Page 1

Rev.4 EM196B3937F

Robot System

Safety and Installation

Read this manual first

Robot Controller RC90-B

Programming Software EPSON RC+ 7.0

Manipulator LS-B series

(LS20-B, LS10-B, LS6-B, LS3-B)

Page 2

Robot System Safety and Installation

(RC90-B / EPSON RC+ 7.0) Rev.4

Page 3

Robot System Safety and Installation

(RC90-B / EPSON RC+ 7.0)

Rev.4

Copyright 2018-2019 SEIKO EPSON CORPORATION. All rights reserved

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 i

Page 4

1. Damage or malfunction caused by improper use which is not described in

the manual, or careless use.

2.

Malfunctions caused by customers’ unauthorized disassembly.

3.

Damage due to improper adjustments or unauthorized repair attempts.

4.

Damage caused by natural disasters such as earthquake, flood, etc.

1. If the robot system associated equipment is used outside of the usage

conditions and product specifications described in the manuals, this

warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we

cannot be responsible for any malfunction or accident, even if the result is

injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this

manual cannot warn the user of all possible hazards.

FOREWORD

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the robot

system.

Please carefully read this manual and other related manuals before installing the

robot system.

Keep this manual handy for easy access at all times.

WARRANTY

The robot system and its optional parts are shipped to our customers only after

being subjected to the strictest quality controls, tests, and inspections to certify its

compliance with our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired

free of charge during the normal warranty period. (Please contact the supplier of

your region for warranty period information.)

However, customers will be charged for repairs in the following cases (even if they

occur during the warranty period):

Warnings, Cautions, Usage:

ii Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 5

Seiko Epson Corporation

3-3-5 Owa, Suwa-shi, Nagano, 392-8502

URL

: http://global.epson.com/company/

: http://www.epson.jp/prod/robots/

Toyoshina Plant

Robotics Solutions Operations Division

6925 Toyoshina Tazawa,

Azumino

J

TEL

: +81-(0)263-72-1530

FAX

: +81-(0)263-72-1495

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

Other brand and product names are trademarks or registered trademarks of the

respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® 7 Operating system

Microsoft® Windows® 8 Operating system

Microsoft® Windows® 10 Operating system

Throughout this manual, Windows 7, Windows 8, and Windows 10 refer to above

respective operating systems. In some cases, Windows refers generically to

Windows 7, Windows 8, and Windows 10.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any

comments regarding its contents.

MANUFACTURER

-shi, Nagano, 399-8285

apan

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 iii

Page 6

North & South

America

Epson America, Inc.

Factory Automation/Robotics

1650 Glenn Curtiss Street

Carson, CA 90746

USA

TEL

: +1-562-290-5900

FAX

: +1-562-290-5999

E-MAIL

: info@robots.epson.com

Europe

Epson Deutschland GmbH

Robotic Solutions

Otto

D

Germany

TEL

: +49-(0)-2159-538-1800

FAX

: +49-(0)-2159-538-3170

E-MAIL

: info.rs@epson.de

URL:

: www.epson.de/robots

China

Epson (China) Co., Ltd.

Factory Automation Division

4F,

81 Jianguo Road,

Beijing, 100025, PRC

TEL

: +86-(0)-10-8522-1199

FAX

: +86-(0)-10-8522-1120

Taiwan

Epson Taiwan Technology & Trading Ltd.

Factory Automation Division

15F., No.100, Songren Rd., Sinyi Dist., Taipei City, 11073

Taiwan

TEL

: +886-(0)-2-8786-6688

FAX

: +886-(0)-2-8786-6600

SUPPLIERS (Country/Region)

-Hahn-St r.4

-40670 Meerbusch

Tow e r 1, China Central Place,

Chaoyang District,

iv Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 7

Korea

Epson Korea Co., Ltd.

Marketing Team (Robot Business)

10F Posco P&

Gangnam

Korea

TEL

: +82-(0)-2-3420-6692

FAX

: +82-(0)-2-558-4271

Southeast Asia

Epson Singapore Pte. Ltd.

Factory Automation System

1 HarbourFront Place, #03

HarbourFront Tower One,

Singapore 098633

TEL

: +65-(0)-6586-5696

FAX

: +65-(0)-6271-3182

India

Epson India Pvt. Ltd.

Sales & Marketing (Factory Automation)

12th Floor, The Millenia, Tower A, No. 1,

Murphy Road, Ulsoor, Bangalore,

India 560008

TEL

: +91-80-3051-5000

FAX

: +91-80-3051-5005

Japan

Epson Sales Japan Corporation

Factory Automation Systems Department

29

S

Japan

TEL

:+81-(0)3-5919-5257

FAX

:+81-(0)3-5919-5402

S Tower, Teheranro 134(Yeoksam-dong)

-gu, Seoul, 06235

-02,

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 v

th

floor, JR Shinjuku Miraina Tower, 4-1-6

hinjuku, Shinjuku-ku, Tokyo 160-8801

Page 8

Regarding battery disposal

The crossed out wheeled bin label that can be found on your product indicates that this

product and incorporated batteries should not be disposed of via the normal household

waste stream. To prevent possible harm to the environment or human health please

separate this product and its batteries from other waste streams to ensure that it can be

recycled in an environmentally sound manner. For more details on available collection

facilities please contact your local government office or the retailer where you purchased

this product. Use of the chemical symbols Pb, Cd or Hg indicates if these metals are

used in the battery.

This information only applies to customers in the European Union, according to

DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

OF 6 September 2006 on batteries and accumulators and waste batteries and

accumulators and repealing Directive 91/157/EEC and legislation transposing and

implementing it into the various national legal systems.

For other countries, please contact your local government to investigate the possibility of

recycling your product.

The battery removal/replacement procedure is described in the following manuals:

Controller manual / Manipulator manual (Maintenance section)

For California customers only

The lithium batteries in this product contain

Perchlorate Material - special handling may apply,

See www.dtsc.ca.gov/hazardouswaste/perchlorate.

vi Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 9

NOTE

NOTE

NOTE

NOTE

Before Reading This Manual

TP port of RC90-B is for the Teach Pendant TP1 and TP2. Do not connect

the followings to TP port of RC90. Connecting to the followings may result in

malfunction of the device since the pin assignments are different.

OPTIONAL DEVICE dummy plug

Operation Pendant OP500

Operator Pendant OP500RC

Jog Pad JP500

Teaching Pendant TP-3** series

Operator Panel OP1

For RC90-B, be sure to install the EPSON RC+7.0 to the development PC

first, then connect the development PC and RC90-B with the USB cable.

If RC90-B and the development PC are connected without installing the

EPSON RC+7.0 to the development PC, [Add New Hardware Wizard]

appears. If this wizard appears, click the <Cancel> button.

Concerning the security support for the network connection:

The network connecting function (Ethernet) on our products assumes the use

in the local network such as the factory LAN network. Do not connect to the

external network such as Internet.

In addition, please take security measure such as for the virus from the

network connection by installing the antivirus software.

Security support for the USB memory:

Make sure the USB memory is not infected with virus when connecting to the

Controller.

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 vii

Page 10

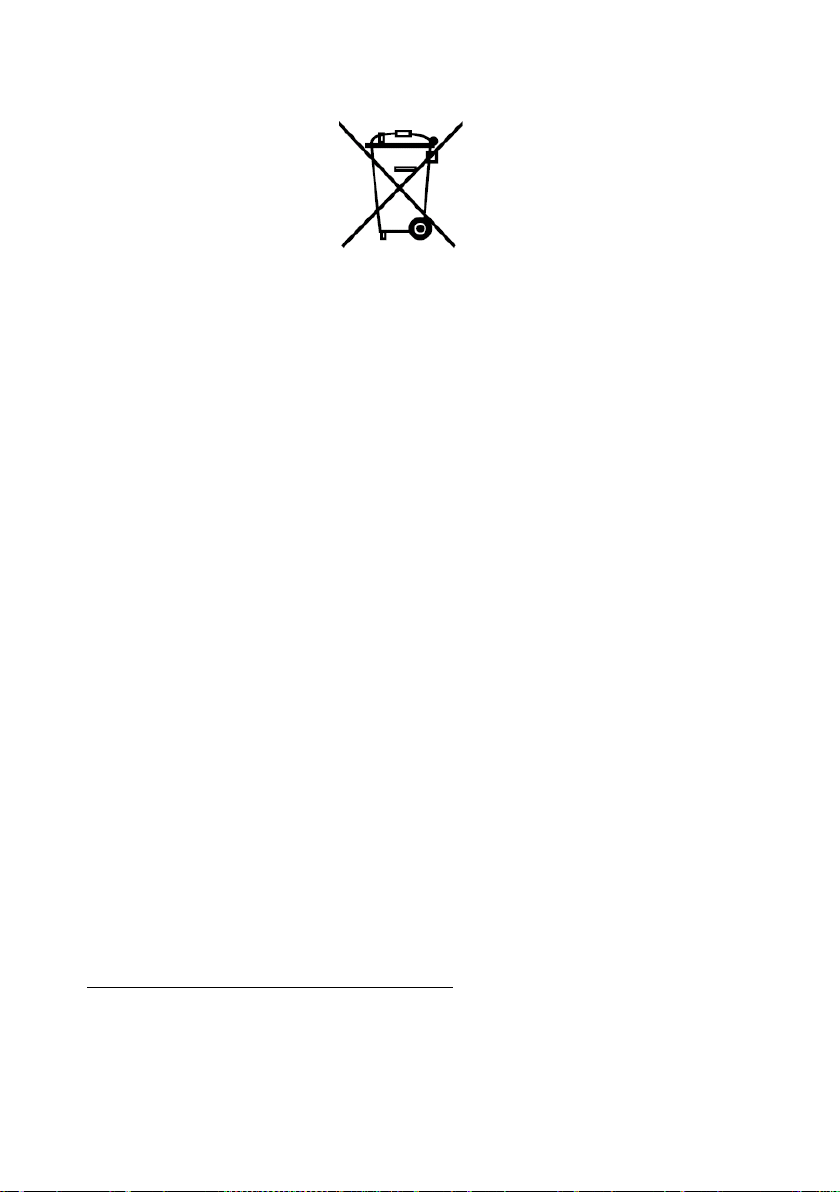

RC90-B controller firmware

Ver.7.4.5 or later

Before Ver.7.4.4

!!!

Ver. 7 . 4.5 or later

OK

RC90-B controller firmware

Ver.7.4.2.1 or later

Before Ver.7.4.1

!!!

