Page 1

®

Laser Printer

EPSON EPL-N2700

SEPG98006

Page 2

Notice:

g

g

g

g

g

g

g

g

g

EPSON is a re

General Notice: Other product names used herein are for identification purpose only and may be trademarks or re

Copyri

hts reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

All ri

electronic, mechanical, photocopyi n

The contents of this manual are subject to chan

All effort have been made to ensure the accuracy of the contents of this manual. However , shoul d any errors be detected, SEIKO EPSON

would

The above not withstandin

thereof.

reatly appreciate being informed of them.

SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

istered trademark of SEIKO EPSON CORPORATION.

respective owners. EPSON disclaims any and all ri

ht © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

e without notice.

istered trademarks of their

hts in those marks.

Page 3

PRECAUTIONS

g

g

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should a lways be observed when performin

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performin

Signals a precaution which, if ignored, could result in damage to equipment.

procedures preceded by DANGER Headings.

repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

Safety Information

g

g

g

g

g

To prevent accidents during a maintenance procedure, strictl y observe the Warnings and Cautions. Do not do anything that is dangerous or not within

the scope of this document.

Do not do anythin

manual, there are many situations and circumstances that ar e dan

that is dangerous even if not specifically described in this manual. In addition to the descriptions below and those given in this

erous. Be aware of these when you are working with the printer.

Power Supply and Other Electrical Devices

Before starting any service procedure, switch off the printer power and

unplu

printer when the power is applie d, be aware of the pot ential for el ectrical

shock and do all tasks by followin

the power cord from the wall outlet. If you must service the

the procedures in this manual.

Do not touch any live part unless you are instructed to

do so by a service procedure.

Mechanical Components

If you service gear or roll, manually rotate a drive assembly . Never

hand-rotate or stop the drive assembly while the main motor is rotatin

.

Page 5

Laser Beam

g

g

g

g

g

g

g

g

g

Safety Component

The laser beam used for exposing process during

printing is a very powerful, straight, narrow beam of

light that produces extreme heat at its focal point. The

laser beam is this printer is invisible. Although you

cannot see the beam, it can still cause severe damage.

Direct eye exposure to the laser beam may cause eye

injury or blindness. Never place a mirror or a reflective

tool or object in the laser beam path.

To avoid permanent eye damage, follow these directions;

Before startin

and unplu

Do not disassemble the ROS Assembly or any laser component

that displays Laser Warnin

Use caution when you are workin

when you are performin

Do not disassemble the printer in such a way that the laser

beam can exit the printer en

ay service procedure, switch o ff the printer power

the power cord from the wall outlet.

Sticker.

around the ROS Assembly or

laser related repair procedures .

ine during a print cycle.

Make sure fuses, interlock switches, covers , and panels are all

functionin

properly after you have reinstalled or replaced them.

Warning/Caution Label

WARNING and CAUTION labels are stuck on dangerous parts in the

printer to make you aware of the potential dan

when you are workin

with those parts.

ers that are present

Page 6

PREFACE

g

g

This manual describes basic functions, theory of el ectrical and mechanical operations, maintenance and repair pro cedures of EPSON EPL-N2700.

The instructions and procedures include d herein are intended for the exper ienced repair technici ans, and attention shou ld be

on the precedin

page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 4. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

iven to the precautions

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector Pin Assignment

• Electrical Circuit Board Component Layout

• Exploded Diagram

• Electrical Circuit Board Schematic

Page 7

Revision Status

Revision Issued Date Description

0 January 26, 1999 Preliminary version

Page 8

Contents

Product Description

OVERVIEW ................................................................................................. 12

BASIC SPECIFICATIONS .......................................................................... 13

CONTROLLER SPECIFICATIONS ........................................................ 13

Configuration ................ ....................................................................... ... 14

ENGINE SPECIFICATIONS ................................................................... 15

PAPER SPECIFICATIONS .................................................................... 17

Process Specifications ........................................................................... 20

Paper Specifications ............................................................................... 20

RELIABILITY, DURABILITY, AND MAINTAINABILITY .......................... 22

ENVIRONMENTAL CONDITION FOR STORAGE AND

TRANSPORTATION (Including Consumables) ..................................... 24

Electrical Specifications .......................................................................... 25

SAFETY APPROVAL ............................................................................. 26

CONSUMABLES ................ .............................................. ...................... 27

External Interface Specifications ............................................................. 28

Host Interface Usage Configurations ..................................................... 28

Parallel Interface ................ ....... ...... .............................................. ......... 29

Serial Interface ....................................................................................... 29

Ethernet I/F ............................................................................................. 30

Type-B I/F ............................................................................................... 31

Panel Operation ......................................................................................... 32

Control Panel. ......................................................................................... 32

Panel Settings ........................................................................................ 34

Setting Items ...................................................................................... 34

User Setting Items which are not include in the Setting Menu ........... 38

Setting Item Description ..................................................................... 38

One-Touch Setting ....................................... ....... ...... ....... ...... ....... ...... ... 41

Special Functions ................................................................................... 41

Maintenance Mode ................................................................................. 43

Engine Status Sheet ........................................................................... 44

List of Data Controlled by the Engine Status Sheet

and Controlling Method...................................................................... 47

Dimensions and Weight ............................................................................ 48

Operating Principles

Printer Mechanism Operating Principles ................................................ 51

General Description of Each Section ..................................................... 52

Gear/Roller Location .............................................................................. 53

Electrical Component Layout ................................................................. 54

Switches and Sensors ........................................................................ 55

Paper Feeding Section ........................................................................... 56

MP Tray .............................................................................................. 56

Cassette 1 .......................................................................................... 60

Paper Feed ......................................................................................... 65

Printhead Unit (Exposure Section) ......................................................... 66

Print Process Sequence ..................................................................... 67

Imaging Cartridge ................................................................................... 68

Part Names and Functions of the Imaging Cartridge ......................... 68

Charging Section ................................................................................ 69

Development Section ......................................................................... 69

Transfer Section ................................................................................. 71

Fusing Section .................................................................................... 72

Paper Exit Section .............................................................................. 74

Detection whether New or Used Imaging Cartridge ............................... 75

Right Door Interlock Switch .................................................................... 75

Electrical Circuit Operating Principles. ................................................... 76

System Layout ....................................................................................... 76

Drive Section ...................................................................................... 76

Electrical Section ................................................................................ 77

Main Circuit (Video Controller) ... ....... ...... ....... ...... ....... ...... ..................... 78

Main Component in the Main Circuit Board ........................................ 78

Page 9

Troubleshooting

Overview ..................................................................................................... 80

Printer Messages ................................................................................... 80

Message List ...................................................................................... 80

Message Descriptions ........................................................................ 82

Service-call Error .................................................................................... 83

Engine Related Error .......................................................................... 83

Controller Related Error List ............................................................... 84

Clearing the Service-call Error ............................................................ 85

Adding on RAM ...................................................................................... 85

Troubleshooting .................. ............. ............. ............. ............. ............. ... 85

The Printer will not Start ..................................................................... 85

The Printer will no Print. ..................................................................... 86

Image Quality Problems ..................................................................... 86

Disassembly/Assembly

Overview ..................................................................................................... 88

Precaution .............................................................................................. 88

Tools ............................. ............. ............. ............. ............. ............. ......... 88

Small Parts ............................................................................................. 89

Disassembly Procedure ............................................................................ 91

ROM DIMM Removal ............................................................................. 92

Paper Eject Sensor Removal ................................................................. 93

1st Cassette Paper Take-up Roller Removal ......................................... 94

Transfer Section ..................................................................................... 95

Transfer Roller Removal .................................................................... 95

Transfer Unit Removal ....................................................................... 96

Timing Roller Front Sensor Removal ................................................. 96

Timing Clutch Removal ...................................................................... 97

Timing Roller Removal ....................................................................... 98

Internal Cooling Fan Removal ............................................................ 99

Separating the Printer ............................................................................ 99

Rear Cover Removal ............................................................................ 100

Transport Motor Removal ..................................................................... 100

I/C Drive Motor Removal ...................................................................... 101

1st Cassette Size Sensor Removal ...................................................... 101

Paper Size Sensor Removal ................................................................ 102

Top Cover Removal ............................................................................. 102

Toner Empty Sensor Removal ............................................................. 103

Main Circuit Board Removal ................................................................ 104

Engine Controller Board Removal ........................................................ 105

Power Supply Unit Cooling Fan Removal ............................................ 107

High Voltage Unit Removal .................................................................. 108

Front Cover Removal ........................................................................... 109

Control Panel Removal ........................................................................ 109

Printhead Unit Removal ....................................................................... 110

Power Supply Unit Removal ................................................................ 112

Fusing Section ..................................................................................... 113

Fuser Unit Removal .......................................................................... 113

Heater Lamp Replacement ............................................................. 114

Fusing Roller Thermistor / Thermostat / Temperature Fuse Removal 115

Upper Paper Separator Finger Removal ......................................... 118

Lower Paper Separator Finger Removal .......................................... 119

Upper Paper Eject Roller Removal ................................................. 119

Lower Paper Eject Roller Removal .................................................. 120

Drive Unit Removal .............................................................................. 121

1st Cassette Paper Take-up Solenoid (SL1) Removal .................... 123

1st Cassette Set Sensor Removal ................................................... 123

1st Cassette Paper Empty Sensor Removal .................................... 123

1st Cassette Paper Near Empty Sensor Removal ........................... 124

2nd Cassette Disassembly ................................................................... 125

Paper Take-up Roller Removal ........................................................ 125

2nd Cassette Paper Empty Sensor Removal ................................... 126

2nd Cassette Paper Near Empty Sensor Removal .......................... 126

Paper Size (Paper Size Switch) Sensor Removal ............................ 127

2nd Cassette Control Board (PWB-A) Removal ............................... 127

2nd Cassette Paper Take-up Solenoid Removal ............................. 128

2nd Cassette Right Door Set Sensor Removal ................................ 129

Updating the Firmware ......................................................................... 130

Updating the Program ROM ................................................................. 130

Error Indications and Measures ....................................................... 130

Copying the DIMM Module ................................................................... 132

Adjustment

Maintenance

Page 10

Overview ................................................................................................... 136

Maintenance by Users .......................................................................... 136

Replacement of Consumable Items ..................................................... 136

Maintenance by Servicers .................................................................... 137

Appendix

Connector Summary ............................................................................... 139

Component Layout .................................................................................. 141

Exploded Diagrams ................................................................................. 142

Housing ................................................................................................ 142

Frames ................................................................................................. 144

Fussing Section (A) .............................................................................. 146

Fusing Section (B) ................................................................................ 148

Transport Section (A) ........................................................................... 150

Transport Section (B) ........................................................................... 152

Electrical Components ......................................................................... 154

Paper Take-up Section ......................................................................... 156

Drive Section ........................................................................................ 158

Paper Tray Unit .................................................................................... 160

Circuit Diagrams ...................................................................................... 162

