Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

D55168

Oil Free Portable Air Compressor

Compresseur d’air portatif sans huile

Compresor de aire sin aceite portátil

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Page 2

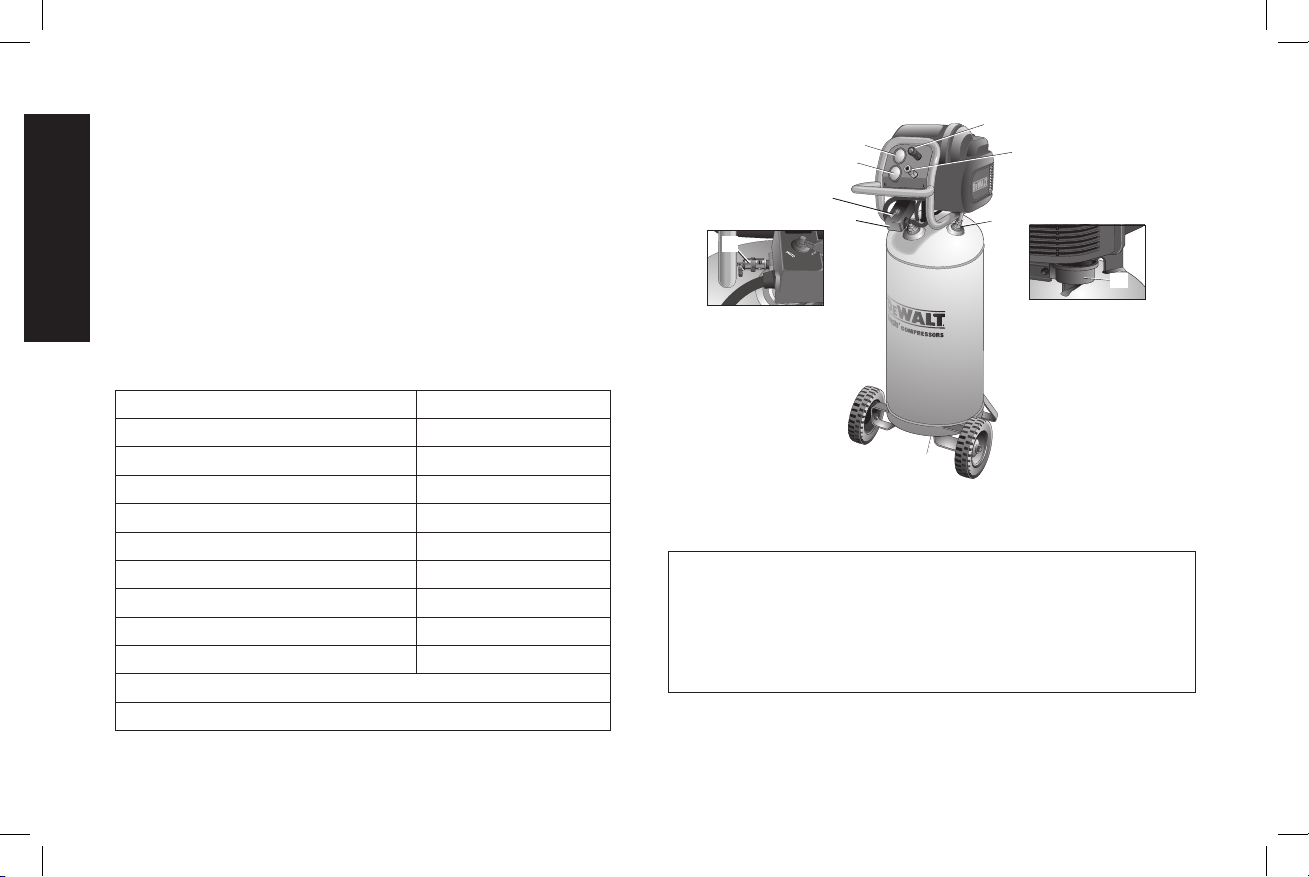

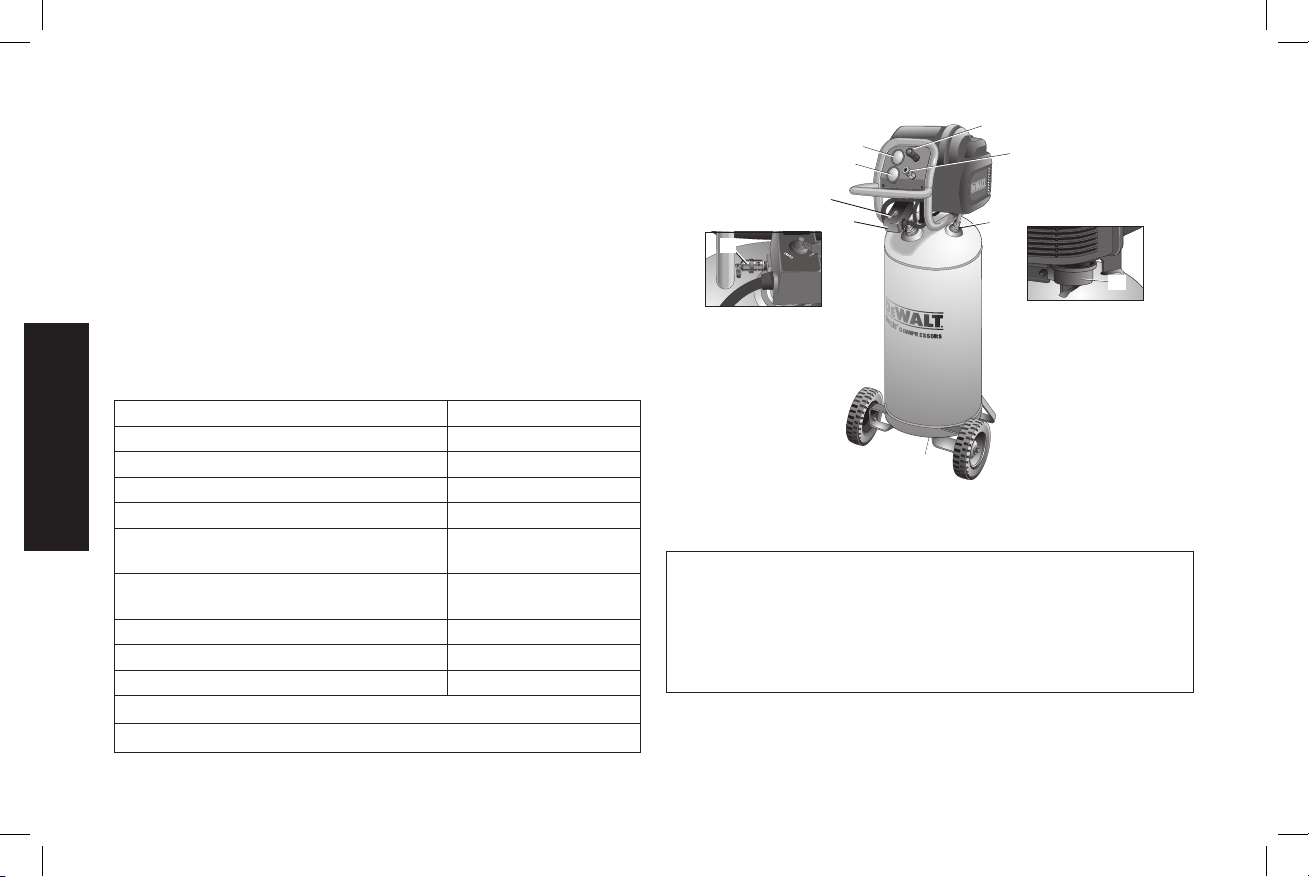

D55168 Air Compressor

A. On/Off Switch

B. Air Tank Pressure Gauge

C. Regulated Pressure Gauge

D. Pressure Regulator

E. Quick Connect

English

Pump/Motor Specifi cations

Voltage: Single Phase 120V

Minimum branch circuit requirement: 15 A

Fuse Type: Time delay

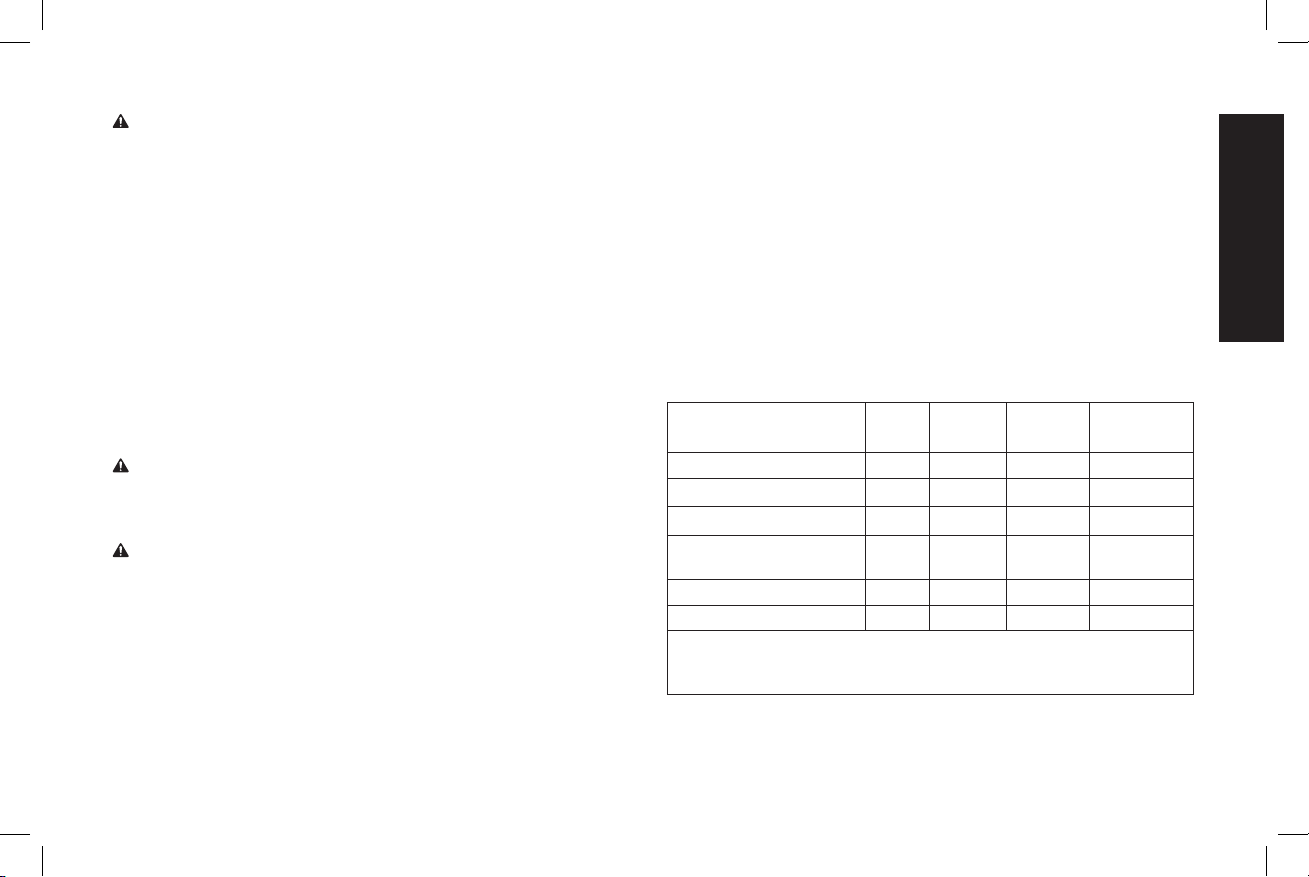

Specifi cations

MODEL

WEIGHT

HEIGHT

WIDTH

LENGTH

AIR TANK CAPACITY (GALLONS)

