Page 1

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus CX9300F/CX9400Fax/

DX9400F

SEMF07-003

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2007 SEIKO EPSON CORPORATION.

Imaging Products CS, PL & Environmental Management

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO

SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED

CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR

OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN USING COMPRESSED AIR PRODUCTS; SUCH AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF SUCH

PRODUCTS CONTAINING FLAMMABLE GAS IS PROHIBITED.

Page 4

About This Manual

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Exploded Diagram

• Parts List

• Circuit Diagrams

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Indicates that a particular task must be carried out according to a certain

standard after disassembly and before re-assembly, otherwise the

quality of the components in question may be adversely affected.

Page 5

Revision Status

Revision Date of Issue Description

A August 29, 2007 First Release

Page 6

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features................................................................................................................ 10

1.2 Printing Specifications......................................................................................... 11

1.2.1 Basic Specifications.................................................................................... 11

1.2.2 Ink Cartridge............................................................................................... 11

1.2.3 Print Mode .................................................................................................. 12

1.2.4 Supported Paper.......................................................................................... 14

1.2.5 Printing Area............................................................................................... 16

1.3 Scanner Specifications......................................................................................... 16

1.3.1 Scanning Range .......................................................................................... 17

1.4 General Specifications......................................................................................... 17

1.4.1 Electrical Specifications ............................................................................. 17

1.4.2 Environmental Conditions .......................................................................... 18

1.4.3 Durability.................................................................................................... 18

1.4.4 Acoustic Noise............................................................................................ 18

1.4.5 Safety Approvals (Safety standards/EMI) .................................................. 18

1.5 Interface............................................................................................................... 19

1.5.1 USB Interface ............................................................................................. 19

1.5.2 FAX Interface ............................................................................................. 19

1.5.3 Memory Card Slots..................................................................................... 20

1.6 Control Panel ....................................................................................................... 21

1.6.1 Operation Buttons & LEDs ........................................................................ 21

1.6.2 Control Panel Functions in Each Mode ...................................................... 23

1.7 Specification for Each Function .......................................................................... 25

1.7.1 Stand-alone Copy Function ........................................................................ 25

1.7.2 Memory Card Direct Print Function........................................................... 27

1.7.3 Camera Direct Print Function(USB Direct Print/PictBridge) .................... 31

1.7.4 Reprint/Restore Photos Function................................................................ 33

1.7.5 Setup Mode................................................................................................. 34

1.7.6 FAX Function ............................................................................................. 36

Chapter 2 OPERATING PRINCIPLES

2.1 Overview ............................................................................................................. 40

2.1.1 Printer Mechanism...................................................................................... 40

2.1.2 Motors & Sensors ....................................................................................... 41

2.2 Printer Mechanism Operating Principle .............................................................. 42

2.2.1 Printhead..................................................................................................... 42

2.2.2 Carriage Mechanism................................................................................... 44

2.2.3 Paper Loading/Paper Feed Mechanism ...................................................... 45

2.2.4 Ink System Mechanism .............................................................................. 50

2.2.5 Ink Sequence............................................................................................... 53

2.3 Scanner Mechanism ............................................................................................ 54

2.3.1 Scanner Carriage Mechanism..................................................................... 54

2.4 ADF Mechanism Operating Principle................................................................. 56

2.4.1 ADF Mechanism......................................................................................... 56

2.4.2 ADF Document Feed Mechanism .............................................................. 57

2.5 Electrical Circuit Operating Principles................................................................ 59

2.5.1 Power Supply Board................................................................................... 59

2.5.2 C696 Main Board ....................................................................................... 60

2.6 FAX Function Operating Principle ..................................................................... 66

2.6.1 Line Connection Function .......................................................................... 66

2.6.2 FAX Image Storing Function ..................................................................... 66

2.6.3 Communication Function ........................................................................... 67

2.6.4 Print Function ............................................................................................. 67

2.6.5 Save Setting Function................................................................................. 67

2.6.6 Data Recording Function............................................................................ 67

2.6.7 External Telephone Function...................................................................... 67

6

Page 7

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

Chapter 3 TROUBLESHOOTING

3.1 Overview ............................................................................................................. 69

3.1.1 Specified Tools ........................................................................................... 69

3.1.2 Preliminary Checks..................................................................................... 69

3.2 Troubleshooting................................................................................................... 70

3.2.1 Motor and Sensor Troubleshooting ............................................................ 70

3.3 Error Indications and Fault Occurrence Causes .................................................. 71

3.3.1 Error Message List...................................................................................... 71

3.3.2 Troubleshooting by Error Message ............................................................ 73

3.3.3 Superficial Phenomenon-Based Troubleshooting ...................................... 91

3.4 FAX Troubleshooting.......................................................................................... 98

3.4.1 FAX Log..................................................................................................... 98

3.4.2 Error Code/Superficial Phenomenon-Based Troubleshooting ................. 102

3.5 Fax Function/External Connection (EXT port) Function Check ...................... 104

3.5.1 Outline ...................................................................................................... 104

3.5.2 Fax Function and External Connection Function Check.......................... 104

Chapter 4 DISASSEMBLY/ASSEMBLY

4.1 Overview ........................................................................................................... 111

4.1.1 Precautions................................................................................................ 111

4.1.2 Tools ......................................................................................................... 111

4.1.3 Work Completion Check .......................................................................... 112

4.2 Disassembly Procedures.................................................................................... 113

4.3 Removing the Housing...................................................................................... 115

4.3.1 Paper Support Assy................................................................................... 115

4.3.2 Stacker Assy ............................................................................................. 115

4.3.3 Scanner Unit/ADF Unit ............................................................................ 116

4.3.4 Upper Housing.......................................................................................... 119

4.3.5 Front Housing ........................................................................................... 120

4.4 Removing the Circuit Boards ............................................................................ 121

4.4.1 Main Board Unit ....................................................................................... 121

4.4.2 Panel Unit ................................................................................................. 124

4.4.3 Power Supply Unit.................................................................................... 126

4.5 Disassembling the Printer Mechanism .............................................................. 127

4.5.1 Printhead ................................................................................................... 127

4.5.2 CR Scale ................................................................................................... 130

4.5.3 Hopper ...................................................................................................... 131

4.5.4 Removing the Printer Mechanism (Lower Housing)/Card Slot Cover .... 132

4.5.5 Left Frame ................................................................................................ 134

4.5.6 Front Frame/Right Frame ......................................................................... 135

4.5.7 Star Wheel Holder Assy ........................................................................... 137

4.5.8 EJ Roller ................................................................................................... 137

4.5.9 PF Encoder Sensor.................................................................................... 138

4.5.10 PF Scale .................................................................................................. 139

4.5.11 PF Motor................................................................................................. 140

4.5.12 CR Motor................................................................................................ 141

4.5.13 Main Frame Assy.................................................................................... 143

4.5.14 CR Unit................................................................................................... 145

4.5.15 Upper Paper Guide ................................................................................. 147

4.5.16 ASF Unit................................................................................................. 147

4.5.17 Ink System Unit ...................................................................................... 149

4.5.18 Front Paper Guide................................................................................... 151

4.5.19 PF Roller................................................................................................. 153

4.5.20 Waste Ink Pads ....................................................................................... 154

4.6 Disassembling the Scanner Unit........................................................................ 155

4.6.1 Separating the Scanner Unit and the ADF Unit ....................................... 155

4.6.2 Upper Scanner Housing............................................................................ 156

4.6.3 Scanner Carriage Unit .............................................................................. 157

4.6.4 Scanner Motor Unit .................................................................................. 159

4.7 Disassembling the ADF Unit ............................................................................ 160

4.7.1 ADF Hinge ............................................................................................... 160

4.7.2 ADF Cover Assy ...................................................................................... 161

4.7.3 ADF Paper Support Assy ......................................................................... 161

4.7.4 ADF Motor Unit ....................................................................................... 162

4.7.5 ADF Frame Assy ...................................................................................... 164

4.7.6 ADF Front Cover...................................................................................... 165

4.7.7 ADF Driven Roller ................................................................................... 165

4.7.8 ADF PF Roller.......................................................................................... 166

7

Page 8

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

Chapter 5 ADJUSTMENT

5.1 Adjustment Items and Overview....................................................................... 168

5.1.1 Servicing Adjustment Item List................................................................ 168

5.1.2 Required Adjustments .............................................................................. 170

5.2 Using the Adjustment Program ......................................................................... 172

5.2.1 TOP Margin Adjustment .......................................................................... 172

5.2.2 First Dot Position Adjustment .................................................................. 172

5.2.3 Head Angular Adjustment ........................................................................ 173

5.2.4 Bi-D Adjustment....................................................................................... 174

5.2.5 PF Adjustment .......................................................................................... 174

5.2.6 PF Band Adjustment................................................................................. 175

5.2.7 Bottom Margin Adjustment...................................................................... 176

Chapter 6 MAINTENANCE

6.1 Overview ........................................................................................................... 178

6.1.1 Cleaning.................................................................................................... 178

6.1.2 Service Maintenance................................................................................. 178

6.1.3 Lubrication................................................................................................ 179

Chapter 7 APPENDIX

7.1 Exploded Diagram / Parts List .......................................................................... 185

7.2 Electrical Circuits .............................................................................................. 185

8

Page 9

PRODUCT DESCRIPTION

CHAPTER

1

Page 10

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

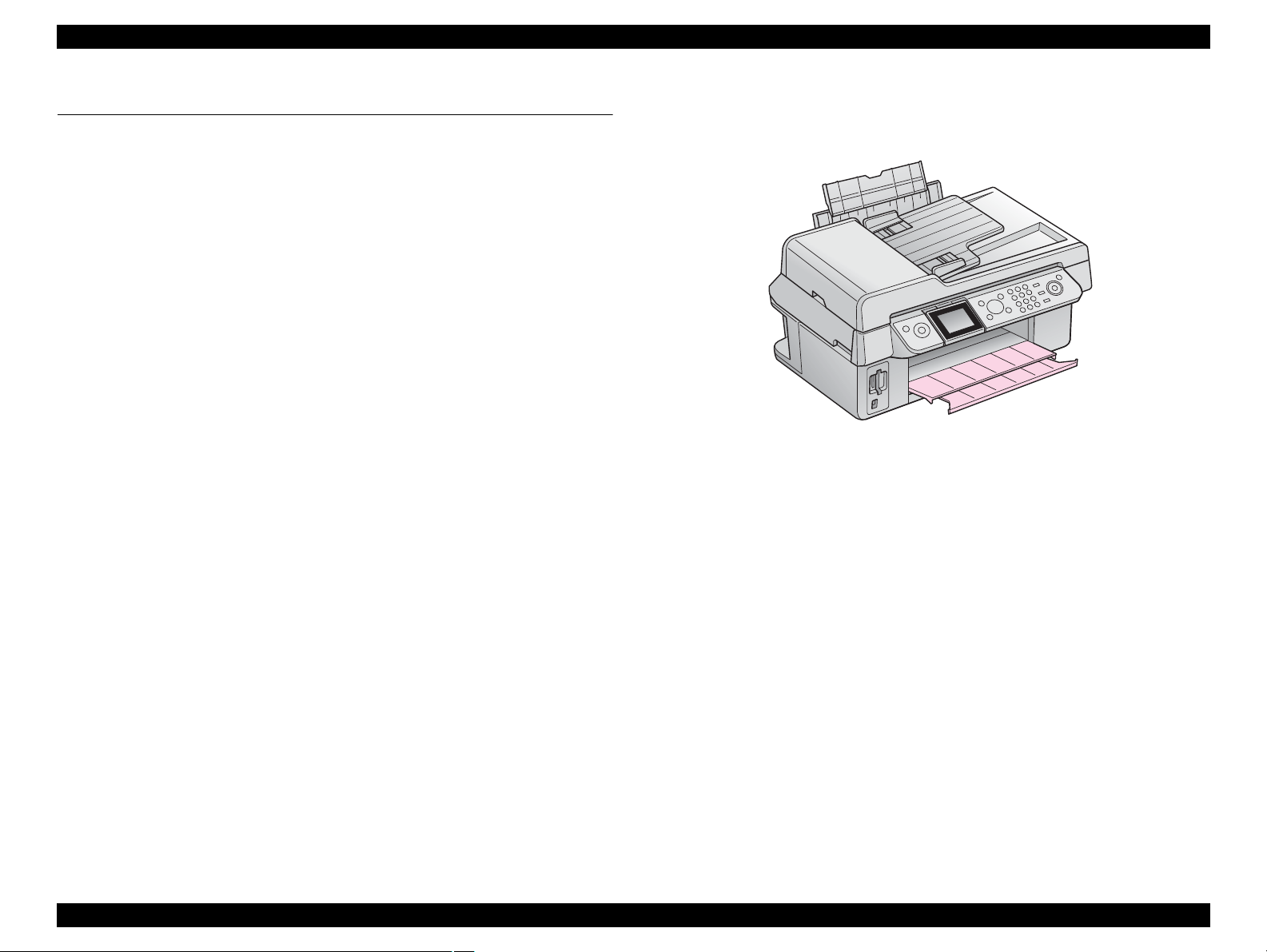

1.1 Features

EPSON Stylus CX9300F/CX9400Fax/DX9400F are color ink-jet printers with scanner

and FAX functions, and have the following features.

Available Functions

Printer

Printing from a computer or directly printing from a memory card

Scanner

Scanning from a computer

Copy

Stand alone copy using the scanning and printing functions

Memory card slot

Available as memory card reader for PC

FAX

Sending/receiving fax

Color LCD

2.5-inch color TFT LCD

ADF

Continuous scanning using an ADF

High speed & High quality

Maximum print resolution: SMGA 5760 (H) x 1440 (V) dpi

D4-chips Turbo II print head achieves higher print speed than ever.

(Black: 90 nozzles x 1, Color: 90 nozzles x 1 per color)

Four independent ink cartridges is installed.

Newly developed pigment ink is employed.

Borderless printing on specified EPSON brand paper is available.

