Page 1

®

EPSON EPL-N1600 Option

Duplex Unit

Page 2

Notice

g

g

g

g

g

g

g

EPSON is a re

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademar ks of their

Copyright © 1998 SEIKO EPSON CORPORATION. Printed in Japan.

hts reserved. No part of t his manual may be r eprod uced, st ored in a r etri eval sy ste m, or t ransmit ted in any for m or by an y means el ectroni c,

All ri

mechanical, photocopyin

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The contents of this manual are subject to chan

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The above not withstandin

thereof.

istered trademark of SEIKO EPSON CORPORATION.

respective owners. EPSON disclaims any and all rights in those marks.

, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

e without notice.

SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

Page 3

PRECAUTIONS

g

g

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performin

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performin

Signals a precaution which, if ignored, could result in damage to equipment.

procedures preceded by DANGER Headings.

repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

1. EPSON WARRANTY.

Page 4

About This Manual

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

This manual describes basi c functions, theory of electrical and mechanical operations, maintenance and repair procedures of the Duplex Unit for the

EPL-N1600. The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be

the precautions on the precedin

page.

iven to

Contents

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for

troubleshootin

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for

disassemblin

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicin

APPENDIX

Provides the followin

reference:

• Connector pin assi

• Electric circuit boards components layout

• Exploded dia

• Electrical circuit boards schematics

eneral overview and specifications of the

.

and assembling the product.

the product.

additional information for

nments

ram

Symbols Used in This Manual

Various symbols are used throughout this manual either to provide

additional information on a specif ic topic or to warn of possible dan

present durin

they are used, and always read WARNING, CAUTION or NOTE

CHECK

PO IN T

es.

messa

W ARNING

CAUTION

a procedure or an action. Be aware of all symbols when

Indicates an operatin

or condition that, if not strictly observed, could result in

injury or loss of life.

Indicates an operatin

or condition that, if not strictly observed, could result in

dama

May indicate an operatin

practice or condition that is necessary to accomplish a task

efficiently. It may also provide additional information that is

related to a specific subject, or comment on the resul ts

achieved throu

e to, or destruction of, equipment.

h a previous action.

or maintenance procedure, practice

or maintenance procedure, practi ce,

or maintenance procedure,

er

Page 5

Revision Status

Revision Issued Date Description

Rev. 0 August 17, 1998 Prelimina ry release. (intended for service training purpose only)

Rev.A October 30, 1998 First release.

Page 6

EPSON EPL-N1600

g

g

g

Table of Contents

Product Descriptions

OVERVIEW ..................................... ...... ....... ...... ....... ...... ............................... 9

Basic specificatio n ........................ ...... ....................................... ..... 9

Paper specification.......................................................................... 9

Reliability/Durability/s ervicea bil it y ................................. ....... ...... ..... 9

dimension and wei

ht...... ...... ......................................................... 9

Operating Principles

OVERVIEW .................................................................................................. 11

Paper Transportation............................................................................... 11

paper transportation control.......................................................... 13

Scannin

Drive Power Transmission ...................................................................... 14

Duplex unit drive power transmission (1)...................................... 15

Duplex unit drive power transmission (2)...................................... 15

Function of Duplex Unit Major Components............................................ 16

Vertical Unit ........ ...... ....... ...... ....... ...... ....... ...... ....... ...... ................ 16

Horizontal Unit .............................................................................. 18

direction in duplex printing............................................ 13

Troubleshooting

Chute Cover............................................................................................ 27

Fan Assembly Duplex ............................................................................. 28

Sensor Assembly (Vertical)..................................................................... 29

Motor Duplex........................................................................................... 30

Solenoid .................................................................................................. 31

Shaft Latch & Lever................................................................................. 32

Rolls Pinch & Roll Assembly Exit............................................................ 33

Chute Lower & Roll Assembly................................................................. 34

Photo Interrupters (Rear I/L & Chute Cover I/L)..................................... 35

Photo Interrupter (PL11.1.9: Rear Interlock)................................. 35

Photo Interrupter (PL11.2.15: Chute Cover Interlock) .................. 35

Chute Upper............................................................................................ 36

Sensor Assembly (Horizontal)................................................................. 37

Roll Assembly #1 & Pinch Roll................................................................ 38

Plate Base............................................................................................... 39

Roll Assemblies #2 & #3 ......................................................................... 40

PWB Assembly Duplex ........................................................................... 41

Bracket & Gear Assembly ....................................................................... 42

Adjustment

Maintenance

DISASSEMBLY AND ASSEMBLY

OVERVIEW .................................................................................................. 23

Precautions ............................................................................................. 23

Tools........................................................................................................ 23

DISASSEMBLY AND ASSEMBLY............................................................... 24

Duplex Unit Removal............................................................................... 25

Duplex Assembly Unit Vertical................................................................ 26

Appendix

Connector Location ...................................................................................... 49

Exploded Dia

ram........................................................................................ 50

Duplex Unit (Optional)................................................................... 50

Duplex Unit Vertical I .................................................................... 52

Duplex Unit Vertical II ................................................................... 54

Duplex Unit Vertical III .................................................................. 56

Rev. 0 6

Page 7

EPSON EPL-N1600

Duplex Unit Horizontal I ................................................................ 58

Duplex Unit Horizontal II ............................................................... 60

Duplex Unit Chute......................................................................... 62

Rev. 0 7

Page 8

PRODUCT DESCRIPTIONS

Page 9

EPSON EPL-N1600/Duplex Unit Chapter 1 Product Descriptions

g

g

g

g

g

g

g

g

1.1 OVERVIEW

This section describes the specification of the 500 Sheets feeder.

BASIC SPECIFICATION

Paper Handlin

Drive Source: Driven by the base printer

Speed: A4 = 7.8PPM / Letter = 8.0PPM

Capacity: 1 sheet (in reverse tray)

Paper Feed Ori

PAPER SPECIFICATION

Paper Type: <Standard Paper>

: Tray reverse

in: Left edge of sheet

Xerox 4024DP 20 lb. (75

<Normal Paper>

60 - 105

- PPC Paper

- Bond paper

- Recycled paper

/m2 (16 - 28 lbs.)

/m2) paper

RELIABILITY/DURABILITY/SERVICEABILITY

MPBF: 25,000 sheets or more

MTBF: 3,000 hours or more

Life: 300,000 sheets or 5 years

(whichever comes first)

Paper Feed Reliability *1:<Jam rate>

1/2000 sheets or less

<Misfeed>

1/2000 sheets or less

<Multiple sheet feed>

1/500 sheets or less

<Folded coners>

1C or more at 1/1000 sheets or less

(1C or less is not included)

NOTE:

*1:With recommended paper and normal conditions

MTTR: 30 minutes or less

DIMENSION AND WEIGHT

Paper Size: A4 (210 x 297mm)

Letter (8.5 x 11 inch)

G-Le

Le

al (8.5 x 13 inch)

al (8.5 x 14 inch)

Dimension: 396 x 517 x 254 mm (W x D x H)

Wei

ht: 6.5 K

Rev. 0 9

Page 10

OPERATING PRINCIPLES

Page 11

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

g

g

g

g

2.1 OVERVIEW

This section describes the operating principles of the Duplex Unit.

