Page 1

LQ-2550

TECHNICAL MANUAL

EPSON

Page 2

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury, and 2) damage

to equipment:

DANGER

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER headings.

DANGER

1.

ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND THE

HOST COMPUTER BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2.

NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

WHEN PERFORMiNG TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT

3.

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1.

REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON

CERTIFIED REPAIR TECHNICIAN.

2.

MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED

VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PROD-

UCT HAS A PRIMARY-AC RATING DIFFERENT FROM THE AVAILABLE POWER

SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3.

ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

KP

IN ORDER TO PROTECT SENSITIVE

4.

DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5.

REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS

RECOMMENDED BY THE MANUFACTURER; INTRODUCTION OF SECOND-SOURCE

ICS

OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND

VOID ANY APPLICABLE EPSON WARRANTY.

CHIPS AND CIRCUITRY, USE STATIC

- ii -

Page 3

PREFACE

This manual describes functions, theory of electrical and mechanical

operations, maintenance, and repair of the

The instructions and procedures included herein are intended for the

experienced repair technician, and attention should be given to the

precautions on the preceding page. The chapters are organized as follows:

LQ-2550.

REV.-A

Chapter 1 -

Chapter 2 -

Chapter 3 -

Chapter 4 -

Chapter 5 -

Chapter 6 -

“

The contents of this manual are subject to change without notice.

Provides a general product overview, lists specifications,

and illustrates the main components of the printer.

Describes the theory of printer operation.

Discusses the options

Includes a step-by-step guide for product disassembly,

assembly, and adjustment.

Provides Epson-approved techniques for troubleshooting.

Describes preventive maintenance techniques and lists

lubricants and adhesives required to service the equipment.

-

iv -

Page 4

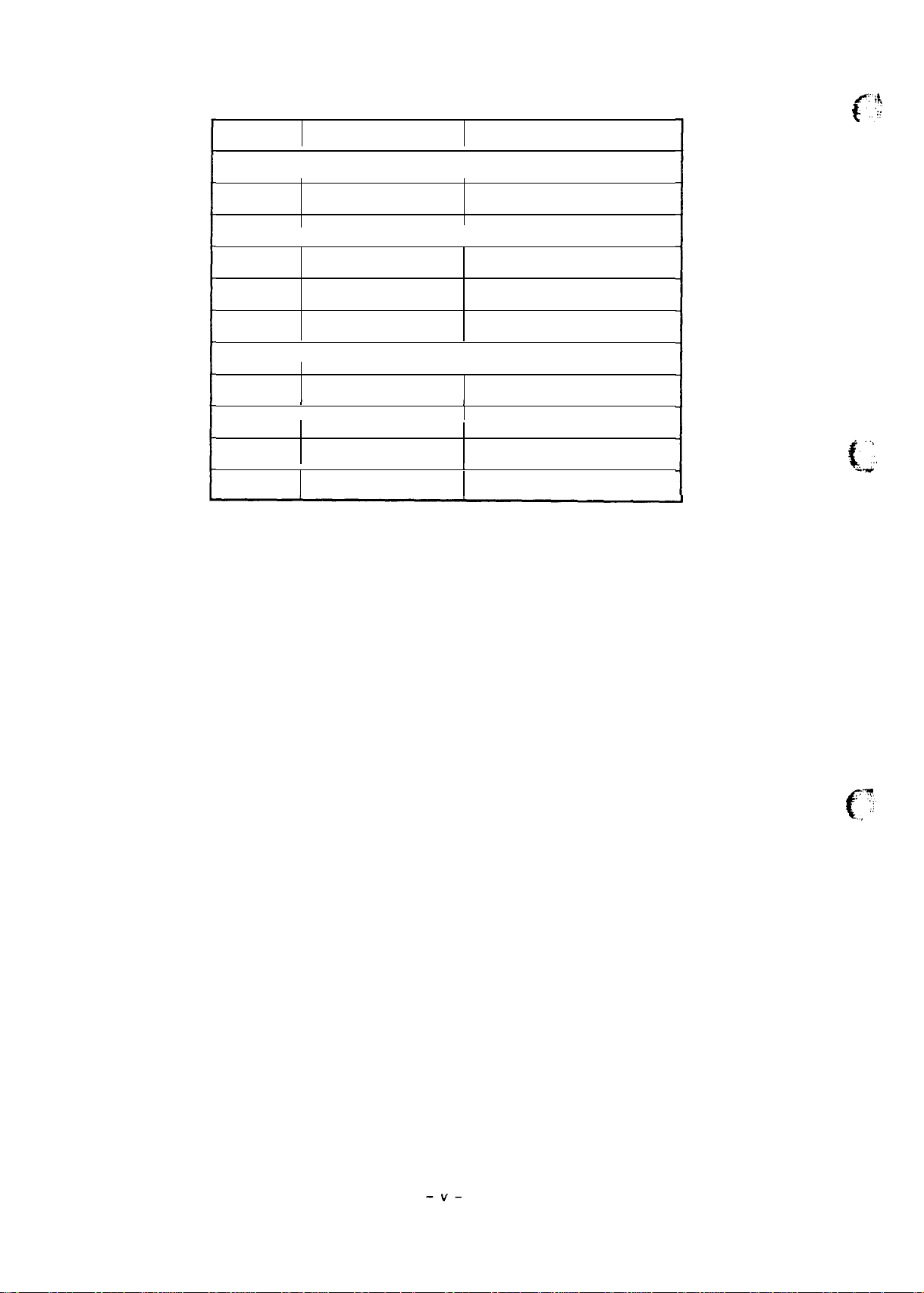

REV.-A

REVISION TABLE

REVISION DATE ISSUED

A

March 31, 1988

I

I

I

I

I

CHANGE DOCUMENT

I

I

1st issue

I

1

1

f’!

.,

t

-.+

.

,:,

-v-

(

.%

:

,.,

.,

.,.:,

~DŠˆ

Page 5

REV.-A

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

OPERATING PRINCIPLES

OPTIONAL EQUIPMENTS

DISASSEMBLY, ASSEMBLY, AND ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

–

vi -

Page 6

CHAPTER 1

GENERAL DESCRIPTION

REV.-A

FEATURES

1.1

1.2

SPECIFICATIONS

1.2.1 Hardware Specifications

1.2.2 Firmware Specifications

INTERFACE OVERVIEW

1.3

1.3.1 8-bit Parallel Interface Specifications

1.3.2

RS-232C

SELF-TEST OPERATION

1.4

1.5

HEXADECIMAL DUMP FUNCTION

PRINTER INITIALIZATION

1.6

1.6.1 Hardware Initialization

1.6.2 Software Initialization

1.6.3 Default Values

ERROR

1.7

1.7.1 Error Conditions

1.7.2 Buzzer Operations

MAIN COMPONENTS

1.8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDITIONS AND BUZZER OPERATION . . . . . . . . . . . . . . . . . . 1-23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3

1-1o

1-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

1-14

1-20

1-21

1-22

1-22

1-22

1-22

1-23

1-23

1-24

1.8.1

1.8.2

1.8.3

1.8.4

1.8.5

1.8.6

Printer Mechanism

1.8.1.1 Overview

1.8.1.2 Paper Handling and Operations

ROMA Board (Main Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.27

ROPS/ROPSE

(Power Supply Circuit Board)

Fan Unit

Housing

Control Panel

1.8.6.1 Hardware Specification

1.8.6.2

SeiecType Function

Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

1-25

1-25

1-26

1-28

1-29

1-29

1-30

1-30

1-32

l-i

Page 7

REV.-A

LIST OF FIGURES

Figure 1-1.

Figure 1-2.

Figure 1-3.

Figure 1-4. Fanfold Paper Printable Area

Figure 1-5.

Figure 1-6.

Figure 1-7.

Figure 1-8.

Figure 1-9.

Figure 1-10. Serial Data Transmission Timing

Figure 1-11. Serial Interface Connector

Figure 1-12. Self-Test Printing

Figure 1-13. Hexadecimal Dump List

Figure 1-14. LQ-2550 Component Locations

Figure 1-15. Model-5560 Printer Mechanism

Figure 1-16. ROMA Board

Exterior Views of the

Printhead Pin Configuration

Cut Sheet Paper Printable Area

Label Printable Area

Character Matrix

Data .Transmission Timing for the

8-bit Parallel Interface

36-pin 57-30360 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handshaking for

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LQ-2550

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(LQ)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-3

1-5

1-6

1-7

1-12

1-14

.

1-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-17

1-18

1-18

1-20

1-21

1-24

1-25

1-27

Figure 1-17.

Figure 1-18. Fan Unit

Figure 1-19. Housing

Figure 1-20. Control Panel

Figure 1-21.

ROPS/ROPSE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SelecType

Operational Sequence

LIST OF TABLES

Table 1-1.

Table 1-2.

Table 1-3.

Table 14.

Table 1-5.

Table 1-6.

Table 1-7.

Optional Units

Optional Interface Boards

Line Feed

Cut Sheet Paper Specified Conditions

Fanfold Paper Specified Conditions

Ribbon Cartridge Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions and Weight

Speeds

Board

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

—

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-28

1-29

1-29

1-30

1-33

1-2

1-2

14

1-5

1-6

1-8

1-8

Table 1-8.

Table 1-9.

Table 1-10.

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Conditions

Printing Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6

.

1-9

1-11

Page 8

REV.-A

Table 1-11. Character Matrix and Character Size

Table 1-12. 8-bit Parallel l/F Connector

Pin Assignments

Table 1-13. Select/Deselect Control

Table 1-14. Serial Interface Handshaking

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-15. RS-232C Serial Interface Connector

Pin Assignments

Table 1-16. Self-Test Operation

Table 1-17. Hexadecimal Dump Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-13

1-15

1-16

1-17

1-19

1-20

1-21

l-iii

Page 9

‘

1.1 FEATURES

The

LQ-2550 printer is a multifunction, 24-pin, impact dot-matrix printer. The main features Of this

printer are:

ESC/P

●

I

I

●

●

●

●

●

●

●

●

●

●

●

●

Expanded is implemented as a standard

Upward

A

maximum print speed of 400

I

Direct selection of font, pitch, and normal/condensed mode, and SelecType function with LCD (Liquid

Crystal Display) which makes panel settings easier

Multiple standard fonts (Roman, Saris Serif, Courier, Prestige, Script, OCR-A, and OCR-B)

Advanced paper handling:

Automatic release function

Automatic platen gap adjustment function

Micro adjustment function

Tear-off function

Automatic

Color printing capability

Low-noise acoustics

Both 8-bit parallel and

Push and (optional) pull tractor feeding ,

Printing of fanfold paper without removal of the cut sheet feeder (option)

Optional interface for the EPSON 8100 series

Optional low-priced, double-bin cut sheet feeder with envelope feeding capability

compatibility with the

paper-loading/ejectin9 function

LQ-2500/LQ-2500+

CPS

in draft mode at 12

RS-232C serial interfaces

CPI

and 133

CPS

in LQ mode at 12

REV.-A

CPI

Figure 1-1 shows exterior views of the printer, Table 1-1 lists optional units that are available, and Table

1-2 lists the optional interface boards (refer to Chapter 3 for more detailed information) for the

Setting for Continuous Paper

Setting for Cut Sheet Paper

LQ-2550.

Figure 1-1. Exterior Views of the

1-1

LQ-2550

Page 10

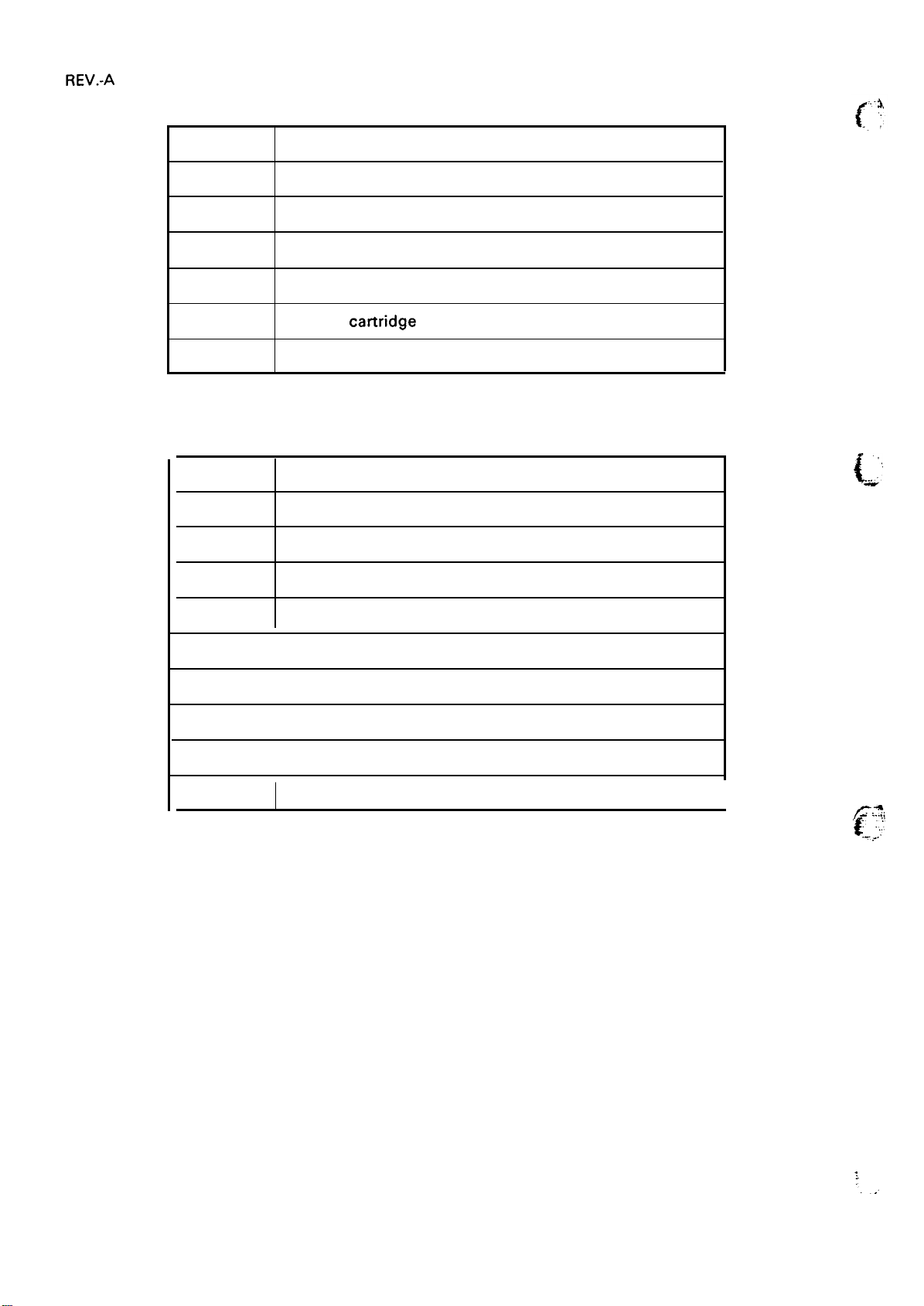

Table 1-1. Optional Units

No.

#73 14

#7343

#7394 Scanner option kit

#7762

#7763

#7764

No.

#8143

#8145 RS-232C current loop interface type II

#8 148 Intelligent serial interface

Name

Pull tractor unit

Double bin cut sheet feeder

Ribbon cartridge (black)

Ribbon

Ribbon cartridge (film-black)

Table 1-2. Optional Interface Boards

Name

New serial interface

cattridge (color)

... ,

{:’”

#8 149 Intelligent serial interface type II

#8 149M

#8 161

#81 65

#8 172

#8 172M 128K-byte buffer parallel interface

Intelligent serial interface type Ill

I

IEEE-488 interface

I

Intelligent IEEE-488 interface

I

32 K-byte buffer parallel interface

I

I

g:;;

.7,

...,

1-2

Page 11

\

1.2 SPECIFICATIONS

The LQ-2550 communicates with a wide variety of host computers, with the aid of the optional Identity

Modules. However, this section describes the specifications for the printer without the Identity Module.

Specifications not affected by firmware (hardware specifications) are the same whether or not the

Identity Module is installed.

