Epson RC170 User Manual

Rev.1a EM068P1378F

RC170 Option

Operator Panel

OP1

ii

RC170 Option Operator Panel OP1 Rev.1a

OP1 Rev.1a i

RC170 Option

Operator Panel

OP1

Rev.1a

Copyright © 2006 SEIKO EPSON CORPORATION. All rights reserved.

ii OP1 Rev.1a

FOREWORD

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the Operator Panel.

Please carefully read this manual and other related manuals before installing the robot

system.

Keep this manual handy for easy access at all times.

WARRANTY

The robot system and its optional parts are shipped to our customers only after being

subjected to the strictest quality controls, tests, and inspections to certify its compliance

with our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please ask your Regional Sales Office for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

1. Damage or malfunction caused by improper use which is not described in the manual,

or careless use.

2. Malfunctions caused by customers’ unauthorized disassembly.

3. Damage due to improper adjustments or unauthorized repair attempts.

4. Damage caused by natural disasters such as earthquake, flood, etc.

Warnings, Cautions, Usage:

1. If the robot system associated equipment is used outside of the usage conditions an

d

product specifications described in the manuals, this warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this manual

cannot warn the user of all possible hazards.

OP1 Rev.1a iii

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® XP Operating system

Microsoft® Windows® 2000 Operating system

Throughout this manual, Windows XP, and Windows 2000 refer to above respective

operating systems. In some cases, Windows refers generically to Windows XP, and

Windows 2000.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

INQUIRIES

Contact the following service center for robot repairs, inspections or adjustments.

If service center information is not indicated below, please contact the supplier office for

your region.

Please prepare the following items before you contact us.

- Your controller model and its serial number

- Your manipulator model and its serial number

- Software and its version in your robot system

- A description of the problem

SERVICE CENTER

iv OP1 Rev.1a

MANUFACTURER & SUPPLIER

Japan & Others

SEIKO EPSON CORPORATION

Suwa Minami Plant

Factory Automation Systems Dept.

1010 Fujimi, Fujimi-machi,

Suwa-gun, Nagano, 399-0295

JAPAN

TEL : +81-(0)266-61-1802

FAX : +81-(0)266-61-1846

SUPPLIERS

North & South America

EPSON AMERICA, INC.

Factory Automation/Robotics

18300 Central Avenue

Carson, CA 90746

TEL : +1-562-290-5900

FAX : +1-562-290-5999

E-MAIL : info@robots.epson.com

Europe

EPSON DEUTSCHLAND GmbH

Factory Automation Division

Otto-Hahn-Str.4

D-40670 Meerbusch

Germany

TEL : +49-(0)-2159-538-1391

FAX : +49-(0)-2159-538-3170

E-MAIL : robot.infos@epson.de

Before Reading This Manual

Do not connect the OP1 to the following Robot Controllers. Connecting to the following

Robot Controllers may result in malfunction of the device since the pin assignments are

different.

RC420 / RC520 / SRC5** / SRC-3** / SRC-2**

)

