Page 1

RS3-55 series

Rev.2 EM110R2082F

SCARA ROBOT

MANIPULATOR MANUAL

Page 2

MANIPULATOR MANUAL RS3-55 series Rev.2

Page 3

SCARA ROBOT

RS3-55 series Manipulator Manual

Rev.2

Copyright © 2010 SEIKO EPSON CORPORATION. All rights reserved.

RS3-55 Rev.2 i

Page 4

d

FOREWORD

Thank you for purchasing our robot products.

This is the attachment manual for RS3-551* series manipulator and contains the

information necessary for the correct use of RS3-55 series. For other information, refer

to RS series manipulator manual. Chapter number in this manual is the same as in RS

series manipulator manual.

Please carefully read this manual and other related manuals before installing the robot

system.

Keep this manual handy for easy access at all times.

WARRANTY

The Manipulator and its optional parts are shipped to our customers only after being

subjected to the strictest quality controls, tests, and inspections to certify its compliance

with our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please ask your Regional Sales Office for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

1. Damage or malfunction caused by improper use which is not described in the manual,

or careless use.

2. Malfunctions caused by customers’ unauthorized disassembly.

3. Damage due to improper adjustments or unauthorized repair attempts.

4. Damage caused by natural disasters such as earthquake, flood, etc.

Warnings, Cautions, Usage:

1. If the Manipulator or associated equipment is used outside of the usage conditions an

product specifications described in the manuals, this warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this manual

cannot warn the user of all possible hazards.

ii RS3-55 Rev.2

Page 5

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

INQUIRIES

Contact the following service center for robot repairs, inspections or adjustments.

If service center information is not indicated below, please contact the supplier office for

your region.

Please prepare the following items before you contact us.

- Your controller model and its serial number

- Your manipulator model and its serial number

- Software and its version in your robot system

- A description of the problem

SERVICE CENTER

RS3-55 Rev.2 iii

Page 6

MANUFACTURER & SUPPLIER

TEL : +81-(0)266-61-1802

FAX : +81-(0)266-61-1846

Japan & Others

SEIKO EPSON CORPORATION

Suwa Minami Plant

Factory Automation Systems Dept.

1010 Fujimi, Fujimi-machi,

Suwa-gun, Nagano, 399-0295

JAPAN

SUPPLIERS

Factory Automation/Robotics

TEL : +1-562-290-5900

FAX : +1-562-290-5999

E-MAIL : info@robots.epson.com

Factory Automation Division

TEL : +49-(0)-2159-538-1391

FAX : +49-(0)-2159-538-3170

E-MAIL : robot.infos@epson.de

North & South America

Europe

EPSON AMERICA, INC.

18300 Central Avenue

Carson, CA 90746

USA

EPSON DEUTSCHLAND GmbH

Otto-Hahn-Str.4

D-40670 Meerbusch

Germany

iv RS3-55 Rev.2

Page 7

For Customers in the European Union

The crossed out wheeled bin label that can be found on your product indicates that this

product and incorporated batteries should not be disposed of via the normal household

waste stream. To prevent possible harm to the environment or human health please

separate this product and its batteries from other waste streams to ensure that it can be

recycled in an environmentally sound manner. For more details on available collection

facilities please contact your local government office or the retailer where you purchased

this product. Use of the chemical symbols Pb, Cd or Hg indicates if these metals are used

in the battery.

This information only applies to customers in the European Union, according to

DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE

COUNCIL OF 6 September 2006 on batteries and accumulators and waste batteries and

accumulators and repealing Directive 91/157/EEC and legislation transposing and

implementing it into the various national legal systems.

For other countries, please contact your local government to investigate the possibility of

recycling your product.

The battery removal/replacement procedure is described in the following manuals:

Controller manual / Manipulator manual (Maintenance section)

RS3-55 Rev.2 v

Page 8

Before Reading This Manual

This section describes what you should know before reading this manual.

Structure of Control System

The RS series Manipulators can be used with the following combinations of Controllers and

software.

The operating methods and descriptions are different depending on which software you are

using. The following icons are put beside appropriate text as necessary. Use the

descriptions that pertain to the software you are using.

Controller Software

RC180 EPSON RC+ 5.0

RC620 EPSON RC+ 6.0

For details on commands, refer to User’s Guide or “On-line help”.

Turning ON/OFF Controller

When you see the instruction “Turn ON/OFF the Controller” in this manual, be sure to

turn ON/OFF all the hardware components. For the Controller composition, refer to the

table above.

Shape of Motors

The shape of the motors used for the Manipulator that you are using may be different from

the shape of the motors described in this manual because of the specifications.