APPROX CUT-IN PRESSURE

APPROX. CUT-OUT PRESSURE

SCFM @ 90 PSI

NOISE LEVEL

*Tested per ISO 1217:1996

+Tested per ISO 3744:1994

F. Check Valve

G. Safety Valve

H. Air Tank Drain Valve

I. Pressure Switch

J. Air Intake Filter

D55168

88 lbs. (39.92 kg)

41.75" (1060.5 mm)

19.0" (482.6 mm)

21.25" (539.8 mm)

15 Gallon (56.8 liters)

160 PSI

200 PSI

*5.4

+78 dBA

FIG. 1

B

C

A

I

G

H

D

E

F

J

Declared Noise Emission Values

per ISO 3744

Noise Emission Values

Sound Pressure Level: LpA = 78.0 dBA re 20µPA

Uncertainty in the Sound Pressure Level: KpA = 3.0 dBA re 20µPA

Sound Power Level: LwA = 92.0 dBA re 1 pw

Uncertainty in the Sound Power Level: KwA = 3.0 dBA re 1 pw

The sum of the emission value and the uncertainty is the limit

below which there is a 95% confidence the value of a single tool

will lie below when the tool is new.

2

Page 3

Defi nitions: Safety Guidelines

Important Safety Instructions

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol

indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry

products

• arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, al ways wear OSHA/MSHA/NIOSH approved, properly

fit ting face mask or res pi ra tor when us ing such tools.

When using air tools, basic safety precautions should always be

followed to reduce the risk of of personal injury.

WARNING: This product contains chemicals, known to the

State of California to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

SAVE THESE INSTRUCTION

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY D

1-800-4-D

E

WALT (1-800-433-9258)

E

WALT TOOL, CALL US TOLL FREE AT:

Important Safety Instructions

WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known

(to the State of California) to cause cancer, birth defects or other

reproductive harm. Some example of these chemicals are:

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• It is normal for electrical contacts within the motor and

pressure switch to spark.

3

• Always operate the compressor in a well ventilated area

free of combustible materials,

gasoline, or solvent vapors.

Page 4

• If electrical sparks from

compressor come into contact with flammable vapors,

they may ignite, causing fire

or explosion.

English

• Restricting any of the compressor ventilation openings

will cause serious overheating and could cause fire.

• Unattended operation of

this product could result in

personal injury or property

damage. To reduce the risk

of fire, do not allow the

compressor to operate unattended.

• If spraying flammable materials, locate compressor at

least 20 feet (6.1 m) away

from spray area. An additional length of hose may be

required.

• Store flammable materials in

a secure location away from

compressor.

• Never place objects against or

on top of compressor.

• Operate compressor in

an open area at least 12"

(30.5 cm) away from any

wall or obstruction that would

restrict the flow of fresh air to

the ventilation openings.

• Operate compressor in a

clean, dry well ventilated area.

Do not operate unit indoors or

in any confined area.

• Always remain in attendance

with the product when it is

operating.

• Always turn off and unplug

unit when not in use.

DANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air directly

from your compressor is not

safe for breathing. The air

stream may contain carbon

monoxide, toxic vapors,

or solid particles from the

air tank. Breathing these

contaminant's can cause

serious injury or death.

• Sprayed materials such as

paint, paint solvents, paint

remover, insecticides, weed

killers, may contain harmful

vapors and poisons.

• Air obtained directly from the

compressor should never be

used to supply air for human

consumption. In order to use air

produced by this compressor

for breathing, suitable filters

and in-line safety equipment

must be properly installed. Inline filters and safety equipment

used in conjunction with the

compressor must be capable

of treating air to all applicable

local and federal codes prior to

human consumption.

• Work in an area with good

cross ventilation. Read and

follow the safety instructions

provided on the label or safety

data sheets for the materials

you are spraying. Always use

certified safety equipment:

OSHA/MSHA/NIOSH

respiratory protection designed

for use with your specific

application.

4

Page 5

WARNING: RISK OF BURSTING

Air Tank: The air tank on your Air Compressor is designed and may

be UM coded (for units with air tanks greater than 6 inch diameter)

according to ASME Section VIII, Div. 1 rules. All pressure vessels

should be inspected once every two years. To find your state pressure

vessels inspector, look under the Division of Labor and Industries in

the government section of a phone book or call 1-800-4-D

assistance.

The following conditions could lead to a weakening of the air tank, and

result in a violent air tank explosion:

WHAT CAN HAPPEN HOW TO PREVENT IT

• Failure to properly drain

condensed water from

air tank, causing rust and

thinning of the steel air tank.

• Modifications or attempted

repairs to the air tank.

• Unauthorized modifications to

the safety valve or any other

components which control air

tank pressure.

• Drain air tank daily or after

each use. If air tank develops

a leak, replace it immediately

with a new air tank or replace

the entire compressor.

• Never drill into, weld, or make

any modifications to the air

tank or its attachments. Never

attempt to repair a damaged or

leaking air tank. Replace with a

new air tank.

• The air tank is designed

to withstand specific

operating pressures. Never

make adjustments or parts

substitutions to alter the factory

set operating pressures.

EWALT for

Attachments & accessories:

• Exceeding the pressure

rating of air tools, spray guns,

air operated accessories,

tires, and other inflatables

can cause them to explode or

fly apart, and could result in

serious injury.

• Over inflation of tires could

result in serious injury and

property damage.

• Follow the equipment

manufacturers

recommendation and never

exceed the maximum allowable

pressure rating of attachments.

Never use compressor to

inflate small low pressure

objects such as children’s toys,

footballs, basketballs, etc.

• Use a tire pressure gauge to

check the tires pressure before

each use and while inflating

tires; see the tire sidewall for

the correct tire pressure.

NOTE: Air tanks, compressors

and similar equipment used to

inflate tires can fill small tires very

rapidly. Adjust pressure regulator

on air supply to no more than the

rating of the tire pressure. Add air

in small increments and frequently

use the tire gauge to prevent over

inflation.

English

5

Page 6

WARNING: RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your air compressor is

English

powered by electricity.

Like any other electrically

powered device, If it is not

used properly it may cause

electric shock.

• Repairs attempted by

unqualified personnel can

result in serious injury or

death by electrocution.

• Electrical Grounding:

Failure to provide adequate

grounding to this product

could result in serious injury

or death from electrocution.

See Grounding

Instructions under

Installation.

• Never operate the compressor

outdoors when it is raining or

in wet conditions.

• Never operate compressor

with protective covers

removed or damaged.

• Any electrical wiring or

repairs required on this

product should be performed

by a D

EWALT factory

service center or a D

EWALT

authorized service center in

accordance with national and

local electrical codes.

• Make certain that the

electrical circuit to which the

compressor is connected

provides proper electrical

grounding, correct voltage and

adequate fuse protection.

WARNING: RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air stream

can cause soft tissue

damage to exposed skin and

can propel dirt, chips, loose

particles, and small objects

at high speed, resulting in

property damage or personal

injury.

• Always wear certified safety

equipment: ANSI Z87.1 eye

protection (CAN/CSA Z94.3)

with side shields when using

the compressor.

• Never point any nozzle or

sprayer toward any part of

the body or at other people or

animals.

• Always turn the compressor off

and bleed pressure from the

air hose and air tank before

attempting maintenance,

attaching tools or accessories.

6

Page 7

WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Touching exposed metal such

as the compressor head,

engine head, engine exhaust

or outlet tubes, can result in

serious burns.

• Never touch any exposed

metal parts on compressor

during or immediately after

operation. Compressor will

remain hot for several minutes

after operation.

• Do not reach around

protective shrouds or attempt

maintenance until unit has

been allowed to cool.

WARNING: RISK FROM MOVING PARTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Moving parts such as the

pulley, flywheel, and belt can

cause serious injury if they

come into contact with you or

your clothing.

• Never operate the compressor

with guards or covers which

are damaged or removed.

• Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long

hair can be caught in moving

parts.

• Air vents may cover moving

parts and should be avoided as

well.

• Attempting to operate

compressor with damaged or

missing parts or attempting

to repair compressor with

protective shrouds removed

can expose you to moving

parts and can result in

serious injury.

WARNING: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe op er a tion of your air

compressor could lead to se rious in ju ry or death to you or

others.

7

• Any repairs required on this

product should be performed

by a D

EWALT factory service

center or a D

EWALT authorized

service center.

• Review and understand all

instructions and warnings in

this manual.

• Be come fa mil iar with the

op eration and con trols of the

air compressor.

• Keep operating area clear of all

persons, pets, and obstacles.

• Keep chil dren away from the air

compressor at all times.

• Do not operate the product

when fatigued or under the

influence of alcohol or drugs.

Stay alert at all times.

• Never defeat the safety features of this prod uct.

English

Page 8

English

WHAT CAN HAPPEN HOW TO PREVENT IT

• A portable compressor

can fall from a table,

workbench, or roof causing

damage to the compressor

and could result in serious

injury or death to the

operator.

WARNING: RISK OF INJURY FROM LIFTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result

from attempting to lift too

heavy an object.

• Equip area of operation with a

fire extinguisher.

• Do not op er ate machine with

missing, broken, or un au thorized parts.

WARNING: RISK OF FALLING

• Always operate compressor

in a stable secure position to

prevent accidental movement

of the unit. Never operate

compressor on a roof or

other elevated position. Use

additional air hose to reach

high locations.

• The compressor is too heavy

to be lifted by one person.

Obtain assistance from

others before lifting.

CAUTION: RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Under some conditions and

duration of use, noise from

this product may contribute

to hearing loss.

