Page 1

Robot Controller RC90

Programming Software EPSON RC+ 7.0

Manipulator LS serie s

(LS3 / LS6 / LS20)

4124972-05

Robot System

Safety and Installation

Read this manual first

Rev.6 EM158B3033F

Page 2

ii Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

Robot System Safety and Installation (RC90 / EPSON RC+

7.0) Rev.6

Page 3

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 i

Robot System Safety and Installation

(RC90 / EPSON RC+ 7.0)

Rev.6

Copyright 2013-2015 SEIKO EPSON CORPORATION. All rights reserved

Page 4

ii Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

FOREWORD

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the Operat or

Panel.

Please carefully read this manual and other related manuals before installing the

robot system.

Keep this manual handy for easy access at all times.

WARRANTY

The robot system and its optional parts are shipped to our customers only after

being subjected to the strictest quality controls, tests, and inspections to certify its

compliance with our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired

free of charge during the no rmal warranty peri od. (Please ask you r Regional S ales

Office for warranty period information.)

However, customers will be charged for repairs in the following cases (even if they

occur during the warranty period):

1. Damage or malfunction caused by improper use which is not described in

the manual, or car eless use.

2.

Malfunctions caused by customers’ unauthorized disassembly.

3.

Damage due to improper adjustments or unauthorized repair attempts.

4.

Damage caused by natu r a

l disasters such as earthquake, flood, etc.

Warnings, Cautions, Usage:

1. If the robot system associated equipment is used outside of the usage

conditions and product specifications described in the manuals, this

warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we

cannot be responsible for any malfunction or accident, even if the result is

injury or death.

3. We can not foresee all possib le dangers and consequences. Therefore, this

manual cannot warn the user of all poss

ible hazards.

Page 5

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 iii

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

Other brand and product names are trademarks or registered trademarks of the

respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Win dows® XP Operating system

Microsoft® Windows® Vista Operating system

Microsoft® Windows® 7 Operating system

Microsoft ® Windows® 8 Operating system

Throughout this manual, Windows XP, Windows Vista, Windows 7 and Windows

8 refer to above respective operating systems. In some cases, Windows refers

generically to Windows XP, Window s Vista, Windows 7 and Windows 8.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any

comments regarding its contents.

INQUIRIES

Contact the following service center for robot repairs, inspec tio ns o r adjustm ents.

If service center information is not indicated below, please contact the supplier

office for your region.

Please prepare the following items before you contact us.

- Your controller model and its serial number

- Your manipulator model and its serial number

- Software and its version in your robot system

- A description of the problem

SERVICE CENTER

Page 6

iv Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

MANUFACTURER

Seiko Epson Corporation

Toyoshina Pla n t

Robotics Solutions Operations Division

6925 Toyoshi

na T azawa,

Azumino

-shi, Nagano, 399-8285

J

apan

TEL

: +81-(0)263-72-1530

FAX

: +81-(0)263-72-1495

SUPPLIERS

North & South

America

Epson America, Inc.

Factory Autom ation/Robotics

18300 Central Avenue

Carson, CA 90746

USA

TEL

: +1-562-290-5900

FAX

: +1-562-290-5999

E-MAIL

: info@robots.epson.com

Europe

Epson Deutschland GmbH

Factory Autom ation Division

Otto

-Hahn-Str.4

D

-40670 Meerbusch

Germany

TEL

: +49-(0)-2159-538-1391

FAX

: +49-(0)-2159-538-3170

E-MAIL

: robot.infos@epson.de

China

Epson (China) Co., Ltd.

Factory Autom ation Division

7F, Jinbao Building No. 89, Jinbao Street,

Dongcheng District, Beijing,

China, 100005

TEL

: +86-(0)-10-8522-1199

FAX

: +86-(0)-10-8522-1120

Page 7

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 v

Taiwan

Epson Taiwan T echnol ogy & T rading Ltd.

Factory Autom ation Division

14F, No.7, Song Ren Road, Taipei 110,

Taiwan, ROC

TEL

: +886-(0)-2-8786-6688

FAX

: +886-(0)-2-8786-6677

Korea

Epson Korea Co., Ltd.

Marketing Team (Robot Business)

27F DaeSung D

-Polis A, 606

Seobusaet

-gil, Geumcheon-gu, Seoul, 153-803

Korea

TEL

: +82-(0)-2-3420-6692

FAX

: +82-(0)-2-558-4271

Southeast Asia

Epson Singapor e Pte. Ltd.

Factory Autom ation System

1 HarbourFront Place, #03

-02,

HarbourFr on t Tower One,

Singapore 09 8633

TEL

: +65-(0)-6586-5696

FAX

: +65-(0)-6271-3182

India

Epson India Pvt. Ltd.

Sales & Marketing (F actory Automation)

12th Floor, The Millenia, Tower A, No. 1,

Murphy Road, Ulsoor, Bangalore,

India 560008

TEL

: +91-80-3051-5000

FAX

: +91-80-3051-5005

Japan

Epson Sales Japan Corporation

Factory Automation Systems Department

Nishi

-Shinjuku Mitsui Bldg.6-24-1

Nishishinjuku, Shinjuku

-ku, Tokyo 160-8324

Japan

TEL

:+81-(0)3-5321-4161

Page 8

vi Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

For Customers in the European Union

The crossed out wheeled bin label that can be found on your product indicates that this

product and incorporated batteries should not be disposed of via the normal household

waste stream. To prevent possible harm to the environment or human health please

separate this product and its batteries from other waste streams to ensure that it can be

recycled in an environmentally sound manner. For more details on available collection

facilities plea se co nta ct y our local gover n me nt of fi ce or t he re tailer where you purchased

this product. Use of the chemical symbols Pb, Cd or Hg indicates if these metals are

used in the battery.

This information only applies to customers in the European Union, according to

DIRECTIVE 2006/66/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

OF 6 September 2006 on batteries and accumulators and waste batteries and

accumulators and repealing Directive 91/157/EEC and legislation transposing and

implementing it into the various national legal systems.

For other countries, please c o nt act y our lo ca l government to inv esti gate the possibil it y of

recycling your product.

The battery removal/replacement procedure is described in the following manuals:

Controller manual / Manipulator manual (Maintenance section)

Page 9

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 vii

Before Reading This Manual

TP port of RC90 is for the Teach Pendant TP1 and TP2. Do not connect

the followings to T P port of RC90. Connecting to the followings may res ult in

malfunction of the device since the pin assignments are different.

OPTIONAL DEVICE dummy plug

Operation Pendant OP500

Operator Pendant OP500RC

Jog Pad JP500

Teaching Pendant TP-3** series

Operator Panel OP1

For RC90, be sure to install the EPSON RC+7.0 to the development PC first,

then connect the development PC and RC90 with the USB c able.

If RC90 and the dev el op ment P C ar e con nect ed without installi ng t he E PS ON

RC+7.0 to the development PC, [Add New Hardware Wizard] appears. If

this wizard appears, click the < Cance l> butt on .

Concerning the security support for the network connection:

The network connecting function (Ethernet) on our products assumes the use

in the local network such as the factory LAN network. Do not connect to the

external network such as Internet.

In addition, please take security measure such as for the virus from the

network connection by installing the antivirus software.

Security support for the USB memory:

Make sure the USB memory is not infected with virus when connecting to the

Controller.

NOTE

NOTE

NOTE

NOTE

Page 10

viii Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

Control System Configuration

This manual explains with the following combinations of Controllers

and software.

Robot Controller RC90 with the following label attached.

Label

Controller

Software

RC90 EPSON RC+ 7.0

Manual PDF for this robot system is available from EPSON RC+ 7.0 Ver. 7.0.2

This option is not available for Robot Controller RC90 (EPSON RC+ 5.0) without

the label.

NOTE

NOTE

Page 11

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 ix

LS3-401*

RC90 controller firmware

Ver.7.0.2.0 or later

EPSON RC+ 7.0

Before Ver.7.0.1

!!!

Ver.7.0.2 or later

OK

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

7.0.2 or later.

Manipulator serial No. : L6**00****

LS6-602*

RC90 controller firmware

Ver.7.0.2.0 or later

EPSON RC+ 7.0

Before Ver.7.0.1

!!!

Ver.7.0.2 or later

OK

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

7.0.2 or later.

Manipulator serial No. : L6**01**** or later

LS6-502*, LS6-602*, LS6-702*

RC90 controller firmware

Ver.7.1.6.* or later

EPSON RC+ 7.0

Before Ver.7.1.2

!!!

Ver.7.1.3 or later

OK

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

7.1.3 or later.

LS20-804*, LS20-A04*

RC90 controller firmware

Ver.7.1.8.* or later

EPSON RC+ 7.0

Before Ver.7.1.3

!!!

Ver.7.1.4 or later

OK

OK: Compatible All functions of the EPSON RC+ 7.0 and the Controller are

available.

