Page 1

Rev.11 EM208C4461F

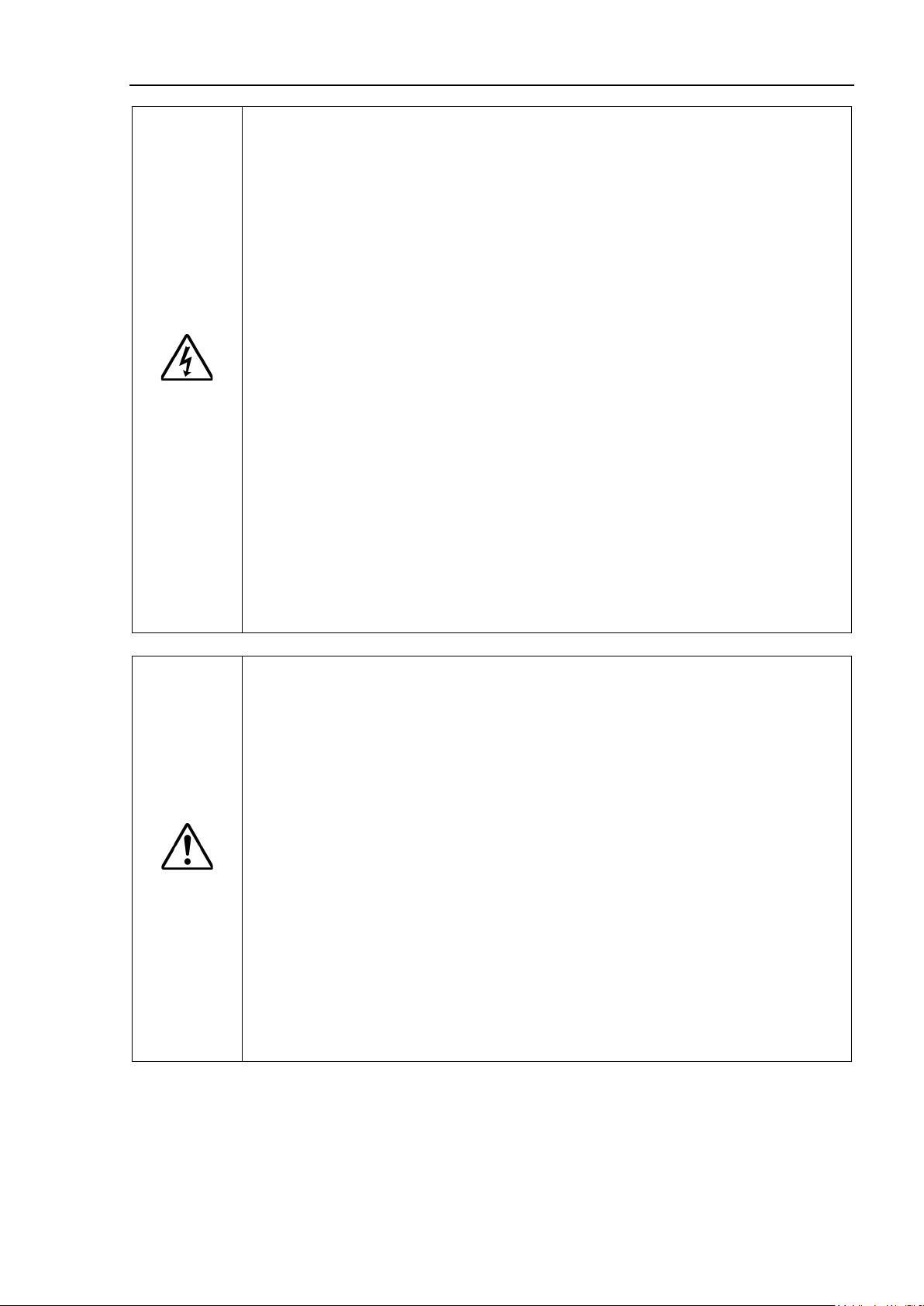

ROBOT CONTROLLER / Drive Unit

RC700DU /

RC700DU-A

Page 2

ROBOT CONTROLLER / Drive Unit RC700DU / RC700DU-A Rev.11

ii

Page 3

ROBOT CONTROLLER / DRIVE UNIT

RC700DU / RC700DU-A

Rev.11

Copyright © 2014-2020 SEIKO EPSON CORPORATION. All rights reserved.

RC700DU / RC700DU-A Rev.11 i

Page 4

FOREWORD

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the Robot Controller

and the Drive Unit.

Please carefully read this manual and other related manuals before installing the robot

system.

Keep this manual handy for easy access at all times.

RC700 / RC700-A robot Controller consists of the following:

This manual contains the information for the RC700 DU / RC700DU-A (Drive Unit).

For RC700 CU / RC700CU-A (Control Unit), refer to the RC700 / RC700-A Robot

Controller manual.

The information for the Robot Controller is describes as below, indicating both RC700 CU

/ RC700CU-A and RC700 DU / RC700DU-A:

The information for the either unit (CU or DU) is described as below:

RC700 CU / RC700CU-A (Control Unit)

RC700 DU / RC700DU-A (Drive Unit)

Robot Controller

Controller

RC700

RC700CU / RC700CU-A Control Unit

RC700DU / RC700DU-A Drive Unit

ii RC700DU / RC700DU-A Rev.11

Page 5

WARRANTY

1. Damage or malfunction caused by improper use which is not described in the manual,

or careless use.

2. Malfunctions caused by customers’ unauthorized disassembly.

3. Damage due to improper adjustments or unauthorized repair attempts.

4.

Damage caused by natural disasters such as earthquake, flood, etc.

1. If the

associated equipment is used outside of the usage conditions and

product

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences.

Therefore, this manual

cannot warn the user of all possible hazards.

The robot system and its optional parts are shipped to our customers only after being

subjected to the strictest quality controls, tests, and inspections to certify its compliance with

our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please contact the supplier of your region for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

Warnings, Cautions, Usage:

robot system

specifications described in the manuals, this warranty is void.

RC700DU / RC700DU-A Rev.11 iii

Page 6

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® 8 Operating system

Microsoft® Windows® 10 Operating system

Throughout this manual, Windows 8 and Windows 10 refer to above respective operating

systems. In some cases, Windows refers generically to Windows 8 and Windows 10.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

MANUFACTURER

CONTACT INFORMATION

Contact information is described in “SUPPLIERS” in the first pages of the following

manual:

Robot System Safety and Installation Read this manual first

iv RC700DU / RC700DU-A Rev.11

Page 7

Safety

1. Safety 3

2. Conventions 3

3. Safety Precautions 4

Setup & Operation

1. Specifications 9

1.1 System Example ....................................................................................... 9

1.2 Drive Unit Standard Specifications ......................................................... 11

1.3 Outer Dimensions ................................................................................... 12

Table of Contents

2. Part Names and Functions 13

2.1 LED ......................................................................................................... 15

2.2 Safety Features ....................................................................................... 16

3. Installation 18

3.1 Unpacking .................................................................................................. 18

3.2 Environmental Requirements ................................................................. 18

3.2.1 Environment ................................................................................ 18

3.2.2 Installation ................................................................................... 19

3.2.3 Wall Mounting Option .................................................................. 20

3.3 Power Supply .......................................................................................... 21

3.3.1 Specifications .............................................................................. 21

3.3.2 AC Power Cable .......................................................................... 22

3.4 Cable Connection ................................................................................... 23

3.4.1 Typical Cable Connection ........................................................... 24

3.4.2 Connecting Manipulator to Drive Unit ......................................... 26

3.5 Noise Countermeasures ......................................................................... 27

4. Drive Unit Connection 28

5. Drive Unit Setup 29

RC700DU / RC700DU-A Rev.11 v

Page 8

Table of Contents

6. EMERGENCY 32

6.1 Safety Door Switch and Latch Release Switch ...................................... 32

6.1.1 Safety Door Switch ..................................................................... 32

6.1.2 Latch Release Switch ................................................................. 33

6.1.3 Checking Latch Release Switch Operation ................................ 33

6.2 Emergency Stop Switch Connection ...................................................... 34

6.2.1 Emergency Stop Switch .............................................................. 34

6.2.2 Checking Emergency Stop Switch Operation ............................ 34

6.2.3 Recovery from Emergency Stop ................................................. 34

6.3 Pin Assignments ..................................................................................... 35

6.4 Circuit and Wiring ................................................................................... 36

6.4.1 Circuit Diagram ........................................................................... 36

6.4.2 Wiring Example for Emergency Stop .......................................... 37

6.4.3 Wiring Example for Safety Door Input / Latch Release Input ..... 39

Maintenance

7. I/O Connector 40

7.1 Input Circuit ............................................................................................. 40

7.2 Output Circuit .......................................................................................... 43

7.3 Pin Assignments ..................................................................................... 45

8. R-I/O Connector 46

8.1 Input Circuit ............................................................................................... 46

8.2 Pin Assignments ..................................................................................... 47

1. Safety Precautions on Maintenance 51

2. Regular Maintenance Inspection 53

3. Drive Unit Structure 54

3.1 Location of Parts ..................................................................................... 54

3.1.1 RC700DU .................................................................................... 54

3.1.2 RC700DU-A ................................................................................ 54

3.2 Diagram of Cable Connections .............................................................. 55

3.2.1 RC700DU .................................................................................... 55

3.2.2 RC700DU-A ................................................................................ 56

vi RC700DU / RC700DU-A Rev.11

Page 9

Table of Contents

4. Maintenance Parts Replacement Procedures 57

4.1 Fan Filter ................................................................................................. 57

4.2 Fan .......................................................................................................... 58

4.2.1 Front Fan ..................................................................................... 58

4.2.2 Fan 2 (RC700DU-A only) ............................................................ 59

4.3 MDB ........................................................................................................ 61

4.4 DMB ........................................................................................................ 65

4.5 DMB-SUB Board ..................................................................................... 67

4.6 DMB-LED Board ..................................................................................... 68

4.6.1 DMB-LED Board (RC700DU) ..................................................... 68

4.6.2 DMB-LED Board (RC700DU-A) .................................................. 69

4.7 DPB ......................................................................................................... 70

5. Verifying Robot System Operation 72

6. Troubleshooting 73

6.1 Error Code Table .................................................................................... 73

7. Maintenance Parts List 74

RC700DU / RC700DU-A Rev.11 vii

Page 10

Table of Contents

viii RC700DU / RC700DU-A Rev.11

Page 11

Safety

This section contains information for safety of the Robot System.