• Always wear certified safety

equipment: ANSI S12.6

(S3.19) hearing protection.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

FEATURES

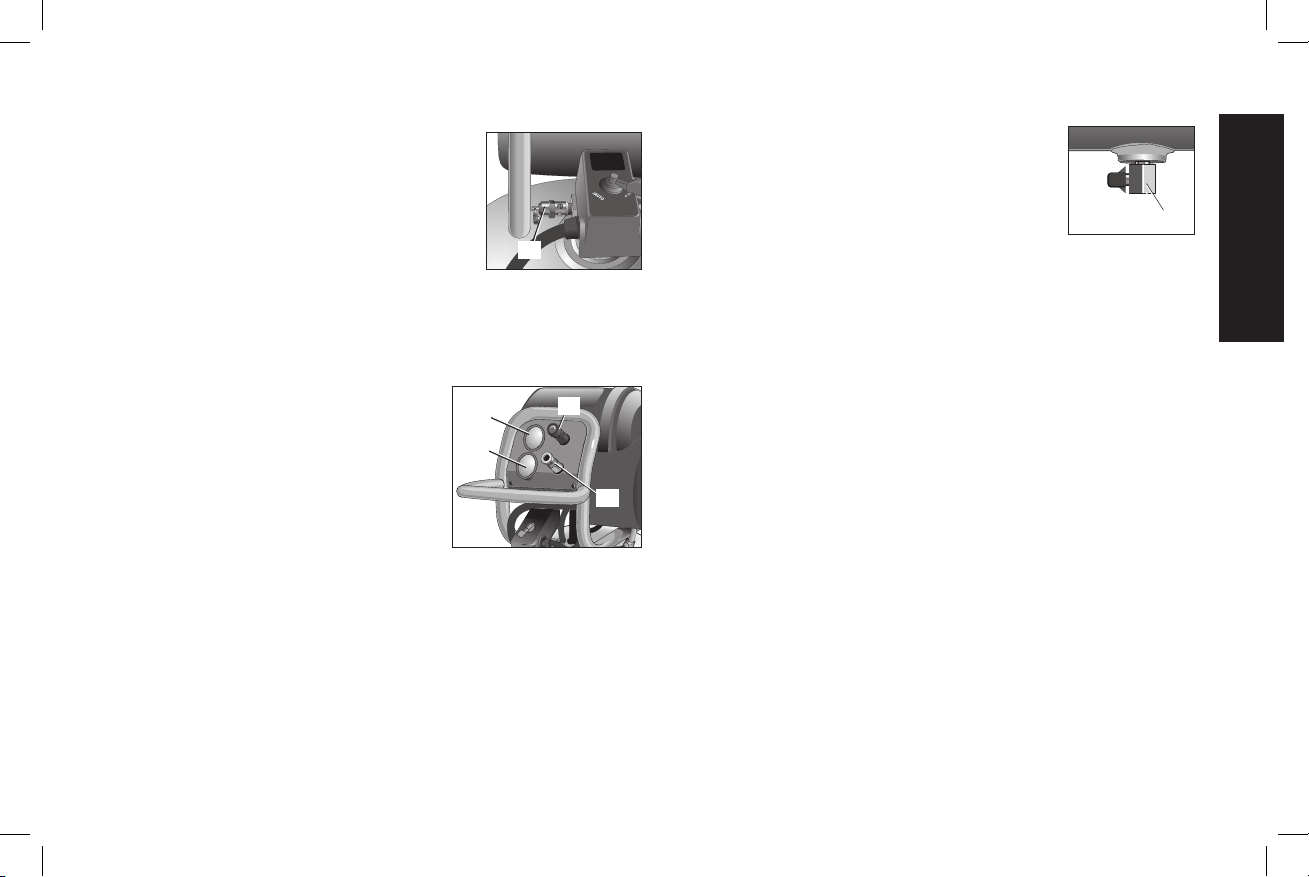

ON/AUTO/OFF SWITCH

Place this switch (A) in the ON/AUTO

position to provide automatic power to the

pressure switch and OFF to remove power

at the end of each use.

PRESSURE SWITCH

The pressure switch (I) automatically

starts the motor when the air tank

pressure drops below the factory set cut-in pressure. It stops the

motor when the air tank pressure reaches the factory set cut-out

pressure.

I

A

F

8

Page 9

SAFETY VALVE

If the pressure switch does not shut off the air

compressor at its cut-out pressure setting, the

safety valve (G) will protect against high

pressure by popping out at its factory set

pressure (slightly higher than the pressure

switch cut-out setting).

G

CHECK VALVE

When the air compressor is operating, the check valve (F) is

open, allowing compressed air to enter the air tank. When the

air compressor reaches cut-out pressure, the check valve closes,

allowing air pressure to remain inside the air tank.

TANK PRESSURE GAUGE

The tank pressure gauge (B) indicates

the reserve air pressure in the tank.

REGULATED PRESSURE GAUGE

B

C

D

The outlet pressure gauge (C) indicates

the air pressure available at the outlet

side of the regulator. This pressure is

E

controlled by the regulator and is always

less than or equal to the tank pressure.

REGULATOR

The regulator (D) controls the air pressure shown on the regulated

pressure gauge. Pull the knob out and turn clockwise to increase

pressure and counterclockwise to decrease pressure. When the

desired pressure is reached push knob in to lock in place.

UNIVERSAL QUICK CONNECT BODY

The universal quick connect body (E) accepts the three most

popular styles of quick connect plugs: Industrial, automotive, and

ARO. One hand push-to-connect operation makes connections

simple and easy.

DRAIN VALVE

The drain valve (H) is located at the base of the air

tank and is used to drain condensation at the end

of each use.

See Draining Air Tank under

Maintenance.

COOLING SYSTEM

This compressor contains an advanced design cooling system.

It is normal for this fan to blow air through the vent holes in large

amounts. The cooling system is working when air is expelled.

AIR COMPRESSOR PUMP

The pump compresses air into the air tank. Working air is not

available until the compressor has raised the air tank pressure

above that required at the air outlet.

AIR INTAKE FILTER

The filter (J) is designed to clean air entering the pump. To ensure

the pump continually receives a clean, cool, and dry air supply the

filter must always be clean and the filter intake must be free from

obstructions.

MOTOR OVERLOAD PROTECTOR

The motor has a thermal overload protector. If the motor overheats

for any reason, the overload protector will shut off the motor. The

motor must be allowed to cool down before restarting. To restart:

1. Set the On/Auto/Off lever to OFF and unplug unit.

2. Allow the motor to cool.

Plug the power cord into the correct branch circuit receptacle.

3.

4. Set the On/Auto/Off lever to ON/AUTO position.

9

English

H

Page 10

INSTALLATION

Assembly

INSTALLING HOSES

WARNING: Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads 0 PSI.

English

2. Grasp the hose at the quick connect plug and push the plug

into the quick connect body (E). Coupler will snap into place.

3. Grasp the hose and pull to ensure coupler is seated.

DISCONNECTING HOSES

WARNING: Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose whip.

1. Ensure regulated pressure gauge reads 0 PSI.

2. Pull coupler on quick connect body back to release Quick

Connect plug on hose.

Grounding Instructions

WARNING: Risk of Electrical Shock. In the event of a short

circuit, grounding reduces the risk of shock by providing an escape

wire for the electric current. This air compressor must be properly

grounded.

The portable air compressor is equipped with a cord having a

grounding wire with an appropriate grounding plug.

1. The cord set and plug (M) with this unit

contains a grounding pin (L). This plug

MUST be used with a grounded

outlet (K).

IMPORTANT: The outlet being used must

be installed and grounded in accordance

with all local codes and ordinances.

M

K

L

2. Ensure the outlet being used has the same configuration as the

grounded plug. DO NOT USE AN ADAPTER.

3. Inspect the plug and cord before each use. Do not use if there

are signs of damage.

4. If these grounding instructions are not completely understood, or

if in doubt as to whether the compressor is properly grounded,

have the installation checked by a qualified electrician.

DANGER: Risk of Electrical Shock. IMPROPER GROUNDING

CAN RESULT IN ELECTRICAL SHOCK.

• Do not modify the plug provided. If it does not fit the available

outlet, a correct outlet should be installed by a qualified electrician.

• Repairs to the cord set or plug MUST be made by a qualified

electrician.

Extension Cords

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding plug, and

a 3-slot receptacle that will accept the plug on the product

• in good condition

• no longer than 50 feet (15.2 m)

• 12 gauge (AWG) or larger. (Wire size increases as gauge number decreases. 10 AWG and 8 AWG may also be used. DO NOT

USE 14 OR 16 AWG.)

CAUTION: The use of an undersized extension cord will cause voltage to drop resulting in power loss to the motor and overheating.

Instead of using an extension cord, increase the working reach of

the air hose by attaching another length of hose to its end. Attach

additional lengths of hose as needed.

10

Page 11

Voltage and Circuit Protection

Refer to the Voltage and Minimum Branch Circuit Requirements

under Pump/Motor Specifications.

CAUTION: Certain air compressors can be operated on a

15 amp circuit if the following conditions are met.

• Voltage supply to circuit must comply with the National

Electrical Code.

• Circuit is not used to supply any other electrical needs.

• Extension cords comply with specifications.

• Circuit is equipped with a 15 amp circuit breaker or 15 amp

time delay fuse. NOTE: If compressor is connected to a circuit protected by fuses, use only time delay fuses. Time delay

fuses should be marked “D” in Canada and “T” in the US.

If any of the above conditions cannot be met, or if operation of the

compressor repeatedly causes interruption of the power, it may be

necessary to operate it from a 20 amp circuit. It is not necessary

to change the cord set.

Compatibility

NOTE: Always use an air line filter to remove moisture and oil vapor

when spraying paint.

Location

Place the air compressor in a clean, dry and well ventilated area

at least 12" (30.5 cm) away from the wall or other obstructions that

will interfere with the flow of air. Keep the compressor away from

areas that have dirt and/or volatile fumes in the atmosphere. These

impurities may clog the intake filter and valves, causing inefficient

operation.

WARNING: The air compressor pump and shroud are designed

to allow for proper cooling. The ventilation openings on the compressor are necessary to maintain proper operating temperature.

Do not place rags or other containers on or near these openings.

Place the air compressor on a flat surface resting on the rubber

feet and wheels.

ELECTRICAL

Refer to all safety instructions before using unit. Observe extension

cord safety instructions if necessary. Always move the On/Auto/Off

switch (A) to the OFF position before removing the plug from the

outlet.

TRANSPORTING

When transporting the compressor in a vehicle, trailer, etc., make

sure the tank is drained and the unit is secured with straps to prevent

tipping. Use care when driving to prevent tipping the unit over in the

vehicle. Damage can occur to the compressor or surrounding items

if the compressor is tipped.