Ver. 7 . 4.2 or later

OK

RC90-B controller firmware

Ver.7.4.3.1 or later

Before Ver.7.4.2

!!!

Ver. 7 . 4.3 or later

OK

RC90-B controller firmware

Ver.7.4.4.2 or later

Before Ver.7.4.3

!!!

Ver.7.4.4 or later

OK

Control System Configuration

This manual explains with the following combinations of Controllers and

software.

LS20-B****

EPSON RC+ 7.0

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

LS10-B****

EPSON RC+ 7.0

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

LS6-B****

available.

7.4.5 or later.

available.

7.4.2 or later.

EPSON RC+ 7.0

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

7.4.3 or later.

LS3-B****

EPSON RC+ 7.0

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0

Ver.7.4.4 or later.

viii Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 11

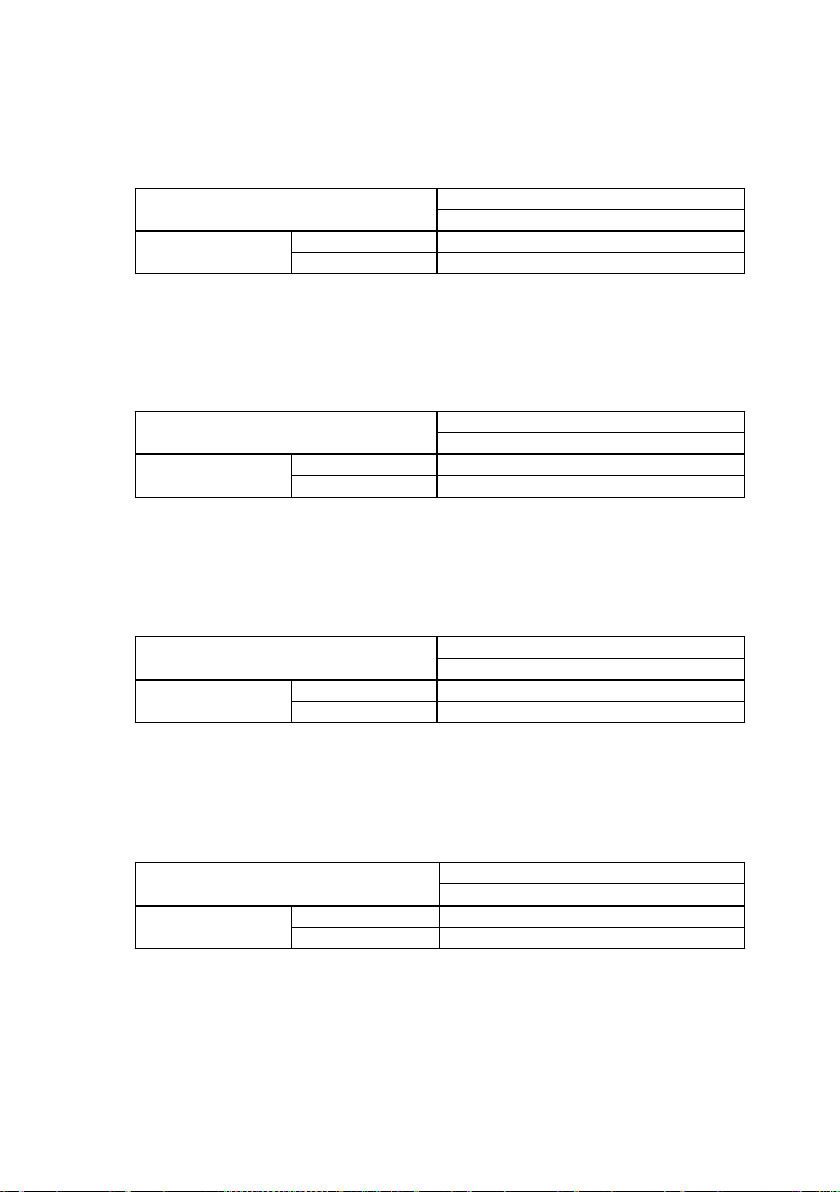

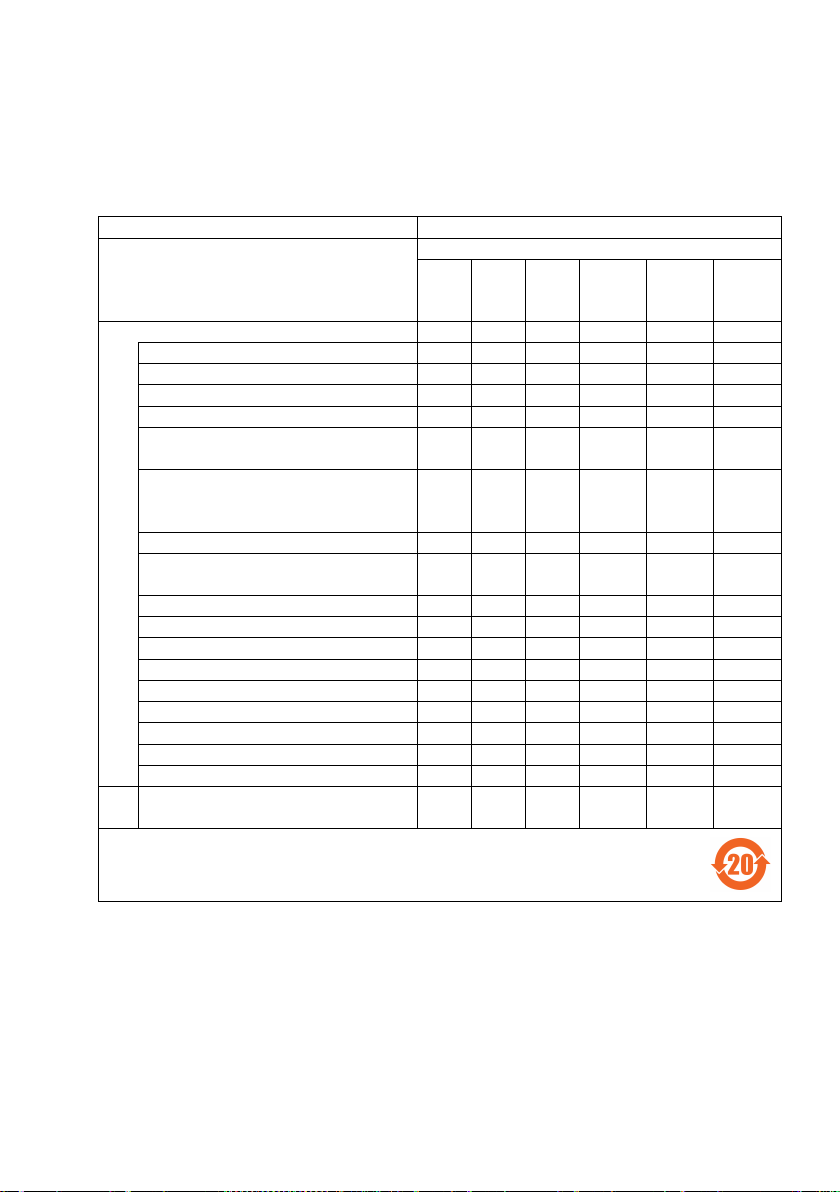

产品中有害物质的名称及含量

机器人型号名称

LS-B系列

部件名称

有害物质

铅 汞 镉

六价铬

多溴

联苯

多溴

二苯醚

(Pb)

(Hg)

(Cd)

(Cr(VI))

(PBB)

(PBDE)

机器人

电机 (执行器单元、电机单元)

减速机单元

电磁制动器

同步皮带

电池单元

(电池、电池固定架、电池基板)

密封

(密封填料、油封、密封脂、垫片、

O型环)

润滑脂

电缆

(M/C电缆、连接电缆)

散热片

LED指示灯

电路板

外罩

滚珠丝杠花键

制动解除开关

伸缩罩

扎带

气管接头

选

件

相机安装板

产品环保使用期限的使用条件

附注:

Note:

China RoHS

This sheet and environmental protection use period label are based on the regulation

in China. These are not necessary to be concerned in other countries.

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

本表格依据SJ/T 11364的规定编制。

○:表示该有害物质在该部件所有均质材料中的含量在GB/T 26572规定的限量要求以下。

×:表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572规定的限量要求。

本产品中含有的有害物质的部件皆因全球技术发展水平限制而无法实现有害物质的替代。

关于适用于在中华人民共和国境内销售的电器电子产品的环保使用期限,在遵守该产品的安全及使用注意

事项的条件下,从生产日期开始计算,在标志的年限内,本产品中含有的有害物质不会对环境造成严重污

染或对人身、财产造成严重损害。

本表格及环保使用期限标志依据中国的有关规定而制定,中国以外的国家/地区则无需关注。

This sheet and environmental protection use period label are based on the regulation

in China. These are not necessary to be concerned in other countries.

