Page 1

®

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUALSERVICE MANUAL

Monochrome Laser Printer

EPSON EPL-N2050 Optional Units

SEPG99010

Page 2

Notice:

n All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

n The contents of this manual are subject to change witho ut notice.

n All efforts have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON

would greatly appreciate being informed of them.

n The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the conse quences

thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

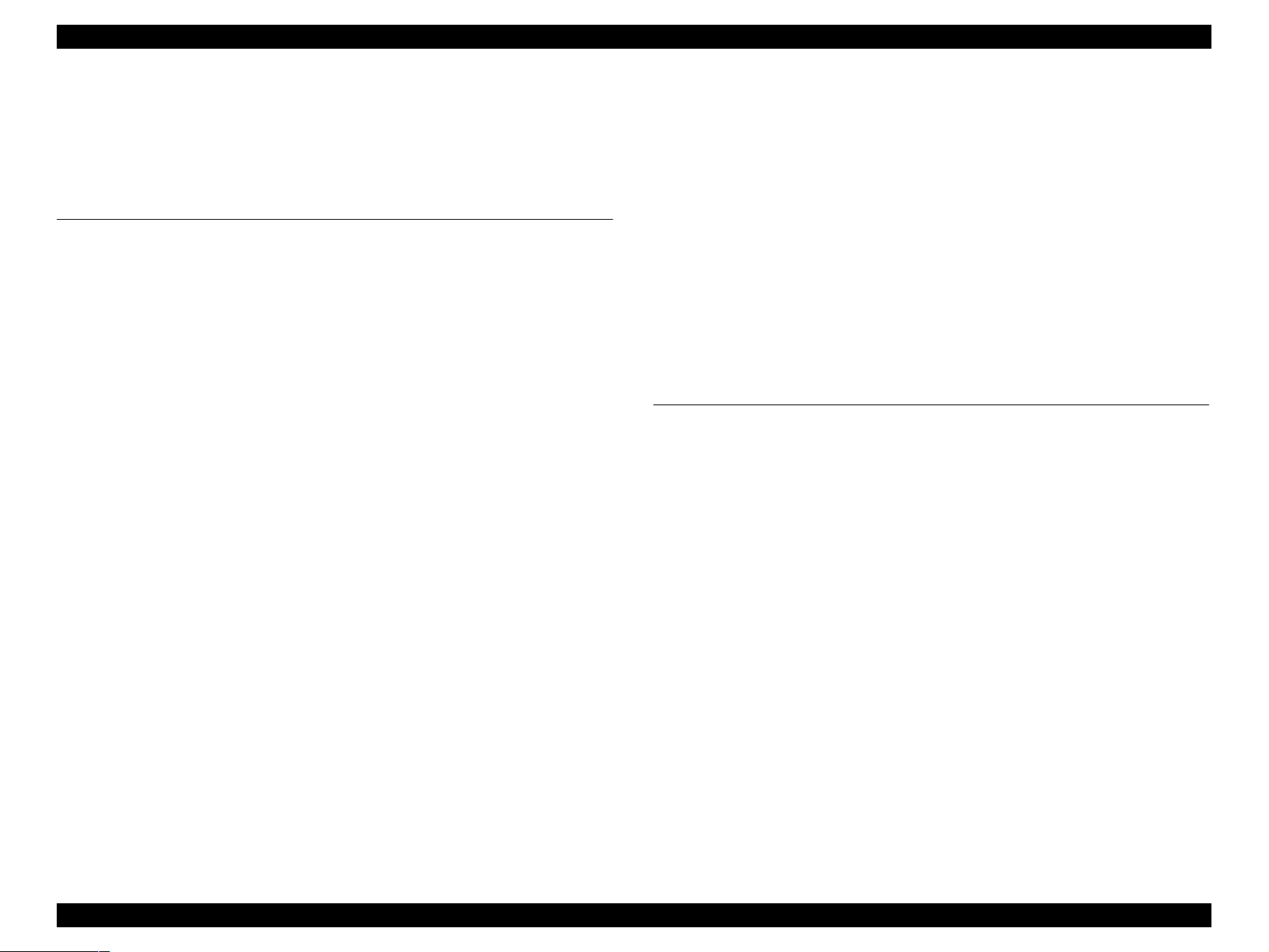

PRECAUTIONS

Precautionary notations through out the text are categorized relative to 1) Personal inj ury and 2) Damage to equipment.

W ARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in

serious or fatal personal injury. Great caution should be

exercised in performing procedures preceded by a

WARNING heading.

CAUTION

Signals a precaution which, if ignored, could result

in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintena nce and repai r procedures of EPL-N2050 Optional

Units. The instructions and procedur es incl uded herei n are int ended for t he experie nced repai r techni cians, and close at tention should be given to the

precautions on the preceding page. Chapters are organized as follows:

CHAPTER 1. Mulibin Unit

CHAPTER 2. Duplex Unit

CHAPTER 3. Shifter

CHAPTER 4. Envelope Feeder

CHAPTER 5. Large Capacity Paper Unit

Page 5

Revision Status

Revision Date of Issue

A December 2 , 1999 First Release

B January 13, 2000 Parts lists and exploded diagrams have been revised.

Description

Page 6

EPSON EPL-N2050 Optional Units Revision B

Contents

Chapter 1 Multibi n Unit

1.1 Installation and Removal of Multibin Unit ........................................ 10

1.1.1 Installation ................ ....... ...... ....... ....................................... ...... ... 10

1.1.2 Removal ....................................... ...... ....... ...... ....... ...... ................ 10

1.2 Specifications

1.2.1 Features .................... ....... ...... ....... ...... ....................................... ... 11

1.2.2 Basic Specification ............................ ....... ...... ....... ...... ....... ...... ... 11

1.2.3 Paper Specification ...................................................................... 12

1.2.4 Reliability, Durability, Serviceability .......................................... 13

1.2.5 Operating Conditions .................................................................. 13

1.2.6 Electrical Characteristics ............................................................. 13

1.2.7 Applicable Standards and Regulations ..................................... 13

1.2.8 External Dimension ..................................................................... 13

1.2.9 Operating Specification .............................................................. 14

1.3 Troubleshooting

1.3.1 If Paper Jam Occured Inside a Tray ........................................... 15

1.4 Disassembly and Ass embly ................................................................ 16

1.4.1 Preparation ......... ...... ....... ...... ....... ...... ....... ...... ....... ...... ................ 16

1.4.2 Notations in the Manual ............................................................. 16

1.4.3 Cover Left, Cover Top and Cover Right ..................................... 17

1.4.4 Chute Rear and Chute Assy Lower

(with 7-10, 24) ............................................................................ 18

1.4.5 Sensor Pass INT .................... ....... ...... ....... ...... ....... ...... ....... ...... ... 19

1.4.6 Tray Assy Multibin Unit 2 (with 36-38): Tray1-9 and

Tray Assy Multibin Unit 1 (with 37, 38, 42): Tray10 ................ 20

1.4.7 Panel Assy, PWBA LED, and Switch Main ................................. 22

1.4.8 Frame Assy LVPS ........................................................................ 23

1.4.9 PWBA Main .................................................................................. 25

1.4.10 Solenoid Assy Link (with 23-25) ............................................... 26

1.4.11 Sensor Stack Full ....................................................................... 28

1.4.12 Stopper Key Lock L .......................... ....... ...... ....... ...... ....... ...... ... 30

1.4.13 Gate ..... ....... ...... ...... ....... ...... ....... ...... ....................................... ... 31

1.4.14 Harness Assy MCU .................................................................... 32

....................................................................................... 11

.................................................................................. 15

1.4.15 Motor Bracket Assembly (with 19, 23, 24, 34) ......................... 33

1.4.16 Solenoid Assy R ........................................................................ 35

1.4.17 Belt Synchronous ...................................................................... 36

1.4.18 Stopper Key Lock R ................................................................... 38

1.4.19 Roll Assy Transport ................................................................... 39

1.4.20 Roll Exit ...................................................................................... 40

1.4.21 Solenoid Direction ..................................................................... 42

1.5 Parts List and Exploded Diagram

...................................................... 44

Chapter 2 Duplex Unit

2.1 Installation and Removal of Duplex Unit .......................................... 49

2.1.1 Installation ................................................................................... 49

2.1.2 Removal ....................................................................................... 49

2.2 Introduction

2.2.1 Preparation .................................................................................. 50

2.2.2 Precautions .................................................................................. 50

2.2.3 Notations in the Manual ............................................................. 50

2.3 Disassembly and Assembly

2.3.1 Chute Assy Turn DUP ................................................................. 51

2.3.2 Chute Assy Connector DUP ........................................................ 52

2.3.3 Chute Assy Upper DUP ............................................................... 53

2.3.4 Cover Drive DUP .......................................................................... 54

2.3.5 Roll Assy DUP: Rear .................................................................... 55

2.3.6 Roll Assy DUP: Middle ................................................................ 57

2.3.7 Roll Assy DUP: Front ................................................................... 59

2.3.8 Stopper Belt DUP ........................................................................ 61

2.3.9 Motor Assy DUP .......................................................................... 62

2.3.10 Belt Synchronous ...................................................................... 63

2.3.11 Sensor Photo IN-H (L) ............................................................... 64

2.3.12 PWBA DUP ................................................................................. 65

2.3.13 Cover DUP .................................................................................. 66

2.3.14 Sensor Assy DUP ...................................................................... 67

......................................................................................... 50

................................................................ 51

6

Page 7

EPSON EPL-N2050 Optional Units Revision B

2.4 Parts List and Exploded Diagram ....................................................... 68

Chapter 3 Shifter

3.1 Installation and Removal of the Shifter ............................................ 72

3.1.1 Installing the Shifter .................................................................... 72

3.1.2 Shifter Removal ........................................................................... 72

3.2 Introduction

3.2.1 Preparation ......... ...... ....... ...... ....... ...... ....... ...... ....... ...... ................ 73

3.2.2 Precaution ............................. ....... ...... ....... ...... ............................. 73

3.2.3 Notations in the Text ................................................................... 73

3.2.4 Tray Exit Assy .............................................................................. 74

3.2.5 Spring Tray .................................................................................. 75

3.2.6 Tray Exit ....................................................................................... 76

3.2.7 Link Weight .................................................................................. 77

3.2.8 Cover Rear .................................................................................... 78

3.2.9 Chute Exit Inner Assy .................................................................. 79

3.2.10 Cover Lower ............................................................................... 80

3.2.11 PWBA OCT ................................................................................. 81

3.2.12 Motor Drive Assy ................ ....... ...... ....... ...... ....... ...... ....... ...... ... 82

3.2.13 Eliminator ...................... ...... ....... ...... ....... ...... ....... ...... ................ 83

3.2.14 Solenoid Direction ..................................................................... 84

3.2.15 Sensor Assy Exit OCT ............................................................... 85

3.2.16 Actuator Full Stack .................................................................... 86

3.2.17 Sensor Full Stack ....................................................................... 87

3.2.18 Roll Assy Offset ......................................................................... 88

3.2.19 Roll Assy MID OCT .................................................................... 90

3.2.20 Chute Exit Inner ......................................................................... 92

3.2.21 Offset Assy ................................................................................. 93

3.2.22 Motor Offset Assy ...................................................................... 95

3.2.23 Sensor OCT Home ..................................................................... 96

3.3 Parts List and Exploded Diagram

......................................................................................... 73

....................................................... 97

Chapter 4 Envelope Feeder

4.1 Installation and Removal of Envelope Feeder ................................ 101

4.1.1 Installation ................................................................................. 101

4.1.2 Removal ..................................................................................... 101

4.2 Introduction

4.2.1 Preparation ................................................................................ 102

4.2.2 Precautions ................................................................................ 102

4.2.3 Notations in Text ....................................................................... 102

4.3 Disassembly and Assembly

4.3.1 Chute Top ................................................................................... 103

4.3.2 Roll Pinch and Shaft Pinch ....................................................... 104

4.3.3 Arm Weight ................................................................................ 105

4.3.4 Cover Bottom ............................................................................. 106

4.3.5 Tray Extension ........................................................................... 107

4.3.6 Sensor Assy Exit ENV ............................................................... 108

4.3.7 Kit Roll Assy Retard ................................................................... 109

4.3.8 Cover Gear ................................................................................. 110

4.3.9 Clutch ELEC 29 ........................................................................... 111

4.3.10 Roll Assy Trans ........................................................................ 112

4.3.11 Roll Assy Bottom ..................................................................... 113

4.3.12 Roll Pinch ENV ......................................................................... 115

4.3.13 Belt Feed .................................................................................. 116

4.3.14 Actuator N/P Envelope ............................................................ 117

4.3.15 Sensor Photo: No Paper ......................................................... 118

4.3.16 Roll Assy Feed 1 ...................................................................... 119

4.3.17 Roll Assy Feed 2 ...................................................................... 121

4.3.18 Roll Feeder: Roll Feed 1 .......................................................... 122

4.3.19 Roll Feeder: Roll Feed 2 .......................................................... 123

4.3.20 Connector ENV ........................................................................ 124

4.3.21 PWBA ENV ............................................................................... 125

4.4 Parts List and Exploded Diagram

....................................................................................... 102

.............................................................. 103

.................................................... 126

7

Page 8

EPSON EPL-N2050 Optional Units Revision B

Chapter 5 Large Capacity Paper Unit

5.1 Installation and Removal of the Large Capacity Paper Unit ......... 130

5.1.1 Installing the Large Capacity Paper Unit ................................. 130

5.1.2 Large Capacity Paper Unit Removal .................... ...... .............. 130

5.2 Introduction

5.2.1 Preparation ......... ...... ....... ...... ....... ...... ....... ...... ........................... 131

5.2.2 Precaution ............................. ....... ...... ....... ...... ....... .................... 131

5.2.3 Notations in the Text ................................................................. 131

5.3 Disassembly and Ass embly

5.3.1 Bracket Assy OPT Gear ............................................................. 132

5.3.2 Plate Top F ......... ...... ....... ...... ....... ...... ....... ...... ....... ...... ....... ...... . 133

5.3.3 Harness Assy Size Option ........................ ...... ....... ...... ....... ...... . 134

5.3.4 PWBA Size Option ..................................................................... 136

5.3.5 Harness Assy Size M ................................................................ . 137

5.3.6 Housing Side R .......................................................................... 138

5.3.7 Feeder ....................... ....... ...... ....... ...... ....... ...... ....... ...... ....... ....... 139

5.3.8 Housing Side L ........................................................................... 140

5.3.9 Size Sensor Housing (with 8-12) .............................................. 141

5.3.10 Housing Assy Size Sensor (with 5-13) ................................... 142

5.3.11 Roll Assy Turn .......................................................................... 143

5.3.12 Spring Chute ............................................................................ 145

5.3.13 Actuator N/P ............................................................................. 146

5.3.14 Sensor Photo: Face Control, Low Paper ................................ 147

5.3.15 Feeder Assy ................... ...... ....... ...... ....... ...... ....... ...... ....... ...... . 148

5.3.16 Roll Assy ........................ ...... ....... ...... ....................................... . 150

5.3.17 PWBA Feeder ........................................................................... 151

5.3.18 Clutch Assy Feed ..................................................................... 152

5.3.19 Socket ...................................................... ...... ....... ...... ....... ...... . 154

5.4 Parts List and Exploded Diagram

....................................................................................... 131

