Page 1

Rev.1 EM208S4407F

EPSON RC+ 7.0 Option

AOI

(Add-On Instructions)

Page 2

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

Page 3

EPSON RC+ 7.0 Option

AOI (Add-On Instructions)

Rev.1

Copyright 2020 SEIKO EPSON CORPORATION. All rights reserved.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 i

Page 4

1.

Damage or malfunction caused by improper use which is not described in the manual, or

careless use.

2.

Malfunctions caused by customers’ unauthorized disassembly.

3.

Damage due to improper adjustments or unauthorized repair attempts.

4.

Damage caused by natural disasters such as earthquake, flood, etc.

1.

If the robot or associated equipment is used outside of the usage conditions and product

specifications described in the manuals, this warranty is void.

2.

If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3.

We cannot foresee all possible dangers and consequences. Therefore, this manual cannot

warn the user of all possible hazards.

FOREWORD

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the Manipulator.

Please carefully read this manual and other related manuals before installing the robot

system.

Keep this manual handy for easy access at all times.

WARRANTY

The robot and its optional parts are shipped to our customers only after being subjected to

the strictest quality controls, tests, and inspections to certify its compliance with our high

performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please ask your Regional Sales Office for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

Warnings, Cautions, Usage:

ii EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

Page 5

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Allen-Bradley and Studio

5000 are registered trademarks of Rockwell Automation, Inc.. Other brand and product

names are trademarks or registered trademarks of the respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® 8 Operating system

Microsoft® Windows® 10 Operating system

Throughout this manual, Windows 8, and Windows 10 refer to above respective operating

systems. In some cases, Windows refers generically to Windows 8, and Windows 10.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

MANUFACTURER

CONTACT INFORMATION

Contact information is described in “SUPPLIERS” in the first pages of the following

manual:

Robot System Safety and Installation Read this manual first

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 iii

Page 6

iv EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

Page 7

Table of Contents

1. Introduction 1

2. Operation 1

2.1 Requirements ...........................................................................................1

2.2 Robot Controller Preparation ...................................................................1

2.3 PLC Project Preparation ..........................................................................1

2.4 SPEL AOI Common Inputs and Outputs..................................................1

2.5 SPEL AOI General Operation ..................................................................2

3. Configuring the Robot Controller 2

4. Creating a PLC Project using SPEL AOIs 4

5. SPEL AOI Reference 14

SPEL_Above .................................................................................................14

SPEL_Accel ..................................................................................................15

SPEL_AccelS ................................................................................................16

SPEL_Arc ......................................................................................................17

SPEL_Arc3 ....................................................................................................18

SPEL_ArchGet ..............................................................................................19

SPEL_ArchSet ..............................................................................................20

SPEL_BaseGet .............................................................................................21

SPEL_BaseSet .............................................................................................22

SPEL_Below .................................................................................................23

SPEL_CPOff .................................................................................................24

SPEL_CPOn .................................................................................................25

SPEL_ExecCmd ...........................................................................................26

SPEL_FineGet ..............................................................................................27

SPEL_FineSet ...............................................................................................28

SPEL_Flip .....................................................................................................29

SPEL_Go ......................................................................................................30

SPEL_In ........................................................................................................31

SPEL_InertiaGet ...........................................................................................32

SPEL_InertiaSet ............................................................................................33

SPEL_Init ......................................................................................................34

SPEL_InW .....................................................................................................36

SPEL_Jog .....................................................................................................37

SPEL_Jump ..................................................................................................38

SPEL_Jump3 ................................................................................................39

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 v

Page 8

Table of Contents

SPEL_Jump3CP ........................................................................................... 40

SPEL_Lefty ................................................................................................... 41

SPEL_LimZ ................................................................................................... 42

SPEL_LocalGet ............................................................................................ 43

SPEL_LocalSet ............................................................................................. 44

SPEL_MemIn ................................................................................................ 45

SPEL_MemInW ............................................................................................ 46

SPEL_MemOff .............................................................................................. 47

SPEL_MemOn .............................................................................................. 48

SPEL_MemOut ............................................................................................. 49

SPEL_MemOutW ......................................................................................... 50

SPEL_MemSw .............................................................................................. 51

SPEL_MotorOff ............................................................................................. 52

SPEL_MotorOn ............................................................................................. 53

SPEL_Move .................................................................................................. 54

SPEL_NoFlip ................................................................................................ 55

SPEL_Off ...................................................................................................... 56

SPEL_On ...................................................................................................... 57

SPEL_Out ..................................................................................................... 58

SPEL_OutW .................................................................................................. 59

SPEL_PowerHigh ......................................................................................... 60

SPEL_PowerLow .......................................................................................... 61

SPEL_ResetError ......................................................................................... 62

SPEL_Righty ................................................................................................. 63

SPEL_SavePoints ........................................................................................ 64

SPEL_Speed ................................................................................................ 65

SPEL_SpeedS .............................................................................................. 66

SPEL_Sw ...................................................................................................... 67

SPEL_Teach ................................................................................................. 68

SPEL_ToolGet .............................................................................................. 69

SPEL_ToolSet ............................................................................................... 70

SPEL_WeightGet .......................................................................................... 71

SPEL_WeightSet .......................................................................................... 72

SPEL_XYLimGet .......................................................................................... 73

SPEL_XYLimSet ........................................................................................... 74

6. Error Codes 75

vi

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

Page 9

1. Introduction

Name of AOI

A local tag that references the name of the AOI.

ExtInputs

These are the input IO mapping.

ExtOutputs

These are the output IO mapping.

Start

This is the input that starts the AOI.

This manual contains instructions on how to use EPSON RC+ 7.0 SPEL AOI (Add-OnInstructions). AOI allows Allen-Bradley® PLC users to execute commands in EPSON

robot controllers from a PLC ladder logic program. EPSON AOI uses extended remote I/O

to communicate with the controller via EtherNet/IP.

2. Operation

2.1 Requirements

To use SPEL Add-On-Instructions, the following are required:

- An EPSON robot controller with an EtherNet/IP Fieldbus slave board installed. The

controller must have firmware version 7.5.0.0 or greater installed.

- A Windows PC with EPSON RC+ 7.0 v7.5.0 or greater installed. This is used to

configure the robot controller for AOI operation, and to create a project in the controller

when a robot point file is used.

2.2 Robot Controller Preparation

To prepare the robot controller for SPEL AOI execution:

1. Introduction

1. Install an EtherNet/IP Fieldbus slave board in the controller and connect it to the Ethernet

network used for communication with the PLC.

2. Configure the robot controller for use with SPEL AOI. See chapter 3. Configuring the

Robot Controller.

2.3 PLC Project Preparation

To prepare the PLC project for SPEL AOI execution:

1. Setup the A1 EtherNet module for communication with the robot controller. You can

import the EpsonEtherNetIP.L5X file (recommended), or you can manually set it up. See

chapter 5, Creating a PLC Program.

2. Either import all SPEL AOIs into the project by importing SPEL_All.L5x, or import the

desired SPEL AOIs separately. You must always import the SPEL_Init AOI.

3. Create a rung for execution of the SPEL_Init AOI. This must be executed once before

executing other AOIs. SPEL_Init executes SPEL_ResetError and checks robot controller

configuration. There are no errors, then AOI execution is allowed.

2.4 SPEL AOI Common Inputs and Outputs

Each SPEL AOI has the following common inputs and outputs:

Inputs:

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 1

Page 10

3. Configuring the Robot Controller

BOOL output bit that indicates the status of execution of the AOI.

If this is high, then the AOI is executing.

BOOL output bit that indicates the status of completion of the AOI.

If this is high, then the AOI execution is complete.

Error

BOOL output bit that indicates if an error occurred during execution.

INT error codes from the robot controller. These should be 0 in

bit is high.

Outputs:

InCycle

Done

ErrCode1 and

ErrCode2

AOIs have additional inputs and/or outputs. These are described separately for each AOI

in the chapter 5.SPEL AOI Reference.

normal operation, and one or both are greater than 0 when the Error

2.5 SPEL AOI General Operation

General operation of all SPEL AOIs is as follows:

1. SPEL_Init AOI must have been executed one time sucessfully before executing other

SPEL AOIs.

2. Set the Start input from low to high to start execution.

3. During execution, the Done and Error output bits are set to low and the InCycle output

bit is set to high.

4. After execution, the Done output bit is set to high and the InCycle output bit is set to

low. If an error occurred during execution, the Error output bit is set to high, and the

error code values ErrCode1 and ErrCode2 are set. See the chapter 6. Error Codes for

more information.

5. If an error occurs, SPEL AOI execution is prevented until the SPEL_ResetError AOI

is executed.

