Page 1

EPSON TERM

NAL PR NTER

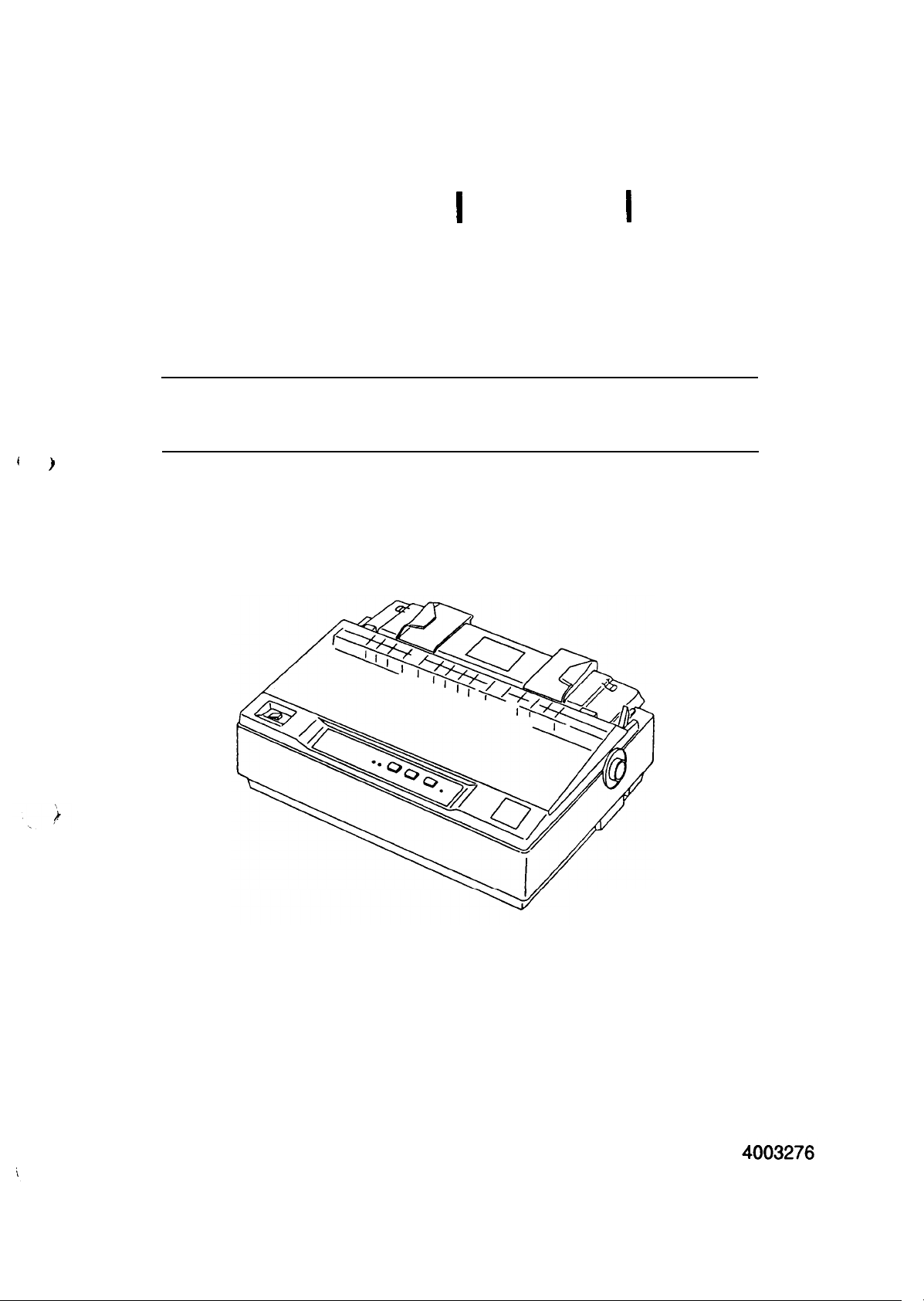

LX-300

SERVICE MANUAL

(

)

EPSON

Page 2

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury and 2)

damage to equipment.

DANGER

WARNING

The precautiomry measures itemized below should always be observed when performin

maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury.

Great caution should be exercised in performing procedures preceded by DANGER

Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

grepair/

DANGER

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURE.

2. NO

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

1.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLT-

AGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT

HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO

NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM

THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4.

IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

ICS

OR

(YI’HER

- ii -

Page 3

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of LX-300.

The instructions and procedures included herein are intended for the experience repair technician, and

attention should be given to the precautions on the preceding page. The chapters are

follows:

CHAPTER 1. PRODUCT DESCRIPTION

Provides a general product overview, lists specifications, and illustrates the main components of the

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory

of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product d

isassembly

and assembly.

CHAPTER 4. ADJUSTMENTS

Includes a step-by-step guide for adjustment.

organizd

pMter.

as

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

-iv-

Page 4

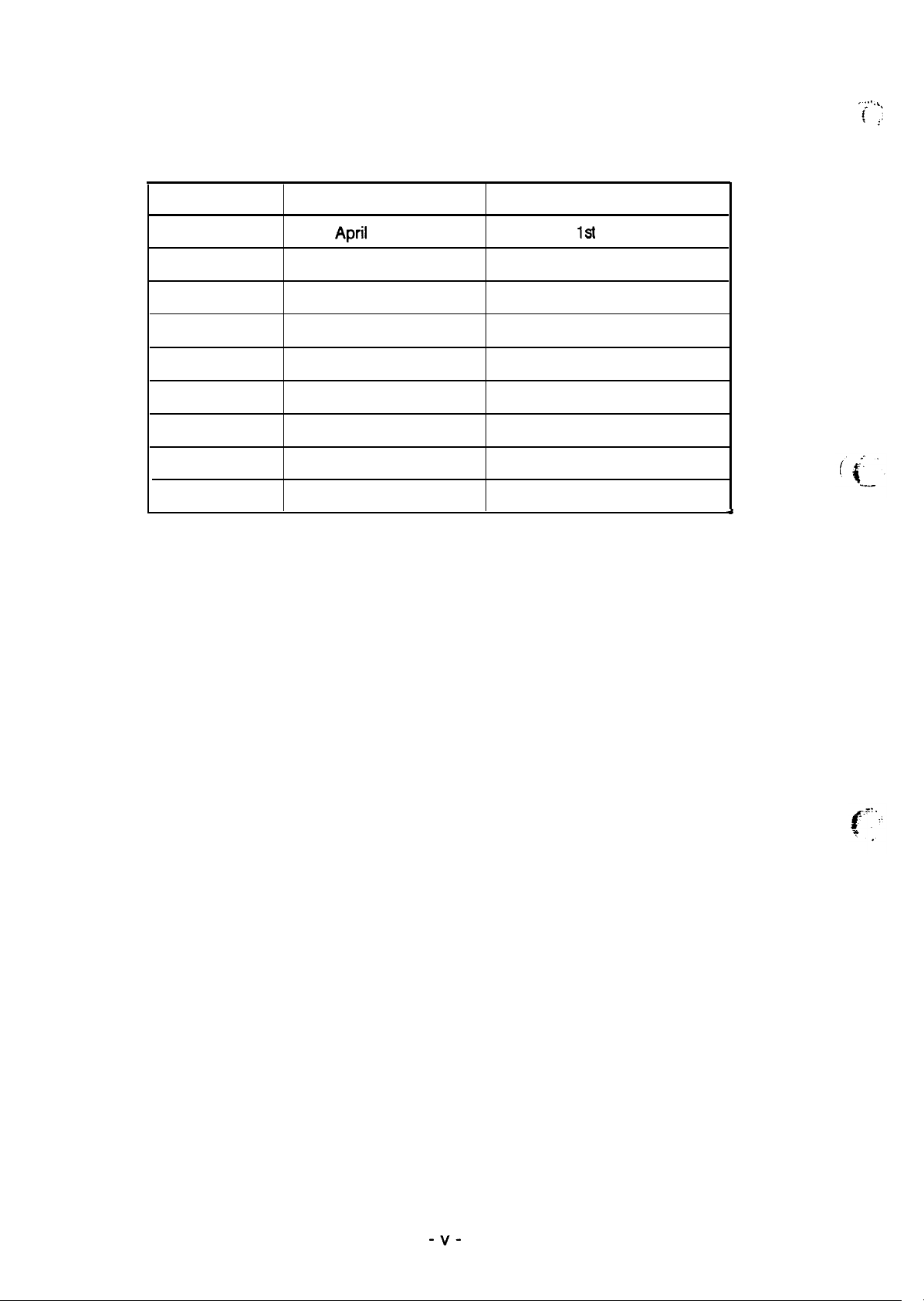

REVISION SHEET

. . . . . .

.

(

( j

Revision

Rev. A

Issue Date

April

6, 1994

Revision Page

1st

issue

4

-v-

Page 5

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

PRODUCT DESCRIPTION

OPERATING PRINCIPLES

DISASSEMBLY AND ASSEMBLY

ADJUSTMENTS

TROUBLESHOOTING

MAINTENANCE

- vi -

Page 6

CHAPTER 1 Product Description

Table of Contents

1.1 FEATURES

1.2 SPECIFICATIONS

1.2.1 Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.1 Paper Handling Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.2 Paper Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.3 Printable Area.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.4 Ribbon Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.5 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.6 Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.7 Reliability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.8 SafetyApprovals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.9 Physical Specifications . . . . . . . ...’..... . . . . . . . . . . . . . . . . .

1.2.2 Firmware Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 INTERFACE SPECIFICATIONS

1.3.1 Parallel Interface Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.3.2 Serial InterfaceSpecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 OPERATING INSTRUCTIONS

1.4.1 Control Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

.

1.4.2 Self-test Function. . . . . . . . . . . . . . . . . . . . .

1.4.3 Hexadecimal Dump Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.4 PrinterStatus Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.5 Selected Font . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.6 Paper Position Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.7 Printer Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.7.1 Hardware Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.7.2 Software Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.8

PrinterSettings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.8.1 Selectable

1.4.8.2 Changing the

PrinterSettings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

DefaultSettings. . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

. . . . . . . . . . . . . . . . . . . . 1-15

1-1

1-2

1-2

1-3

1-4

1-5

1-7

1-8

1-8

1-8

1-8

1-8

1-9

1-11

1-13

1-14

1.5 MAIN COMPONENTS

1.5.1

1.5,2 C130

Ct30

MAIN Board. , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

PSB/PSE Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

1-21

Page 7

List of Figures

.P.::k

f

(’.

Figure 1-1.

Figure 1-2.

Figure 1-3.

Figure 1-4.

Figure 1-5.

Figure 1-6.

Figure 1-7.

Figure 1-8.

Figure 1-9.

Figure 1-10.

Exterior View of the LX-300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Pin Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

PrintableArea forCut Sheets Using Manual Insertion. . . . . . . . . . . 1-5

Printable Area for Cut Sheets with the CSF. . . . . . . . . . . . . . . . . . .

PrintableArea forContinuous Paper . . . . . . . . . . . . . . . . . . . . . . . . 1-6

PrintableArea

Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Panel Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

C130 MAIN Board Component Layout. . . . . . . . . . . . . . . . . . . . . . 1-21

C130

PSB/PSE

forRoll

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Board Component Layout . . . . . . . . . . . . . . . . . 1-21

1=6

List of Tables

Table l-1. Optional Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Table 1-2. Feeding Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table l-3. Adjust LeverSettings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Table 1-4. Specifications for Cut Sheet Paper (Manual Insertion) . . . . . . . . . . . 1-4

Table 1-5. Specifications for Cut Sheet Paper

Table l-6. Envelope Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-7. Specifications for Continuous Paper (Single Sheet and Multi-Part) . 1-4

Table 1-8. Specifications for Continuous Paper with a Label. . . . . . . . . . . . . . . 1-5

Table l-9. Roil Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table l-10. Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table 1-11,

Table 1-12.

Table 1-13.

Table 1-14,

Table

Table 1-16.

Table 1-17

Table 1-18

Table 1-19

Table 1-20

Table 1-21

Table

Table

Table

Table

Table

Table

Table 1-28. Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table 1-29. Bit Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table 1-30. Parity Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Table 1-31. Data Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Table 1-32.

1-15

Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Character Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Printing Speed.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Signal and Connector Pin Assignments for the Parallel Interface. 1-12

Signal and Connector Pin Assignments for the Serial Interface . . 1-13

Font Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Font Lights and Language Selection. . . . . . . . . . . . . . . . . . . . . . . 1-17

Default Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Character Spacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Shape of Zero. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

-22

Skip Over Perforation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

-23

Character Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

-24

Auto Line Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

-25

Page Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

-26

Auto Tear Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

-27

Tractor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

EWACK.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(CSF). . . . . . . . . . . . . . . . . . . . . 1-4

l-2o

(T

‘:”””

Page 8

LX-300 Service Manual

1.1

FEATURES

Product

Daadption

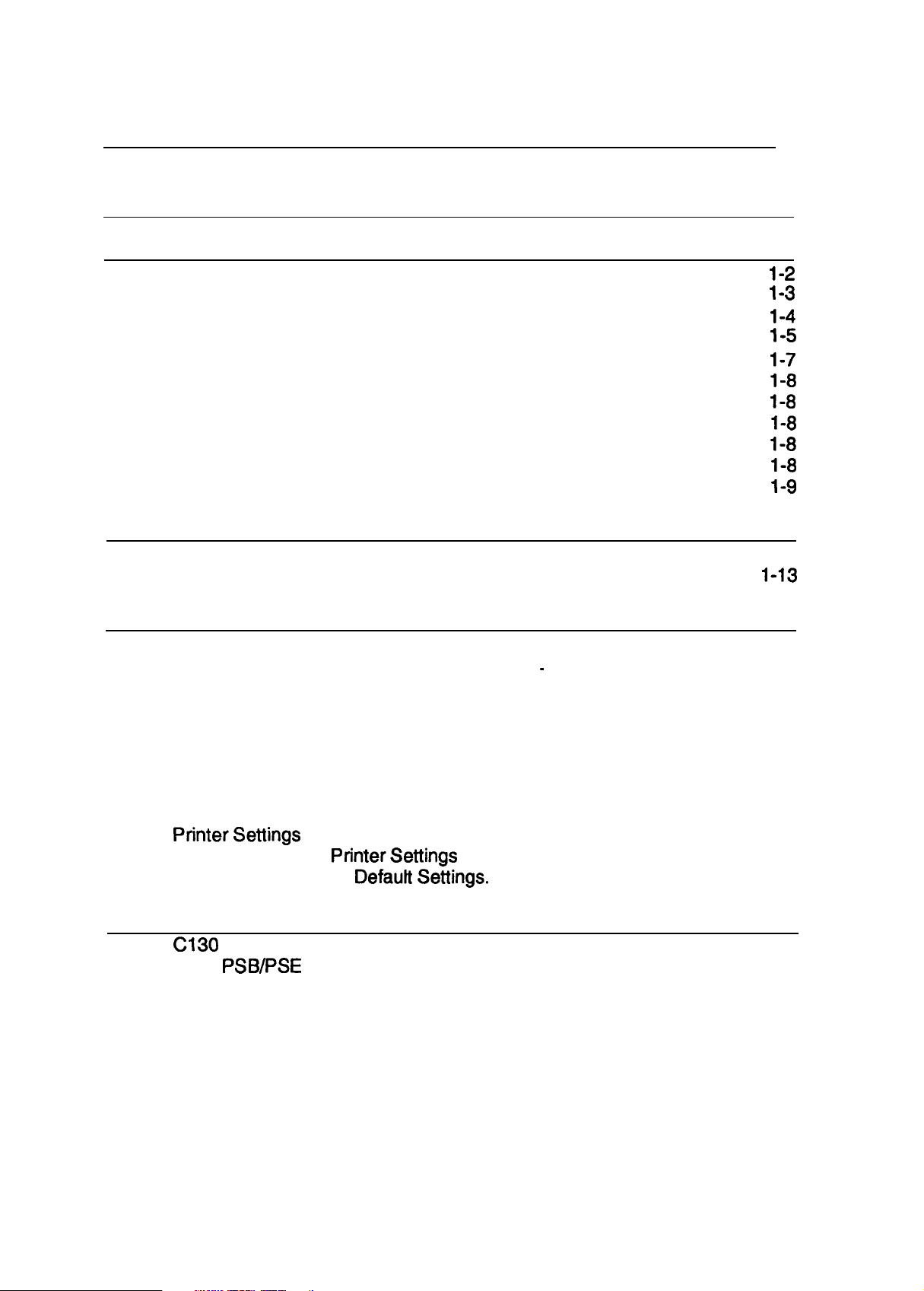

The LX-300 is a small, light-weight, 9-pin

personal use. The major features of this printer areas follows:

0

Fast printing of

Cl

Compact design saves precious workspace

Cl

Easy-to-operate panel

LI

Quiet printing

CI

Standard 8-bit parallel interface and

D

Printing of up to 66 lines on

~

Optional color printing usinga color ribbon (black, magenta, cyan, yellow)

~

Detachable push and pull tractor

Figure 1-1 shows an exterior view of the LX-300 and Table 1-1 lists the optional units available for

the LX-300.

Edge guties

Power

~

YA&

10-cpi

draft characters at 220 cps

A4-size

or 62 lines on letter-size paper

~p”perwppof’s

serial

EIA-232D

A

impact dot-matrix color printer suitable for

serial interface

lease

r

feed

b

Model

I

#8750

#8758

S015073

I

C80837*

.. ./,

w

Pfintercover

Sprocket unit

Paper

#/<

Jpport

/’=

A%

5

A

-

Troctof

Figure 1-1. Exterior”View of the LX-300

Table 1-1. Optional Units

Description

Ribbon cartridge (monochrome)

Ribbon cartridge (monochrome,

,

I

Ribbon cartridge (color)

Single-bin cut sheet feeder

sub-mtridge)

Print head

I

I

Rev. A

C83208*

I C80030* [

#8310

I

Color upgrade kit

Pulitractorunit

I

Roil paper holder

I

I

1-1

Page 9

a

Product Description

LX-300

Sarvice Mimual

1.2 SPECIFICATIONS

This section provides detailed information about the LX-300.

1.2.1 Hardware Specifications

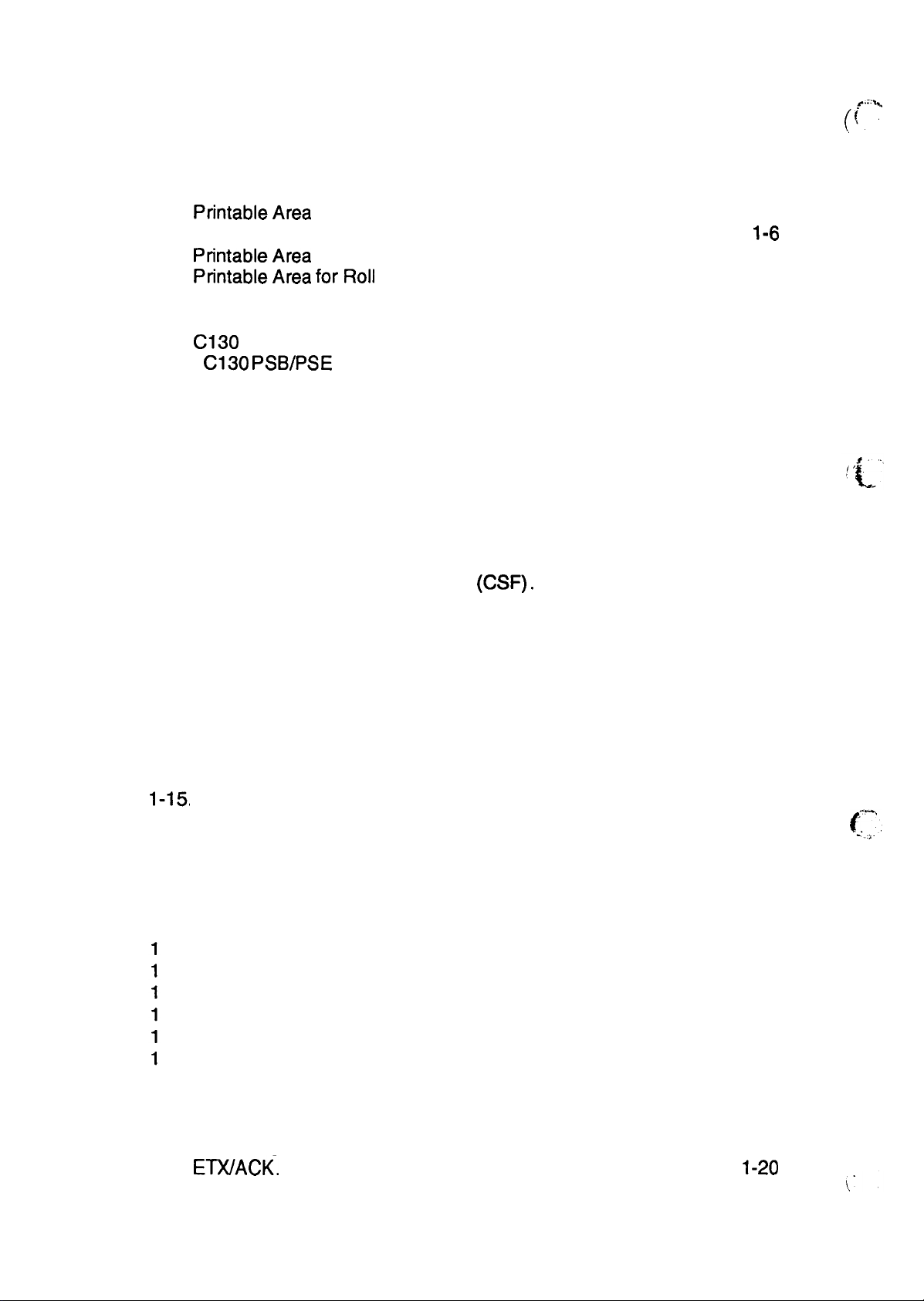

Printing method:

Pin configuration:

Pin diameter:

Serial impact dot matrix

9 wires

0.29

mm

,.

