Page 1

User's Manual

PRP-080 Series

THERMAL RECEIPT PRINTER

Specifications subjects to

change without notice

Page 2

Contents

1. General Information

1.1) Main Features...................................................................... 2

1.2) PRP-080I (Standard) & PRP-080II

(Advanced) Function Comparison

2. Quick Start

2.1) Unpacking & Parts Identification

2.2) Loading the Paper Roll

3. Printer Interface and Connection

3.1) Connecting the Interface Cable

3.2) Connecting to a Cash Drawer

3.3) Connecting the AC Adapter

4. Configuration

4.1) Panel LED indicators

4.2) DIP Switch Settings

4.3) Printer Self Test

4.4) Driver Installation

5. Safety and Maintenance

5.1) Safety Information

5.2) Periodical Cleaning

5.3) Preventing Paper Jams

5.4) Fixing Paper Jam

....................................................... 5

...........................................................10

............................................................. 12

................................................................... 12

................................................................12

............................................................... 14

..............................................................14

.........................................................14

................................................................. 15

...................................... 3

....................................... 4

........................................... 8

............................................. 8

................................................ 9

6. Appendix

- Product Specifications

- Configuration......................

................................................................ 16

........................................................ 19

...................................................... 247. General Printer Commands

-1-

Page 3

1. General Information

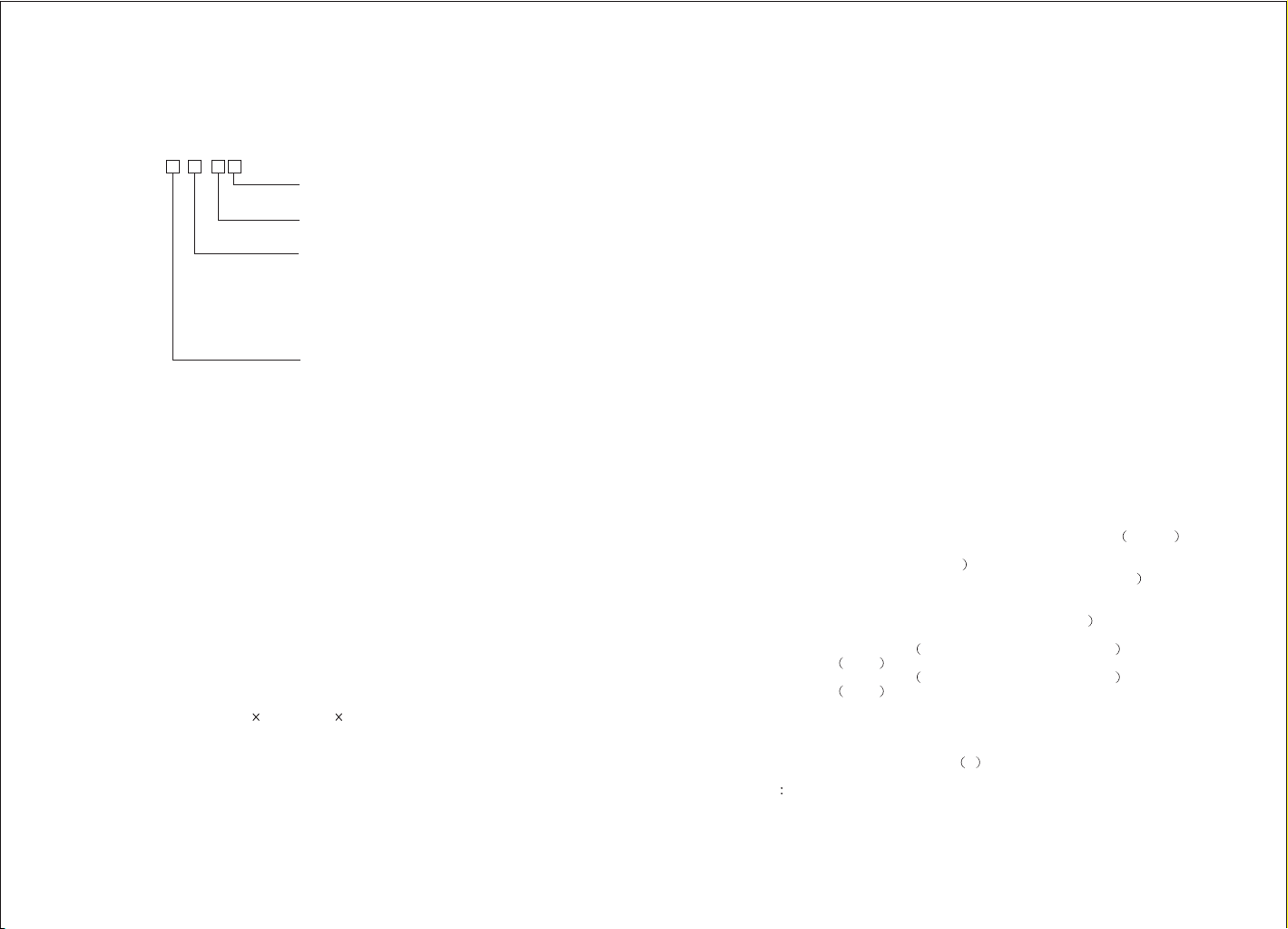

Models

PRP-080 - -

Note: International font can be combined with others, for example

PRP-080I-BI-MS, standard, Big5+International, beige, serial

Interface

Color

Font

Version

P = Parallel

S = Serial

M = Beige

B = Black

I = International font

B = Big 5 Chinese font

G = GB Chinese font

K = Korean font

J = Japanese font

(without cutter model is optional)

I = Standard

II = Advanced*

1.1) Main Features

1. High speed printing:

160 (for PRP-080II)~220 (for PRP-080I) mm/s maximum print speed.

·

Low-noise thermal printing.

·

High reliability due to a stable mechanism.

·

2. Application Software:

·

Command protocol is based on the ESC/POS standard.

·

Various Layouts are possible by using page mode (#).

·

Characters can be scaled up to 64 times as large as the standard size.

·

Smoothing is also possible.

·

Repeated operation and copy printing are possible by using macro

definitions.

·

Character font size (12 24 font or 24 24 font) can be selected using a

command.

