Page 1

LQ-500 L-1000

TECHNICAL MANUAL

EPSON

Page 2

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment uses and generates radio frequency energy and if not installed and used properly, that is,

in strict accordance with the manufacturer’s instructions, may cause interference to radio and television reception. It has been type tested and found to comply with limits for a Class B computing device in accordance

with Sub-part J of Part 15 of FCC Rules, which are designed to provide reasonable protection against such

interference in a residential installation. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause interference to radio or television reception, which can

be determined by turning the equipment on and off, the user is encouraged to try to correct the interference

by one or more of the following measures:

l reorient the receiving antenna

l relocate the computer with respect to the receiver

l move the computer away from the receiver

l plug the computer into a different outlet so that the computer and receiver are on different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional

suggestions. The user may find the following booklet, prepared by the Federal Communications Commission, helpful: “ How to Identify and Resolve Radio-TV Interference Problems.” This booklet is available from

the U.S. Government Printing Office, Washington, D.C., 20402, Stock No. 004-000-00345-4.

© 1988 Seiko Epson Corporation

Epson America, Inc.

Service

23610 Telo Avenue

Torrance, California 90505

All rights reserved. No portion of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electric, mechanical, photocopying, recording, or otherwise, without the

written permission of Epson America, Inc. No patent liability is assumed with respect to use of the information contained herein. While every precaution has been taken in the preparation of this book, Epson America,

Inc., assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained herein.

Epson@

is a registered trademark of Seiko Epson Corporation

LQ-500TM is a trademark of Epson America, Inc.

LQ-500/L-1000

iii

Page 3

REVISION SHEET

REV.-A

iv

LQ-500/ L-1000

Page 4

REV.-A

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) personal injury, and 2) damage

to equipment:

DANGER

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

a DANGER heading.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below always should be observed when performing

repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2. NO WORKSHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE

POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. Repairs on Epson products should be performed only by an Epson-certified repair

technician.

2 Make certain that the source voltage is the same as the rated voltage, listed on the serial

number/rating plate. If the Epson product has a primary AC rating different from the

available power source, do not connect it to the power source.

3. Always verify that the Epson product has been disconnected from the power source before

removing or replacing printed circuit boards and/or individual chips.

4. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static wrist straps, when accessing internal components.

5. Replace malfunctioning components only with those components recommended by the

manufacturer,. introduction of second-source ICs or other nonapproved components may

damage the product and void any applicable Epson warranty.

LQ-500/L-1000

V

Page 5

REV.-A

PREFACE

This manual describes functions, theory of electrical and mechanical operations,

maintenance, and repair of the LQ-500 and the L-1000. Thoughout this manual both

printers are discussed. When an item is unique to one printer, special notation is

made. Common items are treated in a general format.

The instructions and procedures included here are intended for the experienced repair

technician, who should pay attention to the precautions on the preceding page. The

chapters are organized as follows:

Chapter 1 - Provides a general product overview, lists specifications, and

illustrates the main components of the printer.

Chapter 2 - Describes the theory of printer operation

Chapter 3 - Discusses the options.

Chapter 4 - Includes a step-by-step guide for product disassembly, assembly,

and adjustment.

Chapter 5 -

Chapter 6 - Describes preventive maintenance techniques and lists lubricants

* The contents of this manual are subject to change without notice.

Provides Epson-approved techniques for troubleshooting.

and adhesives required to service the equipment.

LQ-500/L-1000

vii

Page 6

REV.-A

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

PRODUCT DESCRIPTION

PRINCIPLES OF OPERATION

OPTIONAL EQUIPMENT

DISASSEMBLY, ASSEMBLY, AND ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

LQ-500/L-1000

ix

Page 7

REV.-A

1.1

1.2

1.3

1.4

1.5

1.6

1.7

CHAPTER

1

GENERAL DESCRIPTION

FEATURES..

SPECIFICATIONS.. ..........................................................................

1.2.1 Hardware

1.2.2

INTERFACE OVERVIEW

DIP

SWITCHES AND JUMPER SETTING ...........................................

1.4.1 DIP Switch

1.4.2 Jumper Setting.. .................................................................

SELECTYPE FUNCTION

OPERATING INSTRUCTIONS

1.6.1 Self-Test

1.6.2

1.6.3 Bit-Image Printing..

1.6.4

1.6.5

1.6.6 Printer Initialization.. ...........................................................

1.6.7

1.6.8

1.6.9

MAIN COMPONENTS

1.7.1

1.7.2

1.7.3

1.7.4

1.7.5

1.7.6

...................................................................................

Specifications

Firmware

Hexadecimal Dump Function

Error

Buzzer Operation

Default

Adjust

Printer Protection

PBMA Board.......................................................................

PEBPNL

PEBFIL

Transformer

Printer Mechanism

Housing

Specifications..

..................................................................

Settings ............................................................

..................................................................

............................................................................

Conditions

Values.. ..................................................................

Lever Operation

Board

Board.. ...................................................................

.............................................................................

.................................................................

.......................................................................

...................................................................

.......................................................................

.......................................................

......................................................

...........................................................

...............................................

.............................................................

................................................................

.......................................................

for Heavy-Duty Printing..

(M-5410) ................................................

..........................

1-1

1-3

1-3

1-7

1-11

1-14

1-14

1-15

1-15

1-16

1-16

1-18

1-19

1-20

1-20

1-20

1-21

1-21

1-22

1-23

1-23

1-24

1-25

1-26

1-27

1-28

FIGURE 1-1.

FIGURE 1-2.

FIGURE 1-3.

FIGURE 1-4.

LQ-500/ L-1000

LIST OF FIGURES

Exterior View of the LQ-500/L-1000..

Pin

Configuration ............................................................

Cut-Sheet Printable Area.. ................................................

Printable Area for Continuous (Sprocket)-Feed Paper

................................

.........

1-2

1-3

1-4

1-5

1

-i

Page 8

REV.-A

FIGURE 1-5.

FIGURE 1-6.

FIGURE 1-7.

FIGURE 1-8.

FIGURE 1-9.

FIGURE 1-10.

FIGURE 1-11.

FIGURE 1-12.

FIGURE 1-13.

FIGURE 1-14.

FIGURE 1-15.

FIGURE 1-16.

Character

Data Transmission

Self-Test

Hexadecimal Dump Function

Lever

LQ-500/ L-1000

PBMA Main Control Board

PEBPNL Control Panel Board

PEBFIL Filter Board

Transformer

Model

Housing

Matrix..

Printout

Position..

5410

..........................................................................

LIST OF TABLES

TABLE 1-1.

TABLE 1-2.

TABLE 1-3.

TABLE 1-4.

TABLE 1-5.

TABLE 1-6.

TABLE 1-7.

TABLE 1-8.

TABLE 1-9.

TABLE 1-10.

TABLE 1-11.

TABLE 1-12.

TABLE 1-13.

TABLE 1-14.

TABLE 1-15.

TABLE 1-16. Lever Position

Interface Options..

Optional Units

Cut-Sheet

Continuous (Sprocket)

Printing

Character Matrix and Character Size

Connector Pin Assignments and Signal Functions..

Printer Select/Deselect Control

Settings for DIP Switch 1 (SWI)

Settings for DIP Switch 2 (SW2)

International Character Set Selection

Font Selection

Character Pitch Selection

Print Density

Bit Image Printing

Specifications ..................................................

Mode..

............................................................

Timing................................................

............................................................

............................................

...............................................................

Component

.........................................................

....................................................................

Printer

Mechanism..

...........................................................

.................................................................

................................................................

.................................................................

...................................................................

............................................................

.................................................................

Layout..

................................................

Paper Specifications

.................................................

..................................

...........................................

.......................................

......................

.................................

...........

........................................

.......................................

.......................................

................................

1-10

1-11

1-16

1-17

1-20

1-22

1-22

1-23

1-23

1-24

1-24

1-25

1-1

1-1

1-3

1-4

1-8

1-9

1-11

1-13

1-14

1-14

1-14

1-15

1-15

1-18

1-18

1-20

1

-ii

LQ-500 / L-1000

Page 9

REV.-A

GENERAL DESCRIPTION

1 .1 FEATURES

The LQ-500/L-1000 are small, light-weight, low-cost printers compatible with the LQ-800. The two printers differ in the housing design. All other features are the same. The main features are as follows:

Expanded ESC/P-code printing, implemented as a standard feature

1.

Printing speeds: 180 CPS (alphanumeric Draft 12 CPI)

2.

150 CPS (alphanumeric Draft 10 CPI)

60 CPS (alphanumeric LQ 12 CPI)

50 CPS (alphanumeric LQ 10 CPI)

3. Optional 8100 series interface

4. Clear, easy-to-read printing with a standard EPSON font

5. Two built-in LQ fonts (Roman and Sans Serif)

Optional Font Module to provide a wide variety of fonts

6.

Front panel switch selection of Draft, Roman, Sans Serif, or slot (Optional Font Module) font

7.

8. Automatic paper-loading function

Easy handling of cut sheets with the optional cut-sheet feeder (CSF)

9.

The LQ-500/L-1000 is equipped with the standard EPSON 8-bit parallel interface. Various interface options

enable users to print data from a wide variety of computers. Table l-l lists the interface options, Table l-2

lists the optional units available for the LQ-500/L-1000, and Figure l-l shows an exterior view of the

LQ-500 / L-1000.

Table l-l. Interface Options

NOTE: Refer to the “Optional Interface Technical Manual” for details.

Table 1-2. Optional Units

LQ-500/ L-1000

l-l

Page 10

GENERAL DESCRIPTION

(Printer Cover A)

R

EV .-A

Figure 1-l.

(Printer Cover B)

Exterior View of the LQ-500/L-I000

LQ-500 / L-1000

1-2

Page 11

REV.-A

1.2 SPECIFICATIONS

This section describes the specifications for the LQ-500/L-1000 printer.

