Page 1

Page 2

®

EPSON

LQ-800 and LQ-1000 Printers

User's Manual

Page 3

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment generates and uses radio frequency energy and if not installed and used

properly, that is, in strict accordance with the manufacturer’s instructions, may cause

interference to radio and television reception. It has been type tested and found to comply

with the limits for a Class B computing device in accordance with the specifications in

Subpart J of part 15 of FCC Rules, which are designed to provide reasonable protection

against such interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

-

Reorient the receiving antenna

-

Relocate the computer with respect to the receiver

- Plug the computer into a different outlet so that the computer and receiver are on

different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user may find the following booklet prepared by the

Federal Communications Commission helpful:

“How to Identify and Resolve Radio-TV Interference Problems.”

This booklet is available from the U.S. Government Printing Office, Washington, DC

20402. Stock No. 004-000-00345-4.

WARNING

The connection of a non-shielded printer interface cable to this printer will invalidate the FCC Certification of this device and may cause interference levels which

exceed the limits established by the FCC for this equipment. If this equipment has

more than one interface connector, do not leave cables connected to unused interfaces.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, mechanical, photocopying, recording or otherwise, without the prior written permission of Seiko Epson Corporation. No

patent liability is assumed with respect to the use of the information contained herein.

While every precaution has been taken in the preparation of this book, Seiko Epson

Corporation assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained herein.

Apple is a registered trademark of Apple Computer, Inc.

Applesoft is a trademark of Apple Computer, Inc.

Centronics is a registered trademark of Data Computer Corporation.

Epson is a registered trademark of Seiko Epson Corporation.

IBM is a registered trademark of International Business Machines Corporation.

Microsoft is a trademark of Microsoft Corporation.

QX-IO is a registered trademark, and QX is a trademark of Epson America, Inc.

Copyright © 1985 by Seiko Epson Corporation

Nagano, Japan

ii

Page 4

Contents

Introduction

Setting Up Your LQ Printer

1

Unpacking Your Printer

Installing the paper feed knob

Selecting the Right Location

Installing the Ribbon

Replacing the ribbon

Loading Single-Sheet Paper

Installing the single-sheet guide

Loading the paper

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Intro-1

.....................

........................

.................

.....................

...........................

........................

.....................

................

...........................

Adjusting the paper thickness lever

Turning On the Power

Operating the Control Panel

OFF LINE/ON LINE

.........................

....................

.........................

FORM FEED/LETTER QUALITY

LINE FEED/DRAFT

.........................

Selecting the Letter Quality or Draft Mode

Running the Self Test

...........................

Connecting Your Printer to Your Computer

The parallel interface

The serial interface

Printing Your First Document

.........................

...........................

....................

.............

..............

.........

........

1-1

1-1

1-3

1-4

1-5

1-8

1-8

1-8

1-9

1-12

1-12

1-14

1-14

1-15

1-15

1-16

1-16

1-17

1-18

1-18

1-19

The Cut Sheet Feeder

2

..........................

Installing the Cut Sheet Feeder

Preparing the Paper for Loading

Loading Paper

................................

Setting up your word processor for a cut sheet

feeder

...................................

Printing with the Cut Sheet Feeder

Removing the Cut Sheet Feeder

Troubleshooting

Maintenance

...............................

..................................

...................

.................

................

..................

2-1

2-1

2-5

2-6

2-8

2-9

2-10

2-12

2-13

iii

Page 5

3

The Tractor Unit

..............................

Setting Up the LQ for Continuous-feed Paper

Installing the Tractor Unit

Loading Paper

................................

Setting the top-of-page position

.......................

...............

Installing the paper separator and tractor cover

Removing the Optional Tractor Unit

4

Using the LQ with Commercial Software . . . . . . . . . .

LQ Features

5

ESCape and ASCII

Demonstration Programs

Running BASIC programs

..................................

............................

.......................

....................

Sending Control Codes to the Printer

Basic Widths

Pica printing

Elite printing

Fifteen mode printing

Letter Quality and Draft

Cancelling Modes

Resetting the Printer

..................................

................................

................................

........................

........................

.............................

...........................

Disabling a program’s reset code

Print Quality Command

Other Widths

.................................

Double-width printing

Condensed printing

Print Enhancements

Emphasized mode

Double-strike

...............................

Underline mode

Proportional mode

Master Select

...............................

Superscript and subscript

International characters

Page Formatting

Margins

...............................

...................................

Skip-over-perforation

Linespacing

Half-Speed Mode

................................

..............................

........................

........................

..........................

............................

...........................

.............................

..........................

.....................

.......................

........................

Printing to the End of the Page

..............

.............

...............

..................

......

...

3-1

3-1

3-2

3-3

3-8

3-8

3-11

4-1

5-1

5-1

5-2

5-3

5-4

5-5

5-5

5-5

5-5

5-6

5-6

5-6

5-7

5-8

5-8

5-8

5-9

5-10

5-10

5-11

5-12

5-12

5-13

5-15

5-15

5-18

5-18

5-19

5-19

5-20

5-20

iv

Page 6

6

Graphics and User-Defined Characters

Graphics

The print head

Dot patterns

Eight-pin graphics

.....................................

..............................

................................

...........................

Twenty-four-pin graphics

Pin labels

Graphics Command

...........

...........................

Column reservation numbers

First graphics program

Using hand-calculated data to print graphics

Individual graphics options commands

Reassigning command

User-Defined Characters

Design grids

................................

........................

........................

Defining Your Own Characters

Data numbers

..............................

Sending information to the LQ

Printing User-Defined Characters

Copying ROM to RAM

Letter Quality characters

Proportional mode characters

Superscripts and subscripts

Mixing print styles

...........................

............

.....................

......................

..................

.......................

.....

..........

..................

................

.................

......................

......................

.................

....................

6-1

6-1

6-2

6-3

6-3

6-3

6-3

6-5

6-6

6-6

6-7

6-10

6-10

6-11

6-11

6-13

6-13

6-14

6-16

6-17

6-18

6-18

6-18

6-19

V

Page 7

Appendixes

The DIP Switches

A

The LQ Character Set and ASCII Table

B

Installing the Option Cartridge

C

The Identity Module

The Font Module

Using the Option Cartridges

Troubleshooting and Maintenance

D

Diagnosing the Problem

Beeper Error Warnings

Hex Dump Mode

IBM PC BASIC Solutions

Applesoft BASIC Solutions

QX-10 and QX-16 Solutions

Maintenance

Changing the print head

Widths of the Proportional Characters

E

The Parallel and Serial Interfaces

F

Choosing and Setting Up Optional Interfaces

G

.............................

...................

...........................

..............................

.....................

........................

.........................

..............................

.......................

.....................

.....................

..................................

......................

...........

................

............

.................

.......

A-1

B-1

C-1

C-2

C-3

C-3

D-1

D-1

D-4

D-4

D-6

D-7

D-8

D-8

D-8

E-1

F-1

G-1

Technical Specifications

H

I

Command Summary

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

vi

.........................

...........................

H-1

I-1

Page 8

Figures

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

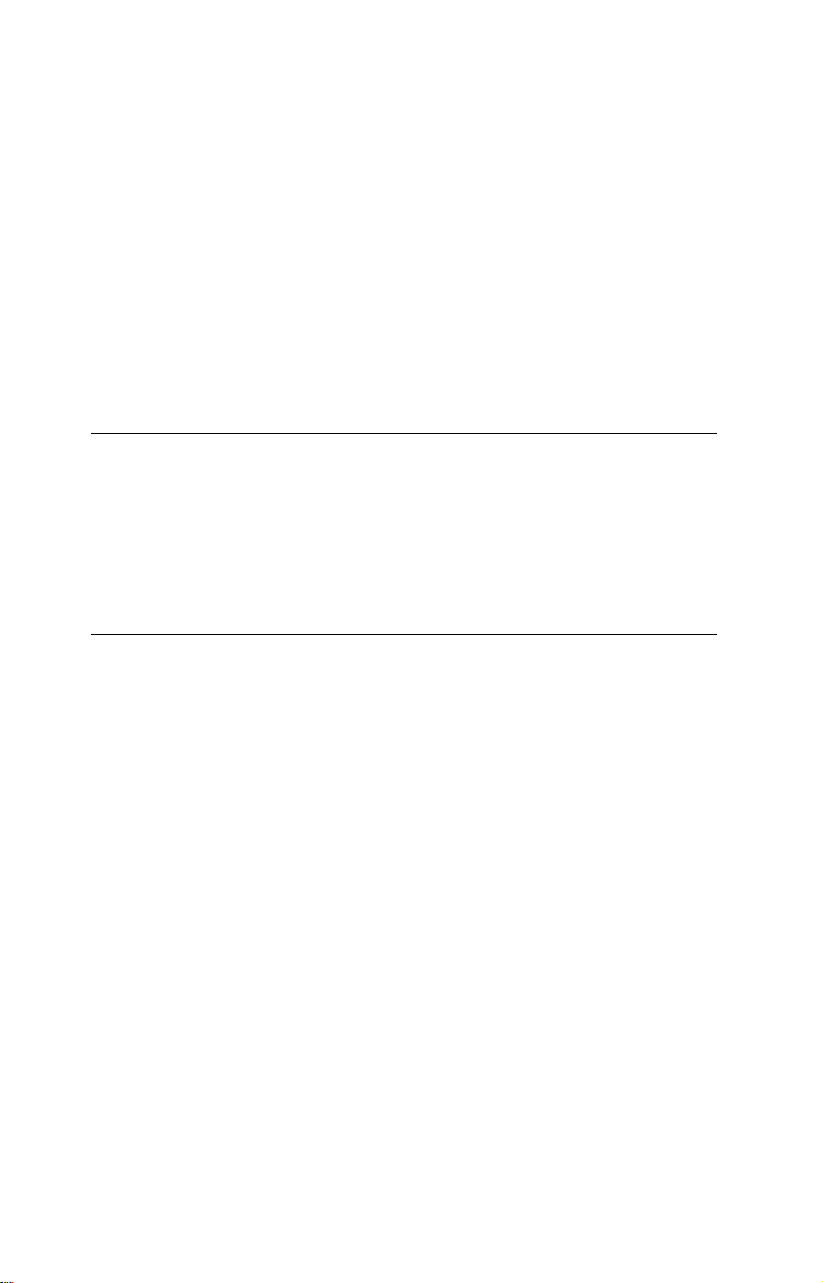

The LQ-800

The LQ-1000

Installing

Tightening

Loading the LQ-800 ribbon cartridge

Loading

Positioning the ribbon

Installing the single-sheet guide

Loading single-sheet paper

Paper thickness lever

Turning on

The LQ control panel

LQ self test in draft and Letter Quality modes

Connecting a parallel interface cable

Preparing the printer for installation

Installing the cut sheet feeder

Installing the small brackets

Installing the large bracket

The LQ-1000 model

Paper support and paper loading lever

Loading paper; adjusting the right paper guide

Turning the power on

Removing the cut sheet feeder

...............................

..............................

the

paper feed knob

the

ribbon

the

LQ-1000 ribbon cartridge

.......................

................

......................

...............

...................

.......................

the

power switch

.................

.......................

...........

...........

.................

..................

...................

........................

.......................

................

..........

.........

...

.........

. .

1-2

1-2

1-3

1-5

1-6

1-6

1-7

1-9

1-10

1-12

1-13

1-14

1-17

1-18

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-9

2-11

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

Continuous-feed paper with printer stand

Continuous-feed paper without stand

Installing the tractor unit

Preparing for paper loading

Moving the pin-feed holders

Opening

the

pin-feed covers

Installing the paper shelf

Loading paper

.............................

Fitting the paper over the pin feeds

Top-of-page position

Installing

the

paper separator

Installing the tractor cover

Removing

the

optional tractor unit

....................

..................

.................

..................

.....................

............

........................

.................

...................

............

......

..........

3-1

3-2

3-2

3-3

3-4

3-5

3-5

3-6

3-7

3-8

3-9

3-10

3-11

vii

Page 9

6-1

6-2

6-3

6-4

6-5

6-6

6-7

6-8

Pin numbering system

Calculations for pin patterns

Pattern on grid

............................

Data layout for 24-pin graphics

Design grids

...............................

User-defined character

Calculating the data

Grids for super/subscript characters

......................

.................

...............

......................

........................

...........

6-4

6-4

6-7

6-8

6-12

6-13

6-14

6-19

A-1

C-1

C-2

D-1

D-2

F-1

G-1

G-2

G-3

G-4

The DIP switch panels

. . . . . . . . . . . . . . . . . . . . . .

Plugging the identity and font

modules together . . . . . . . . . . . . . . . . . . . . . . . . .

Installing an option cartridge . . . . . . . . . . . . . . . . .

Print head replacement

Removing the ribbon cables

......................

..................

Parallel interface timing . . . . . . . . . . . . . . . . . . . . .

Removing the upper case

Removing the control panel

Main circuit board

....................

..................

.........................

Interface board mounted on main circuit board . .

A-1

C-1

C-2

D-9

D-10

F-3

G-3

G-4

G-5

G-6

viii

Page 10

Tables

5-1

5-2

5-3

5-4

5-5

6-1

6-2

6-3

6-4

A-1

A-2

A-3

A-4

A-5

C-1

E-1

F-1

F-2

F-3

LQ character widths . . . . . . . . . . . . . . . . . . . . . . . .

