Page 1

IM-300

Using this online user's guide

The words on the left side of this screen are bookmarks for all

the topics in this manual.

Use the scroll bar next to the bookmarks to find any topic you

want. Click a bookmark to instantly jump to its topic. (If you

wish, you can increase the size of the bookmark area by

dragging the dividing bar to the right.)

Use the zoom tools to magnify or reduce the page display.

Click the Find button if you want to search for a particular

term. (However, using the bookmarks is usually quicker.)

Complete online documentation for Acrobat Reader is located in the Help directory for Acrobat

Reader.

Page 2

IM-300

User's Manual

4008676

01

Page 3

Copyright Information

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written

permission of Seiko Epson Corporation. No patent liability is assumed with

respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, Seiko Epson

Corporation assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information

contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the

purchaser of this product or third parties for damages, losses, costs, or

expenses incurred by the purchasers or third parties as a result of accident,

misuse, or abuse of this product or unauthorized modifications, repairs, or

alterations to this product, or (excluding the U.S.) failure to strictly comply

with Seiko Epson Corporation's operating and maintenance instructions.

Seiko Epson Corporation shall not be liable against any damages or problems

arising from the use of any options or any consumable products other than

those designated as Original EPSON Products or EPSON Approved Products

by Seiko Epson Corporation.

EPSON and ESC/POS are registered trademarks of Seiko Epson Corporation.

Intel and Pentium are registered trademarks, and MMX is a trademark of Intel

Corporation.

Award Software International is a registered trademark of Award Software

International Inc.

IBM, PC/AT, and PS/2 are registered trademarks of International Business

Machines Corporation.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

General Notice: Other product and company names used herein are for

identification purposes only and may be trademarks of their respective

companies.

Notice

The contents of this manual are subject to change without notice.

Copyright 1997, 1998 © by Seiko Epson Corporation, Nagano, Japan.

ii

Page 4

FCC CLASS A

FCC COMPLIANCE STATEMENT FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his own expense.

WARNING

The connection of a non-shielded interface cable to this product will invalidate the FCC

Verification of this device and may cause interference levels which exceed the limits

established by the FCC for this equipment.

You are cautioned that changes or modifications not expressly approved by the party

responsible for compliance could void your authority to operate the equipment.

FOR CANADIAN USERS

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigenves du Règlement sur le matériel brouileur

du Canada.

iii

Page 5

Contents

Handling Guidelines

Introduction

Chapter 1 Setup

Precautions on Setting up.................................................................................................. 1-1

Unpacking the IM-300....................................................................................................... 1-2

Setting up the IM-300........................................................................................................ 1-3

Removing a Side Cover/Side Panel/Rear Cover.......................................................... 1-4

Setting the Jumpers and DIP Switches....................................................................... 1-6

Installing a CPU..........................................................................................................1-12

Installing a SIMM.......................................................................................................1-14

Installing a User ROM................................................................................................1-16

Installing a Battery Unit..............................................................................................1-17

Installing a Keyboard Unit...........................................................................................1-19

Installing an LCD Unit................................................................................................1-23

Installing an MSR Unit................................................................................................1-25

Mounting a Printer Tray..............................................................................................1-27

Installing a Printer.......................................................................................................1-29

Installing a DM Display...............................................................................................1-29

Installing an ISA/PCI Board.......................................................................................1-30

Installing a PCMCIA Expansion Module.....................................................................1-32

Installing a Hard Disk Drive........................................................................................1-34

Attaching a Side Cover Panel/Side Panel....................................................................1-37

Installing other Peripherals..........................................................................................1-38

Attaching a Power Cable............................................................................................1-39

Attaching the Rear Cover...........................................................................................1-40

Charging Lithium Batteries.........................................................................................1-42

Chapter 2 Operation

Power ON and Off........................................................................................................... 2-2

Key Lock Keys................................................................................................................. 2-3

Security Key...................................................................................................................... 2-4

iv

Page 6

Inserting and Removing a Floppy Disk.............................................................................. 2-5

Reset................................................................................................................................. 2-6

Paper Feed Button............................................................................................................ 2-7

LCD Contrast Adjustment................................................................................................. 2-7

LCD/Keyboard Angle Adjustment.................................................................................... 2-8

How to Read a Magnetic Stripe Card............................................................................... 2-8

Chapter 3 System Utilities

BIOS Setup Utility............................................................................................................. 3-1

Starting the BIOS Setup.............................................................................................. 3-2

Help Windows............................................................................................................. 3-2

When a Problem Occurs.............................................................................................. 3-2

Legend Keys............................................................................................................... 3-3

Main Menu.................................................................................................................. 3-4

Standard CMOS Setup................................................................................................ 3-5

BIOS Features Setup.................................................................................................. 3-7

Power Management.................................................................................................... 3-8

PnP/PCI Configuration............................................................................................... 3-9

Integrated Peripherals.................................................................................................3-10

Password Setting.........................................................................................................3-12

Device Diagnostics Utility.................................................................................................3-13

Device Diagnostics Utility Requirements....................................................................3-13

Starting Device Diagnostics........................................................................................3-14

Device Diagnostics Utility Screen..............................................................................3-15

Using the Setup Menu.................................................................................................3-21

Drawer On Time.........................................................................................................3-21

Running Device Tests..................................................................................................3-22

Initializing Device Diagnostics.....................................................................................3-25

Exiting Device Diagnostics..........................................................................................3-25

84-Key Configuration Utility..............................................................................................3-26

Start..........................................................................................................................3-26

Speed Buttons.............................................................................................................3-27

Defining Keys.............................................................................................................3-28

v

Page 7

Setting a Key Label.....................................................................................................3-29

Setting Keytop Colors.................................................................................................3-29

Running the Key Program...........................................................................................3-30

Saving the Settings......................................................................................................3-30

Loading the Settings....................................................................................................3-30

New..........................................................................................................................3-31

Viewing Keytops.........................................................................................................3-31

Printing the Settings.....................................................................................................3-31

Exit ..........................................................................................................................3-31

Key Lock Configuration Utility.........................................................................................3-32

Start..........................................................................................................................3-32

Speed Buttons.............................................................................................................3-33

Defining Keys.............................................................................................................3-34

Setting a Key Label.....................................................................................................3-34

Running the Key Program...........................................................................................3-35

Saving the Settings......................................................................................................3-35

Loading the Settings....................................................................................................3-36

New..........................................................................................................................3-36

Exit ..........................................................................................................................3-36

POS Key Mode Setting Utility...........................................................................................3-37

Start..........................................................................................................................3-37

Commands..................................................................................................................3-37

Messages....................................................................................................................3-39

Key Definition Utility (For MS-DOS)................................................................................3-40

Start..........................................................................................................................3-41

File Command.............................................................................................................3-42

Load Command...........................................................................................................3-43

Save Command...........................................................................................................3-43

Edit Command.............................................................................................................3-44

Download Command...................................................................................................3-46

Quit Command............................................................................................................3-46

Key Table...................................................................................................................3-47

Key Data File..............................................................................................................3-48

Error Messages...........................................................................................................3-49

vi

Page 8

Chapter 4 Troubleshooting

Messages .......................................................................................................................... 4-1

Troubleshooting................................................................................................................. 4-4

The IM-300 Will Not Start .......................................................................................... 4-5

The IM-300 Always Stops at Bootup .......................................................................... 4-6

The IM-300 Does Not Respond .................................................................................. 4-6

The IM-300 Shuts Down............................................................................................. 4-6

The IM-300 Can't Be Turned Off ............................................................................... 4-6

Keyboard Problems..................................................................................................... 4-7

Monitor Problems........................................................................................................ 4-7

EPSON DM-D Display Problems............................................................................... 4-8

Floppy Disk Problems ................................................................................................. 4-8

Hard Disk Problems.................................................................................................... 4-9

TM Printer Problems .................................................................................................. 4-9

Serial Port Problems ................................................................................................... 4-10

Parallel Port Problems................................................................................................. 4-10

Cash Drawer Problems............................................................................................... 4-10

PC Card Problems ...................................................................................................... 4-11

Appendix A Specifications

CPU and Memory ............................................................................................................. A-1

Controllers......................................................................................................................... A-2

Interfaces .......................................................................................................................... A-2

Expansion Slots.................................................................................................................. A-3

Disk Drives ....................................................................................................................... A-3

Security ............................................................................................................................. A-4

Switches............................................................................................................................ A-4

Indicators........................................................................................................................... A-5

System Utilities.................................................................................................................. A-5

Power................................................................................................................................ A-5

Power Limits ..................................................................................................................... A-7

vii

Page 9

Lithium Batteries...............................................................................................................A-7

Dimensions........................................................................................................................A-8

Environmental Requirements.............................................................................................A-9

DMA Assignments............................................................................................................A-10

Hardware Interrupts...........................................................................................................A-11

System Memory Map........................................................................................................A-12

I/O Addresses....................................................................................................................A-13

Connector Pin Assignments................................................................................................A-14

Appendix B Loop-Back Connector

Appendix C Memory Specifications

SIMM Specifications.........................................................................................................C-1

User ROM Specifications....................................................................................................C-2

viii

Page 10

Introduction

The IM-300 is an intelligent terminal developed for the POS environment.

The IM-300 has the following features.

1.An Intel Pentium processor or Intel MMX technology Pentium

processor can be used. This high speed CPU processor provides the

power and speed necessary for data processing.

2.Using it in combination with a variety of options and peripheral devices

allows you to construct a system that suits your needs best.

3.The security on the front panel allows only the key owner to take out the

floppy disk and the hard disk drive.

4.The keylock keys allow setting of the user's authority.

5.The refined power management function supplies power by the amount

necessary for data processing, assuring optimum power saving.

6.Use of an updatable 256KB flash ROM for system ROM.

7.Use of PC/AT compatible BIOS. This allows you to execute not only

specific application software but also any PC program of your choice.

8.Use of a built-in Device Diagnostics utility allows quick and easy error

handling.

9.Support of Plug & Play function

10. Capability of supplying +5V or +12V to all serial ports.

11. Equipped with 32KB NVRAM for POS

12. Uses a PC-based open architecture to increase system expandability,

providing one ISA slot, one PCI/ISA slot, and one special extension slot.

13. Input/output units include the keyboard unit, which allows free definition

of key functions and the LCD unit. A touch-panel type of LCD unit is also

available, which allows you to do the free layout of the screen.

14. The built-in IBM PS/2 keyboard port supports IBM PC/AT compatible

keyboards.Therefore, it is possible to connect any commercially

available keyboard in accordance with your environment.

15. Use of standard SIMMs allows you to install memory of up to 64MB.

16. Four serial ports and one parallel port allow connection of industry standard peripheral devices, increasing system expandability.

17. In addition to the standard 3.5-inch floppy disk drive, up to two 2.5-inch

hard disk drives can be installed.

Introduction 1

Page 11

18. The hard disk drive can easily be removed or mounted. In the event of a

system failure, the hard disk can be moved immediately to another IM 300 to continue the processing.

19. Use of design consistent with EPSON POS system TM series printers. A

TM printer can be mounted on the IM-300, so it does not occupy much

space.

