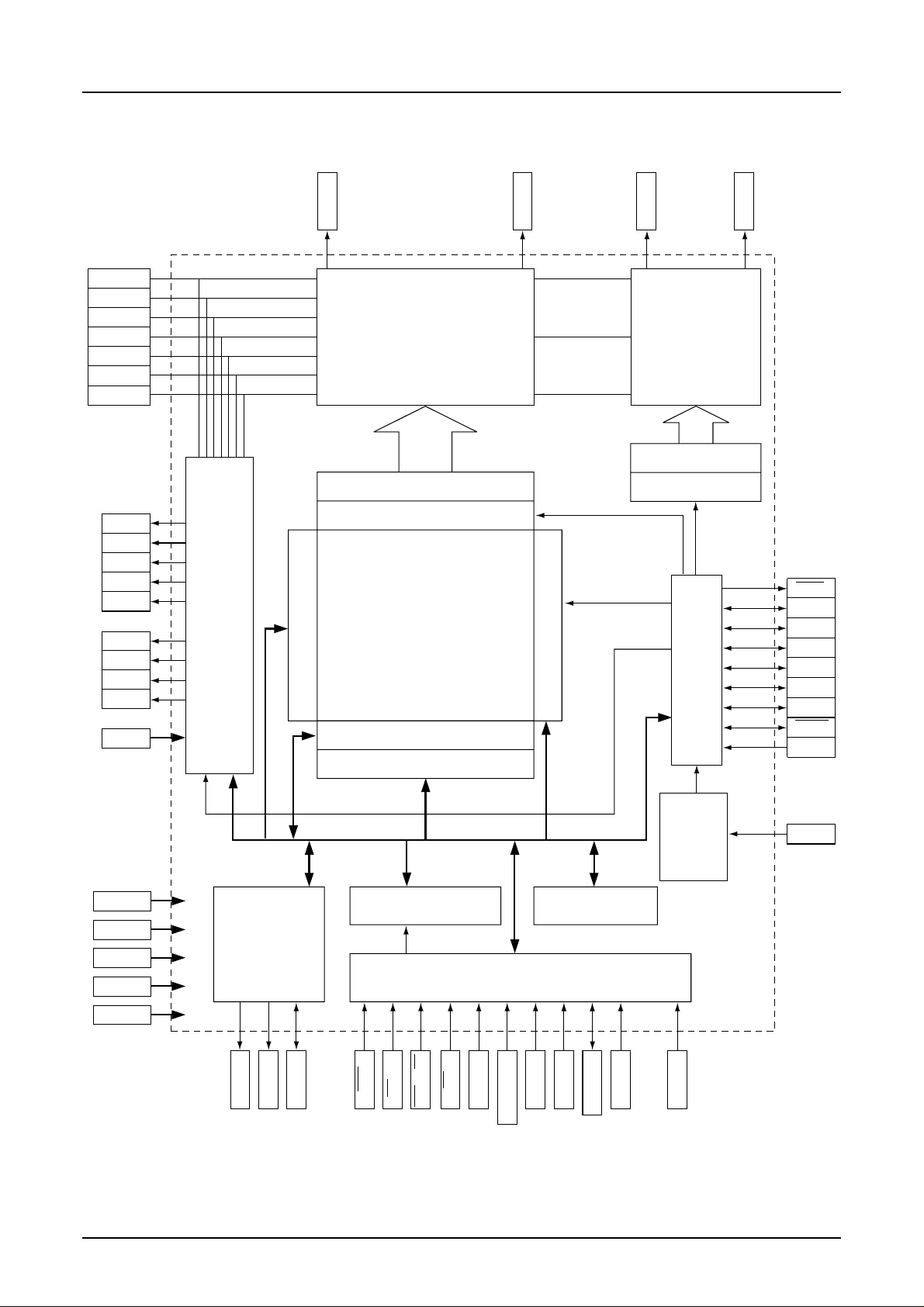

3. BLOCK DIAGRAM

V

3

V

2

V

1

V

C

MV

1

MV2(GND)

MV

3

• • • • • • • • • • • • • • • • • • • • • • • • • • • •

SEG1

SEG396

COM1

SEG Drivers COM Drivers

COM decoder

COM160

CAP1+

CAP1–

CAP2+

CAP2–

V

CAP4+

CAP4–

CAP5+

CPP5–

V

V

DD3

V

V

GND

CLS

DD2

DD

DDI

to

SEG decoder

Shift register

Display data latch

SLP

YSCL

F1,F2

CA

FR

Power circuit

Page address

DDRAM

396 x 168 x 4

Block address

SYNC

CL

DOFF

M/S

I/O buffer

generation circuit

Display timing signal

Column address

Oscillation

circuit

5

Command decoder

Bus holder

CLS

EEPROM

interface

MPU interface

GND2 to

4

RESET

CLOCK

SDA

RES

RD(E)

CS

WR(R/W)

A0

SI

IF1,IF2,IF3

SCL

TEST

D15 to D0

SRCM

2 EPSON Rev. 1.0

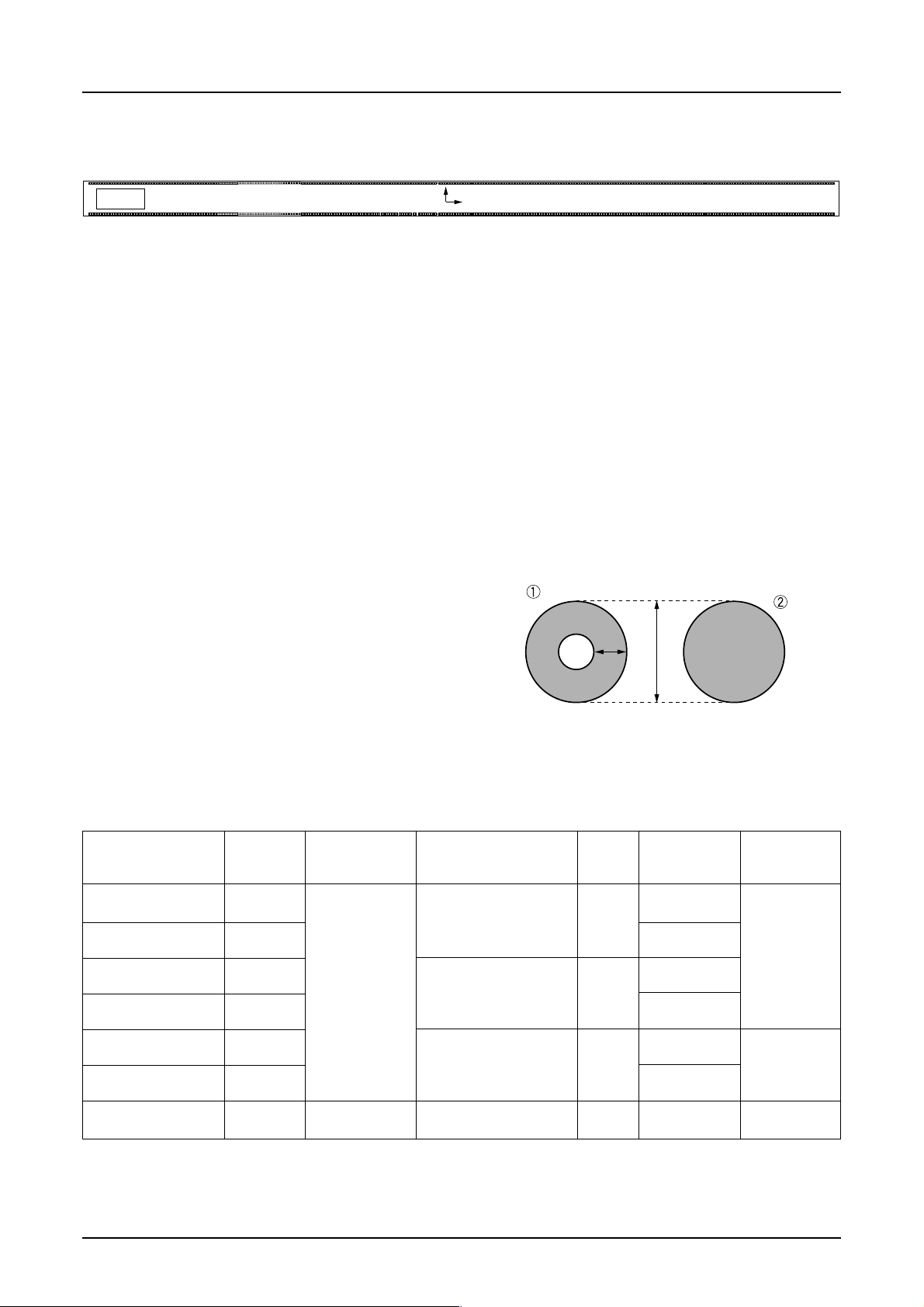

4. PIN LAYOUT

b

a

S1D15G00 Series

792

Die No.

1

Y

(0,0)

X

Chip size 25.04 mm × 2.70 mm

Chip thickness 725 µm±25 µm (for reference)

Die No. See Section 5 “List of Device Models.”

Potential on board GND

Bump size Tolerance: bump of the shorter side ±3 µm, bump of the longer side ±4 µm (reference)

Driver output side: 30 µm × 137 µm

Driver input side:

82 µm × 109 µm

Bump pitch Driver output side: 4 2 µm

I/O signal line side:100 µm min.

Bump height 22.5 µm±4 µm (for reference) : S1D15G00D0

B0

*

Alignment coordinate

1 (–11974.2, –639.2)

2 (12091.8, –730.4)

Mark size a = 80 µm

b = 20 µm

205

204

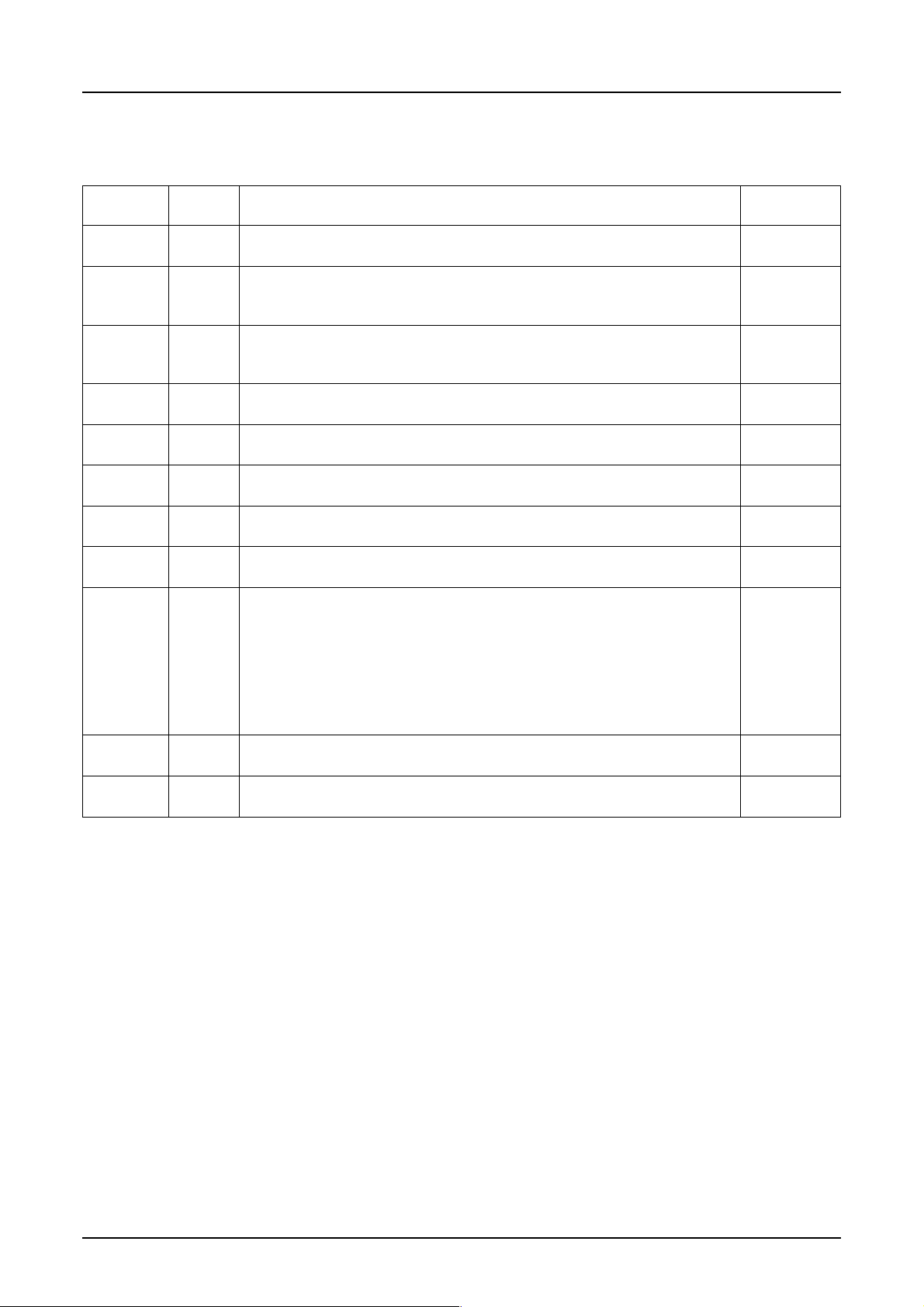

5. LIST OF DEVICE MODELS

Model name Die No. control resistor

S1D15G00D00*100 D15G0D0B Segment: 396 Internal only Unable to read 130 Hz

(#)

S1D15G00D05*100 D15G0D5B controlled via Read enabled

S1D15G00D01*100 D15G0D1B External only × Unable to read

(#)

S1D15G00D06*100 D15G0D6B via VR pin Read enabled

S1D15G00D03*100 D15G0D3B External only × Unable to read 180 Hz

(#)

S1D15G00D08*100 D15G0D8B via VR pin Read enabled

S1D15G00D10*100 D15G0DAB Segment: 300 External only (voltage × Unable to read 130 Hz

(#) Common: 120 via VR pin resistance) /31.2 kHz

Output

count

Common: 160 (voltage electronically /41.6 kHz

V2 voltage

External/Internal

electronic volume)

(voltage controlled

resistance)

(voltage controlled /57.6 kHz

resistance)

Access MPU RAM

to EEPROM

read

(Note)

For “unable to read” models in the above diagram, the MPU cannot read the RAM. If the RAM must be read, use “read

enabled” models.

(#) : These models will be discontinued.

