Page 1

Rev.26 EM208C4443F

ROBOT CONTROLLER

RC90 / RC90-B

(EPSON RC+ 7.0)

Page 2

ROBOT CONTROLLER RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 3

ROBOT CONTROLLER

RC90 / RC90-B

(EPSON RC+ 7.0)

Rev.26

Copyright © 2013-2020 SEIKO EPSON CORPORATION. All rights reserved.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 i

Page 4

FOREWORD

1. Damage or malfunction caused by improper use which is not described in the manual, or

careless use.

2. Malfunctions caused by customers’ unauthorized disassembly.

3. Damage due to improper adjustments or unauthorized repair attempts.

4. Damage caused by natural

1. If the robot system associated equipment is used outside of the usage conditions and

product specifications described in the manuals, this warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this manual cannot

warn the user of al

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the robot controller.

Please carefully read this manual and other related manuals before installing the robot

system.

Keep this manual handy for easy access at all times.

WARRANTY

The robot system and its optional parts are shipped to our customers only after being

subjected to the strictest quality controls, tests, and inspections to certify its compliance with

our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please contact the supplier of your region for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

disasters such as earthquake, flood, etc.

Warnings, Cautions, Usage:

l possible hazards.

ii RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 5

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® 8 Operating system

Microsoft® Windows® 10 Operating system

Throughout this manual, Windows 8, and Windows 10 refer to above respective

operating systems. In some cases, Windows refers generically to Windows 8, and

Windows 10.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

MANUFACTURER

CONTACT INFORMATION

Contact information is described in “SUPPLIERS” in the first pages of the following

manual:

Robot System Safety and Installation Read this manual first

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 iii

Page 6

Before Reading This Manual

NOTE

NOTE

NOTE

NOTE

Do not connect the followings to the TP/OP port of RC90 / RC90-B. Connecting to the

followings may result in malfunction of the device since the pin assignments are different.

OPTIONAL DEVICE dummy plug

Operation Pendant OP500

Operator Pendant OP500RC

Jog Pad JP500

Teaching Pendant TP-3**

Operator Panel OP1

For RC90 / RC90-B, be sure to install the EPSON RC+ 7.0 to the development PC first,

then connect the development PC and RC90 / RC90-B with the USB cable.

If RC90 / RC90-B and the development PC are connected without installing the EPSON

RC+ 7.0 to the development PC, [Add New Hardware Wizard] appears. If this wizard

appears, click the <Cancel> button.

Concerning the security support for the network connection:

The network connecting function (Ethernet) on our products assumes the use in the local

network such as the factory LAN network. Do not connect to the external network such as

Internet.

In addition, please take security measure such as for the virus from the network connection

by installing the antivirus software.

Security support for the USB memory:

Make sure the USB memory is not infected with virus when connecting to the Controller.

iv RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 7

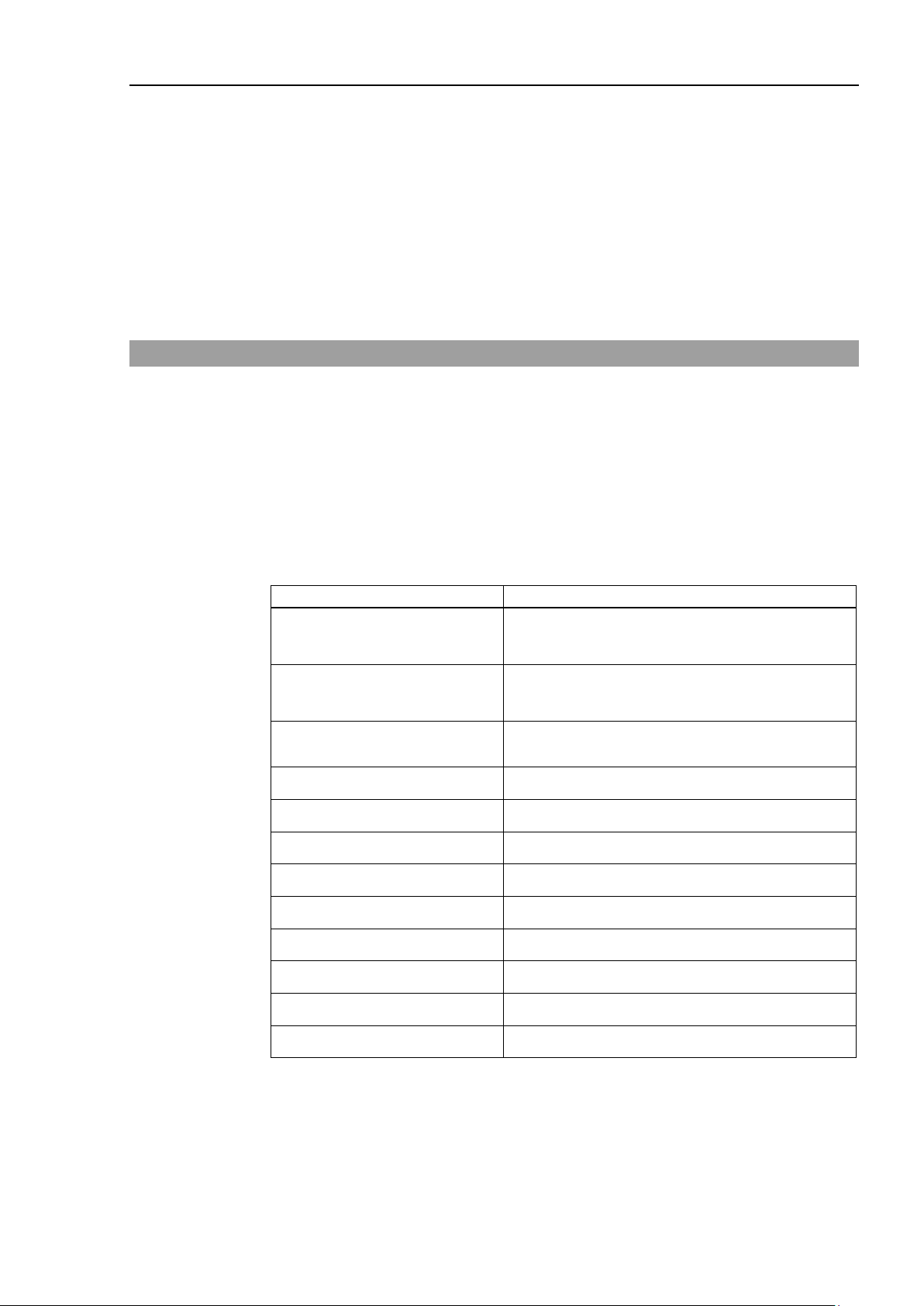

Label

Controller

Software

RC90 controller firmware

Ver.7.0.2.0 or later

Before Ver.7.0.1

!!!

Ver.7.0.2 or later

OK

RC90-B controller firmware

Ver.7.4.2.0 or later

Before Ver.7.4.1

!!!