International characters in Letter Quality mode . .

International characters in draft mode . . . . . . . . .

International characters in proportional mode . . .

Maximum right margin settings . . . . . . . . . . . . . . .

Graphics options

Individual graphics options commands

Character width limits

Super/subscript widths

DIP switch panel

DIP switch panel

International DIP switch settings

Interface selection

Baud rate selection

Print styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Proportional character widths . . . . . . . . . . . . . . . .

Pins and signals

Printing enabled/disabled signals and control

conditions

Pins and signals

...........................

.........

......................

......................

.........................

1

.........................

2

..............

..........................

.........................

............................

..............................

............................

5-10

5-16

5-17

5-17

5-19

6-5

6-10

6-15

6-19

A-3

A-4

A-5

A-5

A-5

c-2

E-1

F-1

F-4

F-5

G-1

G-2

G-3

G-4

G-5

G-6

Baud rate settings for

Baud rate settings for

Baud rate settings for

Parity check settings for

Parity check settings for

Parity check settings for

8143

8148

8149

8143

8148

8149

...................

...................

...................

................

................

................

G-7

G-7

G-8

G-8

G-8

G-8

ix

Page 11

Introduction

The Epson LQ-800 and LQ-1000 are state-of-the-art, X-pin dotmatrix printers that deliver exceptional speed and sharpness in either

Letter Quality or draft style.

The LQ-800 and LQ-1000 are also capable of a wide variety of print

enhancements, including:

LETTER QUALITY

Bold

Italic

Underlining

Subscript Subscript

Superscript

Double-width

Double width

DRAFT

Bold

Italic

Underlining

Superscript

The LQ-800 and LQ-1000 combine the versatility and reliability of

Epson products, with a wide range of exciting new features.

l

You can select either the Letter Quality or draft typestyle with a

touch of a front panel button-there are no codes to learn.

l

The 24-pin print head produces sharp, crisp draft characters, and

Letter Quality characters that look like they came from a type-

writer.

l

The LQ has built-in connectors for both parallel and serial interface

cables, so there’s no need for extra options or modifications.

l

Option cartridges are available to further extend the capabilities of

the LQ-800 and LQ-1000. These cartridges provide additional type

fonts, and will also allow you to use programs designed for other

popular printers.

Intro-1

Page 12

l

The compact design and light weight of the LQ make it ideal for

home and business applications.

l

A 7K buffer frees your computer so you can work on one document

while printing another.

Using this manual

To make it easier to set up your new LQ-800 or

LQ-1000,

this manual includes a 10-step guide to setting up your printer. These steps take

you from unpacking, through ribbon and paper loading, to printing

your first document.

Easy-to-read tabs make it simple for beginners or experienced users

to find information. Additional sections describe how to use your new

printer with word processors, create graphics, define your own characters, and more.

If you are familiar with earlier Epson manuals, you’ll find two terms

changed to make them more descriptive. In this manual, double-

width

is used instead of expanded, and condensed is used in place of

compressed.

Intro-2

Page 13

Chapter 1

Setting Up Your LQ Printer

Setting up your new LQ is easy. Simply follow the steps in this

chapter.

Note

The LQ-800 and LQ-1000 are essentially the same printer

except that the LQ-1000 can accept wider paper. Therefore,

most of the illustrations in this manual show only the LQ-800.

If there is a difference that you need to know about, a separate

illustration shows the LQ-1000.

Unpacking Your Printer

1

First, remove the printer from the box and take off all outside

plastic covering and foam supports. See that you have received all the

parts shown in the illustrations on the next page. (You’ll find the paper

feed knob inserted in the foam packing material.)

1-1

Page 14

Figure 1-1. The LQ-800

Figure 1-2. The LQ-1000

1-2

Page 15

Remove the tape that holds the dust cover in place during shipping

and take the cover off the printer. Simply tilt the dust cover up and lift

it off the printer.

WARNING

The print head is protected by two plastic bumpers during shipping.

Both of these bumpers

must

be removed before turning on the printer.

Remove the long bumper to the right of the print head first, then move

the print head to the center of the LQ and remove the small bumper

on the left side of the print head.

There is a clear plastic overlay on the control panel to protect it

from scratching and discoloration. It’s up to you whether you remove

the overlay or leave it on.

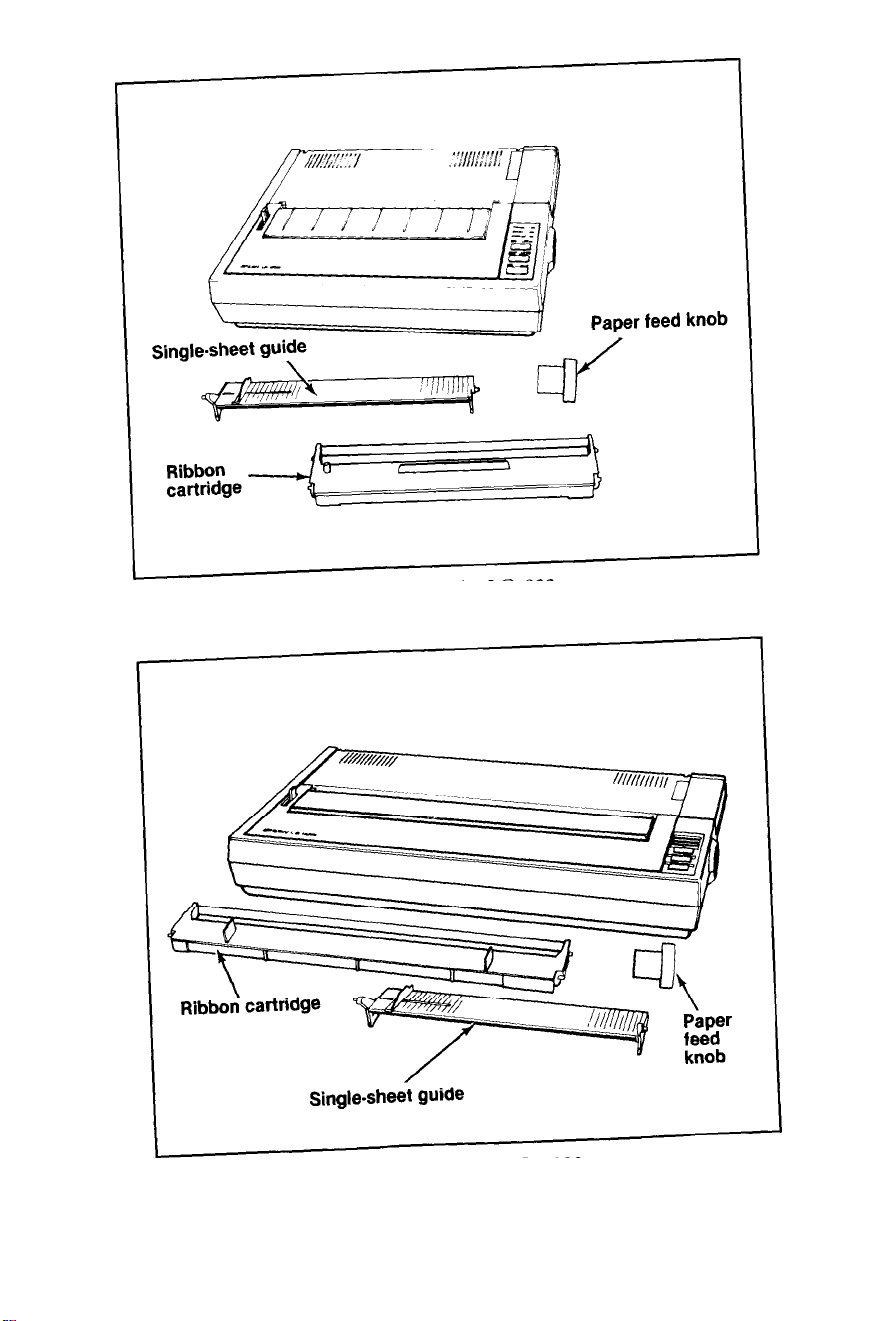

Installing the paper feed knob

Next install the paper feed knob. To install the knob, simply push it

onto the shaft on the right side of the printer, as shown in Figure 1-3.

The shaft has one flat side that must be matched with the flat side of

the hole in the knob.

Figure 1-3. Installing the paper feed knob

1-3

Page 16

Now that you’ve installed the paper feed knob, use it to remove the

sheet of paper wrapped around the printer’s platen (the black roller).

Selecting the Right Location

2

The most important consideration in choosing a location for

your printer is that it be close enough to connect a cable to your computer. But also keep the following tips in mind:

l

Place the printer or printer stand on a solid and level foundation.

Avoid setting it on carpet, chairs, or unstable surfaces.

l

Use a grounded outlet-one that has three holes to match the power

plug on the printer. Don’t use an adapter plug.

l

Avoid using electrical outlets that are controlled by wall switches-

if you accidentally turn off a switch, you could wipe out valuable

information and stop your printing.

l

Keep your printer and computer away from base units for cordless

telephones.

l

Avoid using an outlet on the same circuit breaker with large electri-

cal machines or appliances that might disrupt the flow of power to

your printer.

l

Protect your printer from direct sunlight, and keep it away from

excessive heat, moisture, and dust. Make sure it’s not too close to a

heater or any other heat source.

1-4

Page 17

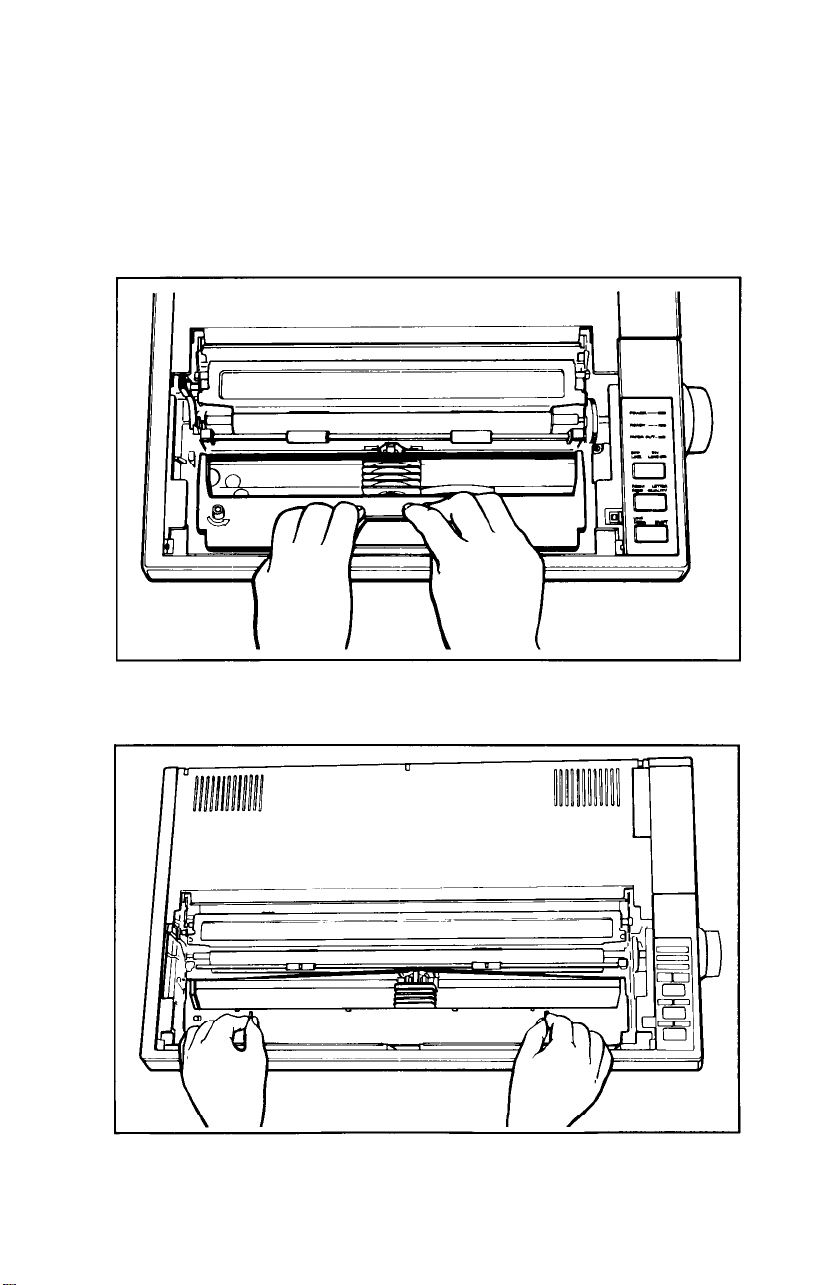

Installing the Ribbon

3

printer for ribbon installation and paper loading. The next time you

install a ribbon or load paper, you can leave the cover on.

1. Manually move the print head to the middle of the platen.

2.

With the dust cover removed, you have easy access to the

Now you’re ready to install the ribbon.

