Page 1

SERVICE MANUAL

Color Inkjet Printer

EPSON B-300/B-308

EPSON B-500DN/B-508DN

EPSON B-310N/B-318N

EPSON B-510DN/B-518DN

Confidential

SEIJ07-013

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2009 SEIKO EPSON CORPORATION.

IJP LP CS Quality Assurance Department

Confidential

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1) Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO

SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIER FROM METAL PARTS WITH SHARP EDGES.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED

CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs OR

OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

6. WHEN USING COMPRESSED AIR PRODUCTS; SUCH AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF SUCH

PRODUCTS CONTAINING FLAMMABLE GAS IS PROHIBITED.

Confidential

Page 4

About This Manual

CAUTION

CHECK

POINT

REASSEMBLY

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Connector Summary

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

ADJUSTMENT

REQUIRED

WARNING

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Indicates that a particular task must be carried out according to a certain

standard after disassembly and before re-assembly, otherwise the quality of the components in question may be adversely affected.

Confidential

Page 5

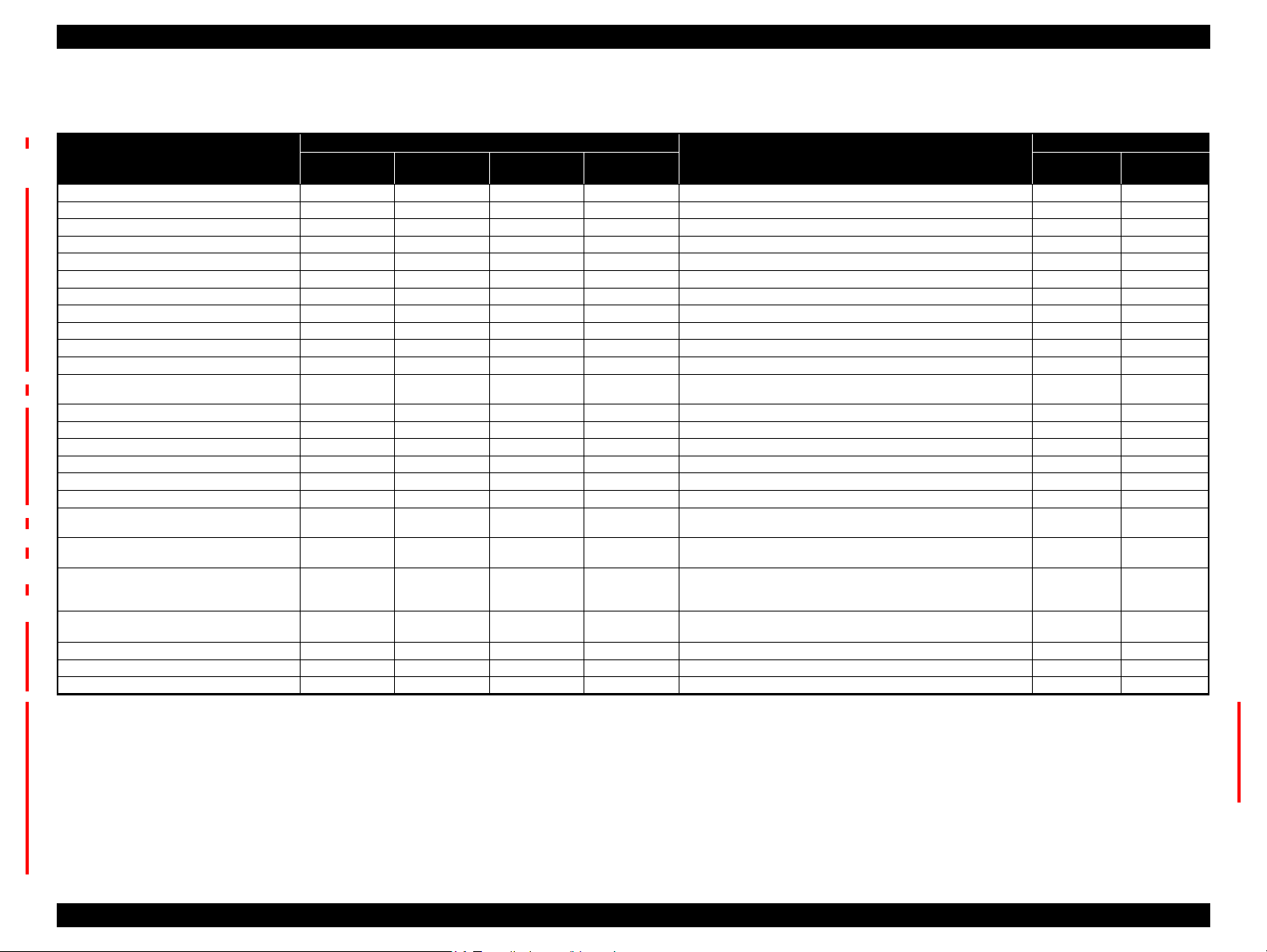

Revision Status

Revision Date of Issue Description

A April 1, 2008 First Release

B May 16, 2008 Revised Contents

Chapter 3

Descriptions have been added in Table 3-26 “Troubleshooting Ink Suction / Waste Ink Problems” (p70).

Chapter 4

Made changes in 4.1.2 Tools (p75).

Made changes in 4.3.4 Using Acetate Tape (p80).

Made changes in 4.5.6.2 Front Housing Assy (p92).

Made changes in 4.5.7.2 Upper Housing (p94).

Made changes in 4.5.7.3 Cover Open Sensor (p96).

Made changes in 4.6.3 AID Board (p100).

Made changes in 4.6.5 Power Supply Unit (p106).

Made changes in 4.7.1.1 IC Holder Assy (p108).

Made changes in 4.7.1.3 CV Drive Assy (p116).

“CAUTION” has been added in 4.7.3.1 Printhead (p121).

Made changes in 4.7.3.3 APG Assy / Sub Board (p125).

Made changes in 4.7.3.4 ASF Encoder Assy (p128).

Made changes in 4.7.3.5 CR Motor (p129).

Made changes in 4.7.3.6 Carriage Assy (p131).

Made changes in 4.7.4.3 ASF Motor Assy (p136).

Made changes in 4.7.4.4 Planet Lock Assy (p138).

Made changes in 4.7.4.9 Paper Guide Bank Assy (p149).

Made changes in 4.7.5.1 PF Motor (p156).

Made changes in 4.7.5.5 Front Paper Guide & EJ Roller Assy (p162).

Made changes in 4.7.6.1 Ink System (p165).

Made changes in 4.7.6.2 EJ Waste Ink Assy (p168).

Made changes in 4.7.6.3 EJC Sensor (p169).

Chapter 5

Made changes in Table 5-1 “Adjustment Items and Overviews” (p171).

Descriptions have been added in Table 5-2 “Maintenance Items” (p174).

Descriptions have been added in Table 5-3 “Additional Functions” (p175).

Made changes in 5.2.6 Head angular adjustment (p181).

Confidential

Page 6

Revision Date of Issue Description

C March 31, 2009 Revised Contents

Chapter 1

Descriptions have been added in Table 1-12 “Power Supply Specifications” (p20).

Chapter 3

Descriptions have been added in Table 3-23 “Troubleshooting Print Quality Problems” (p67).

Descriptions have been added in Table 3-25 “Troubleshooting Ink Supply Problems” (p69).

Chapter 4

Descriptions have been added in 4.3.1 Releasing Carriage Lock (p79).

“REASSEMBLY” has been added in 4.7.1.1 IC Holder Assy (p108).

“REASSEMBLY” has been added in 4.7.1.3 CV Drive Assy (p116).

Chapter 5

Made changes in Table 5-1 “Adjustment Items and Overviews” (p171).

Made changes in Table 5-4 “Adjustment Items” (p176).

Made changes in 5.2.6 Head angular adjustment (p181).

Made changes in 5.2.7 AID inspection (p184).

Descriptions have been added in 5.2.10 Paper Skew Adjustment (p187).

Descriptions have been added in 5.2.11 ACL Failed Counter Initialization (p189).

Chapter 6

Descriptions have been added in Table 6-2 “Specified Lubricant” (p198).

Confidential

Page 7

Revision Date of Issue Description

D September 17, 2009 Revised Contents

Chapter 2

Made changes in Figure 2-1 “Printer Mechanism Block Diagram” (p31).

Made changes in Table 2-1 “PG Settings / Cam Diagram” (p32).

Descriptions have been added in 2.3 Optical Sensor Control (p34).

Chapter 3

Made changes in Table 3-3 “Error Messages and Possible Causes” (p37).

Descriptions have been added in 3.3.2 Fatal Error (p48).

Chapter 4

Made changes in 4.7.3.1 Printhead (p121).

“ADJUSTMENT REQUIRED” has been changed in 4.7.3.5 CR Motor (p129).

“ADJUSTMENT REQUIRED” has been changed in 4.7.5.1 PF Motor (p156).

Chapter 5

Made changes in Table 5-1 “Adjustment Items and Overviews” (p171).

Descriptions have been added in Table 5-2 “Maintenance Items” (p174).

“CHECKPOINT” has been added and made changes in 5.2.11 ACL Failed Counter Initialization (p189).

Made changes in 5.3.2 PF Belt Tension Adjustment (p193).

Made changes in 5.3.3 FD Belt Tension Adjustment (p194).

Confidential

Page 8

Revision Date of Issue Description

E November 26, 2009 Revised Contents

All chapters

Descriptions about B-310N/B-318N/B-510DN/B-518DN are added.

Chapter 1

Made changes in 1.1 Features (p14)

Made changes in Table 1-3 “Product No. of Ink Cartridges” (p15)

Made changes in Table 1-6 “Print Mode (Color/Monochrome)” (p16)

Made changes in Table 1-7 “Supported Paper” (p17)

Made changes in Table 1-12 “Power Supply Specifications” (p20)

Made changes in Table 1-14 “Operation Buttons, LED, LCD (B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-

518DN)” (p22)

Made changes in Table 1-16 “LEDs and LCD Indications” (p23)

1.6 Various Settings (p24) has been added

Made changes in Figure 1-10 “Network Status Sheet Sample (2)” (p29)

Chapter 3

Made changes in Table 3-3 “Error Messages and Possible Causes” (p37)

Made changes in Table 3-12 “Check Point for Fatal Error of Each Phenomenon” (p52)

Made changes in Table 3-19 “FFC/harness Connection Error (SUB Board)” (p65)

Confidential

Page 9

Revision Date of Issue Description

E November 26, 2009

Chapter 4

“CHECKPOINT” has been added and made changes in 4.4.3 Cassette Assy (p85)

Made changes in 4.5.6.2 Front Housing Assy (p92)

Made changes in 4.6.2 Network Board (B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only) (p99)

Made changes in 4.6.3 AID Board (p100)

Made changes in 4.7.1.1 IC Holder Assy (p108)

Made changes in 4.7.1.3 CV Drive Assy (p116)

Made changes in 4.7.2 Lower Housing (p117)

“CHECKPOINT” has been added and made changes in 4.7.3.1 Printhead (p121)

“CHECKPOINT” has been added and made changes in 4.7.3.3 APG Assy / Sub Board (p125)

“CHECKPOINT” has been added in 4.7.3.4 ASF Encoder Assy (p128)

“CHECKPOINT” has been added and made changes in 4.7.4.4 Planet Lock Assy (p138)

“CHECKPOINT” has been added in 4.7.4.5 ASF Sub Encoder (p142)

Made changes in 4.7.4.6 Retard Transfer Assy (p143)

Made changes in 4.7.4.7 FASF Retard Assy (p144)

“CHECKPOINT” has been added and made changes in 4.7.5.4 Left/Right Upper Paper Guide (p160)

Made changes in 4.7.6.1 Ink System (p165)

Chapter 5

Made changes in Table 5-3 “Additional Functions” (p175)

Chapter 6

Made changes in Table 6-2 “Specified Lubricant” (p198)

Made changes in 6.1.3 Lubrication (p198)

Chapter 7

Made changes in Figure 7-1 “Block Diagram” (p208)

Confidential

Page 10

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Features............................................................................................................... 14

1.2 Printing Specifications........................................................................................ 15

1.2.1 Basic Specifications................................................................................. 15

1.2.2 Ink Cartridges .......................................................................................... 15

1.2.3 Maintenance Box..................................................................................... 16

1.2.4 Print Mode ............................................................................................... 16

1.2.5 Supported Paper....................................................................................... 17

1.2.6 Printing Area ........................................................................................... 19

1.3 Interface.............................................................................................................. 19

1.3.1 USB Interface .......................................................................................... 19

1.3.2 Network Interface

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only) .......... 19

1.4 General Specifications........................................................................................ 20

1.4.1 Electrical Specifications .......................................................................... 20

1.4.2 Safety Approvals (Safety standards/EMI) ............................................... 20

1.4.3 Environmental Conditions....................................................................... 21

1.4.4 Durability................................................................................................. 21

1.5 Control Panel ...................................................................................................... 22

1.5.1 Operation Buttons.................................................................................... 22

1.5.2 LEDs and LCD Indications ..................................................................... 23

1.6 Various Settings.................................................................................................. 24

1.6.1 Panel Operation ....................................................................................... 24

1.6.1.1 Menu Configuration

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only) .... 24

1.6.1.2 Panel Operation Lock Setting

(B-310N/B-318N/B-510DN/B-518DN only) ...................................... 25

1.6.1.3 Forced Power OFF ............................................................................. 26

1.6.2 AID Function Setting .............................................................................. 26

1.6.2.1 AID Detection Cleaning

(B-310N/B-318N/B-510DN/B-518DN only) ...................................... 26

1.6.2.2 AID High Quality Mode/Dot Missing Tolerance Mode .................... 27

1.6.2.3 Monochrome Priority Mode ............................................................... 27

1.6.3 Low Speed Mode (MPBF Priority Mode)

(B-310N/B-318N/B-510DN/B-518DN only)............................................ 28

1.7 Status Sheet ........................................................................................................ 28

Chapter 2 Operating Principles

2.1 Overview ............................................................................................................ 31