Page 12

Page 13

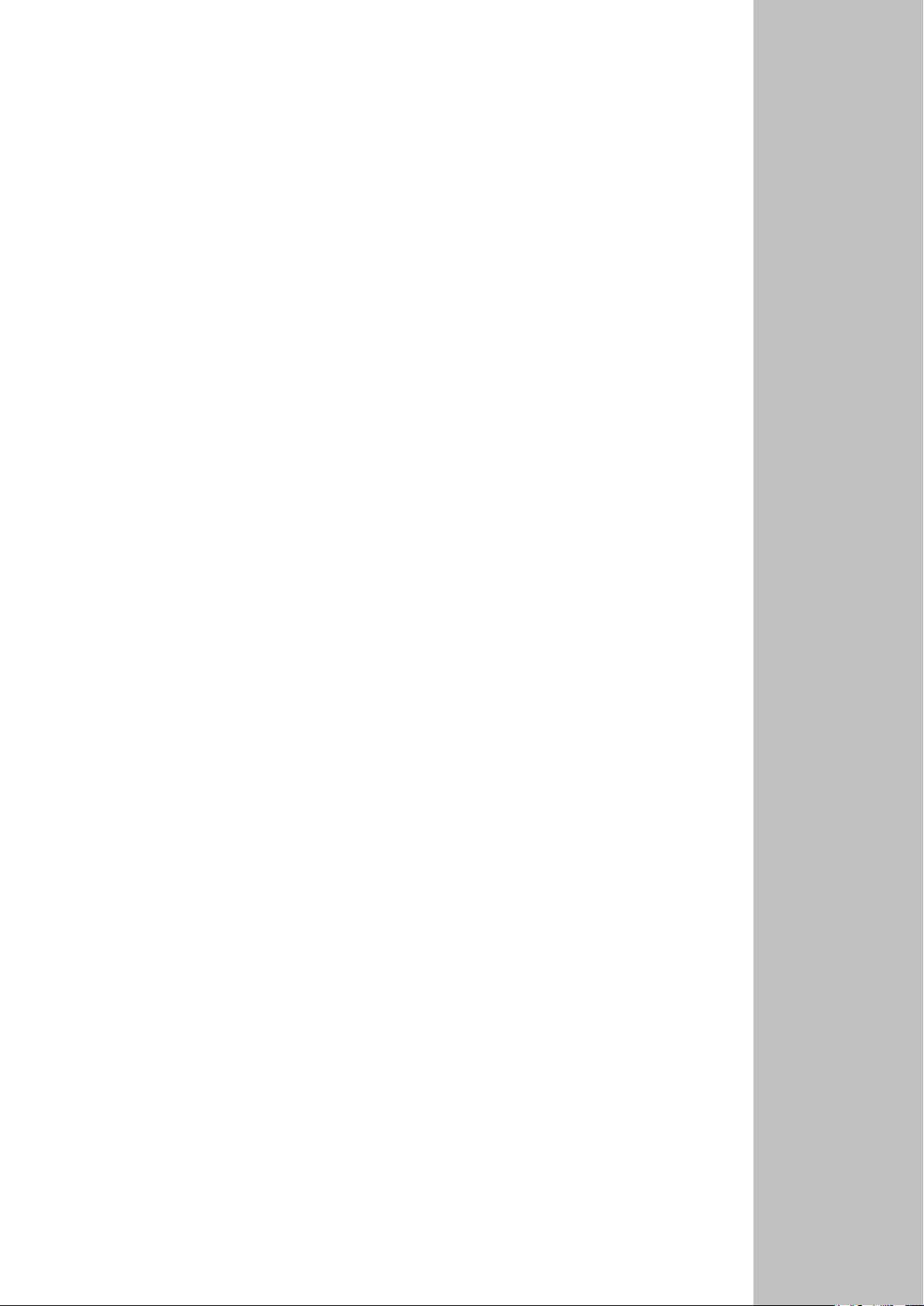

WARNING

properly.

WARNING

This symbol indicates that a danger of possible harm to people

not followed properly.

CAUTION

instructions are not followed properly.

1. Safety

Installation and transportation of Manipulators and robotic equipment shall be performed

by qualified personnel and should conform to all national and local codes.

Please read this manual and other related manuals before installing the robot system or

before connecting cables. Keep this manual in a handy location for easy access at all times.

2. Conventions

Important safety considerations are indicated throughout the manual by the following

symbols. Be sure to read the descriptions shown with each symbol.

Safety 1. Safety

This symbol indicates that a danger of possible serious injury or

death exists if the associated instructions are not followed

caused by electric shock exists if the associated instructions are

This symbol indicates that a danger of possible harm to people or

physical damage to equipment and facilities exists if the associated

RC700DU / RC700DU-A Rev.11 3

Page 14

Safety 3. Safety Precautions

Personnel

read the Safety chapter in User

before designing and/or constructing the robot system. Designing and/or

constructing the robot system withou

extremely hazardous, may result in serious bodily injury and/or severe equipment

damage to the robot system, and may cause serious safety problems.

The Manipulator and the

must be used within the environmental

conditions described in their respective manuals. This product has been

designed and manufactured strictly for use in a normal indoor environment.

Using the product in an environment that exceeds the specified enviro

conditions may not only shorten the life cycle of the

serious safety problems.

The

the manuals.

may

problem

The interlock of the Safety Door must be functioning when the

operated.

be turned ON/OFF. (I.E. the condition where the switch is disabled)

(Example: Tape is put around the switch to hold it closed.) Operating the robot

system when the switch is not

may

s as the Safety Door input cannot fulfill its

intended function

Connect input signal wires for Emergency Stop and Safety Door to the

EMERGENCY connector so that the Emergency Stop switch in the

always functions. (Refer to the typical application diagram in

6

3. Safety Precautions

Only trained personnel should design and install the robot system.

Trained personnel are defined as those who have taken robot system training class held by

the manufacturer, dealer, or local representative company, or those who understand the

manuals thoroughly and have the same knowledge and skill level as those who have

completed the training courses.

The following items are safety precautions for qualified design or installation

personnel:

WARNING

who design and/or construct the robot system with this product must

’s Guide to understand the safety requirements

t understanding the safety requirements is

Drive Unit

product but may also cause

robot system must be used within the installation requirements described in

Using the robot system outside of the installation requirements

not only shorten the life cycle of the product but also cause serious safety

s.

robot system is

Do not operate the system under the condition that the switch cannot

nmental

functioning properly is extremely hazardous and

cause serious safety problem

.

.4 Circuit and Wiring.)

4 RC700DU / RC700DU-A Rev.11

whole system

Setup & Operation

Page 15

Safety 3. Safety Precautions

Do not open the cover(s) of the

the cover(s) of the

shock

the

Make sure that the power to the

disconnecting any cables.

any cables with the

power ON

ma

Be sure to connect the cables properly. Do not allow unnecessary strain on the

cables. (Do not put heavy objects on the cables. Do not bend or pull the cables

forcibly.) The unnecessary strain on the cables may

cables, disconnection, and/or contact failure. Damaged cables, disconnection,

or a contact failure is extremely hazardous and may result in electric shock and/or

improper function of the system.

When

by qualified personnel. When connecting the plug,

wire of the AC power cable colored green/yellow

terminal of the factory power supply.

at all times to avoid the risk of electric shock.

receptacle

(Field wiring)

The serial number of the

Connection Check Label

nit and the

Manipulator correctly.

nit and the

Manipulator may cause improper function of the rob

problems.

When using remote I/O, always make sure of the following. Using the robot

system under

conditions may cause malfunction of the system

and/or safety problems.

-

-

input/output signals

- When verifying the robot system operation, prepare for failures with initial

WARNING

even when its main power is OFF because of the high voltage charge inside

Drive Unit.

is extremely hazardous and may result in electric shock and/or

lfunction of the Drive Unit.

connecting the plug to fit the outlet in your factory, make sure that it is done

. Never connect the Drive Unit directly to the factory power supply.

Drive Unit except while maintaining it. Opening

Drive Unit is extremely hazardous and may result in electric

Drive Unit is turned OFF before connecting or

Connecting or disconnecting

result in damage to the

be sure to connect the earth

on the Drive Unit to the earth

The equipment must be grounded properly

Always use a power plug and

Manipulator that should be connected is indicated on the

on the Drive Unit. Connect the Drive U

Improper connection between the Drive U

unsatisfactory

CAUTION

Assign remote functions to inputs/outputs correctly and wire correctly when

setting up remote I/O signals.

Make sure that the functions correspond to the correct

before turning ON the system.

settings or wiring. If the Manipulator functions unusually by the failures with

initial settings or wiring, press the Emergency Stop switch immediately to stop

the Manipulator.

ot system and also safety

RC700DU / RC700DU-A Rev.11 5

Page 16

Safety 3. Safety Precautions

The interlock of the Safety Door must be functioning when the

operated.

be turned ON/OFF. (I.E. the condition where the switch is disabled)

(Example: Tape is put around

system when the switch is not

may

s as the Safety Door input cannot fulfill its

intended function

Do not open the

the cover(s) of the

shock

the

The following items are safety precautions for qualified operator personnel:

WARNING

WARNING

robot system is

Do not operate the system under the condition that the switch cannot

the switch to hold it closed.) Operating the robot

functioning properly is extremely hazardous and

cause serious safety problem

.

cover(s) of the Drive Unit except while maintaining it. Opening

Drive Unit is extremely hazardous and may result in electric

even when its main power is OFF because of the high voltage charge inside

Drive Unit.

6 RC700DU / RC700DU-A Rev.11

Page 17

Setup & Operation

This section contains information for setup and operation of the Drive Unit.

Page 18

Page 19

RC700 / RC700-A

RC700DU / RC700DU-A

・EMERGENCY

・Standard I/O

・Remote I/O

・R-I/O

Standard Installation

C4 series

C8 series

G series

RS series

* 2

* 1

X5

N6 series

C4

C8

C12 G RS

N2

N6

X5

RC700DU

- - - - - - - RC700DU-A

-

-

1. Specifications

1.1 System Example

Setup & Operation 1. Specifications

*1 Control Unit

For details, refer to the following manual.

*2 Any one of the Manipulators can be controlled.

Available combinations are as follows. (: connectable)

Robot Controller RC700 / RC700-A

RC700DU / RC700DU-A Rev.11 9

Page 20

Setup & Operation 1. Specifications

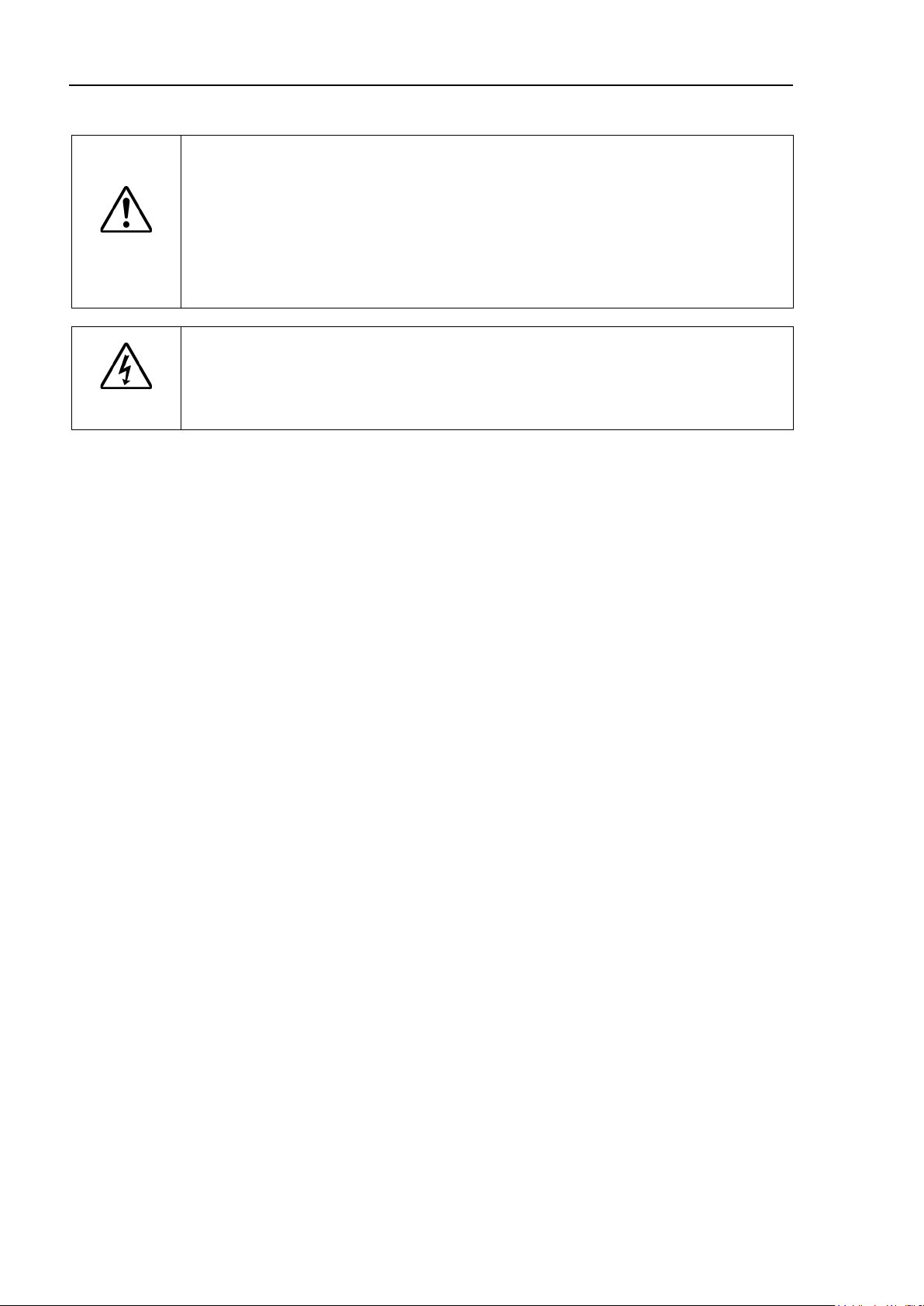

DU2

B

A

DU IN

DU1 CU

DU IN

DU OUT

DU OUT

DU3

C

DU IN

DU OUT

NOTE

Drive Unit is the auxiliary unit connected with the control unit using the special cable.