Ver.7.4.2 or later

OK

NOTE

NOTE

NOTE

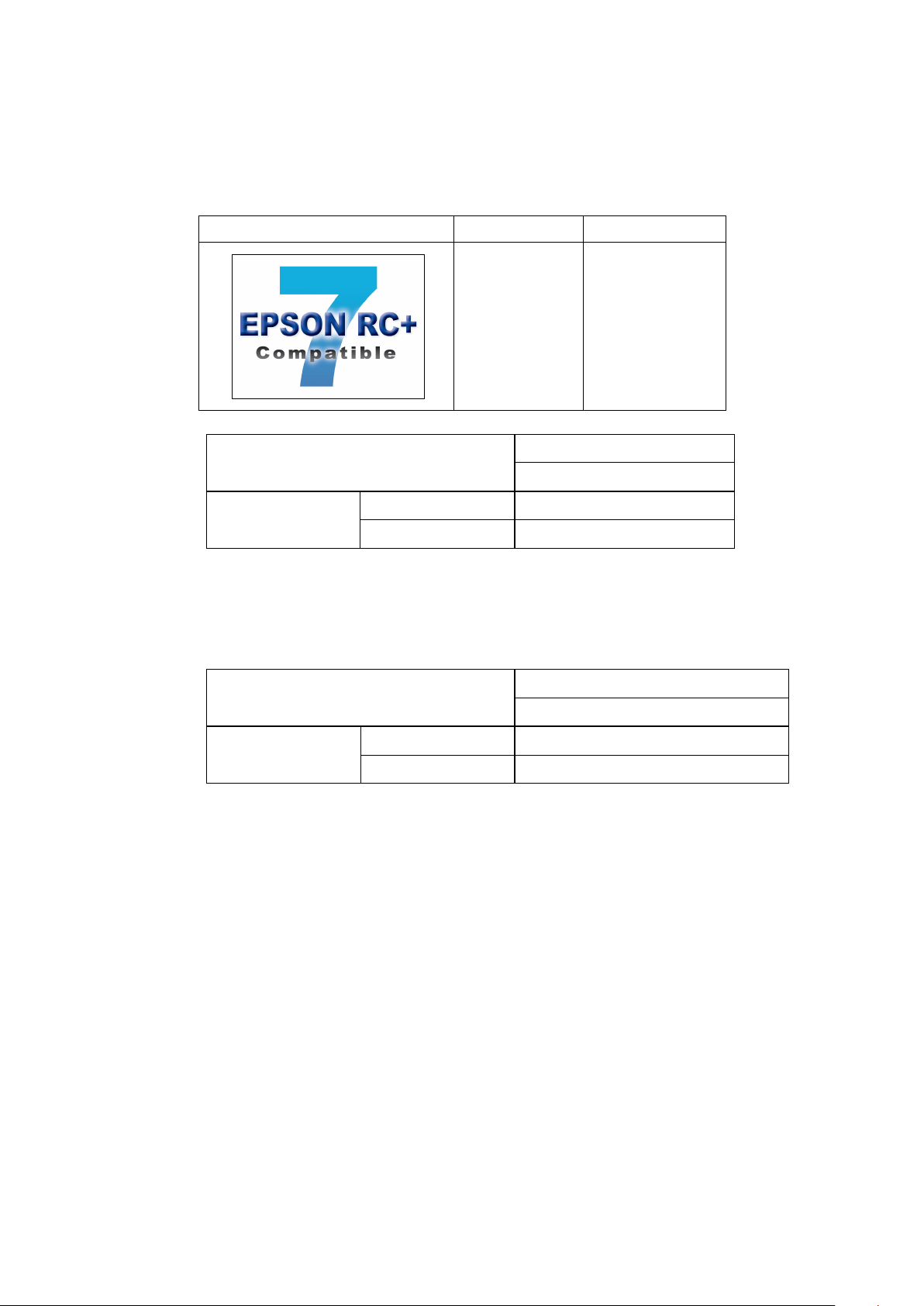

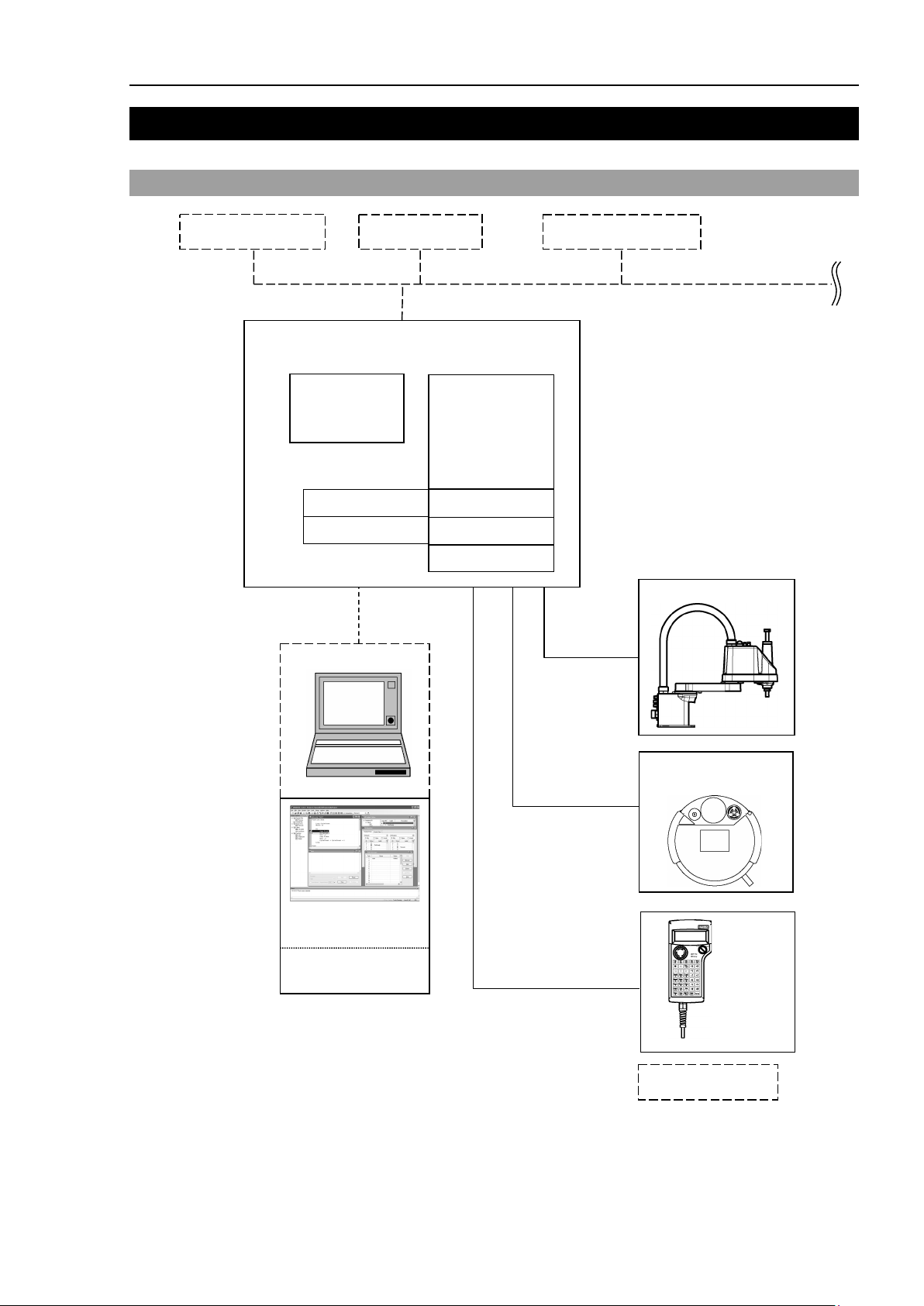

Control System Configuration

This manual explains with the following combinations of Controllers and software.

Robot Controller RC90 with the following label attached:

RC90

EPSON RC+ 7.0

EPSON RC+ 7.0

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver. 7.0.2 or later.

Robot Controller RC90-B:

EPSON RC+ 7.0

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver. 7.4.2 or later.

There is no label on RC90-B.

Manual PDF for this robot system is available from EPSON RC+ 7.0 Ver. 7.0.2

This option is not available for Robot Controller RC90 (EPSON RC+ 5.0) without the label.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 v