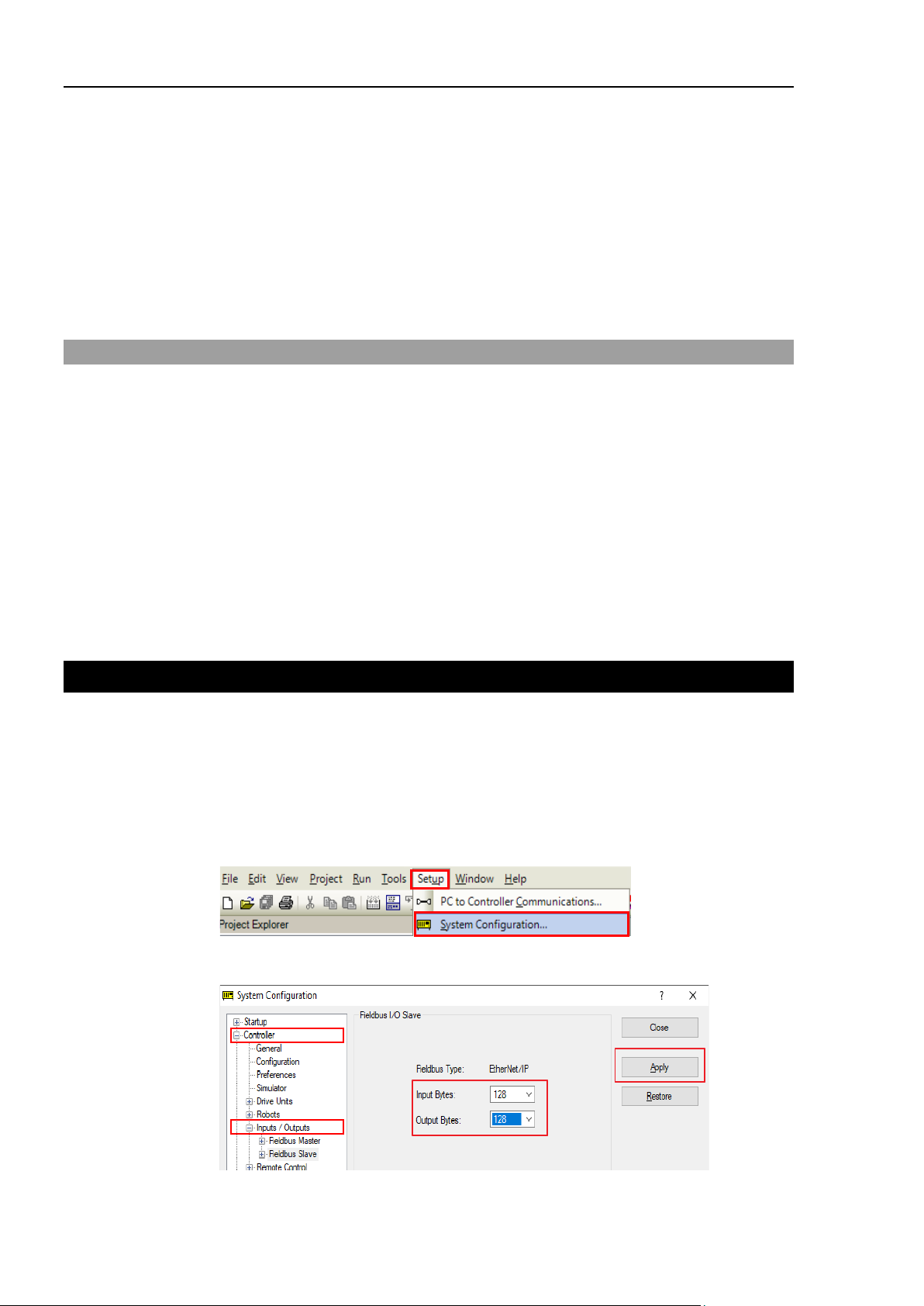

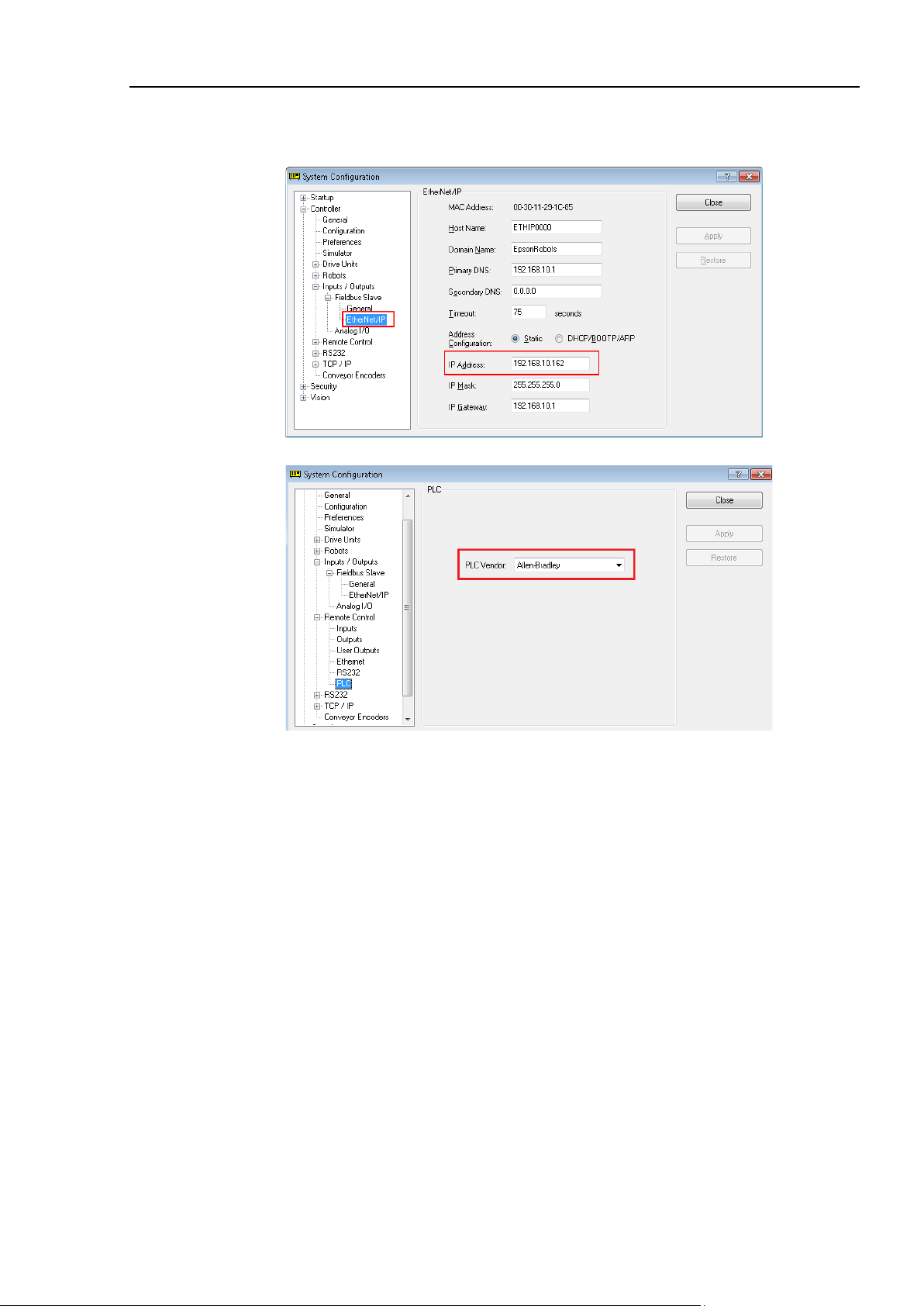

3. Configuring the Robot Controller

In this chapter we will describe how to configure the robot controller Fieldbus slave to

work with the PLC when using SPEL AOIs. Perform the following steps:

1. Start EPSON RC+ 7.0 on your PC.

2. Connect to the robot controller. You may need to configure a connection to the robot

controller in [Setup]-[PC to Controller Communications]. See the EPSON RC+ 7.0

User's Guide for instructions.

3. From the [Setup] menu, select [System Configuration].

4. Click [Controller]-[Inputs/Outputs]-[Fieldbus Slave]. Configure the number of input and

output bytes to 128 as shown below, then click <Apply>.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

2

Page 11

3. Configuring the Robot Controller

5. Expand [Fieldbus Slave] in the tree and select [Ethernet/IP].

Set the IP address, mask, and gateway that will be used for communication from the

A1 EtherNet module in the PLC.

6. Select [Remote Control]-[PLC] and select Allen-Bradley® as the PLC Vendor.

7. Click “Close” on the [System Configuration] dialog. The controller will restart.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 3

Page 12

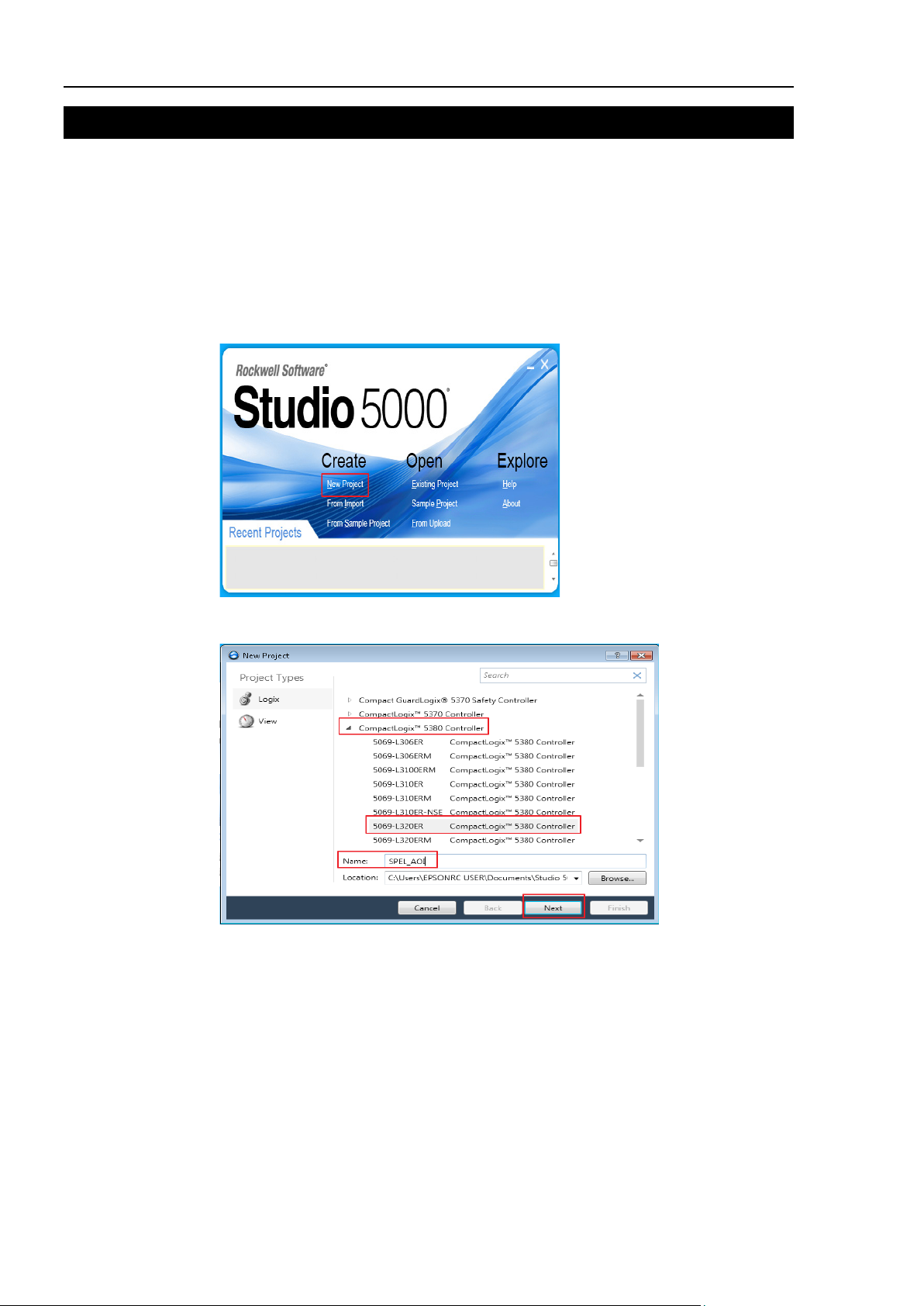

4. Creating a PLC Project using SPEL AOIs

4. Creating a PLC Project using SPEL AOIs

EPSON RC+ 7.0 users are provided with Allen-Bradley® Logix Designer files which are

installed on the user PC by the EPSON RC+ v7.5.0 or greater installer. The files are

located in \EpsonRC70\Fieldbus\EtherNetIP\AOI on the user PC.

In this chapter, we will show how to create a simple example project to turn robot motors

on and off using SPEL AOIs.

To create a new project, make sure you are in offline mode and follow these steps:

1. Start the Studio 5000® software, then click [New Project]. The New Project dialog will

be displayed.

2. Choose your Controller family and PLC controller model number. Enter a project name

under [Name], then click <Next>.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

4

Page 13

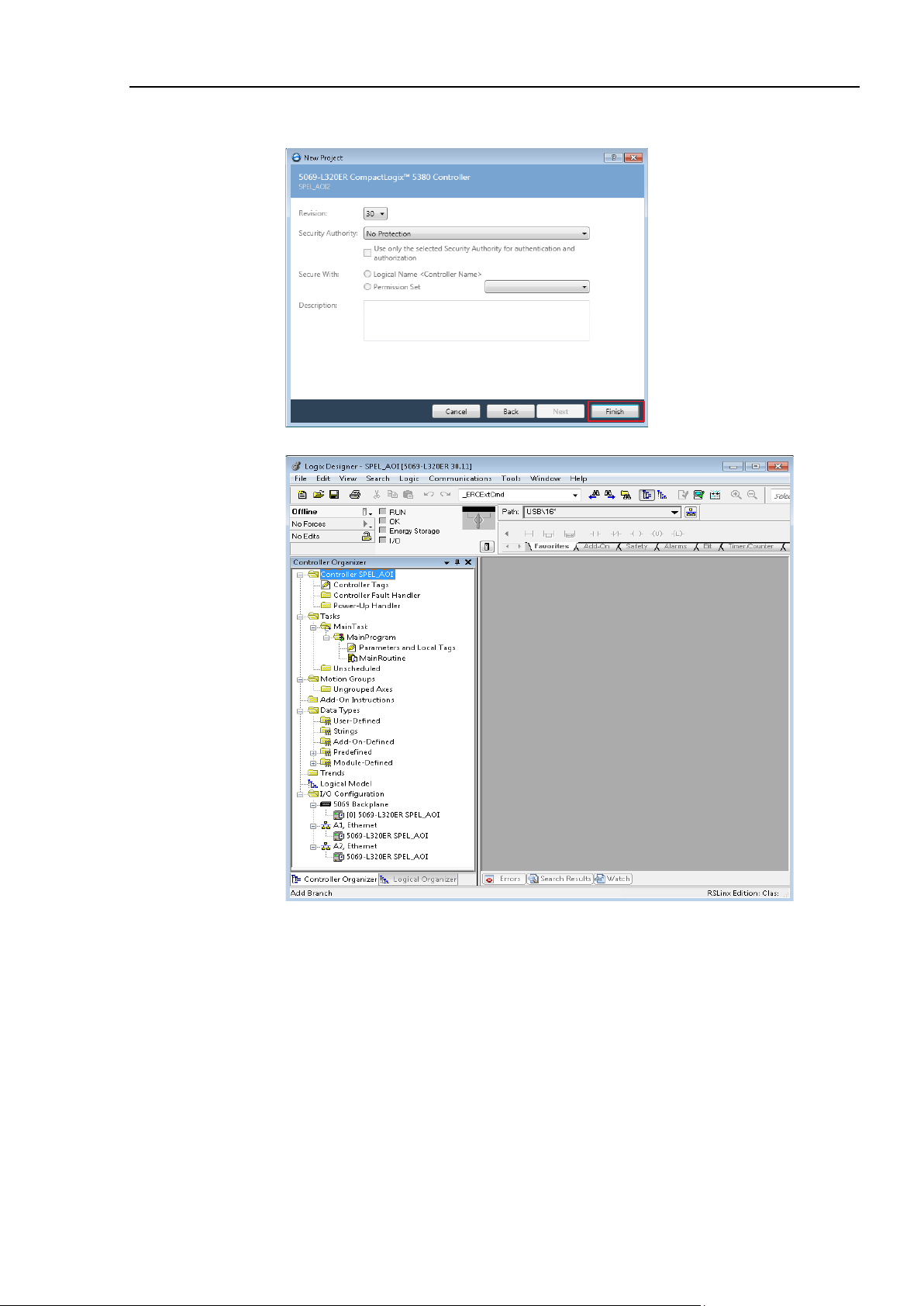

4. Creating a PLC Project using SPEL AOIs

3. The dialog shown below will be displayed. Leave all choices as default, then click

<Finish>.