NOTE

OP1 Rev.1a v

TABLE OF CONTENTS

1. Safety 1

1.1 Conventions...................................................................................................1

1.2 Safety Precautions ........................................................................................1

1.3 Emergency Stop............................................................................................3

2. Specifications 4

2.1 Specification Tables ......................................................................................4

2.1.1 Electrical Specifications................................................................... 4

2.1.2 Environmental Specifications .......................................................... 4

2.1.3 Appearance Specifications.............................................................. 4

2.2 Part Names and Functions............................................................................5

2.3 Appearance and Dimensions ........................................................................6

2.3.1 Appearance (without mounting metal hasps) ................................. 7

2.3.2 Appearance (with mounting metal hasps)....................................... 7

2.3.3 Panel Cutout Dimensions................................................................ 8

2.3.4 Mounting Metal Hasps Dimensions ................................................ 8

3. Installation 9

3.1 Unpacking......................................................................................................9

3.2 Installation......................................................................................................9

3.2.1 Gasket................................................................................................. 9

3.2.2 Mounting Holes ................................................................................. 10

3.2.3 Installing Operator Panel .................................................................. 11

3.3 Connecting Cables......................................................................................12

3.4 Teach Pendant Connection.........................................................................13

4. Operation 14

4.1 Basic Operations .........................................................................................14

4.2 Startup Screen.............................................................................................15

4.3 Program Execution Screen .........................................................................16

4.4 Task Monitor Screen ...................................................................................19

4.5 I/O Monitor Screen ......................................................................................20

4.6 System History Screen ................................................................................22

4.7 Application Screen ......................................................................................23

4.8 Setup Screen...............................................................................................25

vi OP1 Rev.1a

5. Programming for Operator Panel 27

5.1 Display on Operator Panel ..........................................................................27

5.1.1 Simple Display Program.................................................................27

5.1.2 Display Device................................................................................28

5.2 Data Input from Operator Panel.................................................................. 28

5.2.1 Value Input ......................................................................................29

5.2.2 String Input......................................................................................30

5.3 About Display Language ............................................................................. 31

6. Maintenance and Inspection 32

6.1 Contrast Adjustment.................................................................................... 32

6.2 Brightness Adjustment ................................................................................ 33

6.3 Firmware Update.........................................................................................34

6.4 Case and Display Cleaning......................................................................... 34

6.5 About Gasket............................................................................................... 35

6.6 Regular Maintenance Inspection ................................................................36

6.7 Backlight Replacement ...............................................................................36

6.8 Maintenance Parts List................................................................................ 36

1. Safety

OP1 Rev.1a 1

1. Safety

1.1 Conventions

Important safety considerations are indicated throughout the manual by the following

symbols. Be sure to read the descriptions shown with each symbol.

WARNING

This symbol indicates that a danger of possible serious injury or

death exists if the associated instructions are not followed

properly.

WARNING

This symbol indicates that a danger of possible harm to people

caused by electric shock exists if the associated instructions are

not followed properly.

CAUTION

This symbol indicates that a danger of possible harm to people or

physical damage to equipment and facilities exists if the

associated instructions are not followed properly.

1.2 Safety Precautions

For details of Safety, refer to the User’s Guide 2. Safety. Please read and understand the chapter

before using the robot system.

Only trained personnel should design and install the robot system. Trained

personnel are defined as those who have taken robot system training and

maintenance training classes held by the manufacturer, dealer, or local

representative company, or those who understand the manuals thoroughly and

have the same knowledge and skill level as those who have completed the

training courses.

WARNING

Only authorized personnel who have taken the safety training should be allowed

to execute teaching or calibration of the robot system.

The safety training is the program for industrial robot operator that follows the

laws and regulations of each nation. The personnel who have taken the safety

training acquire knowledge of industrial robots (operations, teaching, etc.).

The personnel who have completed the robot system-training class held by the

manufacturer, dealer, or locally-incorporated company are allowed to maintain

the robot system.

1. Safety

2 OP1 Rev.1a

Only authorized personnel who have taken the safety training should be allowed

to maintain the robot system.

The safety training is the program for industrial robot operator that follows the laws

and regulations of each nation. The personnel who have taken the safety training

acquire knowledge of industrial robots (operations, teaching, etc.), knowledge of

inspections, and knowledge of related rules/regulations. The personnel who have

completed the robot system-training and maintenance-training classes held by

the manufacturer, dealer, or locally incorporated company are allowed to maintain

the robot system.

WARNING

Immediately press the EMERGENCY STOP switch whenever you suspect any

danger.

The Operator Panel is equipped with an EMERGENCY STOP switch. Before

operating the Operator Panel, make sure that the EMERGENCY STOP switch on

the Operator Panel functions properly. Operating the Operator Panel when the

switch does not function properly is extremely hazardous and may result in

serious bodily injury and/or serious damage to the equipment, as the switch

cannot fulfill its intended function in an emergency.