Dimensions

Dimensions: 460 mm (W) x 410 mm (D) x 236 mm (H)

(Paper support and stacker are closed. Rubber feet are included)

Weight: 7.6 kg

(Ink cartridge and power cable are excluded)

Figure 1-1. External View

PRODUCT DESCRIPTION Features 10

Page 11

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

C A U T I O N

1.2 Printing Specifications

1.2.1 Basic Specifications

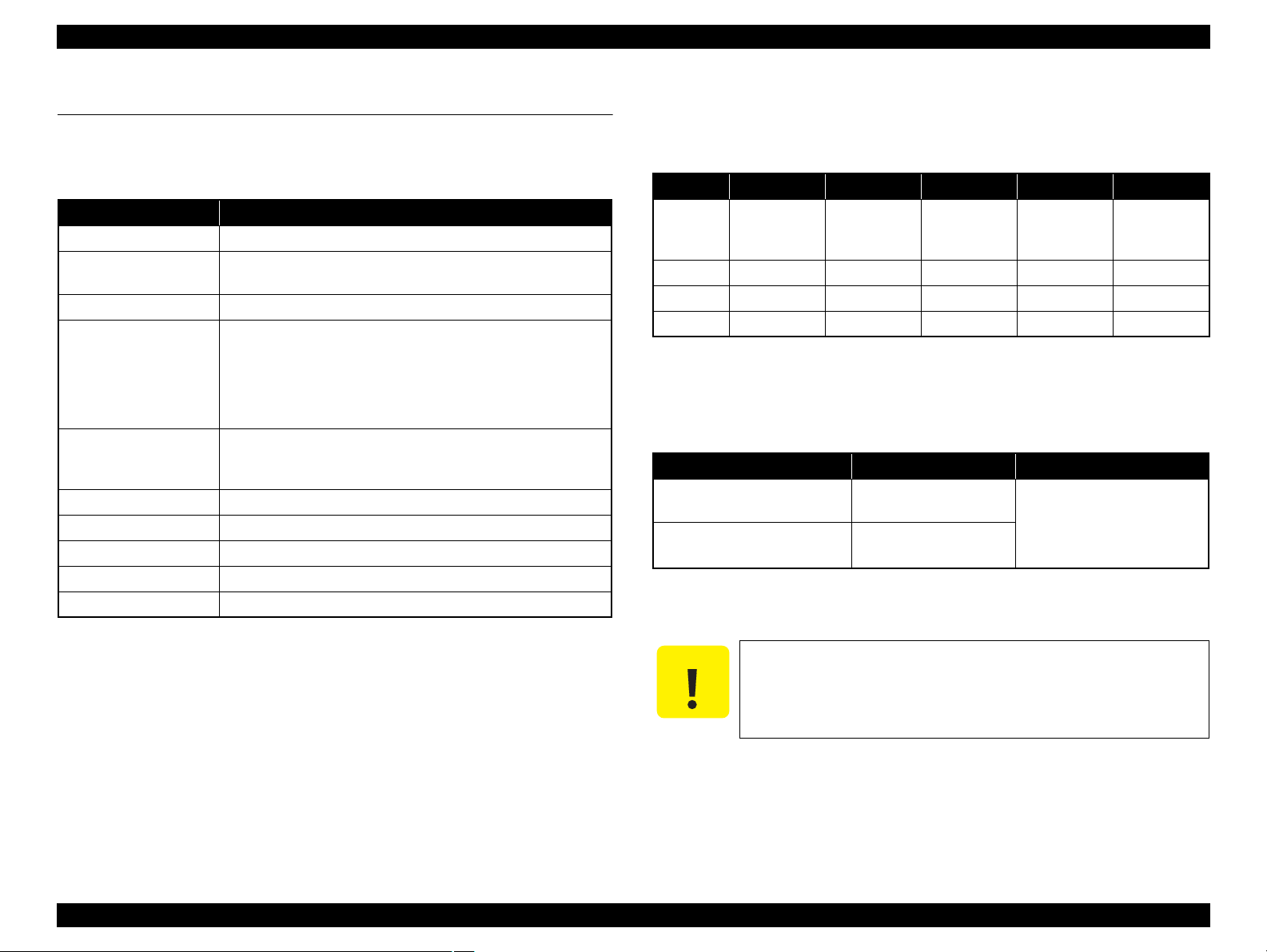

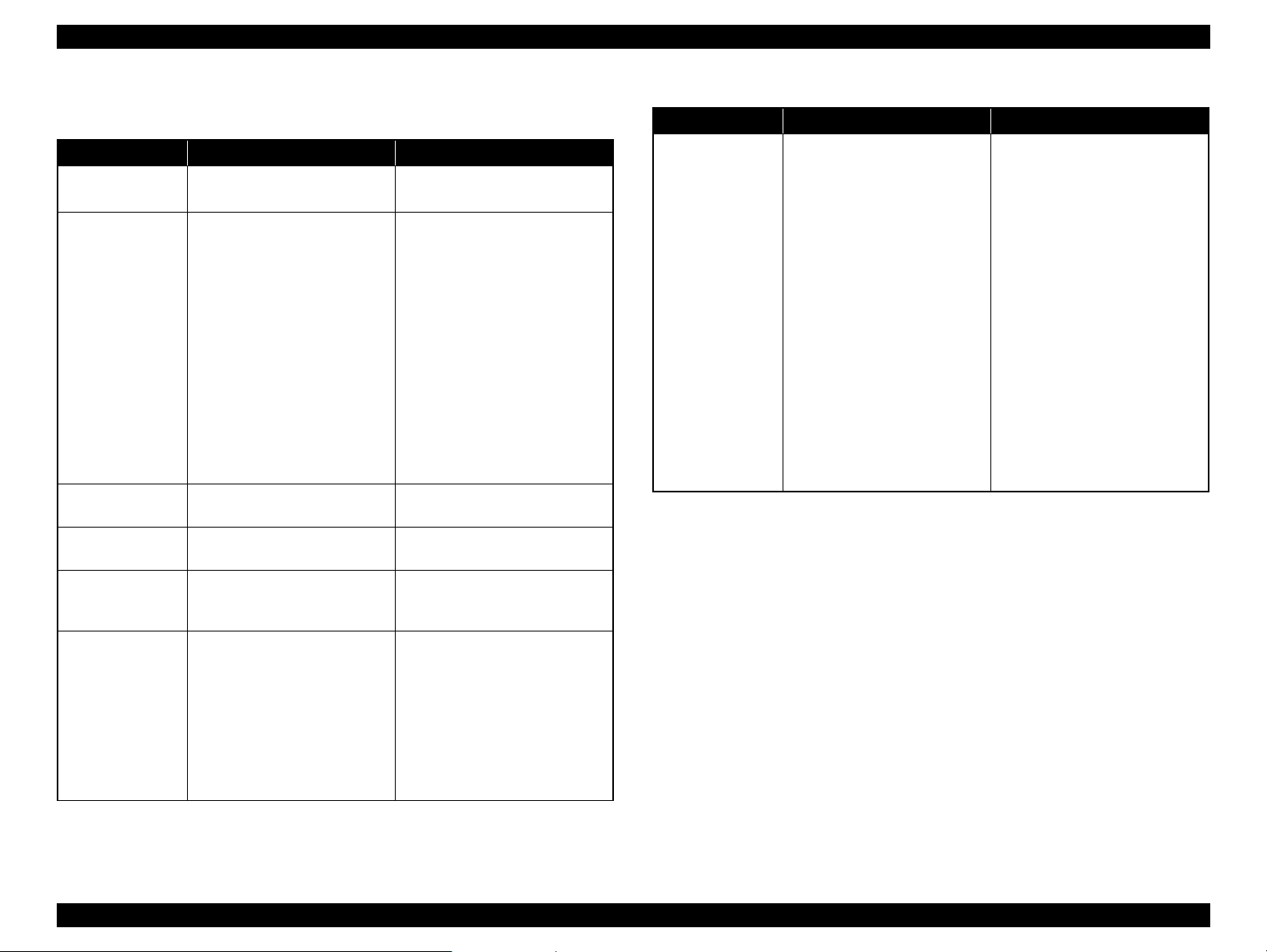

Table 1-1. Printer Specifications

Item Specification

Print method On-demand ink jet

Nozzle configuration

Print direction Bi-directional minimum distance printing, Unidirectional printing

Print resolution

Control code

Input buffer size 64 Kbytes

Paper feed method Friction feed, using the ASF (Auto Sheet Feeder)

Paper path Top feed, front out

Paper feed rates T.B.D. mm/sec (at 25.4 mm feed)

PF interval Programmable in 0.01764 mm (1/1440 inch) steps

Black: 90 nozzles x 1

Color: 90 nozzles x 3 (Cyan, Magenta, Yellow)

Horizontal x Vertical (dpi)

• 360 x 120 • 1440 x 720

• 360 x 360 • 1440 x 1440

• 360 x 720 • SMGA 5760 x 1440 (2880 x 1440)

• 720 x 720

• ESC/P Raster command

• ESC/P-R (RGB) command

• EPSON Remote command

1.2.2 Ink Cartridge

The product numbers of the EPSON ink cartridges for this printer are shown below.

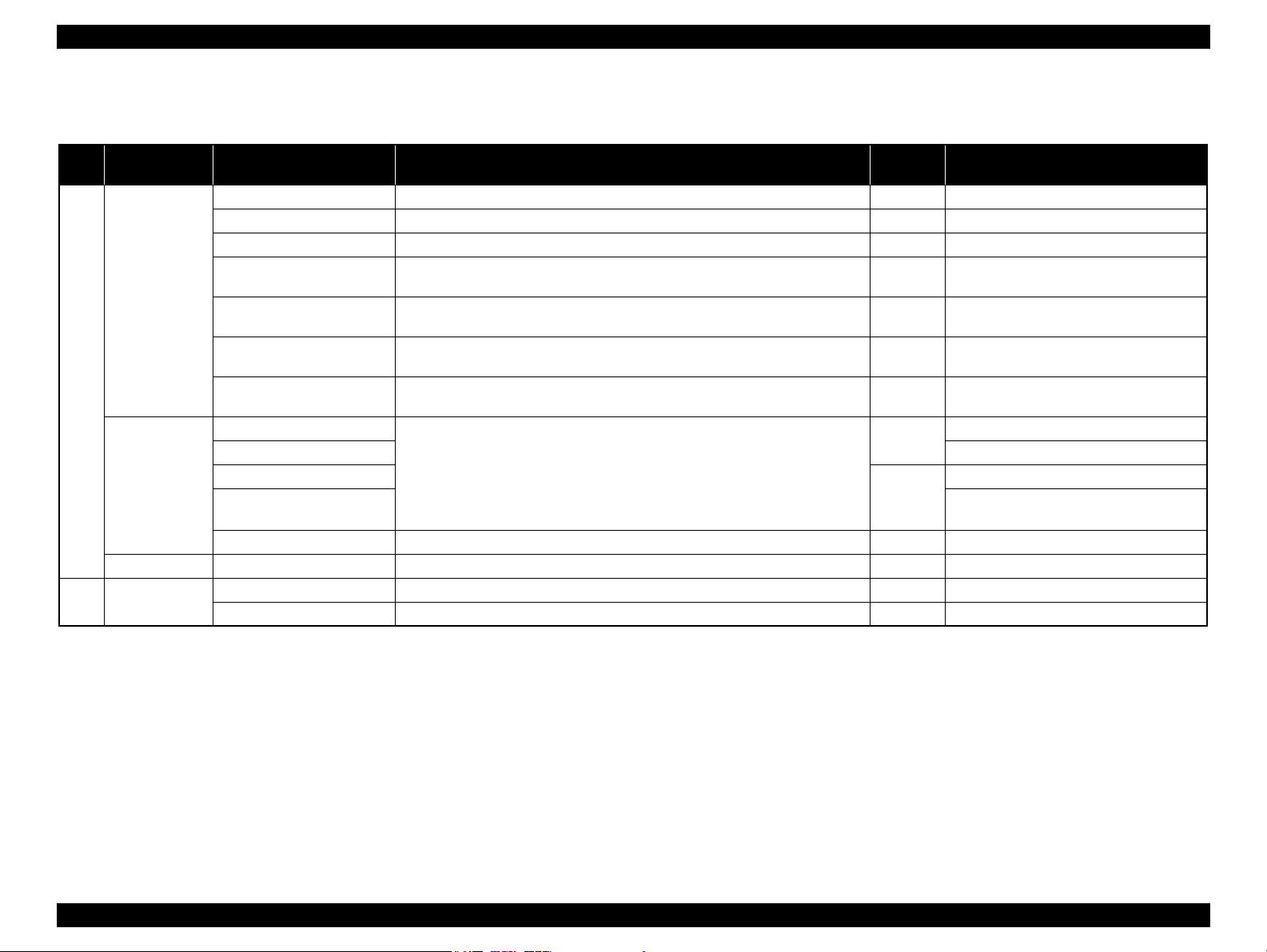

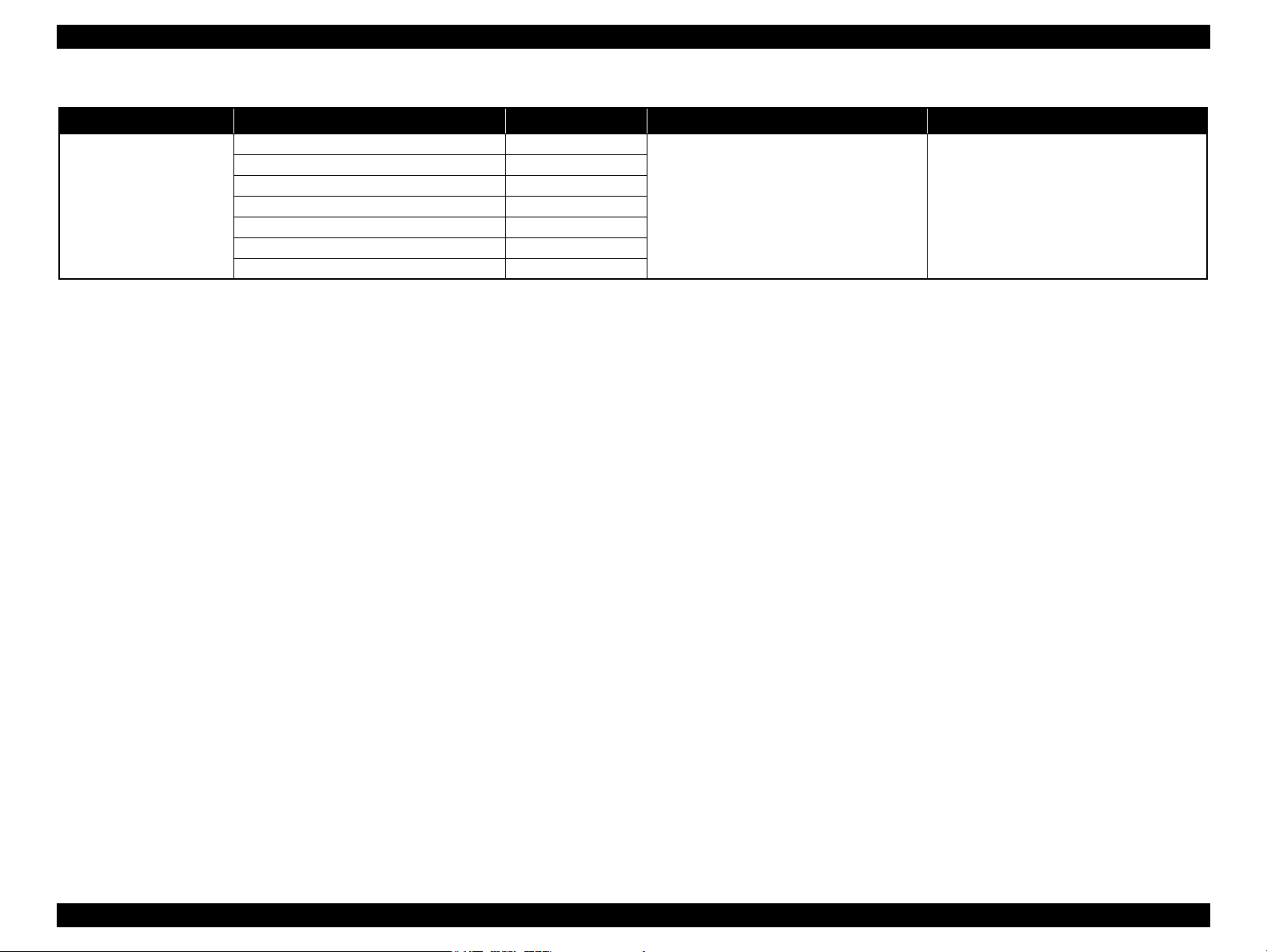

Table 1-2. Product No. of Ink Cartridges

Color EAI Latin Euro CISMEA Asia

Black

Cyan T0692 (3S) T0732 (3S) T0712 (3S) T0732 (3S) T0732 (3S)

Magenta T0693 (3S) T0733 (3S) T0713 (3S) T0733 (3S) T0733 (3S)

Yellow T0694 (3S) T0734 (3S) T0714 (3S) T0734 (3S) T0734 (3S)

T0681 (S)

T0691 (2S)

Shelf life

Two years from production date (if unopened), six months after opening package.

Storage Temperature

Situation Storage Temperature Limit

When stored in individual boxes

When installed in main unit

Dimension

12.7 mm (W) x 68 mm (D) x 47 mm (H)

T0731H (S)

T0731 (2S)

T0901 (3S)

T0711H (S)

T0711 (2S)

T0731H (S)

T0731 (2S)

Table 1-3. Storage Temperature

-20 oC to 40 oC

(-4oF to 104oF)

-20 oC to 40 oC

(-4oF to 104oF)

1 month max. at 40 oC (104oF)

T0731 (2S)

Do not use expired ink cartridges.