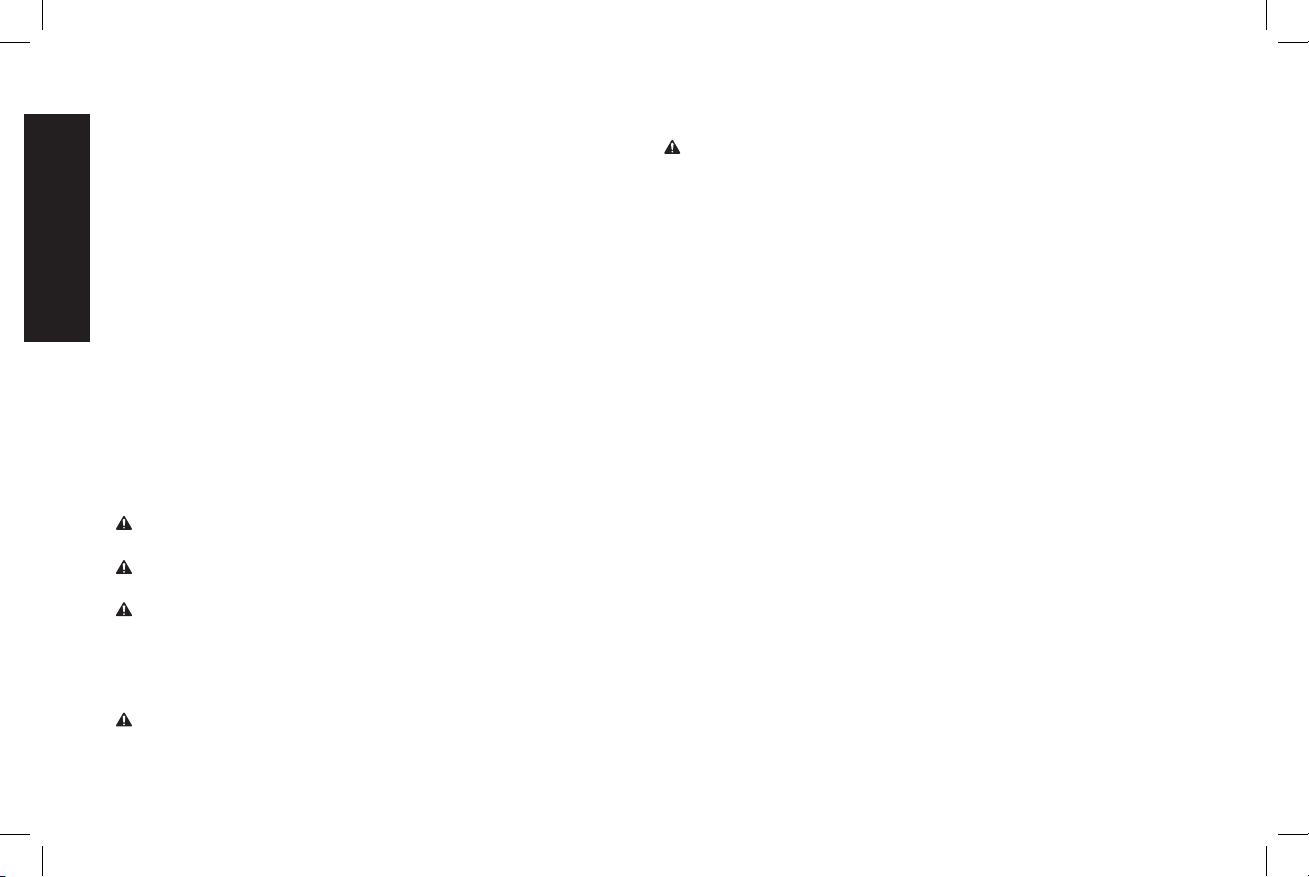

LIFTING

Always use two people when lifting and lift

from the recommended lift points (N). DO

NOT lift by wheels or shroud.

MOVING

CAUTION: The wheels and handle do not

provide adequate clearance, stability, or support for pulling the unit up and down stairs or

steps. The unit must be lifted or pushed up a

ramp.

1. Grasp handle of compressor and tilt compressor back to rest on wheels.

WARNING: Risk of Unsafe Operation. Ensure proper footing and

use caution when rolling compressor so that unit does not tip or

cause loss of balance.

11

N

English

N

Page 12

2. When location is reached slowly lower compressor to ground.

Always store compressor in a vertical position resting on

the rubber bumpers and wheels.

PREPARATION FOR USE

Pre-Start Checklist (Fig. 1)

1.

Ensure the On/Auto/Off switch (A) is in the OFF position.

2.

English

Plug the power cord into the correct branch circuit receptacle.

See Voltage and Circuit Protection under Installation.

3. Ensure air tank is drained, see Draining Air Tank under

Maintenance.

4. Ensure the drain valve (H) is closed.

5. Ensure safety valve (G) is functioning properly, see Checking

Safety Valve under Maintenance.

6. Pull the regulator knob (D) out and turn counterclockwise until fully

closed. Ensure regulated pressure gauge reads 0 PSI. Push knob

in to lock in place.

7. Attach hose and accessories. NOTE: Always use a minimum

3/8" (9.5 mm) or greater air hose rated at 300 PSI.

WARNING: Risk of unsafe operation. Firmly grasp air hose in hand

when installing or disconnecting to prevent hose whip.

WARNING:

worn accessories.

WARNING: Risk of Bursting. Too much air pressure causes a

hazardous risk of bursting. Check the manufacturer’s maximum

pressure rating for air tools and accessories. The regulator outlet

pressure must never exceed the maximum pressure rating.

Initial Set-up

WARNING: Do not operate this unit until you read and understand

this instruction manual for safety, operation and maintenance

instructions.

Risk of unsafe operation. Do not use damaged or

(Fig. 1)

BREAK-IN PROCEDURE

WARNING: Risk of property damage. Serious damage may result if

the following break-in instructions are not closely followed.

This procedure is required before the air compressor is put into

service for the first time and when the check valve or a compressor

pump/motor has been replaced.

1. Ensure the On/Auto/Off switch (A) is in the OFF position.

NOTE: If hose is not connected to Quick Connect body, pull coupler

back until it clicks to prevent air from escaping through the quick

connect.

2.

Plug the power cord into the correct branch circuit receptacle.

Voltage and Circuit Protection under Installation.

3. Open the drain valve (turn lever counter-clockwise) fully to permit

air to escape and prevent air pressure build up in the air tank

during the break-in period.

4. Move the On/Auto/Off switch to the ON position. The compressor

will start.

5. Run the compressor for 15 minutes.

6. After 15 minutes, close the drain valve by turning lever

clockwise. The tank will fill to cut-out pressure and the motor

will stop.

7. Compressed air will be available until it is used or bled off.

OPERATING PROCEDURES

Start-up (Fig. 1)

1. Follow Pre-Start Checklist under Preparation for Use.

2. Move the On/Auto/Off switch to the ON position and allow tank

pressure to build. Motor will stop when tank pressure reaches

cut-out pressure.

12

See

Page 13

CAUTION: Risk of unsafe operation. Compressed air from the

unit may contain wa ter condensation and oil mist. Do not spray un filtered air at an item that could be damaged by moisture. Some air

op er ated tools or de vic es may require filtered air. Read the in struc-

tions for the air tool or device.

3. Adjust regulator (D) to desired setting. See Regulator under

Features.

Shut-down (Fig. 1)

1. Move On/Auto/Off switch (A) to the OFF position. NOTE: If

finished using compressor, follow Steps 2 - 6.

NOTE: When the unit has been turned off, it is normal to hear a short

hiss of air being released.

2. Pull the regulator knob (D) out and turn counterclockwise until fully

closed. Ensure regulated pressure gauge reads 0 PSI. Push knob

in to lock in place.

3. Remove hose and accessory.

WARNING: Risk of unsafe operation. Firmly grasp air hose in hand

when installing or disconnecting to prevent hose whip.

4. Drain the air tank,

see Draining Air Tank under Maintenance

Ensure air tank pressure gauge reads 0 PSI.

WARNING: Risk of bursting. Drain air tank daily. Water will

condense in air tank. If not drained, water will corrode and weaken

the air tank causing a risk of air tank rupture.

5. Allow the compressor to cool down.

6. Wipe air compressor clean and store in a safe, non-freezing area.

MAINTENANCE

The following procedures must be followed when maintenance or

service is performed on the air compressor.

1. Ensure On/Auto/Off switch is in the OFF position.

2. Remove air compressor plug from outlet.

3. Drain air tank.

4. Allow air compressor to cool down before starting service.

NOTE: All compressed air systems contain maintenance parts (e.g.,

oil, filters, separators) that are periodically replaced. These used parts

may contain substances that are regulated and must be disposed of in

accordance with local, state, and federal laws and regulations.

NOTE: Take note of the positions and locations of parts during

disassembly to make reassembly easier.

NOTE: Any service operations not included in this section should

be performed by a D

E

WALT factory service center or a DEWALT

authorized service center.

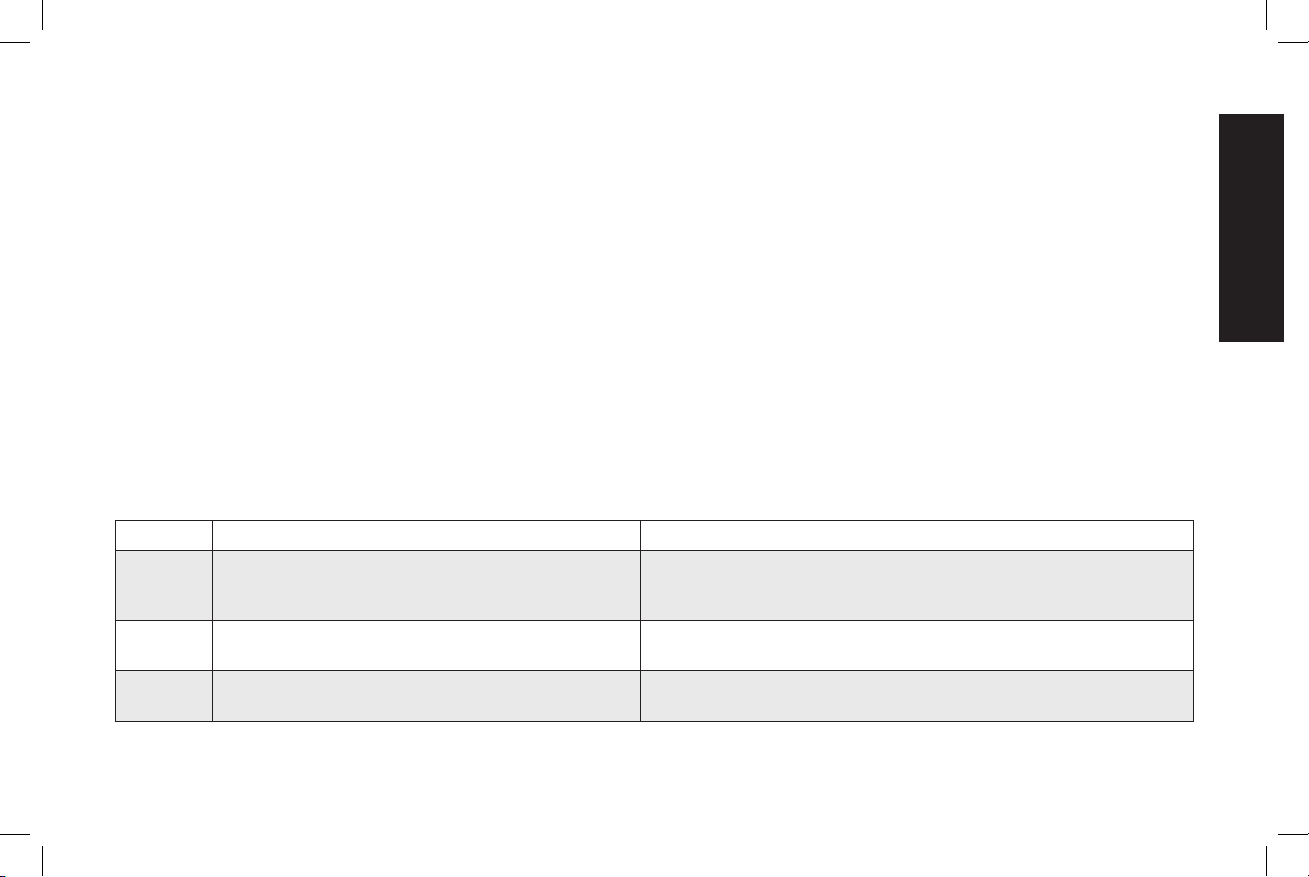

Maintenance Chart

Procedure Daily Weekly Monthly 1 year or

Check safety valve

Inspect air filter

.