20. Connection of the dedicated MSR (magnetic stripe reader) unit (option)

makes it possible to read magnetic cards.

21. Mounting of a battery unit (option) provides data backup function (Save

To Disk Function) when the power is off accidentally.

22. Capability to mount user ROMs of up to 2MB.

2 Introduction

Page 12

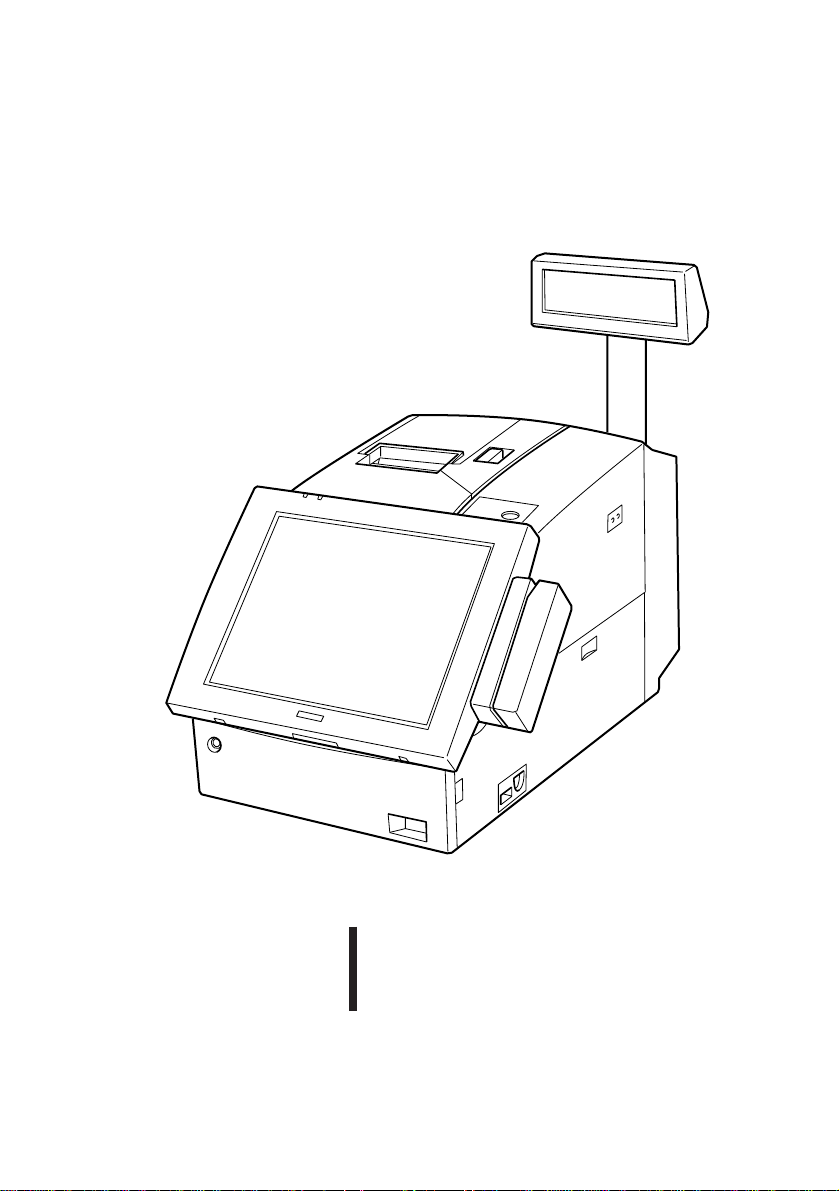

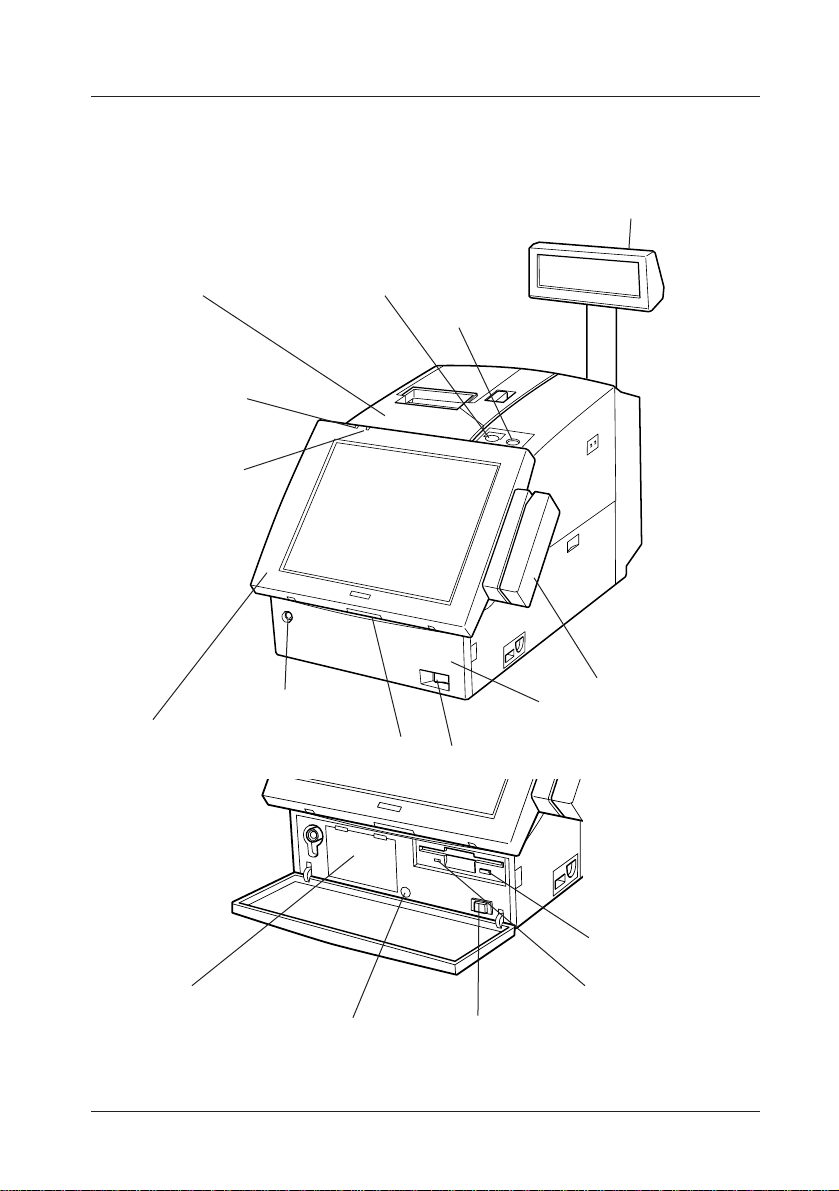

Part Names

Illustrations below show the part names of this product.

Customer Display (Option)

Printer Unit (Option)

Power Indicator

HDD Indicator

LCD unit (Option)

Paper Feed Switch

Front Cover Lock

Lock Switch

Keylock

MSR Unit (Option)

Front Cover

Front Power Switch

HDD slot

Reset Switch

Eject Button

FDD Indicator

Front Power Switch

Front View

Introduction 3

Page 13

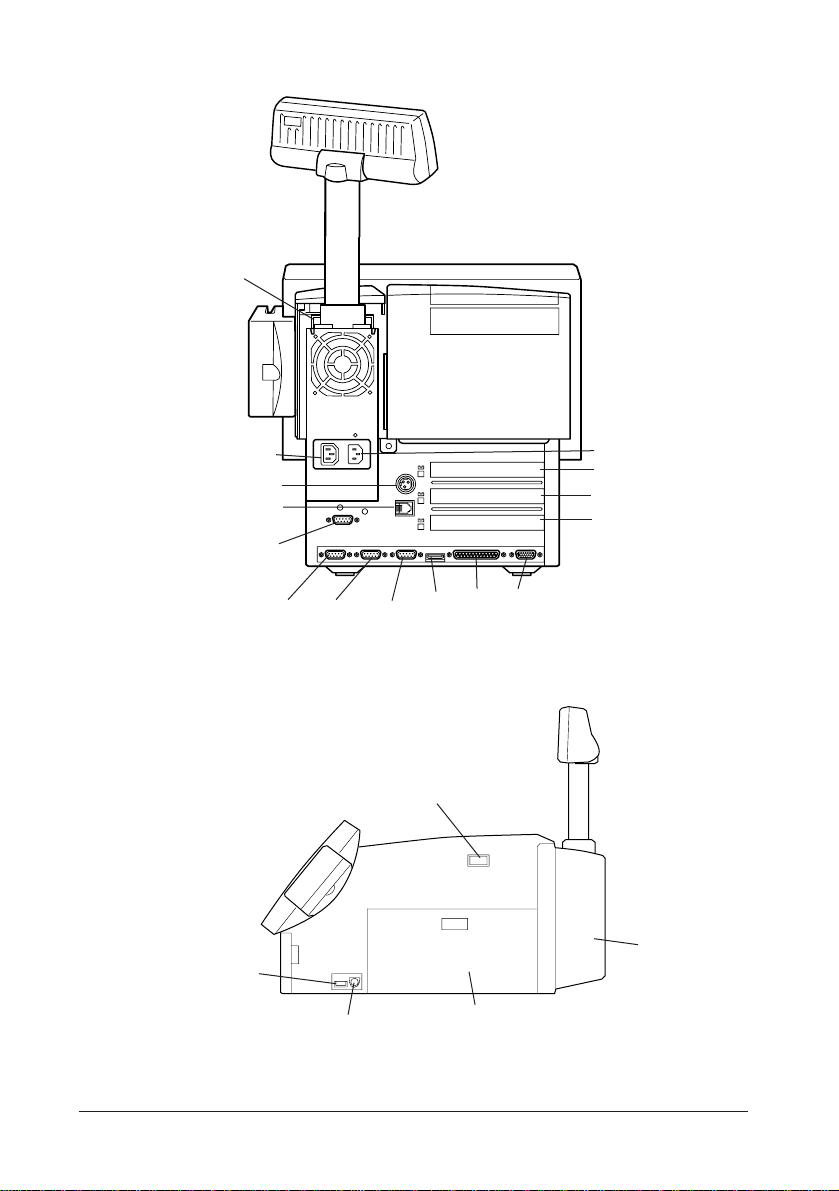

DM-D (at the base of the

customer display)

AC Outlet

TM Power Supply Connector

DKD Connector

COM4

COM3 COM2 COM1

USB2 Connector

Keyboard/Mouse Connector

LPT CRT

USB1

Rear View

Side Power Switch

Side View

AC Inlet

Exclusive Slot

ISA Slot

PCI/ISA Slot

Rear Cover

Side Cover

4 Introduction

Page 14

Handling Guidelines

Warnings, Cautions, and Notes

Notes and precautions in this manual are identified by their level of

importance, as defined below.

WARNING

Provides information that must be observed to prevent harm (not lifethreatening) to the user.

Caution

Provides information that must be observed to prevent damage to the

equipment or loss of data.

Note:

Provides important information and useful tips on handling the equipment.

