Page 1

®

6HUYLFH 0DQXDO

6HUYLFH 0DQXDO

6HUYLFH 0DQXDO6HUYLFH 0DQXDO

Color Digital Camera

EPSON PhotoPC-750Z

SEDC98002

Page 2

EPSON PhotoPC-750Z Revision A

CAUTION

PRECAUTIONS

There are cautionary notes throughout the text to help you avoid personal injury or equipment damage.

W ARNING

Signals a precaution which, if ignored, could result

in serious or fatal personal injury. Great caution

should be exercised in performing procedures

preceded by a WARNING heading.

Always observe the measures listed below when performing repair or maintenance procedures.

Signals a precaution which, if ignored, could result

in damage to equipment.

WARNING

1. Always disconnect the product from both the power source and host computer before performing any maintenance or repair procedure.

2. No work should be performed on the unit by persons unfamiliar with basic safety measures dictated for all electronics technicians in their line of

work.

3. In performing testing described in this manual, do not connect the unit to a power source until instructed to do so. When the power supply cable

must be connected, use extreme caution in working on the power supply and other electronic components.

CAUTION

1. Repairs on EPSON products should be performed only by an EPSON-certified repair technician.

2. Make certain that the source voltage is the same as the rated voltage liste d on the seri al number/rati ng plate. If the EPSON product has a pr imary

AC rating different from the available power source, do not connect it to the power source.

3. Always verify that the EPSON product has been disconnected from the power source before removing or replacing printed circuit boards and/or

individual chips.

4. To protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static wrist straps, when accessing inter nal

components.

5. Replace malfunctioning components only with those components recommended by the manufacturer; i ntroduction of second-source I Cs or other

nonapproved components may damage the product and void any applicable EPSON warranty.

2

Page 3

EPSON PhotoPC-750Z Revision A

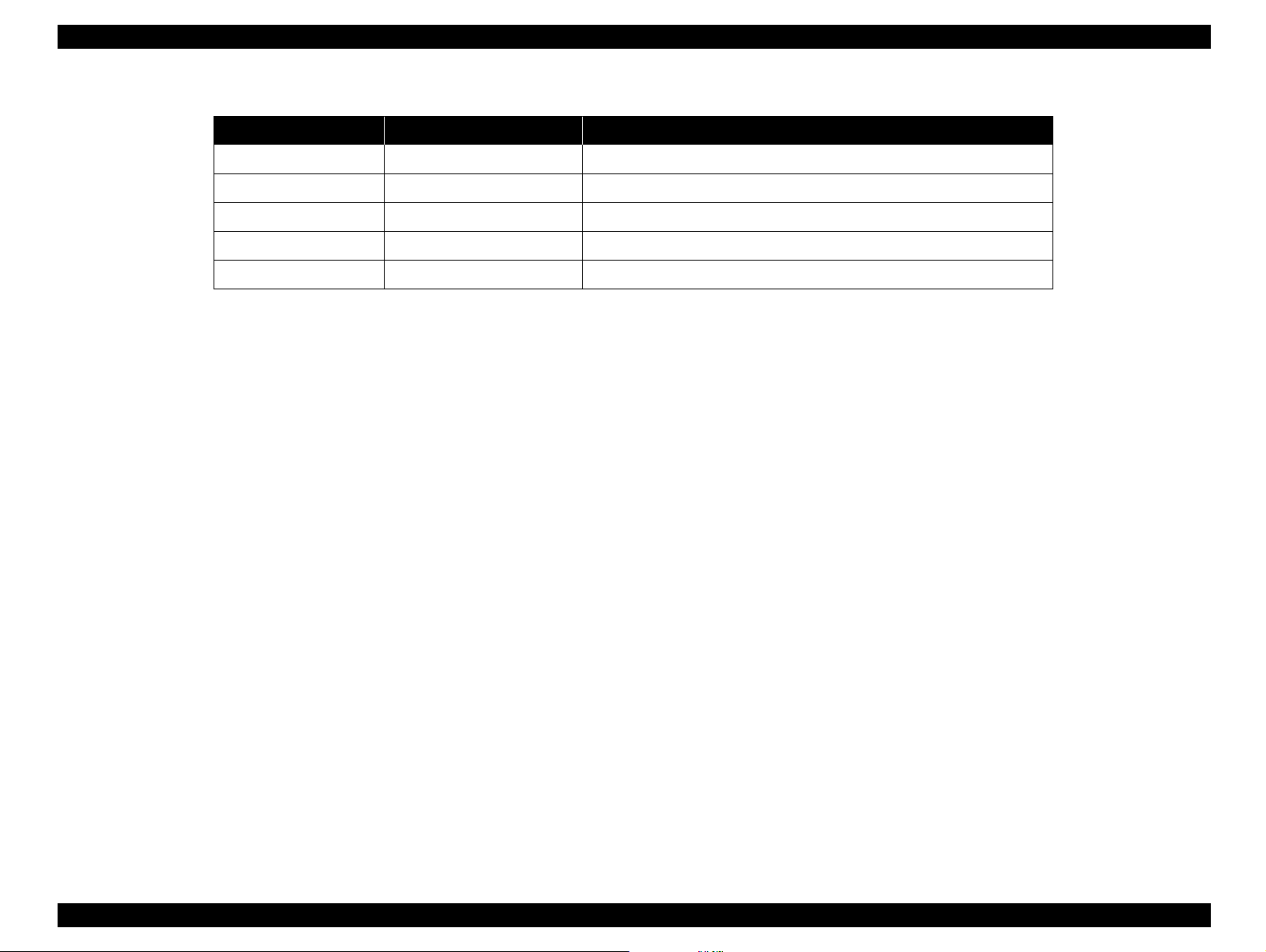

Revision Status

Revision Issued Date Description

Rev.A February 16, 1999 First Release

3

Page 4

EPSON PhotoPC-750Z Revision A

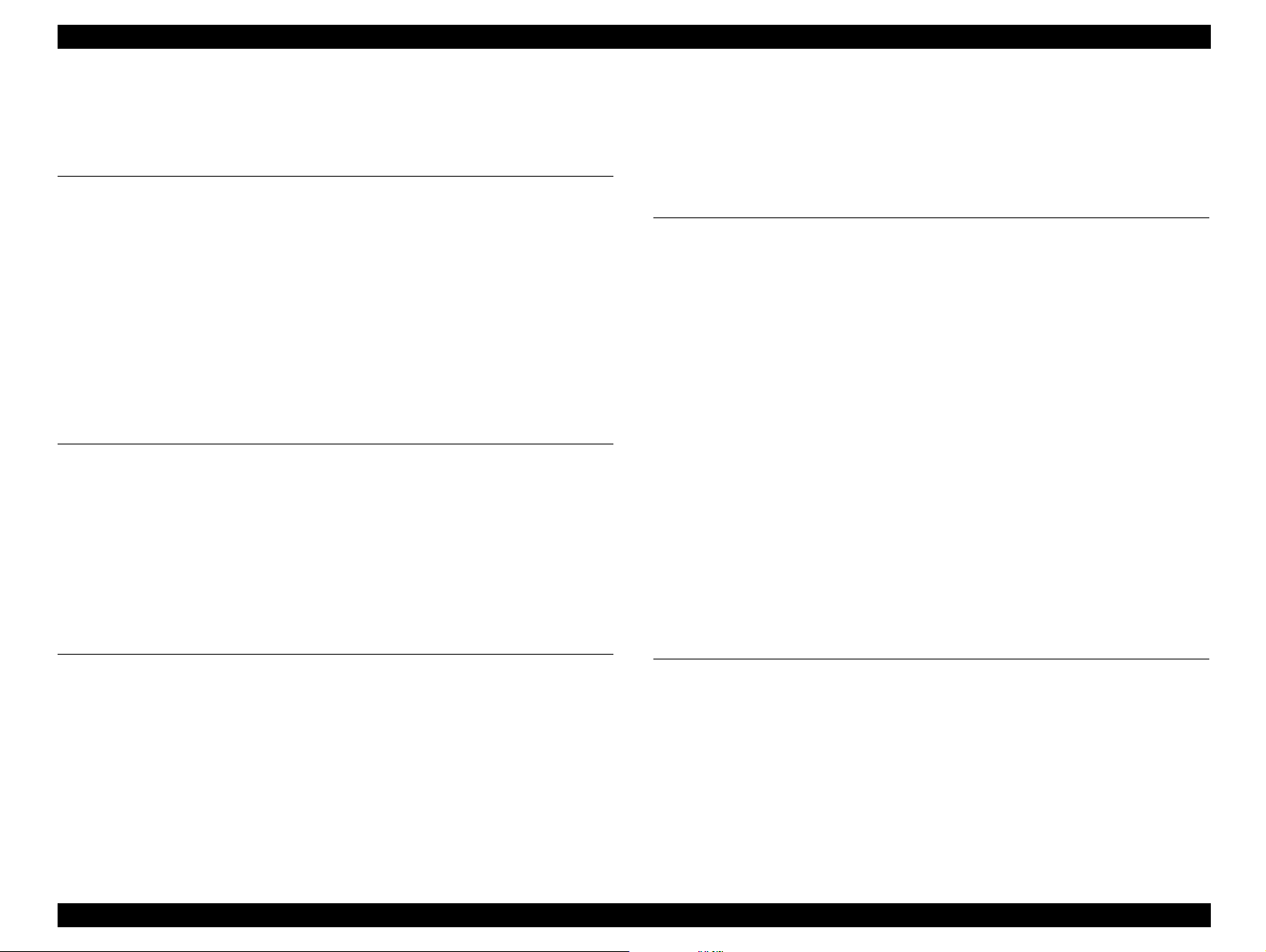

Table of Contents

Product Description

Features ... ....... ...... ....... ...... ...... ....... ............................................. ....... ...... ..... 7

Product Description................................................................................... 9

Control Panel........................................................................................... 16

Control Buttons........................................................................................ 18

Capturing Mode Indication ...................................................................... 19

Operation Specification . ...... ....... ...... ....... ...... ....... ...... ............................. 19

Cable Specification.................................................................................. 21

Options.................................................................................................... 22

Environmental Conditions ....................................................................... 22

Power...................................................................................................... 22

Safety and others .................................................................................... 22

Operating principles

Board Component ........................................................................................ 24

Out line of Operating Principles............................................................... 25

CA1 Board............................................................................................... 25

CA2 board............................................................................................... 26

ST1 Board............................................................................................... 26

SY1 Board............................................................................................... 27

TB1 Board............................................................................................... 28

TB2 Board............................................................................................... 28

Picture is blurry or out of focus................................................................ 36

Disassembly and Assembly

Overview ...................................................................................................... 38

Precautions ............................................................................................. 38

Tools ....................................................................................................... 39

Screws .................................................................................................... 39

Disassembly and Assembly .................................................................... 40

Cabinet Parts Removal ........................................................................... 41

SY1 Board, TB1 Board and FPC Unit Removal...................................... 42

CA1 Board Removal ............................................................................... 43

DEC Lens, PW1, CA2 Board, Cover Connector, Lens Unit and Holder Lens Removal

43

Assembly................................................................................................. 45

Installing parts to the (front) Cabinet....................................................... 45

Installing parts to the CA1 Board ............................................................ 46

Setting-Up the CA2 Board..................................... ....... ...... ..................... 48

ST1 Board Setting-Up............................................................................. 49

ST1 Board Setting-Up (2)........................................................................ 50

CA2 Board Setting-Up (2) ....................................................................... 50

Installing Parts to the CA1 Board (2)....................................................... 51

Connecting Boards.................................................................................. 51

Installing the Cabinets............................................................................. 56

Troubleshooting

Overview....................................................................................................... 30

The Camera has no power...................................................................... 31

LED red light blinks / No green light........................................................ 33

Shutter does not work ............................................................................. 33

Image is taken out of cross mark in the viewfinder (Not using LCD monitor)

34

Nothing appears on the Camera and Computer screen (All black)......... 34

Unable to transfer the image data to PC................................................. 35

No Images on the LCD (All black)........................................................... 35

Unable to use the Optional Compact Flash............................................. 36

Adjustment

Overview ...................................................................................................... 60

Getting Ready for Adjustment................................................................. 61

Initialization ............................................................................................. 63

Flange-back Adjustment ........................................................................ 64

AWB5100K Adjustment...................... ...... ....... ...... ....... ...... ..................... 65

Color Matrix Adjustment.......................................................................... 66

CCD Defect Detect Adjustment............................................................... 67

Uploading the Firmware.......................................................................... 67

4

Page 5

EPSON PhotoPC-750Z Revision A

Maintenance

Preventive Maintenance............................................................................... 71

Check Points ........................................................................................... 71

Appendix

Circuit Shematics.......................................................................................... 73

5

Page 6

PRODUCT DESCRIPTION

&+$37(5

4

Page 7

EPSON PhotoPC-750Z Revision A

1.1 Features

PhotoPC-750Z is a compact and high performance digital still camera

equipped with 1.3 million pixels high resolution color CCD and built-in

Color LCD view monitor. Following shows overview and characterist ics

of this product.

[Intended User]

† Professional Users

† Individual Users (Advanced or Intermediate Users)

† For Business Users (For making reports with pictures)

[Recommended Usage]

† For making Home Pages for Web

† For making proceedings with pictures

† For making post cards with pictures

† For making calendar with pictures

[Overview of product]

† 2-way lighting source LCD monitor

2 inches low temperature poly-silicon LCD monit or lit up by sunlight

or a fluorenscent back light. Using sunlight, it leads the power

saving.

† Available selection either skylight feature in bright sunlight /

Backlight in the indoor

† Energy Saving type LCD monitor. (unlike the surface type in the

previous models, 1 line fluorenscent type is applied)

† HyPicT mode

Providing a high quality image based on an EPSON original picture

enhancement technology. Super high quality image by high image

correction skill, equivalent to 2000K pixels CCD.

† Quick Shooti ng Mode:

Taking photos at intervals of under 2 seconds

† Variet y of Shooting Mode:

More available shooting modes than previous models.

† Direct Printing:

A4 direct printing just by connecting the camera and print e r without

using PC.