Setting by Using Software

This manual contains setting procedures by using software. They are marked with the

following icon.

EPSON

RC+

Figures in this Manual

The figures of manipulators indicated in this manual are basically Standard-model

Manipulator. Unless special instruction is provided, the specifications of Standard-model

and Cleanroom-model are the same.

vi RS3-55 Rev.2

Page 9

TABLE OF CONTENTS

Before Reading This Manual........................................................................... vi

Setup & Operation

1. Safety 1

1.4 Emergency Stop ......................................................................................1

1.5 Emergency Movement Without Drive Power ...........................................2

1.6 Manipulator Labels ..................................................................................3

2. Specifications 6

2.2 Model Number and Model Differences ....................................................6

2.3 Part Names and Outer Dimensions .........................................................7

2.4 Specifications.........................................................................................11

3. Environments and Installation 14

3.2 Base Table.............................................................................................14

3.3 Mounting Dimensions ............................................................................15

3.4 Unpacking and Transportation...............................................................16

3.7 User Wires and Pneumatic Tubes .........................................................17

4. Setting of End Effectors 18

TABLE OF CONTENTS

Maintenance

4.2 Attaching Cameras and Air valves.........................................................18

4.3 Weight and Inertia Settings....................................................................19

4.4 Precautions for Auto Acceleration/Deceleration of Joint #3 ..................20

5. Motion Range 21

5.1 Motion Range Setting by Pulse Range ..................................................21

5.1.1 Max. Pulse Range of Joint #1 ....................................................21

5.4 Standard Motion Range .........................................................................22

14. Maintenance Parts List 23

14.1 Common Parts ...................................................................................23

14.2 Parts by Environment Model ..............................................................24

14.2.1 S: Standard-model .................................................................24

14.2.2 C: Cleanroom-model ..............................................................24

RS3-55 Rev.2 vii

Page 10

TABLE OF CONTENTS

viii RS3-55 Rev.2

Page 11

Setup & Operation 1. Safety

1.4 Emergency Stop

If the Manipulator moves abnormally during operation, immediately press the Emergency

Stop switch. Stops the power supply to the motor, and the arm stops in the shortest

distance with the dynamic brake and mechanical brake.

However, avoid pressing the Emergency Stop switch unnecessarily while the Manipulator

is running normally. Otherwise, the Manipulator may hit the peripheral equipment since

the operating trajectory while the robot system stops is different from that in normal

operation.

To place the system in emergency mode during normal operation, press the Emergency

Stop switch when the Manipulator is not moving.

Refer to the Controller manual for instructions on how to wire the Emergency Stop switch

circuit.

Setup & Operation 1. Safety

Free running distance in emergency

The operating Manipulator cannot stop immediately after the Emergency Stop switch is

pressed.

The free running time/angle/distance of the Manipulator are shown below. However,

remember that the values vary depending on following conditions.

Weight of the end effector Weight of work piece Operating pose

Weight Speed Accel etc.

RS3-55 Rev.2 1

Page 12

Setup & Operation 1. Safety

Conditions for Measurement

Accel Setting 100

Speed Setting 100

Load [kg] 4

Weight Setting 4

Start point of

operation

Point where the

emergency stop

signal is input

Joint #1

Stop point

Joi nt #2

Target point

Controller RC180 / RC620

Manipulator RS3-551*

Free running time

Free running angle

Free running distance Joint #3 [mm] 75

Joint #1 + Joint #2 [sec.] 0.7

Joint #3 [sec.] 0.4

Joint #1 [deg.] 30

Joint #2 [deg.] 50

Joint #1 + Joint #2 [deg.] 80

2 RS3-55 Rev.2

Page 13

e

1.5 Emergency Movement Without Drive Power

When the system is placed in emergency mode, push the arm or joint of the

Manipulator by hand as shown below:

Arm #1 ...........Push the arm by hand.

Arm #2 ...........Push the arm by hand.

Joint #3 The joint cannot be moved up/down by hand until the

electromagnetic brake applied to the joint has been released.

Move the joint up/down while pressing the brake release

button.

Joint #4 ..........Rotate the shaft by hand.

Joi nt #1

(rotating)

−

+

Setup & Operation 1. Safety

Joint #2

Base

Arm #1

Arm #2

Joint #3

(up and down)

+

−

−

Joint #4

(rotating)

+

Shaft

(rot ati ng)

−

+

Joint #3

brake release

button

Bas

Arm #1

Arm #2

NOTE

Be careful of the shaft while the brake release button is pressed,

)

because the shaft may be lowered by the weight of an end effector.

RS3-55 Rev.2 3

Page 14

Setup & Operation 1. Safety

1.6 Manipulator Labels

The following labels are attached near the locations of the Manipulator where specific

dangers exist.