3. Printer Handling:

·

Easy paper-roll installation.

·

Equipped with an auto cutter.

·

The printer allows easy maintenance for tasks such as head cleaning.

·

Two different print densities can be selected by DIP switches.

·

The built-in interface provides control capability for one cash drawer.

-2-

1.2) PRP-080I (Standard) & PRP-080II (Advanced)

Function Comparison

1. PRP-080I (Standard)

1. Maximum printing speed 220mm/sec

2. EPSON ESC/POS commands compatible

(see PRP-080 command sets for programming reference)

3. Characters can be scaled up to 4 times larger than standard size (double width,

double height)

4. Transmit status not supported

5. Print data in page mode not supported

6. Support Font A (12*24) characters

7. NV Image Download not supported

8. Two indicator LEDs (Power and Status)

Two Panel Buttons (Feed and Online)

9. Two indicator LEDs (Power and Status)

Two Panel Buttons (Feed and Online)

10. Warning beep sounds not supported

11. Dip switch to select Chinese / ASCII mode not supported

12. Support printer server printing

13. Support 4800, 9600, 19200, 38400bps baud rate

14. Print with 90 rotation not supported

2. PRP-080II (Advanced)

1. Maximum printing speed 160mm/sec (576 dots or 150mm/sec 512 dots

2. Fully-compatible with EPSON ESC/POS commands (see PRP-080 command

sets for programming reference

3. Characters can be scaled up to 8 times larger than standard size (*

4. Support transmit status

5. Support print data in page mode

6. Support Font A (12*24) and Font B (9*17) characters (*

7. Support NV Image Download

8. Three indicator LEDs POWER, ERROR, and Paper roll out and One Panel

button FEED

9. Three indicator LEDs POWER, ERROR, and Paper roll out and One Panel

button FEED

10. Support warning beep sound

11. Support dip switch to select Chinese / ASCII mode

12. Support printer server printing

13. Support 4800, 9600, 19200, 38400bps baud rate

14. Support print with 90 rotation *

Note (*) items are the functions that will affect printing speed

o

o

-3-

Page 4

1. General Information

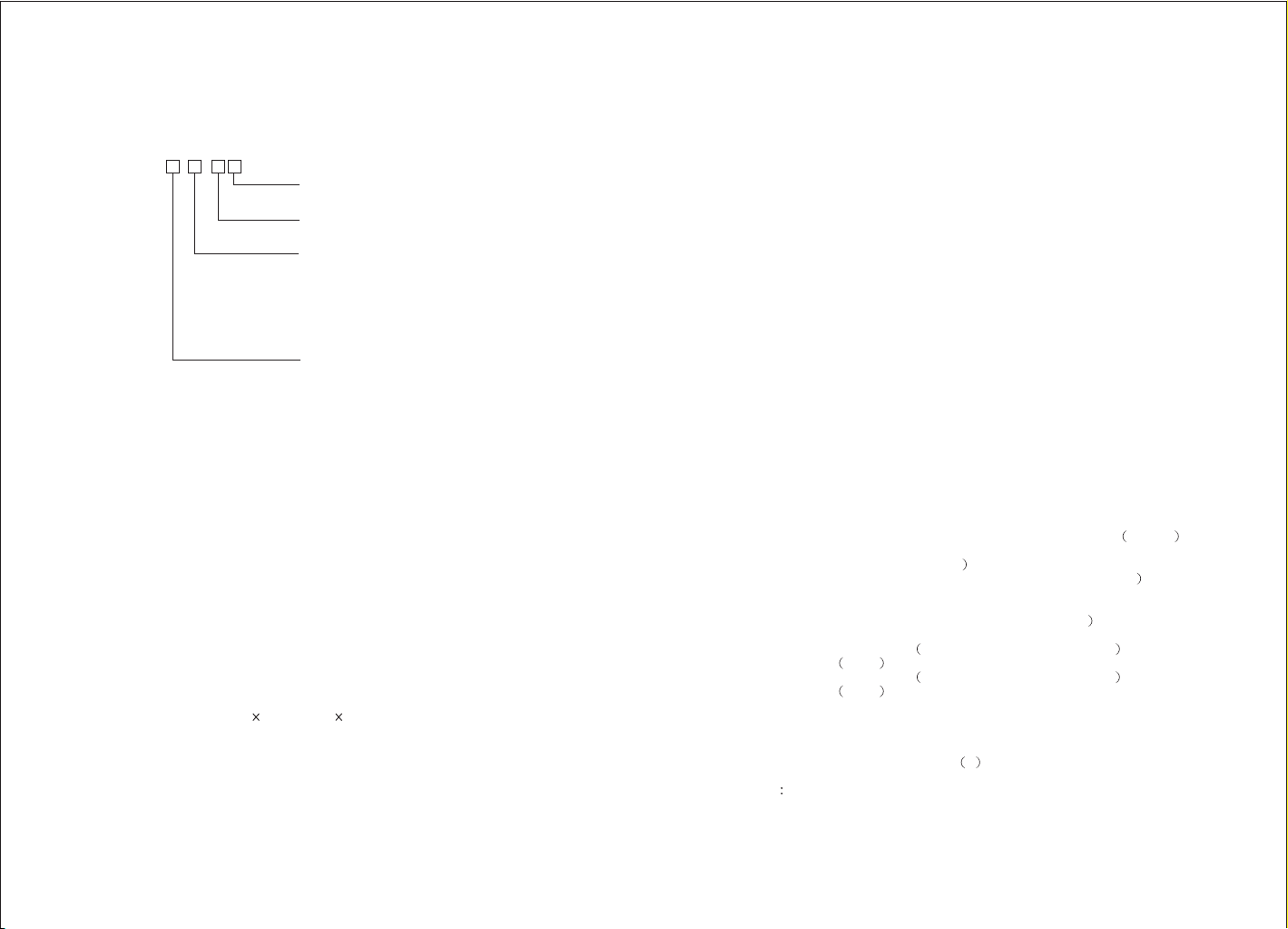

Models

PRP-080 - -

Note: International font can be combined with others, for example

PRP-080I-BI-MS, standard, Big5+International, beige, serial

Interface

Color

Font

Version

P = Parallel

S = Serial

M = Beige

B = Black

I = International font

B = Big 5 Chinese font

G = GB Chinese font

K = Korean font

J = Japanese font

(without cutter model is optional)

I = Standard

II = Advanced*

1.1) Main Features

1. High speed printing:

160 (for PRP-080II)~220 (for PRP-080I) mm/s maximum print speed.