Drain air tank

Check for unusual noise/

vibration

Check for air leaks*

Clean compressor exterior

* To check for air leaks apply a solution of soapy water around joints.

While compressor is pumping to pressure and after pressure cuts out,

look for air bubbles to form.

X

X

X

X

X

X

200 Hours

English

13

Page 14

Checking Safety Valve

WARNING: Risk of bursting. If the safety valve does not work

properly, over-pressurization may occur, causing air tank rupture or

an explosion.

WARNING: Risk from flying objects. Always wear certified safety

equipment: ANSI Z87.1 eye protection (CAN/CSA Z94.3) with side

shields when using the compressor.

English

Before starting compressor, pull the ring on the safety valve to

make sure that the safety valve operates freely. NOTE: Ring may

be difficult to pull when air tank pressure is at 0 PSI. If the valve is

stuck or does not operate smoothly, it must be replaced with the

same type of valve.

Draining Air Tank (Fig. 1)

WARNING: Risk of unsafe operation. Risk from noise. Air tanks

contain high pressure air. Keep face and other body parts away from

outlet of drain. Use eye protection [ANSI Z87.1 (CAN/CSA Z94.3)]

when draining as debris can be kicked up into face.

WARNING: Risk from noise. Use ear protection [ANSI S12.6

(S3.19)] as air flow noise is loud when draining.

NOTE: All compressed air systems generate condensate that

accumulates in any drain point (e.g. tanks, filter, aftercoolers, dryers).

This condensate contains lubricating oil and/or substances which

may be regulated and must be disposed of in accordance with local,

state, and federal laws and regulations.

1. Ensure On/Auto/Off switch is in the OFF position.

2. Place a suitable container under the drain valve (H) to catch

discharge.

3. Grasp lever on drain valve.

4. Slowly rotate lever to gradually bleed air from air tank.

WARNING: Risk of bursting. Drain air tank daily. Water will con-

dense in air tank. If not drained, water will corrode and weaken the

air tank causing a risk of air tank rupture.

CAUTION: Risk of property damage. Drain water from air tank may

contain oil and rust, which can cause stains.

5. When air tank pressure gauge reads 10 PSI, rotate valve to the

fully open position.

6. Close drain valve when finished.

Checking Air Filter Element (Fig. 1)

WARNING: Hot surfaces. Risk of burn. Outlet tube, pump head,

and surrounding parts are very hot, do not touch. Allow compressor

to cool prior to servicing.

1. Ensure ON/OFF switch (A) is in the OFF Position.

2. Allow unit to cool.

3. Remove filter cover (J) from base.

4. Remove element from filter base.

5. Place new element back in filter

base. Purchase replacement parts

from your local dealer or authorized

service center. Always use identical

replacement parts.

6. Snap filter cover to filter base.

CAUTION: Risk of unsafe operation.

Do not operate without air inlet filter

J

ACCESSORIES

Recommended accessories for use with your tool are available

for purchase from your local dealer or authorized service center.

If you need assistance in locating any accessory for your tool,

please contact D

Baltimore, MD 21286, call 1-800-4-D

our website www.dewalt.com.

WARNING: The use of any other accessory not recommended for

use with this tool could be hazardous. Use only accessories rated

equal to or higher than the rating of the air compressor.

14

E

WALT Industrial Tool Co., 701 East Joppa Road,

E

WALT (1-800-433-9258) or visit

Page 15

SERVICE INFORMATION

Please have the following information available for all service calls:

Model Number ____________ Serial Number _________________

Date and Place of Purchase ______________________________

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment should be performed by a D

center, a D

E

WALT authorized service center or other qualified

E

WALT factory service

service personnel. Always use identical replacement parts.

Full One Year Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due

to faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

E

WALT. This warranty does not apply to accessories

specific warranty information contained either in the packaging, call

the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

E

WALT for a free

replacement.

WARNING

DO NOT ADJUST FACTORY SETTINGS.

TO REDUCE RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVER.

Pressurecontrols set at factory for

maximum safe ope ration.

ADVERTENCIA

NO HAGA CAMBIOS EN LOS AJUSTES

DE FÁBRICA. NO RETIRE LATAPA PARA

REDUCIR EL RIESGO DE CHOQUE ELÉ CTRICO.

Los controles de presión se ajustan en la

fábrica para máxima seguridad en la operación.

AVERTISSEMENT

WARNING HO T SURFACES

ADVERTENCIA SUPERFICIESC ALIENTES

AVERTISSEMENT

SURFACES CHAUDES

English

15

Page 16

GLOSSARY

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSI: Pounds per square inch; a unit of measure of pressure.

kPa (kilopascal): Metric pressure measurement. 1 kilopascal equal 1000 pascals.

English

Code Certification: Products that bear one or more of the following marks: UL, CUL, ETL, CETL, have been evaluated by OSHA certified

independent safety laboratories and meet the applicable Underwriters Laboratories Standards for Safety.

Cut-In Pressure: While the motor is off, air tank pressure drops when accessory is used. When the tank pressure drops to a certain low

level the motor will restart automatically. The low pressure at which the motor automatically restarts is called cut-in pressure.

Cut-Out Pressure: When an air compressor is turned on and begins to run, air pressure in the air tank begins to build. It builds to a certain

high pressure before the motor automatically shuts off, protecting your air tank from pressure higher than its capacity. The high pressure

at which the motor shuts off is called cut-out pressure.

Branch Circuit: The circuit carrying electricity from electrical panel to outlet.

Duty Cycle: This air compressor pump is capable of running continuously. However, to prolong the life of your air compressor, it is

recommended that a 50%-75% average duty cycle be maintained; that is, the air compressor pump should not run more than 30-45 minutes

in any given hour.

16

Page 17

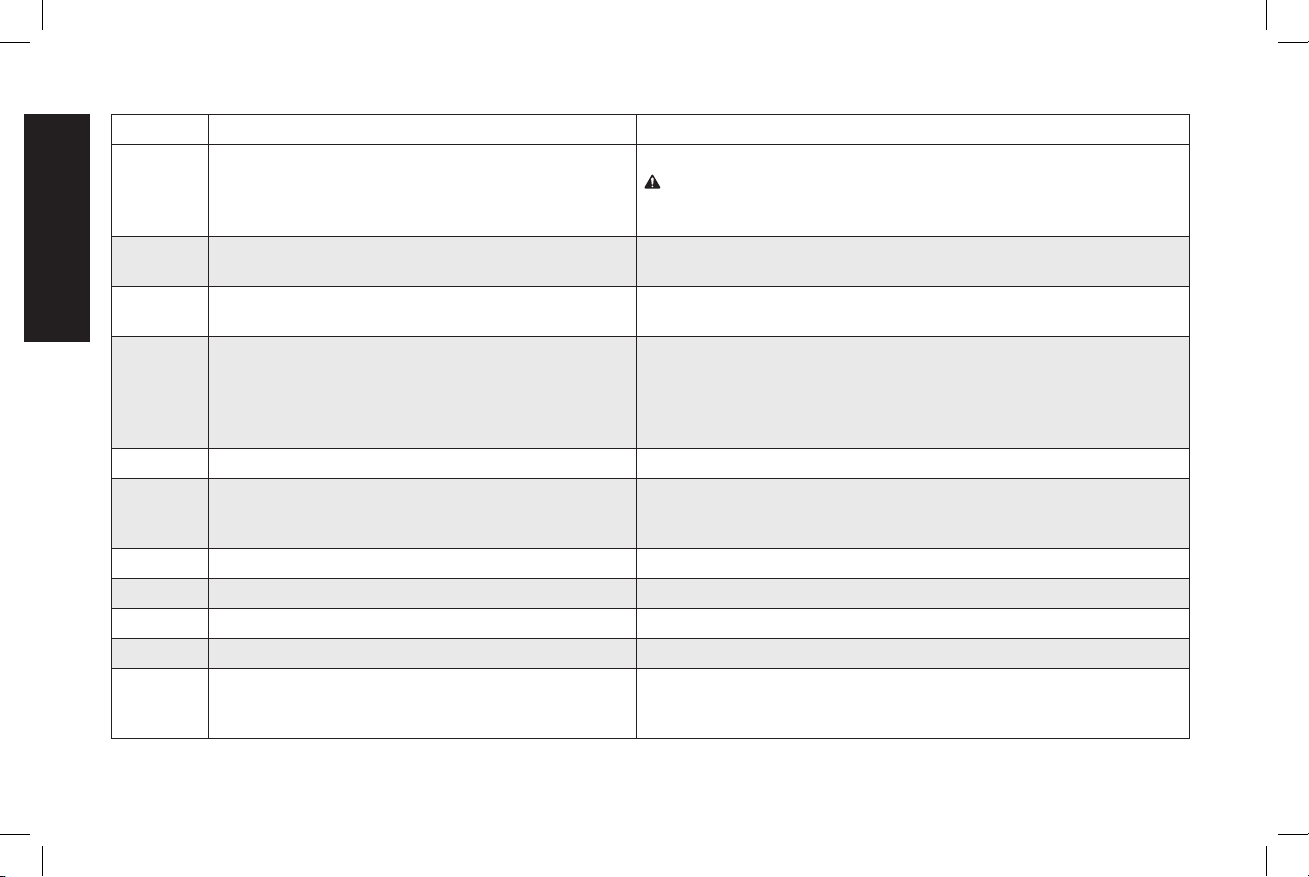

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or maintenance

personnel can perform some corrective actions, and others may require the assistance of a qualified D

Problem Code

Excessive air tank pressure-safety valve pops off ......................................................................1, 2

Air leaks ....................................................................................................................................3

Air leaks in air tank or at air tank welds ....................................................................................4

Air leaks between head and valve plate ....................................................................................5

Air leaks from safety valve .........................................................................................................6

Knocking Noise ..........................................................................................................................6

Pressure reading on the regulated pressure gauge drops when an accessory is used ...........7

Compressor is not supplying enough air to operate accessories..............................................8, 9, 10, 11, 12, 22

Regulator knob has continuous air leak ....................................................................................13

Regulator will not shut off air outlet ........................................................................................... 13

Motor will not run .......................................................................................................................6, 14, 15, 16, 17, 18, 19, 20

Squealing Sound .......................................................................................................................21

EWALT technician or your dealer.

Troubleshooting Codes

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

1 Pressure switch does not shut off motor when

compressor reaches cut-out pressure

2 Pressure switch cut-out too high Contact a DEWALT factory service center or a DEWALT authorized

3 Tube fittings are not tight enough Tighten fittings where air can be heard escaping. Check fittings

Set the On/Off switch to OFF, if the unit does not shut off contact

a DEWALT factory service center or a DEWALT authorized service

center.

service center.

with soapy water solution. Do Not Overtighten.

English

17

Page 18

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

4 Defective air tank Air tank must be replaced. Do not repair the leak.

WARNING: Risk of bursting. Do not drill into, weld or other-

wise modify air tank or it will weaken. The air tank can rupture or

explode.

5 Leaking seals Contact a D

English

service center.

6 Defective safety valve Operate safety valve manually by pulling on ring. If valve still leaks,

it must be replaced.