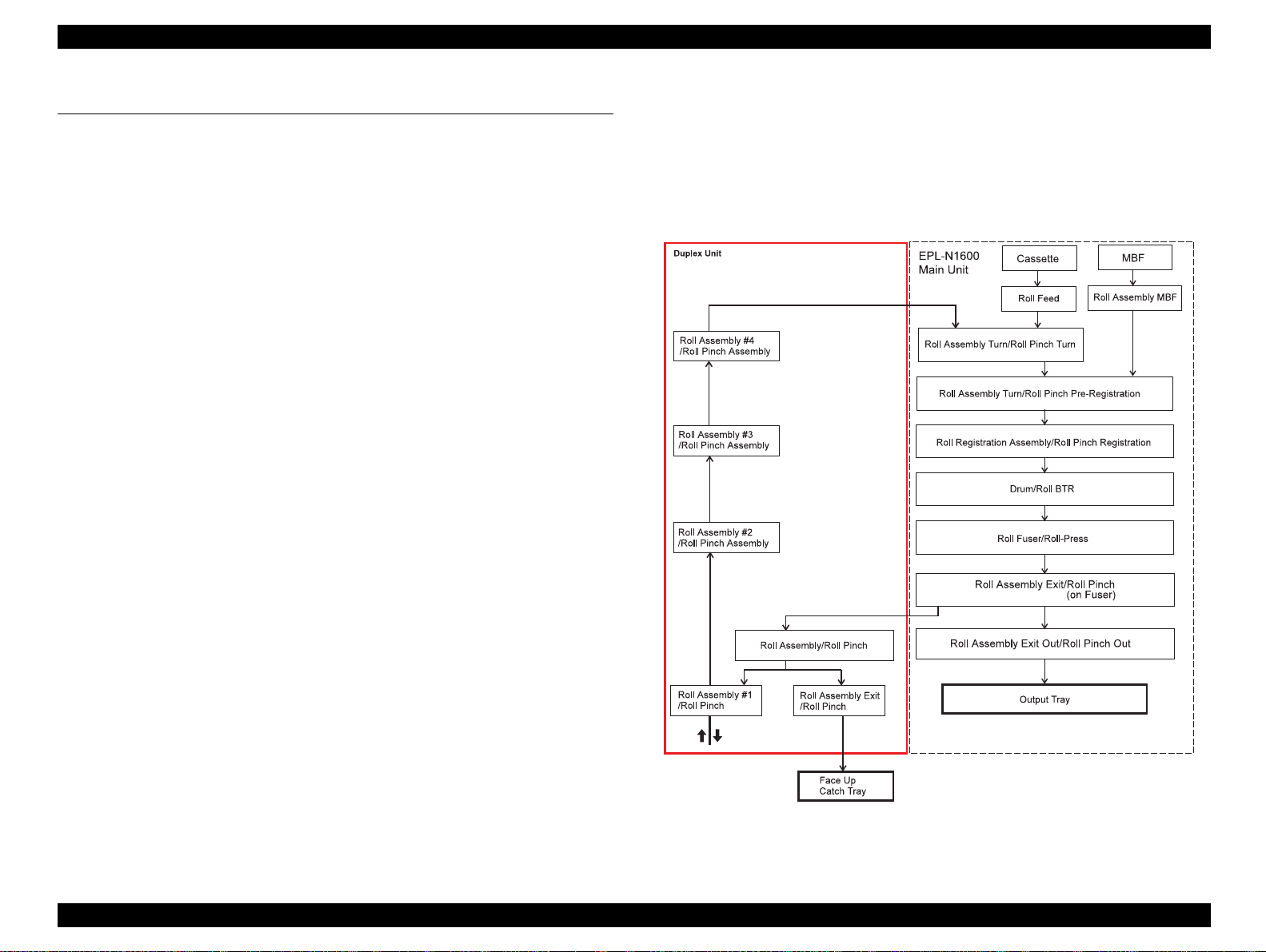

2.1.1 Paper Transportation

Paper is transported through the printer Base Engine and the Duplex

Unit alon

Mode is selected or the optional Face UP Catch Tray is installed and

selected. In the Duplex Mode, a sheet of paper printed on one side is

uided into the Duplex Unit to re-feed, turned over in the Duplex Unit,

reversed, and fed a

Catch Tray is selected, a sheet print ed on one side in the Simplex Mode

or a sheet printed on both sides is delivered into the Face Up Catch

Tray throu

the paper path shown in the Figure below when the Duplex

ain into the Base Engine. When the optional Offset

h the Duplex Unit.

Figure 2-1. Paper Transport Path

Rev. 0 11

Page 12

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

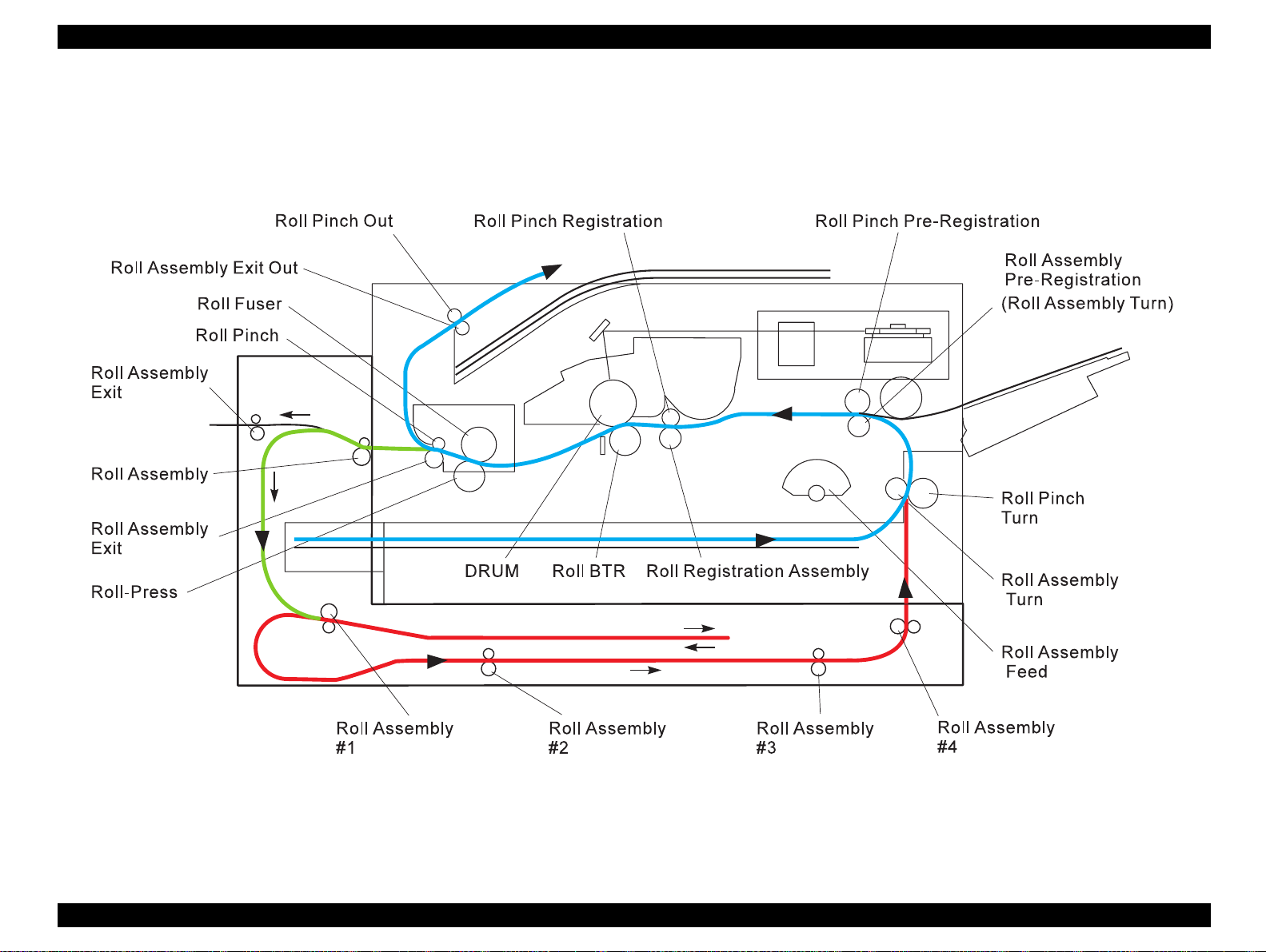

The Figure below is a cut-section side view of the EPL-N1600 with the

optional Duplex Unit attached that shows the paper path and the major

components directly related to the paper transportation.