Be sure to comply with descriptions and warnings on the labels to operate and maintain

the Manipulator safely.

Do not tear, damage, or remove the labels. Use meticulous care when handling those

parts or units to which the following labels are attached as well as the nearby areas:

Label NOTE

A

B

C

D

Before loosening the base mounting screws,

hold the arm and secure it tightly with a band

to prevent hands or fingers from being caught

in the Manipulator.

Hazardous voltage exists while the

Manipulator is ON. To avoid electric shock,

do not touch any internal electric parts.

You can catch your hand or fingers between

the shaft and Arm #1 when bringing your

hand close to moving parts.

Only authorized personnel should perform

sling work and operate a crane and a forklift.

When these operations are performed by

E

F

unauthorized personnel, it is extremely

hazardous and may result in serious bodily

injury and/or severe equipment damage to

the robot system.

Be careful of the hand falling and rotation

while the brake release button is being

pressed.

4 RS3-55 Rev.2

Page 15

Setup & Operation 1. Safety

A

Label NOTE

G

H

Location of Labels

H

Top

C

C

Side

D

Front

C

F(Back side)

E

B (Both sides)

C

G

Bottom

RS3-55 Rev.2 5

Page 16

Setup & Operation 2. Specifications

Setup & Operation 2. Specifications

2.2 Model Number

RS3-55 1 S

Environment

S : Standard

C : Cleanroom & ESD (Anti-Static)

Joint #3 stroke

: 130 mm

1

: 100 mm (with bellows)

Arm length

Environment

Cleanroom-model

This model has additional features that reduce dust emitted by the Manipulator to enable

use in clean room environments.

For details of the specifications, refer to Setup & Operation: 2.4 Specifications.