1.2.1 Hardware Specifications

GENERAL DESCRIPTION

Printing Method

Pin Configuration

Serial, impact, dot matrix

24 wires (12 x 2 staggered, diameter 0.2 mm)

Feeding Method

Line Spacing

Paper Insertion

Paper-Feed Speed

Paper Specifications

LQ-500/ L-1000

Figure 1-2. Pin Configuration

Friction feed, tractor feed (pull tractor)

1/6 inch, or programmable in units of 1/l80 inch

From rear

100 ms/line (at 1/6-inch feed)

2.2 inches per second (continuous feed)

See Tables 1-3 and 1-4

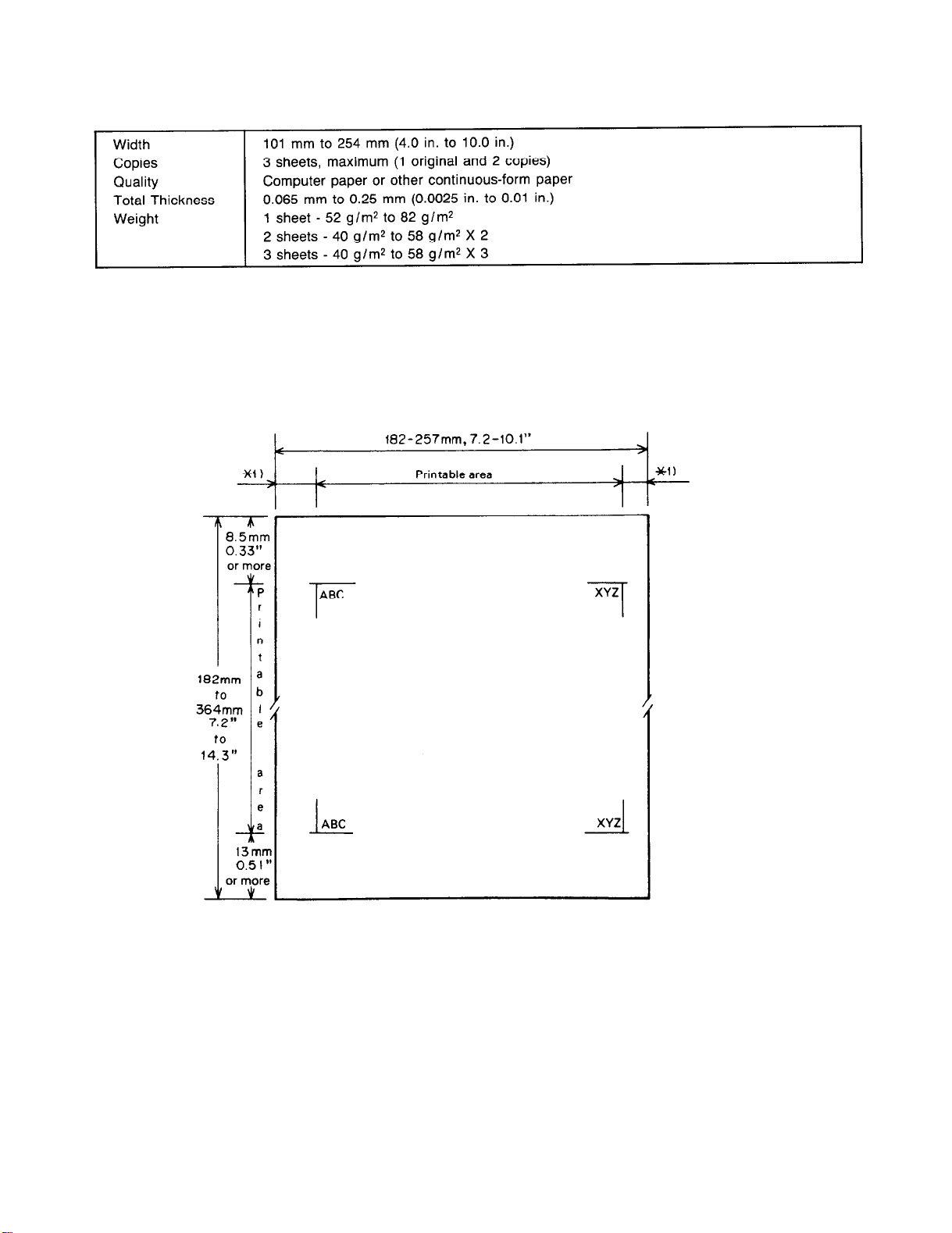

Table 1-3. Cut-Sheet Specifications

1-3

Page 12

GENERAL DESCRIPTION

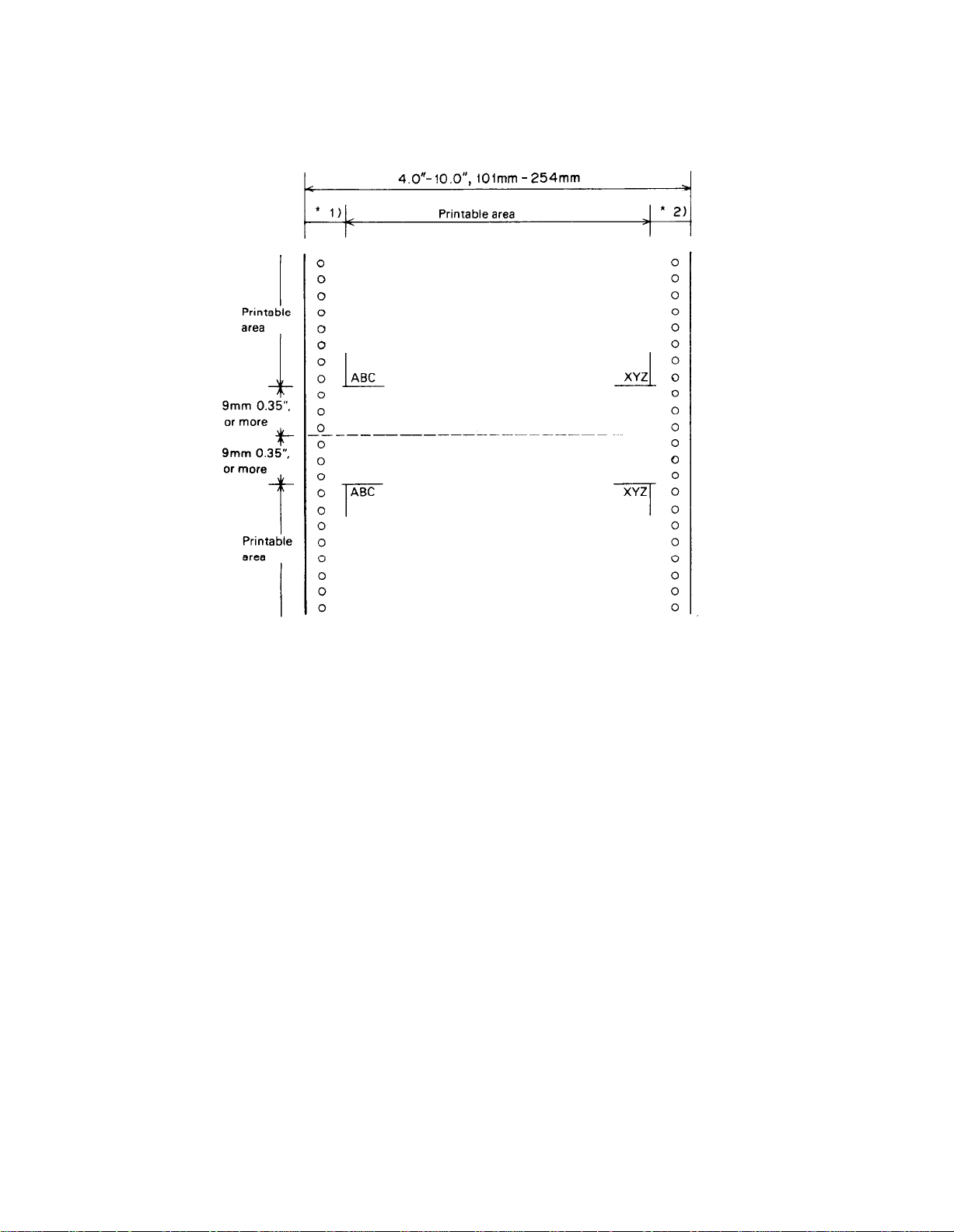

Table 1-4. Continuous (Sprocket) Paper Specifications

Printable Area

The figure below illustrates the printable area for cut sheets.

REV.-A

*1) 3 mm or more using 182 mm to 229 mm (7.2 in. to 9 in.) width paper.

27 mm or more using 257 mm (10.1 in.) width paper.

Figure 1-3. Cut-Sheet Printable Area

1-4

LQ-500/ L-1000

Page 13

REV.-A

GENERAL DESCRIPTION

*1) 13 mm or more using 101 mm to 242 mm (4 in. to 9.5 in.) width paper.

26 mm or more using 254 mm (10 in.) width paper.

l 2) 13 mm or more using 101 mm to 242 mm (4 in. to 9.5 in.) width paper.

24 mm or more using 254 mm (10 in.) width paper.

Figure 1-4. Printable Area for Continuous (Sprocket) -Feed Paper

LQ-500/ L-1000

1-5

Page 14

GENERAL DESCRIPTION

Ink Ribbon

Type

Color

Reliability

Dimensions of Ribbon

Cartridge

Reliability

Mean Cycles Between Failures

(MCBF)

Mean Time Between Failures

(MTBF)

REV.-A

Exclusive ribbon cartridge

Black

2 million characters at 48 dots/character

293 mm (width) x 34 mm (height) x 72 mm (depth)

3 million lines (excluding printhead)

4000 POH (25% duty)

Life of Printhead

200 million strokes

Safety Approvals

Safety Standards

UL478 (U.S. version)

CSA22.2#154

VDE0806 (TUV) (European version)

Radio Frequency

Interference (RFI)

FCC class B (U.S. version)

VDE0871 (Self-certification) (European version)

Electrical Specifications

Power Conditions

120 VAC ± 10% (120 V version)

220 VAC ± 10% (220 V version)

240 VAC ± 10% (240 V version)

Frequency Range

49.5 to 50.5 Hz (50 Hz version)

59.5 to 60.5 Hz (60 Hz version)

Rating Current

1.8A (120 V version)

0.9A (220 V version)

0.9A (240 V version)

Insulation Resistance

10 Megohms min. (Between AC Line and Chassis)

Dielectric Strength

(Between AC Line and Chassis) 1250 VAC (rms), 1 minute (120 V version)

3750 VAC (rms), 1 minute (220/240 V version)

Environmental Conditions

Temperature

Humidity

Resistance to Shock

Resistance to Vibration

Physical Specifications

Weight

Dimensions

1-6

5 to 35 degrees C -operating

-30 to 60 degrees C -in shipment container

10 to 80 % RH -operating

5 to 85 % RH -storage

1 G, within 1 ms -operating

2 G, within 1 ms -storage

0.25 G, 55 Hz max. -operating

0.50 G, 55 Hz max. -storage

7 Kg

390 mm (width) x 320 (depth) x 139 mm (height), excluding knobs

and paper guides

LQ-500/ L-1000

Page 15

REV.-A

1.2.2 Firmware Specifications (ESC/P)

GENERAL DESCRIPTION

Control Code

Printing Direction

Input Data Buffer

Character Code

Character Set

Family

Fonts

Printing Mode

Printing Speed

Printing Columns

Character Matrix

Character Size

ESC/PTM level ESC/P-83 (EPSON Standard Code for Printers)

Bidirectional (text)

Bidirectional (bit-image) (when SW 2-6 is ON)

Unidirectional (bit-image) (when SW 2-6 is OFF)

8K bytes (when SW 2-5 is ON)*

1K byte (when SW 2-5 is OFF)

*When DIP SW 2-5 is set on ON, downloading will be ignored.

8 bits

96 ASCII and 13 international character sets

EPSON Roman (Family number: 0)

EPSON Sans Serif (Family number: 1)

EPSON Roman 10, EPSON Roman 12, EPSON Roman 15,

EPSON Roman Proportional;

EPSON Sans Serif 10, EPSON Sans Serif 12,

EPSON Sans Serif 15, EPSON Sans Serif Proportional;

EPSON Draft 10, EPSON Draft 12, EPSON Draft 15.