Page 8

vi RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 9

Safety

1. Safety 3

2. Conventions 3

3. Safety Precautions 4

Setup & Operation

1. Specifications 9

1.1 System Example ......................................................................................9

1.2 Standard Specifications .........................................................................10

1.3 Outer Dimensions ..................................................................................12

2. Part Names and Functions 13

Table of Contents

2.1 Part Names ............................................................................................13

2.2 Functions ...............................................................................................13

2.3 LED ........................................................................................................15

2.4 Safety Features......................................................................................16

3. Installation 18

3.1 Unpacking ..............................................................................................18

3.2 Environmental Requirements ................................................................18

3.2.1 Environment ...............................................................................18

3.2.2 Installation ..................................................................................19

3.3 Power Supply .........................................................................................20

3.3.1 Specifications .............................................................................20

3.3.2 AC Power Cable .........................................................................21

3.3.3 M/C Power Cable .......................................................................22

3.4 Cable Connection ..................................................................................23

3.4.1 Typical Cable Connection ..........................................................24

3.4.2 Connecting Manipulator to Controller ........................................26

3.5 Noise Countermeasures ........................................................................28

4. Operation Mode (TEACH/AUTO/TEST) 29

4.1 Overview ................................................................................................29

4.2 Switch Operation Mode .........................................................................29

4.3 Program Mode (AUTO) ..........................................................................30

4.3.1 What is Program Mode (AUTO)? ...............................................30

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 vii

Page 10

Table of Contents

4.3.2 Setup from EPSON RC+ 7.0 ..................................................... 30

4.4 Auto Mode (AUTO) ................................................................................ 31

4.4.1 What is Auto mode (AUTO)? ..................................................... 31

4.4.2 Setup from EPSON RC+ 7.0 ..................................................... 31

4.4.3 Setup from Control Device ......................................................... 32

5. Development PC Connection Port 33

5.1 About Development PC Connection Port .............................................. 33

5.2 Precaution .............................................................................................. 34

5.3 Software Setup and Connection Check ................................................ 34

5.4 Disconnection of Development PC and Controller ................................ 35

6. Memory Port 36

6.1 What is Controller Status Storage Function? ........................................ 36

6.2 Before Using Controller Status Storage Function ................................. 36

6.2.1 Precautions ................................................................................ 36

6.2.2 Adoptable USB Memory ............................................................ 36

6.3 Controller Status Storage Function ....................................................... 37

6.3.1 Controller Status Storage with Trigger Button ........................... 37

6.3.2 Load Data with EPSON RC+ 7.0 ............................................... 37

6.3.3 Transfer with E-mail ................................................................... 39

6.4 Details of Data ....................................................................................... 39

7. LAN (Ethernet Communication) Port 40

7.1 About the LAN (Ethernet Communication) Port .................................... 40

7.2 IP Address ............................................................................................. 40

7.3 Changing Controller IP Address ............................................................ 41

7.4 Connection of Development PC and Controller with Ethernet .............. 42

7.5 Disconnection of Development PC and Controller with Ethernet ......... 43

8. TP Port 44

8.1 What is the TP Port? ............................................................................. 44

8.2 Teach Pendant Connection ................................................................... 44

9. EMERGENCY 45

9.1 Safety Door Switch and Latch Release Switch ..................................... 45

9.1.1 Safety Door Switch .................................................................... 46

9.1.2 Latch Release Switch ................................................................ 46

9.1.3 Checking Latch Release Switch Operation ............................... 47

viii RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 11

Table of Contents

9.2 Emergency Stop Switch Connection .....................................................48

9.2.1 Emergency Stop Switch .............................................................48

9.2.2 Checking Emergency Stop Switch Operation ............................48

9.2.3 Recovery from Emergency Stop ................................................48

9.3 Pin Assignments ....................................................................................49

9.4 Circuit Diagrams ....................................................................................50

9.4.1 Example 1: External emergency stop switch typical application50

9.4.2 Example 2: External safety relay typical application..................51

10. Standard RS-232C Port 52

10.1 About the RS-232C Port ......................................................................52

10.2 Confirmation with EPSON RC+ 7.0 (RS-232C) ..................................52

10.3 RS-232C Software Communication Setup (RS-232C) .......................53

10.4 Communication Cable (RS-232C) .......................................................53

11. I/O Connector 54

11.1 RC90 (I/O Connector) ..........................................................................55

11.1.1 Input Circuit (RC90) .................................................................55

11.1.2 Output Circuit (RC90)...............................................................57

11.2 RC90-B (I/O Connector) ......................................................................60

11.2.1 Input Circuit (RC90-B) ..............................................................60

11.2.2 Output Circuit (RC90-B) ...........................................................62

11.3 Pin Assignments ..................................................................................64

12. I/O Remote Settings 65

12.1 I/O Signal Description ..........................................................................66

12.1.1 Remote Input Signals ...............................................................66

12.1.2 Remote Output Signals ............................................................70

12.2 Timing Specifications ...........................................................................73

12.2.1 Design Notes for Remote Input Signals...................................73

12.2.2 Timing Diagram for Operation Execution Sequence ...............73

12.2.3 Timing Diagram for Program Execution Sequence .................73

12.2.4 Timing Diagram for Safety Door Input Sequence ....................74

12.2.5 Timing Diagram for Emergency Stop Sequence .....................74

13. Option Slots 75

13.1 About Option Slots ...............................................................................75

13.2 Expansion I/O Board ............................................................................75

13.2.1 About Expansion I/O Board .....................................................75

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 ix

Page 12

Table of Contents

13.2.2 Board Configuration (Expansion I/O)....................................... 75

13.2.3 Confirmation with EPSON RC+ 7.0 ......................................... 76

13.2.4 Input Circuit .............................................................................. 76

13.2.5 Output Circuit ........................................................................... 78

13.2.6 Pin Assignments ...................................................................... 81

13.3 Fieldbus I/O Board ............................................................................... 82

13.4 RS-232C Board ................................................................................... 82

13.4.1 RS-232C Board ........................................................................ 82

13.4.2 Board Setup (RS-232C) ........................................................... 82

13.4.3 Confirmation with EPSON RC+ 7.0 (RS-232C) ...................... 83

13.4.4 RS-232C Software Communication Setup (RS-232C) ............ 83

13.4.5 Communication Cable (RS-232C) ........................................... 84

13.5 Analog I/O Board ................................................................................. 85

13.5.1 About Analog I/O Board ........................................................... 85

13.5.2 Board Configuration (Analog I/O Board) ................................. 86

13.5.3 Confirmation with EPSON RC+ (Analog I/O Board) ................ 89

13.5.4 Input Circuit (Analog I/O Board) .............................................. 90

13.5.5 Output Circuit (Analog I/O Board) ............................................ 90

13.5.6 Pin Assignments (Analog I/O Board) ....................................... 91

13.6 EUROMAP67 Board ............................................................................ 92

13.6.1 Notes on the EUROMAP67 Board .......................................... 93

13.6.2 Board Settings (EUROMAP67 Board) ..................................... 95

13.6.3 Installation (EUROMAP67 Board) ........................................... 95

13.6.4 Confirming with EPSON RC+ 7.0 (EUROMAP67 Board) ....... 97

13.6.5 Sample Project (EUROMAP67 Board) .................................... 97

13.6.6 Circuit Overview (EUROMAP67 Board) .................................. 98

13.6.7 Input Circuit (EUROMAP67 Board) ......................................... 99

13.6.8 Output Circuit (EUROMAP67 Board) ...................................... 99

13.6.9 Emergency Stop, Safeguard (EUROMAP67 Board) ............. 100

13.6.10 I/O Pin Assignments (EUROMAP67 Board) ........................ 101

13.6.11 Emergency stop connecter Pin Assignments

(EUROMAP67 Board) ......................................................... 102

x RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 13

Maintenance

Table of Contents

1. Safety Precautions on Maintenance 107

1.1 Safety Precautions .............................................................................. 107

1.2 Lockout / Tagout ................................................................................. 108

2. Regular Maintenance Inspection 110

3. Controller Structure 111

3.1 Location of Parts ................................................................................. 111

3.1.1 RC90 (for LS3, LS6) ................................................................ 111

3.1.2 RC90 (for LS20) ...................................................................... 111

3.1.3 RC90-B (for LS3-B, LS6-B) ..................................................... 112

3.1.4 RC90-B (for LS10-B, LS20-B) ................................................. 112

3.2 Diagram of Cable Connections ........................................................... 113

3.2.1 RC90 (for LS3, LS6), RC90-B( for LS3-B, LS6-B) .................. 113

3.2.2 RC90 (for LS20), RC90-B (for LS10-B, LS20-B) .................... 114

4. Backup and Restore 115

4.1 What is the Backup Controller Function? ........................................... 115

4.2 Backup Data Types ............................................................................ 115

4.3 Backup ................................................................................................ 116

4.4 Restore ............................................................................................... 117

5. Firmware Update 120

5.1 Updating Firmware ............................................................................. 120

5.2 Firmware Upgrade Procedure ............................................................ 120

5.3 Controller Recovery ............................................................................ 123

5.4 Firmware Initialization Procedure ....................................................... 124

5.5 Adding Confirmation Steps by Strengthening Security of EtherNet

Connection .......................................................................................... 126

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 xi

Page 14

Table of Contents

6. Alarm 130

6.1 Before Controller Firmware Ver.7.1.8.x ............................................... 131

6.1.1 Alarm Configuration ................................................................. 131

6.1.2 How to View the Alarm Information ......................................... 132

6.1.3 How to Edit the Alarm Information ........................................... 133

6.1.4 Alarm Notifying Method ........................................................... 133

6.1.5 How to Cancel the Alarm ......................................................... 134

6.2 Controller Firmware Ver.7.2.0.x or later .............................................. 135

6.2.1 Maintenance Information ......................................................... 135

6.2.2 How to View the Maintenance Information .............................. 136

6.2.3 How to Edit the Maintenance Information ............................... 138

6.2.4 Alarm Notifying Method ........................................................... 139

6.2.5 How to Cancel the Alarm ......................................................... 139

7. Maintenance Parts Replacement Procedures 140

7.1 Fan Filter .............................................................................................. 141

7.2 Fan ....................................................................................................... 142

7.3 Battery ................................................................................................. 143

7.4 CF (Compact Flash) ............................................................................ 145

7.5 MDB ..................................................................................................... 146

7.6 DMB ..................................................................................................... 148

7.7 DMB Sub Board ................................................................................... 152

7.8 DPB...................................................................................................... 153

7.9 Option Board........................................................................................ 155

8. Verifying Robot System Operation 157

9. Troubleshooting 158

9.1 Error Code Table ................................................................................. 158

9.2 Cannot Connect the Development PC and the Controller using the USB

cable .................................................................................................... 291

9.2.1 Confirmation Using Windows Device Manager ....................... 292

9.2.2 When recognized under “Other devices”

in Windows Device Manager ................................................... 294

10. Maintenance Parts List 295

xii RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 15

Safety

This section contains information for safety of the Robot System.

Page 16

Page 17

1. Safety

Installation and transportation of robots and robotic equipment shall be performed by

qualified personnel and should conform to all national and local codes.

Please read this manual and other related manuals before installing the robot system or

before connecting cables. Keep this manual in a handy location for easy access at all times.

2. Conventions

Important safety considerations are indicated throughout the manual by the following

symbols. Be sure to read the descriptions shown with each symbol.

WARNING

WARNING

Safety 1. Safety

This symbol indicates that a danger of possible serious injury or death

exists if the associated instructions are not followed properly.

This symbol indicates that a danger of possible harm to people caused

by electric shock exists if the associated instructions are not followed

properly.

CAUTION

This symbol indicates that a danger of possible harm to people or

physical damage to equipment and facilities exists if the associated

instructions are not followed properly.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 3

Page 18

Safety 3. Safety Precautions

Personnel

read the Safety chapter in User

before designing and/or constructing the robot system. Designing and/or

constructing the robot system withou

extremely hazardous, may result in serious bodily injury and/or severe equipment

damage to the robot system, and may cause serious safety problems.

The Manipulator and the Controller must be used within the environmental

conditions described in their respective manuals. This product has been

designed and manufactured strictly for use in a normal indoor environment.

Using the product in an environmen

conditions may not only shorten the life cycle of the

serious safety problems.

The

the manuals.

may

problem

The interlock of the Safety Door must be functioning when the

operated.

be turned ON/OFF. (I.E. the condition where the switch is disabled)

(Example: Tape is put around the switch to hold it closed.) Operating the robot

system when the s

may

s as the Safety Door input cannot fulfill its

intended function

Connect input signal wires for Emergency Stop and Safety Door to the

EMERGENCY connector so that the Emergency Stop switch in the Teach

Pendant connected to the TP port always functions. (Refer to the typical

application diagram in Setup & Operation 9.4

3. Safety Precautions

Only trained personnel should design and install the robot system.

Trained personnel are defined as those who have taken robot system training class held by

the manufacturer, dealer, or local representative company, or those who understand the

manuals thoroughly and have the same knowledge and skill level as those who have

completed the training courses.

The following items are safety precautions for qualified design or installation

personnel:

WARNING

who design and/or construct the robot system with this product must

’s Guide to understand the safety requirements

t understanding the safety requirements is

t that exceeds the specified environmental

product but may also cause

robot system must be used within the installation requirements described in

Using the robot system outside of the installation requirements

not only shorten the life cycle of the product but also cause serious safety

s.

robot system is

Do not operate the system under the condition that the switch cannot

witch is not functioning properly is extremely hazardous and

cause serious safety problem

.

Circuit Diagrams.)

4 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 19

Do not open the cover(s) of the Controller except while maintaining it. Opening

the cover(s) of the Controller is extremely hazardous and may result in electric

shock even when its main power is OFF because of t

the Controller.

Make sure that the power to the Controller is turned OFF before connecting or

disconnecting any cables. Connecting or disconnecting any cables with the

power ON is extremely hazardous and may result in electric shock and/or

malfunction of the Controller.

Be sure to connect the cables properly. Do not allow unnecessary strain on the

cables. (Do not put heavy objects on the cables. Do not bend or pull the cables

forcibly.) The unnecessary strain on the cables may result in damage to the

cables, disconnection, and/or contact failure. Damaged cables, disconnection,

or a contact failure is extremely hazardous and may result in electric shock and/or

improper function of the system.

When connecting the plug to fit the outlet in your factory, make sure that it is done

by qualified personnel. When connecting the plug, be sure to connect the earth

wire of the AC power cable colored green/yellow on the Controller to the earth

termin

at all times to avoid the risk of electric shock. Always use a power plug and

receptacle. Never connect the Controller directly to the factory power supply.

(Field wiring)

The serial number of the Manipulator that should be connected is indicated on the

Connection Check Label on the Controller. Connect the Controller and the

Manipulator correctly. Improper connection between the Controller and the

Manipulator may

problems.

When using remote I/O, always make sure of the following. Using the robot

system under

conditions may cause malfunction of the system

and/or safety problems.

-

-

- When verifying the robot system operation, prepare for failures with initial

WARNING

Safety 3. Safety Precautions

The following items are safety precautions for qualified design or installation

personnel: (cont.)

he high voltage charge inside

CAUTION

al of the factory power supply. The equipment must be grounded properly

cause improper function of the robot system and also safety

unsatisfactory

Assign remote functions to inputs/outputs correctly and wire correctly when

setting up remote I/O signals.