4. You have just created a new empty PLC project

5. Now you need to add and configure the Ethernet module for communications with the

robot controller. There are two methods: Import the file EpsonEtherNetIP.L5X, or

perform manual configuration.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 5

Page 14

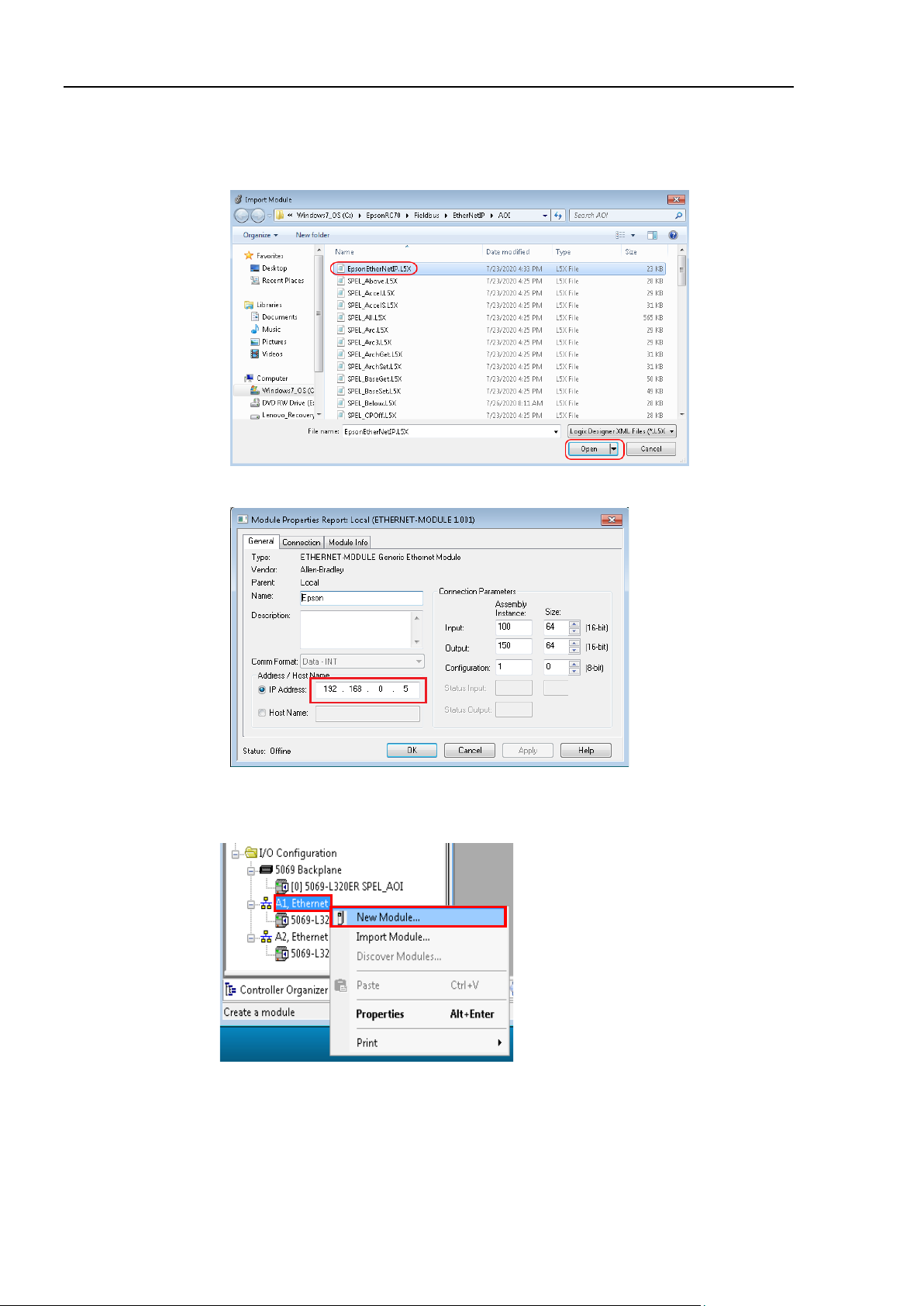

4. Creating a PLC Project using SPEL AOIs

Importing the Ethernet configuration

1. Right click on [A1, Ethernet], then click [Import Module].

2. Navigate to \EpsonRC70\Fieldbus\EtherNetIP\AOI and select the file

EpsonEtherNetIP.L5X.

3. After import, right-click on the module and select Properties. Change the default IP

address to be the address of the robot controller's EtherNetIP slave board.

Manual Ethernet configuration

1. Right click on [A1, Ethernet], then click [New Module].

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

6

Page 15

4. Creating a PLC Project using SPEL AOIs

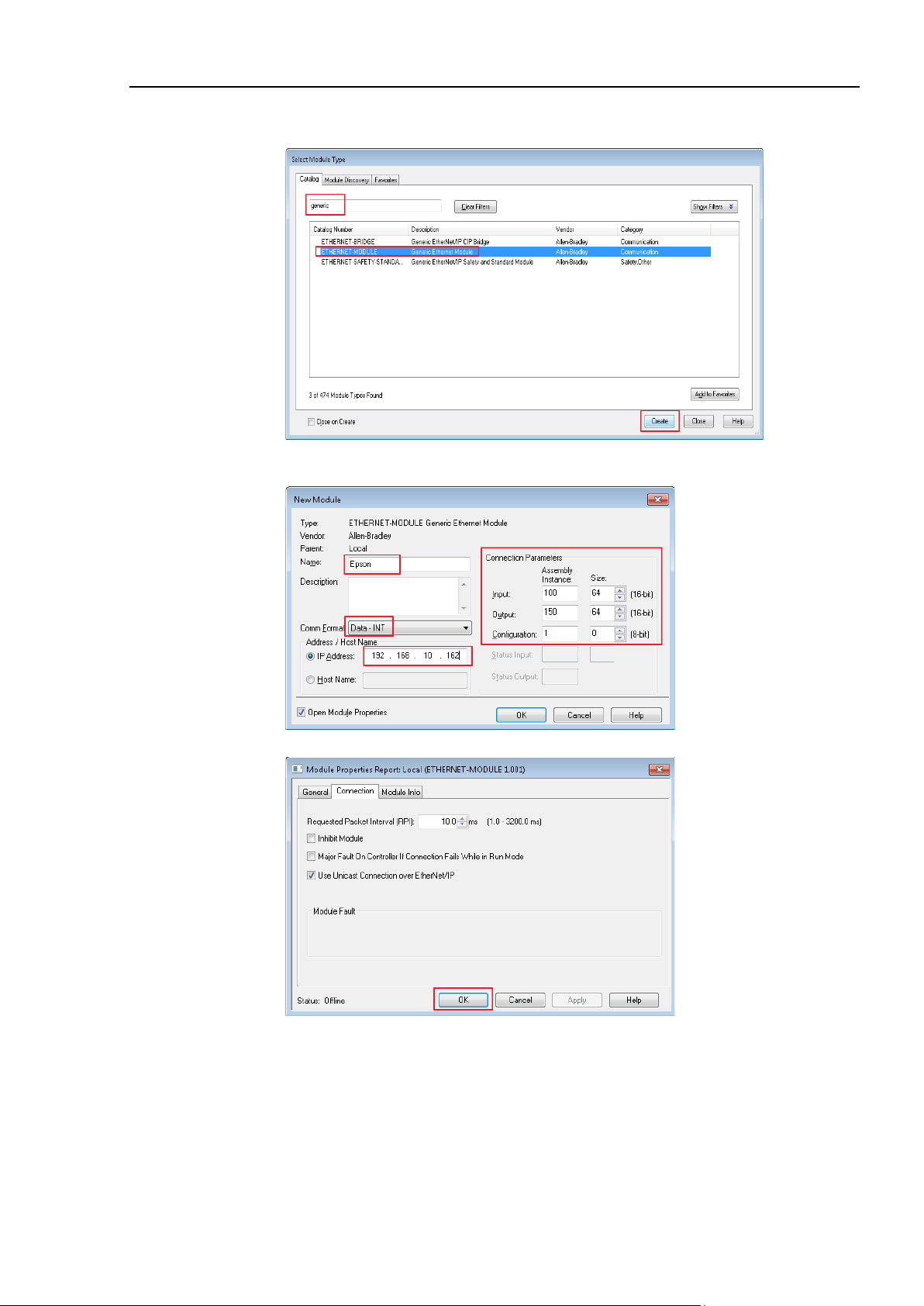

2. Type in “generic” in the search field. Click “ETHERNET MODULE” under catalog

number, then click <Create>.

3. Enter the values as shown, and use the IP address of the robot controller EtherNet/IP

slave, then click <OK>.

4. Click <OK> on the next window.

Saving your project at this stage is a good idea. When creating a new Ethernet module,

please note that connection parameter values should match your robot controller values.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 7

Page 16

4. Creating a PLC Project using SPEL AOIs

Import SPEL AOIs in to the new project

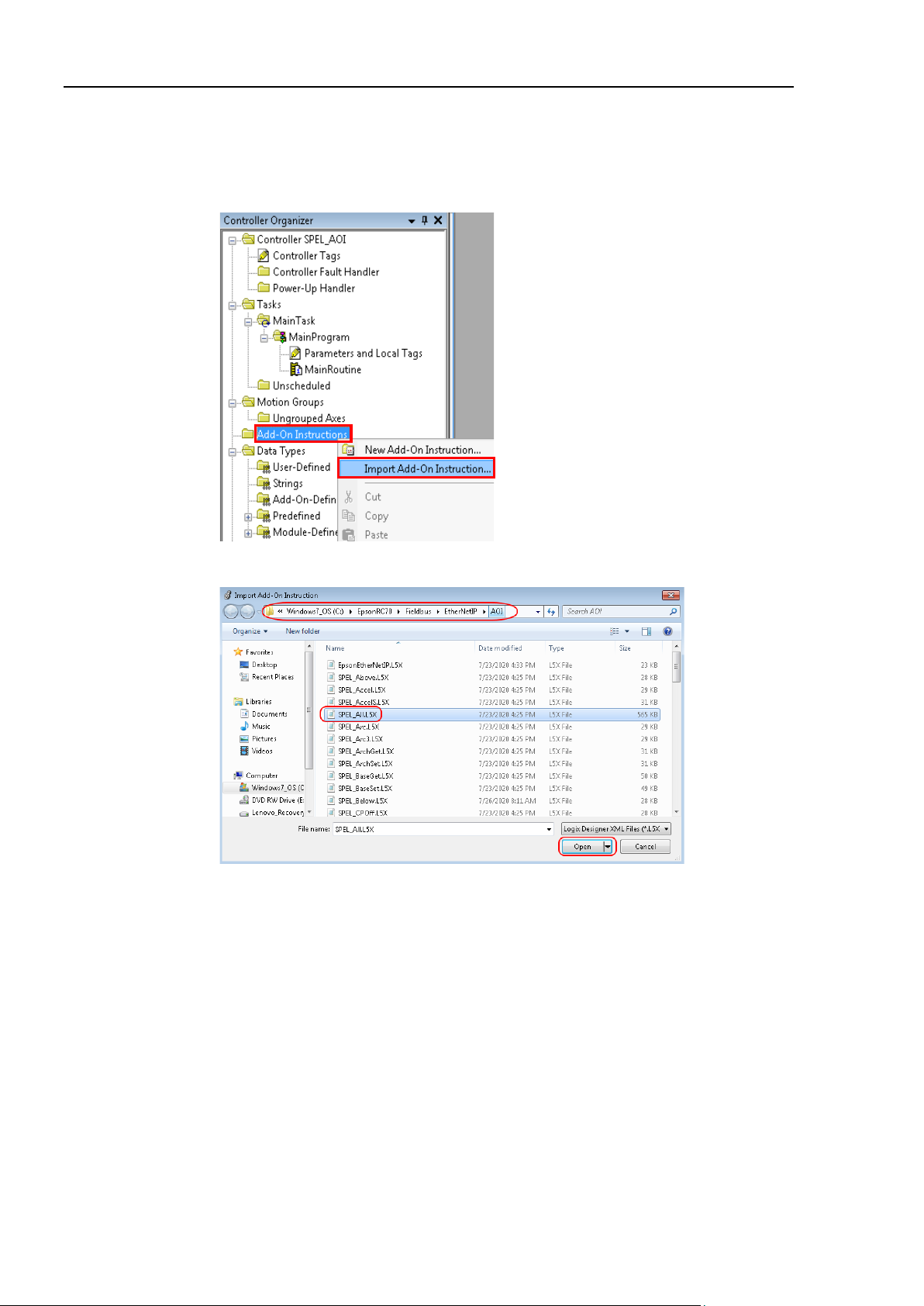

1. Now you need to import AOIs in the new project. For this example, you will import

all SPEL AOIs. You can also import individual AOIs.