55 : 550 mm

6 RS3-55 Rev.2

Page 17

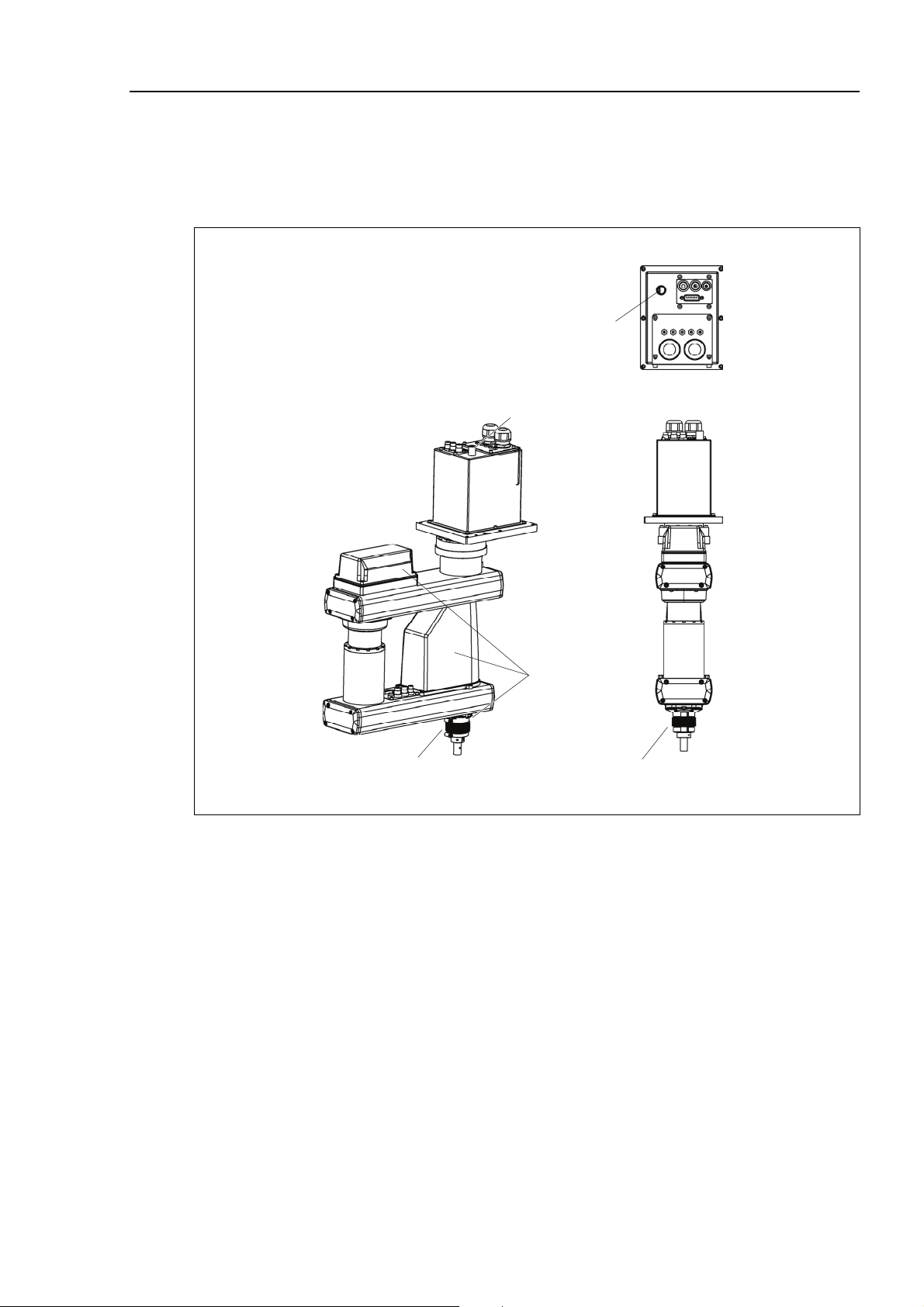

2.3 Part Names and Outer Dimensions

Standard-model RS3-551S

Power Cable

Setup & Operation 2. Specifications

Signal Cable

Base

Arm #1

Arm #2

Joint #1

(rotating)

−

+

User Connector

(15-pin D-sub Connector)

Fitting (white)

for ø4 mm pneumatic tube

for ø 6 mm pneum atic tube

Joint #2

(rotating)

−

+

Fitting (black)

Fitting (white)

Fitting (black)

Signal Cable

for ø4 mm

pneumatic tube

for ø 6 mm

pneumatic tube

Fitting (white)

for ø 6 mm

pneumatic tube

Power Cable

Base

Arm #1

Arm #2

Joint #3

(up and down)

+

−

−

(rotating)

Joint #4

+

Shaft

User Connector

(15-pin D-sub Connector)

LED lamp

Fitting (white)

for ø 6 mm

pneumatic tube

Joint #3 and #4

brake release button

CE label

Signature label

(Serial No. of Manipulator)

RS3-55 Rev.2 7

Page 18

Setup & Operation 2. Specifications Setup & Operation 2. Specifications

90 or more

90 or more

Space f or cab les

Space f or cab les

← Manipu l ator

← Manipu l ator

ins tallation pos ition

ins tallation pos ition

(*) indicates th e strok e margin by mech anical stop.

(*) indicates th e strok e margin by mech anical stop.

3-M6 t hrough hole

3-M6 t hrough hole

1 mm flat cu t

1 mm flat cu t

Ø3,90° Conical h ol e

Ø3,90° Conical h ol e

(Original orientation of Joint #3, #4)

(Original orientation of Joint #3, #4)

Enlarged view from A

Enlarged view from A

Max.ø11 thro ugh hole

Max.ø11 thro ugh hole

h7 sh aft d iameter

h7 sh aft d iameter

Mechan ical stop diameter

Mechan ical stop diameter

Reference through hole

Reference through hole

(View from the top of the base)

(View from the top of the base)

For manipulator mounting

For manipulator mounting

6-6.5 t hrough hole

6-6.5 t hrough hole

ø11 spot f acing dept h 6.5

ø11 spot f acing dept h 6.5

(from back side)

(from back side)

8 RS3-55 Rev.2

8 RS3-55 Rev.2

Page 19

Cleanroom-model RS3-551C

The following figures show the special parts for Cleanroom-model.

These parts are different in appearance from Standard-model.

Setup & Operation 2. Specifications

Exhaust port

Exhaust port

Plate cover

(For Anti-static)

Bellows

Bellows

RS3-55 Rev.2 9

Page 20

Setup & Operation 2. Specifications Setup & Operation 2. Specifications

←

←

90 or more

90 or more

Spac e f or cab les

Spac e f or cab les

Mani pul ator

Mani pul ator

i nst allation posit ion

i nst allation posit ion

(*) indicates the stroke m argin by mecha nic al stop.

(*) indicates the stroke m argin by mecha nic al stop.

