Page 1

SERVICE MANUAL

Color Still Digital Camera

EPSON PhotoPC600

®

4008224

Page 2

NOTICE

n All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

n The contents of this manual are subject to change without notice.

n All effort have been made to ensure the accuracy of the contents of this manual. However,

should any errors be detected, SEIKO EPSON would greatly appreciate being informed of

them.

n The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for

any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may

be trademarks or registered trademarks of their respective owners. EPSON

disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2)

damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could r esult in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POW ER SOURCE AND PERIPHERAL

DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIER WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED

VOLTAGE, LISTED ON T HE SERIAL NUMBER/RATING PLATE. I F THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAI LABLE POW ER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations,

maintenance and repair procedures of PhotoPC600. The instructions and procedures included

herein are intended for the experienced repair t echnicians, and attention should be given to the

precautions on the preceding page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved lubricants and

adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Page 5

REVISION STATUS

Rev. Date Page(s) Contents

A 1997/08/12 All First release

Page 6

TABLE OF CONTENTS

PRODUCT DESCRIPTION

1.1 FEATURES...........................................................................................1-1

1.2 SPECIFICATION .................................................................................. 1-2

1.2.1 Environmental Conditions........................................................................... 1-6

1.2.2 Electrical Specification ................................................................................ 1-6

1.2.3 EMI and Safety Standard.............................................................................. 1-6

1.2.4 Reliability....................................................................................................... 1-6

1.2.5 Operating Conditions................................................................................... 1-6

1.3 INTERFACE .........................................................................................1-7

1.3.1 Specification................................................................................................. 1-7

1.3.2 Control Panel (Display Panel)...................................................................... 1-8

1.4 CAMERA OPERATION........................................................................1-9

1.4.1 Control Buttons ............................................................................................ 1-9

1.4.2 LED Specification....................................................................................... 1-11

1.4.3 Operation Specification ............................................................................. 1-12

1.4.3.1 Basic Operation................................................................................. 1-12

1.4.3.2 Photo Format Setting........................................................................ 1-14

1.4.3.3 Macro Mode (Close Range Shooting)...............................................1-15

1.4.3.4 Basic LCD Settings........................................................................... 1-18

1.4.3.5 Setting the Playback Mode ............................................................... 1-21

1.4.3.6 Other Settings................................................................................... 1-22

OPERATING PRINCIPLES

2.1 OPERATING PRINCIPLES .................................................................. 2-1

2.1.1 Out line of Operating Principles.................................................................. 2-2

Page 7

TROUBLESHOOTING

3.1 OVERVIEW ..........................................................................................3-1

3.1.1 The camera has no power ........................................................................... 3-2

3.1.2 Red LED Light Blinking................................................................................ 3-3

3.1.3 Shutter does not work.................................................................................. 3-3

3.1.4 Image is taken out of cross mark in the viewfinder (Not using LCD

monitor).................................................................................................................. 3-3

3.1.5 Nothing appears on the Camera and Computer screens (All black)........ 3-4

3.1.6 Unable to transfer image data to PC........................................................... 3-4

3.1.7 No images on the LCD screen..................................................................... 3-5

3.1.8 Unable to use optional Compact Flash Card ............................................. 3-5

3.1.9 Picture is blurry or out of focus .................................................................. 3-5

DISASSEMBLY AND ASSEMBLY

4.1 OVERVIEW ..........................................................................................4-1

4.1.1 Precautions................................................................................................... 4-1

4.1.2 Tools.............................................................................................................. 4-2

4.1.3 Specification for Screws.............................................................................. 4-2

4.1.4 Procedure for Disassembly......................................................................... 4-3

4.1.4.1 Removing the Cabinet Parts............................................................... 4-4

4.1.4.2 Removing SY1 Board and ST1 Board ................................................ 4-5

4.1.4.3 Removing CA1 Board, CA2 Board, LCD and CCD............................. 4-6

4.1.5 Procedure for Assembly .............................................................................. 4-7

4.1.5.1 Installing the parts to the Front Cabinet.............................................. 4-8

4.1.5.2 Installing the parts to the Rear Cabinet............................................. 4-14

4.1.5.3 Connecting Holder Chassis and Lens Viewfinder............................. 4-18

4.1.5.4 Installing CCD and Lens Unit to the CA1 Board................................ 4-18

4.1.5.5 Connecting CA1 Board and CA2 Board............................................ 4-20

4.1.5.6 Connecting Holder Chassis and CA1 Board..................................... 4-26

4.1.5.7 Connecting LCD Monitor and LCD Holder........................................ 4-26

4.1.5.8 Connecting LCD Holder and CA2 Board........................................... 4-28

4.1.5.9 Connecting ST1 Board and CA2 Board............................................ 4-30

4.1.5.10 Connecting SY1 Board and CA2 Board.......................................... 4-34

4.1.5.11 Installing the Top Cover and Front Cabinet .................................... 4-38

4.1.5.12 Installing the Rear Cabinet and Battery Cover................................ 4-42

Page 8

ADJUSTMENT

5.1 ADJSUTMENT OVERVIEW ................................................................. 5-1

5.1.1 Preparation for Adjustment ......................................................................... 5-2

5.1.2 Initialization................................................................................................... 5-4

5.1.3 Downloading Firmware................................................................................ 5-6

5.1.4 5100K AWB Adjustment............................................................................... 5-7

5.1.5 Flange-Back Adjustment.............................................................................. 5-8

5.1.6 LCD H AFC Adjustment................................................................................ 5-9

5.1.7 LCD RGB Offset Adjustment ..................................................................... 5-11

5.1.8 LCD Gain Adjustment................................................................................. 5-12

5.1.9 LCD Blue Brightness Adjustment............................................................. 5-13

5.1.10 LCD Red Brightness Adjustment............................................................ 5-14

MAINTENANCE

6.1 PREVENTIVE MAINTENANCE............................................................ 6-1

6.1.1 Check Point................................................................................................... 6-1

APPENDIX

7.1 OVERVIEW ..........................................................................................7-1

7.1.1 Connection Between Boards....................................................................... 7-1

7.1.2 Connector Signals........................................................................................ 7-2

7.1.2.1 Major connector signals on the SY1 board ......................................... 7-2

7.1.2.2 Major connector signals on the ST1 board ......................................... 7-3

7.1.2.3 Major connector signals on the CA2 board......................................... 7-4

7.1.2.4 Major connector signals on the TB1 board ......................................... 7-4

7.1.3 Cable Connection Diagram.......................................................................... 7-5

Page 9

CHAPTER

PRODUCT DESCRIPTION

1

Page 10

PhotoPC600

Chapter 1 Product Description

1.1 FEATURES

PhotoPC 600 is high performance still digital camera equipped with 810K pixels and built in

Color LCD view monitor. Major features are following;

q High resolution color CCD applied

n Optical size: 1/3 inch format

n Total Pixels: 1016(H) x 774(V)

n Available Pixels: 962(H) x 774(V), 24 bit output

q Built in 2 inches color TFT LCD view monitor

q Built in High speed serial interface

Maximum data transfer speed is 115.2K bps, but PC requires serial port rate 19200 bps or

higher.

q Video output

n NTSC/PAL video output function

n Images can be displayed on the home TV by connecting the cable for the video to TV.

q Power supply

n 4 AA batteries(single-use alkaline, single-use lithium, rechargeable Ni-Cd, or rechargeable

Ni-MH)

*AA manganese can not be used.

n AC adapter available

q Automatic Focus: Automatic Exposure by CCD

q Internal memory: 4MB(for image and firmware and optional programs)

q External memory: Compact Flash memory available (4MB, 10MB, 15MB)

q Available photo modes

n Superfine mode (XGA)

n Fine mode (XGA)

n Standard mode (VGA)

q Direct print function

By using optional direct print adapter, direct printing from Stylus Photo is available.

Following shows optional products for PhotoPC600.

Table 1-1. Options for PhotoPC600

Item Name Code

Compact Flash Memory 4MB Compact Flash Card B808311

10MB Compact Flash Card ---

15MB Compact Flash Card B808301

AC Adapter 100-120 V/220-240 V B86703*

Stylus Photo Direct Print

Adapter

Communication kit Exclusive PhotoPC500 Software T.B.D

Exclusive Stylus Photo Software T.B.D

Note*)

Rev. A

The number represented by an asterisk varies, depending on the country.

1-1

Page 11

Chapter 1 Product Description

2

1.2 SPECIFICATION

IMAGE DATA

q CCD: ICX081AK (SONY)

q Size: 1/3 inch format, square pixel

q Total pixel: 1016(H) x 794(V) Approx.810K pixels

q Available pixels: 962(H) x 774(V) Approx.740K pixels

q Color: 16700K colors, 24 bits

q Resolution: Super fine mode (1024x768 pixels)

Fine mode (1024x768 pixels)

Monochrome super fine (1024x768 pixels)

Monochrome fine mode (1024x768 pixels)

Standard mode (640x480 pixels)

q Compression: JPEG

OPTICAL

PhotoPC600

q Lens: F2.8 (equivalent to 36mm lens on a 35mm camera)

q Aperture: F2.8, F5.6, F11 automatic change

q Focus: Auto Focus

q Range: 0.2m-0.5m (Macro mode)

0.5m-infinity (Normal mode)

q Shutter: Electronic shutter (1/8-1/500 sec.)

q Exposure: Equivalent to ISO100

q White Balance: Auto white balance (Rely on AWB adjustment circuit)

Full auto TTL

q Exposure Control: Program auto exposure by CCD detection

q Optical: Optical real image view finder, View range 80%,

Viewfinder Indication in the finder is marked by the cross mark

q Flash Range 0.2~2.4m(Flash control button; Auto®Forced flash On®Forced flash

Off)

Rev. A

1-

Page 12

Chapter 1 Product Description

3

INTERNAL IMAGES

q Internal compression: JPG format

q Internal Memory: 4MB

q Available number of images(photos) with memories.(See the Table below)

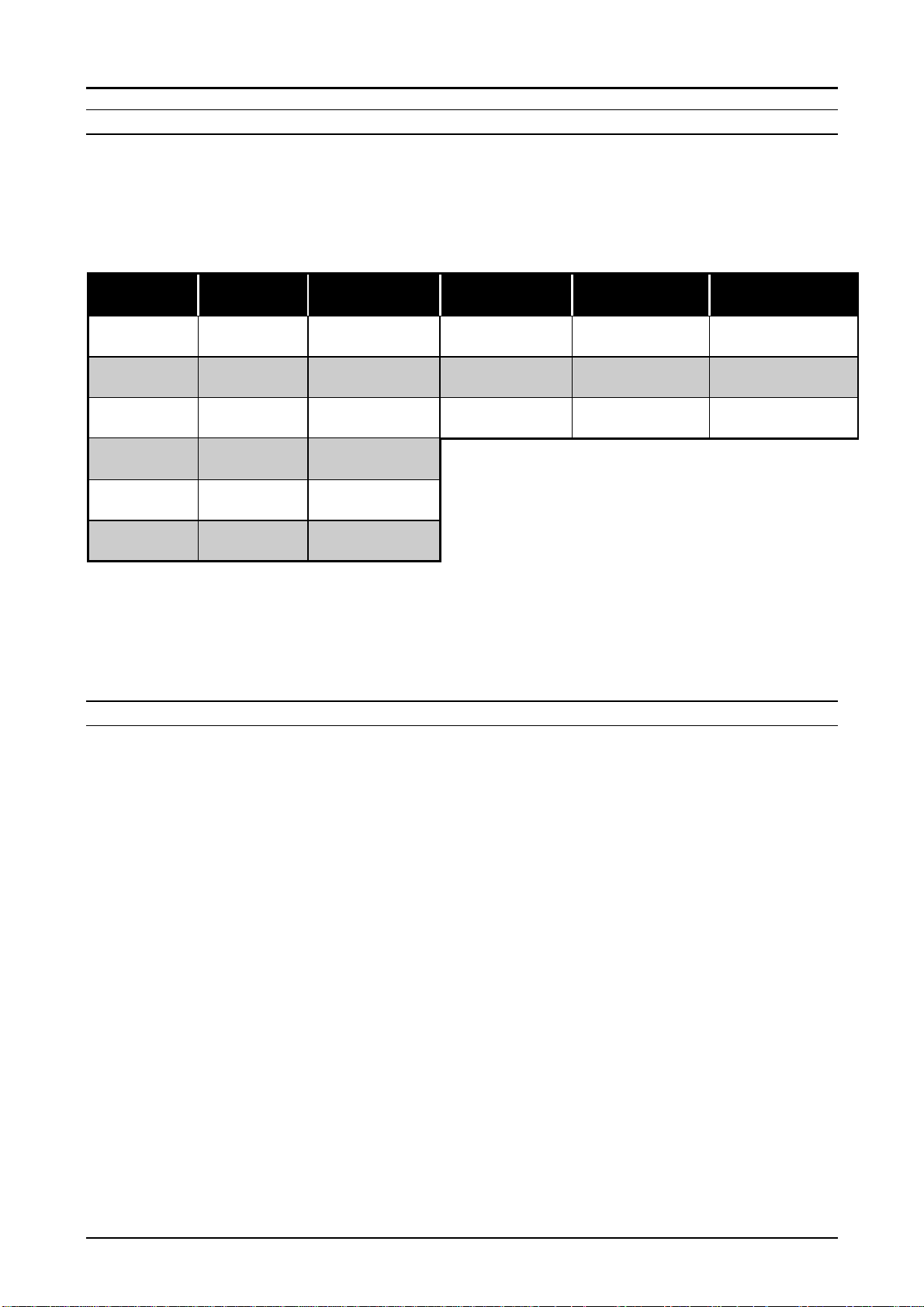

Table 1-2. Number of Available Images with Optional Memories

PhotoPC600

Mode Setting

Display

Super fine

Fine

Standard

Super fine

Panorama

Fine

Panorama

Zoom/Multiframe

Note1)

Note2)

SHOOTING MODES

In case the optional flash card is installed, internal memory(4MB) becomes invalid.

Therefore, the available number of images does not simply equal to the total number

of internal memory + compact flash memory. Using optional flash memory make it possible

to share the image data with PhotoPC500 or portable type of PC.

If the flash memory card is removed or installed while the camera is On, all the data will be

reset.

