Page 1

DOT MATRIX PRINTER

LC- 4511

LC- 4521

TECHNICAL MANUAL

[

SECOND EDITION

]

Page 2

NOTICE

• All rights reserved. Reproduction of any part of this manual in any

form whatsoever, without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents

of this manual at the time of going to press. However, should any

errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility

for any errors in this manual.

© Copyright 1996 Star Micronics Co.,Ltd.

Page 3

INTRODUCTION

This manual describes the LC-4511,4521 dot matrix printer.

It is designed for use as a reference for periodic inspections and maintenance procedures to be executed by

service personnel. It is not intended for the general user. Users of this manual should have a basic knowledge

and understanding of the English language.

• This manual is divided into the following sections:

Chapter 1 General Specifications

Chapter 2 Theory of Operation

Chapter 3 Adjustments

Chapter 4 Parts Replacement

Chapter 5 Maintenance and Lubrication

Chapter 6 Troubleshooting

Chapter 7 Parts List

1

2

3

4

• First edition : Mar. 1996

Second edition : Aug. 1997

5

6

7

Page 4

Page 5

CHAPTER 1

GENERAL SPECIFICATIONS

1. General Specifications..........................................................................................3

2. External Appearance and Composition ..............................................................6

3. Control Panel .........................................................................................................8

3-1. Switch Combination Functions ............................................................................. 8

3-2. EDS Mode Settings................................................................................................. 9

4. Parallel Interface..................................................................................................10

4-1. General Specifications ......................................................................................... 10

4-2. Connector Signals ................................................................................................ 10

1

5. Serial Interface (optional) ...................................................................................11

5-1. General Specifications ......................................................................................... 11

5-2. Connector Signal and Functional Descriptions (SPC-8K, IS-8H192)............... 12

5-3. DIP Switch Settings (SPC-8K, IS-8H192) ............................................................ 12

6. EE-PROM mode ...................................................................................................13

6-1. Outline ................................................................................................................... 13

6-2. Explanation of special control codes ................................................................. 13

6-3. EE-PROM MAP ...................................................................................................... 14

6-4. Rewriting the EE-PROM ....................................................................................... 17

Page 6

Page 7

GENERAL SPECIFICATIONS

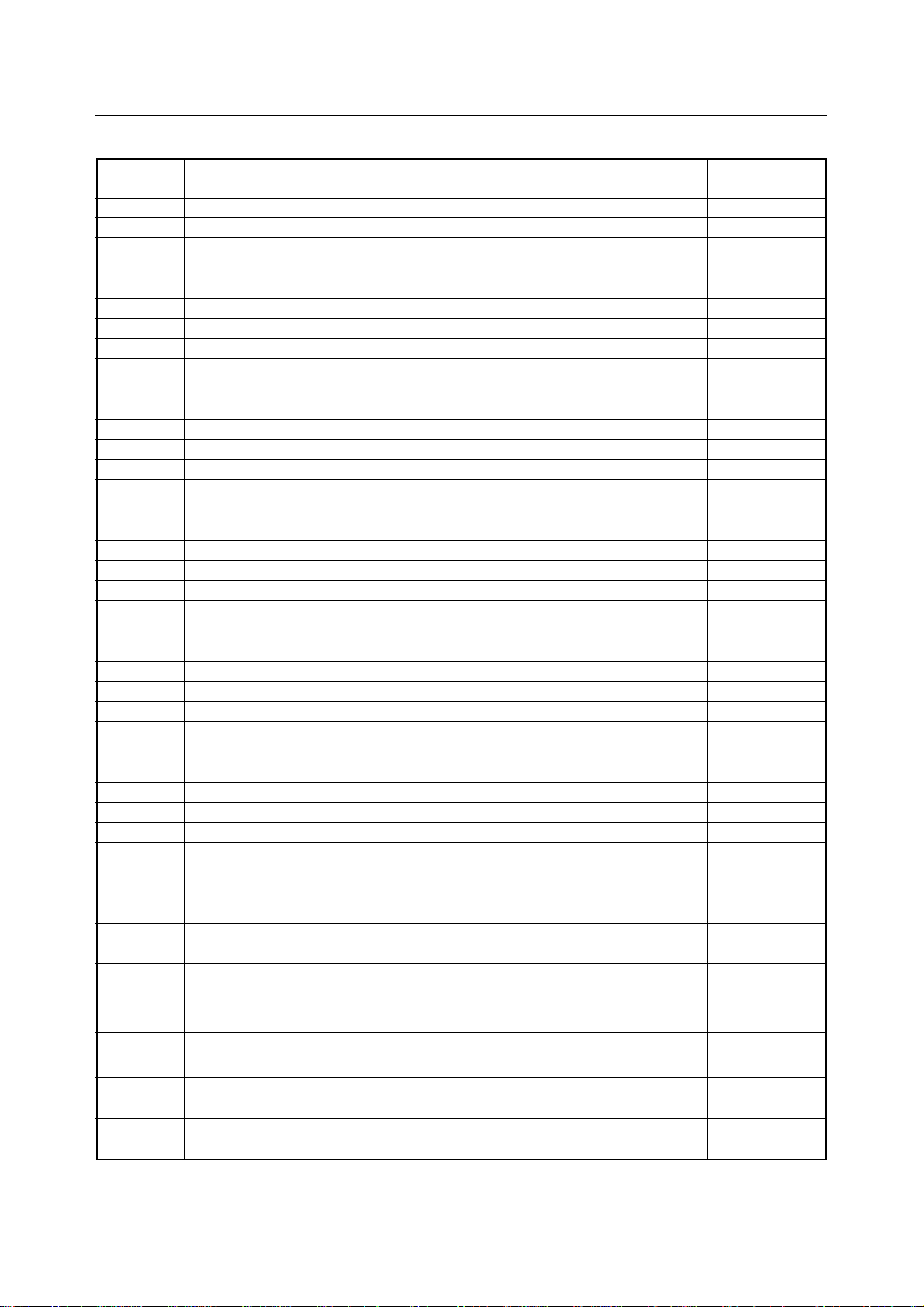

1. General Specifications

Printing System Serial Impact Dot-Matrix

Printing Speed Pitch Draft (cps/dpi) LQ (cps/dpi)

LC-4521

LC-4511 Pica (10 cpi) 225/120H 75/360H

Print Direction Draft: Bi-directional logic seeking

Print Head Number of pins: 24

Line Spacing 1/6”, 1/8”,7/60”,n/180”,n/360”

Character Matrix Pitch Draft LQ

LC-4521

LC-4511 Pica (10 cpi) 24 × 9H 24 × 31H

Pica (10 cpi)

Elite (12 cpi) 360/120H 120/360H

Semi-condensed(15 cpi(S)) 450/120H 150/360H

Semi-condensed(15 cpi(I)) 225/240H 150/360H

Condensed pica (17 cpi) 255/240H 170/360H

Condensed elite (20 cpi) 300/240H 198/360H

24cpi (I) 360/240H 238/360H

Elite (12 cpi) 270/120H 90/360H

Semi-condensed(15 cpi(S)) 337/120H 112/360H

Semi-condensed(15 cpi(I)) 168/240H 1112/360H

Condensed pica (17 cpi) 191/240H 127/360H

Condensed elite (20 cpi) 225/240H 149/360H

24cpi (I) 270/240H 178/360H

H: half-dot

(S) : Standard mode only

(I) : IBM mode only

LQ: Bi-directional logic seeking

Bit-Image: Uni-directional/ bi-directional logic seeking (selectable)

Life: 200 million dots/pin (Normal Mode)

7/72”, n/72”, n/216” : software

Pica (10 cpi)

Elite (12 cpi) 24 × 9H 24 × 27H

Semi-condensed(15 cpi(S)) 16 × 7H 16 × 21H

Semi-condensed(15 cpi(I)) 24 × 9H 24 × 16H

Condensed pica (17 cpi) 24 × 9H 24 × 16H

Condensed pica (20 cpi) 24 × 9H 24 × 16H

24cpi (I) 24 × 9H 24 × 14H

Elite (12 cpi) 24 × 9H 24 × 27H

Semi-condensed(15 cpi(S)) 16 × 7H 16 × 21H

Semi-condensed(15 cpi(I)) 24 × 9H 24 × 16H

Condensed pica (17 cpi) 24 × 9H 24 × 16H

Condensed elite (20 cpi) 24 × 9H 24 × 16H

24cpi (I) 24 × 9H 24 × 14H

300/120H (Normal)

400/80H (HS)

100 million dots/pin (Multi-Part Mode)

24 × 9H (Normal)

24 × 7H (HS)

– 3 –

100/360H

24 × 31H

Page 8

GENERAL SPECIFICATIONS

H: half-dot

(S) : Standard mode only

(I) : IBM mode only

Environment Operating temperature: 41°F to 95°F (5°C to 35°C)

Storage temperature: –22°F to 149°F (–30°C to 65°C)

Operating humidity: 30% to 80% (non-condensing)

Storage humidity: 20% to 90% (non-condensing)

Paper Cut-sheet (manual feeding)

Paper width: 7” to 16.54” / 178 to 420 mm

Paper length: 5.5” to 14” / 140 to 356 mm

Paper thickness: 0.00276” to 0.00472” / 0.07 to 0.12 mm

Paper weight: 14 to 24 lbs. / 52 to 90 g/m2 / 45 to 77 kg

Cut-sheet (with optional automatic sheet feeder)

Paper size: B5, A4, LT, B4, A3, Legal

Paper thickness: 0.00315” to 0.00472” / 0.08 to 0.12 mm

Paper weight: 16 to 24 lbs. / 60 to 90 g/m2 / 52 to 77 kg

Hopper: 50 sheets of 64 g/m

30 sheets of 80 g/m

Stacker: 10 sheets

Fanfold (with push tractor feeder)

Paper width: 4” to 16.5” / 101.6 to 419 mm

Paper thickness: 0.00276” to 0.00433” / 0.07 to 0.11 mm (one-ply)

0.01378” / 0.35 mm maximum (total thickness of multi-ply

paper, non-carbon)

Paper weight: 14 to 22 lbs. / 52 to 82 g/m2 / 45 to 70 kg (one-ply)

11 to 14 lbs. / 40 to 52 g/m2 / 34 to 45 kg (multi-ply)

Copies: Original + 1 or 2 (Normal Mode)

Original + 3 or 4 (Multi-Part Mode)

* Multi-Part Mode is recommended when using optional

pull tractor unit.

Fanfold (with optional pull tractor feeder)

Paper width: 4” to 16.0” / 101.6 to 406 mm

Paper thickness: 0.00276” to 0.00433” / 0.07 to 0.11 mm (one-ply)

0.01378” / 0.35 mm maximum (total thickness of multi-ply

paper, non-carbon)

Paper weight: 14 to 22 lbs. / 52 to 82 g/m2 / 45 to 70 kg (one-ply)

11 to 14 lbs. / 40 to 52 g/m2 / 34 to 45 kg (multi-ply)

Copies: Original + 1 or 2 (Normal Mode)

Original + 3 or 4 (Multi-Part Mode)

Labels

Backing sheet: 4.5” to 16.5” / 114 to 419 mm

Thickness

Backing sheet: 0.00268” to 0.0035” / 0.07 to 0.09mm

Total: 0.0075” / 0.19mm max.

2

2

– 4 –

Page 9

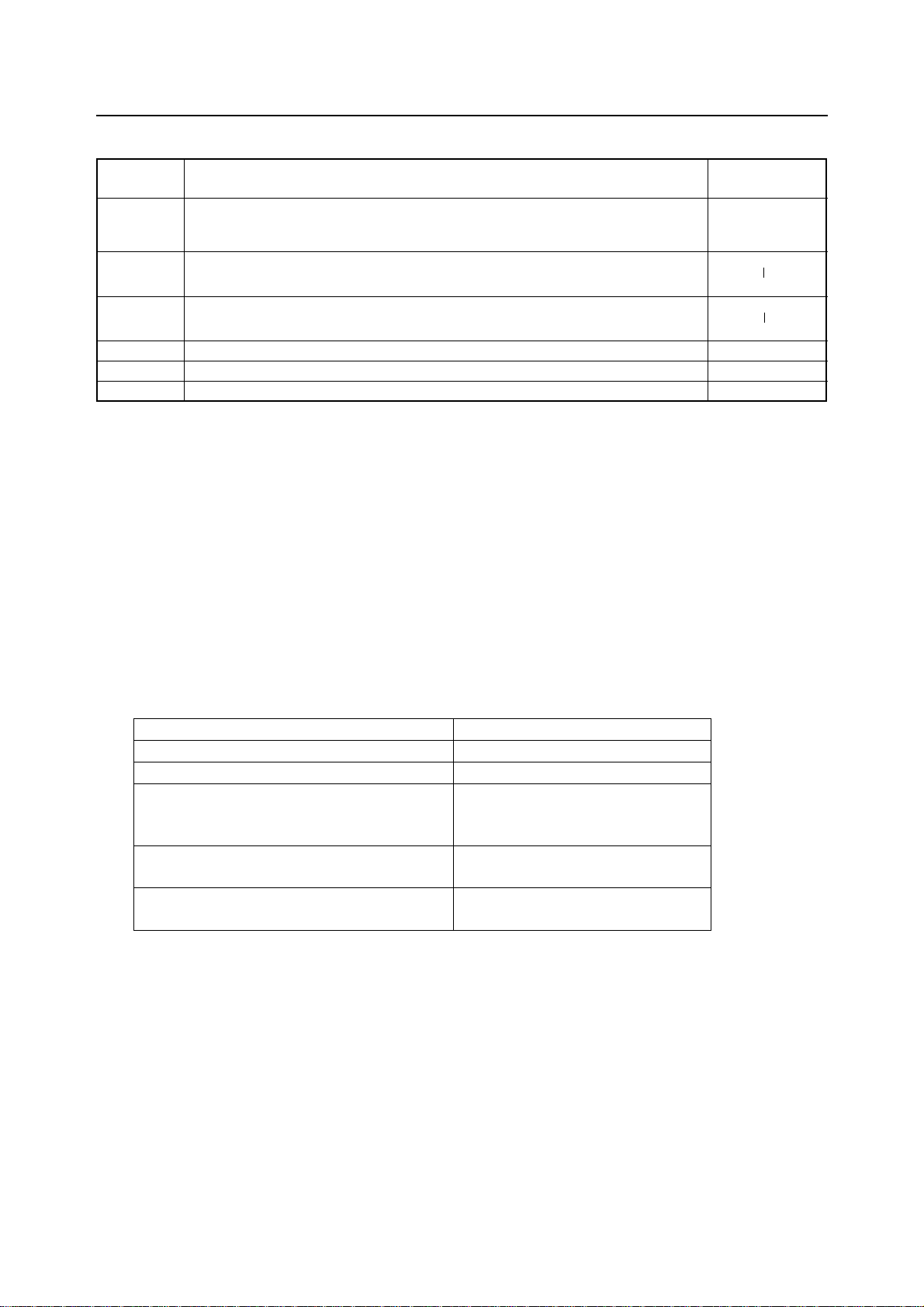

GENERAL SPECIFICATIONS

Emulation Standard Mode: EPSON ESC/P (24-pin)

NEC Graphic compatible

IBM Mode: Proprinter XL24E

Interface Standard: Centronics parallel

Option: RS-232C/RS-422 serial

Ribbon Type On-carriage, dedicated

Monochrome (Y24WH), Black only

Ribbon Life 2.5 million characters (Draft 10 cpi)

Power Supply 120V AC +10%/–17%, 230V AC +14%/–13%; 50/60Hz

(depending on country of purchase)