Page 11

PRODUCT DESCRIPTION

Page 12

EPL-N2700 Revision A

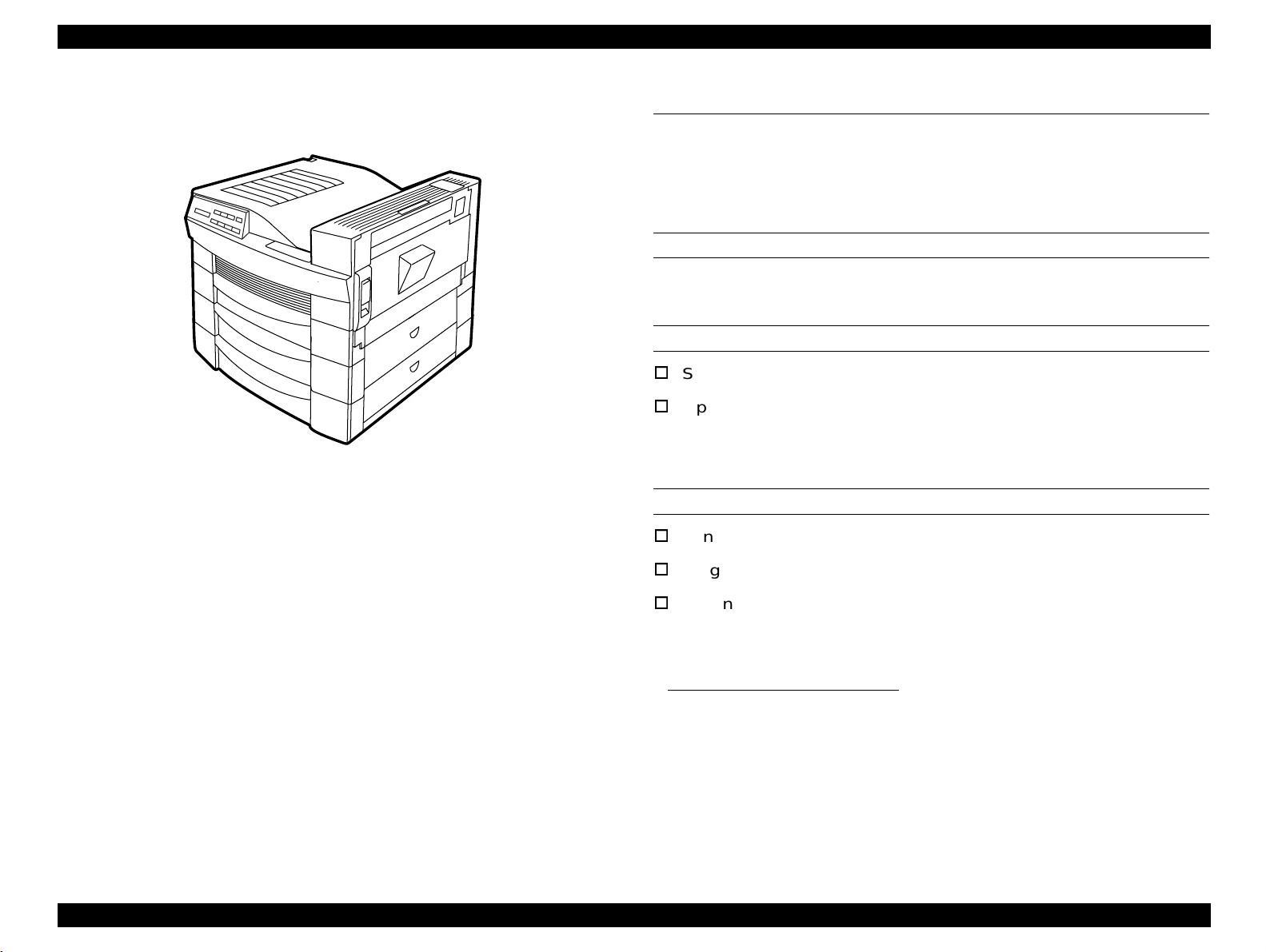

1.1 Overview

The EPL-N2700 is a business-oriented page printer making the most

use of the laser diode and the electrical photo technology. The main

feature of the printer are as follows:

ENGINE FEATURES

High-speed, highly reliable A3 Engine (Maximum duty cyc le is

100,000 sheets per month).

Resolution is 600 dpi, with a printing speed of 27 ppm when feeding

A4 from Cassette 1. (26 ppm for Letter)

Standard paper capacity is 750 sheets, 250 in the MP tray and 500

in the Cassette 1.

Holds optional cassettes to increased paper loading capacity:

One Lower Cassette (500 sheets) + Large Capacity Paper

Cassette (2500 sheets for A4 of Letter)

Up to three Lower Cassettes

SOFTWARE

IEEE l284 based parallel interface (supports ECP)

RS-232C serial interface

Ethernet Interface (100/10Base-TX)

One slot for Type B interface card

Supports Enhanced MicroGray

Supported Emulation

ESC/Page

PCL5e

ESC/P2

FX

1239X

EPSON GL2

PostScript 3 (Optional item provided on a ROM DIMM board)

Rewriting the Flash DIMM

Flash ROM in Slot A and program slot can be rewritten.

*1

Wide variety of options

Duplex unit

5-bin Multibin unit

10-bin Multibin unit.

CONTROLLER FEATURES

A new CPU (166MHz, VR4310) used for a high-speed controller

Use of SDRAM DIMM for an optional RAM will expand the standard

16-MB memory up to 256 MB.

Three types of standard interface

*1. Uninteded for users

Product Description Overview 12

Page 13

EPL-N2700 Revision A

1.2 Basic Specifications

This section describes the basic specifications of the EPL-N2700.

1.2.1 Controller Specifications

CPU

VR4310 / 166MHz

RAM

Figure 1-1. Exterior View of the EPL-N2700

Standard 16MB (on-board)

Optional 8MB*2/16MB*2/32MB/64MB/128MB/

*3

256MB

(SDRAM type,1 slot)

*1

Can be expanded up to 256MB.

ROM

Font: 2Mbytes (on-board)

Program: 4Mbytes (on Flash ROM-DIMM board)

Expansion ROM: 3 ROM-DIMM slots (Can be removed/

installed at power on only)

Available for NLSP FONT DIMM and

PostScript 3 DIMM

*1. 8MB (TBD) is alloca ted for the pr ogram area. The RAM Check at

startup shows the attached memory size, while th e status sheet

shows the size with the program code size deducted as well as the

attached memory.

*2. Not mentioned in any catalog nor specifications, since they are

hardly distributed.

*3. Availability of 25 6MB RAM , which ma y be dis tribu ted in futu re, will

be determined after the printer is in market.

Product Description Basic Specifications 13

Page 14

EPL-N2700 Revision A

INTERFACES

Standard interface:

Parallel interface:

Bidirectional parallel I/F (B type connector)

(IEEE-1284 compliant / Compatibility, Nibble and ECP mode)

Serial interface:

RS-232C

Ethernet 100/10BaseTX

Optional interface: Type-B interface slot (1 slot)

CONTROL PANEL

Consists of the 8 push-button switches, 6 LED lamps, and 20-digi t LCD

INSTALLATION FORMAT

Direct attachment

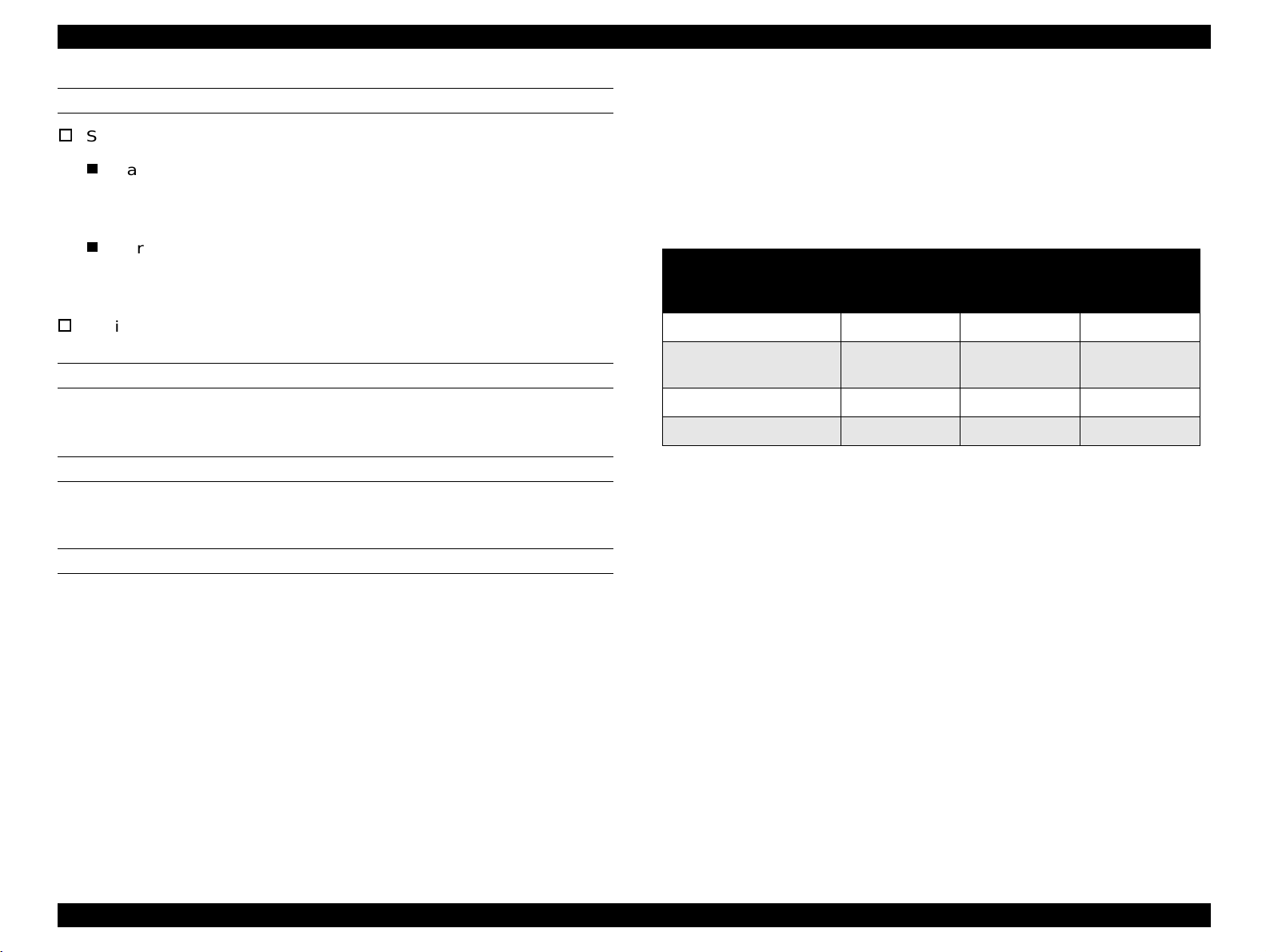

1.2.2 Configuration

The following configuration set on the controller varies according to the

destination. (See Table 1-1.) Settings are made in factory using the

jumper resistance.

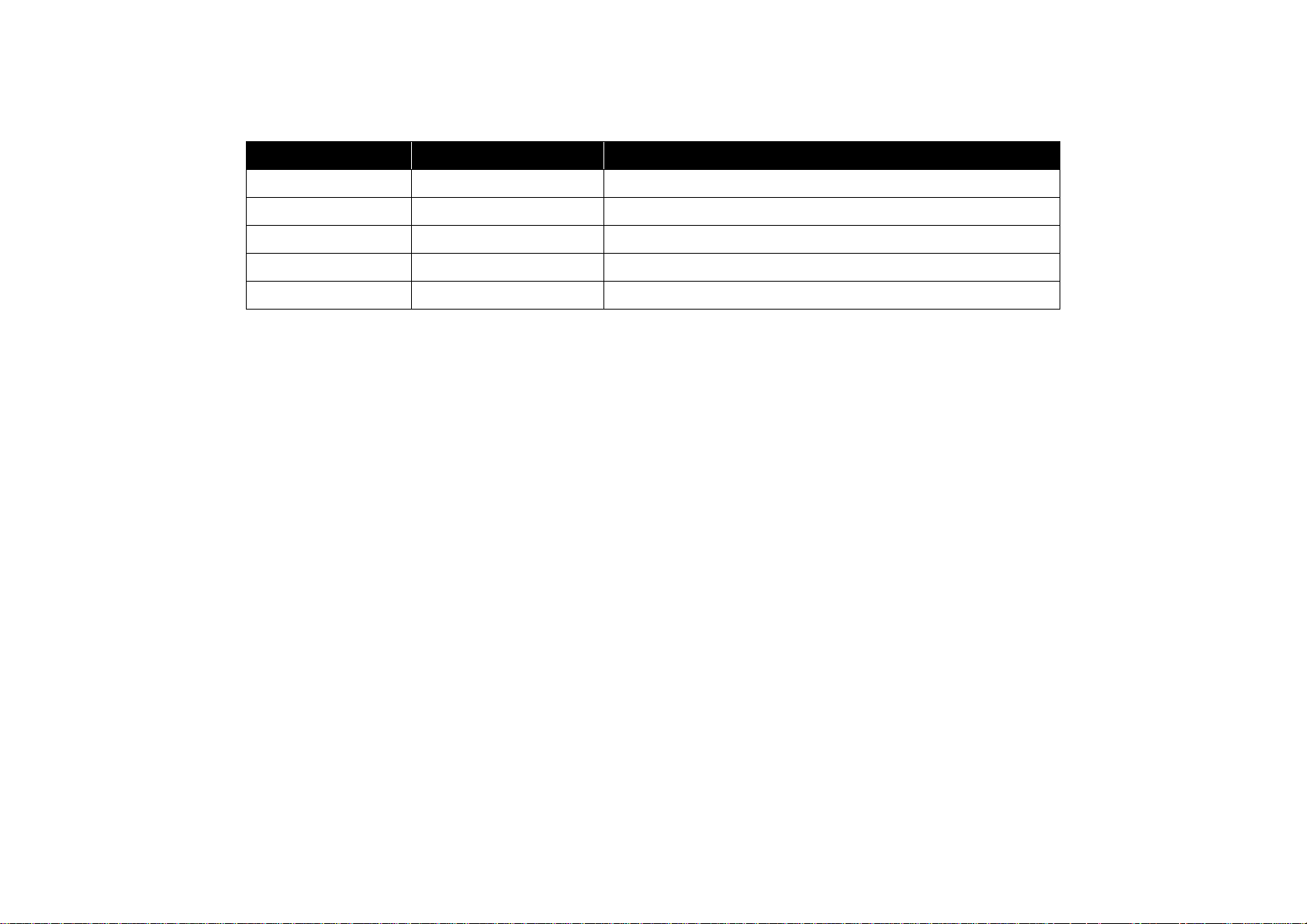

Table 1-1. Configuration Classification

Version (Destination)

South American Letter

European, Pacific,

South American, Korean

North European A4

Taiwanese A4

Default for

Paper Size

A4

NLSP (Slot C)

Unsupported Unsupported

Unsupported Unsupported

Supported Unsupported

Unsupported Unsupported

Chinese

character fonts

(Slot C)

OTHER FEATURE

Does not support mechanism controller.