!!!: Compatible Connection is OK. We recommend using EPSON RC+7.0 Ver.

7.1.4 or later.

Page 12

x Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

Page 13

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 xi

TABLE OF CONTENTS

1. Safety 1

1.1 Conventions .............................................................................. 1

1.2 Design and Installation Safety ................................................... 2

1.2.1 Relevant Manuals .......................................................... 2

1.2.2 Designing a Safe Robot System .................................... 3

1.3 Operation Safety ....................................................................... 7

1.3.1 Safety-related Requirements ......................................... 8

1.3.2 Part Names / Arm Motion ............................................... 9

1.3.3 Operation Modes ......................................................... 14

1.4 Maintenance Safety ................................................................. 15

1.5 Emergency Stop ...................................................................... 18

1.5.1 Free running distance in emergency ............................ 18

1.5.2 How to Reset the Emergency Mode ............................ 25

1.6 Labels ...................................................................................... 26

1.6.1 Controller ..................................................................... 26

1.6.2 Manipulator .................................................................. 27

1.7 Safety Features ....................................................................... 31

1.8 Lockout / Tagout ...................................................................... 34

1.9 Manipulator Specifications ...................................................... 36

1.10 Motion Range Setting by Mechanical Stops .......................... 41

1.11 End User Training .................................................................. 42

2. Installation 43

System Example .............................................................................. 44

2.1 Outline from Unpacking to Operation of Robot Sys tem ........... 45

2.2 Unpacking ............................................................................... 46

2.2.1 Package Components Example................................... 46

2.2.2 Unpacking Precautions ................................................ 46

2.3 Transportation ......................................................................... 47

2.3.1 Transportation Precautions .......................................... 47

2.3.2 Manipulator Transportation .......................................... 48

2.4 Manipulator Installation ........................................................... 51

2.4.1 Installation Precautions ................................................ 51

2.4.2 Environment................................................................. 51

2.4.3 Noise level ................................................................... 52

2.4.4 Base Table ................................................................... 53

2.4.5 Installation Procedure .................................................. 54

2.5 Controller Installation ............................................................... 58

2.5.1 Installation Precautions ................................................ 58

2.5.2 Installation.................................................................... 59

Page 14

xii Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

2.6 Connection to EMERGENCY Connector (Controller) .............. 61

2.6.1 Safety Door Switch and Latch Release Switch ............ 61

2.6.2 Safety Door Switch ...................................................... 61

2.6.3 Latch Release Switch .................................................. 62

2.6.4 Checking Latch Release Switch Operation .................. 63

2.6.5 Emergency Stop Switch ............................................... 64

2.6.6 Checking Emergency Stop Switch Operation .............. 64

2.6.7 Pin Assignm ents .......................................................... 65

2.6.8 Circuit Diagrams .......................................................... 66

2.7 Power supply / AC power cable / Breaker ............................... 68

2.7.1 Power Supply .............................................................. 68

2.7.2 AC Power Cable .......................................................... 69

2.8 Connecting Manipulator and Controller ................................... 71

2.8.1 Connecting Precautions ............................................... 71

2.9 Power-on ................................................................................. 72

2.9.1 Power-on Precautions ................................................. 72

2.9.2 Power ON Procedure ................................................... 73

2.10 Saving Default Status ............................................................ 74

3. First Step 75

3.1 Installing EPSON RC+ 7.0 Software ....................................... 75

3.2 Development PC and Controller Connection ........................... 78

3.2.1 About Development PC Connection Port ..................... 78

3.2.2 Precaution ................................................................... 79

3.2.3 Software Setup and Connection Check ....................... 79

3.2.4 Backup the initial condition of the Controller ................ 80

3.2.5 Disconnection of Development PC and Controller ....... 81

3.2.6 Moving the Robot to Initial Position.............................. 81

3.3 Writing your first program ........................................................ 86

4. Second Step 93

4.1 Connection with External Equipment....................................... 93

4.1.1 Remote Control............................................................ 93

4.1.2 Ethernet ....................................................................... 93

4.1.3 RS-232C (Option) ........................................................ 93

4.2 Ethernet Connection of Development PC and Controller ........ 94

4.3 Connection of Option Teaching Pendant ................................. 94

Page 15

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 xiii

5. General Maintenance 95

5.1 Schedule for Maintenance Inspection ..................................... 95

5.1.1 Manipulator .................................................................. 95

5.1.2 Controller ..................................................................... 98

5.2 Overhaul .................................................................................. 99

5.3 Tightening Hexagon Socket Head Cap Bolts ........................ 101

5.4 Greasing ................................................................................ 102

5.5 Handling and Disposal of Batteries ....................................... 103

6. Manuals 105

Software ......................................................................................... 105

Software Options ........................................................................... 105

Controller ....................................................................................... 106

Controller Options .......................................................................... 106

Manipulator .................................................................................... 106

7. Directives and Norms 107

Page 16

xiv Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

Page 17

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 1

1. Safety

Installation and transportation of robots and robotic equipment shall be performed

by qualified personnel and should conform to all national and local codes.

Please read this manual and other related manuals before installing the robot

system or before connecting cables.

Keep this manual handy for easy access at all times.

1.1 Conventions

Important safety considerations are indicated throughout the manual by the

following symbols. Be sure to read the descriptions shown with each symbol.

WARNING

This symbol indicates that a danger of possible serious injury

or death exists if the associated instructions are not followed

properly.

WARNING

This symbol indicates that a danger of possible harm to

people caused by electric shock exists if the associated

instructions are not followed properly.

CAUTION

This symbol indicates that a danger of possible harm to

people or physical damage to equipment and facilities exists

if the associated instructions are not followed properly.

Page 18

1. Safety

2 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

1.2 Design and Installation Safety

Only trained personnel should design and install the robot system. Trained

personnel are defined as those who have taken robot system training held by the

manufacturer, dealer, or local representative compan y, or those who understand the

manuals thoroughly and have the same knowledge and skill level as those who

have completed the training courses.

To ensure safety, a safeguard must be installed for the robot system. Fo r details

on the safeguard, refer to the Installation and Design Precautions in the Safety

chapter of the EPSON RC+ User’s Guide.

The following items are safety precautions for design personnel:

WARNING

■

Personnel who design and/or construct the robot system with this

product must rea d the

Safety c hapter in the EPSON RC+ User’s Guide

to understand the safety requirements before designing and/or

constructing the robot system.

Designing and/or constructing the

robot system without understanding the safety requirements is

extremely hazardous,

and may result in serious bodily injury and/or

severe equipment damage to the robot system.

■

The Manipulator and the Controller must be used within the

environmental conditi ons de sc ribed in their resp ect iv e manu als.

This

product has been designed and manufactured strictly for use in a

normal indoor environ ment.

Using the product in an env ir o nmen t th at

exceeds the specified environmental conditions may not only shorten

the life cycle of the product but may also cause serious safety

problems.

■

The robot system must be used within the installation requirements

described in the manuals.

Using the robot system outside of the

installation require men ts may not only shor ten the life cycl e of the

product but also cause serious safety problems.

Further precautions for installation are mentioned in the following manuals.

Please read this ch apter carefull y to understan d safe install ation proced ures before

installing the robots and robotic equipment.

1.2.1 Relevant Manuals

Refer

This manual : 2. Installation

Manipulator manual : Setup & Operation 3. Environment and Installation

Controller manual : Setup & Operation 3. Installation

Page 19

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 3

1.2.2 Designi ng a Safe Robot System

It is important to operate robots safely. It is also important for robot users to gi ve

careful consideration to the safety of the overall robot system design.

This section summarizes the minimum conditions that should be observed when

using EPSON robots in your robot systems.

Please design and manufacture robot systems in accordance with the principles

described in this and the following sections.

Environmental Conditions

Carefully observe the conditions for installing robots and robot systems that are

listed in the “Environmental Conditions” tables included in the manuals for all

equipment used in the system.

System Layout

When designing the layout for a robot system, carefully consider the possibility of

error between robots and peripheral equipment. Emergency stops require

particular attention, since a robot will stop after following a path that is different

from its normal movement path. The layout design should provide enough

margins for safety. Refer to the manuals for each manipulator, and ensure that

the layout secures ample space for maintenance and inspection work.

When designing a robot system to restrict the area of motion of the robots, do so in

accordance with th e methods descri bed in each manipulator manual. Utilize both

software and mechan ical stops as measures to restrict motion.

Install the emergenc y stop s witch at a location near the operation unit for the robot

system where the operator can easily press and hold it in an emergency.

Do not install the controller at a location where water or other liquids can leak

inside the controller. In addition, never use liquids to clean the controller.

Disabling Power to the System using lock out / tag out

The power connection for the robot controller should be such that it can be locked

and tagged in the off position to prevent anyone from turning on power while

someone else is in th e s afeguar ded area.

