Page 1

®

EPSON EPL-N2700 Optional Units

SEPG98007

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However , shoul d any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademar ks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PREFACE

This manual describes basic functions, theory of el ectrical and mechanical operations, maintenance and repair procedures of EPSON EPL-N2700

Optional Units. The in struct ions a nd pr ocedures inc luded her ein ar e in tended for t he experienc ed r epair tec hnician s, and attenti on should be given to

the precautions on the preceding page. The chapters are organized as follows:

PCHAPTER 1. DOUBLE CASSETTE UNIT

Describes the step-by-step procedures for disassembling and assembling the

Double Cassette Unit.

CHAPTER 2. DUPLEX UNIT

Describes the step-by-step procedures for disassembling and assembling the

Duplex Unit.

CHAPTER 3. LCC UNIT

Describes the step-by-step procedures for disassembling and assembling the

LCC Unit.

CHAPTER 4. 5-BIN UNIT

Describes the step-by-step procedures for disassembling and assembling the 5Bin Unit.

CHAPTER 5. 10-BIN UNIT

Describes the step-by-step procedures for disassembling and assembling the

Double Cassette Unit.

CHAPTER 6. Operating Principles for Optional Units

Explains the operating principles of each optional unit.

Page 4

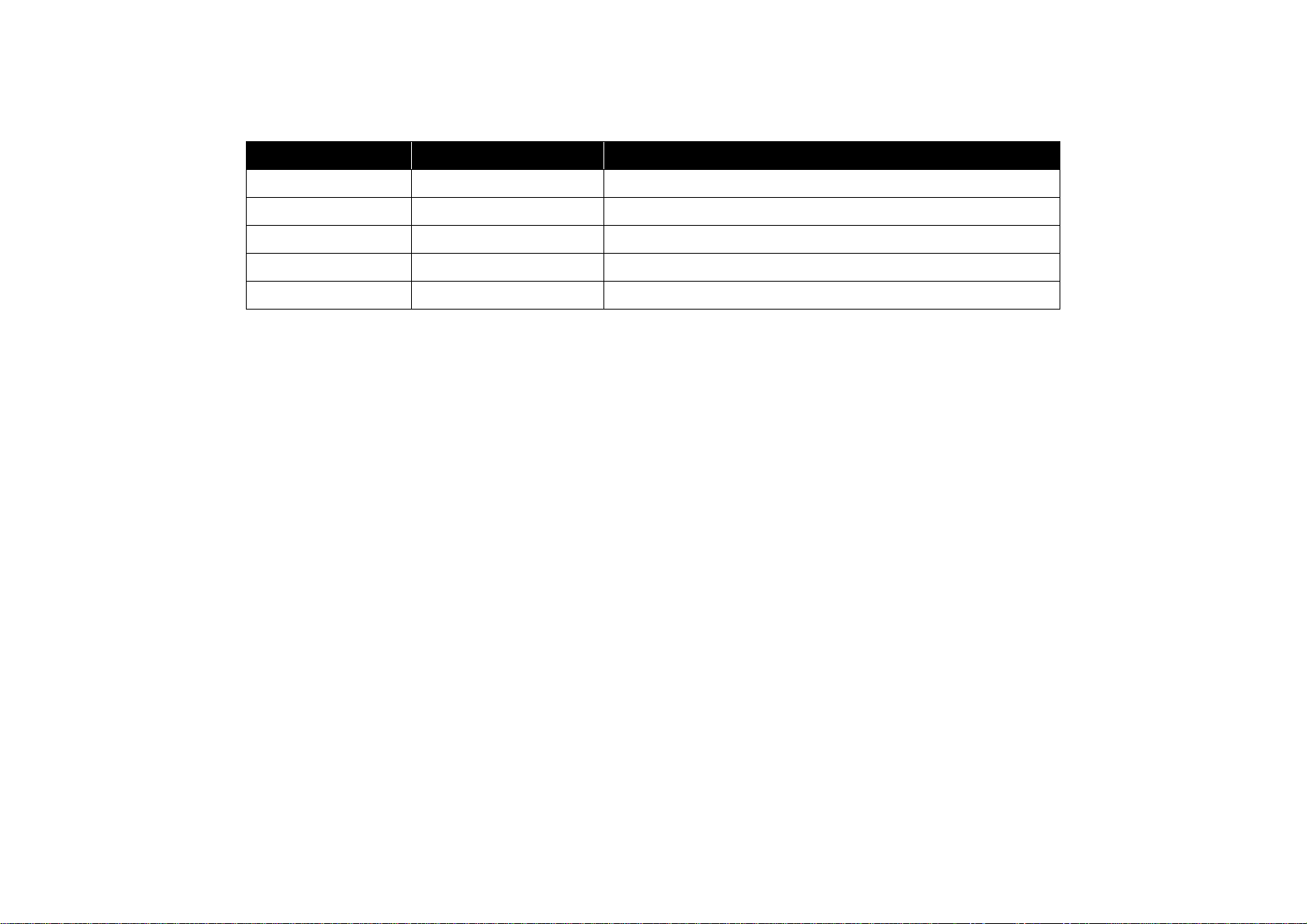

Revision Status

Revision Issued Date Description

A Fuburary 10, 1999 Revision A

Page 5

Contents

Double Cassette Unit

Installing the Doubl e Cassette Unit ................................................................. 9

Disassembly and Assembly of the Double Cassette Unit ............................... 11

Paper Take-up Roller Removal ........................................................................... 11

Paper Empty Sensor Removal ............................................................................ 11

Paper Near Empty Sensor Removal ................................................................... 12

Paper Feed Sensor Removal .............................................................................. 12

Paper Size Sensor (Paper Size Switch) Removal ............................................... 13

Controller Board (PWB-A) Removal .................................................................... 13

Paper Take-up Solenoid Removal ...................................................................... 14

Right Door Set Sensor Removal ......................................................................... 15

Maintenance of the Double Cassette Unit

Cleaning the Paper Take-up Roller .......... ............ ............................................... 16

Cleaning the Transport Roller ........ ..................................................................... 16

Exploded Diagrams for Double Cassette Unit

Housing ............................................................................................................... 17

Paper Take-up Section ........................................................................................ 19

Paper Tray Unit ................................................................................................... 21

...................................................... 16

................................................ 17

Duplex Unit

Installing the Dupl ex Unit .............................................................................. 24

Disassembly and Assembly of the Duplex Unit ............................................. 26

Duplex Unit Door Set Sensor Removal ............................................................... 26

Main Board Removal ........................................................................................... 27

Switch Back Motor Removal ............................................................................... 28

Transport Motor Removal .................................................................................... 29

Transport Roller Removal ................................................................................... 30

Maintenance of the Duplex Unit

Cleaning the Transport Roller ........ ..................................................................... 31

Exploded Diagrams for Duplex Unit

.................................................................... 31

.............................................................. 32

LCC Unit

Installing the LCC Unit .................................................................................. 35

Disassembly and Assembly of the LCC Unit

.................................................. 37

Separate Roller/Torque Limiter Removal ............................................................ 37

Feed Roller Removal .......... ............................................................... ................. 37

Paper Take-up Unit Removal ....................... .. .. .......... .. ....................................... 38

Lift-up Sensor Removal ...................................................................... 39

Paper Take-up Roller (Right) Assembly Removal .............................. 40

Right Paper Take-up Clutch Removal ................................................ 42

Paper Take-up Roller (Left) Assembly Removal ................................ 43

Paper Take-up Clutch (Left) Removal ................................................ 45

Paper Take-up Roller Removal .......................................................... 45

LCC Paper Take-up Sensor (PPS0) Removal ................................... 46

Paper Empty Sensor 1 (PPS1) Removal ........................................... 46

Paper Empty Sensor 2 (PPS2) Removal ........................................... 46

Paper Stand-by Position Sensor Removal ......................................... 47

Registration Sensor Removal ............................................................. 47

Side Cover Set Sensor Removal ........................................................ 48

Registration Clutch (RCL) Removal ................................................... 49

Separate Clutch Removal .................................................................. 49

Registration Roller Removal ............................................................... 51

Separate Roller Shaft Removal .......................................................... 51

Feed Roller Shaft Removal ................................................................ 51

Drive Section Disassembly ................................................................................. 52

LCC Transport Motor Removal .......................................................... 52

LCC Set Sensor Removal .................................................................. 53

Paper Near Empty Sensor Removal .................................................. 53

LCC Lift-up Motor Removal ................................................................ 54

LCC Main Board Removal .................................................................. 55

Paper Tray Unit Disassembly ............... .......... .. .................... .. .......... .. ................. 56

Roller with the Torque Limiter Removal ............................................. 56

Timing Belt Removal .......................................................................... 57

Lifter Drive Shaft Removal ................................................................. 59

Maintenance of the LCC Unit ......................................................................... 60

Maintenance Items .............................................................................................. 60

Cleaning the Paper Take-up Roller ..................................................................... 60

Cleaning the Feed/Separate Roller ..................................................................... 61

Cleaning the Vertical Transport Roller / Roller (Driven) ...................................... 61

Cleaning the Roller with a Torque Limiter ........................................................... 62

Page 6

Exploded Diagrams for LCC Unit ................................................................... 63

Housing ............................................................................................................... 63

Paper Take-up Section (A) .................................................................................. 65

Paper Take-up Section (B) .................................................................................. 67

Drive Section ....................................................................................................... 69

Paper Tray Unit (A) ............................................................................................. 71

Paper Tray Unit (B) ............................................................................................. 73

5-Bin Unit

Installing the 5- Bin Unit ................................................................................. 76

Disassembly and Assembly of the 5-Bin Unit ................................................ 80

Front Cover Removal .......................................................................................... 80

Rear Cover Removal ........................................................................................... 80

Jammed Paper Remove Door Removal .............................................................. 80

Shift Motor (M2) Removal ................................................................................... 81

Guide Position Sensor (PC3) Removal ............................................................... 82

Control Board (PWB-A) Removal ........................................................................ 82

Bin 4/ Bin 5 Switch Solenoid (SL2) Re moval ............ ....................... ................... 83

Jammed Paper Remove Door Sensor (PC1) Removal ....................................... 84

Transport Motor (M1) Removal ........................................................................... 84

Paper Guide Drive Motor (M3) Removal ............................................................. 85

Transfer Switch Sol enoid (SL1) Removal ........... ............ .................... .. ............ .. 86

Paper Guide Home Position Sensor (PC2) Removal .......................................... 87

Bin 1 Shift Home Position Sensor (PC4) Removal .............................................. 88

Paper Empty Sensor Board (PWB-B/D1-3/E) Removal ...................................... 89

Eject Sensor Board (PWB-C) Removal ............................................................... 90

Shift Guide Plate Removal .................................................................................. 91

Eject Roller Shaft Removal ................................................................................. 92

Bin 1 Eject Roller Shaft Removal ....................................................... 92

Bin 2 Eject Roller Shaft Removal ....................................................... 92

Bin 3 - 5 Eject Roller Shaft Removal .................................................. 93

Movable Paper Guide Removal .......................................................................... 94

Transfer Switch Guide Lever Removal ................................................................ 95

Bin 4 /Bin 5 Switch Guide Lever Removal ........................................................... 95

Maintenance of the 5-Bin Unit

Maintenance Items .............................................................................................. 96

Cleaning the Paper Take-up Roller .......... ............ ............................................... 96

Exploded Diagrams for 5-Bin Unit

Housing ............................................................................................................... 96

Paper Exit Section ............................................................................................... 98

Paper Transport Section (A) .............................................................................. 100

Paper Transport Section (B) .............................................................................. 102

....................................................................... 96

................................................................. 96

Paper Transport Section (C) ............................................................................. 104

10-bin Unit

Installing the 10-bin Unit ............................................................................. 107

Installing the 10-bin Unit .................................................................................... 107

Levelness Adjustment of the 10-bin Unit ........................................................... 113

Disassembly and Assembly of the 10-bin Unit

Outer Cover Removal ....................................................................................... 114

Tray Section Disassembly/Assembly ................................................................ 115

Transport Motor (M1) Removal ........................................................ 115

Transport Motor Pulse Detection Switch (PC1) Removal ................ 116

Sorter Set Switch (S1) Removal ....................................................... 117

Controller Board (PWB-A) Removal ................................................. 117

Sort/Non-Sort Switch Solenoid (SL1) Removal . ............................... 118

Solenoid Assembly (SL2, SL3) Removal . ........................................ 118

Bin 1/Bin 6 Paper Empty Sensor Board Removal (PWB-B/D5) ....... 119

Paper Empty Sensor Board (PWB-D1-D4, D6-D9) Removal ........... 120

Eject Sensor Board (PWB-C) Removal ............................................ 121

Vertical Transport Roller Removal ................................................... 122

Eject Roller Removal ........................................................................ 123

Bin Switch Guide Removal ............................................................... 124

Eject Guide Removal ........................................................................ 125

Sort/Non-Sort Switch Guide Removal .............................................. 126

Transport Roller Removal ................................................................ 127

Horizontal Transport Unit Disassembly/Assembly ............................................ 128

Rear Cover Removal ........................................................................ 128

Non-Sort Bin Jam Sensor (PC1) Removal ....................................... 128

Horizontal Transport Door Sensor (PC4) Removal .......................... 129

Horizontal Transport Unit Paper Empty Sensor (PC6) Removal ...... 129

Paper Path Switch Solenoid Removal .............................................. 130

Horizontal Transport Roller Removal ............................................... 131

Adjustment ................................................................................................. 132

Timing Belt Tension Adjustment ....................................................................... 132

Test Mode ......................................................................................................... 132

Pre-Operation ................................................................................... 132

Activating the Test Mode .................................................................. 133

Cancelling the Test Mode ................................................................. 133

Details of Each Test Mode ............................................................... 133

Adjusting the Eject Sensor ................................................................................ 139

Maintenance

............................................................................................... 140

............................................. 114

Page 7

Maintenance Items ............................................................................................ 140

Cleaning the Paper Take-up Roller .......... ............ ............................................. 140

Exploded Diagrams

Housing ............................................................................................................. 141

Frames .............................................................................................................. 143

Paper Transportation Section (A) ...................................................................... 145

Paper Transportation Section (B) ...................................................................... 147

Paper Transportation Section (C) ...................................................................... 149

Paper Transportation Section (D) ...................................................................... 151

Paper Transportation Section (E) ...................................................................... 153

Drive Section ..................................................................................................... 155

Horizontal Transport Unit (A) ............................................................................. 157

Horizontal Transport Unit (B) ............................................................................. 159

...... ............................ .................................................. 141

Operating principles

Double Cassette Unit ......... .............. ........................................................... 162

Structure ............................................................................................................ 162

Drive System .................................................................................... 162

Electrical Components Layout .......................................................... 162

Mechanical Operations ...................................................................................... 163

Paper Size Regulating Plate ............................................................ 163

Paper Lifting Plate ............................................................................ 163

Paper Size Setting ............................................................................ 163

Paper Near Empty Detection ............................................................ 164

Paper Empty Detection ................................................. .. ....... .......... 164

Paper Separation Mechanism .......................................................... 165

Paper Take-up Roller .......................... .. ..... .. ....... ..... ..... .. ..... ....... ..... 166

Paper Take-Up Retry Control ........................................................... 166

Duplex Unit ......... ....... ................................................................ ................. 167

Structure ............................................................................................................ 167

Drive System .................................................................................... 167

Electrical Components Layout .......................................................... 168

Mechanical Operations ...................................................................................... 168

Switchback Mechanism .................................................................... 168

Transport/Feedback Mechanism ...................................................... 169

Duplex Print Schemes ...................................................................... 170

LCC Unit Unit ................................................... ........................................... 172

Structure ............................................................................................................ 172

Drive System Layout ........................................................................ 172

Electrical Components Layout .......................................................... 173

Mechanical Operation ....................................................................................... 174

Vertical Transport Mechanism .......................................................... 174

Paper Take-up Mechanism .............................................................. 175

Paper Take-Up Retry Control ........................................................... 178

Paper Separating Mechanism .......................................................... 179

Paper Pressure Releasing Mechanism ............................................ 180

Paper Take-up Roller Retracting Mechanism . ................................. 180

Paper Size Regulating Plate ............................................................ 181

Paper Size Setting ............................................................................ 181

LCC Set Detection ............................................................................ 182

Lifting Mechanism ............................................................................ 183

Paper Near Empty Detection ............................................................ 185

Paper Empty Detection .................................................................... 185

5-Bin Unit ................................................................................................... 186

Structure ............................................................................................................ 186

Drive Section Layout ........................................................................ 186

Electrical Component Layout ........................................................... 187

Mechanical Operati ons ...................... .......... .......... ..................... .......... .......... .. 188

Paper Exit Path ................................................................................ 188

Single/Duplex Print Switch Mechanism ............................................ 189

Paper Guide Mechanism .................................................................. 189

Bin 4/Bin 5 Switch Mechanism ......................................................... 190

Shift Mechanism ............................................................................... 190

Paper Empty Detection Mechanism ................................................. 191

Paper Full Detection Mechanism . .................................................... 192

10-bin Unit .................................................................................................. 193

Structure ............................................................................................................ 193

Drive Section Layout ........................................................................ 194

Electrical Component Layout ........................................................... 195

Mechanical Operati ons ...................... .......... .......... ..................... .......... .......... .. 196

Paper Exit Path ................................................................................ 196

Paper Transport Mechanism (Horizontal Transport Unit) ................. 198

Bin Switch Mechanism ..................................................................... 198

Paper Empty Detection Mechanism ................................................. 199

Paper Full Detection Mechanism . .................................................... 199

Mode Description .............................................................................................. 200

Normal Mode (Non-Sort Mode) ........................................................ 200

Large Capacity Mode (Stacker Mode) .............................................. 200

Mailbox Mode ................................................................................... 200

Sorter Mode ........................................................................... .. ....... .. 200

Multiple Sorter Mode ........................................................................ 200

Page 8

DOUBLE CASSETTE UNIT

Page 9

EPL-N2700 Optional Units Revision A

1.1 Installing the Double Cassette Unit

This section describes how to install the Double Cassette Unit to the

printer main body. Note you are required to remove any optional unit

such as the Double Cassette Unit when servicing the printer. The

procedure for removing the Double Cassette Unit is not included since

you can remove it by reversing the installation procedure.