WARNING

Be sure to connect the cables between the Controller and the Operator Panel

properly. Do not allow unnecessary strain on the cables. (Do not put heavy

objects on the cables. Do not bend or pull the cables forcibly.) The unnecessary

strain on the cables may result in damage to the cables, disconnection, and/or

contact failure. Damaged cables, disconnection, or contact failure is extremely

hazardous and may result in electric shock and/or improper function of the

system. Do not use the cables near heat or fire.

Do not shock the Operator Panel physically or place any object on Operator

Panel. A liquid crystal display is used for the Operator Panel display. If the

display is damaged, liquid crystal may leak out. Liquid crystal is harmful. If it

sticks on your skin or clothes, immediately wash your skin and clothes thoroughly

with clean water and soap immediately.

The Operator Panel must be used within the environmental conditions described

in this manual. This product has been designed and manufactured strictly for use

in a normal indoor environment. Using this product in the environment that

exceeds the conditions may not only shorten the life cycle of the product but also

cause serious safety problems.

Do not disassemble, repair, or modify the Operator Panel by yourself. Improper

disassembly, repair, or modification of the Operator Panel may cause not only

improper function of the robot system but also serious safety problems.

CAUTION

Be sure to turn OFF the Controller before connecting and disconnecting cables.

Connecting or disconnecting the cables with the power ON may result in

malfunction of the robot system.

1. Safety

OP1 Rev.1a 3

1.3 Emergency Stop

WARNING

Immediately press the EMERGENCY STOP switch whenever you suspect any

danger.

The Operator Panel is equipped with an EMERGENCY STOP switch. Before

operating the Operator Panel, make sure that the EMERGENCY STOP switch

on the Operator Panel functions properly. Operating the Operator Panel when

the switch does not function properly is extremely hazardous and may result in

serious bodily injury and/or serious damage to the equipment, as the switch

cannot fulfill its intended function in an emergency.

Furthermore, the EMERGENCY STOP switch does not function when nothing is

displayed on the Operator Pendant screen for the disconnection of the Operator

Pendant to the Controller.

Press the EMERGENCY STOP switch to stop the program execution, and turn OFF the

robot axis motors. The program, pause data and other data will not be destroyed.

When the EMERGENCY STOP switch is pressed, the Emergency Stop state is held both

mechanically and electrically.

To resume operation, follow the procedure below to reset the emergency stop state.

How to Reset an Emergency Stop State

(1) Remove the cause of the Emergency Stop, and make sure that the robot can be operated

safely when robot operation is resumed.

(2) Release the EMERGENCY STOP switch. To release a mechanical hold, turn the

EMERGENCY STOP switch to the right.

(3) Display the program execution screen and touch the Reset button.

When the Emergency Stop is released, the “EMERGENCY STOP” on the Operator Panel

Program Execution Screen turns OFF (displays

).

