Page 1

10" Professional

RS830

Radial Arm Saw

Professionnelle de

254 mm (10 po)

Scie à bras radial

Profesional de

254 mm (10 pulg.)

Sierra de brazo

radial.

A18640 - 4-17-08 Rev. A

Copyright © 2006, 2008 Delta Machinery

Instruction Manual

Manuel d’Utilisation

Manual de Instrucciones

FRANÇAIS (30) ESPAÑOL (58)

www.deltaportercable.com

(800) 223-7278 - US

(800) 463-3582 - CANADA

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ........................ 2

SAFETY GUIDELINES - DEFINITIONS ......................... 2

GENERAL SAFETY RULES ........................................... 3

ADDITIONAL SPECIFIC SAFETY RULES .................... 6

FUNCTIONAL DESCRIPTION .......................................7

CARTON CONTENTS ...................................................8

ASSEMBLY ..................................................................... 9

OPERATION ................................................................... 18

TROUBLESHOOTING .................................................... 26

MAINTENANCE .............................................................. 26

SERVICE ......................................................................... 28

ACCESSORIES ............................................................... 28

WARRANTY .................................................................... 28

FRANÇAIS ...................................................................... 30

ESPAÑOL ........................................................................ 58

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and operating instructions before using any tool or equipment. When

using tools or equipment, basic safety precautions should always be followed to reduce the risk of

personal injury. Improper operation, maintenance or modification of tools or equipment could result in

serious injury and property damage. There are certain applications for which tools and equipment are

designed. Delta Machinery strongly recommends that this product NOT be modified and/or used for any application

other than for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written Delta Machinery and

we have advised you. Contact us online at www.deltaportercable.com or by mail at Technical Service Manager, Delta

Machinery, 4825 Highway 45 North, Jackson, TN 38305. In Canada,125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool is available from the following sources:

• PowerToolInstitute,1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.org

• NationalSafetyCouncil, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• AmericanNationalStandardsInstitute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S.DepartmentofLabor regulations www.osha.gov

SAVE THESE INSTRUCTIONS!

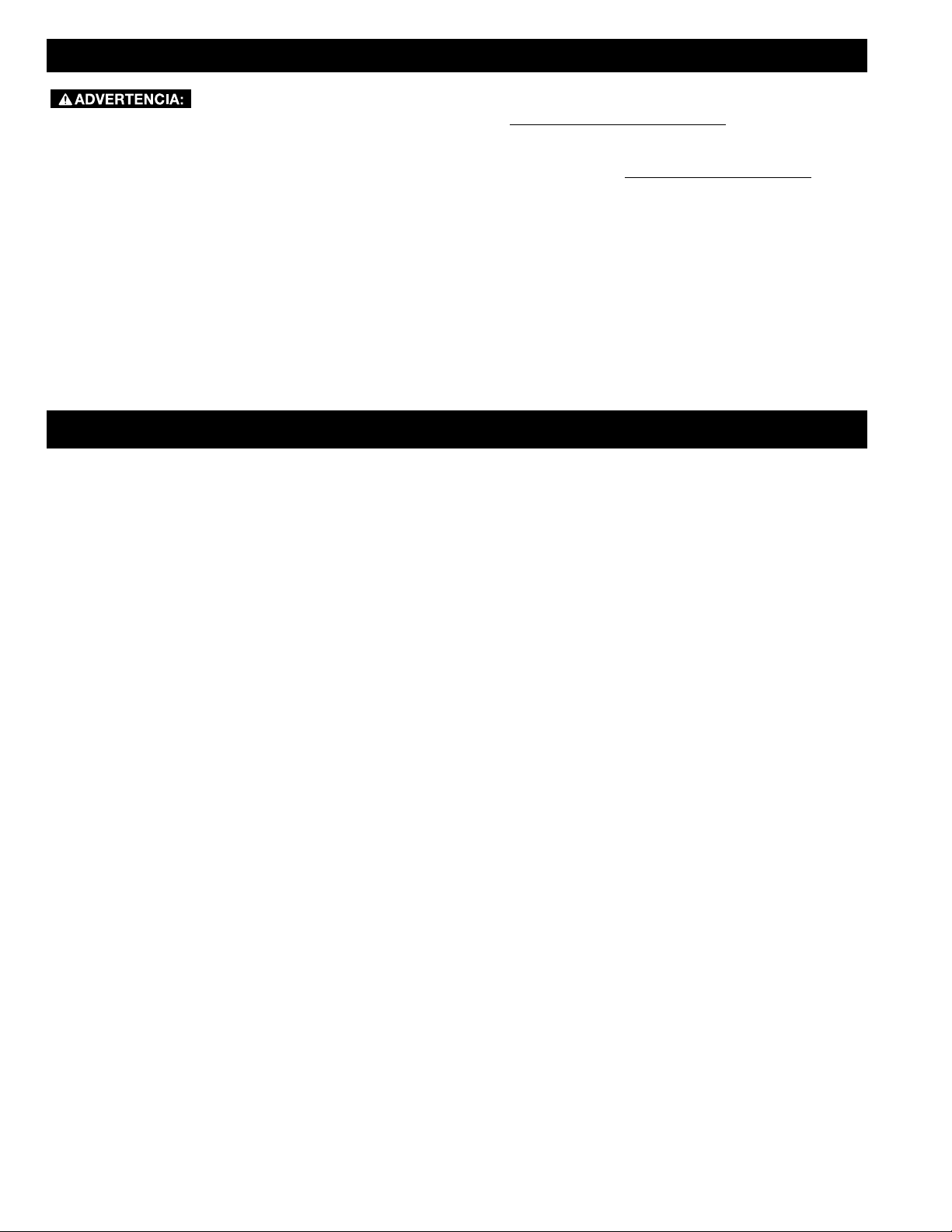

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR SAFETY

and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• leadfromlead-basedpaints,

• crystallinesilicafrombricksandcementandothermasonryproducts,and

• arsenicandchromiumfromchemically-treatedlumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, al ways

wear NIOSH/OSHA approved, properly fit ting face mask or res pi ra tor when us ing such tools.

2

Page 3

GENERAL SAFETY RULES

To reduce the risk of injury, read, understand, and follow the instruction manual before using any tool

or equipment. When using tools or equipment, basic safety precautions should always be followed to reduce the risk

of personal injury. Improper operation, maintenance, or modification of tools or equipment could result in serious

injury and property damage. There are certain applications for which tools and equipment are designed. There are

specific limitations and special hazards associated with each tool. Do not modify and/or use for any application other

than for which it was designed.

SAVE THESE INSTRUCTIONS!

GROUNDING INSTRUCTIONS

FOLLOW ALL WIRING CODES and recommended electrical connections to prevent shock or

electrocution.

If the saw is of grounded construction, read the following instructions.

SHOCK HAZARD. THIS MACHINE MUST BE GROUNDED WHILE IN USE. SERIOUS INJURY COULD

RESULT.

ALL GROUNDED, CORD-CONNECTED MACHINES

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce

the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance

with all local codes and ordinances. Do not modify the plug provided - if it will not fit the outlet, have the proper outlet

installed by a qualified electrician. Improper connection of the equipment-grounding conductor can result in risk of

electric shock. The conductor with insulation having an outer surface that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal. Check with a qualified electrician or service personnel if the grounding

instructions are not completely understood, or if in doubt as to whether the machine is properly grounded. Use only

three-wire extension cords that have three-prong grounding type plugs and matching three-conductor receptacles that

accept the machine's plug, as shown in Fig. A. Repair or replace damaged or worn cord immediately.

GROUNDED, CORD-CONNECTED MACHINES INTENDED FOR USE ON A SUPPLY CIRCUIT HAVING A NOMINAL

RATING LESS THAN 150 VOLTS

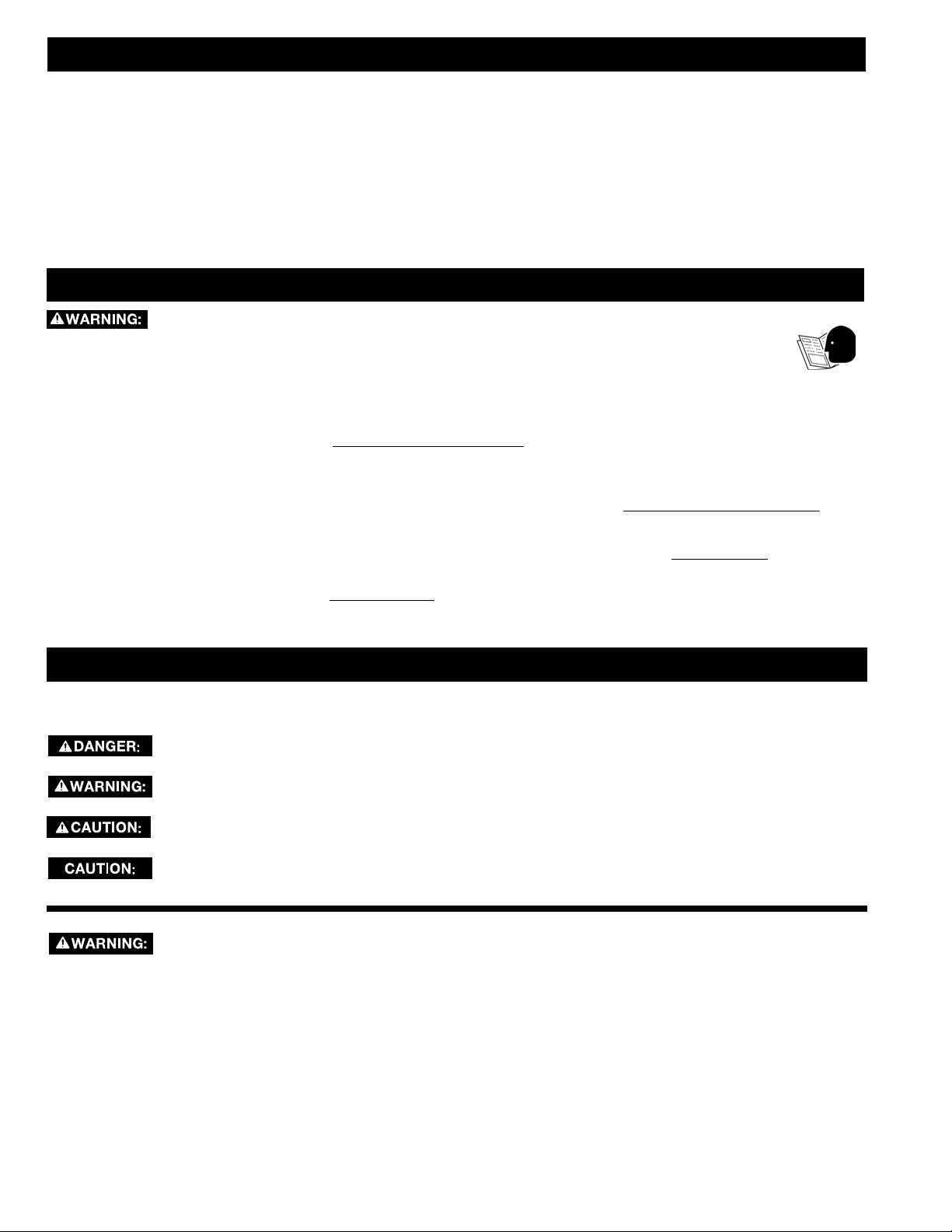

If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the machine

will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adaptor, which looks like the adapter

illustrated in Fig. B may be used to connect this plug to a matching two-conductor receptacle as shown in Fig. B if a

properly grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet

can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending from the adapter must

be connected to a permanent ground such as a properly grounded outlet box. Whenever the adapter is used, it must

be held in place with a metal screw.

A B

Grounded Outlet

Grounding Pin

Box

C

Grounding

Means

Adapter

D

Grounding Pin

IN ALL CASES, MAKE CERTAIN THAT THE RECEPTACLE IN QUESTION IS PROPERLY GROUNDED.

iF YOU ARE NOT SURE, HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

3

Page 4

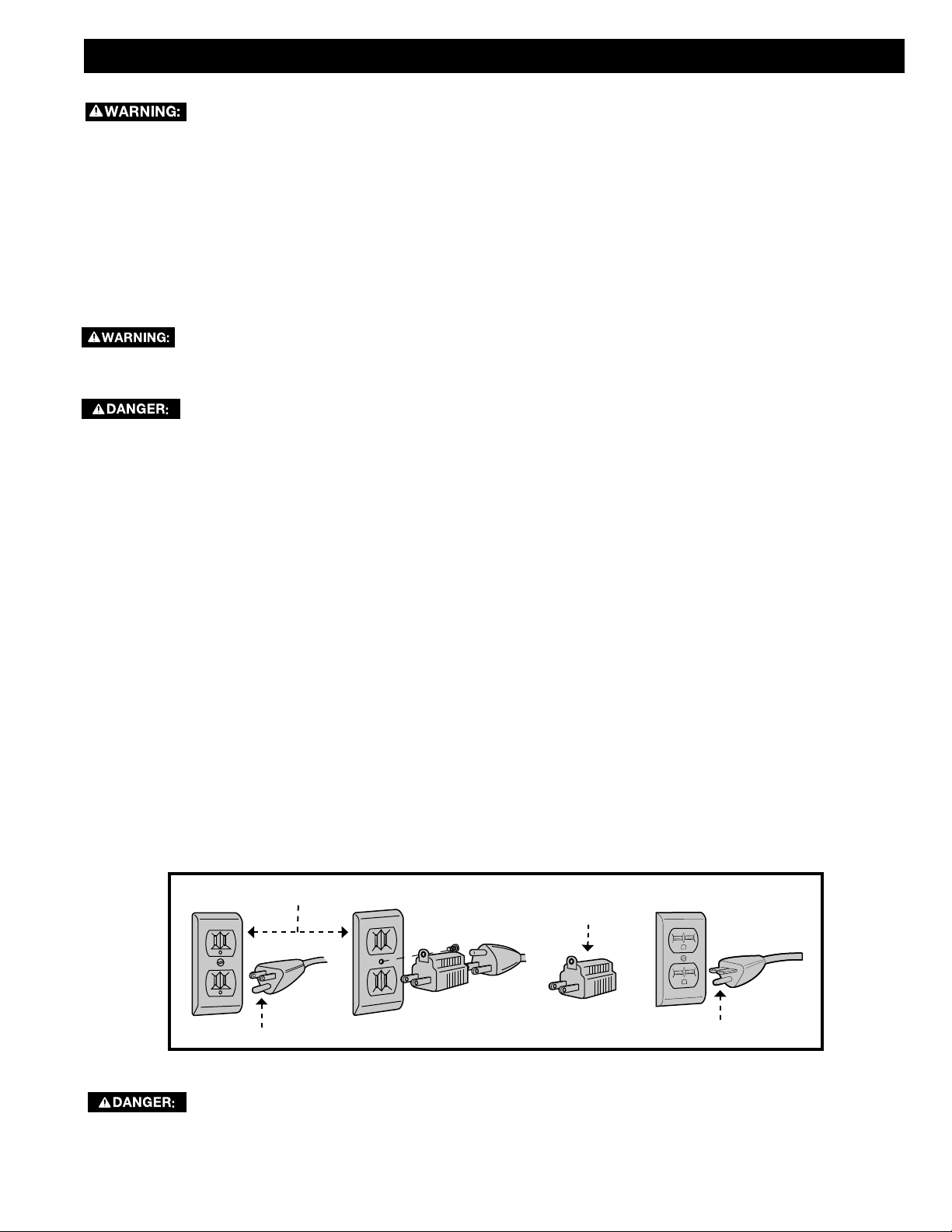

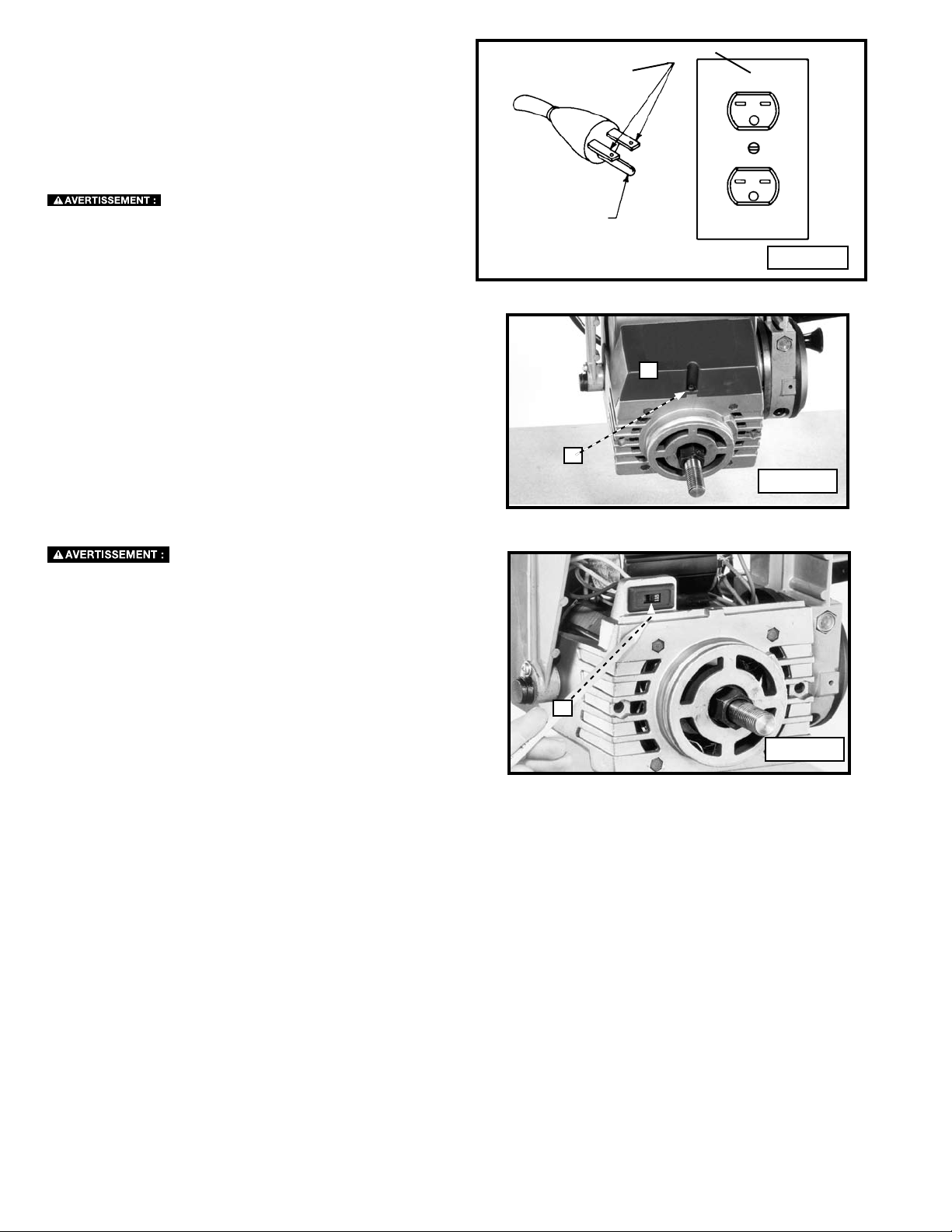

240 VOLT SINGLE PHASE OPERATION

The 120/240 volt, dual-voltage motor supplied with your

machine was shipped prepared for 120 volt operation. It

can be converted for 240 volt operation.

Use the following instructions to convert your saw to 240

volts.

To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing

and removing accessories, before adjusting or changing

set-ups or when making repairs. An accidental start-up

can cause injury.

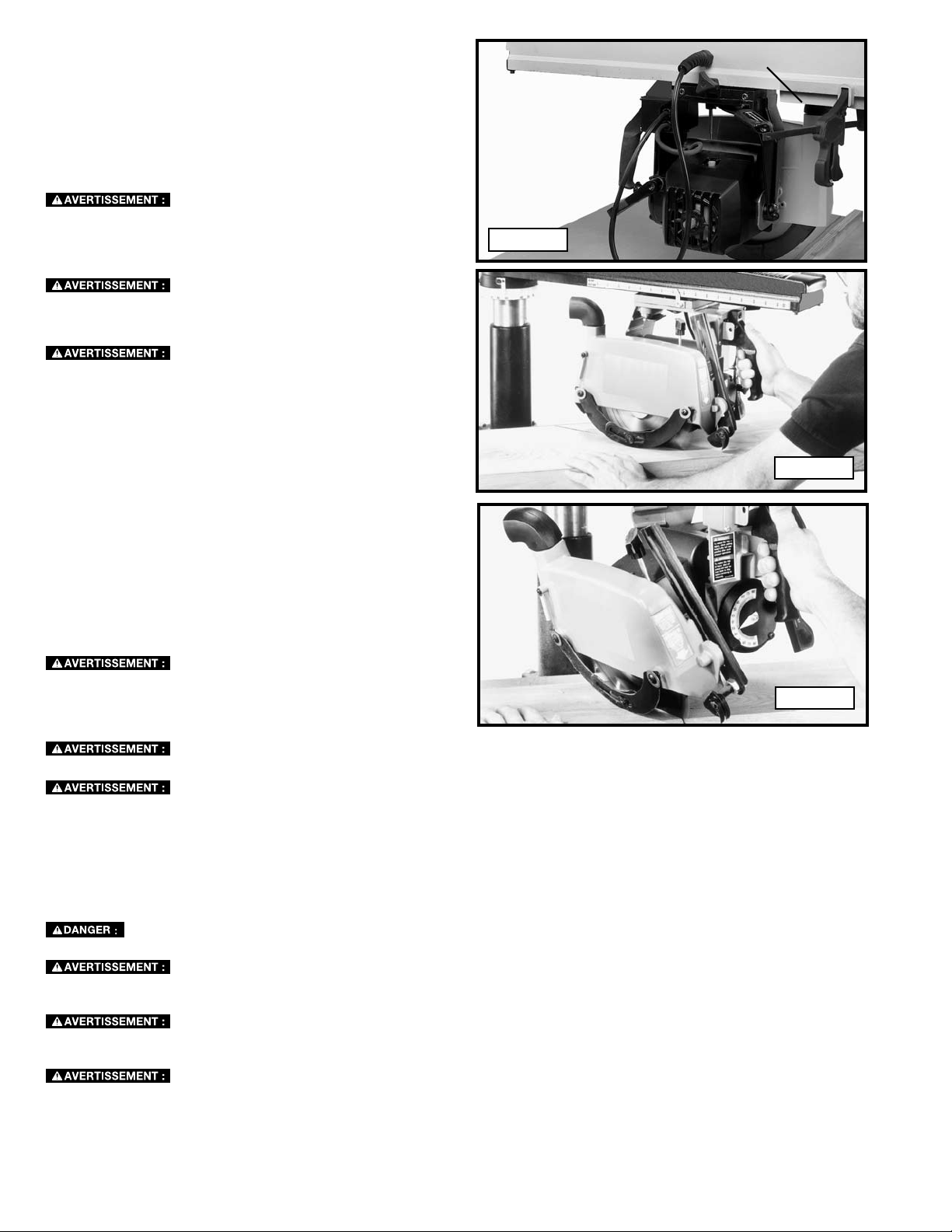

1. Remove the screw (A) Fig. D and remove the plastic

cover (B).

2. Carefully slide the switch (C) Fig. E in the motor

junction box to read 240 volts. Replace the plastic

cover and screw that were removed in STEP 1.

3. You must also replace the 120 volt plug with a UL/CSA

listed plug suitable for 240 volts and the rated current

of the saw.

Either use a qualified electrician to do the conversion, or

take the machine to an Authorized Delta Service Center.

The machine must conform to the National Electric Code

and all local codes and ordinances.

Use the 240 volt plug ONLY in an outlet that has the same

configuration as the plug illustrated in Fig. C. DO NOT use

an adapter with the 240 volt plug.

In all cases, make certain that the

receptacle in question is properly grounded. If you

are not sure, have a qualified electrician check the

receptacle.

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES.

B

A

Fig. C

Fig. D

C

Fig. E

IMPORTANT SAFETY INSTRUCTIONS

1. TO REDUCE THE RISK OF KICKBACK AND OTHER INJURIES, KEEP GUARDS IN PLACE, and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are

removed from spindle before turning tool on. Tools, scrap pieces, and other debris can be thrown at high speed, causing

injury.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT. The use of power tools in damp or wet locations

or in rain can cause shock or electrocution. Keep your work area well-lit to avoid tripping or placing arms, hands, and

fingers in danger.

4

Page 5

5. KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area. Your shop is a potentially

dangerous environment.

6. MAKE WORKSHOP CHILDPROOF with padlocks, master switches, or by removing starter keys. The unauthorized

start-up of a machine by a child or visitor may result in injury.

7. DO NOT FORCE TOOL. It will do the job better and be safer at the rate for which it was designed.

8. USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not designed. Using the incorrect tool or

attachment may result in personal injury.

9. USE PROPER EXTENSION CORD. Make sure that your extension cord is in good condition. If your product is equipped

a cord set, use only three-wire extension cords that have three-prong grounding-type plugs, and three-pole receptacles

that accept the tool's plug. When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. The

following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the cord.

MINIMUM GAUGE FOR CORD SETS

Volts Total Length of Cord in Feet

120V

240V

0-25

0-50

26-50

51-100

51-100

101-200

101-150

201-300

Ampere Rating

More

Than

Not More

Than

0 - 6

6 - 10

10 - 12

12 - 16

18

18

16

14

AWG

16

16

16

12

16

14

14

Not Recommended

14

12

12

10. WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry to get caught in

moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain long hair. Air vents may

cover moving parts and should also be avoided.

11. ALWAYS USE SAFETY GLASSES. Everyday glasses are NOT safety glasses. Also use face or dust mask if cutting

operation is dusty. ALWAYS wear certified safety equipment:

l ANSI A87.1 eye protection (CAN/CSA Z94.3)

l ANSI S12.6 (S3.19) hearing protection

l NIOSH/OSHA respiratory protection

12. DO NOT OVERREACH. Keep proper footing and balance at all times. Loss of balance may cause personal injury.

13. MAINTAIN TOOLS WITH CARE. Keep blades sharp and clean for best and safest performance. Follow instructions

for lubricating and changing accessories. Poorly maintained blades and machines can further damage the blade or

machine and/or cause injury.

14. TURN THE MACHINE "OFF" AND DISCONNECT THE MACHINE FROM THE POWER SOURCE before installing or

removing accessories, before adjusting or changing set-ups, when making repairs or changing locations. Do not touch

the plug's metal prongs when unplugging or plugging in the cord. An accidental start-up can cause injury.

15. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is in the "OFF" position before

plugging in the power cord. In the event of a power failure, move the switch to the "OFF" position. An accidental startup can cause injury.

16 USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended by the manufacturer for

your model. Accessories that may be suitable for one tool may be hazardous when used on another tool. Consult

the instruction manual for recommended accessories. The use of improper accessories may cause risk of injury to

persons.

17. NEVER STAND ON THE TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally

contacted.

18. CHECK FOR DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged should be properly repaired or replaced. Do not use tool if switch does

not turn it on and off. Damaged parts can cause further damage to the machine and/or personal injury.

19. DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

20. NEVER LEAVE THE TOOL RUNNING UNATTENDED. TURN THE POWER OFF. Don't leave tool until it comes to a

complete stop. Serious injury can result.

21. DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN GASEOUS OR EXPLOSIVE

ATMOSPHERES. Motors and switches in these tools may spark and ignite fumes.

22. STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE. DO NOT USE THE MACHINE WHEN

YOU ARE TIRED OR UNDER THE INFLUENCE OF DRUGS, ALCOHOL, OR MEDICATION. A moment of inattention

while operating power tools may result in serious injury.

23. DO NOT ALLOW FAMILIARITY (gained from frequent use of your saw) TO REPLACE SAFETY RULES. Always

remember that a careless fraction of a second is sufficient to inflict severe injury.

5

Page 6

ADDITIONAL SPECIFIC SAFETY RULES

Failure to follow these rules may result in serious personal injury.

1. ALWAYS USE SAFETY GLASSES. Everyday glasses are NOT safety glasses. Also use face or dust mask if cutting

operation is dusty. ALWAYS wear certified safety equipment:

l ANSI A87.1 eye protection (CAN/CSA Z94.3)

l ANSI S12.6 (S3.19) hearing protection

l NIOSH/OSHA respiratory protection

2. AVOID AWKWARD POSITIONS where a sudden slip could cause a hand to move into a saw blade or other cutting

tool.

3. KEEP ARMS, HANDS, AND FINGERS AWAY from the blade to prevent serious injury.

4. USE A PUSH STICK OR PUSH BLOCK THAT IS APPROPRIATE TO THE APPLICATION TO PUSH WORKPIECES

THROUGH THE SAW. A push stick is a wooden or non-metallic stick, usually homemade that should be used whenever

the size or shape of the workpiece would cause you to place your hands within six inches of the blade.