Figure 2-2. Duplex Printing Paper Path

Rev. 0 12

Page 13

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

g

g

g

g

g

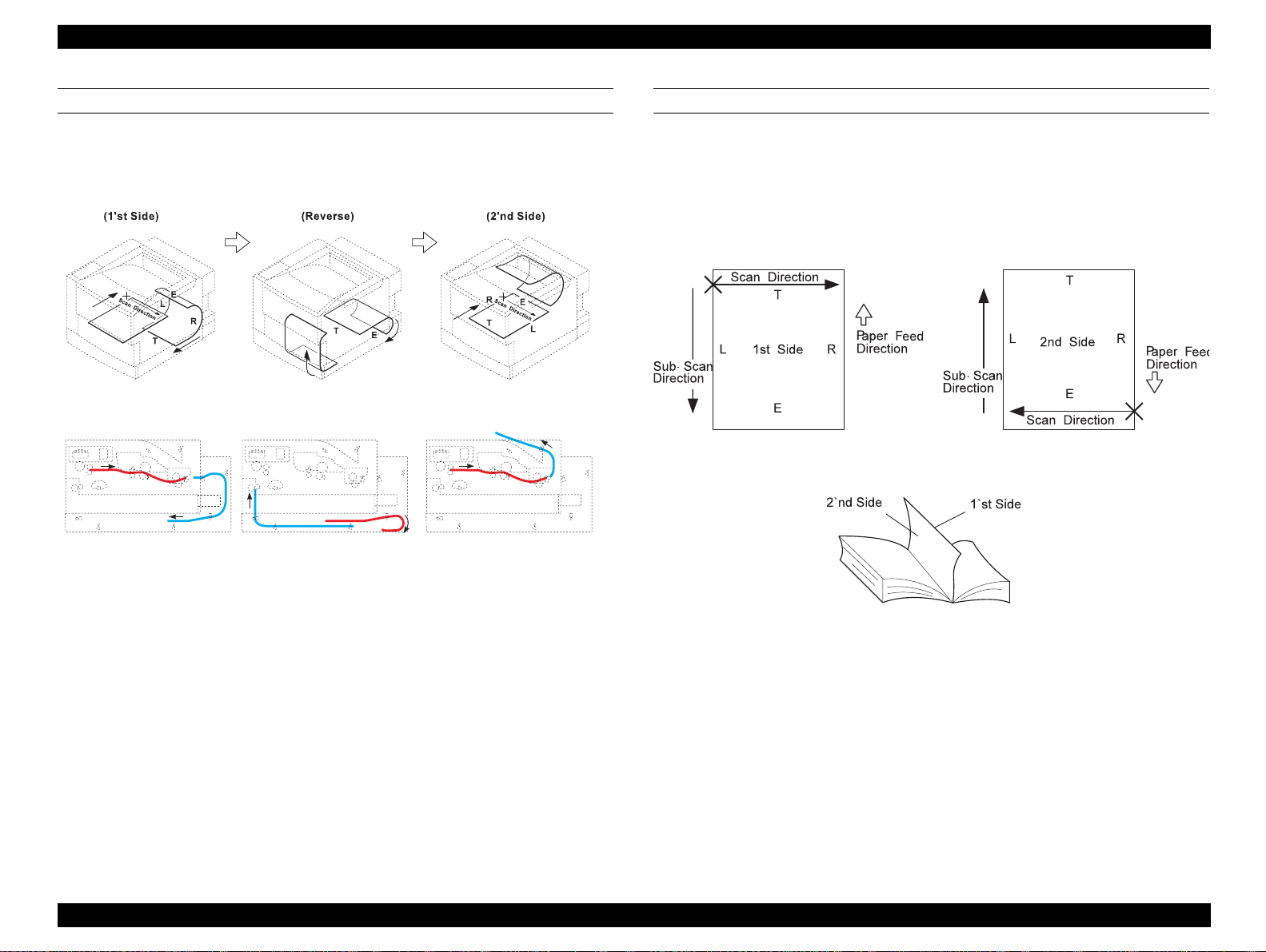

PAPER TRANSPORTATION CONTROL

The fi

ure below shows the paper movements in duplex printing mode.

SCANNING DIRECTION IN DUPLEX PRINTING

The fi

scannin

controller sends the ima

order of pa

ure below shows the relationship between the main and sub

direction and a side of the page printed in duplex pri nting. The

e data to the engine according to the printing

es, lines (raster lin es) on each page and pixels on each line.

Figure 2-3. Paper Movement Control

Figure 2-4. Scanning Direction

Rev. 0 13

Page 14

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

g

g

g

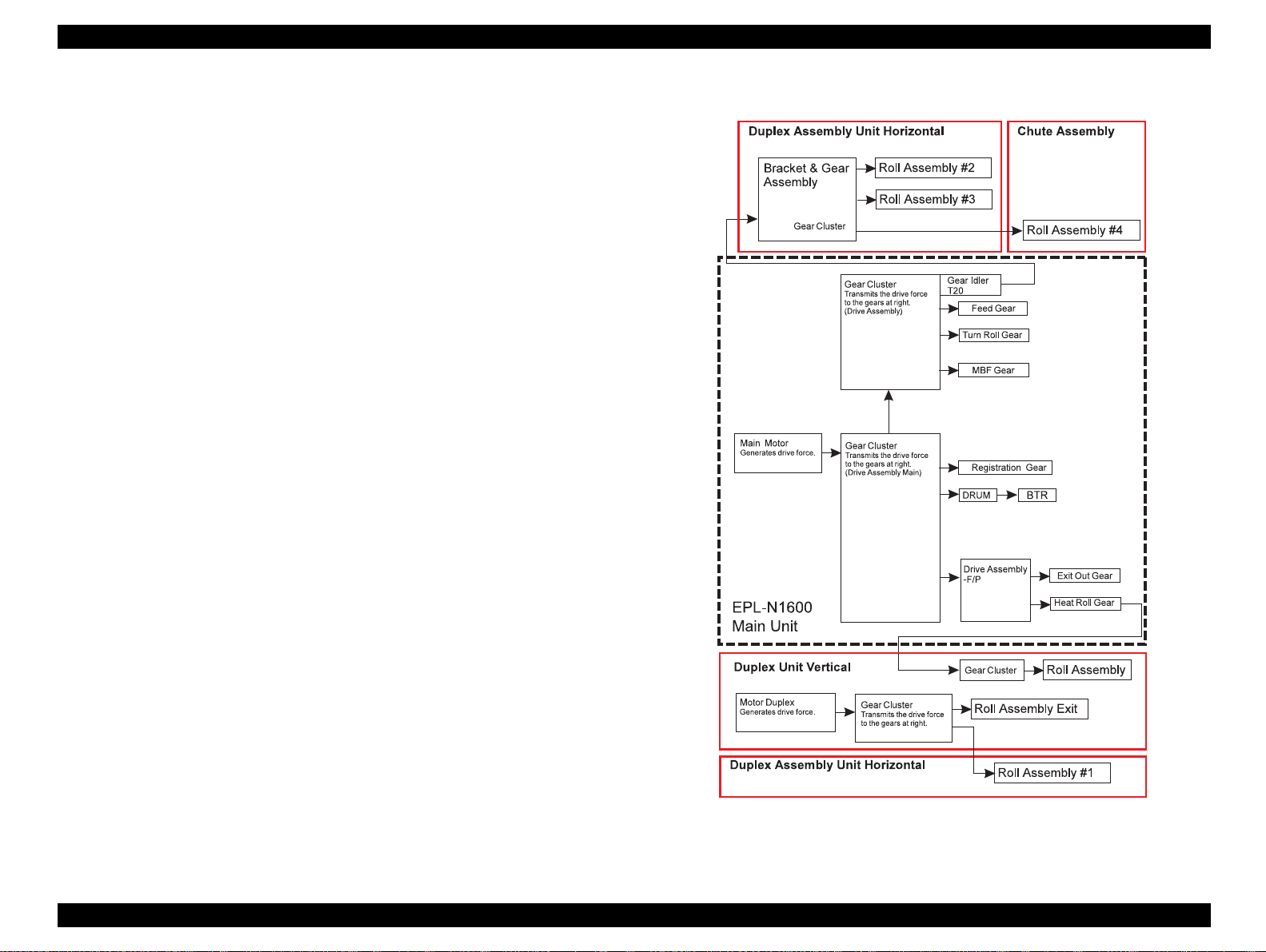

2.1.2 Drive Power Transmission

The Duplex Unit is operated by the drive power generated by the Main

Motor and the Paper Handlin

drive power

ure in right shows the relations of each components.