Handling Precautions 1

Page 15

WARNING

• Turn off the side power switch immediately if it produces smoke, a

strange odor, or unusual noise. Continued use may lead to fire or electric

shock.

Immediately unplug the power cord and contact your dealer or a SEIKO EPSON

service center for advice.

•Never attempt to repair this product yourself. Improper repair work can

be dangerous.

•Never disassemble or modify this product.

Tampering with this product may result in injury, fire, or electric shock.

• Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

• Do not allow foreign objects to fall into this product.

Penetration by foreign objects may lead to fire or shock.

• If water or other liquid spills into the this product, turn off the side power

switch, unplug the power cord immediately, and then contact your dealer

or a SEIKO EPSON service center for advice.

Continued usage may lead to fire or shock.

• Do not place multiple loads on the power outlet (wall outlet).

Overloading the outlet may lead to fire.

• Always supply power directly from a standard domestic power outlet.

• Handle the power cable with care.

• Do not attempt to open or disassemble the internal Vanadium-Lithium

battery, which could result in burns or release of hazardous chemicals.

• Do not charge or leave the internal Vanadium-Lithium battery in a hot

place, such as near a fire or on a heater, as it could overheat and ignite.

• When you dispose of the internal Vanadium-Lithium battery, insulate it

by wrapping the terminals with a tape.

Mixing the battery with other metals or batteries may lead to fire, heat, or

explosion.

2 Handling Precautions

Page 16

Caution

• Be sure your power cable meets the relevant safety standards and includes

a power-system ground terminal (PE terminal).

• Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

• Do not use in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage, fire, or shock.

• Do not place heavy objects on top of this product.

Equipment may fall or collapse, causing breakage and possible injury.

• To ensure safety, please unplug this product prior to leaving it unused for

an extended period.

• Do not drop, bump or otherwise subject this product to strong vibration or

impact.

• Be sure to attach the rear cover after setup.

If the rear cover isn't attached, some foreign matter may enter this product causing

trouble.

• Be sure to attach the side covers and the side panels after setup.

Handling Precautions 3

Page 17

4 Handling Precautions

Page 18

Chapter 1

Setup

This chapter explains how to set up your hardware. For configuring your

system using the BIOS Setup, see the next chapter.

Precautions on Setting up

This section describes items to observe when setting up the IM-300.

In addition to the above, there are warning instructions and cautions to

observe at each work stage. They are given in each explanation.

Caution

• Turn off the power of all equipment including the IM-300 and all the

peripherals before setup. Be sure to turn off the side power switch for

the IM-300 to turn it off.

When power is on, the IM-300 or peripherals units may be

damaged during setup.

• Before setup, discharge static electricity on your body.

If you do not allow static electricity to discharge, trouble could

result. Touch a grounded metal surface to allow static electricity

to discharge.

• Do not touch the connectors.

Dirt may cause a malfunction.

Setup 1-1

Page 19

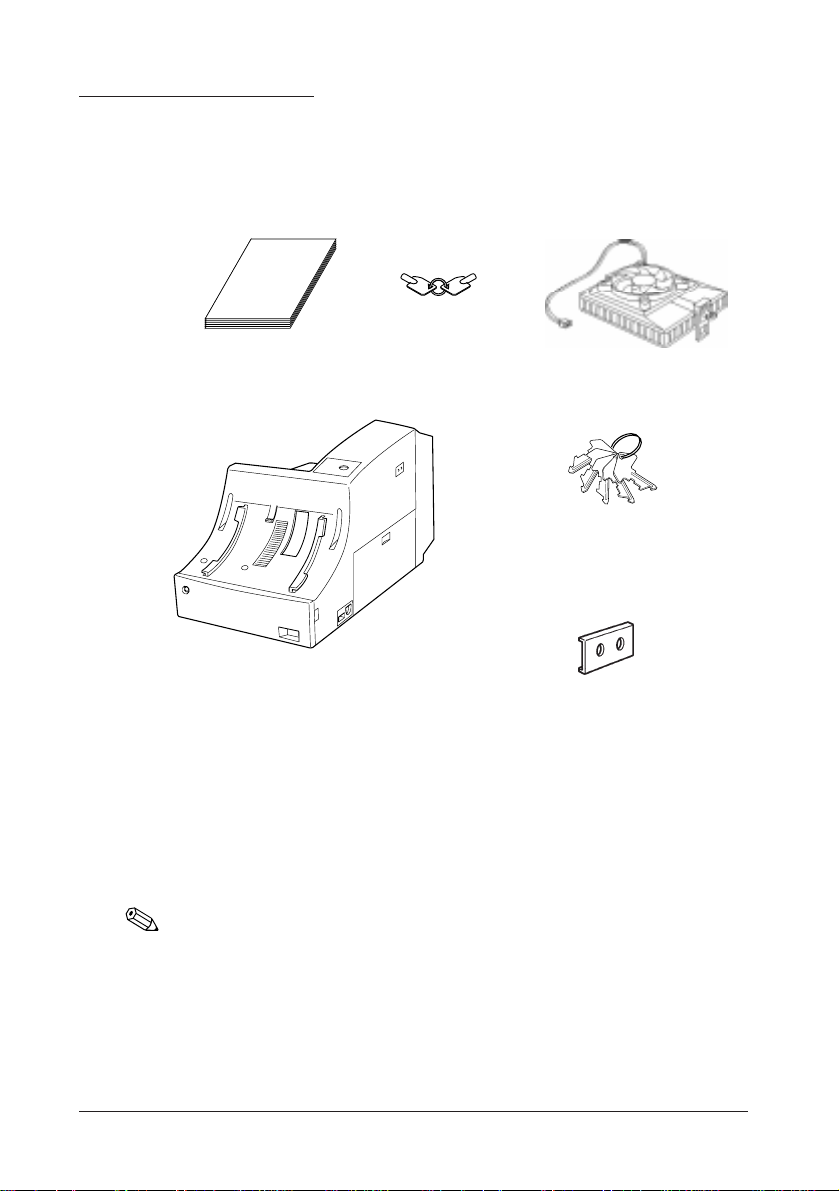

Unpacking the IM-300

When you unpack the IM-300, make sure you have these itmes:

User's manual

IM-300

Front keys

(2 pieces)

CPU cooling fan

Keylock keys

(5 pieces)

Switch covers (2)

Screws to fix the HDD (4)

Confirm that the package includes the items above. If any of these items are

damaged or missing, please contact your dealer for assistance.

1-2 Setup

Note:

After unpacking, save the packaging materials so that you can reuse them, if

necessary

.

Page 20

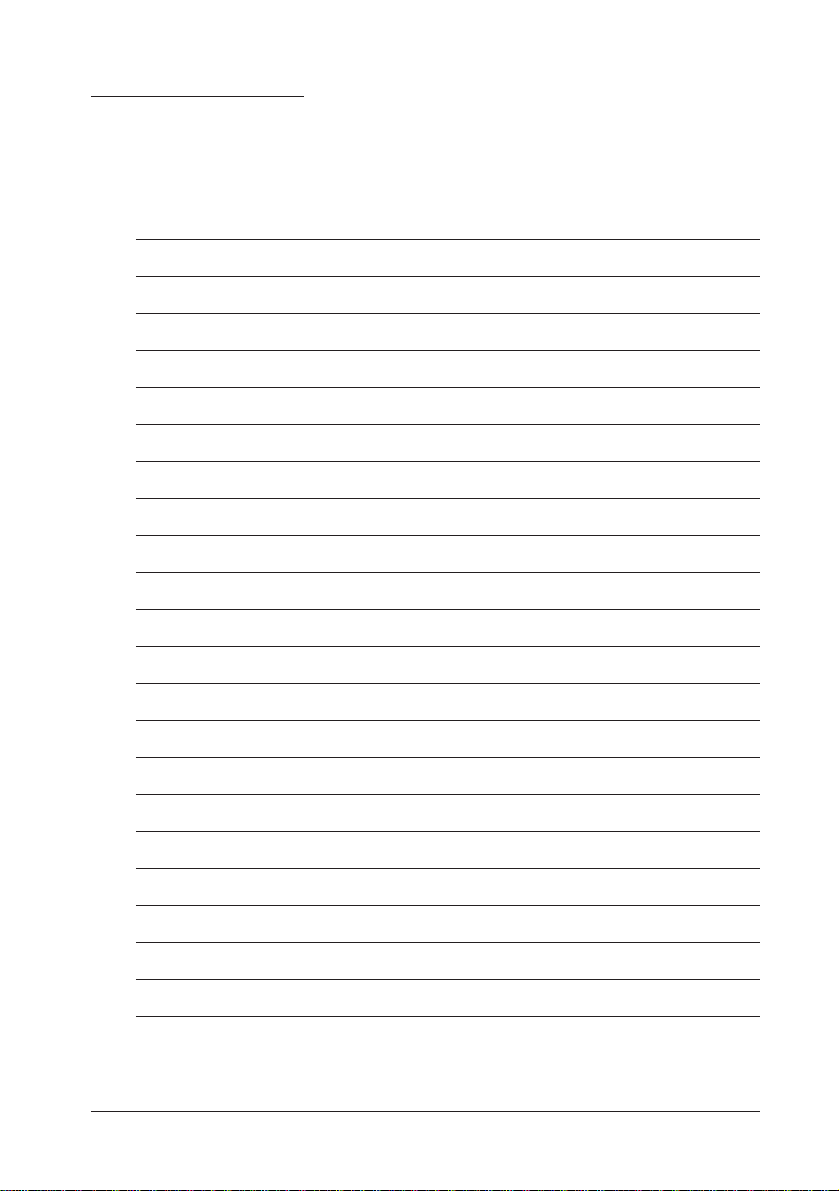

Setting Up the IM-300

Set up the IM-300 in the following steps. If you don't use the specified

options, skip that step.

Step Page

Removing a Side Cover/Side Panel/Rear Cover 1-4

Setting the Jumpers 1-6

Installing a CPU 1-12

Installing SIMMs 1-14

Installing User ROMs 1-16

Installing a Battery Unit 1-17

Installing a Keyboard Unit 1-19

Installing an LCD Unit 1-23

Installing an MSR Unit 1-25

Mounting a Printer Tray 1-27

Installing a Printer 1-29

Installing a DM Display 1-29

Installing an ISA/PCI Board 1-30

Installing a PCMCIA Expansion Module 1-32

Installing an HDD 1-34

Attaching a Side Cover/Side Panel 1-37

Installing Peripherals 1-38

Attaching a Power Cable 1-39

Attaching a Rear Cover 1-40

Charging Lithium Batteries 1-41

Setup 1-3

Page 21

Removing a Side Cover/Side Panel/Rear Cover

Remove the side covers and the side panels on both sides of the IM-300.