1.2.1 Hardware Specifications

REV.-A

Printing

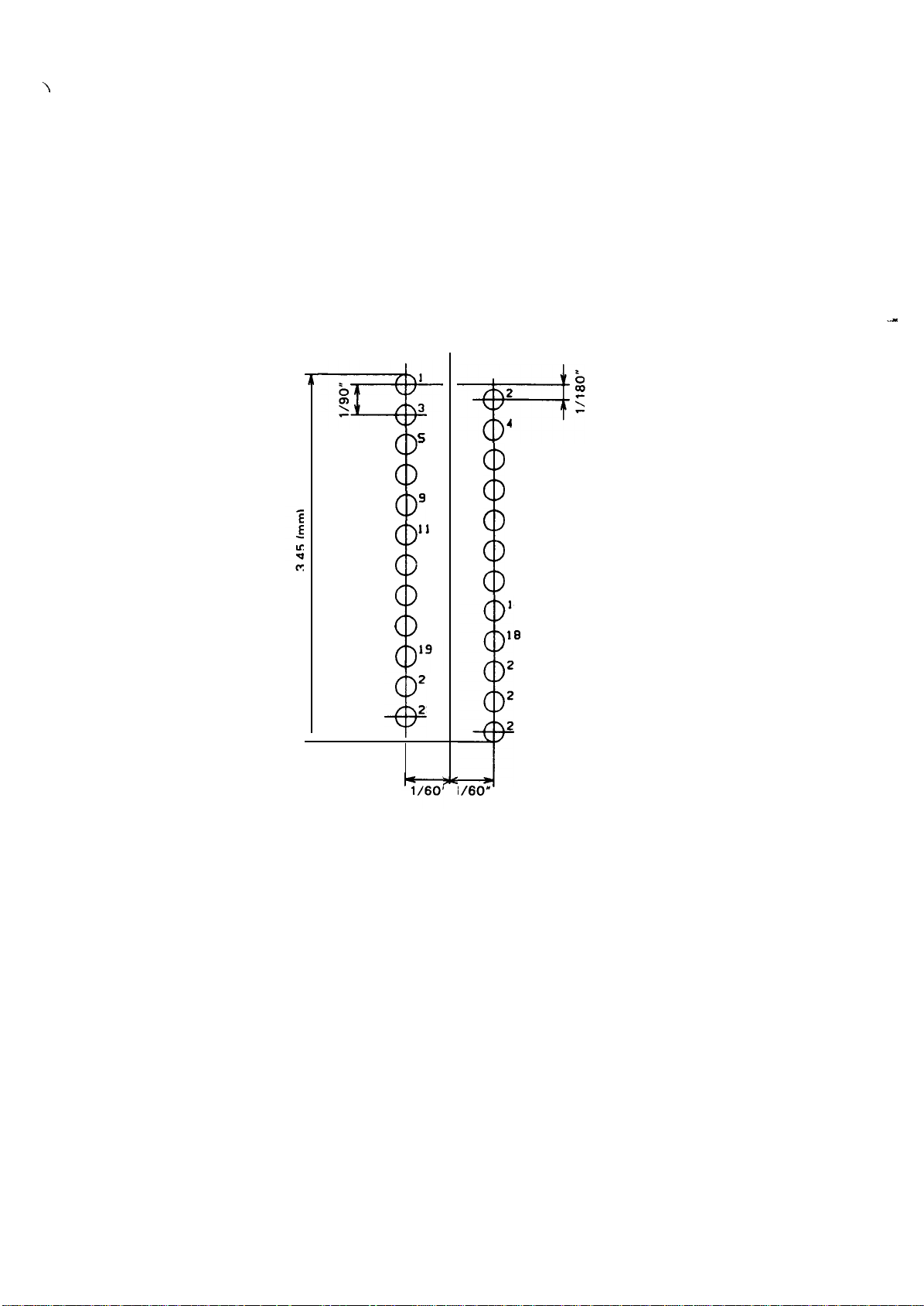

Pin Configuration

Method

Serial, impact dot matrix

See Figure 1-2 (1 2x2 staggered, diameter: 0.2 mm).

0

OJ

\

5

=’

7

$

11

13

15

17

I

1’

21

23

$’-

2

4

6

8

10

12

14

16

la

20

22

24

..=

4

1160”

Figure 1-2. Printhead Pin Configuration

1-3

Page 12

REV.-A

Feeding Method

Friction feed

Tractor feed (push: standard, push-pull: optional)

NOTES: 1. When using friction feed:

● Select friction feed on the control panel.

● Do not use continuous (fanfold) paper.

● Do not use a single sheet paper shorter than 92mm or longer than 364mm

● Do not perform any reverse paper feed operations within the top 8.5 mm and bottom

22 mm of the paper.

● Do not perform reverse feed beyond 1/6” after the paper end has been detected.

● Do not use multi-part, single-sheet forms.

2. When using push-pull tractor feed:

● Select tractor feed on the control panel.

● Mount the pull tractor unit (optional).

● Do not loosen the paper between the platen and the pull sprocket.

● Precisely align the horizontal position of the pull sprocket and push tractor.

● Do not perform reverse feeding for more than 1/6”.

● Do not perform reverse feeding after the paper end has been detected.

● Multiple copy paper must be pasted together using line or dots.

● Copy paper must be carbonless multi-part paper.

Paper Loading Directions

Fanfold paper

Cut sheet paper

Line Spacing

Line Feed Speed

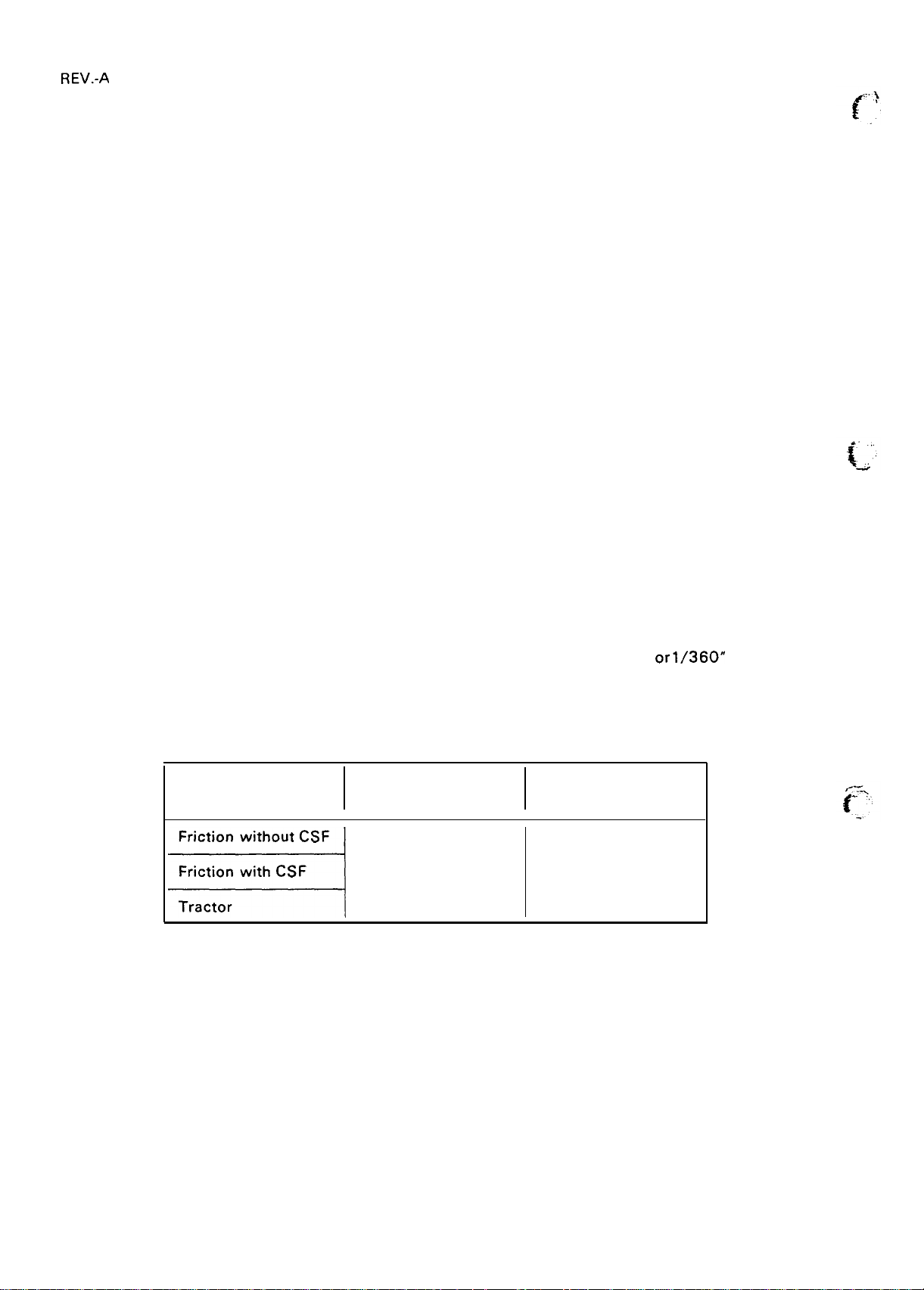

Feeding Method

Friction without

Friction with

Tractor

=

Inserted from the rear

Inserted from the top

1/6”, 1/8”, or programmable in units of 1/1 80”

See Table 1-3.

Table 1-3. Line Feed Speeds

1/6” line spacing

Continuous

[ins/line] [inch/s]

CSF

CSF

84 4.0

orl/360”

1-4

Page 13

\

Paper Specifications

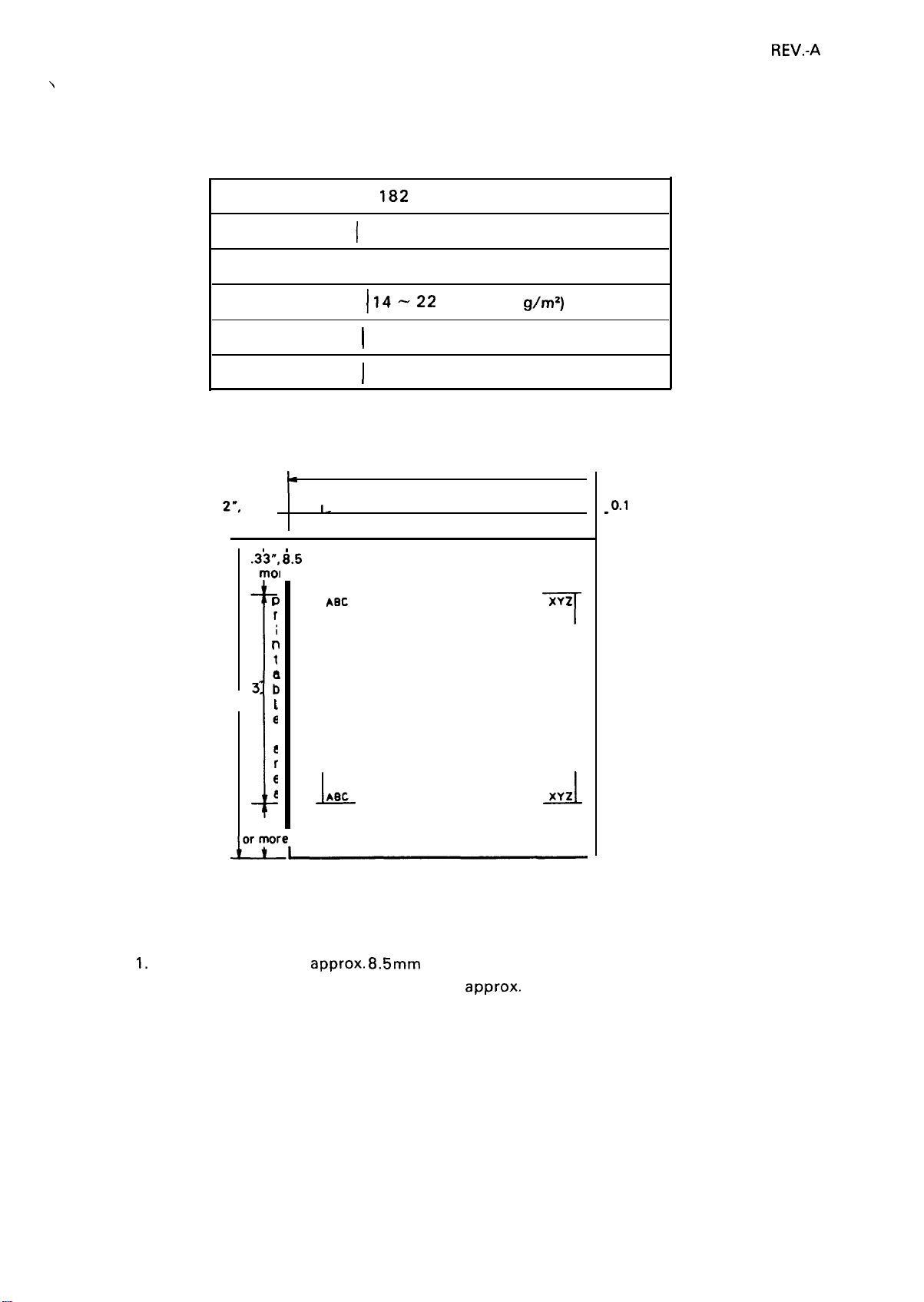

Cut sheet paper

Refer to Table 1-4 and

REV.-A

Figure 1-3.

Table 1-4. Cut Sheet Paper

Width

Length

Thickness [mm]

Weight

Quality

Copies

0.1

2“,

3 mm.

or more

.33”, 6.5

r

mol

t

mm

[mm]

[mm]

[lb]

7.2-14.3”,

1-

Specified Conditions

-364 (7.2 - 14.3”)

182

I

I

364 (14.3”) max.

0.065-0.10 (0.0025 - 0.004”)

I

I 14-22

I

Plain paper

I

Not available

(52 -82

182 ’364 mm

Printable area

g/m2)

1

I

-0.1

2“, 3

or more

mm

NOTES:

XYZ

T

XYZ

J

t

MAX. . .

364mm

3;

v

r

i

n

t

I

e

a

r

e

a

ABC

T

ABC

L

1

0.52”,

1.

Printing is possible approx.

accuracy can not be assured in the area

Printing is possible approximately 45.9mm past the point where end-of-page has been

2.

detected. Thus, the value 13.3mm (0.52”) (lowest print position) is given for reference only.

Paper feed accuracy cannot be

bottom of the page.

3mm

8.5mm

(0.33”) from the top of the paper. But the paper feed

approx. 22mm (0.87”) from the top of the paper.

assured in the area approximately 22mm(0.87”) from the

Figure

1-3. Cut

Sheet Paper Printable Area

1-5

Page 14

REV.-A

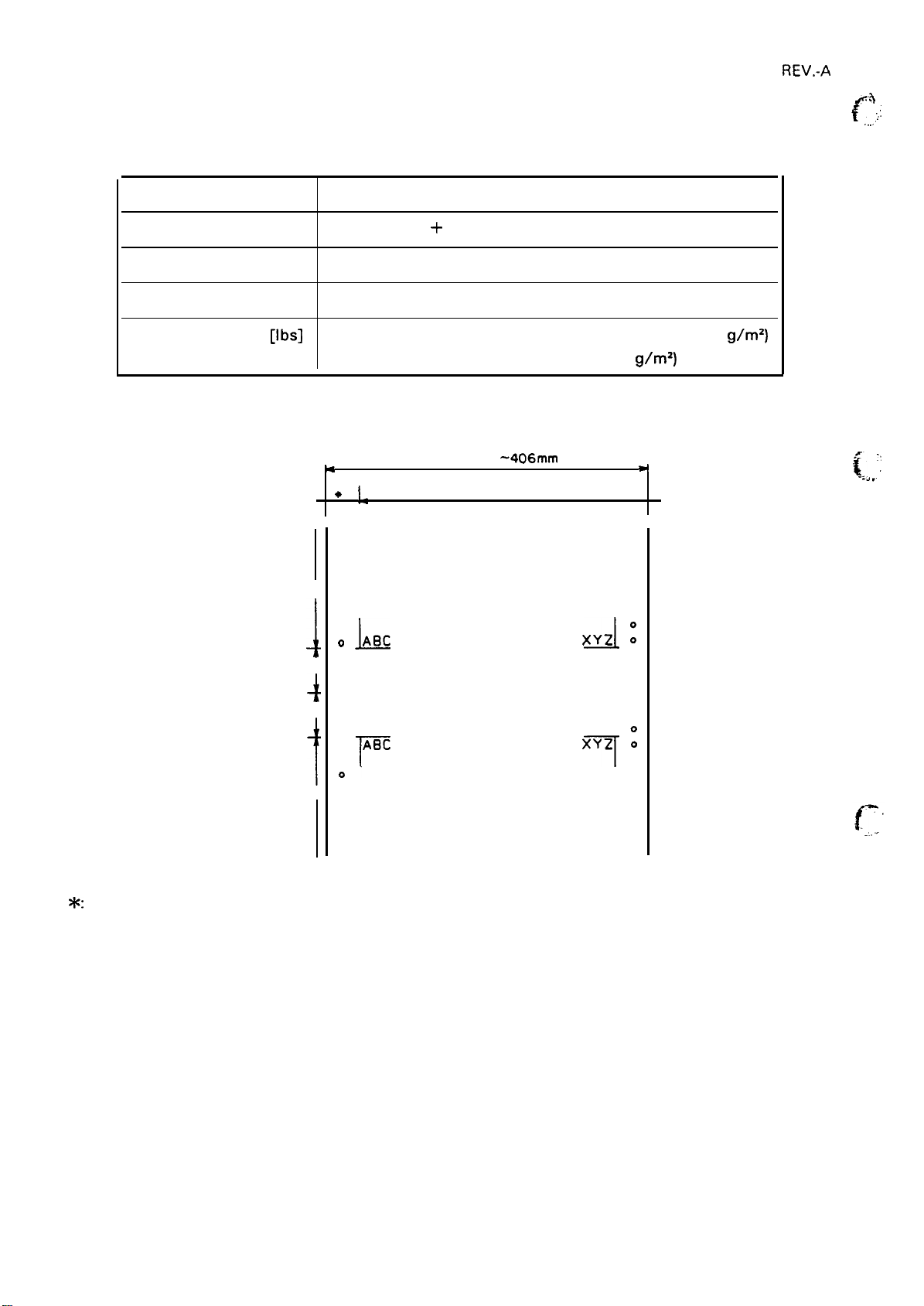

Fanfold paper

Width

Copies

Quality

Total Thickness [mm]

Weight

Refer to Table 1-5 and Figure 1-4.

