Page 1

EPSON

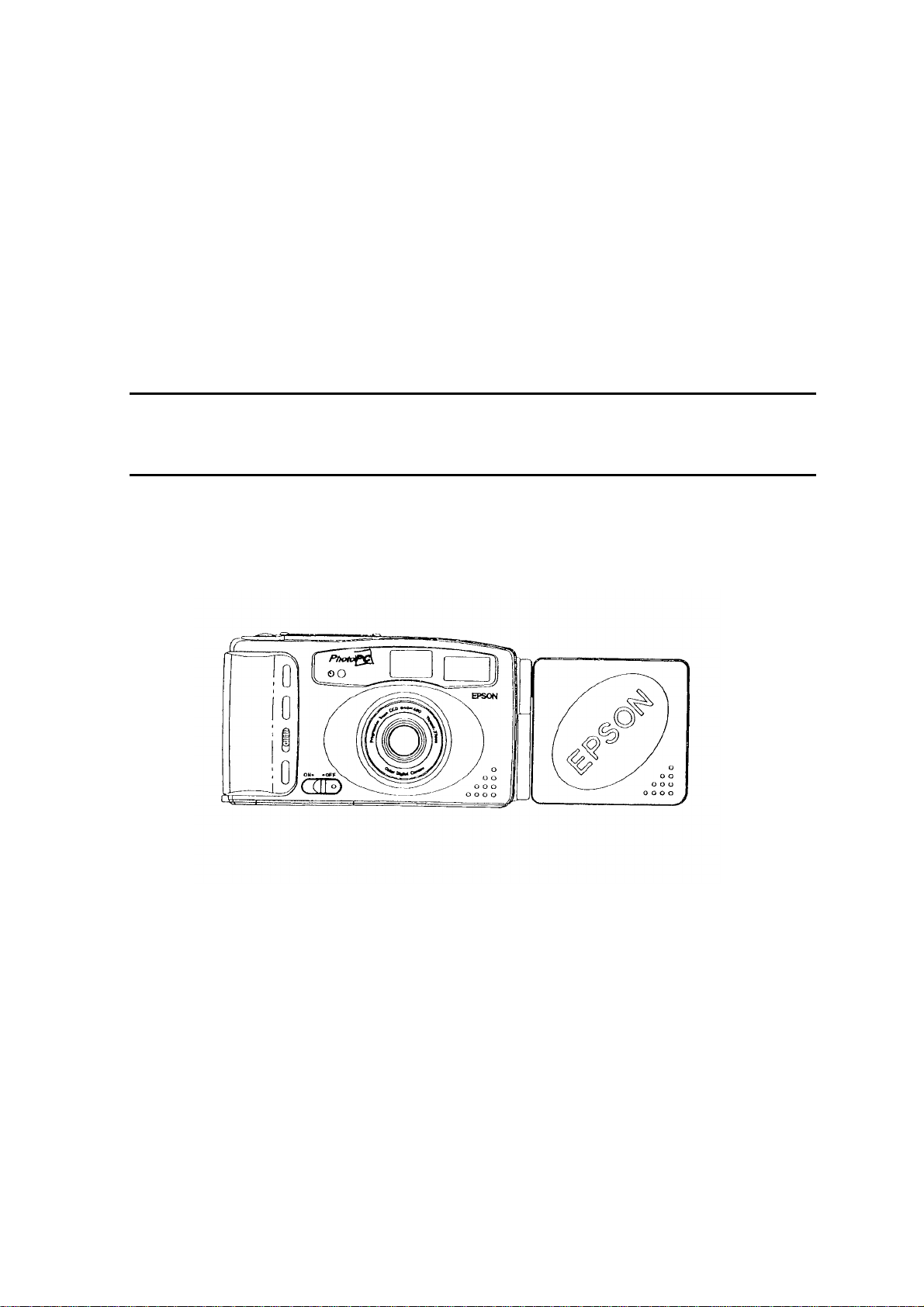

EPSON PhotoPC 500

SERVICE MANUAL

DIGITAL CAMERA

SEIKO EPSON CORPORATION

Rev.A

4006988

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever

without SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for any

errors in this manual or the consequences thereof.

Epson is a registered trademark of Seiko Epson Corporation.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks or registered trademarks of their respective companies.

Copyright 1996 by SEIKO EPSON CORPORATION

Nagano, Japan

ii

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

DANGER

WARNING

The precautioary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could res ult in ser ious or f atal per sonal injury.

Great caution should be exercised in perfor ming procedures pr eceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIER WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING T ESTING AS DICTAED W ITHIN T HIS MANUAL. DO NOT CONNECT

THE UNIT TO A POW ER SOURCE UNTIL INSTRUCTED TO DO SO. W HEN THE POW ER

SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED O NLY BY EPSON CERTIFIED

REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT T HE SOURCE VOLT AGE IS THE SAME AS T HE RATED VOLT AGE,

LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A

PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT T HE EPSON PRODUCT HAS BEEN DISCONNECT ED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSIT IVEMICROPROC ESSORS AND CIRCUIT RY, USE STAT IC

DISCHARGE EQUIPMENT, SUCH AS ANTI-ST ATIC WRIST ST RAPS, WHEN ACCESSING

INTERNAL COMPONENTS.

5. REPLACE MALFUCNTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

iii

Page 4

REVISION STATUS

Revision Issued Data Contents

Rev A October 29,1996 1st issued

EPSON OVERSEAS MARKETING LOCATIONS

EPSON America, Inc

20770 Madrona Avenue,

P.O. Box 2842

Torrance, CA 90509-2842

Phone: (800)922-8911

Fax: (310)782-5220

EPSON UK LTD.

Campus 100, Maylands Avenue,

Hemel Hempstead, Herts, HP2 7TJ

U.K.

Phone: 1442-61144

Fax: 1442-227227

EPSON IBERICA, S.A.

Avda. de Roma, 18-26

08290 CERDANYOLA DEL VALLES

Balcerona, Spain

Phone: 582.15.00

Fax: 582.15.55

EPSON AUSTRALIA PTY. LIMITED

1/70 Gibbes Street,

Chatswood 2067 NSW

Australia

Phone: 02-415-9000

Fax: 02-417-0077

EPSON HONG KONG LTD.

20/F, Harbour Centre,

25 Harbour Road, Wanchai, HONG KONG

Phone: 585-4600

Fax: 827-4346

SEIKO EPSON CORPORATION

Imaging & Information Products Division

EPSON DEUTCHLAND GmBH

Zülpicher Straße 6, 4000 Düsseldorf 11

F.R. Germany

Phone: 0211-56030

Fax: 0211-504-7787

EPSON FRANCE S.A.

68 bis, rue Marjolin 92300,

Levallois-Perret

France

Phone: 1-4087-3737

Fax: 1-4737-1510

EPSON ITALIA S.p.A.

V. le F. lli Casiraghi, 427

20099 Sesto S. Giovanni (MI)

Italy

Phone: 02-26233-1

Fax: 02-2440705

EPSON SINGAPORE PTE. LTD.

NO.1 Raffles Place #26-00

OUB Centre

Singapore 0104

Phone: 5330477

Fax: 5338119

EPSON TAIWAN TECHNOLOGY &

TRADING LTD.

10F, No. 287 Nonking E. Road, Sec. 3,

Taipei, Taiwan, R.O.C.

Phone: 2-717-7360

Fax: 2-712-9164

80 Harashinden, Hirooka, Shiojiri-Shi, Nagano-Ken 399-07 JAPAN

Phone: 0263-52-2552

Fax: 0263-54-4007

iv

Page 5

As of July, 1996

v

Page 6

HAPTER

C

1. P

RODUCT DESCRIPTION

................................................................................................

...............................................................................................................1.2. Specifiation2

.............................................................................................

..........................................................................................................1.2.2. Environmental conditions4

...............................................................................................................1.2.3. Electrical Specification4

..........................................................................................................1.2.4. Safety Standards and EMI4

.....................................................................................................................................1.2.5. Reliability5

.................................................................................................................1.2.6. Operating Conditions5

.............................................................................

................................................................................................

...................................................................................

.....................................................................................................

....................................................................................................................................1.4.2. LCD Panel9

...............................................................................................................................1.4.3. LED Indicator10

......................................................................................................1.4.4. Buttons on the LCD monitor11

.......................................................................................................................1.4.5. Functional Setting12

....................................................................................

1.2.1. General specification2

1.3. Interface Specification5

1.3.1. Cable Specification6

1.4. Camera Operation8

1.5. Main Component13

1.1. Features1

1.4.1. Control buttons8

.1.

Page 7

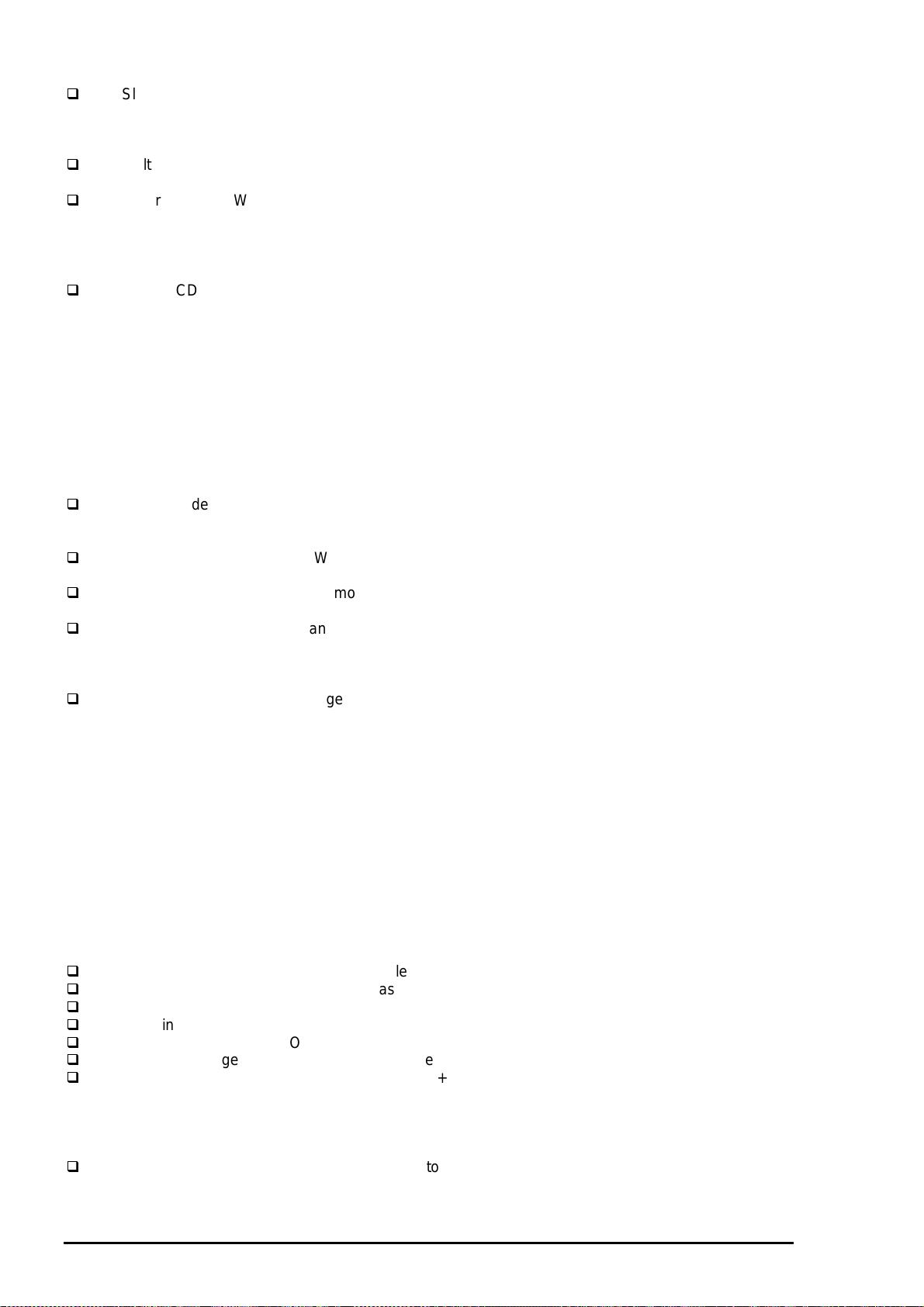

.2. Features

PhotoPC 500 is the digital still camera that has high image quality but inexpensive for its high

performance.

The major camera features are;

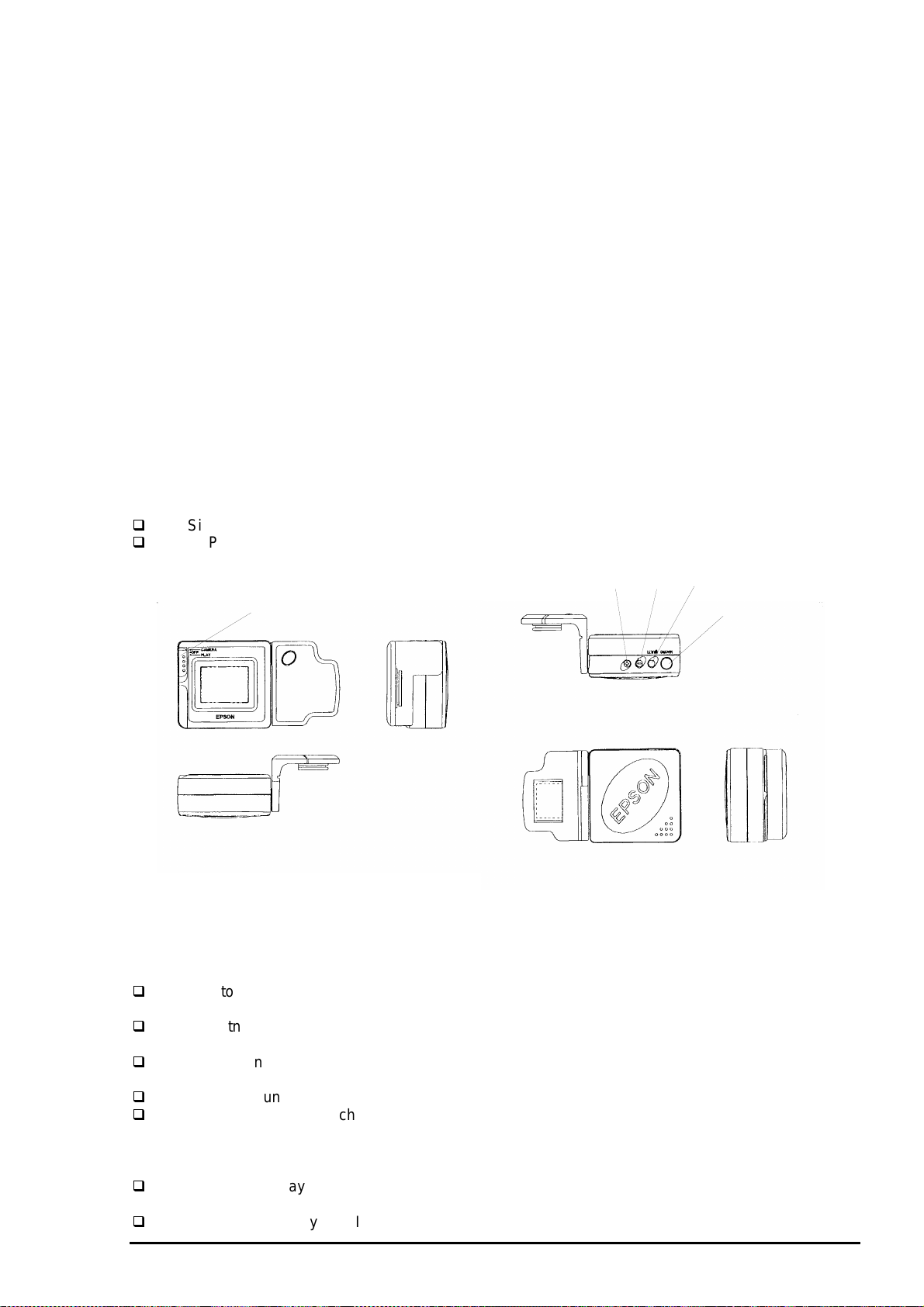

* The Table 1-1 shows printable photos with optional memories and the figure below shows exterior view

of PhotoPC 500.