: f

.

/- :.,,

Printing direction:

Figure 1-2. Pin Configuration

Bidirectional with logic seeking for draft text with monochrome

printing.

Unidirectional printing for graphics, NLQ text, bit image, and color

printing.

1-2

Rev.

A

Page 10

LX-XXI Sarvka

Manual

Product Description

1.2.1.1 Paper

Feeding system:

Feeding method

Cut sheets:

Continuous paper:

Feeding pitch:

Paper paths

Cut sheet path:

Continuous paper paths:

Continuous paper parking:

CSF:

Paper-feeding speed:

Handling Specifications

Feeding

Friction

Tractor (single)

Friction feed or tractor (push and pull) feed

Manual insertion (top entry) and feeding with the

optional cut sheet feeder

Push and pull tractor feeding

li~ in~, 1A in~, or pr~ammable

of

%16 inch, minimum

Top entry (manual insertion or the

Rear entry (push tractor feed)

Rear entry (pull tractor feed)

Possible, using push tractor

Single bin, manual insertion using optional

See Table 1-2.

Table 1-2. Feeding Speed

l/G

inoh

Line Feed

79

rns/line

2.78

(CSF)

feeding in

optioml CSF)

in~ments

CSF

Continuous Feed

incheskecond

(top entry)

2.08

Tractor (double)

Friction feed

●

Set the release lever to the friction

. When a sheet is inserted into the

.

Donotperform

Push tractor feed

. Set the release lever to the tractor position.

.

Donotperform reverse feeds greater than O.27 inch (6.8 mm).

. During printing ofiabels, never perforrnreverse feeding.

. After printing labels, do not eject them from the rear.

Pull

tractor feed

0 Remove the tractor unit from the push position and mount it in the pull position.

●

Do not perform reverse feeding.

The adjust lever must be set to proper position for the paper thickness, as shown below.

reverse feeds greater than

96 redline

msition.

t;p

slot, place its left edge at the marked position.

O.27inch(6.8

mm).

inoheakxond

Table 1-3. Adjust Lever Settings

Lever Position Paper Thickness

o

1

0.065

mm -0.16 mm

0.16 mm -0.25 mm (0.0063 in. -0.0098

(0.0026 in. -0.0063

in.)

in.)

Rev. A

b

2

0.25

mm -0.48 mm

(0.0098 in. -0.0189 in.)

14

Page 11

Product Description

LX-WI

Service Manual

1.2.1.2 Paper Specifications

Table 1-4. Specifications for Cut Sheet Papar (Manual Insertion)

Width

Length

Thickness

Weight

Quality

182 mm -257 mm (7.2 in. -10.1 in.)

182 mm -364 mm (7.2 in. -14.3 in.)

0.065 mm -0.14 mm (0.0025 in. -0.0055

52.3-90

Plain paper, recycled paper

Table 1-5. Specifications for Cut Sheet Paper

Size

Thickness

Weight

QuaMy

A4 (W x L: 210 mm (8.3 in.) x 297 mm (11.7 in.))

Letter (’W x L: 216 mm (8.5 in.) x 279 mm (11.0 m.))

0.065 mm -0.14 mm (0.0025 in. -0.0055

64-90

Plain paper, recycled paper

Table 1-6. Envelope Specifications

Size

NO.6

No.1O Width 240 mm x Length 104 mm (9.5 in. x 4.1 in.)

in.)

g/m2

(14 -24 lb.)

(CSF)

in.)

@m*

(17 -24 lb.)

Width 166 mm x Length 92 mm (6.5 in. x 3.6 in.)

,..

(i

‘-’;

Thickness

Weight

Quality

Notes:

.

Printing of envelopes is guaranteed only when the temperature is room temperature

and humidity is normal (15 - 25° C (59 - 77” F), 20-

●

Variations in envelope thickness must be less than 0.25 mm (0.0098 in.).

●

When inserting envelopes, keep the longer side horizontal.

0.16 mm - 0.48 mm (0.0063 in. -0.019 in.)

45-90

Bond paper (not curled, folded, or crumpled), plain paper, airmail paper

g/m2

(12 1-24 lb.)

&l’Y. RI-I).

Table 1-7. Specifications for Continuous Paper (Single Sheet and Multi-Part)

Width

I

Total thickness

Weights

copies

Quality

101.6 mm - 254 mm (4.0 in. - 10.0 in.)

I

I

0.065 mm- 0.25 mm (0.0025 in. -

52.3- 82

40- 58.2

3 sheets (1 original + 2 copies)

Plain paper, recycled paper, carbonless multi-part paper

g/m2

14-22 lb. — not multi-part

g/m2

12 - 15 lb. — multi-part

[

)

0.0098in.)

I

(“:.

14

Rev. A

Page 12

LX-300 Service Manual

Table 1-8. Specifications for Continuous Paper with a Label

Prvduct

Description

Label size (W x L)

Width of base paper

Thickness of base

paper

Total thickness

Weight

Quality

Notes:

●

Use only continuous-type labels and use them only with the tractor.

●

Example of labels

●

Printing of envelopes is guaranteed only when the temperature is room temperature

63.5 mm (min.) x 23.8 mm (min.) [ 2.5 in. (min.)

101.6 mm -254 mm (4.0 in. x 10.0 in.)

0.07 mm - 0.09 mm (0.0028 in. - 0.0035 in.)

0.16 mm - 0.19 mm (0.0063 in. -0.0075

64g/m2(17 lb.)

Plain paper

and humidity is normal (15 - 25° C (59 - 77° F), 20-

Table 1-9. Roll Paper Specifications

Width

Diameter 127 mm

Thickness

Weiaht

213 mm -219 mm (8.38 in. -8.62 in.)

0.070 mm -0.090 mm (0.0028 in. - 0.0035 in.)

I 52-

64a/m2

in.)

— Avery Continuous Form Labels

— Avery Mini-Line Labels

(5.0

in.)

(14

-17

lb.)

6(YXO

x

15/16 in. (min.)]

RI-l).

I

I

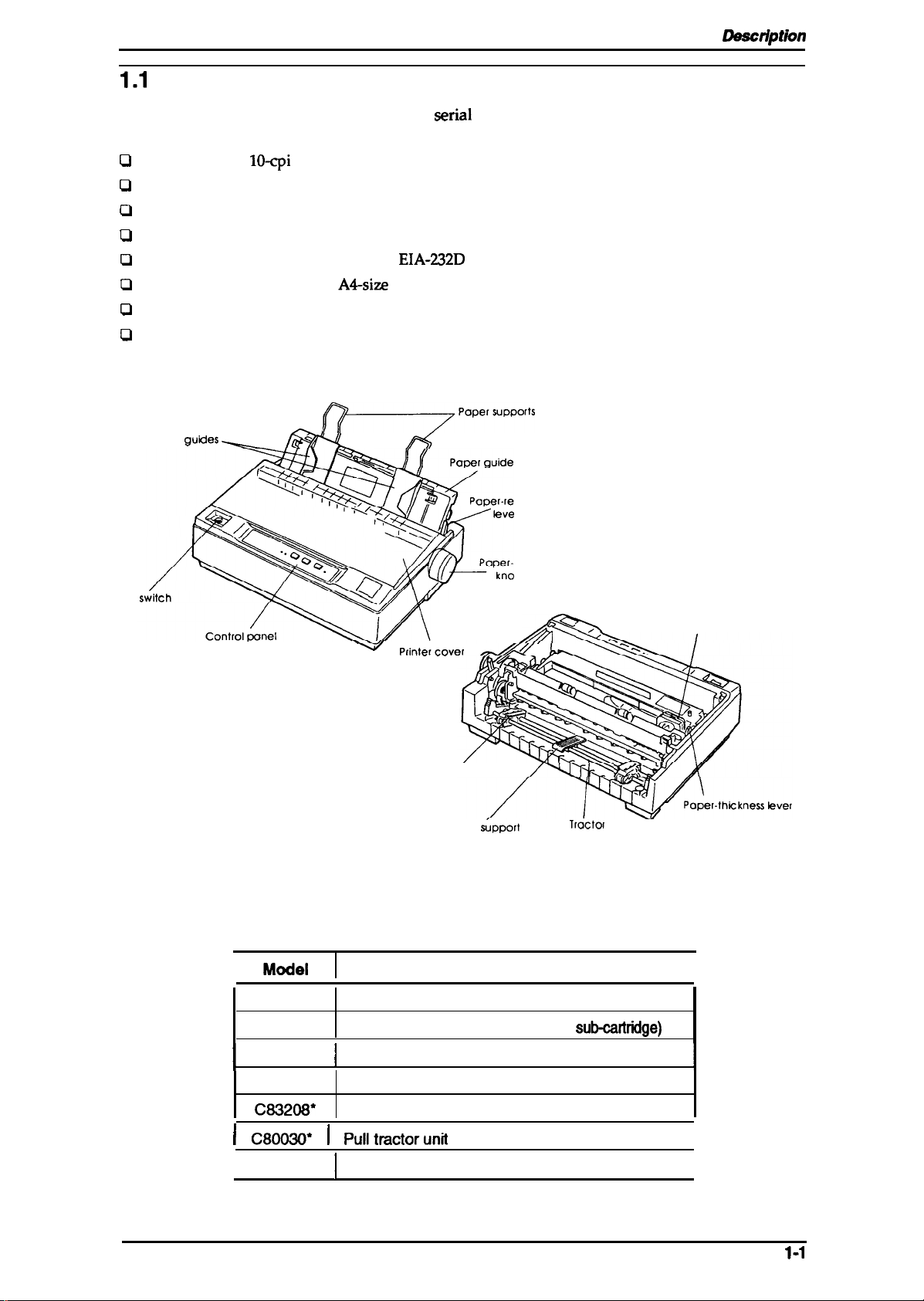

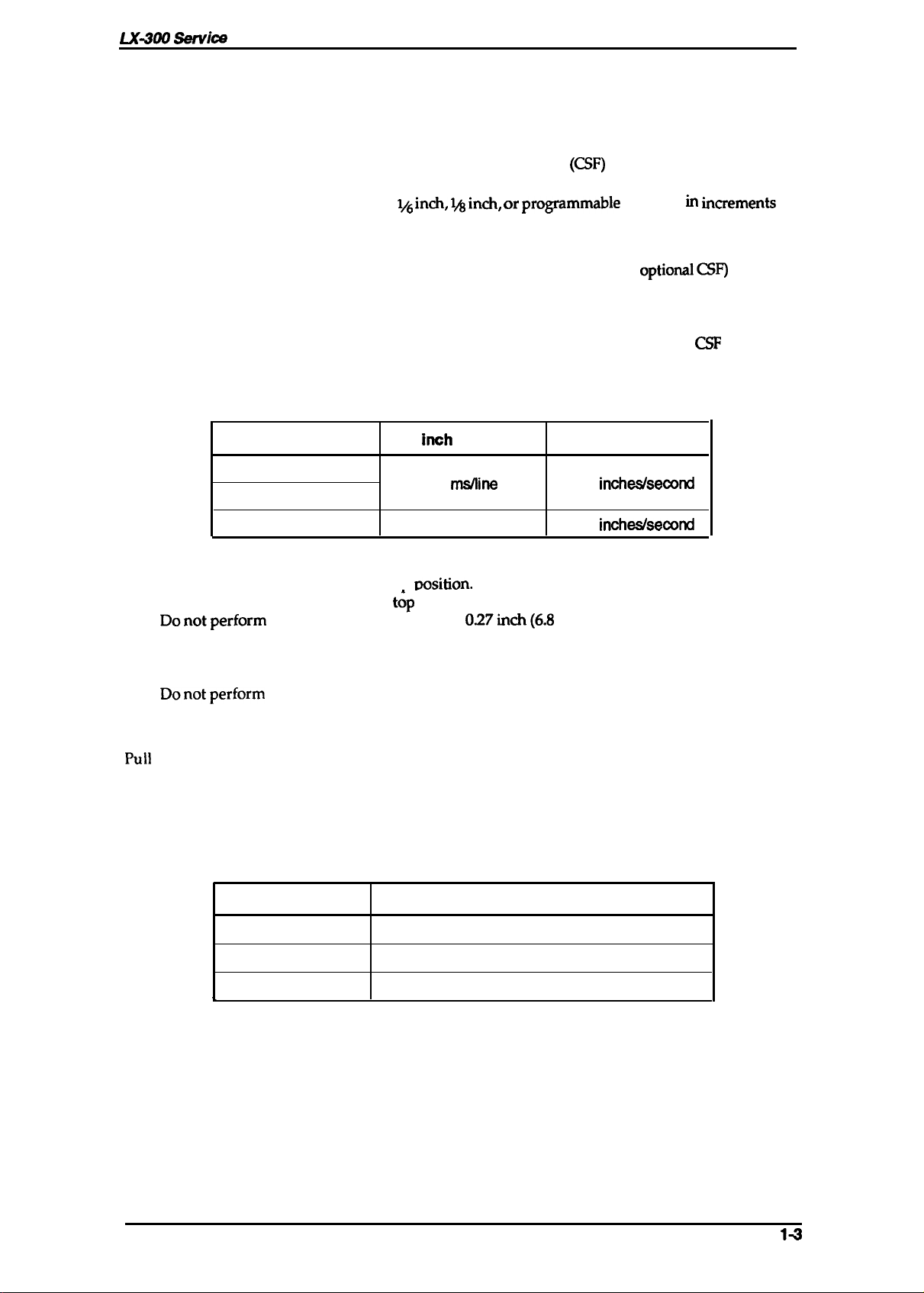

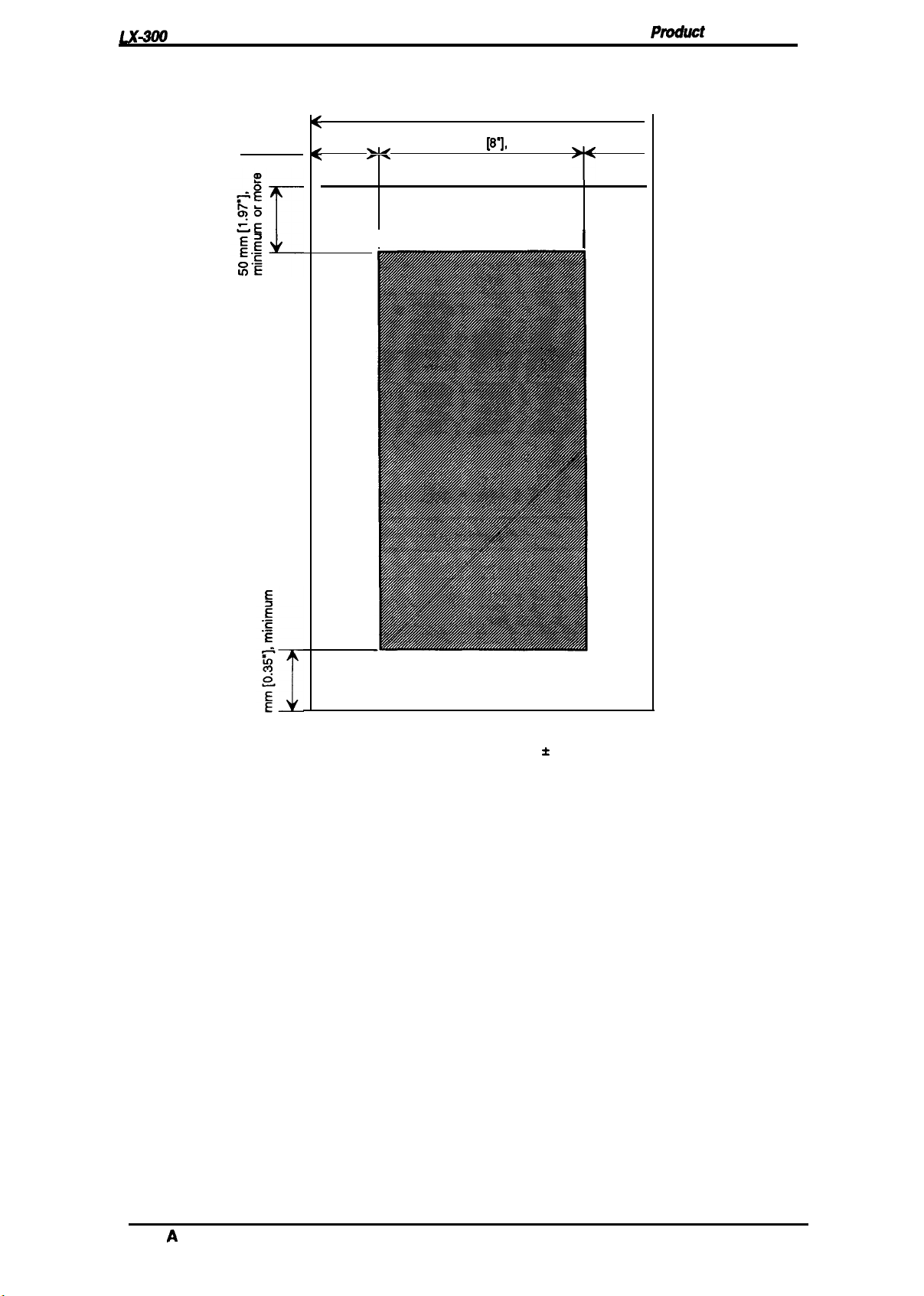

1.2.1.3 Printable Area

Cut

shaets

using manual

[0

insartion

3

mm

1%], nym.m

—

—

—

3

mm

[0.12’].

Ilirimbm

. . . . . .

. . . . . .

\

F

L

Printable Area

209.2 mm

BC

BC

,.. - . . ,

10~. MEximum

XYz

7

)wz

-J

Rev.