2.1.1 Printer Mechanism .................................................................................. 31

2.1.2 Printhead.................................................................................................. 31

2.1.3 PG Setting................................................................................................ 32

2.2 Motors and Sensors ............................................................................................ 33

2.3 Optical Sensor Control ....................................................................................... 34

Chapter 3 Troubleshooting

3.1 Overview ............................................................................................................ 36

3.1.1 Troubleshooting on Motors and Sensors................................................. 36

3.2 Error Messages and Possible Causes.................................................................. 37

3.2.1 List of Error Indications .......................................................................... 37

3.3 Troubleshooting.................................................................................................. 39

3.3.1 Troubleshooting by Error Message ......................................................... 39

3.3.2 Fatal Error................................................................................................ 48

3.3.2.1 Check Point for Fatal Error of Each Phenomenon ............................. 52

3.3.2.2 Check Result of Fatal Errors when Abnormality Occurs................... 60

3.4 Troubleshooting by Symptom (no error indications)......................................... 66

3.4.1 Troubleshooting Printer Mechanism Problems....................................... 66

3.4.2 Troubleshooting Electrical Problems ...................................................... 68

3.4.3 Troubleshooting Ink Supply / Waste Ink Problems ................................ 69

3.4.4 Troubleshooting I/F-related Problems..................................................... 71

3.5 Troubleshooting Duplex Unit Problems............................................................. 72

10

Confidential

Page 11

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

Chapter 4 Disassembly and Assembly

4.1 Overview ............................................................................................................ 74

4.1.1 Precautions .............................................................................................. 74

4.1.2 Tools ........................................................................................................ 75

4.1.3 Screws...................................................................................................... 75

4.1.4 Work Completion Checklist .................................................................... 75

4.1.5 Preparation for Disassembling ................................................................ 76

4.1.6 Orientation Definition ............................................................................. 76

4.2 Disassembly Flowchart ...................................................................................... 77

4.3 Basic Operations................................................................................................. 79

4.3.1 Releasing Carriage Lock ......................................................................... 79

4.3.2 Handling Ink Supply Parts....................................................................... 80

4.3.3 Handling Ink System Parts ...................................................................... 80

4.3.4 Using Acetate Tape ................................................................................. 80

4.3.5 Protection for Transportation .................................................................. 81

4.4 Consumables & Accessories .............................................................................. 83

4.4.1 Ink Cartridge............................................................................................ 83

4.4.2 Maintenance Box Assy............................................................................ 84

4.4.3 Cassette Assy........................................................................................... 85

4.4.4 Rear Cover / Duplex Unit........................................................................ 86

4.5 Removing Exterior Parts .................................................................................... 87

4.5.1 IC Holder Cover ...................................................................................... 87

4.5.2 Cover Ink Eject Box ................................................................................ 88

4.5.3 Front ASF Cover Assy ............................................................................ 88

4.5.4 Stacker Assy / Paper Support .................................................................. 89

4.5.4.1 Stacker Assy ....................................................................................... 89

4.5.4.2 Paper Support ..................................................................................... 89

4.5.5 Panel Unit ................................................................................................ 90

4.5.6 Cover Printer Assy /Housing Front Assy ................................................ 91

4.5.6.1 Cover Printer Assy ............................................................................. 91

4.5.6.2 Front Housing Assy............................................................................ 92

4.5.7 Connector Cover / Upper Housing .......................................................... 94

4.5.7.1 Connector Cover................................................................................. 94

4.5.7.2 Upper Housing ................................................................................... 94

4.5.7.3 Cover Open Sensor............................................................................. 96

4.6 Removing the Circuit Boards ............................................................................. 97

4.6.1 Main Board .............................................................................................. 97

4.6.2 Network Board

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only) .......... 99

4.6.3 AID Board ............................................................................................. 100

4.6.4 Disassembling the Panel Unit................................................................ 103

4.6.4.1 Panel Board ...................................................................................... 104

4.6.4.2 Optical Tube, Buttons ...................................................................... 105

4.6.5 Power Supply Unit ................................................................................ 106

4.7 Removing the Printer Major Components........................................................ 108

4.7.1 Removing the Ink System Components ................................................ 108

4.7.1.1 IC Holder Assy................................................................................. 108

4.7.1.2 Sub-B Board..................................................................................... 115

4.7.1.3 CV Drive Assy ................................................................................. 116

4.7.2 Lower Housing ...................................................................................... 117

4.7.3 Disassembling the Carriage Components.............................................. 121

4.7.3.1 Printhead........................................................................................... 121

4.7.3.2 CR Scale ........................................................................................... 124

4.7.3.3 APG Assy / Sub Board..................................................................... 125

4.7.3.4 ASF Encoder Assy ........................................................................... 128

4.7.3.5 CR Motor.......................................................................................... 129

4.7.3.6 Carriage Assy ................................................................................... 131

4.7.4 Disassembling the Paper Loading Mechanism Components ................ 133

4.7.4.1 Rear ASF Assy ................................................................................. 133

4.7.4.2 RH Sensor / RP Sensor.................................................................... 135

4.7.4.3 ASF Motor Assy............................................................................... 136

4.7.4.4 Planet Lock Assy.............................................................................. 138

4.7.4.5 ASF Sub Encoder ............................................................................. 142

4.7.4.6 Retard Transfer Assy........................................................................ 143

4.7.4.7 FASF Retard Assy............................................................................ 144

4.7.4.8 LD Roller / Retard Roller................................................................. 146

4.7.4.9 Paper Guide Bank Assy.................................................................... 149

4.7.4.10 PEF Sensor ..................................................................................... 153

4.7.4.11 PER Sensor..................................................................................... 153

4.7.4.12 Rear Paper Guide / PE Sensor....................................................... 154

4.7.4.13 Pick-up Assy .................................................................................. 155

4.7.5 Disassembling the Paper Feed Mechanism Components...................... 156

4.7.5.1 PF Motor .......................................................................................... 156

4.7.5.2 PF Encoder ....................................................................................... 158

4.7.5.3 EJ Frame Assy.................................................................................. 159

4.7.5.4 Left/Right Upper Paper Guide ......................................................... 160

4.7.5.5 Front Paper Guide & EJ Roller Assy ............................................... 162

4.7.5.6 PF Roller Assy ................................................................................. 163

4.7.6 Disassembling the Ink System Components ......................................... 165

11

Confidential

Page 12

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

4.7.6.1 Ink System. ....................................................................................... 165

4.7.6.2 EJ Waste Ink Assy. ........................................................................... 168

4.7.6.3 EJC Sensor . ...................................................................................... 169

Chapter 5 ADJUSTMENT

5.1 Adjustment Items and Overview ...................................................................... 171

5.1.1 Servicing Adjustment Item List............................................................. 171

5.1.2 Required Adjustments . .......................................................................... 176

5.2 Adjustment by Using Adjustment Program ..................................................... 178

5.2.1 Top Margin Adjustment (Rear/Front) ................................................... 178

5.2.2 Bi-D Adjustment ................................................................................... 178

5.2.3 First Dot Position Adjustment (Front/Rear). ......................................... 179

5.2.4 PW Adjustment ..................................................................................... 179

5.2.5 PF Adjustment (Rear/Front) .................................................................. 180

5.2.6 Head angular adjustment ....................................................................... 181

5.2.7 AID inspection. ...................................................................................... 184

5.2.8 Printer Mechanism Operation Check .................................................... 184

5.2.9 MAC Address Setting (B-500DN/B-508DN/B-310N/B-318N/B-510DN/

B-518DN only) ........................................................................................ 185

5.2.10 Paper Skew Adjustment . ..................................................................... 187

5.2.11 ACL Failed Counter Initialization....................................................... 189

5.2.12 Compulsion Uni-d Print Setting .......................................................... 190

5.3 Adjustment without Using Adjustment Program ............................................. 191

5.3.1 PG Adjustment ...................................................................................... 191

5.3.2 PF Belt Tension Adjustment ................................................................. 193

5.3.3 FD Belt Tension Adjustment. ................................................................ 194

Chapter 7 APPENDIX

7.1 Connector Summary. ........................................................................................ 208

Chapter 6 MAINTENANCE

6.1 Overview .......................................................................................................... 196

6.1.1 Cleaning. ................................................................................................ 196

6.1.2 Service Maintenance ............................................................................. 197

6.1.2.1 Printhead cleaning ............................................................................ 197

6.1.2.2 Service Call ...................................................................................... 197

6.1.3 Lubrication ............................................................................................ 198

12

Confidential

Page 13

PRODUCT DESCRIPTION

CHAPTER

1

Confidential

Page 14

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

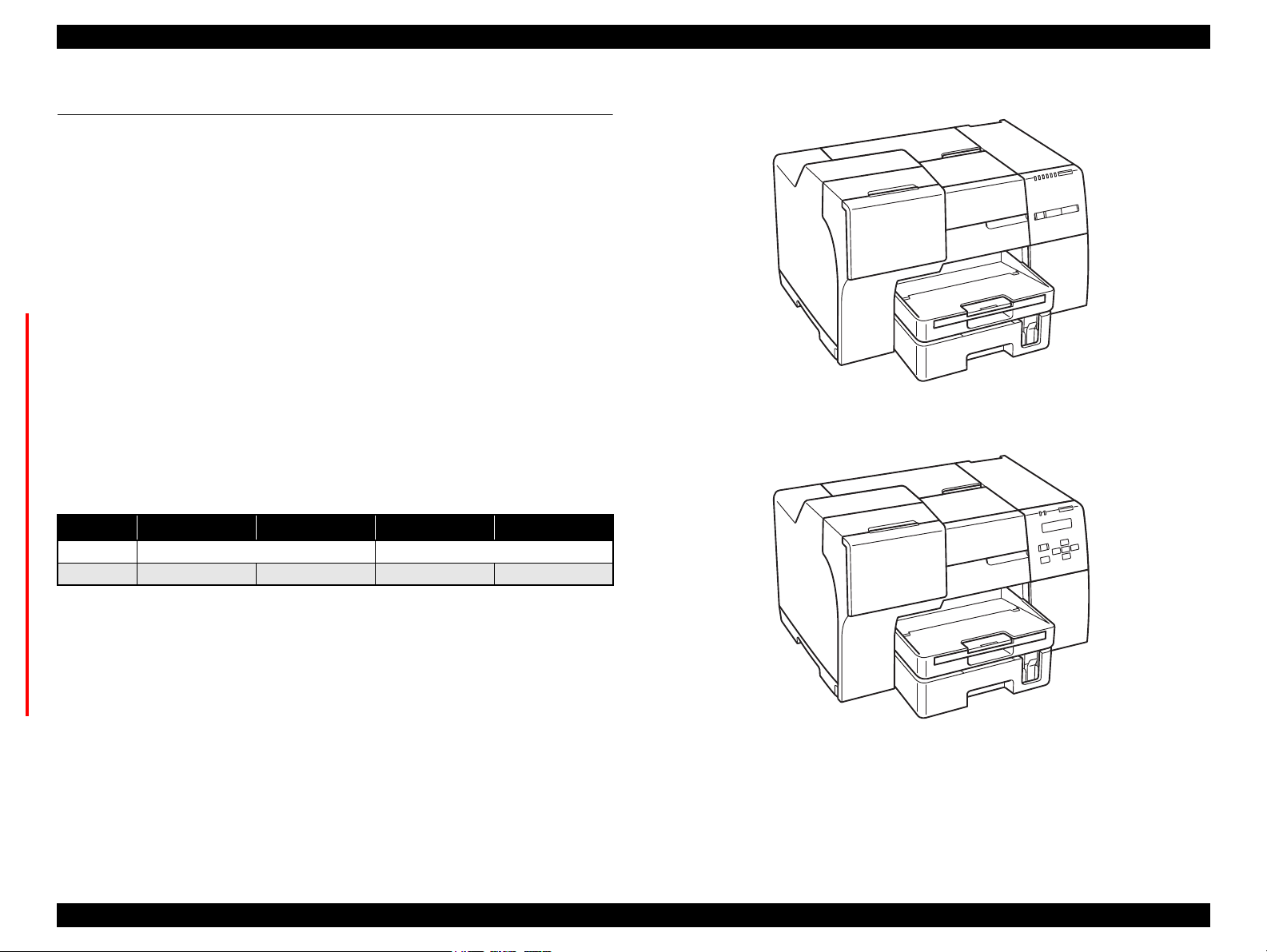

B-300/B-308

B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN

1.1 Features

B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN is businessoriented A4 inkjet printers, which offers high print quality and high durability with low

running costs like laser printers. The main features are:

F-Mach Turbo 2 (180 nozzles x 8 columns) Printhead

High durability (up to 100,000 sheets can be printed)

The default mode enables high-speed printing on plain paper

Large capacity ink cartridges

Large capacity paper feeders (front: 500 sheets, rear: 150 sheets)

Automatic duplex printing using the duplex unit

(B-500DN/B-508DN/B-510DN/B-518DN include the unit as standard. For B-300/

B-308/B-310N/B-318N, the unit is available as an option.)

2 Line LCD on the control panel offers high level of visibility and operability.

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only)

Wired LAN is supported.

