Page 1

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus C87/C88/D88

SEIJ05-002

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2005 SEIKO EPSON CORPORATION.

I&I CS/Quality Management & PL Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO

SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED

CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR

OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN USING COMPRESSED AIR PRODUCTS; SUCH AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF SUCH

PRODUCTS CONTAINING FLAMMABLE GAS IS PROHIBITED.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Exploded Diagram

• Parts List

• Circuit Diagrams

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Indicates that a particular task must be carried out according to a certain

standard after disassembly and before re-assembly, otherwise the quality of the components in question may be adversely affected.

Page 5

Revision Status

Revision Date of Issue Description

A August 1 , 2005 First Release

Page 6

EPSON Stylus C87/C88/D88 Revision A

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features.................................................................................................................. 9

1.2 Specifications ...................................................................................................... 10

1.2.1 Physical Specification................................................................................. 10

1.2.2 Printing Specification ................................................................................. 10

1.2.3 Paper Feeding ............................................................................................. 11

1.2.4 Input Data Buffer........................................................................................ 11

1.2.5 Electric Specification.................................................................................. 11

1.2.6 Reliability ................................................................................................... 12

1.2.7 Acoustic Noise............................................................................................ 12

1.2.8 Black Ink Save Mode.................................................................................. 13

1.3 Operator Controls ................................................................................................ 14

1.3.1 Operation Switch ........................................................................................ 14

1.3.2 Panel Functions........................................................................................... 14

1.3.3 Printer Condition and LED Status .............................................................. 15

1.3.4 Duplex Printing........................................................................................... 15

1.3.5 Errors .......................................................................................................... 15

1.4 Paper .................................................................................................................... 16

1.4.1 Paper Support.............................................................................................. 16

1.5 Ink Cartridge........................................................................................................ 21

1.5.1 Ink Cartridge Specification......................................................................... 21

Chapter 2 OPERATING PRINCIPLES

Chapter 3 TROUBLESHOOTING

3.1 Overview ............................................................................................................. 30

3.1.1 Specified Tools ........................................................................................... 30

3.1.2 Preliminary Checks..................................................................................... 30

3.2 Troubleshooting With LED Error Indications.................................................... 31

3.2.1 Fatal Error................................................................................................... 33

3.3 Troubleshooting for Motors and Sensors ............................................................ 35

Chapter 4 DISASSEMBLY/ASSEMBLY

4.1 Overview ............................................................................................................. 37

4.1.1 Precautions.................................................................................................. 37

4.1.2 Tools ........................................................................................................... 37

4.1.3 Screws (T.B.D)........................................................................................... 38

4.1.4 Work Completion Check ............................................................................ 39

4.2 Caution regarding Assembling/Disassembling of the Printer Mechanism,

and How to Ensure of Quality on Re-assembled Product................................... 40

4.3 Dissasembly Procedures...................................................................................... 42

4.3.1 Removing Housings ................................................................................... 44

4.3.2 Removing Boards ....................................................................................... 57

4.3.3 Disassembling Printer Mechanism ............................................................. 62

Chapter 5 ADJUSTMENT

2.1 Overview ............................................................................................................. 24

2.2 Printer Mechanism............................................................................................... 24

2.2.1 Printhead Specifications ............................................................................. 25

2.2.2 Carriage Mechanism................................................................................... 25

2.2.3 Paper Loading/Feeding Mechanism ........................................................... 26

2.2.4 Ink System Mechanism............................................................................... 27

2.3 Electrical Circuit Operating Principles................................................................ 27

2.3.1 C528 PSH Board......................................................................................... 28

2.3.2 C528 Main Board ....................................................................................... 28

5.1 Adjustment Items and Overview......................................................................... 81

5.1.1 Servicing Adjustment Item List.................................................................. 81

5.1.2 Replacement Part-Based Adjustment Priorities ......................................... 84

5.2 Adjustment by Using Adjustment Program ........................................................ 85

5.2.1 Market ID Setting ....................................................................................... 85

5.2.2 USB ID Input.............................................................................................. 85

5.2.3 Head ID Input ............................................................................................. 85

5.2.4 Head Angular Adjustment.......................................................................... 86

5.2.5 Bi-D Adjustment......................................................................................... 86

6

Page 7

EPSON Stylus C87/C88/D88 Revision A

5.2.6 PF Adjustment ............................................................................................ 87

5.2.7 PW Sensor adjustment................................................................................ 87

5.2.8 First Dot Adjustment .................................................................................. 88

5.2.9 Top Margin Adjustment ............................................................................. 88

5.2.10 Offset input for CR Motor Calorific Limitation ....................................... 89

5.2.11 A4 Normal Paper print.............................................................................. 89

5.2.12 A4 Photo Quality Inkjet Paper Print........................................................ 90

5.3 Adjustment Except Adjustment Program ............................................................ 91

5.3.1 CR Timing Belt Tension adjustment .......................................................... 91

Chapter 6 MAINTENANCE

6.1 Overview ............................................................................................................. 93

6.1.1 Cleaning...................................................................................................... 93

6.1.2 Service Maintenance................................................................................... 93

6.1.3 Lubrication.................................................................................................. 95

Chapter 7 APPENDIX

7.1 Exploded Diagram............................................................................................... 99

7.2 Parts List............................................................................................................ 105

7.3 Circuit Diagram ................................................................................................. 106

7

Page 8

PRODUCT DESCRIPTION

CHAPTER

1

Page 9

EPSON Stylus C87/C88/D88 Revision A

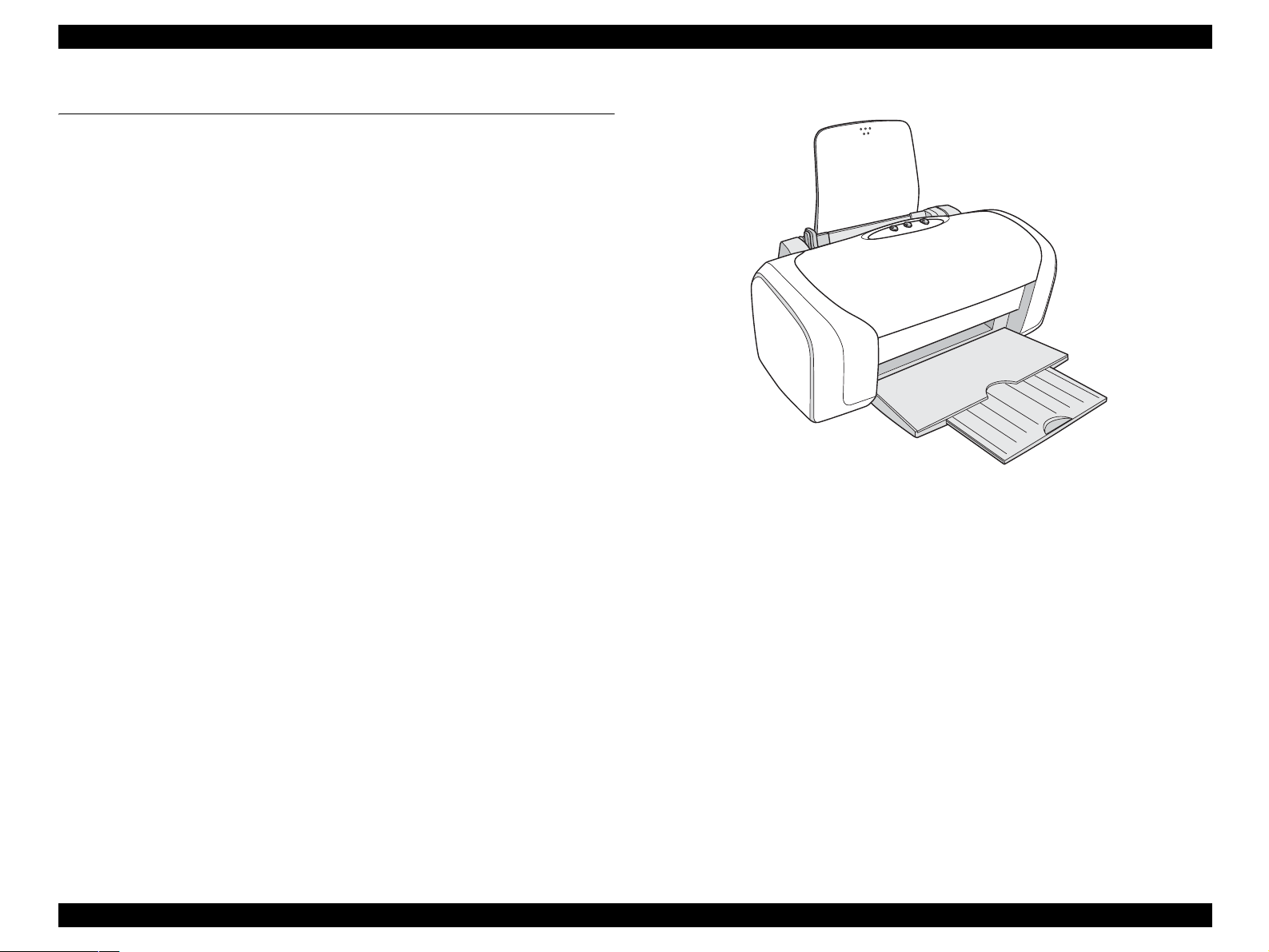

1.1 Features

The major features of EPSON Stylus C87/C88/D88 are:

High color print quality

4-color pigment ink installed

High quality printing on plain papers

2880 (H) x 1440 (V) dpi printing (Max resolution)

Supports two types of I/F

Bidirectional parallel I/F

USB

Windows/Macintosh exclusive

Built-in auto sheet feeder (ASF)

Comes equipped with the ASF that supports from postcard-sized papers to

A4-sized papers

CSIC compatible fully independent ink cartridges

Borderfree printing for all sides

Prevents printing on platen with the optical sensor

Cancel print jobs function

Reduced noise during paper feeding

Figure 1-1. Product Appearance

PRODUCT DESCRIPTION Features 9

Page 10

EPSON Stylus C87/C88/D88 Revision A

1.2 Specifications

This section covers specifications of the printer.

1.2.1 Physical Specification

Weight: 4.2 kg (without the ink cartridges)

Dimension

Storage: 460 mm (W) x 242 mm (D) x 191.2 mm (H)

Printing: 460 mm (W) x 437 mm (D) x 309 mm (H)

1.2.2 Printing Specification

Print method

On demand ink jet

Nozzle configuration

monochrome: 180 nozzles

color: 59 nozzles x 3 (Cyan, Magenta, Yellow)

Print direction

Bi-direction with logic seeking

Print speed & Printable columns

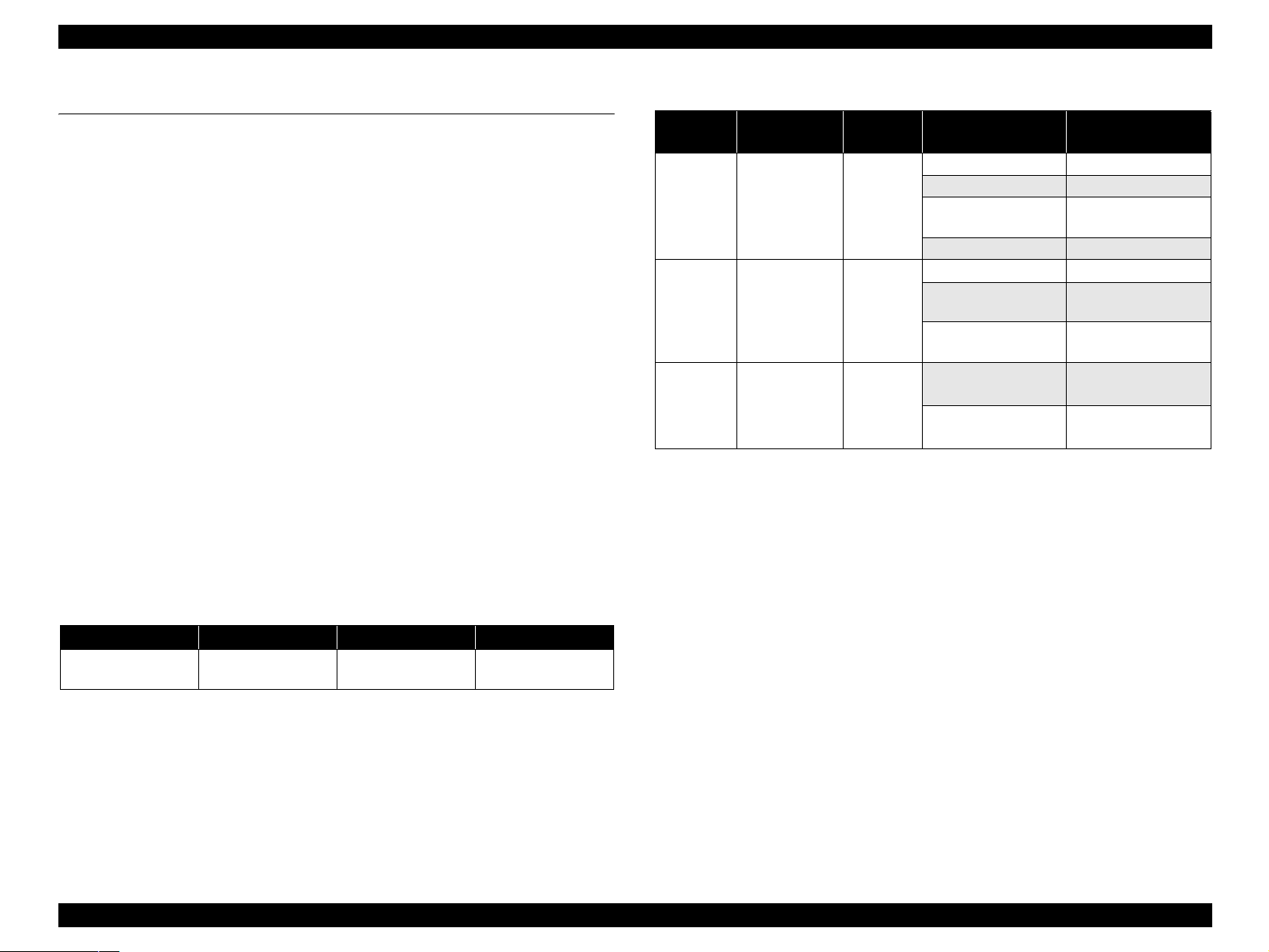

Table 1-1. Character Mode

Character Quality Character Pitch Printable Columns CR Speed

High quality 10 CPI (Pitch) 80 digits

622.3 mm/s

(245 CPS)

