Page 1

Return to main menu

IM-X4 0

Using this online operator’s guid e

The words on the left side of this screen are

bookmark s

for all the

topics in this guide .

Use the

scroll ba r

next to the bookmarks to find any topic you

want. Click a bookmark to instantly jump to its topic. (If you wish,

you can increase the size of the bookmark area by dragging the

dividing bar to the right. )

Use the

Click the

zoo m

Fin d

tools to magnify or reduce the page display .

button if you want to search for a particular term.

(However, using the bookmarks is usually quicker. )

Complete online documentation for Acrobat Reader is located in the Help directory for Acrobat Reader .

Page 2

IM-X40

User’s Manual

Page 3

Printed in Japan

-iii

Page 4

Copyright Information

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of Seiko

Epson Corporation. No patent liability is assumed with respect to the use of the

information contained herein. While every precaution has been taken in the

preparation of this book, Seiko Epson Corporation assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the

use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of

this product or third parties for damages, losses, costs, or expenses incurred by the

purchasers or third parties as a result of accident, misuse, or abuse of this product or

unauthorized modifications, repairs, or alterations to this product, or (excluding the

U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

Seiko Epson Corporation shall not be liable against any damages or problems arising

from the use of any options or any consumable products other than those designated

as Original EPSON Products or EPSON Approved Products by Seiko Epson

Corporation.

EPSON is a registered trademark of Seiko Epson Corporation.

Intel is a registered trademark of Intel Corporation.

i486 is a trademark of Intel Corporation.

IBM, PC/AT, and PS/2 are registered trademarks of International Business

Machines Corporation.

MAXIMIZER is a trademark of SystemSoft Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation.

General Notice: Other product and company names used herein are for

identification purposes only and may be trademarks of their respective companies.

NOTICE:

The contents of this manual are subject to change without notice.

Copyright 1996 © by Seiko Epson Corporation, Nagano, Japan.

400575700

ii

Page 5

FCC CLASS A

FCC COMPLIANCE STATEMENT FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to

correct the interference at his own expense.

WARNING

The connection of a non-shielded interface cable to this product will invalidate the

FCC Verification of this device and may cause interference levels which exceed the

limits established by the FCC for this equipment.

You are cautioned that changes or modifications not expressly approved by the

party responsible for compliance could void your authority to operate the

equipment.

FOR CANADIAN USERS

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement

sur le matériel brouilleur du Canada.

iii

Page 6

Nickel-Cadmium (Ni-Cd) Rechargeable Battery

Aufladbare Nickel-Cadmium (Ni-Cd) Batterie

Batterie rechargeable au Nickel-Cadmium (Ni-Cd)

R

PBRC

B

R

C

PBRC

Ni-Cd

Ni-Cd Cd

Attention:

The product that you have purchased contains a Ni-Cd rechargeable battery. The

battery should be recycled or disposed of properly. When your battery can no longer

be recharged, please disconnect the battery according to this manual’s instructions,

and check with your local solid waste officials for details in your area for recycling

options or proper disposal.

Achtung:

Das von Ihnen erworbene Produkt enthält eine aufladbare Ni-Cd-Batterie. Die

Batterie sollte wiederverwertet bzw. korrekt entsorgt werden. Kann die Batterie

nicht mehr aufgeladen werden, entfernen Sie die Batterie, wie in dieser Anleitung

beschrieben, und erkundigen Sie sich bei der an Ihrem Wohnort zuständigen

Behörde bezüglich Wiederverwertung bzw. korrekter Entsorgung.

Attention:

Le produit que vous venez d’acheter contient une batterie rechargeable Ni-Cd. La

batterie doit être recyclée ou jetée convenablement. Lorsque la batterie est morte, ne

pouvant plus être rechargée, la déconnecter conformément aux instructions du

mode d’emploi et vérifier avec les autorités locales pour les détails sur le recyclage et

la collecte sélective des ordures.

iv

Page 7

Modular type connector

You see the following caution label near the modular type connector on the back

panel of the product.

Caution:

The product uses a modular type connector exclusively for the DM display. Never

plug a telephone line into this connector.

v

Page 8

Introduction

The IM-X40 control unit (referred to as the control unit in this

document) is an intelligent terminal for the point of sale (POS)

environment. The control unit offers the following features:

❏ A fast SL enhanced Intel

®

i486™SX2 processor gives you the

power and speed you need to process your transactions.

❏ Because the TM printer fits on top of the control unit, you can

install it in a small area, giving you more counter space.

❏ The PC-based, open-architecture control unit contains one

standard 16-bit ISA expansion slot and a second expansion slot

for a PCMCIA expansion module, allowing you to expand your

system.

❏ Using a standard SIMM, you can install up to 32MB of memory

in a control unit.

❏ The built-in IBM

PC/AT

®

compatible keyboards, so you can select the best one

®

PS/2® keyboard port can support a variety of

for your environment.

❏ Four serial ports and a combined parallel/optical coupled

interface adapter (OCIA) port allow you to connect several

industry-standard peripherals to meet your specific transaction

processing needs.

❏ The built-in DM display port allows you to install an EPSON

®

DM-D102 or DM-D203 customer display without requiring you

to use one of the additional serial ports.

❏ The built-in VGA port allows you to connect a standard VGA

or SVGA monitor directly to the control unit.

Introduction 1

Page 9

❏ A Nickel-Cadmium (Ni-Cd) battery is available as a option. In

the event of a power failure, the Ni-Cd battery backup gives

you time (about a minute) to save your current transaction

before the control unit shuts down.

❏ Several levels of security keep your critical data safe. The front

panel locks, ensuring controlled access to the floppy disk drive

and making the removal of the IM module impossible. Multiple

levels of passwords keep your system, your data, and your

cash drawer secure.

❏ Sophisticated power management functions ensure that you

use only the power you need to process your transactions.

❏ The hard disk drive is easy to remove and reinstall. If a system

fails, you can be using your same data on a different control

unit almost immediately.

❏ The easy-to-update flash ROM has 112KB available for a user-

defined program, while 144KB is used by the system.

❏ The BIOS is PC/AT compatible—this means you can run all

your favorite PC programs as well as your application-specific

software.

❏ Built-in device diagnostics make troubleshooting fast and easy.

❏ Local bus video.