Product Description Basic Specifications 14

Page 15

EPL-N2700 Revision A

1.2.3 Engine Specifications

PRINTING METHOD

Semiconductor laser beam scan + dry-powdered single-component

magnetic toner electro-photographic printing

RESOLUTION

600DPI

PRINTING SPEED

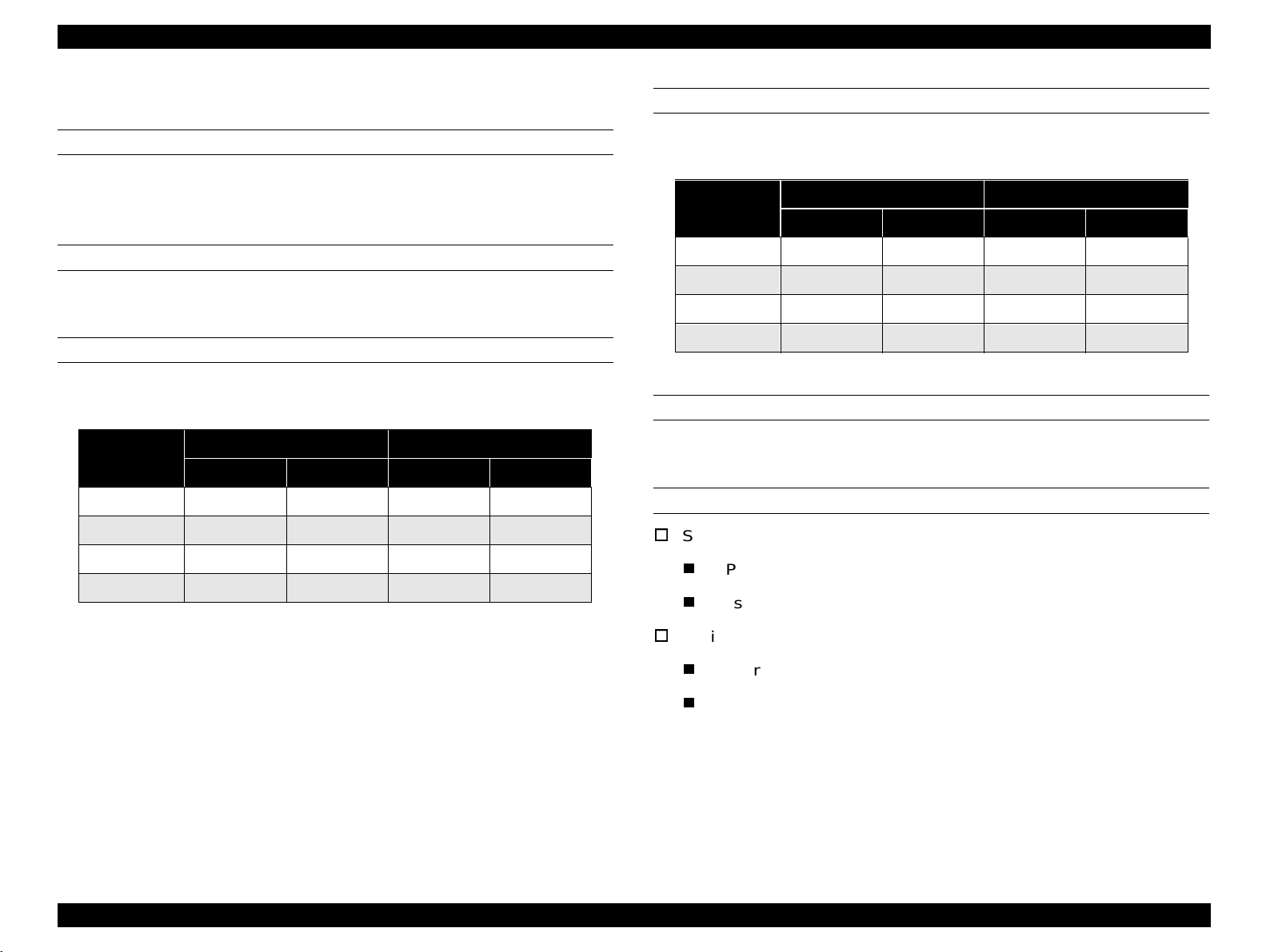

Table 1-2. Printing Speed (Sheet / Minute)

Paper Size

A4 (SEF)* 26.0 27.0 16.9 17.0

A3 (LEF)** 14.1 14.2 8.5 8.5

A5 (SEF) 33.0

LTR (SEF) 25.4 26.0 16.7 16.7

SEF: Short Edge First, LEF: Long Edge First

NOTE:

For non-standard size paper, the printer pr ints at a lower

MP Cassette Cassette 1 MP Cassette Cassette 1

speed since the printer automatically performs cleaning.

Single Print Duplex Print

−

19.7

−

FIRST PRINT

Table 1-3. First Print

Paper Size

MP Cassette Casse tte 1 MP Cassette Cassette 1

A4 (LEF*) 11.2 11.2 20.1 20.1

A3 (SEF**) 13.3 13.3 22.4 22.4

A5 (LEF) 10.9

LTR (LEF) 11.3 11.3 20.3 20.3

*SEF: Short Edge First, **LEF: Long Edge First

Single Print Duplex Print

−

17.7

WARM-UP TIME

60 seconds or less (at 23

°C / at rated voltage

)

PAPER SOURCES

Standard

MP (Multi Purpose) cassette

Cassette 1 (Universal Paper Cassette)

Optional

Lower Cassette Unit (Universal Cassette)

−

Large Capacity Lower Cassette

NOTE:

Up to 3 optional Paper Cassette Units can be installed.

Product Description Basic Specifications 15

Page 16

EPL-N2700 Revision A

See Table 1-4 for paper source specifications.

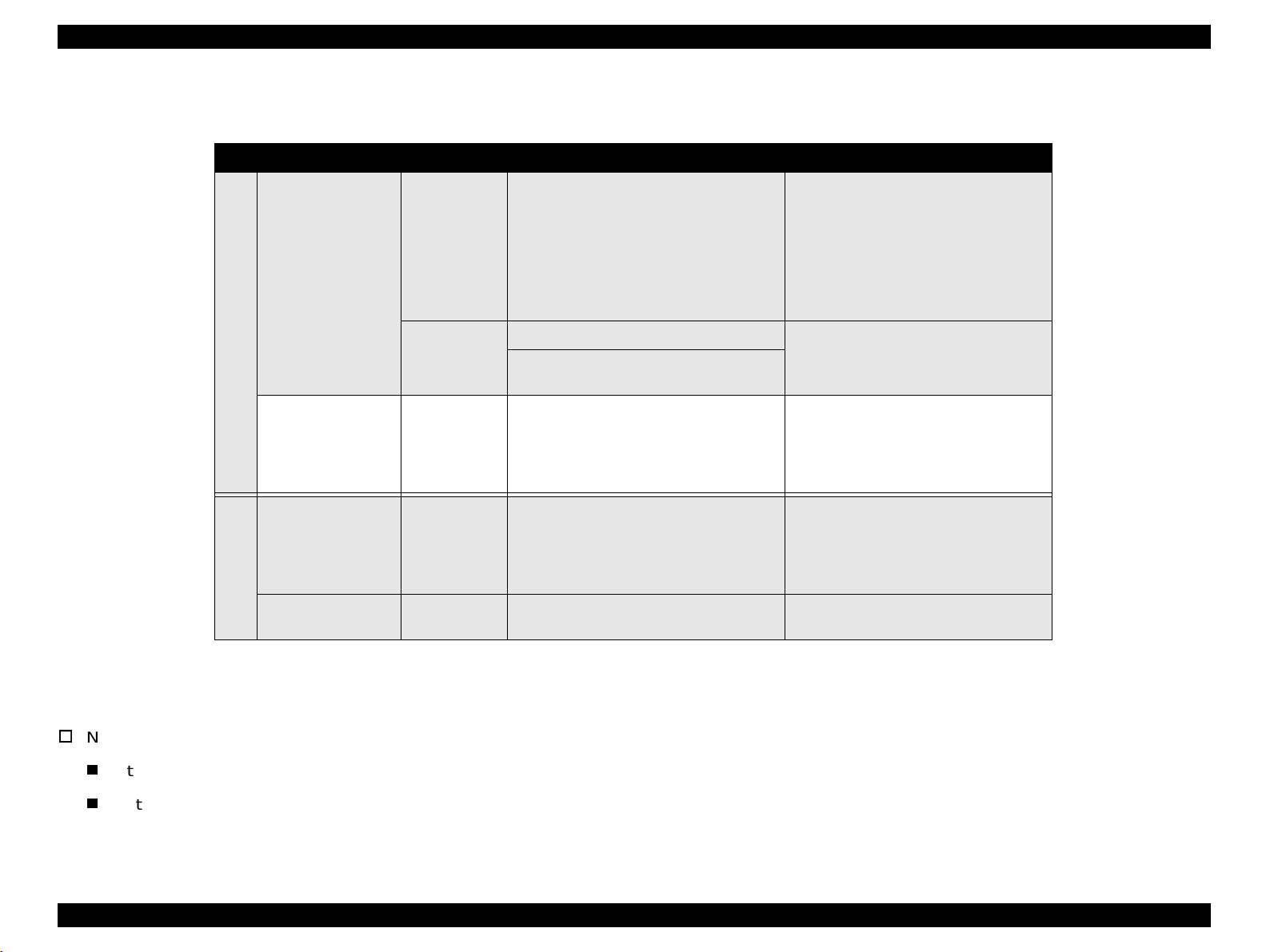

Table 1-4. Paper Supply / Paper Size / Capacity

Paper Source / Capacity Paper Size Available Paper Thickness Available

250 sheets

MP Tray

Standard

Cassette 1 500 sheets

20 sheets

• Standard size paper within the size of:

A5(LEF

Half Letter - Ledger(SEF)

(8.5" x 5.5") (11" x 17")

• Custom size paper

Any size of paper within the range of:

Width: 86 - 297 mm

Length: 140 - 432 mm

Envelopes (Monarch, C10, DL, C5, C6)

Labels, OHP sheet, Thick paper,

Letterhead

A3(SEF), A4(LEF),

Ledger (SEF) (11" x 17")

Legal (SEF) (14" x 805")

Letter (LEF) (11" x 8.5")

G.Letter (LEF) (10.5" x 8")

*1

) - A3(LEF*2)

Normal paper:60 - 90g/m² (16 - 24lb)

• Special paper (Labels, OHP sheet)

• Normal paper: 60 - 90g/m² (16 - 24lb)

• Thick paper: 90 - 163 g/m²

Normal paper: 60 - 90g/m² (16 - 24lb)

A3(SEF), A4(LEF),

Lower Cassette

(500-sheet cassette

*3

)

unit

Option

Large Capacity

Lower Cassette

500 sheets

2500 sheets

Ledger (SEF) (11" x 17")

Legal (SEF) (14" x 805")

Letter (LEF) (11" x 8.5")

G.Letter (LEF) (10.5" x 8")

A4 (LEF)

*4

Letter (LEF) (11" x 8.5")

Normal paper: 60 - 90g/m² (16 - 24lb)

Normal paper: 60 - 90g/m² (16 - 24lb)

*1: Set paper with the Long Edge First.

*2: Set paper with the Short Edge First

*3: Up to 3 optional Lower Cassette Units can be installed.