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only)

Dimensions & Weight

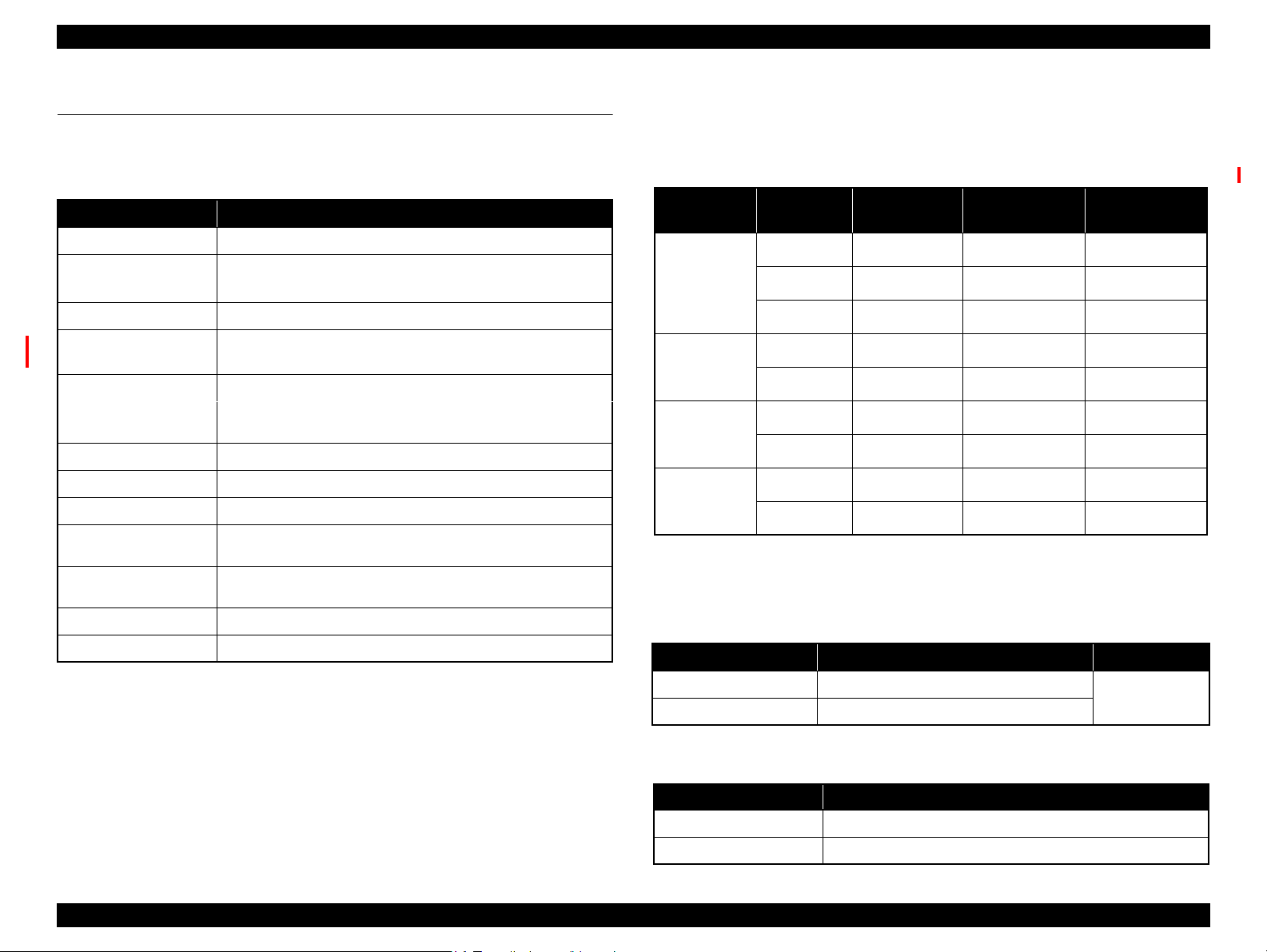

Table 1-1. Dimensions & Weight

B-300/B-308 B-310N/B-318N

Dimensions

Weight 9.85 kg

480 mm (W) x 420 mm (D) x 312 mm (H)*1480 mm (W) x 489 mm (D) x 312 mm (H)

*3

9.95 kg

*3

B-500DN/B-508DN B-510DN/B-518DN

*3

10.69 kg

10.70 kg*4/10.79 kg

*2

*5

*1:The optional duplex unit is not included. The stackers are retracted.

*2:The duplex unit is included. The stackers are retracted.

*3:The ink cartridges, the power cord and the duplex unit are not included.

*4:The ink cartridges and the power cord are not included.

*5:For the EAI model, the ink cartridges, the power cord, and the Casstte Assy are not

included, but the Cassette Assy for legal size paper is included instead.

Figure 1-1. External View

PRODUCT DESCRIPTION Features 14

Confidential

Page 15

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

1.2 Printing Specifications

1.2.1 Basic Specifications

Table 1-2. Printer Specifications

Item Specifications

Print method On-demand inkjet

Printhead

Colors Cyan, Yellow, Magenta, Black

Print direction

Print resolution

Control code ESC/P Raster command

Input buffer size 256 KBytes

Paper feed method Friction feed

Paper feeders

Paper path

Feed speed 100 ms (25.4 mm feed)

Line pitch Programmable in units of 0.01764 mm (1/1440 inch)

Black: 360 nozzles (180 nozzles x 2 columns)

Color: 1,080 nozzles (180 nozzles x 2 columns per color)

Bi-directional minimum distance printing (logic seeking),

unidirectional printing

Horizontal x Vertical (dpi)

• 360 x 360

• 1440 x 720

• Front: 500 sheets (plain paper)

• Rear: 150 sheets (plain paper)

• Rear feed, front out

• Front feed, front out

• 720 x 720

• 5760 x 1440

1.2.2 Ink Cartridges

The product numbers of the Epson ink cartridges for this printer are shown below.

Product No.

Table 1-3. Product No. of Ink Cartridges

Color Size

Black

Cyan

Magenta

Yellow

LL

L

M Τ6161 Τ6161

L

M Τ6162

L

M Τ6163

L

M Τ6164

B-300/B-308/

B-310N/B-318N

N/A

N/A

N/A

N/A

N/A

Shelf life

Two years from production date (if unopened), six months after opening package.

Storage Temperature

Table 1-4. Storage Temperature

Situation Storage Temperature Limit

Packed in the package

Installed on the printer

o

C to 40 oC (-4oF to 104oF)

-20

-20 oC to 40 oC (-4oF to 104oF)

B-500DN/

B-510DN

Τ6181

Τ6171

B-508DN/

B-518DN

Τ6271

Τ6261

Τ6251

Τ6172

Τ6262

Τ6162 Τ6252

Τ6173

Τ6263

Τ6163 Τ6253

Τ6174

Τ6264

Τ6164 Τ6254

1 month max.

o

at 40

C (104oF)

Dimensions

Table 1-5. Dimensions

Ink Cartridge Size Dimensions

M/L

LL

165.8 mm (W) x 106.6 mm (D) x 25.1 mm (H)

280.8 mm (W) x 106.6 mm (D) x 25.1 mm (H)

PRODUCT DESCRIPTION Printing Specifications 15

Confidential

Page 16

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

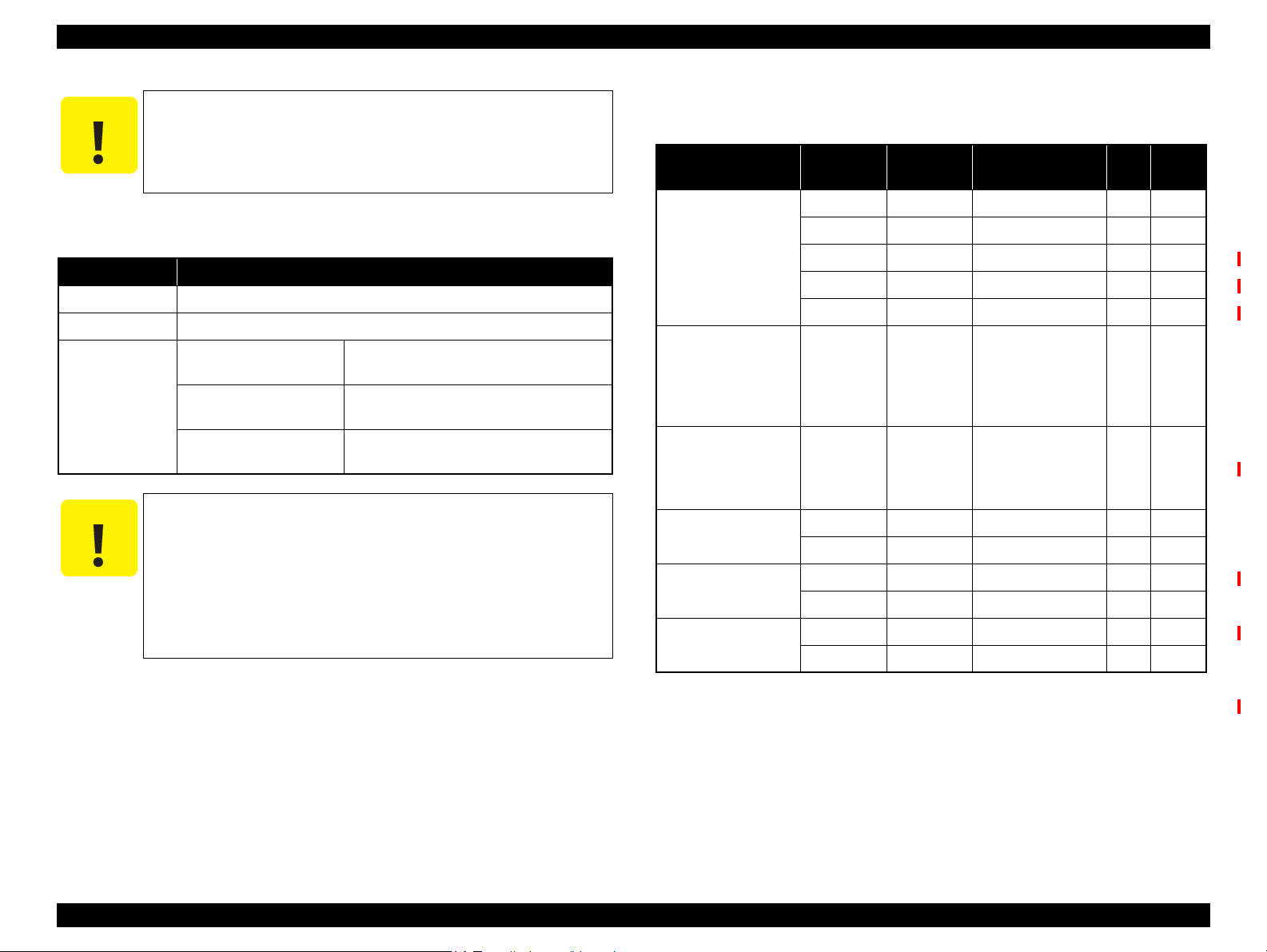

CAUTION

CAUTION

Do not use expired ink cartridge.

Ink in the cartridges freezes if the cartridges left under a

temperature of 10

o

C or lower. Once ink becomes frozen, it takes

about three hours to thaw it under a temperature of 25

moved from -20

o

C environment.)

1.2.3 Maintenance Box

Item Specifications

Model number T6190

Dimensions 86.2mm (W) x 236.9mm (D) x 56.5mm (H)

o

C to 40oC* (-4oF to 104oF)

-20

*1 month max. at 40 oC (104oF)

-20oC to 40oC* (-4oF to 104oF)

*1 month max. at 40 oC (104oF)

o

C to 60oC* (-4oF to 140oF)

-20

*Within five days at 60

Ambient temp.

Packed in the package

Installed on the printer

Transported with packed

Do not disassemble the maintenance box.

Do not touch the CSIC on the maintenance box.

Do not remove the film attached to the upper surface of the

maintenance box.

When disposing of a used maintenance box, do not tilt it before

putting it into a plastic bag.

If the maintenance box is removed and left unused for a long

time, do not reuse it.

o

C (140oF)

o

C. (when

1.2.4 Print Mode

Table 1-6. Print Mode (Color/Monochrome)

Media Print Mode

• Plain paper

• Premium Bright

White Paper (EAI)

• Bright White Inkjet

Paper (Euro, Asia)

• Premium

Presentation Paper

Matte (EAI)

• Matte Paper Heavyweight (Euro, Asia)

• Presentation Paper

Matte (EAI)

• Photo Quality Inkjet

Paper (Euro, Asia)

• Envelope

• Photo Paper

• Professional Flyer

Paper

Note *1: cps = character per second

*2: B-310N/B-318N/B-510DN/B-518DN only

Draft 360x360 Eco (450cps) ON OFF

Normal 360x360 VSD-1 (360cps) ON OFF

Fine 360x360 VSD-1 (360cps) ON OFF

Photo 360x720 VSD-1 (360cps) ON OFF

Best Photo

Best Photo 1440x720 VSD-3 (200cps) ON ON

Normal 360x360 VSD-1 (360cps) OFF OFF

Photo

Best Photo 1440x1440 VSD-3 (200cps) ON ON

Best Photo 1440x1440 VSD-3 (200cps) ON ON

*2

Photo 1440x720 VSD-3 (200cps) ON ON

Photo 720x720 VSD-2 (200cps) OFF ON

*2

Photo 1440x720 VSD-3 (200cps) ON ON

Resolution

(H x V) dpi

720x720 VSD-2 (200cps) ON ON

720x720 VSD-2 (200cps) ON ON

Dot Size

(cps*1)