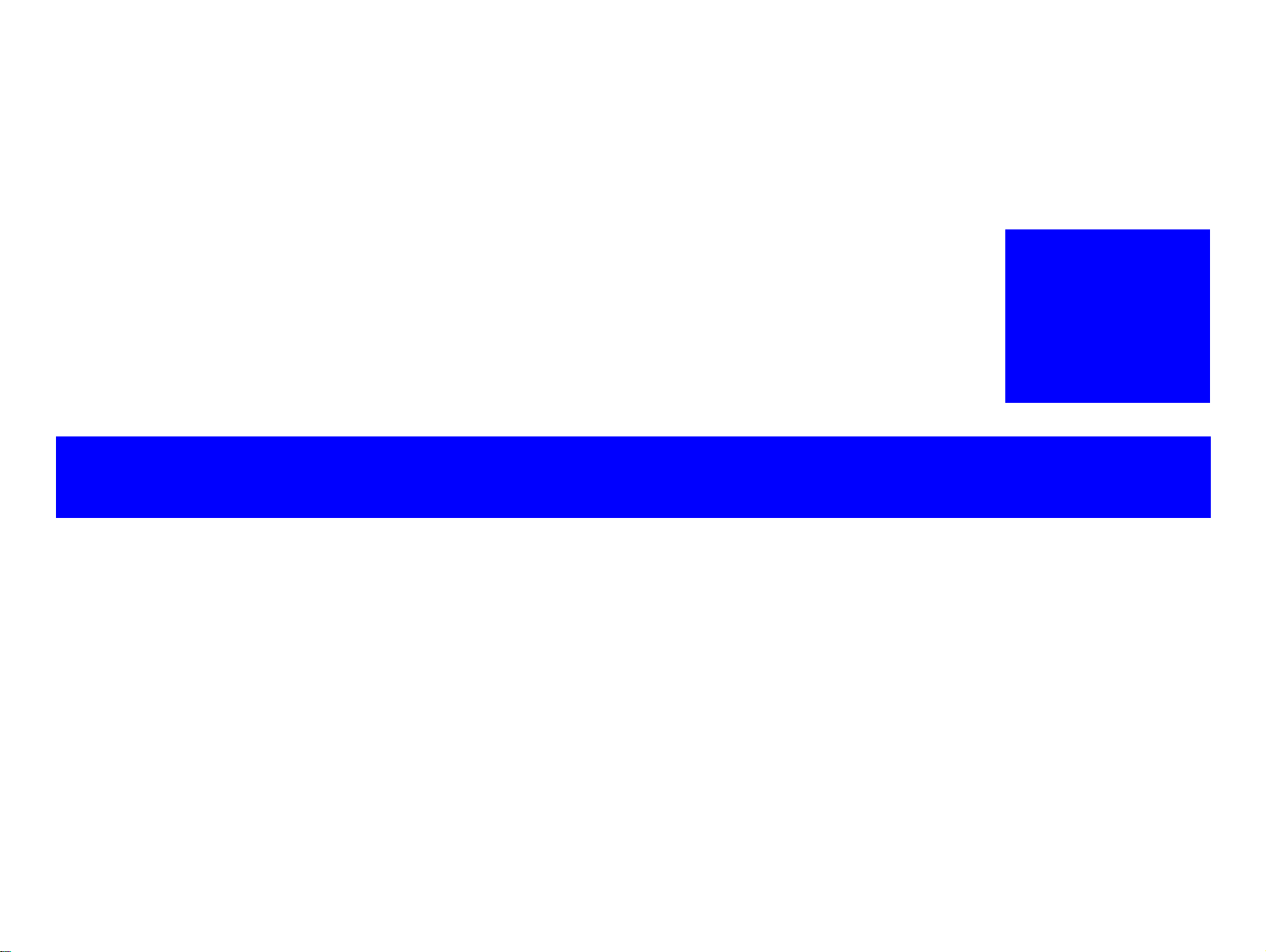

1. Open the packing carton and get a Double Cassette Unit and the

user’s manual.

2. Pull out the paper cassette and remove the protection materials.

Figure 1-2. Removing the Protection Pads

3. Turn the printer power off and disconnect the AC power cable and

interface cable.

4. Remove the bottom cover from the bottom part of the printer.

Figure 1-1. Unpacking

CAUTION

After removing the packing materials, please keep

them out of children’s reach.

Figure 1-3. Bottom Cover Removal

Double Cassette Unit Installing the Double Cassette Unit 9

Page 10

EPL-N2700 Optional Units Revision A

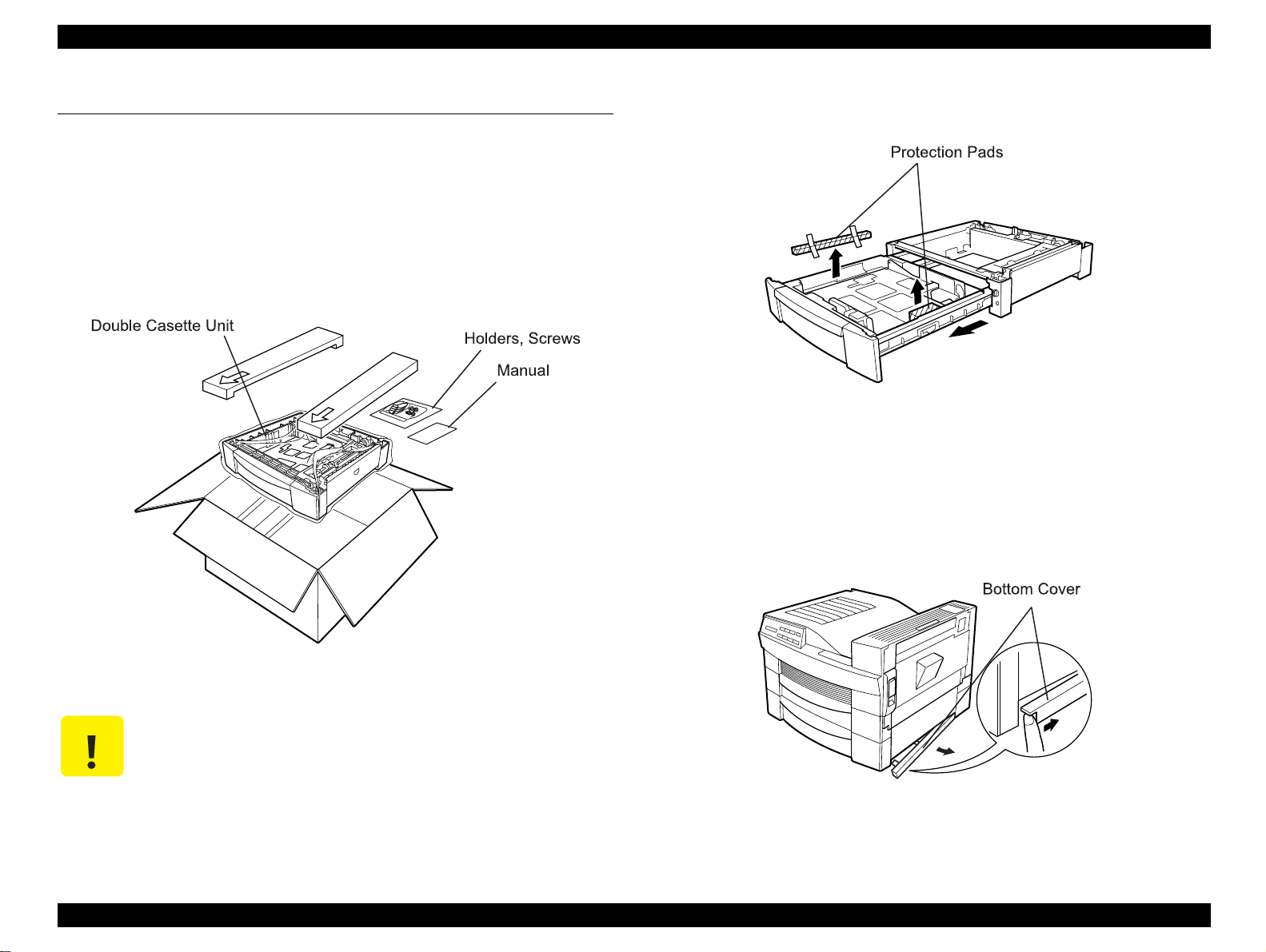

5. Place the printer main body on the Double Cassette Unit.

Figure 1-4. Placing the Printer on the Double Cassette Unit

CHECK

PO INT

When placing the printer, make sure the following:

The blue levers on the cassette and the printer are

facing in the same direction.

All corners of the printer are properly aligned with

the corresponding ones of the cassette unit.

6. Attache the bottom cover to the bottom part of the Double Cassette

Unit.

Figure 1-5. Installing the Bottom Cover

7. Secure the corners for t he printer and the Do uble Cassette Unit with

the holders and screws (1603).

CAUTION

2 people are required

to lift the printer as

shown in the figure.

Figure 1-6. Attaching the Holders

8. Connect the interface cable and the AC power cable to the printer

and turn the printer on.

Double Cassette Unit Installing the Double Cassette Unit 10

Page 11

EPL-N2700 Optional Units Revision A

1.2 Disassembly and Assembly of the Double Cassette Unit

This section provides the disassembly procedure for the Double

Cassette Unit. Unless otherwis e specified, assembly can be performed

by following the disassembly procedure in reverse order.

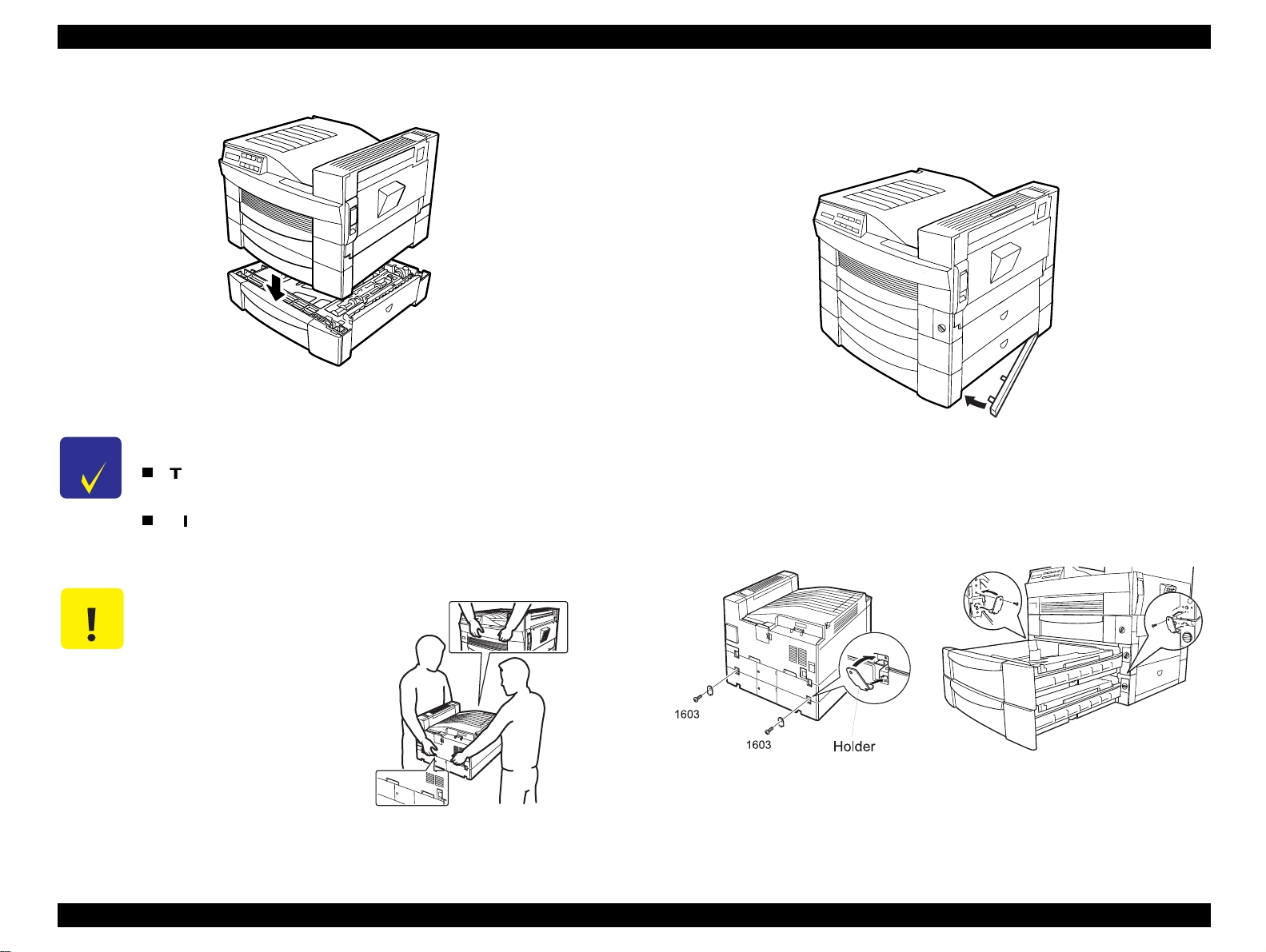

1.2.1 Paper Take-up Roller Removal

1. Release the lock on the Paper Take-up Roller and slide the roller

along the axle plate to remove the roller.

CAUTION

If you have replaced the Paper Take-up Roller, perform

“LC2 Counter Clear” in the maintenance menu. In case

2 Double Cassette Unit are connected, perform “LC3

Counter Clear” as well.

1.2.2 Paper Empty Sensor Removal

1. Release three hooks attaching the holder to the guide plate and

remove the holder. (See Figure 1-8.)

2. Remove the screw (3501) securing the paper empty sensor brack et

to the guide plate. (See Figure 1-8.)

3. Remove the stopper for the Paper Empty Sensor and remove the

sensor. (See Figure 1-8.)

4. Disconnect the harness from the Paper Empty Sensor.

Figure 1-7. Paper Take-up Roller Removal

CHECK

PO INT

When installing the Paper Take-up Roller, ensure the

roller is securely locked as shown in the figure below.

Double Cassette Unit Disassembly and Assembly of the Double Cassette Unit 11

Page 12

EPL-N2700 Optional Units Revision A

9302

3501

3704

3501

3501

3501

3704

9302

3501

S5

S4

3704

3704

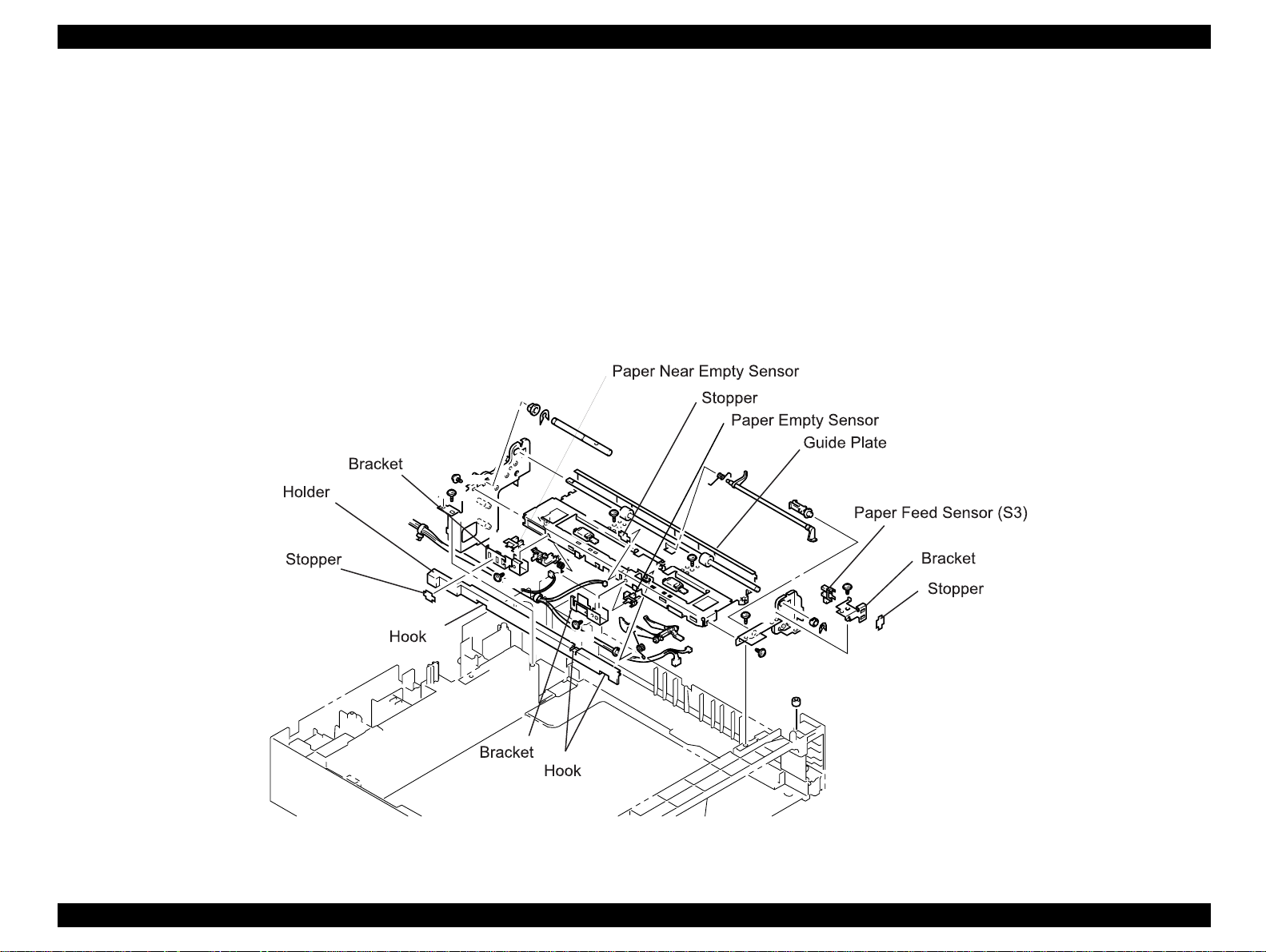

1.2.3 Paper Near Empty Sensor Removal

1. Release three hooks attaching the holder to the gui de plate and

remove the holder.

2. Remove the screw (3501) securing the paper near empty sensor

bracket to the guide plate.

3. Remove the stopper for the Paper Near Empty Sensor and remove

the sensor.