Selection and mixture of the following modes are allowed, except 15 CPI

Condensed Mode

0 Printing quality (draft/letter quality)

0 Character pitch (10, 12, 15, or proportional)

0 Condensed

0 Double-width

l Double-height

0 Emphasized

0 Double-strike

0

Italic

l Underlined

0 Outline

0 Shadow

See Table 1-5.

See Table 1-5.

See Table 1-6.

See Table 1-6.

LQ-500/ L-1000

1-7

Page 16

GENERAL DESCRIPTION

REV.-A

Table 1-5. Printing Mode

NOTES:

1. “Max.” means the value when characters of the maximum width were printed.

2. “Min.” means the value when characters of the minimum width were printed.

3. “-" means that “LQ” character set is automatically selected when proportional pitch is specified.

1-8

LQ-500/ L-1000

Page 17

REV.-A

GENERAL DESCRIPTION

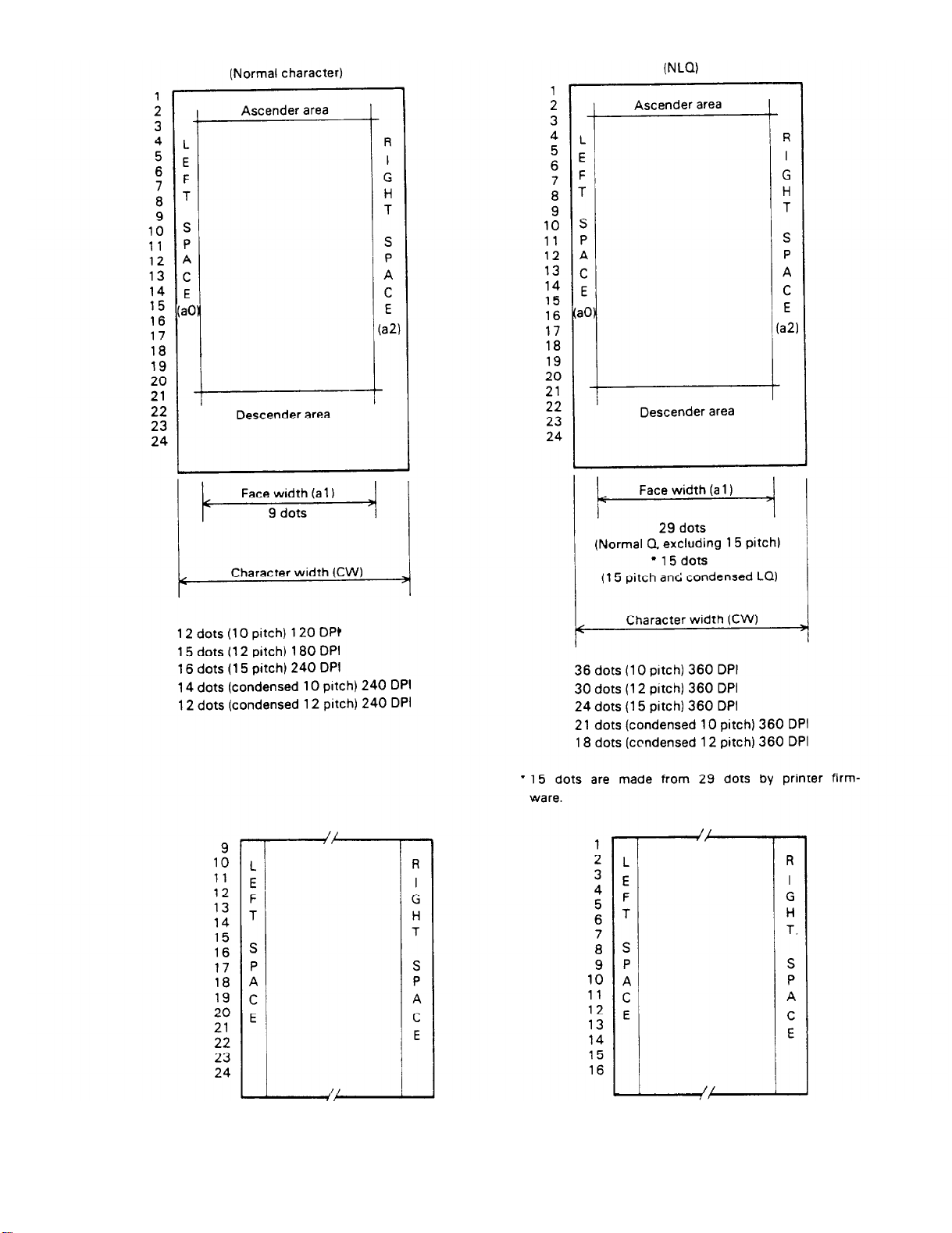

Table 1-6. Character Matrix and Character Size

NOTES:

HDD is horizontal dot density in dots per inch.

1.

Face matrix and character size indicate the size of the maximum character, and this value will be changed

2.

by differences in paper, ribbon, etc.

Unit ESC sp (which also can be sent as the unit followed by the character string CHR$ (&h20)) indicates

3.

the minimum length to be added to the right of the character that can be specified with the ESC sp control

code.

4. 4.""indicates that character matrix is reshaped by printer firmware. Character width becomes half

of noncondensed character width.

LQ-500/L-1000

1-9

Page 18

GENERAL DESCRIPTION

REV.-A

1-10

Figure 1-5. Character Matrix

LQ-500/ L-1000

Page 19

REV.-A

GENERAL DESCRIPTION

1.3 INTERFACE OVERVIEW

The 8-bit parallel interface, provided standard with this printer, has the following specifications:

Data Format

Synchronization

Handshaking

Signal Level

Adaptable Connector

Data Transmission Timing

8-bit parallel

By STROBE pulse

By BUSY and ACKNLG signal

TTL-compatible

57-30360 (Amphenol) or equivalent

See Figure 1-6

Figure 1-6. Data Transmission Timing

Table 1-7 shows the connector pin assignments and signal functions of the 8-bit parallel interface.

Table 1-7. Connector Pin Assignments and Signal Functions

LQ-500 / L-1000

1-11

Page 20

GENERAL DESCRIPTION

Table 1-7. Connector Pin Assignments and Signal Functions (Cont.)

REV.-A

NOTES:

1.

“Dir.” refers to the direction of the signal flow as viewed from the printer.

2.

“Return” denotes a twisted-pair return line.

3. The cable used must be shielded to prevent noise.

4.

All interface conditions are based on TTL levels. Both the rise and fall times of all signals must be less

than 0.2 µs.

5.

The AUTO FEED-XT signal can be set at LOW by DIP switch 2-4.

6.

The SELECT-IN signal can be set at LOW by jumper 6.

7.

Printing tests, including those of the interface circuits, can be performed without using external equipment

by setting DATA 1-8 of the interface connector to certain codes and connecting the ACKNLG signal to the

STROBE signal.

1-12

LQ-500/ L-1000

Page 21

REV.-A

GENERAL DESCRIPTION

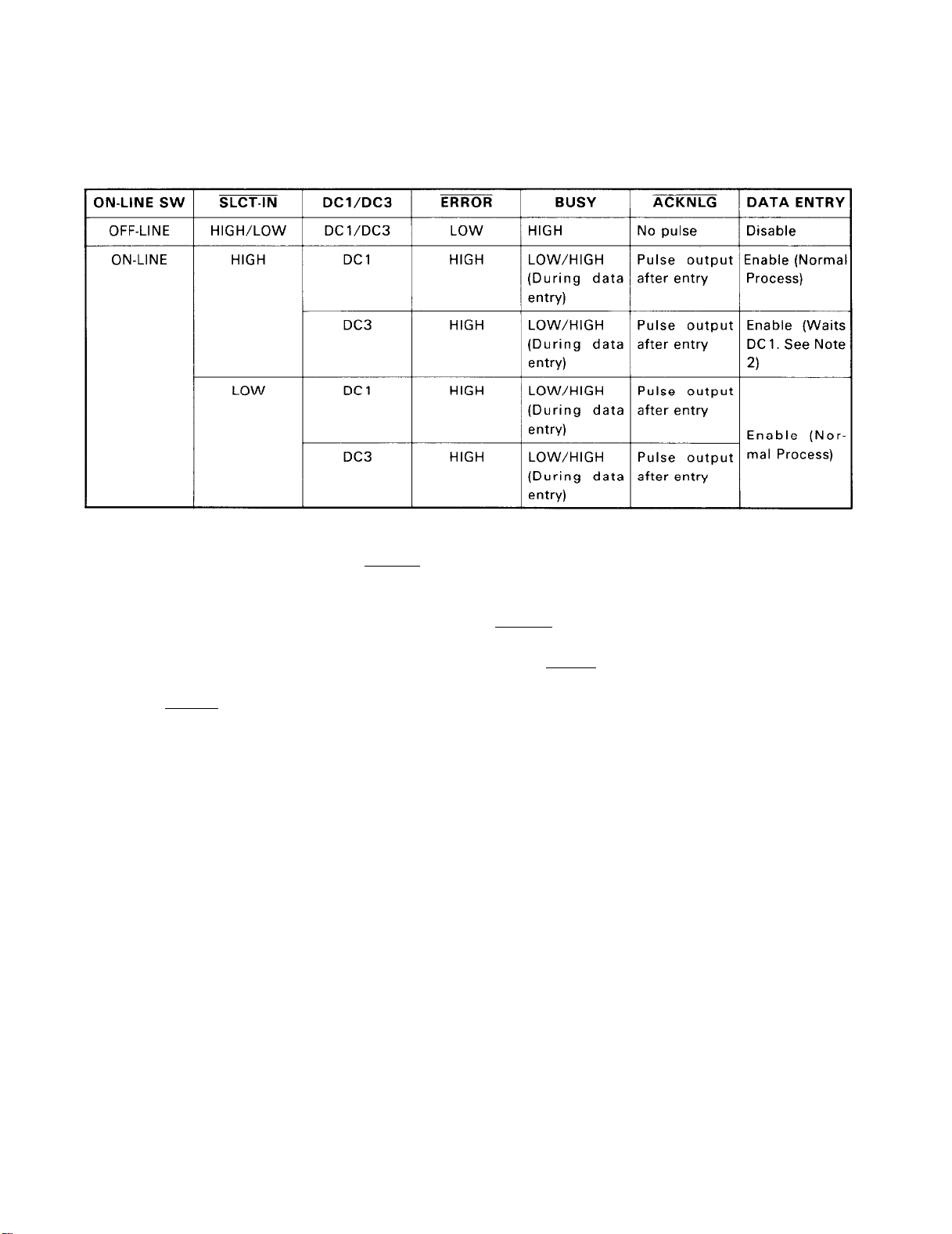

Table 1-8 shows the printer select/deselect (DC1 /DC3) control, including relations among ON-LINE, SELECT-IN

input, DC1 /DC3, and interface signals.