2 Introduction

Page 10

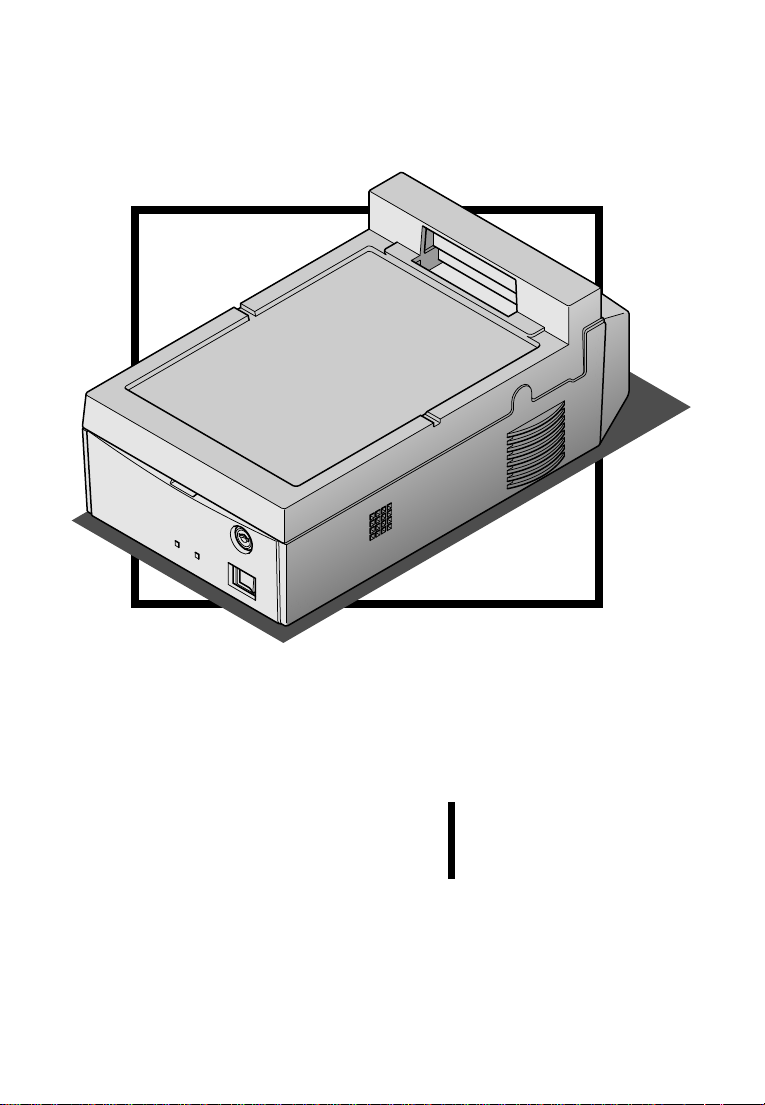

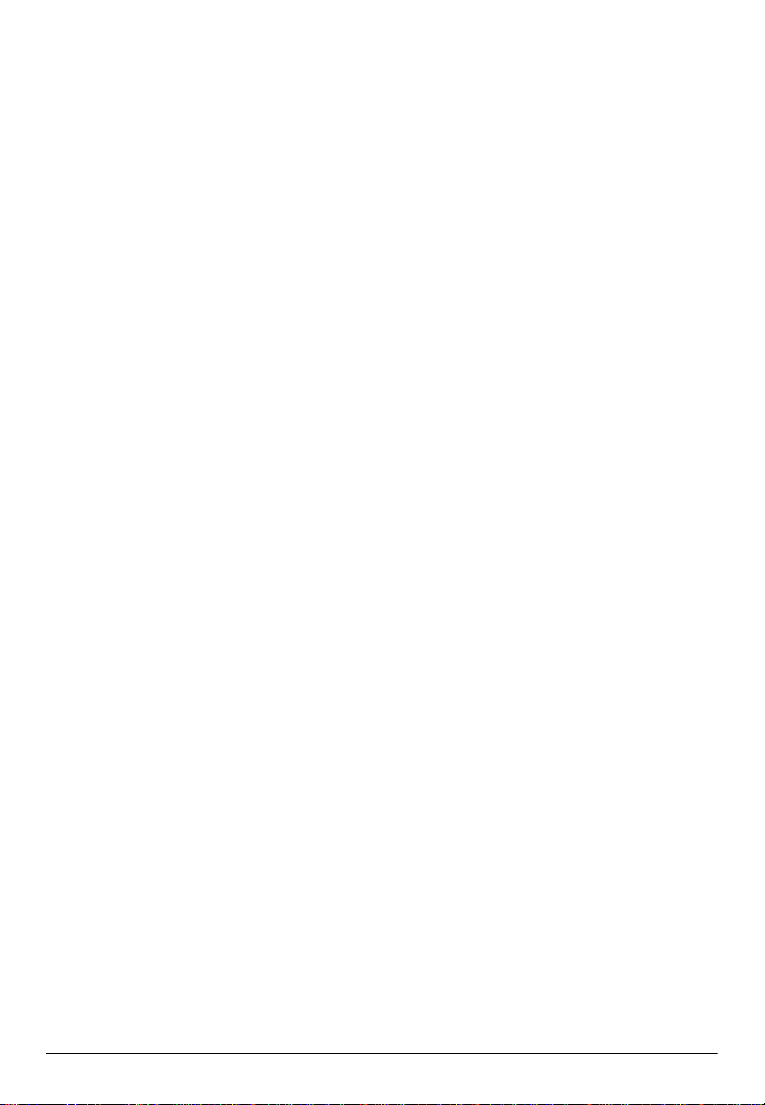

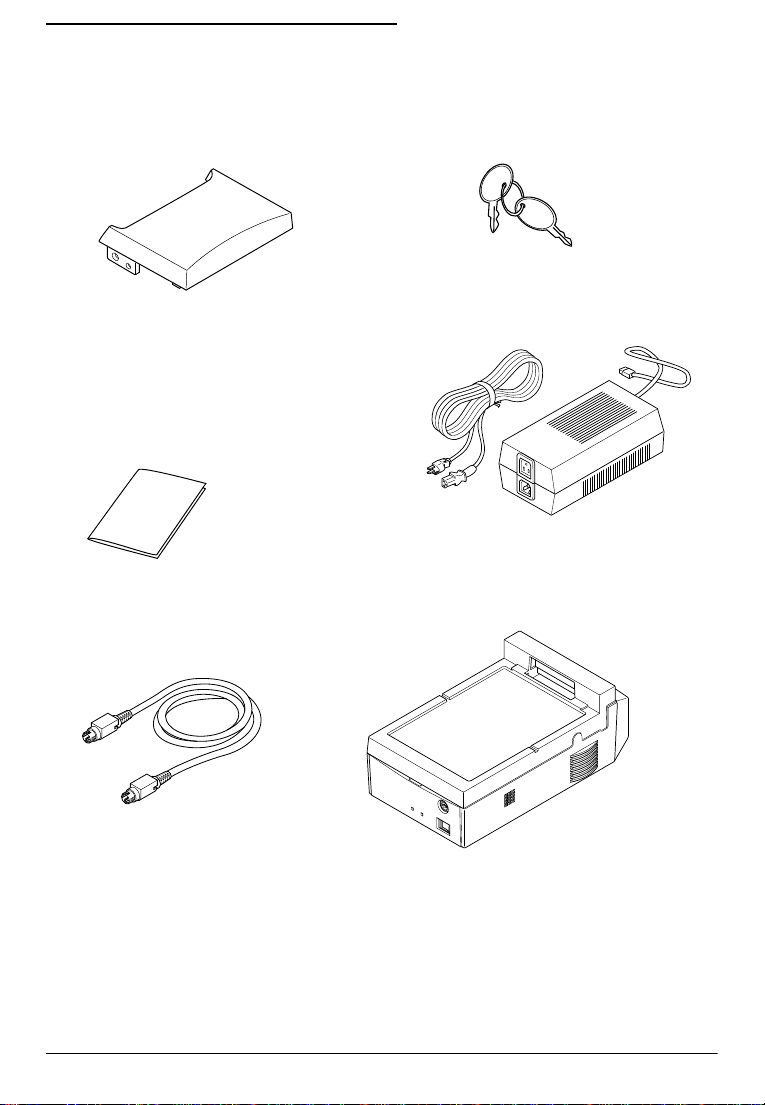

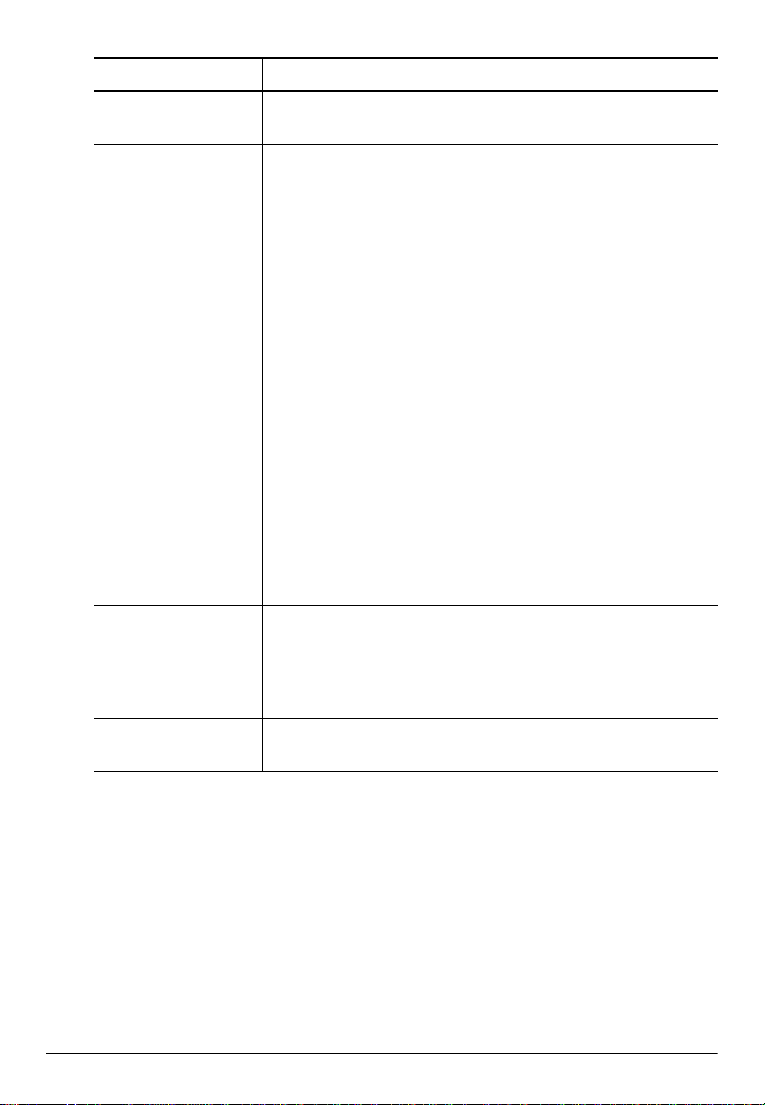

The illustrations below show the part names of the control unit.

(These illustrations show the floppy disk drive installed.)

COM1 port

TM printer

power outlet

Floppy disk drive

Hard disk

access LED

IM-X40

control unit

Power LED

DM display port

Power inlet

Transportation

screw storage hole

COM2 port

Power switch

Reset

Key lock

COM4 port

COM3 port

LPT1/OCIA port

Keyboard port

VGA port

Control unit overview

Introduction 3

Page 11

Handling Guidelines

Observe these guidelines when handling the control unit:

❏ Make sure you read the safety instructions for the power

supply before you attach or remove it.

❏ Never plug a telephone line into the DM display port.

❏ Make sure you always set a password for accessing the drawer

kickout test in the device diagnostics utility. The drawer

kickout test checks if the cash drawer opens correctly.

However, anyone can access the test if you do not define a

password.

❏ Make sure you charge the batteries (Ni-Cd* and Lithium

batteries) in the control unit. These rechargeable batteries are

not charged fully at the factory. (*Ni-Cd battery is an option.)

❏ Do not block any slots or openings on the control unit. These

are provided for the ventilation necessary to ensure reliable

operation and protection from overheating.

❏ Make sure that any device connected to the AC outlet of the

power supply does not consume more than 150 VA.

❏ Make sure that the total power requirements of all the devices

getting their power from the control unit do not exceed the

control unit power limitations.

❏ When you transport the control unit in its shipping container,

make sure you replace the transportation screw.

❏ Make sure you lock the IM module to the lower plastic housing

using the lock on the front panel. The module could fall from

the housing if it isn’t secured.

❏ Never hold the control unit by the back cover. This cover

cannot support the weight of the unit, so it may fall onto the

floor.

4 Introduction

Page 12

❏ You see the following label on the back panel of the control

unit:

This connector

cannot be used.

Do not remove this label.

Option

❏ PCMCIA expansion module

This expansion module supports two Type I or Type II PC

cards or one Type III PC card.

❏ Ni-Cd battery

The rechargeable Ni-Cd battery supplies power to the control

unit for approximately one minute in the event of a power

failure. This allows you to save your current transaction before

the control unit shuts down.

A 3.5-inch floppy disk drive, 2.5-inch hard disk drives, and

SIMMs are also available for the control unit.

Introduction 5

Page 13

List of Terms

The following list identifies terms used in this manual and the

corresponding names printed on each circuit board.

Manual term Printed name on circuit board

Connector board I/C board

External I/O board EXT I/O board

Modular board MO board

PCMCIA expansion module PCMCIA board

Power board PWR board

System board CPU board

Warnings, Cautions, and Notes

Notes and precautions in this manual are identified by their level of

importance, as defined below.

WARNINGS

provide information that must be observed to prevent harm

(not life-threatening) to the user.

Cautions

provide information that must be observed to prevent

damage to the equipment or loss of data.

Notes:

provide important information and useful tips on handling the

equipment.

6 Introduction

Page 14

Contents

Chapter 1

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unpacking the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Setting Up the IM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Removing the Transportation Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Removing the IM Module From the Plastic Housing . . . . . . . . . . . . . . . . . . . . 1-5

Removing the External I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Removing the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Locating Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Setting the Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Installing or Removing a SIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Installing a Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Installing a Floppy Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Installing a PCMCIA Expansion Module (option) . . . . . . . . . . . . . . . . . . . . . . 1-26

Installing an ISA Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Installing the Battery Pack (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Installieren der Batterie-Einheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Installation de la batterie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Setting Up the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Connecting the TM printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Connecting Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Connecting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Attaching the Back Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

Setting a Password for the Drawer Kick-out Test . . . . . . . . . . . . . . . . . . . . . . . 1-42

Charging the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

Lithium Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

Ni-Cd Battery (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

Installation

Chapter 2

Using the System Configuration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Starting the System Configuration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Changing Options in the System Configuration Utility . . . . . . . . . . . . . . . . . . 2-3

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Setting the COM Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Setting the LPT Port Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Setting the LPT Port MODE Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Setting the Floppy Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting the Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting the Video Display Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Using System Utilities

vii

Page 15

Setting the Quick Boot Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Setting the Num Lock Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting the Boot Speed (CPU Speed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting the Keyboard Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Enabling the On-board Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Setting Memory Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Exiting the System Configuration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Setting Power Management Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Setting the Power Management Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Defining System Power Management Criteria . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Defining Device Power Management Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Exiting From the Power Management Utility . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Using Device Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Device Diagnostics Utility Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Starting Device Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Device Diagnostics Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

TM/Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

DM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Using the Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Running Device-Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Initializing Device Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Leaving Device Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Chapter 3 Troubleshooting

Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Fatal Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Beep Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

The Control Unit Will Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Battery Backup Does Not Work (optional Ni-Cd battery) . . . . . . . . . . . . . . . . . . . . 3-6

The Control Unit Does Not Respond . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

The Control Unit Shuts Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Keyboard Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Monitor Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

The EPSON DM-D Display Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Floppy Disk Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Floppy Disk Drive Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Hard Disk Drive Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

TM Printer Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Serial Port Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Parallel or OCIA Port Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Cash Drawer Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

PC Card Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Port 80h Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

viii

Page 16

Appendix A Control Unit Specifications

CPU and Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Indicators (LEDs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

System Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Power Supply Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Power Limits of the Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

DMA Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Hardware Interrupts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

System Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

System I/O Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

Appendix B Loop Back Connectors

Appendix C SIMM Specifications

ix

Page 17

Chapter 1

Installation

This chapter explains how to set up your hardware. For

configuring your system using the system utility software, see the

next chapter.

How to Use This Chapter

For a list of the components included with the control unit, see

page 1-3.

If you install the optional battery pack in your control unit, turn to

page 1-31. To remove the transportation screw, turn to page 1-4.

The IM module is a control unit without the housing. Before you

can install internal components or change jumper settings, you

need to remove the IM module from the plastic housing, and then

remove the external I/O board and the cover.

Check the table below to see where these procedures are described;

then follow the instructions on that page.

If you want to See page

Remove the IM module from the plastic housing 1-5

Remove the external I/O board from the IM module 1-7

Remove the cover from the IM module 1-9

Installation 1-1

Page 18

Once you have the cover off of the IM module, turn to the

appropriate sections in this chapter and follow the instructions for

installing the component.

If you want to See page

Set jumpers 1-12

Install a SIMM 1-18

Install a hard disk drive 1-20

Install a floppy disk drive 1-22

Install a PCMCIA expansion module 1-26

Install an ISA card 1-29

When you have the components installed, replace the cover and the

external I/O board; then return the IM module to the plastic

housing. Then turn to page 1-36 for instructions on setting up the

control unit.

1-2 Installation

Page 19

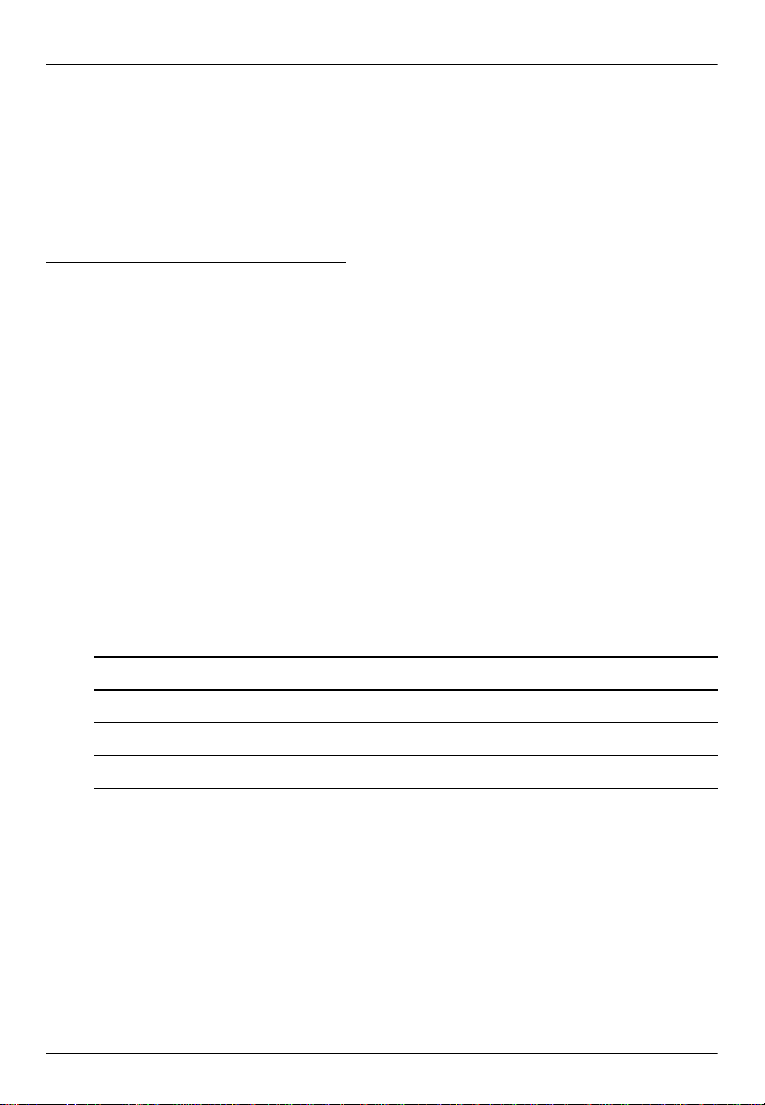

Unpacking the Control Unit

When you unpack the control unit, make sure you have these

items:

Keys (2 pieces)

Back cover

Safety instructions

TM printer power cable

Power cord

Power supply

Control unit

If any of these items are damaged or missing, please contact your

dealer for assistance.

Installation 1-3

Page 20

Setting Up the IM Module

Before you perform any steps described in this section, make sure

the control unit and any peripheral devices are off. Disconnect the

power supply from the control unit. Also disconnect any cables

that are connected to the control unit.

Caution

Never install options, change jumper settings, or connect

peripherals when the control unit is turned on or the power

supply is connected to the control unit.

Removing the Transportation Screw

The IM module is secured to the plastic housing during shipping

by a transportation screw. Follow these steps to remove this screw:

1. Turn the control unit over so that the bottom of the plastic

housing is facing up; then locate the transportation screw.

2. Use a small coin or a flat head screwdriver to turn the screw

counterclockwise and remove it.

1-4 Installation

Page 21

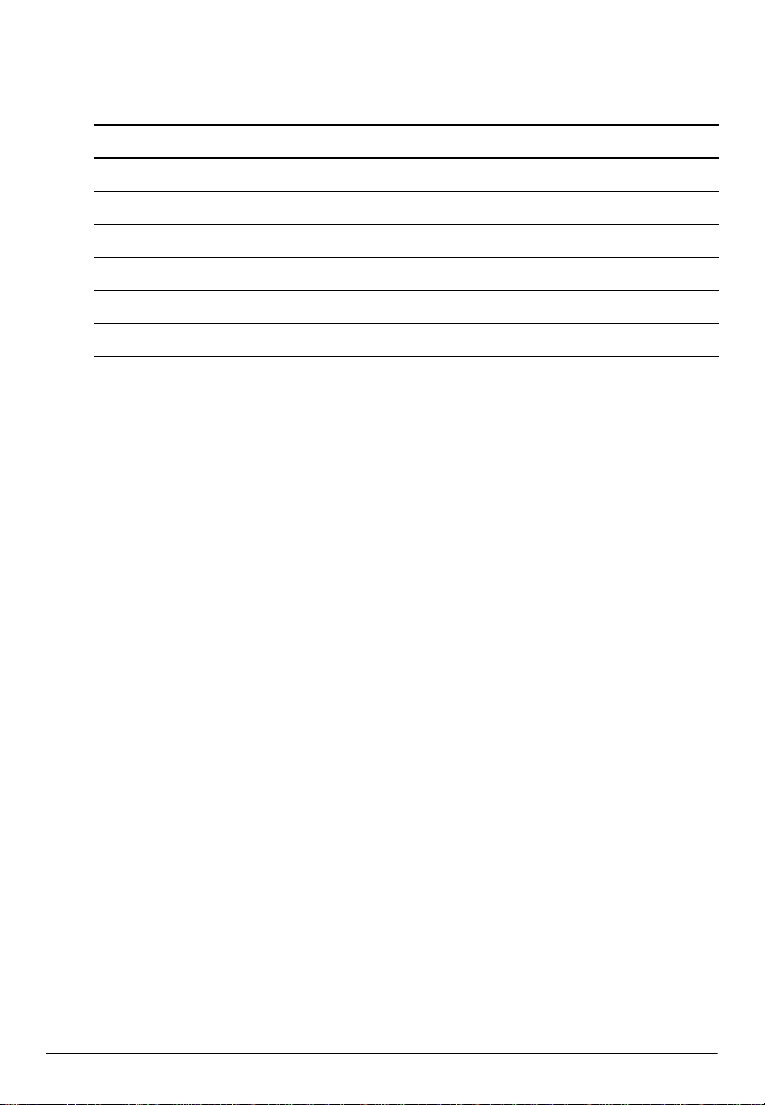

3. Locate the storage hole on the back panel of the control unit.

4. Secure the transportation screw to the storage hole in the back

panel.