For further details, refer to the following section:

1.8 Lockout/Tagout

Page 20

1. Safety

4 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

End Effector Design

Provide wiring and piping that will prevent the robot end effector from releasing

the object held (the work piece) when the robot system power is shut off.

Design the robot end effector such that its weight and moment of inertia do not

exceed the allowable l imits. Use of values th at exceed the allowable limits can

subject the robot to excessive loads. This will not only shorten the service life o f

the robot but can lead to unexpectedly dangerous situations due to additional

external forces ap plied to the end effector and th e work piece.

Design the size of the end effector with care, since the robot body and robot end

effector can interfere with each other.

Peripheral Equipment Design

When designing equipment that removes and supplies parts and materials to the

robot system, ensure that the design provides the operator with sufficient safety.

If there is a need to remove and supply materials without stopping the robot, install

a shuttle device or take o ther measures t o ensure th at the operator does not need to

enter a potentially dangerous zone.

Ensure that an interruption to the power supply (power shutoff) of peripheral

equipment does not lead to a dangerous situation. Take measures that not only

prevent a work piece held from being released as mentioned in “End effector

Design” but that also ensure peripheral equipment other than the robots can stop

safely. Verify equipment safety to ensure that, when the power shuts off, the area

is safe.

Remote Control

To prevent operation by remote control from being dangerous, start signals from

the remote con tro ll er are all owed o n ly when t he co n trol d evice i s s et to RE MOTE,

TEACH mode is OFF, and the system is configured to accept remote signals.

Also when remote is valid, motion command execution and I/O output are

available only fro m remote. F or the safet y of the overall system, h owever, safety

measures are needed to eliminate the risks associated with the start-up and

shutdown of peripheral equipment by remote control.

Emergency Stop

Each robot system needs equipment that will allow the operator to immediately

stop the system’s operation. Install an emergency stop device that utilizes

emergency stop input from the controller and all other equipment.

During an emergency stop, the power that is supplied to the motor driving the

robot is shut off, and the robot is stopped by dynamic braking.

Page 21

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 5

The emergency stop circuit should also remove power from all external

components that must be turned off during an emergency. Do not assume that the

robot controller will turn off all outputs if configured to. For example, if an I/O

card is faulty, the controller cannot turn off a component connected to an output.

The emergency stop on the controller is hardwired to remove motor power from

the robot, but not external power supplies.

For details of the Safeguard system, refer to the following manuals.

1.5 Emergency Stop

Safeguard System

To ensure safety, a safeguard system should be installed for the robot system.

When installing the safeguard system, strictly observe the following points:

Refer to each rob o t manual , an d instal l th e safegu ard syste m ou tsi de th e maxi mum

space. Carefully consid er the size of the end effector and the work p ieces to be

held so that there will be no error between the moving parts and the safeguard

system.

Manufacture th e safeguard system to withst and calculated external force s (forces

that will be added during operation and forces from the surrounding environment).

When designing the safeguard system, make sure that it is free of sharp corners

and projections, and that the safeguard system itself is not a hazard.

Make sure that the safeguard system can on ly be removed by using a tool.

There are several types of safeguard devices, including safety doors, safety barriers,

light curtains, safety gates, and safety floor mats. Install the interlocking function

in the safeguard device. The safeguard interlock must be installed so that the

safeguard interlock is forced to work in case of a device failure or other

unexpected accident. For example, when using a door with a switch as the

interlock, do not rely on the switch’s own spring force to open the contact. The

contact mechanism must open immediately in case of an accident.

Connect the interlock switch to the safeguard input of the drive unit’s

EMERGENCY connector. The safeguard input informs the robot controller that

an operator may be inside the safeguard area. When the safeguard input is

activated, the robot stops immediately and enters pause status, as well as either

operation-prohibited status or restricted status (low power status).

Make sure not to enter the safeguarded area except through the point where the

safeguard interlock is installed.

Page 22

1. Safety

6 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

The safeguard interlock must be installed so that it can maintain a safe condition

until the interlock is released on purpose once it initiates. The latch-release input

is provided for the EMERGENCY connector on the Controller to release the latch

condition of the safeguard interlock. The latch release switch of the safeguard

interlock must be installed outside of the safeguarded area and wired to the

latch-release input.

It is dangerou s to allo w someon e else t o rel ease th e sa feguar d i nt erlo ck by mist ake

while the operator is working inside the safeguarded area. To protect the operator

working inside the safeguarded area, take measures to lock out and tag out the

latch-release switch.

Presence Sensing Device

The above mentioned safeguard interlock is a type of presence sensing device

since it indicates the possibility of somebody being inside the safeguard system.

When separately installing a presence sensing device, however, perform a

satisfactory risk assessment and pay thorough attention to its dependability.

Here are precautions that should be noted :

Design the system so that when th e presence sensin g device is not acti vated

or a dangerous situation still exists that no personnel can go inside the

safeguard area or place their hands inside it.

Design the presence sensing device so that regardless of the situation the

system operates safely.

If the robot stops operating when the presence sensing device is activated, it

is necessary to ensure t hat it does not s tart again until the detected object has

been removed. Make sure that the robot cannot automatical ly restart.

Resetting the Safeguard

Ensure that the robot system can only be restarted through careful operation from

outside the safeguarded system. The robot will n ever restart simply b y resetting

the safeguard interlock switch. Apply this concept to the interlock gates and

presence sensin g devices for the entire system.

Robot Operation Panel

When using the robot operation panel, it must be installed so as to operate the

robot system from outside the safeguard.

Page 23

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 7

1.3 Operation Safety

The following items are safety precautions for qualified Operator personnel:

WARNING

■

Please carefully read the

Safety-related Requirements before

operating the robot system. Operating the robot system without

understanding the safety requirements is extremely hazardous and

may result in serious bodily injury and/or sever

e equipment damage to

the robot system.

■

Do not enter the operating area of the Manipulator while the power to

the robot system is turned ON.

Entering the operating area with the

power ON is extremely hazardous and may cause serious safety

problems as the Manipulator may mov e ev en if i t s ee ms t o be stopped.

■

Before operating the robot system, make sure that no one is inside the

safeguarded area.

The robot system can be oper ate d in the mode for

teaching

even when someone is inside the safeguarded area.

The motion of the Manipulator is always in restricted

status (low

speeds and low power) to secure the safety of an operator.

However,

operating the robot system while someone is inside the safeguarded

area is extremely h az ar dou s a nd m ay resu lt i n serious

safety problem s

in case that the Manipulator moves unexpectedly.

■

Immediately press the Emergency Stop switch whenever the

Manipul

ator moves abnormally while the robot system is operated.

Continuing the operating the robot system while the Manipulator

moves abnormally is extremely hazardous and may result in serious

bodily injury and/or severe equipment change to the robot system.

WARNING

■

Be sure to connect the AC power cable to a power receptacle. DO

NOT connect it directly to a factory power source. To shut off power

to the robot system, pull out the power plug from the power source.

Performing any work while connecting the AC power ca

ble to a factory

power source is extremely hazardous and may result in

electric shock

and/or malfunction of the robot system.

Page 24

1. Safety

8 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

1.3.1 Safety-related Requirements

Specific tolerances and operating conditions for safety are contained in the

manuals for the robot, controller and other devices. Be sure to read those

manuals as well.

For the installation and operation of the robot system, be sure to comply with the

applicable local and national regulations.

Robot systems safety standards and other examples are given in this chapter.

Therefore, to ensure that safety measures are complete, please refer to the other

standards listed as well.

(Note: The following is only a partial list of the necessary safety standards.)

EN ISO 10218-1

Robots and robotic devices -- Safety requirements for industrial

robots -- Part 1: Robots

EN ISO 10218-2

Robots and robotic devices -- Safety requirements for industrial

robots -- Part 2: Robot systems and integration

ANSI/RIA R15.06

American National Standard for Industrial Robots and Robot

Systems -- Safety Requir ements

EN ISO 12100

Safety of machinery -- General principles for design -- Risk

assessment and r isk reduction

EN ISO 13849-1

Safety of machinery -- Safety-related parts of control systems --

Part 1: General principles for design

EN ISO 13850

Safety of machin ery -- Emergency stop -- Principles for design

EN ISO 13855

Safety of machinery -- P ositioning of safeguards with respect to the

approach speeds of parts of the human body.

EN ISO 13857

Safety of machinery -- Safety distances to prevent hazard zones

being reached by upper and lower limbs.