Rev. 1.0 EPSON 3

Frame frequency

/built-in oscillation

frequency

S1D15G00 Series

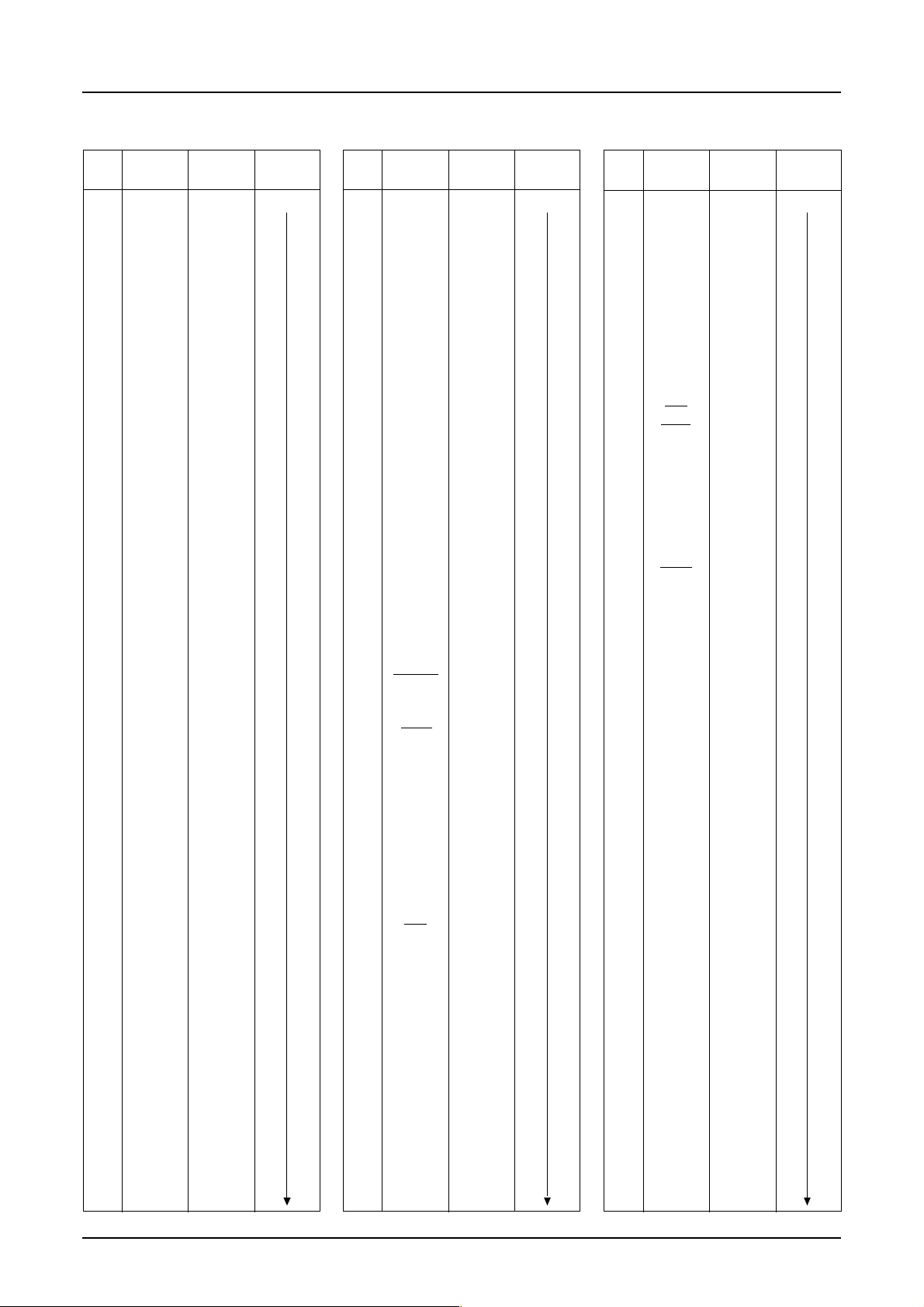

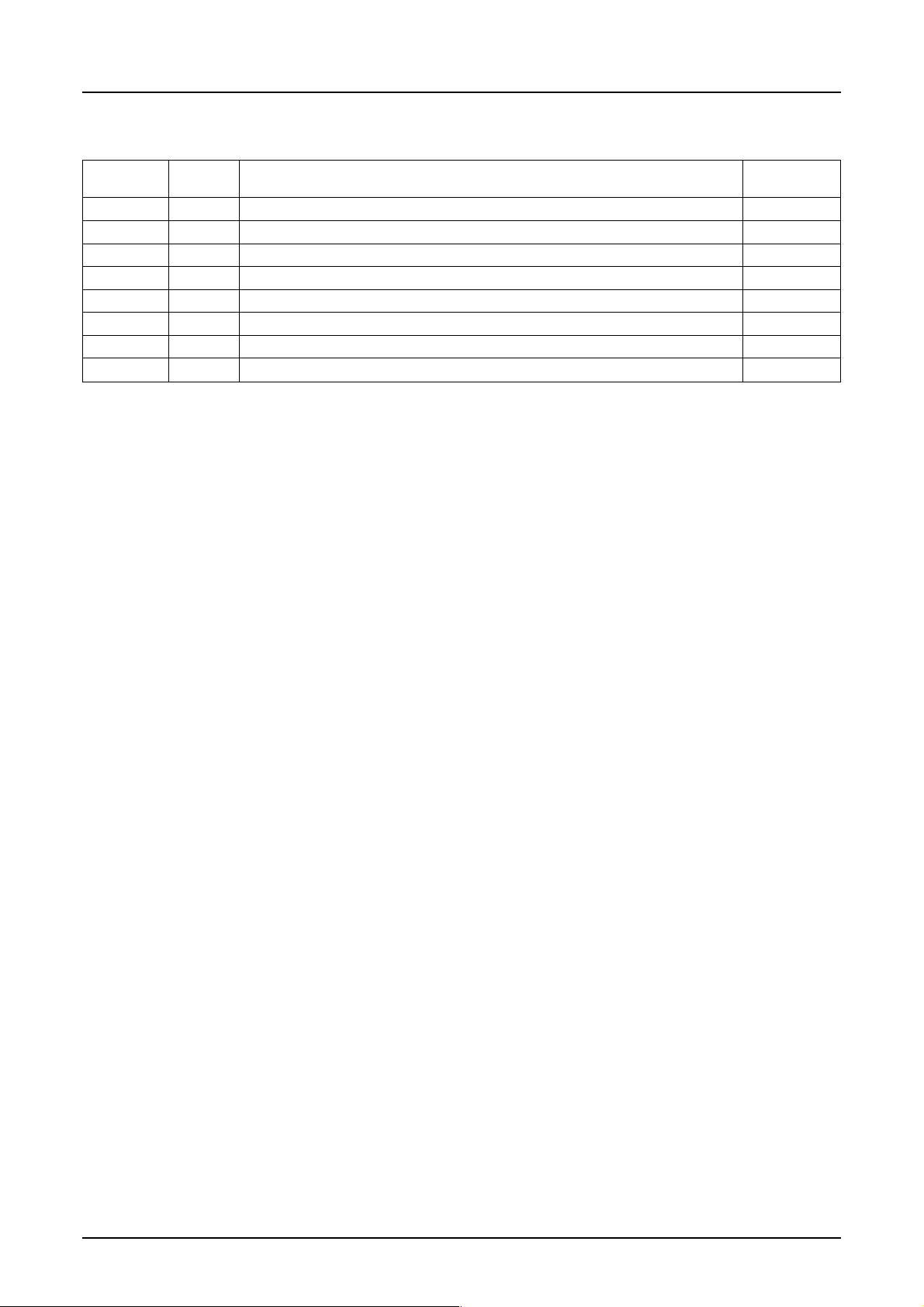

6. PIN COORDINATE

PAD Pin

No. Name

1NC–12331 –1188.5

2NC–12211

3V

3L –12091

4V3L –11971

5V3L –11851

6V2L –11731

7V2L –11611

8V2L –11491

9V2L –11371

10 V1L –11251

11 V1L –11131

12 V1L –11011

13 V1L –10891

14 VCL –10771

15 VCL –10651

16 VCL –10531

17 VCL –10411

18 VCLSL –10291

19 VCLSL –10171

20 VCLSL –10051

21 VCLSL –9931

22 MV1L –9811

23 MV1L –9691

24 MV1L –9571

25 MV1L –9451

26 MV3L –9331

27 MV3L –9211

28 MV3L –9091

29 TESTA –8971

30 TESTB –8871

31 TESTC –8771

32 TESTD –8671

33 TESTE –8571

34 TESTF –8451

35 TESTF –8336

36 TESTF –8221

37 TESTF –8106

38 TESTF –7991

39 CAP2+ –7871

40 CAP2+ –7756

41 CAP2+ –7641

42 CAP2+ –7526

43 CAP2+ –7411

44 CAP2––7291

45 CAP2––7176

46 CAP2––7061

47 CAP2––6946

48 CAP2––6831

49 CAP1+ –6711

50 CAP1+ –6596

51 CAP1+ –6481

52 CAP1+ –6366

53 CAP1+ –6251

54 CAP1––6131

55 CAP1––6016

56 CAP1––5901

57 CAP1––5786

XY

PAD Pin

No. Name

XY

58 CAP1––5671 –1188.5

59 GND2 –5551

60 GND2 –5446

61 GND2 –5341

62 GND2 –

63 GND2 –

64 GND3 –

5236.05

5131.05

5026.05

65 GND3 –4921

66 GND3 –4816

67 GND –4711

68 GND –4606

69 GND –4501

70 V

DD3 –4396

71 VDD3 –4291

72 VDD4 –4186

73 VDD4 –4081

74 TESTG –3976

75 VDD –3871

76 VDD –3766

77 VDDI –3661

78 VDDI –3556

79 VDDI –3451

80 VDDI –3346

81 FR –3235

82 YSCL –3081

83 F1 –2927

84 F2 –2773

85 DOFF –2619

86 CA –2465

87 SYNC –2311

88 SLP –2157

89 SDA –2003

90 RESET –1849

91 CLOCK –1695

92 TEST1 –1541

93 GND *6 –1387

94 V

DDI *6 –1287

95 CL –1187

96 CLS –1033

97 GND *6 –879

98 VDDI *6 –779

99 CS –679

100 A0 –525

101 GND *6 –371

102 VDDI *6 –271

103 SCL –171

104 SI –17

105 GND *6 137

106 VDDI *6 237

107 D0 337

108 D1 491

109 D2 645

110 D3 799

111 D4 953

112 D5 1107

113 D6 1261

114 D7 1415

Unit: µm

PAD Pin

No. Name

XY

115 GND *6 1569 –1188.5

116 V

DDI *6 1669

117 D8 1769

118 D9 1923

119 D10 2077

120 D11 2231

121 D12 2385

122 D13 2539

123 D14 2693

124 D15 2847

125 GND *6 3001

126 V

DDI *6 3101

127 RD 3201

128 WR 3355

129 GND *6 3509

130 VDDI *6 3609

131 IF1 3709

132 IF2 3863

133 IF3 4017

134 GND *6 4171

135 V

DDI *6 4271

136 RES 4371

137 TESTH 4525

138 MS 4679

139 VDDI 4833

140 VDDI 4938

141 GND 5043

142 GND 5148

143 GND 5253.05

144 GND 5358.05

145 GND4 5463.05

146 GND4 5568.05

147 GND4 5673.05

148 GND4 5778.05

149 GND4 5883.05

150 V

DD 5988.05

151 VDD 6093.05

152 VDD5 6198.05

153 VDD5 6303.05

154 VDD2 6446.05

155 VDD2 6551.05

156 VDD2 6656.05

157 VDD2 6761.05

158 VDD2 6866.05

159 VDD2 6971.05

160 CAP4+ 7113.05

161 CAP4+ 7228.05

162 CAP4+ 7343.05

163 CAP4+ 7458.05

164 CAP4+ 7573.05

165 CAP4– 7693.05

166 CAP4– 7808.05

167 CAP4– 7923.05

168 CAP4– 8038.05

169 CAP4– 8153.05

170 CAP5+ 8273.05

171 CAP5+ 8388.05

4 EPSON Rev. 1.0

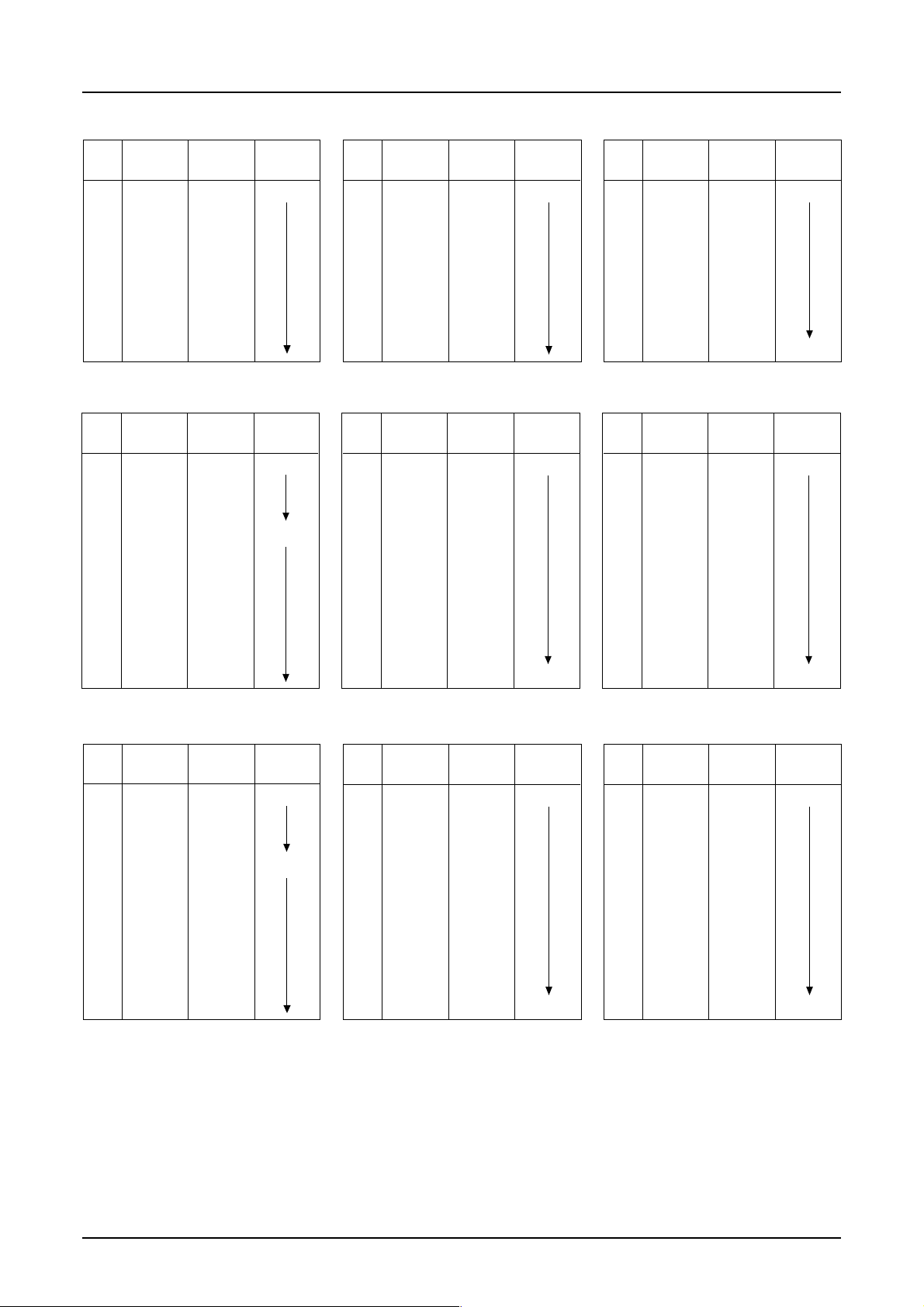

S1D15G00 Series

Unit: µm

PAD Pin

No. Name

XY

172 CAP5+ 8503.05 –1188.5

173 CAP5+ 8618.05

174 CAP5+ 8733.05

175 CAP5– 8853

176 CAP5– 8968

177 CAP5– 9083

178 CAP5– 9198

179 CAP5– 9313

180 MV

3R 9433

181 MV3R 9553

Models other than the S1D15G00D10*000 Unit: µm

PAD Pin

No. Name

XY

201 V3R 11953 –1188.5

202 V3R 12073

203 NC 12193

204 NC 12313

205 NC 12327 1177

206 NC 12285

207 COM1 12243

208 COM2 12201

209 COM3 *1

to to

284 COM78 9009

285 COM79 8967

286 COM80 8925

PAD Pin

No. Name

XY

182 MV3R 9673 –1188.5

183 MV1R 9793

184 MV1R 9913

185 MV1R 10033

186 MV1R 10152.9

187

VCLSR/VR*7

10273

188 VCR 10393

189 VCR 10513

190 VCR 10633

191 VCR 10753

PAD Pin

No. Name

XY

287 NC 8883 1177

288 to

299

NC *2

300 NC 8337

301 SEG396 8295

302 SEG395 8253

303 SEG394 *3

to to

694 SEG3 –8211

695 SEG2 –8253

696 SEG1 –8295

697 NC –8337

PAD Pin

No. Name

XY

192 V1R 10873 –1188.5

193 V1R 10993

194 V1R 11113

195 V1R 11233

196 V2R 11353

197 V2R 11473

198 V2R 11593

199 V2R 11713

200 V3R 11833

PAD Pin

No. Name

698 to

709

NC *4

XY

1177

710 NC –8883

711 COM81 –8925

712 COM82 –8967

713 COM83 *5

to to

788 COM158 –12159

789 COM159 –12201

790 COM160 –12243

791 NC –12285

792 NC –12327

S1D15G00D10*000 Unit: µm

PAD Pin

No. Name

XY

201 V3R 11953 –1188.5

202 V3R 12073

203 NC 12193

204 NC 12313

205 NC 12327 1177

206 NC 12285

207 COM1 12243

208 COM2 12201

209 COM3 *1

to to

264 COM58 9849

265 COM59 9807

PAD Pin

No. Name

XY

287 NC 8883 1177

288 to

299

NC *2

300 NC 8337

349 SEG348 6279

350 SEG347 6237

351 SEG346 * 8

to to

649 SEG51

650 SEG50

651 SEG49

697 NC –8337

PAD Pin

No. Name

698 to

709

NC *4

XY

710 NC –8883

711 COM61 –8925

712 COM62 –8967

713 COM63 *5

to to

768

769

770

COM118

COM119

COM120

–11319

–11361

–11403

791 NC –12285

792 NC –12327

1177

266 COM60 9765

*1: You can determine the position on X coordinate from the formula “12159–42* (n–209)”, where the BUMP No. is “n”.