Transportation

screw storage hole

Plastic housing

Caution

When you transport the control unit in its shipping container,

make sure you replace the transportation screw in the

bottom of the control unit.

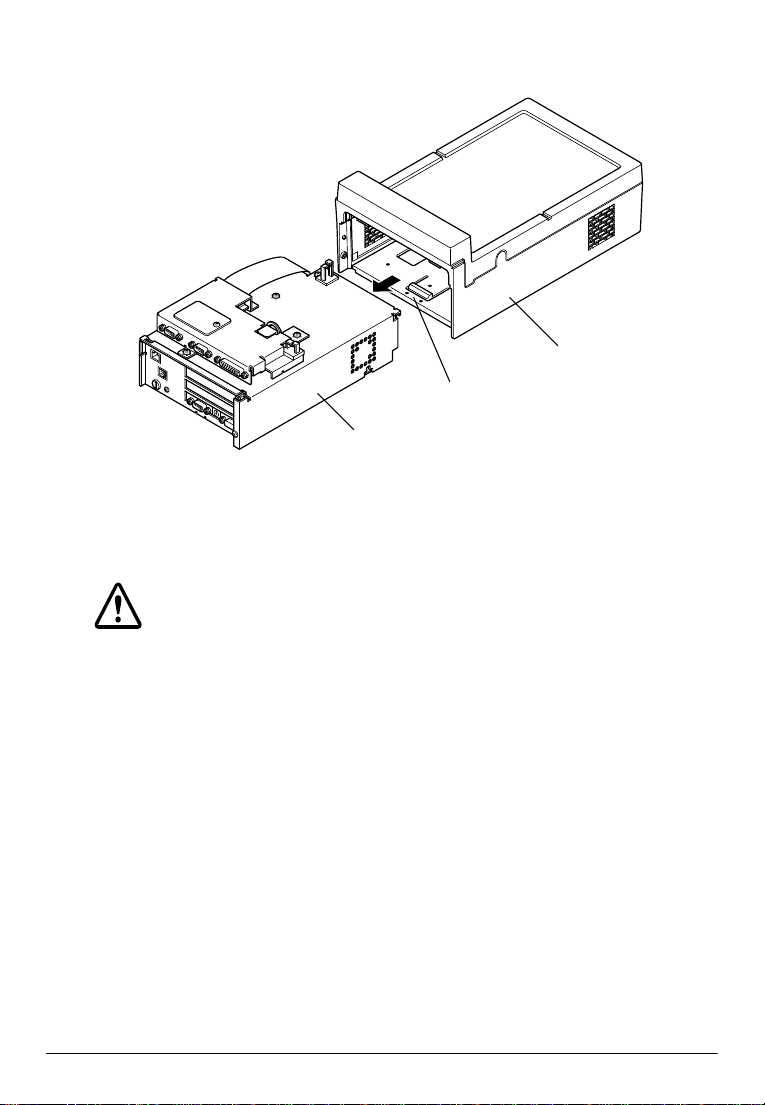

Removing the IM Module From the Plastic Housing

Before you can install or remove any components from the IM

module or change jumper settings, you need to remove the IM

module from the plastic housing. Follow these steps:

1. Make sure that the transportation screw has been removed.

(See page 1-4.)

2. Use the key provided to open the lock on the front panel of the

plastic housing; then open the front panel.

Installation 1-5

Page 22

3. Hold down the tab on the plastic housing as you pull the IM

module out, as shown below:

Plastic housing

Tab

IM Module

When you are ready to replace the IM module in the plastic

housing, slide it in, until it is all the way in the housing. Close the

front panel and use the key to lock it.

Caution

Make sure you lock the IM module to the plastic housing

using the lock on the front panel. The module could fall from

the housing if it isn’t secured.

1-6 Installation

Page 23

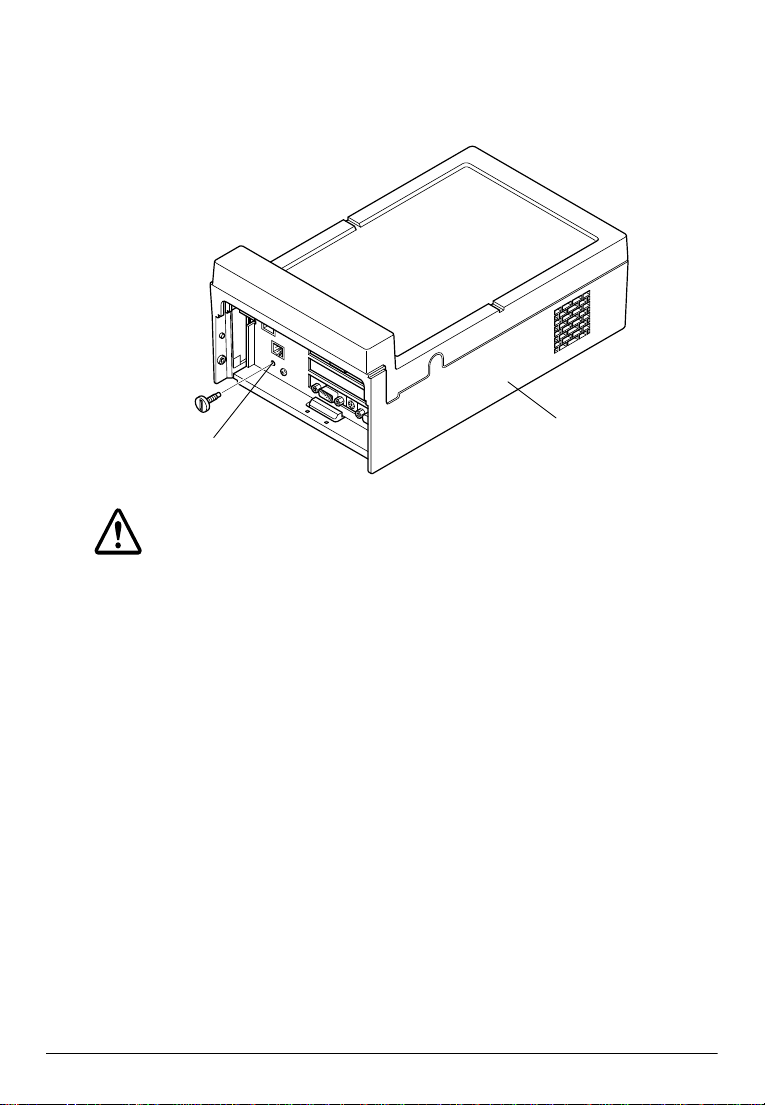

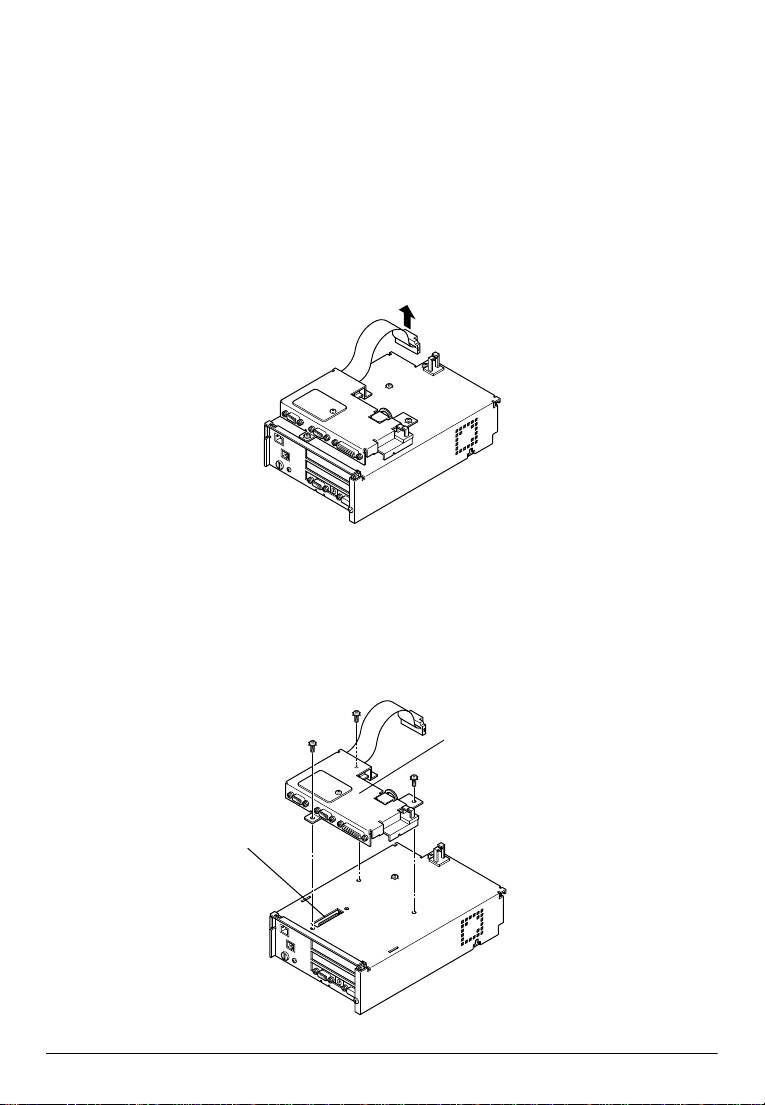

Removing the External I/O Board

The external I/O board connects to the connector board of the IM

module to provide three additional serial ports (COM1, COM3 and

COM4) and a parallel port that can also function as an OCIA port

(LPT1/OCIA). You must remove the external I/O board before you

can remove the cover on the IM module. Follow these steps:

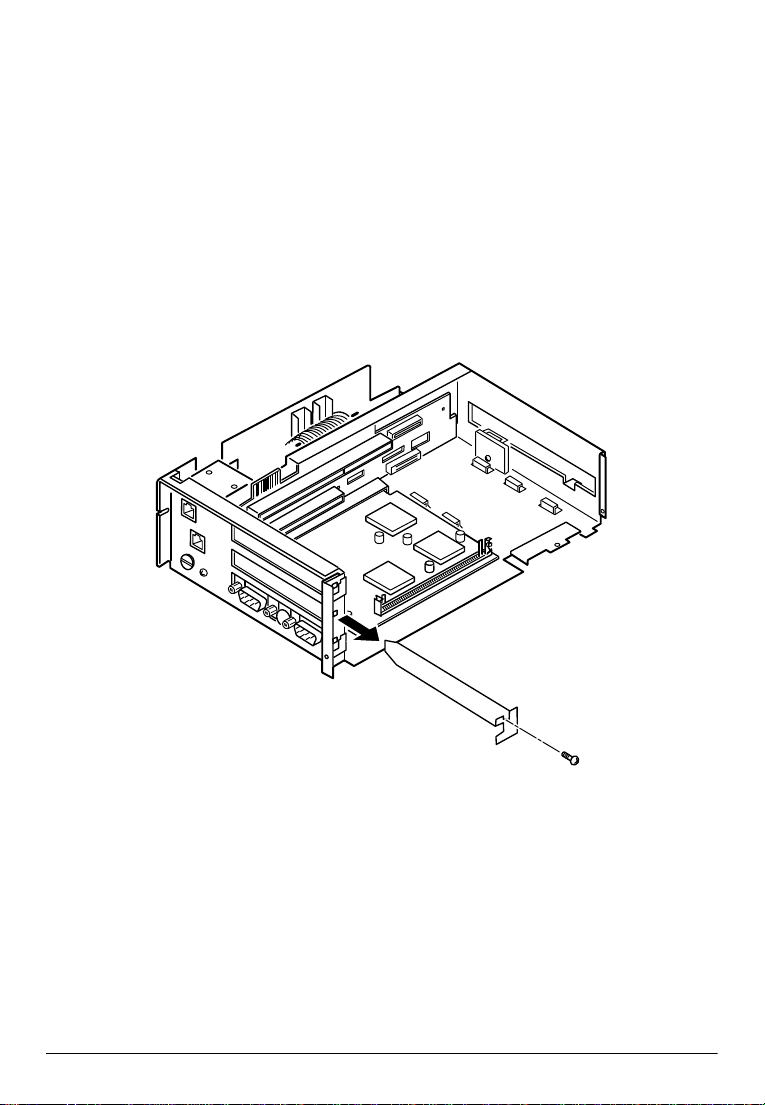

1. Disconnect the connector as shown in the illustration below.

2. Use a Phillips screwdriver to remove the three screws securing

the external I/O board to the cover.

3. Lift the external I/O board straight up to disconnect it from the

IM module, as shown below; then set it aside.

External I/O

board connector

External

I/O board

Installation 1-7

Page 24

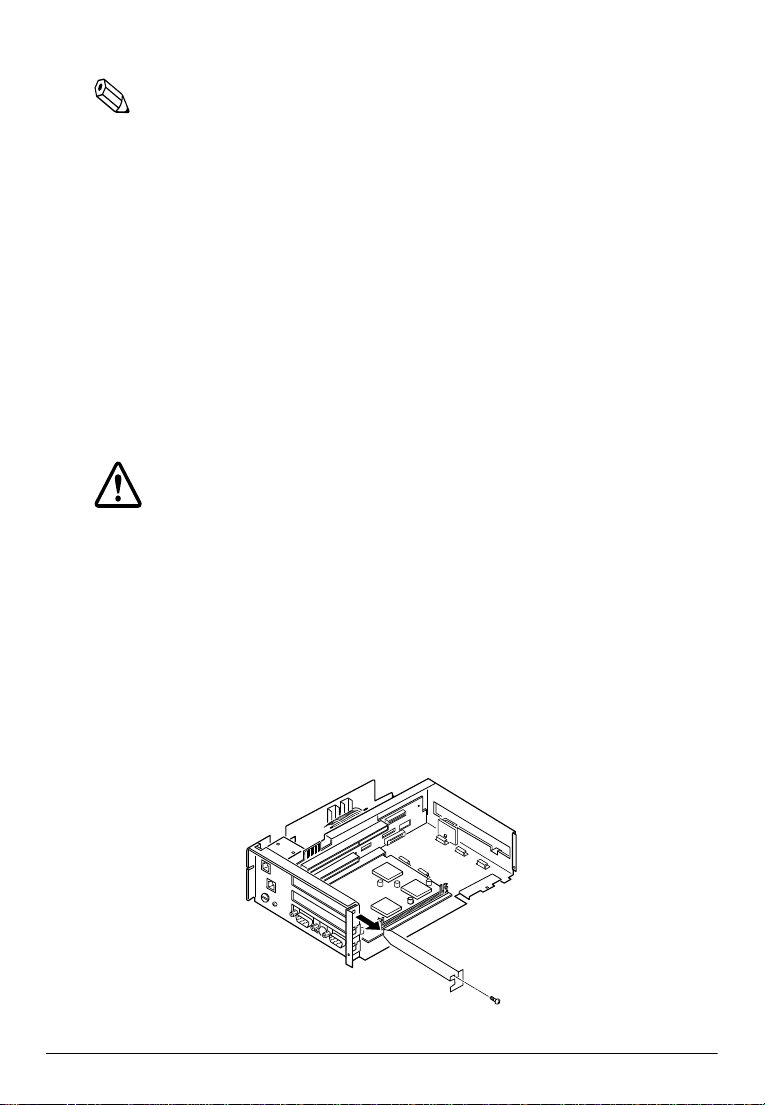

Once you have replaced the cover, you can replace the external

I/O board. Follow these steps:

Caution

Be sure to follow the steps below to replace the external I/O

board. If you replace the external I/O board incorrectly, you

could damage the connectors on the external I/O board

and the IM module.