Table 1-8. Printer Select/Deselect Control

NOTES:

1.

In Table 1-8, it is assumed that no ERROR status exists other than that attributable to OFF-LINE mode.

2.

Once the printer is deselected by the DC3 code, the printer will not revert to the selected state unless the

DC1 code is input again. (In the deselected state, the printer ignores input data until the DC1 code is received.)

3.

The DC1 and DC3 codes are enabled only when the SLCT-IN signal (Input Connector 36 for the parallel

interface unit) is HIGH and printer power is initialized.

4.

If the SLCT-IN signal is LOW when the printer is initialized, DC1 /DC3 printer select/deselect control is

invalidated, and these control codes are ignored.

5.

If the SLCT-IN signal is HIGH and is not set to LOW by jumper 6 when printer initialized, the printer

starts from the selected (DCl) state.

LQ-500/ L-1000

1-13

Page 22

GENERAL DESCRIPTION

REV.-A

1.4 DIP SWITCHES AND JUMPER SETTING

This section describes the DIP switch selections and the jumper setting for the LQ-500/L-1000 printer.

1.4.1 DIP Switch Settings

The two DIP switches for the printer are located inside the ROM cartridge slot cover and function as shown

in Tables 1-9 through 1-13. (Note that the status of the DIP switches is read only at power on or upon receipt

of the INIT signal.)

Table 1-9. Settings for DIP Switch 1 (SW1)

* Unidirectional printing is selected by default, however input of ESC U O can be used to set the print direction to

Bidirectional.

Table 1-11. International Character Set Selection

1-14

LQ-500/ L-1000

Page 23

REV.-A

GENERAL DESCRIPTION

Table 1-12. Font Selection

1-4 1-5

Off Off

On

Off On

On On

Off

Font

Roman

Sans Serif

Slot

Draft

Table 1-13. Character Pitch Selection

2-7 2-8

Off

On

Off On

On On

Off

Off

Character Pitch

10 CPI

12 CPI

15 CPI

Proportional

1.4.2 Jumper Setting

Jumper 6, which is user-selectable, is located inside the ROM cartridge slot cover. If the jumper is connected,

the SLCT-IN signal is fixed to LOW, and DC1 /DC3 printer select control is ignored.

1.5 SELECTYPE FUNCTION

Selectype allows the user to choose fonts easily while the printer is ON-LINE. This function provides for selec-

tion of Draft, Roman, Sans Serif, or the slot (ROM cartridge) font. SelecType is effective only when the printer

is ON-LINE and is not printing. Font selection is performed by pressing the FORM-FEED switch with the printer

ON-LINE and not printing. The printer’s control panel indicates which font has been specified.

LQ-500/ L-1000

1-15

Page 24

GENERAL DESCRIPTION

REV.-A

1.6 OPERATING INSTRUCTIONS

This section describes the self-test and hexadecimal dump functions and also includes the error states, printer

initialization, and the buzzer operation.

1.6.1 Self-Test

To begin printing the self-test using Draft mode, turn the printer ON while pressing the LINE-FEED button. To

begin printing the self-test using the Letter Quality (LQ) mode, turn the printer power ON while pressing

FORM-FEED.

Self-test printing can be stopped or started by pressing ON-LINE (ON-LINE indicator is not lit). To finish the

self-test, stop the printing by pressing the ON-LINE switch and turn OFF the printer power.

The firmware revision number is printed as the first line of the self-test, and subsequently, current DIP switch

settings are printed.

1-16

Figure 1-7. Self-Test Printout

LQ-500/ L-1000

Page 25

REV.-A

GENERAL DESCRIPTION

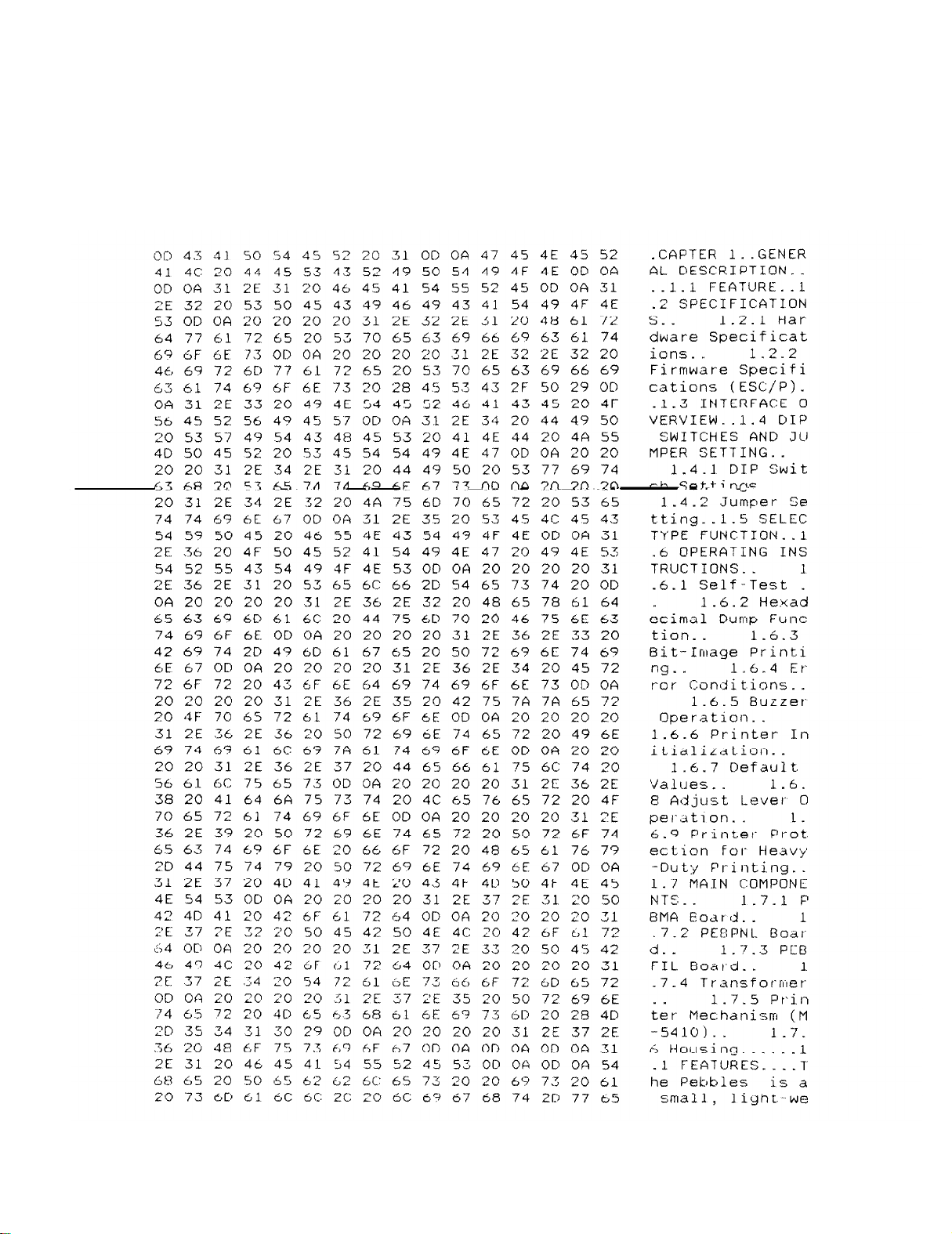

1.6.2 Hexadecimal Dump Function

The printer enters HEX-DUMP mode when it is powered on while the LINE-FEED and FORM-FEED buttons

are pressed down. In HEX-DUMP mode, the hexadecimal representation of the input data is printed out, along

with corresponding ASCII characters. This function is valuable for checking the data the printer has received

from the host. If input data is a control code rather than a character code, a period (.) is printed in the ASCII column.

Data Dump Mode

LQ-500/ L-1000

Figure 1-8. Hexadecimal Dump Function

1-17

Page 26

GENERAL DESCRIPTION

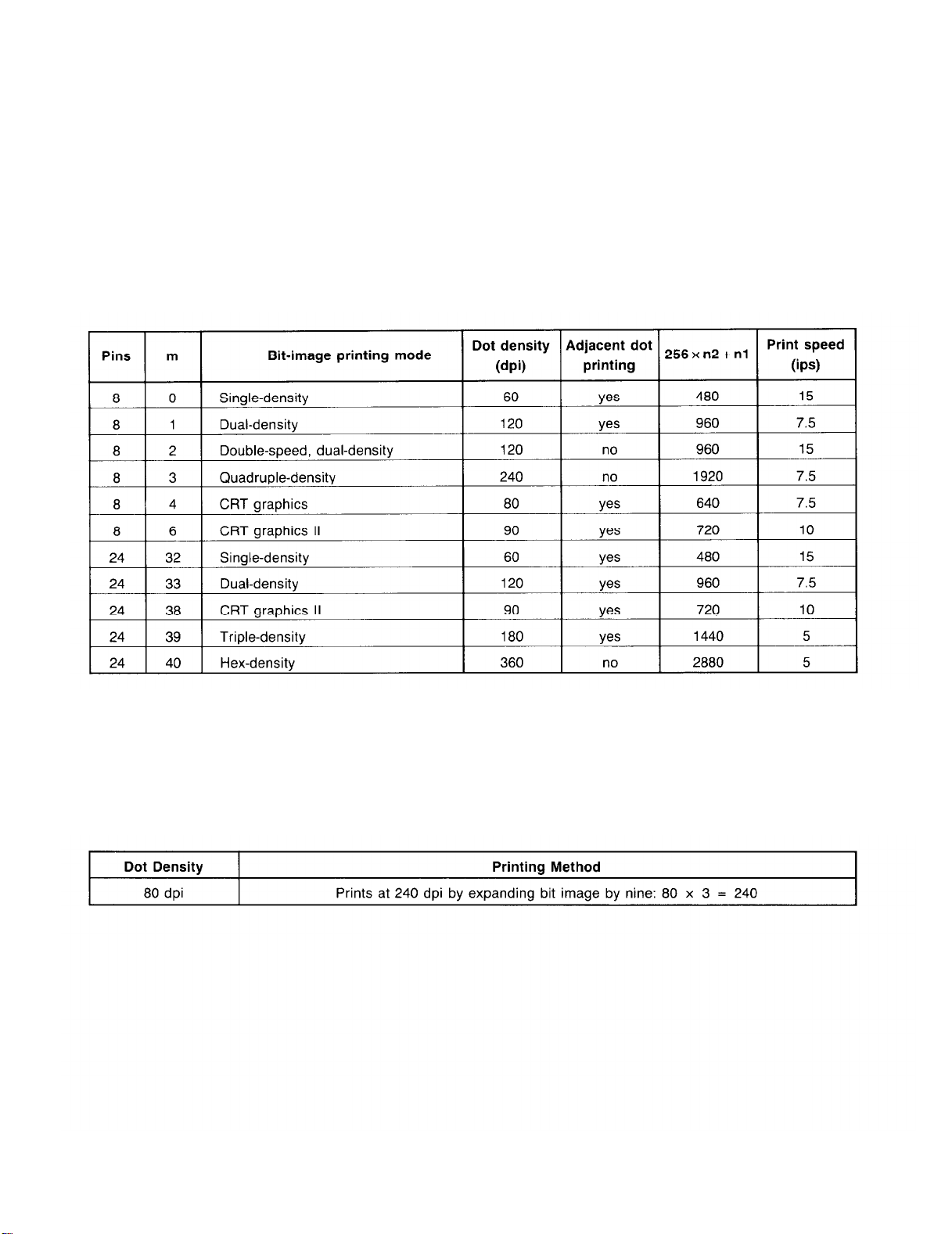

1.6.3 Bit-Image Printing

This printer has four standard print densities, listed below in dots per inch (dpi):

120 dpi (including half dots): Triple speed

180 dpi (including half dots): Double speed

240 dpi (including half dots): 1.5 speed

360 dpi (including half dots): Normal speed

The firmware, however, implements the print densities as shown in Table 1-14

Table 1-14. Print Density

REV.-A

NOTES: ESC* m n1 n2 [DATA] n2 x 256 + n1

dpi = dots per inch

ips = inches per second

The firmware handles the print densities as shown in Table 1-15.