Table 1-2. Raster Graphics Mode

Horizontal

resolution

360 dpi

720 dpi

1440 dpi

Printable area

209.8 mm

(8.26 inch)

209.8 mm

(8.26 inch)

209.8 mm

(8.26 inch)

Available

dot

2976

5952

11904

Control Code

ESC/P2 expanded raster graphics code

EPSON Remote command

Character tables

none (ASCII 20H to 7FH code support)

Internal fonts

Alphanumeric characters: Courier 10 CPI

Dot size CR speed

Eco 863.6 mm/s (340 CPS)

VSD1 622.3 mm/s (245 CPS)

VSD2

(Color)

VSD4 571.5 mm/s (225 CPS)

VSD2 622.3 mm/s (245 CPS)

VSD2'

(Black)

VSD3’

(Color)

VSD3

VSD3’

(Black)

622.3 mm/s (245 CPS)

622.3 mm/s (245 CPS)

736.6 mm/s (190 CPS)

736.6 mm/s (190 CPS)

736.6 mm/s (190 CPS)

PRODUCT DESCRIPTION Specifications 10

Page 11

EPSON Stylus C87/C88/D88 Revision A

1.2.3 Paper Feeding

Paper feeding method

Friction feed with ASF

PF interval

Programmable in 0.0175 mm (1/1440 inch)

Paper loading method

Friction feed

Feed speed

196.39 mm/sec (19.05 mm (0.75 inch) feed) (T.B.D)

352.8 mm/sec (High speed /Continuous feed) (T.B.D)

1.2.4 Input Data Buffer

Input buffer size: 128 KB

1.2.5 Electric Specification

Rated voltage: AC100 V - 240 V

Input voltage range: AC90 - 264 V

Safety approvals

UPS version:

Safety standards : UL1950

CSA C22.2 No.950

: EN 60950(VDE)

EMI : FCC part15 subpart B class B

CSA C108.8 class B

: EN 55022(CISPR Pub.22) class B

: AS/NZS 3548 class B

CE Marking

UPS version:

Low Voltage Directive 73/23/EEC : EN60950

EMC Directive 89/336/EEC : EN55022 Class B

EN61000-3-2

EN61000-3-3

EN55024

Rated frequency range: 50 - 60 Hz

Input frequency range: 49.5 - 60.5 Hz

Rated current: 0.4 A - 0.2 A

Power consumption: ISO10561 Letter Pattern: 19W

Sleep Mode: 4.5 W

Power Off Mode: 0.8 W

Dielectric resistance: 10 MΩ or more

(between AC line and chassis at DC 500 V)

Dielectric strength: AC 1500 V rms. 1 second

(between AC line and chassis)

PRODUCT DESCRIPTION Specifications 11

Page 12

EPSON Stylus C87/C88/D88 Revision A

Environmental Condition

Table 1-3. Environmental Condition

Operating Non-operating

Temperature

Humidity (should be no

condensation)

Resistance to shock

(X, Y, and Z directions)

Resistance to vibration

(X, Y, and Z directions)

Note *1: One month at 40°C and 120 hours at 60°C

*2: Packed in the shipment container

*3: Under the following conditions

*1

Humidity(%)

10~35 °C

20~80 % RH 5~85 % RH ---

1 G, within 1 ms 2 G, within 2 ms ---

90

80

70

60

50

40

30

20

*3

0.15 G 0.50 G ---

-20~60 °C

*2

1 month at 40 °C

120 hours at 60 °C

C A U T I O N

Remarks

1.2.6 Reliability

Total print volume: 50,000 pages (A4, Letter) or five years,

Print Head Life: Three billion shots (per nozzle) or five years,

1.2.7 Acoustic Noise

Level: Approx. 42 db (A)

Printhead must be capped during storage.

When transporting the printer, make sure that the printhead is

capped and the ink cartridges are installed in the printer.

If the printhead is not capped when the printer is turned off,

turn the printer on with the ink cartridges installed, cap the

printhead, and turn the power off.

Ink inside the ink cartridges freezes if it is left to stand at

temperature of -4°C or less. If this is the case, allow the ink to

stand for about three hours at 25°C temperature.

whichever comes first.

whichever comes first.

27

10

20

35

30

40

Temperature (°C)

Figure 1-2. Temperature/Humidity Range

PRODUCT DESCRIPTION Specifications 12

Page 13

EPSON Stylus C87/C88/D88 Revision A

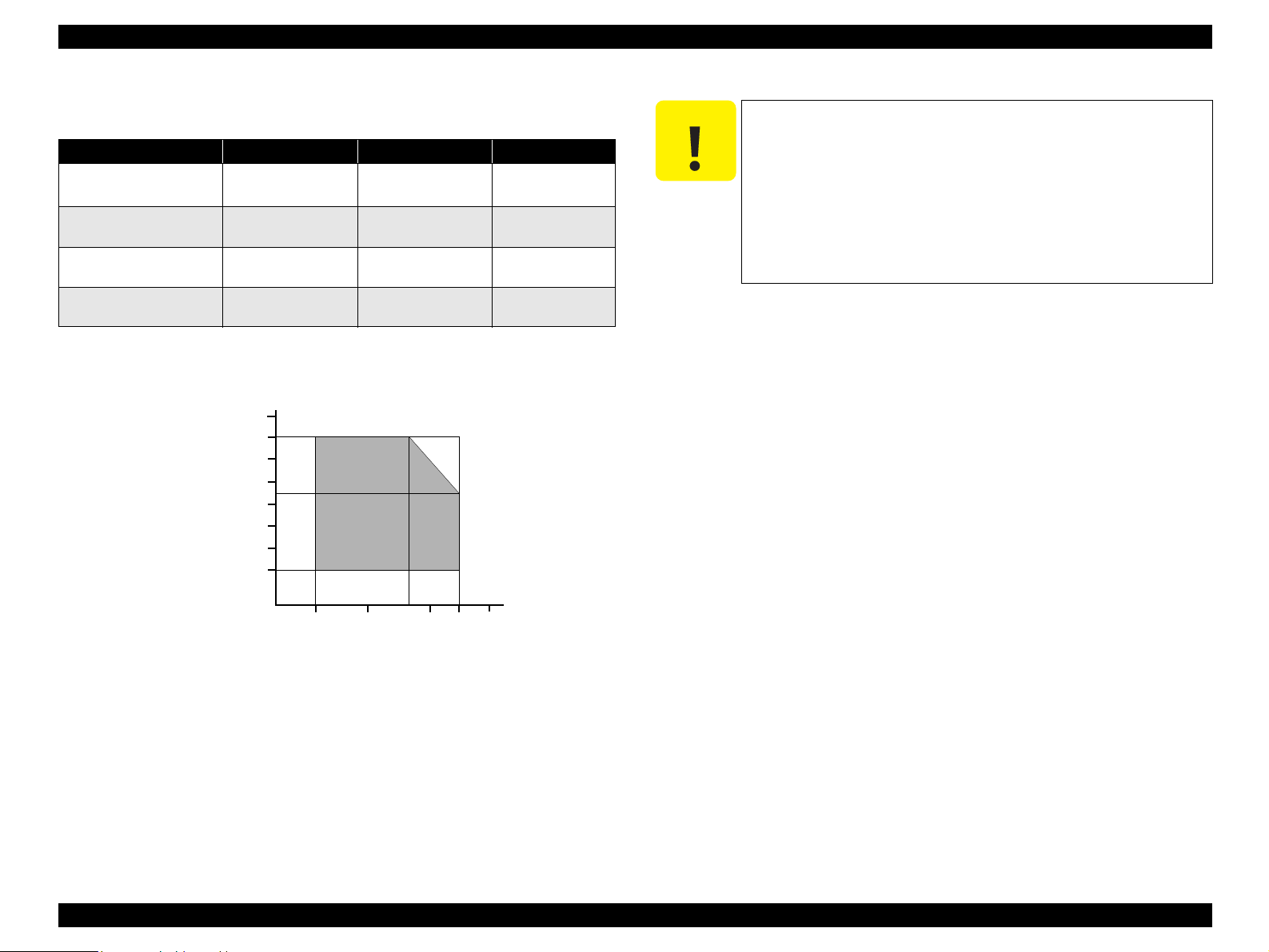

1.2.8 Black Ink Save Mode

“Black ink save mode” allows you to print images with color ink only when the

remaining amount of black ink is low. This mode can be selected when the remaining

amount of color ink is sufficient since black areas of the images are printed with a

mixture of other colors.

Supported OS: Windows NT4.0, 95, 98, ME, 2000, XP

Printing mode: Plain Paper & Text Mode (360 dpi)

Operating procedure

1. User carries out printing from an application.

2. The printer driver checks both the printing mode and the amount of remaining ink,

and displays the specific window if the conditions described below are all

satisfied.

Selected printing mode supports black ink save mode.

Remaining amount of black ink is less than 5 %, or the status of the black ink

is “ink low”.

Remaining amount of all the color ink is more than 10 %, or the status of all

the color ink is NOT “ink low”.

Starts printing in black ink save mode.

Starts printing in a

normal manner.

Starts printing in a

normal manner.

This window will not be

displayed until the black

ink cartridges is replaced.

Figure 1-3. Black Ink Save Mode Window

PRODUCT DESCRIPTION Specifications 13

Page 14

EPSON Stylus C87/C88/D88 Revision A

1.3 Operator Controls

1.3.1 Operation Switch

Operation switch is located on top center of the main unit.

1.3.1.1 Switches

There are three non-lock type push switches and three LEDs.

Ink switch

Ink LED

Paper switch

Paper LED

Power switch

Power LED

1.3.2 Panel Functions

Table 1-4. Panel Functions

Switch Function

Paper

Ink

Ink

(Holding down for three seconds)

Table 1-5. Panel functions with power on

Switch Pressing with Power On function

Paper + Power Starts status printings.

• Loads or ejects paper.

• Restarts when paper jam occurred.

• In the condition of printing, cancel the print job.

• Starts the ink cartridge change sequence. Moves the

carriage to cartridge change position.

• In the condition of ‘Ink Low’, ‘Ink Out’ or ‘No Ink

Cartridge’, moves the carriage to the ink check

position.

• When the carriage is on the ink check position, moves

carriage to next ink check position or cartridge change

position.

• When carriage is on the ink change position, returns

carriage from ink cartridge change position.

• Starts the cleaning of head.

• In the condition of 'Ink Low', 'Ink Out' or 'No Ink

Cartridge', starts the ink cartridge change sequence.

*

Figure 1-4. Control Panel

1.3.1.2 Indicators

Power LED [Green]

Lights when the power switch is “ON” and AC power is supplied.

Flashes when data is processed or ink system is operating.

Note *: Holding down the [Paper] switch, press [Power].

Table 1-6. Panel functions with power off

Switch Pressing with Power Off function

Ink + Power

Note *: Holding down the [Power] switch, press [Ink] for about seven seconds.