Table 1-5. Fanfold Paper Specified Conditions

-406 (4.0 - 16.0”)

[mm]

[sheets]

101

6 (1 original + 5 ) over the entire temperature range

Plain paper

0.06-0.46 (0.0023 -0.0 18“)

IIbs]

Printable

area

0.35”, 9 mm

or more

0.35”, 9 mm

or

more

Printable

area

1 sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 sheets ...................12

M

i

4

i

4-16” ,

*

~

o

0

0

0

0

0

0

o

ABC

L

o

0

0

-----------------------------

o

0

0

o ABC

o

T

0’

0

0

0

0

0

Printable area

-15 (40 - 58.2

101

-4C)6mm

-22 (40 -82

g/m2)

d

*

I

0

0

0

0

0

0

XYZ

XYZ

:

d

0

0

0

0

0

:

0

T

o

0

0

0

0

0

g/m2)

each sheet

.“3

f ~

. . . . .

{ ;

.., ,.

,,.

*:

101 - 381 mm (4 -

15“) wide paper . . . . . . . . . . . . . . . . . . . . . 13mm or more,

406 mm ( 16“) wide paper . . . . . . . . . . . . . . . . . . . . . 26mm or more

Figure 1-4. Fanfold Paper Printable Area

1-6

Page 15

.

.

REV.-A

Envelopes

Size

No. 6 165 x 92 mm (6.5 x 3.63”)

No. 10241 x 105mm (9.5 x 4. 13“)

Quality

Thickness

Bond paper, xerographic copier paper, airmail paper

0.16-0.52 mm (0.0063 -0.01 97”)

NOTE: Differences in thickness within printing area must be less than 0.25 mm (0.0098”).

g/m2)

Weight

12- 24 lb (45

-91

\

NOTES: 1. Envelope

2. Keep the

printing is only available at normal temperature.

longer side of the envelope horizontal.

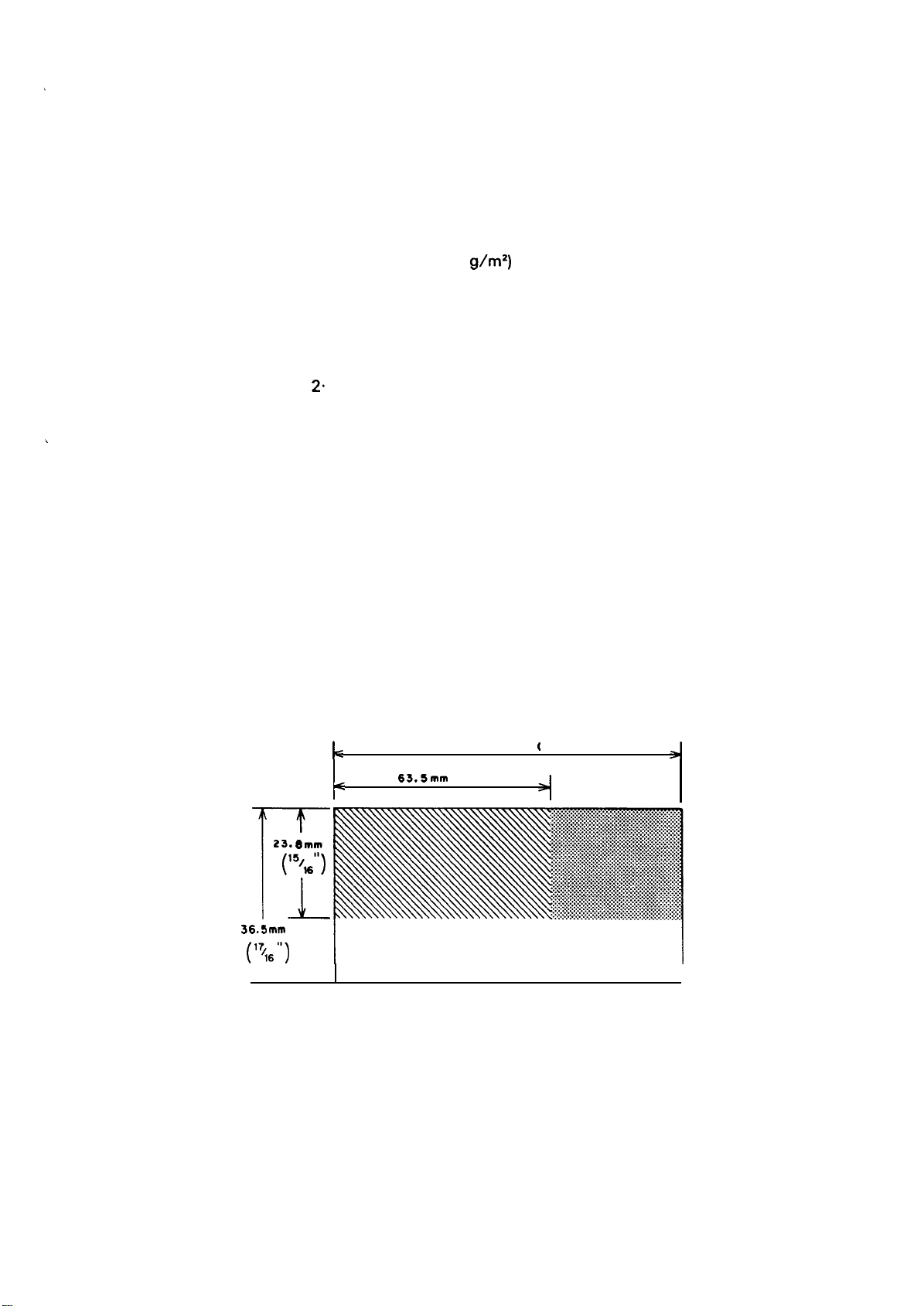

Labels

2.

Size

Thickness

1/2 X 15/1 6“, 4 X 15/1 6“, 4 X 1“7/16“

O.19 mm (0.0075”) max.

NOTE: Thickness excluding the base paper must be less than or equal to 0.12 mm (0.0047”).

NOTES: 1.

Printing of labels is only possible at normal temperature.

Labels must be fanfold.

2.

Labels with pressure-sensitive paper must be joined by dot or line pasting, and the total

3.

thickness must be less than or equal to 0.3 mm (0.01 1 8“) and should be printed under

conditions between 5 to 35 ‘C and 20 to 80% RH.

4.

Examples of labels: AVERY CONTINUOUS FORM LABELS

AVERY MINI-LINE LABELS

Printable

area

See Figure 1-5.

r

36.5mm

(176”)

23.

(’5+6”)

J_

101.6 mm

Emm

k

<

63.5mm (2 ”}2”)

Figure 1-5. Label Printable Area

[

4“ )

A

1-7

Page 16

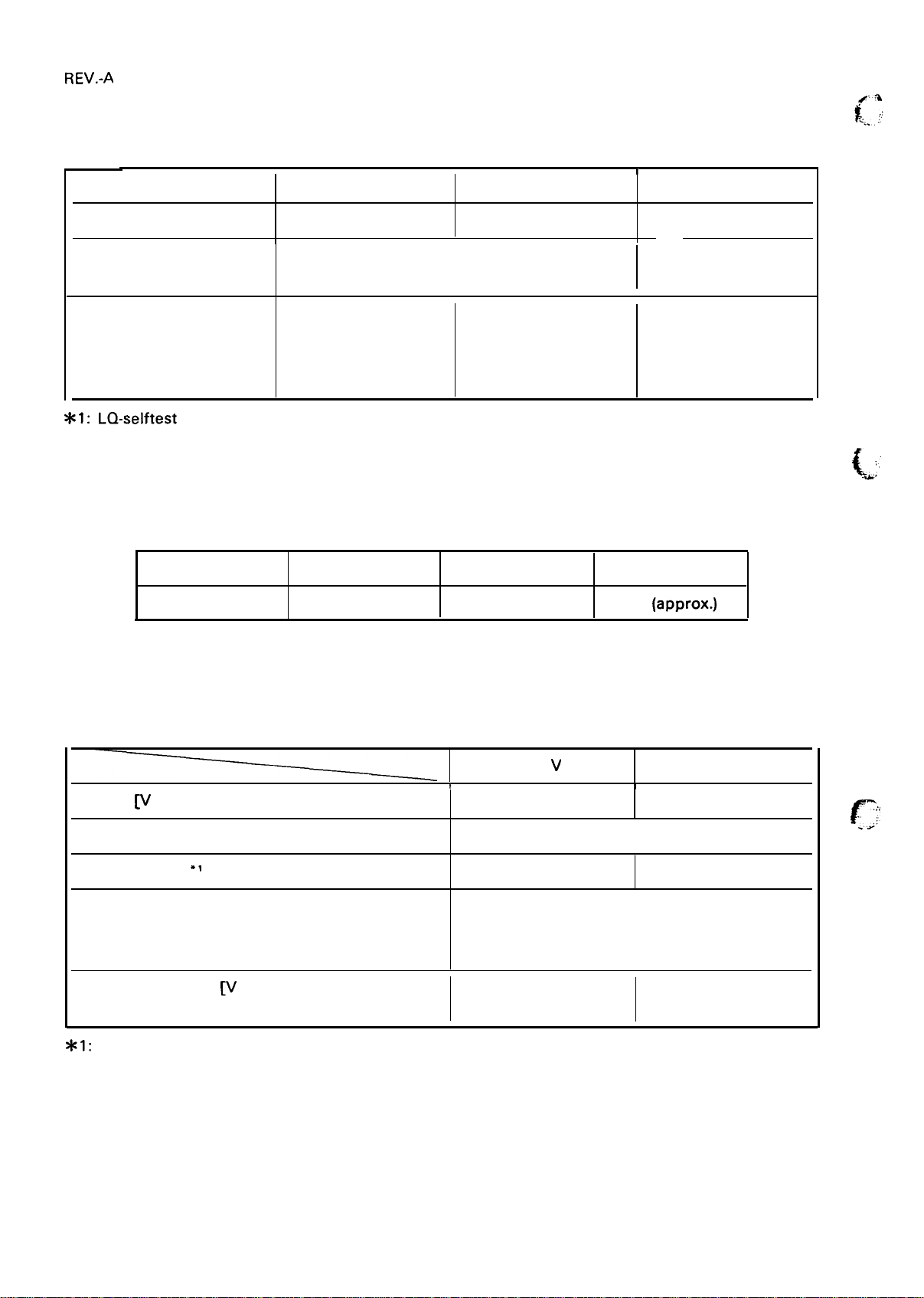

REV.-A

Ribbon

Ribbon Model No.

Type

Color

Life

[million/characters]*’

xl: LQ-selftest

Dimensions

Weight

Cartridge

See Table 1-6.

Table 1-6. Ribbon Cartridge Specification

I

#7762

Normal

Black

3

See Table 1-7 (Details are shown in Figure A-59.)

See Table 1-7.

Table 1-7. Dimensions and Weight

#7764 #7763

Film

0.2

[

Multi-color

Black, Cyan,

Magenta, and yellow

Black: 1

Cyan: 0.7

Magenta: 0.7

Yellow: 0.5

c

.4

. . .

‘

Width [mm] Height [mm]

676

NOTE: Including the paper feed knob and paper guide.

Electrical Specifications See Table 1-8.

Table 1-8. Electrical Specifications

Voltage ~ AC] 108- 132

Frequency Range [Hz]

“’

Rating Current

Insulation Resistance

[M ohm] min.

(between AC line and chassis)

Dielectric Strength ~ AC, rms]

(1 minute, between AC line and chassis)

[A]

198

Depth [mm]

100-

f

I

535

120

V

1.6

10

1250

Version

Weight [Kg]

(approx.)

20

220-240 V Version

I

49.5 -60.5

I

198-264

1.0

3750

f-

,,.,,

-..+,

*1:

At draft-selftest printing.

1-8

Page 17

REV.-A

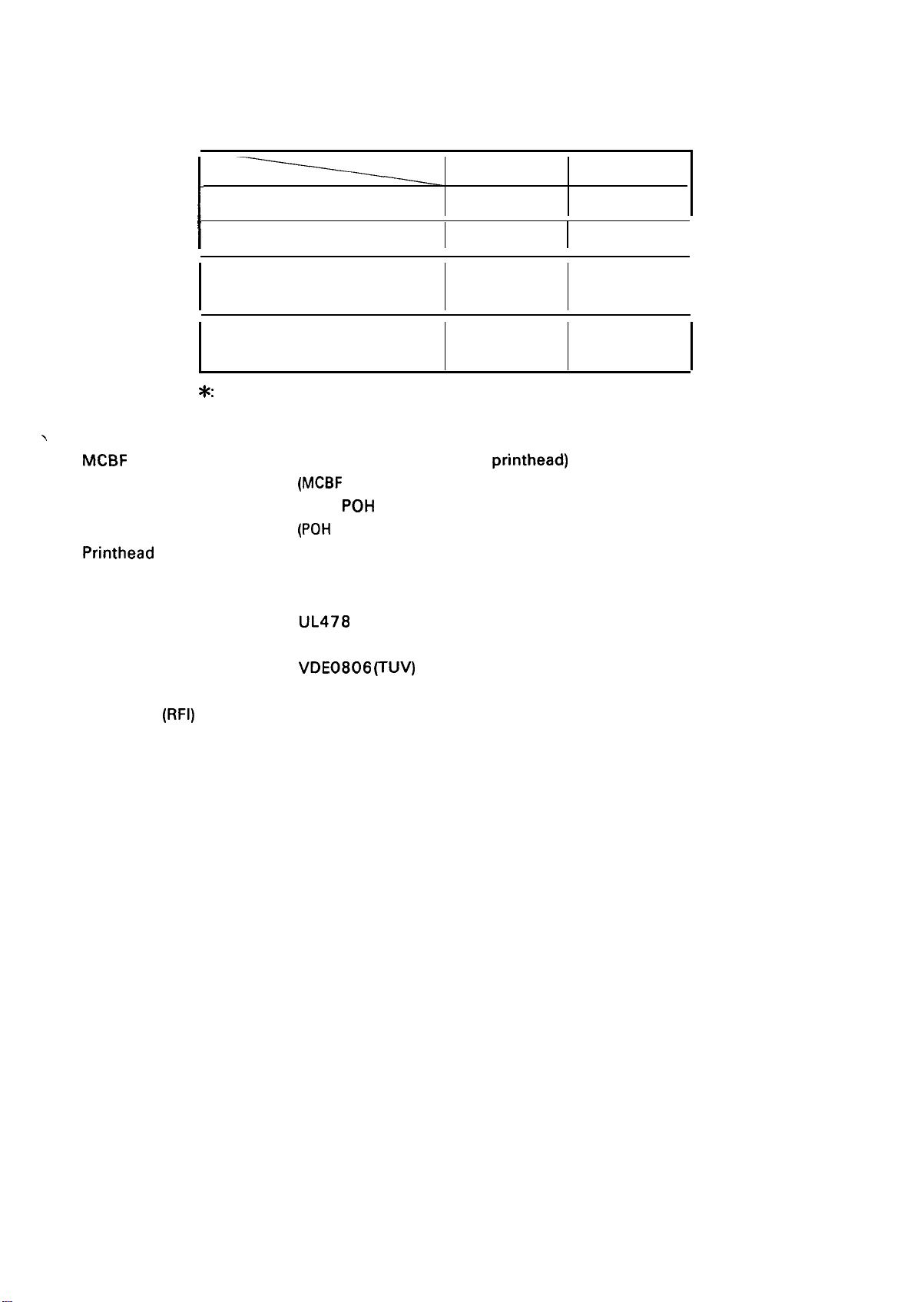

Environmental Conditions

I

x: With shipment container

‘.

Reliability

MCBF

MTBF

Printhead life

Refer to Table 1-9.

Table 1-9. Environmental Conditions

Temperature [“C]

Humidity [% RH]

Resistance to shock [G]

1 (within 1 ms)

Resistance to Vibration [G]

(55 Hz, max.)

5 million lines (excluding

(MCBF . . .

6000

(POH

200 million strokes/wire

Mean Cycles Between Failure)

POH

(duty 25%)

. . .