4. Disconnect the harness from the Paper Near Empty Sensor.

1.2.4 Paper Feed Sensor Removal

1. Remove the screw (3501) securing the paper feed sensor bracket to

the guide plate and remove the bracket.

2. Remove the stopper for the Paper Feed Sensor and remove the

sensor.

3. Disconnect the harness from the Paper Feed sensor.

Figure 1-8. Removal of the Paper Empty / Paper Near Empty / Paper Feed Sensors

Double Cassette Unit Disassembly and Assembly of the Double Cassette Unit 12

Page 13

EPL-N2700 Optional Units Revision A

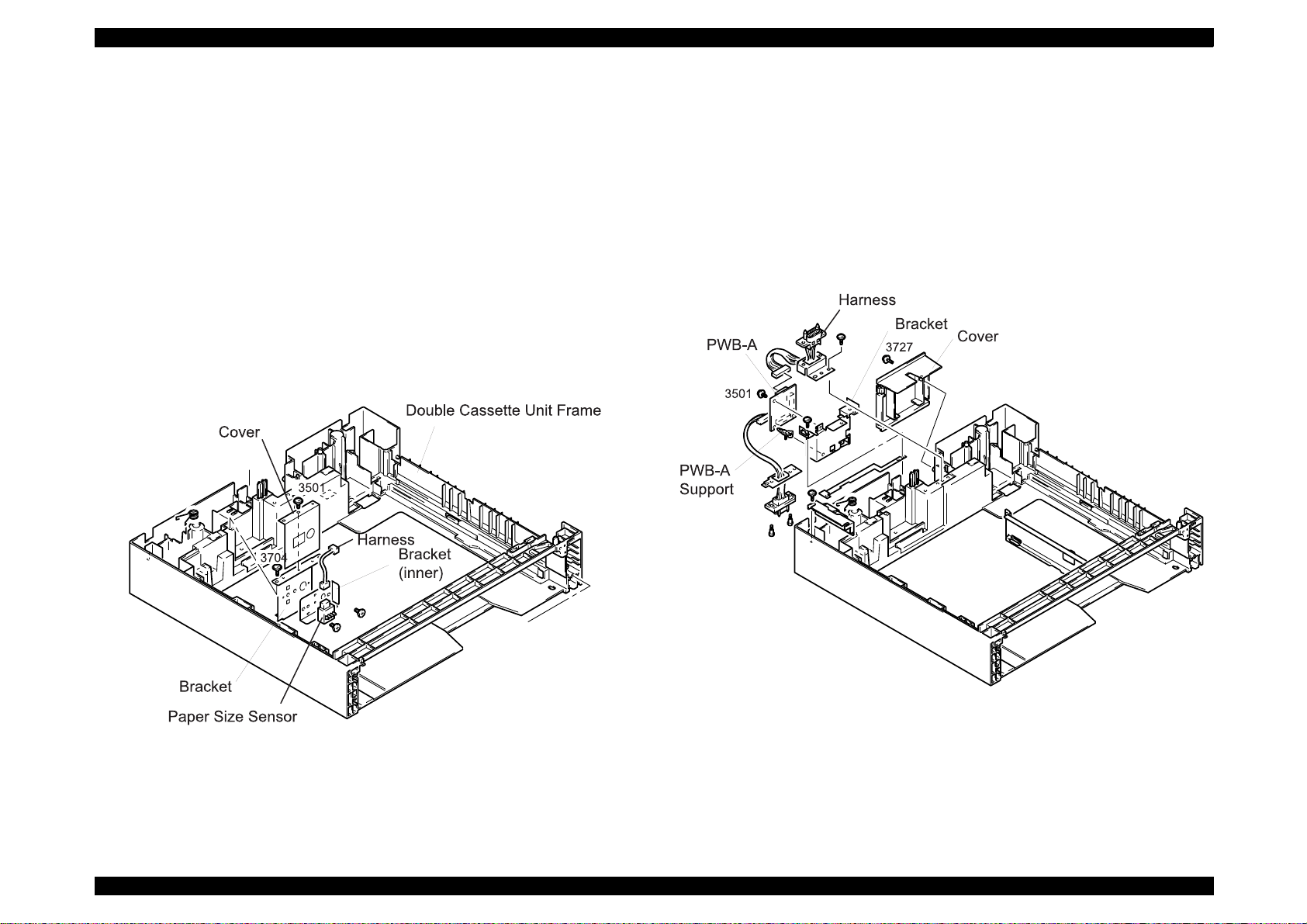

1.2.5 Paper Si ze Sensor (Paper Size Switch) Removal

1. Remove three screws (3704) securing the paper size sensor

bracket to the frame in the Double Cassette Unit, and remove the

bracket along with the paper size sensor.

2. Remove the screw (3501) securing the paper size sensor cover to

the bracket and remove the c ov er from the bracket .

3. Releas e the hook secur ing the Paper Size Sensor to the inner

bracket and remove the se ns or from the bracket.

4. Disconnect the harness from the Paper Size Sensor.

1.2.6 Controller Board (PWB-A) Removal

1. Remove the screw (3727) securing the cover and remove the cover.

2. Remove harnesses from the connectors on the PWB-A.

3. Remove two screws (3501) securing the PWB-A to the bracket and

the PWB s upport, and remov e the PWB-A.

Figure 1-10. PWB-A Removal

Figure 1-9. Paper Size Sensor Removal

Double Cassette Unit Disassembly and Assembly of the Double Cassette Unit 13

Page 14

EPL-N2700 Optional Units Revision A

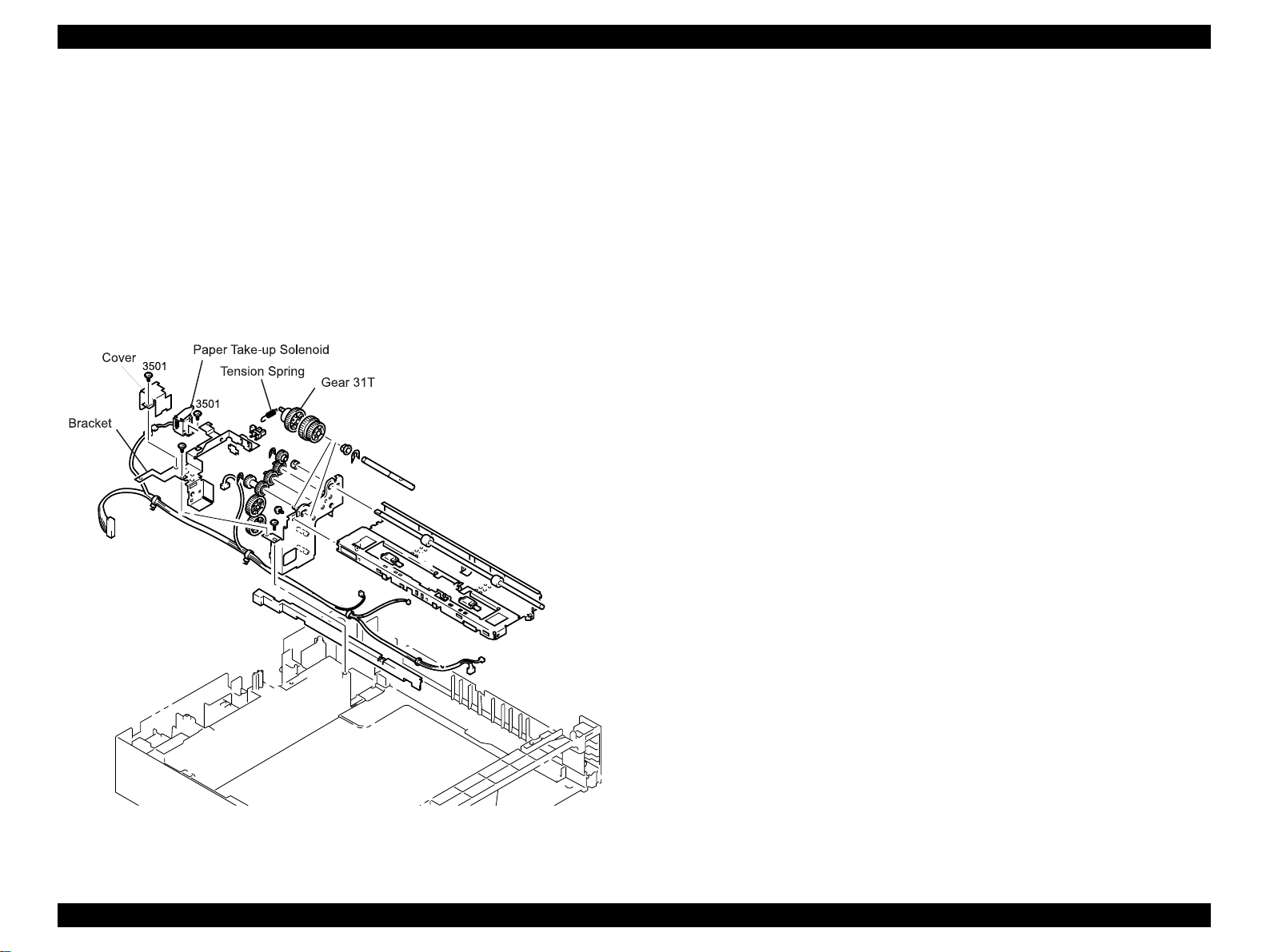

1.2.7 Paper Take-up Solenoid Removal

1. Remove the tension spring hooked to the gear 31T.

2. Remove the screw (3501) securing the paper take-up solenoi d

cover to the bracket and remove the cover.

3. Remove the screw (3501) securing the Paper Take-up Solenoid to

the bracket and remove the solenoid from the bracket.

4. Disconnect the harness from the connector on the solenoid.

Figure 1-11. Paper Take-up Solenoid Removal

Double Cassette Unit Disassembly and Assembly of the Double Cassette Unit 14

Page 15

EPL-N2700 Optional Units Revision A

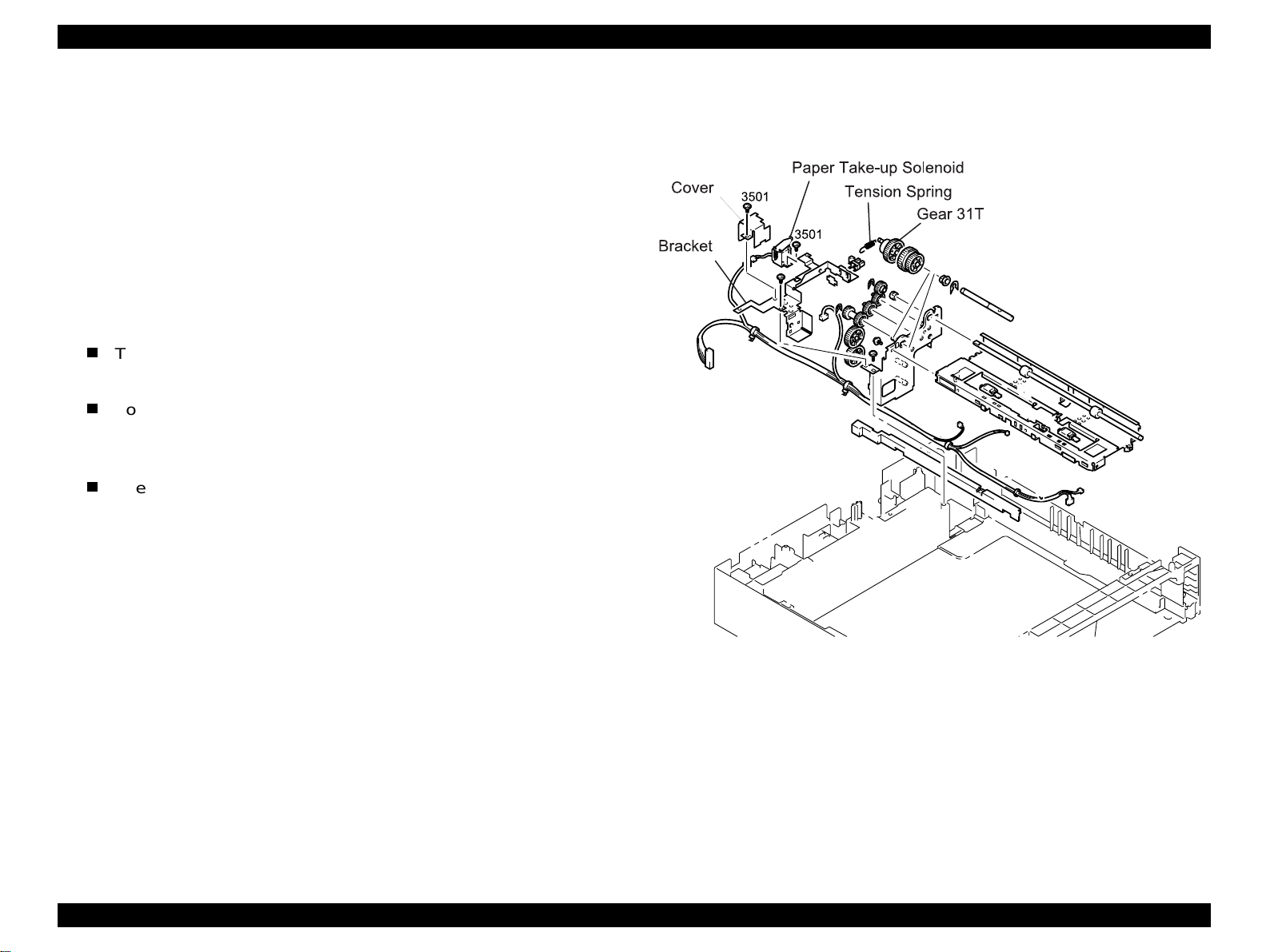

1.2.8 Right Door Set Sensor Removal

1. Remove the tension spring hooked to the gear 31T.

2. Remove two screws (3704) securing the PWB-A board bracket to

the Double Cassette Unit Frame and remove the bracket. (See

Section 1.2.7.)

3. Remove the screw (3501) securing the plate spring to the bracket

and remove the plate spring from the bracket.

4. Remove the following screws:

Two screws (3704) securing the solenoid bracket to the Double

Cassette Unit Frame.

Four screws (3704) securing the Paper Take-up Mechanism

(including the axle plate, guide plat e, and bracket) to the 2nd

Cassette Frame.

The screw (3501) securing the rail and axle plate.

5. Lift up the Paper Take-up Solenoid and bracket.

6. Remove two screws (3501) securing the solenoid bracket to the

Paper Take-up mechanism and remove the solenoid bracket.

7. Remove the stopper securing the Right Door Set Sensor to the

solenoid bracket.

8. Release the hook fixing the Right Door Set Sensor to the solenoid

bracket and remove the sensor.

9. Disconnect the harness from the connector on the Right Door Set

Sensor.

Figure 1-12. Right Door Set Sensor Removal

Double Cassette Unit Disassembly and Assembly of the Double Cassette Unit 15

Page 16

EPL-N2700 Optional Units Revision A

1.3 Maintenance of the Double Cassette Unit

The maintenance method of the Double Cassette Unit is mostly the

same as for the printer body. Therefore, this section only describes the

method specific to the Double Cassette Unit.

CAUTION

1.3.1 Cleaning the Paper Take-up Roller

1. Remove the Paper Take-up Roller. (Refer to Section 1.2.1.)

2. Wipe the Paper Take-up Roller with a soft cloth moistened with

water.

Do not use any solvent, including alcohol.

