Page 1

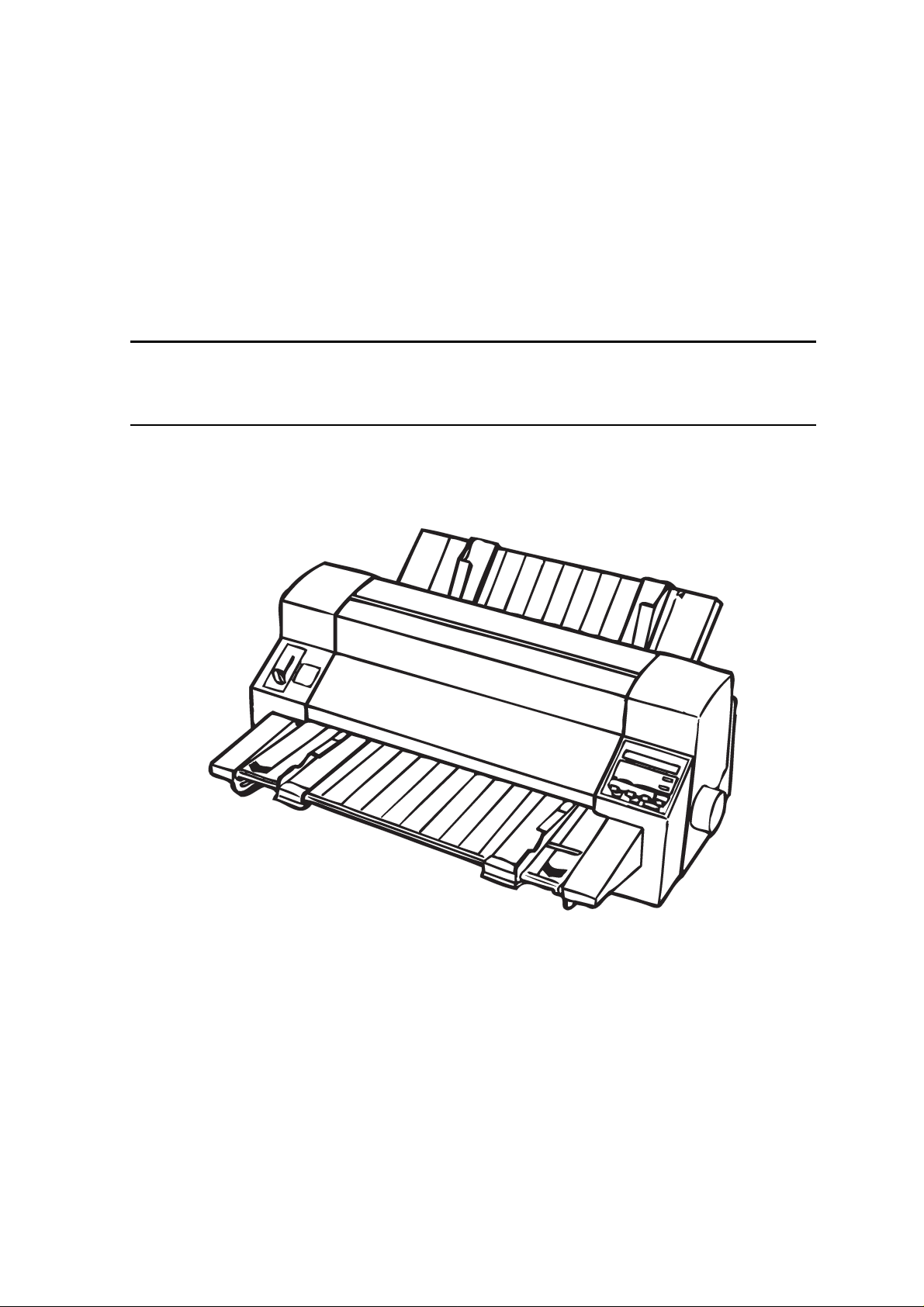

EPSON

24-PIN DOT MATRIX PRINTER

SERVICE MANUAL

EPSON DLQ-3000+

SEIKO EPSON CORPORATION

4008259

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever

without SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual.

However, should any errors be detected, SEIKO EPSON would greatly appreciate

being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for an y erro rs

in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice:

Other product names used herein are for identification purposes only and may be

trademarks or registered trademarks of their respective companies.

Copyright 1997 by SEIKO EPSON CORPORATION

Nagano, Japan

ii

Page 3

PRECAUTIONS

Precautionar y notations throughout the tex t are categorized rel ative t o 1) personal i njury and 2)

damage to equipment.

WARNING

CAUTION

The precautionary measures itemized below should always be observed when performing

repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal

injury. Great caution should be exercised in performing procedures preceded by

WARNING Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

WARNING

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO W ORK SHOULD BE PERFO RMED ON THE UNIT BY PERSONS UNF AMILIAR W ITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL. DO NOT

CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN

WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

CAUTION

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY EPSON

CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VO LT AG E,

LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A

PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DI SCONNECTED FROM T HE

POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS

AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE

STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY

THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR OTHER

NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY

APPLICABLE EPSON WARRANTY.

iii

Page 4

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance,

and repair of DLQ-3000+.

The instruct ions and procedur es incl uded herei n are i ntended for the ex peri ence repai r tec hnic ian,

and attention should be given to die precautions on the preceding page. The Chapters are

organized as follows:

CHAPTER 1. GENERAL DESCRIPTION

Prov ides a general product ov erview, l ists specific ations, and illustrates the main components of

the printer.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENT

Includes a step-by-step guide for adjustment.

CHAPTER 5. TROUBLESHOOTING

Provides EPSON-approved techniques for troubleshooting.

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to

service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and

exploded diagram.

The contents of this manual are subject to change without notice.

iv

Page 5

REVISION SHEET

Revision Issued Data Contents

Rev. A August 21 1997 First Release

v

Page 6

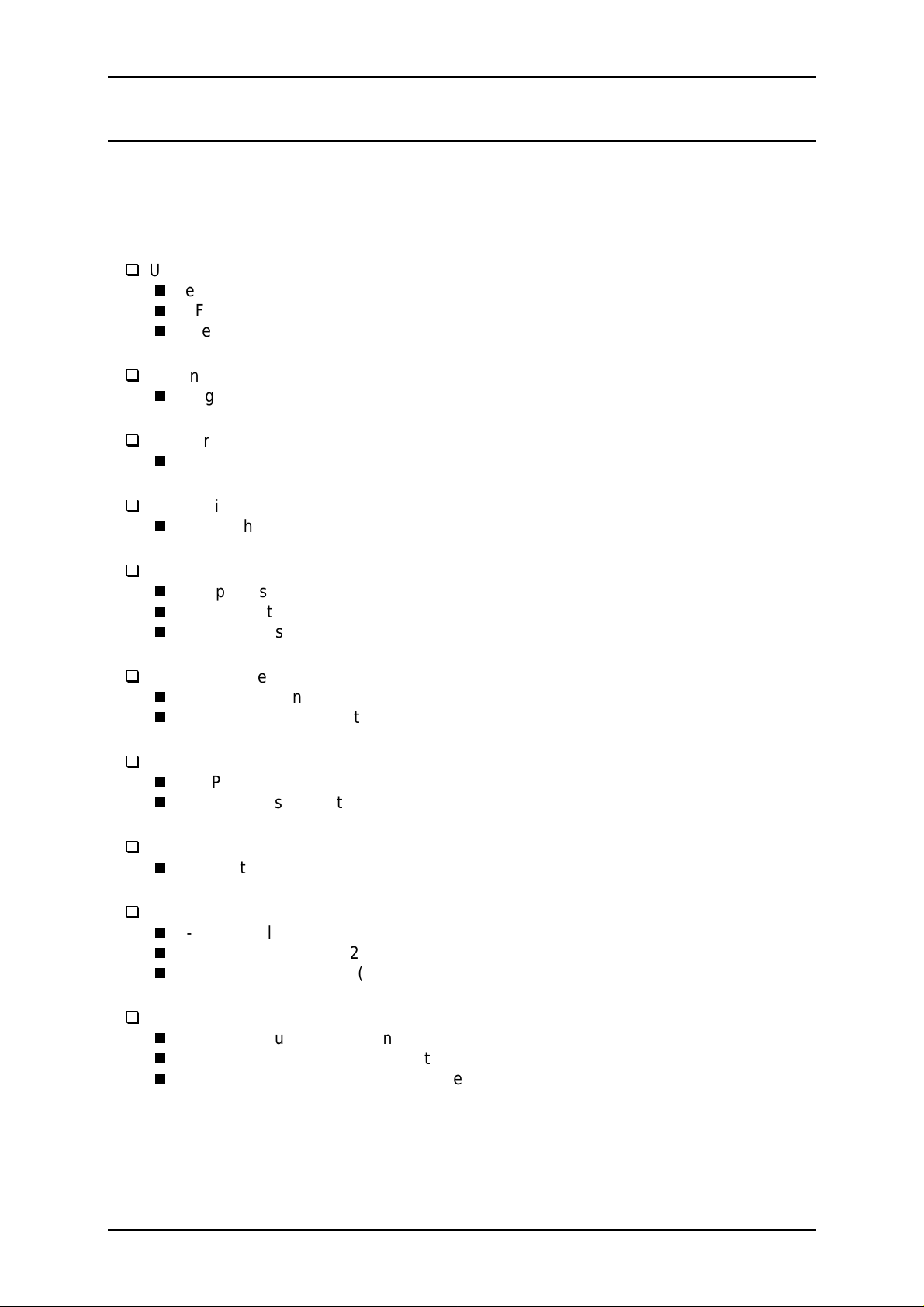

TABLE OF CONTENTS

CHAPTER 1. GENERAL DESCRIPTION

CHAPTER 2. OPERATING PRINCIPLES

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

CHAPTER 4. ADJUSTMENT

CHAPTER 5. TROUBLESHOOTING

CHAPTER 6. MAINTENANCE

APPENDIX

vi

Page 7

Chapter 1

Product Description

1.1 Features ..................................................................................................1-1

1.2 Consumables and Options....................................................................1-3

1.3 Hardware Specification..........................................................................1-4

1.3.1 printing Specification....................................................................1-4

1.3.2 Character Specifications and Control Codes.............................1-7

1.3.2.1 Coded Character Sets.........................................................1-7

1.3.2.2 Type Faces..........................................................................1-7

1.3.2.3 Rendition .............................................................................1-7

1.3.2.4 Combination of character tables and typefaces ..................1-8

1.3.2.5 Memory Size........................................................................1-9

1.3.2.6 Character Size.....................................................................1-9

1.3.2.7 Control Codes......................................................................1-9

1.3.3 Paper Feed Specification............................................................1-10

1.3.3.1 Friction Feed (Cut sheet)...................................................1-10

1.3.3.2 Tractor Feed (Continuous paper)......................................1-10

1.3.3.3 Paper Feed Speed and Accuracy......................................1-10

1.3.4 Paper Specification.....................................................................1-11

1.3.5 Printable Area..............................................................................1-17

1.3.6 Paper Thickness Detection ........................................................1-24

1.3.7 Ribbon Cartridge.........................................................................1-25

1.3.7.1 Monochrome ribbon cartridge............................................1-25

1.3.7.2 Color ribbon cartridge........................................................1-25

1.3.8 Input Data Buffer .........................................................................1-26

1.3.9 Electric Specifications................................................................1-26

1.3.10 Safety Approvals .......................................................................1-26

1.3.11 CE Marking.................................................................................1-26

1.3.12 Acoustic Noise...........................................................................1-27

1.3.13 Reliability....................................................................................1-27

1.3.14 Environmental Conditions........................................................1-27

Page 8

1.4 Interfaces ..............................................................................................1-28

1.4.1 Parallel Interface..........................................................................1-28

1.4.2 Serial Interface.............................................................................1-33

1.4.3 Optional Interface........................................................................1-34

1.4.4 Printer language..........................................................................1-35

1.4.5 Prevention Hosts from Data Transfer Time-out .......................1-36

1.4.6 Interface Selection ......................................................................1-36

1.5 Operation ..............................................................................................1-37

1.5.1 Control Panel...............................................................................1-37

1.5.1.1 Button Operations..............................................................1-37

1.5.1.2 Printer Status and LCD/LED Indicator Conditions.............1-39

1.5.1.3 Printer Status and Buzzer..................................................1-40

1.5.2 SelecType.....................................................................................1-41

1.5.2.1 SelecType Phase ..............................................................1-41

1.5.2.2 SelecType Operation.........................................................1-42

1.5.2.3 SelecType Option..............................................................1-43

1.5.3 Functions at Power On ...............................................................1-45

1.5.4 Bi-D Adjustment Mode................................................................1-46

1.5.5 Program Reload Mode................................................................1-46

1.5.6 Initialization..................................................................................1-47

1.5.6.1 Printer Initialization............................................................1-47

1.5.6.2 Initialize Defaults to the Standard......................................1-48

1.6 Main Components................................................................................1-49

1.6.1 C210MAIN Board.........................................................................1-49

1.6.2 C124PSB/PSE Board...................................................................1-50

1.6.3 Printer Mechanism......................................................................1-50

1.6.4 Housing........................................................................................1-51

Page 9

Product Description

1.1 Features

The DLQ 3000+, equipped with a Bi-directional parallel interface, is the most advanced

EPSON 24-pin impact-dot printer. It prints on continuous multi-part form as well as on single

sheet, which makes the printer highly usable in office environment . The main features of

this printer are:

Used in Network environment with parallel interface supported

Memory

CSF paper quantity sensor

Paper jam detection

Enhanced duplex printing

1 original plus 6 duplications in the copy mode

Wide printable area

70 line / A4 (0 mm can be set for the top and bottom margins at single print mode.)

Paper thickness detection function supported

Enables the auto and manual platen gap adjustment

Fonts

Bitmap fonts: 9 LQ and 1 draft typefaces

Scalable fonts: 4 typefaces

Bar-code fonts: 8 typefaces

Character tables

Standard version: 11 tables

NLSP version: 30 tables

Control codes

ESC/P2

IBM 2391 Plus Emulation

Input buffer

128 K byte

Interface

Bi-directional parallel interface (IEEE-1284 nibble mode supported)

Serial interface (EIA-232D)

Type-B interface level 2 (Optional)

Reliability

Total print volume: 9 million lines

Printhead life: 200 million strokes

Ribbon life: 6 million characters

Rev. A

1-1

Page 10

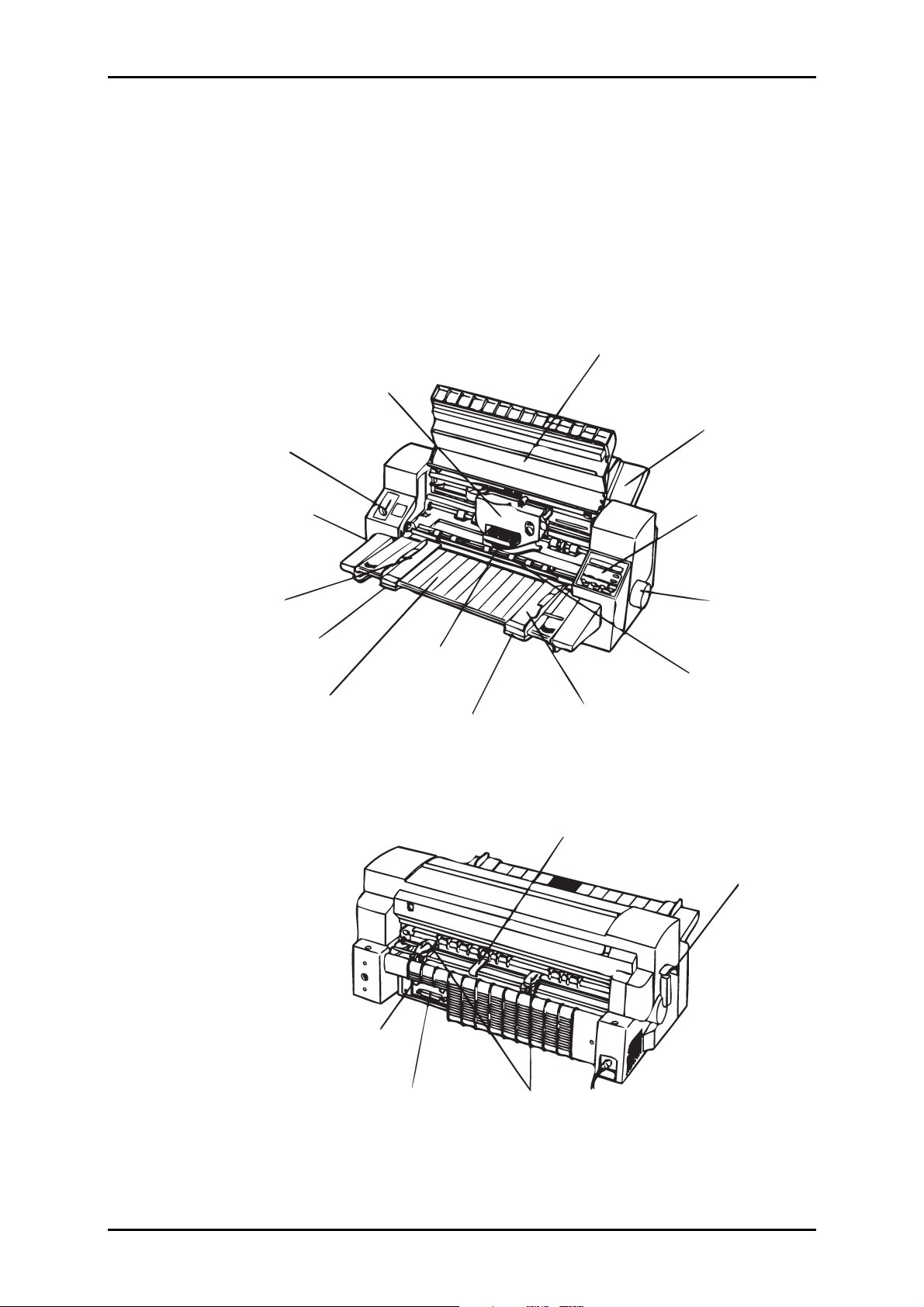

DLQ-3000+

Paper Thickness Adjust Lever

Printer Cover

Ribbon Cartridge

Rear Paper Guide

Power Switch

Left Guide Edge

Left Guide Edge Lock

Front Paper Guide

Printhead

Right Guide Edge Lock

Control Panel

Knob

Paper Bail

Right Guide Edge

Paper Support

Release Lever

1-2

Parallel Interface

Serial Interface

Tractor Unit

Figure 1-1. Exterior View of DLQ 3000+

Rev. A

Page 11

3

1.2 Consumables and Options

Table 1-1. Accessories and Options

Part Number Description

Consumable Supplies

S015066

S015067 Ribbon cartridge (Color)

Optional Equipment

C806830 Cut sheet feeder

C82307∗ / C82308∗

C82310∗ / C82311∗

C82312∗

C82313∗

C82314∗

C82315∗

C82331∗

C82345* IEEE-1284 parallel I/F card

C82346 Multi Protocol Ethernet I/F card

Accessory Equipment

Ribbon cartridge (Black)

32KB intelligent serial I/F card

32KB intelligent parallel I/F card

Localtalk™ card

32KB IEEE-488 I/F card

Coax I/F card

Twin-Ax I/F card

Ethernet I/F card

Power supply cable

Product Description

2

*

Note:

1. Asterisk at the end of the part numbers replaces the last digit of the part number,

which varies by the market.