Power On Hour)

Storage

–30 - 65*

1

5-85

0.50

printhead)

Operating

5-35

10-80

2

1

I

I

0.25

Safety Approvals

Safety standards

Radio frequency

Interface

(RFI)

UL478 (U.S.A. version)

CSA22.2#154

VDE0806 (TUV)

FCC class B (U.S.A. version)

VDE0871 (self-certification)

(European version)

(European version)

1-9

Page 18

REV.-A

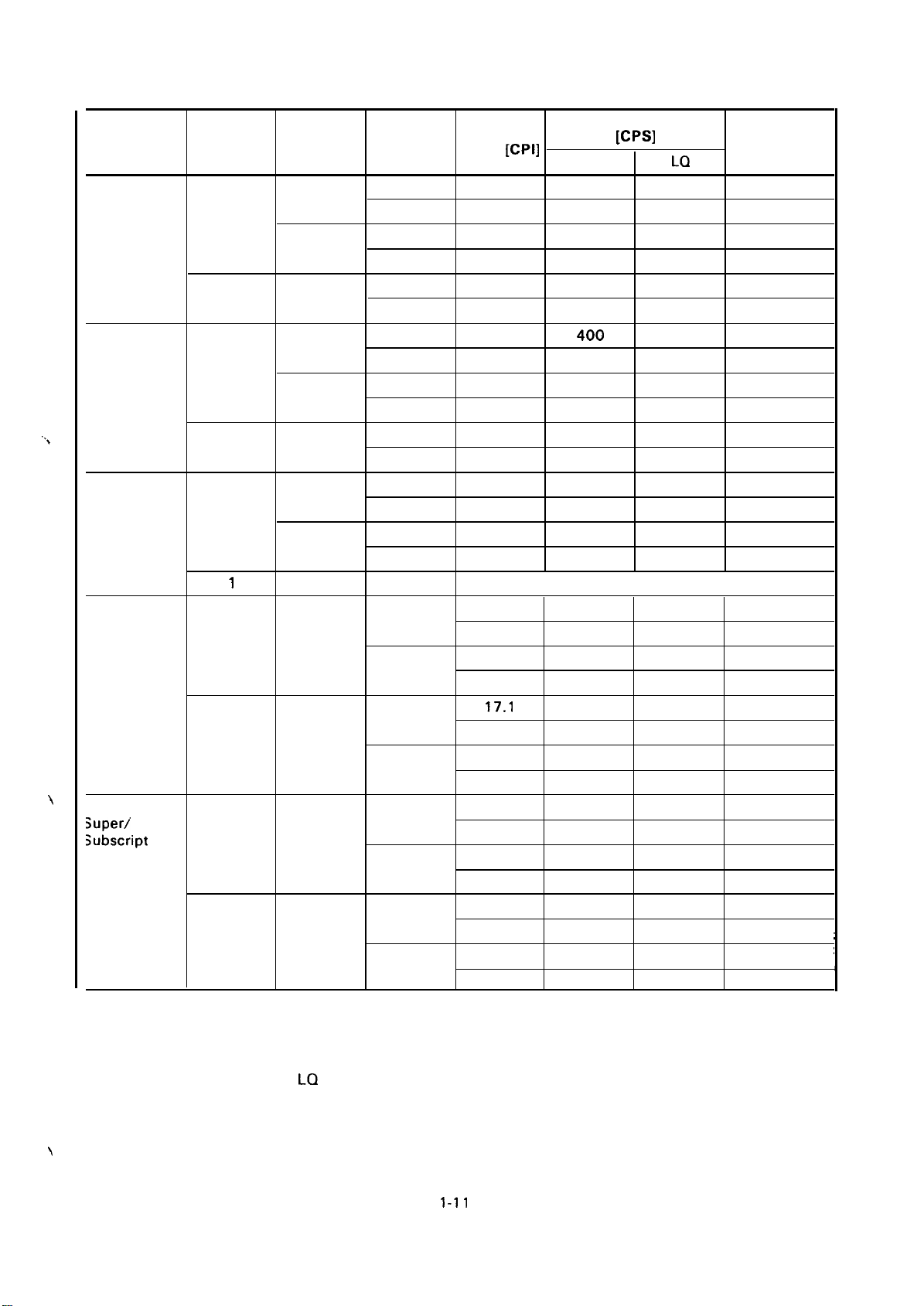

1.2.2 Firmware Specifications

Control Code

Printing Direction

Input Data Buffer

Character Code

Character Set

Family

Font and Character Spacing Roman:

Printing Mode

NOTE: A condensed mode for 15

ESC/P-83 Expanded

Bidirectional logic

8K-bytes

8 bits

96 ASCII and 13 international character sets

Roman:

SansSerif:

Courier:

Prestige:

Script:

OCR-B:

OCR-A:

SansSerif:

Courier:

Prestige:

Script:

OCR-B:

OCR-A:

Draft:

Printing quality

Character pitch (10, 12, 15

Condensed

Double-width

Double-height

Emphasized

Double-strike

Italic

Underlined

Outline

Shadow

CPI

seeking

No. O

No. 1

No. 2

No. 3

No. 4

No. 5

No. 6

10, 12, 15, Proportional

10, 12, 15, Proportional

10, 12, 15, Proportional

10, 12, 15, Proportional

10, 12, 15, Proportional

10, 12, Proportional

10, 12 Proportional

10, 12, 15

(Draft/LQ)

CPI

or Propotiional)

characters is not available.

f’

-+

- ,:

Print Speed Refer to Table 1-10.

1-10

Page 19

Table 1-10. Printing Mode

REV.-A

.,,

\

Print

Pitch

10 0

12

15

‘proportional

‘proportional

Superl’

subscript

Condensed Emphasized

0

1

1

0 0 0

1

0 0 0

1

o

1

o

1

x

1

x

1

x x

x

x

x

x

Double

Width

0 10

1

0

1

o

1

1

0

1

o

1

1

0

1

o

1

o 17.1

1

o

1

o

1

Pitch

Character

ICPI] Columns

5

Draft

333

167

10 167

Printing

5

17.1

8.5 142 94 116

12

6

12

6

20 333 221 272

10 167

15

15

7.5 250 167

7.5 124

8.6 —

20 221

4.3

10 111

40

8.6 —

20

12.8 —

30

6.4 —

15

25.7 —

60

12.8

30

83

285 189 233

400

200 67

200 133 163

100

500 167

250

[CPS]

Ignored

Speed

LQ

111

55 68

111

55

133 163

67

111

83

83 102

94 Max. 116

50

189 Max. 233

444 Min. 544

94

221

142

333 Min. 408

71

167

285 Max. 174

667

142

333 Min. 204

Printable

Min. 272

Max. 58

Min. 136

Max. 116

Min. 272

Max. 174

Max. 87

Min. 204

Min. 816

Max. 87

136

136

68

81

81

136

204

204

102

;

~

4

NOTES: 1. Max. means the value when the maximum width characters are printed.

2. Min. means the value when the minimum width characters are printed.

3. “

—“ means that

specified.

LQ

character set is automatically selected when proportional pitch is

\

1-11

Page 20

REV.-A

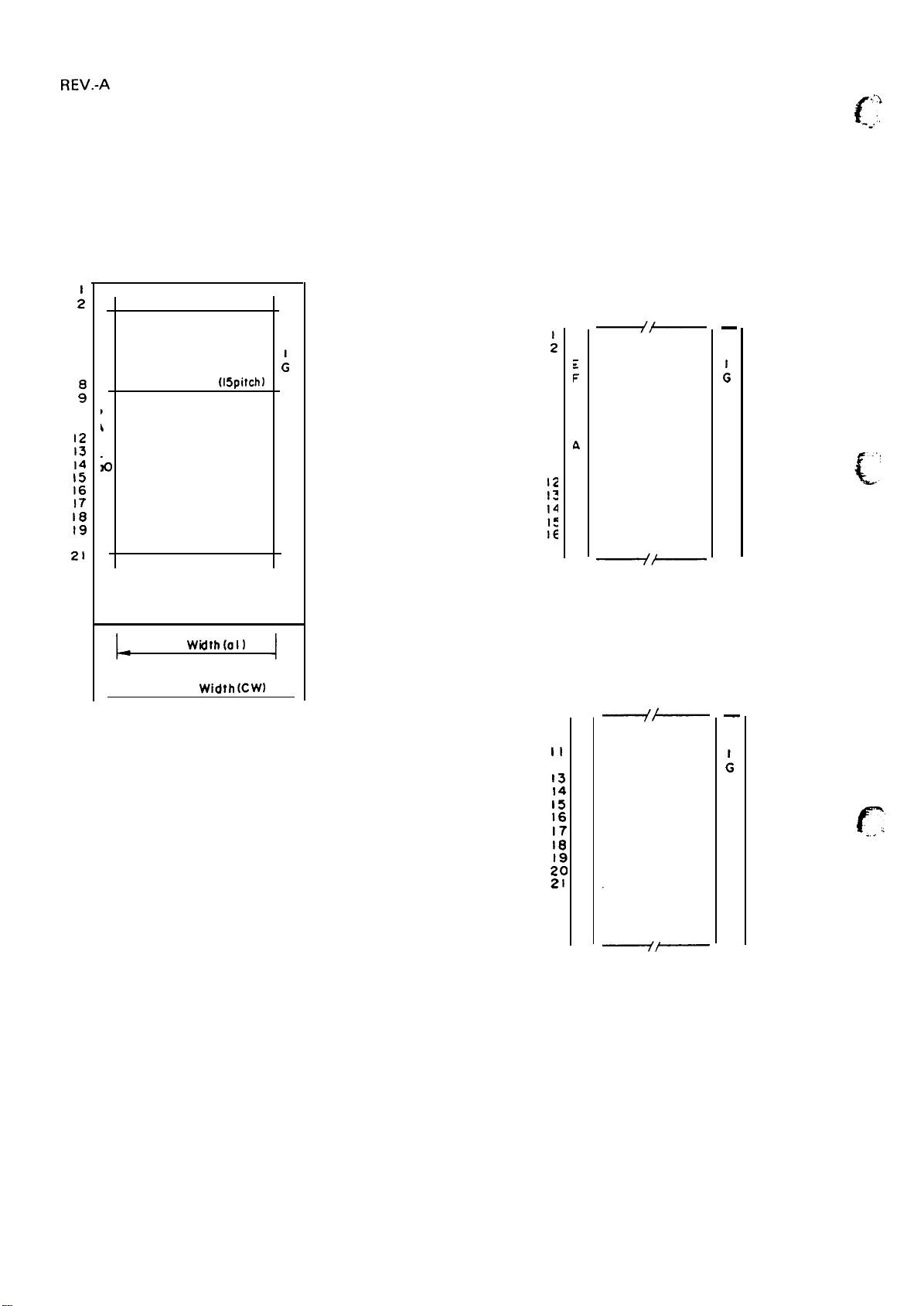

character Matrix

(Normal Character)

See Figure 1-6.

(Superscript Character)

Pin Nos. 17 to 24 are not used for superscript

printing.

. . .

1

,

,

f:

--,

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

:

3

4

5

6

7

:

Ascender Area

Ascender Area

,

1

L

i)

.

Descender Area

Face

Character

(15pi!Ch)

Wid!h(al)

Width (CW)

4

R

A

H

T

s

P

A

c

E

(a 2

—

10

II

12

I?

14

;

r

3

4

;

5

T

6

7

s

8

P

9

A

c

E

R

k

H

T

s

P

A

c

E

—

(Subscript Character)

Pin Nos. 1 to 8 are not used for subscript printing.

—

R

A

H

T

s

P

A

—

c

E

10

II

12

13

14

15

16

17

18

;:

21

22

23

24

9

L

E

F

T

s

P

A

c

E

—

. .

.

L

r’

... ;

Figure 1-6. Character Matrix

1-12

Page 21

REV.-A

Character Size

See Table 1-11.

Table 1-11. Character Matrix and Character Size

Face

Printing Mode

DRAFT, 10 pitch

DRAFT, 12 pitch

DRAFT, 15 pitch

DRAFT, 10 pitch, condensed

DRAFT, 12 pitch, condensed

LQ,

10 pitch

LQ,

12

pitch 29 X 23 360 2.0 X 3.2

LQ,

15 pitch

LQ,

10 pitch, condensed

LQ,

12 pitch, condensed

LQ,

proportional Max. 39 x 23 360 2.6 X 3.2

I

I

I

I

Matrix

9 X 23

9

X 23

9

X 16 120 1.0 X 2.3 120

. . .

. . .

X 23 360 2.0 X 3.2

29

X 16 360 1.0 X 2.3 180

15

. . .

. . .

Min. 18 x 23 360 1.0

HDD

I

1

120

I

240

240

I

360 I . . .

360

I

I

120 1.9

‘1

. . .

Character Size

H. x V. [mm]

1.9 X 3.2

X 3.2 120

. . .

. . .

X 3.2

Unit

ESC

I

]

120

I

240

240

180

180

I

360

360

180

SP

LQ,

proportional, condensed

LQ,

proportional, super/subscript Max. 28 x 16

LQ

proportional, super/subscript,

condensed

. . .

. . .

Min. 12 x 16 360 0.7

. . .

. . .

360

360

360 1.8

360

360

. . .

. . .

X 2.3

X 2.3

. . .

. .

NOTES: 1. “HDD” means the Horizontal dot density, and the units are dots per inch.

2. “Face matrix” and “character size” indicate the maximum size of characters and this vail

will change with condition of paper.

3. “Unit

4. “...” indicates that the character matrix is reformed

ESC sp” indicates the minimum length which

that can be specified with

becomes half of a non-condensed character.

ESC sp control code.

is added to the right of the character

by printer firmware. Character width

360

180

360

1-13

Page 22

REV.-A

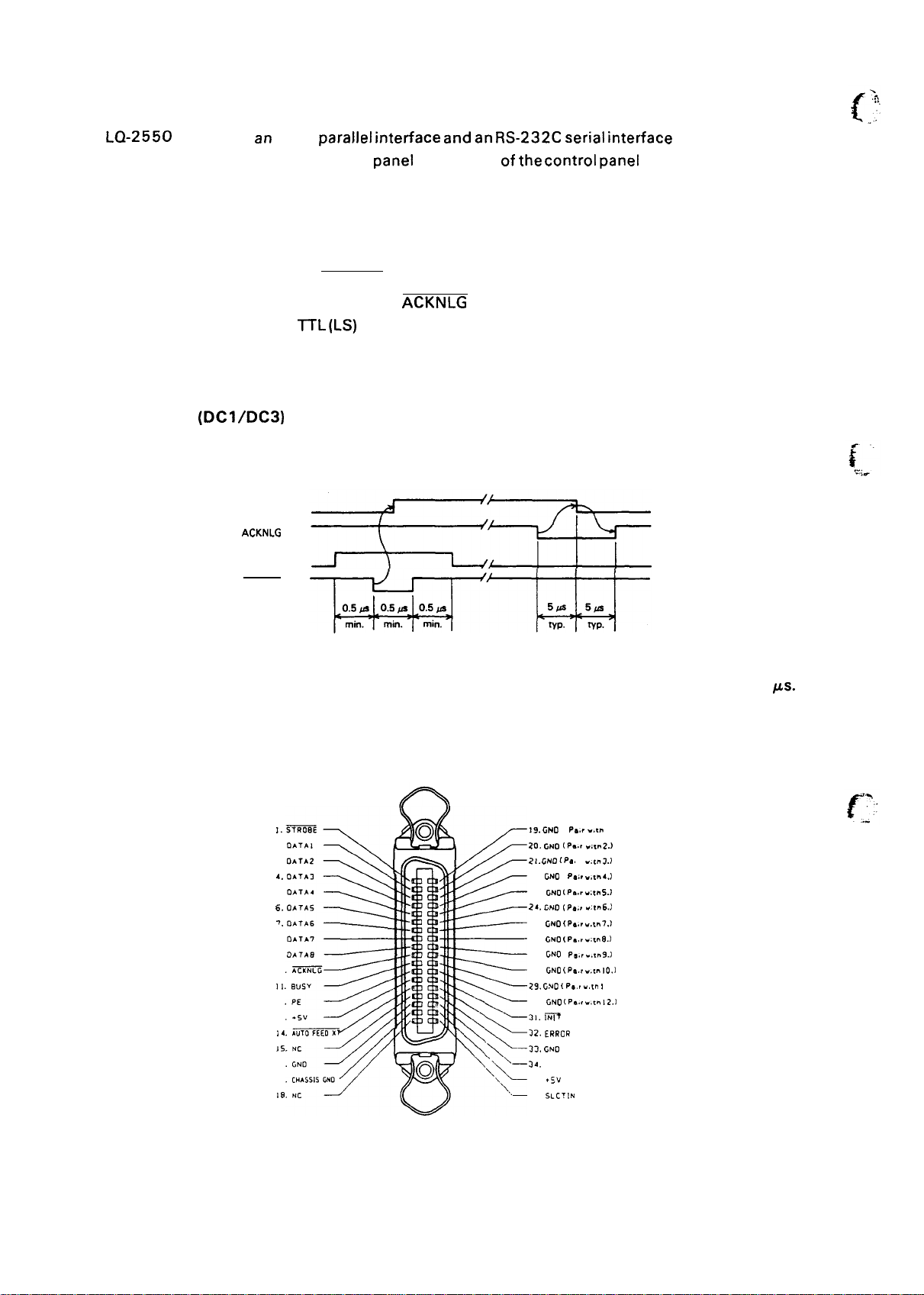

1.3 INTERFACE OVERVIEW

The LQ-2550 has both an 8-bit

interface can be selected from the control

Parallel

interface

Panel

(For details of

1.8.6.2.).