1. Insert the tab on one side of the external I/O board into the slit

on the top of the cover, as shown below:

2. Gently lower the other side of the external I/O board, then

push the external I/O board in gently until you feel the

connector fit into place.

1-8 Installation

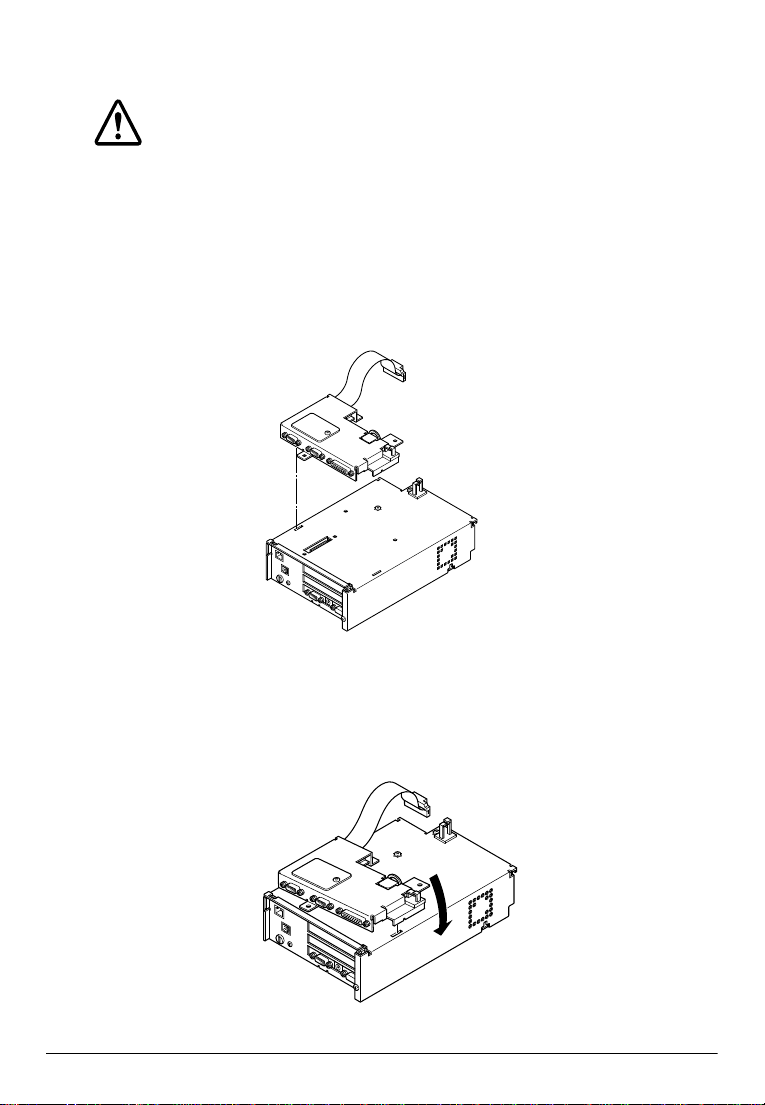

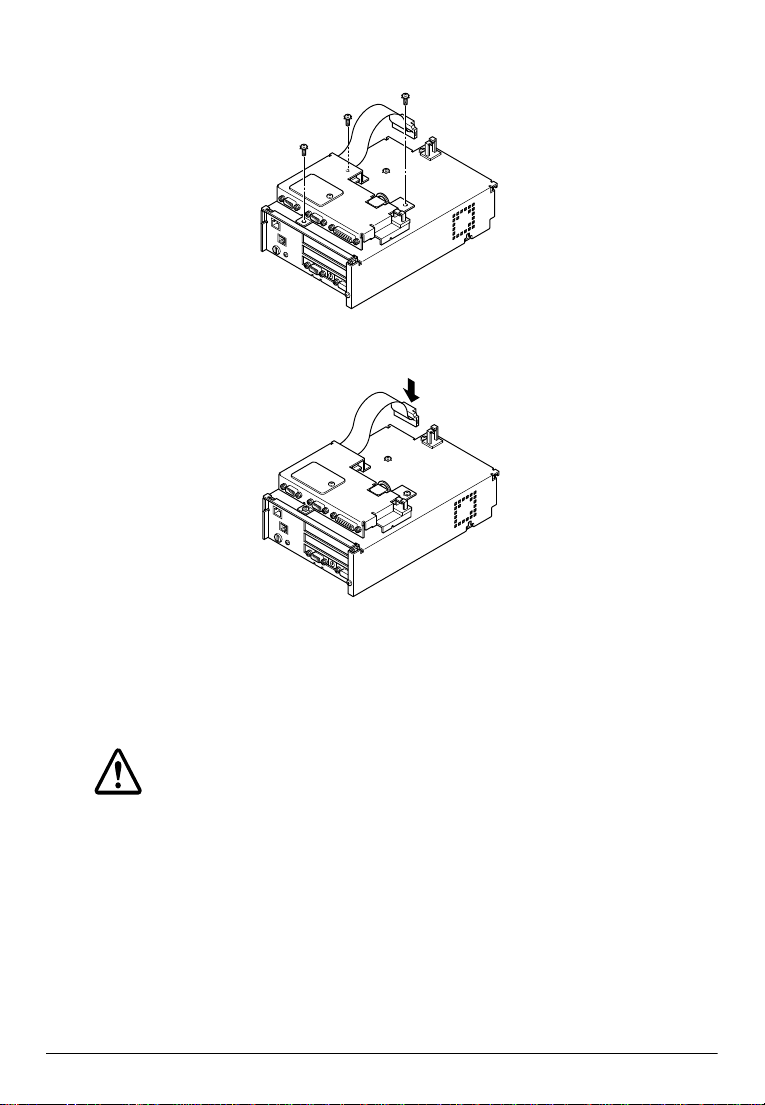

Page 25

3. Secure the external I/O board to the IM module with the three

retaining screws.

4. Connect the connector shown below.

Removing the Cover

You need to remove the cover on the IM module to install drives or

other internal components or to change jumper settings.

Caution

Components on the internal boards can get hot. After you

turn off the control unit, wait at least 10 minutes for the

component to cool before you remove the IM module cover.

Follow these steps:

1. Remove the external I/O board, as described above.

Installation 1-9

Page 26

2. Use a Phillips screwdriver to remove the two additional screws

on the top of the cover that secure it to the control unit. Also

remove the two screws that secure the cover to the sides of the

chassis.

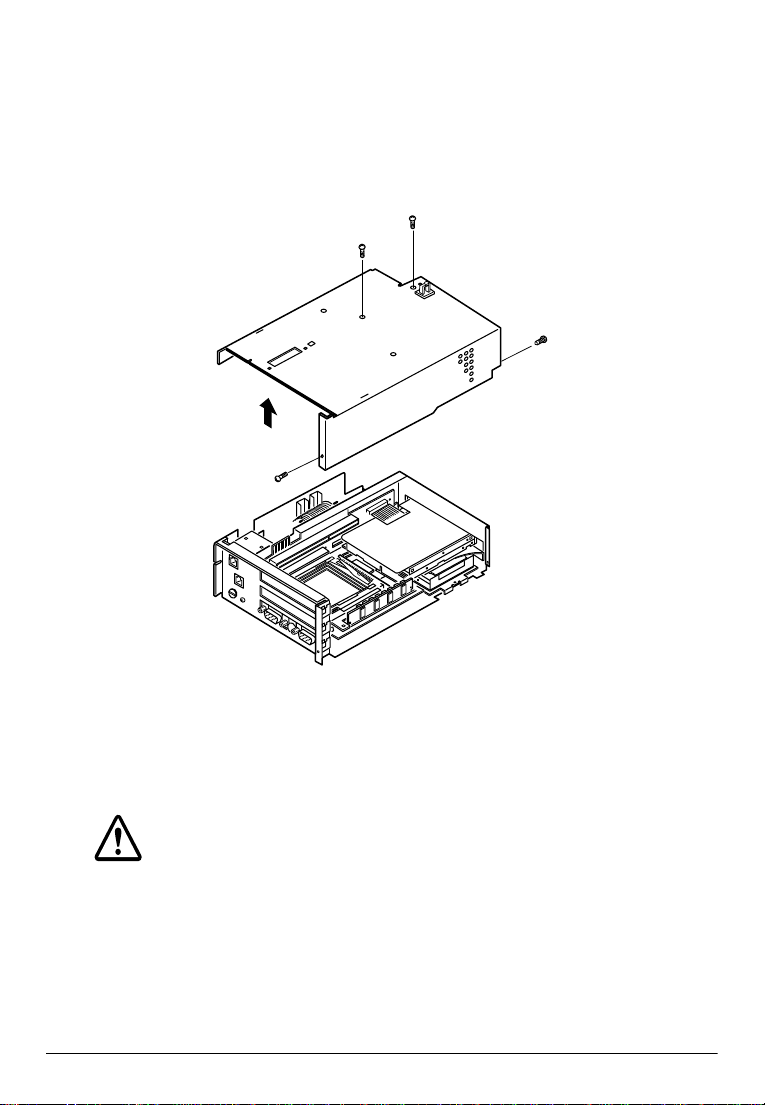

3. Lift the cover straight up, until it clears the chassis, as shown

below.

4. Set the cover aside.

5. Ground yourself to the IM module by touching a grounded

metal surface.

Caution

Be sure to ground yourself by touching a grounded metal

surface every time you remove the cover. If you are not

properly grounded, you could generate an electrical shock

that could damage a component when you touch it.

1-10 Installation

Page 27

When you are ready to replace the cover, align the cover over the

IM module and guide it straight down. Secure the cover with two

screws on top and two screws in the side of the chassis. (Three

additional screws secure the external I/O board to the cover and

the chassis.)

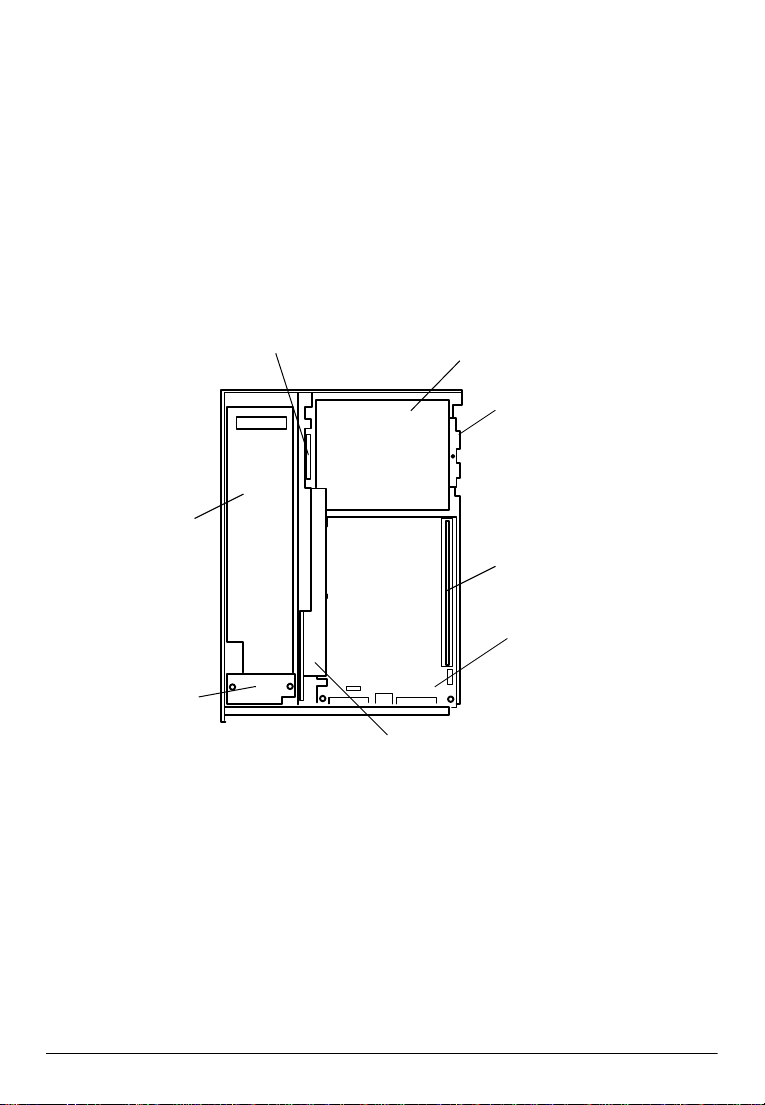

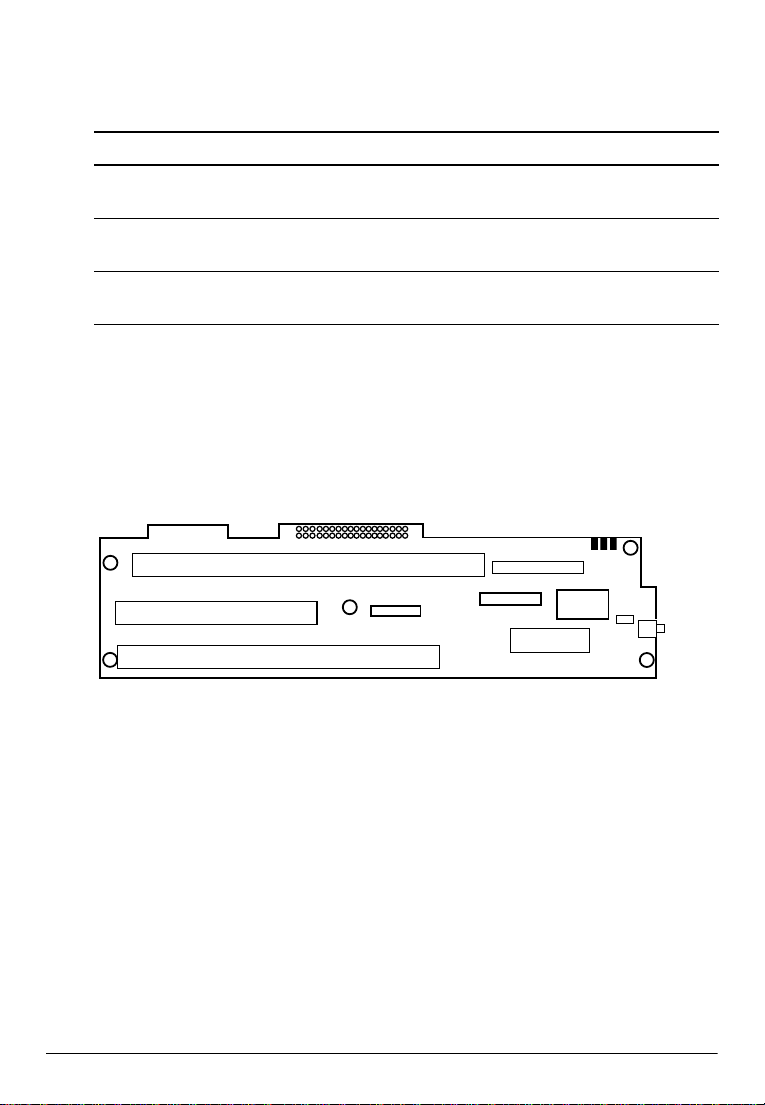

Locating Components

The following illustration shows the major components in the IM

module. As you install components, refer to this diagram to locate

the ones you need.