Drive Unit cannot operate alone.

Up to three Drive Units can be used per robot system.

A: Control Unit and 1st Drive Unit (CU-DU1)

st

B: 1

Drive Unit and 2nd Drive Unit (DU1-DU2)

nd

C: 2

Drive Unit and 3rd Drive Unit (DU2-DU3)

10 RC700DU / RC700DU-A Rev.11

Page 21

Item

Specification

Model

Drive Unit RC700DU / RC700DU-A

Controllable axes

Up to six (6) connectable AC servo motors

1.2 Drive Unit Standard Specifications

Setup & Operation 1. Specifications

External input/output

signals (standard)

Drive Unit connect interface

(standard)

Safety features

Standard I/O

2 channel

- Emergency stop switch

- Safety door input

- Low power mode

- Dynamic brake

- Motor overload detection

- Irregular motor torque (out-of-control Manipulator) detection

- Motor speed error detection

- Positioning overflow - servo error - detection

- Speed overflow - servo error - detection

- CPU irregularity detection

- Memory check-sum error detection

- Overheat detection at the Motor Driver Module

- Relay welding detection

- Over-voltage detection

- AC power supply voltage reduction detection

- Temperature error detection

- Fan error detection

Input : 24

Output : 16

per Drive Unit

Power Source

Maximum Rated Capacity 2.5 kVA (Depending on the Manipulator model)

Insulation Resistance 100 MΩ or more

Rated Ambient

Temperature

Rated Relative Humidity 20 to 80% (with no condensation)

Weight *1 9 kg

Degree of protection IP20

*1 Weight of the unit is indicated on the Drive Unit itself.

Make sure to check the weight before units transfer or relocation and prevent throwing out your back

at holding the unit.

Also, make sure to keep your hands, fingers, and feet safe from being caught or serious injury.

200 to 240 VAC

Single phase 50/60 Hz

5 to 40 deg.

RC700DU / RC700DU-A Rev.11 11

Page 22

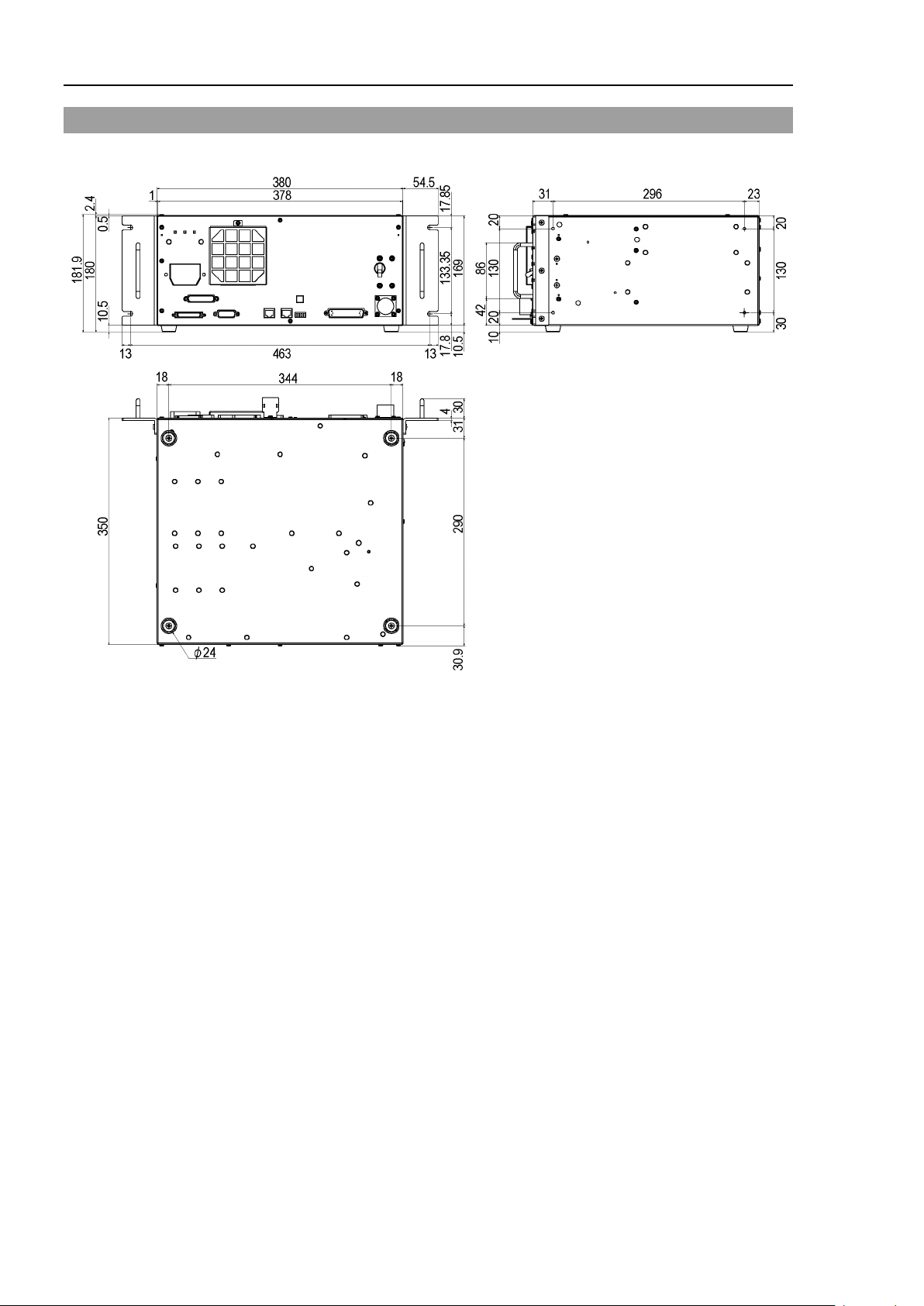

Setup & Operation 1. Specifications

1.3 Outer Dimensions

[Unit : mm]

12 RC700DU / RC700DU-A Rev.11

Page 23

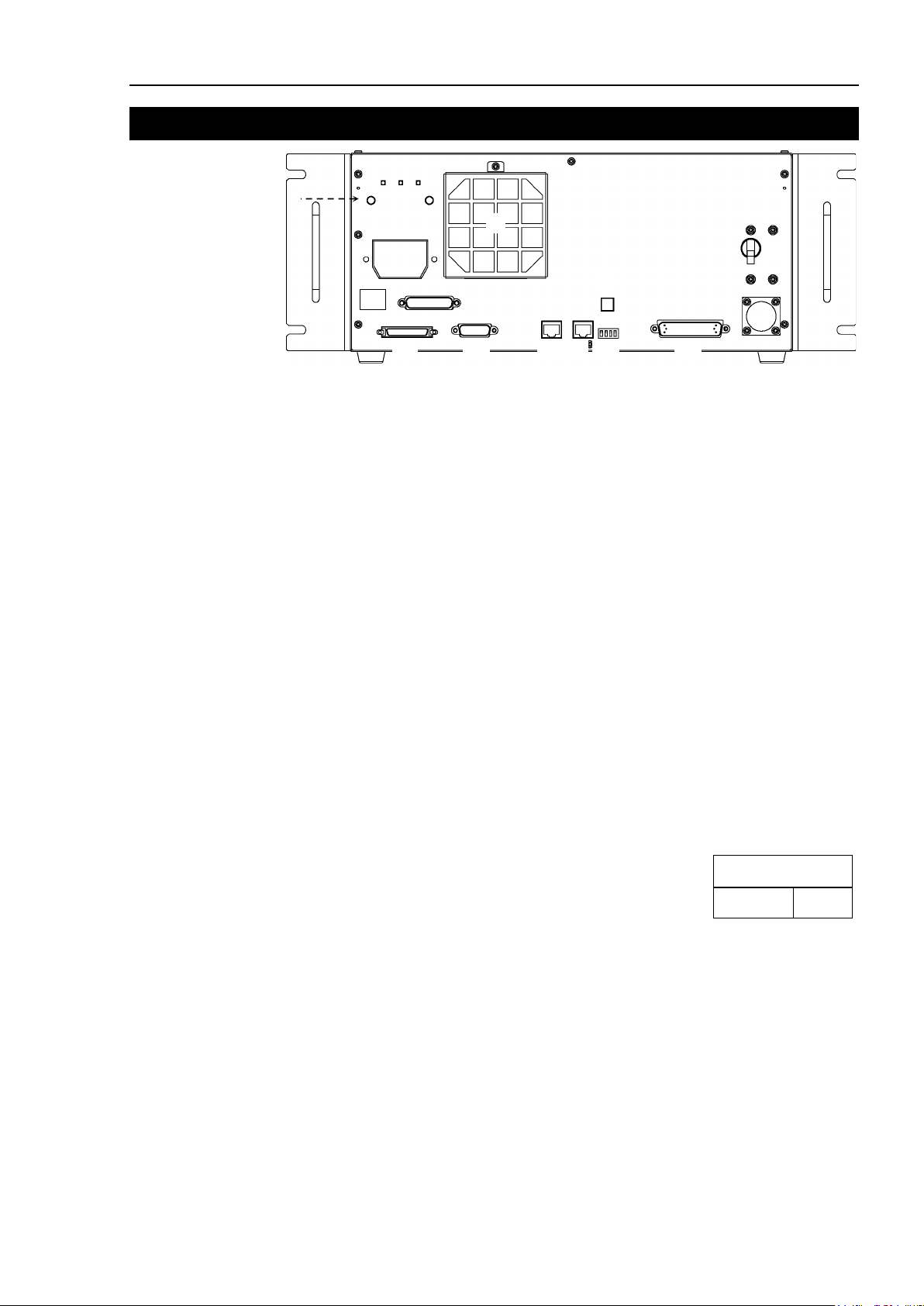

Setup & Operation 2. Part Names and Functions

(2)

(3)

(1)

(Left side)

(4)

(5)

(7) (8)

(6)

(10)

(13)

(14)

(15)

(16)

(11)(12)

(9)

The details of the Manipulator to be connected are recorded

Manipulator model and Manipulator serial number.

MANIPULATOR

00001 C4-A600S

2. Part Names and Functions

(1) Signature label (top panel)

The serial number of the Drive Unit and other information are shown.