Figure 1-3. Printable Area for Cut Sheets Using

Manual Insertion

A

1-s

Page 13

Product Description

LK300

Service Manual

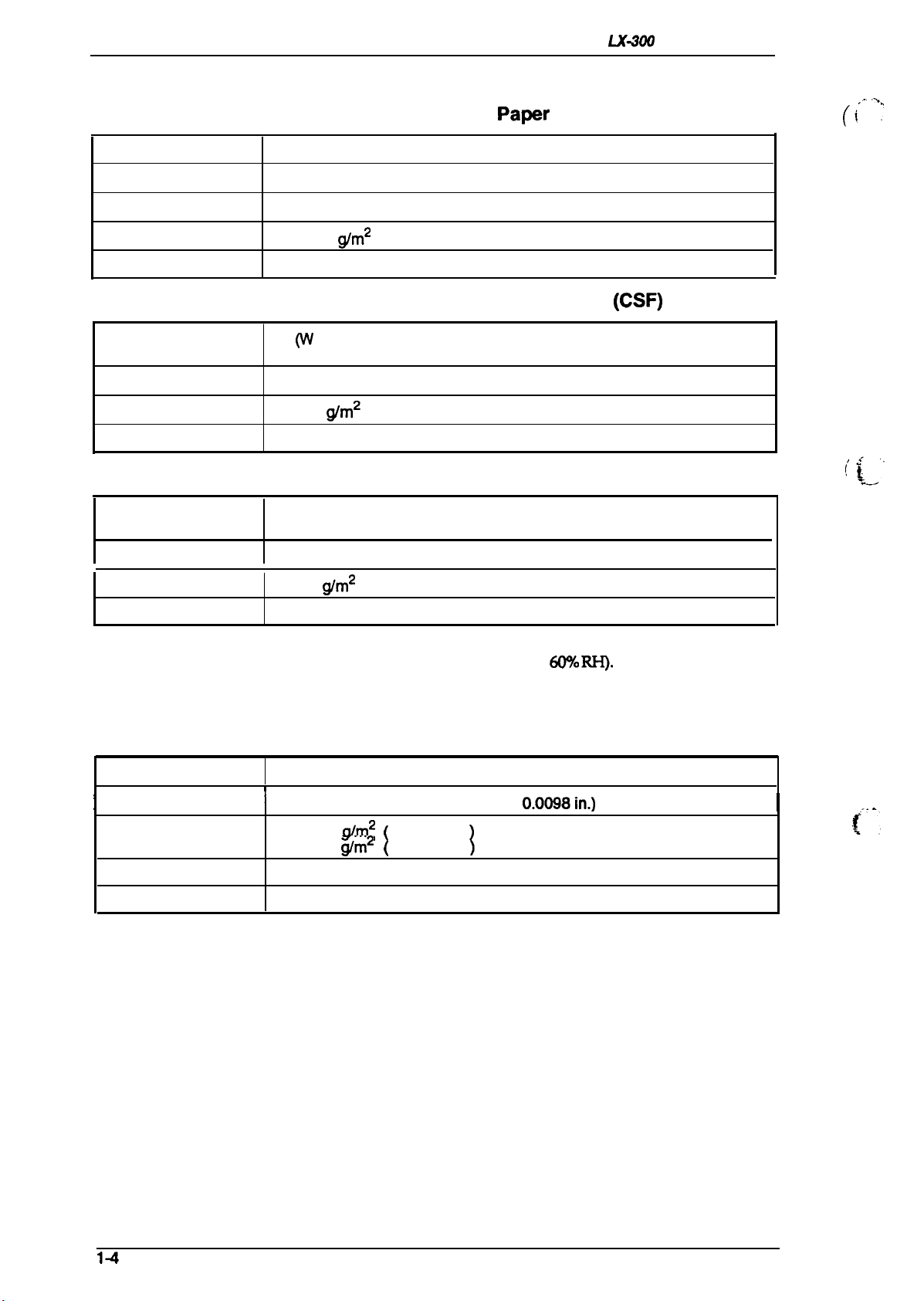

Cut Sheets Using the

(XF

3 mm

10.12”1.

Figure 1-4. Printable Area for Cut Sheets

mm,mum

L

BC

XY

A

Using the CSF

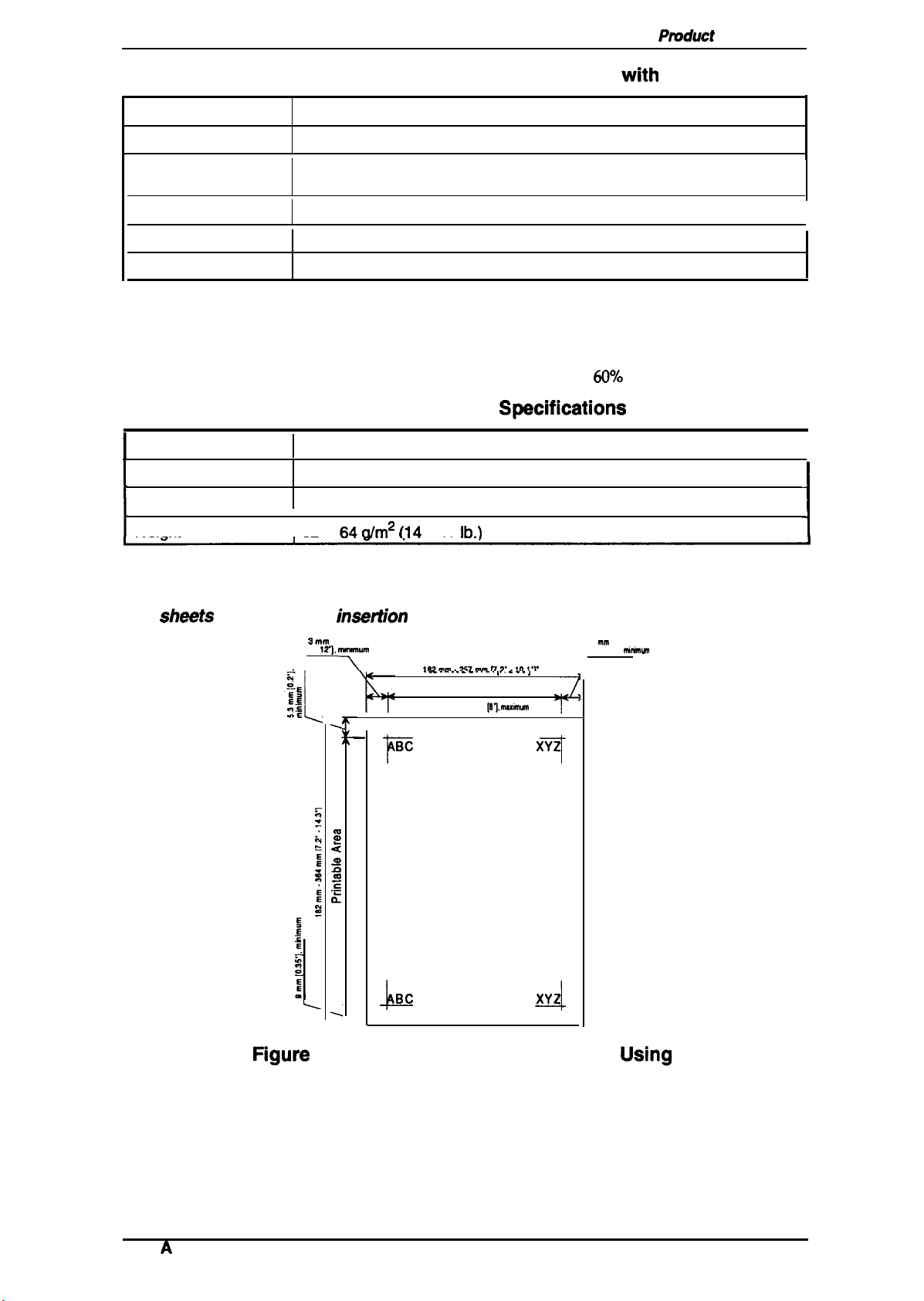

Continuous paper

101.6

t-m-n

-

2S4 nun

[4” -

10~, masinwm

0

0

I

o

0

0

0

0

0

0

0

0

0

0

0

42

0

0

0 0

0 0

0

0

0

o

0

0

0

0

0

0

0

0

0

0

0

0

a

o

0

0

0

PfintaM9

Area

1:

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

a

o

0

0

0

a

o

a

a

a

a

a

a

a

—

f“’.

-

.;.

14

“ 13 mm (0.51”) or more

30

mm

(1. W) w

whm ppar wid?h

mwe

when w

of 101.6 MM (4-) to 241.3 mm (9.5-) is

w+dth of 2S4

mm

(10.)

is

usad.

usd

Figure 1-5. Printable Area for Continuous Paper

Rev.

A

Page 14

LX4tW

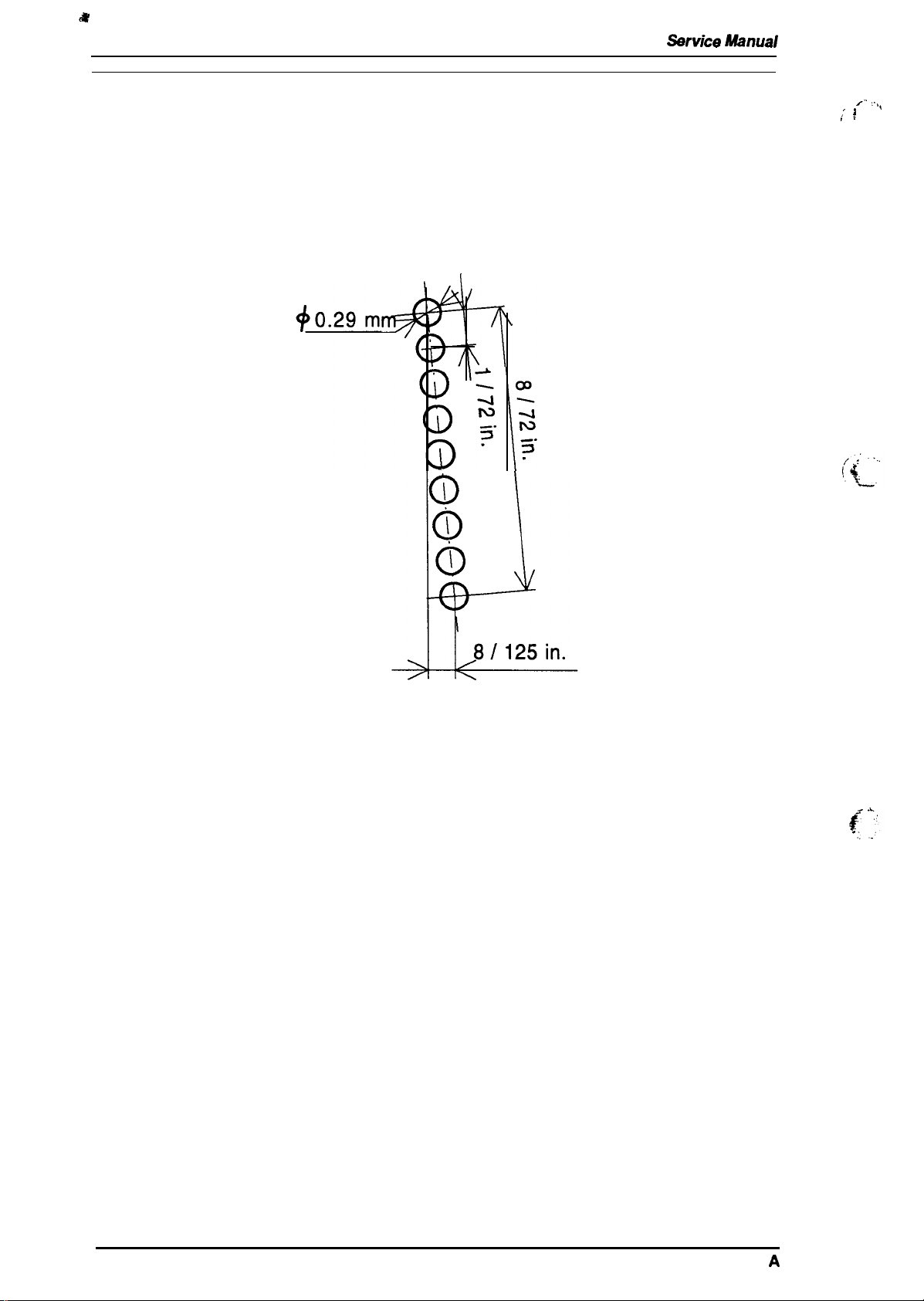

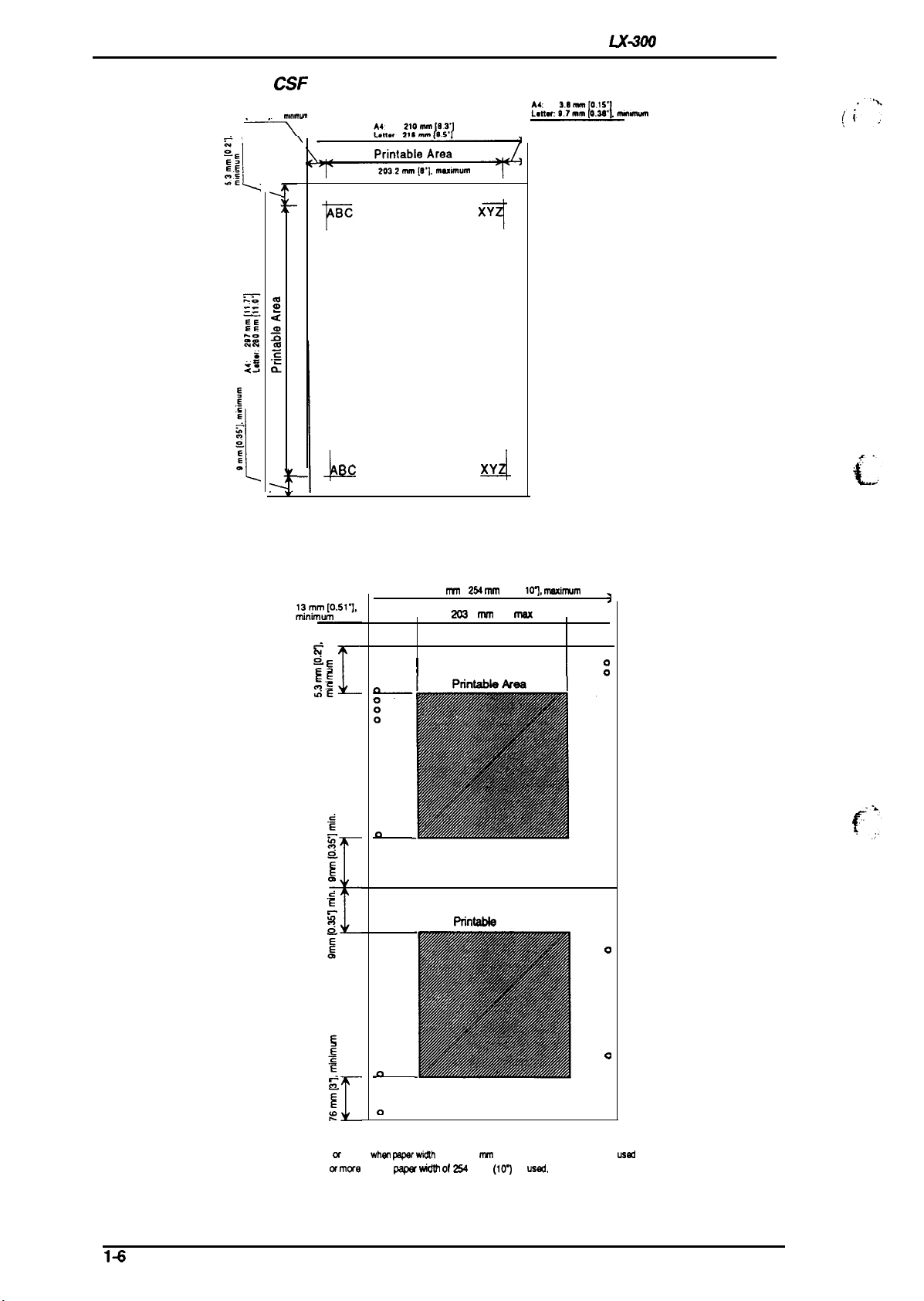

Roll paper

Service Manual

Prvduct

Description

3

mm

[0.12”

minimum

213 mm -219 mm [8.38’ - 8.62’]

w

I

203.2 mm

Printable Area

[8’J

maximum

>

*

)

I

m

‘ 9.8

mm

(0.39”) or more

Figure 1-6. Printable Area for Roll Paper

1.2.1.4 Ribbon Specifications

Ribbon cartridge (mono):

Ribbon cartridge (color):

Ribbon color:

Black ribbon life:

Color ribbon life

Black:

Magenta:

Cyan:

Yellow:

#8750

#8758

S015073

Black, magenta, cyan, yellow

3 million characters (14 dots/character)

1 million characters (14 dots/character)

0.7 million characters (14 dots/character)

0.7 million characters (14 dots/character)

0.5 million characters (14 dots/character)

when a

paper widthof216 f 3

(sub-cartridge)

mm is

used.

Rev.

A

1-7

Page 15

Product Description

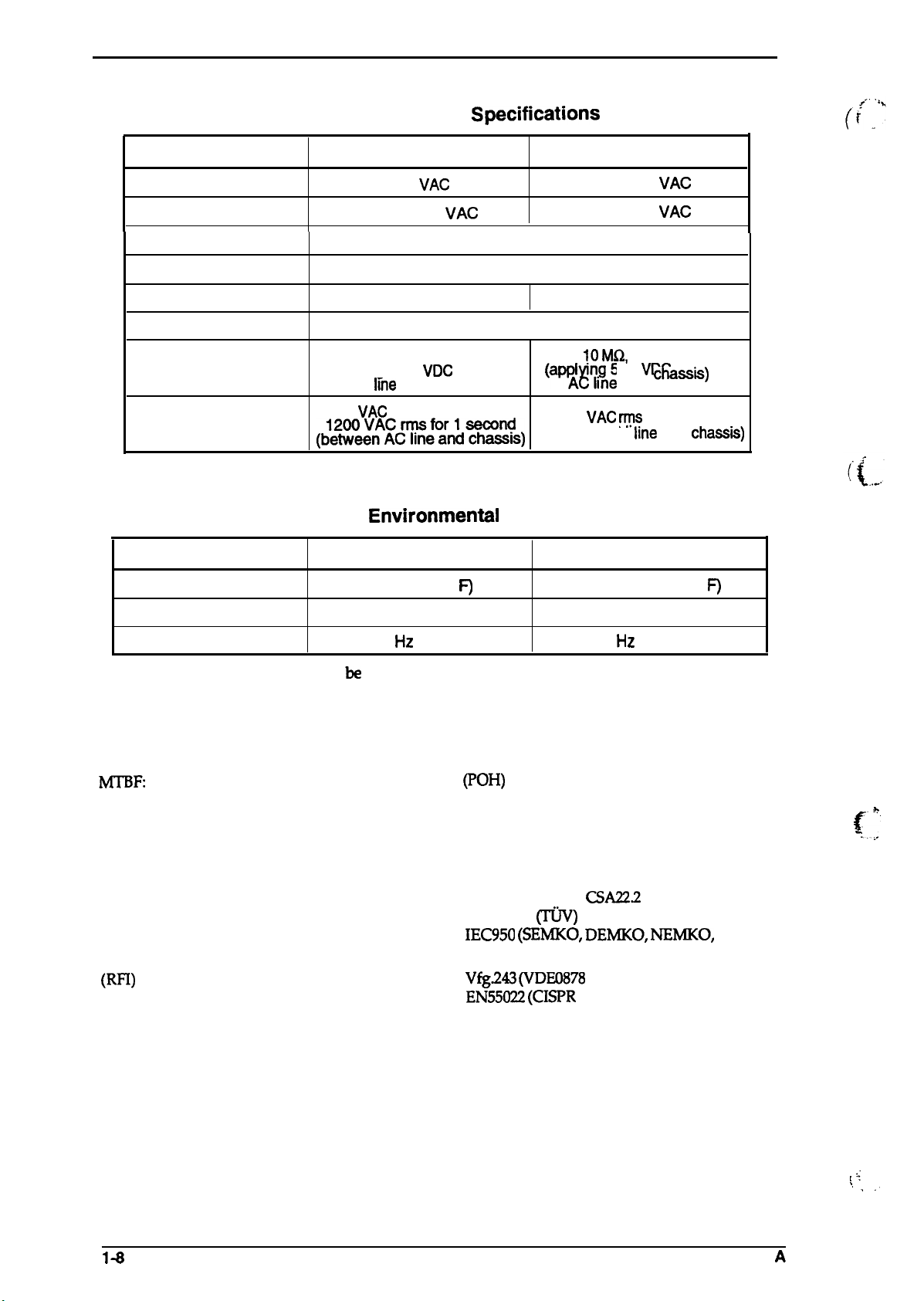

1.2.1.5 Electrical Specifications

Table 1-10. Electrical Specifications

LX-300 Service Manual

Description

Rated voltage

Input voltage range

r

Rated

frequency range

Input frequency range

Rated current

Power mnsumption

Insulation resistance

(applying 500

AC

1000

Dielectric strength

VAC

(&~O~v:~C~&d~~~s)

1.2.1.6 Environmental Conditions

Table 1-11.