5. DO NOT PERFORM RIPPING, CROSSCUTTING, OR ANY OTHER OPERATION FREEHAND.

6. NEVER reach around or over the saw blade.

7. STABILITY. Make sure that the radial arm saw is firmly mounted to a secure surface before use and does not move. If

the mobility kit is installed, raise the moveable caster(s) so that the saw is in its stationary position.

8. NEVER CUT FERROUS METALS (those with iron or steel content) or masonry. Damage to the saw and personal injury

may result.

9. USE THE CORRECT SAW BLADE FOR THE INTENDED OPERATION. Follow instructions in operation section of the

manual for proper procedure for any kind of cut. Always tighten the blade arbor nut securely. Before use, inspect the

blade for cracks or missing teeth. Do not use a damaged blade.

10. NEVER ATTEMPT TO FREE A STALLED SAW BLADE WITHOUT FIRST TURNING THE MACHINE OFF. If a

workpiece or cut-off piece becomes trapped inside the guard, turn the saw off, disconnect the machine from the power

source and wait for the blade to stop before lifting the guard and removing the piece.

11. NEVER START THE MACHINE with the workpiece against the blade to reduce the risk of a thrown workpiece and

personal injury.

12. NEVER run the workpiece between the fence and a molding cutterhead to reduce the risk of a thrown workpiece and

personal injury.

13. AVOID AWKWARD OPERATIONS AND HAND POSITIONS where a sudden slip could cause a hand to move into the

blade.

14. NEVER HAVE ANY PART OF YOUR BODY IN LINE WITH THE PATH OF THE SAW BLADE. Personal injury may

occur.

15. NEVER PERFORM LAYOUT, ASSEMBLY, OR SET-UP WORK on the table/work area when the machine is running. A

sudden slip could cause a hand to move into the blade. Severe injury can result.

16. CLEAN THE TABLE/WORK AREA BEFORE LEAVING THE MACHINE. Lock the switch in the "OFF" position to

prevent unauthorized use.

17. DO NOT LEAVE A LONG BOARD (OR OTHER WORKPIECE) UNSUPPORTED SO THE SPRING OF THE BOARD

CAUSES IT TO SHIFT ON THE TABLE RESULTING IN LOSS OF CONTROL AND POSSIBLE INJURY. Provide proper

support for the workpiece, based on its size and the type of operation to be performed. Hold the work firmly against

the fence and down against the table surface. If supports are attached to the saw, be certain that the saw will not tip

under the load.

18. DO NOT OPERATE THIS MACHINE until it is completely assembled and installed according to the instructions. A

machine incorrectly assembled can cause serious injury.

19. OBTAIN ADVICE from your supervisor, instructor, or another qualified person if you are not thoroughly familiar with the

operation of this machine. Knowledge is safety.

20. ADDITIONAL INFORMATION regarding the safe and proper operation of power tools (i.e. a safety video) is available

from the Power Tool Institute, 1300 Sunmer Avenue, Cleveland, OH 44115-2581 (www.powertoolinstitute.com).

Information is also available from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201. Please

refer to the American National Standards Institute ANSI 01.1 Safety Requirements for Woodworking Machines and the

U.S. Department of Labor OSHA 1910.213 Regulations.

The lower retractable blade guard provides operator protection along the sides of the sawblade. To

reduce the risk of potential hazards, use the following rules:

a, KEEP YOUR HANDS AWAY FROM THE GUARD. As the blade cuts, the guard will lift and leave part of the blade

exposed.

b. TURN THE UNIT OFF AND DISCONNECT THE MACHINE FROM THE POWER SOURCE BEFORE FREEING A

JAMMED LOWER GUARD. The guard can get jammed in previous kerfs in the table or fence. Always anticipate the path

of the guard.

c. USE CAUTION when making bevel cuts to be sure that the lower guard is never pinched toward the blade.

d. THE LOWER GUARD CAN JAM AGAINST THE FENCE DURING NARROW IN-RIPS. Should the guard jam against the

fence, disconnect the saw from the power, wait for the blade to stop, then lift the blade guard and rest it on top of the

fence.

6

Page 7

TERMS: The following terms will be used throughout the manual and you should become familiar with them.

• Through-sawing refers to any cut that completely severs the work piece.

• Push Stick refers to a wooden stick, usually homemade, that is used to push small work piece through the saw and keeps

the operator’s hands clear of the blade.

• Kickback occurs when the saw blade binds in the cut and violently thrusts the work piece back toward the operator.

• Freehand refers to cutting without the use of a miter gauge or rip fence or any other means of guiding or holding the work

piece other than the operator’s hand.

SAW BLADE GUARD AND SPLITTER

Your radial arm saw is equipped with a blade guard, splitter and anti-kickback fingers. The splitter fits into the cut made by

the saw blade when ripping and effectively fights kickback by lessening the tendency of the blade to bind in the cut. Use the

spreader and blade guard for all cuts. Two anti-kickback pawls are located on the sides of the splitter that allow the wood to

pass through the blade in the cutting direction, but lock if the wood tries to move backward toward the operator.

KICKBACKS

How to avoid them and protect yourself from possible injury.

a. Be certain that the rip fence is parallel to the saw blade.

b. Do not rip by applying the feed force to the section of the workpiece that will become the cut-off (free) piece. Feed force

when ripping should always be applied between the saw blade and the fence. Use a push stick for short work, 6" (152

mm) wide or less.

c. Keep saw blade guard, splitter, and anti-kickback teeth in place and operating properly. Keep teeth sharp. If teeth are not

operational, return your unit to the nearest authorized Delta service center for repair. The splitter must be in alignment

with the saw blade and the teeth must stop a kickback once it has started. Check their action before ripping by pushing

the wood under the anti-kickback teeth. The teeth must prevent the wood from being pulled toward the front of the

saw.

d. Plastic and composition (like hardboard) materials may be cut on your saw. However, since these are usually quite hard

and slippery, the anti-kickback pawls may not stop a kickback. Therefore, be especially attentive to following proper

set-up and cutting procedures for ripping.

e. Use saw blade guard for every operation for which it can be used, including all through-sawing.

f. Push the workpiece past the saw blade prior to release when ripping.

g. NEVER rip a workpiece that is twisted or warped, or does not have a straight edge to guid along the fence.

h. NEVER saw a large workpiece that cannot be controlled.

i. NEVER saw a workpiece with loose knots, flaws, nails, or other foreign objects.

j. NEVER rip a workpiece shorter than 10".

k. Always use anti-kickback fingers when ripping. Lower the guard on the infeed end and adjust the anti-kickback

attachment properly.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals know to the State of California to cause cancer, birth defects, or other reproductive harm. Some examples of

these are:

l Lead from Lead-based paints,

l Crystalline silica from bricks and cement and other masonry products, and

l arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these

chemicals: work in a well-ventilated area, and work with approved safety equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

l Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes,

or lay on the skin may promote absorption of harmful chemicals.

Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles

away from face and body. Always operated tool in a well-ventilated area and provide for proper dust removal. Use dust

collection system wherever possible.

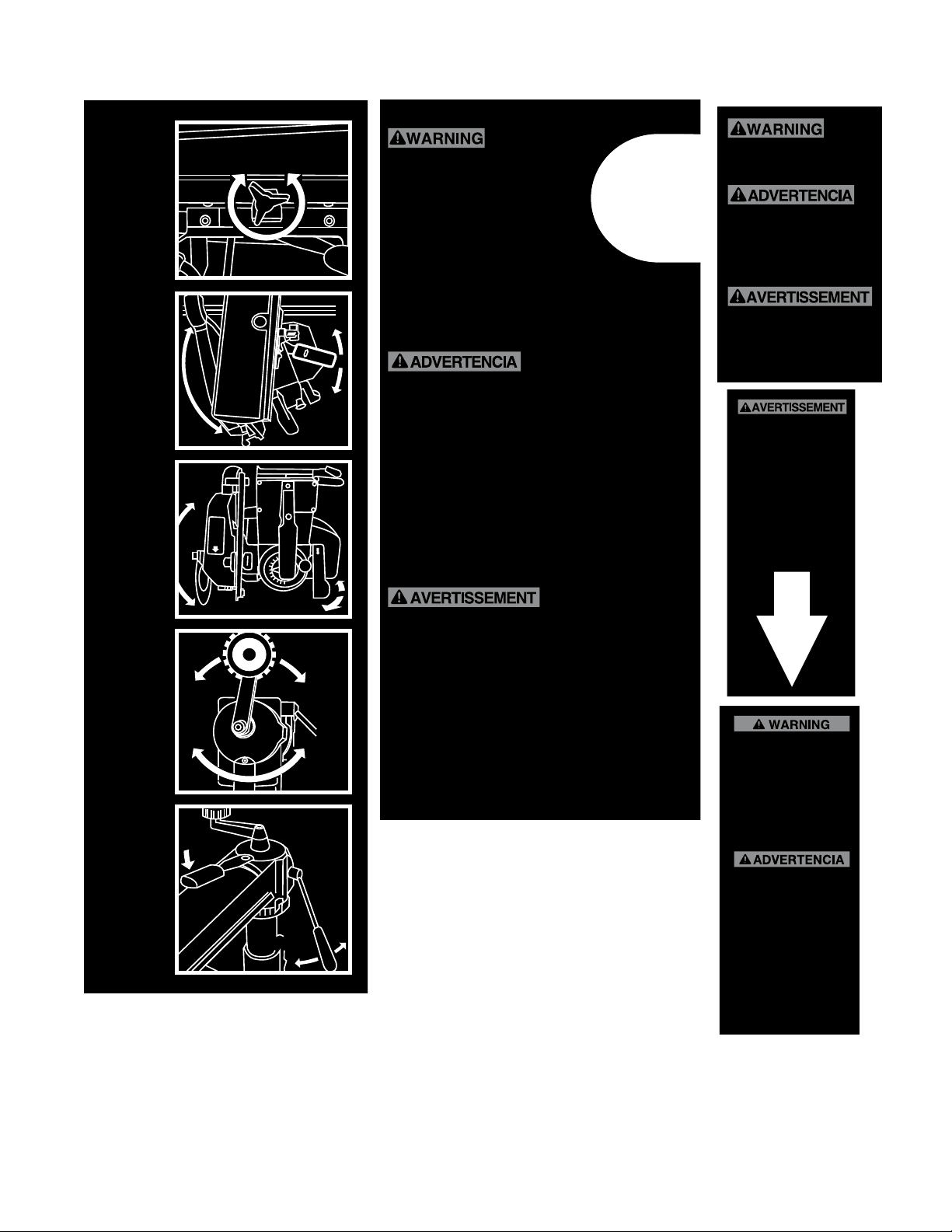

FUNCTIONAL DESCRIPTION

FOREWORD

The Delta Model RS830 is a 10" (254mm) Professional Radial Arm Saw with a maximum cutting capacity of 16" (406mm)

crosscut, 2-3/4" (70mm) depth at 90°, and 2-1/2" (64mm) depth at 45° bevel. This tool has positive bevel stops at 0°, 45° and

90°, and positive miter stops at 0° and 45°, both right and left. The unit includes a 1-1/2 HP, 120/240V motor, an automatic

blade brake, a saw blade, wrenches, a steel stand, a cast-iron track, and an extra-large table.

NOTICE: The image on the manual cover illustrates the current production model. All other illustrations contained in the

manual are representative only and may not depict the actual labeling or accessories included. These are intended to illustrate

technique only.

7

Page 8

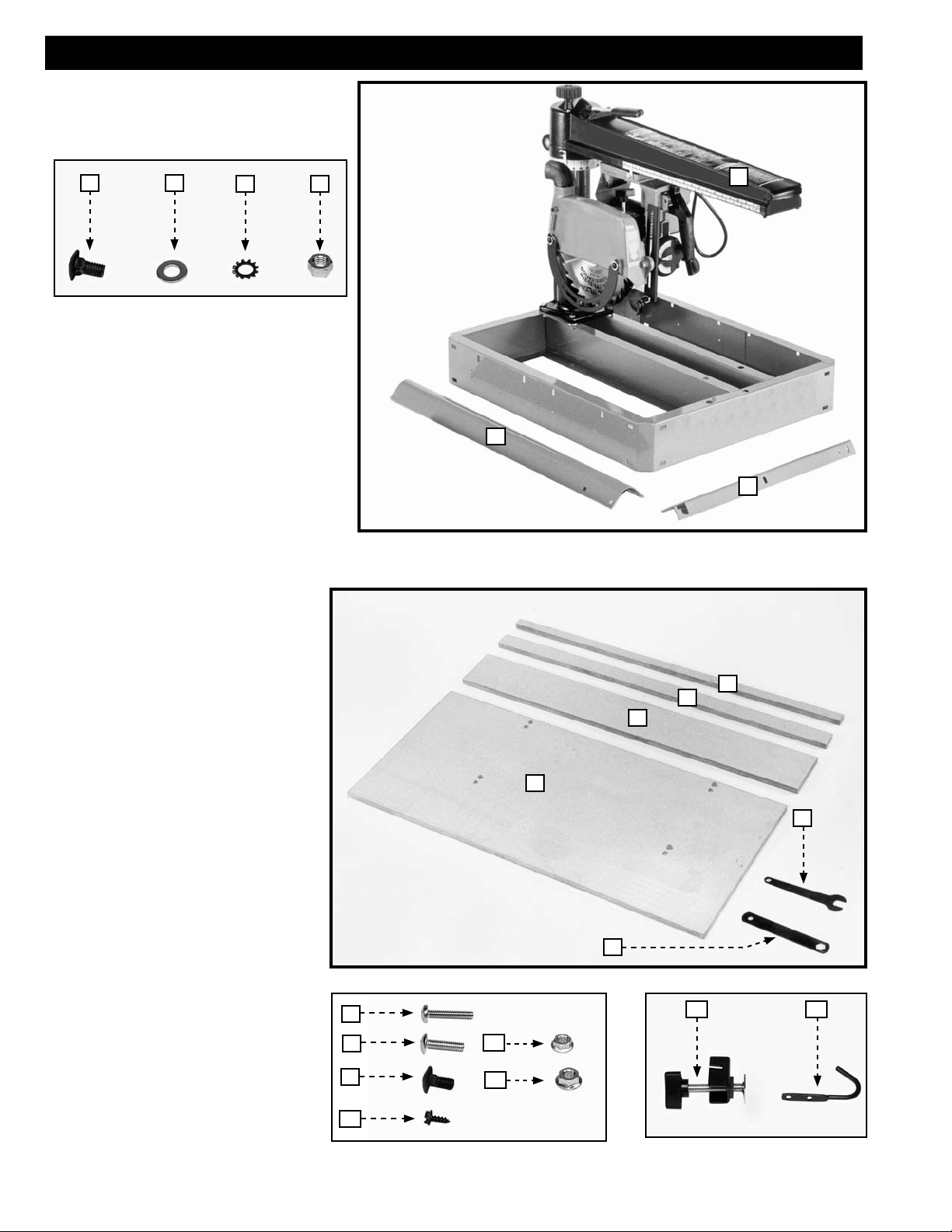

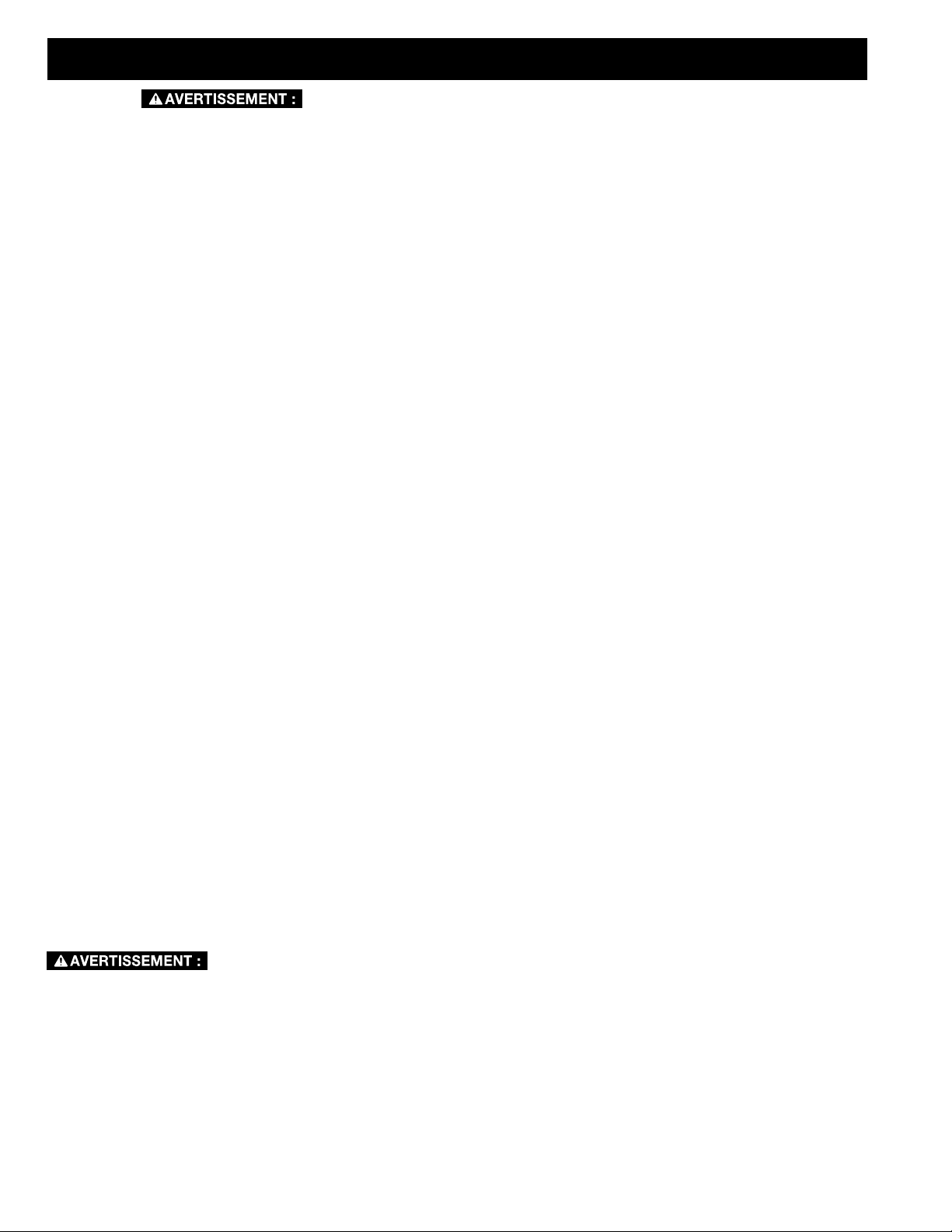

RADIAL ARM SAW PARTS

CARTON CONTENTS

4 5

1. Radial Arm Saw

2. Legs (4)

3. Table Supports (2)

4. 5/16-18x5/8" Carriage Head Screws (16)

5. 5/16" Flat Washers (16)

6. 5/16" External Tooth Lockwashers (16)

7. 5/16-18 Hex Nuts (16)

6 7

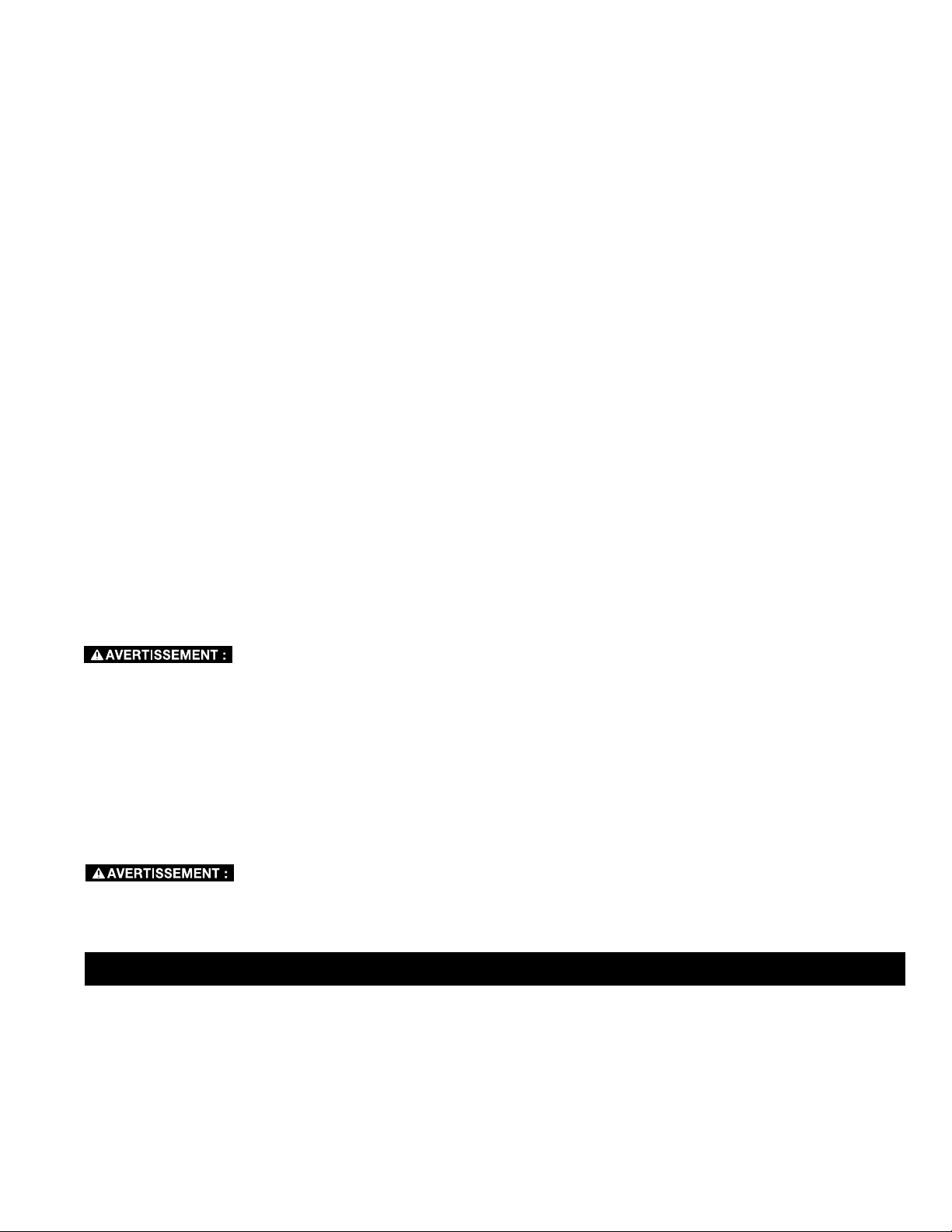

TABLE BOARD PARTS

1. Fence Board

1

2

3

2. Middle Table Board

3. Rear Table Board

4. Front Table Board

5. 7/8" Open End - 1/2" Box Wrench

6. 7/8" x 1/2" Box Wrench

7. 1/4-20x1¼" Round Head Screw (4)

8. 1/4-20x1" Round Head Screw (4)

9. 5/16-18x5/8" Carriage Head Screw

(6)

10. #10x1/2" Sheet Metal Screw (2)

11. 1/4-20 Flange Hex Nut (4)

12. 5/16-18 Flange Hex Nut (6)

13. Table Board Clamp (2)

14. Wrench Hook

1

2

3

4

5

6

7

8

9

11

12

13 14

10

8

Page 9

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil from

unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer thinner for cleaning your

machine.