ISO14120

EN953

Safety of machinery -- Guards -- General requirements for the

design and construction of fixed and movable guards

IEC 60204-1

EN 60204-1

Safety of machiner y -- El ectrical equipment of machines -- P art 1:

General requirements

CISPR11

EN55011

Industrial, scientific and medical (ISM) radio-frequency equipment

-- Electromagnetic disturbance characteristics --

Limits and

methods of measurement

IEC 61000-6-2

EN 61000-6-2

Electromagnetic compatibility (EMC) -- Part 6-2: Generic

standards -- Immunity for industrial environments

Page 25

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 9

1.3.2 Part Names / Arm Motion

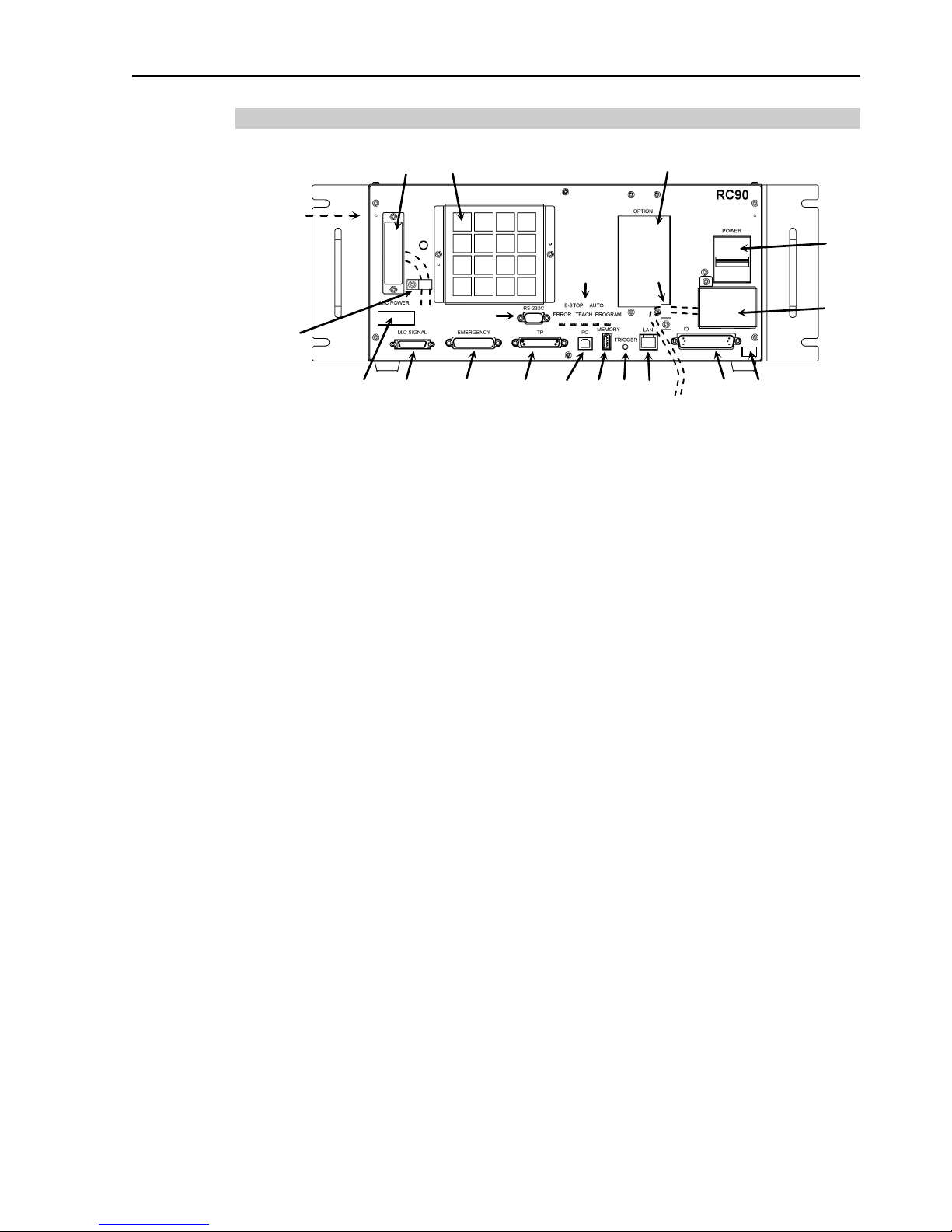

(3)

(19)

(12) (13) (14) (15) (16) (17) (7)

(4)

(1)

(11) (10)

(9)

(20)

(20)

(18)

(5)

(6)

(Left side)

(2)

(8)

(1) POWER switch

(2) AC IN

(3) LED

(4) Fan Filter

(5) Signature label

(6) MT label

(7) Controller Nu mber lab el

(8) Connectio n Check labe l

(9) M/C PO WER connector

(10) M/C SIGNAL connector

(11) EMERGENCY connector

(12) TP port

(13) Development PC connection port

(14) Memory port

(15) Trigg er Switch

(16) LAN (Ethernet communication) port

(17) I/O connector

(18) Standard RS-232C port

(19) Option slot

(20) Cable Clamp

(21) Battery (Mounted inside the controller)

Page 26

1. Safety

10 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

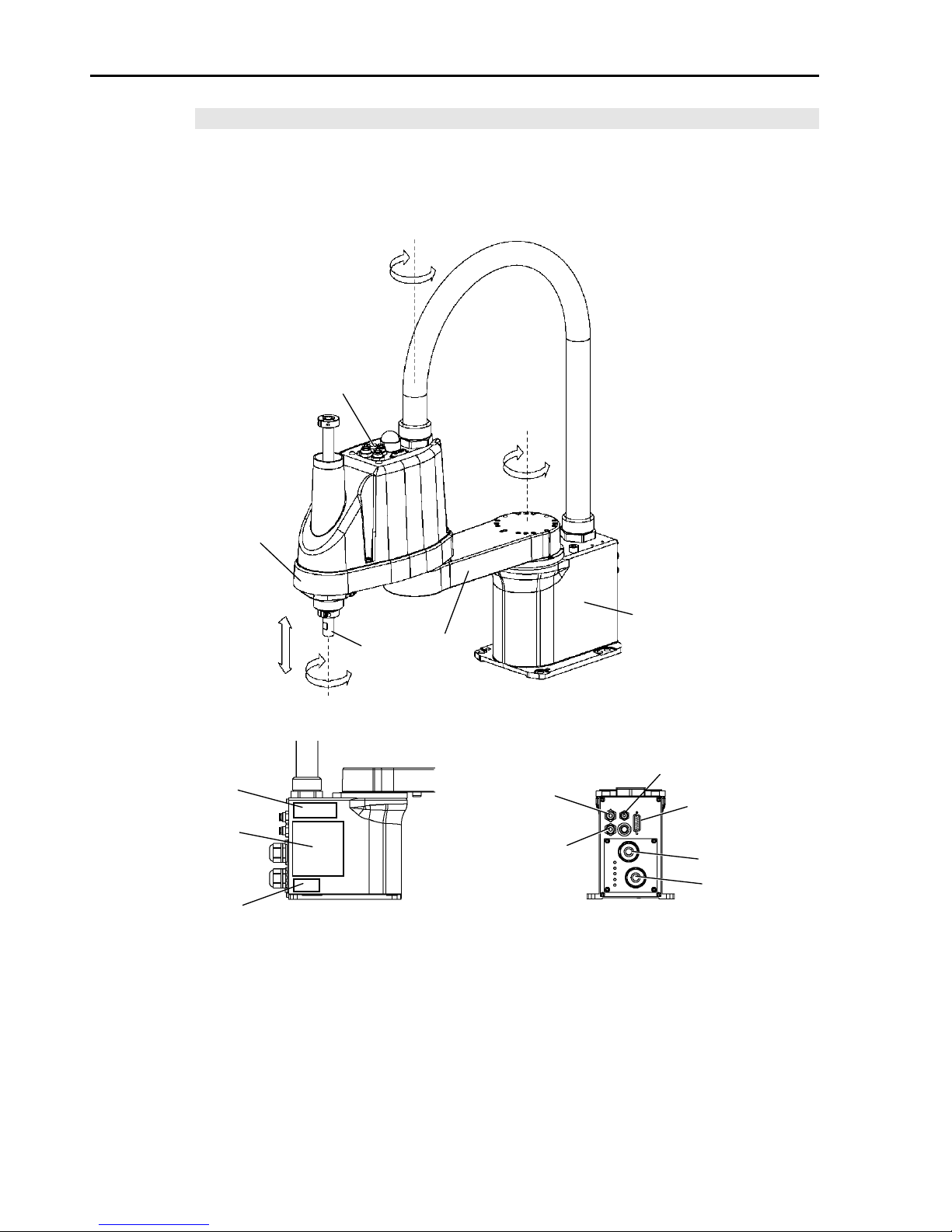

LS3 / LS6

The motion range of each arm is shown in the figure below. Take all

necessary safety precautions.

