Page 1

®

Color Laser Printer

EPSON ColorPage -C8200

SEPG99-003

Page 2

Notice

g

g

g

g

g

g

g

g

g

g

EPSON is a re

General Notice: Other product names used herein are for identification purpose only and may be trademarks or re

Copyri

hts reserved. No part of t his manual may be r eprod uced, st ored in a r etri eval sy ste m, or t ransmit ted in any for m or by an y means el ectroni c,

All ri

mechanical, photocopyin

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The contents of this manual are subject to chan

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The above not withstandin

thereof.

istered trademark of SEIKO EPSON CORPORATION.

respective owners. EPSON disclaims any and all ri

ht © 1999 SEIKO EPSON CORPORATION. Printed in Japan.

, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

e without notice.

SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

istered trademarks of their

hts in those marks.

Page 3

PRECAUTIONS

g

g

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performin

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performin

Signals a precaution which, if ignored, could result in damage to equipment.

procedures preceded by DANGER Headings.

repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

EPSON WARRANTY.

Page 4

About this manual

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

W ARNING

CAUTIO N

NOTE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the EPSON EPLC8200. The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be

precautions on the precedin

page.

iven to the

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. DISASSEMBLY / ASSEMBLY AND ADJUSTMENT

Describes the step-by-step procedur es for

disassemblin

CHAPTER 4. DIAGNOSTICS

Provides Epson-approved methods for dia

CHAPTER 5. TROUBLESHOOTING

Provides the step-by-step procedure s for

troubleshootin

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicin

APPENDIX

Provides the followin

reference:

• Connector pin assi

• Electric circuit boards components layout

• Exploded dia

• Electrical circuit boards schematics

eneral overview and specifications of the

/assembling and adjusting the product.

nostics.

.

the product.

additional information for

nments

ram

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide

additional information on a specif ic topic or to warn of possible dan

present durin

they are used, and always read NOTE, CAUTION, or WARNING

CHECK

PO INT

es.

messa

a procedure or an action. Be aware of all symbols when

Indicates an operatin

or condition that, if not strictly observed, could result in

injury or loss of life.

Indicates an operatin

or condition that, if not strictly observed, could result in

dama

May indicate an operatin

practice or condition that is necessar y to accomplish a task

efficiently. It may also provid e additional information that is

related to a specific subject, or comment on the results

achieved throu

e to, or destruction of, equipment.

h a previous action.

or maintenance procedure, practice

or maintenance procedure, practi ce,

or maintenance procedure,

er

Page 5

Abbreviation

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

ADC = Automatic Density Control

AG = Analo

ASSY = Assembly

AUX. = Auxiliary

B/W = Black and White

BCR = Bias Char

Bk = Black

BK = Black

BTR = Bias Transfer Roll

BUR = Back Up Roll

C = Cyan

CART. = Cartrid

CCW = Counterclockwise

CL. = Clutch

CLN = Cleanin

CLK = Clock

CONT. = Controller

CR = Char

CRU = Customer Replaceable Unit

CRUM = CRU Monitor

CW = Clockwise

DB = Developin

DEVE. = Developer

DIAG. = Dia

dpi = dots per inch

DTS = Detach Saw

ELEC. = Electric

EP = Electrophoto

Ground

e Roll

e

(or Cleaner)

e Roll

Bias

nostic

raphy

FDR = Feeder

FG = Frame Ground

FRU = Field Replaceable Unit

GND = Ground

H/R = Heat Roll

Hex = Hexadecimal

HVPS = Hi

I/F = Interface

IBT = Intermediate Belt Transfer

ID = Ima

L = Left

L/H = Left Hand

L/P = Low Paper

LD = Laser Diode

LEF = Lon

LVPS = Low Volta

M = Ma

MAG. = Ma

MCU = Machine Control Unit

MECH. = Mechanical

MOT. = Motor

MSI = Multi Sheet Inserter

N/F = Normal Force

N/P = No Paper

NVM = Non Volatile Memory

O/H = Option Hin

OHP = Overhead Projector

(In this manual, OHP means OHP film)

h Voltage Power Supply

e Density (or Identification)

Edge Feed

e Power Supply

enta

netic

e

OPC = Or

P/H = Paper Handlin

P/R = Pressure Roll

PCDC = Pixel Count Dispense Control

Pixel = Picture Cell

PPM = Prints Per Minute

PV = Print Volume

PWB = Printed Wirin

R = Ri

R/H = Ri

REGI. = Re

ROS = Raster Output Scanner

RTN = Ret urn

SEF = Short Ed

SG = Si

SNR = Sensor

SOL. = Solenoid

SOS = Start Of Scan

SPI = Scans Per Inch

SYNC. = Synchronous

TC = Toner Concentration

TEMP. = Temperature

TR = Transfer

TRANS. = Transport

WDD = Wide Ran

XERO. = Xero

Y = Yellow

YMCBk = Yellow, Ma

anic Photo Conductor

Board

ht

ht Hand

istration

e Feed

nal Ground

e Dynamic Damper

raphic

enta, Cyan, Black

Page 6

Safety Information

g

g

g

g

g

g

To prevent accidents during a maintenance procedure, strictly observe

the Warnin

within the scope of this document.

Do not do anythin

in this manual. In addition to the descriptions below and those

this manual, there are many situations and circumstances that are

erous. Be aware of these when you are working with the print e r.

dan

s and Cautions. Do not do anything that is dangerous or not

that is dangerous even if not specifically described

iven in

Power Supply

Before starting any service procedure, switch off the printer power and

unplu

printer when the power is applied, be aware of the pot ential for el ectrical

shock and do all tasks by followin

the power cord from the wall outlet. If you must service the

the procedures in this manual.

W ARNING

Do not touch any live part unless you are instructed to

do so by a service procedure. The LVPS power supply

switch/inlet part is li ve even when the power switch has

been turned off. Do not touch any live part.

Page 7

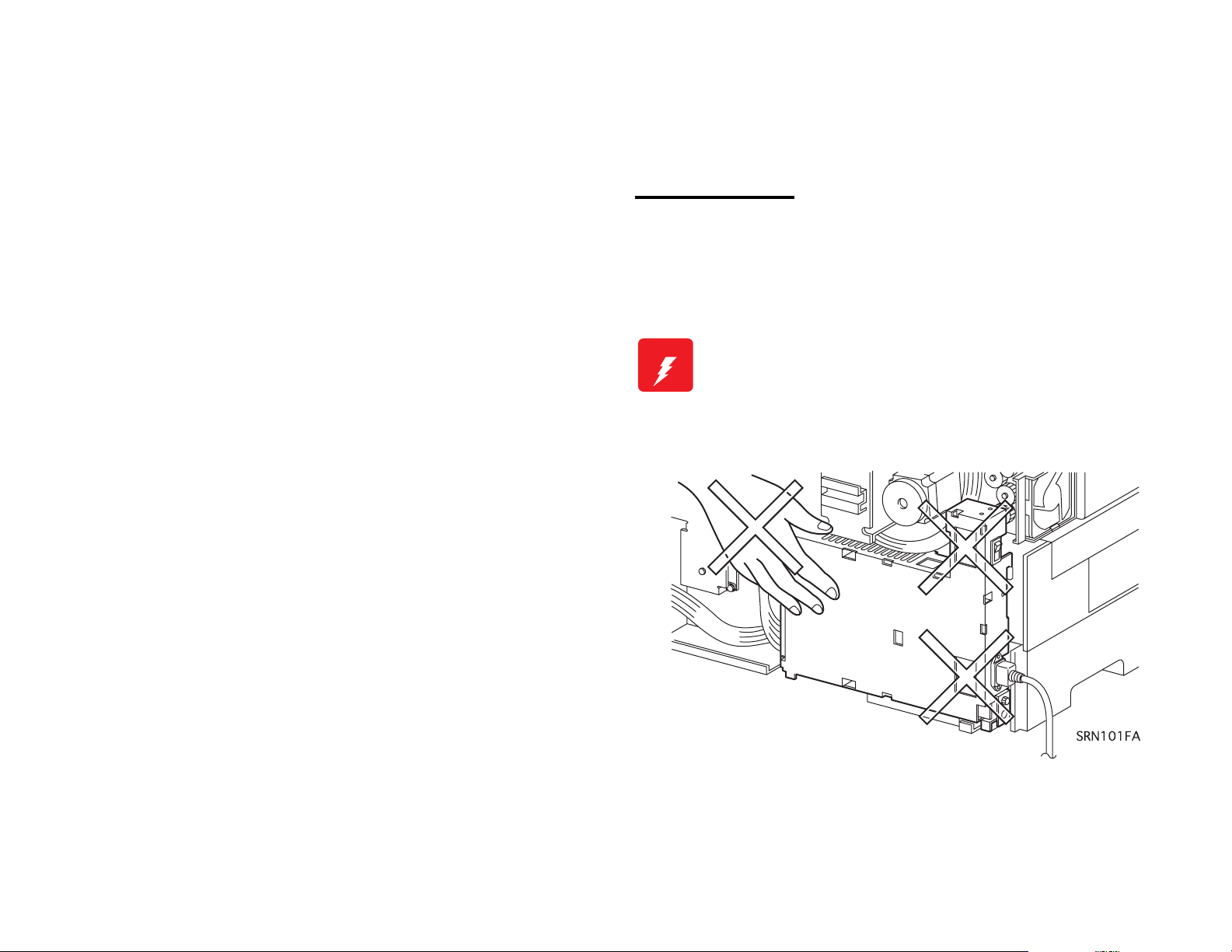

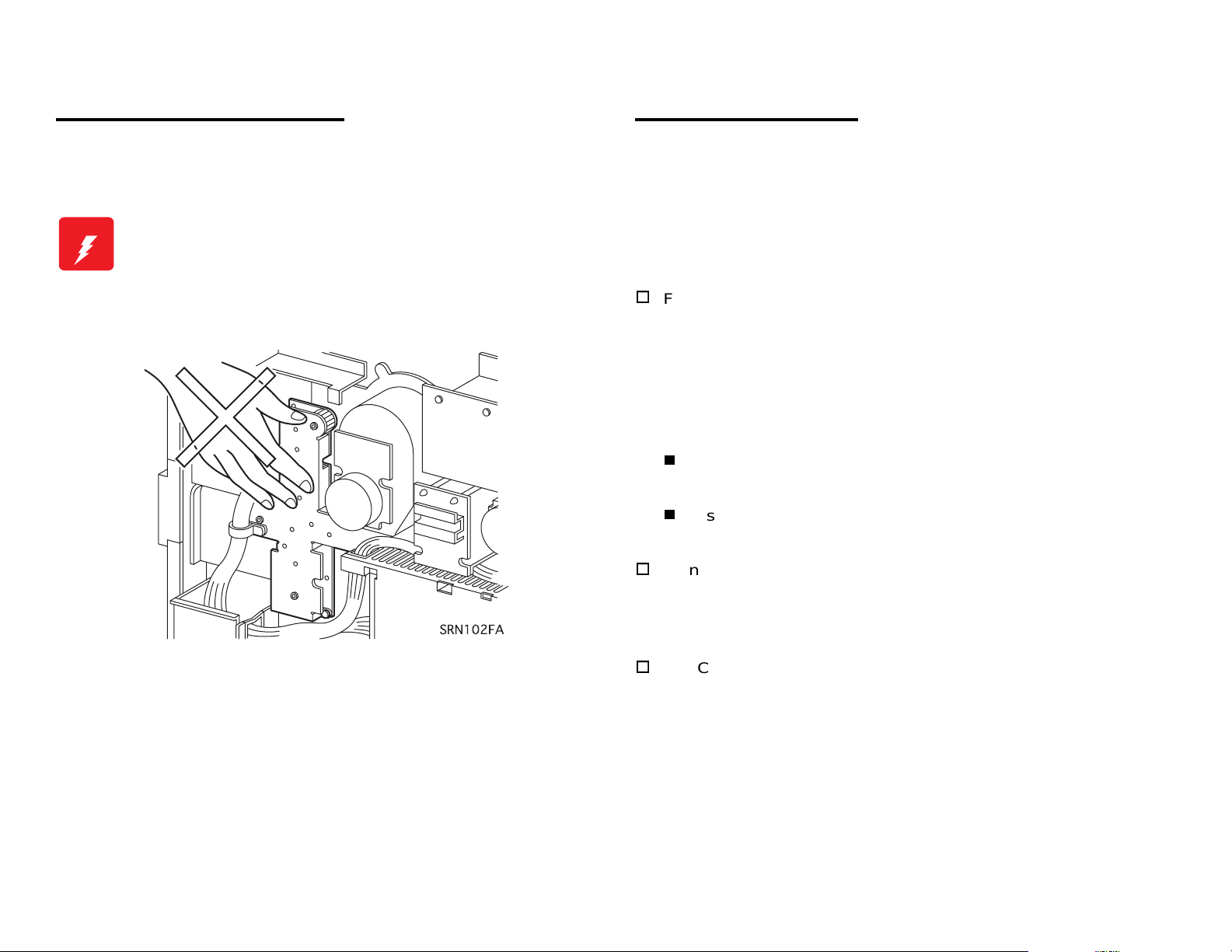

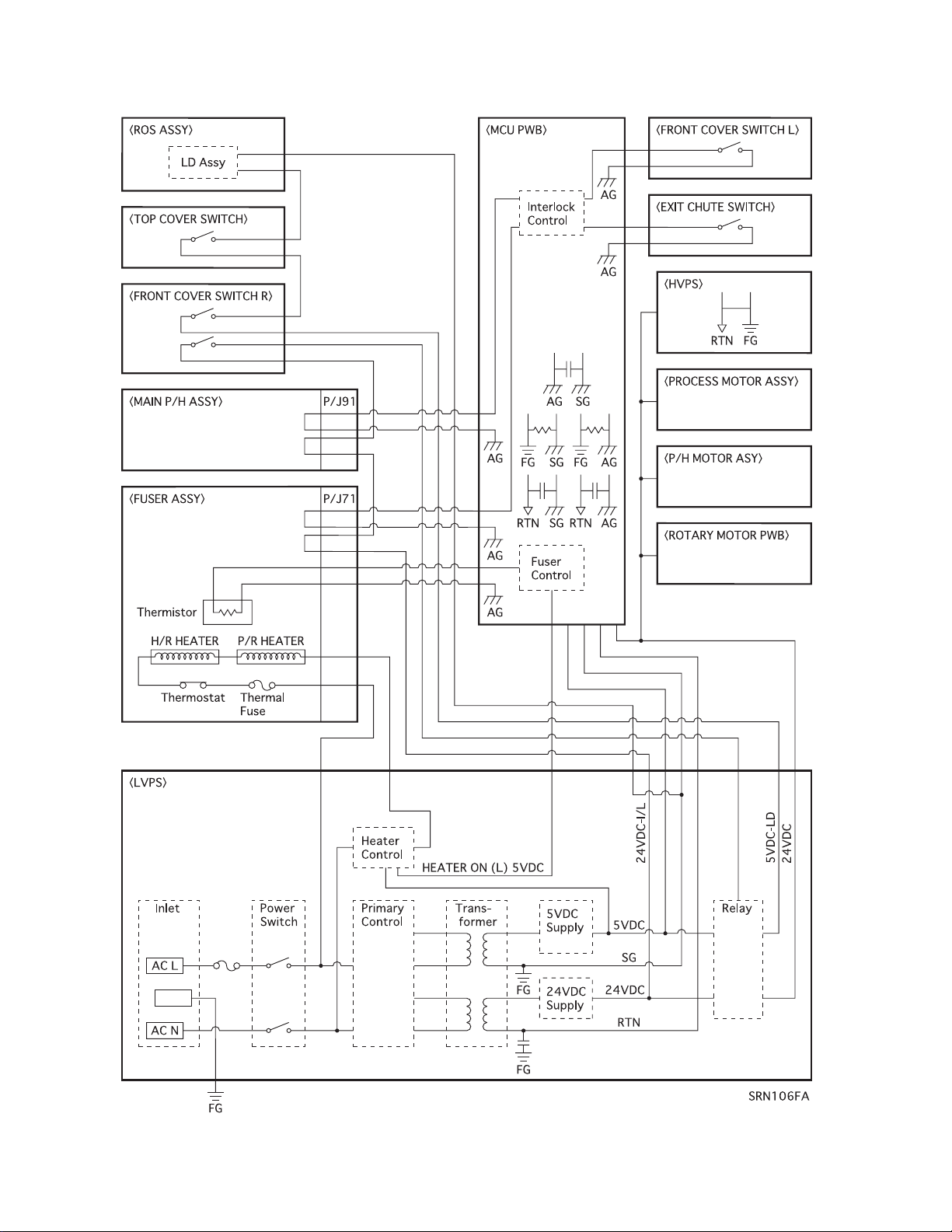

Mechanical Components

g

g

g

g

g

g

g

g

Safety Components

If you service a driving assembly (e.g., gears), first turn off the power

and unplu

W ARNING

the power cord. Then manually rotate the assembly.

Do not touch the driving part (e.g., gears) while the

assembly (printer) is being driven.

