Page 1

®

Digital Still Camera

EPSON PhotoPC 850Z

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However , shoul d any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademar ks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

W ARNING

The precautionary measures itemized below should a lways be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in

serious or fatal personal injury. Great caution should be

exercised in performing procedures preceded by a

WARNING heading.

CAUTION

Signals a precaution which, if ignored, could result

in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of el ectrical and mechanical operations, maintenance and repair procedures of PhotoPC 850Z. The

instructions and procedures included herein are intended for the experienced repair technicians, and close attention should be given to the

precautions on the preceding page. Chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENT

Provides adjusting procedures.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures.

APPENDIX

Provides the following addition information for reference:

- Circuit Boards Component Layout

- Exploded Diagrams

- Circuit Schematics

Page 5

Revision Status

Revision Date of Issue

A September 16, 1999 First Release

Description

Page 6

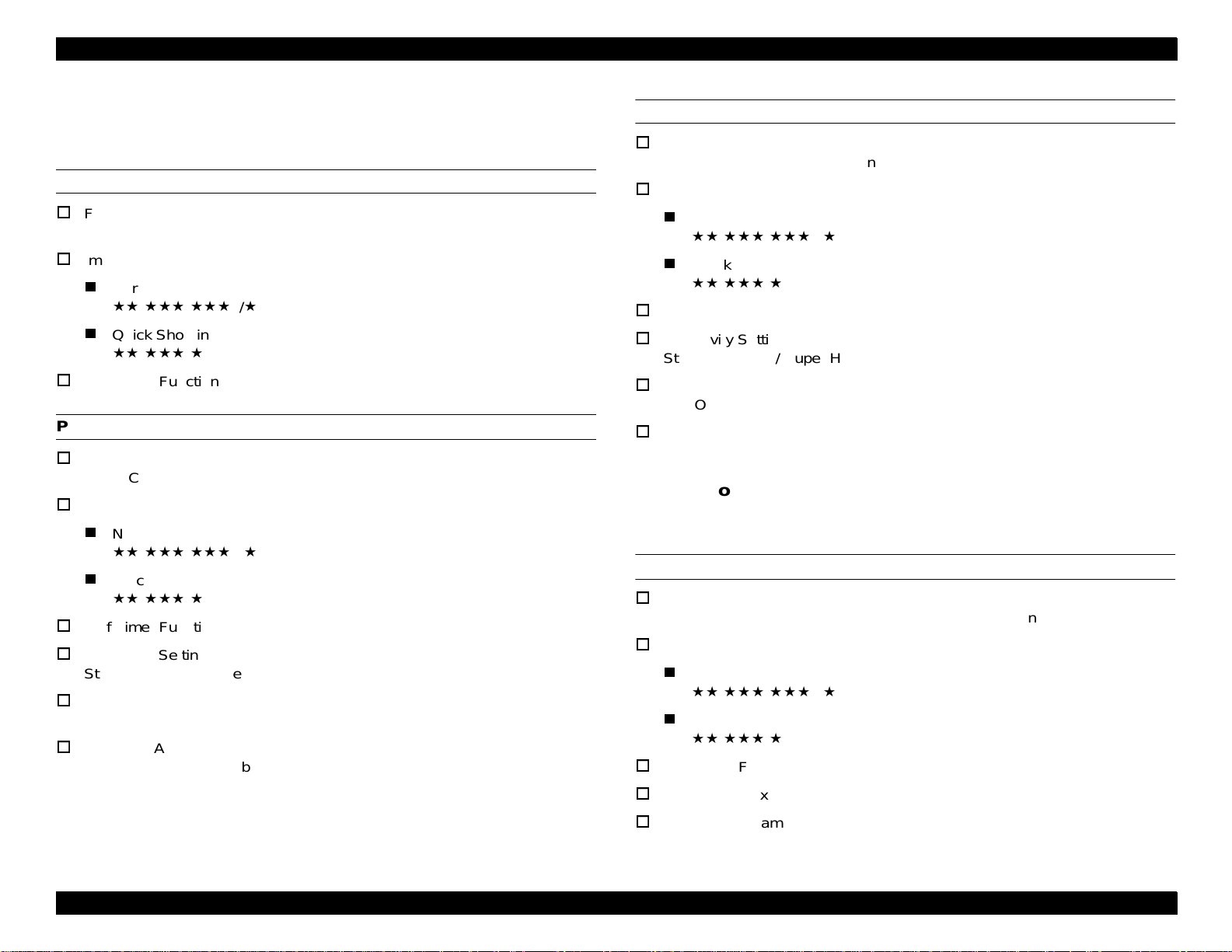

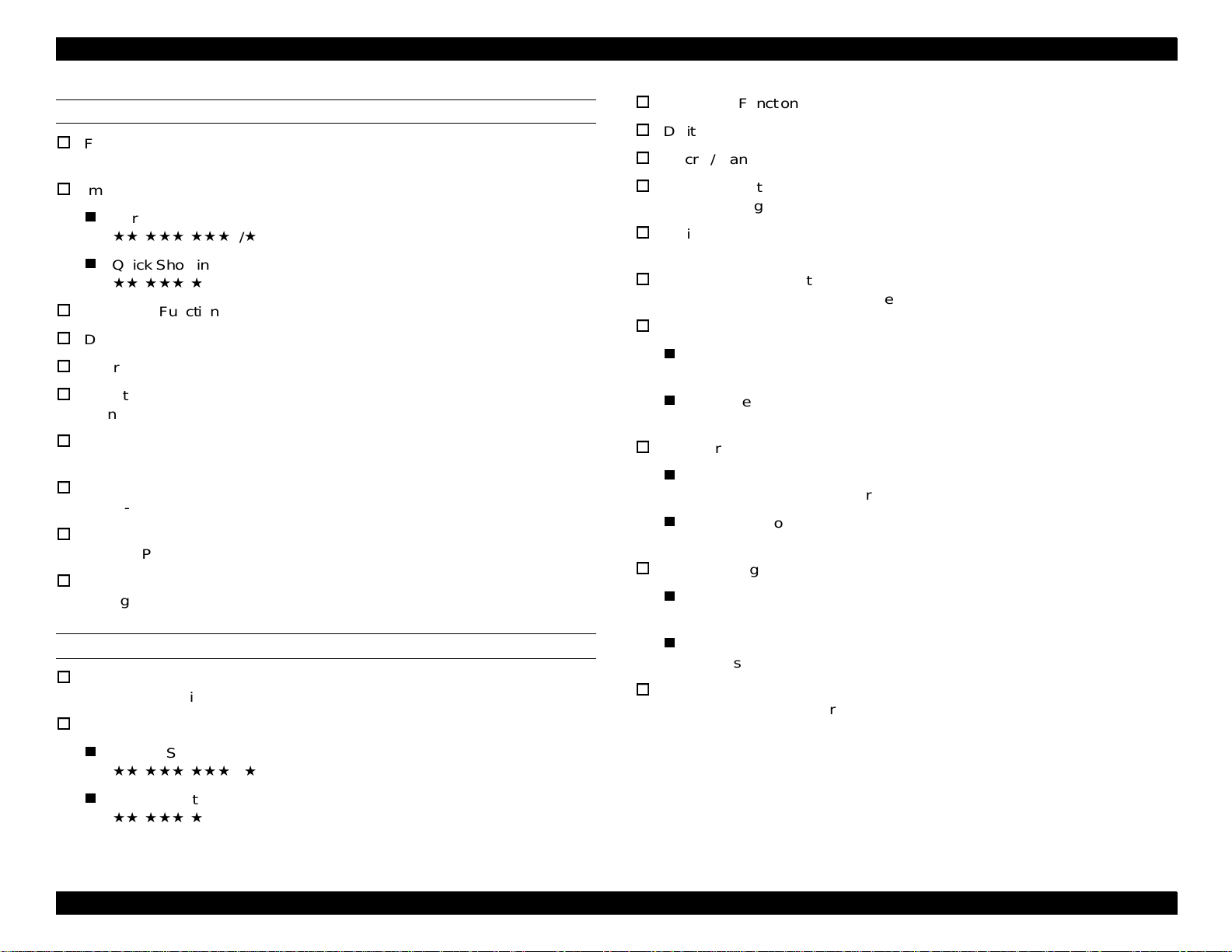

Table of Contents

Product Description

Features ....................................................................................................... 10

Product Features..................................................................................... 10

Exterior......................................................................................................... 12

Weight and Dimension ............................................................................ 12

Functional Specifications.............................................................................. 13

Images..................................................................................................... 13

Optics..................................................................................................13

Others .................................................................................................14

Shooting Mode ........................................................................................ 15

Memory ................................................................................................... 16

Users Guide Function and Others........................................................... 16

GUI Menu Operation (Summary) ............................................................ 18

SETUP Mode ........................ ...... ....... ...... ....... ...... ....... ...... ....... ...... ....18

VF Mode (LCD Monitor Off) ................................................................19

Monitor Shooting Mode......................................... ....... ...... ....... ...... .... 1 9

Confirmation Image.............................................................................21

Special Shooting Mode.......................................................................21

Playback Mode....................................................................................21

Time Required for Disposing Images...................................................... 22

File Size and the Number of Pictures...................................................... 22

File Size ..............................................................................................22

Average Number of Pictures Saved into the

External Memory...................................................................22

Interface Connectors and Others............................................................ 23

Serial Interface....................................................................................23

Power...................................................................................................... 24

Battery Life .............................................................................................. 24

Automatic Shutting Down Mode.............................................................. 25

Visual Guidance and Switch Function.......................................................... 26

Information Indicated on the Control LCD............................................... 26

Switch Function...................................................................................26

LED Condition.....................................................................................27

Control LCD ........................................................................................27

LCD Monitor.......................................................... ..............................28

Setting Items ........................................................................................... 29

Full Auto Shooting Mode.....................................................................29

Program Mode ....................................................................................30

Manual Mode ......................................................................................31

Attach Products............................................................................................ 32

Attach Cable............................................................................................ 32

DOS/V Connector Cable.....................................................................32

Macintosh Connector Cable....................... ...... ....... ............................32

USB Interface Cable ...........................................................................33

Interface Cable for Video and Audio...................................................33

Other Attached Products......................................................................... 33

Option........................................................................................................... 34

Standard Option...................................................................................... 34

Environmental Conditions ............................................................................ 35

Safety and Others ........................................................................................ 36

Inhibitions and Cautions ............................................................................... 37

Operating Principles

Overview ...................................................................................................... 39

Operating Principles of Circuit Boards ......................................................... 40

CA1 Circuit Description ........................................................................... 41

IC903 (CCD) .......................................................................................41

IC902 (H Driver) and IC904 (V Driver)................................................43

Lens Drive Block................................. ....... ...... ...................................44

CA2 Circuit Description ........................................................................... 45

Circuit Description...............................................................................45

Operation Outline................................................................................47

LCD Block........................................... ....... ...... ....... ...... ....... ...... .........47

PW1 Power Circuit Description............................................................... 48

Outline.................................................................................................48

Switching Controller (IC501)...............................................................49

Shot-Circuit Protection Circuit.............................................................49

Digital 5V and Analog System Power Output .....................................49

Digital 3.25V System Power Output....................................................49

Page 7

LCD System Power Output................................................ ....... ...... ....49

Backlight Power Supply Output...........................................................49

PW1 Strobe Circuit Description............................................................... 50

Charging Circuit ..................................................................................50

Light Emission Circuit ..... ....... ...... ....... ............................................. ....51

SY1 Circuit Description ........................................................................... 52

Configuration and Functions...............................................................52

Internal Communication Bus...............................................................54

Key Operation .....................................................................................55

Power Supply Control .........................................................................55

Troubleshooting

Overview....................................................................................................... 58

Error Indications ...................................................................................... 58

Trouble Shooting .......................................................................................... 58

Camera Has No Power ........................................................................... 58

No Shooting............................................................................................. 59

Image Cannot be Taken.......................................................................... 59

Disassembly and Assembly

Overview....................................................................................................... 61

Precautions ............................................................................................. 61

Equipment and Tools .............................................................................. 62

Diassembly and Assembly ........................................................................... 64

Removal of Cabinet Parts ....................................................................... 65

Discharging Electricity from Capacitor ................................................66

Removal of SY1 Board and Holder Battery............................................. 67

Removal of SY2 Board, LCD, and CA2 Board........................................ 68

Removal of PW1 Board and CA1 Board ................................................. 69

Assembly Procedure .................................................................................... 70

Assembly of Lens Assy........................................................................... 70

Assembly of Lens VF .............................................................................. 71

Installation of Lens Assy.......................................................................... 72

Installation of CA2 Board......................................................................... 73

Installation of LCD................................................................................... 74

Installation of Spacer Monitor..............................................................74

Installation of LCD...............................................................................75

Installation of Door Monitor.................................................................76

Installation of Microphone and SY2 Board.............................................. 77

Installation of Speaker............................................................................. 78