*2: You can determine the position on X coordinate from the formula “8841–42* (n–288)”, where the BUMP No. is “n”.

*3: You can determine the position on X coordinate from the formula “8211–42* (n–303)”, where the BUMP No. is “n”.

*4: You can determine the position on X coordinate from the formula “-8379–42* (n–698)”, where the BUMP No. is “n”.

*5: You can determine the position on X coordinate from the formula “-9009–42* (n–713)”, where the BUMP No. is “n”.

*6: This pin is used to pull up or pull down nearby pins. Thus, it can’t be used for feeding power.

*7: The pin function differs among device models.

External resisting device: It functions as the primary boost voltage output pin (VCLSR).

Internal resisting device: It functions as the regulator inverse input pin (VR).

*8: You can determine the position on X coordinate from formula “6145-42*(n–351)” where the Bump No. is “n”.

Rev. 1.0 EPSON 5

S1D15G00 Series

7. PIN DESCRIPTION

7.1 Power Supply Pins

Pin name I/O Description

Number of

pins

VDDI Input They are used to connect the power for input signals. 6

power

VDD Power They are connected to VCC - the system power. When the system 4

supply power is smaller than 2.6V, they must be connected another 2.6V

or greater power supply.

VDD2 Step-up They are used to connect the power supply for the primary step-up. 6

power The relative magnitude of potential among the pins, namely

VDD2≥VDD≥VDD1, must be observed.

VDD3,VDD5 Power They are power supply pins on the power circuit *1. 4

supply

VDD4 Power They are power supply pins on the oscillation circuit *1. 2

supply

GND Power They are connected to the system ground. 7

supply

GND2, Power They are grounding pins on the power circuit *2. 9

GND4 supply

GND3 Power They are grounding pins on the oscillation circuit *2. 3

supply

V3L, V3R Power These pins are provided on the multi-level power supply for liquid 44

V2L, V2R supply crystal drive. Relative magnitude of potential among the pins,

V1L, V1R namely V3L(R)≥V2L(R)≥V1L(R)≥VCL(R)≥MV1L(R)≥GND≥MV3L(R),

VCL, VCR must be observed.

MV1L, MV

MV3L, MV

1R

3R

When the master operation is turned on or the internal power supply

is turned on, predetermined voltage is output at respective pins.

When S1D15G00 series are used in the master/slave array, they

connect the pins on both the master and slave drivers.

VCLSL Power They are provided on the common driver operating power supply. 4

supply

VCLSR,VR Input Common driver operating power supply/regulator input pins *3. 1

power

*1: Since VDD, VDD3, VDD4 and VDD5 are not internally connected, they must be externally connected to VCC - the

system power.

*2: Since GND, GND2, GND3 and GND4 are not internally connected, they must be externally connected to the system

GND (ground).

*3: The pin function differs among device models.

6 EPSON Rev. 1.0

7.2 Pins on Liquid Crystal Drive Power Circuit

S1D15G00 Series

Pin name I/O Description

CAP1+ O

CAP1– O

CAP2+ O

CAP2– O

CAP4+ O

CAP4– O

CAP5+ O

CAP5– O

They connect the positive going side of the primary step-up capacitor.

They connect the negative going side of the primary step-up capacitor.

They connect the positive going side of the secondary step-up capacitor.

They connect the negative going side of the secondary step-up capacitor.

They connect the positive going side of the tertiary step-up capacitor.

They connect the negative going side of the tertiary step-up capacitor.

They connect the positive going side of the tertiary step-up capacitor.

They connect the positive going side of the tertiary step-up capacitor.

Number of

pins

5

5

5

5

5

5

5

5

Rev. 1.0 EPSON 7

S1D15G00 Series

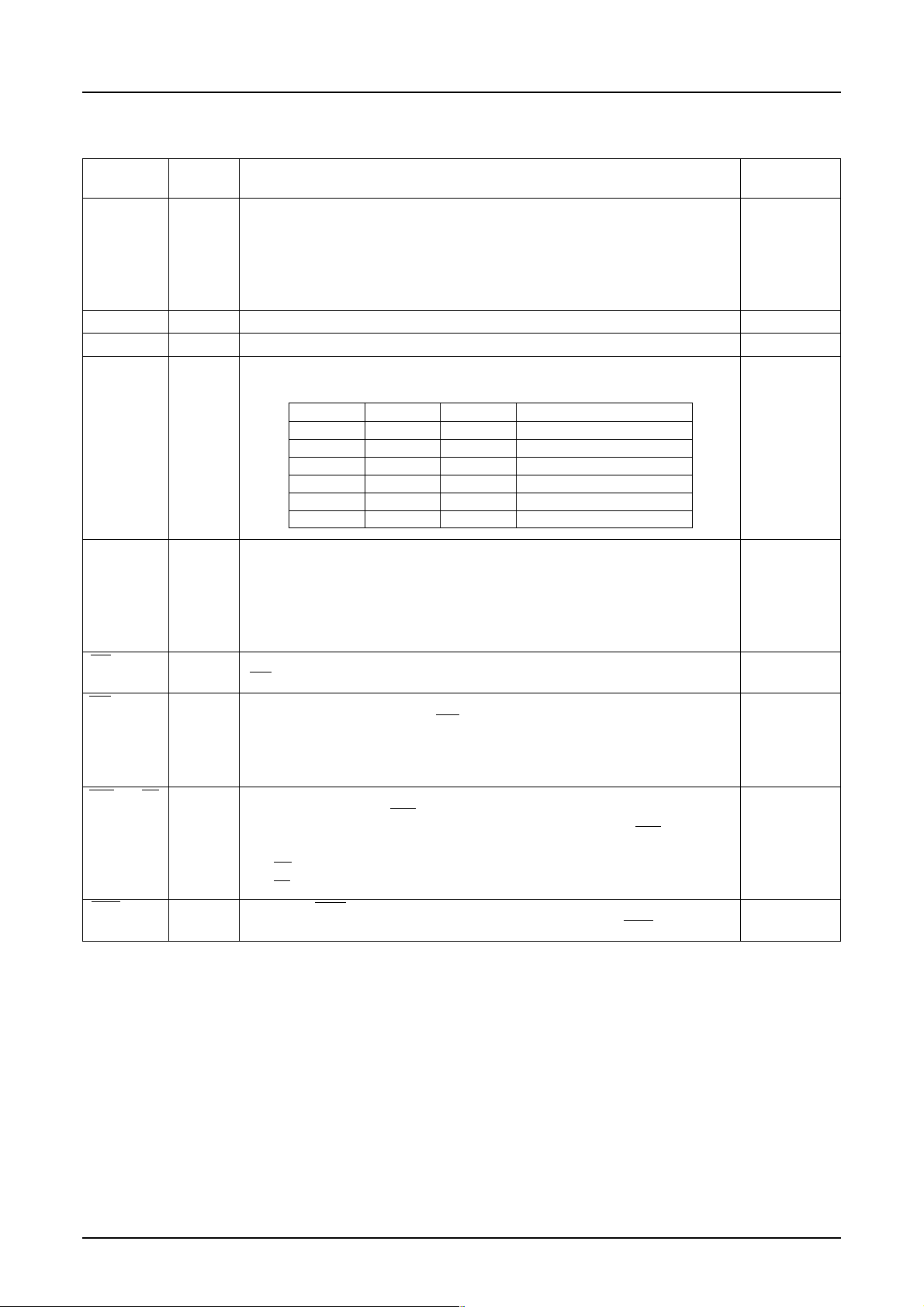

7.3 MPU Interface Pins

Pin name I/O Description

D15 to D0 I/O They connect to the standard 8-bit or 16-bit MPU bus via the 16

8/16-bit bi-directional bus.

When the following interface is selected and the CS pin is high, the

impedance of the pin becomes high.

1 8-bit parallel: D15-D18 are in the state of high impedance

2 Serial interface: D15-D0 are in the state of high impedance

SI I

SCL I

IF1, IF2 I These pins are used to select either of the MPU interfaces. 3

IF3

A0 I Normally, the least significant bit of the MPU’s address bus is 1

CS I This pin is used to enter chip select signal. It is activated when 1

RD (E) I • It goes active LOW when connected to the 80 series MPU. 1

WR (R/W) I • It goes active LOW when connected to the 80 series MPU. 1

RES I Causing RES to LOW performs initialization. 1

This pin is used to input serial data when the serial interface is selected

This pin is used to input serial clock when the serial interface is selected.

Depending on status of IF1, IF2 and IF3, following selection is made.

IF1 IF2 IF3 MPU interface type

HIGH HIGH HIGH 80 series 16-bit parallel

HIGH HIGH LOW 80 series 8-bit parallel

HIGH LOW LOW 68 series 16-bit parallel

LOW HIGH HIGH 68 series 8-bit parallel

LOW LOW HIGH 9-bit serial

LOW LOW LOW 8-bit serial

connected to identify a parameter or display data from a command.

HIGH: Indicates that data entered to D15 to D0 or SI is a

parameter or display data.

LOW: Indicates that data entered to D15 to D0 or SI is a command.

This function is disabled when the 9-bit serial interface is selected.

CS = LOW, enabling interface with MPU.

This pin is used to connect RD signal from the 80 series MPU. The data

bus is maintained in the output status as long as this signal is LOW.

• It goes active HIGH when connected to the 68 series MPU.

In this case, this pin is used to enter the enable clock from 68 series MPU.

This pin connects WR signal from the 80 series MPU. Signal on

the data bus is latched at the positive going edge of WR signal.

•

This pin enters the read/write signal when connected to the 68 series MPU.

R/W = HIGH: Read

R/W = LOW: Write

Reset operation is performed according the level of RES signal.

Number of

pins

.1

1

8 EPSON Rev. 1.0

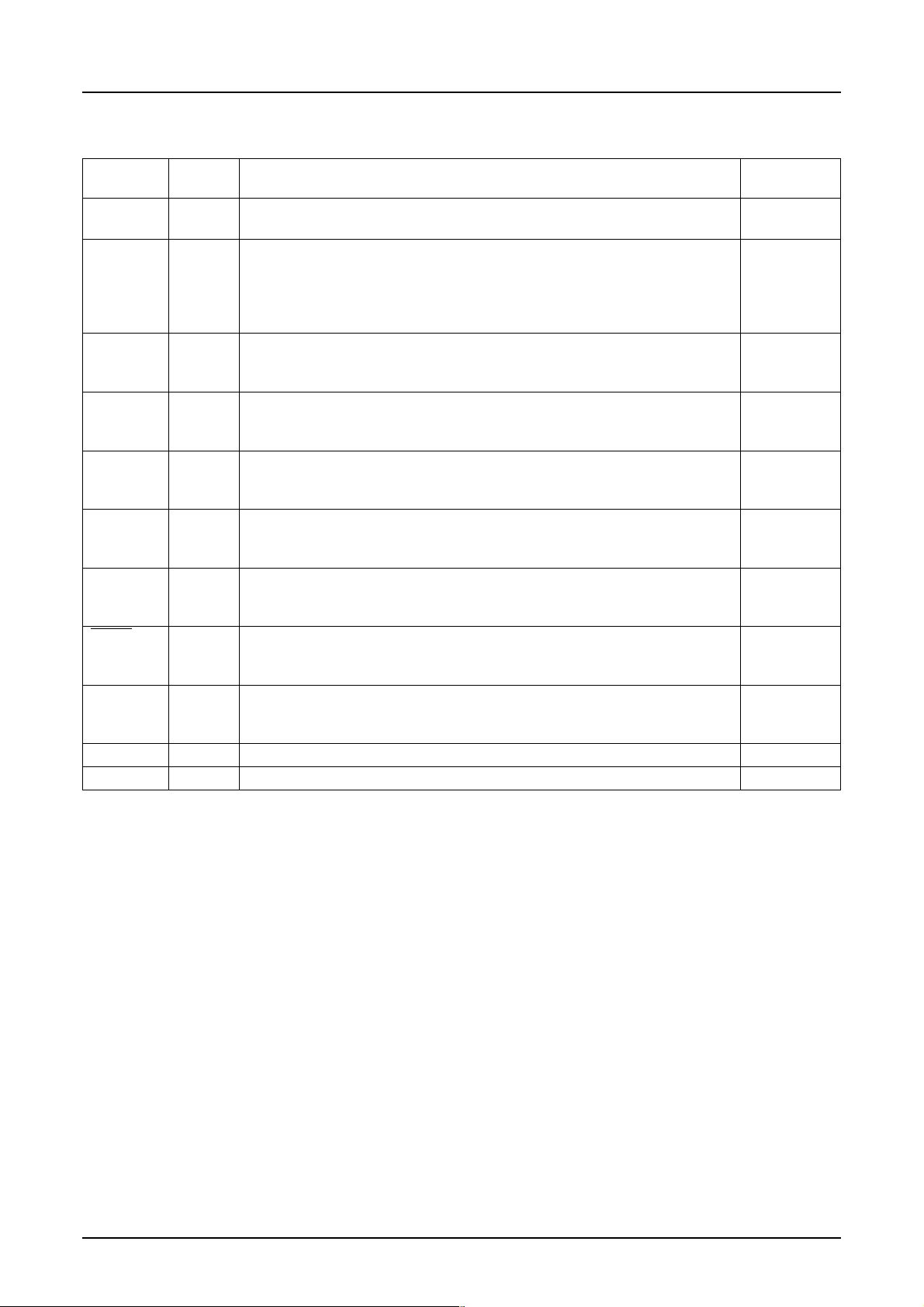

7.4 Liquid Crystal Drive Circuit Signals

S1D15G00 Series

Pin name I/O Description

M/S I This pin is used to select either the master or slave operation. 1

M/S = HIGH: Master operation

CLS I It is used to select the display clock. 1

CLS = HIGH: Built-in CR oscillation is used.

CLS = LOW: External clock is used.