2. Can be an accessory item according as market.

Rev. A

1-

Page 12

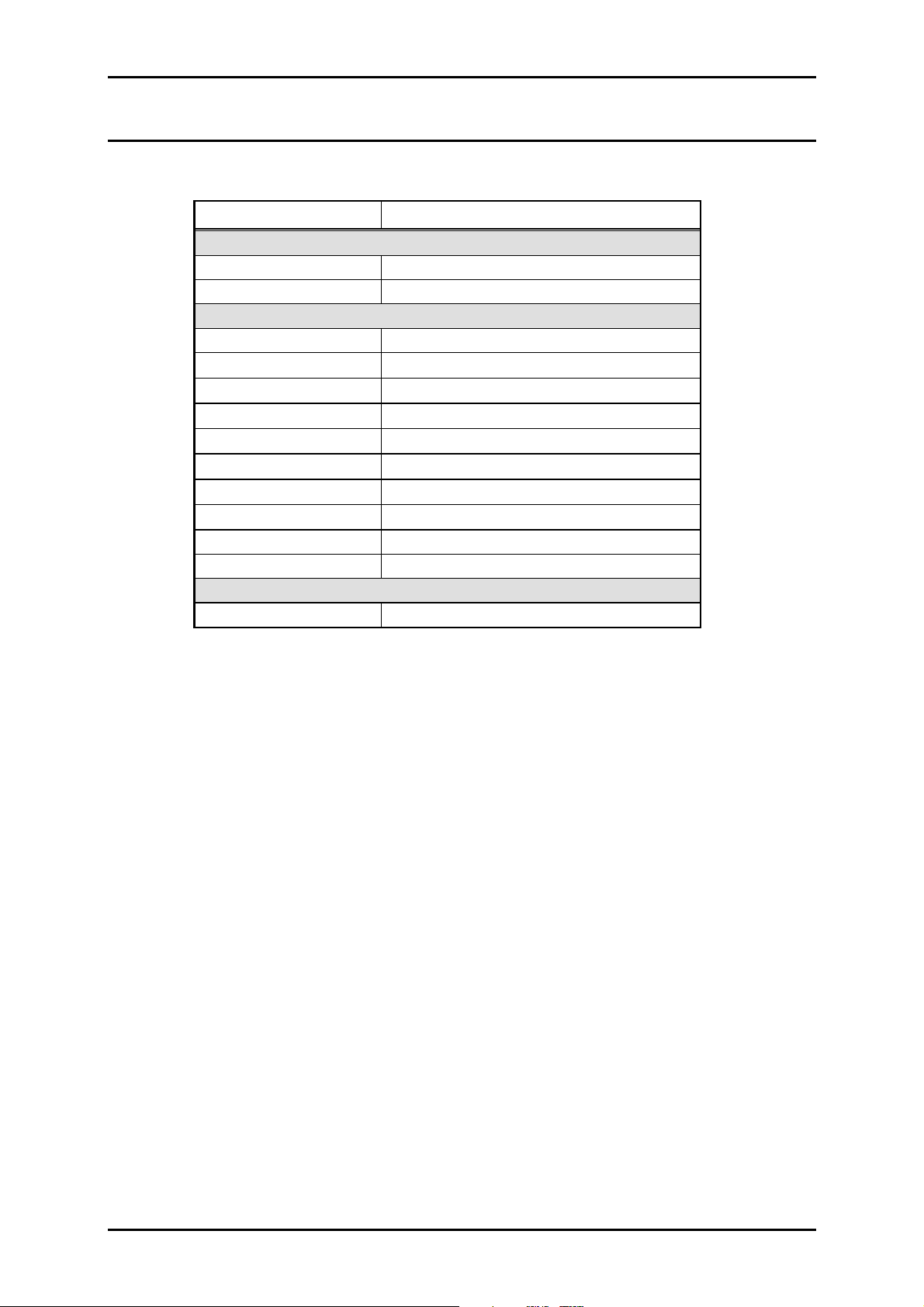

DLQ-3000+

1.3 Hardware Specification

1.3.1 printing Specification

Print method Impact-dot matrix

Print pin arrangement 24-pin rhombus (See Figure 1-2.)

0.86 m m =1/30"+1/2160"

6x0.023m m (=1-1080")

#1 #2

3.25m m (=1/180"x23)

11x0.28m m (=1/90")

#23

6x0.023m m (=1-1080")

#24

0.14 m m (=1/180")

11x0.28m m (=1/90")

Figure 1-2. Pin Arrangement

Printing direction Bi-directional printing with logic seeking

Resolution See Table 1-2.

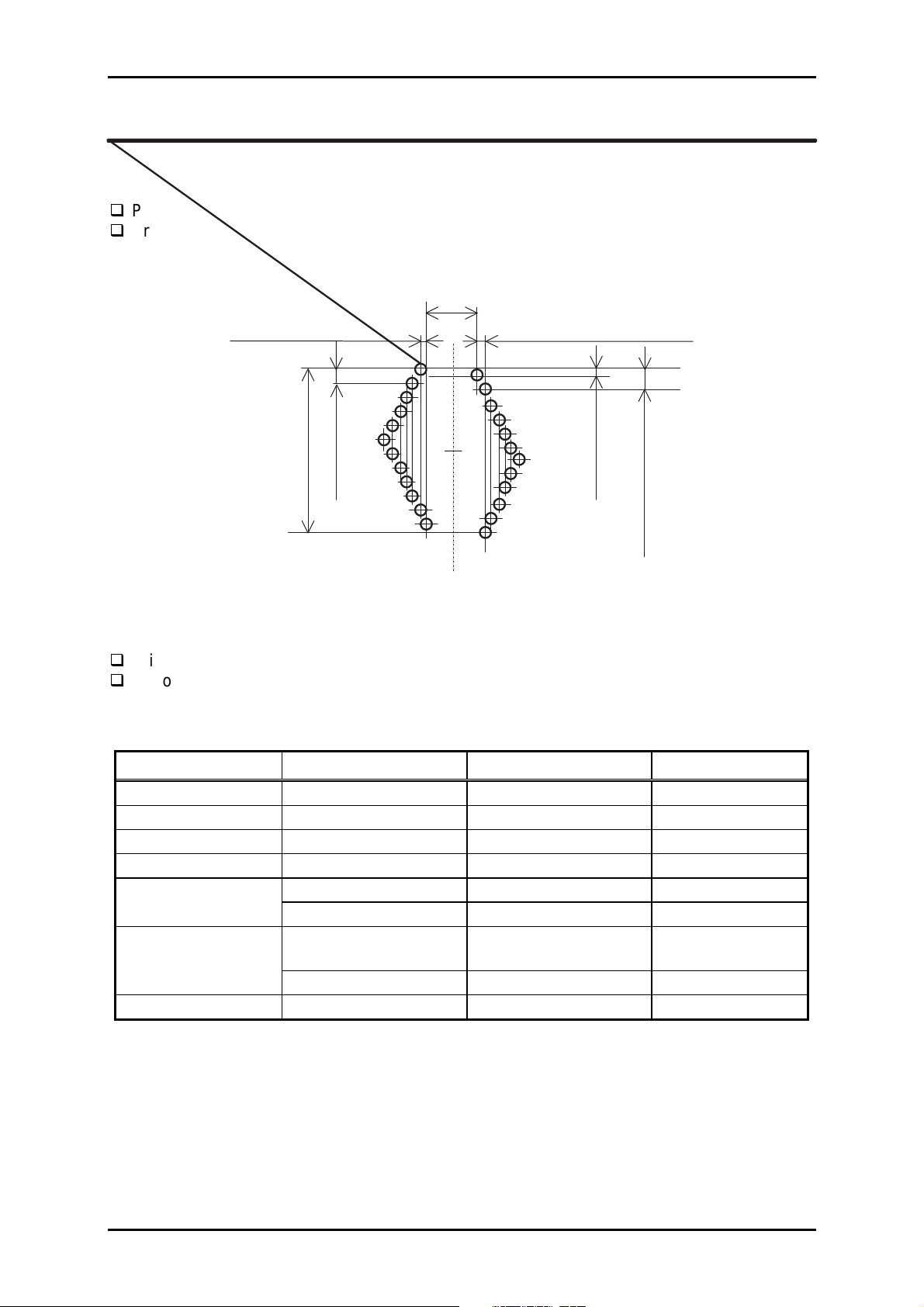

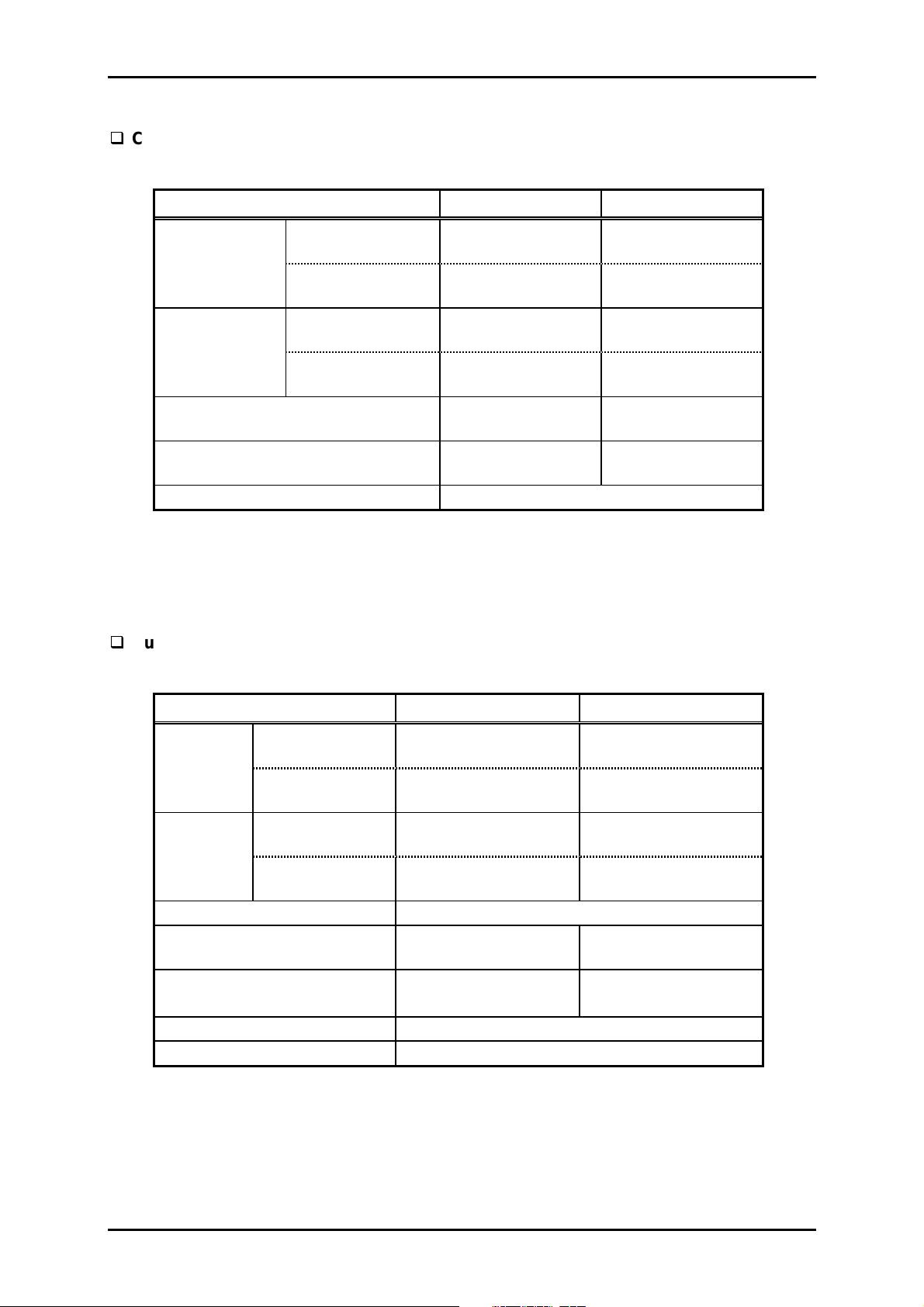

Table 1-2 .Printing Resolution

Printing Mode Horizontal Density Vertical Density Adjacent Dot Print

High speed draft 90 dpi 180 dpi No

Draft 120 dpi 180 dpi No

Draft condensed 240 dpi 180 dpi No

LQ 360 dpi 180 dpi No

8-pin bit image 60, 80, 90 or 120 dpi 60 dpi Yes

120 or 240 dpi 60 dpi No

24-pin bit image 60, 90, 120 or 180

180 dpi Yes

dpi

360 dpi 180 dpi No

Raster graphics 180 or 360 dpi 180 or 360 * dpi Yes

Note:When a color ribbon is installed, the printer can not print vertical 360 dpi graphics. In

that case, the printer changes vertical density to 180 dpi.

1-4

Rev. A

Page 13

Product Description

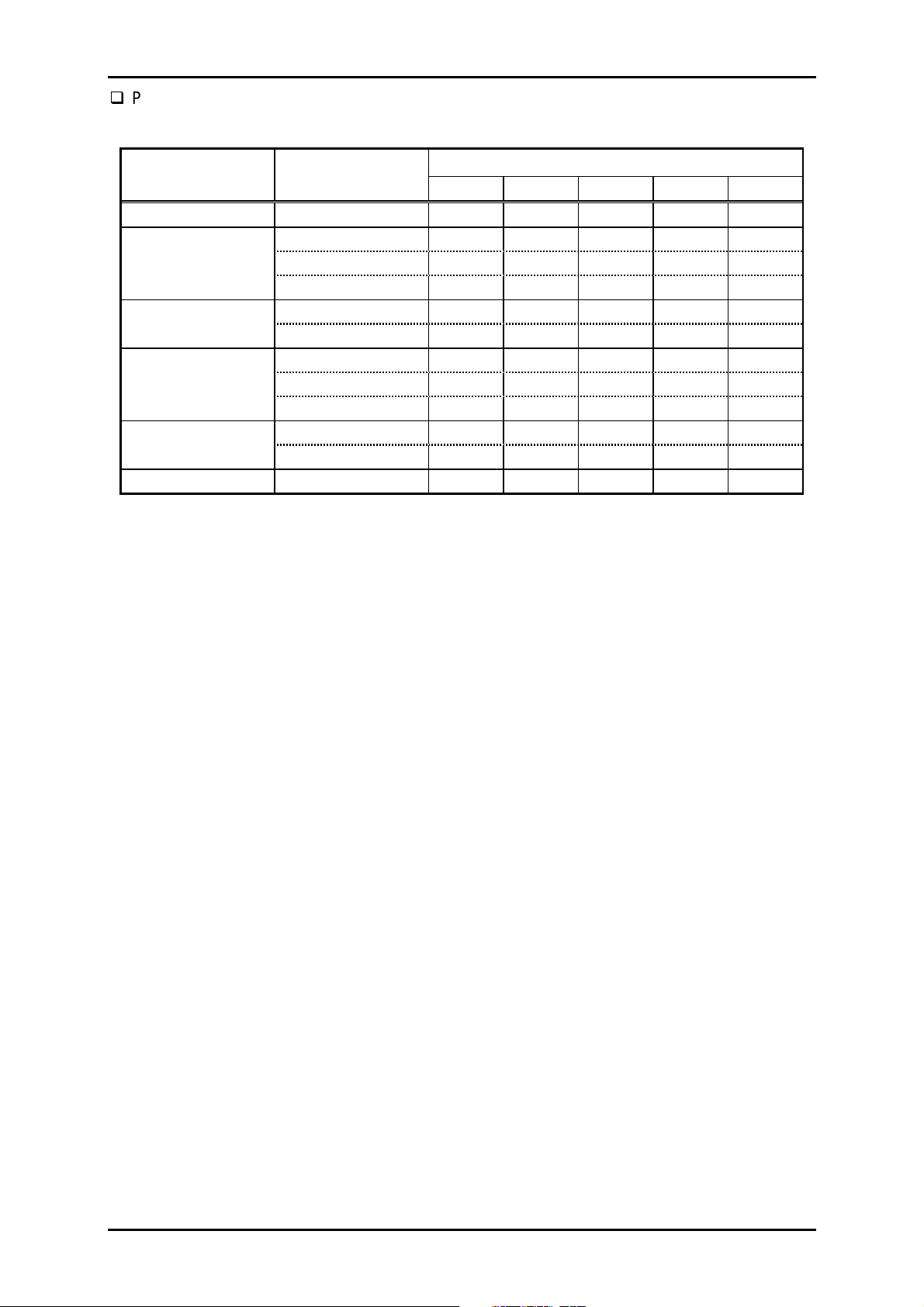

5

Printing speed See Table 1-3.