·

Low-noise thermal printing.

·

High reliability due to a stable mechanism.

·

2. Application Software:

·

Command protocol is based on the ESC/POS standard.

·

Various Layouts are possible by using page mode (#).

·

Characters can be scaled up to 64 times as large as the standard size.

·

Smoothing is also possible.

·

Repeated operation and copy printing are possible by using macro

definitions.

·

Character font size (12 24 font or 24 24 font) can be selected using a

command.

3. Printer Handling:

·

Easy paper-roll installation.

·

Equipped with an auto cutter.

·

The printer allows easy maintenance for tasks such as head cleaning.

·

Two different print densities can be selected by DIP switches.

·

The built-in interface provides control capability for one cash drawer.

-2-

1.2) PRP-080I (Standard) & PRP-080II (Advanced)

Function Comparison

1. PRP-080I (Standard)

1. Maximum printing speed 220mm/sec

2. EPSON ESC/POS commands compatible

(see PRP-080 command sets for programming reference)

3. Characters can be scaled up to 4 times larger than standard size (double width,

double height)

4. Transmit status not supported

5. Print data in page mode not supported

6. Support Font A (12*24) characters

7. NV Image Download not supported

8. Two indicator LEDs (Power and Status)

Two Panel Buttons (Feed and Online)

9. Two indicator LEDs (Power and Status)

Two Panel Buttons (Feed and Online)

10. Warning beep sounds not supported

11. Dip switch to select Chinese / ASCII mode not supported

12. Support printer server printing

13. Support 4800, 9600, 19200, 38400bps baud rate

14. Print with 90 rotation not supported

2. PRP-080II (Advanced)

1. Maximum printing speed 160mm/sec (576 dots or 150mm/sec 512 dots

2. Fully-compatible with EPSON ESC/POS commands (see PRP-080 command

sets for programming reference

3. Characters can be scaled up to 8 times larger than standard size (*

4. Support transmit status

5. Support print data in page mode

6. Support Font A (12*24) and Font B (9*17) characters (*

7. Support NV Image Download

8. Three indicator LEDs POWER, ERROR, and Paper roll out and One Panel

button FEED

9. Three indicator LEDs POWER, ERROR, and Paper roll out and One Panel

button FEED

10. Support warning beep sound

11. Support dip switch to select Chinese / ASCII mode

12. Support printer server printing

13. Support 4800, 9600, 19200, 38400bps baud rate

14. Support print with 90 rotation *

Note (*) items are the functions that will affect printing speed

o

o

-3-

Page 5

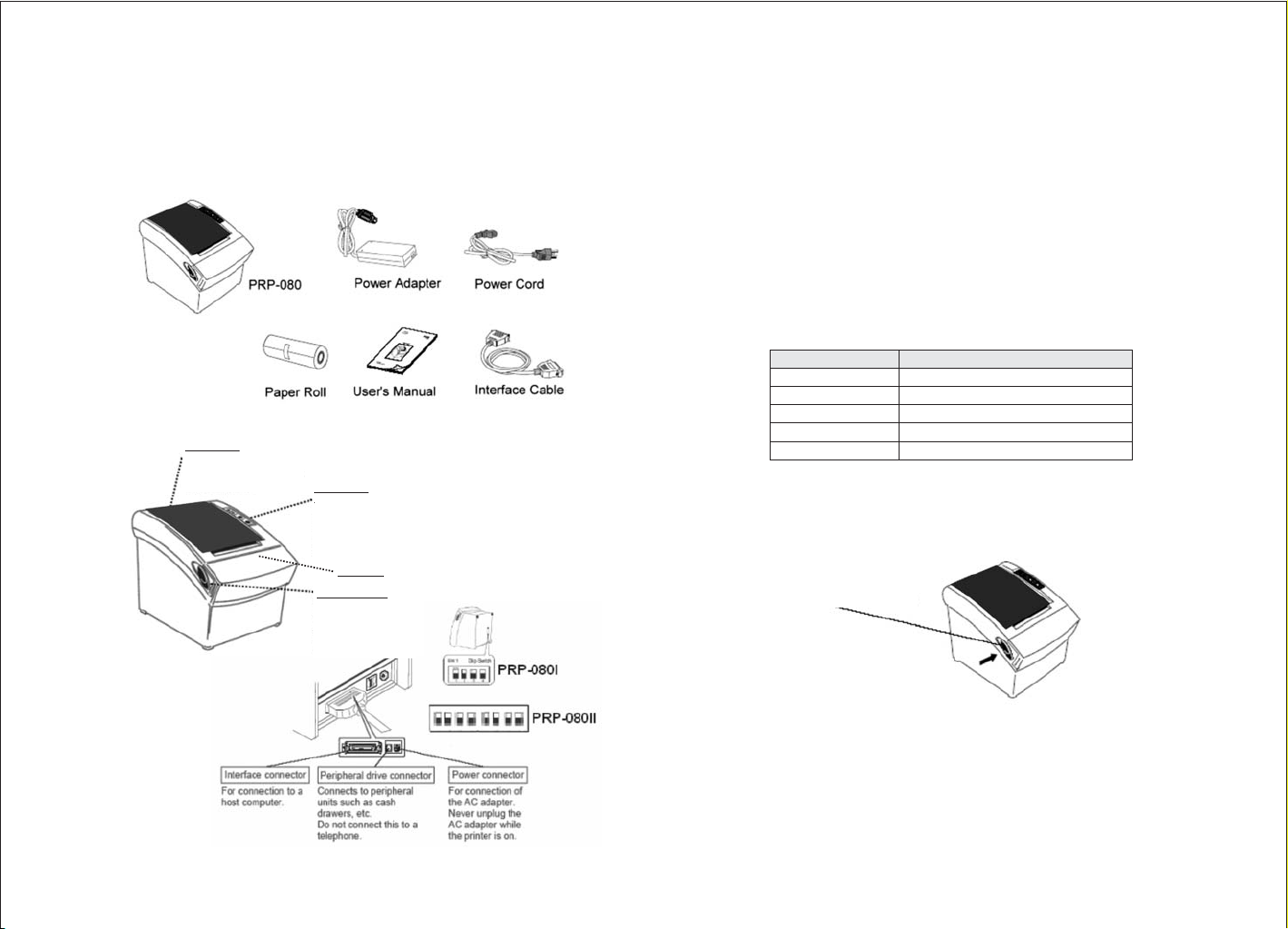

2. Quick Start

2.1) Unpacking & Parts Identification

a. Unpacking:

B. Parts Identification:

Printer cover

Open this cover to load

or replace paper.