Power Consumption

LC-4521 14W during standby / 63W during ASCII draft printing

LC-4511 9W during standby / 45W during ASCII draft printing

Options PT-15HA Pull Tractor Unit

SF-15HA Single-Bin Automatic Sheet Feeder

IS-8H192 Serial Interface Unit

IS-32H768 Serial Interface Unit

SPC-8K Serial-To-Parallel Converter

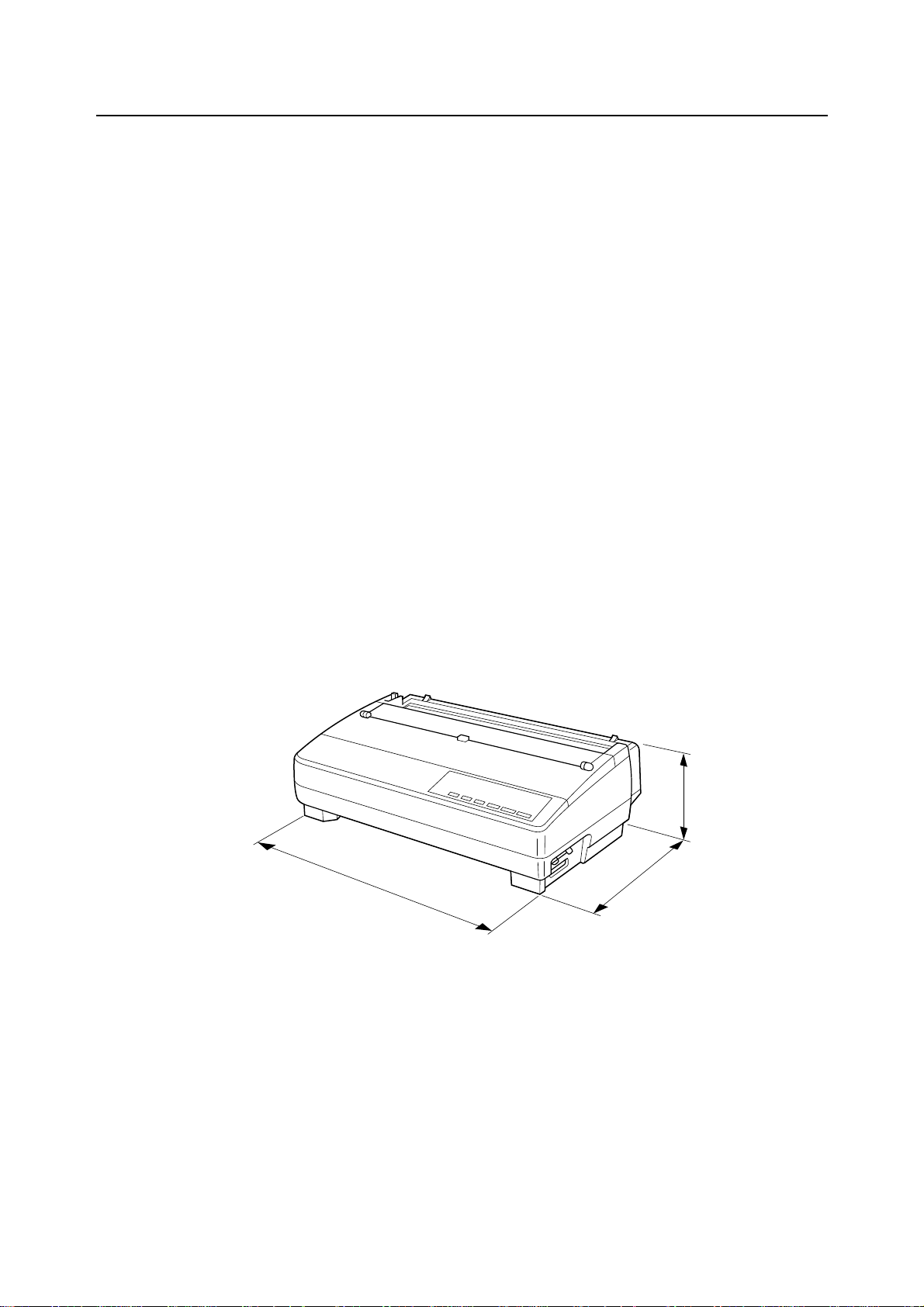

Weight : 19.2lbs/8.7kg

590mm

23.2"

Fig. 1-1 External dimensions

– 5 –

355mm

13.9"

7.3"