fi

enerated by the Motor Duplex within t he Duplex Unit. The

Motor of the Base Engine and by the

Figure 2-5. Drive Power Transmission

Rev. 0 14

Page 15

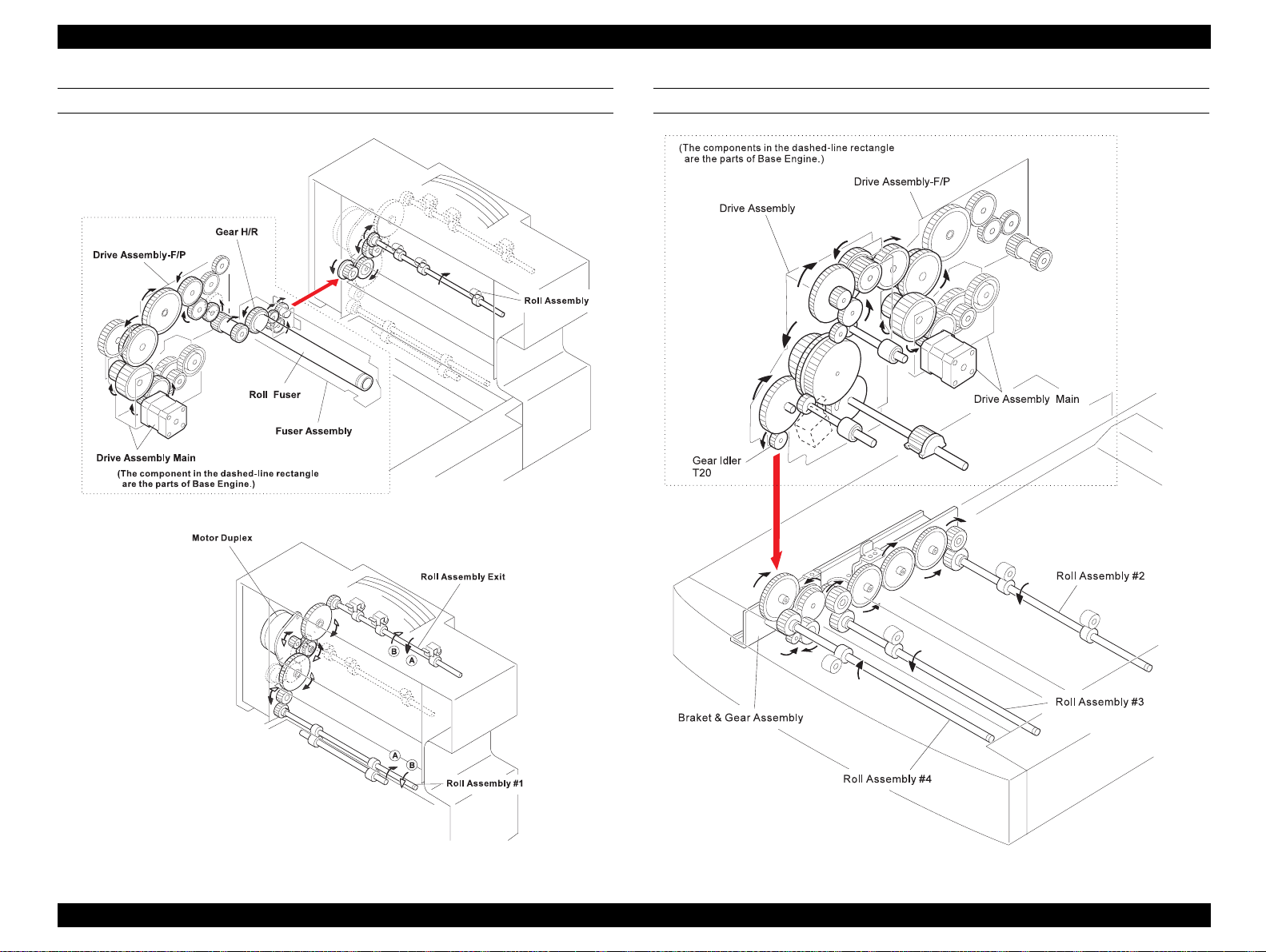

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

DUPLEX UNIT DRIVE POWER TRANSMISSION (1) DUPLEX UNIT DRIVE POWER TRANSMISSION (2)

Rev. 0 15

Page 16

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

gag

gag

g

g

g

g

gg

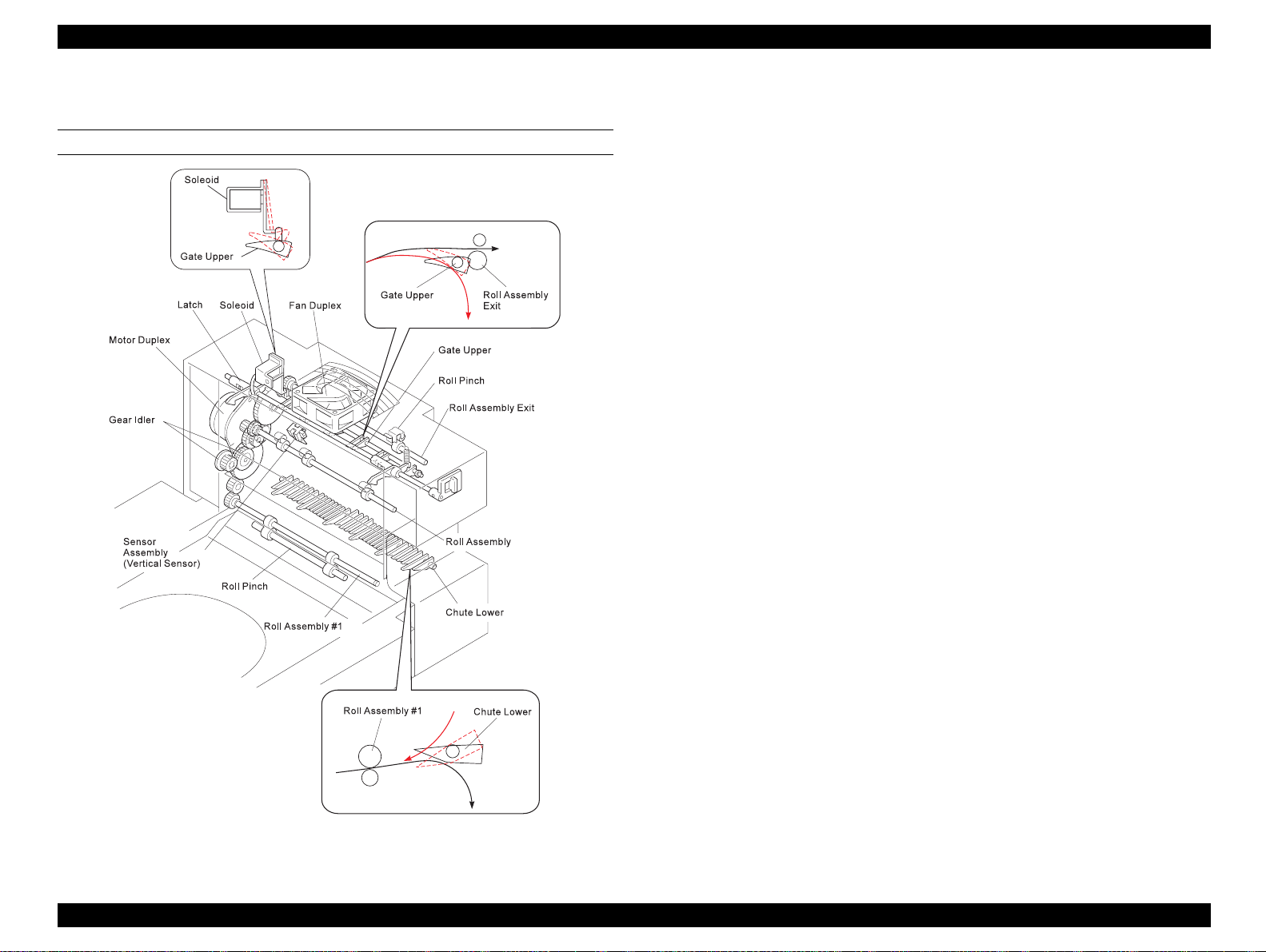

2.1.3 Function of Duplex Unit Major Components

VERTICAL UNIT

Motor Duplex: Generates the drive power for the Duplex

Unit.