*

Compulsory power off.

*

Paper LED [Red]

Lights during the paper out/multi-feed condition, and flashes during the paper jam

condition.

Ink LED [Red]

Lights during no ink condition, and flashes during ink low condition.

PRODUCT DESCRIPTION Operator Controls 14

Page 15

EPSON Stylus C87/C88/D88 Revision A

1.3.3 Printer Condition and LED Status

Table 1-7. Printer Condition and LED Status

Printer status

Power on On -- -- 11

Ink level low -- -- Flashes 10

Data processing Flashes -- -- 9

No ink cartridge or ink end -- -- On 8

CSIC Error -- -- On 8

Ink sequence Flashes -- -- 7

Ink cartridge change mode Flashes -- -- 6

Paper out -- On -- 5

Multi-feed --- On --- 5

Paper jam condition -- Flashes -- 4

Maintenance request

(Waste ink counter overflow)

Fatal error Off Flashes on

Power off Flashes on

Reset request On On On --

Note *: “---” indicates that the indicator status varies according to the printer condition at

that time.

Power LED Paper LED Ink LED

Off

high speed

Indicators

Flashes

alternately

high speed

Off Off 1

Flashes

alternately

Flashes on

high speed

Priority

3

2

1.3.5 Errors

Errors that may occur with this printer are described below.

Table 1-8. Error Status

Error Description

Ink out The predetermined level of ink is used.

Paper out The printer fails to load a sheet.

Occurs under the following conditions:

• Papers could not be ejected after the specified number of times

Paper jam

Multi-feed Multiple papers are fed to the printer.

No ink-cartridge /

Cartridge Error

Maintenance request Total quantity of waste ink has reached the specified level.

Fatal errors Non-recoverable error such as carriage control error.

of paper feed operation.

• Papers could not be ejected by FF command or pressing the

Paper switch.

Occurs under the following conditions:

• Ink cartridge is not installed or removed.

• CSIC information could not be read/written normally.

1.3.4 Duplex Printing

Select the duplex printing mode from the printer driver, and follow the steps below to

perform the duplex printing.

1. Print all the odd pages.

2. Turn over the ejected pages on the paper eject tray, and load them on the ASF.

3. Print all the even pages.

PRODUCT DESCRIPTION Operator Controls 15

Page 16

EPSON Stylus C87/C88/D88 Revision A

1.4 Paper

1.4.1 Paper Support

Cut sheets

Dimensions

Paper size

A4 210 297

A5 148 210

A6 105 148

Half Letter

B5 182 257

Letter

Legal

User

defined

C A U T I O N

Width

(mm)

139.7

(5.5”)

215.9

(8.5”)

215.9

(8.5”)

50.8-329

It is necessary that there is no winkle, nap, tear, fold and so on

in the form.

The curve of form must be five mm or below.

The printer only accepts A4-sized papers for borderfree

printing.

Table 1-9. Cut sheets

Length

(mm)

215.9

(8.5”)

279.4

(11”)

355.6

(14”)

127-

1117.6

Thickness

(mm)

0.08-0.11

Weight

2

(g/m

)

64-90

(17-24(lb))

Quality

Common paper

Recycled paper

Envelopes

Table 1-10. Envelopes

Paper type

*2

#10

*2

DL

*2

C6

Note *1: Borderfree printing is not supported for envelops.

*2: There is flap in the long side part, and it is fold down.

C A U T I O N

Use paper under normal conditions.

Dimensions (mm)

Width Length

104.8 241.3

110 220

(20-24 (lb))

114 162

• Temperature 15 to 25°C (59 to 77°F)

• Humidity 40 to 60% RH

It is necessary that there is no winkle, nap, tear, fold and so on

in the form.

The curve and swell of the form must be three mm or below.

Don't use the adhesive envelope.

Don't use sleeve insert envelope and cellophane window

envelope.

As for double-flap envelope, if the envelope is damaged or bent

during printing, load the envelope with its flap facing in the

opposite direction. (Feeding direction should be changed as well

from the printer driver.)

If the printed images are skewed or misaligned from the proper

position, fold four sides of the envelope tightly.

If multi-feed occurs, press the [Paper] switch to feed the

envelope before starting printing again.

*1

Weight

(g/m

75-90

2

)

Quality

Bond paper

PPC paper

PRODUCT DESCRIPTION Paper 16

Page 17

EPSON Stylus C87/C88/D88 Revision A

Exclusive papers

Quality: EPSON Exclusive paper

Table 1-11. Exclusive papers

Dimensions

Item

Premium Ink Jet Plain Paper A4 210 297 0.11 80

Bright White Ink Jet Paper A4 210 297 0.13 92.5

Photo Paper

Premium Glossy Photo Paper

Premium Semigloss Photo Paper

Matte Paper-Heavyweight

Double-sided Matte Paper

Economy Photo Paper A4 210 297 0.23 188

Photo Quality Ink Jet paper

Glossy Photo Paper

Premium Glossy Photo Paper (RC-X) 4" x 6" 101.6 152.4 0.25 238

Ultra Glossy Photo Paper

Ultra Premium Glossy Photo Paper

*1

*2

Size

A4 210 297

4" x 6" 101.6 152.4

Letter 215.9 279.4

A4 210 297

8" x 10" 203.2 254

5" x 7" 127 178

4" x 6" 101.6 152.4

3R 89 127

Letter 215.9 279.4

4" x 6" 101.6 152.4

Letter 215.9 279.4

A4 210 297

Letter 215.9 279.4

A4 210 297

Letter 215.9 279.4

A4 210 297

Letter 215.9 279.4

4" x 6" 101.6 152.4

Letter 215.9 279.4

A4 210 297

8" x 10" 203.2 254

*3

5" x 7" 127 178

4" x 6" 101.6 152.4

Width

(mm)

Length

(mm)

Note *1: Borderfree printing is not supported for Photo Quality Ink Jet Paper.

*2: For Stylus C87/D88 only.

*3: For Stylus C88 only.

Thickness

(mm)

0.23 194

0.27 255

0.27 250A4 210 297

0.23 167

0.25 178

0.12 102

0.23 188

0.29 290

Weight

2

(g/m

C A U T I O N

Use paper under normal conditions.

• Temperature 15 to 25°C (59 to 77°F)

• Humidity 40 to 60% RH

It is necessary that there is no winkle, nap, tear, fold and so on

)

in the form.

The curve of form must be five mm or below.

PRODUCT DESCRIPTION Paper 17

Page 18

EPSON Stylus C87/C88/D88 Revision A

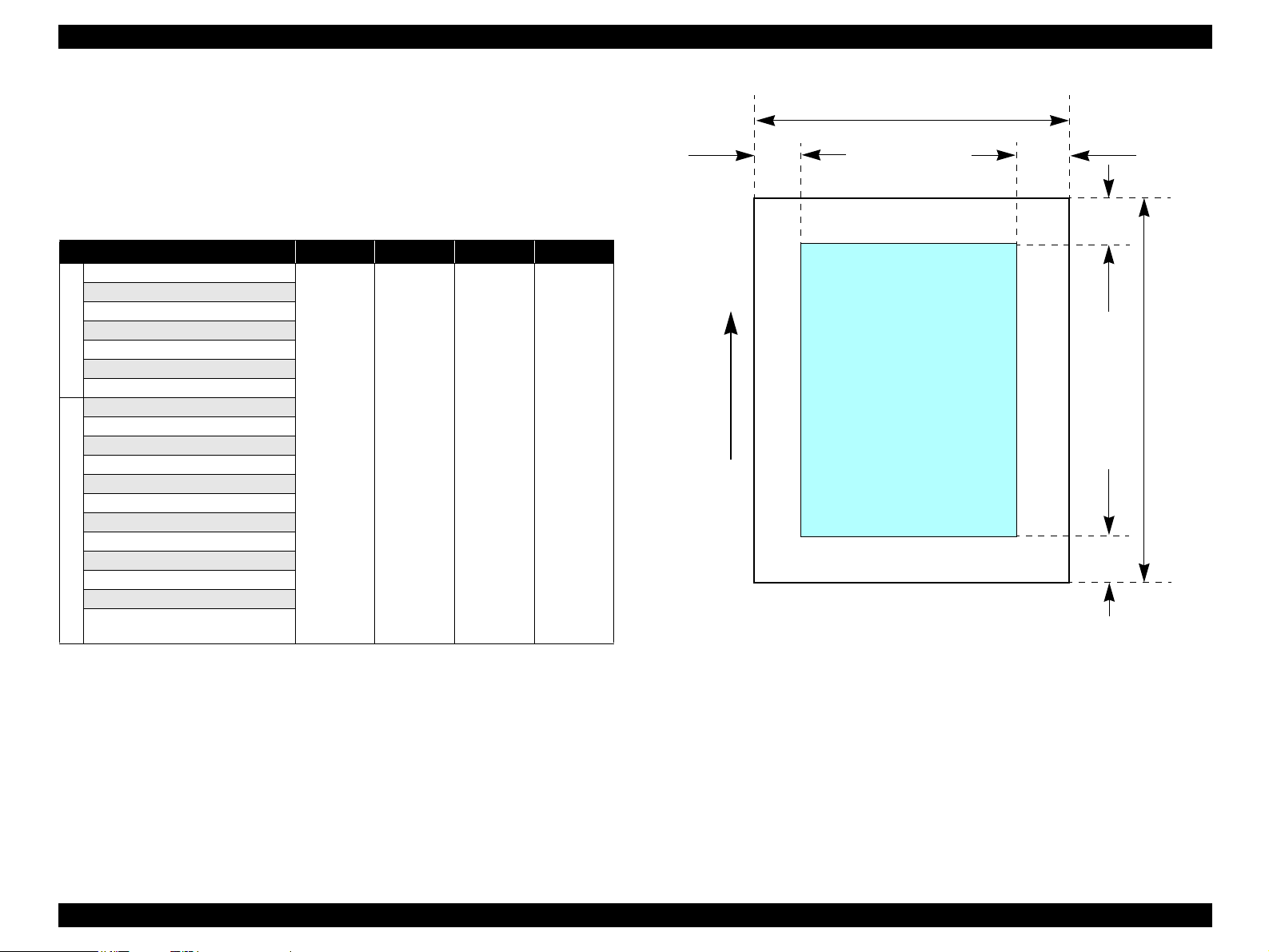

1.4.1.1 Printable Area

Cut sheet (standard printing)

Printable area

For paper width (PW) and paper length (PL), refer to 1.4.1 Paper Support

(p16).