WARNING

The power must be OFF when moving the print head. Moving

the print head when the power is ON may damage your

printer. If you’ve been using your printer just before changing

the ribbon cartridge, be careful not to touch the print head

because it becomes hot during use.

Before loading the cartridge into the printer, turn the small knob on

top in the direction of the arrow to tighten the ribbon as shown in

Figure

1-4.

Figure 1-4. Tightening the ribbon

1-5

Page 18

3. For the LQ-800, hold the ribbon cartridge by the raised plastic fin

on top of the cartridge; for the LQ-1000 hold the cartridge by the

two plastic tabs. Lower the cartridge into the printer, guiding the

two square pins on each. end of the cartridge into the slots in

the printer frame, as shown in Figures 1-5 and 1-6. Press firmly on

each end of the cartridge to make sure the pins are firmly seated in

the slots.

1-6

Figure 1-5. Loading the LQ-800 ribbon cartridge

Figure 1-6. Loading the LQ-1000 ribbon cartridge

Page 19

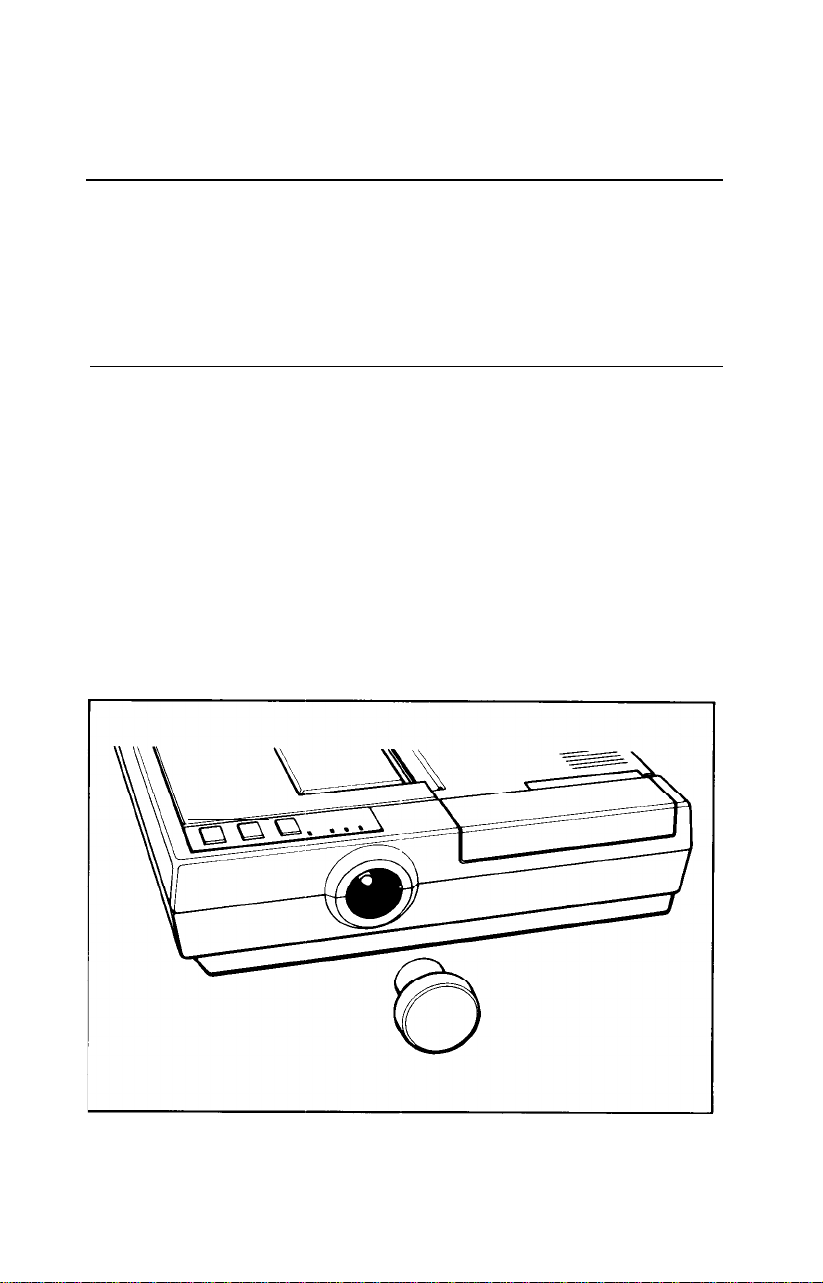

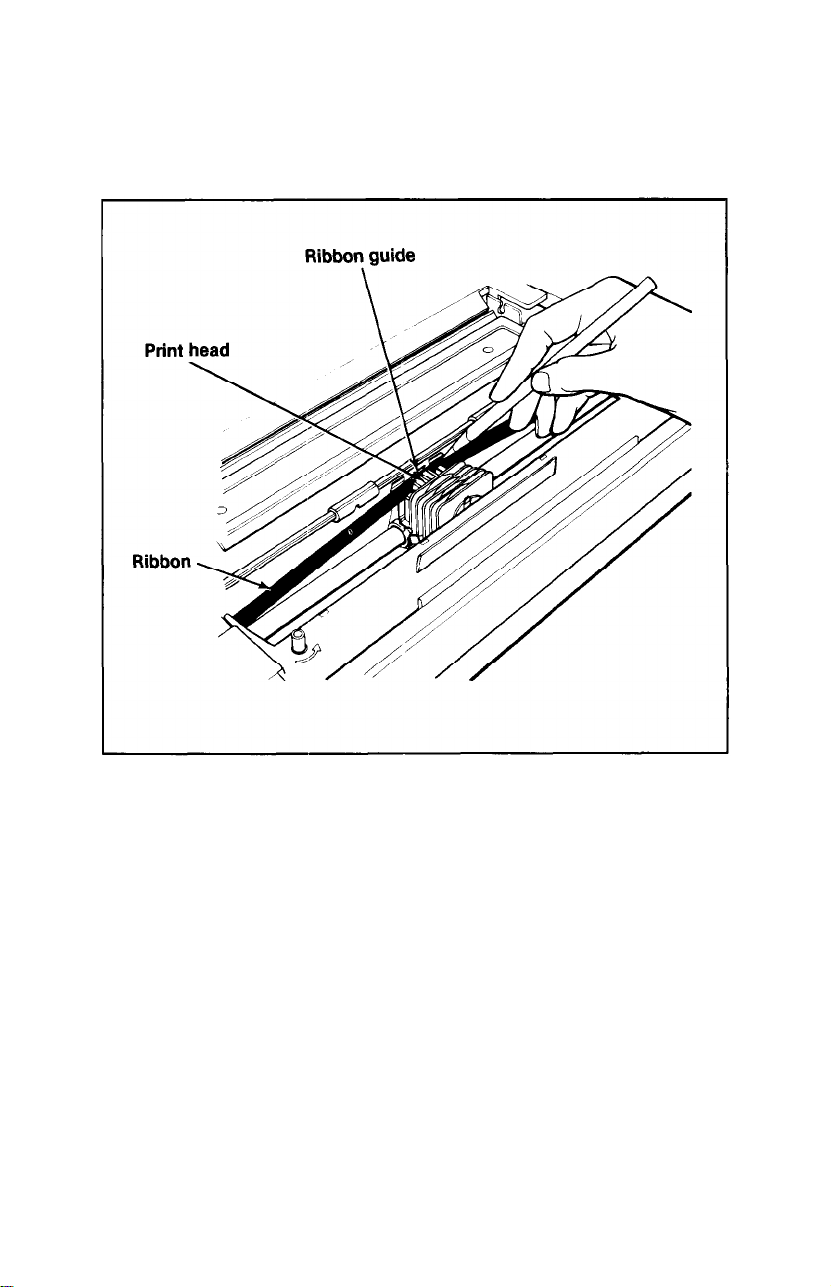

4. Now use the point of a pencil to guide the ribbon into place

between the ribbon guide and the print head as shown in Figure

1-7. (There is also a diagram on the top of the ribbon cartridge

itself.)

Figure 1-7. Positioning the ribbon

5. With the cartridge in place, again turn the ribbon knob in the direction of the arrow to tighten the ribbon.

And that’s it-the ribbon is now installed.

1-7

Page 20

Replacing the ribbon. . .

When buying new ribbon cartridges for the LQ-800 or 1000, be sure

you get a ribbon specifically for the LQ-800 or 1000. Ribbon cartridges

for other Epson printers, such as the FX series, may closely resemble

an LQ ribbon, but their use can damage the LQ print head. Also,

ribbon cartridges for the LQ-1500 will not fit the LQ-800 or 1000, and

the Epson ribbon replacement pack #8758 should not be used as a

replacement ribbon.

The LQ uses a continuous-loop, inked fabric ribbon. When your

printing becomes too light, replace the ribbon with a fresh cartridge.

To replace the ribbon, just pull up on the raised fin on top of the

LQ-800 cartridge, or the two plastic tabs on the LQ-1000 and lift the

cartridge out of the printer. To install a new ribbon, follow the preced-

ing steps.

Loading Single-Sheet Paper

4

of paper.

ing systems (the cut sheet feeder or the tractor unit), you should

complete the remaining setup steps before installing either of the

optional systems.

your computer (Step 9) before you install an optional system. After

completing the setup steps, see Chapter 2 for installing the cut sheet

feeder, or Chapter 3 for installing the tractor unit.

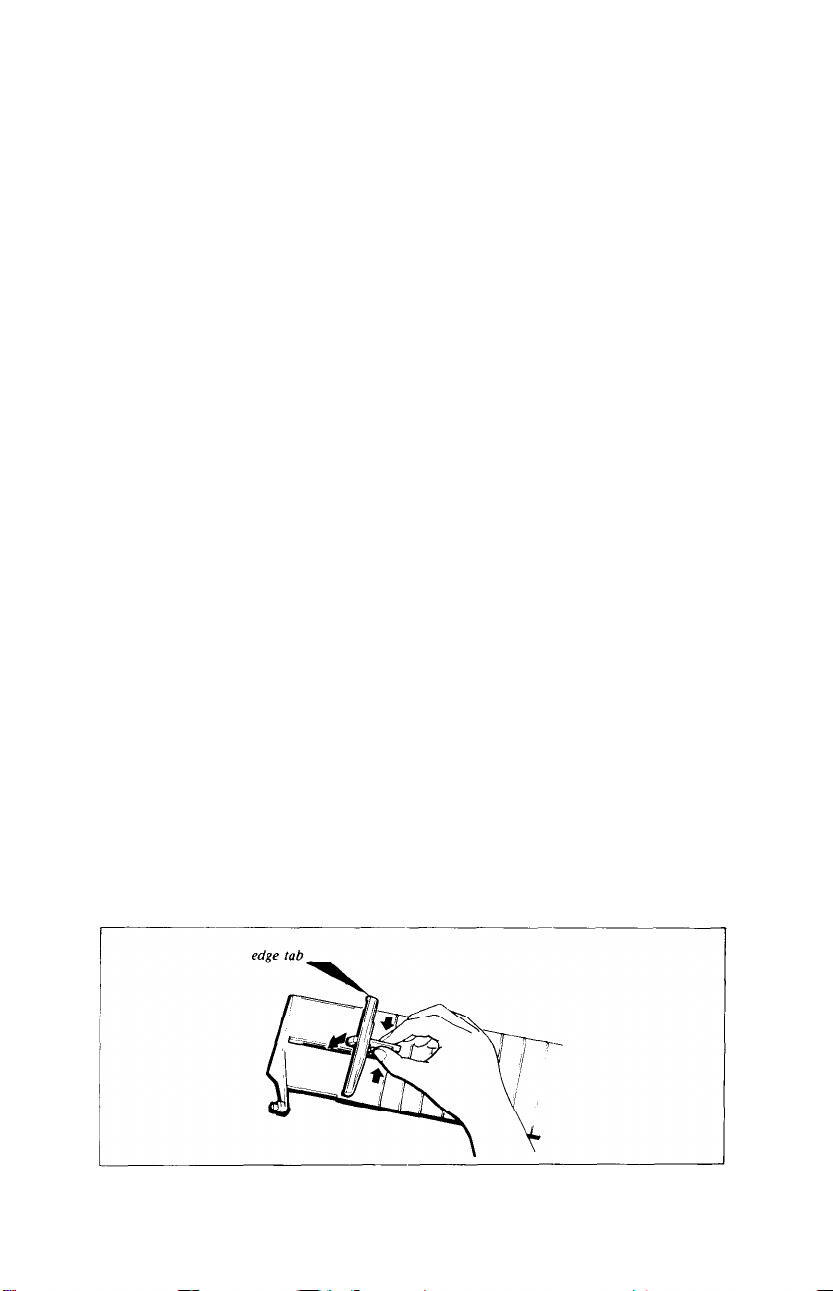

Installing the single-sheet guide

sheets of paper into the LQ.

spring, insert it into

When you receive your LQ, it is set up to print on single sheets

Even if you have purchased one of the optional paper feed-

first

It is much easier to run the self test (Step 8) and to connect the LQ to

Now install the single-sheet guide. It helps you feed individual

First, put the edge tab into the guide frame. Holding the plastic

the groove as shown below.

1-8

Assembling the single-sheet guide

Page 21

The guide has rounded pins on each end. These pins fit into notches

on each end of the paper slot.