High Image Quality

VGA (640 x 480 pixels, 24bit color)

Sensor

Color Area CCD (Progressive Scan type)

Focus

Fixed

Exposure

Automatic

Internal memory

2MB (for image and firmware)

Built-in-Flash

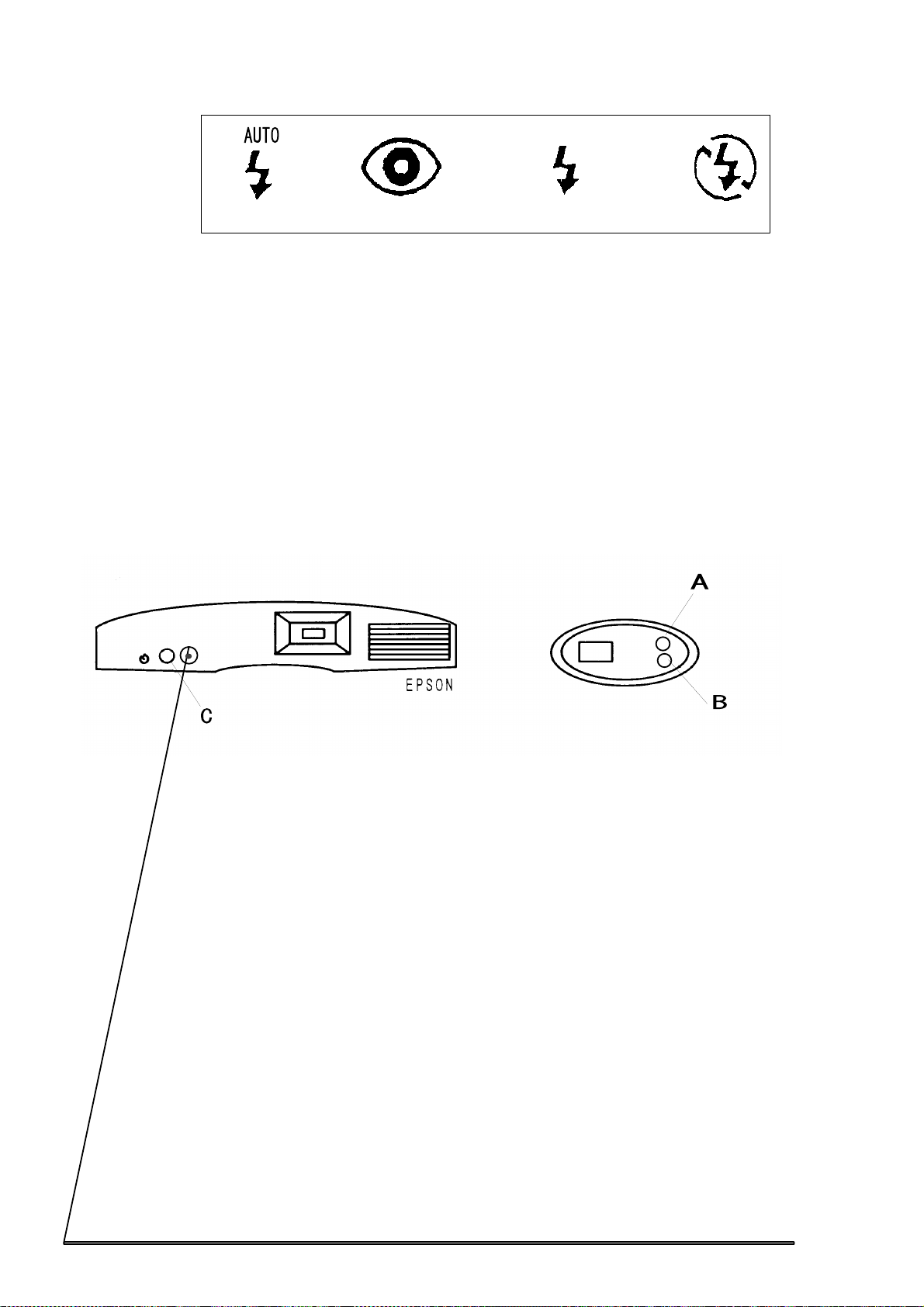

4 mode : Auto/No-red eyes Auto/Off/Forced flash

Power

AA-size batteries (Alkaline/Ni-Cadium/Lithium)

Size

20% Smaller than CP-100

Interface

High Speed Serial interface : 19200bps (min.)1 15.2Kbps (max.)

Option

Expand Memory 2/4MB (See Table 1-1)

AC adapter

LCD monitor

Camera control is available from the PC.

Various filters and lenses for 37mm video camera can be attached to the front lens.

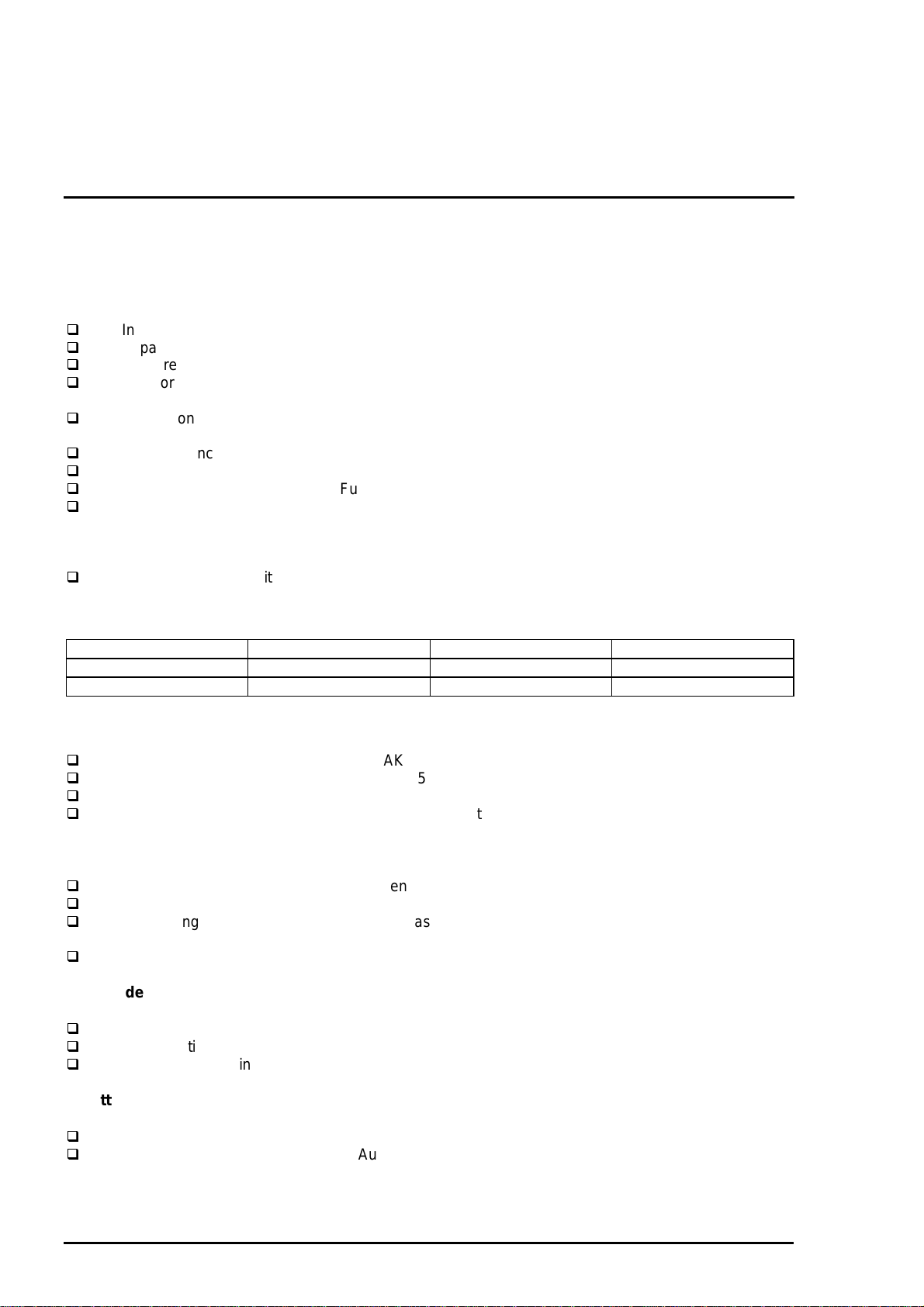

Table 1-1. Optional Units

Unit Model No.

Expansion Memory module (2MB) B808201

Expansion Memory module (4MB) B808211

Figure 1-1. Exterior of PhotoPC 500

Page 8

PHOTOPC 500 SERVICE MANUAL Service Manual

.3. Specifiation

This section describes detailed specifications of the camera.

1.

[ Recorded Image]

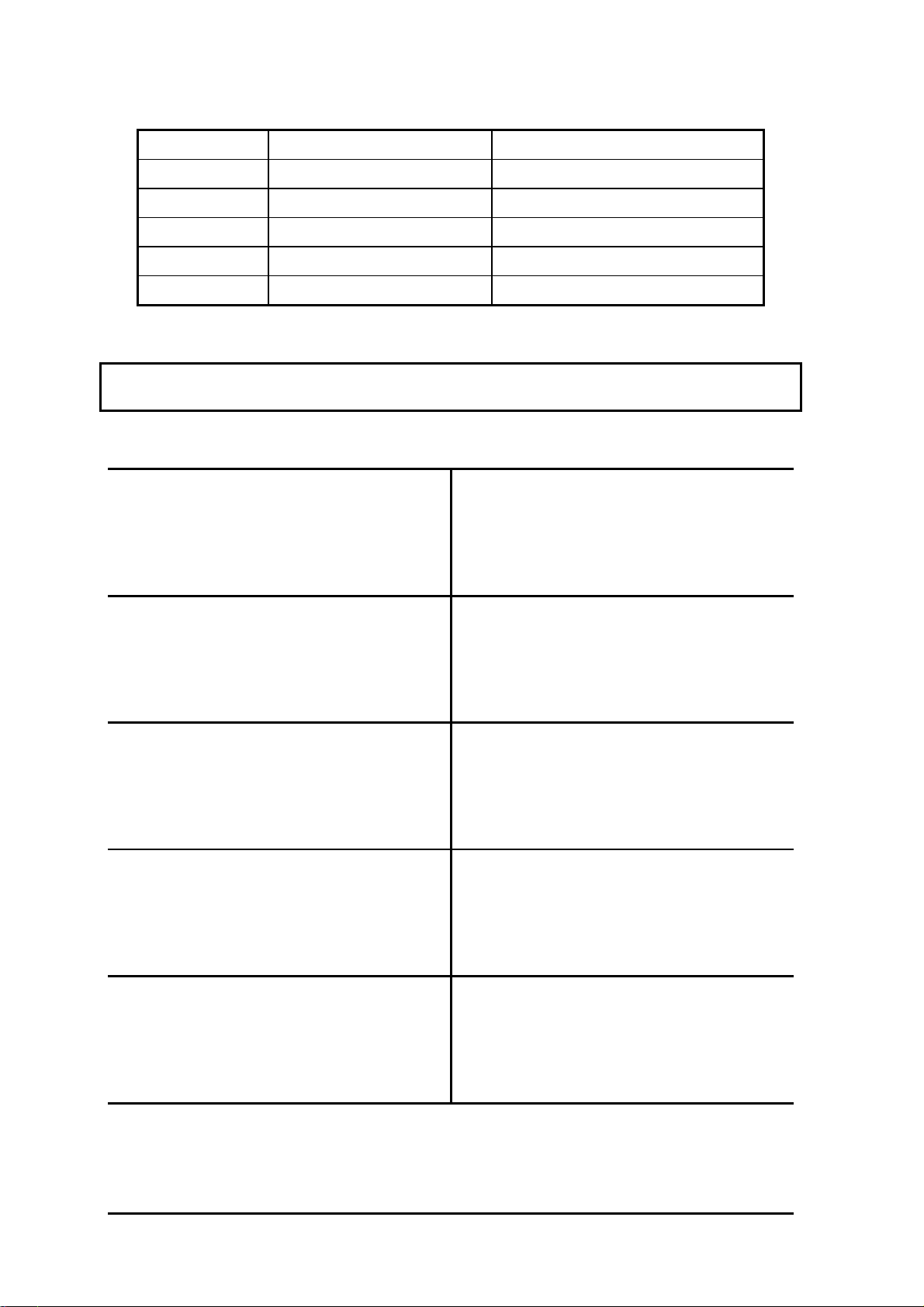

High resolution 30 65 100

Standard resolution 60 130 200

General specification

Internal memory : 2MB (including approx.300KB Program Area)

Expandable Memory : Expandable Memory Module 2MB/4MB(Same as CP-100)

Compression : JPEG

File Format : JPEG. Including thumbnail (H80xV64 pixels), Date and time

information

Resolution : High resolution 640 x 480 pixels

: Standard resolution 320 x 240 pixels

White Balance : Automatic adjustment

Sensitivity : ISO 130 equivalent

Color : 24bit Full Color (8bit pixel x3)

Processing Time : High resolution Approx. 6 sec

Standard resolution Approx. 2 sec

* Red LED on side of viewfinder will flash during processing.

Number of images with Expandable Memory Module (see below Table 1-2)

Table 1-2. Printable photos with memory

Default +2MB +4MB

[CCD]

[Lens]

[Viewfinder]

[Shutter]

While connecting to PC, you can adjust from Application. But it

returns to Automatic mode after disconnecting from PC.

[Iris]

Feature : 1/3» ICX084AK (SONY) Square pixel

Total Pixels : 692(H) x 504(V) Approx. 350K pixels

Available Pixels : 659(H) x 494(V) Approx. 330K pixels

Transfer : Progressive scan type

Focus Distance : 6mm equivalent to 43mm lens on a 35mm camera

Aperture Ratio : 1:2.8

Focus range : 60cm infinity (Flash available by 3.0m)

20cm infinity (available with LCD monitor)

Structure : 5 set 5 pieces

Type : Optical Virtual Image

Magnification : x0.65

Indicator in Viewfinder : Guide Frame

Method : Electronic shutter

Exposure : Automatic 1/30 1/10000 sec.

2

Rev. A

Page 9

3

Method

is

[Exposure Control]

Method : Exposure control by iris-Shutter change program (Automatic)

[Measurement]

Chapter 1 Product Description

:

Fixed mechanical iris F2.8/F8 (When the optional LCD monitor

installed, F8 is fixed at close distance photo mode)

Method : Center-prioritized light measurement

Sensor : As both for CCD image capturing sensor

[Built-in Flash]

Type : Fixed Built-in Flash

Mode : Auto/ No red-eyes Auto/Off/Forced flash

Exposure Control Method : Automatic Luminance Control by Pre-flash

Color temperature : 5500K degree

Distance : 0.45m3m

Guide number : G No 8.4 (ISO100 Equivalent) G No 9.6 (ISO130 Equivalent)

[Self-Timer]

Time : 10 sec. (cancelable by pushing timer switch)

[Power]

Main power supply : AA Alkaline x 4 or

Battery Life : > 200 pictures (without LCD monitor, 50% flash, Alkaline

AC adapter : Optional

: Auto/ No red-eyes Auto:Auto flashing against low brightness and

backlight

AA Ni-cd x 4 or

AA Ni- MH x 4 or

AA Lithium x4

* Mixing different type of batteries are not acceptable.

* Can not charge Ni-Cd or Ni-MH by camera.

* Battery life indicator is useful only on Alkaline Battery.

Battery)

[External interface]

DC input : NewEIAJ Type3, 5.5mm diameter, center plus

Output : RS232C, Mini Din 8pin

LCD monitor adapter terminal : yes

[Date/Time]

Recording Method : Digital data recorded in file

(year/month/day/time/minute/second)

Date/Time Setting : Only adjustable from PC

Back up : Date and Time will be cleared when batteries are dead or

after the batteries are replaced exchanging.

[Erase]

All Erase : Camera: Erase+Selftimer button

PC : From Application

Erase one image : Camera: Erase for last image

LCD Monitor attached allows to erase selected one.

PC : Selected image erasable from Application

Erase Time : All erase <10 sec. (When no Expand Memory)

Erase one image < 0.5 sec.

Rev. A

Page 10

PHOTOPC 500 SERVICE MANUAL Service Manual

4

[Sound]

[Auto Shut Off]

PhotoPC 500 goes to Power Save mode under following conditions.

Camera only : Default 1min (Adjustable from PC Application)

Connecting with PC : Default 5min (Not adjustable)

Using AC adapter : No power saving

[Others]

Beep sound : After picture is taken and during image processing. (Once:pi)

Error beep sound occur when pushing shutter during image

processing. (Twice:pipi)

Without LCD Monitor

With LCD Monitor

View Mode : Camera On as same as camera only

Camera Off Turn Off 10 sec. after warming sign

Playback Mode : Default 5min (Not adjustable)

To return from Power saving : Push the Shutter button

Screw for tripod : Yes

37mm thread for additional lens or filter available

[Exterior]

2.

[Acceptable environment]

3.

Max.: DC 8V

4.

EN61000-3-3,

EN55082-1

IEC801-2

Dimensions : 141.2 (W) x 81 (H) x 52.6 (D) mm (Camera only)

221.5 mm x 81mm x 60.6 mm ( With the optional LCD monitor )

Weight : Under 300g (Without batteries, without LCD monitor)

Environmental conditions

Temperature Operating : 0 to 40 degree

Storage : -20 to 60 degree

Humidity Operating : 30 to 90% no condensation

Storage : 10t o 90% no condensation

Electrical Specification

Requirement of supply voltage for DC input (AC adapter)

Min.: DC 6.3V

Absolute maximum supply voltage for DC input

Max.: DC 10V

Safety Standards and EMI

USA : FC Class B

Europe : EN55022 Class B,

EN61000-3-2,

IEC801-3

IEC801-4

Rev. A

Page 11

Chapter 1 Product Description

5.

6.

Place : Ordinary home, office or outside

Reliability

FLASH memory life : 10K cycle write for FLASH memory

Operating Conditions

.4. Interface Specification

PhotoPC 500 can be connected to the PC only by the serial interface(RS-232C compatible).

The minimum s peed requirem ent of serial inter fac e of PC is 19200bps . T his sec tion descr ibes the use of

serial interface and cable.

[Serial Interface]

Data format: RS-232C

Communication method: Asynchronous. 8bit, Non Parity

Speed: 19200,38400,57600,115200 bps

Rev. A

5

Page 12

PHOTOPC 500 SERVICE MANUAL Service Manual

6

1.