Table 1-3. Printing Speed

Printing Mode Character Size Maximum Printing Speed

Mode 0 Mode 1 Mode 2 Mode 3 Mode 4

High speed draft 10 cpi 444 444 160 160 240

10 cpi 360 333 240 120 180

Draft 12 cpi 432 400 288 144 216

15 cpi 540 500 360 180 270

Craft condensed 17 cpi 309 286 206 103 154

20 cpi 360 333 240 120 180

10 cpi 120 111 80 40 60

LQ 12 cpi 144 133 96 48 72

15 cpi 180 167 120 60 90

LQ condensed 17 cpi 206 190 137 68 103

20 cpi 240 222 160 80 120

Raster (360 dpi) 10 cpi 20 20 20 20 20

Printing Speed Mode Selection

This printer is designed to control the printing speed according to the power supply voltage

and printhead temperature. When the power supply voltage drops to the limit, the printer

stops printing, then resumes the job at a slower speed to print the remaining data for the

line. When the printhead temperature rises to the limit, the printer stops printing. Then it

resumes printing at a slower speed if the printhead temperature recovers to the specified

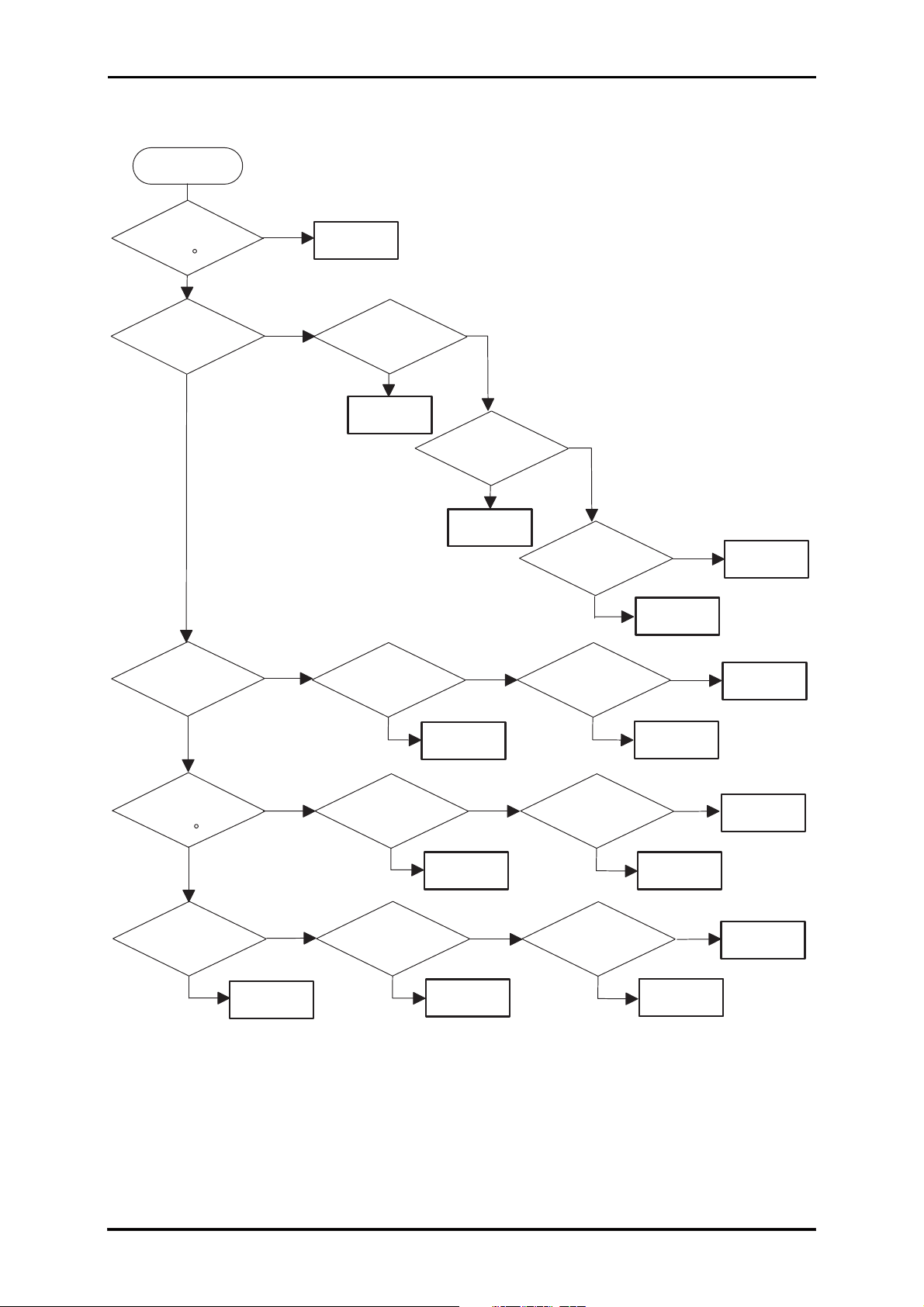

level. The printing speed mode is determined according to the flowchart shown in Page 1-6.

Rev. A

1-

Page 14

DLQ-3000+

START

Is th e

head tem perature

<

1 2 C ?

NO

P-Down* ?

NO

Is p rin t d u ty

>

5 0 % ?

=

YES

YES

NO

M ode 4

B lack color print?

NO

M ode 2

B lack color print?

YES

Is paper

thickness

>

0.19 m m ?

=

NO

M ode 2M ode 2

YES

YES

C opy 2 m ode?

NO

NO

Is paper

thickness

>

0.19 m m ?

=

YES

M ode 2M ode 2

YES

M ode 3

M ode 1

YES

Is the head

tem perature

>

3 8 C ?

=

YES

B lack color print?

NO

NO

YES

M ode 2

NO

B lack color print?

NO

Is paper

thickness

>

0.19 m m ?

=

NO

M ode 0

YES

M ode 0

YES

M ode 2

M ode 2

C opy 2 m ode?

NO

Is paper

thickness

>

0.19 m m ?

=

NO

NO

M ode 0

YES

M ode 1

M ode 0

YES

M ode 3

M ode 2M ode 2

P-D ow n : M eans that the line is the reprinted line after the pow er supply voltage drops. It is to prevent

the printhead and the printer m echanism from being driven under the im proper pow er

supply voltage.

Figure 1-3. Printing Speed Selection Mode

1-6

Rev. A

Page 15

7

1.3.2 Character Specifications and Control Codes

1.3.2.1 Coded Character Sets

ASCII international and Legal international character sets *

USA France Germany UK

Denmark 1 Sweden Italy Spain 1

Japan Norway Denmark 2 Spain 2

Latin America Korea Legal

Note: The codes for the international and legal characters are as follows:

23H, 24H, 40H, 5BH, 5CH, 5DH, 5EH, 60H, 7BH, 7CH, 7DH, 7EH

Standard version (11 character tables)

Italic table PC437 (US, Standard Europe)

PC850 (Multilingual) PC860 (Portuguese)

PC861 (Icelandic) PC863 (Canadian French)

PC865 (Nordic) Abicomp

BRASCII Roman 8

ISO Latin 1

NLSP version (30 character tables)

Italic table PC 437 (US, Standard Europe)

PC 850 (Multilingual) PC 437 (Greek)

PC 852 (East Europe) PC 853 (Turkish)

PC 855 (Cyrillic)PC 860 PC 857 ( Turkish)

PC 866 (Russian) PC 869 (Greek)

MAZOAWIA (Poland) Code MJK (CSFR)

ISO 8559-7 (Latin, Greek) ISO Latin 1T (Turkish)

Bulgaria (Bulgaria) PC 864 (Arabic)

Estonia PC 774 (LST 1283:1933)

ISO 8859-2 PC 866 LAT. (Latvian)

PC 860 (Portuguese) PC 861 (Icelandic)

PC 865 (Nordic) PCAPTEC (Arabic)

PC 708 (Arabic) PC 720 (Arabic)

PCAR864 (Arabic) Hebrew7 *

Hebrew8 *

1

PC862(Hebrew) *

Note 1: Theses character tables are not selected in the SelecType mode.

1

1

Product Description

1.3.2.2 Type Faces

Bitmap fonts (10 type faces)

Roman Sans Serif Courier Prestige

Script Script C OCR B

Orator Orator S Draft

Scalable fonts (4 type faces)

Roman Sans Serif Roman T Sans Serif H

Bar-code fonts (8 type faces)

EAN 13 EAN-8 Interleaved 2 of 5 UPC-A

UPC-E Code 39 Code 128 POSTNET

1.3.2.3 Rendition

ASCII

Double-width Double-height Condensed

Bolded Double-strike Italics

Super/subscript Outlined Shadowed

Underlined (Single, Double, Single-broken, Double-broken line)

Strike-through (Single, Double, Single-broken, Double-broken line)

Over-scored (Single, Double, Single-broken, Double-broken line)

Rev. A

1-

Page 16

DLQ-3000+

1.3.2.4 Combination of character tables and typefaces

Table 1-4. Character Tables and Type Faces

Character Tables Bitmap Fonts Scalable Fonts

Standard

version

NLSP

version

*

Italic table

1

PC 437 (US Stand ard Europe)

PC 850 (Multilingual)

PC 860 (Portuguese))

PC 861 (Icelandic)

PC 863 (Canadian-French)

PC 865 (Nordic)

BRASCII

Abicomp

Roman 8

ISO Latin 1

Italic table

1

*

PC 437 (US Stand ard Europe)

PC 850 (Multilingual)

PC 860 (Portuguese)

PC861 (Icelandic)

PC 865 (Nordic)

PC 864 (Arabic) EPSON Draft

PC 437 (Greek)

PC 852 (East Europe)

PC 853 (Turkish)

PC 855 (Cyrillic)

PC 857 (Turkish)

PC 866 (Russian)

PC 869 (Greek)

MAZOWIA ( P oland)

Code MJK (CSFR)

ISO 8859-7 (Lat in/Greek)

ISO Latin 1T (Turkish)

Bulgaria ( B ulgaria)

Estonia

PC 774 (LST 1283:1993)

ISO 8859-2

PC 866 LAT. (Latvian)

PCAPTEC (Arabic)

PC 708 (Arabic)

PC 720 (Arabic)

PCAR864 (Arabic)

EPSON Draft

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON OCR-B

EPSON Orator

EPSON Orator-S

Epson Script C

EPSON Draft

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON OCR-B

EPSON Orator

EPSON Orator-S

Epson Script C

EPSON Roman

EPSON Draft

EPSON Roman

EPSON Sans Serif

EPSON Courier

EPSON Prestige

EPSON Script

EPSON Draft (Arabic)

EPSON Naskh

(Roman)

EPSON Kufi (Sans Serif)

EPSON Roman

EPSON Sans Serif

EPSON Roman T

EPSON Sans Serif H

EPSON Roman

EPSON Sans Serif

EPSON Roman T

EPSON Sans Serif H

(Not supported)

(Not supported)

(Not supported)

Hebrew7 *

Hebrew8 *

PC862(Hebrew) *

2

2

2

EPSON Draft (Hebrew)

EPSON Miriam (Roman)

EPSON David

(Not supported)

(Courier)

Note:

1: ESC R command is effective on the character tables with bold weight.

2: These character tables are not selected in the SelecType mode.

1-8

Rev. A

Page 17

Product Description

9

1.3.2.5 Memory Size

Input buffer 128 K byte or 1k byte

Download memory Approximately 10 K byte

CG ROM NLSP Version: 8 M bit, Standard Version: 4 M bit

1.3.2.6 Character Size

Character size

• Bit map font 10.5 point

• Scalable font 10.5 point

Character matrixes See Table 1-5.

Table 1-5. Character Matrixes

Character Horizontal Dots Vertical Dots

Draft 10 cpi 12 24

Draft 12 cpi 10 24

Draft 15 cpi 8 16

LQ 10 cpi 36 24

LQ 12 cpi 30 24

LQ 15 cpi 24 16

LQ proportional 48 (maximum) 24

Notes:

1. The character matrixes for high speed draft 10 cpi characters are made from the draft

12 cpi matrixes.

2. The character matrixes for 15 cpi character are also used for superscript and

subscript characters.

1.3.2.7 Control Codes

ESC/P2

IBM 2391 Plus Emulation

Rev. A

1-

Page 18

DLQ-3000+

1.3.3 Paper Feed Specification

1.3.3.1 Friction Feed (Cut sheet)

Paper Path

• Single sheet, envelopes Front and rear insertion (Manual/CSF insertion)

• Multi-part form Rear entry (Manual/CSF insertion)

Notes:

1. Set the release lever to “FRICTION”.

2. Do not load continuous paper (including folding paper).

3. Set the longer side of the envelope horizontally.

4. When setting No.6 envelope, align the left sheet edge guide with the marked position.

1.3.3.2 Tractor Feed (Continuous paper)

Paper Path

• Rear entry push tractor feed with paper parking function

Notes:

1. Set the release lever to “TRACTOR”.

2. Do not perform reverse feed for more than 1/6 inch.

3. Set the left and right sheet edge guides to the right and left ends of the front paper

guide, respectively.

1.3.3.3 Paper Feed Speed and Accuracy

Minimum feed length 1/360 inch (1/6, 1/8 or programmable with the

increment of 1/360 inch)

Feed speed

• 1/6 inch line feed 42 ms

• Continuous feed 6.0 IPS (inch/second)

0.152 MPS (m/second)

1-10

Rev. A

Page 19

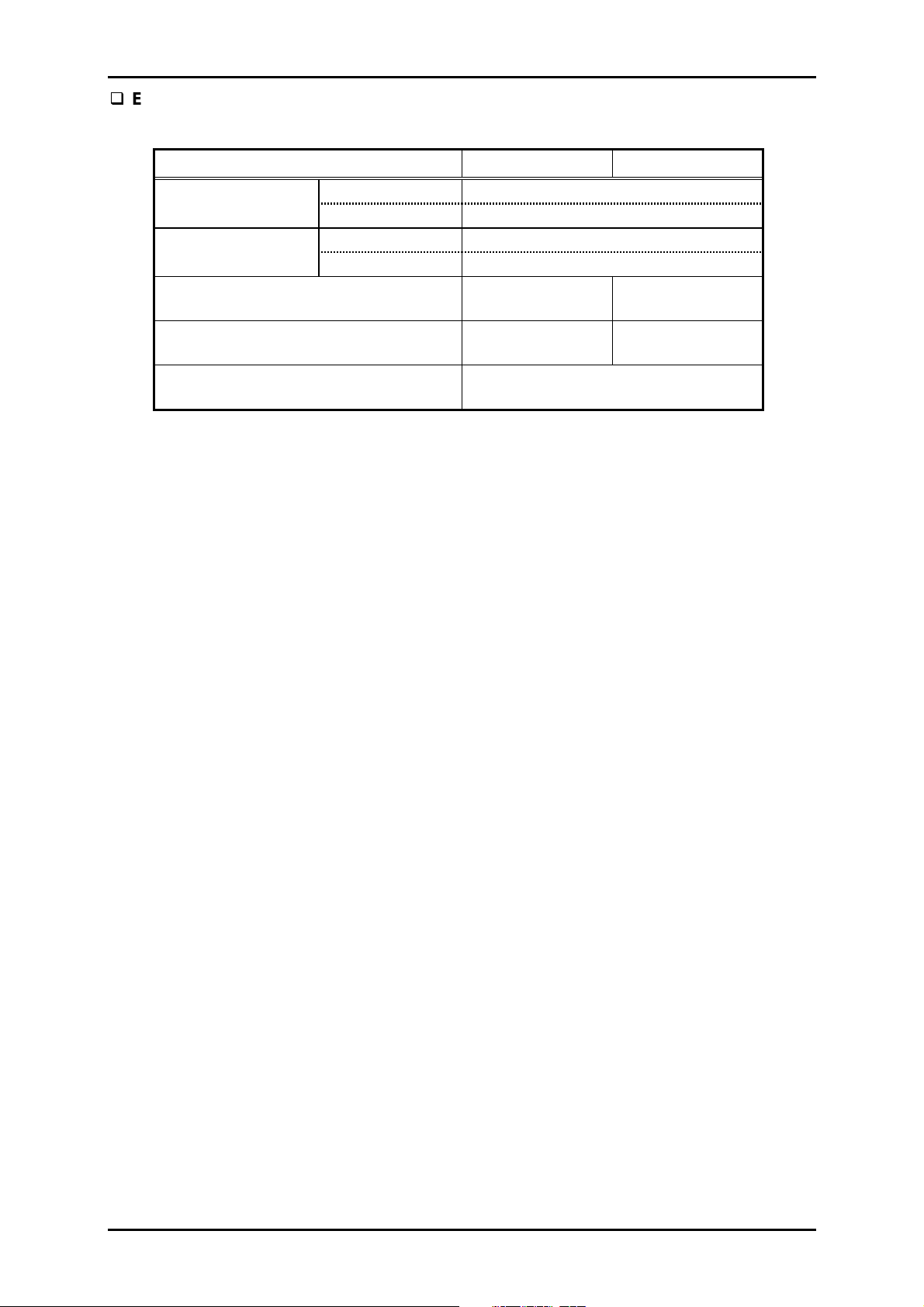

1.3.4 Paper Specification

Cut sheet (Single sheet)

Table 1-6. Cut sheet Specification : Single Sheet

Product Description

Minimum Maximum

Width

Length

Thickness

Weight

Manual insertion

CSF

Manual insertion

CSF

3.6 inch

92 mm

3.9 inch

100 mm

3.5 inch

92 mm

3.6 inch

92 mm

0.0025 inch

0.065 mm

52 g/m²

14 lb.

16.5 inch

420 mm

16.5 inch

420 mm

16.5 inch

420 mm

14.3 inch

364 mm

0.0047 inch

0.12 mm

105 g/m²

27 lb.

Quality Plain paper, Reclaimed paper

Notes:

1. Reclaimed paper can be used under condition of room temperatures only.

2. Ensure that the paper is not curled, folded or crumpled.

Cut sheet (Multi-part form)

Table 1-7. Cut sheet Specification : Multi-part Form

Minimum Maximum

Width

Length

Manual insertion

CSF

Manual insertion

CSF

3.6 inch

92 mm

3.9 inch

100 mm

3.5 inch

92 mm

3.6 inch

92 mm

16.5 inch

420 mm

16.5 inch

420 mm

16.5 inch

420 mm *

14.3 inch

364 mm *

1

1

Copies 1 original and 6 copies

Thickness

Weight

(I sheet of a multi-part form)

0.0047 inch

0.12 mm

40 g/m²

11 lb.

0.021 inch

0.53 mm

58 g/m²

15 lb.

Quality Carbon-less multi-part paper

Jointing Line glue (top, right and left side)

Notes:

1. Ensure that the paper is not curled, folded or crumpled.

2. The maximum length for the carbon-less multi-part paper is 297 mm with the left or

right side of the form line-glued.

3. CSF does not feed paper which is glued by the right or left side.

Rev. A

1-11

Page 20

DLQ-3000+

Envelopes

Table 1-8. Envelope Specification

Minimum Maximum

Envelopes (No.6) Width 6.5 inch/165 mm

Length 3.6 inch/92 mm

Envelopes (No.10) Width 9.5 inch/241 mm

Length 4.1 inch/105 mm

Thickness

Weight

Quality

0.0063 inch

0.16 mm

45 g/m²

12 lb. /m²

Bond paper, Plain paper

Airmail paper without glue at a flap

0.021 inch

0.52 mm

91 g/m²

24 lb./m²

Notes:

1. Fold the flap of the envelope inside before loading at CSF or manual insertion.

2. Difference in thickness within the same printable area must be 0.0098 inch or less.

1-12

Rev. A

Page 21

3

Continuous paper

Table 1-9. Continuous Paper Specification : Single Paper/Multi-Part Form

Product Description

Minimum Maximum

Length (1 page)

Total

Thickness

Weight

Quality

Jointing *

Width 4.0 inch

101.6 mm

4.0 inch

101.6 mm

3.5 inch

92 mm

Copies 1 original and 6 copies

Single sheet

1 sheet of

multi-part form

Cut sheet

1 sheet of

multi-part form

0.0025 inch

0.065 mm

0.0047 inch

0.12 mm

52.3 g/m²

14 lb.

40 g/m²

11 lb.

Plain paper, Reclaimed paper

Carbon-less multi-part form

Must be one of the followings:

1

- Point glue on the both sides

- Tape staple on the both sides

- Point glue on one side and tape staple on

the other side

Note: Do not use the paper which is glued by

the side or stapled.

16 inch

406.4 mm

22.0 inch

558.8 mm

16.4 inch

420 mm *

0.047 inch

0.12 mm

0.021 inch

0.53 mm

105 g/m²

27 lb.

58 g/m²

15 lb.