Table 1-15. Bit-Image Printing

1-18

LQ-500/ L-1000

Page 27

REV.-A

GENERAL DESCRIPTION

1.6.4 Error Conditions

If any of the following error conditions is detected, the printer automatically enters OFF-LINE mode.

0 Home position is not detected at printer mechanism initialization.

e Home position is detected during printing.

0 ON-LINE is pressed, and the printer enters OFF-LINE.

l A paper-out signal is detected and forms-override is finished.

0 Paper out is detected after the printer performs a paper-loading operation with the cut-sheet feeder enabled.

The following interface signals are output to indicate the error and to halt data transmission:

BUSY signal becomes HIGH.

ERROR becomes LOW.

No ACKNLG pulse is sent.

1.6.5 Buzzer Operation

The buzzer sounds under the following circumstances:

0 When the BEL code is sent to the printer (0.5-second ring).

0

When a paper-out error is detected, the buzzer sounds 3 times (rings for 0.1 second with a 0.1-second interval).

0 When abnormal carriage movement is detected, the buzzer sounds 5 times (rings for 0.5 second, with a 0.5-

second interval).

l When a panel setting is accepted (0.1-second ring).

1.6.6 Printer Initialization

There are two initialization methods: hardware initialization and software initialization.

Hardware Initialization

This type of initialization takes place when the printer power switch is turned ON (and the AC power cord is

plugged in) or when the INIT signal is received over the parallel interface line.

When the printer is initialized, it performs the following actions:

(a) Initializes printer mechanism.

(b) Clears input data buffer.

(c) Clears downloaded character set.

(d) Clears the print buffer.

(e) Returns printer settings to their default values.

Software Initialization

This type of initialization takes place when the printer receives the software initialize code. Upon receipt of this

code, the printer does not perform the functions listed above under (a), (b), and (c). The settings changed by

the last SelecType operation are reset.

LQ-500/ L-1000

1-19

Page 28

GENERAL DESCRIPTION

1.6.7 Default Values

When the printer is initialized, the following default values or functions are set:

REV.-A

Page Position

Left and Right Margins

Line Spacing

Vertical Tabs

Horizontal Tabs

VFH Channel

Category of Type Style

Current paper position becomes top-of-form position

Released

116 inch

Cleared

Every 8 characters (relative)

Channel 0

SelecType - Software initialization

DIP switch - Hardware initialization

Downloaded Characters

Deselected - Software initialization

Cleared - Hardware initialization

Justification

Character Spacing

Bit-Image Mode Assignment

Left justification

10 CPI

ESC K = ESC + 0, ESC L = ESC * 1

ESC Y = ESC * 2, ESC Z = ESC * 3

Printing Effects

Cleared

1.6.8 Adjust Lever Operation

The head adjust lever must be set to the proper position according to the paper thickness. See Table 1-16

and Figure 1-9.

Table 1-16. Lever Position Operation

1-20

Figure 1-9. Lever Position

LQ-500/ L-1000

Page 29

REV.-A.

GENERAL DESCRIPTION

1.6.9 Printer Protection for Heavy-Duty Printing

This printer has “printhead protection” to safeguard the printhead from overheating or from voltage dropping

to the head driver.

If head temperature exceeds upper limit value, then printing is automatically stopped until head temperature

has dropped to a certain value to resume printing.

If heavy-duty printing causes the voltage supplied to the head drive circuit to drop to the lower limit, then printing is interrupted immediately, and thereafter, if power supply voltage is recovered to a certain value, then the

remaining print line will be printed. This protection will occur when half or more of the wires are activated

simultaneously and continuously.

LQ-500/L-1000

1-21

Page 30

GENERAL DESCRIPTION

REV.-A

1.7 MAIN COMPONENTS

The main components of the LQ-500/L-1000 printer are designed for easy removal and replacement to maintain/repair the printer. The main components are:

1) PBMA board:

2) PEBPNL board:

3) PEBFIL board:

4) Transformer

5) M-5410:

The main control board; the CPU on this board controls all main functions

The control panel board.

The filter circuit board.

The printer mechanism.

Figure 1-10. LQ-500/L-1000 Component Layout

1.7.1 PBMA Board

The use of the µPD7810HG CPU makes the main control board simple in its circuit design.

Figure 1-11. PBMA Main Control Board

1-22

LQ-500/ L-1000

Page 31

REV.-A

GENERAL DESCRIPTION

1.7.2 PEBPNL Board

The PEBPNL board is the LQ-500/L-1000 control panel, which contains the indicator LEDs, switches, and buzzer.

Figure 1-12. PEBPNL Control Panel Board

1.7.3 PEBFIL Board

The PEBFIL board eliminates noise from the AC line to the printer and from the printer to the outer line. The

fuse used on this board prevents overheating.

LQ-500/L-1000

(120 V Version) (220/240 V Version)

Figure 1-13. PEBFIL Filter Board

1-23

Page 32

GENERAL DESCRIPTION

REV.-A

1.7.4 Transformer

This transformer changes the input AC from the filter circuit into 26 VAC and 12 VAC in order to supply the

necessary voltages to the control circuit board.

(120 V Version)

(220 V Version)

(240 V Version)

Figure 1-14. Transformer

1.7.5 Printer Mechanism (M-5410)

The M-5410 printer mechanism was developed expressly for use with LQ-500/L-1000 printer: the components

include a carriage motor, carriage mechanism, paper-feed motor, paper-feed mechanism, ribbon-feed

mechanism, printhead, and sensors.

1-24

Figure 1-15. Model 5410 Printer Mechanism

LQ-500/ L-1000

Page 33

REV.-A

1.7.6 Housing

LQ-500/L-1000 housing consists of the upper and lower cases. The upper case houses the control panel. The

lower case contains the printer mechanism and the main control board. The printer cartridge is easily removable

and can be replaced simply by lifting the upper case.

GENERAL DESCRIPTION

Figure 1-16. Housing

LQ-500/L-1000

1-25

Page 34

REV.-A

CHAPTER 2

PRINCIPLES OF OPERATION

2.1

2.2

OVERVIEW

2.1.1 SummaryofConnectors..

2.1.2 Overview of Printer

2.1.3

2.1.4

PRINCIPLES

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

.....................................................................................

Mechanism

2.1.2.1

2.1.2.2

2.1.2.3

OverviewofCircuitry.. ........................................................

Firmware Overview

Power Supply Circuit ..........................................................

2.2.1.1

2.2.1.2 Chopper-Type Switching

2.2.1.3

2.2.1.4 Transformer

2.2.1.5 Rectifier and Smoothing

2.2.1.6

2.2.1.7

2.2.1.8 + 24 VDC

2.2.1.9

2.2.1 .10 Vx

Reset Circuit

Firmware OperationatReset..

Address Decorder and

Carriage Operation

2.2.5.1

2.2.5.2

2.2.5.3

2.2.5.4

2.2.5.5

2.2.5.6

Paper Feed

2.2.6.1

2.2.6.2

Sensors.. .............................................................

Motors

Printhead

OF

OPERATION..

Power Supply Circuit Block Diagram

Filter

+ 5

Pulse-Width Modulation

+ 12

Carriage Mechanism

Carriage

Carriage Motor Drive Circuit Block Diagram..

Gate Array EOlA05KA Operation in Carriage

Motor Drive Circuit

Carriage Motor Drive Circuit

Carriage

Paper-Feed Mechanism Operation

Paper-Feed

................................................................

............................................................

.............................................................

.........................................................

Circuit

.........................................................

VDC

Regulator Circuit

Regulator Circuit..

VDC

Supply

Voltage

......................................................................

........................................................................

Supply

.............................................................

Motor Specifications...............................

Motor Software

Motor Specifications..

....................................................

Operation.. ..........................

.....................

Regulator Circuit.. ...........

........................................................

Circuit

(PWM) Circuit..

Circuit.. .....................................

Circuit..

.............................................

Bank

Register..

.............................................

...............................................

Control.. .........................

............................

....................................

.................

.................................

...................................

.................................

.........

.................................

.........................

.........................

2-1

2-1

2-3

2-4

2-6

2-6

2-7

2-8

2-9

2-9

2-9

2-13

2-12

2-12

2-11

2-14

2-16

2-18

2-20

2-21

2-22

2-26

2-30

2-32

2-32

2-32

2-33

2-34

2-36

2-42

2-49

2-49

2-51

LQ-500/L-1000

2-i

Page 35

REV.-A

2.2.7

2.2.8

2.2.9

2.2.10

2.2.11

Circuit

2.2.6.3

2.2.6.4

Printhead

2.2.7.1

2.2.7.2

2.2.7.3

2.2.7.4

2.2.7.5

2.2.7.6

A/D Converter Circuit..

Host

Buffer and Data Flow..

2.2.10.1

2.2.10.2

Ribbon-Feed

Paper-Feed

Paper-Feed

...........................................................................

Printhead Printing Operation

Printhead Specifications

Printhead Drive Circuit Block Diagram..

Gate Array E05A02LA Operation in Printhead

Drive Circuit

Printhead

Printhead

Interface ....................................................................

Buffer

Data Flow..

Mechanism

Motor

Motor Software

Drive

Software

.................................................................

..........................................................

Drive

.......................................

........................................................

Circuit

.......................................................

........................................................

.....................................................

.........................................

Control..

.............................

Control.. .....................

.................................

.................................

.................

2-51

2-52

2-54

2-54

2-55

2-55

2-56

2-58

2-59

2-61

2-64

2-67

2-67

2-70

2-72

FIGURE 2-1.

FIGURE 2-2.

FIGURE 2-3.

FIGURE 2-4.

FIGURE 2-5.

FIGURE 2-6.

FIGURE 2-7.

FIGURE 2-8.

FIGURE 2-9.

FIGURE 2-10.

FIGURE 2-11.

FIGURE 2-12.