After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

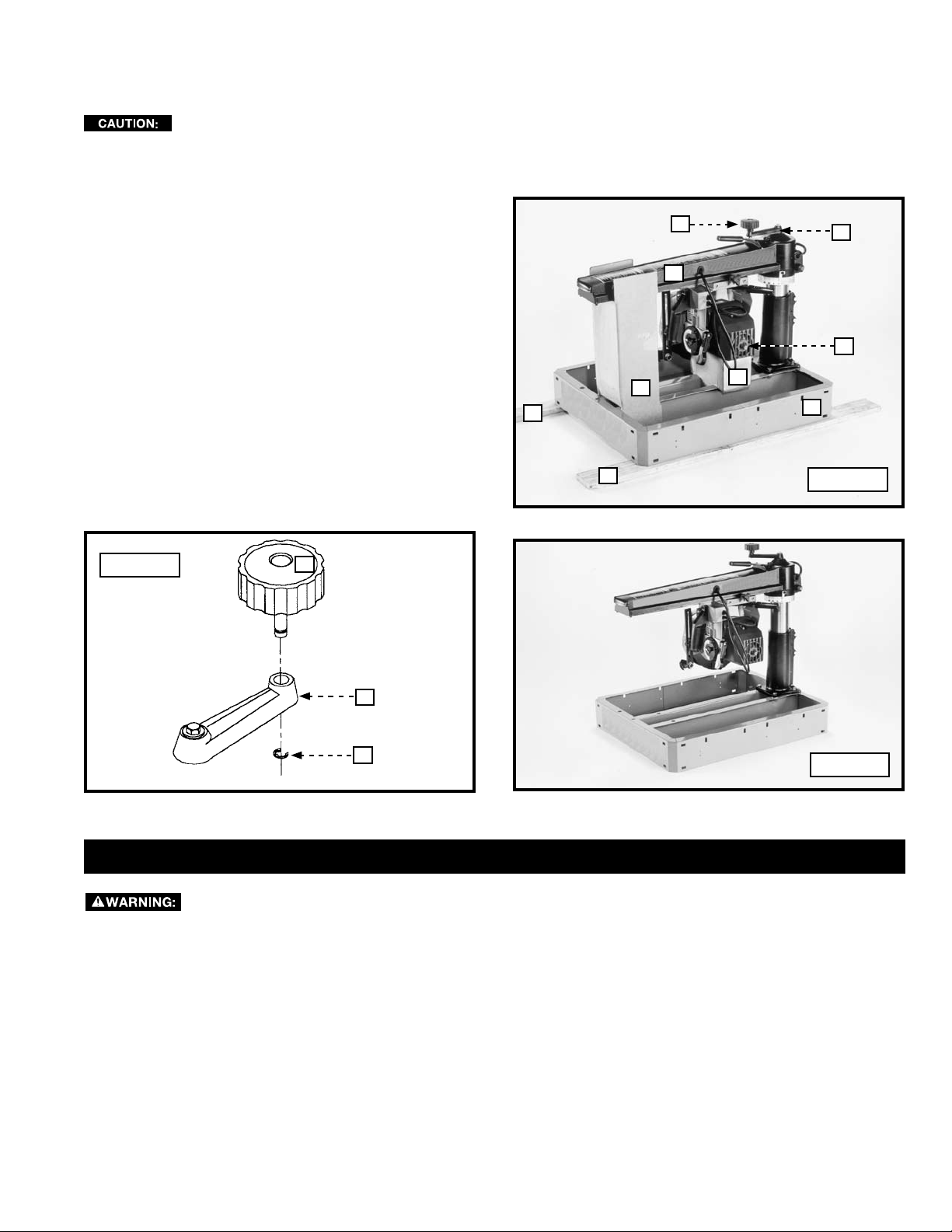

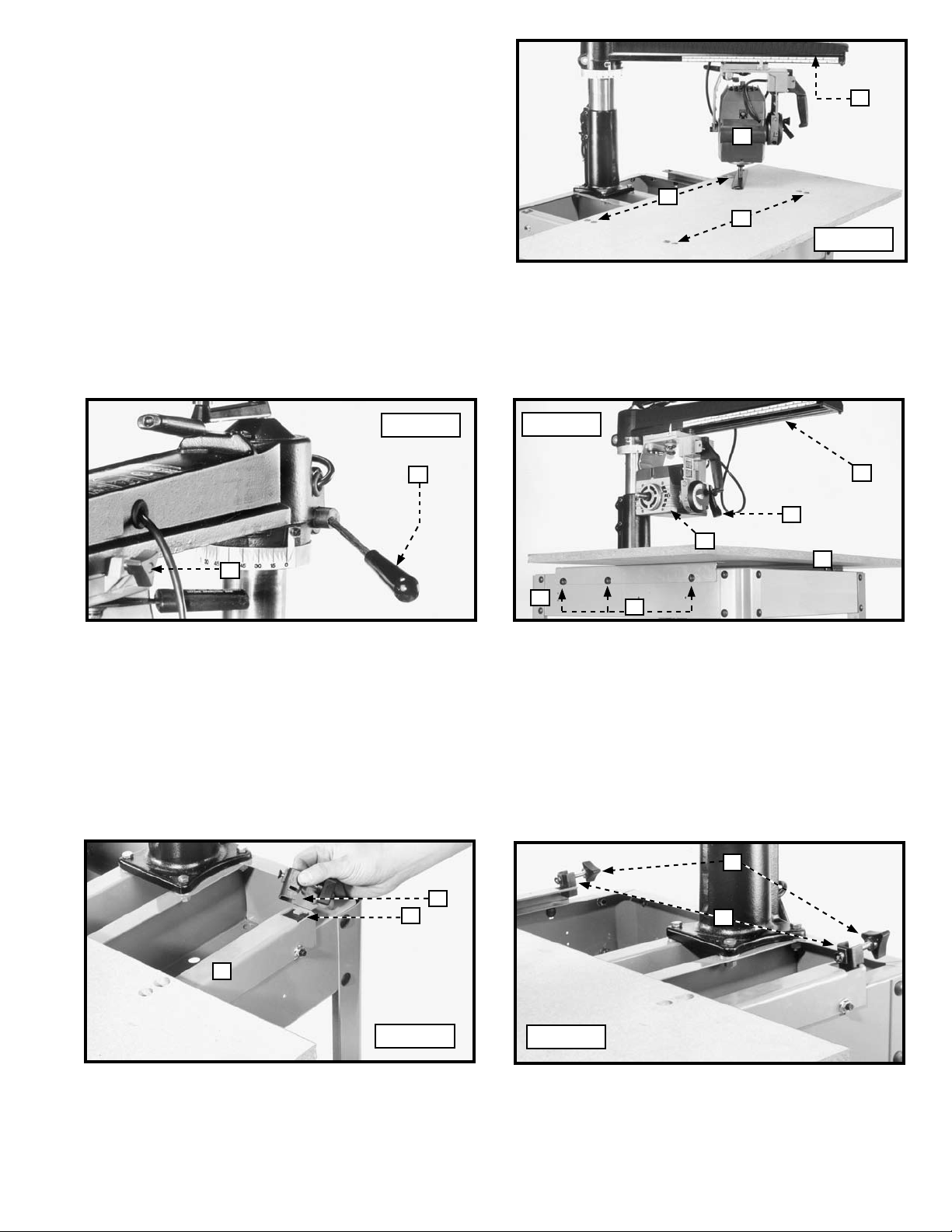

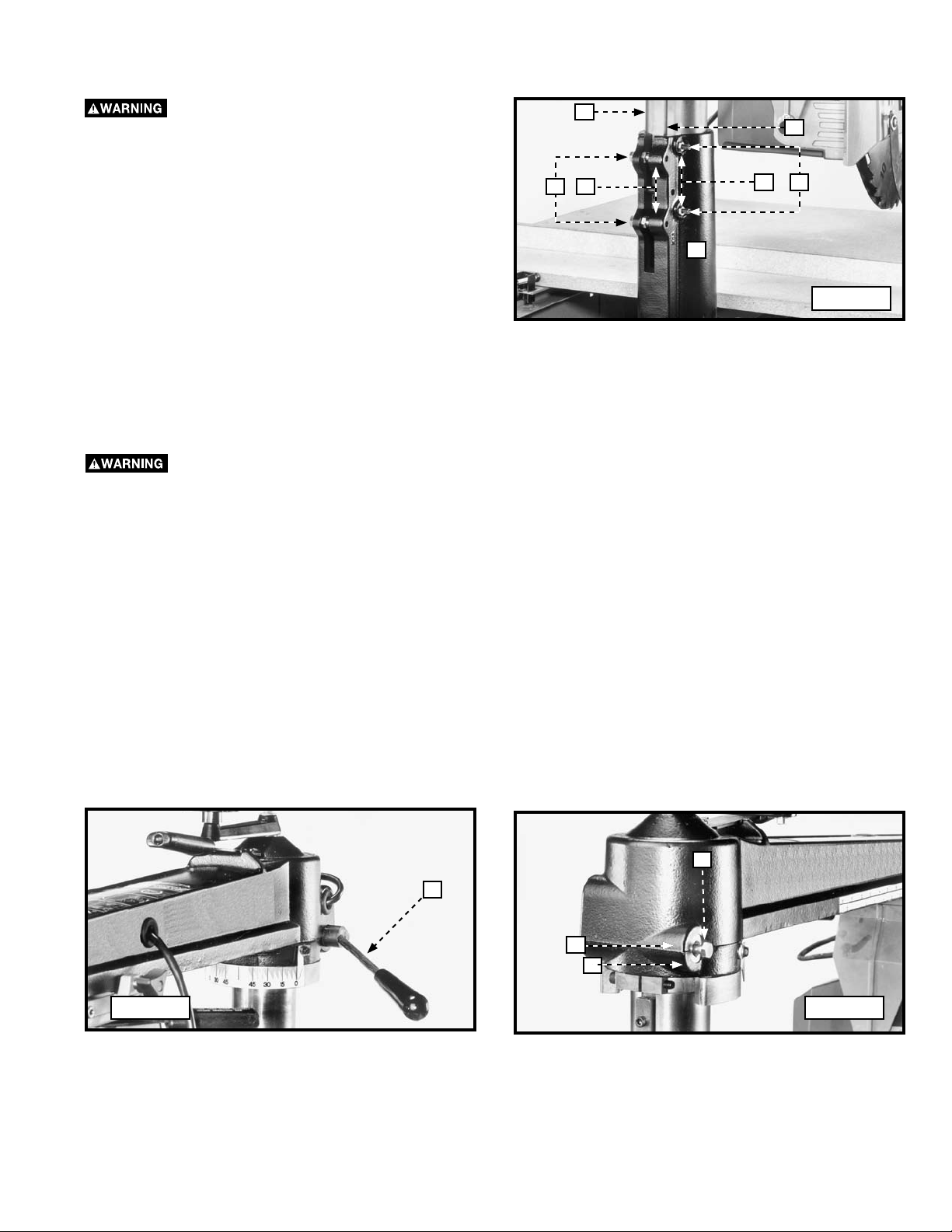

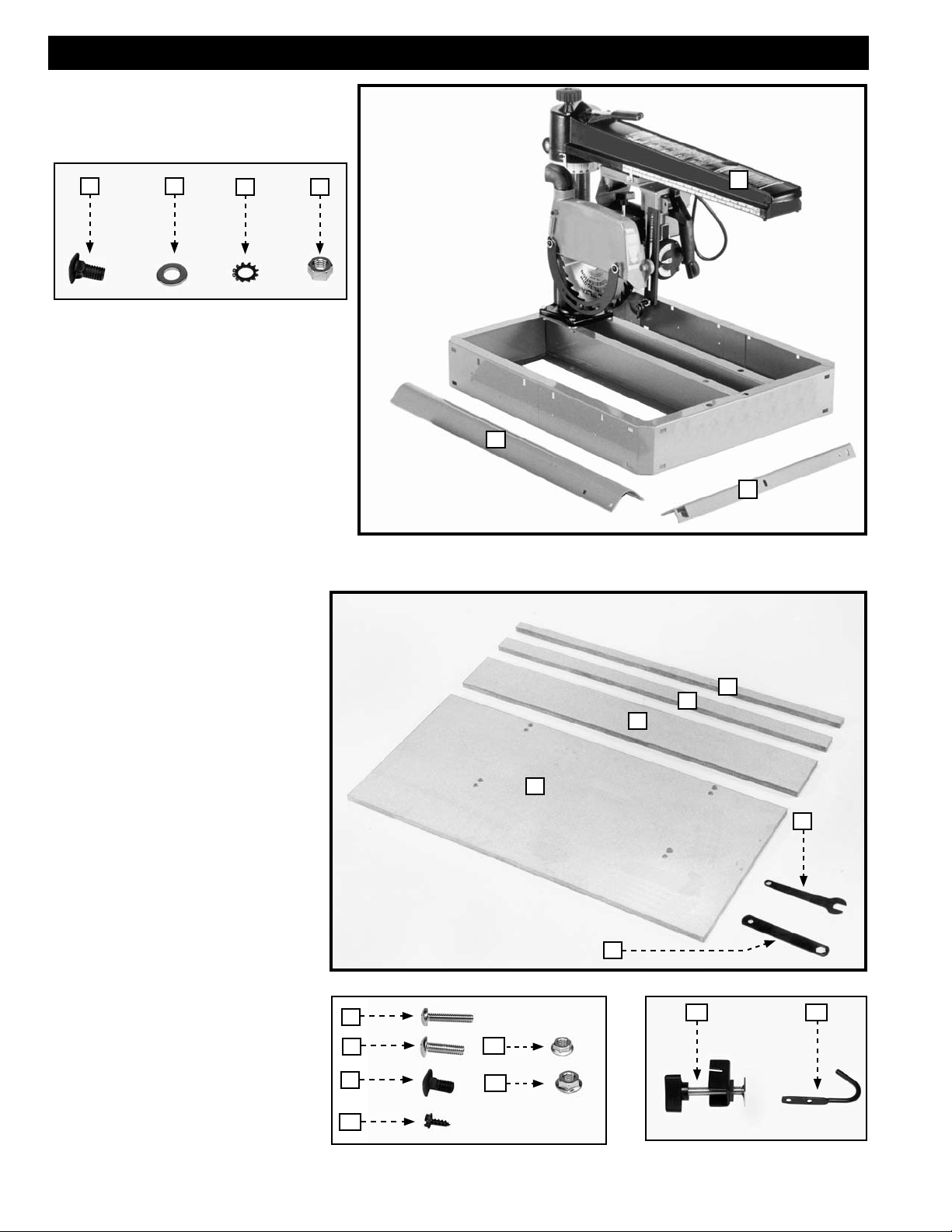

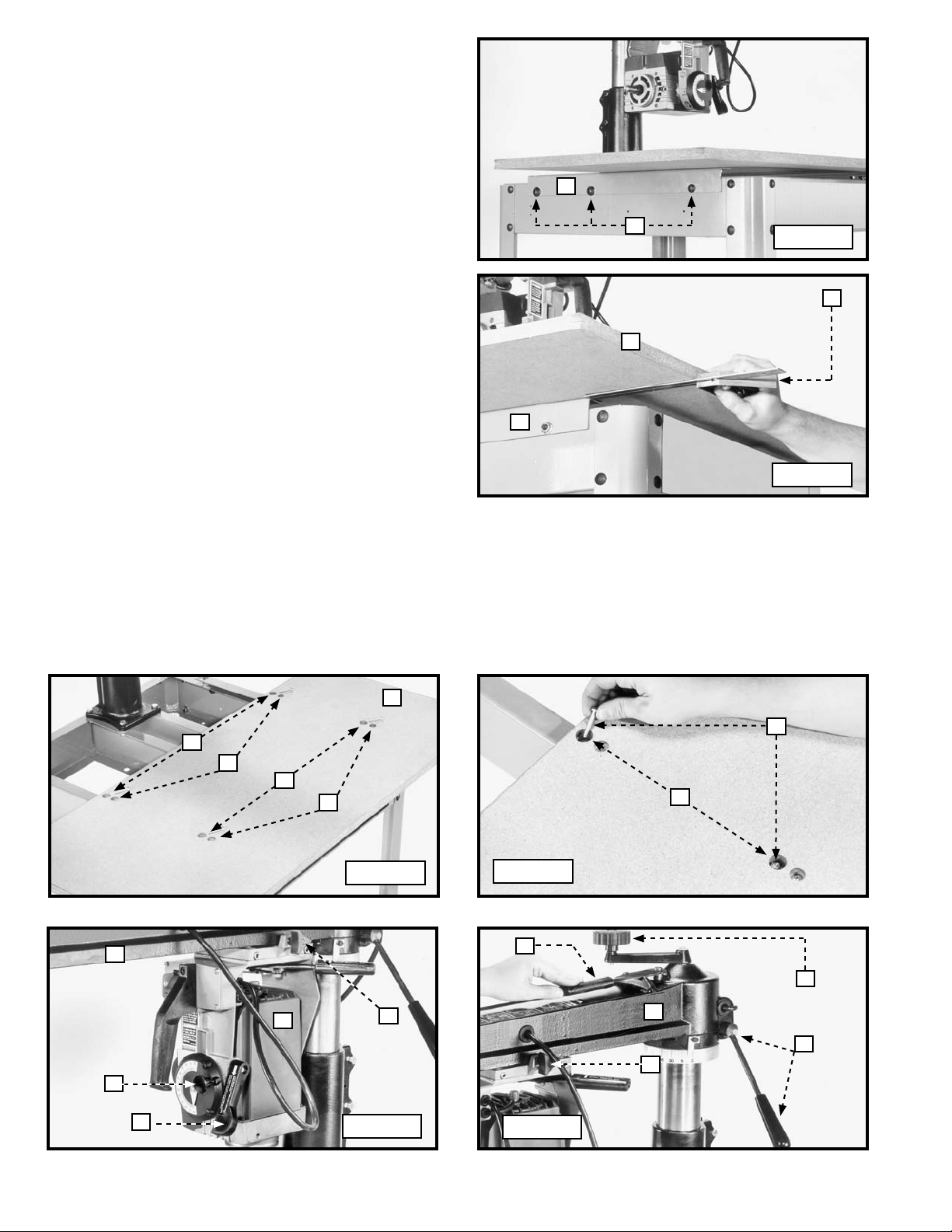

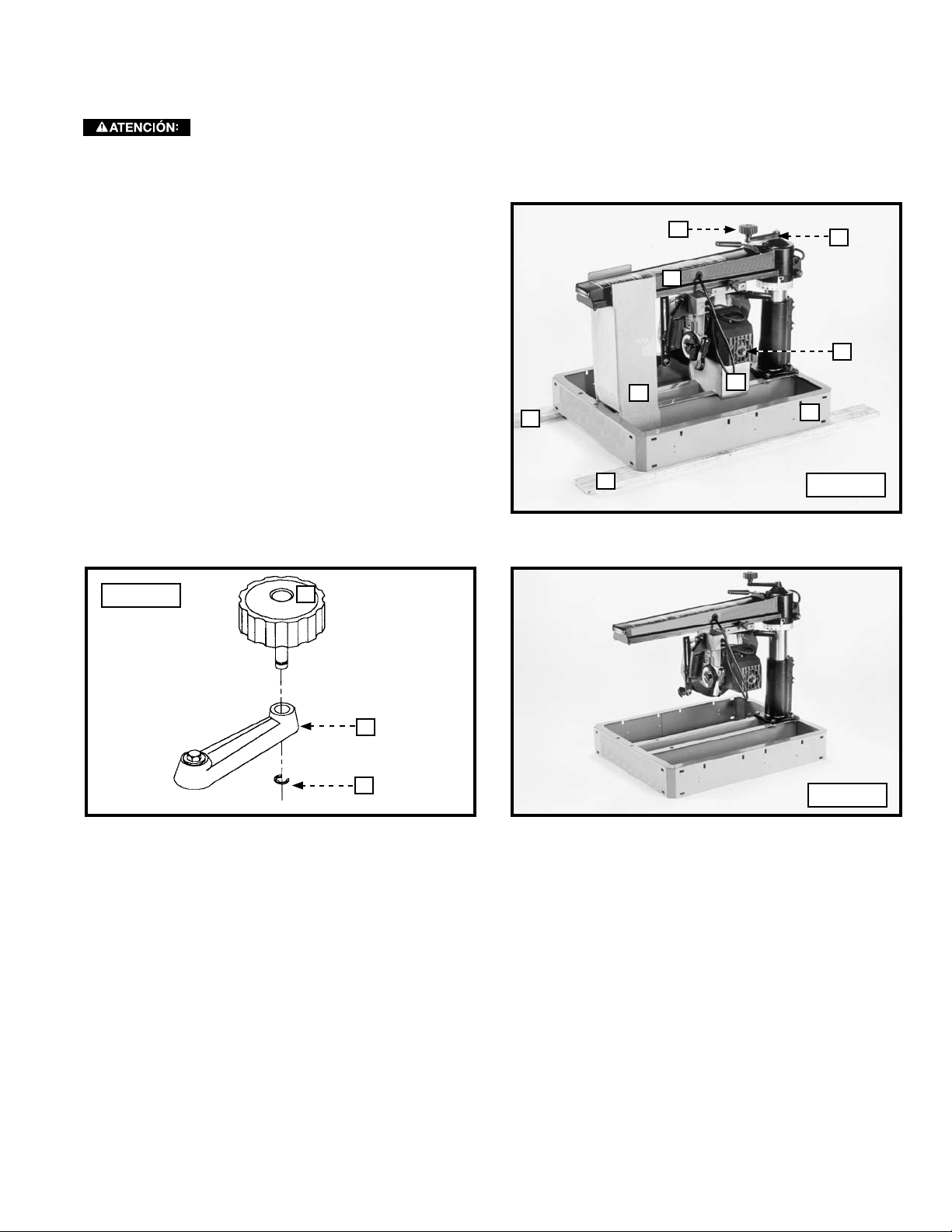

1. The saw was packed at the factory with support blocks

(A) Fig. A1 under the cutter-head (B) and the track arm

(C). Shipping boards (D) Fig. A1 were fastened to saw

base (G). To prevent damage during shipment, the

track arm elevating knob (H) was removed from the

lever (E). Insert the post of the knob (H) Fig. A2 through

the hole in the lever (E). Attach the E-ring (K) to the slot

in the post.

2. You can remove the support blocks (A) Fig. A1 by rotating

the track arm elevating knob (H) clockwise. Remove the

shipping boards (D) by taking out the hold-down screws

(not shown), located inside the saw base. Discard the

support blocks (A) and the shipping boards (D).

3 The saw with the support blocks and shipping boards

removed is illustrated in Fig. A3.

D

H

E

C

B

A

A

G

D

Fig. A2

H

E

K

ASSEMBLY

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and remov-

ing accessories, before adjusting or when making repairs. An accidental start-up can cause injury.

Fig. A1

Fig. A3

ASSEMBLY TOOLS REQUIRED

7/8" Open End - 1/2" Box Wrench (included)

7/8" x 1/2" Box Wrench (included)

1/2” and 3/8” Wrenches, Open End or Socket

Flathead Screwdriver

ASSEMBLY TIME ESTIMATE

Assembly for this machine takes approximately 2-3 hours.

9

Page 10

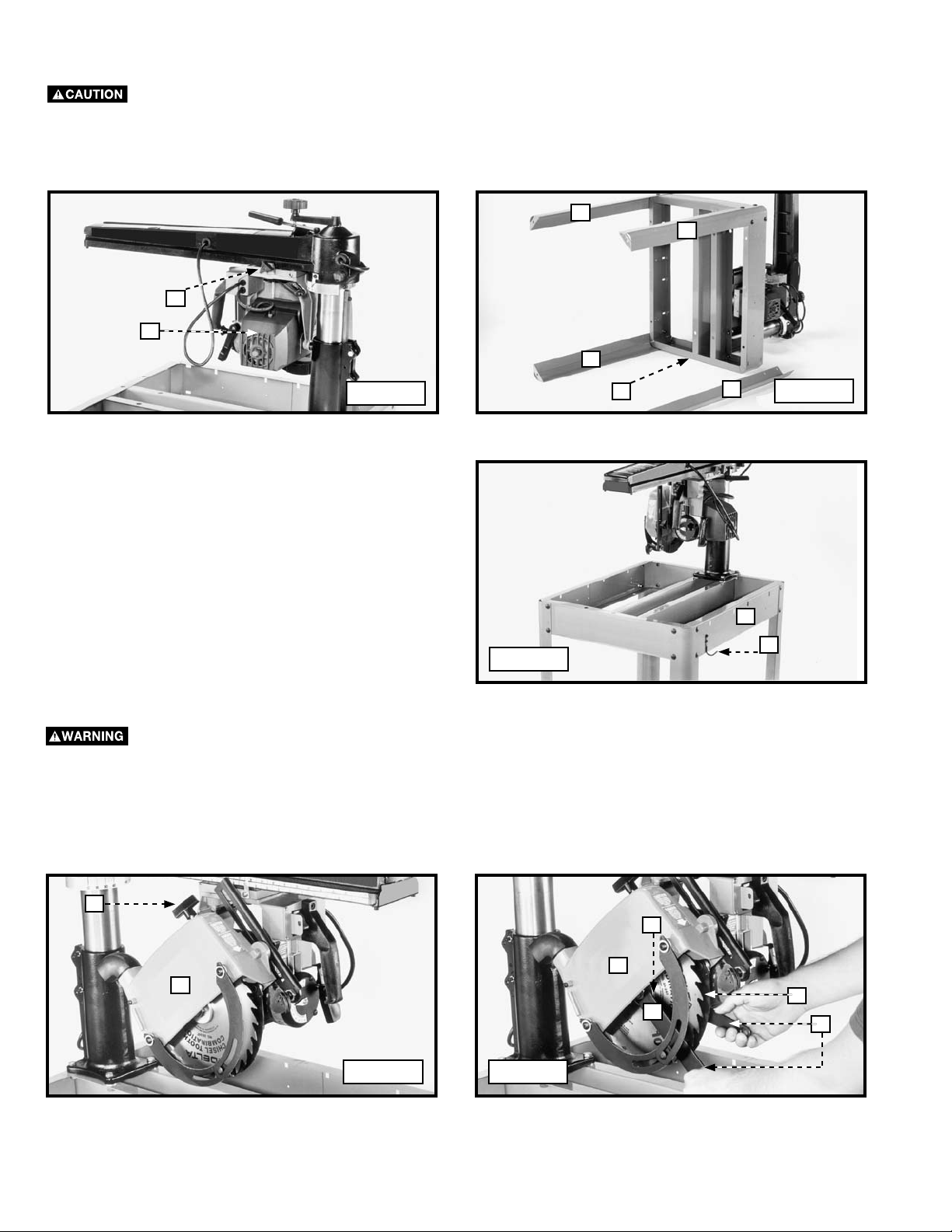

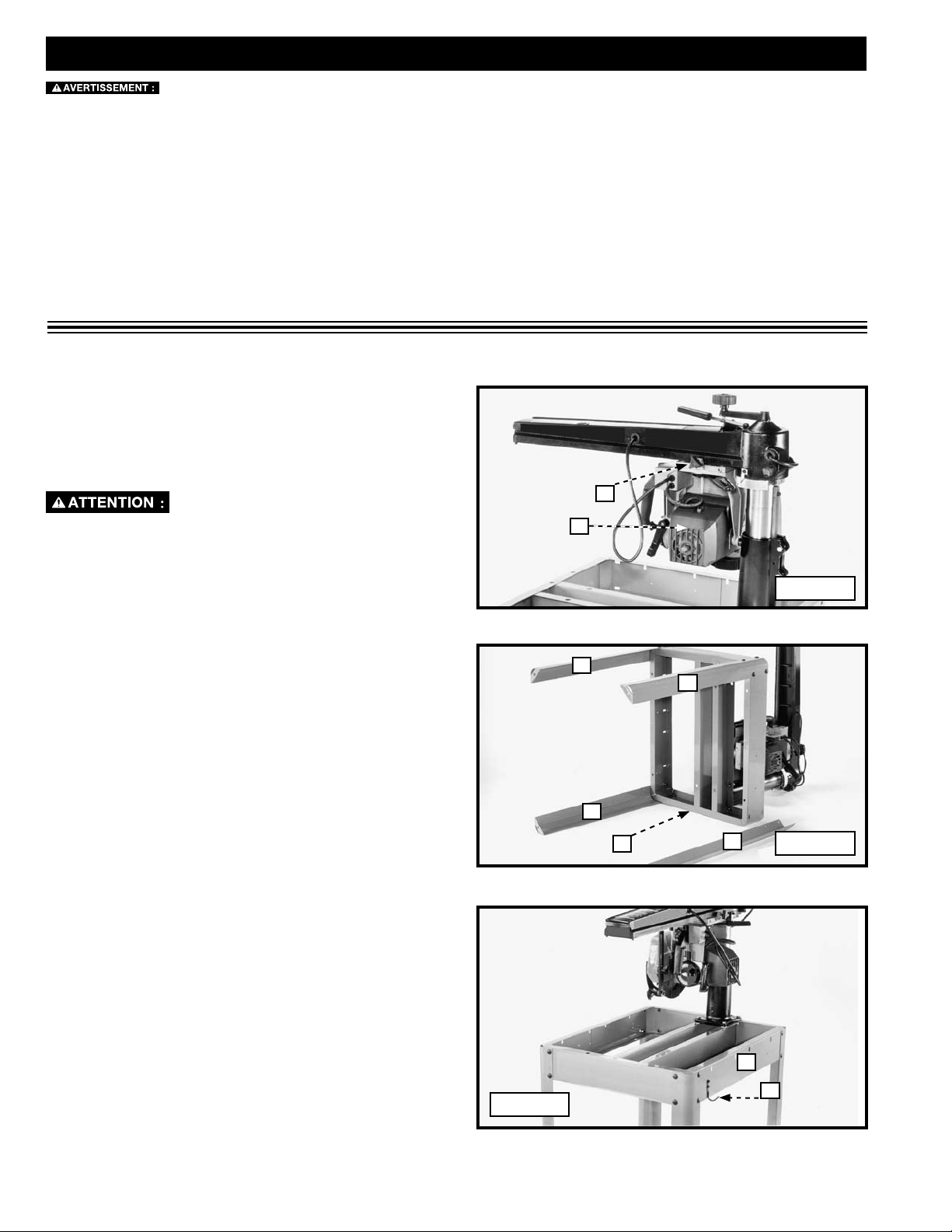

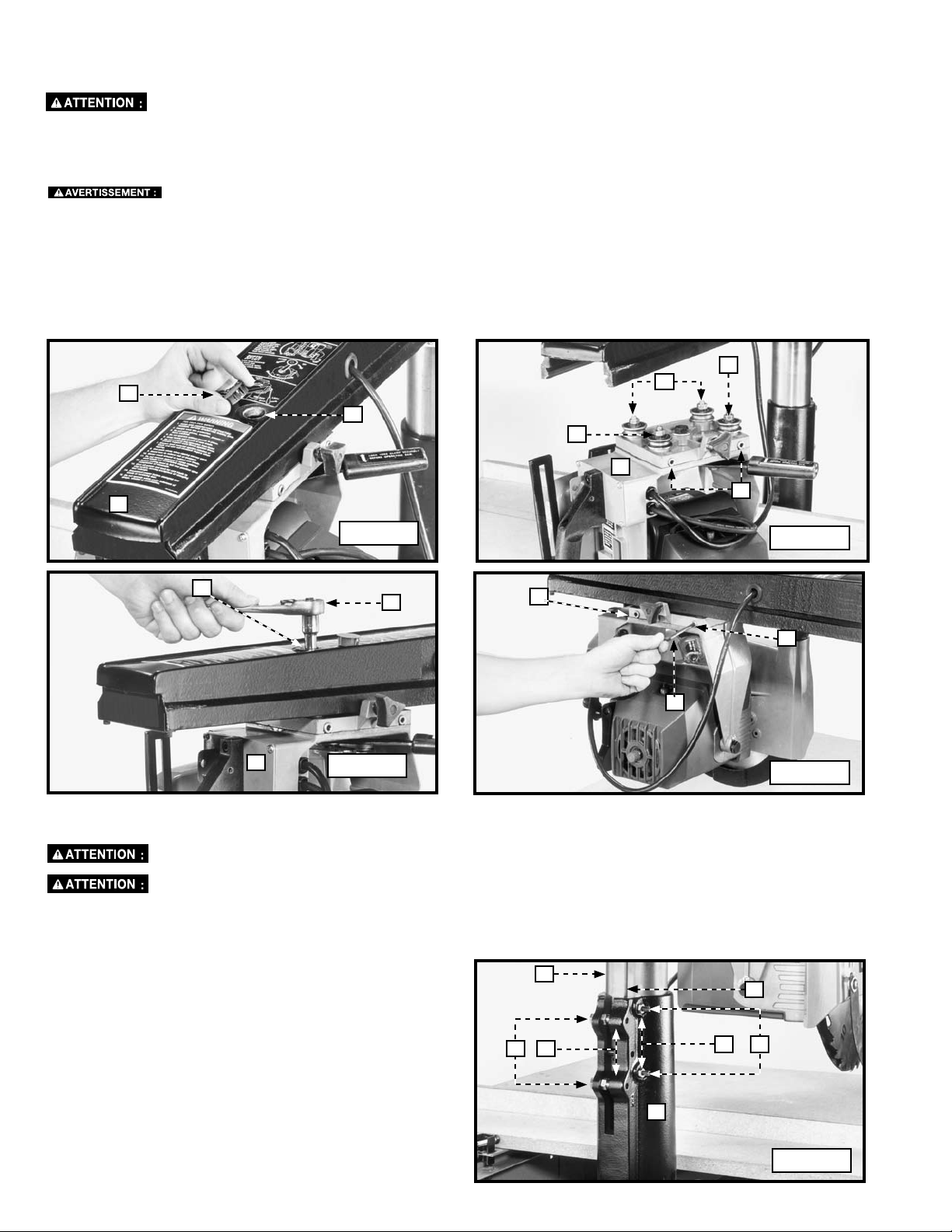

ATTACHING THE LEGS TO THE SAW BASE

1. Loosen the lock knob (A) Fig. 1, and move the cutting-head (B) to the rear position. Tighten the knob (A).

Clamp the cuttinghead at the back of the track arm securely.