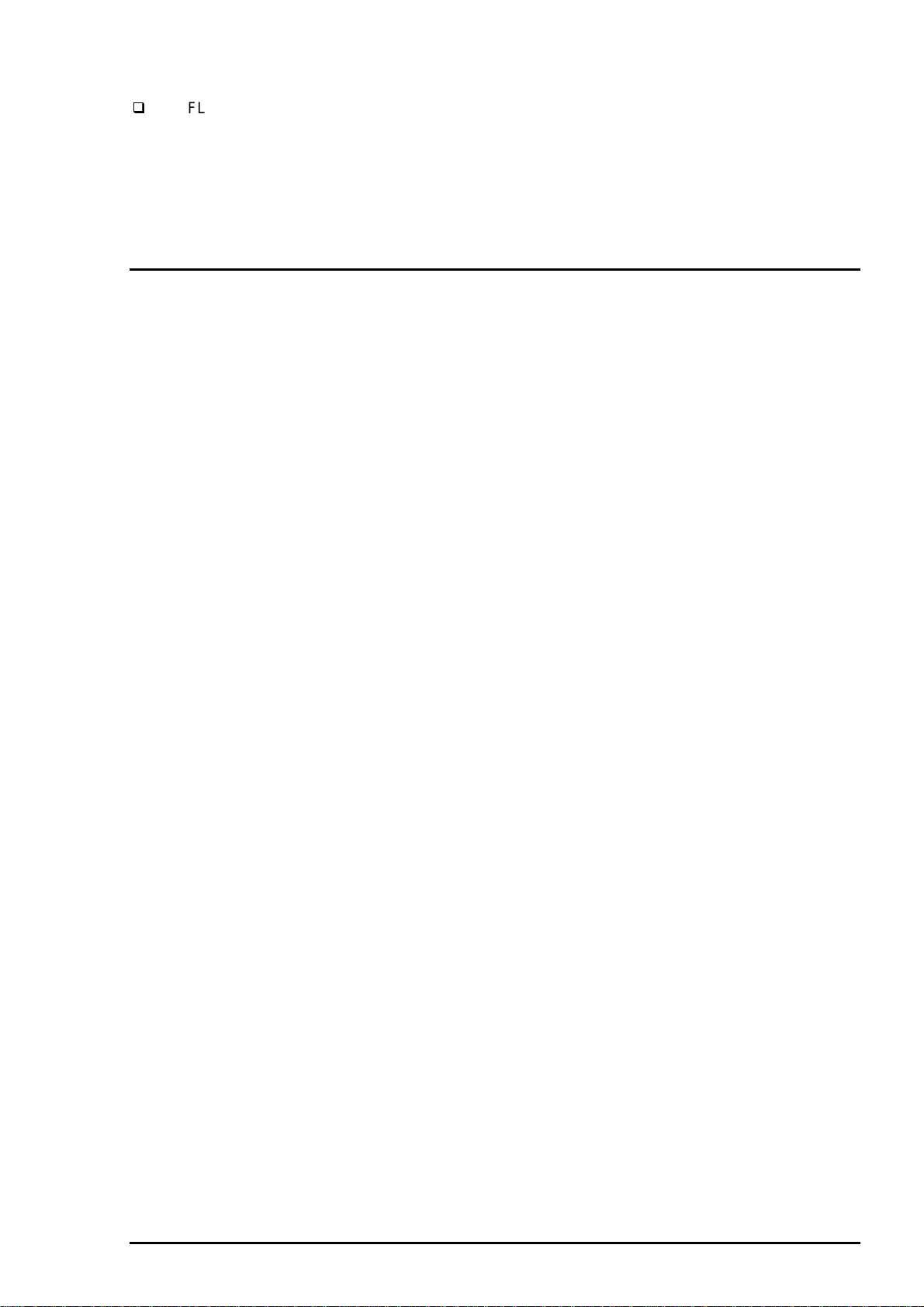

This section describes DOS/V connector cable and conversion connector for Mac.

3

[Cable/connector description 1: DOS/V Cable]

The following figure shows the connection diagram of DOS/V cable.

Cable Specification

7

6

4

8

5

2

1

Figure 1-2. Cable for PC

1

2

3

4

5

6

7

8

9

Figure 1-3. Connection for diagram for DOC/V cable

Rev. A

Page 13

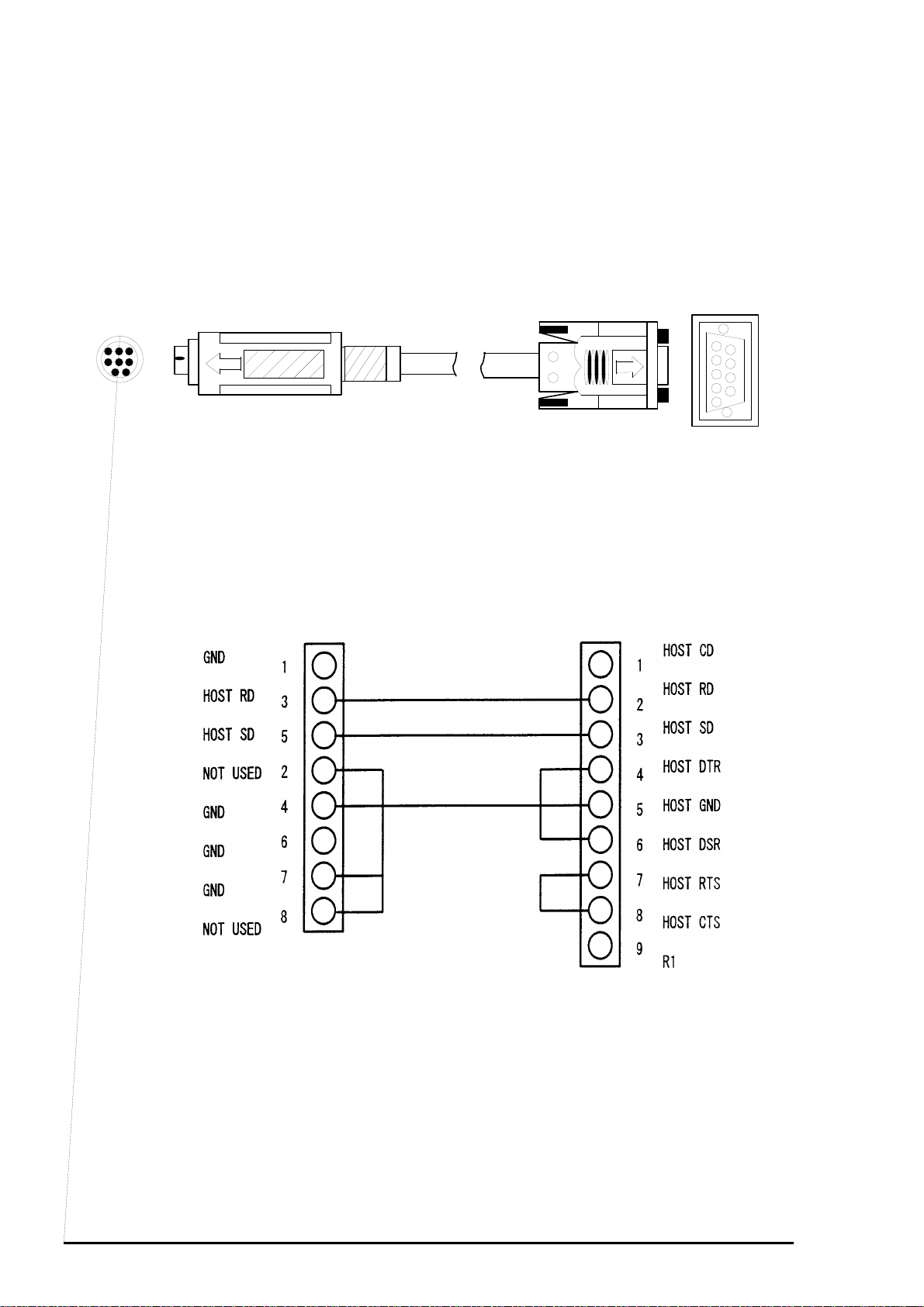

[Cable/Connector description 2: MAC adapter]

7

6

4

3

8

5

2

1

Figure 1-4. Mac adapter

Chapter 1 Product Description

1

2

3

4

5

6

7

8

9

The following figure shows the connection diagram of MAC Cable.

Figure 1-5. Connection for Mac cable

Rev. A

7

Page 14

PHOTOPC 500 SERVICE MANUAL Service Manual

8

.5. Camera Operation

This section describes LCD panel display and its functions.

1.

The LCD panel consist of 5 buttons and displays the camera operation. The power s witch is loc ated under

the lens and move along with the closing and opening movement of shutter. The following Figure1-6

shows

these 5 buttons on the LCD Panel and their functions.

Control buttons

Figure 1-6. Control buttons

Button A

*

Button B:

*

Button C:

*

Button D:

*

Button E:

*

: Shutter Button. Photo shooting.

Erase button. Function is different according to the following conditions.

*Without LCD monitor : erase last image

* With LCD monitor :

Playback mode : erase displayed image

Off or View mode : erase last image

*All images erase : push Self-Timer button while pressing Erase button

Flash mode button. Flash mode will be changing cyclically as following;

AutoNo red-eyes autoOffForced flashAuto

Resolution button. Change resolution alternatively between High resolution and

Standard resolution.

Self-timer button. When pushing, Self-timer indicator will flash. Under this condition

picture will be taken after 10 seconds from pushing shutter.

Rev. A

Page 15

Chapter 1 Product Description

9

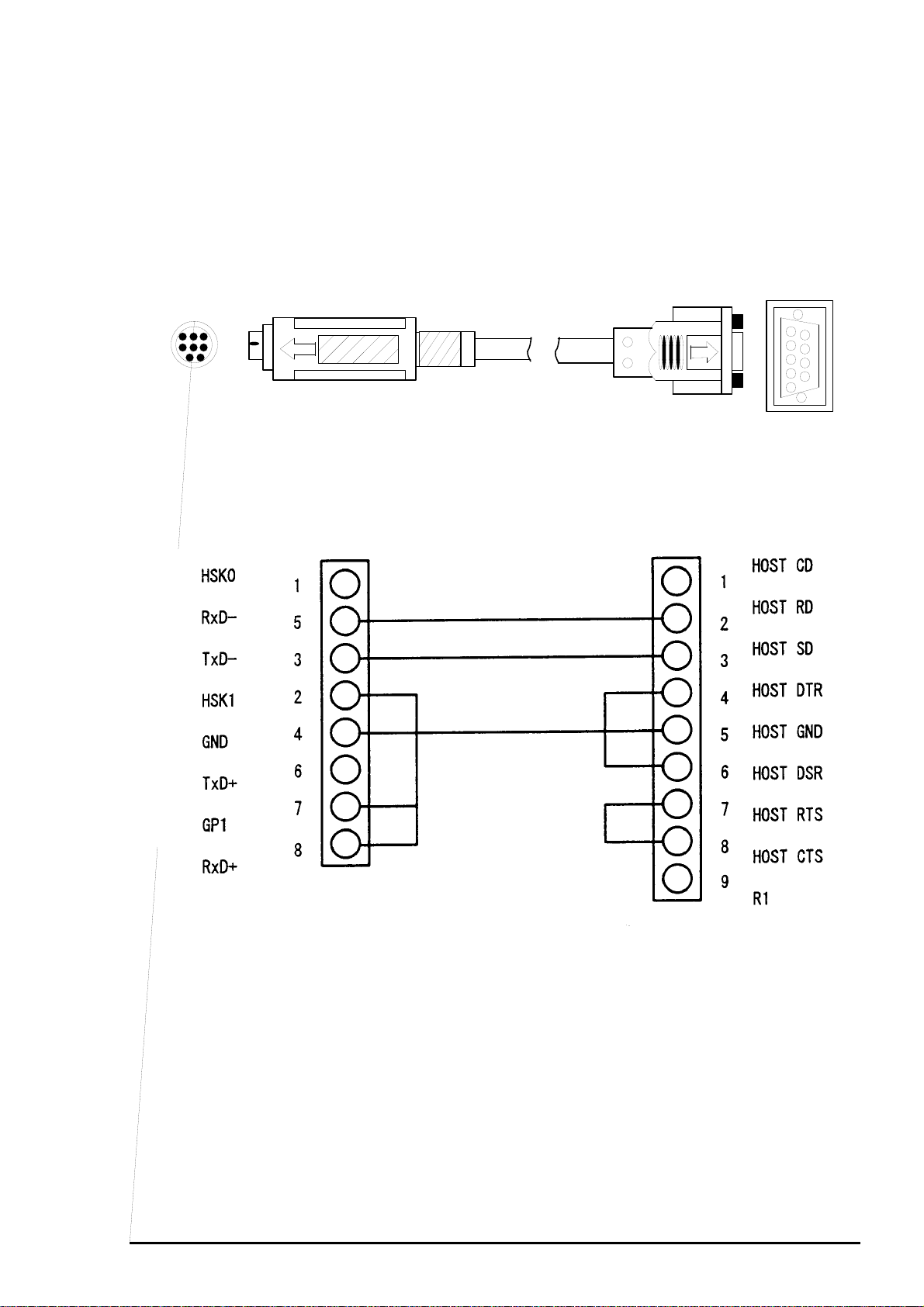

2.

The camera operation mode is displayed on the LCD. The following figure 1-7 shows its exterior and

its 8 displays.

Display A :

LCD Panel

Figure 1-7. LCD Panel

The number of pictures taken is indicated. If the camera is controlled by the PC,

the frame around the numbers flashes.

Display B :

S: Standard Resolution

Hi: High Resolution

Display C :

Display D:

Display E:

will flash and then turn off the power.

Display F:

Display G:

Display H:

communication with PC.

The present resolution type is indicated.

Erase indicator. This indicator flashes while the camera is deleting a picture.

Self-timer indicator. Indicator will flash when selftimer enable.

Battery life indicator. This indicates the 7 battery levels. When empty, indicator

Flash mode. Auto/No red-eyes auto/Forced flash/ Off. Refer to the

following figure. (See figure 1-8.)

Number of pictures remaining. This depends on the resolution setting you have chosen.

Connecting to PC. Line around the number of pictures taken will flash under

Line under the number of pictures taken will appear when cable is connected to

PhotoPC 500.

Rev. A

Page 16

PHOTOPC 500 SERVICE MANUAL Service Manual

0

Auto

3.

PhotoPC 500 has two indicators located on beside viewfinder and one on the left side above

of lens. The followings describe the location of indicators and description of these indicators.

LED Indicator

No red-eyes auto

Figure 1-8. Flash mode

Forced flash

Off

Figure 1-9. LED indicator

Indicator A:

*Red LED Red flashing: Photo shooting not available under following

conditions;

Image Processing/ Changing Flash/ Processing after Power ON

Red light : Full memory

Indicator B:

*

Stand -by Green LED Green light : Photo shooting available

Indicator C:

*Selftimer LED (red) After you set the self-timer;

0-7sec. light7-10 sec.flashing10 sec. Photo shooting

1

Rev. A

Page 17

Chapter 1 Product Description

4.

[Type]

Buttons on the LCD monitor

Size/LCD 1.8» TFT Color LCD

Of Pixels 61,000pixels H279 x V220

Power/Mode switch

Figure 1-10. Exterior view of LCD monitor

+ button

- button

MACRO button

MULTI button

[View (Recording) Mode]

[Playback Mode]

Monitor Display image from CCD in real time, display ratio: 1/30 sec.

Freezing image during processing

Brightness Adjustable with ‘+,-’ switch in only VIEW mode

Display level of brightness in adjustment (disappear in 3 sec.)

On-Screen Display Brightness level in VIEW mode

Macro mode

Close-up Function Macro switch (from 0.45cm)

Other If switch is set to VIEW mode under Power OFF, display warning message

in 10 sec. and then LCD power goes to OFF.

Playback Display Default: Full screen display for last picture

Selectable with ‘+,-’

On-Screen Display Image Number (disappear in 10 sec.)

Rev. A

11

Page 18

PHOTOPC 500 SERVICE MANUAL Service Manual

No image icon

[ERASE]

* After erasing, image number will be renumbered.

Slide Show 4sec./image

Start slide show by keep pushing ‘+’

Recycling all images

(Power save will be effective after one cycle of slide show)

Multi-Screen Multi-Screen in playback mode 9 image on screen using

thumbnail data

Other When PLAYBACK mode, control panel shows «LCD».

Even if camera’s Power switch is OFF, the camera can go to

PLAYBACK mode.

When LCD monitor is;

OFF : Erase last image by pushing Erase button

VIEW mode : Erase last image by pushing Erase button

PLAYBACK mode : Erase displayed image by pushing Erase button

(e.g. if #10 image erased, #11 will become #10 image)

[When connecting to PC]

[Button on LCD monitor]

5.

PhotoPC 500 has 2 methods in order to set or change the various functions ; either by the method

directly from the body or by using utility soft from the PC.

The following describes functions that can be set from the camera body or from the PC.

Power/mode switch OFF : LCD monitor power OFF

+button VIEW mode : Brightness control of LCD monitor

-button VIEW mode : Brightness control of LCD monitor

MACRO button Change mode alternately between MACRO recording mode

MULTI button Change mode alternately between 9 image display mode

Functional Setting

LCD monitor will be OFF, when connecting to PC.

(See figure1-10)

VIEW :VIEW mode

PLAYBACK :PLAYBACK mode

PLAYBACK mode: display next image

PLAYBACK mode: display previous image

and Normal recording mode.

This button is effective only VIEW mode.

Power ON default is Normal mode.

and Normal display mode.

This button is effective only PLAYBACK mode.

Power ON default is Normal mode.

[Available functions from the body]

[Available functions from the PC]

Resolution : Available either High Resolution or Standard Resolution

Flash : auto/forced flash/off by one button

Self-timer : On/Off

Shooting : Available

Power : On/Off

Erase one image : Erase for the last image

Erase all images : Erase button + Self timer button

Shutter speed : Available among Auto,1/30, 1/60, 1/125, 1/250, 1/1000.1/2000,

1/4000,1/10000 sec.