1

Rev. A

1-1

Page 22

DLQ-3000+

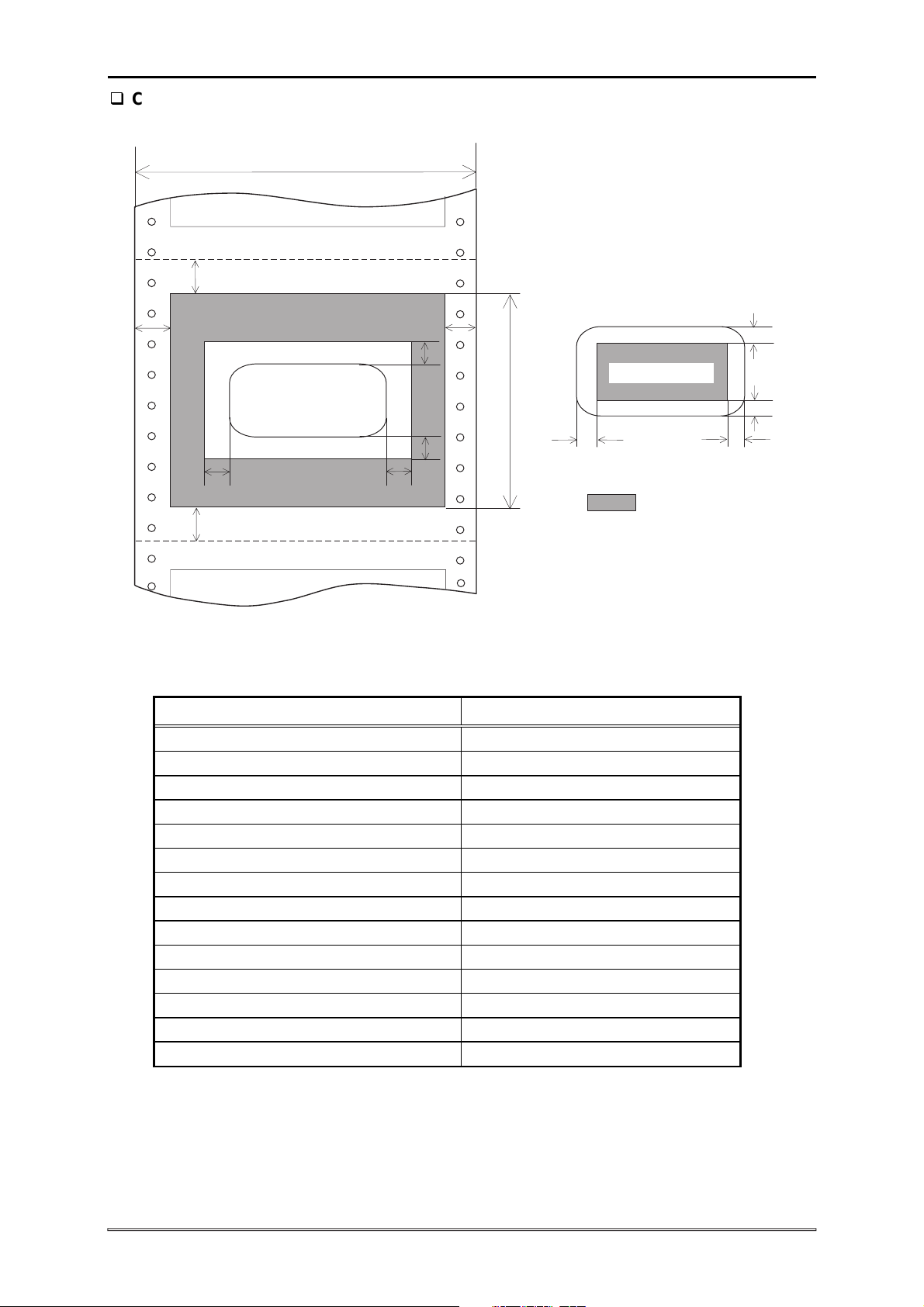

Labels

Table 1-10. Label Specification

Minimum Maximum

Label size See Figure 1-4.

Base sheet width 4.0 inch 16.0 inch

101.6 mm 406.4 mm

Base sheet length 4.0 inch 22.0 inch

(1 page) 101.6 mm 559 mm

Base sheet thickness

Total thickness

0.0028 inch

0.07 mm

0.0063 inch

0.16 mm

0.0035 inch

0.09 mm

0.0075 inch

0.19 mm

Label weight 64 g/m²/17 lb.

Quality Plain paper or equivalent

The base sheet must be continuous paper.

Notes:

1. Use labels in the condition of the room temperature only.

2. Labels backed with the continuous base sheet can be used only.

3. When the label sheet whose base sheet is exposed around the labels, adjust the

platen gap manually to the portion covered with the label using PG adjust lever.

15/16 inch

(23.8mm or more)

2-1/2 inch

(63.5mm or more)

R 0.1inch (R 2.5m m or m ore)

Figure 1-4. Label Size

1-14

Rev. A

Page 23

5

Pre-print paper

Table 1-11. Pre-Print Paper Specification

Width 4.0 inch 16.0 inch

Length 4.0 inch 22.0 inch

(1 page) 101.6 mm 559 mm

Total thickness

Quality

Continuous forms with labels

Table 1-12. Continuous Forms with Labels Specification

Product Description

Minimum Maximum

101.6 mm 406.4 mm

0.0025 inch

0.065 mm

The paper printed with the color which has

the reflective rate of less than 60 %, such as

black.

Minimum Maximum

0.047 inch

0.12 mm

Base sheet width 4.0 inch 16.0 inch

101.6 mm 406.4 mm

Base sheet length 4.0 inch 22.0 inch

(1 page) 101.6 mm 559 mm

Total thickness

Quality

–

–

Plain paper or equivalent

Airmail paper without glue at a flap

0.021 inch

0.53 mm

Note:

When using the continuous forms with labels, the label position must be registered

properly. It can be performed through the utility “Label Position Registering Utility”.

Rev. A

1-1

Page 24

DLQ-3000+

Overlapping multi-part forms

Table 1-13. Overlapping Multi-Part Form Specification

Base sheet width 4.0 inch 16.0 inch

Base sheet length 4.0 inch 22.0 inch

(1 page) 101.6 mm 559 mm

Total thickness

Jointing

Minimum Maximum

101.6 mm 406.4 mm

–

–

0.026 inch

0.65 mm

Multi-part forms :Point glue

Joint for the base sheet and multi-part form

:Point glue

Total Thickness

Glue

Maximum 13.3 mm

Maximum 3.3 mm

Maximum 17 mm

Base Sheet

Figure 1-5. Overlapping multi-part Form Specification

Overlapping multi-part forms with labels

Table 1-14. Overlapping Multi-Part Form with Labels Specification

Minimum Maximum

Base sheet width 4.0 inch 16.0 inch

101.6 mm 406.4 mm

Base sheet length 4.0 inch 22.0 inch

(1 page) 101.6 mm 559 mm

Total thickness

–

–

0.026 inch

0.65 mm

Multi-part forms :Point glue

Jointing

Joint for the base sheet and multi-part form

:Point glue

Note: When using overlapping multi-part forms with labels, the label position must be

registered properly. It can be performed through the utility “Label Position

Registering Utility”.

1-16

Total Thickness

Glue

Maximum 13.3 mm

Maximum 17 mm

Label

Maximum 3.3 mm

Maximum 0.53 mm

Base Sheet

Figure 1-6. Overlapping multi-part Form with Labels Specification

Rev. A

Page 25

7

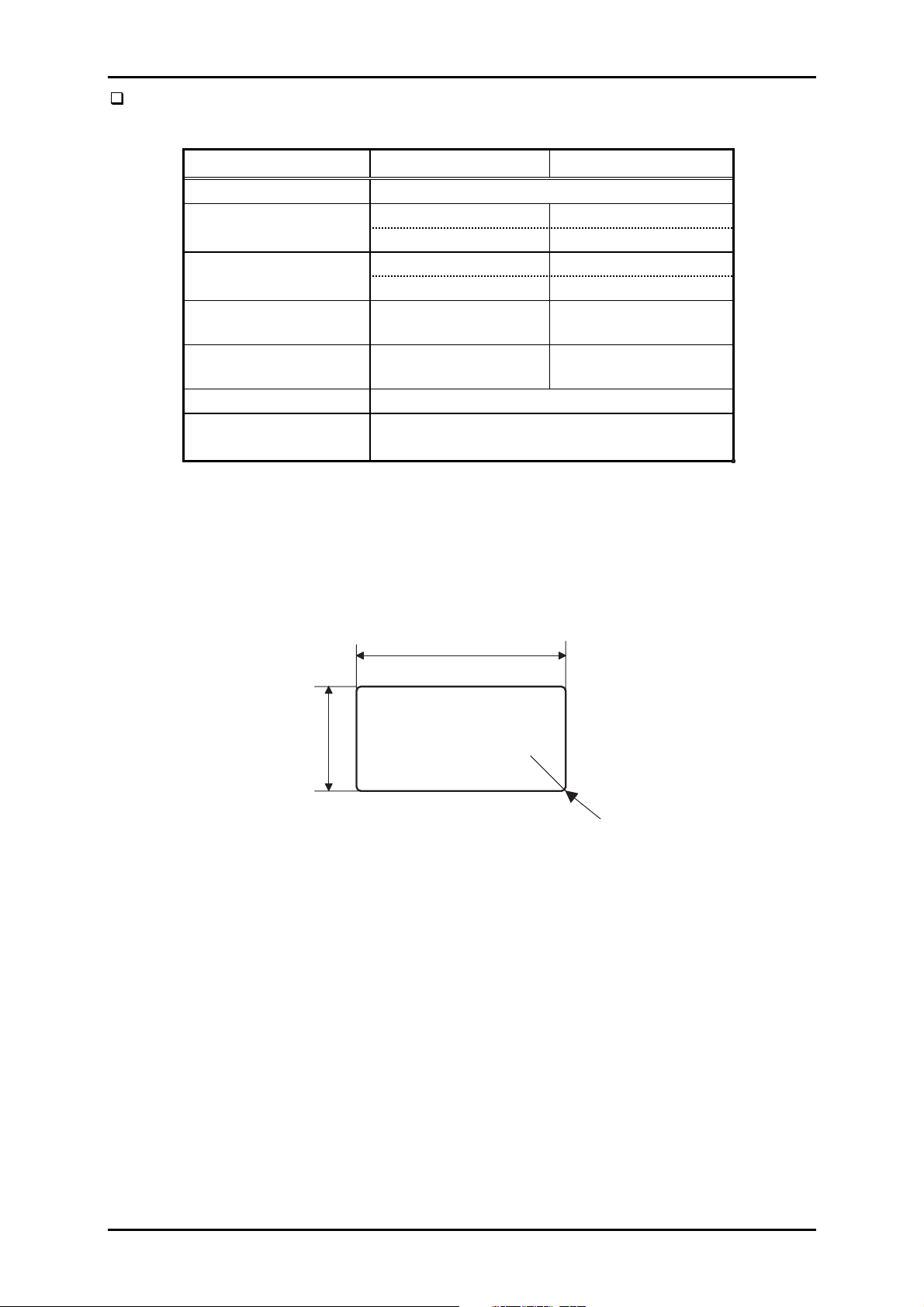

1.3.5 Printable Area

This section describes printable area for various types of paper.

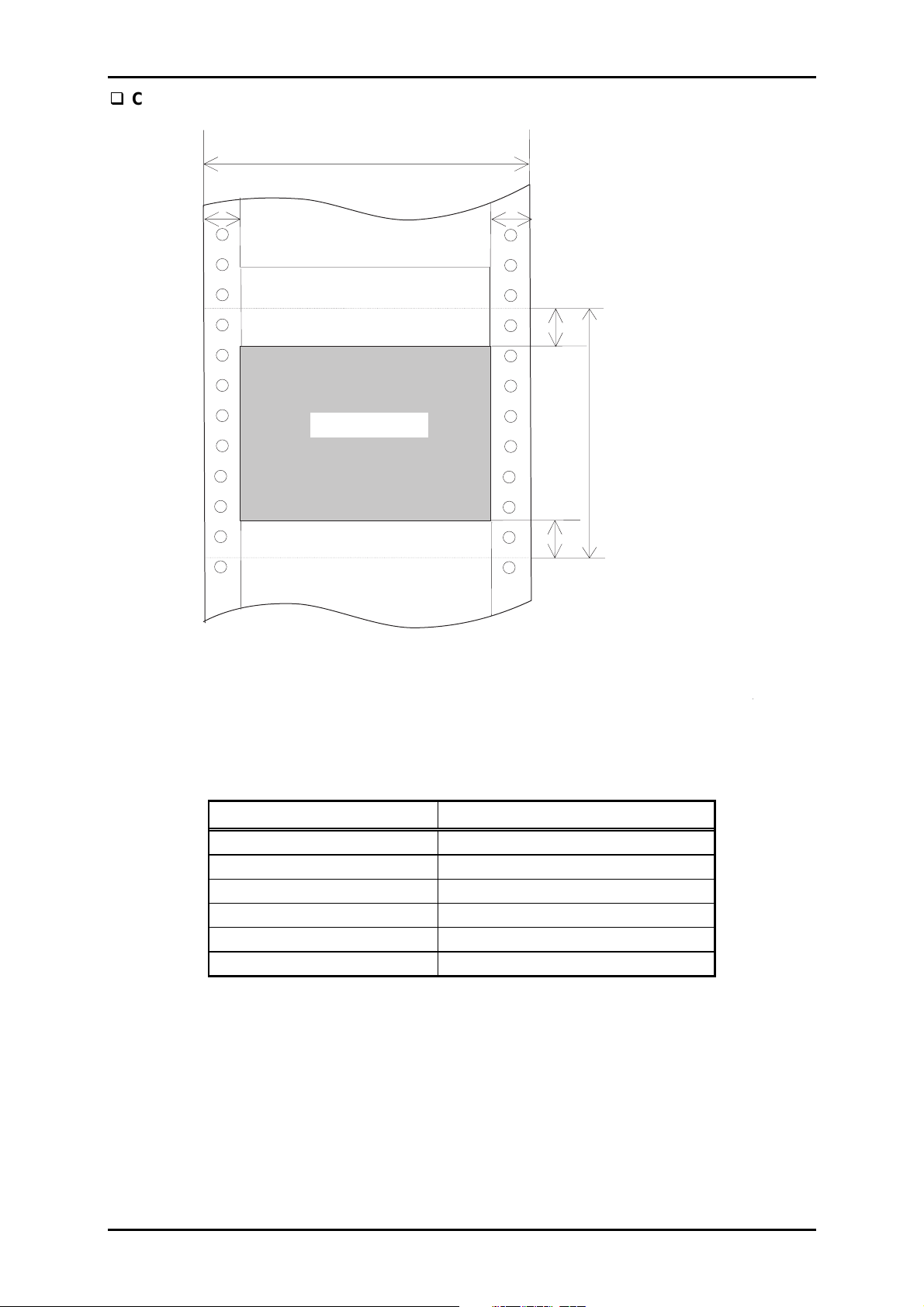

Cut sheet

PW

Product Description

TM

LM

Printable A rea

RM

Figure 1-7. Printable Area for Cut Sheet

Table 1-15. Printing Area for Cut sheet

PL

BM

Single cut sheet Multi-part cut sheet

Paper width (PW) Refer to Section 1.3.4. Refer to Section 1.3.4.

Paper length (PL) Refer to Section 1.3.4. Refer to Section 1.3.4.

Left margin (LM) 3 mm (0.118”) or more 3 mm (0.118”) or more

[A3 landscape]

31 mm (1.22”) or more

[A3 landscape]

31 mm (1.22”) or more

Right margin (RM) 3 mm (0.118”) or more 3 mm (0.118”) or more

[A3 landscape]

20 mm (0.78”) or more

[A3 landscape]

20 mm (0.78”) or more

Top margin (TM) 0 mm (0”) or more 0 mm (0”) or more

Bottom margin (BM) 0 mm (0”) or more 0 mm (0”) or more

Width of printing area

Maximum 346 mm

(13.62”)

Maximum 346 mm

(13.62”)

(WPA)