★★★

★★★

★★

★

★★

★

4M Internal

Memory

7 pictures

(Average:8)

16 pictures

(Average:18)

50 pictures

(Average:56)

14 pictures

(Average:16)

32 pictures

(Average:37)

50 pictures

(Average:56)

4M Compact

Flash Memory

Average 9 Average 25 Average 35

Average 21 Average 55 Average 79

Average 63 Average165 Average 238

10M Compact

Flash Memory

15M Compact

Flash Memory

q Normal shooting: Color image Super fine mode 1024x768 pixels

Fine mode 1024 x768 pixels

Standard mode 640x480 pixels

Note1)

q Self-timer mode: Picture will be taken 10 seconds by the clock counter.

q Macro mode range: 0.2m~0.5m

q Multi-frame mode: Continuous taking 9 images in a same picture at four intervals

Note2)

q Zoom mode: Digital step zoom (x1, x1.3, x1.6, x2.0, x2.5, x3.0)

Note3)

q Panorama mode: Panorama size image (1024x384)

Note4)

In the super fine and fine mode, quantity of information (File size) that image data

has varies even their resolution is the same.(Refer to the Table on the next page for

details.) Therefore, as a result, some differences are seen on the images even with the

same resolution.

(total time : 0.5, 1.0, 2.0, 3.0 seconds)

At the multi-frame mode, the shooting data is fixed at 640x480 pixels(VGA class).

At the zoom image mode, the shooting data is fixed at 640x480 pixels(VGA class).

Change the shooting size from 1024x768 to the rectangular

1024x384

In the panorama mode, since unused area appears on the top and bottom, the

available number of images increases.

Rev. A

1-

Page 13

PhotoPC600

4

Chapter 1 Product Description

q Monochrome mode: For taking black and white pictures (Monochrome fine and

Monochrome super fine)

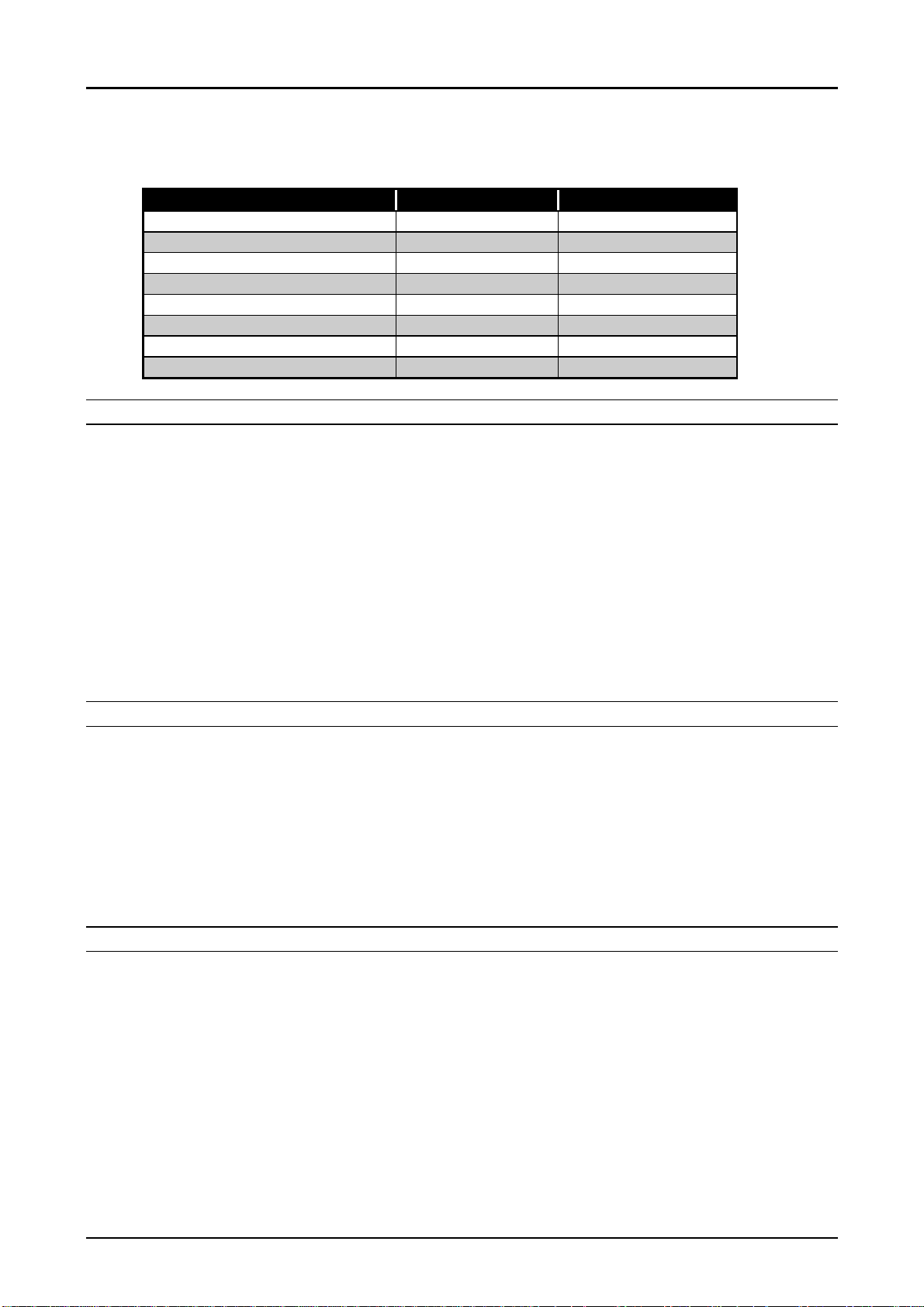

Table 1-3. File Size and Resolution with Various Modes

Shooting Mode Resolution File Size

Super fine 1024x768 320KB

Fine 1024x768 160KB

Standard 640x480 60KB

Super fine (Panorama) 1024x384 160KB

Fine (Panorama) 1024x384 80KB

Zoom/Multi image 640x480 120KB

Super fine (Monochrome) 1024x768 160KB

Fine (Monochrome) 1024x768 80KB

INDICATOR/MONITOR

q LCD Monitor: 2 inches TFT color LCD

q Indications on the LCD monitor: 1)The number of pictures remaining

2)Image quality information

3)Flash mode

4)Macro mode

5)Self-timer mode

q Beep: On/Off

q Self-timer: Shooting in 10 seconds: blink slow(8 seconds) + blink

fast (last 2 seconds) = total 10 seconds

q Clock: No battery back up

Note)

Date and Time will be cleared when the batteries are removed from the camera.

(same as PhotoPC and PhotoPC500)

DATA PROCESSING

q Recording period: Standard mode About 11 sec.

Fine mode About 11 sec.

Super fine mode About 14~15 sec.

q Playback: Standard mode About 3 sec.

Fine mode About 6 sec.

Super fine mode About 8~11 sec.

Note)

SWITCHES

q Main power SW: Rotary switch with lens cover

q Monitor mode SW: 1)LCD view

q Control buttons: Macro mode (on/off)

q Select SW: Select, Back, Navigation buttons(4/5and

This processing time is only for internal memory. In case of using the optional flash

memory, these values varies, depending on the ability of access time by the memory.

2)Off

3)Image playback mode

Image quality (Standard/ Fine/Super fine)

Self-timer button(on/off)

Flash mode (on/off/Auto)

Shutter (half shutter: AF lock)

3/6buttons)

Rev. A

1-

Page 14

PhotoPC600

5

Chapter 1 Product Description

PHYSICAL DIMENSIONS AND WEIGHT

q Dimensions: 142.5mm(W) x 69.8mm(H) x 48.8mm(D)

q Weight: Under 250g (without batteries)

POWER SUPPLY

q Power supply: Require 4 batteries(single-use alkaline, single-use lithium,

rechargeable Ni-Cd, or rechargeable Ni-MH)

*AA manganese can not be used.

AC adapter available

CAUTION

Even AA size manganese batteries can be initially used, it is not

acknowledged as specification here since the battery life ends after

taking just a few images.

WARNING

Use only the AC adapter designed for PhotoPC600. Use of any other

adapter enables AC jack in the camera to operate abnormally and may

cause constant charging to the batteries.

EXPANSION CONNECTOR

q Video out: NTSC/PAL (NTSC model/PAL mode)

q DC input terminal: AC adapter(7V)

q Serial communication: Data input/output terminal (RS-422/423)

BATTERY LIFE

q Continuous shooting(without Flash operation): More than 400 pictures

q Shooting in View mode: Approximately 30 minutes

q Shooting in Playback mode: Approximately 90 minutes

Rev. A

1-

Page 15

Chapter 1 Product Description

6

1.2.1 Environmental Conditions

q Temperature: Operating 0 to 40 °C

Storage -20 to 60 °C

q Humidity: Operating 30 to 90% (no condensation)

Storage 10 to 90% (no condensation)

1.2.2 Electrical Specification

q Requirement of supply voltage for DC input (AC adapter)

Min. :DC 6.3 V

Max.:DC 8 V

q Absolute maximum supply voltage for DC input

Max. :DC 10 V

1.2.3 EMI and Safety Standard

PhotoPC600

q USA: FCC part15 subpart B class B

q Canada: CSA C108.8 class B

q Europe: EMC Directive 89/336/EEC EN55022 Class B

(CE-marking) EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

Europe(NEMKO): EN55022(CISPR pub.22) class B

q Australia: AS/NZS 3548 class B

q Taiwan: EMI: CNS13438-C6357

1.2.4 Reliability

q FLASH memory life: 10K cycle write for FLASH memory

1.2.5 Operating Conditions

q Place: Ordinary home, office or outside

Rev. A

1-

Page 16

PhotoPC600

7

Chapter 1 Product Description

1.3 INTERFACE

PhotoPC600 can be connected to PC only by the serial interface (RS-232C compatible).

The minimum speed requirement of serial interface for PC is 19200 bps.

1.3.1 Specification

ASYNCHRONOUS

q Standard: RS-232C

q Communication Method: Asynchronous, 8bit, Non parity

q Communication speed: 19200, 38400, 57600,115200 bps

SYNCHRONOUS

q Standard: RS-422,423

q Communication Method: Synchronous, 8 bit, Non parity

q Communication speed: 230k bps - 900k bps

Rev. A

1-

Page 17

PhotoPC600

8

Chapter 1 Product Description

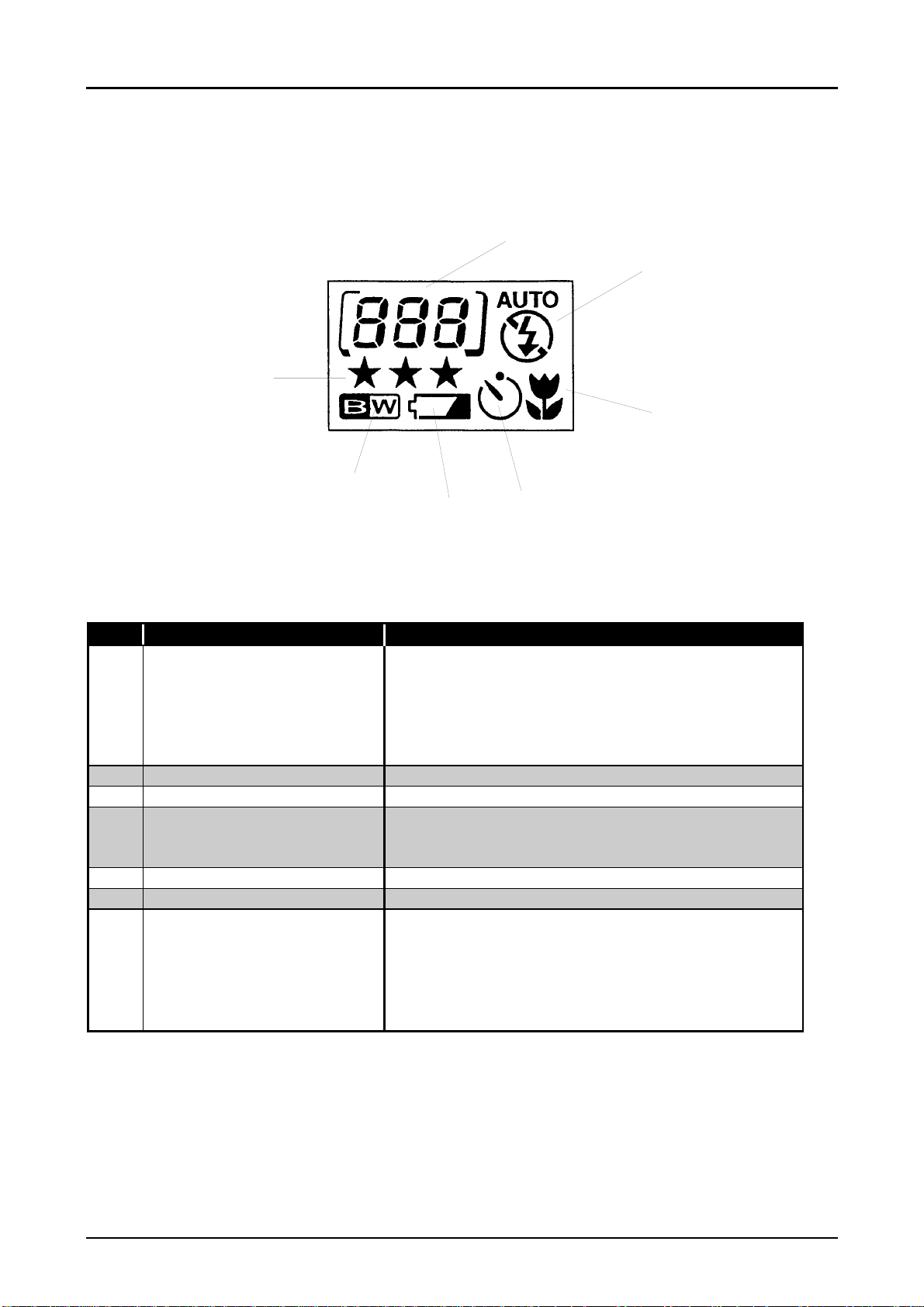

1.3.2 Control Panel (Display Panel)

The camera operation modes are displayed on the LCD. The following figure shows their

exteriors and 7 displays. Refer to the table below for the list of display meaning.