Control panel

Features LED indicators

to indicate printer

status and buttons to

operate the printer.

Front cover

Cover Open lever

Pull this lever in the

direction of the

arrow to open the

printer cover.

2.2) Loading the Paper Roll

a. Make sure that the paper roll matches the printer's specification. Do not use

paper rolls that have the paper glued to the core because the printer cannot

detect the paper end correctly.

Important:

b. Open the paper roll cover by pressing the cover-open button

The printing quality and lifespan of the thermal head cannot be

guaranteed if any paper other than that recommended is used. Thus,

the warranty will be void automatically if any fault occurs due to

the use of wrong paper rolls.

Recommended Paper Rolls

Part Number Manufacturer

HPK-110 Hansol Patech Co. Ltd.

AF50KS-E JUJO Paper Co. Ltd.

TF-50KS-E Nippon Paper Industries Co. Ltd.

PD-160R New Oji Paper Mfg. Co. Ltd.

F380 Nansaki Specialty Papers Inc.

Cover-Open lever

-4-

mportant:

I Do not pull the cover open lever and open the printer cover when

printing is in progress.

-5-

Page 6

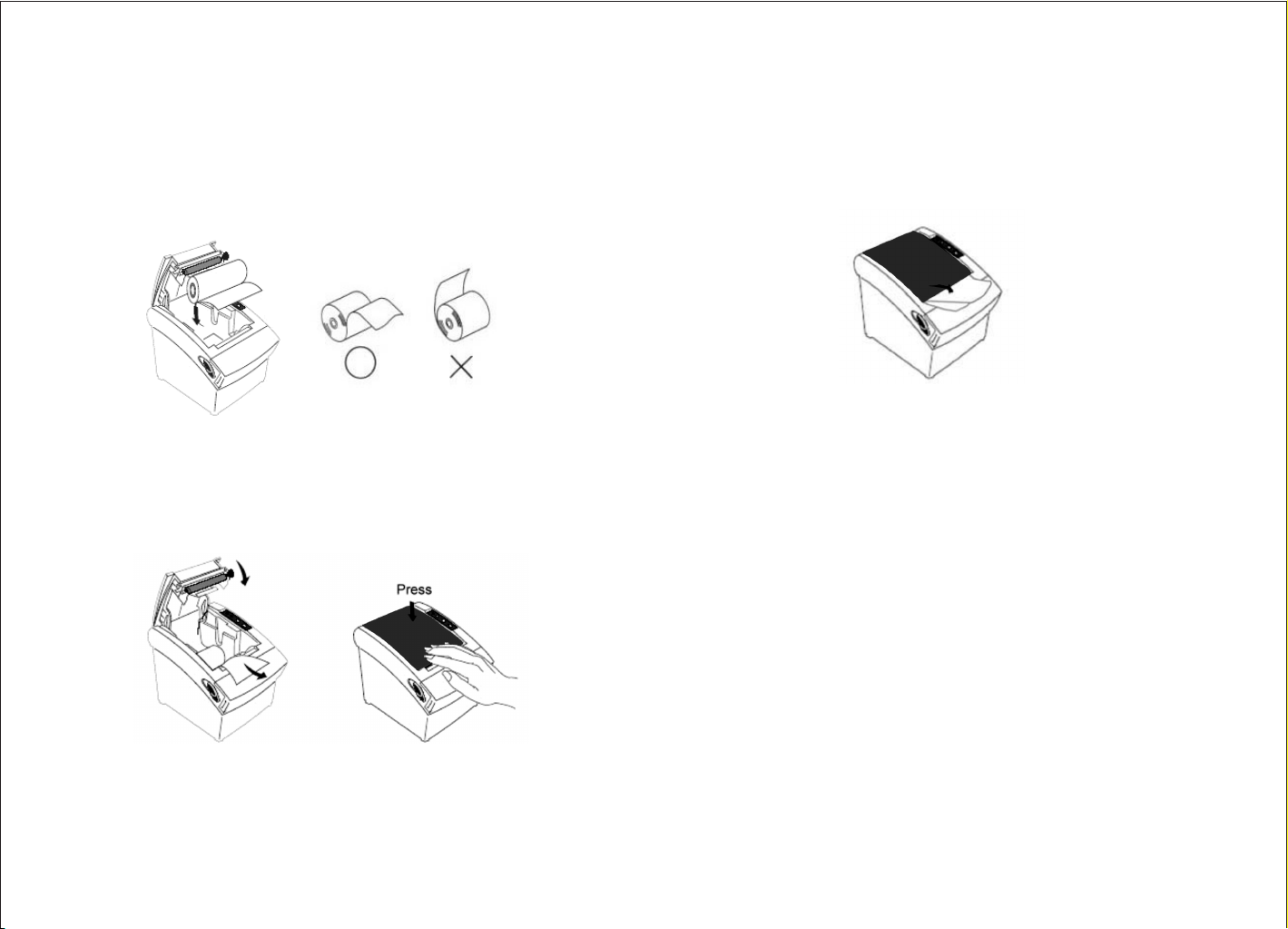

c. While observing the direction of the roll, set the paper roll into the hollow, and

pull on the leading edge of the paper toward you as shown:

d. Close the cover: When closing the cover, press the center of printer cover

firmly to prevent paper miss-loading

e. Tear off the paper outside the cover as shown.

-6-

-7-

Page 7

3. Printer Interface and Connection

3.1) Connecting the Interface Cable

a. Before connecting/disconnecting the interface cable, make sure that power

to the printer and all the devices connected to the printer is turned off.

b. Connect the interface cable to the connector on the rear panel of the printer.

c. In the case of a serial interface, tighten the connector screws. In the case of a

parallel interface, fasten the connector clasps.