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 ix

Page 12

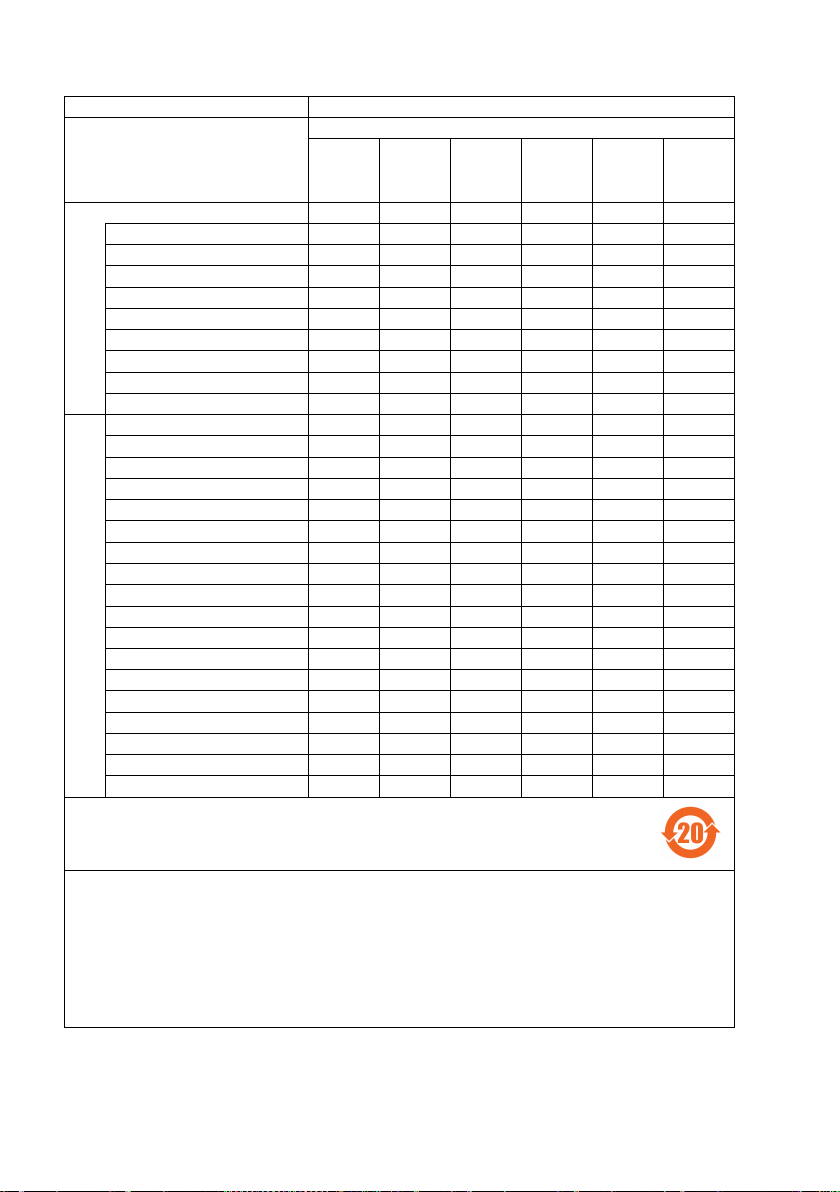

产品中有害物质的名称及含量

控制器型号名称

RC90-B系列

部件名称

有害物质

铅 汞 镉

六价铬

多溴

联苯

多溴

二苯醚

(Pb)

(Hg)

(Cd)

(Cr(VI))

(PBB)

(PBDE)

控制器

机壳

电路板

开关电源

风扇

线束

电源保护装置

存储卡

电池

连接器附件

选

件

电路板

接线

接线端子

紧急停止开关

TP1

TP2

墙面安装金属件

CK1

CV1

CV2

相机

延长管

GigE相机PoE转换器

GigE相机PoE交换集线器

GigE相机三脚架适配器

以太网交换机

USB选件密钥

VRT

产品环保使用期限的使用条件

附注:

Note:

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

○ ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

本表格依据SJ/T 11364的规定编制。

○:表示该有害物质在该部件所有均质材料中的含量在GB/T 26572规定的限量要求以下。

×:表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572规定的限量要求。

本产品中含有的有害物质的部件皆因全球技术发展水平限制而无法实现有害物质的替代。

关于适用于在中华人民共和国境内销售的电器电子产品的环保使用期限,在遵守该产品的安全及使用注

意事项的条件下,从生产日期开始计算,在标志的年限内,本产品中含有的有害物质不会对环境造成严

重污染或对人身、财产造成严重损害。

本表格及环保使用期限标志依据中国的有关规定而制定,中国以外的国家/地区则无需关注。

This sheet and environmental protection use period label are based on the regulation

in China. These are not necessary to be concerned in other countries.

x Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 13

Table of Contents

1. Safety 1

1.1 Conventions .............................................................................. 1

1.2 Design and Installation Safety ................................................... 2

1.3 Operation Safety ....................................................................... 7

1.4 Maintenance Safety ................................................................. 16

1.5 Emergency Stop ...................................................................... 19

1.6 Labels ...................................................................................... 24

1.7 Safety Features ....................................................................... 31

1.8 Lockout / Tagout ...................................................................... 34

1.9 Manipulator Specifications ...................................................... 36

1.10 Motion Range Setting by Mechanical Stops .......................... 43

1.11 End User Training .................................................................. 44

2. Installation 45

System Example .............................................................................. 46

2.1 Outline from Unpacking to Operation of Robot System ........... 47

2.2 Unpacking ............................................................................... 48

2.3 Transportation ......................................................................... 49

2.4 Manipulator Installation ........................................................... 51

2.5 Controller Installation ............................................................... 58

1.2.1 Relevant Manuals .......................................................... 2

1.2.2 Designing a Safe Robot System .................................... 3

1.3.1 Safety-related Requirements ....................................... 10

1.3.2 Part Names / Arm Motion .............................................. 11

1.3.3 Operation Modes ......................................................... 15

1.5.1 Free running distance in emergency ............................ 19

1.5.2 How to Reset the Emergency Mode ............................ 24

1.6.1 Controller ..................................................................... 25

1.6.2 Manipulator .................................................................. 26

Installing the Lockout Attachment ............................................ 34

Padlock Size and Weight ........................................................ 35

Safety Precautions .................................................................. 35

2.3.1 Transportation Precautions .......................................... 49

2.3.2 Manipulator Transportation .......................................... 50

2.4.1 Installation Precautions ................................................ 51

2.4.2 Environment................................................................. 52

2.4.3 Noise level ................................................................... 53

2.4.4 Base Table ................................................................... 54

2.4.5 Installation Procedure .................................................. 55

2.5.1 Installation Precautions ................................................ 58

2.5.2 Environment................................................................. 59

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 xi

Page 14

2.5.3 Installation ................................................................... 60

2.6 Connection to EMERGENCY Connector (Controller) .............. 62

2.6.1 Safety Door Switch and Latch Release Switch ............ 62

2.6.2 Safety Door Switch ...................................................... 63

2.6.3 Latch Release Switch .................................................. 64

2.6.4 Checking Latch Release Switch Operation .................. 65

2.6.5 Emergency Stop Switch ............................................... 65

2.6.6 Checking Emergency Stop Switch Operation .............. 66

2.6.7 Pin Assignments .......................................................... 67

2.6.8 Circuit Diagrams .......................................................... 68

2.7 Power Source .......................................................................... 70

2.7.1 Power Supply .............................................................. 70

2.7.2 AC Power Cable .......................................................... 71

2.7.3 M/C Power Cable Connection ..................................... 72

2.8 Connecting Manipulator and Controller ................................... 73

2.9 Power-on ................................................................................. 74

2.9.1 Power-on Precautions ................................................. 74

2.9.2 Power ON Procedure ................................................... 75

2.10 Saving Default Status ............................................................ 75

3. First Step 76

3.1 Installing EPSON RC+ 7.0 Software ....................................... 76

3.2 Development PC and Controller Connection ........................... 79

3.2.1 About Development PC Connection Port ..................... 79

3.2.2 Precaution ................................................................... 80

3.2.3 Software Setup and Connection Check ....................... 80

3.2.4 Backup the initial condition of the Controller ................ 81

3.2.5 Disconnection of Development PC and Controller ....... 82

3.2.6 Moving the Robot to Initial Position.............................. 82

3.3 Writing your first program ........................................................ 86

4. Second Step 93

4.1 Connection with External Equipment....................................... 93

4.1.1 Remote Control............................................................ 93

4.1.2 Ethernet ....................................................................... 93

4.1.3 RS-232C (Option) ........................................................ 93

4.1.4 Analog I/O (Option) ...................................................... 93

4.2 Ethernet Connection of Development PC and Controller ........ 94

4.3 Connection of Option Teaching Pendant ................................. 94

Table of Contents

xii Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 15

Table of Contents

5. General Maintenance 95

5.1 Schedule for Maintenance Inspection ..................................... 95

5.1.1 Manipulator .................................................................. 95

5.1.2 Controller ..................................................................... 98

5.2 Overhaul (Parts Replacement) ................................................ 99

5.3 Tightening Hexagon Socket Head Cap Bolts ........................ 101

5.4 Greasing ................................................................................ 102

5.5 Handling and Disposal of Batteries ....................................... 104

6. Manuals 106

Software ......................................................................................... 106

Software Options ........................................................................... 106

Controller ....................................................................................... 107

Controller Options .......................................................................... 107

Manipulator .................................................................................... 107

7. Directives and Norms 108

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 xiii

Page 16

Table of Contents

xiv Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 17

1. Safety

or death exists if the associated instructions are not followed

This symbol indicates that a danger of possible harm to

Installation and transportation of robots and robotic equipment shall be performed

by qualified personnel and should conform to all national and local codes.

Please read this manual and other related manuals before installing the robot

system or before connecting cables.

Keep this manual handy for easy access at all times.

1.1 Conventions

Important safety considerations are indicated throughout the manual by the

following symbols. Be sure to read the descriptions shown with each symbol.

This symbol indicates that a danger of possible serious injury

WARNING

WARNING

CAUTION

properly.

This symbol indicates that a danger of possible harm to

people caused by electric shock exists if the associated

instructions are not followed properly.

people or physical damage to equipment and facilities exists

if the associated instructions are not followed properly.

1. Safety

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 1

Page 18

1. Safety

Personnel who

must read the

the safety requirements before designing and/or constructing the robot

system. Designing and/or constructing the robot system without

understanding the safety requirements is extremely hazardous, and may

result in serious bodily injury and/

system.

The Manipulator and the Controller must be used within the environmental

conditions described in their respective manuals. This product has been

designed and manufactured strictly for use in a normal

Using the product in an environment that exceeds the specified

environmental conditions may not only shorten the life cycle of the product

but may also cause serious safety problems.

The robot system must be used within the

in the manuals. Using the robot system outside of the installation

requirements may not only shorten the life cycle of the product but also

cause serious safety problems.

Controller manual : Setup & Operation 3. Installation

1.2 Design and Installation Safety

Only trained personnel should design and install the robot system. Trained

personnel are defined as those who have taken robot system training held by the

manufacturer, dealer, or local representative company, or those who understand the

manuals thoroughly and have the same knowledge and skill level as those who

have completed the training courses.

To ensure safety, a safeguard must be installed for the robot system. For details

on the safeguard, refer to the Installation and Design Precautions in the Safety

chapter of the EPSON RC+ User’s Guide.

The following items are safety precautions for design personnel:

■

■

WARNING

2 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

■

Further precautions for installation are mentioned in the following manuals.

Please read this chapter carefully to understand safe installation procedures before

installing the robots and robotic equipment.

Refer

1.2.1 Relevant Manuals

This manual : 2. Installation

Manipulator manual : Setup & Operation 3. Environment and Installation

design and/or construct the robot system with this product

Safety chapter in the EPSON RC+ User’s Guide to understand

or severe equipment damage to the robot

indoor environment.

installation requirements described

Page 19

1. Safety

1.2.2 Designing a Safe Robot System

It is important to operate robots safely. It is also important for robot users to give

careful consideration to the safety of the overall robot system design.