Description

Temperature

5to 35° c (41 - 95° F) (*1)

120 V Version

120

VAC

103.5-132

VAC

49.5 -60.5 Hz

1.0 A

30 W (self-test in 10 cpi draft)

10 MQ, minimum

VDC

hne

and chassis)

between

ma for 1 minute or

Envh’onmental

Operating

220-240 V Version

50-60 Hz

(a~A~~{e and

1500

(between AC

Conditions

–20to 55° c (-4 - 131° F) (*2)

220-240

198-264

0.5 A

1.0 MK2,

minimum

500

VAC rrps

Storage

VAC

VAC

VDC

between

CkSSIS)

for 1 minute

hne

and

chasa.s)

Humidity

Resistance to vibration

30 to 80% RH (*1,*3)

0.25 G, 55

Hz

(*1)

*1= Operating conditions must be within this range.

*2= When the printer is in the shipping container.

*3 = Without condensation.

1.2.1.7 Reliability

4000

M’T’BF:

Printhead life:

power on hours

200 million strokes/wire (with monochrome ribbon)

100 million strokes/wire (with color ribbon)

1.2.1.8 Safety Approvals

Safety standards:

U.S. version:

European version:

Radio frequency interference:

(RFI)

U.S. version:

European version:

1.2.1.9 Physical Specifications

5 to 85% RH (*2,*3)

0.50 G, 55 Hz (*2)

(POH)

UL1950 with D3,

EN 60950

~)

CSA22.2

#950 with D3

IEC950 (SEMKO, DEMKO, NEMKO,

FCC part 15 subpart B class B

Vfg.243 (VDE0878

EN55022 (CISPR

part 3, part 30)

PUB. 22) class B

J.

[;’

SETI)

Dimensions (W x

Weight:

1+

D x H):

366 x 275 x 132 (mm) (14.4 x 10.8 x 5.20 (inches)

(without pull tractor)

4 kg (8.8 lb.) without pull tractor

Rev.

, :;

,,

. .,

A

Page 16

LX-3(M

Service Manual

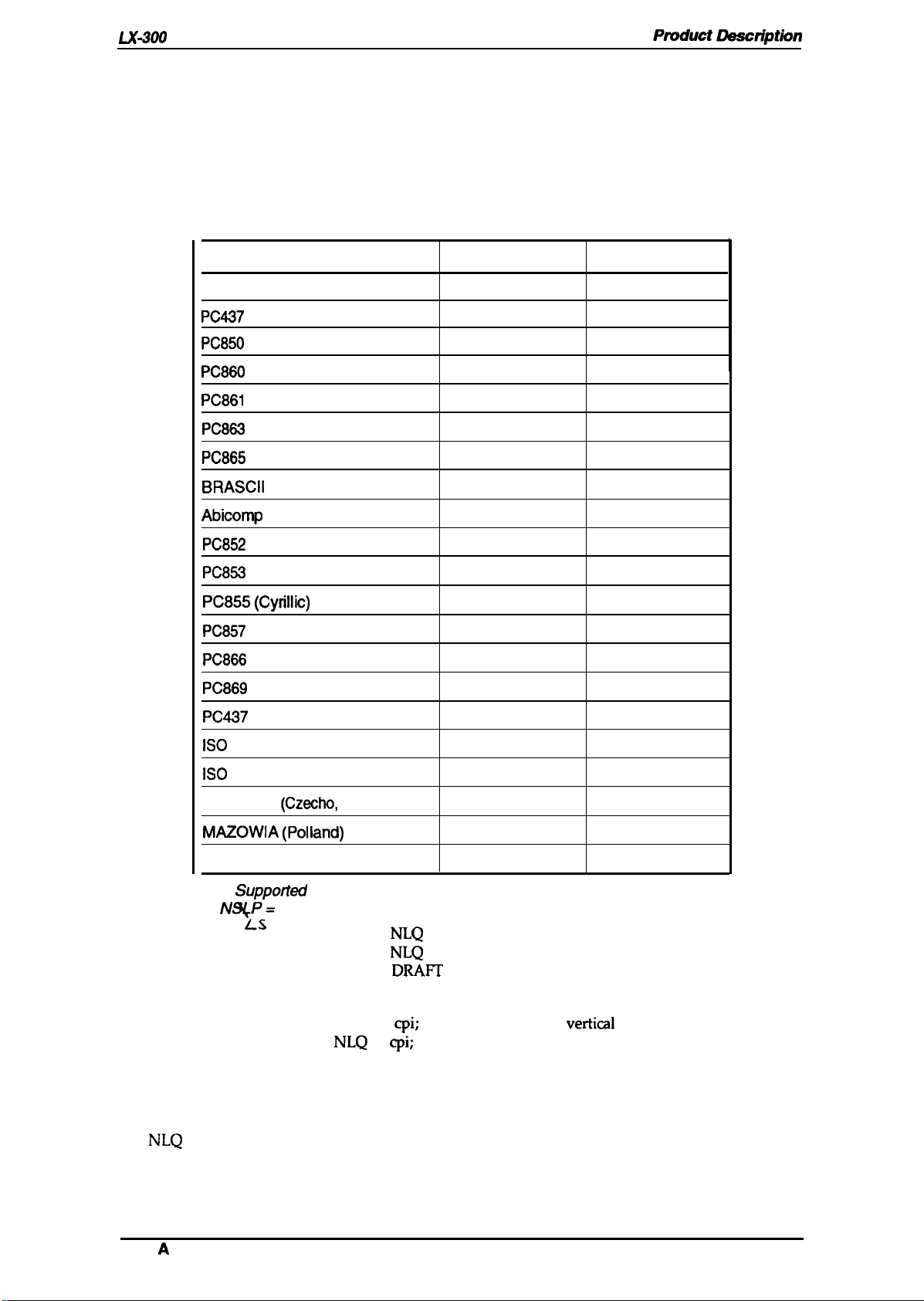

1.2.2 Firmware Specifications

Ptvduct Lkacription

Control codes:

Input data buffer:

Character sets:

Character tables:

ITALIC

PC437

PC850

PC860

PC861

PC863

PC865

BRASCII

Abicomp

PC852

EsC/r

4KB

13 international character sets

See the table below.

Table 1-12. Character Tables

Character Table

(US, Standard Europe)

(Multilingual)

(Portuguese)

(Icelandic)

(Canadian-French)

(Norwegian)

(East Europe)

Standard Model

o

o

o

o

o

o

o

o

o

x

NLSP* Model

0

0

0

x

x

x

x

x

x

o

PC853

PC855 (Cyriliic)

PC857

PC866

PC869

PC437

ISO

ISO

Code MJK

MAZOWIA (Polland)

Bulgaria (Bulgaria)

0

*

Bitmap fonts:

Character size

(Turkish)

(Turkish)

(Russian)

(Greek)

Greek

Latin IT (Turkish)

8859-7

Suppofted

N~P=

(Greek)

(Czecho,

Slovakia)

X Not supported

National Language Support

LS

EPSON

EPSON

EPSON

10.5 points

NLQ

Roman

NLQ

Saris Serif

DRAIT

x

x

x

x

x

x

x

x

x

x

x

o

o

o

o

o

o

o

o

o

o

o

Character matrix

Print mode

Draft mode:

NLQ

mode:

Printing speed:

Printable columns:

Rev.

A

Draft 10

NLQ

10

cpi;

11 horizontal dots, 9

cpi;

23 horizontal dots, 18 vertical dots

Double-width

Double-strike

Super/subscript

Double-width

Italics

See Table 1-13.

See Table 1-13.

vertid

Condensed

Underlined

Emphasized

Super/subscript

dots

Emphasized

Italics

Underlined

1-9

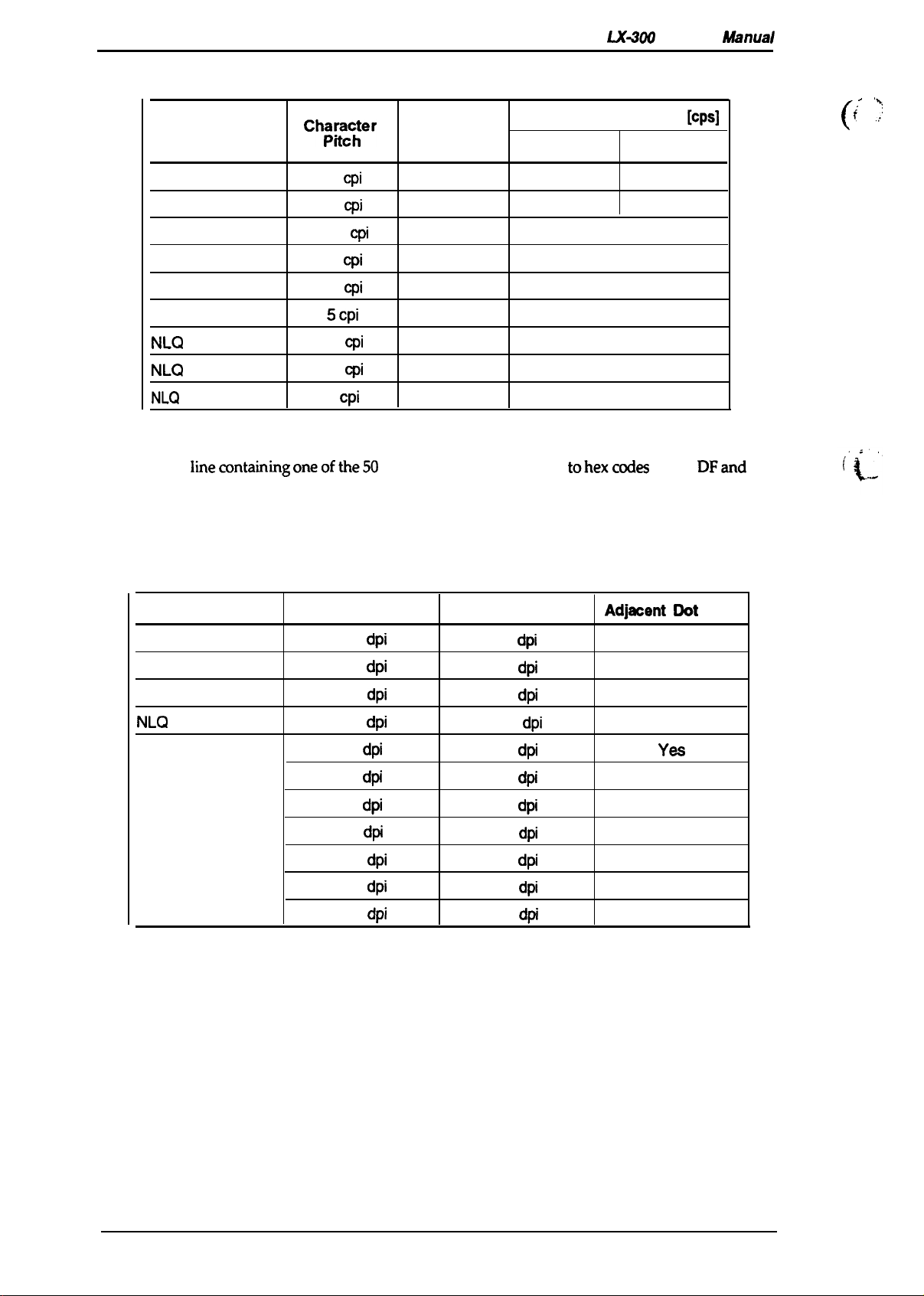

Page 17

Product Description

Printing Mode

Table 1-13. Printing Speed

Ch~m&:er

Printable

Columns

Monochrome Color

LX-W)

Maximum Print Speed

Service

[cps]

Mhnual

(

.

‘x:

i

,:’

Notes:

10

12

17.1

20

10

5 cpi

10

12

5

cpi

cpi

cpi

cpi

cpi

cpi

cpi

cpi

characters corresponding tohexcodes BO to DFand F4

Draft

Draft

Draft condensed

Draft condensed

Draft emphasized

Draft double width

NLQ

NLQ

NLQ

double width

Data in parentheses indicates the speed on a line containing at least one of the following:

- A line containing a userdefined character.

- A

linecontaining oneofthe50

and F5.

- A line that is printing when printhead driving voltage drops from over-duty printing.

(When voltage drops below the lower limit, the printer stops printing in the middle of

the line, and then prints the rest of the line at a slower speed.)

80

96

137

160

80

40

80

96

40 22 (16)

220 (165)

264 (198) 198 (198)

188 (141)

220 (165)

110 (83)

110 (83)

165 (1 65)

44 (33)

53 (40)

Table 1-14. Resolution

Printing Mode

Horizontal Density

Vertical Density

Adjaoent

Dot

Print

Draft

Draft condensed

Draft emphasized

NLQ

Bit image

120

240

120

240

60

72

80

90

120

120

240

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

72

72

72

144

72

72

72

72

72

72

72

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

dpi

No

No

Yes

No

Yss

Yes

Yes

Yes

Yes

No

No

~.:?”;,

‘---

1-10

Rev. A

Page 18

LX-3(3O Service Manual

1.3 INTERFACE SPECIFICATIONS

Prvduct

Description

LX-300

has parallel interface and serial interface, one of which can be selected in default setting

mode. Auto selection is also available.

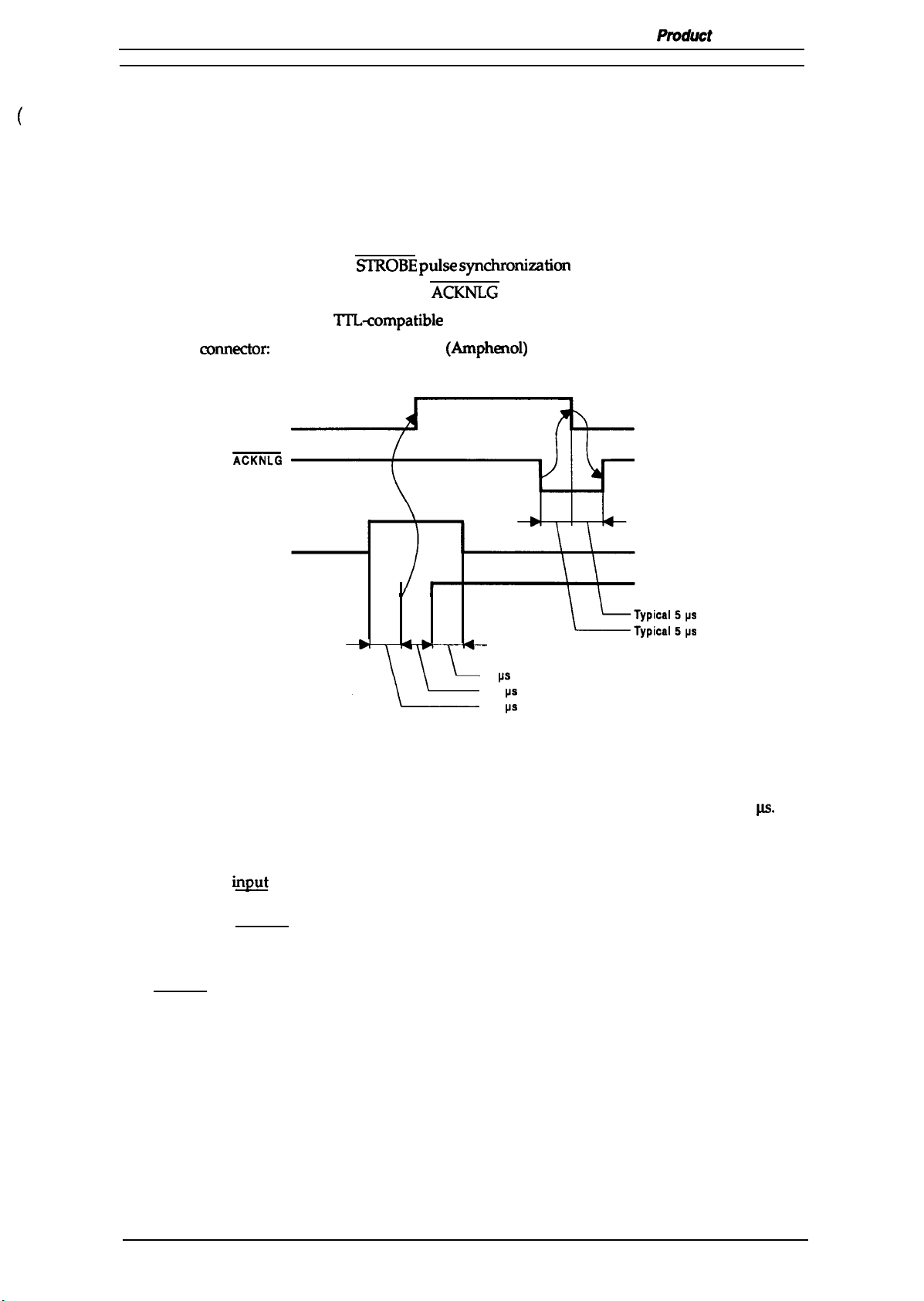

1.3.1 Parallel Interface Specifications

The LX-300

Data format:

Synchronization:

Handshaking:

Signal level:

Adaptable

Data transmission timing:

is equipped with an 8-bit parallel interface, standard.

8-bit parallel

By

SIROBE pulse

comectm

By BUSY and

TTL-compatible

%-pm 57-30360

ACKNLG

level

See Figure 1-7.

BUSY

ACKNLG

DATA

SyIIChrOIliZZItiOll

signals

(Amphenol)

or equivalent

STROBE —

—

—

h

0.5 ps (minimum)

0.5

ps

(minimum)

0.5

IIS

(minimum)

Figure 1-7. Data Transmission Timing

Note:

The Busy signal is active (HIGH) under the following conditions:

The ERROR signal is active (LOW) under the following conditions:

Transition time (rise time and fall time) of every input signal must be less than 0.2

- During data reception (See Figure 1-7.)

- When the

innt

buffer is full

- When the INIT input signal is active

- During initialization

- When the ERROR signal is active

- During the self-test mode

- During the default-setting mode

- When a paper-out error occurs

- When a release lever operation error occurs

- When a fatal error occurs

M.

The PE signal is active (HIGH) under the following conditions:

- When a paper-out error occurs

Rev. A

1-11

Page 19

I

-1 . .

.

—-

.

[

}..

.