Plug the cable connector securely

into the printer's interface connector.

Attach the other end of the

cable to the computer

3.2) Connecting to a Cash Drawer

3.3) Connecting the AC Adapter

a. Connect the AC power cord to the inlet of AC adapter, and then connect the

power cord plug to a suitable electrical outlet.

b. Connect the adapter cable to power connector of printer; make sure the

printer power switch is OFF before making any connections.

CAUTION:

DO NOT USE ANY AC POWER ADAPTERS OTHER THAN SPECIFIED.

c. Set the power switch as shown. The POWER lamp on the control panel will

light up.

Important:

··Make sure that the printer is turned off and unplugged from the AC outlet

and that the computer is turned off before making connections.

Do not connect a telephone line into the peripheral drive connector. Failure

to observe this may result in damage to the printer.

-8-

-9-

Page 8

4. Configuration

Printer Control Panel & Status Indication

4.1) Panel LED indicators

a. PRP-080I (Standard)

(Blue LED) The POWER light is on whenever

the printer is on.

(Red LED) This indicates printer online/offline

status or an error

(Button) Press the FEED button to feed roll paper.

(Button) Press the ONLINE button to set printer

ONLINE/OFFLINE

Printer Status (Red LED)

·

Red light ON: Indicates that the printer is online.

·

Red light OFF: Indicates that the printer is offline.

·

Red light flashes: Indicates the printer error(s) such as out of paper, paper

jammed, or printer cover is not closed properly

b. PRP-080II (Advanced)

1. Power (POWER) LED: Green

On:Power is stable

Off:Power is not stable

2. Error (ERROR) LED: Red

On: Off line (except during paper feeding using the FEED button and

test printing, and the error state.)

Off: Normal condition

3. Paper roll end (PAPER OUT) LED: Red

On: The paper roll near end is detected.

Off: Paper is loaded (Normal condition).

-10-

4.2) DIP Switch Settings

The DIP switch panel is locating at bottom of the printer as shown:

a.

PRP-080I (Standard)

DIP Switch Functions:

Switch Function ON OFF Default

1 Baud Rate (*) 38400 19200 OFF

2 Auto Cutter No Yes OFF

3 Color Deepness Deeper Normal OFF

4 Beep Yes No OFF

b.

PRP-080II (Advanced)

DIP Switch Functions:

Switch Function ON OFF Default

SW-1 Select cutter No Yes OFF

SW-2 Select beeper Yes No OFF

SW-3 Print density Dark Light OFF

SW-4 Two-byte character code No Yes OFF

SW-5 Reserve OFF

SW-6 Reserve OFF

SW-7 Select Baud rate OFF

SW-8 Select Baud rate OFF

SW-7 SW-8 Baudrate(bps)

ON ON 38400

OFF ON 4800

ON OFF 9600

OFF OFF 19200

Note:

Before configure the DIP switch settings, please first turn the printer

power off and remove the paper roll.

(*) Baud Rate is only available for serial interface models.

-11-

Page 9

4.3) Printer Self Test

This is to test whether the printer is working properly or not and also checks the

printing quality, firmware version, and DIP switch settings

1. Hold the ONLINE (*) button first and then turn on the power at the same

time, release the button after around 1 second.

2. If the printer is working properly, it should then automatically print the self-

testing result that indicating the firmware version number, printer connection

type, English alphanumeric characters, and few Taiwan fonts.

3. The test print will be ended with the following message:

*** COMPLETED ***

(*) For PRP-080II, please press FEED button. The above procedure does

Note:

not test parallel or serial ports. Please use communication utility such as

Windows HyperTerminal to test the printer connection.

4.4) Driver Installation

1. To install the PRP-080 (*) driver, please insert the bundled CD disk into the

CD-ROM drive.

2. In the CD-Rom menu, please go to Receipt Printer > PRP-080 and double

click the setupEN 4.0.exe file to begin the driver installation process and

follow the installation instructions.

3. Please choose the OS that matches with your computer system and press

Next.

4. Please select PRP-080 Series for Install Module. For Printer Port Setting, if

you are connecting the printer to PC COM ports via RS-232 connection, the

FlowControl must be set to Hardware. Press Finish when you done all the

setting to end installation.

-12-

-13-

Page 10

5. Safety and Maintenance

5.1) Safety Information

1. Do not touch the HEAD of printer with anything.

2. Do not touch the cutter blade.

3. Only use the power supply that is come along with the printer.

4. Do not bend the power cord excessively or place any heavy objects onto it.

5. When connecting or disconnecting the plug, always hold the plug- not the

cord.

6. Keep the desiccant out of children's reach.

7. Use only approved accessories and do not try to disassemble, repair or

remodel it for yourself.

8. Do not let water or other foreign objects in the printer.

9. Install the printer on the stable surface. -Choose a firm, level surface where

the printer will not be exposed to vibration.

10. Do not use the printer when it is out of order. This can cause a fire or an

electrocution.

11. Do not connect a telephone line into the peripheral drive connector.

12. We recommend that you unplug the printer from the power outlet whenever

you do not plan to use it for long periods.

5.2) Periodical Cleaning

Printed characters may become partially unclear due to accumulated paper dust

and dirt. To prevent such a problem, paper dust collected in the paper holder

and paper transport section and on the surface of the thermal head must be

removed periodically. Such cleaning is recommended to be carried out once six

month or one million lines.

a. Cleaning the Thermal Head

To remove blackish dust collected on the surface of the thermal head, wipe it

with Isopropyl alcohol (IPA).

Note: The thermal head is easy to damage, so clean it gently with a soft cloth.

Take sufficient care not to scratch it when cleaning it.

5.4) Fixing Paper Jam

The Status LED (Red) on the printer control panel will flash with beeps if paper

is jammed. Please follow the below instruction to remove paper jam.

a. Switch the printer power off.

b. Open the printer cover by pushing the

Cover-Open button.

c. If the printer cover opens, removed the

jammed paper gently

touch the printer head.)

the paper roll.