The ink in the ink cartridge freezes at -16 °C (3.2 oF). It takes

about three hours under 25 °C (77

o

F) until the ink thaws and

becomes usable.

PRODUCT DESCRIPTION Printing Specifications 11

Page 12

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

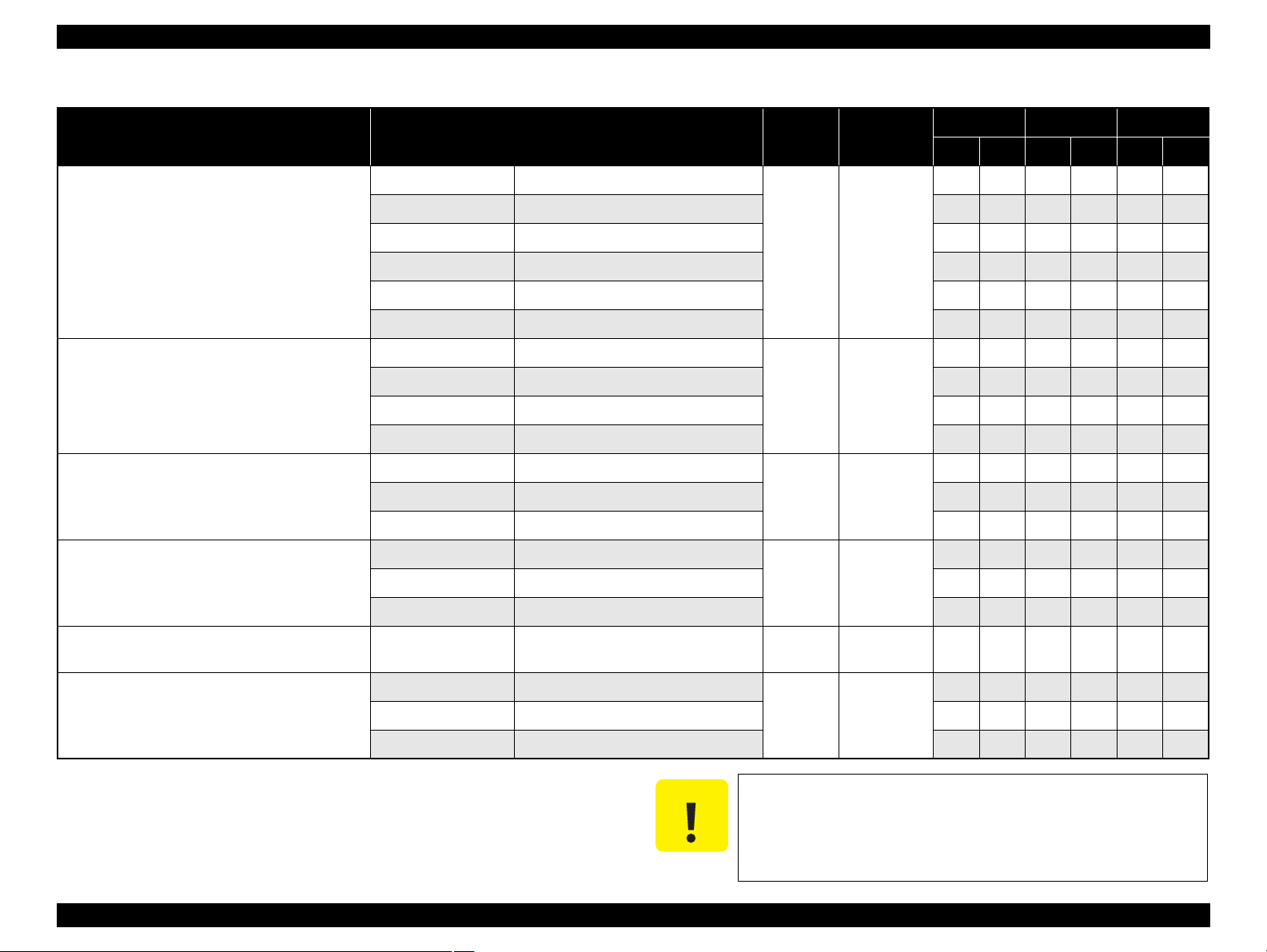

1.2.3 Print Mode

Media Print Mode

• Plain paper

• Premium Bright

White Paper (EAI)

• Premium Bright

White Inkjet Paper

(others)

• Ultra Premium

Glossy Photo Paper

(EAI)

• Ultra Glossy Photo

Paper (others)

• Photo Paper Glossy

(EAI)

• Glossy Photo Paper

(others)

• Premium Photo

Paper Glossy (EAI)

• Premium Glossy

Photo Paper (others)

• Premium Photo

Paper Semi-Gloss

(EAI)

• Premium Semigloss

Photo Paper (other)

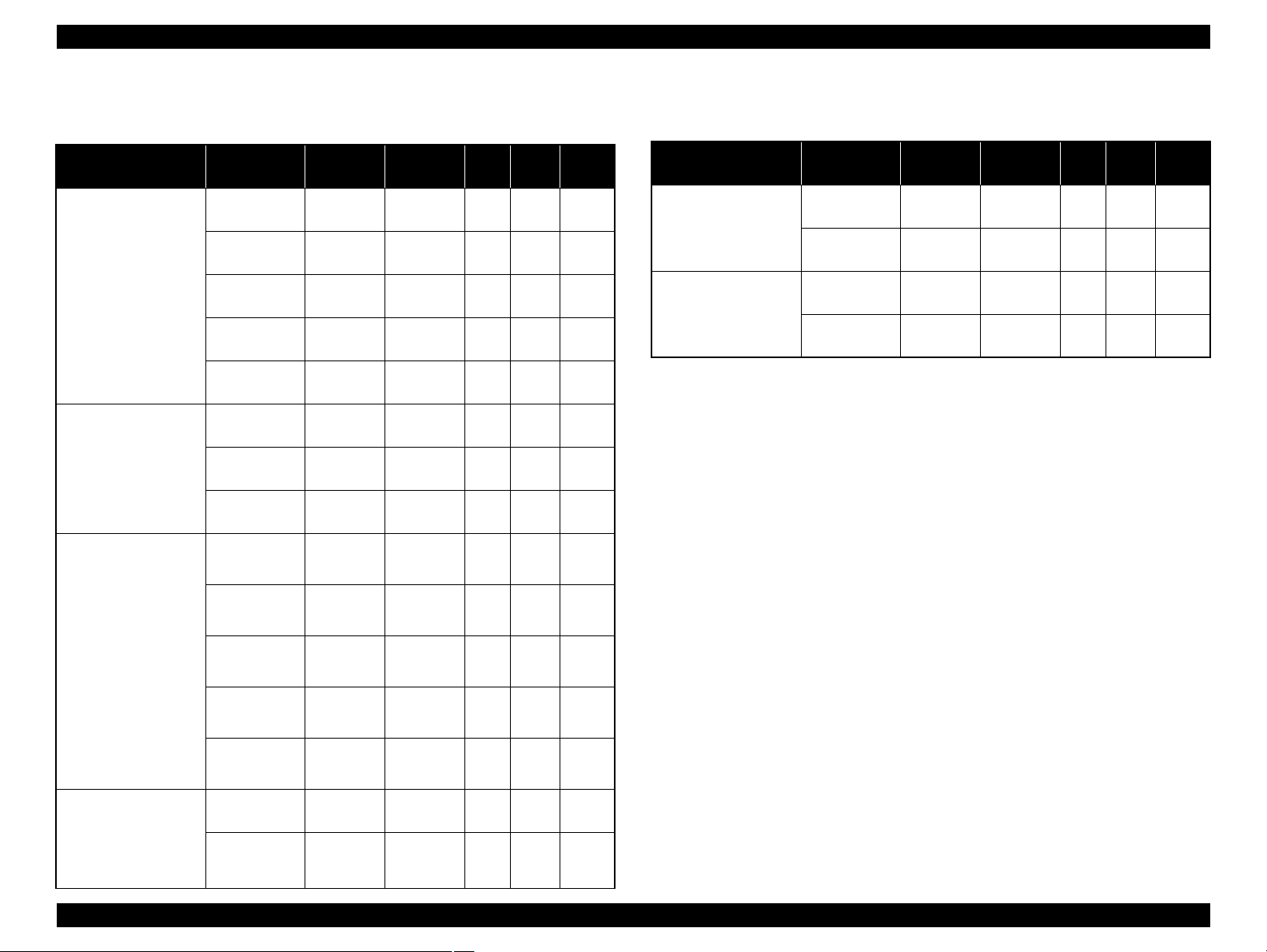

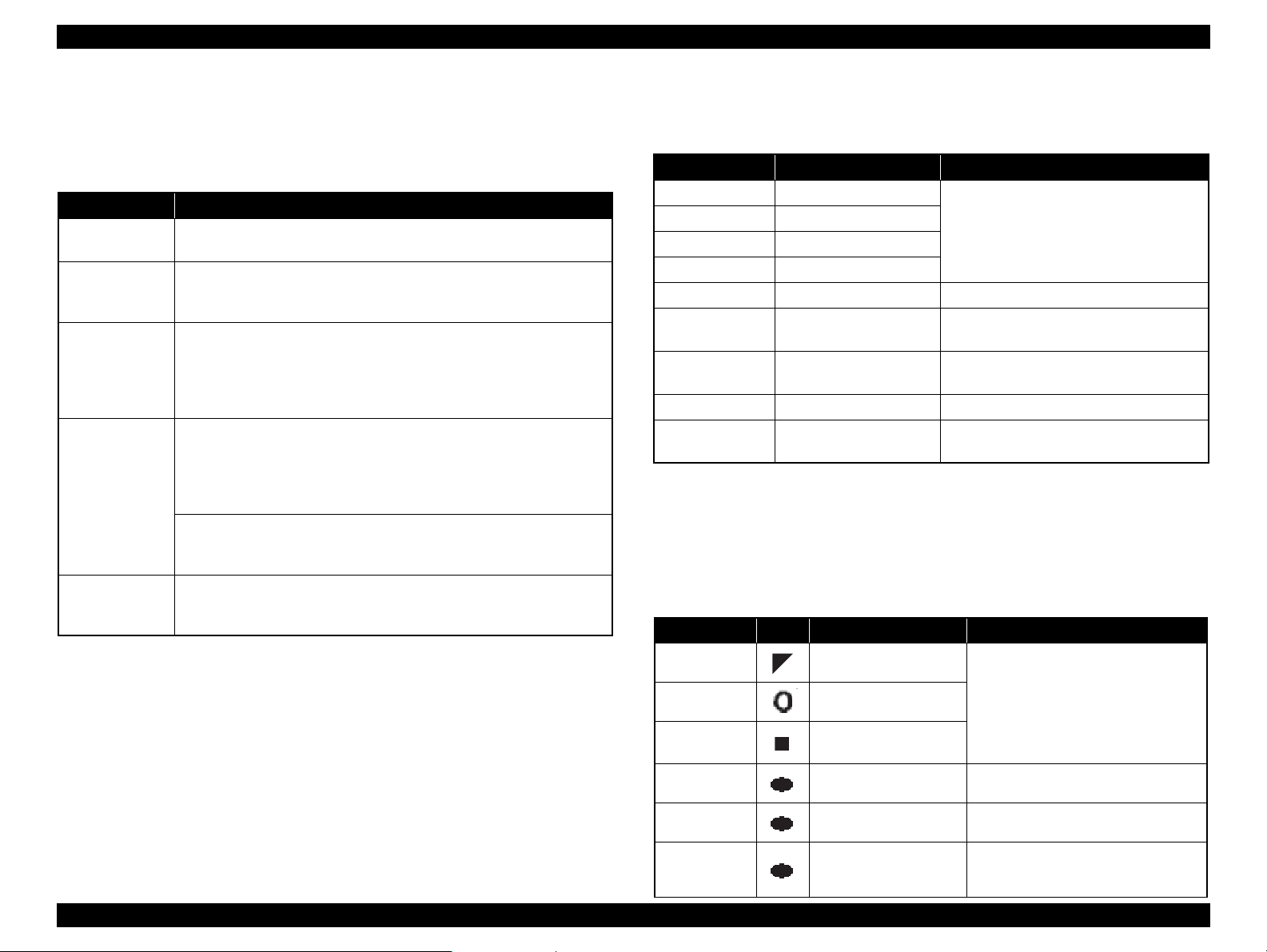

Table 1-4. Print Mode (Color)

Resolution

(H x V dpi)

Fast Economy

Economy

Draft 360x120

Normal 360x360

Fine (360) 360x720

Fine (720) 720x720

Photo (1440) 1440x720

Photo2 (1440) 1440x1440

Photo (5760) 2880x1440

Photo Draft 360x720

Photo (720) 720x720

Photo (1440) 1440x720

Photo2 (1440) 1440x1440

Photo (5760) 2880x1440

/

360x120

Dot Size

(cps)

Eco

(400cps)

Eco

(400cps)

VSD1

(245cps)

VSD2

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD1

(245cps)

VSD2

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD3

(285cps)

Micro

Bi-d

Weave

ON OFF

ON OFF

ON OFF

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

Border-

less

N/A

N/A

N/A

N/A

N/A

OK

OK

OK

N/A

OK

OK

OK

OK

Media Print Mode

• Photo Quality Inkjet

Paper* (others)

Photo (1440) 1440x720

Envelope

Note* : Not supported in EAI.

Table 1-4. Print Mode (Color)

Resolution

(H x V dpi)

Photo (720) 720x720

Normal 360x360

Fine (720) 720x720

Dot Size

VSD2

(285cps)

VSD3

(285cps)

VSD1

(245cps)

VSD3

(285cps)

(cps)

Micro

Bi-d

Weave

ON ON

ON ON

OFF OFF

OFF ON

Border-

less

N/A

N/A

N/A

N/A

• Premium

Presentation Paper

Matte (EAI)

• Matte Paper Heavyweight (others)

Photo (720) 720x720

Photo (1440) 1440x720

VSD2

(285cps)

VSD3

(285cps)

ON ON

ON ON

OK

OK

PRODUCT DESCRIPTION Printing Specifications 12

Page 13

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

Media Print Mode

• Plain paper

• Premium Bright

White Paper (EAI)

• Premium Bright

White Inkjet Paper

(others)

• Ultra Premium

Glossy Photo Paper

(EAI)

• Ultra Glossy Photo

Paper (others)

• Photo Paper Glossy

(EAI)

• Glossy Photo Paper

(others)

• Premium Photo

Paper Glossy (EAI)

• Premium Glossy

Photo Paper (others)

• Premium Photo

Paper Semi-Gloss

(EAI)

• Premium Semigloss

Photo Paper (other)