Remove the side covers and the side panels in the following cases:

Right Side (on which the side power switch is located)

Setting the jumpers and DIP switches

(For CPU speed setting, CPU voltage, pin 1 function of

COM1 to COM4 and COM3 function)

Installing a CPU, installing SIMMs

Left Side

Setting the jumpers

(For gate array mode and CMOS RAM clear)

Installing user ROMs

Installing ISA/PCI cards

Installing a PCMCIA expansion module

Remove the side covers and side panels using the following procedure:

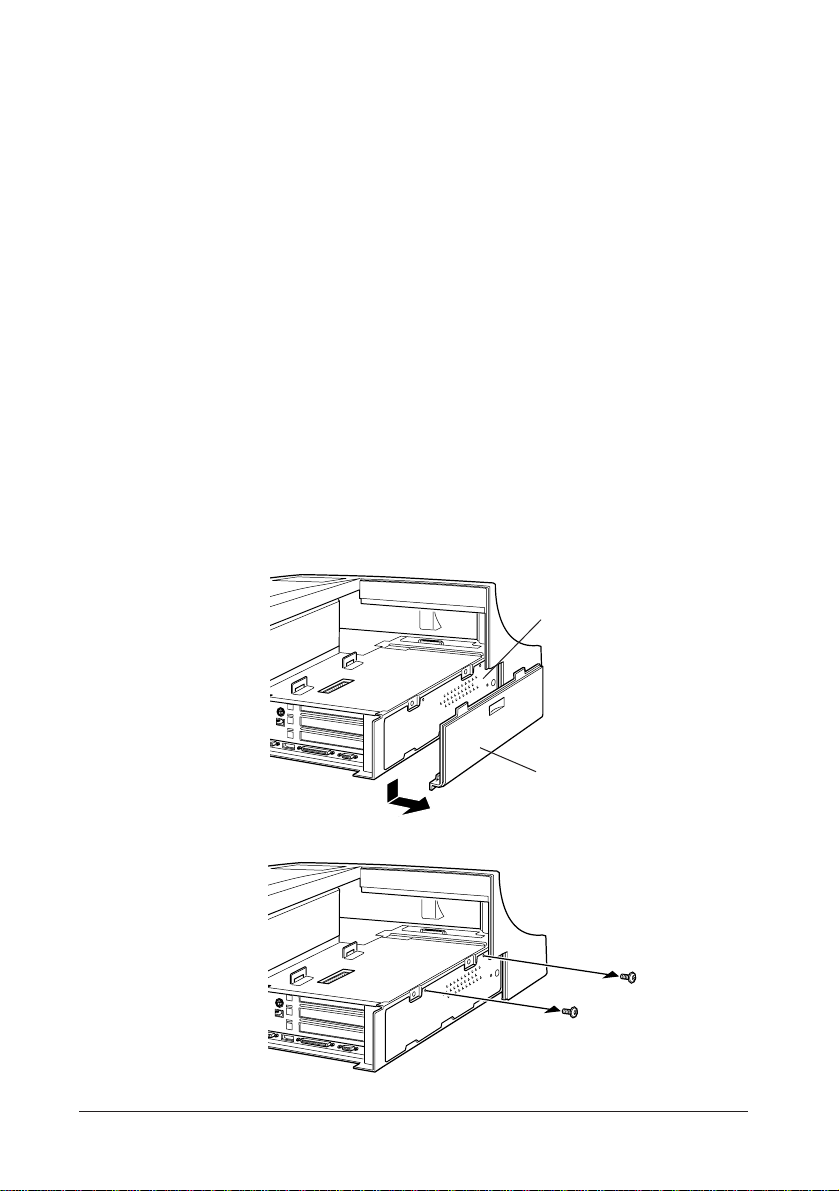

1. Remove the side cover by sliding downward.

Side Panel

2. Remove two screws, which fix the side panel.

3. Remove the side panel.

1-4 Setup

Side Cover (Left)

Page 22

If a rear cover is attached to the IM-300, remove it using the following

procedure.

1. Loosen a screw that fastens the rear cover.

screw

2. Remove the rear cover from the IM-300 by pulling the upper part of the

rear cover backward then downward.

Setup 1-5

Page 23

Setting Jumpers and DIP Switches

There are jumpers and DIP switches on the board of the IM-300. You can

set them to control how the system operates.

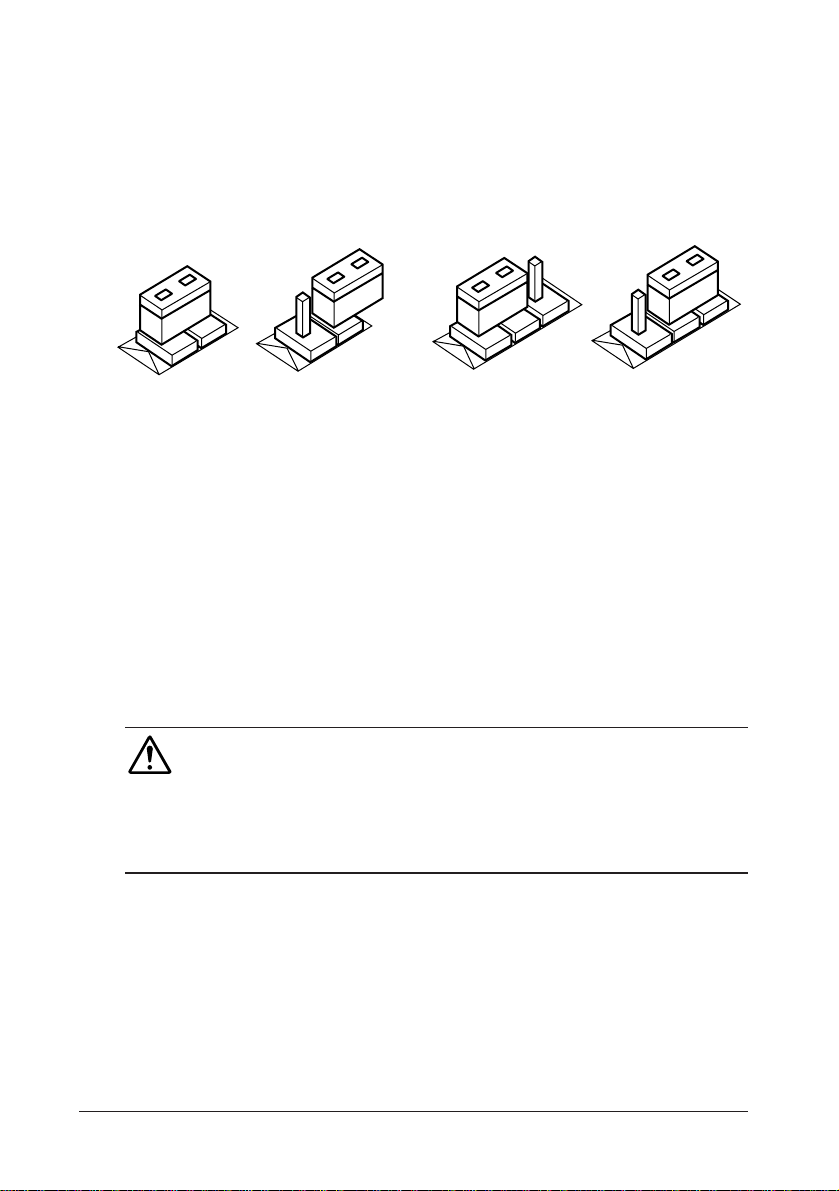

There are two types of jumpers - the 2-pin jumper and 3-pin jumper.

3

On

2-pin jumper 3-pin jumper

Off

1

1-2

1

For two-pin jumpers, the jumper is either on (it connects the two pins) or off

(it doesn't connect the two pins).

For three-pin jumpers, the jumper setting is 1-2 when the jumper connects

pins 1 and 2. The setting is 2-3 when pins 2 and 3 are connected. You see a

1 and a 3 printed on the circuit board to identify these pins. Also, one of the

lines surrounding jumpers is thick, which indicates pin NO.1.

To move a jumper from one position to another, use needle-nose pliers or

tweezers to pull it off the pins and move it to the desired position.

Caution

• Be careful not to bend the jumper pins or damage any components on the board.

• Do not change settings for jumpers and DIP switches not covered in this

manual.

3

2-3

1-6 Setup

Page 24

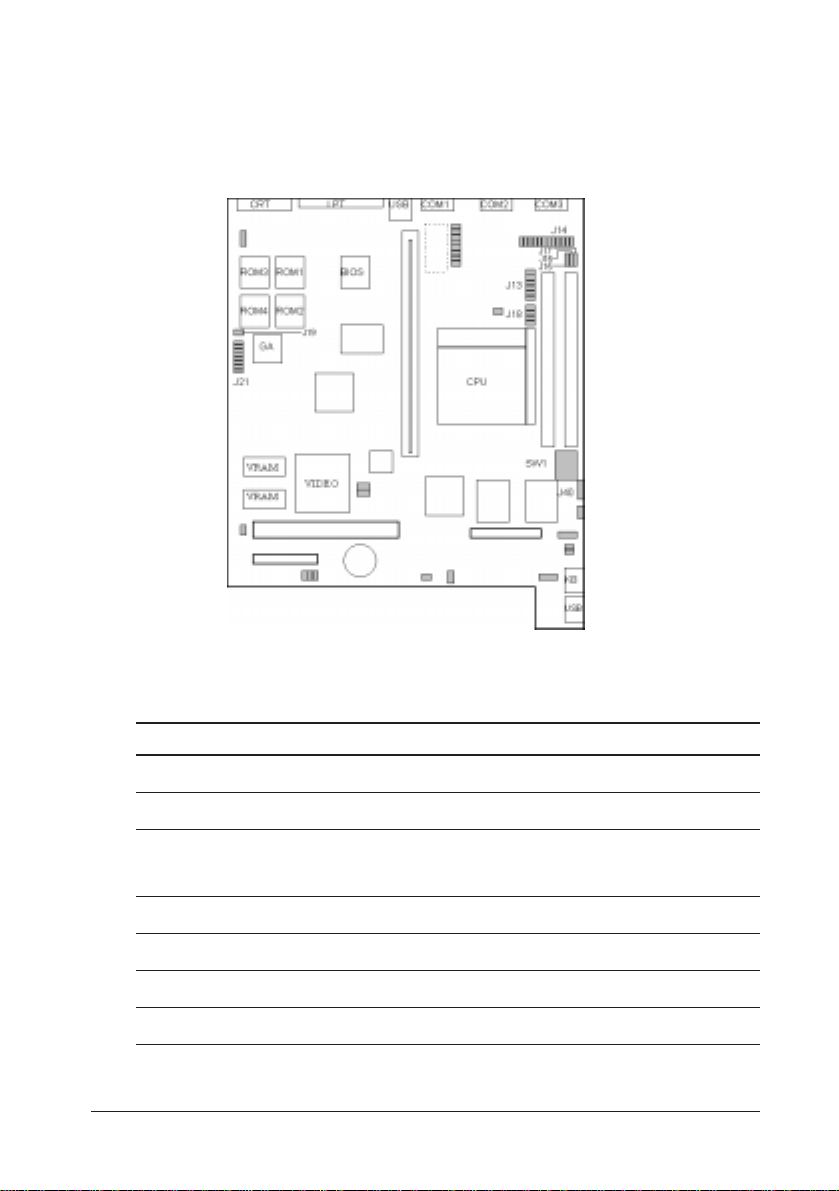

Jumpers and DIP Switches Locations

The figure below shows the locations of jumpers and the DIP switches on

the IM-300 main board.