Make sure that the functions correspond to the correct input/output signals

before turning ON the system.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 5

settings or wiring. If the Manipulator functions unusually by the failures with

initial settings or wiring, press the Emergency Stop switch immediately to stop

the Manipulator.

Page 20

Safety 3. Safety Precautions

The interlock of the Safety Door must be functioning when the

operated.

be turned ON/OFF. (I.E. the condition where the switch is disabled)

(Example: Tape is put around the switch to hold it closed.) Operating the robot

system when the switch is not

is extremely hazardous and

may

s as the Safety Door input cannot fulfill its

intended function

Do not open the cover(s) of the Control

the cover(s) of the Controller is

and may result in electric

shock

the Control

The following items are safety precautions for qualified operator personnel:

WARNING

WARNING

robot system is

Do not operate the system under the condition that the switch cannot

functioning properly

cause serious safety problem

.

ler except while maintaining it. Opening

extremely hazardous

even when its main power is OFF because of the high voltage charge inside

ler.

6 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 21

Setup & Operation

This section contains information for setup and operation of the Robot Controller.

Page 22

Page 23

Setup & Operation 1. Specifications

*1 EPSON RC+ 7.0 supports the following OS

Wi

ndows 8.1 Pro

(EPSON RC+7.0 Ver.7.1.0

or later

)

Windows 10 Pro

(EPSON RC+7.0 Ver.7.2.0 or later)

Operation panel

Motion Controller

RC90 / RC90-B

Expansion I/O Board

Fieldbus

PROFIBUS-DP

DeviceNet

CC-Link

EtherNet/IP

PROFINET

EtherCAT

RS-232C Board

Windows *1

PC

EPSON RC+ 7.0

Software

Option

USB 2.0

or

Ethernet

TP2

(Option)

Standard I/O

Remote I/O

Ethernet

RS-232C

Requires preparation

by users

LS / LS-B series

PLC (Sequencer)

Option

Standard

PG Board

TP1

(Option)

AnalogI/O Board

EUROMAP67 Board

1. Specifications

1.1 System Example

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 9

Page 24

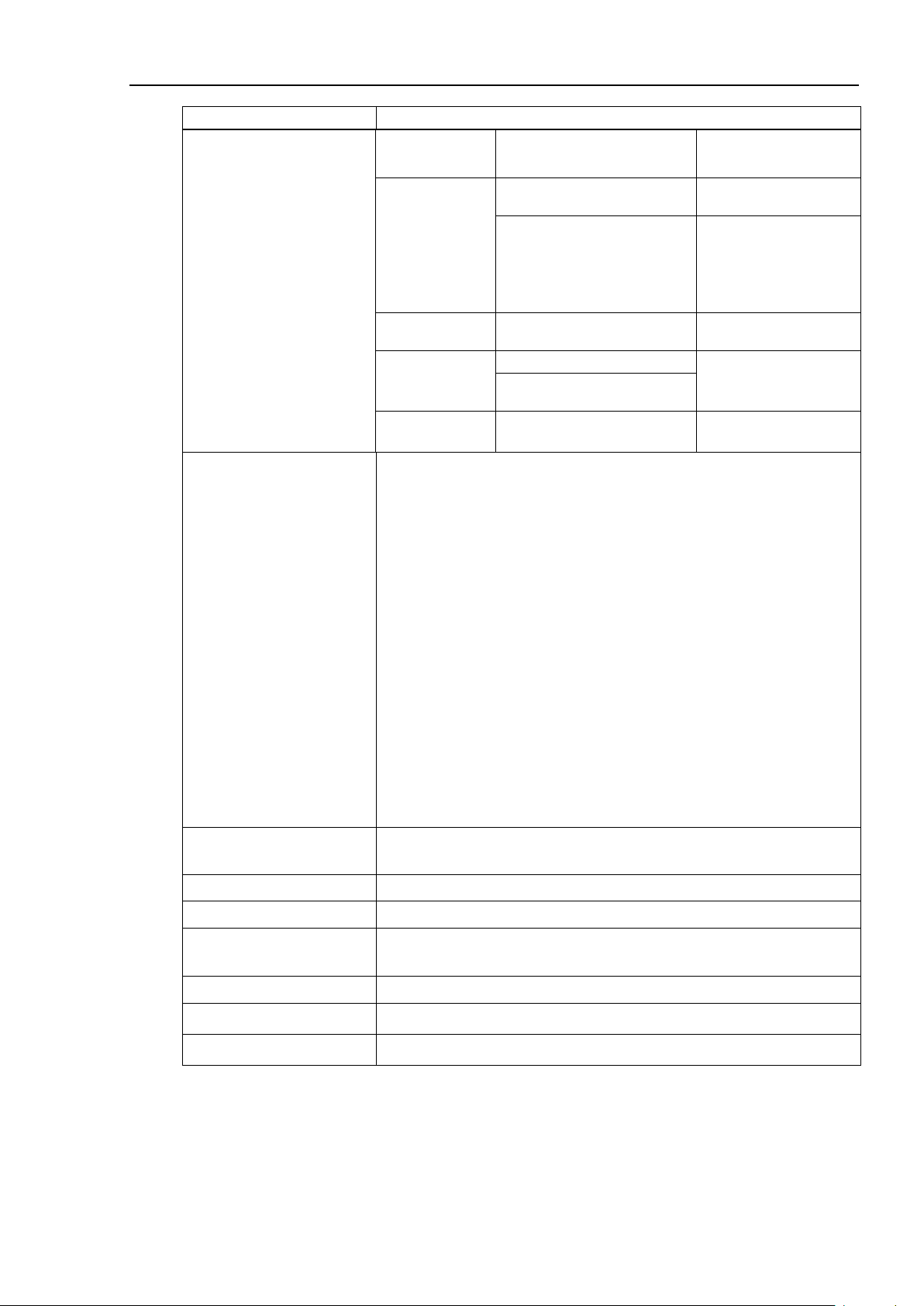

Setup & Operation 1. Specifications

Item

Specification

Model

Robot Controller RC90 / RC90-B

Controllable axes

4 AC servo motors

Programming

software

Up to 4 joints simultaneous control

Software AC servo control

PTP motion : Programmable in the range of

to be manually entered.)

PTP motion : Programmable in the range of

to be manually entered.)

Maximum Object Size : 4 MB

of array variables.)

Including 8 inputs,

allowed

RS-232C port

1 port

1.2 Standard Specifications

CPU 32 bits Micro Processor

Robot manipulator

control

Positioning control

Memory capacity

Teaching method

language and

Robot control

Joint Control

Speed Control

Acceleration/

deceleration

control

PTP (Point-To-Point control)

CP (Continuous Path control)

Point data area : 1000 points (per file)

Backup variable area : Max. 100 KB (Includes the memory area for

Remote

Direct

MDI (Manual Data Input)

EPSON RC+ 7.0 (multi-tasking robot language)

Ver.7.0.2 or later is recommended.

1 to 100%

CP motion : Programmable (Actual value

1 to 100%; Automatic

CP motion : Programmable (Actual value

the management table.)

Approx. 1000 variables (Depends on the size

External

input/output

signals (standard)

Communication

interface (standard)

10 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Standard I/O

Ethernet 1 channel

Input : 24

Output : 16

8 outputs with remote

function assigned

Assignment change

Page 25

Setup & Operation 1. Specifications

Item

Specification

Addition of

2 boards allowed

EtherCAT

1 board from the left

Controllable joints

4 joints/board

Addition of

2 board allowed

SKU1

Output: 1ch

Addition of

2 board from the left

Output: 2ch

Input: 2ch

Input : 15

Output : 16

Addition of

1 board allowed

Rated Ambient

Options

(Max. 2 slots)

Safety features

Expansion I/O

Input : 24 per board

Output : 16 per board

Addition of

2 boards allowed

RS-232C : 2ch per board

Communication

interface

Fieldbus I/O : 1ch per board

PROFIBUS-DP,

DeviceNet, CC-Link,

EtherNet/IP, PROFINET,

Addition of

allowed

PG

Analog I/O

SKU2

allowed

EUROMAP67

- Emergency stop switch

- Safety door input

- Low power mode

- Dynamic brake

- Motor overload detection

- Irregular motor torque (out-of-control Manipulator) detection

- Motor speed error detection

- Positioning overflow - servo error - detection

- Speed overflow - servo error - detection

- CPU irregularity detection

- Memory check-sum error detection

- Overheat detection at the Motor Driver Module

- Relay welding detection

- Over-voltage detection

- AC power supply voltage reduction detection

- Temperature error detection

- Fan error detection

Power Source

Maximum Rated Capacity 2.5 kVA (Depending on the Manipulator model)

Insulation Resistance 100 MΩ or more

Temperature

Rated Relative Humidity 20% to 80% (with no condensation)

Weight *1 7.5 kg or 10 kg (Depending on the Manipulator model)

Degree of protection IP20

*1 Weight of the unit is indicated on the Controller itself.

Make sure to check the weight before units transfer or relocation and prevent throwing out your back

at holding the unit.