* In case of Auto, range will be set automatically from 1/30 to 1/10000.

12

Rev. A

Page 19

Chapter 1 Product Description

3

* When you down load the taken image data to the PC from the camera, the LCD on the camera indicate

« Low battery». Although this status appears even when the new batteries are installed, it is inevitable

phenomenon since it is done by voltage from battery detection.

Resolution : Available either High Resolution or Standard Resolution

Flash : auto/ forced flash/ off by one button

Self-timer : On/Off

Erase : Erase for the last image. Erase button + Self timer button erase all

images.

Date/Time : Set the same time as PC has. Available

year/month/date/time/second

setting.

Continuos image transfer

Communication speed 19200/38400/57600/115200 bps (This speed varies according to

the PC, O/S and application software.)

.6. Main Component

The followings are the main component of PhotoPC 500. Please refer to Chapter 2 for its location

and function.

1) SY1 Board 4) CA2 Board 7) Camera mechanism

2) CA1 Board 5) PW1 Board 8) TB2 Board

3) TB1 Board 6) ST1 Board 9) Housing

Rev. A

1

Page 20

HAPTER

C

2. O

PERATING PRINCIPLES

...............................................................................

..........................................................................................

............................................................................... 2.1.1.1. IC Function on CA1 Board2

..............................................................................................

......................................................................................................................2.1.3. Circuit Description11

.............................................................................................................2.1.4. PW1 Circuit Description12

..............................................................................................................2.1.5. SY1 Circuit Description13

............................................................................ 2.1.5.1. Internal Communication Bus14

.................................................................................................... 2.1.5.2. Power Supply Control14

..........................................................................................

............................................................................................. 2.1.6.1. Charging Circuit15

.................................................................................................... 2.1.6.2. Light Emission Circuit16

............................................................................................................

2.1. Operating Principles1

2.1.1. CA1 Circuit Description2

2.1.2. Outline of Operation11

2.1.6. ST1 Circuit Description15

2.1.7. LCD Block16

.1.

Page 21

.2. Operating Principles

This section desc ribes operation principle of c amera. Since the PhotoPC 500 is s till digital camera, there

is no complicated mechanism and most of the operation is done by the control of electric circuit. The

figure below explains location of each major electric circuit.

TB2 board

SY1 board

CA1 board

TB1 board

PW1 board

ST1 board

Figure 2- 1. PhotoPC 500 Board Location

Page 22

PhotoPC 500 Service Manual

1.

CA1 Circuit Description

The followings explain operating features on the CA1 board.

Independent storage and retrieval for each pixel

Square pixel unit cell

VGA compatible

R,G,B primary color mosaic filter

Continues variable speed electric shutter function

1.

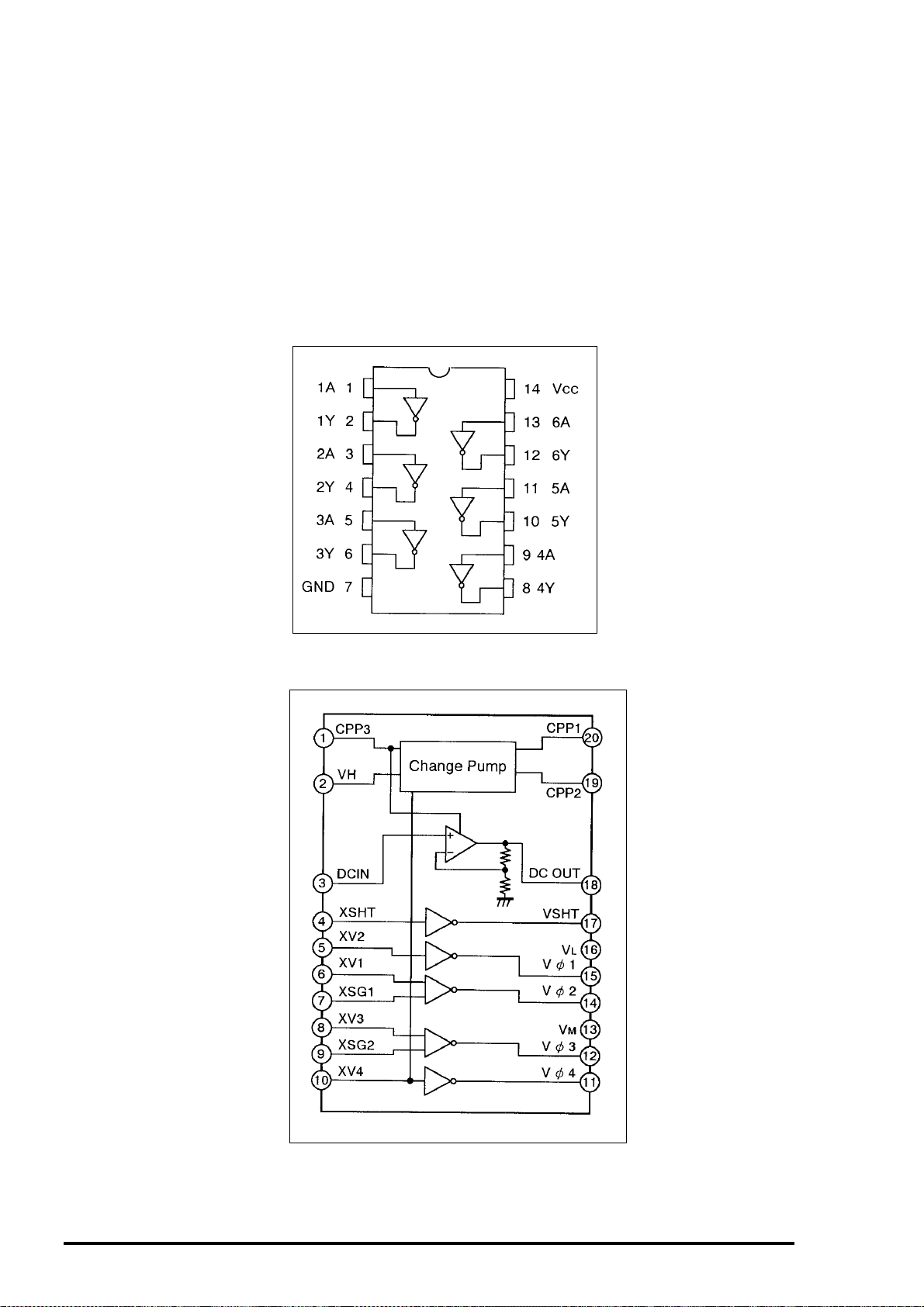

IC Function on CA1 Board

IC903 (ICX084AK) CCD imager

IC902 (MC74HC04) H driver

IC904 (CXD1267AN) V driver

IC905 (CXA1690Q) CDS/AGC

IC906 (CXD2311AR) A/D converter

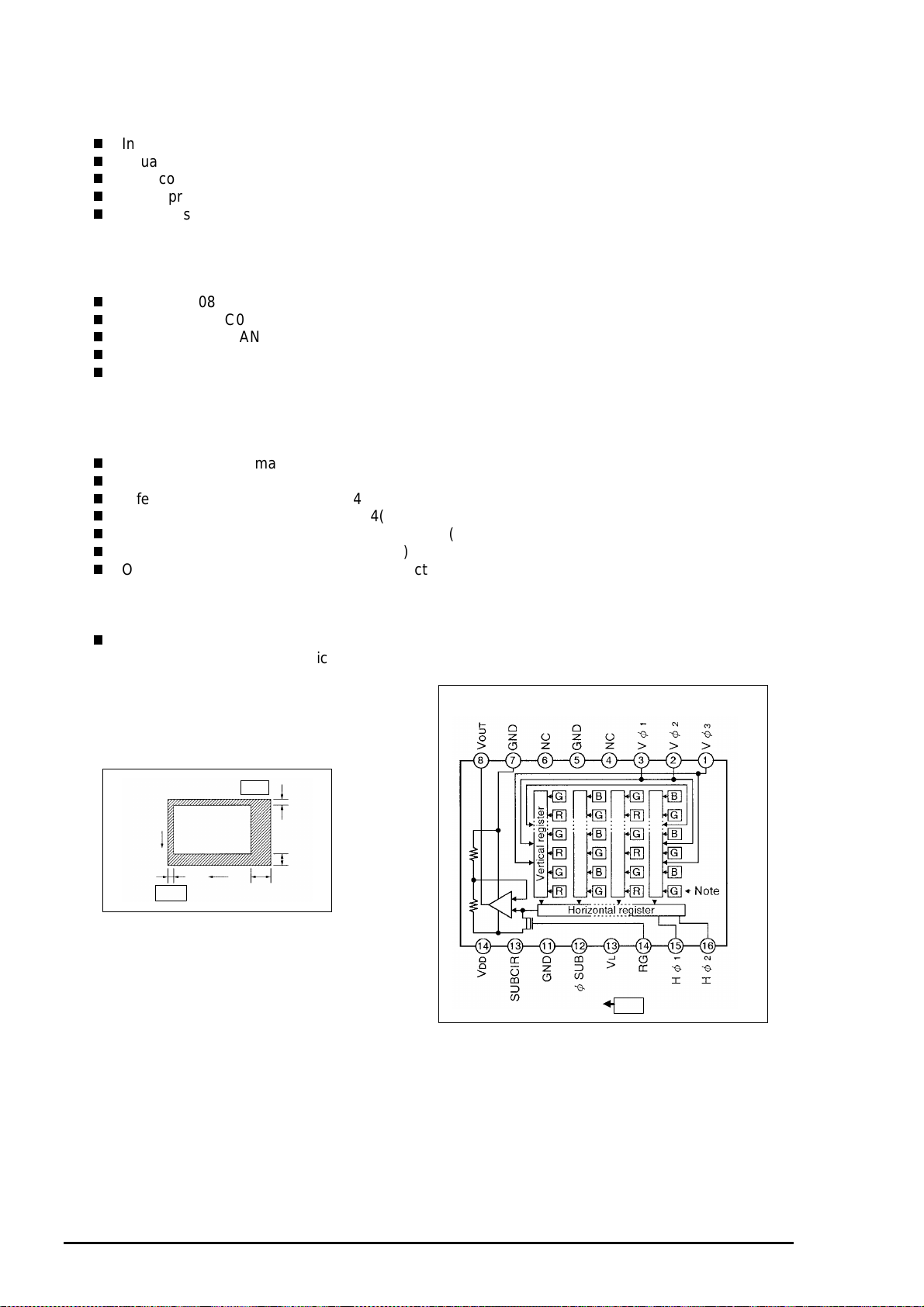

[1. IC903 (CCD)]

**Structure**

Interline type CCD image sensor

Optical size 1/3 inch

Effective pixels 659(H) x 494(V)

Pixels in total 692(H) x 504(V)

Chip size 5.84mm (H) x 4.94mm (V)

Unit cell size 7.4m(H) x 7.4 (V)

Optical black Horizontal (H) direction:

Front 2pixels, Rear 2pixels1

Vertical(V) direction:

Front 8pixels, Rear 2pixels

Dummy bit number Horizontal: 16

Vertical : 5

2

V

Pin 9

Pin 1

H

2

8

31

Figure 2- 3. Optional Black

Location

Note:

Photo sensor

Figure 2- 2. CCD Block Diagram

2

Rev. A

Page 23

3

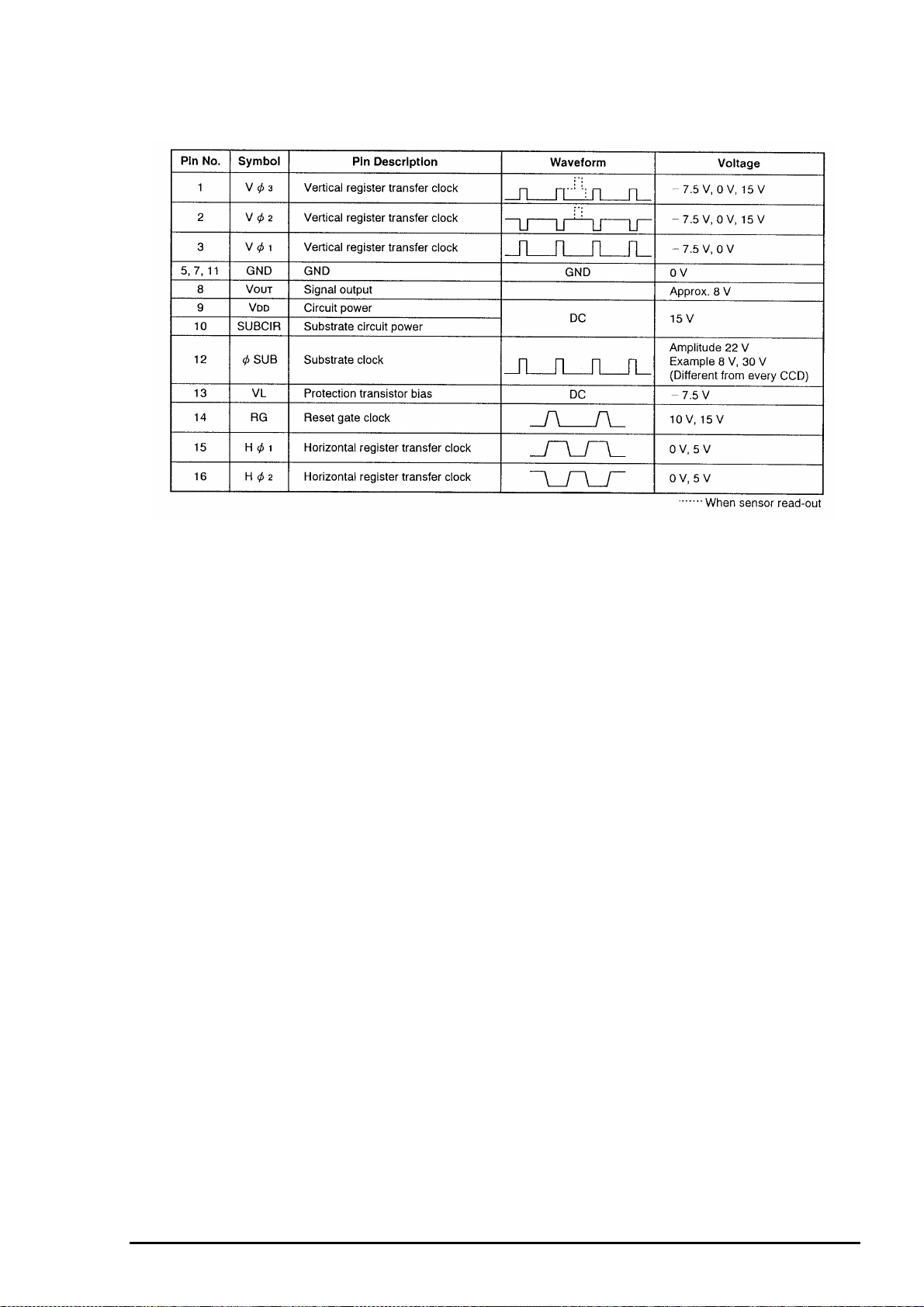

The following shows CCD Pin Description (IC903).

Chapter 2 Operating Principles

Figure 2- 4. IC903(CCD) Pin Description

Rev. A

Page 24

PhotoPC 500 Service Manual

4

[2. H-Driver (IC902) and V-Driver (IC904)]

An H driver (IC902) and V driver (IC904) are necessary in order to generate the clocks (vertical transfer

clock, horizontal transfer clock and electronic shutter clock) which drive the CCD.

IC902 is an inverter IC which drives the horizontal CCDs(H1 and H2). In addition the XV1-XV3 signals

which are output from Pins(39)-(41) of IC102 on the CA2 circuit board are the vertical transfer clocks, and

the XSG signal which is output from Pin(43) of IC102 is superimposed onto XV2 and XV3 at IC904 in

order to generate a ternary pulse. In addition, the XSUB signal which is output from Pin(42) of IC102 is

used as the sweep pulse for the electronic shutter, and the RG signal which is output from Pin(38) of

IC102 is the reset gate clock.