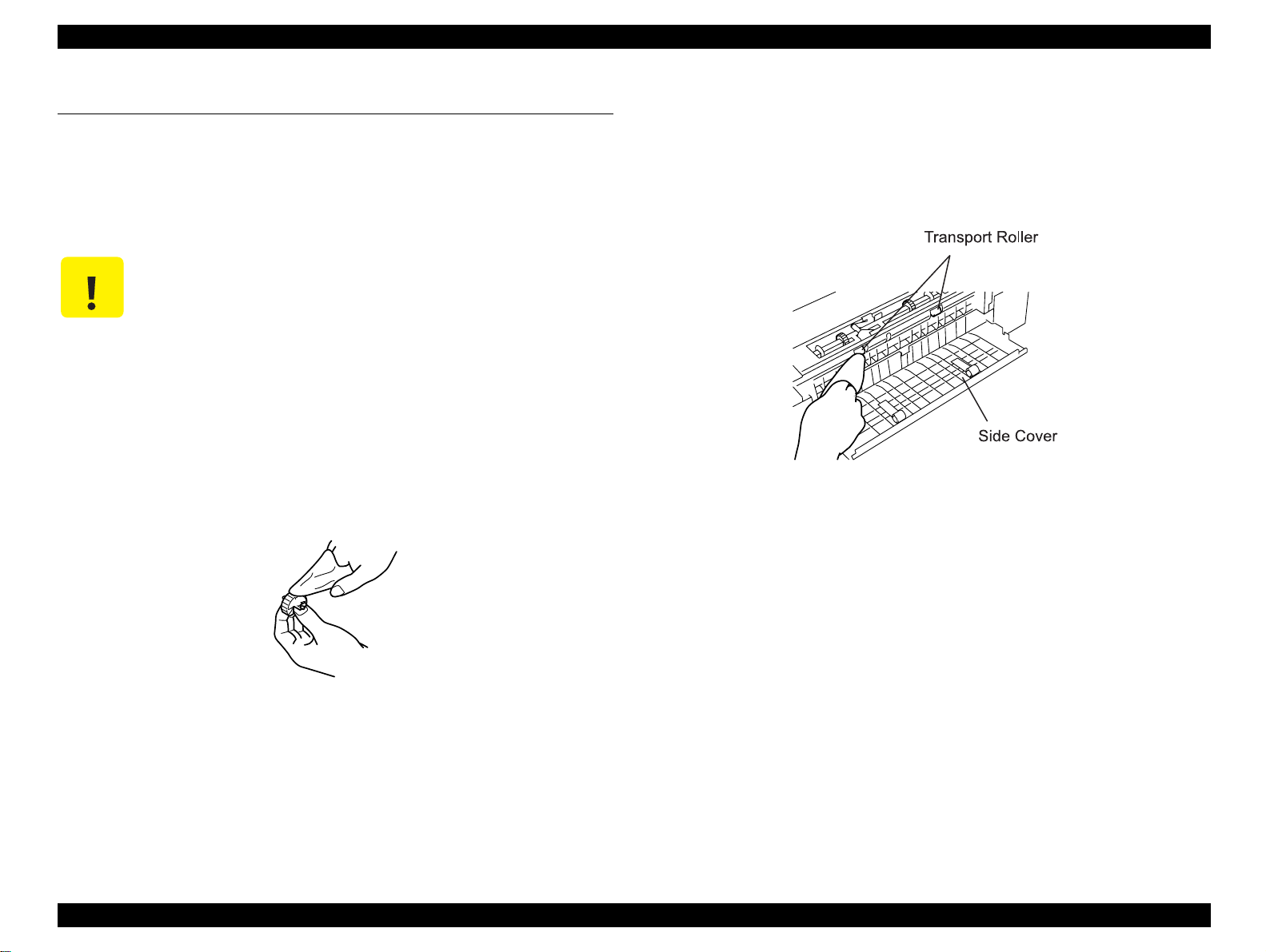

1.3.2 Cleaning the Transport Roller

1. Open the side cover.

2. Wipe the Transport Roller with a soft cloth moistened with water.

Figure 1-14. Cleaning the Transport Roller

Figure 1-13. Cleaning the Paper Take-up Roller

Double Cassette Unit Maintenance of the Double Cassette Unit 16

Page 17

EPL-N2700 Optional Units Revision A

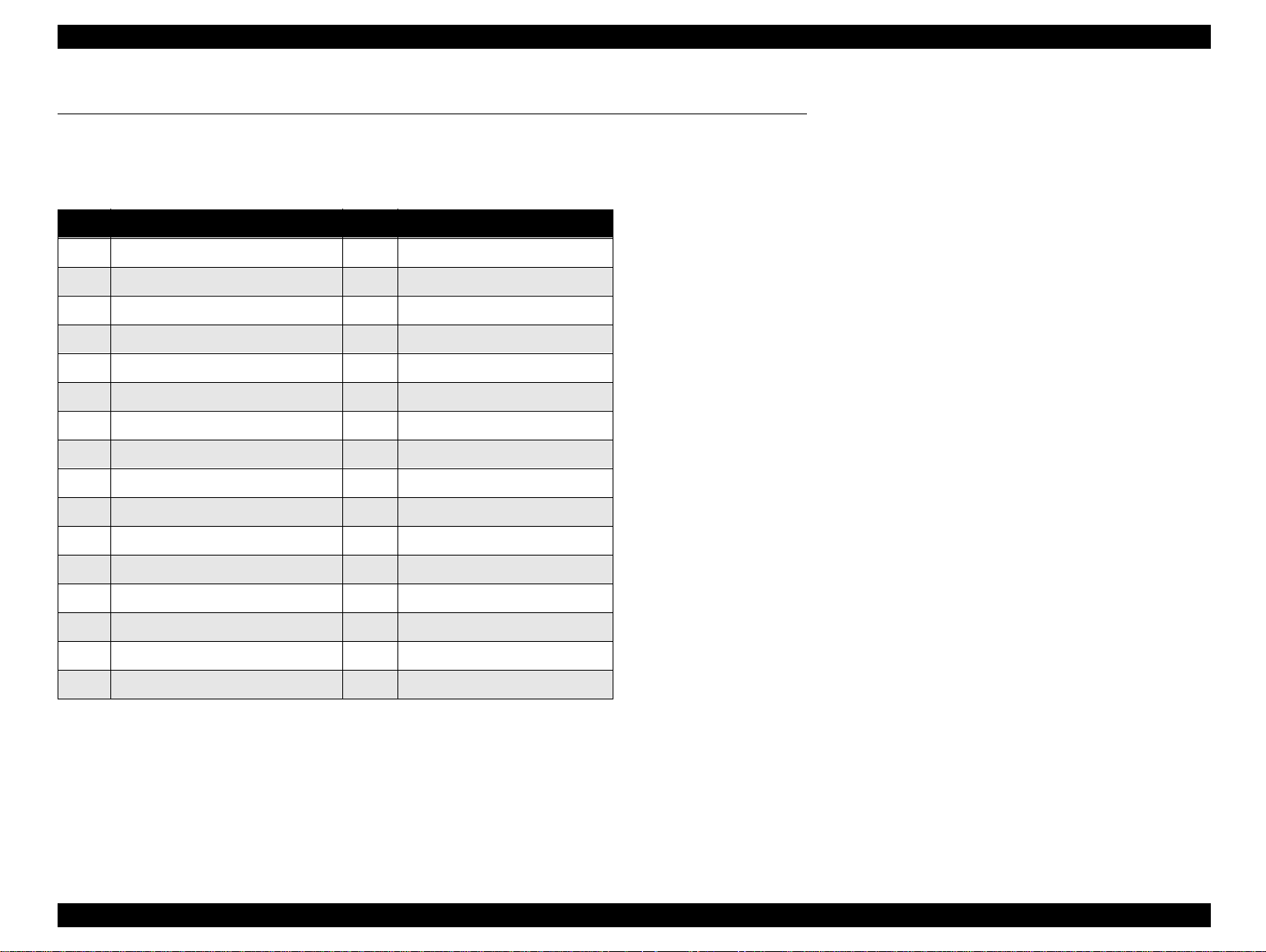

1.4 Exploded Diagrams for Double Cassette Unit

1.4.1 Housing

Table 1-1. Part List - Housing

No. Part Name No. Part Name

01 GUIDE 17 HOLDER

02 BRACKET 18 SPRING

03 PLATE SPRING 19 BRACKET

04 RUBBER FOOT 20 BRACKET

05 FRAME 21 SHOULDER SCREW

06 COVER 22 SWITCH, SIZE (S1)

07 GROUND PLATE 23 HARNESS

08 BRACKET 24 COVER

09 HARNESS 25 RUBBER FOOT

10 BRACKET 26 BRACKET

11 PW BOARD-A, MAIN (PWB-A) 27 BRACKET

12 PWB SUPPORT 6.35H 28 RAIL

13 HARNESS 29 PLATE SPRING

14 BRACKET 30 BRACKET

15 SHOULDER SCREW 31 HOLDER

16 RUBBER FOOT

− −

Double Cassette Unit Exploded Diagrams for Double Cassette Unit 17

Page 18

EPL-N2700 Optional Units Revision A

09

10

3704

08

3727

06

05

3501

03

01

11

3501

PWB-A

3704

04

02

07

12

3704

13

3704

14

3501

24

18

15

15

17

3704

23

22

19

31

1603

03

02

3501

3704

16

20

25

S1

21

3714

26

21

28

27

3704

3704

3714

3704

25

29

30

3704

Double Cassette Unit Exploded Diagrams for Double Cassette Unit 18

Page 19

EPL-N2700 Optional Units Revision A

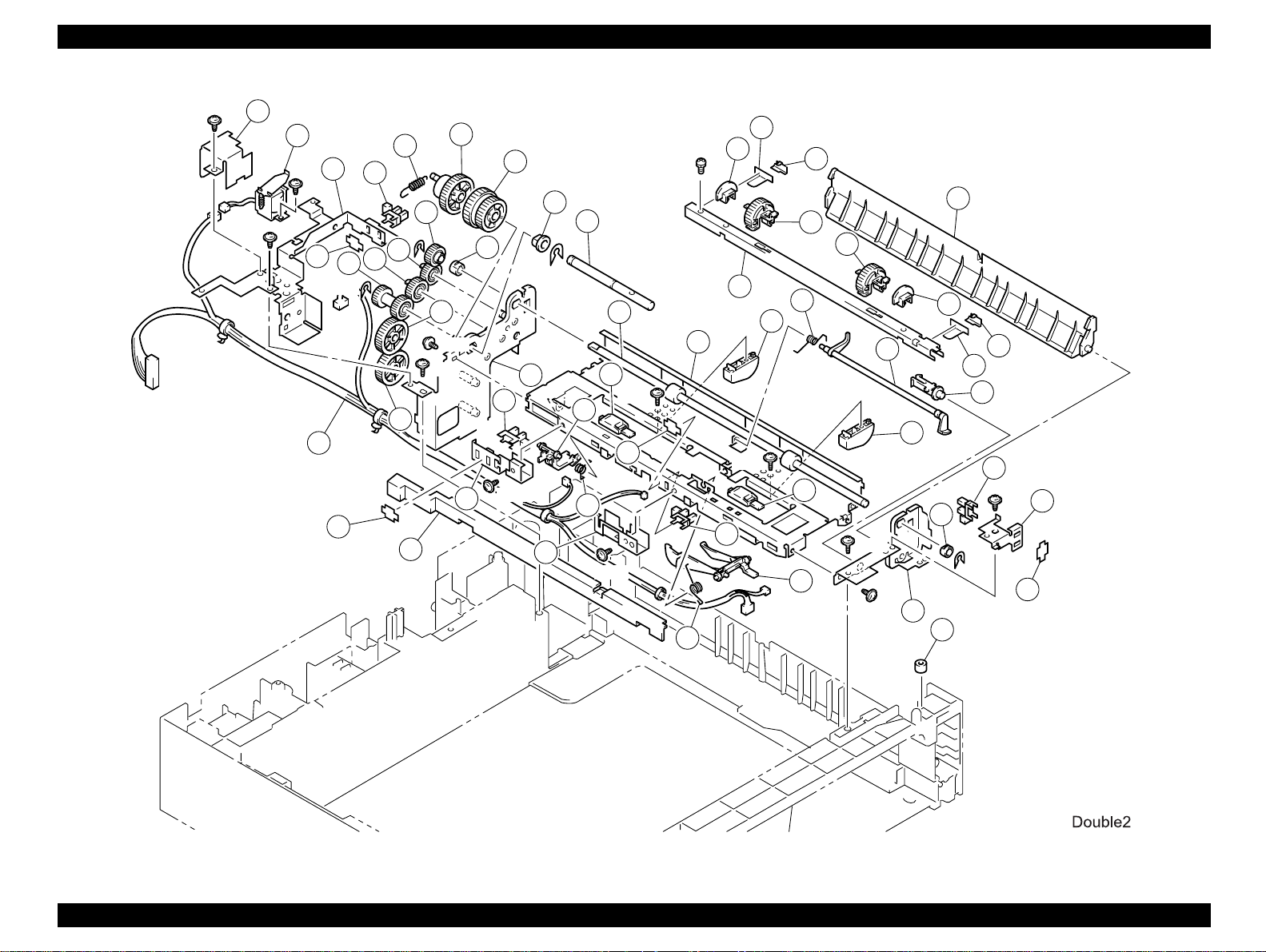

1.4.2 Paper Take-up Section

Table 1-2. Part List - Paper Take-up Section

No. Part Name No. Part Name

01 GUIDE PLATE 21 BUSHING

02 HOLDER 22 GEAR 34T

03 POLYESTER FILM 23 HARNESS

04 COLLAR 24 HOLDER

05 ROLLER 25 BRACKET

06 SHAFT 26 LEVER

07 AXLE PLATE 27 AXLE PLATE

08 ROLLER 28 SPACER

09 BUSHING 29 TORSION SPRING

10 GEAR 30/36T 30 BRACKET

11 GEAR 31T 31 TORSION SPRING

12 TENSION SPRINT 32 ACTUATOR

13 PHOTO INTERRUPTER (2S-5) 33 BRACKET

14 BRACKET 34 COLLAR

15 SOLENOID, TAKE-UP (SL1) 35 BRACKET

16 BRACKET 36 SHAFT

17 STOPPER 37 ACTUATOR

18 GEAR 16/20T 38 TORSION SPRING

19 GEAR 20T 39 GUIDE PLATE

20 GEAR 18T 40 GUIDE

Double Cassette Unit Exploded Diagrams for Double Cassette Unit 19

Page 20

EPL-N2700 Optional Units Revision A

3501

16

13

04

07

3704

03

40

38

28

32

02

05

05

3704

3501

37

40

33

21

34

04

01

S3

03

36

9302

02

13

3501

35

17

3501

SL1

15

3501

17

23

14

9301

17

18

S2

13

19

12

19

22

9302

24

20

22

3501

3704

11

25

21

S5

10

13

3501

27

1208

09

06

9302

08

39

28

3704

26

17

29

S4

30

3501

31

Double Cassette Unit Exploded Diagrams for Double Cassette Unit 20

Page 21

EPL-N2700 Optional Units Revision A

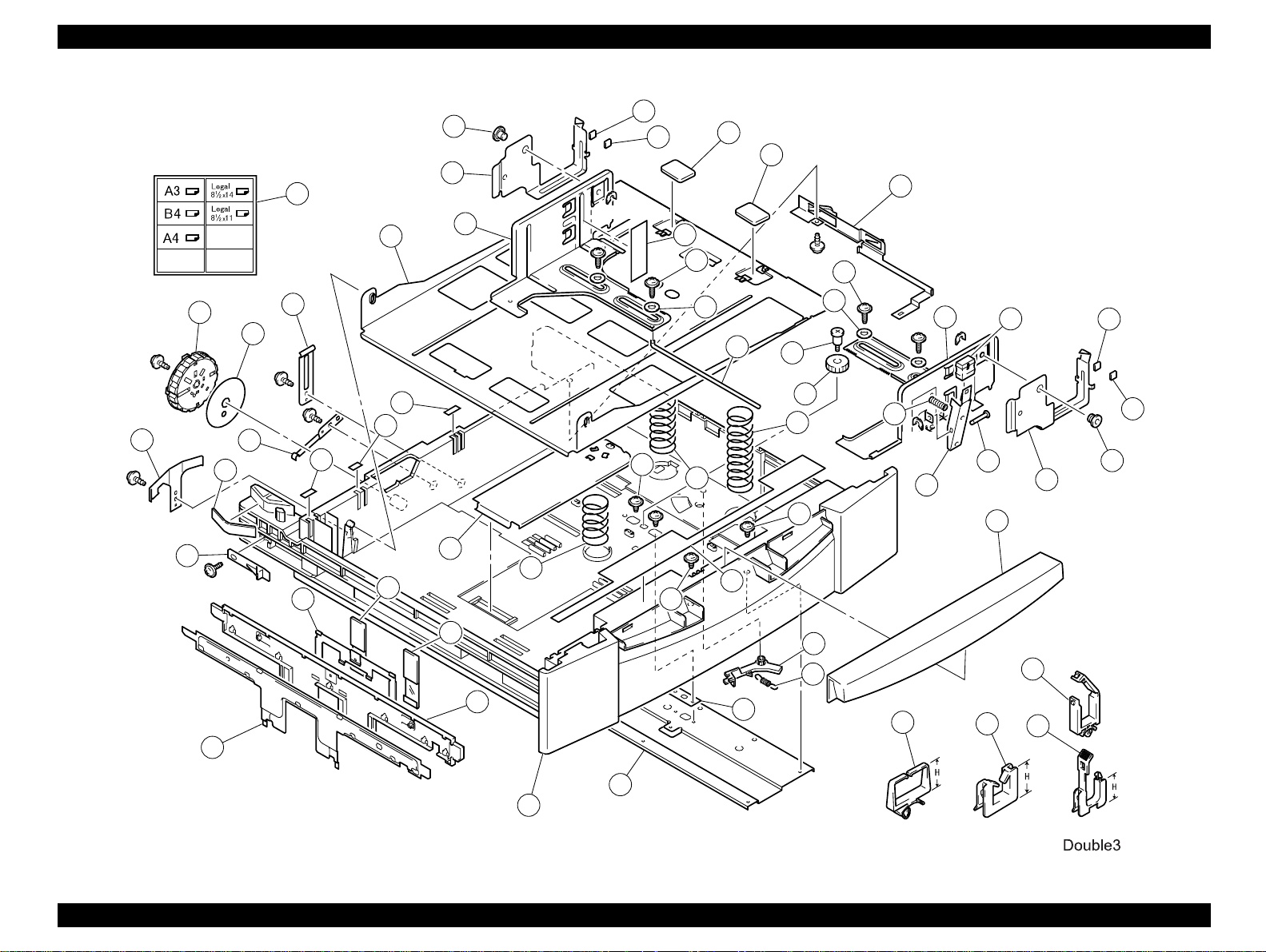

1.4.3 Paper Tray Unit

Table 1-3. Part List - Paper Tray Unit

No. Part Name No. Part Name No. Part Name

01 GROUND PLATE 18 STOPPER 35 SHOULDER SPRING

02 CORK 19 REINFORCE PLATE 36 SHAFT

03 COLLAR 20 PLATE SPRING 37 WASHER

04 HOLD PLATE 21 SHEET 38 SCREW

05 GUIDE PLATE 22 LIFTING PLATE 39 LABEL MAX LEVEL

06 REGULATING PLATE 23 PRESSURE SPRING 40 KNOB

07 LIFTING PLATE 24 REGULATING PLATE 41 REGULATING PLATE

08 LABEL PAPER SIZE 25 CASSETTE BODY 42 PRESSURE SPRING

09 PLATE SPRING 26 REINFORCE PLATE 43 LAVER

10 LABEL PAPER SIZE 27 SCREW 44 SHAFT

11 LEVER 28 PLATE 45 GUIDE PLATE

12 PLATE SPRING 29 TENSION SPRING 46 HANDLE

13 PLATE SPRING 30 LEVER 47 WIRING SADDLE 5.2H

14 FRICTION SHEET 31 LABEL CASSETTE 48 EDGE COVER 15.4H

15 LABEL 32 SCREW 49 EDGE COVER 8.5H

16 LABEL 33 PRESSURE SPRING 50 WIRE SADDLE 6.4H

17 LABEL 34 GEAR 14T

−−

Double Cassette Unit Exploded Diagrams for Double Cassette Unit 21

Page 22

EPL-N2700 Optional Units Revision A

12

3704

3704

18

11

3704

14

10

13

3704