This section summarizes the minimum conditions that should be observed when

using EPSON robots in your robot systems.

Please design and manufacture robot systems in accordance with the principles

described in this and the following sections.

Environmental Conditions

Carefully observe the conditions for installing robots and robot systems that are

listed in the “Environmental Conditions” tables included in the manuals for all

equipment used in the system.

System Layout

When designing the layout for a robot system, carefully consider the possibility of

error between robots and peripheral equipment. Emergency stops require

particular attention, since a robot will stop after following a path that is different

from its normal movement path. The layout design should provide enough

margins for safety. Refer to the manuals for each manipulator, and ensure that

the layout secures ample space for maintenance and inspection work.

When designing a robot system to restrict the area of motion of the robots, do so in

accordance with the methods described in each manipulator manual. Utilize both

software and mechanical stops as measures to restrict motion.

Install the emergency stop switch at a location near the operation unit for the robot

system where the operator can easily press and hold it in an emergency.

Do not install the controller at a location where water or other liquids can leak

inside the controller. In addition, never use liquids to clean the controller.

Disabling Power to the System using lock out / tag out

The power connection for the robot controller should be such that it can be locked

and tagged in the off position to prevent anyone from turning on power while

someone else is in the safeguarded area.

For further details, refer to the following section:

1.8 Lockout/Tagout

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 3

Page 20

1. Safety

End Effector Design

Provide wiring and piping that will prevent the robot end effector from releasing

the object held (the work piece) when the robot system power is shut off.

Design the robot end effector such that its weight and moment of inertia do not

exceed the allowable limits. Use of values that exceed the allowable limits can

subject the robot to excessive loads. This will not only shorten the service life of

the robot but can lead to unexpectedly dangerous situations due to additional

external forces applied to the end effector and the work piece.

Design the size of the end effector with care, since the robot body and robot end

effector can interfere with each other.

Peripheral Equipment Design

When designing equipment that removes and supplies parts and materials to the

robot system, ensure that the design provides the operator with sufficient safety.

If there is a need to remove and supply materials without stopping the robot, install

a shuttle device or take other measures to ensure that the operator does not need to

enter a potentially dangerous zone.

Ensure that an interruption to the power supply (power shutoff) of peripheral

equipment does not lead to a dangerous situation. Take measures that not only

prevent a work piece held from being released as mentioned in “End effector

Design” but that also ensure peripheral equipment other than the robots can stop

safely. Verify equipment safety to ensure that, when the power shuts off, the area

is safe.

Remote Control

To prevent operation by remote control from being dangerous, start signals from

the remote controller are allowed only when the control device is set to REMOTE,

TEACH mode is OFF, and the system is configured to accept remote signals.

Also when remote is valid, motion command execution and I/O output are

available only from remote. For the safety of the overall system, however, safety

measures are needed to eliminate the risks associated with the start-up and

shutdown of peripheral equipment by remote control.

Emergency Stop

Each robot system needs equipment that will allow the operator to immediately

stop the system’s operation. Install an emergency stop device that utilizes

emergency stop input from the controller and all other equipment.

During the emergency stop, the power supplied to the motor for driving the robot

is shut off, and the robot is stopped due to the dynamic brake.

4 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 21

1. Safety

Make sure that all external components that shut off the power in case of

emergency are turned OFF by the emergency stop circuit. Do not design to turn

OFF the robot controller by using outputs of all I/O boards. For example, if the

I/O board is faulty, the controller cannot turn OFF the power of external

components. The emergency stop on the controller is hardwired to disconnect the

motor power from the robot, but not the external power supplies.

For details of the Safeguard system, refer to the following section.

1.5 Emergency Stop

Safeguard System

To ensure safety, a safeguard system should be installed for the robot system.

When installing the safeguard system, strictly observe the following points:

Refer to each robot manual, and install the safeguard system outside the maximum

space. Carefully consider the size of the end effector and the work pieces to be

held so that there will be no error between the moving parts and the safeguard

system.

Manufacture the safeguard system to withstand calculated external forces (forces

that will be added during operation and forces from the surrounding environment).

When designing the safeguard system, make sure that it is free from sharp corners

and projections, and that the safeguard system itself is not dangerous.

Make sure that the safeguard system can only be removed by using a tool.

There are several types of safeguard devices, including safety doors, safety

barriers, light curtains, safety gates, and safety floor mats. Install the interlocking

function in the safeguard device. The safeguard interlock must be installed so

that the safeguard interlock is forced to work in case of a device failure or other

unexpected accident. For example, when using a door with a switch as the

interlock, do not rely on the switch’s own spring force to open the contact. The

contact mechanism must open immediately in case of an accident.

Connect the interlock switch to the safeguard input of the drive unit’s

EMERGENCY connector. The safeguard input informs the robot controller that

an operator may be inside the safeguard area. When the safeguard input is

activated, the robot stops immediately and enters pause status, as well as either

operation-prohibited status or restricted status (low power status).

Make sure not to enter the safeguarded area except through the point where the

safeguard interlock is installed.

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 5

Page 22

1. Safety

The safeguard interlock must be installed so that it can maintain a safe condition

until the interlock is released on purpose once it initiates. The latch-release input

is provided for the EMERGENCY connector on the Controller to release the latch

condition of the safeguard interlock. The latch release switch of the safeguard

interlock must be installed outside of the safeguarded area and wired to the

latch-release input.

It is dangerous to allow someone else to release the safeguard interlock by mistake

while the operator is working inside the safeguarded area. To protect the operator

working inside the safeguarded area, take measures to lock out and tag out the

latch-release switch.

Presence Sensing Device

The above mentioned safeguard interlock is a type of presence sensing device

since it indicates the possibility of somebody being inside the safeguard system.

When separately installing a presence sensing device, however, perform a

satisfactory risk assessment and pay thorough attention to its dependability.

Here are precautions that should be noted:

- Design the system so that when the presence sensing device is not

activated or a dangerous situation still exists that no personnel can go

inside the safeguard area or place their hands inside it.

- Design the presence sensing device so that regardless of the situation the

system operates safely.

- If the robot stops operating when the presence sensing device is activated,

it is necessary to ensure that it does not start again until the detected

object has been removed. Make sure that the robot cannot

automatically restart.

Resetting the Safeguard

Ensure that the robot system can only be restarted through careful operation from

outside the safeguarded system. The robot will never restart simply by resetting

the safeguard interlock switch. Apply this concept to the interlock gates and

presence sensing devices for the entire system.

Robot Operation Panel

When using the robot operation panel, it must be installed so as to operate the

robot system from outside the safeguard.

6 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 23

1.3 Operation Safety

Please carefully read the Safety-related Requirements before

operating the robot system.

the robot system without

understanding the safety requirements is extremely hazardous and

may result in serious bodily injury and/or sever

the robot system.

Do not enter the operating area of the Manipulator while the power to

the robot system is turned ON.

power ON is extremely hazardous and may cause serious safety

problems as the Manipulator may move even if it seems to

Before operating the robot system, make sure that no one is inside the

safeguarded area.

teaching

The motion of the Manipulator is always in restricted

and low power) to secure the safety of an operator.

operating the robot system while someone is inside the safeguarded

area is extremely hazardous and may result in serious s

in case that the Manipulator moves unexpectedly.

Immediately press the Emergency Stop switch whenever the

Manipul

Continuing operation of the robot system while the Manipulator mo

abnormally is extremely hazardous and may result in serious bodily

injury and/or severe equipment change to the robot system.

To shut off power

the power source. Be sure to connect the AC power cable to a power

receptacle.

DO NOT connect it directly to a factory power source.

The following items are safety precautions for qualified Operator personnel:

■

■

■

WARNING

1. Safety

Operating

e equipment damage to

Entering the operating area with the

be stopped.

The robot system can be operated in the mode for

even when someone is inside the safeguarded area.

status (low speed

However,

■

ator moves abnormally while the robot system is operated.

WARNING

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 7

■

to the robot system, disconnect the power plug from

afety problems

ves

Page 24

1. Safety

Before

C

from the power source.

Performing any replacement procedure with the power ON is

extremely hazardous and may result in electric shock and/or

malfunction of the robot system.

Do not connect or disconnect the motor connectors while the power to

the robot system is turned ON. Connecting or disconnecting the

motor connectors

result

abnormally, and also may result in

the robot system.

Whenever possible, only one person should operate the robot system.

If it is necessary to operate the robot system with more than one

person, ensure that all people involved communicate with each other

as to what they are doing and take all necessary safety precautions.

Joint #1, #2, and #4:

If the joints are operated

5 degrees, they may get damaged early because the bearings are

likely to cause oil film shortage in such situation. To prevent early

breakdown, move the joints larger than 50 degrees

ten times a day.

Joint #3:

If the up

a half of the maximum stroke for five to ten times a day.

LS20-B : less than 50 mm

WARNING

■

■

■

performing any replacement procedure, turn OFF the

ontroller and related equipment, and then disconnect the power plug

with the power ON is extremely hazardous and may

in serious bodily injury as the Manipulator may move

electric shock and/or malfunction of

■

CAUTION

8 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

-and-down motion of the hand is the following, move the joint

LS3-B : less than 32 mm

LS6-B : less than 40 mm

LS10-B : less than 50 mm

repeatedly with the operating angle less than

for about five to

Page 25

■

Oscillation (resonance) may occur continuously depending on the

combination of robot motion speed, Arm orientation, and end effector

load.

and can be

Manipulator may be warmed up due to motor heat or similar causes.

Do not touch the Manipulator

the temperature of the Manipulator falls and

it.

Oscillation arises from natural oscillation frequency of the Arm

controlled by following measures.

Changing Manipulator speed

CAUTION

Changing the teach points

Changing the end effector load

■

Then perform teaching or maintenance.

1. Safety

until temperature falls. Also, make sure

is not hot when you touch

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 9

Page 26

1. Safety

EN ISO 10218-1

Robots and robotic devices -- Safety requirements for industrial

EN ISO 10218-2

Robots and robotic devices -- Safety requirements for industrial

ANSI/RIA R15.06

American National Standard for Industrial Robots and Robot

EN ISO 12100

Safety of machinery -- General principles for design -- Risk

EN ISO 13849-1

Safety of machinery -- Safety-related parts of control systems --

EN ISO 13850

Safety of machinery -- Emergency stop function-- Principles for

Safety of machinery -- Positioning of safeguards with respect to the

Safety of machinery -- Safety distances to prevent hazard zones

EN ISO14120

Safety of machinery -- Guards -- General requirements for the

IEC 60204-1

Safety of machinery -- Electrical equipment of machines -- Part 1:

CISPR11

Industrial, scientific and medical (ISM) radio-frequency equipment

Limits and

IEC 61000-6-2

Electromagnetic compatibility (EMC) -- Part 6-2: Generic

1.3.1 Safety-related Requirements

Specific tolerances and operating conditions for safety are contained in the

manuals for the robot, controller and other devices. Be sure to read those

manuals as well.