If the printer cover will not open

d. , please restart the printer by switching

power off/on, and try again, if the cover is still unable to open please follow

the instructions below:

1. Set the printer power OFF

2. Slide off the front cover to reveal

the auto cutter

3. Roll the little gear as shown until

the warning beeps is stopped.

CAUTION:

Since working on the cutter may be dangerous, be sure to turn off the printer

first.

Note:

Do not apply extreme force to open the front cover to prevent damages to the

cutter. If the front cover will not open properly, please contact your dealer.

e. Return the cutter to its home-position and release or clean out the jammed

paper in inside the front cover. Open the top cover, and then reinstall paper

roll.

(take care not to

And reinstall

b. Cleaning the Paper Holder

Use a soft cloth to remove paper dust from the paper holder and paper

transport section.

5.3) Preventing Paper Jams

The paper should not be touched during printing. Shift the paper during paper

ejection may cause a feed failure or paper jam.

-14-

(Reinstall Paper Poll) (Tear off the paper as shown)

-15-

Page 11

6. Appendix

1. Product Specifications

1.1) Printing Specifications

1. Printing method: Thermal line printing

2. Dot density: 203 dpi 203 dpi.

3. Printing direction: Unidirectional with friction feed

4. Printing width: 72 mm (2.83"), 576 dot positions

5. Characters per line (default): Font A: 48, English Font B: 24, Chinese

6. Character spacing (default): Font A: 0.25 mm (.01") (2 dots)

7. Printing speed:

8. High speed mode: 160 mm/second, maximum (at 24V, 20C

(68F), Density level 2. Speeds are switched

automatically depending on the voltage

applied to the printer and head

temperature conditions.)

NOTE: There may be variations in printing after switching the mode of the

printing speed. To prevent this for logo printing with ESC command,

using a downloaded bit image is recommended. Change in printing

speed does not occur during down loaded bit image printing. Printing

speed may be slower depending on the data transmission speed and

the combination of control commands. Low transmission speed may

cause intermittent printing. It is recommended to transmit data to the

printer as quickly as possible.

1.2) Auto Cutter

1. Partial cut: Cutting with one point left uncut

NOTE: To prevent dot displacement, after cutting, paper must be fed

approximately 1 mm (14/360 inches) or more before printing.

1.3) Paper Roll Supply Device

1.4) Paper Specification

1. Paper type: Specified thermal paper

2. Form: Paper roll

3. Paper width: 79.5 0.5 mm (3.13" 0.02")

4. Paper roll size: Roll diameter: Maximum 83 mm

5. Specified paper: Specified thermal roll paper;

6. Paper roll spool diameter: Inside: 12 mm (.47")

NOTE:

Paper must not be pasted to the paper roll spool.

NTP080-80

Original paper: PD 160R

(Oji Paper Mfg. Co. Ltd.)

Original paper: AF50KS-E

(Jujo Thermal Oy (Finland))

Original paper: P350 (F380), P310, P300

Outside: 18 mm (.71")

1.5) Internal Buffer

1. Receive buffer useable 20K bytes.

2. User-defined buffer (both for user-defined characters and user-defined bit

images): 12K bytes

1.6) Electrical Characteristics

1. Supply voltage: +24 VDC 8% (optional power supply)

2. Current consumption (at 24V): High speed mode:

Mean: Approximately 1.8A(Character font

A -N, capital letters, 36-character rolling

pattern, 42 columns printing)

Peak: Approximately 8A

Low power consumption mode:

Mean: Approximately 1.2A

Peak: Approximately 6.6 A Standby:

Mean: Approximately 0.2A

1. Supply method: Drop-in paper roll

-16-

NOTE:

Maximum 1A for drawer kick-out driving.

-17-

Page 12

1.7) Reliability

1. Life Span: Mechanism: 15,000,000 lines

Thermal head: 100 million pulses, 100 Km

Auto cutter: 1,500,000 cuts

(End of life span is defined to have reached

the end of its life when it reaches the

beginning of the Wear out Period.)

2. MTBF: 360,000 hours

(Failure is defined as Random Failure

occurring at the time of the Random Failure

Period.)

3. MCBF: 52,000,000 lines

(This is an average failure interval based on

failures relating to wear out and random

failures up to the life of 15 million lines.)

1.8) Environmental Conditions

1. Temperature: Operating: 5 to 45C (41 to 113F)

Storage: -10 to 50C (14 to 122F)

(except paper)

2. Humidity: Operating: 10 to 90% RH

Storage: 10 to 90% RH (except for paper)

NOTE: If the printer is not used for a long time with paper installed, some part

of the printing may be light due to the deformation of the paper. If the

printer is not used for a long time with paper installed, be sure to feed

paper approximately 30 mm before printing

3. Acoustic noise (Operating): When using auto cutter Approximately 50

dB (Bystander position) When not using

auto cutter: Approximately 40 dB

(Bystander position)

2. CONFIGURATION

2.1) Interface

a. RS-232 serial interface

a.1) RS-232 Specifications

1. Data transmission: Serial

2. Synchronization: Asynchronous

3. Handshaking: DTR/DSR or XON/XOFF control

4. Signal levels: MARK = -3 to -15 V: Logic "1"/ OFF

5. Baud rate: 4800, 9600, 19200, 38400 bps

6. Data word length: 8 bits

7. Parity Settings: None

8. Stop bits: 1 or more

9. Connector (printer side): Female DSUB-25 pin connector

NOTE:

The data word length, baud rate, and parity depend on the DIP switch

settings.

The stop bit for the printer side is fixed to 1.

a.2) Serial interface connection example

Printer Side DB-25 POS RS-232 Connection DB9

SPACE = +3 to +15 V: Logic "0"/ ON

1.9) Installation

The PRP-080P series printer must be installed horizontally. (Vibration during

paper cutting and using a drawer should be considered. Take measures to

prevent the printer from moving. Affixing tapes are provided as an option.) An

optional hanging bracket can attach the printer to a wall. (Following the

procedures describes in the installation manual, install the wall mount and

change the location of the paper roll near-end sensor, then install the paper roll

stopper and other parts.)

-18-

NOTE:

Set the handshaking so that the transmit data can be received.

Transmit data to the printer after turning on the power and initializing

the printer.