Gear Cluster: Transmits the drive power from the Motor

Duplex to the Roll Assembly Exit and to Roll

Assembly #1 (part of the Horizontal Unit).

When the Vertical Unit is in place, the Idle r

Gear in the Gear Cluster en

the end of the Roll Assembly #1 shaft, and

transmits the drive power to Roll Assembly

#1. When the Vertical Unit is tilted back, the

Idler Gear disen

Roll Assembly #1 shaft.

Roll Assembly: Works with Rolls Pinch to drive paper from

the Fuser Exit Roll Assembly into the Vertical

Unit. The drive power is transmitted from the

Base En

the Duplex Gear Assembly of the Base

En

Roll Assembly Exit: Works with Rolls Pinch to drive paper out into

the Face Up Catch Tray. The drive power for

the Roll Assembly Exit is trans mitted fr om the

Motor Duplex throu

ine to the Roll Assembly, through

ine and the gears in the Duplex Unit.

e from the gear on the

h the Gear Cluster.

es the gear on

Gate Upper: A movin

to either Roll Assembly #1 or to the Roll

Assembly Exit.

Solenoid: To

Figure 2-6. Duplex Unit - Vertical unit Components

baffle that switches the paper path

les the Gate Upper.

Rev. 0 16

Page 17

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

g

g

g

g

g

g

g

Sensor Assembly: Sensor in the Vertical Unit which is located

near the inlet and det ects paper which enters

the Duplex Unit. This sensor i s also called the

Vertical Sensor.

Chute Lower: Pushed down by the paper comin

Gate Upper, allowin

to Roll Assembly #1. Without the wei

the paper pushin

its raised position. Then the sh eet of paper,

driven in the reverse direction by Roll

Assembly #1, is

the Gate Lower to Roll Assembly #2.

Fan Duplex: Expels the air inside the Duplex Unit (and the

printer throu

introduces fresh air into the Duplex Unit and

the printer) to prevent an excessive r ise of the

inside temperature.

Latch: Secures the Vertical Unit to the rear of the

Base En

h the rear exit of the printer) and

ine.

the paper to proceed on

it down, the Gate returns to

uided by the bottom side of

from the

ht of

Rev. 0 17

Page 18

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

g

g

g

g

g

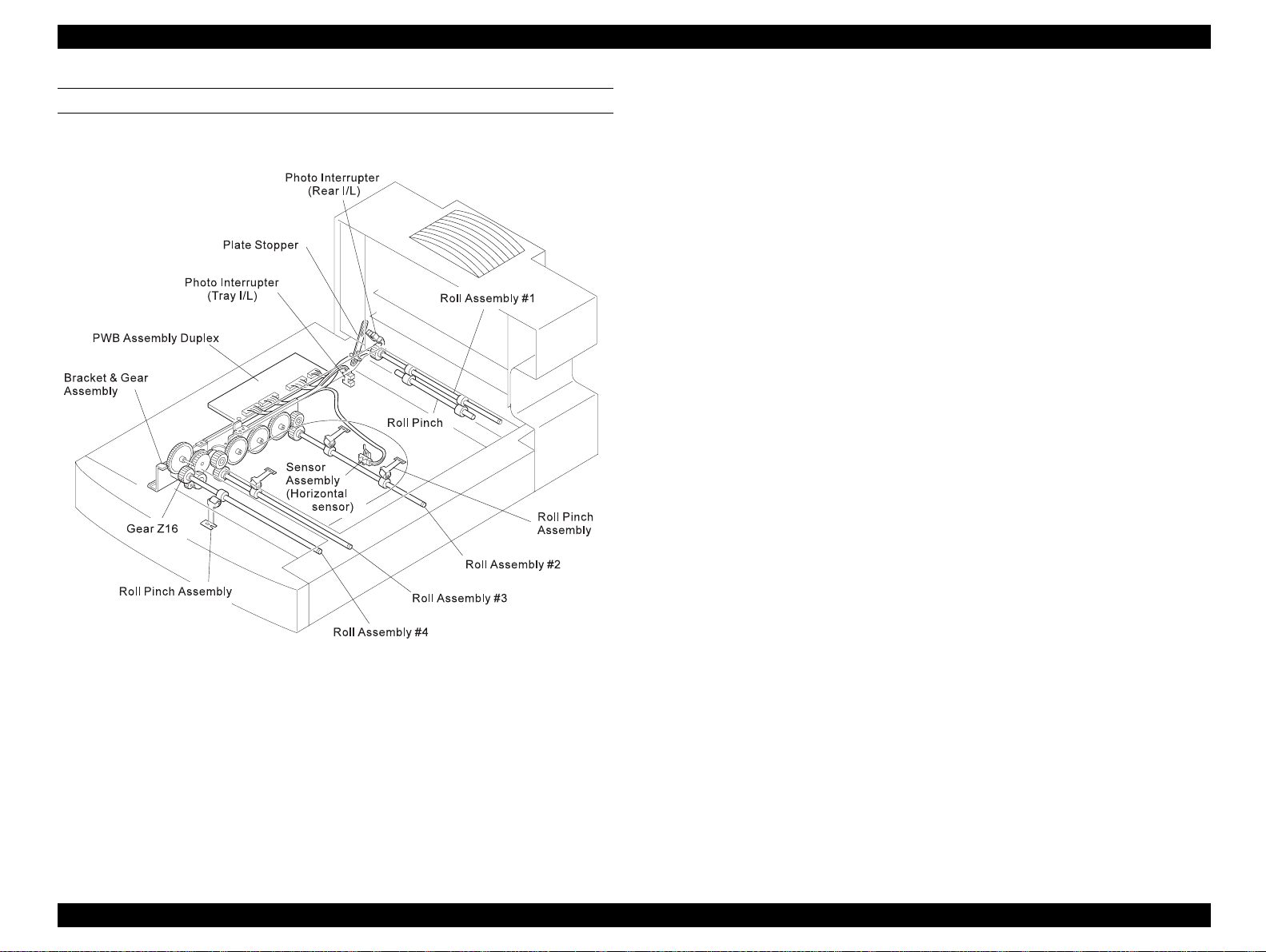

HORIZONTAL UNIT

Bracket & Gear Assembly:Receives the drive power from the Base

ine, and transmits it to Roll Assemblies

En

#2, #3, and #4 of the Horizontal Unit.

Roll Assembly #: Receives the drive power from the Motor

Duplex and Gear Cluster which are p art of the

Vertical Unit. Roll Assembly #1 rotates

forward when receivin

the first side printed. Roll Assembly #1 then

rotates in reverse to drive the sheet to Roll

Assembly #2 in preparation for printin

second side of the sheet.

Roll Assemblies#2/3/4: Drive the paper into and out of the Duplex

Unit.

PWBA Assembly Duplex: Controls the Duplex Unit operation. The 4-bit

MPU on the PWBA Duplex receives

commands from the PWBA MMCU, receives

nals from the Sensors within the Duplex

si

Unit, actuates the Solenoid Duplex, and the

Motor Duplex, and returns the status of the

Duplex Unit.

a sheet of paper with

the

Horizontal Sensor: Detects when a sheet of paper reaches Roll

Assembly #2.