To do this, right click on [Add-On Instructions] folder from [Controller Organizer],

click [Import Add-On Instruction].

2. Navigate to \EpsonRC70\Fieldbus\EtherNetIP\AOI, then select “SPEL_All.L5X” file

and click <Open>.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

8

Page 17

4. Creating a PLC Project using SPEL AOIs

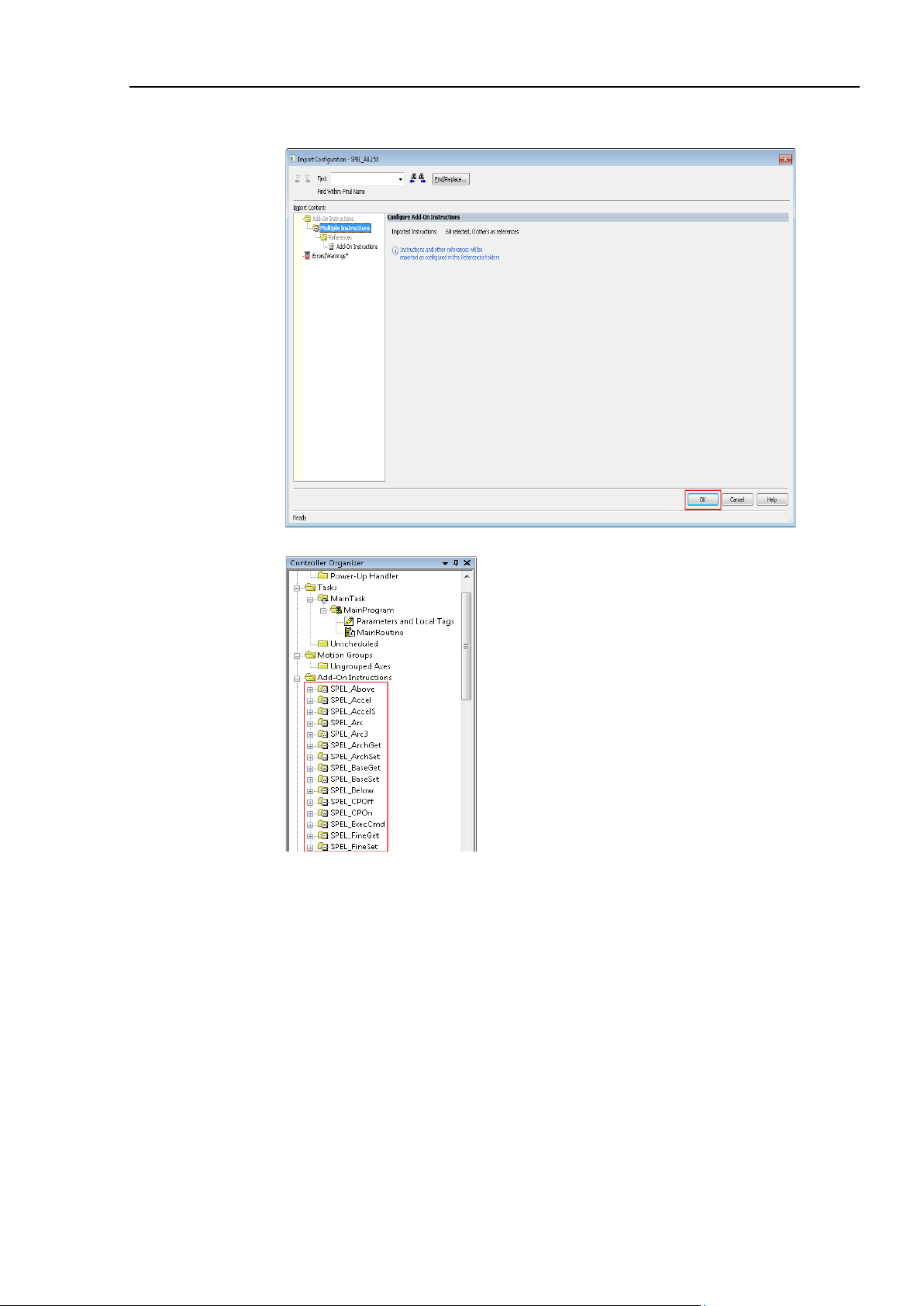

3. The dialog below is displayed. Check to make sure that there are no errors, then click

<OK>.

4. Now you should see the list of all SPEL AOIs in the project.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 9

Page 18

4. Creating a PLC Project using SPEL AOIs

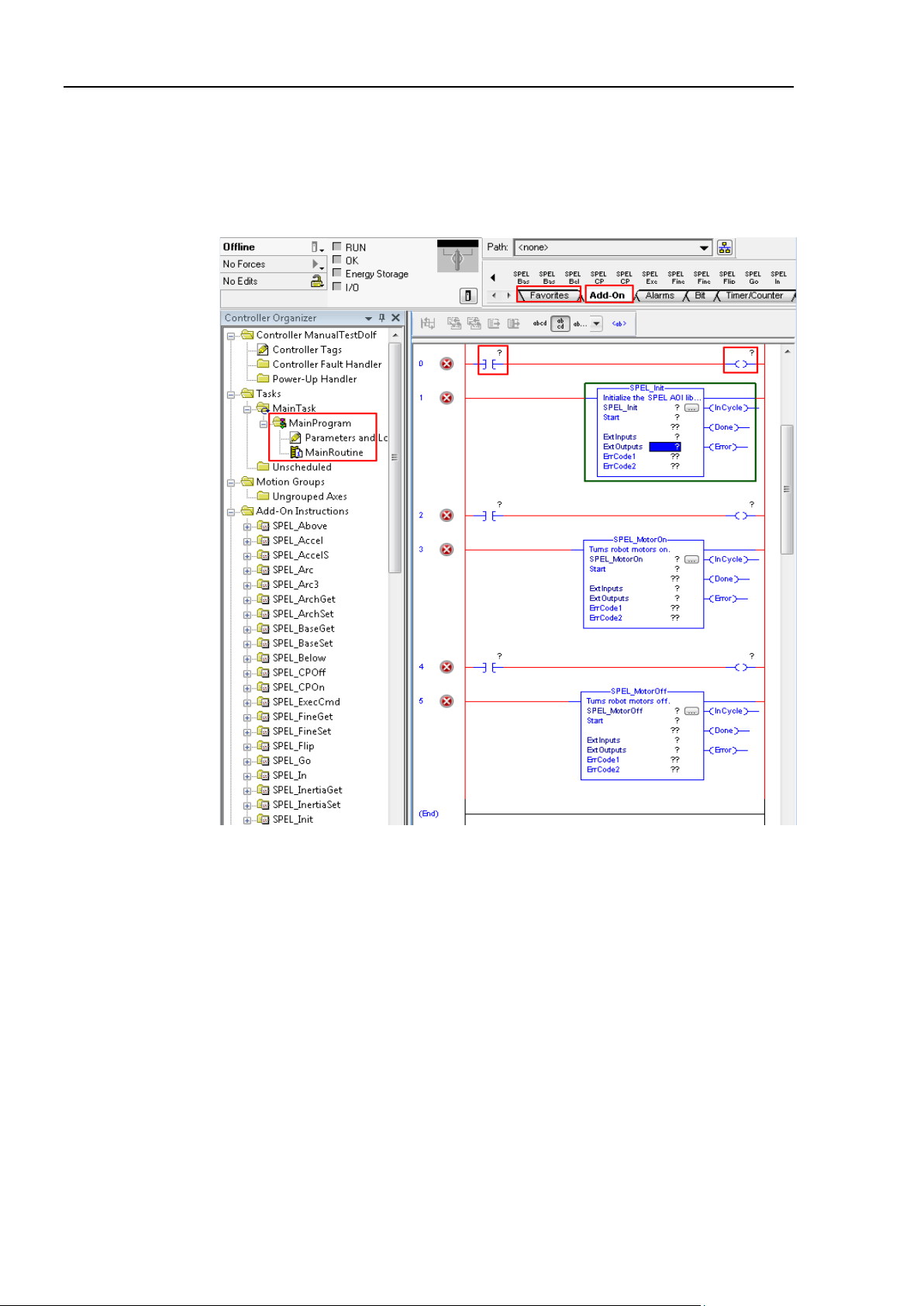

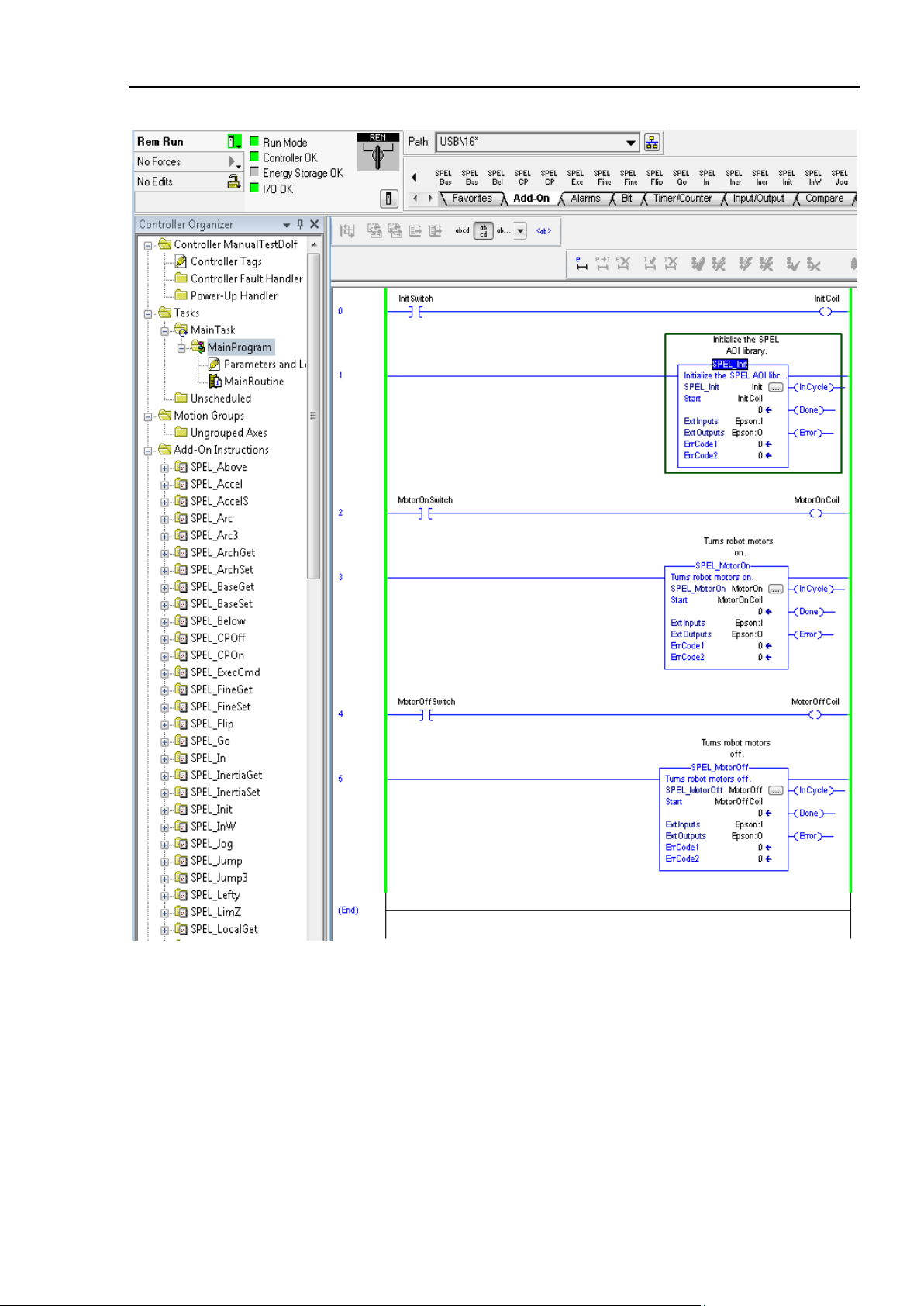

5. Now you can create a program.

5-1. Expand [MainProgram], then double click on [MainRoutine].