3704

08

09

20

17

07

16

21

15

04

05

22

06

23

9302

03

32

03

27

39

38

33

37

02

31

36

02

35

33

27

3704

34

37

38

01

42

9303

43

41

9302

44

46

40

03

03

04

45

21

24

28

30

29

50

49

47

48

19

26

25

Double Cassette Unit Exploded Diagrams for Double Cassette Unit 22

Page 23

DUPLEX UNIT

Page 24

EPL-N2700 Optional Units Revision A

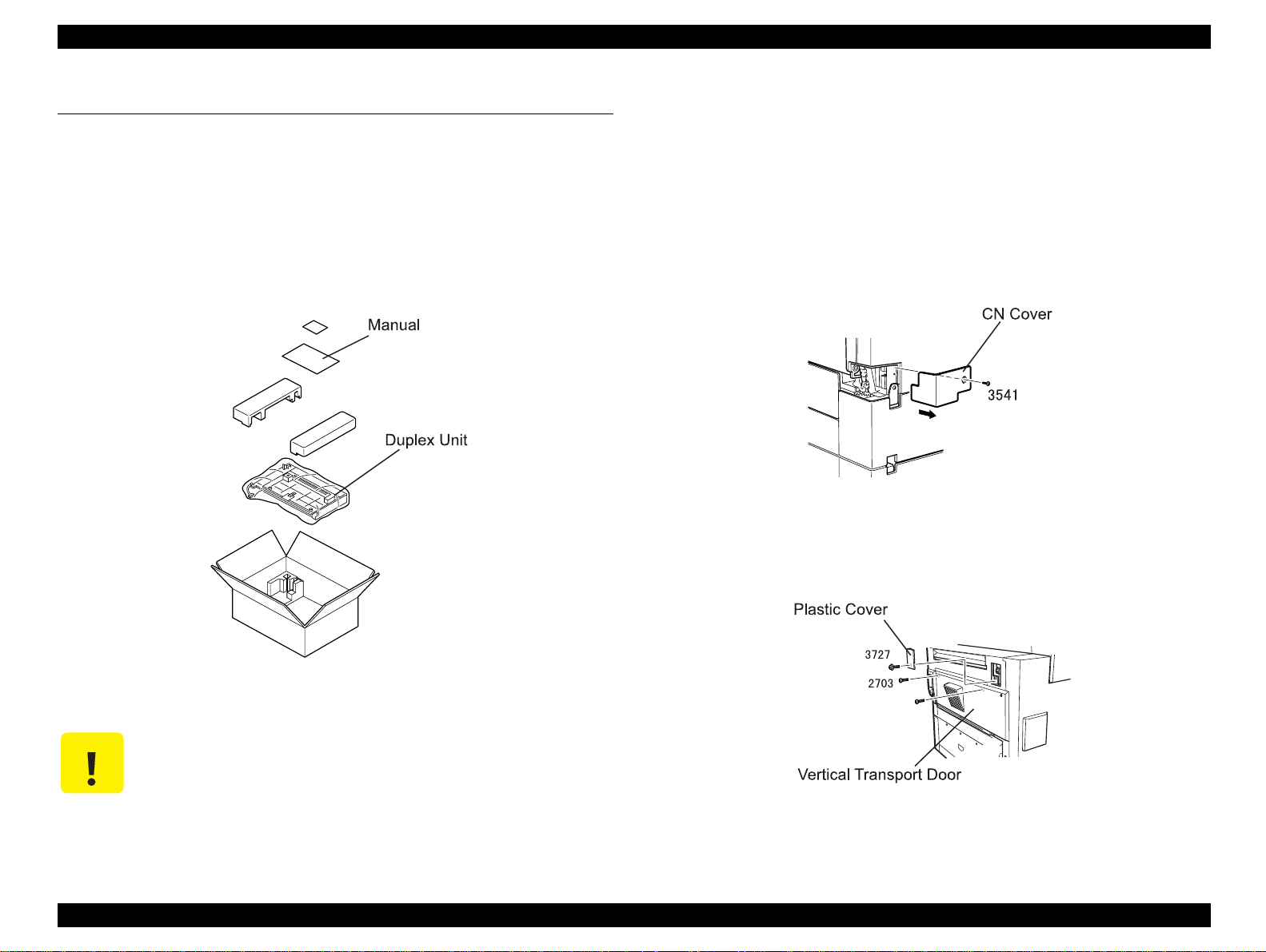

2.1 Installing the Duplex Unit

This section describes how to install the Duplex Unit to t he printer main

body. Note you are required to remove optional units such as the

Duplex Unit when servicing the printer. The procedure for removing the

Duplex Unit is not included since you can remove it by reversing the

installation procedure.

1. Open the packing carton and get a Duplex Unit and a user’s

manual.

2. Remove the protection materials and tapes from the Duplex Unit .

3. Turn the printer power off and disconnect the AC power cable and

interface cable.

4. Remove the plastic cover covering the harness connecti ng the

duplex unit to the printer main body.

5. Remove the screw (3541) securing the CN cover to the rear right

corner of the printer body and remove the CN cover.

Figure 2-2. CN Cover Removal

6. Remove the screw (3727) securing the gear cover to the f user cover

and remove the gear cover.

Figure 2-1. Unpacking

CAUTION

After removing the packing materials, please keep

them out of children’s reach.

Figure 2-3. Plastic Cover Removal

Duplex Unit Installing the Duplex Unit 24

Page 25

EPL-N2700 Optional Units Revision A

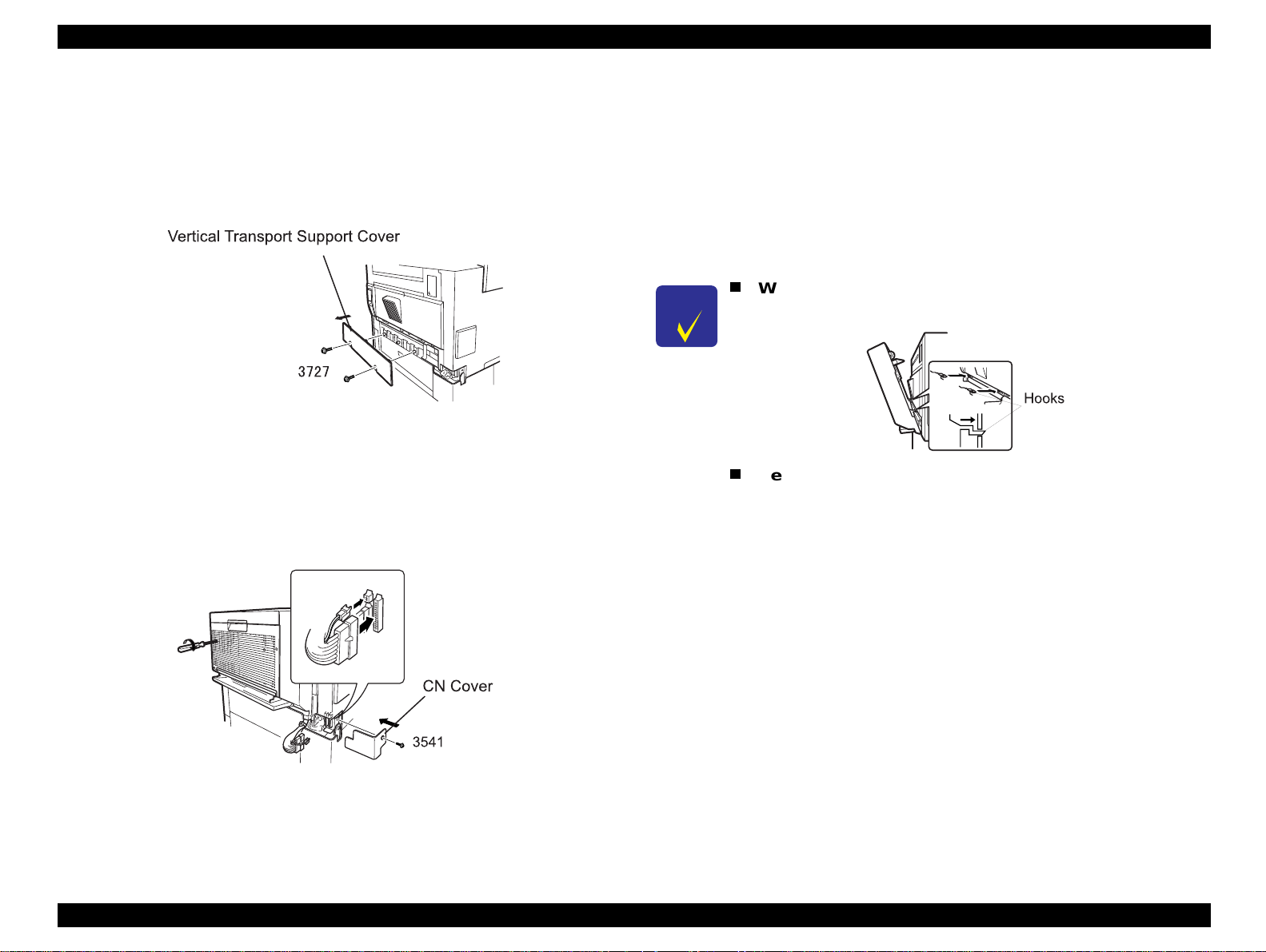

7. Remove two screws (2703) attached to the vertical trans port door.

8. Remove two screws (3727) securing the vertical trans port support

cover to the bottom part of the printer and remove the vertical

transport support cover.

Figure 2-4. Support Cover Removal

9. Using a phillips screw driver, secure the install the Duplex Unit to

the vertical transport door using two screws included with the

Duplex Unit.

10. Connect the harness from the Duplex Unit to the connector on the

printer main body.

11. Fasten three screws (3727) (attachment of the unit) to secure the

new sub cover included with the Duplex Unit to the printer.

12. Fasten the screw (3541) to fix the CN cover to the printer.

CHECK

PO INT

When placing the Duplex Unit, make sure two hooks

securely fit in the installation holes on the printer.

Before attaching the CN cover, make sure printer

connection harness is securely connected

13. Connect the interface cable and the AC power cable to the printer

and turn the printer on.

Figure 2-5. Duplex Unit Installation

Duplex Unit Installing the Duplex Unit 25

Page 26

EPL-N2700 Optional Units Revision A

2.2 Disassembly and Assembly of the Duplex Unit

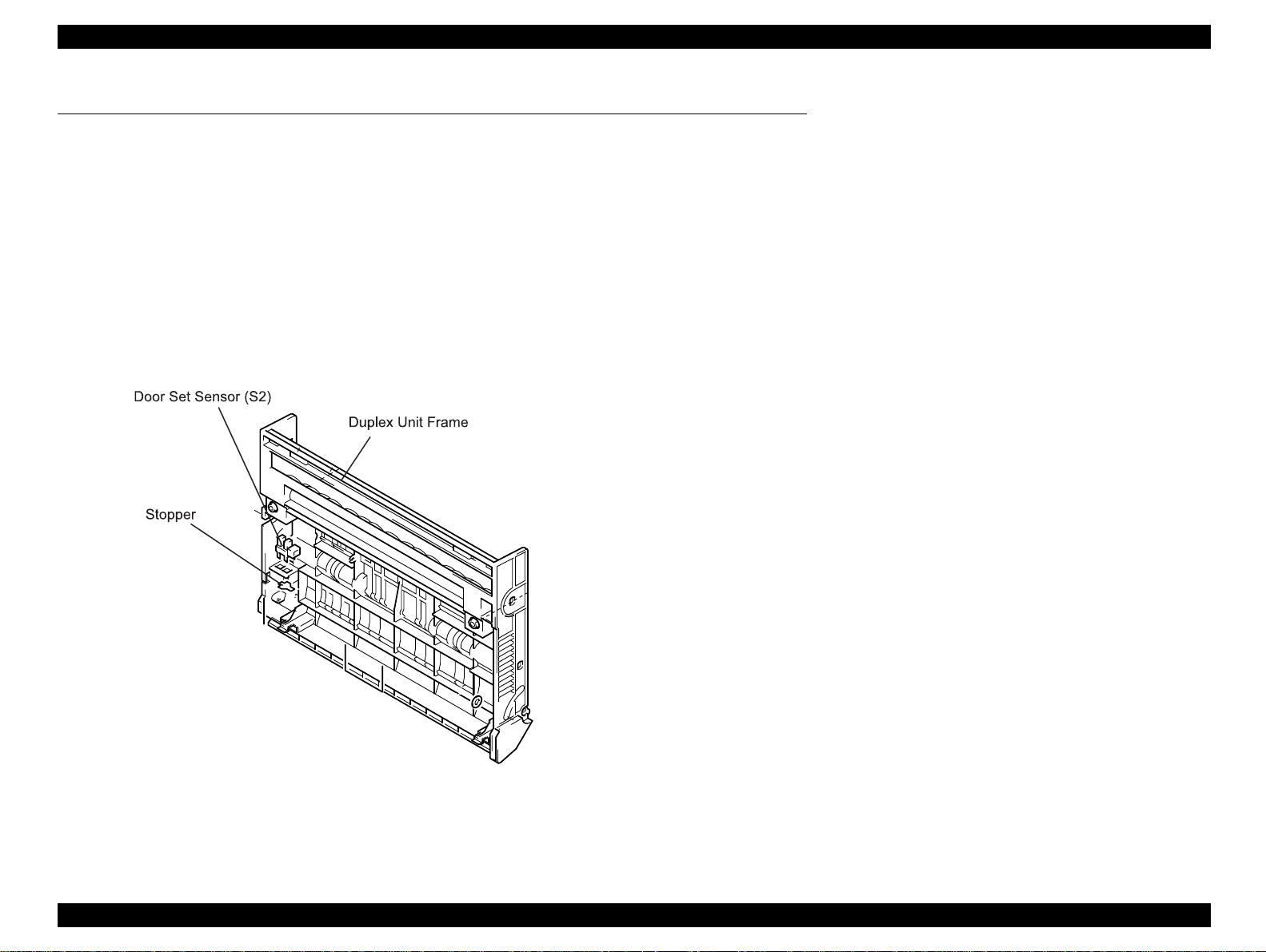

2.2.1 Duplex Unit Door Set Sensor Removal

1. Remove the Duplex Unit. (Refer to Section 2.1.)

2. Open the Duplex Unit Door.

3. Remove the stopper securing the door set sensor to the Duplex Unit

Frame and unhook the sensor from the frame.

4. Disconnect the harness from the connector on the sensor.

Figure 2-6. Paper Take-up Roller Removal

Duplex Unit Disassembly and Assembly of the Duplex Unit 26

Page 27

EPL-N2700 Optional Units Revision A

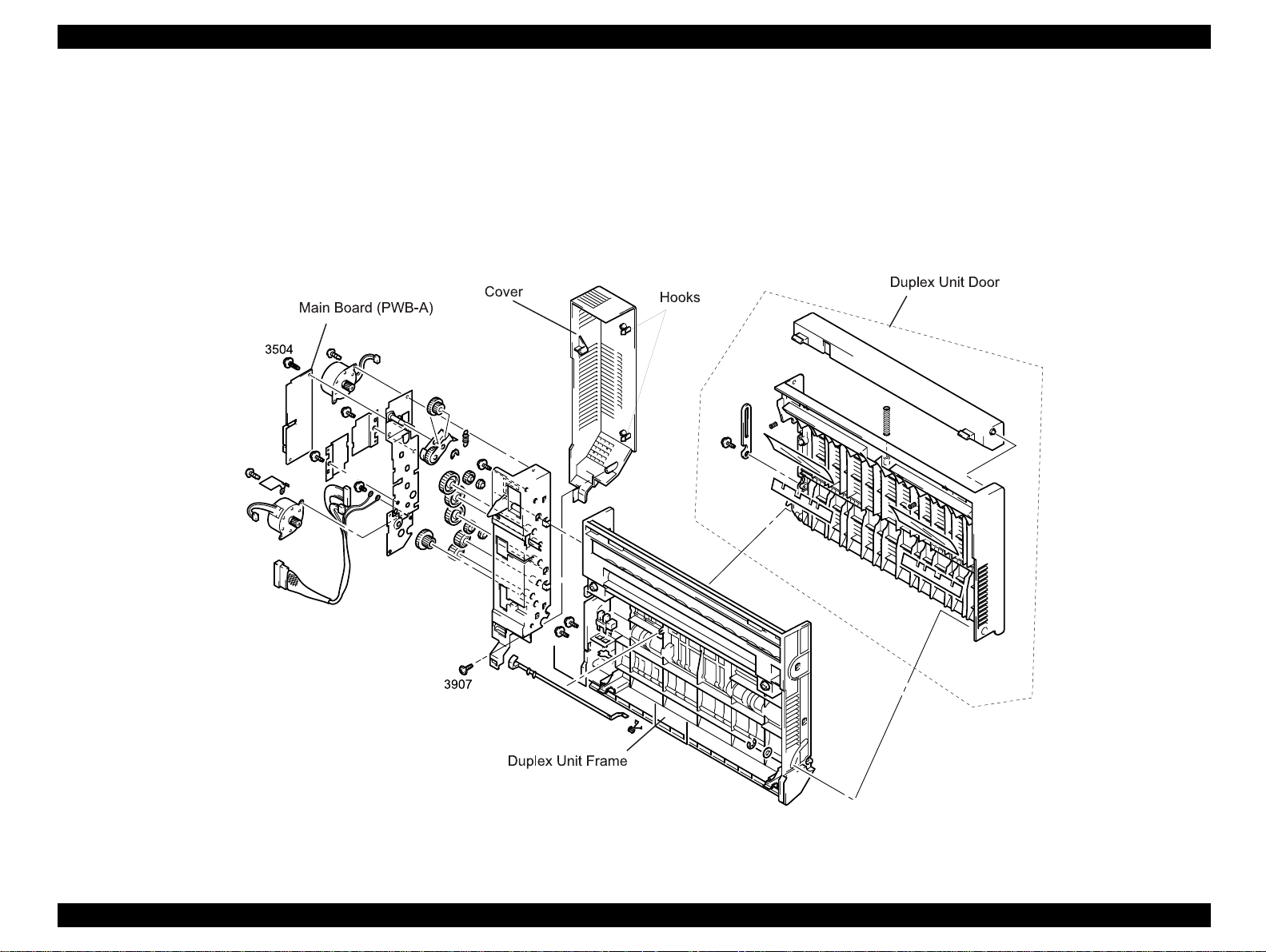

2.2.2 Main Board Removal

1. Remove the Duplex Unit. (Refer to Section 2.1.)

2. Remove two screws securing the cover to the Duplex Unit.

3. Open the Duplex Unit door and release two hooks securing the

cover to the Duplex Unit Frame, and remove the cover.

4. Disconnect the harness from the connector on the Main Board.

5. Remove two screws (3504) securing the Main Board to the Duplex

Unit and remove the Main Board.