Also, make sure to keep your hands, fingers, and feet safe from being caught or serious injury.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 11

200 VAC to 240 VAC

Single phase 50/60 Hz

5 to 40

°C

Page 26

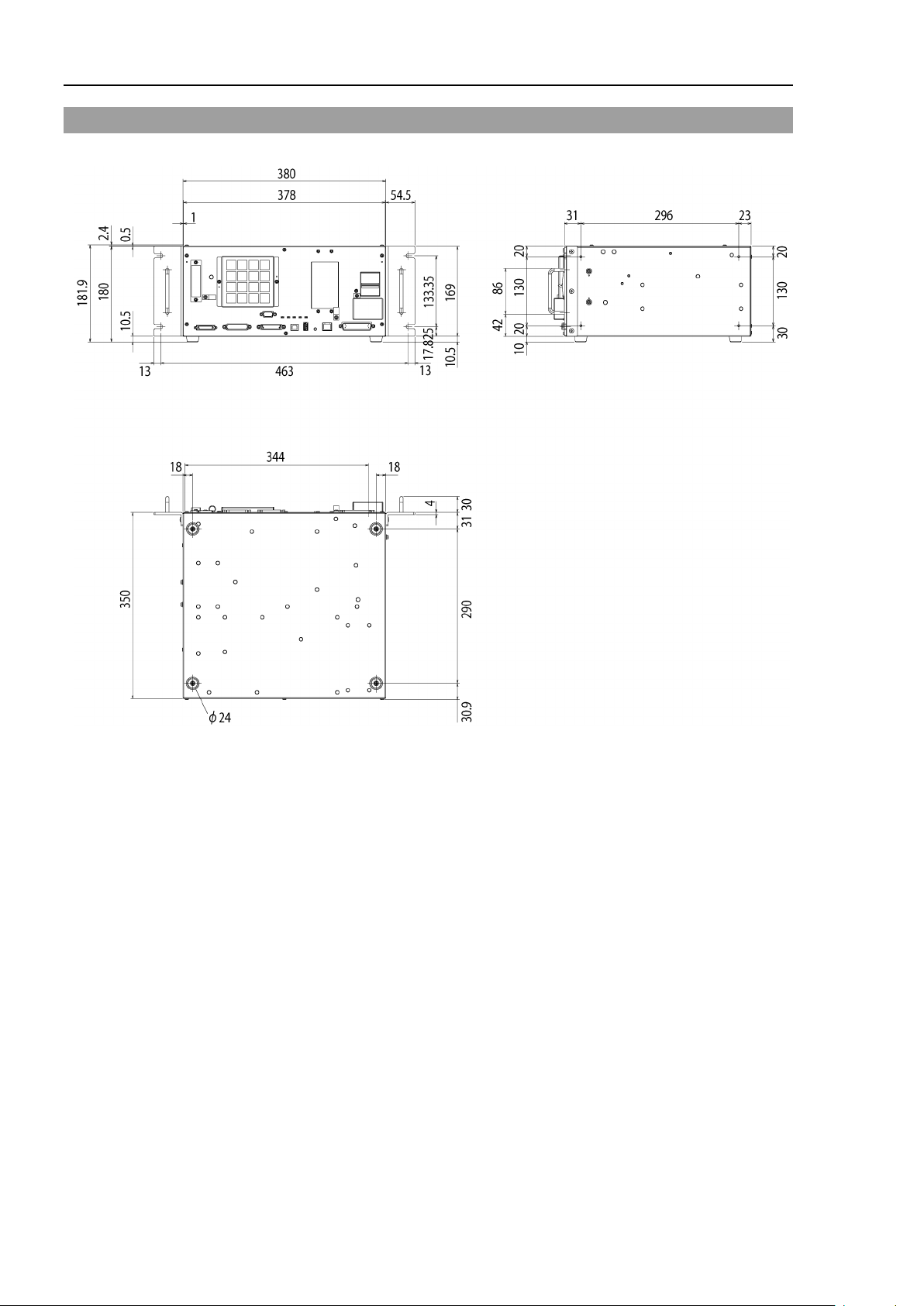

Setup & Operation 1. Specifications

1.3 Outer Dimensions

[Unit : mm]

12 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

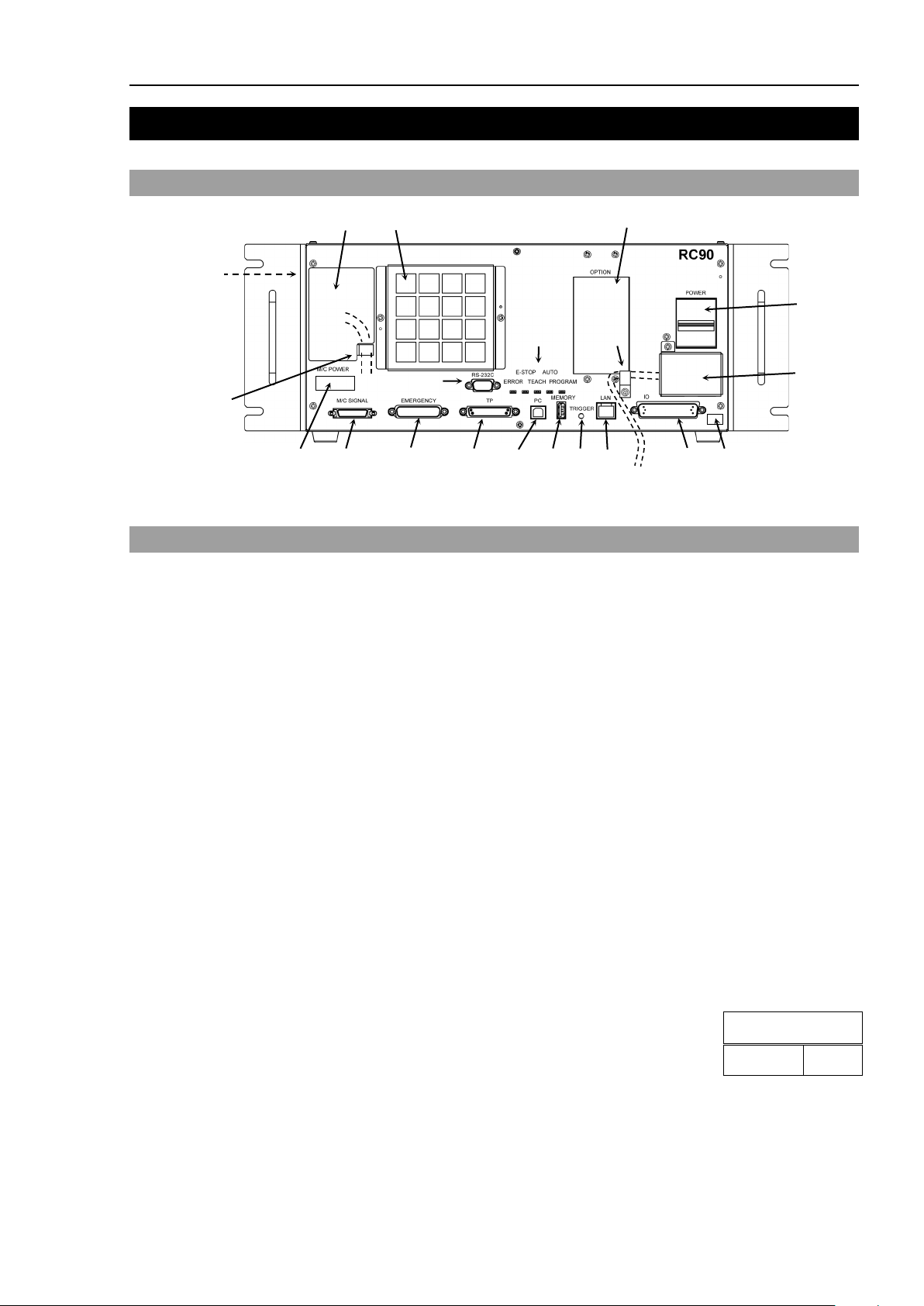

Page 27

Setup & Operation 2. Part Names and Functions

(3)

(18)

(11) (12) (13) (14) (15) (16) (6)

(4)

(1)

(10) (9)

(8)

(19)

(19)

(17)

(5)

(Left side)

(2)

(7)

The details of the Manipulator to be connected are recorded on

label indicates the

Manipulator model and Manipulator serial number.

MANIPULATOR

00002

LS3-401S

NOTE

2. Part Names and Functions

2.1 Part Names

Illustration is RC90. Part names and functions of RC90 and RC90-B are the same.

2.2 Functions

(1) POWER switch

(2) AC IN

(3) LED

(4) Fan Filter

(5) Signature label

(6) Controller Number label

(7) Connection Check label

Turns ON or OFF the Controller.

The terminal block for 200VAC power input.

For details, refer to Setup & Operation 3.3.2 AC Power Cable.

The LED indicates current operation mode (ERROR, E-STOP, TEACH, AUTO, or

PROGRAM mode). For details, refer to Setup & Operation 2.3 LED.

A protective filter is installed in front of the fan to filter out dust.

Check the condition of the filter regularly and clean it when necessary. A dirty filter

may result in malfunction of the robot system due to temperature rise of the Controller.

The serial number of the Controller and other information are shown.

The serial number of the Controller is indicated.

the label as shown in the right. The

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 13

Page 28

Setup & Operation 2. Part Names and Functions

NOTE

(8) M/C POWER connector

A connector for the Manipulator power source.

Connect the dedicated power cable attached to the Manipulator.

(9) M/C SIGNAL connector

This connector is used for signals such as the manipulator’s motor position detector,

etc. Connect the Manipulator’s dedicated signal cable.

(10) EMERGENCY connector

This connector is used for input/output from/to Emergency Stop and Safety Door

switches. For details, refer to the Setup & Operation 9. EMERGENCY.

(11) TP port

Connects Teach Pendant TP1 (Option), TP2 (Option) and TP bypass plug. For details,

refer to Setup & Operation 8. TP Port.

Do not connect the following to the TP port of RC90 / RC90-B. Connecting to the

followings may result in malfunction of the device since the pin assignments are

different.

OPTIONAL DEVICE dummy plug

Operation Pendant OP500

Operator Pendant OP500RC

Jog Pad JP500

Teaching Pendant TP-3**

Operator Panel OP1

(12) Development PC connection port

This port connects the Controller and the Development PC using a USB cable.

Do not connect other devices except the Development PC.

For details, refer to Setup & Operation 5. Development PC Connection Port.

(13) Memory port

This port connects the common USB memory for Controller status storage function.

Do not connect other USB devices except the USB memory.

For details, refer to Setup & Operation 6. Memory Port.

(14) Trigger Switch

This switch is for Controller status storage function using the USB memory.

For details, refer to Setup & Operation 6. Memory Port.

(15) LAN (Ethernet communication) port

This port connects the Controller and the Development PC using an Ethernet cable.

100BASE-TX / 10BASE-T communication are available.

For details, refer to Setup & Operation 7. LAN (Ethernet communication) Port.

(16) I/O connector

This connector is used for input/output device. There are 24 inputs and 16 outputs.

For details, refer to Setup & Operation 11. I/O Connector.

(17) Standard RS-232C port

This port is used for the RS-232C communication with external devices.

For details, refer to

Setup & Operation 10. Standard RS-232C Port.