Rev. A

1-1

Page 26

DLQ-3000+

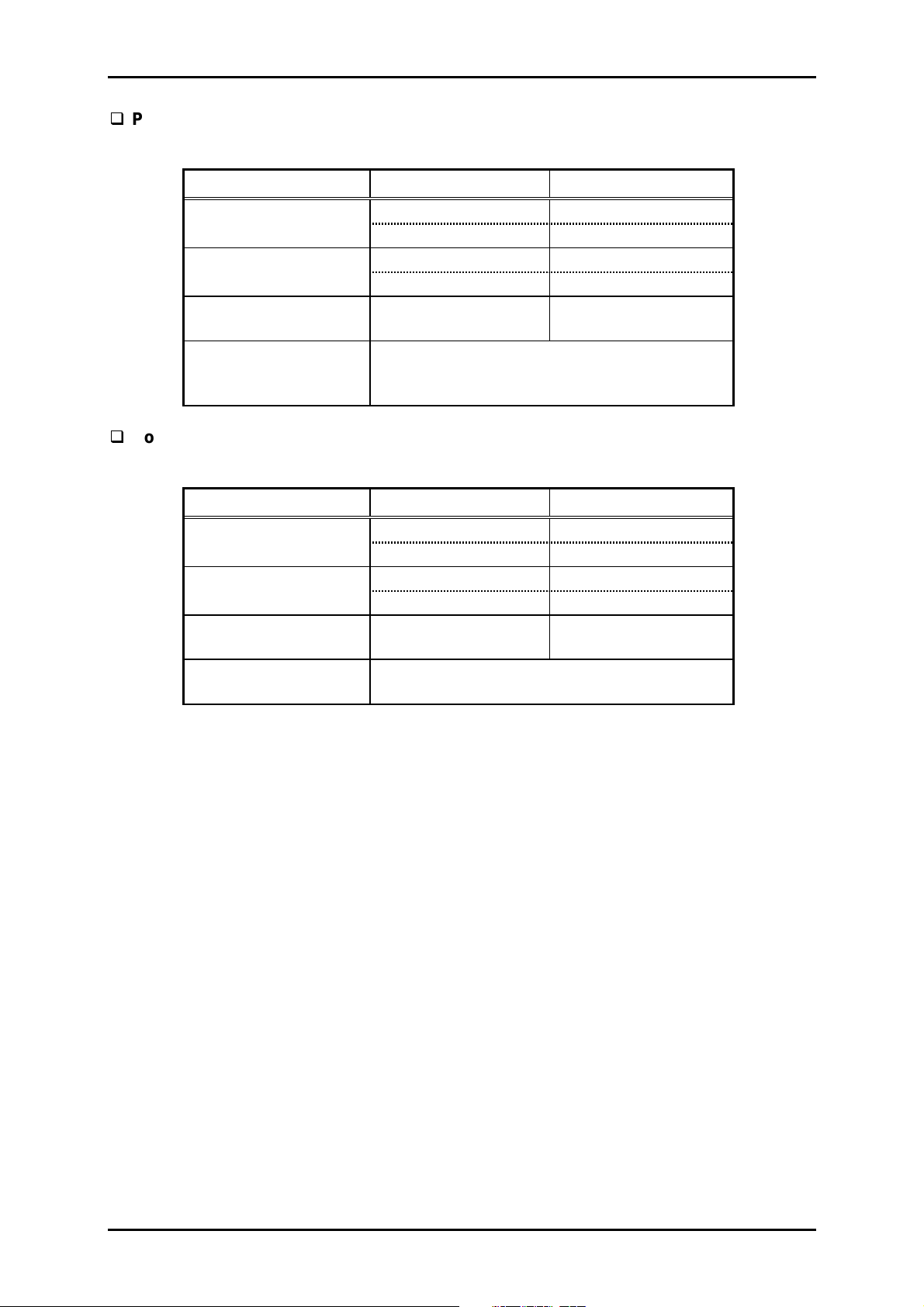

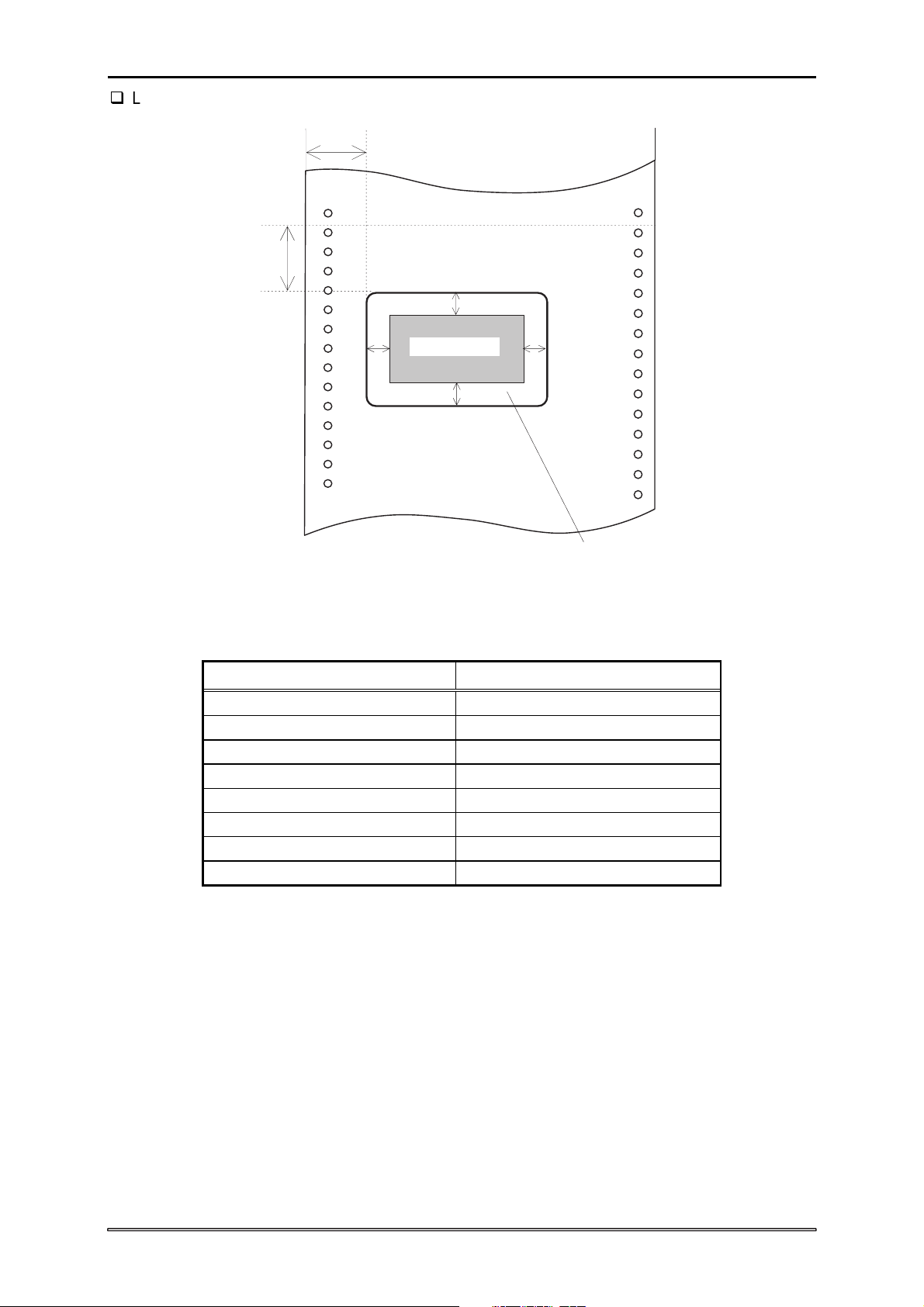

Continuous paper

PW

LM

Perforation

Printable A rea

Perforation

RM

TM

PL

BM

Figure 1-8. Printable Area for Continuous Paper

Continuous paper

Paper width (PW) Refer to Section 1.3.4.

Paper length (PL) Refer to Section 1.3.4.

Left margin (PM) 9 mm (0.354”) or more

Right margin (LM) 9 mm (0.354”) or more

Top margin (TM) 4.2 mm (0.165”) or more

Bottom margin (BM) 4.2 mm (0.165”) or more

Notes:

1. In the top 75 mm are, the paper feeding pitch may be irregular.

2. Forms-override printing is available for 2 lines after the paper end is detected.(Paper

feeding pitch is not guaranteed.) The end of the printable area is 4.2 m or more apart

from the bottom edge of the paper.

3. When the page width is 16 inches, note the followings:

• LM is 18 mm or more with the left tractor set at the farthest side toward the 136th

column.

• RM is 18 mm or more with the right tractor set at the farthest side toward the 1st

column.

1-18

Rev. A

Page 27

9

Product Description

Labels

LM

TM

TO L

LO L

Printable Area

BOL

ROL

P r in tin g p ro h ib ite d

Figure 1-9. Printable Area for Labels

Table 1-16. Printable Area for Labels

Continuous paper

Paper width (PW) Refer to Section 1.3.4.

Paper length (PL) Refer to Section 1.3.4.

Left margin (LM) 12 mm (0.472”) or more

Top margin (TM) 1.2 mm (0.0472) or more

Left margin on label (LOL) 3 mm (0.118”) or more

Right margin on label (ROL) 3 mm (0.118”) or more

Top margin on label (TOL) 3 mm (0.118”) or more

Bottom margin on label (BOL) 3 mm (0.118”) or more

Notes:

1. Do not feed paper backward.

2. Use only the specified paper path for continuous paper.

3. The paper feeding pitch in the top 75 mm (2.9”) may be irregular.

Rev. A

1-1

Page 28

DLQ-3000+

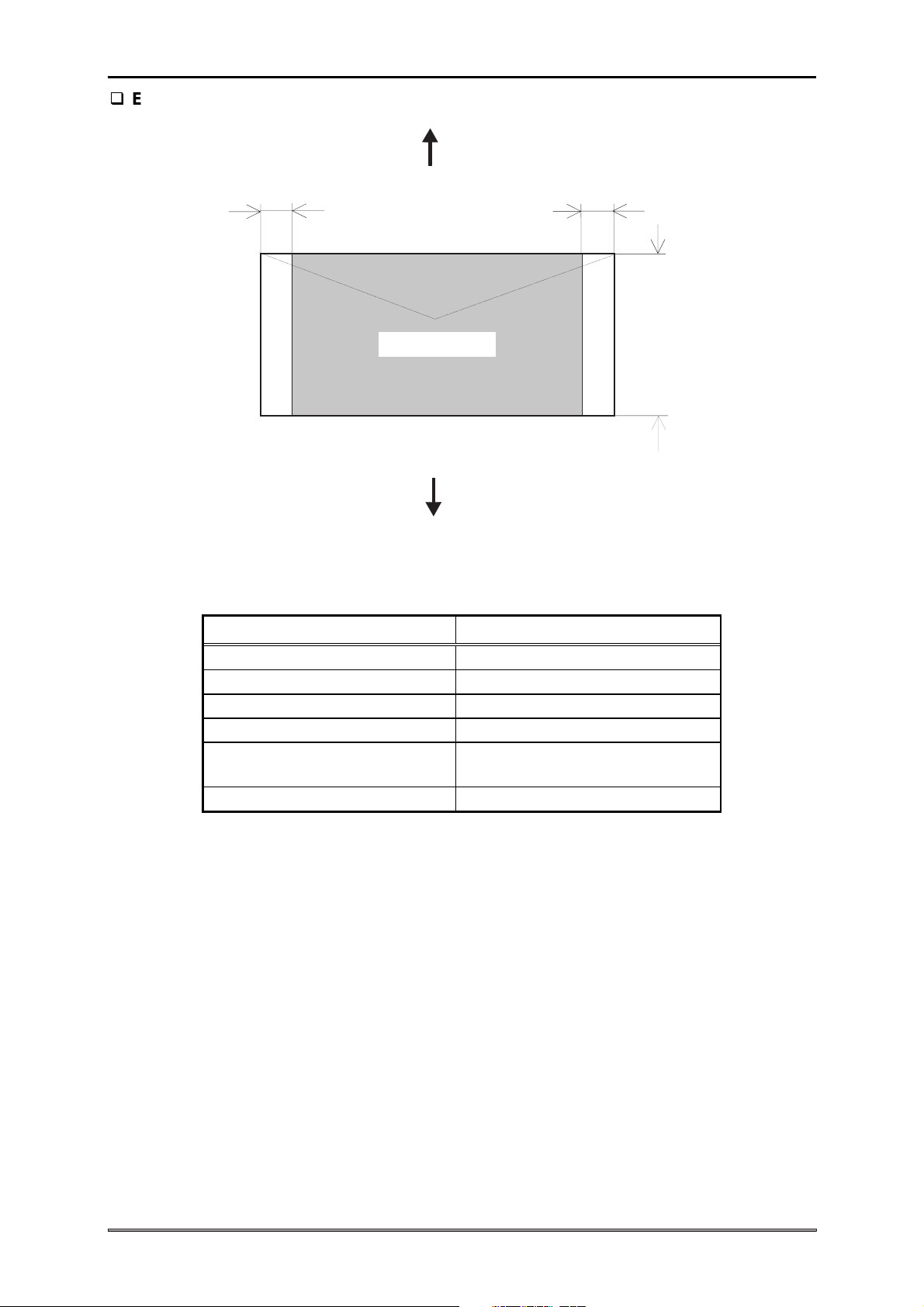

Envelops

Print Direction

LM

(M anual insertion from the rear/C S F)

Printable Area

Print Direction

(M anual insertion form the front)

Figure 1-10. Printable Area for Envelopes

Table 1-17. Printable Area for Envelops

RM

TM

BM

Continuous paper

Paper width (PW) Refer to Section 1.3.4.

Paper length (PL) Refer to Section 1.3.4.

Left margin (LM) 3 mm(0.118”) or more

Right margin (RM) 3 mm(0.118”) or more

Top margin (TM)

0 mm (0”) or more *

Bottom margin (BM) 0 mm (0”) or more

Note 1: At CSF insertion:

4.2 mm (0.16”) or more

1

1-20

Rev. A

Page 29

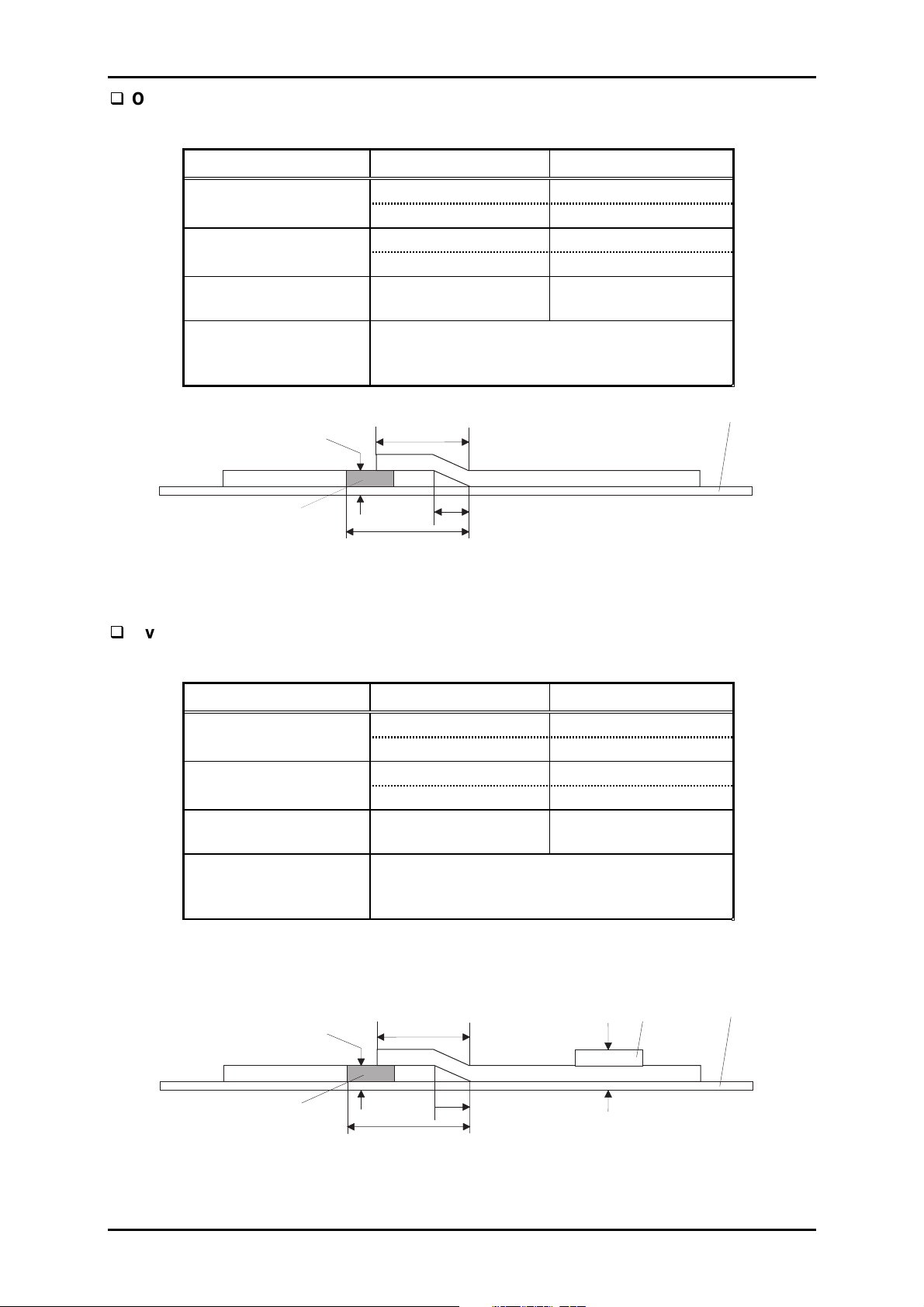

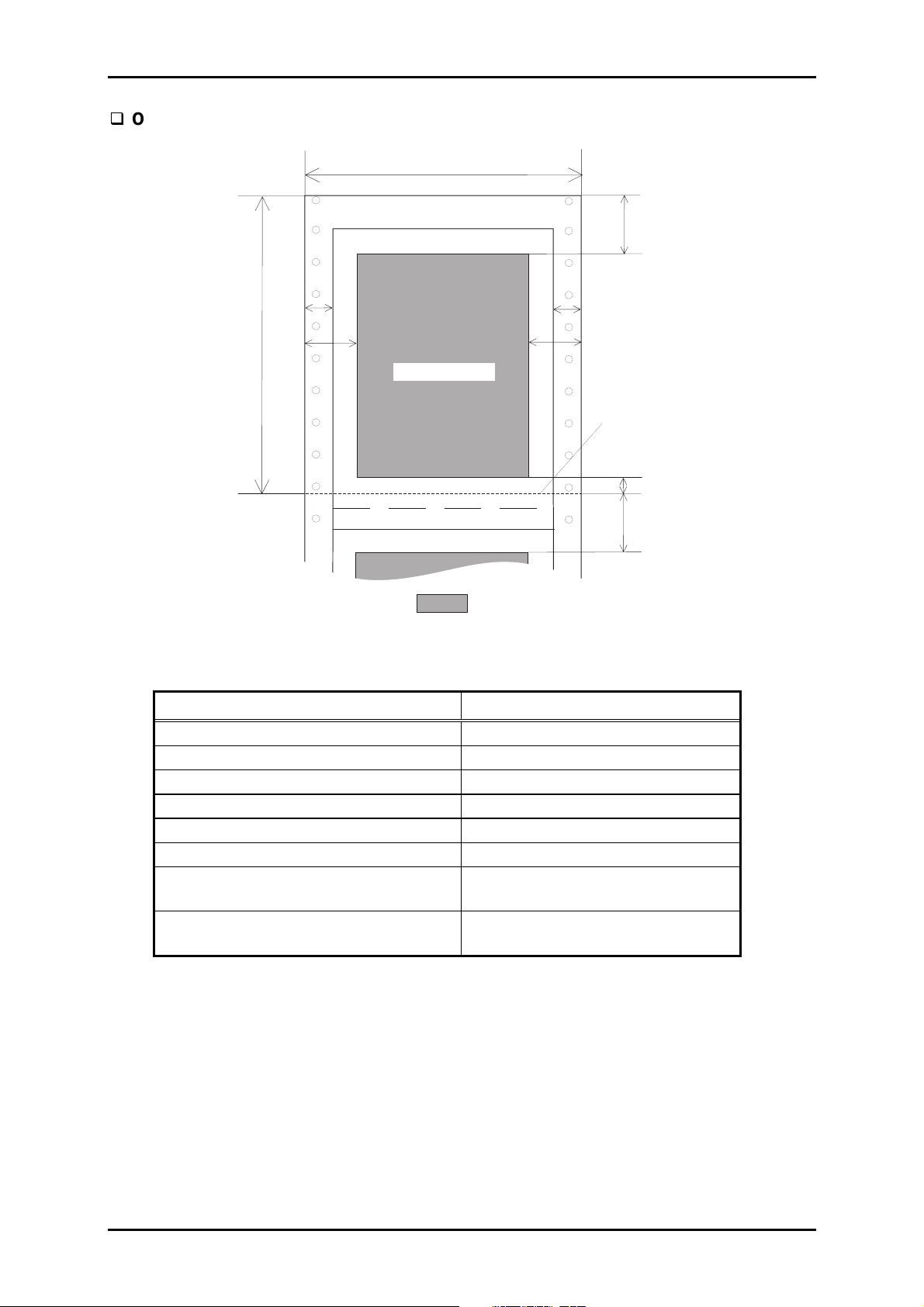

Overlapping multi-part forms

Product Description

PW

TM

PL

LM B

LM

Printable A rea

: Printable A rea

RMB

RM

Perforation

BM

TM

Figure 1-11. Printing Area for Overlapping Multi-part Forms

Table 1-18. Printing Area for Overlapping Multi-part Forms

Continuous paper

Paper width (PW) Refer to Section 1.3.4.

Paper length (PL) Refer to Section 1.3.4.