A

B

G

C

F

E

D

Figure 1-1. Display Panel

Table 1-4. Control Panel Indications

No. Display Meaning Additional Information

A The number of the

pictures remaining

B Flash mode 3 flash settings; Auto/Forced flash/Forced flash off

C Macro mode Indicates On/Off. (Range:0.2~0.5m)

D Self timer Shooting 10 seconds after pressing the shutter

E Battery life Indicate 3 battery conditions; Full/Half/End

F Monochrome mode Indicates On/Off

G Resolution (image quality) Indicates Standard/Fine/Super fine. However, the

Although the number of pictures you can take

increases or decreases depending on information

quantity (file size) that image data has, the minimum

number that you can take is guaranteed.

(The brackets

compact flash cards.)

button. (Timer light blinks 8 seconds slowly and 2

seconds fast.)

image quality for the following modes are

determined and Super fine resolution can not be

used.

·Zoom mode: Standard resolution(640x480)

·Multi-image mode: Standard resolution(640x480)

[ ]

appears when using an optional

Rev. A

1-

Page 18

9

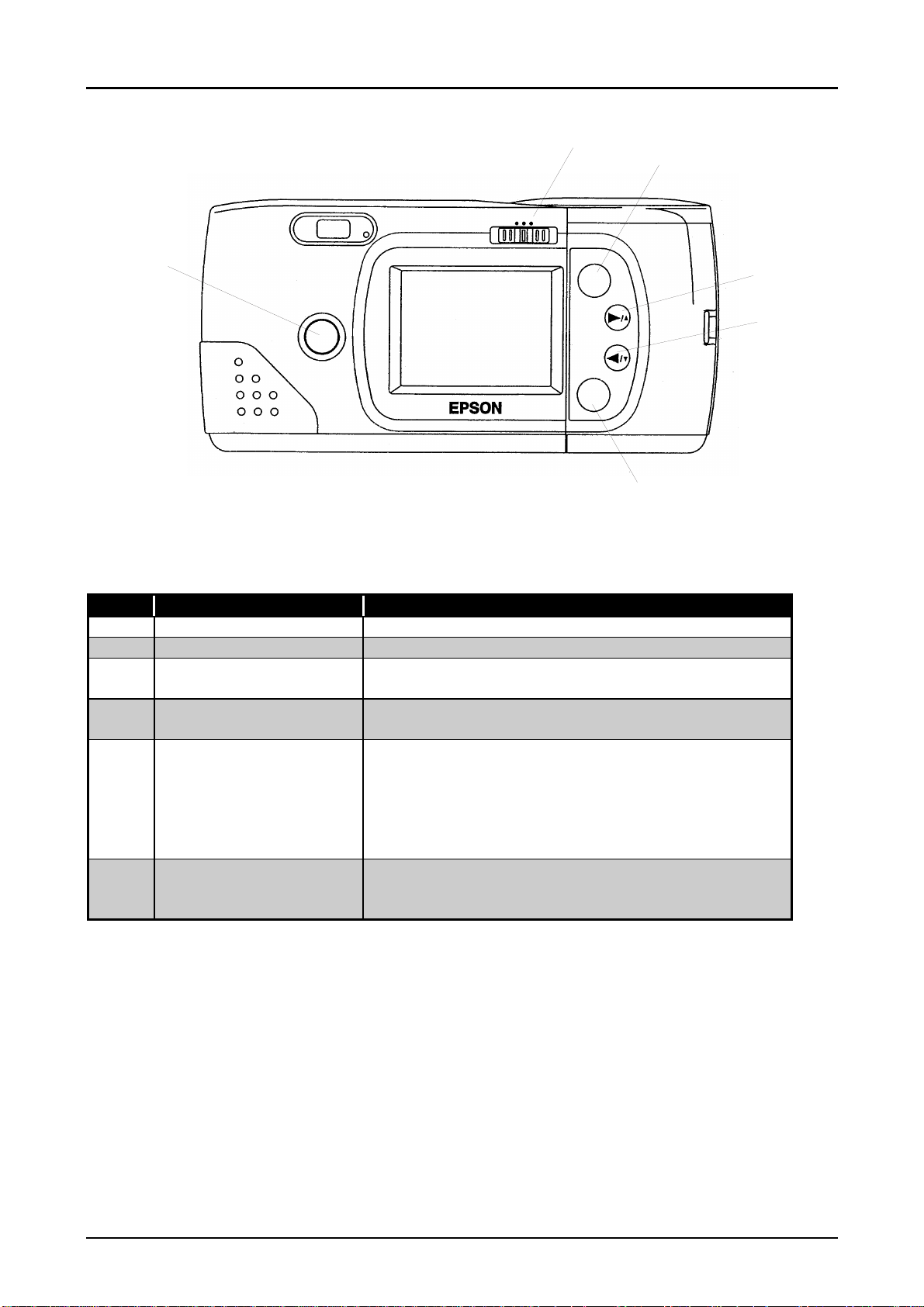

1.4 CAMERA OPERATION

This section describes various buttons.

1.4.1 Control Buttons

DIGITAL AF CAMERA

1028x768 pixels

PhotoPC600

Chapter 1 Product Description

A

B

C

Figure 1-2. Control Buttons on the Top

Table 1-5. Button Functions on the Top

No. Button Name Function and Additional Information

A Shutter Shooting shutter (half shutter: AF lock)

B Image quality Pressing this button cycles the image quality

from one setting to another;

Standard/Fine/Super fine/Monochrome fine/

Monochrome super fine.

C Flash 3 modes; Auto/Forced flash/Forced flash off

D Self-timer Self timer On/Off

E Macro mode Macro mode On/Off

D

E

Rev. A

1-

Page 19

0

VIEW

OFF

PhotoPC600

Chapter 1 Product Description

F

G

PLAYBACK

K

Zoom.

Panorama

Multi.

SELECT

BACK

J

Figure 1-3. Buttons on the Back

Table 1-6. Button Functions on the Back

No. Button Name Function and Additional Information

F (LCD)Monitor mode SW 3LCD modes ; View/Off/Playback

G Select Select items during function settings

H Navigation button(1) Forward pictures or increase numbers during

the function settings.

I Navigation button(2) Backward pictures or decrease numbers

during the function settings.

J Back Back or exit from the present mode; Go back

to the image or screen before the function

setting, or go back to the previous number

during the date and time setting. Holding

down this button eventually leads to the

playback or view mode.

K Photo format button After entering to zoom mode by this button,

Panorama, Multi-frame can be set by the

navigation buttons.

H

I

Rev. A

1-1

Page 20

Chapter 1 Product Description

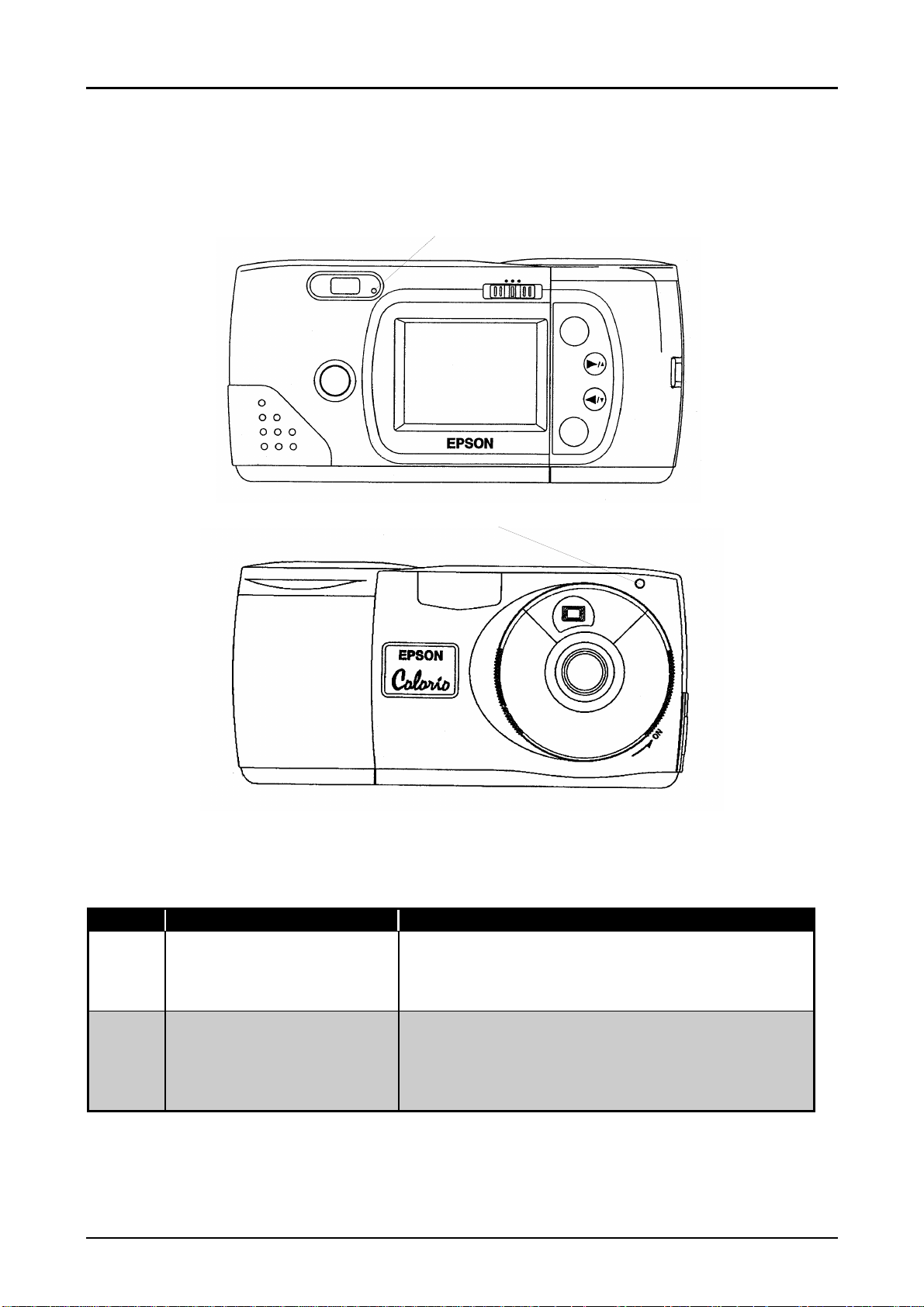

1.4.2 LED Specification

The following figure and table show the locations of the (LED) indicator lights and their

functions.

A

OFF

PLAYBACK

VIEW

PhotoPC600

Zoom.

Panorama

Multi.

SELECT

BACK

B

Figure 1-4. Locations of LED Lights

Table 1-7. LED Lights Indications

No. Name of light Function and Additional information

A Status Light During the image processing, red light

blinks. Green light is on when the camera is

ready for taking photo. Red light is on when the

shutter is half pushed.

B Timer Light After the self timer is set and the shutter

button is pressed, this light blinks slowly for

8 seconds and blinks fast for 2 seconds

(total 10 seconds) and then the picture is

taken.

Rev. A

1-11

Page 21

PhotoPC600

2

Chapter 1 Product Description

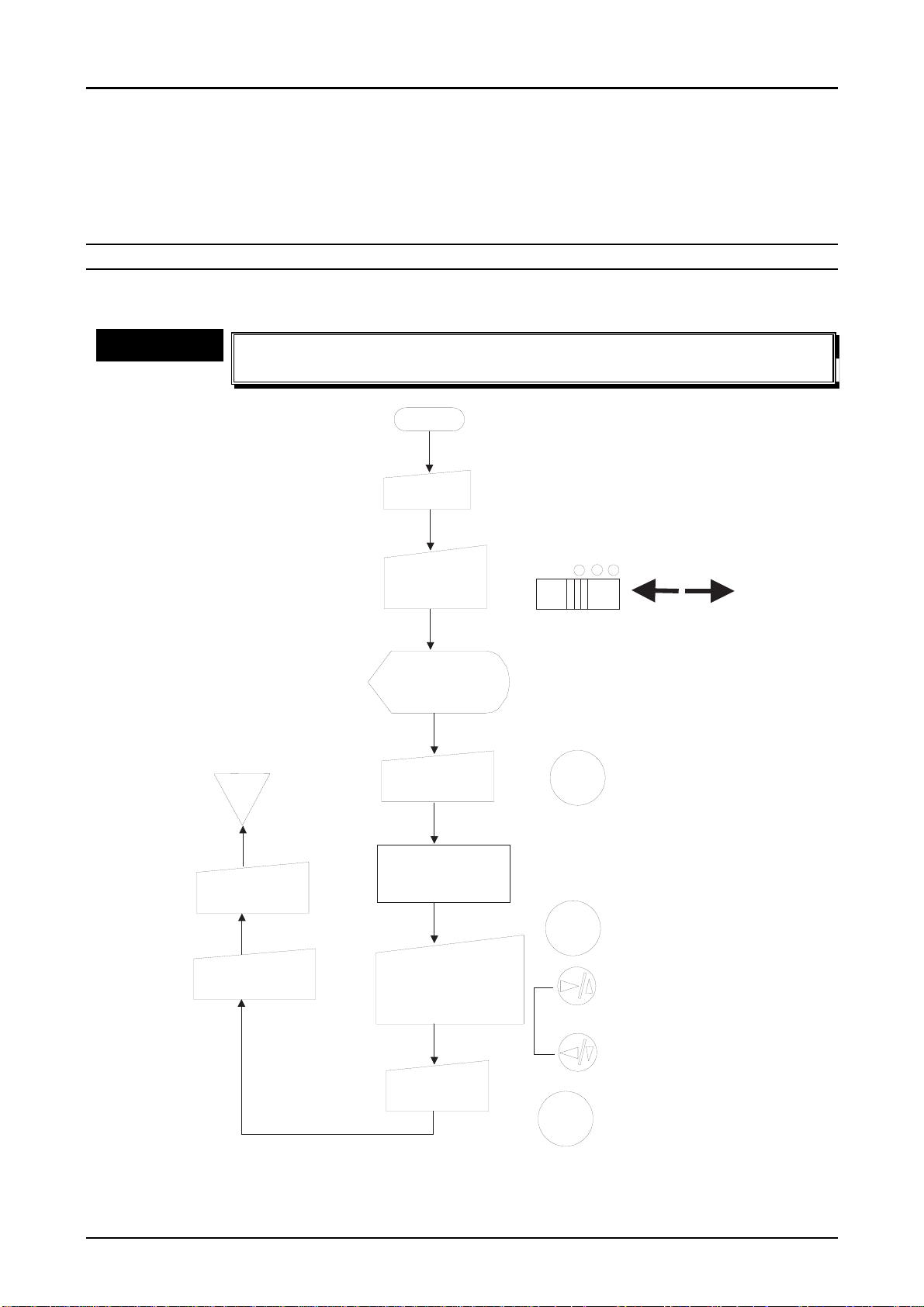

1.4.3 Operation Specification

Following flow charts show each operation methods.