14 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 29

Controller status

LED display

Execute Controller status

USB memory

TEACH, AUTO, PROGRAM turn ON

ERROR turns OFF even if an error occurs.

2.3 LED

Setup & Operation 2. Part Names and Functions

(18) Option slot

Option boards such as expansion I/O board, Fieldbus I/O board, RS-232C board, PG

board, Analog I/O board can be installed. Two slots are available.

For details, refer to Setup & Operation 13.Option Slots.

(19) Cable Clamp

This can be used to secure the M/C Power Cable and the AC Power cable.

(20) Battery (Mounted inside the controller)

This is a lithium battery for data backup.

Five LEDs are located on the front panel of the Controller.

LEDs (ERROR, E-S TO P, TEACH, AUTO, PROGRAM) turn ON according to the

controller status (error, Emergency Stop, TEACH mode, Auto mode, Program mode).

From turning ON the Controller to completing startup

Three LEDs (TEACH, AUTO, PROGRAM) blink.

After Controller Startup

storage function to the

Complete Controller status

storage to USB memory

Failure of Controller status

storage to USB memory

Error ERROR turns ON.

Warning ERROR blinks.

Emergency Stop E-STOP turns ON.

TEACH mode TEACH blinks.

Auto mode (AUTO mode) AUTO blinks.

Program mode (AUTO mode) PROGRAM blinks.

Recovery mode ERROR, TEACH, PROGRAM turn ON.

TEACH, AUTO, PROGRAM blink.

(for 2 seconds).

ERROR, TEACH, AUTO, PROGRAM turn ON

(for 2 seconds).

AC power supply drop TEACH, AUTO turn ON.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 15

Test mode TEACH turns ON.

Page 30

Setup & Operation 2. Part Names and Functions

2.4 Safety Features

The robot control system supports safety features described below. However, it is

recommended to strictly follow the proper usage of the robot system by thoroughly reading

the attached manuals before using the system. Failure to read and understand the proper

usage of the safety functions is highly dangerous.

Among the following safety features, the Emergency Stop Switch and Safety Door Input are

particularly important. Make sure that these and other features function properly before

operating the robot system.

For details, refer to the Setup & Operation 9. EMERGENCY.

Emergency Stop Switch

The EMERGENCY connector on the Controller has expansion Emergency Stop input

terminals used for connecting the Emergency Stop switches.

Pressing any Emergency Stop switch can shut off the motor power immediately and the

robot system will enter the Emergency Stop condition.

Safety Door Input

In order to activate this feature, make sure that the Safety Door Input switch is connected to

the EMERGENCY connector at the Controller.

When the safety door is opened, normally the Manipulator immediately stops the current

operation, and the status of Manipulator power is operation-prohibited until the safety door

is closed and the latched condition is released. In order to execute the Manipulator

operation while the safety door is open, you must change the mode selector key switch on

the Teach Pendant to the “Teach” mode. Manipulator operation is available only when the

enable switch is on. In this case, the Manipulator is operated in low power status.

Low Power Mode

The motor power is reduced in this mode.

Executing a power status change instruction will change to the restricted (low power) status

regardless of conditions of the safety door or operation mode. The restricted (low power)

status ensures the safety of the operator and reduces the possibility of peripheral equipment

destruction or damage caused by careless operation.

Dynamic Brake

The dynamic brake circuit includes relays that short the motor armatures. The dynamic

brake circuit is activated when there is an Emergency Stop input or when any of the

following errors is detected: encoder cable disconnection, motor overload, irregular motor

torque, motor speed error, servo error (positioning or speed overflow), irregular CPU,

memory check-sum error and overheat condition inside the Motor Driver Module.

Motor Overload Detection

The dynamic brake circuit is activated when the system detects that the load on the motor

has exceeded its capacity.

Irregular Motor Torque (out-of-control manipulator) Detection

The dynamic brake circuit is activated when irregularity with motor torque (motor output)

is detected (in which case the Manipulator is out of control).

16 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 31

Setup & Operation 2. Part Names and Functions

Motor Speed Error Detection

The dynamic brake circuit is activated when the system detects that the motor is running at

incorrect speed.

Positioning Overflow –Servo Error- Detection

The dynamic brake circuit is activated when the system detects that the difference between

the Manipulator’s actual position and commanded position exceeds the margin of error

allowed.

Speed Overflow –Servo Error- Detection

The dynamic brake circuit is activated when the Manipulator’s actual speed is detected to

mark an overflow (the actual speed is outside the nominal range) error.

CPU Irregularity Detection

Irregularity of CPU that controls the motor is detected by the watchdog timer. The system

CPU and the motor controlling CPU inside the Controller are also designed to constantly

check each other for any discrepancies. If a discrepancy is detected, the dynamic brake

circuit is activated.

Memory Check-sum Error Detection

The dynamic brake circuit is activated when a memory check-sum error is detected.

Overheat Detection at the Motor Driver Module

The dynamic brake circuit is activated when the temperature of the power device inside the

Motor Driver module is above the nominal limit.

Relay Deposition Detection

The dynamic brake circuit is activated when relay deposition, junction error, or open fault

is detected.

Over-Voltage Detection

The dynamic brake circuit is activated when the voltage of the Controller is above the

normal limit.

AC Power Supply Voltage Drop Detection

The dynamic brake circuit is activated when the drop of the power supply voltage is detected.

Temperature Anomaly Detection

The temperature anomaly is detected.

Fan Malfunction Detection

Malfunction of the fan rotation speed is detected.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 17

Page 32

Setup & Operation 3. Installation

The Manipulator and the Controller must be used within the environmental

conditions described in their manuals. This product has been designed and

manufactured strictly for use in a normal indoor environment

in the environment that exc

of the

Item

Condition

Use a base table that is at least 100 mm off the floor.

3. Installation

3.1 Unpacking

TP/OP Bypass Plug 1 unit

EMERGENCY Port Connector 1 set

I/O Connector 1 set

Rack-Mount Plate 1 set

3.2 Environmental Requirements

■

WARNING

eeds the conditions may not only shorten the life cycle

product but also cause serious safety problems.

. Using the product

3.2.1 Environment

In order to optimize the robot system’s performance for safety, the Controller must be placed

in an environment that satisfies the following conditions:

- The Controller is not designed for clean-room specification. If it must be installed in a

clean room, be sure to install it in a proper enclosure with adequate ventilation and cooling.

- Install Controller in a location that allows easy connection / disconnection of cables.

Ambient temperature

Ambient relative humidity 20% to 80% (with no condensation)

Fast transient burst noise 2 kV or less (Power supply wire)

Electrostatic noise 4 kV or less

Base table

5 to 40 °C (with minimal variation)

1 kV or less (Signal wire)

Placing the Controller directly on the floor could allow

dust penetration leading to malfunction.

If the Controller must be used in an environment that does not fulfill the conditions

mentioned above, take adequate countermeasures. For example, the Controller may be

enclosed in a cabinet with adequate ventilation and cooling.

- Install indoors only.

- Place in a well-ventilated area.

- Keep away from direct sunlight and radiation heat.

- Keep away from dust, oily mist, oil, salinity, metal powder or other contaminants.

- Keep away from water.

- Keep away from shocks or vibrations.

- Keep away from sources of electronic noise

- Keep away from strong electric or magnetic fields.

18 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 33

Setup & Operation 3. Installation

* The rubber foot needs to be replaced.

* Rack-mount plate is required.

133.35 mm

463 mm

50 mm

50 mm

100 mm

Excluding the installation

side such as base table

Air flow of the Controller Fan

100 mm

200 mm

NOTE

3.2.2 Installation

Install the controller on a flat surface such as wall, floor, and controller box in the direction

shown from (A) to (C).

(A) Flat Mounting

(B) Upright Mounting (C) Rack Mounting

For installing the Controller to the Controller box or the base table, process screw holes as

follows.

Ensure the draft around the in/out and prevent the other equipment, walls and install the

Controller by keeping the distance as follows for maintenance.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 19

- Hot air with higher temperature than the ambient temperature (about 10 °C) comes out

from the Controller. Make sure that heat sensitive devices are not placed near the outlet.

- Arrange the cables in front of the Controller so that you can pull the Controller forward.

Page 34

Setup & Operation 3. Installation

Phase

Single phase

For approximate power consumption of each model, refer to

LS3 : 1.0 kVA

LS6 : 1.1 kVA

LS20 : 2.4 kVA

LS3-B: 1.0 kVA

LS6-B : 1.1 kVA

LS20-B : 2.4 kVA

LS10-B : 1.8 kVA

3.3 Power Supply

3.3.1 Specifications

Ensure that the available power meets following specifications.

Item Specification

Voltage 200 to 240 VAC

Frequency 50/60 Hz

Momentary Power

Interrupt

Rated Capacity Max. 2.5 kVA

Input voltage should be with in ±10 % of the rated voltage.

10 ms or less

Actual power consumption depends on the model, motion, and

load of the Manipulator.

the following values

Peak Current When power is turned ON : approximately 70 A (2 ms.)

Leakage Current Max. 10 mA

Ground Resistance

Install an earth leakage circuit breaker or a circuit breaker in the AC power cable line at 15

A or less rated electric current. Both should be a two-pole disconnect type. If you install

an earth leakage circuit breaker, make sure to use an inverter type that does not operate by

induction of a 10 kHz or more leakage current. If you install a circuit breaker, please select

one that will handle the above mentioned “peak current”.

The power receptacle shall be installed near the equipment and shall be easily accessible.

Refer to the Manipulator manual for rated capacity of the

Manipulator motor.

When motor is ON : approximately 50 A (2 ms.)

100 Ω or less

20 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 35

Setup & Operation 3. Installation

Make sure that

B

terminal of the factory power supply.

at all times to avoid the risk of electric shock.

Always use a power plug

for power connecting cable.

Never connect the Controller directly to the factory power supply.

Select the plug

which conform safety standards for

nations.

Ground wire

Green / Yellow

3.3.2 AC Power Cable

■

■

e sure to connect the earth wire (green/yellow) of the AC power cable to the earth

WARNING

■

■

AC power wire (2 cables)

Cable length 3 m

Terminal M4 round solderless terminal

operations are done by a qualified personal.