1.3.1 8-bit Parallel Interface Specifications

Data Transmission Mode

Synchronization

Handshaking

Logic Level

Data Transmission Timing

Connector

Connector Pin Assignment

Select/Deselect

(DC1/DC3)

Control

BUSY

ACKNLG

DATA

STROBE

8-bit parallel

By STROBE pulse

By

BUSY and

ITL (LS)

compatible

ACKNLG

See Figure 1-7.

57-30360 (AMPHENOL) or equivalent (See Figure 1-8.)

Refer to Table 1-12.

Refer to Table 1-13.

and an

RS-232C

the control Panel

(either or both)

serial

interface as standard. The

settings, refer to Section

NOTE: Transmission time

Figure 1-7.

(rising and falling time) of every input signal must be less than 0.2

Data Transmission Timing for the 8-bit Parallel Interface

19. GNO

( Pa.,

..,ml.

(Pm.. w,tn2.)

IPa, c w.tn3.)

( Pair

.,,”4.)

(Pa;, w:,n6.)

Pa,. w,,n?.]

w:m8.)

(

Pm,, .,,.9.)

(Pa.<

.,,-12.1

)

l.)

1.

2.

3.

4.

5. 23.

6,

?.

e.

9.

10

II

12

13

14

J5

16

17

19

20.

21.

22.

28,

25.

26.

2’7.

28.

29,

30.

31.

32,

33,

34. NC

3s.

36. SLCTIN

GNO

GNO

GNO

CJNO [Pa., w:tm5.1

GNO

GNO (

GNO ( Per

GNO

GNO (P,., .,,.10,1

GNO ( Par -,. I

GNO

Fit

ERRGR

GNO

.5V

—.

#s.

Figure 1-8. 36-Pin 57-30360 Connector

1-14

Page 23

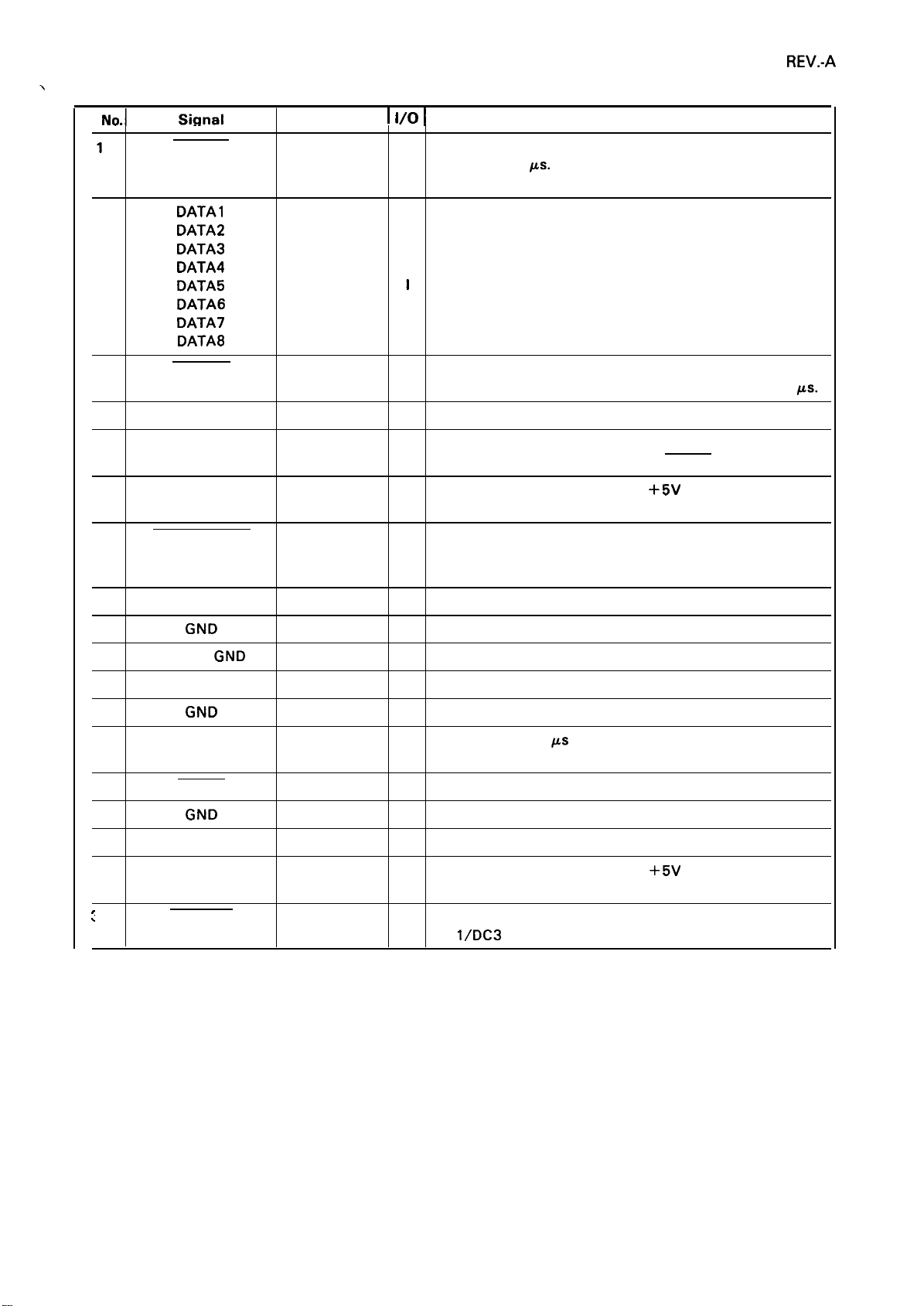

\

Pin

No.1

1

2

3

4

5

6

7

8

9

Signal

STROBE

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7 26

DATA8

Table 1-12. 8-bit Parallel l/F Connector Pin Assignments

Return

19

20

21

22

23

24

25

27

I 1/0 I

I

Strobe pulse to read the input data. Pulse width must be

more than 0.5

this signal.

I

Parallel input data to the printer.

I

“HIGH” level means data “l”.

I

“LOW’” level means data “O”.

I

I

I

I

I

KS.

Description

Input data is latched after falling edge of

10

11

12

13 SLCT

14 AUTOFEED-XT

15

16

17

18

19

to

30

31

.

.

32

33

.

.

34

.

35

.

#

36

<

ACKNLG

BUSY

PE

NC

GND

Chassis GND

NC

GND

INIT

ERROR

GND

NC

+ 5V

SLECT-IN

28 0 This pulse indicates data are received and the printer is

29 0

30 0

—

—

—

—

—

—

—

16

—

—

—

—

—

ready to accept next data. Pulse width is approx. 11

“HIGH” indicates printer can not accept data.

“HIGH” indicates paper-out.

This signal is effective only when ERROR signal is “LOW”.

o

Always “HIGH”. (Pulled up to

resistor.)

I

If this signal is “LOW” when the printer is initialized, a line

feed is automatically performed by input of “CR” code (Auto

LF).

—

Not used.

— Ground for twisted-pair.

— Printer chassis ground.

— Not used.

— Ground for twisted-pair.

I

Pulse (width: 50 WS min., active “LOW”) input for printer

initialization.

“LOW” indicates that some error has occurred in the printer.

o

— Ground for twisted-pair.

— Not used.

o

Always “HIGH”. (Pulled up to

resistor.)

I

If the signal is “LOW” when printer is initialized, the

DC

l/DC3

control is disabled.

+5V

through 3.3 K ohms

+5V

through 3.3 K ohms

IJS.

NOTES: 1. “Direction” of signal flow is as viewed from the printer.

“Return” denotes “TWISTED PAIR RETURN” and is to be connected at signal ground level.

2.

As to the wiring

never fail to connect the return side.

for the interface, be sure to use a twisted-pair cable for each signal and

To prevent noise, cables should be shielded and

connected to the chassis of the host computer and the printer.

1-15

Page 24

REV.-A

ON-LINE

Sw

OFF-LINE

ON-LINE

SLCT-IN

HIGH/LOW

HIGH

LOW

Dcl/Dc3

DC

l/DC3

DC 1

DC3

DC1

DC3

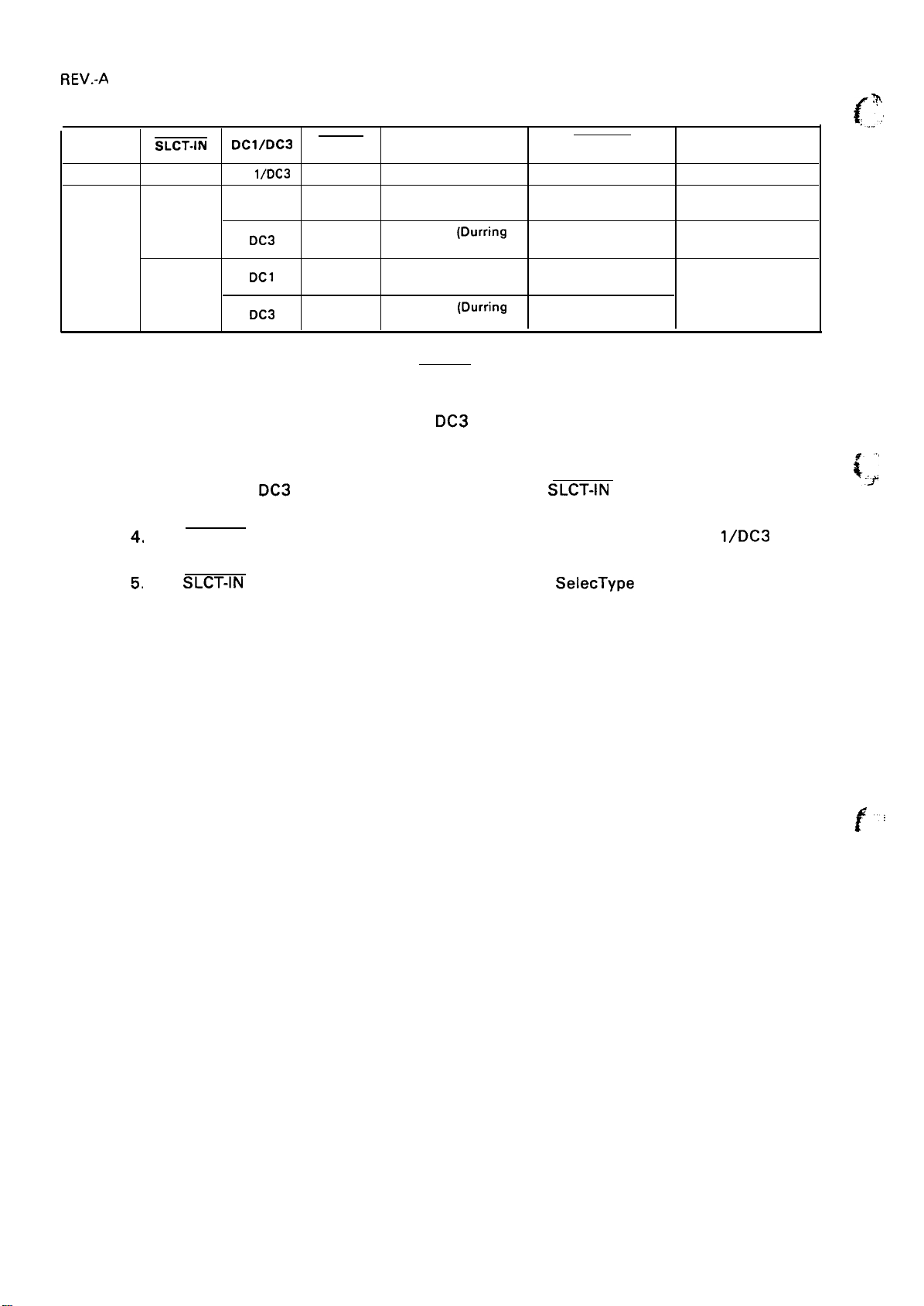

Table 1-13. Select/Deselect Control

ERROR

LOW

HIGH

HIGH

HIGH

HIGH

HIGH

LOW/HIGH (During

data entry)

LOW/HIGH

data entry)

LOW/HIGH (During

data entry)

LOW/HIGH

data entry)

BUSY

(Durring

(Durring

No pulse

Pulse output after Enable

entry)

Pulse output after

entry See Note 2)

Pulse output after Enable (Normal

entry

Pulse output after

entry

ACKNLG

>

(’.

DATA ENTRY

Disable

(Normal Process)

Enable (Waits DC 1.

Process)

NOTES: 1.

2.

3.

4,

5.

In Table 1-13, it is assumed that no ERROR status exists other than that attributable to the

OFF-LINE mode.

Once the printer is deselected by the

DC3

code, the printer will not revert to the selected

state until the DC 1 code is input (In the deselected state, input data is ignored until DC 1

is received.).

The DC 1 and

DC3

codes are enabled only when the

SLCT-IN

signal (Input Connector Pin

No. 36 when the parallel interface unit is used) is HIGH and the printer is initialized.

The SLCT4N signal is LOW when the printer is initialized. At this time the DC

l/DC3

printer

select/deselect control is invalidated, and these control codes are ignored.

The

SLCT-IN

signal is HIGH, and it is not set to LOW by SelecType function when the printer

is initialized. The printer will start from the selected (DC 1 ) state.

(.;

f

.

‘“’

.

1-16

‘. ,

Page 25

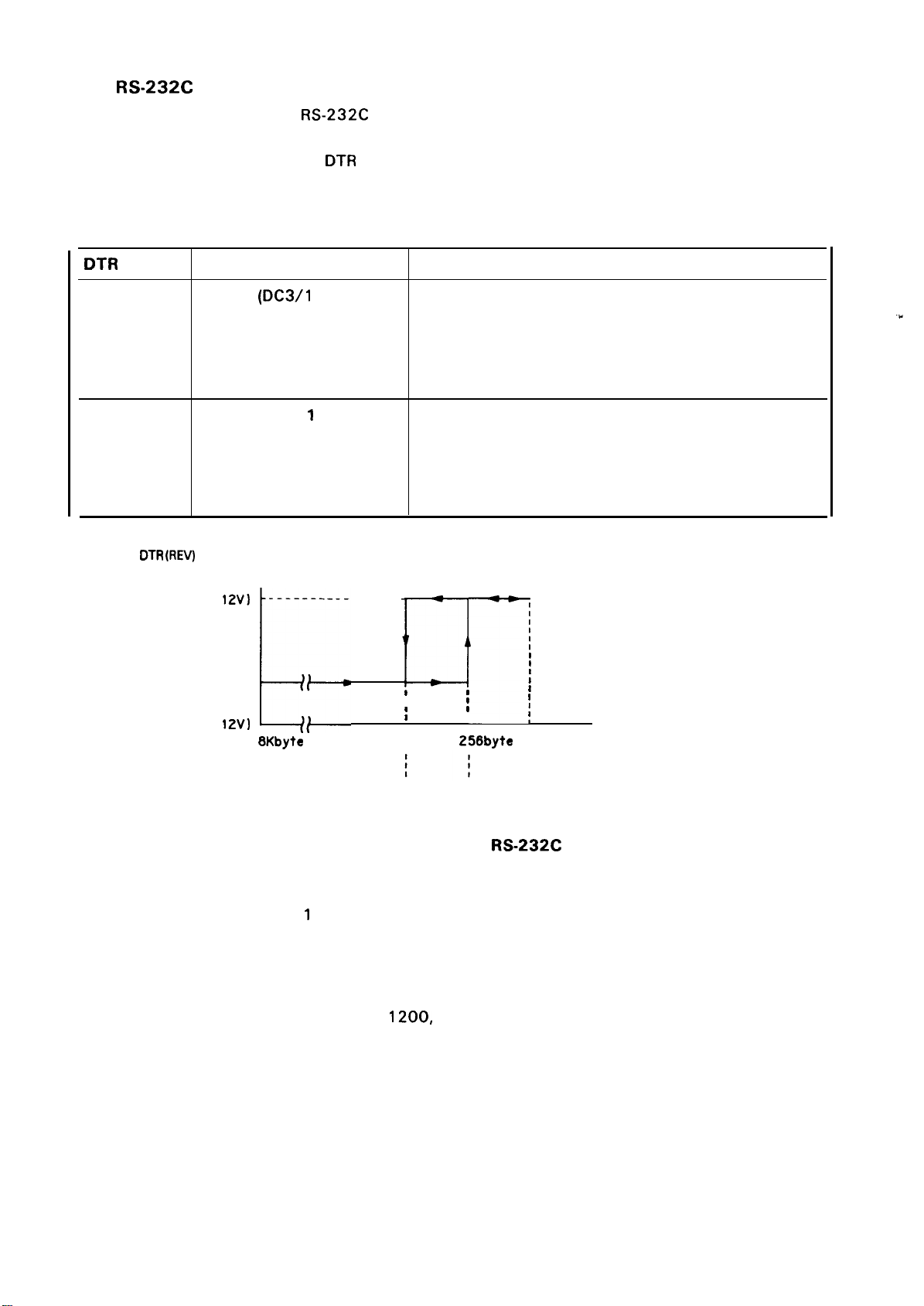

1.3.2 RS-232C Serial Interface Specifications

\

Data Transmission Mode

Synchronization

Handshaking

RS-232C serial

Asynchronous

By

DTR

(REV) signal or X-ON/OFF protocol

Refer to Table 1-14 and Figure 1-9.