3-M 6 thr ough hole

3-M 6 thr ough hole

1 mm flat cut

1 mm flat cut

Ø3,90°

Ø3,90°

Conic al h ole

Conic al h ole

Max.ø11 thro ugh hole

Max.ø11 thro ugh hole

h7 Sh aft diameter

h7 Sh aft diameter

Mechanical stop diam eter

Mechanical stop diam eter

Enlarged view from A

Enlarged view from A

(Orig inal orientation of Joint #3, #4)

(Orig inal orientation of Joint #3, #4)

Referenc e through hole

Referenc e through hole

(View from the top of the base)

(View from the top of the base)

F or Mani pulat or mou ntin g

F or Mani pulat or mou ntin g

6-6. 5 thr ough hol e

6-6. 5 thr ough hol e

Ø11 spot faci ng d epth 6.5

Ø11 spot faci ng d epth 6.5

(from back side)

(from back side)

10 RS3-55 Rev.2 10 RS3-55 Rev.2

Page 21

2.4 Specifications

Item RS3-55 series

Setup & Operation 2. Specifications

Arm length

Max.

operating speed *1

Repeatability

Payload (Load)

Joint #4 allowable

moment of inertia *2

Max.

motion range

Arm #1, #2

Arm #1

Arm #2

Joints #1, #2

550 mm

275 mm

275 mm

7400 mm/s

Joints # 3 1100 mm/s

Joint #4 2600 deg/s

Joints #1, #2

Joints # 3

Joint #4

± 0.015 mm

± 0.01 mm

± 0.01 deg

Rated 1 kg

Max.

Rated

Max.

Joint #1

Joint #2

4 kg

0.005 kg⋅m2

0.05 kg⋅m

2

± 225 deg

± 225 deg

Joint #3 130 mm

Joint #4

Joint #1

± 720 deg

−4096000 ~ + 9557334 pulse

Max.

Joint #2

± 4177920 pulse

pulse range

(pulse)

Joint #3

Joint #4

Joint #1

− 1479112 pulse to 0 pulse

± 3145728 pulse

0.0000330deg/pulse

Joint #2 0.0000538 deg/pulse

Resolution

Joint #3 0.0000879 mm/pulse

Joint #4 0.000229 deg/pulse

Mounting ø 16 mm

Hand diameter

Hollow ø 11 mm

Mounting hole 6-M6

Weight (cables not included)

19 kg : 42 lb

Driving method AC servo motor

Joint #1 400 W

Motor power

Joint #2

400 W

consumption

Joint #3 150 W

Joint #4 100 W

RS3-55 Rev.2 11

Page 22

Setup & Operation 2. Specifications

Item RS3-55 series

Option Environment Cleanroom *3 & ESD

Joint #3 down force 150 N

Installed wire for customer use 15 wires: D-sub / 15 pin connectors

Installed pneumatic tube for customer use

2 pneumatic tubes (ø 6 mm): 0.59 Mpa (6 kgf/cm2 : 86 psi)

1 pneumatic tube (ø 4 mm): 0.59 Mpa (6 kgf/cm2 : 86 psi)

Ambient temperature

5 to 40°C (with minimum temperature variation)

Environmental

Ambient relative

requirements

10 to 80% RH (no condensation)

humidity

Noise level *4

LAeq = 70 dB(A) or less

Applicable Controller RC180, RC620

Assignable Value

( ) Default values

MTBF

SPEED

ACCEL *5

SPEEDS

ACCELS

FINE

WEIGHT

1 to (5) to100

1 to (10) to 120

1 to (50) to 2000

1 to (200) to 25000

0 to (10000) to 65000

0,130 to (1,130) to

3 years

ANSI/RIA R15.06-1999

NFPA 79 (2007 Edition)

4,130

Safety standard

CSA/CAN Z434-03 (February 2003)

CE Marking −

Machinery Directive, Low Voltage Directive, EMC

Directive

*1: In the case of PTP command. Maximum operating speed for CP command is 2000 mm/s on horizontal

plane.

*2: In the case where the center of gravity is at the center of Joint #4.

If the center of gravity is not at the center of Joint #4, set the parameter using Inertia command.

12 RS3-55 Rev.2

Page 23

Setup & Operation 2. Specifications

*3: The exhaust system in the Cleanroom-model Manipulator draws air from the base interior and arm cover

interior together.

A crack or other opening in the base unit can cause loss of negative air pressure in the outer part of the

arm, which can cause increased dust emission.

Do not remove the maintenance cover on the front of the base.

Seal the exhaust port and the exhaust tube with vinyl tape so that the joint is airtight.

If the exhaust flow is not sufficient, dust particle emission may exceed the specified maximum level.

Cleanliness level: Class ISO 3 (ISO14644-1)

In previous criteria; Clean Class: 10 or its equivalent

Amount of Dust (0.1 µm diameter or larger) in 28317 cm

3

(1cft)

sample-air around the center of the motion rang: 10 particles or

less.)

Exhaust System: Exhaust port diameter: Inner diameter: ø12 mm / Outer diameter: ø16 mm

Exhaust tube : Polyurethane tube

Outer diameter: ø12 mm (Inner diameter: ø8 mm)

or Inner diameter ø16mm or larger

Recommended exhaust flow rate: approx. 1000 cm

3

/s (Normal)

*4: Conditions of Manipulator during measurement as follows:

Operating conditions : Under rated load, 4-joints simultaneous motion, maximum speed, maximum

acceleration, and duty 50%.