186mm

Page 10

GENERAL SPECIFICATIONS

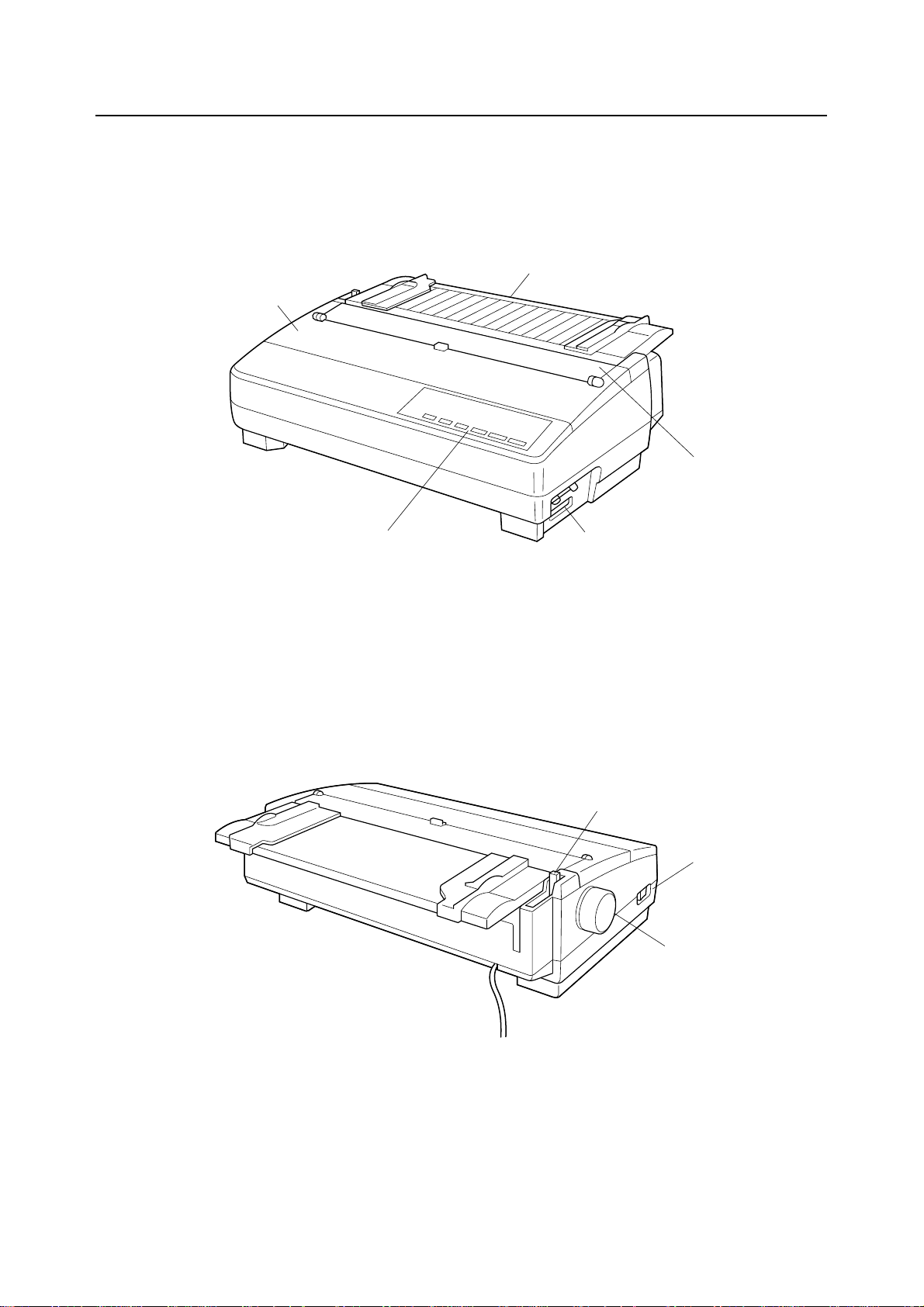

2. External Appearance and Composition

Front cover

Paper guide

Mute cover

Control panel

Fig. 1-2 Front view of the Printer

Interface connector

Release lever

Power switch

Platen knob

Fig. 1-3 Rear view of the Printer

– 6 –

Page 11

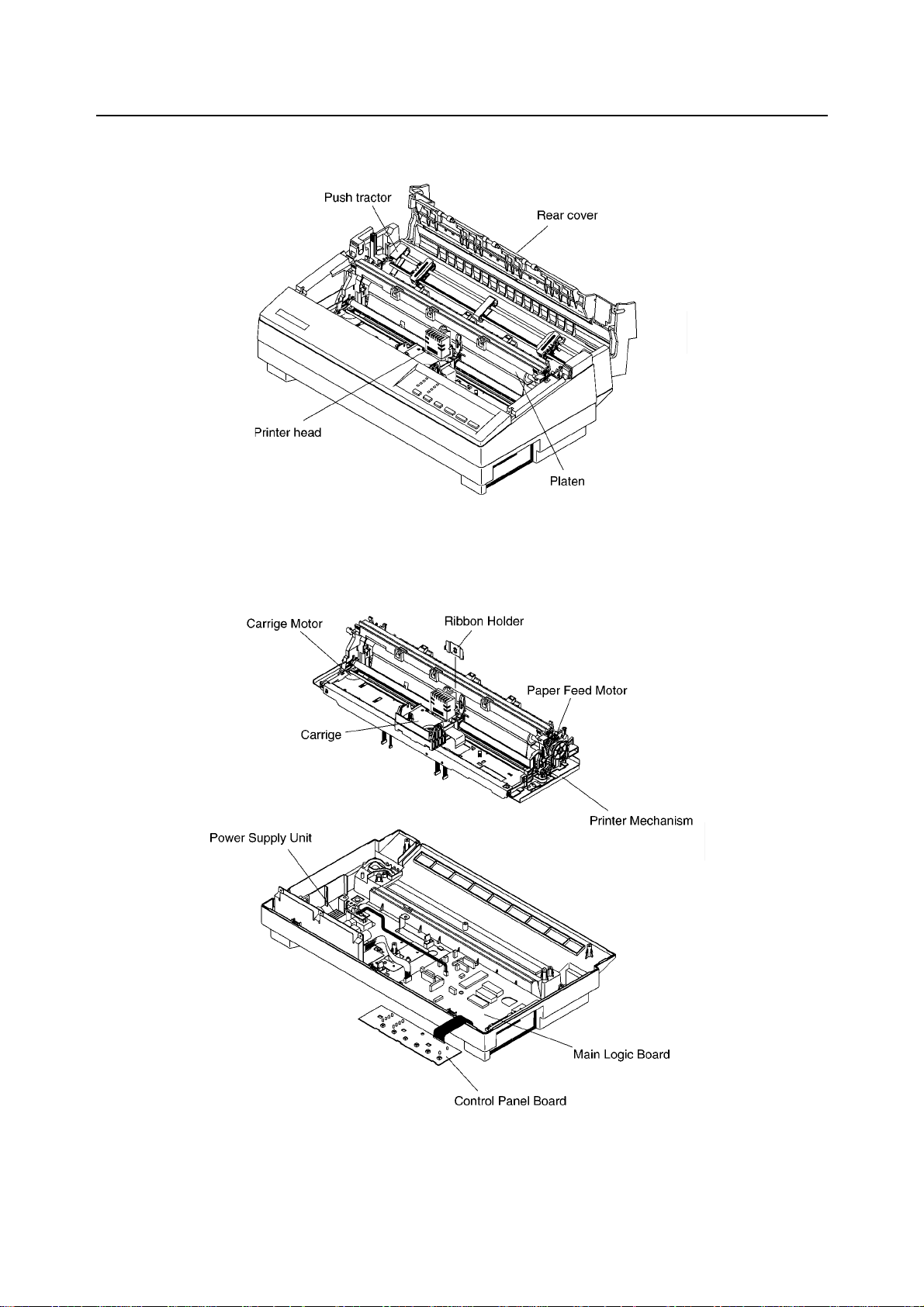

Fig. 1-4 Front cover removed

GENERAL SPECIFICATIONS

Fig. 1-5 Diagram of internal layout

– 7 –

Page 12

GENERAL SPECIFICATIONS

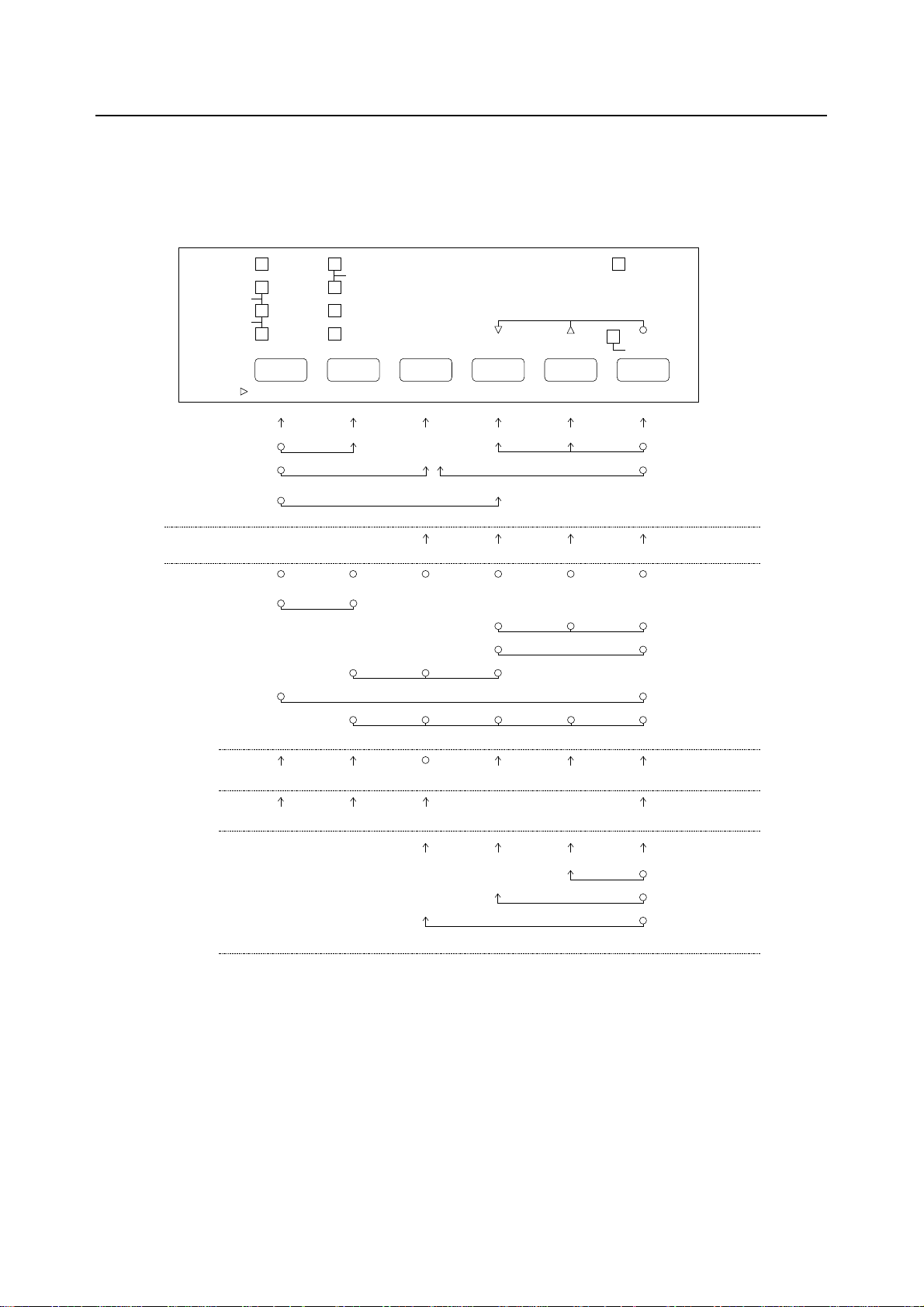

3. Control Panel

3-1. Switch Combination Functions

HS-DRAFT/DRAFT

ROMAN

SANSERIF

COURIER

PRESTIGE

ORATOR

EDS

BANK

SW

D4

A1

E5

B2

F6

C3

FONT

BANK

Panel Macro

Set TOF

Buffer Clear & All Reset

Font & Pitch Lock

10 CPI

12 CPI

15 CPI

COND

PROP

PITCH

SWITCH

SET/EJECT

PARK

STATUS

Hex Dump ModePitch Lock

Aging Mode

Dot-Adjustment Print Mode

MICRO FEED

FORM FEED

ON/OFF

Auto Loading Position Change Mode

Dot-Adjustment Mode

LINE FEED

PRINT

Forward

EDS Mode

POWER

ON LINE

EXIT

On-LineLine FeedForm FeedPitch Selection Set/Eject/ParkFont Selection

Micro FeedBack ward

Off-LineTear off (Short) Tear off (Long) Quiet Mode

Short Test Long Test Multi-part ModeFont Lock

OFF-LINE

ON-LINE

NextRightLeft

EE-PROM Data Initialize

On/Off

Factory settings

PrintSwitch StatusBank

ForwardPaper Loading Back ward

Save

Exit

Exit

Cancel

Set

AUTO LOADING POSITION CHANGE MODE

POWER-ON

EDS MODE

DOT-ADJUSTMENT MODE

– 8 –

Page 13

GENERAL SPECIFICATIONS

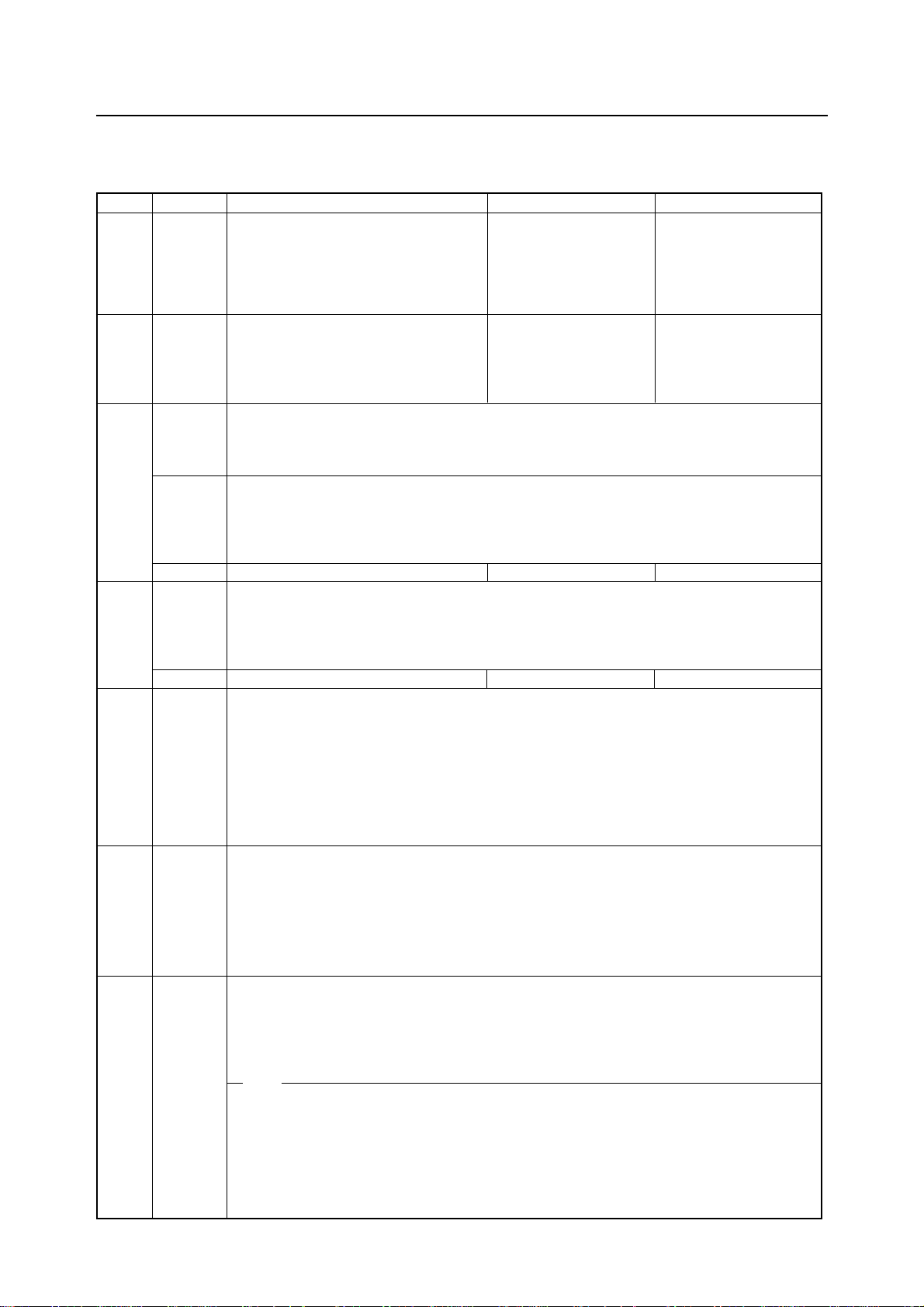

3-2. EDS Mode Settings

Bank Switch Function ON OFF

A 1 Emulation STANDARD / EPSON IBM

B 1 Graphics Direction Bi-directional Uni-directional

C 1, 2 Print Mode

D 1,2,3,4 Page Length

E 1,2,3,4,5 IBM Code Page (CT=Graphics, IBM #1, #2)

F 1, 2, 3, 4, 5 NLQ Font Selection

2 Character Table (CT) Standard / EPSON mode Graphics Italics

IBM mode IBM #2 IBM #1

3 RAM Usage Input Buffer Download Buffer

4 Auto Sheet Feeder Not installed Installed

5 Paper Out Enabled Disabled

6 Multi-Part Mode Disabled Enabled

2 Tear-off Disabled Enabled

3 Line Spacing 1/6" 1/8"

4 Auto LF with CR Disabled Enabled

5 Zero Style Normal Slashed

6 Strobe Timing Normal Reverse

LQ ON ON

Draft OFF ON

HS-Draft ON OFF

3,4,5 Print Pitch

10cpi ON ON ON Proportional OFF ON OFF

12cpi OFF ON ON

15cpi ON OFF ON

17cpi OFF OFF ON

20cpi ON ON OFF

6 Quiet Disabled Enabled

11"/Letter ON ON ON ON 14"/Legal OFF ON OFF ON

8" OFF ON ON ON 10.5"/Executive ON OFF OFF ON

11.7"/A4 ON OFF ON ON 7.25"/Executive OFF OFF OFF ON

12" OFF OFF ON ON 3.5" ON ON ON OFF

8.5"/Letter ON ON OFF ON 5.5" OFF ON ON OFF

5 CR Centering Position Long Short

#437 ON ON ON ON ON #3844 ON OFF ON OFF ON

#850 OFF ON ON ON ON #3845 OFF OFF ON OFF ON

#860 ON OFF ON ON ON #3846 ON ON OFF OFF ON

#861 OFF OFF ON ON ON #3847 OFF ON OFF OFF ON

#863 ON ON OFF ON ON #3848 ON OFF OFF OFF ON

#865 OFF ON OFF ON ON #852 OFF OFF OFF OFF ON

#866 ON OFF OFF ON ON #737 ON ON ON ON OFF

#3840 OFF OFF OFF ON ON #851 OFF ON ON ON OFF

#3841 ON ON ON OFF ON #869 ON OFF ON ON OFF

#3843 OFF ON ON OFF ON #928 OFF OFF ON ON OFF

International Character Set (CT=Italics)

U.S.A. ON ON ON ON ON Japan ON ON ON OFF ON

France OFF ON ON ON ON Norway OFF ON ON OFF ON

Germany ON OFF ON ON ON Denmark-2 ON OFF ON OFF ON

England OFF OFF ON ON ON Spain-2 OFF OFF ON OFF ON

Denmark-1 ON ON OFF ON ON Latin America ON ON OFF OFF ON

Sweden OFF ON OFF ON ON Korea OFF ON OFF OFF ON

Italy ON OFF OFF ON ON Ireland ON OFF OFF OFF ON

Spain-1 OFF OFF OFF ON ON Legal OFF OFF OFF OFF ON

Roman ON ON ON ON ON

Sanserif OFF ON ON ON ON

Courier ON OFF ON ON ON

Prestige OFF OFF ON ON ON

Orator OFF OFF OFF ON ON

Option

Script ON ON OFF ON ON Cinema ON OFF OFF OFF ON

OCR-B OFF ON OFF ON ON Code 39 OFF OFF OFF OFF ON

OCR-A ON OFF OFF ON ON UPC/EAN ON ON ON ON OFF

Orator-2 ON ON ON OFF ON Old-Stile OFF ON ON ON OFF

TW-Light OFF ON ON OFF ON Firenze ON OFF ON ON OFF

L-Gothic ON OFF ON OFF ON Arabic Naskh OFF OFF ON ON OFF

Blippo OFF OFF ON OFF ON Arabic Koufi ON ON OFF ON OFF

H-Gothic ON ON OFF OFF ON

Orane OFF ON OFF OFF ON

Arabic Naskh-Eilani

OFF ON OFF ON OFF

– 9 –

Page 14

GENERAL SPECIFICATIONS

4. Parallel Interface

4-1. General Specifications

Item Specifications

Interface Centronics-compatible

Synchronization System Via externally supplied STROBE pulse

I/F Protocol Using ACK and BUSY signals

Logic Level Compatible with TTL level

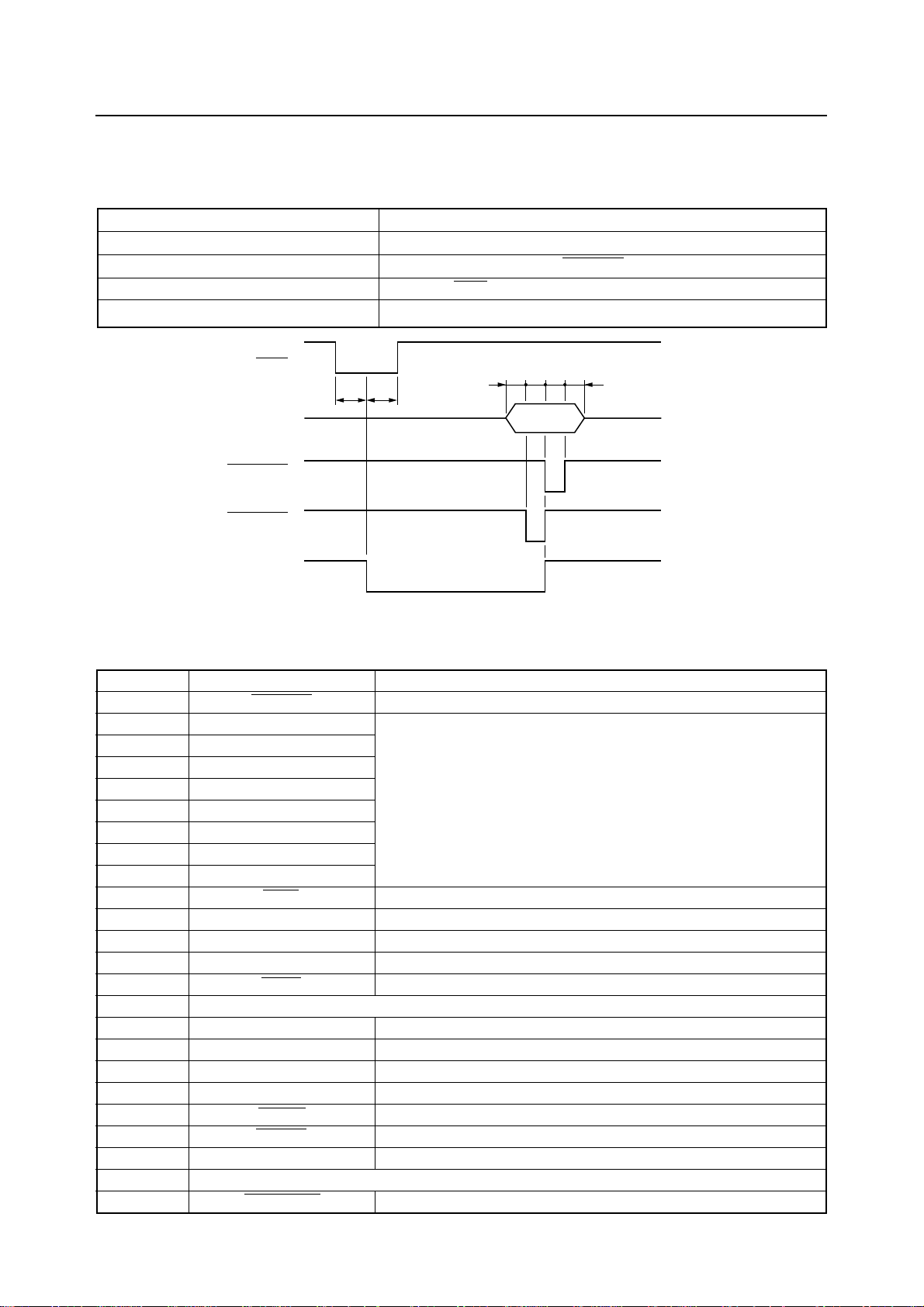

ACK

Data

STROBE

(EDS B-6 : ON)

STROBE

(EDS B-6 : OFF)

BUSY

5µs

5µs

tttt

t : More than 0.5µs

Fig. 1-6 Timing Charts for Parallel Interface

4-2. Connector Signals

Pin Name Function

1 STROBE Goes low for ≥ 0.5µs when active.

2 DATA0

3 DATA1

4 DATA2

5 DATA3

6 DATA4

7 DATA5

8 DATA6

9 DATA7

10 ACK 10µs low to acknowledge receipt of data.

11 BUSY Printer sets line low when ready to receive data.

12 PAPER High when paper runs out.

13 SELECT High when printer is on-line.

14 AFXT Printer ignores this signal.

15 Not used.

16 SIGNAL GND Signal ground

17 CHASSIS Chassis ground (isolated from signal ground)

18 +5V +5V DC output from printer

19~30 GND Twisted pair ground return

31 RESET Printer is reset when this signal goes low.

32 ERROR Low when printing cannot continue due to error.

33 EXT GND External ground

34~35 Not used

36 SELECT IN Printer ignores this signal.

These signals represent information for the 1st through 8th bit of

parallel data, respectively. Each signal is HIGH when data is logical 1,

and LOW when logical 0.

– 10 –

Page 15

GENERAL SPECIFICATIONS

5. Serial Interface (optional)

When using the serial interface, the optional Serial-Parallel Converter must be connected to the printer.

5-1. General Specifications

(SPC-8K)

Interface RS-232C-level

Synchronization Asynchronous

Baud rate 150, 300, 600, 1200, 2400, 4800, 9600, 19200 BPS (selectable)

Word length

Start bit 1

Data bits 7 or 8 (selectable)

Parity bit Odd, even, none (selectable)

Stop bits One or more

Signal polarity

Mark Logical 1 (-3V to -15V)

Space Logical 0 (+3V to +15V)

Handshaking DTR, XON/XOFF, ETX/ACK

Data buffer 8 kbytes (standard)

(IS-8H192)

Interface RS-232C-level only

Synchronization Asynchronous

Baud rate 150, 300, 600, 1200, 2400, 4800, 9600, 19200 BPS (selectable)

Word length

Start bit 1

Data bits 7 or 8 (selectable)

Parity bit Odd, even, none (selectable)

Stop bits One or more

Signal polarity

Mark Logical 1 (–3V to –15V)

Space Logical 0 (+3V to +15V)

Handshaking DTR, XON/XOFF, ETX/ACK

Data buffer 8 kbytes (standard)

(IS-32H768)

RS-232C Interface

Synchronization Asynchronous

Baud rate 150, 300, 600, 1200, 2400, 4800, 9600, 19200 BPS (selectable)

Word length

Start bit 1

Data bits 7 or 8 (selectable)

Parity bit Odd, even, none (selectable)

Stop bits One or more

Signal polarity

Mark Logical 1 (–3V to –15V)

Space Logical 0 (+3V to +15V)

Handshaking DTR, XON/XOFF, ETX/ACK

Data buffer 32 kbytes (standard)

RS-422A Interface

Synchronization Asynchronous

Baud rate 150, 300, 600, 1200, 2400, 4800, 9600, 19200 , 38400, 76800 BPS (selectable)

Word length

Start bit 1

Data bits 7 or 8 (selectable)

Parity bit Odd, even, none (selectable)

Stop bits One or more

Signal polarity

Mark Logical 1 (A is –0.2 V or less than B)

Space Logical 0 (A is +0.2 V or more than B)

Handshaking DTR, XON/XOFF, ETX/ACK

Data buffer 32 kbytes (standard)

– 11 –

Page 16

GENERAL SPECIFICATIONS

5-2. Connector Signal and Functional Descriptions (SPC-8K, IS-8H192)

Pin No. Signal name Direction Function

1 GND —

2 TXD OUT

3 RXD IN

4 RTS OUT

5 CTS —

6NC

7 GND —

8~10 NC

11 RCH OUT

12~19 NC

20 DTR OUT

21~25 NC

Printer chassis ground.

This pin carries data from the printer.

This pin carries data to the printer.

Always space.

This signal is space when the computer is ready to send data.

The printer does not check this pin.

Unused.

Signal ground.

Unused.

The printer sets this signal to space when it is ready to receive data.

This line carries the same signal as pin 20.

Unused.

The printer sets this signal to space when it is ready to receive data.

Unused.

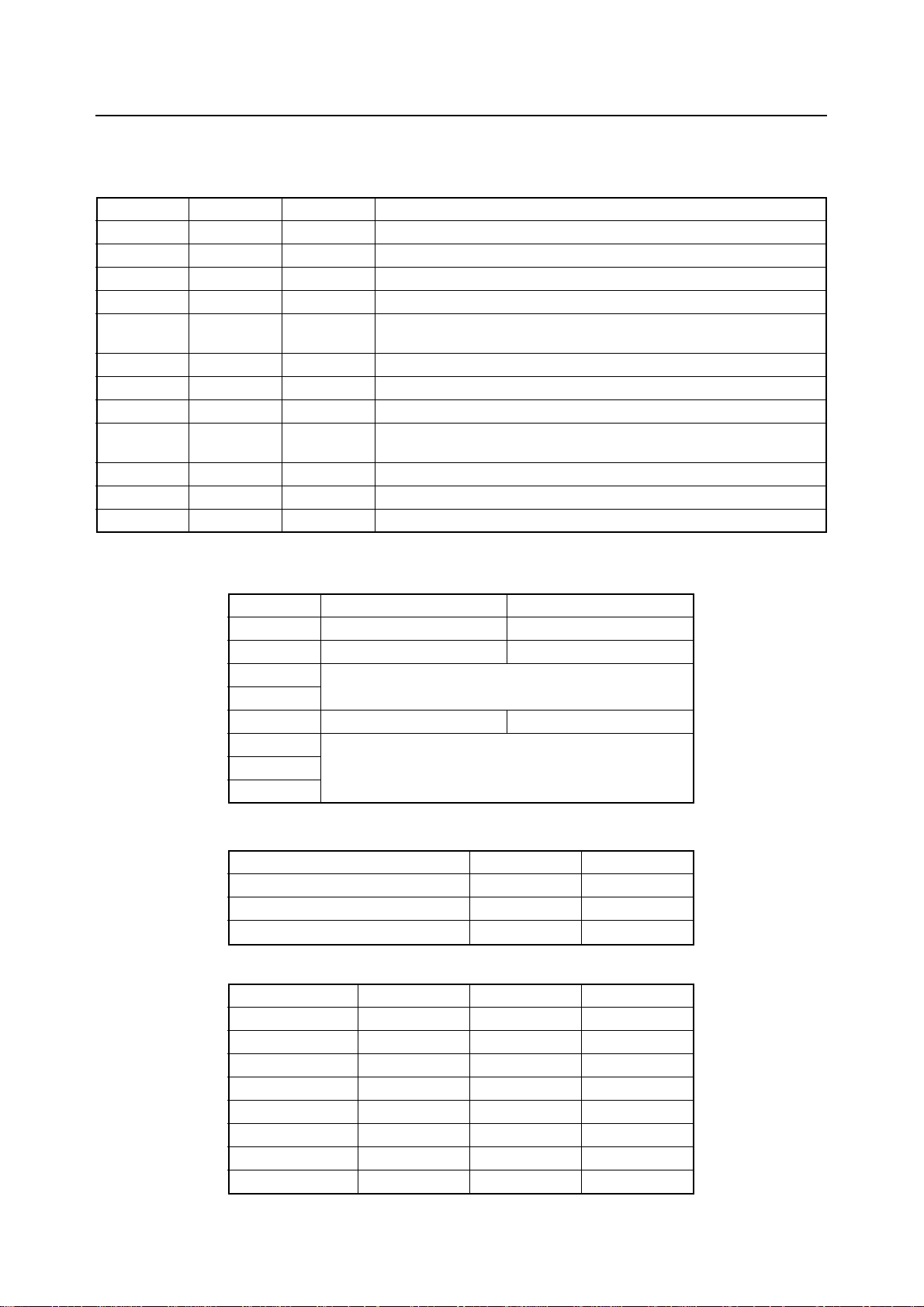

5-3. DIP Switch Settings (SPC-8K, IS-8H192)

Switch ON OFF

1 8 data bits 7 data bits

2 No parity Parity checked

3

4

5 Odd parity Even parity

6

7 Data transfer rate – see table below

8

All switches are set to ON before the printer leaves the factory.