Floppy disk drive

connector

Power board

Floppy disk drive

Hard disk drive

(under floppy disk drive)

SIMM socket

Modular board

System board

Connector board

Installation 1-11

Page 28

Setting the Jumpers

The IM module contains three circuit boards with jumpers you can

set to control how the system operates. The following sections

describe setting the jumpers on each of these boards.

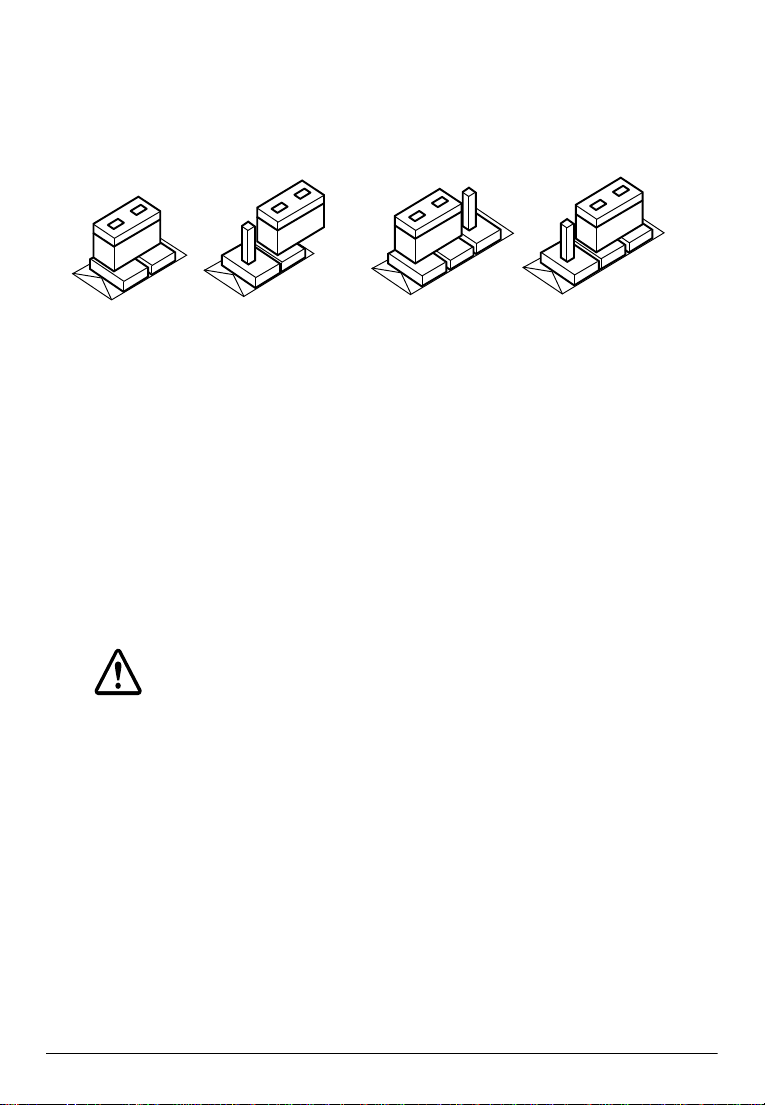

3

On

2-pin jumper 3-pin jumper

Off

1

1-2

1

3

2-3

For two-pin jumpers, the jumper is either on (it connects the two

pins) or off (it doesn’t connect the two pins).

For three-pin jumpers, the jumper setting is 1-2 when the jumper

connects pins 1 and 2. The setting is 2-3 when pins 2 and 3 are

connected. You see a 1 and a 3 printed on the circuit board to

identify these pins.

To move a jumper from one position to another, use needle-nose

pliers or tweezers to pull it off the pins and move it to the desired

position.

Caution

Be careful not to bend the jumper pins or damage any

components on the board.

1-12 Installation

Page 29

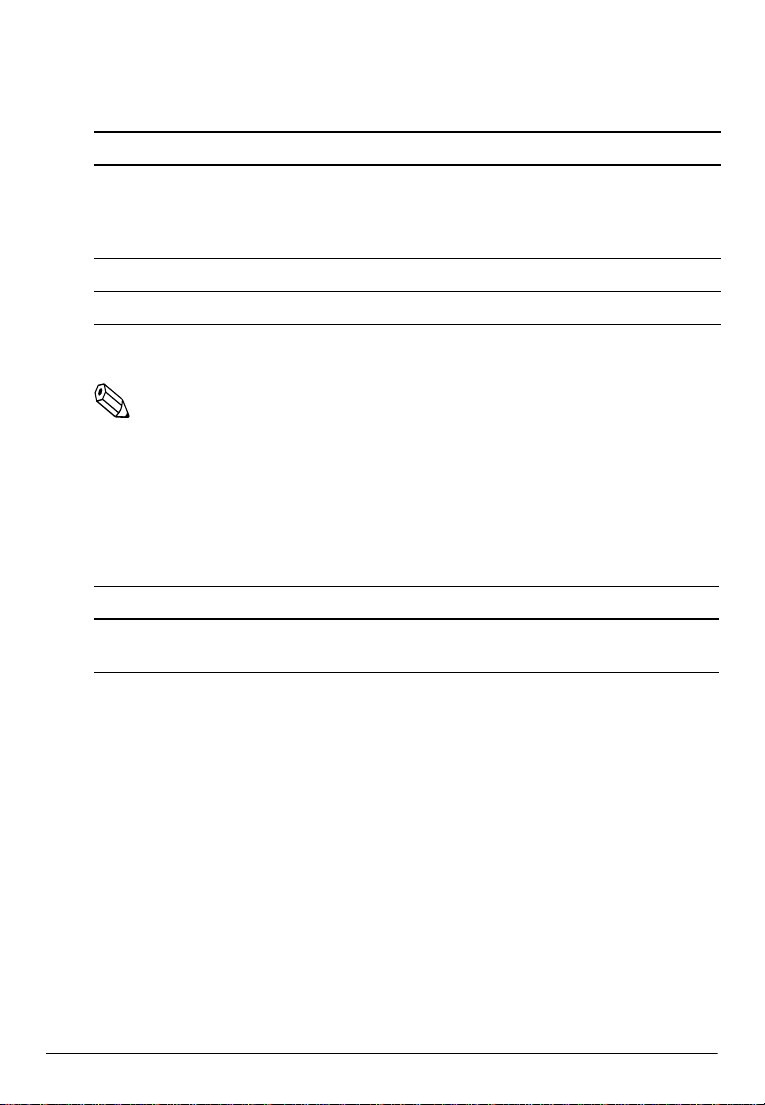

System board jumper settings

The system board contains three sets of jumpers. Two jumpers

control the voltages for the SIMM and COM2. A third jumper

controls bank configurations for the SIMM.

The diagram below shows the location of the jumpers on the

system board.

JP2

13

1

CN3

JP3

JP3

CN3

JP2

3

CN2

CN2

1

1

3

3

CN4

CN4

JP1

CN1

CN1

JP1

13

1

JP4

12

3

If an ISA card or a PCMCIA expansion module is installed in the

IM module, remove it so that you can access the jumpers on the

system board. (See pages 1-26 and 1-29 for more information.) You

may also need to remove the SIMM if you cannot easily change the

setting for jumper JP1. (See page 1-18.)

Installation 1-13

Page 30

Use the information in the following table to change the jumpers on

the system board.

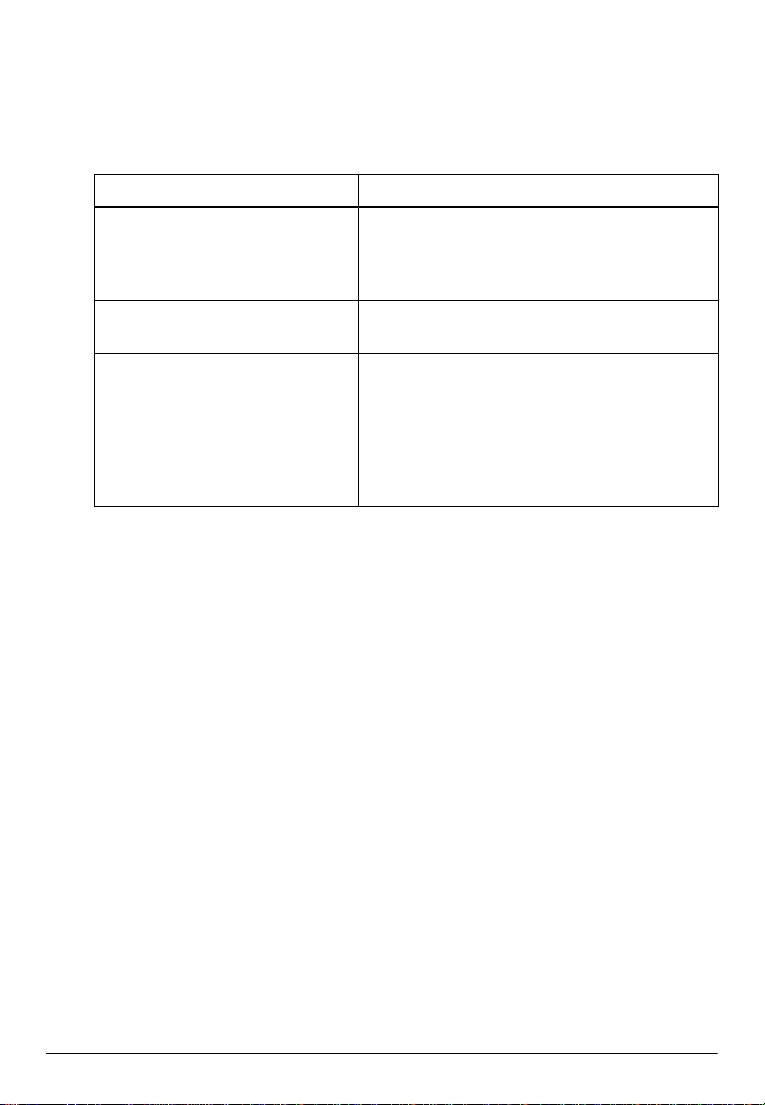

System board jumper settings

Jumper Position Function

JP1 1-2*

2-3

JP2 1-2*

2-3

JP3 1-2

2-3*

**Default setting

Configures the system to access a single bank SIMM

Configures the system to access a dual bank SIMM

Configures the system for a +5 V SIMM

Configures the system for a +3.3 V SIMM

Defines the signal for pin 1 of COM2 as +5 V

Defines the signal for pin 1 of COM2 as DCD

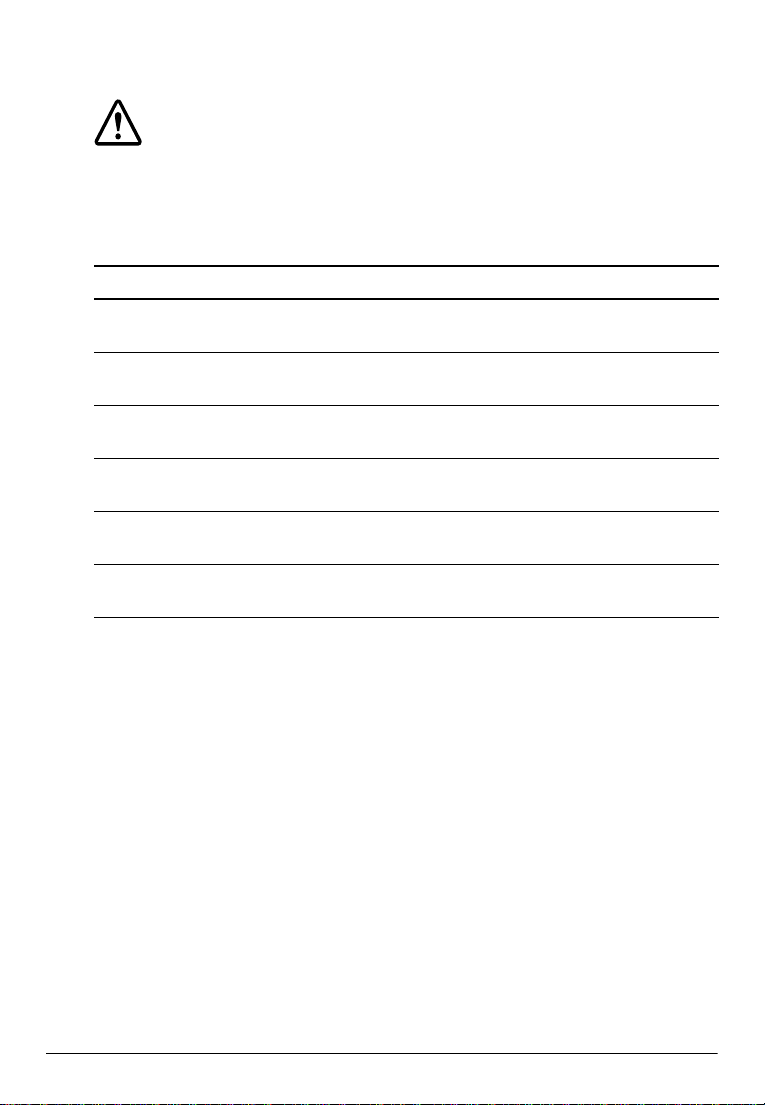

Connector board jumper settings

The jumper on the connector board sets the handshake signals of

the COM1 port.