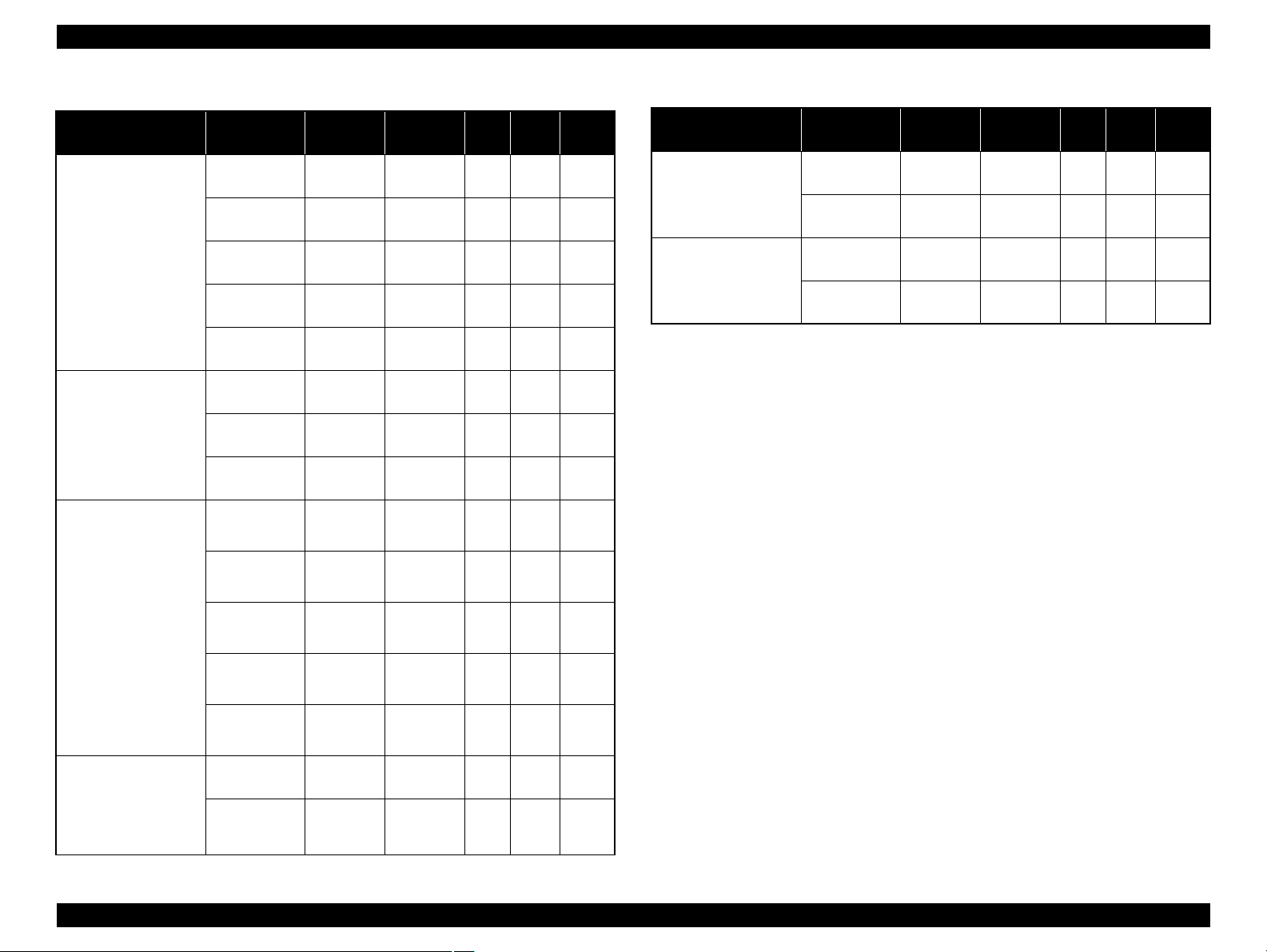

Table 1-5. Print Mode (Monochrome)

Resolution

(H x V dpi)

Fast Economy

Economy

Draft 360x120

Normal 360x360

Fine (360) 360x720

Fine (720) 720x720

Photo (1440) 1440x720

Photo2 (1440) 1440x1440

Photo (5760) 2880x1440

Photo Draft 360x720

Photo (720) 720x720

Photo (1440) 1440x720

Photo2 (1440) 1440x1440

Photo (5760) 2880x1440

/

360x120

Dot Size

(cps)

Eco

(400cps)

Eco

(400cps)

VSD1

(245cps)

VSD2

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD1

(245cps)

VSD2

(285cps)

VSD3

(285cps)

VSD3

(285cps)

VSD3

(285cps)

Micro

Bi-d

Weave

ON OFF

ON OFF

ON OFF

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

ON ON

Border-

less

N/A

N/A

N/A

N/A

N/A

OK

OK

OK

OK

OK

OK

OK

OK

Table 1-5. Print Mode (Monochrome)

Media Print Mode

• Photo Quality Inkjet

Paper* (others)

Photo (1440) 1440x720

Envelope

Note* : Not supported in EAI.

Resolution

(H x V dpi)

Photo (720) 720x720

Normal 360x360

Fine (720) 360x720

Dot Size

(cps)

VSD2

(285cps)

VSD3

(285cps)

VSD1

(320cps)

VSD3

(285cps)

Micro

Bi-d

Weave

ON ON

ON ON

OFF OFF

OFF ON

Border-

less

N/A

N/A

N/A

N/A

• Premium

Presentation Paper

Matte (EAI)

• Matte Paper Heavyweight (others)

Photo (720) 720x720

Photo (1440) 1440x720

VSD2

(285cps)

VSD3

(285cps)

ON ON

ON ON

OK

OK

PRODUCT DESCRIPTION Printing Specifications 13

Page 14

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

C A U T I O N

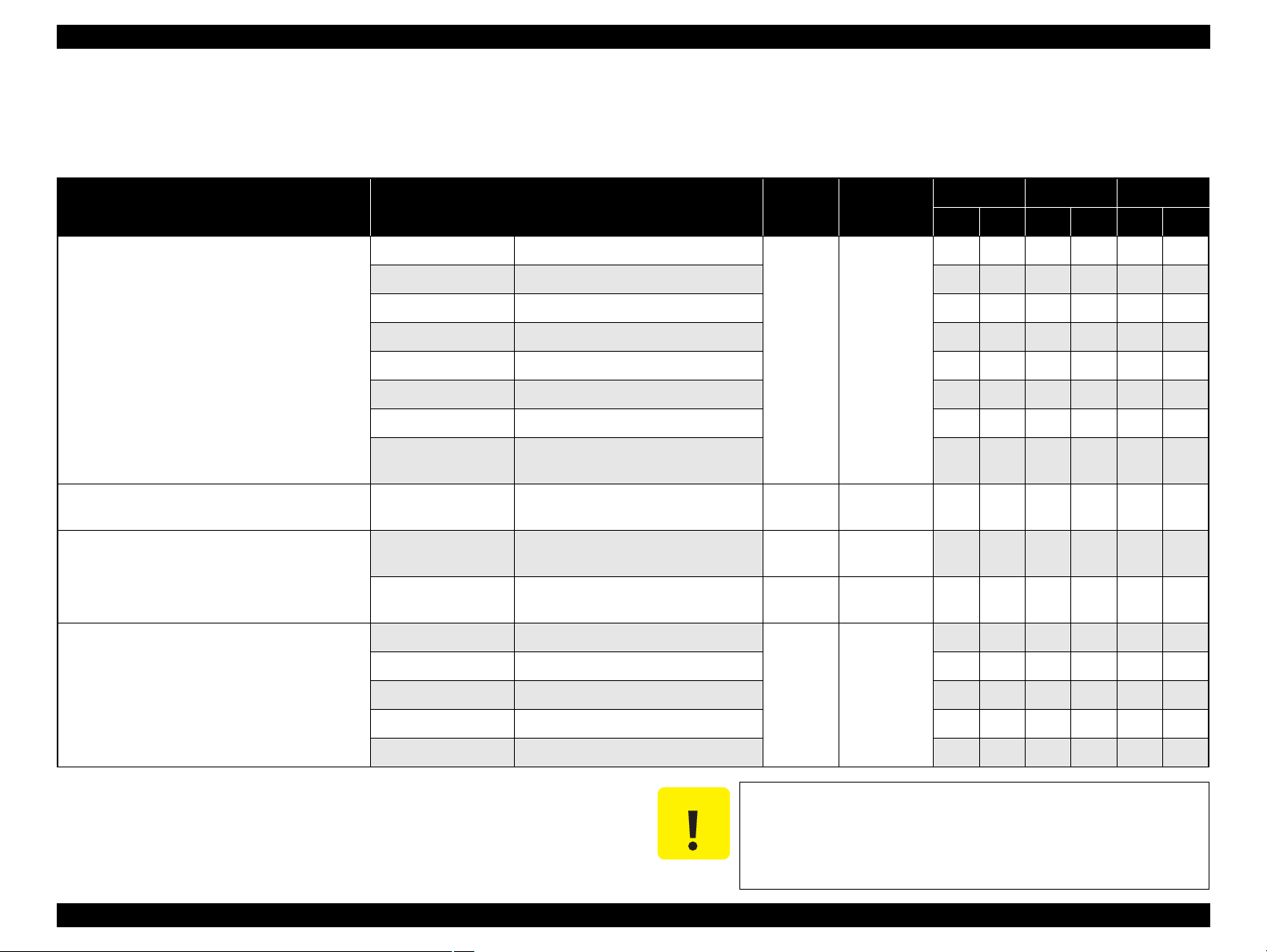

1.2.4 Supported Paper

The table below lists the paper type and sizes supported by the printer. The supported paper type and sizes vary depending on destinations (between EAI, EUR, and Asia).

Table 1-6. Supported Paper

Paper Name Paper Size

Thickness

(mm)

Legal 215.9 x 355.6 mm (8.5”x14”)

Letter 215.9 x 279.4 mm (8.5”x11”) Y - Y - Y -

A4 210 x 297 mm (8.3”x11.7”) Y - Y - Y -

B5 182 x 257 mm (7.2”x10.1”) - - Y - Y -

Plain paper

A5 148 x 210 mm (5.8”x8.3”) - - Y - Y -

0.08-0.11

Half Letter 139.7 x 215.9 mm (5.5”x8.5”) Y - - - - -

A6 105 x 148 mm (4.2”x5.8”) Y - Y - Y -

User Defined

89 x 127- 329 x 1117.6 mm

(3.56”x 5.08” - 13.16”x44.7”)

Premium Inkjet Plain Paper A4 210 x 297 mm (8.3”x11.7”) 0.11

Letter 215.9 x 279.4 mm (8.5”x11”) 0.11

Premium Bright White Paper (EAI)

Bright White Inkjet Paper (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) 0.13

Letter 215.9 x 279.4 mm (8.5”x11”)

Weight

64-90 g/m

(17-24 lb.)

80 g/m

(21 lb.)

90 g/m

(24 lb.)

92.5 g/m

(25 lb.)

EAI EUR Asia

*1

*2

P

B

*1

P

Y - Y - Y -

2

Y - Y - Y -

2

- - Y - Y -

2

Y - - - - -

2

- - Y - Y -

Y Y - - - -

*2

*1

B

P

*2

B

A4 210 x 297 mm (8.3”x11.7”) - - Y Y Y Y

Ultra Premium Glossy Photo Paper (EAI)

Ultra Glossy Photo Paper (Euro, Asia)

8” x 10” 203.2 x 254 mm Y Y - - - -

5” x 7” 127 x 178 mm Y Y Y Y - -

4” x 6” 101.6 x 152.4 mm Y Y Y Y Y Y

Note *1 : “Y” in the “P” column stands for “the paper type/size is Supported”.

*2 : “Y” in the “B” column stands for “Borderless printing is available”.

PRODUCT DESCRIPTION Printing Specifications 14

0.30

290 g/m

2

(77 lb.)

Make sure the paper is not wrinkled, fluffed, torn, or folded.

The curve of paper must be 5 mm or below.

When printing on an envelope, be sure the flap is folded neatly.

Do not use the adhesive envelopes.

Do not use double envelopes and cellophane window envelopes.

Page 15

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

C A U T I O N

Table 1-6. Supported Paper

Paper Name Paper Size

Thickness

(mm)

Letter 215.9 x 279.4 mm (8.5”x11”)

A4 210 x 297 mm (8.3”x11.7”) Y Y Y Y Y Y

Premium Photo Paper Glossy (EAI)

Premium Glossy Photo Paper (Euro, Asia)

8” x 10” 203.2 x 254 mm Y Y - - - -

0.27

5” x 7” 127 x 178 mm Y Y Y Y Y Y

4” x 6

”

101.6 x 152.4 mm Y Y Y Y Y Y

16:9 wide 101.6 x 180.6 mm Y Y Y Y Y Y

Letter 215.9 x 279.4 mm (8.5”x11”)

Photo Paper Glossy (EAI)

Glossy Photo Paper (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) Y Y Y Y Y Y

0.25

5” x 7” 127 x 178 mm - - Y Y - -

4” x 6” 101.6 x 152.4 mm Y Y Y Y Y Y

Letter 215.9 x 279.4 mm (8.5”x11”)

Premium Photo Paper Semi-Gloss (EAI)

Premium Semigloss Photo Paper (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) - - Y Y Y Y

0.27

4” x 6” 101.6 x 152.4 mm Y Y Y Y Y Y

Letter 215.9 x 279.4 mm (8.5”x11”)

Premium Presentation Paper Matte (EAI)

Matte Paper-Heavyweight (Euro, Asia)

A4 210 x 297 mm (8.3”x11.7”) - - Y Y Y Y

0.23

8” x 10” 203.2 x 254 mm Y Y - - - -

Photo Quality Inkjet Paper A4 210 x 297 mm (8.3”x11.7”) 0.13

Weight

255 g/m

(68 lb.)

258 g/m

(68 lb.)

250 g/m

(66 lb.)

167 g/m

(44 lb.)

102 g/m

(27 lb.)

EAI EUR Asia

*1

*2

P

B

*1

P

B

Y Y - - - -

2

Y Y - - - -

2

Y Y - - - -

2

Y Y - - - -

2

2

- - Y - Y -

*2

*1

P

*2

B

#10 104.8 x 241.3 mm (4.125”x9.5”)

Envelopes

#DL 110 x 220 mm - - Y - Y -

#C6 114 x 162 mm - - Y - Y -

Note *1 : “Y” in the “P” column stands for “the paper type/size is Supported”.

*2 : “Y” in the “B” column stands for “Borderless printing is available”.

PRODUCT DESCRIPTION Printing Specifications 15

Y - Y - Y -

-

75-100 g/m

(20-27 lb.)

2

Make sure the paper is not wrinkled, fluffed, torn, or folded.

The curve of paper must be 5 mm or below.

When printing on an envelope, be sure the flap is folded neatly.

Do not use the adhesive envelopes.

Do not use double envelopes and cellophane window envelopes.