Baud rate Switch 6 Switch 7 Switch 8

150 OFF OFF OFF

300 OFF OFF ON

600 OFF ON OFF

1200 OFF ON ON

2400 ON OFF OFF

4800 ON OFF ON

9600 ON ON OFF

19200 ON ON ON

Handshaking protocols – see table below

Protocol Switch 3 Switch 4

DTR mode ON ON

XON/XOFF mode ON OFF

ETX/ACK mode OFF ON

– 12 –

Page 17

GENERAL SPECIFICATIONS

6. EE-PROM mode

6-1. Outline

These settings can be changed in the EE-PROM mode by writing data directly to the EE-PROM on the main logic board:

Setting EE-PROM mode

• Send <ESC><SUB>(09)H command.

Canceling EE-PROM mode

• Initialize the printer by sending <ESC>@

6-2. Explanation of special control codes

<ESC>@ Exits printer from EE-PROM mode and initializes the printer.

<ESC>M@ Returns all data in the EE-PROM to the factory settings. After the buffer is cleared, the buzzer sounds. If

the printer is powered off before the buzzer sounds, all data in the buffer is not cleared.

If all data is not cleared from the buffer, operation is not guaranteed. Be sure to allow the buzzer

to sound before you turn the printer off!

<ESC>MWn

Code Function Address Capacity

<ESC>MW0 <data> Stores data into entire area of EE-PROM. 00H-7FH 128bytes

<ESC>MW1nm Stores data (m) into the address (n) nH 1 byte

<ESC>MW2<data> Stores auto-start software data into 40H-5EH 30bytes

EE-PROM. 5FH-7DH 30bytes

• The data (m) used in the commands above are stored in the specified address in order (n).

• When the data to be stored exceeds the specified capacity, subsequent data are ignored.

• Data are stored in the EE-PROM according to the memory map. (See section 3. EDS mode setting and

6-3. EE-PROM Map.)

• After all data are stored, a beep indicates the completion of storage.

• If the printer is powered off during data storage, data stored before power off are valid, but subsequent

operation of the printer is not guaranteed.

Do not power off the printer while data is being stored!

<ESC>MR Dumps all data in the EE-PROM to a hard copy.

For an example of using these control codes, see section 6-4. For the corresponding EE-PROM addresses, see the

EE-PROM memory map in section 3-2. EDS mode setting and 6-3 EE-PROM Map.

– 13 –

Page 18

GENERAL SPECIFICATIONS

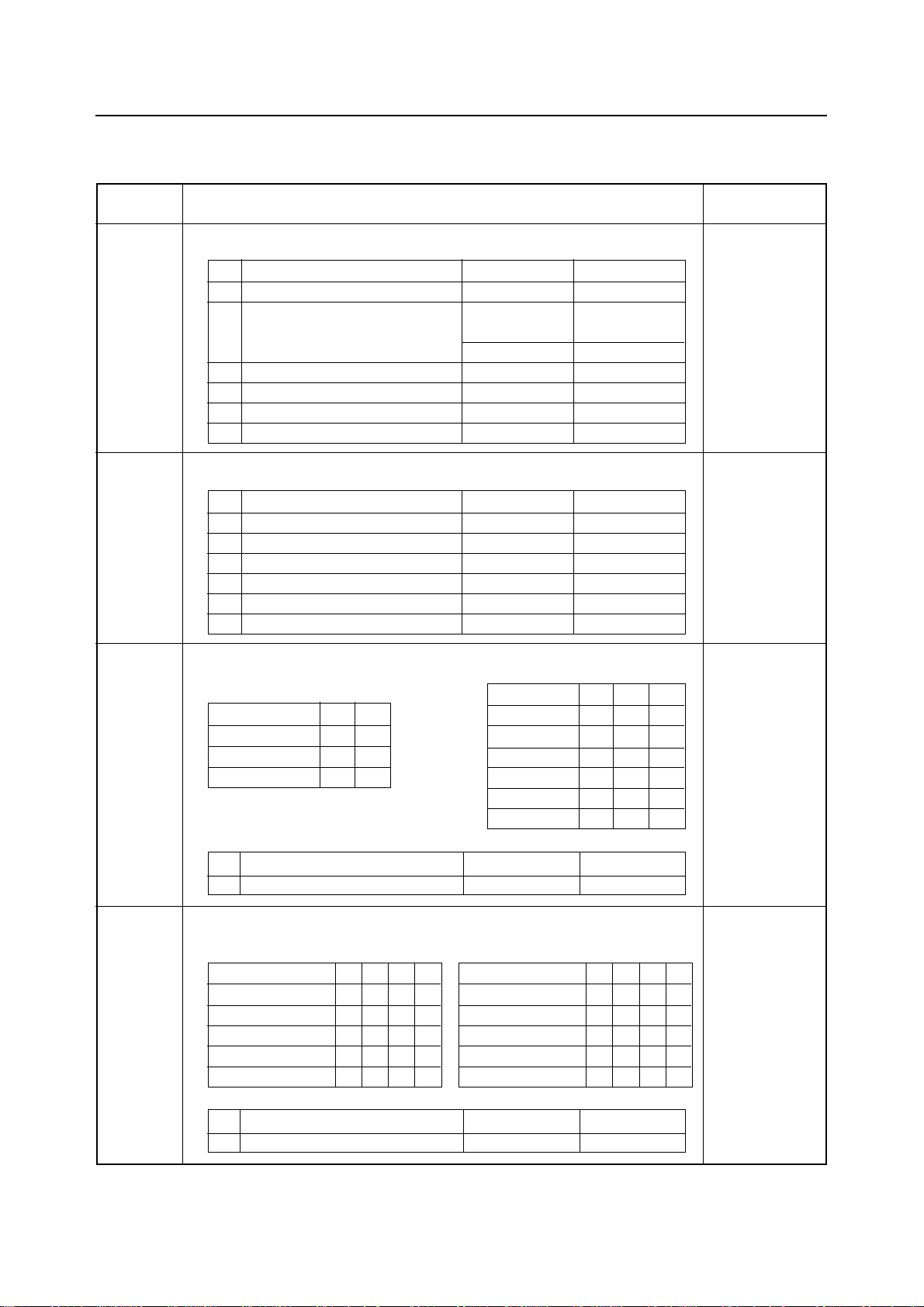

6-3. EE-PROM MAP

Address Function Factory data

00H EDS setting FFH

Bit Function 1 0

b0 Emulation

Character Table

b1 Standard / EPSON mode Graphics Italics

IBM mode IBM #2 IBM #1

b2 RAM Usage Input Buffer

b3 Auto Sheet Feeder Not installed Installed

b4 Paper out Detector Enabled Disabled

b5 Multi-Part Mode Disabled Enabled

01H EDS setting FFH

Bit Function 1 0

b0 Graphics Direction Bi-directional Uni-directional

b1 Tear-off Disabled Enabled

b2 Line Spacing 1/6" 1/8"

b3 Auto LF with CR Disabled Enabled

b4 Zero Style Normal Slashed

b5 Strobe Timing Normal Reverse

STANDARD/EPSON

IBM

Download Buffer

02H EDS setting FFH

Print Mode Function b2 b3 b4

Function b0 b1 10cpi 1 1 1

LQ 1 1 12cpi 0 1 1

Draft 0 1 15cpi 1 0 1

HS-Draft 1 0 17cpi 0 0 1

20cpi 1 1 0

Proportional 0 1 0

Bit Function 1 0

b5 Quiet Disabled Enabled

03H EDS setting FFH

Page Length

Function b0 b1 b2 b3 Function b0 b1 b2 b3

11"/Letter 1111 14"/Legal 0 1 0 1

8" 0111 10.5"/Executive 1 0 0 1

11.7"/A4 1011 7.25"/Executive 0 0 0 1

12" 0011 3.5" 1 1 1 0

8.5"/Letter 1101 5.5" 0 1 1 0

Print Pitch

Bit Function 1 0

b4 CR Centering Position Long Short

– 14 –

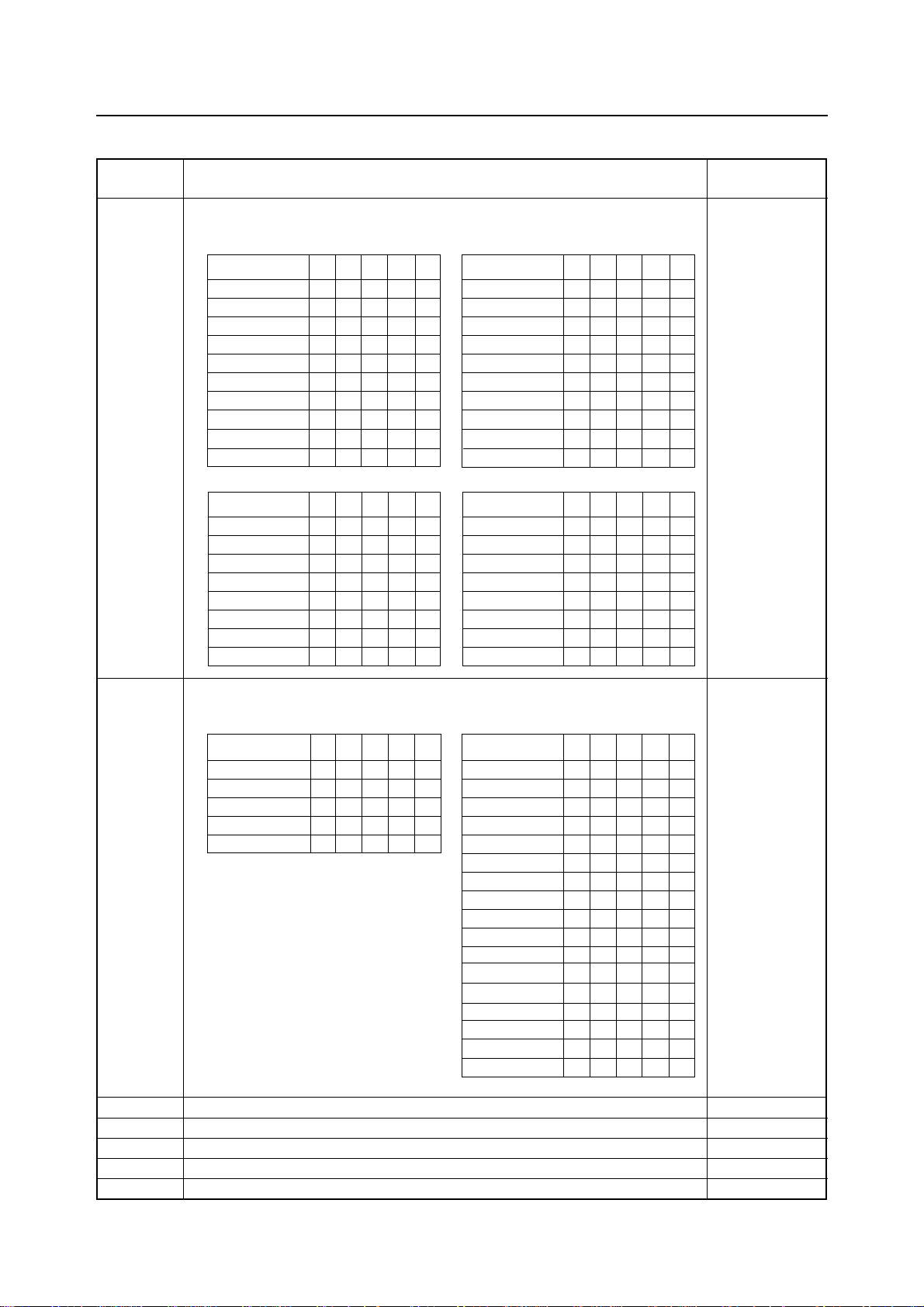

Page 19

GENERAL SPECIFICATIONS

Address Function Factory data

04H EDS setting FFH

IBM Code Page (Character Table=Graphics, IBM#1, #2)

Function b0 b1 b2 b3 b4 Function b0 b1 b2 b3 b4

#437 1 1 1 1 1 #3844 1 0 1 0 1

#850 0 1 1 1 1 #3845 0 0 1 0 1

#860 1 0 1 1 1 #3846 1 1 0 0 1

#861 0 0 1 1 1 #3847 0 1 0 0 1

#863 1 1 0 1 1 #3848 1 0 0 0 1

#865 0 1 0 1 1 #852 0 0 0 0 1

#866 1 0 0 1 1 #737 1 1 1 1 0

#3840 0 0 0 1 1 #851 0 1 1 1 0

#3841 1 1 1 0 1 #869 1 0 1 1 0

#3843 0 1 1 0 1 #928 0 0 1 1 0

International Character Set (Character Table=Italics)

Function b0 b1 b2 b3 b4 Function b0 b1 b2 b3 b4

U.S.A. 1 1 1 1 1 Japan 1 1 1 0 1

France 0 1 1 1 1 Norway 0 1 1 0 1

Germany 1 0 1 1 1 Denmark-2 1 0 1 0 1

England 0 0 1 1 1 Spain-2 0 0 1 0 1

Denmark-1 1 1 0 1 1

Sweden 0 1 0 1 1 Korea 0 1 0 0 1

Italy 1 0 0 1 1 Ireland 1 0 0 0 1

Spain-1 0 0 0 1 1 Legal 0 0 0 0 1

Latin America

11001

05H EDS setting FDH

NLQ Font Selection Option

Function b0 b1 b2 b3 b4 Function b0 b1 b2 b3 b4

Roman 1 1 1 1 1 Script 1 1 0 1 1

Sanserif 0 1 1 1 1 OCR-B 0 1 0 1 1

Courier 1 0 1 1 1 OCR-A 1 0 0 1 1

Prestige 0 0 1 1 1 Orator-2 1 1 1 0 1

Orator 0 0 0 1 1 TW-Light 0 1 1 0 1

L-Gothic 1 0 1 0 1

Blippo 0 0 1 0 1

H-Gothic 1 1 0 0 1

Orane 0 1 0 0 1

Cinema 1 0 0 0 1

Code 39 0 0 0 0 1

UPC/EAN 1 1 1 1 0

Old-Style 0 1 1 1 0

Firenze 1 0 1 1 0

Arabic Naskn 0 0 1 1 0

Arabic koufi 1 1 0 1 0

Arabic Naskn-Eilani

06H (Not used) 00H

07H Misalignment correction 60 DPI (F) 80H

08H Misalignment correction 80 DPI (H) HS-DRAFT 80H

09H Misalignment correction 80 DPI (F) 80H

0AH Misalignment correction 120 DPI (H) 80H

01010

– 15 –

Page 20

GENERAL SPECIFICATIONS

Address Function Factory data

0BH Misalignment correction 120 DPI (F) 80H

0CH Misalignment correction 180 DPI (H) 80H

0DH Misalignment correction 180 DPI (F) 80H

0EH Misalignment correction 240 DPI (H) 80H

0FH Misalignment correction 360 DPI (H) 80H

10H Misalignment correction 120 DPI (H) DRAFT-TEXT 80H

11H Misalignment correction 360 DPI (H) LQ-TEXT 80H

12H (Not used) 00H

13H Misalignment correction Multi-part Mode 60 DPI (F) 80H

14H Misalignment correction Multi-part Mode 80 DPI (H) HS-DRAFT 80H

15H Misalignment correction 80 DPI (F) 80H

16H Misalignment correction Multi-part Mode 120 DPI (H) 80H

17H Misalignment correction Multi-part Mode 120 DPI (F) 80H

18H Misalignment correction Multi-part Mode 180 DPI (H) 80H

19H Misalignment correction Multi-part Mode 180 DPI (F) 80H

1AH Misalignment correction Multi-part Made 240 DPI (H) 80H

1BH Misalignment correction Multi-part Made 360 DPI (H) 80H

1CH Misalignment correction Multi-part Made 120 DPI (H) DRAFT-TEXT 80H

1DH Misalignment correction Multi-part Made 360 DPI (H) LQ-TEXT 80H

1EH (Not used) 00H

1FH Misalignment correction Half-dot Made 60 DPI (F) 80H

20H Misalignment correction Half-dot Made 80 DPI (H) HS-DRAFT 80H

21H Misalignment correction 80 DPI (F) 80H

22H Misalignment correction Half-dot Made 120DPI (H) 80H

23H Misalignment correction Half-dot Made 120 DPI (F) 80H

24H Misalignment correction Half-dot Made 180 DPI (H) 80H

25H Misalignment correction Half-dot Made 180 DPI (F) 80H

26H Misalignment correction Half-dot Made 240 DPI (H) 80H

27H Misalignment correction Half-dot Made 360 DPI (H) 80H

28H Misalignment correction Half-dot Made 120 DPI (H) DRAFT-TEXT 80H

29H Misalignment correction Half-dotMade 360 DPI (H) LQ-TEXT 80H

2AH (Not used) 00H

2BH, 2CH Top Margin in Auto-loading Friction 3CH

00H

2DH, 2EH Top Margin in Auto-loading Tractor 3CH

00H

2FH, 30H Top Margin in Auto-loading ASF 3CH

00H

31H Paper End Sensor A/D Valve 99H

32H~35H Macro set for Standard/EPSON Mode 00H

00H

36H~39H Macro set for IBM Mode 00H

00H

3AH, 3BH TEAR OFF (Short) 00H

80H

3CH, 3DH TEAR OFF (Long) 00H

80H

– 16 –

Page 21

GENERAL SPECIFICATIONS

Address Function Factory data

3EH, 3FH IBM Initial Condition Area FFH

FFH

40H~5EH Auto Start Area for Standard/EPSON Mode 00H

00H

5FH~7CH Auto Start Area for IBM Mode 00H

00H

7DH <FF> Control Code (00H = Space / 0FH = Null) 00H

7EH Colour Information 00H

7FH EE-PROM Check Code 01H

6-4. Rewriting the EE-PROM

Follow this procedure to rewrite the EE-PROM.