Table 1-14. Serial Interface Handshaking

REV.-A

DTR Signal

MARK

SPACE

DTR {REV)

MARK ( -

SPASE ( +

X-ON/OFF protocol

X-OFF

(DC3\l

3H)

X-ON (DC 1/1 1 H)

Signal

I

12V)

12V)

----------------

L,-

8Kbyte

When the number of bytes remaining in the input

buffer reaches 256 or less, the signal level goes to

MARK, or an X-OFF code is sent to the host computer.

This indicates that the printer is not ready to receive

data.

When the number of bytes remaining in the input

buffer reaches 528 or more, the signal level goes to

SPACE, or an X-ON code is sent to the host computer.

This indicates that the printer is ready to receive data.

I

1

I

I

‘

‘:’

512 byte 256byte O

Description

-.

I

I

I

I

I

I

:

I

I

I

1

‘-

t

I

I

I

byte Input Buffer Vacant Area

Word Length

bit

Start

Data bits

Parity

Stop bits

Bit Rate

Logic Level

X-ON

Figure 1-9. Handshaking for

X-OFF

RS-232C

1

8

Odd, Even, or none

or more

1 bit

1200,

300, 600,

EIA level, MARK: logical 1 (–3 - –27 V)

SPACE: logical O (+3 - +27 V)

2400, 4800, 9600, or 19200 BPS

1-17

X-ON/X-OFF Protocol

Interface

Page 26

REV.-A

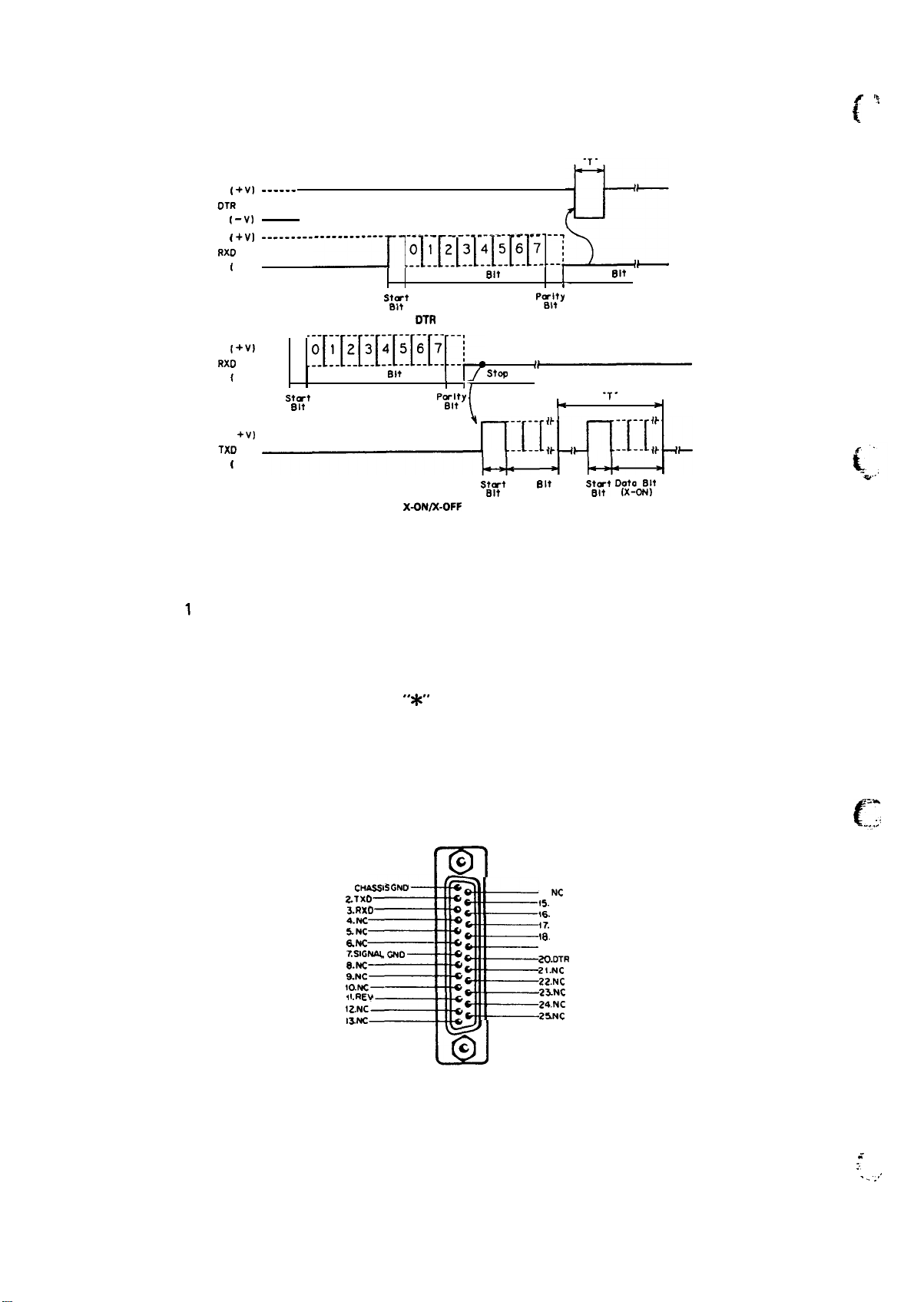

Data Transmission Timing

------

[

+V)

DTR

( -v)

---------------------

(

+V)

RXD

[

-v)

(

+V)

RXO –“

( -v]

(

+V)

TXD

(

-v)

See Figure

1

—-

‘IIM!l!m

Stmf

Blt

1-10.

-- -- -- -- -- -- --

:s!Mik16k

s;t&*

Data

Blt

X-ONDZ-OFF

DTR

Handshake

J

POrli/y

Data

Bit

StW

17

\

.stu-t

Blt

Protocol

Bit

Data

[X-OFF)

--

Pcr:;y

,,—

Blt

--7

.1

1-

L

stop

S::t

Blt

“T-

D~t:at:t

. .

.

~

{

“

...

,’

m

NOTES: 1. The value of “T” varies according to the input data.

2. The word structure of serial data is 1 start bit + 8 data bits + parity (Odd, Even, or none)

1

or more stop bits.

+

Figure 1-10. Serial Data Transmission Timing

Error Detection

Connector

Connector Pin Assignments

Parity error:

Overrun error: Ignored

Framing error: Ignored

D-SUB 25-pin connector (See Figure 1-1 1.)

Refer to Table 1-15.

1. CHA5.51S

Z.TXO

3.RxD

4.NC

5.NC

SAC

7.SIGW

e.Nc

9.NC

to.Nc

t I.REv

IZ.NC

IXNC

—

#

“*”

GND

GNO

is printed.

E

34.

45.

\6.

!7. Nc

18.

19. NC

2D.DTR

2i.NC

Z2.NC

2%NC

Z4.NC

2SNC

NC

NC

NC

Zn

.

.,

f

-..

,,,

Nc

Figure 1-11. Serial Interface Connector

1-18

.-

:.,

. . .,

,’

Page 27

\

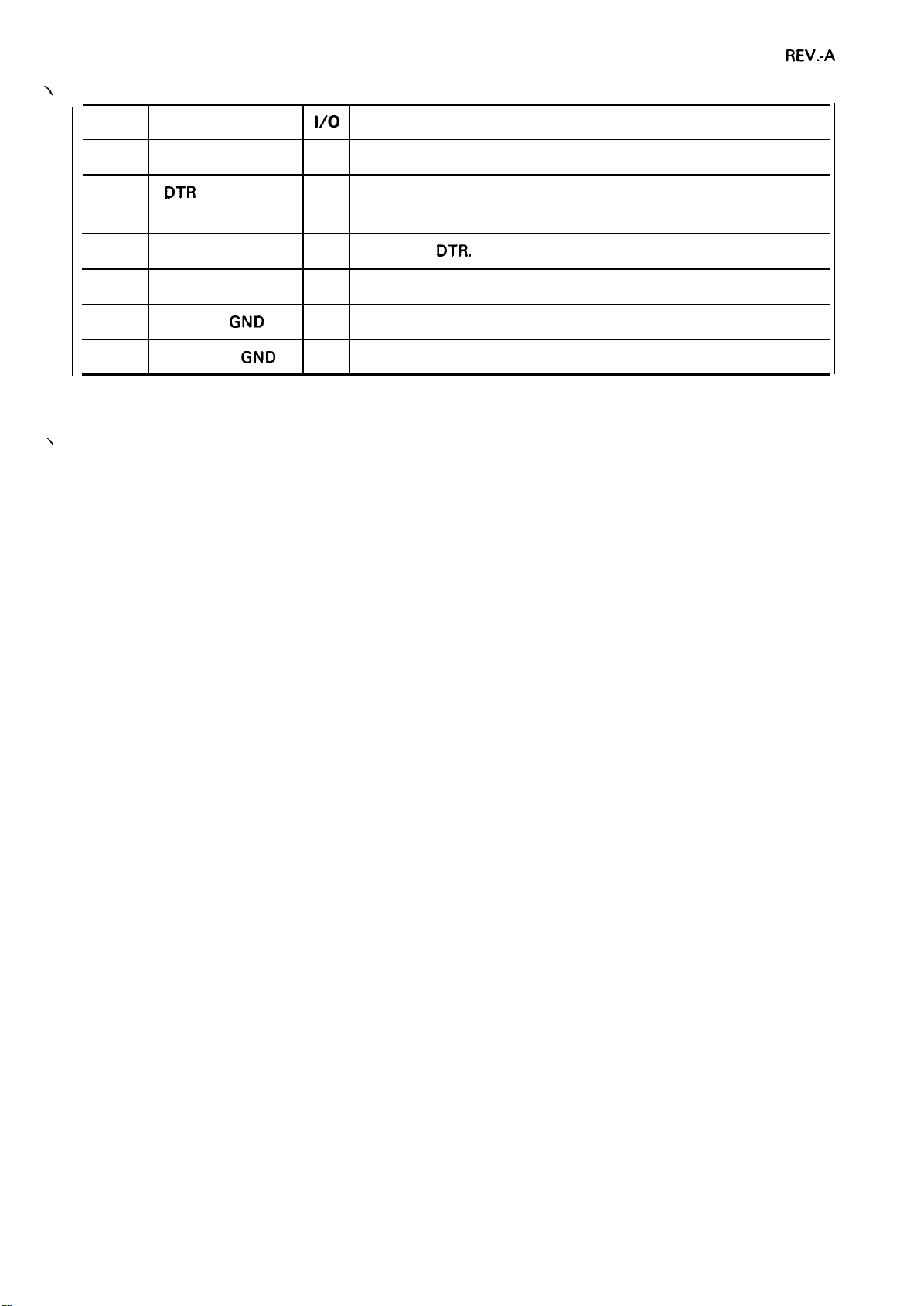

Table 1-15. RS-232C Serial Interface Connector Pin Assignments

Pin No. Signal

I

2

20

TXD o

DTR

1/0

o

Transmit data.

Indicates when printer is ready to receive data. “MARK” level

indicates printer is not ready to receive data.

11

3

7

REV(=2nd RTS)

RXD

SIGNAL

1

CHASSIS

GND

GND

—

—

o

I

Same as

Receive data.

DTR.

Signal (Logic) ground level.

Printer chassis ground.

NOTE: “Direction” of signal flow is as viewed from the printer.

\

Description

1-19

Page 28

REV.-A

1.4 SELF-TEST OPERATION

-’%

f

The LQ-2550 printer has the following self-test functions. The current and default settings at the control -‘“

panel are printed when the self-test is executed.

is printed out at the end of the first page.

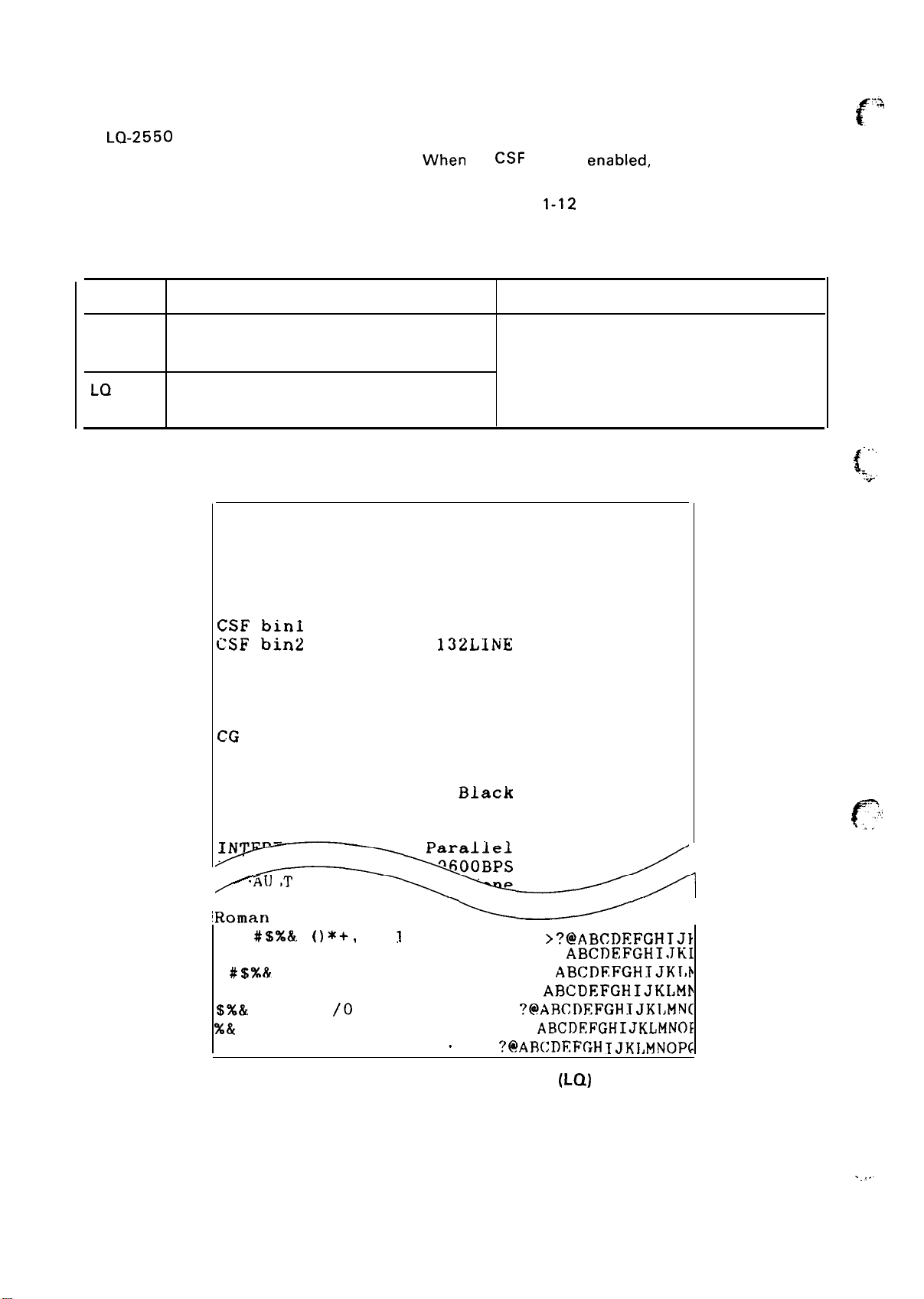

Table 1-16 lists the self-test operating instructions and Figure

Table 1-16. Self-Test Operation

Type-face

Draft

LQ

Turn the power ON while pressing the

LINE FEED switch.

Turn the power ON while pressing the

FORM FEED switch.

Start

Current setting

FONT

PITCH

CONDENSED

FORM

LNG

Tractor 66LINE

CSF

binl

CSF bin2

1“ SKIP

AUTO TEAR OFF

LEFT MARGIN

RIGHT MARGIN

CG

TABLE

COUNTRY

PRINT DIR. Bi-d

COLOR

Default setting

When

the

Roman

10CPI

132LINE

132LINE

Italic

Black

C-SF

mode is

Push the ON LINE switch, and turn the

power OFF.

enabIed,

1-12 shows the self-test printing.

the current sheet length

stop

off

off

off

o

136

USA

# . .

&

.+’

. . .

c“

- ,,. .

.

. .

.

A{]

I

IT

MACRO

1

IRoman

! “

#$%&.

‘ (

)*+,

-. /0 I 234 56789: ; < =

! “ #$%&‘ ( )*+ , -. /01234 56789 : ; < = > ?@

“

#$%&.

‘ ( )*+ ,-. /0123456789 : ; < = > ?@

#$%& ‘ ( )*+ ,-. /0 123456789 : ; < = > ?@

$%&.

‘ ( )*+ ,-. /0 123456789

%&

‘ ( )*+ , -. /0 123456789

& ‘ ( )*+ , -

. /0 1234 56789:

Figure 1-12. Self-Test Printing (LQ)

: ; < = >

: ; < = > ?@!

“

, < = >

1-20

?@i4FWT)J?FGH

ABCI)EFGHIJKLMNOE

?@.A~c:~F.F~H T

I

>?@ABCI)EFcHTJ}

ABCllEFGHI.JKI

ABCDFFGHIJKIIh

A13CDEFGHIJKLMb

IJKl,MN(

JK],MNOPG

. . . . .