FIGURE 2-13.

FIGURE 2-14.

FIGURE 2-15.

FIGURE 2-16.

FIGURE 2-17.

FIGURE 2-18.

FIGURE 2-19.

LIST OF FIGURES

Cable

Printer Mechanism

Paper-End

Thermal Sensor (Printhead Temperature Detection).

Connectors..

Sensor..

Home-Position Sensor

Printhead

Circuit Block Diagram

Memory Map (64K

Power Supply Circuit

Step-Down

Step-Down Timings

PEBFIL Filter Circuit

Transformer Circuit

Rectifier and Smoothing Circuit

+5 V Regulator Circuit

Oscillator

Constant Voltage Control (+ 5 VDC)

AMP

NJM2355 Internal Circuit

........................................................................

Circuit..

Waveform

Output

1

..........................................................

Block Diagram

..........................................................

.....................................................

......................................................

Bytes)

.................................................................

.................................................

Block Diagram..

..........................................................

.........................................................

Board

..........................................................

........................................................

..............................................

....................................................

..................................................

....................................

...............................

........................................

..................................

..........

2-2

2-3

2-4

2-4

2-5

2-6

2-7

2-8

2-9

2-11

2-11

2-12

2-12

2-13

2-14

2-14

2-15

2-15

2-16

2-ii

LQ-500 / L-1 000

Page 36

REV.-A

FIGURE 2-20.

FIGURE 2-21.

FIGURE 2-22.

FIGURE 2-23.

FIGURE 2-24.

FIGURE 2-25.

FIGURE 2-26.

FIGURE 2-27.

FIGURE 2-28.

FIGURE 2-29.

FIGURE 2-30.

FIGURE 2-31.

FIGURE 2-32.

FIGURE 2-33.

FIGURE 2-34.

FIGURE 2-35.

FIGURE 2-36.

FIGURE 2-37.

FIGURE 2-38.

FIGURE 2-39.

FIGURE 2-40.

FIGURE 2-41.

FIGURE 2-42.

FIGURE 2-43.

FIGURE 2-44.

FIGURE 2-45.

FIGURE 2-46.

FIGURE 2-47.

FIGURE 2-48.

FIGURE 2-49.

FIGURE 2-50.

FIGURE 2-51.

FIGURE 2-52.

FIGURE 2-53.

FIGURE 2-54.

FIGURE 2-55.

FIGURE 2-56.

FIGURE 2-57.

Output Transistor Drive Waveform

+24 V Regulator Circuit

Constant-Voltage Control (+ 24 VDC)

Over-Current Protection (OCP)

+ 12 VDC Circuit

Vx Voltage Circuit

Reset Circuit

RESET Output

RESET Pulse Oscillation Process (Module Mounted) ..........

RESET Pulse Oscillation Process (Module Removed) .........

Initialization

Memory

Carriage Mechanism

Carriage Drive Circuit Block Diagram

Gate Array Operation

Carriage Motor Drive

STK-6981 B Circuit Diagram

Reference

Constant Current Control

Chopping

Schmitt

Chopping

Carriage Motor

Home-Position

Printing

Friction-Feed Operation

Sprocket-Feed Operation.. ................................................

Paper-Feed Motor Drive

Paper-Feed Motor

Printhead Printing Operation

Printhead Drive Circuit Block Diagram

E05A02LA

Printhead Drive Circuit

Printhead Driving

Print

Relationship between Head Driver Voltage and Print

Driving Pulse

A/D

Host

Map

Voltage

Waveforms.. .....................................................

Trigger Circuit.. ...................................................

Current and

Area and

Block

Timing.. ..................................................................

Converter Circuit

Interface .................................................................

.............................................................

...................................................................

.................................................................

Program

...................................................................

Control.. ...................................................

Seek.. .......................................................

Diagram.. ...............................................

Width.. .......................................................

...................................................

............................................................

Flowchart.. ......................................

........................................................

.......................................................

Circuit.............................................

..............................................

Generation Circuit

Circuit..

Drive

Printing

Drive Timing

Waveforms

Timing.....................................

...................................................

Circuit..

.....................................................

......................................................

....................................

................................

..........................................

................................

...............................

.....................................

Speed.. .................................

.......................................

Chart

...............................

............................................

..............................

...........................................

2-17

2-18

2-19

2-19

2-20

2-21

2-22

2-23

2-24

2-25

2-26

2-29

2-31

2-32

2-33

2-35

2-36

2-37

2-38

2-39

2-40

2-42

2-43

2-47

2-48

2-49

2-50

2-51

2-52

2-54

2-55

2-56

2-58

2-58

2-59

2-59

2-60

2-62

LQ-500/L-1000

2-iii

Page 37

REV.-A

FIGURE 2-58.

FIGURE 2-59.

FIGURE 2-60.

FIGURE 2-61.

FIGURE 2-62.

FIGURE 2-63.

FIGURE 2-64.

FIGURE 2-65.

TABLE 2-1.

TABLE 2-2.

TABLE 2-3.

TABLE 2-4.

TABLE 2-5.

TABLE 2-6.

TABLE 2-7.

TABLE 2-8.

TABLE 2-9.

TABLE 2-10.

TABLE 2-11.

TABLE 2-12.

TABLE 2-13.

TABLE 2-14.

TABLE 2-15.

TABLE 2-16.

TABLE 2-17.

TABLE 2-18.

TABLE 2-19.

TABLE 2-20.

TABLE 2-21.

Buffer

Input

Line Buffer Structure

Image Buffer Structure

Queue

Download

Routine.. .................................................................

Main

Printing

Ribbon-Feed

Buffer

Buffer

Routine

Structure..

Structure..

..............................................................

Mechanism

....................................................

.......................................................

.....................................................

..................................................

Structure..

.............................................

..................................................

LIST OF TABLES

Board

Power

Control

Control

Reference

Current

Phase-Excitation

Drive

Drive

Chopping

Time

Acceleration Time Data (2-2 Excitation)

Deceleration

Acceleration

Deceleration

Excitation Sequence (Clockwise: Paper Feeds Forward).

Setting

E05A02LA

Scan

Control

Ribbon-Feed

Connector Summary

Supply Applications

Commands..

Commands..

Voltage ...........................................................

Values for

Sequence

Sequence

Current............................................................

Constants

Time Data (2-2

Time Data (1-2

Time Data (1-2

Time

...................................................................

Gate

Lines

and

Commands..........................................................

Gear Train

........................................................

........................................................

Reference

Method..

Excitation).

(2-2

Excitation). .......................................

(1-2

Speeds.. ............................................

for

Array

Switches..

DIP

..............................................

...............................................

Voltages..

................................................

.......................................

Excitation). ............................

Excitation). ............................

Excitation). ............................

Functions.. .....................................

.........................................

...................................................

............................

.............................

....

2-65

2-65

2-66

2-66

2-67

2-68

2-69

2-70

2-1

2-10

2-30

2-34

2-37

2-39

2-41

2-41

2-42

2-43

2-43

2-44

2-44

2-45

2-46

2-52

2-53

2-57

2-61

2-63

2-70

2-iv

LQ-500/ L-1000

Page 38

REV.-A

PRINCIPLES OF OPERATION

2.1 OVERVIEW

This chapter describes the signals at the various connectors that link the primary Components of the

LQ-500/L-1000, including the printer mechanism, power supply circuits, and control circuits. The chapter also

describes the operation of the printer’s circuitry and printer mechanism.

2.1.1 Summary of Connectors

The interconnection of the primary components is shown in Figure 2-1. Table 2-l summarizes the function,

size, and type of the connectors designated in the figure.

Table 2-1. Board Connector Summary

LQ-500/L-1000

2-l

Page 39

PRINCIPLES OF OPERATION

REV.-A

2-2

Figure 2-1. Cable Connections

LQ-500/L-1000

Page 40

REV.-A

2.1.2 Overview of Printer Mechanism Operation

The Model 5410 printer mechanism is a serial, impact, dot-matrix printer that prints at 180 dots per inch (DPI)

in both the horizontal and vertical directions. Figure 2-2 shows a block diagram of the Model 5410 printer

mechanism.

PRINCIPLES OF OPERATION

Figure 2-2. Printer Mechanism Block Diagram

LQ-500 / L-1000 2-3

Page 41

PRINCIPLES OF OPERATION

2.1.2.1 Sensors

The printer mechanism is equipped with the following sensors:

Paper-End (PE) Sensor

Home-Position (HP) Sensor

Thermal Sensor (Printhead Temperature)

Paper-End Sensor (PE Sensor)

Figure 2-3 shows the paper-end sensor. This sensor switch is ON when paper runs out.

Paper-out state - ON + LOW level

Paper present - OFF - HIGH level

REV.-A

Figure 2-3. Paper-End Sensor

Home-Position Sensor (HP Sensor)

Figure 2-4 shows the home-position sensor. This sensor switch is ON when the carriage is at the home position.

Home position - ON + LOW level

Other position - OFF + HIGH level

The reference position for the carriage driver is determined by this sensor.

2-4

Figure 2-4. Home-Position Sensor

LQ-500/ L-1000

Page 42

REV.-A

Thermal Sensor (Printhead Temperature Detection)

The thermal sensor in the printhead monitors printhead temperature. If head temperature exceeds the upper

limit value, then printing is automatically stopped until head temperature drops to a certain value before resuming printing.

Figure 2-5 below illustrates the printer’s thermal-sensor circuit.

PRINCIPLES OF OPERATION

Figure 2-5. Thermal Sensor (Printhead Temperature Detection)

LQ-500 / L-1000

2-5

Page 43

PRINCIPLES OF OPERATION

REV.-A

2.1.2.2 Motors

This printer has the following motors:

Carriage motor (stepper motor)

Paper-feed motor (stepper motor)

Carriage Motor

The carriage motor is used to move the carriage right and left along the platen. This unit employs a 4-phase,

48-step motor using either 1-2 or 2-2 phase excitation and is controlled by an open-loop system.

Paper-Feed Motor

Paper feeding is carried out by a 4-phase, 48-step motor. This unit is designed to advance the paper l/180

inch for each step (phase switch), using 2-2 phase excitation. The motor is controlled by the CPU in an openloop configuration.

2.1.2.3 Printhead

Figure 2-6 shows the dot-wire operation. The head-driving coil is energized, so that the dot wire is pushed out.

The dot wire strikes the ribbon against the paper, printing a dot.

2-6

Figure 2-6. Printhead

LQ-500/L-1000

Page 44

Page 45

PRINCIPLES OF OPERATION

2.1.4 Firmware Overview

This printer has a µPD7810HG CPU with 64K bytes of address space. Figure 2-8 shows a memory map of this

address space.

REV.-A

NOTE: CG = character generator.

GA = gate array.

2-8

Figure 2-8. Memory Map (64K Bytes)

LQ-500/ L-1000

Page 46

REV.-A

PRINCIPLES OF OPERATION

2.2 PRINCIPLES OF OPERATION

This section describes the operation of each component.