.............................................................. 132

..................................................... 155

8

Page 9

MULTIBIN UNIT

CHAPTER

1

Page 10

EPSON EPL-N2050 Optional Units Revision B

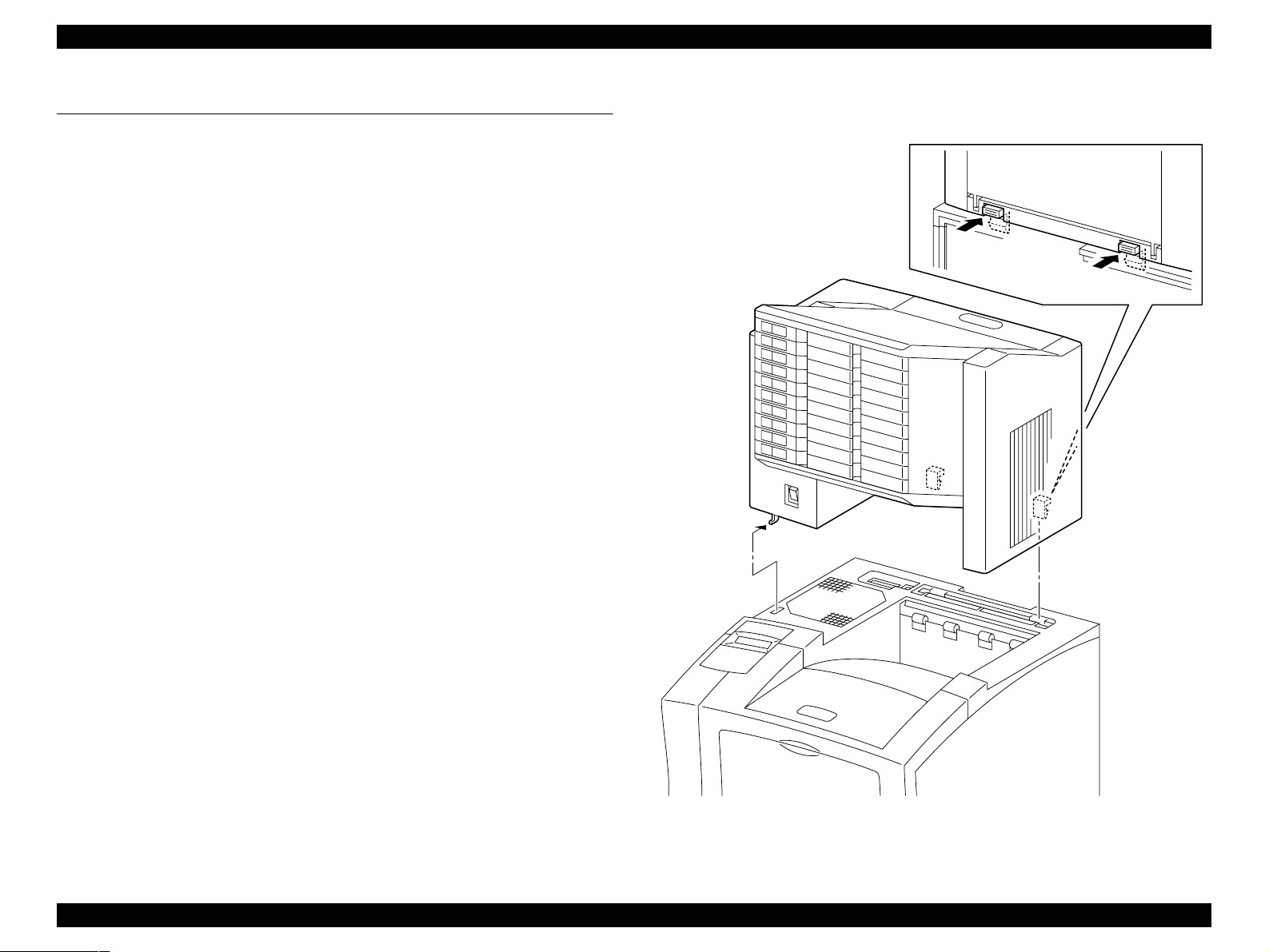

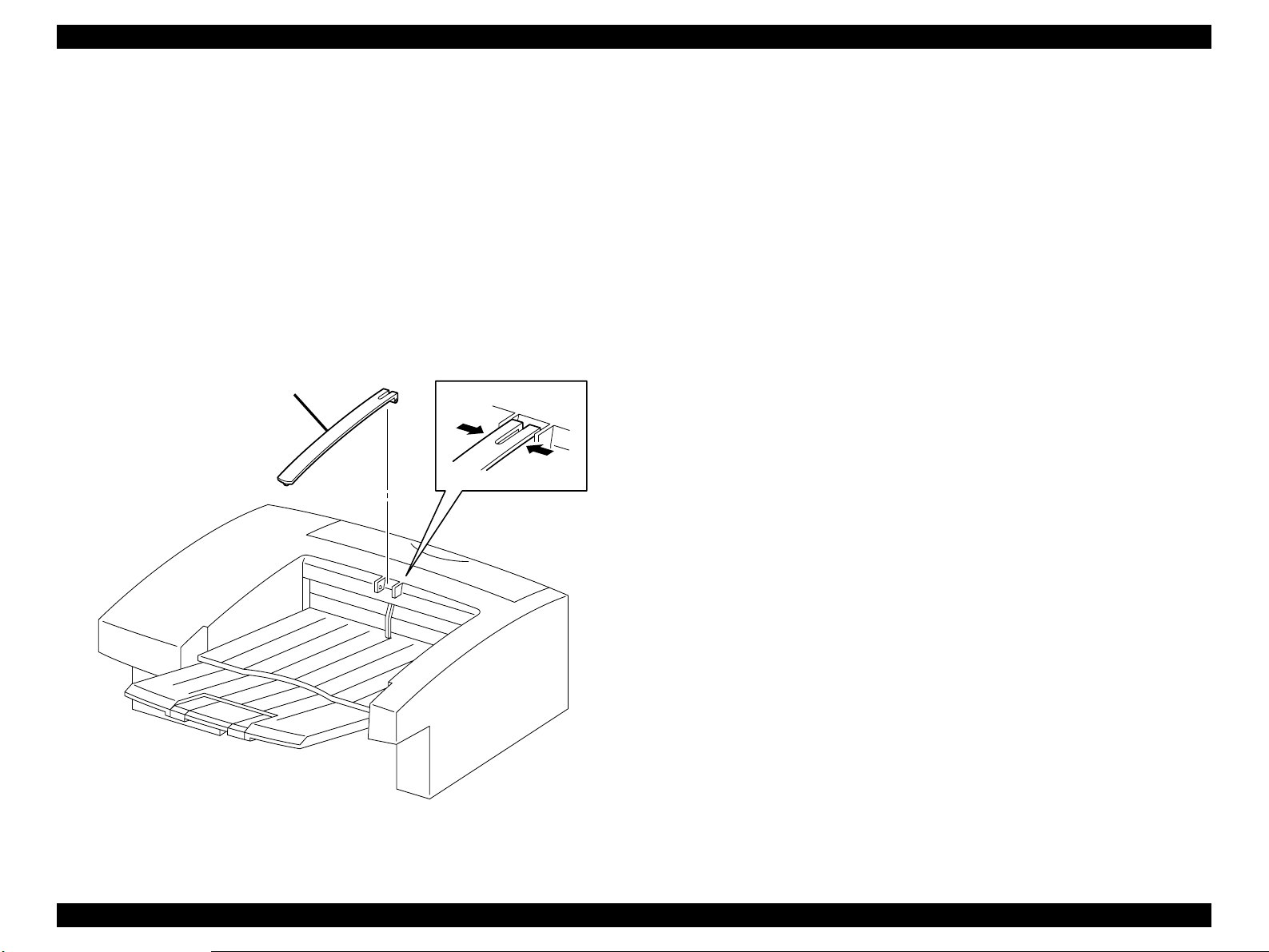

1.1 Installation and Removal of Multibin Unit

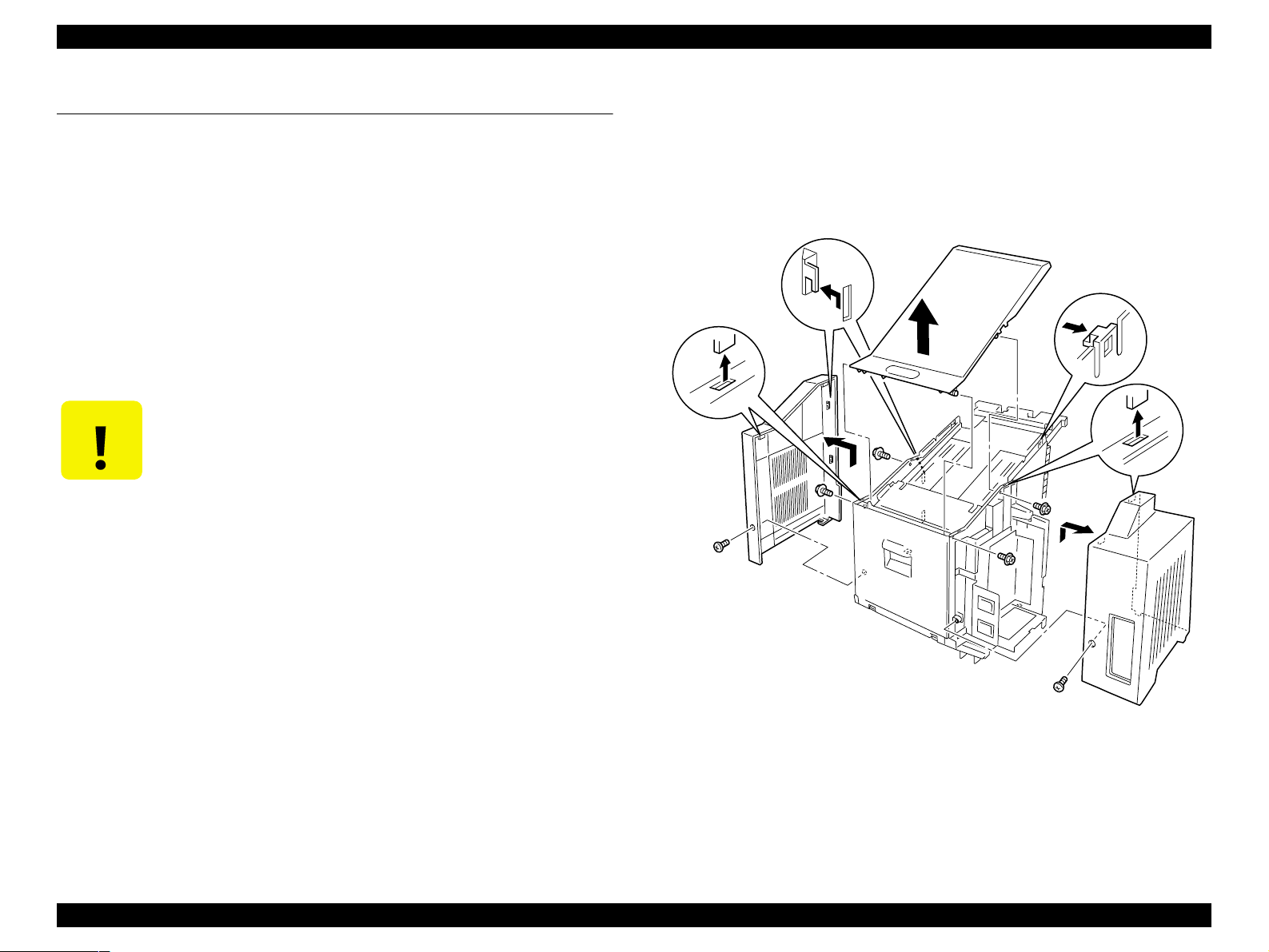

1.1.1 Installation

1. Switch off the printer’s power.

2. Place one hand under the Multibin Unit Bins and the other hand on the

Chute Rear handle.

3. Position the Multibin Unit over the printer.

4. Slide the positioning hook into the slot on the printer Cover Assy Top.

5. Lower the rear of the Multibin Unit onto the Cover Assy Top, carefully

lining up the P/J at the bottom rear of the Multibin Unit with the

corresponding P/J in the open Cover Option hole.

6. Press down on the rear of Multibin Unit until it snaps into place on the

Cover Assy Top.

7. Reconnect all AC power cords to the rear of the Multibin Unit.

1.1.2 Removal

1. Make sure the printer is off.

NOTE: Place a thick plate under the bottom plate of Multibin Unit to

protect metallic hook and the Chute Lower and the P/J

connector at the bottom of Multibin Unit.

2. Disconnect all AC power cords from the rear of the Multibin Unit.

3. Press the two latches that are located at the bottom-rear of the Multibin

Unit while you lift up the rear of the Multibin Unit.

4. Slide the positioning hook out of the Cover Assy Top and remove the

Multibin Unit.

NOTE: Mount the Cover Option on t he Cover Assy Top, if the Mu ltibin

Unit is removed from the printer for a long time.

Figure 1-1. Multibin Unit

Multibin Unit Installation and Removal of Multibin Unit 10

Page 11

EPSON EPL-N2050 Optional Units Revision B

1.2 Specifications

1.2.1 Features

o The Mult ibin Unit is installed on top of the printer. This Unit is

electrically connected to the printer by connectors, and when the

printer is switched on, it can automatically detect if the Multibin Unit

is installed, and each bin is full or not full, on condition t hat the switch

of the Multibin Unit is on before the printer is turned on.

o The Mu ltibin Unit has independ ent drive and logic. The switching flap

installed in the upper part of the printer switches the paper path

between the printer output tray and the Multibin Unit.

o Each bin can hold up to 45 sheets of paper, and the entire Unit can

hold a total of 450 sheets (See Table 1-1 on the right).

o Bins are drawer-type trays that are locked by solenoid and lock levers

all the time. All ten bins can be unlocked by pressing the Multibin

Open button.

o Pass word to open e ach bin can be s et. Once pa sswords ar e set for the

bins, only the authenticated bin can be unlocked.

1.2.2 Basic Specification

o Name Multibin Unit

o Paper Output Method

Straight Output, Switching Flap

o Installation Installed on top of the printer exit (desk top type

installed by users)

o Drive Method Built-in Motor Drive

o Interface Transmit: Installation of the Unit, bin full,

bin open/closed.

Receive: Signal to determine which bin paper

should be output to.

o Paper Type / Size Standard paper, normal paper (60-105g/m

16-28lb), special paper, and A4 or Letter (LT)