Installation of Holder Chassis B .............................................................. 79

Installation of Holder Battery................................................................... 80

Assembly of Cover Top........................................................................... 81

Installation of SY1 Board......................................................................... 81

Installation of Unit Dial and Cover Top.................................................... 82

Assembly of Cabinet Front...................................................................... 83

Assembly of Lens Barrier....................................................................83

Installation of Cabinet Back..................................................................... 86

Installation of Cabinet Front .................................................................... 87

Installation of Door Card ......................................................................... 88

Adjustment

Overview ...................................................................................................... 90

Adjustment Items and Order ................................................................... 90

Getting Ready for Adjustment................................................................. 90

System Requirements.........................................................................90

Installation of Calibration Software .....................................................90

Color Viewer .......................................................................................90

Connecting Camera to Computer ........................................................... 91

Adjustment ................................................................................................... 92

Initialization Operation............................................................................. 92

Positions for Measuring and Adjusting on

PW1 Board.................................................................................... 93

Preparation .........................................................................................93

IC501 Oscillation Frequency Adjustment............................................93

5.1V (A) Voltage Adjustment...............................................................93

3.25V (D) Voltage Adjustment ............................................................93

12.4V (L) Voltage Adjustment.............................................................94

7.7V (L) Voltage Adjustment...............................................................94

AWB Adjustment ..................................................................................... 95

Color Matrix Adjustment.......................................................................... 96

CCD Defect Detection Adjustment.......................................................... 96

Lens Adjustment ...... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... .............. 97

LCD Panel Adjustment [CA2 Board (Side A)] ......................................... 98

LCD H AFC Adjustment ......................................................................98

LCD RGB Offset Adjustment ..............................................................99

Page 8

LCD Gain Adjustment ........................ ...... ....... ...... ....... .......................99

LCD Blue Brightness Adjustment......................................................100

LCD Red Brightness Adjustment ......................................................100

Uploading Firmware .............................................................................. 101

Maintenance

Overview..................................................................................................... 103

Check Points ......................................................................................... 103

Appendix

Connection Among Boards......................................................................... 106

Circuit Boards Component Layout.............................................................. 108

Exploded Diagram...................................................................................... 113

Circuit Schematics...................................................................................... 116

Siemens Star Chart .................................................................................... 124

Page 9

PRODUCT DESCRIPTION

Page 10

EPSON PhotoPC 850Z Revision A

Power Saving Function:

1.1 Features

1.1.1 Product Features

HyPict Mode:

1984 x 1488 (HyPict)

1984 x 744 (Panorama HyPict)

Quick Taking Mode:

Intervals are less than 1.5 seconds.

External Memory:

Compact Flash memory card (CF card) available.

Automatic shut-down mode

(Setting time: 10 sec., 30 sec., 1 min., 3 min., and 5 min.)

Power Source:

Four Ni-MH batteries

Interface:

USB, DOS/V serial, and Mac serial

Video Output:

NTSC and PAL (different model)

Image and Sound File Format:

Exif 2.1 compatible

NOTE:

Cannot use internal ROM for image data.

Shooting Modes:

Continuous Shooting Mode, Interval Shooting Mode,

VF Shooting Mode (using the optical view finder, rear LCD-monitor off),

Monitor Shooting Mode (using the LCD-monitor), and Panorama, Macro,

and Monochrome Modes

Manual Exposure Mode:

Shutter speed setting: 4 - 1/800 (66 steps)

Aperture setting: F2.0 - and F11 (Wide), F2.8 and F11 (Tele)

Program Exposure Mode:

Sports Program: High speed shutter mode

Portrait Program:

Wide: Aperture F2.0 and shutter speed AE

Tele: Aperture F2.8 and shutter speed AE

Landscape Program: Aperture F11 and shutter speed AE

Normal Program: AE

White Balance:

User custom mode, fixed mode (5200K), and auto

Voice Annotation:

Capable of recording a voice (3 sec., 5 sec., and 10 sec.)

Playback Mode:

Slide show, play back mode, after recording, and playing voice

Recording Rule:

DCF (Design rule for camera file system)

HARDWARE FEATURES

High Resolution CCD:

2.0 Mega pixels CCD (Interline Transfer)

High Image Quality:

2.5 x VGA (1600 x 1200 pixels, 24bit color)

Full Specifications Built-in:

2-inch dual lighting source color TFT LCD monitor

(Low-temperature poly-silicon TFT-LCD)

View Finder, microphone, speaker, and hot synch flash shoe

Image Quality:

1600 x 1200 pixels (Super-Fine) low compression

1600 x 1200 pixels (Fine) high compression

640 x 480 pixels (Standard)

1600 x 600 pixels (Panorama, Super-Fine)

1600 x 600 pixels (Panorama, Fine)

640 x 240 pixels (Panorama, Standard)

Product Description Features 10

Page 11

EPSON PhotoPC 850Z Revision A

SOFTWARE FEATURES (TWAIN DRIVER, STANDALONE UTILITY)

Function Summary:

Standalone Utility / TWAIN Driver / OLE2 Server

Supported OS:

Win95 and later, WinNT 4.0 and later, and Macintosh System 7.5 and later

are supported.

NOTE:

68K Mac is not supported.

Function Details:

- Downloading pictures and voices from camera to PC

- Uploading pictures and voices from PC to camera

- Rotating images

- Auto photo fine function

- Showing thumbnail images

SOFTWARE FEATURES (DIRECT PRINTING)

Function Summary:

Image print, index print, album print, sticker print

Information (on the image) print function, auto photo fine function

(automatically applies to all images).

Printer:

EPSON STYLUS PHOTO, STYLUS PHOTO 700, STYLUS PHOTO EX,

STYLUS PHOTO 750, STYLUS COLOR 740, STYLUS PHOTO 1200

OPTIONS

AC Adapter:

EU-40 (Input: 100-240V, Output: DC7.0V, 2.0A)

Ni-MH Battery Charger:

EU-38 (Input: 100-240V)

Ni-MH Battery:

EU-24 (1500mAh)

Paper Size (T.B.D):

A3 (Glossy Film, Photo Paper, Glossy Paper, Glossy Sticker)

A4 (Glossy Film, Photo Paper, Glossy Paper, Glossy Sticker)

Post Card (Photo Paper, Glossy Paper)

A6 (Photo Paper)

Printing Functions:

Color, monochrome, sepia, and blue print

Product Description Features 11

Page 12

EPSON PhotoPC 850Z Revision A

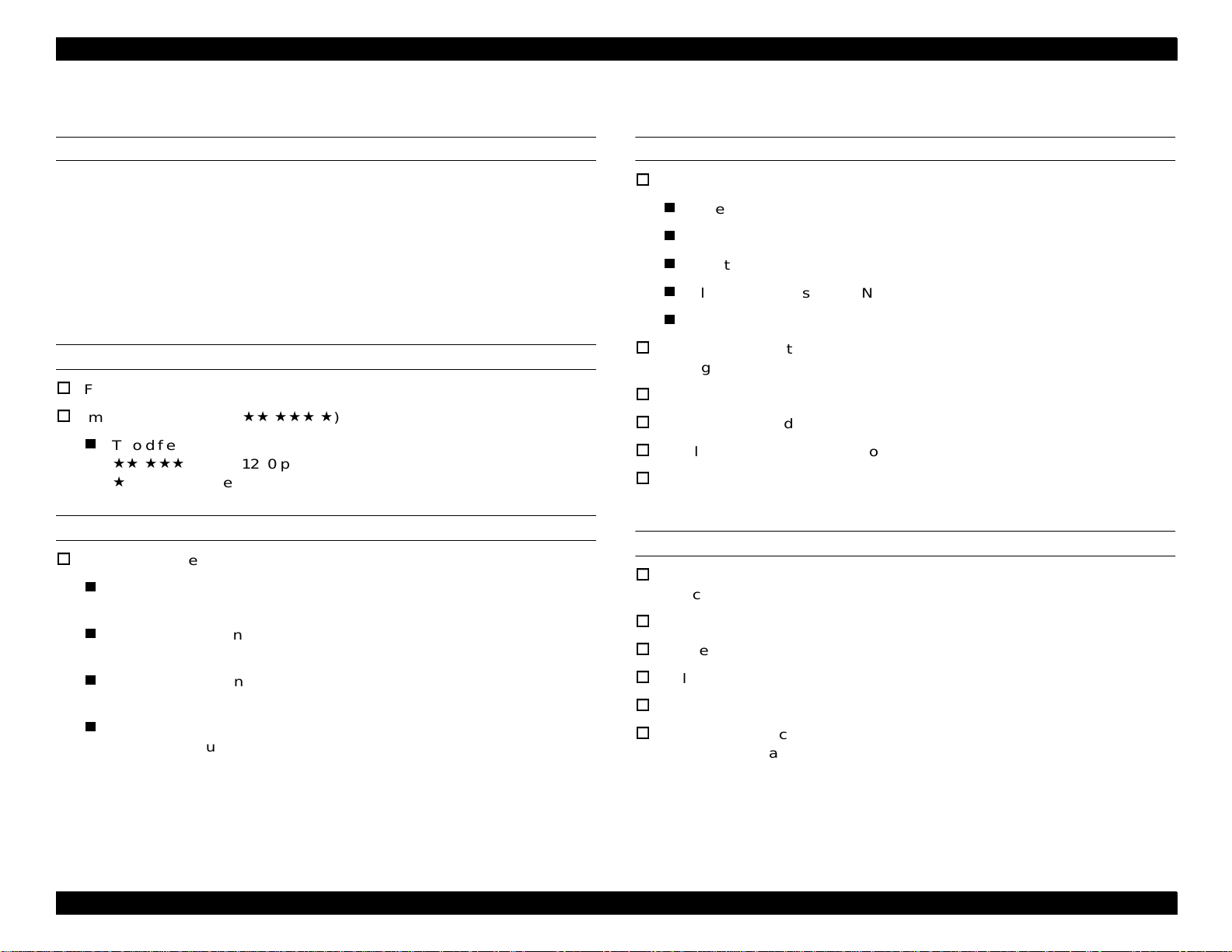

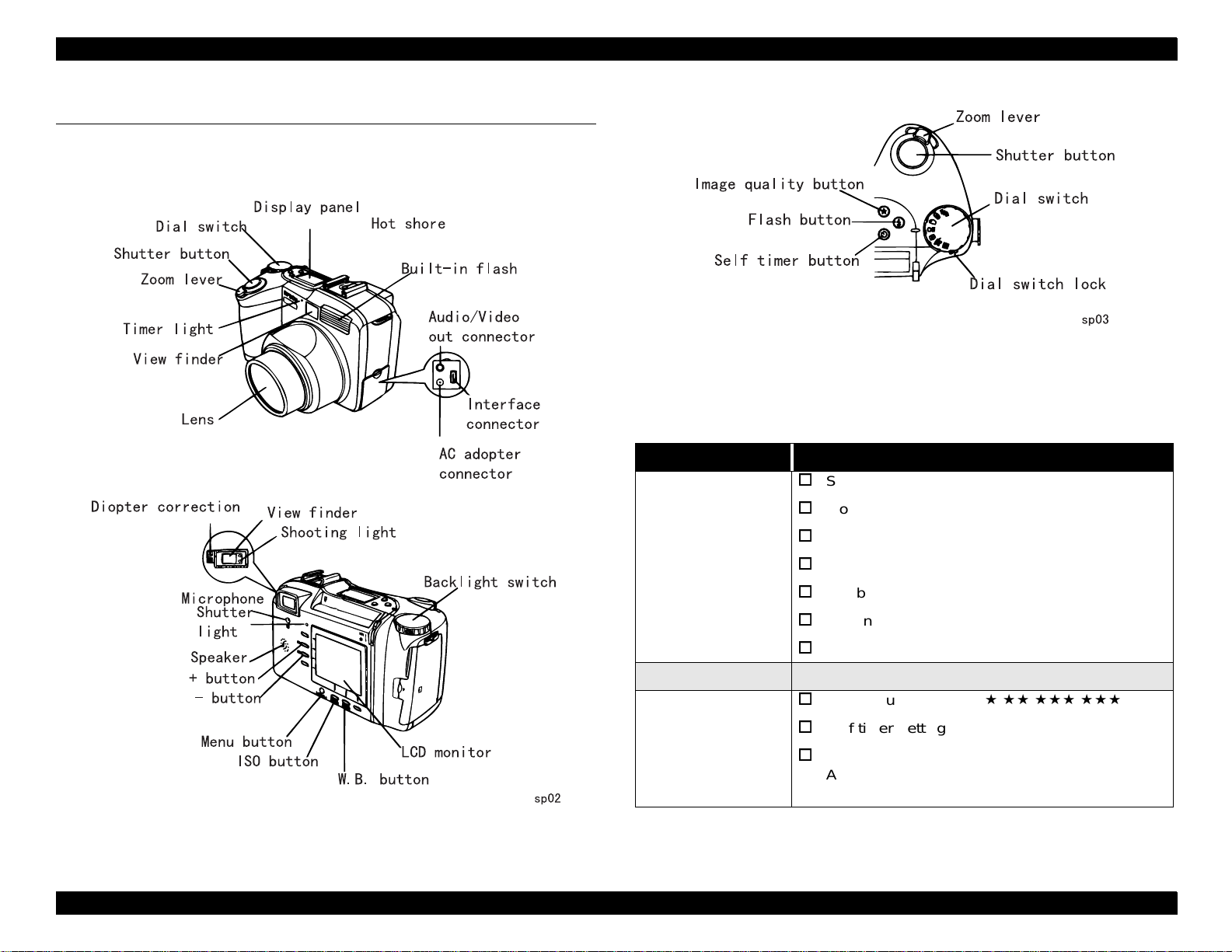

1.2 Exterior

1.2.1 Weight and Dimension

Dimension:

126 x 82 x 72 (mm)

Weight:

400g: (without batteries, strap and CF card)

Others:

Tripod mountable

EXTERNAL VIEW

Figure 1-1. External View

Product Description Exterior 12

Page 13

EPSON PhotoPC 850Z Revision A

1.3 Functional Specifications

1.3.1 Images

RECORDING RULE

DCF (Design rule for camera file system)

THUMBNAIL RESOLUTION

160 x 120 pixels

IMAGE RESOLUTION

1984 x 1488 pixels (

1984 x 744 pixels (

1600 x 1200 pixels (

1600 x 1200 pixels ( Fine)

1600 x 600 pixels (

1600 x 600 pixels ( Panorama Fine)

H

Hypict)

H

Panorama Hypict)

Super Fine)

Panorama Super Fine)

LENS

f = 6.5 -19.5mm (equivalent to 35-105mm on a camera using 35mm films)

8 elements in 6 groups construction

APERTURE

F2.0-F11 (Wide), F2.8-F11 (Tele) 1/3EV STEP

VIEW FINDER

Real image optical finder

Visual field covers more than 90% of a capturing image field

Markers indicating a target area for foreclosing

Markers indicating the picture plane of 80cm subject distance

Diopter collecting

FOCUS

Auto Focus / Manual Focus

640 x 480 pixels ( Standard)

COLOR

24 bit color or monochrome

FOCUSING RANGE

0.2 - 0.5 (m) (Macro mode)

0.5m - ∞ (Normal)

1.3.1.1 Optics

CCD

1/2” color area CCD (2.0 Mega pixels) with complementary filters.

Total pixels: 1688 x 1248 (Effective pixels: 1636 x 1236)

(Real use pixels: 1620 x 1220)

Product Description Functional Specifications 13

Page 14

EPSON PhotoPC 850Z Revision A

SHUTTER

Electronic Iris control shutter with mechanical shutter

1/30 -1/1800 sec (when Flash mode is auto or compulsion is On.)

4 - 1/800 sec (when Flash mode is Off or slow sync. is On.)

NOTE:

Automatic focusing function may not work correctly when taking

photos under bad contrast conditions or low illuminated conditions

(particularly when flash is necessary).

The automatic focusing function is programmed to set the distance

at 1.5m when it cannot measure the correct distance.

1.3.1.2 Others

METERING SYSTEM

Divided brightness measuring programmed AE

(Aperture and shutter speed are variable)

Spot metering programmed AE

(Aperture and shutter speed are variable)

EXPOSURE ADJUSTMENT

WHITE BALANCE

Through the taking lens automatic white balancing

Fixed mode (color temperature: 5200K)

Customizing mode (users’ setting available)

FLASH

Auto, prohibition, compulsion, red-eye reduction, external

Slow synchro mode (night view mode, user select trailing or leading)

FLASH EFFECTIVE RANGE

Macro mode: 0.2 m - 0.8 m

Normal mode: 0.8 m - 3.7 m

NOTE:

It causes over -exp osur e to take ph otos wi th stro be at 0.2 m subjec t

distance on macro-photographic mode.

Manual adjustment possible (-2EV ~ +2EV, 0.5EV / 0.2EV step)

AE temporary lock function

SENSITIVITY

Equivalent to ISO 100 (normal mode)

Equivalent to ISO 200 (high sensitivity mode)

Equivalent to ISO 400 (super high sensitivity mode)

Product Description Functional Specifications 14

Page 15

EPSON PhotoPC 850Z Revision A

1.3.2 Shooting Mode

LCD DISPLAY

Live picture shown on the LCD monitor (refresh rate 1/30 sec)

Visual field covers more than 98% of a capturing image field.

SELF TIMER

10 sec timer (fixed)

(Slow blinking for the first 8 sec, and fast blinking for the last 2 sec.)

MACRO

Working Range: 0.2m- 0.5m

QUICK TAKING MODE

Pictures taken are temporally saved into the DRAM in order to provide the

shortest intervals between shooting. After capturing photos, photo files are

transferred from DRAM to the Compact Flash Memory Card.

Interval time is approximately 1.5 sec.

(When taking pictures in (

) Super Fine mode without flash charge.)

DIGITAL ZOOM

Digital x2 zoom function

Available at any picture size; however, taking pictures in HyPict mode

needs longer time for processing than the others

(simple complement).

PANORAMA

Size: 1600 x 600 pixels (

/

Super Fine / Fine)

MONOCHROME

Size: 1600 x 600 pixels (

/

Super Fine / Fine)

INTERVAL SHOOTING

Minimum Interval: 10 sec. (except HyPict or voice recording setting)

Maximum Interval: 24 hours

Interval Step: 1 sec.

PROGRAM SHOOTING FUNCTION

Writing speed to the CF card is approximately 130KB/sec.

The quick taking function is available until the 8M DRAM becomes full of

photo files. (The number of image files is limited to 10.)

Sports mode, portrait mode, landscape mode, and normal mode

CONTINUOUS SHOOTING

VGA (640 x 480): Approx. 2 images/sec.

Full-pixels (/

A capacity of DRAM for continuous shooting is 4.0 MB.

Flash: Forcibly change to no flash mode.

1600 x 1200): Approx. 1 image/ sec.

Product Description Functional Specifications 15

Page 16

EPSON PhotoPC 850Z Revision A

1.3.3 Memory

INTERNAL RAM

8 MB

INTERNAL ROM

4 MB (only for program 2MB)

EXTERNAL MEMORY

Compact Flash Memory Card

PC-DOS format: 512B/Sector

12bit FAT (up to 15MB)/ 16bit FAT

1.3.4 Users Guide Function and Others

LCD MONITOR

2.0” low-temperature poly-silicon TFT color LCD

(110 thousands pixels: 512 x 218 pixels

A visual field covers more than 100% of a capturing image field.

Displaying taken pictures at playback mode, 100% of an image field will be

guaranteed.

BEEP SOUND

Always / shutter / never mode available

SELF TIMER INDICATION

First 8 seconds: slow blinking

Last 2 seconds: high speed blinking

CONTROL LCD PANEL (MONOCHROME DISPLAY)

Indicates the remaining number of images to be taken (in 3 digits).

With the Quick Taking mode ON, the panel indicates the number of images

in the internal RAM (up to 9 images).

Aperture is indicated by half-shutter.

(Only with Program or Manual mode)

Shutter speed is indicat ed by half- shu tter .

(Only with Program or Manual mode)

Indicatde exposure adjustment.

Indicated quality of image (including Monochrome and Hypict)

Product Description Functional Specifications 16

Page 17

EPSON PhotoPC 850Z Revision A

Others

White Balance

Sensitivity

Self Timer Mark

Flash Mode

Battery Warming Mark

LED LOCATED NEXT TO THE VIEW FINDER

Green (On / Blinking / Off)

Red (On / Blinking / Off)

REAR LED (CAMERA CONDITION LED)

Green (On / Blinking / Off)

BUILT-IN CLOCK

Date and time are recorded into the picture files.

Super capacitor keeps track of date and time even during the battery

replacement.

When USB connection is used, the camera does not shut down until its

battery level becomes low.

*Operation on any button is impossible once the above setting time has

passed.

When the AC adapter is connected, the camera shuts down after 15

minutes (Interval shooti ng is OK).

POWER SAVING

Automatic Shut-down Mode

(Setting Time: 10sec, 30sec, 1min, 3min, and 5min)

*Operation on any button is impossible once the above setting has passed.

(Only at shooting mode or playback mode)

In the case of Slide Show, the camera shuts down after replaying a cycle.

With Power Saving Mode Off, the camera does not shut down until its

battery level becomes low.

When connected to PC, the camera shuts down after 1 minutes.

Product Description Functional Specifications 17

Page 18

EPSON PhotoPC 850Z Revision A

1.3.5 GUI Menu Operation (Summary)

DIAL-SWITCH (D-SW)

Dial Switch has the following six functions:

SETUP Mode

VF Mode (LCD off)

Monitor Shooting Mode

Special Shooting Mode

Playback Mode

Option Mode

COMMUNICATION POSSIBLE MODE

This is an optional function mode. Communication is possible even if you forgot

to set the date.

1.3.5.1 SETUP Mode

GENERAL SETTING

CAMERA SETTING

Power Saving Function

10 sec. / 30 sec. / 1 min. / 3 min. / 5 min.

Brightness of the LCD Monitor

-3 / -2 / -1 / 0 / 1 / 2 / 3

Beep Sound

Always / Shutter / None

Voice Annotation

Off / 3 sec. / 5 sec. / 10 sec.

SHOOTING SETTING

Slow Synchro (Trailling / Leading)

Flash Setting (INT / EXT)

White Balance Setting

Color Setting (B/W)

MEMORY SETTING

Selecting a directory

Adding options

Date setting

01/01/1999, 00:00 (Y.M.D. for Japan and China; M.D.Y for others)

Select a shooting mode (Full Auto / Program / Manual)

Setting a shooting function (Normal Mode / Quick Taking Mode)

Formatting the Compact Flash Memory Card

LANGUAGE SETTING

Japanese / English / Italian / Portuguese / German / Spanish / French /

Chinese

Product Description Functional Specifications 18

Page 19

EPSON PhotoPC 850Z Revision A

1.3.5.2 VF Mode (LCD Monitor Off)

This is the shooting mode with LCD monitor off.

FULL AUTO

Flash Setting

Auto / Compulsion / Prohibition / Red-eye reduction

Image Quality Setting

Normal Shooting

//

Quick Shooting

//

Self Timer Function

PROGRAM

Flash Setting

Auto / Comp u ls io n / Pr oh ib i ti o n / Slow Synchro n iza t i on / R e d- ey e r edu ct i on

Image Quality Setting

Normal Shooting

//

Quick Shooting

//

Self Timer Function

Sensitivit y Setting

Standard / High / Super High

White Balance

AUTO / FIX / CUSTOM

Exposure Adjustment

From -2 to +2 (9 steps by 0.5 degree)

H

/

H

/

MANUAL

Flash Setting

Auto / Compulsion / Prohibition / Slow Synchronization / Red-eye reduction

Image Quality Setting

Normal Shooting

//

Quick Shooting

//

Self Timer Fu n c t io n

Sensitivity Setting

Standard / High / Super High

White Balance

AUTO / FIX / CUSTOM

Exposure Adjustment

From -2 to +2 (21 steps by 0.2 step)

H

/

1.3.5.3 Monitor Shooting Mode

This is the shotting mode with the LCD monitor on.

FULL AUTO

Flash Setting

Auto / Compulsion / Prohibition / Slow Synchronization / Red-eye reduction

Image Quality Setting

Normal Shooting

//

Quick Shooting

//

Self Timer Fu n c t io n

H

/

Digital Zoom (x2)

Macro / Panorama

Product Description Functional Specifications 19

Page 20

EPSON PhotoPC 850Z Revision A

Self Timer Fu n c t io n

PROGRAM

Flash Setting

Auto / Comp u ls io n / Pr oh ib i ti o n / Slow Synchro n iza t i on / R e d- ey e r edu ct i on

Image Quality Setting

Normal Shooting

//

Quick Shooting

//

Self Timer Function

Digital Zoom (x2)

Macro / Panorama

Sensitivit y Setting

Standard / High / Super High

White Balance

AUTO / FIX / CUSTOM

Exposure Adjustment

From -2 to +2 (9 steps by 0.5 degree)

Exposure Program

Sports / Portrait / Landscape / Normal

Simple PLAY BACK Mode

Enlargement / Delete / Multi / Sound Play

H

/

Digital Zoom (x2)

Macro / Panorama

Sensitivity Setting

Standard / High / Super High

White Balance

AUTO / FIX / CUSTOM

Exposure Adjustment

From -2 to +2 (21 steps by 0.2 degree)

Manual Exposure

Shutter Speed Settin g

64 steps

Aperture Select

F 2.0 / 2.8 / 4.0 / 5.6 / 8 / 11

Exposure Program

Shutter Priority

Shutter Speed = AE, Aperture

Aperture Priority

Shutter Speed, Aperture = AE

Focus Setting

Except Macro Mode

3 steps + AF

Macro Mode

MANUAL

Flash Setting

Auto / Comp u ls io n / Pr oh ib i ti o n / Slow Synchro n iza t i on / R e d- ey e r edu ct i on

Image Quality Setting

Normal Shooting

//

Quick Shooting

//

H

/

2 steps / AF

Metering System

Divided brightness metering / Spot metering

Product Description Functional Specifications 20

Page 21

EPSON PhotoPC 850Z Revision A

1.3.5.4 Confirmation Image

CONFIRMATION IMAGE

Immediately after shooting, users can delete an image while transferring the

image to the Compact Flash Memory Card, except for the images that are

already recorded.