Joint #3

Brake release switch

Arm #1

Arm #2

Base

Shaft

MT label

(only for custom

specification)

Signature label

(Serial No.

of Manipulator)

Signal cable

Power cable

Fittings (black or blue)

for ø4 mm pneumati c tub e

Fittings (black or blue)

for ø6 mm

pneumatic tube

Fittings (white)

for ø6 mm

pneumatic tube

User connector

(15-pin

D-sub connector)

CE label

+

+

+

+

-

-

-

-

Joint #2

(Rotation)

Joint #1

(Rotation)

Joint #3

(Up/Down)

Joint #4

(Rotation)

Page 27

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 11

When the system is placed in emergency mode, push the arm or joint of

the Manipulator by hand as shown below:

Arm #1 Push the arm by hand.

Arm #2 Push the arm by hand.

Joint #3 The joint cannot be moved up/down by hand until the

solenoid brake applied to the joint has been released.

Move the joint up/down while pressing the brake release

switch.

Joint #4 LS3: Rotate the shaft by hand.

LS6: The shaft cannot be rotated by hand until the

solenoid brake applied to the shaft has been

released. Move the shaft while pressing the

brake release switch.

LS3: The brake release switch affects only Joint #3. When the brake

release switch is p ressed in emergency mode, th e brake for Joint #3

is released.

Be careful of the shaft while the brake release switch is pressed

because the shaft may be lowered by the weight of an end effector.

LS6: The brake release switch affects both Joints #3 and #4. When the

brake release switch is p ress ed in emergen cy mod e, th e b rake for both

Joints #3 and #4 are released simultaneously.

Be careful of the shaft falling and rotating while the brake release

switch is pressed because the shaft may be lowered by the weight of

an end effector.

NOTE

Page 28

1. Safety

12 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

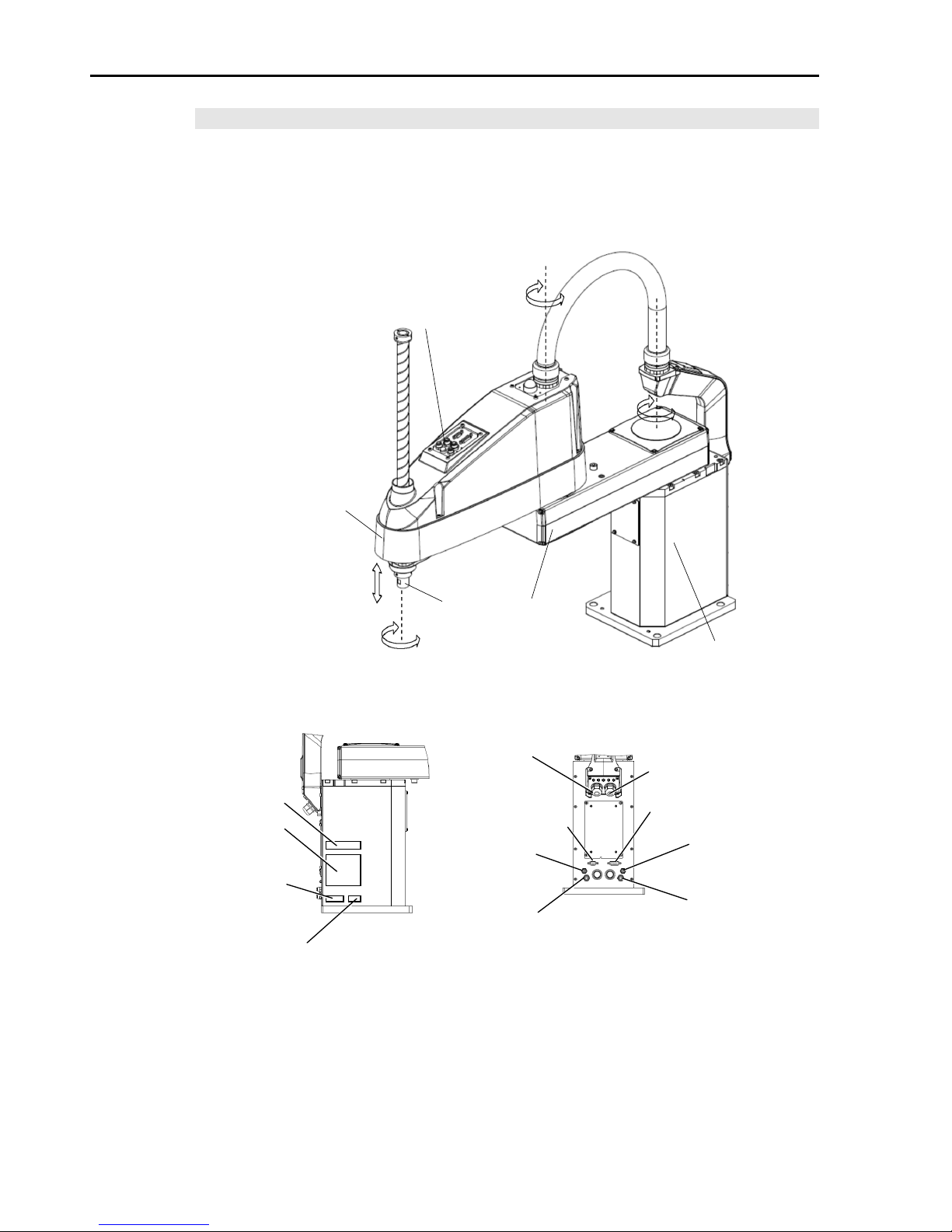

LS20

The motion range of each arm is shown in the figure below. Take all

necessary safety precautions.

Joint #3 / Joint #4

Brake release switch

Joint #1

(Rotation)

Joint #2

(Rotation)

Joint #3

(Up/Down)

Joint #4

(Rotation)

Arm #1

Arm #2

+

-

+

- + -

+

-

Shaft

(Figure: LS20-804S)

Base

MT label

(only for custom

specification)

Signature label

(Serial No.

of Manipulator)

Signal cable

Power cable

Fittings (blue)

for ø4 mm

pneumatic tube

Fittings (blue) for

ø6 mm

pneumatic tube

Fittings (white) fo r

ø6 mm

pneumatic tube

User connector

(15-pin D-sub connector)

CE label

User connector

(9-pin D-sub connector)

Fittings (white) fo r

ø4

mm

pneumatic tube

KC Mark

Page 29

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 13

When the system is placed in emergency mode, push the arm or joint of

the Manipulator by hand as shown below:

Arm #1 Push the arm by hand.

Arm #2 Push the arm by hand.

Joint #3 The joint cannot be moved up/down by hand until the

solenoid brake applied to the joint has been released.

Move the joint up/down while pressing the brake release

switch.

Joint #4 The shaft cannot be rotated by hand until the solenoid

brake applied to the shaft has been released. Move the

shaft while pressing the brake release switch.

The brake release s witch affects both Joints #3 and #4. When the brake

release switch is p ressed in emergency mode, the brakes for both Joints

#3 and #4 are released simultaneously. Be careful of the shaft falling

and rotating while the brake release switch is pressed because the shaft

may be lowered by the weight of an end effector.

NOTE

Page 30

1. Safety

14 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

1.3.3 Operation Modes

The operation mode is defined as the single control point for the controller,

therefore you cannot use more than one ope r a ti on mode at the s am e time .

There are four operation modes for the controller: AUTO, PROGRAM,

TEACH, and TEST.

- AUTO operation modes allow you to execute programs in the

controller when the safeguard is closed.

- PROGRAM operation mode allows you to execute and debug

programs when the safeguard is closed.

- TEACH operation mode allows you to jog and teach the robot at

slow speed while in s ide the safeguarded ar ea.

- TEST operation mode allows you to execute a program at slow speed

while the safeguard is opened.

Page 31

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 15

1.4 Maintenance Safety

Please read this section, Maintenance of the Manipulator manual, Maintenance of

the Controller manual, and other related manuals carefully to understand safe

maintenance pr ocedures before performing any maintenance.

Only authorized personnel who have taken the safety training should be allowed to

maintain the robot system. The safety training is the program for the industrial

robot operator that follows the laws and regulations of each nation.

The personnel who have taken the safety training acquire knowledge of industrial

robots (operations, teaching, etc.), knowledge of inspections, and knowledge of

related rules/regulations. Only personnel who have completed the robot

system-training and maintenance-training classes held by the man ufactu rer, dealer,

or locally-incorporated company shoul d be allowed to maintain the robot system.

WARNING

■

Do not remove any parts that are not covered in th

is manual. Follow

the maintenance procedure strictly as described in this manual

,

Maintenance

of the Manipulator manual, and Maintenance of the

Controller manual

. Improper removal of parts or impro per

maintenance may not only cause impr oper funct ion of th e robot sy stem

but also serious safety problems.

■

Keep away from the Manipulator while

the power is ON if you have not

taken the training courses.

Do not enter the operating area while the

power

is ON. Entering the operating area with the power ON is

extremely hazardous and may cause serious safety problems as the

Manipulator may move

even though it seems to be stopped.

■

When you check the operation of the

Manipulator after replacing parts,

be sure to

check it while you are outside of the safeguarded area.