Measurement point : In front of the Manipulator, 1000 mm apart from the motion range, 50 mm above

the base-installed surface.

*5: In general use, Accel setting 100 is the optimum setting that maintains the balance of acceleration and

vibration when positioning.

However, you may require an operation with high acceleration to shorten the cycle time by decreasing the

vibration at positioning. In this case, set Accel to larger than 100.

If you specify a larger Accel value, the frequency of the overload error and over heat may rise during

continuous operation. The use of large Accel setting is recommended only for necessary motions.

RS3-55 Rev.2 13

Page 24

Setup & Operation 3. Environments and Installation

Setup & Operation 3. Environments and Installation

3.2 Base Table

A base table for anchoring the Manipulator is not supplied. Please make or obtain the

base table for your Manipulator. The shape and size of the base table differs depending

on the use of the robot system. For your reference, we list some Manipulator table

requirements here.

The base table must not only be able to bear the weight of the Manipulator but also be able

to withstand the dynamic movement of the Manipulator when the Manipulator operates at

maximum acceleration. Ensure that there is enough strength on the base table by

attaching reinforcing materials such as crossbeams.

The torque and reaction force produced by the movement of the Manipulator are as

follows:

Max. Reaction torque on the horizontal plate : 500 Nm

Max. Horizontal reaction force : 1400 N

Max. Vertical reaction force : 1100 N

The threaded holes required for mounting the Manipulator base are M6. Use mounting

bolts with specifications conforming to ISO898-1 property class: 10.9 or 12.9.

For dimensions, refer to Setup & Operation: 3.3 Mounting Dimensions.

14 RS3-55 Rev.2

Page 25

3.3 Mounting Dimensions

The maximum space described in figures shows that the radius of the end effector is 50

mm or less. If the radius of the end effector exceeds 50 mm, define the radius as the

distance to the outer edge of maximum space.

If a camera or electromagnetic valve extends outside of the arm, set the maximum range

including the space that they may reach.

Be sure to allow for the following extra spaces in addition to the space required for

mounting the Manipulator, Controller, and peripheral equipment.

space for teaching

space for maintenance and inspection

Ensure a space to open the arm #1 cover, rear side cover and the maintenance

cover for maintenance.

space for cables

The minimum bend radius of the power cable is 90 mm. When installing the

Setup & Operation 3. Environments and Installation

cable, be sure to maintain sufficient distance from obstacles. In addition, leave

enough space for other cables so that they are not bent forcibly.

Ensure distance to the safeguard from the maximum motion range is more than 50 mm.

Center of Joint #3

275 mm

Maximum range

Y

X

± 225 degree

± 225 degree

Arm #1 Length

Arm #2 Length

275 mm

275 mm

RS3-551*

Joint #1 Motion range

Joint #2 Motion range

RS3-55 Rev.2 15

Page 26

Setup & Operation 3. Environments and Installation

3.4 Unpacking and Transportation

THE INSTALLATION SHALL BE PREFORMED BY QUALIFIED INSTALLATION

PERSONNEL AND SHOULD CONFORM TO ALL NATIONAL AND LOCAL

CODES.

■

Only authorized personnel should perform sling work and operate a crane

and a forklift. When these operations are performed by unauthorized

WARNING

personnel, it is extremely hazardous and may result in serious bodily injury

and/or severe equipment damage to the robot system.

■ Using a cart or similar equipment, transport the Manipulator in the same

manner as it was delivered.

■ After removing the bolts securing the Manipulator to the delivery equipment,

the Manipulator can fall. Be careful not to get hands or fingers caught.

CAUTION

■ The arm is secured with a wire tie. Leave the wire tie secured until you

finish the installation so as not to get hands or fingers caught.

■ To carry the Manipulator, have two or more people to work on it and secure

the Manipulator to the delivery equipment or hold the areas indicated in gray

in the figure (bottom of Arm #1 and bottom of the base) by hand.

When holding the bottom of the base by hand, be very careful not to get

your hands or fingers caught.

RS3-551* : approx. 19 kg : 42 lb.

■ Stabilize the Manipulator with your hands when hoisting it.

■ When transporting the Manipulator for a long distance, secure it to the

delivery equipment directly so that the Manipulator never falls.

If necessary, pack the Manipulator in the same style as it was delivered.

16 RS3-55 Rev.2

Page 27

Setup & Operation 3. Environments and Installation

3.7 User Wires and Pneumatic Tubes

■

Only authorized or certified personnel should be allowed to perform wiring.