Page 29

.,

1.5 HEXADECIMAL DUMP FUNCTION

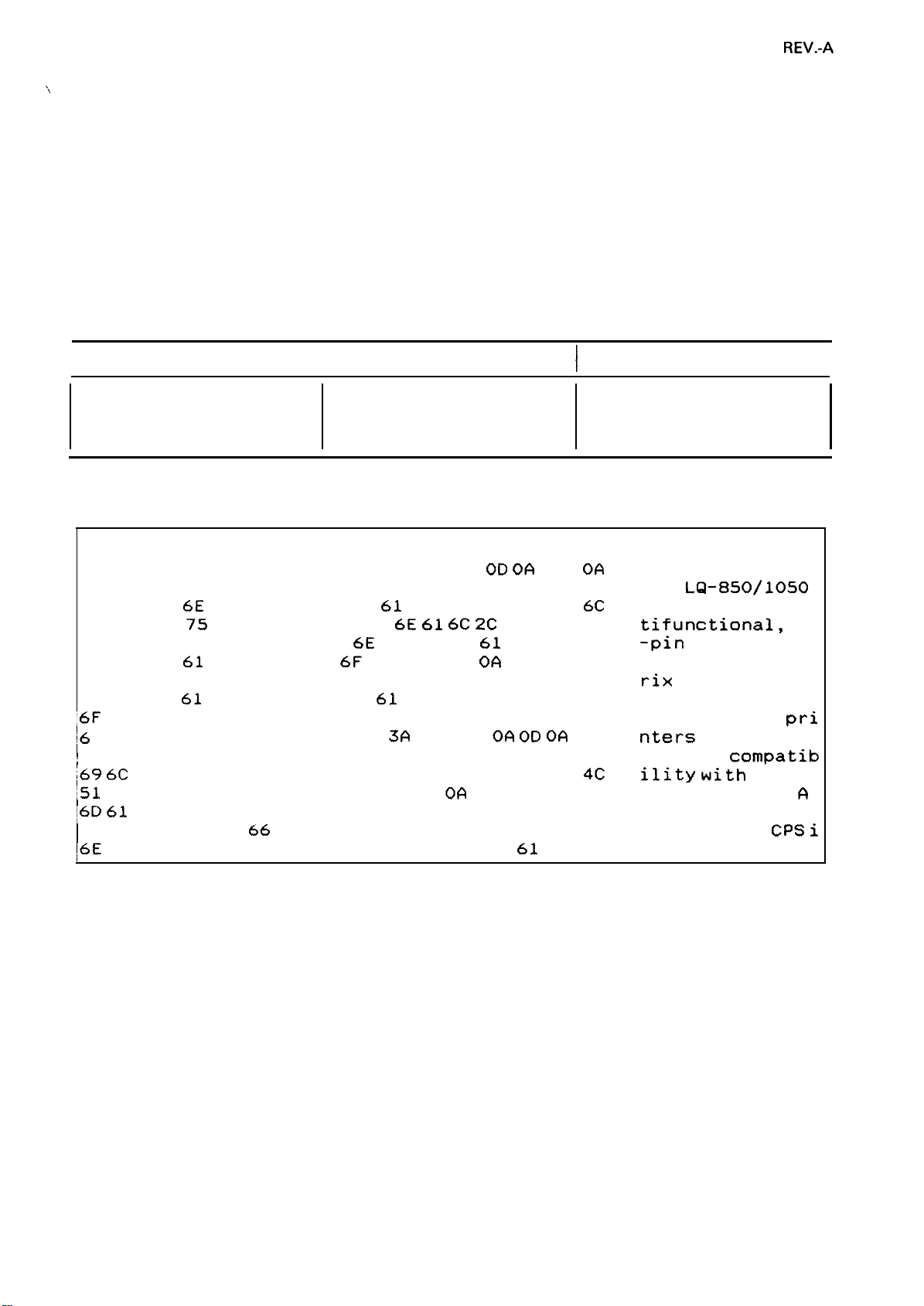

In hexadecimal dump mode, the printer prints out the data it receives in hexadecimal format. The printer

prints a column of 16 hexadecimal values, followed by a column containing the 16 corresponding ASCII

characters. If there is no corresponding printable character for a value (e.g., a control code, such as

a carriage return or line feed), a period (.) is printed in the ASCII column in the position of the code.

Each line of the dump contains 16 values, printed in the order they were received, and any remaining

data (less than 16 values on the final line) can be printed by operating the ON LINE switch. Table 1-17

explains the hexadecimal dump operation and Figure 1-13 shows a sample printout of the operation.

Table 1-17. Hexadecimal Dump Operation

REV.-A

I

Hexadecimal dump mode

\

Data Dump Mode

31 2E 31 20 46 45 41 54 55 52 45 53

54 68 65 20 4C 51 2D 38 35 30 2F 31 30 35 30 20

70 72 69

74 69 66

2D 70 69 6E 20 70 72 69

69 6D 70

72 69 78 20 70 72 69 6E 74 65 72 73 2E 20 54 68

65 20 6D

6F

66 20 74 68 65 20 74 68 65 73 65 20 70 72 69

6

E 74 65 72 73 20 61 72 65 3A 20 OD OA OD OA 2E

~ 20 55 70 77 61 72 64 20 63 6 F 6D 70 61 74 69 62

69

6C 69 74 79 20 77 69 74 68 20 74 68 65 20 4C

51

2D 38 30 30 2F 31 30 30 30 OD

,6D 61 78 69 6D 75 6D 20 70 72 69 6E 74 20 73 70

65 65 64 20 6F

,6E 20 64 72 61 66 74 20 6D 6F 64 65 20

Function

6E 74 65 72 73 20 61 72 65 20 6D 75 6C

75

6E 63 74 69 6F

61

63 74 20 64 6F 74 2D OD 06 6D 61 74

61

69 6E 20 66 65 61 74 75 ‘72 65 73 20

66

20 32 36 34 20 43 50 53 20 69

I

Turn the power ON while Turn the power OFF.

pressing both the LINE FEED

and FORM FEED switches.

6E

Operation

OD 06

6E 61

74 68 65 61 64 2C 20

6C 2C 20 32 34

OA

2 E 20 41 20

61

I

OD

OA

74 20

stop

1.1 FEATURES. . . .

The

LQ-850/1050

printers are mul

tifunctlonal,

-pin

print head,

impact dot- . . mat

rix

printers. Th

e main f eatu res

of the these

nters

ility

Q-800 /1000...

maximum print sp

eed of 264

n draft mode at

are: . . . . .

Upward

with

compatib

24

pri

the L

A

CPS

I

i

Fig 1-13. Hexadecimal Dump List

1-21

Page 30

REV.-A

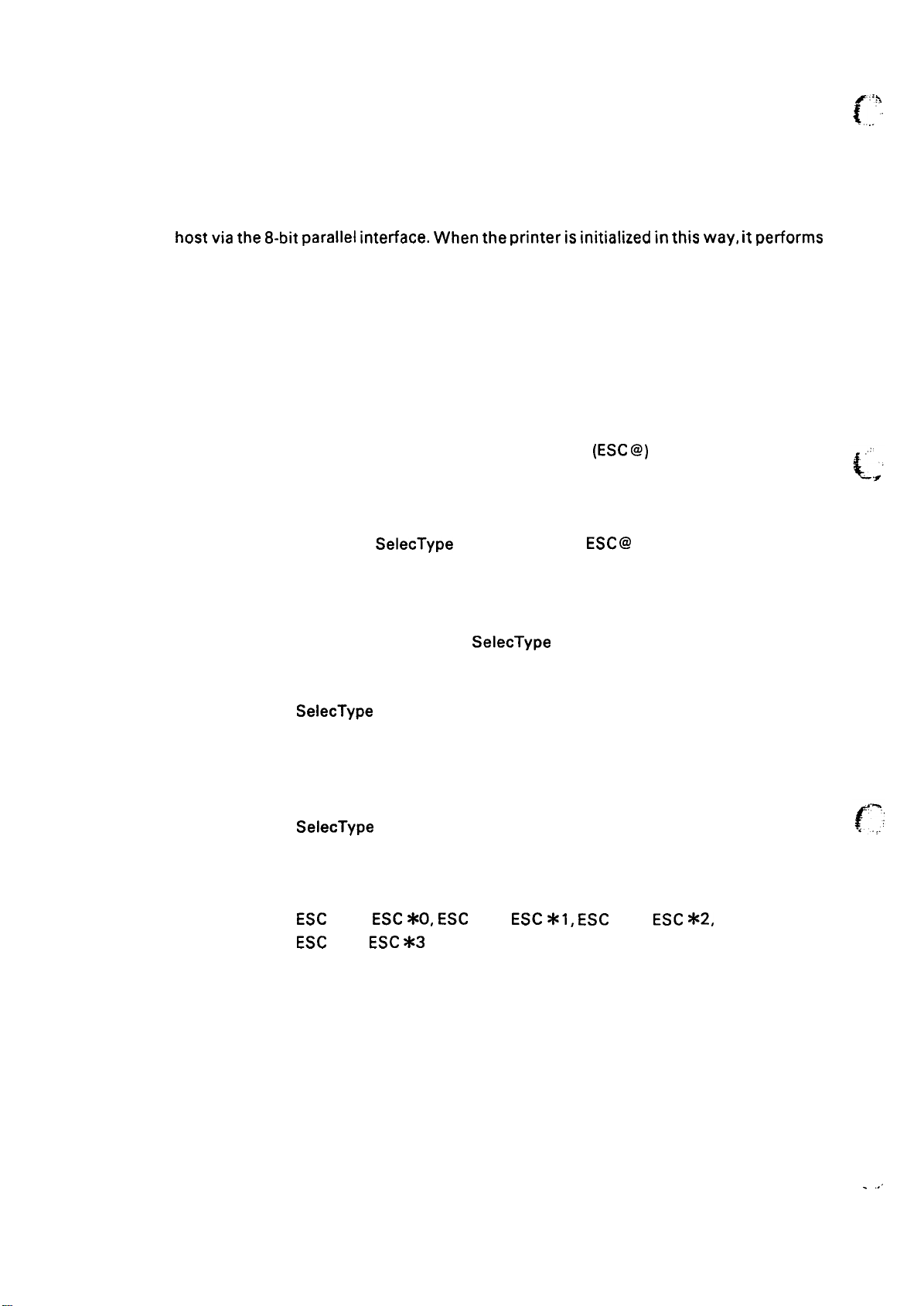

1.6 PRINTER INITIALIZATION

There are two initialization methods: hardware

1.6.1 Hardware Initialization

This type of initialization occurs when printer power is turned on or when the printer receives the I NIT

signal from the

the following actions:

● Initializes the printer mechanism

● Clears the downloaded character set

● Clears the input data buffer

● Clears the image buffer

● Sets printer selections to their default values (Refer to Section 1.6.3.)

1.6.2

This type of initialization occurs when the printer receives a command

printer is initialized in this way, it performs the following actions:

● Clears the image buffer

● Sets printer selections to their default values

(Several settings are changed by the last

1.6.3.).

host via the 8-bjt Parallel interface. When the

Software Initialization

initialization and software initialization.

winter is

SelecType operation before

initialized in this wwt it Performs

(ESC @)

ESC@

via software. When the

is input (Refer to Section

1.6.3

The default values set by the default setting mode of the

initialization. The printer’s default values are as follows:

Page

Left and Right Margin

Line Spacing

Vertical Tab Positions

Horizontal Tab Positions

VFU Channel

Family Number

Downloaded Characters

Justification

Character Spacing

Bit Image Mode Assignment

Default Values

Position

of Type Style

SelecType

Preset paper position becomes top-of-form position

SelecType setting

1/6”

Cleared

Every 8 characters (relative)

Channel O

SelecType setting

Deselected

Left justification

No additional spacing

ESC

ESC

K =

Z =

ESC *O, ESC

ESC

X3

L =

function are only reset by a hardware

ESC xl, ESC

Y =

ESC X2,

1-22

. .,,

Page 31

REV.-A

‘ 1.7 ERROR CONDITIONS

This section describes the error conditions and buzzer operation of the printer.

AND BUZZER OPERATION

1.7.1 Error Conditions

If any of the following errors occur, the printer automatically enters the OFF LINE mode and outputs

the appropriate interface signal.

● Carriage and platen gap home positons are not detected at printer mechanism initialization.

● The ON LINE switch is pressed, causing the printer to enter OFF-LINE mode.

● Paper-out is detected.

● A paper-out signal is detected after the printer has

cut sheet feeder enabled.

For information concerning the status of the interface signals, refer to Table I-l 2.

perFormed

a paper loading operation with the

1.7.2 Buzzer Operation

. .

The buzzer rings as follows:

When a BEL code is sent to the printer, the buzzer sounds for 0.1 seconds.

●

When an error has occurred,

●

Carriage Trouble:

Paper End:

●

When a panel setting is accepted, the buzzer sounds for 0.1 seconds.

Sounds 5 times (rings for 0.5 seconds with 0.5 second intervals.)

Sounds 3 times (rings for 0.1 seconds with 0.1 second intervals.)

1-23

Page 32

REV.-A

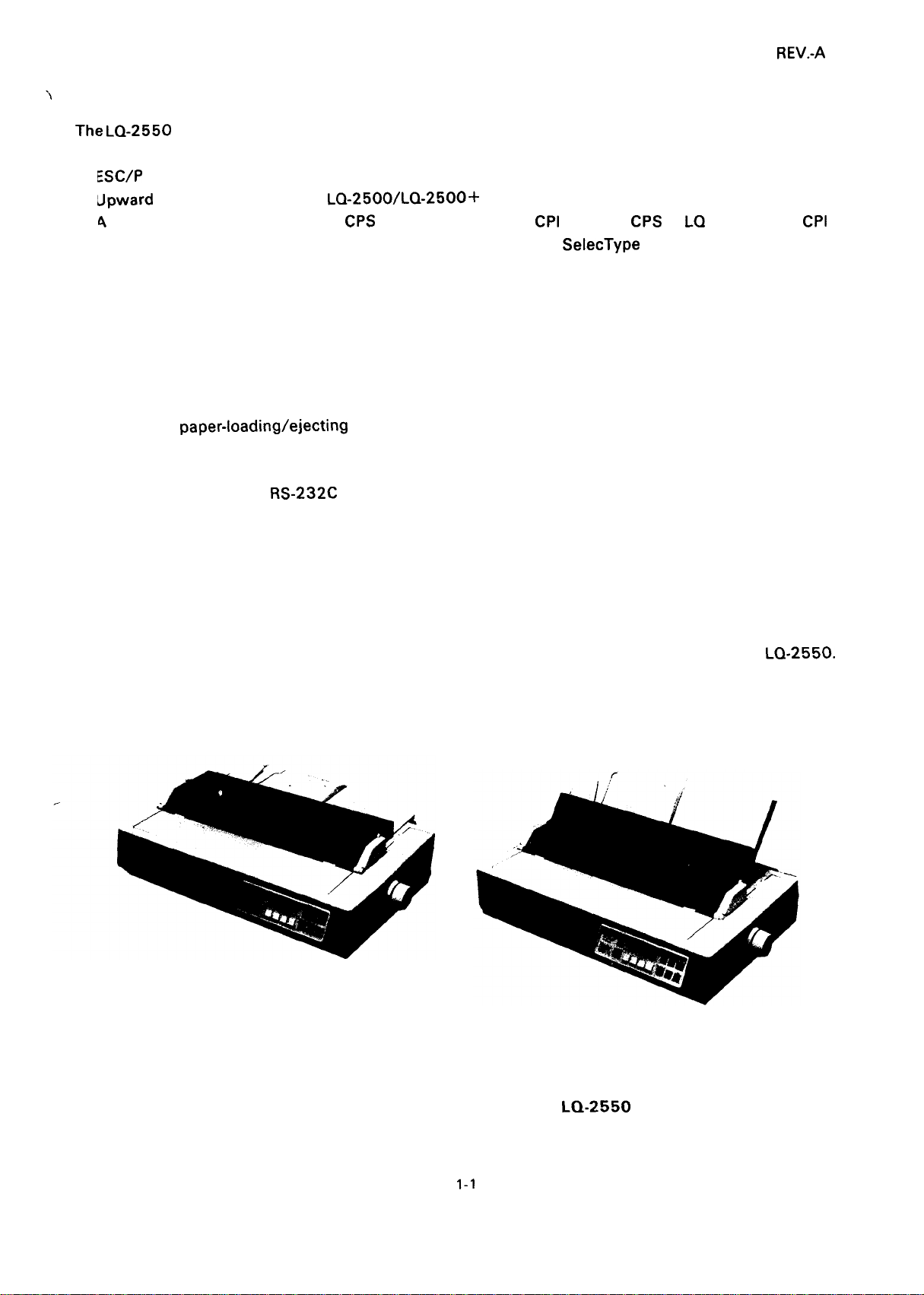

1.8 MAIN COMPONENTS

The LQ-2550 printer includes the following major subassemblies:

●

Model-5560 printer mechanism

●

ROMA board (main board)

●

ROPS/ROPSE board (power supply board, 100- 120V and 220Fan Unit

●

Housing

●

c

ROPNL-W

Figure 1-14 shows

Fan Unit

board

\

(control panel)

LQ-2550 component locations.

the

240V

versions)

Figure 1-14.