Checking the operation of the Manipulator while you are inside of the

safeguarded area may cause serious safety problems as the

Manipulator may move unex

pectedly.

■

Before

operating the ro bot system, make sur e tha t both the Emergency

S

top switches and safeguard switches function properly. Operating

the robot system when the switches do not function properly is

extremely hazardous and may result in serious bodily injury and/or

serious damage

to the robot system as the switches cannot fulfill their

intended functions in an emergency.

Page 32

1. Safety

16 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

WARNING

■

Be sure to connect the AC power cable to a power receptacle. DO

NOT connect it directly to a factory power source. To shut off power

to

the robot system, pull out the power plug from the power source.

Performing any work while connecting the A

C power cable to a factory

power source is extremely hazardous and may result in

electr ic shock

and/or malfunction of the robot system.

■

Before

performing any replacement procedure, turn OF F the Controller

and related equipment ,

and then pul l out t h e power plug from the power

source.

Performing any replacement procedure with the power ON is extremely

hazardous and may result in

electric shock and/or malfunction of the

robot system.

■

Be sure to connect the cables properly.

Do not allow unnecessary

strain on the cables.

(Do not put heavy obje cts on the cables. Do not

bend or pull the cables for ci bly.)

The unnecessary strai n on the cables

may result in damage to the cables, disconnection, and/or contact

failure.

Damaged cables, dis connect ion, or contact fa ilure i s ex tremely

hazardous and may result in electric shock and/or improper function of

the robot system.

CAUTION

■

Carefully use

alcohol, liquid gasket, and adhesive following respective

instructions

and also in structi o ns below. Careless use o f alc ohol, liq uid

gasket, or adhesive may cause a fire and/or safety problems.

- Never put alcohol, liquid gasket, or adhesive close to fire.

- Use alcohol, liquid gasket, or adhesive while ventilating the room.

-

Wear protective gear including a mask, protective goggles, and

oil-resistant gloves.

- If alcohol, liquid gas ket, or ad h esive gets on your sk in, wash t he area

thoroughly with soap and water.

- If alcohol, liquid gasket, or adhesive gets into your eyes or mouth,

flush your eyes or wash out your mouth with clean water thoroughly,

and then see a doctor immediately.

Page 33

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 17

CAUTION

■

Wear protective gear inc lud ing a mask, protect iv e goggle s, and

oil

-resistant gloves during grease up. If grease gets into your eyes,

mouth, or on your skin, follow the instructions below.

If grease gets into your eyes:

Flush them thoroughly with clean water, and then see a doctor

immediately.

If grease gets into your mouth:

If swallowed, do not induce vomiting. See a doctor immediately.

If grease just gets into your mouth, wash out your mouth with

water thoroughly.

If grease gets on your skin:

Wash the area thoroughly with soap and water.

Page 34

1. Safety

18 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

1.5 Emergency Stop

Emergency stop motions of the Manipulator vary depending on the controller

firmware. See the section for the Controller firmware of your Control ler.

1.5.1 Free running distance in emergency

Controller Firmware Ver. 7.0.2.3 or earlier

If the Manipulator moves abnormally during operation, immediately press the

Emergency Stop switch. The mot or power will be turned OFF, and t he arm

motion by inertia will be stopped with the electromagnetic brake and dynamic

brake.

However, avoid pressing the Emergency Stop switch unnecessarily while the

Manipulator is running normally. Otherwise, the Manipulator may hit the

peripheral equipment since the operating trajectory while the robot system stops is

different from that in normal operation. It may also result in short life of the

reduction gear u nit due to the shock or the electromagnetic brake du e to the worn

friction plate.

To place the robot system in emergency mode during normal operation, press the

Emergency Stop switch when the Manipulator is not moving.

Refer to the Controller manual for instructions on how to wire the Emergency Stop

switch circuit.

Do not press the Emergency Stop switch unnecessarily while the Manipulator is

operating. Pressing the switch during the operation makes the brakes work.

This will shorten the life of the brakes due to the worn friction plates.

Normal brake life cycle: About 2 years (when the br akes ar e used 100 times/day)

Do not turn OFF the Controller while the Manipulator is operating.

If you attempt to stop the Manipulator in emergency situations such as “Safeguard

Open”, make sure to stop the Manipulator using the E-STOP switch of the

Controller.

If the Manipulator is stopped by turning OFF the Controller while it is operating,

following problems may occur.

Reduction of the life and damage of the reduction gear unit

Position gap at the joints

In addition, if the Controller was forced to be turned OFF by blackouts and the like

while the Manipulator is operating, make sure to check the following points after

power restoration.

Whether or not the reduction gear is damaged

Whether or not the joints are in their proper positions

Page 35

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 19

If there is a position gap, perform calibration by referring to Maintenance:

Calibration in the manipulator manual.

Manipulator manuals contain information on the Emergency Stop. Please also

read the descriptions in the manuals and use the robot system properly.

Before using the Emergency Stop switch, be aware of the followings.

- The Emergency Stop (E-STOP) switch should be used to stop the

Manipulato r only in case of emergencies.

- To stop the Manipulator operating the program except in emergency, use

Pause (halt) or STOP (program stop) commands

Pause and STOP commands do not turn OFF the motors. Therefore, the

brake does not function.

- For the Safeguard system, do not use the circuit for E-STOP.

For details of the Safeguard system, refer to the following manuals.

EPSON RC+ User ’s Guide

2 . Safety - Installation and Design Precautions - Safeguard System

Safety and Installation

2.6 Connection to EMERGENCY Connector

To check brake problems, refer to the following manuals.

Manipulator Manual Maintenance

2.1.2 Inspection Point - Inspection While the Power is ON

(Manipulator is operat i n g)

Safety and Installation

5.1.1 Manipulator - Inspection While the Power is ON

(Manipulator is operat i n g)

Page 36

1. Safety

20 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

The operating Manipulator cannot stop immediately after the Emergency Stop

switch is pressed.

The free running time/angle/distance of the Manipulator are shown below.

However, remember that the values vary depending on following conditions.

Weight of the end effector Weight of work piece Operating pose

Weight Speed Accel etc.

Point where the

emergency stop

signal is input

Joint #1

Start point of

operation

Target point

Stop point

Joint #2

Conditions for Measurement

LS3-401*

LS6-602*

Accel Setting

100

100

Speed Setting

100

100

Load [kg]

3

4

Weight Setting

3

4

Controller

RC90

Manipulator

LS3-401*

LS6-602*

Free running time

Joint #1 + Joint #2 [sec.]

0.4

0.7

Joint #3 [sec.]

0.1

0.2

Free running angle

Joint #1 [deg.]

110

100

Joint #2 [deg.]

20

45

Joint #1 + Joint #2 [deg.]

130

130

Free running distance

Joint #3 [mm]

20

50

Page 37

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 21

Controller Firmware Ver. 7.0.2.4 or later

If the Manipulator moves abnormally during operation, immediately press the

Emergency Stop switch. Pressing the Emergency Stop switch immediately

changes the manipulator to deceleration motion and stops it at the maximum

deceleration s peed.

However, avoid pressing the Emergency Stop switch unnecessarily while the

Manipulator is running normally. Pressing the Emergency Stop switch locks the

brake and it may cause we ar on the friction plate of the brake, resulting in the short

life of the brake.

Normal brake life cycle: About 2 years (when the b rakes are used 100 times/day)

To place the system in emergency mode during normal operation, press the

Emergency Stop switch when the Manipulator is not moving.

Refer to the Controller manual for instructions on how to wire the Emergency Stop

switch circuit.

Do not turn OFF the Controller while the Manipulator is operating.

If you attempt to stop the Manipulator in emergency situations such as “Safeguard

Open”, make sure to stop the Manipulator using the Emergency Stop switch of the

Controller.

If the Manipulator is stopped by turning OFF the Controller while it is operating,

following problems may occur.

Reduction of the life and damage of the reduction gear unit

Position gap at the joints

In addition, if the Controller was forced to be turned OFF by blackouts and the like

while the Manipulator is operating, make sure t o check the following points after

power restoration.

Whether or not the reduction gear is damaged

Whether or not the joints are in their proper positions

If there is a position gap, perform calibration by referring to the Maintenance 13.

Calibration in this manual.

Before using the Emergency Stop switch, be aware of the followings.

- The Emergency Stop (E-STOP) switch should be used to stop the

Manipulato r only in case of emergencies.

- To stop the Manipulator operating the program except in emergency, use

Pause (halt) or STOP (program stop) commands

Pause and STOP commands do not turn OFF the motors. Therefore, the

brake does not function.

- For the Safeguard system, do not use the circuit for E-STOP.

Page 38

1. Safety

22 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

For details of the Safeguard system, refer to the following manuals.