Bi-d

Micro

Weave

PRODUCT DESCRIPTION Printing Specifications 16

Confidential

Page 17

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

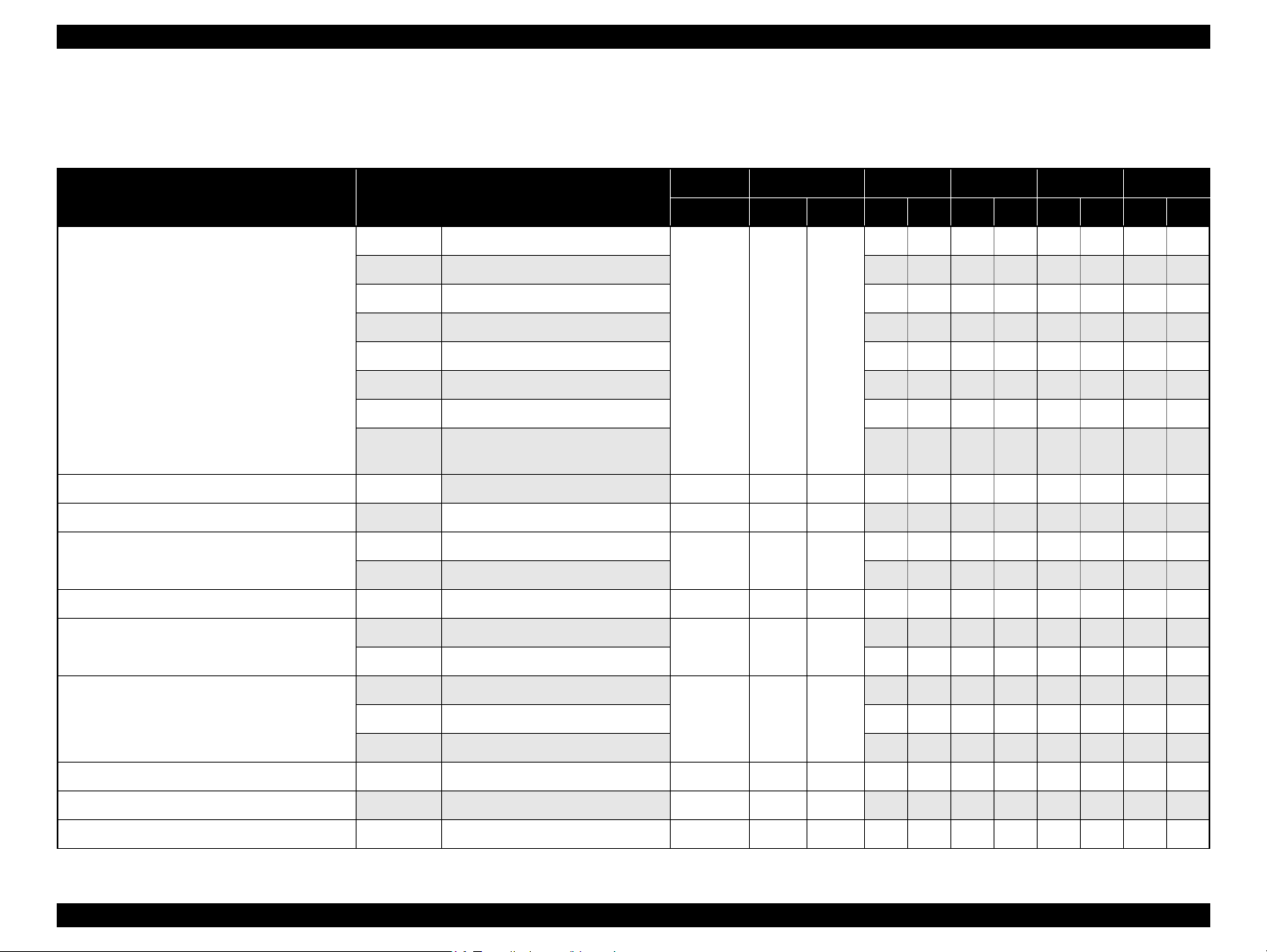

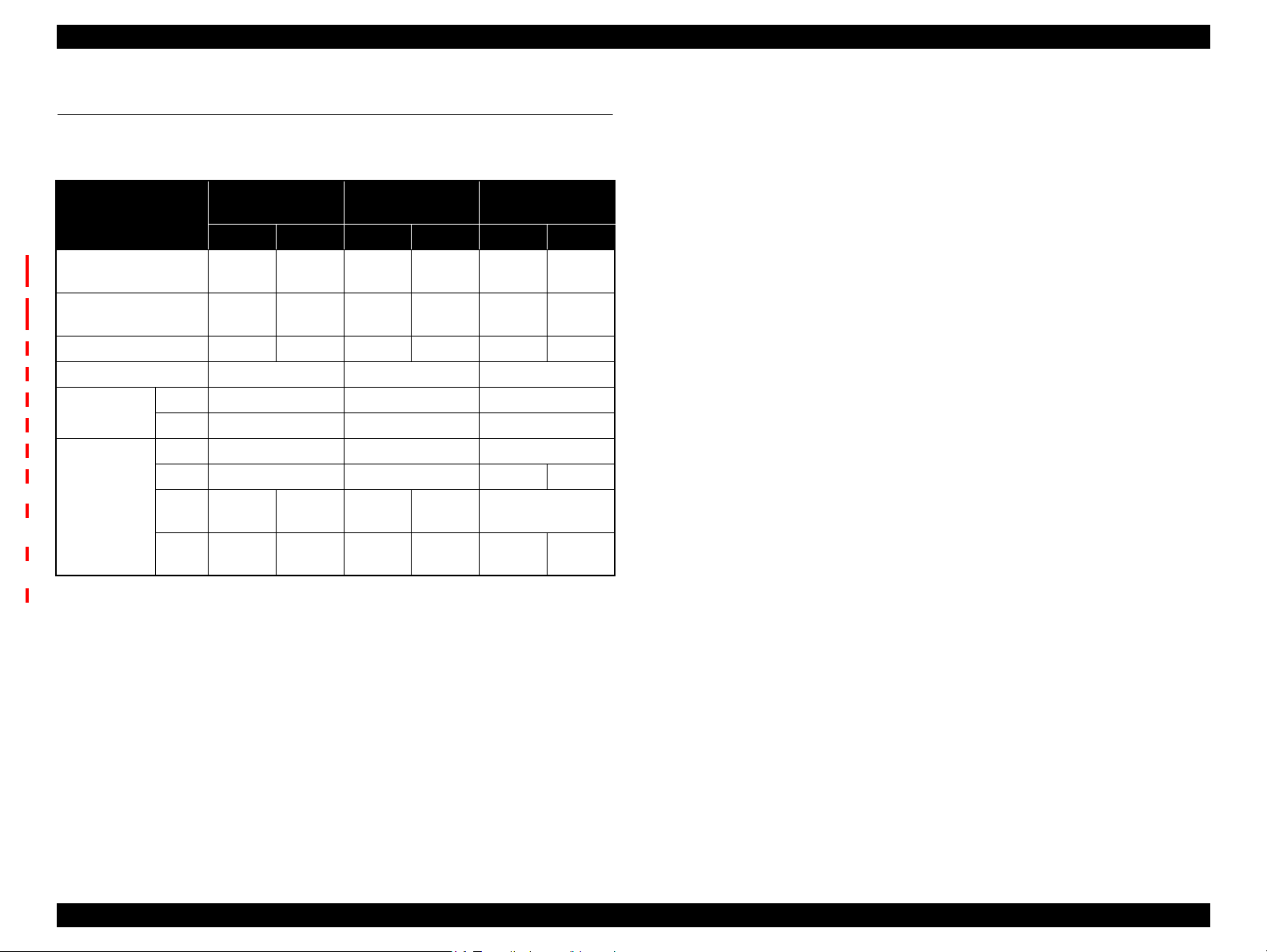

1.2.5 Supported Paper

The table below lists the paper type and sizes supported by the printer. The Supported paper type and sizes vary depending on destinations (between EAI, EUR, and Asia).

Table 1-7. Supported Paper

Paper Name Paper Size

Legal 215.9 x 355.6 mm (8.5”x14”)

Letter 215.9 x 279.4 mm (8.5”x11”) Y Y Y Y Y Y Y Y

A4 210 x 297 mm (8.3”x11.7”) YYYYYYYY

B5 182 x 257 mm (7.2”x10.1”) - - Y Y Y Y Y Y

Plain paper

Premium Bright White Paper (EAI) Letter

Bright White Inkjet Paper (Euro, Asia) A4 210 x 297 mm (8.3”x11.7”) 0.13 32.5 25 - - Y Y Y Y Y Y

Premium Presentation Paper Matte (EAI)

Matte Paper Heavy-weight (Euro, Asia)

Double-sided Matte Paper (Euro, Asia) A4 210 x 297 mm (8.3”x11.7”) 0.25 178 47 - - Y - Y - Y Y

Presentation Paper Matte (EAI)

Photo Quality Inkjet Paper (others)

A5 148 x 210 mm (5.8”x8.3”) - - Y - Y - Y Y

Half Letter 139.7 x 215.9 mm (5.5"x8.5”) Y - - - - - Y Y

A6 105 x 148 mm (4.1”x5.8”) Y - Y - Y - Y Y

User

Defined

Letter 215.9 x 279.4 mm (8.5”x11”)

A4 210 x 297 mm (8.3”x11.7”) - - Y - Y - - Y

Letter 215.9 x 279.4 mm (8.5”x11”)

A4 210 x 297 mm (8.3”x11.7”) Y - Y - Y - - Y

50.8 x 127- 216 x 1117.6 mm

100 x 148 - 216 x 297 mm

215.9 x 279.4 mm (8.5”x11”) 0.11 90 24 Y Y ----YY

*5

*6

Thickness

mm g/m

0.08-0.11 64-90 17-24

0.23 167 44

0.12 102 27

Weight EAI EUR Asia Paper Path

2

lb. P*1D*2P*1D*2P*1D*2F*3R*

Y-Y-Y- -Y

Y - Y - Y - Y Y

Y------Y

Y - - - - - - Y

4

#10 104.8 x 241.3 mm (4.125”x9.5”)

Envelopes

Photo Quality Self Adhesive Sheet A4 210 x 297 mm (8.3”x11.7”) 0.11 89 24 Y - Y - Y - - Y

Professional Flyer Paper

Photo Paper A4 210 x 297 mm (8.3”x11.7”) 0.24 190 51 Y - Y - Y - - Y

#DL 110 x 220 mm - - Y - Y - - Y

#C6 114 x 162 mm - - Y - Y - - Y

A4 210 x 297 mm (8.3”x11.7”) 0.09 90 24 Y - Y - Y - - Y

- 75-90 20-24

Y - Y - Y - - Y

PRODUCT DESCRIPTION Printing Specifications 17

Confidential

Page 18

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

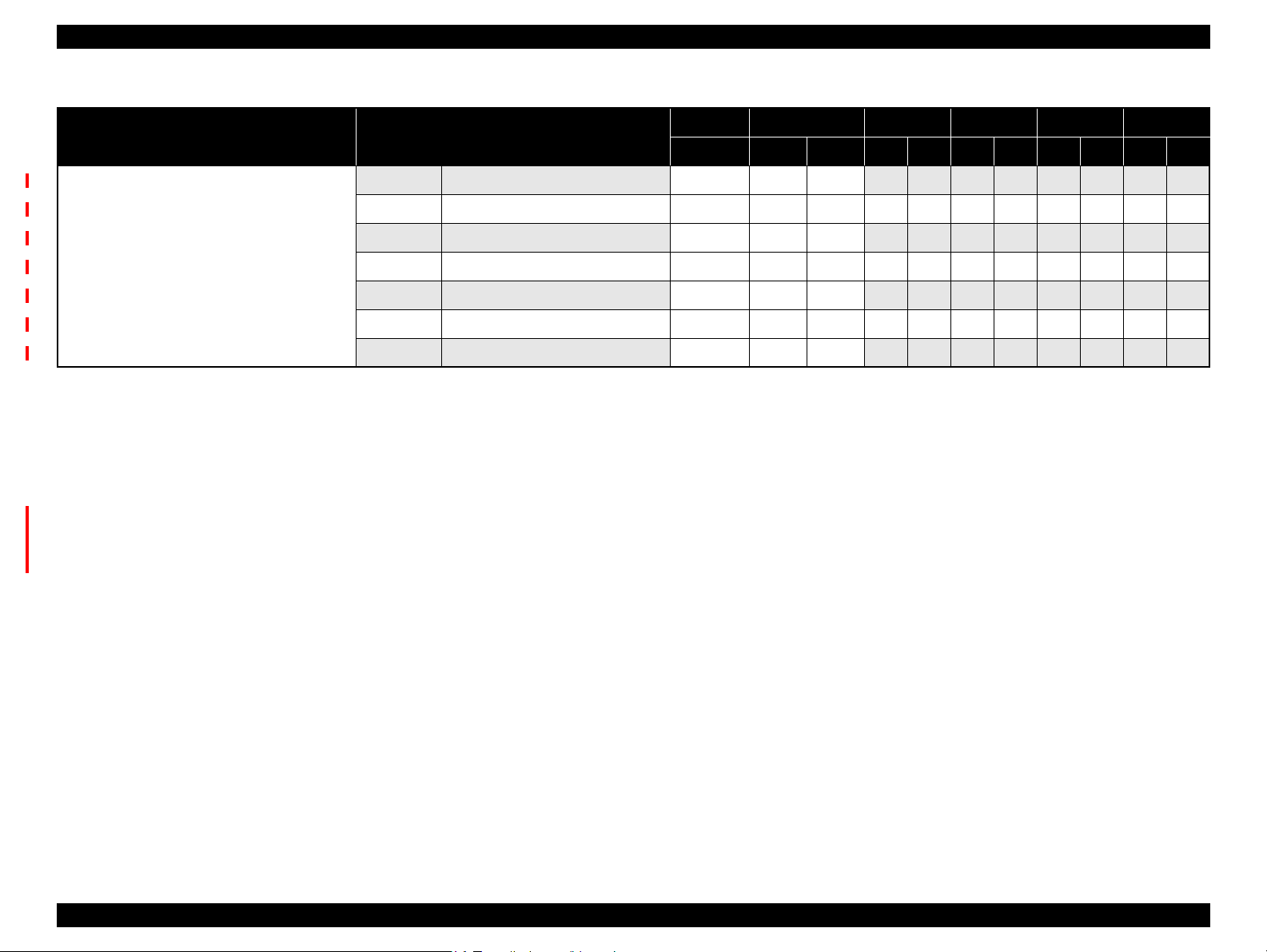

Table 1-7. Supported Paper

Paper Name Paper Size

Legal 215.9 x 355.6 mm (8.5”x14”) - - - Y Y Y Y Y Y - Y

Letter 215.9 x 279.4 mm (8.5”x11”) - - - YYYYYY - Y

A4 210 x 297 mm (8.3”x11.7”) - - - Y Y Y Y Y Y - Y

Sheet with holes

*7

B5 182 x 257 mm (7.2”x10.1”) - - - - - YYYY - Y

A5 148 x 210 mm (5.8”x8.3”) - - - - - Y - Y - - Y

A6 105 x 148 mm (4.1”x5.8”) - - - Y - Y - Y - - Y

Half Letter 139.7 x 215.9 mm (5.5"x8.5”) - - - Y - - - - - - Y

Note 1: “Y” in the “P” columns indicates that the paper is supported.

2: “Y” in the “D” columns indicates that the paper is available for duplexing.

3: “Y” in the “F” columns indicates that the paper can be fed from the Front ASF.

4: “Y” in the “R” columns indicates that the paper can be fed from the Rear ASF.

5: When using the Rear ASF.

6: When using the Front ASF.