Use the information in the following table to change the jumpers and the DIP

switches.

Jumpers/DIP Switches Functions

SW1, J40 Selection of CPU operation speed

J13 Selection of CPU power voltage

J14 Serial port pin 1 assignment

(DCD, +5V, +12 select)

J18 Selection of CPU power voltage

J21 Selection of gate array operation mode

J15, J16, J17 Selection of COM3

J19 CMOS RAM clear

Setup 1-7

Page 25

Settings of SW1 and J40:

These DIP switches determine the CPU operation speed. Change the DIP

switch settings for the installed CPU.

Selection of CPU operation speed

CPU Frequency J40SW1SW1SW1SW1

1-2 1-3 1-4 1-5

Pentium 90 MHz 1-2 OFFOFFON ON

Pentium 100 MHz 1-2 OFFOFFOFFON

Pentium 120 MHz 2-3 OFFOFFONON

Pentium (*) 133 MHz 2-3 OFFOFFOFFON

Pentium 150 MHz 2-3 ON OFFONON

Pentium 166 MHz 2-3 ON OFFOFFON

Pentium 200 MHz 1-2 ON OFFOFFON

Pentium MMX166 MHz 2-3 ON OFFOFFON

Pentium MMX200 MHz 1-2 ON OFFOFFON

* Default settings

1-8 Setup

Page 26

Settings of J13/J18:

These jumpers determine the CPU power voltage. Change the jumper

settings for the installed CPU.

Selection of CPU power voltage

CPU Frequency J13 J13 J13 J13 J18 J18 J18 J18

1-2 3-4 5-6 7-8 1-2 3-4 5-6 7-8

Pentium 90 MHz ON OFF ON ON OFF OFF ON ON

Pentium 100 MHz ON OFF ON ON OFF OFF ON ON

Pentium 120 MHz ON OFF ON O N OFF OFF ON ON

Pentium (*) 133 MHz ON OFF ON ON OFF OFF ON ON

Pentium 150 MHz ON OFF ON O N OFF OFF ON ON

Pentium 166 MHz ON OFF ON O N OFF OFF ON ON

Pentium 200 MHz ON OFF ON O N OFF OFF ON ON

Pentium MMX 166 MHz ON OFF OFF OFF ON ON OFF OFF

Pentium MMX 200 MHz ON OFF OFF OFF ON ON OFF OFF

* Default settings

Setup 1-9

Page 27

Settings of J14:

This jumper determines the pin 1 function of COM1 to COM4 serial port.

Selection of the serial port pin 1 assignment

COM1 COM2 Pin 1 Function

1-2 3-4 5-6 7-8 9-10 11-12

ON OFF OFF ON OFF OFF DCD (*)

OFF ON OFF OFF ON OFF +5V

OFF OFF ON OFF OF F O N +12V

COM3 COM4 Pin 1 function

13-14 15-16 17-18 19-20 21-22 23-24

ON OFF OFF ON OFF OFF DCD (*)

OFF ON OFF OFF ON OFF +5V

OFF OFF ON OFF OF F O N +12V

* Default settings

Settings of J21:

This jumper sets gate array operations, such as user ROM control, use of

NVRAM for POS, and so on.

Settings of Gate Array

Switch Function Setting Description

1 to 6 User ROM control Refer to next table

7-8 (SW4) Use of NVRAM for POS OFF (*) Not used.

ON Used.

9-10 (SW5) Use of user ROM for POS OFF (*) Not used.

ON Used.

11-12 (SW6) Selection of gate array mode OFF Reserved.

ON (*) Fixed to ON.

* Default settings

1-10 Setup

Page 28

User ROM Control Settings

SW1 (1-2) SW2 (3-4) SW3 (5-6) Description

ON(*) ON(*) ON(*) Normal ROM mode

ON OFF O N Extended ROM mode, starting address D0000h

ON OFF O FF Extended ROM mode, starting address D8000h

OFF - - Bootstrap ROM mode (BIOS ROM mode)

- Do not care

* Default settings

Settings of J15, J16 and J17:

Jumper Function Settings Description

J15 COM3 RXD 1-2 Use RXD of the external COM3

connector on the motherboard

2-3 Use RXD of the internal connectors (*)

J16 COM3 DSR Selection 1-2 Use DSR of the external COM3

connector on the motherboard

2-3 Use DSR of the internal connectors (*)

J17 COM3 CTS Selection 1-2 Use CTS of the external COM3 connector

on the motherboard

2-3 Use DSR of the internal connectors (*)

* Default settings

Settings of J19:

Jumper Function Settings Description

J19 CMOS Clear OFF (*) CMOS RAM data remains.

ON Clears CMOS RAM data.

* Default settings

Setup 1-11

Page 29

Installing a CPU

IM-300 contains a Socket 7, which can accept the following CPU types:.

• Intel Pentium 100 MHz to 200 MHz

• Intel MMX technology Pentium 166/200 MHz

Be sure to attach a CPU cooling fan to the CPU included in the package

after you install the CPU. It prevents the CPU from overheating.

Caution

• To avoid generating static electricity and damaging the CPU, ground yourself by

touching a grounded metal surface before you touch the CPU.

• Do not remove the rubber under the CPU cooling fan.

• Do not touch the pins of the CPU.

Dirt may cause a malfunction.

Follow these steps to install the CPU:

1. Confirm that the DIP switches are correctly set for the CPU you are going

to install.

2. Lift the release lever of the Socket 7.

3. Align the pins of the CPU to the pin holes of the Socket 7. Be sure to pay

attention to the direction of the CPU.

lever

4. Push down the CPU into the Socket 7.

5. Push down the release lever and lock it.

1-12 Setup

Page 30

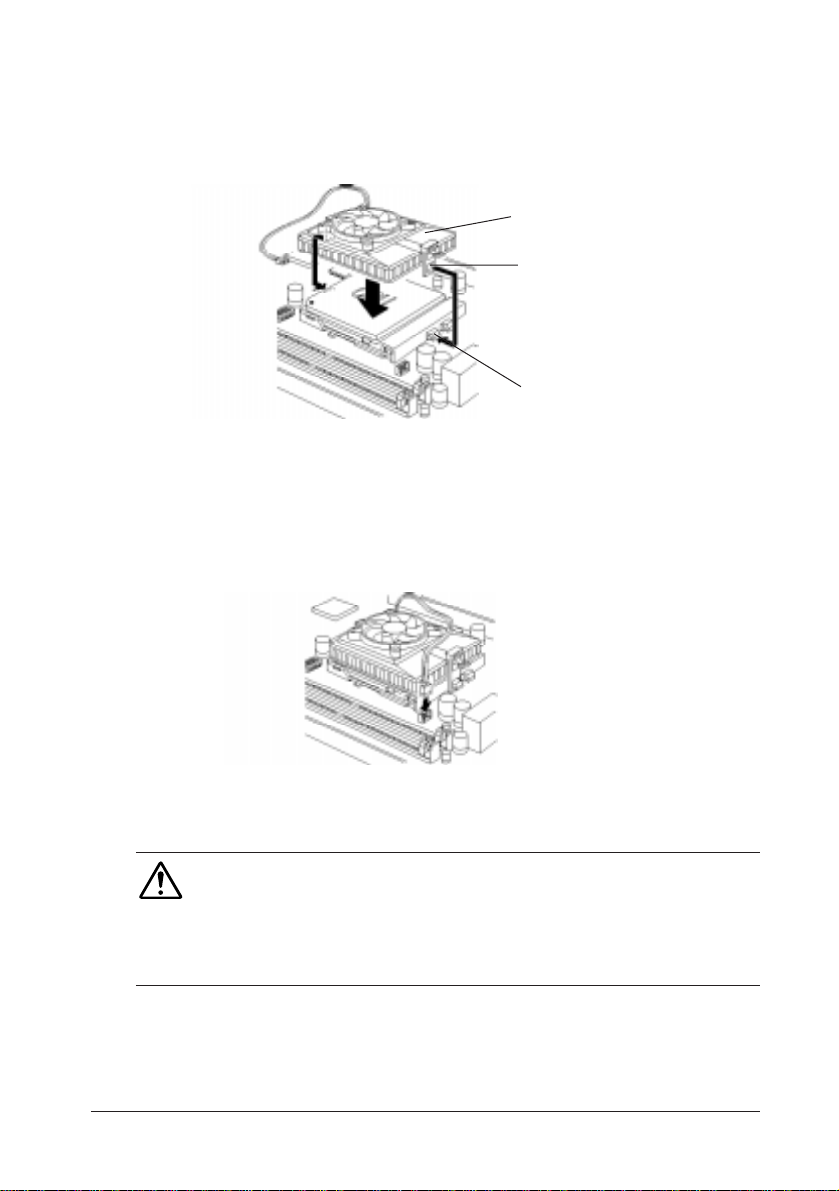

6.Hook the hole in EIF clip for the CPU cooling fan onto the notch on the

Socket 7.

7.Place the CPU cooling fan on the CPU surface.

Heat radiation plate

EIF clip

Notch

8.Push down the opposite side of the EIF clip and hook it.

9.Slide the head of the clip to left and lock it.

10. Connect the cooling fan cable to the socket as shown below. Be careful

not to place the cable on the CPU cooling fan.

Removing a CPU:

Caution

Before removing the CPU, turn off the IM-300 power; then wait for about 20 minutes until

the heat radiation plate of the cooling fan and the CPU cool down.

The CPU and the heat radiation plate are hot. They may cause burns.

To remove the CPU, reverse the installation steps.

Setup 1-13

Page 31

Installing a SIMM

The main board contains two SIMM sockets. You can insert one SIMM or

two SIMMs. However, it is recommended that you use two SIMMs of the

same type and access speed.

The SIMMs must meet the specifications in Appendix C.

Caution

• To avoid generating static electricity and damaging the SIMM, ground

yourself by touching a grounded metal surface before you touch the SIMM.

•Do not touch the connector of the SIMM.

Dirt may cause a malfunction.

Follow these steps to install the SIMMs:

1.Hold the SIMM with its notch to the front side of the IM-300 and insert

it completely into the socket at an angle of about 45 degrees. A SIMM

should be inserted into the inner socket first.

2.Tilt the SIMM until it is upright, guiding the hole at each end of the

SIMM over the retaining post at each end of the SIMM socket.

1-14 Setup

Page 32

Note:

If SIMM does not go in smoothly, do not force it. Pull it all the way out and try

again.

Caution

Make sure the SIMM is properly installed and locked by the tabs on both sides of

the socket.

3.If you install two SIMMs, install the second SIMM using the same

procedure as above.

Removing a SIMM:

To remove the SIMM, use your fingers or a small screwdriver to carefully

pull away the metal tabs that secure the SIMM at each end. The SIMM falls

to the side. Lift it out of the socket.

Make sure you store the SIMM in an anti-static bag.

Setup 1-15

Page 33

Installing a User ROM

On the IM-300, up to four user ROMs storing independent user programs

can be installed. Using the special driver, they can be used as virtual

memories with a capacity of 2MB max.