EPSON RC+ User ’s Guide

2 . Safety - Installation and Design Precautions - Safeguard System

Safety and Installation

2.6 Connection to EMERGENCY Connector

To check brake problems, refer to the following manuals.

Manipulator Manual Maintenance

2.1.2 Inspection Point - Inspection While the Power is ON

(Manipulator is operat i n g)

Safety and Installation

5.1.1 Manipulator - Inspection While the Power is ON

(Manipulator is operat i n g)

Free running distance in emergency

The operating M anipulator cannot stop immedi ately after the Emergency Stop

switch is pressed.

The free running time/angle/distance of the Manipulator are shown below.

However, remember that the values vary depending on following conditions.

Weight of the end effector Weight of work piece Operating pose

Weight Speed Accel etc.

Page 39

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 23

LS3 / LS6

Conditions for

Measurement

LS3-401* LS6-502*, 602*, 702*

Accel Setting

100

100

Speed Setting

100 100

Load [kg]

3 6

Weight Setting

3

6

Joint #1

Joint #2

Stop point

Point where the

emergency stop

signal is input

Target point

Start point of

operation

Controller RC90

Manipulator LS3-401* LS6-502* LS6-602* LS6-702*

Free running

time

Joint #1 + Joint #2 [sec.] 0.4 0.4 0.7 0.7

Joint #3 [sec.] 0.1 0.2

Free running

angle

Joint #1 [deg.] 110 42 100 85

Joint #2 [deg.] 20 42 45 50

Joint #1 + Joint #2 [deg.] 130 84 130 135

Free running

distance

Joint #3 [mm] 20 90

Page 40

1. Safety

24 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

LS20

Conditions for

Measurement

LS20-804*

LS20

-A04*

Accel Setting

100

100

Speed Setting

100

100

Load [kg]

20

20

Weight Setting

20

20

Joint #1

Stop point

Point where the

emergency stop

signal is input

Target point

Start point of

operation

Joint #2

Controller RC90

Manipulator LS20-804* LS20-A04*

Free running time

Joint #1 + Joint #2 [sec.] 0.65 0.7

Joint #3 [sec.] 0.3

Free running angle

Joint #1 [deg.] 65 70

Joint #2 [deg.] 50 50

Joint #1 + Joint #2 [deg.] 115 120

Free running distance Joint #3 [mm] 110

Page 41

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 25

1.5.2 How to Reset the Emergency Mode

Select EPSON RC+ [Tools] – [Robot Manager] – [Control Panel] tab, and then

click <Reset>.

The Control Panel page contains buttons for basic robot operations, such as

turning motors on/off and homing the robot. It also shows status for Emergency

Stop, Safeguard, Motors, and Power.

Page 42

1. Safety

26 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

1.6 Labels

Labels are attached around the locations of the Controller and Manipulator where

specific dangers exi st.

Be sure to comply with descriptions and warnings on the labels to operate and

maintain the Robot System safely.

Do not tear, damage, or remove the labels. Use meticulous care when handling

those parts or units to which the following labels are attached as well as the nearby

areas:

1.6.1 Controller

Location

Label

Note

A

Residual voltage exists. To avoid

electric shock, do not open the cover

while the Power is ON, or for 300

seconds after the Power is OFF.

B

Disconnect and lockout main power

before performing maintenance and

repair.

C

TP port of RC90 is for the Teach Pendant

TP1 and TP2. Do not connect the

followings to TP port of RC90.

Connecting to the followings may result in

malfunction of the device.

OPTIONAL DEVICE dummy plug,

OP500, OP500RC, JP50 0, T P -3** seri es,

and OP1

Refer to 4.3 Connection of Option

Teaching Pendant.

A

C

B

Page 43

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 27

1.6.2 Manipulator

Location

Label

Note

A

Before lo

osening the base mounting

screws, hold the arm a nd secu re it tig htly

with a band to prevent hands or fingers

from being caught in the Manipulator.

For installation and transportation of

robots

, follow the directions in this

manual.

B

Do not enter the opera tion ar ea w hile the

Manipulator is moving. The robot arm

may collide against the operator. This

is extremely hazardous and may result

in serious safety problems.

C

Hazardous voltage exists while the

Manipulator is ON. To avoid electric

shock, do not touch any internal electric

parts.

D

You can catch your hand or fingers

between the shaft and cover when

bringing your hand close to moving

parts.

Manipulators with bellows do not have

this label for no danger of your hand or

fingers being caught

E

Only authorized personnel should

perform sling work and operate a crane

and a forklift. When these operations

are performed

by unauthorized

personnel, it is extremely haz a rdous and

may result in serious bodily injury and/or

severe equipment damage to the robot

system.

Page 44

1. Safety

28 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

Location

Label

Note

F

Be careful of the

shaft falling and

rotating while the brake release switch

is pressed because

the shaft may be

lowered by the weight of the end

effector.

Page 45

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 29

LS3

C

A

D

B

C

(Figure: LS3-401S)

LS6

C (Arm #1 Cover)

A

D

B

C

(Figure: LS6-602S)

Page 46

1. Safety

30 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

LS20

C A D

B

C

E

(Opposite side)

F

(Figure: LS20-804S)

Page 47

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 31

1.7 Safety Features

The robot control system supports safety features described below. However, the

user is recommended to strictly follow the proper usage of the robot system by

thoroughly readi ng the attach ed manuals befo re using the system. Fai lure to read

and understand the proper usage of the safety functions is highly dangerous.

Among the following safety features, the Emergency Stop Switch and Safety Door

Input are particu larly importan t. Make sure that these and other featur es functio n

properly before operating the robot system.

For details, refer to the 2.5 Controller Installation - Safety Door Swit ch and La tch

Release Switch.

Emergency Stop Switch

The EMERGENCY connector on the Controller has expansion Emergency Stop

input terminals used for connecting the Emergency Stop switches.

Pressing any Emergency Stop switch can shut off the motor power immediately

and the robot system will enter the Emergency Stop condition.

Safety Door Input

In order to activate this feature, make sure that the Safety Door Input switch is

connected to the EMERGENCY connector at the Controller.

When the safety door is opened, normally the Manipulator immediately stops the

current operation, and the status of Manipulator power is operation-prohibited

until the safety door is closed and the latched condition is released. In order to

execute the Mani pulator operation while the safety door is open, you must change

the mode selector key switch on the Teach Pendant to the “Teach” mode.

Manipulator operation is available only when the enable switch is on. In this

case, the Manipulator is operated in low power status.

Page 48

1. Safety

32 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

Low Power Mode

The motor power is reduced in this mode.

Executing a power status change instruction will change to the restricted (low

power) status regardless of conditions of the safety door or operation mode. The

restricted (lo w power)

status ensures the safety of the operator and reduces the

possibility of peripheral equipment destruction or damage caused by careless

operation.

Dynamic Brake

The dynamic brake circuit includes relays that short the motor armatures. The

dynamic brake circuit is activated when t here is an Emergenc y Stop input or when

any of the following errors is detected: encoder cable disconnection, motor

overload, irregular motor torque, motor speed error, servo error (positioning or

speed overflo w), irregular CPU, me mory check-sum erro r and overheat condition

inside the Motor Driver Module.

Motor Overload Detection

The dynamic brake circuit is activated when the system detects that the load on the

motor has exceeded its capacity.

Irregular Motor Torque (out-of-contr ol mani pul ator ) Det ec tion

The dynamic brake circuit is activated when irregularity with motor torque (motor

output) is detected (in which case the Manipulator is out of contro l).

Motor Speed Error Detection

The dynamic brake ci rcuit is activated when the system detects that th e motor is

running at incorrect speed.

Positioning Overflow -Servo Error- Detection

The dynamic brake circuit is activated when the syste m detects that t he difference

between the Manipulator’s actual position and commanded position exceeds the

margin of error allowed.

Speed Overflow -Servo Error- Detection

The dynamic brake circuit is activated when the Manipulator’s actual speed is

detected to mark an overflow (the actual sp eed is outside the nominal range) er ror.

Page 49

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 33

CPU Irregularity Detection

Irregularity of CPU that controls the motor is detected by the watchdog timer.

The system CPU and the motor controlling CPU inside the Controller are also

designed to const antly check each o ther for any discr epan cies. If a discrepancy is

detected, th e dynamic brake circuit is activated.

Memory Check-sum Error Detection

The dynamic brake circuit is activated when a memory check-sum error is

detected.

Overheat Detection at the Motor Driver Module

The dynamic brake circuit is activated when the temperature o f the power device

inside the Motor Driver module is above the nominal limit.

Relay Deposition Detection

The dynamic brake circuit is activated when relay deposition is detected.

Over-Voltage Detection

The dynamic brake circuit is activated when the voltage of the Controller is above

the normal limit.

AC Power Supply Voltage Drop Detection

The dynamic bra ke circuit is a ctivated when the drop of the power supply voltage

is detected.