o Capacity

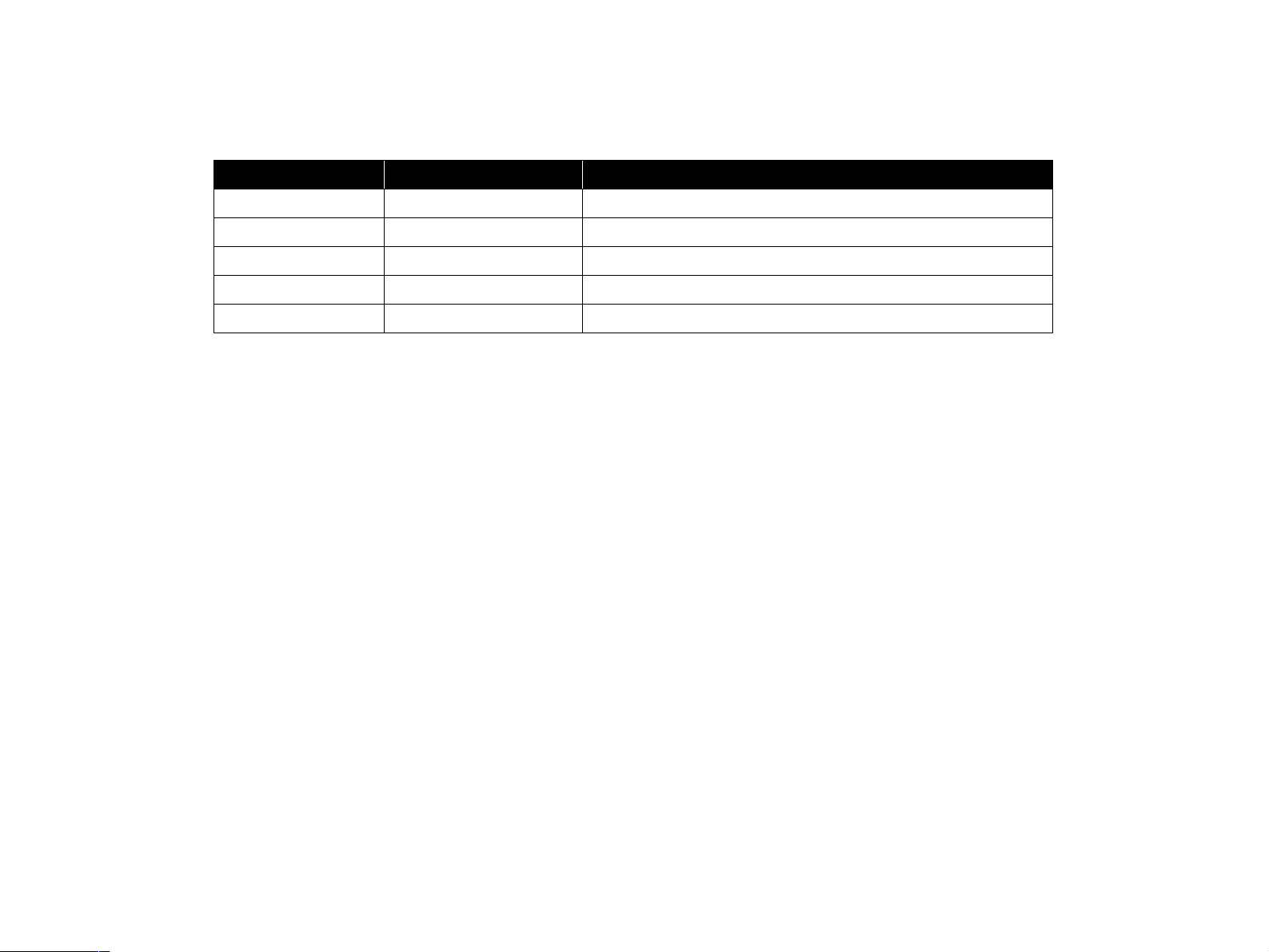

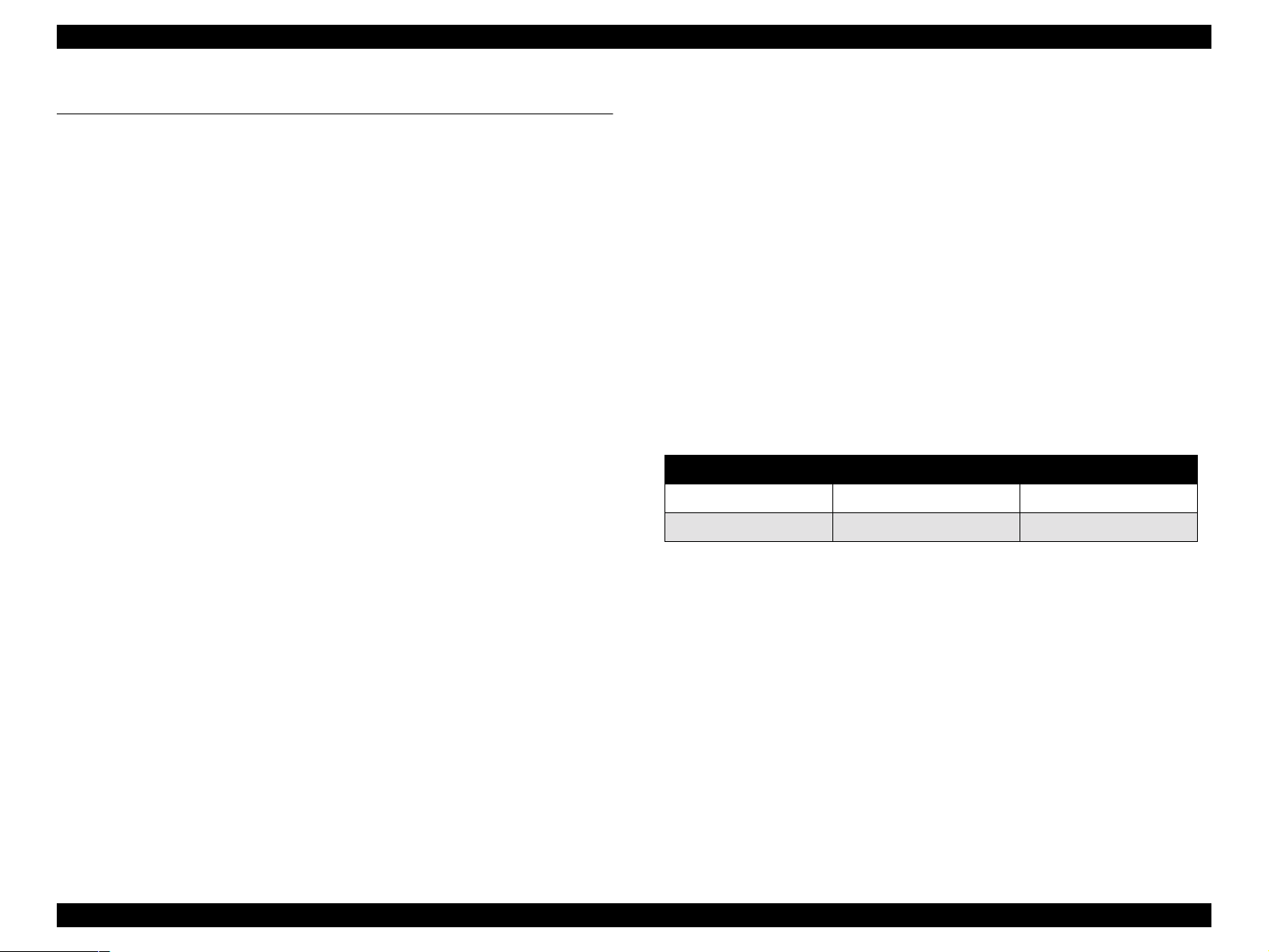

Table 1-1. Capacity

Condition Capacity of Each Bin Total Capacity (10 bins)

10°C/30% to 27°C/65% 45 sheets 450 sheets

28°C/85% 30 sheets 300 sheets

2

:

NOTE: When standard paper is used.

o Paper Fe ed Standard Center-line reference for each paper size

o Detection Structure

n

Paper Full: Automatic detection by Photo Sensor + Actuator

n

Bin Open/Closed: Automatic detection by Micro Switch

o Dimension 403mm (W) x 360mm (D) x 364 mm (H)*

*Protrusions at the bottom of the Unit are not

included.

o Weight 9.2 kg

o Acoustic Noise Max. of 51.5db (A) when instald on the printer.

(Based on ISO7779)

Multibin Unit Specifications 11

Page 12

EPSON EPL-N2050 Optional Units Revision B

o Power Consumption

Table 1-2. Power Consumption

100V/115V 220V/240V

Maximum 74W 69W

Average (Continuous Printing) 36W 37W

All bins closed* 8W 12W

Average

(Stand-by)

*When Energy Star Mode is used.

1 bin open 17W 20W

5 bin open 33W 34W

All bins open (TBD) (TBD)

o Power Supply

Universal type which meets the following specifications:

100V Model: 100V/120V 90V-140V (50/60Hz ±3%)

200V Model: 220V/240V 198V-264V (50Hz ±3%)

1.2.3 Paper Specification

o Supported Paper Type

n

Standard Paper: LT: Xerox-4024

A4: Xerox-RX80, FX-L

n

Normal Paper: 60-105g/m2 (16-28lb)

Commonly used copy paper, bond paper, and

recycled paper

n

Special Paper: Labels, OHP Films

o Supported Paper Size

n

Letter (216 x 279mm: 8.5 x 11”)

n

A4 (210 x 297mm)

NOTE: Use of paper other than the above size will cause paper jam,

or such paper cannot be removed from the paper exit tray

easily.

It is therefore necessary to reject such paper the controller

operation.

Multibin Unit Specifications 12

Page 13

EPSON EPL-N2050 Optional Units Revision B

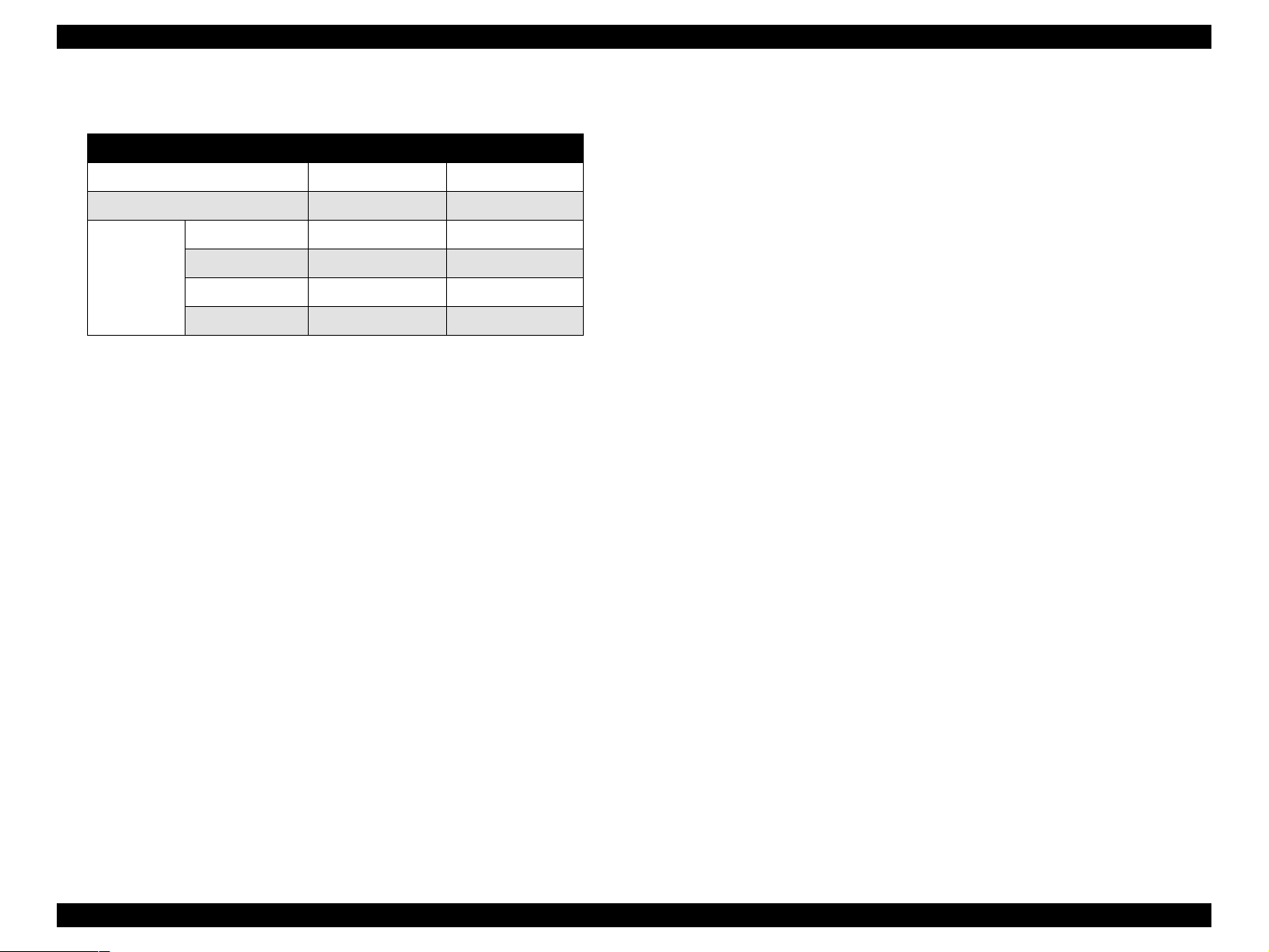

1.2.4 Reliability, Dur ability, Serviceab i li ty

o MPBF 300,000 pages

o Printing Volume Maximum 25,000 pages/month

Average 5,000 pages/month

o Paper Feeding Reliability

o Jam Rate (Condition: 18-27°C/20-65%)

One-side Printing Duplex Printing

Standard Paper 1/5000 1/3333

o Durability 600,000 pages or 5 years, whichever comes

earlier.

o Serviceability MTTR: Within 30 minutes

1.2.5 Operating Conditions

Refer to Chapter 1 of the printer’s Service Manual.

1.2.6 Electrical Characteristics

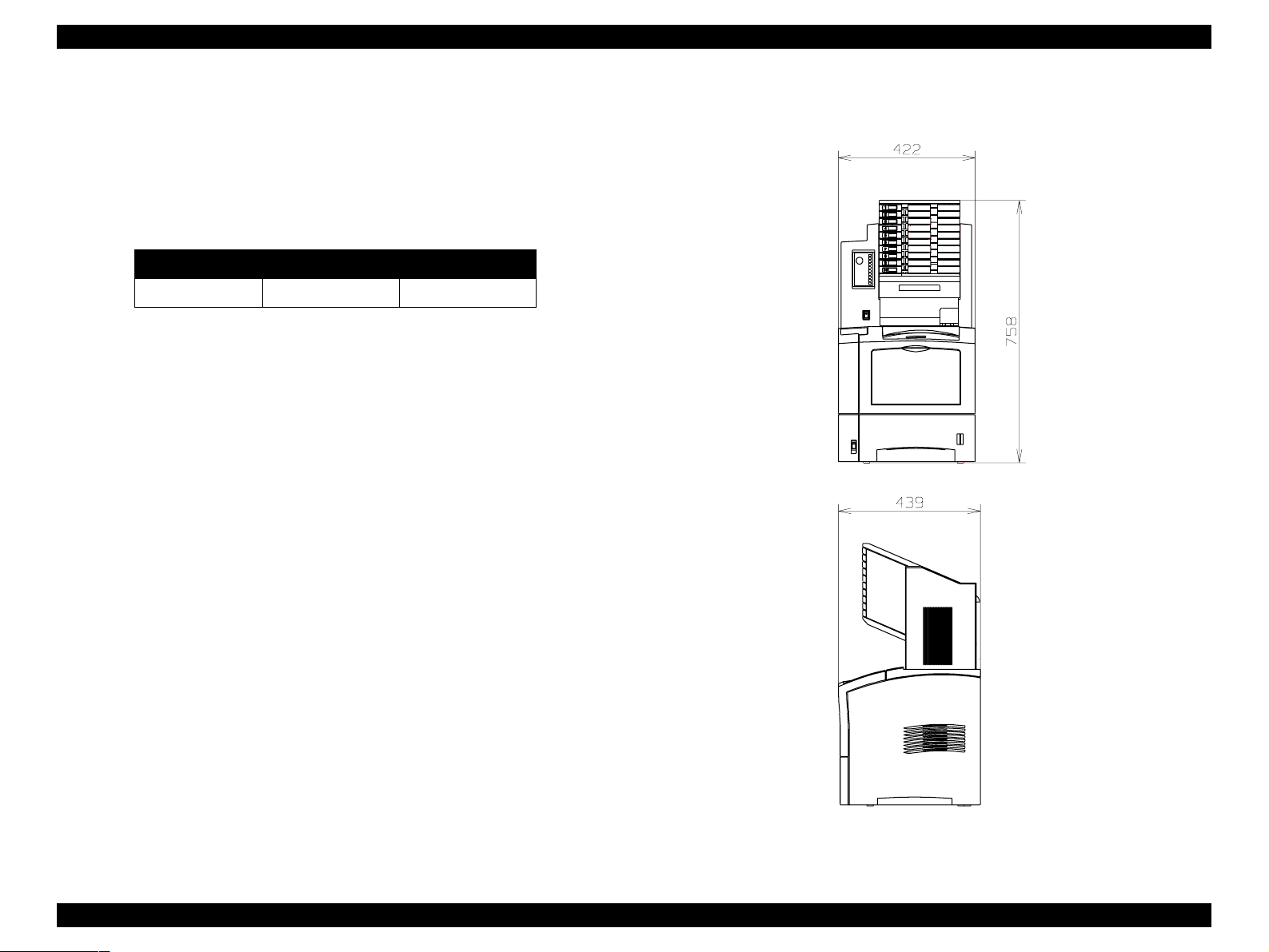

1.2.8 External Dimension

mm

o Leak Current Maximum of 3.5mA (100V/115V)

Maximum of 3.5mA (220V/240V)

Refer to Chapter 1 of the printer’s Service Manual for other items.

1.2.7 Applicable Standards and Regulations

When connected to the printer;

o Safety Regulations (Laser Radiation)

None

Refer to Chapter 1 of the printer’s Service Manual for other items.

Figure 1-2. External Dimension

Multibin Unit Specifications 13

Page 14

EPSON EPL-N2050 Optional Units Revision B

1.2.9 Operating Specification

1.2.9.1 How to Open Bins

1. Display is changed to user authentication mode when the Open button on

the Multibin Unit is pressed.

Display: Enter Password = XXXX

NOTE: When the Open button on the Multibin Unit is pressed, the

LED of the bin(s) for which password is disabled goes on. At

this time, this bin(s) can be opened. If there is no bin for which

password is enab led , Enter Password=XXXX is not displayed,

and Open Multibin Unit is displayed.

2. Enter password by pressing 4 switches, and all bins which matched the

password will open. The LED of the bin(s) that can be opened goes o n,

and Open Multibin Unit is displayed on the LCD.

If the entered password is incorrect, Password Error is displayed for two

seconds, and Enter Pasword=XXXX is once again displayed afterwards.

3. The bin(s) will be automatically locked 20 seconds after the Open button

is pressed. The Unit goes Off-Line when the Open button is pressed, and

for the next 20 seconds, no operation on the panel except for entering

password is possible.

1.2.9.2 Period in which the Multibin Unit can be opened

o Can be opened When the printer is in a status of lower priority

than XXX Error yyy.

o Cannot be opened During the printer is in SelecType mode, or

during printing.

NOTE: Bins can be opened when the Multibin Unit is not installed on

the printer (mechanical specification).