† High resolution color CCD applied

† 1.3 million pixels CCD sensor. 1/2.7 inches hig hly sensitive CCD

with complementary color filters.

† Optical 3x powered zooming

† Equivalent to 35 mm

(Wide angle lens

<Actual range: 34mm

∼105mm focal length on a 35mm camera.

∼ Telephoto lens: 35 mm film camera equivalent)

∼ 102 mm>

Product Description Features 7

Page 8

EPSON PhotoPC-750Z Revision A

[Product Characteristics]

† High resolution:

4 x VGA (1280 x 960 pixels, 24-bit Color)

† CCD Sensor:

1/2.7 inch color area CCD sensor (1.3M pixels)

† Optical Lens:

Equivalent to 35mm

(Wide angle lens

<Actual range, 34mm

∼ 105mm lens, Optical 3 x powered zooming

∼ Telephoto lens: 35 mm film camera equivalent)

∼ 102 mm>

† Color LCD Monitor:

2-inch 2-way lighting source color TFT LCD monitor.

(Low -temperature Polycrystlline Silicon TFT active matrix)

† Focus Adjustment:

Automatic Focus (TTL type AI Auto Focus)

† Exposure Control:

Program auto exposure (Auto measure by CCD, but manual

adjustment is also available)

† White Balance:

Auto white balance/ Fixed mode(sun light) / User defined mode

(customize)

† Built-in RAM:

2 D-RAMs (4M) for temporal storage of the image data, and inpu t or

output of the image data at View mode.

† Buil t- in Memory (I nternal Memory):

4MB(for recording images, firm ware and optional programs), but

more than 2 M with program area will be consumed when installing

the optional direct print function.

† Image file format:

Based on JPEG (3 modes; Super fine, Fine, Standard)

† Image size:

1280 x 960 (Super fine/Fine), 640 x 480(Standard), 1280 x 480

(Panorama), 1600 x 1200 (HyPict)

† Built-in Flash:

Auto, Flash Off, Forced Flash

† Optical Viewfinder:

Optical real image view finder interlocked with zooming

† Visual effect:

Digital 2x zoom, Panorama, Continuous shooting, Black&White

† Power source:

Four AA-size (Alkaline, Ni-Cd, Lithium, Ni-MH)

† PC I/F:

High speed serial interface (Auto/19200/38400/57600/115200/

230400 bps)

† Video Output:

NTSC video output function (Japan, US)

PAL video output function (EU)

† Direct Printing: Available with following printers;

Stylus Photo, Stylus Photo 700, Stylus Pho to 750, St ylus Phot o EX,

Stylus Photo 1200.

† Options:

See the table on next page.

† External Memory:

Compact Flash memory cards are available.

Product Description Features 8

Page 9

EPSON PhotoPC-750Z Revision A

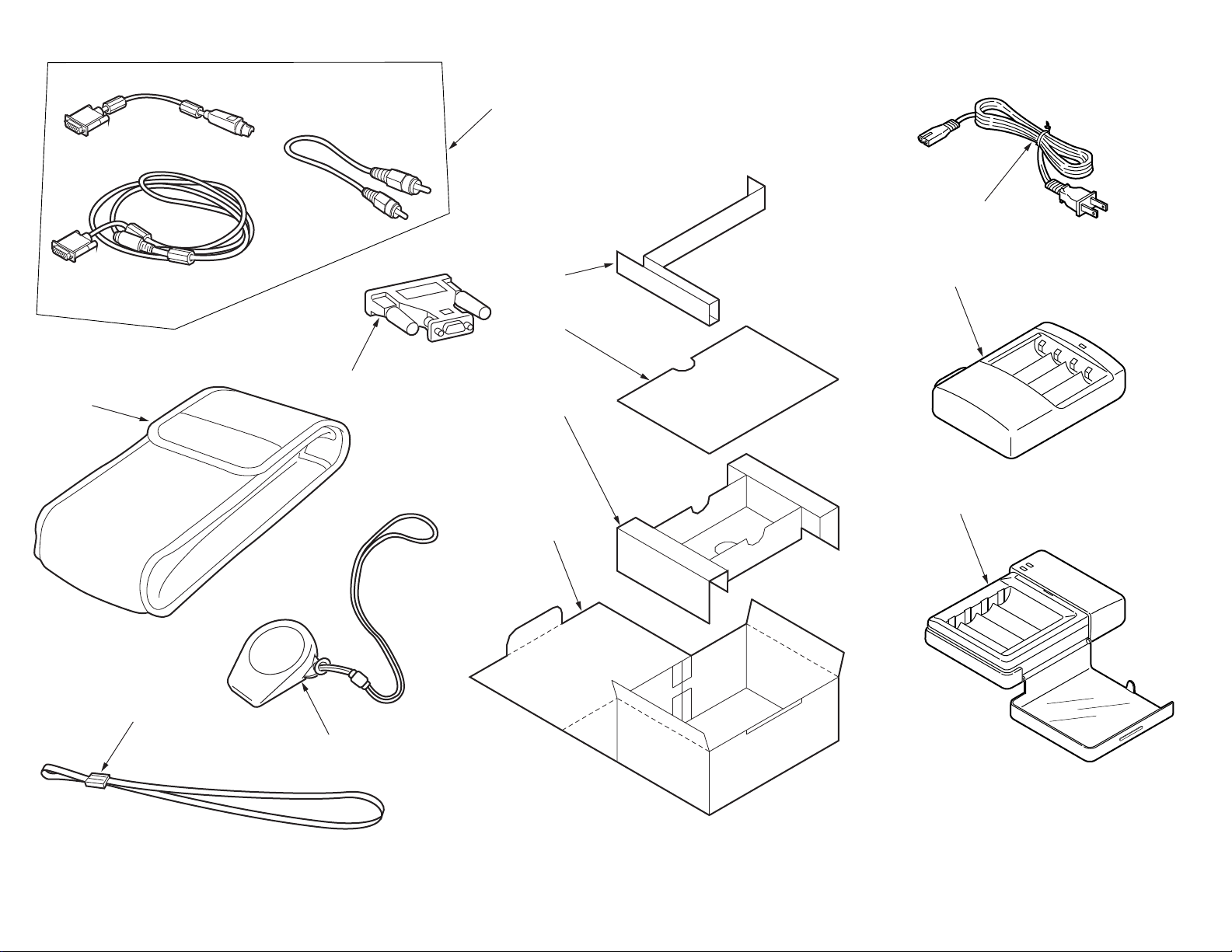

Table below shows the optional items of PhotoPC-750Z.

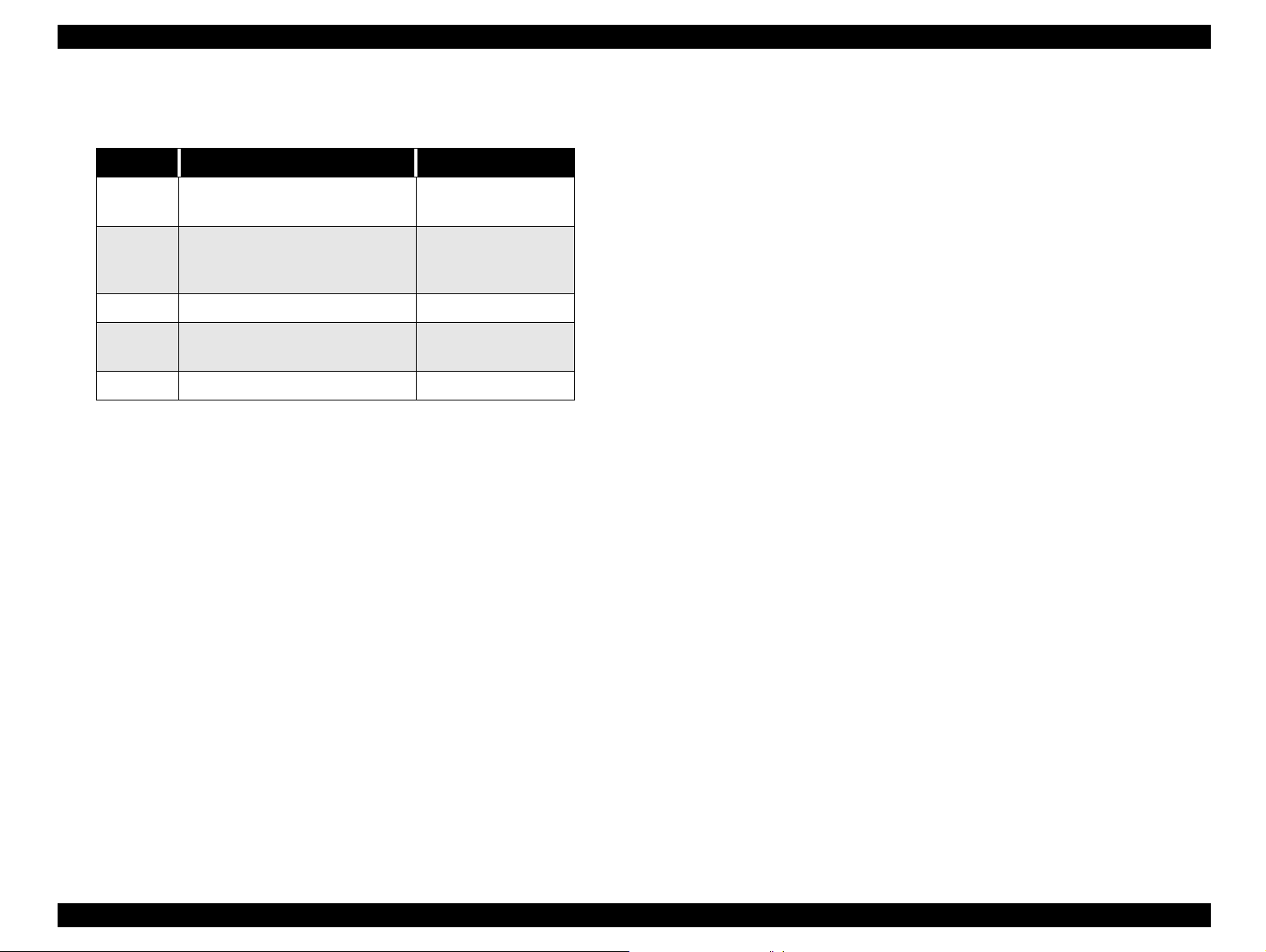

Table 1-1. Options

No. Name Code No.

1

2

3 NI-MH Rechargeable Batteries (4) B81811*

4 Compact Flash Cards

5 PCMCIA adapter B867041

EPSON AC Adapter

(input:100V, output:DC7V-2A)

Power Pack

(Ni-MH Charger + Ni-MH

rechargeable batteries)

B86703*

B81812*

4MB: B808311

15MB:B808301

NOTE:The asterisk in the code No. is a substitute for the last di git,

which varies by country.

1.1.1 Product Description

† Data Type: JEPG (Based on JFIF)

† Thumb nail Image: 160 x 120 pixel

† Image size: 1600 x 1200 pixel (HyPict)

1600 x 600 pixel (HyPict Panorama)

1280 x 960 pixel (Super fine, Fine)

1280 x 480 pixel (Panorama Super Fine, Panorama

Fine)

640 x 480 pixel (Standard)

† Color: 24-bit Full Color/Monochrome

NOTE: In case of HyPict, it is necessary to upload the included

program.

[Optical]

† CCD: 1/2.7 color area CCD (1300K pixels)

Complementary Filter

† Total Pixel: 1343 x 972

† Effective pixel: 1290 x 966

† Actually used pixel:1280 x 960

NOTE: Effective pixel - Actually used pixel = Opti cal black on the

CCD.

† Lens: f=5.2 ∼ 15.6 mm (equivalent to 35mm to

105mm lens on a 35 mm camera)

† Brightness: F2.8 (at f=5.2mm)

∼ F4.7 (at f=15.6 mm)

† Lens Construction: 7 elements in 7 groups

† Focus: F2.8 (opening) / F8

Product Description Features 9

Page 10

EPSON PhotoPC-750Z Revision A

† Viewfinder: Optical real image view finder interlocked with

zooming (View range over 80%)

Correction frame for 80 cm distance from an object

with AF target mark is available.

Cross (+) mark in the finder.

† Sensitivity: Equivalent to ISO 90 (at Standard)

ISO 180/360 high sensitivity is availabl e

† White Balance: TTL type Auto White Balance (rely on AWB

adjustment circuit) Fixed mode or User defined

(customize) mode is available.

† Flash: Aut omatic luminance control flash;

Forced flush, Flash off, Slow Synchro Flash (for

taking pictures at night or in dark place) mode.

Full Auto TTL

† Exposure Time: Program auto exposure by CCD

† Flash Range: 0.2m

∼2.4m for all modes except for wide angle and

zoom (Auto

→Forced on →Forced Off by operation

button)

NOTE:When shooting at macro mode, exposure over will occur if

flash is emitted in 0.2 m (maximum range). In order to avoid

this, use tripod without using flash, avoiding hand vibration.

[Shooting Mode]

† LED Indication:TTL Image Playback (Playback rate 1/30 second)

† Self-Timer: 10-second timer (Slow blinking for 8 seconds,

fast blinking for 2 seconds)

† Macro Mode: Shooting range 20cm

∼ 80cm

† Quick Shooting Mode: In this mode, processing time from one

shooting to the second shooting is shortened by saving the taken

images in the built-in D-RAM. Usually, the image data i n the D-RAM

is processed by

γ correction and in the AWB correction circuit, then

stored in the built-in or external memory. However, in this mode,

these process are not performed but uses the available area of DRM(2M out of 4M) and save the processing time.

*220 KB (Super fine Panorama): 2 seconds

*640 KB (HyPict): 5.6 seconds

Table 1-2. Flash Range

Sensitivity setting Wide angle Zoom

Std. (ISO 90) 0.8

Med. (ISO 180) 0.8 ∼ 3.9m 0.8 ∼ 2.2m

High (ISO 360) 0.8 ∼ 5.6m 0.8 ∼ 3.2m

2.8m 0.8 ∼ 1.6m

∼

NOTE:Maximum available shooting in this mode is up to 20

pictures.