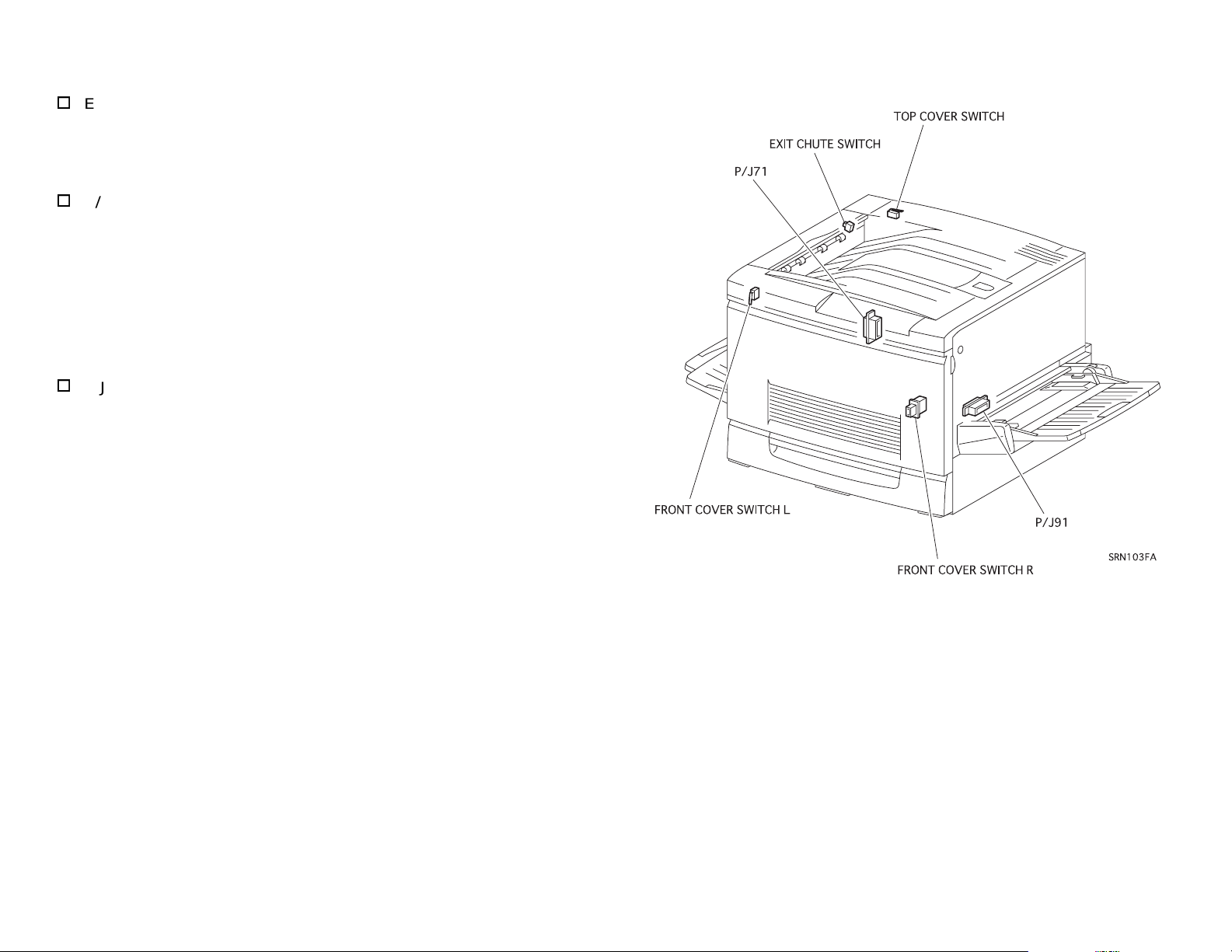

The printer is equipped with safety components (e.g., interlock

switches, fuses, thermostat) and safety switches for protectin

and service personnel from injury and the equipment from dama

The printer has two interlock switches, two saf ety switches and two

interlock connectors that serve as the main safety mechanism.

Front Cover Switch R

This switch is turned off when the Front Cover Assembly is opened.

It cuts off the power supply (24VDC, 5VDC-LD) from the power

supply unit to stop all operat ions and di sconnec ts the out put (5VDCLD) circuit from the power supply and stops the laser beam

emission.

This switch consists of the followin

A switch that cuts off the power supply (24VDC, 5VDC-LD) to

the control circuits and related parts.

A switch that directly cuts off the power supply circuit (5VDC-LD)

to the laser beam output circuit.

Front Cover Switch L

This is a safety switch. This switch is turned off when the Front

Cover Assembly is opened, causin

to stop operatin

.

two switches:

the printer without control units

users

e.

Top Cover Switch

This is an interlock switch that directly cuts off the power supply

(5VDC-LD) circuit to the laser beam output circuit. This switch is

turned off when the Top Cover Assembly is removed, cuttin

output (5VDC-LD) circuit from the power supply unit and stoppin

the laser beam emission.

off the

Page 8

g

g

g

g

g

Exit Chute Switch

This switch is a safety switch. Thi s switch i s turned off when t he Exit

Upper Assembly (the cover on the upper left side of the printer) is

opened.

P/J91 (Connector that connects the Main Harness Assembly and

istration Harness Assembly)

Re

This is an interlock connector that cuts off the power supply

(24VDC, 5VDC-LD) to the control circuit and related parts.

This connector is disconnected when the Main P/H Assembly (pullout type unit on the ri

the output (24VDC, 5VDC-LD) from the power supply and stoppin

the printer operation without control units.

P/J71 (Connector that connects the Fuser Connector and Fuser

Harness Assembly)

This is an interlock connector that cuts off the power supply

(24VDC, 5VDC-LD) to the control circuit and related parts.

This connector is disconnected when the Fuser Assembly (pull-out

type unit on the left side of the printer) is pulled out, cuttin

output (24VDC, 5VDC-LD) from the power supply and stoppin

printer operation without control units.

ht side of the printer) is pulled out, cutting off

off the

the

Page 9

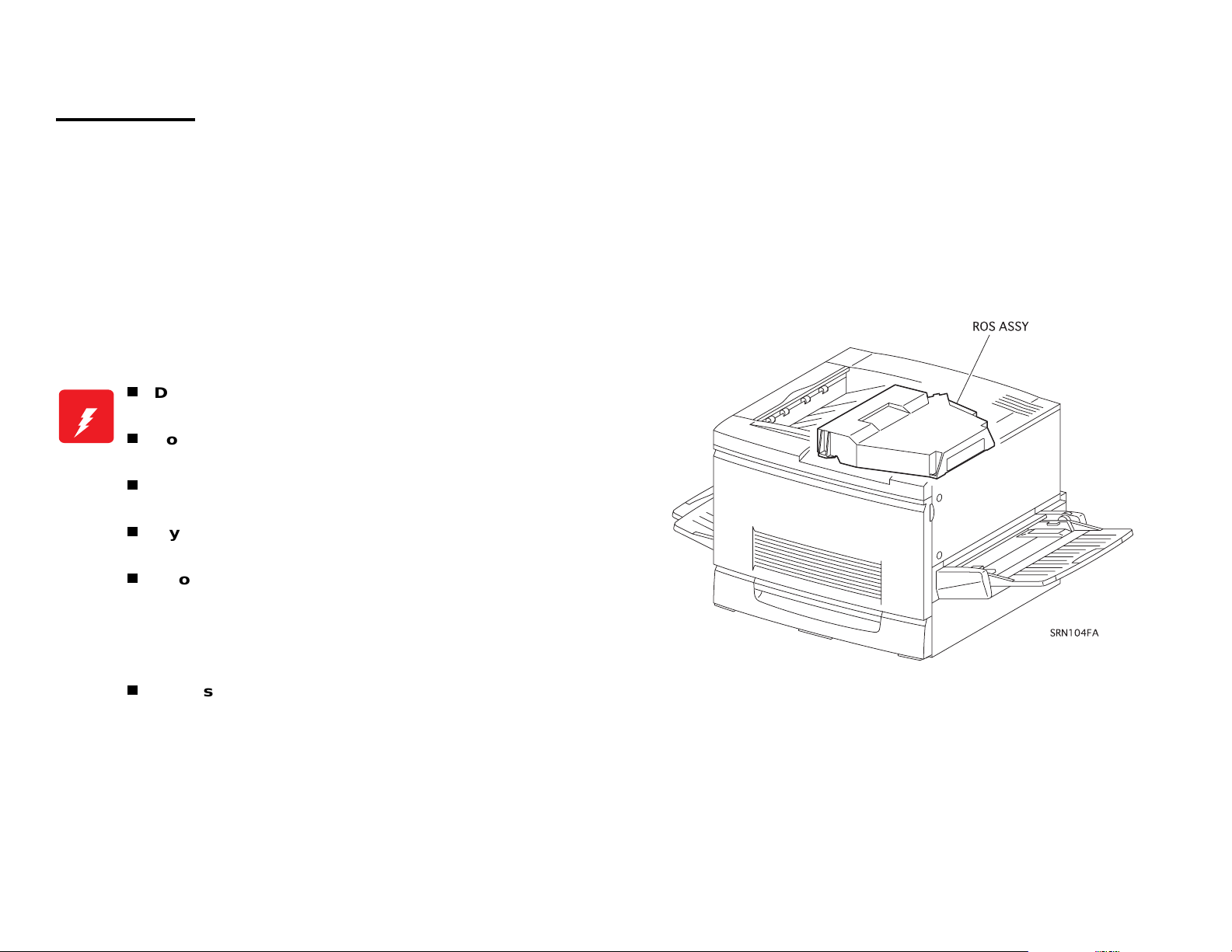

Laser Beam

g

The printer has two interlock switches: the Front Cover Switch R and

the Top Cover Switch. The purpose of these switches is to turn off the

laser beam emission if any of t he pri nter cover s ha ve been op ened; this

protects the user or service personnel from exposure to the laser beam

from the ROS Assembly.

NOTE:The laser beam has a narrower frequency band and more

coherent phases than any other light (s unlight , electr ic light ).

It has excellent monochromaticity and convergence. A thin

laser beam reaches long distances. Because of its

convergence characteristic, the laser beam converges into

one point, causing high density and high temperature. A

laser beam is harmful to the human body.

A laser beam may be emitted durin

turn on these interlock switches simultaneously under any

circumstances except in a normal operation.

W ARNING

Do not expose yourself to the laser beam to prevent

injury (blindness).

Do not open the cover that has the laser beam

warning label.

If you disassemble or assemble the printer, turn off

the power.

If you need to work on the printer with power applied,

strictly follow the instructions in thi s manual.

If you have to activate the printer while pressing the

Front Cover Switch R by hand or with a tool, remove

the Top Cover. (Do not turn on these interlock

switches simultaneously under any circumstances

except in a normal operation.)

Understand how the laser beam functions and take

maximum precautions not to injure yourself or anyone

around you.

a maintenance operation. Do not

NOTE:The laser beam in this printer is invisible.

Page 10

High Temperature Assembly

g

g

g

g

g

Parts

To prevent you from becoming injured or burned, do the following:

Before workin

Assembly), turn off the power, unplu

cools down.

W ARNING

with a high temperature Assembly (e.g., Fuser

the power cord and wait until it

The high temperature Assembly is very hot

immediately after any printer operations. Wait at least

40 minutes before you start working on the printer.

To prevent you from becoming injured, keep the following in mind:

When handlin

posture to protect your back whenever you lift, move or place parts.

W ARNING

Be careful not to injure yourself with the sharp ed

Do not work with wet or oily hands-you may drop a part or injure

yourself. Dry your hands first.

When pullin

force. Pull out the part carefully and slowly step by step.

Do not lift, move or place heavy parts in a body posture

that is likely to cause injury to yourself or cause the

part to drop.

heavy parts (including the printer itself), use good

es of the parts.

out a part (including a harness), do not use too much

Page 11

Consumables

g

g

g

g

Improper Printer Use

Some parts may cause a particulate explosion or fire if handled

improperly. Do not handle these parts near fire or throw into a fire.

Some materials (e.

Do not swallow or inhale these materials or allow them to come in

contact with the eyes.

Help to protect those around you and follow the prohibiti ons a

swallowin

all times.

Place a sheet inside or under the printer so that the floor or workbench

is protected.

If the Developer or Fuser Oi l

wash with clean water.

NOTE:The printer has the following consumable parts:

or inhaling those materials. Be caref ul to protect the eyes at

•

Drum Cartridge

•

Oil Roll Assembly

•

Toner Cartridge M

•

Toner Cartridge Bk

., Developer or Fuser Oil) may cause bodily injury.

ainst

ets on your clothing, dry it with a c loth and

•

Waste Toner Box

•

Toner Cartridge Y

•

Toner Cartridge C

Modifying, revising, tampering with the printer, especially to the safety

mechanism, is strictly prohibited in all circumstances.

Page 12

Page 13

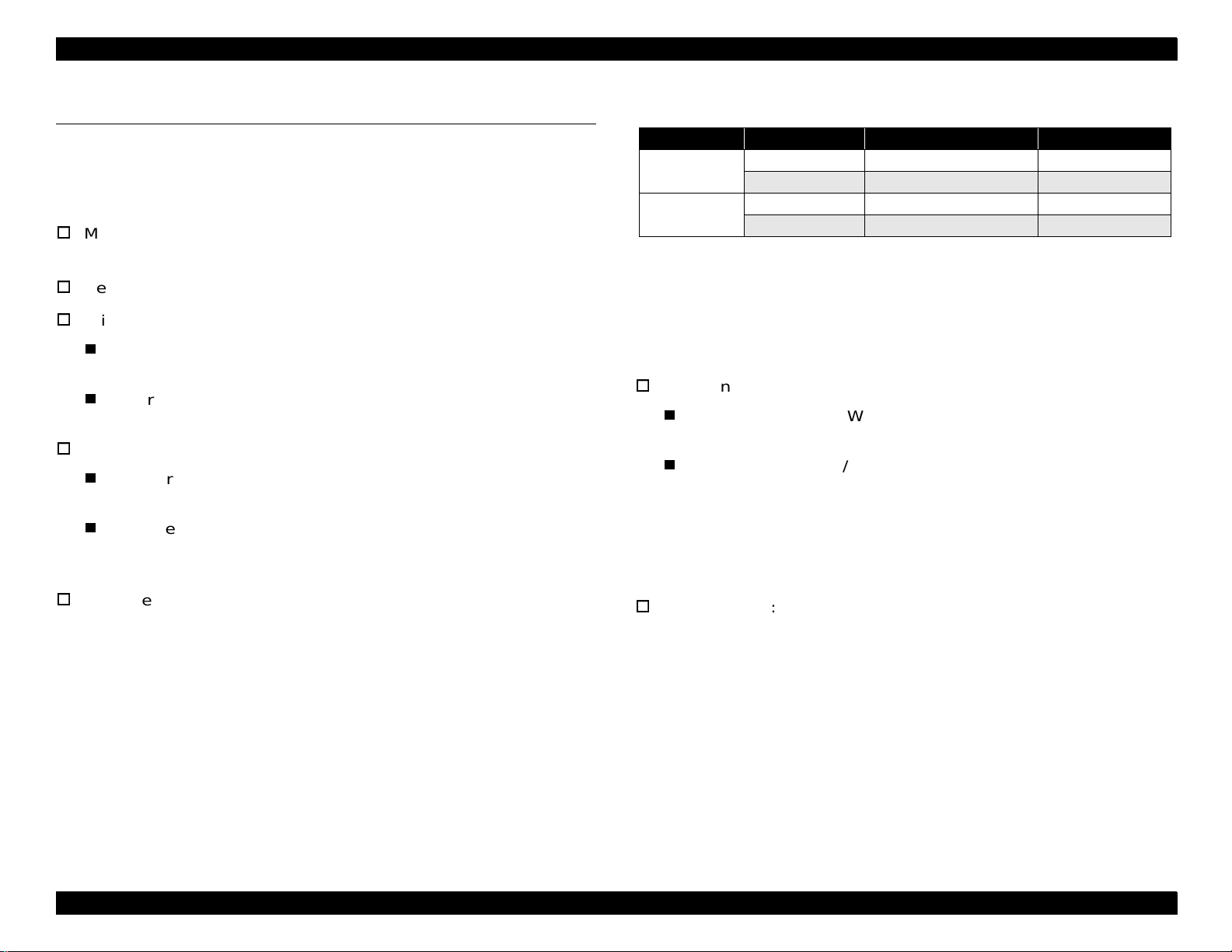

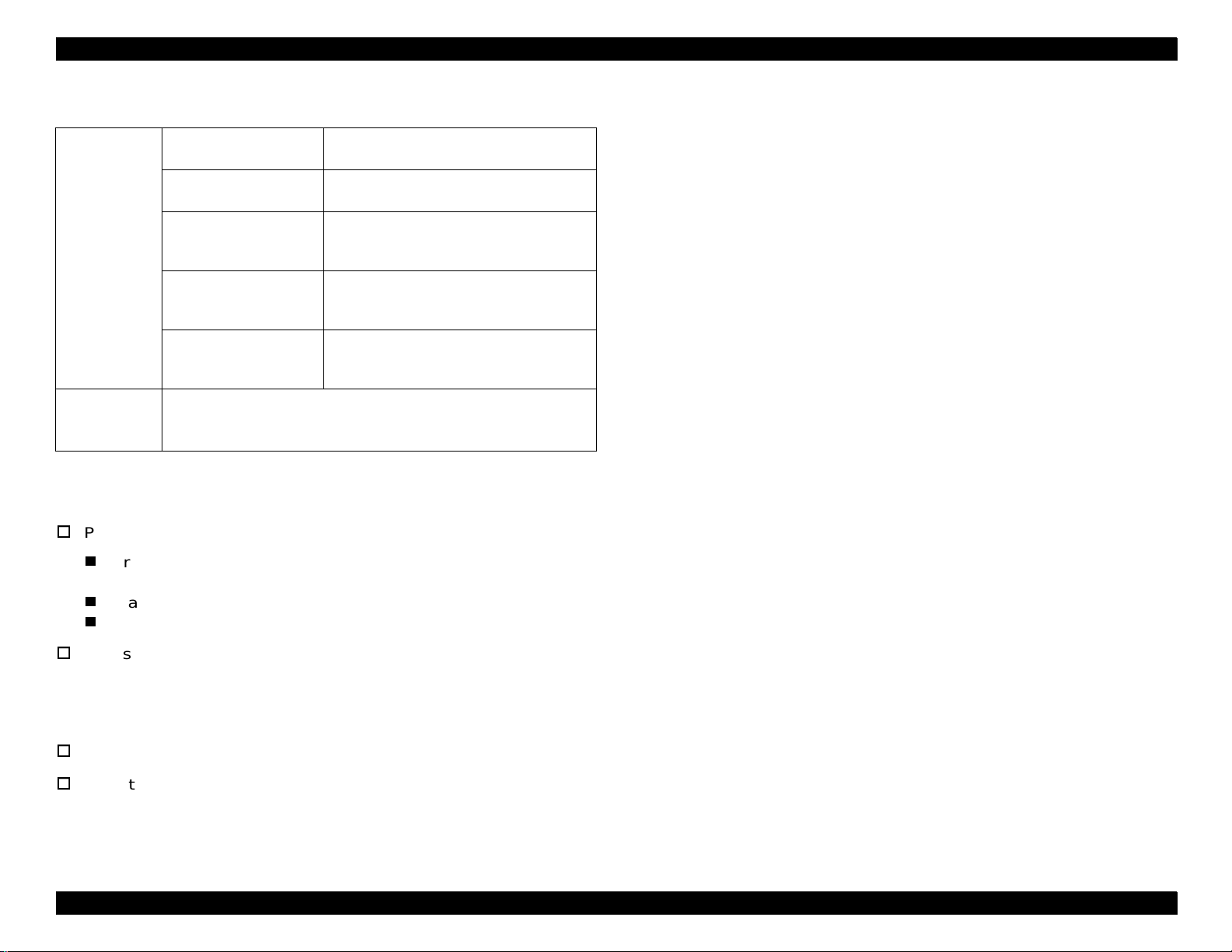

Manual Contents

y

Chapter 1 Product Descriptions

Chapter 2 Operating Principles

Chapter 3 Disassembly and Assembly / Adjustment

Chapter 4 Diagnostics

Chapter 5 Troubleshooting

Chapter 6 Maintenance

Appendix

Revision Status

Revision Issued Date Description

(Preliminar

revision)