1.3.5.5 Special Shooting Mode

Use the LCD setting mode to enter the special shooting mode.

“Confirmation image” and “Quick Taking” functions are not operated.

CONTINUOUS SHOOTING

Flash Setting: Prohib iti on

Image Quality Setting (/

Two different image processing speeds

/

(640 x 480 pixels): 2 images / sec.

(1600 x 1200 pixels): 1 image/ sec.

INTERVAL SHOOTING

Interval Time Setting

Except in HyPict or Voice Annotation Mode

10 sec - 24 hour: 1 sec step

HyPict or Voice Annotation Mode

20 sec - 24 hour: 1 sec step

With Micro Drive inserted

20 sec - 24 hour: 1 sec step

Others

10sec - 24 hour: 1 sec step

/

)

1.3.5.6 Playback Mode

NORMAL REPLAY

Image Information

Date

Shutter Speed

Aperture

Flash Mode: Flashing or Non-flashing

W/B Mode

Multi-screen Function

4 images / 9 images are indicated at a stretch.

Lock images

Delete images and sounds

Display the enlarged image (double in size)

After Recording

3 sec. / 5 sec. / 10 sec.

SLIDE SHOW

Slide Interval Time Setting

3 sec. / 5 sec. / 10 sec. / Manual

Pause during the Slide Show

Delete an image from Slide Show

Select / Delete slide images

Rotate images ± 90

Multi-screen Function

4 images / 9 images are indicated at a stretch.

°

Product Description Functional Specifications 21

Page 22

EPSON PhotoPC 850Z Revision A

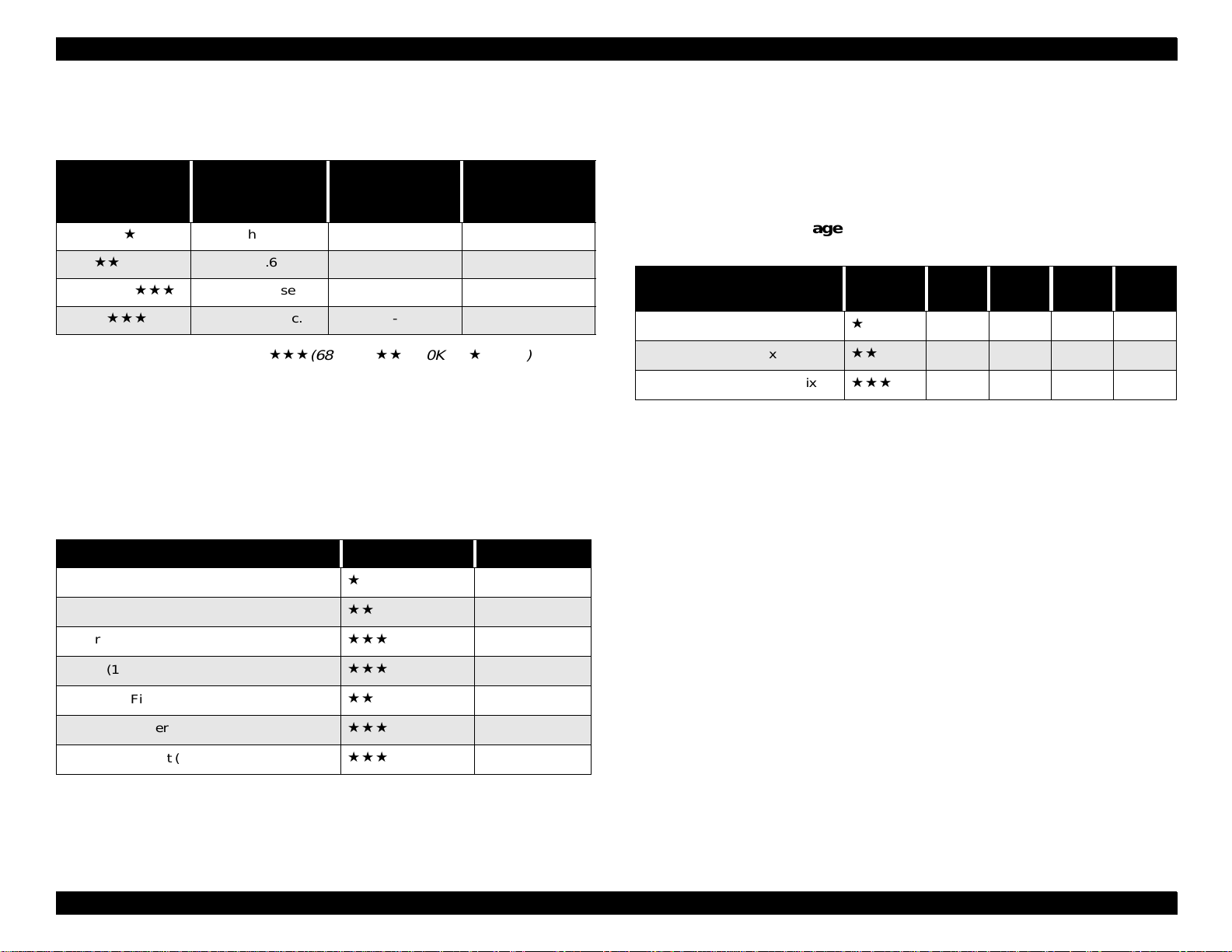

1.3.6 Time Required for Disposing Images

Table 1-1. Time Required After Shooting (T.B.D)

Image Quality

Standard

Fine

Super Fine

HyPict

NOTE:

Approximate file size:

Shooting Interval

(Normal Shooting)

Less than 2 sec About 1.0 sec Less than 0.5 sec

About 2.6 sec About 1.5 sec About 1.0 se c

About 3.2 sec About 1.5 sec About 1.5 sec

H

About 12 sec. - About 2.0 sec.

Shooting Interval

(Quick Taking

Mode)

(680KB), (340KB), (67KB)

Image Changing

Interval

(Playback Mode)

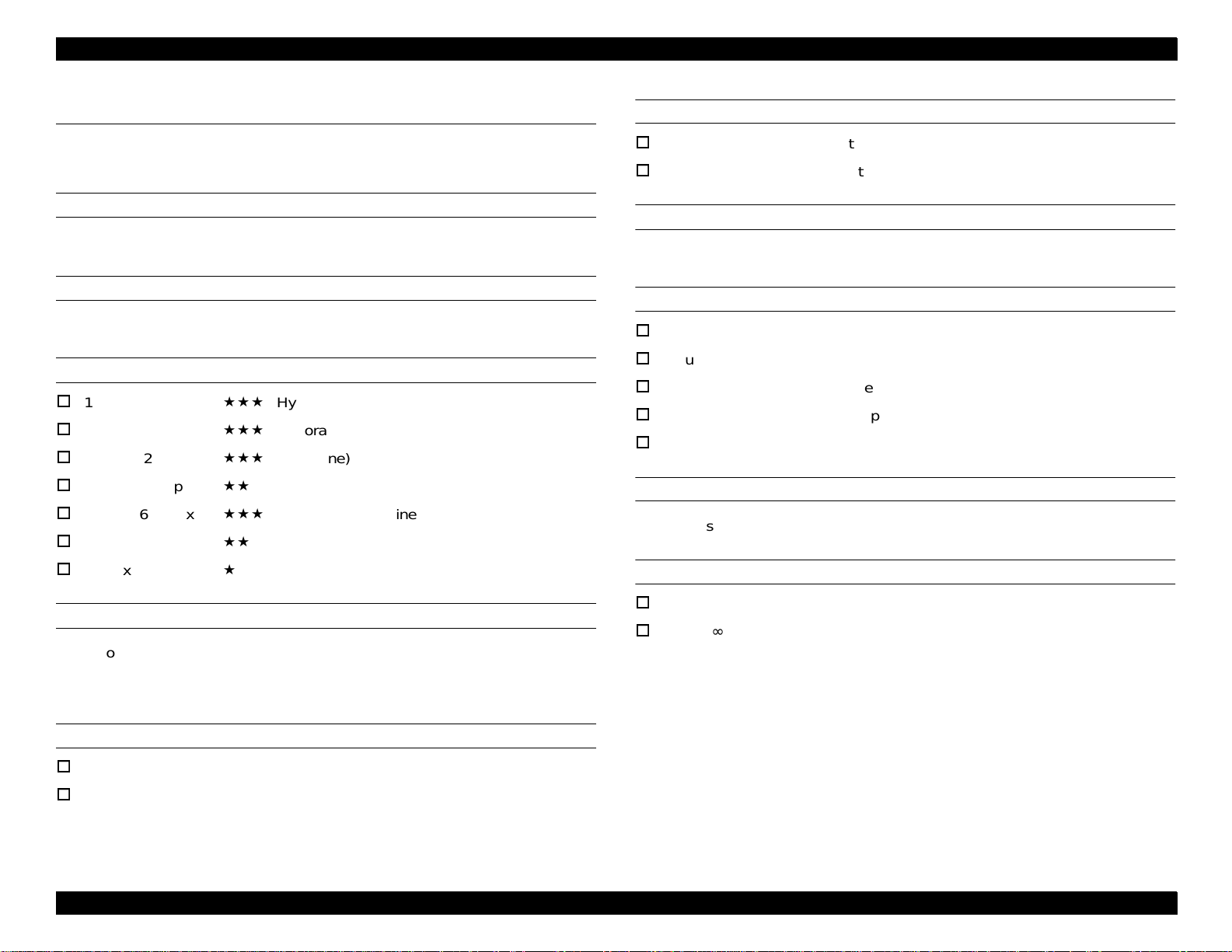

1.3.7 File Size and the Number of Pictures

1.3.7.1 File Size

A captured image file will be compressed by the JPEG method. The number of

pictures to be taken may vary depending on the complexity of the captured file.

Table 1-2. File Size (TBD)

Image Quality Indicated Marks File Size

1.3.7.2 Average Number of Pictures Saved into the

External Memory

A captured image file will be compressed by the JPEG method. The number of

pictures to be taken may vary depending on the complexity of the captured

image.

Table 1-3. Average Number of Pictures Saved into the

External Memory (Reference Value) T.B.D.

Image Quality

Standard (640 x 480 pixels)

Fine (1600 x 1200 pixels)

Super Fine (1600 x 1 200 p ix els )

Note 1: The number of images that can be taken depends on our measurement

conditions on the assumption that no other files is in an external

memory.

Note 2: A maximum number of images that can be stored in one flash memory

is 999.

Indicated

Marks

8MB 15MB 26MB 24MB

120 250 333 400

24 49 65 78

12 24 32 39

Standard (640 x 480 pixels)

Fine (1600 x 1200 pixels)

Super Fine (1600 x 1200 pixels)

HyPict (1984 x 1488 pixels)

Panorama Fine (1600 x 600 pixels)

Panorama Super Fine (1600 x 600 pixels)

Panorama HyPict (1984 x744 pixels)

H

H

About 60 KB

About 306 KB

About 612 KB

About 700 KB

About 153 KB

About 306 KB

About 350 KB

Product Description Functional Specifications 22

Page 23

EPSON PhotoPC 850Z Revision A

1.3.8 Interface Connectors and Others

VIDEO OUTPUT

NTSC, PAL

INLET FOR DC POWER SUPPLY

DC power is supplied from AC adapter (7.0V), EIAJ Type2 ø4.4

SERIAL INTERFACE

14-pin dual line terminal

Recognition of connection by detecting GND

TCX3080 made by Hoshiden Corporation

COMPACT FLASH CARD SLOT

Compact flash card interface

EXTERNAL FLASH

Hot Sync Flash Shoe

SPECIFICATIONS

Table 1-4. Specifications (should not be disclosed)

RS-232C

1) Asynchronous Mode

2) Synchronous Mode

8 bit data, non parity

19.2 / 38.4 / 57.6 / 115.2 / 230.4 kbps

RS-422, 42 3

8 bit data, non parity

230 kbps / 1.8 mbps

USING CIRCUITS

14-pin dual line terminal

Plug-in detection

Table 1-5. Using Circuits (should not be disclosed)

Pin

Assign.

1 VDD VDD

2 D+ I/O D+

Camera To DOS/V

Circuits I/O Circuits I/O Circuits I/O Circuits

shell

To printer and

Mac

To MODEM

1.3.8.1 Serial Interface

OUTLINE

The serial interface is EPSON original for connecting PC/MAC, printer, or

modem, and other specifications are not open to the public.