7

Regulator is not adjusted correctly for accessory

being used

It is normal for some pressure drop to occur when an accessory

is used, adjust the regulator as instructed in Regulator under

Features if pressure drop is excessive.

NOTE: Adjust the regulated pressure under flow conditions while

accessory is being used.

8 Prolonged excessive use of air Decrease amount of air usage.

9 Compressor is not large enough for accessory Check the accessory air requirement. If it is higher than the CFM

or pressure supplied by your air compressor, a larger compressor

is needed to operate accessory.

10 Hole in air hose Replace air hose.

11 Check valve restricted Remove, clean or replace.

12 Air leaks Tighten fittings.

13 Regulator is damaged Replace.

14 Motor overload protection switch has tripped Refer to Motor Overload Protection under Features. If motor over-

load protection trips frequently, contact a D

center or a D

E

WALT factory service center or a DEWALT authorized

E

WALT factory service

E

WALT authorized service center.

18

Page 19

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

15 Tank pressure exceeds pressure switch cut-in

16 Extension cord is wrong length or gauge Check for proper gauge wire and cord length refer to the Extension

17 Loose electrical connections Check wiring connection inside pressure switch and terminal box

18 Possible defective motor Contact a D

19 Paint spray on internal motor parts Contact a DEWALT factory service center or a DEWALT authorized

20 Fuse blown, circuit breaker tripped 1. Check fuse box for blown fuse and replace as necessary. Reset

21

22 Restricted air intake filter Clean or replace air intake filter. Do not operate the air compressor

pressure

Worn Belt Contact a DEWALT factory service center or a DEWALT authorized

Motor will start automatically when tank pressure drops below cutin pressure of pressure switch.

Cords under Installation.

area.

E

service center.

service center. Do not operate the compressor in the paint spray

area. See flammable vapor warning.

circuit breaker. Do not use a fuse or circuit breaker with higher

rating than that specified for our particular branch circuit.

2. Check for proper fuse. You should use a time delay fuse.

3. Check for low voltage conditions and/or proper extension cord.

4. Disconnect the other electrical appliances from circuit or operate

the compressor on its own branch circuit.

service center.

with the filter removed. Refer to the Air Filter paragraph in the

Maintenance section.

WALT factory service center or a DEWALT authorized

English

19

Page 20

Compresseur d’air, modèle D55168

A. Interrupteur Marche/Arrêt

B. Manomètre du réservoir d’air

C. Manomètre régulé

D. Régulateur de pression

E. Branchements rapides

F. Clapet

G. Soupape de sûreté

H. Soupape de purge du

réservoir d’air

I. Rembobineur de cordon

d’alimentation

J. Filtre d’admission d’air

Fiche technique de la pompe/du moteur

Tension : monophasé, 120V

Exigence minimale du circuit de dérivation : 15 A

Type de fusible : temporisation

Fiche technique

MODÈLE

POIDS

HAUTEUR

Français

LARGEUR

LONGUEUR

CAPACITÉ DU RÉSERVOIR D’AIR

(GALLONS)

PRESSION D’ENCLENCHEMENT

APPROX.

ENV. PRESSION DE DÉCLENCHEMENT

PI3/MIN STANDARD À 90 PSI

NIVEAU SONORE

* Testé conformément à la norme ISO 1217:1996

+ Testé conformément à la norme ISO 3744:1994

D55168

39,92 kg (88 livres)

1060,5, mm (41,75 po)

482,6 mm (19,0 po)

539,8 mm (21,25 po)

15 (56,8 liters)

160 PSI

200 PSI

*5,4

+78 dBA

FIG. 1

B

C

A

I

G

H

D

E

F

J

Declared Noise Emission Values

per ISO 3744

Noise Emission Values

Sound Pressure Level: LpA = 78.0 dBA re 20µPA

Uncertainty in the Sound Pressure Level: KpA = 3.0 dBA re 20µPA

Sound Power Level: LwA = 92.0 dBA re 1 pw

Uncertainty in the Sound Power Level: KwA = 3.0 dBA re 1 pw

The sum of the emission value and the uncertainty is the limit

below which there is a 95% confidence the value of a single tool

will lie below when the tool is new.

20

Page 21

Défi nitions : lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de gravité pour

chaque symbole. Veuillez lire le mode d’emploi et porter une attention particulière à ces symboles.

DANGER : Indique une situation dangereuse imminente qui, si

elle n’est pas évitée, causera la mort ou des blessures graves.

AVERTISSEMENT :

gereuse qui, si elle n’est pas évitée, pourrait se solder par un

décès ou des blessures graves.

MISE EN GARDE : Indique une situation potentiellement dan-

gereuse qui, si elle n’est pas évitée pourrait se solder par des

blessures mineures ou modérées.

MISE EN GARDE : Utilisé sans le symbole d’alerte à la sécurité,

indique une situation potentiellement dangereuse qui, si elle n'est

pas évitée pourrait se solder par des dommages à la propriété.

Indique une situation potentiellement dan-

• la silice cristalline provenant de la brique, du ciment et d’autres

produits de maçonnerie;

• l’arsenic et chrome provenant de bois traité chimiquement.

Les risques reliés à l’exposition à ces poussières varient selon la

fréquence à laquelle l’utilisateur travaille avec ce type de matériaux.

Pour réduire votre exposition à ces produits chimiques : travailler dans

un endroit bien ventilé et porter un équipement de sécurité approuvé

par l’OSHA/MSHA/NIOSH comme un masque anti-poussières

spécialement adapté ou un respirateur lors de l’utilisation de ces outils.

Lors de l’utilisation d’outils pneumatiques, des précautions de base

en matière de sécurité doivent être suivies afin de réduire le risque de

blessure personnelle.

AVERTISSEMENT : Ce produit contient des produits chimiques,

reconnus par l’État de Californie comme étant cancérigènes

et pouvant entraîner des anomalies congénitales et d’autres

dangers relatifs à la reproduction. Se laver le

manipulation.

s mains après toute

Français

POUR TOUTES QUESTIONS OU COMMENTAIRES RELATIFS(VES)

À L’OUTIL OU À PROPOS DE TOUT AUTRE OUTIL D

COMPOSER SANS FRAIS LE : 1-800-4-D

EWALT (1-800-433-9258)

EWALT,

Directives de sécurité importantes

AVERTISSEMENT : Ne pas utiliser cet appareil avant d’avoir lu

et compris le mode d’emploi ainsi que l’intégralité des directives de

sécurité, d’utilisation et d’entretien.

AVERTISSEMENT : Nertaines poussières produites par les travaux

de ponçage, sciage, meulage, perçage et autres peuvent contenir des

produits chimiques pouvant (selon l’état de Californie) causer le cancer,

des anomalies congénitales ou d’autres problèmes liés aux fonctions

reproductrices. Voici quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

CONSERVER CES DIRECTIVES

DANGER :

Ce qui peut se produire Comment l’Éviter

• Il est normal que des

contacts électriques dans le

moteur et le manocontacteur

fassent une étincelle.

21

RISQUE D’EXPLOSION OU D’INCENDIE

• Faites toujours fonctionner

le compresseur dans une

zone bien aérée sans matière

combustible, essence ou

vapeur de solvant.

Page 22

• Si une étincelle électrique

provenant du compresseur

entre en contact avec des

vapeurs inflammables,

elle peut s’enflammer et

causer un incendie ou une

explosion.

• Le fait de limiter les

ouvertures d’aération de

compresseur causera une

importante surchauffe et

pourrait causer un incendie.

Français

• Si vous aspergez des

matériaux inflammables,

placez le compresseur à

au moins 6,1 m (20 pieds)

de la zone pulvérisée. Il est

possible que vous ayez besoin

d’une longueur de tuyau

additionnelle.

• Entreposez les matières

inflammables dans un

endroit sécuritaire, éloigné du

compresseur.

• Ne placez jamais des objets

contre le compresseur ou sur

celui-ci.

• Faites fonctionner le

compresseur dans un endroit

aéré à au moins 30,5 cm

(12 po) du mur ou de

l’obstruction qui pourrait limiter

le débit d’air frais dans les

ouvertures d’aération.

• Faites fonctionner le

compresseur dans un endroit

propre, sec et bien aéré.

Ne pas utiliser l’appareil à

l’intérieur ou dans un endroit

exigu.

• Le fonctionnement de ce

produit sans surveillance

pourrait se solder par des

blessures personnelles

ou des dommages à la

propriété. Afin de réduire

le risque d’incendie, ne

pas laisser le compresseur

fonctionner sans surveillance.

DANGER : RISQUE REPIRATOIRE (ASPHYXIE)

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Il est dangereux de respirer

l’air comprimé sortant du

compresseur. Le flux d’air

peut contenir du monoxyde

de carbone, des vapeurs

toxiques ou des particules

solides provenant du réservoir

d’air. L’inhalation de ces

contaminants peut provoquer

de sérieuses blessures, voire

un décès.

22

• Être toujours présent lorsque

le produit est en marche.

• Toujours éteindre et

débrancher l'appareil si non

utilisé.

• L’air qui s’obtient directement du

compresseur ne devrait jamais

être utilisé pour alimenter l’air

destiné à la consommation

humaine. Pour utiliser l’air

produit par le compresseur

pour la respiration, installer

correctement des filtres

convenables et un équipement

de sécurité en ligne. Les

filtres en ligne et l’équipement

de sécurité utilisés avec

le compresseur doivent

être capables de traiter l’air

conformément à tous les codes

locaux et fédéraux en vigueur

avant toute consommation

humaine.

Page 23

• Les matériaux vaporisés

comme la peinture, les

solvants de peinture, les

décapants, les insecticides,

les herbicides, pourraient

contenir des vapeurs nocives

et du poison.

AVERTISSEMENT : RISQUE D’ÉCLATEMENT

Réservoir d’air : le réservoir dont est doté le compresseur d’air porte le

code « UM » (dans le cas d’appareils munis de réservoirs supérieurs à

152 mm (6 po) de diamètre) et il est conçu conformément à la section

VII Div. 1 de l’ASME. Tous les récipients sous pression devraient être

inspectés une fois tous les deux ans. Pour localiser l’inspecteur des

récipients sous pression de votre région, consulter la section appropriée

des organismes gouvernementaux de l’annuaire téléphonique ou

composer le 1-800-4-D

Les conditions indiquées ci-après pourraient affaiblir le réservoir d’air et

se solder par une violente explosion de celui-ci :

EWALT pour obtenir de l’aide.

• Travailler dans un endroit

ayant une bonne ventilation

transversale. Lire et respecter

les directives en matière

de sécurité imprimées sur

l’étiquette ou les fiches

signalétiques des matériaux qui

sont pulvérisés. Toujours utiliser

un équipement de sécurité

homologué : une protection

respiratoire conforme aux

normes OSHA/MSHA/NIOSH,

conçue spécifiquement pour

une utilisation particulière.

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• L’eau condensée n’est pas

correctement vidangée du

réservoir d’air provoquant

ainsi la formation de rouille

et un amincissement du

réservoir d’air en acier.

• Modifications apportées au

réservoir d’air ou tentatives de

réparation.

• Des modifications non

autorisées de la soupape

de sûreté ou de tous autres

composants qui régissent la

pression du réservoir d’air.