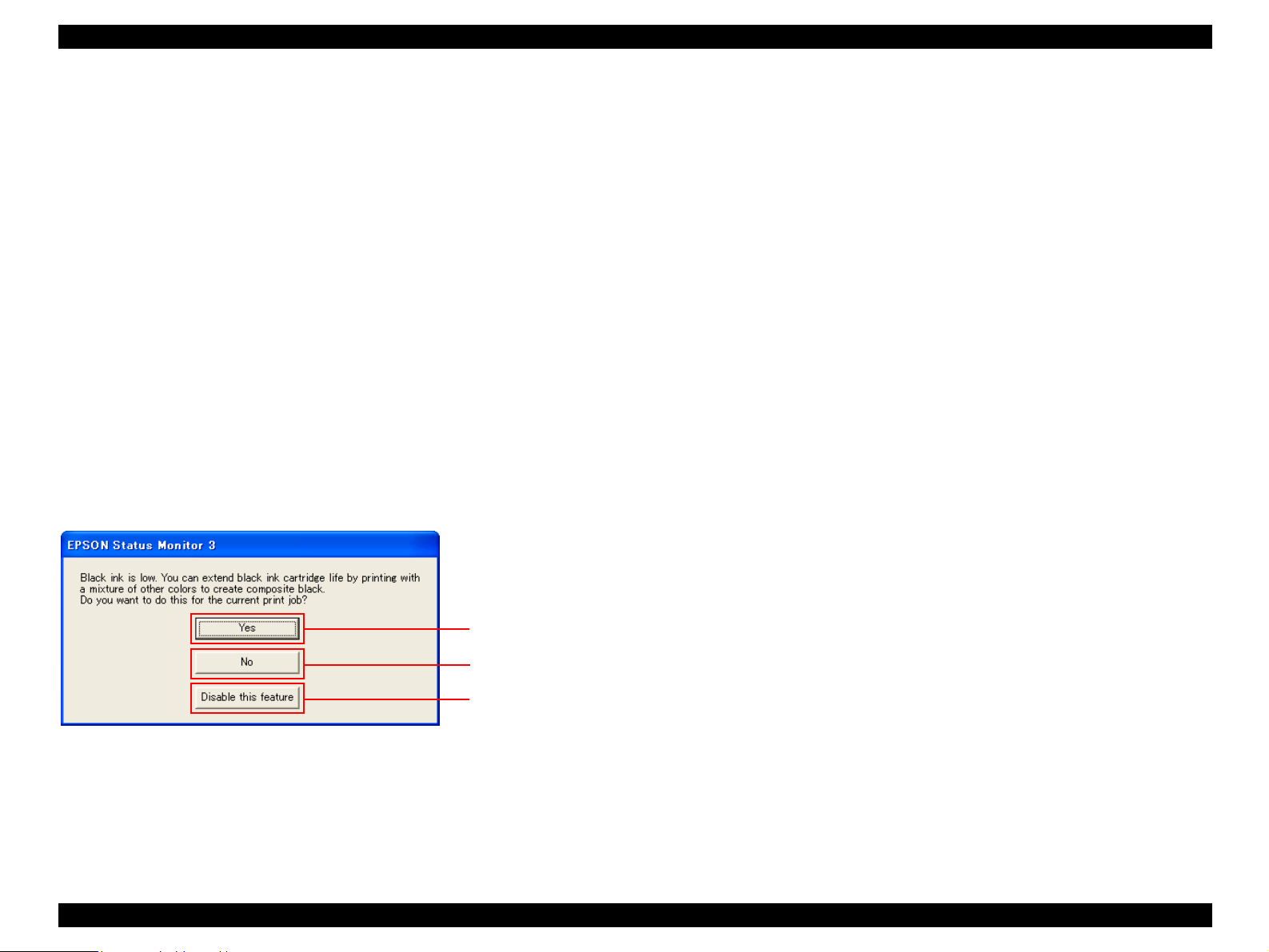

Table 1-12. Applicable Paper/Printing Area

Paper type LM RM TM BM

A4

A5

A6

B5

Letter

Cut Sheet

Legal

User defined

Premium Inkjet Plain Paper

Bright White Ink Jet Paper

Photo Paper

Premium Glossy Photo Paper

Premium Semigloss Photo Paper

Matte Paper-Heavyweight

Double-sided Matte Paper

Economy Photo Paper

Photo Quality Ink Jet Paper

Exclusive papers

Glossy Photo Paper

Premium Glossy Photo Paper (RC-X)

Ultra Glossy Photo Paper

Ultra Premium Glossy Photo Paper

3 mm 3 mm 3 mm

12.5 mm/

*1

3 mm

PW

LM

Printable area

Paper Feed Direction

Figure 1-5. Printable Area for Cut Sheet (Standard Printing)

RM

TM

PL

BM

Note *: It is possible to set the margins for all sides to zero under the special conditions.

Note *1: Bottom margin is expanded to 3 mm when paper dimension is defined by using

command (ESC (S and Remote “SN”), otherwise it is not expanded (12.5 mm).

From a form lower end 3 mm as for 12.5 mm area a printing may scramble.

PRODUCT DESCRIPTION Paper 18

Page 19

EPSON Stylus C87/C88/D88 Revision A

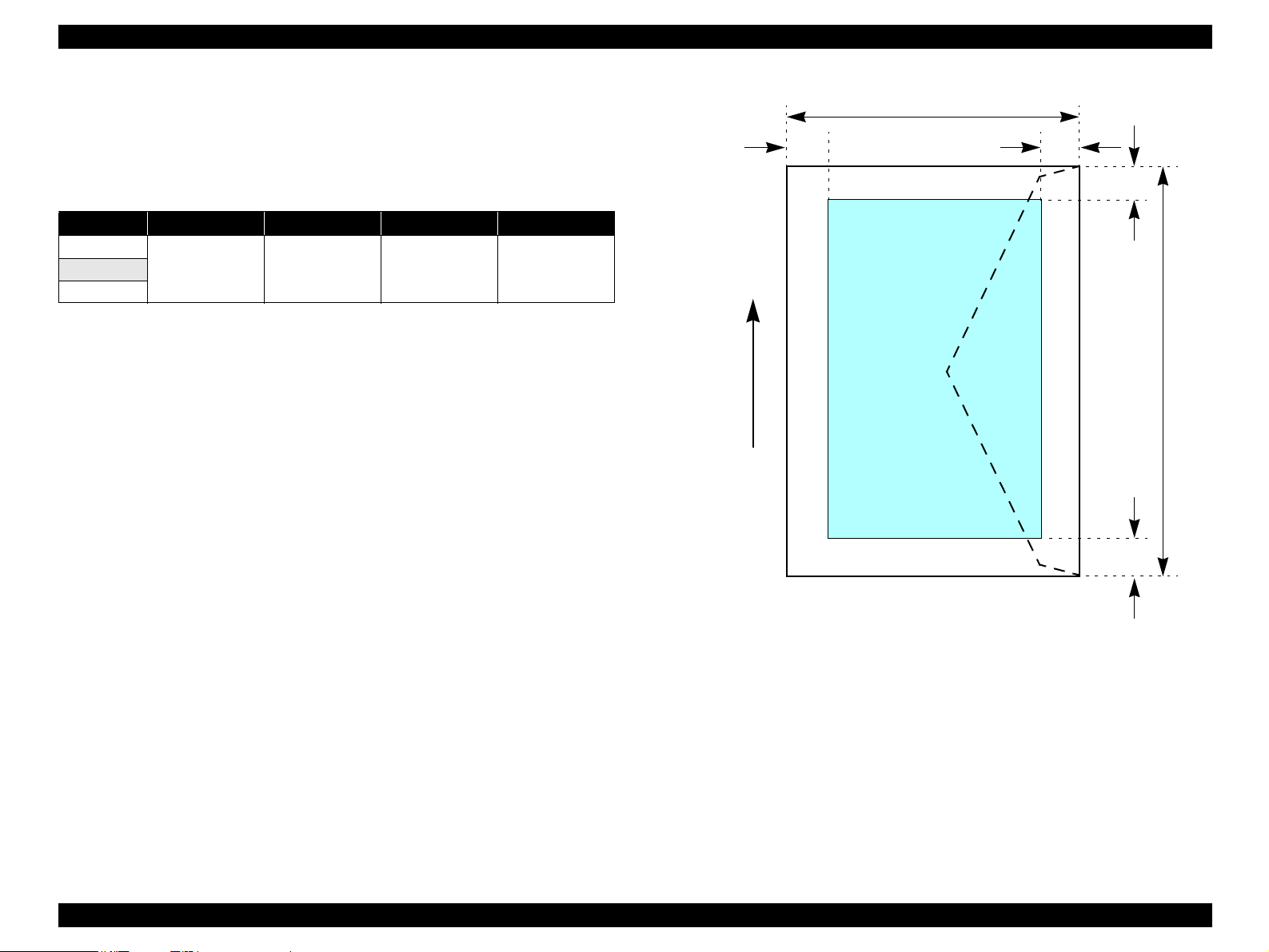

Envelopes

Printable area

For paper width (PW) and paper length (PL), refer to 1.4.1 Paper Support

(p16).

Table 1-13. Applicable Paper/Printing Area

Paper type LM RM TM BM

#10

3 mm 3 mm 3 mm 20 mmDL

C6

PW

LM

RM

TM

Printable area

PL

Paper Feed Direction

BM

Figure 1-6. Printable Area for Envelopes

PRODUCT DESCRIPTION Paper 19

Page 20

EPSON Stylus C87/C88/D88 Revision A

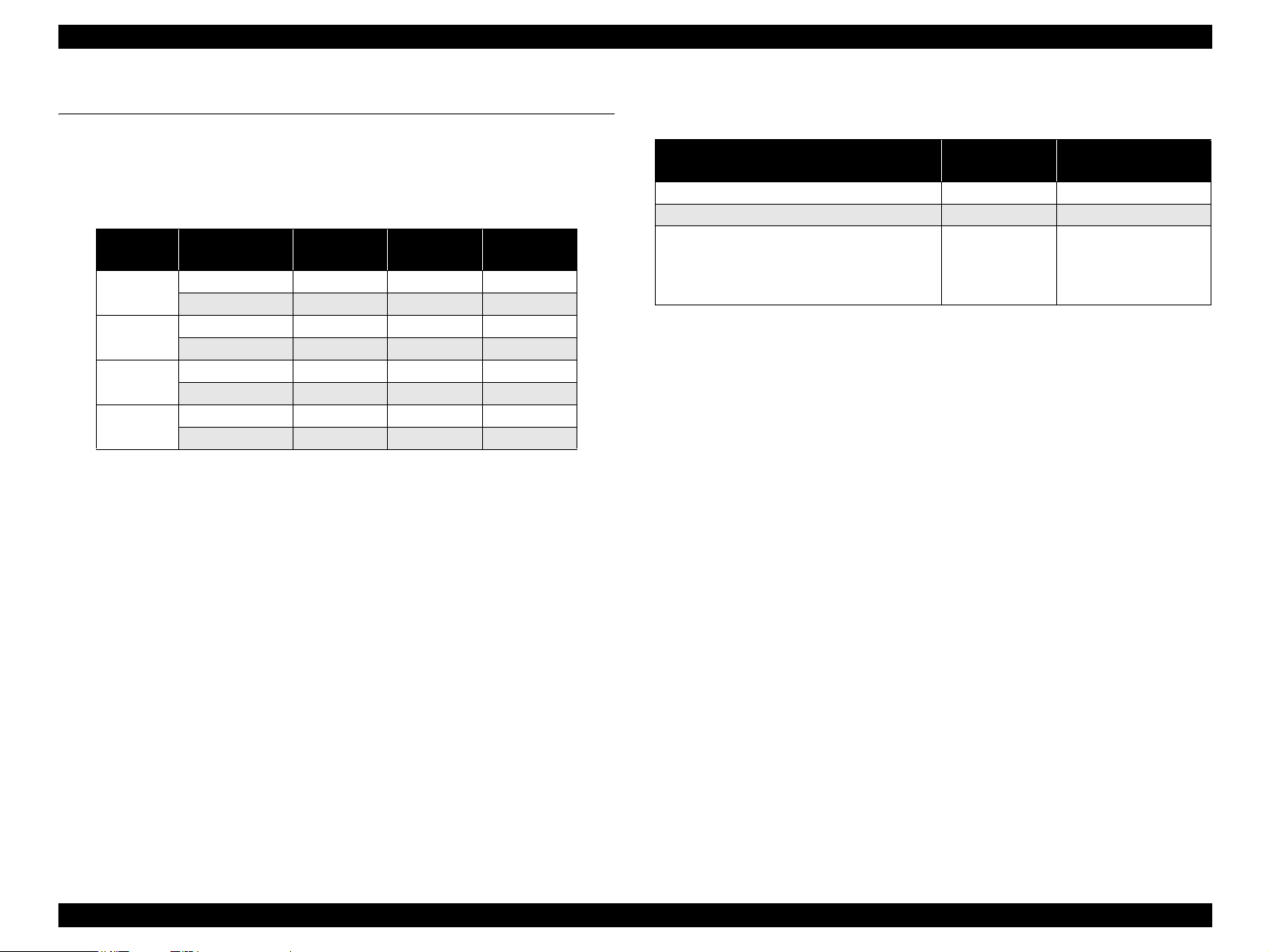

Cut sheet (border-free printing)

Printable area

For paper width (PW) and paper length (PL), refer to 1.4.1 Paper Support

(p16).