When the external clock is used (CLS = LOW), the signal is

entered to CL pin.

CL I/O This pin inputs or outputs the display clock. 1

It outputs the display clock only when M/S = HIGH and CLS = HIGH.

Other than the above: External clock input

FR I/O This pin inputs or outputs the liquid crystal frame signal. 1

M/S = HIGH: Outputs the signal

M/S = LOW: Inputs the signal

SYNC I/O This pin inputs or outputs the liquid crystal synchronization signal. 1

M/S = HIGH: Outputs the signal

M/S = LOW: Inputs the signal

CA I/O This pin inputs or outputs the field start signal. 1

M/S = HIGH: Outputs the signal

M/S = LOW: Inputs the signal

F1, F2 I/O This pin inputs or outputs the drive pattern signal. 1

M/S = HIGH: Outputs the signal

M/S = LOW: Inputs the signal

DOFF I/O This pin is used to control blanking of liquid crystal display. 1

M/S = HIGH: Outputs the signal

M/S = LOW: Inputs the signal

YSCL I/O This pin inputs or outputs the line clock.

M/S = HIGH: Outputs the signal

M/S = LOW: Inputs the signal

SEGn O They output the signal for the segment drive of liquid crystal. 396

COMn O They output the signal for common drive of liquid crystal. 160

Number of

pins

Rev. 1.0 EPSON 9

S1D15G00 Series

7.5 EEPROM Interface Pins

Pin name I/O Description

SDA O Connected to the SDA pin of S1F65170. *11

RESET O Connected to the XRST pin of S1F65170. *11

CLOCK O Connected to the SCK pin of S1F65170. *11

* Always open if the S1F65170 is not used.

Number of

pins

7.6 Control Signals

Pin name I/O Description

SLP O It is the sleep control pin. It outputs LOW level when the sleep-in 1

command is executed.

PO0 O This pin constantly outputs LOW level. It must be maintained open. 1

Number of

pins

7.7 Test Signals

Pin name I/O Description

TESTA to O It is the test pin. 1

TESTG Since it outputs signals, it must be kept open.

TESTH I This pin must be fixed at HIGH or LOW. 1

TEST1 I It is the IC chip test pin. This pin must be fixed at LOW. 1

Number of

pins

10 EPSON Rev. 1.0

S1D15G00 Series

8. FUNCTIONAL DESCRIPTION

8.1 MPU Interfaces

8.1.1 Selecting an MPU Interface Type

S1D15G00 transfers data via the 8/16-bit bi-directional data bus or serial data input.

You can select a desired interface face through the combinations of settings of IF1, IF2 and IF2 as shown in Table 8.1.1.

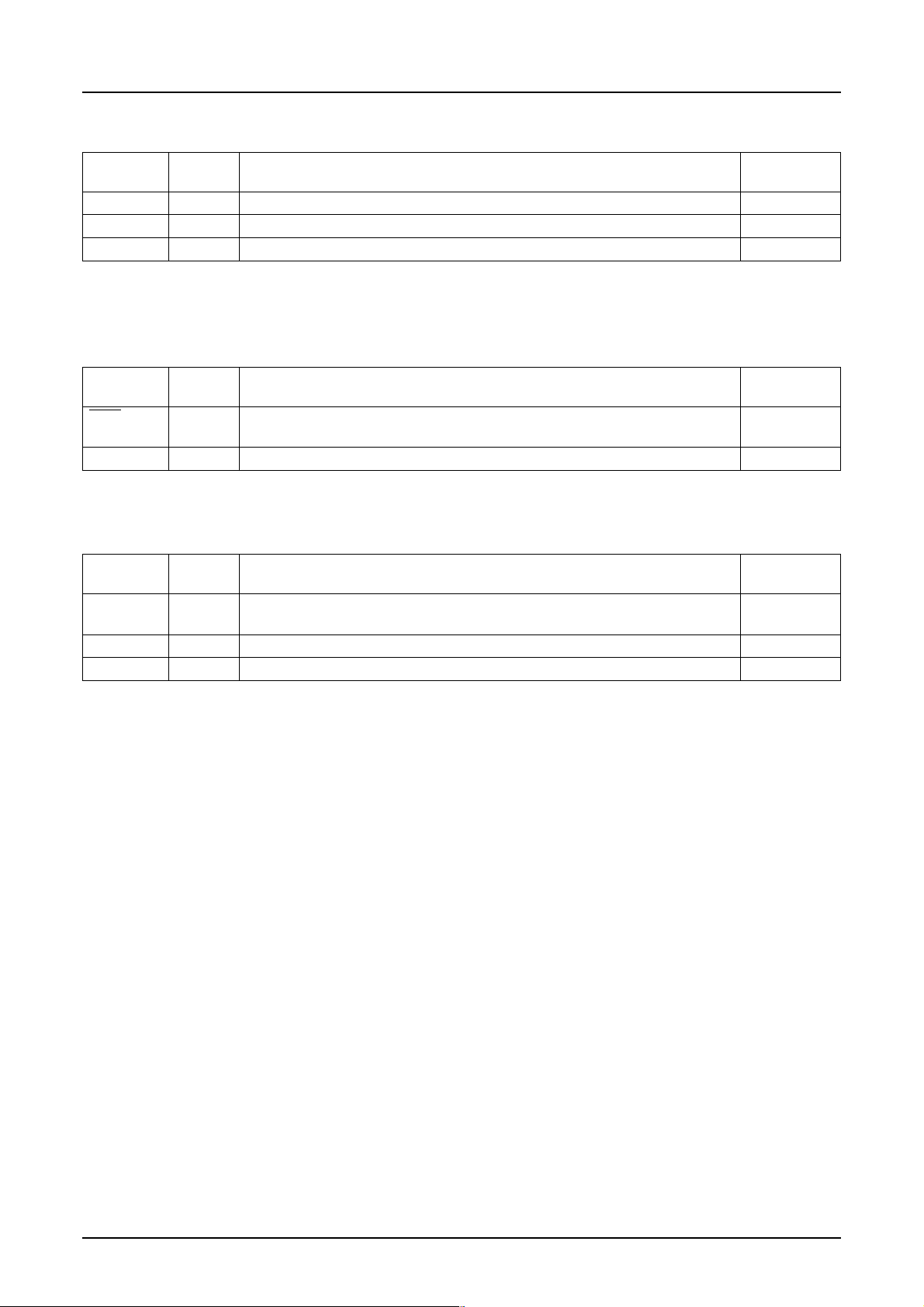

Table 8.1.1

IF1 IF2 IF3 Interface type CS A0 RD WR D15 to D8 D7 to D0 SI SCL

E R/W

HIGH HIGH HIGH 80 series 16-bit parallel CS A0 RD WR D15 to D8 D7 to D0 ––

HIGH HIGH LOW 80 series 8-bit parallel CS A0 RD WR (HZ) D7 to D0 ––

HIGH LOW LOW 68 series 16-bit parallel CS A0 E R/W D15 to D8 D7 to D0 ––

LOW HIGH HIGH 68 series 8-bit parallel CS A0 E R/W (HZ) D7 to D0 ––

LOW LOW HIGH 9-bit serial CS ––– (HZ) (HZ) SI SCL

LOW LOW LOW 8-bit serial CS A0 –– (HZ) (HZ) SI SCL

– : Must be fixed to either HIGH or LOW.

HZ is in the state of Hight Impedance.

8.1.2 8- or 16-bit Parallel Interface

S1D15G00 identifies type of the data bus signals according to combinations of A0, RD (E) and WR (R/W) signals as

shown in Table 8.1.2.

Table 8.1.2

68 series 80 series

A0 R/W E RD WR Function

1 0 1 1 0 Parameters or display data write.

1 1 1 0 1 Display data read.

0 1 1 0 1 Status read.

0 0 1 1 0 Control data write (command).

Except when the CS=LOW is taking place, D15 to D0 on S1D15G00 are caused to high impedance, disabling input of

A0, RD (E) and WR (R/W).

Relation between Data Bus and Gradation Data

S1D15G00 offers the 256-color display (8 gray-scale) out of 4096 colors as well as the 4096-color display (16 grayscale). When using 256-color display out of 4096 colors, you can specify color for each of R, G and B using the palette

function.

(1) 256-color display out of 4096 colors

Using RGBSET8 command enables you to set color for each of R, G and B by turning on the palette function

prepared to convert 3- or 2-bit data to 4-bit data.

1 8-bit mode

D7, D6, D5, D4, D3, D2, D1, D0: RRRGGGBB (8 bits) data is converted to RRRRGGGGBBBB (12 bits) and then

stored on the display RAM.

2 16-bit mode

D15, D14, D13, D12, D11, D10, D9, D8: RRRGGGBB (8 bits)

D7, D6, D5, D4, D3, D2, D1, D0: RRRGGGBB (8 bits)

Data of two pixels is respectively converted to RRRRGGGGBBBB (12 bits) data and then simultaneously written

to two addresses on the display RAM.

Rev. 1.0 EPSON 11

S1D15G00 Series

4096 color display

1 8-bit mode

D7, D6, D5, D4, D3, D2, D1, D0: RRRRGGGG (8 bits) 1st write

D7, D6, D5, D4, D3, D2, D1, D0: BBBBRRRR (8 bits) 2nd write

D7, D6, D5, D4, D3, D2, D1, D0: GGGGBBBB (8 bits) 3rd write

Data is acquired through write operations as shown above and then that of two pixels is written to the display RAM.

2 16-bit mode

D15, D14, D13, D12, D11, D10, D9, D8, D7, D6, D5, D4, D3, D2, D1, D0: RRRRGGGGBBBBXXXX (12 bits)

Data is acquired through single write operation and then written to the display RAM.

“XXXX” are dummy bits, and they are ignored for display.

8.1.3 8- and 9-bit Serial Interface

The 8-bit serial interface uses four pins - CS, SI, SCL and A0 - to enter commands and data. Meanwhile, the 9-bit serial

interface uses three pins - CS, SI and SCL - for the same purpose.

Data read is not available with the serial interface. Data entered must be 8 bits. Refer to the following chart for entering

commands, parameters or gray-scale data.

The relation between gray-scale data and data bus in the serial input is the same as that in the 8-bit parallel interface

mode (described in the preceding section) at every gradation.

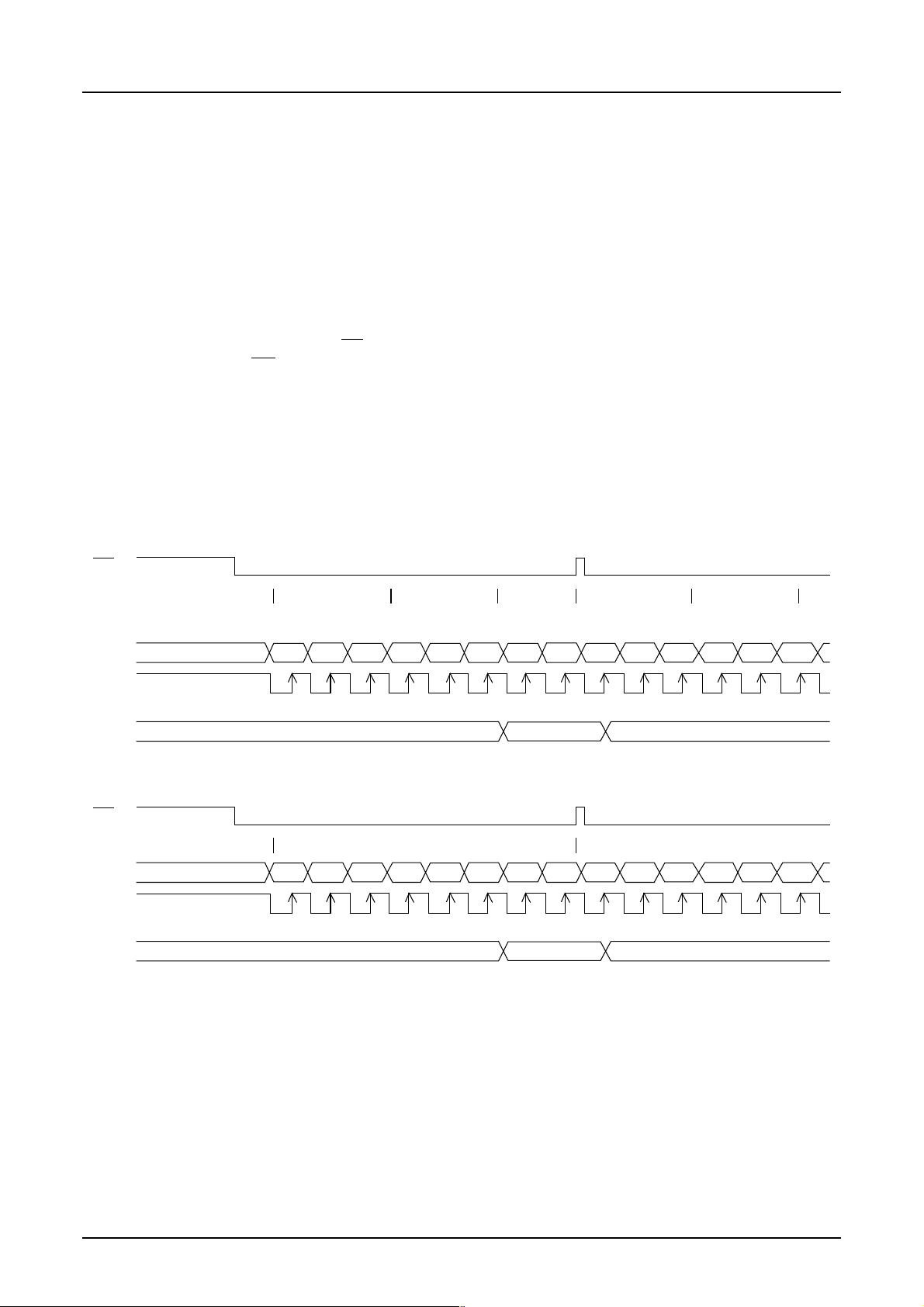

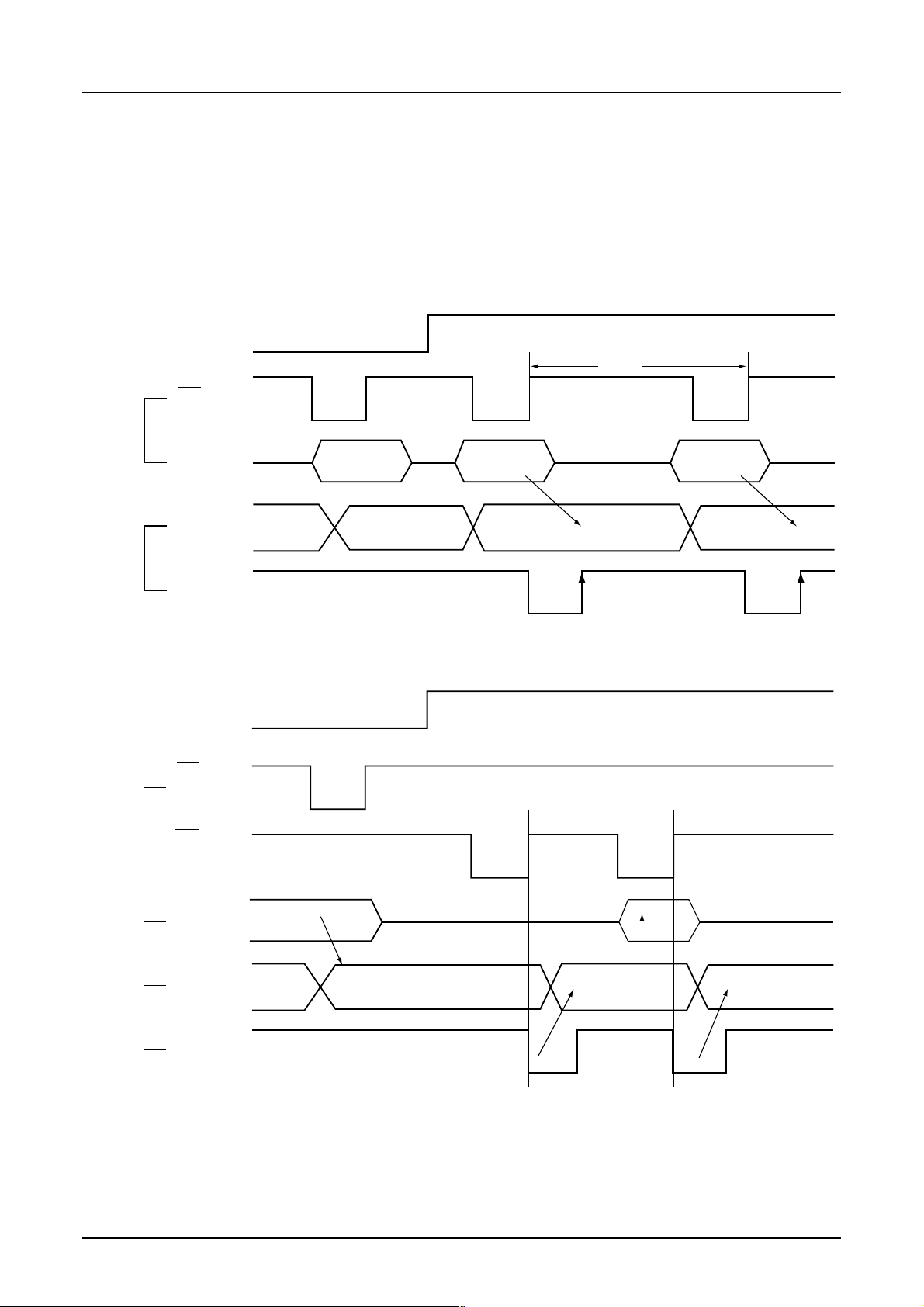

(1) 8-bit serial interface

When entering data (parameters): A0 = HIGH at the rising edge of the 8th SCL.