Page 14

PRODUCT DESCRIPTIONS

Page 15

Tabl e of Co nt en t s

Features.................................................................................................. 1

Specifications........................................................................................ 3

Basic Specifications.......................................................................... 3

Paper Specification......................................................................... .. 8

Reliability and Durability.................................................................. 11

Operating Environment................................................................... 13

Environmental Conditions for Storage and Transportation............. 14

Electrical Specification.................................................................... 14

Process Specifications .................................................................... 15

Applicable Standards ...................................................................... 16

Options and Consumable Products ................................................ 16

Toner cartridge 17

Drum Cartridge 18

Fuser Oil Roll 18

Waste Toner Box 19

Regularly Replaced Parts ............................................................... 19

Exterior Dimensions........................................................................ 19

Controller Specifications................................................................. 20

Controller Board Jumper Settings................................................... 21

Interface Specifications . ..................................................................... 21

Parallel Interface Specification........................................................ 22

Ethernet Interface........................................................................... 24

Type B Interface.............................................................................. 25

Control Panel....................................................................................... 26

Appearance and Descriptions......................................................... 26

LED Description 27

Button Functions............................................................................. 28

Service Functions................................................................................ 30

Hex Dump Mode............................................................................. 30

Support Mode ................................................................................. 30

EEPROM Initialization..................................................................... 30

Formatting the Flash ROM Module................................................. 31

Updating the Program ROM ........................................................... 31

ROM Module Copy ......................................................................... 31

Panel Setting Initialization............................................................... 31

Maintenance Mode......................................................................... 31

Error Recovery Operation............................................................... 32

Panel Setting........................................................................................ 33

Setting Methods.............................................................................. 33

OneTouch mode 33

Sele cType mode 33

SelecType Setting Menu List. ......................................................... 35

Details of Menus and Settings........................................................ 39

RAM Expansion.............................................................................. 45

Page 16

EPSON ColorPage EPL-C8200 Revision A

1.1 Features

64-bit high speed memory: SDRAM DIMM

(Same as EPL-C8000)

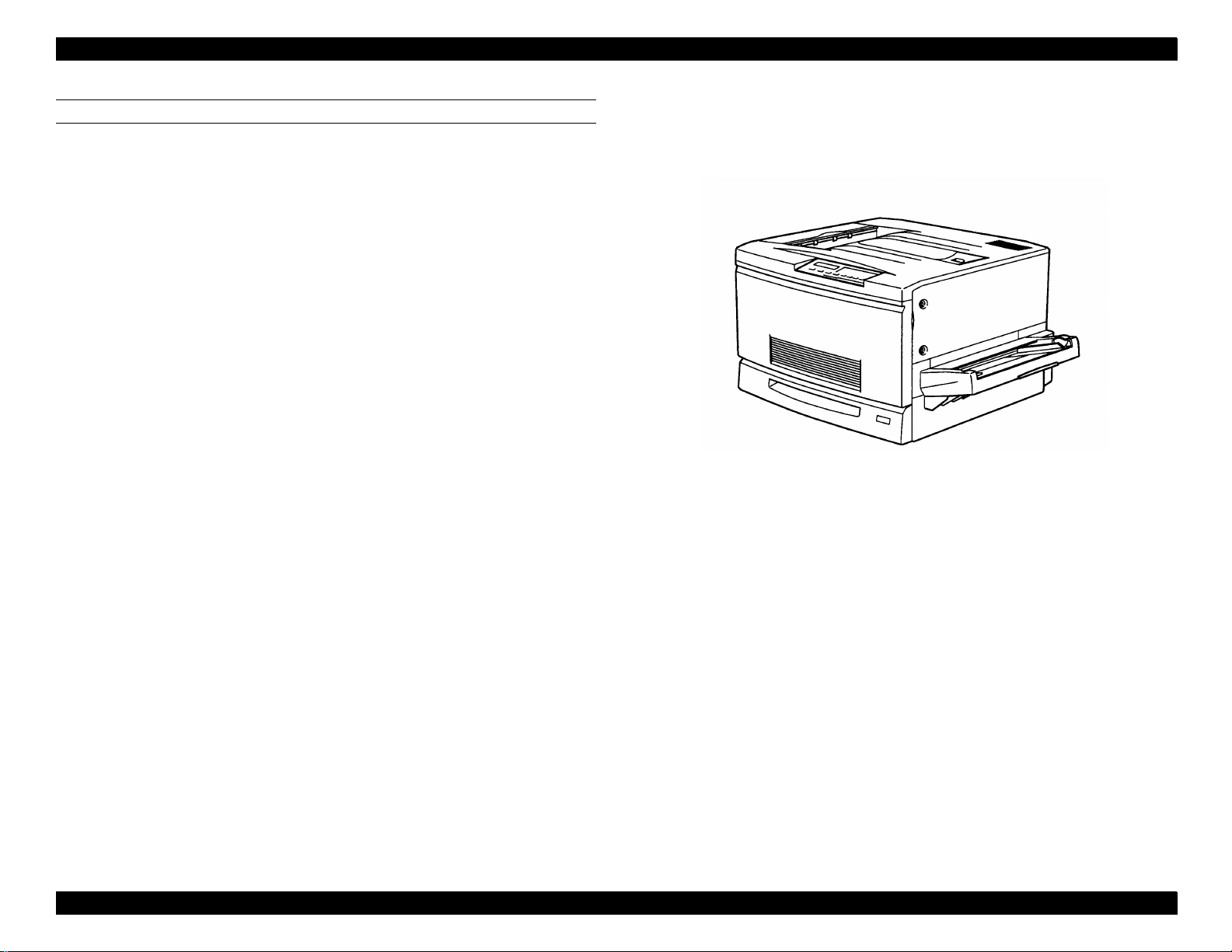

The EPSON ColorPage EPL-C8200 is a non-impact color page printer

that is designed based on the EPL-C8000. This printer is mainly

improved on a controller basis. The main features of the pri n ter are as

follows:

Engine features (Same as for EPL-C8000)

1. Designed for performance in true business environments. Supports

sizes from A5 to A3W. Printing speed (on A4/Letter) is 4ppm for

color printing, 16ppm for monochrome printing.

2. Supports high-resolution full color (True 600dpi).

3. Can generate high-quality prints on special (dedicated) paper.

4. Supports thick sheets and OHP (dedicated OHP sheets).

5. Easy to maintain for a color laser printer.

6. The printer is equipped with the 2 standard paper feed bins; Paper

tray (150 sheets; A3W) and standard universal cassett e (250

sheets: A3).

7. Installing an optional 500-Sheet Paper Cassette Unit provides 4

bins with a maximum capacity of 900 sheets.

With a Large Capacity Paper Unit installed, the printer has 5 bins

holding up to 1150 sheets.

64MB RAM standard: expandable up to 256MB (2 expansion

slots) (Same as EPL-C8000)

2. Color management technology

Enhanced ASIC supported

Color management technology included in hardware for faster

image manipulation

AcuLaser Color Halftoning and CRIT (Color RIT) supported

New compression technology enables further reduction in RAM

use compared to EPL-C8000.

3. Monochrome print technology

AcuLaser Color Halftoning (for Color Copy Stati on 8200) and

RIT supported

4. Two standard interfaces

Bi-directional parallel I/F: IEEE1284 compliance, ECP

Ethernet interface (100Base -TX/10Base-T)

5. installation of expansion RAM (DIMMs) improves the fol lowing:

AcuLaser Color Halftoning drawing area

Print data processing speed

Resolution

6. Toner save mode for both black and monochrome prints enabled.

8. Standard paper ejection is face down (up to 250 sheets). Face-up

ejection is also available (up to 150 sheets).

Controller features (Specific to EPL-C8200)

1. Newly developed high-speed controller

New 64-bit RISC CPU: R5000- 200MHz

7. ROM update function with a flash DIMM installed (for RCC)

8. HDD (Hard Disk Drive) can be installed.

Chapter 1 Product Descriptions 1-1

Page 17

EPSON ColorPage EPL-C8200 Revision A

Software features

1. ESC/Page-Color increases AcuLaser Color Halftoning speed.

2. Bidirectional EJL and MIB can retri eve printer status and mo nitor the

printer environment.

3. Remote panel function using the Web browser (for JAVA JSSK1.1)

4. Electrical sort system with an optional HDD

Expanded I/F data buffer size (for Ethernet I/ F only)

Font registration in the PostScript3 mode

5. Full compatibility with the EPL-N2700:

LJ4, GL2, 1239X, ESC/Page (monochrome)

6. Supports PostScript3 when used with an optional EPSON RIP

Station XXXX or Adobe PostScrip 3 Module.

7. Used with SC6000 (optional), color copy (EPSON Color Copy

Station) is enabled.

8. Font Management function by the EPSON FONT Manager

Supports 96 screen fonts, including 31 fonts suppor ted by the

printer.

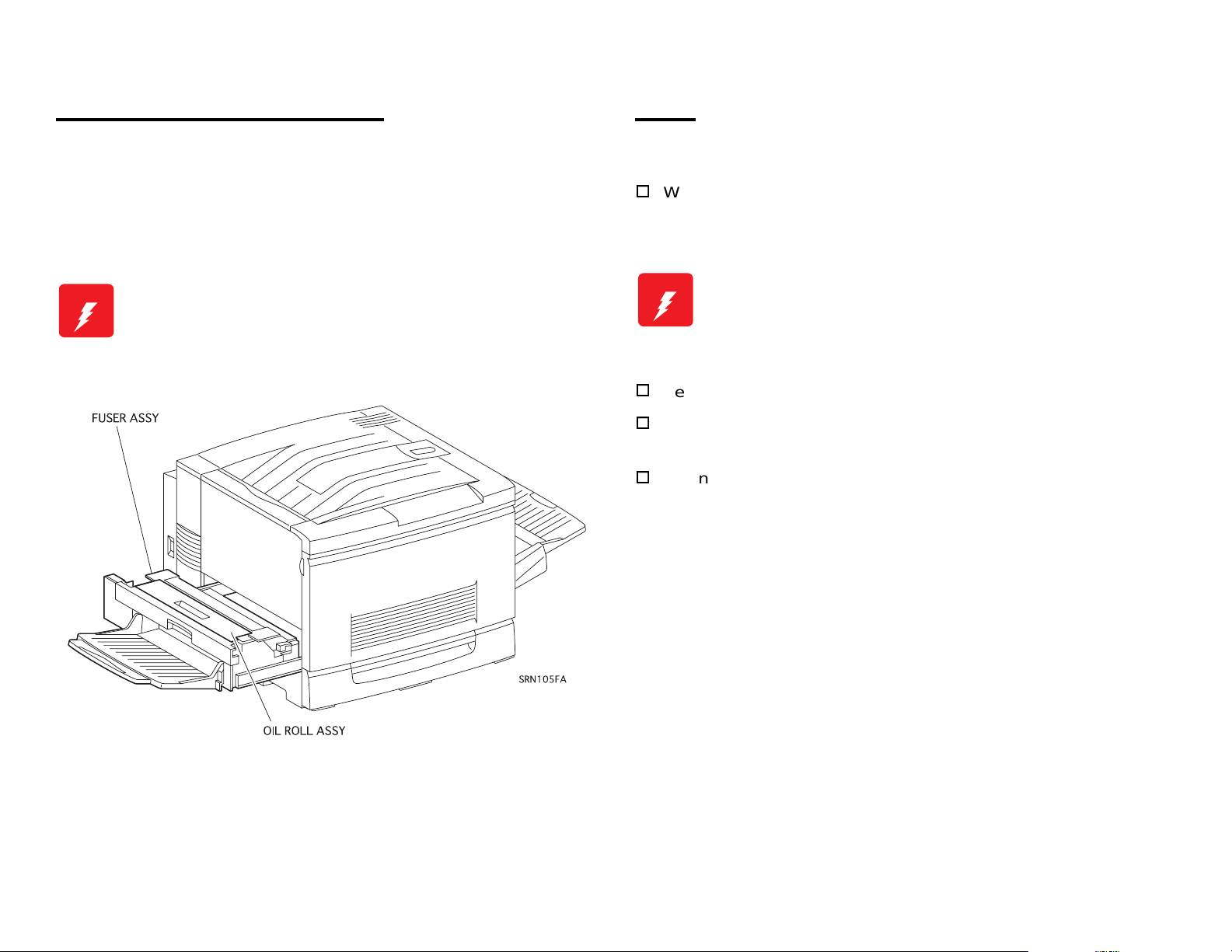

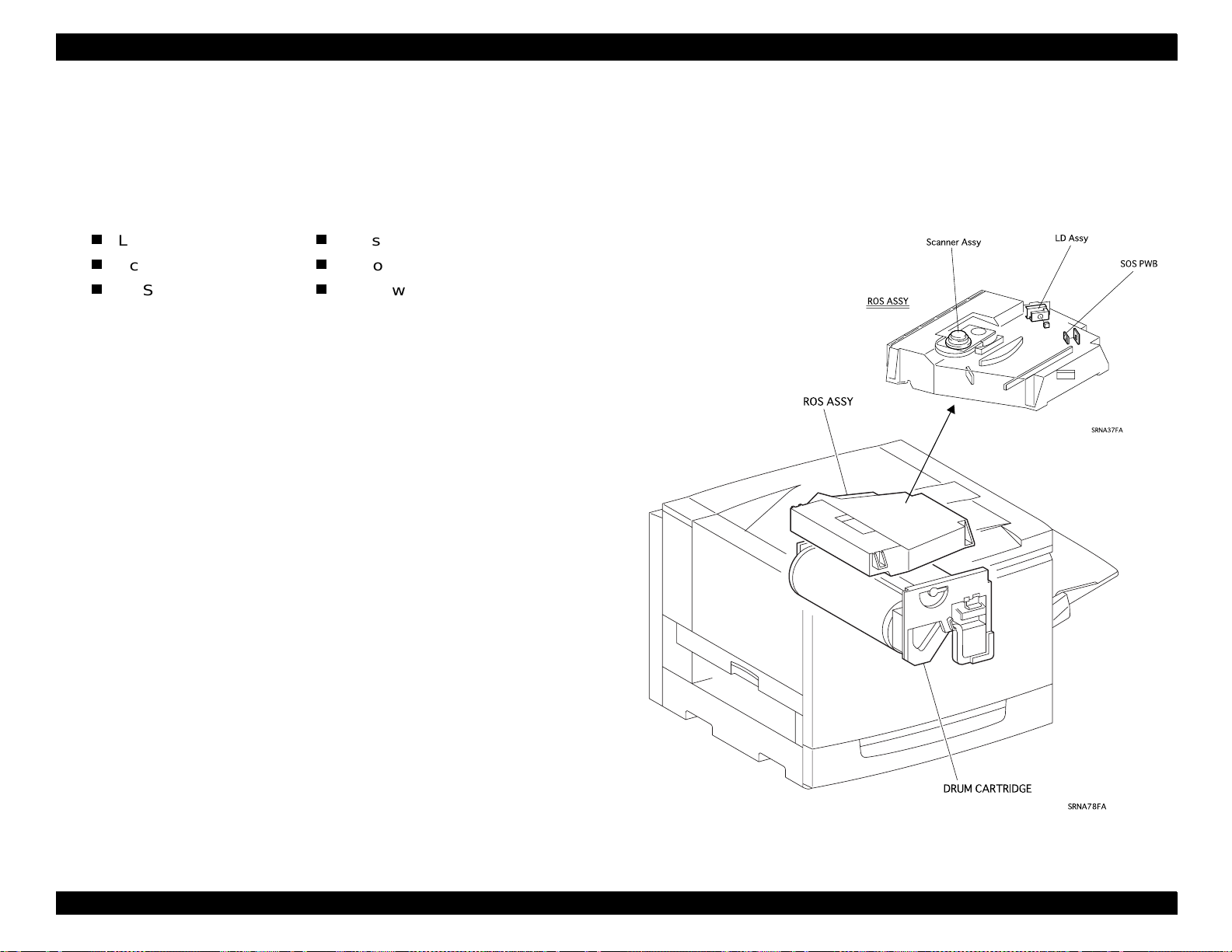

Figure 1-1. Exterior View of the EPL-C8200

Chapter 1 Product Descriptions 1-2

Page 18

EPSON ColorPage EPL-C8200 Revision A

1.2 Specifications

This section describes specifications for this printer.

1.2.1 Basic Specifications

Method: Semi-conductive laser beam scanning and

dry electrophotographic process

Resolution: 600 DPI

Print mode:

B/W mode: St andard monochrome print mode that

supports the fastest speed.

Color mode: Color mode which uses the color toner of Y,

M, C, and BK.

Speed mode:

Standard mode: Transports paper at the highest speed

supported by the printer.

Half speed mode: Low speed mode that enables better fusing

for thick paper (over 105 g/m

OHP sheet.

Print speed: See Table 1-1.

2

) envelopes, and

Table 1-1. Speed Mode

Print mode Speed mode LT/A4 LEF*1 2UP

B/W Standard mode 16 PPM or more 8PPM or more

Half speed mode 2.7 PPM or more 1.3PPM or more

Color Standard mode 4 PPM or more 2PPM or more

half speed mode 1.8 PPM or more 0.9PPM or more

*1: [LEF, or Long Edge Feed]

The longer edge of the paper is the top toward the paper feed direction.

[SEF, or Short Edge Feed]

The shorter edge of the paper is the top toward the paper feed direction.

*2: In this mode, the printer prints two print images on the IBT bel t and the images

are transferred in seque nc e on to two sh eets of paper. It is available for L T/A4

(LEF) or smaller.

First print*:

Face-up: B/W: 20 seconds or less (LT/A4 LEF)

*2

B(LD)/A3 SEF

Color: 42.6 seconds or less (LT/A4 LEF)

Face-down: B/W: 24.9 seconds or less (LT/A4 LEF)

Color: 47.6 seconds or less (LT/A4 LEF)

NOTE: First print is def ined as the du ration taken a fter receiv ing the

start command until outputting the first pri n t. It is applicable

when a feeder is selected in the standard mode. (Not

applied during the process control opera ti on.)