When connected to a PC/MAC (RS422), the interface is compatible with RS232C. In this case, PC/MAC is required to support at least 19.2kbps

transmitting rates.

3 GND GND S.G

4 HSKI I SCLK

5 RXD+ I TXD+

6TXD+ ORXD+

7DIN C.

8 DIN C2

9 D- I/O D10 GND GND

11 GPI

Product Description Functional Specifications 23

Page 24

EPSON PhotoPC 850Z Revision A

Table 1-5. Using Circuits (should not be disclosed)

Pin

Assign.

12 HSKO CTS

13 RXD- I host SD I TXD14 TXD- O host RD O RXD-

Camera To DOS/V

Circuits I/O Circuits I/O Circuits I/O Circuits

To printer and

VIDEO OUTPUT

NTSC, PAL a standard

AC ADAPTER INPUT

Exclusive AC adapter (DC7.0V)

COMPACT FLASH CARD

Compact Flash Interface

Mac

To MODEM

1.3.9 Power

BATTERIES

Four Ni-MH batteries

NOTE:

Do not use Mn batteries.

CONVERTER

AC-DC (7.0V) converter, EU-40 (7.0V, 2.0A)

1.3.10 Battery Life

Table 1-6. Battery Life

Ni-MH Batteries

Power Saving Mode 30 sec.

Shooting in LCD ON Mode -

(Back light ON / OFF)

Shooting in LCD OFF Mode More than 1000 images

Playback Mo de

(Back light ON / OFF)

130 / 155 [T.B.D]

230 / 310 [T.B.D]

NOTE:

Measurement conditions: saving mode on, strobe once in two

shots, one minute interval.

Product Description Functional Specifications 24

Page 25

EPSON PhotoPC 850Z Revision A

1.3.11 Automatic Shutting Down Mode

This mode does not apply to the 8-bit CPU.

APPLIED CASE

Effective only when performing by batteries.

Not effective when performing by AC adapter.

TAKING WITH LCD ON/OFF

Power Saving Mode = “10 sec”

Shut down after 10 sec of not pressing any button.

Power Saving Mode = “30 sec”

Shut down after 30 sec of not pressing any button.

Power Saving Mode = “1 min”

Shut down after 1 min of not pressing any button.

Power Saving Mode = “3 min”

Shut down after 3 min of not pressing any button.

Power Saving Mode = “5 min”

Shut down after 5 min of not pressing any button.

SLIDE SHOW

In the Slide Show, the camera shuts down after replaying a cycle;

however, in the Power Saving Off Mode, the camera does not shut down

until battery level becomes low.

When connected with PC, only camera shuts down after 1 min.

When connected with USB, the camera does not shut down until battery

level becomes low.

When connected with AC adapter, the camera shuts down after 15 min.

RECOVERY FROM THE SHUTTING DOWN MODE

When taking photos;

Use half stroke shutter or turn the switch on again in a shooting mode.

When not taking photos;

Press the rear function button or turn the switch on again in a different

mode.

PLAYBACK MODE

Power Saving Mode = “10 sec”

Shut down after 10 sec of not pressing any button.

Power Saving Mode = “30 sec”

Shut down after 30 sec of not pressing any button.

Power Saving Mode = “1 min”

Shut down after 3 min of not pressing any button.

Power Saving Mode = “5 min”

Shut down after 5 min of not pressing any button.

Product Description Functional Specifications 25

Page 26

EPSON PhotoPC 850Z Revision A

1.4 Visual Guidance and Switch Function

1.4.1 Information Indicated on the Control LCD

Figure 1-3. Top

1.4.1.1 Switch Function

Table 1-7. Switch Function

Name Function

Special Shooting Mode with LCD monitor on.

Monitor Shooting Mode

VF Shooting Mode (LCD monitor off)

Dial Switch

(Rotary-type)

Shutter 2 strokes shutter button (half / full stroke)

Top Buttons

OFF (Power off)

Playback Mode

Option Mode

Set-up Mode

Image Quality Setting (//

Self-timer Setting (on / off)

Flash Mode Setting

AUTO / Red Eyes Flat / Compulsion / Prohibition /

Slow Synchronization)

/

H

)

Figure 1-2. Front and Rear View

Product Description Visual Guidance and Switch Function 26

Page 27

EPSON PhotoPC 850Z Revision A

Table 1-7. Switch Function

Name Function

Zoom Lever Optical Zoom Lever (W/T)

Rear-function Button

Diopter Switch VF (View Finder) Diopter collecting Switch

Operate by 7 buttons independ entl y

(Rear to 8. GUI explanation)

1.4.1.2 LED Condition

Table 1-8. LED

Camera

Condition

Green-LED

Ready to Shoot Turn on Turn on

Focusing Turn on

Focus Lock Turn on Turn on

Moving the taken

photo file to compact

flash memory card.

Full External Memory

Low Battery Warning

Error Turn on

Self-timer Start Turn on

Blink

(0.8 sec step)

Shooting

Condition

Red-LED

Blink

(0.8 sec step)

Blink

(1.0 sec step)

Shooting

Condition

Green-LED

Blink

(0.2 sec step)

Self-timer

Condition

Red-LED

Accelerating

blink

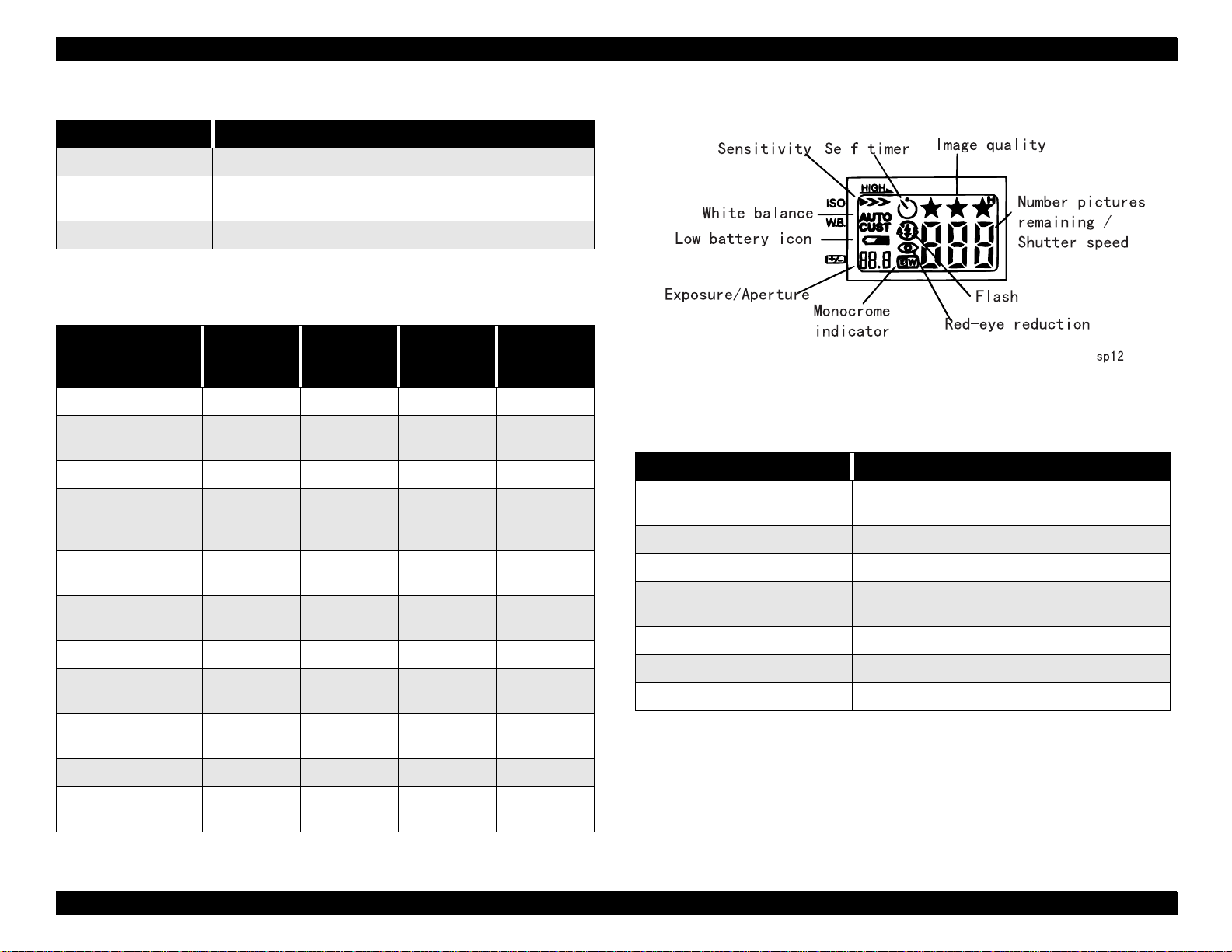

1.4.1.3 Control LCD

Figure 1-4. Control LCD Panel

Table 1-9. Control LCD Functions

Name Function

ISO Sensitivity Setting

White Balance Setting Indicates white balance setting.

Low-battery Warning Indicates when the battery is low.

Exposure Adjustment Value

Image Quality Setting Indicates image quality setting.

HyPict Indicates HyPict mode.

Monochrome Indicates on monochrome mode.

Indicates ISO sensitivity setting (Standard

ISO100 / Fine 200 / Super Fine 400).

Indicates exposure adjustment value

(when using half shutter).

Turn the switch on

(Only shooting mode)

Charging Flash Turn on Blink

Playback Mo de

Setup Mode

Turn on

Turn on

Blink

(0.2 sec step)

Product Description Visual Guidance and Switch Function 27

Page 28

EPSON PhotoPC 850Z Revision A

Table 1-9. Control LCD Functions

Name Function

Self Timer Indicates when self-timer is set.

Flash Indicates flash setting.

Available remaining pictures

Available remaining pictures in buffer in

Available Remaining Pictures

quick taking mode

Shutter speed by half-shutter

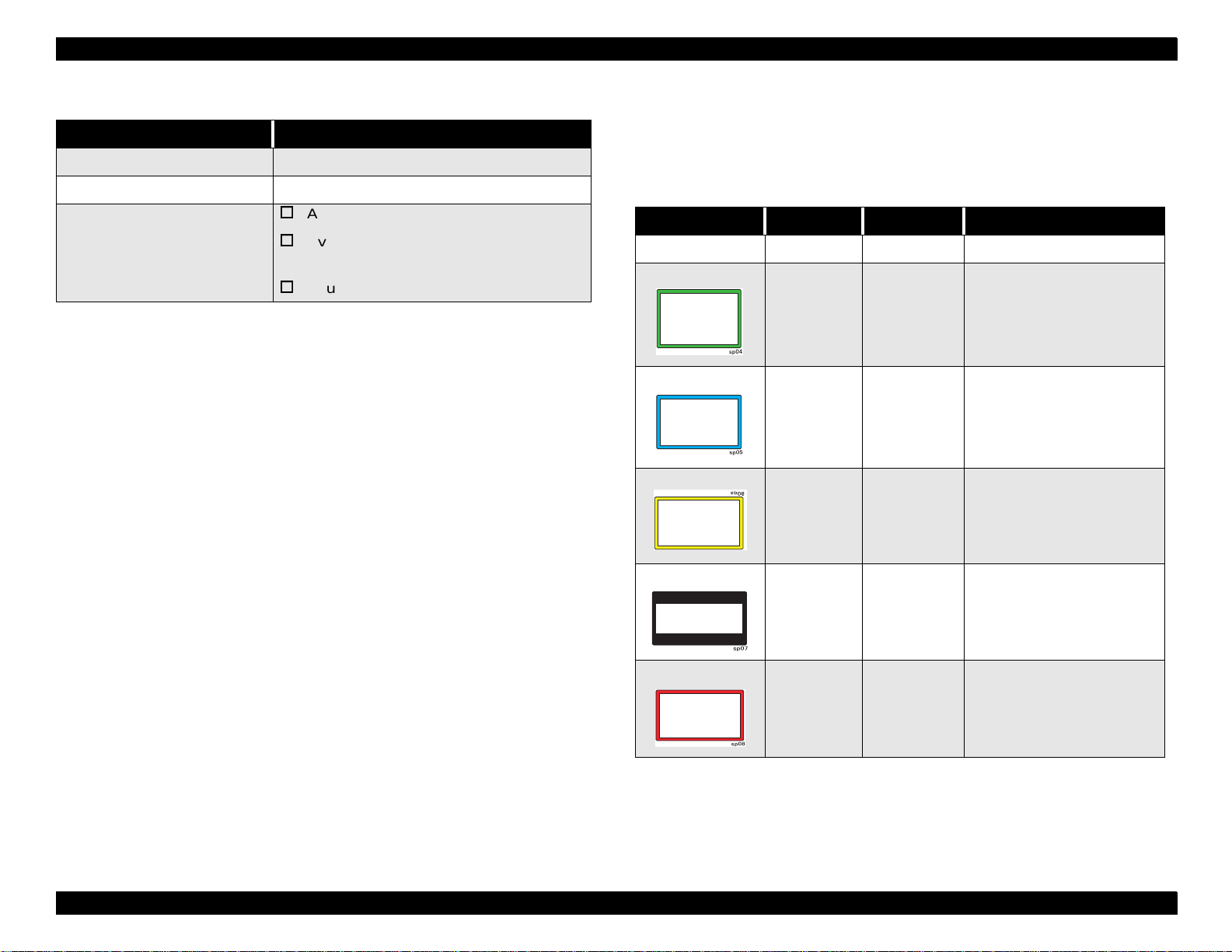

1.4.1.4 LCD Monitor

LCD monitor displays a different color frame for each function only when

shooting in LCD mode and continuous shooting mode are on.