CS

dot0(R)

R1R2 R0 G2 G1 G0 B1 B0 R2 R0R1 G2 G1 G0

SI

SCL

12345 678123 4 56

A0

dot1(G)

dot2(B)

When entering command: A0 = LOW at the rising edge of the 8th SCL.

CS

command command

SI

SCL

12345 678123 4 56

A0

dot3(R) dot4(R)

D2D3D4D5D6D7D0D1D2D3D4D5D6D7

D2D3D4D5D6D7D0D1D2D3D4D5D6D7

12 EPSON Rev. 1.0

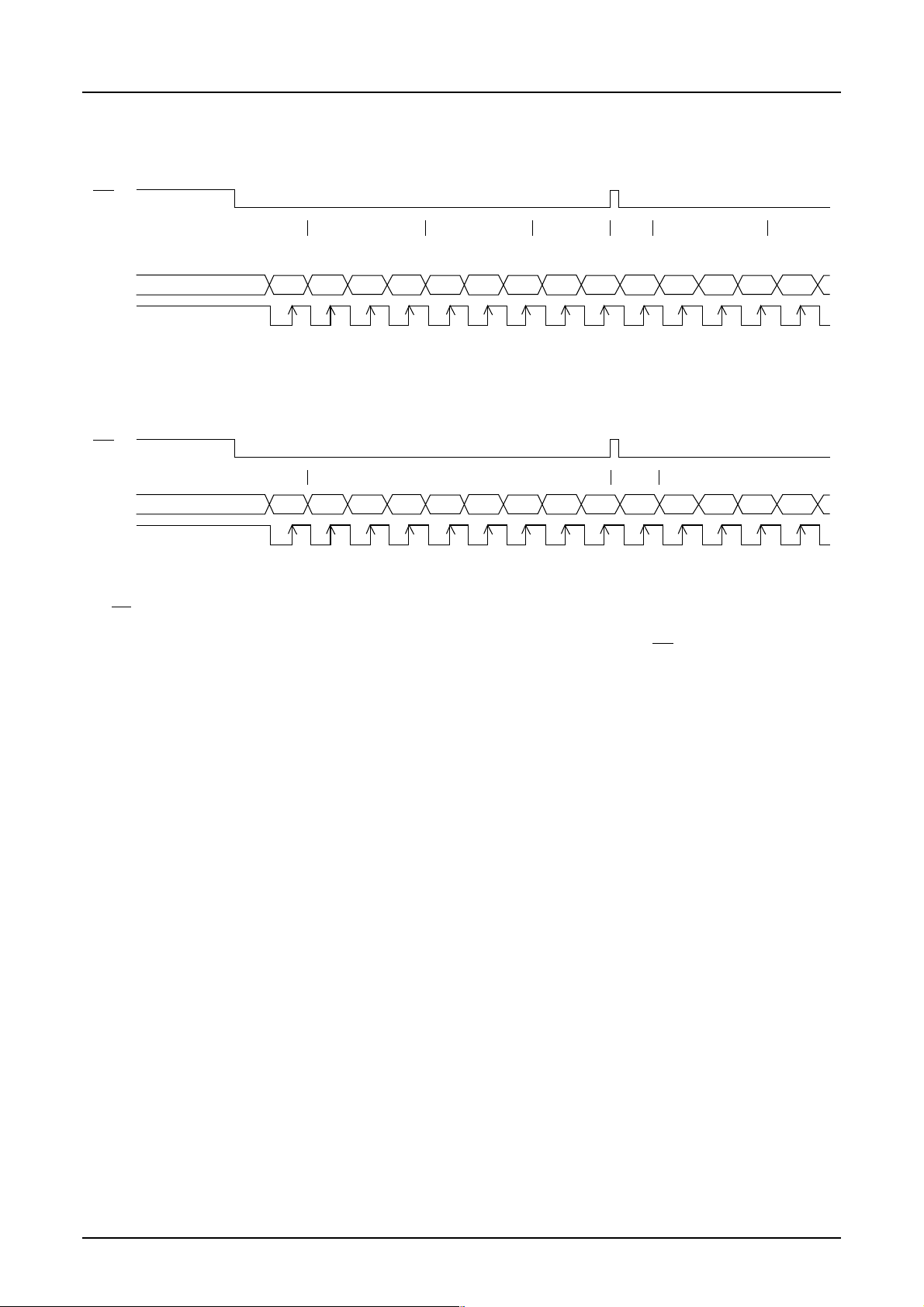

(2) 9-bit serial interface

When entering data (parameters): SI = HIGH at the rising edge of the 1st SCL.

CS

S1D15G00 Series

SI

SCL

dot0(R)

R2 R1 R0 G2 G1 G0 B1 B0 R2 R1 R0

12345 678912 3 45

dot1(G)

dot2(B)

dot3(R)

D4D5D6D7D/CD0D1D2D3D4D5D6D7D/C

When entering commands: SI = LOW at the rising edge of the 1st SCL.

CS

command command

SI

SCL

12345 678912 3 45

D4D5D6D7D/CD0D1D2D3D4D5D6D7D/C

* If CS is caused to HIGH before 8 bits from D7 to D0 are entered, the data concerned is invalidated. Before entering

succeeding sets of data, you must correctly input the data concerned again.

* In order to avoid data transfer error due to incoming noise, it is recommended to set CS at HIGH on byte basis to

initialize the serial-to-parallel conversion counter and the register.

Rev. 1.0 EPSON 13

S1D15G00 Series

8.2 Access to DDRAM and Internal Registers

S1G15G00 realizes high-speed data transfer because the access from MPU is a sort of pipeline processing done via the

bus holder attached to the internal, requiring the cycle time alone without needing the wait time.

For example, when MPU writes data to the DDRAM, the data is once held by the bus holder and then written to the

DDRAM before the succeeding write cycle is started. When MPU reads data from the DDRAM, the first read cycle

is dummy and the data read in the dummy cycle is held by the bus holder, and then it is read from the bus holder to the

system bus in the succeeding read cycle. Fig. 8.2.1 illustrates these relations.

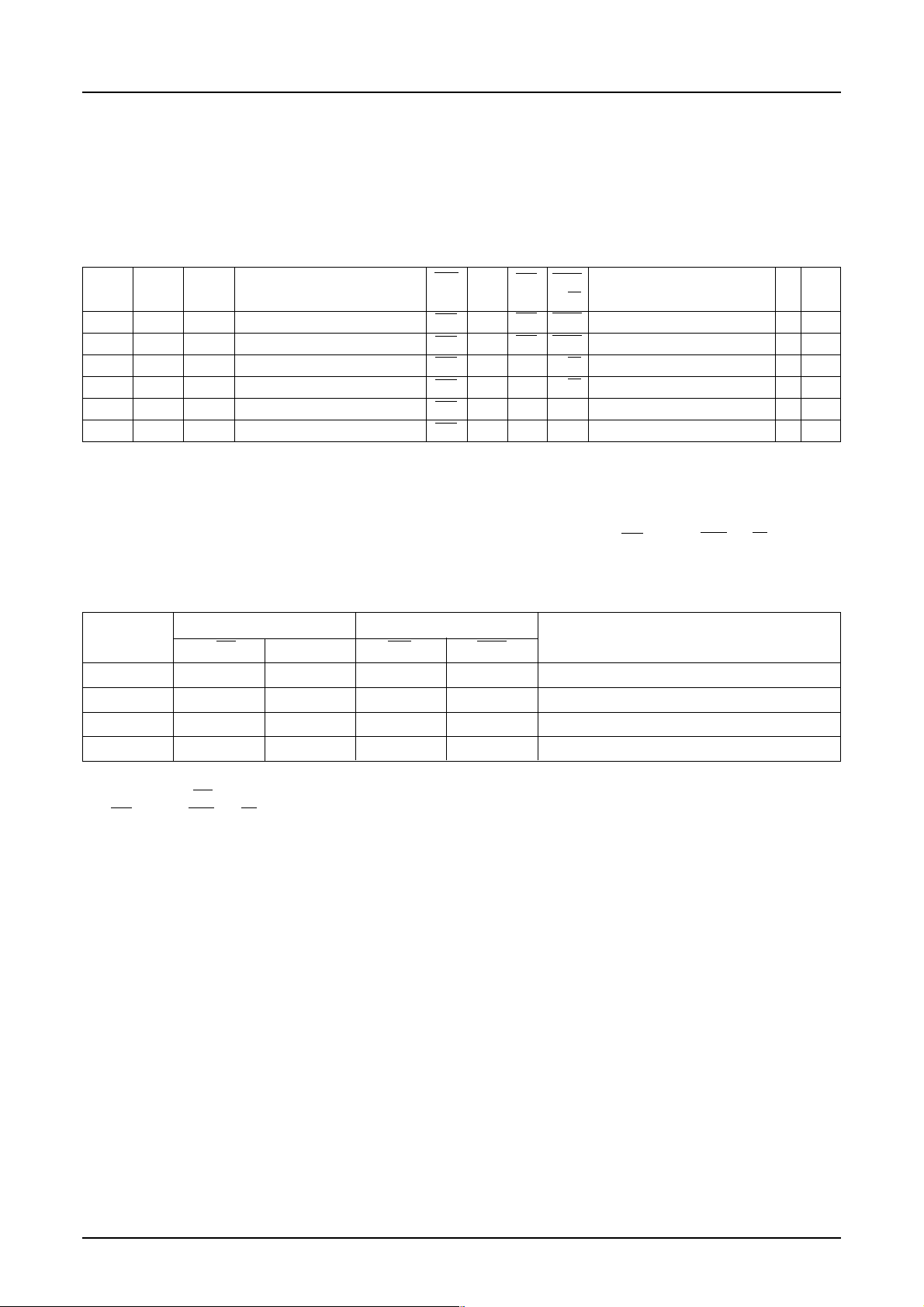

* Write operation

A0

tcyc

WR

MPU

DATA

Bus holder

Internal

Data write

signal

* Read operation

A0

WR

RD

MPU

Command write Data write Data write

Command write

Dummy read Data read

External pulse

Bus holder

Internal

Data Read

signal

Command

RAM dataRAM data

Fig. 8.2.1

* There is a restriction in the read sequence of the DDRAM. Namely, the data at the specified address is not output

in the first data read conducted immediately after the memory read command (dummy read). It is read in the second

data read.

14 EPSON Rev. 1.0

S1D15G00 Series

8.3 DDRAM

8.3.1 DDRAM

It is 396 × 168 × 4 bits capacity RAM prepared for storing dot data. You can access a desired bit by specifying the page

address and column address.

Since display data from MPU - D7 to D0 and D1 to D8 - correspond to one or two pixels of RGB, data transfer-related

restrictions are reduced, realizing the display flexibly.

The RAM on S1D15G00 is separated to a block per 4 line to allow the display system to process data on the block basis.

MPU’s read and write operations to and from the RAM are performed via the I/O buffer circuit. Reading of the RAM

for the liquid crystal drive is controlled from another separate circuit.

Refer to the following memory map for the RAM configuration.

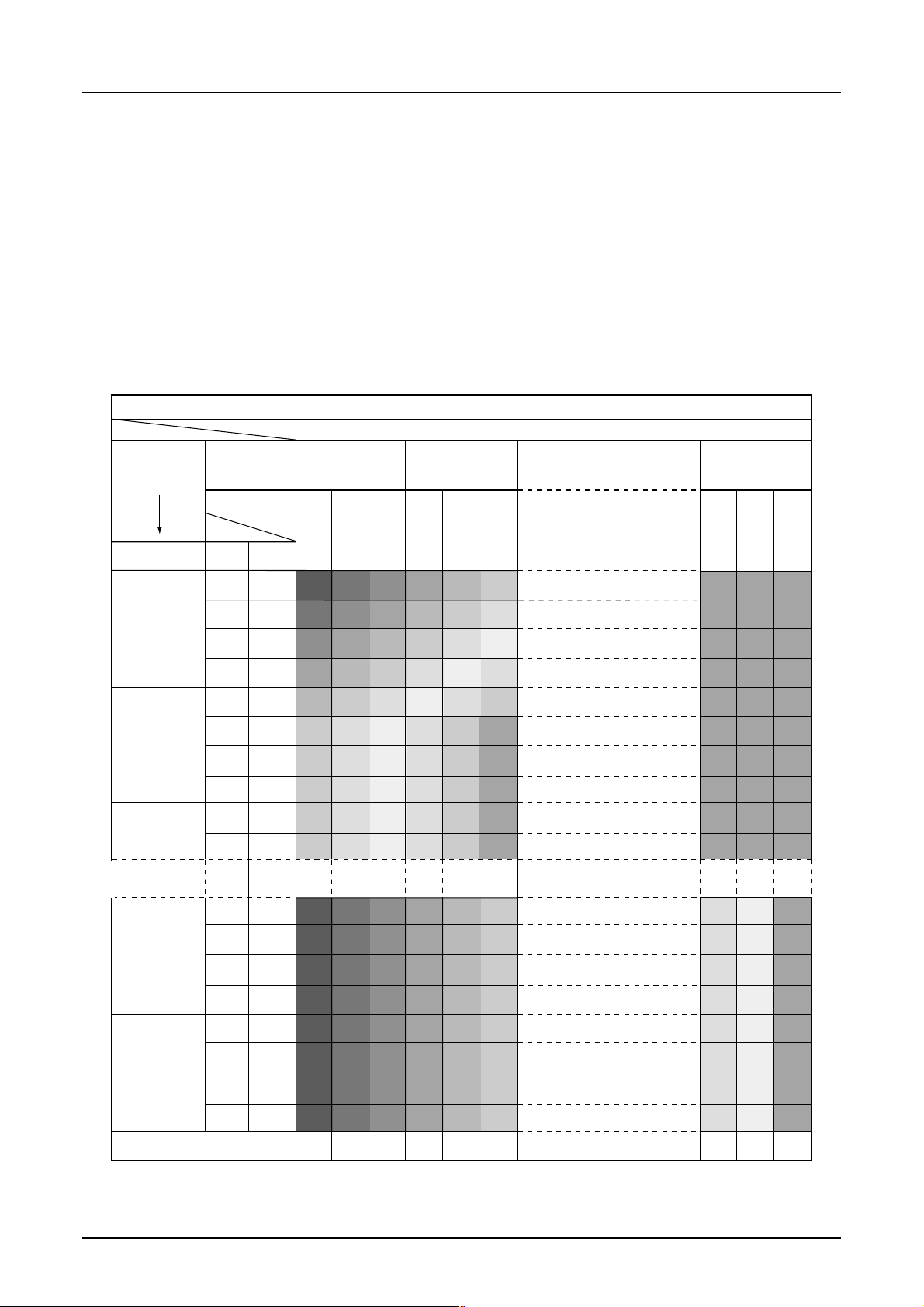

1Models other than the S1D15G00D10*100 (models that have 132 RGB × 160 output)

Memory Map (When using the 8 gray-scale. 8-bit mode)

RGB alignment (Command of data control parameter2=000)

Column

LCD

read

direction

Block

0 0 167

P11:0

P11:1

Color

Page

P10:0 P10:1

Data

D7

D6

D5

0

131

GB

D4

D1D0D7

D3

D2

D6

D5

1

132

D4

D3

D2

D1

D0

RGBRGBR

D7

D6

D5

131

0

D4

D3

D2

D1

D0

1

2

40

41

1 166

2 165

3 164

4 163

5 162

6 161

7 160

8 159

9 158

160 7

161 6

162 5

163 4

164 3

165 2

166 1

167 0

SEGout

123456 394395396

Each of RGB data entered to D7 to D0 (3 or 2 bits) is converted to 4 bits before written to the RAM. You can change

position of R and B with DATCTL command.