Table 1-14. Applicable Paper/Printing Area

Paper type Size LO RO TO BO

Photo Paper

Premium Glossy Photo Paper

Premium Semigloss Photo Paper

Matte Paper-Heavyweight

Exclusive papers

Double-sided Matte Paper

Economy Photo Paper A4 2.54 2.54 2.96 4.02

Glossy Photo Paper Letter 2.54 2.54 2.96 4.02

Premium Glossy Photo Paper (RC-X) 4” x 6” 2.54 2.54 1.34 2.54

Ultra Premium Glossy Photo Paper

Ultra Glossy Photo Paper

A4 2.54 2.54 2.96 4.02

4” x 6” 2.54 2.54 1.34 2.54

Letter 2.54 2.54 2.96 4.02

A4 2.54 2.54 2.96 4.02

8” x 10” 2.54 2.54 2.96 4.02

5” x 7” 2.54 2.54 2.96 4.02

4” x 6” 2.54 2.54 1.34 2.54

3R 2.54 2.54 1.34 2.54

Letter 2.54 2.54 2.96 4.02

A4 2.54 2.54 2.96 4.02

4” x 6” 2.54 2.54 1.34 2.54

Letter 2.54 2.54 2.96 4.02

A4 2.54 2.54 2.96 4.02

Letter 2.54 2.54 2.96 4.02

A4 2.54 2.54 2.96 4.02

Letter 2.54 2.54 2.96 4.02

A4 2.54 2.54 2.96 4.02

8” x 10” 2.54 2.54 2.96 4.02

5” x 7” 2.54 2.54 2.96 4.02

4” x 6” 2.54 2.54 1.34 2.54

LO ROPW

Paper size

Paper Feed Direction

Printable area

Figure 1-7. Printable Area for Cut Sheet (Border-free Printing)

TO

PL

BO

PRODUCT DESCRIPTION Paper 20

Page 21

EPSON Stylus C87/C88/D88 Revision A

1.5 Ink Cartridge

1.5.1 Ink Cartridge Specification

Type/Color: Separate ink cartridges for each color

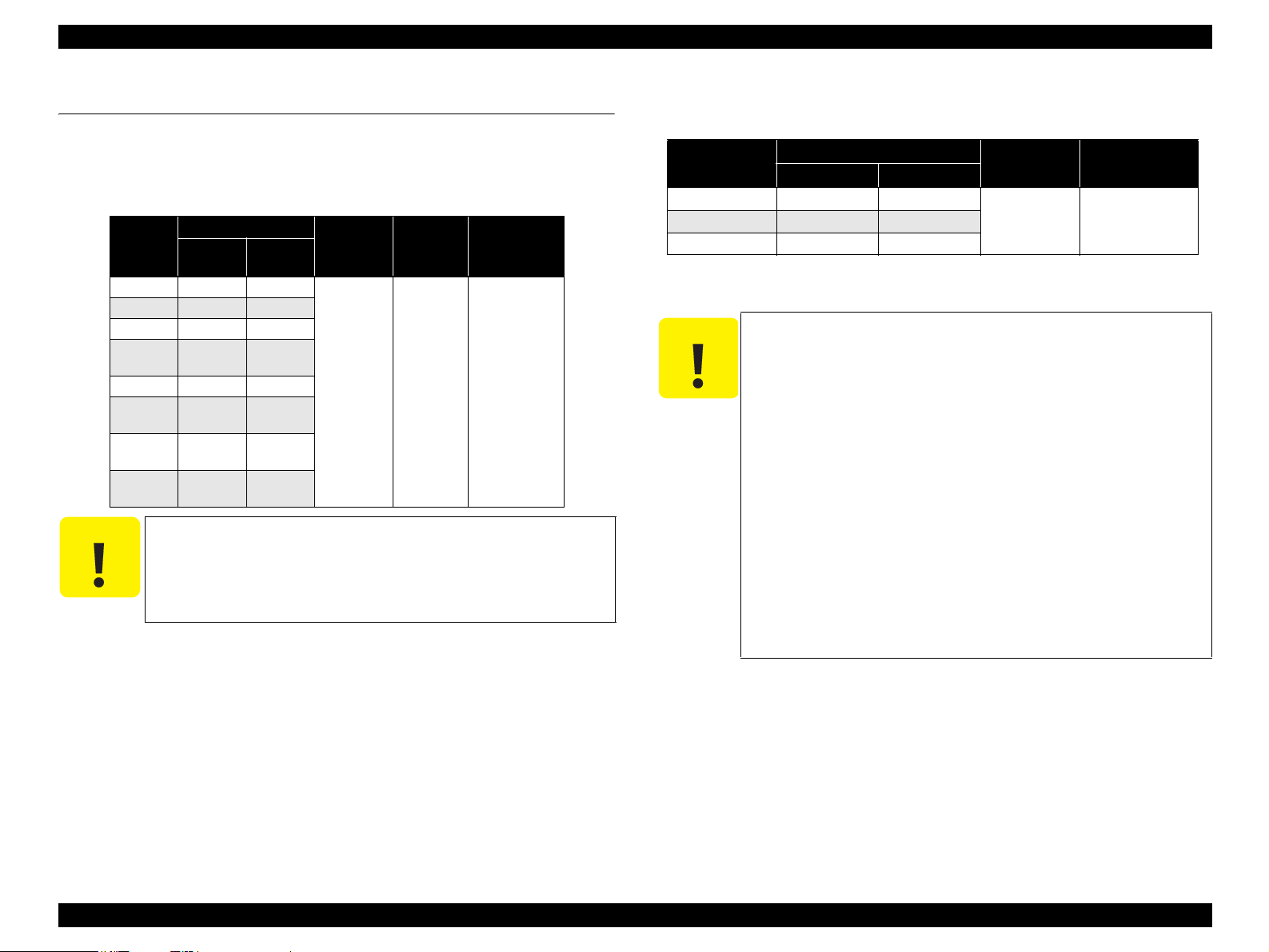

Table 1-15. Ink Cartridge

Color Size EAI

Black

Cyan

Magenta

Yellow

Ink life:

Black ink cartridge

Print capacity

SS Size --- T0631 T0611

S Size T0601 T0621 T0641

SS Size --- T0632 T0612

S Size T0602 --- ---

SS Size --- T0633 T0613

S Size T0603 --- ---

SS Size --- T0634 T0614

S Size T0604 --- ---

S size: 430 pages /A4 (360 dpi, 5% duty each color)

SS size: 250 pages /A4 (360 dpi, 5% duty each color)

Latin/Asia/

Pac

EUR

Storage temperature

Table 1-16. Storage Temperature

Situation

When transported in individual boxes -30°C ~ 50°C Within 10 days at 50°C

When stored in individual boxes -30°C ~ 40°C Within 1 month at 40°C

When installed in main unit -20°C ~ 40°C Within 1 month at 40°C

Storage

temperature

Limit

Temperature difference

should be less than 45°C

in this period.

Color ink cartridge

Print capacity

S size: 470 pages /A4 (360 dpi, 5% duty each color)

SS size: 280 pages /A4 (360 dpi, 5% duty each color)

Expiration date: Two years

(include both the time interval that the ink cartridge is

unopened and the period after it is unpacked)

PRODUCT DESCRIPTION Ink Cartridge 21

Page 22

EPSON Stylus C87/C88/D88 Revision A

Dimension: 12.7 mm (W) x 73.46 mm (D) x 55.25 mm (H)

12.7mm

Base View

73.46mm

Figure 1-8. Ink Cartridge

C A U T I O N

Ink cartridge can not re-fill, only ink cartridge is prepared for

article of consumption.

Do not use the ink cartridge which has expired.

Ink will be frozen under -16 °C environment, however it will be

usable after placing it more than three hours at room

temperature.

PRODUCT DESCRIPTION Ink Cartridge 22

Page 23

OPERATING PRINCIPLES

CHAPTER

2

Page 24

EPSON Stylus C87/C88/D88 Revision A

2.1 Overview

This section describes the operating principles of the printer mechanism and electrical

circuit boards.

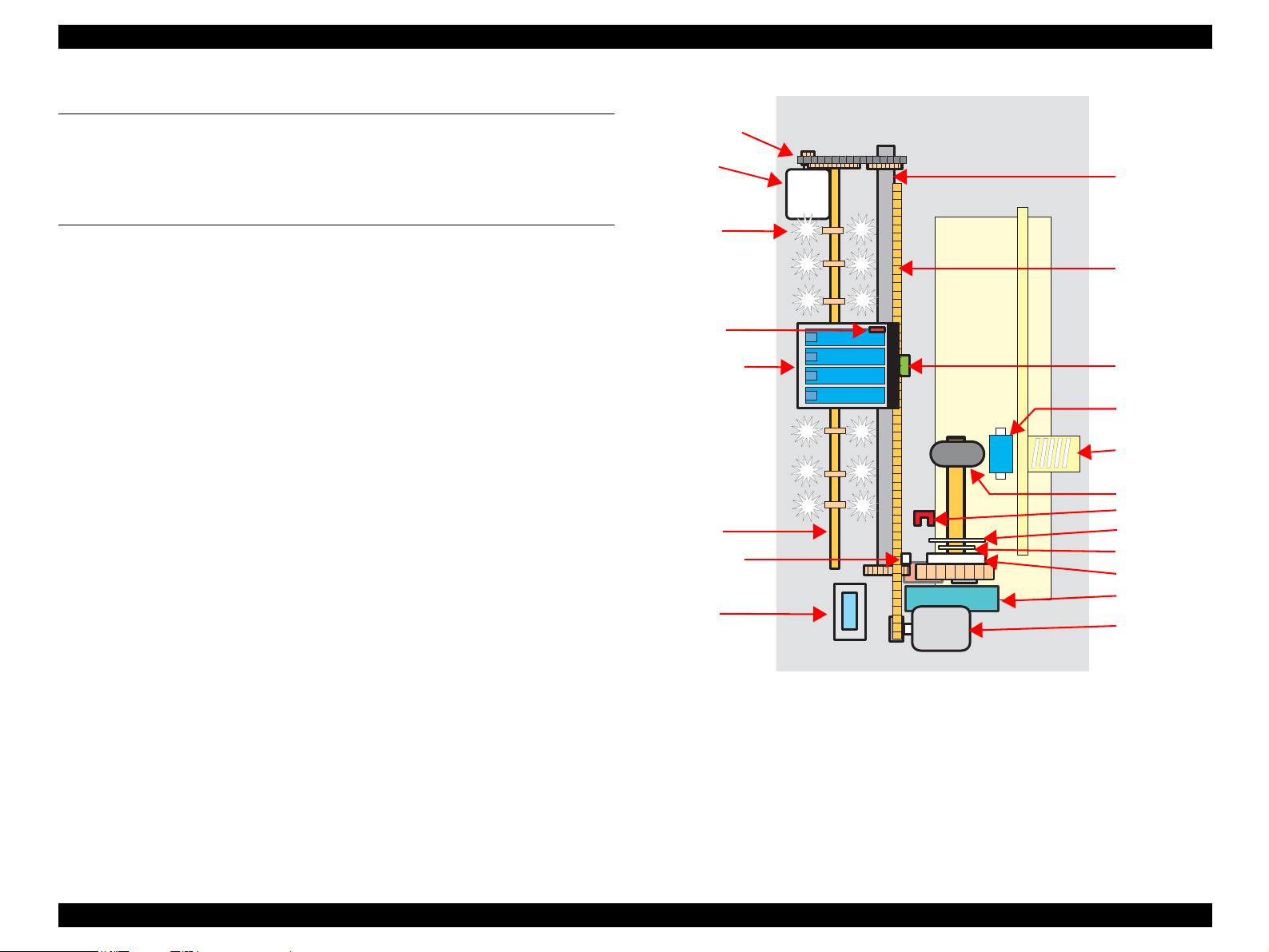

2.2 Printer Mechanism

Printer mechanism of Stylus C87/C88/D88 consists of printhead, carriage mechanism,

paper loading mechanism, paper feeding mechanism, and ink system.

As in the case of conventional models, Stylus C87/C88/D88 has two DC motors; one is

for paper loading/feeding mechanism and the pump mechanism, and the other is for

carriage mechanism.

Papers are fed from the backside and ejected from the front side of the printer.

Paper feeding mechanism, which is also similar to conventional models, feeds papers

using the LD roller and the retard roller.

PF timing belt

PF motor

Star wheel

rollers

PW sensor

Carriage unit

Paper eject

roller

Change lever

Cap unit

PF roller

CR timing belt

CR encoder

sensor

Retard roller

Compression

spring

LD roller

PE sensor

Cam, large

Cam, small

Clutch

Pump unit

CR motor

Figure 2-1. Printer Mechanism Outline

OPERATING PRINCIPLES Overview 24

Page 25

EPSON Stylus C87/C88/D88 Revision A

2.2.1 Printhead Specifications

This printer employs P-Match type printhead, which enables the product to perform

both the variable dot printing and the economy dot printing.