5-2. Click [Favorites] tab, add 5 extra rungs. Then drag “Examine On” and “Output

Energize” to rung 0, 2 and 4.

5-3. Click [Add-On] tab, drag “SPEL_Init” to rung 1, “SPEL_MotorOn” to rung 3,

and “SPEL_MotorOff” to rung 5, like shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

10

Page 19

4. Creating a PLC Project using SPEL AOIs

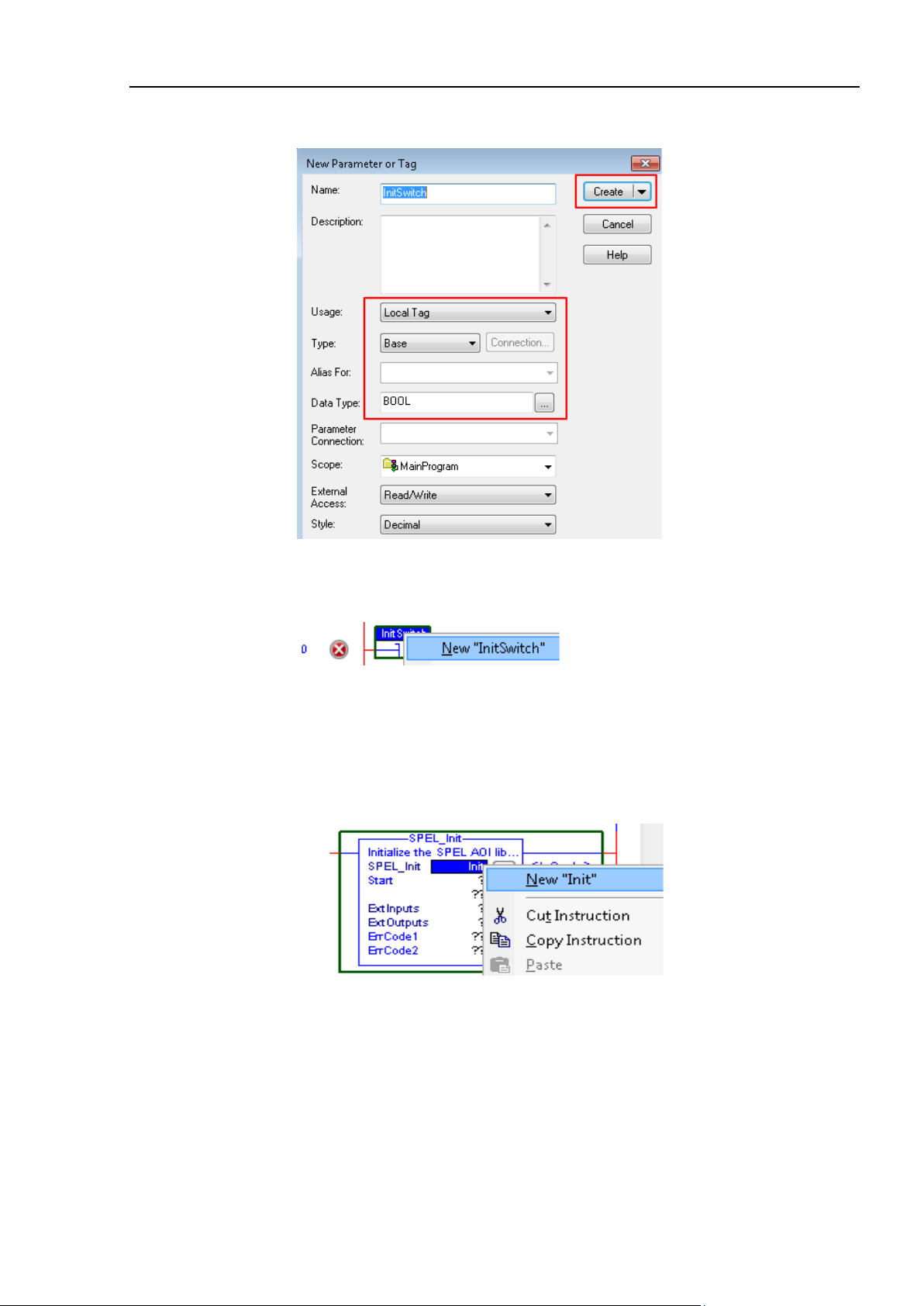

6. In rung 0, double click at [?] of “Examine On”, type in the name of the variable. In this

case we will use “InitSwitch”.

7. Do the same step as above, in rung 0, double click on [?] of the “Output Energize”, and

type “InitCoil”.

8. Right click on [InitSwitch], click on [New “InitSwitch”], then click <Create>, as shown

below.

9. Create new variable “InitCoil” same method used in “InitSwitch”.

10. Do same steps in 14 to 17 for rung 2 and 4 to create new variables. Use variable name

“MotorOnSwitch”, “MotorOnCoil” for rung 2, and “MotorOffSwitch”, “MotorOffCoil”

for rung 4.

11. Now we configure SPEL_Init AOI inputs.

11-1. Inside “SPEL_Init” block, click [?] to the right of [SPE_Init], and type “Init”.

11-2. Right click on [Init], choose [New “Init”]. then click <Create>.

“Init” will be the name of the structure that holds all internal variable of

“SPEL_Init” AOI.

11-3. Click [?] next to “Start”, type “InitCoil”, you do not need to create a new

variable.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 11

Page 20

4. Creating a PLC Project using SPEL AOIs

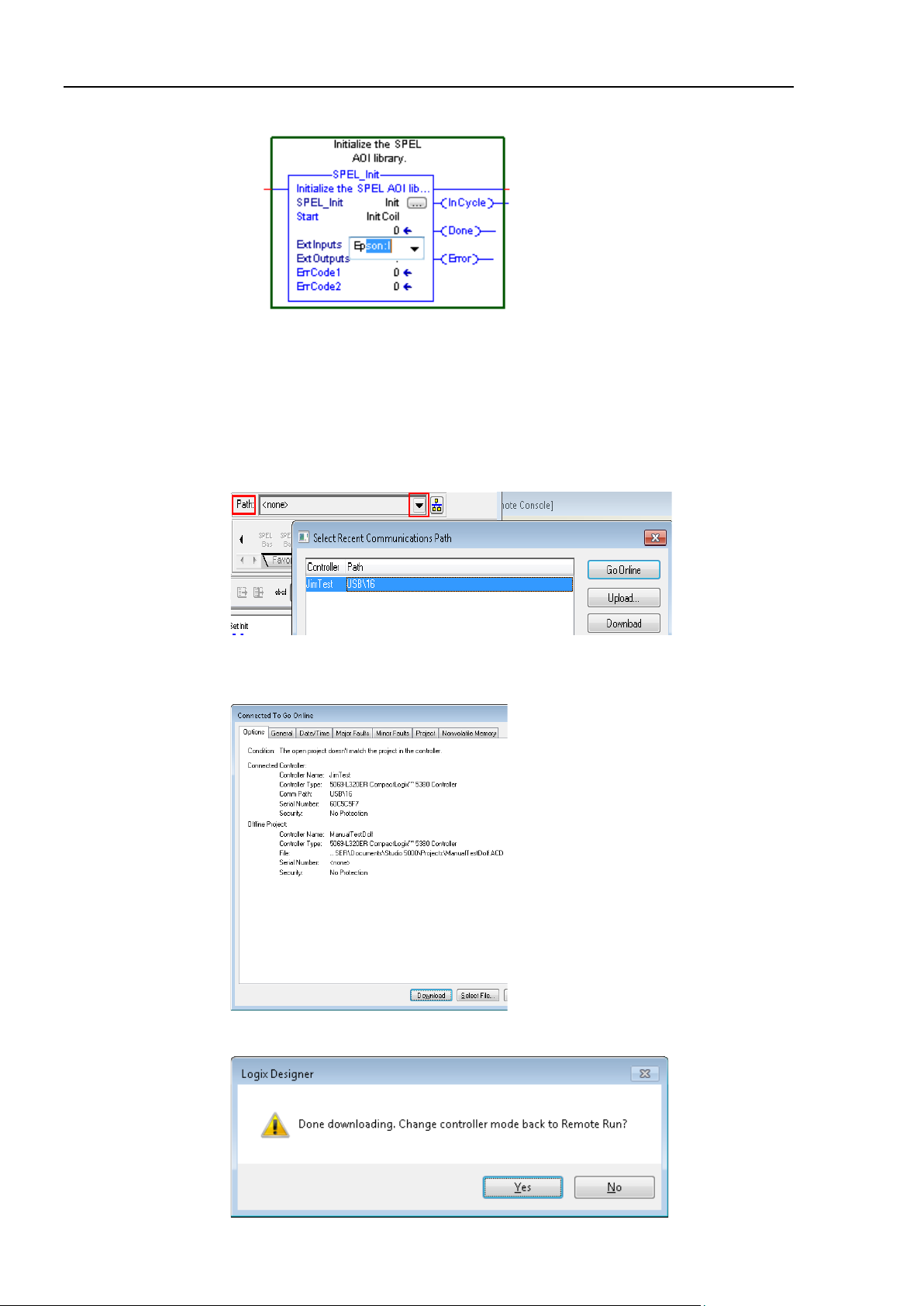

11-4. Click [?] next to [ExtInputs], type “Ep”, it will auto populate, press <Enter>.

11-5. Do same step to [ExtOutputs]. “SPEL_Init” is now configured and the rung lines

should change from red to blue.

11-6. Do the same steps as in 11-1 to 11-2 for rung 3 and 5. Choose “MotorOn” for

rung 3, “MotorOff” for rung 5.

11-7. Do the same steps as in 11-3 for rung 3 and 5. Use “MotorOnCoil” for rung 3,

“MotorOffCoil” for rung 5.

12. The program in now complete. Save the project.

13. Click the down arrow right to [Path] to choose communication path with controller.

In this example I am using USB to connect my PC to the PLC controller.

14. Double click on “USB” to close the window, then click <Download> in the next

window to transfer program to PLC controller.

15. Click <Yes> in the next window if prompted to change PLC into “Remote Run” mode,

like shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

12

Page 21

4. Creating a PLC Project using SPEL AOIs

16. PLC now in run mode and program is ready to be executed.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 13

Page 22

5. SPEL AOI Reference

5. SPEL AOI Reference

In this chapter each SPEL AOI is described.

For AOI operation in general, refer to section 2.5, SPEL AOI General Operation.

For each AOI in the Operation section, there is also a referal to the corresponding SPEL+

command in the SPEL+ Language Reference manual which has more details about the

command.

Each AOI has a simple example.

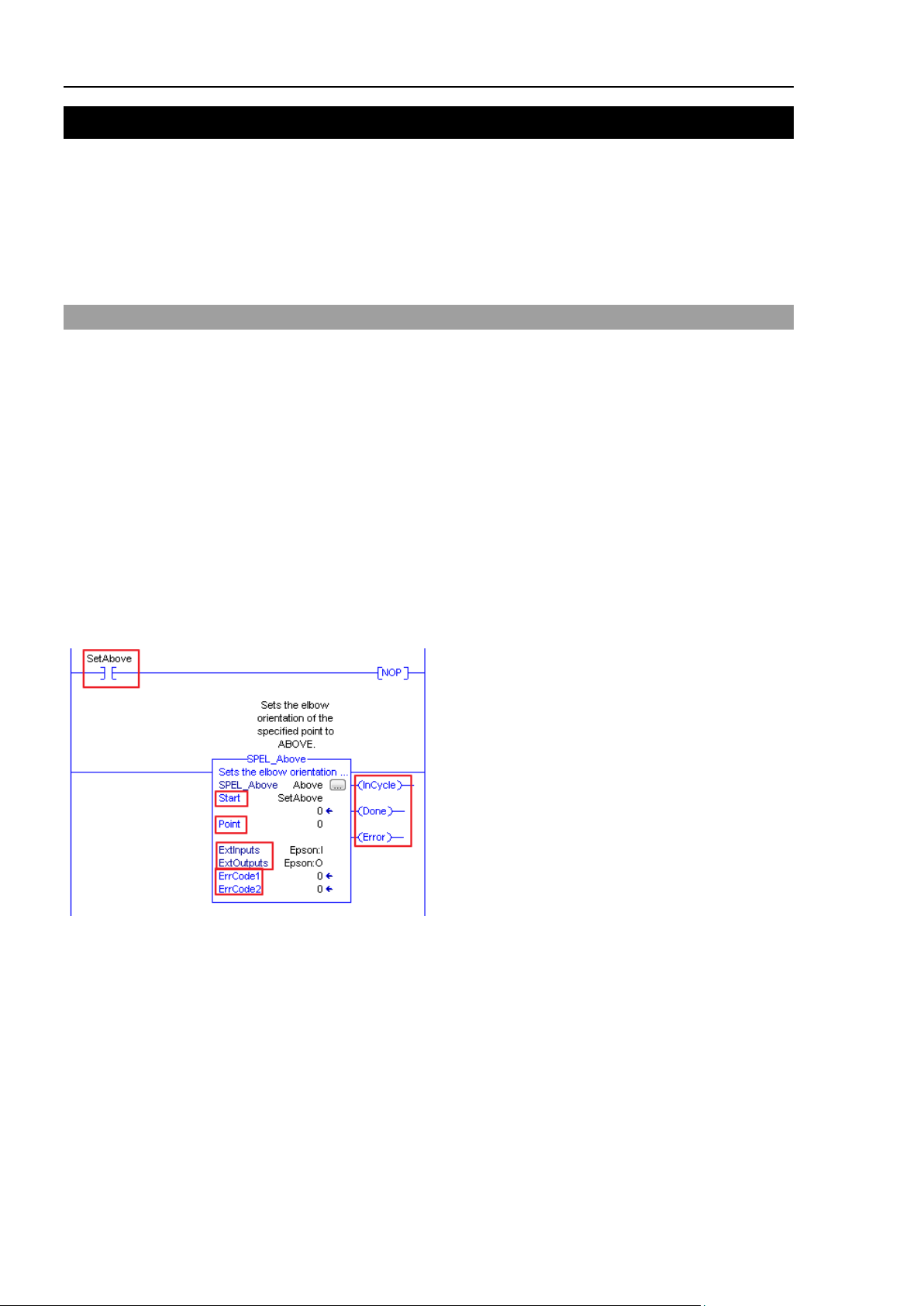

SPEL_Above

Description

Sets the elbow orientation of the specified point to Above.