Page 16

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

Print Area

LM RM

TM

BM

BM

Cut Sheet (Standard)

Cut Sheet (Borderless)

Paper SIze

LM

RM

TM

BM

Print Area

LM RM

Print Area

Envelope

Paper Size

TM

Paper Feed Direction

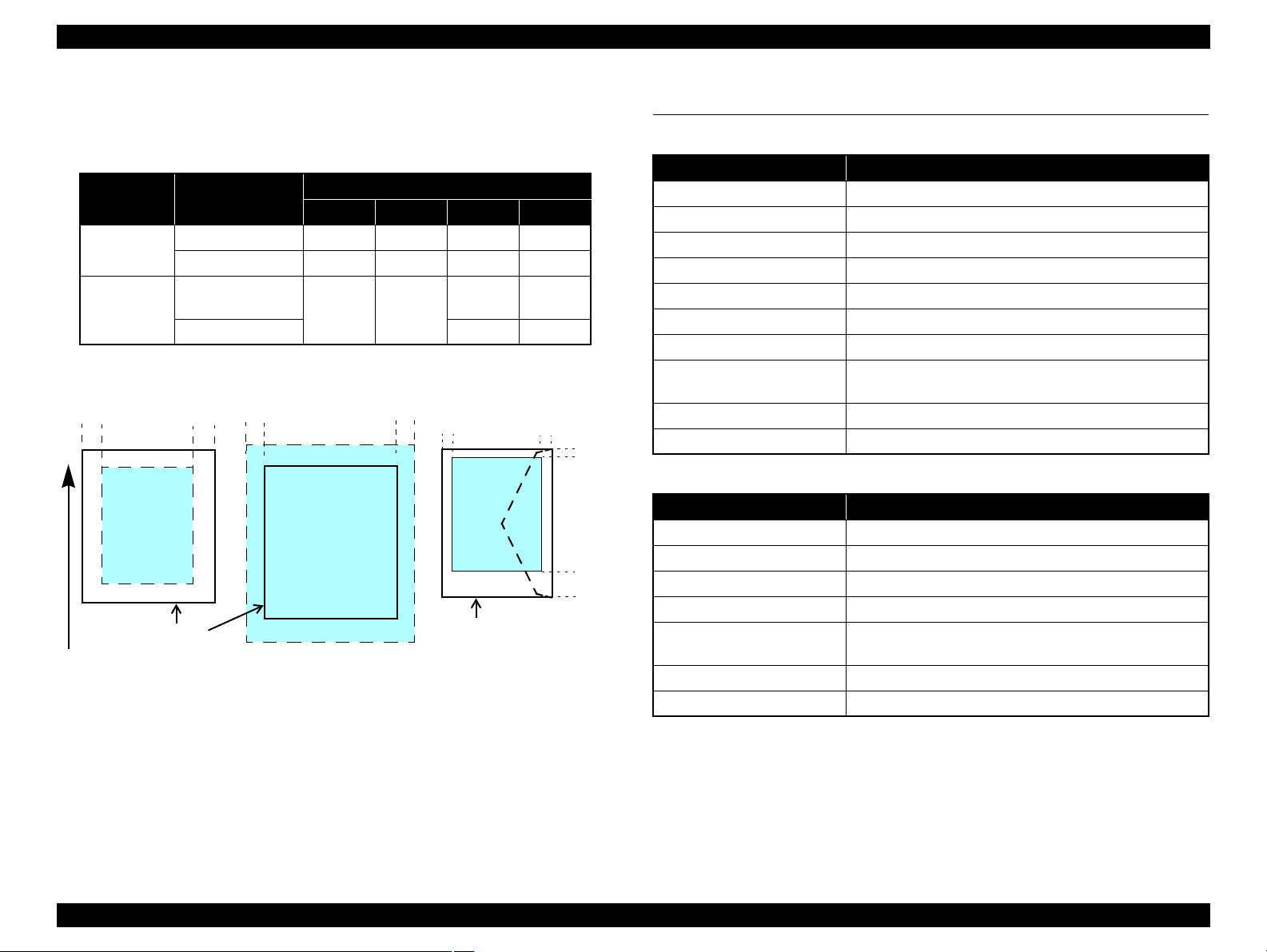

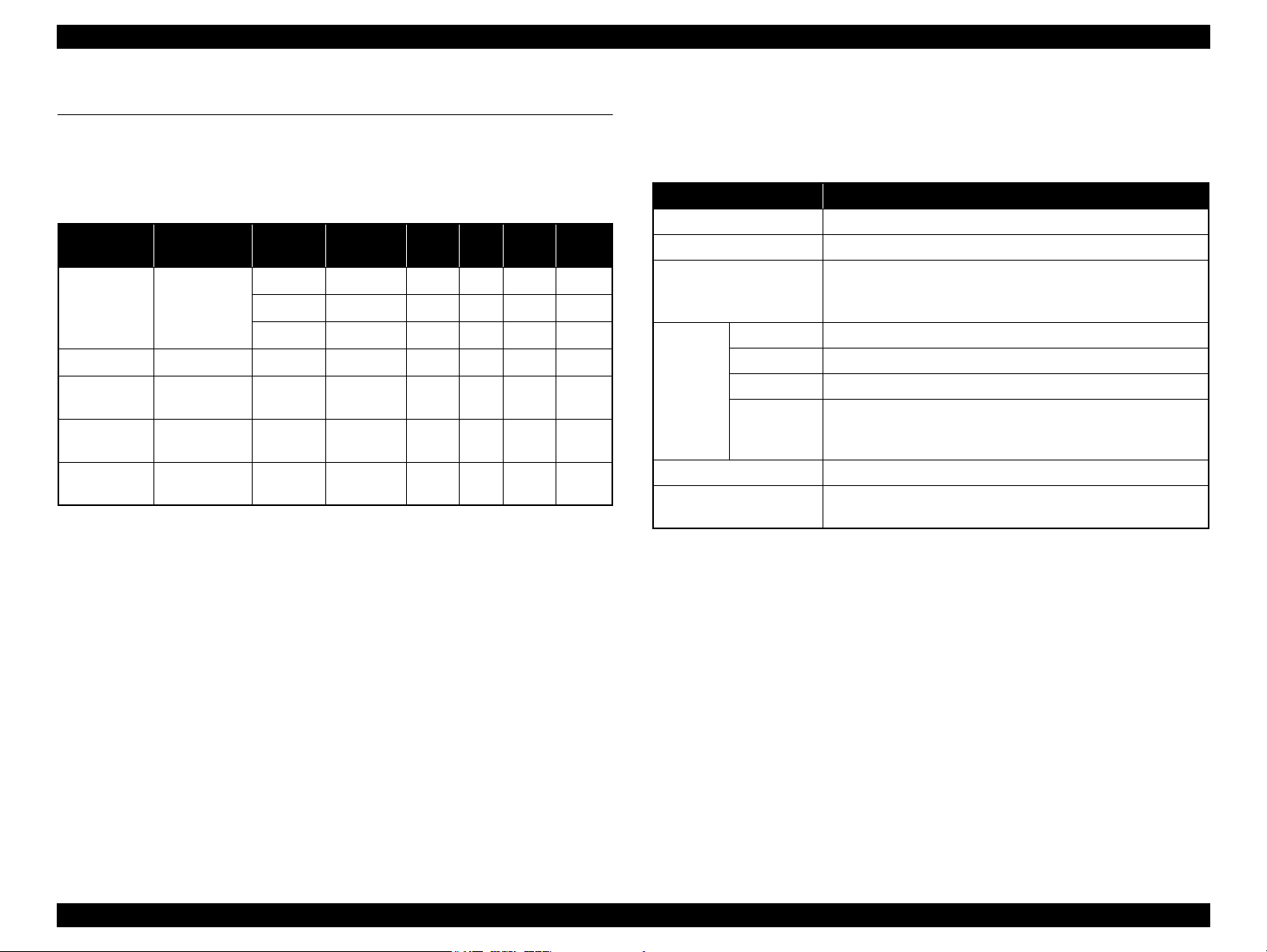

1.2.5 Printing Area

The printing area for this printer is shown below.

Table 1-7. Printing Area (Margins)

Margin

2.96 mm* 3.39 mm*

2.82 mm* 3.39 mm*

Print Mode Paper Size

Standard print

Borderless

print

Note * : The margins for Borderless print are margins that bleed off the edges of paper.

Any size

Envelope

A4/Letter to

5” x 7” / Hi-Vision

4” x 6”

Figure 1-2. Printing Area

Left Right Top Bottom

3 mm 3 mm 3 mm 3 mm

5 mm 5 mm 3 mm 20 mm

2.54 mm* 2.54 mm*

1.3 Scanner Specifications

Table 1-8. Basic Specifications

Item Specification

Scanner type Flatbed, color

Scanning method Moving carriage, stationary document

Home position The rear left corner

Photoelectric device CIS

Light source LED

Maximum document sizes A4 or US letter

Scanning range 8.5” x 11.7” (216 mm x 297 mm)

Maximum resolution

Maximum effective pixels 10,200 x 14,040 pixels (CIS optical resolution x Microstep drive)

Pixel depth 16 bit per pixel (input) and 8 bit per pixel (output).

Item Specification

Document loading Face-up

Maximum document sizes A4 or US letter or Legal

Supported paper type Plain paper only

Paper thickness 60 to 95 g/m

Maximum number of

documents which can be set

Document path Feeds from upper tray and ejects to lower tray

Document set position Center of document tray

Main scan: 1200 dpi

Sub scan: 2400 dpi

Table 1-9. ADF Specifications

2

30 sheets (Xerox-P 64 g/m2) or 3mm (A4,US Letter) / 10

sheet (Legal)

PRODUCT DESCRIPTION Scanner Specifications 16

Page 17

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

a

RW

RL

OTM

OLM

Scanning start position

Home position

Scanning range

Scan bed

Original

(face down)

Scanning direction

1.3.1 Scanning Range

Table 1-10. Scanning Range

RL (read length) RW (read width) OLM (left margin) OTM (top margin)

297 mm 216 mm 1.5 mm 1.5 mm

Figure 1-3. Scanning Range

1.4 General Specifications

1.4.1 Electrical Specifications

Table 1-11. Primary Power Specifications

Item 100-120 V model 220-240 V model

Rated power supply voltage 100 to 120 VAC 220 to 240 VAC

Input voltage range 90 to 132 VAC 198 to 264 VAC

Rated current (Max. rated current) T.B.D. A (T.B.D. A) T.B.D. A (T.B.D. A)

Rated frequency 50 to 60 Hz

Input frequency range 49.5 to 60.5 Hz

Insulation resistance 3000 V (for one minute)

Energy conservation International Energy Star Program compliant

Printing

(ISO10561 Letter Pattern)

Power

consumption

Note 1: If the printer or scanner is not operated for more than three minutes, the printer goes

into the power save mode within five minutes.

2: When no operation is made with the control panel for more than 13 minutes, the panel

goes to the power save mode within 15 minutes.

Low-power mode T.B.D. W T.B.D. W

Sleep mode T.B.D. W T.B.D. W

Standby mode (power-off) T.B.D. W T.B.D. W

T.B.D. W T.B.D. W

PRODUCT DESCRIPTION General Specifications 17

Page 18

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

C A U T I O N

10/50

27/80

35/9520/68

Temperature (°C/°F)

20

30

40

50

90

80

70

60

Humidity (%)

30/86 40/104

1.4.2 Environmental Conditions

Table 1-12. Environmental Conditions

°F)

*1

3

Humidity

20 to 80%

Condition Temperature

Operating

Storage

(unpacked)

Note *1 : The combined Temperature and Humidity conditions must be within the blue-shaded

range in

*2 : N o condensation

*3 : Must be less than 1 month at 40°C.

10 to 35°C

(50 to 95

-20 to 40°C*

(-4°F to 104°F)

Fig.1-4.

Figure 1-4. Temperature/Humidity Range

When returning the repaired printer to the customer, make sure

the Printhead is covered with the cap and the ink cartridge is

installed.

If the Printhead is not covered with the cap when the printer is

off, turn on the printer with the ink cartridge installed, make

sure the Printhead is covered with the cap, and then turn the

printer off.

5 to 85%

*1,2

Shock Vibration

1G

(1 msec or less)

2G

(2 msec or less)

10

10

0.15G,

to 55Hz

0.50G,

to 55Hz

1.4.3 Durability

Total print life: Black 20,000 pages (A4, 3.5% duty),

Color 10,000 pages (A4, ISO FDC24712),

or five years whichever comes first

Printhead: Five billions shots (per nozzle) or five years whichever

comes first

Scanner carriage: 30,000 cycles of carriage movement

Total ADF feeding: 10,000 pages

1.4.4 Acoustic Noise

T.B.D. dB

(when printing from PC, on Premium Glossy Photo Paper, in highest quality)

T.B.D. dB (when scanning, default setting)

1.4.5 Safety Approvals (Safety standards/EMI)

USA UL60950-1

FCC Part15 Subpart B Class B

Canada CSA No.60950-1

CAN/CSA-CEI/IEC CISPR 22 Class B

Mexico NOM-019-SCFI-1998

Taiwan CNS13438 Class B

CNS14336

EU EN60950-1

EN55022 Class B

EN61000-3-2, EN61000-3-3

EN55024

Germany EN60950-1

Russia GOST-R (IEC60950-1, CISPR 22)

Singapore IEC60950-1

Korea K60950-1

KN22 Class B

KN61000-4-2/-3/-4/-5/-6/-11

China GB4943

GB9254 Class B, GB17625.1

Hong Kong IEC60950-1

Argentina IEC60950-1

Australia AS/NZS CISPR22 Class B

PRODUCT DESCRIPTION General Specifications 18

Page 19

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

1.5 Interface

This printer has USB interface and memory card slots of the following specifications.

1.5.1 USB Interface

The table below describes the specifications of the two USB ports; USB device port for

connecting with a host such as a computer, and the USB host port for connecting with

an external devices such as a DSC (digital still camera).

Table 1-13. USB Interface Specifications

Item USB Device port USB Host port*

• Universal Serial Bus

Specifications Revision 2.0

Compatible standards

Transfer rate

• Universal Serial Bus Device

Class Definition for Printing

Devices Version 1.1

480 Mbps (High Speed) 12 Mbps (Full Speed)

Data format

Compatible connector

Max. cable length

Note* : External devices that can be connected to the USB device port are:

DSC compliant with the USB Direct Print Protocol specification Rev 1.0

DSC compliant with the CIPA DC-001-2003 (PictBridge) specifications

USB Series B USB Series A

• Universal Serial Bus

Specifications Revision 2.0

• Universal Serial Bus Mass

Storage Class Bulk-Only

Transport Revision 1.0

NRZI

2 [m] or less

The “Model Name” is replaced as shown in the following table.

Table 1-15. Model Names Indicated in the Device ID

Destination Model Name

North America Stylus CX9400Fax

Euro Stylus DX9400F

Asia/Pacific Stylus CX9300F

1.5.2 FAX Interface

Port Name Connector Description

Line port RJ11 Connects to phone cable from modular wall jack.

EXT port RJ11 Connects to TAM or Telephone.

Table 1-14. Device ID

When IEEE 1284.4 is Enabled When IEEE 1284.4 is Disabled

MFG:EPSON;

CMD:ESCPL2,BDC,D4,D4PX,ESCPR1;

MDL:Model Name;

CLS:PRINTER;

DES:EPSON[SP]Model Name;

MFG:EPSON;

CMD:ESCPL2,BDC,ESCPR1;

MDL:Model Name;

CLS:PRINTER;

DES:EPSON[SP]Model Name;

PRODUCT DESCRIPTION Interface 19

Page 20

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

1.5.3 Memory Card Slots

Table 1-16. List of Supported Memory Card

Priority

1

2

Slot Compatible memory card Standard

Memory Stick/

Memory Stick

PRO

SD/MMC SD (Security Digital) SD Memory Card Specifications / PART1. Physical Layer Specification Ver. 2.0

xD-Picture card xD-Picture card xD-Picture Card Specification Ver.1.20 compatible 2GB Type M/H supported

CF Type II Compact Flash CF+ and CompactFlash Specification Revision 3.0 compatible 4GB True-IDE compatible memory card only

Memory Stick “MemoryStick Standard” Format Specification Ver.1.42-00 compatible 128MB Includes versions with memory select function

MagicGate Memory Stick 128MB Copy protection function is not supported

MagicGate Memory Stick Duo An adapter should be used

Memory Stick PRO Memory Stick PRO Format Specifications-without security specifications Ver.1.02-00

compatible

Memory Stick Duo MemoryStick Duo Format Specification Ver.1.11-00 compatible

Memory Stick Pro Duo MemoryStick PRO Duo Format Specification Ver.1.02-00 compatible

Memory Stick micro Memory Stick Micro Format Specification Ver.1.02-00 compatible The Memory Stick adapter for standard size

miniSD/microSD

SDHC

miniSDHC/microSDHC

MultiMediaCard MultiMediaCard Standard Ver. 4.1 compatible 64MB

Microdrive

compatible

Max.

capacity

4GB

2GB

4GB

Remarks

Copy protection function is not supported

The Memory Stick Duo adapter should be

used

The Memory Stick Duo adapter should be

used.

should be used.

The SD adapter should be used

Speed Class is not supported

The SD adapter should be used

Speed Class is not supported

Note: • Memory Stick/PRO, SD/MMC and xD-Picture Card shares the same slot.

• When cards are inserted in the two slots at once, the slot which will be accessed first is determined according to the priority shown in the table.

• To select a card that has been inserted in a non-active slot, first remove the card in the active slot.

• In memory card direct printing mode, the image files in the active slot are valid and have assigned frame numbers. The number of images will not change if a card is inserted in another

nonselected slot.

• When the card inserted in the slot is accessed from the PC, only one drive is displayed at a time as a removable disk* and only the card that is in the active slot can be accessed via the

removable disk. A card that has been inserted into a non-selected slot cannot be accessed.

(This is for Windows. For Macintosh, the card in the active slot will be mounted on the desktop.)

• Does not support 5V type of memory cards.

• When a memory card is being accessed, do not touch the memory card.