(2) LED

The LED indicates current operation mode (RUN, AUTO, ERROR/E-STOP).

For details, refer to Setup & Operation 2.1 LED.

(3) M/C POWER connector

A connector for the Manipulator power source.

Connect the dedicated power cable attached to the Manipulator.

(4) Fan Filter

A protective filter is installed in front of the fan to filter out dust.

Check the condition of the filter regularly and clean it when necessary. A dirty filter

may result in malfunction of the robot system due to temperature rise of the Drive Unit.

For inspection, cleaning, and replacement, refer to the Maintenance 4.1 Fan Filter, 4.2

Fan.

(5) POWER switch

Turns ON or OFF the Drive Unit.

(6) Connection Check label

on the label as shown in the right. The label indicates the

(7) EMERGENCY connector

This connector is used for input/output from/to Emergency Stop and Safety Door

switches. For details, refer to the Setup & Operation 6. EMERGENCY.

RC700DU / RC700DU-A Rev.11 13

Page 24

Setup & Operation 2. Part Names and Functions

Switch

M/C Cable Length

1

3 m 2 5 m

3

10 m

4

15, 20 m

(8) Encoder Voltage Adjustment Switch

Use this switch to adjust voltage according to length of M/C cable. (adjusted as a

factory default)

Wrong setting may result in Robot system malfunction. Do not change the switch.

(9) M/C SIGNAL connector

This connector is used for signals such as the Manipulator’s motor encoders, etc.

Connect the Manipulator’s dedicated signal cable.

(10) R-I/O connector

This connector is for the input signals used for the real time I/O function.

(11) RC700DU: DU OUT Connector / RC700DU-A: OUT Connector

To connect the 2

nd

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU IN connector of the

nd

Drive Unit.

2

To connect the 3

rd

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU IN connector of the

rd

Drive Unit.

3

(12) RC700DU: DU IN Connector / RC700DU-A: IN Connector

st

For the 1

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU OUT connector of

the Control Unit.

nd

For the 2

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU OUT connector of

st

Control Unit.

the 1

rd

For the 3

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU OUT connector of

nd

Control Unit.

the 2

(13) RC700DU / RC700DU-A No. Setting Switch

This switch indicated the Drive Unit number.

For details, refer to the Setup & Operation

(14) I/O connector

This connector is used for input/output device. There are 24 inputs and 16 outputs.

For details, refer to Setup & Operation 7. I/O Connector.

(15) AC IN

The cable for 200VAC power input.

For details, refer to Setup & Operation 3.3.2 AC Power Cable.

(16) Drive Unit Number label

The serial number of the Drive Unit is indicated.

5. Drive Unit Setup.

14 RC700DU / RC700DU-A Rev.11

Page 25

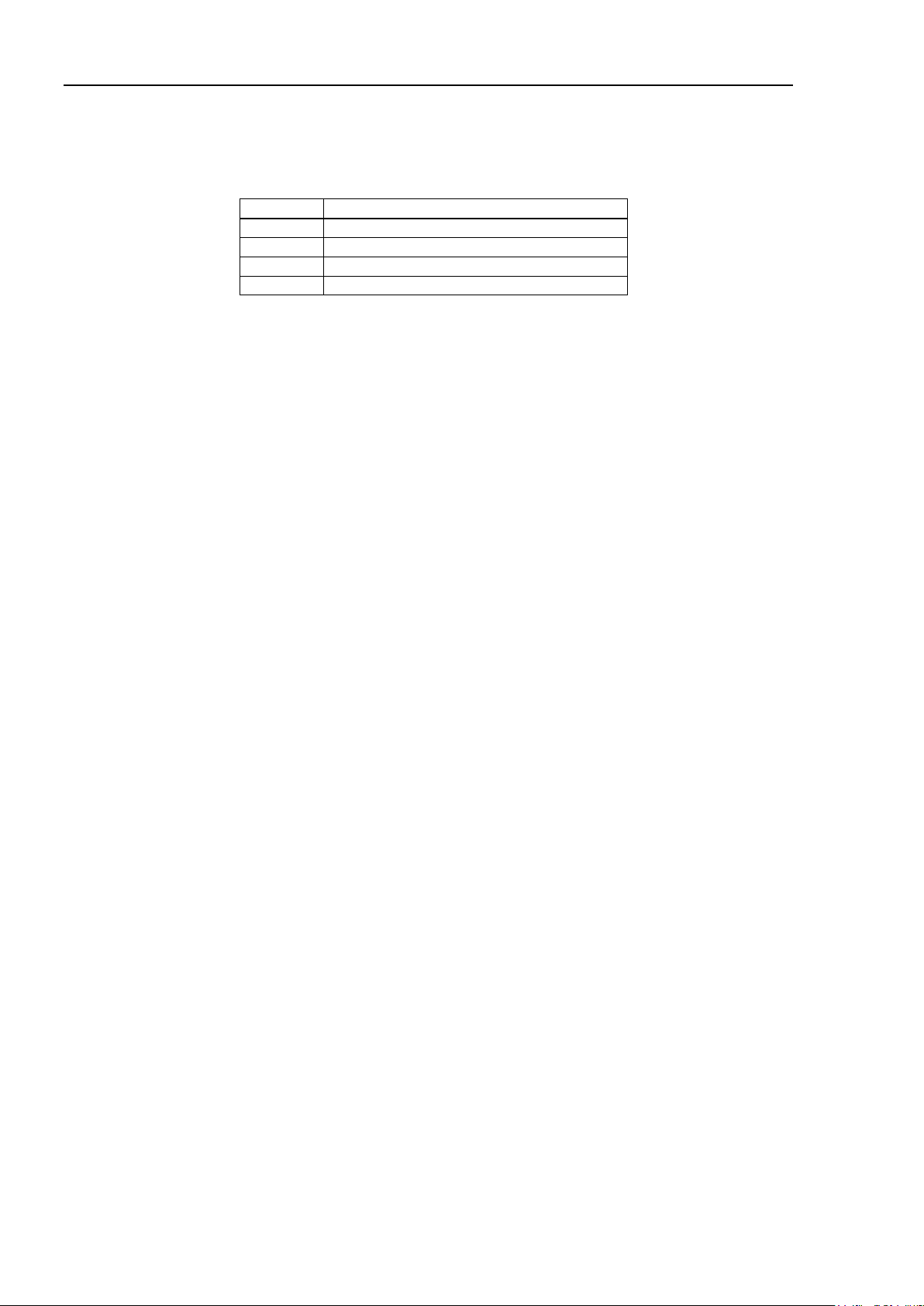

LED

Color

Status

RUN

Green

ON / Flashing / OFF

AUTO

Green

ON / OFF

ERR/E-STOP

Red

ON / Flashing / OFF

DU IN

connector

RUN

AUTO

ERR/E-STOP

LINK (Green)

Power OFF

OFF

OFF

OFF

OFF

Power ON

Flashing

OFF

OFF

OFF

Establishing

the connection

Normally operating

ON

OFF

OFF

Flashing rapidly

LED

Status

Auto mode

ON

ON

-

Flashing rapidly

Program mode

Teach mode

Robot error

ON

-

Flashing

Flashing rapidly

Emergency stop

ON - ON

Flashing rapidly

NOTE

2.1 LED

Setup & Operation 2. Part Names and Functions

Three LEDs are mounted on Drive Unit. They have the following status patterns.

From applying current to Drive Unit to completing startup

Drive Unit LED

Flashing OFF OFF Flashing rapidly

After the connection to Drive Unit is completed

The error information is displayed on the seven-segment display of the Control Unit.

For details, refer to the RC700 / RC700-A Robot Controller manual: Setup & Operation 2.1

LED and Seven-segment LED .

ON OFF - Flashing rapidly

RC700DU / RC700DU-A Rev.11 15

Page 26

Setup & Operation 2. Part Names and Functions

2.2 Safety Features

The robot control system supports safety features described below. However, the user is

recommended to strictly follow the proper usage of the robot system by thoroughly reading

the attached manuals before using the system. Failure to read and understand the proper

usage of the safety functions is highly dangerous.

Among the following safety features, the Emergency Stop Switch and Safety Door Input are

particularly important. Make sure that these and other features function properly before

operating the robot system.

For details, refer to the Setup & Operation 6. EMERGENCY.

Emergency Stop Switch

The EMERGENCY connector on the Drive Unit has expansion Emergency Stop input

terminals used for connecting the Emergency Stop switches.

Pressing any Emergency Stop switch can shut off the motor power immediately and the

robot system will enter the Emergency Stop condition.

Stop category of Emergency Stop input: Category 0 (refer to Safety Standard IEC60204-1)

Safety Door Input

Low Power Mode

Dynamic Brake

In order to activate this feature, make sure that the Safety Door Input switch is connected to

the EMERGENCY connector at the Drive Unit.

When the safety door is opened, normally the Manipulator immediately stops the current

operation, and the status of Manipulator power is operation-prohibited until the safety door

is closed and the latched condition is released. In order to execute the Manipulator

operation while the safety door is open, you must change the mode selector key switch on

the Teach Pendant to the “Teach” mode. Manipulator operation is available only when the

enable switch is on. In this case, the Manipulator is operated in low power status.

Stop category of Safety door input: Category 1 (refer to Safety Standard IEC60204-1)

The motor power is reduced in this mode.

Executing a power status change instruction will change to the restricted (low power) status

regardless of conditions of the safety door or operation mode. The restricted (low power)

status ensures the safety of the operator and reduces the possibility of peripheral equipment

destruction or damage caused by careless operation.

The dynamic brake circuit includes relays that short the motor armatures. The dynamic

brake circuit is activated when there is an Emergency Stop input or when any of the

following errors is detected: encoder cable disconnection, motor overload, irregular motor

torque, motor speed error, servo error (positioning or speed overflow), irregular CPU,

memory check-sum error and overheat condition inside the Motor Driver Module.

Motor Overload Detection

The dynamic brake circuit is activated when the system detects the overload status of the

motor.

Irregular Motor Torque (out-of-control Manipulator) Detection

The dynamic brake circuit is activated when irregular motor torque (motor output) is

detected.

16 RC700DU / RC700DU-A Rev.11

Page 27

Motor Speed Error Detection

The dynamic brake circuit is activated when the system detects that the motor is running at

incorrect speed.

Positioning Overflow –Servo Error- Detection

The dynamic brake circuit is activated when the system detects that the difference between

the Manipulator’s actual position and commanded position exceeds the margin of error

allowed.

Speed Overflow –Servo Error- Detection

The dynamic brake circuit is activated when the Manipulator’s actual speed is detected to

mark an overflow (the actual speed is outside the nominal range) error.

CPU Irregularity Detection

Irregularity of CPU that controls the motor is detected by the watchdog timer. The system

CPU and the motor controlling CPU inside the Drive Unit are also designed to constantly

check each other for any discrepancies. If a discrepancy is detected, the dynamic brake

circuit is activated.

Setup & Operation 2. Part Names and Functions

Memory Check-sum Error Detection

The dynamic brake circuit is activated when a memory check-sum error is detected.

Overheat Detection at the Motor Driver Module

The dynamic brake circuit is activated when the temperature of the power device inside the

Motor Driver module is above the nominal limit.

Relay Deposition Detection

The dynamic brake circuit is activated when relay deposition, junction error, or open fault

is detected.

Over-Voltage Detection

The dynamic brake circuit is activated when the voltage of the Drive Unit is above the

normal limit.

AC Power Supply Voltage Drop Detection

The dynamic brake circuit is activated when the drop of the power supply voltage is detected.

Temperature Anomaly Detection

The temperature anomaly is detected.