Rev. 1.0 EPSON 15

S1D15G00 Series

Memory Map (When using the 8 gray-scale, 16-bit mode)

RGB alignment (Command of data control parameter2=000)

Column

LCD

read

direction

Block

0

1

2

P11: 0

P11: 1

Color

Data

Page

P10:0 P10:1

0 167

1 166

2 165

3 164

4 163

5 162

6 161

7 160

8 159

R

D15

D14

D13

0

65

G

BRGBRGBRGB RGB

D12

D9

D11

D8

D10

011

65 64 64 0

D15

D12

D7

D6

D5

D4

D3

D2

D1

D0

D14

D13

D9D8D7

D11

D10

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

65

D4

D3

D2

D1

D0

9 158

40

41

SEGout

160 7

161 6

162 5

163 4

164 3

165 2

166 1

167 0

123456789101112 394395396

Each of RGB data entered to D7 to D0 (3 or 2 bits) is converted to 4 bits before written to the RAM. You can change

position of R and B with DATCTL command.

16 EPSON Rev. 1.0

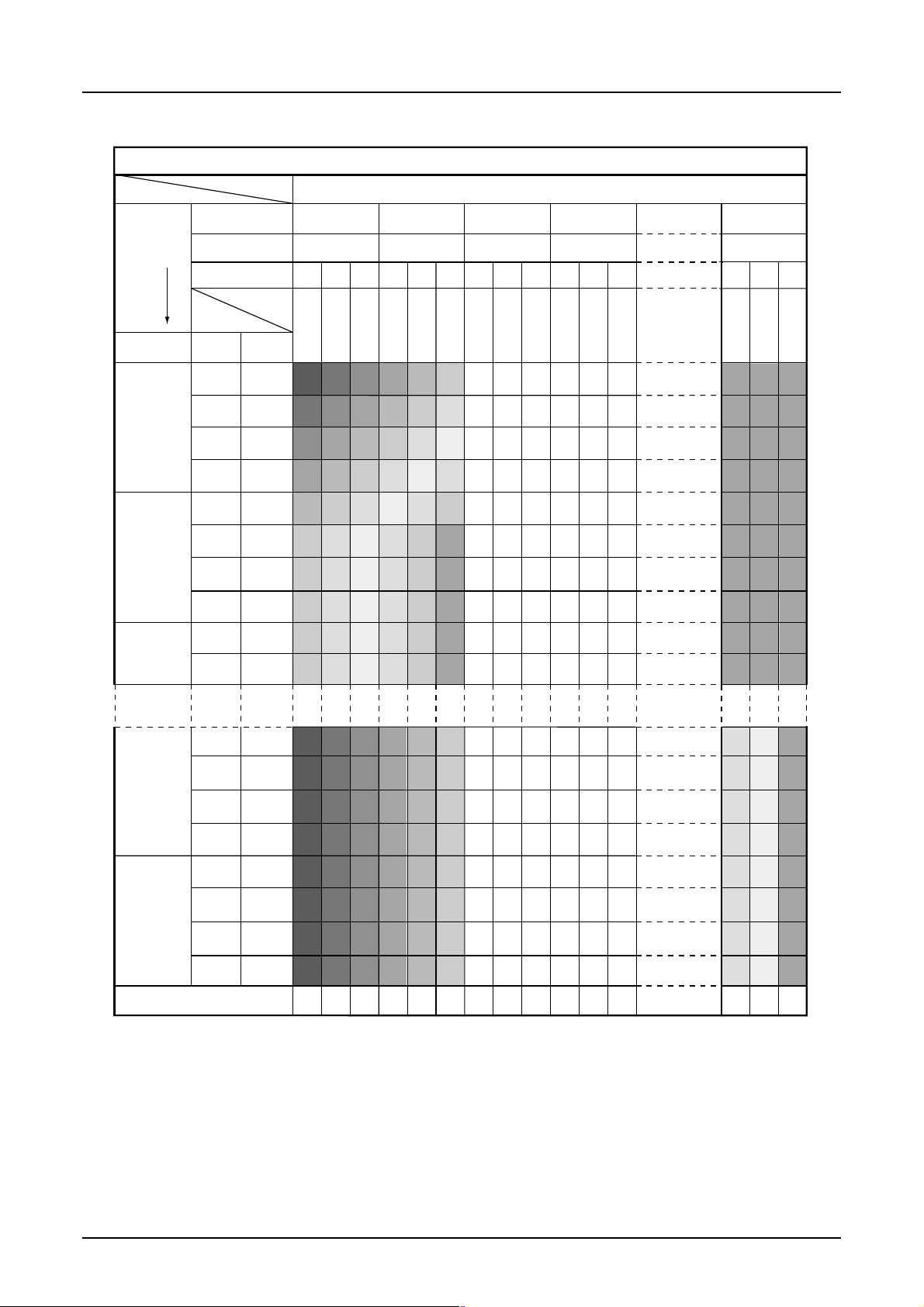

Memory Map (When using the 16 gray-scale 8-bit mode)

RGB alignment (Command of data control parameter2=000)

S1D15G00 Series

Column

LCD

read

direction

Block

0

1

2

P11: 0

P11: 1

Color

Data

Page

P10:0 P10:1

0 167

1 166

2 165

3 164

4 163

5 162

6 161

7 160

8 159

0

65

R1 G1 B1 R2 G2 B2 R1 G1 B1 R G2 B2 R2 G2 B2

D7

D3

D7

D6

D2

D6

D5

D1

D5

D4

D0

D4

011

65 64 64 0

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D3

D2

D1

D0

65

D7

D6

D5

D4

D3

D2

D1

D0

9 158

40

41

SEGout

160 7

161 6

162 5

163 4

164 3

165 2

166 1

167 0

1 2 3 4 5 6 7 8 9 10 11 12 394 395 396

You can change position of R and B with DATCTL command.

Rev. 1.0 EPSON 17

S1D15G00 Series

Memory Map (When using the 16 gray-scale 16-bit mode)

RGB alignment (Command of data control parameter2=000)

LCD

read

direction

Block

0 0 167

P11:0

P11:1

Color

Data

Page

P10:0 P10:1

1 166

2 165

3 164

D15

D14

D13

D12

0

131

GB

D11

D7

D10

D6

D9

D5

D8

D4

D15

D14

D13

D12

1

130

D11

D10

D9

D8

D7

D6

D5

D4

Column

RGBRG BR

D15

D14

D13

D12

131

D11

D10

D9

D8

0

D7

D6

D5

D4

1

2

40

41

4 163

5 162

6 161

7 160

8 159

9 158

160 7

161 6

162 5

163 4

164 3

165 2

166 1

167 0

SEGout

123456 394395396

You can change position of R and B with DATCTL command

18 EPSON Rev. 1.0

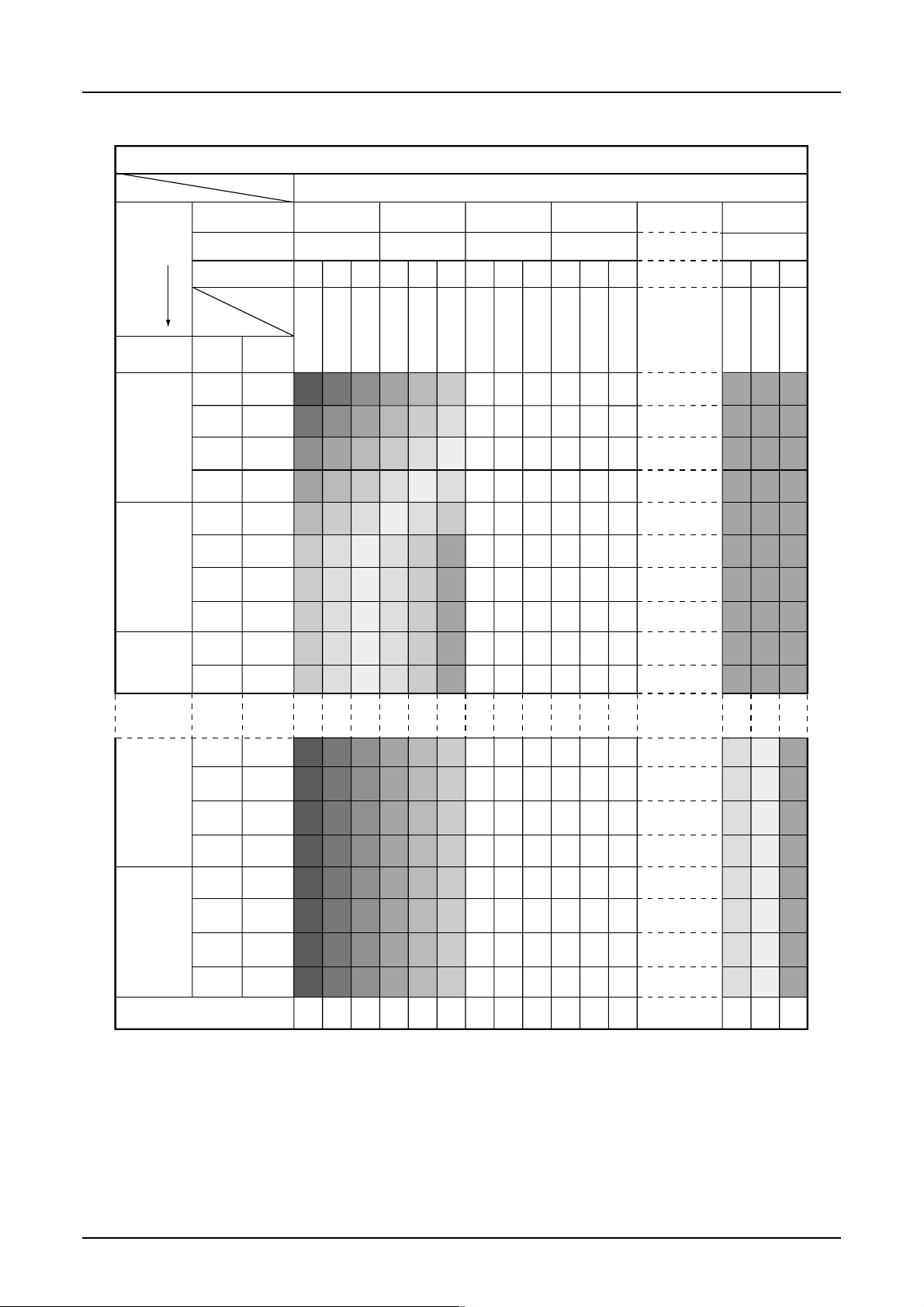

2 S1D15G00D10*100 (100 RGB × 120 output)

Memory map (when 8-tone, 8-bit mode is used)

RGB alignment (Command of data control parameter2=000)

LCD

read

direction

Block

0 0 167

P11:0

P11:1

Color

Page

P10:0 P10:1

1 166

2 165

3 164

Data

D7

D6

D5

16

115

GB

D4

D1D0D7

D3

D2

D6

D5

17

114

D4

D3

D2

D1

D0

Column

S1D15G00 Series

115

16

RGBRGBR

D7

D4

D1

D6

D3

D0

D5

D2

1

2

28

29

SEGout

4 163

5 162

6 161

7 160

8 159

9 158

112 55

113 54

114 53

115 52

116 51

117 50

118 49

119 48

49 50 51 52 53 54 346 347 348

Although data is described as D7 - D0 (3 bits or 2 bits), all RGB data will be converted to 4 bits and written to the RAM.

Positions of R and B can be changed using the DATCTL command.

Rev. 1.0 EPSON 19

S1D15G00 Series

Memory map (when 8-tone, 16-bit mode is used)

RGB alignment (Command of data control parameter2=000)

Column

LCD

read

direction

Block

0

1

2

P11: 0

P11: 1

Color

Page

P10:0 P10:1

0 167

1 166

2 165

3 164

4 163

5 162

6 161

7 160

8 159

9 158

Data

R

D15

D14

D13

8

57

BRGBRGBRGB RGB

G

D9

D12

D8

D11

D10

899

57 56 56 8

D1

D7

D6

D5

D4

D3

D2

D0

D15

D14

D13

D12

D11

D10

D9D8D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

57

D4

D3

D2

D1

D0

28

29

SEGout

112 55

113 54

114 53

115 52

116 51

117 50

118 49

119 48

49 50 51 52 53 54 55 56 57 58 59 60 346 347 348

Although data is described as D7 - D0 (3 bits or 2 bits), all RGB data will be converted to 4 bits and written to the RAM.

Positions of R and B can be changed using the DATCTL command.

20 EPSON Rev. 1.0

Memory map (when 16-tone, 8-bit mode is used)

RGB alignment (Command of data control parameter2=000)

S1D15G00 Series

Column

LCD

read

direction

Block

0

1

2

P11: 0

P11: 1

Color

Data

Page

P10:0 P10:1

0 167

1 166

2 165

3 164

4 163

5 162

6 161

7 160

8 159

8

57

R1 G1 B1 R2 G2 B2 R1 G1 B1 R2 G2 B2 R2 G2 B2

D7

D3

D7

D6

D2

D6

D5

D1

D5

D4

D0

D4

899

57 56 56 8

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D7

D6

D5

D4

D3

D2

D1

D0

D3

D2

D1

D0

57

D7

D6

D5

D4

D3

D2

D1

D0

9 158

28

29

SEGout

112 55

113 54

114 53

115 52

116 51

117 50

118 49

119 48

49 50 51 52 53 54 55 56 57 58 59 60 346 347 348

Positions of R and B can be changed using the DATCTL command.