The location of the jumper on the connector board is shown below.

CN9

CN3

CN1

CN2

CN4

CN5

CN6

If you have an ISA card installed, you may need to remove it to

access the jumpers on this board. See page 1-30.

1-14 Installation

JP1

JP2

CN7

JP3

SW1

Page 31

Use the information in the following table to change the jumper on

the connector board.

Connector board jumper settings

Jumper Position Function

JP1 On*

Off

JP2 Off* Undefined (fixed to off)

JP3 Off* Undefined (fixed to off)

*Default settings

Handshake of COM1 is DTR/DSR and DM status (pin

5) of DM display is received through the CTS terminal

Handshake of COM1 is RTS/CTS and DM status (pin 5)

of DM display is received through the DSR terminal

Note:

The control unit does not have a TM printer reset signal. However,

you can reset the TM printer using an interface signal. (Note that

the TM printer reset can be disabled by the DIP switches of the TM

printer.) The source of the reset can be changed by the JP1 as listed

below.

Source of TM printer reset

Jumper Setting Effect

JP1 On

Off

DTR

RTS

Installation 1-15

Page 32

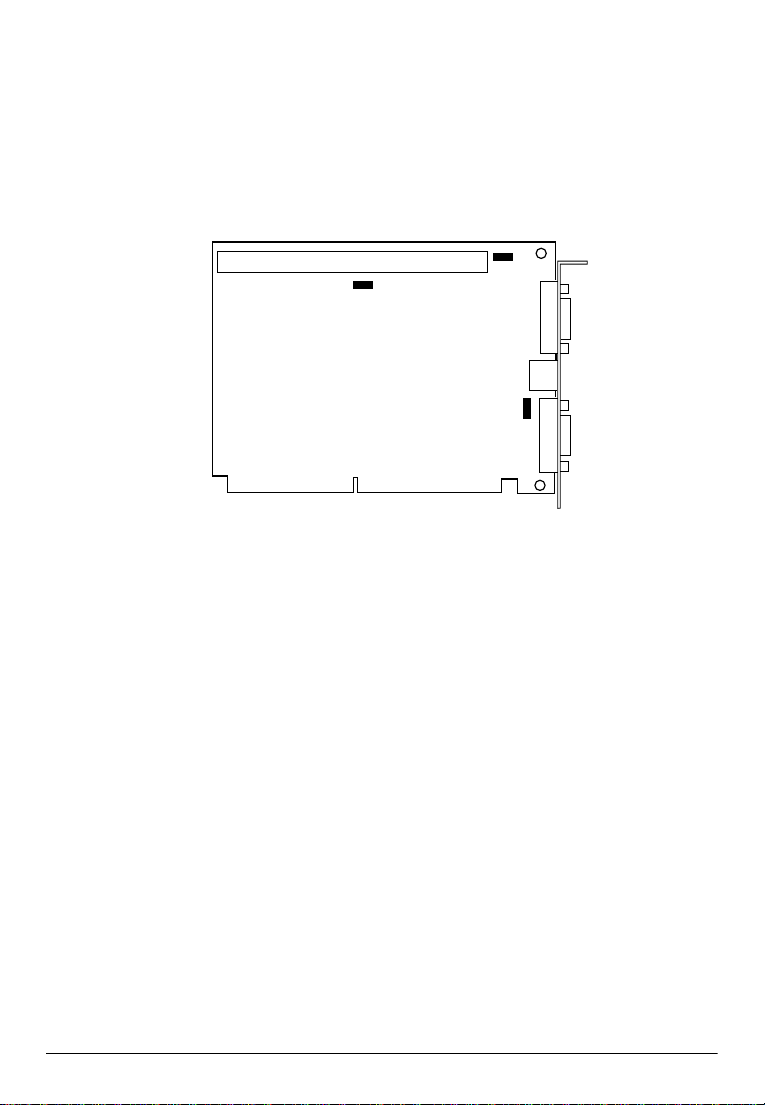

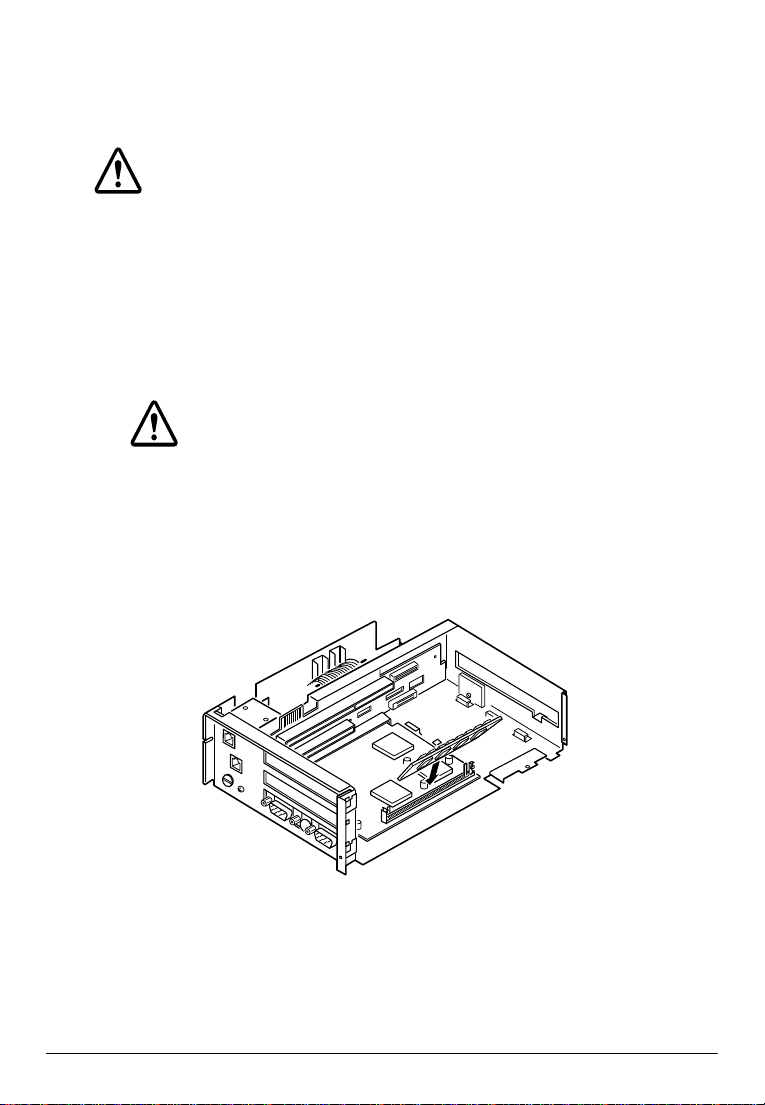

External I/O board jumper settings

The jumpers on the external I/O board control functions for the

ports on this board.

The location of the jumpers on the external I/O board are shown

below.

JP1

JP2

JP2

JP4

JP6

JP1

JP3

JP4

JP3

JP5

JP6

JP5

To access the jumpers on the external I/O board, remove the cover

plate as shown below:

Cover plate

External I/O board

1-16 Installation

Page 33

Use the information in the following table to change the jumpers on

the external I/O board.

Caution

Before you change the setting of JP6 to 1-2, make sure that

pin 21 of the parallel/OCIA port is not grounded.

External I/O board jumper settings

Jumper Position Function

JP1 1-2

2-3*

JP2 1-2

2-3*

JP3 1-2

2-3*

JP4 1-2

2-3*

JP5 1-2

2-3*

JP6 1-2

2-3*

Defines the signal for pin 1 of COM3 as +5 V

Defines the signal for pin 1 of COM3 as DCD

Defines the signal for pin 1 of COM4 as +5 V

Defines the signal for pin 1 of COM4 as DCD

Enables the OCIA function (LPT2)

Disables the OCIA function (LPT2)

Disables COM4

Enables COM4

Disables COM3

Enables COM3

Defines pin 21 of LPT1 as OCIA return

Defines pin 21 of LPT1 as NC

*Default settings

Installation 1-17

Page 34

Installing or Removing a SIMM

The system board contains a single SIMM socket that can contain

one SIMM. The SIMM must meet the specifications in Appendix B.

Caution

To avoid generating static electricity and damaging the

SIMM, ground yourself by touching a grounded metal surface

before you touch the SIMM.

Follow these steps to install the SIMM:

1. If an ISA card is blocking the SIMM, remove it.

Caution

To avoid contamination, do not touch the connectors on

the SIMM.

2. Position the SIMM at an angle over the socket. The notch on the

SIMM points toward the floppy disk drive, as shown below:

3. Push the SIMM into the socket until it is seated firmly.

1-18 Installation

Page 35

4. Tilt the SIMM until it is upright, guiding the hole at each end of

the SIMM over the retaining post at each end of the SIMM

socket. If it does not go in smoothly, do not force it; pull it all

the way out and try again.

Caution

Make sure the SIMM is properly installed and locked by the

tabs on both sides of the socket.

Tabs

5. If you removed an ISA card, replace it.

Note:

After you have installed the SIMM, make sure the jumper settings

are correct for the type of SIMM you installed (page 1-14); then run

the System Configuration Utility to set the parity for a 32-bit or

36-bit SIMM.

When you want to remove the SIMM, use your fingers or a small

screwdriver to carefully pull away the metal tabs that secure the

SIMM at each end. The SIMM falls to the side. Lift it out of the

socket. Make sure you store the SIMM in an anti-static bag.

Installation 1-19

Page 36

Installing a Hard Disk Drive

You can install a 2.5-inch hard disk drive (0.5 inch high) in the

IM module. EPSON-supplied drives come with the necessary

mounting bracket and adapter.

Caution

Handle the hard disk drive gently. Small shocks or vibrations

could damage the drive.

Note:

You do not need to remove an installed floppy disk drive before you

install the hard disk drive in the IM module. The hard disk drive

assembly slides under the floppy disk drive.

Follow these steps to install this hard disk drive assembly:

1. Locate the tabs on the bottom of the chassis.

Caution

To avoid contamination, do not touch the drive

connectors.

2. Slide the drive assembly into the chassis so that the notches

along the bottom of the assembly are under the chassis tabs.

1-20 Installation

Tabs

Page 37

3. Push the drive assembly in gently until you feel the connector

fit into place.

4. Secure the mounting bracket to the IM module with the

retaining screw, as shown below.

Tab

Note:

After you have installed a hard disk drive, run the System

Configuration Utility and use the hard disk drive auto-sensing

feature to set the hard disk drive type.

To remove the hard disk drive, remove the screw that secures the

mounting bracket to the IM module chassis. Then pull the hard

disk drive straight out of the chassis. The tabs at the end of the

bracket provide a convenient place for you to place your fingers

when you pull the hard disk drive assembly out.

Installation 1-21

Page 38

Installing a Floppy Disk Drive

You can install a 3.5-inch floppy disk drive in the IM module.

EPSON-supplied drives come with the necessary mounting bracket

and ribbon cable.

Follow these steps to install the floppy disk drive assembly:

1. If necessary, remove the slot cover at the front of the IM

module. Remove the screw securing the slot cover to the

chassis, as shown below; then lift the slot cover out and replace

the screw to secure the LED board again. Store the slot cover in

case you remove the floppy disk drive later.

LED board

2. If a SIMM is installed in the control unit, remove it. (See page

1-18.)

1-22 Installation

Page 39

3. Slide the floppy disk drive assembly as far as it will go to the

front of the IM module.

4. Then move the drive toward the connector board until the two

tabs on the floppy disk drive mounting bracket slide into the

corresponding slots in the connector board and chassis. (If you

look at the area from the other side of the chassis partition, you

can see the tabs as they come through the slots.) You should

feel the two locator pins on the mounting bracket fit into the

corresponding holes in the chassis.

Installation 1-23

Page 40

5. Hold the drive assembly in place as you secure it to the chassis.

6. Locate the connector for the floppy disk drive ribbon cable.

7. Gently pull both ends of the connector toward you until you

can see a slit in the connector. You may need to use a small

screwdriver or a pair of tweezers to pull out the left side.

Caution

To avoid contamination, do not touch the cable

connector.

8. Insert the ribbon cable all the way into the slit.

1-24 Installation

Page 41

9. Hold the ribbon cable firmly in the connector and push in the

ends of the connector. You may need to use a small screwdriver

or tweezers to push in the left side of the connector.

10. If you removed a SIMM, reinstall it. (See page 1-18.)

Note:

After you have installed a floppy disk drive, run the System

Configuration Utility and use the Disk ette Drive option to set

the size of the drive.

To remove the floppy disk drive, reverse the steps above.

Installation 1-25

Page 42

Installing a PCMCIA Expansion Module (option)

You can install an optional PCMCIA expansion module in the

middle slot on the connector board. (The system board occupies the

bottom slot.) The PCMCIA expansion module can support two

Type I or Type II cards or a single Type III card.

1. If a SIMM is installed in the IM module, remove it. (See page 1-18.)

2. Remove the retaining screw securing the slot cover to the IM

module, as shown below. (Keep the screw to secure the

PCMCIA expansion module to the control unit.)

3. Slide the slot cover out and set it aside. Store the slot cover in

case you remove the PCMCIA expansion module later.

1-26 Installation

Page 43

4. Push both sides of the PCMCIA slot cover inside the cover, and

remove it.

Caution

To avoid contamination, do not touch the connectors on

the PCMCIA expansion module.

5. Hold the PCMCIA expansion module along the top corners

and guide it into the connector, as shown below:

Connector

PCMCIA

expansion

module

Installation 1-27

Page 44

Once the connectors on the PCMCIA expansion module reach

the slot, push them in firmly (but carefully). You should feel

them fit into place. If the expansion module does not go in

smoothly, do not force it; pull it all the way out and try again.

6. Secure the end of the PCMCIA expansion module to the IM

module with the retaining screw.

7. Find the PCMCIA slot cover you removed in step 4.

8. Insert the tab on one side of the PCMCIA slot cover into the

notch on the PCMCIA expansion module; then push the tab on

the other side into place.

Notches

Tabs

Caution

When you connect the PC card(s), make sure the drawing

current of the card(s) does not exceed the capacity limits

shown in Appendix A.

Note:

You need to remove the PCMCIA slot cover before you install or

remove the PC cards.

Caution

Make sure you always attach the slot cover to the PCMCIA

expansion module. The slot cover discharges the static electricity in

your body. If you do not attach the cover, the control unit could lock

up when you insert or remove the PC cards.

1-28 Installation

Page 45

9. If you removed a SIMM, replace it.

Note:

You need to install card and socket services software on your control

unit before it can recognize PC cards in the slots on the PCMCIA

expansion module. See the documentation provided with the module.

If you want to remove the PCMCIA expansion module, remove the

slot cover, remove the SIMM installed in the control unit, then remove

the retaining screw securing the PCMCIA expansion module to the IM

module. Pull the expansion module straight out of the slot and replace

the slot cover. Make sure you replace the SIMM.