2. Specifications

4 OP1 Rev.1a

2. Specifications

2.1 Specification Tables

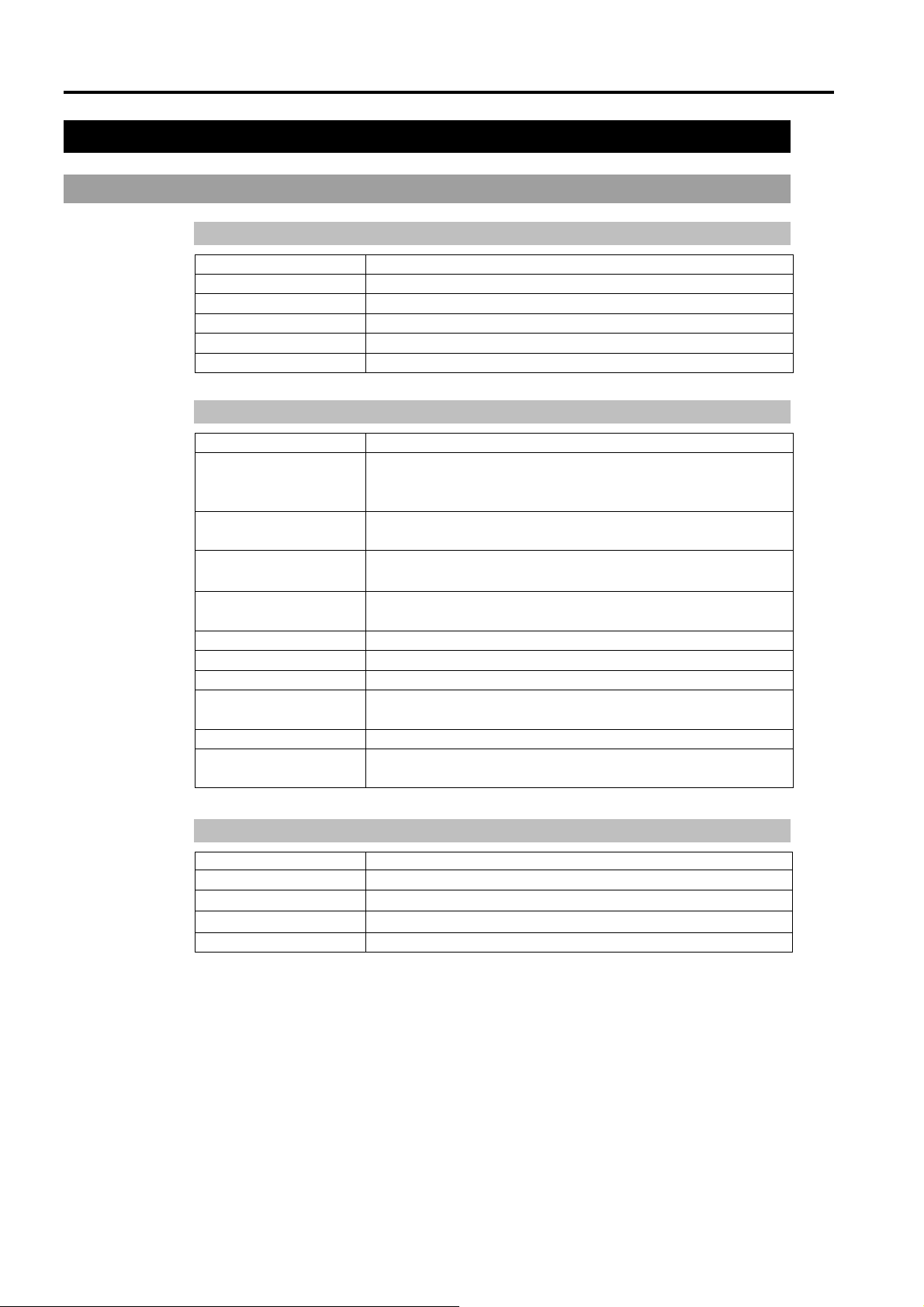

2.1.1 Electrical Specifications

Item Specifications

Rated voltage DC 24 V

Voltage range DC 21.6 to 26.4 V

Power consumption 7 W or less

Dielectric strength AC 500 V 20 mA per minute (across charger and FG terminals)

Insulation resistance 500 VDC 20 MΩ or more (across charger and FG terminals)

2.1.2 Environmental Specifications

Item Specifications

Ambient temperature

(in panel and at sides of

display screen)

5 to 40 deg C (with minimal variation)

Storage ambient

temperature

−25 to 55 deg C

Operating ambient

humidity

20 to 80% (no condensation)

Storage ambient

humidity

20 to 80% (no condensation)

Dust 0.1 mg/m

3

or less (no conductive dust)