Left margin (LM) 19 mm (0.748”) or more

Right margin (RM) 19 mm (0.748”) or more

Top margin (TM) 21.2 mm (0.835”) or more

Bottom margin (BM) 4.2 mm (0.165”) or more

Left margin from the multi-part form to

13 mm (0.512”) ± 3 mm (0.118”)

the base sheet (LMB)

Right margin from the multi-part form

13 mm (0.512”) ± 3 mm (0.118”)

to the base sheet (RMB)

Notes:

1. Do not feed paper backward.

2. Use only the specified paper path for continuous paper.

3. The paper feeding pitch in the top 75 mm (2.9”) may be irregular.

4. Forms-override printing is available for 2 lines after the paper end is detected. The end of

the printable area is 4.2 mm or more apart from the bottom edge of the paper.

Rev. A

1-21

Page 30

DLQ-3000+

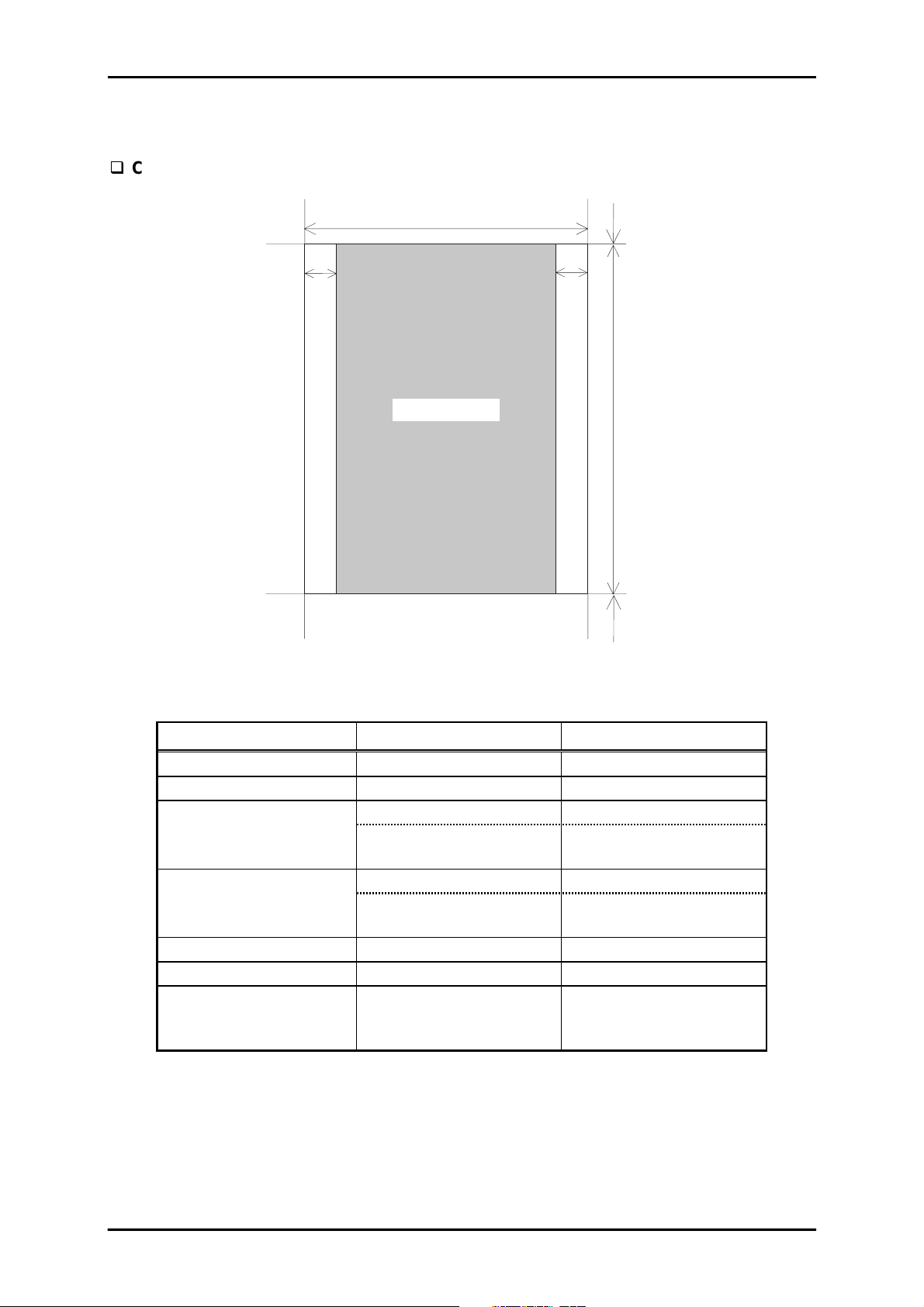

Continuous forms with labels

PW

TM

LM

N on-printable Area

Label

LFL

BM

RFL

TFL

BFL

RM

Printable Area

PL

LO L

: P rintable Area

Figure 1-12. Printable Area for Continuous Forms with Labels

Table 1-19. Printable Area for Continuous Forms with Labels

Continuous paper

Paper width (PW) Refer to Section 1.3.4.

Paper length (PL) Refer to Section 1.3.4.

Left margin (LM) 9 mm (0.354”) or more

Right margin (RM) 9 mm (0.354”) or more

Top margin (TM) 4.2 mm (0.165”) or more

Bottom margin (BM) 4.2 mm (0.165”) or more

Left margin for label (LFL) 45 mm (1.77) or more

Right margin from label (RFL) 45 mm (1.77) or more

Top margin from label (TFL) 25 mm(0.984”) or more

Bottom margin from label (BFL) 25 mm(0.984”) or more

Left margin on label (LOL) 3 mm (0.118”) or more

Right margin on label (ROL) 3 mm (0.118”) or more

Top margin on label (TOL) 3 mm (0.118”) or more

Bottom margin on label (BOL) 3 mm (0.118”) or more

Notes:

1. Do not feed paper backward.

2. Use only the specified paper path for the continuous paper.

3. The paper feeding pitch in the top 75 mm (2.9”) may be irregular.

4. Forms-override printing is available for 20 lines after the paper end is detected.

(Paper feeding pitch is not guaranteed.) The end of the printable are is 4.2 mm or

more apart from the bottom edge of the paper.

TO L

BOL

ROL

1-22

Rev. A

Page 31

3

Overlapping multi-part forms with labels

PW

Product Description

TM

PL

LM B

LM

Printable A rea

LFL

TFL

Label

BFL

RFL

RMB

RM

Perforation

LO L

BM

TM

Figure 1-13. Printable Area for Overlapping Multi-Part Forms with Labels

Table 1-20. Printable Area for Overlapping Multi-Part Forms

Continuous paper

Paper width (PW) Refer to Section 1.3.4.

Paper length (PL) Refer to Section 1.3.4.

Left margin (LM) 19 mm (0.748”) or more

Right margin (RM) 19 mm (0.748”) or more

Left margin from the multi-part forms

13 mm (0.552”) ± 3 mm (0.118”)

to the base sheet (LMB)

Right margin from the multi-part forms

13 mm (0.552”) ± 3 mm (0.118”)

to the base sheet (RMB)

Top margin (TM) 21.2 mm (0.835”) or more

Bottom margin (BM) 4.2 mm (0.165”) or more

Non-printable area (NA) 25.4 mm (1.0”) or more

Left margin from label (LFL) 45 mm (1.77”) or more

Right margin from label (RFL) 45 mm (1.77”) or more

Top margin from label (TFL) 25 mm(0.984”) or more

Bottom margin from label (BFL) 25 mm(0.984”) or more

Left margin on label (LOL) 3 mm (0.118”) or more

Right margin on label (ROL) 3 mm (0.118”) or more

Top margin on label (TOL) 3 mm (0.118”) or more

Bottom margin on label (BOL) 3 mm (0.118”) or more

Notes:

1. Do not feed paper backward.

2. The paper feeding pitch in the top 75 mm (2.9”) may be irregular.

ROL

TO L

Printable A rea

BOL

Label

: P rintable A rea

Rev. A

1-2

Page 32

DLQ-3000+

3. Forms-override printing is available for 20 lines after the paper end is detected.

(Paper feeding pitch is not guaranteed.) The end of the printable are is 4.2 mm or

more apart from the bottom edge of the paper

1.3.6 Paper Thickness Detection

This printer is equipped with the automatic paper thickness adjust function. When the paper

thickness lever is set to “Auto position”, the printer automatically measures thickness of

each paper loaded to set the proper PG (platen Gap) the detected thickness. PG is also

adjusted manually. See Table 1-21 which shows the adjust lever position and

corresponding paper thickness and platen gap.

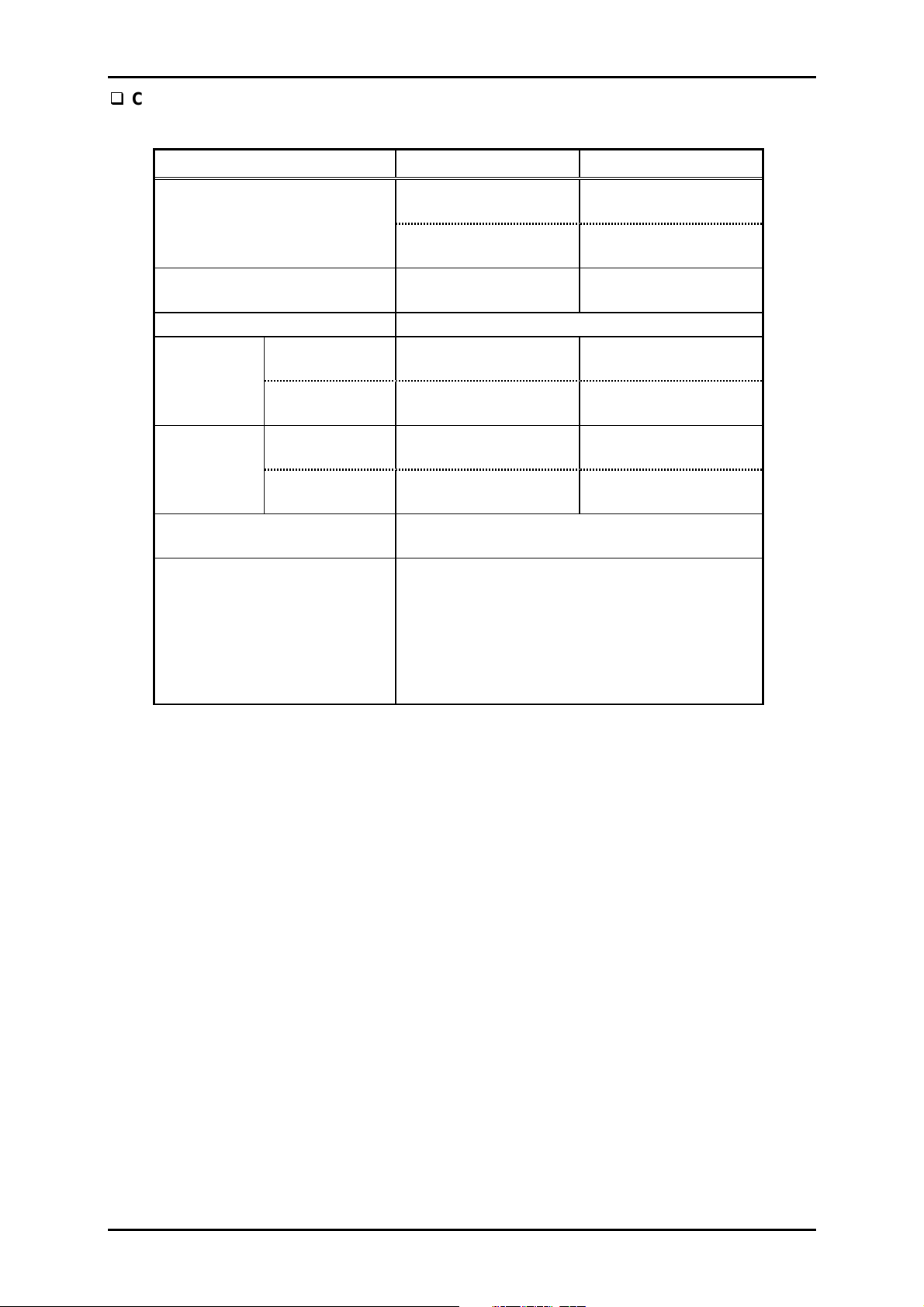

Table 1-21. PG Adjust Lever

Adjust lever Paper thickness (inch) Paper thickness (mm) PG

position Maximum Minimum Maximum Minimum Inch mm

-1 0.0024 0.0043 0.06 0.11 0.0138 0.35

0 0.0024 0.0043 0.06 0.11 0.0154 0.39

1 0.0043 0.0059 0.11 0.15 0.0169 0.43

2 0.0059 0.0075 0.15 0.19 0.0181 0.46

3 0.0075 0.0098 0.19 0.25 0.0197 0.50

4 0.0098 0.0122 0.25 0.30 0.0217 0.55

5 0.0122 0.0146 0.30 0.36 0.0240 0.61

6 0.0146 0.0165 0.36 0.42 0.0264 0.67

7 0.0165 0.0185 0.42 0.46 0.0280 0.71

8 0.0185 0.0201 0.46 0.49 0.0291 0.74

9 0.0201 0.0217 0.49 0.53 0.0307 0.78

Notes: Switching to “Dark” in the copy mode is effective under the following conditions:

In the “Auto” mode: Paper thickness is 0.2 mm or more.

Manual adjustment: The lever is set to one of the positions in the range from

3 to 9.

1-24

Rev. A

Page 33

Product Description

5

1.3.7 Ribbon Cartridge

1.3.7.1 Monochrome ribbon cartridge

Color Black

Ribbon fabric Nylon 66

Ribbon dimension 25.5 mm (W) X 17 mm (L) X 1.5 mm (D)

ribbon thickness 0.128 mm ± 0.007 mm

Cartridge dimension 153 mm/6.0” (W) X 33 mm/1.3” (H) X 105 mm/4.1” (D)

Ribbon life * 6 million characters

Ribbon replacement Whole cartridge

Item No. S015066

∗ At 10 cpi printing in the LQ mode. (48 dots per character)

1.3.7.2 Color ribbon cartridge

Color Black Magenta, Cyan, Yellow

Ribbon fabric Nylon 66

Ribbon dimension 25.5 mm (W) X 17 mm (L) X 1.5 mm (D)

ribbon thickness 0.128 mm ± 0.007 mm

Cartridge dimension 153 mm/6.0” (W) X 33 mm/1.3” (H) X 105 mm/4.1” (D)

Ribbon life * Black: 1.5 million characters

Magenta 1.1 million characters

Cyan 1.1 million characters

Yellow 0.8 million characters

Ribbon replacement Whole cartridge

Item No. S015067

∗ At 10 cpi printing in the LQ mode. (48 dots per character)

Rev. A

1-2

Page 34

DLQ-3000+

1.3.8 Input Data Buffer

Approximately 128 K byte/1K byte

1.3.9 Electric Specifications

120 V version

Rated voltage AC 120 V

Input voltage range AC 103.5 to 132 V

Rated frequency renege 50 to 60 Hz

Input frequency range 49.5 to 60.5 Hz

Rated current 7 A (maximum)

Power consumption Approximately 60 W (ISO/IEC 10561 Letter pattern)

Insulation resistance 10 M ohms minute

Dielectric strength AC 1,000 V rms. for 1 minute or

220 - 240V version

Rated voltage AC 220 to 240 V

Input voltage range AC 198 to 264 V

Rated frequency renege 50 to 60 Hz

Input frequency range 49.5 to 60.5 Hz

Rated current 0.7 A (maximum)

Power consumption Approximately 60 W (ISO/IEC 10561 Letter pattern)

Insulation resistance 10 M ohms min.

Dielectric strength AC 1,500 Vrms. For 1 minute

Energy Star program compliant

(Between AC line and chassis, 500 VDC)

AC 1,200 V rms. for 1 second

(Between AC line and chassis)

Energy Star program compliant

(Between AC line and chassis, DC 500 V)

(Between AC line and chassis)

1.3.10 Safety Approvals

120 V version

Safety standards UL1950 with D3

EMI FCC part15 subpart B class B

220 - 240 V version

Safety standards EN 60950 (TÜV, NEMKO)

EMI EN 55022 (CISPR Pub.22) class B

1.3.11 CE Marking

220 - 240 V version

Low Voltage Directive 73/23/EEC EN60950

EMC Directive 89/336/EEC EN55022 class B

CSA22.2 No. 950 with D3

CSA C108.8 class B

AS/NZS 3548 class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

1-26

Rev. A

Page 35

Product Description

7

1.3.12 Acoustic Noise

Noise level Approximately 55 dB (A) (According to ISO 7779)

1.3.13 Reliability

Total print volume 9 million lines (excluding printhead)

Printhead life 200 million strokes/pin (Monochrome ribbon)

100 million strokes/pin (Color ribbon)

Ribbon life

• Fabric black ribbon life 6 million characters*

• Fabric color ribbon Black : 1.5 million characters*

Magenta: 1.1 million characters*

Cyan: 1.1 million characters*

Yellow: 0.8 million characters*

* 1 character is formed with 48 dots.

At 10-cpi printing (LQ mode)

1.3.14 Environmental Conditions

Table 1-22. Environmental Condition

Operating Non-operating

5 to 35 °C -30 to 65 °C

Temperature 15 to 35 °C *

15 to 25 °C *

10 to 80 % 5 to 85 %

Humidity *

3

10 to 80 % *

20 to 60 % *

Resistance to shock 0.25G, 10 to 55 Hz

(Directions: X,Y and Z)

Resistance to Vibration 1G, Within 1 ms

(Directions: X,Y and Z)

Notes:

1. When the optional film ribbon is used.

2. When the envelopes or labels are printed.

3. Without condensation

1

2

1

2

-20 to 40 °C *

5 to 85 % *

1

1

0.50G, 10 to 55 Hz

(Directions: X,Y and Z)

2G, Within 1 ms

(Directions: X,Y and Z)

Rev. A

1-2

Page 36

DLQ-3000+

1.4 Interfaces

The EPSON DLQ-3000+ is equipped with the parallel and Mac serial interfaces and a card

slot for an optional Type-B interface. This section provides information on each interface.

1.4.1 Parallel Interface

Forward Channel

Transmission mode 8 bit parallel, IEEE-1284 compatibility mode

Synchronization By /STROBE pulse

Handshaking By /BUSY and /ACKNLG signal

Signal level TTL compatible (IEEE-1284 level 1 device)

Adaptable connector 57-30360 (Amphenol) or equivalent

Table 1-23. Signal level of TTL Compatible (IEEE-1284 level 1 device)

Parameter Minimum Maximum Condition

VOH* - 5.5 V

VOL* -0.5 V IOH* - 0.32 mA VOH = 2.4 V

IOL* - 12 mA VOL = 0.4 V

CO - 50 pf

VIH - 2.0 V

VIL 0.8 V IIH - 0.32 mA VIH = 2.0 V

IIL - 12 mA VIL = 0.8 V

CI - 50 pf

∗ A LOW logic level on the Logic H signal is as follows:

2.0 V or less when the printer is powered off.

3.0 V or more when the printer is powered on.

The receiver provides an impedance equivalent to 7.5 K ohms to ground.