Fan Malfunction Detection

Malfunction of the fan rotation speed is detected.

RC700DU / RC700DU-A Rev.11 17

Page 28

Setup & Operation 3. Installation

■

The Manipulator and the

must be used within the environmental

conditions described in their manuals. This product has been designed and

manufactured strictly for use in a normal indoor environment

in the environment that exc

of the

Item

Condition

Use a base table that is at least 100 mm off the floor.

NOTE

3. Installation

3.1 Unpacking

I/O Connector 1 set

Rack-Mount Plate 1 set

Power Cable 1 cable

EMERGENCY port connector 1 set

Connecting cable for RC700DU 1 cable

3.2 Environmental Requirements

Drive Unit

WARNING

. Using the product

eeds the conditions may not only shorten the life cycle

product but also cause serious safety problems.

3.2.1 Environment

In order to optimize the robot system’s performance for safety, the Drive Unit must be placed

in an environment that satisfies the following conditions:

- The Drive Unit is not designed for clean-room specification. If it must be installed in a

clean room, be sure to install it in a proper enclosure with adequate ventilation and cooling.

- Install Drive Unit in a location that allows easy connection / disconnection of cables.

Ambient temperature 5 to 40 deg. (with minimal variation)

Ambient relative humidity 20 to 80% (with no condensation)

Fast transient burst noise 2 kV or less (Power supply wire)

1 kV or less (Signal wire)

Electrostatic noise 4 kV or less

Base table

Placing the Drive Unit directly on the floor could allow

dust penetration leading to malfunction.

If the Drive Unit must be used in an environment that does not fulfill the conditions

mentioned above, take adequate countermeasures. For example, the Drive Unit may be

enclosed in a cabinet with adequate ventilation and cooling.

- Install indoors only.

- Place in a well-ventilated area.

- Keep away from direct sunlight and radiation heat.

- Keep away from dust, oily mist, oil, salinity, metal powder or other contaminants.

- Keep away from water.

- Keep away from shocks or vibrations.

- Keep away from sources of electronic noise

18 RC700DU / RC700DU-A Rev.11

- Do not apply strong electric or magnetic field.

Page 29

Setup & Operation 3. Installation

(A) Flat Mounting

* The rubber foot needs to be replaced.

* A plate for rack mounting is required.

100 mm

200 mm

Excluding the installation side such as base table

Air Flow of

the Drive Unit Fan

50 mm

50 mm

200 mm

NOTE

3.2.2 Installation

Install the Drive Unit on a flat surface such as wall, floor, and Controller box in the direction

shown from (A) to (C).

(B) Upright Mounting (C) Rack Mounting

For Drive Unit installation to the Controller box or the base table, process screw holes as

follows.

- Ensure the draft around the in/out and prevent the other equipment, walls and install the

Drive Unit by keeping the distance as follows for maintenance.

- Hot air with higher temperature than the ambient temperature (about 10 deg.C) comes out

from the Drive Unit. Make sure that heat sensitive devices are not placed near the outlet.

- Arrange the cables in front of the Drive Unit so that you can pull the Drive Unit forward.

RC700DU / RC700DU-A Rev.11 19

Page 30

Setup & Operation 3. Installation

3.2.3 Wall Mounting Option

The Drive Unit has a wall mounting option.

Wall mounting with the front side down Wall mounting with the front side up

Included items of the wall mounting option

WALL FIXING BRACKET 2 brackets

LED DISPLAY FIXING PLATE 1 plate

LED DISPLAY PLATE 1 plate

Screw (M3 × 6 mm) 4 screws

Screw (M4 × 8 mm) 4 screws

Refer to one of the following for the Installation Procedure.

Installation Procedure sheet attached to the Wall Mounting option.

Manual: ROBOT CONTROLLER RC700 / RC700-A

Setup & Operation 3.2.3 Wall Mounting Option

20 RC700DU / RC700DU-A Rev.11

Page 31

Item

Specification

Momentary Power

For approximate power consumption of each model, refer to

model. For details, please contact the supplier of your region.

3.3 Power Supply

3.3.1 Specifications

Ensure that the available power meets following specifications.

Voltage 200 to 240 VAC

Phase Single phase

Frequency 50/60 Hz

Setup & Operation 3. Installation

(

Input voltage should be with in ±10 % of the rated voltage.)

Interrupt

Rated Capacity Maximum : 2.5 kVA

Peak Current When power is turned ON : approximately 85 A (2 ms.)

Leakage Current Max. 10 mA

Ground Resistance

10 msec. or less

Actual power consumption depends on the model, motion, and

load of the Manipulator.

the followings.

C4 : 1.7 kVA

C8 : 2.5 kVA

N6 : 2.2 kVA

G1 : 0.5 kVA

G3 : 1.1 kVA

G6 : 1.5 kVA

G10 : 2.4 kVA

G20 : 2.4 kVA

RS3 : 1.2 kVA

RS4 : 1.4 kVA

Refer to the Manipulator manual for Manipulator rated

capacity.

Rated capacity of X5 varies depending on the Manipulator

When motor is ON : approximately 75 A (2 ms.)

100 Ω or less

Install an earth leakage circuit breaker or a circuit breaker in the AC power cable line at 15

A or less rated electric current. Both should be a two-pole disconnect type. If you install

RC700DU / RC700DU-A Rev.11 21

an earth leakage circuit breaker, make sure to use an inverter type that does not operate by

induction of a 10 kHz or more leakage current. If you install a circuit breaker, please select

one that will handle the above mentioned “peak current”.

The power receptacle shall be installed near the equipment and shall be easily accessible.

Page 32

Setup & Operation 3. Installation

■

Make sure that

■

Be

terminal of the factory power supply. The

at all times to avoid the risk of electric shock.

■

Always use a power plug

for power connecting cable.

Never connect the

■

Select the plug or a disconnecting device which conform safety standards for

nations.

Item

Specification

Black, Black

or Black, White

Ground wire

Green / Yellow

Cable length

3 m

Terminal

M4 round solderless terminal

3.3.2 AC Power Cable

sure to connect the earth wire (green/yellow) of the AC power cable to the earth

WARNING

Make sure to insert the plug of the AC power cable firmly when connecting to the Drive

Unit.

AC power wire (2 cables)

operations are done by a qualified personal.

equipment must be grounded properly

or a disconnecting device

Drive Unit directly to the factory power supply.

22 RC700DU / RC700DU-A Rev.11

Page 33

■

Make sure that the power to the

disconnected

Connecting or

disconnecting

result in

■

Be sure to connect the cables properly. Do not allow un

cables. (Do not put heavy objects on the cables. Do not bend or pull the cables

forcibly.) The unnecessary strain on the cables may result in damage to the

cables, disconnection, and/or contact failure. Damaged cables, disconnec

contact failure is extremely hazardous and may result in electric shock and/or

improper function of the system.

■

The serial number of the Manipulator that should be connected is indicated on the

Connection Check Label on the Drive Unit. Connect the Drive Unit and the

Manipulator correctly. Improper connection between the Drive Unit and the

Manipulator may cause not only improper function of the robot system but also

safety problems.

■

Before connecting the connector, make sure

the pins are not bent.

Connecting with

of

3.4 Cable Connection

electric shock and malfunction of the Drive Unit.

Setup & Operation 3. Installation

Drive Unit is turned OFF and the power plug is

before connecting or disconnecting any cables.

any cables with the power ON is extremely hazardous and may

WARNING

CAUTION

the robot system.

necessary strain on the

tion, or

that

the pins bent may damage the connector and result in malfunction

RC700DU / RC700DU-A Rev.11 23

Page 34

Setup & Operation 3. Installation

Manipulator

1st Drive Unit

(1) AC Power Terminal Block

(2) M/C Power Cable

(3) M/C Signal Cable

(4) EMERGENCY

AC200V-240V

(5) I/O connector

(6) R-I/O connector

(7) DU IN connector

(8) DU OUT connector

Emergency Stop

Safety Door, etc.

Input/Output Device

Disconnectable connector

Cable attached at delivery

Cable prepared by users

2rd Drive Unit

Control Unit

Input/Output Device

Manipulator

2nd Drive Unit

(1) AC Power Terminal Block

(2) M/C Power Cable

(3) M/C Signal Cable

(4) EMERGENCY

AC200V-240V

(5) I/O connector

(6) R-I/O connector

(7) DU IN connector

(8) DU OUT connector

Emergency

Stop

Safety Door, etc.

Input/Output

1st Drive Unit

Input/Output

Manipulator

3rd Drive Unit

(1) AC Power Terminal Block

(2) M/C Power Cable

(3) M/C Signal Cable

(4) EMERGENCY

AC200V-

240V

(5) I/O connector

(6) R-I/O connector

(7) DU IN connector

(8) DU OUT connector

(D

o not connect anything.)

Emergency Stop

Safety Door, etc.

Input/Output

2nd Drive Unit

Input/Output

3rd Drive Unit

3.4.1 Typical Cable Connection

24 RC700DU / RC700DU-A Rev.11

Page 35

Setup & Operation 3. Installation

(1)

AC Power terminal block

(2)

M/C Power cable

the Manipulator and the M/C POWER

(3)

M/C Signal cable

(4)

EMERGENCY

(5)

I/O connector

(6)

R-I/O Connector

(7)

DU IN connector

(8)

DU OUT connector

connector on the 2nd Drive Unit.

Terminal block for 200VAC power input to the Drive Unit.

The cable with 50-pin connector on the Drive Unit side.

Connect the POWER connector on

connector on the Drive Unit. Insert the connectors until you hear a “click”.

The cable with 50-pin connector on the Drive Unit side.

Connect the signal cable to the SIGNAL connector on the Manipulator and the M/C

SIGNAL connector on the Drive Unit.

The EMERGENCY connector has inputs to connect the Emergency Stop switch

and the Safety Door switch. For safety reasons, connect proper switches for these

input devices.

For details, refer to the Setup & Operation 6. EMERGENCY.

This connector is used for input/output devices of the user.

When there are input/output devices, use this connector.

There are I/O cable (option) and terminal block (option) for the I/O connector.

For details, refer to the Setup & Operation 7. I/O Connector.

This connector is used for connecting with input signals necessary for real time I/O

function.

For details, refer to the Setup & Operation 13. R-I/O Connector.

For the 1st Drive Unit:

Use the cable attached for Drive Unit and connect with the DU OUT connector of

the Control Unit.

For the 2

nd

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU OUT connector

of the 1

For the 3

st

Control Unit.

rd

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU OUT connector

of the 2

nd

Control Unit.

RC700DU / RC700DU-A Rev.11 25

To connect the 2nd Drive Unit:

Use the cable attached for Drive Unit and connect with the DU IN connector of the

nd

2

Drive Unit.

To connect the 3

rd

Drive Unit:

Use the cable attached for Drive Unit and connect with the DU IN connector of

rd

the 3

Drive Unit.

* Be sure not to connect anything to this connector when using only one Drive

rd

Unit. Also, when using the 3

Drive Unit, do not connect anything to this

Page 36

Setup & Operation 3. Installation

■

Make sure that the power to the

turned OFF before connecting or

disconnecting any cables.

ON

Drive Unit

■

Be sure to connect the cables properly. Do not allow unnecessary strain on the

cables. (Do not put heavy objects on the cables. Do not bend or pull the

forcibly.) The unnecessary strain on the cables may result in damage to the cables,

disconnection, and/or contact failure. Damaged cables, disconnection, or contact

failure is extremely hazardous and may result in electric shock and/or improper

fu

■

The serial number of the Manipulator that should be connected is indicated on the

Improper

Manipulator may cause not only improper

NOTE

3.4.2 Connecting Manipulator to Drive Unit

Connect the Manipulator to the Drive Unit by using the Power cable and the Signal cable.

is extremely hazardous and may result in electric shock and malfunction of the

.