Rev. 1.0 EPSON 21

S1D15G00 Series

Memory map (when 16-tone, 16-bit mode is used)

RGB alignment (Command of data control parameter2=000)

LCD

read

direction

Block

0 0 167

P11:0

P11:1

Color

Page

P10:0 P10:1

Data

1 166

2 165

3 164

D15

D14

D13

D12

16

115

GB

D7

D11

D6

D10

D5

D9

D4

D8

D15

D14

D13

D12

17

114

D11

D10

D9

D8

D7

D6

D5

D4

Column

D1

D1

D1

D1

115

16

RGBRG BR

D7

D11

D6

D10

D5

D9

D4

D8

1

2

28

29

4 163

5 162

6 161

7 160

8 159

9 158

112 55

113 54

114 53

115 52

116 51

117 50

118 49

119 48

SEGout

49 50 51 52 53 54 346 347 348

Positions of R and B can be changed using the DATCTL command.

22 EPSON Rev. 1.0

S1D15G00 Series

8.3.2 Page Address Control Circuit

This circuit is used to control the address in the page direction when MPU accesses the DDRAM or when reading the

DDRAM to display image on the LCD.

You can specify a scope of the page address (start and end page) with PASET (page address set) command. When the

page-direction scan is specified with DATCTL (data control) command and the addresses are incremented from the start

up to the end page, the column address is incremented by 1 and the page address returns to the start page.

The DDRAM supports up to 168 lines

*1: S1D15G00D10*000 supports up to 120 lines and the total number of pages is 120.

In the read operation, as the end page is reached, the column address is automatically incremented by 1 and the page

address is returned to the start page.

Using the address normal/inverse parameter of DATCTL command allows you to inverse the correspondence between

the DDRAM address and common output.

8.3.3 Column Address Control Circuit

This circuit is used to control the address in the column direction when MPU accesses the DDRAM. You can specify

a scope of the column address (start and end column) using CASET (column address set). When the column-direction

scan is specified with DATCTL command and the addresses are incremented from the start to the end up to the end

column, the page address is incremented by 1 and the column address returns to the start column.

In the read operation, too, the column address is automatically incremented by 1 and returns to the start page as the end

column is reached.

Just like the page address control circuit, using the column address normal/inverse parameter of DATCTL command

enables to inverse the correspondence between the DDRAM column address and segment output. This arrangement

relaxes restrictions in the chip layout on the LCD module.

*1

, and thus the total page becomes 168.

8.3.4 I/O Buffer Circuit

It is the bi-directional buffer used when MPU reads or writes the DDRAM. Since MPU’s read or write of the DDRAM

is performed independently from data output to the display data latch circuit, asynchronous access to the DDRAM while

the LCD is turned on does not cause troubles such as flicking of the display images.

8.3.5 Block Address Circuit

This circuit associates pages on the DDRAM with COM output. S1D15G00 processes signals for the liquid crystal

display on 4-page basis (block basis). Thus, when specifying a specific area in the area scroll display or partial display,

you must designate it in block.

8.3.6 Display Data Latch Circuit

This circuit is used to temporarily hold display data to be output from the DDRAM to the SEG decoder circuit. Since

DISNOR/DISINV (display normal/inverse) and DISON/DISOFF (display on/display off) commands are used to

control data in the latch circuit alone, they do not modify data in the DDRAM.

Rev. 1.0 EPSON 23

S1D15G00 Series

8.4 Area Scroll Display

Using ASCSET (area scroll set) and SCSTART (scroll start set) commands allows you to scroll the display screen

partially. You can select any one of the following four scroll patterns.

Center screen scroll Top screen scroll Bottom screen scroll Whole screen scroll

: Fixed area

: Scroll area

Fig. 8.4.1

When, for example, 1/128 duty (Display area: 32 blocks = 128 lines) is selected, and the top 2 blocks = 8 lines and bottom

2 blocks = 8 lines are specified as the fixed areas and the remaining 28 blocks = 112 lines as the scroll area, 10 blocks

= 40 lines on the DDRAM can be used as the background area.

DDRAM block

0

1

2

LCD panel

32 blocks

=128 line

29

30

39

40

41

Fixed area

Display area

Scroll area

Background area

24 EPSON Rev. 1.0

S1D15G00 Series

8.5 Partial Display

Using PTLIN (partial in) command allows you to turn on the partial display (division by line) of the screen. This mode

requires less current consumption than the whole screen display, making it suitable for the mobile equipment in the

standby state.

: Display area (partial display area)

: Non-display area

8.6 Gray-Scale Display

This function represents gray-scale by frame modulating the gray-scale date written on the display data RAM. In the

256-out-of-4096 colors (8 gray-scale) display, you can specify display colors using the command.

Normally black liquid crystal in the reverse display mode - 8 gray scale display

R (D7,D6,D5)

G (D4,D3,D2)

B (D1,D0)

Black

(0,0,0) (0,0,1) (0,1,0) (0,1,1) (1,0,0) (1,0,1) (1,1,0) (1,1,1)

Black

(0,0,0) (0,0,1) (0,1,0) (0,1,1) (1,0,0) (1,0,1) (1,1,0) (1,1,1)

Black

(0,0) (0,1) (0,1) (0,1) (1,0) (1,0) (1,0) (1,1)

Any one of above

Any one of above

Red

Green

Blue

Respective data on red, green and blue are converted to the display data to be specified by the parameters of RGBSET8

command, and then written to the DDRAM. Blue is displayed in 4 gray-scale.

8.7 Oscillation Circuit

S1G15G00 contains the oscillation circuit whose operation does not require any external part. The oscillation circuit

is enabled only when M/S = HIGH and CLS = HIGH. When the external clock signal is (CLS = LOW or M/S = LOW),

the clock is entered from CL pin.

8.8 Display Timing Generation Circuit

This circuit generates the timing signal for display (CL, FR, SYNC, CA, F1, F2, DOFF) using the clock from the builtin oscillation circuit or the external clock.

It is also used to generate the clock to turn on the liquid crystal-drive power circuit.

When using S1D15G00 in multi-chip array, the display timing signal (CL, FR, SYNC, CA, F1, F2, DOFF) must be sent

from the master to the slave.

8.9 SEG Decoder Circuit

This circuit outputs the segment driver control signal based on display data for 4-page and the timing signal.

8.10 Liquid Crystal Drive Circuit

It outputs liquid crystal drive voltage. Responding to the decoder output signal and the display-timing signal, the

segment output pin outputs one of potentials V2, V1, VC, MV1 or MV2 and the common output pin outputs one of

potentials V3, VC or MV3.

Rev. 1.0 EPSON 25

S1D15G00 Series

8.11 Liquid Crystal-Drive Power Circuit

The power circuit contained in S1D15G00 generates voltage required to drive liquid crystal. This low power

consumption type power circuit is consisted the voltage regulator, booster circuits (primary, secondary) and voltage

follower. The power circuit is enabled only when the master operation mode is turned on.

The power control circuit turns on or off the voltage regulator, booster circuits, Reference voltage generation circuit

and voltage follower responding to PWRCTR (power control set) command. Thus, function of the external and internal

power supplies can be partly used in parallel.

Table 8.11.1 lists the functions controlled by the 4-bit data - parameter of PWRCTR. Table 8.11.2 shows combinations

of 4 bits (combinations shown in Table 8.11.2 alone are valid).

Table 8.11.1

Item State

“1” “0”

D3 Primary booster circuits control bit ON OFF

D2 Secondary booster circuit control bit ON OFF

D1 Reference voltage generation circuit control bit ON OFF

D0 Voltage adjusting circuit/Voltage follower control bit ON OFF

Table 8.11.2

Function turned on D3 D2 D1 D0

External power input pins

1. Entire built-in power circuit is turned on 1 1 1 1 –

2. Other than the secondary booster and step-down circuits 1 0 1 1 V3, MV3

3. External power supply alone 0 0 0 0 V3, V2, VC, MV1, MV3

8.11.2 Voltage Transform Circuit

The charge pump booster circuit and the operational amplifier’s voltage follower generate each potential required to

drive the liquid crystal based on the reference voltage generated by the voltage regulator.

Ground potentials (abbreviated as GND in the following description) of the power circuit in the IC are GND2 and

GND4.

Fig. 8.11.1 illustrates mutual relationship between potentials.

Secondary

Primary

boorster circuit

V

DD2

VCLS

V2 V1, VC, MV1,

generation circuit

boorster circuit

V

V2

V1

VC

3

MV1

GND

Secondary

boorster circuit

MV2

MV3

Fig. 8.11.1 Mutual Relationship between Voltage Transform Circuits

26 EPSON Rev. 1.0

S1D15G00 Series

Table 8.11.3 shows the theoretical expression of respective potentials. Since these are theoretical values, they can differ

from actual voltages depending on load on the liquid crystal.

Table 8.11.3 Theoretical Expression of Potentials

Signal name Theoretical expression Theoretical expression

(relative to GND = 0V) (relative to VC = 0V)

V3 2×(V2–GND) 2×(VC–GND)

V2 Output from voltage regulator VC–GND

V1 3/4×(V2–GND) 1/2×(VC–GND)

VC 2/3×(V2–GND) 0V

MV1 1/3×(V2–GND) –1/2×(VC–GND)

GND(MV2)0V –(VC–GND)

MV3 –(V2–GND) –2×(VC–GND)

8.11.3 Primary Booster Circuit

The built-in booster circuit triples the voltage of VDD2-GND.

VDD2-GND voltage is tripled by capacitor C connected across CAP1+ and CAP1,CAP2+ and CAP2- as well as VCSL

and GND (or VDD2), and then output at VCSL pin.

In the case of double boosting, short circuit the CAP2+ and VCSL pin.

Fig. 8.11.2 shows how the voltage is stepped up by the capacitors connected.

CSL=

3xV

C

+

C

+

C

+

GND or V

V

CAP2—

CAP2+

CAP1—

CAP1+

CSL

DD2

V

DD2

GND

V

DD2

C

+

C

+

GND or V

V

CAP2—

CAP2+

CAP1—

CAP1+

CLS

DD2

V

DD2

GND

V

CLS=

2xV

DD2

Fig. 8.11.2 Relation between Capacitors and Voltage Step-up

8.11.4 Voltage Regulator Circuit

The voltage regulator circuit generates the liquid crystal drive voltage V2 using VCSL from the primary booster circuit.

S1D15G00 incorporates the high-precision constant voltage source, 64-step electronic volume control function and

resistor to regulate V2 voltage. The voltage regulator circuit covers a wider temperature range with fewer numbers of

parts thanks to the temperature gradient control function as well as the temperature sensing function.

However, capacitors may be required for voltage regulation between V2 and GND pins due to the load of LCD panel.

Insert the capacitors, if necessary, by observing the voltage waveforms and current consumption.

1 Built-in Resistor for V2 Voltage Regulation

The contents described in this document apply only to models that use a V2 voltage control resistor inside the IC.

Using this resistor and the electronic volume control function allows you to control the liquid crystal drive voltage V2

to an optimum level for the LCD panel with the command alone, without resorting to external resistors.

V2 output voltage can be determined from Equation A-1 as long as the relation V2 < VCSL is met.

However, set the voltage of V2 by allowing for a drop in the voltage due to load, so that it becomes at or below 80 %

of VCSL.

Rb

V

111

=+

V

EV REG2

•=+

Ra

Rb

Ra

•

α

218

2

+

•–

(Equation A-1)

V

Note: VREG is the constant voltage source inside the IC. It is 1.2V (Typ.) at Ta = 25°C.

Rev. 1.0 EPSON 27

S1D15G00 Series

VCSL

VEV (Constant voltage source +

Electronic volume controller)

Built-in Rb

Built-in Ra

GND

V2

Fig. 8.11.3 Voltage Regulator Circuit

Rb/Ra in Equation A-1 is the resistance ratio of the built-in V2 voltage-regulating resistance. This ratio can be varied

in 8 levels by changing parameters 2(P2) of electronic volum control command. Reference ratios of “1 + Rb/Ra” are

shown in Table 8.11.4.

Table 8.11.4 Resistance Ratio of Built-in V2 Voltage-Regulating Resistance: Parameters and “1+

R/Ra” Ratio (For reference)

Parameter

P22 P21 P20

1+Rb/Ra ratio V1 voltage value

0 0 0 3.95 Small

0 0 1 4.27

0 1 0 4.60 •

0 1 1 4.93 •

1 0 0 5.26 •

1 0 1 5.59 •

1 1 0 5.92

1 1 1 6.25 Large

2V2 voltage control external resistor

The contents described in this document apply only to models that use an external V2 voltage control resistor.

If you use an external resistance control model, you can set the V2 voltage using an external resistor.

Use a semi-fixed resistor for V2 voltage regulation.

CSL

V

VEV

(Fixed voltage source and

Electronic volume control)

GND

+

–

VR

V

2

GND

V

2

External resistor Rb

External resistor Ra

Fig. 8.11.4 Voltage Regulator Circuit

Select the external Ra and Rb values to allow stable voltage supply by observing the V2 voltage waveforms.

As the VR pin has a high input impedance and it is susceptible to ambient noise, the resistors and their leads must be

placed in a short distance and they must be away from the clock source.

3Constant Voltage Source and Electronic Volume Control Circuit

The constant voltage source generates V

REG - the reference voltage inside the IC. You can specify one of four types

of temperature gradients with parameters of electronic volum control command. See Fig. 8.11.5.

28 EPSON Rev. 1.0

Table 8.11.5 Parameters and VREG Temperature Gradient

S1D15G00 Series

Parameter

Temperature gradient (%/C)

00 –0.05

01 –0.1

10 –0.15

11 –0.2

The electronic volume control circuit varies α in Equation A-1 according to parameters 1(P1) of electronic volum

control command. Table 8.11.6 lists relation between the parameters and α.

Table 8.11.6 Parameters and Electronic Volume

Parameter

P15 P14 P13 P12 P11 P10

α

V1 voltage value

000000 63 Small

000001 62

000010 61

•••

•••

•••

111101 2

111110 1

111111 0

Large

8.11.5 Voltage Divider/Voltage Follower Circuit

The voltage divider/voltage follower circuit V2 output from the voltage regulator circuit and then generates liquid

crystal drive voltages V1,VC and MV1 using the operational amplifier-featured voltage follower.

Capacitors may be required for voltage regulation between the GND and each of V1, VC and MV1 pins due to the load

of LCD panel. Insert the capacitors, if necessary, by observing the voltage waveforms and current consumption.

V1 = 3/4×V2

VC = 2/4×V2

MV1 = 1/4×V2

8.11.6 Secondary Booster Circuit and Tertiary Booster/Step-Down Circuit

The secondary booster circuit boosts or steps down based on V2 and produces V3 and MV3.

Their potential relationship is expressed with the following theoretical equation:

V3 = 2×V2

MV3 = –V2

8.11.7 Samples of Connections Peripheral to Power Circuit (For your information)

Following illustrates the connections when the entire power circuit is used.

Sample of common setting

Item Setting Unit

C1 1.0 to 4.7 µF

C2 0.47 to 1.0

Optimum values of C1 and C2 above vary

depending on the LCD panel to be driven.

Above values should be referenced as

information only. It is recommended to

check how patterns with high load are

displayed before finalizing the values.

C between V

DD2 and GND signifies a

C1

C1

C1

C1

+

+

+

+

CAP1+

CAP1–

CAP2+

CAP2–

CAP4+

CAP4–

CAP5+

CAP5–

VDD2

VCSL

GND

V

V2

V1

VC

MV1

MV3

+

+

3

+

C1

C2

2

2

bias capacitor.

Rev. 1.0 EPSON 29

S1D15G00 Series

9. COMMANDS

9.1 Command List

Following table lists the control signals and commands using the 80 series interface as the example.