7: B-310N/B-318N/B-510DN/B-518DN only. Make sure to use the paper which does not

have a hole in the following area.

One-side printing: 26.6 mm ± 4 mm from 0-digit side of the paper

Duplex printing: 26.6 mm ± 7 mm from 0-digit side of the paper

Thickness

mm g/m

Weight EAI EUR Asia Paper Path

2

lb. P*1D*2P*1D*2P*1D*2F*3R*

4

PRODUCT DESCRIPTION Printing Specifications 18

Confidential

Page 19

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

Print Area

LM

RM

TM

BM

Cut Sheet

Paper Size

Paper Feed Direction

LM

RM

TM

BM

Print Area

Paper Feed Direction

Envelope

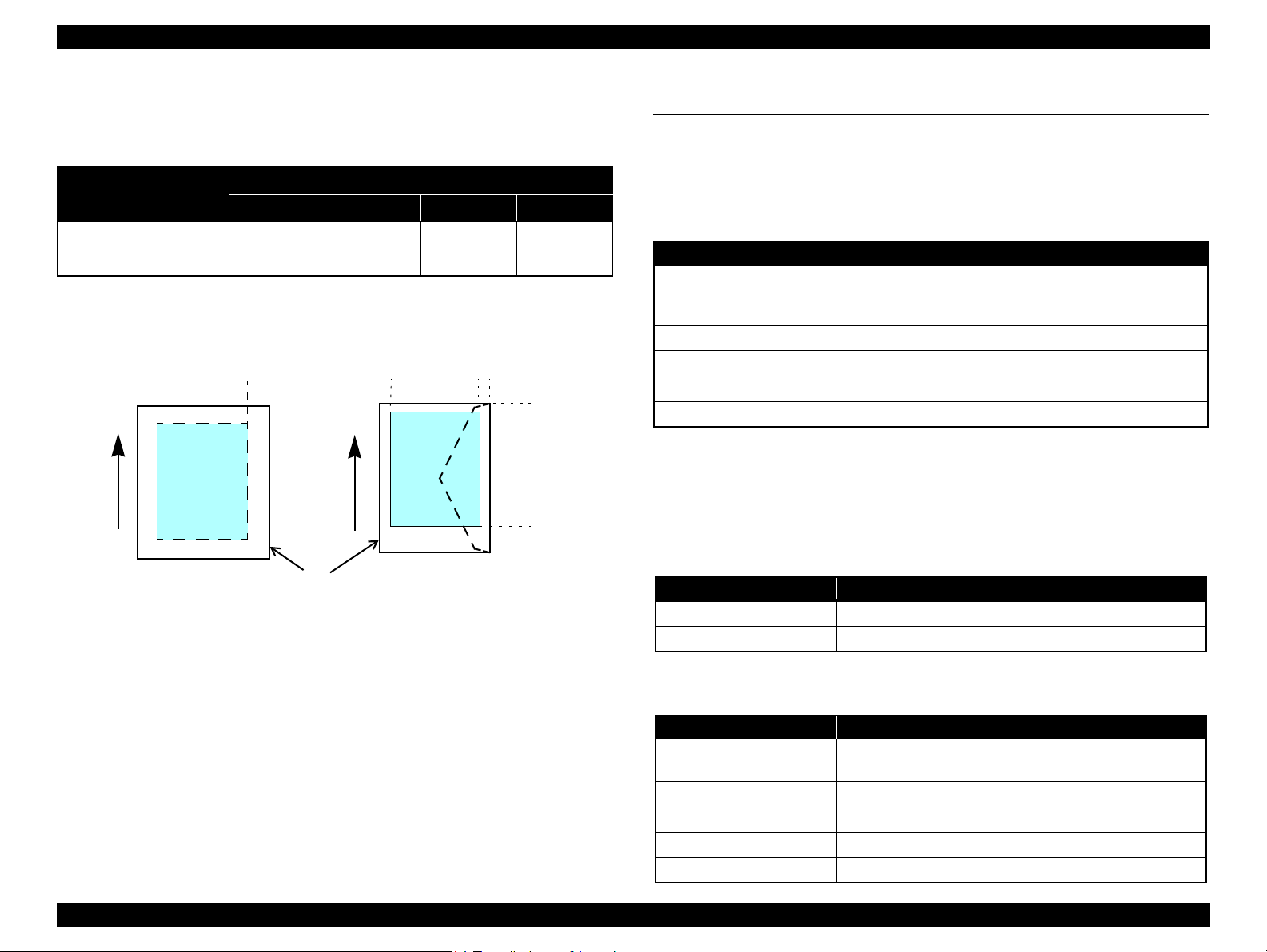

1.2.6 Printing Area

The printing area of this printer is shown below.

Table 1-8. Printing Area (Margins)

Paper Size

Any size of cut sheet

Envelope

Note* : The bottom margin becomes 16mm when duplex printing is performed using plain

paper.

Left (LM) Right (RM) Top (TM) Bottom (BM)

3 mm 3 mm 3 mm 3 mm*

5 mm 5 mm 3 mm 20 mm

Figure 1-2. Printing Area

Margin

1.3 Interface

The printer has a USB and network interfaces of the following specifications.

1.3.1 USB Interface

A USB interface is provided for connecting with a PC. The specifications are as

follows.

Table 1-9. USB Interface Specifications

Item Specifications

• Universal Serial Bus Specifications Revision 2.0

Compatible standards

Transfer rate

Data format

Compatible connector

Max. cable length

1.3.2 Network Interface (B-500DN/B-508DN/B-310N/B318N/B-510DN/B-518DN only)

B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN incorporates a print server.

This allows the user to use the printer via a wired LAN. The network interface

specifications are as follows.

Table 1-10. Wired LAN

Item Specifications

Communication mode 100BASE-TX/10BASE-T

Port type Selectable from Auto, MDI, and MDI-X.

• Universal Serial Bus Device Class Definition for Printing

Devices Version 1.1

480 Mbps (High Speed)

NRZIt

USB Series B

2 m or less

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN)

Table 1-11. Wired LAN Settings

10Base-T or 100Base-TX is automatically selected by the

hardware.

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN)

Setting on the printer Setting on the destination

Auto

10Base-T Half Duplex Fixed to 10Base-T and half-duplex communication mode.

10Base-T Full Duplex Fixed to 10Base-T and full-duplex communication mode.

100Base-TX Half Duplex Fixed to 100Base-TX and half-duplex communication mode.

100Base-TX Full Duplex Fixed to 100Base-TX and full-duplex communication mode.

PRODUCT DESCRIPTION Interface 19

Confidential

Page 20

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

1.4 General Specifications

1.4.1 Electrical Specifications

Table 1-12. Power Supply Specifications

Item

Rated power supply

voltage

Input voltage range

Rated current 0.7 A 0.4 A 0.7 A 0.4 A 0.7 A 0.7 A

Rated frequency 50 - 60 Hz 50 - 60 Hz 50 - 60 Hz

Input frequency

range

Power

consumption

*The values are

approximate.

50 Hz 49 - 51 Hz 49 - 51 Hz 49 - 51 Hz

60 Hz 58.8 - 61.2 Hz 58.8 - 61.2 Hz 58.8 - 61.2 Hz

Printing 30 W 32 W 30 W

Ready 6 W 8 W 6.5 W 7.0 W

Sleep

mode

Power

off

B-300/B-308 B-500DN/B-508DN

100-120V 220-240V 100-120V 220-240V 100-120V 220-240V

100-120

VAC

90-132

VAC

3 W 3.5 W 4.5 W 5 W 3.5 W

0.3 W 0.6 W 0.3 W 0.6 W 0.2 W 0.4 W

220-240

VAC

198-264

VAC

100-120

VAC

90-132

VAC

220-240

VAC

198-264

VAC

B-310N/B-318N/

B-510DN/B-518DN

100-120

VAC

90-132

VAC

220-240

VAC

198-264

VAC

1.4.2 Safety Approvals (Safety standards/EMI)

Taiwan CNS13438 Class B

CNS14336

EU EN55022 Class B

EN55024

EN61000-3-2, EN61000-3-3

EU/ Germany EN60950-1

Russia GOST-R (IEC60950-1, CISPR 22)

Singapore IEC60950-1

Korea K60950-1

KN22 Class B

K61000-4-2/-3/-4/-5/-6/-11

Note 1: B-300/B-308/B-310N/B-318N/B-510DN/B-518DN conform to Energy Star.

2: When the printer is not operated for more than three minutes, the printer goes into the

power save mode within five minutes.

PRODUCT DESCRIPTION General Specifications 20

Confidential

Page 21

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

CAUTION

10

27

30

35

40

20

Temperature (oC)

20

30

40

50

80

70

60

Humidity (%)

90

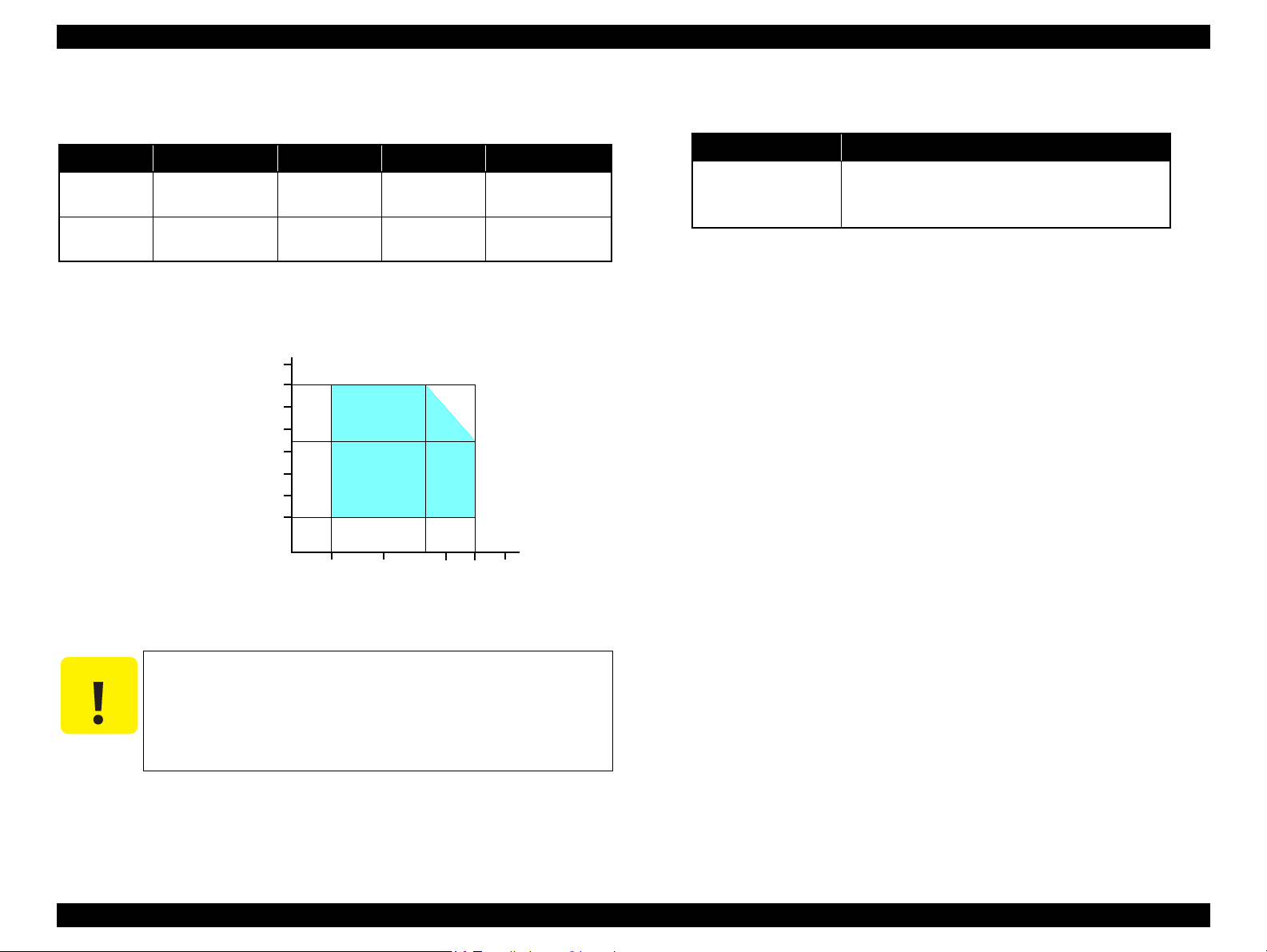

1.4.3 Environmental Conditions

Table 1-13. Environmental Conditions

Condition Temperature*

Operating

Unpacked

10 to 35

(50 to 95oF)

-20 to 40

(-4 to 104oF)

1

Humidity*

o

C

o

3

C*

20 to 80%

5 to 85%

Note *1: The combined Temperature and Humidity conditions must be within the blue-shaded

range in Figure 1-3.

*2: No condensation

*3: Must be less than 1 month at 40

o

C.

1,2

(1 msec or less)

(2 msec or less)

Shock Vibration

1G

2G

0.15G (10 to 55Hz)

0.50G (10 to 55Hz)

1.4.4 Durability

Item Specifications

Printer mechanism life

Until any one of the following conditions is met.

• 100,000 sheets

• Five years

Figure 1-3. Temperature/Humidity Range

When not using the printer, make sure the Printhead is covered

with the cap and the ink cartridge is installed.

If the Printhead is not covered with the cap when the printer is

off, turn on the printer with the ink cartridge installed, make

sure the Printhead is covered with the cap, and then turn the

printer off.