-19-

Page 13

1.nterface connector terminal assignments and signal functions

b.2) Parallel Interface Pin Assignments for Each Mode

Pin number Signal name Signal Source Description

2 TXD Printer When using XON/XOFF

handshake protocol, printer

transmits control code XON/XOFF

3 RXD Host Printer receives data from host

4 RTS Printer Indicates printer current status,

whether the printer is Busy or

Ready to receive data

7 GND Signal ground

20 DTR Printer Same as RTS (pin 4)

b. IEEE 1284 Bidirectional Parallel Interface(Parallel Interface

Specifications)

b.1) Parallel Specifications

1. Data transmission: Parallel

2. Synchronization: Externally supplied nStrobe signals

3. Handshaking: nAck and Busy signals

4. Signal levels: TTL compatible

5. Data word length: 8 bits

6. Connector (printer side): 36 pins Centronics connector

Pin Mode Source

1 /STB Host The computer presents the data on the

data lines, and pulses STB

2 DATA0 Host Indicates the 1st data bit through 8th

data bit

3 DATA1 Host

4 DATA2 Host

5 DATA3 Host

6 DATA4 Host

7 DATA5 Host

8 DATA6 Host

9 DATA7 Host

10 nAck Printer Printer acknowledge signal which

indicates that printer has received

previous data bit

11 BUSY Printer Printer is busy and cannot receive

data

12 GND Ground

13 Select Printer High electric potential

14 15 NC No Connect

16 17 GND Ground

18 Logic-H Printer High electric potential

19 30 GND Ground

31 NC No Connect

32 Nerror Printer Printer Error Signal

(nFault)

33 GND Ground

34 36 NC No Connect

-20-

-21-

Page 14

2.2) Connectors

a. Interface Connectors

Refer to Interface explain.

b. Power Supply Connector

This connector is used to connect the printer to an external power source.

Power Supply Connector Pin Assignments

Pin Number Signal Name

1 +24 VDC

2 GND

3NC

Shell Frame GND

c. Drawer Kick-out Connector (Modular Connector)

The pulse specified by ESC p or DLE DC4 is output to this connector. The

host can confirm the status of the input signal by using the DLE EOT, GS a,

or GS r commands.

1. Pin assignments: Refer to Table

2. Connector model: Printer side: MOLEX 52065-6615 or

RJ11 telephone jack

User side: 6-position 6-contact

(RJ11 telephone jack)

Drawer Kick-out Connector Pin Assignments

Pin Number Signal Name Direction

1NC

2 Frame GND Output

3NC

4 Drawer kick-out drive signal Output

5NC

6NC

3. Drawer kick-out drive signal

Output signal: Output voltage: Approximately 24 V

Output current: 1A or less

-22-

-23-

Page 15

General Printer Commands

Command Lists:

Command Code Description Function Description

(Hex)

HT 09 Horizontal tab

LF 0A Print and line feed

CR 0D Print and carriage return

ESC SP n 1B 20 n 0 n 255 Set right-side character spacing

ESC ! n 1B 21 n 0 n 255 Select print mode(s)

ESC$nLnH 1B24nLnH

ESC % n 1B 25 n Select/cancel user-defined

ESC&yc1c2 1B26yc1c2

ESC*mnLnHd1 dk 1B2AmnLnHd1 dk Select bit-image mode

ESC n 1B 2D n Turn underline mode on/off

ESC 2 1B 32 Select default line spacing

ESC 3 n 1B 33 n 0 n 255 Set line spacing

ESC ? n 1B 3F n 32 n 126 Cancel user-defined characters

ESC @ 1B 40 Initialize printer

ESC D n1 nk NUL 1B 44 n1 nk 00 Set horizontal tab positions

ESC G n 1B 47 n 0 n 255 Turn on/off double-strike mode

ESC J n 1B 4A n 0 n 255 Print and feed paper

ESC\nLnH 1B5CnLnH

ESCc5n 1B6335n

ESC d n 1B 64 n 0 n 255 Print and feed n lines

ESCpmt1t2 1B70mt1t2

0 nL 255

0 nH 255

0 n 255 character set

y=3 32 c1 c2 126

m=0,1,32,33

0 nH 3 0 d 255

0n248n50

1 n 255 0 k 32

0 nL 255

0 nH 255

0 n 255

m=0,1,48,49

0 t1 255 0 t2 255

0 nL 255

Set absolute print position

Define user-defined characters

Set relative print position

Enable/disable panel buttons

Generate pulse

Command Code Description Function Description

(Hex)

GS*xyd1 d(x y 8) 1D2Axyd1(x y 8) Define downloaded bit image

GS / m 1D 2F m

GSLnLnH 1D4CnLnH

GSWnLnH 1D57nLnH

ESC E n 1B 45 n 0 n 255 Turn emphasized mode on/off

ESC R n 1B 52 n 0 n 13 Select an international

ESC a n 1B 61 n

ESC t n 1B 74 n 0 n 7 n=19 Select character code table

ESC { n 1B 7B n 0 n 255 Turns on/off upside-down

GS H n 1D 48 n

(1) GS V m 1D 56 m m=0,1,49 Select cut mode and cut paper

(2) GS V m n 1D 56 m n m=66

GS h n 1D 68 n 1 n 255 Select bar code height

(1)GSkmd1 dkNUL1D6Bmd1 dk00 Print bar code

(2)GSkmnd1 dn 1D6Bmnd1 dn

GSv0mxLxHyLyH 1D7630mxLxHyL Print raster bit image

d1 dk yH d1 dk

GS w n 1D 77 n 2 n 6 Set bar code width

1 x 255 1 y 48

x y 1536 0 d 255

0m348m51

0 nL 255

0 nH 255

0 nL 255

0 nH 255

0n248n50

0 n 3 48 n 51 for HRI characters

0 n 255

0m6

65 m 73

0m348m51

0 xL 255 0 xH 255

0 yL 255 0 d 255

k=(xL+xH 256) (yL+yH

256)