(1) Turn the printer on.

(2) Turn the computer on.

(3) Load a BASIC disk in the computer.

(4) Set a sheet of paper in the printer, and press the SET switch.

(5) Enter the program listed below and run the program.

10 LPRINT CHR$(27);CHR$(26);CHR$(&H09)

20 LPRINT CHR$(27);”MW1";CHR$(&H01);CHR$(&HFB)

30 LPRINT CHR$(27);”MR”

BASIC Program Code What It Does

10 LPRINT CHR$(27);CHR$(26);CHR$(&H09) Enters the EE-PROM mode.

20 LPRINT CHR$(27);”MW1"; Starts rewriting the EE-PROM.

CHR$(&H01); Address data from &H01 will show

EDS mode from the EE-PROM memory

map.

CHR$(&HFB) Data from &HFB will change the Line

spacing from 1/6" to 1/8".

30 LPRINT CHR$(27);”MR” Dumps all EE-PROM data to hexadeci-

mal.

(6) To complete the setting, turn the printer off.

– 17 –

Page 22

Page 23

CHAPTER 2

THEORY OF OPERATION

1. Block Diagram .....................................................................................................21

2. General Flow Chart (Main Logic Board)............................................................22

3. Power Supply Circuit ..........................................................................................23

4. Mechanism...........................................................................................................24

4-1. Print Head Mechanism ......................................................................................... 24

4-2. Print Head Carrying Mechanism ......................................................................... 25

4-3. Ink ribbon feed mechanism ................................................................................. 26

4-4. Paper Feed Mechanism........................................................................................ 27

2

4-5. Detectors ............................................................................................................... 28

Page 24

Page 25

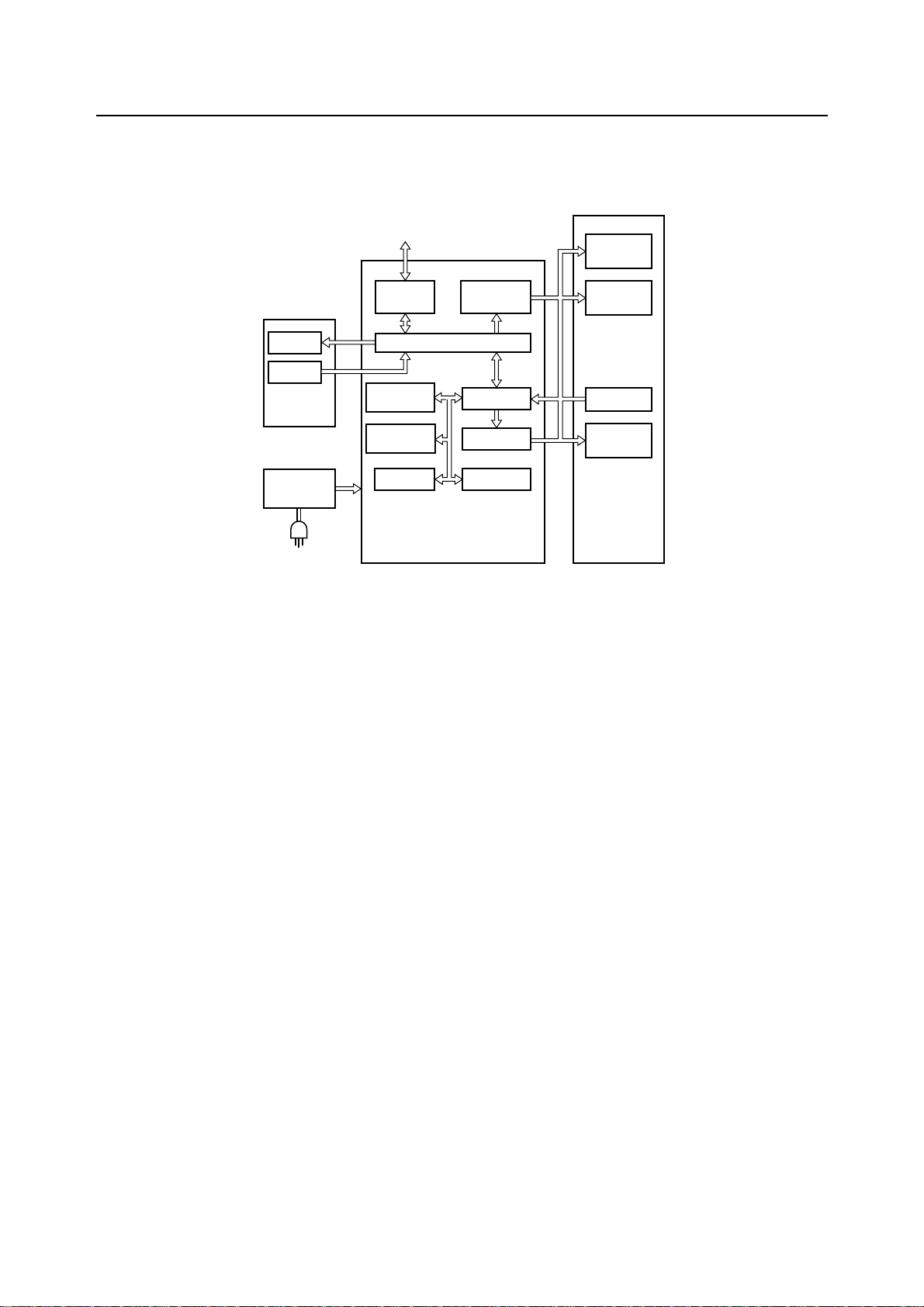

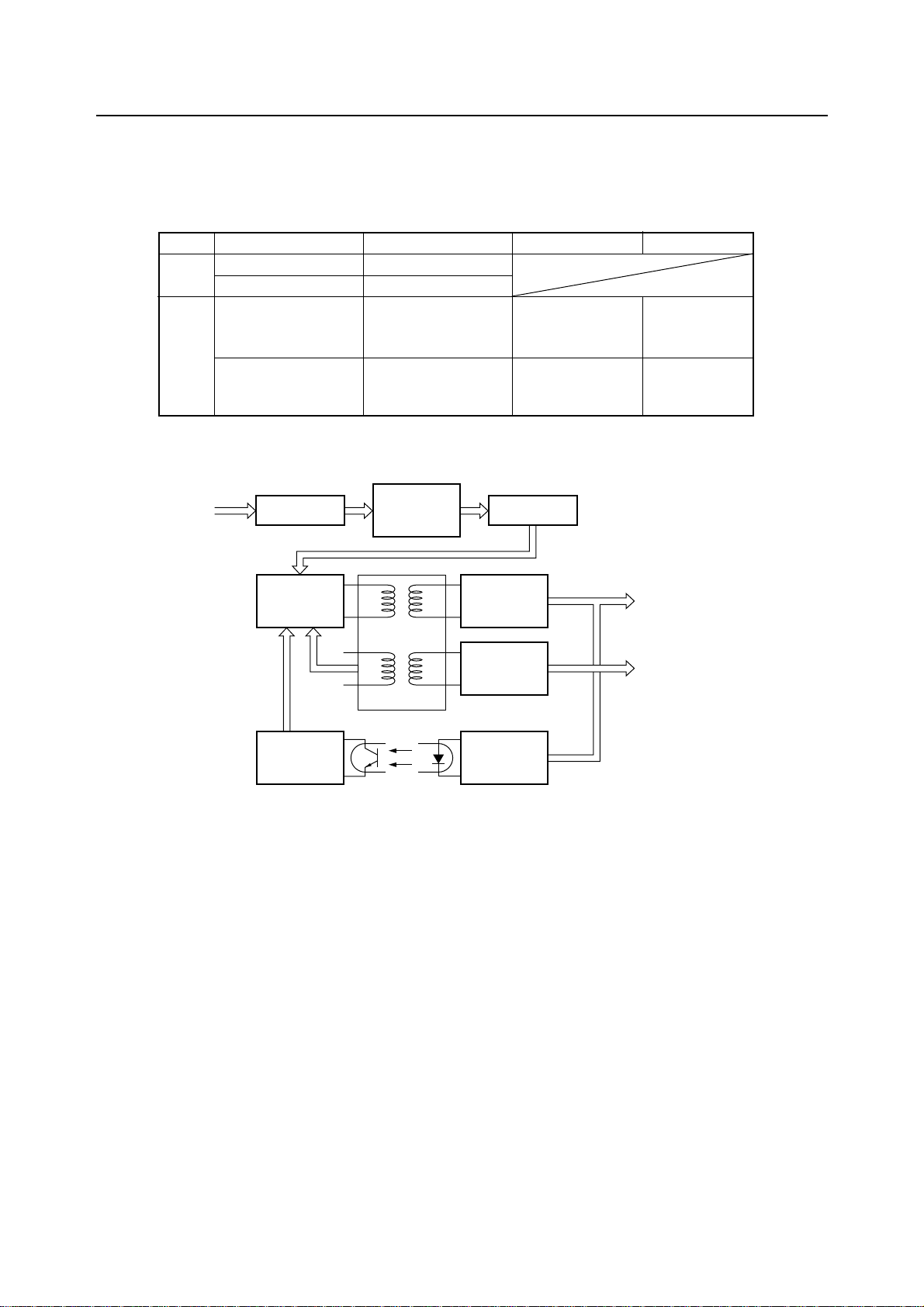

1. Block Diagram

The block diagram of this printer is shown in Fig. 2-1.

Data (From Host Computer)

THEORY OF OPERATION

Print head

LED

Switch

Control

panel board

Power

supply unit

AC Power

Parallel

interface

Gate array

Masked ROM

4M

UVE-PROM

1M

EE-PROM

Main logic board

Driver

CPU

Driver

RAM

Carriage

motor

Detectors

Paper feed

motor

Printer

mechanism

Fig. 2-1 Block Diagram

(1) Main Logic Board

This board receives data from the host computer and stores it in the RAM in the order it arrives. The CPU on this

board reads the data from the RAM, and edits it according to the program stored in the ROM.

When editing is completed, various drive signals from the CPU are sent to the printer mechanism to perform

printing.

Explanation

• CPU TMP90C041

Controls this printer.

• UVE-PROM 1M bit

Contains the program which executes control of the printer. UVE-PROM is not provided with some versions of the

software.

• Masked ROM 4M bit

Contains the character font.

• EE-PROM KM93C46 64 × 16 bits

Contains the data (EDS data and so on) in the memory switch.

• RAM 512K bit

Used as a stack area, work area and data buffer of the CPU.

• Parallel interface

• Gate array (custom IC)

Inputs/outputs several signals.

• Driver

The data edited by the CPU and gate array are sent to the printer mechanism after conversion to the signal for the

print head drive and motor drives.

(2) Control panel board

Panel circuit for manual control of the printer.

(3) Printer Mechanism

Consists of a print head, carriage motor, paper feed motor, and detectors.

(4) Power Supply Unit

Converts AC power to LC-4511 : 33VDC , LC-4521 : 40VDC and 5VDC.

– 21 –

Page 26

THEORY OF OPERATION

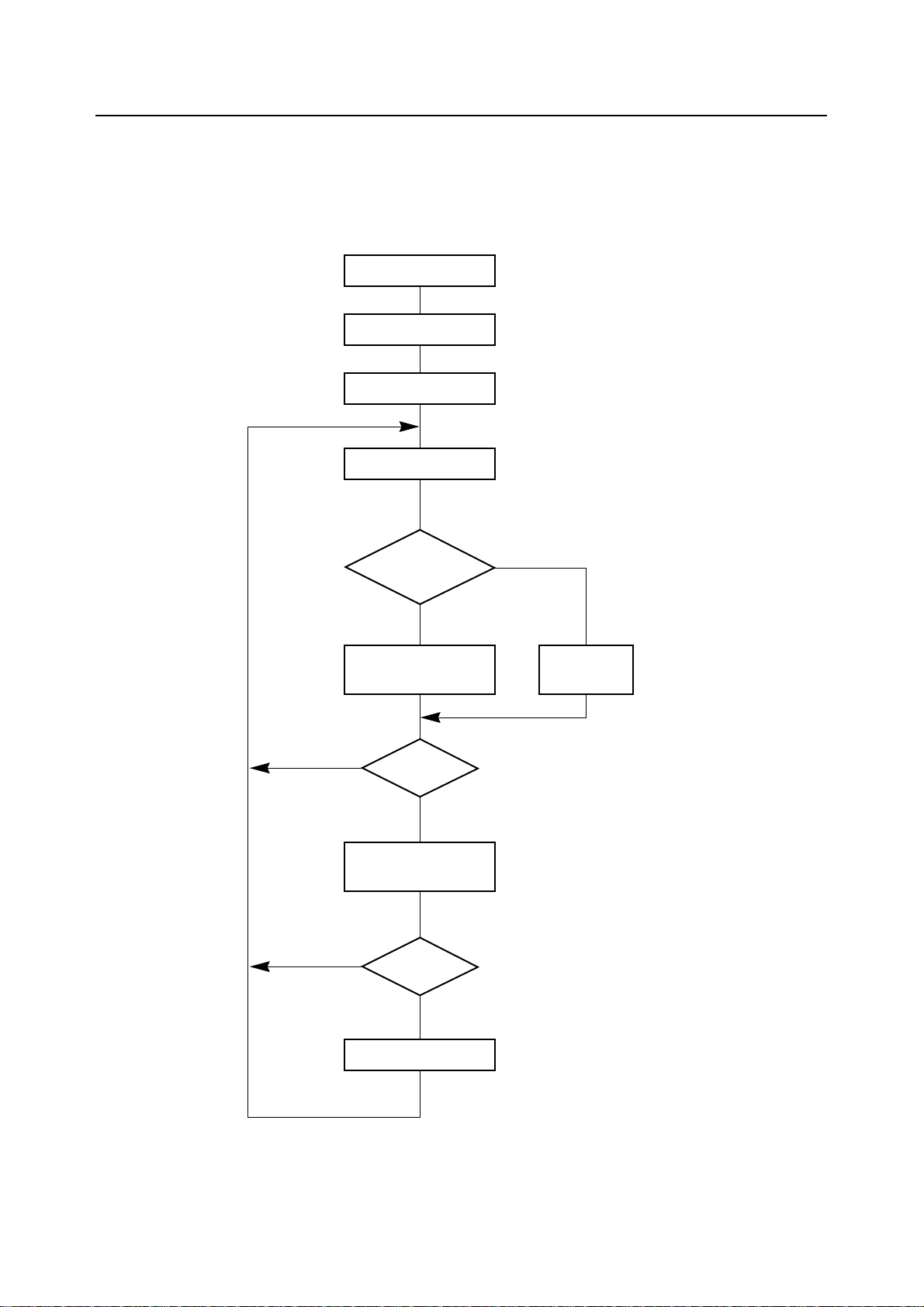

2. General Flow Chart (Main Logic Board)

The flow chart below shows you the general flow of editing and printing operations.

POWER ON

Initialization

Ready state

Read data

Control code

NO

Data processing

NO

Control

code?

YES

processing

Print?

YES

or printing

Return?