Figure 2-7. Duplex Unit - Horizontal Unit Components

Duplex Unit ChuteCover Interlock:

Photo interrupter (PL11.24) that monitors

whether or not the Duplex Unit Chute Cover

is in place.

Vertical Unit Interlock: Photo interrupter (PL11.24) that monitors

whether or not the Vertical Unit is in position

ainst the rear of the Base Engine.

a

Rev. 0 18

Page 19

EPSON EPL-N1600/Duplex Unit Chapter 2 Operating Principles

gg

Plate Stopper: Support and limiting arm for the Vertical Unit

Solenoid: To

les the Gate Upper.

Rev. 0 19

Page 20

TROUBLESHOOTING

Page 21

EPSON EPL-N1600/Duplex Unit Chapter 3 Troubleshooting

This chapter is not appliacble to the Duplex Unit.

Rev. 0 21

Page 22

DISASSEMBLY AND ASSEMBLY

Page 23

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

4.1 OVERVIEW

This chapter explains how to disassemble the Duplex Unit and its

various mechanisms. Except where otherwise indicated, the

reassembly procedure is the reverse of the disassembly procedure.

4.1.1 Precautions

This section describes the precautions you must take to prevent

accidents durin

out all work in accordance with the pre cautions and

provided in this manual.

CAUTION

disassembly and reassembly work. Be sure to carry

eneral instructions

Be careful to avoid injury from frame edges and other

sharp or protruding areas of the printer.

Avoid touching IC elements with bare hands, so as to

prevent possible damage from electrostatic

discharge. If you need to touch these areas, wear

appropriate electrostatic protection gear

(electrostatic wrist band, etc.) .

To ensure work efficiency and safety, use only the

tools specified in this manual.

The unit uses screws of many differen t types. Be sur e

to note the correct location for each screw before

removing it. Inserting screws into the wrong places

may strip or damage the screw holes.

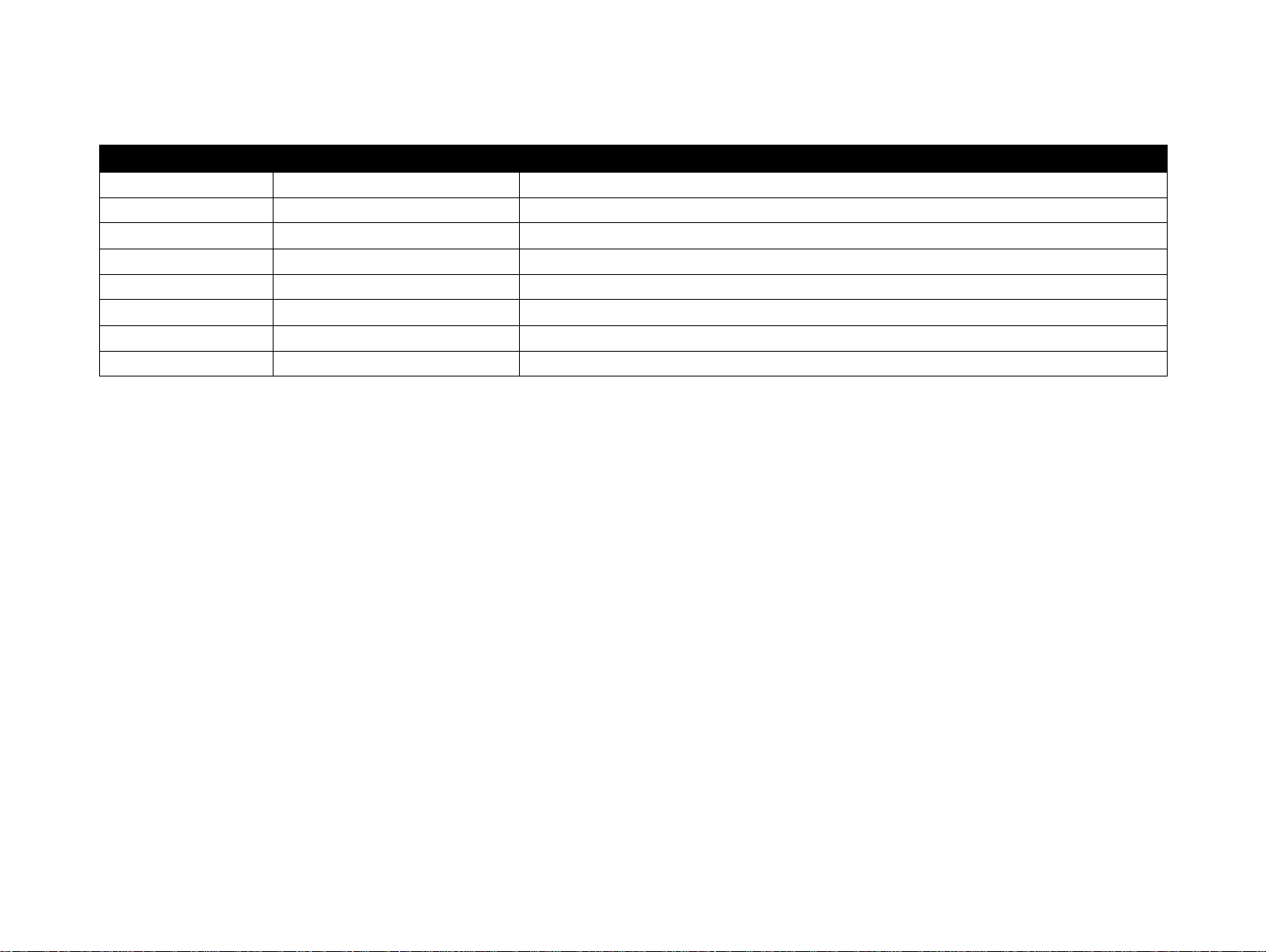

4.1.2 Tools

The following table lists the tools you need to disassemble and

reassemble the printer.

Table 4-1. Required Tools

Market

Tool

Phillips screwdriver Yes B743800200

Tweezers Yes B641000100

Round nose pliers Yes B740400100

Availability

Code

Rev. 0 23

Page 24

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2 DISASSEMBLY AND ASSEMBLY

This section describes the procedures for disassembling the Duplex

Unit. The assembly of the unit can be made by performin

disassembly step in reverse order unless otherwise specified, and the

assembly procedure is therefore omitted in thi s manual.

the

Rev. 0 24

Page 25

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

g

F4-1a

4.2.1 Duplex Unit Removal

1. Switch OFF printer power and remove the AC power cord from the

rear of the printer.

2. Disconnect all interface cable s from the rear of the printer.

3. Remove the 500 Sheet Feeder, if one is installed.

4. Push the Vertical Unit release lever to the rear (1) and tilt the

Vertical Unit away from the printer (2).

5. Press the Feeder Joint Clips to

feeder joints securin

the Duplex Unit to the Printer.

ether and remove the two rear

6. Remove the 250 Sheet Cassette and the Chute Assembly (4).

7. Press the feeder joint clips to

joints securin

8. Lift the base en

the Duplex Unit to the printer (5).

ine off of the Duplex Unit.

ether and remove the two front feeder

F4-1b

Figure 4-1. Duplex Unit Removal

Rev. 0 25

Page 26

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

4.2.2 Duplex Assembly Unit Vertical

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Slide the end of the Plate Stopper off of the post on the Frame L/H

(1).

4. Tilt back the Vertical Unit (2).

5. Remove the wire clamp that holds the harness.

6. Remove the Bracket Sensor of t he Rear Inter lock Swi tch ( PL11.1 .9:

Photo Interrupter) (4).

7. Disconnect J230 (5).

F4-2a

8. Remove the two screws that are securin

round wire to the Frame L/H (6).

and

the Plate Assembly Pivot

9. Pry off the Plate Assembly Pivot (7).

10. Slide the Duplex Assembly Unit Vertical to the left to free the ri

ht

pivot from the Horizontal Unit, and remove the Vertical Un it.