For the installation and operation of the robot system, be sure to comply with the

applicable local and national regulations.

Robot system safety standards and other examples are given in this chapter.

To ensure that safety measures are satisfied, also refer to these standards.

(Note: The following is a partial list of the necessary safety standards.)

robots -- Part 1: Robots

robots -- Part 2: Robot systems and integration

Systems -- Safety Requirements

assessment and risk reduction

Part 1: General principles for design

design

EN ISO 13855

EN ISO 13857

EN 60204-1

EN55011

EN 61000-6-2

approach speeds of parts of the human body.

being reached by upper and lower limbs.

design and construction of fixed and movable guards

General requirements

-- Electromagnetic disturbance characteristics -methods of measurement

standards -- Immunity for industrial environments

10 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 27

1.3.2 Part Names / Arm Motion

(3)

(18)

(11) (12) (13) (14) (15) (16) (6)

(4)

(1)

(10)

(9)

(8)

(19)

(19)

(17)

(5)

(Left side)

(2)

(7)

(10) EMERGENCY connector

(20) Battery (Mounted inside the controller)

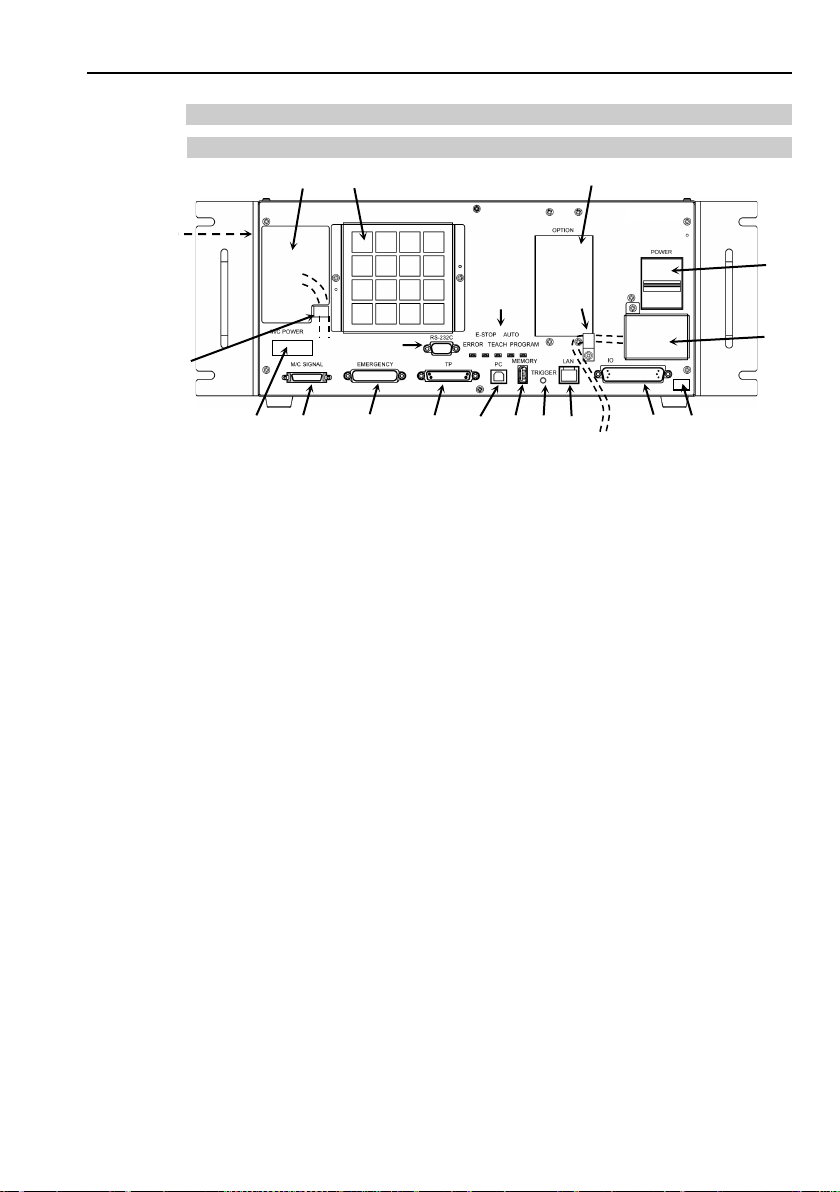

RC90-B

(1)

POWER switch

(2) AC IN

(3) LED

(4) Fan Filter

(5) Signature label

(6) Controller Number label

(7) Connection Check label

(8) M/C POWER connector

(9) M/C SIGNAL connector

1. Safety

(11) TP port

(12) Development PC connection port

(13) Memory port

(14) Trigger Switch

(15) LAN (Ethernet communication) port

(16) I/O connector

(17) Standard RS-232C port

(18) Option slot

(19) Cable Clamp

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 11

Page 28

1. Safety

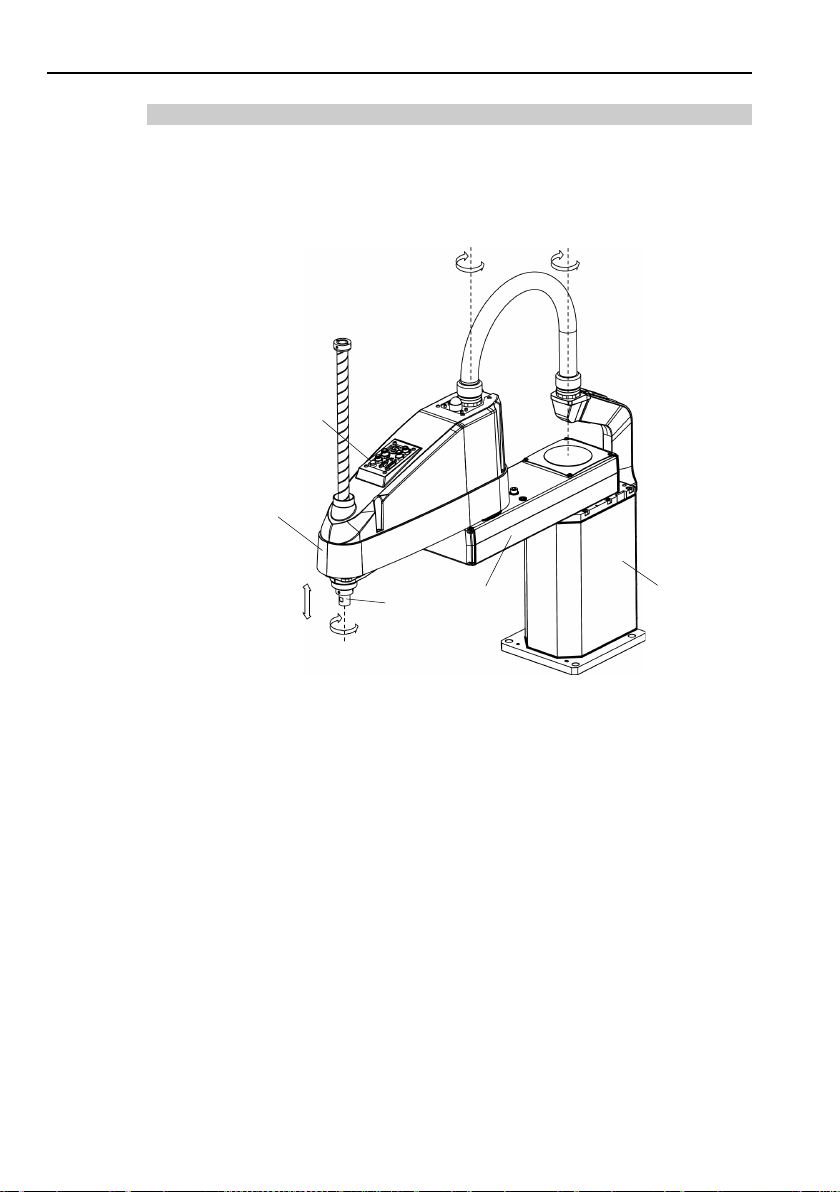

Brake release switch

Joint #1

(Rotation)

Joint #2

(Rotation)

Joint #3

(Up/Down)

Joint #4

(Rotation)

Arm #1

Arm #2

+

−

+

−

+ − +

−

Shaft

(Figure: LS20-B804S)

Base

NOTE

LS20-B

The motion range of each arm is shown in the figure below. Take all

necessary safety precautions.

When the system is placed in emergency mode, push the arm or joint of the

Manipulator by hand as shown below:

Arm #1 Push the arm by hand.

Arm #2 Push the arm by hand.

Joint #3 The joint cannot be moved up/down by hand until the

electromagnetic brake applied to the joint has been released.

Move the joint up/down while pressing the brake release switch.

Joint #4 The shaft cannot be rotated by hand until the electromagnetic

brake applied to the shaft has been released. Move the shaft

while pressing the brake release switch.

The brake release switch affects both Joints #3 and #4. When the brake

release switch is pressed in emergency mode, the brakes for both Joints #3

and #4 are released simultaneously. Be careful of the shaft falling and

rotating while the brake release switch is pressed because the shaft may be

lowered by the weight of an end effector.