† Continuous Shooting Mode: 2 pictures per second

NOTE:1.Need to press the shutter continuously when using this

function.

NOTE:When shooting a object with bad contrast or with low

illuminance, auto focus may not work correctly. Auto focus

does not work for the object which require the flash emiss ion

forcefully. In this ca se, take about 1.5 m between the camera

and the object forcefully for shooting.

2.Single push results only one picture .

3.Beep sound will be heard every shooting.

4.Flash is forced to be Off, since the necessary charging

time can not keep up with the shooting speed.

5.Available up to 16 pictures at VGA image.

Product Description Features 10

Page 11

EPSON PhotoPC-750Z Revision A

† Digital Zoom: 2 x digital zoom without relying on the optical zoom.

Therefore, digital zoom + optical zoom = 6 x zoom is

available.

[Memory]

† Buil t- in RAM: D-RAM 2MB x 2 (Total 4M)

† Built-inROM: 4 MB (Recorded image + program + included

utility)

† External Memory: Compact Flash Card

† PC-DOS for m at : 512B/Sect

[Indication Function and others]

† LCD Monit or: 2 inch TFT color LCD monitor with dual lightin g

system, electric backlight and skyli ght

(110K pixels: 512 x 218 pixels)

† View rate at shooting:More than 90%

† Playback view range: 100%

5)Indicates fixed white balance mode

6)Indicates High sensitivity mode

7)Indicates continuous shooting mode

8)Indicates self-timer mode

9)Indicates Flash mode

10)Indicates Low battery

† LED next to VF: Green/Orange/Red-blinking/Red

† Timer: Built-in Timer IC (Year/Month/Date, Time/Minute/

Second)

NOTE:However, Timer IC operates when the battery is installed.

When the batteries are exchanged, about 30 minu tes wi ll be

keep counting the time until the electricity in the capacitor

located under SY1 board goes out completely.

† Power saving function: Effective only at battery mode. Save or

Norm.

*Save: Power off right after shooting.

*Norm: Power off 30 seconds after shooting.

NOTE:No power saving function when using the AC adapter.

† Beep soun d: Available (On/Off setting: However, beeping

sound is forced to be ON at continuous shooting,

everytime the picture is taken.)

† Self- Timer Indication: Timer for 10 seconds

† Control LCD Panel:

1)Indicates the number of available pictures (3 digits)

2)Indicates current exposure value when the

Function button is pressed.

3)Indicates the setting of image quality mode

(includes black and white, HyPict mode)

4)Indicates installation of Memory Card

Product Description Features 11

Page 12

EPSON PhotoPC-750Z Revision A

[UI Menu (View Mode Menu)]

† Conditions: Continuous / quick shooting mode

White balance (Auto/Fixed/ Customize)

Exposure value (Auto/ Adjust <9-step>)

Sensitivity (St d ./Med./High)

Flash (Standard, Slow-synchroniz ation strobe)

† Settings: Date and time setting (year/month/day/time),

indicating order of year, month and day setting.

Beep sound condition (On/Off)

Brightness of color LCD display (7 levels)

Power saving mode (Save/ Norm)

† Information: Super imposing information on an image (On/Off)

[UI Menu (Playback Mode Menu)]

† Settings: Date and time setting (year/month/day/time),

indicating order of year, month and day setting.

Beep sound condition (On/Off)

Brightness of color LCD display (7 levels)

Power saving mode (Save/ Norm)

† Slide Show: Automatic playback / Pausing function

† Software: Optional software addition / erasing /execution

Direct printing

† Language: English, Japanese, French, German, Spanish,

Italian, Portuguese (PAL model)

English, Japanese (NTSC model)

[Processing Time]

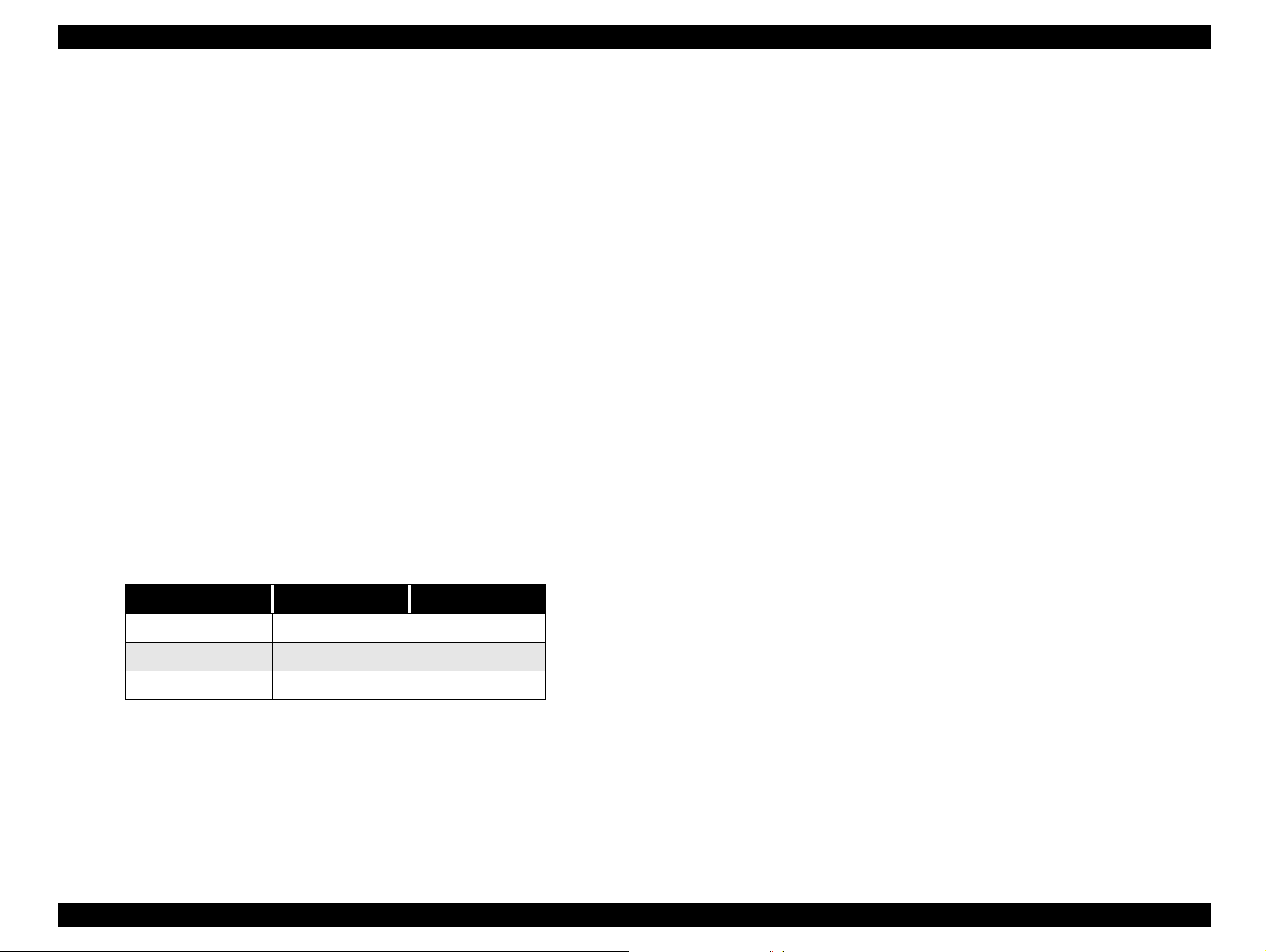

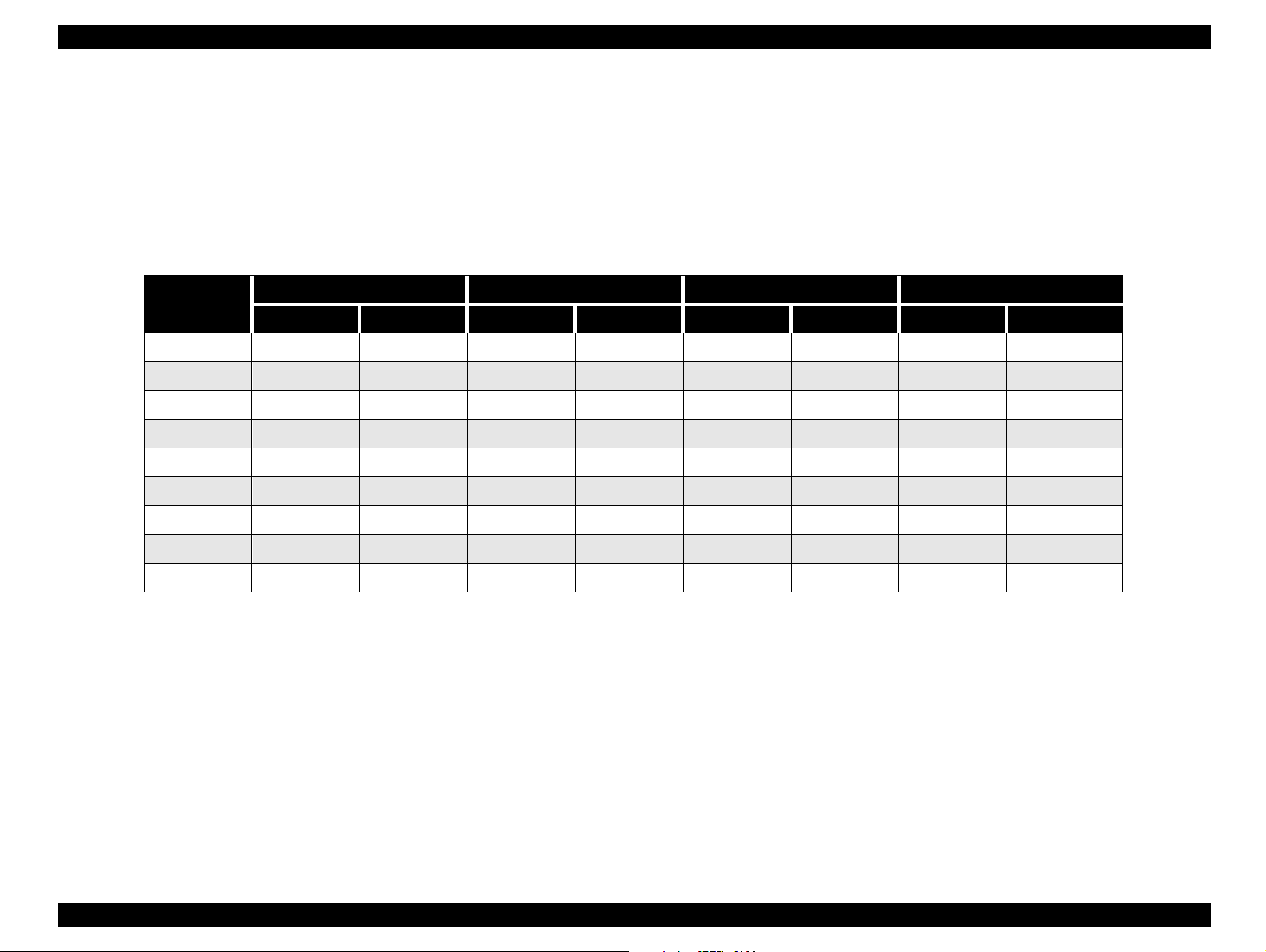

Table 1-3. Processing Time

Quality and

indications

Standard

Fine

Super-fine

•

••

•••

Capturing a

picture

(normal)

about 2 sec about 1 sec.) about 2.5 sec.

about 4.5 sec about 1.5 sec. about 5 sec.

about 6.5 sec about 2 sec. about 6 sec.

Interval time for the

next shot (quick

shooting)

Playback

NOTE:Use the values above as reference. Values above may vary

more or less because of the slight dispersion of internal

memory or circuit.

† In formation: Information about numbers of taken pictures,

remaining shots and date and time of capturing.

Indication of information (On/Off)

† Playback mode: Single picture display / 9 multiple pictures display

† Magnification: 2 x expansion and scroll functions are available.

† Photo Co ntrol: Erase: Single/All

Lock: Select/ All/Unlock

Image: Indicate Information

Copy: from internal memory to CF card/ Vice versa

Formatting CF card

Product Description Features 12

Page 13

EPSON PhotoPC-750Z Revision A

CAUTION

Table 1-4. Average storage capacity

NTSC model PAL model

Standard

(continuous shooting)

Fine

Super fine

HyPict

••

•

•••

H 3 2

•••

35 32

10 9

54

NOTE:1:Figures shown above represent storage capacity when

optional program are not installed in the camera’s internal

memory. If you remove the Direct Print program from the

camera, the storage capacity will increase and you can take

more pictures.

2:The number of pictures you can take depends on the

complexity of each photo, even if the image quality is the

same for all the photos.

[Reference for storage capacity wit h comp act flash card]

Table 1-5. Storage Capacity with Compact Flash Card

2: Figures shown above represent stroage capacity when there is no

image data in the internal memory and no opti onal sof tware is instal le d.

If other file is stored in the memory, available storage capacity

decreases according to the file volume.

[Power]

† Batter ies: 4 AA alkaline (lithium, Ni-Cd, Ni-MH batteries)

† Converter:AC-DC(7V) converter

Table 1-6. Battery Life

Alkaline Batteries

Shooting Mode Power Save Mode Normal Mode

View Mode (LCD on) 80 pictures available 40 pictures available

Finder mode (LCD off) more than 800 pictures available

Playback (LCD on) about 90 min.

NOTE:Measurement conditions: Save mode on. Strobe once in two

shots. 1 min. taking interval.