F4-2b

Figure 4-2. Duplex Assembly Unit Vertical Removal

Rev. 0 26

Page 27

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2.3 Chute Cover

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the two screws that sec ure the Plate Cover to the Frame L/

H, and remove the Plate Cover.

5. Remove the seven screws that are securin

Duplex Assembly Unit Vertical.

6. Lift the Duplex Assembly Unit Vertical out of the Chute Cover.

the Chute Cover to the

Figure 4-3. Chute Cover Removal

Rev. 0 27

Page 28

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

4

4.2.4 Fan Assembly Duplex

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the Chute Cover.

5. Disconnect P249/J2491 and route the Harness Vertical out of the

Frame.

6. Remove the two screws that secure the Fan Assembly Duplex to

the Bracket Fan.

7. Remove the Fan.

Figure 4-4. Fan Assembly Duplex Removal

Rev. 0 28

F4-

Page 29

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2.5 Sensor Assembly (Vertical)

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the Chute Cover.

5. Remove the Fan Assembly Duplex.

6. Disconnect J246 from the Sensor Assembly (Vertical).

7. Press in on the latchin

Frame, and remove the Sensor.

clips that are securing the Sensor to the

Figure 4-5. Sensor Assembly (Vertical) Removal

Rev. 0 29

Page 30

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2.6 Motor Duplex

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the Chute Cover.

5. Disconnect J244 from the Motor Duplex.

6. Remove the two screws that are securin

Bracket, and remove the Motor.

the Motor Duplex to the

Figure 4-6. Motor Duplex Removal

Rev. 0 30

Page 31

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2.7 Solenoid

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the Chute Cover.

5. Disconnect J2471 (Solenoid) from P247.

6. Free the harness of the Solenoid from the wire clamp.

7. Turn the Chute Cover upside down.

8. Remove the screw that is securin

9. Remove the Solenoid.

the Solenoid to the Frame L/H.

Figure 4-7. Solenoid Removal

Rev. 0 31

Page 32

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

4.2.8 Shaft Latch & Lever

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the Chute Cover.

5. Remove the screw that is securin

and remove the Latch.

6. Remove the Sprin

7. Remove the screw that is securin

and remove the Latch.

8. Slide the Shaft Latch, alon

out of the Frame.

that is attached to the right Latch.

with the attached Lever, to the right and

the left Latch to the Shaft Latch,

the right Latch to the Shaf t Latch,

Figure 4-8. Shaft Latch/Lever Removal

Rev. 0 32

Page 33

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

g

-

4.2.9 Rolls Pinch & Roll Assembly Exit

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the Chute Cover.

5. Remove the Fan Assembly Duplex.

6. Remove the three screws that secure the Bracket Fan to the Chute

Upper 2 and Plate Tie.

7. Remove the E-rin

s from both ends of the shaft of the Roll

Assembly Exit.

8. Remove the Bearin

9. Remove the Gear and Bearin

10. Slide the shaft to the left until the ri

11. Slide the shaft to the ri

from the right end of the shaft.

from the left end of the shaft.

ht end is freed from the Frame.

ht and out of the Frame.

12. Press down each Roll Pinch clip and remove the three Pinch Rolls

from the Chute.

F4

Figure 4-9. Rolls Pinch/Roll Assembly Exit Removal

Rev. 0 33

Page 34

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

g

g

4.2.10 Chute Lower & Roll Assembly

1. Remove the Duplex Unit.

2. Remove the Chute Upper.

3. Remove the Duplex Assembly Unit Vertical.

4. Remove the Chute Cover.

5. Remove the two screws that are securi n

the Frame R/H and Bracket Pivot R/H.

6. Pull the Frame R/H away from the Chute Invert-V/TRA so you can

free the Chute Lower ri

7. Slide the Chute Lower to the ri

pivot from the Frame L/H and remove the Chute Lower from the

Frame.

8. Remove the E-rin

Assembly.

9. Remove the Bearin

10. Remove the Gear and Bearin

11. Lift the Roll Assembly off of the Chute Lower.

ht pivot from the Frame R/H.

ht and free the Chute Lower left

s from both ends of the shaft of the Roll

from the right end of the shaft:

from the left end of the shaft.

the Chute Invert-V/TRA to

Figure 4-10. Chute Lower/Roll Assembly Removal

Rev. 0 34

Page 35

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

4.2.11 Photo Interrupters (Rear I/L & Chute Cover I/ L)

1. Remove the Duplex Unit.

2. Slide the end of the Plate Stopper off of the post on the Frame L/H.

See the illustration (1).

3. Tilt back the Duplex Assembly Unit Vertical.

PHOTO INTERRUPTER (PL11.1.9: REAR INTERLOCK)

4. Remove the two screws that is securin

Sensor to the Frame.

5. Remove the Bracket, alon

6. Disconnect J2732 from the Rear Interlock Swit ch.

7. Press in on the lockin

from the Bracket.

PHOTO INTERRUPTER (PL11.2.15: CHUTE COVER INTERLOCK)

8. Remove the Chute Upper.

9. Slide the Chute Assembly out of Duplex Unit.

10. Press in on the lockin

Switch from the Support Duplex-L/H.

11. Disconnect J2733 from the Chute Cover Interlock Switch.

with the attached Rear I nt erlock Switch.

clips and remove the Rear Interlock Switch

clips and remove the Cute Cover Interlock

the Rear Interlock Bracket

Figure 4-11. Photo Interrupter (Rear I/L, Chute Cover I/L) Removal

Rev. 0 35

Page 36

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2.12 Chute Upper

1. Tilt back the Duplex Assembly Unit Vertical.

2. Remove the four screws that are securin

Horizontal Unit.

3. Remove the Chute Upper.

the Chute Upper to the

Figure 4-12. Chute Upper Removal

Rev. 0 36

Page 37

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

F

4.2.13 Sensor Assembly (Horizontal)

1. Remove the Duplex Unit.

2. Remove the Chute Assembly.

3. Remove the Plate Base.

4. Disconnect J2731 from the Sensor Assembly (Horizontal).

5. Press in on the lockin

(Horizontal) from the Chute Assembly.

clips and remove the Sensor Assembly

Figure 4-13. Sensor Assembly (Horizontal) Removal

Rev. 0 37

Page 38

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

g

g

g

4.2.14 Roll Assembly #1 & Pinch Roll

1. Remove the Duplex Unit.

2. Slide the end of the Plate Stopper off of the post on the Frame L/H.

See illustration (1).

3. Tilt back the Duplex Assembly Unit Vertical.

4. Remove the Chute Upper.

5. Remove the two screws that are securin

Duplex R/H and L/H and remove the Chute (1).

6. Loosen the screw that secures the Rear Interl ock Swit ch (PL11.1. 8:

Bracket Sensor) to the Duplex Unit Horizontal II (PL11.2) (2).

7. Remove the E-rin

8. Remove the bearin

9. Remove the

#1.

10. Lift the shaft up and out of the Chute.

11. Slide the shaft to the ri

12. Unhook and remove the two Sprin

the Chute.

13. Remove the two Brackets Pinch alon

Chute.

s from both ends of Roll Assembly #1.

from the right end of the Roll Assembly #1.

ear and bearing from the left end of the Roll Assembly

ht and out of the Chute.

the Chute to the Supports

s that hold the Brackets Pinch to

with the Roll Pinch from the

14. Remove the two Brackets Pinch from the ends of the Pinch Roll.

Figure 4-14. Roll Assembly #1/Pinch Roll Removal

Rev. 0 38

Page 39

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2.15 Plate Base

1. Remove the Duplex Unit.

2. Slide the end of the Plate Stopper off of the post on the Frame L/H.

See the illustration (1).

3. Tilt back the Vertical Unit.

4. Turn the Duplex Unit upside down.

5. Remove the ei

Horizontal Unit, and remove the Plate Base.

ht screws that are securing the Plate Base to the

Figure 4-15. Plate Base Removal

Rev. 0 39

Page 40

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

g

g

g

4.2.16 Roll Assemblies #2 & #3

1. Remove the Duplex Unit.

2. Remove the Plate Base.

3. Set the Horizontal Unit on the Support Duplex L/H-.

4. Remove the two screws that are securin

the Support Duplex-R/H.