CAUTION

Wiring by unauthorized or uncertified personnel may result in bodily injury and/or

malfunction of the robot system.

User electrical wires and pneumatic tubes are contained in the cable unit.

Electrical Wires

Rated Voltage

Allowable

Current

Wires Nominal Sectional Area Outer Diameter Note

AC/DC30 V 1 A 15 0.211 mm2 ø8.3±0.3 mm Shielded

Maker Standard

15 pin

Suitable Connector JAE DA-15PF-N (Solder type)

Clamp Hood JAE

DA-C8-J10-F2-1R (Connector setscrew: #4-40 NC)

Pins with the same number, indicated on the connectors on both ends of the cables, are

connected.

Pneumatic Tubes

Max. Usable Pneumatic Pressure Pneumatic Tubes Outer Diameter × Inner Diameter

0.59 MPa (6 kgf/cm2 : 86 psi)

2 ø6 mm × ø4 mm

1 ø4 mm × ø2.5 mm

Fittings for ø6 mm and ø4 mm (outer diameter) pneumatic tubes are supplied on both ends

of the pneumatic tubes.

User connector

(15-pin D-sub connector)

Fitting (white)

Fitting (white)

for ø4 mm

pneumatic tube

User connector

(15-pin D-sub connector)

Fitting (black)

for ø6 mm

pneumatic tube

Fitting (white)

for ø4 mm pneumatic tube

Fitting (blac k)

for ø6 mm pneumatic tube

Fitting (white)

for ø6 mm pneumatic tub e

Joint #3

break release switch

for ø4 mm

pneumatic tube

NOTE

The Joint #4 (rotating) motion range is ±720 degrees. Be careful not to let the

wires/tubes caught in the end effector.

RS3-55 Rev.2 17

Page 28

Setup & Operation 4. Setting of End Effectors

Setup & Operation 4. Setting of End Effectors

4.2 Attaching Cameras and Air valves

Arm #2 has threaded holes as shown in the figure below. Use these holes for attaching

cameras, air valves, and other equipment.

[Unit: mm]

4-M4 depth5

4-M4 depth5

NOTE

- When cameras and air valves are attached, it can limit the motion range by wires and

pneumatic tubes. Take extra care when designing and attaching.

- The Joint #4 (rotating) motion range is ±720 degrees. Be careful not to let the

wires/tubes caught in the end effector.

18 RS3-55 Rev.2

Page 29

4.3 Weight and Inertia Settings

4.3.1 Weight Setting

■

The total weight of the end effector and the work piece must not exceed 3 kg.

The RS series Manipulators are not designed to work with loads exceeding 3 kg.

Setup & Operation 4. Setting of End Effectors

CAUTION

(%)

Always set the Weight parameters according to the load. Setting a value that is

smaller than the actual load may cause errors, excessive shock, insufficient

function of the Manipulator, and/or shorten the life cycle of parts/mechanisms.

The acceptable weight capacity (end effector and work piece) in RS series is 1 kg at the

default rating and 3 kg at the maximum. When the load (weight of the end effector and

work piece) exceeds the rating, change the setting of Weight parameter.

After the setting is changed, the maximum acceleration/deceleration speed of the robot

system at PTP motion corresponding to the “Weight Parameter” is set automatically.

Automatic speed setting by Weight

140

120

100 100 100 100

100

80

60

40

* The percentage in

100

the graph is based

on the speed at rated

weight (1 kg) as

100%.

(%)140

120

100

80

60

40

20

20

0 0.5 1 1.5 2 2.5 3 3.5 4 (kg)

Wei g h t sett ing

Automatic acceleration/deceleration setting by Weight

120

120

100

0

40

0.5 1 1.5 2 2.5 3 3.5 4 (kg) Weight sett in g

* The per centage in the

graph is based on the

acceleration /

deceleration at rated

weight (1 kg) as 100%.

30

RS3-55 Rev.2 19

Page 30

Setup & Operation 4. Setting of End Effectors

4.3.2 Inertia Setting

Automatic acceleration/deceleration setting by Inertia (eccentric quantity)

120

(%)

100

80

60

40

20

100

80

40

* The percentage in the graph is based

on the acceleration/deceleration at

rated eccentricity (0 mm) as 100%.

20

0 25 5 0 75 100 (mm) Eccentricity setting

4.4 Precautions for Auto Acceleration/Deceleration of Joint #3

When you move the Manipulator in horizontal PTP motion with Joint #3 (Z) at a high

position, the motion time will be faster.