Figure 2-7. Main Board Removal

Duplex Unit Disassembly and Assembly of the Duplex Unit 27

Page 28

EPL-N2700 Optional Units Revision A

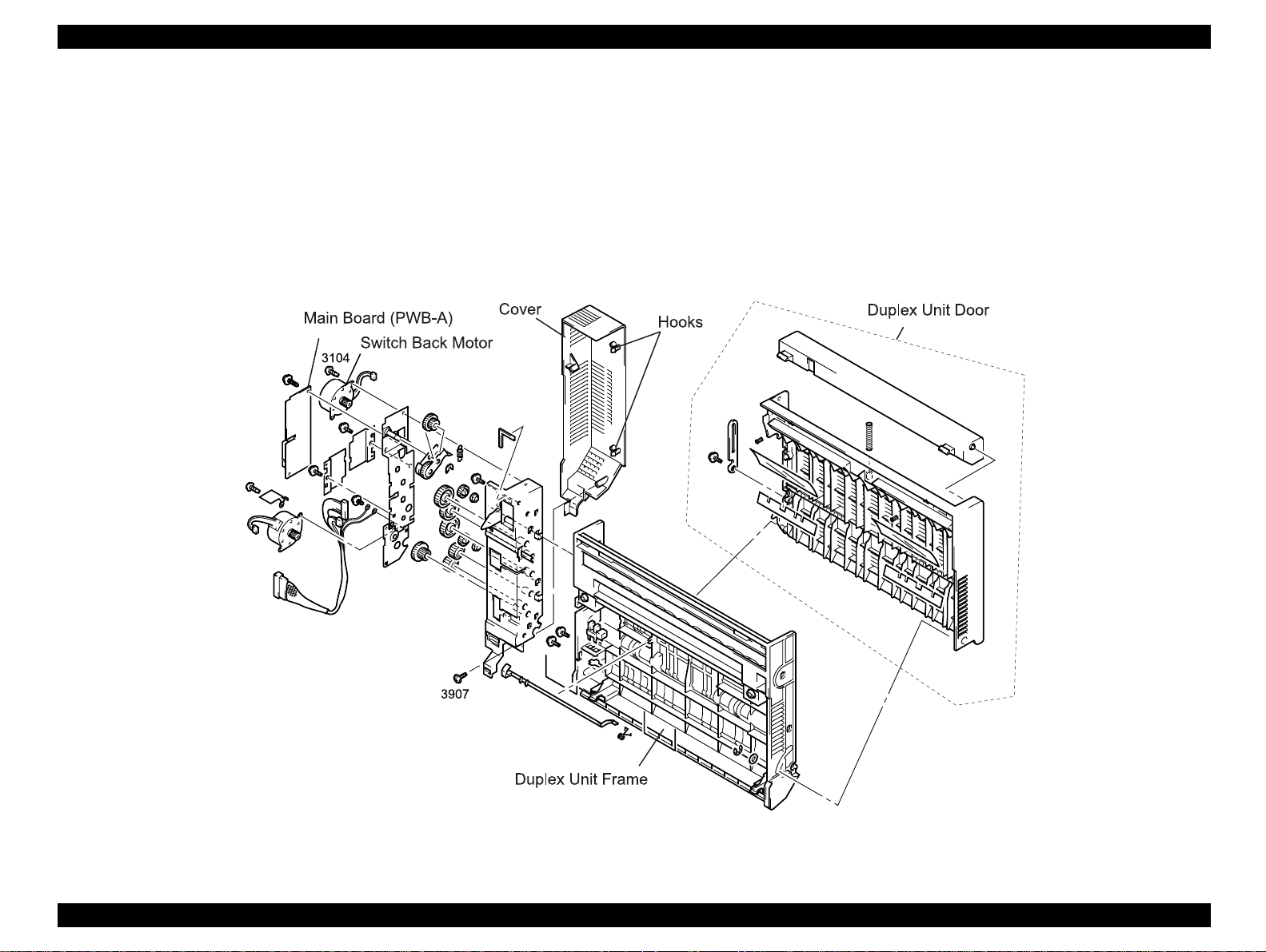

2.2.3 Switch Back Motor Removal

1. Remove the Duplex Unit. (Refer to Section 2.1.)

2. Remove two screws (3907) securing the cover to the Duplex Unit.

3. Open the Duplex Unit door and r elease two hook s fixing the cover to

the Duplex Unit frame. Then remove the cover.

4. Remove the harness for the Switch Back Motor from the connector

on the Main Board.

5. Remove two screws (3104) securing the Switch Back Motor to the

Duplex Unit and remove the Switch Back Motor.

Figure 2-8. Switch Back Motor Removal

Duplex Unit Disassembly and Assembly of the Duplex Unit 28

Page 29

EPL-N2700 Optional Units Revision A

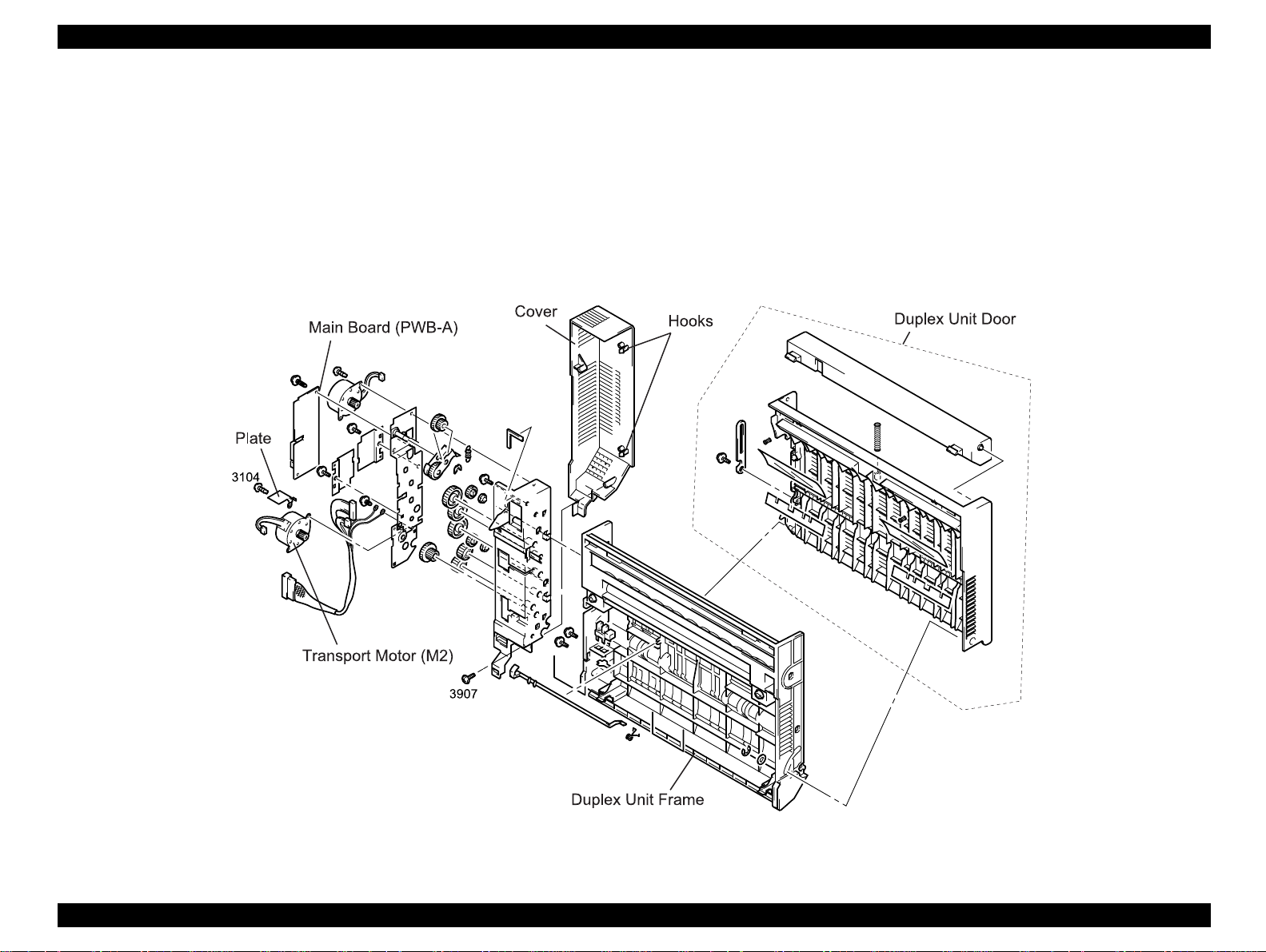

2.2.4 Transport Motor Removal

1. Remove the Duplex Unit. (Refer to Section 2.1.)

2. Remove two screws (3907) securing the cover to the Duplex Unit.

3. Open the Duplex Unit door and r elease two hook s fixing the cover to

the Duplex Unit frame. Then remove the cover.

4. Remove the harness for the Transport Motor from the connector on

the main aboard.

5. Remove two screws (3104) securing the Transport Motor to the

Duplex Unit and remove the Transport Motor and the plate.

Figure 2-9. Transport Motor Removal

Duplex Unit Disassembly and Assembly of the Duplex Unit 29

Page 30

EPL-N2700 Optional Units Revision A

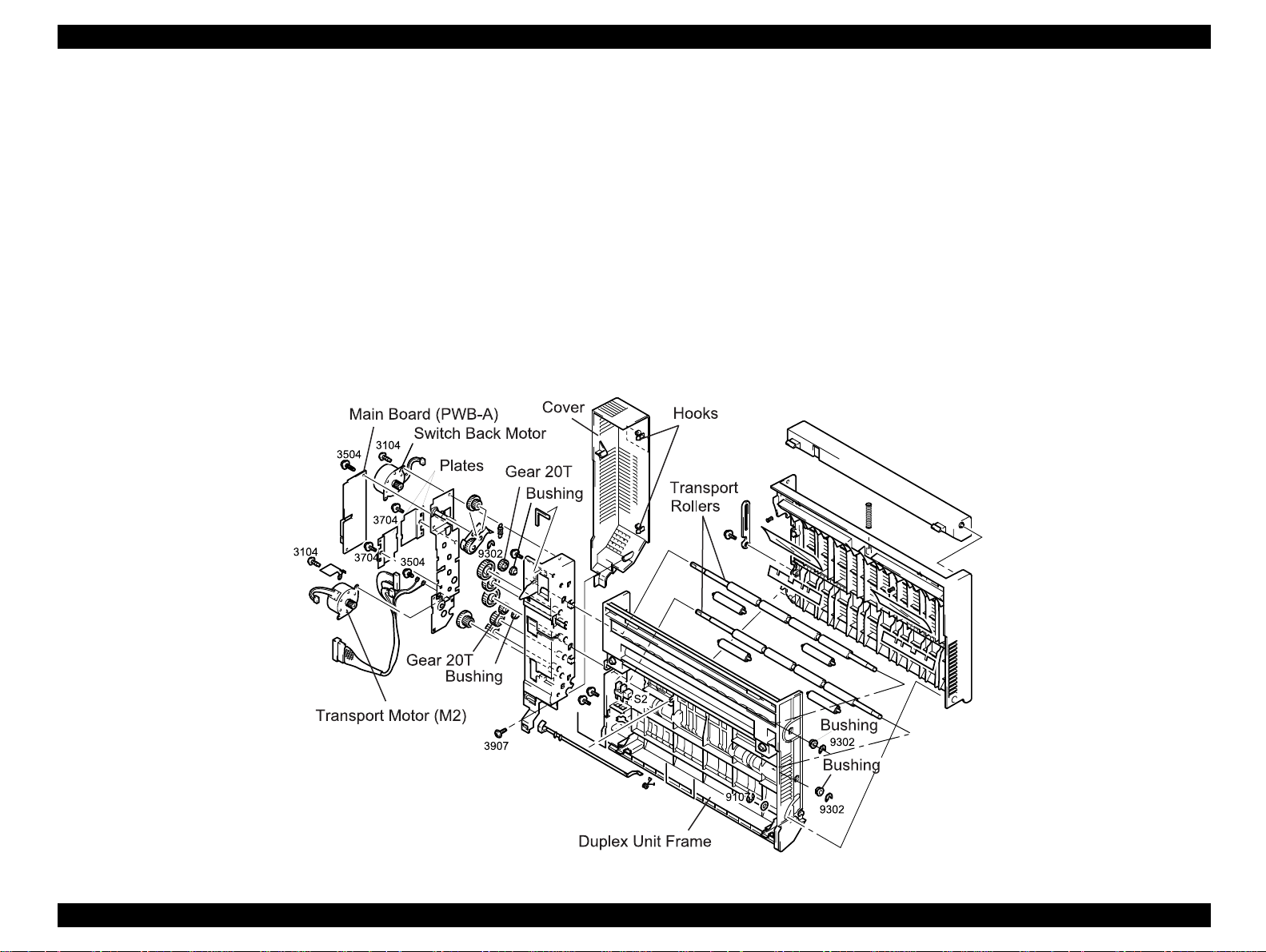

2.2.5 Transport Roller Removal

1. Remove the Duplex Unit. (Refer to Section 2.1.)

2. Remove two screws (3907) securing the cover to the Duplex Unit.

3. Open the Duplex Unit door and r elease two hook s fixing the cover to

the Duplex Unit frame. Then remove the cover.

4. Remove the Main Board. (Refer to Section 2.2.2.)

5. Remove the Switch Back Motor. (Refer to Section 2.2.3.)

6. Remove the Transport Motor. (Refer to Section 2.2.4.)

7. Remove the screw (3504) securing the ground cable to the axle

plate and remove the ground cable.

8. Remove three screws (3704) securing two plates to the holders

through the axel plate and remove the plates and the axel plate.

9. Release the hooks on the gears 20T attached to the Transport

Rollers and remove the gears 20T and the bushings.

10. Remove the E-ring (9302) from each transport roller shaft and

remove the bushing from the transport roller shaft.

11. Remove the Transport Rollers from the Duplex Unit.

Figure 2-10.

Transport Roller Removal

Duplex Unit Disassembly and Assembly of the Duplex Unit 30

Page 31

EPL-N2700 Optional Units Revision A

2.3 Maintenance of the Duplex Unit

The maintenance method of the Duplex Unit is mostly the same as for

the printer body. Therefore, this se ction only describes the method

specific to the Duplex Unit.

2.3.1 Cleaning the Transport Roller

1. Open the Duplex Unit door. (Refer to Section 2.2.1.)

2. Wipe the Transport Roller with a soft cloth moistened with water.

CAUTION

Do not use any solvent, including alcohol.

Figure 2-11. Cleaning the Transport Roller

Duplex Unit Maintenance of the Duplex Unit 31

Page 32

EPL-N2700 Optional Units Revision A

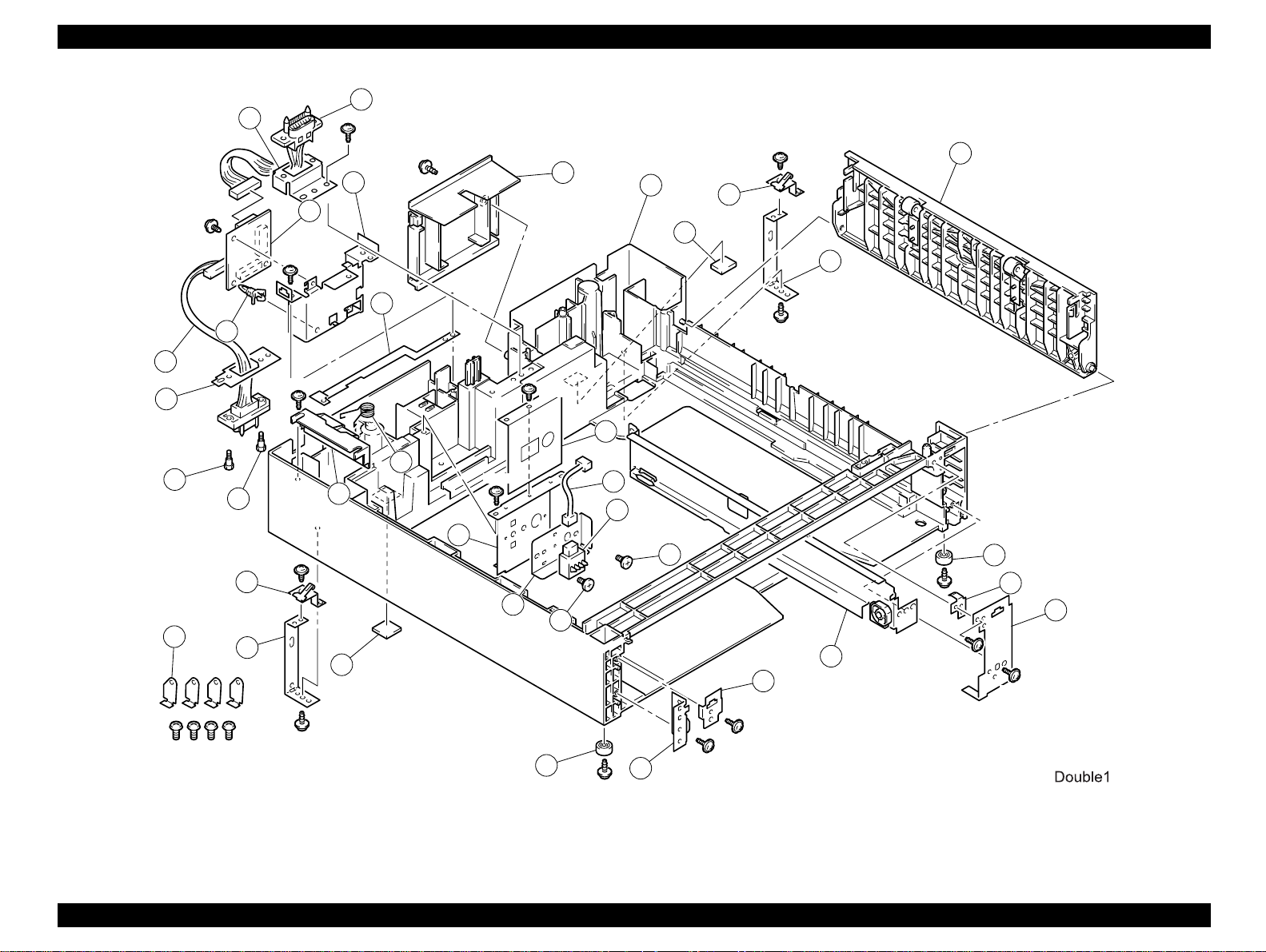

2.4 Exploded Diagrams for Duplex Unit

Table 2-1. Part List

No. Part Name No. Part Name

01 LEVER 20 PW BOARD-A, MAIN (PWB-A)

02 PRESSURE SPRING 21 PLATE

03 COVER 22 PLATE

04 PRESSURE SPRING 23 GEAR 35T

05 POLYESTER FILM 24 GEAR 24T

06 STOPPER 25 GEAR 17/45T

07 POLYESTER FILM 26 HARNESS

08 ROLLER 27 HOLDER

09 ROLL 28 SPRING

10 SHOULDER SCREW 29

11 COVER 30 STOPPER

12 SEAL 31 ACTUATOR

13 BUSHING 32 TORSION SPRING

14 GEAR 20T 33 FRAME

15 TENSION SPRING 34 COVER

16 LEVER 35 POLYESTER FILM

17 GEAR 12/40T 36 WASHER

18 AXLE PLATE 37 LABEL

19 MOTOR (M1, 2) - -

PHOTO INTERRUPTER,

DOOR SET (S2)

Duplex Unit Exploded Diagrams for Duplex Unit 32

Page 33

EPL-N2700 Optional Units Revision A

20

PWB-A

21

3104

3504

3704

M2

19

3104

22

19

M1

3704

3504

26

22

18

25

23

23

23

24

17

27

16

9302

3907

24

15

14

3704

14

12

13

13

31

28

11

3704

3704

28

30

32

S2

28

10

29

09

09

08

37

28

06

3704

9107

36

07

04

03

09

05

13

10

9302

9302

33

02

13

09

01

04

08

05

35

34

Duplex Unit Exploded Diagrams for Duplex Unit 33

Page 34

LCC UNIT

Page 35

EPL-N2700 Optional Units Revision A

3.1 Installing the LCC Unit

This section describes how to install the LCC Unit, or Large Capacity

Cassette Unit, to the printer main body. Note you are required to

remove optional units such as the LCC Unit when servicing the printer.