*4: With 80g/m² paper

Number of sheets loaded

Standard: 750 sheets (250 + 500)

With options: Up to 3,750 sheets in total. (Standard: 250 + 500, Optional 500 + 2,500)

Product Description Basic Specifications 16

Page 17

EPL-N2700 Revision A

1.2.4 Paper Specifications

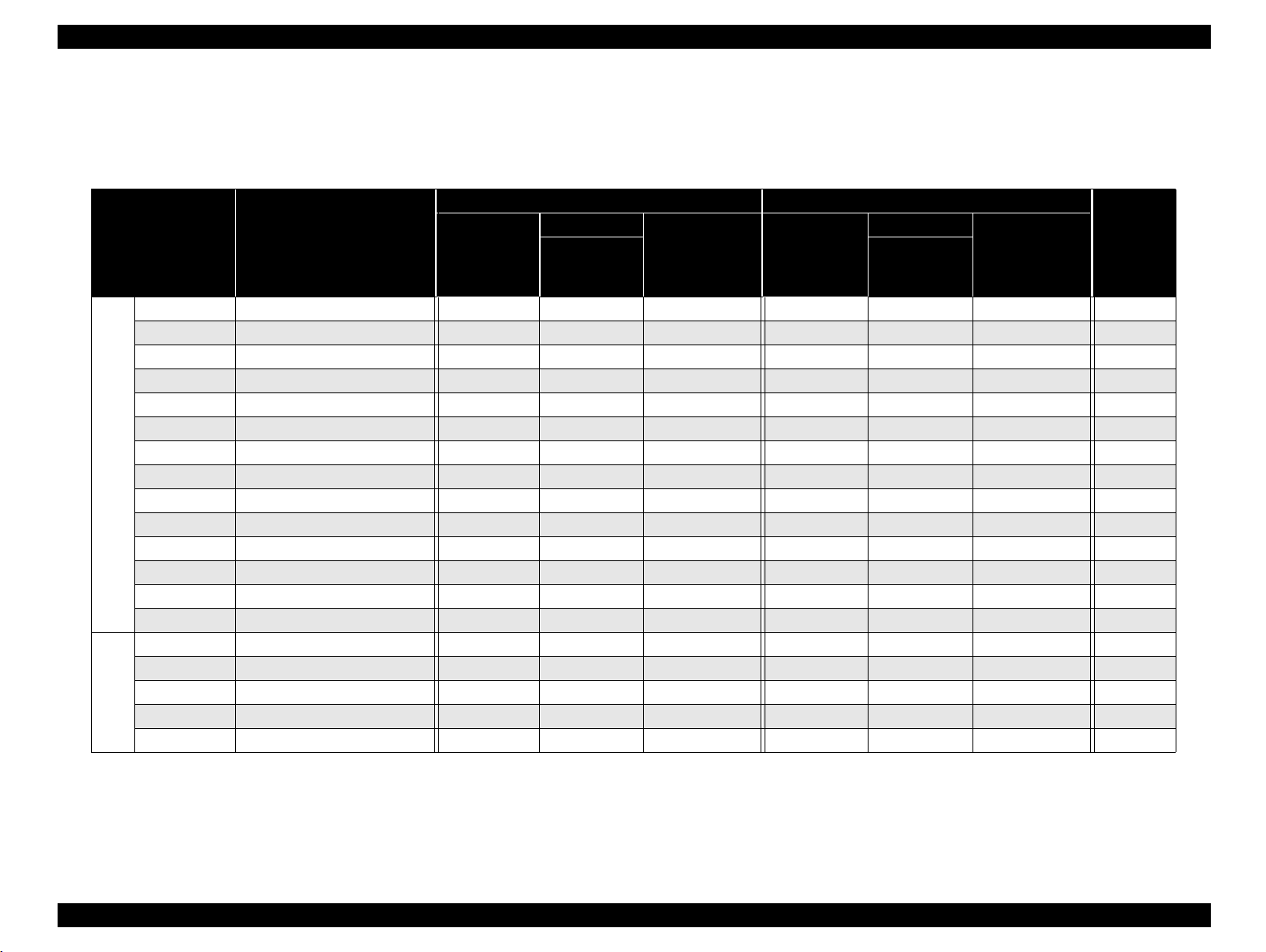

See Table 1-5 for the paper sources and their paper availability.

Table 1-5. Paper Sources and their Paper Availability

North America Europe

Type

A3 297 x 420 AC AM AA AM AC

A4 (LEF) 210 x 297 AC AM AA AM AA AC

A5 (LEF) 148 x 210 AC AA AC

JIS-B5 (LEF) 182 x 257 AC AC AC

ISO-B5 (LEF) AC AA AC

LTR (LEF) 215.9 x 279.4 (8.5 x 11") AA AM AA AA AM AA AC

HLT (LEF) 139.7 x 215.9 (5.5 x 8.5") AA AC AC

LGL 215.9 x 355.6 (8.5 x 14") AA AM AA AM AC

EXE (LEF) 184.15 x 266.7 (7.25 x 10.5") AA AC AC

Normal Paper

GLG 215.9 x 330.2 (8.5 x 13") AA AC AC

GLT (LEF) 203.2 x 266.7 (8 x 10.5") AA AM AC AM AC

B AA AM AC AM AC

F4 210 x 360 AC AA AC

Nonstandard 330 x 275 AC AC

MON 98.43 x 190.5 (37/8 x 7½") AC AC

C10 104.78 x 241.3 (41/8 x 9½") AC AC

DL 110 x 220 AC AC

C5 162 x 229 AC AC

special paper

C6 114 x 162 AC AC

Size

mm (inch)

MP Cassette

Cassette 1

500 -Sheet

Lower

cassette

Large Capacity

Lower Cassette

MP Cassette

Cassette 1

500-Sheet

Lower

cassette

Large Capacity

Lower Cassette

Duplex

Unit

NOTE:

AA: Available (Automatic paper size detection is supported for MP cassette.)

AM: Available (Manual paper size detection is supported. Paper size is set with dials.)

AC: Available (Paper size is set though the control panel.)

Product Description Basic Specifications 17

Page 18

EPL-N2700 Revision A

CONSUMABLES AND OPTIONS

Imaging Cartridge

With a 5-bin Unit installed:

Table 1-6. Paper Ejection Capacity with 5-bin Unit

SUPPORTED PAPER SIZES

MP Cassette:

Width =86 to 297 mm (3.39 to 11.7 ")

Cassette 1:

Width = 215.9 to 297 mm (3.9 to 11.7 ")

Length = 203.2 mm to 431.8 mm (8 to 17 ")

Available paper size = A3 (SEF), A4 (LEF),

Letter (SEF), Letter (LEF), G.Letter (LEF)

Lower Cassette: Same as for the Cassette 1.

Large Capacity Lower Cassette:

Available paper size = A4(LEF), Letter(LEF)

PAPER FEED ALIGNMENT

Center alignment for all paper sizes

Paper Type

Normal paper

(60 - 90 g / m

Envelopes, OHP sheets

Thick paper

(90 - 163 g / m2)

NOTE:

With a 10-bin unit installed:

2

)

Each bin is equipped with the full stack sensor.

Table 1-7. Paper Ejection Capacity with 10-bin Unit

Normal paper (60 - 90 g / m

Envelopes, OHP sheets

Thick paper (90 - 163 g / m

NOTE:

Each bin is equipped with the full stack sensor.

Bin 1

Normal Shifting

250 sheets 250 sheets 50 sheets 100 sheets

10 sheets

(TBD)

2

) 200 sheets 200 sheets

2

)

− − −

10 sheets

(TBD)

Bin 2 - 4 Bin 5

Bin 1 Bin 2 - 20

−

PAPER EJECTION

Standard: Face-down ejection only

2

g / m

)

With options:

Holds up to 500 sheets (75

See Table 1-6 and Table 1-7 for paper ejection capacity with the

optional 5-bin/10-bin Unit installed.

Product Description Basic Specifications 18

Page 19

EPL-N2700 Revision A

POWER CONSUMPTION

Average consumption current:

1.3 A or less (24V)

Printer Main Body: See Table 1-8.

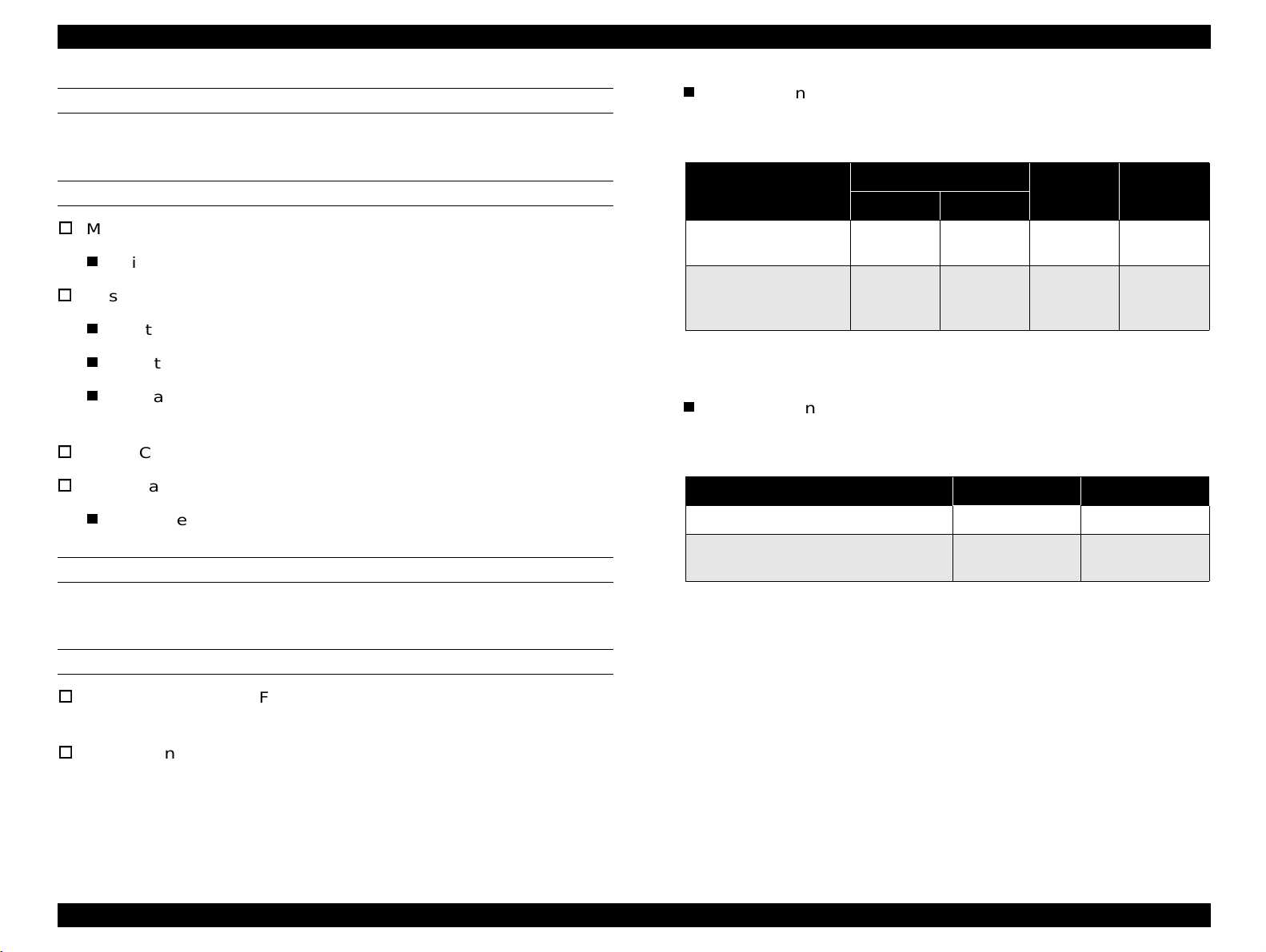

Table 1-8. Power Supply Specification

Item 100V Model 200V Model

Input Voltage

Rated Frequency 50 - 60Hz ±3Hz 50 - 60Hz ±3Hz

Rated Current 11.5 A 6.0 A

• Maximum: 1050W

Power

Consumption

Large Capacity Paper Cassette Unit

• Continuous printing: 750W

• Stand-by (H eater ON): 200W

• Stand-by (Heater OFF): 45W

120V ±10%

(90 to 132V)

220 - 240V ±10%

(198 to 264V)

NOISE:

0.5 A or less (5V)

Power consumption:

32 W or less (TBD)

5-bin Unit

DC24 V and DC5 V are supplied from the printer.