Common inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT point number to set its orientation to ABOVE.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Elbow Statement in the SPEL+ Language Reference manual.

Example

To set P0 orientation to Above, set [Point] to “0”, as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

14

Page 23

5. SPEL AOI Reference

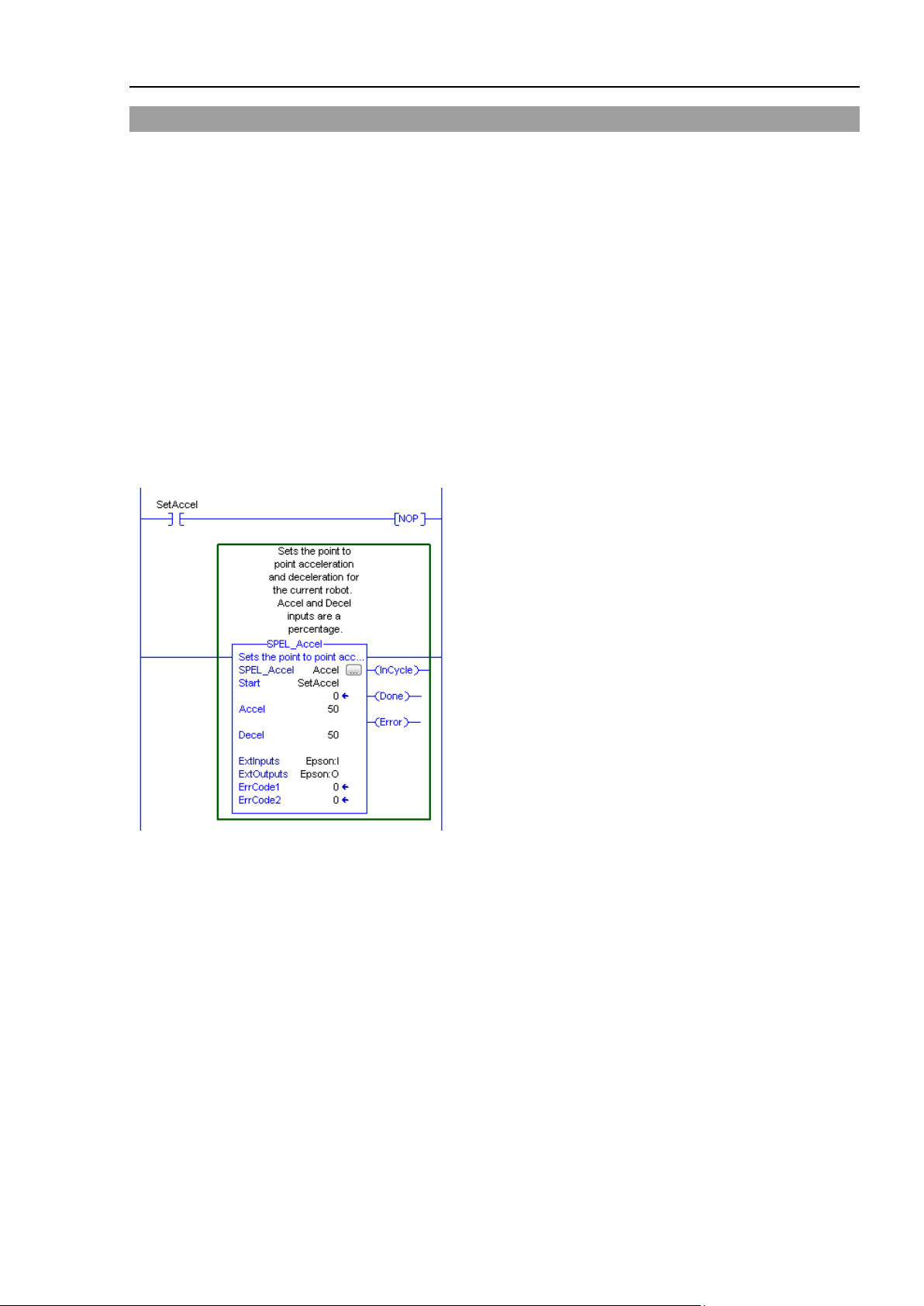

SPEL_Accel

Description

Sets the point to point acceleration and deceleration. Specifies the ratio (%) of the maximum

acceleration/deceleration using an integer equals to or greater than 1.

Common inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Accel INT value of acceleration as percentage.

Decel INT value of deceleration as percentage.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Accel Statement in the SPEL+ Language Reference manual.

Example

To set acceleration to 50% and deceleration to 50%, set [Accel] to “50” and [Decel] to “50”, as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 15

Page 24

5. SPEL AOI Reference

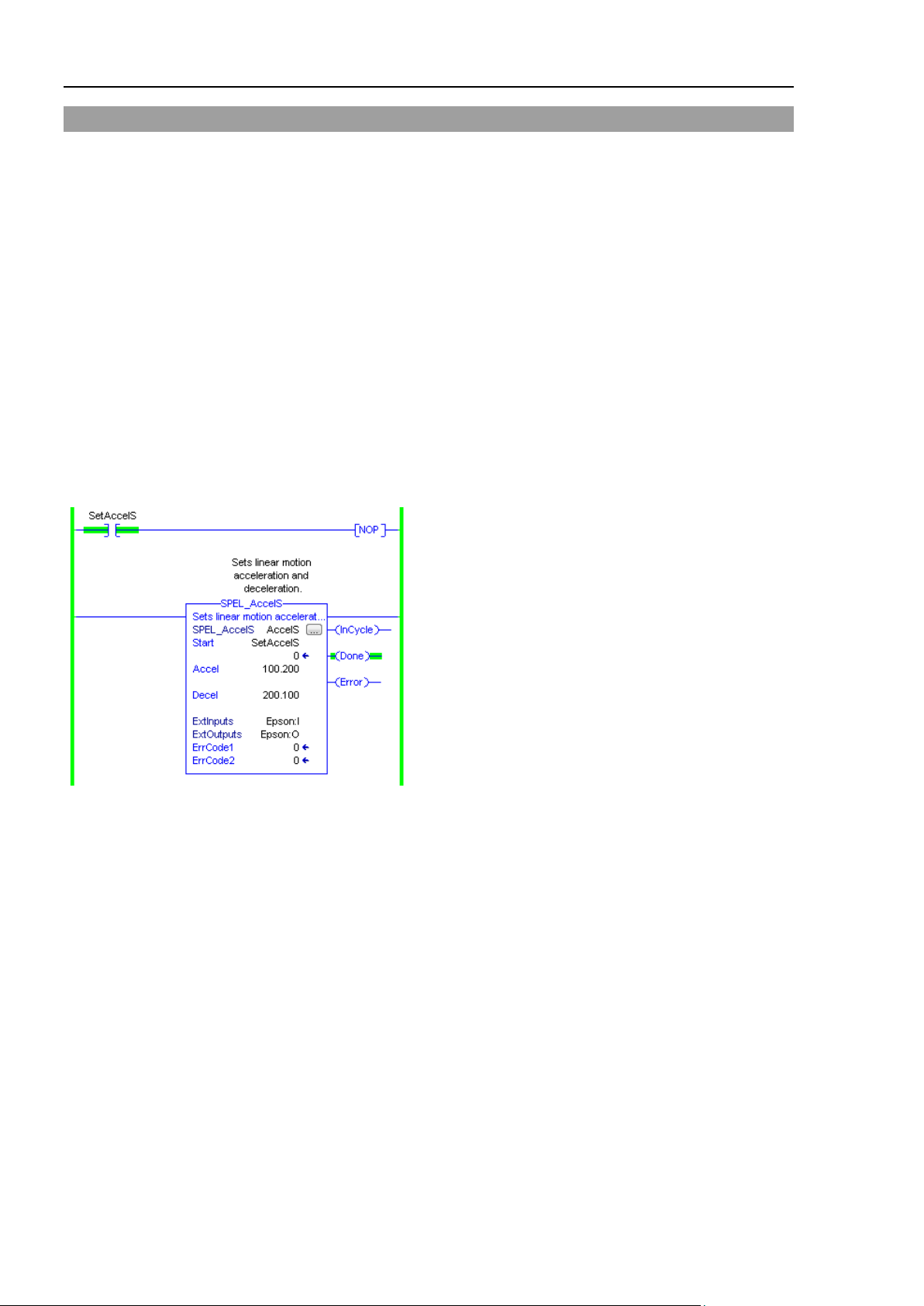

SPEL_AccelS

Description

Sets acceleration and deceleration. Specifies the value which is the actual acceleration/deceleration in linear or

CP motion (Unit: mm/sec2).

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Accel REAL value of acceleration.

Decel REAL value of deceleration.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to AccelS Statement in the SPEL+ Language Reference manual.

Example

To set acceleration to 100.200, deceleration to 200.100, set [Accel] to “100.200”, [Decel] to “200.100”, as shown

below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

16

Page 25

5. SPEL AOI Reference

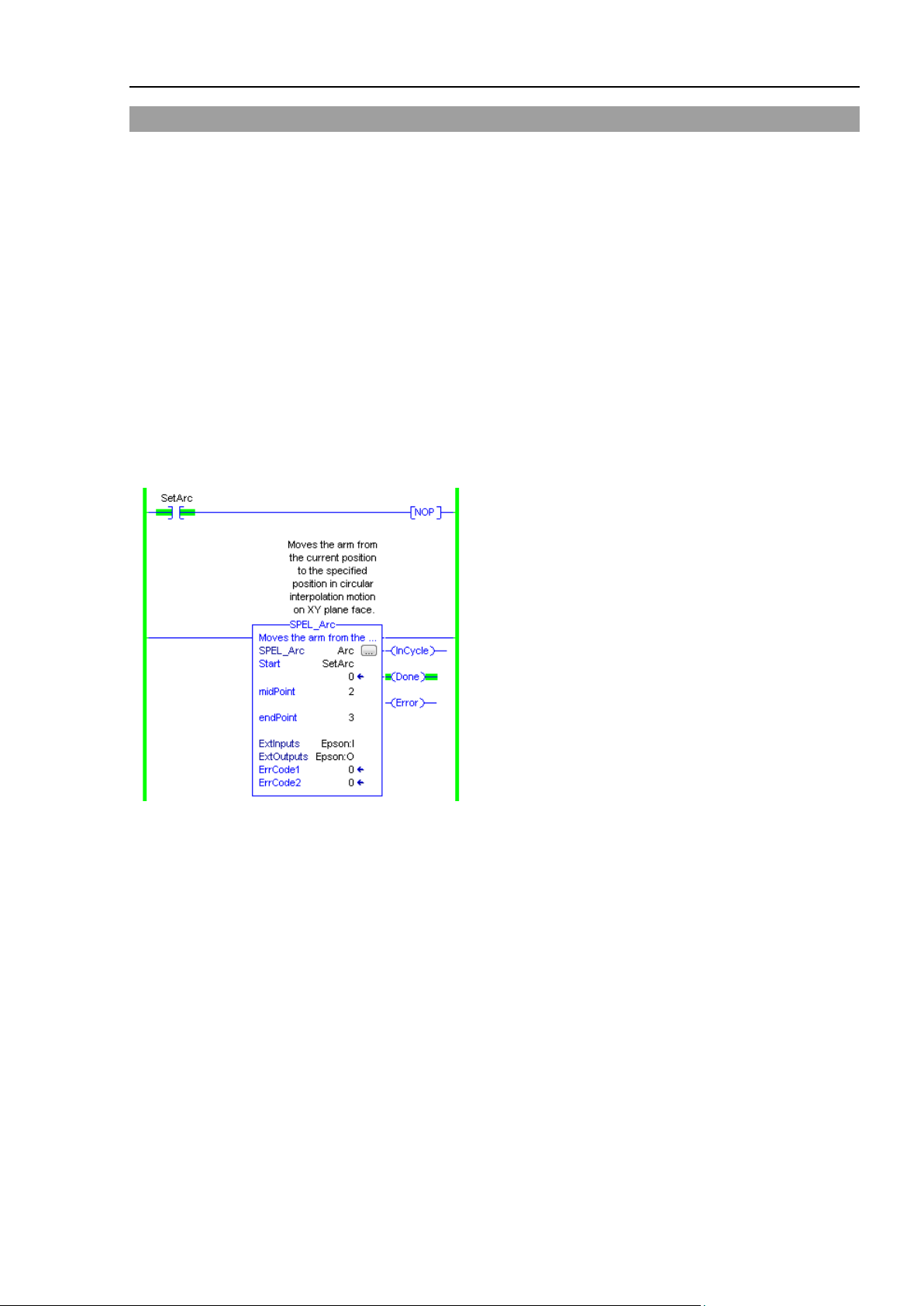

SPEL_Arc

Description

Moves the arm from the current position to the specified position in circular interpolation motion on XY plane

face.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

midPoint INT middle point in Arc command.