2. Place the radial arm saw on its back. Use sixteen 5/16-18 x 5/8" carriage head screws to attach the legs (C) Fig. 2 (three of

which are shown attached) to each corner of saw base (D). Place the screws through the stand, then use a flat washer, a

lock washer, and a nut to secure them. Hand tighten the nuts.

3. Stand the saw in the upright position and securely tighten all stand hardware.

C

C

A

B

C

Fig. 1

D

C

Fig. 2

ATTACHING THE WRENCH HOOK

Attach the wrench hook (K) Fig. 3 to the front

right or back left side of saw base (D), using two

#10 x 1/2" sheet metal screws.

D

K

Fig. 3

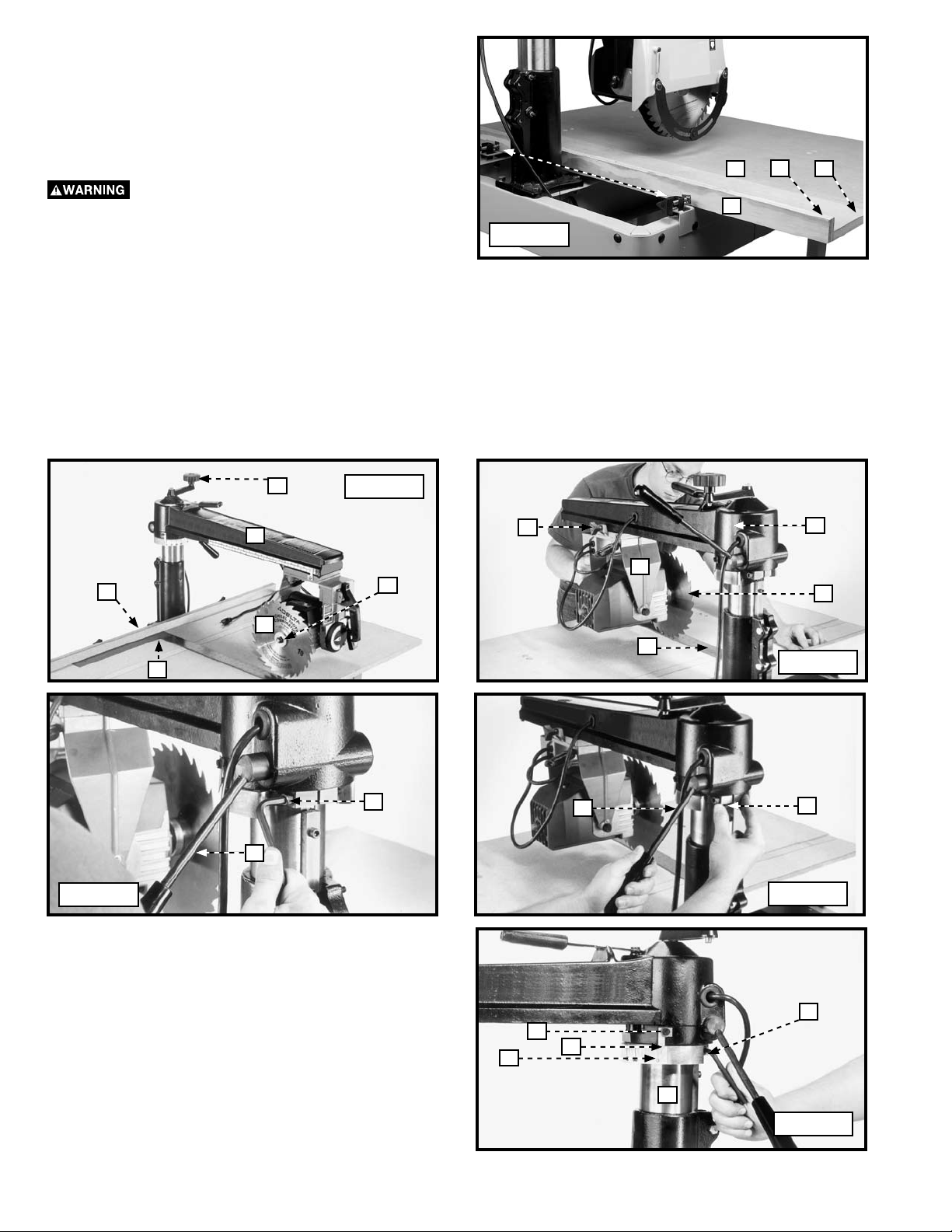

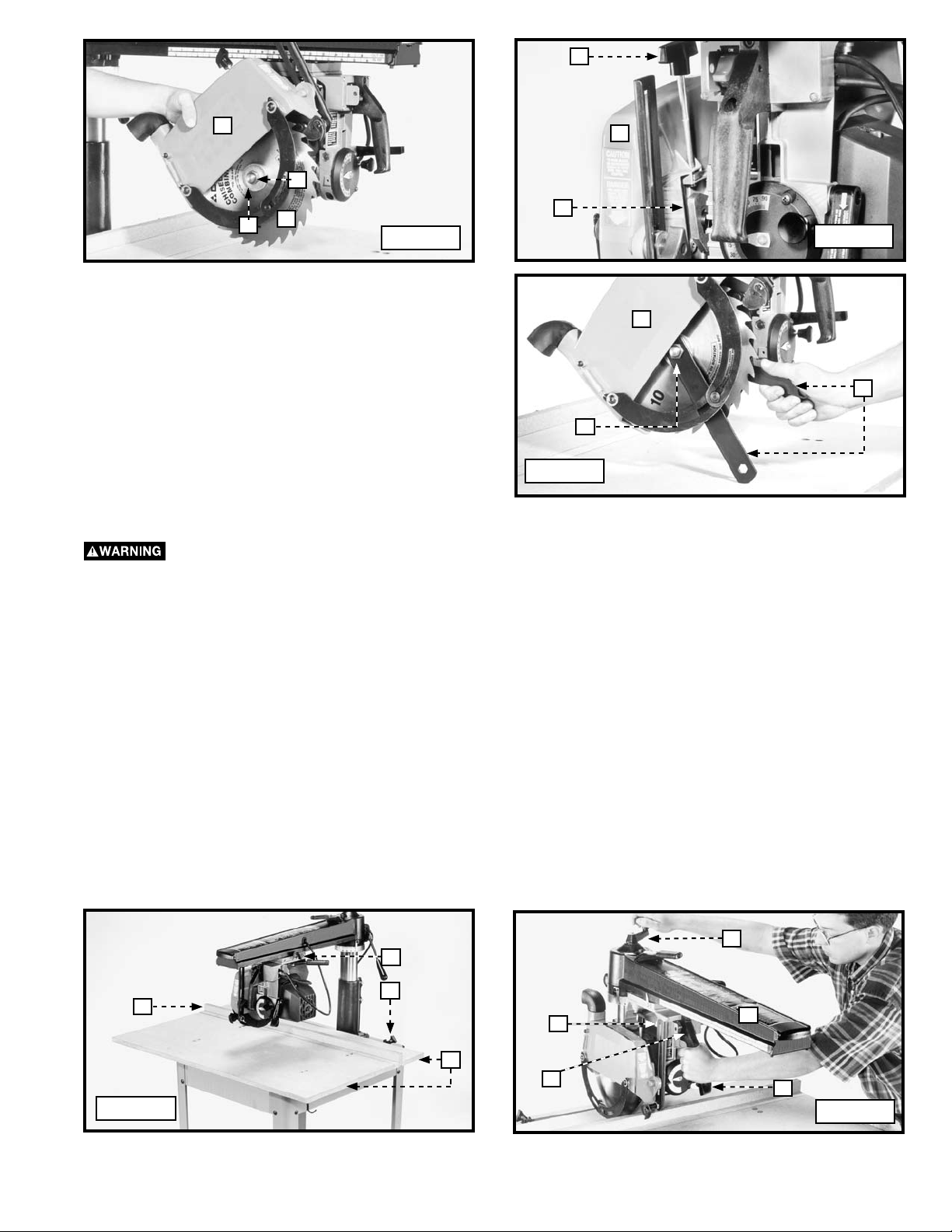

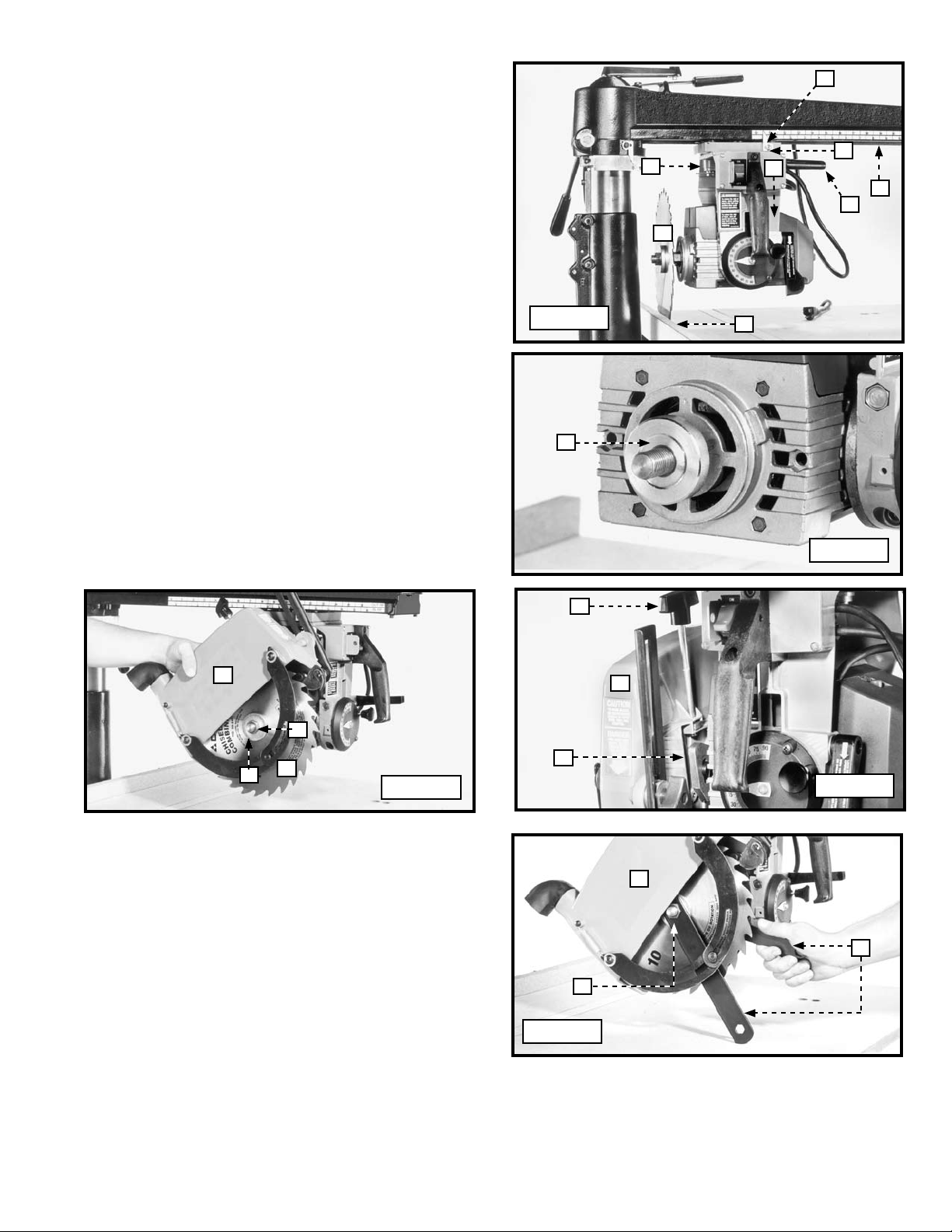

REMOVING THE BLADE AND BLADE GUARD FROM THE SAW

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause

injury.

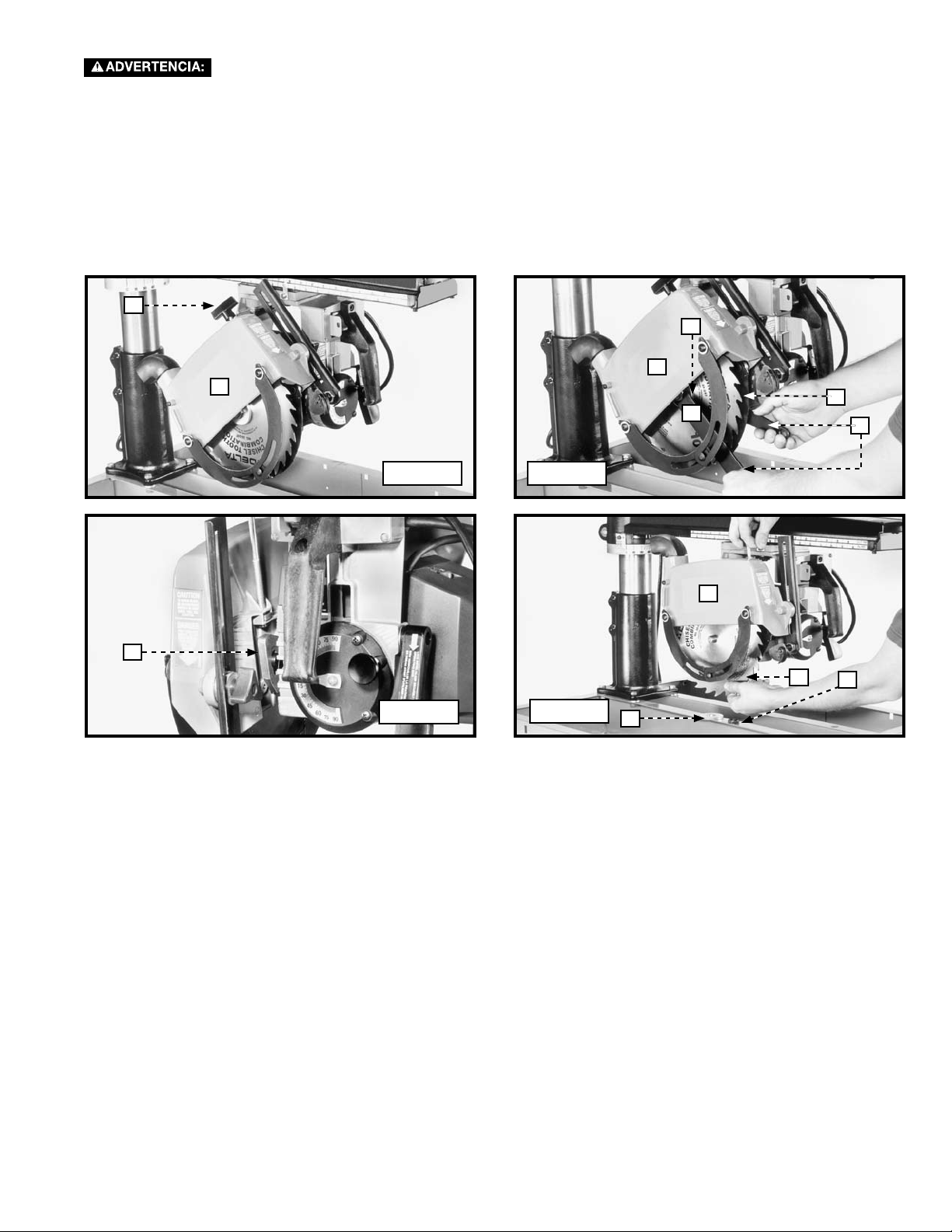

1. Loosen the blade guard clamp knob (A) Fig. 4 and rotate the blade guard (B) to the position shown.

2. Use the wrenches (C) Fig. 5 to loosen the arbor nut (D).

NOTE: Arbor nut has left-hand threads.

A

F

B

B

G

D

C

Fig. 4

10

Fig. 5

Page 11

3. Lift the cam (E) Fig. 6 that holds the blade guard (B) Fig. 5 in position. Move the blade guard (B), the outer blade flange

(F), and the blade (G) out.

4. Lift the blade guard (B) Fig. 7. Remove the arbor nut (D), the outer blade flange (F), and the blade (G).

5. Remove the blade guard (B).

B

E

G

D

Fig. 6

Fig. 7

F

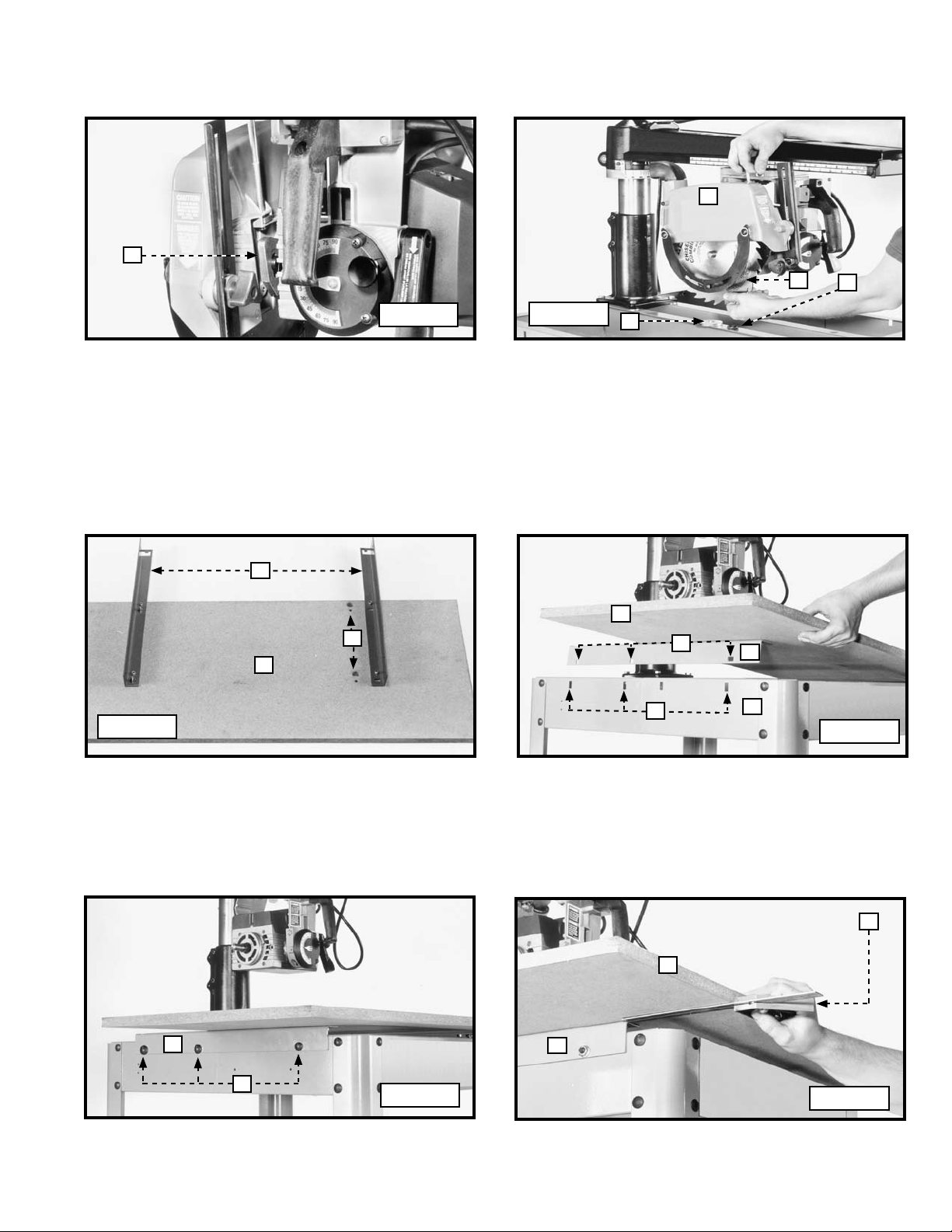

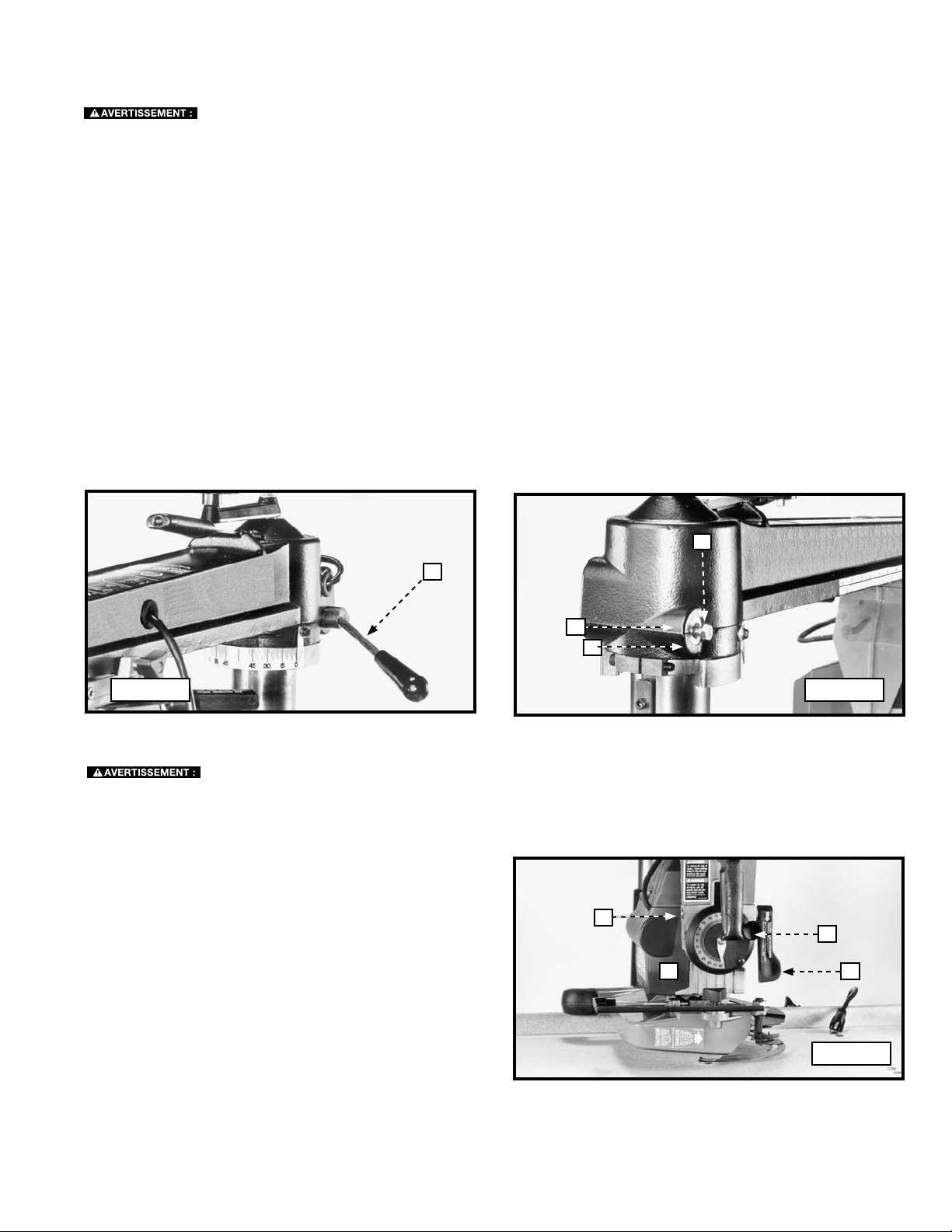

TABLE SUPPORTS

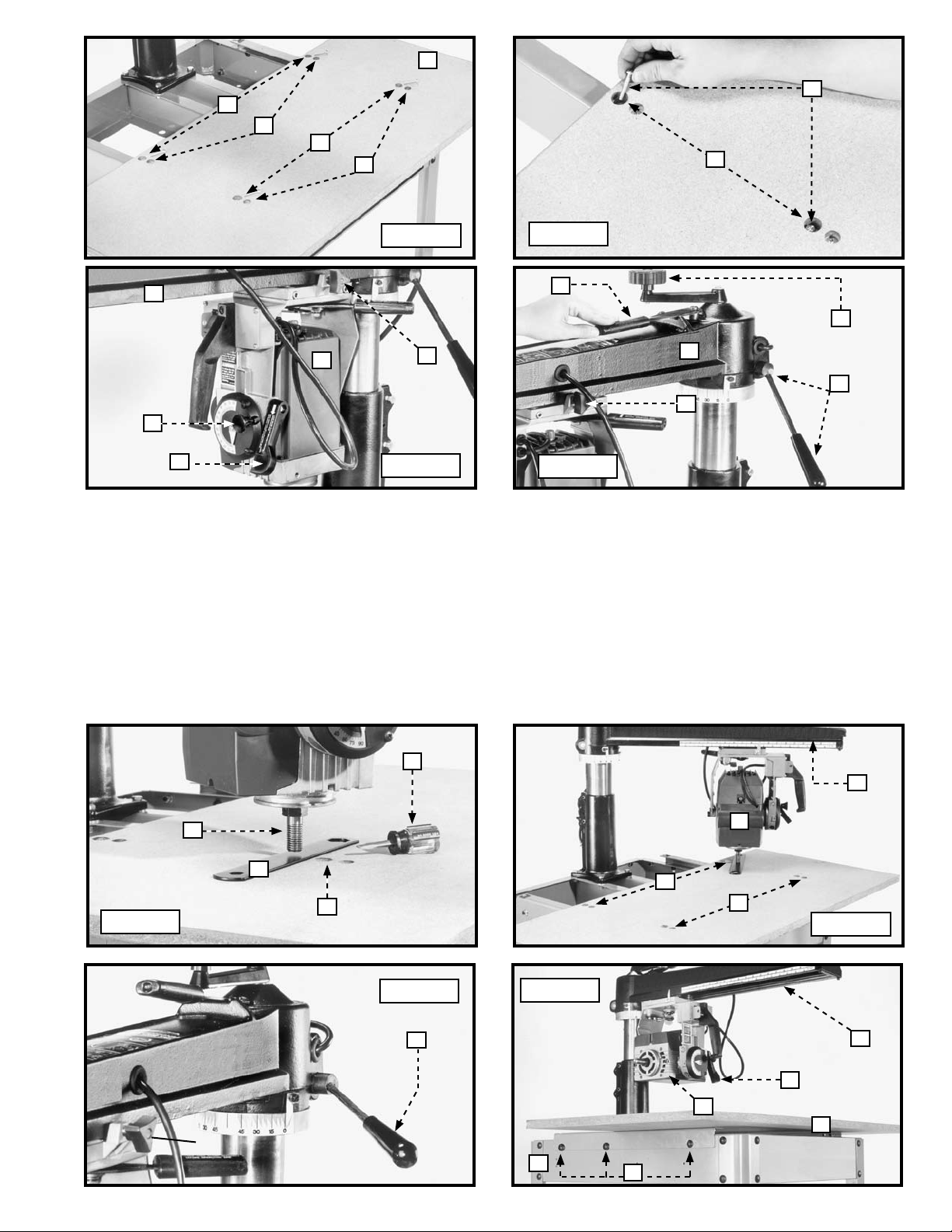

1. Place the front table board (A) Fig. 8 on a stable surface (counter-bored holes down) with one side of the board off the

edge of the surface to expose the counter-bored holes. Insert a 1/4-20 x 1" round head screw up through one of the

holes and a table support. Secure loosely with a 1/4-20 hex nut. Do the same with the other hole.

2. Follow the same procedure to attach the other table support.

3. Place the front table board (A) Fig. 9 on the saw base (G) so that table supports (B) straddle the outside of the saw base

(G) and three holes (H) in each table support (B) align with the three slots (J) in each side of saw base (G).

B

A

D

A

Fig. 8

H

J

B

G

Fig. 9

4. Secure the table supports (one of which is shown at(B) Fig. 10) to each side of the saw base using six 5/16-18 x 5/8"

carriage head screws (L) and six 5/16-18 flanged hex nuts. Loosely tighten the nuts for further adjustment.

IMPORTANT: Insert the screws through the table supports and the saw base from the outside.

5. Use a combination square (M) Fig. 11 to check the left and right front edge of table board (A). Both sides should be the

same distance from the edge of the table supports (B) Fig. 11.