Figure 2- 5. IC902 Block Diagram

Figure 2- 6. IC904 Block Diagram

Rev. A

Page 25

Chapter 2 Operating Principles

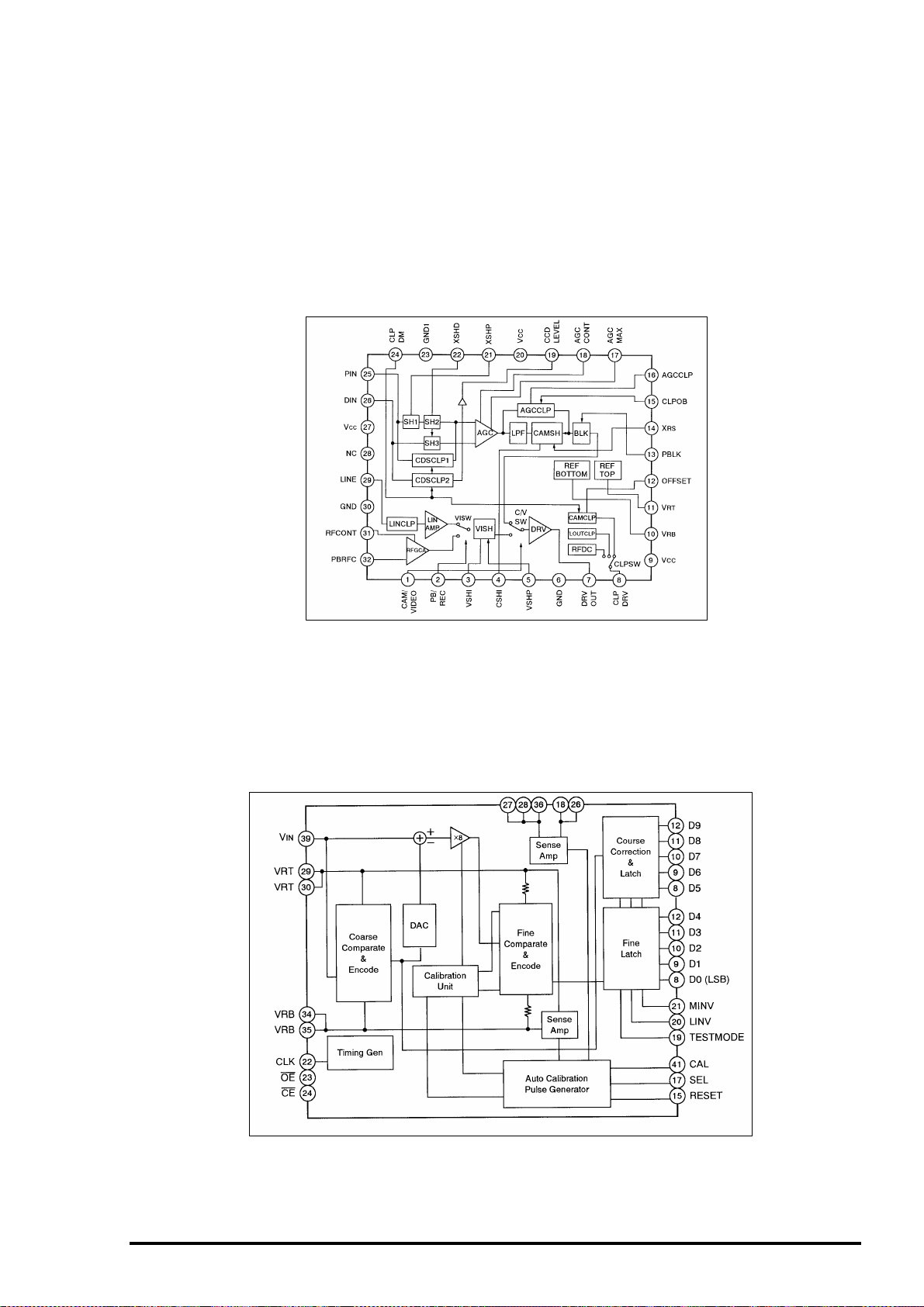

[3.IC905 (CDS/AGC Circuit)]

The video which is output from the CCD is input to Pins (25) and (26) of IC905. There are S/H blocks

inside IC905. There are S/H blocks inside IC905 generated from the XSHP and XSHD pulses, and it is

here that CDS (correlated double sampling) is carried out.

After passing through the CDS circuit, the signals pass through the AGC amplifier, LPF (low-pass

filter), S/H, blanking processing circuit, driver and clamper, after which they are sent to IC906.

The PWM voltage at Pin(18) is output from Pin(65) of IC102 and passes through the AND buffer of

IC907, after which it is smoothed, and this voltage controls the AGC amplifier gain.

Figure 2- 7. IC905 Block Diagram

[4. IC906 (A/D Converter)]

The video signal which is output from Pin(7) of IC905 and input to Pin(39) of IC906 is A/D-converted

to 10-bit signals inside this IC, and are then input to IC102.

A/D conversion is synchronized with the clock at Pin(22), and the reference voltages VRT(approximately

4.0V) and VRB(approximately 2.0V) are supplied from IC905.

Rev. A

Figure 2- 8. IC906 Block Diagram

5

Page 26

PhotoPC 500 Service Manual

6

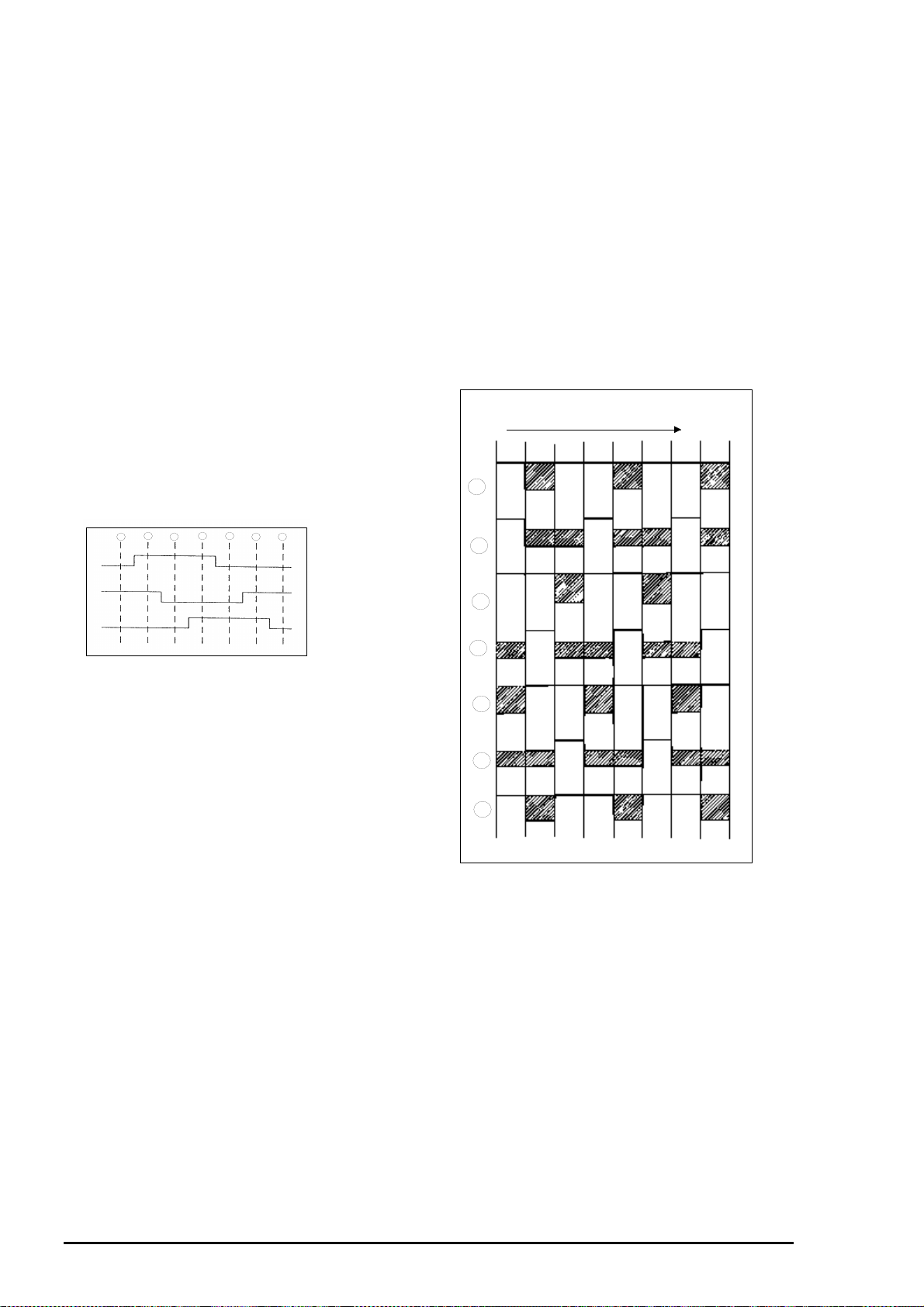

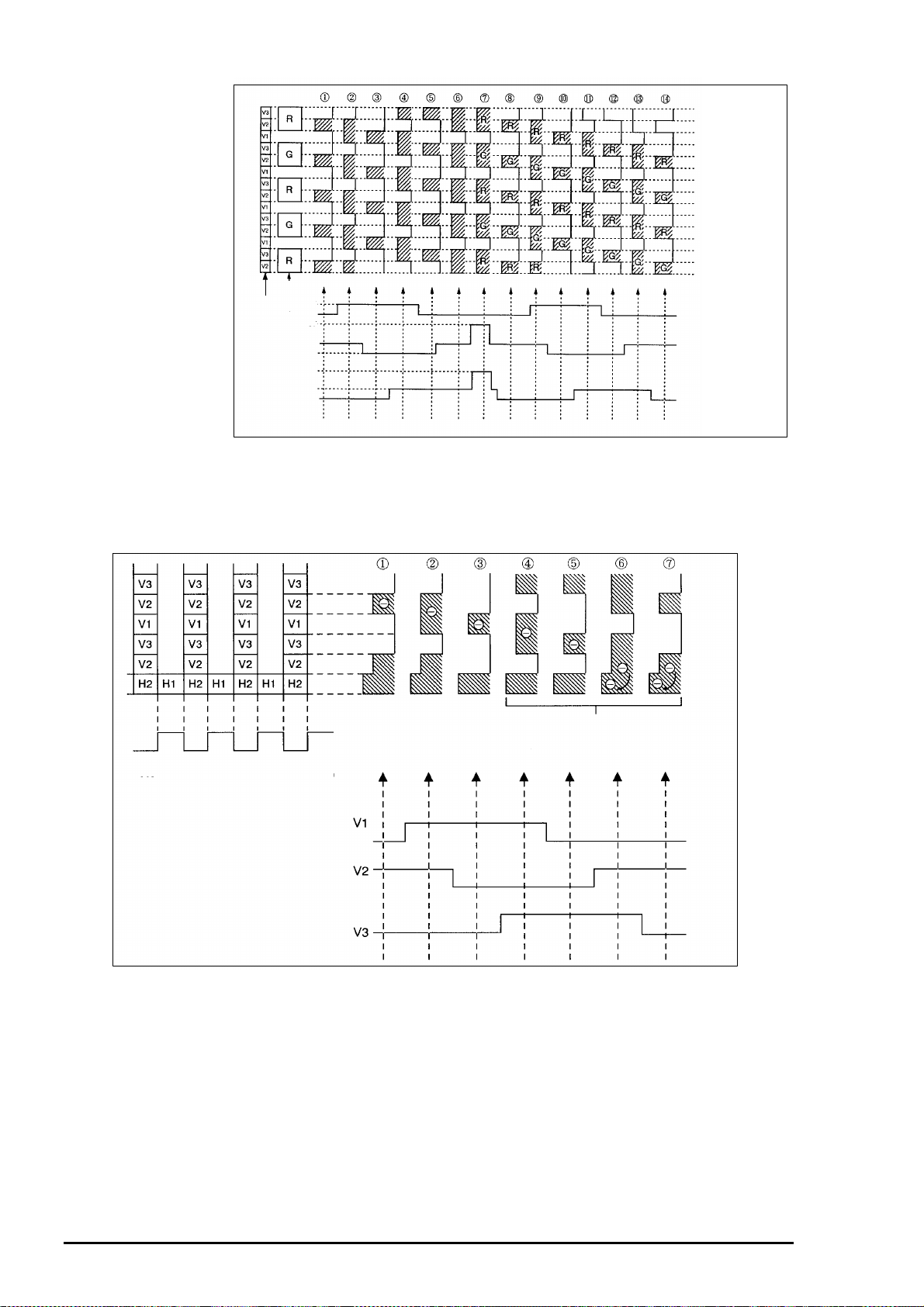

[5. Vertical Transfer Operation of the V Register]

The V register has three different electrodes which are designated as V1, V2 and V3. In step , the

potential at V2 is high and the potentials at V1 and 3 are low, so that there is a well at V2 for the

signal’s electric charge. In step , the potential at V1 becomes high, and so the well becomes wider

to include both V1 and V2. In step , the potential at V2 becomes low, causing the charge to accumulate

in the well at V1.The charge has thus been transferred by one electrode compared to the condition in

step . The condition at step represents a transfer of one pixel from the condition in step .

Direction of

transfer

V3 V2

1

V1

V3

V3

V2

V1V2

2

1

V1

V2

V3

4

3

5

6

7

Figure 2- 10. V1,V2 and V3

During the Horizontal Blanking

Period

2

3

4

5

6

7

Figure 2- 9. 3-Phase Drive Model Chart

Rev. A

Page 27

Chapter 2 Operating Principles

[6. V Register Read Operation from Photo Sensor]

This system employs the 3-value drive V register as shown in figure2-11.

During transfer of the V register, the applied voltage at the V register electrode is low. Therefore, the

electric charge for the signal cannot be output from the photo sensor section. However, since the

applied voltage during reading becomes high, the electric charge for the signal is transferred to the

V register.

Applied voltage

During transfer

During read

operation

V register(during transfer)

V3

V2

V1

V3

V2

V1

Direction of transfer

V register electrode

Light beam

Sensor electrode

Signal electric

charge

When reading P-Si

Photo sensor

section

During read

operation

A more detailed explanation is given below.

The transfer operation from the photo sensor

section to the V register is shown in Figure 2-12.

In Figure 2-12, V1 to V3 change as shown in

to . When V1(to V3) is -7.5V, the potential of the

V register becomes a barrier, and it becomes a

well when they are 0V. The potentials of V2 and

V3 and that of the sensor gate become the lowest

well under the condition at. Thus the signal

electric charges from the sensor section move to

V2 and V3 respectively, and are transferred as

shown in to.

Rev. A

Figure 2- 11. Read Out by 3-Value Drive

7

Page 28

PhotoPC 500 Service Manual

8

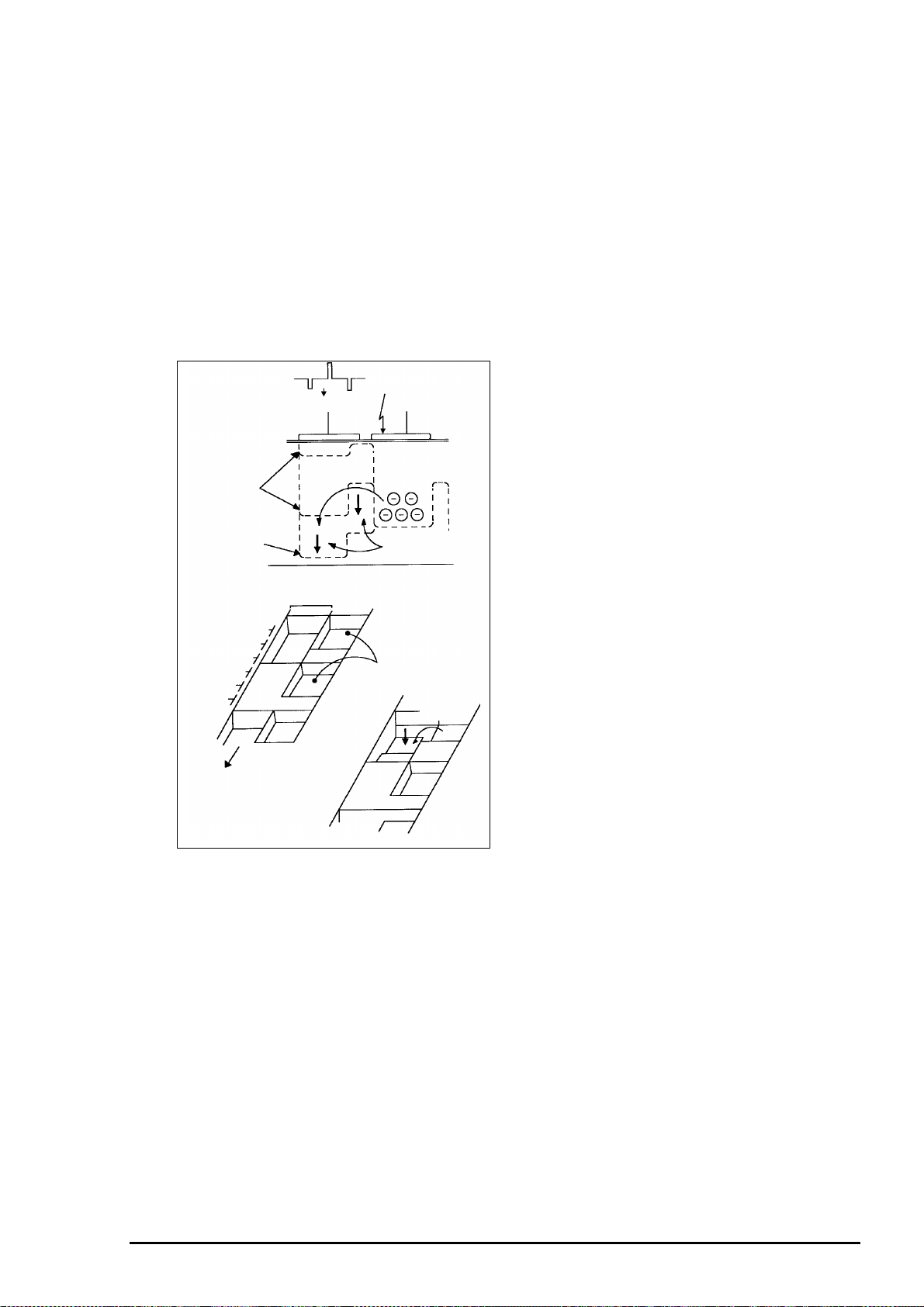

[7. Transfer of

Electric Charge by V

Register]

The H register sets H2

to a low potential

during H blanking, and

switches to a state of

waiting for a signal

from the V regis ter, as

shown in figure 2-13.