Warm-up time: Within 300 seconds

(at 22

°C, 55% Rh, rated voltage)

*1

Chapter 1 Product Descriptions 1-3

Page 19

EPSON ColorPage EPL-C8200 Revision A

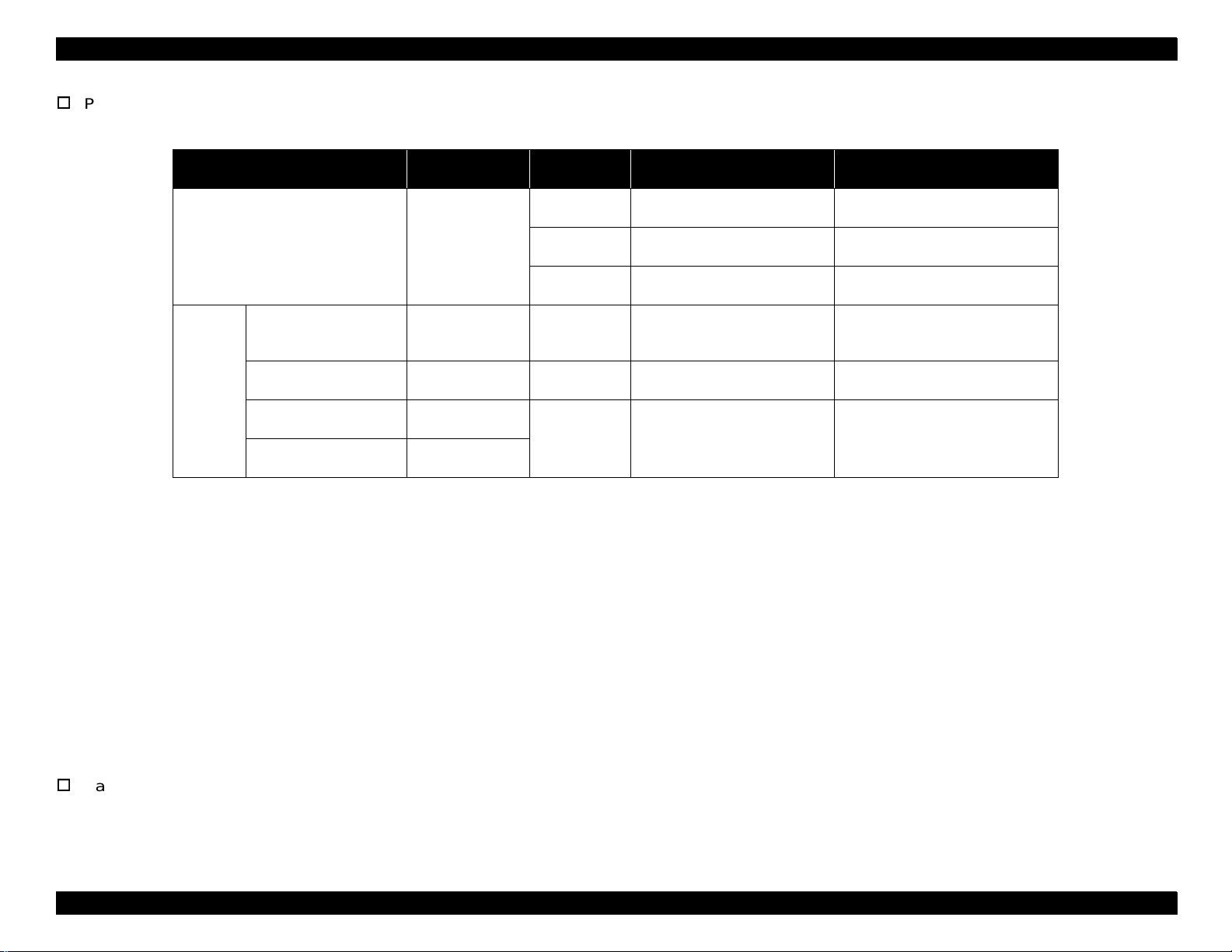

Paper handling: See Table 1-2.

Table 1-2. Paper Feeding

Paper source Available feeder

Standard Tray (MSI)

Cassette

Unit*

Standard universal

2 *7

cassette

*1 *6

Standard feeder 250 sheets

Optional A3W cassette Standard feeder 250 sheets

Optional Large

Capacity Paper Unit *

Optional 500-Sheet

Paper Cassette Unit *

250 x 3 feeder

3

(option)

250 x 2 feeder

4

(option)

*1: Change the side guide position in the MSI tray for paper whose width is more than 304.8mm (12”)

*2: Each casssettes is equi pped with the side guide a nd end guide that als o serve to detect paper siz e. They are set by the use r. With an optional

Large Capacity Paper Unit installed, 4 cassettes (maximum) can be used and, including a standard tray, up to 1150 sheets can be set.

*3: Composed of 3 p ap er c as set ts (eac h h ol ds 250 sheets). Each pa per cassette unit is c om pa tib le with a standard uni ve rsa l c as sette and can

be set in any slot.

*4: Composed of 2 p ap er c as set ts (eac h h ol ds 250 sheets). Each pa per cassette unit is c om pa tib le with a standard uni ve rsa l c as sette and can

be inserted in any slot.

*5: Note the following points when setting envelopes:

- Open flaps and set them facing to the tailing side.

- Set envelopes with the longer edges first. Length (excluding flap) must be shorter than width.

- The minimum length with a flap open must be 143mm.

- The minimum width must be 90mm.

*6: Paper out condition is detected.

*7: Paper out and paper near empty conditions are detected for each cassette.

Paper near empty condition: 40 sheets ± 30 sheets (condition: Fuji Xerox L paper, 64g/m

Capacity

(Thickness)

150 sheets

90 x 139.7 - 330.2 x 457.2 mm 60 - 105g/m2, 16 - 20 lb (N ormal

Paper size Available paper thickness

(16mm)

75 sheets 90 x 139.7 - 330.2 x 457.2 mm

OHP sheet/Labels/Thick paper

20 sheets Envelopes

*5

Monarch, C10, DL, C6

B5 LEF, Letter LEF, A4 LEF,

(28mm)

B4, A3, Legal, Executive LEF,

Ledger (B)

A3W (304.8 x 420 - 328 x 453

(28mm)

250 sheets

(28mm)

mm)

Letter LEF, A4LEF, B4, A3,

Legal LEF, Executive LEF,

Ledger (B)

2

)

paper, Recommended paper)

105 - 220g/m

2

(Thick paper, Special paper)

2

60 - 105g/m

(Normal paper,

Recommended paper)

60 - 105g/m2 (Normal paper,

Recommended paper)

60 - 105g/m2 (Normal paper,

Recommended paper)

Paper size: See Table 1-3 .

Chapter 1 Product Descriptions 1-4

Page 20

EPSON ColorPage EPL-C8200 Revision A

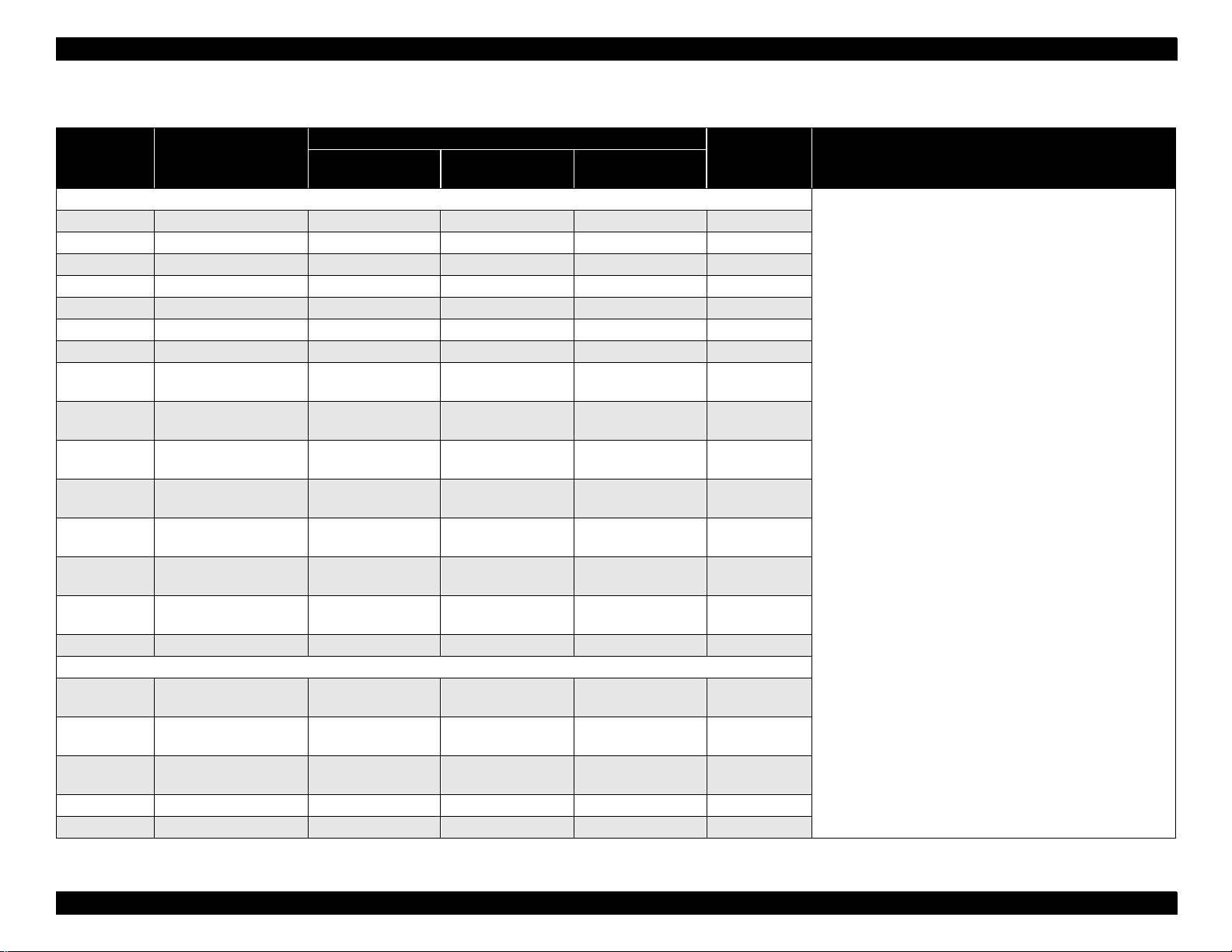

Table 1-3. Paper Size / 2-UP Mode Availability

Paper setting orientation

Paper Size

Standard tray

(MSI)

Standard cassette A3W cassette

Normal paper

A3W 328 x 453mm SEF SEF Unavailable

A3 297 x 420mm SEF SEF Unavailable

A4 210 x 297mm LEF LEF Available

A5 148 x 210mm LEF Available

B4 257 x 364mm SEF SEF Unavailable

B5 182 x 257mm LEF Available

I-B5 176 x 250 LEF Available

LT

HLT

LG

EXE

GLG

GLT

B (LD)

F4 210 x 330 SEF Unavailable

8.5 x 11”

(215.9 x 27 9.4mm)

5.5 x 8.5”

(139.7X215.9mm)

8.5 x l4”

(215.9X355.6mm)

7.25 x 10.5”

(184.15X266.7mm)

8.5 x 13”

(215.9X330.2mm)

8 x 10.5”

(203.2 x 26 6.7mm)

11 x 17”

(279.4 x 43 1.8mm)

LEF LEF Available

LEF Available

SEF SEF Unavailable

LEF LEF Available

SEF Unavailable

LEF Available

SEF SEF Unavailable

Special paper

OHP Sheet

MON

C10

DL 110 x 220mm LEF* Available

C6 114 x 162 LEF* Available

8.5 x 11”

(210 x 297mm)

3 7/8” x 71/2”

(98.43 x 19 0.5mm)

41/8 x 91/2

(104.78 x 241.3mm)

LEF Available

LEF* Available

LEF* Available

2UP mode

availability

Notes

• LEF: Long edge is loaded first.

• SEF: Short edge is loaded first.

• 2UP is available only for paper size of LT(LEF) or

smaller. For custom size paper, paper length along

the loading direction must be 8.5 inch or shorter. As

for envelopes, the total length including the opened

flap part must be 8.5 inch or shorter.

• The minimum size of paper set in the standard

universal paper cassette is EXE (LEF).

• The maximum size of paper set in the MSI tray is

330.2 x 457.2 mm (13” x 18”).

• When setting envelopes (LEF*), open their flaps and

set the rear ends of the flaps toward paper feeding

direction.

• A3W cassette have capability for only A3W paper.

Chapter 1 Product Descriptions 1-5

Page 21

EPSON ColorPage EPL-C8200 Revision A

Paper aligning: Single side aligning (front side) for all sizes

(both standard tray (MSI) and each cassette)

Consumables:

TONER CARTRIDGE (Black, Cyan, Magenta, Yellow)

DRUM CARTRIDGE (including one WASTE TONER BOX)

WASTE TONER BOX

OIL ROLL

Regularly replaced parts:

MAIN FUSER ASSEMBLY

Air filter (replaced with the MAIN FUSER ASSEMBLY

BELT CLEANER ASSEMBLY

2ND BTR ASSEMBLY

Normal paper A3W Available HLT Unavailable

Special paper OHP sheet FU* C10 FU*

Table 1-4. Face-Down Output Availability

Paper Size FD Availability Paper Size FD Availability

A3 Available LG Available

A4 Available EXE Available

A5 Unavailable GLG Available

B4 Available GLT Available

B5 Available B(LD) Available

LT Available F4 Available

I-B5 Unavailable

Postcard FU* DL FU*

MON FU* C6 FU*

Paper output:

Face-down (FD):

250 sheets (B5/EXE or larger, up to 105g/m

Face-up (FU):

150 sheets (smaller than A4)

50 sheets (A4 or larger)

See Table 1-4 FD availability for each paper size.

2

or 28lb

NOTE

1. The minimum paper size available for FD ejection is 182 mm in the paper feeding

direction x 210 mm vertical to the paper feeding direction.

2. “FU*” in the FD availability columns means face-up ejection for OHP, thick paper,

and envelope.

Dimensions (without option):

728 (W)* mm x 641 (D)* mm x 490 (H) mm (tolerances:

± 1%)

* When the standard tray (MSI) and Output tray (FU) are stored.)

Weight: 68.4 kg ± 1% (without option)

Voltage: 110V/120V

220V/240V

Power consumption, Rated current:See Table 1-5.

± 10%, 50/60Hz ± 3Hz

± 10%, 50/60Hz ± 3Hz

Chapter 1 Product Descriptions 1-6

Page 22

EPSON ColorPage EPL-C8200 Revision A

Table 1-5. Power Consumption Specifications

Operating (color)

Operating (B/W)

Power

consumption

Rated current

*1:

Saves more energy than in standby mode. Time required for warning up

Standby mode

Energy save mode 1

Energy save mode 2*2

• 100 V: 11A or less (at rated voltage)

• 115V: 10A or less (at rated voltage)

• 240V: 5A or less (at rated voltage)

is shorter.

*2:

Completely non-operating condition. Complies with the Energy Star.

• Average: 400Wh or less

• Maximum: 1100W or less (Fuser: On)

• Average: 500Wh or less

• Maximum: 1100W or less (Fuser: On)

• Average: 250Wh or less

• Maximum: 1000W or less (Fuser: On)

100W or less (Fuser: Off)

• Average: 200Wh or less

*1

• Maximum: 1000W or less (Fuser: On)

100W or less (Fuser: Off)

• Average: 45Wh or less

• Maximum: 1000W or less (Fuser: On)

100W or less (Fuser: Off)

Product life

Printer: Approximately 180,000 printed pages on A4 LEF

(450,000 images) or five years, whichever comes first.

Standard tray (MSI): 72,000 sheets

250 sheets x 3 feeders: 135,000 sheets (45,000 sheets x 3)

Acoustic noise: Operating = 54.8dB (A) or less

Stand-by = 38.3dB (A) or less

Energy Save mode 1 = 38.3dB (A) or less

Energy Save mode 2 = 35.0dB (A) or less

Ozone emission: 0.02 ppm (time waited average value) or less.

Toxicity: Photo conductor, toner, carrier , plastic

material have no effect on human body.

Chapter 1 Product Descriptions 1-7

Page 23

EPSON ColorPage EPL-C8200 Revision A

1.2.2 Paper Specification

Paper specifications: See Table 1-6.

Table 1-6. Paper Specifications

Paper Type

Recommended paper 4024 paper (B/W), X-pression paper (color)

Normal Paper Normal copier paper, Recycled paper,

Special Paper OHP film, Card stock, Labels, Color paper, Thick

NOTE: lb: Ream Weight = lb/500sheets/17” x 22”

2

g/m

= 0.2659763 lb

1

NOTE: Before purchasing a large amount of paper, try it ou t and

check that it is properly fed.

NOTE: Avoid using the types of paper listed below to prevent

abnormal printing, paper jam, and printer malfunction.

- C arbon paper, non-carbon paper, thermal paper, impact paper,

acidic paper

- Paper that has gone through a thermal or an ink-jet printer.

- Paper that is too thick or thin.

- Wet (damp) paper

- Paper to which a special coating has been applied, or colored

paper that has gone through surface process.

- Paper that has been lubricated (too smooth or slippery).

- Paper whose texture is different on the front and back.

- Paper with holes for binders and perforations.

- Paper with irregular shape or not cut with right angles.

- Paper with labels that come off and stick easily.

- Paper with glue, staples, or paper clips attached.

- Special ink-jet paper (Super Fine Paper, glossy film, and so on.)

- OHP sheets for other color laser printers, monochr ome printers,

and photocopiers.

2

- 105g/m2 (16lb - 28lb)

60g/m

paper (105g/m

2

- 220g/m2), DTP paper, Envelopes

- Paper that has gone through other color laser printers,

monochrome printers, and photocopiers.