I

I

~

I

~s

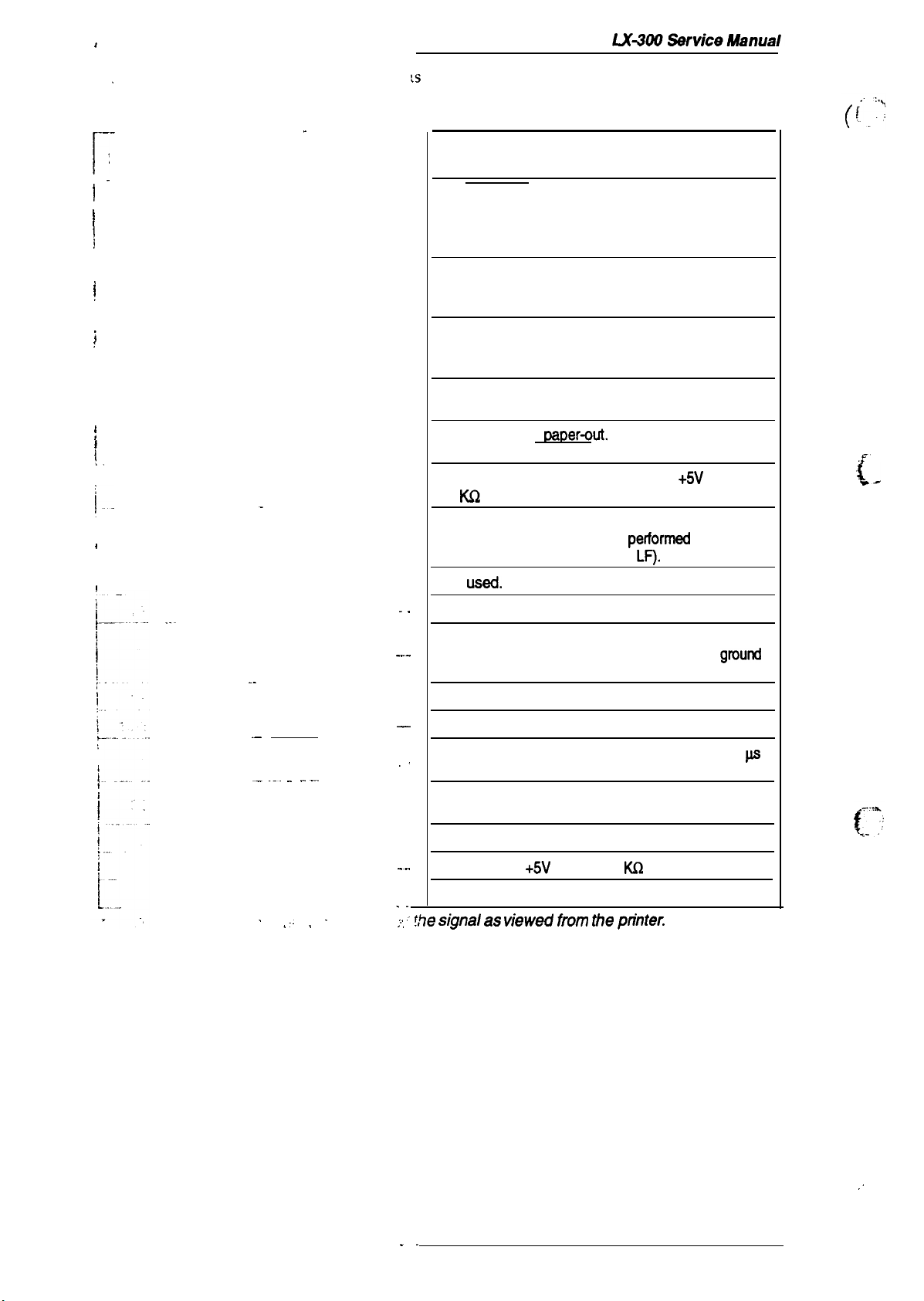

and signal functions for the 8-bit parallel interface.

Pin Assignments for Parallel Interface

.

Description

The STROBE pulse is used to read the input

data. The pulse width must be more than

Input data is latched after the falling edge of this

signal.

Parallel input data to the printer.

A HIGH level means data 1.

A LOW level means data O.

0.5 p.s.

i

I

!.

1-

1

1

. . .

.

--

.—

— .-. .

..—

This pulse indicates data has been received

the printer is ready to accept more data. The

pulse width is approximately 12 pa.

HIGH indicates the printer cannot accept more

data.

HIGH indicates

rm~er-out.

This signal is effective

only when the ERROR signal is LOW.

Always HIGH output. (Pulled up to

3.3

KQ

resistor.)

+5V

through

If the signal is LOW when the printer is initialized

a line feed is automatically

receipt of the CR code (auto

Not

USed.

. .

Signal ground.

petformecf

upon

LF).

Chassis ground.

—.

In the printer, chassis ground and signal

ground

are short-circuited.

A

HIGH level means that printer power is on.

—

Signal ground.

Input for printer initialization. Pulse width 50

,,

minimum, active LOW.

LOW indicates that some error has occurred in

the printer.

and

f

L

~

. . .

.: !

Signal ground.

-..

Pulled up to

Ignored.

. .

~~ ~~•

f$e

s@f@ as

.,,

.,

. .

+5V

viewed

through 1 KQ resistor.

from the

@ter.

,,

Rev. A

Page 20

LX-3(IO Service Manual

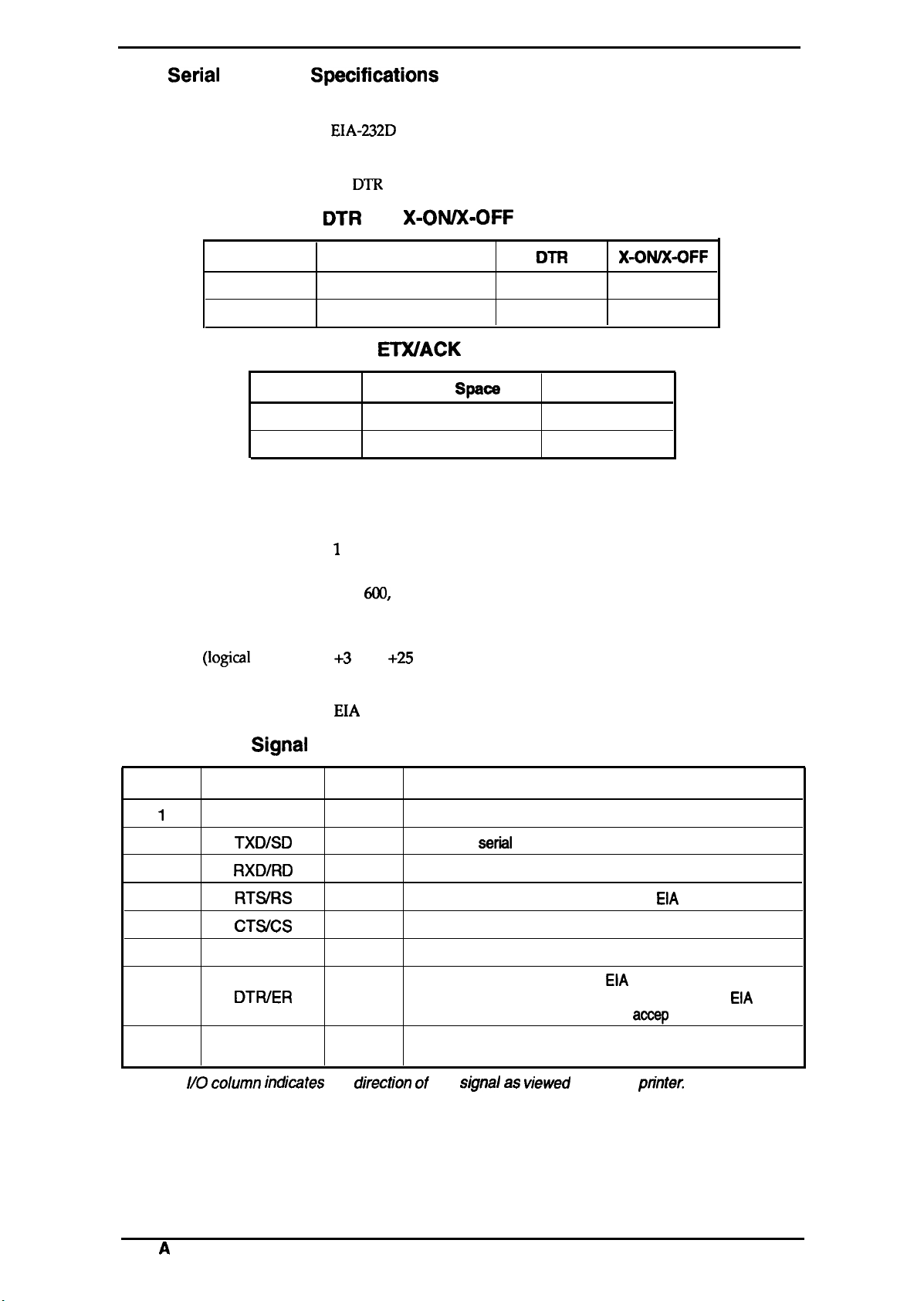

1.3.2 Serial Interface Specifkations

The LX-300 is equipped with an 8-bit serial interface, standard.

Product Description

Data format:

Synchronization:

Handshaking:

Busy

Ready

Word length

Start bits:

Data bits:

Parity bit:

Stop bits:

Bit rate:

State

Busy

Ready

EIA-232D

serial

Asynchronous

By

DTR

signal and X-ON/X-OFF protocol

DTR

and X-OIVX-OFF Protocol

Buffer Space

Less than 256 bytes

More than 512 bytes

ETX/ACK Protocol

State

1 bit

7 or 8 bit (selectable)

O or 1 bit (selectable)

1

bit (transmitting)

1 bit or more (receiving)

300,

Buffer

Less than 256 bytes

256 bytes or more

6(X),

1200,2400,4800,9600, 19200 bps (selectable)

Spaoe

DTR

off

On

X-OWX-OFF

X-OFF

X-ON

Response Code

NAK

ACK

Logic level

MARK (logical 1):

SPACE

(logical

O):

–3 V to –25 V

+3

v to

+-25

v

Parity check: Odd, even, or no parity bit (selectable)

EIA

Connector:

standard 25-pin D-SUB female comector

Table 1-16. Signal and Connector Pin Assignments for Serial Interface

the

110*

—

out

In

out

In

—

out

—

djrectkm d

Description

Chassis ground.

Transmit

seriil

data.

Receive serial data.

This signal is

always at the positive

EIA

level.

Ignored.

Return path for data and control signals.

This signal is at the positive

EIA

level when the printer is

ready to accept data entry and at the negative

when the printer is not ready to

accep

t data entry.

No connection (not used).

the

sjgnal as vjewed

from the

printec

Pin No.

1

2

3

4

5

7

11,20

6,8-10,12-

19,21-25

●

The

//0 column irxbtes

Signal Name

FG

TXDJSD

RXDIRD

RTS/RS

CTSVCS

SG

DTWER

NC

EIA

level

Rev.

A

1-13

Page 21

Product Description

UiWtJ

Service

Mhnual

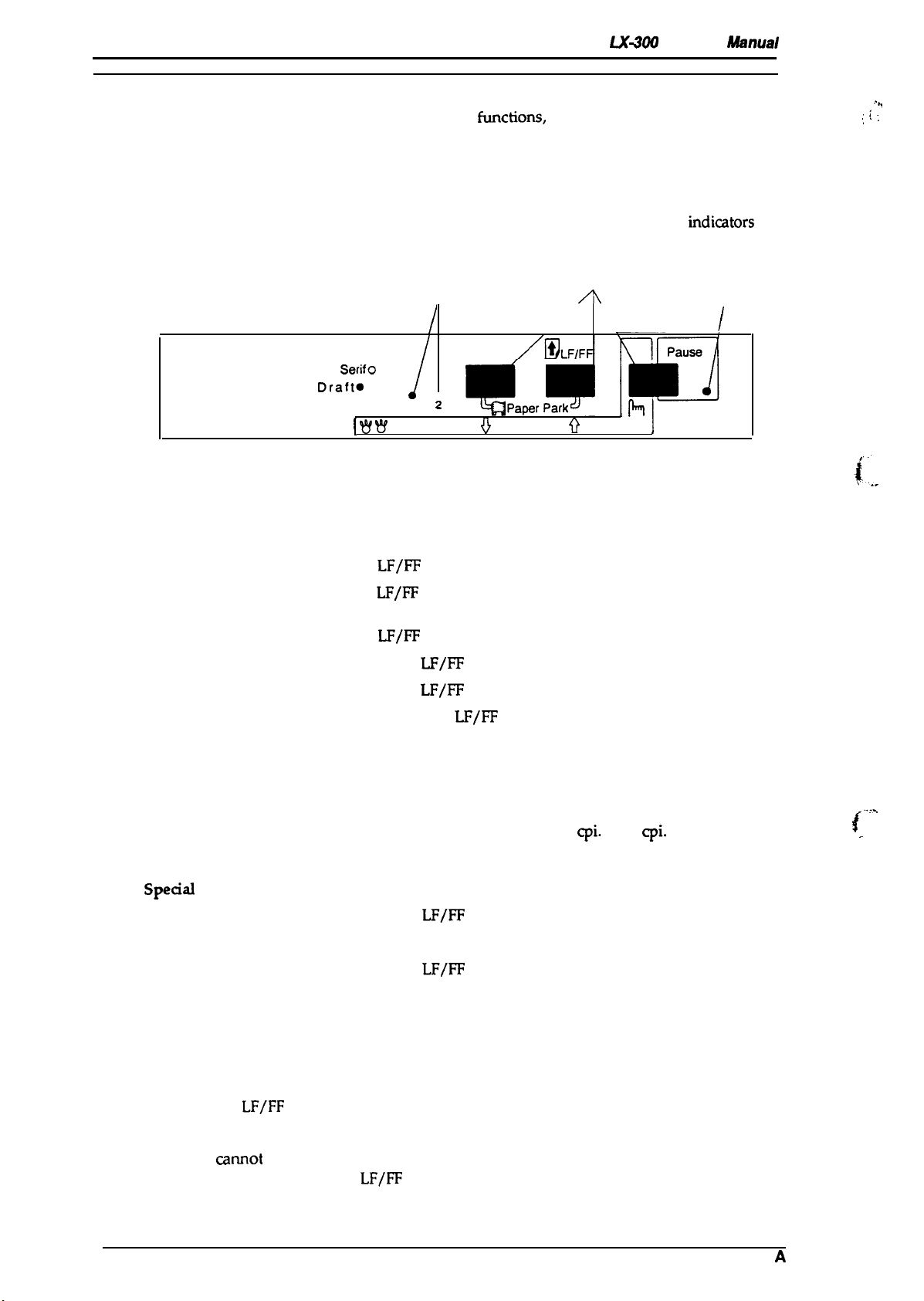

1.4 OPERATING INSTRUCTIONS

This section describes control panel operation

~ctions,

demonstration functions, and printer initialization methods.

self-test, hexadecimal dump, ~n ~

1.4.1 Control Panel Operation

The printer control panel contains three non-lock-type push buttons and three LED

easy operation of the various printer functions.

Lights

Roman O O

SerifO ●

Saris

Draft.

o

Draft Condensed. ● I

I W W

Micro Adjust

/

Font

●

2

o

Buttons

A

Q

3sec

indimtors

Figure 1-8. Panel Apperance

Light

/

for

.“

,, .

L

“II

~

Paper Feeding

Load:

Load (manual insertion):

Line feed:

Eject cut sheet:

Form feed (continuous):

Paper park (continuous):

Tear-off (continuous):

Character Selection

Font selection:

Pitch selection:

Condensed selection:

Enter

Speaal

Mode

Self-test mode:

Default-setting mode:

Hex dump mode:

Demonstration mode:

Press the

Press the

LF/FF

button.

LF/FF

button or the printer waits 2 seconds after insertion

of a cut sheet to load paper automatically.

Press the

Hold down the

Hold down the

Press the FONT and

LF/FF

button once.

LF/FF

LF/FF

button continuously.

button continuously.

LF/FF

buttons at the same time.

Only uses auto tear-off function.

Press the FONT button.

Selectable indefault-setting mode: 10

cpi.

or 12

cpi.

Press the FONT button. Only draft condensed is selectable.

Hold down the

LF/FF

button and turn on the printer.

Hold down the FONT button and turn on the printer.

Hold down the

LF/FF

and FONT button and turn on the printer.

Not available.

~..,,

.

1.4.2 Self-test Function

This section explain how to run the self-test.

Hold down the

1.

2. If paper is not loaded, the printer attempts to load it.

3. If the printer

insert paper again and press the

4. The printer prints alphanumeric characters continuously.

5. Quit self-test mode printing by pressing the PAUSE button and turning the printer off.

1-14

LF/FF

button and turn on the printer to start the self-test.

camot

load paper, it indicates this by turning on the PAUSE light. In this case,

LF/FF

button.

Rev.

A

Page 22

LX#O

Service Manual

Pfvduct LMacription

1.4.3 Hexadecimal Dump Function

The hexadecimal dump is a useful tool for troubleshooting data control problems. This section

describes how to run a hex dump.

1.

Turn on the printer while holding down the

LF/FF

and FONT buttons.

2. If paper is not loaded, the printer attempts it (either single sheet or continuous paper).

3. If the printer cannot load the paper, it indi~tes a paper-out error. In this

case, insert

paper

again, and press the PAUSE button.

4. The printer waits for data after printing the message “Hex dump.”

5. Received data is printed as both hexadecimal codes and ASCII characters. If a corresponding

printable character does not exist, the printer outputs a period (.).

6.

Quit

Note:

hexadecimzd

In

hex dump mode, the character table depends on the default

dump printing by pressing the PAUSE button and tumingtheprinter off.

settin&

and 10

cpi

draft is

selected automatically.

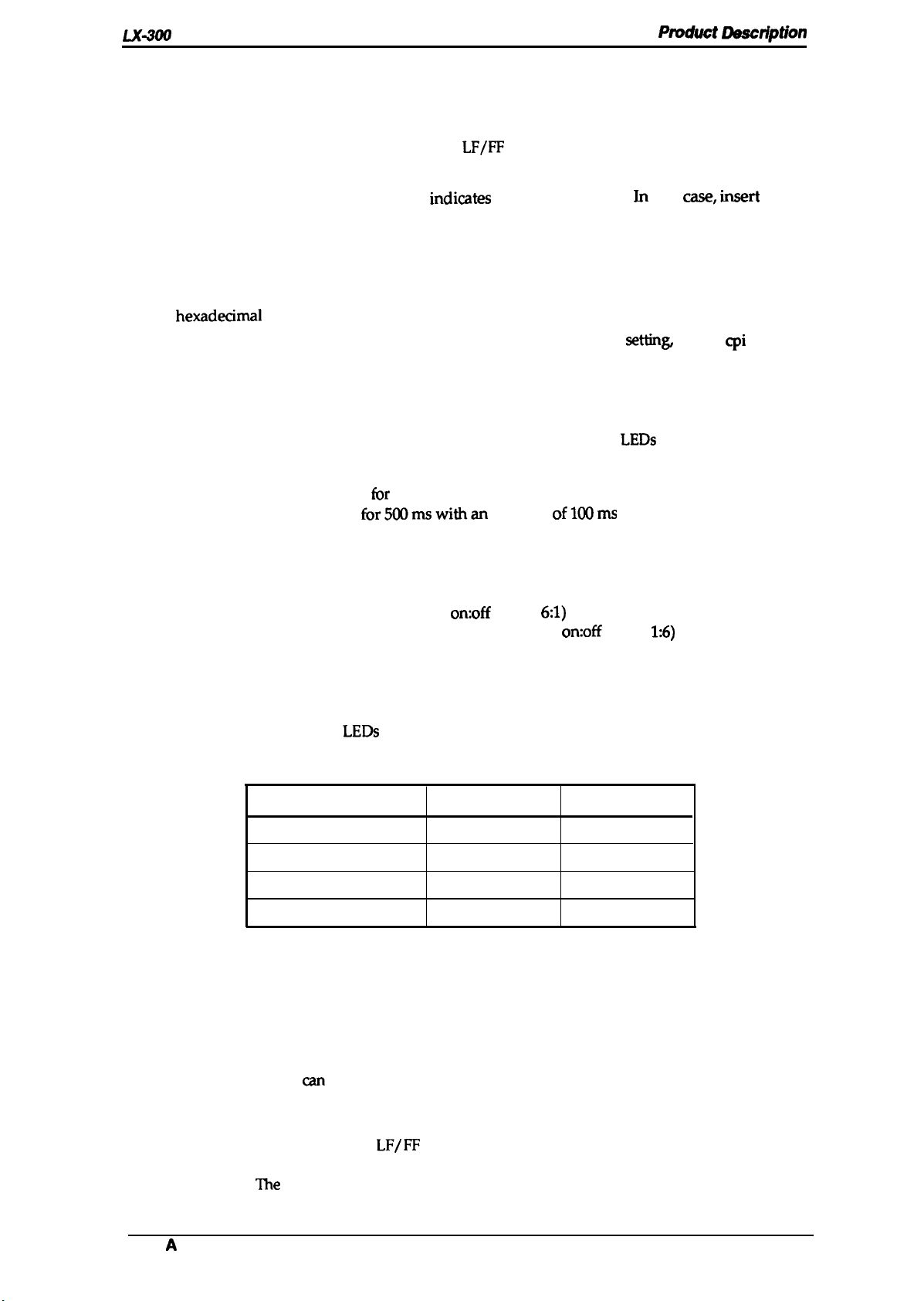

1.4.4 Printer Status Indication

It describes how this printer indicates status and error conditions using

LEDs

The symbols below describe the frequency of beeper sounds.