Drive Unit is

Connecting or disconnecting any cables with the power

WARNING

nction of the system.

CAUTION

Drive Unit. Connect the Drive Unit and the Manipulator correctly.

connection between the Drive Unit and the

function of the robot system but also serious safety problems.

The configuration data for the Manipulator and Manipulator model are stored in the Drive

Unit. Therefore the Drive Unit should be connected to the Manipulator whose serial

number is specified in the Connection Check label attached on the front of the Drive Unit.

The Manipulator’s serial number is indicated on the signature label on the back of the

Manipulator.

cables

26 RC700DU / RC700DU-A Rev.11

Page 37

AC Line duct

DC line duct

As far as possible

3.5 Noise Countermeasures

To minimize electrical noise conditions, the following items must be observed in the

system’s cable wiring:

To minimize electrical noise condition, be sure of followings for wiring.

- The earth wire of the power supply should be grounded. (Ground resistance: 100 Ω or

less) It is important to ground the frame of Drive Unit not only for prevention from

electric shock, but also for reducing the influence of electric noise around the Drive Unit.

Therefore, be sure to connect the earth wire (yellow/green) of the Drive Unit’s power

cable to the ground terminal of the factory power supply. For details about the plug

and AC power cable, refer to the Setup & Operation 3.3 Power Supply.

- Do not tap power from a power line that connects to any equipment which may cause

noise.

- When you tap power for the Drive Unit and the single-phase AC motor from the same

power line, change the phase of one or the other. Ensure that they will not be the same

phase.

- Use a twisted pair motor power line.

Setup & Operation 3. Installation

- Do not run AC power lines and DC power lines in the same wiring duct, and separate

them as far as possible. For example, separate the AC motor power line and the Drive

Unit power line as far as possible from the sensor or valve I/O lines; and do not bundle

both sets of wiring with the same cable tie. If more than one duct/cable must cross each

other, they should cross perpendicularly. The preferable example is shown in the right

figure.

- Wire as short as possible to the I/O connector and EMERGENCY connector. Use a

shielded cable and clamp the shield to the attached connector interior. Make sure to

keep away from the peripheral noise source as far as possible.

- Make sure that the induction elements used to connect to the Drive Unit’s I/O (such as

relays and solenoid valves) have surge suppressors. If an induction element without a

surge suppressor is used, make sure to connect a rectifying diode located at the induction

element in parallel with it. In selecting a rectifying diode, make sure that it can handle

the voltage and current incurred by the induction load.

- To start and change revolutions of the conveyer’s (or the like’s) AC motor (ex: an

induction motor or three-phase induction motor) regularly or abruptly, make sure to

install a spark suppressor between the wires. The spark suppressor is more effective

when placed closer to the motor.

- As they are easily influenced by noise, keep cable such as USB, Ethernet, RS-232C, or

fieldbus away from peripheral noise sources.

RC700DU / RC700DU-A Rev.11 27

Page 38

Setup & Operation 4. Drive Unit Connection

DU IN*

DU OUT

*

DU OUT*

Drive Unit (DU): RC700DU / RC700DU-A

Control Unit (CU): RC700CU / RC700CU-A

DU2

B

A

DU IN

DU1 CU

DU IN

DU OUT

DU OUT

DU3

C

DU IN

DU OUT

NOTE

NOTE

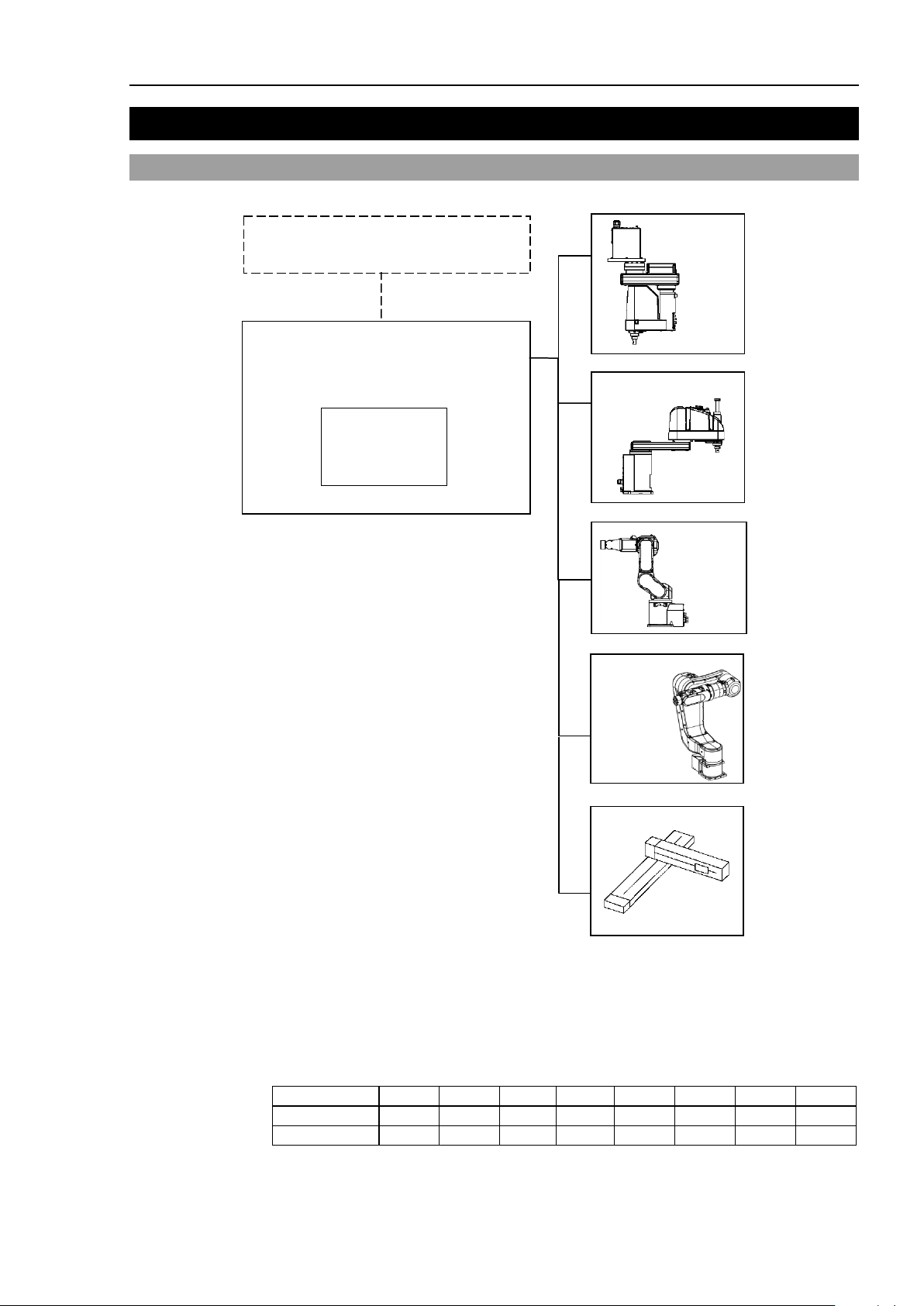

4. Drive Unit Connection

Drive Unit is connected to the Control Unit using the attached connection cable.

Up to three Drive Units can be connected to the Control Unit.

A: Control Unit and 1st Drive Unit (CU-DU1)

st

B: 1

Drive Unit and 2nd Drive Unit (DU1-DU2)

nd

C: 2

Drive Unit and 3rd Drive Unit (DU2-DU3)

(Figure: RC700DU , RC700)

* Name: RC700-A, RC700DU-A: OUT, IN

When you use one Drive Unit

:

Connect nothing to DU OUT of the 1st Drive Unit (DU1). Otherwise, it results in the Robot

Controller malfunction.

When you use two Drive Units

:

Connect nothing to DU OUT of the 2nd Drive Unit (DU2). Otherwise, it results in the

Robot Controller malfunction.

When you use three Drive Units

:

Connect nothing to DU OUT of the 3rd Drive Unit (DU3). Otherwise, it results in the Robot

Controller malfunction.

When connecting the connection cable, make sure to connect to DU IN and DU OUT

properly. Improper connection may cause malfunction.

Do not use any LAN cables on the market. Otherwise, it results in the Robot Controller

malfunction.

How to turn on the power switch:

Check the connection first. Then, make sure to turn on the power switch of Drive Unit

before turning on the power switch of Control Unit.

28 RC700DU / RC700DU-A Rev.11

Page 39

5. Drive Unit Setup

(1) Turn OFF the Drive Unit.

(2) Change the DIP

DIP switch

1 2 3 4

ON

OFF

ALL OFF

1 2 3 4

ON

OFF

ON : 1

OFF : 2, 3, 4

1 2 3 4

ON

OFF

ON : 2

OFF : 1, 3, 4

(3) A

(4) Plug in

The DIP switch is equipped on the front side to configure 1st, 2nd ,and 3rd Drive Unit.

Follow the steps below to set up the Drive Unit.

Setup & Operation 5. Drive Unit Setup

switch.

1st Drive Unit

2nd Drive Unit

3rd Drive Unit

ttach the DU number label on Drive Unit.

DU1 : 1

DU2 : 2

DU3 : 3rd Drive Unit

the power connector. Turn ON the Drive Unit.

st

Drive Unit

nd

Drive Unit

RC700DU / RC700DU-A Rev.11 29

Page 40

Setup & Operation 5. Drive Unit Setup

(1) Select t

[System Configuration] dialog box will appear.

(2)

(3)

(2) Click

(3) Click <

[Add New Robot] dialog box will appear.

(4)

Adding of information of the new system is required only for customers who purchased the

Drive Unit singly.

Set up the Control Unit and Drive Unit and turn on the robot system. If information of the new

system was not added, follow the steps below to add information.

he EPSON RC+ 7.0-[Setup]-[System Configuration].

[Controller]-[Robots] in the tree on the left.

Add> button.

30 RC700DU / RC700DU-A Rev.11

Page 41

Setup & Operation 5. Drive Unit Setup

(4) Enter the following items by referring to the

Sheet

Item

Description

Robot Name :

Type in a name for the new Manipulator. (Example: RB1

Robot1)

Robot Serial # :

Type in “Serial No.” on the Hofs sheet.

number described above.

Motion System :

Select “Standard”.

be already selected.

Drive Unit :

Select a Drive Unit for your Manipulator. (DU1, DU2, DU3)

and indicated by the indication labels.

Robot Type :

Select a Manipulator type.

Robot Joints :

This item cannot be changed.

Series :

Select a Manipulator series.

Model :

Select a Manipulator model.

in the Drive Unit will be displayed.

(5) Click <

(6) Click

Following dialog box will appear.

(6)

(7)

(8)

(9)

(7) Type in the values on the Hofs sheet to [CalPls] and [Hofs].

(8) Click

(9) Click

RC700DU Robot System Hofs Data

(hereinafter referred to as Hofs sheet) which is included with shipment.

(or the serial number on the Manipulator’s nameplate)

Any serial number can be used, but it is recommended to use the

If there are no other motion systems installed, “Standard” should

DU numbers are configured by the dip switch on the front side

All Manipulators available for the motor driver currently installed

OK> button. The EPSON RC+ will restart.

[Controller]-[Robots]-[Robot **]-[Calibration] in the tree on the left.

<Apply> button.

<Close> button.

RC700DU / RC700DU-A Rev.11 31

Page 42

Setup & Operation 6. EMERGENCY

WARNING

■

Not only when turning on the device, but also changing use environment such as

add options or replace

or safety door work properly.

WARNING

■

Before connecting the connector, make sure

the pins are not bent.