- Pasted paper

Chapter 1 Product Descriptions 1-8

Page 24

EPSON ColorPage EPL-C8200 Revision A

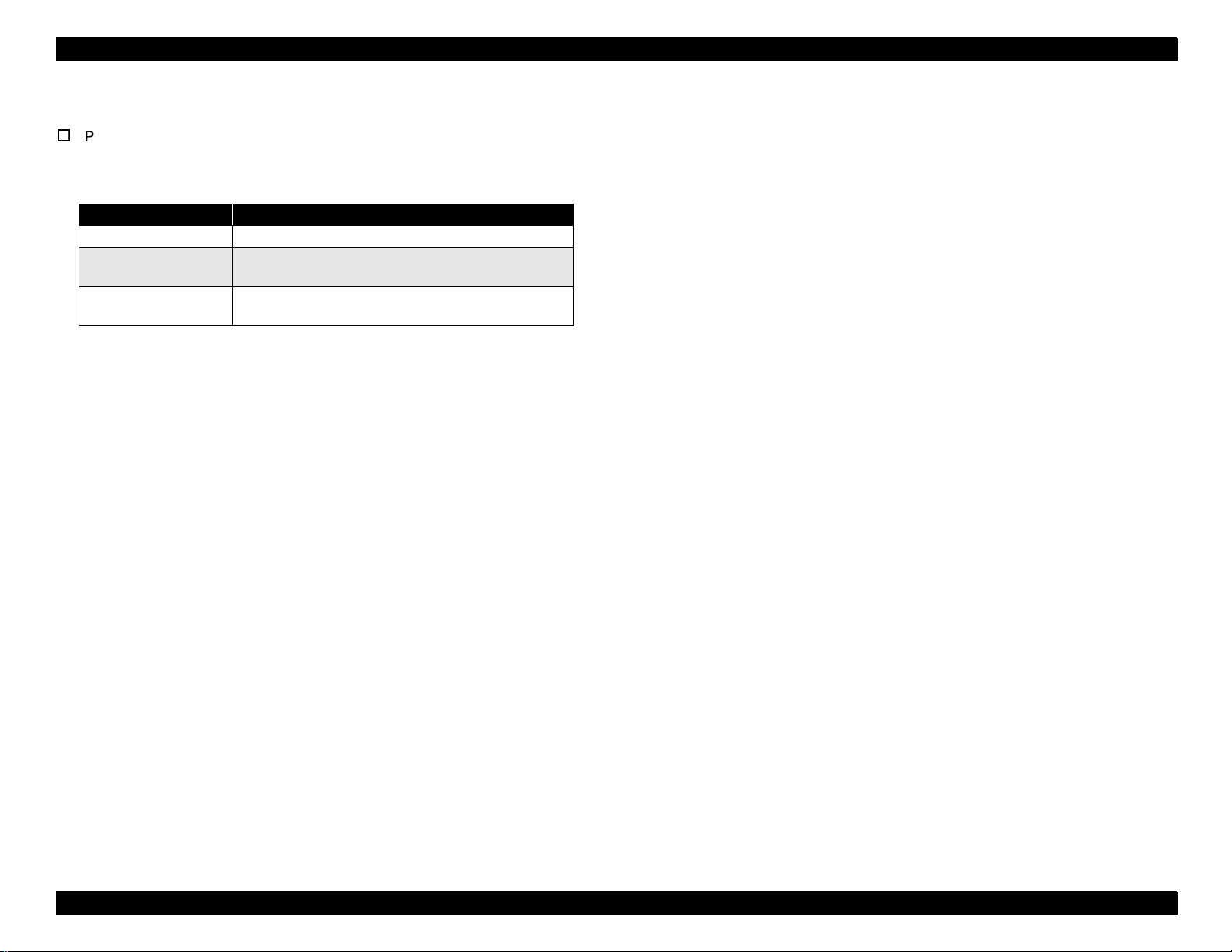

Paper source classification:See Table 1-7.

Table 1-7. Paper Usability for Each Paper Source

Paper source

Standard (MSI) tray RF P P P P P P

Standard universal cassette RF P N N N N N

A3W cassette*

Large Capacity Paper Unit

500-Sheet Paper Cassette Unit

3

*3

Recommended

paper

RF P NNNNN

RF P N N N N N

Normal

paper

OHP

sheet

Postcard Labels

Special paper

Thick

paper*

1

Envelope

2

*

NOTE: RF

*1:

105 - 220g/m

*2:

MON, C10, DL, C6

*3:

Option

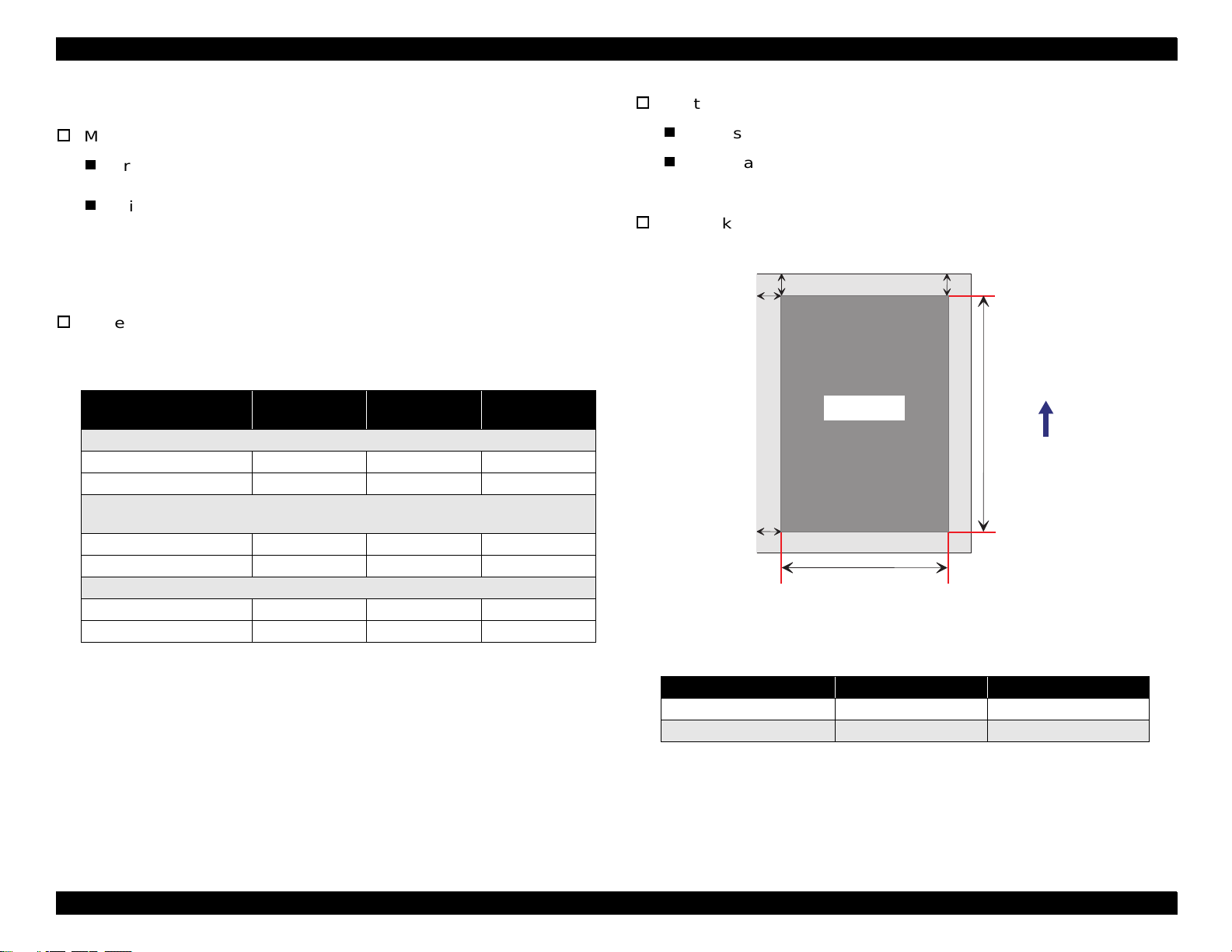

Guaranteed print area: See Figure 1-2.

: Reliable feeding and good image quality, P: Possible, but limited to paper generally available, N: Not supported

2

4m m 4m m

4m m

G uaranteed

print area

4m m

Maximum guaranteed print area:

Area with a margin of 4 mm from each side

Applied to a paper size up to 297mm (11.7”) width x 431.8mm (17”)

length.

Maximum printable area:

320mm (12.6”) width x 449.2mm (17.7”) length

Figure 1-2. Guaranteed Print Area

Chapter 1 Product Descriptions 1-9

Page 25

EPSON ColorPage EPL-C8200 Revision A

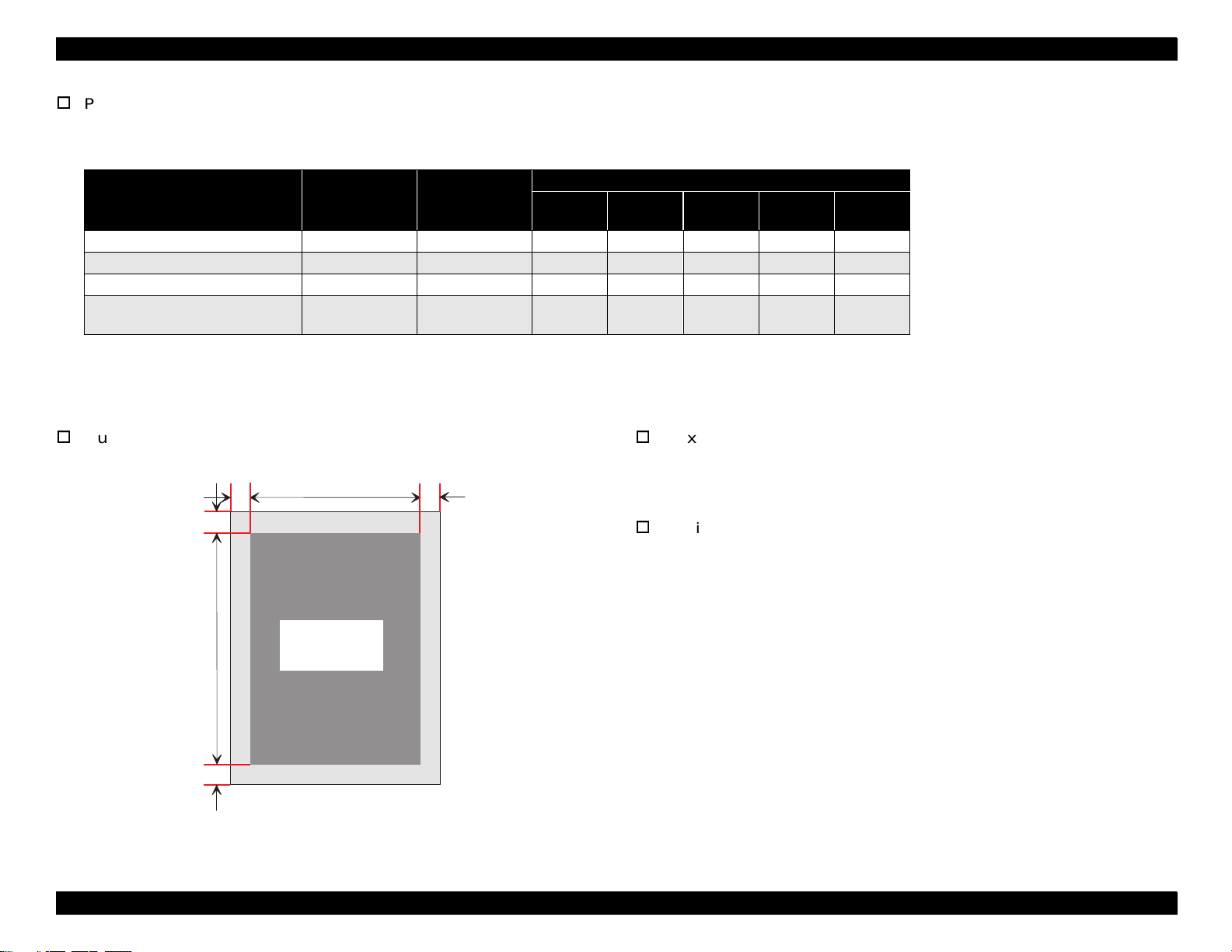

r

Printable area:

Paper whose width is 304.8mm (12”) or shorter: From the edge

When the standard universal cassette, Large Capacity Pape r

Unit, or 500-Sheet Paper Cassette Unit is used.

Paper whose width is longer than 304.8mm (12”)*: From the point

with a margin of 5mm

* When loading paper whose width is more than 304.8 mm (12”),

4m m

4m m

304.8m m (12,6")

296.8m m (11.7")

4m m

the standard cassette (MSI) is shi fted and pri nt positi on starts with

a margin of 5 mm from the paper edge (a). This change is applied

to paper loaded from the A3W cassette.

When the standard tray (MSI) or A3W cassette is used.

330.2m m (13")

4m m

457.2m m (18")

(a )

320m m (12,6")

297m m (11.7")

Printable

area

Paper feeding direction

457.2m m (18")

431.8m m (17")

Printable area

Paper feeding direction

Side guide position for paper w hose w idth is 304.8 m m (12") or less

M axim um size of paper: 304.8 m m (11.2") w idth x 457.2 m m (18") length

Printable area: 296.8 m m (11.7") w idth x 449.2 m m (17.7") length

G uaranteed print area: 296.8 m m (11.7") w idth x 431.8 m m (17") length

Figure 1-4. Printable Area 2

Side guide position for paper w hose w idth is 304.8 m m or shorte

Side guide position for paper w hose w idth is m ore than 304.8 m m

Length betw een the guides is 12.6m m

M axim um size of paper: 330.2 m m (13") w idth x 457.2 m m (18") length

Printable area: 320.0 m m (12.6") w idth x 449.2 m m (17.7") length

G uaranteed print area: 297 m m (11.7") w idth x 431.8 m m (17") length

Figure 1-3. Printable Area 1

Chapter 1 Product Descriptions 1-10

Page 26

EPSON ColorPage EPL-C8200 Revision A

a

b

c

d

e

f

Print area

Paper feeding direction

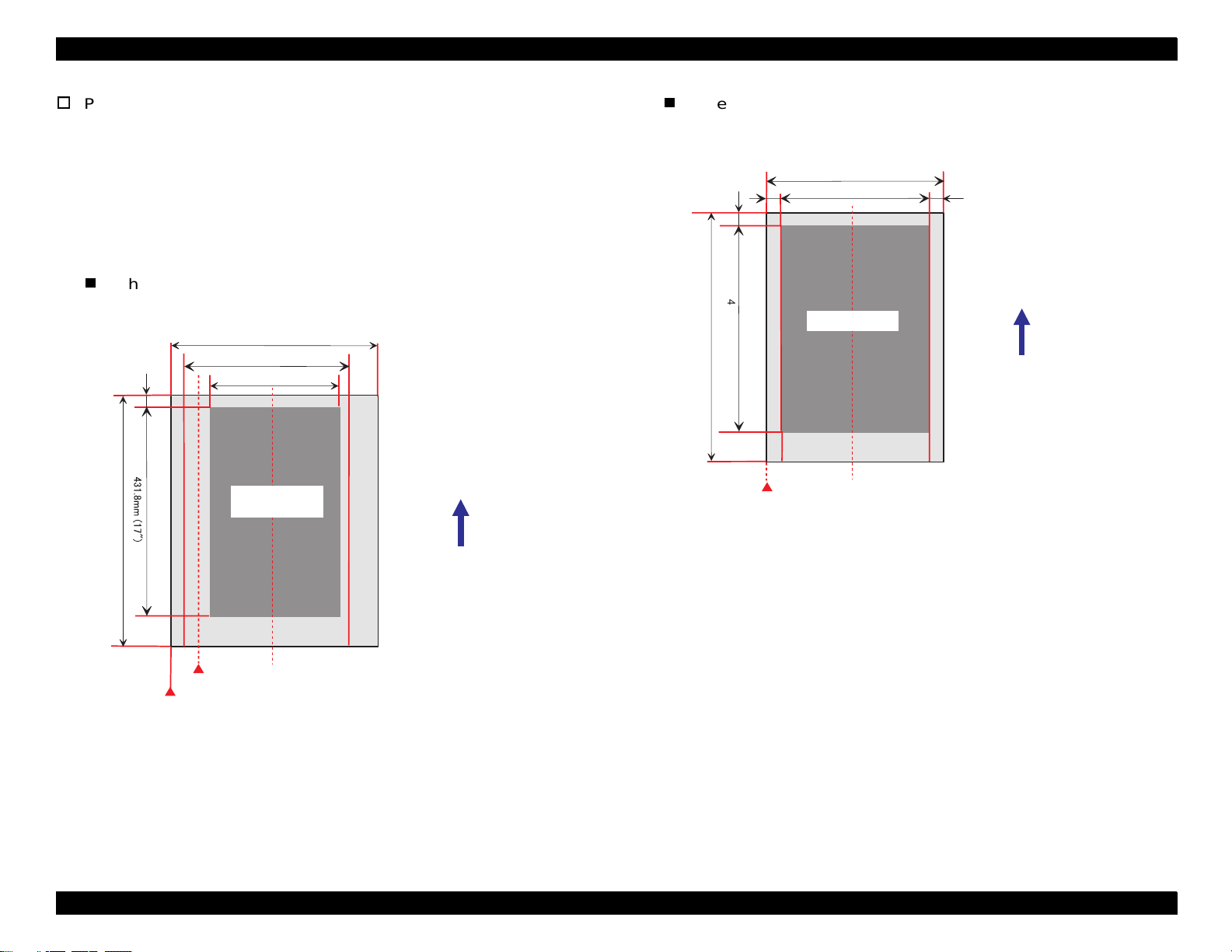

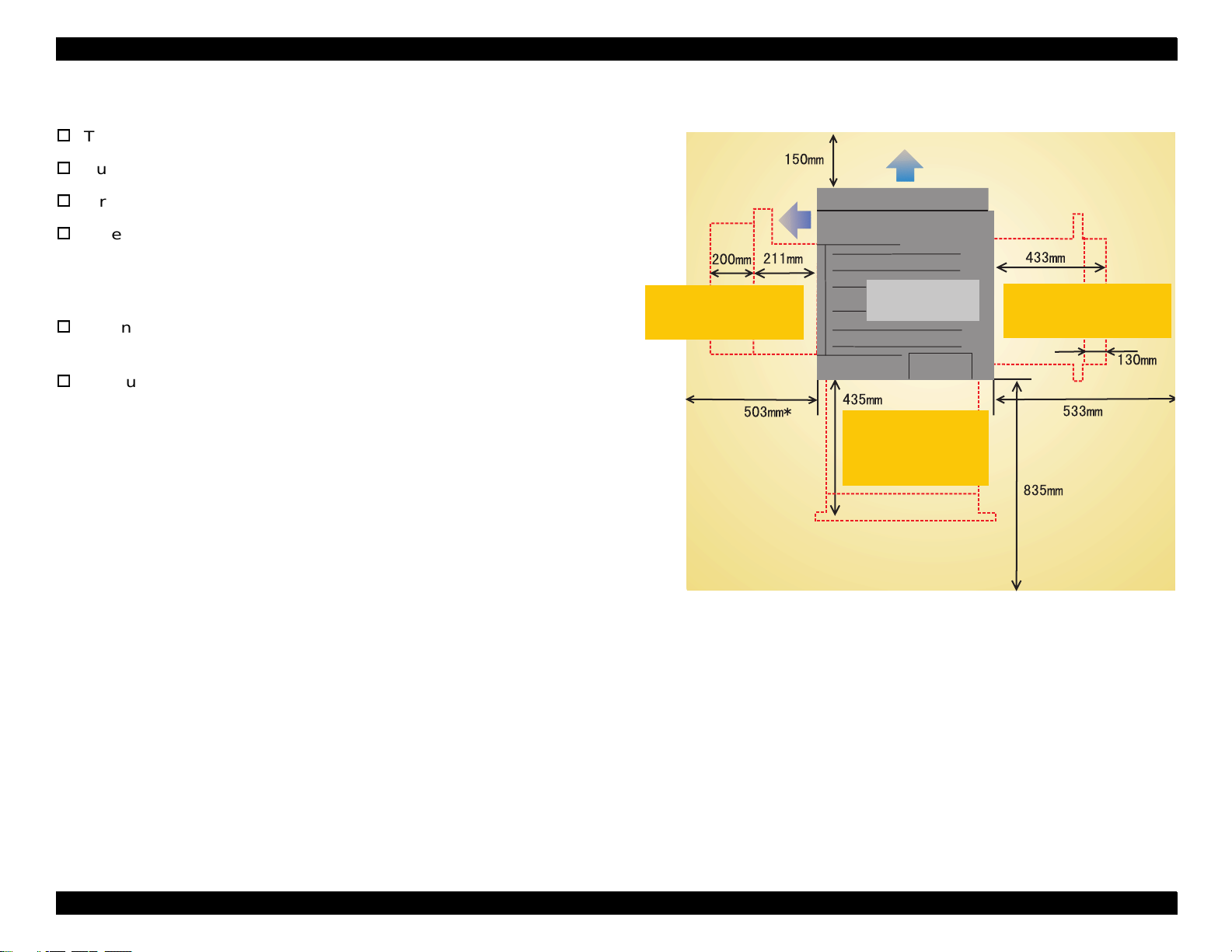

1.2.3 Reliability and Durability

MPBF:

Printer including standard tray (MSI):

38,000 pages or more (95,000 images or more*)

Printer including optional 250 sheet x 3 feeders:

32,000 pages or more (80,000 images or more*)

Print position accuracy:

Main scan direction:Reference position (c)

Sub scan direction:Reference position (a)

± 2.5 mm

± 2.0 mm

See Figure 1-5.