2.2.1 Power Supply Circuit The paragraphs below provide details of power supply circuit operations.

2.2.1.1 Power Supply Circuit Block Diagram

120/220/240 VAC are applied to the step-down transformer via the filter circuit to create 26 VAC and 12 VAC,

which are then input to the power supply circuit on the main board. The 26 VAC are converted into about 36

VDC via the full-wave rectifier and smoothing circuit, and input to the regulator circuits for + 24 VDC and + 5

VDC to be supplied to the control circuit. The + 24 VDC and + 5 VDC are also supplied to the Vx voltage circuit

and, while generating the Vx voltage, transferred to the control circuit.

The 12 VAC supplies a nonstabilized + 12 V to the control circuit via the positive terminal of the half-wave rec-

tifier and smoothing circuit.

LQ-500/ L-1000

Figure 2-9. Power Supply Circuit Block Diagram

2-9

Page 47

PRINCIPLES OF OPERATION

REV.-A

Table 2-2. Power Supply Applications

2-10

LQ-500 / L- 1000

Page 48

REV.-A

PRINCIPLES OF OPERATION

2.2.1.2 Chopper-Type Switching Regulator Circuit

A chopper-type switching regulator is employed in the power supply circuit. Operation of the step-down circuit

is as follows:

Figure 2-10. Step-Down Circuit

Figure 2-10 shows the chopper-type, step-down switching regulator circuit. When the transistor is ON, voltage

Vi is applied to coil L and capacitor C, and load current IL flows. At this time, electromagnetic energy WL is

accumulated in choke coil L. When the transistor turns off, energy WL is applied to the load via flywheel diode

D so that output voltage Vo becomes the average value:

LQ-500/L-1000

Figure 2-11. Step-Down Timings

2-11

Page 49

PRINCIPLES OF OPERATION

REV.-A

2.2.1.3 Filter Circuit

The AC line voltage passes through the power switch, then is input to the filter circuit. A fuse, F1, is used on

the PEBFIL board. The filter circuit attenuates external noise and inhibits noise generated in the printer from

going out via the AC line. Either Cl or C2 drains leakage current between the primary coil and the case. Figure

2-12 shows the filter circuit.

Figure 2-12. PEBFIL Filter Circuit Board

2.2.1.4 Transformer

AC voltages (120 VAC, 220 VAC, 240 VAC) that pass through the filter circuit are divided into 26 VAC and

12 VAC and supplied to the PBMA circuit. Figure 2-13 shows a schematic drawing of the power transformer.

Figure 2-13. Transformer Circuit

2-12

LQ-500/ L-1000

Page 50

REV.-A

2.2.1.5 Rectifier and Smoothing Circuit

The 26 VAC from the secondary coil of the transformer are full-wave rectified by diode bridge DB1, and converted to approximately 36 VDC by smoothing capacitor C40. The + 24 VDC and + 5 VDC voltages are converted from this DC voltage, which is used as the power supply voltage for the switching regulator IC at the

next stage.

PRINCIPLES OF OPERATION

Figure 2-14. Rectifier and Smoothing Circuit

LQ-5001 L-1000

2-13

Page 51

PRINCIPLES OF OPERATION

REV.-A

2.2.1.6 + 5 V Regulator Circuit

Figure 2-15 shows the +5 VDC regulator circuit. An NJM2355 switching regulator IC is used for constant-

frequency pulse-width modulation. The circuit shown above employs an NJM2355 configured as a chopper-

style switching regulator circuit.

This IC has a built-in oscillator. The oscillation frequency is determined by external components connected

to pins 2 and 3. Therefore, R105 and C34 cause the circuit to oscillate at about 30 KHz. The oscillator waveform

is shown in Figure 2-16.

2-14

Figure 2-15. + 5 V Regulator Circuit

Figure 2-16. Oscillator Waveform

LQ-500 / L- 1000

Page 52

REV.-A

PRINCIPLES OF OPERATION

AMP 1 in the IC is an error amplifier used to monitor the output voltage. Figure 2-17 shows the constant-voltage

control circuit. Pin 1 of the IC provides a 5 V reference output (Vref), which is applied to the negative terminal

of AMP 1. The error amplifier adjusts its output according to the voltages applied to the positive and negative

input terminals. This has the effect of maintaining the voltage at the positive terminal at 5 V.

Figure 2-18 shows the output from AMP 1. When the voltage at pin 4 becomes higher than that at pin 5 (over

voltage), AMP 1 outputs current modulated by pulse-width modulation (PWM) to reduce the output voltage of

the circuit. PWM is described below.

Figure 2-17. Constant Voltage

Figure 2-18. AMP 1 Output

Control (+ 5 VDC)

R108 and C35 compensate for phase lag in the error amplifier to prevent abnormal oscillation.

LQ-500/ L-1000

2-15

Page 53

PRINCIPLES OF OPERATION

REV.-A

2.2.1.7 Pulse-Width Modulation (PWM) Circuit

Figure 2-19 shows the internal circuit of the NJM2355 IC. The PWM comparator operates as follows:

In circuit 1 the output from AMP 1 flows into the negative terminal of comparator 1, and the outputs from AMP

2 and AMP 3 in circuit 2 flow into the negative terminal of PWM comparator 2 without wired OR. Dead-time

control voltage is also input to additional negative terminals of both PWM comparators 1 and 2.

A sawtooth waveform from the oscillator is input to the positive terminals. The sawtooth waveform from the

oscillator causes the comparators to generate pulses as shown in Figure 2-20.

2-16

Figure 2-19. NJM2355 Internal Circuit

LQ-500/ L-1000

Page 54

REV.-A

As shown in Figure 2-20, when the potential at the NJM2355 is lower than the preset voltage or current value,

it is controlled by the dead-time control voltage. When it exceeds the preset value, it is controlled by the error

amplifier to keep it lower than the preset value.

PRINCIPLES OF OPERATION

Figure 2-20. Output Transistor Drive Waveform

LQ-5001 L-1000

2-17

Page 55

PRINCIPLES OF OPERATION

2.2.1.8 + 24 VDC Regulator Circuit

Figure 2-21 shows the + 24 V regulator circuit. The + 24 VDC regulator circuit has almost the same function

and employs the same oscillation circuit as the +5 VDC regulator circuit. Here, the error amplifier AMP 2 is

used for over-current control, and AMP 3 for constant-voltage control. The operation of the error amplifier AMP

REV.-A

Figure 2-21. +24 V Regulator Circuit

2-18

LQ-500/ L-1000

Page 56

REV.-A

PRINCIPLES OF OPERATION

The negative terminal of AMP 3 receives VREF (5 V). Consequently, the voltage applied to the positive terminal

is adjusted to 5 V. Therefore, based on Figure 2-22, the output voltage is set to the following value:

Figure 2-22. Constant-Voltage Control (+ 24 VDC)

AMP 2 operates as follows for over-current control: + 24 V is applied to the negative terminal, and the positive

terminal will receive an equal voltage when, based on Figure 2-23, a negative current of the following value flows.

Figure 2-23. Over-Current Protection (OCP)

Dead-time control has no bearing in this case, because pin 3 of IC1 is grounded.

LQ-500/ L-1000

2-19

Page 57

PRINCIPLES OF OPERATION

2.2.1.9 + 12 VDC Supply Circuit

The 12 VAC from the transformer is half-wave rectified by diode D19 and is converted to + 12 VDC. As shown

by Figure 2-24, the half-wave rectified voltages pass through the capacitor smoothing circuit so that the ripple

is small, and the average DC voltage rises when no load current flows and drops as load current increases.

Figure 2-24. + 12 VDC Circuit

REV.-A

2-20

LQ-500/ L-1000

Page 58

REV.-A

PRINCIPLES OF OPERATION

2.2.1.10 Vx Voltage Supply Circuit

When the +24 V power supply line reaches 18.6 V (18 V + 0.6 V), transistors Q25 and Q26 turn on and Vx

( + 5 V) is output. On the other hand, if the + 24 V power supply line drops to 18.6 V or less, Q25 and Q26

turn off and the Vx voltage is shut off.

The Vx voltage is used to prevent abnormal operation of the printer when the power is switched on or off.

0 Reset Circuit Power Supply

When the power is switched on or off, the circuit is reset so that it will not drive the printer until the power

supply becomes stable.

0

Pull-ups for the Printhead Signal Lines

These prevent printhead malfunctions when power is switched on or off.

0 Pull-ups for the Paper-Feed Motor Signal Lines

These prevent paper-feed motor malfunctions when power is switched on or off.

LQ-500/ L-1000

Figure 2-25. Vx Voltage Circuit

2-21

Page 59

PRINCIPLES OF OPERATION

REV.-A

2.2.2 Reset Circuit

Figure 2-26 shows the reset circuit. The RESET signal generated here is sent to the RESET terminal of CPU

µPD781 OHG (46) and to connector CN2-13 (optional interface) as a hardware initialization signal. The RESET

signal is output from the circuit when any of the following occurs:

0 Power is turned on or off.

0 The INIT signal is input from either the host interface or an optional interface.

l A module (font or identity) is mounted or removed.

Figure 2-26. Reset Circuit

Power On or Off

D14, R69, and C26 in Figure 2-26 comprise an ON/OFF reset circuit. The purpose of this circuit is to make

the CPU start from address 0000 hex. when power is applied and prevent CPU malfunctions when the power

is switched off.

2-22

LQ-500/ L-1000

Page 60

REV.-A

PRINCIPLES OF OPERATION

The rising edge of the Vx voltage cancels the RESET signal after a delay of time constant T = R69 x C26

produced by the integration circuit of resistor R69 and capacitor C26. The falling

edge of the Vx voltage ac-

tivates a RESET signal by discharging capacitor C26 via diode D14.

The gate array (pins 49 to 51) is used for waveform shaping.

Figure 2-27. RESET Output

INIT Signal Input (from CN1 or CN2)

The external INIT signal (50 µsec or less) is passed through the low-pass filter of R31 and C22, and waveformshaped in the gate array (pin 47 of IC6C) to set the DISC terminal LOW, discharge capacitor C26, and set the

gate array THLD terminal LOW. Following this, the ROUT terminal outputs the RESET signal.

LQ-500/ L-1000

2-23

Page 61

PRINCIPLES OF OPERATION

REV.-A

Module Installation or Removal

Figure 2-28 shows the RESET pulse generation process that occurs when a ROM cartridge is mounted. Numbers

in parentheses below correspond to circled numbers in the figure. After the ROM cartridge is mounted, the

LOW signal flows into the CAR terminal of the gate array (6C), and a LOW signal is correspondingly output

from the DISC terminal and RESET is output from the ROUT terminal.

As the DISC terminal goes LOW, capacitor C26 is discharged with a time constant = R70 x C26. When

the discharge of C26 reduces the potential at the THLD terminal to threshold voltage Vth, the RESET signal

is canceled, and the DISC terminal goes HIGH. After the DISC terminal goes HIGH, Vx voltage

discharges C31 at time constant = R69 x C26 again.