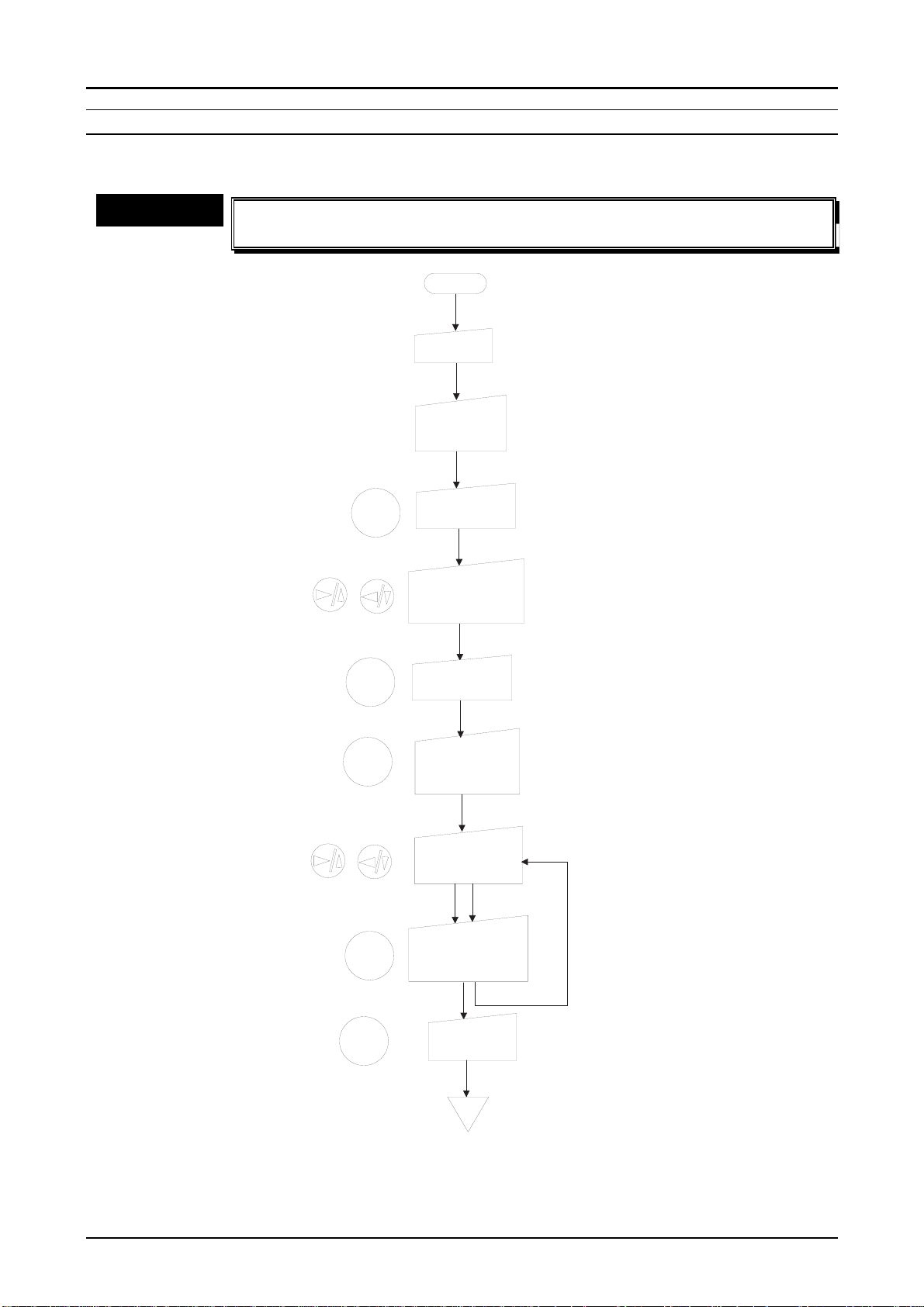

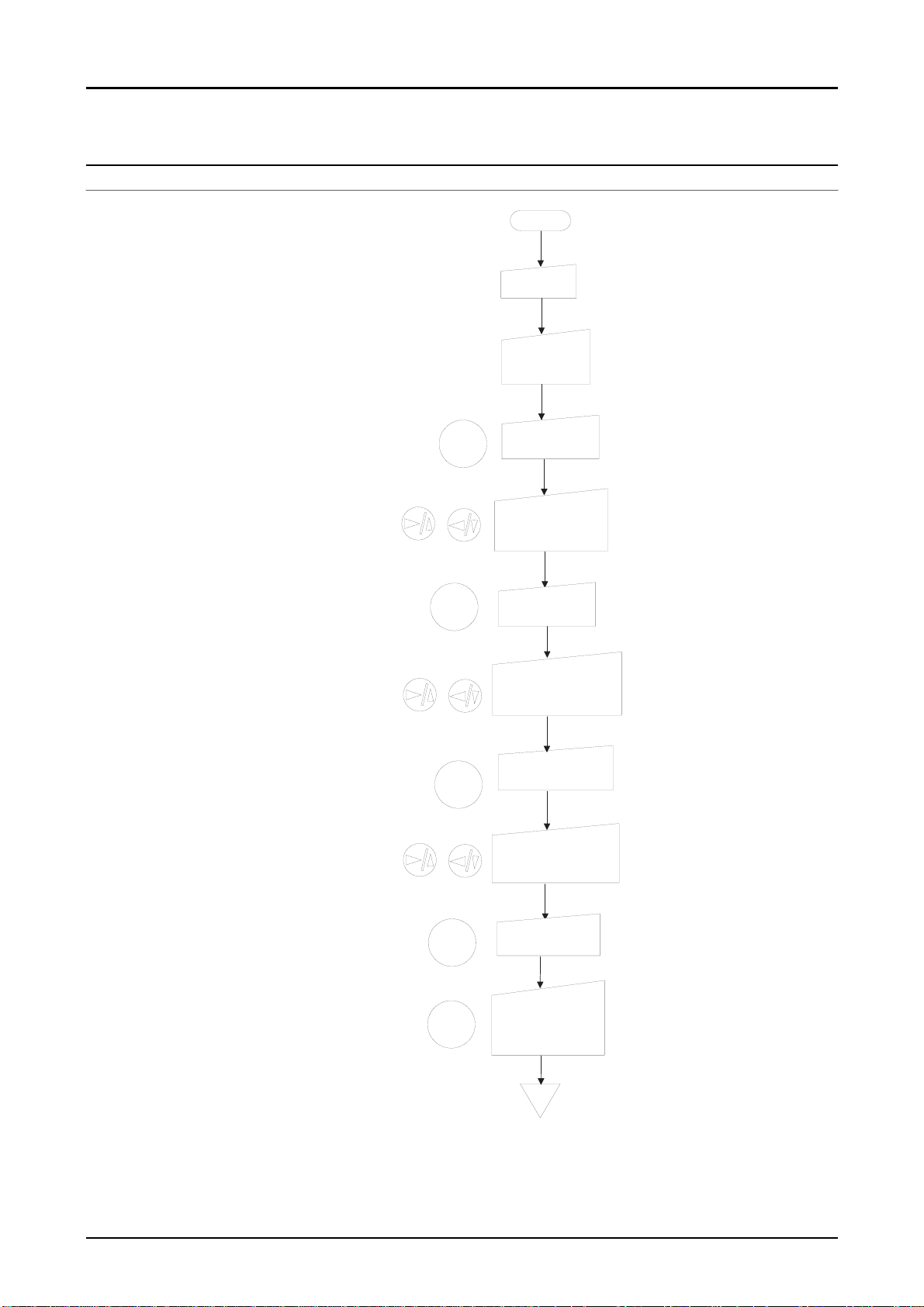

1.4.3.1 Basic Operation

SETTING THE DATE AND TIME(1)

The camera requests this setting automatically on the LCD monitor when the batteries are

installed for the first time or replaced.

CHECK POINT

üüüü

n

n

Since the PhotoPC 600 does not have back-up batteries, the date and

n n

time need to be set when the battery energy runs out.

START

Power O N

View O FF P layback

SELECT

END

Either V iew

m ode or

Playback O N .

Screen to reset

the date and tim e

appears.

Press the

SELECT button.

Screen for the

Trun off the

Power

T u rn o ff th e

M onitor m odeSW

selection for date

and tim e appears.

C onfirm by the

SE LEC T button and

change the num bers

by navigation buttons.

S e t to ta l

5 item s.

SELECT

BACK

G o to the next

item after

cinfirm ing

selection.

Increase or

decrease the

num ber.

Press this button

to g o b a c k to th e

previous item .

Figure 1-5. Setting the Date and Time (1)

Rev. A

1-1

Page 22

PhotoPC600

3

Chapter 1 Product Description

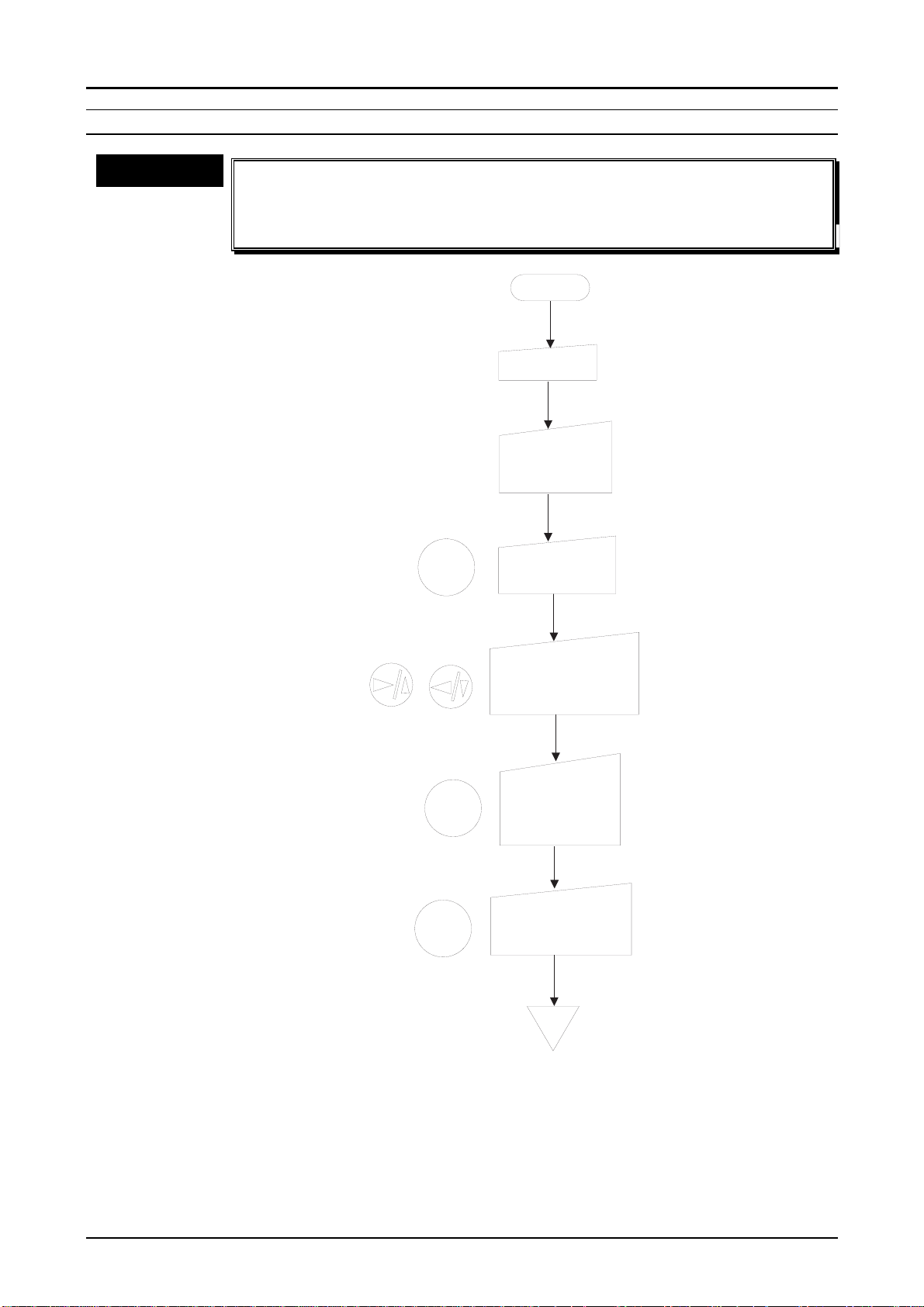

SETTING THE DATE AND TIME(2)

This setting is performed when you want to change the date or time even though they are

already set.

CHECK POINT

üüüü

n

n

Since the PhotoPC 600 does not have back-up batteries, the date and

n n

time need to be set when the battery energy runs out.

START

Power ON

Either View

mode or

Playback ON.

Press the

SELECT button.

Select "Settings"

menu by using

navigation buttons.

Press the

SELECT button.

At this time,

it enters the

clock setting

mode.

SELECT

SELECT

There is a red cursor

on the year.

At this time, the red

cursor moves to next

number.

Figure 1-6. Setting the Date and Time (2)

SELECT

SELECT

BACK

Press the

SELECT button

one more time.

Change the year

by the navigation

buttons.

Press SELECT

button after

changing numbers.

Press BACK

button twice.

END

Repeat this steps

for adjusting the rest

of month/date/hour/

minute.