The equipment must be grounded properly

or a disconnecting device

or a disconnecting device

Item Specification

Black, Black

or Black, White

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 21

Page 36

Setup & Operation 3. Installation

(1)

Mount the M/C Power Cable as shown

e picture and

form the cables.

(2)

Set the M/C Power Cable in the clamp for the M/C Power

Cable.

(3)

Mount the cover for the M/C Power

(4)

Secure the cover with the screw.

3.3.3 M/C Power Cable

in th

Connector.

22 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 37

Make sure that the power to the Control

disconnected

Connecting or

disconnecting

result in electric shock and malfunction of the Controller.

Be sure to connect the cables properly. Do not

cables. (Do not put heavy objects on the cables. Do not bend or pull the cables

forcibly.) The unnecessary strain on the cables may result in damage to the

cables, disconnection, and/or contact failure. Damaged cables, d

contact failure is extremely hazardous and may result in electric shock and/or

improper function of the system.

The serial number of the Manipulator that should be connected is indicated on the

Connection Check Label on the Controller. Connect the Controller and the

Manipulator correctly. Improper connection between the Controller and the

Manipulator may cause not only improper function of the robot system but also

safety problems.

Before connecting the connector, make sure

the pins are not bent.

Connecting with

of the robot system.

3.4 Cable Connection

Setup & Operation 3. Installation

■

■

WARNING

■

CAUTION

■

ler is turned OFF and the power plug is

before connecting or disconnecting any cables.

any cables with the power ON is extremely hazardous and may

allow unnecessary strain on the

isconnection, or

that

the pins bent may damage the connector and result in malfunction

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 23

Page 38

Setup & Operation 3. Installation

Manipulator

(6) USB Memory

PC for Development

Input/Output Device

Connect by (5) or (7)

*1

*1

Controller

(1) AC Power Terminal Block

(2) M/C Power Connector

(3) M/C Signal Connector

(4) EMERGENCY Connector

(5) Development PC Connection Port

200VAC-240VAC

(7) LAN (Ethernet Communication)

(8) I/O Connector

(9) TP Connector

(10) Standard RS-232C Connector

Emergency Stop

Safety Door, etc.

Teach

Pendant

Option

FieldBus I/O

Expansion I/O

RS-232C

PG board

Analog I/O

EUROMAP67

Detachable connector

Cable attached at shipping

Cable prepared by users

(1)

AC Power terminal block

(2)

M/C Power cable

.

(3)

M/C Signal cable

(4)

EMERGENCY

3.4.1 Typical Cable Connection

*1: Only LS-B series is detachable.

Terminal block for 200VAC power input to the Controller.

The cable with 20-pin connector on the Controller side.

Connect the Manipulator and the M/C POWER connector on the Controller

Insert the connectors until you hear a “click”.

The cable with 36-pin connector on the Controller side.

Connect the Manipulator and the M/C SIGNAL connector on the Controller.

The EMERGENCY connector has inputs to connect the Emergency Stop switch

and the Safety Door switch. For safety reasons, connect proper switches for these

input devices.

For details, refer to the Setup & Operation 9. EMERGENCY.

24 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 39

Setup & Operation 3. Installation

(5)

PC for development

(6)

USB memory

(7)

LAN (EtherNet Communication)

(8)

I/O connector

(9)

TP cable

(10)

Standard RS-232C port

Connect the PC for development.

For details, refer to the Setup & Operation 5. Development PC Port.

Connect the USB memory.

For details, refer to the Setup & Operation 6. Memory Port.

Connect the EtherNet cable.

For details, refer to the Setup & Operation 7. LAN (Ethernet Communication) Port.

This connector is used for input/output devices of the user.

When there are input/output devices, use this connector.

There are I/O cable (option) and terminal block (option) for the I/O connector.

For details, refer to the Setup & Operation 11. I/O Connector.

Connect the option Teach Pendant.

For details, refer to the Setup & Operation 8.TP Port.

This port is used for the RS-232C communication with external devices.

For details, refer to Setup & Operation 10. Standard RS-232C Port.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 25

Page 40

Setup & Operation 3. Installation

Make sure that the power to the Control

turned OFF before connecting or

disconnecting any cables.

any cables with the

power ON

of

Be sure to connect the cables

cables. (Do not put heavy objects on the cables. Do not bend or pull the cables

forcibly.) The unnecessary strain on the cables may result in damage to the

cables, disconnection, and/or contact failure.

contact failure is extremely hazardous and may result in electric shock and/or

improper function of the system.

on the Controller. Connect the Controller and the

Improper connection between the Controller and the

When connecting the Manipulator to the Controller, make sure that the serial

numbers on each equipment match. Improper connection between the

Manipulator and Controller may not only cause improper function of the robot

3.4.2 Connecting Manipulator to Controller

Connect the Manipulator to the Controller by using the Power cable and the Signal cable.

■

is extremely hazardous and may result in electric shock and malfunction

the Controller.

■

WARNING

■ The serial number of the Manipulator that should be connected is indicated on the

Connection Check Label

Manipulator correctly.

Manipulator may cause not only improper function of the robot system but also

safety problems.

CAUTION

■

system but also serious safety problems. The connection method varies with the

Controller used. For details on the connection, refer to the Controller manual.

ler is

Connecting or disconnecting

properly. Do not allow unnecessary strain on the

Damaged cables, disconnection, or

26 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 41

Setup & Operation 3. Installation

LS3 series Manipulator

(Figure: LS3-401S)

RC90 Controller

M/C Power Cable

M/C Signal Cable

NOTE

The configuration data for the Manipulator and Manipulator model are stored in the

Controller. Therefore the Controller should be connected to the Manipulator whose serial

number is specified in the Connection Check label attached on the front of the Controller.

The Manipulator’s serial number is indicated on the signature label of the Manipulator.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 27

Page 42

Setup & Operation 3. Installation

preferable example is shown in the right figure.

AC Line duct

DC line duct

As far as

possible

3.5 Noise Countermeasures

To minimize electrical noise conditions, the following items must be observed in the

system’s cable wiring:

To minimize electrical noise condition, be sure of followings for wiring.

- The earth wire of the power supply should be grounded. (Ground resistance: 100 Ω or

less) It is important to ground the frame of Controller not only for prevention from

electric shock, but also for reducing the influence of electric noise around the Controller.

Therefore, be sure to connect the earth wire (yellow/green) of the Controller’s power

cable to the ground terminal of the factory power supply. For details about the plug

and AC power cable, refer to the Setup & Operation 3.3 Power Supply.

- Do not tap power from a power line that connects to any equipment which may cause

noise.

- When you tap power for the Controller and the single-phase AC motor from the same

power line, change the phase of one or the other. Ensure that they will not be the same

phase.

- Use a twisted pair motor power line.

- Do not run AC power lines and DC power lines in

the same wiring duct, and separate them as far as

possible. For example, separate the AC motor

power line and the Controller power line as far as

possible from the sensor or valve I/O lines; and do

not bundle both sets of wiring with the same cable

tie. If more than one duct/cable must cross each

other, they should cross perpendicularly. The

- Wire as short as possible to the I/O connector and EMERGENCY connector. Use a

shielded cable and clamp the shield to the attached connector interior. Make sure to

keep away from the peripheral noise source as far as possible.

- Make sure that the induction elements used to connect to the Controller’s I/O (such as

relays and solenoid valves) are noise suppression parts. If an induction element without

protection against noise is used, make sure to connect a noise suppression part such as a

diode located at the induction element in parallel with it. In selecting noise suppression

parts, make sure that they can handle the voltage and current incurred by the induction

load.

- To start and change revolutions of the conveyer’s (or the like’s) AC motor (ex: an

induction motor or three-phase induction motor) regularly or abruptly, make sure to

install a spark suppressor between the wires. The spark suppressor is more effective

when placed closer to the motor.

- As they are easily influenced by noise, keep cable such as USB, Ethernet, RS-232C, or

fieldbus away from peripheral noise sources.

28 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 43

Setup & Operation 4. Operation Mode (TEACH/AUTO/TEST)

In this mode the Robot operates in Low power status.

This mode enables automatic operation (program execution) of the

This mode cannot operate the Robots or run programs with the Safety

Door open.

This is a low speed program verification function (T1: manual

task, multi-manipulator / single-manipulator at low speed.

The operating Robot stops by Quick Pause.

and turn on the latch

release input signal for AUTO mode.

mode.

[Test Mode] in [Jog & Teach] dialog of TEACH mode.

The mode will be changed to TEST

4. Operation Mode (TEACH/AUTO/TEST)

4.1 Overview

The Robot system has three operation modes.

TEACH mode This mode enables point data teaching and checking close to the Robot

using the Teach Pendant.

AUTO mode

Robot system for the manufacturing operation, and also programming,

debug, adjustment, and maintenance of the Robot system.

TEST mode

4.2 Switch Operation Mode

Change the operation mode using the mode selector key switch on the Teach Pendant.

TEACH mode Turn the mode selector key switch to “Teach” for TEACH mode.

AUTO mode Turn the mode selector key switch to “Auto”

TEST mode Turn the mode selector key switch to “Teach” for “TEACH”

This mode enables program verification while the Enable Switch is

held down and the safeguard is open.

deceleration mode) which is defined in Safety Standards.

This mode can operate the specified Function with multi-task / single-

Switching to TEACH mode pauses the program if it was running.

Push <F1> key-

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 29

Page 44

Setup & Operation 4. Operation Mode (TEACH/AUTO/TEST)

(2)

(5)

(3)

(4)

4.3 Program Mode (AUTO)

4.3.1 What is Program Mode (AUTO)?

Program mode is for programming, debug, adjustment, and maintenance of the Robot

system.

Follow the procedures below to switch to the Program mode.

4.3.2 Setup from EPSON RC+ 7.0

Switch the mode to Program mode from the EPSON RC+ 7.0.

(1) Select EPSON RC+ 7.0 menu-[Setup]-[System Configuration] to display the [System

Configuration] dialog.

(2) Select [Startup].

(3) Select [Start mode]-<Program> button.

(4) Click the <Apply> button.

(5) Click the <Close> button.

30 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 45

(2)

(5)

(3)

(4)

NOTE

4.4 Auto Mode (AUTO)

4.4.1 What is Auto mode (AUTO)?

Auto mode (AUTO) is for automatic operation of the Robot system.