1.2.9.3 Display of Each Bin’s LED

o Paper Loaded: -

o Locked: Off

o Unlocked: On

o Full: Flash

The bin which is opened at that time will be locked immediately after it is

closed.

If no password is entered and 20 seconds passed after Enter

Password=XXXX is displayed, LCD display returns to the normal state.

NOTE: Bins can be opened during the following period:

20 seconds minus time required from the moment the Open

button is pressed until the password is authenticated.

From the moment the password is authenticated until the bin

will automatically locked, no operation on the panel is

possible.

Multibin Unit Specifications 14

Page 15

EPSON EPL-N2050 Optional Units Revision B

1.3 Troubleshooting

1.3.1 If Paper Jam Occured Inside a Tray

1. Switch off the Multibin Unit and disconnect the power cable.

2. Remove the Unit from the printer.

3. Remove the housing parts (Cover Left, Cover Right, and Cover Top) by

releasing the screws.

4. Remove the Stopper Tray (L & R).

5. Unlock the corresponding Stopper Key by releasing the solenoid.

6. Draw out the corresponding tray and take out the jammed paper.

7. Reassemble and install the Unit.

CAUTION

This operation is for service personnel only.

Figure 1-3. Cover Left, Cover Right, Cover Top

Multibin Unit Troubleshooting 15

Page 16

EPSON EPL-N2050 Optional Units Revision B

1.4 Disassembly and Assembly

This section contains the removal and assembly procedures for the Multibin Unit option.

1.4.1 Preparation

Before you begin any Removal and Assembly Procedure;

1. Switch OFF the main power.

2. If this manual instructs you to remove the Multibin Unit from the base

engine, place the Multibin Unit on a stable worktable.

3. Unless otherwise specified, position the Multibin Unit so the rear,

including the Low Chute and the P/J connector, hang over the edge of the

worktable.

4. Wear an electrostatic discharge wrist strap to protect sensitive Multibin

Unit parts from damage.

1.4.2 Notations in the Manual

o Arrows in an illustrat ion show direct ion of m ovement when r emoving

a component.

o Slas hes in a p art name indicate that n ume rous com ponents sha re the

same heading and function. For example, “Gears In/Feed/O ut” refers

to Gear In, Gear Feed, and Gear Out.

Multibin Unit Disassembly an d A s se mbly 16

Page 17

EPSON EPL-N2050 Optional Units Revision B

1.4.3 Cover Left, Cover Top and Cover Right

1.4.3.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the screw (located at the rear of the Cover Left) that is securing

the Cover Left to the Multibin Unit.

3. Slide the Cover Left up, and remove it. (See “Cover Left, Cover Top and

Cover Right” on page 17)

4. Remove the screw (located at the rear of the Cover Right) that is securing

the Cover Right to the Multibin Unit.

5. Slide the Cover Right up, and remove it.

6. Remove the four screws that secure the Cover Top to the Multibin Unit.

7. Open the Chute Rear.

8. Open the Stopper Key Lock R, and push a screwdriver into a square hole

in the Stopper Key Lock R.

9. Press the Solenoid Assy Link to unlock the Multibin Unit Bins and pull out

the top Bin.

10. Release the two Cover Top latches (accessed through the open Bin), and

carefully lift the front of the Cover Top off of the Multibin Unit.

6. Use four screws to secure the Cover Top to the Multibin Unit.

7. Position the Cover Left at the top of the right side of the Multibin Unit.

8. Slide the Cover Left down, repositioning as necessary to clear the LCD

Panel at the front, and the AC receptacles at the rear.

9. Use one screw to secure the Cover Left to the Multibin Unit.

10. Position the Cover Right at the top of the left side of the Multibin Unit.

11. Slide the Cover Right down.

12. Use one screw to secure the Cover Right to the Multibin Unit.

13. Close the Chute Rear.

14. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

11. Remove the Cover Top. (See “C over Left, Cover Top and Cover Right” on

page 17)

1.4.3.2 Assembly

1. Remove the screwdriver wedging open Stopper Key Lock R and allow the

Lock to close.

2. Open the Chute Rear.

3. Position the rear of the Cover Top at the rear of the Multibin Unit.

4. Snap the rear into place first, the lower the Cover Top onto the Multibin

Unit.

5. Press down on the Cover Top until it snaps into place.

Multibin Unit Disassembly an d A s se mbly 17

Figure 1-4. Cover Left, Cover Top, Cover Right

Page 18

EPSON EPL-N2050 Optional Units Revision B

1.4.4 Chute Rear and Chute Assy Lower

(with 7-10, 24)

1.4.4.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left and Cover Right. (See “Cover Left, Cover Top and

Cover Right” on page 17)

3. Position the Multibin Unit so the rear of the Multibin Unit hangs over the

edge of the worktable.

4. Open the Chute Rear.

5. Remove the screw that is securing the Support Tape to the Chute Rear.

6. Remove two screws securing the Eliminator S to the Chute Assy Lower,

and remove the Eliminator S.

7. Remove two screws securing the Eliminator to the Chute Assy Lower,and

remove the Eliminator.

8. Close the Chute Rear.

9. Remove the two screws (one at each end of the Chute Assy Lower) that

are securing the Chute Assy Lower to the Multibin Unit.

6. Secure the Eliminator S to the Chute Assy Lower with two screws.

7. Use one screw to secure the Support Tape to the Chute Rear.

8. Close the Chute Rear.

9. Reinstall the Cover Left and Cover Right. (See “Cover Left, Cover Top and

Cover Right” on page 17)

10. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

10. Remove the Chute Assy Lower. (See “Chute Rear and Chute Assy Lower (with 7-10, 24)” on page 18)

11. Remove the Chute Rear.

1.4.4.2 Assembly

1. Reinstall the Chute Rear (See the illustration for correct positioning). (See

“Chute Rear and Chute Assy Lower (with 7-10, 24)” on page 18)

2. Reinstall the Chute Assy Lower (See the illustration for correct

positioning).

3. Use two screws to secure the Chute Assy Lower to the Multibin Unit.

4. Open the Chute Rear.

5. Secure the Eliminator to the C hute Assy Lower with two screws.

Multibin Unit Disassembly an d A s se mbly 18

Figure 1-5. Chute Rear and Chute Assy Lower

Page 19

EPSON EPL-N2050 Optional Units Revision B

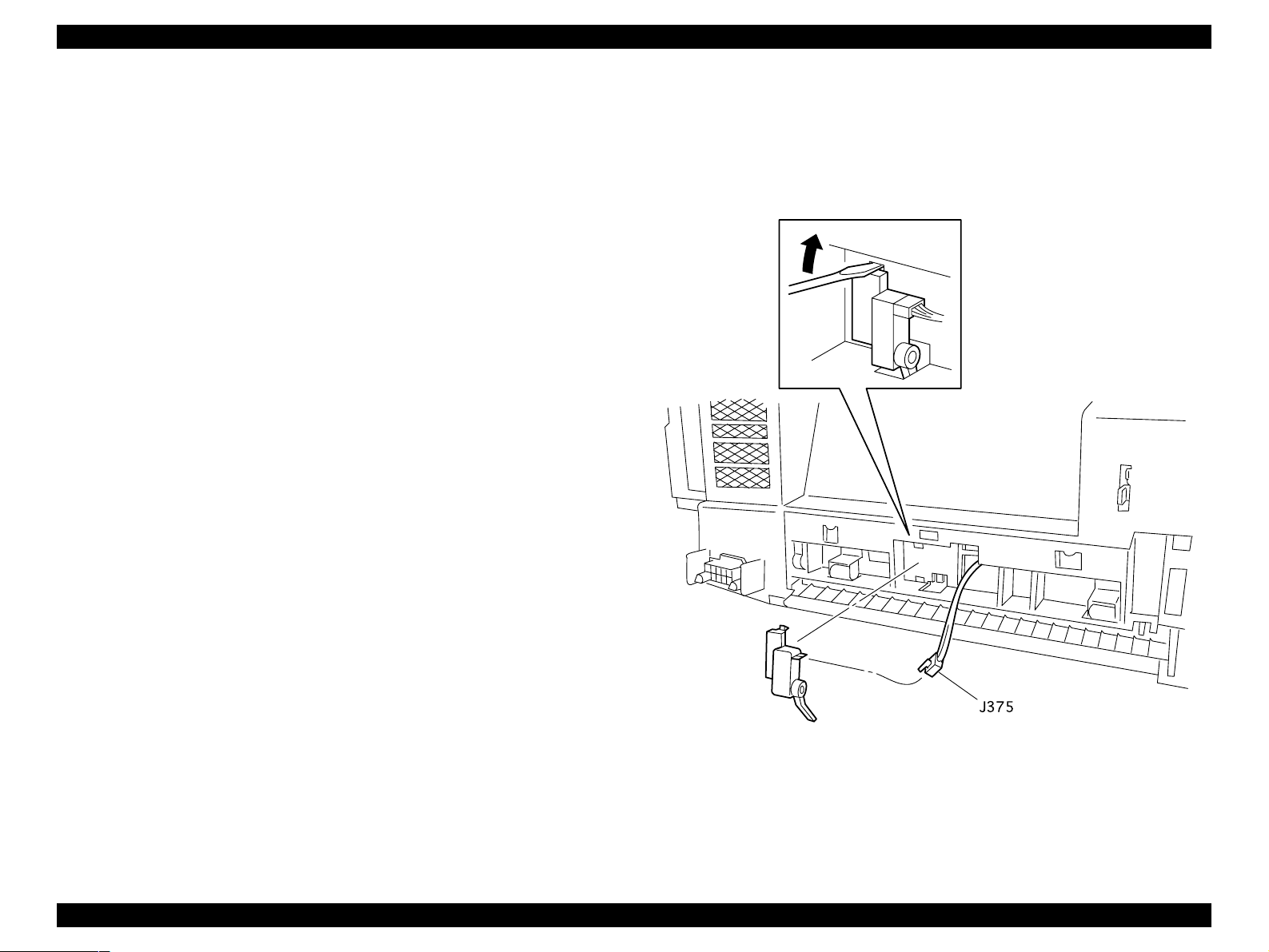

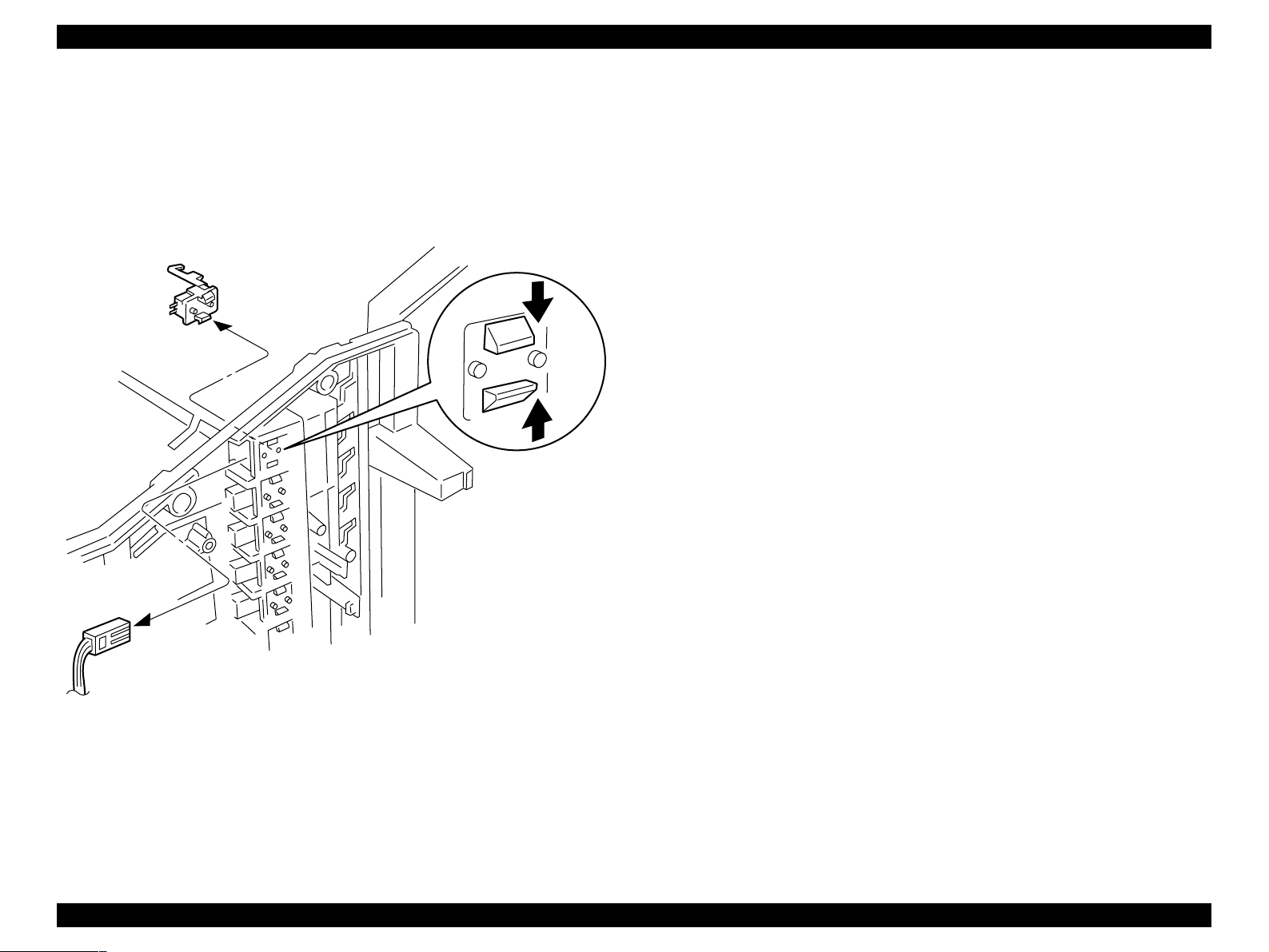

1.4.5 Sensor Pass INT

1.4.5.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Position the Multibin Unit so it is resting on the Chute Rear.

3. Disconnect J375 from the Sensor Pass INT.

4. Use a small, flat screwdriver blade to pry the upper part of the Sensor

Pass INT away from the Multibin Unit, and remove the Sensor.

1.4.5.2 Assembly

1. Position the Multibin Unit so it is resting on the Chute Rear.

2. Reinstall the lower part of the Sensor Pass INT (the bottom clip and the

sensor actuator arm) into the corresponding holes in the Multibin Unit.

3. Press the upper part of the Sensor against the Multibin Unit.

4. Use a small, flat screwdriver blade to press down on the upper clip so it

slips into the corresponding hole in the Multibin Unit.

5. Make sure the Sensor actuator moves freely and does not bind.

6. Reconnect J375.

7. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

Figure 1-6. Sensor Pass INT

Multibin Unit Disassembly an d A s se mbly 19

Page 20

EPSON EPL-N2050 Optional Units Revision B

1.4.6 Tray Assy Multibin Unit 2 (with 36-38): Tray1-9 and

Tray Assy Multibin Unit 1 (with 37, 38, 42): Tray10

1.4.6.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Left, Right, and Cover Tops.

3. Remove the two screws that are securing the Stopper Tray: Left to the

Multibin Unit frame.

4. Squeeze the latches at the top of the Stopper and remove the Stopper

Tray: Left from the frame.

5. Remove the two screws that are securing the Stopper Tray: Right to the

Multibin Unit frame.

6. Squeeze the latches at the top of the Stopper and remove the Stopper

Tray: right from the frame.

7. Remove the four screws that secure the Plate Assy Top to the Multibin

Unit.

8. Keep the Chute Rear closed during the remainder of this Removal

Procedure.

NOTE: With the Plate Assy Top removed, the ten Gates and ten Roll

Exits tend to slip out of place unless the Chute Rear is closed.

9. Press in on the Solenoid Assy R plunger to open the Stopper Key Lock R.

1.4.6.2 Assembly

1. Open the Chute Rear.

2. Slide the first Tray half-way into the lowest vacant slot in the Multibin

Unit.

3. Lift the Link Assy Paper L and Link Assy Paper R out of the way.

4. Slide the first Tray all the way into the slot, making sure the Sensor S tack

Full actuator does not hang up on the edge of the Tray.

5. Lower one Link Assy Paper L and one Link Assy Paper R onto the bed of

the reinstalled Tray.

6. Slide the next Tray all the way into the slot, making sure the Sensor Stack

Full actuator does not hang up on the edge of the Tray.

7. Lower one Link Assy Paper L and one Link Assy Paper R onto the bed of

the reinstalled Tray.