Average consumption current:

1.0 A or less (24V)

0.3 A or less (5V)

Power consumption:

24 W or less (TBD)

DC24 V and DC5 V are supplied from the printer.

Average consumption current:

Stand-by: Approximately 38.0 dB (A) or less

Operating: Approximately 55.0 dB (A) or less

1.0 A or less (24V)

0.5 A or less (5V)

Peak current:

1.5 A or less (24V)

OZONE DENSITY

0.1 ppm or less

0.5 A or less (5V)

Lower Cassette Unit:

DC24 V and DC5 V are supplied from the printer.

Average consumption:

TOXICITY

OPC, toner, and plastic materials are all nontoxic.

TBD (24V)

TBD (5V)

10-bin Unit:

DC24 V and DC5 V are supplied from the printer.

Product Description Basic Specifications 19

Page 20

EPL-N2700 Revision A

1.2.5 Process Specifications

Printing system: Dry single-component toner

electrophotographic process

Carbon paper, "non-carbon" paper

Thermal paper, pressure-sensitive paper, Acidic paper

Paper already printed on by thermal-transfer printer or ink jet

printer

Exposing source: Semi-conductor laser beam

Exposed object: OPC drum

Charging system: Rotating charging brush system

Developing system: Exposed area developing system

Thin or thick paper (exceeding the specificati on)

Wet (damp) paper

Paper with coated or processed color surface

Paper with extra smooth or extra rough surface

Paper whose smoothness on the both sides are largely different

Toner: Single-component nonmagnetic toner

Transfer system: Roller transfer system

Fixing system: Heat roller system

Paper with perforation or binder holes

Folded, curled, or torn paper

Paper of irregular shape

Paper cut at off-angle

Density control: Variable developer bias (can be set by yser)

Label sheets that peel too easily

Paper with clips, staples, glue, and so on.

1.2.6 Paper Specifications

Paper exclusively designed for ink jet print ers (s uper fine paper ,

PAPER TYPE

Standard paper: Xerox 4024 DP paper 20lb (75 g/m

Normal paper: 60 g/m

2

- 90 g/m2 (16 lbs - 24 lbs)

Copy paper, bond paper, and recycled paper

that are generally used

2

)

glossy paper, glossy film, and so on.)

Transparency film designed for color photo copier or color laser

page printer.

Paper already printed on with a color/monochro me laser printer

or photo copier.

Paper pasted together

Special paper: Labels, OHP film, Color paper, Thick paper

2

(90 - 157 g/m

), DTP paper, and Letterhead

CAUTION

Use of illustrated postcard may leave paper debris on

the paper loading roller, which causes the printer to

NOTE:

Do not use the following papers in this pri n ter. Use of any of

the following papers will causes the printer malfunctions

such as print problem and paper jam, and also damage the

feed paper improperly. If this problem occurs, clean

the paper loading roller. (Refer to Chapter 6

“Maintenance” for cleaning method.)

printer.

Product Description Basic Specifications 20

Page 21

EPL-N2700 Revision A

G uaranteed

print area

4m m

4m m

4m m 4m m

PAPER PATH AVAILABILITY

Table 1-9. Paper Path Availability

Special Paper

Standard

paper

MP Cassette RF R PPPPP

Cassette 1 RF R N N N N N

500-sheet lower

cassette unit

Large Capacity

Lower Cassette

Duplex Unit RF R NNNNN

RF: Reliable feeding and good image quality.

R: Reliable feeding and good image quality, but limited to paper generally available.

P: Possible, but limited to paper generally available.

N: Not supported

RF R NNNNN

RF R N N N N N

Normal

paper

OHP sheet

Postcard

Label

Thick paper

Envelope

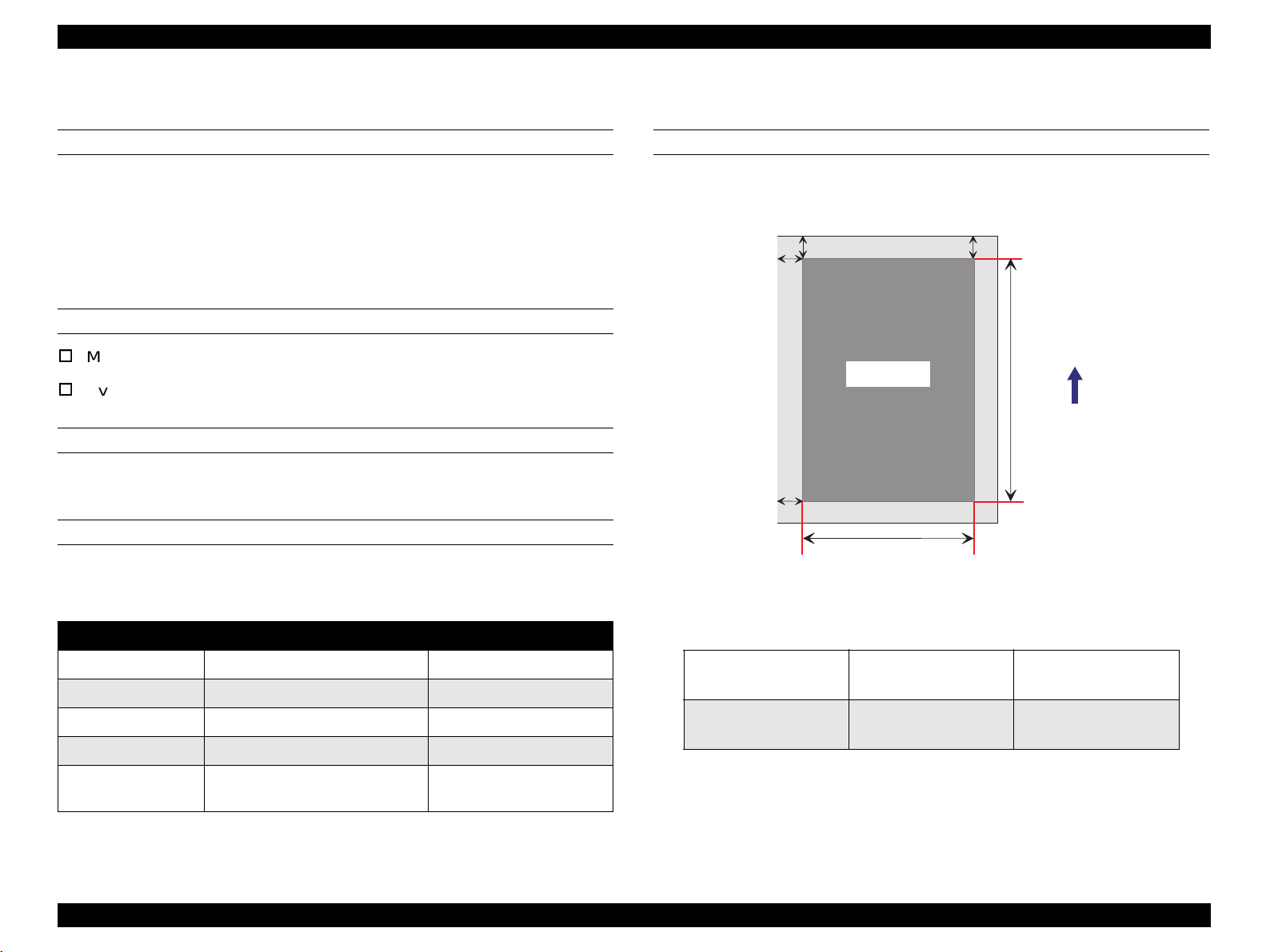

PRINTABLE AREA

Printable area: TBD

Guaranteed print area:Area other than 4 mm inward from each

edge. (See Figure 1-2.)

NOTE:

Guaranteed printable area may vary depending on the

printer mode.

Figure 1-2. Guaranteed Printable Area

Product Description Basic Specifications 21

Page 22

EPL-N2700 Revision A

a

b

c

d

e

f

Print area

Paper feeding direction

1.2.7 Reliability, Durability, And Maintainability

MPBF

60,000 sheets (For single-side print)

NOTE:

MPBF is an average number of sheets printed between

failures, where "failure" indicates a condition that requires

part replacement or that cannot be corrected by user.

PRINT VOLUME

Maximum = 100,000 sheets / month

Average = 10,000 sheets / month

MTBF

3,000 H (10 months) or more

PAPER FEED RELIABILITY

When standard paper is used in the standard environment:

Table 1-10. Paper Feed Reliability

PRINT POSITION ACCURACY

Jam rate

Feed failure 1/2000 or less TBD

Multiple paper feeds 1/500 or less TBD

Paper wrinkle 1/1000 or less 1/500 or less

*1

Edge bent

*1: Multiple feed is not included.

*2: 1C means 1 corner bent by 1 mm or less.

Single-side Print Duplex print

1/2000 or less 1/1000 or less

1/1000 or less for 1C or more

(Less than 1C is disregarded.)

1/500 or less

*2

Single-side print

Duplex print

Table 1-11. Print Position Accuracy

Main scan direction (c)

Sub scan direction (a)

Main scan direction (c)

Sub scan direction (a)

±2.mm

TBD

±3.mm

TBD

Product Description Basic Specifications 22

Page 23

EPL-N2700 Revision A

SKEW

Ambient Illumination: 3000 lux or less

(Must avoid direct sunlight.)

Table 1-12. Paper Skew

Space Requirement:

Print mode Direction A4 (LEF) A3 (SEF)

Single-side

print

Duplex print

Main scan direction (c

Sub scan direction (a

Main scan direction (c − d)

Sub scan direction (a − b)

d)

−

b)

−

±2.mm TBD

±1.5.mm TBD

±3.mm TBD

±2.5.mm TBD

DURABILITY

5 years or 600,000 sheet, whichever comes first.

MAINTAINABILITY

MTTR* = Within 30 minutes (average)

*

MTTR: Mean Time To Repair

EJECTION CURL

Normal paper:

OHP Sheet:

± 15 mm or less (TBD)

± 10 mm or less (TBD)

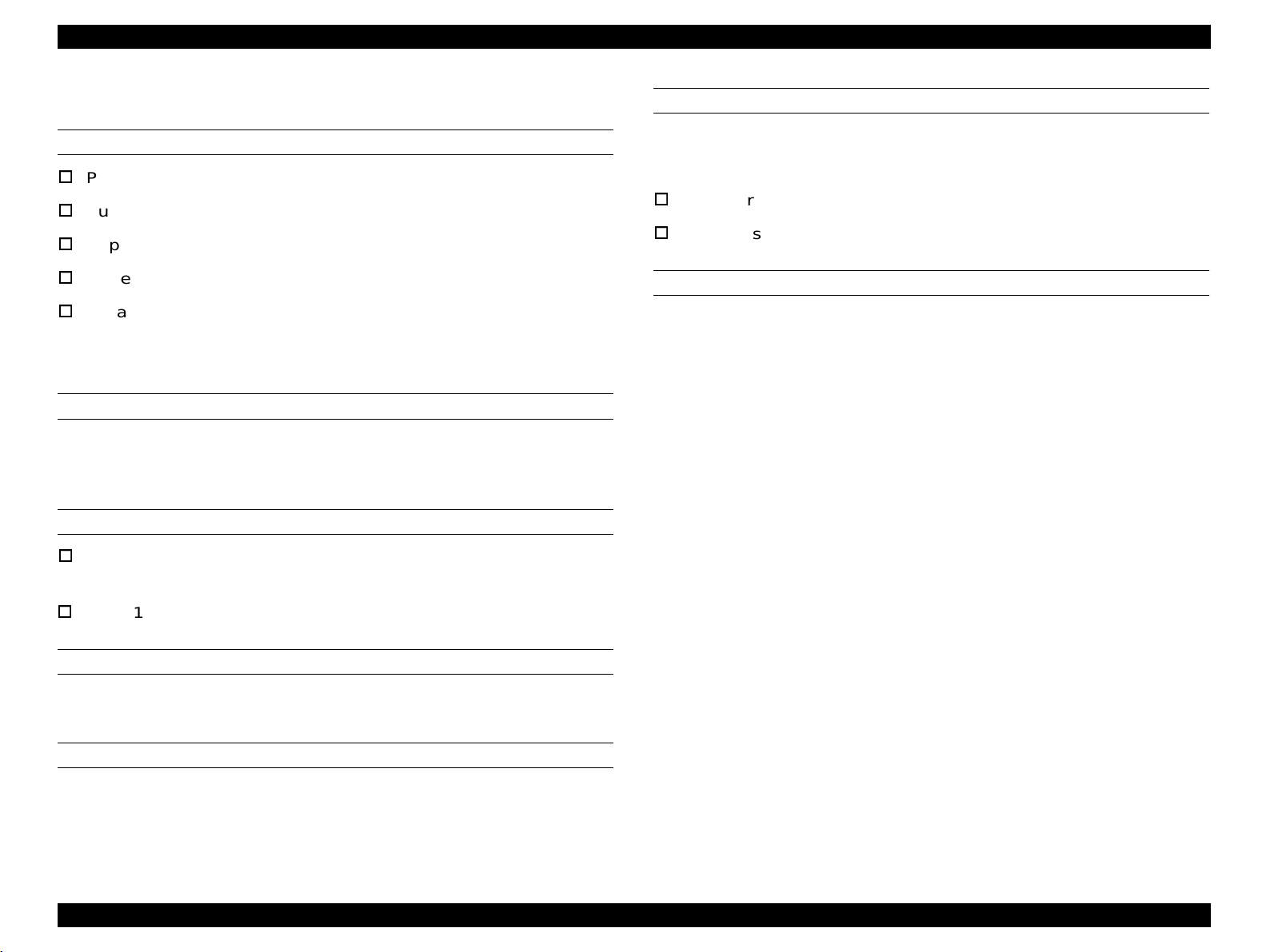

To ensure proper operation of the printer, sufficient open space

must be left around printer, as indicated in Figure 1-3.