The procedure for removing the LCC Unit is not included since you can

remove it by reversing the install ation procedure.

1. Open the packing carton and get a LCC Unit, four pairs of holder

and screw, and a user’s manual.

2. Remove the protection materials and tapes from the LCC Unit.

Figure 3-2. Protection Material & Tape Removal

3. Remove the protection pads from the tray.

Figure 3-3. Protection Pad Removal

4. Shut the cassette in to the cabinet.

5. Turning the adjuster located at the front right corner of bottom part

of the LCC Unit, set the unit on the floor.

Figure 3-4. Fixing The LCC Unit

CAUTION

Figure 3-1. Unpacking

After removing the packing materials, please keep

them out of children’s reach.

LCC Unit Installing the LCC Unit 35

Page 36

EPL-N2700 Optional Units Revision A

6. Remove the bottom cover from the bottom part of the prin ter.

Figure 3-5. Bottom Cover Removal

7. Turn the printer power off and disconnec t the AC power cable and a

interface cable.

8. Place the printer on the LCC Unit.

CAUTION

Two people are required to lift the printer safely.

9. Secure the printer and the LCC Unit by each c orner using the holde r

and the screw (1603).

Figure 3-7. Securing the Printer to the LCC Unit

CHECK

PO INT

Figure 3-6. Placing the Printer on the LCC Unit

When placing the printer, make sure the blue

10. Connect the interface cable and the AC power cable to the printer

and turn the printer on.

handouts of the printer and the LCC Unit are al l facing

the same direction and all corners of the printer and

the LCC Unit are aligned.

LCC Unit Installing the LCC Unit 36

Page 37

EPL-N2700 Optional Units Revision A

3.2 Disassembly and Assembly of the LCC Unit

3.2.1 Separate Roller/Torque Limiter Removal

1. Open the side cover of the LCC Unit.

2. Remove the C-Ring from the separate roller shaft and re mov e the

Separate Roller first and then the Torque Limit er.

Figure 3-8. Separate Roller / Torque Limiter Removal

3.2.2 Feed Roller Removal

1. Open the side cover of the LCC Unit.

2. Remove the C-Ring from the feed roller shaft and remove the Feed

Roller.

Figure 3-9. Reed Roller Removal

CAUTION

Always replace the Feed Roller, Separate Roller, and

CAUTION

the Torque Limiter together since they have the same

length of life.

Always replace the Feed Roller, Separate Roller, and

the Torque Limiter together since they have the same

length of life.

LCC Unit Disassembly and Assembly of the LCC Unit 37

Page 38

EPL-N2700 Optional Units Revision A

3.2.3 Paper Take-up Unit Removal

1. Pull out the paper cassette.

2. Remove four screws (1723) securing the Paper Tray Unit to the

LCC Unit and remove the Paper Tray Unit.

Figure 3-10. Paper Tray Unit Removal

3. Release three connectors and code clump inside the unit and

remove the harness.

Figure 3-11. Harness Removal

4. Remove two screws (4021) securing the r ight co ver t o the LCC Unit

and remove the right cover.

Figure 3-12. Right Cover Removal

LCC Unit Disassembly and Assembly of the LCC Unit 38

Page 39

EPL-N2700 Optional Units Revision A

5. Remove the side cover.

6. Remove two screws (4012) securing the Paper Take-up Unit to the

LCC Unit and remove the Paper Take-up Unit.

Figure 3-13. Paper Take-up Unit Removal

3.2.3.1 Lift-up Sensor Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the stopper fixing the Lift-up Sensor to the Paper Take-up

Unit.

3. Push down the Paper Take-up Roller to release the actuator from

the sensor and remove the sensor.

4. Remove the harness from the connector on the sensor.

Figure 3-14. Lift-up Sensor Removal

LCC Unit Disassembly and Assembly of the LCC Unit 39

Page 40

EPL-N2700 Optional Units Revision A

3.2.3.2 Paper Take-up Roller (Right) Assembly Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the harness for the Lift-up Sensor. (Refer to Section

3.2.3.1.)

3. Remove the harness for the right paper take-up clutch.

4. Remove two springs on the Paper Take-up Roller Assembly.

6. Release the Paper Take-up Roller Assembly from the Paper Takeup Unit to loosen the timing belt, then remove the paper take-up

Roller Assembly.

Figure 3-16. Paper Take-up Roller Assembly (Right) Removal (2)

CHECK

PO INT

When installing the Paper Take-up Roller Assembly,

set the edge of the assembly to the indicated position

in the figure below.

Figure 3-15. Paper Take-up Roller (Right) Assembly Removal (1)

5. Remove the shoulder screw securing the Paper Take-up Roller

Assembly to the Paper Take-up Unit.

LCC Unit Disassembly and Assembly of the LCC Unit 40

Page 41

EPL-N2700 Optional Units Revision A

„

CAUTION

Always replace the Paper Take-up Roller 1 and 2

together since they have the same length of life.

„

When the Paper Take-up Roller in the LCC Unit is

replaced while 1 optional Double Cassette Unit is

connected, perform “LC3 Counter Clear” in the

maintenance mode. (See EPL-N2700 Service Manual /

Chapter 1.)

„

When the Paper Take-up Roller in the LCC Unit is

replaced while optional Double Cassette Unit is

disconnected, perform “LC2 Counter Clear” in the

maintenance mode. (See EPL-N2700 Service Manual /

Chapter 1.)

LCC Unit Disassembly and Assembly of the LCC Unit 41

Page 42

EPL-N2700 Optional Units Revision A

3.2.3.3 Right Paper Take-up Clutch Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the Paper Take-up Roller Assembly. (Refer to Section

3.2.3.2.)

3. Release the hook securing the Paper Take-up Clutch to the Paper

Take-up Roller Shaft and remove the clutch to the rear.

4. Disconnect the harness for the Paper Take-up Clutch from the

connector.

CHECK

PO INT

Be sure to hook th e cl u tch to the arm in the Paper

Take-up Unit as shown in the figure below.

Figure 3-17. Paper Take-up Clutch Removal

LCC Unit Disassembly and Assembly of the LCC Unit 42

Page 43

EPL-N2700 Optional Units Revision A

3.2.3.4 Paper Take-up Rol ler (Left) Assembly Removal

CHECK

PO INT

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the harness for the Lift-up Sensor. (Refer to Section

3.2.3.1.)

3. Remove the harness for the Paper Take-up Clutch (Left).

4. Remove two springs on the Paper Take-up Roller Assembly.

Be sure to hook the clutch to the arm in the Paper

Take-up Unit.

5. Remove the shoulder screw securing the Paper Take-up Roller

Assembly to the Paper Take-up Unit.

6. Remove the Paper Take-up Roller Assembly.

Figure 3-19. Paper Take-up Roller(Left) Assembly Removal (2)

CHECK

PO INT

When installing the Paper Take-up Roller Assembly,

set the edge of the assembly to the indicated position

in the figure below.

Figure 3-18. Paper Take-up Roller (Left) Assembly Removal (1)

LCC Unit Disassembly and Assembly of the LCC Unit 43

Page 44

EPL-N2700 Optional Units Revision A

„

CAUTION

Always replace the Paper Take-up Roller 1 and 2

together since they have the same length of life.

„

When the Paper Take-up Roller in the LCC Unit is

replaced while 1 optional Double Cassette Unit is

connected, perform “LC3 Counter Clear” in the

maintenance mode. (See EPL-N2700 Service Manual /

Chapter 1.)

„

When the Paper Take-up Roller in the LCC Unit is

replaced while optional Double Cassette Unit is

disconnected, perform “LC2 Counter Clear” in the

maintenance mode. (See EPL-N2700 Service Manual /

Chapter 1.)

LCC Unit Disassembly and Assembly of the LCC Unit 44

Page 45

EPL-N2700 Optional Units Revision A

3.2.3.5 Paper Take-up Clutch (Left) Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the Paper Take-up Roller Assembly. (Refer to Section

3.2.3.4.)

3. Release the hook securing the Paper Take-up Clutch to the Paper

Take-up Roller Shaft and remove the clutch to the rear.

4. Disconnect the harness for the Paper Take-up Clutch from the

connector.

CHECK

PO INT

Be sure to hook the clutch to the arm in the Paper

Take-up Unit.

3.2.3.6 Paper Take-up Roller Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the Paper Take-up Roller Assembly. (Refer to Section

3.2.3.2.)

3. Remove the C-Ring from the Paper Take-up Roller Shaft.

4. Pull out the Paper Take-up Roller Shaft to the E-Ring side and

remove the Paper Take-up Roller.

Figure 3-20. Paper Take-up Roller Removal

CHECK

PO INT

When installing the Paper Take-up Roller, face the CRing in the direction indicated in the figure below.

LCC Unit Disassembly and Assembly of the LCC Unit 45

Page 46

EPL-N2700 Optional Units Revision A

u

3.2.3.7 LCC Paper Take-up Sensor (PPS0) Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the shoulder screw securing the LCC Paper Take-up

Sensor to the Paper Take-up Unit and remove the sensor.

3. Disconnect the harness from the connector on the LCC Paper Takeup Sensor.

3.2.3.8 Paper Empty Sensor 1 (PPS1) Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the tension spring set between the paper take-up roller act

arm and Paper Take-up Unit.

3. Sliding the paper take-up roller act arm to the left, release the arm

from the connection pin on the Paper Take -up Uni t, and r emove the

link arm.

4. Remove the shoulder screw securing the Paper Empty Sensor to

the Paper Take-up Unit and remove the sensor.

5. Disconnect the harness from the connector on the Paper Empty

Sensor 1.

3.2.3.9 Paper Empty Sensor 2 (PPS2) Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

Tension Spring

Paper T ake-up Roller Act Arm

Paper Empty Sensor 1 (PPS1)

Paper Empty Sensor 2 (PPS2)

Paper Take-up Unit

Shoulder Screws

Link Arm

LCC Paper TakeSensor (PPS0)

Shoulder Screw

Figure 3-21. Sensor Removal

(LCC Paper Take-up Sensor, Paper Empty Sensor 1 and 2)

2. Remove the shoulder screw securing the Paper Empty Sensor 2 to

the Paper Take-up Unit and remove the sensor.

3. Disconnect the harness from the connector on the Paper Empty

Sensor 2.

LCC Unit Disassembly and Assembly of the LCC Unit 46

Page 47

EPL-N2700 Optional Units Revision A

3.2.3.10 Paper Stand-by Position Sensor Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the screw (1306) securing the bracket for the Paper Standby Position Sensor to the reinforce plate and remove the Paper

Stand-by Position Sensor along with the bracket.

3. Remove the screw (1306) securing the Paper Stand-by Position

Sensor to the bracket and remove the Paper Stand-by Position

Sensor.

4. Disconnect the harness from the connector on the Paper Stand-by

Position Sensor.

3.2.3.11 Registration Sensor Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the screw (1306) securing the Registration Sensor to the

bracket and remove the Registration Sensor.

3. Disconnect the harness from the connector on the Registration

Sensor.

Figure 3-22. Sensor Removal

(Paper Stand-by Position Sensor / Registration Sensor)

LCC Unit Disassembly and Assembly of the LCC Unit 47

Page 48

EPL-N2700 Optional Units Revision A

3.2.3.12 Side Co ver Set Sensor Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Unhook the Side Cover Set Sensor from the axle plate and remove

the Side Cover Set Sensor.

3. Disconnect the harness from the connector on the Side Cover Set

Sensor.

Figure 3-23. Side Cover Set Sensor Removal

LCC Unit Disassembly and Assembly of the LCC Unit 48

Page 49

EPL-N2700 Optional Units Revision A

3.2.3.13 Registration C lutch (RCL) Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Disconnect the harness for the Side Cover Set Sensor from the

sensor. (Refer to Section 3.2.3.12.)

3. Disconnect the harnesses for the Registration Clutch and the

Separate Clutch from the relay connectors and release them from

the cable clamp on the clutch bracket.

4. Remove two screws (4012) securing the clutch bracket to the axle

plate and remove the clutch and the bracket.

5. Remove the registration clutch shaft and then remove the

Registration Clutch and the bushing.

3.2.3.14 Separate Clutch Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Disconnect the harness for the Side Cover Set Sensor from the

sensor. (Refer to Section 3.2.3.12.)

3. Disconnect the harnesses for the Registration Clutch and the

Separate Clutch from the relay connectors and release them from

the harness clamp on the clutch bracket.

4. Remove two screws (4012) securing the clutch bracket to the axle

plate and remove the clutch, bracket, and the ti ming belt.

5. Release the hook securing the Separate Clutch to the shaft and the

E-Ring (9108), then remove the shaft and the busing from the

Separate Clutch.

Figure 3-24. Registration/Separate Clutch Removal

LCC Unit Disassembly and Assembly of the LCC Unit 49

Page 50

EPL-N2700 Optional Units Revision A

„

CHECK

PO INT

Since the pins for the clutches can come off easily,

be careful when handling the clutches.

„

When installing the clutch, be sure to fit the fixing

part of the clutch in the arm of the bracket.

LCC Unit Disassembly and Assembly of the LCC Unit 50

Page 51

EPL-N2700 Optional Units Revision A

3.2.3.15 Registration Roller Remova l

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the E-Ring (9151) attached to the front end of the

Registration Roller’s shaft and remove th e Regist ration Roller and

the bushing from the frame.

3. Remove three screws (4012) and two shoulder scr ews securi ng the

frame to the Paper Take-up Unit.

4. Remove the pin and the gear 26T from the rear part of the

Registration Roller.

5. Remove the bushing from the rear end of the Registration Roller

and pull the Registration Roller out to the front.

3.2.3.16 Separate Roller Shaft Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the E-Ring (9108) securing the separate roller shaft to the

axle plate.

3. Remove the Separate Roller by pulling it forward.

3.2.3.17 Feed Roller Shaft Removal

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Remove the E-Ring (9151) attached to the front end of the

Registration Roller’s shaft and remove the Registration Roller and

the bushing from the frame.

3. Remove the Separate Roller. (Refer to Section 3.2.3.16.)

4. Remove the screw (4012) and two shoulder screws securing the

frame to the Paper Take-up Unit.

5. Remove the screw (4012, on the axle plate side) securing the

bracket to the axle plate and remove the frame and the bracket.

6. Remove the E-Ring (9111) fixing the Feed Roller Shaft, bushing,

and pulley (20T) to the axle plate and release the timing belt from

the pulley.

7. Remove the bushing and the pulley (20T) from the Feed Roller

Shaft.

8. Remove the E-Ring (9111) fixing the bushing and the pull ey (14T) to

the Feed Roller Shaft and remove the Feed Roller Shaft from the

Paper Take-up Unit.

Figure 3-25.

Registration Roller/Separate Roll er/ Feed Roller Shaft Removal

LCC Unit Disassembly and Assembly of the LCC Unit 51

Page 52

EPL-N2700 Optional Units Revision A

3.2.4 Drive Section Disassembly

3.2.4.1 LCC Transport Motor Removal

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Remove the screw (4020) securing the maintenance cover to the

LCC Unit and remove the maintenance cover.

3. Remove four screws (4021) securing t he re ar co ver to t he LCC Unit

and remove the rear cover.

4. Disconnect the harness from the connector on the LCC transport

motor board.

5. Remove two screws (1322) securing the LCC Transport Motor to

the LCC Unit.

6. Release the timing belt from the pulley (18T) and remove the LCC

Transport Motor.

Figure 3-27. LCC Transport Motor Removal

Figure 3-26. Rear Cover Removal (1)

LCC Unit Disassembly and Assembly of the LCC Unit 52

Page 53

EPL-N2700 Optional Units Revision A

3.2.4.2 LCC Set Sensor Rem o val

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Remove the rear cover. (Refer to Section 3.2.4. 1.)

3. Unhook the LCC Set Sensor from the LCC Unit Frame and remove

the sensor.

4. Disconnect the harness from the LCC Set Sensor.

3.2.4.3 Paper Near Empty Sensor Removal

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Remove the rear cover. (Refer to Section 3.2.4.1.)

3. Remove the screw (3501) securing the br acket f or t he sensor to t he

LCC Unit Frame and remove the bracket along with the sensor.

4. Remove the E-Ring (9106) fixing the lever for the Paper Near Empty

Sensor to the bracket and remove the lever.

5. Unhook the Paper Near Empty Sensor from the br acket and remove

the Paper Near Empty Sensor.

6. Disconnect the harness from the Paper Near Empty Sensor.

Figure 3-28. LCC Set Sensor Removal

Figure 3-29. Paper Near Empty Sensor Removal

LCC Unit Disassembly and Assembly of the LCC Unit 53

Page 54

EPL-N2700 Optional Units Revision A

3.2.4.4 LCC Lift-up Motor Removal

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Remove the rear cover. (Refer to Section 3.2.4. 1.)