• For detailed information on the supported file system and formatting the memory card, refer to “ 1.7.2 Memory Card Direct Print Function ( p. 27 ) ”.

PRODUCT DESCRIPTION Interface 20

Page 21

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

LCD

Power

button

Copy button

Memory Card button

Photo button FAX button

Setup button Display/Crop button

Cross Key and OK button

Menu button Back button

Start button

Stop/Clear Settings button

Ten keys

Auto Answer/Space button

Speed Dial/Back Space button

Redial/Pause button

Auto Answer LED

Power LED

Mode LED

Mode LED

1.6 Control Panel

1.6.1 Operation Buttons & LEDs

Figure 1-5. Control Panel

Table 1-17. Button Functions

Button Function

Power Turns the power ON/OFF.

Copy Goes to the stand alone Copy mode.

Memory Card Goes to the memory card direct print mode.

Photo Goes to the special mode that provides Reprint/Restore Photos function.

Fax Goes to the mode that provides fax transmission.

Setup Goes to the Setup mode that provides maintenance menu (head cleaning, head alignment, etc.) and various setting menu.

Display/Crop

Menu Goes to the print setting menu screen.

Cross Key (Up/Down/Left/Right) Selects a menu item or a setting value.

OK Accepts the changed settings

Back Cancels the previous operation.

Start Starts printing.

• Goes to the zoom setting screen for the selected image.

• Changes the image preview layout on the LCD.

Continued on next page

PRODUCT DESCRIPTION Control Panel 21

Page 22

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

Table 1-17. Button Functions

Button Function

• Stops operation and displays the menu screen.

Stop/Clear Settings

Ten keys Enters alphameric characters.

Auto Answer/Space Turns ON/OFF the auto answer settings.

Speed Dial/Back Space Goes to the call-up screen for speed dials.

Redial/Pause Calls at the last dialed number.

LED Function

Power (Green)

Mode LED

Auto Answer • Lights when Auto answer is on.

Card Access*2 (Green)

Note *1 : In the Setup mode, the mode LED corresponding to the previous mode lights.

*2 : The Card Access LED is provided near the memory card slot.

• Stops printing and ejects paper.

• Returns the print settings in the current mode to their defaults and displays the Top screen.

(Returns to the previous screen during printing maintaining the current settings)

Table 1-18. LED Functions

• Flashes while powering ON/OFF.

• Flashes during some sequence is in progress.

• Flashes when a fatal error occurs.

• Lights when the status is other than above.

• All the mode LEDs are off while powering ON.

• The current mode LED lights while powering OFF.

• All the mode LEDs flash when a fatal error occurs.

• The current mode LED lights when in stand-by or in setting operation using the control panel.

• The current mode LED lights during some sequence is in progress.*

• The memory card mode LED lights during slide show is being displayed.

• The current mode LED lights during screen saver is being displayed.*

• All the mode LEDs light sequentially at one minute intervals when in power saver mode.

• Lights when a memory card is inserted.

• Flashes when a memory card is being identified or accessed.

1

1

PRODUCT DESCRIPTION Control Panel 22

Page 23

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

1.6.2 Control Panel Functions in Each Mode

1.6.2.1 Control Panel Functions

The table below shows the print setting menu items for each mode and their defaults, and when the settings are saved or returned to their defaults. Explanations on detailed control

panel functions of the CX9300F/CX9400Fax/DX9400F are omitted here, because the LCD displays the detailed instruction.

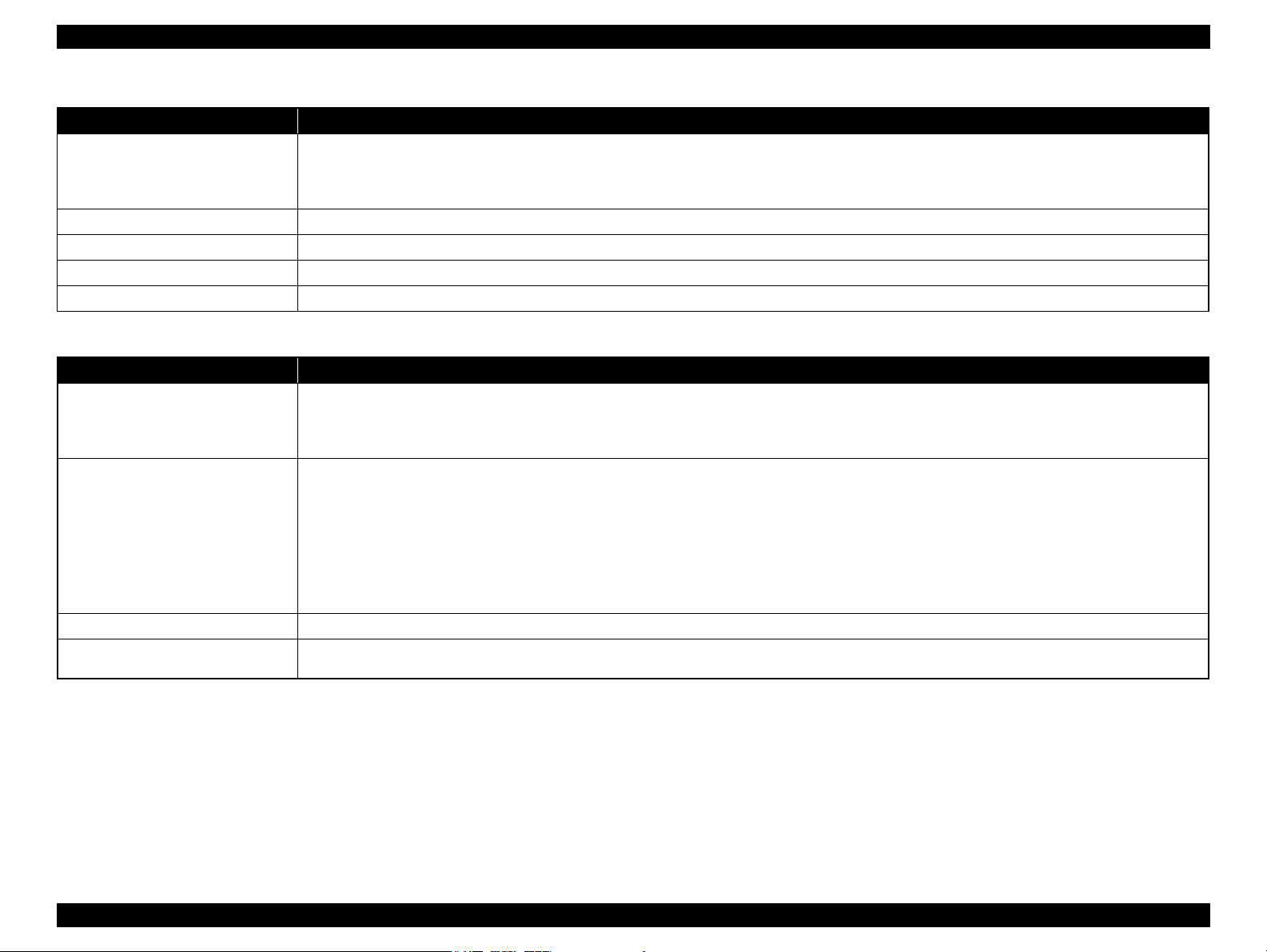

Table 1-19. Timing of Saving or Initializing Control Panel Settings

Mode Print Setting Default Value Saving Timing Initializing Timing*

Copy

Memory Card

Photo

FAX

Copy Type Color

Layout With Border

Number of copies 1

Zoom Actual

Paper Type Plain Paper

Paper Size A4, Letter (for EAI)

Quality Standard

Density ±0

Expansion Standard

Paper Type Prem. Glossy

Paper Size 4x6 inch

Layout Borderless

Quality Standard

Expansion Standard

Date None

Bidirectional On

Select (Print Index Sheet setting) All Photos

Information (Print Index Sheet setting) (EAI only) File Name

Paper Type Prem. Glossy

Paper Size 4x6 inch

Layout Borderless

Expansion Standard

Resolution Standard

Contrast ±0

Fax Delay Off

Fax Mode Sending

When the Start button is pressed When the Stop/Clear button is pressed

When the Start button is pressed When the Stop/Clear button is pressed

When the Start button is pressed When the Stop/Clear button is pressed

When the Start button is pressed When the Stop/Clear button is pressed

PRODUCT DESCRIPTION Control Panel 23

Page 24

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

Table 1-19. Timing of Saving or Initializing Control Panel Settings

Mode Print Setting Default Value Saving Timing Initializing Timing*

Camera Direct

Note * : All the settings except “LCD Brightness” of Setup menu return to their defaults when the “Restore Default Settings” of the Setup menu is executed with the OK button.

Paper type Prem. Glossy

Paper size 4x6 inch

Layout Borderless

Quality Standard

Expansion Standard

Date None

Bidirectional On

When the settings are made in the PictBridge Setup

of the Setup menu.

When the Stop/Clear button is pressed while

making the settings.

1.6.2.2 Control Panel Power Saver Mode

If no operation is made on the control panel for approximately 13 minutes, both the CX9300F/CX9400Fax/DX9400F automatically enter control panel power saver mode. The

details of control panel power save mode are shown below.

Conditions for not entering the control panel power save mode

• The printer or scanner is in operation

• During printing or scanning from PC

• Camera direct is in operation

• Slide show is being displayed

• An error is being displayed

• Mechanical adjustment is being made in setup mode

• Firmware is being updated

Conditions recovering from the control panel power save mode

• Any button other than the power button is pressed (when the power button is pressed, the power is turned OFF)

• A memory card or a camera direct device is connected

• Operation from PC (printing / scanning / maintenance)

NOTE: See “ 1.7.3.4 Operating Specifications during Connecting DSC ( p. 32 ) ” for information on the panel operation during connecting a camera to the EXT.IF.

PRODUCT DESCRIPTION Control Panel 24

Page 25

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

1.7 Specification for Each Function

1.7.1 Stand-alone Copy Function

1.7.1.1 Supported Paper and Copy Mode

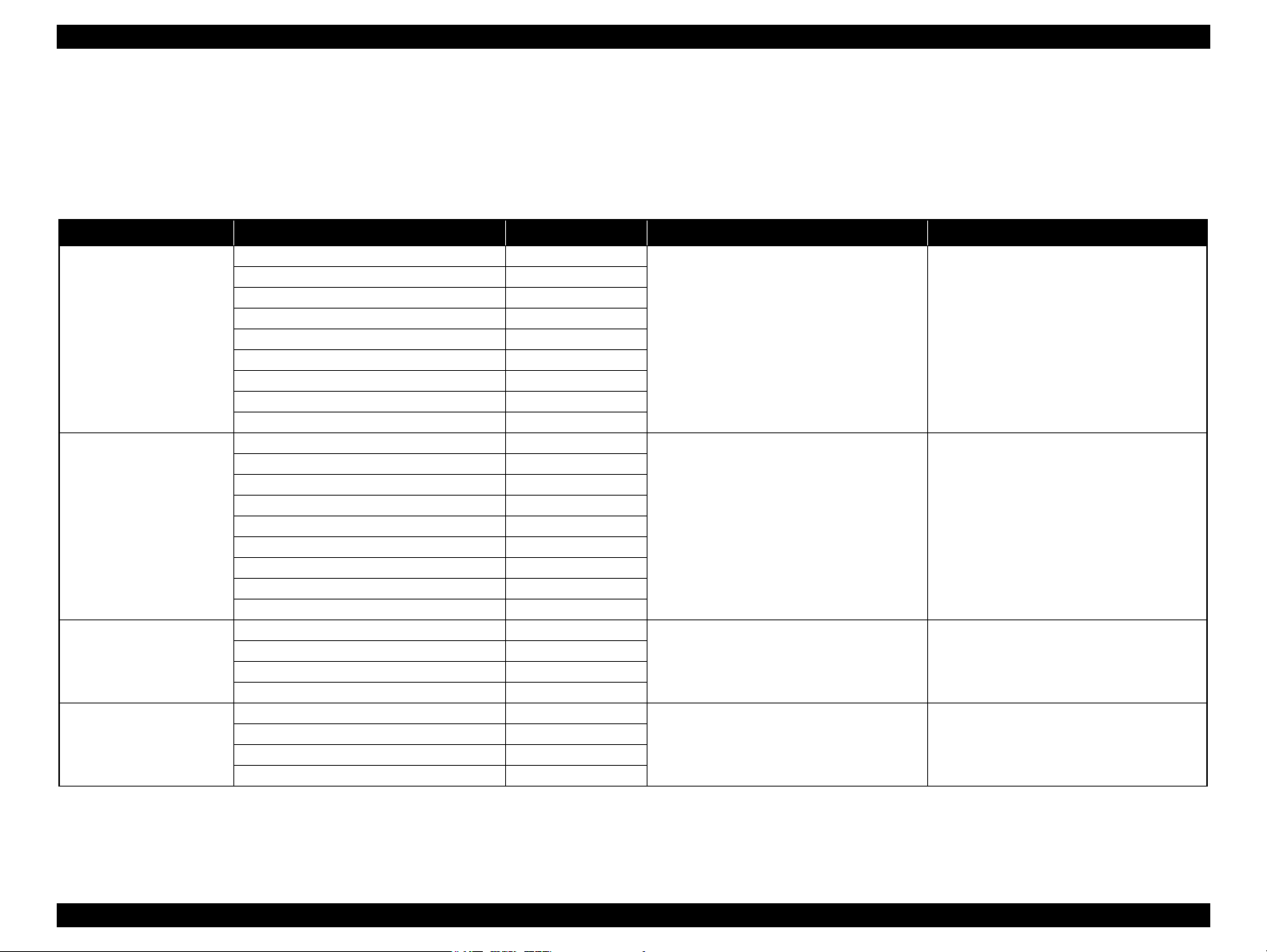

Table 1-20. Supported Paper and Copy Mode

*1

*1

*1

*1

*1

Print

Quality

Draft

Standard

Best

Standard

Standard

Standard

Standard

Resolution

360x120 Eco ON OFF

360x360 VSD1 ON OFF

720x720 VSD3 ON ON

1440x720 VSD3 ON ON

1440x720 VSD3 ON ON

1440x720 VSD3 ON ON

1440x720 VSD3 ON ON

Paper Type

Plain paper A4*1, Letter

Matte paper A4*1, Letter

Photo Paper

Prem. Glossy

Ultra Glossy

Note *1 : The model for Latin supports both the letter and A4 sizes. The model for North

*2 : Borderless printing of 5x7 size is not supported for EAI.

Note : In the case of copy using ADF, only the plain paper is available.

A4*1, Letter

A4*1, Letter

A4

America supports letter size only, and the other destination models support A4 size

only.

1

Size*

4x6, 5x7,

4x6, 5x7,

4x6, 5x7,

*1

, Letter

Dot

Size

Bi-d

Micro

Weave

Border-

OK*

less

NA

NA

NA

OK

OK

OK

1.7.1.2 Stand-alone Copy Menu

The stand-alone copy mode menu for the CX9300F/CX9400Fax/DX9400F (settable

items) are shown in the following tables.

Table 1-21. Copy Menus

Menu Function

Number of copies Sets the number of copies within the range of 1 to 99.

Copy type Selects either color or monochrome.

Selects from the following two layouts:

Layout

Paper type Selects paper type from the options shown in Table 1-20.

Paper size Selects paper size from the options shown in Table 1-20.

2

Print

setting

Density Selects from the nine density levels of -4 to +/-0 to +4.

Expansion

(for borderless print)

Quality Selects print quality from the options shown in Table 1-20.

Zoom

• With Border (normal layout with 3mm margins)

• Borderless (no margins)

Selects Actual or Auto Fit Page.

Or reduction/enlargement ratio can be specified within the range

of 25% to 400%.