Contamination level 2

Corrosive gasses Free of corrosive gasses

Air pressure resistance

(operation altitude)

800 to 1114 hPa (Max. 2000 m)

Noise resistance 1 kV (EN61000-4-4)

Electrostatic discharge

immunity

4 kV (EN61000-4-2 level 2)

2.1.3 Appearance Specifications

Item Specifications

Protective structure* JEM1030 IP65 or equivalent NEMA#250 TYPE4X/12

External dimensions

W215 mm × H155 mm × D46 mm (excluding connector hood)

Weight

Approx. 800 g (Including Bypass Plug. Excluding the cable.)

Cooling method Air-cooling without blower

* The protective structure is for the front part when the Operator Panel is installed. Though

conformity has been confirmed under applicable testing conditions, use under all

environments is not guaranteed. Before you start to use the Operator Panel, confirm use

in the operating environment. Also, gasket that is used for long periods of time or once

has been installed on the panel is scratched or dirty, and may cause lose sufficient

protection performance. To ensure consistent protection performance, replace the gasket

periodically.

2. Specifications

OP1 Rev.1a 5

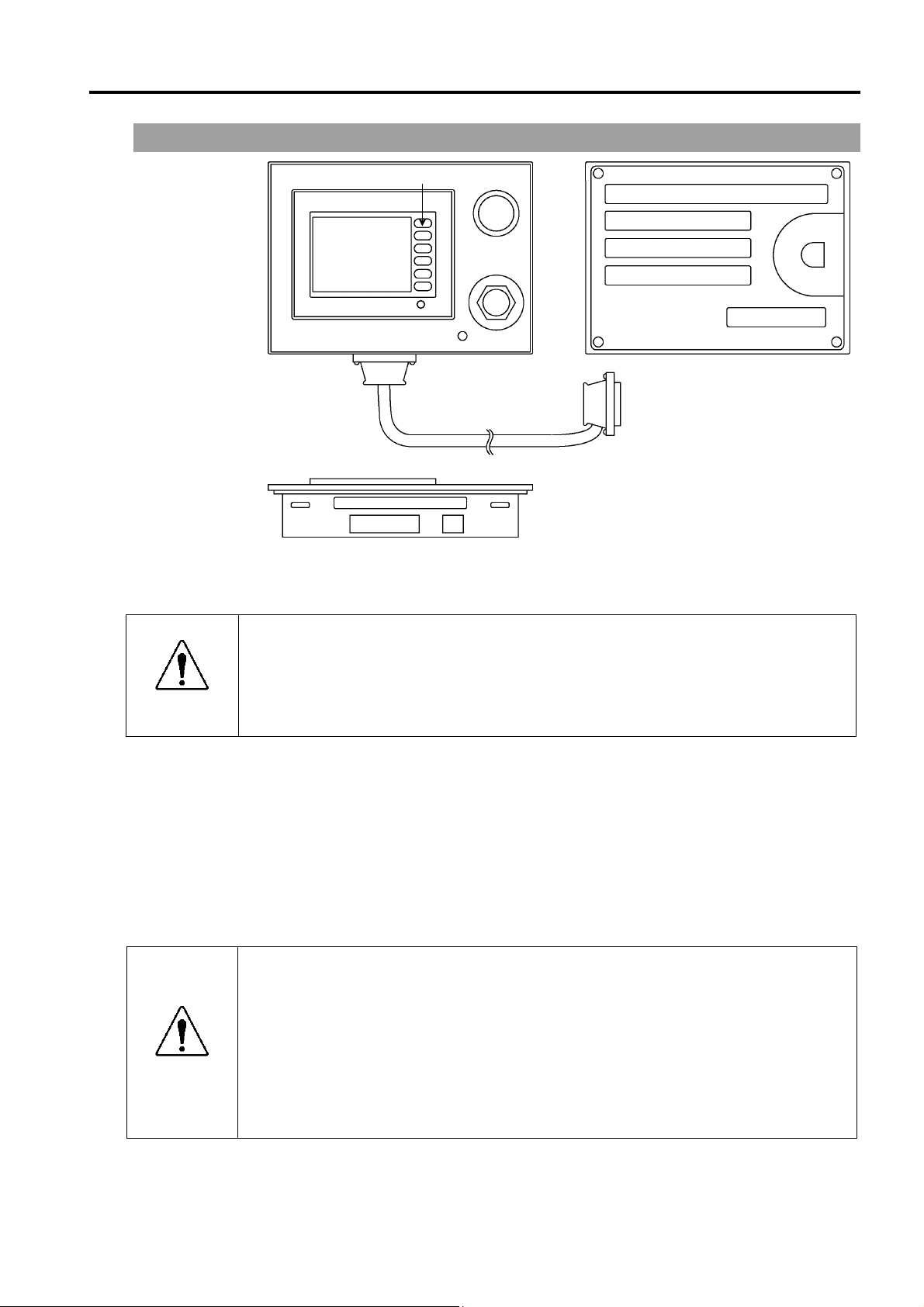

2.2 Part Names and Functions

(1)

(3)

(4)

(6)

(7)

(8)

(9)

(2)

(5)

(8)

(10)

(1) Touch Panel

This screen displays various information, and is used for automatic operation, data entry,

and other operations.

WARNING

When the backlight of the touch panel goes out, the screen turns completely black

and you can no longer see what is on the screen. The touch switches, however,

are enabled. When nothing is displayed on the LCD screen even though the

power lamp is ON, the backlight may have gone out. Stop to use it immediately

and repair the Operator Panel.

(2) Function switches

These switches are used for entering data from the Operator Panel.

(3) EMERGENCY STOP switch

This switch is for Emergency Stop. When this switch is pressed, the Emergency Stop state is

held both mechanically and electrically. When an emergency stop is performed, the motor