The BUSY signal is HIGH in the following cases:

During data entry

When the input data buffer is full.

While /INIT signal is at low level

During hardware initialization

During the signal /ERROR or PE is LOW or HIGH, respectively.

During the self-test printing mode.

During the default setting mode.

During the adjustment mode.

The /ERROR signal is LOW when one of the following errors has occurred:

Printer hardware error (fatal error)

Paper-out error

The PE signal is HIGH when the following error has occurred:

Paper-out error

1-28

Rev. A

Page 37

9

Table 1-24. Data Transmission Timing

Parameter Minimum Maximum

Product Description

tsetup 500 ns

thold 500 ns

tstb 500 ns

tready 0

tbusy

treply

tack 500 ns

tnbusy 0

tnext 0

tt-out *

tt-in *

1

2

Note:

1. Rise and fall time for output signals

2. Rise and fall time for input signal

DATA (n)

DATA

thold

500 ns

10 µs

120 ns

200 ns

DATA (n+1)

STOR BE

ts tb

tsetup

BUSY

tready

tbusy

ACKNLG

tre p ly

ta c k

tnbusy

Figure 1-14. Data Transmission Timing Chart

tnext

Rev. A

1-2

Page 38

DLQ-3000+

16,33,19-30

g

Table 1-25 shows the connector pin assignment and signals for forward channel of the

parallel interface.

Table 1-25. Connector Pin Assignments and Signals (Forward Channel)

Pin No. Signal Name

1

/STROBE

Return

GND Pin

19 I

I/O Description

The strobe pulse. Read-in of data is

performed at the falling edge of this

pulse.

The data 0 to data 7 signals

2-9

DATA 1- 8

20-27 I

represent data bits 0 to 7,

respectively. Each signal is at a HIGH

level when data is logical 1 and a

LOW level when data is logical 0.

This signal is a negative pulse

10

/ACKNLG

28 O

indicating that the printer can again

accept data.

11

12

13

14

BUSY

PE

SLCT

/AFXT

29 O

28 O

28 O

30 I Not used.

When this signal is at a HIGH level,

the printer is not ready to accept data.

When this signal is at a HIGH level,

the paper empty status is detected.

Always at a HIGH level when the

printer is powered on.

The falling edge of a negative pulse

31

/INIT

30 I

or a LOW signal on this line causes

the printer to initialize. Minimum 50 us

pulse is necessary.

32

36

18

35

/ERROR

/SLIN

Logic H

+5V

29 O

30 I Not used.

When the printer detects an error, this

signal goes LOW.

Pulled up to +5V via 3.9 K-ohm

O

resistor.

O Pulled up to +5V via 3.3 K-ohm

resistor.

15,34

Note)

17

Chassis GND

GND

NC

Chassis ground.

Si

nal ground.

Not connected.

1. */* at the beginning of a signal means active low.

2. The I/O column indicates the direction of the signal as viewed form the printer.

1-30

Rev. A

Page 39

Product Description

Reverse Channel

Transmission mode IEEE-1284 nibble mode

Adaptable connector Same as for the forward channel

Synchronization Refer to the IEEE-1284 specification

Handshaking Refer to the IEEE-1284 specification

Data transmission timing Ref e r to the IEEE-1284 specification

Signal level IEEE-1284 level 1 device

See the forward channel.

Table 1-26 shows the connector pin assignment and signals for reverse channel of the

parallel interface.

Table 1-26. Connector Pin Assignment and Signals (Reverse Channel)

Pin No. Signal Name

1 HostClk 19 I Clock signal from the host computer.

2-9 DATA 1-8 20-27 I

10 PtrClk 28 O Clock signal from the printer

11

12

13 Xflag/Data bit

14 HostBusy 30 I Busy signal from the host computer

31 /INIT 30 I Not used

32

36 1284-Active 30 I 1284 active signal.

18 Logic-H

35 +5V

17 Chassis GND

16,33,

19-30

15,34 NC

Note)

PtrBusy /

Data bit 3,7

AckDatareq /

Data Bit 2,6

1,5

/Data Avail /

Data bit 0,4

GND

Return

GND Pin

29 O

28 O

28 O

29 O

I/O Description

O

O

These signals represent parallel data

on bits 2 to 9. Each signal is High

when the data is logical 1 and LOW

when the data is logical 0.

Busy signal from the printer.

Data bit 3 or 7 in reverse channel.

Acknowledge request signal.

Data bit 2 or 6 in reverse channel.

X flag signal.

Data bit 1 or 5 in reverse channel.

Data available signal.

Data bit 0 or 4 in reverse channel.

Pulled up to +5V via 3.9 K-ohm

resistor.

Pulled up to +5V via 3.3 K-ohm

resistor.

Chassis ground for the printer.

Signal ground.

Not connected.

1. */* at the beginning of a signal means active low.

2. The I/O column indicates the direction of the signal as viewed form the printer.

Rev. A

1-31

Page 40

DLQ-3000+

Extensibility Request

The printer responds affirmatively when the extensibility request values are 00H or 04H,

as follows:

00H Request nibble mode reverse channel transfer.

04H Request device ID using nibble mode rev channel transfer

Device ID

The printer sends following device ID string upon request:

[00H] [3DH]

MFG EPSON;

CMD ESCPL2, PRPXL24, BDC;

MDL DLQ-3000+;

CLS PRINTER;

1-32

Rev. A

Page 41

Product Description

3

1.4.2 Serial Interface

Synchronization Asynchronous

Signal level EIA-232D

MARK (logical 1): -3 V to -25 V

SPACE (logical): +3 V to +25 V

Word format Start bit: 1 bit

Data bit: 8 bit

Parity bit: Odd, Even or Non

Stop bit: 1 bit

Baud rate 300, 600, 1200, 2400, 4800, 9600 or 19200 bps

Handshaking DTR signal and XON/XOFF

DTR = MARK, XOFF: Indicates that the printer cannot receive data.

DTR = SPACE, XON: Indicates that the printer is ready to receive data.

The DTR signal is MARK and XOFF code (DC3, 13H) is transmitted when the rest of

the input buffer becomes 256 byte. The DTR signal is SPACE and XON code (DC1,

11H) is transmitted when the rest of the input buffer becomes 256 byte.

Error handling Parity error is detected only.

(Overrun error and framing error are ignored.)

Connector 25-pin sub-miniature D-shell connector. (female)

Table 1-27. Connector Pin Assignment for Serial Interface

Pin No. Signal Name I/O Function Description

1 Chassis GND

2 TXD Out Transmits data

3 RXD In Receives data

4 RTS Out

7 Signal GND

11 REV Out Connected directly to the DTR signal.

20 DTR Out Data terminal ready

others NC

Chassis GND

Request to send. Always SPACE level

when the printer is powered on. Pulled

up to +12 V via 4.7 L ohm resistor.

Signal GND

Not used. Not connected.

Note: In and Out refers to the direction of the signal flow from the printer’s point of

view.

Rev. A

1-3

Page 42

DLQ-3000+

1.4.3 Optional Interface

The EPSON DLQ-3000+ supports an optional Type-B interface (Level 2) with the following

characteristics.

Reply message

Table 1-28. Reply Message

Reply message ESC/P2 IBM 2391 Plus

Main-type MT24p, PW136cl10cpi, PRG(W0xxxx)rev

Product name DLQ-3000+

Emulation type ESCPL2, PRPXL24, BDC

Entity type EPSONLQ2 EPSONPRPXL24

Reply for optional command

Table 1-29. Reply for Option Command

Option command No. command name Reply-A Reply-B

00h No Operation

01h Start Hard Ware Reset Accept Execute OK

02h Start Soft Ware Reset Reject

03h Send Main System Type Accept Execute OK

04h Send Name Data Reject

05h Inquire Name Data Accept Execute OK

06h Send Product Name Accept Execute OK

07h

08h Complete Buffered Data Accept Execute OK

09h Stop Procedure Reject

0Ah Return Buffered Data Reject

0Bh Send Entity Type Accept Execute OK

0Ch Send Status Accept Execute OK

0Dh Quit Procedure Reject

0Eh Inquire ASCII Message Reject

0Fh Send ASCII Message Accept Execute OK

10h - 13h (Reserved) Unknown

14h Inquire Emergency Message Accept Execute OK

15h Send Emergency Reply Accept Execute OK

16h - 1Fh (Reserved) Unknown

Send Soft Ware Emulation

Type

Accept

Execute OK

1-34

Rev. A

Page 43

Product Description

5

Supported Main Command and Sending Timing

Table 1-30. Supported Main Command and Sending Timing

Main Command Command name Sending Timing

01h Start Software Reset

02h Send option type

04h Send Name Data

07h

0Eh Inquire ASCII Message

14h Inquire Emergency Reply

15h Send Emergency Message

Emergency Command

Inquire Software Emulation

Name

/INIT signal on the standard parallel I/F

Type-B I/F option command : 01h

Panel Reset

Cold Start

Deciding the level of type-B I/F after

power on.

Type-B I/F option command : 05h

Changing software Emulation Type

Writing to DBIN register

Reply for Emergency command

Receive Emergency Command

Table 1-31. Emergency Command

Command No. Command name

0x00 Get device IC

0x01 Get all status

1.4.4 Printer language

ESC/P2

IBM 2391 Plus emulation

EPSON Remote

Rev. A

1-3

Page 44

DLQ-3000+

1.4.5 Prevention Hosts from Data Transfer Time-out

Generally, hosts abandon data transfer to peripherals when a peripheral is BUSY

continuously for dozens of seconds. To prevent this kind of time-out, the printer receives

data very slowly, several bytes par minute, even the printer is in a busy state. This

slowdown starts when the remainder of input buffer drops under several hundreds of bytes.

Finally, the printer is BUSY continuously when the input buffer is full.

1.4.6 Interface Selection

The EPSON DLQ-3000+ has three types of interfaces: Parallel, Serial, and optional Type-B.

Each interface can be selected manually by SelecType or automatically. Both modes are

selected thorough the default setting mode.

Manual selection

One of the 3 interfaces can be selected by SelecType.

Automatic selection mode (Enabled by SelecType)

When the printer is powered on, the printer is initialized to the idle state scanning which

interface receives data. Then the interface that receives data first is selected. When the

host stops data transfer and the printer is in stand-by state for the seconds specified by

SelecType, the printer is returned to the idle state. As long as the host sends data or the

printer interface is busy state, the selected interface is left as it is.

Interface selection and interface state

Interface selection and the corresponding interface states are as follows:

When an interface other than parallel interface is selected, the interface goes into

the BUSY state.

When an interface other than serial interface is selected, the interface sends XOFF

and sets the DTR signal MARK.

When an interface other than optional interface is selected, the printer sets

“OFFLINE” bit of MNSTS register to the optional interface.

When the printer is initialized and returned to the idle state:

• The parallel interface goes into ready state.

• The serial interface sends XON and sets the DTR SPACE and the printer

resets OFFLINE bit of MNSTS register to the optional interface.

Note: An interrupt signal such as /INIT signal on the parallel interface is not effective while

that interface is not selected.

Idle State

1-36

Selected State

Figure 1-15. Interface Selection

Non-selected State

Rev. A

Page 45

Product Description

7

1.5 Operation

This section describes the function of each button on the control panel and LED printer

status indicators.

1.5.1 Control Panel

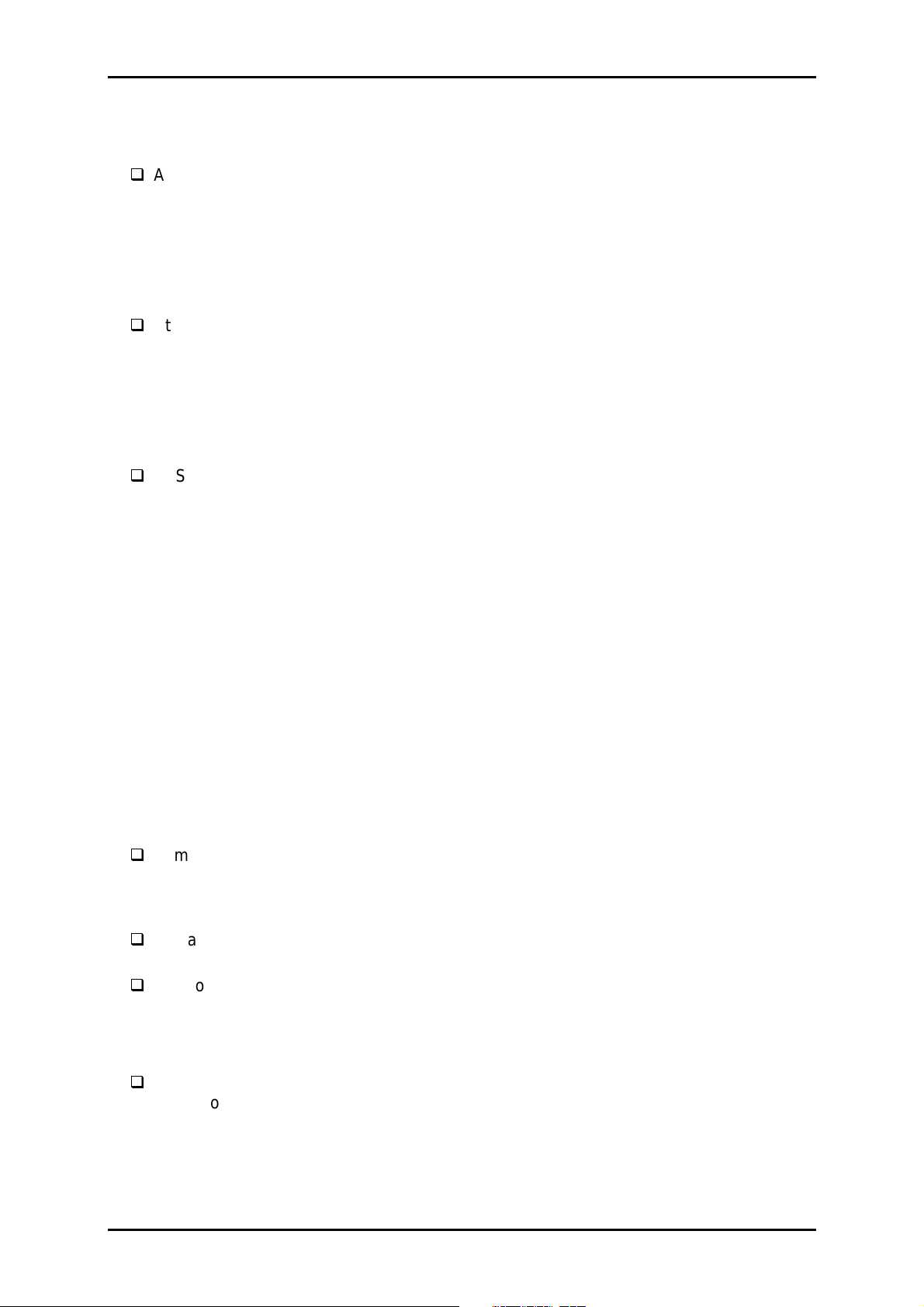

The control panel for this printer consists of 10 non-lock type push buttons, 4 LED indicators

and 1 LCD. See Figure 1-16.

Power

Tear O ff

Font

1.5.1.1 Button Operations

Paper O ut

16-character LC D

S ele cT ype

Paper select

LF/FF

Pitch

Load/E ject

-----R e s e t-----

Pause

Figure 1-16. Control Panel

LCD: 16 characters

Power LEDs: Green

Paper Out LED: Red

Tear-off LED: Orange

Pause LED: Orange

Effectiveness

Basically, all button operations are always effective except for the following cases.

• During printing, only the

• The

•

Pause functions

• Press the

• Press the

Even if the

SelecType

Load/Eject

Pause

button is only effective during the printer is in the standby status.

and “

Pause

Pause

button to stop printing.

button again to resume printing.

button is pressed, the interface continues to receive data until the

Pause

Pause

button is effective.

” buttons are not effective during the SelecType mode.

input buffer is full and the CR moves to the ribbon changing position.

Reset function

Press the

Pause

Load/Eject

and

buttons simultaneously to initialize the printer. Refer to

Section 1.5.5.

Rev. A

1-3

Page 46

DLQ-3000+

Paper feed function

Table 1-32 shows the button operations and the corresponding paper feed functions

Table 1-32. Paper Feed Functions

Operations Function

Paper loaded Paper out

.

Press LF/FF

shortly. Tractor feed Line feed *¹ Load continuous paper

Press LF/FF for

a few seconds. Tractor feed Form feed *¹ Load continuous paper

Press. Friction feed Eject Load a sheet *².

Load/Eject

Press ↓.

Press ↑.

Insert a sheet to the manual

insertion slot. (Friction feed)

Friction feed Line feed Load a sheet *².

Friction feed Form feed Load a sheet *².

Tractor feed Paper park*¹ Load continuous paper

Friction feed Micro feed (forward) —

Tractor feed Micro feed (forward) *³ —

Friction feed Micro feed (backward) —

Tractor feed Micro feed (backward)*³ —

—

Load the inserted sheet.

*².

Notes)

1. When the printer is in the tear-off state, these functions are performed after returning

from the tear-off position.

2. Once a sheet is manually inserted, the printer enters manual insertion mode. While the

mode is active, even if data is remaining in the buffer, the printer goes into a paper-out

error state at each end of a sheet and waits for the next sheet to be inserted. CSF

insertion is enabled again by loading sheets into the CSF or by initializing the printer.

3. ↓↓ and ↑↑ buttons are used as described below:

Pressing the button continuously feeds paper forward*/backward* with a increment

•

of 1/180 inch.

Pressing the button continuously feeds paper forward*/backward* slowly.

•

When the printer is in the tear-off state, these buttons are used to adjust tear-off

•

position. The adjusted position is stored in the EEPROM.

* To feed forward or backward means toward the front or rear of the printer,

respectively.

Tear -off function

The printer has 2 types of tear-off functions; manual tear-off and auto tear-off. The

manual tea-off is performed by pressing the Tear Off button . The auto tear-off is

enabled by SelecType. These functions are same as for the conventional EPSON

printers.

Paper select function

Press the Paper Select button to select one of the following paper memory numbers.

• 0: All cases

• a(9): When the printer has the special paper information.

Note: The Paper Select button is only effective without any paper set.