Rev. A

1-1

Page 23

4

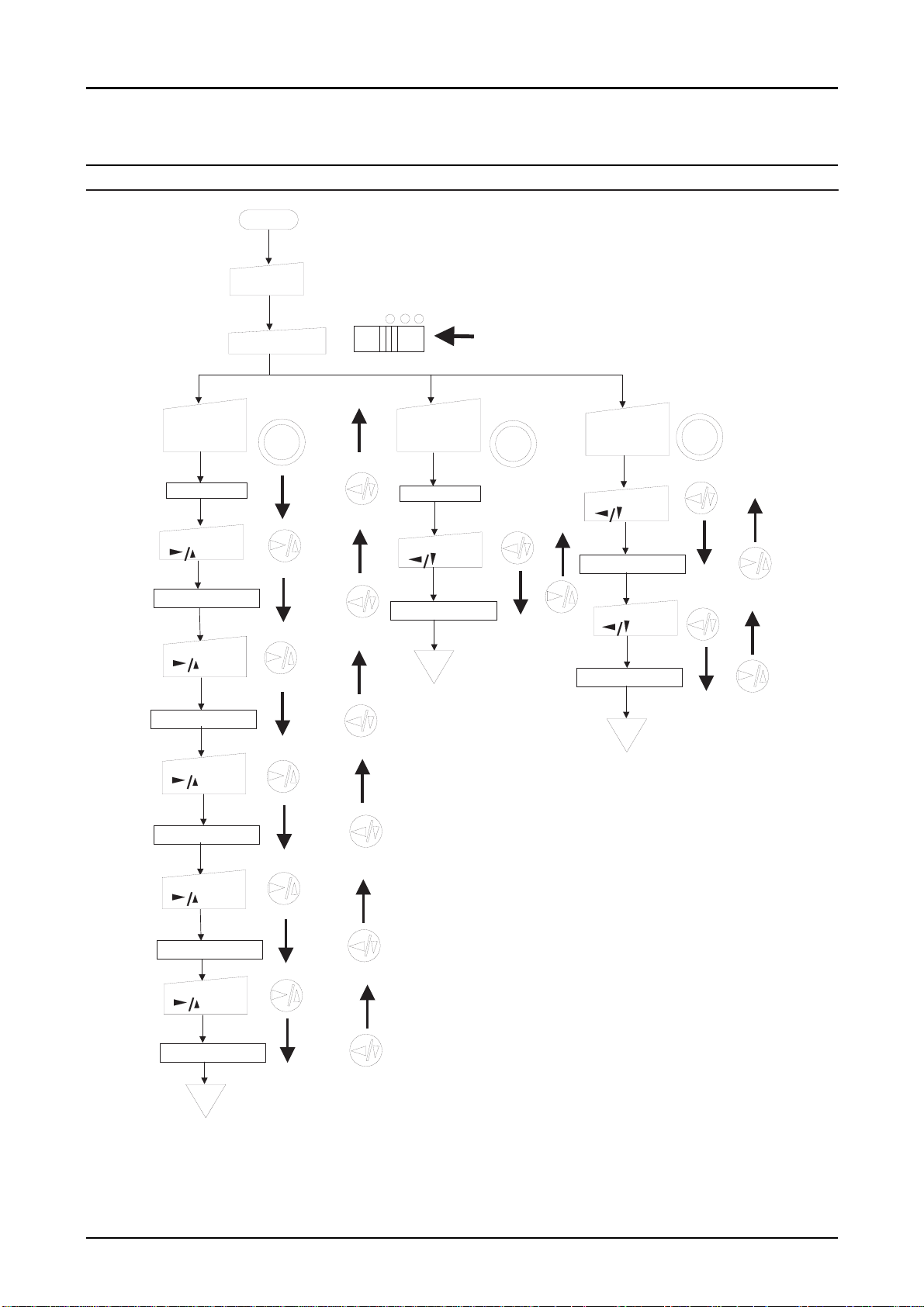

1.4.3.2 Photo Format Setting

ZOOM / PANORAMA / MULTI-FRAME

START

Pow er O N

View O FF P layback

View m ode O N .

Zoom

Zoom

Press the

photo form at

button.

Panoram a

M u lti.

P anoram a

P anoram a

Press the

photo form at

button.

Zoom

Panoram a

M u lti.

PhotoPC600

Chapter 1 Product Description

M u lti- fr a m e

Press the

photo form at

button.

Zoom

Panoram a

M u lti.

Zoom x1

Press

b u tto n

Zoom x 1.3 tim es

Press

b u tto n

Zoom x 1.6 tim es

Press

b u tto n

Zoom x 2.0 tim es

Press

b u tto n

Zoom x1

Press

b u tto n

Panoram a m ode

END

Zoom

Panoram a m ode

M ulti fram e m ode

Press

Zoom

b u tto n

Press

b u tto n

END

Zoom x 2.5 tim es

Press

b u tto n

Zoom x 3.0 tim es

END

Figure 1-7. Photo Format Shooting

Rev. A

1-1

Page 24

5

1.4.3.3 Macro Mode (Close Range Shooting)

PhotoPC600

Chapter 1 Product Description

CHECK POINT

üüüü

1. Turn the camera on and slide the monitor mode switch to View mode.

2. Press the macro button to enter the macro mode.

Note1)

3. Focus on the subject and check it on the LCD monitor. Then push the shutter button half

Note2)

4. Push the Shutter button until it stops completely.

At this time, a green frame appears around the previewed image on the LCD monitor

and Macro mark, which is represented by a flower mark, appears on the control panel.

in order to lock the auto focus.

Check that a green "O" mark appears on the right top of the monitor when checking

the subject by the LCD monitor, and the red status light turns into green when trying

to take a photo only by the viewfinder.

n

n

In the macro mode, the camera can approach to the subject up to

n n

maximum 20 cm. Release the macro mode, in case of taking a photo

further than 50 cm.

n

n

It is recommended to use the LCD monitor in the view mode rather

n n

than the viewfinder when taking a photo in macro mode. Otherwise,

the image you are seeing may not fit to the frame when you get

closer to the subject, looking at viewfinder.

n

n

Unlike the previous models; PhotoPC and PhotoPC500, taking a

n n

photo with wearing a close up lens is impossible

MONOCHROME MODE

CHECK POINT

üüüü

1. Turn the camera on and slide the monitor switch to View mode.

2. Press the image quality button two or three times until it sets monochrome mode(BW).

Note)

You can choose either Monochrome fine mode or Monochrome super-fine mode by

pressing the image quality button.

n

n

It is recommended to use the LCD monitor when taking a photo of

n n

documents at Monochrome modes.

Rev. A

1-1

Page 25

6

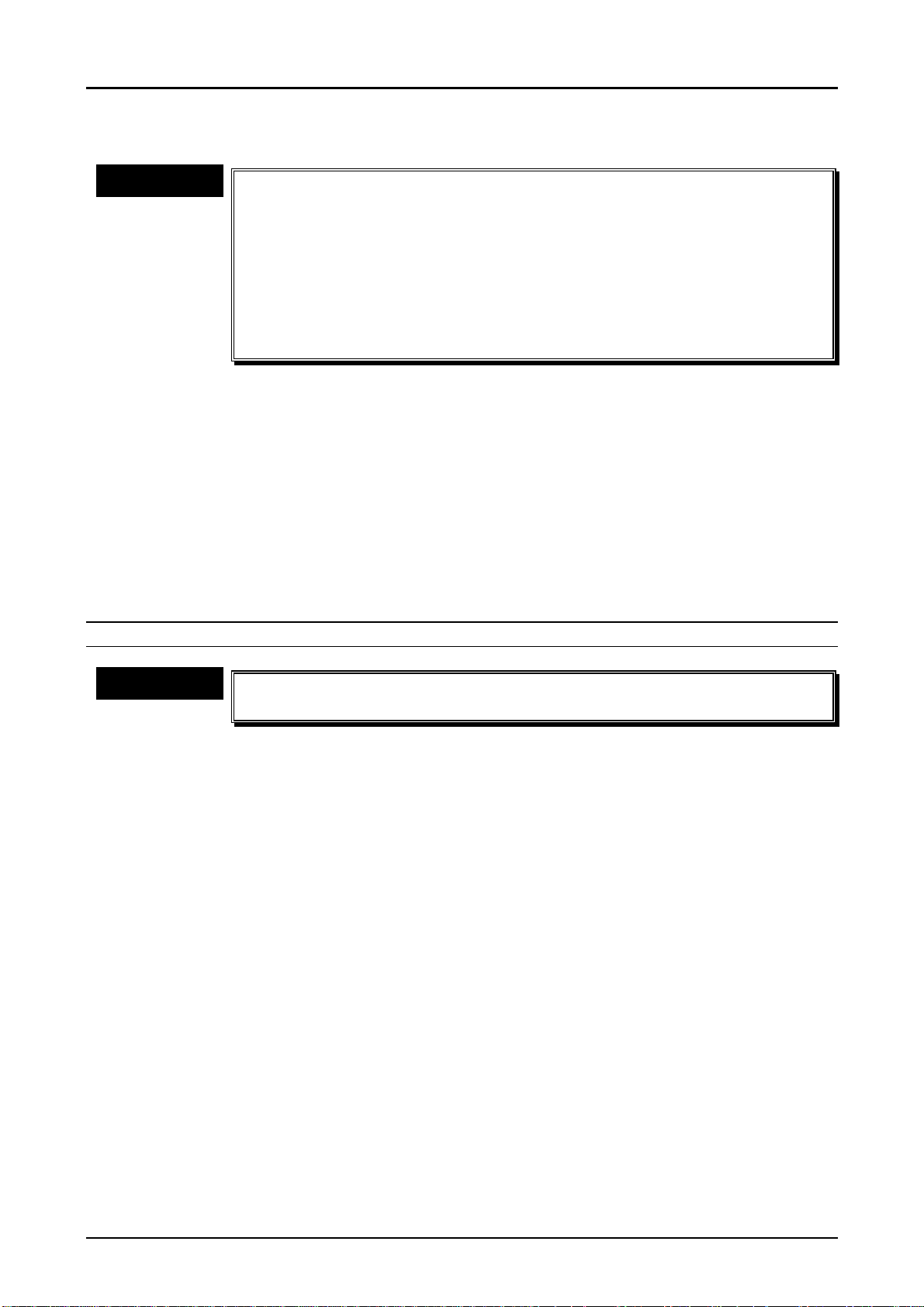

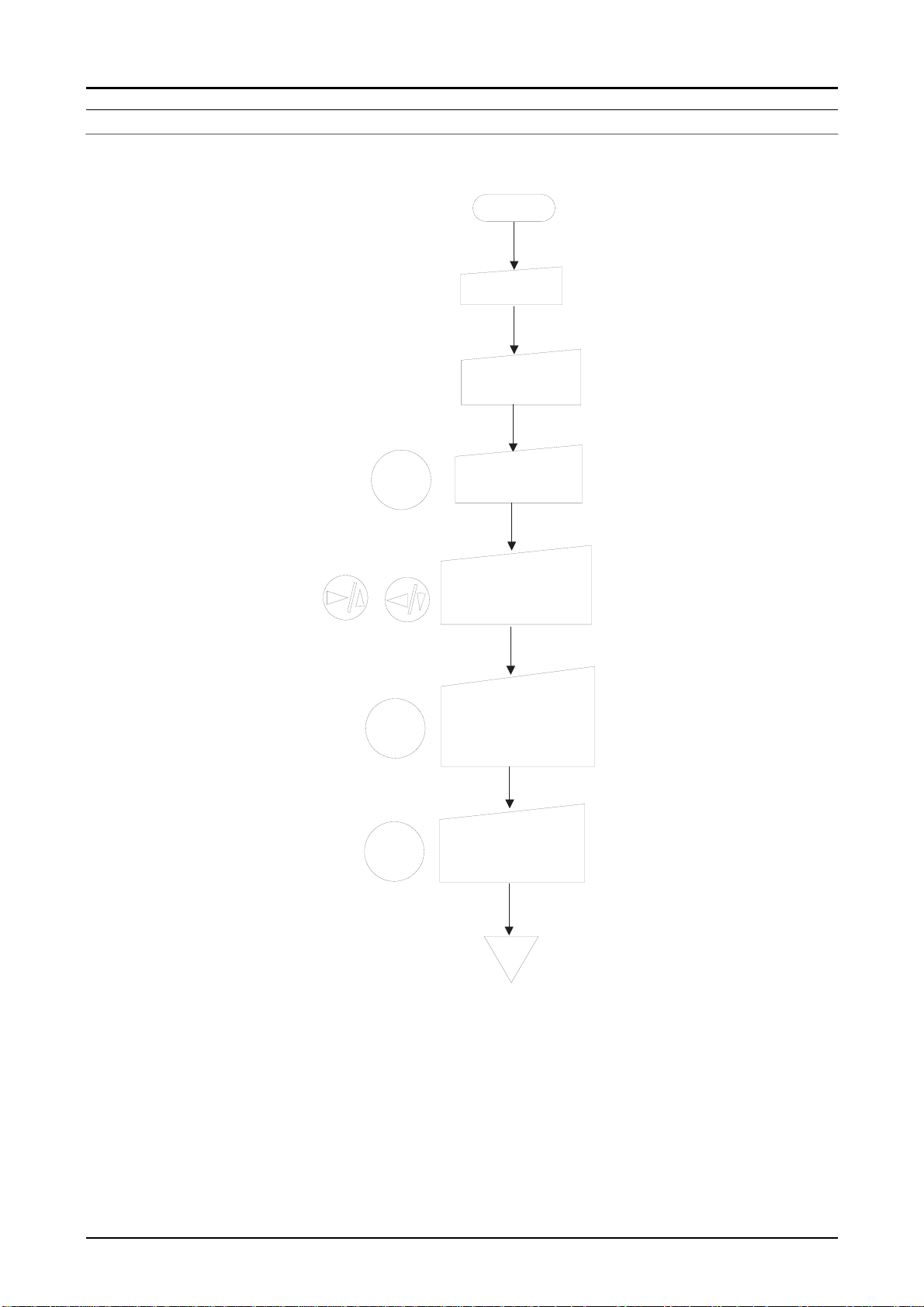

MULTI-FRAME SHOOTING TIME

PhotoPC600

Chapter 1 Product Description

CHECK POINT

üüüü

n

n

The shooting times; 0.5, 1, 2 or 3 which are displayed on the LCD

n n

monitor, are the seconds as the total shooting time and the nine

frames are taken in that seconds. The initial setting is set at 0.5 sec.

START

Power ON

Either View

mode or

Playback ON.

SELECT

Press the

SELECT button.

Select "Settings"

menu by using

navigation buttons.

This saves the setting

and returns to the

Setting menu.

At this time, the current

selection is highlighted.

SELECT

SELECT

BACK

BACK

Press the

SELECT button.

Select "Multiframe shooting

time" by the navigation buttons.

Press the SELECT

button to select the

shooting time.

(0.5,1.2, or 3 sec.)

Press the BACK

button after choosing

the shooting time.

Screen returns to

the Setting menu.

Press the BACK

button to go back

to the normal mode.