YES

No

Data

storage

(Line buffer determination)

(Print out of data)

Return action

Fig. 2-2 General Flow Chart of Editing and Printing

– 22 –

Page 27

THEORY OF OPERATION

3. Power Supply Circuit

A ringing choke converter type circuit is used with a dropper type circuit in the power supply unit, fulfilling the input and

output conditions described in the chart below.

Voltage Range Max. Current Output Service Circuit Type

Input

Output

120VAC 1.0 A

220Vto 240VAC 0.6 A

5 VDC ±5% 0.3A Dropper

For logic circuit

drive, for motor

holding.

33 VDC ±5% (LC-4511) 3.2A(LC-4511) Ringing choke

40 VDC ±5% (LC-4521) 4.4A (LC-4521) converter.

For print head

drive, for motor

drive.

Input

120VAC

220VAC

230VAC

240VAC

Noise filter

circuit

Switching

section

(Transistor Q1)

Control

circuit

In rush current

protection

circuit

Transformer T1

PC1

Photo-Coupler

Rectifier

circuit

Ringing

choke

converter

Dropper

circuit

Voltage

reference

Fig. 2-3 Power Supply unit block diagram

Out put

33V DC ; LC-4511

40V DC ; LC-4521

Out put

5V DC

– 23 –

Page 28

THEORY OF OPERATION

4. Mechanism

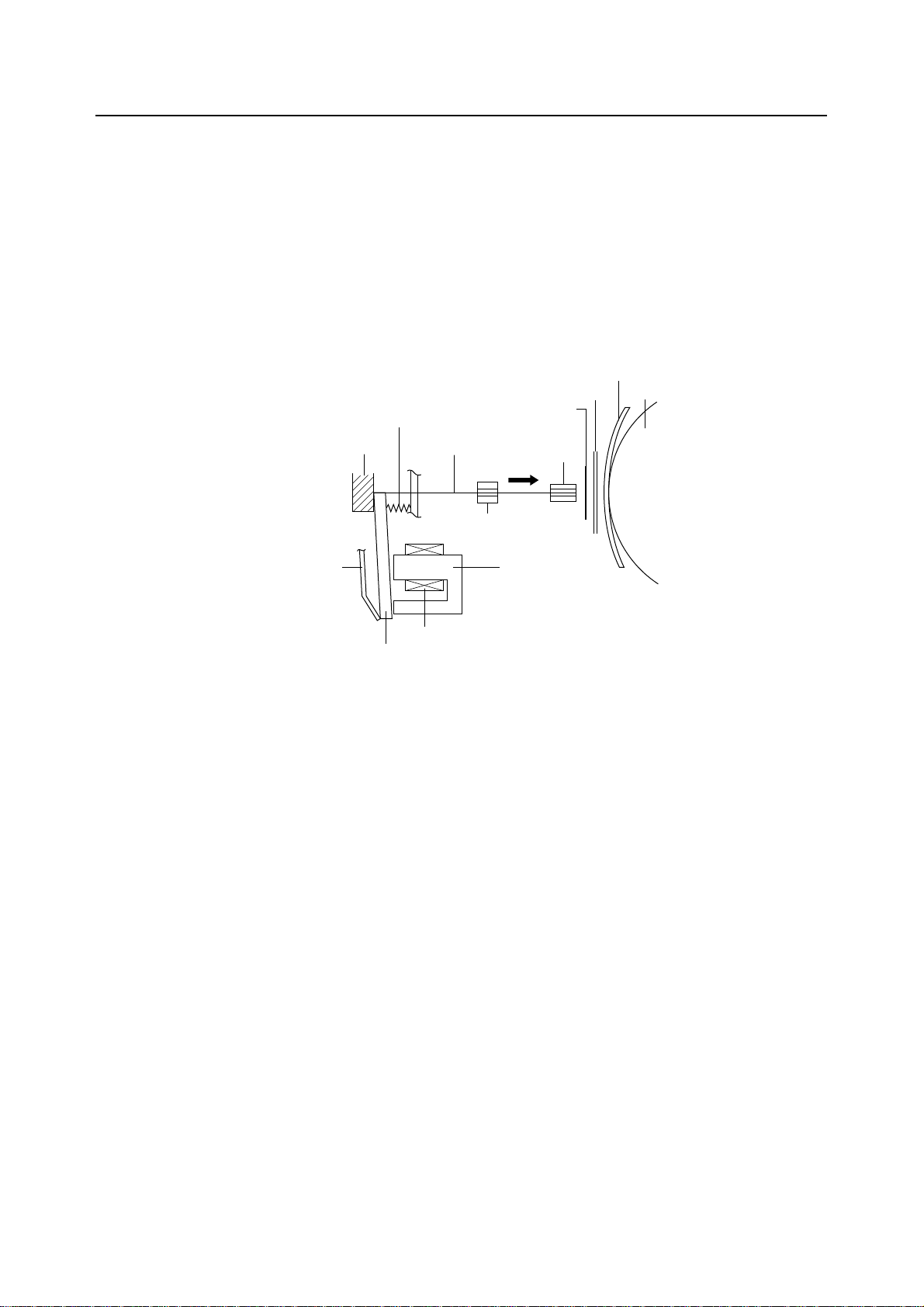

4-1. Print Head Mechanism

The print head consists of 24 needle wires and 24 print solenoids. The following explains how each needle wire

operates during printing.

(1) When the print solenoid is energized, the clapper is attracted by the iron core and the needle wire is driven toward

the platen.

(2) This needle wire hits the platen via the ink ribbon and paper. A single dot is printed on the paper.

(3) When the print solenoid is de-energized, the needle wire is returned to its original position by rebound energy and

spring and clapper holder (leaf spring) force.

Paper

Platen

Spring

Paper guide

Ink ribbon

Clapper holder

Stopper

Clapper

Needle wire

Print solenoid

Guide

Subguide

Iron core

Fig. 2-4 Outline of Print Head Mechanism

– 24 –

Page 29

THEORY OF OPERATION

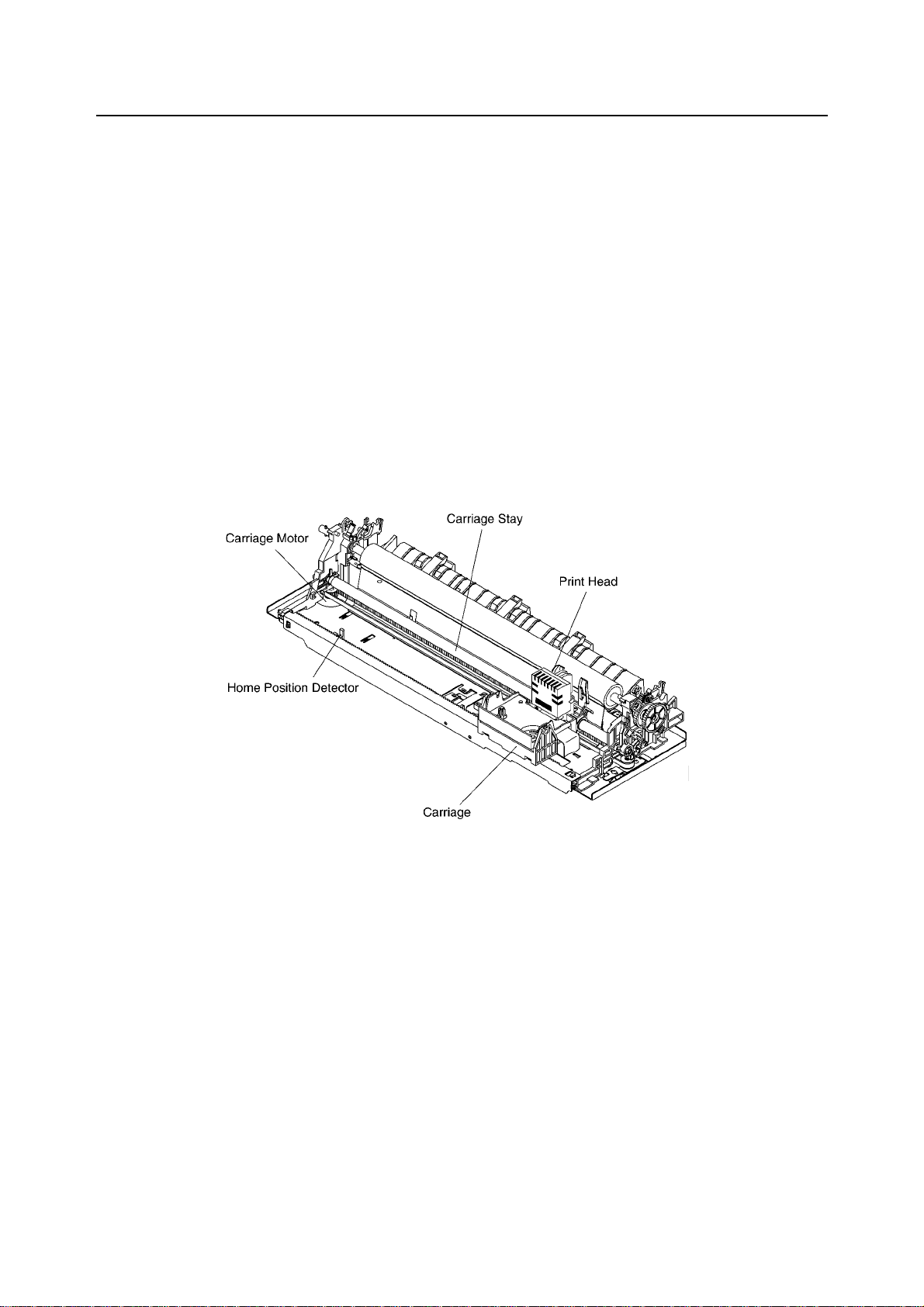

4-2. Print Head Carrying Mechanism

The print head carrying mechanism consists of a carriage, timing belt, carriage motor, and home position detector.

Carriage

The carriage is supported horizontally by the carriage stay and rear angle. The carriage moves from side to side with

the print head mounted above it. A timing belt is clamped to the base of the carriage and a shield plate is mounted

at the base for home position detection.

Timing Belt

The timing belt is suspended between the timing pulley of the carriage motor and the timing pulley of the tension

lever. The timing belt maintains a constant tension.

The timing belt is also clamped to the base of the carriage so that it can move the carriage accurately with driving

force from the carriage motor.

Carriage Motor

The carriage motor is a PM (permanent magnet) 4-phase, 48-pole pulse motor driven by pulse signals from the

control circuit. The rotational rate depends on the number of pulses per unit time. By varying this rotational rate

(carriage carrying rate), the size of the horizontal letters can be changed in each print mode.

Fig. 2-5 Print Head Carrying Mechanism

– 25 –

Page 30

THEORY OF OPERATION

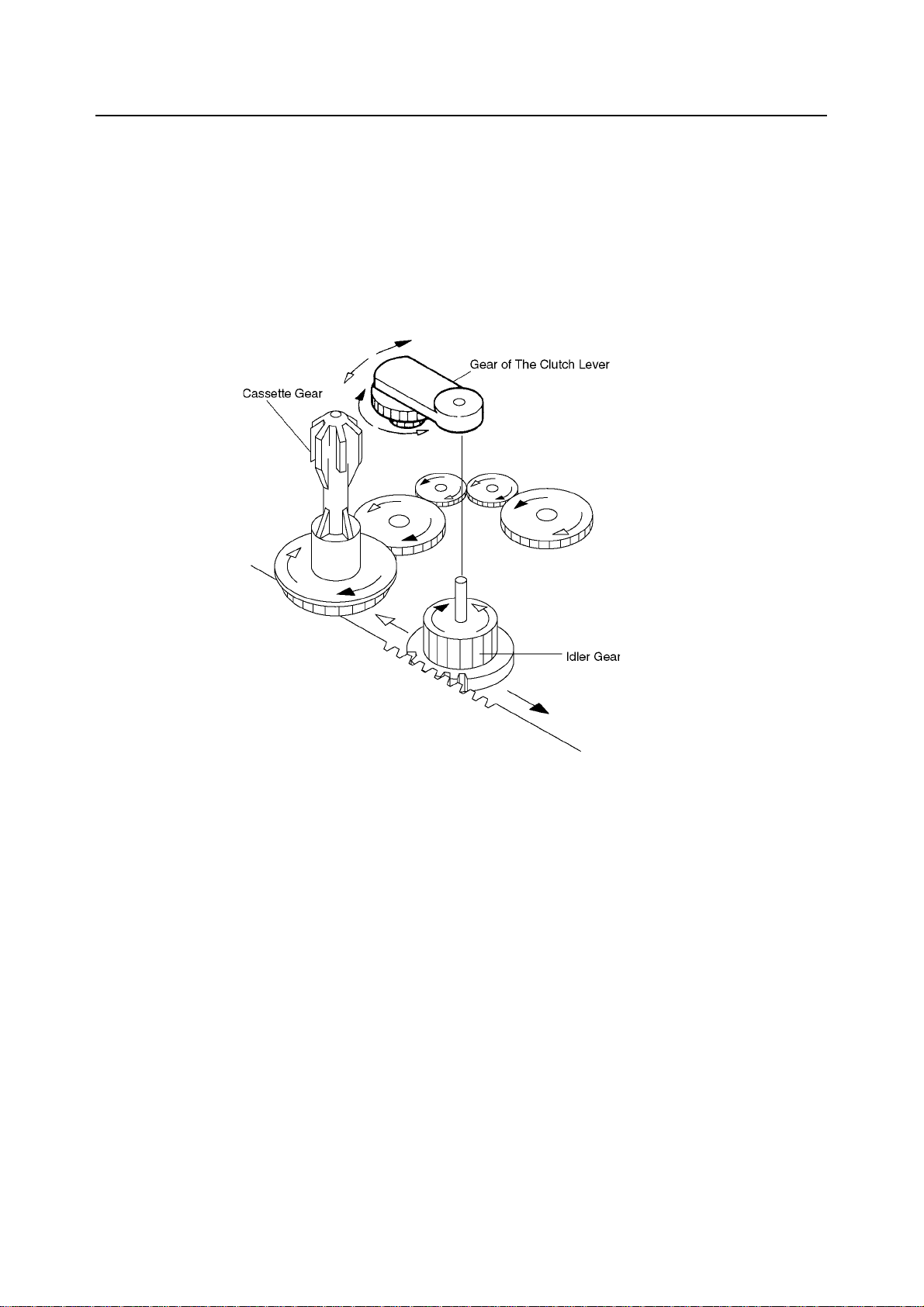

4-3. Ink ribbon feed mechanism

The ink ribbon feed mechanism is linked to the print head carrying mechanism so the ink ribbon always winds

automatically in the same direction while the carriage moves left and right.

The movement of the carriage along the serrated edge of the rear angle of the printer mechanism drives the idler gear. The

rotation of the idler gear is conveyed sequentially to the gears that work and wind the ribbon. The carriage has a clutch

lever that keeps the direction of the cassette gear rotation constant, regardless of the direction of the idler gear rotation

as the carriage moves left and right.

Fig. 2-6 Ribbon feed mechanism

– 26 –

Page 31

THEORY OF OPERATION

4-4. Paper Feed Mechanism

The paper feed mechanism consists of a paper feed motor, an idler gear, a platen and a traction unit.

The paper feed motor is a PM (Permanent Magnet) 4-phase and 48 pulse motor.

There are two ways of feeding paper into the printer: the friction method and the tractor method. You can select the

method you want to use by setting the release lever on the push tractor unit.

Position of release lever [1] [2]

Linkage between tractor gear

and PF idler gear

Platen roller and Pinch roller Pressed Not

Release lever position detector OFF ON

Paper feeding method Friction Tractor

(1) Friction Method

Friction method is selected when the release lever is position [1].

With this method, paper is pressed between the Platen roller and the Pinch roller therefore, paper is fed as the rollers

turn.

As the paper feed motor is driven, the motor gear, through the idler gear, turns the platen gear in the paper feeding

direction. However, since the tractor gear and the PF idler gear are not linked at this time, the tractor unit will not

be driven.

(2) Tractor Method

Tractor method is selected when the release lever is position [2].

Paper feeding is facilitated by rotation of the sprocket pin of the tractor unit. When the tractor method is selected,

the tractor gear is linked to the PF idler gear, enabling the drive force generated by the paper feed motor to be

transferred to the tractor unit via the idler gear.

Not linked Linked

Fig. 2-7 Paper Feed Mechanism

– 27 –

Page 32

THEORY OF OPERATION

4-5. Detectors

(1) Print head temperature detectors

The A/D converter in the CPU detects the print head temperature at power on and before each line begins to print.

+5V +5V

Thermistor

V

REF

L1

AN1

R1

CPU

Fig. 2-8 Printer head temperature detector circuit

Control Method (by Text printing)

Print Temperature °C (± 8°C)

(LC-4511) (LC-4521)

Normal print ~ 130 ~ 120

Unidirectional print 130 ~ 135 120 ~ 130

Print Stop Over 135 Over 130

L2

R2

(2) Home Position Detector

A photo-interrupter is used in the home detector on the printer.

ON/OFF signals are generated according to the position of the carriage. (Shield plate mounted at the base of the

carriage.) The printing position is determined by these signals.