Selects the margins level (margins bleed off the edges of paper)

from the Standard (100%), Mid. (50%) or Min. (0%).*

PRODUCT DESCRIPTION Specification for Each Function 25

Page 26

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

a

a

a

a

Scan / Print direction

A

A

B

B

C

C

D

D

E

E

F

F

Readable Length

Paper Length

Paper

Width

Paper Length

Readable

Width

Readable Length

OTM

OTM

OLM

LM

LM

RM

RM

TM

BM

TM

OLM

Home position

Home position

BM

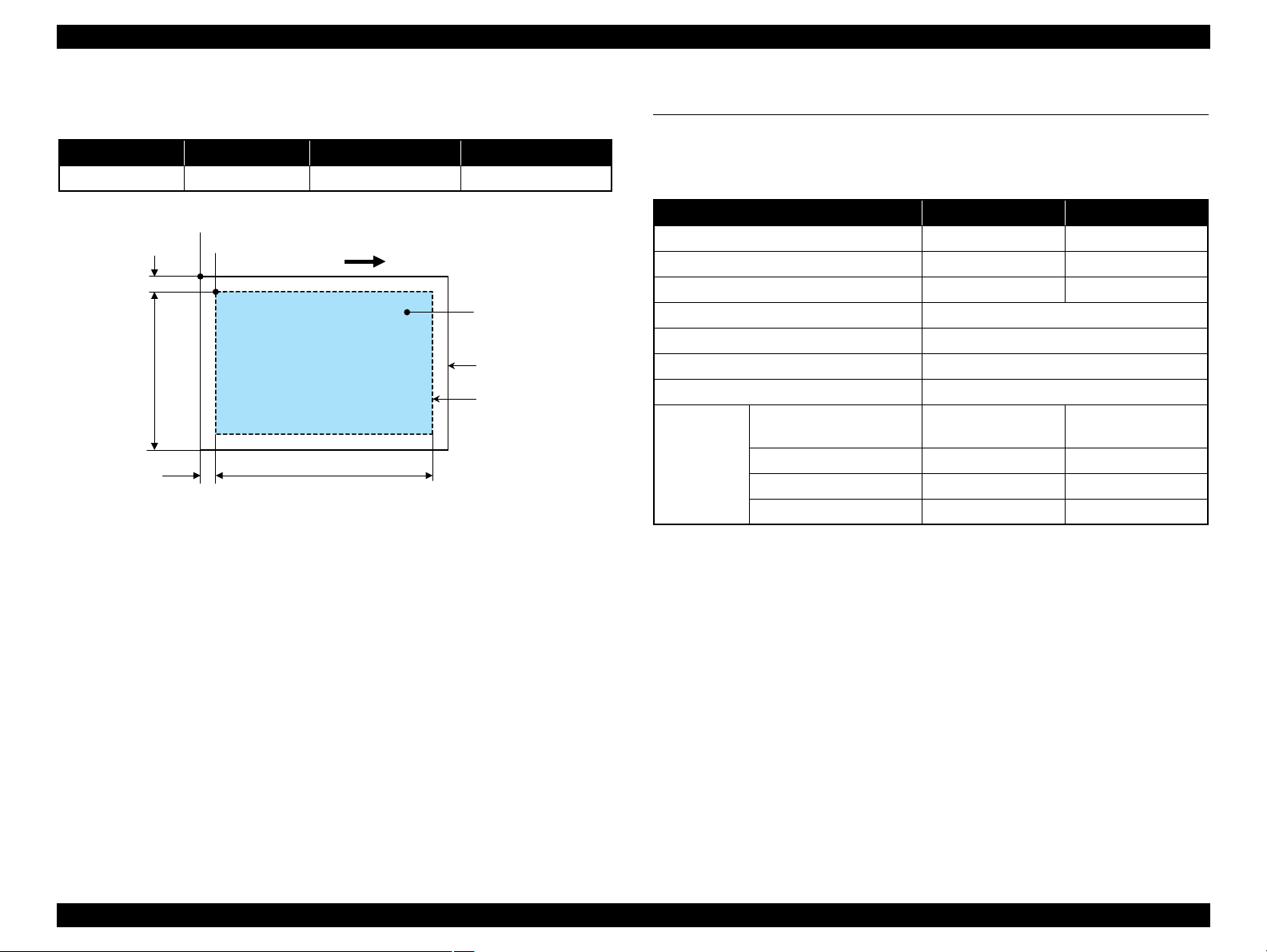

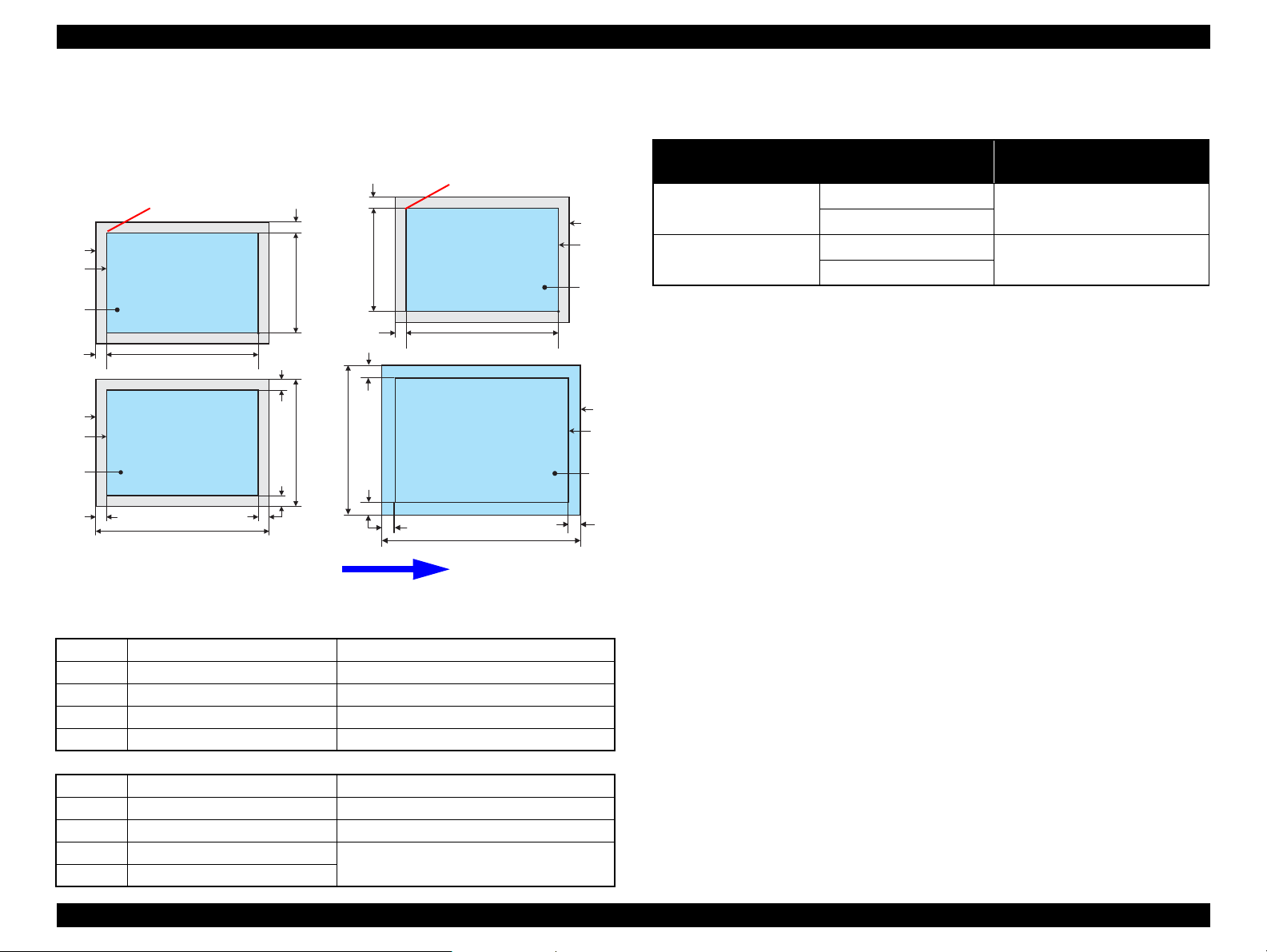

1.7.1.3 Relation Between Original and Copy

The scanning start position is located on the front right of the scan bed. The relations

between the original placed face down and its copy are as follows.

Figure 1-6. Relation Between Original and Copy (Borderless/With Borders)

Original Document

A Scan bed ---

B Scan area “ 1-10 Scanning Range ” (p.17)

C Original (face down) ---

OTM Top margin (out of scan range) “ 1-10 Scanning Range ” (p.17)

OLM Left margin (out of scan range) “ 1-10 Scanning Range ” (p.17)

Copied Document

D Copied paper ---

EPrint area “ 1-7 Printing Area (Margins) ” (p.16)

FCopy ---

LM, RM Left margin, Right margin* “ 1-7 Printing Area (Margins) ” (p.16)

TM, BM Top margin, Bottom margin*

PRODUCT DESCRIPTION Specification for Each Function 26

1.7.1.4 Copy Speed

Copy Conditions

(eMemo2, A4 size)

Draft 360 x 120

Default 360 x 360

Table 1-22. Copy Speed

Monochrome copy

Color copy

Monochrome copy

Color copy

Copy Speed

T.B.D. cpm

T.B.D. cpm

Page 27

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

C H E C K

P O I N T

1.7.2 Memory Card Direct Print Function

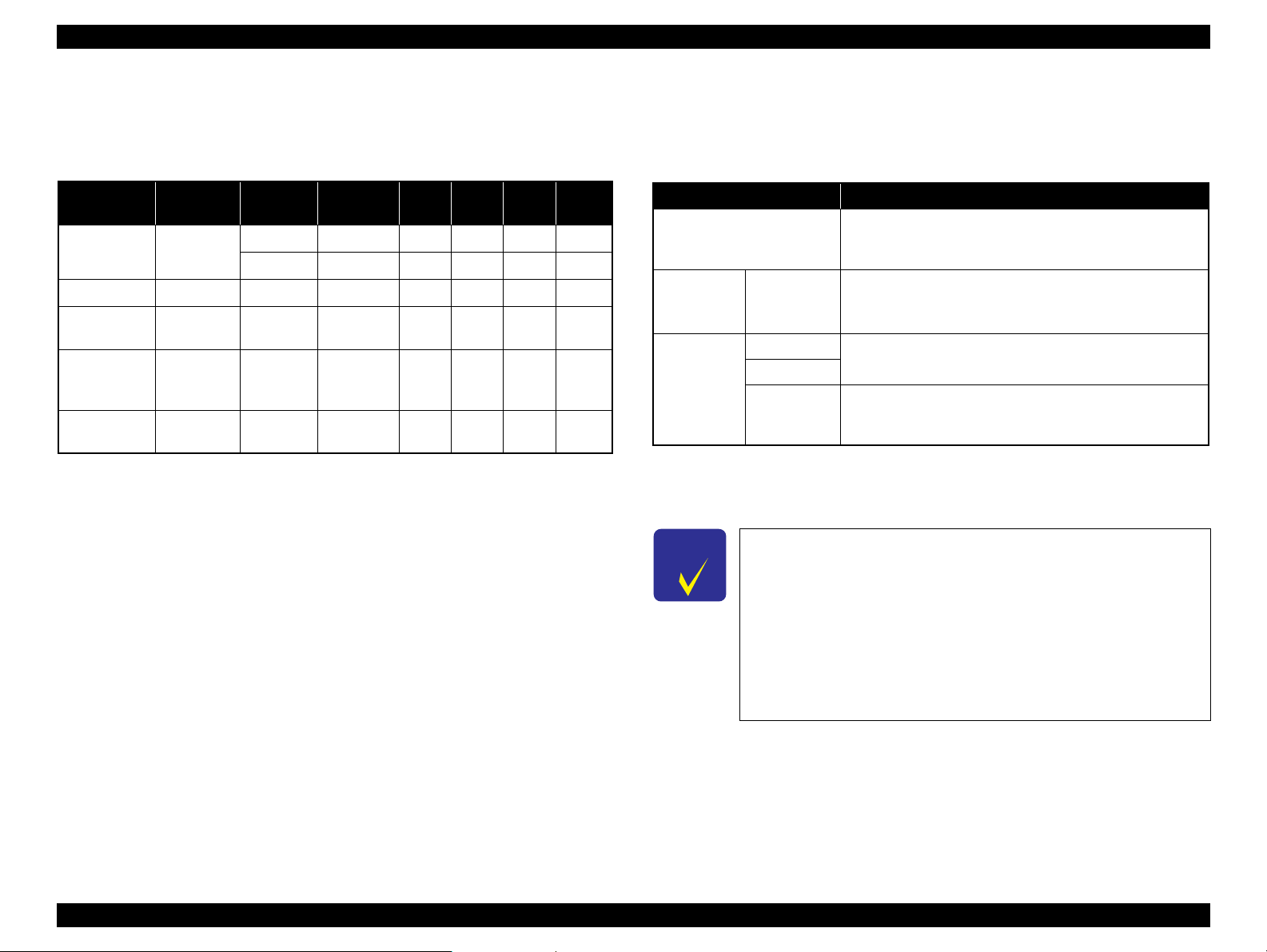

1.7.2.1 Supported Paper and Print Mode

Table 1-23. Supported Paper Type & Print Mode

*1

*1

*1

*1

Print

Quality

Standard

Best

Standard

Standard

Standard

Resolution

360x360 VSD1 ON OFF

720x720 VSD3 ON ON

1440x720 VSD3 ON ON

1440x720 VSD3 ON ON

1440x720 VSD3 ON ON

1440x720 VSD3 ON ON

Paper Type Size

Plain Paper A4, Letter

Matte Paper A4, Letter*1Standard

Photo Paper

Prem. Glossy

Ultra Glossy

Note *1 : Letter size is supported for EAI only.

*2 : The Photo Paper 5x7 size and Prem. Glossy 16:9 wide are not supported for EAI.

4x6, 5x7*2,

A4, Letter

4x6, 5x7,

16:9 wide*2,

A4, Letter

4x6, 5x7,

A4, Letter

Dot

Size

Bi-d

Micro

Weave

Border-

less

NA

NA

OK

OK

OK

OK

1.7.2.2 Supported File Type and Media Type

The followings describe the file system, media format, and file type supported by the

memory card direct function.

Table 1-24. Supported File System, Types and Media Format

Item Specification

DCF Version 1.0 or 2.0 *1 compliant. Other than those does

File system

Media format Memory card

JPEG (*.JPG)

TIFF (*.TIF)

File type

Note *1: Refer to the Camera File System Standard; “DCF Version 2.0, JEIDA-CP-3461” for

*2 : Available only when the memory card supports FAT32.

Camera

definition file

(*.MRK)

more details.

The printer does not detect any files stored under the following

directories or their sub-directories.

• Directories containing system properties or hidden properties.

• “RECYCLED” (Windows directory for deleted files)

• “PREVIEW” (directories of CASIO DSC for thumbnail images)

• “SCENE” (directories of CASIO DSC for its Best Shot function)

• “MSSONY” (directories of SONY DSC for e-mail images, voice memos,

movies, or non-compressed images)

• “DCIM\ALBUM\IMAGE” (directories of CASIO DSC for its album

function)

not ensure proper operation. File systems available with the

card reader function are restricted by the host’s specification.

• DCF Version 1.0 or 2.0 compliant

• DOS FAT format (FAT12/FAT16/FAT32 *2) with single

partition (basic partitioned)

Image files conform to Exif Version 2.21. (Exif version 1.0/

2.0/2.1/2.2/2.21 are supported)

Camera definition files used for DPOF mode.

“\MISC\AUTOPRINT.MRK” file is valid.

1.7.2.3 Automatic Detection of Images in Memory Card

When a memory card is inserted in the card slot on the printer, or when a memory card

is detected at power-on, the printer automatically searches for all images stored in the

card. When the card is removed, the printer erases the information on the all detected

files.