The user ROMs must meet the specifications in Appendix C.

User ROMs should be installed in the sockets in order as shown below.

(1)

(3)

(2)

(4)

Caution

• To avoid generating static electricity and damaging the ROM, ground yourself by

touching a grounded metal surface before you touch the user ROM.

• Do not touch the connectors of the user ROM.

Dirt may cause a malfunction.

Follow these steps to install the user ROM:

1. Confirm that the jumpers are correctly set for the user ROMs you are going

to install.

2. Confirm the direction of the user ROM. A mark on the user ROM should be

located as shown below.

3. Push down the user ROM into the socket.

1-16 Setup

Page 34

Installing a Battery Unit

The battery unit is the Ni-Cd battery that backs up operations during data

saves to the hard disk drive by the STD (Suspend To Disk) function, which

happens automatically if the power turns off abruptly, such as in case of a

power interruption.

The specifications for the battery unit are as follows:

Type: Ni-Cd 8-cell, 600 mAh

Charging time: About 32 hours

Charging method: Trickle

The charging time and backup time change according to the environmental

conditions.

Note: (Users in the USA)

The product you have purchased is powered by a nickel cadmium battery

which is recyclable. At the end of its useful life, under various state and local

laws, it is illegal to dispose of this battery into your municipal waste stream.

Please call 1-800-8-BATTERY for information on how to recycle this battery.

Note:

The nickel cadmium battery must be recycled or disposed of properly.

The battery unit begins to be charged when the IM-300 power is turned on.

Install the battery unit by following the procedure below.

1. Open the battery unit box.

Setup 1-17

Page 35

2. Insert a battery unit into the battery unit box.

3. Close the battery unit box.

4. Connect the cable of the battery unit as shown below.

Note:

To enable the battery unit, change the "System Battery" setting in the Power

Management menu of the BIOS setup to "Equipped." See to Chapter 4 for

details.

Removing a Battery Unit:

To remove the battery unit, reverse the installation steps.

1-18 Setup

Page 36

Installing a Keyboard Unit

The keyboard unit is an option for data entry. It has a total of 84 keys, in 12

rows by 7 columns. A function can be freely assigned to each key. By

assigning the same function to two or more keys, you can also handle the

multiple keys as one large key. For this purpose, the keyboard unit box also

contains keytops measuring 1 by 2 and 2 by 2.

The slide mechanism allows the keyboard surface inclination to slide

vertically for setting the optimum angle.

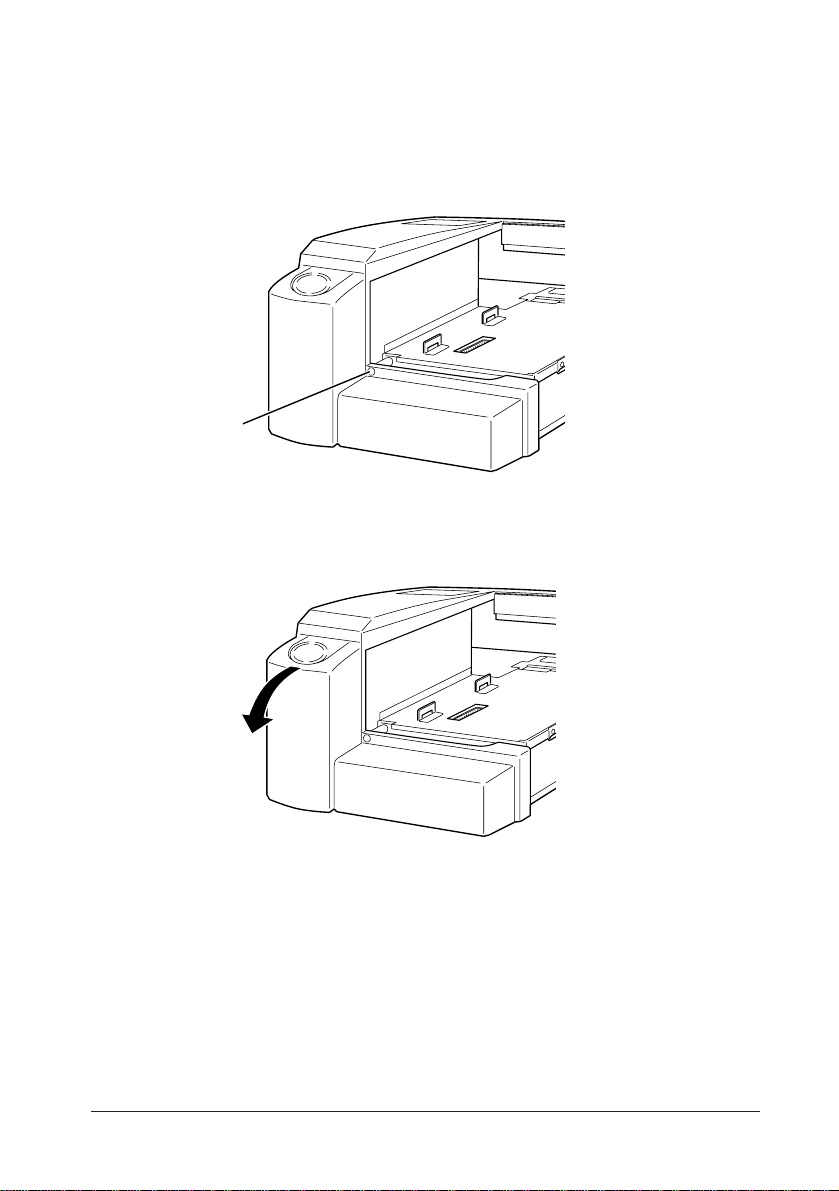

Follow these steps to install a keyboard unit:

1. Check that the lock switch in the lower part of the keyboard unit is set in the

release position.

2. Place the keyboard unit on the IM-300 and slide it downward. At this time,

the keyboard unit and IM-300 should be aligned with each other.

3. Incline the keyboard unit to the desired angle.

4. Set the keyboard unit lock switch to the lock position, and secure the

keyboard.

Setup 1-19

Page 37

5. Connect the cable of the keyboard unit as shown below. At this time, do not

bend the connector pins.

Changing a Keytop:

To change a keytop on the keyboard unit, follow the procedure below.

1. Fit the keytop remover (contained in the keyboard unit package) over the

desired keytop, as shown below.

2. Lift the keytop remover to detach the keytop.

3. To detach more than one keytop, repeat steps 1 and 2.

4. Fit the new keytop straight from above.

1-20 Setup

Page 38

Mounting a Keytop Cover:

The keyboard unit package also contains keytop covers. A keytop is indented

on top. Mount the keytop cover over the indent. Then, you can see the function

of the key with ease.

Place the keytop cover in position with the procedure below.

1. Insert a label for the key function on the keytop.

2. Fit the keytop cover, with its concave side up, over the keytop. Then, fit the

cover securely, until you hear a snap.

Removing a Keytop Cover:

To remove the keytop cover, follow the procedure below.

1. Remove the keytop using the keytop remover.

2. Remove the keytop, turn it over, and push the keytop cover out with a

pointed object such as a pin.

Setup 1-21

Page 39

Removing a Keyboard Unit:

To remove the keyboard unit, follow the procedure below.

1. Detach the keyboard unit cable from the connector.

Caution

Be careful not to injure yourself on the edges of the case when you detach the

keyboard unit cable.

2. Slide the lock switch of the keyboard unit to the release position.

3. As shown below, slide the lock of the keyboard unit while pulling it up with

your fingers and lift it up as shown.

1-22 Setup

Page 40

Installing an LCD Unit

There are two types of LCD unit: with touch panel or without touch panel.

The specifications for the LCD unit are as follows:

LCD panel: 10.4-inches, color DSTN type

640 x 480, 256 colors

Back light life: 25,000 hours until brightness is reduced

to half.

Touch panel: Resistor film type

Serial communication COM4, 9600 bps

(Touch panel)

A slide mechanism lets the LCD surface inclination slide vertically for

setting the optimum angle.

Follow these steps to install an LCD unit:

1. Check that the lock switch in the lower part of the LCD unit is set in the

release position.

2. Set the LCD unit on the IM-300 and slide it downward. At this time, the

LCD unit and IM-300 should be aligned with each other, as shown below.

3. Incline the LCD unit to the desired angle.

4. Set the LCD unit lock switch to the lock position, and secure the LCD.

Setup 1-23

Page 41

5. Connect the two cables for the LCD unit to the connectors. At this time, do

not bend the connector pins.

Removing an LCD Unit:

To remove the LCD unit, follow the procedure below.

1. Detach the LCD unit cables from the connector.

Caution

Be careful not to injure yourself on the edges of the case when you detach the

LCD unit cable.

2. Slide the lock switch of the LCD unit to the release position.

3. As shown below, slide the lock of the LCD unit while pulling it up with your

fingers and lift it up as shown.

1-24 Setup

Page 42

Installing an MSR Unit

The LCD unit and keyboard unit are equipped with an interface for a

connection to a magnetic stripe reader (MSR).

Two types of MSR units can be connected to the IM-300. They differ in

specification of readable magnetic card.

Model Name Specification of readable magnetic card

DM-MR111-012 ISO conforming to JIS1, track 1+2

DM-MR111-013 ISO conforming to JIS1, track 2+3

Mount the MSR unit by following the procedure described below.

1. Open the connector cover on the right side of the LCD unit or keyboard

unit.

2. Connect the MSR unit to the MSR interface.

Setup 1-25

Page 43

3. Secure the MSR unit using the two screws in the package for the MSR unit.

Removing an MSR Unit:

To remove the MSR unit, reverse the installation steps.

Note:

When you remove the screws and then want to fix them again, first turn them

counterclockwise slightly, and then fix them.

1-26 Setup

Page 44

Mounting a Printer Tray

When using the IM-300 either with or without an EPSON TM printer, mount

the printer tray as a top cover for the IM-300. The TM printer can be set on the

printer tray.

Mount the printer tray by following the procedure below. If you are not using

a TM printer, begin with step 3.

1. Separate the hatched part of the printer tray from the rest of the printer tray.

Then cut off the two plastic connecting pieces (burrs) with a cutter and pull

the piece down toward you. Bend the part back and forth two or three

times, so that you can cut the part off. You can now pass the cable through

the new opening.

Caution

•If burrs are left after the hatched part is removed, you may cut or scratch your fingers, etc.

Remove the burrs left on the printer tray with a cutter or file them down.

2. When setting up the TM printer on the printer tray, wrap the cable around

the poles on the other side of the tray, as shown below, to keep it out of the

way.

Setup 1-27

Page 45

3. Slide the printer tray in the direction of the arrow and fit the hooks on the

printer tray into the slots in the IM-300 base unit.

4. Secure the printer tray with two screws.

5. To set up the TM printer, it should be inserted on the printer tray.

Removing a Printer Tray:

To remove the printer tray, reverse the installation steps.

1-28 Setup

Page 46

Installing a Printer

EPSON TM series printers and the printer unit for the IM-300 can be

connected to the IM-300. For how to connect the printer unit, please refer to

the printer unit installation manual.