+5V

R2

Detecting

signal

+5V

C1

R1

R3

Fig. 2-9 Carriage home position detector circuit

Output (V) Decision

5 in home position (with shield plate)

0 not in home position (without shield plate)

– 28 –

Page 33

THEORY OF OPERATION

(3) Paper end Detector

The paper end Detector is located in the paper chute unit. The A/D converter in the CPU detects the presence or

absence of paper.

(4) Release lever switch

CPU

+5V

+5V

R2

C1

R1

R3

VRef

AN

Fig. 2-10 Paper end detector circuit

Paper

Detecting

signal

+5V

R2

R1

Leaf switch

Fig. 2-11 Release lever switch circuit

Control Method

Output

(V)

Release

Lever SW

0 Tractor

5 Friction

– 29 –

Page 34

Page 35

CHAPTER 3

ADJUSTMENTS

This printer has undergone various adjustments so that it will attain a given standard of performance.

In this chapter, a brief explanation is given of the methods for making adjustments.

Follow the instructions when performing maintenance inspections or when replacing parts to correct

malfunctions.

1. Adjustment of Gap Between Print Head and Platen ........................................33

2. Adjustment of Timing Belt Tension...................................................................34

3. Adjustment of Paper end detector.....................................................................35

3

Page 36

Page 37

ADJUSTMENTS

1. Adjustment of Gap Between Print Head and Platen

(1) Remove the Printer cover and ribbon holder [1].

(2) Loosen nut [3] using jig [2].

(3) Adjust the head gap at the specified left and right positions (two places).

* Adjust by moving jig [5] forward or backward.

* Use bushing [4] to adjust the gap on the left side until it equals that on the right side.

Gap adjustment values : 0.30 to 0.35mm

Be sure to adjust with the rear cover installed. (Adjustment with rear cover off will increase the gap by about 0.1mm.)

(4) Hold jig [5] in place and push jig [2] toward the rear so as to tighten nut [3].

(5) Confirm that the setting is correct.

Fig. 3-1 Mechanism

55mm 55mmPlaten [6]

Platen [6]

LR

Carriage [7]

Fig. 3-2 Positioning the carriage unit

gauge [8]

Head gap

0.30~0.35mm

Fig. 3-3 Gap measurement

– 33 –

Page 38

ADJUSTMENTS

2. Adjustment of Timing Belt Tension

(1) Remove the upper case unit according to the procedures described in chapter 4.

(2) Loosen screw [1].

(3) Move the carriage [2] once from left to right, then return it to the left.

(4) Set the tension gauge [3] to the position indicated in Fig. 3-5 below.

(5) Using a regular screwdriver, move tension lever [4] to the right until it matches the minimum tension setting

(23.0 if LC-4511; 28.0 if LC-4521).

(6) Tighten screw [1].

(7) Confirm that the setting is correct.

(8) Remove tension gauge [3]. Move the carriage [2] all the way to the right and then back to the left, and check the

setting once again.

Fig. 3-4 Gap measurement

Platen

Gauge lever

position

Timing belt

0~10mm

Fig. 3-5 Positioning the carriage unit Fig. 3-6 Measuring tension

– 34 –

Page 39

ADJUSTMENTS

3. Adjustment of Paper end detector

After replacing the paper-end detector, adjust the new detector as described here. First enter the dedicated command, then

flow chart below.

Dedicated command: <ESC> <SUB> (50)H n Automatic Sheet Feeder; n=01

Tractor and Friction ; n=01

LPRIN CHR$(27);CHR$(26);

Send

CHR$(&H50);CHR$(01)

command

n = 01 ?

Yes

Tractor or Friction ?

Friction

Paper eject

Paper out?

Yes

No

Tractor

No

Tractor or Friction ?

Friction

Tractor

Paper Park

E

Paper out?

Yes

No

E

Paper eject

Paper out?

Yes

No

E

Enter paper-out value (A)

Loading cut-sheet paper

Paper in?

Yes

A

No

Enter paper-out value (A)

Loading fanfold paper

E

Paper in?

Yes

B

No

Enter paper-out value (A)

No

Press paper feed switch

E

Loading cut-sheet paper

Yes

C

– 35 –

Page 40

ADJUSTMENTS

A

Enter paper-in value (B)

Find average (center value) of

(A) and (B)

B

C

Paper in?

Yes

No

E

Nomal range?

YES

Print the new Paper end

detector A/D value

** PAPER END SENSOR : **

Register the new Paper end

detector A/D value (1 beep)

Fanfold paper: From feed

Cut-sheet paper: Eject paper

No

E

Adjustment error / New value

not recorded (3 beeps)

– 36 –

Page 41

CHAPTER 4

PARTS REPLACEMENT

This chapter explains disassembly and reassembly of the printer. Note the following regarding disassembly

and reassembly.

1. Disconnect the printer from the wall outlet before servicing it.

2. Assy is the reverse of disassembly unless otherwise specified.

3. After reassembly, coat the screw heads with locking sealant.

4. Lubrication information is not provided in this chapter. Refer to section 2 in chapter 5.

1. Push Tractor Unit ................................................................................................39

2. Upper Case Unit ..................................................................................................39

3. Printer Machanism ..............................................................................................40

4. Main Logic Board Unit ........................................................................................40

4

5. Power Supply Unit...............................................................................................41

6. Fuse ......................................................................................................................41

7. Print Head ............................................................................................................42

8. Carriage Motor Unit.............................................................................................43

9. Platen Unit............................................................................................................43

10. Detector Unit........................................................................................................44

Page 42

Page 43

1. Push Tractor Unit

PARTS REPLACEMENT

(1) Turn OFF the power switch.

(2) Remove the power cord from the AC output socket.

(3) Remove

• Printer cover

• Rear cover unit [1]

• Push tractor unit [2]

Set the release lever [3] to FRICTION.

Lift the hook [4] at each side of the push tractor.

2. Upper Case Unit

(1) Remove

• Push tractor unit as described above1.

• Platen knob unit [1]

• Four screws [2]

(2) Move the carriage unit to the right.

(3) Remove

• Upper case unit [3]

Pull the upper case unit [3] forward and remove it

from the hooks [4].

• Control board [5]

Detach the two hooks.

Caution regarding assembly;

• When carrying out reassembly, pay due attention to

the upper case unit’s internal sheet and the mechanism’s detector.

– 39 –

Page 44

PARTS REPLACEMENT

3. Printer Machanism

(1) Remove

• Upper case unit as described above 2.

(2) Move the carriage unit to the left.

(3) Remove

• Cable holder [1]

• Two head cable [2]

• Six screws [3]

• Two screws [4]

• Printer mechanism [5]

Remove the connectors from the main logic board.

Caution regarding assembly;

• Cross CN5 over when

connecting.

CN8

• Attach the head cable [2]

as illustrated at right.

Cross over

CN5

4. Main Logic Board Unit

Slide into position.

(1) Remove

• Printer mechanism as described above 3

• Connector [1]

• Four screws [2]

• Home position board [3]

• Main logic board unit [4]

Caution regarding assembly;

• Be sure that the height and angle of the main-logic-

board transistors (TR13,14, 15, 16) and the controlboard LEDs are within the limits indicated below.

(LED angle)

<

θ ±10°

=

(Height for TR13,14,15,16)

12.5mm max.

Main logic board

1.3mm max.

Control board

θ

– 40 –

• Be sure that the ground spring at the rear of the main

logic board has a height of at least 7.3mm.

7.3mm

Ground spring

Page 45

5. Power Supply Unit

PARTS REPLACEMENT

(1) Remove

• Upper case unit as described above 2.

• Three screws [1]

• Screw [2]

• Power supply unit [3]

6. Fuse

(1) Remove

• Upper case unit as described above 2.

(2) Inspect

• Fuse F1

Defective → Replace fuse as follows:

AC voltage Fose Type

120V 5TT2A-125V

220V to 240V 215-2.5A-250V

– 41 –

Page 46

PARTS REPLACEMENT

7. Print Head

(1) Remove

• Top guide unit [1]

• Colour ribbon holder assy [2]

• Cable holder [3]

• Ribbon holder [4]

• Two screws [5]

• Print head [6]

WARNING

The print head gets hot after printing.

Do not touch it until it cools.

(2) Adjust

• Gap between print head and platen. Refer to

section 1 of Chapter 3.

Note:

Fold the head cables according to the dimensions shown below.

°

5

.

0

°

0

9

76 1

Size : mm

9 1

( Cable S ) ( Cable L )

84 1

0

°

0

9

Size : mm

°

5

.

9 1

– 42 –

Page 47

8. Carriage Motor Unit

PARTS REPLACEMENT

(1) Remove

• Printer mechanism as descrbed above 3.

(2) Loosen the screw [1].

(3) Remove

• Two screws [2]

• Carriage motor unit [3]

(4) Adjust

For details about belt-tension adjustment, refer to

section 2 of Chapter 3.

9. Platen Unit

(1) Remove

• Upper case unit as described above 2.

• Top guide unit [1]

• Stack guide unit [2]

The stack guide unit may break if it is forcibly removed. Therefore, hold the gears tightly when removing the stack guide unit.

• Spring [8]

• Idler gear [3]

• PF idler gear [4]

• Spring [5]

• Stop ring [6]

• Platen unit [7]

Move the platen holder as shown in the diagram below

and remove the platen unit.

Platen Holder

– 43 –

Fig.a

Fig.b

Page 48

PARTS REPLACEMENT

10. Detector Unit

(1) Remove

• Platen unit as described above 9.

(2) Turn over the printer mechanism.

(3) Remove

• Paper chute unit [1]

Remove the nine paper sheet hooks [3] on the bottom

of the frame base assembly [2] and remove the Paper

chute unit [1].

• Detector unit [4]

– 44 –

Page 49

CHAPTER 5

MAINTENANCE AND LUBRICATION

1. Maintenance.........................................................................................................47

1-1. Cleaning ................................................................................................................ 47

1-2. Checks................................................................................................................... 47

2. Lubrication...........................................................................................................48

2-1. Lubricant ............................................................................................................... 48

2-2. Lubricating Method .............................................................................................. 48

2-3. Lubricated Areas .................................................................................................. 48

5

Page 50

Page 51

MAINTENANCE AND LUBRICATION

1. Maintenance

In order to maintain the optimum performance of this printer and to prevent trouble, maintenance must be carried out

according to the following items.

1-1. Cleaning

(1) Removal of dirt

Wipe off dirt with a soft cloth soaked in alcohol or benzine.

Note: Do not use thinner, trichlene or ketone solvents because they may damage plastic parts. Also during

cleaning, be careful not to moisten or damage electronic parts, wiring, or mechanical parts.

(2) Removal of dust, pile, etc.

Vacuum cleaning (with an electric cleaner) is preferred. Remove all dust, etc., inside the printer.

Note: After cleaning, check the oil level. If it is not adequate due to cleaning, replenish it.

1-2. Checks

Checks must be carried out at two levels: a “daily check” which the operator can easily carry out during operation, and

a “periodic check” which an expert should carry out.

(1) Daily check

When the printer is used on a daily basis, check that the printer is used properly. Make sure that the printer is

operating under the best conditions.

• Is any paper stuck in the paper box or printer case?

• Is the cartridge ribbon set at the right position?

• Is there any foreign matter inside the printer? (Remove if any.)

• Is the print head getting excessively dirty?

(2) Periodic check

After 6 months or printing 1 million lines, the periodic check and lubrication must be carried out.

• Check for deformation of springs.

• Check the gap between the platen and the print head.

• Remove dust, dirt, etc., around the detectors.

– 47 –

Page 52

MAINTENANCE AND LUBRICATION

2. Lubrication

Lubrication is very important to maintain optimum performance and to prevent trouble.

2-1. Lubricant

The type of lubricant greatly affects the performance and durability of the printer, especially in a low temperature

environment. We recommend use of the grease and lubrication oils listed below for this printer

Type of oil Product name Maker

Grease MOLYKOTE EM-30L DOW CORNING ASIA LTD

Lubricant Mobil 1 Mobil oil

Silicone oil KF96-1000CS Shin Etsu Chemicals Industry Co, LTD

2-2. Lubricating Method

When lubrication is carried out in assembly and disassembly, wash parts well to remove dust and dirt before lubrication.

Lubrication must be carried out regularly once every 6 months or after 1 million lines have been printed. Lubrication is

necessary irrespective of the regular lubrication whenever lubricant becomes deficient after cleaning or whenever parts

have been disassembled or replaced.

2-3. Lubricated Areas

NO. LubricationProduct Name

[1] Rubbing surfaces of Felt Mobil 1

[2] Rubbing surfaces of Frame R and Adjusting lever EM-30L

[3] Rubbing surfaces of Platen and Platen spping EM-30L

[4] Rubbing surfaces of Frame R, L and Stack guide EM-30L

[5] Rubbing surfaces of Carriage unit and Color ribbon holder EM-30L

[6] Rubbing surfaces of Carrige stay Mobil 1

[7] Rubbing surfaces of Pully shaft and Pully EM-30L

[8] Rubbing surfaces of Frame R and RF idler gear EM-30L

[9] Rubbing surfaces of Tractor shaft EM-30L

[10] Rubbing surfaces of Release lever and Tractor frame L EM-30L

[11] Rubbing surfaces of Roller shaft EM-30L

[12] Rubbing surfaces of Shaft EM-30L

[13] Rubbing surfaces of Ribbon shaft lever KF96-1000CS

[14] Rubbing surfaces of Gear EM-30L

[15] Rubbing surfaces of Shift cam EM-30L

[16] Rubbing surfaces of back of Gear cover EM-30L

[17] Rubbing surfaces of PF idler gear and shaft of Tractor Fram R EM-30L

[18] Rubbing surfaces of Tactor shaft EM-30L

[19] Rubbing surfaces of Feed roller shaft and Fram L, R EM-30L

– 48 –

Page 53

MAINTENANCE AND LUBRICATION

Fig. 5-1 Lubricated Areas (printer mechanism)

– 49 –

Page 54

MAINTENANCE AND LUBRICATION

Fig. 5-2 Lubricated Areas (Frame R unit)

Fig. 5-3 Lubricated Areas (push tractor unit)

– 50 –

Page 55

(LC-4511)

MAINTENANCE AND LUBRICATION

(LC-4521)

(Shift cum) (Back side of gear cover)

Fig. 5-4 Lubricated Areas (Carriage unit)

– 51 –

Page 56

MAINTENANCE AND LUBRICATION

Fig. 5-5 Lubricated Areas (Pull tractor unit)

Fig. 5-6 Lubricated Areas (ASF)

– 52 –

Page 57

CHAPTER 6

TROUBLESHOOTING

1. Troubleshooting Procedures .............................................................................55

2. Unit Replacement Priority Chart ........................................................................56

3. Repair by Unit Replacement...............................................................................57

4. Repair by Parts Replacement.............................................................................63

4-1. Does not Operate at All with Power on............................................................... 63

4-2. Power Supply Circuit Abnormal.......................................................................... 64

4-3. Defective Motor Operation................................................................................... 65

4-4. Defective Print Head Operation........................................................................... 66

4-5. Defective Interface Operation.............................................................................. 67

6

Page 58

Page 59

TROUBLESHOOTING

1. Troubleshooting Procedures

Troubleshooting is never easy because various problems arise depending upon the particular location of the breakdown.

The following procedures should be taken in making repairs.

(1) The first method is to make repairs through unit replacements. The two display codes appearing in the flow chart

are defined as follows: 1) indicates main logic board replacement; and 2) indicates printer mechanism replacement,

to be carried out if the problem has not been corrected.

1) Main Logic Board Replacement

2) Printer Mechanism Replacement

Check again at this time whether the replaced unit is malfunctioning. (This is done to rule out trouble caused by improper

contact of connectors.)

Replaceable units consist of the following:

• Power supply unit

• Main logic board

• Printer mechanism

• Control panel board

In replacing these units, always refer to the unit replacement priority chart.

(2) The second method is to make repairs by parts replacement to replace defective elements inside a particular unit.

(Note 1) Before starting to repair, be sure to check visually the contact of the connector and the mounting of the IC in

the IC socket.

(Note 2) Always turn off power source and remove power plug before replacing any units or parts.

(Note 3) All check items shown in the flow chart must be checked. Otherwise, newly mounted parts or units may become

damaged.

(Note 4) If, in the process of making repairs, there is any confusion about proper procedures, restart the job from the

beginning.

(Note 5) Be careful to avoid injury from static electricity when handling ICs and main logic board.

– 55 –

Page 60

TROUBLESHOOTING

2. Unit Replacement Priority Chart

Category Remarks

Operation related

Motor related

related

Print head

related

Detector

Problem

Details

Specific display

lamp only will

not glow

Specific switch

only cannot be

input

Buzzer does not

sound (sound

volume

inadequate)

Strange sounds

during operation

No motor

holding power

(power very

weak)

Dots skipped

Print is too light

Ink ribbon

entanglement

(wire sticks out)

Absence of paper

not detected

Lever position

not detected

Incorrect printing

Ink ribbon not

forwarded

No operation at

EDS setting

Power

supply unit

2

Unit Exchange Sequence

Main

logic board

2

2

1

1

1

2

2

2

2

1

1

1

Printer

mechanism

2

2

1

1

1

1

2

1

Control

panel board

1

1

Replace ink ribbon

Check I/F cable

Faulty operation

when power is

turned on/off

Abnormal motor

operating speed

(slow)

Interface related and others

Fuse blown

during operation

Error detection of

head temperature

Carriage motor

error

Paper handling

error

Error indication

EE-PROM &

RAM error

Watch dog timer

error

Note: The figures 1, 2 and 3 mean the priority of replacement.