END

Figure 1-8. Multi-Frame Shooting Time

Rev. A

1-1

Page 26

7

SETTING THE ALERT BEEP; ON/OFF

PhotoPC600

Chapter 1 Product Description

START

Power ON

Either View

mode or

Playback ON.

SELECT

SELECT

SELECT

Press the

SELECT button.

Select "Settings"

menu by using

navigation buttons.

Press the

SELECT button.

Select the beep

setting icon by the

naviagation buttons.

Press the SELECT

button to select

ON or OFF.

This saves the setting

and returns to the

Setting menu.

At this time, the current

selection is highlighted.

BACK

BACK

Press the BACK

button after choosing

ON or OFF.

Screen returns to

the Setting menu.

Press the BACK

button to go back

to the normal mode.

END

Figure 1-9. Setting the Alert Beep

Rev. A

1-1

Page 27

8

1.4.3.4 Basic LCD Settings

SETTING LCD BRIGHTNESS

PhotoPC600

Chapter 1 Product Description

START

Power ON

Either View

mode or

Playback ON.

The mark on the

brightness setting

slide bar turns orange.

SELECT

SELECT

SELECT

Press the

SELECT button.

Select "Settings"

menu by using

navigation buttons.

Press the

SELECT button.

Select the brightness

icon by the

naviagation buttons.

Press the SELECT

button again.

Adjust the screen

brightness by the

navigations buttons.

This saves the setting

and returns to the

Setting menu.

BACK

BACK

Press the BACK

button.

Press the BACK

button twice to go

back to the normal

mode.

END

Figure 1-10. Setting the LCD Brightness

Rev. A

1-1

Page 28

9

SETTING THE INFORMATION DISPLAY

PhotoPC600

Chapter 1 Product Description

CHECK POINT

üüüü

n

n

During multi-photo play back mode, the information that are

n n

indicated on the normal play back mode, such as the image quality

setting, the number of photos you can take, and the number of

photos taken are not indicated

START

Power ON

Either View

mode or

Playback ON.

SELECT

Press the

SELECT button.

Select "information"

menu by using

navigation buttons.

Press the

Choosing ON is

for displaying

photo information

SELECT

SELECT button

to select ON or

OFF.

on the LCD screen.

Press the BACK

BACK

button to save the

setting.

END

Figure 1-11. Setting Information Display

Rev. A

1-1

Page 29

Chapter 1 Product Description

0

SETTING THE LANGUAGE

English, Japanese, French, German, Italian, Portuguese or Spanish is available.

START

Power O N

Turn the Playb a c k O N .

PhotoPC600

SELECT

SELECT

BACK

Press the

SE LEC T button.

Select "Language"

m enu by using

navigation buttons.

Press the

S E L E C T b u tto n

to s e le c t th e

language you w ant.

Press the BACK

b u tto n to s a v e th e

setting.

END

Figure 1-12. Setting the Language

Rev. A

1-2

Page 30

1.4.3.5 Setting the Playback Mode

NORMAL PLAYBACK MODE

PhotoPC600

Chapter 1 Product Description

CHECK POINT

üüüü

1. After turning the camera ON, Slide the monitor switch to Playback.

2. The last photo you took is displayed in the full size. Pressing the navigation buttons

allows you to see the next photo or the previous one.

MULTI-PHOTO PLAYBACK MODE

CHECK POINT

üüüü

1. After turning the camera ON, Slide the monitor switch to Playback.

2. The last photo you took is displayed in the full size.

3. Press the SELECT button. ("Setting" menu appears on the initial monitor)

4. Indicate the "Playback Mode Menu" by using the navigation buttons.

5. Every time you press the SELECT button, it switches between Normal and Multi-photo

Playback modes.

6. Press the BACK button to save your setting.

Note)

After selecting the photo to check by using the navigation buttons, the selected photo

can be full size by pressing the SELECT button twice. Also, at this time, you can

remove other unnecessary indications by pressing the BACK button.

n

n

Since the data is red from the internal memory of the camera during

n n

the playback mode, it is not influenced by ON and OFF of the main

power.

n

n

Once the multi-photo playback mode is confirmed, that mode is

n n

stored and it is not lost even after the power is turned off.

n

n

This setting need to be reset when batteries are replaced without

n n

using the AC adapter.

SLIDE SHOW MENU

CHECK POINT

üüüü

1. After turning the camera ON, Slide the monitor switch to Playback.

2. The last photo you took is displayed in the full size. (If the Multi-photo playback mode is

already set, 9-frame images appear)

3. Press the SELECT button. ("Setting" menu appears on the initial monitor)

4. Indicate the "Slide Show Menu" by using the navigation buttons.

5. Press the SELECT button. ("Slide show" is indicated on the top of the monitor for 3

seconds, and automatic playback starts)

6. Press the BACK button to stop the slide show and return to the normal Playback mode.

n

n

This mode automatically keeps playing back all the photos in the

n n

camera by one by until external operation is done.

n

n

During this mode, press the 3333/6666button to move back through the

n n

photos manually.

n

n

During this mode, press the 8888/5555button to move forward through the

n n

photos manually.

n

n

During this mode, pressing the SELECT button pauses the screen.

n n

(At this time, the pause icon and current picture count appear on the

bottom of the screen)Pressing the SELECT button again during this

pause, the rest of photos are played.

Rev. A

1-21

Page 31

PhotoPC600

2

Chapter 1 Product Description

1.4.3.6 Other Settings

LOCK / UNLOCK ALL PHOTOS

1. After turning the camera ON, Slide the monitor switch to Playback.

2. Press the SELECT button. ("Setting" menu appears on the initial monitor)

3. Indicate the "Photo Control Menu" by using the navigation buttons.

4. Press the SELECT button. (5 items for photo control menu are displayed)

5. Press the navigation buttons until "Lock" is highlighted in orange, and press the SELECT

button to enter the Lock mode.

6. 3 Lock menu items appear. Choose an item you want to perform by using the navigation

buttons. Then, press the SELECT button again.

[Select Lock/Unlock]

7. Select the photo you want to lock or unlock by using the navigation buttons. Press the

SELECT button, then a lock icon appears at the bottom of the screen, or disappear if it

was locked originally. If you want to lock or unlock other photos at the same time, use the

navigation buttons to display them, then press the SELECT button.

8. Press the BACK button after you have selected all the photos you want to lock or unlock.

A message appears asking you to confirm your selections.

9. *Press the SELECT button to lock or unlock the images and return to the "Photo Control

Menu". Press the BACK button to lock or unlock again, or cancel for locking or unlocking the

photos.

CAUTION

n

n

When the monitor is on the multi-photo mode, the operation method

n n

is the same except for operating 9 images at the same time.

n

n

*Among the lock items, if you select "Lock All" or "Unlock All" by the

n n

SELECT button, the rest of operation is the same as procedure 9

written above.

Rev. A

1-2

Page 32

3

ERASING PHOTOS

Erasing a selected

picture

START

Power ON

Playback

mode ON.

View OFF Playback

Erasing selected pictures

PhotoPC600

Chapter 1 Product Description

Erase All

Select a image to

erase by the

navigation buttons.

Press SELECT

button

Select "Erase Photo

Menu" by the navigation buttons.

Press SELECT

button

A message appears

to confirm the image

to erase.

SELECT: Erase

BACK :Cancel

Press BACK

button to return

to the Playback

mode.

END

SELECT

SELECT

SELECT

BACK

Repeat these steps

to select several

images.

Press SELECT

button

Select the "Photo

Control Menu" by

the navigation buttons.

Press SELECT

button

Photo Control Menu is

displayed.

Select "Erase" by

the navigation

buttons.

Press SELECT

button

Erase Menu is indicated

Choose "Select

Photo" by the

navigation buttons.

Press SELECT

button

The last Playback

screen is indicated

Select images to

erase by the navigation

buttons.

Press SELECT

button

An orange frame appears

around the image

SELECT

SELECT

SELECT

SELECT

SELECT

Press SELECT

button

Select the "Photo

Control Menu" by

the navigation buttons.

Press SELECT

button

Photo Control Menu is

displayed.

Select "Erase" by

the navigation

buttons.

Press SELECT

button

Erase Menu is indicated

Choose "Erase

All" by the

navigation buttons.

Press SELECT

button

A message appears

to confirm the image

to erase.

SELECT: Erase

BACK :Cancel

Press BACK

button to return

to the Playback

mode.

SELECT

SELECT

SELECT

SELECT

SELECT

BACK

BACK

SELECT

END

END

Press the

BACK button

Press SELECT

button

Figure 1-13. Erasing Photos

Rev. A

1-2

Page 33

4

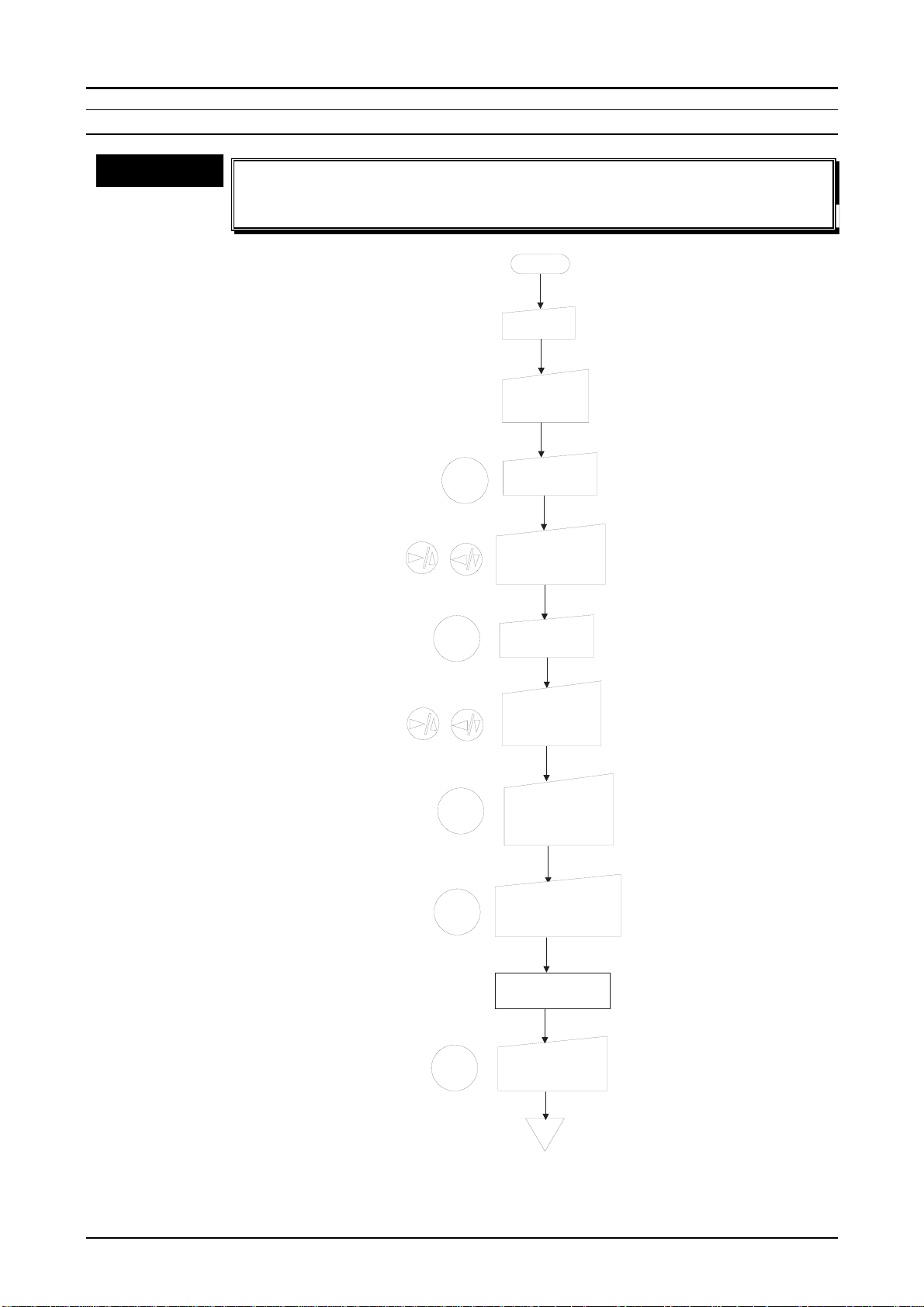

MEMORY INFORMATION

PhotoPC600

Chapter 1 Product Description

START

Power ON

Playback ON

SELECT

SELECT

SELECT

Press the

SELECT button.

Select "Photo Control

Menu" by using

navigation buttons.

Press the SELECT

buttton to confirm

the "Photo Control

Menu".

Select "Memory

Info" by the

navigation button.

Press the

SELECT button.

Rev. A

Memory information

is indicated.

SELECT

Press the

SELECT button

3 times.

Normal mode

is indicated.

END

Figure 1-14. Getting Memory Information

1-2

Page 34

5

COPYING PHOTOS

PhotoPC600

Chapter 1 Product Description

CAUTION

n

n

This function is to copy photos between the camera's internal

n n

memory and the memory card.

n

n

Install or remove the memory flash card when the camera is turned

n n

off. If the memory card is installed or removed while the camera is

On, the internal data of images are all lost.

START

Power ON

Playback ON

Press the

SELECT

SELECT

SELECT button.

Select "Photo Control

Menu" by using

navigation buttons.

Press the SELECT

buttton to confirm

the "Photo Control

Menu".

SELECT

BACK

SELECT

END

Select "Copy" by

the navigation

buttons.

Press the

SELECT button.

Select the copy

destination by the

navigation buttons;

Camera Card or

Card Camera

Select photos to

copy.

Press the BACK

button to confirm

after the selection

is made.

Press the

SELECT button.

Press the

SELECT button

3 times.

Note) Procedure for selecting

photoes is the same as the one

of "Select Photo" in the Ersaing

photos.

SELECT

Figure 1-15. Copying Photos

Rev. A

1-2

Page 35

6

FORMATTING MEMORY CARD

PhotoPC600

Chapter 1 Product Description

CHECK POINT

üüüü

n

n

Since the EPSON Compact Flash Cards are already formatted in the

n n

factory, it is not necessary to perform this operation unless the

memory cards fall into the abnormal situations and become unable

to use without formatting.

START

Power ON

Playback ON

Press the

SELECT

SELECT button.

Select "Photo Control

Menu" by using

navigation buttons.