When Joint #3 gets below a certain point, then auto acceleration/deceleration is used to

reduce acceleration/deceleration. (Refer to the figure below.) The higher the position of

the shaft is, the faster the motion acceleration/deceleration is. However, it takes more

time to move Joint #3 up and down. Adjust the position of Joint #3 for the Manipulator

motion after considering the relation between the current position and the destination

position.

The upper limit of Joint #3 during horizontal motion using Jump command can be set by

the LimZ command.

Automatic acceleration/deceleration vs. Joint #3 position

120

(%)

100

80

60

40

100

100

50

* The percentage in the gr aph is

based on the acceleration /

deceleration at the upper-limited

position of Joint #3

20

Height of the shaft

NOTE

0 -20 -60 -100 -140 (mm)

When moving the Manipulator horizontally while the shaft is being lowered, it may cause

over-shoot at the time of final positioning.

20 RS3-55 Rev.2

Page 31

Setup & Operation 5. Motion Range

5.1 Motion Range Setting by Pulse Range

5.1.1 Max. Pulse Range of Joint #1

The 0 (zero) pulse position of Joint #1 is the position where Arm #1 faces toward the

positive (+) direction on the X-coordinate axis.

When the 0 pulse is a starting point, the counterclockwise pulse value is defined as the

positive (+) and the clockwise pulse value is defined as the negative (-).

View from

this point

Setup & Operation 5. Motion Range

0 pulse

A : Max. motion range : ± 225 °

B : Max. pulse range : −4096000 to + 9557334 pulse

RS3-55 Rev.2 21

Page 32

Setup & Operation 5. Motion Range

5.4 Standard Motion Range

The following “motion range” diagrams show the standard (maximum) specification.

When each Joint motor is under servo control, the center of Joint #3’s (shaft’s) lowest

point moves in the areas shown in the figure.

“Area limited by mechanical stop” is the area where the center of Joint #3’s lowest point

can be moved when each joint motor is not under servo control.

“Mechanical stop” sets the limited motion range so that the center of Joint #3 cannot move

beyond the area mechanically.

Motion range

Center of Joint #3

Type

(unit: mm)

n : Joint #3 range to hit upper mechanical stop

m : Joint #3 strok e

p : Joint #3 range to hit lower mechanical stop

22 RS3-55 Rev.2

Page 33

Setup & Operation 5. Motion Range

Maintenance 14. Maintenance Parts List

14.1 Common Parts

Part Name Code Note

Joint #1

AC

Servo Motor

Reduction Gear

Unit

Solenoid Brake Joint #3

Timing Belt

Battery Board

Battery Unit

O-ring

Joint #2

Joint #3

Joint #4

Joint #1

Joint #2

Joint #3

Joint #1

Joint #2

Joint #3

Joint #4

Joint #1

Joint #2

Joint #1

Joint #2

R13B000616

R13B000616

R13B000615

R13B000617

R13B010029

R13B010019

R13B010020

R13B030503

R13B030216

R13B030217

R13B030218

R13B030219

R13B041203

R13ZA00600300

R13B031206 O-ring S90A

R13B031236

R13B031237 O-ring S30A

R13A031200700 O-ring S71A

400 W

400 W

150 W

100 W

Width 15 mm Length 270 mm

Width

Width

Width

No lithium battery

Installed in Base

Spare lithium battery

ER17330V (TOSHIBA)

O-ring S65A

10 mm

9 mm

12 mm

Length

Length

Length

246 mm

246 mm

339 mm

Joint #2

Ball Screw Spline

Grease

Oil seal unit (Arm #2)

M/C cable

LED Lamp

Brake Release Switch

Ball Screw Spline

Cable Unit

Arm#2 Cover

RS3-55 Rev.2 23

Reduction Gear Unit

Cable

Cable Length 3 m

Cable Length 5 m

Cable Length 10 m

R13B031238

R13ZA00330200

R13ZA00330100

R13B030304

R13B031239

R12B020434

R12B020435

R12B020436

R13B030004

R13Z702640100

R13B010222

R13B020054

R13B030425

O-ring S53A

AFB grease (400 g)

SK-1A (500 g)

GPL-224 (227g)

Page 34

Maintenance 14. Maintenance Parts List

14.2 Parts by Environment Model

14.2.1 S: Standard-model

Part Name Code Note

Ball Screw Spline

Cable Unit R13B020054

Arm#2 Cover R13B030425

14.2.2 C: Cleanroom-model

Part Name Code Note

Ball Screw Spline R13B010222

Cable Unit R13B020054

Arm#2 Cover R13B030425

Bellows R13B010222

Gasket Unit R13B020054

Liquid gasket R13B030425

R13B010222

24 RS3-55 Rev.2

Loading...

Loading...