8. Repeat this process until all of the Trays are reinstalled in the Multibin

Unit.

9. Remove the screwdriver wedging open Stopper Key Lock R and allow the

Lock to close.

10. Reinstall the Plate Assy Top.

11. Use four screws to secure the Plate Assy Top to the Multibin Unit.

10. Use a screwdriver to wedge the Stopper Key Lock R open.

11. Starting with the top Solenoid Assy L, press in and hold the Solenoid

plunger as you slide out the top Multibin Unit tray.

12. Repeat step 10 until you have rem oved all, or the necessary, Multibin Unit

trays.

NOTE: Do not fully tighten the screws at this time.

12. Carefully examine the Gates and Roll Exits.

13. Replace any Gates or Roll Exits that may have been dislodged during Tray

removal or reinstallation.

14. Once all of the Gate and Roll Exits are in place, tighten the four screws

that secure the Plate Assy Top to the Multibin Unit.

15. Reinstall the Stopper Tray: right into the cutouts in the Multibin Unit

frame.

Multibin Unit Disassembly an d A s se mbly 20

Page 21

EPSON EPL-N2050 Optional Units Revision B

16. Use two screws to secure the Stopper Tray: right.

17. Reinstall the Stopper Tray: left into the cutouts in the Multibin Unit frame.

18. Use two screws to secure the Stopper Tray: left.

19. Reinstall the Left, Right, and Cover Tops.

20. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

Figure 1-7. Tray Assy Multibin Unit 2 (with 36-38): Tray1-9 and

Tray Assy Multibin Unit 1 (with 37, 38, 42): Tray10

Multibin Unit Disassembly an d A s se mbly 21

Page 22

EPSON EPL-N2050 Optional Units Revision B

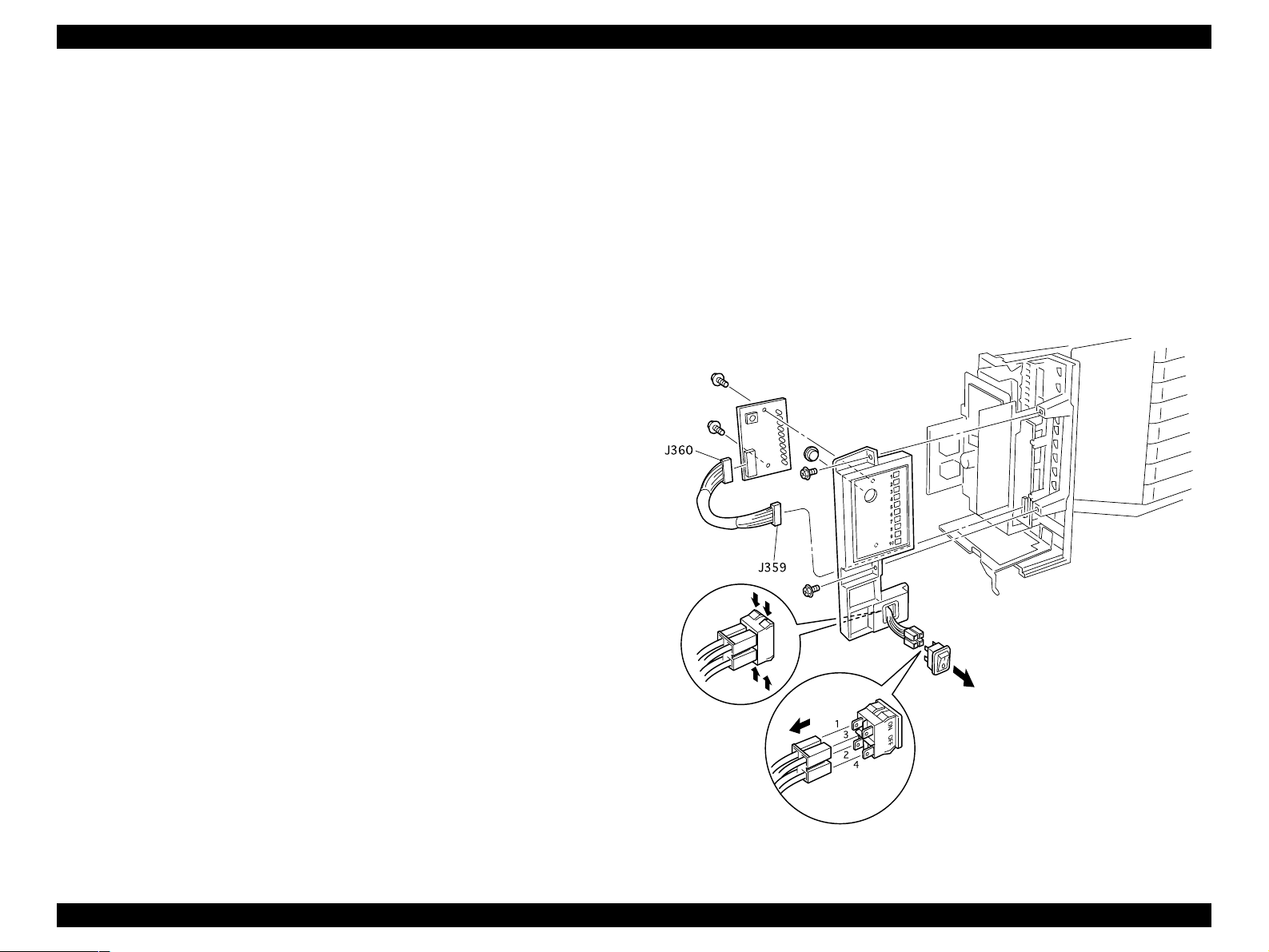

1.4.7 Panel Assy, PWBA LED, and Switch Main

1.4.7.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

3. Remove the two screws that are securing the Panel Assy Indicator to the

Multibin Unit frame.

4. Disconnect J359 from the PWBA Main.

5. Disconnect the P/J that is attached to the Switch Main.

6. Remove the Panel Assy Indicator.

7. Remove the two screws that are securing the PWBA LED to the Panel

Assy Indicator, and remove the PWBA LED.

8. Disconnect J360 from the PWBA LED

9. Press in on the latches that secure the Switch Main to the Panel Assy

Indicator, and remove the Switch.

1.4.7.2 Assembly

8. Reinstall the Panel Assy Indicator onto the Multibin Unit frame, by first

sliding the tab that is located at the bottom of the Panel into the

corresponding hole in the Multibin Unit frame, then sliding the Panel into

position.

9. Use two screws to secure the Panel Assy Indicator to the Multibin Unit

frame.

10. Reinstall the Cover Left. (See “Cover Left, Cover Top and Cover R ight” on

page 17)

11. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

1. Reinstall the Switch Main into the opening in the Panel Assy Indicator.

Position the Switch Main so the O is at the bottom and the l is on the top.

2. Reinstall the Button into the opening in the Panel Assy Indicator.

3. Reconnect the PWBA LED Harness to J360 on the PWBA LED.

4. Reinstall the PWBA LED into the Panel Assy Indicator, making sure the

LEDs on the PWB fit into the square opening on the back of the Panel

Assy Indicator.

5. Use two screws to secure the PWBA LED to the Panel Assy Indicator.

6. Reconnect the four wire P/J to the Switch Main.

7. Reconnect J359 to the PWBA Main.

Figure 1-8. Panel Assy, PWBA LED, and Switch Main

Multibin Unit Disassembly an d A s se mbly 22

Page 23

EPSON EPL-N2050 Optional Units Revision B

1.4.8 Frame Assy LVPS

1.4.8.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

3. Remove the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

4. Squeeze the tie wrap latch to release the tie wrap from the Multibin Unit

frame, and remove the tie wrap and harness from the frame.

5. Disconnect J350 from the PWBA LVPS.

6. Remove the four screws (1 through 4) that are securing the Frame Assy

LVPS to the Multibin Unit frame.

7. Remove ground wires T351 and T355 from the PWBA LVPS (secured by

screw 3).

8. Remove the screw that is securing ground wire T300 (item I) to the PWBA

LVPS and remove the wire.

NOTE: The screw that secures T300 to the PWBA LVPS is different

from the other screws on the PWBA LVPS. Do not substitute

screws.

9. Remove the screw that is securing ground wire T353 (item S) to the

PWBA LVPS and remove the wire.

1.4.8.2 Assembly

1. Reinstall the Frame Assy LVPS onto the Multibin Unit frame.

2. Reinstall ground wire T353 (item S) onto the PWBA LVPS and secure it

with one screw.

3. Reinstall ground wire T300 (item I) onto the PWBA LVPS and secure it

with one screw.

NOTE: The screw that secures T300 onto the PWBA LVPS is different

from the other screws on the PWBA LVPS. Do not substitute

screws.

4. Reinstall the ground wires T351 and T355 onto the PWBA LVPS at screw

hole 3, and secure them with one screw.

5. Use the other three screws to secure the PWBA LVPS to the Multibin Unit

frame.

6. Reconnect J350 to the PWBA LVPS.

7. Press the tie wrap, with the wire harness, into the hole in the Multibin

Unit frame.

8. Reinstall the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

9. Reinstall the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

10. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

10. Remove the Frame Assy LVPS from the Multibin Unit frame.

Multibin Unit Disassembly an d A s se mbly 23

Page 24

EPSON EPL-N2050 Optional Units Revision B

Figure 1-9. Frame Assy LVPS

Multibin Unit Disassembly an d A s se mbly 24

Page 25

EPSON EPL-N2050 Optional Units Revision B

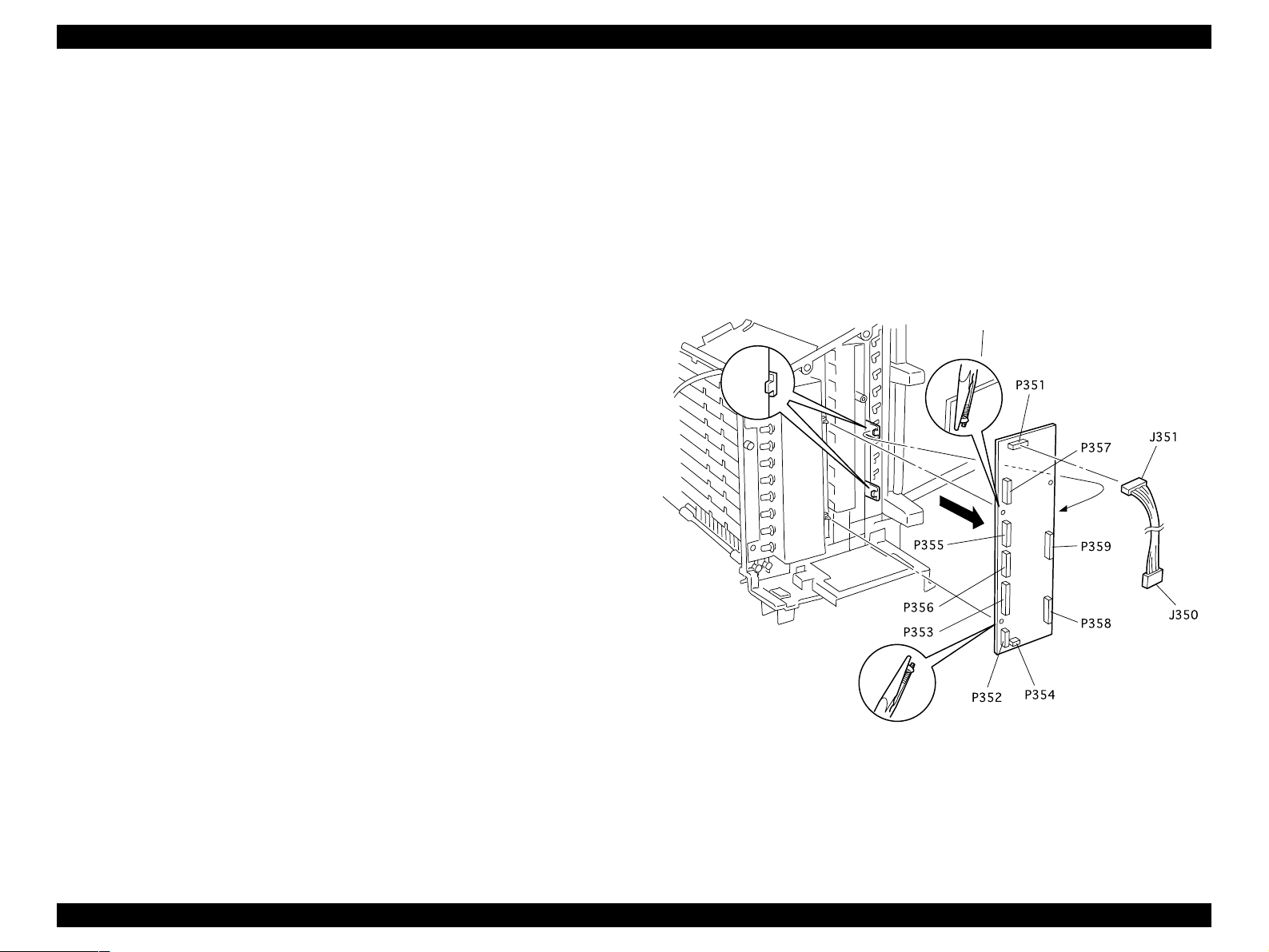

1.4.9 PWBA Main

1.4.9.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

3. Remove the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

4. Remove the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

5. Disconnect all of the P/Js that are attached to the PWBA Main.

P/Js 351, 352, 353, 354, 355, 356, 357, 358

6. Press in on the two latches that secure the left side of the PWBA Main to

the Multibin Unit frame, and pull free the left side of the PWB.

7. Slide the right side of the PWB out from under the two tabs that are

located on the right.

8. Remove the PWBA Main.

1.4.9.2 Assembly

7. Reinstall the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

8. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

1. Slide the right side of the PWBA Main under the two tabs that are located

on the right.

2. Position the two holes in the left side of the PWBA Main with the two

latches on the Multibin Unit frame.

3. Press the left side of the PWBA Main onto the tabs until the PWB snaps

into place.