5. Carefully pull the Chute Assembly a few inches away from the

Support.

6. Remove the E-rin

rubber rolls).

7. Remove the bearin

8. Slide the Roll Assembly #2 down to free the bearin

end of the Assembly.

9. Pull the top end of the Roll Assembly #2 away from the Horizontal

Unit and remove the Assembly.

10. Remove the E-rin

rubber roll).

11. Remove the bearin

12. 1Slide Roll Assembly #3 down to free the bearin

of the Assembly.

from the end of Roll Assembly #2 (shaft with two

from the top end of Roll Assembly #2.

from the end of Roll Assembly #3 (shaft with one

from the top end of Roll Assembly #3.

the Chute Assembly to

at the bottom

at the bottom end

13. Pull the top end of the Roll Assembly #3 away from the Horizontal

Unit and remove the Assembly.

Figure 4-16. Roll Assemblies #2/#3 Removal

Rev. 0 40

Page 41

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.2.17 PWB Assembly Duplex

1. Remove the Duplex Unit.

2. Disconnect J263, J272, J273, and J274 from the PWB Assembly

Duplex.

3. Remove the screw that is securin

the Support Duplex-L/H.

4. Slide the end of the PWB out of the slot in the Support Duplex L/H

and remove the PWB.

the PWB Assembly Duplex to

Figure 4-17. PWB Assembly Duplex Removal

Rev. 0 41

Page 42

EPSON EPL-N1600 / Duplex Unit Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

4.2.18 Bracket & Gear Assembly

1. Remove the Duplex Unit.

2. Remove the PWB Assembly Duplex.

3. Slide the Chute Assembly out from the Duplex Unit.

4. Remove the two screws that are securin

the Plate Tie to the

Support Duplex-L/H and Support Duplex-R/H, and remove the Pl ate

Tie.

5. Remove the three screws that are securin

the Bracket & Gear

Assembly to the Support Duplex L/H. The rear screw also secures a

round wire to the Bracket. The middle screw also secures the

Bracket PWBA to the Gear Assembly Bracket.

6. Pull up and tilt back the Gear Assembly as you carefu lly re mov e the

Gear Assembly from the Support Duplex L/H.

CAUTION

The Gear Assembly gears are not secured to their

respective shafts, and they can slide off during Gear

Assembly removal. Tilt the Gear Assembly back to

keep the gears in place during removal and

replacement.

Figure 4-18. Bracket & Gear Assembly Removal

Rev. 0 42

Page 43

ADJUSTMENT

Page 44

EPSON EPL-N1600/Duplex Unit Chapter 5 Adjustment

There is no adjustment required when repairing the Duplex Unit.

Rev. 0 45

Page 45

MAINTENANCE

Page 46

EPSON EPL-N1600/Duplex Unit Chapter 6 Maintenance

There is no specific maintenance required for the duplex unit.

Rev. 0 47

Page 47

APPENDIX

Page 48

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

7.1 Connector Location

Connector Location Harness

J229

P/J230

P/J244 9 Harness Vertical

P/J246 10 Harness Vertical

P/J247

J2471

P/J249

J2491

J252 5 Harness 15P

P/J263 3 Harness 15P

P/J272 4 Harness 7P

P/J273 1 Harness Sensor 9P

P/J2731 13 Harness Sensor 9P

P/J2732 11 Harness Sensor 9P

P/J2733 12 Harness Sensor 9P

P/J274 2 Harness Sensor Horizontal

P/J282 14 Harness 7P

6 Harness Sensor Horizontal

Harness Vertical

8 @ Solenoid *1

Harness Vertical

7 @ Fan Assembly Duplex

Harness Vertical

*1:"@" mark at the beginning of a harness name indicates that the subject harness is a

part of the component from where the harness extends.

Figure 7-1. Connector Location Diagram

Rev. 0 49

Page 49

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

7.2 Exploded Diagram

DUPLEX UNIT (OPTIONAL)

1. Duplex Unit

(with PL10.2, PL10.3, PL10.4, PL11.1, PL11.2, PL12.1 and 5~8)

2. Reference only (Exploded on PL10.2, PL10.3, PL10.4)

3. Reference only (Exploded on PL11.1, PL11.2)

4. Reference only (Exploded on PL12.1)

5. Clip Chute $

6. Chute Duplex

7. Plate Cap

8. Joint Feeder (PL9.1.22) $

Rev. 0 50

Page 50

Page 51

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

DUPLEX UNIT VERTICAL I

1. Duplex Assembly Unit Vertical (with 2 - 5, PL10.3, PL10.4) $

2. Sensor Assembly $

3. Bracket Fan

4. Fan Assembly Duplex $

5. Chute Cover

6. --

Rev. 0 52

Page 52

Page 53

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

g

g

g

g

DUPLEX UNIT VERTICAL II

1. Harness Vertical

2. Clamp NSB1207

3. Bracket

4. Motor Duplex $

5. Gear

6. Wire

7. Plate Cover

8. Gear

9. Sprin

10. Gear

11. Gear

Torsion-Latch LH

19. Bracket

20. Frame R/H

21. Sprin

22. Plate Assembly Pivot

Torsion-Latch RH

12. Frame L/H

13. Solenoid $

14. Gear

15. Gear Idler

16. Sprin

17. Roll Trackin

18. Gear Idler

Extension

Rev. 0 54

Page 54

Page 55

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

g

g

g

g

g

g

g

DUPLEX UNIT VERTICAL III

1. Chute Lower

2. Bearin

3. Roll Assembly

4. Bearin

5. Gear

6. Chute Lower

7. Sprin

8. Chute Invert-V/TRA

9. Chute Upper

10. Sprin

11. Sprin

Earth

R

L

19. Sprin

20. Roll Assembly Exit

21. Gate Upper

22. Lever

23. Bracket Pivot R/H

12. Plate Tie

13. Roll Pinch

14. Chute Upper 2

15. Bearin

16. Gear

17. Latch

18. Shaft Latch

Rev. 0 56

Page 56

Page 57

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

g

g

g

g

DUPLEX UNIT HORIZONTAL I

1. Duplex Assembly Unit Horizontal (with 2 - 24, PL11.2, PL12.1) $

2. Roll Assembly #3

3. Roll Assembly #2

4. Chute Assembly

5. Bearin

6. Gear Z16

7. Guide

8. Bracket Sensor

9. Photo Interrupter $

10. Chute Upper

11. GearA

19. Chute Lower

20. Plate Pivot R/H

21. Sprin

22. Sensor Assembly $

23. Support Duplex-R/H

24. Plate Base

Earth

12. Roll Assembly #1

13. Bearin

14. Chute

15. Bracket Pinch

16. Sprin

17. Roll Pinch

18. Plate Tie

Rev. 0 58

Page 58

Page 59

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

g

g

g

DUPLEX UNIT HORIZONTAL II

1. Support Duplex-L/H

2. Bracket & Gear Assembly

3. Bracket PWBA

4. Sprin

5. Sprin

6. PWBA Assembly Duplex $

7. Harness Sensor 9P

8. Harness Sensor Horizontal

9. Plate Stopper

10. Pin

11. Harness 15P

12. Sprin

13. Plate Pivot L/H

14. Harness 7P

15. Photo Interrupter $

Earth

Earth

Rev. 0 60

Page 60

Page 61

EPSON EPL-N1600/Duplex Unit Chapter 7 Appendix

g

g

g

DUPLEX UNIT CHUTE

1. Chute Assembly (with 2 - 13) $

2. Chute

3. Roll Pinch Assembly

4. Roll Pinch Assembly

5. Chute Pass A

6. Sprin

7. Chute Pass B

8. Roller Assembly # 4

9. Sprin

10. Bearin

11. Gear Z16

12. Roll Pinch Assembly

13. Cover Front

Earth

Earth

Rev. 0 62

Page 62

Loading...

Loading...