TBD

TBD

< Top View >

734 m m (W ith the R ight C over open)

950 m m

OPERATING CONDITIONS (INCLUDING CONSUMABLES)

Temperature: 10 to 35°C

Humidity: 15 to 85%RH (without condensation)

Air Pressure (Altitude):760hPa or more (below 2500m)

Tilt: 1° or less (rear

↔ back, right ↔ left)

(W ith the C assette extended to the m axim um )

Figure 1-3. Space Requirement

Product Description Basic Specifications 23

Page 24

EPL-N2700 Revision A

1.2.8 Environmental Condition For Storage And Transportation (Including Consumable Items)

TEMPERATURE AND HUMIDITY

Table 1-13. Environmental Conditions - Main Unit

Item Conditions

Normal 0 to 35°C

Extreme

(1/30 of the total st orage

period)

Temperature

Normal 30 to 80%RH

Extreme

(1/30 of the total st orage

Humidity

period)

Storage duration Within 18 months from the production

*1: 35 - 55 °C without an ET Cartridge

High temperature 35 to 40°C *1

Low temperature -20 to 0°C

High humidity 85 to 95%RH

Low humidity 10 to 30%RH

AIR PRESSURE

74.0 to 101.3 kPa (Max. 555 - 760 mm Hg)

VIBRATION TOLERANCE

Vibration: 5 to 100Hz / 100 to 5Hz

Acceleration: 1G

Sweep time: 10 minutes (one way)

Direction: Three directions (X/Y/Z)

Time: 60 minutes in each direction

DROP TOLERANCE

No damage when tested in accordance with JIS Z0200-1987 level 1

Direction: 1 corner, 6 sides, 3 edges

Product Description Basic Specifications 24

Page 25

EPL-N2700 Revision A

1.2.9 Electrical Specifications

AC LINE NOISE

Pulse width: 50 to 1000 ns

Pulse polarity: + / -

Repetition: Asynchronous

Modes: Common / Normal

Voltage: 1KV

(Parts must be able to withstand 2KV without

damage)

TRANSIENT OUTAGE

DIP 100% (at rated voltage - 10%) 1 cycle

(No abnormal print quality)

ELECTROSTATIC TOLERANCE

Up to 10KV: No hard error, no user-nonrecoverable

software error

DIELECTRIC STRENGTH

Insulation shall not break down when the following voltage is applied

between primary circuit and chassis for 1 minute:

100V version: AC1000V

200V version: AC1500V

LEAKAGE CURRENT

3.5mA or less

Up to 15KV: No damage to parts

SURGE CURRENT

1/2-cycle / Not above 50A

INSULATION RESISTANCE

Ω or more

10M

Product Description Basic Specifications 25

Page 26

EPL-N2700 Revision A

1.2.10 Safety Approval

SAFETY REGULATION

Table 1-14. Safety Regulation

Model Applicable Standard

100V version

200V version

SAFETY REGULATION (LASER RADIATION)

Table 1-15. Safety Regulation (Laser Radiation)

Model Applicable Standard

100V version FDA (NCDRH) Class 1

200V version TUV-GS (EN60825)

• UL 1950

• CSA 22.2 No.950

• TUV-GS (EN60950)

•CCIB

• Complies with a safety regulation of the following countries:

Russia, Singapore, Hong Kong (IEC950), Korea

POWER CONSUMPTION

In compliance with International Energy Star program

OTHERS

Toner:

No effect on human health.

(In compliance with OSHA, TSCA, EINECS, worker saf ety laws an d

CSCL)

OPC:

No effect on human health. (In compliance with OSHA)

Ozone:

In compliance with UL478 5th Edition

Materials:

In compliance with Swiss environment protecti on law (no CdS

content)

EMC

Table 1-16. Safety Regulation (EMC)

Model Applicable Standard

100V version

200V version

• CNS 13438 (for Taiwan)

• FCC Part15 Subpart B Class B / CSA C108.8 Class B

• EC EMC directive 89/336/EEC

• EN55022 Class B

• EN61000-3-2

• EN61000-3-3

• EN50082-1

• AS/NZS 3548 class B (for Australia)

• Korea EMC class B

Product Description Basic Specifications 26

Page 27

EPL-N2700 Revision A

1.2.11 Consumable Item

This printer's only consumable part is the Imaging Cartridge.

SPECIFICATIONS

Table 1-17. Imaging Cartridge Specifications

Name Components Life Weight

•OPC Drum

• Charging unit

ET Cartridge

*1: Toner life is estim ated based on continu ous pri nting on A 4 (LEF) size paper

with 5% print co verage. Toner life will vary accordin g to print coverage and

printing method (continuous or intermittent, print density, and toner-save

mode).

*2: If the number of photo conductor rotation reaches the values equivalent to

25,000 sheets (A4 LEF / continuous) before toner life-end is detected, the

printer detects t he c ond iti on as t one r empty, same as the c ond iti on "ET Toner

Cartridge has expired its life".

• Development unit

• Single-component

unmagnetic black

toner

Average:

15,000 pages

Approximately 2.5

*1 *2

Kg

ENVIRONMENTAL CONDITION FOR STORAGE AND

TRANSPORTATION

Table 1-18. Environmental Conditions - Consumables

Item Conditions

Normal 0 to 35°C

Extreme

(1/30 of the total

storage period)

Temperature

Normal 30 to 85%RH

Extreme

(1/30 of the total

Humidity

storage period)

Air Pressure: 74.0 - 101.3 KPa (555 to 760mmHg)

Storage duration Within 18 months from the production

High temperature 35 to 40°C

Low temperature -20 to 0°C

High humidity 85 to 95%RH

Low humidity 10 to 30%RH

(unpacked)

DROP TEST

Same as for the printer main body.

VIBRATION

Same as for the printer main body.

Product Description Basic Specifications 27

Page 28

EPL-N2700 Revision A

)

1.3 External Interface Specifications

The EPL-N2700 supports the following interfaces .

Bidirectional parallel I/F (standard)

RS-232C serial (standard)

Ethernet I/F

Type-B interface slot (option)

See Figure 1-4 for the locations of the Interface slots.

Ethernet I/F C onnector

(1 )

(2 )

O ptional TypeB S lot

Parallel I/F C onnector

(IE E E 1284 B C onnector

1.3.1 Host Interface Usage Configurations

The EPL-N2700 has the automatic interface switching mode. however,

the interface to be used can be fixed by a control panel operation.

Table 1-19. Host Interface Usage Configurations

Parallel I/F Serial I/F Ethernet I/F Type B I/F

1. Automatic I/F

switching

2. Fixed I/F

(Parallel)

3. Fixed I/F

(Serial)

4. Fixed I/F

(Ethernet)

5. Fixed I/F

(Type B I/F))

Usable Usable Usable Usable

Usable Not Usable Not Usable Not Usable

Not Usable Usable Not Usable Not Usable

Not Usable Not Usable Usable Usable

Not Usable Not Usable Not Usable Usable

S e ria l I/F C o n n e c to r

(1) 100Base/10B ase Lam p (C olor: O range)

(2) Link/Reception Lam p (C olor: G reen)

Figure 1-4. Interface Slot Location

Product Description External Interface Specificati ons 28

Page 29

EPL-N2700 Revision A

1.3.2 Parallel Interface

Interface type: IEEE1284 bidirectional high-speed parallel

interface

Operation modes: Compatibility, Nibble, ECP

Connector: 57RE-40360-830B(D7A) DDK or equivalent

Applicable plug: Amphenole equivalent

Device ID:

*1;

MFG:

CMD:

MDL:

CLS:

DES:

*1. Total length of Device ID + 2 (hex) are entered in hexadecimal.

*2. The following character string appears when an optional ROM DIMM is

*3. Displays model name: EPL-N2700

EPSON;

PJL, EJL, ESCPL2-00, ESCP9-84, PRPXL24-01, HP ENHANCED

PCL5, HPGL2-01, ESCPAGE-04, ESCPAGE-04

*3

PRINTER;

EPSON EPL-N2700;

installed:

- PostScript 3 DIMM: ,POSTSCRIPT (TBD)

∗∗

*2;

1.3.3 Serial Interface

Type: RS-232C

Synchronization: Asynchronous

Transmission rates: 300 to 115200 bps

Parity bit: Even, Odd or NONE

Start bit: 1

Stop bit: 1 / 2

Data length: 7 or 8 bits

Hardware protocols: DTR/DSR

Software protocol: XON/XOFF (Robust mode is supported)

Connector: 17LE-13250-27(D57) DDK or equivalent

NOTES:

Page returns have been inserted in the explanation above to

make it easier to read, but it is actually given in a serial string

format without any breaks.

The CMD parameters are shown in random order. The items

MODE and STATUS are not included.

DES has the values for the MFG and MDL which are connected

with a space in between.

Product Description External Interface Specificati ons 29

Page 30

EPL-N2700 Revision A

1.3.4 Ethernet I/F

I/F type: 10BaseT, 100Base T , Half Duplex, Full

Duplex (Switched at power on)

Communication protocol:

IPX/SPX (IPX, SPX, NCP, RIP, SAP, PrintServer,

RemotePrinter, NDS, SNMP)

NetBIOS (SMB)

NetBEUI

TCP/IP (IP, UDP, TCP, LPR, FTP, TELNET, APR, ICMP,

RARP, BOOTP, DHCP, SNMP, HTTP)

AppleTalk (ELAP, DDP, ATP, PAP, AARP, NBP, ZIP, RTMP)

(When AppleTalk is used, items such as printer name must be

set on the Web browser. EPSON Net and EPSON Net2 can not

be used.)

Connector: RJ45

Applicable cable: 2-pair category 3, 4 or 5 UTP (10BaseT,

100BaseT)

(To conforms with ECC Class B, EN55022

Class B, VCCI Class B, a shielded cable must

be used.) (T BD)

Table 1-20. Ethernet I\F Pin Assignment

Pin Signal Name I/O

1Tx+ O

2Tx- O

3Rx+ I

4N.C.

5N.C.

6 Rx- I

7N.C.

8N.C.

−

−

−

−

Pin assignment: See Table 1-20.

Product Description External Interface Specificati ons 30

Page 31

EPL-N2700 Revision A

1.3.5 Type-B I/F

This printer is equipped with one slot for an optional Type-B interface

card.

Main System Type: MTP600dpi,PW7016dt600dpi,PRG(

AP1300ma,SPD0fast

∗∗∗∗: ROM version)

(

Printer Name: Factory value is the same as the Product

Name.

Product Name: EPL-N2700

Emulation type: See Table 1-21.

Entity type: See Table 1-21.

When the emulation is set to "Auto", the following Entity Types are

returned:

If PS is supported:

EPSONPCL5, EPSONPAGE4, EPSONLQ2

(EPSONHPGL2, EPSONFX, EPSONPRPXL24)*

∗∗∗∗)rev,

Table 1-21. Emulations Available

Emulation Emulation Type Entity Type

LJ4 PCL5E-00 EPSONPCL5

GL/2 HPGL2-01 EPSONHPGL2

PS POSTSCRIPT-00 LaserWriter

FX ESCP9-84 EPSONFX

ESCP2 ESCPL2-00 EPSONLQ2

1239X PRPXL24-01 EPSONPRPXL24

ESC/Page ESCPAGE-04 EPSONPAGE4

ESCPC ESCP24C-84 EPSONLQ0C

RCC *1

*1: Can not be selected by users.