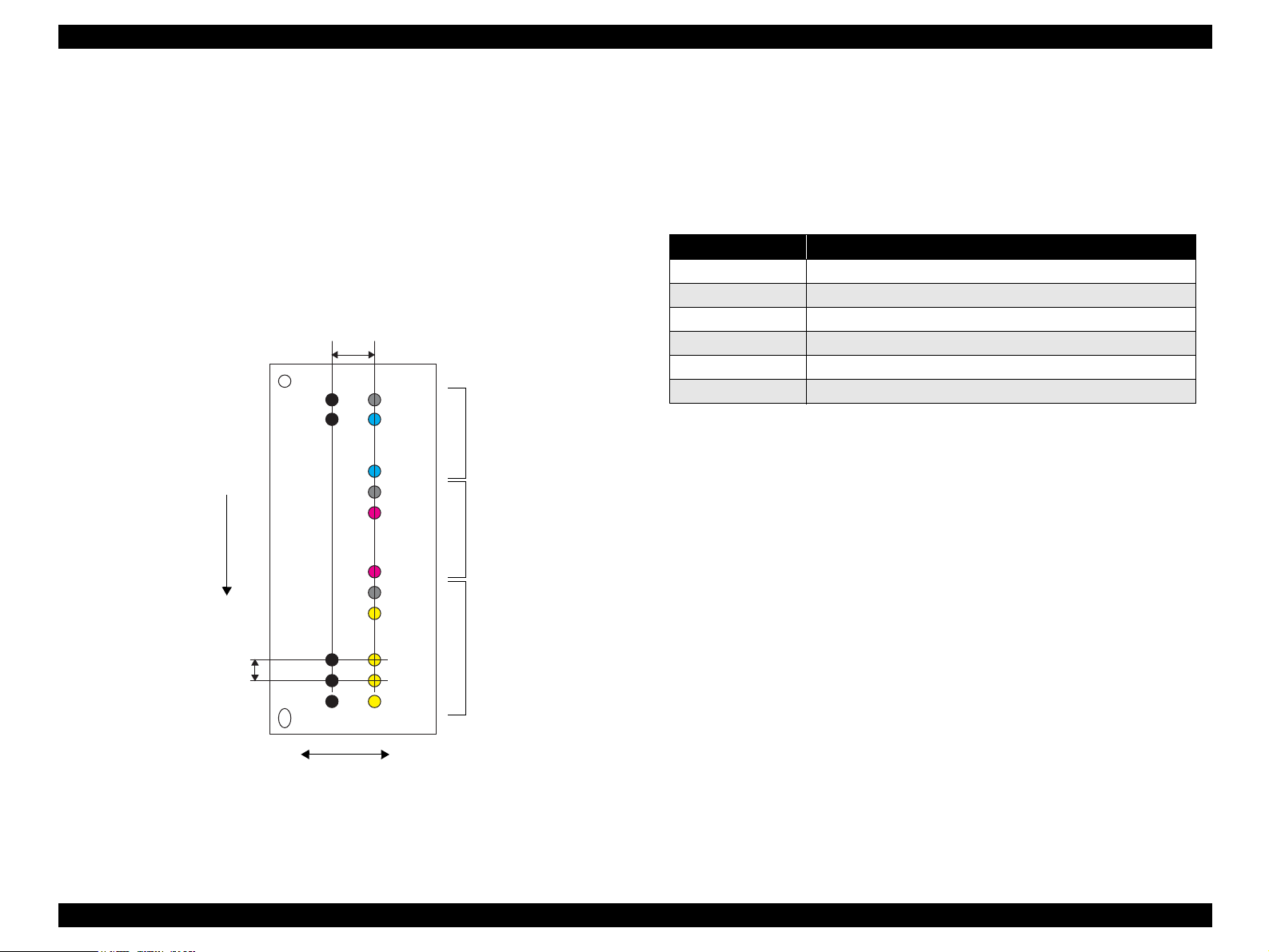

Nozzle configuration

Monochrome: 180 nozzles

Color: 59 nozzles x 3 rows/color (Cyan, Magenta, Yellow)

The following shows the arrangement of the nozzles and the color arrangement of each

nozzle line when viewed the printhead from behind.

2.258mm

(32/360 inch)

C#60K#180

K#179

Paper Loading Direction

C#59

Cyan: 59nozzles

C#1

M#60

M#59

Magenta: 59nozzles

2.2.2 Carriage Mechanism

Main components of the carriage mechanism are carriage unit (including printhead,

CR encoder sensor, PW sensor), CR motor, timing belt, and CR scale.

2.2.2.1 CR Motor Specifications

Table 2-1. CR Motor Specifications

Item

Type Motor with DC brush

Drive voltage +42 V ± 5% (applied voltage to the driver)

Electric resistance 22.65 Ω ± 10%

Inductance 17.3 mH ± 25%

Drive method PWM, constant-current chopping

Drive IC A6615

Specification

M#1

Color

Y#60

Y#59

Y#3

Y#2

Y#1

Yellow: 59nozzles

0.1411mm

(1/180 inch)

Black

K#3

K#2

K#1

Carriage Moving Direction

Figure 2-2. Nozzle Rear View

NOTE: #60 nozzles of each color are not used for printing, but for flushing.

OPERATING PRINCIPLES Printer Mechanism 25

Page 26

EPSON Stylus C87/C88/D88 Revision A

2.2.3 Paper Loading/Feeding Mechanism

Paper loading/feeding mechanism consist of switching lever inside the ink system,

holder shaft unit (including clutch mechanism), and ASF unit.

Switching lever and clutch mechanism play an important role in paper loading

mechanism. Refer to 2.2.3.2 Drive Process (p26) for details.

2.2.3.1 PF Motor Specifications (For both ASF and Pump motor)

Table 2-2. PF Motor Specification

Item Specification

Type 4-phase, 200-pole HB stepping motor

Drive voltage +42 V ± 5 % (applied voltage to the driver)

Wire wound

resistance

Inductance 3.5 mH ± 20% (1KH, 1Vrms)

Drive method

Drive IC A6628

2-2 phase, 1-2 phase, W1-2, 2W1-2, 4W1-2 phase constant-current drive

3.0 Ω ± 10% (per one phase at 25 °C)

Bipolar drive

2.2.3.2 Drive Process

1. Drive of the PF motor is transmitted to the paper eject roller and the PF roller via

the PF timing belt, however, it is not transmitted to the LD roller and the retard

roller owing to the clutch of the holder shaft unit.

2. The carriage unit moves to the ASF trigger position once the paper loading

command is received.

3. PF motor is rotated counter clockwise, and the clutch is released by the change

lever.

4. After the clutch is released, the PF motor rotates clockwise. Drive is transmitted to

the LD roller and the paper loading operation begins.

5. During paper loading operation, papers are fed from the ASF unit to inside the

printer by the rotating movement of the two cams of the LD roller.

Cam, large: releases hopper

Cam, small: releases paper back lever

6. Once a sheet of paper is fed, the hopper and the paper back lever bring back rest of

the papers to the position in readiness by the rotating movement of the two cams

mentioned above.

7. When the LD roller is turned a full circle, the change lever release the clutch and

the drive to the LD roller is interfered.

OPERATING PRINCIPLES Printer Mechanism 26

Page 27

EPSON Stylus C87/C88/D88 Revision A

2.2.4 Ink System Mechanism

The Ink system mechanism consists of pump mechanism and capping mechanism with

wiper mechanism.

2.2.4.1 Pump Unit Mechanism

The PF motor is a source of power to activate the pump unit.

Table 2-3. PF Motor Rotational Direction & Ink System Mechanism

Directions

Counterclockwise

Clockwise

Note *: The PF Motor rotational direction = seen from the left side of the printer.

2.2.4.2 Capping Mechanism

The Capping mechanism covers the printhead with the cap to prevent the nozzle from

increasing viscosity when the printer is in stand-by state or when the printer is off.

*

• Absorbs the ink by the Pump Unit

• Release pump.

Functions

2.3 Electrical Circuit Operating Principles

The electric circuit of the Stylus C87/C88/D88 consists of the following boards.

Main board: C528 MAIN Board

Power supply board: C528 PSB/PSB board

Panel board: C528 PNL board

This section provides block diagram of both C528 MAIN Board and C528 PSB/PSE

Board,C528 PNL board.

C528 PNL Board

Printer Mechanism

CR Motor

PF Motor

C528 Main Board

Head Driver Board

Sensors

CSIC Unit

+42V

C528 PSB/C528 PSE Board

Figure 2-3. Electrical Circuit Block Diagram

PowerOFF

OPERATING PRINCIPLES Electrical Circuit Operating Principles 27

Page 28

EPSON Stylus C87/C88/D88 Revision A

2.3.1 C528 PSH Board

PSH board of Stylus C87/C88/D88 employs ZC-RRC circuit method, and supplies +42

VDC/+5VDC to the drive line.

AC voltage input from AC inlet first goes through filter circuit that removes high

frequency components and is then converted to DC voltage via the rectifier circuit and

the smoothing circuit.

2.3.2 C528 Main Board

The logic circuit of the C528 Main Board is composed of the following;

Logic line (CPU-ASIC 4 in 1, DRAM and so on)

Motor control/drive circuit (CR Motor, PF Motor)

Head control/drive circuit

Parallel interface control circuit

Sensor circuit

Reset circuit

EEPROM circuit

Table 2-4. C528 MAIN Board Major Components and Primary Functions

IC Location Function

Parallel I/F

Controller

Reset Regulator IC1

DRAM IC8

EEPROM IC4 Makes back up of default setting values and parameters.

Motor Driver IC6

Head Driver IC7 Generates trapezoidal waveform, drives 42 V.

ASIC IC10

Transceiver for centronics IF that responds to IEEE1284 and ECP

IC2

or more, data transfer, and 3.3 V drive.

Reset signal is generated under the following conditions.

• Pressure reduction from 42 V line to 35.8 V.

• Pressure reduction from 5 V line to 4.2 V line.

16 Mbit DRAM with 2 CAS-type page access function.

3.3 V drive.

Drives CR/PF motors, controls PWM by the program timer, drives

42 V.

Drives CPU (H8S/2323 base), internal 8 K bit RAM, internal

MASK ROM, 24 Mhz, 3.3 V drive.

Figure 2-4. C528 Main Board Block Diagram

OPERATING PRINCIPLES Electrical Circuit Operating Principles 28

Page 29

TROUBLESHOOTING

ICHAPTER

3

Page 30

EPSON Stylus C87/C88/D88 Revision A

3.1 Overview

This chapter describes how to solve problems.

W A R N I N G

C H E C K

P O I N T

Be careful to avoid electric shocks when checking the electrical

circuit boards (C528 MAIN and C528 PSE boards) while the

power is turned on.

Touching an FET, transistor or heat sink with one hand while

touching a metal part of the mechanism with the other hand

could result in an electric shock, so carefully avoid this.

After initial filling of ink has been repeated several times,

immediate moving or tilting of the printer could result in

leaking of ink that has not been completely absorbed by the

Waste Ink Pad. When initial filling of ink has been repeated

several times, check the ink remaining in the tip of the Waste

Ink Tube and the waste ink not absorbed by the Waste Ink Pad

before moving the printer.

Disassembly and reassembly of parts is often required when

identifying the causes of problems. The parts should be

disassembled and re-assembled correctly while referring to

Chapter 4 “DISASSEMBLY/ASSEMBLY” (p.36) so that the

operation and status of each check item can be correctly

verified.

Some individual part and units may require adjustment once

they are removed or replaced. If removing or replacing parts

which have specific instructions for adjustment included in

Chapter 4 “DISASSEMBLY/ASSEMBLY” (p.36), be sure to

make these adjustments after repairing the problem location.

3.1.2 Preliminary Checks

Before starting troubleshooting, be sure to verify that the following conditions

are all met:

The power supply voltage must be within the specification limits. (Measure the

voltage at the wall socket.)

The power code must be free from damage, short circuit or breakage, or miswiring

in the power code.

The printer must be grounded properly.

The printer should not be located in a place where it can be exposed to too high or

low temperature, too high or low humidity, or abrupt temperature change.

The printer should not be located near waterworks, near humidifiers, near heaters

or near flames, in a dusty atmosphere or in a place where the printer can be

exposed to blast from an air conditioner.

The printer should not be located in a place where volatile or inflammable gases

are produced.

The printer should not be located in a place where it can be exposed to direct rays

of the sun.

The printer must be located in a well-ventilated place.

The printer must be placed on a strong and steady level table (without an

inclination larger than five degrees).

The paper used must conform to the specification.

There is no error in handling of the printer.

Check the inside of the printer, and remove foreign matters if any, such as paper

clips, staples, bits of paper, paper dust or toner.

3.1.1 Specified Tools

This printer does not require any specified tools for troubleshooting.

Clean the inside of the printer and the rubber rolls.

TROUBLESHOOTING Overview 30

Page 31

EPSON Stylus C87/C88/D88 Revision A

3.2 Troubleshooting With LED Error Indications

LED error display, cause, and remedy are explained here.

Table 3-1. Troubleshooting With LED Error Indications

Error

Ink end/ No ink cartridge/

CSIC error

Paper Out

Multi-feed error

Power Paper Ink

--- --- On

--- On ---

--- On ---

LED status

Cause Remedy

• Ink inside Bk, Y, M, C ink cartridges has run out.

• Ink cartridge(s) is not installed.

• Non-genuine ink cartridge(s) is installed.

• Paper loading operation is executed when there is no paper.

• Papers stopped before the PE Sensor or could not be fed.

• Papers are fed without being placed against the right edge

guide.

• Connector of the PE sensor is disconnected.

• When performing duplex printing, blank paper is ejected.

• The printer detected that the paper is too long upon ejection.

• Check the ink cartridge(s) and reinstall it correctly.

• Replace the ink cartridge(s) with a genuine one.