PRODUCT DESCRIPTION General Specifications 21

Confidential

Page 22

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

Power button

OK button, Arrow buttons

Cancel button

LCD

Power LED

Ink LED

Paper LED

Power button

Paper button

Ink button

Power LED

Ink LED

Paper LED

Ink LEDs

(Black, Cyan, Magenta, Yellow)

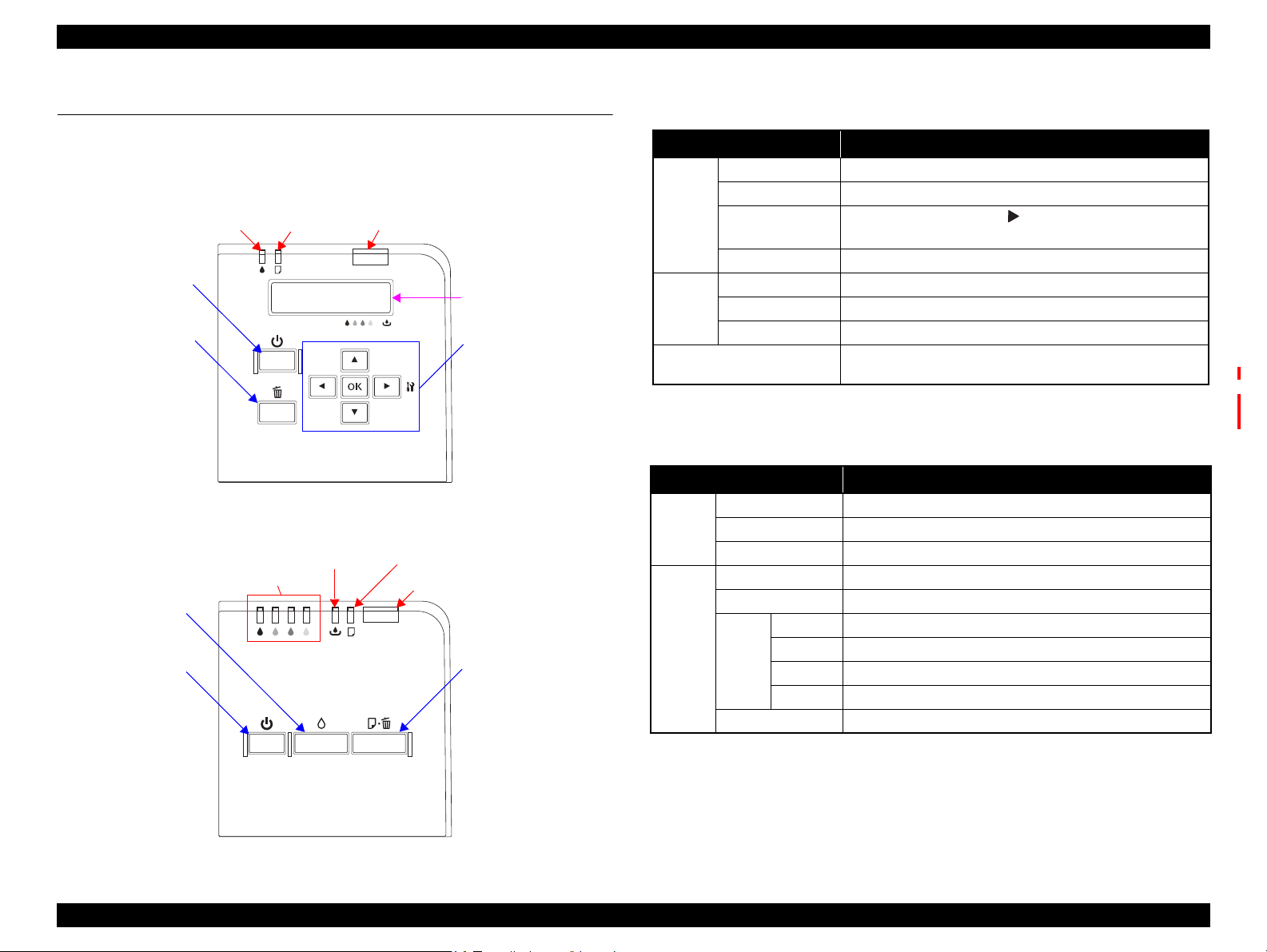

1.5 Control Panel

1.5.1 Operation Buttons

The operation buttons, LEDs, and LCD (B-500DN/B-508DN/B-310N/B-318N/B510DN/B-518DN only) are shown below.

Figure 1-4. Control Panel

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN)

Table 1-14. Operation Buttons, LED, LCD

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN)

Buttons/LEDs/LCD Function

Power Turns the power ON/OFF.

OK Clears an error and accepts a selected menu setting.

Button

LED

LCD

Arrows

Cancel Cancels the menu selection, or cancels a job.

Power Indicates the power-on status, or operating status.

*1

Ink Indicates an error status regarding to ink and maintenance box.

Paper Indicates an error status regarding to paper.

*1

• Displays the menu screen. ( button)

• Goes to the next item in the menu.

Indicates the printer status, error, and menu screen.

Indicates fatal error code

*2

Note *1: See Table 1-16 for more details about the LEDs and LCD.

*2: B-310N/B-318N/B-510DN/B-518DN only

Table 1-15. Operation buttons, LED (B-300/B-308)

Operation buttons/LEDs Function

Power Turns the power ON/OFF.

Button

LED

Note * : See Table 1-16 for more details about LEDs.

Ink Runs a cleaning.

Paper Feeds / ejects paper

Power Indicates the power-on status, or operating status.

Ink Indicates an error status regarding to ink and maintenance box.

Black Indicates an error status of black ink.

*

Ink

Paper Indicates an error status of paper.

Cyan Indicates an error status of cyan ink.

Magenta Indicates an error status of magenta ink.

Yellow Indicates an error status of yellow ink.

Figure 1-5. Control Panel (B-300/B-308)

PRODUCT DESCRIPTION Control Panel 22

Confidential

Page 23

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

1.5.2 LEDs and LCD Indications

Table 1-16. LEDs and LCD Indications

Status

Powering ON

Printing is available

Powering ON

Switching monochrome priority mode on/off

*3

*3

*4

*3

Maintenance call --- --- --Ink level low --Maintenance box near full --Processing data

Feeding / ejecting paper

Executing ink sequence

Printer cover open error ---

Power LED Ink LED Paper LED Ink LEDs*

Flash

--- --- --- PLEASE WAIT --- ---

ON --- --- --- READY --- 22

*

5

Flash / ON

OFF

--- --- --- PLEASE WAIT 21 ---

Flash at high speed Flash at high speed 2

Flash

Flash

Flash

Flash

Flash

Flash

--- --- --- --- 17 17

--- --- --- --- 16 16

--- --- --- --- 15 15

Flash

2

---

Flash

--- --- REPLACE MAINT ICON 18 18

Flash

2 --- CLOSE PRINTER COVER 14 14

Paper out error --- --- ON ---

LEDs

No duplex unit error --- ---

Flash

2 --- SET DUPLEX UNIT 12 12

1

LCD Message*

--- --- --- 21

2 NOZZLE MAINT ERROR SEE GUIDE 20 20

6

*

REPLACE INK CARTRIDGE ICON 19 19

(Front) SET PAPER IN CASSETTE OK

(Rear) SET PAPER IN AUTO FEEDER OK

2

B-300/B-308/

B-500DN/B-510DN

Multi-feed error --- --- ON --- DOUBLE FEED JAM REMOVE PAPER OK 11 11

Ink cartridge CSIC error --- ON --- ON*

No ink cartridge or no ink error --- ON --- ON*

6

REPLACE INK CARTRIDGE ICON

6

SET INK CARTRIDGE ICON

Maintenance cartridge CSIC error --- ON --- --- SET MAINT BOX ICON

No maintenance cartridge or no ink error --- ON --- --- SET MAINT BOX ICON

Ink lock lever open error --- ON --- ---

Maintenance box cover open error --- ON --- ---

Paper jam --- ---

Flash

---

MOVE INK LEVER DOWN ICON

SET INK CARTRIDGE

CLOSE MAINT BOX COVER ICON

SET MAINT BOX

(Front) REMOVE JAMMED PAPER OK

(Rear) REMOVE JAMMED PAPER OK

*8

*9

ICON

ICON

*7

*7

*7

*7

*7

*7

*7

*7

(Duplex) DUPLEX UNIT JAM REMOVE PAPER OK

Fatal error OFF

Flash at high speed Flash at high speed

---

PRINTER ERROR RESTART PRINTER

*10

XXXX

Service call OFF Alternate Flash 2 Alternate Flash 1 --- SERVICE CALL SEE GUIDE 2 2

Power OFF

Reset request*

11

Note *1: B-300/B-308 only

*2: B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only

*3: B-310N/B-318N/B-510DN/B-518DN only

*4: B-300/B-308/B-500DN/B-508DN only

*5: B-300/B-308 power LED flashes, and that of B-500DN/B-508DN turns ON.

*6: The corresponding LED flashes or lights.

*7: See “Table 1-17. LCD Icon Display (B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only)” on

page24 for the icons shape.

Flash at high speed

ON*4 /

Flash

*

3

OFF OFF OFF POWER OFF 1 1

ON*4/ --- *

3

ON*4/ --- *

3

ON --- --- ---

Note : ---: No change

Flash: Repeats ON for 1.25 seconds, OFF for 1.25 seconds

Flash 2: Repeats ON for 0.5 second, OFF for 0.5 second, ON for 0.5 second

Flash at high speed: Repeats ON for 0.5 second, OFF for 0.5 second

Flash at high speed 2: Repeats OFF for 0.5 second, ON for 0.5 second

Alternate Flash1: Same as the above Flash.

Alternate Flash1: Repeats OFF for 1.25 seconds, ON for 1.25 seconds

and OFF for 1.0 second.

*8: B-500DN/B-508DN only. The LED turns ON when the ink lever is moved to its upper position after an error occurs.

*9: The LED turns ON when the maintenance cover is opened after an error occurs.

*10: The fatal error code is indicated only for B-310N/B-318N/B-510DN/B-518DN. See “ 3.3.2 Fatal Error” on

page48 for the details.

*11: When a reset request occurs, the LED lights for 0.2 seconds.

Priority

B-310N/B-318N/

B-510DN/B-518DN

13 13

10 10

99

88

77

66

55

44

33

PRODUCT DESCRIPTION Control Panel 23

Confidential

Page 24

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

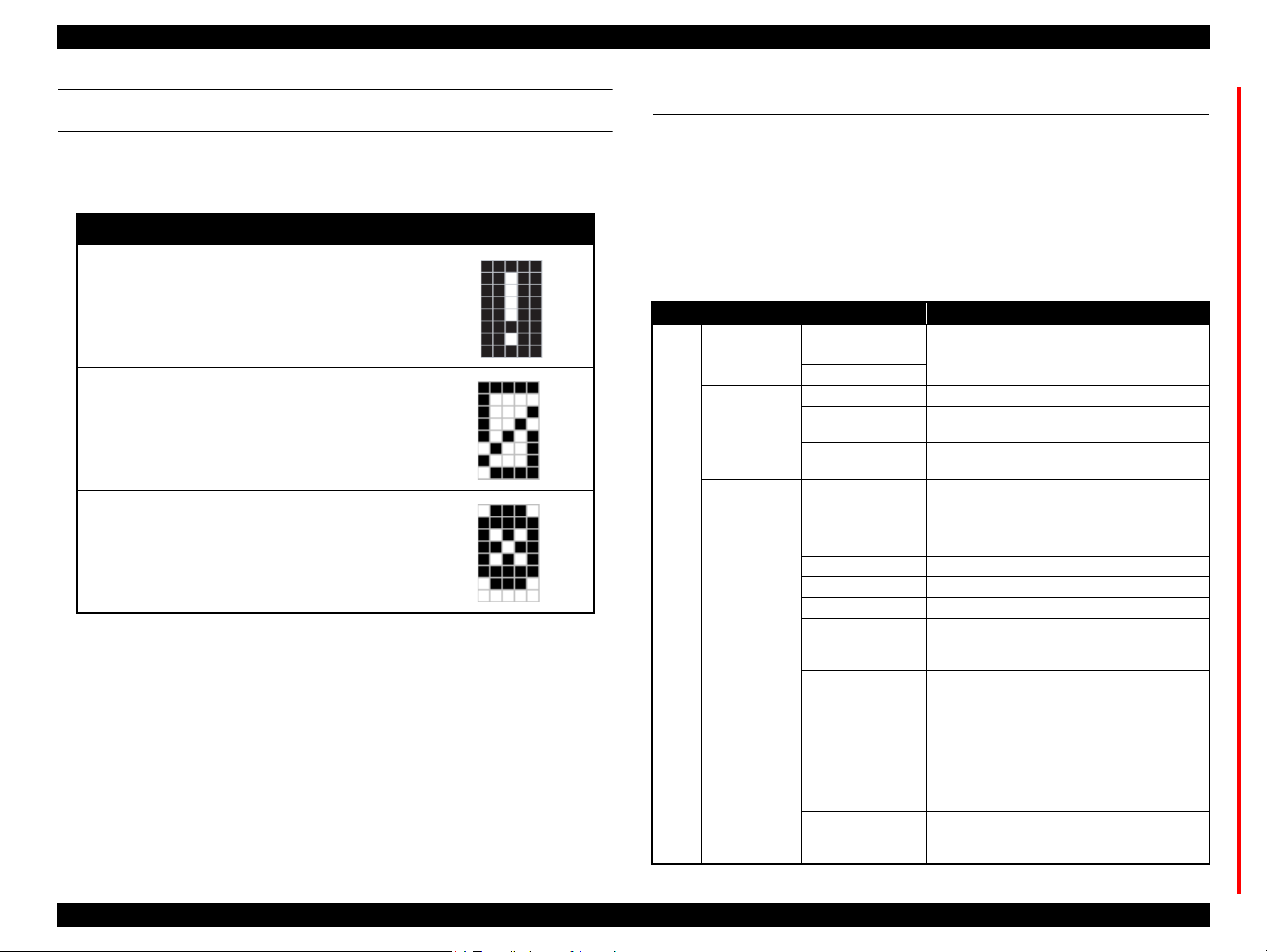

LCD ICON DISPLAY

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN)

The following icons appear on the LCD according to the printer status.

Table 1-17. LCD Icon Display

(B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN only)

Printer Status Icon

• Ink level low

• Maintenance box near full

• No ink

• Maintenance box full

• Ink cartridge CSIC error

• No ink cartridge

1.6 Various Settings

1.6.1 Panel Operation

1.6.1.1 Menu Configuration (B-500DN/B-508DN/B-310N/B-318N/ B-510DN/B-518DN only)

The setting screen is displayed by pressing the right arrow button on ready mode (the

LCD display is “READY” or “POWER SAVE”). The following explains the menu

structure and the outline of the menu functions.