Paper skew: See Figure 1-5 and Table 1-9.

NOTE: Figured out based on the MPBF in condition that the job

ratio of the color and monochrome prints is 1: 1, since 1

page of color print is formed with 4 images.

Paper feed reliability: See Table 1-8.

Table 1-8. Paper Feed Reliability

Recommended

paper

Standard paper tray

Paper jam rate 1/500 or less 1/100 or less 1/100

Multiple feeding rate 1/ 80 or less 1/50 or less 1/50

Standard universal cassette / Large Capacity Paper Unit / 500-Sheet Paper

Cassette Unit(option)

Paper jam rate 1/3,000 or less 1/2,000 or less

Multiple feeding rate 1/800 or less 1/500 or less

A3W cassette (option)

Paper jam rate 1/2,000 or less

Multiple feeding rate 1/500 or less

* Do not feed envelopes at high temperature to avoid adhering.

* Statistics for envelopes only apply to front fac e feeding u nder norma l temper-

ature. (back side feeding is not in cluded.)

NOTE: Paper jam or multiple feeding occurred to the top sheet of

Normal paper Special paper *

Figure 1-5. Paper Skew

Table 1-9. Paper Skew

Direction A4 (landscape) A3

Main scan direction (|c-d| )

Sub scan direction (|a-b|)±2.0mm(e=271mm)

1.5mm(f=196mm)

±

3.0mm(f=406mm)

±

2.0mm(f=271mm)

±

an added stack of paper is ignored.

Chapter 1 Product Descriptions 1-11

Page 27

EPSON ColorPage EPL-C8200 Revision A

Durability:

Printer:

180,000 sheets* (450,000 images) A4 LEF or 5 years,

whichever comes first. Parts regularly repl aced by the service is

ignored.

* 450,000 sheets if the printer is used for monochrome print only. In

color printing, one page is formed with 4 images, and the value

“180,000” sheets is figured out in the condition that the job ratio of

monochrome and color printings is 1:1.

Standard tray (MSI): 72,000 sheets

250sheets x 3 feeders: 135,000 sheets (45,000 sheets x 3)

MTTR: Within 30 minutes (average)

Curl height at ejection:Less than

± 15mm (Color printing with the

image ratio of 5% in non- aligned condition,

which varies depending on the image rate

and aligning pattern.)

Chapter 1 Product Descriptions 1-12

Page 28

EPSON ColorPage EPL-C8200 Revision A

1.2.4 Operating Environment

Temperature: 10 to 32°C

Humidity: 15% to 85% RH (without condensation)

Air pressure (altitude):760 hPa or more (2500 meters or les s)

Levelness:

Front - rear direction on the table:5mm or less (within 641mm)

Right - left direction on the table:10 mm or less (within 560mm)

Luminosity: 3000 lux or less (not to exposed to direct

sunlight)

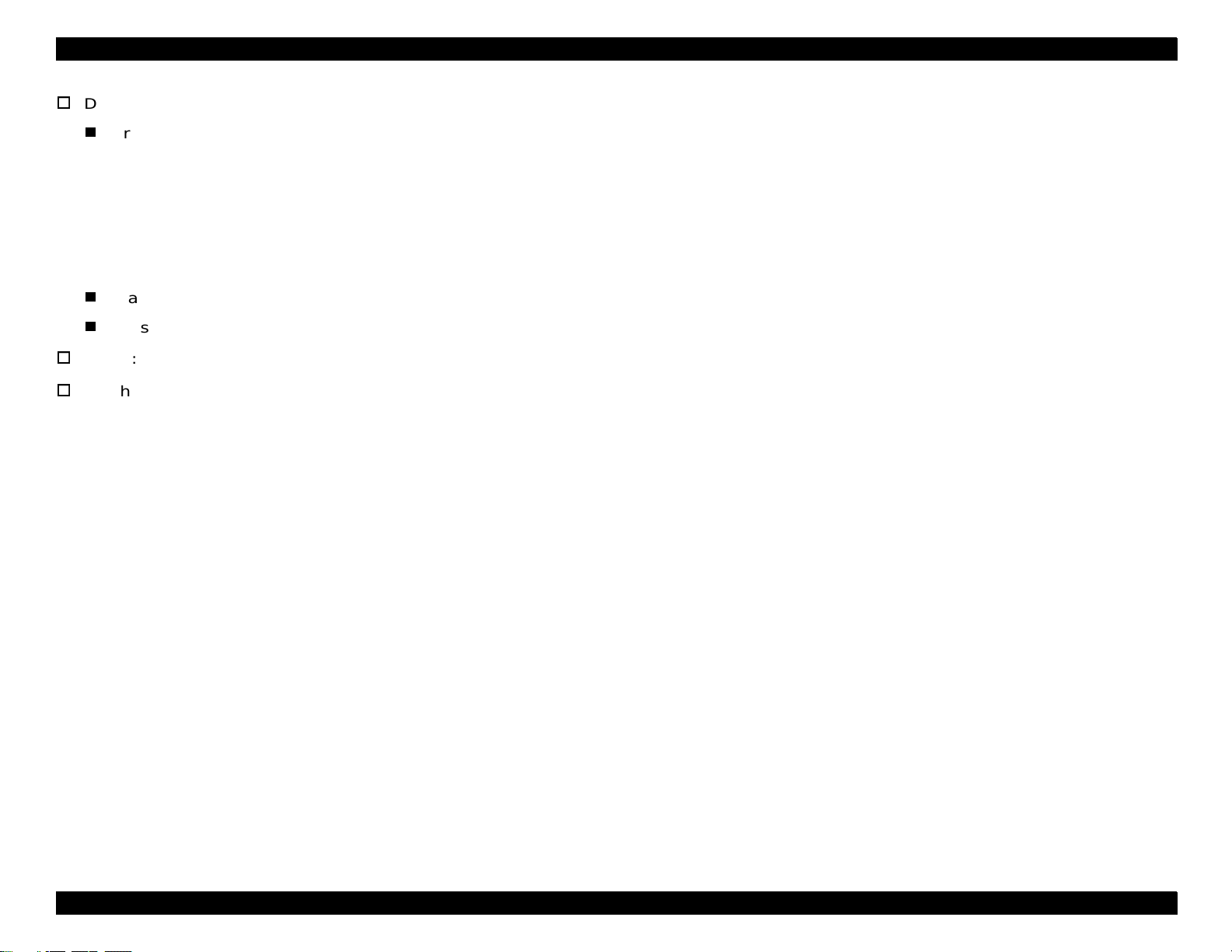

Surrounding environment:See Figure 1-6.

Ventilation

R equired w hen pullin g

out the FU SE R U N IT

to remove jammed paper.

* 511 m m w ith a face-up tray installed.

Ventilation

R equired w hen pulling out

the paper path unit to

rem ove jam m ed paper.

R equired w hen pullin g

out the standard paper

c a s s e tte u n it to lo a d

paper.

Figure 1-6. Space Requirement

Chapter 1 Product Descriptions 1-13

Page 29

EPSON ColorPage EPL-C8200 Revision A

1.2.5 Environmental Conditions for Storage and Transportation

temperature and Humidity:See Table 1-10.

Table 1-10. Environmental Conditions 1

Temperature Humidity Guaranty

Normal condition 0 - 35

Extreme condition High: 35 - 40 °C

*1:

Without condensation.

Storage air pressure (altitude)

C 15 - 80%RH

°

Low: -20 - 0

C

°

High: 80 - 95%RH*

Low: 5 - 15%RH*

0 - 2500 meters (0 up to 15000m is possible during ai r shippi ng, but

the air pressure in the cargo room must be 0.7 hPA or more.)

Drop test: See Table 1-11.

Table 1-11. Drop Test

Height Test times

Bottom: 457 mm (18”) Once

Free drop

Ridge drop 45 7 mm (18”)

Resistance to vibration

Frequency: 2 - 500 Hz

Acceleration: 12.6 m/s

Direction: 3 directions (X, Y, Z)

Duration: 30 minutes (single way)

Other than bottom: 305mm (12”)

2

(on a vibrating board)

*1: Overall rms value

*2: Z=vertical, X and Y=horizontal

*1

Once for each surface

(total of 5 times)

Once for each side

(total of 4 times)

*

2

For 12 months

One month (Max.)

*

1

1.2.6 Electrical Specifications

AC line noise

Pulse width: 50 to 1000 ns

Pulse polarity:

Repeat: Not synchronized

Modes: Common/normal

Voltage: 1kv (However, the parts can withstand up to

Instant cutoff: DIP 100% (at rated voltage-10%) for one

Electrostatic durability:

No possibility of any error which affects on print quality under the

following conditions.

Atmospheric discharging:

Contact discharging:

Rush current: 1/2 cycle, 100A or less

Insulation resistance: 10 M Ω or more

Dielectric strength:

There is no breakdown when the following voltages are applied for

one minute.

100V/120V model:

AC 2000V (Between primary and secondary sides)

AC 1000V (Between primary side and chassis)

220V/240V model:

AC 2000V (Between primary and secondary sides)

AC 1500V (Between primary side and chassis)

+/−

2kv without damage.)

cycle with normal print quality.

± 8KV

± 6KV

Chapter 1 Product Descriptions 1-14

Page 30

EPSON ColorPage EPL-C8200 Revision A

Leakage current:

100 V model: 0.5mA or less

120V model: 3.5mA or less

220V/240V model: 3.5mmA or less

Condition: 1.5K Ω, 0.15uF

(between non-metallic parts and frames)

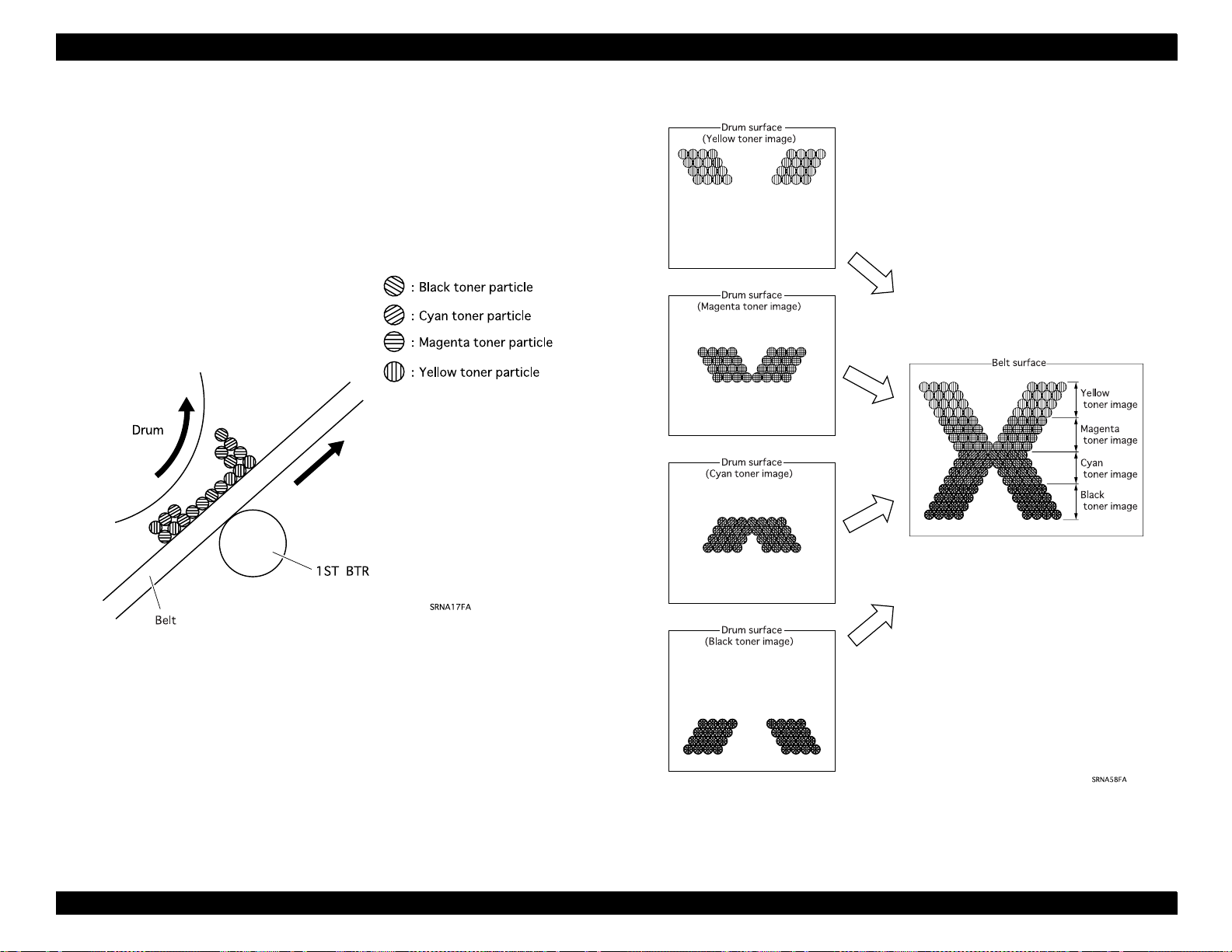

1.2.7 Process Specifications

Printing method: Dry electrophotographic with 2 ingredients

Using the intermediate belt transfer system

Light source: Semi-conductive laser beam

Exposed object: OPC drum (organic photo conductor)

Charging method: Roller transfer system

Developing method: Exposed part developing system

Toner: Single-ingredient nonmagnetic toner with

carrier

1st transfer: Intermediate belt transfer system

2nd transfer: Roller transfer system

Fusing: Heat roller system

Density adjustment: Automatic (can not be set by user)

Chapter 1 Product Descriptions 1-15

Page 31

EPSON ColorPage EPL-C8200 Revision A

1.2.8 Applicable Standards

Safety standards

100V/120V:

UL1950 2nd Edition, CSA C22.2 No. 950-M89

220V/240V:

IEC950 2nd Edition/1991 by VDE with GS-mark

Safety regulations

100V/120V:

FDA21CFR Chapter 1, Subchapter L, Section 1010, 1040

220V/240V:

IEC825 Class l Laser Product

NOTE: Laser power: 5mW (rated)

+

10/-15nm (at 25 °C)

Wavelength: 785nm

EMI

US: FCCPart15 SubpartB, ClassB(ANSI 63.4/11.4D)

Europe: EN55022(CISPR Pubilication22), ClassB

Followings will become effective in January,

2001:

EN61000-3-2 (Hamonics)

EN61000-3-3 (Flicker)

Others

Toner: No effect on human health (OSHA, TSCA,

EINECS)

Carrier: No effect on human health

1.2.9 Options and Consumable Products

The following table shows the options and consumable products for

EPL-C8200.

Table 1-12. Options and Consumable Products for EPL-C8200

Options Code Consumable Products Code

Large Capacity Paper Unit C81301* Toner Cartridge (Yellow) S050016

500-Sheet Paper Cassette

Unit

250 Sheet Lower Paper

Cassette Unit A3W

Hard Disc Drive C82377* Toner Cartridge (Black) S050019

Adobe PostScript 3 Kit C83236* Waste Toner Collector

EPSON RIP Station XXXX Fuser Oil Roll S052002

32KB Serial Interface Card C82307* Photoconductor unit (DRUM

32KB Parallel Interface Card C82310* EPSON Color Laser Paper

Coax Interface Card C82314* EPSON Color Laser Paper

Twinax Interface Card C82315* EPSON Color Laser Paper

LocalTalk Interface Card C82312* EPSON Color Laser Paper

GPIB Interface Card C82313* EPSON Color Laser

- - EPSON Color Laser

C81335* Toner Cartridge (Magenta) S050017

C81302* Toner Cartridge (Cyan) S050018

S050020

(WASTE TONER BOX)

S051061

CARTRIDGE)

S041215

(A4)

S041216

(A3)

S041217

(A3W)

S041218

(Letter)

S041175

Transparencies (A4)

S041174

Transparencies (Letter)

OPC: No effect on human health (OSHA)

Ozone: UL478 (5th edition)

Material: SWISS environmental law (must contain no Cds)

* Asterisk varies depending on the market.

Chapter 1 Product Descriptions 1-16

Page 32

EPSON ColorPage EPL-C8200 Revision A

1.2.9.1 Toner cartridge

Toner Cartridge life: See Table 1-13.