Print downloaded bit image

Set left margin

Set printing area width

character set

Select justification

printing mode

Select printing position

-24-

-25-

Page 16

PRP-080I & II COMMANDS COMPARISON

Command Name PRP-080I PRP-080II

HT Horizontal tab * *

LF Print and line feed * *

FF Print and return to standard *

CR Print and carriage return * *

CAN Cancel print data in page mode *

DLE EOT n Real-time status transmission *

DLE ENQ n Real-time request to printer *

DLE DC4 n m t Generate pulse at real-time *

ESC FF Print data in page mode *

ESC SP n Set right-side character spacing *

ESC ! N Select print mode(s) *

ESC $ nL nH Set absolute print position *

ESC % n Select/cancel user-defined character set * *

ESC & y c1 c2 Define user-defined characters * *

ESC & y c1 c2 [x1 d1 d(y X x1)] [xk d1 d(y X xk)] * *

ESC * m nL nH Select bit-image mode * *

D1 dk

ESC - n Turn underline mode on/off * *

ESC 2 Select default line spacing * *

ESC 3 n Set line spacing * *

ESC = n Set peripheral device * *

ESC ? N Cancel user-defined characters * *

ESC @ Initialize printer * *

ESC D n1 Set horizontal tab positions * *

nk Annual

ESC E n Turn emphasized mode on/off * *

ESC G n Turn double-strike mode on/off * *

ESC J n Print and feed paper * *

ESC L Select page mode *

ESC M n Select character font *

ESC S Select standard mode *

ESC T n Select print direction in page mode *

ESC V n Turn 90 clockwise rotation mode on/off *

ESC W xL xH Set printing area in page mode ESC *

yL yH dxL dxH W xL xH yL yH dxL dxH dyL dyH *

dyL dyH

ESC \ nL nH Set relative print position * *

ESC a n Select justification * *

ESCc5n Enable/disable panel buttons * *

ESC d n Print and feed n lines * *

mode in page mode

o

(Standard) (Advanced)

Command Name PRP-080I PRP-080II

(Standard) (Advanced)

ESC p m t1 t2 General pulse * *

ESC { n Turns on/off upside-down printing mode * *

FSpnm Print NV bit image *

GS ! N Select character size *

GS # n Define NV bit image number *

GS $ nL nH Set absolute vertical print position *

in page mode

GS*xyd1 Define downloaded bit image * *

d(xXyX8) GS*xyd1 d(xXyX8)

GS / m Print downloaded bit image * *

GS : Start/end macro definition *

GS B n Turn white/black reverse printing mode *

GS H n Select printing position for HRI characters *

GS L nL nH Set left margin * *

GS P x y Set horizontal and vertical motion units *

GS V m / Select cut mode and cut paper * *

GS V m n

GS W nL nH Set printing area width * *

GS \ nL nH Set relative vertical print position *

in page mode

GS^rtm Execute macro *

GS f n Select font for HRI characters *

GS h n Select barcode height *

GS r n Transmit status *

GSv0mxLxH Print raster bit image *

yLyHd1 dk GSv0mxLxHyLyHd1 dk

GS w n Set barcode width *

FS ! n Set print mode(s) for Kanji characters * *

FS & Select Kanji character mode *

FS n Turn underline mode on/off for * *

Kanji characters

FS . Cancel Kanji character mode *

FS 2 c1 c2 Define user-defined Kanji characters * *

D1 dk FS2c1c2d1 dk

FS S n1 n2 Set left- and right-side Kanji * *

character spacing

FS W n Turn quadruple-size mode on/off for * *

Kanji characters

Command classification

Executing: Printer executes the command, which does not then affect the following data.

Setting: Printer uses flags to make settings, and those settings affect the following data.

-26-

-27-

Page 17

Command classification

Executing: Printer executes the command, which does not then affect

Setting: Printer use flags to make setting and those setting affect the

Note:

Commands for International Fonts

ESCRn Select an International Character Set Format

ASC ESC R n

the following data.

Hex 1B 52 n

Range 0 n 13

Description Selects an international character set n from the

Default n=0

Decimal 27 82 n

<<

following table:

N Character set

0 U.S.A.

1 Franch

2 Germany

3 U.K.

4 Denmark

5 Sweden

6 Italy

7 Spain

8 Japan

9 Norway

10 Denmark

11 Spain

12 Latin America

13 Korea

ESCtn Select character code table

Format ASC ESC t n

Range

Description Selects a page n from the character code table:

n Page Comment

0 Pc437:

1 Katakana

2 PC850 [Multilingual]

3 PC860 [Portuguese]

4 PC863 [Canadian-French]

5 PC865 [Nordic]

6 West Europe

7 Greek

8 Hebrew

9 PC755 [Latvian/East Europe]

10 Iran

16 WPC1252

17 PC866 [Cyrillic#2]

18 PC852 [Latin2]

19 PC858

Default n=0

Hex 1B 74 n

Decimal 27 116 n

0 <= n < =10, 16<= n < =19,

[USA, Standard Europe]

[Japanese]

Big 5 Chinese Optional

GB Chinese Optional

Korean

Japanese Kanji (JIS)

Optional

Optional

-28-

-29-

Page 18

Character code can also be selected by utility program.

1. To install the PRP-080 Default Code Page Setting utility, please insert the

bundled CD disk into the CD-ROM drive.

2. In the CD-Rom menu, please go to Receipt Printer > PRP-080 > Code Page

and double click the setup.exe file to begin the installation process and

follow the installation instructions.

3. After installation is done, go to Program Files > CodePageSet >

CodePageSet to start the utility.

4. For Serial interface connection, please select the proper COM port and baud

rate which matches the current setting of the printer. For Parallel interface

connection, select the proper LPT ports.

-30-

-31-

Page 19

Optional multilingual character model supports printing with one of the

following characters:

a. B - Traditional Chinese (Big 5)

b. G - Simplify Chinese (GB)

c. K - Korean

d. J- Japanese Kanji (JIS)

To enable/disable the multilingual character code use the following

commands: (*)

FS & Select Multilingual Character Mode ON

[Format] ASCII FS &

Hex 1C 26

Decimal 28 38

[Description] Enable multilingual character mode

-----------------------------------------------------------------------

FS . Select Multilingual Character Mode OFF

[Format] ASCII FS .

Hex 1C 2E

Decimal 28 46

[Description] Disable multilingual character mode

(*)Note: This command enable/disable the specific language according to

the model (B, G, K or J)

-32-

Loading...

Loading...