−−

If PS is unsupported:

LaserWriter, EPSONPCL5, EPSONPAGE4

(EPSONNLQ2, EPSONHPGL2, EPSONFX, EPSONPRPXL24)*

* The Entity Types in the brackets are returned when the

number of multi-entity is 3 or more.

Product Description External Interface Specificati ons 31

Page 32

EPL-N2700 Revision A

1.4 Panel Operation

Data LED (Yellow)

ON: Printer contains data that has not yet been proces sed.

The control panel of the EPL-N2700 includes a variety of buttons and

indicator lamps, together with an LCD. The user can use the panel to

select the printer's operating mode, to set the various printer functions,

and to view settings and status information.

OFF: Printer has finished processing all print data.

(If data is not effective print da ta, light will not be on.)

(If control code is not terminated, however, this lamp will

be ON.)

Blinking: Printer is currently processing data.

1.4.1 Control Panel.

Continue LED (Red)

Blinking: Printer is in an error state. User can clear the error

by pressing the Continue button.

AB C

D

E

F

G

One-Touch Mode 1 LED (Green)

Indicate that the printer is in One-Touch mode 1. This mode offers

O rientation

Toner Save

Value Enter

Mode

N

O

the direct access to the following items:

Paper Source, Paper Size, Manual Feed, Orientation

One-Touch Mode 2 LED (Green)

Indicate that panel is in One-Touch mode 2. This mode offers the

direct access to the following items:

On Line

H

Form Feed

I

Paper Source P aper S ize M anual Feed

C ontinue

JK

Reset

SelecType

ALT

RITech

Menu Item

L

MP Tray Size

C opies

M

RITech, Copies, MP Tray Size, Out Bin

Figure 1-5. EPL-N2700 - Control Panel

SelecType (Green)

Indicates that printer is in SelecType setting mode.

LCD PANEL

NOTE:

All LEDs come on when a service-call error has occurred.

1-line by 20 column LCD display equipped with backlog, and it is used

for displaying printer status and setup menus

LED INDICATORS

On Line LED (Green)

ON: Printer is ready to receive data and print.

BUTTONS

On Line button

Toggles printer ON-LINE state on and off. (If printer is in one of the

setup modes, this switch releases the mode and sets the printer to

On-Line state.)

OFF: Printer is not for receiving print data.

Product Description Panel Operation 32

Page 33

EPL-N2700 Revision A

Form Feed button

If the printer contains data but is not enabled for printing (if Form

Feed lamp is on), this switch causes print er to output printing r esults

and eject the paper. (This button does not cause ejection if Form

Feed lamp is off.)

Continue button

Clears error (if pressed while Continue LED is blinki ng). When

printer is in On-Line state, this butt on will also clear any warning

display that may appear on the LCD.

SelecType / ALT button

Selects the panel setting mode: OneTouch Mode 1, OneTouch

Mode 2, or SelecType Mode. Also operates as a ALT key. Panel

button operations vary according to the currently selected panel

setting mode.

MENU button

Selects the corresponding OneTouch mode setting l isted above t his

button, or selects the SelecType menu if in SelecType mode. Press

this button when the printer is on-line to enter SelecType mode.

setting when in SelecType mode.

Press this button twice when the printer is on-line to pri nt the Status

Sheet.

RESET (ALT + Continue)

Pressing the Continue button while h olding down the ALT b utton will

reset the printer. The LCD will display the message RESET. To

generate a complete reset (warm boot), continue t o hold down these

buttons for approximately five seconds after the RESET message

appears; the message will then change to RESET ALL and the

printer will start warm-up processing.

CAUTION

1. This printer has a non-volatile memory (EEPROM) to

store various setting values and print data. If the

printer power is turned off while it is writing data, the

ongoing writing operation is not completed and an

error may occur at the next power on. Therefore, be

sure not to turn the printer off when the printer is in

any of the following conditions because a writing

operation is processing.

ITEM button

Selects the corresponding OneTouch mo de option listed above this

button, or selects the function available within the current menu,

after entering the SelecType mode.

VALUE button

Selects the corresponding OneTouch mo de option listed above this

2. To stop printing, press the On Line button or perform

Printer is turned on but the On Line LED has not

come on yet.

On Line LED is blinking.

Printer is printing. (PF motor is live.)

Job Cancel / Reset operation.

button, or selects the parameter available within the current item,

after entering the Item of the SelecType mode.

ENTER button / Status Sheet print

Selects the corresponding OneTouch mo de option listed above this

button, or accepts the setting currently shown on the LCD as a new

Product Description Panel Operation 33

Page 34

EPL-N2700 Revision A

1.4.2 Panel Settings

Table 1-23. SelecType Option (2/7)

1.4.2.1 Setting Items

The following tables show the panel setting options available.

Table 1-22. SelecType Option (1/7)

MENU Button

ITEM Button VALUE Button

Test Menu

Status Sheet

Network Status Sheet

PS3 Status sheet

PS3 Font Sample

ESC/Page Font Sample

LJ4 FOnt Sample

FX Font Sample

1239S Font Sample

Emulation Menu

Parallel / Serial /

Network / AUX

Printing Menu

Paper Source

Page Size

Wide A4

Orientation

Out Bin

Copies

Quantity

*26

Manual Feed

Resolution

Skip Blank Page

Duplex

Binding

*10

*10

(Continued to the next table)

*1

*1

*4

Auto / LJ4 / ESCP2 / FX / I239X / PS3 *1 /

*2

GL2

Auto / MP / LC1 / LC2

*20

A4

/ A3 / A5 / B4 / B5 / LT

*3

/ LC3

*3

*19

/ B / HLT /

LGL /GLT / GLG / EXE / F4 / MON / C10 / DL

/ C5 / C6 / IB5 / CTM

OFF / ON

Port

/ Land

Face-Down / Stacker *6 / Staple *8 /

Mailbox 1

*7

− 10 *7 / Sorter

*25

1 − 999

1 − 999

OFF

/ ON

600 / 300

*9

OFF / ON

OFF

/ ON

Long Edge / Short Edge

MENU Button

ITEM Button VALUE Button

Printing Menu

(Continued from the previous table)

Start Page

Offset Stacking

Finish

Staple Position

Punch

*10

*11

*12

*12

*12

Tray Menu

MP Mode

MP Tray Size

LC1 Size

LC2 SIze - LC3 Size

*13

*3 *13

MP Type

LC1 Type

LC2 Type *3, LC3 Type

*3

Config Menu

RITech

Toner Save

Density

Top Offset

Left Offset

*10

*10

T Offset B.

L Offset B.

Size Ignore

Auto Cont

Page Protect

Image Optimum

Paper Type

Front / Back

OFF

/ ON

None / Staple

Left / Right

None / Punch

Normal / Last

Auto *5 / A4 / A3 / A5 / B4 / B5 / B / LT /

HLT / LGL / GLT / GLG / EXE / F4 / MON /

C10 / DL / C5 / C6 / IB5

A4 / A3 / B4 / LT / B / LGL / GLT

A4 / A3 / B4 / LT / B / LGL / GLT (Universal

Cassette), A4, LT, B5 (LCC)

/ Preprinted / Letterhead / Bond /

Plain

Recycle / Color / Transprncy / Labels

/ Preprinted / Recycle / Color

Plain

Plain

/ Preprinted / Recycle / Color

ON / OFF

OFF / ON

3

/ 4 / 5 / 1 / 2

-150.0 - 0.0 - 150.0 (step: 0.5mm)

-150.0 - 0.0 - 150.0 (step: 0.5mm)

-150.0 - 0.0

- 150.0 (step: 0.5mm)

-150.0 - 0.0 - 150.0 (step: 0.5mm)

OFF / ON

OFF

/ ON

Auto / ON

Auto / OFF / ON

Normal / Thick W / Thick N / Trnsprnc /

Ltrhead

Product Description Panel Operation 34

Page 35

EPL-N2700 Revision A

Table 1-24. SelecType Option (3/7)

MENU Button

ITEM Button VALUE Button

Setup Menu

Interface

Time Out

Standby

*14

Lang

Panel Lock

Toner

Multibin

Finisher

Page Count

*15

*13

*27

*12

*13

SelecType Init

Parallel Menu

Speed

Bi-D

Buffer Size

Serial Menu

Word Length

Baud Rate

Parity

Stop Bit

DTR

Xon/Xoff

Buffer Size

Network Menu

Get IPAddress

IP Byte 1 - IP Byte 4

SM Byte 1 - SM Byte 4

GW Byte 1 - GW Byte 4

Buffer Size

AUX Menu *2

Buffer Size Normal / Maximum / Minimum

Auto / Parallel / Serial / Network / AUX

0, 5 - 60 - 300 (step: 1)

Enable / Disable

English

/ Français / Deutsch / ITALIANO / ESPANOL /

SVENSKA / Dansk / Nerderl. /SUOMI / Português

OFF

/ ON

E****F

−

E

F

Mailbox / Stacker / Sorter / MultiSort

Mailbox / Stacker / Sorter / MultiSort

0 - 99999999

Fast / Normal

Nibble / ECP / OFF

Normal

/ Maximum / Minimum

8 / 7

9600 / 19200 / 38400 / 57600 / 76800 / 115200 / 300 /

600 / 1200 / 2400 / 4800

/ Even / Odd

None

1

/ 2

ON / OFF

ON / OFF / Robust

Normal / Maximum / Mi nimum

Panel / DHCP / PING

0 − 255

0

− 255

0 − 255

Normal / Maximum / Minimum

Table 1-25. SelecType Option (4/7)

MENU Button

ITEM Button VALUE Button

*22

*4

On / Off

On

/ Off

CR / CR+FF

CR+FF / LF

CR+FF

/ FF

Ignore / Space

Off / On

On

/ Off

Resident / Download / ROM A

*23

/ ROM B

*23

0 - available (max. 65535)

0.44 - 10.00

- 99.99 (step:0.1cpi)

4.00 - 12.00 - 999.75 (step:0.25pt)

IBM-US / Roman-8 / ECM94-1 / 8859-2 ISO / 8859-9 ISO /

IBM-DM / PcMultiling / PcE.Europe / PcTk437 / WiAnsi /

WiE.Europe / WiTurkish / DeskTop / PsText / VeInternati /

VeUS / MsPublishin / Math-8 /PsMath / VeMath / PiFont /

Legal /UK / ANSI ASCII / Swedish2 / Italian / Spanish /

German / Norweg1 / French2 / Windows / Pclcelandic

*18

*18

PcLt774

PcTurk2

3 ISO

WiLatvian

BpAbicomp

8859-7 ISO

PcCy866

Bulgarian

Hebrew8

8859-6 ISO

5 - 60

*18

/ PcTurk1

*18

/ PcCanFrench

*18

/ 8859-4 ISO

*18

*18

*18

*18

/ PcLt866

*18

*18

/ PcHe862

*18

*19

- 64

0 - 277 - 3199

0 - 277 - 3199

CR

/ CR+LF

/ Mazowia

/ PcUkr866

*18

/ PcPortugues

*18

*18

/ PcGK437

/ WiGreek

*18

*18

/ OCR A

*20

*18

- 128

*18

/ PcSl437

/ WiBaltic

*18

/ CodeMJK

*18

/ PcGk851

*18

/ Europe3

/ 8859-5 ISO

*18

/ Hebrew7

/ Arabic8

/ OCR B

*18

*18

*18

/ PcEt850

*18

/ PcNordic

/ WiEstonian

*18

/ BpBRASCII

*18

/ PcGk869

*18

/ PcCy855

*18

/ WiCyrillic

*18

/ 8859-8 ISO

/ PcAr864

LF / CR+LF

*18

*18

*18

/

*18

/

*18

/ 8859-

/

*18

*18

*18

/

*18

/

*18

/

/

/

/

ESC/Page Menu

*2

Auto CR

AutoFF

CR Function

LF Function

FF Function

Error Code

Avoid Error

PGI

LJ4 Menu

FontSorce

Font Number

*22

Pitch

Height

SymSet

Form

Source Symset

Dest Symset

CR Function

LF Function

Product Description Panel Operation 35

Page 36

EPL-N2700 Revision A

Table 1-26. SelecType Option (5/7)

MENU Button

ITEM Button VALUE Button

GL2 Menu

GL-Mode

Scale

Origin

Pen

End

Join

Pen0/1

*16

Pen2

PS3 Menu

- 6

*1

Error Sheet OFF / ON

ESCP2 Menu

Font

Pitch

Condensed

T.Margin

Text

CGTable

Country

Auto CR

Auto LF

Bit Image

ZeroChar

GLlike / LJ4GL

OFF / A0 / A1 / A2 / A3

Corner / Center

*16

Pen0 / 1 / 2

- 6

*16

Butt / Square / Triangular / Round

Mitered / Miteredveveled / Triangular / Round / Beveled / None

0.05 - 0.35 - 5.00 (step:0.05mm)

*16

0.05 - 0.35 - 5.00 (step:0.05mm)

Courier / Prestige / Roman / Sans serif / Roman T / Orator S /

Sans H / Script / OCR A / OCR B

/ 12cpi / 15cpi / Prop.