Installing an ISA Card

You can install an ISA card in the ISA expansion slot on the

connector board. For the size of the card, see Appendix A.

Caution

When you connect the ISA card, make sure the drawing

current of the card does not exceed the capacity limits

shown in Appendix A.

1. If a SIMM is installed in the IM module, you may want to

remove it so you can access the ISA card slot more easily. (See

page 1-18.)

2. Remove the retaining screw securing the top slot cover, as shown

below. (Keep the screw to secure the ISA card to the IM module.)

Installation 1-29

Page 46

3. Slide the slot cover out and set it aside. Store the slot cover in

case you remove the ISA card later.

Caution

To avoid contamination, do not touch the card connectors.

4. Hold the card along the top corners and guide it into the

connector, as shown below:

Connector

ISA card

Once the connectors reach the slot, push the card in firmly (but

carefully) to insert it fully. You should feel the connectors fit

into place. If the card does not go in smoothly, do not force it;

pull it all the way out and try again.

5. Secure the end of the ISA card to the IM module with the

retaining screw.

6. If you removed a SIMM, replace it. (See page 1-18.)

If you want to remove the ISA card, remove the SIMM, then

remove the retaining screw securing the card. Pull the card straight

out of the slot, then replace the slot cover and the SIMM.

1-30 Installation

Page 47

Installing the Battery Pack (option)

Installieren der Batterie-Einheit (option)

Installation de la batterie (proposée en option)

The optional battery pack contains a Nickel-Cadmium (Ni-Cd)

battery. When there is a power failure, the battery supplies power

to the control unit for about a minute, which allows you to save any

transactions in progress. Follow these steps to install the battery

pack:

Die optionale Batterie-Einheit enthält eine Nickel-Cadmium (NiCd) Batterie. Bei einem Stromausfall, versorgt die Batterie die

Steuereinheit ca. eine Minute lang mit Strom, damit Sie

gegenwärtig ablaufende Vorgänge speichem können. Führen Sie

zur Installation der Batterie-Einheit die folgenden Schritte durch:

La batterie proposée en option contient un accumulateur NickelCadmium (Ni-Cd). Lorsqu’il y a une coupure de courant, la

batterie alimente l’ordinateur pendant environ une minute,

permettant ainsi de sauvegarder les opérations en cours. Suivre les

étapes suivantes pour installer la batterie:

1. Remove the IM module from the plastic housing. (See page

1-5.)

Nehmem Sie das IM-Modul aus dem Plastikgehäuse. (Siehe

Seite 1-5.)

Retirer le module IM du boîtier plastique. (Voir page 1-5.)

Note:

You can install the battery pack without removing the IM

module from the plastic housing. It is easier to install the battery

pack, however, when the IM module is not in the housing.

Installation 1-31

Page 48

Hinweis:

Sie können die Batterie-Einheit auch installieren, ohne das IMModul aus dem Plastikgehäuse herauszunehmen. Die BatterieEinheit läßt sich allerdings leichter installieren, wenn sich das

IM-Modul nicht im Gehäuse befindet.

Remarque:

Il est possible d’installer la batterie sans retirer le module IM de

son habitacle plastique. Il est, toutefois, plus facile d’installer la

batterire lorsque le module IM n’est pas dans le boîtier.

2. Use a coin or a flat head screwdriver to loosen the screw

securing the battery cover. (You cannot remove the screw

completely.)

Lockern Sie mit einer Münze oder einem Schraubenzieher die

Schraube, die die Batterieabdeckung festhält. (Die Schraube

kann nicht völlig entfernt werden.)

Utiliser une pièce de monnaie ou un tournevis plat pour

desserrer la vis du couvercle de la batterie (il n’est pas possible

de retirer complètement la vis).

3. Lift the side of the battery cover containing the screw away

from the IM module; then pull the tab out of the slot, as shown

below:

Heben Sie den Teil der Batterieabdeckung, auf dem sich die

Schraube befindet, vom IM-Modul ab und ziehen Sie

anschließend, wie unten abgebildet, den Führungsstift aus dem

Schlitz heraus.

1-32 Installation

Page 49

Soulever le côté du couvercle de la batterie contenant la vis du

module IM, puis retirer la languette de la fente tel qu’indiqué

ci-dessous.

Tab

ü

Führungsstift

Languette

Slot

Schacht

Fente

4. If it is the first time to install the battery, disconnect the dummy

connector from the IM module.

Wenn die Batterie zum ersten Mal installiert wird, ziechen Sie

den Blindstecker vom IM-Module ab.

Si c’est la première fois que l’on installe la batterie, détacher le

connecteur factice du module IM.

Dummy connector

Blindstecker

Connecteur factice

Installation 1-33

Page 50

5. Locate the connector on the battery pack.

Machen Sie den Anschlußstecker der Batterie-Einheit

ausfindig.

Localiser le connecteur sur la batterie.

6. Align the tab in the casing of the battery connector with the

notch in the socket on the IM module; then insert the connector

in the socket.

Richten Sie den Führungsstift am Gehäuse des Batteriesteckers

an der Aussparung in der Anschlußbuchse des IM-Moduls aus.

Stecken Sie anschließend den Stecker in die Buchse.

Verifier que le détrompeur de la fiche de la batterie est bien

positionné par rapport au connecteur du module IM, puis

insérer la fiche dans le connecteur.

Connector

Stecker

Fiche

Socket

Anschlußbuchse

Connecteur

7. Slide the battery pack into the compartment.

Schieben Sie die Batterie-Einheit ins Fach.

Glisser la batterie dans le compartiment.

1-34 Installation

Page 51

8. Replace the battery cover by sliding the tab into the slot and

lowering the cover over the battery.

Bringen Sie die Abdeckung wieder an, indem Sie den

Führungsstift in den Schlitz einschieben und die Abdeckung

auf die Batterie absenken.

Remettre le couvercle de la batterie en glissant la languette

dans la fente et en baissant le couvercle sur la batterie.

Caution

Be careful the battery cable is not caught between the

battery cover and the chassis as you replace the cover.

Achtung

Achten Sie darauf, daß beim Anbringen der Abdeckung

das Batteriekabel nicht zwischen der Batterieabdeckung

und dem Gehäuse eingeklemmt wird.

Précaution

Faire attention à ne pas coincer le câble entre le

couvercle de la batterie et le chassis lorsque l’on remettra

le couvercle en place.

9. Secure the battery cover to the IM module by tightening the

screw.

Befestigen Sie die Batterieabdeckung am IM-Modul, indem Sie

die Schraube anziehen.

Visser le couvercle de la batterie au module IM en serrant la

vis.

Installation 1-35

Page 52

10. Return the IM module to the plastic housing.

Setzen Sie das IM-Modul wieder in das Plastikgehäuse ein.

Remettre le module IM dans le boîtier plastique.

Leave the control unit on for 48 hours for full charging.

Lassen Sie den Control unit zum vollständigen Aufladen 48

Stunden eingeschaltet.

Laisser l’ordinateur sous tension pendant environ 48 heures pour

une charge complète.

To remove the battery pack, reverse the steps above.

Zum Entfernen der Batterie-Einheit die obigen Schritte in

umgekehrter Reihenfolge ausführen.

Pour retirer la batterie, refaire les étapes précédentes en sens

inverse.

Setting Up the Control Unit

Connecting the TM printer

This section describes how to connect the TM printer to the control

unit.

For setting up the TM printer itself, see the operator’s manual for

the TM printer.

Follow these steps to connect the TM printer:

1. Remove the IM module from the plastic housing. (See page 1-5.)

2. Connect the power cable and interface cable to the IM module.

For the interface cable, tighten the screws on both sides of the

cable connector.

1-36 Installation

Page 53

Note:

You need an appropriate interface cable. The interface cable is not

enclosed with your control unit box.

Screws

Interface

cable

TM power cable

3. Form the power cable and interface cable as shown below then

lock them by two clips on the IM module.

Clips

Installation 1-37

Page 54

4. Replace the IM module into the plastic housing.

Caution

Be careful the cables are not caught between the

housing and the IM module.

Caution

Make sure you lock the IM module to the plastic housing

using the lock on the front panel. The module could fall

from the housing if it isn’t secured.

1-38 Installation

Page 55

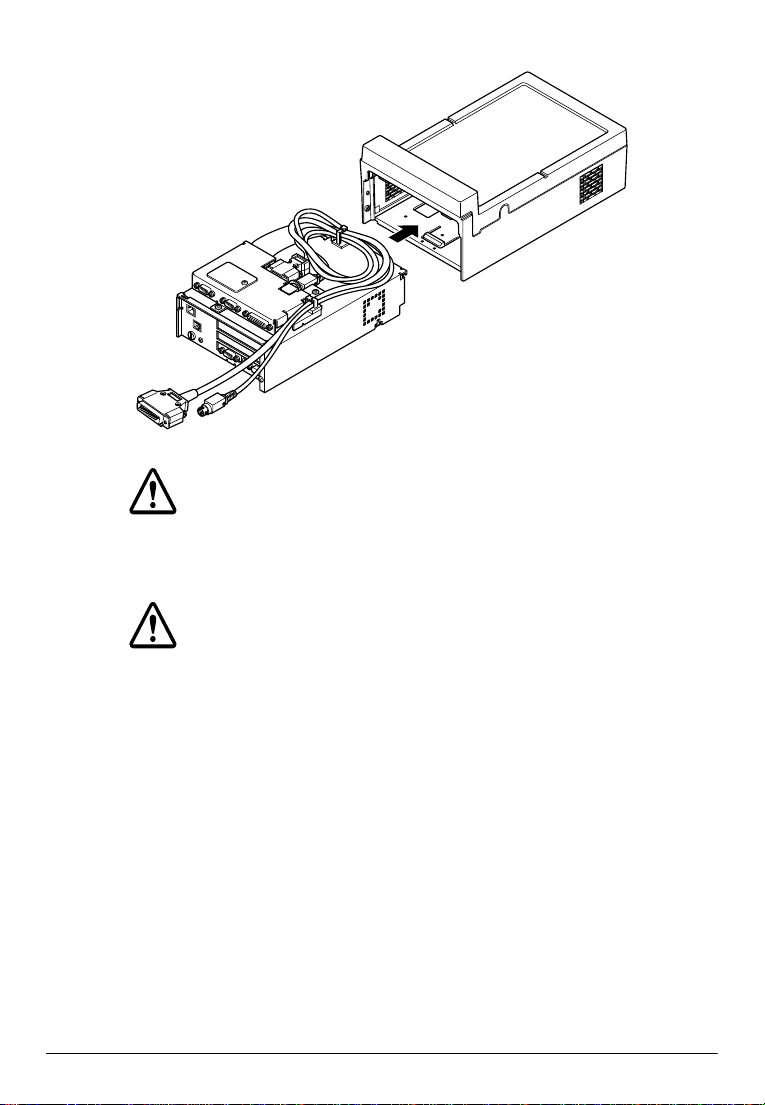

5. Lead the power and interface cables into the hole on the back of

the plastic housing.

6. Connect the power and interface cables to the TM printer

referring to the operator’s manual of the TM printer.

7. Set the TM printer on the control unit.

TM printer

Control unit

Connecting Peripherals

You can connect various peripherals to the control unit using the

connectors on the back panel.

Installation 1-39

Page 56

Caution

See Appendix A for power limitations for any device that

draws its power from the control unit.

24 VDC

connector

Note:

For some peripherals, you may need to change the jumper settings.

See page 1-12 for more information.

Caution

Never plug a telephone line into the DM display port.

Connecting the Power Supply

The power supply that came with the control unit contains a DC

cable connector that connects to the 24 VDC connector on the back

panel of the control unit. Follow these steps to connect the power

supply:

1. Unpack the power supply. Make sure you read the safety

instruction sheet that came with the power supply.

1-40 Installation

Page 57

2. Connect the DC cable connector of the power supply to the 24

VDC connector on the control unit. Push the connector in as far

as it will go.

24 VDC

connector

3. Insert the power cord into an electrical outlet.

See Appendix A for additional information on the power supply.

Installation 1-41

Page 58

Attaching the Back Cover

The control unit comes with a back cover that provides a protective

covering for your cables. After you have connected all the

peripherals to the control unit, attach the back cover. Insert the tabs

on one side of the cover first; then push the tabs on the other side

into place.

Back cover

Caution

Never lift the control unit by the back cover. This cover

cannot support the weight of the control unit, so it could

drop.

Setting a Password for the Drawer Kick-out Test

If you plan to use a drawer, you must set a password for accessing

the drawer kickout test in the device diagnostics utility.

Caution

Make sure you always set a password. The drawer kickout test

checks whether the cash drawer opens correctly. Anyone can

access the test, however, if you do not define a password.

1-42 Installation

Page 59

To set a password see Chapter 2.

Charging the Batteries

Lithium Battery

The control unit contains a rechargeable Lithium battery that backs

up the real-time clock and the CMOS RAM data. The Lithium

battery is not charged fully at the factory. You need to charge the

battery before you use the control unit for the first time. If you

replaced the battery or you have not used the control unit for a long

time, you still need to charge it.

Follow these steps to charge the battery:

Caution

Charge the Lithium battery before you first use the control

unit. If the Lithium battery is not fully charged, your system

configuration settings in the CMOS RAM may be incorrect

when you start the control unit.

1. Connect the power supply to the control unit.

2. Turn on the power switch of the control unit. The Lithium

battery is charged when the power LED light is on.

The Lithium battery is being charged when the control unit is being

turned on. Use the following table for time of charging.

Time for full charge 40 hours or more (from factory condition)

Backup time 30 days or more (with full charge)

Installation 1-43

Page 60

Ni-Cd Battery (option)

The optional rechargeable Nickel-Cadmium (Ni-Cd) battery

provides power to the control unit for about a minute in the event

of a power failure. The Ni-Cd battery is not charged fully at the

factory. You need to charge the battery before you use the control

unit. If you have already replaced the battery or you have not used

the control unit for a long time, you still need to charge it. Follow

these steps to charge the battery:

Caution

Charge the Ni-Cd battery before you use the control unit. If

the Ni-Cd battery is not fully charged, it may not be able to

provide power to the control unit for a full minute.

1. Connect the power supply to the control unit.

2. Turn on the power switch of the control unit. The Ni-Cd

battery is charged when the power LED light is in green.

The Ni-Cd battery is being charged when the control unit is being

turned on. Use the following table for time of charging.

Time for full charge 48 hours or more (from factory condition)

Backup time 1 minute (with full charge)

1-44 Installation

Page 61

Chapter 2

Using System Utilities

The control unit comes with the following utility programs in the

System ROM:

❏ System Configuration Utility, for defining the configuration of

the system.

❏ Power management, for establishing power management

criteria.

❏ Device Diagnostics, for troubleshooting devices attached to the

control unit.

You can access the system configuration and power management

utilities directly from DOS or from some other application that

doesn’t control keyboard input. You can also access the power

management utility from within the System Configuration Utility.