3. Disconnect the LCC Lift-up Motor harness from the relay connector.

4. Remove three screws (3501) securing the axle plate with the LCC

Lift-up Motor attached on it to the LCC Unit Frame. Then remove the

axle along with the LCC Lift-up Motor.

5. Remove two E-Rings (9111) fixing the gears 72T to the axle plate

and remove the gears.

6. Release the harness for the LCC Lift-up Moto r from the cable clump

in the axle plate.

7. Remove two screws (1379) securing the LCC Lift-up Motor to the

axle plate and remove the motor.

CAUTION

Note the gears 72T integrate the one-way clutches that

rotate in the opposite direction from each other.

Therefore, be sure to set each gear to the correct

position according to the distinguishable color of each

gear.

Figure 3-30. LCC Lift-up Motor Removal

LCC Unit Disassembly and Assembly of the LCC Unit 54

Page 55

EPL-N2700 Optional Units Revision A

3.2.4.5 LCC Main Board Remo val

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Remove the rear cover. (Refer to Section 3.2.4. 1.)

3. Remove two screws (4020) securing the pap er size set swit ch cover

to the LCC Unit Frame and remove the cover.

4. Disconnect the harness from the connector on the LCC Main Board.

5. Remove the screw (3501) securing the LCC Main Boar d to the LCC

Unit Frame.

6. Remove the PWB support and remove the LCC Main Board.

Figure 3-31. LCC Main Board Removal

LCC Unit Disassembly and Assembly of the LCC Unit 55

Page 56

EPL-N2700 Optional Units Revision A

3.2.5 Paper Tray Unit Disassembly

3.2.5.1 Roller with the Torque Limiter Removal

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Release the hook securing the Rol ler with the Torque Limiter on it t o

the lifter and remove the roller.

Figure 3-32. Roller with the Torque Limiter Removal

LCC Unit Disassembly and Assembly of the LCC Unit 56

Page 57

EPL-N2700 Optional Units Revision A

3.2.5.2 Timing Belt Removal

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Remove three shoulder screws securing the Front Cover to the

Paper Tray Unit.

3. Remove the E-Ring (9111) fixing the cam shaft to the bracket .

4. Remove three screws (3305) securing the br acket to the Pap er Tray

Unit, then remove the pulley (32T) and the bra cket along with the

timing belt.

5. Release the hook securing the ground plate for the lifter drive shaft

to the pulley (20T) and remove the ground plate from the pulley.

6. Disengage the end of the timing belt from the pulley (20T).

7. Remove the E-Ring (9151) fixing the s haft for t he pulley ( 32T) to the

bracket.

8. Sliding the pulley (32T) towar d the b racket t o r emove the pin (0531)

and remove the pulley (32T) and the torsion spring from the shaft.

9. Remove the timing belt from the pulley (32T).

Figure 3-33. Front Cover Removal Figure 3-34. Timing Belt Removal

LCC Unit Disassembly and Assembly of the LCC Unit 57

Page 58

EPL-N2700 Optional Units Revision A

CHECK

PO INT

Be sure to install the timing belt to the pulley 20T and

pulley 32T correctly as shown below;

CHECK

PO INT

When assembling the torsion spring and the pulley

32T, make sure one end of the torsion spring is

properly inserted into the fixing part i n the holder.

LCC Unit Disassembly and Assembly of the LCC Unit 58

Page 59

EPL-N2700 Optional Units Revision A

3.2.5.3 Lifter Drive Shaft Removal

1. Pull out the paper cassette and remove the Paper Tray Unit. (Refer

to Section 3.2.3.)

2. Remove three shoulder screws securing the Front Cover to the

Paper Tray Unit. (Refer to Section 3.2.5.2.)

3. Release the hook fixing the ground plate f or the Lifter Drive Shaft to

the pulley 20T and remove the ground plate from the pulley 20T.

4. Remove the E-Ring (9151) fixing the pulley 20T to the Lifter Drive

Shaft and remove the pulley 20T from the Lifter Drive Shaft.

5. Remove two E-Rings (9151) securing two gear 24T beside the

pulley 20T to the Lifter Drive Shaft and remove the gears 24T and

the pin (0510) from the shaft.

6. Remove two E-Rings (9151) securing two gears 24T located in front

of the Paper Tray Unit to the Lifter Drive Shaft, and remove the

gears 24T from the shaft.

7. Remove the lifter from the Paper Tray Unit.

8. Remove six E-Rings (9151) securing the Lifter Drive Shaft to the

lifter and remove Lifter Drive Shaft.

Figure 3-35. Lifter Driver Shaft Removal

LCC Unit Disassembly and Assembly of the LCC Unit 59

Page 60

EPL-N2700 Optional Units Revision A

3.3 Maintenance of the LCC Unit

The maintenance method of the LCC Unit is mostly same as for the

printer body. Therefore, this section only describe the method specific

to the LCC Unit.

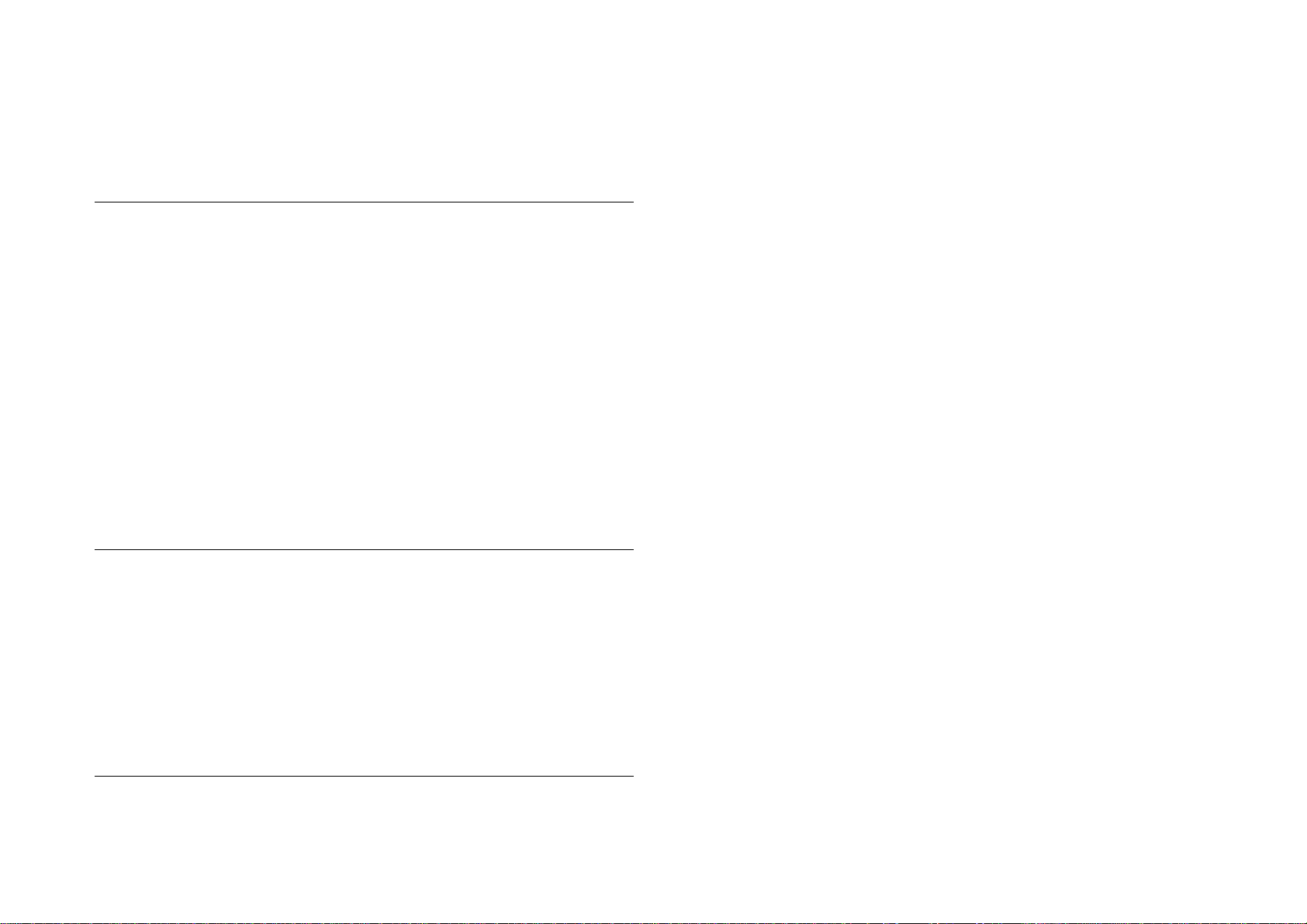

3.3.1 Maintenance Items

The LCC parts that require maintenance are as listed in the following

table.

Table 3-1. Maintenance Items

Maintenance Item Operations required Replacement Cycle

Paper Take-up Roller 1 Cleaning / Replacement 300,000 sheets

Paper Take-up Roller 2 Cleaning / Replacement 300,000 sheets

Roller with a Torque Limiter Cleaning / Replacement 300,000 sheets

Feed Roller Cleaning / Replacement 200,000 sheets

Separate Roller Cleaning / Replacement 200,000 sheets

Torque Limiter Assembly Replacement 200,000 sheets

3.3.2 Cleaning the Paper Take-up Roller

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Wipe the Paper Take-up Roller with a soft cloth moistened with

water.

Figure 3-36. Cleaning the Paper Take-up Roller

Vertical Transport Roller Cleaning / Replacement Vertical Transport Roller

(driven)

CAUTION

Do not use any solvent, including alcohol.

Cleaning / Replacement 300,000 sheets

LCC Unit Maintenance of the LCC Unit 60

Page 61

EPL-N2700 Optional Units Revision A

3.3.3 Cleaning the Feed/Separate Roller

1. Open the side cover.

2. Wipe the Paper the roller with a soft cloth moistened with water.

Figure 3-37. Cleaning the Feed/Separate Roller

3.3.4 Cleaning the Vertical Transport Roller / Roller

(Driven)

1. Remove the Paper Take-up Unit. (Refer to Section 3.2.3.)

2. Wipe the Vertical Transport Roller / Roller (Dri ven) with a soft cloth

moistened with water.

Figure 3-38. Cleaning the Vertical Transport Roll er / Roller (Driven)

LCC Unit Maintenance of the LCC Unit 61

Page 62

EPL-N2700 Optional Units Revision A

3.3.5 Cleaning the Roller with a Torque Limiter

1. Remove the paper cassette. (Refer to Section 3.2.3.)

2. Wipe the Paper the Roller with a Torque Limiter with a soft cloth

moistened with water.

Figure 3-39. Cleaning the Roller with a Torque Limiter

LCC Unit Maintenance of the LCC Unit 62

Page 63

EPL-N2700 Optional Units Revision A

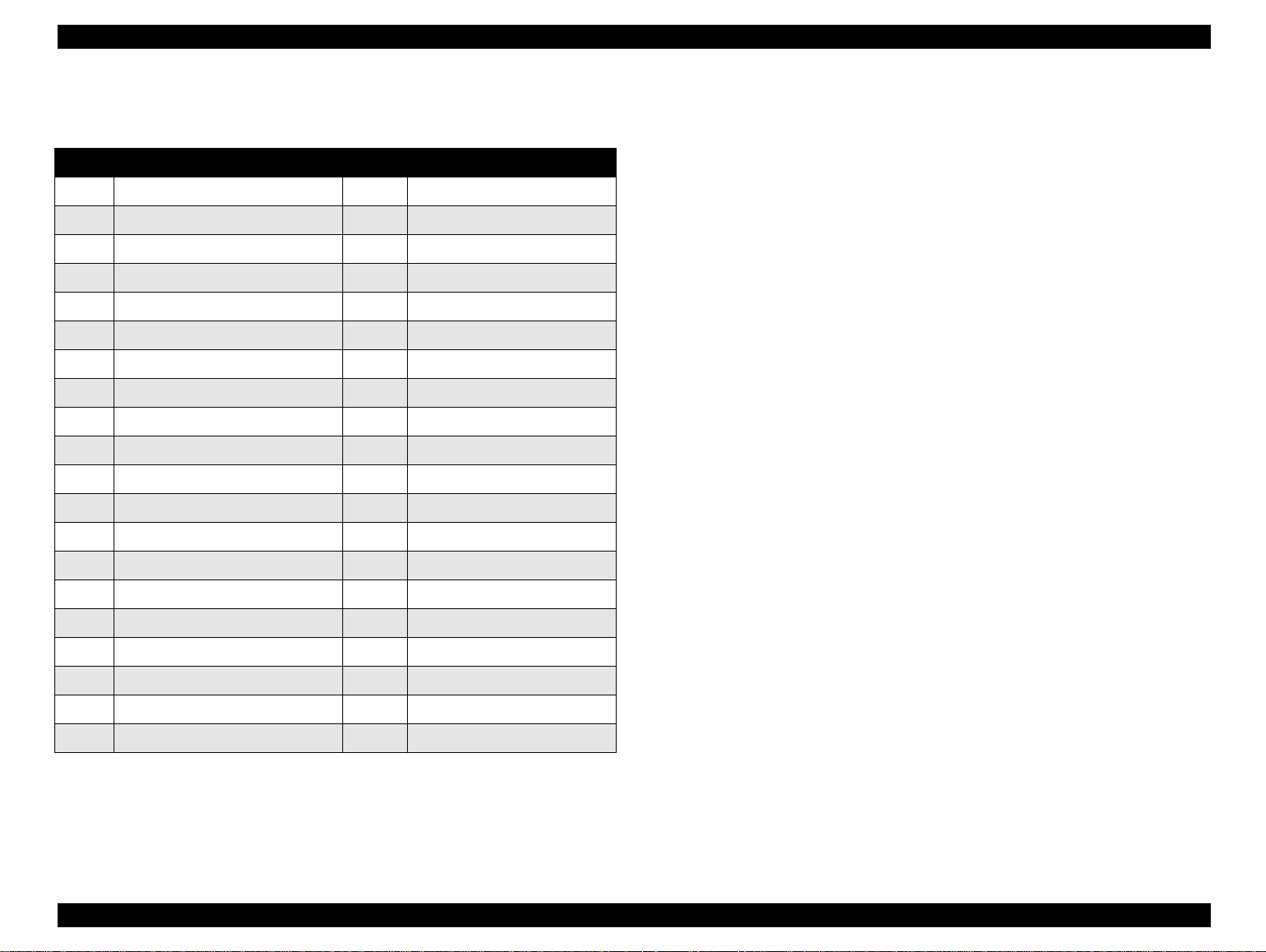

3.4 Exploded Diagrams for LCC Unit

3.4.1 Housing

Table 3-2. Part List - Housing

No. Part Name No. Part Name

1 COVER 13 COVER

2 SHEET 14 REAR COVER

3 SHEET 15 POLYESTER FILM

4 RIGHT COVER 16 HOLDER

5 GROUND PLATE 17 LEFT COVER

6 SHOULDER SCREW 18 COVER

7 STOPPER 19 LABEL WARNING

8 BRACKET 20 COVER

9 SHOULDER SCREW 21 REGULATING PLATE

10 GROUND PLATE 22 SHOULDER SCREW

11 BRACKET 23 HOLDER

12 HANDLE - -

LCC Unit Exploded Diagrams for LCC Unit 63

Page 64

EPL-N2700 Optional Units Revision A

13

14

09

11

4020

05

20

4012

08

4012

4020

4021

12

12

11

16

4012

15

4012

4012

05

04

11

12

4012

12

01

03

02

19

10

4012

11

21

17

4021

3504

23

1603

22

LCC Unit Exploded Diagrams for LCC Unit 64

Page 65

EPL-N2700 Optional Units Revision A

3.4.2 Paper Take-up Section (A)

Table 3-3. Part List - Paper Take-up Section (A)

No. Part Name No. Part Name

1 GUIDE PLATE 18 SHAFT

PHOTO INTERRUPTER (PPS0-

2

2)

3 SHOULDER SCREW 20 SHAFT

4 REINFORCE PLATE 21 ARM

5 BRACKET 22 GEAR 26T

6 POLYESTER FILM 23 SHAFT

7 HOLDER 24 PULLEY 20T

PHOTO INTERRUPTER (RSEN,

8

S1)

9 ARM 26 TIMING BELT

19 STOPPER RING

25 TENSION SPRING

10 TENSION SPRING 27 CLUTCH (P1CL, PC2L)

11 ARM 28 PULLEY 18T

12 STOPPER 29 ARM

13 BRACKET 30 PULLEY 26T

14 GROUND PLATE 31 HARNESS

15 BUSHING 32 HARNESS

16 PHOTO INTERRUPTER (ls1, 2) 33 HARNESS

17 TENSION SPRING

−−

LCC Unit Exploded Diagrams for LCC Unit 65

Page 66

EPL-N2700 Optional Units Revision A

P2CL

29

9111

27

25

9111

P1CL

24

9111

9111

15

16

17

28

27

9111

29

LS2

21

03

30

26

23

12

13

25

9111

22

20

24

9111

9111

15

21

16

17

19

LS1

03

18

11

08

12

15

RSEN

13

9111

1309

07

06

14

4012

02

1309

03

PPS1

S1

06

10

08

PPS0

09

07

4012

05

04

03

02

01

9111

15

30

23

22

19

31

18

03

20

33

32

PPS2

02

LCC Unit Exploded Diagrams for LCC Unit 66

Page 67

EPL-N2700 Optional Units Revision A

3.4.3 Paper Take-up Section (B)

Table 3-4. Part List - Paper Take-up Section (B)

No. Part Name No. Part Name

1 ROLLER 24 GEAR 24T

2 PLATE SPRING 25 GEAR 20/35T

3 SHAFT 26 PULLEY 14T

4 BRACKET 27 ROLLER

5 LABEL 28 LEVER

6 AXLE PLATE 29 SHAFT

PHOTO INTERRUPTER,

7

DOORSET (SIDE)

8 BUSHING 31 SHAFT

9 GEAR 18T 32 SHAFT

10 GEAR 22/29T 33 PLY GEAR 14/26T

11 PLATE SPRING 34 TIMING BELT

30 SHAFT

12 GEAR 26T 35 PLY GEAR 14/26T

13 BUSHING 36 SHAFT

14 PULLEY 20 37 POLYESTER FILM

15 SHOULDER SCREW 38 BRACKET

16 GEAR 20T 39 TENSION SPRING

17 SHAFT 40 ARBOR ASSY