for each manipulator axis turns OFF and the robot stops immediately.

For details on how to release an Emergency Stop, refer to 1.3 Emergency Stop.

WARNING

Immediately press the EMERGENCY STOP switch whenever you suspect any

danger.

The Operator Panel is equipped with an EMERGENCY STOP switch. Before

operating the Operator Panel, make sure that the EMERGENCY STOP switch on

the Operator Panel functions properly. Operating the Operator Panel when the

switch does not function properly is extremely hazardous and may result in

serious bodily injury and/or serious damage to the equipment, as the switch

cannot fulfill its intended function in an emergency.

2. Specifications

6 OP1 Rev.1a

(4) Power Lamp

This lights (green) when the controller's power switch is turned ON.

(5) Teach Pendant connector (Bypass Plug)

This connector is for connecting the optional Teach Pendant for Robot Controller RC170.

When the Teach Pendant does not need to be connected, connect the Bypass Plug. The

robot status will be the Emergency Stop state unless the Teach Pendant or Bypass Plug is

connected.

WARNING

To ensure that the dust and drip-proof function properly, be sure to attach the

Bypass Plug when the Teach Pendant is not connected. Make sure to secure the

Teach Pendant connect or the Bypass Plug.

(6)

Controller connector

This connector connects the cable from the Operator Panel to the Controller.

(D-Sub 25-pin)

(7) HCOM connector

This connector is for connecting the high-speed communications connector. (RJ45)

(8) Mounting metal hasp

These metal hasps are for installing the Operator Panel on a panel.

2 holes both at top and bottom (total 4 locations)

(9) TOOL connector

This connector is for connecting the communications cable to change the display firmware.

(10) OP1 cable

Connects the straight connector to the Operator Panel and right angle connector to the

RC170.

Secure the connector on the RC170 side with hexagon head screws.