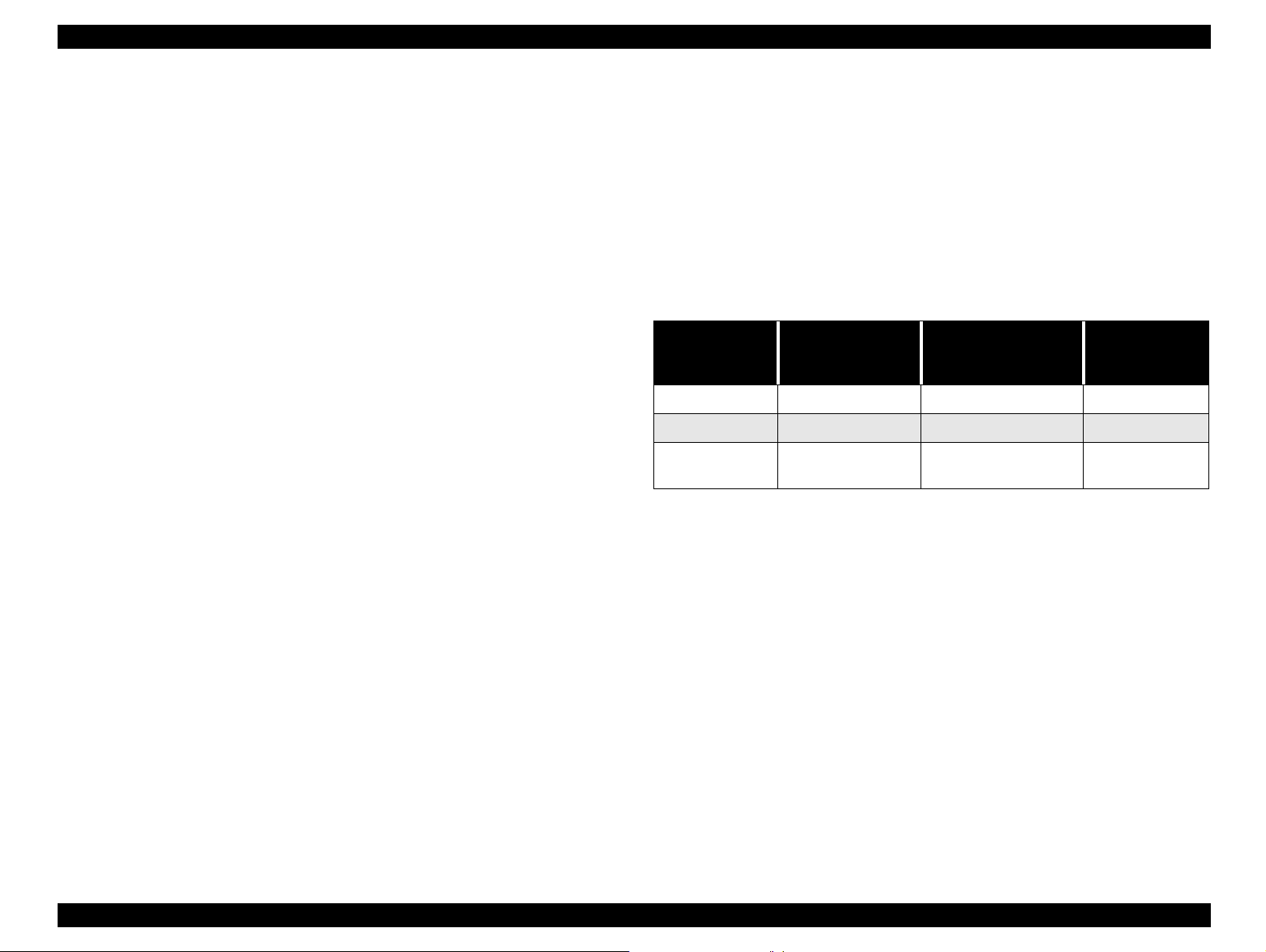

Selected

Mode

Standard

Fine

Super fine

Indicated

Marks

•

••

•••

4MB 10MB 15MB 20MB 48MB

60 158 227 304 365

19 20 72 97 116

9 25364959

NOTE:1: The maximum amount of pictures stored in the memory

card is 999.

Product Description Features 13

Although AA size MN (manganese) batteries can work

first for a while, it is not admitted in the specification

because its battery life allows only to take a few

pictures.

Page 14

EPSON PhotoPC-750Z Revision A

[Physical Dimensions]

† Width: 137.5mm

† Height: 76.4mm

† Depth: 61.8mm

† Weight: 310g (without batteries and strap)

† Tripod socket is available for installing the tripod

[Interface connectors and others]

† Video output: NTSC (NTSC model) or PAL (PAL model) video

output

W ARNING

Use only the AC adapter designed for the PhotoPC-

750Z. Since using any other adapter could keep

charging the batteries without pr oper operation of AC

Jack, it is prohibited to use other adapter.

† Inlet for DC power supply: DC power is supplied from AC adapter

(7V).

† Serial Interface: RS-422, 423 serial port (mini DIN 8 pins

terminals).

(Max. 230 k bps is available only on a PC

supporting this speed. In case of direct

printing, 900kbps or 1.8Mbps

synchronous transmission is available)

† Compact fl ash card slot: Compact flash type 1 card interface.

Product Description Features 14

Page 15

EPSON PhotoPC-750Z Revision A

[Serial Interfa c e ]

The serial interface should be announced as EPSON original

specifications for connecting to a PC/MAC, a pri n ter or a modem, and

the specifications are not open t o the public. Connect ing a PC/MAC. the

interface is compatible with RS-232C. A PC/MAC is required to support

19.2 kbps transmission rates at the minimum.

Table 1-7. Signal Name for Serial Communication Interface

Camera to PC to printer to modem

Pin assign. Circuits I/O Circuits I/O Circuits I/O Circuits I/O

1 HSKo O prCTS O HSKo O

2 HSKi I -- prSCK I HSKi I

3 TXD- O host RD O TXD- O TXD- O

4 GND GND GND GND

5 RXD- I host SD I RXD- I RXD- I

6 TXD+ O TXD+ O TXD+ O

7 GPi I prDTR I GPi I

8 RXD+ I -- RXD+ I RXD+ I

SHELL shell

Product Description Features 15

Page 16

EPSON PhotoPC-750Z Revision A

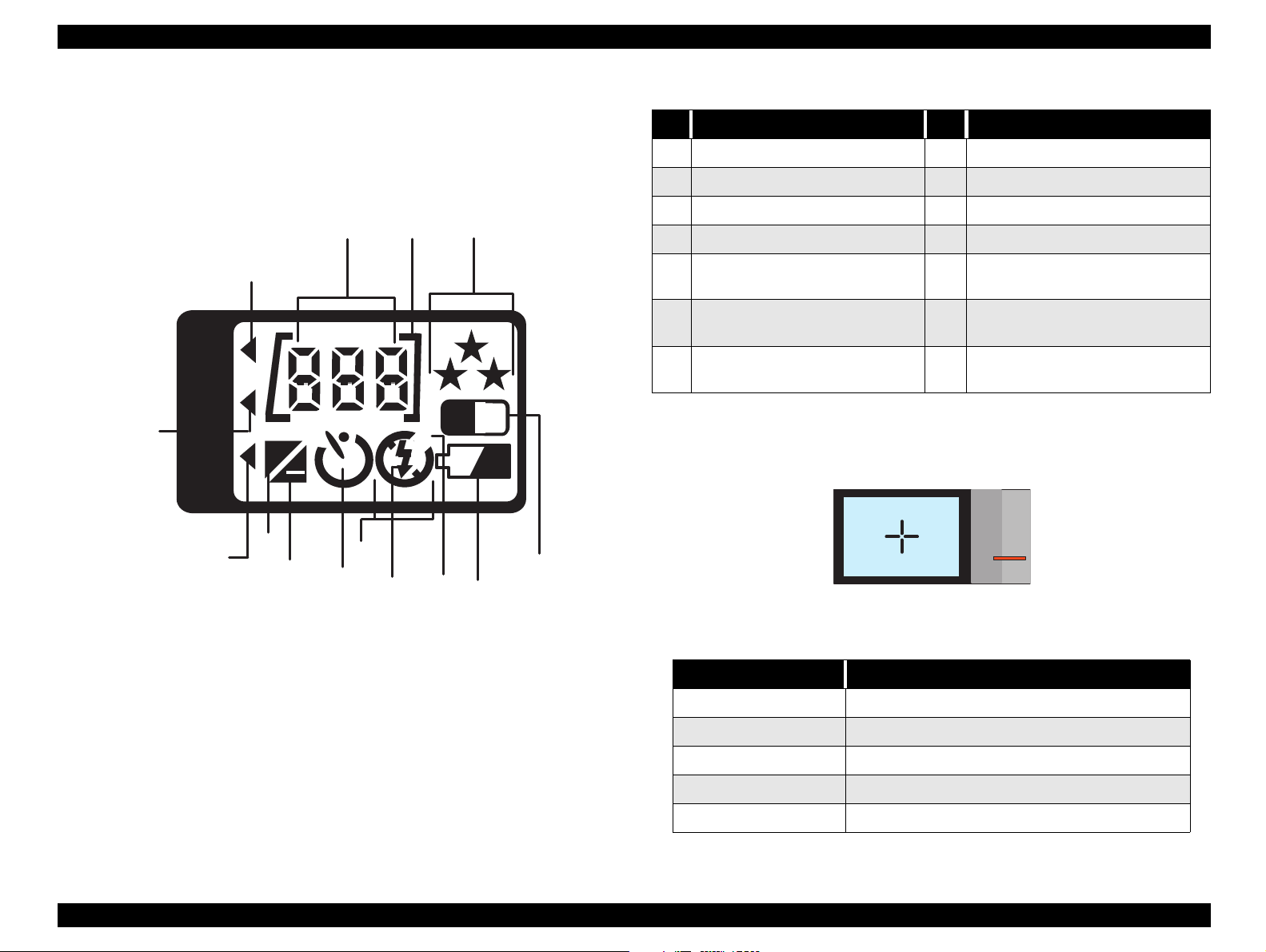

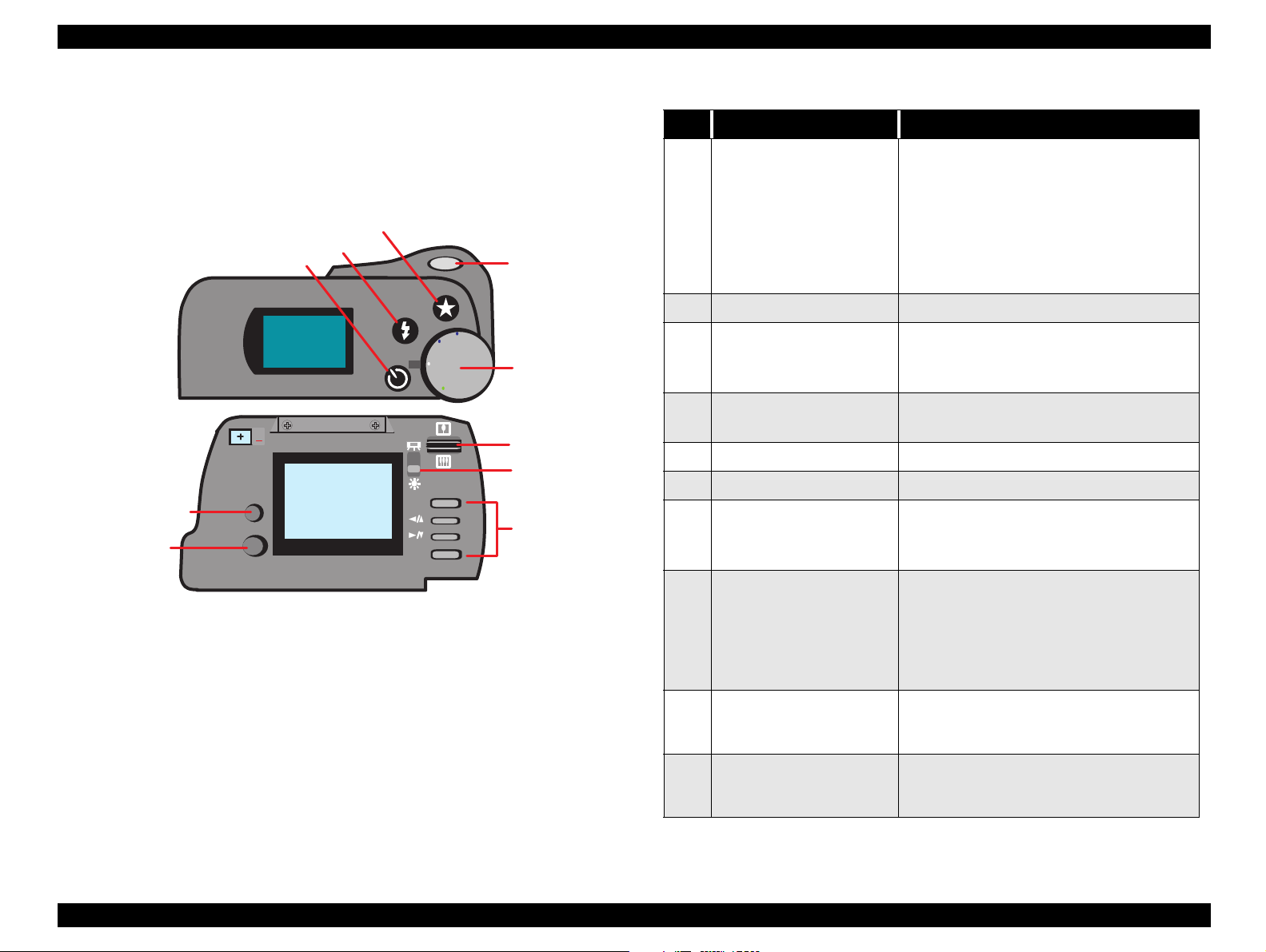

1.1.2 Control Panel

The figure below shows all indications on the LCD panel and table1-8

shows meaning of each mark.

1

2 3

14

WB

H

IS O

13

H

Cnt

12

+

11

10

9

8

7

B

W

A

4

6

5

Table 1-8. LCD panel

No. Display Meaning No. Display Meaning

1 Remaining shots number 8 Strobe off mode indicator

2 CF card insertion marker 9 Self-timer conditions indicator

3 Image quality indica tors 10 Exposure value decreasing indic at or

4 Monochrome mode indicator 11 Exposure value increasing indicator

5 Caution mark for batteries’ level 12

Automatic strobe (flash) mode

6

indicator

Coercive strobe (Forced flash)

7

mode indicator

Figure and table below show the indicati on of LED (st atus light ) besid es

Viewfinder.