• If there is a possibility of CSIC error, see

3.3 Troubleshooting for Motors and Sensors (p35).

1. If there is no paper on the paper tray, load papers.

2. If the paper has stopped halfway, remove the paper,

check if the paper is not bent, fan the paper, and load

it against the edge guide.

3. Press the [Paper] switch to release the error.

1. Remove the blank paper, or check the paper size.

2. Press the [Paper] switch to eject the paper and release

the error.

TROUBLESHOOTING Troubleshooting With LED Error Indications 31

Page 32

EPSON Stylus C87/C88/D88 Revision A

Table 3-1. Troubleshooting With LED Error Indications

Error

Paper jam

Maintenance request

(Waste ink overflow)

Fatal error

Power Paper Ink

--- Flashes ---

Off

Off

LED status

Flashes

alternately

Flashes on

high speed

Flashes

alternately

Flashes on

high speed

Cause Remedy

Even though paper feeding operation is carried out for

predetermined times, leading edge or back-end of the paper

could not be detected.

As a result of cleaning and flushing, total emission of ink has

exceeded the specific level.

• Home position of the carriage could not be detected.

• Abnormal external pressure is applied to the printer when

the power is on.

• Carriage movement is interfered during printing.

1. Press the [Paper] switch on the panel.

2. If paper jam occurred again after pressing the switch,

open the printer cover and remove all the papers

inside the printer and papers set on the hopper.

3. Making sure there is no paper inside the printer, load

paper on the hopper and press [Paper].

Replace the waste ink pad, and reset the waste ink

counter (protection counter A) using the adjustment

program. Refer to Chapter 6 “MAINTENANCE”

(p.92) for details.

1. Turn the power off, wait for a few seconds, and turn

the power back on again.

2. If the fatal error still appears, turn the power off,

remove the papers on the hopper, and check the

following:

• Open the printer cover, check the ink cartridges, and

reinstall them correctly.

• Check is there is no foreign material or papers inside

the printer. If there is any, remove them.

3. Turn the printer power on.

4. If the fatal error appears again, refer to 3.2.1 Fatal

Error (p33) and examine/replace the parts.

TROUBLESHOOTING Troubleshooting With LED Error Indications 32

Page 33

EPSON Stylus C87/C88/D88 Revision A

3.2.1 Fatal Error

C H E C K

P O I N T

As the most recent fatal error (fatal error code) is stored in the

EEPROM (Address: 0AH), it is possible to check the error by using

the adjustment program.

Check the parts according to the contents of the fatal error, and replace the parts as necessary.

Classification Item Description Remedy

DC Error PID aveTi max Error Something is wrong with the CR motor. Check the parts listed below, and replace them as necessary.

PID Overspeed Error Carriage movement speed is abnormal.

PID Lock Error Carriage has been locked for a certain period of time due to

PID Reverse Rotation Detection Error The number of the carriage reverse rotation has exceeded the

Encoder Abnormality Error (CR Driving

Time Over Error)

Load Positioning Overspeed Error Abnormal carriage movement speed is detected during load

Load Positioning Lock Error It is detected that the carriage has been locked for a certain

Load Positioning Cumulative Movement

Distance Error

Head Error Transistor Environment Temperature

Abnormality Error

Pre-printing X-HOT Detection Error During pre-printing X-Hot detection, the temperature of the

Post-flushing X-HOT Detection Error During post-printing X-Hot detection, the temperature of the

external factors.

predetermined times due to external factors.

One-pass movement cannot be completed though the CR

motor has been driving longer than the specified time.

positioning control.

period of time during load positioning control.

The cumulative movement distance during the load

positioning control has exceeded the given level

The environment temperature of the transistor that generates

head driving waveform on the Main board is abnormal.

head driver IC has exceeded the given level for more than two

seconds.

head driver IC has exceeded the given level for more than two

seconds.

• CR Motor

• CR Encoder

• CR Encoder Scale

• Timing Belt

•Main Board

• Connectors and harnesses of each motor or encoder

Check the parts listed below, and replace them as necessary.

• Printhead

• Head FFC

•Main Board

TROUBLESHOOTING Troubleshooting With LED Error Indications 33

Page 34

EPSON Stylus C87/C88/D88 Revision A

Classification Item Description Remedy

Sequence Error Left Frame Shock Detection Error Abnormal pressure has being added to the carriage due to

Between Left Frame and [TF] Shock

Detection Error

Between [TF] and [HOME] Shock

Detection Error

external factors.

Make sure that there is no obstruction on the carriage moving

path, check the parts listed below, and replace them as necessary.

• CR Motor

• CR Encoder

• CR Encoder Scale

• Timing Belt

•Main Board

TROUBLESHOOTING Troubleshooting With LED Error Indications 34

Page 35

EPSON Stylus C87/C88/D88 Revision A

3.3 Troubleshooting for Motors and Sensors

Motor

Table 3-2. Motor Resistance and Check Points

Motor name Type Location

CR motor Motor with DC brush CN5 Pin 1&3 22.65 Ω ± 10%

PF motor 4-phase, 200-pole HB stepping

motor

CN6 Pin 1&3

Check

point

Pin 2&4

Resistance

3.0 Ω ± 10%

Sensor

Table 3-3. Sensor Check

Sensor name Detecting system Location Signal level Sensor status

PE sensor Transmission photo

interrupter

PW sensor Reflective photo

interrupter

CN9 pin 1&2 2.4 V or more Paper loaded

0.4 V or less No paper

T.B.D Low Low: Paper loaded

High High: No paper

TROUBLESHOOTING Troubleshooting for Motors and Sensors 35

Page 36

DISASSEMBLY/ASSEMBLY

CHAPTER

4

Page 37

EPSON Stylus C87/C88/D88 Revision A

4.1 Overview

This section describes procedures for disassembling the main components of the

product. Unless otherwise specified, disassembled units or components can be

reassembled by reversing the disassembly procedure.

Procedures which, if not strictly observed, could result in personal injury are described

under the heading “WARNING”.

“CAUTION” signals a precaution which, if ignored, could result in damage to

equipment.

Important tips for procedures are described under the heading “CHECK POINT”.

If the assembly procedure is different from the reversed disassembly procedure, the

correct procedure is described under the heading “REASSEMBLY”.

Any adjustments required after reassembly of components or parts are described under

the heading “ADJUSTMENT REQUIRED”.

When you have to remove any components or parts that are not described in this

chapter, refer to the exploded diagrams in the appendix.

4.1.1 Precautions

See the precautions given under the handling “WARNING” and “CAUTION” in the

following columns when disassembling or assembling EPSON Stylus C87/C88/D88.

W A R N I N G

Disconnect the power cable before disassembling or assembling

the printer. If you need to work on the printer with power

applied, strictly follow the instructions in this manual.

Always wear gloves for disassembly and reassembly to avoid

injury from sharp metal edges.

To protect sensitive microprocessors and circuitry, use static

discharge equipment, such as anti-static wrist straps, when

accessing internal components.

C A U T I O N

Make sure that there is enough work space for disassembly/

reassembly.

Use only recommended tools for disassembling, assembling or

adjusting the printer.

Observe the specified torque when tightening screws.

Apply lubricants as specified.

(See Chapter 6 “Lubrication” (p.95) for details.)

The pictures of the product in this manual are of prototype

model. There may be differences in configurations or colors

compared to the actual model, however, it has no effect on

dissasembly/assembly.

When using compressed air products; such as air duster, for

cleaning during repair and maintenance, the use of such

products containing flammable gas is prohibited.

4.1.2 Tools

Use only specified tools to avoid damaging the printer.

Table 4-1. Tools

Name Supplier Parts No.

(+) Phillips screwdriver #0

(+) Phillips screwdriver #1

Flathead screwdriver

Tweezer

Longnose pilers

Hexagonal Box Driver [B741700100]

EPSON 1080531

EPSON 1080530

EPSON 1080527

EPSON 1080561

EPSON 1080564

EPSON

1080584

DISASSEMBLY/ASSEMBLY Overview 37

Page 38

EPSON Stylus C87/C88/D88 Revision A

4.1.3 Screws (T.B.D)

Screws used on the Stylus C87/C88/D88 are shown below.

Table 4-2. Screws

No. Image Name Type

C.B.S. 3 x 6 C.B.S-TITE SCREW

1

C.B.S. 3x 10 C.B.S-TITE SCREW

2

C.B.S. 3 x 14 C.B.S-TITE SCREW

3

C.B.S.(P4) 3 x 6 C.B.S-TITE (P4) SCREW

4

C.B.P. 2.5 x 8 C.B.P-TITE SCREW

5

Table 4-2. Screws

No. Image Name Type

C.P. 3 x 4 C.P. SCREW

8

C.P.B. (P1) 1.7 x 5 T.B.D

9

Hexagon nut, normal, M3 T.B.D

10

C.B.P. 3 x 8 C.B.P-TITE SCREW

6

C.B.P. (P2) 3 x 8 C.B.P-TITE (P2) SCREW

7

DISASSEMBLY/ASSEMBLY Overview 38

Page 39

EPSON Stylus C87/C88/D88 Revision A

4.1.4 Work Completion Check

If any service is made to the printer, use the checklist shown below to confirm all

works are completed properly and the printer is ready to be returned to the user.

Table 4-3. Work Completion Check

Classification Item Check Point Status

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Main Unit

Adjustment

Lubrication

Self-test Is the operation normal?

ON-line Test Is the printing successful

Printhead

Carriage

Mechanism

Paper Feeding

Mchanism

Specified

Adjustment

Specified

Lubrication

Is ink discharged normally from all

the nozzles?

Does it move smoothly?

Is there any abnormal noise during its

operation?

Is there any dirt or foreign objects on

the CR Guide Shaft?

Is the CR Motor at the correct

temperature? (Not too hot to touch?)

Is paper advanced smoothly?

No paper jamming?

No paper skew?

No multiple feeding?

No abnormal noise?

Is the PF Motor at correct

temperature?

Is the paper path free of any

obstructions?

Are all the adjustment done correctly?

Are all the lubrication made at the

specified points?

Is the amount of lubrication correct?

Table 4-3. Work Completion Check

Classification Item Check Point Status

Function ROM Version Version:

Are the ink cartridges installed

correctly?

Have all relevant protective materials

been attached to the printer?

Have all the relevant items been

included in the package?

Packing

Others

Ink Cartridge

Protective

materials

Attachments,

Accessories

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

Checked

Not necessary

DISASSEMBLY/ASSEMBLY Overview 39

Page 40

EPSON Stylus C87/C88/D88 Revision A

4.2 Caution regarding Assembling/Disassembling

of the Printer Mechanism, and How to Ensure of

Quality on Re-assembled Product

On current low end models, we’ve basically forbidden to remove Housing, Lower from

Printer mechanism in your repair. This is because there is a possibility of main frame

deformation when a part (such as Ink system) is removed from Printer mechanism

without Housing, Lower.

For this reason, if you want to replace Ink system/PF motor, we recommend to replace

with new Printer mechanism with Housing, Lower. On these models, you have to

remove Housing, Lower from printer mechanism when replacing Waste Ink Pad with a

new one.

Therefore, we clarify caution regarding assembling/disassembling of the printer

mechanism without Housing, Lower, and how to ensure of quality on repaired products

in this section.

[Caution regarding assembling/disassembling of the printer mechanism]

1) Main frame

(a) Control of assembled standard position.

[Reason]

The assembled accuracy of each part composed of Printer mechanism is based

on Housing, Lower.

[Service treatment]

Confirm that there is no gap between main frame and Housing, Lower.

[Reference]

To ensure the assembled accuracy, you have to control the assembled

standard position of main frame against X/Y/Z-axis direction.

[X-axis direction]

- Make sure that main frame is correctly placed on the groove of Housing,

Lower.

- Make sure that there is no gap between main frame and Housing, Lower.

[Y-axis direction]

Make sure that cut-out portion of main frame is correctly placed on the square

protrusion of Housing, Lower.

[Z-axis direction]

- Make sure that there is no gap between main frame and Housing, Lower.

- Make sure that the left side of Printer mechanism is correctly fixed by two

tabs.

(b) Control of vertical level of guide rail (Guide rail means the portion latched by

hooks of IC holder & Print head assy.)

[Reason]

There is a possibility that printing failure/operation failure occurs by guide

rail deformation.

[Service treatment]

- Do not remove [Mounting Plate, M/B] from Printer mechanism.

- Hold up the specified position of main frame to avoid the deformation.

(c) How to assemble of ASF unit/Circuit board/Paper guide upper

[Reason]

There is a possibility that main frame deformation is caused extra force in

assembling. As the result, printing failure/operation failure occurs.

[Service treatment]

Hold the opposite side with hand while you are installing the above parts.