Slide one of the guide’s pins into one notch. Then, with gentle pres-

sure, snap the other pin into the other notch as shown in Figure 1-8.

Figure 1-8. Installing the single-sheet guide

The edge tab on the left side of the guide is movable, with a click

stop for its middle position. For standard-sized (8½-inch wide) paper,

see that the tab is in the click-stop position.

Loading the paper

Loading single-sheet paper in the LQ is simple-it’s just like loading

paper in a typewriter.

1-9

Page 22

1.

Check that the dust cover is tilted up to make it easier to see inside

the printer, as shown in Figure 1-9.

2. Make sure the paper release lever is pushed back in the direction of

the arrow in the figure, and that the paper bail is pulled away from

the platen.

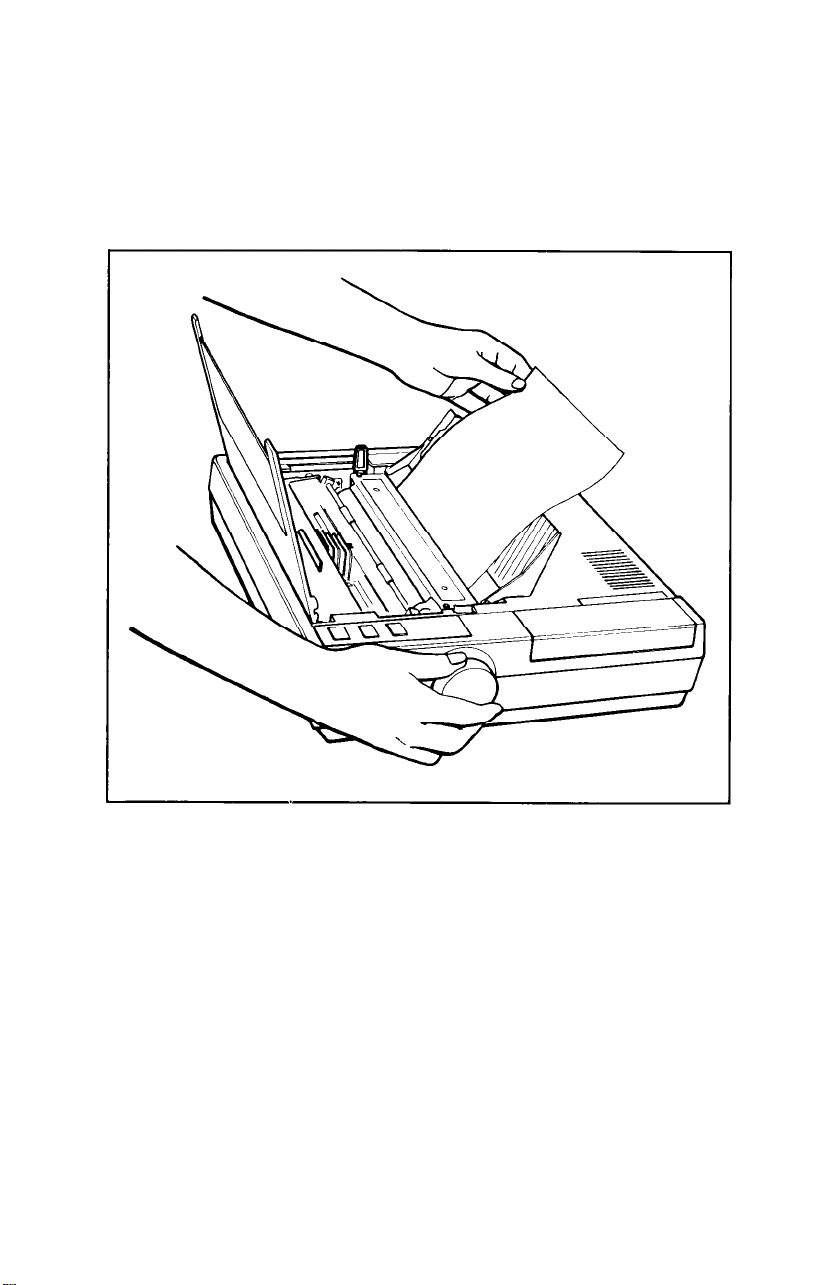

Figure 1-9. Loading single-sheet paper

3. Insert a single sheet of paper behind the platen as shown in Figure

1-9. Put the left edge of the paper against the edge tab on the single

sheet guide.

4. With the power OFF use the paper feed knob to roll the paper into

the printer far enough to be held by the paper bail. (If the power is

ON, use the LINE FEED button as described in Step 6.)

5.

Push the paper bail back against the paper, and the paper is ready.

1-10

Page 23

Caution

Never use the manual paper feed knob while the power is ON

because you can damage the paper feed motor. Always use

the

LINE FEED

the paper feed knob turns easily when the power is

difficult to turn while the power is

or

FORM FEED

button. You will also find that

OFF,

but is

ON.

When loading single-sheet paper, you may find that the LQ finishes

pages at different places than your word processor or applications

program does.

To ensure that your word processor and the LQ finish pages at the

same point:

1. Print out a page on the LQ. Check that the LQ and your word

processor have the same page length. If they differ, note how many

lines they differ by. For example, if your word processor is set up to

print 55 lines, but the LQ only prints 53 lines before ejecting the

page, there is a difference of two lines.

2. You now have three choices:

a) Compensate for the two-line difference when rolling the paper

into the printer.

b) Use the installation procedure on your word processor to

change the default page length.

c) Use commands in your word processing program to alter the

page or margin lengths in each file to accommodate the LQ’s

page length.

Once you’ve established the best settings, always load the paper so

3.

that your printer starts at the same place on each page. For example, you may find that when you roll the paper one inch above the

print head, the page finishes where you want it to-then each time

you load paper, load it the same way.

With single-sheet paper, the key to consistent page formatting is to

establish the settings that work best for you, then position the paper in

the

same place every time.

1-11

Page 24

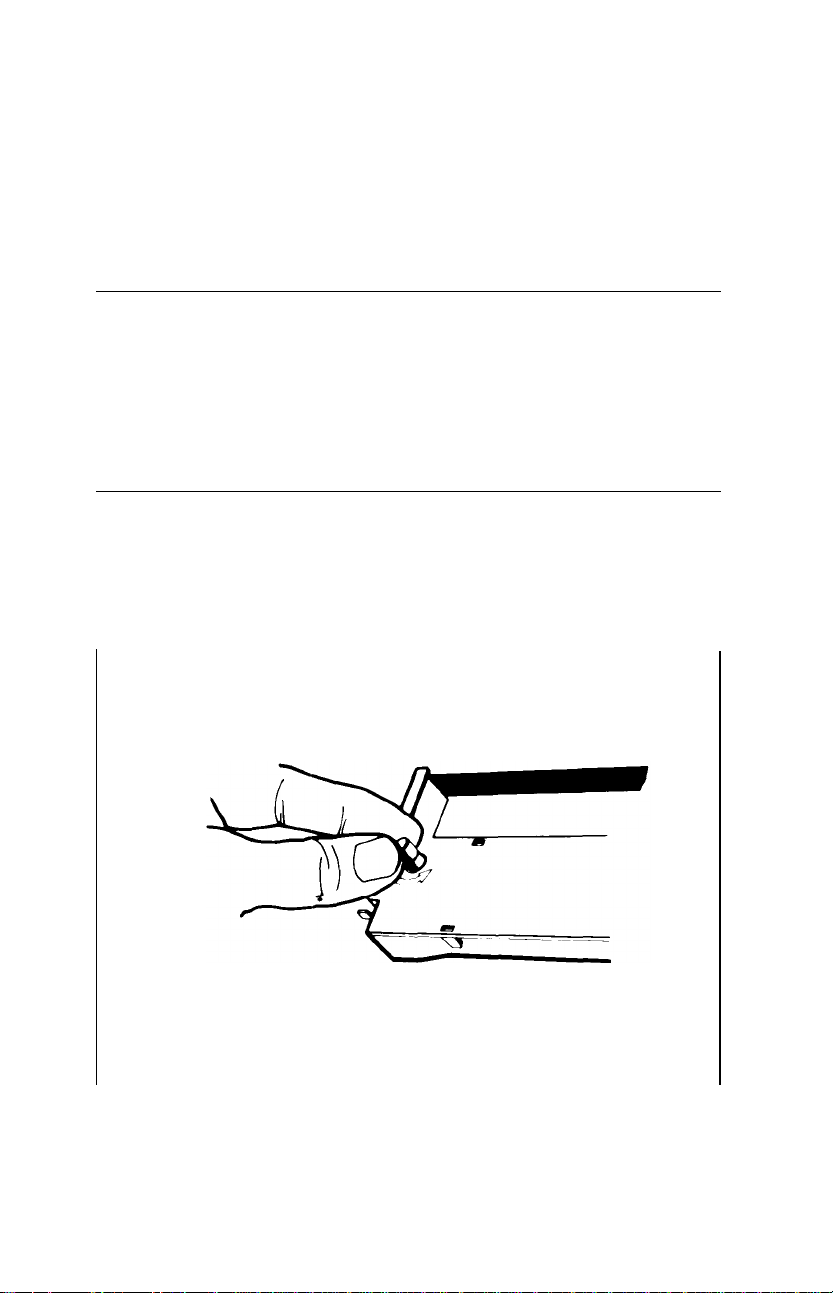

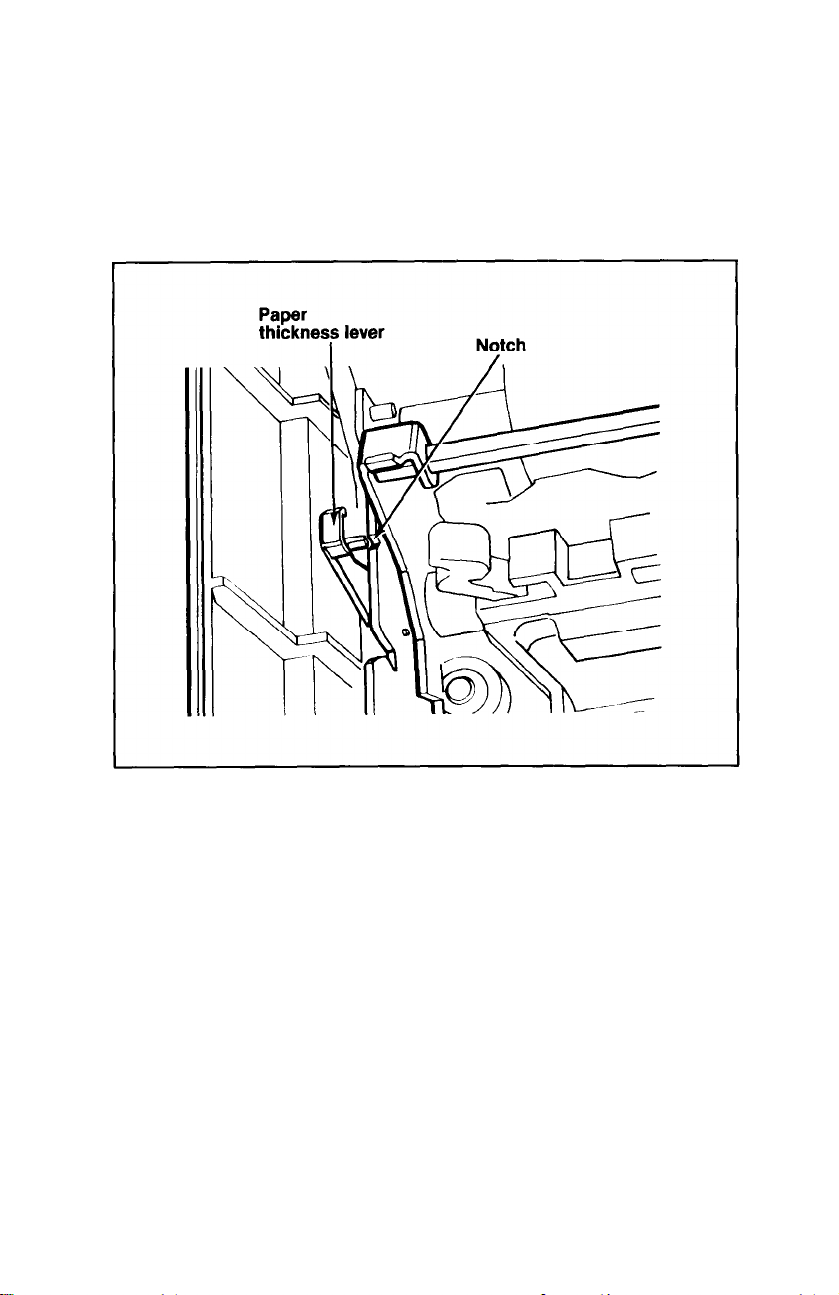

Adjusting the paper thickness lever

The LQ is equipped with a paper thickness lever that can be

adjusted to accommodate varying thicknesses of paper.

The lever is located in front of the paper release lever on the left side

of the printer as shown in Figure

1-10.