LQ-2550

Component Locations

Printer

Mechanism

.

r’

1-24

Page 33

REV.-A

1.8.1 Printer Mechanism

This section describes over view of the printer mechanism, and paper handling and operations.

1.8.1.1 Overview

To improve paper handling, the following functions are newly incorporated in this 24-pin printer in

addition to the conventional ones.

● Automatic release mechanism

● Automatic paper thickness detection nechanism

● Automatic platen gap adjustment mechanism

● Automatic paper width detection mechanism

● Automatic loading lever open/close mechanism

Figure 1-15. Model-5560 Printer Mechanism

-

1-25

Page 34

REV.-A

1.8.1.2 Paper Handling and Operations

Paper Loading and Ejection

Since the paper release lever is controlled automatically, the pApER SELECT and LOAD/EJECT switches

highly

on the control panel provide

(continuous) and single sheet paper and loading/ejecting paper are performed automatically.

a) Single Sheet Loading and Ejection

To load a sheet of paper, press the PAPER SELECT switch and select FRICTION feed. If fanfold paper

is loaded, the paper is ejected backward (automatic back out). Place the page along the paper guide,

and press the LOAD/EJECT switch. This loads the paper at the top-of-form position. If the

LOAD/EJECT switch is pressed after paper has been loaded, it causes the paper to be ejected

forward.

b) Fanfold Paper Loading and Ejection (Back Out)

Set the fanfold paper into the push-tractor unit. To load fanfold paper, press the PAPER SELECT

switch and select TRACTOR feed. If single sheet paper is loaded, the paper is ejected forward and

the fanfold paper is loaded. When the TRACTOR feed has already been selected, pressing the

LOAD/EJECT switch loads the paper automatically to the top-of-form position. If LOAD\ EJECT

switch is pressed after the fanfold paper has been loaded, the printer ejects the paper backward

to the push tractor. To back out several pages, press the LOAD\ EJECT switch several times, since

reverse feed is performed on a page-by-page basis.

improved paper handling. That is, change over between fanfold

f “:;

{;,,

Micro Adjustment Function

In either case a) or b) above, the top-of-form position is adjustable using the MICRO FEED switch (the

LEDs

message “TOF ADJUST” is displayed on the LCD, and the MICRO FEED, V, and A

ofl/1

the FORM FEED switch advances the paper forward in increments

the switch is held down, and pressing the LINE FEED switch moves the paper in reverse in increments

of 1/180”. Moving the paper with these switches is called micro adjustment. The adjusted position

is stored in the memory and remains effective at the next loading even if the power is cycled. But the

tractor feed is selected, the adjusted position is remained even if the power is turned off.

Auto-Tear-Off Function

To enable the auto-tear-off function, select AUTO TEAR OFF using the

function is activated and the PAPER SELECT is FRICTION, paper is fed in the following way: after the

input data buffer becomes empty, while the printer is ON-LINE, the printer feeds the paper so that the

perforation at the form’s end is moved automatically to the tear-off edge of the printer cover. After the

printer has positioned the paper, the message “TEAR OFF ADJUST” is displayed on the LCD, and the

A, and MICRO FEED

V,

adjustment of the tear-off position. The adjusted position is stored in the memory and remains effective

at the next tear-off even if the power is turned off and on. If subsequent data is input to the printer,

the paper will be reversed to its original position automatically and printing will start. If the ON-LINE

switch is pressed (taking the printer OFF-LINE) while the paper is advanced to the tear-off position, then

the printer will reverse the paper to its original position. The manual tear-off function selected by the

TEAR OFF switch is also called a tear-off function.

LEDs

are lit. The FORM FEED and LINE FEED switches are then available for micro

80” continuously as long as

SelecType function. When this

are lit.). Pressing

,:. ,

(-’

J.-,

1-26

.., -.,,.

Page 35

‘1

1.8.2

REV.-A

ROMA

Board (Main Board)

Figure 1-16 shows the

ROMA

board, which contains an HD64 180R1 P6 (main) CPU andaPPD7810HG

(sub) CPU to control the operation of the printer. Driver circuits for the motors, solenoids,

ICS

and sensors are also included on this board. The main

on the ROMA board are:

CPU

●

HD64180R1 P6 (1 3A) . . . . . . . . . . .

●

pPD7810HG

Gate

●

EO5A1OAA (1 4A) . . . . . . . . . . . . . . . . . . .

●

E05A02LA (2A) . . . . . . . . . . . . . . . . . . . . . .

●

E05A09BA

(7B)

. . . . . . . . . . . . . . . . . .

Array

IC

(4B) . . . . . . . . . . . . . . . . . . . . .

8-bit one-chip CPU (main control)

8-bit one-chip CPU (sub control)

Memory management unit

Printhead

data control

Carriage (CR) and paper feed

(MMU)

IC

(PF)

IC

motors phase pulse control unit

(MCU) IC

● E05A09BA

. . . . . . . . . . . . . . . . . . . . .

(3B)

Platen gap

(PG)

and color select

(CS)

motors phase pulse control unit

(MCU) IC

“)

Memory IC

●

EP-ROM

(1 1A) . . . . . . . . . . . . . . . . . . . . . . . . .

●

EP-ROM

(7A) . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

MASK-ROM (1 2A) . . . . . . . . . . . . . . . . . .

●

PS-RAM (9A) . . . . . . . . . . . . . . . . . . . . . . . . . . .

●

ST-RAM* (1OA) . . . . . . . . . . . . . . . . . . . . . . .

x: This memory is backed-up by

Universal

●

M546 10P (1 1 B) . . . . . . . . . . . . . . . . . . . . .

●

S17304

●

STK6981 H (7D) . . . . . . . . . . . . . . . . . . . . .

●

H8D2148

●

STK66082E (1A) . . . . . . . . . . . . . . . . . . .

IC

(7C) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(2C) . . . . . . . . . . . . . . . . . . . . . . . .

Main CPU program, 256 K-bit

Sub CPU program, 256 K-bit

Character generator, 2M-bit

Buffers, working area, 256 K-bit

Holds status data, panel data, 256 K-bit

a lithium battery.

8-bit parallel interface

CR motor driver

PF motor driver

Head fan

Printhead

(HF)

driver

IC

IC

motor controller and driver

IC

IC

IC

printhead,

LA 3B

)

1A --

,,—

2°C

Figure 1-16.

7A 7B 9A 10A 1 1A 12A

,

-

,

7’D 7C

ROMA

1-27

i

IB

Board

13A

14A

Page 36

REV.-A

1.8.3 ROPS\ROPSE Board (Power Supply Circuit Board)

The power supply circuit board is one of two boards, the

ROPSE

contains a fuse, line filter, and switching regulator circuit. Compact circuitry is made possible by the

use of a DC-to-DC converter.

for 220-

240 V operation. The basic construction of the two boards are the same: each board

ROPS

for 100- 120 V AC operation or

the

. . .

..Y

:\

f ~~•

“-”

. . .

L

ROPS

Board

--+

f“

- ,,,:.,

.’

.-

.—. +

ROPSE

Board

——-————

.-

Figure 1-17.

ROPS/ROPSE

1-28

Board

Page 37

REV.-A

) 1.8.4 Fan Unit

A fan unit is used to lower the internal temperature of the printer. It removes heat within the printer

housing that is generated by the electric circuits.

.

Figure 1-18. Fan Unit

1.8.5 Housing

The housing consists of the upper and lower cases and accommodates the control panel, printer

mechanism, control circuit board, power circuit, and fan unit. The optional cartridges (e.g., font and

identity modules) can be mounted easily without removing the upper case. Figure 1-19 shows the

LQ-2250 housings.

)

.

Figure. 1-19. Housing

1-29

Page 38

REV.-A

1.8.6 Control Panel

This section describes the control panel functions.

1.8.6.1 Hardware Specification

On the control

Crystal Display) as shown in Figure 1-20.

immediately below the illustration.

ON LINE Switch

This switch toggles the printer between ON-LINE and OFF-LINE. If the printer is set OFF-LINE, printing

is stopped and the printer becomes BUSY. This switch is also used in the

ON LINE LED (Green) Lights in the ON-LINE mode. Blinks when the printhead temperature is too high.

Panel, there are

r

0

POWER

0

READY

0

PAPER OUT

o

ON LINE

pig=

twelve

0

TEAR

~

❑

non-locking

fjfyyj

ON

UNE

Figure 1-20. Control Panel

switches, sixteen

The functions of the switches and indicators are given

LCD

FONM

FEEO

LINE FEED

LOAOIE.JfCl

LEDs,

@s$aQ

-,

and a 20-column LCD (Liquid

1

SelecType function.

c

FORM FEED Switch

Pressing this switch

top-of-form position.

adjustment function,

LINE FEED Switch

When the printer is OFF-LINE, the paper advances continuously one line at a time if this switch is pressed

for more than 0.5 seconds. The space between lines of text is set using the line spacing command.

This switch is also used for the micro adjustment function, the platen gap adjustment function, and

SelecType function.

the

LOAD/EJECT Switch

Pressing this switch when the printer is OFF-LINE, loads or ejects the paper (If a page is inserted in the

cut sheet feeder, it is loaded; if a page is already loaded, it is ejected). Details of the paper loading and

ejection process are described in Section 1.8.1.2. This

once while the printer is OFF-LINE, advances the paper

This switch is also used for

and the

SelecType function.

the micro adjustment function, the platen gap

switch is also used in the

ve~ically to the next

SelecType

function.

.,,

(“-

:..

-

1-30

.:

..

...

Page 39

FONT Switch

)

Pressing this switch selects a font, and holding the switch for more than 1.0 second cycles through

the fonts sequentially. The LCD displays the currently selected font.

PITCH Switch

Pressing this switch selects

through the character pitches sequentially. The LCD displays the currently selected character pitch.

CONDENSED Switch

Pressing this switch selects normal or condensed printing.

CONDENSED LED (Green) Lights when condensed mode is selected.

PAPER SELECT Switch

Selects the paper. Each time this switch is pressed, the paper handling method changes in the following

order: TRACTOR, FRICTION,

paper handling.

.) TRACTOR LED (Green) Lights when tractor feed is selected.

FRICTION LED (Green) Lights

CSF LED (Green) Lights when

the

character pitch, and holding

CSF

BIN 1,

when friction feed is selected.

CSF

CSF

BIN2. Each LED and the LCD displays the currently selected

mode is selected.

the switch for more than 1.0 second cycles

REV.-A

TEAR

Advance the paper to the tear-off position. This switch is only effective for the tractor feed (Refer to

Section 1.8.1.2.).

TEAR OFF LED (Orange) Lights when the tear-off function is enabled.

MICRO FEED Switch

Selects or cancels the micro adjustment function. When this function is enabled, the LED on this switch

and the

backward and the FORM FEED switch is used to feed the paper forward. Paper feed performed in this

micro feed mode does not affect the page position control. This function is also used to adjust the paper

loading position and to adjust the paper to meet the tear-off edge (Refer to Section 1.8.1.2.).

)

MICRO FEED LED (Orange) Lights when micro feed is enabled.

PLATEN GAP ADJUST Switch

Selects or cancels the platen gap adjustment function. When this function is selected, three

V,

and decrease the platen gap respectively. The relative platen gap value message is displayed on the

LCD.

+0. 14mm

PLATEN GAP ADJUST LED (Orange) Lights when the platen gap adjustment function is enabled.

OFF Switch

V and A

and the LED on this switch) are lit and the LINE FEED and FORM FEED switches are used to increase

“+”

level means to be widened. “-” level means to be narrowed. The limits of adjustment are

to –O. 1 4mm.

LEDs

are lit. In the micro feed mode, the LINE FEED switch is used to feed the paper

LEDs

(A,

SelecType Switch

Selects or cancels the

switch is lit and the functions of the ON LINE, FORM FEED, LINE FEED, and LOAD/EJECT switches are

changed for the

SelecType

)

LED (Orange) Lights when

SelecType

SelecType function. When the SelecType function is selected, the LED on this

function.

SelecType mode is selected.

1-31

Page 40

REV.-A

Other LEDs

POWER LED (Green) Lights when power is ON.

READY LED (Green) Lights

PAPER OUT LED (Red)

D

a

A V LED (Yellow) Lights the setting for the

when the printer can receive data.

Lights when the paper is at the end.

SelecType,

adjustment functions.

tear-off, micro adjustment, and platen gap

1.8.6.2

This function is invoked when the SelecType switch is pressed (except during ‘printing). When” this

function is invoked, the printer beeps and the message

SelecType function, major functions can be set by operating the ON LINE

(V), and LOAD/EJECT

this mode and returns to the ON-LINE

DEFAULTS” means that MACRO settings or DEFAULT settings will not be stored in the backup memory.

●

The SelecType mode has five menus. While the message “SeiecType MODE” is displayed, every time

the LINE FEED (V) switch is pressed, the main menu of this mode is displayed in the order:

LOAD MACRO

Function in which the settings stored in one of the four macro channels can be read out and set as

the current

CHANGE MACRO

Function in which the current settings can be changed and stored into one of the four macro channels.

The twelve settings and their options are shown in Table 1-18.

SelecType Function

(D) switches. By pressing the SelecType switch the second time the printer exits

Refer to Figure 1-21 for the entire

SelecType settings.

‘“SelecType MODE’”

(a).

is displayed.. In the

FORM FEED (A), LINE FEED

mode. Exiting without performing “SAVE MACRO” or “SAVE

SelecType

operational sequence.

[

“

~’

CHANGE DEFAULTS

Functions in which the default settings shown can be changed. the default settings and options are

shown in Table 1-19.

PRINT OUT SETTINGS

Function in which all settings

CLEAR ALL MACROS

Function which all settings in

in macro channels and the defaults can be printed out.

macro channels are cleared.

.7

,,

. . . . .

.

(’

,.,

1-32

Page 41

CHAPTER 2

OPERATING PRINCIPLES

REV.-A

2.1 General

2.1.1 Connector Descriptions

2.1.2 Printer Mechanism Operations

2.2 POWER SUPPLY CIRCUIT OPERATION

(ROPS/ROPSE Board)

2.2.1

2.2.2 Input Filter Circuit

2.2.3 Rectifier, Smoothing,

2.2.4 Main Switching Circuit 1

2.2.5 +5 V and +12 V Supply Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

2.1.2.1 Printing Mechanism

2.1.2.2 Platen Gap Adjustment Mechanism . . . . . . . . . . . . . 2-8

2.1.2.3 Carriage Mechanism

2.1.2.4 Paper

ROPS/ROPSE

and Surge-suppression Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.2.5.1 +5 V Current Limiting and Voltage

Feed Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulator Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-2

2-4

2-5

2-11

2-25

.

2-25

2-27

2-28

.

2-32

2.2.6 Main Switching Circuit 2 (+35 V Supply Circuit) . . . . . 2-34

2.2.7 +35 V Current Limiting and Voltage

Regulator Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.8 Over Voltage Protection Circuit

2.3 CONTROL CIRCUIT BOARD

2.3.1 Reset Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1.1 VX (Drive System Pull-up) Voltage

2.3.1.2 Power ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1.3 INIT Signal Input from CN1 or CN2 . . . . . . . . . . . . . 2-45

2.3.1.4 Font/Identity Module Installation

and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1.5 ST-RAM (1 OA) Battery Backup Circuit . . . . . . . . 2-47

2.3.2 interface...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2.1

2.3.2.2

2.3.3 Control

(ROMA

Supply Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-Bit Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

RS-232C

Panel Interface Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . 2-48

.

2-36

2-39

.

. . . . . . 2-42

.

2-43

.

2-44

.

. . . . . 2-46

2.3.3.1

LED Drive Section

Z.i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-56

Page 42

REV.-A

2.3.3.2 Switch Status Read Section

2.3.3.3 LCD Control/Drive Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2.3.4 State Detection and Sensor Signal Input Circuits . . . . . 2-61

2.3.4.1 Reference Voltage Supply Circuit . . . . . . . . . . . . . . . . . . 2-63

2.3.4.2 35 V Line Voltage Detection Circuit . . . . . . . . . . . . . 2-64

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-57

,

‘-’,

i..

2.3.4.3

2.3.4.4

2.3.4.5 PW Sensor Circuit

2.3.4.6 PT Sensor Circuit

2.3.4.7 PG HP Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

2.3.4.8 CR HP Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

2.3.4.9 PE Sensor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4.10 RL/LD Sensor Circuit

2.3.4.11 Case Open Sensor Circuit

2.3.5

Printhead Control/Drive Circuit

2.3.5.1 E05A02LA Gate Array (2A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

2.3.5.2 Printhead Drive Circuit

2.3.5.3 Relationship Between Paper Thickness

2.3.5.4 Relationship Between the First

2.3.6 HF Motor Control/Drive Circuit

VR1/VR2

Printhead Temperature Detection Circuit... 2-66

and Print Mode

Pulse Width and +35 V Line Voltage . . . . . . . . . . 2-79

Reading Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printhead Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-65

2-67

2-68

.

2-71

2-72

2-73

2-74

2-76

2-78

2-80

‘i.,<,’