4. Reconnect all of the P/Js that were attached to the PWBA Main.

P/Js 351, 352, 353, 354, 355, 356, 357, 358

5. Reinstall the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

6. Reinstall the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

Figure 1-10. PWBA Main

Multibin Unit Disassembly an d A s se mbly 25

Page 26

EPSON EPL-N2050 Optional Units Revision B

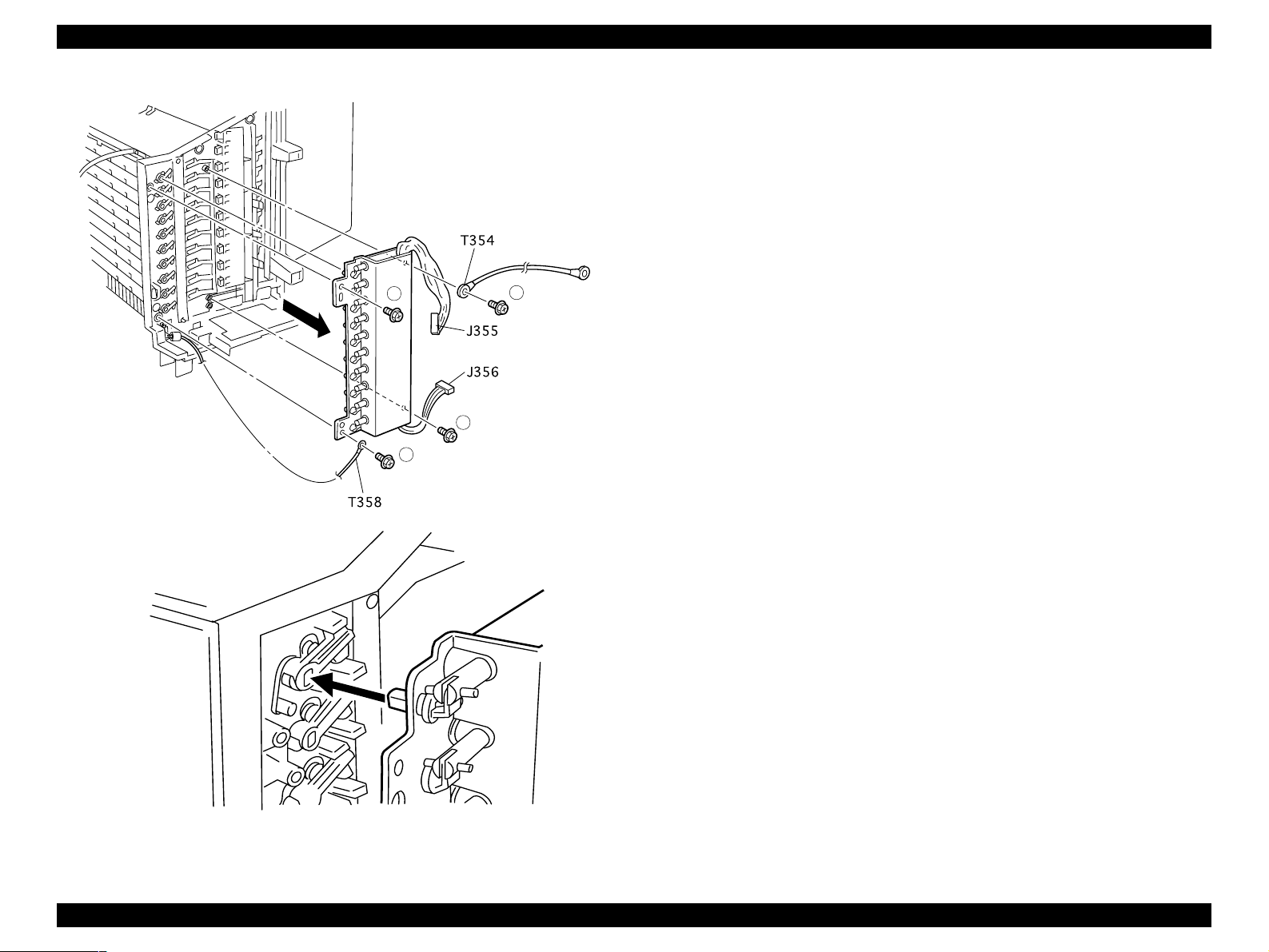

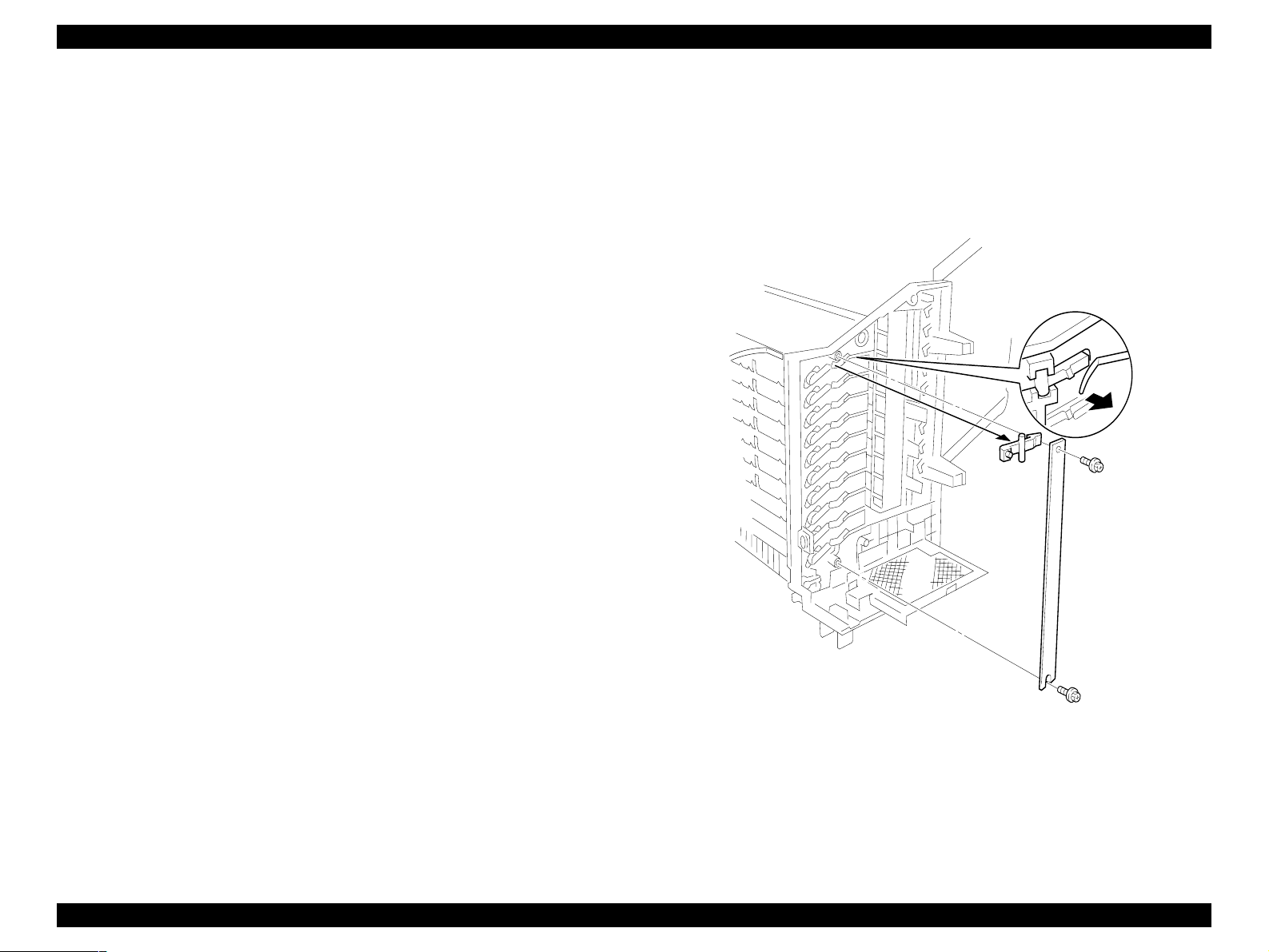

1.4.10 Solenoid Assy Link (with 23-25)

1.4.10.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

3. Remove the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

4. Remove the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

5. Remove the PWBA Main. (See “PWBA Main” on page 25)

6. Remove the four screws that are securing the Solenoid Assy L to the

Multibin Unit frame.

NOTE: The top right screw also secures the ground wire T354 to the

Assembly.

NOTE: The bottom left screw also secures the ground wi re T358 to

the Assembly.

7. Pull the Solenoid Assy Link straight out, and remove it from the Multibin

Unit frame.

6. Reinstall the green ground wire T354 against the top right screw hole in

the Solenoid Assy Link.

7. Use one screw to secure the ground wire and the Assembly to the

Multibin Unit frame (item 1).

8. Reinstall the ground wire T358 against the bottom left screw hole in the

Solenoid Assy Link.

9. Use one screw to secure the ground wire and the Assembly to the

Multibin Unit frame (item 4).

10. Reinstall the PWBA Main. (See “PW BA Main” on page 25)

11. Reinstall the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

12. Reinstall the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

13. Reinstall the Cover Left. (See “Cover Left, Cover Top and Cover R ight” on

page 17)

14. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

1.4.10.2 Assembly

1. Reinstall the Solenoid Assy Link onto the Multibin Unit frame.

2. Slide the plunger out of each of the ten solenoids.

3. Align each of the ten LInk Solenoids with the ten corresponding openings

in the Gates.

NOTE: If any one of the ten Links fails to line up with the

corresponding Gate opening, you will not be able to correct

seat the Solenoid Assy Link.

4. Press the Solenoid Assy Link against the Multibin Unit frame.

5. Use two screws to secure the Solenoid Assy Link to the Multibin Unit

frame.

Multibin Unit Disassembly an d A s se mbly 26

Page 27

EPSON EPL-N2050 Optional Units Revision B

2

3

4

1

Figure 1-11. Solenoid Assy Link (with 23-25)

Multibin Unit Disassembly an d A s se mbly 27

Page 28

EPSON EPL-N2050 Optional Units Revision B

1.4.11 Sensor Stack Full

1.4.11.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

3. Remove the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

4. Remove the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

5. Remove the PWBA Main. (See “PWBA Main” on page 25)

6. Remove the Solenoid Assy Link.

7. Remove all of the Multibin Unit Trays necessary to access the Sensor

Stack Full that you want to remove.

8. Disconnect the P/J that is attached to the Sensor Stack Full you want to

remove.

9. Press in on the latches that secure the Sensor Stack Full to the Multibin

Unit frame and pull the Sensor Stack Full in the direction of the Multibin

Unit Trays.

10. Remove the Sensor Stack Full.

1.4.11.2 Assembly

3. Reconnect the P/J to the Sensor.

The P/Js are numbered:

P/J361 goes to Sensor Stack Full 1 (the top Sensor).

P/J362 goes to Sensor Stack Full 2.

P/J363 goes to Sensor Stack Full 3.

P/J364 goes to Sensor Stack Full 4.

P/J365 goes to Sensor Stack Full 5.

P/J366 goes to Sensor Stack Full 6.

P/J367 goes to Sensor Stack Full 7.

P/J368 goes to Sensor Stack Full 8.

P/J369 goes to Sensor Stack Full 9.

P/J370 goes to Sensor Stack Full 10 (the bottom Sensor).

4. Reinstall the Multibin Unit Trays.

5. Reinstall the Solenoid Assy Link.

6. Reinstall the PWBA Main. (See “PWBA Main” on page 25)

7. Reinstall the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

8. Reinstall the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

9. Reinstall the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

1. Reinstall the Sensor Stack Full by sliding it from the Tray side, into the

correct Sensor slot. (See the illustration for correct positioning).

2. Press the two tabs and two latches located on the back of the Sensor

Stack Full, into the corresponding holes in the Sensor Stack Full slot.

The Sensor Stack Full snaps into place.

10. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

Multibin Unit Disassembly an d A s se mbly 28

Page 29

EPSON EPL-N2050 Optional Units Revision B

Figure 1-12. Sensor Stack Full

Multibin Unit Disassembly an d A s se mbly 29

Page 30

EPSON EPL-N2050 Optional Units Revision B

1.4.12 Stopper Key Lock L

1.4.12.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

3. Remove the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

4. Remove the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

5. Remove the PWBA Main. (See “PWBA Main” on page 25)

6. Remove the Solenoid Assy Link. (See “Solenoid Assy Link (with 23-25)”

on page 26)

7. Remove the two screws that are securing the Support Key Lock L to the

Multibin Unit frame, and remove the Support.

8. Remove a specific Stopper Key Lock L by lifting it from its slot.

1.4.12.2 Assembly

1. Reinstall the Stopper Key Lock L. (See the illustration for correct

positioning).

9. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

2. Reinstall the Support Key Lock L. (See the illustration for correct

positioning).

3. Use two screws to secure the Support Key Lock L.

4. Reinstall the Solenoid Assy Link. (See “Solenoid Assy Link (with 23-25)”

on page 26)

5. Reinstall the PWBA Main. (See “PWBA Main” on page 25)

6. Reinstall the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

7. Reinstall the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

8. Reinstall the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

Figure 1-13. Stopper Key Lock L

Multibin Unit Disassembly an d A s se mbly 30

Page 31

EPSON EPL-N2050 Optional Units Revision B

1.4.13 Gate

1.4.13.1 Removal

1. Remove the Cover Right, Cover Top, and Cover Left.

2. Remove the Chute Rear. (See “Chute Rear and Chute Assy Lower (with 710, 24)” on page 18)

3. Slide the Gate to the left.

4. Pull out on the center of the Gate and slide the other end of the Gate out

of the bearing in the Multibin Unit frame and remove the Gate.

5. Repeat this procedure for all of the Link Gates and Gates you want to

remove.

1.4.13.2 Assembly

1. Reinstall the Gate by first inserting the left end of the Gate into the

bearing in the Multibin Unit frame. (See the illustration for correct

positioning).

2. Bow the Gate enough to allow you to slide the right end of the Gate into

the Link Gate.

3. Press down on the Link Gate to make sure the Gate opens and closes

correctly.

4. Reinstall the Chute Rear. (See “Chute Rear and Chute Assy Lower (with 710, 24)” on page 18)

5. Reinstall the Cover Right, Cover Top, and Cover Left.

Figure 1-14. Gate

Multibin Unit Disassembly an d A s se mbly 31

Page 32

EPSON EPL-N2050 Optional Units Revision B

1.4.14 Harness Assy MCU

1.4.14.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

3. Remove the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

4. Remove the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

5. Disconnect P352 on the PWBA Main. (See “PWBA Main” on page 25)

6. Remove the screw that is securing ground wire T355 to the frame, and

remove the wire.

7. Position the Multibin Unit on the Cover Left.

8. Use a screwdriver blade to pry up the two Support MCU that secure the

Harness Assy MCU to the Multibin Unit frame.

9. Remove the Harness Assy MCU from the frame.

1.4.14.2 Assembly

9. Reinstall the Multibin Unit onto the base engine. (See “Installation” on page 10)

Make sure J202 mates with P202.

1. Orient the Harness Assy MCU J202 so it mates with P202 on the base

engine.

2. Thread the Harness through the opening in the Multibin Unit frame.

3. Reinstall the J202 into the opening in the Multibin Unit frame.

4. Use two Support MCU to secure J202 to the frame.

5. Reconnect P352 on the PWBA Main. (See “PWBA Main” on page 25)

6. Reinstall the Frame Assy LVPS. (See “Frame Assy LVPS” on page 23)

7. Reinstall the Panel Assy Indicator. (See “Panel Assy, PWBA LED, and

Switch Main” on page 22)

8. Reinstall the Cover Left. (See “Cover Left, Cover Top and Cover Right” on

page 17)

Figure 1-15. Harness Assy MCU

Multibin Unit Disassembly an d A s se mbly 32

Page 33

EPSON EPL-N2050 Optional Units Revision B

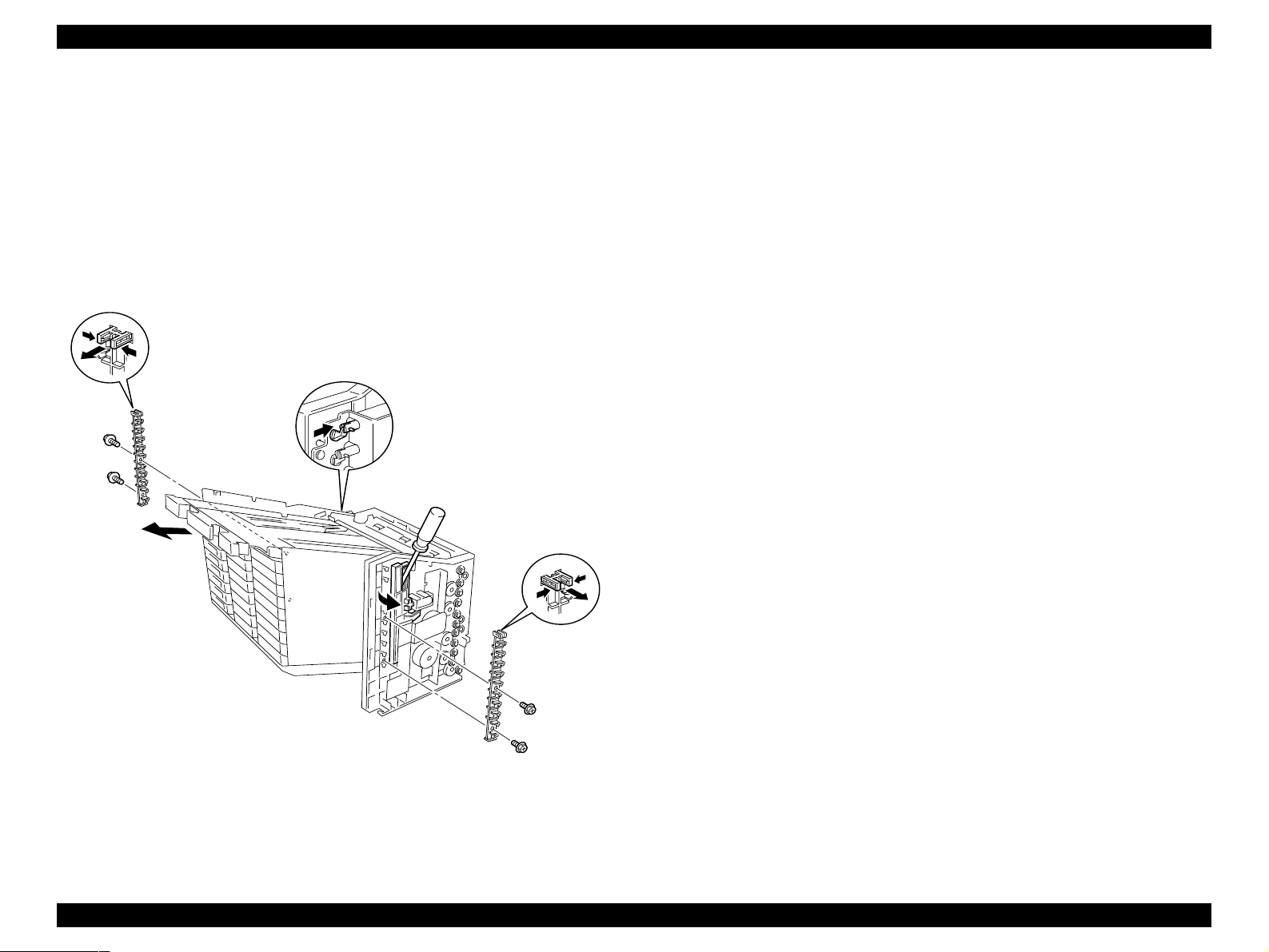

1.4.15 Motor Bracket Assembly (with 19, 23, 24, 34)

1.4.15.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

3. Cut the tie wrap that secures the wire harness to the Bracket Motor.

4. Disconnect J372 and J373 from the Motor Assys.

5. Disconnect the J374-1 from J374 leading to the Solenoid Assy R.

6. Remove the Solenoid Assy R harness from the Motor Bracket Assembly.

7. Remove the screw that is securing the ground wire T352 to the Motor

Bracket Assembly, and remove the wire.