Figure 1-10. Paper thickness lever

When you receive your LQ, the lever is set for standard paper thickness (about

ness lever set in the notch shown in Figure

For thicker paper or multiple copies, pull the lever toward the front

of the printer. To return the lever to the standard position, push it back

until it clicks into the standard setting.

1/500th

of an inch), with the small arm on the paper thick-

1-10.

Turning On the Power

5

the printer on and become acquainted with the power-up sequence.

1-12

With the ribbon and paper installed in the LQ, it’s time to turn

Page 25

Plug in the printer’s power cord, making sure the outlet is properly

grounded. Turn the power ON with the switch on the left side of the

printer (see Figure

1-11).

Figure 1-11. Turning on the power switch

When the power is turned ON:

l

The print head moves back and forth and stops at the left side of the

printer.

l

The printer

printer is reset to its

is initialized-any

default

(or preset) values. See Appendix I for a

previous settings are erased, and the

list of default values.

l

The three green lights on the control panel--POWER, READY, and

ON LINE-go on. (The red PAPER OUT light does not go on unless

the

printer

is out of

paper.)

1-13

Page 26

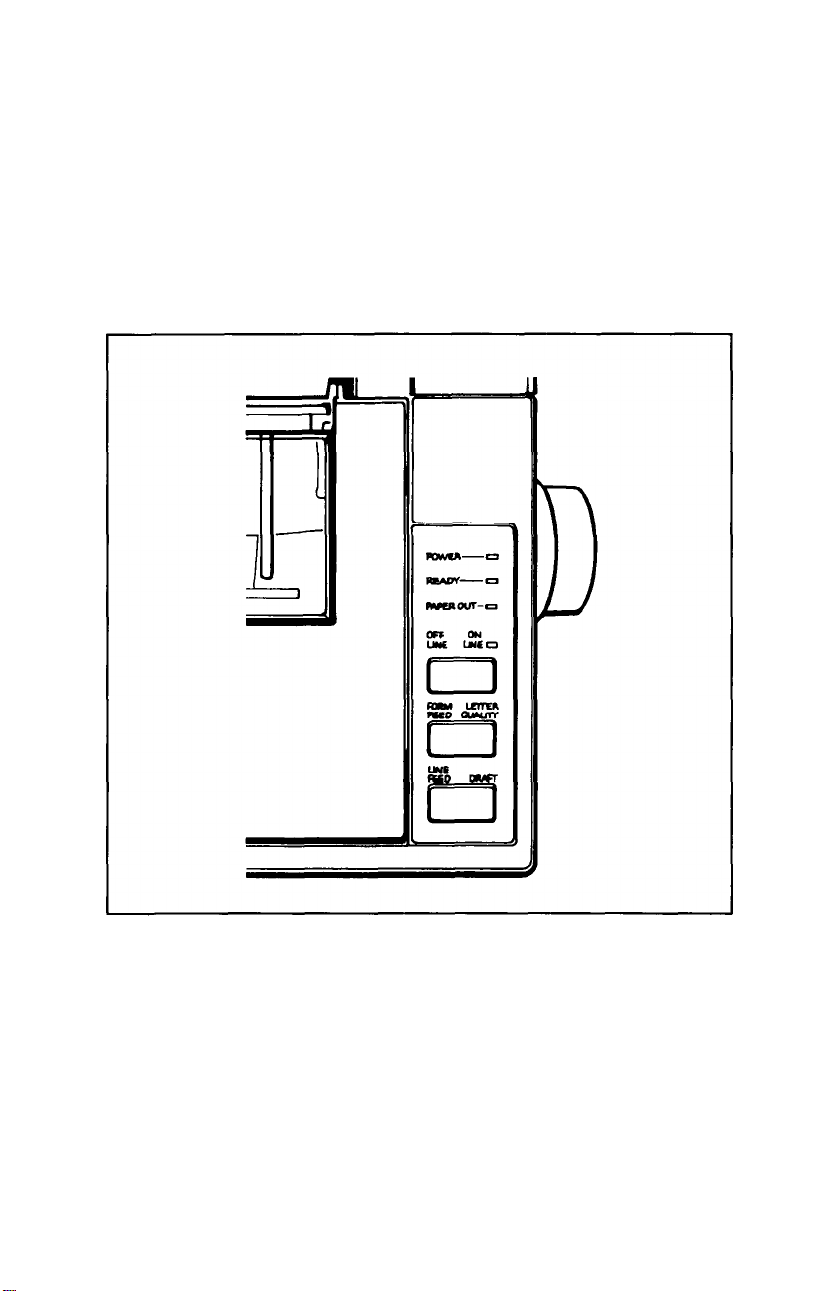

Operating the Control Panel

6

1-12) has two functions-the functions marked in blue (ON LINE,

LETTER QUALITY, and DRAFT) are active when the printer is on

line; the functions marked in black (OFF LINE, FORM FEED, and

LINE FEED) are active when the printer is off

line when the ON LINE light is on; it is off line when the ON LINE

light is off.

Each of the three buttons on the LQ control panel (see Figure

line.

The printer is on

Figure 1-12. The LQ control panel

OFF LINE/ON LINE

OFF LINE--If you press this button when the green light beside it is

on, the ON LINE and READY lights go off, the print head moves to

the center of the platen, and the printer is set

on but the LQ won’t print. This enables the form feed and line feed

functions to work.

1-14

off line-the

power is still

Page 27

ON LINE-The green ON LINE light indicates that the printer is on

line

and ready to receive data. When the LQ is on line, you can select

either the Letter Quality or draft mode.

FORM FEED/LETTER QUALITY

FORM

FEED-Pressing this button advances the paper to the top of

the next page if you’re using continuous-feed paper (see Chapter 3,

“Installing the Tractor Unit”). If you’re using single-sheet paper, it fully

ejects one sheet. The form feed function works only when the printer

is off line.

LETTER QUALITY-Pressing this button selects the Letter Quality

typestyle (for more information on Letter Quality, see Step 7). The

printer beeps twice to acknowledge the Letter Quality selection. You

can select the Letter Quality typestyle with this button only when the

printer is on line.

LINE FEED/DRAFT

LINE FEED-Pressing this button advances the paper one line at a

time, either while you’re loading paper, or when you’re adjusting

where you want printing to begin. If you hold this button down, the

paper advances continuously. The line feed function works only when

the printer is off line.

DRAFT-Pressing this button selects the draft typestyle. The printer

beeps once to acknowledge the draft selection. The draft function

works only when the printer is on line.

Note

Use the LETTER QUALITY or DRAFT buttons before you

tell the computer to print. Do not use them while the LQ is

printing.

1-15

Page 28

Selecting the Letter Quality or Draft Mode

7

Quality mode. As shown in the sample below, the Letter Quality

characters are fully formed and are ideal for formal correspondence or

other presentation-quality work.

draft mode, also shown below. In draft mode, the LQ prints more

quickly, because fewer dots are used to form each letter.

draft mode.

l Control panel-You can choose between the Letter Quality and

l

l

When you receive your LQ, it is preset to print in the Letter

For

those

times when you need only a rough draft, the LQ also

This is the Letter Quality style

This is the draft Style

The LQ gives you three ways to select either the Letter Quality or

draft modes with the appropriate button

DIP switch-A switch on the back of the printer selects either Letter

Quality or draft as the

turn the power

Software command-You

ity and draft modes by sending a command to the printer as

explained in Chapter 5.

default

on).

See Appendix A for details.

typestyle (the style in effect when you

can

also switch between the Letter Qual-

on

the control panel.

has a

These three choices allow you to tailor the LQ to your printing

needs. If you find you use the Letter Quality mode most of the time,

you can leave the settings just as they are. If you print in draft mode

more than Letter Quality, just reset the DIP switch as outlined in

Appendix A. But no matter what you choose, you can always use the

buttons on the control panel to switch between the two styles.

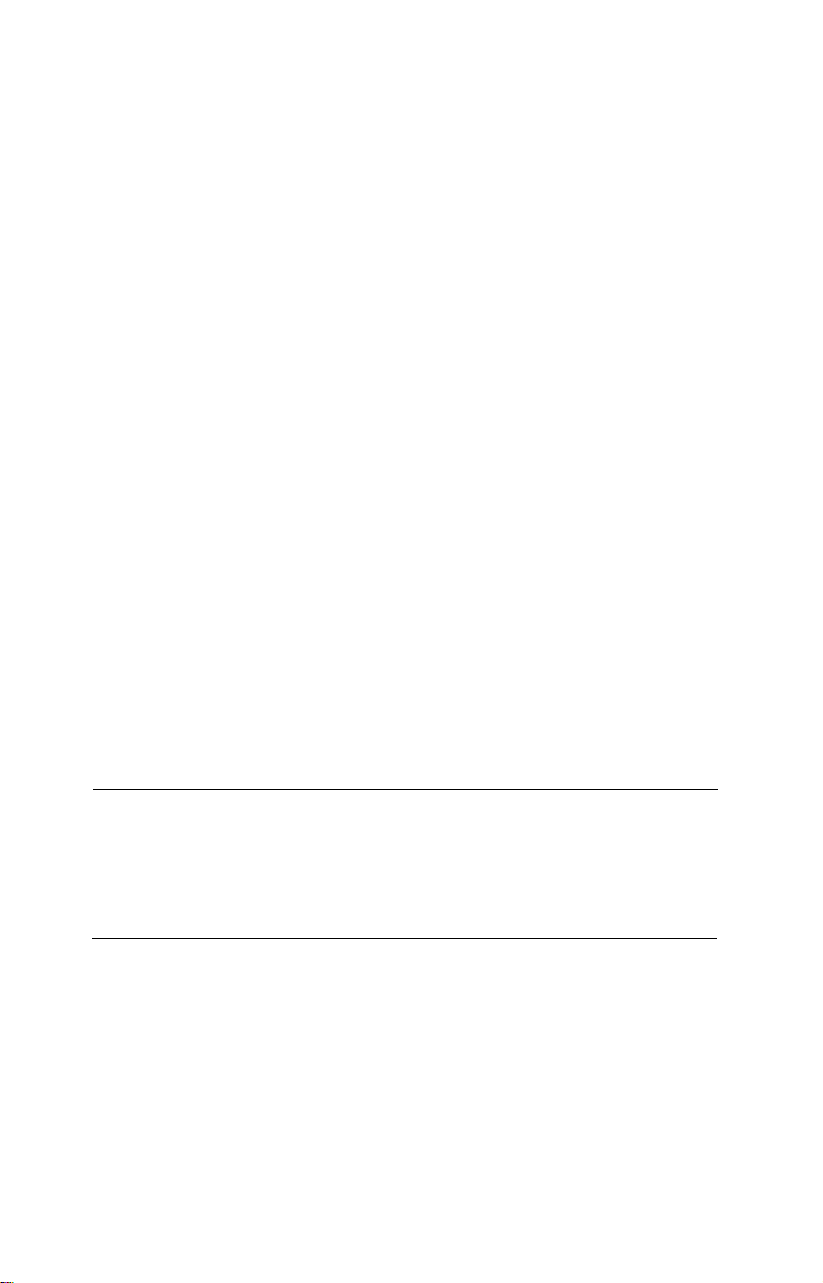

Running the Self Test

8

prints out all of the characters in the selected character set-either

Letter Quality or draft.

printer and that the power is turned OFF. If you have an LQ-1000, be

sure to use 14-inch-wide paper to avoid printing on the platen.

1-16

The LQ has a built-in self test function that automatically

Before running the self test, make sure that paper is loaded in the

Page 29

To run the self test in the Letter Quality mode, hold down the

LETTER QUALITY button while you turn the power switch ON. To

run the test in the draft mode, hold down the DRAFT button while

turning the power ON. The self test then takes over.

The self test prints a version identification number, the name of the

installed typeface family, then (as you can see in Figure 1-13) all of the

characters in the selected character set.

The self test continues until you turn the printer off or until it runs

out of paper.