On the other hand,

during H blanking, the

V register

Light receiving section

V register

-7.5V

+15V

-7.5V

+15V

-7.5V

0V

0V

0V

which stopped during

the H scanning period

after switching V2 to

Figure 2- 12. Read Timing at the Sensor Section

low potential makes a

transfer

operation for one line based on 3-phase drive as shown by to in the figure.

Shaded section : Well

Other : Barrier

(Potential variations of H register during

the hrozontal blanking period.)

Figure 2- 13. Ve rtical Transfer of CCD and Application of Electric Charge

to the H Register

Because the H1 potential is lower than

the V2 potential, electric charges move

to H1 of the register.

Rev. A

Page 29

Chapter 2 Operating Principles

9

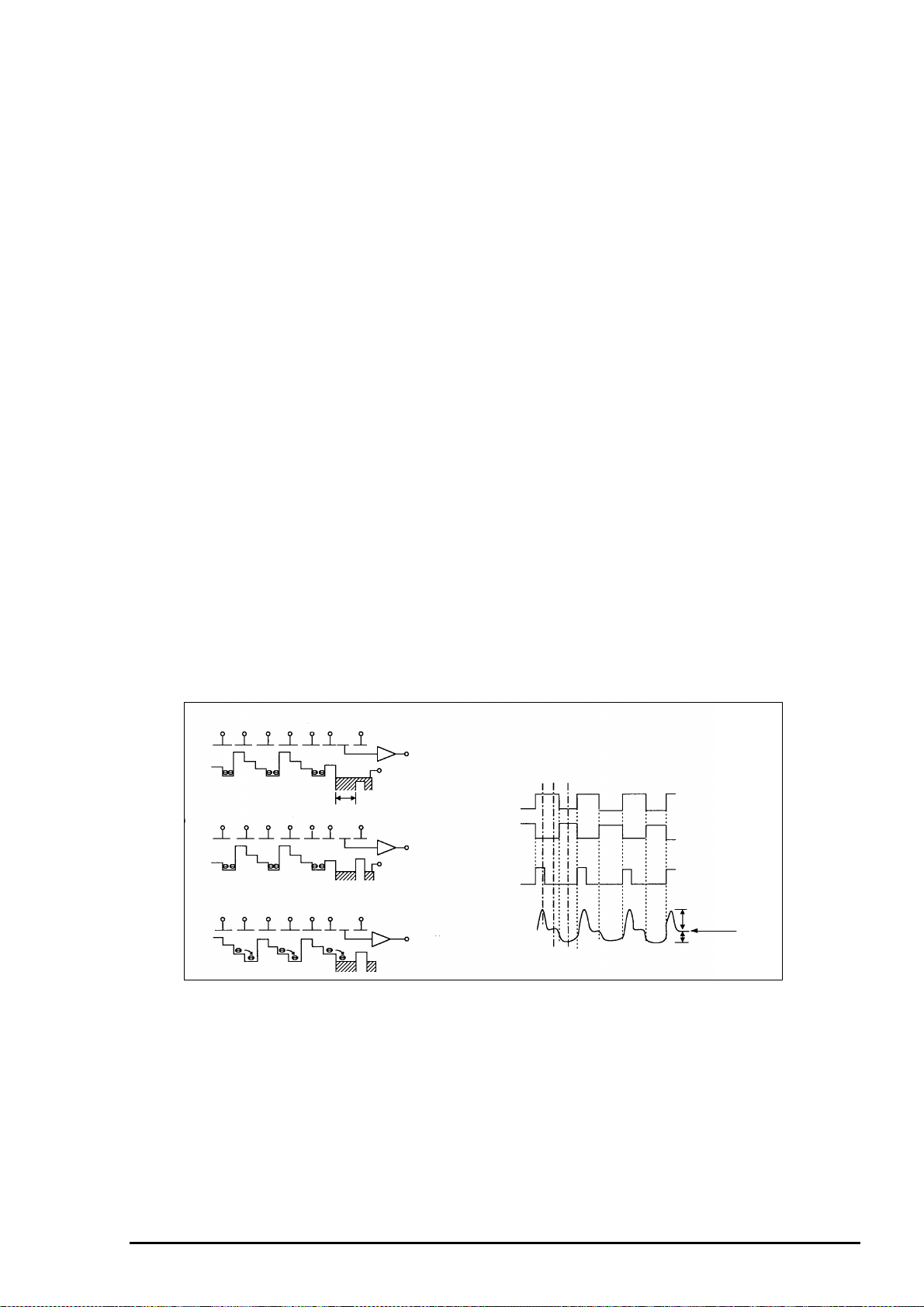

[8. Transfer of Electric Charge by the H Register]

The transfer system for the horizontal CCD employs a 2-phase drive method.

The electric charges sent to the final stage of the horizontal CCD are transferred to the floating

diffusion, as shown in figure 2-14. RG is turned on by the timing (1), and the floating diffusion is charged

to the potential of PD. The RG is turned off by the timing in (2). In this condition, the floating diffusion is

floated at high impedance.

The H1 potential becomes shallow by the timing in (3), and the electric charge now moves to the

floating diffusion.

Here, the electric charges are converted into voltages at the rate of V=Q/C by the equivalent capacitance

C. RG is then turned on again by the timing in (1) when the H1 potential becomes deep.

Thus, the potential of the floating diffusion charges in proportion to the quantity of transferred electric

charge, and becomes CCD output after being received by the source follower. The equivalent circuit

for the output circuit is shown in figure 2-15.

H1

H2

H2 H1

H1

H1

H1

H2

H1

H2

H2

H1

H1

H1

H2

HOG

HOG

HOG

RG

RG

RG

PD

PD

CCD OUT

CCD OUT

H1

H2

RG

CCD OUT

(1) (2) (3)

5V

0V

5V

0V

5V

0V

RG pulse leak signal

Signal voltage

Black level

Figure 2- 14. Horizontal Transfer of CCD Imager and Extraction of Signal Voltage

Rev. A

Page 30

PhotoPC 500 Service Manual

0

Reset gate

pulse

Direction of transfer

H Register

Electric

charge

Floating diffusion gate is

floated at a high impedance.

C is charged

equivalently

+B 15V Pre-charge

drain bias (PD)

Figure 2- 15. Theory of Signal Extraction

Operation

Voltage output

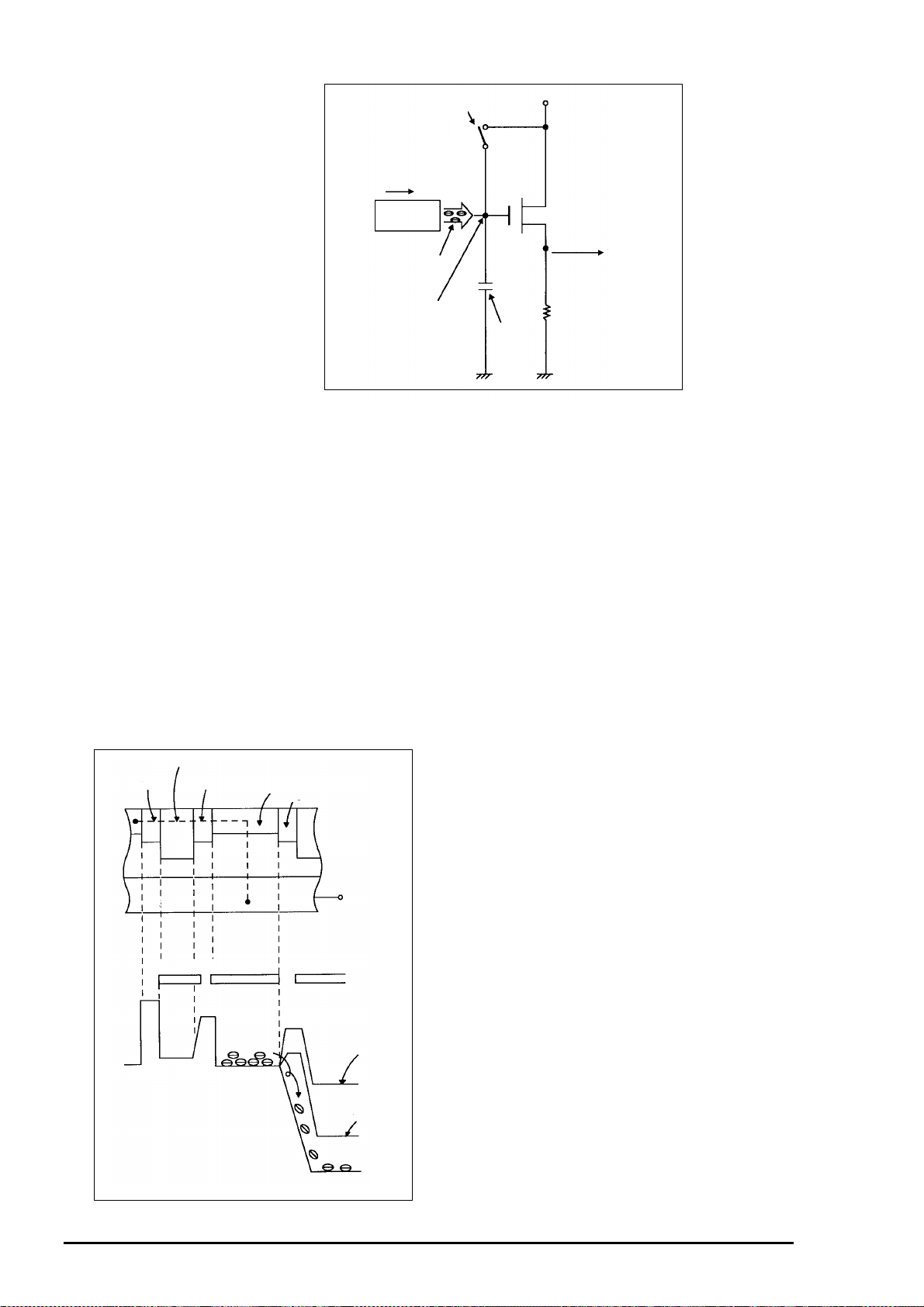

[9. Vertical Overflow Drain (VOFD)]

The CCD of this system is configured as shown in Figure 2-16. An imager which has OFD(SUB) provided

in the vertical direction(in the direction of depth) of a CCD chip is referred to as a CCD with a vertical

overflow drain (VOFD) construction. When the potential along the dotted line(A-A’) is seen from (a), it

appears as (b). The height of the potential barrier is decided by applying DC bias to the OFD from

outside.

This is the same as deterring the saturated electric amount Qs (equals the dynamic range) at the sensor.

Although a larger Qs is preferable, a Qs which is too large causes blooming (a phenomenon where the

electric charge becomes too large and leaks into other picture elements), which causes the picture

quality to deteriorate. Therefore, it is necessary to

V register

CS

A

ROG

Sensor

CS

apply a well-balanced DC bias.

[10. Electric Shutter]

During normal operations, read-out of the signal

charge can be made once for each field. Thus, the

storage time for the electric charge is 1/30 sec.

(a)

N-Si

A'

SUB(OFD)

However, the actual storage time can be shortened

by throwing away the electric charge during storage.

(Refer to figure2-17.) The electric shutter needs

this kind of electric charge throwaway operation.

The electric charge throw-away operation necessar y

for the electronic shutter in this system is controlled

V register

Sensor

SUB(OFD)

by the DC bias applied to the SUB.

Actually, the throwaway operation is done during the

horizontal blanking period in order to keep the

picture free from any noise that may appear. Under

(b)

Qs

VSUB=V1

normal conditions, the DC bias of the SUB is

overlapped by pulse. (Refer to figure2-18.)

In theory, it is possible to use the above system

to control an electric shutter with a storage time of

VSUB=V2

1/30 sec to 1/10000 sec, in units of 1/15750.

VSUB=V3

V1<V2<V3

Figure 2- 16. VOFD and Potential Chart

1

Rev. A

Page 31

Chapter 2 Operating Principles

Read-out pulse

Electronic

shutter control pulse

(electronic charge

throwaway pulse)

Read-out

1 field

Throwaway period

Throwaway

Actual

storage

time

Figure 2- 17. Theory of Electric shutter

operation

V(1/30 sec)

H

(1/15750 sec)

Storage time

(1/30 to1/10000 sec)

V(1/30 sec)

Storing time

(1/30 to1/10000)

Read-out

DC bias of OFD

Figure 2- 18. Actual Electric Shutter Control

2.

Outline of Operation

When the shutter opens, the reset signals (ASICand CPU) and the serial signals («take a picture»

commands) from the 4-bit microprocessor are input and operation starts. When the T G drives the CCD,

picture data passes through the A/D and is then input to the ASIC as 10- bit data. This data then passes

through the DCLP, AWB and circuits after which it is input to the DRAM. The AWB, shutter, and AGC

values are computed from this data, and three exposures are made to obtain the optimum picture.

The data which has already been stored in the DRAM is ready by the CPU and pixels interpolation is

carried out. Each pixel is interpolated from the surrounding data as being either R, G or B pr imary color

data to produce R, G and B data. At this time, cor rection of the lens distor tion which is a characteristic of

wide-angle lenses is carried out. The data is then compressed by the JPEG method and is then written to

flash memory.

When the data is to be output to an ex ternal device, it is read from the flash m emory and output via the

SIO.

3.

Circuit Description

1. Digital clamp circuit

The optical black section of the CCD extracts 16 pixel averaged values from the subsequent data to make

the black level of the CCD output data uniform for each line. The 16 pixel averaged value for each

line is taken as the sum of the value for the previous line multiplied by the coefficient k and the value f or

the the current line multiplied by the coefficient 1-k.

2. White balance circuit

The circuit controls the white balance by using the AWB judgment value computed by the CPU to

control the gain for each R, G and B pixel based on the CCD data which has been read.

3.circuit

This circuit performs (gamma) correction in order to maintain a linear relationship between the light

input to the camera and the light output from the picture screen.

Rev. A

11

Page 32

PhotoPC 500 Service Manual

4. 8-16 converter

This combines two clock sections of the 8-bit data which is output from the circuit and outputs

the resulting signal as 16-bit data.

5. DRAM controller

This circuit outputs address, RAS, CAS and AS data for controlling the DRAM. It also refreshes the

DRAM.

6.SIO

This circuit is used to send serial data to a personal computer. It conforms to RS-232C standards.

7.PIO

This is the interface for the 4-bit microprocessor.

8. TG block

This is the timing generation circuit which generates the clocks(vertical transfer clock, horizontal

transfer clock and electronic shutter clock) which drive the CCD.

4.

This is the main power circuit, and is comprised of the following blocks.

The followings explains the three major circuits.

1. Switching Controller (IC311,IC312)

This is the basic circuit which is necessary for controlling the power supply for a PWM-type switching

regulator, and is provided with two built-in channels. Feedback from both 5V(D) and 5V(A) power

supply outputs is received, and the PWM duty is varied so that each one is maintained at the correct

voltage setting level.

is recontrolled to restore output.

PW1 Circuit Description

Switching controller (IC311, IC312)

Digital system power output (T3101,Q3101)

Analog system power supply (T3102,Q3102)

Timer latch method short-circuit protection circuit

If output is short-circuited for the length of time determined by the condenser which is connected

to IC311 and Pin (2j) of IC312, all output is turned off. The control signal (P ON, P(A) ON)

Mis-operation prevention circuit for cases of low input voltage

Because there is a chance of mis-operation of the switching controller occurring under the

transit conditions which occur when the power is turned on and when there is a voltage

drop in the IC311 and IC312 power supply line, the power supply voltage level is monitored.

2. Digital System Power Output

5V(D) is output. Feedback is provided to the switching controller (IC311) so that PWM control can be

carried out.

3. Analog System Power Output

12

Rev. A

Page 33

Chapter 2 Operating Principles

3

5V (A),15V(A) and -7.5 V are output. Feedback for the 5V(A) line is provided to the switching controller

(IC312) so that PWM control can be carried out.

4. Output Control

The table below shows the relationship between both control signals (P ON, P(A) ON) and output.

Table 2-1. Control signal and output

Control Output

P-ON P(A)ON Digital Analog

5V(D) 5V(A) 15V(A) -7.5V(A)

L L OFF OFF OFF OFF

L H OFFONONON

H L ON OFF OFF OFF

H H ON ON ON ON

5. Specification

The following shows output at the Preview mode.

Table 2-2. Output at the Preview mode

5V(D) 5V(A) 15V(A) -7.5V(A)

Voltage

Electric current [mA]

5.

For the overall configuration of the SY1 circuit board, refer to the block diagram.

The configuration of the SY1 circuit board centers around a 4-bit microprocessor (IC301).

The 4-bit microprocessor handles the following functions.