Temperature Anomaly Detection

The temperature an omaly is detected.

Fan Malfunction Detection

Malfunction of the fan rotation speed is detected.

Page 50

1. Safety

34 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

1.8 Lockout / Tagout

Lockout / tagout is a method to prevent anyone from turning ON the robot system

by mistake while so meone else is within the safeguarded area for maintenance o r

repair.

When performing maintenance and repair, lockout and tagout using the following

procedure. Use the lockout attachment for RC90.

Installing the Lockout Attachment

(1) Turn OFF the POWER switch and place the lockout attachment on the

POWER switch.

Insert the pin in t he hole s unde r the retractable actuator.

Push the pin in the

direction of arrows, and

insert the pin in the holes.

POWER

switch

Lockout

Attachment

Hole

Pin

(2) Turn the lockout

attachment.

(3) Install the lockout

attachment on the switch.

(4) Slide the pin to

the lock position.

Lock position

Page 51

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 35

Padlock Size and Weight

The padlock is not supplied with the lockout attachment and must be supplied by

the user.

The total weight of the padlock can be a maximum of 45 g.

Make sure the padlock weight does not exceed 45 g, otherwise th e POWER switch

may be damaged.

Applicable Padlock

Safety Precautions

When using the padlock, do not use the controller where it is subject to vibration

or shock, oth er wise failure or damage may result.

Do not apply a force of more than 50N on the lockout attachment; otherwise the

lockout attachment will be damaged.

Page 52

1. Safety

36 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

1.9 Manipulator Specifications

LS3 / LS6

Item

LS3-401*

LS6-602*

Arm length

Arm # 1, #2 400 mm

50

500 mm

60

600 mm

70

700 mm

Arm # 1 225 mm

50 225 mm

60

325 mm

70 425 mm

Arm # 2

175 mm

275 mm

Max.

operating speed

*1

Joints #1, #2 6000 mm/s

50

6150 mm/s

60

6800 mm/s

70 7450 mm/s

Joint #3 1100 mm/s

Joint #4

2600 deg./s

2000 deg/s

Repeatability

Joints #1, #2

± 0.01 mm

± 0.02 mm

Joint #3 ± 0.01 mm

Joint #4

±

0.01 deg.

Payload (Load)

Rated

1 kg

2 kg

Max.

3 kg

6 kg

Joint #4 allowable

moment of inertia

*2

Rated

0.005 kg· m2

0.01 kg·m2

Max.

0.05 kg·m2

0.12 kg·m2

Resolution

Joint #1

0.00043 9 deg./pulse

0.00027 5 deg/pulse

Joint #2

0.00043 9 deg./pulse

Joint #3

0.000799 mm/pulse

0.000814 mm/pulse

Joint #4

0.00192 7 deg./pulse

0.00146 5 deg/pulse

Hand

Shaft diameter

ø 16 mm

ø 20 mm

Through hole

ø 11 mm

ø 14 mm

Mounting hole

120 × 120 mm / 135 × 120 mm

(Free choice of either hole.)

150 × 150 m m

4-M8

Weight (cables not included)

14 kg : 31 lb

50

17 kg : 37.5 lb

60

17 kg : 37.5 lb

70

18 kg : 39.7 lb

Driving method

All joints

AC servo motor

Page 53

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 37

Item

LS3-401*

LS6-602*

Motor

energy consumption

Joint #1

200 W

Joint #2

100 W

200 W

Joint #3 100 W

Joint #4

100 W

Option

Installation

environment

Cleanroom *3

Joint #3 down force

100 N

Installed wire for customer use 15 (15 pin: D-sub)

Installed pneumatic

tube for customer use

2 pneumatic tubes (ø6 mm) : 0.59 Mpa (6 kgf/cm2 : 86 psi)

1 pneumatic tubes (ø4 mm) : 0.59 Mpa (6 kgf/cm2 : 86 psi)

Environmental

requirements

Ambient Temp. 5 to 40 degrees C (with minimum temperature variation)

Ambient relative

humidity

10 to 80% (no condensation )

Noise level *4

L

Aeq

= 70 dB (A)

Applicab le Controller

RC90

Assig nable Value

( ) Default values

SPEED

1 to (5) to100

ACCEL *5

1 to (10) to 120

SPEEDS

1 to (50) to 2000

ACCELS

1 to (200) to 25000

FINE 0 to (1250) to 65000

WEIGHT

0,175 to (1,175) to 3,175

0,275 to (2,275) to 6,275

Safety standard

CE Mark

EMC Directive

Machinery Directive

RoHS Directive

KC Mark / KCs Mark

Item

LS3-401S

LS3-401C

LS6-**2S

LS6**02C

Max.

motion

range

Joint #1

± 132 deg

Joint #2

± 141 deg

± 150 deg

Joint #3

150 mm

120 mm

200 mm

170 mm

Joint #4

± 360 deg

Max.

pulse

range

Joint #1

- 95574~505174 pulse

- 152918~808278 pulse

Joint #2

± 320854 pulse

± 341334 pulse

Joint #3

-187734~ 0 pulse

-150187~ 0 pulse

-245760~ 0 pulse

-208896~0 pulse

Joint #4

± 186778 pulse

± 245760 pulse

Page 54

1. Safety

38 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

LS20

Item LS20-804* LS20-A04*

Arm length

Arm # 1, #2

800 mm

1000 mm

Arm # 1 350 mm 550 mm

Arm # 2

450 mm

450 mm

Max.

operating speed

*1

Joints #1, #2

9940 mm/s

11250 mm/s

Joint #3

2020 mm/s

Joint #4

1400 deg/s

Repeatability

Joints #1, #2

±

0.025 mm

Joint #3

±

0.01 mm

Joint #4

± 0.01 deg

Payload (Load)

Rated

10 kg

Max.

20 kg

Joint #4 allowable

moment of inertia *2

Rated

0.05 kg·m2

Max.

0.45 kg·m2

Resolution

Joints #1

0.00027 5 deg/pulse

Joint #2

0.00043 9 deg/pulse

Joint #3

0.00148 mm/pulse

Joint #4

0.00104 6 deg/pulse

Hand

Shaft diameter

ø 25 mm

Through hole

ø 18 mm

Mounting hole

200 × 200 mm

4 × ø16

Weight (cables not included)

47 kg : 103.6 lb

50 kg : 110.2 lb

Driving method

All joints

AC servo motor

Motor

energy consumption

Joint #1

750 W

Joint #2 600 W

Joint #3

400 W

Joint #4

150 W

Option

Installation environment

Cleanroom *3

Joint #3 down force

250 N

Installed wire for customer use

15 pin: D-sub, 9 pin: D-sub

Installed pneumatic

tube for customer use

2 pneumatic tubes (ø6 mm) : 0.59 Mpa (6 kgf/cm2 : 86 psi)

2 pneumatic tubes (ø4 mm) : 0.59 Mpa (6 kgf/cm2 : 86 psi)

Page 55

1. Safety

Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6 39

Item LS20-804* LS20-A04*

Environmental

requirements

Ambient Temp.

5 to 40 °C (with minimum temperature variation)

Ambient relative humidity

10 to 80 % (no condensation)

Noise level *4

L

Aeq

= 70 dB (A)

Applicab le Controller RC90

Assig nable Value

( ) Default values

Speed

1 to (5) to 100

Accel *5

1 to (10) to 120

SpeedS

1 to (50) to 2,000

AccelS

1 to (200) to 10,000

Fine

0 to (1,250) to 65,000

Weight

0,450 to (10,450) to 20,450

Safety standard

CE Mark

EMC Directive

Machinery Directive

RoHS Directive

KC Mark / KCs Mark

Item

LS20-804S

LS20-A04S

LS20-804C

LS20-A04C

Max.

motion range

Joint #1

± 132 deg

Joint #2

± 152 deg

Joint #3

420 mm

390 mm

Joint #4

± 360 deg

Max.

pulse range

Joint #1

- 152918 to 808278

Joint #2

± 345885

Joint #3

-283853 to 0

-263578 to 0

Joint #4

± 344064

Page 56

1. Safety

40 Safety and Installation (RC90 / EPSON RC+ 7.0) Rev.6

*1: In the case of PTP command.

Maximum operating speed for CP command is 2000 mm/s on horizontal plane.

*2: In the case where the center of gravity is at the center of Joint #4.

If the center of gravity is not at the center of Joint #4, set the parameter using Inertia

command.

*3: The exhaust system in the Cleanroom-model Manipulator draws air from the base interior

and arm cover interi or together.

A crack or other openi ng in the base unit can cause loss o f negative air p ressure in th e outer

part of the arm, which can cause increased dust emission.

Seal the exhaust port and the exhaust tube with vinyl tape so that the joint is airtight.

If the exhaust flow is not sufficient, dust particle emission may exceed the specified

maximum level.

Cleanliness level : Class ISO 4 (ISO14644-1)