Draft

Letter Quality

Figure 1-13. LQ self test in draft and Letter Quality modes

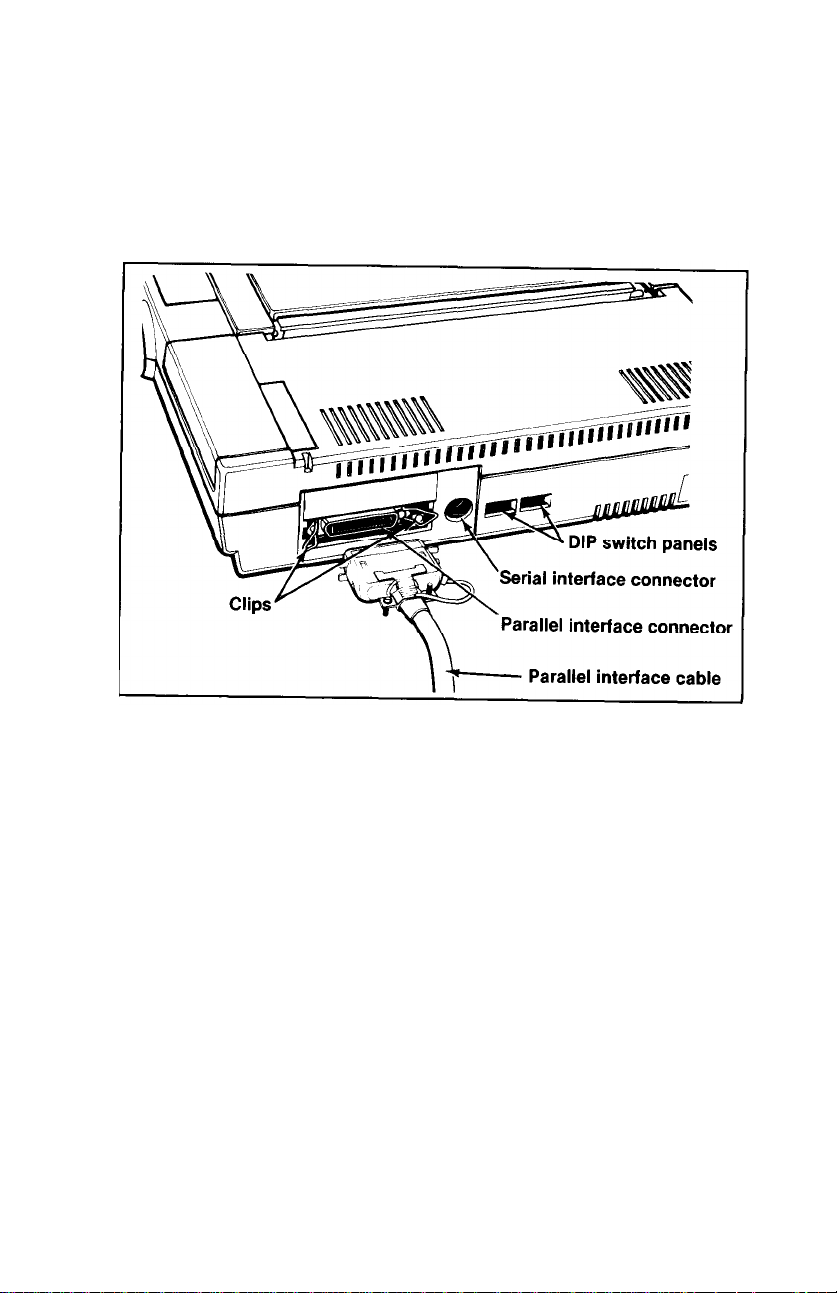

Connecting Your Printer to Your Computer

9

Your LQ printer comes equipped with separate connections

for

both

serial and parallel interfaces, so be sure to use the type your

computer requires. Check your computer’s documentation if you’re

unsure which interface you have. (If your computer requires a

different type of interface, see your Epson dealer.)

1-17

Page 30

The parallel interface

The connector on a parallel interface cable, as shown in Figure 1-14,

is secured to both the LQ and your computer by two clips. After plugging the cable into the LQ and your computer, be sure to snap the clips

in place, and connect the ground strap if the cable is equipped with

one.

Figure 1-14. Connecting a parallel interface cable

Once you’ve connected a parallel cable, you’re ready to print. The

parallel interface does not require any additional settings.

The serial interface

If your computer is equipped with a serial interface, you should use

an Epson serial interface cable-#8239 for the Apple® IIc, #8293 for

the Apple IIe

or

Epson QX™-16, and #8294 for the IBM® PC. Plug the

cable into the connector to the right of the parallel connector.

When using the serial interface, you need to reset four DIP switches

so that your computer and printer will communicate properly. See

Appendix A for a complete explanation of the DIP switches and how

to set them for your serial interface.

1-18

Page 31

Printing Your First Document

10

ing steps, your LQ is ready to print. The following chapter explains

how to set up your word processor to work with the LQ.

Additional chapters and appendixes cover programming, control

codes and ESCape sequences, technical specifications and maintenance .

If you have any difficulty printing your first document, check the

following list to make sure you’ve completed all the setup steps.

q

Did you remove the plastic tab that holds the print head in place?

q

Is the power source (power strip, etc.) turned ON?

q

Is the ribbon properly installed? Make sure the ribbon is in front of

the print head, not riding above it.

q

Have you loaded the paper correctly? (Read Chapter 2 or 3 if you

are using the optional cut sheet feeder or tractor unit.)

q

Are the green POWER, ON LINE, and READY lights on the con-

trol panel ON? If not, press the ON LINE button to place the LQ

on line. If the red PAPER OUT light is ON, check that you’ve

loaded the paper correctly.

Now that you’ve completed the basic setup and operat-

q

Were you able to successfully run the self test in Step 8? If not,

check the DIP switch settings and try again.

q Is your printer properly connected to your computer? Are you

using the correct interface (serial or parallel)? If you’re using a

serial interface, have you set the DIP switches accordingly?

If you’re still having trouble printing, read the troubleshooting sec-

tion in Appendix D.

1-19

Page 32

Chapter 2

The Cut Sheet Feeder

The cut sheet feeder automatically loads single sheets of paper into

the LQ, allowing you to print on letterhead, bond, or individual

forms.

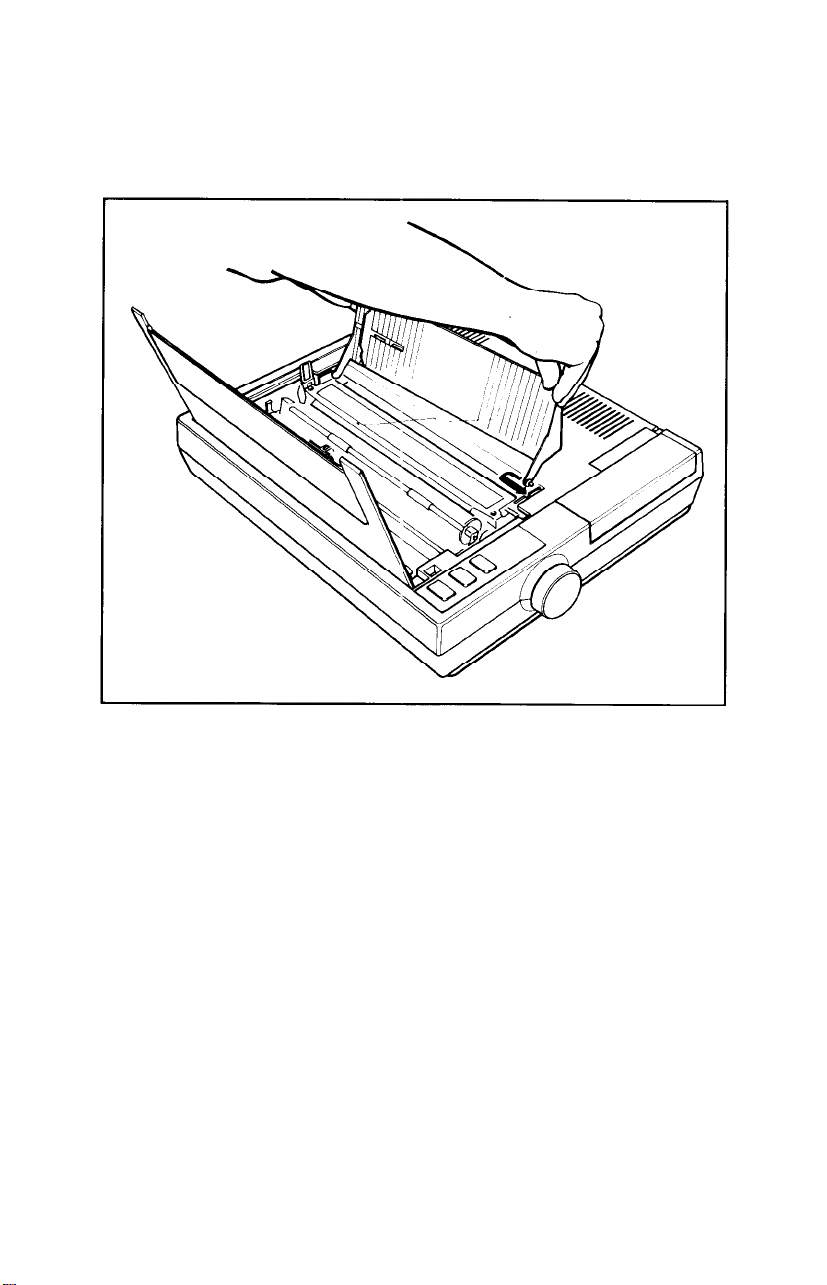

Installing the Cut Sheet Feeder

1. Make sure the power is OFF.

2.

Set DIP switch 1-8 on the back of the printer to the ON position

and DIP switch 1-7 to the OFF position to select the cut sheet

feeder. See Appendix A for information on resetting the DIP

switches.

3. Remove the front cover that came installed on your LQ by tilting it

up and lifting it off the printer. Replace it with the new cover

included with the cut sheet feeder, as shown in Figure

new cover in an upright position so you can see inside the printer.

Also remove the single-sheet guide.

2-1.

Leave the

Figure 2-1. Preparing the printer for installation

2-1

Page 33

4. Make sure the paper release lever is pushed back as shown in Figure

2-1.

If this lever is not pushed back, the cut sheet feeder will not

fit or operate properly.

5. Pull the paper bail away from the platen (the black roller) as shown

in Figure 2-1. The paper bail should remain in this position whenever the cut sheet feeder is installed.

6. Now locate the rear mounting pins on the LQ as shown in Figure

2-2. The rear notches on the cut sheet feeder unit rest on these

mounting pins.

2-2

Figure 2-2. Installing the cut sheet feeder

Page 34

7.

Hold the cut sheet feeder assembly in two hands, and press the two

cut sheet feeder release levers shown in Figure 2-1.

8. Now stand directly over the printer, look

through

the top of the cut

sheet feeder, and guide the rear notches on the cut sheet feeder onto

the rear mounting pins on the printer.

9. Tilt the cut sheet feeder forward until the front latches of the cut

sheet feeder engage the front mounting pins on the printer. Release

the levers and the cut sheet feeder locks in place.

Note

When the cut sheet feeder is properly installed, it

is

possible to

tilt it forward slightly, but you cannot remove it from the

printer without pressing the release levers. If you can remove

the cut sheet feeder by simply lifting it off the LQ, reread the

installation instructions, paying special attention to setting

the rear notches of the feeder on the rear mounting pins of the

printer.

10. With the cut sheet feeder in place, you can now install the three

brackets supplied with the unit. To install the two small brackets,

squeeze them together and insert them into the holes on top of the

paper supports, as shown in Figure 2-3.

Figure 2-3. Installing the small brackets

2-3

Page 35

11.

For the LQ-800 model, install the large bracket in the stacker as

shown in Figure 2-4. Slip the legs of the bracket into the metal

slots on the bottom of the cut sheet feeder and make sure the

bracket fits into the retaining clips on the upper part of the

stacker.

Figure 2-4. Installing the large bracket

For the LQ-1000 model, there are two large brackets. Install them

both as described above and also install the paper stand shown in

Figure

2-4

2-5.

Page 36

Figure 2-5. The LQ-1000 model

Preparing the Paper for Loading

1.

The paper

curled or uneven, it will not feed correctly.

2. The cut sheet feeder holds a maximum of 60 sheets of standard

weight (20 lb.) paper. If you use a lighter or heavier weight of

paper, compensate accordingly. (If more than one sheet of paper is

being loaded at a time, remove some of the paper from the paper

bin.)

3. Loosen the paper stack by rifling through it a couple of times, then

tap it on a flat surface to make it even.

must

be straight and clean. If the paper is slightly bent,

2-5

Page 37

Loading Paper

1. Align the arrow on the left paper guide with the arrow stamped

into the metal lip of the stacker, as shown in Figure

Figure 2-6. Paper support and paper loading lever

2-6.

2.

Pull the paper loading lever forward until it locks in the open position, as shown in Figure

2-6

2-6.

Page 38

3.

Set the stack of paper in the paper bin, aligning it against the left

paper guide as shown in Figure

2-7.

Move the right paper guide

over to the edge of the stack of paper, but leave a little room so the

paper doesn’t bind. Make sure the paper is

behind

the angled metal

tabs at the bottom of the left and right paper guides.

Figure 2-7. Loading paper; adjusting the right paper guide

4.

Push the paper loading lever back, and the stack of paper is pushed

forward against the two feeder rollers.

2-7

Page 39

setting up your word processor for a cut sheet feeder. . .

If you‘ve never used a cut sheet feeder before, you may have to set

up your word processor accordingly.

When the cut sheet feeder positions the paper for printing, it automatically leaves a one-inch margin at the top of a page. If you’ve been

printing with continuous-feed paper, you11 need to adjust the settings

on your word processor so that the pages print the same with the cut

sheet feeder.

There are three settings you’ll probably need to change: Page

Length, Top Margin, and bottom Margin. Most word processors

have preset (or default) settings that are in effect each time you use the

program. Check the program’s documentation to find these settings,

and how to change them.

The following is an example of a typical conversion.

To maintain 55 printed lines per page:

Continuous-feed

settings

Change Page Length

Change Top Margin

Change Bottom Margin

Many word processors give you two choices in changing these settings: 1) You can change the settings in each individual file you print,

or; 2) You can change the program’s default settings so that every time

you use the program, these new settings are in effect.

If your program has additional features, such as headers and foot-

notes, you will have to compensate accordingly. (For example, many

programs include the header as part of the top margin. If you set the

top margin to 0, you11 lose the header.)