Table 1-18. Menu Configuration

Menu Description

LANGUAGE Selects the language displayed on the LCD.

USB

Network

NOZZLE CHECK Prints a printhead nozzle check pattern.

STATUS SHEET

NETWORK SHEET

VERSION Displays the firmware version.

MAINTENANCE

BOX

HEAD ALIGNMENT Adjusts the printhead alignment.

CLEANING Runs a printhead cleaning.

CLEANING SHEET Runs a cleaning for the rollers inside the printer.

CONTRAST ADJ. Adjusts the contrast of the LCD.

AUTO CLEANING

LOW SPEED MODE

NETWORK SETUP Selects the method to configure the network settings.

PASSWORD SET.

LOCK SETTING

Selects the printer control language for the port.

Prints a status sheet for current printer status. (See

Figure 1-8

Prints a network status sheet for current settings of the

network interface. (See Figure 1-9 and Figure 1-10

Displays the rough estimate of the remaining

capacity of the Maintenance Box.

Changes the setting of the AID detection cleaning.

(See “1.6.2.1 AID Detection Cleaning (B-310N/B-

318N/B-510DN/B-518DN only)” on page26.)

Changes the setting of the low speed mode (MPBF

priority mode). (See “1.6.3 Low Speed Mode (MPBF

Priority Mode) (B-310N/B-318N/B-510DN/B518DN only)” on page28.)

Sets a password.

(See “ Password setting” on page26.)

Changes the setting of the panel operation lock. (See

“1.6.1.2 Panel Operation Lock Setting (B-310N/B318N/B-510DN/B-518DN only)” on page25.)

.)

.)

MENU

PRINTER

SETTING

TEST PRINT

PRINTER

STATUS

MAINTENANCE

NETWORK

SETTING

PASSWORD

*

MENU

Note* : B-310N/B-318N/B-510DN/B-518DN only.

PRODUCT DESCRIPTION Various Settings 24

Confidential

Page 25

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

CAUTION

1.6.1.2 Panel Operation Lock Setting (B-310N/B-318N/B-510DN/B-518DN only)

For B-310N/B-318N/B-510DN/B-518DN, the panel operation can be locked after

setting the password. (See Password setting (p.26).)

Table 1-19. Panel Operation Lock Setting

ON OFF

On ready mode (the LCD display is

“READY” or “POWER SAVE”), the

password is required to go to the setting

screen.

If the correct password is entered, goes to

the setting screen.

“WRONG PASSWORD” is displayed if a

wrong password is entered, and the access

to the setting screen is denied. After the

error is displayed for a while, the printer

returns to the ready mode (the LCD

display is “READY”).

Error reset and powering off are still

available.

Note : The lock/unlock condition is not printed on the printed sheets such as the nozzle check

pattern or the status sheets.

Setting Method

1. Perform Password setting (p.26) by operating the control panel.

2. Select “LOCK SETTING” from “MENU” (Table 1-18), and select “ON” or

“OFF”.

Entering the password is not required to go to

the setting screen even the password is

registered.

Resetting the Password/Unlocking the Panel Operation Lock

If you need to reset the password or unlock the panel operation because of

forgetting the password and such, follow the steps below to reset them.

Do not disclose the following method to the end users.

Resetting/Unlocking method

1. Press and hold the right arrow button, left arrow button and OK button and

then turn on the printer.

2. Release all the buttons after the printer is turned on.

Settings after reset

• Password: Not set

• Panel operation lock: OFF

Note 1: If the cancel button is pressed during its setting or when “ON” is set, the printer

returns to the ready mode (the LCD display is “READY” or “POWER SAVE”).

2: After “ON” is set, the panel operation is locked immediately.

3: When “OFF” is set, the display returns to “PASSWORD MENU”.

4: Once the password is set, the panel operation can be locked by performing Step 2.

PRODUCT DESCRIPTION Various Settings 25

Confidential

Page 26

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

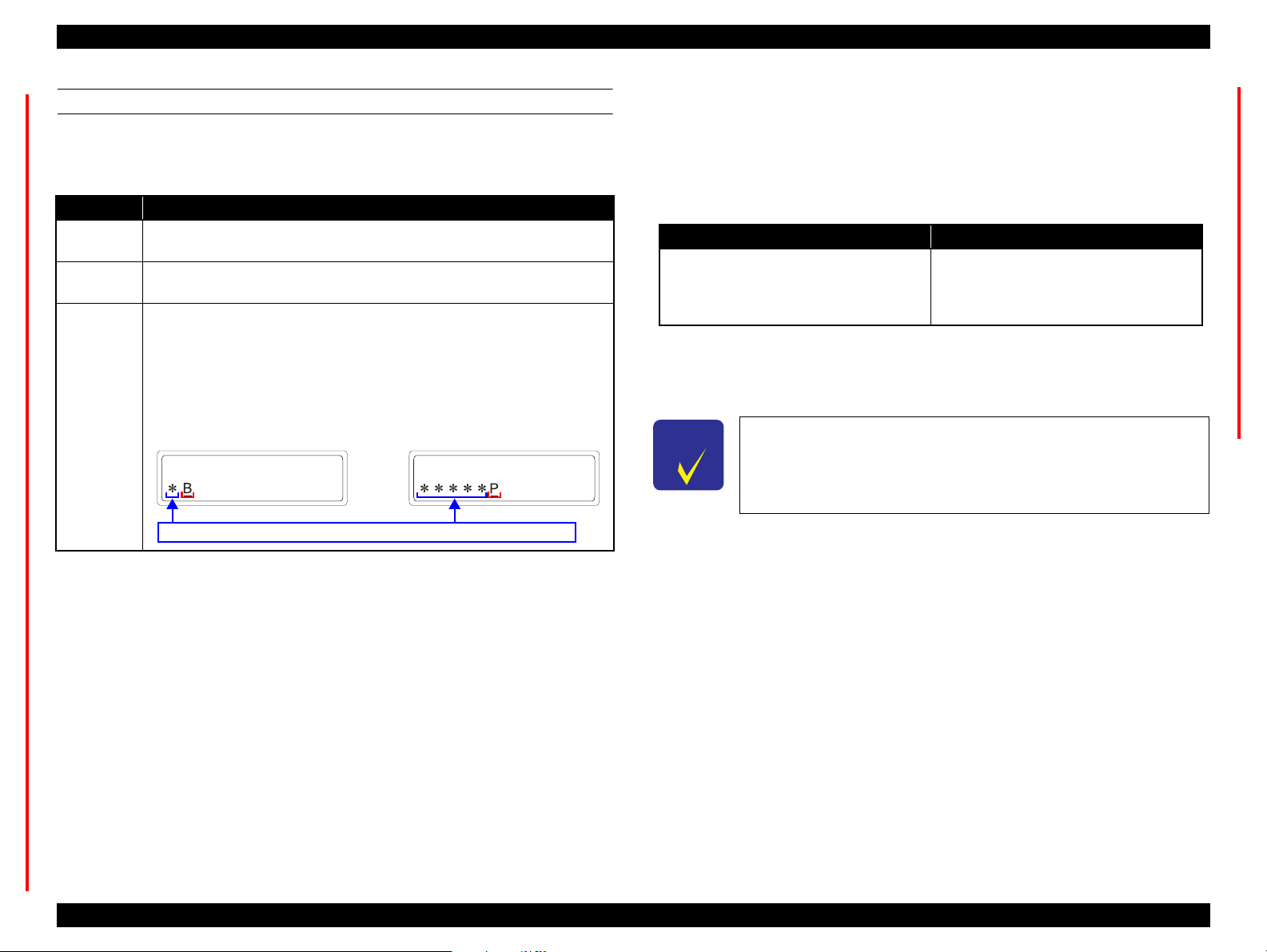

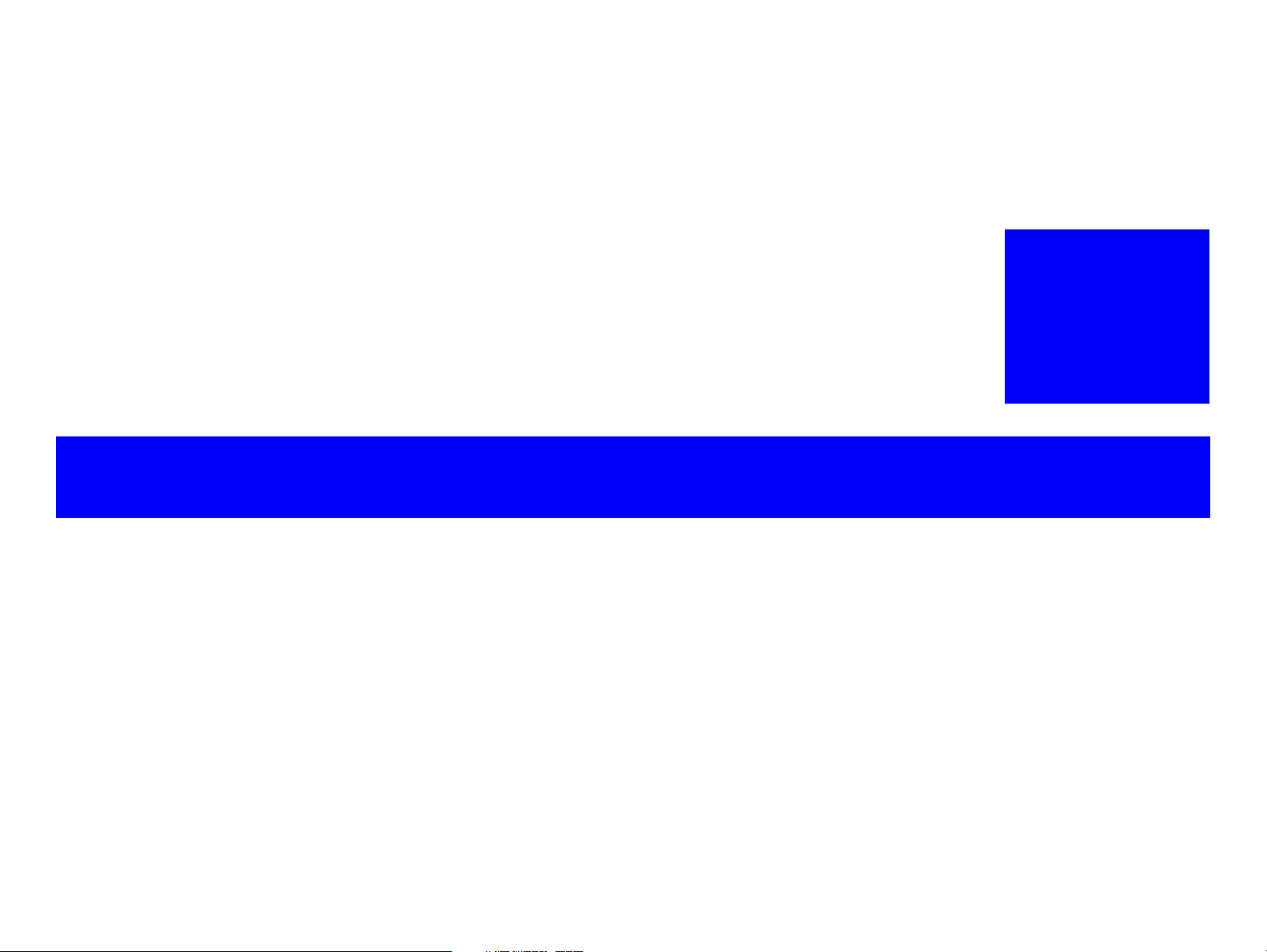

NEW PASSWORD NEW PASSWORD

An input character changes to “* (asterisk)” each time it is accepted.

PASSWORD SETTING

Select the “PASSWORD SET.” from the “MENU” (Table 1-18) to set or change

the password.

Table 1-20. Password Setting

Item Description

Digit of the

password

Available

characters

Method

Within 1 to 8

Space,!”#$%&'()*+,-./, 0 to 9, ;:<=>?@, A to Z, [\]^_`, a to z, {|}~

Select the characters with the up and down arrow buttons, and move to the next

digit with the right arrow button. When pressing the right arrow button, the input

character is masked with “* (asterisk)”. The characters which are masked with “*

(asterisk)” will be saved on the EEPROM as the password after pressing the OK

button. To set the password, entries are required three time according to the

instruction displayed on the LCD (“CURRENT PASSWORD”, “NEW

PASSWORD” and “REENTER NEW PASSWORD”).

1.6.2 AID Function Setting

1.6.2.1 AID Detection Cleaning (B-310N/B-318N/B-510DN/B-518DN only)

For B-310N/B-318N/B-510DN/B-518DN, the AID detection cleaning can be set on/off.

Table 1-21. AID Detection Cleaning

ON OFF

Automatically checks the printhead nozzles

with AID function and carries out printhead

cleaning if they are clogged.

Setting Method

Select “AUTO CLEANING” from “MENU” (Table 1-18), and select “ON” or

“OFF”.

CHECK

POINT

This setting is not available for B-300/B-308/B-500DN/B-508DN.

The nozzle check with the AID function and

auto cleaning is not carried out. Carries out

the printhead cleaning only when selecting

“CLEANING” from “MENU” (Table 1-18).

Note 1: The password is not set when shipping from the factory.

2: If there is a wrong entry to “CURRENT PASSWORD” or “REENTER NEW

PASSWORD”, “WRONG PASSWORD” is displayed and then returned to the

“PASSWORD MENU” screen.

3: After the password is entered in “REENTER NEW PASSWORD”, the change is

completed and the display returns to “PASSWORD MENU”.

4: The password is stored on the EEPROM (not NMI area), and kept even the power is off.

1.6.1.3 Forced Power OFF

For B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN, the

power can be turned off forcibly by the following panel operation. If the power is

turned off forcibly, the same process of the normal power-off is executed.

Operation Method

1. Press and hold the power button and the OK button for seven seconds or

more.