M

A

B

L

Fig. 10

11

B

Fig. 11

Page 12

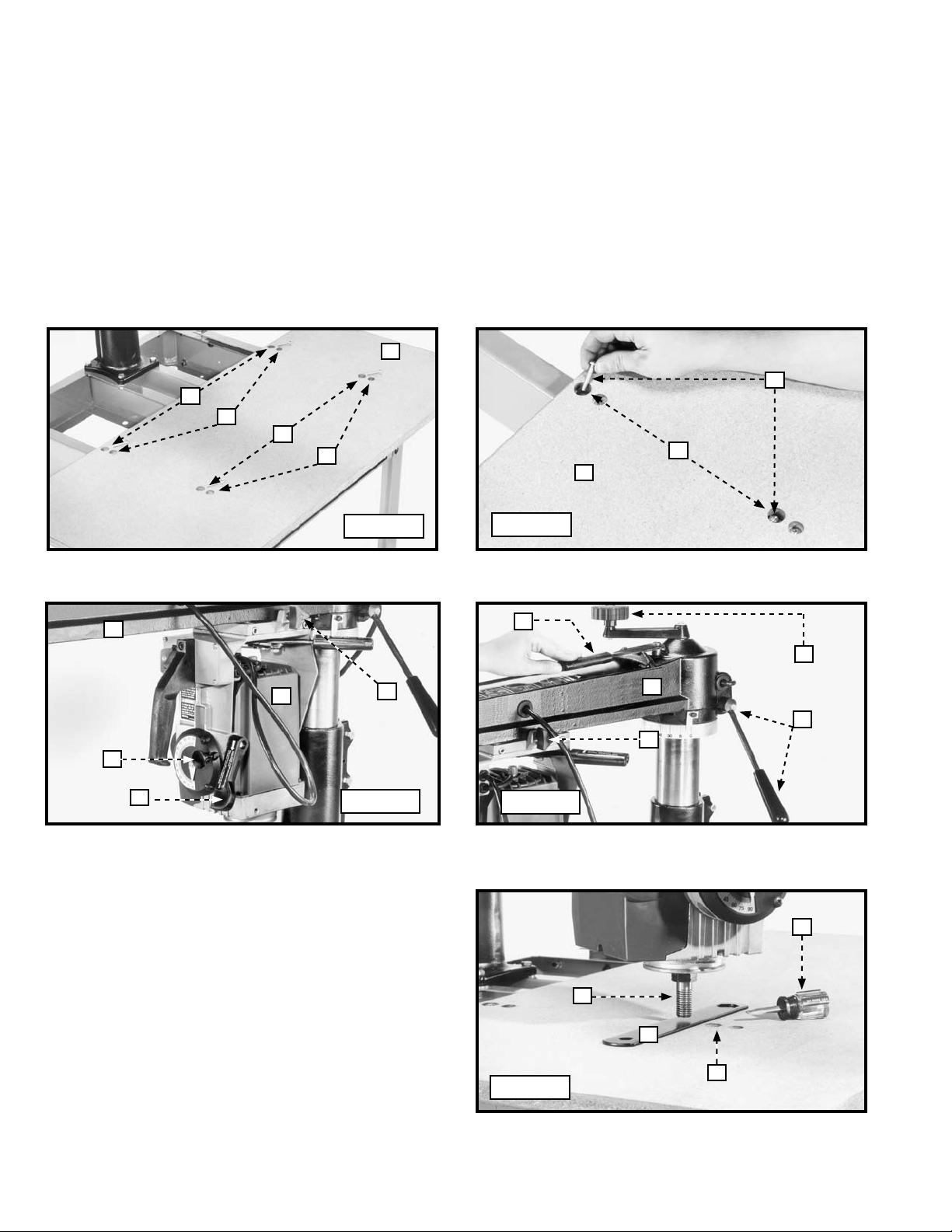

6. After adjusting, tighten the four screws located in holes (N) Fig. 12 of the front table board (A).

7. Insert four 1/4-20 x 1-1/4" round-head screws (P) Fig. 12 in the holes (R) Figs. 11 and 12 of the table board. Tighten

each of the screws until each corner of the table board raises approximately 1/8".

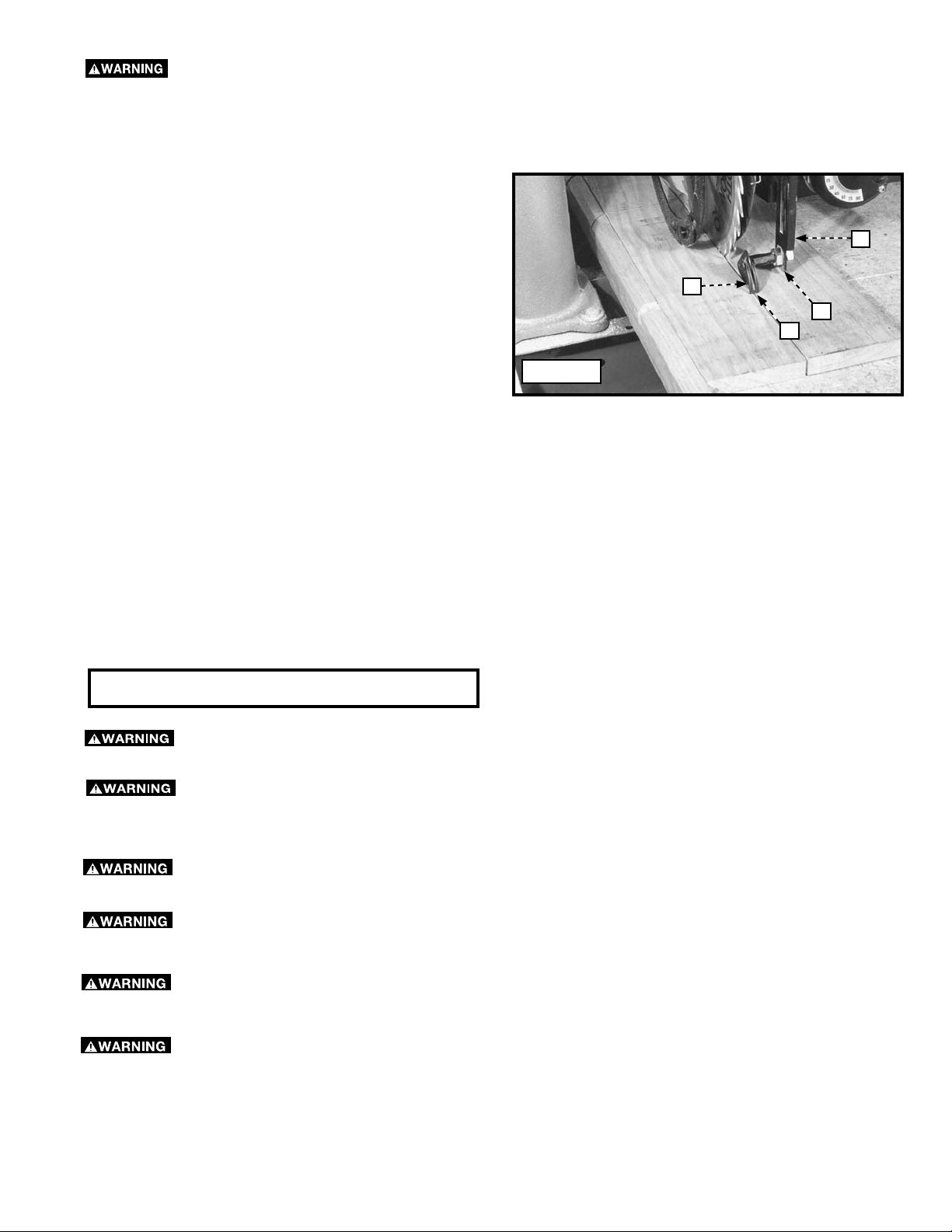

8. Loosen the bevel clamp lever (S) Fig. 14, pull out the bevel index knob (T), and rotate the motor (V) to the vertical

position until the bevel index engages. Tighten the bevel clamp lever (S).

NOTE: If the motor shaft contacts the table board before the motor is fully rotated, raise the track arm (X) Fig. 15 by turning the

elevating handle (C).

9. Loosen the cuttinghead clamp knob (W) Fig. 15. Move the cuttinghead to the front of the track arm (X). Tighten the

cuttinghead clamp knob (W).

10. Loosen the track arm clamp handle (Y) Fig. 15.

NOTE: The track arm clamp handle (Y) Fig. 15 has left-handed threads. Press down on the indexing release handle (Z) Fig.

15, and pivot the track arm (X) to the left until the motor shaft (B) Fig. 16 is near the front left adjustment screw (P) Fig. 13 of

table board (C) Fig. 13. Tighten the track arm clamp handle (Y) Fig. 15.

C

P

R

N

R

N

R

C

Fig. 12

X

V

W

T

S

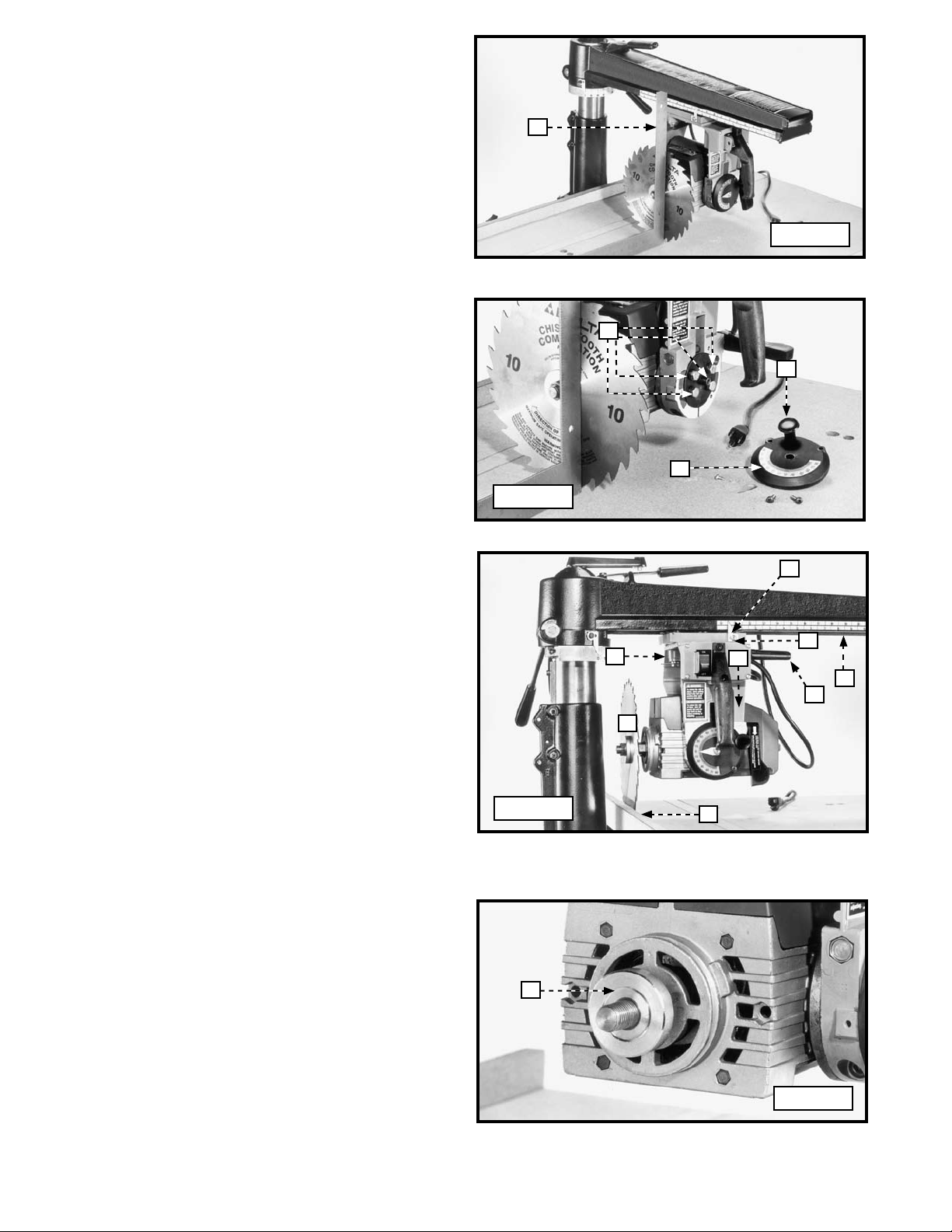

11. Place an arbor wrench (D) Fig.16 between the table

board (A) and the motor shaft (B). Lower the track arm

(X) Fig. 15 by turning the elevating handle (C) counterclockwise until the motor shaft (B) Fig. 16 touches the

arbor wrench.

Fig. 14

Fig. 13

Z

C

X

Y

W

Fig. 15

A

B

D

12

P

Fig. 16

Page 13

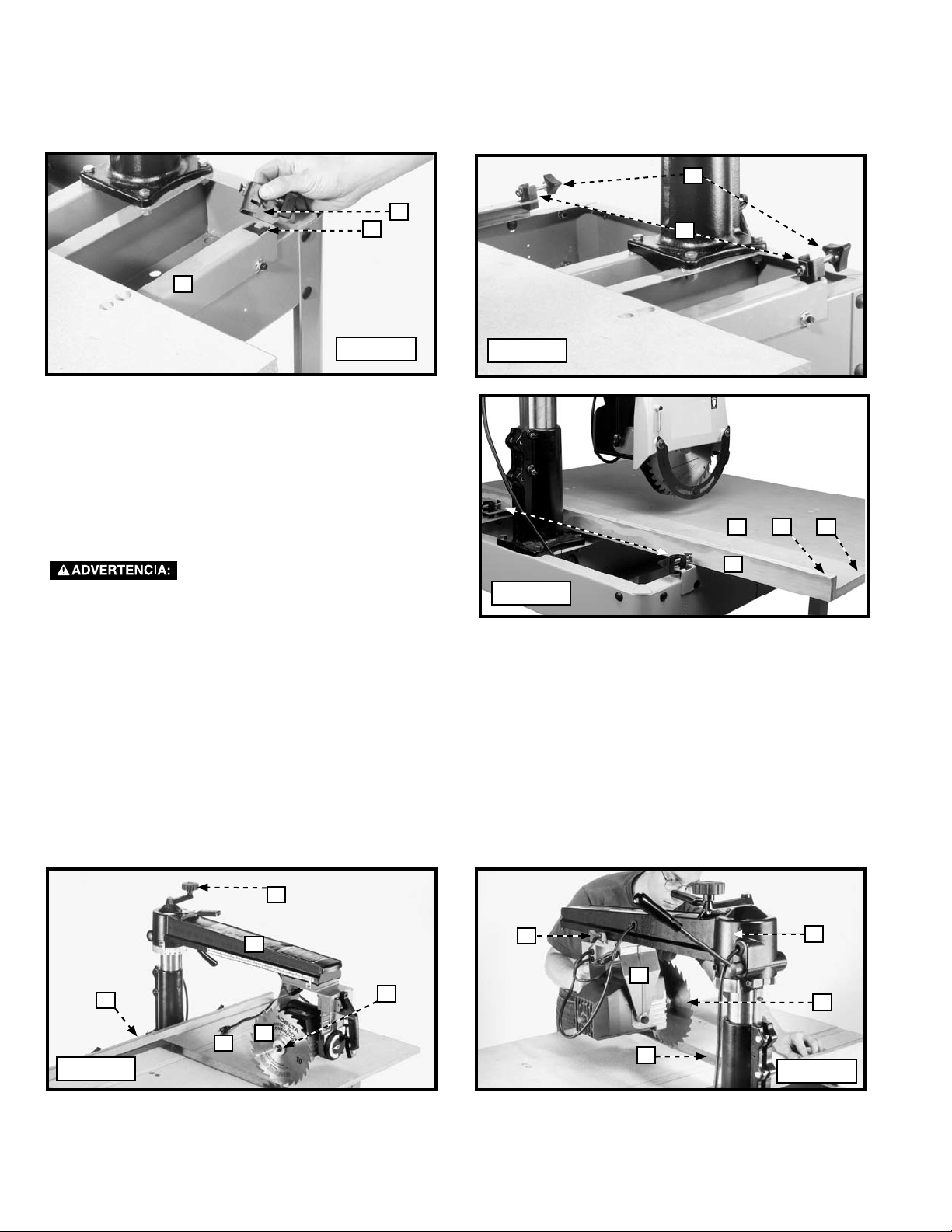

12. Check the height of the table board above the other

three table board adjustment screws (E) Fig. 17 by

repositioning the track arm (X), and the cuttinghead

assembly (V) until you determine the highest point of the

table.

NOTE: Make certain that the cuttinghead clamp knob

(W) Fig. 18 and the track arm clamp handle shaft (Y) are

located above each of the adjustment screws. Do not

change the height of the track arm (X) Fig. 17 until you

determine the highest screw and have adjusted all four

corners of the table board.

13. Position the motor shaft over the three lower corners of the table board. Adjust the table adjustment screws (E) Fig. 17

until the arbor wrench fits between the arbor shaft and table board in each location.

14. Tighten the three screws (G) Fig. 19 on each side of saw base (H). Return the track arm (X) and the motor (V) to the 90°

position. Tighten the bevel clamp lever (S) and the track arm clamp handle (Y) Fig. 18.

E

V

E

X

Fig. 17

Fig. 18

Y

Fig. 19

X

S

V

W

H

G

A

TABLE BOARD CLAMPS AND TABLE BOARDS

1. Locate the table board clamps (A) Fig. 20. Insert one clamp into each of the slotted holes (B) located at the rear of each

table support bracket (C) Fig. 20.

2. Turn the adjusting screw (D) Fig. 21 counter-clockwise, so that the knobs (A) are in the rear position.

D

A

B

A

C

Fig. 20

13

Fig. 21

Page 14

3. Place a 1-1/4" wide board (E) Fig. 22 against the front

of the table board (G), and a 5-3/4" wide board (J)

against the 1-1/4" wide board (E). Place the 1-3/4"

wide board (H) in the upright position against the

5-3/4" wide board (J). Tighten the knobs (D) until the

table boards are securely clamped.

ADJUSTING AND CHECKING

THE SAW BLADE TRAVEL

To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing

and removing accessories, before adjusting or changing

set-ups or when making repairs. An accidental start-up

can cause injury.

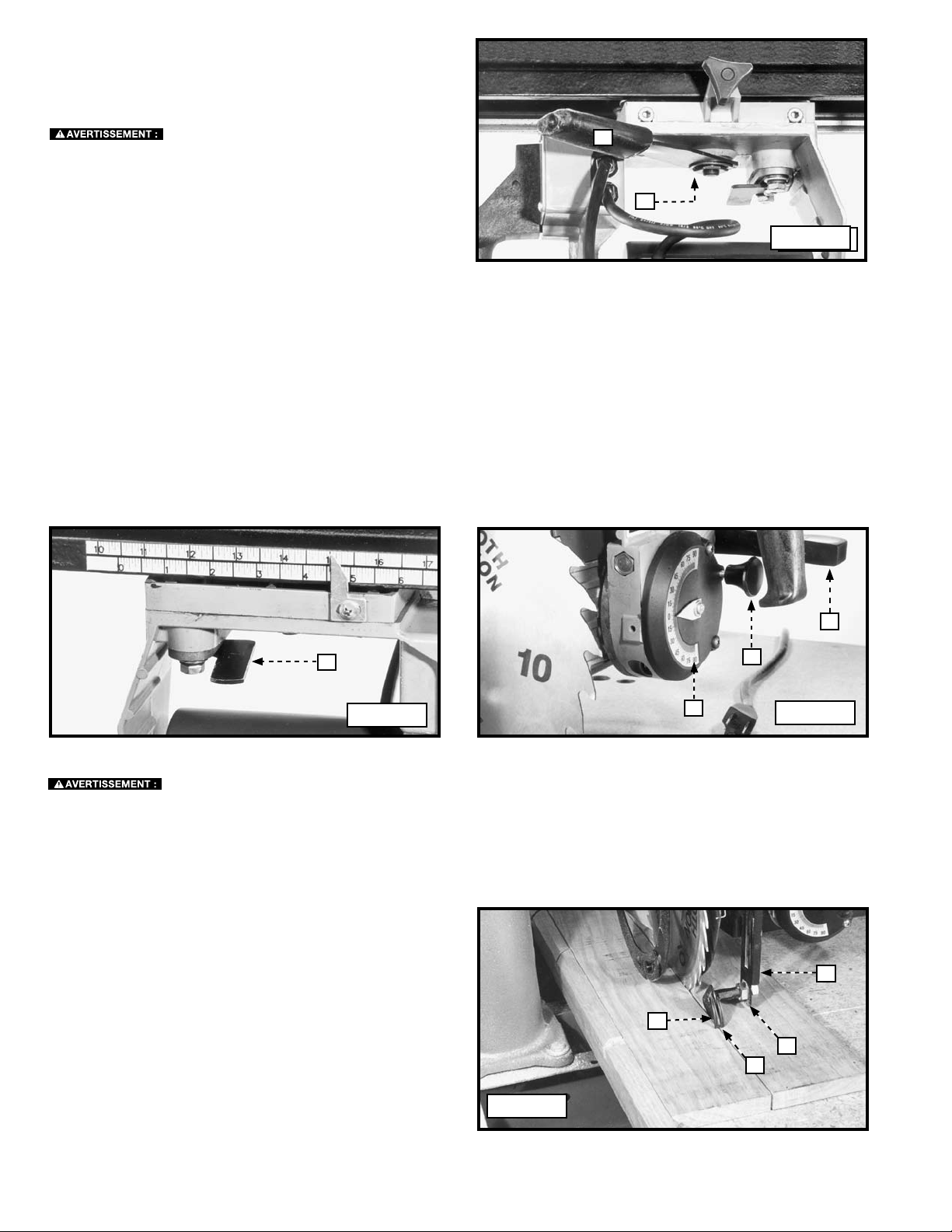

1. Raise the track arm (A) Fig. 23 by turning the elevating handle (B) until you can attach the blade (C) on the motor shaft.

Tighten the arbor nut (D) using the supplied wrenches.

2. Place a framing square (E) Fig. 23 against the fence (H). Lower the track arm (A) Fig. 23 until the blade clears the table

surface.

3. Loosen the cuttinghead clamp knob (S) Fig. 24. Slide the cuttinghead (T) the entire length of track arm (A) to determine if

the blade (C) travels parallel to the square (E).

4. To adjust, loosen the index-ring locking screw (J) Fig. 25, and the track arm clamp handle (K).

5. Rotate the track arm (A) Fig. 24 until the blade (C) travels parallel to the square (E). Tighten the track arm clamp

handle (K) Fig. 26.

6. With the track arm clamp handle (K) Fig. 26 tightened, rotate the index ring (L) counter-clockwise until it stops. Tighten

the index ring locking screw (J) Fig. 27.

Fig. 22

H

J

G E

H

Fig. 25

B

A

Fig. 23

S

A

T

D

C

C

E

E

J

K

Fig. 24

L

K

Fig. 26

7. Two miter index pointers are on this machine, one of

which is shown at (M) Fig. 27. To adjust, loosen the

screw (N) and move the pointer (M) until it aligns with

the “zero” mark on the miter scale (P). Tighten the

screw (N). Adjust the miter index pointer located on the

other side of column (R) in the same manner.

14

J

N

P

M

R

Fig. 27

Page 15

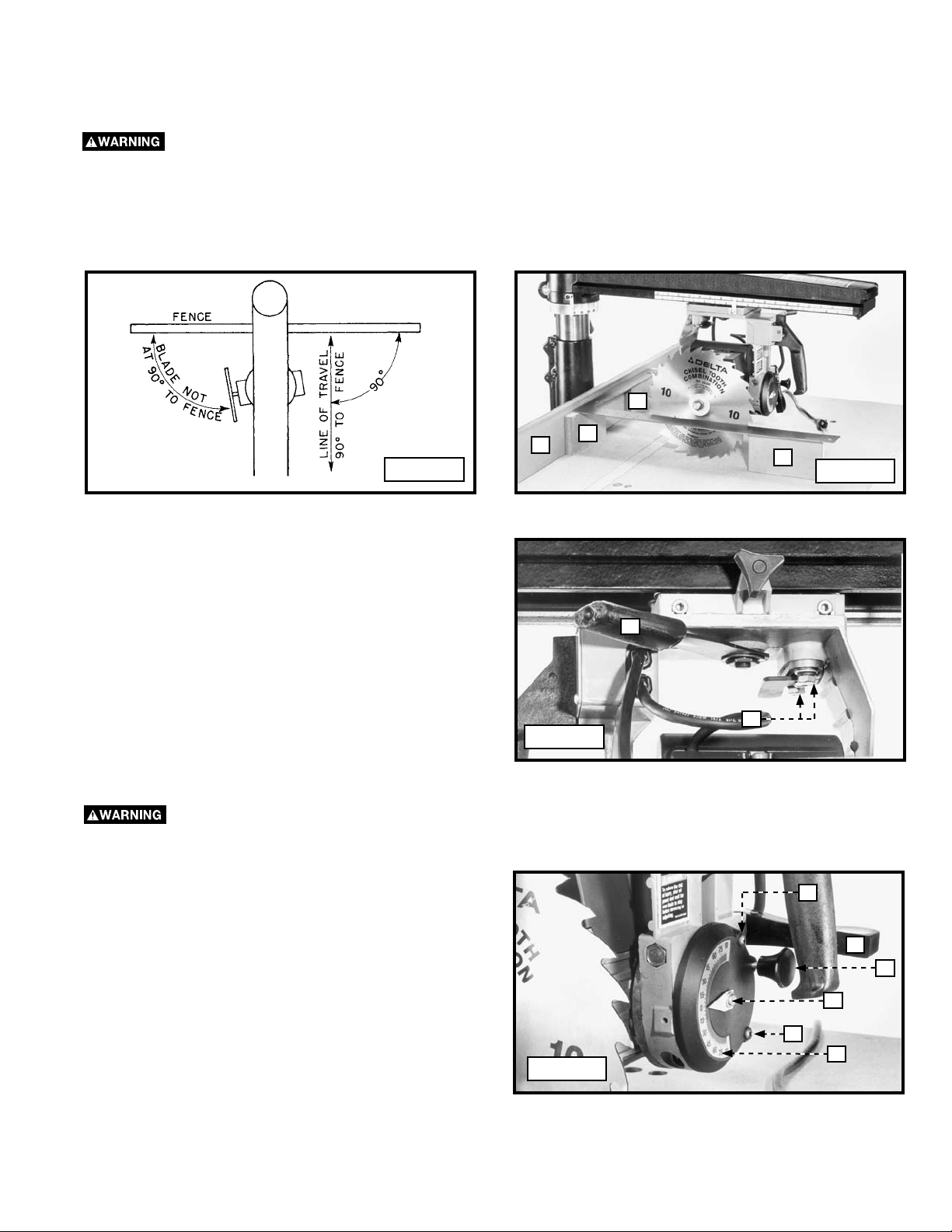

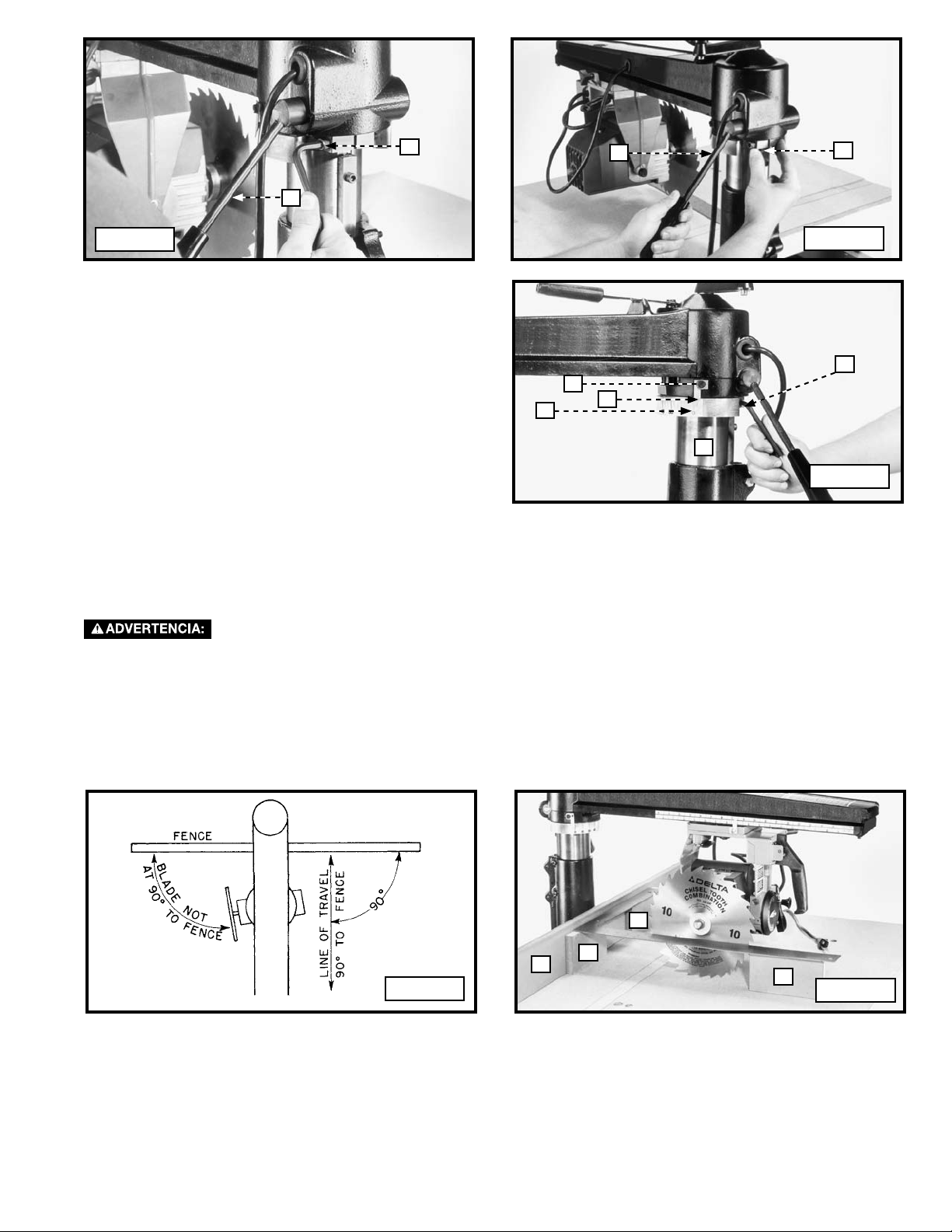

REMOVING “HEELING”

Even though the cuttinghead travel may be perfectly aligned at 90° to the fence, the blade itself may not be 90° or square

with the fence (Fig. 28). This condition is known as “heeling.”