With a little bit of experimenting, you’ll find the best equivalent

settings to use.

from

from

from

66

3 (default) to 0

8 (default) to 6

Cut sheet

feeder settings

to 61

2-8

Page 40

Printing with the Cut Sheet Feeder

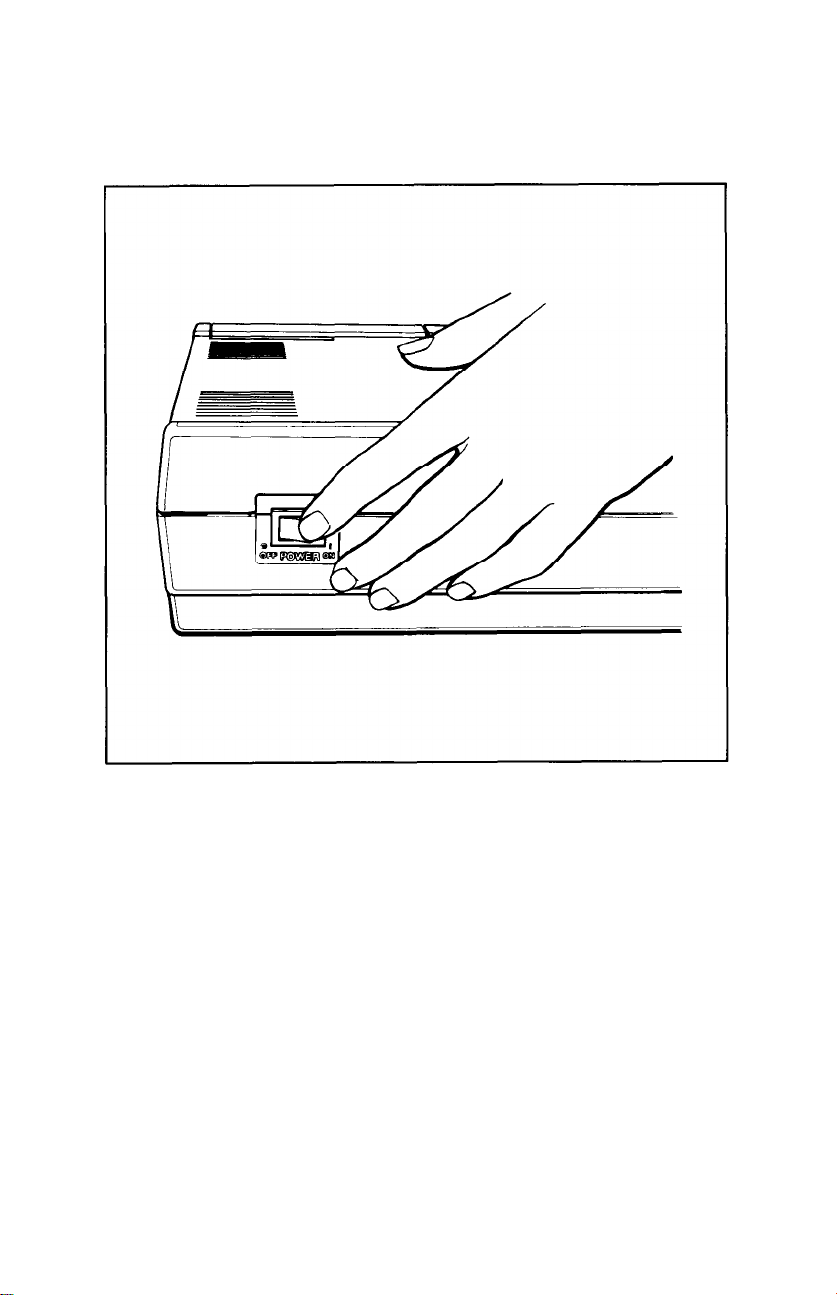

1. Turn the power ON with the switch on the left side of the printer, as

shown in Figure

2-8.

Figure 2-8. Turning the power on

2. When you turn the power ON:

l

The print head moves to the left side.

l

The POWER, READY, and ON LINE lights glow green.

l The red PAPER OUT light goes on. (The PAPER OUT light

remains on until paper is fed into the printer.)

3. Now print a document with your word processor as you normally

would. When you print a document:

l The print head moves to the center of the platen to facilitate

paper loading.

l

The feeder rollers feed one sheet of paper into the printer, and

position the page with a one-inch margin at the top. (See the

previous note “Setting up your word processor for a cut sheet

feeder. . ."

for information on adjusting margin and page length

settings.)

2-9

Page 41

l The red PAPER OUT light goes out while there’s paper in the

printer.

l

Printing begins.

When the LQ finishes printing a document, you have three options.

If you wish

to

continue printing-You can print another document as

you normally would; the cut sheet feeder ejects the last page from the

previous job, then loads and prints the new document.

If you want to fully eject the last page of a document-First take the

LQ off line by pressing the ON LINE button (the green ON LINE light

goes out). Press the FORM FEED button to eject the last page into the

paper stacker, and a new sheet is automatically loaded.

If you’re finished printing-Remove the unused paper from the bin,

take the printer off line, then use the FORM FEED button to eject the

last sheet of paper. (If you press FORM FEED without removing the

remaining paper from the bin, another sheet is loaded.) You can also

shut the power OFF, then use the manual paper feed knob to roll the

remaining sheet out of the printer.

Caution

When the power is ON, you should use only the FORM FEED

or LINE FEED button to eject paper from the cut sheet feeder.

If you use the manual paper feed knob, the power should

always be OFF to prevent damage to the paper feed motor.

Removing the Cut Sheet Feeder

To remove the cut sheet feeder:

1. Turn the power for the printer OFF.

2. Remove all the unused paper from the bin, and any printed sheets

from the stacker.

3. If a sheet of paper is still loaded in the printer, use the manual paper

feed knob to remove it.

2-10

Page 42

4. Hold the cut sheet feeder on each side, press the release levers as

shown in Figure 2-9, and lift the unit off the printer.

Figure 2-9. Removing the cut sheet feeder

Remember, if you decide to print with another type of paper feed

system, such as the optional tractor feed, you’ll

l

Reset DIP switch 1-8 from ON back to OFF. (Don’t forget to turn

have to:

the power OFF then ON again so the printer will record the new

setting.) Reset DIP switch 1-7 (skip-over perforation) if you’re using

continuous-feed paper.

l

Check any settings you might have changed in your word processor

to compensate for the cut sheet feeder.

l

Replace the original front cover if you’re loading individual sheets

of paper (you can leave the narrow front cover on if you’re using

the optional tractor feed unit).

2-11

Page 43

Troubleshooting

If you have any difficulties operating the cut sheet feeder, check the

troubleshooting list shown below. If you continue to have difficulty,

consult your authorized Epson dealer.

Problem

Cut sheet feeder does not fit flush

on the printer.

Printer doesn’t print; cut sheet

feeder doesn’t operate.

Cut sheet feeder operates but

doesn’t load paper.

Paper loads unevenly from the

paper bin.

Recommendation

Check that the paper release lever

on the left side of the printer is

pushed back, and that the paper

bail is pulled away from the platen.

Review the installation instructions.

Make sure the cable is properly

connected to the printer and computer.

Check that DIP switch 1-8 is ON

and 1-7 is OFF, and that the printer

has been switched OFF, then ON

again to recognize the settings.

Review the paper loading instructions-you must open the paper

loading lever first, then set the

paper on the paper shelf. If you set

the paper on the gray rollers then

open the paper loading lever, the

paper drops down too far, becomes

uneven, and does not load properly.

If too much paper is loaded, it spills

off the paper shelf.

Paper jams when it feeds through

the cut sheet feeder.

2-12

Check to see that the paper is

stacked evenly

Check to see if there is too much

space between the paper stack and

the right paper guide, causing

paper movement and unevenness.

Page 44

Problem

Recommendation

Two or more sheets of paper are

loaded instead of one.

Printing starts too low on the page.

Printing is too close or too far from

the left side of the paper.

Paper doesn’t eject evenly.

Remove paper and fan it. Paper

was not sufficiently loosened

before being loaded into the paper

bin.

Make sure paper is loaded behind

the metal tabs on the bottom of the

left and right paper guides,

Too much paper was loaded into

the paper bin-remove some of the

unused sheets.

The weight of the paper is too light.

Add paper.

Your word processor may not be

set up properly. Review “Setting up

your word processor for a cut sheet

feeder . . .”

Make sure the arrow on the left

paper guide is aligned with the

arrow stamped on the lip of the

stacker.

Check that there’s enough room in

the stacker. If not, remove some of

the printed sheets.

More than one sheet of paper may

have been loaded, which causes

the paper to eject unevenly Make

sure that paper was separated and

loaded properly

Maintenance

To keep your cut sheet feeder working smoothly, keep it away from

dust, grease, and any heat sources. A safe temperature range is 41° to

95°F.

Use a soft, clean cloth dampened with water to clean the outside of

the cut sheet feeder case. Stubborn stains can be removed with nonabrasive household cleaners.

2-13

Page 45

Periodically, the inside of the cut sheet feeder should be cleaned to

get rid of dust and paper lint. First, turn the power OFF and remove

the cut sheet feeder from the printer. Then use a soft brush to clean the

inside areas. Make sure the gray rollers are kept free of dust so that the

paper feeds evenly.

If you have any problems, contact your authorized Epson dealer.

2-14

Page 46

Chapter 3

The Tractor Unit

The tractor unit for the LQ is easy to install and use. Before you

begin the installation, make sure you have received the following:

l

The tractor unit

l

The smoke-colored tractor cover

l

The narrow front lid

l

The paper separator

l

The paper shelf

Setting Up the LQ for Continuous-feed Paper

Before installing the tractor unit, you should set up your LQ so that

continuous-feed paper can flow freely in and out of the printer.

Use any arrangement that allows you to put the paper underneath or

behind the printer. There are many types of printer stands you can use;

one example is shown in Figure 3-1. If you prefer, you can stack the paper

behind the printer as shown in Figure 3-2.

Figure 3-1. Continuous-feed paper with printer stand

3-1

Page 47

Figure 3-2. Continuous-feed paper without stand

Installing the Tractor Unit

1.

Remove the original dust cover that was included with your LQ.

Replace it with the front lid packaged with the tractor unit, and

leave it tilted up, as shown in Figure

3-3.

Figure 3-3. Installing the tractor unit

2. Hold the tractor with the gears to the right, and fit the rear notches

on the tractor unit over the rear mounting pins on the printer, as

shown in Figure

3-2

3-3.

Page 48

3. Tilt the tractor unit toward you until the front latches click in place

over the front mounting pins on the printer.

Loading Paper

To load continuous-feed paper, follow these instructions:

1. Make sure that the printer is turned OFF.

2. Move the print head to the center of the printer, pull the paper bail

away from the platen, and pull the paper release lever forward, as

shown in Figure 3-4.

Figure 3-4. Preparing for paper loading

3-3

Page 49

3. Using Figure

3-5

as a guide, pull the locking levers on the pin-feed

holders forward so that you can move the holders to the left and

right.

Figure 3-5. Moving the pin-feed holders

4. Position the left holder all the way to the left and push the locking

lever back to lock that holder in place. Leave the right holder

unlocked.

5.

Open the pin-feed covers as shown in Figure

3-4

3-6.

Page 50

Figure 3-6. Opening the pin-feed covers

Now install the paper shelf by fitting it into the two notches on the

6.

back of the printer, as shown in Figure 3-7. The paper shelf keeps

the paper from getting caught on the interface cable.

Figure 3-7. Installing the paper shelf

3-5

Page 51

If you have an LQ-800, center the one support in the middle of the

7.

tractor as shown in Figure

3-7.

If you have an LQ-1000, space the

two paper supports evenly along the width of the paper.

Now guide the paper behind the platen, and push it through until it

8.

comes up between the ribbon guide and the platen as shown in

Figure 3-8. (Moving the paper with a side-to-side motion makes it

easier to push the paper through.)

3-6

Figure 3-8. Loading paper

Page 52

9. Pull the paper up until the top is above the pin-feed holders. Fit

the holes on the left side of the paper over the pins in the left

holder (as shown in Figure 3-9) and close the cover.

Figure 3-9. Fitting the paper over the pin feeds

10. Fit the right side of the paper into the right holder, moving the

holder as needed to match the width of the paper.

11. Close the right cover, making sure the paper has no dips or

wrinkles and lock the right holder in place.

Push the paper bail against the paper and that’s it . . . the paper is

12.

ready.

3-7

Page 53

Figure 3-10. Top-of-page position

Setting the top-of-page position . . .

Once you‘ve loaded continuous-feed paper into your LQ, you need

to establish a top-of-page position so that the printed pages end where

you want them to and do not cross over a perforation between pages.

To set the top-of-page position, make sure the power is OFF and

use the paper feed knob to advance the paper until a perforation

between sheets lines up evenly with the top of the ribbon guide, as

shown in Figure 3-10.

Now turn the printer ON. This records the top-of-page setting.

The printer remembers this setting and uses it when any program tells

it to move to the top of the next page, or when you use the FORM

FEED button to advance the paper.