Command A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function Hex

1 DISON 01010101111Display on AF None

2 DISOFF 01010101110Display off AE None

3 DISNOR 01010100110Normal display A6 None

4DISINV 01010100111Inverse display A7 None

5COMSCN01010111011Common scan direction BB 1byte

6 DISCTL 01011001010Display control CA 3byte

7 SLPIN 01010010101Sleep in 95 None

8 SLPOUT 01010010100Sleep out 94 None

9 PASET 01001110101Page address set 75 2byte

10 CASET 01000010101Column address set 15 2byte

11 DATCTL 01010111100Data scan direction, etc. BC 3byte

12

RGBSET8

13 RAMWR 01001011100Writing to memory 5C Data

14 RAMRD 01001011101Reading from memory 5D Data

15 PTLIN 01010101000Partial display in A8 2byte

16 PTLOUT 01010101001Partial display out A9 None

01011001110256-color position set CE 20byte

Parameter

17RMWIN 01011100000Read and modify write E0 None

18 RMWOUT 01011101110End EE None

19 ASCSET 01010101010Area scroll set AA 4byte

20 SCSTART 01010101011Scroll start set AB 1byte

21 OSCON 01011010001Internal oscillation on D1 None

22 OSCOFF 01011010010Internal oscillation off D2 None

23 PWRCTR 01000100000Power control 20 1byte

24 VOLCTR 01010000001Electronic volume control 81 2byte

25 VOLUP 01011010110

26

VOLDOWN

27TMPGRD01010000010Temperature gradient set 82 1 byte

28EPCTIN 01011001101Control EEPROM CD 1 byte

29EPCOUT01011001100Cancel EEPROM control CC None

30 EPMWR 01011111100Write into EEPROM FC None

31 EPMRD 01011111101Read from EEPROM FD None

32

EPSRRD1

33

EPSRRD2

34NOP 01000100101NOP instruction 25 None

01011010111

01001111100Read register 1 7C None

01001111101Read register 2 7D None

Increment electronic control by 1

Decrement electronic control by 1

D6 None

D7 None

35 STREAD 0 0 1 Status Status read

30 EPSON Rev. 1.0

S1D15G00 Series

(1) Display ON (DISON) Command: 1 Parameter: None

It is used to turn the display on. When the display is turned on, segment outputs and common outputs are generated

at the level corresponding to the display data and display timing. You can’t turn on the display as long as the sleep mode

is selected. Thus, whenever using this command, you must cancel the sleep mode first.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01010101111

(2) Display OFF (DISOFF) Command: 1 Parameter: 0

It is used to forcibly turn the display off. As long as the display is turned off, every segment and common outputs are

forced to VC level and DOFF pin is caused to LOW.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01010101110

(3) Normal display (DISNOR) Command: 1 Parameter: 0

It is used to normally highlight the display area without modifying contents of the display data RAM.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01010100110

(4) Inverse display (DISINV) Command: 1 Parameter: 0

It is used to inversely highlight the display area without modifying contents of the display data RAM. This command

does not invert non-display areas in case of using partial display.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01010100111

(5) Common scan (COMSCAN) Command: 1 Parameter: 1

It is used to specify the common output scan direction. This command helps increasing degrees of freedom of wiring

on the LCD panel.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01010111011

Parameter1 (P1)

When 1/160 is selected for the display duty, pins and common output are scanned in the order shown below.

P12 P11 P10 Common scan direction

000 1 → 80 81 → 160

001 1 → 80 160 ← 81

010 80 ← 181→ 160

011 80 ← 1 160 ← 81

110*****P12 P11 P10 Common scan direction

COM1 pin COM80 pin COM81 pin COM160 pin

Rev. 1.0 EPSON 31

S1D15G00 Series

(6) Display control (DISCTL) Command: 1 Parameter: 3

This command and succeeding parameters are used to perform the display timing-related setups. This command must

be selected before using SLPOUT. Don’t change this command while the display is turned on.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01011001010

Parameter1 (P1)

Parameter2 (P2)

Parameter3 (P3)

P1: It is used to specify the CL dividing ratio, F1 and F2 drive-pattern switching period.

P13, P12: CL dividing ratio. They are used to change number of dividing stages of external or internal clock.

P13 P12 CL dividing ratio

0 0 2 divisions (default)

0 1 4 divisions

1 0 8 divisions

1 1 Not divide

110****P13 P12 P11 P10 CL dividing ratio, F1 and

F2 drive pattern.

110**P25 P24 P23 P22 P21 P20 Drive duty

110***1 P33 P32 P31 P30 FR inverse-set value

*: Invalid bits irrelevant to the operation.

P11, P10: They are used to change F1 and F2 drive-pattern switching period.

P11 P10 F1, F2 switching period

0 0 8H (default)

01 4H

1 0 16H

1 1 Field

P2: It is used to specify the duty of the module on block basis.

Duty **P25 P24 P23 P22 P21 P20 (Numbers of display lines)/4-1

Example: 1/128 duty 00011111 128/4–1=31

Example: 1/160 duty 00100111 160/4–1=39

P3: It is used to specify number of lines to be inversely highlighted on LCD panel (lines can be inversely highlighted

in the range of 2 to 16)

Inversely highlighted lines

Example: 11H 00001010 11–1=10

Example: 13H 00001100 13–1=12

In the default, 11H inverse highlight is selected.

(7) Seep in (SLPIN) Command: 1 Parameter: 0

Entering this command generates LOW at SLP pin.

**P25 P24 P23 P22 P21 P20 Inversely highlighted lines –1

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01010010101

DOFF (LCD panel blanking control pin) on S1D15G00 is caused to LOW when the sleep in mode is turned on.

The LCD power supply and the boost circuit output is jumpered with GND during Sleep In.

32 EPSON Rev. 1.0

S1D15G00 Series

(8) Sleep out (SLPOUT) Command: 1 Parameter: 0

Entering this command generates HIGH at SLP pin.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01010010100

(9) Page address set (PASET) Command: 1 Parameter: 2

When MPU makes access to the display data RAM, this command and succeeding parameters are used to specify the

page address area. As the addresses are incremented from the start to the end page in the page-direction scan, the column

address is incremented by 1 and the page address is returned to the start page. Note that the start and end page must

be specified as a pair. Also, the relation “start page < end page” must be maintained.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01001110101

Parameter1 (P1)

Parameter2 (P2)

(10) Column address set (CASET) Command: 1 Parameter: 2

When MPU makes access to the display data RAM, this command and succeeding parameters are used to specify the

column address area. As the addresses are incremented from the start to the end column in the column-direction scan,

the page address is incremented by 1 and the column address is returned to the start column. Note that the start and end

page must be specified as a pair. Also, the relation “start column < end column” must be maintained.

1 1 0 P17 P16 P15 P14 P13 P12 P11 P10 Start page

1 1 0 P27 P26 P25 P24 P23 P22 P21 P20 End page

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01000010101

Parameter1 (P1)

Parameter2 (P2)

* Note that in the 8- and16-bit access, or 8 and 16 gray-scale, a different approach is employed for specifying the address.

1 1 0 P17 P16 P15 P14 P13 P12 P11 P10 Start address

1 1 0 P27 P26 P25 P24 P23 P22 P21 P20 End address

Rev. 1.0 EPSON 33

S1D15G00 Series

(11) Data control (DATCTL) Command: 1 Parameters: 2

This command and succeeding parameters are used to perform various setups needed when MPU operates display data

stored on the built-in RAM.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01010111100

Parameter1 (P1)

Parameter2 (P2)

Parameter3 (P3)

P1: It is used to specify the normal or inverse display of the page address and also to specify the page address scanning

direction.

P10: Normal/inverse display of the page address. P10 = 0: Normal and P10 = “1”: Inverse.

P11: Normal/reverse turn of column address. P11 = “0”: Normal rotation and P11 = “1”: Reverse rotation

P12: Address-scan direction. P12 = “0”: In the column direction and P12 = “1”: In the page direction.

P2: RGB arrangement. This parameter allows you to change RGB arrangement of the segment output according to RGB

arrangement on the LCD panel. In this case, writing position of data {R = (D7, D6, D5), G = (D4, D3, D2), B =

(D1, D0)} on the display memory is changed.

110*****P12 P11 P10

Normal/inverse display of page

address and page-address

scan direction.

110*****P22 P21 P20 RGB arrangement

110*****P32 P31 P30 Gray-scale setup

P22,P21,P20

line SEG0 SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 SEG7 •••

000 Even page R G B R G B R G ••• B

Odd page R G B R G B R G ••• B

001 1 B G R B G R B G ••• R

2BGRBGRBG••• R

010 1 R G B B G R R G ••• R

2 RGBBGRRG••• R

011 1 B G R R G B B G ••• B

2BGRRGBBG••• B

100 1 R G B R G B R G ••• B

2BGRBGRBG••• R

101 1 B G R B G R B G ••• R

2RGBRGBRG••• B

110 1 R G B B G R R G ••• R

2BGRRGBBG••• B

111 1 B G R R G B B G ••• B

2 RGBBGRRG••• R

In the default, (P22, P21, P20) = (0, 0, 0) is selected.

SEG395

P3: Gray-scale setup. Using this parameter, you can a select desired display colors between the 256 colors (8 gray-scale)

or 4096 colors (16 gray-scale) for the display color. For 16 gray-scale display, you can select the Type-A or Type-B

display mode depending on the difference in RGB data arrangement you use.

P32 P31 P30 Numbers of gray-scale

0 0 1 8 gray-scale

0 1 0 16 gray-scale display

34 EPSON Rev. 1.0

S1D15G00 Series

(12) 256-color position set (RGBSET8) Command: 1 Parameter: 0

When turning on 256-color display (8 gray-scale), this command allows you to choose colors to represent each of red,

green and blue from 4096 colors.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01011001110

Parameter1 (P1)

110****P13 P12 P11 P10 Intermediate red tone 000

Parameter4 (P8)

Parameter9 (P9)

Parameter16 (P16)

Parameter17 (P17)

Parameter20 (P20)

110****P83 P82 P81 P80 Intermediate red tone 111

110****P93 P92 P91 P90 Intermediate green tone 000

110****

110****

110****

P163 P162 P161 P160

P173 P172 P171 P170

P203 P202 P201 P200

Intermediate green tone 111

Intermediate blue tone 00

Intermediate blue tone 11

Data (Red and Green: 3 bits and Blue: 2 bits) to be written from the MPU to the DDRAM are converted to 4-bit data

before the write operation takes place. When reading data from the DDRAM, data on red and green are converted to

3 bits and that on blue are converted to 2 bits before the output.

(13) Memory write (RAMWR) Command: 1 Parameter: Numbers of data written

When MPU writes data to the display memory, this command turns on the data entry mode. Entering this command

always sets the page and column addresses at the start address. You can rewrite contents of the display data RAM by

entering data succeeding to this command. At the same time, this operation increments the page or column address as

applicable. The write mode is automatically cancelled if any other command is entered.

1 8-bit bus

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01001011100

Parameter 1 1 0 Data to be written Data to be written

2 16-bit bus

Command name

A0 RD WR

D15 D14 D13 D12 D11 D10

D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 0 1 0 ********0 1 0 1 1 1 0 0 Memory write

Data to be written

1 1 0 Data to be written Write data

(14) Memory read (RAMRD) Command: 1 Parameter: Numbers of data read

When MPU reads data from the display memory, this command turns on the data read mode. Entering this command

always sets the page and column addresses at the start address. After entering this command, you can read contents of

the display data RAM. At the same time, this operation increments the page or column address as applicable. The data

read mode is automatically cancelled if any other command is entered.

1 8-bit bus

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01001011101

Parameter 1 0 1 Data to be read Data to be read

2 16-bit bus

Command name

A0 RD WR

D15 D14 D13 D12 D11 D10

D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 0 1 0 ********0 1 0 1 1 1 0 1 Memory read

Data to be read

1 0 1 Data to be read Read data

Rev. 1.0 EPSON 35

S1D15G00 Series

(15) Partial in (PTLIN) Command: 1 Parameter: 2

This command and succeeding parameters specify the partial display area. This command is used to turn on partial

display of the screen (dividing screen by lines) in order to save power. Since S1D15G00 processes the liquid crystal

display signals on 4-line basis (block basis), the display and non-display areas are also specified on 4-bit line (block

basis).

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01010101000

Parameter1 (P1)

Parameter2 (P2)

*: Invalid bits irrelevant with the operation.

A block address that can be specified for the partial display must be the displayed one (don’t try to specify an address

not to be displayed when scrolled).

When the partial display mode is turned on, following state is introduced to S1D15G00 in the non-display area:

* LOW is output to DOFF pin.

* All COM pins output V

* All SEG pins output V1 or MV1.

SEG output is forced to V1 or MV1 depending on state of FR in the last display line. When FR is HIGH, V1 is output

and when FR is LOW, MV1 is output. Phase of FR is constantly reversed at start of a frame.

(16) Partial out (PTLOUT) Command: 1 Parameter: 0

This command is used to exit from the partial display mode.

110**P15 P14 P13 P12 P11 P10 Start block address

110**P25 P24 P23 P22 P21 P20 End block address

C.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01010101001

(17) Read modify write in (RMWIN) Command: 1 Parameter: 0

This command is used along with the column address set command, page address set command and read modify write

out command. This function is used when frequently modifying data to specify a specific display area such as blinking

cursor. First set a specific display area using the column and page address commands. Then, enter this command to

set the column and page addresses at the start address of the specific area. When this operation is complete, the column

(page) address won’t be modified by the display data read command. It is incremented only when the display data write

command is used. You can cancel this mode by entering the read modify write out or any other command.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01011100000

Page address set

No

Column address set

Read modify write in

Is modification

complete?

Yes

Read modify write out

Dummy read

Data read

Data write

36 EPSON Rev. 1.0

S1D15G00 Series

(18) Read modify write out (RMWOUT) Command: 1 Parameter: 0

Entering this command cancels the read modify write mode.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0

Command 01011101110

(19) Area scroll set (ASCSET) Command: 1 Parameter: 4

It is used when scrolling only the specified portion of the screen (dividing the screen by lines). This command and

succeeding parameters specify the type of area scroll, FIX area and scroll area.

A0 RD WR D7 D6 D5 D4 D3 D2 D1 D0 Function

Command 01010101010

Parameter1 (P1)

Parameter2 (P2)

Parameter3 (P3)

Parameter4 (P4)

*: Invalid bits irrelevant with the operation.

P4: It is used to specify an area scroll mode.

P41 P40 Types of area scroll

0 0 Center screen scroll

0 1 Top screen scroll

1 0 Bottom screen scroll

1 1 Whole screen scroll

110**P15 P14 P13 P12 P11 P10 Top block address

110**P25 P24 P23 P22 P21 P20 Bottom block address

110**P35 P34 P33 P32 P31 P30 Number of specified blocks

110******P41 P40 Area scroll mode

Center screen scroll Top screen scroll Bottom screen scroll Whole screen scroll

: Fixed area

: Scroll area

Since S1D15G00 processes the liquid crystal display signals on the four-line basis (block basis), FIX and scroll areas

are also specified on the four-line basis (block basis).

DDRAM address corresponding to the top FIX area is set in the block address incrementing direction starting with 0

block. DDRAM address corresponding to the bottom FIX area is set in the block address decreasing direction starting

with 41st block. Other DDRAM blocks excluding the top and bottom FIX areas are assigned to the scroll + background

areas.

P1: It is used to specify the top block address of the scroll + background areas. Specify the 0th block for the top screen

scroll or whole screen scroll.

The scroll start block address is also set at this top block address until the scroll-start block set command specifies

the address.

P2: It specifies the bottom address of the scroll + background areas. Specify the 41st block for the bottom or whole

screen scroll.

Required relation between the start and end blocks (start block < end block) must be maintained.

P3: It specifies a specific number of blocks {Numbers of (Top FIX area + Scroll area) blocks - 1}. When the bottom