2-24

Figure 2-28. RESET Pulse Oscillation Process (Module Mounted)

LQ-500/L-1000

Page 62

REV.-A

When the ROM cartridge is removed (see Figure 2-29), the CAR terminal of the gate array (6C) receives a HIGH

signal. Then the DISC terminal outputs a LOW signal, and the ROUT terminal outputs a RESET signal.

The remainder of the sequence is similar to that when a ROM cartridge is mounted, so please refer to the

preceding page.

PRINCIPLES OF OPERATION

LQ-500/ L-1000

Figure 2-29. RESET Pulse Oscillation Process (Module Removed)

2-25

Page 63

PRINCIPLES OF OPERATION

2.2.3 Firmware Operation at Reset

After being reset, the CPU executes the initialization program from address 0000 hex. When this program has

completed normally, the CPU enters the standby state and waits for data. Figure 2-30 shows the initialization

program flowchart.

REV.-A

2-26

Figure 2-30. Initialization Program Flowchart

LQ-500/ L-1000

Page 64

REV.-A

PRINCIPLES OF OPERATION

LQ-500/L-1000

Figure 2-30. Initialization Program Flowchart (Cont.)

2-27

Page 65

PRINCIPLES OF OPERATION

REV.-A

2-28

Figure 2-30. Initialization Program Flowchart (Cont.)

LQ-500I L-1000

Page 66

REV.-A

PRINCIPLES OF OPERATION

2.2.4 Address Decoder and Bank Register

This section describes the address decoder and bank register.

Address Decoder

This unit includes an address decoder in gate array E01A05KA (6C). The address decoder outputs a chip-select

signal to the internal PROM (3C), external PROM, 4MCG (5C), 1 MCG (2C), external CG, RAM (2C), HEAD gate

array (7A) via address lines AB12 through AB15 and bank lines 7 and 6 (in the gate array). However, the chip

select for the CS is generated in conjunction with the RD signal, and that of the RAM is generated in conjunction

with the ALE signal.

Software control of firmware can check whether an external PROM is mounted or not, and if the correct PROM

is mounted, the memory map shown in Figure 2-31 is obtained by writing bit 7 LOW at address FOOl hex.

LQ-500I L-1000

Figure 2-31. Memory Map

2-29

Page 67

PRINCIPLES OF OPERATION

Bank Register

This unit has a bank register in gate array EOlA05KA (6C). The bank lines are set by writing to address FO02

hex., and they can be checked by reading the same address.

bits and bank lines.

Table 2-3. Control Commands

Table 2-3 shows the relationship between data

REV.-A

2-30

LQ-500/ L-1000

Page 68

REV.-A

2.2.5 Carriage Operation

This section describes the carriage.

2.2.5.1 Carriage Mechanism

The carriage mechanism includes the printhead, the carriage, the timing belt, the carriage motor, and the platen.

Figure 2-32 shows the carriage mechanism.

The timing belt is connected into the bottom of the carriage. This belt is driven by the carriage motor and moved

via the belt-driven pulley. The printhead is mounted on the carriage, and the entire unit is moved right and

left along the carriage guide shaft and plate.

PRINCIPLES OF OPERATION

Figure 2-32. Carriage Mechanism

2.2.5.2 Carriage Motor Specifications

Carriage motor specifications are as follows:

Type

Drive Voltage

Coil Resistance

Current

LQ-500/ L-1000

4-phase, 48-pole stepper motor

24 V f 10%

21 ohms f 7% at 25 degrees C

Maximum 0.34 A (rush current)

Driving: 0.3 A (typical) (triple speed, 24 V)

0.23 A (typical) (double speed, 1.5 speed, normal speed, 24 V)

Holding: 0.17 A f 20%

2-31

Page 69

PRINCIPLES OF OPERATION

2.2.5.3 Carriage Drive Circuit Block Diagram

REV.-A

Figure 2-33 shows a block diagram of the carriage motor drive circuit.

the carriage motor is not directly executed by the CPU, but by the gate array (6C) using pulses from the CPU.

STK-6981 B is employed to drive the carriage motor using a stabilized current.

Figure 2-33. Carriage Drive Circuit Block Diagram

In this circuit, the phase switching for

2-32

LQ-500/ L-1000

Page 70

REV.-A

2.2.5.4 Gate Array EOlA05KA Operation in Carriage Motor Drive Circuit

The phase switching for the carriage motor (stepper motor) is performed by gate array EOlA05KA (6C). This

gate array first sets the excitation system (2-2 phase or 1-2 phase) and rotation direction (clockwise Or

counterclockwise). Then, after the CPU outputs a pulse to the TM terminal of the gate array, executes auto

phase switching to drive the stepper motor. Figure 2-34 shows this process.

PRINCIPLES OF OPERATION

LQ-500 / L-1000

Figure 2-34. Gate Array Operation

2-33

Page 71

PRINCIPLES OF OPERATION

The carriage motor control port of the gate array is assigned to address FO03 hex. Control commands for the

carriage motor (via the gate array) are listed in Table 2-4.

Table 2-4. Control Commands

When power is turned on

REV.-A

(CW = clockwise; CCW = counterclockwise)

2-34

LQ-500/ L-1000

Page 72

REV.-A

PRINCIPLES OF OPERATION

2.2.5.5 Carriage Motor Drive Circuit

The LQ-500 employs the STK-69816, which is a hybrid IC used to drive stepper motors. STK-6981B (IC8C)

drives the stepper motor with a constant current. The value of the current is determined by an external voltage

level. The IC operation can be separated into phases AB and CD, which are completely equivalent. Phase CD

is described here as a model. Figure 2-35 shows the carriage motor drive circuit. Figure 2-36 shows the

STK-6981 B circuit diagram

LQ-5001 L-1000

Figure 2-35. Carriage Motor Drive Circuit

2-35

Page 73

PRINCIPLES OF OPERATION

REV.-A

NOTE: Phase AB is equivalent to the above.

Figure 2-36. STK-6981 B Circuit Diagram

2-36

LQ-500/ L-1000

Page 74

REV.-A

Reference Voltage Generation Circuit

Figure 2-37 shows the reference voltage generation circuit and Table 2-5 shows the reference voltage.

PRINCIPLES OF OPERATION

Figure 2-37. Reference Voltage Generation Circuit

Table 2-5. Reference Voltage

LQ-500/ L-1000

2-37

Page 75

PRINCIPLES OF OPERATION

REV.-A

Constant Current Drive Circuit

The carriage motor-drive current is given by the following equation:

I = VrCD/R79 = VrCD/1.2 ohms

When the carriage stops, port PB5 of the CPU is set HIGH, the input to the chopping circuit becomes 0 V,

and current is applied from the + 5 V line to the motor via resistor R1 and diode D1. This current is given by:

I =

(5 V - VD15 - VD5)

R76 - 21 ohms/phase + R79

Figure 2-38 shows the constant current circuit; Table 2-6 lists the current values for reference voltages.

2-38

Figure 2-38. Constant Current Control Circuit

LQ-500 / L-1000

Page 76

REV.-A

PRINCIPLES OF OPERATION

Table 2-6. Current Values for Reference Voltages

With positive feedback through R9, a hysteresis, whose upper bound is the reference voltage, is generated

in the comparator of ICl. The comparator works as a Schmitt trigger, which senses a difference only when

the feedback (inverse terminal) is slightly larger or smaller than the hysteresis level. Reference voltage-a and

the feedback voltage are compared by the comparator in IC1. If reference voltage-a is HIGH, TR6 turns on,

applying approximately 25 VDC to the coil. The current rises linearly due to inductance, and TR6 turns off when

the feedback voltage reaches reference voltage. In this manner an almost constant current can be applied to

the coil.

Figure 2-39 shows the drive current waveform (pin 12) of the carriage motor and the chopping waveform (pin

17) of the drive voltage (+ 25 V), at 900 PPS. Figure 2-39 shows the Schmitt trigger circuit.

Figure 2-39. Chopping

Waveforms

LQ-500/ L-1000

2-39

Page 77

PRINCIPLES OF OPERATION

REV.-A

Figure 2-40. Schmitt Trigger Circuit

2-40

LQ-500/L-1000

Page 78

REV.-A

PRINCIPLES OF OPERATION

2.2.5.6 Carriage Motor Software Control

This section describes the carriage motor software control.

Excitation System

The excitation system is determined by the firmware and is executed in accordance with the carriage speed,

as shown in Table 2-7. The motor drive sequence for each excitation system is shown in Tables 2-8 and 2-9.

Table 2-7. Phase-Excitation Method

Table 2-8. Drive Sequence (2-2 Excitation)

LQ-500/ L-1000

2-41

Page 79

PRINCIPLES OF OPERATION

REV.-A

Table 2-9. Drive Sequence (1-2 Excitation)

Since a stepper motor is used for the carriage motor, it is possible to hold at any position and switch printing

direction. The carriage motor control system is an open-loop system which switches the phases in accordance

with set speeds.

The drive chopping current is switched at the drive frequency for the carriage motor. The relationship between

drive speed and switching current value is shown in Figure 2-41, and values for the drive chopping current

are listed in Table 2-10.

2-42

Figure 2-41. Chopping Current and Drive Speed

LQ-500/L-1000

Page 80

REV.-A

Table 2-10. Chopping Current

The times for constant speed, acceleration control, and deceleration control are shown below. The a marks

in the acceleration and deceleration columns control items in the tables and indicate switching times from Al

to A2 or 62 to B1.

PRINCIPLES OF OPERATION

Figure 2-42. Carriage Motor Control

Table 2-11. Time Constants for Speeds

LQ-500/L-1000

2-43

Page 81

PRINCIPLES OF OPERATION

Table 2-12. Acceleration Time Data (2-2 Excitation)

REV.-A

Table 2-13. Deceleration Time Data (2-2 Excitation)

2-44

LQ-500/ L-1000

Page 82

REV.-A

PRINCIPLES OF OPERATION

Table 2-14. Acceleration Time Data (1-2 Excitation)

LQ-500/L-1000

2-45

Page 83

PRINCIPLES OF OPERATION

Table 2-15. Deceleration Time Data (1-2 Excitation)

REV.-A

2-46

LQ-500/L-1000

Page 84

REV.-A

PRINCIPLES OF OPERATION

Home-Position Seek

The control that causes the carriage to move to the home position when the power is turned on is called home-

position seek. Figure 2-43 shows the home-position seek operation. After power is applied, the printer executes

2-2 phase excitation for 20 or 30 ms and checks the HOME signal, regardless of the phase switching timing.

The result of this check determines whether the starting position should be 1 or 2. The carriage enters the

home position only once during the initialization.

LQ-5001 L-1000

Figure 2-43. Home-Position Seek

2-47

Page 85

PRINCIPLES OF OPERATION

Printing Area

The printing area is defined as starting 22 phase switching times after the home position.

REV.-A

Figure 2-44. Printing Area and Printing Timing

Abnormal Carriage Operation

This unit does not employ a print timing signal (PTS) sensor and cannot detect abnormal carriage operation.

Therefore, no error occurs even if carriage movement is prevented by external forces. An error will only occur