If you are using a word processor or other applications program

and the printing is too high or too low on the page, adjust your top-ofpage setting accordingly,

Installing the paper separator and tractor cover

Once you’ve loaded paper into the LQ and are familiar with the

steps, you can attach the paper separator that comes packaged in the

cardboard enclosure. The separator ensures that the paper coming out

of the printer is not pulled back in.

3-8

Page 54

The separator has rounded pins on each end that fit into notches

located just behind the tractor unit. Slide one of the separator’s pins

into one notch, then with a gentle pressure, snap the other pin into the

other notch as shown in Figure 3-11.

Figure 3-11. Installing the paper separator

3-9

Page 55

The smoked plastic tractor cover is the finishing touch. Simply

place it over the tractor unit, making sure the notches on the side of

the cover fit into the slots on the printer, as shown in Figure

3-12.

3-10

Figure 3-12. Installing the tractor cover

Page 56

Removing the Optional Tractor Unit

When you want to remove the optional tractor unit from the LQ

simply push back on the tractor release levers as shown in Figure 3-13,

tilt the unit back, and lift it off the printer.

Figure 3-13. Removing the optional tractor unit

3-11

Page 57

Chapter

4

Using the LQ with Commercial Software

Now that you have set up and tested your printer, you can do any

of these things:

l

Use the printer with commercial software (such as a word proces-

sor, spreadsheet, or database).

l

Learn about the features of the printer.

l

Write programs to use the features of the printer.

Most of you probably want to begin using your LQ with commercial software to print such items as documents, reports, letters,

spreadsheets, and graphics. This chapter tells you what you need to

know.

If you want to learn more about the features of the LQ, also read

Chapters 5 and 6. For programmers the important parts of the manual

are the command summary and the other appendixes.

Using Commercial Software

Commercial software programs usually need to know what type of

printer you are using. You normally supply this information as part of

a setup or installation process. Either the manual for your program or

an on-screen menu should explain this process for you.

The program may list a number of printers from which you can

choose. Pick LQ-800 or LQ-1000, depending on which printer you

have.

4-1

Page 58

If neither one of these printers is listed, choose

LQ-1500

because

that printer recognizes virtually the same codes that the LQ-800 and

LQ-1000 use. (If you have a program that does not list the LQ-1500 as

an option, you may be able to obtain an update from the manufacturer. Contact your software dealer or the manufacturer to see if an

update that includes the LQ-1500, LQ-1000, or LQ-800 is available.)

If your program does not list any LQ printers, choose a printer from

the list below. They are listed in order of preference.

FX

LX

Rx

MX

Epson printer

Draft printer

Once you have set up or installed your commercial software pro-

gram for your printer, simply follow the program’s printing instruc-

tions. If you have any trouble

when

you print, turn to the first section

in Appendix D for help.

4-2

Page 59

Chapter 5

LQ Features

This chapter describes many of the printing features of the LQ. You

can read this chapter if you wish, but you may not need to. Whether

or not you use the rest of this manual depends upon your expertise,

your interest, and the software you use.

The demonstration programs in this chapter enable you to see LQ

features and print styles in action. Below are a few of the many fea-

tures covered:

Letter Quality

High

Emphasized

Double-strike

Italics

Elite

Fifteen Characters Per Inch

Underlined

Double-width

Condensed

Superscript

Proportional

Speed Draft

Subscript

ESCape and ASCII

The details of printer-computer communication are complex, but

for most purposes all you need to know is that the computer sends a

series of codes (each consisting of one or more numbers) to the printer,

and the printer interprets them.

5-1

Page 60

Some codes tell the printer to print a character, and other codes tell

it to turn on or off certain printer functions, such as emphasized or

Letter Quality. Because the codes between 0 and 127 are basically

standardized by the American Standard Code for Information Interchange (ASCII), they are referred to as ASCII numbers in this manual.

Nearly all of the codes for printer functions require more than one

number and begin with a special code, called the escape

code.

This

code signals that the next number is a code for a printer function and

its name is usually printed with the first three letters capitalized

(Escape) or it is abbreviated ESC or (ESC) .

In the demonstration programs in this manual, you’ll see how

ASCII and ESCape codes are used in the BASIC programming language.

l

LPRINT signals that information is to be sent to the printer.

l

The CHR$ (character string) function is used for numerical codes.

l

CHR$(27) is the ESCape code.

l

Quotation marks are used for printable characters, such as letters of

the alphabet.

Your word processing or business program may use other methods

to send those codes, such as pressing the ESC key for the ESCape

code. See your software manual for further information and use

Appendix B of this manual to find the proper codes. Appendix D also

has some suggestions on using LQ features with applications soft-

ware.

Demonstration Programs

To enable you to see the LQ features in action, this manual includes

demonstrations in the BASIC programming language. Although you

will probably not do much of your printing using BASIC, the demon-

strations are in BASIC because nearly all personal computer systems

include some version of this language. Therefore, almost everyone

can try the examples.

As you run the programs (or even as you read the explanations and

look at the printed examples), you learn how the LQ responds to the

messages your computer sends it by printing letters, numbers, symbols, and graphics in various print modes.

5-2

Page 61

Even if you never use BASIC again, you will know the capabilities

of your printer, capabilities that can often solve your printing problems. For example, if you need a special symbol, such as a Greek letter, you will

know that

you can turn to the chapter on user-defined

characters and create such a character.

If you don’t want to do

In most cases the software

or graphics does

the

the

exercises in BASIC, you don’t have to.

that

you use for word processing, business,

calculating and communicating with the printer

for you. All you need to do is install your software as explained in

Chapter 4.

Running BASIC programs. . .

This section describes how to run the BASIC demonstration pro-

grams in this manual; it is not a tutorial in BASIC programming.

Although there are many versions of BASIC, the programs in this

manual are designed to work with the two most popular ones: Microsoft™ BASIC and IBM PC BASIC. If you have another version, you

can run these demonstration programs by making a few changes.

Appendix D has instructions for using Applesoft™ BASIC; for other

versions of BASIC, consult the appropriate manual.

When you type these programs, be sure to include all spaces and

punctuation marks, especially semicolons. Press

of each line. (On your computer the

or ENTER.) Computers that use a 40-column display may break

some lines into two parts on the screen, but that does not affect the

operation of the program. If you make a typing mistake, retype

whole line, including the line number; the new line will replace the old

one.

RETURN

RETURN

key may be marked

at the end

the

When you

to run the program.

If you have made changes to a program and want to see all of it on

the screen, type

your screen. When you are completely through with one program

and want to start another, type NEW and press RETURN.

have

typed all

LIST and then press

the lines,

type

RUN and press

RETURN

to see the program on

RETURN

5-3

Page 62

Sending Control Codes to the Printer

The short program that follows illustrates the concepts of control

codes and ESCape sequences. This exercise may help you make better

use of this chapter and the next. Type and run the program. It should

produce the printout you see below it. After the printout you’ll find a

detailed description of the operation of the program.

10 LPRINT "BASIC programs for the"

20 LPRINT CHR$(76)CHR$(81)CHR$(45);

25 LPRINT CHR$(56)CHR$(48)CHR$(48);

30

LPRINT

40

LPRINT "W1 "CHR$(87)CHR$(49)

50 LPRINT CHR$(27)"W1";"Double-width print"

60 LPRINT "Still double-width"

Basic programs for the

LQ-800 and LQ-1000

W1 W1

Double-width

Still

" and LQ-1000"

print

double-width

In each line LPRINT signals that the rest of the information on the

line is to be sent to the printer. In lines 10 and 30 the letters inside the

quotation marks are printed just as they appear in the program.

Lines 20-25 show an alternate way of printing characters. They

use the CHR$ (character string) function with the decimal code for

each letter to print “LQ-800.”

Line 40 prints the characters W1 using the two different methods

(quotation marks and the character string function). Line 50 shows

that if the ESCape code, which is CHR$(27) in BASIC, comes before

the characters W1, those characters are not printed. Instead, they

become part of the ESCape sequence that turns on double-width

printing, which is demonstrated with the letters in quotation marks

after the ESCape sequence. Line 60 shows that the double-width mode

stays on for more than one line.

This program is only an introduction. The demonstration pro-

grams that follow allow you to see many more of the features of your

LQ in action.

5-4

Page 63

Basic Widths

The first programs print characters in the LQ’s three basic widths.

Further programs show you how to produce other character widths

by condensing and widening the basic ones.

Pica printing

The first program prints a sample line of characters in pica. This is

the

default

receives a command to use one of the other two basic widths.

Now run the program to print the results you see below-10 characters per inch:

ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_'abcdefghi

Elite printing

width on the LQ, which means it is used unless the printer

40

FOR X=65 TO 105

50 LPRINT CHR$(X);

60 NEXT X: LPRINT: LPRINT

To print the same line of characters in elite (which is

per inch) add the following line to your program. (Just type the new

line; you don’t have to retype the other lines.)

12

characters

20 LPRINT CHR$(27)"M";

Now run the program to produce a sample of elite printing.

ABCDEFGHIJKLMNOPQRSTUVWXYZ

Fifteen mode printing

To print the same characters in the fifteen mode (which is

ters per inch) enter this new line 20.

[\]^_'abcdefghi

15

charac-

20 LPRINT CHR$(27)"g";

5-5

Page 64

Now run the program to produce a sample of printing in the fifteen

mode.

ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]ˆ_'abcdefghi

Letter Quality and Draft

Your LQ is set at the factory to print in the Letter Quality mode

unless you turn on the draft mode with the DRAFT button on the

control panel or with a DIP switch (described in Appendix A). Therefore, the printouts in this manual are shown in Letter Quality. If you

want to see how a feature looks in the draft mode, press the DRAFT

button before you run the program. Here’s a comparison of Letter

Quality and Draft modes in pica width.

ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]ˆ'abcdefghi

ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]ˆ'abcdefghi

Cancelling Modes

With only a few exceptions, the LQ printing modes stay

on

until

they are turned off. In fact, the modes can stay on even if you change

from one type of software to another. For example, if you run a

BASIC program that turns on elite and then use a word processing

program to print a document, the LQ prints that document in the elite

mode.

There are two methods to turn off a printing mode when you no

longer need it.

l

With a specific cancelling code. Each mode has a cancelling code,

which you can find in the discussion of the mode and also in Appendix I.

l

By resetting the printer, a method explained in the next section.

Resetting the Printer

Resetting your LQ cancels all modes that are turned on. You can

reset the printer with one of two methods:

l

Sending the reset code (Escape “@”)

l

Turning the printer off and then on.

5-6

Page 65

Either one of these methods returns the printer to what are called its

defaults, which are the standard settings in effect every time you turn

the printer on. Resetting the printer has two main effects. It returns the

printing to single-strike pica, thus cancelling any other pitches or

enhancements you may have turned on, and the current position of

the print head becomes the top-of-page setting. The reset code does

not cancel the draft mode if it has been selected with the panel button,

but turning off the printer does cancel the draft setting.

Some of the demonstration programs end with a reset code

(Escape “@”) so that the commands from one program will not interfere with the commands in the next one. After you run a program with

a reset code in it, remember to change the top-of-page setting before

you begin printing full pages.

Disabling a program’s reset code

Some word processors and other applications programs send a reset

code or initialization signal to the printer before sending data to be

printed. Basically, the purpose of this code or signal is to cancel any

settings that might interfere with the program’s print control options.

In most instances, this is fine. However, if you decide you want to

set up the LQ to do something your applications program won’t do,

you have to make sure a reset code doesn’t wipe out your new settings.

Some initialization codes can be removed by using the setup or

installation procedures that are part of many applications programs.

Once you’re into the setup procedure, find the section that deals with

initialization, and see if the program has a list of codes it sends to the

printer. If it does, the setup procedure usually allows you to cancel or

remove the initialization settings.

If the initialization code cannot be disabled or removed from your

applications program,. you can usually use the program’s print options

function to control formatting and typestyles. Look in the manual for

the program to find out how to select print options.

5-7

Page 66

Print Quality Command

Although you can turn on the draft mode with one of the panel

buttons, you can also use a software command to switch between

draft and Letter Quality.

Enter and run the following program to see how Letter Quality and

draft are turned on and off by an ESCape sequence (note that you use

a lowercase x, not a capital X, in line

NEW

10 LPRINT CHR$(27)"x0";

20 LPRINT "This is draft."

30

LPRINT CHR$(27)"x1";

40 LPRINT "This is Letter Quality."

10).

This

This is Letter Quality.

As you can see in this program, Letter Quality is one of the Epson

modes with an ESCape code that uses a letter with the numeral one to

turn on

these modes, the one or zero can be inside the quotation marks, as

shown above, or as a separate character string value, as shown below:

the mode and a letter with the numeral zero to turn it off. For

is draft.

10 LPRINT CHR$(27)"x"CHR$(0);

Other Widths

The three

with each other. If one is on, the other two are off. There are, how-

ever, two width modes that can be combined with the basic modes

and with each other. These two are double-width and condensed. All

characters printed by the LQ are widened by double-width and narrowed by condensed.

Double-width printing

The double-width mode doubles the width of each character. To see

double-width pica printing, which is the widest typestyle available on

the LQ, enter and run the program below.

basic

widths (pica, elite, and fifteen) cannot be combined

5-8