Storage air pressure:

0 - 2,500m (0 up to 15,000 m is possible during air shi ppin g, but the

air pressure in the cargo room must be 0.7 hPA or more.)

Table 1-13. Toner Cartridge Life

Item Life

Toner Cartridge (Black) 4,500 images

Toner Cartridge (Cyan) 6,000 images*

Toner Cartridge (Magenta) 6,000 images*

Toner Cartridge (Yellow) 6,000 images*

*: Defined under the con diti on s t hat the im ag e ra tio is 5% on A4 (LEF) paper during

continuous printing, and different in color printing. Also, life varies depending on

the image ratio and printer usage, weather continuous or intermittent.

Dimensions and weight:

See Table 1-14. (Tolerances for dimensions and weight are both

±

Drop test:

Height: 91 cm

Resistance to vibration:

Frequency: 5 - 100 Hz

Acceleration: 0.7G

Direction: 3 directions (X, Y, Z) *2

Duration: 50 minutes (single way) for each direction

(1 corner, 3 sides, 6 surfaces)

1%)

Table 1-14. Dimensions and Weight

Unpacked Packed

Dimensions (WxDxH) 50 mm(W) x 400mm (D) x

54.5mm (H)

Weight Black: 0.39kg

Y/M/C: 0.39kg

85 mm(W) x 435mm (D) x

80mm (H)

Black: 0.48kg

Y/M/C: 0.48kg

Environmental conditions for storage and tr ansportation:

Temperature/Humidity: See Table 1-15.

Table 1-15. Temperature/Humidity

Temperature Humidity Guaranty *1

Normal condition 0 - 35

Extreme condition High: 35 - 45 °C

*1: Without condensatio n

*2: 12 months for unpacked cartridges under the used condition.

C 15 - 80% RH *1 24 months

°

High: 80 - 95% Rh*1

Low: -20 - 0

C

°

Low: 5 - 15% Rh*1

1 month (Max.)

Chapter 1 Product Descriptions 1-17

Page 33

EPSON ColorPage EPL-C8200 Revision A

1.2.9.2 Drum Cartridge

Specifications: See Table 1-16.

Table 1-16. Photoconductor Unit Specifications

Specifications

Formation Photoconductor, drum cleaner, waste toner box

Life 20,000 sheets *1 (same for the waste toner box)

Dimension (WxDxH)

2

*

Weight • Unpacked: 2.45 kg

Environmental

condition f or storage

and transportation

*1: Defined under the co ndi tio ns t hat the image ratio is 5% on A4 (LEF ) pap er

during continuous printing, and different in color printing. Also, life varies

depending on the im age ratio and printer usage , w ea ther continuous or intermittent printing.

*2: Tolerances for dimensions and weight are both

• Unpacked: 213 mm(W) x510 mm (D) x 181 mm (H)

• Packed: 318 mm(W) x 618 mm (D) x 280 mm (H)

• Packed: 3.5 kg

Same as for Toner Cartridge

1%

±

1.2.9.3 Fuser Oil Roll

OIL Roll specifications: See Table 1-17.

Table 1-17. Fuser Oil Roll Unit Specifications

Specifications

Formation Oil roll

Life 20,000 sheets *1

Dimensions (WxDxH)

2

*

Weight • Unpacked: 0.68 kg

Environmental

condition for storage

and transportation

*1: Varies depending on the operating conditions, as follows:

- Operating rate is 120 sheets / day or more: 20,000 sheets

- Operating rate is 120 sheets / day or less: 11,000 sheets

*2: Tolerances for dimensions and weight are both

• Unpacked: 75 mm(W) x 421 mm (D) x 48 mm (H)

• Packed: 160 mm(W) x 600 mm (D) x 130 mm (H)

• Packed: 1 kg

Same as for Toner Cartridge

±

1%

Chapter 1 Product Descriptions 1-18

Page 34

EPSON ColorPage EPL-C8200 Revision A

(

)

1.2.9.4 Waste Toner Box

WASTE TONER BOX specifications:See Table 1-18.

Table 1-18. Waste Toner Box

Specifications

Formation Waste toner box and others

Life 20,000 sheets *1

Dimensions (WxDxH)

2

*

Weight • Unpacked: 0.45 kg

Environmental

condition f or storage

and transportation

*1: Defined under the c onditions that the i mage ratio is 5% o n A4 (LEF) printing

at 4P/J. Life varies depen ding on the i mage ratio and p rinter usag e, weather continuous or intermittent printing.

*2: Tolerances for dimensions and weight are both

• Unpacked: 80 mm(W) x 444 mm (D) x 131 mm (H)

• Packed: 149 mm(W) x 495 mm (D) x 192 mm (H)

• Packed: 0.87 kg

Same as for Toner Cartridge

1%

±

1.2.10 Regularly Replaced Parts

The regularly replaced parts (replaced by servi ce engineers) and their

lives are as follows.

1.2.11 Exterior Dimensions

Exterior dimensions of the EPL-C8200 are as follows.

641m m (D )

560m m (W )

H

490m m

728m m (W )

1367.4m m (M ax.)

MAIN FUSER ASSEMBLY 100,000 sheets

Figure 1-7. Exterior Dimensions of EPL-C8200

(including the ventilation filter)

2ND BTR ASSEMBLY: 100,000 sheets

Chapter 1 Product Descriptions 1-19

Page 35

EPSON ColorPage EPL-C8200 Revision A

1.2.12 Controller Specifications

CPU: R5000 (200MHz)

Enhancement technologies:

AcuLaser Color Halftoning (monochrome print)

RIT, CRIT

RAM: SDRAM 64-bit-wide DIMM (168-pin, 3.3V)

Maximum: 256MB

3 RAM slots, including 1 used for the standard

RAM

Standard: 64MB

Expansion: 32MB, 64MB, 128MB, 256MB

ROM: 32-bit-wide

Program: 4MB (ROM DIMM)

Font: 4MB

Expansion ROM: 3 slots (ROM DIMM slots)

Printer modes:

Standard: ESC/Page-Color, ESC/Page (B/W), LJ4 (B/W), GL2

(B/W), ESCP2 (B/W), FX (B/W), 1239X (B/W)

Optional: Postscript3 (PostScr ipt3 module, Peacock-B)

Others: EJL, PJL, RCC

Supplementary software:

Status sheet

Network Status Sheet

Opt I/F Status Sheet (with a Type-B level 3 I/F installed)

Font Sample (each mode)

Hex dump

Support Mode

Maintenance mode (Engine Status Sheet)

Slot A, B: Font ROM module, PostScript3 module, CM table

Slot C: NLSP font ROM module only

Panel: 1-line 20-Character LCD, 6 LEDs, 8 switches

Interfaces:

Standard: Parallel, 1ch

1EEE-1284-compliant bidirectional

B-type connector

Compatibility

Nibble

ECP

Ethernet

100Base/TX, 10Base/T, 1ch

Optional: Type-B - 1 slots (for l evel 3)

Printer settings: Made through the panel setting mode, EJL

commands, and MIB

Chapter 1 Product Descriptions 1-20

Page 36

EPSON ColorPage EPL-C8200 Revision A

1.2.13 Controller Board Jumper Settings

The controller board confi guration of th is printer ca n be set for the t arget

market (destination) as indicated bel ow. The settings are made at

factory (by jumper resistor).

Factory paper default switch setting betwee n A4 and Letter:

[Letter] North/South American

[A4] European

Pacific/Russian

Taiwanese

Chinese

Korean

Paper size switch setting for the cassette:

[EXE] North/South America

European

Pacific/Russia

[B5] Taiwanese

Chinese

Korean

1.3 Interface Specifications

The EPL-C8200 supports the following external interfaces.

Standard: 1. Parallel interface

2. Ethernet interface

Optional: Type-B host interfaces (1 slot)

The host interface usage configurations are as follows.

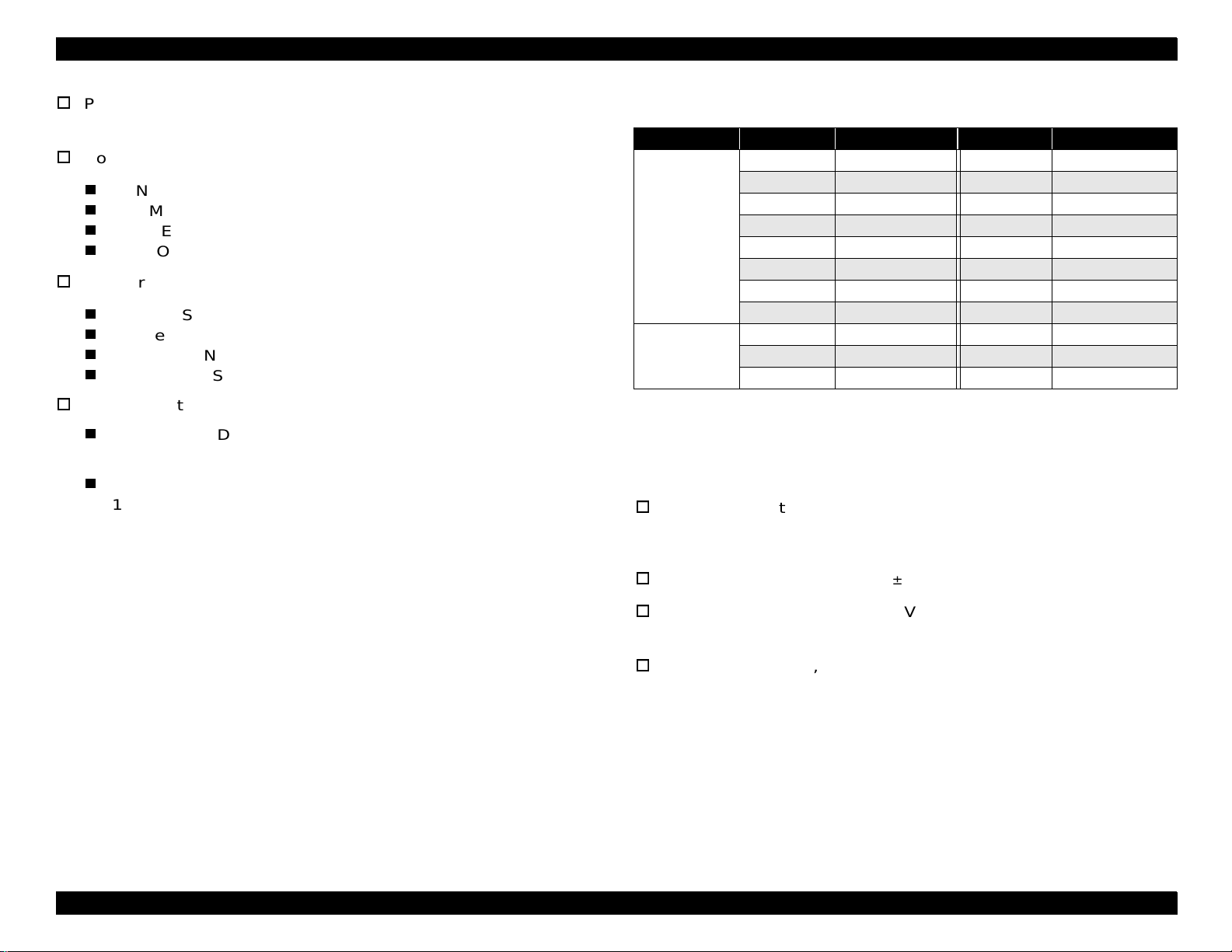

Table 1-19. Host Interface Usage Configurations

Parallel I/F Ethernet I/F

1. Automatic I/F switching Usable Usable Usable

2. Fixed I/F (Parallel) Usable Not Usable Not Usable

3. Fixed I/F (Etherent) Not Usable Usable Not Usable

4. Fixed I/F (AUX) Not Usable Not Usable Usable

Figure below shows the locations of these interfaces.

Type B (AUX)

I/F

Short/Open condition for RJ3 and RJ4:

[RJ3] Open

T y p e -B (A U X ) In te rfa c e

Parallele Interface

(IE E E1284 B -type)

[RJ4] Short

Link/R eception Lam p (G reen)

100Base/10B ase Lam p (O range)

E th e r n e t In te rfa c e

(100BaseTX /10BaseT)

Figure 1-8. Locations of the Interface Slots

Chapter 1 Product Descriptions 1-21

Page 37

EPSON ColorPage EPL-C8200 Revision A

g

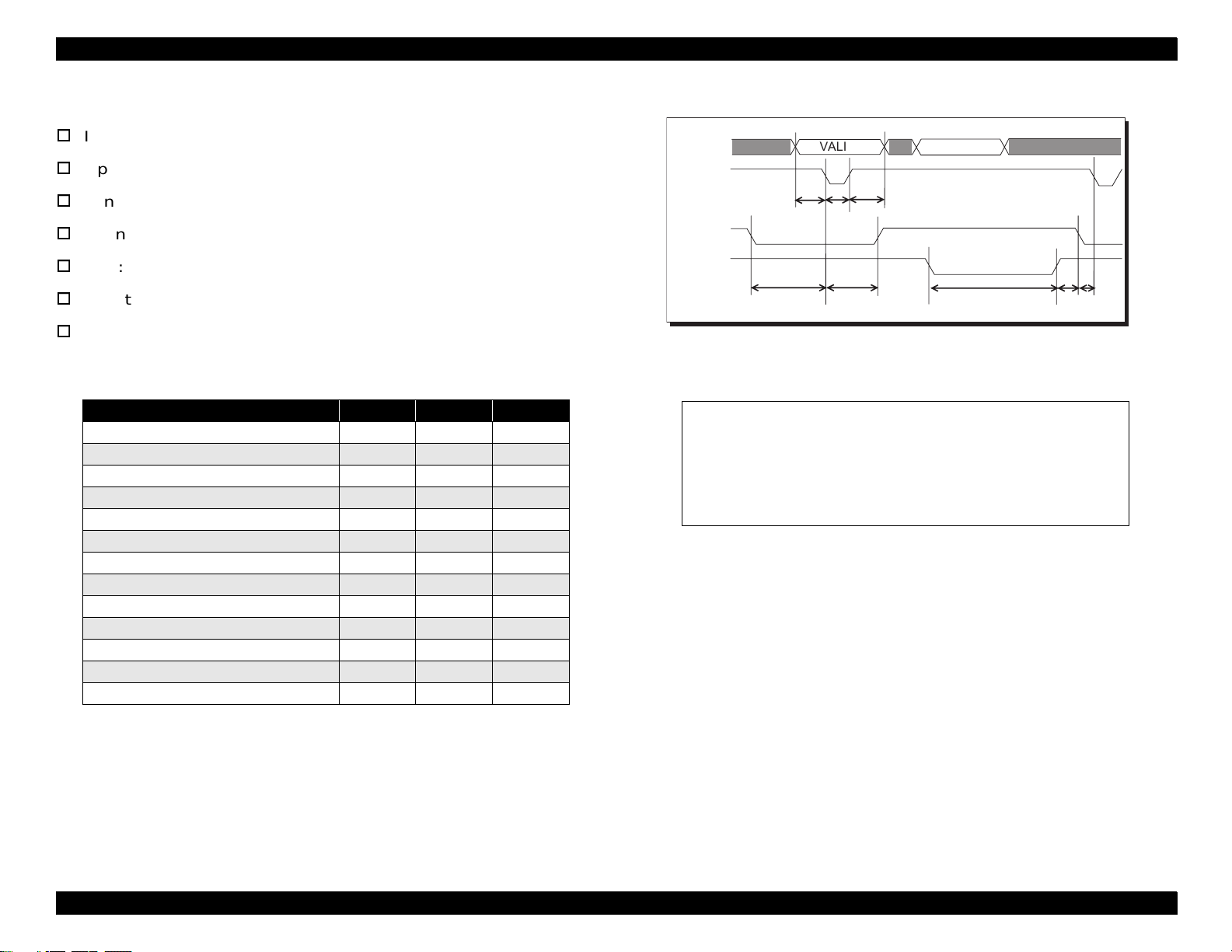

1.3.1 Parallel Interface Specification

Interface type: IEEE 1284 High-Speed Bi-directional Parallel I/F

Operating modes: Compatibility, Nibble, ECP

Synchronization: /STROBE pulse

Connector type: 57RE-40360-830B(D7A)DDK or equivalent

DATA

STRBX

BUSY

(1 )

VALID

1

VALID

(2 ) (3 )

3

VALID

VALID

2

Plug: Amphenol equivalent

Data transmission timing:Refer to Table 1-20 and Figure 1-9.

Device ID: See Table 1-21.

Table 1-20. Data Transmission Timing

Min. Typ. Max

(1) Data hold setup 0.5 us

(2) Data hold 0.5 us

(3) Strobe pulse 0.5 us

(4) BUSY to STRBX 0 us

(5) STROB to BUSY 0.5 us

(6) BUSY to STRBX 0 us

(7) ACKX pulse width 0.5 us 1 us*

(8) ACKX to BUSY 0 s

(9) BUSY to PE or ERRX 2 ms*

(10) PE or ERRX to BUSY 2 ms*

(11) Power on to signal output valid 05 s

(12) PE or ERRX to ACKX 2 ms*

(13) STRBX to ACKX 0 s*

ACKX

(4 ) (5 ) (6 )(7 ) (8 )

7

8

6

8

6

Figure 1-9. Data Transmission Timing

Table 1-21. Device ID

*1;

MFG:

CMD:

MDL:

CLS:

DES:

EPSON;

PJL, EJL, ESCPL2, ESCP9, PRPXL24-01, PCL, HPGL201, ESCPAGE-04, ESCPAGECOLOR-01*2;

*3;

PRINTER;

*4;

*1: Total length of Device ID + 2 (hex)

*2:

POSTSCRIP

*3: Model name

*4: Manufacture and product name

is added when a PostScript module is installed.

EPL-C8200

EPSON ColorPa

e EPL-C8200

Note the MFG, MDL, DES, and CID can be defined by the users. The

CID field, which does not reply at initialized device ID, only repl ies with a

user-defined character s trin g. The devic e I D at r e-defi nit ion i s as sho wn

below. A “*****” represents a user-defined character string.

MFG: *****;

CMD: Same as above

MDL: *****;

CLS: PRINTER

DES: *****;

CID: *****;

Chapter 1 Product Descriptions 1-22

Page 38

EPSON ColorPage EPL-C8200 Revision A

Table 1-22. Centronics Parallel Interface Pin Assignment

Pin # Signal Names I/O Descriptions

1 STRBX I Latch pulse used to read data. DATA is valid when the signal is LOW.

2-9 DATA 1-8 I DATA 8 is MSB and DATA 1 is LSB.