Continuous or quick shooting mode

indicator

13 High sensitivity mode indicator

14 Manual white balance

Figure 1-1. LCD Panel Indication

LED (Status Light) Indication meaning

Off No power supply for camera (Power switch is off)

Green light On Power is On, Ready for shooting.

Orange light On Half-stroke shutter condition (AF locked)

Red light blink Image processing or preparing for shooting ready.

Red light On Memory is full (unable to shoot), Camera is broken.

Product Description Features 16

Table 1-9. LED (Status light)

Page 17

EPSON PhotoPC-750Z Revision A

CAUTION

When the camera is broken, sometimes error code is

indicated on the LCD. Table below shows the meaning

of the error code. However, since these error codes

are used in the developing stage and not reliable to

find out specific malfunction parts correctly.

Therefore, use this table as reference but find out

malfunction parts correctly by referring to Chapter 3.

Table 1-10. Error Code List

Error Code Indication Meaning

30s (such as 31, 32,..) Read/Write Error to CF card (includes downloading to PC)

80s (such as 81, 82,83..) Read/Write Error to CF card (except above)

60s Read/Write Error to internal Flash

90s Data write error to the external memory

100s Data write error to internal Flash

254s Access error to the incorrect address

Corresponding Ch circuit does not get activated, even

0

after 4-bit CPU on the SY1 board ouputs Wake-up signal

to the PW1.

Product Description Features 17

Page 18

EPSON PhotoPC-750Z Revision A

1.1.3 Control Buttons

Figure below shows layout of buttons and switches ,and table shows

function of each button.

3

4

10

5

WB

IS O

H

Cnt

Mode

9

Function

EPSO N

Figure 1-2. Switch Location

ESC

SEL.

Off

On

View

Play

2

1

6

7

8

Table 1-11. Meaning of buttons

No. Name of button Meanings and functions

• Off: Power off state.

• On: Mode for taking pictures with a view

finder. (pushing out the lens cylinder)

1 Rotary Switch

2 Shutter 2 stoke shutter button (half/full stroke)

3 Image Quality (Resolution)

4 Strobe (flash)

5 Self-timer Self-timer setting button

6 Zoom Zooming switch.

7 Back Light

8 Menu Buttons

9MODE

• View: Mode for taking pictures with a color

LCD monitor.

• Play: Playback mode of captured pictures

and the last picture will be shown first. (the

lens cylinder is still collapsed)

Image quality selection button

• Color: Standard, Fine, Superfine, HyPict

• Monochrome: Fine, Super fine, HyPict

Strobe mode selection button

(Auto

Forced On→Forced Off)

→

Save energy by;

Setting top: for shooting indoor, or

Setting down: for shooting outside

• ESC.:Exit from menu.

• Selecting function button (1): Move toward

left of upper side.

• Selecting function button (2): Move toward

right or lower side.

• SEL.:Execution function button.

Mode selection button.

(Standard

zooming

Panorama→Digital

→

Macro-photography mode)

→

Providing additional functions with pressing

10 FUNC.

other buttons. (for quick shooting, setting

exposure)

Product Description Features 18

Page 19

EPSON PhotoPC-750Z Revision A

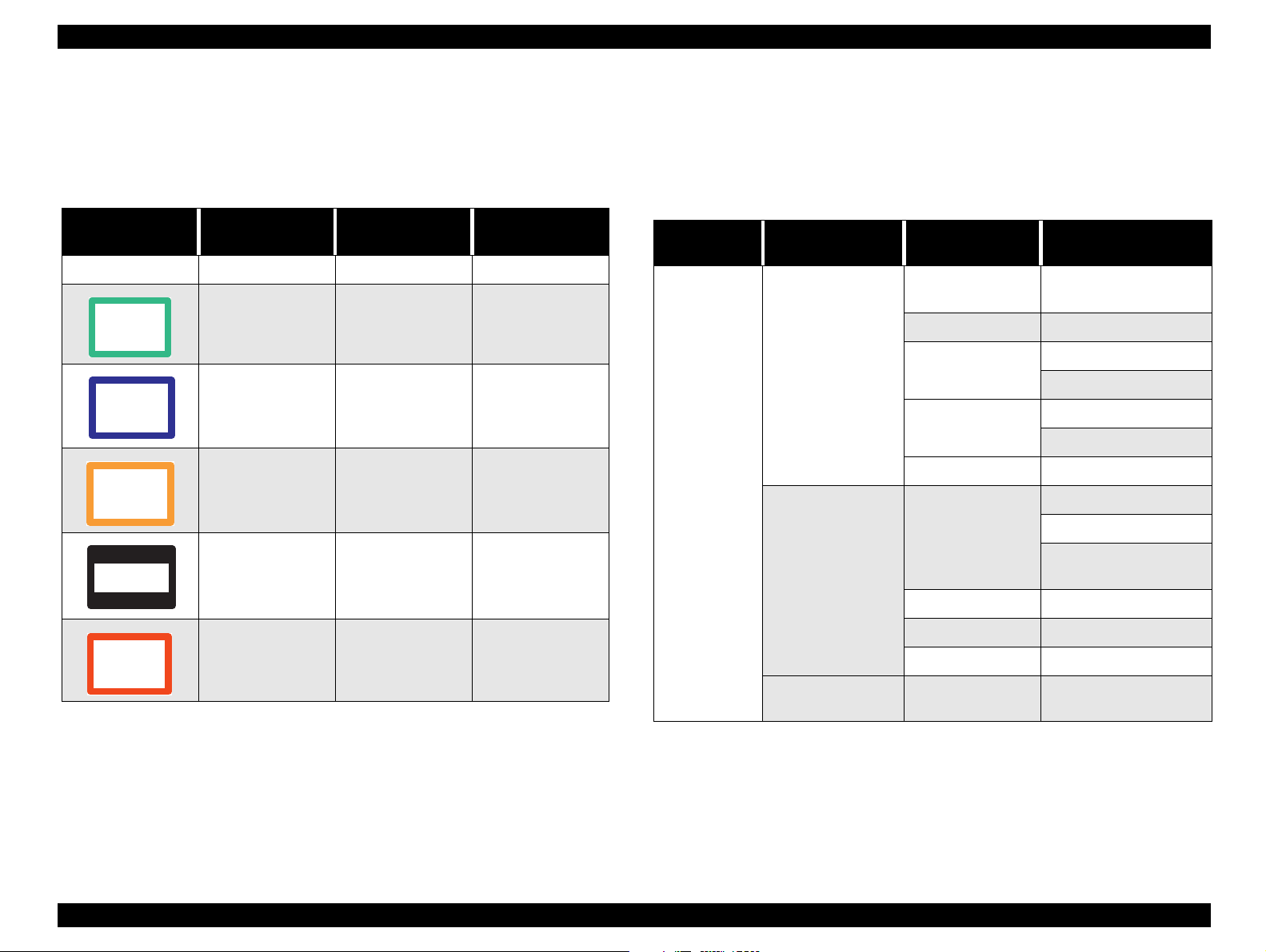

1.1.4 Capturing Mode Indication

There are several color frame indicators showing a current capturing

mode on the LCD monitor in the VIEW mode.

Table 1-12. Frame indication

Frame Indicator Frame Color Mode

Nothing Nothing Standard ---

Green Macro

Blue Monochrome

Orange Digital 2 x zooming

Upper and lower

fields are veiled by

black bands

Panorama

Characters and

indication period

MACRO

a few seconds

MONOCHROME

a few seconds

ZOOM

a few seconds

PANORAMA

a few seconds

1.1.5 Operation Specification

Table below shows each operation menu.

† View Mode

Table 1-13. Operation Menu at View Mode

Camera Mode

View Mode

Menu Items in

View Mode

Capturing(shooting)

mode setting

Configuration

Setting

Item Name Function

Continuous/Quick

shooting

Auto/Manual Auto/Manual

White Balance

Exposure

Adjustment

Sensitivity Standard/Medium/High

Date and Time

Beep On/Off

Off/Continuous/Quick

Auto/Fixed/Custom

Customizing

Auto/Adjust.

Adjustment

Year/Month/date

Hours/ Minutes

Y.M.D / M.D.Y /D.M.Y

order

Power saving Save/Normal

Red

Continuous

shooting

CONTINUOUS

a few seconds

Information

indication

Luminance of LCD 5 levels

Display / Non

display

---

Product Description Features 19

Page 20

EPSON PhotoPC-750Z Revision A

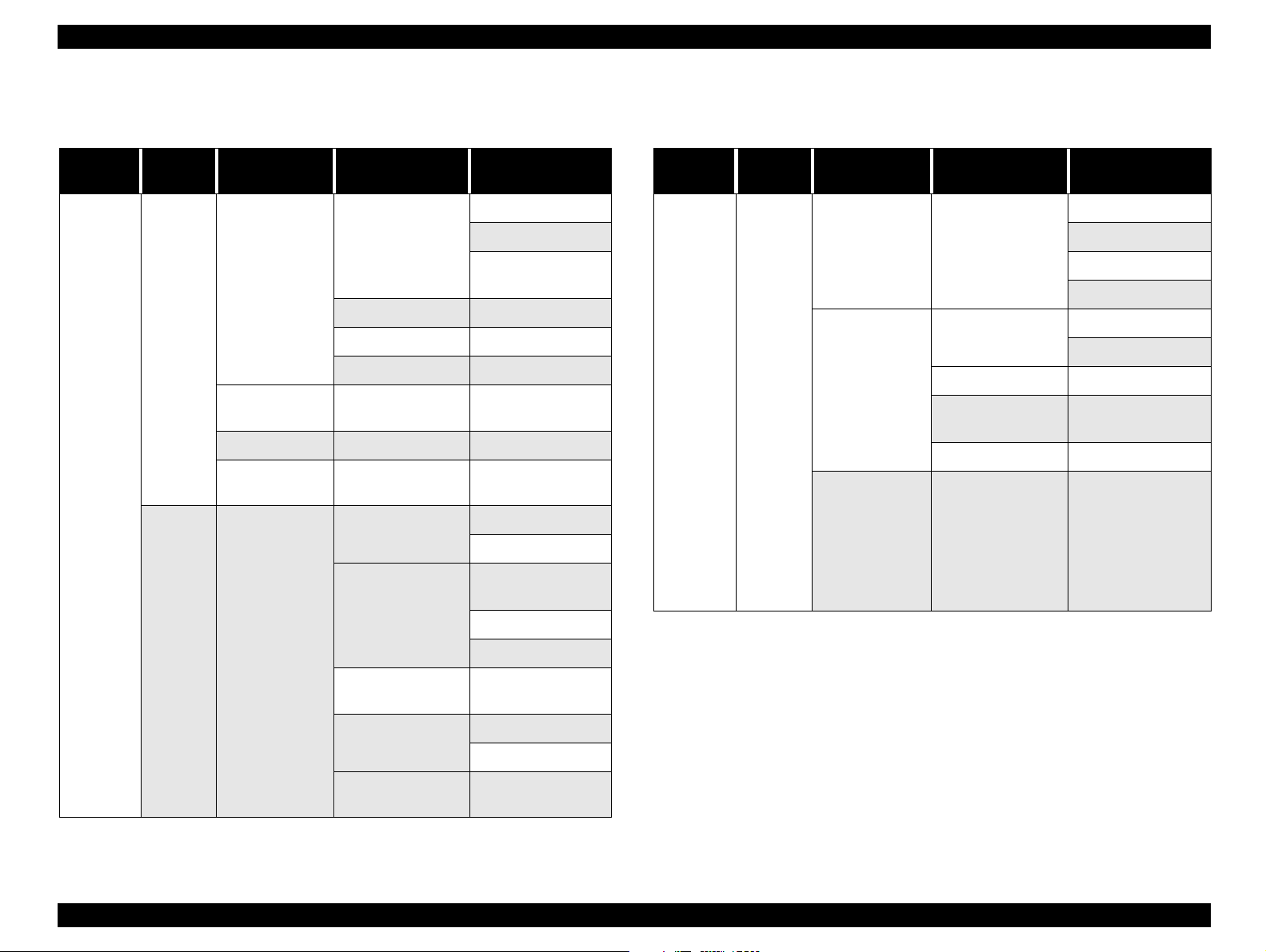

† Playback Mode

Table 1-14. Operation Menu at Playback Table 1-15. Operation Menu at Playback

Camera

Mode

Playback

Screen

First

screen

Menu Items in

View Mode

Configuration

Setting

Information

indication

Playback mo de Single / Multiple --2 x

magnification

Item Name Function

Year/Month/date

Date and Time

Beep On/Off

Power saving Save/Normal

Luminance of LCD 5 levels

display / Non

display

9 areas can be

selected.