( ● ):

(—): The beeper sounds

While initialize signal is active:

During initialization:

Ready to print or printing:

Paper-out error:

Tear-off:

Operating error, fatal error:

The beeper sounds

for5~mswithan

tbr

100 rns with an interval of 100 ms between beeps.

interval

of100ms

between beeps.

PAUSE light is on.

PAUSE light blinks and beeper sounds

PAUSE light is off

Beeper sounds (

(light

on:off

PAUSE light blinks (light

Beeper sounds (

● ●

. )

and PAUSE light blinks.

ratio=

6:1)

on:off

ratio=

————— ) and PAUSE light is on.

1.4.5 Selected Font

The combination of two FONT

LEDs

(1 and 2) is used to indicate the selected font.

Table 1-17. Font Selection

Selected Font

Roman

Saris Serif

Draft

FONT 1

ON ON

ON

OFF

FONT 2

OFF

ON

and the beeper.

1:6)

Draft condensed

OFF OFF

1.4.6 Paper Position Adjustments

To enter adjustment mode, press the PAUSE button for three seconds, until the printer beeps once

and the FONT lights blink to indicate that the adjustment operation is available. If the printer state

is not one of the conditions shown below, this operation is ignored.

. TOF position adjustment:

The position mn be adjusted just after the paper is loaded.

. Tear-off position adjustment:

The position can be adjusted when paper is actually located at the tear-off position.

In the adjustment mode, press the

feed paper backward. You can cancel adjustment mode bypressingthe PAUSE button or inputting

a print command.

Rev.

A

The

adjusted position is stored in non-volatile memory.

LF/FF

button to feed paper forward and the FONT button to

1-15

Page 23

LXiWO

Product Description

Service Manual

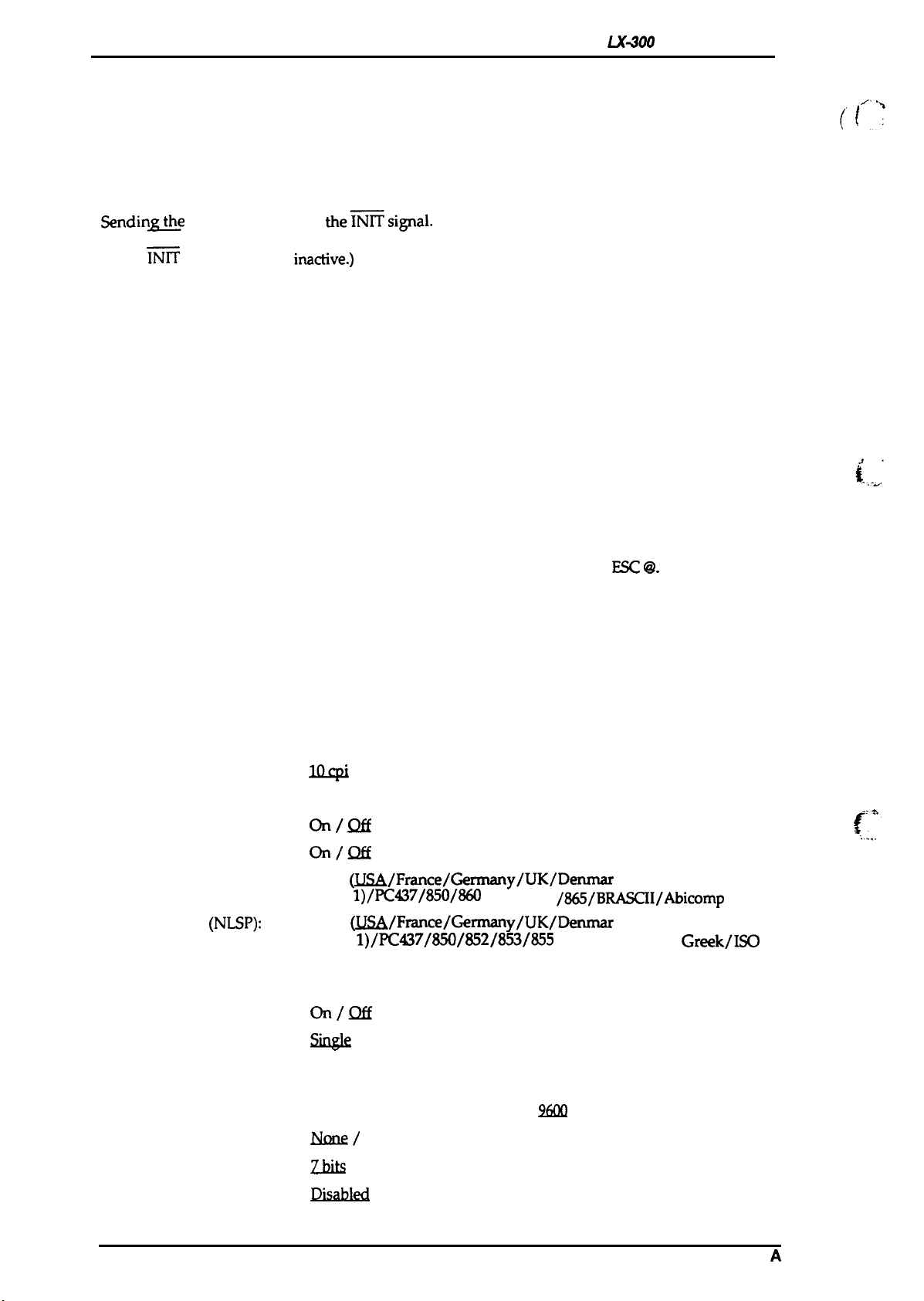

1.4.7 Printer Initialization

There are two types of initialization: hardware initialization and software initialization.

1.4.7.1 Hardware Initialization

Hardware initialization is performed by:

. Turning on the printer.

.

Sendiny@e parallel interface

(If the INIT signal is active when the printer is turned on, hardware initialization is started when

the

~

signal becomes

When hardware initialization is performed:

. The printer mechanism is initialized.

. Print data in the input buffer is cleared.

. Download character definitions are cleared.

. The printer’s settings are returned to the defaults.

. The printer is set to the standby condition, if no fatal error occurs.

. Continuous paper home-seeking is performed.

In continuous paper home-seeking:

. The printer feeds continuous paper to the paper park position.

●

The printer then loads the paper again.

●

If ejection to the paper park position cannot be completed within 16 inches, paper is returned to

its previous position.

the~signal.

imctive.)

1.4.7.2 Software Initialization

Software initialization is performed upon receipt of the control code

initialization is performed:

. Print characters in the buffer are not cleared.

. The printer setting is changed to the default, but the download character definition is not cleared.

ESC C?.

When software

1.4.8 Printer Settings

1.4.8.1 Selectable Printer Settings

The following printer settings can be changed by users in default-setting mode:

.lQc@

Character spacing:

Shape of zero:

1 inch skip-over-perforation:

Auto line feed:

Character table (Standard):

Character table

(NLSP):

Page length:

/ 12cpi

Slashed / Not slashed

on/Qff

on/Qff

Italic

(JJSA/France/Germany/UK/Denmark l/Sweden/Italy/

Spain

1)/PC437/850/860

Italic

&?SA/France/German

Spain

1)/KG7/~/S2/8S/E5

/861/863

/865/BRASCII/Abicomp

k l/Sweden/Italy/y/UK/Denmar

/857/=/869/07

Greek/ISO

Latin IT /1S0 8859-7/Code MJK/Mazowia/Bulgaria

11/ 12/ 8.5 / 70/6 inches

~?

.. . .

... -

.

.

Auto tear off:

Tractor:

interface:

Bit rate (serial I/F):

Parity bit (serial I/F):

Data length (serial I/F):

ETX/ACK (serial I/F):

Note:

Underlines show factory setting.

1-16

on/Qff

Single

/ Double

~/ Auto selection (30 sec wait) / Parallel

/ Serial

300 / 600/ 12(MI / 2400 / 4800 /

Mm/

Z.Ms

~

Odd / Even

/ 8 bits

/ Enabled

$?6Ul

/ 19200 bps

Rev.

A

Page 24

LX-300 Service Manual

Product Description

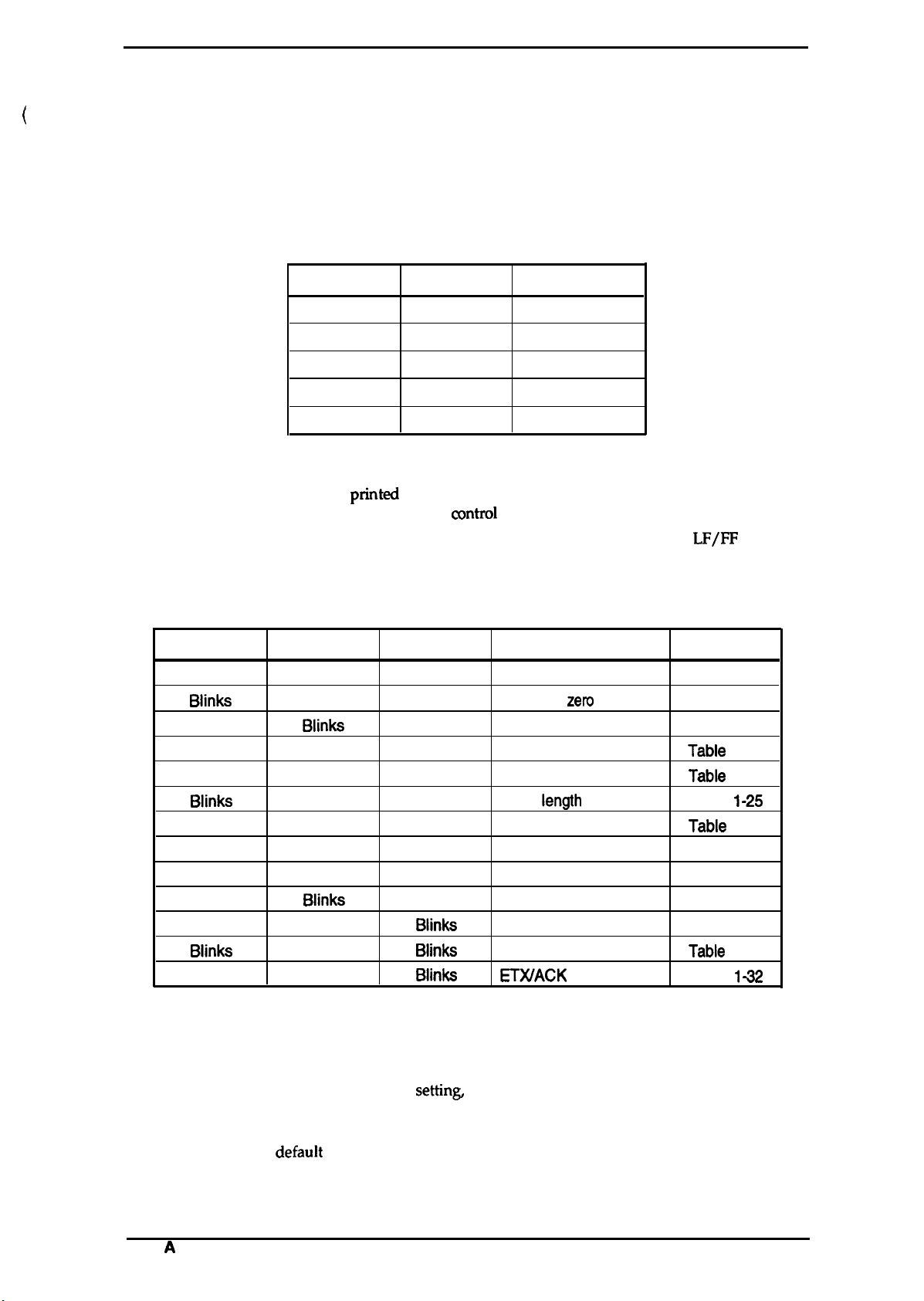

1.4.8.2 Changing the Default Settings

You can change some parameters that the printer refers to at printer initialization.

To enter the default setting mode, turn on the printer while holding down the FONT button.

1.

The printer prints out the firmware version.

If paper is not loaded, insert a sheet of paper.

2. The printer automatically loads the paper and prints a table of languages to choose from:

English, French, German, Italian, and Spanish. The Footlights indicate the currently selected

language, as shown in the table below.

Table 1-18. Font Lights and Language Selection

FONT Light 1

OFF

OFF

ON

ON

ON

3.

Press the FONT button to change the language, and press the LF/FFbutton to select.

FONT Light 2

ON

Blinks

OFF

ON

Blinks

Language

English

French

German

Italian

Spanish

4. Press the FONT button again after selecting a language. The printer prints help text to guide

you in setting defaults. The pMted instructions include submenu tables listing all the settings

you can change and showing you how the

5. To change the settings, press the FONT button to move down and press the

mntrol

panel lights appear for each selection.

LF/FF

button to

move up in the menu of options shown below. The printer beeps once each time you press the

FONT button while you are in this menu.

Table 1-19. Default Options

FONT Light 1

Blinks

Biinks

OFF

ON

Blinks

Biinks

Blinks

OFF

ON

Blinks Biinks

OFF OFF

Biinks

ON

When you reach the setting you want to change, press the PAUSE button once. The printer

6.

FONT Light 2 PAUSE Light

OFF

ON

Biinks

Blinks

Blinks

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON ON

Blinks

Blinks

ON

ON

ON

Biinks

OFF

OFF

Biinks

Biinks

Character spacing

Shape of

Skip over perforation

Character table

Auto line feed

Page

Auto tear off

Tractor

Interface

Bit rate

Parity

Data length

ETWACK

Setting

zem

iength

automatically enters the submenu for that setting.

Press the FONT button to move the through the settings in the submenu. The printer beeps

7.

twice each time you press the FONT button while in a submenu.

When the lights match your desired

8.

settin~

press the PAUSE button to make your selection.

The printer saves the new setting and returns to the menu shown above.

Repeat steps 5 through 8 for each additional setting you want to change, or skip to step 10 to

9.

exit the printer’s

defauit

setting mode.

Submenu

Table 1-20

Table 1-21

Table 1-22

Tabie

1-23

Tabie

1-24

Table

1-25

Tabie

1-26

Table 1-27

Table 1-28

Table 1-29

Table 1-30

Tabie

1-31

Table

142

10.

When you are finished, turn the printer off. Any settings you have made remain in effect until

you change them again.

Rev.

A

1-17

Page 25

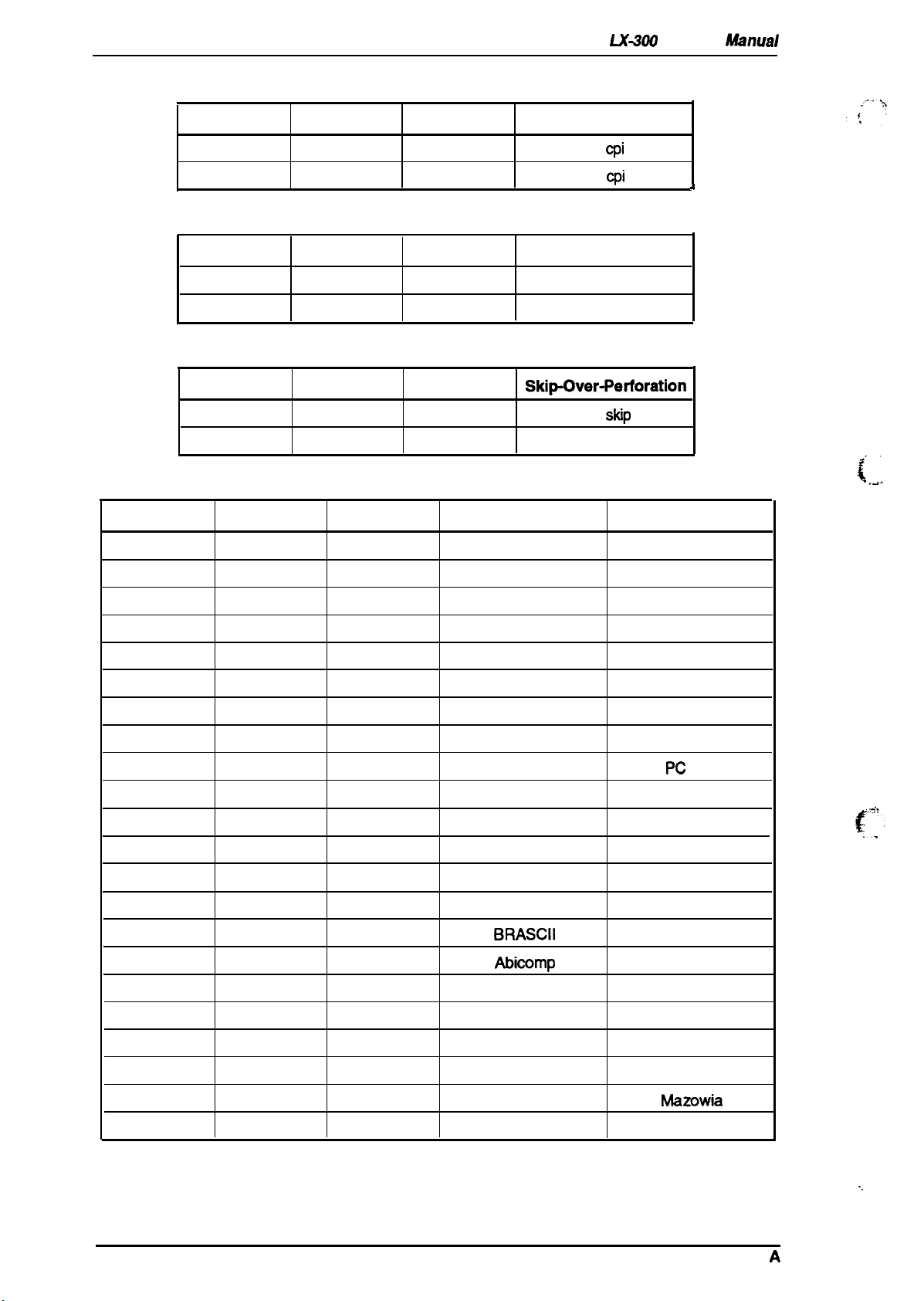

Product Description

Table 1-20. Character Spacing

LX300

Service M%ual

FONT Light 1

FONT

FONT Light 1

FONT Light 1

OFF

FONT Light 2

OFF

ON

Light 1

FONT Light 2

OFF

ON

Table 1-22. Skip Over Perforation

FONT Light 2

OFF

ON

FONT Light 2

OFF

Character Spacing

10

cpi

12

cpi

OFF

ON

PAUSE Light

OFF

ON

Table 1-21. Shape of Zero

PAUSE Light

OFF

ON

OFF

ON

PAUSE Light

OFF

ON ON

OFF

Space of Zero

o

0

SkipOver-Petioration

No

Skip

skip

Table 1-23. Character Table

PAUSE Light Standard Table NLSP Table

OFF

Italic — US

Italic — US

A

1

ON

Blinks

OFF

ON

Blinks

OFF

Blinks

OFF

ON

Blinks

OFF

ON

Blinks

OFF

ON

OFF

OFF

ON

ON

ON

Blinks

Blinks

OFF

OFF

OFF

ON

ON

ON ON

Blinks

Blinks

Blinks Blinks

OFF

ON

Blinks

OFF

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

Italic — France

Italic —

Germany

Italic — UK

Italic — Denmark 1

Italic — Denmark 1

Italic — Sweden

Italic —

Italy

Italic — Spain 1

Pc 437 Pc 437

PC 850 PC 850

Italic — France

Italic

— Germany

Italic — UK

Italic — Sweden

Italic —

Italic — Spain 1

ON PC 860 PC 852

ON Pc 861

ON PC 863

PC 865

ON BRASCII

ON

ON

Blinks

Blinks

Blinks

Blinks

Blinks

Abicomp

—

—

—

—

—

—

PC 853

Pc 855

PC 857

PC 866

PC 869

PC 437 Greek

ISO Latin IT

1s0 8859-7

Code MJK

Mazowia

Bulgaria

Italy

1-18

Rev.