12 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 29

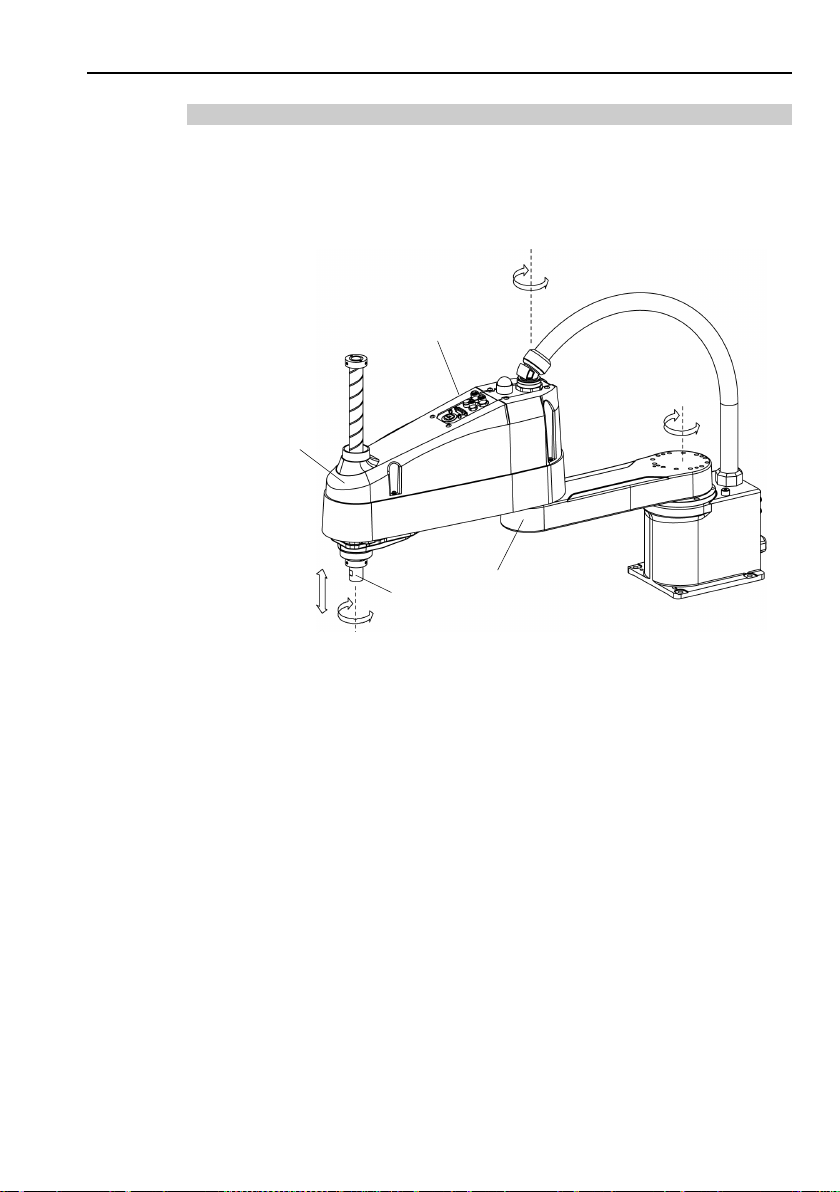

LS10-B

Joint #3, #4

Brake release switch

Joint #1

(Rotation)

Joint #2

(Rotation)

Joint #3

(Up/Down)

Joint #4

(Rotation)

Arm #1

Arm #2

+

−

+

−

+

−

+

−

Shaft

(Figure: LS10-B702S)

NOTE

The motion range of each arm is shown in the figure below. Take all

necessary safety precautions.

1. Safety

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 13

When the system is placed in emergency mode, push the arm or joint of the

Manipulator by hand as shown below:

Arm #1 Push the arm by hand.

Arm #2 Push the arm by hand.

Joint #3 The joint cannot be moved up/down by hand until the

Joint #4 The shaft cannot be rotated by hand until the electromagnetic

The brake release switch affects both Joints #3 and #4. When the brake

release switch is pressed in emergency mode, the brakes for both Joints #3

and #4 are released simultaneously. Be careful of the shaft falling and

rotating while the brake release switch is pressed because the shaft may be

lowered by the weight of an end effector.

electromagnetic brake applied to the joint has been released.

Move the joint up/down while pressing the brake release switch.

brake applied to the shaft has been released. Move the shaft

while pressing the brake release switch.

Page 30

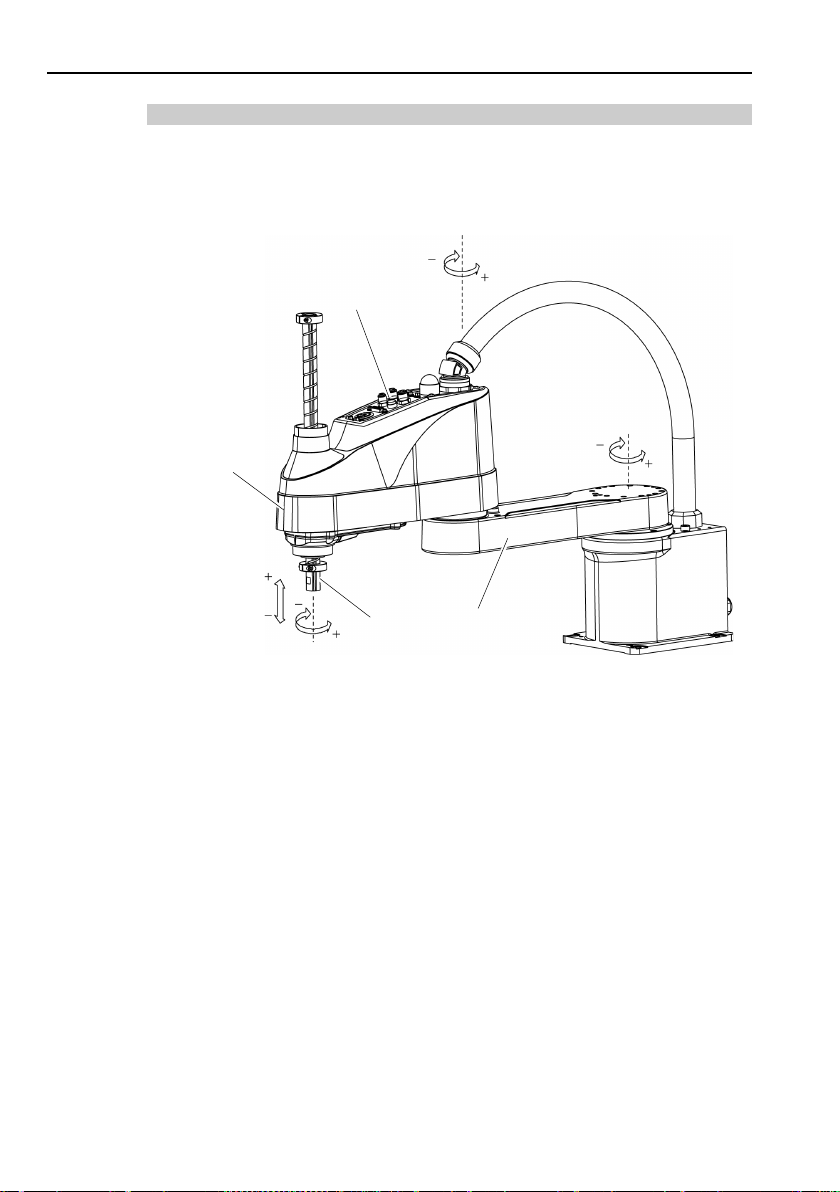

1. Safety

Brake release switch

Joint #1

(Rotation)

Joint #2

(Rotation)

Joint #4

(Rotation)

Joint #3

(Up/Down)

Arm #1

Arm #2

Shaft

(Figure: LS6-B602S)

LS3-B, LS6-B

The motion range of each arm is shown in the figure below. Take all

necessary safety precautions.

When the system is placed in emergency mode, push the arm or joint of the

Manipulator by hand as shown below:

Arm #1 Push the arm by hand.

Arm #2 Push the arm by hand.

Joint #3 The joint cannot be moved up/down by hand until the

electromagnetic brake applied to the joint has been released.

Move the joint up/down while pressing the brake release switch.

Joint #4 LS3-B Rotate the shaft by hand.

LS6-B The shaft cannot be rotated by hand until the

electromagnetic brake applied to the shaft has been

released. Move the shaft while pressing the brake

release switch.

14 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 31

LS3-B: The brake release switch is applied to Joint #3. When the brake release

NOTE

switch is pressed in emergency mode, the brake for Joint #3 is released.

Be careful of the shaft falling while the brake release switch is pressed

because the shaft may be lowered by the weight of an end effector.

LS6-B: The brake release switch is applied to both Joint #3 and Joint #4. When

the brake release switch is pressed in emergency mode, the brakes for both

Joints #3 and #4 are released simultaneously. Be careful of the shaft

falling and rotating while the brake release switch is pressed because the

shaft may be lowered by the weight of an end effector.

1.3.3 Operation Modes

The operation mode is defined as the single control point for the controller, therefore

you cannot use more than one operation mode at the same time.

There are four operation modes for the controller: AUTO, PROGRAM, TEACH, and

TEST.

- AUTO operation modes allow you to execute programs in the controller when

the safeguard is closed.

- PROGRAM operation mode allows you to execute and debug programs when

the safeguard is closed.

- TEACH operation mode allows you to jog and teach the robot at slow speed

while inside the safeguarded area.

- TEST operation mode allows you to execute a program at slow speed while the

safeguard is opened.

1. Safety

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 15

Page 32

1. Safety

Do not remove any parts that are not covered in th

the maintenance procedure strictly as described in this manual

Maintenance

Controller manual

maintenance may not only cause improper function of the robot sy

but also serious safety problems.

Keep away from the Manipulator while

taken the training courses.

power

extremely

Manipulator may move

When you check the operation of the Manipulator a

be sure to

Checking the operation of the Manipulator while you are inside of the

safeguarded area may cause serious safety problems as the

Manipulator may move unexpectedly.

Before

S

the robot system when the switches do not function properly is

extremely hazardous and may result in serious bodily injury and/or

serious damage

inten

1.4 Maintenance Safety

Please read this section, Maintenance of the Manipulator manual, Maintenance of

the Controller manual, and other related manuals carefully to understand safe

maintenance procedures before performing any maintenance.

Only authorized personnel who have taken the safety training should be allowed to

maintain the robot system. The safety training is the program for the industrial

robot operator that follows the laws and regulations of each nation.

The personnel who have taken the safety training acquire knowledge of industrial

robots (operations, teaching, etc.), knowledge of inspections, and knowledge of

related rules/regulations. Only personnel who have completed the robot

system-training and maintenance-training classes held by the manufacturer, dealer,

or locally-incorporated company should be allowed to maintain the robot system.

WARNING

■

of the Manipulator manual, and Maintenance of the

. Improper removal of parts or improper

■

Do not enter the operating area while the

is ON. Entering the operating area with the power ON is

hazardous and may cause serious safety problems as the

even though it seems to be stopped.

■

check it while you are outside of the safeguarded area.