8. Remove the four screws that are securing the Motor Bracket As se m bl y to

the Multibin Unit frame.

9. Pull the Motor Bracket Assemb ly away from the frame and slightly to the

right to free the two Belt Synchronous from the Gear Pulley 19/42T on the

Motor shafts.

10. Remove the Motor Bracket Assembly by pulling it away from the frame.

1.4.15.2 Assembly

5. Maintain tension on the Motor Bracket Assembly, so the belts do not slip

out of place, and start to press the Motor Bracket Assembly against the

frame.

6. Press down on the ground strap that is located at the top of the Bracket,

and continue pressing the Bracket against the frame so the ground strap

goes under the metal tab that is protruding out of the frame.

7. Press the Bracket firmly against the frame and reposition the Bracket so

all of the screw holes in the Bracket line up with the screw holes in the

frame.

8. Use four screws to secure the Motor Bracket Assembly to the Multibin

Unit frame.

9. Use one screw to secure ground wire T352 to the Motor Bracket

Assembly.

10. Reconnect the J374-1 to J374 leading to the Solenoid Assy R.

11. Reconnect J372 and J373 to the Motor Assy.

12. Dress all of the wires so they are clear of all moving parts and use a tie

wrap to secure the harness (item R).

13. Reinstall the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

14. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

1. Hold the Solenoid Assy R harness out of the way so it does not get

trapped between the Motor Bracket Assembl y and the Multibin Unit

frame.

2. Position the Motor Bracket Assembly slightly away from the Multibin Unit

frame. (See the illustration for correct positioning).

3. Thread the wire harness through the opening located at the bottom of the

Bracket.

4. Reposition the Motor Bracke t Ass embly so the two Belt synchronous loop

the two Gear Pulley 19/42T on the Motor shafts.

Multibin Unit Disassembly an d A s se mbly 33

Page 34

EPSON EPL-N2050 Optional Units Revision B

Figure 1-16. Motor Bracket Assy (with 19, 23, 24, 34)

Multibin Unit Disassembly an d A s se mbly 34

Page 35

EPSON EPL-N2050 Optional Units Revision B

1.4.16 Solenoid Assy R

1.4.16.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

3. Disconnect J374-1 from the in-line connector located near the bottom

Motor.

4. Spread the four latches and pull the Solenoid Assy R way from the frame.

1.4.16.2 Assembly

1. Reinstall the Solenoid Assy R. (See the illustration for correct

positioning).

2. Reposition the Solenoid plunger so the pin is vertical and fits into the slot

in the Stopper Key Lock R.

3. Press the Solenoid Assy R against the Multibin Unit frame so the four

latches snap into place.

4. Press and release the Solenoid plunger to make sure the Stopper Key

Lock R opens and closes correctly.

5. Reconnect J374-1.

6. Reroute the Solenoid Harness so it is away from all moving parts.

7. Reinstall the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

8. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

Figure 1-17. Solenoid Assy R

Multibin Unit Disassembly an d A s se mbly 35

Page 36

EPSON EPL-N2050 Optional Units Revision B

1.4.17 Belt Synchronous

1.4.17.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

3. Remove the Motor Bracket Assembly. (See “Harness Assy MCU” on

page 32)

4. To remove the Belt Synchronous Top:

5. Open the gear latches and remove the Gear Idler 16T 2, 3, 4, and 5

(number 1 is the top gear in the line).

6. Remove the two Gear Idler 30T that contact the Gear Pulley 19/42T:Top.

7. Remove the Gear Pulley 19/42T:Top that is driving the Belt Synchronous:

Top.

8. Remove the Belt Synchronous: Top.

9. To remove the Belt Synchronous Bottom:

10. Open the gear latches and remove the Gear Idler 16T numbers 7, 8, 9, and

10 (number 10 is the bottom gear in the line).

1.4.17.2 Assembly

1. To reinstall the Belt Synchronous Bottom:

2. Loop the belt over the Gear Pulley 19/42T: Bottom. (See the illustration for

correction positioning).

3. Slide the belt and Gear Pulley 19/42T: Bottom onto the large diameter

shaft.

NOTE: The belt should rest against the Multibin Unit frame.

4. Slide two Gear Idler 30T onto the two shafts that are located next to the

Gear Pulley 19/42T: Bottom.

NOTE: The teeth of the Gear Idler 30T should mesh with the teeth of

Gear Pulley 19/42T: Bottom.

5. Position Gear Idler 16T number 10 (the bottom gear in the line) so the

latch faces away from the Multibin Unit frame and the gear teeth face the

Multibin Unit frame.

6. Line up the flat part of the gear hole with the flat part of the shaft, and

slide the Idler Gear onto the shaft.

The Gear latch snaps into place.

7. Repeat these steps and reinstall Gear Idler 16T numbers 9, 8, and 7.

11. Remove the two Gear Idler 30T that contact the Gear Pulley 19/42T:

Bottom.

12. Remove the Gear Pulley 19/42T: Bottom that is driving the Belt

Synchronous: Bottom.

13. Remove the Belt Synchronous: Bottom.

8. To reinstall the Belt Synchronous Top:

9. Loop the belt over the Gear Pulley 19/42T:Top. (See the illustration for

correction positioning).

10. Slide the belt and Gear Pulley 19/42T:Top onto the large diameter shaft.

NOTE: The belt should rest against the Multibin Unit frame.

11. Slide two Gear Idler 30T onto the two shafts that are located next to the

Gear Pulley 19/42T:Top.

NOTE: The teeth of the Gear Idler 30T should mesh with the teeth of

Gear Pulley 19/42T:Top.

Multibin Unit Disassembly an d A s se mbly 36

Page 37

EPSON EPL-N2050 Optional Units Revision B

12. Position Gear Idler 16T number 2 (number 1 is the top gear in the line) so

the latch faces away from the Multibin Unit frame and the gear teeth face

the Multibin Unit frame.

13. Line up the flat part of the gear hole with the flat part of the shaft, and

slide the Gear Idler 16T onto the shaft.

NOTE: The Gear latch snaps into place.

14. Repeat these steps and reinstall Gear Idler 16T numbers 3, 4, and 5.

15. Reinstall the Motor Bracket Assembly. (See “Harness Assy MCU” on

page 32)

16. Reinstall the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

17. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

Figure 1-18. Belt Synchronous

Multibin Unit Disassembly an d A s se mbly 37

Page 38

EPSON EPL-N2050 Optional Units Revision B

1.4.18 Stopper Key Lock R

1.4.18.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

3. Remove the Motor Bracket Assembly. (See “Harness Assy MCU” on

page 32)

4. Remove the Solenoid Assy R. (See “Solenoid Assy R” on page 35)

5. Bow the Stopper Key Lock R and slide the top pivot out of the pivot hole

in the Multibin Unit frame.

6. Remove the Stopper Key Lock R and the attached Spring Lock.

1.4.18.2 Assembly

1. Reinstall the Spring Lock onto the back of the Stopper Key Lock R.

2. Insert the bottom pivot of the Stopper Key Lock R into the pivot hole in

the Multibin Unit frame. (See the illustration for correct positioning ).

3. Press the Stopper Key Lock R against the Multibin Unit frame, making

sure the free end of the Spring Lock fits over the tab on the Multibin Unit

frame.

4. Bow the Stopper Key Lock R and slide the top pivot into the pivot hole in

the Multibin Unit frame.

5. Press and release the Stopper Key Lock R to make sure it moves freely

and has a spring-action return.

6. Reinstall the Solenoid Assy R. (See “Solenoid Assy R” on page 35)

7. Reinstall the Motor Bracket Assembly. (See “Harness Assy MCU” on

page 32)

8. Reinstall the Cover Right. (See “Cover Left, Cover Top and Cover Right”

on page 17)

9. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

Figure 1-19. Stopper Key Lock R

Multibin Unit Disassembly an d A s se mbly 38

Page 39

EPSON EPL-N2050 Optional Units Revision B

1.4.19 Roll Assy Transport

1.4.19.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left and Cover Right. (See “Cover Left, Cover Top and

Cover Right” on page 17)

3. Remove the Chute Rear and Chute Assy Lower.

4. Open the gear latch and remove the Gear Idler 16T that is attached to the

Roll Assy Transport (1).

5. Remove the E Ring from the Roll Assy Transport (2).

6. Slide the Bearing out of the bearing hole (3).

7. Slide the Roll Assy Transport to the Right (4), then pull it away from the

Multibin Unit frame (5).

8. Remove an E-ring attached to the left side of Roll Assy Transport. (6)

9. Remove the Roll Assy Transport.

1.4.19.2 Assembly

1. Attach an E-ring to the left side of Roll Assy Transport.

10. Reinstall the Cover Left and Cover Right. (S ee “Cover Left, Cover Top and

Cover Right” on page 17)

11. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

2. Reinstall the Bearing 6 into the left bearing hole. (See the illustration for

correct positioning).

3. Slide the Bearing onto the right end of the Roll Assy Transport. (See the

illustration for correct positioning).

4. Slide the right end of the Roll Assy Transport into the right bearing hole.

5. Slide the left end of the Roll Assy Transport into the left bearing.

6. Slide the Bearing along the shaft and into the right bearing hole.

7. Use an E Ring to secure the right end of the Roll Assy Transport.

8. Reinstall the Gear Idler 16T on the right end of the Roll Assy Transport.

9. Reinstall the Chute Rear and Chute Assy Lower.)

Figure 1-20. Roll Assy Transport

Multibin Unit Disassembly an d A s se mbly 39

Page 40

EPSON EPL-N2050 Optional Units Revision B

1.4.20 Roll Exit

1.4.20.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left and Cover Right. (See “Cover Left, Cover Top and

Cover Right” on page 17)

3. Remove the Chute Rear and Chute Assy Lower. (See “Chute Rear and

Chute Assy Lower (with 7-10, 24)” on page 18)

4. Press in on the Solenoid Assy R plunger to open the Stopper Key Lock R.

5. Use a screwdriver to wedge the Stopper Key Lock R open.

6. Press in the Solenoid Assy L plunger to open the Bins, and slide the

Multibin Unit trays out as far as they go.

7. Remove the Gate that is associated with the Roll Exit you want to remove.

8. Remove the Gate just above the Gate you removed in step 2.

9. Open the gear latch and remove the Gear Idler 16T from the Roll Exit you

want to remove (1).

10. Unhook the Link Assy Paper L (2) and the Link Assy Paper R from the Roll

Exit shaft.

11. Remove the E Ring from Right end of the shaft (3).

12. Slide Bearing 6 out of the bearing hole.

13. Slide the Roll Exit to the right (4), then pull it away from the Multibin Unit

frame (5).

1.4.20.2 Assembly

1. Remove the screwdriver wedging open Stopper Key Lock R and allow the

Lock to close.

2. Reinstall the Bearing 6 into the left bearing hole. (See the illustration for

correct positioning).

3. Slide the Bearing onto the right end of the Roll Exit. (See the illustration

for correct positioning).

4. Slide the right end of the Roll Exit into the right bearing hole.

5. Slide the left end of the Roll Exit into the Bearing 6.

6. Slide the Bearing along the shaft and into the right bearing hole.

7. Use an E Ring to secure the right end of the Roll Exit.

8. Reattach the Link Assy Paper L (2) and the Link Assy Paper R to the Roll

Exit shaft.

9. Reinstall the Gear Idler 16T on the right end of the Roll Exit.

10. Reinstall the Gates. (See “Gate” on page 31)

11. Reinstall the Chute Rear and Chute Assy Lower. (See “Chute Rear and

Chute Assy Lower (with 7-10, 24)” on page 18)

12. Reinstall the Cover Left and Cover Right. (S ee “Cover Left, Cover Top and

Cover Right” on page 17)

13. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

14. Remove the Roll Exit (6).

Multibin Unit Disassembly an d A s se mbly 40

Page 41

EPSON EPL-N2050 Optional Units Revision B

1

2

3

4

5

6

Figure 1-21. Roll Exit

Multibin Unit Disassembly an d A s se mbly 41

Page 42

EPSON EPL-N2050 Optional Units Revision B

1.4.21 Solenoid Direction

1.4.21.1 Removal

1. Remove the Multibin Unit from the base engine. (See “Removal” on

page 10)

2. Remove the Cover Left and Cover Right. (See “Cover Left, Cover Top and

Cover Right” on page 17)

3. Remove the Chute Rear and Chute Assy Lower.

4. Press in on the Solenoid Assy R plunger to open the Stopper Key Lock R.

5. Use a screwdriver to wedge the Stopper Key Lock R open.

6. Press the Solenoid Assy L plunger to open the Bins, and slide the bottom

three Multibin Unit trays out as far as possible.

7. Remove the bottom four Gates. (See “Gate” on page 31)

8. Remove the bottom three Roll Exits. (See “Roll Exit” on page 40)

9. Remove the two screws that secure the Solenoid Direction to the M ultibin

Unit frame.

NOTE: The two screws are located just below the bottom Motor, and

are accessed through the cutouts in the Bracket Motor.

10. Slide the Solenoid Direction forward to free the plunger from the frame.

11. Disconnect J371-1 from J371.

12. Remove the Solenoid Direction.

1.4.21.2 Assembly

1. Remove the screwdriver wedging open Stopper Key Lock R and allow the

Lock to close.

2. Reconnect J371-1 to J371.

3. Slide the Solenoid Direction plunger into the slot in the Multibin Unit

frame.

4. Position the Solenoid Direction so the two screw holes in the Solenoid

Direction line up with the two screw holes in the Multibin Unit frame.

5. Use two screws to secure the Solenoid Direction to the frame.

6. Route the Solenoid wire harness under the plastic clip.

7. Reinstall the bottom three Roll Exits. (See “Roll Exit” on page 40)

8. Reinstall any other Roll Exits that may have been dislodged during the

removal of the Solenoid Direction.

9. Reinstall the bottom four Gates. (See “Gate” on page 31)

10. Reinstall any other Gates that may have been dislodged during the

removal of the Solenoid Direction.