• Vidanger le réservoir d’air

quotidiennement ou après

chaque utilisation. Si le réservoir

présente une fuite, le remplacer

immédiatement par un nouveau

réservoir d’air ou par un

nouveau compresseur.

• Ne jamais percer un trou

dans le réservoir d’air ou ses

accessoires, y faire de la

soudure ou y apporter quelque

modification que ce soit. Ne

jamais essayer de réparer un

réservoir d’air endommagé ou

avec des fuites. Le remplacer

par un nouveau réservoir d’air.

• Le réservoir d’air a été conçu

pour supporter des pressions

spécifiques de fonctionnement.

Ne faites jamais effectuer de

réglages ou de substitutions de

pièces en vue de modifier les

pressions de fonctionnement

réglées en usine.

Français

23

Page 24

Accessoires :

• Lorsqu’on excède la

pression nominale des

outils pneumatiques, des

pistolets pulvérisateurs, des

accessoires à commande

pneumatique, des pneus

et d’autres dispositifs

pneumatiques, on risque de

les faire exploser ou de les

projeter et ainsi entraîner des

blessures graves.

• Des pneus surgonflés

pourraient provoquer des

blessures graves et des

dommages à la propriété.

Français

• Respecter les recommandations du fabricant de l’équipement et ne jamais dépasser la

pression nominale maximale

permise des accessoires. Ne

jamais utiliser le compresseur

pour gonfler de petits objets

à basse pression comme des

jouets d’enfant, des ballons de

football et de basket-ball, etc.

• Utiliser un manomètre pour

vérifier la pression des pneus

avant chaque utilisation et lors

du gonflage; consulter le flanc

de pneu pour obtenir la pression

correcte.

REMARQUE : des réservoirs d’air,

des compresseurs et d’autres

appareils similaires utilisés pour

gonfler les pneus peuvent remplir

de petits pneus à ces pressions

très rapidement. Régler le régulateur de pression d’air à une pression moindre que celle indiquée sur

le pneu. Ajouter de l’air par petite

quantité et utiliser fréquemment

le manomètre pour empêcher un

surgonflage.

AVERTISSEMENT : RISQUE DE CHOC ÉLECTRIQUE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Votre compresseur d’air est

alimenté à l’électricité. Tout

comme n’importe quel autre

dispositif alimenté de façon

électrique, s’il n’est pas

utilisé correctement, il peut

causer un choc électrique.

• Ne faites jamais fonctionner

le compresseur à l’extérieur

lorsqu’il pleut ou dans des

conditions humides.

• Ne faites jamais fonctionner

le compresseur avec les

couvercles de protection

enlevés ou endommagés.

• Les tentatives de réparation

par un personnel non qualifié

peuvent résulter en de

graves blessures, voire la

mort par électrocution.

• Tout câblage électrique ou

toute réparation nécessaire

pour ce produit doit être pris

en charge par un centre de

réparation en usine autorisé

D

EWALT ou un centre

de réparation D

EWALT

conformément aux codes

électriques nationaux et

locaux.

24

Page 25

•

Mise à la terre

électrique :

ne pas faire une mise à

la terre adéquate de ce

produit pourrait résulter en

des blessures graves voire

la mort par électrocution.

Consulter

relatives à la mise à la

terre

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Le flux d’air comprimé peut

endommager les tissus mous

de la peau exposée et peut

projeter la poussière, des

fragments, des particules

détachées et des petits

objets à haute vitesse, ce qui

entraînerait des dommages et

des blessures personnelles.

le fait de

les directives

sous

Installation.

AVERTISSEMENT : RISQUE PROVENANT DES

OBJETS PROJETÉS EN L’AIR

• Assurez-vous que le

circuit électrique auquel le

compresseur est branché

fournit une mise à la terre

électrique adéquate, une

tension appropriée et une

bonne protection des fusibles.

• Toujours utiliser de l’équipement

de sécurité homologué :

protection oculaire conforme

à la norme ANSI Z87.1 (CAN/

CSA Z94.3) munie d’écrans

latéraux lors de l’utilisation du

compresseur.

• Ne jamais pointer une buse

ou un pulvérisateur vers une

partie du corps ou vers d’autres

personnes ou des animaux.

• Toujours mettre le compresseur

hors tension et purger la

pression du tuyau à air et du

réservoir d’air avant d’effectuer

l’entretien, de fixer des outils ou

des accessoires.

AVERTISSEMENT : ATTENTION SURFACES CHAUDES

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Toucher à du métal

exposé comme la tête

du compresseur ou du

moteur, la tubulure des

gaz d’échappement ou de

sortie, peut se solder en de

sérieuses brûlures.

• Ne jamais toucher à des

pièces métalliques exposées

sur le compresseur pendant

ou immédiatement après son

utilisation. Le compresseur

reste chaud pendant plusieurs

minutes après son utilisation.

• Ne pas toucher ni effectuer

des réparations aux coiffes de

protection avant que l’appareil

n’ait refroidi.

Français

25

Page 26

AVERTISSEMENT : RISQUE ASSOCIÉ

AUX PIÈCES MOBILES

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Les pièces mobiles comme

une poulie, un volant ou une

courroie peuvent provoquer

de graves blessures si elles

entrent en contact avec vous

ou vos vêtements.

• Ne jamais utiliser le

compresseur si les protecteurs

ou les couvercles sont

endommagés ou retirés.

• Tenir les cheveux, les

vêtements et les gants hors

de portée des pièces en

mouvement. Les vêtements

amples, bijoux ou cheveux

longs peuvent s’enchevêtrer

dans les pièces mobiles.

Français

• S’éloigner des évents car ces

derniers pourraient camoufler

des pièces mobiles.

• Utiliser le compresseur avec

des pièces endommagées

ou manquantes ou le réparer

sans coiffes de protection

risque de vous exposer à

des pièces mobiles et peut

• Toutes les réparations requises

pour ce produit devraient être

effectuées par un centre de

réparation de l’usine D

ou un centre de réparation

autorisé D

se solder par de graves

blessures.

EWALT.

EWALT

AVERTISSEMENT : RISQUE ASSOCIÉ À

UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Une utilisation dangereuse

de votre compresseur d’air

pourrait provoquer de graves

blessures, voire votre décès

ou celle d’autres personnes.

• Revoir et comprendre toutes les

directives et les avertissements

contenus dans le présent mode

d’emploi.

• Se familiariser avec le

fonctionnement et les

commandes du compresseur

d’air.

• Dégager la zone de travail de

toutes personnes, animaux et

obstacles.

• Tenir les enfants hors de portée

du compresseur d’air en tout

temps.

• Ne pas utiliser le produit en cas

de fatigue ou sous l’emprise

d’alcool ou de drogues. Rester

vigilant en tout temps.

• Ne jamais rendre inopérant les

fonctionnalités de sécurité du

produit.

• Installer un extincteur dans la

zone de travail.

26

Page 27

• Ne pas utiliser l’appareil lorsqu’il

manque des pièces ou que

des pièces sont brisées ou non

autorisées.

AVERTISSEMENT

• Un compresseur portatif peut

tomber d’une table, d’un établi

ou d’un toit et causer des

dommages au compresseur,

ce qui pourrait résulter en de

graves blessures, voire la mort

de l’opérateur.

AVERTISSEMENT : RISQUE DE BLESSURE

EN SOULEVANT LE PRODUIT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Soulever un objet trop lourd

peut se solder par de graves

blessures.

: RISQUE DE CHUTE

• Toujours faire fonctionner le

compresseur alors qu’il est

dans uns position sécuritaire

et stable afin d’empêcher

un mouvement accidentel

de l’appareil. Ne jamais faire

fonctionner le compresseur

sur un toit ou sur toute autre

position élevée. Utiliser un

tuyau d’air supplémentaire pour

atteindre les emplacements en

hauteur.

• Le compresseur est trop lourd

pour être soulevé par une

seule personne. Demander de

l’aide avant de le soulever.

MISE EN GARDE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Dans certaines conditions et

selon la durée d’utilisation, le

bruit provoqué par ce produit

peut contribuer à une perte

auditive.

: RISQUE ASSOCIÉ AU BRUIT

• Toujours utiliser un équipement

de sécurité homologué :

protection auditive conforme à

la norme ANSI S12.6 (S3.19).

CONSERVER CES DIRECTIVES

POUR UN USAGE ULTÉRIEURC

CARACTÉRISTIQUES

INTERRUPTEUR MARCHE/AUTO/ARRÊT

Mettre cet interrupteur (A) sur la position

MARCHE/AUTO pour avoir une

alimentation automatique au

manocontacteur et sur la position ARRÊT

pour la mise hors tension à la fin de

chaque utilisation.

MANOCONTACTEUR

Le manocontacteur démarre automatiquement le moteur lorsque la

pression du réservoir d’air chute sous la pression d’enclenchement

réglée en usine. Il arrête le moteur lorsque la pression du réservoir

d’air atteint la pression de déclenchement réglée en usine.

I

A

F

Français

27

Page 28

SOUPAPE DE SÛRETÉ

Si le manocontacteur ne met pas hors tension

le compresseur d’air à sa pression de

déclenchement réglée, la soupape de

sûreté (G) sert de protection contre une

pression élevée en allant à la pression réglée

en usine (pression légèrement plus élevée

que le réglage de déclenchement du

G

manocontacteur).

CLAPET

Lorsque le compresseur d’air fonctionne, le clapet (F) est ouvert,

ce qui permet à l’air comprimé d’entrer dans le réservoir d’air.

Lorsque le compresseur d’air atteint la pression de déclenchement,

le clapet se ferme, ce qui permet à la pression d’air de rester dans

le réservoir d’air.

MANOMÈTRE DE RÉSERVOIR

Le manomètre de réservoir (B) indique la

pression d’air de réserve dans le

Français

réservoir.

MANOMÈTRE DE PRISE DE COURANT

B

C

D

Le manomètre de prise (C) indique la

pression d’air disponible du côté de la

prise du régulateur. Cette pression est

contrôlée par le régulateur et est toujours

inférieure ou égale à la pression du réservoir.

RÉGULATEUR

Le régulateur (D) contrôle la pression d'air indiqué sur le manomètre

de sortie. Tirez le bouton et tournez-le dans le sens des aiguilles

d'une montre pour augmenter la pression et dans le sens contraire pour réduire la pression. Une fois que la pression désirée est

atteinte, poussez le bouton pour le verrouiller.

CORP DE BRANCHEMENT RAPIDE UNIVERSEL

Le corps de branchement rapide universel (E) accepte les trois

styles de prises de branchement rapide les plus populaires :

industrielle, automobile, et ARO. Il suffit tout simplement d’appuyer

une seule fois pour connecter le corps de branchement rapide à la

prise. Les deux corps de branchement rapide permettent d’utiliser

deux outils en même temps.

ROBINET DE PURGE

Le robinet de purge (H) se trouve à la base du

réservoir d’air et est utilisé pour vidanger la

condensation à la fin de chaque utilisation.

Consulter le chapitre Vidange du réservoir sous

Entretien.

H

SYSTÈME DE REFROIDISSEMENT

Ce compresseur contient un système de refroidissement de

conception évoluée. Il est tout à fait normal pour ce ventilateur de

souffler de l’air par les orifices d’aération en grandes quantités. Le

système de refroidissement fonctionne lorsque l’air est expulsé.