■

operating the robot system, make sure that both the Emergency

top switches and safeguard switches function properly. Operating

the power is ON if you have not

is manual. Follow

fter replacing parts,

,

stem

16 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

ded functions in an emergency.

to the robot system as the switches cannot fulfill their

Page 33

■

Be sure to connect the AC power cable to a power receptacle. DO

NOT connect it directly to a factory power source. To shut off power

the

the power plug from the power source.

Performing any work while connecting the AC power cable to a factory

power source is extremely hazardous and may result in

and/or malfunction of the robot system.

Before

and related equipment,

power source.

Performing any replacement procedure with the power ON is extremely

hazardous and may result in

robot system.

Be sure to connect the cables properly.

strain on the cables.

bend or pull the cables forcibly.)

may result in damage to the cables, disconnection, and/or contact

failure.

hazardous and may result in electric shock and/or improper function of

the robot system.

Carefully use

instructions

gasket, or adhesive may cause a fire and/or safety problems.

Wear protective gear including a mask, protective goggles, and

robot system, disconnect

1. Safety

to

electric shock

■

WARNING

■

performing any replacement procedure, turn OFF the Controller

and then disconnect the power plug from the

electric shock and/or malfunction of the

Do not allow unnecessary

(Do not put heavy objects on the cables. Do not

The unnecessary strain on the cables

Damaged cables, disconnection, or contact failure is extremely

■

- Never put alcohol, liquid gasket, or adhesive close to fire.

CAUTION

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 17

- Use alcohol, liquid gasket, or adhesive while ventilating the room.

-

oil-resistant gloves.

- If alcohol, liquid gasket, or adhesive gets on your skin, wash the area

thoroughly with soap and water.

- If alcohol, liquid gasket, or adhesive gets into your eyes or mouth,

flush your eyes or wash out your mouth with clean water thoroughly,

and then see a doctor immediately.

alcohol, liquid gasket, and adhesive following respective

and also instructions below. Careless use of alcohol, liquid

Page 34

1. Safety

Wear protective gear including a mask, protective goggles, and

oil

mouth, or on your skin, follow the instructions below.

Manipulator may be warmed up due to motor heat or similar causes.

Do not touch the Manipulator

the temperature of the Manipulator falls and you

you touch it.

■

-resistant gloves during grease up. If grease gets into your eyes,

If grease gets into your eyes:

Flush them thoroughly with clean water, and then see a doctor

immediately.

If grease gets into your mouth:

If swallowed, do not induce vomiting. See a doctor immediately.

CAUTION

■

If grease just gets into your mouth, wash out your mouth with

water thoroughly.

If grease gets on your skin:

Wash the area thoroughly with soap and water.

Then perform teaching or maintenance.

until temperature falls. Also, make sure

do not feel hot when

18 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 35

1.5 Emergency Stop

1.5.1 Free running distance in emergency

If the Manipulator moves abnormally during operation, immediately press the

Emergency Stop switch. The motor power will be turned OFF, and the arm

motion by inertia will be stopped with the electromagnetic brake and dynamic

brake.

However, avoid pressing the Emergency Stop switch unnecessarily while the

Manipulator is running normally. Pressing the switch during the operation makes

the brakes work. This will shorten the life of the brakes due to the worn friction

plates.

Normal brake life cycle: About 2 years (when the brakes are used 100 times/day)

To place the robot system in emergency mode during normal operation, press the

Emergency Stop switch when the Manipulator is not moving.

Refer to the Controller manual for instructions on how to wire the Emergency Stop

switch circuit.

Do not turn OFF the Controller while the Manipulator is operating.

If you attempt to stop the Manipulator in emergency situations such as “Safeguard

Open”, make sure to stop the Manipulator using the E-STOP switch of the

Controller.

If the Manipulator is stopped by turning OFF the Controller while it is operating,

following problems may occur.

Reduction of the life and damage of the reduction gear unit

Position gap at the joints

In addition, if the Controller was forced to be turned OFF by blackouts and the like

while the Manipulator is operating, make sure to check the following points after

power restoration.

Whether or not the reduction gear is damaged

Whether or not the joints are in their proper positions

If there is a position gap, perform calibration by referring to Maintenance: 13.

Calibration in the manipulator manual.

Manipulator manuals contain information on the Emergency Stop. Please also

read the descriptions in the manual and use the robot system properly.

1. Safety

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 19

Page 36

1. Safety

Before using the Emergency Stop switch, be aware of the followings.

- The Emergency Stop (E-STOP) switch should be used to stop the

Manipulator only in case of emergencies.

- To stop the Manipulator operating the program except in emergency, use

Pause (halt) or STOP (program stop) commands

Pause and STOP commands do not turn OFF the motors. Therefore, the

brake does not function.

- For the Safeguard system, do not use the circuit for E-S TOP.

For details of the Safeguard system, refer to the following manuals.

EPSON RC+ User’s Guide

2. Safety - Installation and Design Precautions - Safeguard System

Safety and Installation

2.6 Connection to EMERGENCY Connector

To check brake problems, refer to the following manuals.

Manipulator Manual Maintenance

2.1.2 Inspection Point - Inspection While the Power is ON

(Manipulator is operating)

Safety and Installation

5.1.1 Manipulator - Inspection While the Power is ON

(Manipulator is operating)

20 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 37

1. Safety

LS20-B**4*

Accel Setting

100

Speed Setting

100

Load [kg]

20

Weight setting

20

Joint #1

Stop point

Point where the

emergency

stop signal is

input

Target point

Start point of

operation

Joint #2

Controller

RC90-B

Manipulator

LS20-B804*

LS20-BA04*

Free

time

Joint #1 + Joint #2 [s]

0.60

0.65

Free

angle

Joint #1 [deg]

65

85

Joint #2 [deg]

63

55

Joint #1 + Joint #2 [deg]

120

125

Free

distance

Free running distance

The Manipulator in operation cannot stop immediately after the Emergency Stop

switch is pressed.

The free running time/angle/distance of the Manipulator are shown below.

However, remember that the values vary depending on following conditions.

Weight of the end effector Weight Accel

Weight of work piece Speed Operating pose etc.

Approximate time and distance of the free running are as follow:

LS20-B

Conditions for Measurement

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 21

running

running

running

Joint #3 [s] 0.3

Joint #3 [mm] 50

Page 38

1. Safety

LS10-B****

Accel Setting

100

Speed Setting

100

Load [kg]

10

Weight setting

10

Joint #1

Stop point

Point where the

emergency

stop signal is

input

Target point

Start point of

operation

Joint #2

Controller

RC90-B

Manipulator

LS10-B60**

LS10-B70**

LS10-B80**

Free

time

Free

angle

Joint #1 [deg]

35

75

65

Joint #2 [deg]

115

105

55

Joint #1 + Joint #2 [deg]

120

135

90

Free

distance

LS10-B

Conditions for Measurement

running

running

running

Joint #1 + Joint #2 [s] 0.7 0.9 0.7

Joint #3 [s] 0.2

Joint #3 [mm] 50

22 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 39

LS3-B, LS6-B

Accel Setting

100

100

Speed Setting

100

100

Load [kg]

6

3

Weight setting

6

3

Joint #1

Stop point

Point where the

emergency

stop signal is

input

Target point

Start point of

operation

Joint #2

Controller

RC90-B

Manipulator

LS6-B502*

LS6-B602*

LS6-B702*

LS3-B401*

Free

time

Joints #1+#2 [s]

0.4

0.7

0.7

0.4

Joint #1 [deg]

42

100

85

110

Joint #2 [deg]

42

45

50

20

Joints #1+#2 [deg]

84

130

135

130

Free

distance

Conditions for Measurement

LS6-B*02* LS3-B401*

1. Safety

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 23

running

Free

running

angle

running

Joint #3 [s]

Joint #3 [mm]

0.2 0.1

90 20

Page 40

1. Safety

1.5.2 How to Reset the Emergency Mode

Select EPSON RC+ [Tools] – [Robot Manager] – [Control Panel] tab, and then

click <Reset>.

The Control Panel page contains buttons for basic robot operations, such as

turning motors on/off and homing the robot. It also shows status for Emergency

Stop, Safeguard, Motors, and Power.

1.6 Labels

Labels are attached around the locations of the Controller and Manipulator where

specific dangers exist.

Be sure to comply with descriptions and warnings on the labels to operate and

maintain the Robot System safely.

Do not tear, damage, or remove the labels. Use meticulous care when handling

those parts or units to which the following labels are attached as well as the nearby

areas:

24 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 41

1.6.1 Controller

Location

Label

Note

Residual voltage exists. To avoid

electric shock, do not open the cover

while the Power is ON, or for 300

Disconnect and lockout main power

A

D

D

C

B

D

1. Safety

A

B

C

D

seconds after the Power is OFF.

before performing maintenance and

repair.

TP port of RC90-B is for the Teach

Pendant TP1 and TP2. Do not connect

the followings to TP port of RC90.

Connecting to the followings may result in

malfunction of the device.

OPTIONAL DEVICE dummy plug,

OP500, OP500RC, JP500, TP-3** series,

and OP1

Refer to 4.3 Connection of Option

Teaching Pendant.

Hazardous voltage exists while the

Manipulator is ON. To avoid electric

shock, do not touch any internal electric

parts.

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 25

Page 42

1. Safety

Location

Label

Note

osening the base mounting

screws, hold the arm and secure it

fingers from being caught in the

, follow the directions in this

the Manipulator is moving. The

robot arm may collide against the

operator. This is extremely

hazardous and may result in serious

Hazardous voltage exists while the

Manipulator is ON. To avoid electric

not touch any internal

You can catch your hand or fingers

between the shaft and cover when

bringing your hand close to moving

this label for no danger of your hand

Only authorized personnel should

work and operate a

unauthorized personnel, it is

hazardous and may result

1.6.2 Manipulator

LS20-B

Before lo

tightly with a band to prevent hands or

A

B

C

D

Manipulator.

For installation and transportation of

robots

manual.

Do not enter the operation area while

safety problems.

shock, do

electric parts.

parts.

Manipulators with bellows do not have

or fingers being caught

perform sling

crane and a forklift.

E

26 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

When these operations are performed

by

extremely

in serious bodily injury and/or severe

equipment damage to the robot

system.

Page 43

1. Safety

Be careful of the shaft falling and

the brake release

Location

Signature plate

Note

rotating while

F

switch is pressed because the shaft

may be lowered by the weight of the

end effector.

G

LS20-B

Manipulator’s serial No.