Erase

Lock

Hours/ Minutes

Y.M.D / M.D.Y /

D.M.Y order

---

---

Select and Erase

Erase All

Select and Lock/

Unlock

Lock All

Camera

Mode

Playback

Screen

Second

screen

Menu Items in

View Mode

Slide show Select

Optional

software

Language

Item Name Function

Addition /Delete

HyPict ---

Direct printing

Others

English/Japanese/

French/German/

Spanish/Italian/

Portuguese (PAL

mode)

English/Japanese

(NTSC)

Pause/ Continue

Forward

Backward

Stop

Addition

Delete

Go to an optional

menu

---

Second

Screen

Editing

Memory

information

Copy

Format

Unlock All

---

Camera to CF card

CF card to camera

Erase data in the

external memory

Product Description Features 20

Page 21

EPSON PhotoPC-750Z Revision A

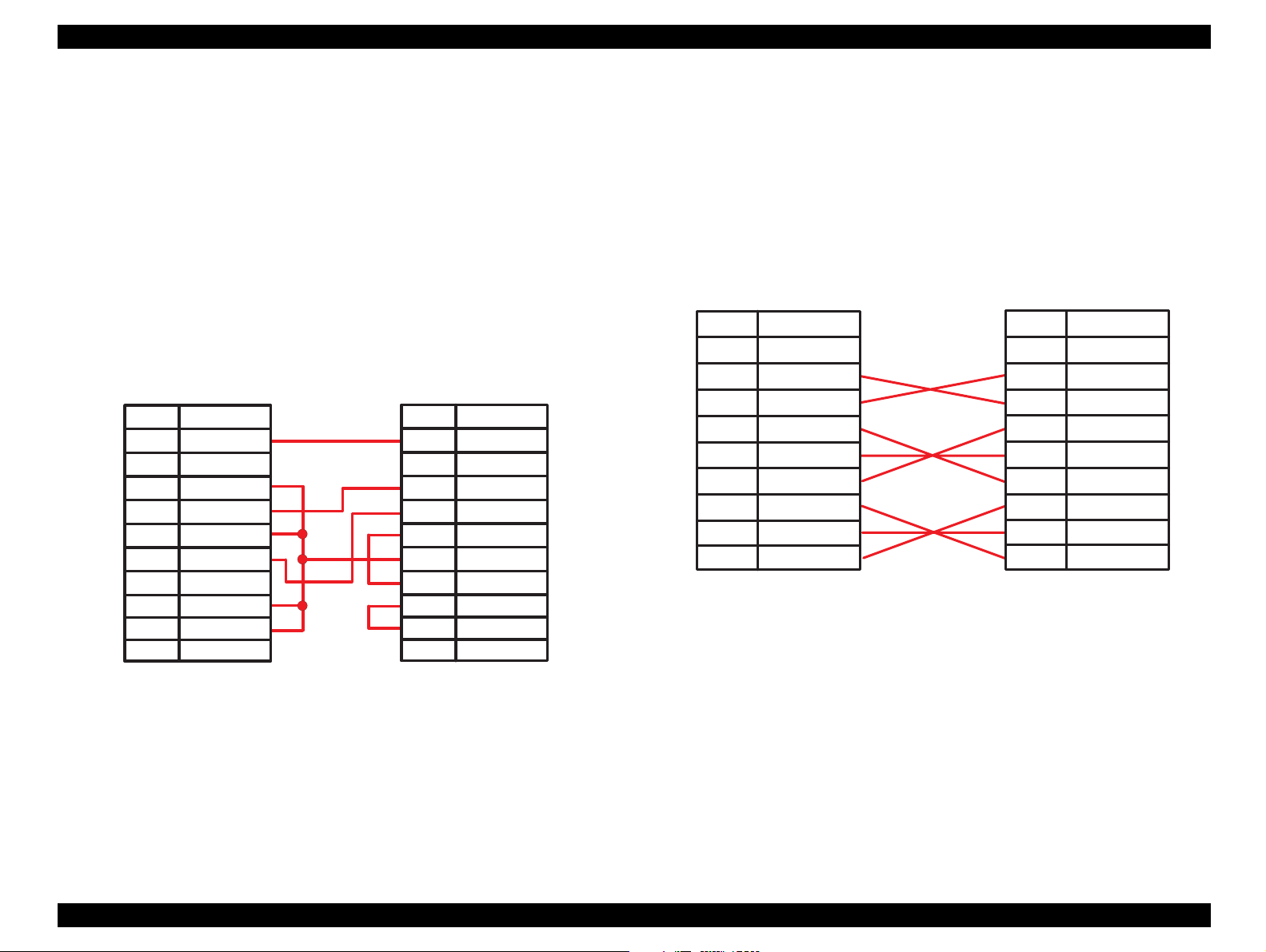

1.1.6 Cable Specification

Figure1-4 and 1-5 show cable connection diagram for DOS. V and

MAC. individually.

[DOS/V Cable]

† Cable Length: 1.5m

† Connector Type:

„ Camera side: 8 pins mini-DIN (male)

„ PC side: 9 pins DSUB (female)

Cam era PC

Pin No.

1

2

3

4

5

6

7

8

S ignal

shell

GND

----

host R D

GND

host SD

GND

GND

----

Pin No.

1

2

3

4

5

6

7

8

9

S ignal

shell

host C D

host R D

host SD

host D TR

GND

host D S R

host R TS

host C TS

RI

[MAC. Cable/Direct printing cable]

† Cable Length: 1.5m

† Connector Type:

„ Camera side: 8 pins mini-DIN (male)

„ PC side: 8 pins mini-DIN (male)

Cam era

Pin No.

S ignal

shell

1

2

3

4

5

6

7

8

HSKo

HSKi

TxD -

GND

RxD-

TxD +

GPi

RxD+

Figure 1-4. Cable Connection for MAC/Direct Print

Pin No.

1

2

3

4

5

6

7

8

Printer

S ignal

shell

SCLK

CTS

TXD -

S.G .

RXD-

TXD +

DTE

RXD+

Figure 1-3. Cable Connection for DOS/V Cable

Product Description Features 21

Page 22

EPSON PhotoPC-750Z Revision A

1.1.7 Options

† AC adapter

„ Model:EU-18

„ Input Voltage:AC110V for Taiwan

„ Output voltage:DC7V 2.0A

„ Model:EU-19

„ Input Voltage:AC120V for North America

„ Output voltage:DC7V 2.0A

„ Model:EU-20

„ Input Voltage:AC220V - AC240V for Europe and others

„ Output voltage:DC7V 2.0A

† Ni-MH Batteries

„ Model:EU-24

„ Output voltage: 1.2V / piece

„ Capacity: 1400 mAH / piece

† Ni-MH Batteries Charger

„ Model:EU-26

„ Input Voltage: AC100V

„ Output Voltage: 1.2V 650 mA x 4

„ Charging time: 2.5H (for 4 pieces)

1.1.8 Environmental Conditions

† Temperature:

„ Operating: 5 to 35

„ Storage: -20 to 60

† Humidity:

„ Operating: 30 to 90%, no condensation

„ Storage: 10 to 90%, no condensation

„ Shock-resistance: 70G (storage)

°C

°C

1.1.9 Power

† DC input volt age (AC adapter): Min. DC 6.3V. Max.:DC 8V

1.1.10 Safety and others

† EMI and safety standards

„ USA: FCC part 15 subpart B class

„ Canada: CSA C108.8 class B

„ Europe: EMC Directive 89 / 336/ EEC EN EN55022 Class B

(CE-marking) EN610000-3-2 (using AC adapter)

EN610000-3-3 (using AC adapter)

EN50082-1

IEC801-2, IEC801-3, IEC801-4

„ Europe: EN55022 (CISPR Pub.22) class B

„ Australia: AS/NZS 13438-C6357

„ Japan: VCCI Class B

NOTE:Flash memory life: 10,000 times writing is guaran teed.

Product Description Features 22

Page 23

OPERATING PRINCIPLES

&+$37(5

5

Page 24

EPSON PhotoPC-750Z Revision A

W ARNING

2.1 Board Component

Majority of the EPSON PhotoPC-750Z consists of the electric circuit

boards. The figure below shows those boards and explains their

functions.

TB 1 Board

TB 2 Board

SY 1 B oard

PW 1 Board

C A1 B oard

Table 2-1. Functions of each board

Name Function

4-bit micro processor as the central system is mounted on

the back of this board . Power supp ly/Stop cont rol, STROBE

SY1

CA1

TB1

ST1

CA2

TB1

charge/discharge control, Clock control and back up for

setting and internal communication bus control are handled

by this board.

CCD is directly soldered on this board. Lens with zoom is

fixed on the CCD. H/V Driver to drive th e CCD, CDS/AGC to

correct the image and A/D converter circuit to transfer the

data to the internal ASIC are mounted on this board.

This board takes po we r fro m the bat teri es . Shu tter switch is

mounted on this board.

This board generates power supply for digital and analog.

Also, electrolytic condenser for flash, connectors for AC

adapter and for video output are mounted on this board.

This board has LCD monitor control, optional memory flash

card control, and also works as the internal control system

for the photographic p rocessing.

Small board mounted on the LED for Self-Timer. It is all

right if this board is no t connected during adjustment and

operation check.

C A2 B oard

Figure 2-1. Board Location

ST1 board has a danger of getting electric shock

because of C5412. Hold the edges of this board and

never touch the board surface when you handle this

board. DIscharge the charged energy of C5412 for

safety before handling this board. (See Chapter 4 for

more details)

Operating principles Board Component 24

Page 25

EPSON PhotoPC-750Z Revision A

2.1.1 Out line of Operating Principles

The figure below shows the block diagram of all boards in PhotoPC750Z. Operation of each board is explained from the next section.

Subject

Lens(X 3 O ptical Zoom + Auto Focus)

Optical

F ilte r

CCD

CDS/AGC

RISK

CPU

Flash

C ontrol

Circuit

S T1 B oard

DC/DC

C onv.

A/D

10bit

CA1Board

DRAM

Address Bus

Data Bus

Scan

C onvertor

ST SG

O utput C ircuit

DMA Control

Circuit

PC

Signal arithmetic Circuit

4M Flash

(x 4 )

O ption Flash

Memory Card

UART

Driver

NTSC

Encoder

af/ae/aw b

Integrator

PIO

4bit

CPU

LC D

Driver

CA2 Board

SY1 Board

Y-C

MIX

Video

O u t

3 .3 V

regutrater

T V

M onitor

LCD Moitor

2.1.1.1 CA1 Board

Major ICs on the CA1 board are listed in the figure below. Starting from

driving the CCD, they perform processing and A/D conversion until

image data is transferred to the internal system.

Table 2-2. Major ICs on the CA1 board

No. IC No. IC Name Function

1 IC903 ICX081AK CCD imager

2 IC902 TC74VHC04

3 IC904 CXD1267AN

4 IC905 CXA2006Q CDS, AGC circuit

5 IC907 CXD2311AR Same function as IC903

H-Driver, Clock for horizontal data

transfer in order to drive CCD.

V-Driver, Clock for horizontal data

transfer in order to driver CCD.

B uzzer

AC Adapter

TB 2 Bo ard

S e lf- T im e r

Power SW

Shutter SW

Function SW

TB 1 B oard

S h u tte r

Through

LC D P anel

AA-size Batteries

Figure 2-2. Block Diagram for Overall Operation

Operating principles Board Component 25

Page 26

EPSON PhotoPC-750Z Revision A

2.1.1.2 CA2 board

Major circuits on the CA2 board are following.

Table 2-3. Major Circuits on the CA2 board

No. Name Function

The optical black section of the CCD extracts

averaged values from the subsequent data to

make the the black level of the CCD output data

1 Digital Clamp

2 Signal Processor Generic name of No.3 to 6 circuits below.

3γ correction circuit

4 Color generation circuit This circuit converts the CCD data to RGB signals.

5 Matrix circuit

Horizon/Perpendicular

6

Aperture

AE/AWB, AF arithmetic

7

(computing) circuit

8 SDRAM Controller

uniform for each line. The optical black section of

the CCD averaged value for each line is taken as

the sum of the value for the p reviou s line multi plied

by the coefficient k and the value o f for the cu rrent

line multiplied by the coefficient 1-k.

This circuit perfor ms (gamma) correction in order to

maintain a linear relationship between the light

input to the camera and the light output from the

picture screen.

This circuit generates Y, R-Y, and B-Y signals from

the RGB signal.

This circuit generates aperture signal.

The AE/AWB carries out computation ba sed on 64segment screen, and the AF carries out

computations based on a 6-segment screen.

This circuit outputs address, RAS, CAS and AS

data for controlling the SDRAM. It also refreshes

the SDRAM.

No. Name Function

8-bit paral lel input and output makes it possible to

12 PIO/PWM/LCD

13 Digital encorder

14 JPEG control circuit

switch between individual input/output and PWM

input/output.

It generates chroma signal from color difference

signal.

Controls the interface for the externally-connected

JPEG IC.

2.1.1.3 ST1 Boar d

ST1 board has mainly 2 blocks; power supply circuit part and

STROBE(flash) control circuit part.

Table 2-4. ST1 Board

No. IC No. Function

This IC has PWM type 4-ch switching regulator circuit;

CH1: Digital 5V, analog system (5V, 15V, -7.5V, 5V (A))

CH2: Digital 3.3V

1IC501

2 T3101 Pressure rise/fall transformer for Analog output voltage

3 T3103 Pressure rise transformer for LCD drive voltage output

CH3: Analog voltage LCD system, (5V, 12V, 15.5V)

CH4: Back light

This regulator has short-circuit protection circuit and

Mis-operation prevention circuit for low input voltage as

safety circuits.

9 Communication circuit Generic name of No.10- to 12 circuits below.

10 USTART circuit

11 SIO circuit Interface for the 4-bit mic roprocessor.

The RS-232C can be used for both synchronous

and asynchronous trans m is sio n.

There are 2 blocks in the strobe(flash) control circuit part; Charging

circuit part and Discharging (Light emission) circuit. Each block is

explained on the next page.

Operating principles Board Component 26

Page 27

EPSON PhotoPC-750Z Revision A

2.1.1.4 SY1 Board

Table 2-5. ST1 Board (Strobe Control Block)

No. Circuit Name Function

When the flash is emitt ed dur ing th e Forc ed or Auto fla sh,

CHQ signal is output high from the SY1 board and

charges the main electrolytic condenser into high voltage

direct current. Charging circuit consists of mainly

following 5 circuits.

1) Power supply filter: It smooth out ripples in the current

which accompany the switching of the oscillation

transformer and LC circuit composition.

1 Charging Circuit

Discharging

2

(Light Emission)

Circuit

2) Oscillation control: Outputs a drive pulse with a

frequency of 15 K Hz to increase DC voltage.

3) Oscillation Transformer: Converts the low voltage

alternating current to a high-voltage alternating current by

this transformer.

4) Rectifier: Converts the high-voltage alternating current

to a high voltage direct current.

5) Voltage monitoring: Monitors the voltage level of

C5412. Detects full charge by 2.7VDC.

Strobe emits light when RDY and TRIG signals are input

from ASIC. Emission circuit consists of mainly the

following 3 circuits.

1) Emission control circuit: When the RDY signal is input

to this circuit, Q5409 which is the main source of the

emission current, is turned on. STOP s ignal turns off

Q5409.