SELECT

SELECT

SELECT

BACK

Press the SELECT

buttton to confirm

the "Photo Control

Menu".

Select "Format

Card" by the

navigation buttons.

Press the

SELECT button.

A message appears stating

that all data on the card will

be erased and asking you

to confirm the procedure.

Press the

SELECT button

again.

Press the BACK

button three times.

This formats the card

and return to the "Photo

Control Menu".

END

Figure 1-16. Formatting the Memory Flash Card

Rev. A

1-2

Page 36

PhotoPC600

7

Chapter 1 Product Description

Rev. A

1-2

Page 37

CHAPTER

OPERATING PRINCIPLES

2

Page 38

PhotoPC600

Chapter 2 Operating Principles

2.1 OPERATING PRINCIPLES

Majority of the PhotoPC600 parts consists of the electric circuits boards. The figure below shows

those boards and explains their functions.

A. SY1 Board

B. LCD Monitor

C. CA1 Board

F. CA2 Board

E. ST1 Board

Front Side

D. TB1 Board

Figure 2-1. PhotoPC600 Board Locations

The Table below shows function of each board.

Table 2-1. Functions of Each Board

No. Name Function

A SY1 4-bit microprocessor as the central system is mounted on the back of this

board. User’s I/F control, Power supply/Stop control, STROBE

charge/discharge control, Clock control and back up for setting, and internal

communication bus control are handled here.

B LCD 1-unit of electric part combined with LCD monitor and light. RGB signal to take

the actual image is controlled from the CA2 board.

C CA1 CCD is soldered directly. This board has H/V driver in order to drive the CCD,

CDS/AGC circuit to correct the image, and A/D converter circuit to transfer the

data to the internal ASIC. Also, the lens unit with AF(auto focus) function is

mounted on the board and automatically adjusts the focus by operating light

that the CCD receives.

D TB1 Small board mounted with a switch for photo modes.

E ST1 Unlike the PhotoPC and PhotoPC500, this board only generates power supply

for the LCD monitor, and digital and analog. Flash is also installed and also an

electrolytic capacitor with large capacity in order to emit light. (Careful attention

is necessary to handle this capacitor) This board also has connectors for AC

adapter and for video output.

F CA2 This board has LCD monitor control, option memory flash card control, and

also works as the internal central system for the photographic processing.

CAUTION

Rev. A

n

n ST1 board has a danger of electric shock because of C5412.

n n

Hold the edges of this board and Never touch the board surface

when you handle this board.

n

n Discharge the charged energy of C5412 for safety before handling

n n

this board. (Refer to Chapter4)

2-1

Page 39

Chapter 2 Operating Principles

2

2.1.1 Out line of Operating Principles

The following figure shows the block diagram about overall operation by PhtoPC600.

Next pages simply explain operation of each board.

Subject

Lens

Optical

Filter

CCD

CDS/AGC

PhotoPC600

RISK

CPU

Flash

control

Circuit

ST1 Board

DC/DC

Conv.

A/D

10bit

CA1Board

AC Adapter

DRAM

Address Bus

Data Bus

Scan

Convertor

ST SG

Output Circuit

DMA Control

Circuit

PC

Option Flash

Memory Card

RS-232C

9-pin Din

Function SW

Signal arithmetic Circuit

4M Flash

(x4)

Power SW

Shutter SW

UART

Driver

NTSC

Encoder

af/ae/awb

Integrator

Buzzer

PIO

LCD

Driver

4bit

CPU

TV

Monitor

LCD Moitor

CA2 Board

SY1 Board

3.3V

regutrater

AA-size Batteries

Figure 2-2. Block Diagram for Overall Operation

Rev. A

2-

Page 40

PhotoPC600

3

Chapter 2 Operating Principles

CA1 BOARD

The following are the major ICs on the CA1 board. Starting from driving the CCD, they perform

processing and A/D conversion until image data is transformed to the internal system.

Table 2-2. Major Components of the CA1 Board

No. Location Parts Name Function

1 IC903 ICX081AK CCD imager

2 IC902 TC74VHC04 H-Driver, Clock for horizontal data transfer in order to

drive CCD

3 IC904 CXD1267AN V-Driver, Clock for horizontal data transfer in order to

drive CCD

4 IC905 CXA2006Q CDS, AGC circuit

5 IC906 CXD2311AR A/D converter IC for internal system transfer

CA2 BOARD

The Table below shows major circuits on the CA2 board.

Table 2-3. Various Control Circuits of the CA2 Board

No. Circuit Name Function

1 Scan converter This is the circuit that converts CCD output signal to the interlace

signal for TV.

2 Signal Processor

3 Digital clamp This circuit compares the optical black section of the CCD and

4 White balance The circuit controls the white balance by using the AWN judgment

5

g

6 Color signal

generation

7 Matrix This circuit generates Y, R-Y and B-Y signals from RGB signal.

8 Horizontal

Aperture

9 DRAM controller This circuit controls RAS and CAS and outputs Refresh signal.

10 UART This circuit transfers the image data to PC on the basis of RS-232C.

11 PIO This is the interface circuit for the 4-bit microprocessor on the SY1

12

TG · SG

13 LCD driver Y/C signal, which is input to this signal, is converted to RGB signal

14 LCD monitor LCD monitor

Generic name of No.3~No.8 circuits below.

image data and makes the black level of the CCD output data

uniform for each line.

value computed by the CPU to control the gain for each R, G and B

pixel based on the CCD data which has been read.

This circuit performs correction in order to maintain a linear

relationship between the light input to the camera and the light

output from the picture screen.

This circuit converts CCD signal to RGB signal.

This circuit generates aperture signal.

board.

This is the generation circuit which generate the vertical data

transfer clock and electric shutter clock.

and synchronized to CLK signal, and is transferred to the LCD.

Rev. A

2-

Page 41

PhotoPC600

4

Chapter 2 Operating Principles

ST1 BOARD

ST1 board can be divided into 2 blocks; power supply circuit part and strobe control circuit part.

Following explains each part.

Table 2-4. ST1 Board (Electric Block)

No. Location Function

1 IC311 This has a PWM-type switching regulator circuit with 6 channels.

Output voltage is;

1) Power supply voltage for LCD 5 V(L), 12 V(L), 15.5V(L)

2) Digital power supply voltage 5 V(D), 3.4 V(D)

3) Analog power supply voltage 5 V(A), 12 V(A), -6.5 V(A)

There are two safety circuits on this regulator;

1) Short-circuit protection circuit

2) Mis-operation prevention circuit for cases of low input voltage

2 T3101 Pressure rise/fall transformer for Analog output voltage

3 T3103 Pressure rise transformer for LCD drive voltage output

There are two parts of circuits in the strobe control circuit part; charge circuit parts and light

emission circuit. They are described below.

Table 2-5. ST1 Board (Strobe Control Block)

No. Circuit Name Function

1 Charge circuit When the flash is emitted during the Forced or Auto flash, CHG

signal is output high from the SY1 board and charges the main

electrolytic capacitor into high voltage direct current.

Charge circuit consists of mainly following 5 circuits.

1) Power supply filter It smooth out ripples in the current

which accompany the switching of

the oscillation transformer and LC

circuit composition.

2) Oscillation control Outputs a drive pulse with a

frequency of 15 K Hz to increase

DC voltage.

3) Oscillation transformer Converts the low voltage alternating

current to a high-voltage alternating

current by this transformer.

4) Rectifier Converts the high-voltage

alternating current to a high voltage

direct current.

5) Voltage monitoring Monitors the voltage level of C5412.

Detects full charge by 2.7 V DC.

2 Light emission

circuit

Strobe emits light when SDY and TRIG signals are input to from

ASIC. Emission circuit consists of mainly the following 3 circuits;

1) Emission control circuit part When the RDY signal is

input to this circuit, Q5409

which is the main source of

the emission current, is

turned on.

2) Trigger circuit D5405 is turned on with

input of TRIG signal.

3) Light emitting element Light is emitted when the

high-voltage pulse is applied

to the light emitting part.

Rev. A

2-

Page 42

PhotoPC600

5

Chapter 2 Operating Principles

SY1 BOARD

SY1 board had 4-bit microprocessor and handles the following the functions.

Table 2-6. Various Circuits of the SY1 Board

No. Circuit Name Function

1 Charge Outputs /CHG On signal to the ST1 board. Also, this circuit monitors

the value of partial pressure of C5412 and controls to stop charging.

Also, it judges if the power supply is AC adapter or battery and

changes the complete time of the battery charge. This prevents the

AC adapter from being heat up.

2 LCD light on Control On/Off of LCD back light. However, characters for explanation

on the LCD are transferred by internal ASIC on CA2 board.

3 Cable Detection When RS-232C cable is installed, this circuit makes all button

functions on the camera invalid.

4 CPU

Communication

5 Power supply

control

6 Battery life

monitor

7 Video terminal

monitor

8 Card installation

monitor

9 Buzzer control On/Off control of buzzer drive.

10 LCD panel

control

11 LED control Controls all 3 LED drives.

Perform serial communication with internal main CPU(SPARC).

Outputs two wake up signals in order to generate power supply for

digital and analog individually.

Monitors the AA-size battery life at the voltage level.

Monitors if the cable for the video output is installed or not.

When the power is on, this circuits reads empty raster and calculates

how many pictures can be taken after detecting the existence of the

compact flash card. Also, after the card detection, internal

memory(4M) is invalid.

Controls the present settings and indication of available photos to take

by the key matrix.

TB1 BOARD

TB1 board is a small board which is mounted with a push button to change over photo

format(modes); Zoom, Panorama, and Multi-frame. The signal to check the button condition is

output periodically from 8-bit CPU on the SY1 board, and mode is changed by recognizing the

change of the button condition.

Rev. A

2-

Page 43

TROUBLESHOOTING

CHAPTER

3

Page 44

PhotoPC600

Chapter3 Troubleshooting

3.1 OVERVIEW

PhotoPC600 does not have a function to display errors by LCD or LED. Also, it is difficult to find

malfunction parts from the symptoms. Therefore, check each check points according to the

procedures in this chapter and perform proper repair service.

WARNING

CAUTION

No. Service Performed Required Adjustment Maintenance

1 Replacing CA1 Board 1) Initialization

2 Replacing the CA2 Board 1) Initialization

3 Replacing the LCD

monitor

4 Replacing the SY1 Board Not required 1st Maintenance

5 Replacing the ST1 Board Not required 1st Maintenance

6 Replacing the TB1 Board Not required 1st Maintenance

n

n Disconnect the AC adapter or batteries before disassembling the

n n

camera.

n

n Discharge the electricity in the electrolytic capacitor by using cement

n n

resistor when you need to touch the ST1 board for repair service.

(See Chapter 4 , page 4-4 for more details) The electrolytic

capacitor(C5412), which is mounted on the ST1 board is for light

emission and to be charged automatically every time the power is

turned on. Therefore, there is a danger of getting electric shock.

n

n In this products, there are 2 repair levels; first maintenance and

n n

second maintenance. The performance of the second maintenance is

allowed to be done only by EPSON Co., Ltd. We do not guarantee the

repair result by the others. Refer to Table below for distinction

between first and second maintenance.

Table 3-1. Criterion of First/Second Maintenance

2nd Maintenance

2) 5100K AWB adjustment

3) Flange-back adjustment

2nd Maintenance

2) 5100K AWB adjustment

3) Flange-back adjustment

4) LCD H AFC adjustment

5) LCD RGB Off Set adjustment

6) LCD Gain adjustment

7) LCD Blue Brightness adjustment

8) LCD Red Brightness adjustment

1) LCD H AFC adjustment

2) LCD RGB Off Set adjustment

3) LCD Gain adjustment

4) LCD Blue Brightness adjustment

5) LCD Red Brightness adjustment

2nd Maintenance

Rev. A

3-1

Page 45

PhotoPC600

2

Chapter3 Troubleshooting

3.1.1 The camera has no power

This section describes check points and solution when LCD is not indicated or red LED light keeps

blinking and does not go to the waiting mode after turning the power switch (rotary switch) on with

batteries or AC adapter. Refer to Tables 3-2~3-4 below.

CHECK POINT

üüüü

n

n If something abnormal occur to 8-bit CPU, which is located under

n n

SY1 board and in charge of controlling user’s I/F, the order signal to

generate digital and analog power for various functions can not be

output. And as a result, the camera falls into no power error. Also,

since this 8-bit CPU communicate with main CPU on the CA2 board,

the same symptom appears when something happens on the CA2

board too.

Table 3-2. Check points when the Camera has no power

Step Checkpoint Solution

1 Is CN303 of SY1 disconnected? Connect CN303 again.

2 When turning the power switch (rotary switch) on and off,

does the micro-switch also really turn on and off,

corresponding to power switch?

3 Is there continuity in the cables(2-pin, red and black) for

micro-switch?

4 Is CN301 of SY1 connected to CN106 of CA2 board? Push SY1 board into

5 Is CN311 of ST1 board connected to CN104 of CA2

board?

6 Is the connector between CN314 of ST1 board and CN305

of SY1 board secured steady?

7 Does each fuse(F3102, F3103) on the both sides of ST1

board has continuity?

8 Is SY1 board defective? Replace SY1 board.

9 Is CA2 board detective? Replace CA2 board.

10 Is ST1 board defective? Replace ST1 board.

Install a micro-switch

again.

Replace the cable.

CA2 board.

Push ST1 board into

CA2 board.

Secure either one of

connectors.

Replace either one of

fuses.

Table 3-3. Check points when the Camera has no power with batteries

Step Check point Solution

1 Is the battery cover fixed steady between the front cabinet

and rear cabinet?

2 Are 2 peaking points for installing the battery cover broken

or damaged?

3 Is the insulating film around the battery blocking electric

poles, because of defective battery?

4 Are there any foreign objects on or around electric poles,

such as remaining of plastic package of battery?

5 Are electric poles for battery located under the SY1 board

worn out?

Table 3-4. Check point when the batteries overheat in only using AC adapter

Step Check Point Solution

1 Is the user using recommended AC adapter or other kind

of adapter?

2 Is the DC Jack in the DC inlet on the ST1 board defective? Replace ST1 board.

Install the battery cover

again.

Replace the battery

cover.

Replace batteries.

Eliminate the foreign

objects.

Replace SY1 board or

correct the angle of

electric poles by hand.

Use the recommended

adapter only.