.,

A

Page 26

LX-3(IO Service Manual

Table 1-24. Auto Line Feed

Product

Lkactiption

FONT Light 1

OFF

ON

FONT Light

1

ON

OFF

ON

OFF

FONT Light 1

OFF

ON

FONT Light 2

OFF

ON

PAUSE Light

OFF

ON

Table 1-25. Page Length

FONT Light 2

OFF

ON

ON

OFF

PAUSE Light

OFF

OFF

OFF

ON

Table 1-26. Auto Tear Off

FONT Light 2

OFF OFF

ON ON

PAUSE Light

Table 1-27. Tractor

Auto Line Feed

off

On

Page Length

11 inches

12 inches

8.5 inches

70/6

inches

Auto Tear Off

off

On

FONT Light 1

OFF OFF

ON ON ON

FONT Light 2 PAUSE Light

OFF

Table 1-28. Interface

FONT Light 1 FONT Light 2 PAUSE Light

ON

OFF

ON ON

OFF OFF

OFF OFF

ON

OFF

OFF

ON

Table 1-29. Bit Rate

FONT Light 1

ON

ON

ON ON

OFF OFF

FONT Light 2 PAUSE Light

OFF OFF

ON

OFF

OFF

ON

Tractor

Single

Double

Interface

Auto selection (10 me wait)

Auto selection (30 rns wait)

Parallel

Serial

Bit Rate

300

b~

600 bps

1200 bps

2400

bps

Rev. A

ON

OFF

ON ON

OFF

I

ON ON

ON

I

ON

I

4800

tx)s

9600 bps

19200 bps

1-19

Page 27

Product Description

,.

U-300 Service Manual

Table 1-30. Parity Bit

FONT Light 1

ON

ON

ON

FONT Light 2

OFF

ON

ON

Table 1-31. Data Length

FONT Light 1 FONT Light 2

OFF

ON

OFF

ON

Table 1-32. ETX/ACK

FONT Light 1 FONT Light 2

OFF

ON

OFF

ON

PAUSE Light

OFF

OFF

OFF

PAUSE Light

OFF

ON

PAUSE Light

OFF off

ON

Parity Bit

None

Even

Data Length

7

bits

8

bits

ETX/ACK

On

((’’”

,

1-20

~ .,....,

,. ..,,-,.

Rev. A

Page 28

LX-3(IO

,,

Sarvice

Manual

Ptvduct Daactiption

1.5 MAIN COMPONENTS

main components of the LX-300 is designed for easy removal and repair. The main

The

components are;

■

C130

MAIN BOARD: Control board

■

C130 PSB/PSE (120V

■

M-3G1O: Printer mechanism

9

Housing

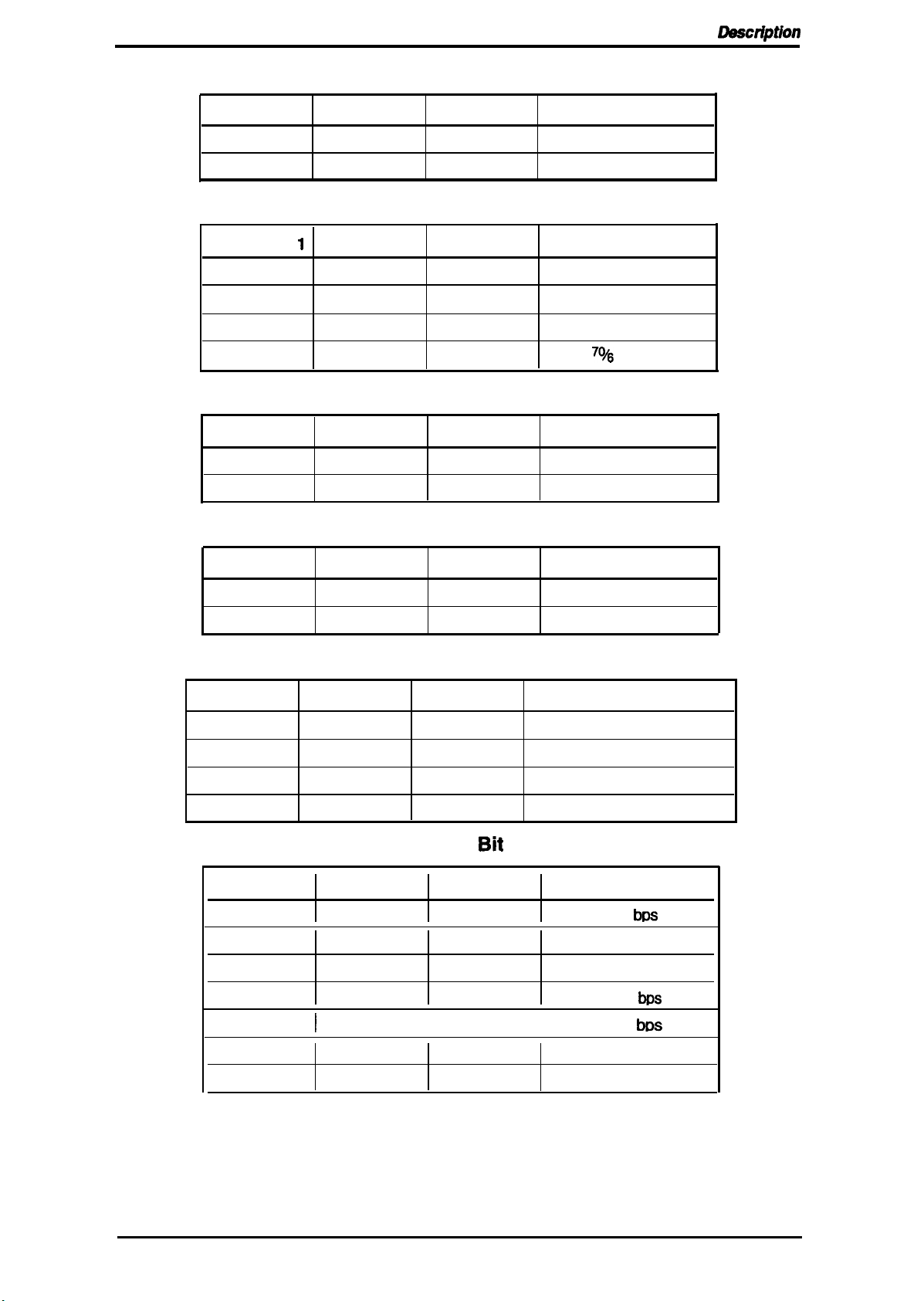

1.5.1

C130

MAIN Board

The

C130

MAINboard consists

etc.

PROM

(Program

1

2SC5060

(PF MOTOR Driver)

SLA7022M

(CR MOTOR

DRIVER)

CG)

/

220-240V)

of an

\

n—

BOARD: Power supply board

E01A09

Iy

(CPU), a

-

/

000

/’

Program/CG

E01A09

(CPU)

>

00

00

000

000

%

ROM, a RAM, an EEPROM,

2SC5~

(Printhead Driver)

UPC78M05AHF

(Regulator

IC)

SUB

PCB

(COLOR OPTION)

Figure 1-9. C130 MAIN Board Component Layout

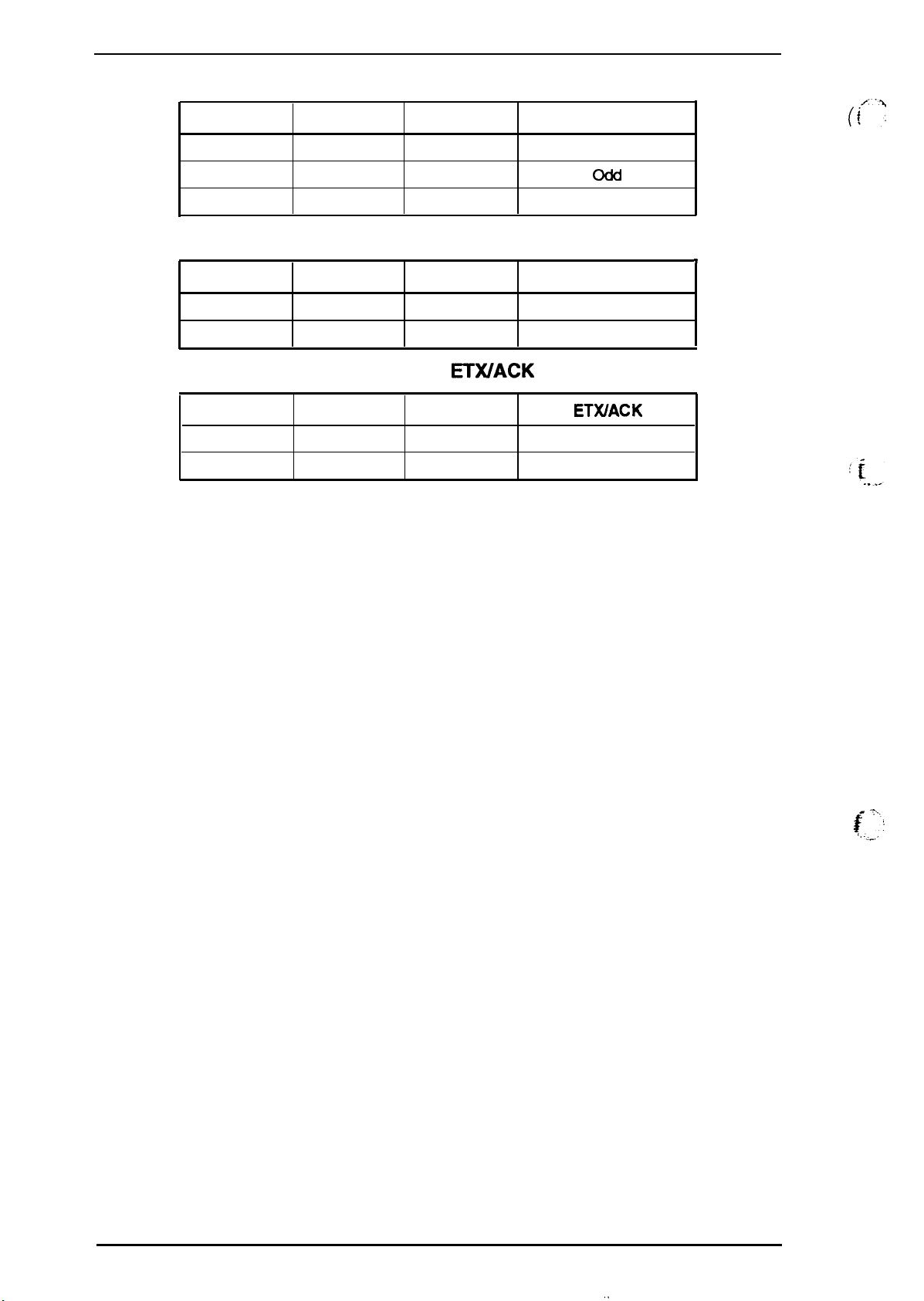

1.5.2

The

diode bridge, etc. This board has two ratings for input AC voltages.

C130 PSB/PSE Board

C130 PSB/PSE

power supply board consists of a transformer, switching

Switching FET

Diodde Bridge

Transformer

/

❑

0

0

\

o

Regulater

IC

“

)

FETs,

regulate

Power Switch

Fuse

IC,

Rev.

Figure 1-10. C130 PSB/PSE Board Component Layout

A

1-21

Page 29

(

CHAPTER 2 Operating Principles

Table of Contents

2.1 PRINTER MECHANISM OPERATION

2.1.1 Printing Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Carriage Movement Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.3 Paper Handling Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.3.1 Paper Feed Mechanisms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.3.2 Paper Advance Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.4 Ribbon Advance Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.1.5 Ribbon Shift Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.1.6 Platen GapAdjustment Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2 POWER SUPPLY OPERATION

2.2.1 Power SupplyOvefview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.2 Power Supply Circuit Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.3 CONTROL CIRCUIT

2.3.1 Control Circuit Operation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.3.2 Power On Reset Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.3.3 Home Position Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.3.4 Paper End Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.5 Release Lever Position Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.6 Carriage

2.3.7 Paper Feed

2.3.8

2.3.9 Interface Circuit.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.3.10

Printhead Drive Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

EEPROM Control Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.3.11

2.3.12 Color Ribbon SensorCircuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

CSMotorAssembly

MotorDriveCircuit

MotorDriveCircuit

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-1

2-1o

2-12

Page 30

List of Figures

Figure 2-1.

Figure 2-2.

Figure 2-3.

Figure 2-4.

Figure 2-5.

Figure 2-6.

Figure 2-7.

Figure 2-8.

Figure 2-9.

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Srintheadoperation principles

i

[

:arriage

I

Friction Advance Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

~ush

I

pu~Tractor paper Advance Mechanism . . . . . . . . . . . . . . . . . . . . . 2-5

I

Push-Pull Tractor PaperAdvance Mechanism . . . . . . . . . . . . . . . . . 2-6

I

Paper Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .2-6

I

I

Ribbon Advance Gear Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

(

ColorShift Mechanism.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Movement Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Tractor paper Advance Mechanism . . . . . . . . . . . . . . . . . . . . 2-4

Platen GapAdjustment Mechanism . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Power Supply Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . 2-11

Control Circuit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Power On Reset Circuit Diagram. .,..... . . . . . . . . . . . . . . . . . 2-13

HomePositionSensorCircuit Diagram . . . . . . . . . . . . . . . . . . . . 2-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

z-l

Figure 2-15. PaperEndSensor Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-16

Figure 2-17

Figure 2-18

Figure 2-19

Figure 2-20

Release Lever Position Sensor Circuit Diagram . . . . . . . . . . . . . 2-14

Carriage Motor DriverCircuit Diagram . . . . . . . . . . . . . . . . . . . . . 2-15

Paper Feed Motor

DriverCircuit Diagram . . . . . . . . . . . . . . . . . . 2-16

Printhead Driver Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Parallel Interface Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-21. Serial interface Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-22

Figure 2-23

Figure 2-24

EEPROM Control Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . 2-18

CSMotorAssemblyCircuit Diagram . . . . . . . . . . . . . . . . . . . . . . 2-18

Color Ribbon SensorCircuit Diagram . . . . . . . . . . . . . . . . . . . . . 2-19

,.

(f

‘ K..d

List of Tables

Table 2-1. CR Motor Assembly Specifications. .

Table 2-2. PF Motor Assembly Specifications . .

Table 2-3. Ribbon Advance Gear Linkage . . . .

Table 2-4. CS Motor Assembly Specifications. .

Table 2-5. Coloring Sequences . . . . . . . . . . . . .

Table 2-6. Power Supply Board. . . . . . . . . . . . .

Table 2-7. Power Supply Output Voltages and Applications . . . . . . . . . . . . . . 2-10

IC.

Table 2-8. Functions of the Main

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Table 2-9. Carriage Motor Drive Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

2-2

2-4

2-7

2-8

2-8

2-10

~ f=::,

-

. .

Page 31

LX-3(XI Service Manual

2.1 PRINTER MECHANISM OPERATION

l%is

section describes the M-3G1O printer mechanism and explains how it works.

2.1.1 Printing Mechanism

Operating

Ptinciph3

The printer mechanism is composed of the

is a 9-pin head for impact dot printing. Each wire has own drive coil, which causes the wire to

move in and out of the

driving wires work.

A drive signal transmitted from the control

1.

the proper

then causes the iron core to become magnetized.

2. The magnetic force draws the actuating plate toward the core, and the dot wire, which is

comected to the core, rushes toward the platen.

3. When the dot wire impacts the platen, pressing against the ribbon and paper, it prints a dot.

4. When the driving voltage stops energizing the coil, the magnetic force from the iron core

vanishes. The actuating plate returns to its original position (the position

energized) with spring action. The dot wire also returns to its original position.

This is the sequence used to print a single dot.

The mechanism is equipped with a built-in thermistor for head temperature detection.

temperature detected by the thermistor is converted to an electric signal and fed back to the control

circuit.

printhead

printhead

driving voltage, which energizes a corresponding coil. The energized coil

to print each dot. The four steps below describe how these

printhead,

arcuit

ink ribbon, and ribbon mask. The

to the

printhead

drive arcuit is converted to

betbre

printhead

coil was

The

Wire Resettin S rin

Stopper

Dot Wire

T’Y____

r

\Actuating Spring

Figure 2-1. Printhead Operation Principles

Rev.A

2-1

Page 32

Operating Principles

LX-WI

Service

Mimual

2.1.2 Carriage Movement Mechanism

The

carriage

belt, driven pulley, HP sensor, etc.

assembly is

movement mechanism consists

The CR motor assembly drives

comected

to the timing belt, which is moved by the CR motor assembly. Figure 2-2

of the carriage assembly, CR motor assembly, timing

tie tifig belt. me

carriage

shows the carriage movement mechanism.

The

printer detects the carriage home position with the HP sensor. This sensor is the basis for

determining the carriage home position.

position.

The sensor is ON, when the carriage is pushed to the right or left.

The HP sensor informs the CPU of

the

carnage home

The

striker on the

carriage actives the sensor to indicate the carriage home position, which toggles the sensor to OFF.

Table 2-1. CR Motor Assembly Specifications

Category

Type

Drive Voltage

Coil Resistance

Drive Pulse Frequency

Excitation Method

Requirement

4-phase, 48-pole, PM-type stepping motor

31.5 -38.5 VDC

180 ohms

Normal Mode Draft

Color Mode Draft

*

7Y0

(per phase, at 25° C, 77°

1320

p~

1980

PPS

F)

Constant-voltage 2-2 phase excitation

1-2 phase excitation

CARRIAGE

ASSY.,

TIMING BELT

.,

,CR

2-2

Figure 2-2. Carriage Movement Mechanism

Rev.A

Page 33

LX-300

Sewica

Manual

Operating

Principla

2.1.3 Paper Handling Mechanism

During normal operation, the paper is fed to the printer, advanced to the specified position, and

ejected from the printer.

These paper handling operations are performed by various paper

handling mechanisms, such as the tractors, rollers, and gears. This section describes the paper

handling mechanism for this printer.

2.1.3.1 Paper Feed Mechanisms

Cut sheets are fed by friction. Continuous paper is fed by a tractor. There are three

ways to feed

with tractors: the push tractor method, the pull tractor method, and the push-pull tractor method.

During normal operation, the printer is set up with only one tractor, which functions as either a

push or a pull tractor, depending on where it is attached on the printer. To use the push-pull

tractor feed method, an optional tractor must be attached.

There are two ways to insert paper into the printer. Cut sheets use the top entrance and continuous

paper use rear insertion.

2.1.3.2 Paper Advance Mechanism

This section describes how the friction and tractor advance mechanisms feed paper through the

printer.