10 ACKNLGX O An acknowledge pulse to the host that indicates the data from the host

computer has been received.

11 BUSY O HIGH status indicates the printer is not ready to accept data.

12 PE O Indicates paper empty status in paper tray or cassette selected.

13 SELOT O Always HIGH.

14 AUTOX I When the signal is LOW, the printer automatically feeds a line as “CR” is

input. The “CR” is detected when the printer is turned on or the interface

selection is switched from the optional I/F to parallel I/F.

15 NC - Not used.

16 GND - Ground level for the twisted pair return.

17 CG - Connected to the printer chassis. The printer chassis GND and the signal

GND are connected each other.

18 NC - Not used.

19-30 GND - Ground level for the twisted pair return.

31 INITX I When the signal is LOW, the STRBX signal is ignored.

32 ERRX O The signal is LOW when the printer is in the following condition:

User maintenance is required.

Service maintenance is required.

Another type of error has occurred.

The printer is off line.

33 GND - Ground level for the twisted pair return.

34 NC - Not used.

35 +5V - Pu lled up to +5V through 1K Ω resistor.

36 SELINX I Always LOW.

Chapter 1 Product Descriptions 1-23

Page 39

EPSON ColorPage EPL-C8200 Revision A

1.3.2 Ethernet Interface

Interface type*: 10BaseT

100BaseTX

Half Duplex

Full Duplex

*: Switched at power on

Communication protocol:

1. IPX/SPX (IPX, SPX, NCP, RIP, SAP, PrintServer,

RemotePrinter, NDS, SNMP, ENPC)

2. NetBIOS (SMB)

NetBEUI

3. TCP/IP (IP, UDP, TCP, LPR, FTP, TELNET, APR, ICMP,

RARP, BOOTP, DHCP, SNMP, HTTP, ENPC)

4. AppleTalk (ELAP, DDP, ATP, PAP, AARP, NBP, ZIP, RTMP,

SNMP, ENPC)

Connector type: RJ45

Table 1-23. Pin Configuration for the Ethernet I/F

Pin Signal Name I/O

1Tx+ O

2Tx- O

3Rx+ I

4N.C. 5N.C. 6 Rx- I

7N.C. 8N.C. -

Applicable cable: 2-pair STP (10BaseT, 100BaseTX)

NOTE: Use a shielded cable to meet FCC Class B, EN55022 Class

B, and VCCI Class B.

Pin configuration: See Table 1-23.

Entity type: See Section 3.3.3 Type B Interface.

Chapter 1 Product Descriptions 1-24

Page 40

EPSON ColorPage EPL-C8200 Revision A

1.3.3 Type B Interface

This printer is equipped with a slot for Type B option al interface.

Main system type: MTP600dpi, PW774dt600doi, PRG(

rev. AP2000ma, SPD0fast, D4

*: “

∗ ∗ ∗ ∗ ∗

Printer name: Same as the Product name at factory.

Product name: EPL-C8200

Emulation type / Entity type: See Table 1-24.

“Represents ROM version.

∗ ∗ ∗ ∗ ∗)*

Entity type

1. Emulation = Auto:See Table 1-24.

2. Emulation Menu = Fixed

The entity type of the default emulation,

EPSONCOLORPAGE is returned.

Table 1-24. Type B I/F Emulation/Entity Type

Emulation Emulation Type Entity Type

*1

PS

ESC/Page Color ESCPAGECOLOR-01 EPSONPAGECOLOR1

ESC/Page ESCPAGE-04

LJ4 PCL5E-00 EPSONPCL5

*2

RCC

1239X PRPXL24-01 EPSONPRPXL24

GL2 HPGL24-01 EPSONHPGL2

FX ESCP9-84 EPSONFX

ESCP2 ESCPL2-00 EPSONLQ2

POSTSCRIPT-00

--

*1

LaserWriter

*1

*1: Added with PostScript3 module attached.

*2: Can not be selected by users.

Emulation type

1. Emulation = Auto

When PS is active: AUTO (Emulation Type 1,2,3,...)

When PS is inactive: EJL(POSTSCRIPT-00, other

Emulation Type 1,2,3...)

2. Emulation Menu = fixed

EJL (Default Emulation Type, Other Emulation Type 1,2,3,

...)

Chapter 1 Product Descriptions 1-25

Page 41

EPSON ColorPage EPL-C8200 Revision A

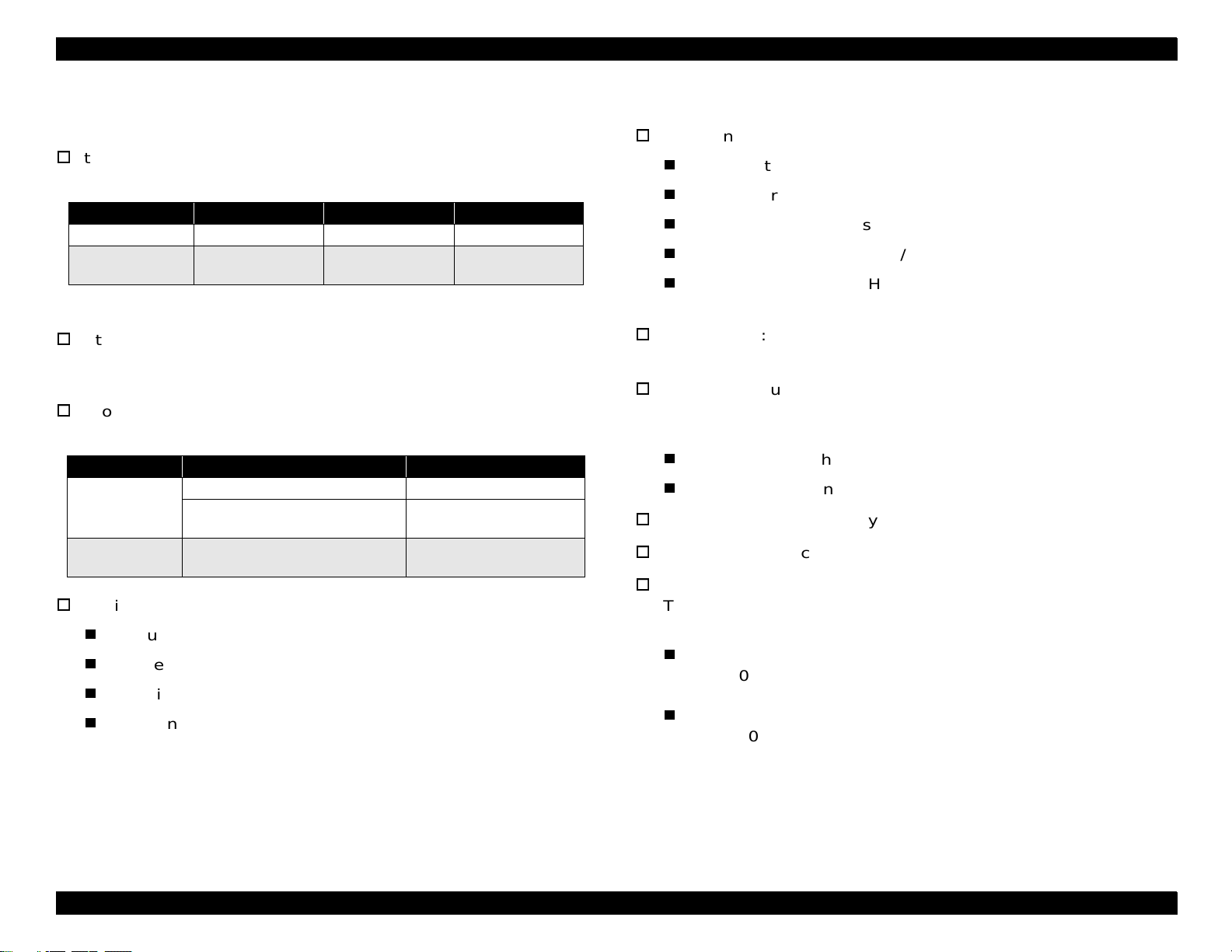

1.4 Control Panel

This section describes the control panel of this printer and its functions.

1.4.1 Appearance and Descriptions

The control panel of this printer consists of the LCD, 8 buttons, and 6

LEDs. See Figure 1-10 and Tabl e 1-25 for th e control panel appearance

and its descriptions, respectively.

J

DE

Paper Source P aper S ize M anual Feed O rientation

SelecType

K

Alt

FG

RITech

Menu Item Value

L

C opies M P Tray Size

MN

Toner Save

Mode

Enter

O

On Line

H

A

B

Form Feed

I

C

C ontinue

Reset

Figure 1-10. Control Panel Appearance

Table 1-25. LEDs and Switches on the Control Panel

LED Button

Location Name Remarks Location Name Remarks

A LCD Panel

B On Line LED Green I Form Feed button

C Data LED Yellow J Continue button

D Continue LED Red K SelecType/Alt button Also serves as the Shift button

E OneTouch Mode 1 LED L Menu Select button

F OneTouch Mode 2 LED M Item Select button

G SelecType Mode LED N Value Select button

- - O Enter button

1 line, 20 characters

(5 x 7 dot matrix)

H On Line button

Chapter 1 Product Descriptions 1-26

Page 42

EPSON ColorPage EPL-C8200 Revision A

1.4.1.1 LED Description

LCD (Liquid Crystal Display) (A)

One-line display for 20 characters (5 x 7 dot matrix)

Normally displays printer status.

In panel setting mode, LCD displays various setting val ues.

On Line LED (B)

On: The printer is on-line.

Off: The printer is a pause status.

Form Feed LED (C)

On: Unprinted data remains in the printer. However, the

lamp is not lit if the remaining data is not effective

print data but other data such as control codes

including commands.

Off: No effective print dat a remains in the printer. If

control codes are not terminated, the indicator is lit.

Blinking: The printer is processing data.

Continue LED (D)

OneTouch Mode 2 LED (F)

On: OneTouch mode 2 is enabled. The following 4 items

can be set in this mode:

- RITech

- Copies

- Mp Tray Size

- Toner Save Mode

SelecType Mode (G)

On: SelecType mode is enabled.

All LEDs

All LEDs come on when a service-call error has occurred.

Blinking: An error has occurred which can be cleared by

pressing the Continue button.

OneTouch Setting Mode 1 LED (E)

On: OneTouch mode 1 is enabled. The following 4 items

can be set in this mode:

- Paper Source

- Paper Size

- Manual Feed

- Orientation

Chapter 1 Product Descriptions 1-27

Page 43

EPSON ColorPage EPL-C8200 Revision A

1.4.2 Button Functions

On Line button (H)

When the printer is on-line, pressing this button puts the printer in

off-line to prevent printing. Pressed during panel setting mode, it

immediately terminates the setti ng mode and brings the prin ter back

to on-line status.

Form Feed button (I)

If the Form Feed lamp is lit in off-line status, pressi ng this button

causes the printer to print a page of data. If data for multipl e pages

has been received, it is printed. If t he Form Feed LED is lit because

the control codes are not terminated, the data recei ved up to that

point is printed. The printer does not eject paper when the Form

Feed LED is on.

Continue button (J)

While the Continue LED is on, pressing this button clears the error.

Also, a warning message indicated during on-line status can be

cleared by pressing this button.

Menu button (L)

Pressing this button activates the SelecType mode, and the

initial level of the mode (“Test Menu”) appears. In the SelecType

mode, this button is used to select the setting menu, t he primary

level of the mode.

In OneTouch mode 1, used to select the value for “Paper

Source”.

In OneTouch mode 2, used to select the item for “RITech”.

In SelecType mode, used to select the setting menu.

NOTE: If this button is pressed with the Shift button held down,

setting values and items scroll backward.

Item button (M)

Pressing this button brings up the item that was last selected.

In OneTouch mode 1, this button is used to select the value for

“Paper Size”.

In OneTouch mode 2, this button is used to select the value for

“Copies”.

In SelecType mode, this but ton is us ed to se lec t the set ting i tem.

NOTE: If this button is pressed with the Shift button held down,

setting values and items scroll backward.

SelecType button (K) (or Shift button)

Used to select OneTouch mode 1 / OneTouch mode 2 / SelecType

mode, as follows:

The first push of the button puts the printer in OneTouch mode

1.

Pressing this button in the OneTouch mode 1 puts the printer in

OneTouch mode 2.

Pressing this button in the OneTouch mode 2 activates the

SelecType mode to enter the initial level of SelecType mode.

(The “Test Menu” appears.)

Value button (N)

Pressing this button enables the item that was last selected.

In OneTouch mode 1, used to select the value for “Manual

Feed”.

In OneTouch mode 2, used to select the value for “MP Tray

Size”.

In SelecType mode, used to select the value for the currently

selected setting item. The next available value for the item is

indicated.

NOTE: If this button is pressed with the Shift button held down,

setting values and items scroll backward.

Chapter 1 Product Descriptions 1-28

Page 44

EPSON ColorPage EPL-C8200 Revision A

Enter button (O)

Pressing this button generates “Status Sheet” in “Test Menu”.

In OneTouch mode 1, used to select the value for “Orientation”.

In OneTouch mode 2, used to select the value for “Toner Save

Mode”.

In SelecType mode, the setting value is confirmed and printing

or other functions are activated.

NOTE: If this button is pressed with the Shift button held down,

setting values and items scroll backward.

Reset button (Continue button + Alt button) (K + J)

Pressing this button with the Alt butt on held down caus es the printer

to stop printing and reset. Af ter th e message “ Reset ” is indi cat ed on

the LCD, if the both buttons are kept pressed for more 5 seconds,

“Reset All” is indicated and warm boot is performed.

Chapter 1 Product Descriptions 1-29

Page 45

EPSON ColorPage EPL-C8200 Revision A

1.5 Service Functions

Turning the printer on while pressing the specified button(s) until RAM

check is completed provides several service functions. The service

functions supported with this print er are as listed below.

Hex Dump Mode

Support Mode

EEPROM Initialization

Panel Setting Initialization

Formatting the Flash ROM Module

Updating the Program ROM

ROM Module Copy

Maintenance Mode

CPU Reset During Service-Call Error

Error Sheet Print

NOTE:Following modes are not supported.

Total page counter clear

Total Counter Clear in the Maintenance Menu is substituted.

Toner level reset

Remaining toner level is evaluated based on the dispense time

on the engine side.

1.5.1 Hex Dump Mode

Buttons: Form Feed + Power on

Functions: “Hex Dump” is indicated. Received data is converted

into hex ASCII. This is vali d for a ll i nte rfaces. The he x

damp sheet contains the following information:

-Dump list with the received data in hex ASCII format

-Data list with 1-byte code characters (Unreadable

characters are expressed by *.*.)

-Page number

-Termination:Press “Reset” button to perform warm

boot or turn the printer off and back on.

1.5.2 Support Mode

Buttons: Value + Power on

Functions: Adds the support mode to t he setting menu list. Once

it is added, the printer performs warm-boot, then the

support mode can be selected and executed. The

support mode enables servicers to set items,

including HDD initialization, that are normally not set

by users.

1.5.3 EEPROM Initialization

Buttons: On Line + Continue + Menu + Power on

Functions: Clears the EEPROM to 00h and writes factor y default

values. All values except for the values below are

cleared; IBT Cleaner, 2ND BTR, Fuser Unit, and

accumulated printed pages counter value. (Ref er to

Section 1.5.8.)

Termination: After initializing, the printer performs warm boot and

returns to the normal states.

Chapter 1 Product Descriptions 1-30

Page 46

EPSON ColorPage EPL-C8200 Revision A

1.5.4 Formatting the Flash ROM Module

Buttons: Alt + Item + Value + Enter + Power on

Termination: After initializing, the printer performs warm boot and

returns to the normal states.

Functions: Clears the flash ROM module inserted in the slot A. It

starts as the message “DIMM A ERASING” appears.

Termination: After formatting the flash ROM module, the printer

performs warm boot and return s to the normal st ates .

1.5.5 Updating the Program ROM

Buttons: On Line + Alt + Value + Power on

Functions: Updates the DIMM inserted in the program socket.

1.5.6 ROM Module Copy

Buttons: On Line + Alt + Enter + Power on

Functions: Copies the contents of the ROM module in the socket

B to the flash ROM module in the socket A. If ther e is

no module in the socket B, the contents of the ROM

module in the code ROM socket is copied. As the

indication “DIMM COPY MODE” appears, press the

Enter button. The contents of the ROM is erased a nd

copy process is carried out.

Termination: After copying, the printer performs warm boot and

returns to the normal states.

1.5.8 Maintenance Mode

Buttons: On Line + Form Feed + Continue + Power on

Functions: Adds the Maintenance menu to the setting menu.

After this operation, the printer automatically

performs warm boot and the Maintenance menu is

enabled. To eliminate this menu from the setting

menus, turn the printer off and back on. Note that all

engine-related Service-Call Errors (Service-Call

Error e f f f f) are ignored (No Service-Call Error

occurs.) while the Maintenance menu is generated.

(Same as for EJL) Note the following points in the

Maintenance mode:

Interfaces are always open. (Disconnected)

Before entering the Maintenance mode to print an

engine status sheet, make sure no engi ne-rel ated

error is indicated in a normal mode (other than

Maintenance mode).

In this mode, the printer only prints engine status

sheet. In case other printouts such as normal

status sheet is needed, be sure to check that no

engine related error is i ndicate d i n a normal mode

(other than Maintenance mode), as described

above.

1.5.7 Panel Setting Initialization

Buttons: Continue + Power on

Functions: All panel settings for total environment and interface-

specific environment are reset t o the factory def aults.

Information such as accumulated printed pages to

which users have no access is not initialized.

Termination: Turn the printer off and back on.

Chapter 1 Product Descriptions 1-31

Page 47

EPSON ColorPage EPL-C8200 Revision A

1.5.9 Error Recovery Operation

By pressing the specified buttons, the foll owing functions are activated.

a) CPU reset when E***** or C2000 Service call error is indicated

Buttons: Alt + Menu + Item + value + Enter

Functions: Returns the printer to the normal states without

turning off and back on the printer.

NOTE:If the message “Printing SysErr?>” appears after this

operation, an error sheet can be printed by pressing the

Enter button. If any other button is pressed, the printer

returns to the normal status without outputting an error

sheet.

b) Display of error details when E***** or C2000 Service-call error

is indicated

Step 1

Step 2

Step 3

: Press the Continue, Alt, and Menu buttons.

“ERR Y x x x x 0x********” (code and address)

appears. - *1

: Press any button.

“ERR TYPE 0x********” (error type) appears.

: Press any button. The display returns to *1.