PRODUCT DESCRIPTION Specification for Each Function 27

Page 28

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

1.7.2.4 Specifications for Handling Image Data

Table 1-25. Specifications for Handling Image Data

Item Specification Remarks

Image size (pixel)

Maximum number

of images

Maximum number

of copies

Valid date and time

Thumbnail image

data

File sorting

• Horizontal: 80 ≤ X ≤ 9200

• Vertical: 80 ≤ Y ≤ 9200

Up to 999 images When a memory card stores 1,000

or more images, the first 999

images are detected and become

valid in the printer. The detecting

order varies depending on the

folder configuration in the card, so

which images are included in the

first 999 cannot be defined.

However, images specified by

camera definition files can be

selected to be printed even when

the total number of images has

exceeded 999. Up to 999 camera

defined image files can be

specified.

99 copies for each image.

Up to 999 sheets in total.

01/01/1980 00:00:00 to

12/31/2099 23:59:59

Supports DCF Ver.1.0 or 2.0compatible data (Exif format,

160x120 pixels)

The printer sorts image files in

ascending ASCII order based on

their full-pathnames such as

“\DCIM\100EPSON\EPSN0000.

JPG”, and assigns a number to

each of them.

Thumbnail images are used for the

Print Index Sheet function.

• The image number assigned by

the printer may be different from

that assigned by the camera.

• If two or more files have the

same full pathname, the sorting

function may not operate

properly. (existence of the same

full-pathname is not allowed

under DOS)

---

---

---

Table 1-25. Specifications for Handling Image Data

Item Specification Remarks

The printer acquires date and time

information included in image

files in the order of precedence

shown below.

1. Shooting date and time

information in digital camera

standard format (Exif)

2. Digitized date and time

Acquisition of date

and time

information

information in digital camera

standard format (Exif)

3. Date and time information in

digital camera standard format

(Exif)

4. Date and time information

applied on DOS-compliant file

system.

5. Fixed date and time

information (01/01/1980,

00:00:00)

Date and time information included

in an image file is not always the

shooting date and time. It changes

each time the image is edited and

restored. The printer acquires the

latest date and time information.

PRODUCT DESCRIPTION Specification for Each Function 28

Page 29

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

1.7.2.5 Memory Card Direct Print Menu

The LCD-equipped CX9300F/CX9400Fax/DX9400F provide the following menus in

the memory card mode.

Table 1-26. Memory Card Mode Menu

Menu Item Function

View and Print

1,2

Photos*

Print All

1,2

Photos*

Print by Date*

Print Index Sheet

Slide Show*

Note *1: 0 to 99 copies can be specified for each of the images. Up to 999 copies in total.

*2 : The images are listed in ASCII descending order.

*3 : While performing the slide show, displaying number of copies, printing from an

external device or from a computer cannot be made.

Prints the selected images.

Prints all images in a memory card. Specified number of copies is applied

to the all images (the default is 1 copy). Specifying it for each of the

images independently also can be made in the preview screen.

The date of the images are listed in the descending order with the number

of images by date. Selecting date from the list selects the images that has

1

the selected date information. Specified number of copies is applied to the

selected images (the default is 1 copy). Specifying it for each of the

images independently also can be made in the preview screen.

Print Index Sheet

Prints an index sheet that prints images in a memory card in thumbnailed

form. The number of images to be included in the sheet can be selected

from the following four options.

“All image” (default), “Latest 30”, “Latest 60”, “Latest 90”*

Make Prints from Index Sheet

Scans the index sheet, and prints images according to markings written on

the sheet.

Starts a slide show on the LCD. Images in a memory card is displayed one

3

by one in the order sorted by the printer. Printing one of the images can be

made from the paused screen.

2

1.7.2.6 Makes Prints from Index Sheet Function

Print settings

Table 1-27. Print Settings

Item Print Index Sheet Makes Prints from Index Sheet

Number of copies ---

Paper Type Plain paper

Paper Size A4

Layout ---

Quality Standard Standard

Expansion ---

Date

YYYY.MM.DD

(2007.09.21)*

1

Bi-directional On On

Print Index Sheet

Setting-Select

According to the setting

made by the control panel.

Note *1: EAI model: MMM.DD.YYYY (Sep. 21.2007)

Rules on reading Index Sheet markings

The user can specify images to be printed and their print settings shown in Table

1-27 by putting marking on the Index Sheet. The printer reads the markings

according to the following rules.

Table 1-28. Rules on Reading Markings

Item

Left edge

(one each)

Right edge

(one each)

Block code

(36 pcs.)

Image selection

(30 pcs. x 3)

Paper type/size

(4 pcs.)

Layout (2 pcs.)

Mark

Description Remarks

Reference position for

reading markings.

Reference position for

reading markings.

Sheet information

(memory card, page)

Selects the image to be

printed.

Selects the paper type/size. An error occurs if two or more markings are

Selects the layout. An error occurs if two or more markings are

According to the marking on the index

sheet.

According to the setting made by the control

panel.

According to the setting made by the control

panel. YYYY.MM.DD (2007.09.21)*

---

An error occurs if these markings cannot be

read due to ink stain or any other cause.

An error occurs if no image selection

marking is read.

read for one image.

read for one image. If no marking is read,

borderless layout is applied.

1

PRODUCT DESCRIPTION Specification for Each Function 29

Page 30

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

<OK example> <NG example>

(not enough)

(too much)

Trimmed areas

Photo frame

(print area)

• When an image is aligned vertically with the photo frame.

• When an image is aligned horizontally with the photo frame.

Photo frame

(print area)

Trimmed

areas

Table 1-28. Rules on Reading Markings

Item

Date Prints the date information. When this marking is read, the date is

Note: • About 50% or more range of the mark area must be marked out to be read by the

printer.

• For running out and excessive marking out, the two white/black search patterns shown

above are superimposed on the mark, and judgement is made according to this

matching ratio.

• The judgement criteria is as follows;

black matching: 80% or more, white matching: 50% or more.

• The figure below shows the judgement example according to the rules described

above.

Mark

Description Remarks

printed on the image.

Index Sheet errors

Table 1-29. Index Sheet Error List

Error Name Description

Index sheet scan error

(incorrect sheet setting)

Index sheet scan error

(incorrect image selection

marking)*

Index sheet scan error

(incorrect paper selection

marking)

Index sheet scan error

(unmatch between memory

card and sheet)

The Index Sheet is not properly placed on the document glass.

Image selection markings are not correct.

Paper selection markings are not correct.

The memory card may have been changed or some images

may have been added or deleted after the Index Sheet is

printed.

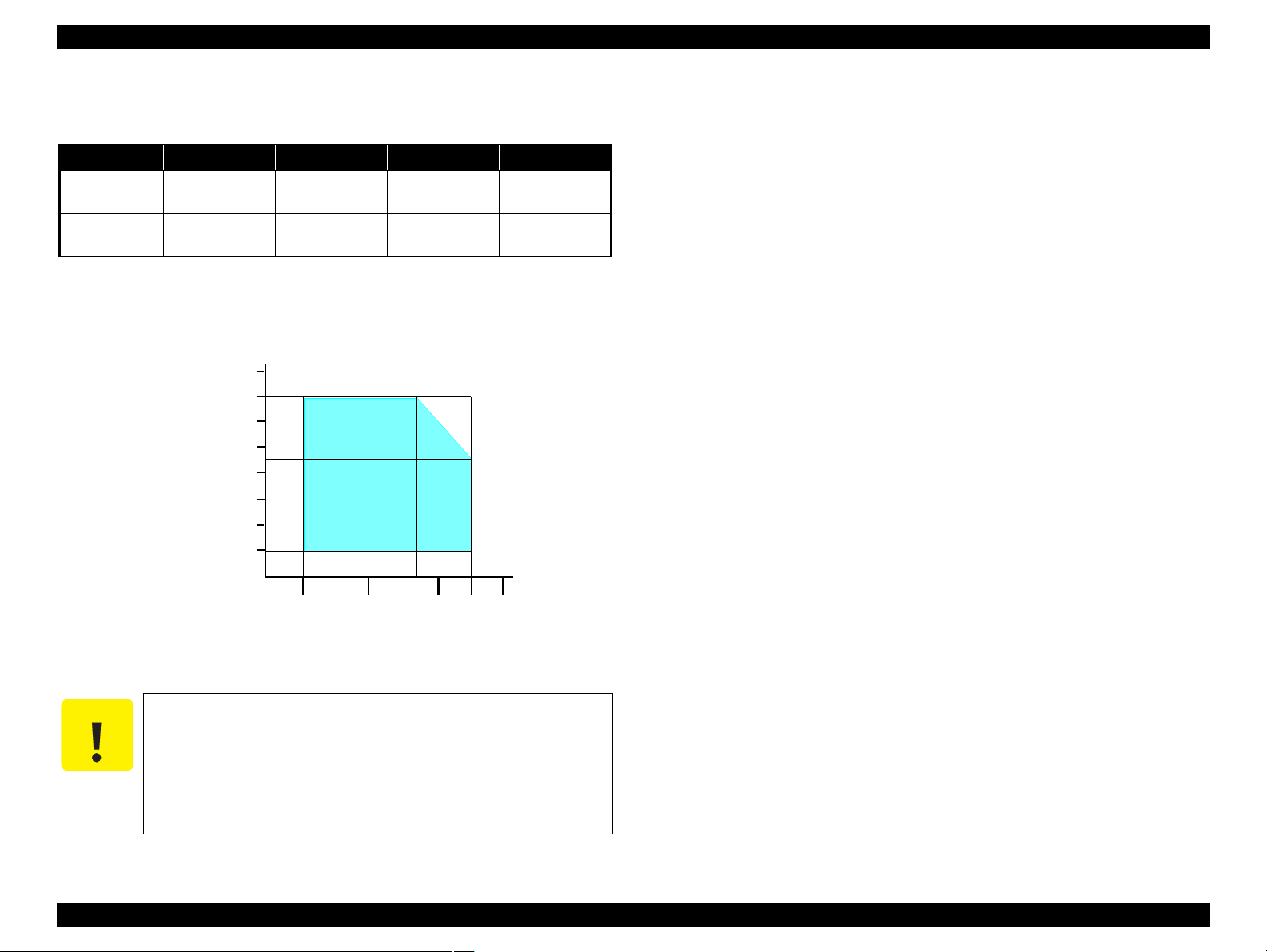

1.7.2.7 Print Layout

The memory card direct print function supports two print layouts for printing images;

Borderless, and With Border. The Borderless layout is not allowed for some type of

paper (refer to

the print area and margins of “Borderless” and “With Border” layouts.

Trimming Function

A trimming function is provided as a means of coordinating an image with the

types of photo frames handled by the printer. This function is always activated so

that the image fits within the photo frames.

This function is described briefly below.

The printed photo frame and an image to be printed are matched in length along

one side and the image is resized along the perpendicular side to fit the frame on

that side. Any part of the image that does not fit within the photo frame is trimmed

away (not printed).

Table 1-23). And see “ 1.2.5 Printing Area ” (p.16) for information on

Figure 1-7. Trimming Function

PRODUCT DESCRIPTION Specification for Each Function 30

Page 31

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

<Borderless>

<With Border>

Paper top edge

Rules on Numbering and Rotating Images

The numbers shown in the figure below indicate the photo frame numbers used for

the print layout. Horizontally oriented images are printed as shown by the

numbers. Vertically oriented images, which has more pixels vertically than

horizontally, the vertical photo data is allocated instead, and the number shown in

the figure below is then rotated 90 degrees before being printed. In Index printing

mode, the numbers are printed as they are shown below, regardless of the shape of

the photo data.

However, when the photo data has an equal number of pixels vertically and

horizontally the photos are printed without rotation, regardless of the layout.

NOTE: The vertical photo data refers to when the photo data file itself is set for a

vertical (portrait) orientation. Photo data is defined as the vertical photo

data if it is taken by a digital camera with a portrait position detecting

function.)

Figure 1-8. Rules on Numbering and Rotating Images

1.7.3 Camera Direct Print Function

(USB Direct Print/PictBridge)

Printing operations (selecting images to be printed, making print settings, starting/

canceling printing, and monitoring print process) can be carried out from a directly

connected DSC (Digital Still Camera) that conforms to the standard described below.

1.7.3.1 Available DSC

Table 1-30. Available DSC

USB Direct Print PictBridge

DSCs conform to USB Direct Print

Protocol Revision 1.0.

1.7.3.2 Print Settings Available from DSC

The following print settings can be made from the DSC. However, depending on the

DSC, some of the settings may not be available.

Table 1-31. Print Settings Available from DSC

Item USB Direct Print PictBridge

How to specify images Single Sheet / DPOF specified Single Sheet / Multiple Sheet /

Paper type Plain Paper/ Glossy Photo / Prem.

Glossy / Matte

Paper size 4x6, 5x7, Letter (EAI model only), A4

Layout Borderless

With Borders

(2-up, 4-up, 8-up are available

when specified by DPOF)

Date On / Off

Quality Not available

Auto Correct Not available

Fit to Frame Available only for a single sheet Available

Print Image Framer Yes / No Not available

Control of printer The following operations are available; Getting the printer status, starting

a print job or canceling it immediately or after printing the current page is

finished. (In the case of the USB Direct Print, resetting the printer is also

available.)

DSCs conform to CIPA DC-001-2003 Digital Photo

Solutions for Imaging Devices (DPS version 1.0) or

the Rev. 2.0.

DPOF specified

Plain Paper/ Prem. Glossy

Borderless

With Borders

PRODUCT DESCRIPTION Specification for Each Function 31

Page 32

EPSON Stylus CX9300F/CX9400Fax/DX9400F Revision A

C H E C K

P O I N T

1.7.3.3 General Operation Procedure

Before connecting the DSC, check that the printer is in the

following status.

• No print job from a computer is processed or performed.

• Direct print from a memory card is not processed or performed.

• Stand alone copy using the scanner function is not operating.

• No paper out error or ink out error is occurring.

The DSC direct print procedure differs depending on the DSC specifications. The

following explains common procedure.

1. Setting on the printer

Before connecting a DSC with a USB cable, make the print settings such as paper

type/size, layout setting on the printer. This may not be required for some DSCs.

2. Setting on the DSC

Make the following settings on the DSC before connecting it to the printer. Some

DSCs may require to first connect to the printer for making the settings.

• When printing multiple images, specify images and number of copies using

the DPOF and Multiple Sheet* menus. The menus may not be available on

some DSCs.

Note*: The Multiple Sheet setting is available when using PictBridge.

• When printing a single image

<USB Direct Print>

Use the Single Sheet menu to specify an image and the number of copies.

The menu may not be available on some DSCs.

<PictBridge>

Specify an image and the number of copies. Specifying the number of

copies may not be available on some DSCs.

• Select the paper type/size, layout, and make the Fit to Frame setting if

necessary. These settings may not be available on some DSCs.

1.7.3.4 Operating Specifications during Connecting DSC

Table 1-32. Operations during Connecting DSC

Operation Specifications

Connecting

DSC

(print start)

Canceling

printing

After printing

is completed

Exclusion

control

When a DSC is connected as described in “ 1.7.3.3 General Operation

Procedure ( p. 32 ) ” Step 3-1, CX9300F/CX9400Fax/DX9400F displays USB

Direct Print or PictBridge logo on the LCD.

A print job can be canceled from the DSC.

The [Stop/Clear setting] button also cancels the print job.

When performing memory card direct print after printing from a DSC, the

USB cable connecting the DSC must be disconnected from the printer in

advance.

Print settings made on both the DSC and the printer can become impossible

settings for the printer due to unsupported combination of paper type, paper

size and layout. In such case, the print settings are automatically changed as

follows.

USB Direct Print

The selected paper type is maintained, and the paper size and layout

settings are changed to the default for the selected paper type.

PictBridge

The settings made on the DSC are maintained. Any print setting items that

are not specified by the DSC are changed in accordance with the DSC

settings. When the paper type is changed, changed to Prem. Glossy, when

the paper size is changed, changed to 4x6 size. And when the layout is