POMPE DE COMPRESSEUR D’AIR

La pompe compresse l’air dans le réservoir d’air. L’air de travail

E

n’est pas disponible avant que le compresseur ait augmenté la

pression du réservoir d’air au-dessus de ce qui est requis à la

sortie d’air.

FILTRE D’ADMISSION D’AIR

Le filtre (J) sert à purifier l’air qui ente dans la pompe. Pour que la

pompe reçoive un flux d’air constant propre, froid et sec, le filtre doit

toujours être propre et l’entrée d’air doit être exempte d’obstructions.

28

Page 29

PROTECTEUR DE SURCHARGE DU MOTEUR

Le moteur dispose d’un protecteur de surcharge thermique. Si le

moteur surchauffe, peu importe la raison, le protecteur de surcharge

met le moteur hors tension. Il faut donner au moteur le temps de

refroidir avant de le redémarrer. Redémarrage :

1. Mettre le levier Marche/Auto/Arrêt en position d’ARRÊT, puis

débrancher l’appareil.

2. Laisser le moteur refroidir.

3. Brancher le cordon d’alimentation dans le bon réceptacle de

circuit de dérivation.

4. Mettre le levier Marche/Auto/Arrêt en position de MARCHE/

AUTO.

INSTALLATION

Assemblage

RACCORDEMENT DES TUYAUX

AVERTISSEMENT : Risque d’utilisation dangereuse. Saisir

fermement le tuyau en main lors du raccordement ou de la

déconnexion pour empêcher un à-coup du tuyau.

1. S’assurer que le manomètre régulé indique 0 PSI.

2. Saisir le tuyau au niveau de la prise de branchement rapide

et enfoncer la prise dans le corps de branchement rapide (E). Le

coupleur se mettra en place.

3. Saisir le tuyau et tirer pour s’assurer que le coupleur est bien en

place.

DÉCONNEXION DES TUYAUX

AVERTISSEMENT : Risque d’utilisation dangereuse. Saisir

fermement le tuyau en main lors du raccordement ou de la

déconnexion pour empêcher un à-coup du tuyau.

1. S’assurer que le manomètre régulé indique 0 PSI.

2. Retirer le coupleur du corps de branchement rapide pour

dégager la prise de branchement rapide du tuyau.

Directives relatives à la mise à la terre

AVERTISSEMENT : Risque de choc électrique. Au cas où un

court-circuit se produirait, la mise à la terre réduit le risque de choc

électrique en fournissant un fil d’échappement pour le courant

électrique. Le compresseur d’air doit être correctement mis à

la terre.

Le compresseur d’air portatif est muni d’un cordon ayant un fil de

mise à terre avec une prise de mise à la terre.

1. Le cordon qui se fixe et se branche (M)

avec cet appareil contient une goupille

de mise à la terre (L). Cette prise DOIT

être utilisée avec une prise correctement

mise à la terre (K).

IMPORTANT : la prise utilisée doit être

installée et mise à la terre en fonction de

tous les codes et de toutes les ordonnances à l’échelle locale.

2. Assurez-vous que la prise utilisée a la même configuration que

la fiche mise à la terre. N’UTILISEZ PAS UN ADAPTATEUR.

3. Inspectez la fiche et le cordon avant chaque utilisation. Ne les

utilisez pas s’ils présentent des signes de dommages.

4. Si ces directives sur la mise à la terre ne sont pas entièrement

comprises, ou si vous n’êtes pas certain que le compresseur a

correctement été mis à la terre, faites vérifier l’installation par un

électricien qualifié.

M

K

L

Français

29

Page 30

DANGER : Risque de choc électrique. UNE MISE À LA TERRE

INADÉQUATE PEUT PROVOQUER UN CHOC ÉLECTRIQUE.

• Ne modifiez pas la fiche fournie. Si elle ne s’incère pas dans

la prise disponible, une prise adéquate doit être installée par

un électricien qualifié.

• Les réparations au cordon ou à la fiche DOIVENT être faites

par un électricien qualifié.

Rallonges

Si une rallonge doit être utilisée, s'assurer :

• d'utiliser une rallonge à trois fils, munie d'une fiche à trois lames

avec mise à la terre et une prise de courant à trois fentes qui

accepte la fiche de la rallonge;

• qu'elle est en bon état;

• qu'elle n'excède pas 50 pi (15,2 m);

• que les fils sont d'un calibre minimum de 12 AWG. (La grosseur

du fil augmente comme le numéro de calibre diminue. Les fils de

Français

calibre 10 AWG et 8 AWG peuvent également être utilisés. NE

PAS UTILISER UN FIL DE CALIBRE 14 OU 16 AWG.)

MISE EN GARDE :

de tension qui entraînera une perte de puissance au moteur ainsi

qu'une surchauffe. Au lieu d'utiliser une rallonge électrique, augmentez plutôt la longueur du boyau d'air en connectant un autre

boyau à l'extrémité. Connectez des boyaux supplémentaires au

besoin.

L'utilisation d'une rallonge produira une chute

Protection de la tension et du circuit

Consulter les Exigences en matière de tension et de circuit

de dérivation minimales sous Fiche technique de la pompe/du

moteur.

MISE EN GARDE : Certains compresseurs d’air peuvent

fonctionner sur un circuit de 15 A si les conditions suivantes sont

réunies.

• L’alimentation en tension doit se conformer au Code électrique

national.

• Le circuit n’est pas utilisé pour alimenter d’autres besoins en

électricité.

• Les rallonges doivent se conformer aux spécifications.

• Le circuit est équipé d’un disjoncteur de 15 A au minimum

ou d’un fusible à temporisation de 15 A. REMARQUE : si le

compresseur est branché à un circuit protégé par des fusibles,

utiliser seulement des circuits à temporisation. Les fusibles de

temporisation devraient avoir l’inscription « D » au Canada et

« T » aux É.-U.

Si une des conditions ci-dessus n’est pas satisfaite, ou si le

fonctionnement du compresseur cause des interruptions du

courant électrique, il peut s’avérer nécessaire de faire fonctionner

l’appareil à partir d’un circuit à 20 A. Il n’est pas nécessaire de

changer les cordons.

Compatibilité

REMARQUE : Toujours utiliser un filtre de canalisation d’air pour

retirer l’humidité et les vapeurs d’huile lors de la pulvérisation de

peinture.

Emplacement

Placer le compresseur d’air dans un endroit propre, sec et bien

aéré à au moins 30,5 cm (12 po) du mur ou d’autres obstructions

qui pourraient interférer avec le débit d’air. Tenir le compresseur

à l’écart des endroits poussiéreux et chargés d’émanations. Ces

impuretés pourraient boucher le filtre et les soupapes d’admission

et s’y agglutiner, nuisant ainsi au bon fonctionnement du

compresseur d’air.

30

Page 31

AVERTISSEMENT : La pompe de compresseur d’air et le

déflecteur ont été conçus pour assurer un refroidissement adéquat.

Les ouvertures d’aération sur le compresseur sont nécessaires

pour garder une température de fonctionnement appropriée. Ne

placez pas de chiffons ou d’autres contenants sur les ouvertures

ou à proximité de celles-ci.

Placer le compresseur d’air sur une surface plane et s’assurer qu’il

repose sur ses pieds de caoutchouc et ses roulettes

ÉLECTRICITÉ

Consulter toutes les directives de sécurité avant d’utiliser l’appareil.

Respecter les directives de sécurité du cordon d’alimentation le cas

échéant. Toujours mettre l’interrupteur Marche/Auto/Arrêt (A) en

position d’ARRÊT avant de retirer la fiche de la prise.

TRANSPORT

Lors du transport du compresseur d’air dans

un véhicule, une remorque, etc. s’assurer que

le réservoir d’air soit bien purgé et que

l’appareil soit bien ancré. Conduire

prudemment pour éviter de basculer l’appareil

dans le véhicule. Un basculement risque

d’endommager le compresseur ou les pièces

contiguës.

LEVAGE

Toujours soulever l'appareil à deux personnes

et utiliser les points de transport (N) recommandés. NE PAS le lever

par la roues ou le déflecteur.

DÉPLACEMENT

MISE EN GARDE : Les roues et la poignée n'offrent pas le

dégagement, la stabilité ou l'appui nécessaire pour descendre ou

monter des escaliers ou des marches avec l'appareil. On doit soulever l'appareil ou le pousser le long d'une rampe.

N

N

1. Pour ce faire, saisir la poignée du compresseur et l'incliner vers

l'arrière sur ses roues.

AVERTISSEMENT : Garder les pieds bien ancrés et faire preuve

d’une grande prudence en transportant le compresseur afin d’éviter

de perdre l’équilibre.

2. Une fois le compresseur à l'endroit voulu, l'abaisser lentement

sur le sol. Toujours ranger le compresseur en position

verticale en l'appuyant sur les amortisseurs et les roues.

MODE D’EMPLOI

Liste de vérifi cation de pré-démarrage

(Fig. 1)

1.

S’assurer que le commutateur Marche/Auto/Arrêt (A) est en

position d’ARRÊT.

2.

Branchez le cordon d’alimentation dans le bon réceptacle de

circuit de dérivation.

sion et du circuit sous Installation.

3. S’assurer que le réservoir d’air soit bien purgé, consulter la rubri-

que

Vidange du réservoir d’air

4. S’assurer que la soupape de purge (H) soit fermée.

5. S’assurer que la soupape de sûreté (G) fonctionne correctement,

consulter la rubrique Vérification de la soupape de sûreté sous

Entretien.

6. Tirez le bouton du régulateur et tourner le bouton du régulateur (D)

en sens antihoraire jusqu’à fermeture complète. S’assurer que

le manomètre régulé indique 0 PSI.

rouiller.

7. Fixez le tuyau et les accessoires. NOTE: Toujours utiliser un

tuyau d’air de 9,5 mm (3/8 po) ou plus prévu pour une pression

de 300 PSI.

31

Consulter la rubrique Protection de la ten-

sous

Entretien.

Poussez le bouton pour le ver-

Français

Page 32

AVERTISSEMENT : Risque d’utilisation dangereuse. Saisir

fermement le tuyau en main lors du raccordement ou de la déconnexion

pour empêcher un à-coup du tuyau.

AVERTISSEMENT : Risque d’utilisation dangereuse. N'utilisez

pas les accessoires endommagés ou portés.

AVERTISSEMENT : Risque d’éclatement. Trop de pression

d’air cause un risque sérieux d’éclatement. Vérifiez la pression

maximum suggérée par le fabricant pour les outils pneumatiques

et les accessoires. La pression de sortie du régulateur ne doit

jamais dépasser une pression nominale maximale.

Réglage initial

AVERTISSEMENT : Ne pas utiliser cet appareil avant d’avoir lu

et compris le mode d’emploi ainsi que l’intégralité des directives de

sécurité, d’utilisation et d’entretien.

PROCÉDURE DE RODAGE

AVERTISSEMENT : Risque de dommages à la propriété. Respecter

à la lettre les directives de rodage ci-dessous pour empêcher de

Français

graves dommages.

Cette procédure est requise avant que le compresseur d’air soit

mis en service et lorsque le clapet ou une pompe de compresseur

complète a été remplacé.