2. Release the power button after the printer is turned off.

PRODUCT DESCRIPTION Various Settings 26

Confidential

Page 27

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

CHECK

POINT

VERSION VERSION

AID high quality mode

Dot missing tolerance mode

* (asterisk)

is indicated

CHECK

POINT

xxxxxxxxxxxxxx* xxxxxxxxxxxxxx

* (asterisk) is printed

Monochrome priority mode is on

Monochrome priority mode is off

1.6.2.2 AID High Quality Mode/Dot Missing Tolerance Mode

For B-310N/B-318N/B-510DN/B-518DN, the AID high quality mode or the dot

missing tolerance mode can be selected by the special operation at power-on when the

AID detection cleaning is on.

For B-300/B-308/B-500DN/B-508DN, this setting is available only

when the firmware is the following version or later. However, the

setting mode is fixed to “dot missing tolerance mode” for B-300/B-

308.

• B-300/B-308: SH1998

• B-500DN/B-508DN: SL1998

Table 1-22. Mode

AID High Quality Mode Dot Missing Tolerance Mode

Checks the nozzle clogging and carries out

appropriate cleaning.

Setting Change Method

Follow the procedure below to switch the cleaning mode between the AID high

quality mode and dot missing tolerance mode.

1. Press and hold the power button and the OK button simultaneously when the

power is off.

2. Release the all buttons when the power is turned on.

How to Check the Current Mode

Select “VERSION” from “MENU” (see Table 1-18), and check the upper right

corner of the LCD. If “*(asterisk)” is displayed, the printer is the AID high quality

mode. The mode status cannot be confirmed from the printed sheets such as the

nozzle check pattern or the status sheets.

If two or less nozzles and no neighboring

nozzles are clogged, the cleaning is not

carried out. For nozzle clogging detection in

the other cases, the cleaning is carried out.

1.6.2.3 Monochrome Priority Mode

For B-310N/B-318N/B-510DN/B-518DN, “monochrome priority mode” with the AID

function is available to check the nozzle clogging only for nozzles of black ink.

This setting is available when the firmware is the following version

or later for B-300/B-308/B-500DN/B-508DN.

• B-300/B-308: SH1998

• B-500DN/B-508DN: SL1998

Table 1-23. Monochrome Priority Mode

Valid Invalid

Checks the nozzle clogging only for nozzles

of black ink, and carries out printhead

cleaning.

Note : The monochrome priority mode is invalid as the default.

Setting Method

Follow the procedure below to switch between valid and invalid.

1. Press and hold the power button and the up arrow button simultaneously.

2.

After the power LED flashes,

button, and press and hold the down arrow button immediately.

3. When the ink LED and the paper LED starts flashing alternately, release the

down arrow button.

How to Check the Current Mode

When the monochrome priority mode is on, “* (asterisk)” is printed on the nozzle

check pattern as shown below. The mode status (valid or invalid) cannot be

confirmed on the LCD.

Checks all the nozzles and carries out

printhead cleaning.

release the

power button and the up arrow

Figure 1-6. How to Check AID High Quality Mode/Dot Missing Tolerance Mode

PRODUCT DESCRIPTION Various Settings 27

Figure 1-7. How to Check Monochrome Priority Mode

Confidential

Page 28

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

1.6.3 Low Speed Mode (MPBF Priority Mode) (B-310N/B-318N/B-510DN/B-518DN only)

To prevent the troubles (printhead clogging or the like) from occurring due to paper dust

caused by the printing-related movement, the low speed mode (MPBF priority mode) is

available for

The carriage always moves from end to end

(full-digit drive) for printing. It can decrease

paper dust caused by the printing-related

movement to prevent printing troubles such as

printhead clogging. However, the printing

speed becomes slower.

Note : The low speed mode is off as the default.

Setting Method

Set by panel operation

Note : The setting is stored in the non-volatile memory and kept when the power is off.

Automatic change

B-310N/B-318N/B-510DN/B-518DN

.

Table 1-24. Low Speed Mode (MPBF Priority Mode)

ON OFF

Carries out the normal printing.

Select “LOW SPEED MODE” from “MENU” (Table 1-18), and select “ON”

or “OFF”.

If all the following conditions are met, the low speed mode (MPBF priority

mode) is turned on even if the setting from the panel is off.

• Stays in ready mode for five to seven minutes.

• More than 100 sheets are printed after the last AID detection.

• Number of accumulated printed sheets is 10 to 400 after the last manual

cleaning.

Note1: When the setting is on by the automatic change, the setting is turned off when the

ink cartridge cover is opened/closed.

1.7 Status Sheet

B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN prints the following printer

status sheet when the Printer Status menu is selected. For B-300/B-308, turn it on while

holding down the Ink button. B-500DN/B-508DN/B-310N/B-318N/B-510DN/B518DN also can print a network status sheet shown on the following pages.

Log Status Sheet

Printer Name "model name"

Serial No. xxxxxxxxxxx

Firmware version SHxxxx(SLxxxx)

First Print Time yyyy/mm/dd hh:mm

Last Print Time yyyy/mm/dd hh:mm

Total Pages 000000

Color Pages 000000

B/W Pages 000000

Print of papers

Total Mono Color

Simplex Duplex Simplex Duplex

A4/Letter 000000 000000 000000 000000 000000

A5 000000 000000 000000 000000 000000

A6/HAGAKI 000000 000000 000000 000000 000000

Envelope 000000 000000 000000 000000 000000

Others 000000 000000 000000 000000 000000

Print of mode[pages]

Simplex Duplex Total

Mono 000000 000000 000000

Color 000000 000000 000000

Total 000000 000000 000000

2: The setting made by the automatic change is not saved in the non-volatile memory,

therefore, the setting is turned off once the power is off.

Figure 1-8. Printer Status Sheet Sample

PRODUCT DESCRIPTION Status Sheet 28

Confidential

Page 29

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HH EPSON Network Status Sheet (1/2) HH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

<General Information>

Card Type EPSON Built-in 10Base-T/100Base-TX Print Server

SerialNumber XXXXXXXXXXXX

MAC Address XX:XX:XX:XX:XX:XX

Hardware XX.XX

Software XX.XX

Printer Model XXXXXXXX

Time YYYY-MM-DD HH:MM:SS GMT+/-HH:MM

<Ethernet>

Network Status Auto(10BASE-T/100BASE-TX, Half/Full Duplex)/

10BASE-T/100BASE-TX, Half/Full Duplex

Port Type Auto/MDI/MDI-X

<TCP/IP>

Get IP Address Auto/Manual

IP Address XXX.XXX.XXX.XXX

Subnet Mask XXX.XXX.XXX.XXX

Default Gateway XXX.XXX.XXX.XXX

APIPA Enable/Disable

Set using PING Enable/Disable

Acquisition way of DNS ADDR Enable/Disable

DNS Server Address XXX.XXX.XXX.XXX

XXX.XXX.XXX.XXX

XXX.XXX.XXX.XXX

Acquire Host/Domain name Enable/Disable

Host Name XXXXXXXX

Domain Name XXXXXXXX

Register the NW I/F to DNS Enable/Disable

Register directly to DNS Enable/Disable

Universal Plug and Play Enable/Disable

Device Name XXXXXXXX

Bonjour Enable/Disable

Bonjour Name XXXXXXXX.local.

Bonjour Printer Name XXXXXXXX

Bonjour Service XXXXXXXX._printer._tcp.local.

XXXXXXXX._http._tcp.local.

<Printing Control>

Printing Control Enable/Disable

Access Control Allow/Deny

Access Control List 1 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 2 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 3 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 4 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 5 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 6 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 7 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 8 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 9 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 10 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 11 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 12 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 13 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 14 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 15 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

Access Control List 16 XXX.XXX.XXX.XXX - XXX.XXX.XXX.XXX

HHHHHHHHHHHHHHHHHHHHHHHHHHHHH Printer Model Name HH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HH EPSON Network Status Sheet (2/2) HH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

<IPP>

IPP URL http://xxx.xxx.xxx.xxx

Printer Name XXXX

<Port Control>

LPR Enable/Disable

Port9100 Enable/Disable

Port2501 Enable/Disable

FTP Enable/Disable

IPP Enable/Disable

<SNMP>

Read Community public

IP Trap 1 Enable/Disable

IP Trap Address 1 XXX.XXX.XXX.XXX

IP Trap Community 1 XXXXXXXX

IP Trap Port 1 XXXX

IP Trap 2 Enable/Disable

IP Trap Address 2 XXX.XXX.XXX.XXX

IP Trap Community 2 XXXXXXXX

IP Trap Port 2 XXXX

IP Trap 3 Enable/Disable

IP Trap Address 3 XXX.XXX.XXX.XXX

IP Trap Community 3 XXXXXXXX

IP Trap Port 3 XXXX

IP Trap 4 Enable/Disable

IP Trap Address 4 XXX.XXX.XXX.XXX

IP Trap Community 4 XXXXXXXX

IP Trap Port 4 XXXX

<Time>

Time Server Enable/Disable

Time Server Address XXX.XXX.XXX.XXX

Synchronize Interval XX

Time Difference(GMT+/-HH:MM) +/-HH:MM

Time Server Status Success/Failure/Synchronize/Invalid

<Idle Timeout>

LPR XXXX sec

Port9100 XXXX sec

IPP xxxx sec

<Software Information>

Network FW XX.XX XXXXX

EPSONNet Config Web XX.XX XXXXX

HHHHHHHHHHHHHHHHHHHHHHHHHHHHH Printer Model Name HH

PRODUCT DESCRIPTION Status Sheet 29

Figure 1-9. Network Status Sheet Sample (1) Figure 1-10. Network Status Sheet Sample (2)

Confidential

Page 30

OPERATING PRINCIPLES

CHAPTER

2

Confidential

Page 31

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

(4) Front ASF

Retard Home

Sensor

PF Encoder

Rear ASF

PW Sensor

CR Encoder

Cover Open Sensor

PF Roller

EJ Roller

Carriage Assy

Printhead

EJ Frame

EJC Sensor

Ink System

APG Phase Sensor

APG Unit

ASF Sub Encoder

ASF Sub Motor

ASF Motor

(1) Rear ASF Phase

Sensor

(3) Duplex Unit

Sensor

(1)

(2)

(3)

(4)

(2) Rear ASF Home

Sensor

CR Motor

ASF Encoder

PE Sensor

CR Shaft

(a) Front ASF

Front Paper Sensor

(b) Front ASF

Paper End Sensor

(a) (b)

Ink Cartridge Lock

Cover Sensor

PF Scale

CR Scale

CR Timing Belt

PF Motor

ASF Scale

ASF Sub Scale

PF Timing Belt

A#180

A#179

A#178

A#3

A#2

A#1

B#180

B#179

B#178

B#3

B#2

B#1

D#180

D#179

D#178

D#3

D#2

D#1

F#180

F#179

F#178

F#3

F#2

F#1

C#180

C#179

C#178

C#3

C#2

C#1

E#180

E#179

E#178

E#3

E#2

E#1

H#180

H#179

H#178

H#3

H#2

H#1

G#180

G#179

G#178

G#3

G#2

G#1

Carriage movement direction

Paper feed direction

2.1 Overview

This chapter describes the operating principles of B-300/B-308/B-500DN/B-508DN/

B-310N/B-318N/B-510DN/B-518DN printer mechanism and electric circuits.

2.1.1 Printer Mechanism

The general diagram of the printer mechanism is shown below.

Operating Principles Overview 31

Figure 2-1. Printer Mechanism Block Diagram

2.1.2 Printhead

Print method: On-demand inkjet

(F8-Mach Turbo 2)

Nozzle configuration

Color Bk, C, M, Y (4 colors)

Number of nozzles 1,440 nozzles (180 nozzles x 2 per color)

Nozzle pitch 0.282mm (1/90 inch), cross-layout

The nozzle layout as seen from behind the Printhead is shown below.

Figure 2-2. Nozzle Layout

Confidential

Page 32

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

PG(-)

PG(Typ)

PG(+)

PG(++)

CL

High Low High Low High Low High Low High Low

Counterclockwise

2.1.3 PG Setting

The following diagram shows the platen gap (PG) settings of B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN.

Table 2-1. PG Settings / Cam Diagram

PG

APG phase sensor

Type

PG value (mm) 1.2 1.7 2.35 2.95 1.2

PG setting name Home Normal Large Maximum Cleaning position

Printing When using Epson paper

Description

Not printing

Rotational direction of

the ASF motor

Pos.1

PG(-) PG(Typ) PG(+) PG(++) CL

• Wiping • This home setting is

→

Pos.2

When using plain paper

Use this setting when

PG(-) is too tight

made after power-on

(after initialization)

•Capping

→

When using envelopes

Use this setting when

PG(Typ) is too tight

Pos.3

→

Use this setting when

PG(+) is too tight

--- ---

Pos.4

→

• Opening/closing of the

choke valve

Pos.5

→

(To Pos.1)

---

Operating Principles Overview 32

Confidential

Page 33

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E

B

1

6

16

4

3

2

7

C

A

D

8

10

11

12

15

9

5

14

13

2.2 Motors and Sensors

The following table lists the motors and sensors.

Table 2-2. List of Motors & Sensors

Mechanism Motor or Sensor No.

Printhead ---

CR motor A

Carriage mechanism

Ink supply mechanism Ink cartridge lock lever sensor (ICL sensor) 4

APG mechanism APG phase sensor (APG sensor) 5

Paper loading/feed

mechanism

Duplex mechanism Duplex unit sensor (DP sensor) 15

Ink system Maintenance box cover sensor (EJC sensor) 16

CR encoder 1

PW sensor 2

Cover open sensor 3

PF motor B

PF encoder 6

PE sensor 7

ASF motor C

ASF encoder 8

ASF sub motor D

ASF sub encoder 9

Front ASF retard home sensor (FP sensor) 10

Rear ASF phase sensor (RP sensor) 11

Rear ASF home sensor (RH sensor) 12

Front ASF paper leading edge detector (PEF sensor) 13

Front ASF paper bottom edge detector (PER sensor) 14

Figure 2-3. Motors & Sensors (front of the printer mechanism)

Figure 2-4. Motors & Sensors (rear of the printer mechanism)

Confidential

Operating Principles Motors and Sensors 33

Page 34

EPSON B-300/B-308/B-500DN/B-508DN/B-310N/B-318N/B-510DN/B-518DN Revision E