To check and adjust:

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause

injury.

1. Install saw blade without the guard.

2. Replace the fence with a flat piece of 3/4" wood (A) Fig. 29 that is at least 5" high. Tighten the table board clamps.

3. Place three identical pieces of wood (B) Fig. 29 on the table. Lay a framing square on them so that the short arm is flush

against the fence and the long arm is against the blade. Be sure that the square is between the teeth of the blade.

B

A

Fig. 28

4. Release the yoke clamp handle (C) Fig. 30 and slightly

loosen the two hex screws (D). Swivel the yoke until

the blade is parallel with the square. Tighten the yoke

clamp handle (C). Tighten the two hex screws (D).

B

B

Fig. 29

C

D

Fig. 30

SQUARING THE SAWBLADE TO THE TABLE

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause

injury.

1. Attach the inner blade flange, saw blade, outer blade

flange, and arbor nut on the saw arbor.

F

2. Place the cuttinghead in a cross-cut position (Fig. 29).

Lower the track arm until the saw blade is clear of the

table. Slide the cuttinghead forward until it is positioned

over the front table board. Clamp the cuttinghead in

position.

3. Engage the bevel index knob (A) Fig. 31. Check to see

that the motor is in a horizontal position. Tighten the

bevel clamp handle (C).

C

A

E

F

B

Fig. 31

15

Page 16

4. Place a square (D) Fig. 32 on the table and against the

saw blade. See if the blade is square with the table.

NOTE: The square should rest between two teeth of the

saw blade.

5. To adjust, tighten the bevel clamp lever (C) Fig. 31.

6. Remove the screw, flat washer, and pointer (E) Fig. 31.

7. Remove the two screws (F) Fig. 31 and the bevel scale

plate (H) Fig. 32 with the index knob (A).

8. Loosen the four hex screws (G) Fig. 33. Tilt the motor

until the saw blade is flush with the square. Tighten the

four hex screws (G).

9. Replace the bevel scale plate (H) Fig. 33 with the bevel

index release knob (A), two screws, and pointer that

were removed earlier.

NOTE: Adjust the pointer to “zero” on the bevel index scale.

D

Fig. 32

G

A

H

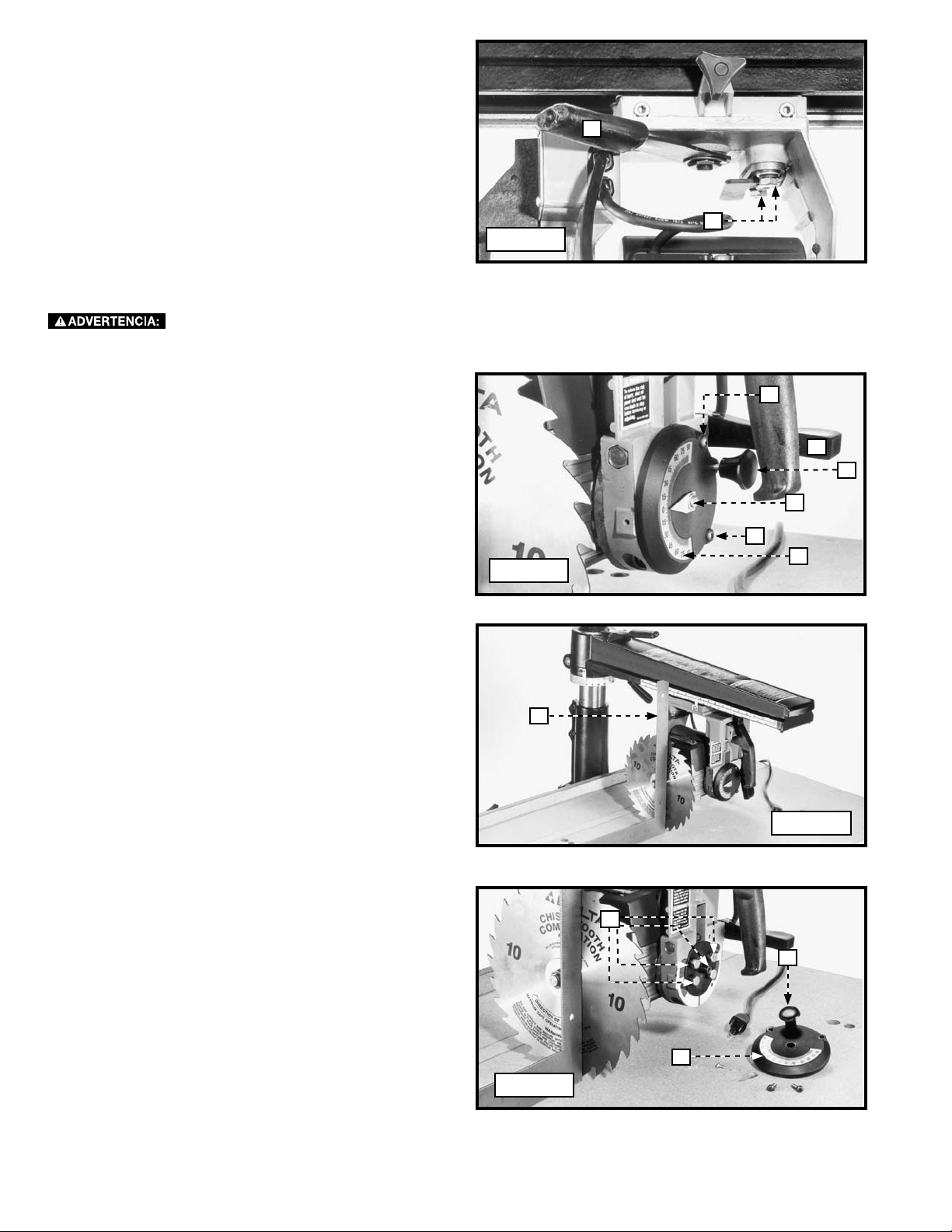

ADJUSTING IN/OUT RIP SCALE

1. Loosen the yoke clamp handle (A) Fig. 34. Release

the yoke index by pressing the release lever (B) up or

down. Rotate the cuttinghead (C) to the in-rip position

(Fig. 34). Tighten yoke clamp handle (A).

2. Position the fence (D) Fig. 34 at the rear of the table.

3. Loosen the cuttinghead clamp knob (C) Fig. 34. Slide

the cuttinghead to the rear of the track arm until the

saw blade (F) is flush against the fence (D).

4. Tighten the cuttinghead clamp knob. Adjust the pointer

(H) Fig. 34 to the “zero” mark on the lower scale (J)

by loosening the screw (K). Tighten the screw when

finished.

ATTACHING THE BLADE AND BLADE GUARD

NOTE: Use only 10" blades with 5/8" arbor holes and

rated for 5000 rpm or higher.

Fig. 33

Fig. 34

H

K

B

C

J

A

F

D

1. Attach the inside (thick) arbor flange (A) Fig. 35 to the

arbor shaft with the recessed side of flange (A) facing

out.

A

Fig. 35

16

Page 17

H

B

B

E

C

D

Fig. 36

2. With the blade guard (B) Fig. 32 in the left hand, insert

the saw blade (C) into the blade guard (B) and on the

arbor shaft.

3. Atttach the outside (thin) blade flange (D) Fig. 36 to the

recessed side of the flange (D) facing in. Place the arbor

nut (E) on the arbor shaft.

NOTE: The arbor nut (E) Fig. 36 has a left-hand thread.

4. Lift the cam (F) Fig. 37. Attach the blade guard (B) to the

cuttinghead assembly.

NOTE: Seat the tongue of the guard in the groove of the

cuttinghead.

5. Pull back on blade guard (B) Fig. 38, so that it rotates to

the rear. Use the 7/8" box wrench around the arbor nut

(E), and the 7/8" open-end wrench on the flat of the arbor to hold it in place.

6. Rotate the blade guard (B) Fig. 38 to the horizontal position and tighten the clamp knob (H) Fig. 37.

Tighten the clamp knob (H) FIG. 37 and secure the blade guard before operating the machine.

The lower retractable blade guard provides operator protection along the sides of the sawblade. To reduce the risk of

potential hazards, use the following rules:

A) KEEP YOUR HANDS AWAY FROM THE GUARD. As the blade cuts, the guard will lift and leave part of the blade

exposed.

B) SHUT OFF THE POWER BEFORE FREEING A JAMMED LOWER GUARD. The guard can get jammed in previous

kerfs in the table or fence. Always anticipate the path of the guard.

C) USE CAUTION when making bevel cuts to ensure that the lower guard is never pinched toward the blade.

D) THE LOWER GUARD CAN JAM AGAINST THE FENCE DURING NARROW IN-RIPS. Should the guard jam against

the fence, disconnect the saw from the power, wait for the blade to stop, then lift the blade guard and rest it on

top of the fence.

F

Fig. 37

B

G

E

Fig. 38

CUTTING INTO THE TABLE BOARDS

1. Attach the table boards (A) Fig. 38 and the fence (B). Secure the boards in place with table clamps, one of which is

shown at (C).

2. Return the cuttinghead (D) Fig. 39 to the rear of the track arm (E). Tighten the cuttinghead clamp knob (G) Fig. 37.

Check to see that the switch (H) Fig. 39 is in the “OFF” position and connect the saw to the power source.

3. While holding cuttinghead handle (L) Fig. 39 firmly, turn the switch (H) “ON”. Lower the track arm (E) by turning the

elevating handle (K). Lower the saw blade until it cuts into the table surface approximately 1/16” deep.

K

G

C

B

D

A

H

Fig. 39

17

E

L

Fig. 40

Page 18

D

E

4. While still holding the cuttinghead handle (L) Fig. 41

firmly, loosen the cuttinghead clamp knob, and slowly

pull the cuttinghead (D) Fig. 41 toward the front of the

track arm (E) until the travel stops. Turn the switch (H)

“OFF”.

5. Wait for the saw blade (M) Fig. 42 to stop, then return

the cuttinghead (D) to the rear of the track arm (E). Note

the saw kerf (N) Fig. 42 in the table boards.

IMPORTANT: Raise the track arm (E) Fig. 42 before

attempting to rotate it. Perform the procedure “CUTTING

INTO THE TABLE BOARDS” for each separate angle cut.

M

H

L

Fig. 41

D

E

N

Fig. 42

If, during operation, the saw has a tendency to tip over, slide, or walk on the supporting surface, secure the

saw to the floor surface through the holes provided on the bottom of each leg.

OPERATION

OPERATIONAL CONTROLS AND ADJUSTMENTS

Before using the saw, verify the following each and every time:

1. ALWAYS wear proper eye, hearing, and respiratory equipment.

2. Blade is tight.

3. Bevel angle and height lock knobs are tight.

4. If ripping, ensure fence lock lever is tight and fence is parallel to the blade.

5. The blade guard is properly attached and the anti-kick teeth are functioning.

6. ALWAYS inspect the guard and splitter for proper alignment operation and clearance with saw blade.

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing

and removing accessories, before adjusting or changing set-ups, or when making repairs. An accidental

start-up can cause injury.

Before connecting the radial arm saw to the power source or operating the saw, always inspect the

guard and splitter for proper operation alignment and clearance with saw blade. Personal injury may

result.

If your saw makes an unfamiliar noise, or if it vibrates excessively, cease operating immmediately until the

source has been located and the problem corrected.

STARTING AND STOPPING

Make sure that the switch is in the “OFF” position before plugging cord into outlet. Do not touch the

plug’s metal prongs when unplugging or plugging in the cord.

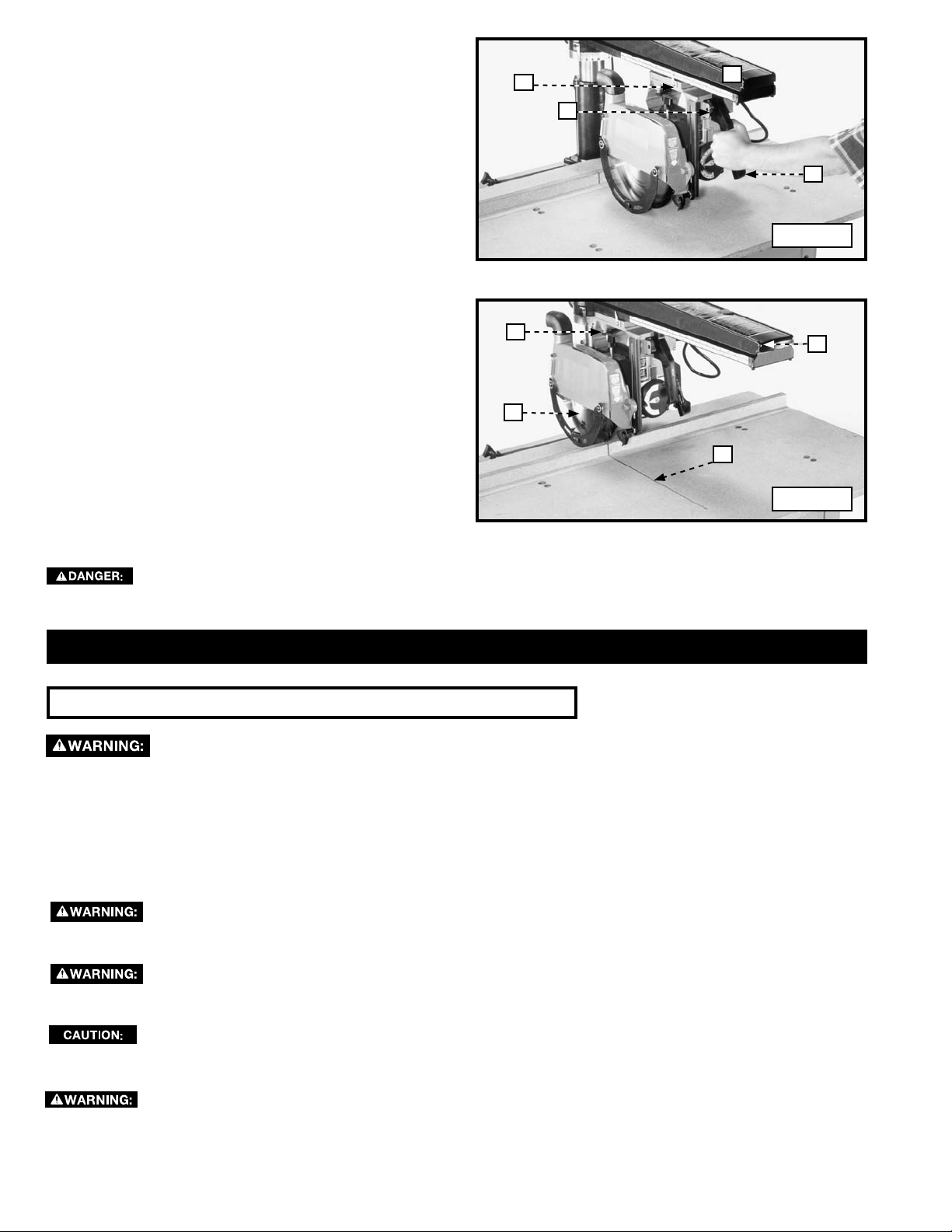

The on/off switch (A) Fig. 43 is located at the front of the cuttinghead. To turn the saw “ON”, move the switch (A) up to the

“ON” position. To turn the saw “OFF”, move the switch down to the “OFF” position.

18

Page 19

LOCKING THE SWITCH IN THE "OFF" POSITION

IMPORTANT: When the machine is not in use, lock the switch in the “OFF” position to prevent unauthorized use, using a

padlock (D) Fig. 44 with a 3/16" diameter shackle

In the event of a power outage (such as a breaker or fuse trip), always move the switch to the “OFF”

position until the main power is restored.

D

A

Fig. 43

Fig. 44

GUIDE TO CONTROLS

Study the following terms and explanations carefully to familiarize yourself with the controls before turning on

the power. Doing otherwise may cause damage to the saw or personal injury (Figs. E and F).

C

D

A

A. THE TABLE CLAMP KNOBS allow you to quickly set

the desired fence position (Fig. G).

B. THE TRACK ARM INDEXING RELEASE HANDLE

releases the indexing pin from the 0° and 45° positions

to allow the arm to rotate. Depress the handle to release

the index pin (Fig. G).

C. THE TRACK ARM ELEVATING HANDLE controls the

depth-of-cut in all operations. Turn the handle clockwise

to raise, or counter-clockwise to lower the track arm

(Fig. G).

D. THE MITER SCALE indicates the degrees left and right

for setting track arm to desired miter angle (Fig. G).

F. THE RIP SCALE indicates the in and out rip positions of

the cutterhead (Fig. E).

G. THE BLADE GUARD CLAMP KNOB clamps the blade

guard at rotated positions for ripping (Fig.G.

H. THE BEVEL CLAMP HANDLE controls the tilt of

the motor for bevel cutting operations. It also locks

the motor at any desired angle on the bevel scale.

Lift the handle to loosen, and push it down to lock

(Fig. G).

J. THE BEVEL INDEX RELEASE KNOB allows the motor to

position in the 0°, 45°, and 90° bevel settings. To tilt the

motor for bevel cutting, loosen the bevel clamp handle.

To release the index, pull out the release knob (Fig. G).

K. THE YOKE INDEXING RELEASE LEVER allows the

saw to achieve a 90° position for ripping or cross-cutting

operations. Loosen the yoke clamp handle to rotate the

yoke. Push the release lever either up or down to release

the indexing pin (Fig. G).

B

K

G

F

N

P

H

M

J

Fig. G

L. THE YOKE CLAMP HANDLE must be loose when

rotating the yoke between the rip and cross-cutting

position. Pull the handle to release and push it to lock

(Fig. H).

M. THE ANTI-KICKBACK DEVICE helps to prevent injury

or damage caused by kickback. When ripping, position

and clamp the yoke so that the blade is parallel to the

fence. Rotate the rear of the blade guard until it almost

touches the workpiece. Lower the anti-kickback rod so

that the fingers catch and hold the workpiece. Never

rip from the anti-kickback end of the blade guard

(Fig. H).

N. THE ON-OFF SWITCH is conveniently located, and can be

turned on or off in an instant for added operation protection.

You can also lock this switch in the "OFF" position to

prevent unauthorized use using an accessory padlock

(Fig. H).

P. THE CUTTING-HEAD CLAMP KNOB locks the

cutting-head at any position on the track arm. Tighten

the clamp knob (Fig. H).

R. THE BEVEL SCALE indicates the degree of rotation

for setting motor bevel positions (Fig. H).

S. THE TRACK ARM CLAMP HANDLE controls the

rotation of the track arm for all miter cutting operations.

It locks the track arm at any miter angle position. To

rotate the track arm to the right, loosen the clamp

handle and rotate the arm. The arm will stop at

45°. To rotate past 45°, depress the indexing release

handle and rotate. The arm will rotate an additional 5°.

To rotate to the left, the operation is the same except

that you must depress the indexing release handle to

19

start the rotation (Fig. H).

S

L

R

Fig. H

Page 20

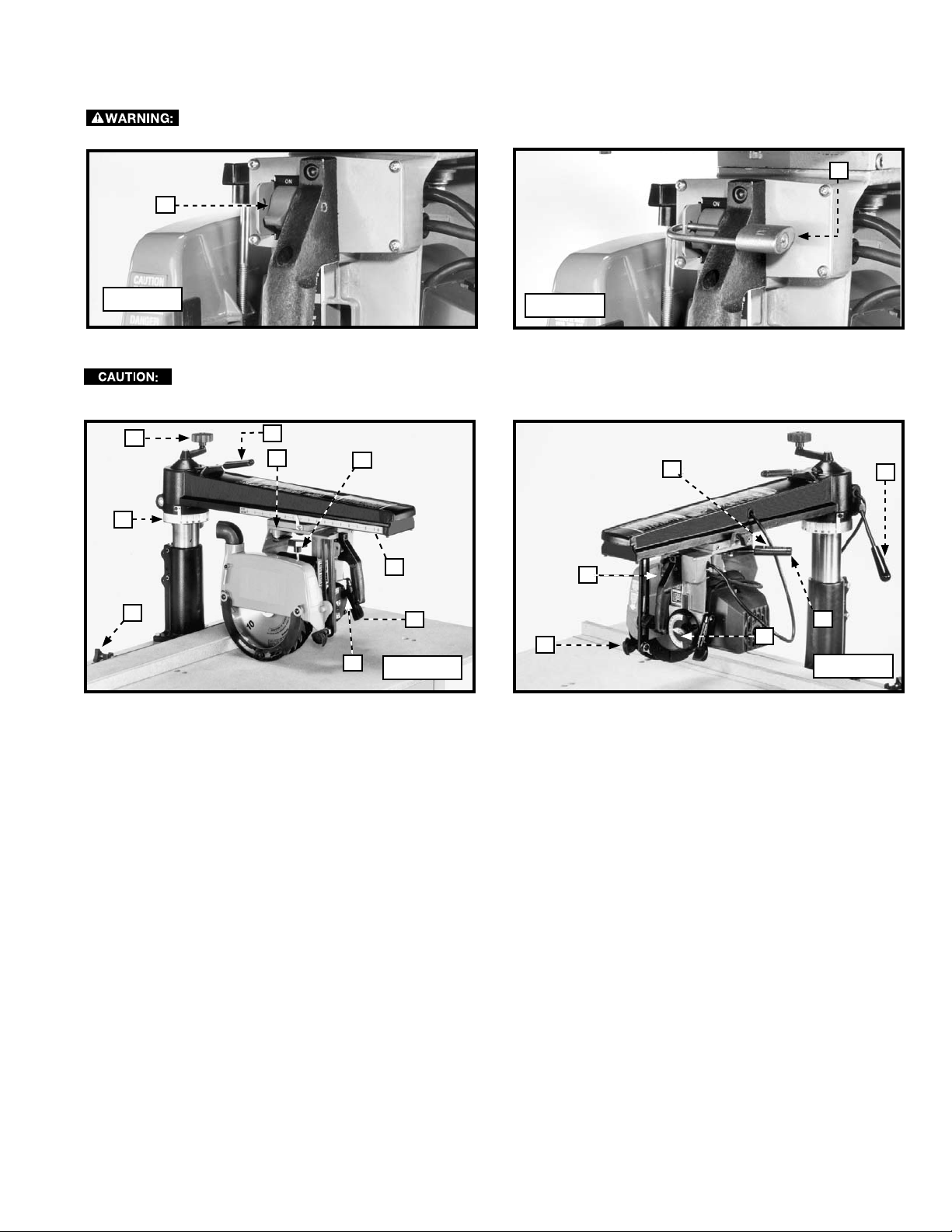

ADJUSTING THE BALL BEARINGS AGAINST THE TRACK

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

The cuttinghead (C) Fig. 46 is suspended from four pre-loaded, lubricated, shielded ball bearings, two of which are on fixed

shafts at (A), and two on adjustable shafts at (B).

The cuttinghead (C) Fig. 46 was removed from the track arm for illustration purposes. DO NOT remove the

cuttinghead from the track arm.

After extended use, wear may develop in the track arm, causing “play” between the ball bearings and the track. The ball

bearings must ride smoothly and evenly in the channels of the track arm. To adjust the ball bearings:

1. Remove the plastic plug (D) Fig. 45 from the top of track arm (E).

2. Slide the cuttinghead (C) Fig. 46 until one of the adjustable bearings (B) Fig. 46 is visible through the hole (G) Fig. 46.

3. Use a 1/2" socket, extension, and ratchet (H) Fig. 47 through the hole (G) in the track arm to slightly loosen the hex nut

on the adjustable shaft (G) Fig. 47 approximately 1/8 turn. Repeat the procedure for the other bearing.

B

D

A

G

B

C

K

E

Fig. 45

G

H

K

Fig. 46

K

J

C

4. Use a 3/16" hex wrench (J) Fig. 48 to turn the adjustment screws (K) Fig. 48 to remove all “play.”

Do not overtighten the adjustment screws (K). This can damage the bearings.

Do not loosen the adjustment screws (K) more than 1/2 turn. The cuttinghead may fall from the track arm.

5. Tighten the two hex nuts loosened in STEP 3. Check the cuttinghead travel for any “play”. Ensure that it moves freely and

smoothly.

6. Replace the plastic plug that was removed in STEP 1.

Fig. 47

Fig. 48

20

Page 21

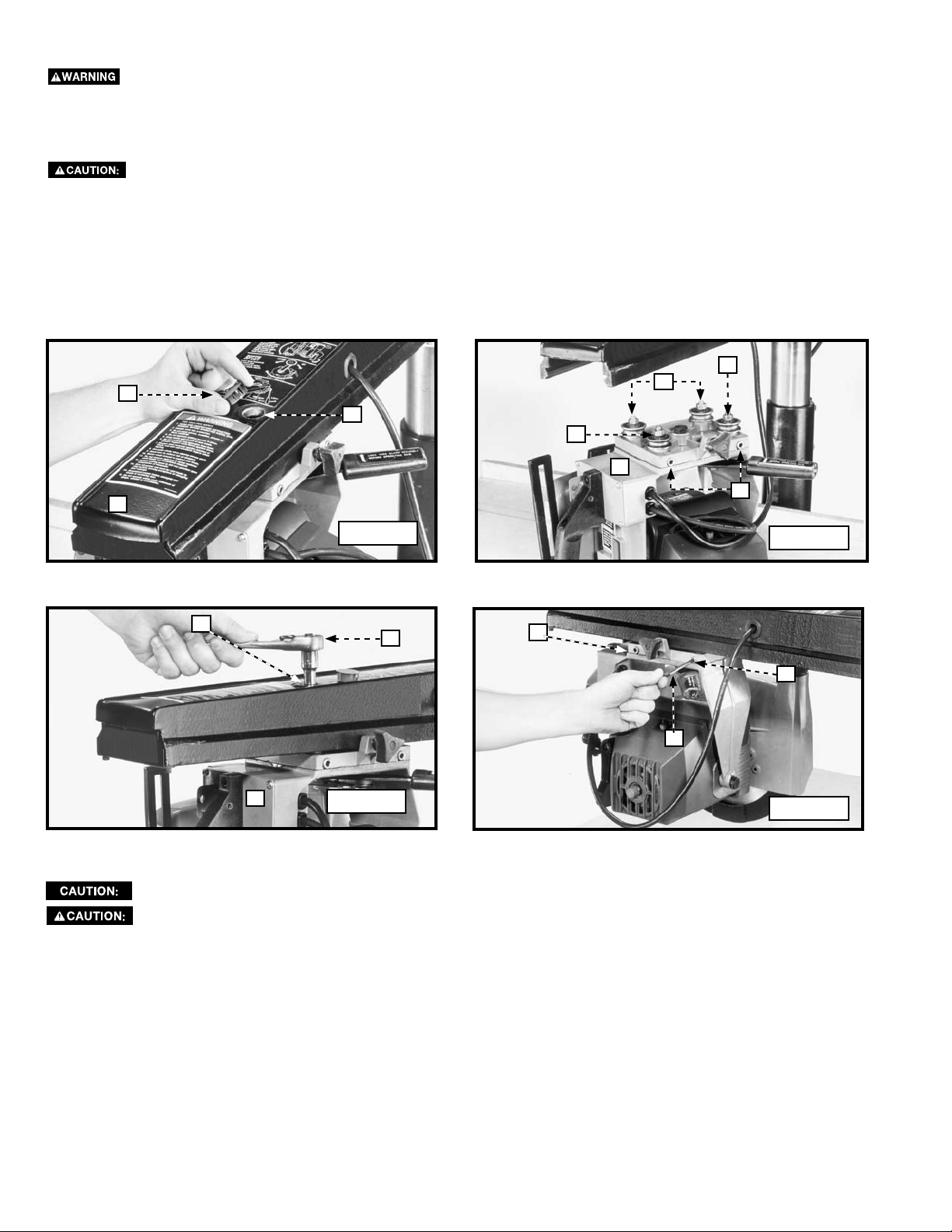

ADJUSTING THE TENSION ON THE ELEVATING COLUMN

Elevating column tension is preset at the factory. “Play” may develop after extended use. To adjust:

To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing

and removing accessories, before adjusting or changing

set-ups or when making repairs. An accidental start-up can

cause injury.