endPoint INT end point in Arc command.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Arc Statement in the SPEL+ Language Reference manual.

Example

To move from current position passing through P2 and ending at P3, in a circular motion.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 17

Page 26

5. SPEL AOI Reference

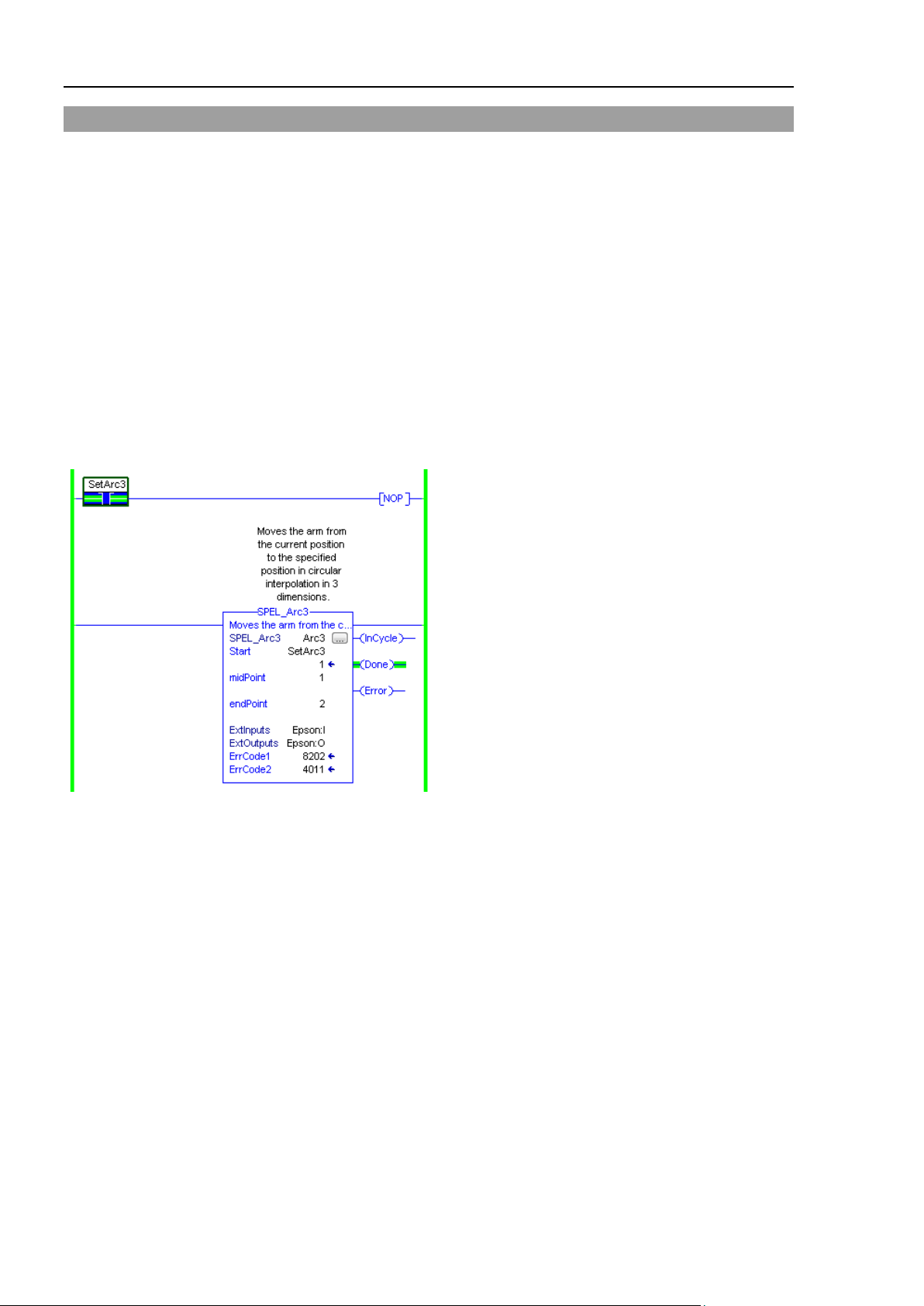

SPEL_Arc3

Description

Moves the arm from the current position to the specified position in circular interpolation in 3 dimensions.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

midPoint INT middle point in Arc3 command.

endPoint INT end point in Arc3 command.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Arc3 Statement in the SPEL+ Language Reference manual.

Example

To move from current position passing through P1 and ending at P2, in a circular motion.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

18

Page 27

5. SPEL AOI Reference

SPEL_ArchGet

Description

Gets the Arch parameter.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

ArchNum INT desired Arch number.

Outputs

DepartDist INT departing distance of the given Arch number.

ApproachDist INT approaching distance of the given Arch number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Arch Function in the SPEL+ Language Reference manual.

Example

To get the current values of approach and depart distances of given Arch, set the Arch number.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 19

Page 28

5. SPEL AOI Reference

SPEL_ArchSet

Description

Sets the Arch parameter.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

ArchNum INT desired Arch number.

DepartDist REAL departing distance of the given Arch number.

ApproachDist REAL approaching distance of the given Arch number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Arch Statement in the SPEL+ Language Reference manual.

Example

To set 60.0, 60.0 as depart and approach distances respectively of Arch 2, see below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

20

Page 29

5. SPEL AOI Reference

SPEL_BaseGet

Description

Gets the base coordinate system.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

NumAxes INT number of robot axes. For a SCARA robot, use 4. For a 6-axis robot, use 6.

Outputs

BaseX REAL base value of coordinate X.

BaseY REAL base value of coordinate Y.

BaseZ REAL base value of coordinate Z.

BaseU REAL base value of coordinate U.

BaseV REAL base value of coordinate V.

BaseW REAL base value of coordinate W.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Base Statement in the SPEL+ Language Reference manual.

Example

To get the base values of X through W coordinates for SCARA robot, plug 4 for NumAxes. Base values will

update as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 21

Page 30

5. SPEL AOI Reference

SPEL_BaseSet

Description

Sets the base coordinate system.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

NumAxes INT number of robot axes. For a SCARA robot, use 4. For a 6-axis robot, use 6.

BaseX REAL base value of coordinate X.

BaseY REAL base value of coordinate Y.

BaseZ REAL base value of coordinate Z.

BaseU REAL base value of coordinate U.

BaseV REAL base value of coordinate V.

BaseW REAL base value of coordinate W.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Base Statement in the SPEL+ Language Reference manual.

Example

To set the base value of a SCARA robot, set NumAxes = 4. Enter the base coordinate value for each axis, as

shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

22

Page 31

SPEL_Below

Description

Sets the elbow orientation of the specified point to Below.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Elbow Statement in the SPEL+ Language Reference manual.

Example

To set orientation of P2 to below, enter 2 as point. As shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 23

Page 32

5. SPEL AOI Reference

SPEL_CPOff

Description

Turns off Continuous Path parameter.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to CP Statement in the SPEL+ Language Reference manual.

Example

To set CP to off, run the AOI like as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

24

Page 33

SPEL_CPOn

Description

Turns on Continuous Path parameter.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to CP Statement in the SPEL+ Language Reference manual.

Example

To set CP to On, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 25

Page 34

5. SPEL AOI Reference

SPEL_ExecCmd

Description

The SPEL_ExecCmd AOI is used by other AOIs to execute a command in the robot controller.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

26

Page 35

SPEL_FineGet

Description

Gets the setting of positioning end judgement range for all joints.

Outputs

Axis INT position accuracy for each joint in encoder pulses.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Fine Function in the SPEL+ Language Reference manual.

Example

To get the position accuracy for the robot, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 27

Page 36

5. SPEL AOI Reference

SPEL_FineSet

Description

Sets the positioning end judgement range for all joints.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Axis1..Axis6 INT position accuracy for each joint in encoder pulses.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Fine Statement in the SPEL+ Language Reference manual.

Example

To set the position accuracy for the robot, enter the Axis values and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

28

Page 37

5. SPEL AOI Reference

SPEL_Flip

Description

Sets the wrist orientation of the specified point to Flip.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Wrist Statement in the SPEL+ Language Reference manual.

Example

To set orientation of robot point P2 to flip, enter 2 as the point number and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 29

Page 38

5. SPEL AOI Reference

SPEL_Go

Description

Moves from the current position to the specified position in PTP motion.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Go Statement in the SPEL+ Language Reference manual.

Example

To move the robot to point 0 using PTP motion, enter “0” as the point and run the AOI, as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

30

Page 39

SPEL_In

Description

Reads a byte of input.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT desired input byte port number.

Outputs

Value INT value of the desired input port.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to In Function in the SPEL+ Language Reference manual.

Example

To read input port number 66, set [PortNum] to “66”.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 31

Page 40

5. SPEL AOI Reference

SPEL_InertiaGet

Description

Gets the load inertia.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Outputs

Inertia REAL acquired Inertia.

Eccentricity REAL acquired Eccentricity.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Inertial Function in the SPEL+ Language Reference manual.

Example

To read load Inertia and Eccentricity, run the AOI, as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

32

Page 41

5. SPEL AOI Reference

SPEL_InertiaSet

Description

Sets the load inertia.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Inertia REAL desired Inertia.

Eccentricity REAL desired Eccentricity.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Inertia Statement in the SPEL+ Language Reference manual.

Example

To set load Inertia and Eccentricity to 0.01, 0.01 respectively, enter the values and run the AOI.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 33

Page 42

5. SPEL AOI Reference

SPEL_Init

Description

Initializes the PLC program for SPEL AOI execution. It is required to execute SPEL_Init before executing any

other AOIs.

Note: If the controller has a system error, then it must be reset before SPEL_Init and other SPEL AOIs can

execute successfully.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Example

As shown below, toggle [

Init Switch] to high to start the AOI.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

34

Page 43

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 35

Page 44

5. SPEL AOI Reference

SPEL_InW

Description

Returns the status if an input word.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT desired port number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to InW Function in the SPEL+ Language Reference manual.

Example

To read content of port number 33, enter the value and run the AOI.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

36

Page 45

5. SPEL AOI Reference

SPEL_Jog

Description

Jogs the robot.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

JogMode INT desired mode. 0=World, 1=Joint.

Axis INT desired axis.

Distance REAL value:

World:

X,Y,Z in mm.

U,V,W in deg.

Joint: J1-J6 in deg.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Example

To move robot in -Y direction for 40mm, enter values and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 37

Page 46

5. SPEL AOI Reference

SPEL_Jump

Description

Moves the arm using gate motion for a SCARA robot.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Jump Statement in the SPEL+ Language Reference manual.

Example

To move the robot to point P2 using gate trajectory, enter the value for Point and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

38

Page 47

5. SPEL AOI Reference

SPEL_Jump3

Description

Moves the arm with 3D gate motion for a 6-axis robot. This is a combination of two CP motion and one PTP

motion.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

DepartPoint INT desired depart point.