The IM-300 assigns the COM3 serial port to printer by default. So, connect

the serial communication cable to the COM3 port of the IM-300 and change

jumpers J15 through J17 to 1-2 (to use the external COM3). Also, if you want

to get printer power from the IM-300, connect the printer power cable (After

service part: DC cable set: 201809900) to TM power supply on the IM-300.

TM power supply

COM3

Caution

• Never connect a printer to the TM printer power supply port that is not listed below:

* TM-U200 series * TM-T85 series *TM-U300 series

* TM-U210 series * TM-U325 series

• If you connect one of the printer models especially designed for the IM-300 (such as TM-

T88R or TM-U210R), never attach the printer to the TM power supply.

Refer to the respective printer manual for the installation procedure.

Installing a DM Display

The EPSON DM-D102 customer display can be connected to the IM-300.

The DM-D102 customer display uses the COM3 serial port by default.

Be sure to connect the DM display cable to the DM display port on the IM-

300. See the DM display manual for installation procedure details.

Setup 1-29

Page 47

DM display connector

Exclusive slot

ISA slot

PCI / IASA slot

USB1

COM3

COM4

TM P/S

COM1 CRTLPT

COM2

DKD

Caution

Never plug a telephone line into the DM display port.

Installing an ISA/PCI Board

The IM-300 has one ISA expansion slot and one ISA/PCI expansion slot. You

can insert one ISA board into the ISA expansion slot, and either one ISA or

one PCI board into the ISA/PCI expansion slot.

ISA

PCI/ISA

The mamimum size of the ISA/PCI boards are as follows:

Length Width Height Height

(Parts side) (Solder side)

195 mm (7.7") 107 mm (4.2") 12 mm (0.5") 10 mm (0.4")

1-30 Setup

Page 48

Install the ISA/PCI board by following the procedure below.

1. Remove the retaining screw securing the slot cover. Keep the screw to

secure the ISA/PCI board.

2. Slide the slot cover out and set it aside. Store the slot cover in case you

remove the ISA/PCI board later.

3. Gently guide the board into the connector.

Push the board in firmly (but carefully) to insert it fully. You should feel

the connectors fit into place. If the board does not go in smoothly, do not

force it; pull it all the way out and try again.

4. Secure the end of the ISA/PCI board to the IM-300 with the retaining

screw.

Removing an ISA/PCI Board:

To remove the ISA/PCI board, remove the retaining screw securing the board.

Pull the board straight out of the slot, then replace the slot cover.

After removing the ISA/PCI board, attach a slot cover.

Setup 1-31

Page 49

Installing a PCMCIA Expansion Module

You can install an optional PCMCIA expansion module (OI-B06) in the

exclusive slot (top slot). The PCMCIA expansion module can support two

Type I or Type II cards or a single Type III card.

Exclusive slot

Install the PCMCIA expansion module using the procedure below.

1. Remove the retaining screw securing the cover for the exclusive slot to the

IM-300, as shown below. Keep the screw to secure the PCMCIA

expansion module to the IM-300.

2. Slide the slot cover out and set it aside. Store the slot cover in case you

remove the PCMCIA expansion module later.

1-32 Setup

Page 50

3. Push both sides of the PCMCIA slot cover inward and remove it from the

PCMCIA expansion module.

PCMCIA slot cover

4. Gently guide the PCMCIA expansion module into the top connector.

Push the module in firmly (but carefully) to insert it fully. You should

feel the connectors fit into place. If the module does not go in smoothly,

do not force it; pull it all the way out and try again.

Note:

Remove the PCMCIA slot cover before you install or remove the PC cards.

Removing a PCMCIA Expansion Module:

To remove the PCMCIA expansion module, reverse the installation steps.

Setup 1-33

Page 51

Installing a Hard Disk Drive

You can install a 2.5 inch hard disk drive (0.74 inch high maximum) in the

IM-300. A mounting bracket and an adapter board must be attached to the

hard disk drive.

Caution

Handle the hard disk drive gently. Do not bump or drop the hard disk drive.

Small shocks or vibrations could damage the drive.

Follow these steps to install the hard disk drive.

1. Open the front panel of the IM-300. If the front panel is locked, unlock it

with the front key. To unlock the front panel, insert the front key into the

front keylock and turn it down pushing slightly.

Front cover

Front key

2. Open the HDD cover. Open it while lightly pushing down the two tabs.

HDD cover

1-34 Setup

Page 52

3. Loosen the screw fixing the HDD mounting bracket.

4. Pull out the HDD mounting bracket as shown below.

HDD mounting bracket

5. Attach the hard disk drive onto it, by sliding the hard disk drive as shown

below and fixing it with four screws.

Caution

The tighting torque for all four screws must not exceed 29.4cN·m{3kgf·cm}.

If the tighting torque exceeds this value, some problems may occur.

6. Slide the HDD mounting bracket into the slot so that the notches along the

bottom are under the tabs of the hard disk slot.

7. Push the HDD mounting bracket in gently until you feel the connector fit

into place.

8. Attach the HDD mounting bracket to the IM-300 with a screw.

9. Close HDD cover.

10. Close the front panel.

Setup 1-35

Page 53

Removing a Hard Disk Drive:

To remove the hard disk drive, reverse the installation steps.

1-36 Setup

Page 54

Attaching Side Covers/Side Panels

Caution

• Be sure to attach the side covers and the side panels after setup.

Follow these steps to attach the side panels and the side covers:

1. Attach the side panel and secure it with two screws. Each side panel has

different positions for the screws.

2. Attach the side covers.

Setup 1-37

Page 55

Installing Other Peripherals

The following options can be attached to the IM-300. Refer to the manual for

each peripheral for the installation procedure.

• Mouse (connected to the keyboard/mouse connector through a branch cable)

• Keyboard (connected to the keyboard/mouse connector)

Keyboard/mouse connector

Note:

• To connect a mouse, a commercially available branch cable is required. Attach

the branch cable to the keyboard/mouse connector and connect the mouse to the

cable.

•With some cables, you need to attach the mouse to the keyboard connector and

the keyboard to the mouse connector.

• Cash drawer (connected to the DKD connector)

DKD connector

Caution

• Never plug a telephone line into the DKD connector.

• When the TM power supply is used, the DKD connector can't be used.

1-38 Setup

Page 56

Attaching a Power Cable

The power cable is an option. Select a power cable that meets the

specifications below.

Input voltage (rating) 90 (100-10%) VAC to

264 (240+10%) VAC

Frequency (rating) 50/60 Hz + 2 Hz

Input power (rating) 180 VA or less

Caution

• Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

• Do not place multiple loads on the power outlet (wall outlet).

Overloading the outlet may lead to fire. Always supply power directly from a power

outlet.

Follow these steps to attach the power cable:

1. Connect the power cable to the IM-300.

2. Connect the power plug to the power outlet.

Setup 1-39

Page 57

Attaching the Rear Cover

The IM-300 comes with a rear cover that provides a protective covering for

your cables. After you have connected all the peripherals to the IM-300, attach

the rear cover.

Caution

• Be sure to attach the rear cover after setup.

If the rear cover isn't attached, foreign objects may enter this product causing problems.

Follow these steps to attach the rear cover.

1. Attach the DM display cover.

If the DM display is installed on the IM-300, cut off the portion of the

DM display cover shown below. Cut off the three connecting pieces with

a cutter.

Cut off this

2. Attach the rear cover as shown below.

1-40 Setup

Page 58

3. Secure the rear cover with a screw.

screw

Charging Lithium Batteries

This product contains rechargeable lithium batteries that back up the realtime clock, the CMOS RAM data, and the NVRAM data. The lithium

batteries are not charged fully at the factory. You need to charge the batteries

before you use this product for the first time. If you have not used this product

for a long time, you need to charge them. If the lithium batteries are not fully

charged, your system configuration settings may be incorrect when you start

this product.

Follow these steps to charge the battery:

1. Connect the power cable to the IM-300 and connect the power cable to a

wall outlet.

2. Turn on the IM-300.

3. Leave the IM-300 for about 40 hours.

The lithium batteries are being charged when the IM-300 is turned on. Use

the following table for time of charging.

Time for full charge 40 hours or more (from factory condition)

Backup time 30 days or more (with full charge)

Setup 1-41

Page 59

1-42 Setup

Page 60

Chapter 2

Operation

This chapter explains the operations described below.

• Power on and off

• Indicators

• Security key

• Key lock keys

• Inserting and removing a floppy disk

• Reset

• Paper feed switch

• LCD contrast adjustment

• LCD/keyboard angle adjustment

• How to read a magnetic stripe card

Operation 2-1

Page 61

Power On and Off

When you use this product for the first time, turn on the side power switch. A

"Ο" mark inscribed on the case indicates power off and a "|" mark indicates

power on.

The side power switch should usually be kept on. Turn off the side power

switch only when attaching pheripherals, transporting this product, and when

not using it for an extended period of time.

The side power switch turns off the IM-300 completely. On the other hand, if

the front power switch is pressed, either the system shuts off or the IM-300 is

put into the standby. This depends on the BIOS setting. However, a small

amount of current is flowing. When the switch is pressed again, the IM-300 is

turned on.

This product package contains two switch covers. When you attach the switch

cover in front of the switch, it prevents the switch from turning off by accident.

To attach the switch cover, place the switch cover in front of the switch,

then push it into the hole.

2-2 Operation

Page 62

When you attach the switch cover, push the power switch through the holes

in the switch cover.

Indicators

Both the LCD unit and the keyboard unit have two indicators and the FDD has

one indicator.

Power Indicator

These indicators have the following meaning:

LED Color Meaning

Power Green Power is turned on.

Orange Save to Disk function occurred.

HDD Green HDD is being accessed.

If no HDD is attached, this indicator has no meaning.

FDD Green FDD is being accessed.

HDD Indicator

FDD Indicator

Operation 2-3

Page 63

Security Key

The security key is for use with the cover lock on the front panel.

Cover lock

With the front panel locked, the floppy disk and hard disk drive can be

removed only by a person with a front key.

Insert the security key into the cover lock hole and turn it while slightly

pushing it.

Lock

Unlock

Key Lock Keys

A set of five access keys is provided. Each key allows the user to access the

function level you define for that key position. The key lock keys are used by

inserting them into the key lock on top of the IM-300.

The key lock keys place restrictions on the functions that can be used by the

operator. The key lock key can be turned to six positions (from 1 to 6). Each

key can be given a different access range to prevent use of higher functions by

an unauthorized users. These restrictions are controlled by softwae..

2-4 Operation

Page 64

Inserting and Removing a Floppy Disk

To insert the floppy disk in the floppy disk drive, follow the procedure below.

1. Insert the floppy disk with the label side up in the floppy disk drive. When

the floppy disk is inserted correctly, the eject button will pop out.

To remove the floppy disk, follow the procedure below.

1. Check that the access lamp of the floppy disk drive is off.

2. When you press the eject button, the floppy disk will come out.

Eject button

3. Take out the floppy disk carefully.

Operation 2-5

Page 65

Reset

This restarts the computer while power in on.