1. Loosen the hex nuts (A) Fig. 49 and the gib adjustment

screws (C).

2. Loosen the hex nuts (D) and turn the screws (E) until the

column base wraps around the column securely and can

be raised or lowered without binding. Tighten the hex

nuts (D) against the column base.

3. Tighten the gib and adjustment screws (C) against the

gib (H) until all side-to-side play is removed. Tighten

the hex nuts (A) against column base.

NOTE: After adjusting column tension, refer to “ADJUSTING SAW BLADE TRAVEL SQUARE WITH FENCE” to determine

if saw blade travel was affected.

F

H

A

E

D

C

B

Fig. 49

CHANGING THE POSITION OF THE TRACK ARM CLAMPING HANDLE

To reposition the track arm clamping handle (A) Fig. 50 when it does not lock in a convenient position:

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

1. Loosen and remove the track arm clamping lever (A) Fig. 50. Push the hex bolt (B) Fig. 51 back through the hole until the

head of the bolt is out of the recessed bushing (C).

NOTE: The track arm clamping lever has a left-hand thread.

2. Rotate hex bolt (B) Fig. 51 in the desired direction.

3. Push the hex bolt (B) Fig. 51 back through hole. Check to see if the head of hex bolt is seated properly in the recessed

bushing (C). Attach the track arm clamping lever.

NOTE: If the track arm clamping lever (A) Fig. 49 tightens before approximately four turns, the clamping bushings (one of which

is shown at (C) Fig. 51 may have rotated. These bushings should seat completely inside the track (D). If they do not, slightly loosen

the clamping lever (A) Fig. 50 and rotate the clamping bushing (C) Fig. 51 until it seats. Check to see if you need to rotate the

bushing on the clamp lever side also.

NOTE: The flats on the clamping bushings should face the front of the saw.

NOTE: The clamp lever (A) Fig. 50 will thread at one of two positions. If, after making the adjustment, the clamp lever (A)

tightens 180° from where desired, slowly unscrew clamp lever (A) while holding in on the hex bolt (B). When the clamp lever (A)

comes off of the hex bolt (B), rotate the clamp lever (A) 180°. Thread the clamp lever.

Fig. 50

B

A

D

C

Fig. 51

21

Page 22

CHANGING THE POSITION OF THE BEVEL CLAMP HANDLE

To reposition the bevel clamp handle:

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

1. Loosen the bevel clamp handle (A) Fig. 52, release the

bevel index release knob (B), and turn the motor (C) to

the vertical position.

NOTE: If the blade guard contacts the table surface, raise

the track arm.

2. Loosen the bevel clamp handle (A) Fig. 52 several

turns until the hex head of the screw (D) can be

pushed out of hex-shaped recess in yoke.

3. Turn the screw (D) Fig. 52 one or two flats of the hex

head in the direction the handle needs to be turned.

Push it back into hex-shaped recess in yoke.

4. Tighten the bevel clamp handle (A) Fig. 52.

NOTE: The screw is left-hand thread - turn the clamp

handle counter-clockwise to tighten.

D

B

C

A

Fig. 52

CHANGING THE POSITION OF THE YOKE CLAMP HANDLE

To reposition the yoke clamp handle (A) Fig. 53:

To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing

and removing accessories, before adjusting or changing

set-ups or when making repairs. An accidental start-up can

cause injury.

1 Remove retaining ring (B) Fig. 53.

2. Reposition yoke clamp handle (A) Fig. 53 on hex clamp

nut.

3. Replace retaining ring (B) Fig. 53

A

B

Fig. 53

POSITIVE STOP YOKE INDEX

The yoke index lever (A) Fig. 54 activates a positive stop that positions the cuttinghead in the cross-cut or rip position. To rotate

the cuttinghead, release the yoke clamp handle, press up or down on yoke index lever (A) to release the positive stop, and

rotate the cuttinghead to either the #1 in-rip or #2 out-rip or #3 cross-cut positions. Release the yoke index lever (A) Fig. 53 and

the cuttinghead will automatically index at each of the three positions.

POSITIVE STOP BEVEL INDEX

The bevel index knob (A) Fig. 55 provides a positive stop when positioning the saw blade at 0°, 45°, and 90° left, and 90° right

on the bevel scale (C). To change the angle of the saw blade, loosen the bevel clamp handle (B), pull out bevel index knob (A),

and tilt the saw blade and motor. For the 0°, 45°, and 90° left, and 90° right positions, release the bevel index knob (A) and the

saw blade will index at each of these positions. Tighten the bevel clamp handle (B). For saw blade angles between positive

stops, set the blade at the desired angle on bevel scale (C) and tighten the bevel clamp handle (B) Fig. 55.

B

A

A

Fig. 54

22

C

Fig. 55

Page 23

ADJUSTING THE SPLITTER AND ANTI-KICKBACK FINGERS

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can cause injury.

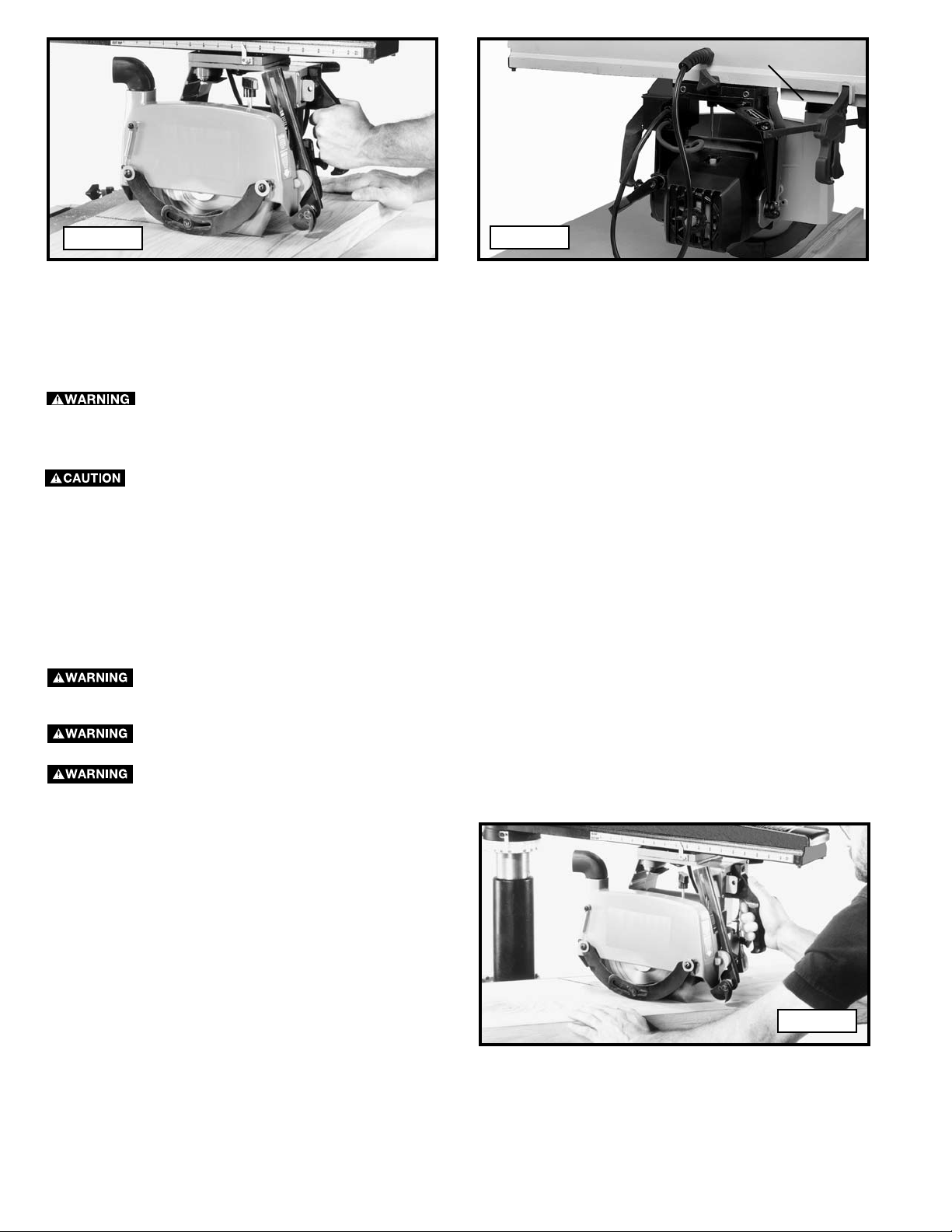

During ripping operations, the splitter (A) Fig. 56 must ride in the saw kerf and the anti-kickback fingers (B) should touch the

workpiece to prevent kickback.

1. Set the saw up in the ripping position with the blade guard lowered on the in-feed side to act as a holddown.

2. Start a piece of material through the saw (Fig. 56).

3. Shut the saw off, and disconnect it from the power

source.

4. Adjust the arm (C) Fig. 56 so that it is vertical and the

splitter (A) is in the saw kerf.

5. If the splitter (A) Fig. 56 does not align with the saw

kerf, loosen the hex nuts (D), and position the splitter

(A) into the saw kerf. Tighten the hex nuts (D) against

the arm (C). The straight side of the splitter should

be toward the blade (Fig. 56), and the anti-kickback

fingers should rest on the workpiece.

NOTE: The clamp knob for arm (C) must be tight. Move

arm (C) front to back while tightening clamp knob with

other hand to be sure clamp is firmly seated and tight.

6. Pull backward on the workpiece to determine if the

anti-kickback fingers bite into the material and prevent

further backward movement. If necessary, readjust the height of the arm (C) Fig. 56.

Fig. 56

A

B

C

D

AUXILIARY TABLE BOARD FACING

To prevent repeated cutting into the table surface which will eventually cause the table to sag, you can cut an auxiliary table

board facing and fit it to the table. Make it from 1/4" plywood or particle board. Cut it to a size that will cover all of the table

boards in front of the fence. Place the auxiliary table board facing flat on the table and butt it against the table fence. Fasten

it to the table with a small brad or finish nail in each corner.

USING A TABLE EXTENSION

When a table extension more than 24" long is attached to the saw, use a sturdy outrigger support or secure the stand or

bench to the floor.

MACHINE USE

To reduce the risk of injury, turn unit off and disconnect the machine from the power source before

installing and removing accessories, before adjusting or changing set-ups, or when making repairs. An

accidental start-up can cause injury.

Before connecting the radial arm saw to the power source or operating the saw, always inspect the guard and

splitter for proper operation alignment and clearance with the saw blade. Personal injury may result.

CROSS-CUTTING

To reduce the risk of injury, turn unit off and disconnect the machine from the power source before

installing and removing accessories, before adjusting or changing set-ups, or when making repairs. An

accidental start-up can cause injury.

NEVER touch the "free end" of the workpiece or a "free Piece" that is cut off while the power is "ON"

and/or the saw blade is rotating. The piece may contact the blade resulting in a thrown workpiece and

possible injury.

NEVER use a length stop on the free end of the workpiece when crosscutting. In short, the cut-off piece

in any through-sawing (cutting completely through the workpiece) operation must never be confined

- it must be allowed to move away from the saw blade to prevent contact with the blade resulting in a

thrown workpiece and possibly injury.

Use caution when starting the cut to prevent binding of the guard against the workpiece resulting in

damage to the saw and possible injury.

23

Page 24

B

Fig. 57

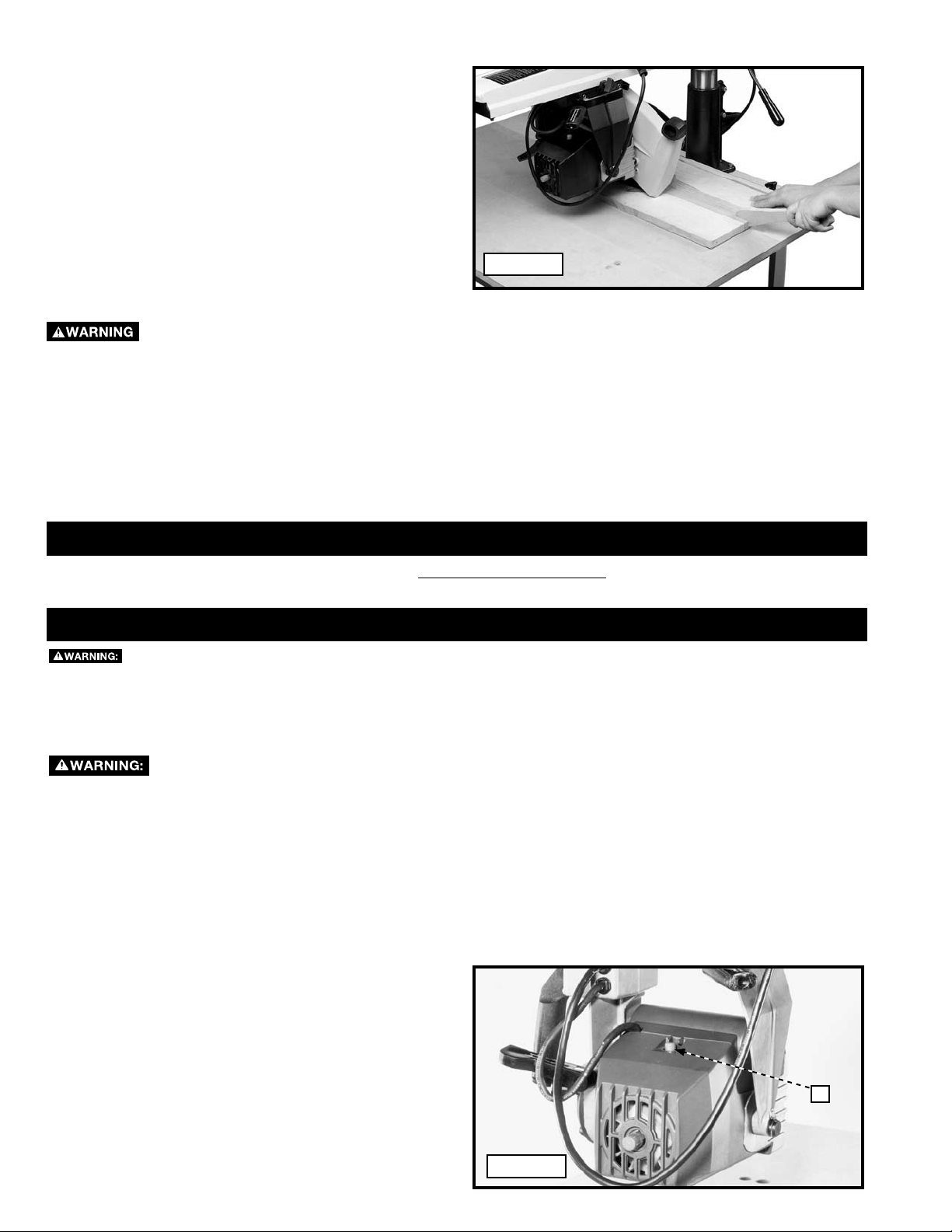

To cross-cut, support the workpiece against the fence and pull the saw blade through the material at right angles to it. (Fig. 57)

When cross-cutting, set the track arm at “0” and tighten the track arm clamp handle. Clamp the fence between the table

boards. Make sure that the saw blade is on the left and behind the fence. Place the workpiece on the table and butt it against

the fence. Make sure that the saw blade is clear of the fence and the table when the machine is turned "ON". Lower the saw

blade until it lightly cuts into the table surface. Position your body a little to the left of the machine for better visibility. Pull the

saw blade across the work, just far enough to complete the cut, then return the saw blade to its starting position. Turn the

machine off, and wait for the blade to stop before touching the cut-off piece.

Always be conscious of your hand position. Make sure that your hands are clear of the blade and that

you are holding the workpiece firmly.

Additionally, you can turn the anti-kickback rod upside down and lock it in place so that the rod just clears the workpiece.

The rod can act as a guard from the exposed teeth of the blade.

Always return the cutterhead carriage to the full rear position after each cross-cut operation.

NOTE: When cross-cutting material more than 1" thick, position the fence immediately behind the fixed front table board.

Fig. 58

CROSS-CUT STOP

A block of wood (B) Fig. 58 clamped to the track arm will prevent unnecessary travel of the cutting-head on the track arm,

especially useful when performing repetitive operations. Clamp the block of wood to the right side of the track arm at a

position which will stop the cuttinghead travel as soon as the saw blade cuts through the workpiece.

MITER CUTTING

To reduce the risk of injury, turn unit off and disconnect the machine from the power source before

installing and removing accessories, before adjusting or changing set-ups, or when making repairs. An accidental

start-up can cause injury.

Use caution when starting the cut to prevent binding of the guard against the workpiece resulting in

damage to the saw and possible personal injury.

Before connecting the radial arm saw to the power source or operating the saw, always inspect the guard

and splitter for proper operation alignment and clearance with the saw blade. Check the alignment after each change

of bevel angle.

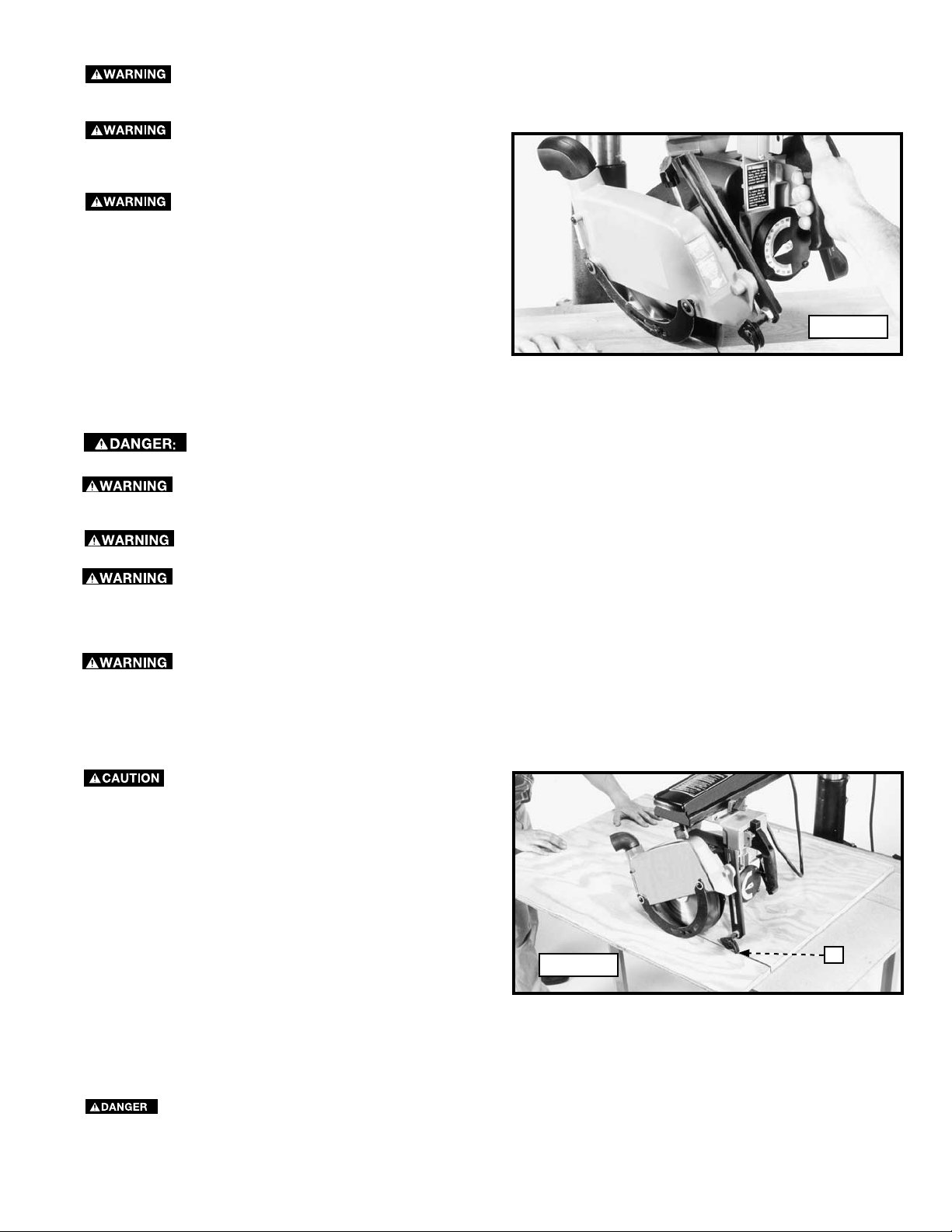

Miter cutting is similar to cross-cutting except the workpiece

is cut at an angle (up to 45° right or left). Perform the settings

and operation in the same manner as cross-cutting except

first position the track arm to the desired angle on the miter

scale before you clamp it in place. Position your hand that

holds the workpiece on the opposite side of the direction of

the miter so that the blade is pulled through the workpiece

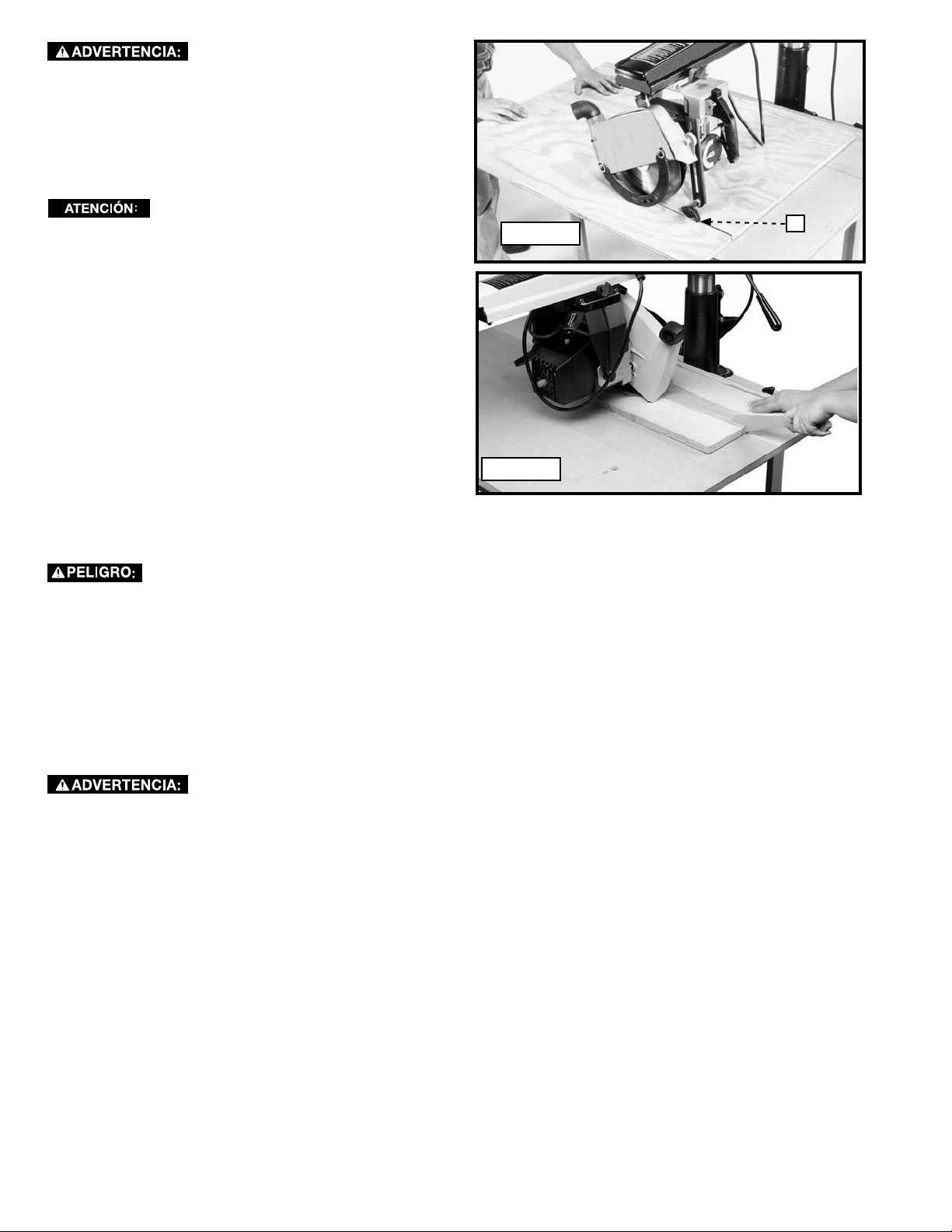

and away from your hand. Fig. 59 shows a typical miter

cutting operation on the radial saw.

Fig. 59

24

Page 25

COMPOUND MITER CUTTING

To reduce the risk of injury, turn unit off and disconnect the machine from the power source before

installing and removing accessories, before adjusting or changing set-ups, or when making repairs. An accidental

start-up can cause injury.

Use caution when starting the cut to

prevent binding of the guard against the workpiece

resulting in damage to the saw and possible personal

injury.

Before connecting the radial arm saw to

the power source or operating the saw, always inspect

the guard and splitter for proper operation alignment

and clearance with the saw blade. Check the alignment

after each change of bevel angle.

Compound miter cutting is performed the same as miter

cutting except that the saw blade is tilted to the desired

angle on the bevel scale and clamped for a bevel cut. See

Fig. 60 for an illustration of the compound miter cut.

Fig. 60

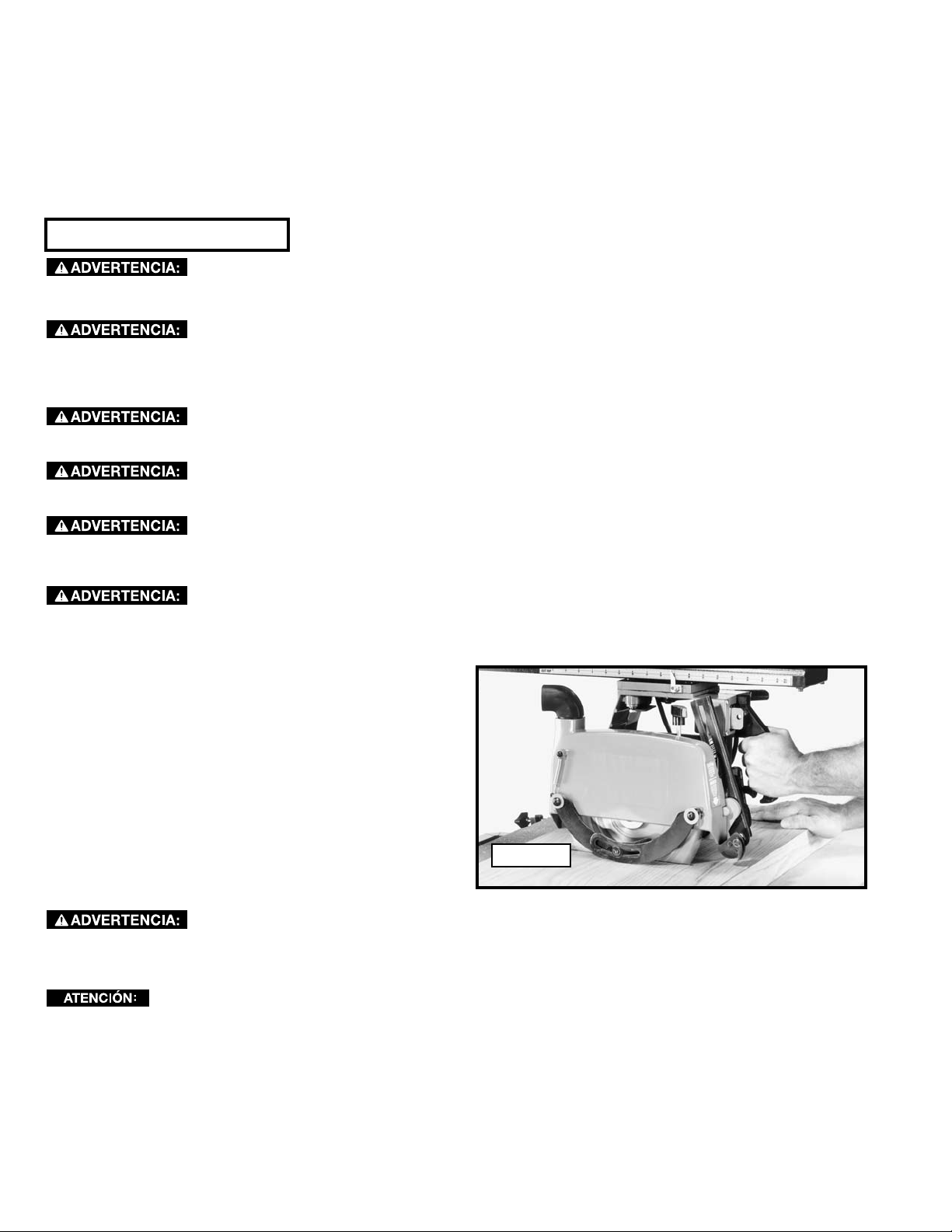

RIPPING

To reduce the risk of injury, the workpiece must never be fed into the outfeed end of the blade guard

or personal injury may result.