DISASSEMBLY/ASSEMBLY Caution regarding Assembling/Disassembling of the Printer Mechanism, and How to Ensure of Quality on Re-assembled

Page 41

EPSON Stylus C87/C88/D88 Revision A

2) Front frame

(a) Control of vertical level

[Reason]

There is a possibility that printing failure occurs by front frame deformation.

[Service treatment]

Handle Front frame in assembling/disassembling carefully.

3) IC holder

(a) Handling of IC holder

[Reason]

If IC holder is damaged in assembling/disassembling of your repair, there is a

possibility that vital problem occurs in user’s further operation.

[Service treatment]

Released two hooks of IC holder from the inside of IC holder by the tweezer.

[How to ensure of quality on re-assembled product]

We judge that the quality of re-assembled product is ensured if there is no

problem about the print result by adjustment program.

DISASSEMBLY/ASSEMBLY Caution regarding Assembling/Disassembling of the Printer Mechanism, and How to Ensure of Quality on Re-assembled

Page 42

EPSON Stylus C87/C88/D88 Revision A

4.3 Dissasembly Procedures

This section explains the procedures for disassembling the product.

Unless otherwise stated, reassembly should be carried out in the reverse order of the disassembly procedure.

For detailed engagement relations among main components, refer to the exploded diagrams in the Appendix.

When disassembling each unit, refer to the pages described in the chart below.

START

“ Housing, Left (p44)”

“ Stacker Assy. (p47)”

“ Housing, Upper Assy

(p47)”

“ ASF Unit (p48)”

“ Housing, Right (p45)”

“ CR Timing Belt (p66)”

“ CR Motor (p67)”

“ Front Frame (p68)”

“ Eject Roller (p75)”

“ Paper Guide, Front Assy.

(p76)”

“ CR Encoder

Scale (p69)”

“ CR Cable Head Cover

(p70)”

“ Paper Guide, Upper

Assy. (p75)”

Figure 4-1. Disassembling Flowchart (1)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 42

Page 43

EPSON Stylus C87/C88/D88 Revision A

* Procedure in the broken-line is NOT the shortest

START

“ ASF Unit (p48)”

removing procedure, but the passing point for the

next removing procedure.

“ Hopper/Retard Roller

Unit (p49)”

“ Holder Shaft Unit

(p62)”

“ Main Board (p57)”

“ PS Board (p61)”

“ Front Frame (p68)”

“ Eject Roller (p75)”

“ Paper Guide, Front Assy.

(p76)”

“ Housing, Lower Assy.

(p51)”

“ Waste Ink Pad (p55)”

“ Panel Board (p60)”

“ Holder Shaft Unit

(p62)”

“ Spool Gear 36.8/Extension

Spring 0.143/Clutch (p64)”

“ PE Sensor Board/PE

Detection Lever/Idle Roller

(p65)”

“ Printhead Assy. (p72)”

“ PF Motor (p79)”

“ Front Frame (p68)”

“ CR Encoder Scale (p69)”

“ CR Cable Head Cover

(p70)”

“ CR Unit (p70)”

“ PW Sensor Board

(p73)”

“ CR Encoder Sensor

Board (p73)”

“ CSIC Board (p74)”

“ Pump Unit/Cap Unit

(p78)”

Figure 4-2. Disassembling Procedure (2)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 43

Page 44

EPSON Stylus C87/C88/D88 Revision A

4.3.1 Removing Housings

C A U T I O N

4.3.1.1 Housing, Left

1) Insert a ruler or a similar tool to the notch on the bottom of the main unit to

Do not damage the tabs in removing the Housings.

Do not tilt the printer too much when removing the Housings

because ink may flow if the Carriage unit is not at the home

position.

release the tab of the I/F cover, and remove the I/F cover.

Bottom

Convex Portion

Housing, Right

Notch

Tab and Stopper

2) Insert a flathead driver or a similar tool to the notch on the backside of the

main unit, and release the tab.

Backside

Tab and Notch

Figure 4-4. Removing Housing, Left (2)

Inside

I/F Cover

Tab

Notch

Figure 4-3. Removing Housing, Left (1)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 44

Page 45

EPSON Stylus C87/C88/D88 Revision A

3) Release the tab on the bottom of the main unit from the stopper.

4) Open the cover of the Housing, Upper Assy, release the two tabs, and remove the Housing, Left.

Cover

Opening

Housing, Left

Tabs

Inside

Tabs

Notch

4.3.1.2 Housing, Right

1) Insert a flathead screwdriver or a similar tool to the notch on the backside of

the main unit, and release the tab.

Backside

Housing, Right

Tab and Notch

Figure 4-6. Removing Housing, Right (1)

2) Release the two tabs on the bottom of the main unit from the stopper.

Bottom

Notch

Tab

Tab and Stopper

Figure 4-7. Removing Housing, Right (2)

Figure 4-5. Removing Housing, Left (3)

3) Open the cover of the Housing, Upper Assy.

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 45

Page 46

EPSON Stylus C87/C88/D88 Revision A

4) Press the CR lock lever to the rear of the main unit to release the lock, and

move the CR unit to the center of the printer.

CR Unit

CR Lock Lever

Figure 4-8. Releasing CR Lock Lever

5) Release the two tabs and remove the Housing, Right.

Cover

Opening

Housing, Right

Tabs

Inside

Notch

Tabs

Tabs

Figure 4-9. Removing Housing, Right (3)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 46

Page 47

EPSON Stylus C87/C88/D88 Revision A

4.3.1.3 Stacker Assy.

1) Remove the Housing, Left. (p44)

2) Open the Stacker Assy.

3) Push the shaft located on the left side of the Stacker Assy. with a flathead

screwdriver or a similar tool, release the shaft from the slot of the Housing,

Lower, and remove the Stacker Assy.

Stacker Assy.

4.3.1.4 Housing, Upper Assy

1) Remove the Housing, Right. (p45)

2) Remove the Stacker Assy.. (p47)

3) Release the two tabs on the front side of the main unit.

Front Side

Figure 4-11. Removing Housing, Upper Assy. (1)

4) Insert a flathead screwdriver or a similar tool to the notch on the backside of

the main unit, release the three tabs, and remove the Housing, Upper Assy.

Housing, Upper Assy.

Tab

Rear Side

Shaft

Notch and Tab

Figure 4-10. Removing Stacker Assy.

Figure 4-12. Removing Housing, Upper Assy. (2)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 47

Page 48

EPSON Stylus C87/C88/D88 Revision A

4.3.1.5 ASF Unit

1) Remove the Housing, Upper Assy. (p47)

2) Remove the three screws that secure the ASF Unit to the main unit, and remove the ASF unit.

• C.B.S. 3 x 6: 1

• C.B.S. (P4) 3 x 6 1

• C.B.P. 3 x 8: 1

Rear Side

3

ASF Unit

1

When installing the ASF Unit to the main unit, follow the steps

described below.

1. Make sure to match the shaft of the ASF Unit with the bearing of the Pump Unit.

2. Make sure to match the guide pin of the ASF Unit with the positioning hole of the main unit.

3. Secure the screws in the order shown in Figure 4-13.

Guide Pin

2

Shaft

Side of ASF Unit

C.B.P. 3 x 8

(6

±1 kgf.cm )

C.B.S. 3 x 6

(8

±1 kgf.cm)

C.B.S. ( P4) 3 x 6

(8

±1 kgf.cm )

Positioning Hole

and Guide Pin

Shaft and Bearing

Figure 4-14. Installing ASF Unit

Figure 4-13. Removing ASF Unit

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 48

Page 49

EPSON Stylus C87/C88/D88 Revision A

A D J U S T M E N T

R E Q U I R E D

When I/C Holder or Printhead Assy. is removed or replaced

with a new one, the following adjustment must be performed in

the order below.

1) Top Margin Adjustment

2) First Dot Adjustment

3) PF Adjustment

When you replace the ASF unit with a new one, lubricate it as

specified. See Chapter 6 “Lubrication” (p.95) for details.

4.3.1.6 Hopper/Retard Roller Unit

C A U T I O N

1) Remove the ASF Unit. (p48)

2) Lift up the Hopper toward the direction of the arrow, release the two tabs, and

Hopper Side

Do not touch the cork on the Retard Roller and the Hopper.

remove the spring and the hopper from the ASF Frame.

ASF Frame Side

Tab

Shaft

Cork

Hopper

Spring

Retard Roller

Figure 4-15. Removing Hopper

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 49

Page 50

EPSON Stylus C87/C88/D88 Revision A

3) Remove Extension Spring 0.585 from both the ASF Frame and the Paper Back Lever.

4) Remove the Paper Back Lever from the bearing of the ASF frame.

5) Remove Compression Spring 1.88 from the ASF Frame, and remove the Retard Roller Unit.

Extension

Spring 0.585

Compression

Spring 1.88

Paper Back

Lever

ASF Frame

Bearing

When installing the Retard Roller or the Paper Back Lever,

attach the two springs as described below.

• Extension Spring 0.585

Attach the spring to the tab of the ASF Frame and the one

of the Paper Back Lever.

• Compression Spring 1.88

Attach the spring to the boss of the ASF Frame and the one

of the Retard Roller Unit.

Tab

Extension Spring 0.585

Tab

Compression

Spring 1.88

Boss

Figure 4-17. Assembling ASF Frame(1)

When installing the spring between the Hopper and the ASF

Frame, match the spring with the positioning hole (circular

dent) of the Hopper and the one of the ASF Frame.

Retard Roller Unit

Hopper Side

ASF Frame Side

Figure 4-16. Removing Retard Roller Unit

Positioning Hole

Positioning Hole

Figure 4-18. Assembling ASF Frame (2)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 50

Page 51

EPSON Stylus C87/C88/D88 Revision A

4.3.1.7 Housing, Lower Assy.

C A U T I O N

1) Remove the Paper Guide, Front Assy.. (p76)

2) Peel and remove the Right Frame Sheet from the printer mechanism.

Do not remove the Housing, Lower Assy. more than is necessary.

Right Frame Sheet

Double-sided

Tape Location

3) Remove the two rubber feet on the PF Motor side.

Rubber Feet

Figure 4-20. Removing Rubber Feet

C A U T I O N

When removing the Waste Ink Tube from the Waste Ink Pad, pay

attention not to spill the ink.

4) Remove the Waste Ink tube from both the groove of the Housing, Lower Assy and the Waste Ink Pad.

Figure 4-19. Removing Right Frame Sheet

Groove

Waste Ink Tube

Waste Ink Pad

Figure 4-21. Removing Waste Ink Tube

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 51

Page 52

EPSON Stylus C87/C88/D88 Revision A

5) Remove the Cap Unit from the two guide pins of the Housing, Lower Assy.

Guide Pin

É_É{

É_É{

Guide Pin

6) Remove the four screws that secure the Printer Mechanism to the Housing, Lower Assy.

• C.B.P. 3 x 8: 3

• C.B.P.(P2) 3 x 8: 1

.

1

2

4

Cap Unit

3

C.B.P. (P2) 3 x 8

( 6

±1 kgf.cm )

Figure 4-22. Removing Cap Unit

C.B.P. 3 x 8

( 6

±1 kgf.cm )

Figure 4-23. Removing Housing Lower Assy. (1)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 52

Page 53

EPSON Stylus C87/C88/D88 Revision A

C A U T I O N

When performing the following work, be sure to hold the places

indicated with dotted circles to avoid deformation of the Main Unit

Frame.

Holding Positions

Figure 4-24. Holding Positions of Housing, Lower Assy.

7) Release the two tabs on the PF Motor side of the Housing, Lower Assy, and

remove the Housing, Lower Assy.

To ensure the assembling accuracy, you have to control the

assembled standard position of the Main Frame against X/Y/Zaxis direction as follows.

[X-axis direction]

• Make sure that main frame is correctly placed on the

groove of Housing (Lower).

• Make sure that there is no gap between main frame and

Housing (Lower).

[Y-axis direction]

• Make sure that cut-out portion of main frame is correctly

placed on the square protrusion of Housing, Lower.

X-axis Assembled Standard Position

Y-axis Assembled Standard Position

Housing,

Lower Assy.

PF Motor

Figure 4-26. X and Y-axis Assembled Standard Position

Tab

Figure 4-25. Removing Housing, Lower Assy. (2)

DISASSEMBLY/ASSEMBLY Dissasembly Procedures 53

Page 54

EPSON Stylus C87/C88/D88 Revision A

[Z-axis direction]

• Make sure that there is no gap between main frame and

Housing, Lower.

• Make sure that the left side of Printer Mechanism is

correctly fixed with two tabs.

Z-axis Assembled

Standard Position

Z-axis Assembled

Tabs

Standard Position

Figure 4-27. Z-axis Assembled Standard Position

When installing the Cap Unit, pay attention to the following

instructions:

• Route the Ink Tube so that the tube is fixed with the tabs of

the Housing, Lower Assy.