1-38

Rev. A

Page 47

Product Description

9

1.5.1.2 Printer Status and LCD/LED Indicator Conditions

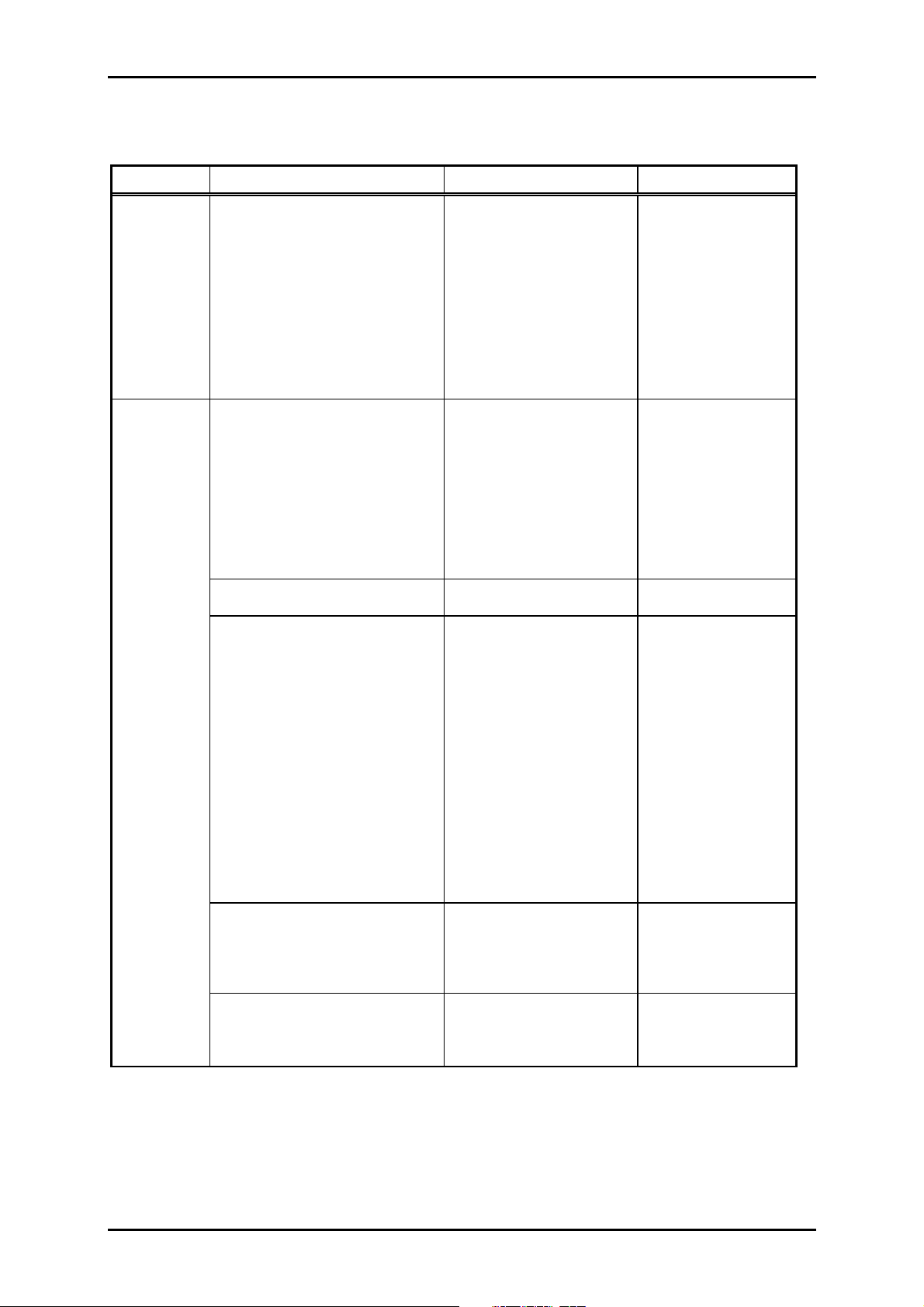

Table 1-33 shows the printer status and When the printer is in more than one status, the

printer indicates the prime status. If they have the same priority, the status occurs first is

indicated. The priority in the first column means that the status with the lower numbers have

higher priority.

Table 1-33. Printer Status and LCD/LED Indicator Conditions

Priority

1 Fatal error *

Printer State LCD message LED

Paper Out

1

Please turn off Blinks Blinks Blinks

Pause Tear-Off

2 Program reload mode Program Mode Off Off Off

3 Cover open error Cover Open On/Off *

4 Release lever operation

error *

2

Put Lever Back Blinks On On/Off

6

On On/Off

5 Paper jam error Paper Jam Blinks On On/Off

6 Paper out error *

7

Incomplete changing

paper path error *

8 Paper size error *

3

4

5

Paper Out On On On/Off

Wrong Paper Path Off On On/Off

Wrong Paper Size Off On On/Off

9 Eject error Pull Paper Out Blinks On On/Off

10 Printhead is overheated. Please Wait Off Blinks On/Off

11 Entry to SelecType 1 SelecType 1 Off Off Off

11 Entry to SelecType 2 SelecType 2 Off Off Off

12 Tear-off Cut the paper Off On/Off

13

Data is in buffer but the

printer is paused

Data in Buffer Off On Off

6

*

14 Pause Pause : #0 Off On Off

15 Bi-D adjustment Bi-d adjustment Off Off Off

15 Hex dump mode Hex dump Off Off O ff

15 Ordinary printing Printing : #0 Off Of f Off

15 Test printing Test Printing Off Off Off

15 Setting printing Setting Printing Off Off Off

16 Standby Ready : #0 Off Off O ff

Notes)

1. Fatal error occurs when the printer is under any of the following conditions:

• Power supply voltage is at an abnormal level.

• The printhead temperature is abnormal.

• Carriage does not move normally.

• Platen gap does not move normally.

• An error occurs while executing EEPROM commands or program reload mode.

• The printer control circuit does not work correctly.

2. This error occurs when the friction lever is not set to the appropriate position.

*

*

*

*

*

*

*

*

On

6

6

6

6

6

6

6

6

Rev. A

1-3

Page 48

DLQ-3000+

3. Paper-out error occurs when the printer is under any of the following conditions:

• The printer does not load paper in spite of the attempt to load it.

• The printer finishes printing 1-page data on a sheet manually inserted.

• The end of the continuous paper has reached.

4. When the printer fails to change the paper path, this error occurs.

5. Paper size error occurs when the printer senses the condition that the currently loaded

paper size does not match the selected paper size.

6. It depends on the combination of the printer status.

1.5.1.3 Printer Status and Buzzer

The printer beeps to indicate several printer error status and failure operation. Printer status

and the corresponding beeper sounds are as described in Table 1-34.

Table 1-34. Printer Status and Buzzer

Printer status Beeper sound

Paper out error has occurred. – – –

Paper size error has occurred. – – –

Incomplete changing paper path error – – –

Eject error has occurred. – – –

Release lever operation error has occurred. — — — — —

Paper jam error has occurred. — — — — —

Fatal error has occurred. — — — — —

Illegal operation in SelecType –

Notes) The symbols “–“ and “—“ represent how a beep sounds.

“–“: Sounds 100 ms with the interval of 100 ms.

“—“: Sounds 500 ms with the interval of 100 ms.

1-40

Rev. A

Page 49

Product Description

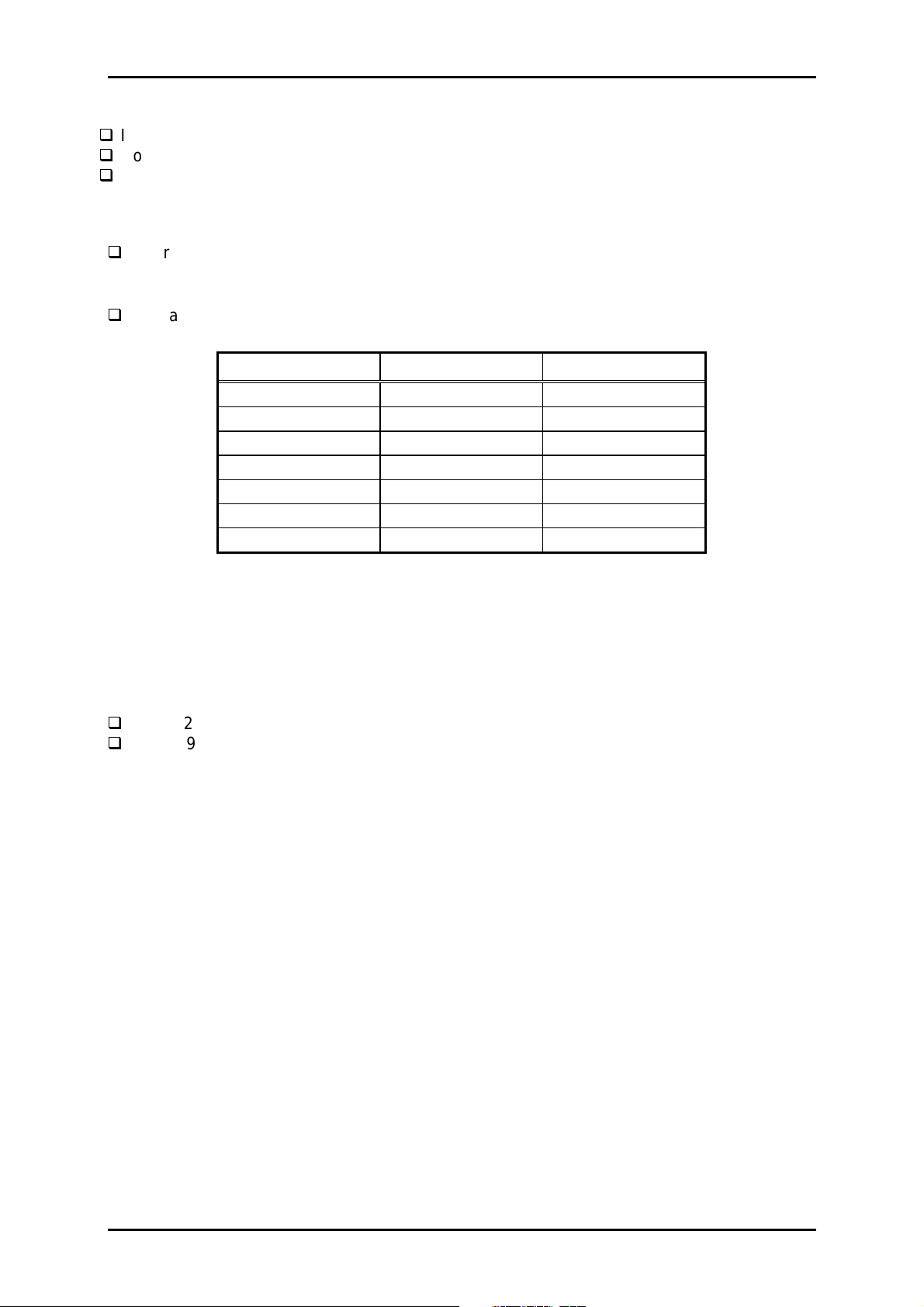

1.5.2 SelecType

This printer provides SelecType function to change default settings.

1.5.2.1 SelecType Phase

See Figure 1-17 which shows the SelecType phase transitions. Boxes show printer states

or SelecType phases. The boxes with shadow involves button operations.

Printer State

Stand by state

SelecType

E n try to

SelecType 1

SelecType

E n try to

SelecType 2

SelecType

SelecType P hase

SelecType 1 p hase

FO NT

PITCH

FO NT

PITCH

SelecType 2 p hase

SelecType

in itn a liz a tio n *

D ata save phase

Font selection p hase

FO NT

Pitch selection phase

SelecType

SelecType

PITCH

SelecType

SelecType

Figure 1-17. SelecType Phase Transitions

Rev. A

1-41

Page 50

DLQ-3000+

1.5.2.2 SelecType Operation

SelecType 1 and 2 operations

Step 1. Selecting the feature

When the SelecType 1 or 2 starts, the first feature appears on the LCD. Scroll the

features by pressing the “↑” (next) or “↓” (previous) button until the desired feature

appears. Then press the “→” (enter) button, and the option menu for the selected

feature is displayed.

Step 2. Keeping/Changing the option

The current option marked with “*” for the menu appears. To keep the option as it is,

press the “←” button (escape) to return to the feature menu. To change the option,

press the “↑” (next) or “↓” (previous) button to scroll the option menu. Then press the

“→” (enter) button to fix the desired option. If the “Other” is selected, another option

menu appears. In this case, select the desirable option in the above mentioned way.

Step 3. Return to the previous menu

Press the “←” button (escape) to return to the previous menu. Pressing the button

several times to return to the SelecType 1 or 2 entry state.

Step 4. Exit

Press the “SelecType” button to exit the SelecType phase. With this operation, new

settings are automatically stored in the EEPROM and are effective until they are

changed again. This process is automatically followed by the SelecType initialization

phase and the printer returns to the stand-by status.

[Initializing all settings to the standard]

Select “Standard Setting” in the SelecType 2 menu. The message “Ready?” is

displayed. Then perform one of the followings:

To execute the initialization:

Press the “→” (enter) button. (All settings are reset to the standard and the printer

returns to the feature menu.

To return to the feature menu without executing the initialization

Press the “←” button (escape).

Press the “

Font and Pitch Select Operation

Step 1.

Displaying the current selection for the font/pitch

When the printer enters the Font/Pitch phase, the current option marked with “*”

appears.

SelecType

” button to exit the SelecType mode.

Step 2.

Step 3.

1-42

Changing the font/pitch

Press the “↑” (next) or “↓” (previous) button until the desired font/pitch appears.

Then press the “→” (enter) button to fix the selection. The selected font/pitch is

marked with “*” as the result.

Exit

Press the “SelecType” button to exit the Font/Pitch phase.

Rev. A

Page 51

Product Description

3

1.5.2.3 SelecType Option

Table 1-35 and Table 1-36 show the options available for the SelecType 1 and SelecType

2, Font and Pitch, respectively.

Table 1-35. SelecType 1 Option

Menu Option Note

T-margin Tractor

T-Margin Manual R

T-Margin Manual L

T-Margin CSF

Character Table

*8.5 mm

from 4.2 mm to 8.5 mm + 25.4 mm

*8.5 mm

from 0 mm to 8.5 mm + 25.4 mm

*8.5 mm

from 0 mm to 8.5 mm + 25.4 mm

*8.5 mm

from 0 mm to 8.5 mm + 25.4 mm

NLSP version

*PC437 PC437 Greek

PC850 PC852, PC853

PC855 PC857 PC864

PC866 PC869 ISO Latin 1T

Code MJK Bulgaria Estonia

ISO 8859-7 MAZOWIA

PC774 ISO 8859-2

PC866LAT PCAPTEC

PC 708 PC720 PCAR864

PC 860 PC865 PC861

USA – KOREA

Increment : 0.14 mm (1/180”)

Increment : 0.14 mm (1/180”)

Increment : 0.14 mm (1/180”)

Increment : 0.14 mm (1/180”)

Standard version

*PC437 PC850 PC860

PC861 PC863 PC865

Abicomp BRASCII ISO Latin 1

Roman 8 U.S.A – Korea

Page Tractor *11 inch 12 inch

8.5 inch 70/6 inch (A4)

Other (See the right column.)

Page CSF *A4 Letter

Other (See the right column.)

B-Margin Tractor

Line spacing *1/6 inch 1/8 inch At 1/6 inch spacing

Left-Margin

Right-Margin

Print Direction

*0.000 inch

From 0 to 1 inch

*0 columns

From 0 to 80 columns

*136 columns

From 1 to 136 columns

*Bi-directional Uni-directional

Auto

Option for “Other”:

xxx lines (from 24 to 132

lines at 1/6 line spacing)

Option for “Other”:

xxx lines (from 24 to *132

lines)

Increment: 1/180 inch

Note: The current options are marked with “*”.

Rev. A

1-4

Page 52

DLQ-3000+

Table 1-36. Options for SelecType 2, Font and Pitch

Menu Option Notes

SelecType 2

Language *English French

German Italian

Spanish Portuguese

Paper Type

Overlapping Form *Off On For continuous paper only

Intensity Mode *Normal Dark Use the copy mode only

Software *ESC/P2 IBM 2391 Plus

Auto CR (IBM) *Off On For IBM 2391 Plus emulation

A.G.M. (IBM) *Off On For IBM 2391 Plus emulation

Interface

I/F Time-out

Input Buffer *On Off

Baud Rate 300 BPS 600 BPS

Parity

Auto Tear-off *Off On

Auto LF *Off On

0 Slash *Off On

Buzzer *On Off

Standard Setting Ready?

*Normal Cards

Envelopes

*Auto Selection Parallel

RS-232C Option Slot

*10 sec.

From 1 to 255 seconds

1200 BPS 2400 BPS

4800 BPS 9600 BPS

*19200 BPS

*None Even

Odd

For cut sheet only

when the depth of multipart form printing is not

enough.

Font

*Roman Sans Serif Courier Prestige

Script OCR B Orator Orator S

Script C Roman T Sans Serif H Draft

H-Speed Draft

Pitch

*10 cpi 12 cpi 15 cpi 17 cpi 20 cpi

Proportional

Note: The current options are marked with “*”.

1-44

Rev. A

Page 53

Product Description

5

1.5.3 Functions at Power On

This printer has the following 7 service modes. To enter each mode, press specified button

(buttons) while holding down the Power switch.

Test Printing

• Button LQ mode:

Draft mode:

• Result Alphanumeric characters are printed continuously.

• Exit Press the

• Interface state All interfaces keep a busy state during the test printing.

Hex Dump Mode

• Buttons

• Result The printer prints the message “Hex Dump” and then starts printing

(period) is printed instead.

• Exit Press the

LF/FF

received data in the both hexadecimal code and corresponding

off the printer to exit the mode.

Pause

and

characters. If corresponding character does not exist, “.”

Pause

LF/FF

Load/Eject

button and turn the printer Off.

Load/Eject

button to print data remaining in buffer. Then turn

button with the power switch On.

button with the power switch On.

buttons with the power switch On.

Setting Printing

• Button

• Result Firmware version and user changeable default setting menu

• Exit When the printing is complete, the printed sheet or continuous paper

printer returns to the standby status.

• Interface State All the interfaces keeps a busy state during the printing.

SelecType

(SelecType menu) along with their options are printed with the

subtitles in the selected language.

button with the power switch On.

is ejected or fed to the tear-off position, respectively. Then the

Note: In each mode mentioned above, when the printer fails to load paper, the printer goes

into the Paper-out error status. In this case, insert a sheet and press the Load/Eject

button. (In the Hex Dump mode, the message “Hex Dump” is printed at first. Then the

printer waits for data.)

Bi-D adjustment (Refer to Section 1.5.4.)

• Button

Program Reload Mode (Refer to Section 1.5.5.)

• Buttons

EEPROM Clear

• Buttons

• Result Resets the printer to the standard factory setting, which is not always

Pause

Tear Off, LF/FF, Load/Eject

switch On.

SelecType, Paper Select

(This function is used only for emergency.)

button with the power switch On.

Pause

and

Pause

, and

On.

proper setting for each market.

buttons with the power

buttons with the power switch

Clear the driving line count for ribbon changing timing

• Button

• Result Clears the value for the driving line count stored in the EEPROM.

Rev. A

Paper Select

button with the power switch On.

1-4

Page 54

DLQ-3000+

1.5.4 Bi-D Adjustment Mode

This printer has the Bi-D adjustment mode which enables users to align vertical lines. Refer

to Table 1-37 and Figure 1-18.

Table 1-37. Bi-D Adjustment Item

Items Order

Draft mode 1

Bit Image (ESC ∗ 26H) mode

LQ mode 3

Start

Turn the printer on w hile

holding dow n "Pause" button.

The printer prints the guide for