Connecting with

of

EMERGENCY Connector

D-sub 25 male pin

■

The interlock of the Safety Door must be functioning when the

operated.

be turned ON/OFF (e.g. The tape is put around the switch.). Operating the robot

system when the switch is not

may

intended function

NOTE

6. EMERGENCY

The details of safety requirements for this section are described in User’s Guide 2. Safety.

Please refer to them to keep the robot system safe.

Connect a safeguard switch or Emergency Stop switch to the Drive Unit EMERGENCY

connector for safety.

When nothing is connected to the EMERGENCY connector, the Drive Unit does not operate

normally.

the robot system.

the pins bent may damage the connector and result in malfunction

parts for maintenance, make sure that the emergency stop

that

6.1 Safety Door Switch and Latch Release Switch

The EMERGENCY connector has input terminals for the Safety Door switch and the

Emergency Stop switch. Be sure to use these input terminals to keep the system safe.

Connector Standard

EMERGENCY connector

(Drive Unit side)

* The connector cable, terminal block, and connector kit are offered as options.

Mounting style #4 - 40

6.1.1 Safety Door Switch

Do not operate the system under the condition that the switch cannot

WARNING

32 RC700DU / RC700DU-A Rev.11

cause serious safety problems as the Safety Door input cannot fulfill its

.

In order to maintain a safe working zone, a safeguard must be erected around the

Manipulator. The safeguard must have an interlock switch at the entrance to the working

zone. The Safety Door that is described in this manual is one of the safeguards and an

interlock of the Safety Door is called a Safety Door switch. Connect the Safety Door

switch to the Safety Door input terminal on the EMERGENCY connector.

The Safety Door switch has safety features such as temporary hold-up of the program or the

operation-prohibited status that are activated whenever the Safety Door is opened.

functioning properly is extremely hazardous and

robot system is

Page 43

Setup & Operation 6. EMERGENCY

NOTE

NOTE

Observe the followings in designing the Safety Door switch and the Safety Door.

- For the Safety Door switch, select a switch that opens as the Safety Door opens, and not

by the spring of the switch itself.

- The signal from the Safety Door (Safety Door input) is designed to input to two

redundant signals. If the signals at the two inputs differ by two seconds or more, the

system recognizes it to be a critical error. Therefore, make sure that the Safety Door

switch has two separate redundant circuits and that each connects to the specified pins at

the EMERGENCY connector on the

Drive Unit.

- The Safety Door must be designed and installed so that it does not close accidentally.

6.1.2 Latch Release Switch

The software latches these conditions:

- The safety door is open.

- The operation mode is set to “TEACH”.

The EMERGENCY connector has an input terminal for a latch release switch that cancels

the latched conditions.

Open : The latch release switch latches conditions that the safety door is open or the

operation mode is “TEACH”.

Closed : The latch release switch releases the latched conditions.

When the latched TEACH mode is released while the safety door is open, the status of

Manipulator power is operation-prohibited because the safety door is open at that time.

To execute a Manipulator operation, close the safety door again, and then close the latch

release input.

6.1.3 Checking Latch Release Switch Operation

After connecting the safety door switch and latch release switch to the EMERGENCY

connector, be sure to check the switch operation for safety by following the procedures

described below before operating the Manipulator.

(1) Turn ON the Controller while the safety door is open in order to boot the software.

(2) Make sure that “Safety” is displayed on the main window status bar.

(3) Close the safety door, and turn ON the switch connecting to the latch release input.

Make sure that the “Safety” is dimmed on the status bar.

The information that the safety door is open can be latched by software based on the

latch release input condition.

Open : The latch release switch latches the condition that the safety door is open.

To cancel the condition, close the safety door, and then close the safety door latch

release input.

Closed : The latch release switch does not latch the condition that the safety door is open.

The latch release input also functions to acknowledge the change of to TEACH mode.

In order to change the latched condition of TEACH mode, turn the mode selector key switch

on the Teach Pendant to “Auto”. Then, close the latch release input.

RC700DU / RC700DU-A Rev.11 33

Page 44

Setup & Operation 6. EMERGENCY

NOTE

6.2 Emergency Stop Switch Connection

6.2.1 Emergency Stop Switch

If it is desired to add an external Emergency Stop switch(es) in addition to the Emergency

Stop on the Teach Pendant, be sure to connect such Emergency Stop switch(es) to the

Emergency Stop input terminal on the EMERGENCY connector.

The Emergency Stop switch connected must comply with the related safety standards (such

as

IEC60947-5-5) and the following:

- It must be a push button switch that is “normally closed”.

- A button that does not automatically return or resume.

- The button must be mushroom-shaped and red.

- The button must have a double contact that is “normally closed”.

The signal from the Emergency Stop switch is designed to use two redundant circuits.

If the signals at the two circuits differ by two seconds or more, the system recognizes it as

a critical error. Therefore, make sure that the Emergency Stop switch has double

contacts and that each circuit connects to the specified pins on the EMERGENCY

connector at the

6.2.2 Checking Emergency Stop Switch Operation

Drive Unit. Refer to the Setup & Operation 6.4 Circuit and Wiring.

Once the Emergency Stop switch is connected to the EMERGENCY connector, continue

the following procedure to make sure that the switch functions properly. For the safety

of the operator, the Manipulator must not be powered ON until the following test is

completed.

(1) Turn ON the Controller to boot the software while pressing the Emergency Stop switch.

(2) Make sure that “ERROR/E-STOP” LED on Drive Unit has been turned ON.

(3) Make sure that “E.Stop” is displayed on the status bar on the EPSON RC+ main

window.

(4) Release the Emergency Stop Switch.

(5) Execute the RESET command.

(6) Make sure that

“ERROR/E-STOP” LED turns OFF and “E-Stop” display fades on the

main window status bar.

6.2.3 Recovery from Emergency Stop

To recover from the emergency stop condition, follow the procedure of safety check as

required by the system.

After safety check, the operations below are required to recover from the emergency stop

condition.

- Release the Emergency Stop Switch

- Execute the RESET command

34 RC700DU / RC700DU-A Rev.11

Page 45

Setup & Operation 6. EMERGENCY

1

ESW11

Emergency Stop switch contact (1) *3

14

ESW21

Emergency Stop switch contact (2) *3

2

ESW12

Emergency Stop switch contact (1) *3

15

ESW22

Emergency Stop switch contact (2) *3

3

ESTOP1+

Emergency Stop circuit 1 (+) *4

16

ESTOP2+

Emergency Stop circuit 2 (+) *4

4

ESTOP1−

Emergency Stop circuit 1 (-) *4

17

ESTOP2−

Emergency Stop circuit 2 (-) *4

5

Not Used

18

SDLATCH1

Safety Door Latch Release

6

Not Used

19

SDLATCH2

Safety Door Latch Release

7

SD11

Safety Door input (1) *2

20

SD21

Safety Door input (2) *2

8

SD12

Safety Door input (1) *2

21

SD22

Safety Door input (2) *2

9

24V

+24V output

22

24V

+24V output

10

24V

+24V output

23

24V

+24V output

11

24VGND

+24V GND output

24

24VGND

+24V GND output

12

24VGND

+24V GND output

25

24VGND

+24V GND output

13

Not Used

■

The 24 V output is for emergency stop. Do not use it for other purposes. Doing

so may result in system

■

The 24 V output is for emergency stop. Do not use it for other purposes. Doing

so may result in system

NOTE

6.3 Pin Assignments

The EMERGENCY connector (D-sub25 male) pin assignments are as follows:

Pin No. Signal Function Pin No. Signal Function

*1

*1

*1 Do not connect anything to these pins.

*2 A critical error occurs if the input values from the Safety Door 1 and Safety Door 2 are

different for two or more seconds. They must be connected to the same switch with

two sets of contacts.

*3 A critical error occurs if the input values from the Emergency Stop switch contact 1

and Emergency Stop switch contact 2 are different for two or more seconds. They

must be connected the same switch with two sets of contacts.

*4 Do not apply reverse voltage to the Emergency Stop circuit.

Emergency Stop switch output rated load +30 V 0.3 A or under 1-2, 14-15 pin

Emergency Stop rated input voltage range

Emergency Stop rated input current

Safety Door rated input voltage range

Safety Door rated input current

Latch Release rated input voltage range

Latch Release rated input current

+24 V ±10%

47.5 mA/+24 V input

+24 V ±10%

10 mA/+24 V input

+24 V ±10%

10 mA/+24 V input

3-4, 16-17 pin

7-8, 20-21 pin

18-19 pin

The total electrical resistance of the Emergency Stop switches and their circuit should be 1

Ω or less.

malfunction.

CAUTION

malfunction.

RC700DU / RC700DU-A Rev.11 35

Page 46

Setup & Operation 6. EMERGENCY

Drive Unit

Safety Door input 1

Safety Door input 2

Latch release input

Main Circuit

Control

Emergency

Stop detection

ESTOP1+

ESTOP2+

ESTOP1−

ESTOP2−

Be careful of

the direction

of voltage

application

6.4 Circuit and Wiring

6.4.1 Circuit Diagram

36 RC700DU / RC700DU-A Rev.11

Page 47

Setup & Operation 6. EMERGENCY

Emergency stop switch

Terminal block

Emergency

Stop switch of

an Operation

Unit (TP)

NOTE

6.4.2 Wiring Example for Emergency Stop

6.4.2.1 External emergency stop switch typical application

The Emergency cable, Emergency cable kit, and Terminal block are offered as options.

Design the cables connecting the units within 20 m long.

RC700DU / RC700DU-A Rev.11 37

Page 48

Setup & Operation 6. EMERGENCY

External

safety relay

External +24V

GND

External +24V

Fuse *

External

+24V

Emergency

Stop switch

Terminal block

External

+24V

GND

External

+24V

GND

External

+24V

GND

6.4.2.2 External safety relay typical application

* Fuse

For the protection of the emergency stop circuit, the fuse’s capacity should be as follows:

- Meets the capacity of the external

- 0.4A or less

38 RC700DU / RC700DU-A Rev.11

Page 49

Setup & Operation 6. EMERGENCY

Safety Door input 1

Safety Door input 2

Latch release input

Latch release input

Close :Latch off

Open :Latch on

External

External

Safety Door input 1

Safety Door input 2

Latch release input

Safety Door input 1

Safety Door input 2

Latch release input

Safety Door input 1

Safety Door input 2

Latch release input

NOTE

6.4.3 Wiring Example for Safety Door Input / Latch Release Input

Design the cables connecting the units within 20 m long.