1. Operation key input

2. Mode LCD display

3. Clock control and backups

4. Power ON/OFF

5. Strobe charge control

SY1 Circuit Description

Pin Signal I/O Outline

1 SCAN OUT3 O Key matrix output

2 /LCD ON O LCD monitor power ON/OFF signal L:ON

3 /P(A) ON O DC/DC converter(analog) ON\OFF signal L:ON

4 /P ON O DC/DC converter(digital) ON/OFF signal L:ON

5 /CHG ON O Flash charge ON/OFF signal L:ON

6 /ASIC TEST O ASIC reset control signal

7 /MAIN RESET O SPARC reset signal L:Reset output

8 ASIC RESET O ASIC reset signal L:Reset output

9 /STBY (R) LED O Standby LED (red) ON/OFF signal L:REset output

10 /STBY (G) LED O Standby LED (green) ON/OFF signal L:LED light

11 /SELF LED O Self-timer LED ON/OFF signal L:LED light

12 BUZ OUT O Buzzer output signal (4kHz)

13 /AD ON O AD converter power ON/OFF signal L:Test mode

14 RXD I RS-232C RXD input terminal

4.80 5.00 15.00 -7.50

380 108 9.7 2.8

Table 2-3. IC301 Pin functions

Rev. A

1

Page 34

PhotoPC 500 Service Manual

4

15 SCK O Serial clock output (ASIC)

16 SO O Serial data output (ASIC)

17 SI I Serial data input (ASIC)

18 /S. REQ I Serial communication request signal (ASIC) L:Serial request

19 DIN CONNECT I DIN jack connection detection signal H:SW ON

20 NOT USED -- --21 /RESET I Reset input

22 XIN I Main clock oscillation terminal (1 MHz)

23 XOUT O Main clock oscillation terminal

24 VSS --- GND

25 VDD --- VDD

26 XCOUT O Main clock oscillation terminal (32.768 MHz)

27 XCIN I Main clock oscillation terminal

28 AVSS --- Analog GND

29 VREF I Analog reference voltage input terminal

30 BATTERY I Battery voltage input (analog input)

31 CHG VOL I Strobe charge voltage input (analog input)

3233 S21-S20 O Mode LCD segment output

3437 SCAN IN 03 I Key matrix input

38 VLC3 I Mode LCD power input terminal

3940 S19S18 O Mode LCD segment output

41 NOT USED -- -4244 COM3-COM1 O Mode LCD common output

4561 S17-S1 O Mode LCD segment output

6264 SCAN OUT 02 O Key matrix output

1.

Internal Communication Bus

The SY1 circuit board carries out overall control of camera operation by detecting the input from the

keyboard and the condition of the camera circuits. The 4-bit microprocessor reads the signals from

each sensor element as input data and outputs this data to the camera circuits (ASIC) or to the

LCD display device as operation mode setting data.

Fig2-19 shows the internal communication between the 4-bit microprocessor, ASIC and SPARC lite

circuits.

Reset

S. REQ

4-bit

Microprocessor

ASIC SO

ASIC SI

ASIC SCK

ASIC

Data Bus

Reset

32-bit

SPARC

lite

Figure 2- 19. Internal Bus Communication System

2.

Power Supply Control

The 4-bit microprocessor controls the power supply for the entire system. The following is a description of

how the power supply is turned on and off.

When the battery is attached, a regulated 3.3V voltage is normally input to the 4-bit microprocessor

(IC301) by IC303, so that clock counting and key scanning is carried out even when the power switch

1

Rev. A

Page 35

Chapter 2 Operating Principles

is turned off, so that the camera can start up again.

When a switch is operated, the 4-bit microprocessor supplies power to the system as required. The 4bit microprocessor first sets both the /P(A) ON signal at pin (3) and the /P ON signal at pin (4) to Low,

and then turns on the DC/DC converter. After this, High signals are output from pins (7) and (8) so

that the ASIC and the SPARC lite are set to the active condition. If the LCD monitor is on, the /LCD

ON signal at pin (2) is set to Low, and the DC/DC converter for the LCD monitor is turned on.

Once SPARC lite processing is completed, the ASIC and the SPARC lite return to the reset condition,

all DC/DC converters are turned off and the power supply to the whole system is halted.

Table 2-4. Camera Mode (Battery Operation)

SPARC

Lite

Supply voltage 5V 5V 3.3V 5.0V 5V(A)

Power Power OFF OFF OFF OFF OFF OFF 32kHz OFF

OFFPlay backONONONONOFF1MHzON

Power SW ON

-

Auto power

down

Shutter SW ON ON ON ON ON ONOFF 1MHz OFF

SwitchONResolution,

Flash

Self timer SW

ON

LCD finder ON ON ON ON ON 1MHz ON

OFF OFF ON OFF OFF 1MHz OFF

OFF OFF ON OFF OFF 1MHz OFF

ASIC,

Memory

MODE

LCD

RS232C

Driver

CCD 4-bit

7.5V-15V

LCD

CPU

3.3V 11V4.8V

Monitor

-18V etc.

Table 2-5. Host Mode (Battery Operation)

SPARC

Lite

Supply voltage 5.0V 5.0V 3.3V 5.0V 5.V(A)

Power switch OFF OFF OFF OFF OFF OFF 32KHz OFF

Power SW ON-

Auto power down

Power Take a picture ON ON ON ON ONOFF 1MHz OFF

Switch Erase image ON ON ON ON OFF 1MHz OFF

ON Download image ON ON ON ON OFF 1MHz OFF

Continuous image ON ON ON ON ON 1MHx OFF

Message from

host

6.

1.

When UNREG power is supplied to the charge circuit and the CHG ON signal becomes High(3.3V),

the charging circuit starts operating and the main electrolytic capacitor is charged with high- voltage

direct current.

However, when the CHG ON signal is Low(0V), the charging circuit does not operate.

ST1 Circuit Description

Charging Circuit

OFF OFF ON OFF OFF 1MHz OFF

ON ON ON ON ON 1MHz OFF

ASIC.

Memory

MODE

LCD

RS232C

Driver

CCD 4-bit

7.5V-15V

LCD

CPU

3.3V 11V 4,8V

Monitor

-18V etc.

Rev. A

15

Page 36

PhotoPC 500 Service Manual

6

Power supply filter

L5401, L5402, C5401 and C5403 constitute the power supply filter. They smooth out ripples

in the current which accompany the switching of the oscillation transformer.

Oscillation control circuit

This circuit generates an AC voltage (pulse) in order to increase the UNREG power supply

voltage when drops in current occur. This circuit generates a drive pulse with a frequency of

approximately 15 kHz and shortens the pulse width in accordance with the state of the input

power supply in order to control the power consumption.

Oscillation transformer

The low-voltage alternating current which is generated by the conversion control circuit is

converted to a high-voltage alternating current by the oscillation transformer.

Rectifier circuit

The high-voltage alternating current which is generated at the secondary side of T5401

is rectified to produce a high voltage direct current and is accumulated at electrolytic capacitor

C5412 on the main circuit board.

Voltage monitoring circuit

This circuit is used to maintain the voltage accumulated at C5412 at a constant level.

After the charging voltage is divided and converted to a lower voltage by R5417, R5419 and

VR542, it is output to the SY1 circuit board as the monitoring voltage VMONIT.

When this VMONIT voltage reaches a specified level at the SY1 circuit board, the CHG

signal is switched to Low and charging is interrupted.

2.

When RDY and TRIG signals are input from the ASIC expansion port, the stroboscope emits light.

stroboscope emits light.

7.

During EE, gamma compensation is carried out for the 10-bit RGB data which is input from the A/D

conversion block of the CCD to the ASIC in order that the RGB data can be displayed on the LCD.

Light Emission Circuit

Emission control circuit

When the RDY signal is input to the emission control circuit, Q5409 switches on and

preparation is made to let current flow to the light emitting element. Moreover, when a STOP

signal is input, the stroboscope stops emitting light.

Trigger circuit

When a TRIG signal is input to the trigger circuit, D5405 switches on, a high-voltage

pulse of several kilovolts is generated inside the trigger circuit, and this pulse is then

applied to the light emitting part.

Light emitting element

When the high-voltage pulse from the trigger circuit is applied to the light emitting part,

current flows to the light emitting element and light is emitted.

LCD Block

1

Rev. A

Page 37

Chapter 2 Operating Principles

The data is converted to 6-bit data at the LCD resolution of 279 x 220 pixels, and is then transferred

to the VRAM. The data which has accumulated in the VRAM is synchronized with the serial clock and

is then sent from the serial port to the ASIC. After D/A conversion is carried out inside the ASIC, the data

is sent to the LCD panel and displayed.

If the shutter button is pressed in this condition, the 10-bit data which is output from the A/D conversion

block of the CCD is sent to the DRAM (DMA transfer) as well as to the VRAM, and is displayed on

the LCD as a freeze-frame image.

During playback, the JPEG image data which has accumulated in the flash memory is converted to

RGB signals, after which it is converted to 6-bit data at the LCD resolution of 279 x 220 pixels.

In the same way as for EE, the data is then sent to the VRAM, after which D/A conversion is carried out

inside the ASIC, and then the data is sent to the LCD panel and displayed.

The LCD panel operates according to seven control signals and four analog signals from the ASIC,

and four power supply signals from PW2.

Of these, the four analog signals from the ASIC (VCOM, R, G, and B) are D/A output with small

amplitudes,

so that they are amplified by an external analog circuit to the amplitudes which are necessary for driving

the LCD panel. Because these analog signals do not include D and C components for the LCD elements

they are transformed at 1H intervals.

Because of the structure of the LCD, the VCOM is applied at a timing which is 1H delayed from the

timing actually measured. Because the LCD elements close more as the difference in potential

between the VCOM signal and the R, G and B signals becomes greater, the display becomes darker;

if the potential difference is smaller, the elements open and the screen becomes lighter. Furthermore, if

the D and C relationships between the VCOM signal and the R, G and B signals become displaced, it will

cause flickering in the LCD, so that adjustment will be necessary.

The D and C levels of VCOM adjust VR323 on the PW2 board in the LCD monitor unit.

Rev. A

17

Page 38

HAPTER

C

3. D

ISASSEBLY AND ASSEMBLY

............................................................................................

..........................................................................................................

.............................................................................................................................................3.1.2. Tools 1

............................................................................................................3.1.3. Specification for Screws 2

..........................................................................................

.................................................................................................................. 3.3. Assembly 7

.......................................................................................

..........................................................................3.3.2. Installing the Holder Chassis and TB1 Board 8

..........................3.3.3. Installing the TB2 Holder with TB2 Board, SY1 Board and Cabinet Top 9

...................................................3.3.4. Installing the PW1, ST1 Board, Lens VF and Reflector Unit 10

...........................................................................................................3.3.5. Installing the Lens Cover 12

.................................................................................... 3.3.6. Installing the Front and Back Cabinets 14

.....................................................................................................3.3.7. Assembling the LCD Monitor 16

................................................................................................................................

3.3.1. Setting up the CA1 Board 7

3.1. OVERVIEW 1

3.1.1. Precautions 1

3.2. Disassembly 3

.1.

Page 39

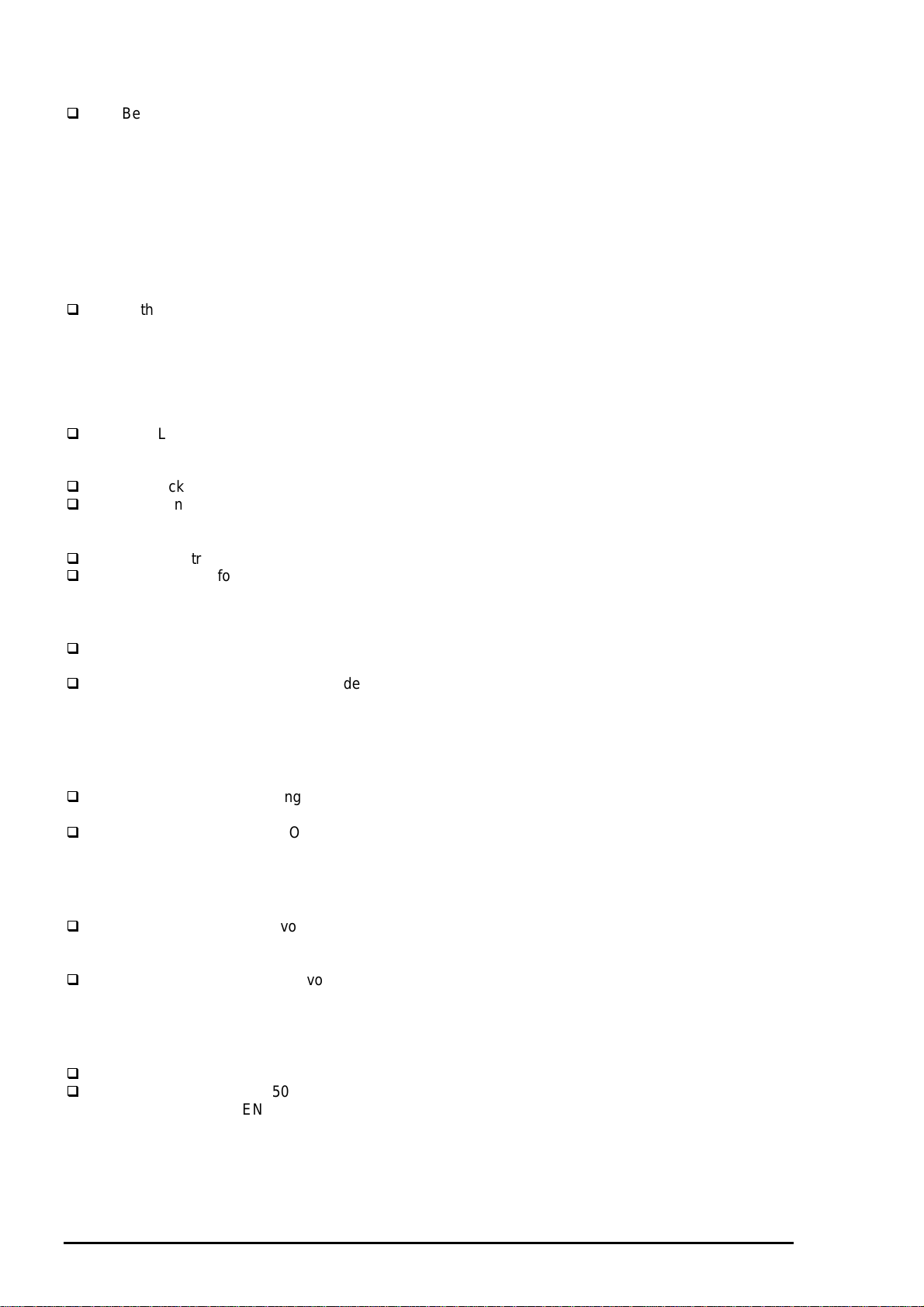

.2. OVERVIEW

This section describes various points to note when disassembling and assembling the camera.

There are two ways of maintenance; first maintenance and second maintenance. The performance

of the second maintenance is allowed to be done only by EPSON Co.,Ltd. The distinction between

first and second maintenance should be referred to Appendix (A-9, A-10 and A-11). Also, since

the assembly is more complicated than disassembly, refer to the section 3.3 when you actually

start assembling after disassembly.

1.

Follow the precautions below for disassembly and assembly.

Precautions

WARNING

There is a danger to get electric shock from the electrolytic condenser for flash. So, make sure

to refer to the section 3.2 (Step 2) and discharge the electric charge when you disassemble or

assemble ST1 board.

Remove all batteries before you start assembly and disassembly.

CAUTION

All the electronic parts on the CA1 board must not be r emoved. (Exc hange and r epair works for

all the electronic parts around the CA1 are allowed to be done only by EPSON. CO.,Ltd.)

When transporting the camera, use the exclusive package material.

2.

Table 3-1 lists the tools recommended for disassembling, assembling or adjusting the camera.

Note)

Note)

Tools

Table 3-1. Recommended Tools

No. Name Purchasable Code

1 Adjustment Program ------2 Color viewer 103058400

3 Tweezers B641000100

4 Soldering iron B740200100

5 Radio cutting pliers B740400100

6 Precison Driver () ------7 WICK (Desoldering wire ) -------

Tool No.1No.3 are used only by EPSON Co.,Ltd.

WICK is much easier to use compared with Soldering Cleaner when you do soldering.

3.

Page 40

Specification for Screws

Figure 3-1 lists the abbreviation of screws and its use.

Abbreviation Part Name Shape

Pan Head

Type of head

Type of threaded

section

Diameter

Length(L)

Configuration (Color)

Biding Head

Abbreviation Part Name

L

Dimension

(mm)

(Black)

(Black)

(Black)

(Gold)

(Gold)

Figure 3-1. Screw Indentification

No symbol Machine Screw

Forming Tight

Forming Tight

Most of PhotoPC-500

parts are fixed by this screws.

Battery cover and spring are fixed

by this screw.

Knob of power switch is fixed by

this screw.

Small screw on the CA1 board

for mounting the lens.

Lens unit is fixed on the CA1 board

from the back by these 2 screws.

Shape

(For plastic)

(For metal)

Location

Also, PhotoPC 500 has 7 boards and each of them is in charge of the following function.

Table 3-2. Board names and their functions

No. Board names Functions

1 SY1 Board Controls user’s interface of camera body.

2 PW1 Board Generates Digital and Analog power.

3 CA1 Board CCD mounted board with lens units.

4 TB1 Board Junction board for serial I/F connector and

inlet for AC adapter.

5 ST1 Board Controls stroboscope board and contains big

capacity of electrolytic capacitor.

6 PW2 Board Power board in the LCD body.

7 LCD Unit Playback, View.

Page 41

.3. Disassembly

Before you start disassembly, read section 3.1.1 carefully. Follow the order for disassembly

as it is described in the figure 3-2 to figure 3-5. Screws not particularly described in the figures

are M2x5.

Note)

When you remove the camera body from the front and back case, the holder terminal should be

Cover Back

Connector

Cover Plug

Slide the cover terminal

up before you start disassembly.

Cover

opened.

Cover Battery

Figure 3-2. Removing the Front and Back cabinets

Page 42

WARNING

Electrolytic capacitor mounted on the ST1 is for flash. If it is charged for flash even once, it

keeps high volume of electricity no matter whether the flash is used or not. Because of this, if the

capacitor is charged even once befor e disassembly, discharge the electricity by the following way

in order to avoid electric shock . Also, it takes 2 or 3 days for the electric ity in the capacitor to be

completely discharged in case of natural discharge.

Remove the ST1 board holding its edge.There is a possibility of getting electric shock if you

touch the soldering parts or elements on the board surface. Follow the direction at the [Step 2] to

release the electricity.