2) Trigger Circuit: D5405 is turned on with input of TRIG

signal.

3) Light emitting element: Light is emitted when the highvoltage pulse is applied to the light emitting part.

4-bit microprocessor is mounted on the SY1 board, and following

operations are handled.

Table 2-6. Various Circuits of the SY1 Board

No. Function Details

This board outputs the /CHG On signal to the ST1

board. Also, it monitors the value of partial pressure of

C5412 and controls to stop charging.

1 Charging

2 LCD light ON

3 Cable Detection

4 CPU communication

5 Power supply control

6 Battery life monitor Monitors the AA-size battery life at the voltage level.

7 Video terminal monitor Monitors if the cable for video output is installed or not.

Card installation

8

monitor

Also, it judges if the power supply is AC adapter or

battery and changes the ending time of the battery

charge subtly. This prevents the AC adapter from

being heat up.

Controls On/Off of LCD back light. However,

characters for explanation on the LCD are transferred

by interna l ASIC.

When RS-232C cable i s install ed, t his circu it mak es all

button functions on the camera invalid.

Performs serial communication with internal main

CPU(SPARC).

Outputs 2 Wake-up signals in order to ge nera te power

supply for digital and analog individually.

When the power is ON, this circuit reads empty raster

and calculates how many pictures can be taken after

detecting the existence of the compact flash card.

Also, after the card is detected, internal memory (4M)

becomes inval id.

9 Buzzer control On/Off control of buzzer drive.

10 LCD panel control

11 LED control Controls all 3 LED drives.

Controls the present various settings and indication of

available photos to take by the key matrix.

Operating principles Board Component 27

Page 28

EPSON PhotoPC-750Z Revision A

2.1.1.5 TB1 Board

TB1 board supplies the power source from the batteries to the ST1

board. Also, the condition when the shutter button is pressed is

monitored by 4-bit CPU on the SY1 board.

2.1.1.6 TB2 Board

LED emission signal is input to this board when the self-timer is set.

Operating principles Board Component 28

Page 29

TROUBLESHOOTING

&+$37(5

6

Page 30

PhotoPC-750Z Revision A

3.1 Overview

There is no function to indicate an error on this camera. Code

indications, which sometimes are indicat ed on the LCD when the

camera is in abnormal situation, are not reli able since they are still in the

developing stage of ASIC, and it is difficult to find the specific

malfunction. Also, sometimes several different malfunctions can be

found from the same symptom. Therefore, check each checkpoints

according to the procedures in this chapter and perform proper repair

service.

W ARNING

Before disassembling the camera, make sure that

batteries are removed or AC adapter is disconnected.

Electrolytic condenser(C5412) mounted on the ST1

board is for flash emission. This condenser is charged

automatically everytime the power is turned on.

Therefore, since there is a possibility to get electric

shock during the service operation, release the

electricity by using the cement resis tance, if you need

to touch the condenser for repair service. (See

Chapter 4 for more details)

Table 3-1. First/Second Maintenance

No. Replaced parts Adjustment Items Maintenance

*Initialization

*AWB 5100K Adjustment

1 CA1 Board

2 CA2 Board Same as above Second Maintenance

3 Lens Unit Same as above Second Maintenance

4 CCD Same as above Second Maintenance

5 LCD Monitor None First Maintenance

6 SY1 Board None First Maintenance

7 ST1 Board None First Maintenance

8 TB1 Board None First Maintenance

9 TB2 Board None First Maintenance

*CCD Defect Detect

Adjustment

*Color Matrix Adjustment

*Flange back Adjustment

Second Maintenance

CAUTIO N

In this products, there are 2 repair levels; first

maintenance and second maintenance. The

performance of the second maintenance is allowed to

be done only by EPSON Co., Ltd. We do not guarantee

the repair result by the others. Refer to the table 3-1

for distinction between first and second maintenance.

Troubleshooting Overview 30

Page 31

PhotoPC-750Z Revision A

3.1.1 The Camera has no power

Refer to the Table 3-2, 3-3, and 3-4, if the LCD is not indicated or red

LED keeps blinking and does not go to the stand-by state when the

rotary switch is turned on after installing the battery or AC adapter.

CAUTIO N

If 4-bit CPU, which controls User I/F, located under

SY1 board becomes abnormal, the signal necessary t o

generate the various digital and analog power source

will not be generated. As the result, the camera goes

to “No Power” state. Also, since this 4-bit CPU

performs serial communication with the main CPU on

the CA2 board, if trouble happens on the CA2 board,

same symptom will appear.

Table 3-2. Check points when the camera has no power

No. Check-Point Solution

Use only recomm en ded a dap ter

Is the user using recommend ed

1

AC-adapter?

Is SY1 board connected firmly

2

to the connectors on the CA1

and CA2 boards?

When the rotary switch turns

3

ON or OFF, does the switch on

the SY1 board also rotate?

Is connector between ST1 and

4

CA2 board (CN501-CN104)

frimly connected?

Is the connector connection

between CA1 and CA2 board

5

(CN101, 102 and CN902 and

901) firmly connected?

Is there electric continuity

between 2 fuses(PR501 and

6

PR502) on the reverse face of

ST 1 board.

(B86703*). Using other kind of

adapter may charge back the

battery.

Re-install the SY1 board.

Re-install the switch.

Push the bottom of ST1 (4-pin

connector, brown) from the top.

Push in the edge of the flash on

the ST1 board and back side of

CA2 board.

Replace either one of fuses.

7 Is SY1 board defective? Replace SY1 board.

8 Is ST1 board defective? Replace ST1 board.

9 Is CA2 board defective? Replace CA2 board.

10 Is CA1 board defective? Replace CA1 board.

Troubleshooting Overview 31

Page 32

PhotoPC-750Z Revision A

Table 3-4. No power only when the batteries are used (2)

Table 3-3. No power only when the batteries are used (1)

No. Check-Point Solution

Are 4 poles for battery located TB1

1

board below bent? or any foreign

objects?

No foreign objects on the poles of

2

the battery cover?

Are 2 protrusions for installing the

3

battery cover damaged?

Is the insulting film around the

4

battery blocking electric poles,

because of defective battery?

Are there any of foreign objects

around electric poles, such as

5

remaining of plastic package of

battery?

Is 2-pin connector (brown) on the

6

ST1 board connected firmly?

Replace or clean TB1 board. If

poles are bent, correct the angle.

Clean the battery cover and pole

area.

Replace the battery cover.

Replace the battery.

Remove the foreign objects.

Re-install CN502.

No. Check-Point Solution

Is the recommended AC-adapter

1

(B86703*) used?

Is SY1 board connected firmly to

the connectors on th e CA1 and CA2

2

boards?

When the rotary switch is turned on

or off, does the switch on the SY1

3

board also rotate along with the

rotary switch’s rotation?

Are the connector connections

4

between ST1 and CA2 boards

(CN501 and CN104) all right?

Are the connector connections

between CA1 and CA2 boards

5

(CN101, 102 and CN902 and 901)

all right?

Is there continuity in 2 fuses

6

(PR501, PR502) on the reverse

face of ST1 board?

7 Is SY1 board defective? Replace SY1 board.

Use the recommended AC-adapter

(B86703*). Using other kind of

adapter may charge bac k the battery.

Re-install SY1 board.

If not, re-install the switch.

Push the bottom of ST1 (4-pin

connector, brown) from the top.

Push in the edge of the flash on the

ST1 board and back side of CA2

board for each other.

Replace either one of fuses (PR501

or PR502).

8 Is ST1 board defective? Replace ST1 board.

9 Is CA2 board defective? Replace CA2 board.

10 Is CA1 board defective? Replace CA1 board.

Table 3-5. Batteries heat up abnormally only when using the AC adapter

No. Check-Point Sol ution

Is a user using the recommended

1

AC adapter?

Is DC Jack in the DC Inlet on the

2

ST1 board broken?

If not, advice the user to use the

recommended adapter.

If yes, replace the ST1 board.

Troubleshooting Overview 32

Page 33

PhotoPC-750Z Revision A

3.1.2 LED red light blinks / No green light

This section explains troubleshooting when the LED (red) located next

to the lens viewfinder blinks or st ays On(red) and never i ndica tes green

light (Stand-by). See the table below.

CAUTIO N

Table 3-6. LED red lights blinks or on and never recovers

When the LED red lights blinks or stays on and never

returns to the green light, it means that 4-bit CPU on

the SY1 board is not communicating well with the

main CPU on the CA2 board.

No. Checkpoints Solution

Is CN301 on the SY1

1

2 Is SY1 board defective? Replace the SY1 board.

3 Is CA2 board defective? Replace the CA2 board.

board firmly connected to

CN106 on the CA2

board?

Push in the SY1 to the

CA2 side.

3.1.3 Shutter does not work

This section explains the checkpoints and solut ion when the data image

can not be taken even when the shutter button is pressed with or

without beep sound. See the table below.

Table 3-7. Shutter does not work

No. Check-Point Solution

Is CN601 on the TB1 board off from the

1

connector?

Is CN304 on the SY1 board off from the

2

connector?

Is cross shaped (+) rib lo ca ted at the rear

3

side of the shutter button worn out?

Is SY1 board connected firmly to the

4

connectors on the CA1 and CA2 boards?

When the rotary switch is turned on or off,

does the switch on the SY1 board also

5

rotate along with the rotary switch’s

rotation?

Are the connector connections between

ST1 and CA2 boards (CN501 and

6

CN104) all right?

Re-connect the connector.

Re-connect the connector.

Replace the shutter button.

Re-install SY1 board.

If not, re-install the switch.

Push the bottom of ST1 (4-pin

connector, brown) from the top.

Are the connector connections between

7

CA1 and CA2 boards (CN101, 102 and

CN902 and 901) all right?

Is there continuity in 2 fuses (PR501,

PR502) on the reverse face of ST1

8

board?

9 Is SY1 board defective? Replace SY1 board.

10 Is ST1 board defective? Replace ST1 board.

11 Is CA2 board defective? Replace CA2 board.

12 Is CA1 board defective? Replace CA1 board.

Push in the edge of the flash on

the ST1 board and back side of

CA2 board for each other.

Replace either one of fuses

(PR501 or PR502).

Troubleshooting Overview 33

Page 34

PhotoPC-750Z Revision A

CAUTIO N

3.1.4 Image is taken out of cross mark in the

viewfinder (Not using LCD monitor)

Here shows checkpoints and solut ion when the images are taken out of

central cross mark when usi ng the lens viewfinder. See the table below.

Table 3-8. Image is taken out of cross mark in the viewfinder

No. Checkpoints Solution

Is the user trying to take a picture

1

within 80cm to the subject without

using Macro mode?

Are 3 fixing screws for lens viewfinder

unit and lens unit removed?

2

(Removing these 3 screws is

prohibited)

Is the CCD soldering on the CA1 board

performed correctly? Especially, the

lens unit determi nes th e p os iti on w h en

3

soldering, perform soldering by

covering the lens uni t without sol dering

only the CCD.

Advise the user to use Macro

mode.

Replace the whole lens unit.

Re-solder the CCD correctly.

3.1.5 Nothing appears on the Camera a nd Computer

screen (All black)

This section shows check points and solution when no images appears

on the LCD even in the playback mode, or the PC monitor is all black

after transferring the image data to th e PC. When this sympt om occurs ,

it will be no images even after changing the LCD switch to View mode.

Camera may work fine even when the CCD is broken

and unable to read images. From the repairing

experiences of PhotoPC 500, main control board

(corresponding to CA2 board in case of PhotoPC750Z) is found defective from the abnormal symptoms

related to CCD. Even when the LCD monitor is not all

black but if red or green are strong, there is a high

possibility that AWB adjustment values are abnormal.

Table 3-9. Nothing appears on the Camera and PC screen

No. Checkpoints Solution

1 Is CA2 board defective? Replace the CA2 board.

2 Is CA1 board defective? Replace the CA1 board.

3 Is CCD defective? Replace the CCD.

If color is obviously abnormal, perform 5100K AWB adjustment again. At

this time, follow the cautions below when using the Color Viewer.

*Avoid entering any lights. *Keep the distance between the Color Viewer

4

and lens within 1cm. (It is OK to let them attach each other) *Set the

volume of Color Viewer to the maximum, and wait about 10 minutes after

turning the Color Viewer On in order to settle the brightness.

Troubleshooting Overview 34

Page 35

PhotoPC-750Z Revision A

3.1.6 Unable to transfer the image data to PC

This section shows checkpoints and solutions when the image data is

unable to be transferred to PC due to the communication failure.

Table 3-10. Unable to transfer the image data to PC

No. Checkpoints Solution

Is the user using PC w ith M ax.9600 -bps

communication speed? Only WIN95/98

1

and Power Mac can be used for

PhotoPC-750Z.

See if the cable terminal on the camera

side is damag ed or not, and check if

2

there is any broken pin or iron piece in

the connector hole or not.

Refer to the cable connection in the

3

Chapter 1 and check if there is

continuity in the serial cable.

4 Is CA2 board defective? Replace the CA2 board.

Following the advice on the

left, use high-speed serial I/F

board and make the

communication speed higher

than 19200-bps.

Replace the serial connector

or CA2 board.

Replace the cable.

3.1.7 No Images on the LCD (All black)

This section shows check points and solution when images do not

appear only on the LCD screen even when images can be transferred

to PC all right.

Table 3-11. No images on the LCD

No. Checkpoints Solution

Camera may have shut off

1

automatically.(Saving energy mode of

the back light)

Is the white connector for LC D back light

2

power supply firmly inserted into CN503

(3-pin, brown) on the ST1 board?

Is FPC of the LCD monitor firmly

3

inserted into CN171(brow n) on the CA1

board?

4 Is ST1 board defective? Replace the ST1 board.

5 Is LCD monitor broken? Replace the LCD monitor.

Explain the dial switch.

Re-insert the white connector

to CN503.

Re-insert the FPC to CN171.