Table 1-10. Color Frames

LCD Frame Color Mode Note

Nothing displayed - Preparing -

Green Macro Indicates “Macro” for seconds.

Blue

Yellow

MONOCHROMEIndicates “MONOCHROME”

for seconds.

x2 Digital

Zoom

Indicates “ZOOM” for

seconds.

NOTE:

Black margin

on the top

and bottom

Red

Priority of Color Frame:

Panorama

Continuous

Shooting

Indicates “Panorama” for

seconds.

indicates “Continuous

shooting” for seconds.

Continuous Shooting > Digital Zoom > Macro > Monochrome

(T.B.D)

Product Description Visual Guidance and Switch Function 28

Page 29

EPSON PhotoPC 850Z Revision A

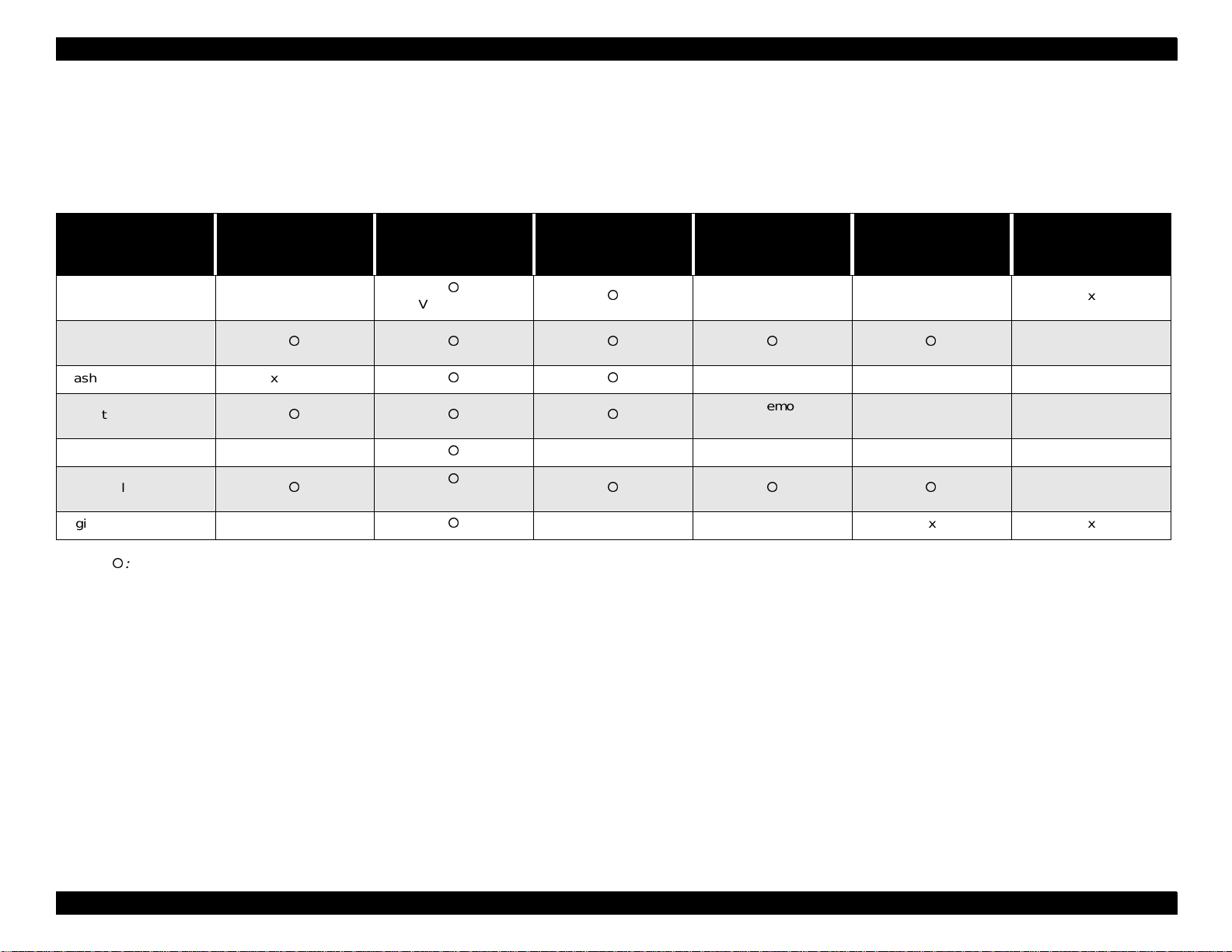

1.4.2 Setting Items

1.4.2.1 Full Auto Shooting Mode

The following items are sustained in VF mode and Monitor Shooting mode.

Table 1-11. Full Auto Shooting Mode (in VF mode and Monitor Shooting mode)

When Rotary Switch

point or pass OFF

Panorama / Macro x

Change image

resolution

Flash x (Auto)

Quick taking mode

Interval value x

Set up value

Digital zoom x

NOTE:

: Encode x: Disable

Rotary Switch

change-over between

shooting modes

(VF mode: x)

(VF mode:x)

Shut down by power

saving mode

xxxx

xxxx

Shut down by low

battery

xxx

xxx

Transfer memories in

buffer to the CF card

Replace battery

(Super Capa effective)

To the normal mode x

Replace battery

(Super Capa

ineffective)

x

x

Product Description Visual Guidance and Switch Function 29

Page 30

EPSON PhotoPC 850Z Revision A

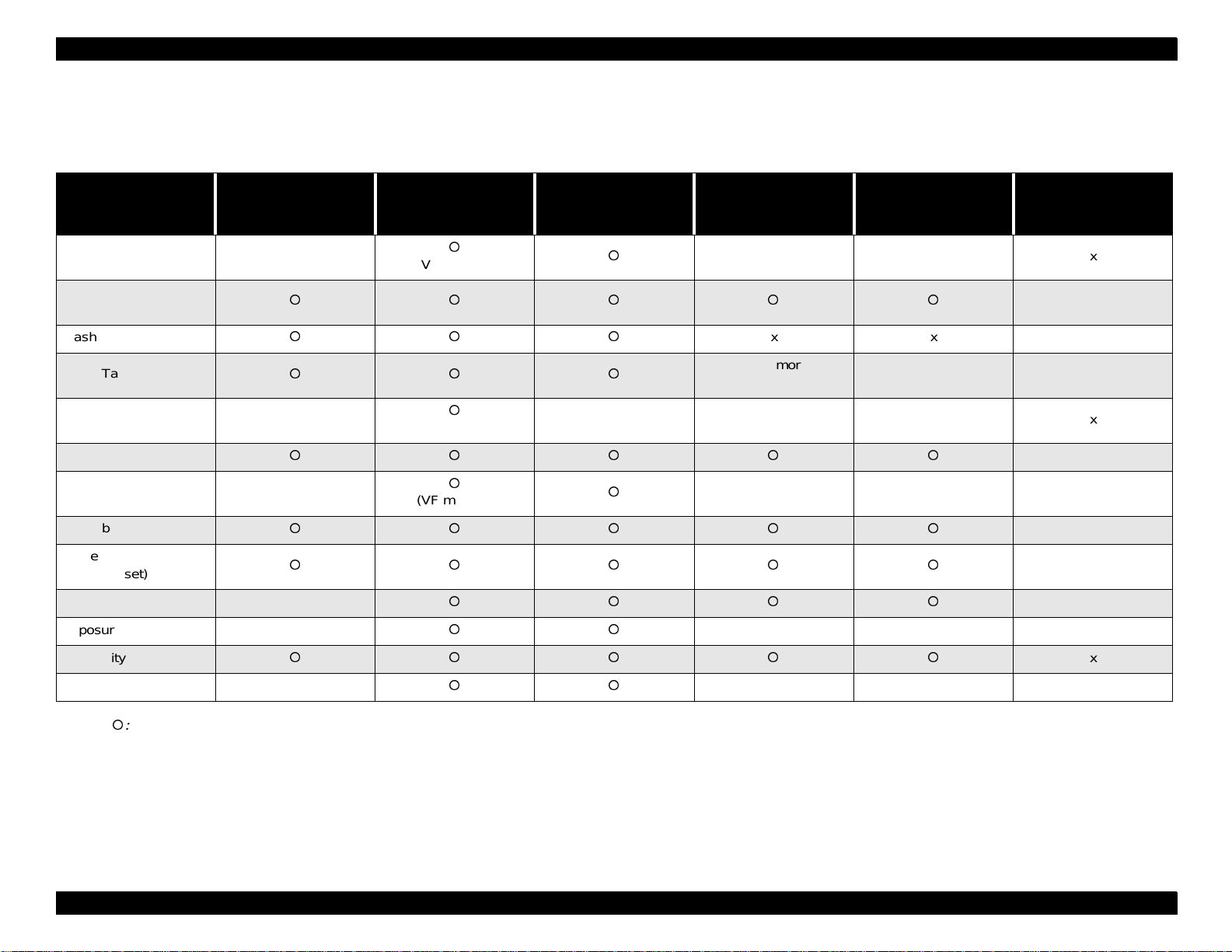

1.4.2.2 Program Mode

The following items are sustained in VF mode and Monitor shooting mode.

Table 1-12. Program Mode (in VF mode and Monitor Shooting mode)

When Rotary Switch

point or pass OFF

Panorama / Macro x

Change image

resolution

Flash

Quick Taking mode

Interval value x

Set up value

Priority mode x

White balance

White balance

(Program set)

Metering system select x

Exposure Adjustment x

Rotary Switch

change-over between

shooting modes

(VF mode:x)

(VF mode:x)

(VF mode:x)

Shut down by power

saving mode

xxxx

Shut down by

low battery

xxx

xxx

Transfer memories in

buffer to the CF card

xxx

xxx

Replace battery

(Super Capa effective)

To the normal mode x

Replace battery

(Super Capa

ineffective)

x

x

x

x

x

Sensitivity

Digital zoom x

NOTE:

: Encode x: Disable

xxx

x

Product Description Visual Guidance and Switch Function 30

Page 31

EPSON PhotoPC 850Z Revision A

1.4.2.3 Manual Mode

The following items are sustained in VF mode and Monitor shooting mode.