To reduce the risk of injury, turn unit off and disconnect the machine from the power source before

installing and removing accessories, before adjusting or changing set-ups, or when making repairs. An accidental

start-up can cause injury.

NEVER touch the "free end" of the workpiece or a "free Piece" that is cut off while the power is "ON"

and/or the saw blade is rotating. The piece may contact the blade resulting in a thrown workpiece and possible injury.

Keep the saw blade guard, splitter, and anti-kickback teeth in place and operating properly. Keep teeth

sharp. If teeth are not operational, return your unit to the nearest authorized Delta service center for repair. The splitter

must be in alignment with the saw blade and the teeth must stop a kickback once it has started. Check their action

before ripping by pushing the wood under the anti-kickback teeth. The teeth must prevent the wood from being pulled

toward the front of the saw.

A rip fence should ALWAYS be used for ripping operations to prevent loss of control and personal injury.

NEVER perform a ripping operation freehand. ALWAYS be sure the fence is locked down.

IMPORTANT: In certain applications, you may need to use two push sticks, and/or featherboards.

Keep all push sticks, featherboards, etc. handy

so that you can reach them without having to get near the

blade.

Ripping involves making a lengthwise cut through a board

along the grain. Clamp the track arm at “0” on the miter scale.

Position and clamp the yoke so that the blade is parallel to the

fence in either the in-rip or out-rip position. When feeding the

workpiece, make sure that one edge rides against the fence

with the flat side resting on the table. Lower the guard

on the in-feed side until it almost touches the workpiece

(Fig. 61) to act as a holddown. Adjust the splitter and antikickback fingers (A) Fig. 61 as described under the section

“ADJUSTING THE SPLITTER AND ANTI-KICKBACK

FINGERS” in this manual. Keep your hands well away from,

and to the side of the blade. When ripping narrow work, always use a push stick (Fig. 62) to push the work between the fence

and blade.

The workpiece must have one straight edge to follow the fence. If the board is bowed, place the hollow side down.

Securely tighten the cuttinghead clamp knob for all ripping operations.

Never feed the workpiece into the outfeed end of the blade guard.

Fig. 61

A

25

Page 26

OUT-RIPPING

Out-ripping is generally the same as ripping except that you

clamp the yoke at a right angle to the track arm with the

blade guard facing the FRONT of the machine. Position the

cuttinghead on the out-rip scale to the desired setting and

clamp it in position. Feed the workpiece from the left side of

the saw. A typical out-ripping operation is illustrated in Fig.

61.

IN-RIPPING

In-ripping is generally the same as ripping except that you

clamp the yoke at a right angle to the track arm with the

blade guard facing the REAR of the machine. Position the

cuttinghead on the in-rip scale to the desired setting and

clamp it in position. Feed the workpiece from the right side

of the saw. A typical in-ripping operation is illustrated in Fig.

62.

When ripping a workpiece less than 6" wide, use a push stick to complete the feed (Fig. 62).

PUSH-STICKS

In order to operate your radial arm saw safely, you must use a push-stick whenever the size or shape of the workpiece would

cause your hands to be within 6" (152mm) of the saw blade or other cutter.

No special wood is needed to make a push-stick as long as it's sturdy and long enough. A length of 12" (305mm) is

recommended with a notch that fits against the edge of the workpiece to prevent slipping. It's a good idea to have several

push-sticks of the same length [12" (305 mm) with different size notches for different workpiece thicknesses.

See the next page for an illustration of a push-stick. The shape can vary to suit your own needs as long as it performs its

intended function of keeping your hands away from the blade.

Fig. 62

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltaportercable.com for a list of service centers or call the

DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

MAINTENANCE

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing

accessories, before adjusting or when making repairs. An accidental start-up can cause injury.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp

cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the

outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a commercially

available protective product designed for this purpose. Follow the manufacturer’s instructions for use and safety.

To clean cast iron tables of rust, you will need the following materials: a sheet of medium Scotch-Brite™ Blending Hand

Pad, a can of WD-40® and a can of degreaser. Apply the WD-40 and polish the table surface with the Scotch-Brite pad.

Degrease the table, then apply the protective product as described above.

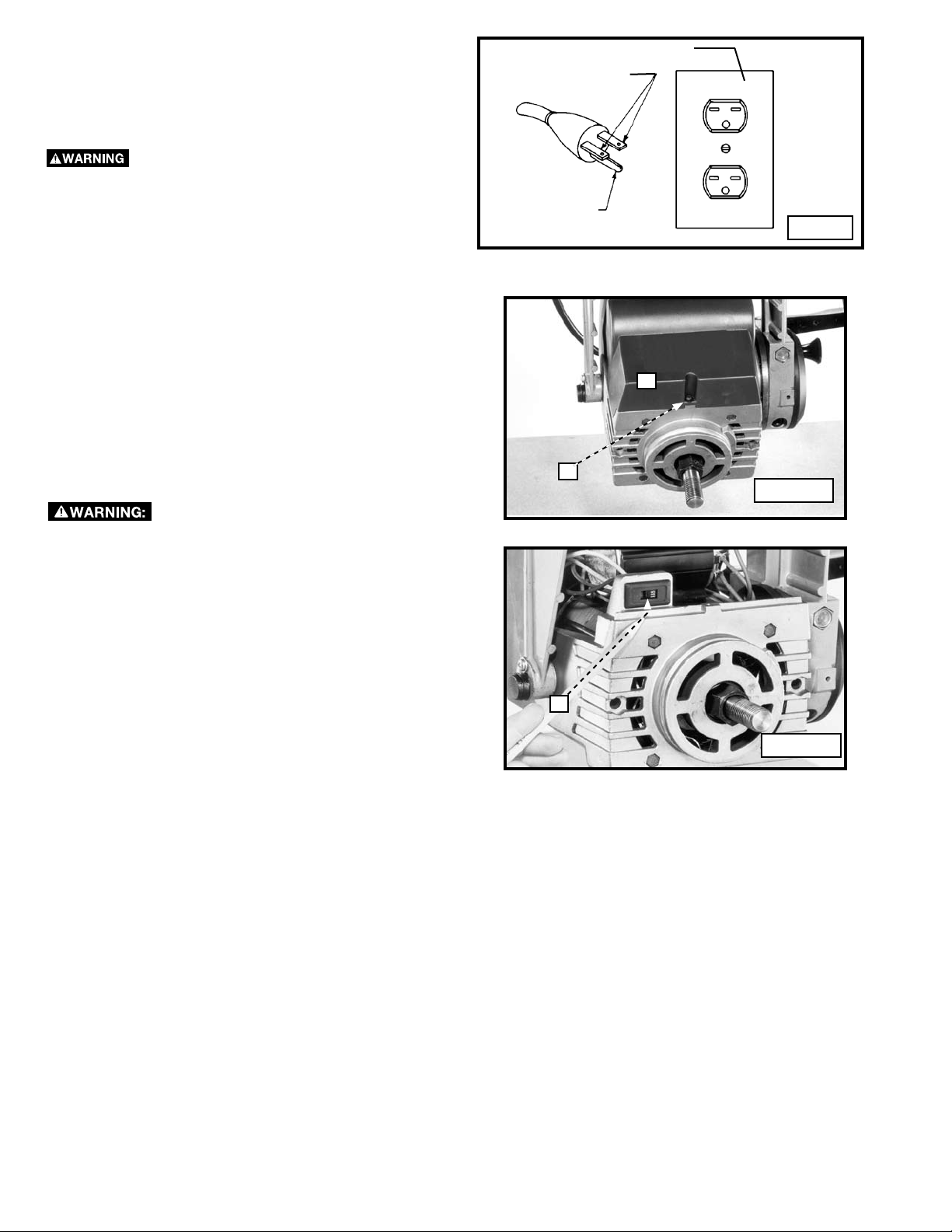

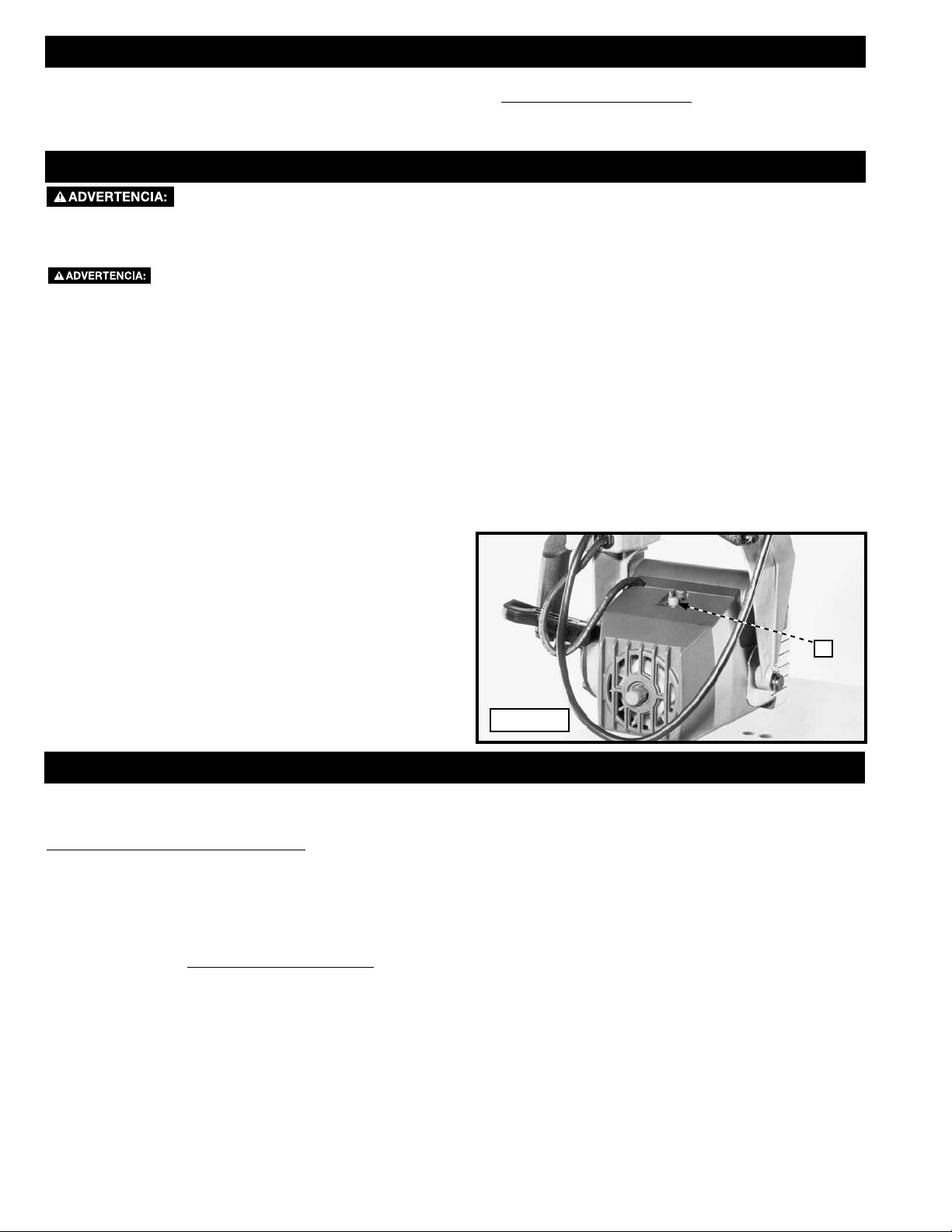

OVERLOAD PROTECTION

Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air.

The motor on your saw is equipped with an overload

relay (A) Fig. 63. If the motor shuts off or fails to start

due to overloading, or low voltage, turn the switch to the

“OFF” position, let the motor cool three to five minutes

then push the reset button (A). The motor can then be

turned on again in the usual manner. Some conditions

that may cause overloading are; cutting stock too fast,

using a dull blade, using the saw beyond its capacity, etc.

A

Fig. 63

26

Page 27

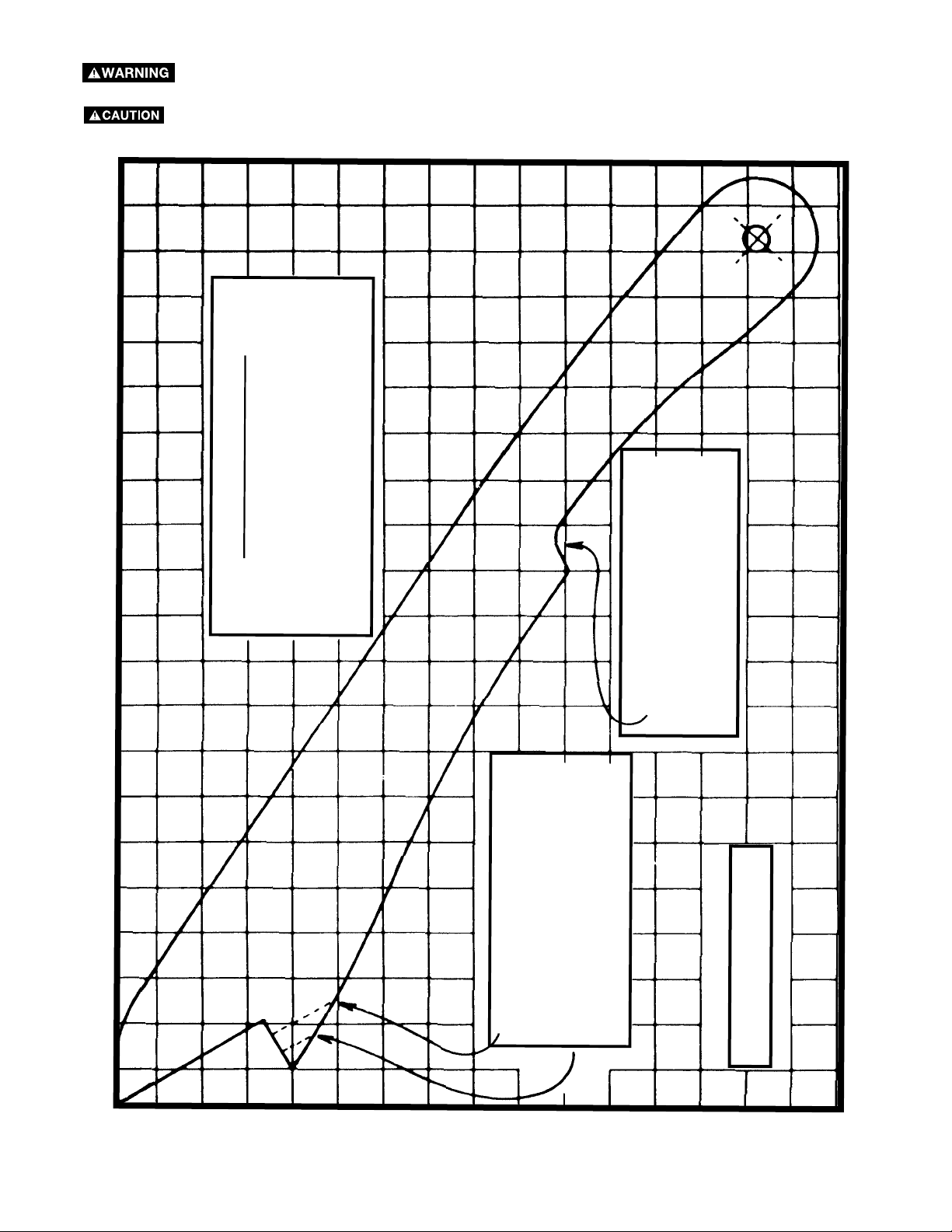

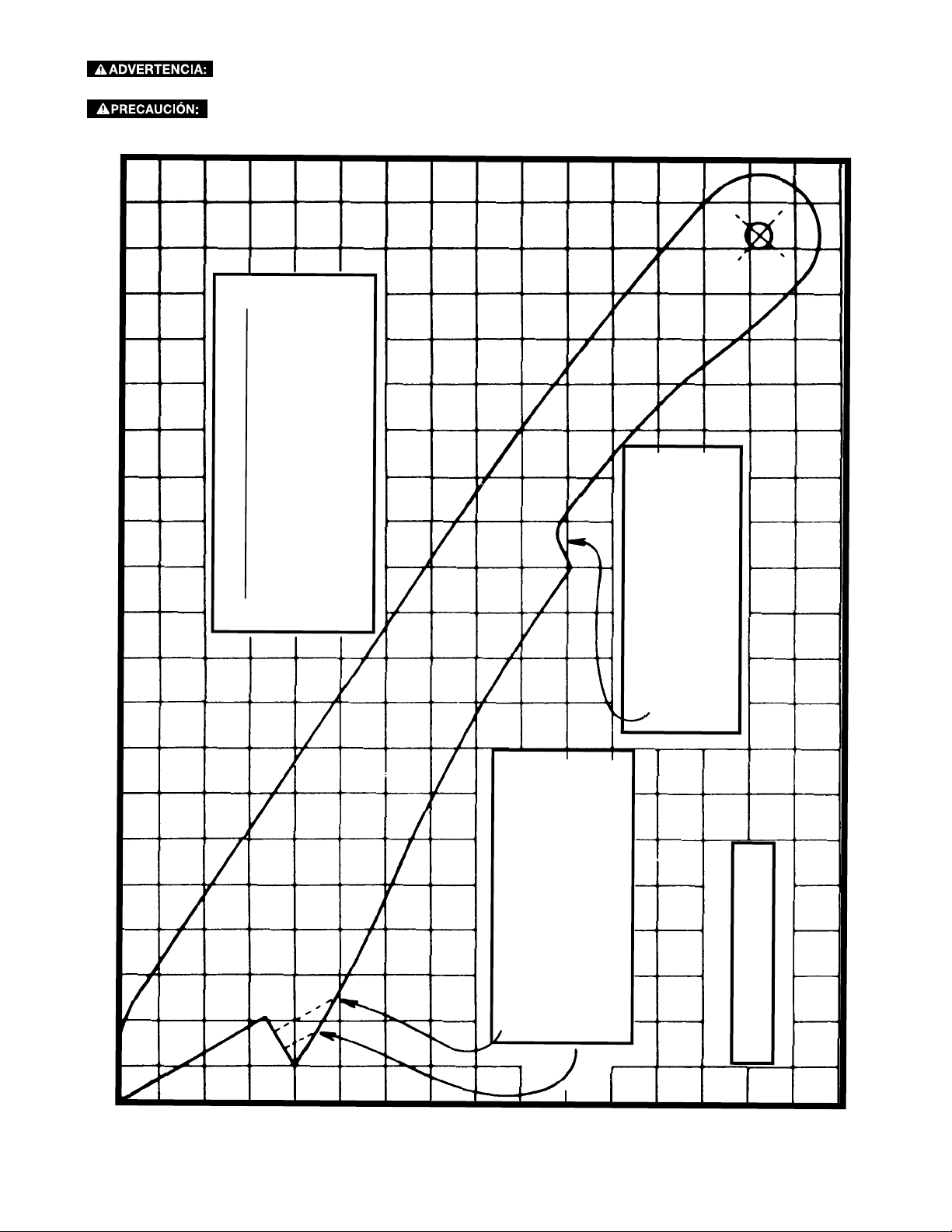

CONSTRUCTING A PUSH STICK

When ripping work less than 6" wide, a push-stick should be used to complete the feed and could easily be

made from scrap material by following the pattern shown in Fig. 83.

Make a push-stick from plywood or softwood, equal to or less than the width of the material to be cut.

PUSH STICK

thickness less than

width of material to be cut.

Make from 1/2" OR 3/4" WOOD or

prevent hand

Notch to help

from slipping.

27

Cut here to push 1/4" wood.

Cut here to push 1/2" wood.

1/2" Squares

Page 28

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our website at

You can also order parts from your nearest factory-owned branch, or by calling our Customer Care Center at 1-800-223-7278 to

receive personalized support from highly-trained technicians.

www.deltaportercableservicenet.com.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about Delta Machinery, its factoryowned branches, or an Authorized Warranty Service Center, visit our website at www.deltaportercable.com or call our Customer

Care Center at 1-800-223-7278. All repairs made by our service centers are fully guaranteed against defective material and

workmanship. We cannot guarantee repairs made or attempted by others.

You can also write to us for information at Delta Machinery, 4825 Highway 45 North, Jackson, Tennessee 38305 - Attention:

Product Service. Be sure to include all of the information shown on the nameplate of your tool (model number, type, serial number,

etc.)

ACCESSORIES

Since accessories other than those offered by Delta have not been tested with this product, use

of such accessories could be hazardous. For safest operation, only Delta recommended accessories should be

used with this product.

A complete line of accessories is available from your Delta Supplier, Porter-Cable • Delta Factory Service Centers, and

Delta Authorized Service Stations. Please visit our Web Site www.deltaportercable.com for a catalog or for the name

of your nearest supplier.

WARRANTY

To register your tool for warranty service visit our website at www.deltaportercable.com.

Two Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory which in normal

use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service

center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity

to verify the alleged defect by inspection. For all refurbished Delta product, the warranty period is 180 days. Delta may require that electric

motors be returned prepaid to a motor manufacturer’s authorized station for inspection and repair or replacement. Delta will not be responsible

for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone

other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for incidental or consequential

damages resulting from defective products. This warranty is Delta’s sole warranty and sets forth the customer’s exclusive remedy, with respect

to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly

disclaimed by Delta.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see coun-

try specific warranty information contained in the packaging, call the local company or see website for warranty information.

28

Page 29

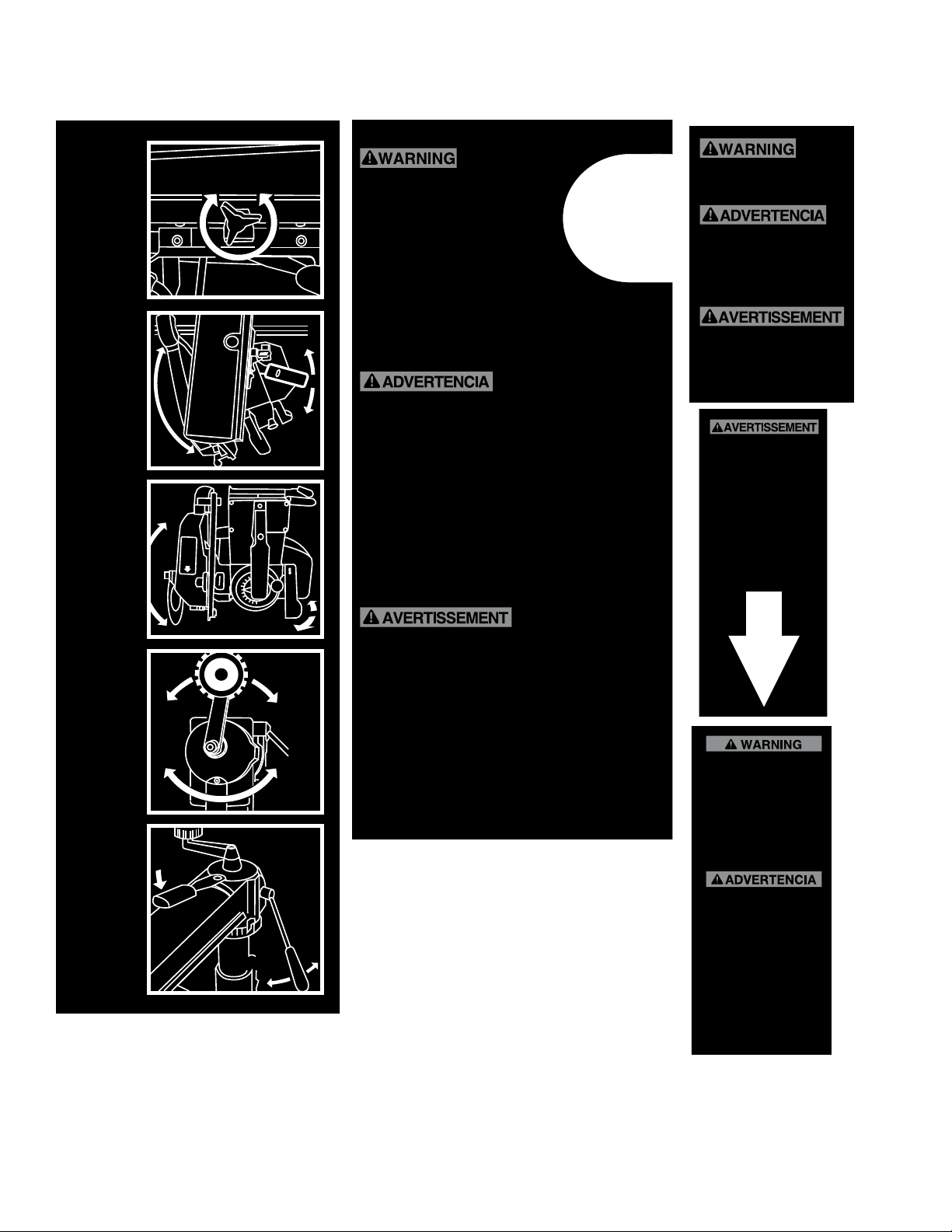

RIP

LOCK

Cutterhead

must be clamped

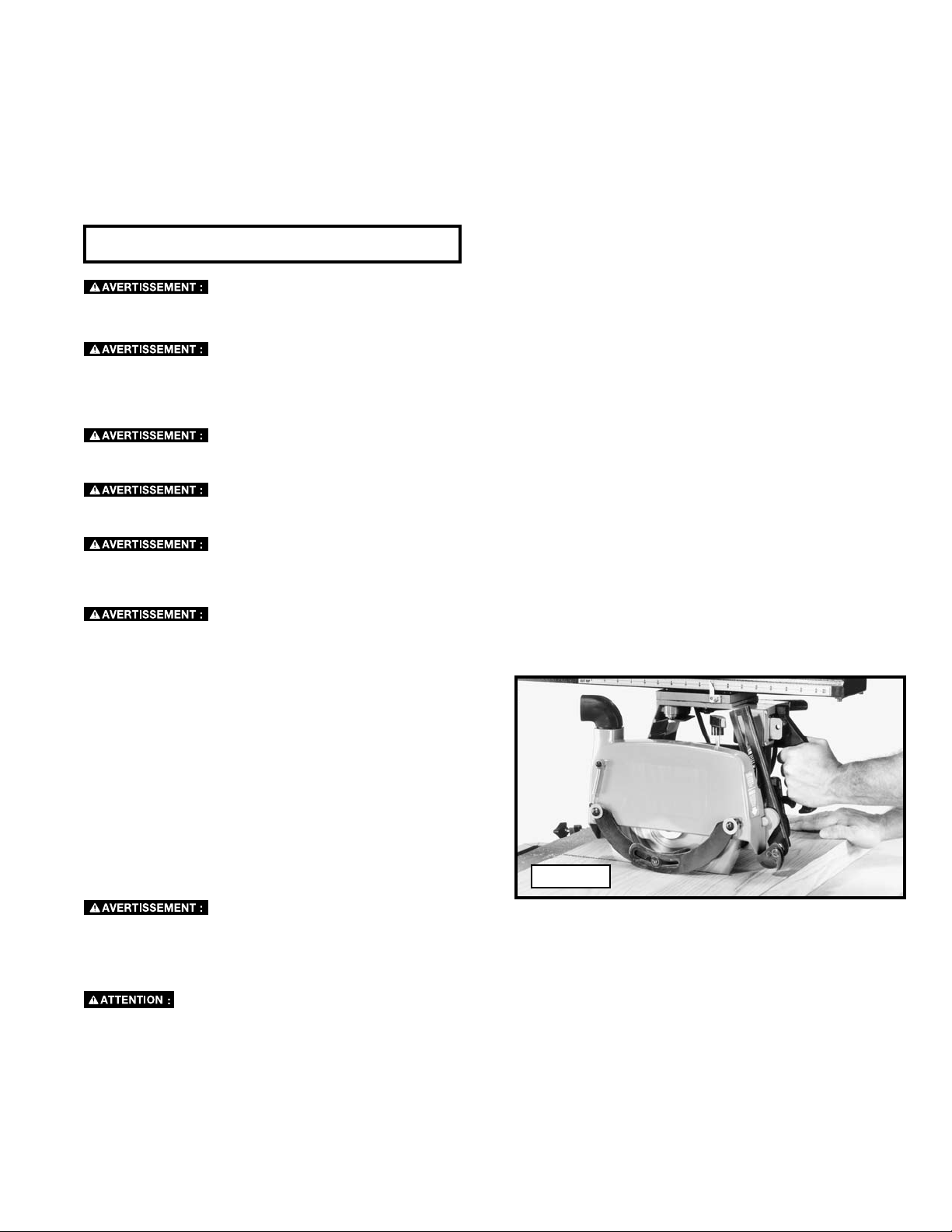

before performing