(Figure: LS20-B804S)

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 27

Page 44

1. Safety

Location

Label

Note

osening the base mounting

with a band to prevent hands or fingers

, follow the directions in this

may collide against the operator. This

is extremely hazardous and may result

Hazardous voltage exists while the

Manipulator is ON. To avoid electric

shock, do not touch any internal electric

You can catch your hand or fingers

between the shaft and cover when

bringing your hand close to moving

with bellows do not have

Location

Signature plate

Note

LS10-B, LS6-B, LS3-B

Before lo

screws, hold the arm and secure it tightly

A

B

C

D

from being caught in the Manipulator.

For installation and transportation of

robots

manual.

Do not enter the operation area while the

Manipulator is moving. The robot arm

in serious safety problems.

parts.

parts.

Manipulators

this label for no danger of your hand or

fingers being caught

E

Manipulator’s serial No.

28 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 45

LS10-B

LS6-B

1. Safety

(Figure: LS10-B702S)

(Figure: LS6-B602S)

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 29

Page 46

1. Safety

LS3-B

(Figure: LS3-B401S)

30 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 47

1.7 Safety Features

The robot control system supports safety features described below. However, the

user is recommended to strictly follow the proper usage of the robot system by

thoroughly reading the attached manuals before using the system. Failure to read

and understand the proper usage of the safety functions is highly dangerous.

Among the following safety features, the Emergency Stop Switch and Safety Door

Input are particularly important. Make sure that these and other features function

properly before operating the robot system.

1. Safety

For details, refer to the 2.6.1 Safety Door Switch and Latch Release Switch.

Emergency Stop Switch

The EMERGENCY connector on the Controller has expansion Emergency Stop

input terminals used for connecting the Emergency Stop switches.

Pressing any Emergency Stop switch can shut off the motor power immediately

and the robot system will enter the Emergency Stop condition.

Stop category of Emergency Stop input: Category 0 (refer to Safety Standard

IEC60204-1)

Safety Door Input

In order to activate this feature, make sure that the Safety Door Input switch is

connected to the EMERGENCY connector at the Controller.

When the safety door is opened, normally the Manipulator immediately stops the

current operation, and the status of Manipulator power is operation-prohibited

until the safety door is closed and the latched condition is released. In order to

execute the Manipulator operation while the safety door is open, you must change

the mode selector key switch on the Teach Pendant to the “Teach” mode.

Manipulator operation is available only when the enable switch is on. In this

case, the Manipulator is operated in low power status.

Stop category of Safety door input: Category 1 (refer to Safety Standard

IEC60204-1)

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 31

Page 48

1. Safety

Low Power Mode

The motor power is reduced in this mode.

Executing a power status change instruction will change to the restricted (low

power) status regardless of conditions of the safety door or operation mode. The

restricted (low power) status ensures the safety of the operator and reduces the

possibility of peripheral equipment destruction or damage caused by careless

operation.

Dynamic Brake

The dynamic brake circuit includes relays that short the motor armatures.

The dynamic brake circuit is activated when there is an Emergency Stop input or

when any of the following errors is detected: encoder cable disconnection, motor

overload, irregular motor torque, motor speed error, servo error (positioning or

speed overflow), irregular CPU, memory check-sum error and overheat condition

inside the Motor Driver Module.

Motor Overload Detection

The dynamic brake circuit is activated when the system detects that the load on the

motor has exceeded its capacity.

Irregular Motor Torque (out-of-control manipulator) Detection

The dynamic brake circuit is activated when irregularity with motor torque (motor

output) is detected (in which case the Manipulator is out of control).

Motor Speed Error Detection

The dynamic brake circuit is activated when the system detects that the motor is

running at incorrect speed.

Positioning Overflow -Servo Error- Detection

The dynamic brake circuit is activated when the system detects that the difference

between the Manipulator’s actual position and commanded position exceeds the

margin of error allowed.

Speed Overflow -Servo Error- Detection

The dynamic brake circuit is activated when the Manipulator’s actual speed is

detected to mark an overflow (the actual speed is outside the nominal range) error.

32 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 49

1. Safety

CPU Irregularity Detection

Irregularity of CPU that controls the motor is detected by the watchdog timer.

The system CPU and the motor controlling CPU inside the Controller are also

designed to constantly check each other for any discrepancies. If a discrepancy is

detected, the dynamic brake circuit is activated.

Memory Check-sum Error Detection

The dynamic brake circuit is activated when a memory check-sum error is

detected.

Overheat Detection at the Motor Driver Module

The dynamic brake circuit is activated when the temperature of the power device

inside the Motor Driver module is above the nominal limit.

Relay Deposition Detection

The dynamic brake circuit is activated when relay deposition is detected.

Over-Voltage Detection

The dynamic brake circuit is activated when the voltage of the Controller is above

the normal limit.

AC Power Supply Voltage Drop Detection

The dynamic brake circuit is activated when the drop of the power supply voltage

is detected.

Temperature Anomaly Detection

The temperature anomaly is detected.

Fan Malfunction Detection

Malfunction of the fan rotation speed is detected.

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 33

Page 50

1. Safety

Push the pin in the

direction of arrows, and

insert the pin in the holes.

POWER

switch

Lockout

Attachment

Hole

Pin

(2) Turn the lockout

attachment.

(3) Install the lockout

attachment on the switch.

(4) Slide the pin to

the lock position.

Lock position

1.8 Lockout / Tagout

Lockout / tagout is a method to prevent anyone from turning ON the robot system

by mistake while someone else is within the safeguarded area for maintenance or

repair.

When performing maintenance and repair, lockout and tagout using the following

procedure. Use the lockout attachment for RC90-B.

Installing the Lockout Attachment

(1) Turn OFF the POWER switch and place the lockout attachment on the

POWER switch.

Insert the pin in the holes under the retractable actuator.

34 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 51

1. Safety

Padlock Size and Weight

The padlock is not supplied with the lockout attachment and must be supplied by

the user.

The total weight of the padlock can be a maximum of 45 g.

Make sure the padlock weight does not exceed 45 g, otherwise the POWER switch

may be damaged.

Applicable Padlock

Safety Precautions

When using the padlock, do not use the controller where it is subject to vibration

or shock, otherwise failure or damage may result.

Do not apply force of more than 50N on the lockout attachment; otherwise the

lockout attachment will be damaged.

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 35

Page 52

1. Safety

800 mm

1000 mm

350 mm

550 mm

Arm #2

450 mm

9940 mm/s

11250 mm/s

2020 mm/s

1400 deg/s

Joints #1, #2

± 0.025 mm

0.01 mm

0.01 deg.

Rated

10 kg

Max.

20 kg

Rated

0.05 kg·m2

Max.

1.00 kg·m2

Joint #1

0.000275 deg/pulse

Joint #2

0.000439 deg/pulse

Joint #3

0.00148 mm/pulse

Joint #4

0.001046 deg/pulse

Shaft diameter

ø 25 mm

200 × 200 mm

4 × ø16

48 kg : 105.8 lb.

51 kg : 112.5 lb.

Driving method

All joints

Joint #1

750 W

Joint #2

520 W

Joint #3

520 W

Joint #4

150 W

environment

Joint #3 down force

250 N

Equivalent to 8 pin (RJ45) Cat.5e

1.9 Manipulator Specifications

LS20-B

Item

Arm #1, #2

Arm length

Arm #1

LS20-B804* LS20-BA04*

Max.

operating speed

Repeatability

Payload (Load)

Joint #4 allowable

moment of inertia

Resolution

Hand

Mounting hole

Weight (cables not included)

Motor

rated capacity

Joints #1, #2

Joint #3

*1

Joint #4

Joint #3

Joints #1, #2

*2

Through hole ø 18 mm

±

±

AC servo motor

Option

Installed wire for customer use

Installation

Cleanroom *3

15 pin: D-sub, 9 pin: D-sub

36 Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4

Page 53

Item

LS20-B804*

LS20-BA04*

tube for customer use

2 pneumatic tubes (ø8 mm) : 0.59 MPa (6 kgf/cm2 : 86 psi)

2 pneumatic tube (ø6 mm) : 0.59 MPa (6 kgf/cm2 : 86 psi)

Ambient Temp.

5 to 40 °C (with minimum temperature variation)

humidity

Noise level *4

L

Aeq

= 70 dB (A) or less

1 ~ (5) ~ 100

1 ~ (10) ~ 120

1 ~ (50) ~ 2000

1 ~ (200) ~ 10000

0 ~ (1250) ~ 65535

0,450 ~ (10,450) ~ 20,450

NF PA 7 9 (2007 Edition)

Item

LS20-B804S

LS20-BA04S

LS20-B804C

LS20-BA04C

Joint #1

132 deg.

152 deg.

420 mm

390 mm

Joint #4

360 deg.

Joint #1

152918 ~ 808278

345885

Joint #3

283853 ~ 0

263578~0

Joint #4

344064

Installed pneumatic

1. Safety

Environmental

requirements

Assignable Value

( ) Default values

Safety standard

Ambient

relative

Speed

Accel *5

SpeedS

AccelS

Fine

Wei gh t

Max.

motion range

Max.

pulse range

Joint #2

Joint #3

Joint #2

10 to 80 % (no condensation)

CE Mark

EMC Directive, Machinery Directive

KC Mark / KCs Mark

ANSI/RIA R15.06-2012

±

±

±

−

±

−

±

−

Safety and Installation (RC90-B / EPSON RC+ 7.0) Rev.4 37

Page 54

1. Safety

Arm #1, #2

600 mm

700 mm

800 mm

Arm #1

225 mm

325 mm

425 mm

Arm #2

375 mm

Joints #1, #2

9100 mm/s

9800 mm/s

10500 mm/s

Joint #3

1100 mm/s

Joint #4

2500 deg/s

Joints #1, #2 ± 0.02 mm

± 0.025 mm

Joint #4

0.01 deg

Rated

5 kg

Max.

10 kg

Max.

Joint #1

0.000275 deg/pulse

Joint #2

0.000439 deg/pulse

Joint #4

Shaft diameter

ø 25 mm

150 × 150 mm

4-M8

Driving method

All joints

Joint #2

Joint #3

Joint #4

Joint #3 down force

Equivalent to 8 pin (RJ45) Cat.5e

tube for customer use

2 pneumatic tubes (ø6 mm) : 0.59 MPa (6 kgf/cm2 : 86 psi)

1 pneumatic tube (ø4 mm) : 0.59 MPa (6 kgf/cm2 : 86 psi)

Environmental

Ambient Temp.

5 to 40 °C (with minimum temperature variation)

LS10-B

Arm length