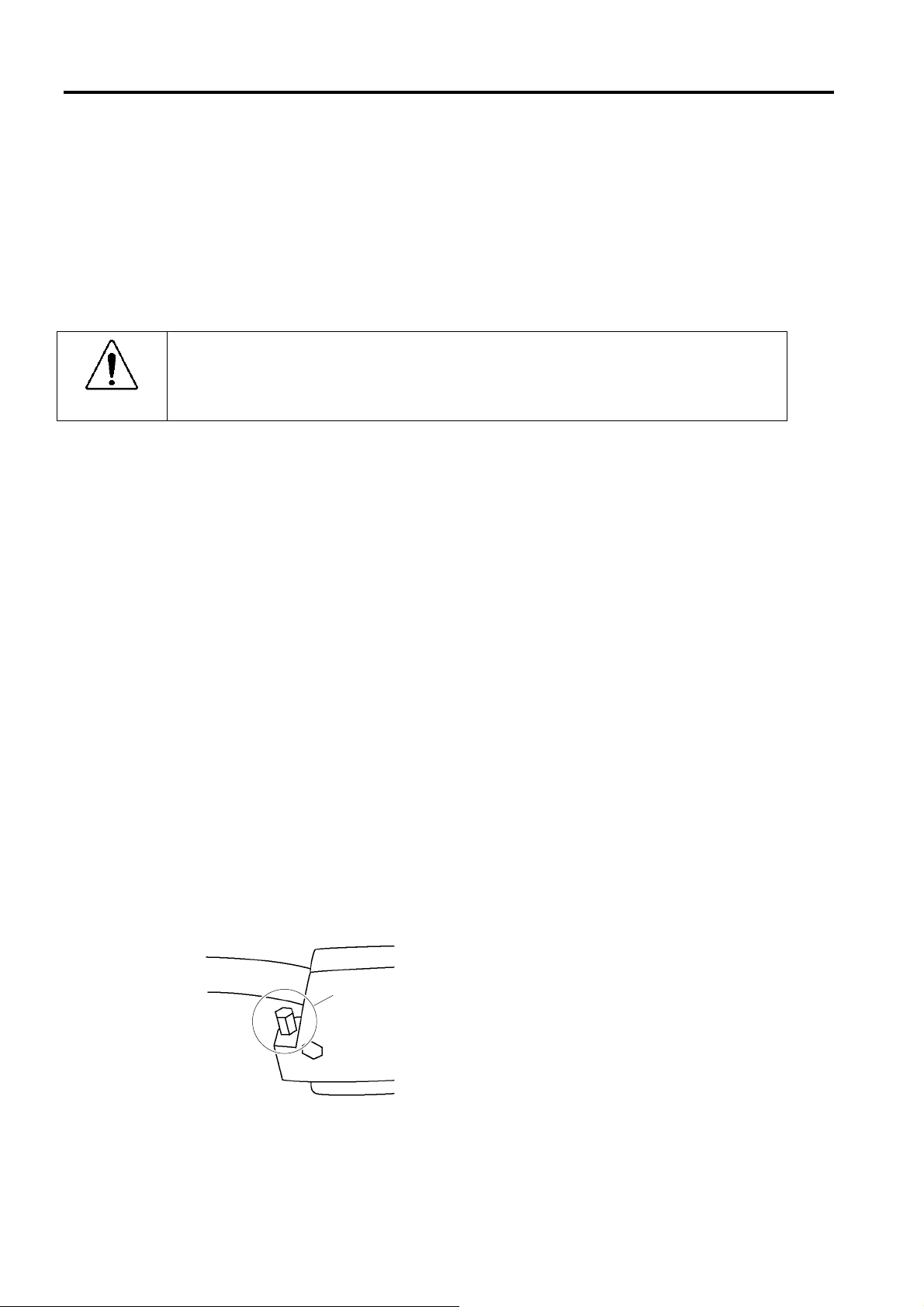

Hexagon Head Screw

(on both side of the connector)

RC170 Side Connector

Loading...

Loading...