Procedures for switching to the Auto mode (AUTO) are the followings.

A : Set the start mode of the EPSON RC+ 7.0 to “Auto” and start the EPSON RC+ 7.0.

(Refer to Setup & Operation 4.4.2 Setup from EPSON RC+ 7.0.)

B : Offline the EPSON RC+ 7.0.

Execute and stop the program from the control device specified by the EPSON RC+ 7.0.

(Refer to Setup & Operation 4.4.3 Setup Control Device.)

4.4.2 Setup from EPSON RC+ 7.0

Switch the mode to Auto mode (AUTO) from the EPSON RC+ 7.0.

(1) Select EPSON RC+ 7.0 menu-[Setup]-[System Configuration] to display the [System

Configuration] dialog.

Setup & Operation 4. Operation Mode (TEACH/AUTO/TEST)

(2) Select [Startup].

(3) Select [Start Mode]-<Auto> button.

(4) Click the <Apply> button.

(5) Click the <Close> button.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 31

Page 46

Setup & Operation 4. Operation Mode (TEACH/AUTO/TEST)

(2)

(5)

(3)

(4)

4.4.3 Setup from Control Device

Set the control device from EPSON RC+ 7.0.

(1) Select EPSON RC+ 7.0 menu-[Setup]-[System Configuration] to display the [System

Configuration] dialog.

(2) Select [Controller]-[Configuration].

(3) Select [Control Device] to select the control device from the following two types.

- PC

- Remote (I/O)

(4) Click the <Apply> button.

(5) Click the <Close> button.

32 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 47

Setup & Operation 5. Development PC Connection Port

Development PC connection Port

NOTE

5. Development PC Connection Port

Development PC connection USB port (USB B series connector)

For other details of development PC and Controller connection, refer to EPSON RC+ 7.0

User’s Guide 5.12.1 PC to Controller Communications Command.

For RC90/RC90-B, be sure to install the EPSON RC+ 7.0 to the development PC first, then

connect the development PC and RC90/RC90-B with the USB cable.

If RC90/RC90-B and the development PC are connected without installing the EPSON RC+

7.0 to the development PC, [Add New Hardware Wizard] appears. If this wizard appears,

click the <Cancel> button.

5.1 About Development PC Connection Port

The development PC connection port supports the following USB types.

- USB2.0 HighSpeed/FullSpeed (Speed auto selection, or FullSpeed mode)

- USB1.1 FullSpeed

Interface Standard : USB specification Ver.2.0 compliant

Connect the Controller and development PC by a USB cable to develop the robot system or

set the Controller configuration with the EPSON RC+ 7.0 software installed in the

development PC.

Development PC connection port supports hot plug feature. Cables insert and remove

from the development PC and the Controller is available when the power is ON.

However, stop occurs when USB cable is removed from the Controller or the development

PC during connection.

(USB Ver.1.1 upward compatible)

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 33

Page 48

Setup & Operation 5. Development PC Connection Port

5.2 Precaution

When connecting the development PC and the Controller, make sure of the following:

- Connect the development PC and the Controller with a 5 m or less USB cable.

Do not use the USB hub or extension cable.

- Make sure that no other devices except the development PC are used for development

PC connection port.

- Use a PC and USB cable that supports USB2.0 HighSpeed mode to operate in USB2.0

HighSpeed mode.

- Do not pull or bend the cable strongly.

- Do not allow unnecessary strain on the cable.

- When the development PC and the Controller are connected, do not insert or remove

other USB devices from the development PC. Connection with the Controller may be

lost.

5.3 Software Setup and Connection Check

Connection of the development PC and the Controller is indicated.

(1) Make sure that software EPSON RC+ 7.0 (Ver.7.0.2 or later is recommended) is

installed to the Controller connected to the development PC.

(Install the software when it is not installed.

Installation or EPSON RC+ 7.0 User’s Guide.

Refer to Robot System Safety and

(2) Connect the development PC and the Controller using a USB cable.

(3) Turn ON the Controller.

(4) Start EPSON RC+ 7.0.

(5) Select the EPSON RC+ 7.0 menu-[Setup]-[PC to Controller Communications] to

display the [PC to Controller Communications] dialog.

(6) Select “No.1 USB” and click the <Connect> button.

34 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 49

Setup & Operation 5. Development PC Connection Port

NOTE

(7) After the development PC and the Controller connection has completed, “Connected”

is displayed at [Connection status]. Make sure that “Connected” is displayed and

click the <Close> button to close the [PC to Controller Communications] dialog.

The connection between the development PC and the Controller is completed. Now the

robot system can be used from EPSON RC+ 7.0.

5.4 Disconnection of Development PC and Controller

Disconnection of the development PC and the Controller communication.

(1) Select the EPSON RC+ 7.0 menu-[Setup]-[PC to Controller Communications] to

display the [PC to Controller Communications] dialog.

(2) Click the <Disconnect> button.

Communication between the Controller and the development PC is disconnected and

the USB cable can be removed.

If the USB cable is removed when the Controller and the development PC are connected,

the Robot will stop. Be sure to click the <Disconnect> button in the [PC to Controller

Communications] dialog before USB cable is removed.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 35

Page 50

Setup & Operation 6. Memory Port

■

Controller status storage function is available at any time and in any Controller

status after starting the Controller.

However, operations form the console including stop and pause are not

while executing this function.

Also,

EPSON

function when operating the robot.

6. Memory Port

Connect a commercial USB memory to the Controller memory port to use the Controller

status storage function to the USB memory.

6.1 What is Controller Status Storage Function?

This function saves various kinds of Controller data with one push to the USB memory.

Data saved in USB memory is loaded to EPSON RC+ 7.0 to get the status of the Controller

and the program simply and accurately.

The saved data can also be used for restoring the Controller.

6.2 Before Using Controller Status Storage Function

6.2.1 Precautions

CAUTION

this function influences the robot cycle time and the communication with

RC+ 7.0. Other than only when it is necessary, do not execute this

available

- Make sure that the USB port is used only for USB memory even though the port on the

Controller is a universal USB port.

- Insert the USB memory directly into the Controller memory port. Connection with

cables or hubs between the Controller and the USB memory is not assured.

- Make sure that the USB memory is inserted or removed slowly.

- Do not edit the saved files with an editor. Operation of the robot system after data

restoration to the Controller is not assured.

6.2.2 Adoptable USB Memory

Use USB memory that meets following conditions.

- USB2.0 supported

- Without security function

USB memory with password input function cannot be used.

- No installation of a driver or software is necessary for Windows 8, or Windows 10.

(For supported operating systems for the EPSON RC+ 7.0, refer to Setup & Operation

1.1 System Example.)

36 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 51

6.3 Controller Status Storage Function

■

Controller status storage function is available at any time and in any Controller

status after starting the Controller.

However, operations form the console including stop and pause are not

while executing this function.

Also, this function

EPSON

function when operating the robot.

NOTE

6.3.1 Controller Status Storage with Trigger Button

CAUTION

influences the robot cycle time and the communication with

RC+ 7.0. Other than only when it is necessary, do not execute this

Use this procedure to save the status of the Controller to USB memory.

(1) Insert the USB memory into the memory port.

(2) Wait approximately 10 seconds for USB memory recognition.

(3) Press the trigger button on the Controller.

When the data transfer starts, the LED of

Wait until the LED status changes.

(The data transfer time varies according to the data size such as of the projects.)

Setup & Operation 6. Memory Port

available

TEACH, AUTO, and PROGRAM starts blinking.

(4) When the controller status storage is completed successfully, the LED of TEACH, AUTO,

and PROGRAM are turned ON for two seconds. Note that the LED of ERROR turns OFF

even in the error status.

If it ends in failure, the LED of ERROR, TEACH, AUTO, and PROGRAM are turned ON

for two seconds.

(5) Remove the USB memory from the Controller.

- USB memory with LED is recommended to check the status changes in procedure (2).

- When storage is executed during Motor ON status, it may fail to store the status.

Use another USB memory or execute the storage during Motor OFF status.

6.3.2 Load Data with EPSON RC+ 7.0

The following shows the procedure to read the data stored in the USB memory by EPSON

RC+ 7.0 and display the Controller status.

(1) Insert the USB memory into the PC with EPSON RC+ 7.0.

(2) Make sure that the following folder is indicated in the USB memory.

B_controller model_serial number_data status was saved

→ Example RC90 : B_RC90_12345_2013-10-29_092951

→ Example RC90-B : B_RC90-B_12345_2013-10-29_092951

(3) Copy the folder confirmed in procedure (2) to the “\EpsonRC70\Backup” folder.

RC90 / RC90-B (EPSON RC+ 7.0) Rev.26 37

Page 52

Setup & Operation 6. Memory Port

(4) Select the EPSON RC+ 7.0 menu-[Tools]-[Controller] to display the [Controller Tools]

dialog.

(5) Click the <View Controller Status…> button.

(6) [Browse For Folder] dialog appears. Select the folder copied in procedure (3) and click

the <OK> button.

(7) [Controller Status Viewer] dialog appears to confirm the Controller status.

For details, refer to View Controller Status in EPSON RC+ 7.0 User’s Guide 5.11.8

Controller Command (Tools Menu).

38 RC90 / RC90-B (EPSON RC+ 7.0) Rev.26

Page 53

6.3.3 Transfer with E-mail

File Name

Outline

for restore

parameter

CurrentStatus.txt

Save status

Saves program and I/O status.

ErrorHistory.csv

Error history

InitFileSrc.txt

Initial setting

Saves various settings of the Controller.

MCSys01.MCD

Robot setting

Saves information of connected robot.

information

Prg file is not included.

variables

information

VXDWORK.bin

When [Include project files when status exported] check box

the project file is stored. Includes program files.

NOTE

Follow this procedure to transfer the data by e-mail that was saved to the USB memory.

(1) Insert the USB memory to a PC that supports sending of e-mail.

(2) Make sure that the USB memory has following folders.

B_controller model_serial number_data status was saved

→ Example RC90 : B_RC90_12345_2013-10-29_092951

→ Example RC90-B : B_RC90-B_12345_2013-10-29_092951

(3) Send all the folders by e-mail.

- Delete files that do not relate to the project before transfer.