11. Close all of the Multibin Unit trays.

12. Reinstall the Chute Rear and Chute Assy Lower.

13. Reinstall the Cover Left and Cover Right. (S ee “Cover Left, Cover Top and

Cover Right” on page 17)

14. Reinstall the Multibin Unit onto the base engine. (See “Installation” on

page 10)

Multibin Unit Disassembly an d A s se mbly 42

Page 43

EPSON EPL-N2050 Optional Units Revision B

Figure 1-22. Solenoid Direction

Multibin Unit Disassembly an d A s se mbly 43

Page 44

EPSON EPL-N2050 Optional Units Revision B

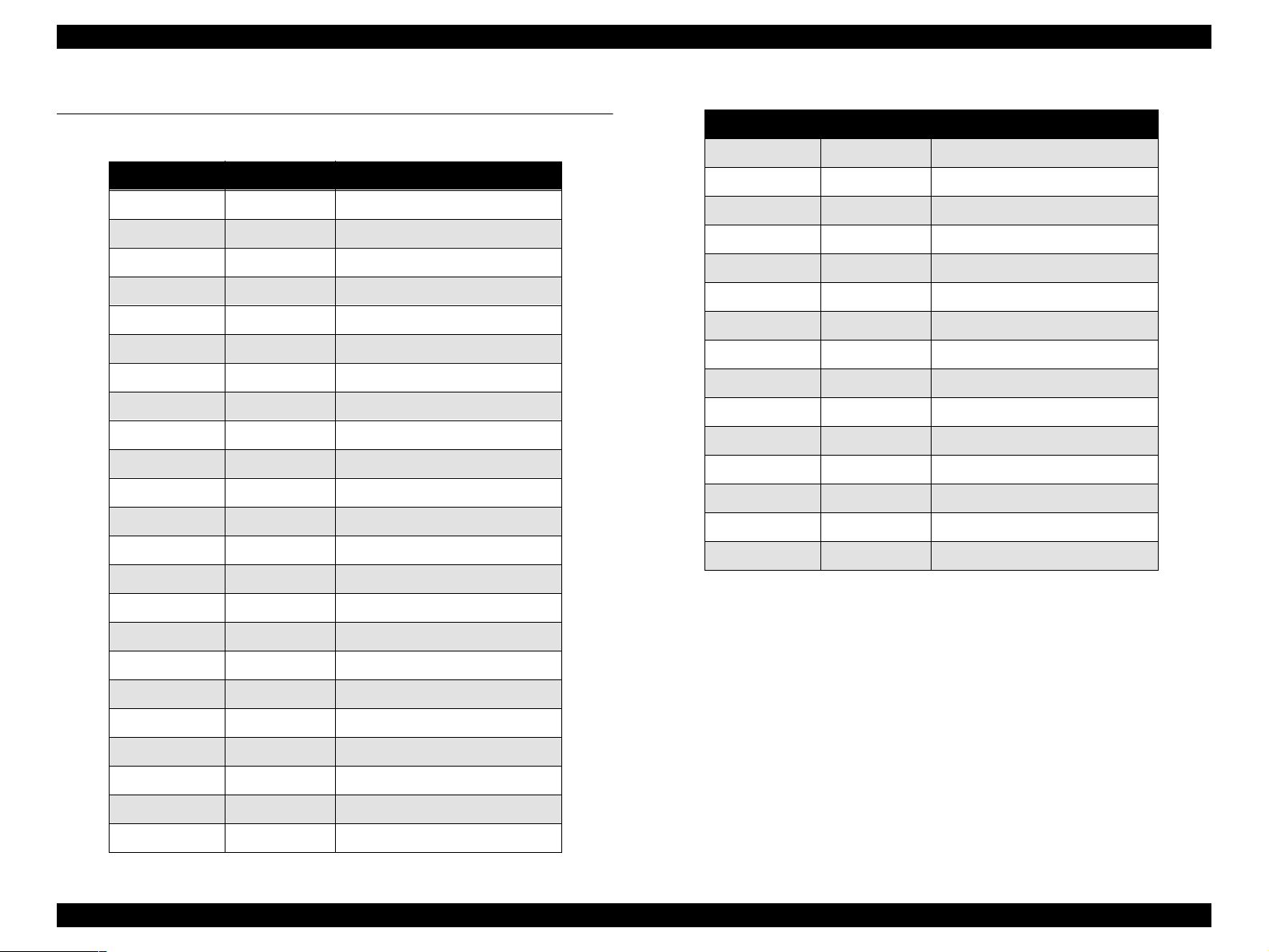

1.5 Parts List and Exploded Diagram

Table 1-3. Parts List

Ref No. Part Code Description

S64.1.2 1051678 COVER LEFT

S64.1.3 1051679 COVER TOP

S64.1.4 1051680 CHUTE REAR

S64.1.6 1051681 CHUTE ASSY LOWER

H1.1.11 1051682 COVER RIGHT

H1.1.12 1051683 FRAME ASSY BOTTOM

H1.1.14 1052073 ROLLER ASSY PINCH

H1.1.20 1052072 ELIMINATOR

H1.1.21 1051684 SUPPORT TAPE

H1.1.22 1052074 ELIMINATOR S

H1.1.23 1052076 ELIMINATOR

H1.2.2 2033508 PANEL ASSY INDICATOR

H1.2.4 2033509 PANEL ASSY

H1.2.5 1051685 BUTTON

Table 1-3. Parts List

Ref No. Part Code Description

1.2.30 2033765 HARNESS S SNR 2

1.2.33 2033770 HARNESS ASSY MAIN

1.2.35 1051652 TRAY ASSY MBX

1.2.41 1051688 TRAY ASSY MBX

1.2.99 2034523 KIT HARNESS MCU MBX

H1.3.1 1051689 LINK ASSY PAPER L

H1.3.2 1051690 LINK ASSY PAPER R

H1.3.4 1051691 ROLL EXIT

H1.3.6 1051694 ROLL ASSY TRANSPORT

H1.3.7 2033516 FRAME ASSY RIGHT

H1.3.14 2033771 SOLENOID DIRECTION

H1.3.15 2033517 SOLENOID ASSY R

H1.3.19 1051695 BRACKET ASSY MOTOR

H1.3.23 2033518 PLATE ASSY MOTOR 2

H1.3.24 2033519 PLATE ASSY MOTOR

H1.2.7 2033510 PWBA LED

H1.2.13 2033511 SENSOR STACK FULL

H1.2.13 2033512 FRAME ASSY LVPS

H1.2.17 2033760 HARNESS ASSY INLET

H1.2.18 2033762 HARNESS LVPS

H1.2.20 2033514 PWBA MAIN

H1.2.22 2033515 SOLENOID ASSY LINK

H1.2.28 1051651 GATE

1.2.29 2033764 HARNESS S SNR 1

Multibin Unit Parts List and Exploded Diagram 44

Page 45

The parts to which no reference number

is assigned will not be available as

after-sale service parts.

EPSON EPL-N2050 Optional Units Revision B

Figure 1-23. Exploded Diagram (1)

Multibin Unit (1.1)

10168 Rev.01

Multibin Unit Parts List and Exploded Diagram 45

Page 46

Figure 1-24. Exploded Diagram (2)

EPSON EPL-N2050 Optional Units Revision B

Multibin Unit Parts List and Exploded Diagram 46

Page 47

The parts to which no reference number

is assigned will not be available as

after-sale service parts.

EPSON EPL-N2050 Optional Units Revision B

Figure 1-25. Exploded Diagram (3)

Multibin Unit (1.3)

10168 Rev.01

Multibin Unit Parts List and Exploded Diagram 47

Page 48

DUPLEX UNIT

CHAPTER

2

Page 49

EPSON EPL-N2050 Optional Units Revision B

2.1 Installation and Removal of Duplex Unit

2.1.1 Installation

1. Make sure the printer’s power is off.

2. Pushing in the left and right levers of Duplex Unit, mount the Duplex Unit

on the printer.

3. Close the Cover Assy Rear from the printer.

2.1.2 Removal

1. Switch off printer’s power.

2. Open the Cover Assy Rear from the printer.

3. Pushing in the left and right levers of Duplex Unit, draw the Duplex Unit

from the printer.

Duplex Unit

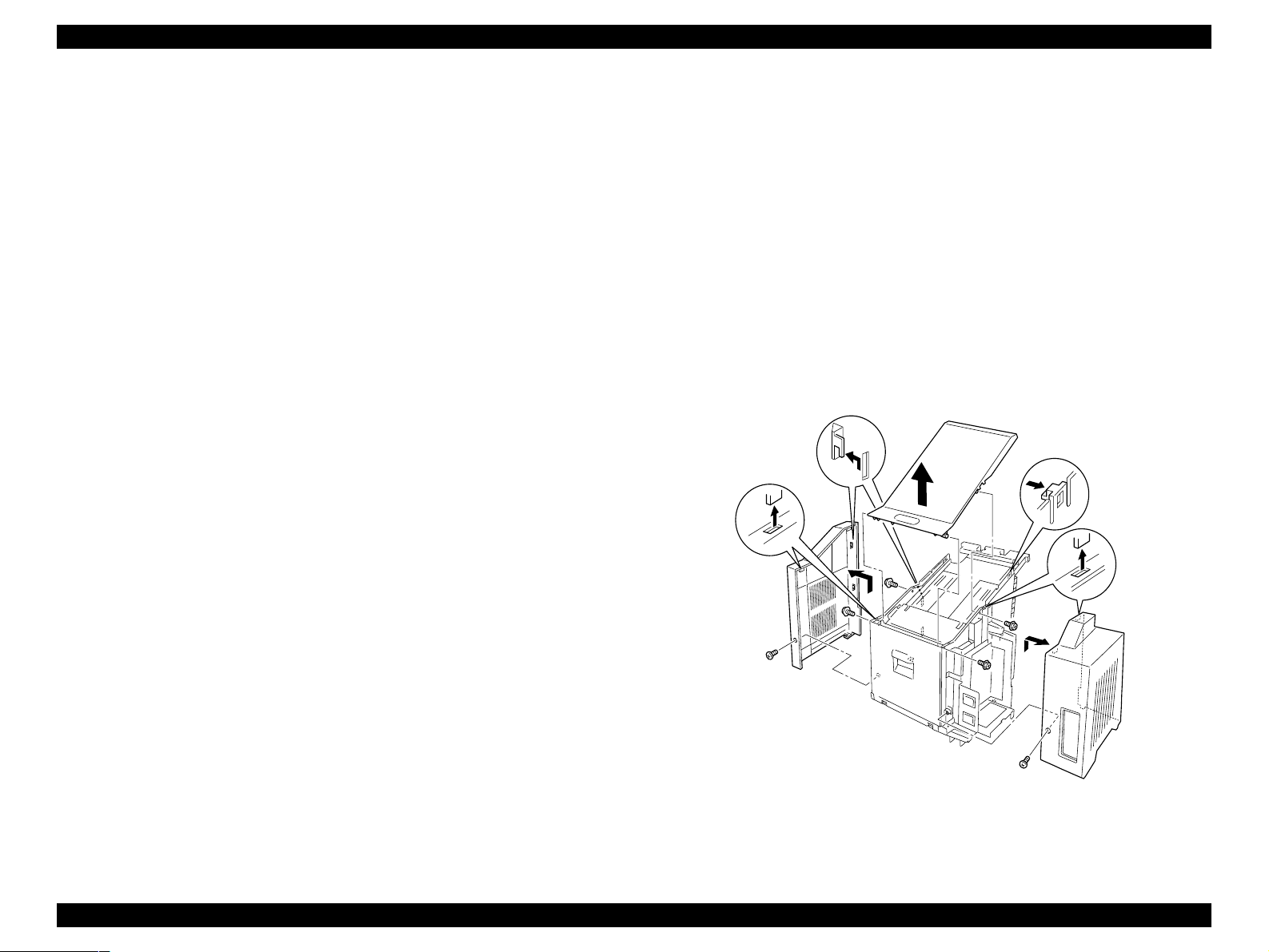

Figure 2-1. Duplex Unit Removal

Duplex Unit Installation and Removal of Duplex Unit 49

Page 50

EPSON EPL-N2050 Optional Units Revision B

2.2 Introduction

This section contains the removal and assembly procedure for main parts

of the Duplex.

2.2.1 Preparation

Before you begin any disassembly and assembly proce dure;

1. Switch OFF the main power.

2. Disconnect the AC power cord from the wall outlet, then start work.

3. Remove the EP cartridge and store it at a dark and safety place free from

direct sunlight.

4. In performing work for the FUSER ASSY periphery, wait until the FUSER

ASSY and its periphery have become cool enough.

5. Disconnect all interface cables from the rear panel of printer.

6. In performing work, to eliminate static electricity in your body, wear

wristbands, etc. to take grounding properly.

2.2.2 Precautions

CAUTION

n Many kinds of screws are used, and do not confuse where

they are used. Using wrong screws could cause the

tapped holes to be broken, or troubles to occur.

n In performing work with parts that are managed as spare

parts but its procedure is not given, make sure how the

parts have been mounted before starting work.

n Optional parts, as a rule, should be removed, but they

may be left in the printer, on condition that they do not

obstruct your work.

2.2.3 Notations in the Manual

The printer orientation expressed in the procedure is defined as follows.

Figure 2-2. Definition of Printer Orientation

o The screws in the illustration imply that they should be loosened and

removed using a cross-tip screw-driver, unless otherwise specified.

o A black arrow in the illustration implies that the part should be moved

in the arrow direction, and when numbers are assigned to black

arrows, the parts should be moved in the order of given numbers.

Duplex Unit Introduction 50

Page 51

EPSON EPL-N2050 Optional Units Revision B

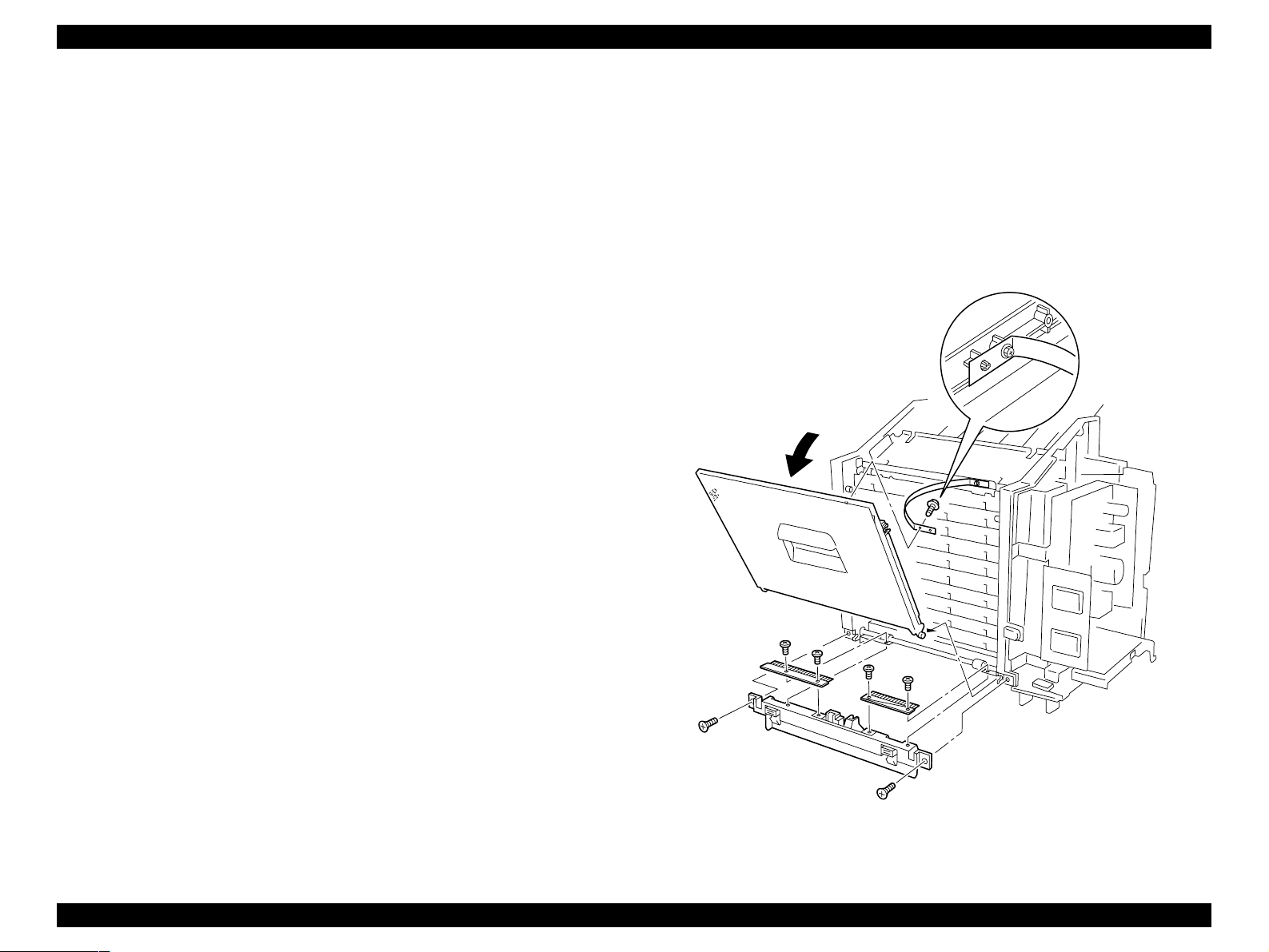

2.3 Disassembly and Assembly

2.3.1 Chute Assy Turn DUP

2.3.1.1 Removal

1. Remove the Duplex Unit. (See “Removal” on page 49)

2. Remove the two screws securing the Chute Assy Turn DUP to the Duplex

Unit.

3. Remove the Chute Assy Turn DUP from the Duplex Unit.

2.3.1.2 Assembly

1. Align the Chute Assy Turn DUP with its mount position to the Duplex

Unit.