Rev. A

3-

Page 46

PhotoPC600

3

Chapter3 Troubleshooting

3.1.2 Red LED Light Blinking

This section shows check points and solution when LED light next to lens viewfinder keeps

blinking and does not indicate waiting mode(green light). Refer to Table3-5 below.

CHECK POINT

üüüü

Step Check Point Solution

1 Is CN301 of SY1 board connected to CN106 of

CA2 board?

2 Is SY1 board defective? Replace SY1 board.

3 Is CA2 board defective? Replace CA2 board.

n

n If red LED light does not stop blinking, it means that 8-bit CPU on the

n n

SY1 board is not communicating well with main CPU on the CA2

board.

Table 3-5. Check points when red LED light blinking

Push SY1 board into CA2

board.

3.1.3 Shutter does not work

Here shows check points and solution when the image data can not be taken or the beep sound of

buzzer does not work even it is set On. Refer to Table3-6 below.

Table 3-6. Check point when the shutter button does not work

Step Check Point Solution

1 Remove the top cover and see if the peaking

located back of the shutter is broken or not.

2 Is S3029 micro-switch on the SY1 board broken? Replace SY1 board.

3 Is the power supply block on the ST1 board

defective?

Replace the shutter button.

Replace ST1 board.

3.1.4 Image is taken out of cross mark in the viewfinder

(Not using LCD monitor)

Here shows check points and solution when the images are taken out of central cross mark in

using the lens viewfinder. Refer to Table3-7 below.

Table 3-7. Check points when image is taken out of cross mark in the viewfinder

Step Check Point Solution

1 Is the user trying to take a picture within 50cm

to the subject without using Macro mode?

2 Is the lens viewfinder installed on the holder

chassis correctly?

3 Is holder chassis connected to CA1 board

correctly?

4 Is soldering CCD on the CA1 board done

correctly?

Rev. A

Advise the user to use Macro

mode.

Install the lens viewfinder

correctly.

Connect the holder chassis

correctly.

Solder CCD correctly.

3-

Page 47

PhotoPC600

4

Chapter3 Troubleshooting

3.1.5 Nothing appears on the Camera and Computer screens (All black)

Here shows check points and solutions when the LCD screen(or computer screen in case of

transferring image data to the computer) is all black even in the Playback mode or View mode

after taking pictures.

CHECK POINT

üüüü

Step Check Point Solution

1 Is CA2 board defective? Replace CA2 board.

2 Is CA1 board defective? Replace CA1 board.

3 Is CCD defective? Replace CCD.

n

n Even when the CCD is broken and unable to take images, the camera

n n

still operates regularly.

n

n Judging from repair experiences of PhotoPC and PhotoPC500, many

n n

cases of this kind of troubles are due to the dropped and broken

main control boards by the users rather than accidental malfunction

around CCD.

Table 3-8. Check points when nothing appears on the screen

3.1.6 Unable to transfer image data to PC

This section shows check points and solution when the image data can not be transferred from the

camera to PC.

Table 3-9. Check points when image data can not be transferred to PC

Step Check Point Solution

1 Is the user using PC with Max.

communication speed 9600bps?

2 See if the cable terminal on the camera

side is damaged or not , and check if there

is any broken iron piece in the connector

hole or not.

3 Refer to the cable connection in the

Appendix and check if there is continuity in

the serial cable.

4 Is ST1 board defective? Replace ST1 board.

Use high-speed serial I/F board.

Replace ST1 board.

Replace the cable.

Rev. A

3-

Page 48

PhotoPC600

5

Chapter3 Troubleshooting

3.1.7 No images on the LCD screen

This section shows check points and solution when images does not appear only on the LCD

screen even when images can be transferred to PC all right.

Table 3-10. Check points when no images on the LCD screen

Step Check Point Solution

1 Is the connector(white) of LCD monitor

inserted to CN315(white) on the ST1

board?

2 Is FPC of LCD monitor inserted to

CN171(brown) on the CA2 board ?

3 Is CN315 on the ST1 board soldered

steady?

4 Is CN171 on the ST1 board soldered

steady?

5 Is LCD monitor defective? Replace LCD monitor.

Insert the connector to CN315

steady.

Insert FPC to CN171 steady.

Replace ST1 board.

Replace ST1 board.

3.1.8 Unable to use optional Compact Flash Card

This section shows check points and solution when the number of pictures you can take does not

change after installing optional Compact Flash Card, or image data can not be red even after

removing the Flash card and connecting to PC or another camera.

Table 3-11. Check points when unable to use the flash card

Step Check Point Solution

1 Is all 50-pin of CN141 on the CA2 board

damaged?

2 Doesn’t the user insert or remove the

flash card when the power is still on?

3 Is the compact flash card itself

defective?

Replace CA2 board.

Give them right instruction.

Replace the Compact Flash

Card.

3.1.9 Picture is blurry or out of focus

Table 3-12. Check points when picture is out of focus

Step Check Point Solution

1 The focus adjustment value stored in

the memory is not correct.

2 Is the lens unit defective? Replace the lens unit.

3 Is CA2 board defective? Replace CA2 board.

Refer to Chapter5 and perform

Flange-back adjustment.

Rev. A

3-

Page 49

CHAPTER

4

DISASSEMBLY AND ASSEMBLY

Page 50

PhotoPC 600

Chapter4 Disassembly and Assembly

4.1 OVERVIEW

This section describes disassembly and assembly of major components of PhotoPC600. Since the

assembly process is relatively complicated, procedures for disassembly and assembly are

explained individually.

4.1.1 Precautions

See the precautions below before disassembling and assembling PhotoPC600.

WARNING

CAUTION

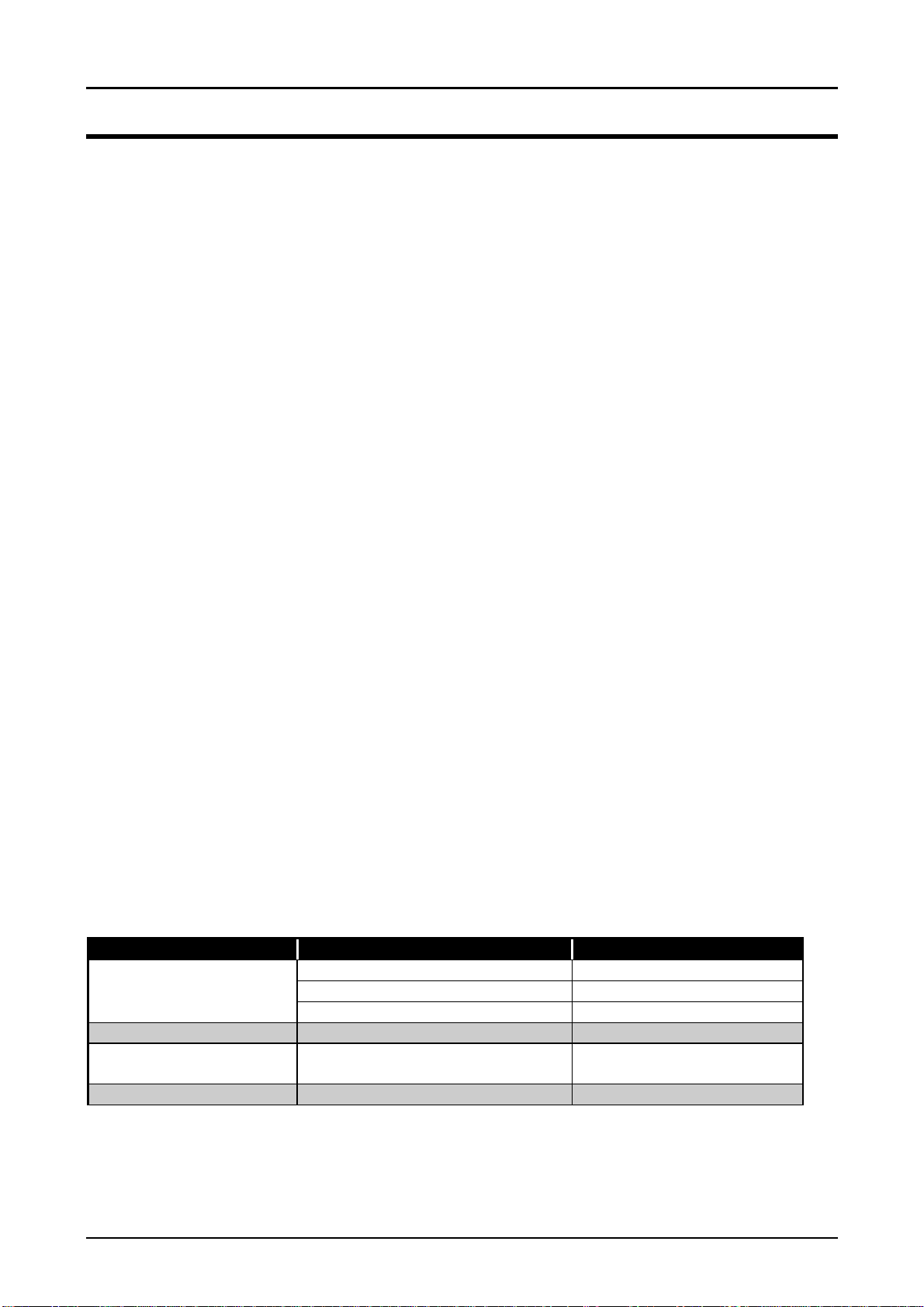

No. Service Performed Required Adjustment Maintenance

1 Replacing CA1 Board 1) Initialization

2 Replacing the CA2 Board 1) Initialization

3 Replacing the LCD

monitor

4 Replacing the SY1 Board Not required 1st Maintenance

5 Replacing the ST1 Board Not required 1st Maintenance

6 Replacing the TB1 Board Not required 1st Maintenance

n

n Disconnect the AC adapter or batteries before disassembling the

n n

camera.

n

n Discharge the electricity in the electrolytic capacitor by using cement

n n

resistor when you need to touch the ST1 board for repair service.

(See page 4-4 for more details)The electrolytic capacitor(C5412),

which is mounted on the ST1 board is for light emission and

arranged to be charged automatically every time the power is turned

on. Therefore, there is a danger of getting electric shock.

n

n In this products, there are 2 repair levels; first maintenance and

n n

second maintenance. The performance of the second maintenance is

allowed to be done only by EPSON Co., Ltd. We do not guarantee the

repair result by the others. Refer to Table below for distinction

between first and second maintenance.

n

n Refer to section 4.1.5 for assembly.

n n

n

n Use the exclusive package material when transporting cameras.

n n

Table 4-1. Criterion of First/2nd Maintenance

2nd Maintenance

2) 5100K AWB adjustment

3) Flange-back adjustment

2nd Maintenance

2) 5100K AWB adjustment

3) Flange-back adjustment

4) LCD H AFC adjustment

5) LCD RGB Off Set adjustment

6) LCD Gain adjustment

7) LCD Blue Brightness adjustment

8) LCD Red Brightness adjustment

1) LCD H AFC adjustment

2) LCD RGB Off Set adjustment

3) LCD Gain adjustment

4) LCD Blue Brightness adjustment

5) LCD Red Brightness adjustment

2nd Maintenance

Rev. A

4-1

Page 51

PhotoPC 600

2

Chapter4 Disassembly and Assembly

4.1.2 Tools

The table below shows the tools recommended for repair service of PhotoPC600.

Table 4-2. Recommended Tools

No. Name Purchasable Code

1 5100 Kelvin color Viewer X 103058400

2 DscCal52 adjustment program X Attached with this manual book.

3 Simens star chart X Included in the end of this book.

4 Precision Driver (+) O ---5 Soldering iron O B740200100

6 Tweezers O B641000100

7 Oscilloscope O --8 Windows95 (require 19200bps or

O ---

higher for serial)

Note):

O means commercially available and X means not

.

4.1.3 Specification for Screws

Figure below shows the abbreviation of screws and its use.

Type of head

Type of threaded

section

Diameter

Length(L)

Configuration (Color)

100

101

102

103

L

(Black)

(Silver)

(Gold)

(Gold)

Abbreviation Part Name Shape

Abbreviation Part Name

Dimension

(mm)

Pan Head

Biding Head

Shape

No symbol Machine Screw

Forming Tight

(For plastic)

Forming Tight

(For metal)

Location

Most of PhotoPC-600

parts are fixed by this screws.

Exterior silver case and cover are

fixed by these 5 screws.

CA1 board and LCD holder are

fixed by these 2 screws.

Lens, spacer (iron)and CA1 board

are fixed by this screw.

104

(Gold)

Lens unit is fixed on the CA1 board

by these 2 screws.

Figure 4-1. Screw Identification

Rev. A

4-

Page 52

3

4.1.4 Procedure for Disassembly

The following shows the flow chart of the assembly.

PhotoPC 600

Chapter4 Disassembly and Assembly

CAUTION

n

n Refer to section 4.1.1 for precaution before starting disassembly.

n n

n

n Follow the numbers in the figure as the disassembly order.

n n

n

n Remove 7 cables for prevention of radiation(electric noise),

n n

according to your necessity. Also, refer to section 4.1.5 “Procedure

for Assembly” for soldering points during assembly.

Page4-4

R em ove the C abinet A ssem bly(R ear/Front), Top C over

and Battery C over.

Page4-5

R em ove SY 1 Board, S T1 B oard and B attery H older.

Page4-6

Rem ove the CA1 Board, LCD M onitor, CCD, CA2 Board,

View finder and LC D H older.

T o ta l

Assem bly

Figure 4-2. Flow Chart of Disassembly

Rev. A

4-

Page 53

PhotoPC 600

4

Chapter4 Disassembly and Assembly

4.1.4.1 Removing the Cabinet Parts

The figure below shows disassembling of Cabinet Assembly (Rear and Front), Top Cover and

Battery Cover.

1. Screw 2x5

(#100)

Grip

11. Remove the top cover.

10. Screw 2x5

(#100)

9. Remove a connector

for power supply.

4. Screw 2x5

(#101)

8. Remove the FPC.

5. Open this cover

by pressing the lever for

the card.

Figure 4-3. Procedure for Disassembly (1)

7. Remove a connector

for TB1.

6. Screw 2x5

(#100)

2. Open the cover.

WARNING

There is a danger of getting electric shock from the electrolytic

capacitor(C5412) mounted on the ST1 board. Discharge the electricity

by using the cement resistor when you need to touch the ST1 Board for

repair service. (See the figure below for details.)

CAUTION

Be careful not to damage the hook inside of grip when you remove the