Troubleshooting Overview 35

Page 36

PhotoPC-750Z Revision A

3.1.8 Unable to use the Optional Compact Flash

This section shows checkpoints and solution when the number of

pictures you can take does not change aft er installi ng optional Compact

Flash Card, or image data ca n not be red even a fter removi ng the Flash

card and connecting to PC or another camera.

Table 3-12. Unable to use the flash card

No. Checkpoints Solution

Is all the 50-pin of CN141 on the CA1

1

board damaged or broken?

Is the user insert or remove the flash

2

card when the power is still ON?

Is the user using the recommended

compact flash card?

3

*4MB (B808311)

*15MB (B808301)

Replace the CA1 board.

Provide right instruction.

Replace the memory card.

3.1.9 Picture is blurry or out of focus

This section shows checkpoints and solution when the taken images to

the PC is blurry or out of focus. See the table below.

Table 3-13. Picture is out of focus

No. Checkpoints Solution

The focus adjustment value stored in

1

the memory is not correct.

2 Is the lens unit defective? Replace the lens unit.

3 Is CA2 board defective? Replace the CA2 board.

Refer to Chapter 5 and

perform “Flange-back

Adjustment”.

Troubleshooting Overview 36

Page 37

DISASSEMBLY AND ASSEMBLY

&+$37(5

7

Page 38

EPSON PhotoPC-750Z Revision A

4.1 Overview

This section describes disassembly and assembly for major

components of PhotoPC-750Z. Since the assembl y process is relati vely

complicated, procedures for disassembly and assembly are explained

individually.

4.1.1 Precautions

See the precautions below before disassembling and assembling

PhotoPC-750Z.

„

W ARNING

CAUTIO N

Disconnect the AC adapter or batteries before

disassembling the camera.

„

Discharge the electricity in the electrolytic

condenser by using cement resistance when you

need to touch the ST1 board for repair service. The

electrolytic condenser (C5412), which is mounted on

the ST1 board is for light emission and designed to

be charged automatically everytime the power is

turned on. Therefore, there is a danger of getting

electric shock. (See “Cabinet Parts Removal” on

page -41)

„

In this products, there are 2 repair levels; first

maintenance and second maintenance. The

performance of the second maintenance is allowed

to be done only by EPSON Co., Ltd. We do not

guarantee the repair result by the othe rs. Refer to the

table 4-1 for distinction between first and second

maintenance.

„

Refer to “Assembly” on page -45 for assembly.

„

Use the exclusive package material when

transporting camera.

No. Service Performed Required Adjustment Maintenance

Table 4-1. Criterion of First and 2nd Maintenance

1.Initialization

2. AWB 5100K adjustment

3.CCD Defect Detect

1 Replacing CA1 Board

2 Replacing CA2 Board Same as above. 2nd Maintenance

3 Lens Same as above. 2nd Maintenance

4 CCD Same as above. 1st Maintenance

5 LCD monitor Same as above. 1st Maintenance

6 SY1 Board Same as above. 1st Maintenance

7 ST1 Board Not required 1st Maintenance

8 TB1 Board Not required 1st Maintenanc e

9 TB2 Board Not required 1st Maintenance

Adjustment

4.Color Matrix adjustment

5.Flange-back adjustment

Note) Follow the order

above.

2nd Maintenance

Disassembly and Assembly Overview 38

Page 39

EPSON PhotoPC-750Z Revision A

CAUTIO N

4.1.2 Tools

The table below shows the recommended tools for repair service.

Table 4-2. Tools

No. Name Purchasable Code

1 5100 Kelvin Color Viewer X 103058400

DscCalDl_121a

2

adjustment program

3 Simens Chart X

4 Precision Driver (+) O --5 Simens Star Chart X 10428B100

6 Color Matrix O B740200100

7 Soldering Iron O B641000100

8 Tweezers O ---

Windows95 or 98 (require

9

19200 bps or higher for

serial)

“O” means commercially available and “X “means not.

Note)

CAUTIO N

Mac. PC can not be used for adjustment.

X

O ---

Attached with this

manual book.

Included in the end

of this book.

4.1.3 Screws

Table below shows the specification of screws.

Since each type of screw has its own usage purpose,

make sure to use the specified screws to the correct

appointed positions.

Table 4-3. Screw Identification

N0. Configuration Dimension(mm) Position

100

101

102

103

104

M1.7 x 5

Black

M1.7 x 5

White

M1.7 x 4

Yellow

M 2 x 2.5

Yellow

M2 x 6

Yellow

Most of PhotoPC-750Z parts

are fixed by this screw.

Half of the screws securing

the cabinet are this screw.

Most of the screws securing

the board are this screw.

One screw to secure the

Spacer for the lens unit.

2 screws for securing the

lens unit.

105

106

M1.7 x 3.5

Black

M1.7 x 3

White

One screw for fixing the fro nt

cabinet below.

2 screws to secure the lens

cover.

Disassembly and Assembly Overview 39

Page 40

EPSON PhotoPC-750Z Revision A

START

Cabinet Assembly(Front/Rear), Holder CF,

Cover Battery, Cover Top Removal

SY1 Board, TB1 Board and FPC Unit

Removal

CA1 Board, DEC Lens, PW1, CA2 Board,

Cover Connector, Lens Unit and Holder Lens

Removal

Total

Disassembly

4.1.4 Disassembly and Assembly

Refer to the flow c hart for disassemb ly .

„

CAUTIO N

Read “Precautions” on page -38 before starting

disassembly.

„

When disassembling the camera, follow the order in

the figure.

„

Remove the cables (total 4 cables) for prevention of

radiation, according to your necessi ty . Also, r efer to

“Assembly” on page -45 for the details about

soldering positions when assembling.

Disassembly and Assembly Overview 40

Figure 4-1. Flowchart of Disassembly Procedure

Page 41

EPSON PhotoPC-750Z Revision A

4.1.4.1 Cabinet Parts Removal

The figure 4-2 shows disassembling of Cabinet Assembly (Rear and

Front), Cover Battery and Cover CF. When removing the parts, foll ow

the number in the figure as procedure order.

W ARNING

There is a danger of getting electric shock from the

electrolytic condenser (C5412) mounted on the ST1

board. Discharge the electricity by using the cement

resistance when you need to touch ST1 board for

repair service. (See the next section)

2)O pen the

cover b attery

9)C over B attery

13)TB 2 B oard

10)C abinet

(F ro n t)

11) C onnector

4) 1 screw (105)

12)1 screw (102)

3) 4 screw s(100)

7)Cover CF

8) C abinet (R ear)

1) O pen the

cover jack.

5) 1 screw (100)

6)1 screw (100)

Figure 4-2. Cabinet parts removal

Disassembly and Assembly Overview 41

Page 42

EPSON PhotoPC-750Z Revision A

A

CAUTIO N

Following shows how to release the electricity from the electrolytic

condenser (C5412) on the ST1 board. If y ou don’t perform this, you will

get a high chance of getting electric shock. Follow the procedures

below.

1. Have a cement resistance, which is higher than 560

Ω /10 W.

2. After removing the front cabinet of the camera, connect 2 lead wires

to the soldering wires of the electrolyti c condenser. (There is no

determined poles)

v o id g e ttin g e le c tric s h o c k

by using insulating tape.

N o fixed direction

U se the resistance at

least 560 ohm s/10W .

4.1.4.2 SY1 Board, TB1 Board and FPC Unit Removal

Here explains disassembly of SY1 Board, TB1 Board and FPC Unit.

Follow the order shown in the figure.

The procedure for removing the cables for prevention

of radiation (electric noise) is not explained her e.

Refer to “Assembly” on page -45 when assembling

and perform soldering of cable parts accurately. The

cable for prevention of radiation f or between boards i s

the black cable between SY1 board and CA1 board.

1) 2 screw s(102)

2) C onnector

5) 5 screw s

(101)

7) TB 1 B oard

3) C onnector

6) C onnector

4) SY1 B oard

*T his cable is from the shield

of back side of the C A 1board.

9) 3 screw s(101)

10)FP C

Figure 4-3. Releasing electricity from the condense r

8) C over G rip

Figure 4-4. SY1, TB1 boards and FPC unit removal

Disassembly and Assembly Overview 42

Page 43

EPSON PhotoPC-750Z Revision A

CAUTIO N

ADJUSTMENT

REQUIRED

4.1.4.3 CA1 Board Removal

Here explains disassembly of CA1 Board, LCD Monitor and Holder

LCD. Follow the order shown in the figure.

ADJUSTMENT

REQUIRED

8) 2 screw s(102)

If the CA1 board is replaced, refer to Chapter 5, and

perform the following adjustments.

1)Initialization, 2)AWB5100 Adjustment, 3)CCD Defect

Detect Adjustment, 4)Color Matrix Adjustment and

5)Flange-Back Adjustment.

2) LC D

3) FP C

1)C onnector

9) C A 1 Board

4) 3 screw s(102)

7)C onnector

4.1.4.4 DEC Lens, PW1, CA2 Board, Cover Connector, Lens

Unit and Holder Lens Removal

Here explains disassembly of DEC lens, PW1, CA2 Board, Cover

Connector, Lens Unit and Holder Lens. Follow the order shown in the

figure.

When assembling the optical filter, refer to

“Assembly” on page -45 since it has a determined

direction to be installed.

If the CA2 board or CCD is replaced, refer to Chapter 5 ,

and perform the following adjustments.

1)Initialization, 2)AWB5100 Adjustment, 3)CCD Defect

Detect Adjustment, 4)Color Matrix Adjustment and

5)Flange-Back Adjustment.

Disassembly and Assembly Overview 43

5) Shield(soldering)

6) 1 screw (102)

Figure 4-5. CA1 board, LCD Monitor and Holder LCD Removal

Page 44

EPSON PhotoPC-750Z Revision A

2

8) C A 2 Board3) Shaft cover

b a tte ry

5) 1 screw (102)

1 0 ) 1 s c re w

D

(1 0 3 )

6)C onnector

)D E C Lens

B

B

C

E

7) 1 screw (102)

A

E

1) 1 screw (102)

11) FP C

C aution:O ptical Filter

D

C

9) 2 screw s(104)

Figure 4-6. DEC Lens, PW1, CA2 Boards, Cover Connector, Lens Unit and Holder Lens Removal

Disassembly and Assembly Overview 44

Page 45

EPSON PhotoPC-750Z Revision A

)

4.1.5 Assembly

Here explains the assembly of PhotoPC-750Z. Since the assembly

process is relatively complicated , procedures for disassembly and

assembly are explained individually.

ADJUSTMENT

REQUIRED

Refer to Table4-1 and perform the proper adjustments

after replacing and assembling the corresponding

units or parts. Also, the performance of the second

maintenance is allowed to be done only by

EPSON.Co.,Ltd.

4.1.5.1 Installing parts to the (front) Cabinet

1. Set the Grip to the front cabinet, and fix them by 2 screws from the

inside of the cabinet.

2. Set the tripod holder from the inside of the cabinet, and fix it by one

screw (102).

Grip

C over Lens

T r ip o d H o ld e r

Figure 4-7. Parts Installation to the Cabinet (front)

1) 2 screw s(102)

3) 2 screw s(102)

2) 2 screw s(102

C abinet(front)

3. Install the cover lens from the front cabine t, and fix it by 2 screws

from the inside of the cabinet.

Disassembly and Assembly Overview 45

Page 46

EPSON PhotoPC-750Z Revision A

4.1.5.2 Installing parts to the CA1 Board

1. Put the insulating film on the board.

2. Leave the mounting lens on the insulating film.

3. Insert the feet of CCD to the notch of the mounting lens, paying

attention to the direction of 1-pin of CCD. (See the figure4-8)

4. Leave the rubber damper on the CCD.

5. Put the optical filter on the rubber damper, paying attention to the

direction of the optical filter. (See the fi gure4-8)

6. Put the lens unit over the installed parts from Step 1 to 5.

7. Fix the lens unit from the back of CA1 board by 2 screws (104).

8. Fix the mounting lens from the back of CA1 board by 1 screw (103).

9. Solder 16 legs of CCD from the back of CA1 Board. (Since the

soldering areas of 1-pin and 16-pin are relatively big, be careful not

to solder the neighboring legs.

CAUTIO N

Soldering CCD must be done before fixing the lens

unit. Fixing position of CCD is determined by the

screw position of lens unit. Optical filter has a

determined position to be installed. (See Figure 4-8)

8) 1 screw (103)

2) M ounting Lens

4) R ubber D am per

6) Lens Unit

1-pin position

3) CCD

5) O ptical Filter

N arrow er w hite area: Lens side

Larger w hite area: C C D side

1 ) In s u la tin g F ilm

7) 2 screw s(104)

CA1

Figure 4-8. Parts Installation to the CA1 Board (1)

Disassembly and Assembly Overview 46

Page 47

EPSON PhotoPC-750Z Revision A

g

10. Solder the shield case from the back of the CA1 board. (Total 6

soldering positions)

11. Solder the one side o f t he black cable (about 5.5 cm) f or prevention

of radiation (electric noise) to the solderi ng point, which is located

below the Viewfinder.

12. Insert FPC cable coming out of the lens unit to CN9511 and fi x it .

CAUTIO N

The destination of the cable soldered on the shield

case is the soldering point around the (-) side of the

power capacity (for backing-up) on the SY1 board.

2) A cable for prevention of

radiation (5.5 cm )

C N 9511

S h ie ld C a s e

Solderin

P o s itio n s

Figure 4-9. Parts Installation to the CA1 Board (2)

Disassembly and Assembly Overview 47

Page 48

EPSON PhotoPC-750Z Revision A

CA2

S h ie ld C a s e

3) A cable for prevention

of radiation (3.5 cm )

1) Soldering position

2) A cable for prevention

of radiation (2.5 cm )

Front face

R everse face

4.1.5.3 Setting-Up the CA2 Board

1. If there are no soldering points on the shield case loc a ted at the

front face of CA2 board, drop one soldering to the position as it is

shown in the Figure 4-10. (Soldering position)

2. Solder the black cable for prevention of radiation (about 2.5 cm) to

the dropped soldering point made at Step 1 above.

3. Solder the black cable (about 3.5 cm) for prevention of radiation to

the soldering point, which is located at the under the ser ial I/F