3

1

1

1

2

2

2

1

1

– 56 –

2

2

1

1

1

“DRAFT” lamp blink

“ROMAN” lamp blink

“COURIER” lamp blink

“10CPI” lamp blink

“COND” lamp blink

Page 61

3. Repair by Unit Replacement

START

* Turn power off.

* Remove I/F cable.

* Mount ink ribbon.

* Set paper.

* Move carriage to center.

Turn power on.

TROUBLESHOOTING

A

Carriage

Moves?

YES

Carriage operates

normally?

YES

Carriage

stops at home

position?

(left side)

NO

NO

NO

B

Carriage motor

operating waveform is

normal? *1

YES

Replace printer mechanism.

A

*1 See (8) and (9) waveform in

item 7 of Chapter 7.

NO

1) Replace main logic

board.

2) Replace printer

mechanism.

YES

1

Home position

switch signal is

normal?

YES

Replace main logic board.

A

NO

1) Replace main logic

board.

2) Replace printer

mechanism.

– 57 –

Page 62

TROUBLESHOOTING

1

On line lamp light?

YES

Press on line switch to take

off line.

On line lamp is out?

YES

Press paper feed switch.

Paper feed switch

operation is normal?

YES

Turn power off.

NO

NO

NO

On line lamp

signal is normal?

YES

Replace control panel board.

A

E

Paper feed

motor drive waveform

is normal? *2

YES

NO

Replace main logic board.

*2 See (10),(11) and (12),(13)wave-

form in item 7 of Chapter 7.

NO

1) Replace main logic board.

2) Replace printer mechanism.

Holding paper feed switch,

turn power on.

Carriage operates

normally?

YES

2

Self

printing:

NO

Replace printer mechanism.

A

Carriage motor

drive waveform is

normal? *1

YES

Replace printer mechanism.

A

*1 See (8) and (9) waveform in

item7 of Chapter 7.

NO

1) Replace main logic board.

2) Replace printer mechanism.

– 58 –

Page 63

TROUBLESHOOTING

2

Printing operation

is normal?

YES

Paper feed

operation is

normal?

YES

Ribbon feed

operation is

normal?

NO

NO

NO

Print head

drive signal waveform is

normal? *3

YES

Replace printer mechanism.

A

motor drive waveform is

*3 See (4),(5) and (6),(7) wave-

form in item 7 of Chapter 7.

NO

1) Replace main logic board.

2) Replace printer mechanism.

*2 See (10),(11) and (12),(13) wave-

form in item 7 of Chapter 7.

Paper feed

NO

normal? *2

YES

NO

1) Replace main logic board.

2) Replace printer mechanism.

YES

Terminates self printing.

Check host computer

connection.

Turn power off and check

I/F cable.

Turn power on.

Send print program from host

computer.

3

1) Replace ink ribbon.

2) Replace printer mechanism.

A

Replace printer mechanism.

A

C

– 59 –

Page 64

TROUBLESHOOTING

3

Printing begins?

YES

Printing

operation normal?

YES

Stop print program.

END

B

Carriage moves

with hand?

YES

NO

NO

NO

D

1) Replace I/F cable.

2) Replace main logic board.

3) Check host computer.

C

Replace printer mechanism.

Output

(+33/40V, +5V)

of power supply unit is

normal? *4

NO

Turn power off.

Fuse blows out?

YES

Replace fuse.

Remove connector CN11

from main logic board

Turn power on.

YES

NO

1) Replace main logic board.

2) Replace printer mechanism.

3) Replace control panel

board.

Replace power supply unit.

*4 Power Supply Unit

LC-4511 +33V Line +33V ± 5%

LC-4521 +40V Line +40V ± 5%

+5V Line +5V ± 5% Between Pin 1 and Pin 2 of CN1

A

Between Pin 4 and Pin 5 of CN1

4

– 60 –

Page 65

TROUBLESHOOTING

4

Output of

power supply unit is

normal? *4

YES

Turn power off.

Connect connector CN11

from main logic board

Turn power on.

Fuse blows out?

YES

Replace fuse.

1) Replace main logic board.

2) Replace printer mechanism.

3) Replace control panel board.

NO

Replace power supply unit.

NO

A

*4 Power Supply Unit

LC-4511 +33V Line +33V ± 5%

LC-4521 +40V Line +40V ± 5%

+5V Line +5V ± 5% Between Pin 1 and Pin 2 of CN1

Between Pin 4 and Pin 5 of CN1

– 61 –

Page 66

TROUBLESHOOTING

D

*5 See (14) waveform in

item 7 of Chapter 7.

I/F signal is

normal? *5

NO

Ready condition?

YES

There is data

transmission?

NO

Check hardware or host

computer print program.

C

YES

NO

YES

I/F mode set

up properly?

NO

Change I/F mode.

YES

1) Replace I/F cable.

2) I/F cartridge

3) Replace main logic board.

A

E

On line switch

goes ON/OFF?

YES

On line lamp

drive signal is

normal?

YES

Replace control panel board.

A

NO

NO

Replace main logic board.

1) Replace control panel board.

2) Replace main logic board.

– 62 –

Page 67

4. Repair by Parts Replacement

4-1. Does not Operate at All with Power on

START

TROUBLESHOOTING

+33/40V, +5V

are

supplied? *1

YES

RESET

signal becomes

HIGH? *2

YES

Crystal

waveform is

normal? *3

YES

ROM OE

signals become

LOW?

YES

Carriage motor abnormal.

NO

NO

NO

NO

DC Power abnormal.

Check RESET circuit;

replace parts.

Check crystal circuit;

replace parts.

1) Replace CPU or ROM.

2) Check relevant circuit.

See 4-2. Power Supply

Circuit Abnormal.

Check operation.

END

*2 See (2) waveform in item 7 of Chapter 7.

*3 See (1) waveform in item 7 of Chapter 7.

*1 Power Supply Unit

LC-4511 +33V Line +33V ± 5%

LC-4521 +40V Line +40V ± 5%

+5V Line +5V ± 5% Between Pin 1 and Pin 2 of CN1

Between Pin 4 and Pin 5 of CN1

– 63 –

Page 68

TROUBLESHOOTING

4-2. Power Supply Circuit Abnormal

(1) Remove connector CN101 from power supply unit.

START

Fuse F1

is blown?

NO

YES

Replace Fuse F1

Fuse is

blown again?

NO

The no load voltages are below;

LC-4511 +33V Line +33V ± 5%

LC-4521 +40V Line +40V ± 5%

+5V Line +5V ± 5% Between Pin 1 and Pin 2 of CN1

YES

Replace

1) Power supply unit

Between Pin 4 and Pin 5 of CN1

Check the 5V line of the

main logic board.

END

– 64 –

Page 69

4-3. Defective Motor Operation

TROUBLESHOOTING

START

LF-CMN

signal is normal?

*4

YES

LF-ø1,

ø2, ø3, ø4 are

normal? *5

YES

Paper Feed Motor Carriage Motor

NO

Check and replace

1) TA7

2) TR19

3) Gate array

NO

Check and replace

1) TA7

2) CPU

START

CR-ø1,

ø2, ø3, ø4 are

normal? *6

YES

Replace

CR motor

Check operation

END

NO

Check and replace

1) TA 8

2) Gate array

Replace

LF motor

Check operation

END

*4 See (10) and (11) waveform in item 7 of Chapter 7.

*5 See (12) and (13) waveform in item 7 of Chapter 7.

*6 See (8) and (9) waveform in item 7 of Chapter 7.

– 65 –

Page 70

TROUBLESHOOTING

4-4. Defective Print Head Operation

START

Does not

print at all?

+33/40V line

is supplied?

Check and replace

1) TR12 ~ TR16

2) Gate array

Head

energizing control

signal is normal?

*7

YES

YES

YES

NO

NO

Check and replace

1) Power supply unit

(Refer to item 4-2.)

NO

Check and replace

1) Gate array

2) CPU

A specific

pin does not

work?

NO

Print is light

as whole?

NO

YES

Check and replace

• TA1 (HD1, 2, 3, 4)

• TA2 (HD5, 6, 7, 8)

• TA3 (HD9, 10, 11, 12)

• TA4 (HD13, 14, 15, 16)

• TA5 (HD17, 18, 19, 20)

• TA6 (HD21, 22,23, 24)

YES

Adjust gap

(Refer to Chapter 3.)

Check and replace

1) Print head

END

*7 See (4) and (5) waveform in item 7 of

Chapter 7.

– 66 –

Page 71

4-5. Defective Interface Operation

START

Press on line switch to

take on line.

Send print program

from host computer.

Is I/F

signal normal? *8

YES

NO

TROUBLESHOOTING

*8 See (14) waveform in

item 7 of Chapter 7.

Incorrect print

generated?

NO

Check operation

END

YES

Check I/F cable.

Check and replace

1) IC 7

2) Gate array

3) CPU

– 67 –

Page 72

Page 73

CHAPTER 7

¤

¤

PARTS LIST

HOW TO USE PARTS LIST

(1) DRWG. NO.

This column shows the drawing number of the illustration.

(2) REVISED EDITION MARK

This column shows a revision number.

Part that have been added in the revised edition are indicated with "#".

Part that have been abolished in the revised edition are indicated with "*".

#1:First edition

(3) PARTS NO.

Parts numbers must be notified when ordering replacement parts. Parts described as “NPN” have no parts number and are not

in stock, i.e., unavailable.

(4) PARTS NAME

Parts names must be notified when ordering replacement parts.

(5) Q’TY

This column shows the number of the part used as indicated in the figure.

(6) REMARKS

Where differences in specifications exist depending on location/destination.

(7) RANK

Parts marked “S” are service parts. Service parts are recommended to be in stock for maintenance.

Second edition *1:First edition

Second edition

1. Printer Assembly ...................................................... 70

1-1. Disassembly Drawing ...................................... 70

1-2. Parts List........................................................... 71

2. Printer Mechanism.................................................... 72

2-1. Disassembly Drawing ...................................... 72

2-2. Parts List........................................................... 73

3. Sub - Assembly ......................................................... 74

3-1. Push Tractor Unit ............................................. 74

3-2. Lower Cace Unit ............................................... 75

3-3. Upper Case Unit ............................................... 76

3-4. Paper Chute Unit .............................................. 77

3-5. Platen Unit ........................................................ 78

3-6. Carriage Unit (LC-4511) ................................... 79

3-7. Carriage Unit (LC-4521) ................................... 80

3-8. Frame L Unit ..................................................... 81

3-9. Frame R Unit..................................................... 82

3-10.Serial IF Unit (Option) ...................................... 83

3-11.Pull Tractor Unit (Option) ................................ 84

3-12.ASF (Option)..................................................... 85

3-13.Serial-Parallel Converter (Option) .................. 86

4. Wiring Scheme of Printer ......................................... 88

5. Electrical Parts .......................................................... 90

5-1. Main Logic Board (LC-4511) ........................... 90

5-1-1. Circuit Diagram ..................................... 90

5-1-2. Component Layout ............................... 92

5-1-3. Parts List................................................ 93

5-2. Main Logic Board (LC-4521) ........................... 96

5-2-1. Circuit Diagram ..................................... 96

5-2-2. Component Layout ............................... 98

5-2-3. Parts List................................................ 99

5-3. Control Panel Board ...................................... 102

5-3-1. Circuit Diagram ................................... 102

5-3-2. Component Layout ............................. 102

5-3-3. Parts List.............................................. 102

5-4. Connected Board ........................................... 103

5-4-1. Circuit Diagram ................................... 103

5-4-2. Component Layout ............................. 103

5-4-3. Parts List.............................................. 103

5-5. Power Supply Unit (LC-4511,LC-4521) ......... 104

5-5-1. Circuit Diagram ................................... 104

5-5-2. Component Layout ............................. 105

5-5-3. Parts List.............................................. 106

5-6. Serial Interface Board IS-8H192 (Option)..... 108

5-6-1. Circuit Diagram ................................... 108

5-6-2. Component Layout ............................. 109

5-6-3. Parts List.............................................. 109

6. Serial - Parallel Converter Board ( Option ).......... 110

6-1. Wiring Scheme ............................................... 110

6-2. I/F Board ......................................................... 111

6-2-1. Circuit diagram.................................... 111

6-2-2. Component Layout ............................. 111

6-2-3. Parts List.............................................. 111

6-3. CPU Board ...................................................... 112

6-3-1. Circuit diagram ..................................... 112

6-3-2. Component Layout ............................. 113

6-3-3. Parts List.............................................. 113

7. Waveform with Oscilloscope ................................. 114

7

Page 74

1. Printer Assembly

1-1. Disassembly Drawing

– 70 –

Page 75

1-2. Parts List

DRWG.NO. REV. PARTS NO. PARTS NAME

1 89429020 MECHANISM WITH HEAD DP605 (D) 1 S

89429040 MECHANISM WITH HEAD DP605H (D) 1 S

2 87817050 PUSH TRACTOR UNIT HA-15(D) 1 1 S

3 87816650 PRINTER COVER UNIT HA-15(D) 1 1 S

4 87816670 REAR COVER UNIT HA-15(D) 1 1 S

5 87816660 PAPER GUIDE UNIT HA-15(D) 1 1 S

6 87815121 MAIN LOGIC BD UNIT HBA-15(D) 1 S

87815131 MAIN LOGIC BD UNIT HBA-15H(D) 1 S

7 *1 87818110 POWER SUPPLY UNIT HBA-15 US(D) 1 FOR US S

#1 87818111 POWER SUPPLY UNIT HBA-15 US(D) 1 FOR US S

*1 87818120 POWER SUPPLY UNIT HBA-15 EC(D) 1 FOR EC S

#1 87818121 POWER SUPPLY UNIT HBA-15 EC(D) 1 FOR EC S

*1 87818130 POWER SUPPLY UNIT HBA-15 UK(D) 1 FOR UK S

#1 87818131 POWER SUPPLY UNIT HBA-15 UK(D) 1 FOR UK S

*1 87818140 POWER SUPPLY UNIT HBA-15 AS(D) 1 FOR AS S

#1 87818141 POWER SUPPLY UNIT HBA-15 AS(D) 1 FOR AS S

*1 87818150 POWER SUPPLY UNIT HBA-15 HK(D) 1 FOR HK S

#1 87818151 POWER SUPPLY UNIT HBA-15 HK(D) 1 FOR HK S

*1 87818160 POWER SUPPLY UNIT HBA15H US(D) 1 FOR US S

#1 87818161 POWER SUPPLY UNIT HBA15H US(D) 1 FOR US S

*1 87818170 POWER SUPPLY UNIT HBA15H EC(D) 1 FOR EC S

#1 87818171 POWER SUPPLY UNIT HBA15H EC(D) 1 FOR EC S

*1 87818180 POWER SUPPLY UNIT HBA15H UK(D) 1 FOR UK S

#1 87818181 POWER SUPPLY UNIT HBA15H UK(D) 1 FOR UK S

*1 87818190 POWER SUPPLY UNIT HBA15H AS(D) 1 FOR AS S

#1 87818191 POWER SUPPLY UNIT HBA15H AS(D) 1 FOR AS S

*1 87818200 POWER SUPPLY UNIT HBA15H HK(D) 1 FOR HK S

#1 87818201 POWER SUPPLY UNIT HBA15H HK(D) 1 FOR HK S

8 87811270 LOWER CASE UNIT HA-15(D) 1 1 S

9 87810470 UPPER CASE UNIT HBA-15(D) 1 S

87810480 UPPER CASE UNIT HBA-15H(D) 1 S

10 89511390 RIBBON CASSETTE JAN Y24WH 1 1 FOR EC,UK,AS S

89511400 RIBBON CASSETTE UPC Y24WH 1 1 FOR US S

89511410 RIBBON CASSETTE SMH Y24WH 1 1 FOR HK S

11 83903560 PLATEN KNOB ZBA-10 1 1 S

12 82902562 RIBBON HOLDER 771 1 1 S

13 80995010 CABLE HOLDER 721 1 1

14 80701830 WIRE 18UL1007BLK055TT 1 1

15 01914031 SCREW TAT 4-12 PT-FL 6 6

16 01914030 SCREW TAT 4-15 PT 4 4

17 01903038 SCREW TAT 3-10 PT-FL 9 9

18 01903088 SCREW TAT 3-6 WS 2 2

19 86424070 TOP GUIDE UNIT 505 1 1

20 89597040 SERIAL IF BD IS-8H192 UPC 1 1 FOR US OPTION

89597050 SERIAL IF BD IS-8H192 JAN 1 1 EXCEPT FOR US OPTION

21 89596180 PULL TRACTOR UNIT PT15HAUPC 1 1 FOR US OPTION

89596190 PULL TRACTOR UNIT PT15HAJAN 1 1 FOR EC,UK,AS OPTION

89596200 PULL TRACTOR UNIT PT15HASMH 1 1 FOR HK OPTION

22 89590530 ASF SF-15HA UPC 1 1 FOR US OPTION

89590540 ASF SF-15HA JAN 1 1 FOR EC,UK,AS OPTION

89590550 ASF SF-15HA SMH 1 1 FOR HK OPTION

23 89595010 S-P CONVERTER SPC-8K UPC 1 1 FOR US OPTION