ApproPoint INT desired approach point.

DestPoint INT desired destination point.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Jump3CP Statement in the SPEL+ Language Reference manual.

Example

To move the robot to point P2 using gate trajectory, enter the values for the points and run the AOI as shown

below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 39

Page 48

5. SPEL AOI Reference

SPEL_Jump3CP

Description

Moves the arm with 3D gate motion for a 6-axis robot. This is a combination of three CP motions.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

DepartPoint INT desired depart point.

ApproPoint INT desired approach point.

DestPoint INT desired destination point.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Jump3CP Statement in the SPEL+ Language Reference manual.

Example

To move the robot to point P2 using gate trajectory, enter the values for the points and run the AOI as shown

below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

40

Page 49

5. SPEL AOI Reference

SPEL_Lefty

Description

Sets the hand orientation of the specified point to Lefty.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Hand Statement in the SPEL+ Language Reference manual.

Example

To change P2’s hand orientation to Lefty, enter values and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 41

Page 50

5. SPEL AOI Reference

SPEL_LimZ

Description

Sets the initial Joint #3 height (Z coordinate value) in Jump command.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Height REAL desired Z limit in mm.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to LimZ Statement in the SPEL+ Language Reference manual.

Example

To set LimZ value of 10mm, enter values and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

42

Page 51

5. SPEL AOI Reference

SPEL_LocalGet

Description

Gets data for a given local coordinate system.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

NumAxes INT number of axes in the robot. For SCARA, use 4, for Articulate robot, use 6.

LocalNum INT desired local number you want to get.

Outputs

LocalX REAL the coordinate value of that axis.

LocalY REAL the coordinate value of that axis.

LocalZ REAL the coordinate value of that axis.

LocalU REAL the coordinate value of that axis.

LocalV REAL the coordinate value of that axis.

LocalW REAL the coordinate value of that axis.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Local Statement in the SPEL+ Language Reference manual.

Example

To get the coordinate values for local number 3 of a SCARA robot, enter values and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 43

Page 52

5. SPEL AOI Reference

SPEL_LocalSet

Description

Sets the local coordinate number.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

NumAxes INT number of axes in the robot. For SCARA, use 4, for Articulate robot, use 6.

LocalNum INT desired local number you want to get.

LocalX REAL the desired coordinate value of X axis.

LocalY REAL the desired coordinate value of Y axis.

LocalZ REAL the desired coordinate value of Z axis.

LocalU REAL the desired coordinate value of U axis.

LocalV REAL the desired coordinate value of V axis.

LocalW REAL the desired coordinate value of W axis.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Local Statement in the SPEL+ Language Reference manual.

Example

To set the coordinate values for local number 3 of a SCARA robot, enter values and run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

44

Page 53

SPEL_MemIn

Description

Reads a byte of memory IO.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT port number to be read. Port number refers to byte number.

Outputs

Value INT value of the port.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to MemIn Function in the SPEL+ Language Reference manual.

Example

To read port number 0 of memory I/O, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 45

Page 54

5. SPEL AOI Reference

SPEL_MemInW

Description

Reads a word of memory IO.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT port number to be read.

Outputs

Value INT value of the port.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to MemInW Function in the SPEL+ Language Reference manual.

Example

To read port number 0 as word, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

46

Page 55

SPEL_MemOff

Description

Turns a memory IO bit off.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Bit INT bit number to be turned off.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to MemOff Statement in the SPEL+ Language Reference manual.

Example

To turn off memory bit number 3, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 47

Page 56

5. SPEL AOI Reference

SPEL_MemOn

Description

Turns a memory IO bit on.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Bit INT bit number to be turned on.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to MemOn Statement in the SPEL+ Language Reference manual.

Example

To turn on memory bit number 3, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

48

Page 57

SPEL_MemOut

Description

Sets a byte of memory IO.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT desired output port number.

OutData INT value of the data to be sent to output port.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to MemOut Statement in the SPEL+ Language Reference manual.

Example

To send 99 to port number 4, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 49

Page 58

5. SPEL AOI Reference

SPEL_MemOutW

Description

Sets a word of memory IO.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT desired output port number.

OutData INT value of the data need to be sent to output port.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to MemOutW Statement in the SPEL+ Language Reference manual.

Example

To send 99 to port number 15, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

50

Page 59

SPEL_MemSw

Description

Reads a single bit of memory IO.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Bit INT desired memory bit number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to MemSw Function in the SPEL+ Language Reference manual.

Example

To read memory bit number 5, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 51

Page 60

5. SPEL AOI Reference

SPEL_MotorOff

Description

Turns robot motors off.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Motor Statement in the SPEL+ Language Reference manual.

Example

To turn off motors, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

52

Page 61

SPEL_MotorOn

Description

Turns robot motors on.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Motor Statement in the SPEL+ Language Reference manual.

Example

To turn on motors, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 53

Page 62

5. SPEL AOI Reference

SPEL_Move

Description

Moves the arm from the current position to the specified position in a linear interpolation motion.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Move Statement in the SPEL+ Language Reference manual.

Example

To move the end effector to point P1, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

54

Page 63

SPEL_NoFlip

Description

Sets the wrist orientation of the specified point to NOFLIP.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Wrist Statement in the SPEL+ Language Reference manual

Example

To set point P2 orientation to NoFlip, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 55

Page 64

5. SPEL AOI Reference

SPEL_Off

Description

Turns an output bit off.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Bit INT desired output bit number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Off Statement in the SPEL+ Language Reference manual.

Example

To turn off bit number 4, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

56

Page 65

SPEL_On

Description

Turns an output bit on.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Bit INT desired output bit number.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to On Statement in the SPEL+ Language Reference manual.

Example

To turn on bit number 4, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 57

Page 66

5. SPEL AOI Reference

SPEL_Out

Description

Sets an output byte to a given value.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT desired output port number.

outData INT desired output port value.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Out Statement in the SPEL+ Language Reference manual.

Example

To set port number 1 with value of 99, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

58

Page 67

SPEL_OutW

Description

Sets an output word to a given value.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

PortNum INT desired output port number.

outData INT desired output port value.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to OutWStatement in the SPEL+ Language Reference manual.

Example

To set port number 0 with value of 99, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 59

Page 68

5. SPEL AOI Reference

SPEL_PowerHigh

Description

Sets the power level of robot to high.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Power Statement in the SPEL+ Language Reference manual.

Example

To set power high to the robot, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

60

Page 69

SPEL_PowerLow

Description

Sets the power level of robot to low.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Power Statement in the SPEL+ Language Reference manual.

Example

To set power low to the robot, run the AOI as shown below..

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 61

Page 70

5. SPEL AOI Reference

SPEL_ResetError

Description

Reset the robot controller AOI error state. After an error has occurred while executing a SPEL AOI, you must

execute SPEL_ResetError successfully before you can execute another AOI.

Note: If the controller has a system error, then it must be reset before SPEL_Init and other SPEL AOIs can

execute successfully.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

62

Page 71

SPEL_Righty

Description

Sets the hand orientation of the specified point to Righty.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Hand Statement in the SPEL+ Language Reference manual

Example

To set orientation of P2 to Righty, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 63

Page 72

5. SPEL AOI Reference

SPEL_SavePoints

Description

Saves the current point data in robot controller memory to the default point file for robot 1 (robot1.pts) in the

robot controller. To use this command, a valid RC+ project must exist in the controller. Typically,

SavePoints is used to save points taught using the SPEL_Teach AOI. When the controller starts up, it loads

the project and the default point file, so the saved points are in memory.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to SavePoints Statement in the SPEL+ Language Reference manual

Example

To save all points in robot controller memory to the file robot1.pts in the robot controller, run the AOI as

shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

64

Page 73

SPEL_Speed

Description

Sets the arm speed setting for PTP motion.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Speed INT desired speed.

ApproSpeed INT desired approach speed, units are %.

DepartSpeed INT desired depart speed, units are %.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Speed Statement in the SPEL+ Language Reference manual.

Example

To set Speed to 100%, Approach, Depart Speed to 50%, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 65

Page 74

5. SPEL AOI Reference

SPEL_SpeedS

Description

Sets the arm speed setting of CP motion. This will set the depart, and approach speed as well.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Speed INT desired speed.

ApproSpeed INT desired approach speed.

DepartSpeed INT desired depart speed.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to SpeedS Statement in the SPEL+ Language Reference manual.

Example

To set Speed to 100, Approach, Depart Speed to 40, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

66

Page 75

SPEL_Sw

Description

Reads the status of an input bit.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Bit INT desired input bit.

Outputs

Value INT the value of the input bit.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Sw Function in the SPEL+ Language Reference manual.

Example

To read the value of input bit number 514, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 67

Page 76

5. SPEL AOI Reference

SPEL_Teach

Description

Teaches specified robot point in the robot controller to the current robot position.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

Point INT desired point.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Here Statement in the SPEL+ Language Reference manual.

Example

To teach current robot position for robot point P5, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

68

Page 77

SPEL_ToolGet

Description

Gets the tool selection status.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Outputs

ToolNum INT the tool selected.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Tool Function in the SPEL+ Language Reference manual.

Example

To read the selected tool by the robot, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 69

Page 78

5. SPEL AOI Reference

SPEL_ToolSet

Description

Sets the tool.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

ToolNum INT the tool to be set.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Tool Statement in the SPEL+ Language Reference manual.

Example

To set current tool to 3, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

70

Page 79

SPEL_WeightGet

Description

Gets the hand weight and arm length parameters.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

HandWeight REAL weight of the hand.

ArmLength REAL length of the arm.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Weight Function in the SPEL+ Language Reference manual.

Example

To get the current hand weight and arm length, run the AOI as shown below.

5. SPEL AOI Reference

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 71

Page 80

5. SPEL AOI Reference

SPEL_WeightSet

Description

Sets the weight parameter.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

HandWeight REAL weight of the hand.

ArmLength REAL length of the arm.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to Wait Statement in the SPEL+ Language Reference manual.

Example

To set the hand weight and arm length, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

72

Page 81

5. SPEL AOI Reference

SPEL_XYLimGet

Description

Gets the value of the allowable motion area by specifying the lower and upper limit positions.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Outputs

XLower REAL X lower limit.

Xupper REAL X upper limit.

YLower REAL Y lower limit.

Yupper REAL Y upper limit.

ZLower REAL Z lower limit.

Zupper REAL Z upper limit.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to XYLim Function in the SPEL+ Language Reference manual.

Example

To get the upper and lower limits of X,Y and Z, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 73

Page 82

5. SPEL AOI Reference

SPEL_XYLimSet

Description

Sets the allowable motion area by specifying the lower and upper limit positions.

Common Inputs and Outputs

Refer to section 2.4 SPEL AOI Common Inputs and Outputs.

Inputs

XLower REAL X lower limit.

Xupper REAL X upper limit.

YLower REAL Y lower limit.

Yupper REAL Y upper limit.

ZLower REAL Z lower limit.

Zupper REAL Z upper limit.

Operation

Refer to section 2.5 SPEL AOI General Operation.

Refer to XYLim Statement in the SPEL+ Language Reference manual.

Example

To set the upper and lower limits of X,Y and Z, run the AOI as shown below.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

74

Page 83

6. Error Codes

0x200A

(8202)

A robot controller error has occurred.

ErrCode2 is the robot controller error.

See the section SPEL+ Error Messages in

the SPEL+ Language Reference manual.

Command not accepted by the controller

The controller is in a state where it cannot

controller.

AOI execution timeout

Ethernet communications was lost during

took too long to execute.

Cannot execute instruction because of

controller is low.

After any error has occurred,

0x3000

(12288)

0x280C

(10252)

Cannot execute instruction because of

invalid robot controller configuration.

Check that Remote I/O and PLC Vendor

settings are correct in the robot controller.

0x3000

(12288)

A robot controller error has occurred.

ErrCode2 is the robot controller error.

See the section SPEL+ Error Messages in

the SPEL+ Language Reference manual.

Each AOI has an Error output bit and two INT error codes: ErrCode1 and ErrCode2. The error

output is set to high when an error has occurred, and ErrCode1, ErrCode2 indicate which error

has occurred as described in the table below.

6. Error Codes

ErrCode1 ErrCode2

1 -9999

0x200B

(8203)

0x3000

(12288)

0x3000

(12288)

0

0x280A

(10250)

0x280B

(10251)

1 -9999

previous error or ExtReset input in the

Description

Cause/Remedy

accept commands. Power cycle the

command execution, or the command

SPEL_ResetError must be executed.

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1 75

Page 84

6. Error Codes

EPSON RC+ 7.0 Option AOI (Add-On Instructions) Rev.1

76

Loading...

Loading...