[Step 1]

[Step 2]

board.

Remove the ST1 board from the CA1 board.(Refer to in the figure3-3)

Let the cement resisor which has at least 560/10W touch the 2 soldering parts of the

capacitor at the back of the

Cement resistor (No fixed direction )

1k 10W 20W)

560

Lens VF

From the back of ST1 board, make the electric

poles touch the soldering parts of 330V and 160

(C5412).

*After removing this screw,

remove the 2-pin connector

F

(brown)on the TB1 board, so

that ST1 board is to be removed

easier.

PW1 Board

Reflector Unit

Holder Terminal

*Slide the cover terminal

up before you start

disassembly.

ST1 Board

*Be careful for electric shock(Refer to "WARNING" above)

Page 43

CAUTION

Since lead wires are connected among boards for pr evention of electrostatic noise, disc onnect

these wires using soldering iron acc ording to your nec essity. The points for as sembly is written on

section 3.3.

It is prohibited to exchange or repair all individual parts on the PW1 board. In stead, PW 1 board

itself should be replaced.

Perform the initialization and 5100K AWB adjustment when the CA1 board or lens parts (lens

unit, optical filter, rubber damper or CCD sensor) is replaced. Also, perform the Flange back

adjustment if the lens unit is replaced.

Assemble the lens unit, optical filter and rubber damper and fix them on the CA1 board with 3

screws before you solder the CCD sensor to the CA1 board.

24 pin connector and lens parts are not included in the spare parts when the CA1 board is

replaced. Therefore, when you assemble these parts by soldering, make sure, Mount the lens

parts, thenConnect the 24pin connector.

Use the rubber gloves when you handle the CCD sensor and be c areful not to touc h the electric

poles directly. Also, pay attention not to get dust or dirt on the CCD.

Cabinet Top

ST1 Board

TB2 board can be

*

removed from the

TB2 holder just

by one screw.

Rubber Damper

Optical Filter

Lens Unit

*Be careful not to drop

the optical filter and

rubber dumper when

you remove the lens unit.

Figure 3-4. Removing the Lens unit, TB1 and SY1 boards

TB2 Holder

CCD Sensor

Floppy Spacer

Connector

Screw

(M2x4, Gold)

Two Screws

(M2x6, Gold)

24pin Connector

* Since this 24pin connector

for LCD monitor is fixed by

soldering, it is required to

use soldering iron when

you remove or re-attach it.

TB1 Board

Holder Chassis

Page 44

WARNING

Solder the FPC cable steadily and correctly on the shield plate of the PW2 board. There is a

possibility of damaging if the cable touches other parts.

Perform the LCD V-com adjustment if the PW2 board or LCD monitor is replaced and make sure

that no thin horizontal lines appear on the screen. (Refer to Chapter 4 for details)

At repairing the LCD, the screen often gets greasy from hands. Using the scoch tapes can easily

clean this dirt. Never use the dry cloth for cleaning. Using the dry cloth for the LCD may cause

damage to the LCD because of static electricity.

FPC

FPC

PW2 Board

Figure 3-5. Removing the LCD monitor

LCD Monitor

Connector

Page 45

.4. Assembly

Since the PhotoPC 500 has rather complicated assembly than disassembly process, disassembly and

assembly process are separated and explained individually.

If you find unclear procedure during service, select the appropriate subject and refer to it.

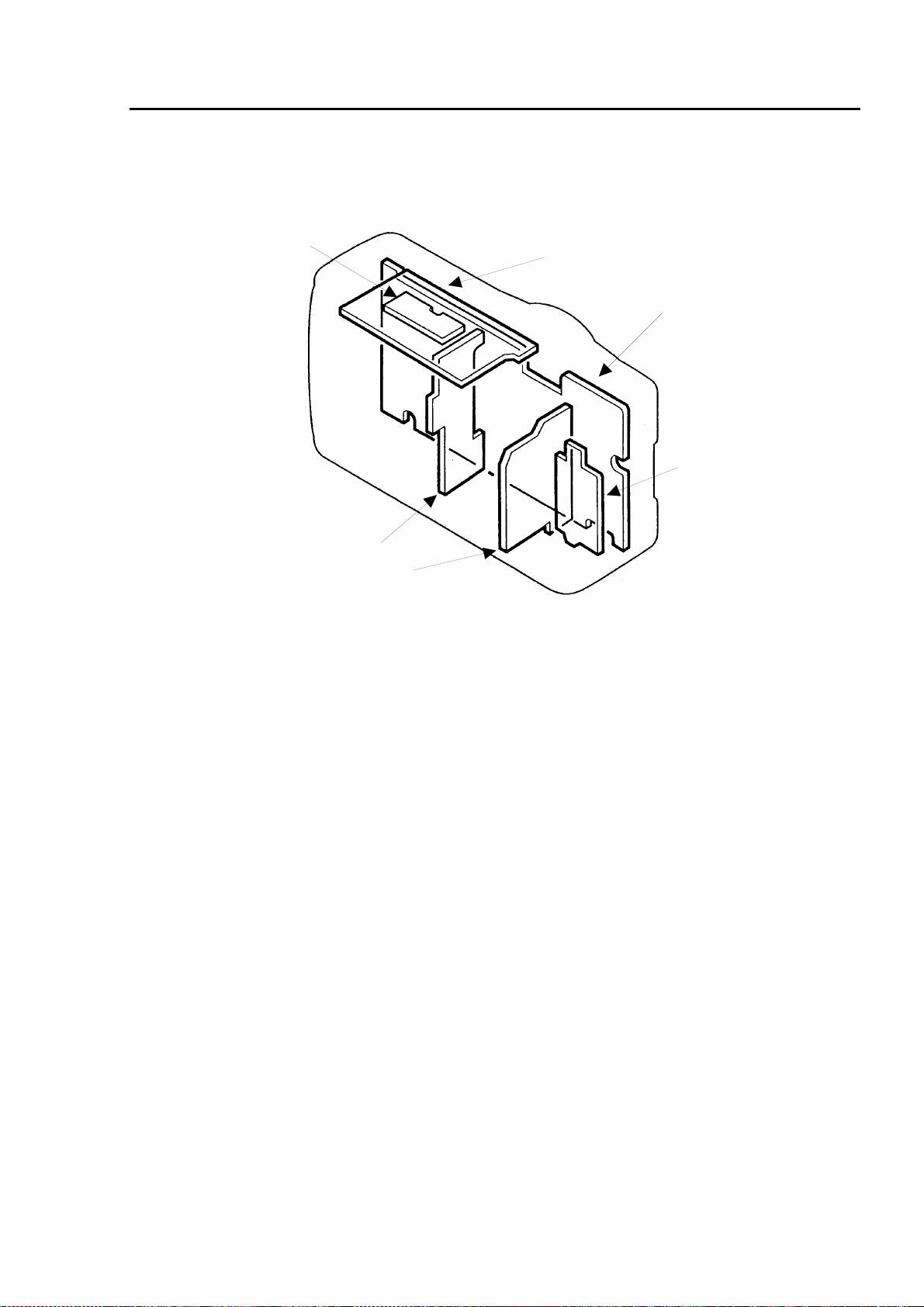

1.

Setting up the CA1 Board

The CA1 board as spare parts does not include the lens related parts and 24 pin connector. Therefore,

this section describes how to assemble these parts.

CAUTION

Use the rubber gloves when you handle the CCD and never touch the CCD with your bare

hands. (Especially, never touch the electric poles)

If the lens related parts on the CA1 board, such as CA1 board itself or the CCD are replaced, it

is required to perform the initialization and 5,100K AWB adjustment. In this case, make sure to

complete these adjustment referring to the Chapter 4.

Insert the optical filter to the inside of the lens unit(crystal blue crystal sandwitch lens), pay ing

attention to the direction of the filter. ( The thinner crystal side should be the lens side) If the

direction is mistaken, the quality of image decreases.

Pick the both sides of optical filter by tweezers when you insert the filter to the inside of the lens

unit. Never touch the surface. If the surface of the filter is dirty, clean it with soft cloth and blow the

dust by the air-gun.

The rubber damper has a determined direction. But if you match the damper to the interior

shape of the lens unit holder, the direction matches automatically and it can be assembled easily.

[Step 1]

Assemble the lens unit as following in the figure 3-6 and fix them with 3 screws form the

back side of the CA1 board. The tightening torque for these screws are 2.5Kg.

Connect the 24-pin connector

to the CN110 on the CA1board

and solder the connector from

the side B of the board.

Optical filter

Lens unit

Floppy spacer

CCD sensor

Rubber damper

24-pin

CN.

(Back side of CA1board)

Fix with 3 screws(Gold)

2(M2x6), 1(M2x4)

Soldering the cable

Shield board

Small screw(M2x4)

Cable (Brown)

Figure 3-6. Installing the Lens unit

Page 46

[Step 2]

[Step 3]

Note)

If you find any dirt, clean it with soft cloth and blow the surface by the air-gun.

Solder all 16 points on the CCD sensor from the back of the CA1 board.

Solder the root of a small screw(M2x4: gold) out of three and a part of shield plate by the

brown cable.

After mounting the lens unit on the CA1 board, blow the surface of lens by the air-gun.

2.

[Step 4]

[Step 5]

[Step 6]

Installing the Holder Chassis and TB1 Board

Attach the TB1 board to the back of Holder chassis and fix them with two screws.

Attach the parts that are assembled at [Step 4] to the CA1 board and fix them with 3screws

from reversed side of the CA1 board.(side B) At this time, connect the connector of TB1

board to the CN105 on the CA1 board.

Attach the Holder terminal to the Holder chassis and fix them with 3 screws(2 screws for the

front and one for back).

Fix the Holder chassis

Install the

Holder terminal

Fix the TB1 board

Figure 3-7. Installing the Holder chassis and TB1 Holder

Page 47

3.

Installing the TB2 Holder with TB2 Board, SY1 Board

and Cabinet Top

[Step 7]

the CA1 board. Match 2 dimples on the CA1 board when you attach the TB2 Holder, so that

you can confirm the attaching points. At this time, Place the 2pin cable (brown) in the

holder hook as it is shown in the Figure below.

[Step 8]

top as it is shown in the figure below and push the Cabinet top into the holes on the SY1

board until it clicks.

Be careful not to remove the LCD board from the SY1 board by accident. Also, Do not

push the LCD board too hard in order to avoid damaging the crystalline liquid in the LCD.

If the LCD cover is removed, put the cover back after making sure that there is no finger

prints or dirt on the LCD surface.

[Step 9]

[Step 7] to the 2 connectors (CN106 and CN108) on the CA1 board.

[Step 10]

Attach the TB2 Holder to the CA1 Board and fix them with one screw from the back of

Insert the Cabinet top to the SY1 board. At this time, confirm the direction of the Cabinet

Connect the 2 connectors located at the bottom of the SY1 board, which is assembled at

Solder the shield plate coming out of SY1 board and top edge of shield plate on the

CA1 board .

Install the Cabinet top

and SY1 Board

*Push the Cabinet from

the right above.

Connect 2 connecters located

at the bottom of SY1 Board

to 2 connecters (CN106,

CN108) on the CA1 Board.

*Place the cable under

this hook.

Install the TB2 Board

Figure 3-8. Installing the TB Holder, SY1 Board and Cabinet

Fix by soldering.

Page 48

4.

Installing the PW1, ST1 Board, Lens VF and Reflector Unit

WARNING

Discharge the electricity in the electrolytic capacitor referring to Page 3-4, since there is a great

possibility of getting electric shock.

[Step 11]

[Step 12]

show in the figure below.

[Step 13]

of PW1 Board.

plate of CA1 Board.

Solder the one side of the cable(red) for electrosatic noise to the JW313 on the PW1 board.

Solder the other side of cable edge to the part of shield plate on the CA1 board, as it is

Solder the one side of the cable(white) to the shield plate on the PW1 board.

CA1 Shield Plate

Solder the cable (red) to JW313 on the side B

Solder the other side of cable on the shield

Figure 3-9. Soldering points for PW1 and SY1 boards.

JW313

(Side-B)

Back side of SY1 Board

Shield Plate on the CA1

Board

Solder the cable (white)to the

shield plate on side A of PW1 Board.

Solder the other side of cable to

the soldering at the back of SY1 board.

[Step 14]

[Step 15]

Note 1)

[Step 16]

Note 2)

At this time, fold the four cables for the flash control and put them together on the

Solder the other side of the cable(white) to the soldering side on the back of the SY1 board.

Connect the connector of the PW1 board to the CN104 on the CA1 board.

Place the 2-pin connector (brown) at the top edge of PW1 board.

Connect the ST1 board to the CN911 on the CA1 board.

electrolytic capacitor of the ST1 board.

Page 49

[Step 17]

Install the Lens VF in the Holder chassis and fix them with one screw. At this time, it is

easier to install this if you insert the Lens VF directly down to the Holder chassis.

In order to remove VF, pull it toward the camera front.

[Step 18]

[Step 19]

Install the reflector unit right side of Lens VF and fix it with one screw.

Connect the black and red cable(2pin, brown) coming out of TB2 holder to the brown

connector located between Holder chassis and ST1 board. At this time, make sure

that 4 cables(yellow, blue, red and white) coming out of reflector unit are located under the

black and red cable. (Refer to the figure below)

[Step 20]

Connect the black and red cable from the bottom of lens unit to the CN903 on the CA1

board.

*Be careful for electric shocks

(Refer to Page 3-4).

Figure 3-10. Installing the Lens VF and Reflector unit

Page 50

5.

Installing the Lens Cover

[Step 21]

[Step 22]

At this time, leave the lens cover closed.

[Step 23]

bottom of the right side ring and then insert the bottom peaking of lever lens to the notch of

cover lens. At this time, leave the lens cover still closed.

[Step 24]

of knob power on the front cabinet.

[Step 25]

from [Step 21] to [Step22], and fix them temporarily with 4 screws according to the

order in the figure below. Then tighten these 4 screws tightly at the same order shown

At this time, tighten screws holding the case by the one hand since the lens cover floats

[Step 26]

Note)

Place the ring along with the lens hole located back of the front cabinet.

Fit the hole of cover lens to the second protruding portion counting from right bottom of ring.

Paying attention for the direction, fit the hole of lever lens to the protruding portion located

Hang the peaking of lever lens on the notch of knob power and insert the knob to the notch

Paying attention to the direction, place the holder lens on the parts you have assembled

in the figure.

if you do this procedure leaving the cover on the desk.

Place the black and red lead wires(2pin) coming out of the leaf switch so that the

protruding portion should be between the soldering parts of wires. (This is for prevention

of short-circuit) Then fix the leaf switch with one screw(M1.7x8).

Knob power should be ON since the lens cover can not be installed correctly if it is OFF.

Page 51

process should be following;

[Step 27]

Perform

ON/OFF, pushing

the knob power

switch from the

behind and confirm

that

knob

power switch is

operating correctly.

Install the ring.

Install the cover lens,

leaving the cover closed.

4

2

3

Install the lever lens.

(Insert the protruding portion located at

bottom of lever to the trench of the ring)

Install the knob power.

1

Fix the holder lens and front

cabinet with screws.(Screw them

according to this order)

Figure 3-1 1. Installing the Lens cover

WARNING

When

the Knob

power

switch is

ON : Leaf

switch is

OFF

(White

actuator of

Leaf SW is

up)

When

the Knob

power

switch is

OFF :

Leaf switch

is ON

(White

actuator of

Leaf SW is

down)

Even if you can

perform ON/OFF normally with knob power, if the leaf switch is installed opposite, the knob power

switch can not be really ON state, but in s tead, it becomes O N state when the k nob power is set OF F.

So, make sure that leaf switch is installed correctly.

[Step 28]

Hang the 2 lead wires coming out of leaf spring on the hooks of the holder lens as it is

shown in the figure below.

Page 52

Black

Red

Note:This is the figure when the knob

power is OFF. Set the knob power

OFF, since it is very hard to fix

the leaf switch if knob power is ON.

Figure 3-12. Placing the Lead wires

Leaf Switch

Protruding portion

should be between

soldering parts.

Hang the lead wires on

these hooks.

6.

[Step 29]

[Step 30]

Installing the Front and Back Cabinets

From behind of the front cabinet, Install the battery cabinet in the right side and fix

it with 2 screws.

Insert the tripod stand into the left side ditch of the reversed front cabinet. Although there

is no determined direction for the tripod, 2 holes of tripod stand and cabinet should match.

Do not fix the tripod with screws at this time yet.

Page 53

Install the Tripod stand.

Install the battery cover.

(Leave the cover closed)

Figure 3-13. Installing the Battery cover and T ripod stand

Install the battery cover

matching with dimples for

location.

Fix it with 2 screws.

[Step 31]

[Step 32]

Install the battery cover.

Assemble the camera body and front cabinet and fix them with 3 screws. Take the black

and red wires from leaf switch out of the cabinet. Lead these wires under the camera

body to the side B of CA1 board, then connect them to the CN303(2pin, white) on the

SY1 board. Fix the wires on the shield plate with the scoch tapes.

[Step 33]

Put the back cabinet on and fix them with 6 screws and also fix the tripod stand

with 2 screws.

[Step 34]

Install the back cover, cover and plug cover.

Page 54

Left side of VF

on the chassis frame

Connect the lead wires from

the leaf SW to the SY1 Board.

(Fix these wires with tape on

the shield plate of CA1 Board)

Attach the cover.

Attach the back cover.

Fix the back cabinet.

CA1Board right

bottom

Attach the plug cover.

Left side of tripod stand

on the chassis frame.

Fix the body and front cabinet with