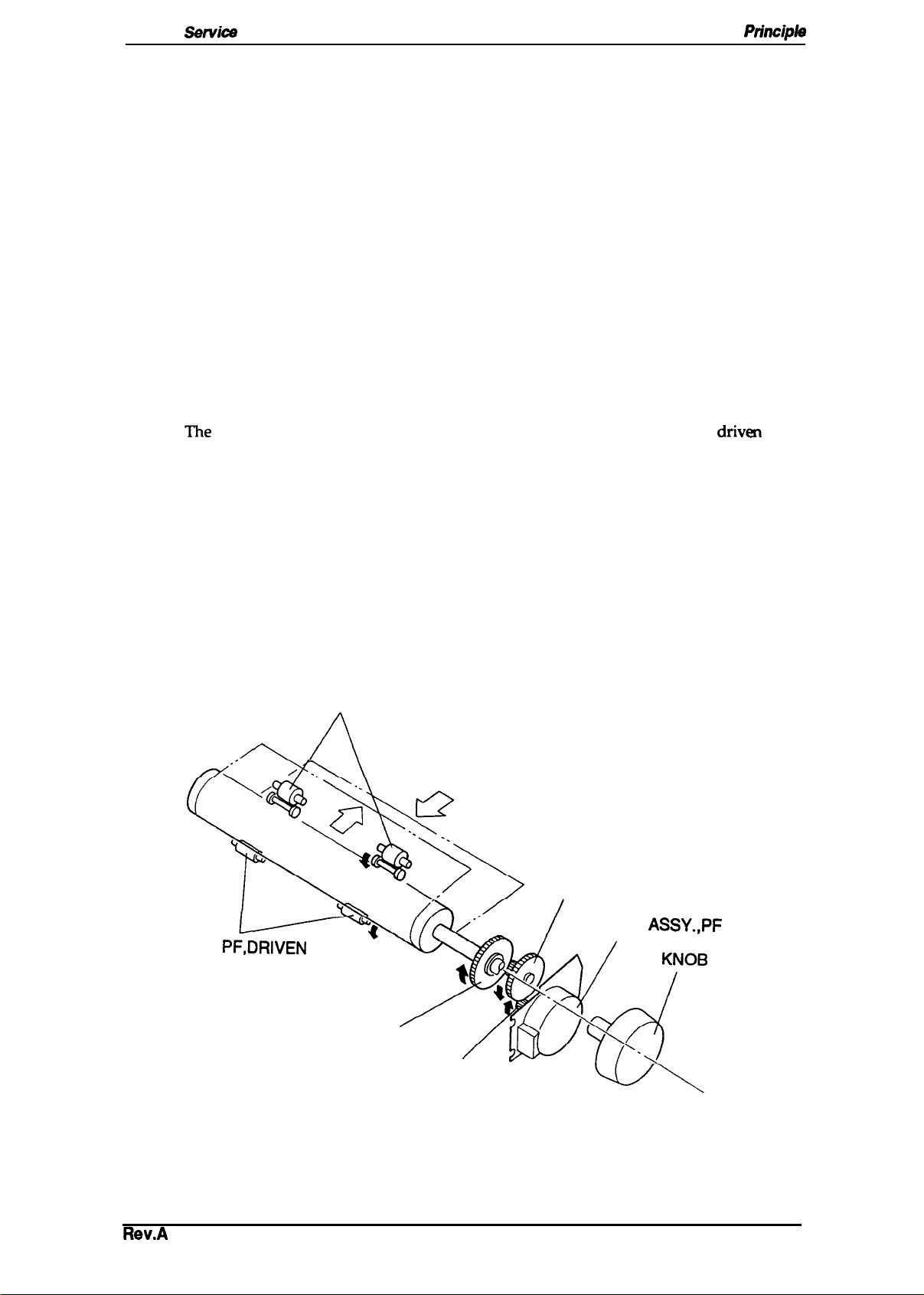

assembly, driven roller cover, tractor assembly, knob, PF gear train, etc. The PF motor assembly

can drive the platen both forward and in reverse.

Friction Advance Method

Paper is held by the platen, the PF driven roller, and the eject roller assembly. Turning in the

direction of the black arrows, the PF motor assembly pinion gear drives the paper advance

reduction gear. The paper advance reduction gear turns the platen gear, PF driven roller, and the

platen. The platen drives the driven roller cover; then the driven roller cover drives to eject the

paper. The paper advances in the direction of white arrows. Figure 2-3 shows the friction advance

method when the paper is fed through the top paper entrance.

The

paper advance mechanism consists of the PF motor assembly, platen,

dtiven

roller

ROLLE

COVER, ROLLER, DRIVEN

,,

R

,

PF,DRIVEN

PLATEN GEAR

Pinion Gear

PAPER ADVANCE

REDUCTION GEAR

MOTOR

ASSY.,PF

Rev.A

Figure 2-3. Friction Advance Mechanism

2-3

Page 34

Operating Principles

Table 2-2. PF Motor Assembly Specifications

LX-300 Service Manual

Categov

Type

Drive Voltage

Coil Resistance

Drive Pulse Frequency

Excitation Method

Push Tractor Method

When the push tractor method is used with the rear entrance, the torque generated by the PF motor

assembly is transmitted to the push tractor gear through the PF motor assembly pinion gear, the

paper advance reduction gear, and the tractor transmission gear. When the PF motor assembly

pinion gear turns in the direction of the black arrows, the tractor gear rotates in the direction of the

black arrow and thus feeds the paper into the printer. The paper is advanced by the platen, which

is also driven by the PF motor assembly through the gear train.

Continuous Paper

Push

/

Tractor

4-phase, 48-pole, PM-type stepping motor

31.5 -38.5 VDC

56 ohms

800,900,1000,1200,1300

Constant-voltage 1-2 phase excitation

f

Requirement

5Y0

(per phase, at

25°C, 77°F)

pps

(’*

.,-,

I tb I

~’v

,r~

UH

PLATEN

. . . . . . . .-

Figure 2-4. Push Tractor Paper Advance Mechanism

COVER, ROLLER,

DRIVEN

PLATEN GEAR

Pinion Gear

\

,,

MOTOR

ASSY.,PF

“.

r

--

2-4

Rev.A

Page 35

LX-300

Sarvica

Manual

Operating

Ptincipla

Pull Tractor Method

The pull tractor advances paper in basically the same way as the push tractor. When the push

tractor is installed at the paper exit instead of paper entrance, the tractor functions as a pull tractor

instead of a push tractor, pulling the paper out of the printer mechanism. Figure 2-5 shows the pull

tractor advance mechanism.

Continuous Paper

PL

,

-.

R

.,PF

Figure 2-5. Pull Tractor Paper Advance Mechanism

Rev.A

2-s

Page 36

Operatjng Prjncjples

U400

Smdce Manual

Push -

Pull Tractor Method

The push-pull tractor method is a combination of

the pull method, using an optional tractor.

pull the paper through the printer mechanism.

The

two

traders

Figure

2-6 shows

the paper is fed through the rear paper entrance.

the

push

method, using the standard

operate simultaneously to push and

push-pull tiadoroperation

tractor, and , ~’ “

when

~.i

,

. .

.

Figure 2-6. Push-Pull Tractor Paper Advance Mechanism

Disengage Lever

The disengage lever switches whether or not the printer transmits the torque of the PF motor

assembly to the tractor transmission gear. (See Figures 2-5 and

The

paper path is different from friction feed and tractor feed. The PF driven roller is not in the

tractor feed paper path, so continuous paper

is not advanced by this roller.

245.)

F@me

2-7 shows the

paper path.

->

SHEET GUIDE

PLATEN

QY

;&TRAcTOR

/

ROLLER, PF, DRIVEN

‘ DETECTOR

Cut Sheet

Continuous paper

ASSY., PE

Figure 2-7. Paper Path

24

,.

Rev.A

Page 37

LX~lW

Service Manual

2.1.4 Ribbon Advance Mechanism

Operating

Principb

The ribbon is held between

roller. When the carriage moves on the CR guide shaft from left to right and vice versa, the timing

belt turns the belt driven pulley. Then the torque is transmitted to the ribbon driving gear through

the gear trains.

carriage moves, because a planetary gear is used in the gear linkage.

The ribbon driving gear rotates counterclockwise no matter what direction the

the ribbon

advance

roller (ribbon driven gear) and

the

ribbon pressure

Table 2-3. Ribbon Advance Gear Linkage

Direction of Carriage Movement

1

Left to right

(indicated by the black arrow)

Right to light

indicated by the white arrow)

The ribbon brake

keeps the ribbon tension at an appropriate level.

brushing against the paper.

Ribbo

Ribbon

sprina

attached to the exit of the cartridge case, prevents slack in the ribbon and

I

Belt driven pulley + Gear(1)+ Gear (2)+

Ribbon driving gear

Belt driven pulley + Gear(1) -+ Gear (3)+

Gear (4)

+

The

Gear Linkage

Ribbon driving gear

ribbon mask prevents the ribbon from

Rev.A

Spring

Figure 2-8. Ribbon Advance Gear Linkage

2-7

Page 38

Operating Principles

2.1.5 Ribbon Shift Mechanism

LX-300 Service Manual

This printer can be equipped with a color upgrade kit to print in color. The printer performs

printing unidirectionally. The option is composed of the

ribbon feed mechanism is shared in common

mechanism shifts the ribbon cartridge up and down.

Table 2-2 shows the CS motor assembly specifications.

that when the color is being changed, the positioning is controlled by stepping pulse.

with

color ribbon

black

ribbon feed mechanism,

The motor control system is open-loop, so

shift mechanism. The

and the shift

color

Color

Table 2-4. CS Motor Assembly Specifications

Category

Type

Drive Voltage

Coil Resistance

Drive Pulse Frequency

Excitation Method

The

ribbon shift mechanism consists of the color ribbon and color upgrade kit. The color upgrade

kit is composed of the

sensor. The l-inch-wide color

The ribbon shift mechanism shifts the ribbon cartridge up and down.

When the color ribbon cartridge is loaded, it is possible to print in up to seven colors. One of the

four colors on the ribbon is selected by the color ribbon cartridge motion, which inserts a portion of

the plastic posts into the slots in the printer mechanism as a fulcrum.

shift mechanism. The mechanism shifts the ribbon cartridge by converting the gear rotation to

liner motion (up and down) of the color ribbon cartridge, using color shift cam gear.

CS

motor assembly,

ribbon

4-phase, 48-pole, PM-type stepping motor

35 VDC * 10Yo

150 ohms

Color shift 500 pps

Constant-vottage 2-2 phase excitation

ribbcm

is separated into four equal-width bands of different colors.

f

shift gear/cam, motor driver

Requirement

5Y0

(per phase, at 25° C or 77°

Figure 2-9 illustrates the color

F)

IC,

and color ribbon

Any color band can be selected

position (the position of the black color band) as a starting point and reference position. Home

position is recognized by the CS motor assembly stepping pulse. When printer is power on, the

motor assembly is exated at any phase position at first. Next, the CS motor assembly is turned for

235 steps ( black + yellow). Then, the motor returns one step (yellow+ black), and the ‘motor is

stopped. Finally, the motor returns 223 steps

position.

Table 2-5 gives coloring sequences.

printing one color on top of another.

by’

rotation of the CS motor assembly, using the color home

(yellow+

For halftones, as shown in the table, a color is created by

black) and stops. This position is home

CS

Table 2-5. Coloring Sequences

Print Ribbon

Print Color

Black

Magenta

Cyan

Yellow

Green

Orange

First Printing

Black

Magenta

cyan

Yellow

Yellow

Yellow

Seoond

cyan

Magenta

Printing

—

—

—

—

f-’””

,,.

Note:

2-8

Violet

The printer prints the brighter color first to prevent the ribbon from

Magenta

Cyan

bt

ng

stained

Rev.A

Page 39

LX-300 Service Manual

Operating Pdncipb

Fulcrum

1/

LEVER,CS

-

-—-

Color Shift Cam Follower

Figure 2-9. Color Shift Mechanism

2.1.6 Platen Gap Adjustment Mechanism

‘The platen gap (the gap between the platen and the printhead) can be adjusted to allow the printer

to use paper of different weights or thicknesses. When the gap adjust lever is moved forward or

backward, the CR guide shaft rotates. This rotation moves the carriage either toward or away from

the platen and changes the platen gap. The correct platen gap is 0.45

lever set to position O.

Color Ribbon Cartridge

HOLDER, CARTRIDGE,COLOR

Pinion of MOTOR

Color Shift Cam

ASSY.,CS

tO.02

mm with the gap adjust

LEVER,G,ADJUST Motion

PG

II

1 \

,LEVER’GJADJUST

,

i’1

.*pfinthead

,,

TL

Platen

Figure 2-10. Platen Gap Adjustment Mechanism

,

i$-

F

“-””l

5

“\

“>

printhad

a

. . — .

SHAFT,CR,GUIDE

.“

Motion”

Rev.A

2-9

Page 40

Operating Principles

2.2 POWER SUPPLY OPERATION

The printer can be powered by either of two power

assembly or the

except for a difference in primary circuitry.

necessary to drive the printer control circuits and drive mechanism.

voltages and fuse ratings for these boards.

C130 PSE (230V)

power supply.

The power

Table 2-6. Power Supply Board

supply

The function of these two boards is the same,

boards:

supply

the C130 F’SB (120V)

board outputs the DC current

Table

LXXX)

Service

2-6 shows the input

Mimual

board

(

( “+

Board

C130 PSB

C130

PSE

Input Voltage

100.5-132

198-284

VAC

VAC

Fuse F1 Rating

2.5A

1125V,

250V

1.25A 1250V

2.2.1 Power Supply Overview

The power supply board has two power outputs for use in the various control

mechanisms. Table 2-7 lists the circuitry and the units that are driven by the two DC output supply

voltages.

arcuits

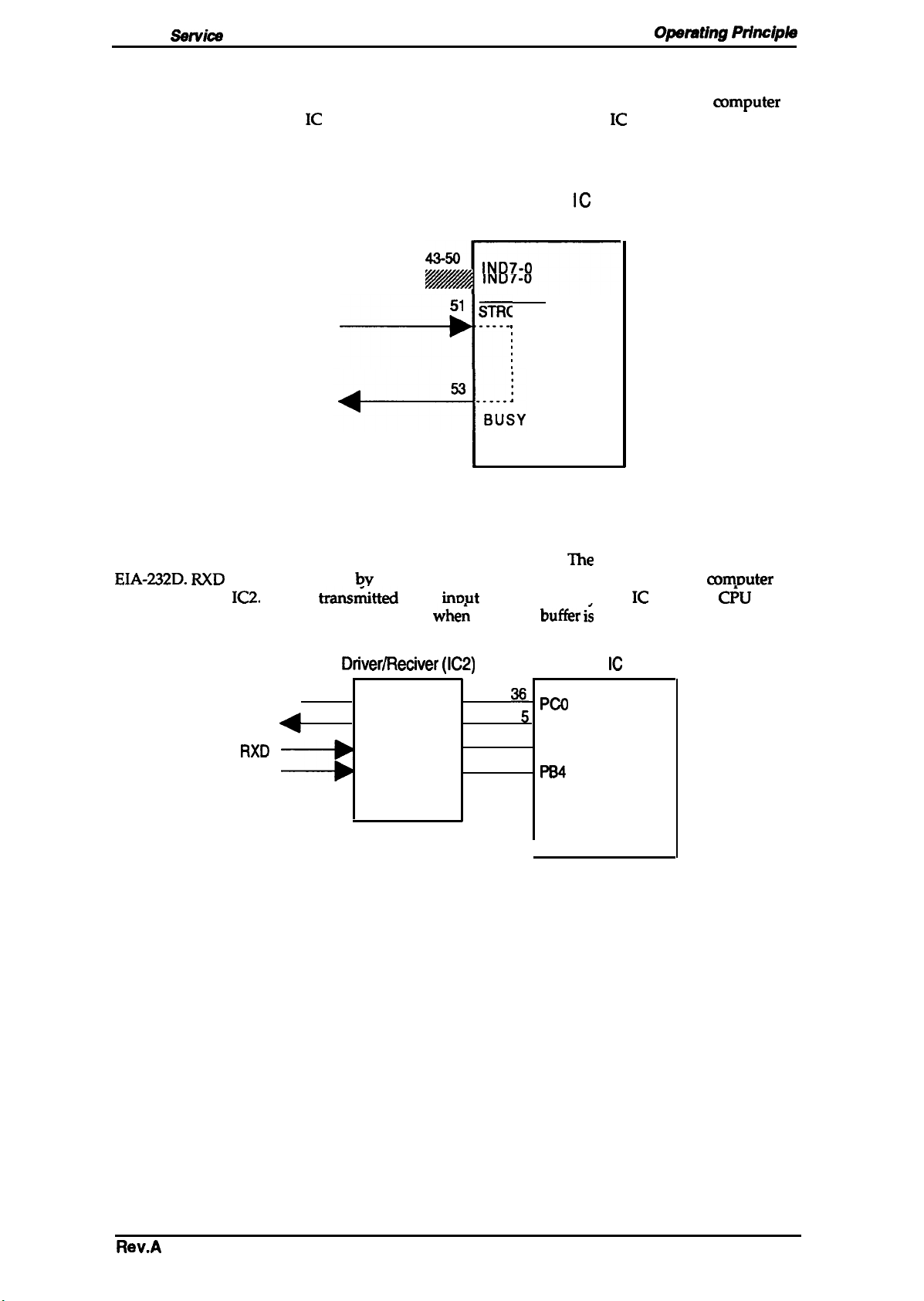

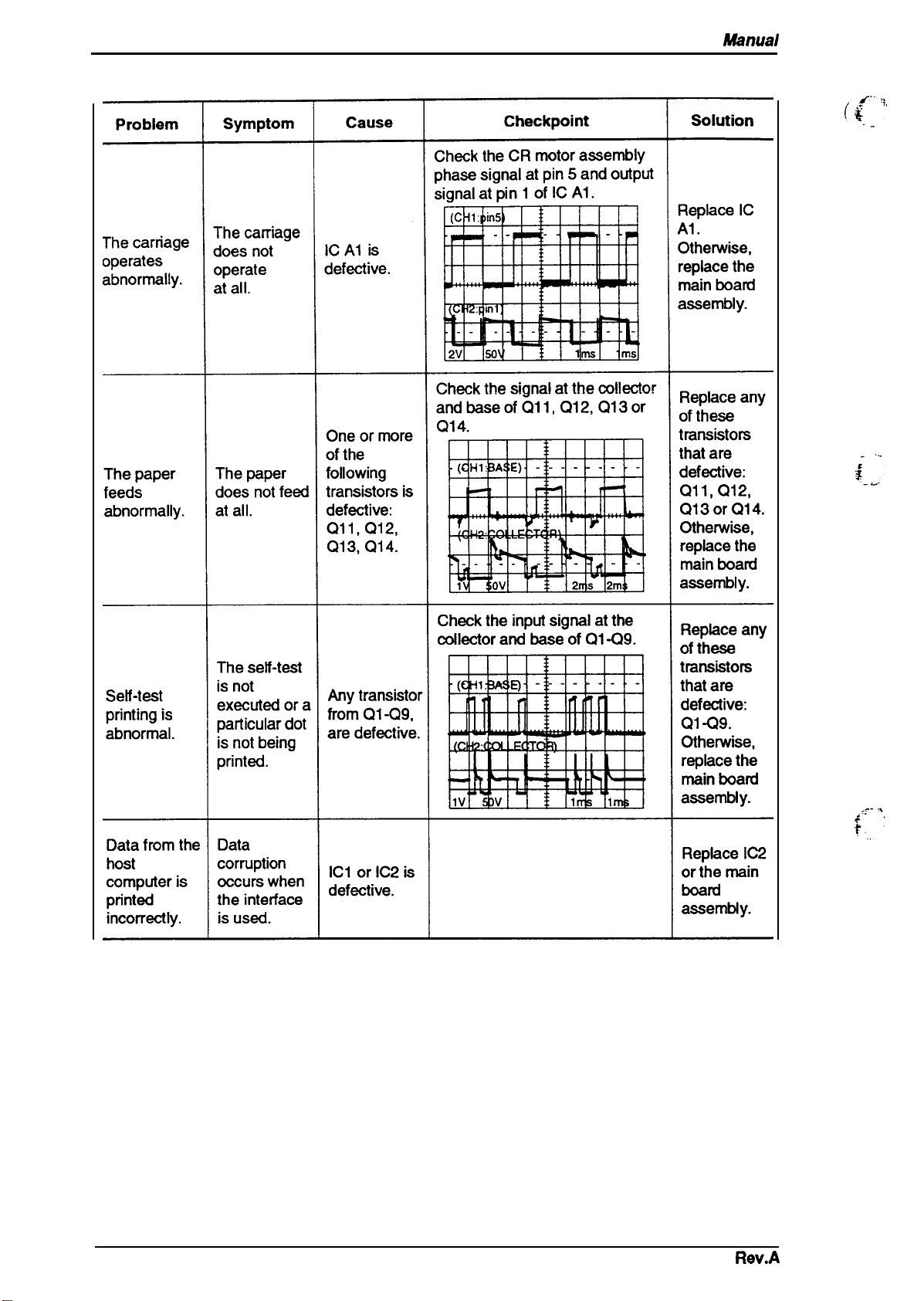

and drive