Reset is necessary in the following cases:

• When a reset instruction has been issued by the operating

software.

• To restart the computer.

• When software has entered an endless loop.

When the system is reset, all data in memory will be lost. Unless software has

entered a loop, save the required data on an external storage medium such as

hard disk before resetting the system.

There are two types of reset: a hard reset done by pressing the reset switch and

a soft reset performed by pressing the Ctrl, Alt, and Delete keys at the same

time.

Perform a hard reset by following the procedure below.

1. Open the front panel. If the front panel is locked, unlock the front panel

using the front key.

2. Push the reset switch with a pointed object such as a pen.

Perform a soft reset by following the procedure below.

1. Press the Ctrl, Alt, and Delete keys at the same time.

2. Messages for confirmation appear on the screen. Proceed by following the

messages.

2-6 Operation

Page 66

Paper Feed Button

Press the paper feed button when the printer unit for the IM-300 is connected

to feed paper.

Paper feed button

LCD Contrast Adjustment

When you use the LCD unit, you can adjust LCD contrast by turning the

contrast dial.

LCD contrast dial

Operation 2-7

Page 67

LCD/Keyboard Angle Adjustment

The angle of the LCD/keyboard unit is adjustable. Follow these steps to

change it:

1. Slide the LCD/keyboard unit lock switch to the unlock position.

Lock switch

2. Adjust the angle any way you like.

3. Set the lock switch to the lock position again.

How to Read a Magnetic Stripe Card

When you attach a MSR unit, you can read magnetic stripe cards.

Hold the card as shown below, and pass it through the MSR unit.

2-8 Operation

Page 68

Chapter 3

System Utilities

This product comes with the following utility programs in System ROM and

on the hard disk drive:

System ROM

• BIOS setup, for defining the configuration of the system

• Device diagnostics, for troubleshooting devices attached to this product

Hard disk

• An 84-key keyboard configuration utility

• A key lock configuration utility

• A POS key mode setting utility

• Key definition utility (For MS-DOS)

BIOS Setup Utility

The BIOS setup defines how the system is configured. You need to run this

program the first time you configure this product. You may need to run it

again if you change the configuration.

You need to connect a PC keyboard to the keyboard connector to run the BIOS

setup utility.

Caution

Do not change the settings for features not described here.

If you change them, it is possible that this product will not work. If this happens, refer

to "When a Problem Occurs" in this chapter.

System Utilites 3-1

Page 69

Starting the BIOS Setup

To start the BIOS setup:

1.Turn on or reboot this product.

2.Press the DEL key immediately after the product is turned on, or press

the DEL key when the following message is displayed during POST

(the Power On Self Test).

Press DEL to enter SETUP.

3.The main menu of the BIOS setup is displayed. If the supervisor password

is set, you must enter it here.

Help Window

Pressing the F1 key on any menu brings up a display area that describes the

legend keys and the selectable items.

Press the ESC key to exit the help window.

When a Problem Occurs

If, after making and saving system changes with the Setup utility, you find

that this product no longer boots, start the BIOS setup and execute either

one of the following.

• Load Setup Default or

• BIOS Setup Default

3-2 System Utilities

Page 70

Legend Keys

Use the keys displayed on the bottom of the screen to make your selections,

exit the current menu, and so on.

The table below shows the available keys:

Legend Keys

Key Function

Arrow keys Move the cursor.

Esc Main Menu:

Quit and do not save changes to CMOS.

Except Main Menu:

Exit current BIOS screen and return to Main Menu.

Page Up, + Increase the numeric value or make changes.

Page Down, - Decrease the numeric value or make changes.

F1 Display the help window.

F2, Shift + F2 Change color from a total 16 colors. Press F2 to select color forward,

Shift + F2 to select backward.

F3 Calendar, only for Status Page Setup Menu.

F5 Restore the previous CMOS value from CMOS, only for Option

Page Setup Menu.

F6 Load the default CMOS value from the BIOS default table,

only for Option Page Setup Menu.

F7 Load the default.

F10 Save all the CMOS changes, only for Main Menu.

Note:

Shift+F2 means that the Shift key and F2 key are pressed at the same time.

System Utilites 3-3

Page 71

Main Menu

When the Main Menu is displayed, the following items can be selected.

Use arrow keys to select items and the Enter key to accept and enter the submenu.

Items Description

STANDARD CMOS SETUP

BIOS FEATURES SETUP

CHIPSET FEATURE

POWER MANAGEMENT SETUP

PnP/PCI CONFIGURATION

INTEGRATED PERIPHERALS

SUPERVISOR/USER PASSWORD

IDE HDD AUTO DETECTION

HDD LOW LEVEL FORMAT

LOAD SETUP DEFAULTS

SAVE & EXIT SETUP

EXIT WITHOUT SAVING

Basic BIOS setup.

Enchanced BIOS setup.

Advanced Power Management (APM) option.

I/O subsystems that depend on the integrated

peripherals controller in this product.

Plug and play setup.

I/O subsystems that depend on the integrated

peripherals controller.

Change, set, or disable a password. Only the supervisor

password permits access to Setup. The user password

generally allows only power-on access.

Automatically detect and configure IDE hard disk

parameters.

Format HDD. (Caution: Contact system administrator.)

Setup defaults are factory settings for optimal

performance of system operations.

Save settings in nonvolatile CMOS and exit setup.

Abandon all changes and exit setup.

3-4 System Utilities

Page 72

Standard CMOS Setup

In the standard CMOS menu, you can set the system clock and calendar,

record disk drive parameters and the video subsystem type, and select the

type of errors that stop the POST ( Power On Self Test).

Items Description

Date

Time

HARD DISKS

LCD & CRT

Set the date. The BIOS determines the day of the

week from the other information. This field is for

information only. Press the left or right arrow key to

move to the desired field (date, month, year). Press the

PgUp or PgDn key to increment the setting, or type the

desired value into the field.

Set the time. The time format is based on the 24-hour

military-time clock. For example, 1 p.m. is 13:00:00.

Press the left or the right arrow key to move to the

desired field. Press the PgUp and PgDn keys to

increment the setting, or type the desired value into the

field.

The BIOS can automatically detect the specifications

and optimal operating mode of almost all IDE hard

drives. When you select type AUTO for a hard drive,

the BIOS detects its specifications during POST. Set

this item to AUTO.

Select the video display device.

LCD LCD display.

CRT Auxiliary monitor

AUTO The BIOS autosenses the device in use.

Both Displays on both devices.

System Utilites 3-5

Page 73

Items Description

Halt On

During POST, the system stops if the BIOS detects a

hardware error. You can tell the BIOS to ignore

certain errors during POST and continue the boot-up

process.

These are the selections:

No Errors

POST does not stop for any errors.

All Errors

If the BIOS detects any non-fatal error, it stops.

All, But Keyboard

POST does not stop for a keyboard error, but

does for all other errors.

All, But Diskette

POST does not stop for diskette drive errors, but

stops for all other errors.

All, But Disk/Key

POST does not stop for a keyboard or disk

error, but stops for all other errors.

3-6 System Utilities

Page 74

BIOS Features Setup

This menu sets up the security.

Items Description

Security

Virus Warning

Quick Power On Self Test

Boot Sequence

Boot Up NumLock Status

Memory Parity/ECC Check

Typematic Rate Setting

Typematic Rate (Chars/Sec)

Typematic Delay

If you have set a password, select whether the

password is required every time the system boots, or

only when you enter setup.

System

Enter the password when the system boots and

when you enter setup.

Setup

Enter the password to run BIOS setup.

When "Enabled" is selected, an error is displayed

when an application tries to write data to the

partition table of HDD.

When "Enabled" is selected, certain steps of the

POST are skipped.

Select the boot drive order.

Select the Num Lock status when the IM-300 is

turned on.

Enable or disable the memory parity check.

Enable or disable the Typematic Rate and Delay.

Select typematic rate (the rate at which character

repeats when you hold down a key).

Select the delay before key strokes begin to repeat

(milliseconds).

System Utilites 3-7

Page 75

Power Management

In the power management menu, you can set the following items for power

management.

Items Description

APM BIOS

BIOS PM on AC

BIOS PM Timers

Video Standby Timer

Suspend Timer

APM/Timer Suspend Mode

System Battery

Select "Enabled" to turn on the BIOS powermanagement features.

If you want the BIOS power-management features to

remain active when the system is connected to an

external power source, set to ON.

After the selected period of inactivity for the subsystems

below (video, hard disk drive, suspend), the subsystem

enters standby mode.

Max Timeouts Maximum inactivity period before

entering standby mode.

User Define Select inactivity period for each

sub system.

Min Saving Minimum inactivity period before

entering standby mode.

Select time until video subsystem transits to the standby

mode.

Select time until the system transits to the standby mode.

Select the suspend mode for APM and global timer.

POS Suspend Power on suspend mode.

Power is on while some subsystems

are turned off.

STD Suspend Save to disk suspend mode. Data is

stored to the HDD and power is off.

When you attach a battery unit to back up the operation of

the devices using a 5V power supply, change this setting

from "Not Equipped" to "Equipped." If you don't set this

setting, the save to disk function won't work.

3-8 System Utilities

Page 76

Items Description

Front Switch Function

16/32-bit OS

Select the functions of the front power switch.

Power OFF System shuts off.

STD SuspendSaves the data to the hard disk and

power is turned off. Next time you

turn it on, it'll start where you leave

off. It isnecessary to secure an STD

area on the disk beforehand if you

want to use the STD Suspend.

Select the OS type when Save to disk function is enabled.

PnP/PCI Configuration

In the PnP/PCI configuration menu, you can set the plug & play standard and

PCI Local Bus configuration.

Items Description

PNP OS Installed

Resource Controlled by

Reset Configuration

Data

Plug & Play support.

If you select AUTO, BIOS automatically assigns

settings, such as DMA and interrupt.

If you select Enabled, ESC data is reset.

IRQ n assigned to

PCI IRQ Activated by

PCI IDE IRQ Map to

Primary IDE INT #

Assign each IRQ type.

Select IRQ trigger level.

IDE IRQ mapping.

Primary IDE interrupt.

System Utilites 3-9

Page 77

Integrated Peripherals

The menu sets up the connections between the CPU and the I/O ports and

the hard disk controllers.

The printer unit specialized for the IM-300 uses COM3 and is assigned to

3E8h/IRQ 11.

The touch panel uses COM4 and is assigned to 2E8h/IRQ 10.

Items Description

IDE Primary Master PIO

IDE HDD Block Mode

On-Chip USB Controller

Onboard Serial Port 1/2/3/4

Onboard Parallel Port

The IDE PIO (Programmed Input/Output) fields let you

set a PIO mode (0-4) for each of the IDE devices that the

onboard IDE interface supports. Modes 0 through 4

provide successively increased performance. In Auto

mode, the system automatically determines the best

mode for each device.

Block mode is also called block transfer, multiple

commands, or multiple sector read/write. If your IDE

hard drive supports block mode (most new drives do),

select Enabled for automatic detection of the optimal

number of block read/writes per sector the drive can

support.