Table 1-13. Manual Mode (in VF mode and Monitor Shooting mode)

When Rotary Switch

point or pass OFF

Panorama / Macro x

change image resolution

Flash

Quick taking mode

Interval value x

Set up value

Priority mode

Manual exposure shooting

mode

White balance

White balance

(Program set)

Metering system select

Rotary Switch

change-over

between shooting

modes

(VF mode:x)

(VF mode:x)

Shut down by power

saving mode

xxxx

Shut down by

low battery

xxx

xxx

Transfer memories in

buffer to the CF card

Replace battery

(Super Capa

effective)

To the normal mode x

Replace battery

(Super Capa

ineffective)

x

x

x

x

x

x

x

Exposure Adjustment

Sensitivity

MF Shooting set x

Shutter speed adjusted x

Digital zoom

NOTE:

: Encode x: Disable

x x x

xxx

x

x

x

Product Description Visual Guidance and Switch Function 31

Page 32

EPSON PhotoPC 850Z Revision A

1.5 Attach Products

1.5.1 Attach Cable

1.5.1.1 DOS/V Connector Cable

Length: 1.5m

Connector:

Camera side: 14-pin connector (female)

PC side: 9-pin D-SUB connector (female)

Camera

PC

1.5.1.2 Macintosh Connector Cable

Length: 1.5m

Connector:

Camera side: 14-pin connector (female)

PC or Printer Connector: 8-pin mini-DIN (male)

)

Camera

Printer / MAC

(exluding iMac)

Figure 1-6. Macintosh Connector Cable

Figure 1-5. DOS/V Connector Cable

Product Description Attach Products 32

Page 33

EPSON PhotoPC 850Z Revision A

1.5.1.3 USB Interf ace Cable

Length: 1.5m

Connector:

Camera side: 14-pin connector (female)

PC side: USB

Camera

USB(iMac)

1.5.1.4 Interface Cable for Video and Audio

Length: 1.5m

Connector:

Camera side: Mini pin

Video side: RCA (yellow)

Audio: RCA (white)

1.5.2 Other Attached Products

Camera case (T.B.D)

Strap

Shoulder belt

Lens accessories adapter

Figure 1-7. USB Interface Cable

Product Description Attach Products 33

Page 34

EPSON PhotoPC 850Z Revision A

1.6 Option

1.6.1 Standard Option

AC ADAPTER

Model Name: EU-40

Input Voltage: AC 100-240V, 50-60 Hz, 30VA (T.B.D)

Output Voltage: DC 7.0V, 2.0A

NI-MH BATTERY

Model Name: EU-24

Output Voltage: 1.2V / one battery

Capacity : 1500 mAH/battery

NI-MH BATTERY CHARGER

Model Name: EU-38

Input Voltage: AC 100-240V, 50-60 Hz 10 VA (T.B.D)

Output Voltage: DC 1.2V 490 mA x 4 (T.B.D)

Charging Time: 2.5H (T.B.D)

Product Description Option 34

Page 35

EPSON PhotoPC 850Z Revision A

1.7 Environmental Conditions

OPERATIONAL CONDITION AND KEEPING CONDITION

Temperature

Operating: 5-35

Keeping: -20-60

Humidity

Operating: 30-90% without condensation

Keeping: 10-90% without condensation

Shock-resistance

Keeping: 70G

POWER SUPPLY

DC input voltage (AC adapter)

Min.: DC 2.96V (T.B.D)

Max.: DC 3.85V (T.B.D)

ASSUMED SITUATION

Place

Home, Office, Outdoor

Water Resistance

Not supported

°C

°C

Product Description Environmental Conditions 35

Page 36

EPSON PhotoPC 850Z Revision A

1.8 Safety and Others

EMI AND SAFETY STANDARD

USA

FCC part 15 subpart B class B

Canada

CSA C108.8 class B

Europe

EMC Directive 89/ 336/ EEC

(CE-marking)

EN55022 Class B

EN61000-3-2 (using AC adapter)

EN61000-3-3 (using AC adapter)

EN50082-1

IEC801-2

IEC801-3

IEC801-4

Europe

EN 55022 (CISPR Pub.22)

Class B

Australia

AS/ NZS 3548 class B

Taiwan

EMI: CNS 13438-C6357

Japan

VCCI Class B

Korea

The rule of Electromagnetic wave in Korea

Product Description Safety and Others 36

Page 37

EPSON PhotoPC 850Z Revision A

1.9 Inhibitions and Cautions

Never see the sun through view finder

W ARNING

CAUTION

Keep young children away from the camera, especially

watch that the long strap does not cause choking

accidents.

Never use any AC adapters and batteries other than the

approved ones.

If the camera will not be in use for a long time, remove

batteries.

Be sure to insert batteries with correct polarity.

Product Description Inhibitions and Cautions 37

Page 38

OPERATING PRINCIPLES

Page 39

EPSON PhotoPC 850Z Revision A

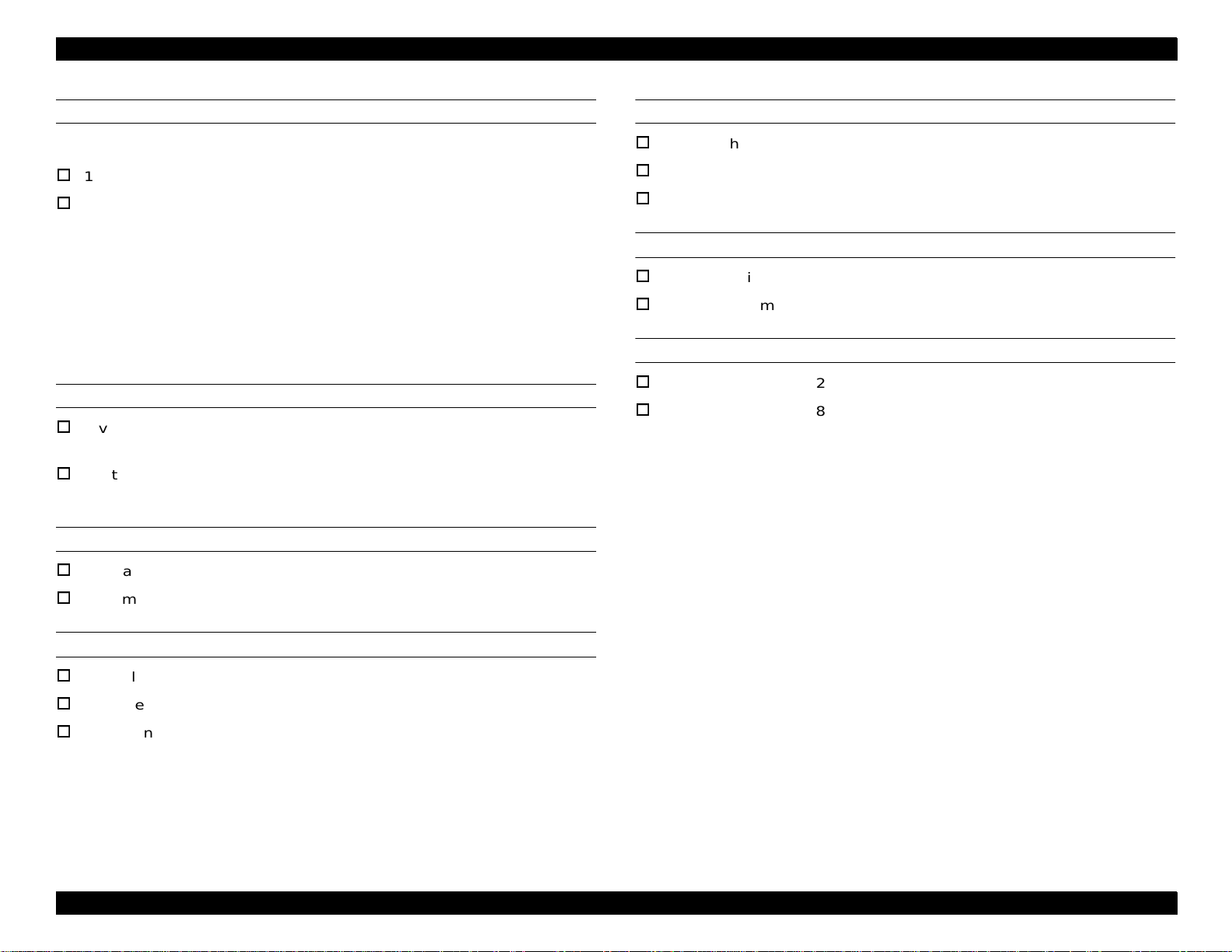

Electric Circuit

2.1 Overview

Major component of PhotoPC 850Z consists of electric circuit and the Lens

Assy. The figure below shows layout of the major electric boards.

The electric circuit consists of CA1, CA2, SY1, SY2, ST1, TB1, TB2, and

PW1 Boards. The table below shows functions of each board.

Table 2-1. Board Function

Board Function

CCD image sensor interline type

• CCD clock drive

CA1

CA2

SY1

• A/D conversion of image data

• Drives the Lens Assy.

(shutter, aperture, focus, and zoom)

Consists of RISC-CPU, ASIC, 8Mbit Flash-ROM, 32Mbit

SDRAM.

• Digital clamp

•γ correction, color generation, matrix, horiz ontal and

vertical aperture

• SDRAM controller

• USB control

8 bit microprocessor

• Operatio n key input

• Controls LCD panel display

• Controls the power circuits

• Controls the flash charging

SY2 LED in the Viewfinder

ST1 Controls the external flash.

Figure 2-1. Major Component

Lens Assy.

Includes the Optical Zoom Mechanism, Shutter Mechanism, Aperture

Mechanism, and Focus Mechanism.

Lens Focus Distance: 6.5 - 19.5mm

Lens Construction: 8 elements in 6 groups

TB1 Battery circuit

TB2

PW1

Barrier switch board

• Monitors opening/closing of the barrier

Power Circuit

• Switch controller, short-circuit protection circuit

• Digital 5V and analog system power output

• Digital 3.25V system pow er output

• LCD system power supply

• Backlight power supply output

Operating Principles Overview 39

Page 40

EPSON PhotoPC 850Z Revision A

2.2 Operating Principles of Circuit Boards

The figure below shows the block diagram of all boards in PhotoPC 850Z.

64Mbit

Compact Flash

Compact Flash

Card

Card

Driver

Driver

LENS

74AC273

74AC273

8Mbit

8Mbit

Frash

Frash

Memory

Memory

1600~1200

RISC

RISC

CPU

CPU

10bitA/D

10bitA/D

@

AGC

CDS

@

AGC

CDS

1600~1200

IS-CCD

IS-CCD

Address2

SDRAM

SDRAM

Controller

Controller

SRAM

SRAM

Controller

Controller

SG/TG

SG/TG

CLK

CLK

GEN

GEN

64Mbit

SDRAM

SDRAM

Data2

Controller

Controller

Signal

Signal

Processor

Processor

USB

USB

JPEG

JPEG

AF/AE.AWB

AF/AE.AWB

Integrator

Integrator

Encoder

Encoder

YC

8bit

8bit

8bit

8bit

D/A

D/A

D/A

D/A

8bit

8bit

D/A

D/A

JPEG

JPEG

SYSTEM

ASIC

Data1

Address1

UART

UART

PIO

PIO

CA2_BLOCK

Driver

Driver

RS232C

CA1

BLOCK

AV JACK

DC JACK

Battery

~

4

1.5V

@

Electoronic

Electoronic

Flash

Flash

2

1

3

+

|

DC-DC

DC-DC

Converter

Converter

PW1_BLOCK

72MHz

48MHz

Y

Driver

Driver

Display

Display

2 inch

2 inch

C

kbc

kbc

kbc

kbc

Y-C

MIX

MIX

Y-C

Video

Video

Driver

Driver

Audio

Audio

AMP

AMP

SY1

BLOCK

SPEAKER

8bit

8bit

CPU

CPU

1MHz

CLK

@

32.768Hz

CLK

Figure 2-2. Block Diagram

Operating Principles Operating Principles of Circuit Boards 40

Page 41

EPSON PhotoPC 850Z Revision A

Pin 1

2

10

48

4

H

V

Pin 11

2.2.1 CA1 Circuit Description

CA1 Board consists of the f ollowing ICs.

IC Configuration

IC903 (ICX224AK): CCD Imager

IC902 (74ACTO4MTC): H Driver

IC904 (CXD3400N): V Driver

The figure below shows the block diagram of the CA1 Board.

2.2.1.1 IC903 (CCD)

Specification of the CCD is shown below.

Structure

Interline Type CCD Image Sensor

Optical Size: 1/2 inch format

Effective Pixels: 636 (H) x 1236 (V)

Total Pixels: 688 (H) x 1248 (V)

Optical Black Sensing:

Horizontal (H) Direction: Front 4 pixels, Rear 48 pixels

Vertical (V) Direction: Front 10 pixels, Rear 2 pixels

Figure 2-4. Optical Black Layout

Number of Dummy Bit:

Horizontal: 28

Vertial: 1

Figure 2-3. CA1 Circuit Block Diagram

Operating Principles Operating Principles of Circuit Boards 41

Page 42

EPSON PhotoPC 850Z Revision A

4

3B

2

1A

1B

D

3A

D

T

CCD block diagram and terminals are shown below. For your reference, Ye is

the Yellow detection cell, Mg is the Magenta detection cell, CY is the Cyan

detection cell, and G is the Green detection cell.

10

11

VOU

VDD

9

12

GN

RG

8

13

NC

H 2

V

GN

7

6

Ye

G

Ye

G

Ye

Vertical register

G

Horizontal register

15

14

GND

H 1

5

16

V

Cy

Mg

Cy

Mg

Cy

Mg

SUB

4

17

V

Ye

Ye

Ye

SUB

C

V

3

2

Cy

G

Mg

Cy

G

Mg

Cy

G

Mg

18

19

VL

V

H 1

V

1

(Note)

20

2

H

Table 2-2. CCD Pin Description

Pin No. Symbol Pin Description Waveform Voltage

1V

2, 3

4V

5, 6

7, 9 GND GND GND 0V

10 VOUT Signal Output Approx. 10V

11 VDD Circuit Power DC 15V

Vφ3A,

Vφ3B

Vφ1A,

Vφ1B

Vertical Register

4

φ

Vertical Register

Vertical Register

2

φ

Vertical Register

Transfer Clock

Transfer Clock

Transfer Clock

Transfer Clock

-7.5V, 0V

-7.5V, 0V,

15V

-7.5V, 0V

-7.5V, 0V,

15V

(Note) :

Photo sensor

12

φ

RG

Reset Gate

Clock

12.5V, 17.5V

Figure 2-5. CCD Block Diagram

Horizontal

13, 20 Hφ2

14, 19 Hφ1

Register Transfer

Clock

Horizontal

Register Transfer

Clock

0V, 5V

0V, 5V

Operating Principles Operating Principles of Circuit Boards 42

Page 43

EPSON PhotoPC 850Z Revision A

1A

1

1Y

2

2A

3

2Y

4

3A

5

3Y

6

GND

7

4Y

8

4A

9

5Y

10

5A

11

6Y

12

6A

13

V

CC

14

Table 2-2. CCD Pin Description (Continued)

Pin No. Symbol Pin Description Waveform Voltage

16

17 CSUB Substrate Bias DC

18 VL

NOTE:

SUB Substrate Clock DC Approx. 8V

φ

Protection

Transistor Bias

DC

----: When the sensor reads-out.