You see a prompt to access Device Diagnostics each time you start

the control unit.

These programs and the factory default options for this control unit

are stored in the ROM. New configuration settings are stored in

CMOS RAM, which is backed up by a battery.

Using the System Configuration Utility

The System Configuration Utility defines how the system is

configured. You need to run this program the first time you

configure the control unit. You may need to run it again if you

change the configuration.

Using System Utilities 2-1

Page 62

Note:

If, for any reason, you remove the system board from the IM module,

you must run the System Configuration Utility to redefine your

configuration.

The System Configuration Utility lets you verify or change the

following:

❏ Standard settings such as date, time, COM port addresses, LPT

port addresses, LPT port mode, floppy disk drive type, hard

disk drive type, and video display

❏ Preferences, such as quick boot, Num Lock settings, CPU (boot)

speed, keystroke settings, passwords, enabling internal hard

disk and floppy disk drive controllers, and enabling keyboard

check.

❏ Memory options, such as shadowing system or video BIOS,

enabling cache, and enabling parity checking for the SIMM.

Starting the System Configuration Utility

You can run the System Configuration Utility by pressing Ctrl Alt S

from DOS or from an application program that does not control

keyboard input.

Caution

When you exit the System Configuration Utility, the system

reboots. Make sure you have saved any data before you

start the utility.

If, during the power-on self test, the system detects an error in your

system configuration, you see an error message on the screen,

followed by this message:

<CTRL-ALT-S> to enter System Configuration Utility,

<CTRL-ALT-P> to enter PM Configuration Util ity,

Press F1 to Continue

2-2 Using System Utilities

Page 63

Press Ctrl Alt S to run the System Configuration Utility and correct

the configuration information.

Changing Options in the System Configuration Utility

The System Configuration Utility uses a series of menu bars, pulldown menus, and dialog boxes to let you change settings. Follow

these guidelines for using the System Configuration Utility

program:

❏ To display a pull-down menu, use the left and right arrow keys

or press the key that corresponds to the highlighted letter in the

title. (Some options, like PowerMgmt, do not have a pull-down

menu.) Select the option and then press Enter to perform the

function or access the selection screen.

❏ To select an option from the pull-down menus, use the up and

down arrow keys to highlight the option; then press Enter to

select it. If additional options are available, you see a dialog

box. If no additional options are available, you see a check

beside the selected options.

❏ To select an item in a dialog box, use the up and down arrow

keys to highlight the option, then press Enter to select it. You

see an X beside the selected option.

❏ Press Esc to close a pull-down menu or leave a dialog box.

Setting the Date and Time

The real-time clock in the control unit continuously tracks the date

and time—even when the control unit is turned off. Once you set

these options, you shouldn’t have to set them again, unless you

adjust the time for daylight savings or a different time zone. (The

control unit automatically changes the date for leap years.)

To change the date, select the Date option from the Standard pulldown menu. Enter the new date in month/day/year format (use

the arrow keys to move between fields); then press Enter.

Using System Utilities 2-3

Page 64

To change the time, select the Time option from the Standard pulldown menu. Enter the new time in hours:minutes:seconds format

(use the arrow keys to move between fields); then press Enter. Use

a 24 hour clock to set this time. For example, 5 p.m. is 17.

Setting the COM Ports

You can disable the COM ports, COM port A (the connector

indicated as COM1 on the control unit) and COM port B (the

connector indicated as COM2 on the control unit), using the COM

Port option on the Standard pull-down menu. Select the COM

port you want to assign. The dialog box allows you to select from

these options:

❏ COM1 (3F8h)

❏ COM2 (2F8h)

❏ Disable.

Addresses for COM3 and COM4 are fixed at 3E8h and 2E8h,

respectively.

Setting the LPT Port Address

You can enable or disable LPT1 using the LPT Port Address

option on the Standard pull-down menu. When you select the

option, a dialog box allows you to select one of these options:

❏ LPT1 (378h)

❏ Disable.

Setting the LPT Port MODE Option

You can define the LPT1 port as one of the following interfaces

using the LPT Port MODE option on the Standard pull-down

menu.

❏ Printer

❏ Bi-directional

2-4 Using System Utilities

Page 65

If you want to set the LPT1 port as a unidirectional interface, select

Printer.

Setting the Floppy Disk Drive

You can set the size of your floppy disk drive using the Diskette

Drive option on the Standard pull-down menu. When you select

the option, you see a dialog box that allows you to select the size of

the drive. Set Drive A to 1.44MB and set Drive B to None.

Setting the Hard Disk Drive

Your control unit comes with a hard disk auto-sensing feature that

allows it to detect the type of hard disk drive you have installed.

When you select the Hard Disk 1 option from the Standard pulldown menu, you can choose from the following options:

❏ Standard

❏ Custom

❏ Auto

❏ None.

Select Auto to have the system automatically supply the correct

hard disk drive parameters for your drive.

Note:

When you select Standard, you see a hard disk drive table. Do not

select a drive type from this table. Use Auto or define a custom

drive.

If none of the parameters in the table match your drive, you need to

define your own drive type. Select Custom; then type the correct

value in each field. Press the down arrow key to move the cursor to

the next field.

Using System Utilities 2-5

Page 66

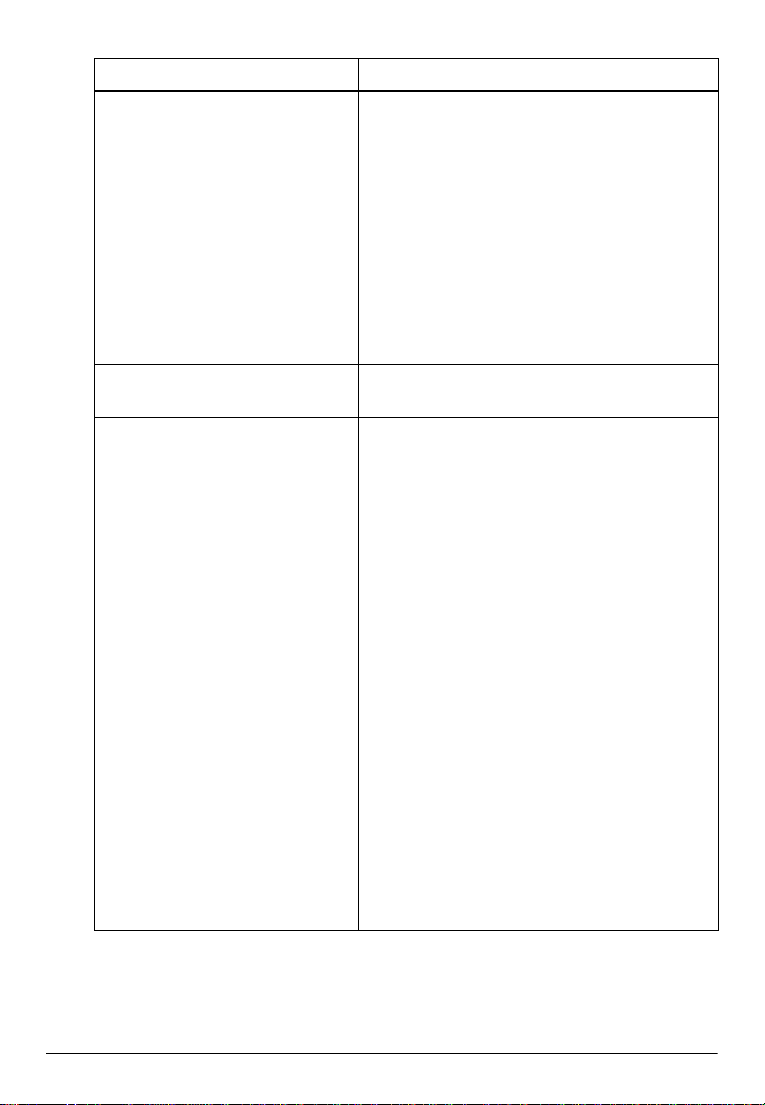

The following table describes the logical parameter you need to

enter in each field. When you have finished entering values, press

Enter.

Drive type options

Field Description

Cyls Number of cylinders

Heads Number of read/write heads

SPT Sectors per track the drive uses

Lzone Landing zone (the area on which the control unit parks the

Precomp Precompensation cylinder

heads)

If you have no hard disk drive installed, select None.

Note:

Always set the Hard Disk 2 option to None.

Setting the Video Display Type

The Standard pull-down menu lets you define the type of display

you have attached to the built-in VGA port. Although the screen

displays several options, the only option available for the control

unit is VGA Display.

Setting the Quick Boot Option

When you select the Quick Boot option from the Preferences

pull-down menu, the system doesn’t test memory during the

power-on self test. When the Quick Boot option is not selected,

the system performs a more comprehensive test of the hardware

and, as a result, takes longer to start. Use the up and down arrow

keys to highlight the Quick Boot option and press Enter. When

the option is selected, you see a check mark beside it.

2-6 Using System Utilities

Page 67

Setting the Num Lock Option

You can determine the initial Num Lock status when the system is

turned on or reset by selecting the Num Lock option from the

Preferences pull-down menu. Use the up and down arrow keys to

highlight the Num Lo ck option and press Enter. When the option is

selected, you see a check mark beside it. Then when you start the

control unit, Num Lock is on.

Setting the Boot Speed (CPU Speed)

The Boot Speed option on the Preferences pull-down menu lets

you set the default CPU speed. When you select Fast Clock in

the dialog box, the CPU operates at 33 MHz. When you select Slow

Clock, the control unit simulates a 16.5 MHz processor to provide

compatibility with older application programs. Select Fast Clock

unless you are using an application program that requires the

slower speed.

Setting the Keyboard Options

The Preferences pull-down menu contains two options that allow

you to determine keyboard speed functions: Typematic Rate

and Typematic De lay.

The Typematic Rate option defines the rate at which the

keyboard repeats a character when you hold it down. You can

select options between 2 characters per second to 30 characters per

second.

The Typematic Delay option defines the interval from when you

start to hold a key down to when the system starts to repeat the

character. You can select options between 250 ms and 1000 ms.

Using System Utilities 2-7

Page 68

Setting Passwords

You can set passwords for both access to the system and access to

the System Configuration Utility using the Boot Password

option and the SCU Pass word option on the Preferences pull-

down menu.

Note:

If you set a password for the System Configuration Utility, you can

still access the power management utility without entering a

password by pressing Ctrl Alt P. You need to enter a password,

however, if you access the power management utility through the

System Configuration Utility.

Defining a password

Follow these steps to define a password:

1. Select the Boot Password option if you want to define a

password for accessing the system. Select the SCU Password

option if you want to define a password for accessing the

System Configuration Utility. You see the following message:

Enter 4 to 8 keystrokes

2. Type the password you want and press Enter. Make sure you

enter at least four alphanumeric characters. You then see this

message:

Re-Enter to Verify

3. Type the same password a second time and press Enter. You

see this message:

Entry IS Verified

Press Any Key To Continue

4. Press any key. The password option you selected from the

Preferences pull-down menu now displays a check mark

beside it.

2-8 Using System Utilities

Page 69

If you defined a boot password, you see the following message

when you start your system:

Enter your BOOT PASSWORD

If you defined a password for the System Configuration Utility,

you see the following message when you press Ctrl Alt S to start the

System Configuration Utility:

Enter your SETUP PASSWORD

Type the password and press Enter.

Deleting a password

Follow these steps to delete a password:

1. Select the password you want to delete from the Preferences

pull-down menu (either Boot Password or SCU Password).

You see this message:

Enter PASSWORD

2. Type your password and press Enter. You no longer see the

check mark beside the password option on the Preferences

pull-down menu, indicating that the option is now disabled.

If you want to change a password, you must delete it first, then

enter the new password as described above.

Enabling the On-board Controllers

The Internal FDC and the Internal IDE options on the

Preferences pull-down menu let you enable or disable the internal

controller for the floppy disk drive (FDC) or the hard disk drive

(IDE). The internal controller is enabled when a check mark

appears beside the option. Highlight the option and press Enter to

toggle the setting on or off.

When these options are disabled, the system uses a controller

inserted into the ISA slot.

Using System Utilities 2-9

Page 70

Checking the Keyboard

The Keyboard Check option in the Preferences pull-down menu

lets you enable or disable the keyboard check during the power-on

self test. The keyboard check is enabled when a check mark

appears beside the option. Highlight the option and press Enter to

toggle the setting on or off.

Note:

If your system does not have a keyboard, always set the option to

disable.

Setting Memory Options

Memory values are displayed on the main System Configuration

Utility screen. You can enable or disable the following options on

the Memory pull-down menu:

❏ Shadow System BIOS

❏ Shadow Video BIOS

❏ Cache Enable

❏ Parity Check Enable.

When the Shadow System BIOS or the Shadow Video BIOS

options are selected, the system copies the contents of its system

and/or video BIOS into RAM, allowing the system to perform

certain operations faster. These options are enabled when you see a

check mark beside them.

You can enable or disable the 8KB of cache on your processor by

selecting the Cache Enable option. A check mark indicates that

the option is enabled.

The Parity Check Enab le option allows you to indicate

whether the SIMM you are using has parity (36-bit) or not (32-bit).

Enable this option if you are using a 36-bit SIMM.

2-10 Using System Utilities

Page 71

Exiting the System Configuration Utility

Select Exit from the menu bar then press Enter to leave the

System Configuration Utility. If you have changed settings, you see

the following message:

Do you wish to save your changes?

ESC to exit - ENTER to save and exit

Any other key to continue

Press Enter to save your changes and leave the utility or press Esc

to leave the utility without saving the changes you have made.

Press any other key to continue making changes.

If you select

following message:

Press Esc to leave the utility. Press any other key to continue

making changes.

Note:

When you exit the System Configuration Utility, the program

restarts the system, even if you have made no changes.

Exit

without changing any settings, you see the

ESC to exit now

Any other key to continue

Setting Power Management Options

The power management utility allows you to establish standby and

suspend criteria for the CPU, the hard disk drive, the VGA

controller, or a combination of these components. It also controls

the battery shutdown function.

You can start the power management utility from DOS or from an

application program that does not control keyboard input by

pressing Ctrl Alt P. You can also select the

the main System Configuration Utility menu and press Enter.

PowerMgmt

option from

Using System Utilities 2-11

Page 72

You see the MAXIMIZER™ power management screen. You can

select options and change settings from this screen just as you did

on the System Configuration Utility screen.

The MAXIMIZER screen provides the following pull-down menus

that allow you to set power management options:

❏ Controls

❏ System

❏ Device.

You can also select the Defaults option to select the power

management defaults and select Exit to leave the MAXIMIZER

screen.

Setting the Power Management Controls

When you display the Controls pull-down menu on the

MAXIMIZER screen, you see a single option, Power Savings.

When you select this option, you see a dialog box that allows you

to have the power management function operating at all times (the

Always option) or to disable the power management function (the