RC700DU / RC700DU-A Rev.11 39

Page 50

Setup & Operation 7. I/O Connector

Pins

Bit number

Input

24

0 to 23

Output

16

0 to 15

Input

24

32 to 55

Output

16

32 to 47

Input

24

256 to 279

Output

16

256 to 271

Input

24

288 to 311

Output

16

288 to 303

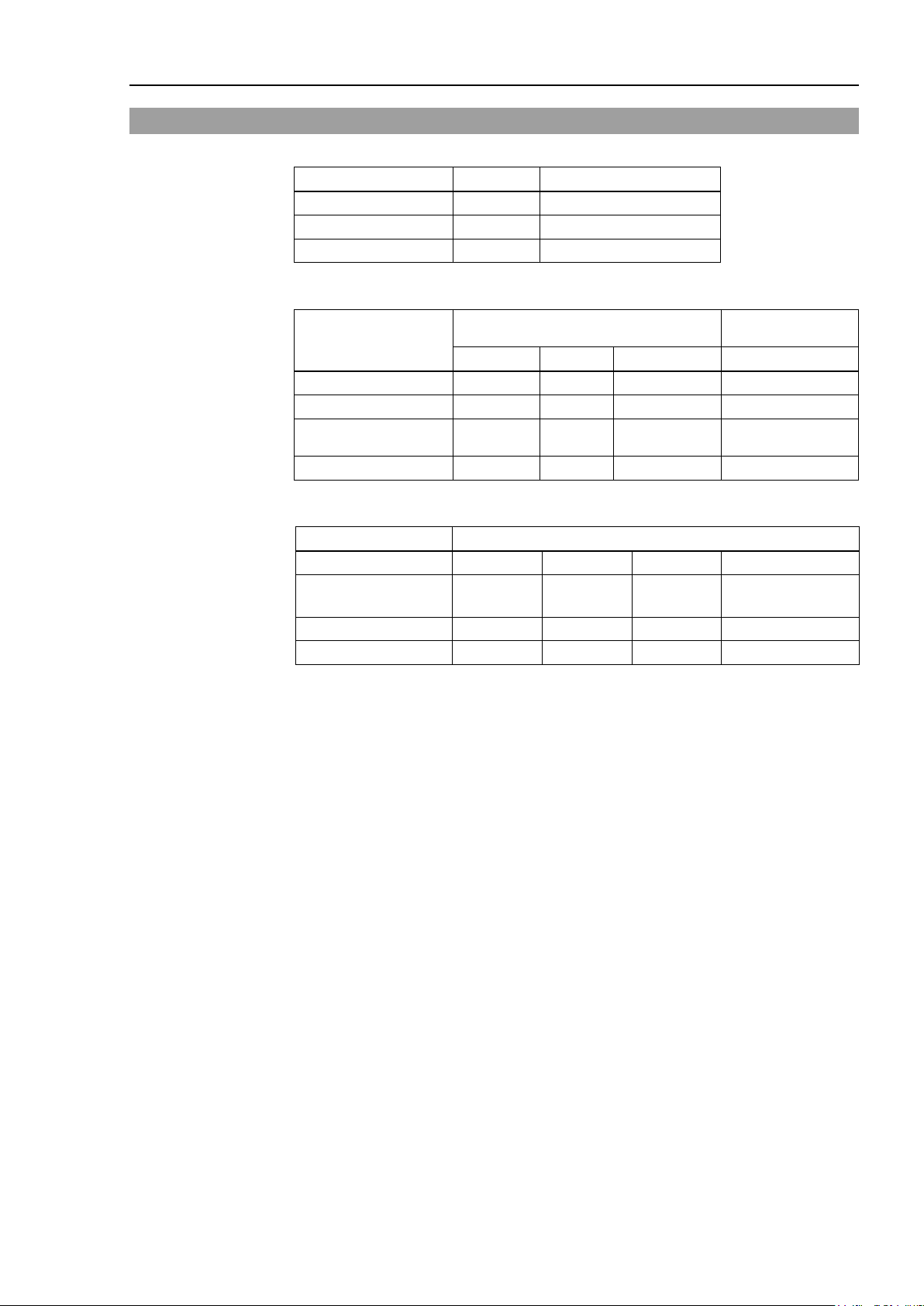

7. I/O Connector

The I/O connector is for connecting your input/output equipment to the system.

Control Unit

Drive Unit 1

Drive Unit 2

Drive Unit 3

For cable wiring, refer to the Setup & Operation 3.5 Noise Countermeasures in order to

prevent noise.

7.1 Input Circuit

Input Voltage Range : +12 to 24 V ±10%

ON Voltage : +10.8 V (min.)

OFF Voltage : +5 V (max.)

Input Current : 10 mA (TYP) at +24 V input

Two types of wiring are available for use with the two-way photo coupler in the input circuit.

40 RC700DU / RC700DU-A Rev.11

Page 51

Typical Input Circuit Application 1

I/O-1

(Same)

Omit

GND +DC

34 Input No.16~23 common

Omit

26 Input No.15

42 Input No.23

35 Input No.16

36 Input No.17

1 Input No.0 to 7 common

2 Input No.0

3 Input No.1

4 Input No.2

5 Input No.3

6 Input No.4

7 Input No.5

8 Input No.6

9 Input No.7

18 Input No.8 to 15 common

19 Input No.8

20 Input No.9

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

Setup & Operation 7. I/O Connector

RC700DU / RC700DU-A Rev.11 41

Page 52

Setup & Operation 7. I/O Connector

I/O-1

(

Same

)

Omit

GND +DC

34 Input No.16~23 common

Omit

26 Input No.15

42 Input No.23

35

Input No.16

36 Input No.17

1 Input No.0 to 7 common

2 Input No.0

3 Input No.1

4 Input No.2

5 Input No.3

6 Input No.4

7 Input No.5

8 Input No.6

9 Input No.7

18 Input No.8 to 15 common

19 Input No.8

20 Input No.9

(Same)

(Same)

(

Same

)

(Same)

(Same)

(Same)

(

Same

)

(Same)

(Same)

(Same)

(Same)

(Same)

Typical Input Circuit Application 2

42 RC700DU / RC700DU-A Rev.11

Page 53

7.2 Output Circuit

10 Output No.0

I/O-1

(Same)

Omit

+DC

29 Output No.8

30 Output No.9

11 Output No.1

12 Output No.2

13 Output No.3

14 Output No.4

15 Output No.5

27 Output No.6

28 Output No.7

17 Output No.0 to 7 common (GND)

Load

L

GND

L

33 Output No.8 to 15 common (GND)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

Rated Output Voltage : +12 V to 24 V ±10%

Maximum Output Current : TYP 100 mA/1 output

Output Driver : PhotoMOS Relay

On-State Resistance (average) : 23.5 Ω or less

Two types of wiring are available for use with the nonpolar PhotoMOS relay in the output

circuit.

Typical Output Circuit Application 1: Sink Type (NPN)

Setup & Operation 7. I/O Connector

RC700DU / RC700DU-A Rev.11 43

Page 54

Setup & Operation 7. I/O Connector

10 Output No.0

I/O-1

(Same)

Omit

+DC

29 Output No.8

30 Output No.9

11 Output No.1

12 Output No.2

13 Output No.3

14 Output No.4

15 Output No.5

27 Output No.6

28 Output No.7

17 Output No.0 to 7 common (+DC)

Load

L

GND

L

33 Output No.8 to 15 common (+DC)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

(Same)

Typical Output Circuit Application 2: Source Type (PNP)

44 RC700DU / RC700DU-A Rev.11

Page 55

7.3 Pin Assignments

Pin

No.

Pin

No.

Pin

No.

1

Input common No. 0 to 7

18

Input common No. 8 to 15

34

Input common No. 16 to 23

2

Input No. 0

19

Input No. 8

35

Input No. 16

3

Input No. 1

20

Input No. 9

36

Input No. 17

4

Input No. 2

21

Input No. 10

37

Input No. 18

5

Input No. 3

22

Input No. 11

38

Input No. 19

6

Input No. 4

23

Input No. 12

39

Input No. 20

7

Input No. 5

24

Input No. 13

40

Input No. 21

8

Input No. 6

25

Input No. 14

41

Input No. 22

9

Input No. 7

26

Input No. 15

42

Input No. 23

10

Output No. 0

27

Output No. 6

43

Output No.11

11

Output No. 1

28

Output No. 7

44

Output No.12

12

Output No. 2

29

Output No. 8

45

Output No.13

13

Output No. 3

30

Output No. 9

46

Output No.14

14

Output No. 4

31

Output No.10

47

Output No.15

15

Output No. 5

32

Not Used

48

Not Used

16

Not Used

33

Output common No. 8 to 15

49

Not Used

17

Output common No. 0 to 7

50

Not Used

Setup & Operation 7. I/O Connector

Signal Name

Signal Name

Signal Name

Remote function is not initially assigned to both input and output. To assign the remote function, refer to

RC700

/ RC700-A Robot Controller: Setup & Operation 12. I/O Remote Settings.

Connector Standard

I/O Connector (Drive Unit side)

D-sub 50 male pin

Mounting style #4 - 40

* The I/O connector, I/O connector cable, terminal block, and I/O connector kit are offered as options.

RC700DU / RC700DU-A Rev.11 45

Page 56

Setup & Operation 8. R-I/O Connector

Pins

Bit number

Drive Unit 1

Input 2 56, 57

Drive Unit 2

Input 2 280, 281

Drive Unit 3

Input 2 312,313

R-I/O

Input No.56-1

Input No.56-2

Input No.57-1

Input No.57-2

GND +24V

8. R-I/O Connector

The I/O connector is for connecting the input signals of the real time I/O function.

By inputting trigger signals to R-I/O, you can keep and get the operating robot position when

trigger is detected. If you use this function with Vision, you can create an application of

parts pickup, alignment, and assembly by robots without stopping.

For details, refer to EPSON RC+7.0 User’s Guide 18. Real time I/O.

8.1 Input Circuit

Input Voltage Range : +24 V ±10%

Input Current : 10 mA (TYP) at +24 V input

The following two types of wiring are available in the input circuit.

Typical Input Circuit Application 1

46 RC700DU / RC700DU-A Rev.11

Page 57

Typical Input Circuit Application 2

R-I/O

Input No.56-1

Input No.56-2

Input No.57-1

Input No.57-2

GND +24V

3

Input No57-1

Input No.281-1

Input No313-1

Connector

Standard

■

When using R

I/O connector without meeting

conditions, it may cause the system

failure and/or safety problems.

8.2 Pin Assignments

Setup & Operation 8. R-I/O Connector

Pin No.

Signal Name

(Drive Unit 1)

Signal Name

(Drive Unit 2)

Signal Name

(Drive Unit 3)

1 Input No.56-1 Input No.280-1 Input No312-1

2 Input No56-2 Input No.280-2 Input No312-2

4 Input No57-2 Input No.281-2 Input No313-2

5 to 15* Not Used

* For the pins 5 to 15, do not connect anything.

I/O Connector (Drive Unit side)

D-sub 50 male pin

Mounting style #4 - 40

-I/O connector, be careful of the following points. If you use the Rthe necessary

CAUTION

- Use a shielded cable and route the cables as far from the surrounding noise

sources as possible.

For details, refer to Setup & Operation: 3.5

- Make sure to check the cable routing before turning on the power supply.

Noise Countermeasures.

RC700DU / RC700DU-A Rev.11 47

Page 58

Setup & Operation 8. R-I/O Connector

48 RC700DU / RC700DU-A Rev.11

Page 59

Maintenance

This section contains maintenance procedures for the Drive Unit.

Page 60

Page 61

Maintenance 1. Safety Precautions on Maintenance

■

Only authorized personnel who have taken the safety training should be allowed

to

The safety training is the program for industrial robot operator that follows the laws

and regulations of each nation. T

acquire knowledge of industrial robots (operations, teaching, etc.).

The personnel who have completed the robot system

manufacturer, dealer, or locally

robot system.

■

Only authorized personnel who have taken the safety training should be allowed

to maintain the robot system.

The safety training is the program for industrial robot operator that follows the laws

and regulations of each nation.

The personnel who have t

robots (operations, teaching, etc.), knowledge of inspections, and knowledge of

related rules/regulations.

The personnel who have completed the robot

training classe

are allowed to maintain the robot system.

■

Make sure to use only dedicated/specified maintenance parts especially for the

optional boards or any other

to be replaced.

Using non

serious safety

■

Do not

maintenance procedure strictly as described in this manual.

using

part or maintain the equipment.

moval of parts or improper

maintenance may cause not only improper function of the robot system but also

serious safety problems.

■

Before performing any maintenance procedure, always make sure that the main

power

voltage charged area is completely discharged.

procedure while the main power is ON or the high voltage charged area

discharged

and/or cause serious safety problems.

■