Approx. 8V

(Different

from every

CCD)

2.2.1.2 IC902 (H Driver) and IC904 (V Driver)

H Driver (IC902) and V Driver (IC904) are necessary to generate the clocks

(vertical transfer clock, horizontal transfer clock, and electronic shutter clock)

which drive the CCD.

IC902 is an inverter IC which drives the horizontal CCDs (H1 and H2). In

addition, the XV1-XV4 signals which are output from IC102 are the vertical

transfer clocks, and the XSG1 and XSG signals output from IC102 are

superimposed onto XV1 and XV3 at IC904 in order to generate a ternary pulse.

Furthermore, the XSUB signal which is output from IC102 is used as the sweep

pulse for the electronic shutter, and the RG signal which is output from IC102 is

the reset gate clock.

Figure 2-6. IC902 Block Diagram

Operating Principles Operating Principles of Circuit Boards 43

Page 44

EPSON PhotoPC 850Z Revision A

8

4

5

6

7

0

9

1

2

3

2.2.1.3 Lens Drive Block

DD

1

2

3

4

5

6

7

8

9

10

V

XSHT

XV3

XSG3B

XSG3A

XV1

XSG1B

XSG1A

XV4

XV2

Input

Buffer

SHT

V3B

V

V3A

V1B

V

V1A

V4

V2

GND

2

1

L

1

1

1

H

1

1

1

1

1

Shutter Drive

The shutter drive signal (PCTRL) which is output from the ASIC expansion

port (IC108) is moved regular current drive for shutter, and the shutter

plunger is opened and closed.

The iris stepping motor drive signals (ACTRL1, ACTRL2, ACTRL3,

ACTRL4) which are output from the ASIC expansion port (IC108) are

driven by the motor driver (IC957), and the iris is moved six times.

Detection of the standard iris positions is carried out by means of the

photointerrupter (P12) inside the lens block.

Focus Drive

The focus stepping motor drive signals (LDIN1, LDIN2, LDIN3, LDIN4)

which are output from the ASIC expansion port (IC107) are driven by the

motor driver (IC954). Detection of the standard focusing positions is carried

out by means of the photo interrupter (PI) inside the lens block.

Zoom Drive

The zoom stepping motor drive signals (ZIN1, ZIN2, ZIN3, ZIN4) which are

output from the ASIC expansion port (IC107) are driven by the motor driver

(IC953). Detection of the standard zooming positions is carried out by

means of the photoreflectors (PR1, PR2 ) insid e the lens block.

Figure 2-7. IC904 Block Diagram

Operating Principles Operating Principles of Circuit Boards 44

Page 45

EPSON PhotoPC 850Z Revision A

2.2.2 CA2 Circuit Description

2.2.2.1 Circuit Description

DIGITAL CLAMP

The optical black section of the CCD extracts the average values from the

subsequent data to make the black level of the CCD output data uniform for

each line.

@

The optical black section of the CCD averaged value for each line is taken as

the sum of the value for the previous line multiplied by the coefficient k and the

value for the current line multiplied by the coefficient 1-k.

@

@

@

@

@

@

Figure 2-8. CA2 Circuit Block Diagram

Operating Principles Operating Principles of Circuit Boards 45

Page 46

EPSON PhotoPC 850Z Revision A

SIGNAL PROCESSOR

Correction Circuit

γ

This circuit performs (gamma) correction in order to maintain a linear

relationship between the light input to the camera and the light output from

the picture screen.

Color Generation Circuit

This circuit converts the CCD data into RGB signals.

Matrix Circuit

This circuit generates Y signals, R-Y signals and B-Y signals from the RGB

signals.

Horizontal and Vertical Aperture Circuit

This circuit is used to generate the aperture signal.

AE/AWB AND AF COMPUTING CIRCUIT

The AE/AWB carries out computations based on a 64-segment screen, and the

AF carries out computations based on a 6-segment screen.

SDRAM CONTROLLER

This circuit outputs address, RAS, CAS, and AS data for controlling the

SDRAM. It also refreshes the SDRAM.

TG/SG

Timing generated for 2 million pixel CCD control.

DIGITAL ENCODER

It generates chroma signal from color difference signal.

COMMUNICATION CONTROL

USART

The RS-232C can be sued for both synchronous and asynchronous

transmission.

SIO

This is the interface for the 4-bit microprocessor.

PIO/PWM/SIO for LCD

8-bit parallel input and output makes it possible to switch between

individual input/output and PW M inpu t/ou tput .

Operating Principles Operating Principles of Circuit Boards 46

Page 47

EPSON PhotoPC 850Z Revision A

2.2.2.2 Operation Outline

When the shutter opens, the reset signals (ASIC and CPU) and the serial

signals (“Take a picture” commands) from the 4-bit microprocessor are input

and operation starts. When the TG/SG drives the CCD, picture data passes

through the A/D and CDS, and is then input to the ASIC as 10-bit data. The AF,

AE, AWB, shutter, and AGC value are computed from this data, and three

exposures are made to obtain the optimum picture.

The data which has already been stored in the SDRAM is read by the CPU and

color generation is carried out. Each pixel is interpolated from the surrounding

data as being either Ye, Cy, Mg, or B primary color data to produce R, G, and B

data. At this time, correction of the lens distortion which is a characteristic of

wide-angle lenses is carried out. After AWB and γ processing are carried out, a

matrix is generated and aperture correction is carried out for the Y signal, and

the data is then compressed by JPEG and is then written to card memory

(smart media).

When data is to be output to an external device, the data is taken from the

memory and output via the USART. When played back on the LCD and

monitor, data is transferred from memory to the SDRAM, and the image is then

elongated so that it is displayed over the SDRAM display area.

2.2.2.3 LCD Block

While monitoring, YUV conversion is carried out for the 10-bit CCD data which

is input from the A/D conversion block to the ASIC and is then transferred to

the DRAM so that the CCD data can be displayed on the LCD.

The data which has accumulated in the DRAM is passed through the NTSC

encoder, and after D/A conversion is carried out to change the data into a Y/C

signal, the data is sent to the LCD panel and displayed.

If the shutter button is pressed in this condition, the 10-bit data which is output

from the A/D conversion block of the CCD is sent to the DRAM (DMA transfer),

and after processor, it is displayed on the LCD as a freeze-frame image.

During playback, the JPEG image data which has accumulated in the flash

memory is converted to YUV signals, and then in the same way as during the

monitoring, it is passed through the NTSC encoder, and after D/A conversion is

carried out to change the data into a Y/C signal, the data is sent to the LCD

panel and displayed.

The two analog signal (Y/C signals) from the ASIC are converted into RGB

signals by the LCD driver, and these RGB signals and the control signal which

is output by the LCD driver are used to drive the LCD panel. The RGB signals

are 1H transposed so that no DC component is present in the LCD element,

and the two horizontal shift register clocks drive the horizontal shift registers

inside the LCD panel so that the 1H transposed RGB signals are applied to the

LCD panel. Since the LCD closes more as the difference in potential between

the COM (common polar voltage: fixed at DC) and the R, G, and B signals

becomes greater the display becomes darker; if the difference in potential is

smaller, the element opens and the LCD becomes brighter.

Operating Principles Operating Principles of Circuit Boards 47

Page 48

EPSON PhotoPC 850Z Revision A

2.2.3 PW1 Power Circuit Description

2.2.3.1 Outline

This is the main power circuit comprising of the following blocks:

Switching controller (IC501)

Digital 5V and analog system power output (T5001, Q5001)

Digital 3.25V system power supply (Q5007)

LCD system power supply (Q5008, T5002)

Backlight power supply output (Q5011, T5003)

Figure 2-9. PW Power Circuit Block Diagram

Operating Principles Operating Principles of Circuit Boards 48

Page 49

EPSON PhotoPC 850Z Revision A

2.2.3.2 Switching Controller (IC501)

This is the basic circuit which is necessary for controlling the power supply for a

PWM-type switching regulator, and it is provided with four built-in channels.

Only CH1 (digital 5V, analog system), CH3 (LCD system), CH2 (digital 3.25V),

and CH4 (backlight) are used. Feedback from 5.1V (D) (CH1), 3.0V (D) (CH2),

5.3V (L) (CH3), and 6.3-8.9V (L) (CH4) power supply outputs is received, and

the PWM duty is varied so that each one is maintained at the correct voltage

setting level.

2.2.3.3 Shot-Circuit Protection Circuit

If output is short-circulated for the length of time determined by the condenser

which is connected to Pin (17) of IC501, all output is turned off. The control

signal (P ON, P(A) ON, and LCD ON) are re-controlled to restore output.

2.2.3.4 Digital 5V and Analog System Power Output

5.1V (D), 15.2V (A), -7.7V (A), and 5.1V (A) are output. Feedback for the 5.1V

(D) is provided to the switching controller (Pins (29) of IC501) so that PWM

control can be carried out.

2.2.3.5 Digital 3.25V System Power Output

3.25V (D) is output. Feedback is provided to the switching controller (Pin (26)

of IC501) so that PWM control can be carried out.

2.2.3.6 LCD System Power Output

5.3V (L), 12.4V (L), and 15V (L) are output. Feedback for the 5.3V (L) is

provided to the switching controller (Pin (11) of IC501) so that PWM control can

be carri ed out.

2.2.3.7 Backlight Power Supply Output

The power which is input to the inverter transformer (T5003) is controlled by

means of Q5011, and 7.7V or 8.9V is output depending on the luminance

mode of the LCD panel.

Operating Principles Operating Principles of Circuit Boards 49

Page 50

EPSON PhotoPC 850Z Revision A

2.2.4 PW1 Strobe Circuit Description

2.2.4.1 Charging Circuit

When UNREG power is supplied to the charge circuit and the CHG signal

becomes High (3.3V), the charging circuit starts operating and the main

electrolytic capacitor is charged with high-voltage direct current.

However, when the CHG signal is Low (0V), the charging circuit does not

operate.

Figure 2-10. PW1 Strobe Circuit Block Diagram

Operating Principles Operating Principles of Circuit Boards 50

Page 51

EPSON PhotoPC 850Z Revision A

W ARNING

POWER SWITCH

When the CHG signal switches to High, Q5406 turns ON and the charging

circuit starts operating.

POWER SUPPLY FILTER

L5401 and C5401 constitute the power supply filter. They smooth out ripples in

the current which accompany the switching of the oscillation transformer.

OSCILLATION CIRCUIT

This circuit generates an AC voltage (pulse) in order to increase the UNREG

power supply voltage when drops in current occur. This circuit generates a

drive pulse with a frequency of approximately 50-100 kHz. Since self-excited

light omission is used, the oscillation frequency changes according to the drive

conditions.

RECTIFIER CIRCUIT

The high-voltage alternating current which is generated at the secondary side

of T5401 is rectified to produce a high-voltage direct current and is

accumulated at electrolytic capacitor C5412 on the main circuit board.

VOLTAGE MONITORING CIRCUIT

This circuit is used to maintain the voltage accumulated at C5412 at a

constance level. After the charging voltage is divided and converted to a lower

voltage by R5417 and R5419, it is output to the SY1 circuit board as the

monitoring voltage VMONIT. When this VMONIT voltage reaches a specified

level at the SY1 circuit board, the CHG signal is switched to Low and charging

is interrupted.

2.2.4.2 Light Emission Circuit

When RDY and TRIG signals are input from the ASIC expansion port, the

stroboscope emits light.

EMISSION CONTROL CIRCUIT

When the RDY signal is input to the emission control ci r cuit, Q5 409 swi tches

on and preparation is made to let current flow to the light emitting element.

When a STOP signal is input, the stroboscope stops emitting light.

TRIGGER CIRCUIT

When a TRIG signal is input to the trigger circuit, D5405 switches on, a highvoltage pulse of several kilovolts is generated inside the trigger circuit, and this

pulse is applied to the light emitting part.

LIGHT EMITTING ELEMENT

When the high-voltage pulse from the trigger circuit is applied to the light

emitting part, current flows to the light emitting element and light is emitted.

There is a danger of getting electric shock from the PW1

board because of C5412. When handling this board, make

sure to hold the edges of the board and never touch the

board surface. For your safety, discharge the charged

energy of C5412 before handling the board. (See Chapter 4

“Disassembly and Assembly” for more details.)