10cpi

OFF

/ ON

0.40 - 0.5 - 1.50 (step:0.05")

1 - 62

PcUSA

*19

*20

- 66

- available (max 111)

/ Italic / PcMultilin / PcPortugue / PcCanFrenc /

PcNordic / PcTurkish2 / PcE.Europe / BpBRASCII /

BpAbicomp 8859-15ISO / PcEur858 / PcS1437

PcTurkish1

CodeMJK

*18

/ PcCy855

ISO

Hebrew7

*18

*18

/ Pclcelandic

*18

/ PcGk437

/ Hebrew8

*18

*18

*18

/ PcGK851

/ PcCy866

*18

/ PcAr864

/ 8859-9 ISO

USA / French / Germany / UK / Denmark / Sweden / Italy /

Spain1 / Japan / Norway / Denmark2 / Spain2 / LatinAmeric /

Korea / Legal

ON

/ OFF

OFF / ON

Dark / Light / BarCode

0

/ 0 (slashed)

*18

*18

/ Bulgarian

*18

/ PcHe862

*18

*18

/ Mazowia

/ PcGk869

*18

/ PcUkr866

*18

/

*18

*18

/

/ 8859-7

*18

Table 1-27. SelecType Option (6/7)

MENU Button

ITEM Button VALUE Button

FX Menu

Font

Pitch

Condensed

T.Margin

Text

CGTable

Country

Auto CR

Auto LF

Bit Image

ZeroChar

I239X Menu

Font

Pitch

Code Page

T.Margin

Text

/

Auto CR

Auto LF

Alt. Graphic

Bit Image

ZeroChar

CharacterSet

Courier / Prestige / Roman / Sans serif / Roman T / Orator S /

Sans H / Script / OCR A / OCR B

10cpi

/ 12cpi / 15cpi / Prop.

OFF / ON

0.40 - 0.5 - 1.50 (step:0.05")

*19

1 - 62

*20

- 66

- available (max 111)

PcUSA / Italic / PcMultilin / PcPortugue / PcCanFrenc /

PcNordic / PcTurkish2 / PcE.Europe / BpBRASCII /

BpAbicomp / 8859-15ISO / PcEur858

/ French / Germany / UK / Denmark / Sweden / Italy /

USA

Spain1 / Japan / Norway / Denmark2 / Spain2 / LatinAmeric

/ OFF

ON

OFF / ON

Dark

/ Light / BarCode

0 / 0 (slashed)

Courier / Prestige / Gothic / Orator / Script / Presentor / Sans

serif

10cpi

/ 12cpi / 15cpi / 17cpi / 20cpi / 24cpi / Prop.

437 / 850 / 860 / 863 / 865

0.30 - 0.40 - 1.50 (step:0.05")

*19

1 - 63

- 67

*20

- available (max 111)

OFF / ON

OFF / ON

OFF

/ ON

Dark / Light

0, 0 (slashed)

*19

*20

1

/ 2

Product Description Panel Operation 36

Page 37

EPL-N2700 Revision A

Table 1-28. SelecType Option (7/7)

MENU Button

ITEM Button VALUE Button

Maintenance Menu

Engine Status Sheet

Fuser Counter Clear

MP Counter Clear

LC1 Counter Clear

LC2 Counter Clear

LC3 Counter Clear

TR Counter Clear

Errlr Long Clear

NOTES:

1: Appears only when an optional PostScript Level 3 DIMM is installed.

2: Appears only when an optional TypeB Interface Card is installed.

3: Appears and can be selected only when an optional lower cassette unit is installed.

4: Does not appear on the panel nor sta tus shee t.

5: When "Auto" is selected, the following paper sizes can be detected.

- North American version: LT, HLT, LGL, EXE, GLG, GLT, B

- Other versions:A3, A4, A5, IB5, LTR, LGL, F4

6: Appears and can be selected only when 5-Bin Unit or 10-Bin Unit is insta lled and

the Stacker mode is enabled.

7: Appears and can be selected only when 5-Bin Unit (Mail box 1 - 4) or 10-Bin Unit

(Mail box 1-9) is installed in the Mailbox mode.

8: Does not appear .

9: Effective only in the ESC/Page or PCL mode.

10: Appears only when an opt ional Duplex Unit is installed.

11: Appears only when an optional 5-Bin Unit or Finisher is installed.

12: Does not appear.

13: Appears but not to be sele cted.

14: STANDBY command of the EJL is also supported. The default is 60 minutes. (Not

intended f or users.)

15: Does not appear on the panel nor status sheet. Only set in EJL.

16: Appears only in the GLike mode.

17: The selected value is not effective until the next warm boot or power on.

18: Appears only when the NLSP Bitmap 3 Plus ROM DIMM is installed.

19: Default for the North American version.

*24

*21

*21

20: Default for the versions other than the North American version.

21: Appears even though the optional unit is not installed. The counter is also cleared.

22: Either “Height” or “Pitch2 appears, depending on the selected font type;

- Constant pitch font: “Pitch”

- Proportional pitch font: “Height”

23: Appears only when an optional Font DIMM is installed in the optional ROM DIMM

Socket.

24: Appears when the maintenance menu is activated by the power-on service

function.

25: Appears and can be selected only when an optional 5-Bin Unit or 10-Bin Unit is

installed in the Sorter or MultiSort mode.

26: Does not appear on the panel nor status sheet but can be set in the EJL or PJL.

27: Appears and can be selected only when an optional 5-Bin Unit or 10-Bin Unit is

installed. After exiting the panel setting mode in which the selection has changed,

warm-boot is executed. Also, after the selection has changed, "Test Menu" is not

shown until the panel setting mode is terminated.

Product Description Panel Operation 37

Page 38

EPL-N2700 Revision A

1.4.2.2 User Setting Items which are not include in the Setting Menu

The items shown below are not included in the setting menu but can be

set by users. The values set by the users are not cleared by the

initialization through the control panel.

Setting Item Setting val ue Default Value Setting method

PrinterName

Device ID MFG

Device ID MDL

Device ID DES

Device ID CID

Mail Bin 1 - 10 NAME 24-byte data (Undefined) EJL

MP Tray

compensation

LC1 - LC3

compensation

Duplex compensation

32-byte character

string

32-byte character

string

32-byte character

string

32-byte character

string

32-byte character

string

-0.4 mm to 4.00 mm

(in 0.5 mm steps)

-0.4 mm to 4.00 mm

(in 0.5 mm steps)

-0.4 mm to 4.00 mm

(in 0.5 mm steps)

EPL-N2700

(Undefined) EJL

(Undefined) EJL

(Undefined) EJL

(Undefined) EJL

0.0 mm EJL

0.0 mm EJL

0.0 mm EJL

EJL, Printer Name

Command

1.4.2.3 Setti ng Item Descripti on

This section provides the information on the product-specific setting

item.

MP Tray Size

“Auto” is added and the North American version automatically detects

LT, HLT, LGL, EXE, GLG, GLT, and B paper sizes, while the versions

for areas other than North America detect the A3, A4, A5, IB5, LTR,

LGL, and F4 paper sizes. When “Auto” is selected, the following

conditions should be considered:

If the edge guide is set to any position other than automatic

selectable paper sizes, the paper size loaded is detected A3.

The automatically selected paper si ze is s hown i n Status Sheet and

EJL status.

MP Type

Selects the paper type for the MP Tray.

If “Paper Source” is set to “Auto”, the printer automatically selects the

paper source that matches the selected paper type from the paper

sources that currently store the selected paper size.

The MP Type selected during paper source selection is only specified

with the EJL command.

In printer modes that have no specification command, oper ations are

the same as when “Plain” is set for “MP Type”.

The EPL-N2700 has the setting item “Paper Type”, if the “Paper Type”

is set to “Normal” and “MP Tray” is set to “Transprnc” or Letterhead” , the

MP Type is also set to the engine side.

Product Description Panel Operation 38

Page 39

EPL-N2700 Revision A

LC1 to LC3 Type

These are basically same as the MP Type but because special paper

cannot be fed from the LC1 - LC3, “Letterhead”, “Bond”, “Tran sprnc”,

and “Labels” can not be selected.

Paper Source

The priority for selecting th e paper source is in the order of MP Tray >

LC1 > LC2 > LC3. (Applicable when “MP Tray Mode” is set to “Normal”.)

The combination of the optiona l paper s ources and the na me during t he

selection is as shown in the below:

Table 1-29. Combination of the Optional Paper Cassette and

Corresponding Names

MP Tray LC1 LC2 LC3 Remarks

Standard Standard --- --- No option installed

Standard Standard

Standard Standard

Standard Standard LCC * --- LCC installed

Standard Standard

500-sheet

cassette unit

500-sheet

cassette unit

500-sheet

cassette unit

---

500-sheet

cassette unit

LCC *

One 500-sheet cassette

unit installed

Two 500-sheet cassette

units installed

One 500-sheet cassette

unit and LCC installed

Table 1-30.

“Multibin” Settings and Corresponding Outbins Avail able

Mailbox Sorter Multisort Stacker

Without option Face-down Face-down Face-down Face-down

Face-down,

5-bin unit

10-bin unit

NOTES:

1. When an optional unit is installed, the standard Face-down can no be used. So,

“Face-down” in this case means another device.

2. If any item which can not be selected due to operation mode of the Outbin is

selected by the EJL or ESC/Page command, the selection is ignored,

3. If Face-down is selected in the 5-bin or 10-bin mailbox mode, paper is output to

Mailbox 1.

Mailbox 1,

Mailbox 2 - 5

Face-down,

Mailbox 1,

Mailbox 2 - 10

Face-down,

Sorter

Face-down,

Sorter

Face-down,

Sorter

Face-down,

Sorter

Face-down,

Stacker

Face-down,

Stacker

Output Tray Selection Specifications

<5-bin unit>

When “Multibin = Stacker” and “Outbin = Stacker” are selected:

The sequence of outbin destinat ions is Bin2 > Bi n3 > ---> Bin 5 >

Bin1.

*: Large Capacity Lower Cassette

The printer searches some consecutive empty bins in the order

of Bin 5 - Bin 2, and paper will be output to the empty bin which

Multibin

The values that can be selected for the “Out Bin” in the “Printing Menu”

vary depending on the selection made f or the “Multibin” in “Setup Menu”

<10-bin unit>

found last in the search.

When “Multibin = Stacker” and “Outbin = Stacker” are selected:

as shown in the following table:

The sequence of outbin destinations is Bin10 > Bin9 > - --> Bin 2

> Bin1

Product Description Panel Operation 39

Page 40

EPL-N2700 Revision A

The printer searches some consecutive empty bins in the order

of Bin 2, Bin 3 - - -, and paper will be output to the empty bin

which found last in the search.

When “Multibin = Sorter” and “Outbin = Sorter” are selected:

The sequence of ejected paper destination is Bin10 > Bin 9 > - Bin1.

When “Multibin = MultiSort” and “Outbin = Sorter” are selected:

If requested copies is 9 or less, ejection starts at Bin 2. If

requested copies is 10 or more, ejection starts at Bin 1, and

when all pages are ejected, next ejection st arts at Bin3 and then

in the following order; 4, 5, - - - 10, and 1.

<Items of restriction on the paper tray>

When the 5-bin or 10-bin is installed:

When the “Out Bin” is set to other than Face-down, “Outbin Select

Error” will occur if the printer is in any of the followi ng conditions:

Paper size is any of the A5, B5, GLT, HLT, EXE, MON, C10, DL,

C5, or custom.

ESC/PAGE command. The setting value is not stored in memory. If onjob data is too large to stor e, the printer shows the war ning “Collate was

disabled” and prints one set only.

Duplex (Printing Menu)

Selects Single of Duplex printing.

<Items of restriction on the duplex printing>