Page 1

®

SERVICE MANUAL ROSCO

A3 Wide Color Laser Printer

EPSON AcuLaser C8600

AcuLaser C7000

SEPG010013

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2002 SEIKO EPSON CORPORATION.

Imaging & Information Product Division

TPCS Quality Assurance Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performing procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE

OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR

ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT

TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTISTATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON

WARRANTY.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for servicing

the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Page 5

Abbreviation

This manual uses original abbreviations, in addition to general abbreviations.

Typical abbreviations are as follows:

ADC ...........................Automatic Density Control

AG .............................................. Analog Ground

ASSY ...................................................Assembly

AUX. ......................................................Auxiliary

B/W ........................................... Black and White

BCR ......................................... Bias Charge Roll

Bk .............................................................. Black

BK .............................................................. Black

BTR ........................................Bias Transfer Roll

BUR ............................................... Back Up Roll

C ................................................................. Cyan

CART. .................................................. Cartridge

CCW ................................... Counter Clock Wise

CL. ............................................................ Clutch

CLN ..................................Cleaning (or Cleaner)

CLK ............................................................ Clock

CONT. .................................................Controller

CR ................................................... Charge Roll

CRU ........................ Customer Replaceable Unit

CRUM ............................................ CRU Monitor

CW .................................................... Clock Wise

DB ............................................. Developing Bias

DEVE. .................................................Developer

DIAG. ................................................. Diagnostic

dpi ...................................................dots per inch

DTS ................................................. Detack Saw

ELEC. ..................................................... Electric

EP ........................................ Electrophotography

FDR .........................................................Feeder

FG ................................................Frame Ground

FRU ................................ Field Replaceable Unit

GND ........................................................ Ground

H/R .......................................................Heat Roll

Hex .................................................Hexadecimal

HVPS ......................High Voltage Power Supply

I/F ..........................................................Interface

IBT ............................. Intermediate Belt Transfer

ID ...................... Image Density (or Identification)

INTL ...................................................... Interlock

L ....................................................................Left

L/H ....................................................... Left Hand

L/P ..................................................... Low Paper

LD .................................................... Laser Diode

LEF ........................................... Long Edge Feed

LV/HV POWER SUPPLY ..... Low Voltage / High

Voltage Power Supply

M ...........................................................Magenta

MAG. .................................................... Magnetic

MCU .................................. Machine Control Unit

MECH. .............................................. Mechanical

MOT. ......................................................... Motor

MSI ...................................... Multi Sheet Inserter

N/F ................................................Normal Force

N/P ...................................................... No Paper

NVM .................................. Non Volatile Memory

O/H .................................................Option Hinge

OHP .................................... Overhead Projector

(In this manual, OHP means OHP film)

OPC ........................... Organic Photo Conductor

P/H .............................................Paper Handling

P/R ................................................ Pressure Roll

PCDC ...................Pixel Count Dispense Control

Pixel ................................................. Picture Cell

PPM ........................................ Prints Per Minute

PV .................................................. Print Volume

PWB ................................... Printed Wiring Board

R .................................................................Right

R/H .................................................... Right Hand

REGI. ...............................................Registration

ROS ............................... Raster Output Scanner

RTN ......................................................... Return

SEF .......................................... Short Edge Feed

SG ................................................ Signal Ground

SNR .........................................................Sensor

SOL. ...................................................... Solenoid

SOS .............................................. Start Of Scan

SPI ..............................................Scans Per Inch

SYNC. ............................................ Synchronous

SW ........................................................... Switch

TC ...................................... Toner Concentration

TEMP. ............................................ Temperature

TR ..........................................................Transfer

TRANS. ................................................Transport

XERO. ..............................................Xerographic

Y .............................................................. Yellow

YMCBk ................ Yellow, Magenta, Cyan, Black

Page 6

Safety Information

To prevent accidents during a maintenance procedure, strictly observe the Warnings and Cautions.

Do not do anything that is dangerous or not within the scope of this document.

Do not do anything that is dangerous even if not specifically described in this manual.

In addition to the descriptions below and those given in this manual, there are many situations and circumstances that are dangerous.

Be aware of these when you are working with the printer.

Power Supply

Before starting any service procedure, switch off the printer power and unplug the

power cord from the wall outlet. If you must service the printer when the power is

applied, be aware of the potential for electrical shock and do all tasks by following the

procedures in this manual.

W A R N I N G

Do not touch any live part unless you are instructed to do so by a

service procedure. The LV/HV POWER SUPPLY power supply

switch/inlet part is live even when the power switch has been

turned off. Do not touch any live part.

Mechanical Components

If you service a driving assembly (e.g., gears), first turn off the power and unplug the

power cord. Then manually rotate the assembly.

W A R N I N G

Do not touch the driving part (e.g., gears) while the assembly

(printer) is being driven.

Page 7

Safety Components

The printer is equipped with safety components (e.g., interlock switches, fuses,

thermostat) and safety switches for protecting users and service personnel from injury

and the equipment from damage.

The printer has three interlock switches, four safety switches and two interlock

connectors that serve as the main safety mechanism.

FRONT COVER SWITCH R

This switch is turned off when the front cover (FRONT COVER ASSY) is opened.

It stops all operations and disconnects the output (5VDC-LD) circuit from the

power supply to stop the laser beam emission.

This switch consists of the following two switches:

A safety switch in the control circuit that stops all operations.

A physical interlock switch that directly cuts off the power supply circuit

(5VDC-LD) to the laser beam output circuit.

FRONT COVER SWITCH L

This is an interlock in the control circuit switch which is turned off when the front

cover (FRONT COVER ASSY) is opened. It cuts off the power supply (24VDC,

5VDC-LD) from the power supply unit to stop all operations.

TURN CHUTE SWITCH

This is a safety switch in the control circuit which is turned off to stop all

operations when the lower right side cover (TURN CHUTE COVER) is opened.

unit on the right side of the printer) is pulled out, cutting off the output (24VDC,

5VDC-LD) from the power supply and stopping the printer operation without

control units.

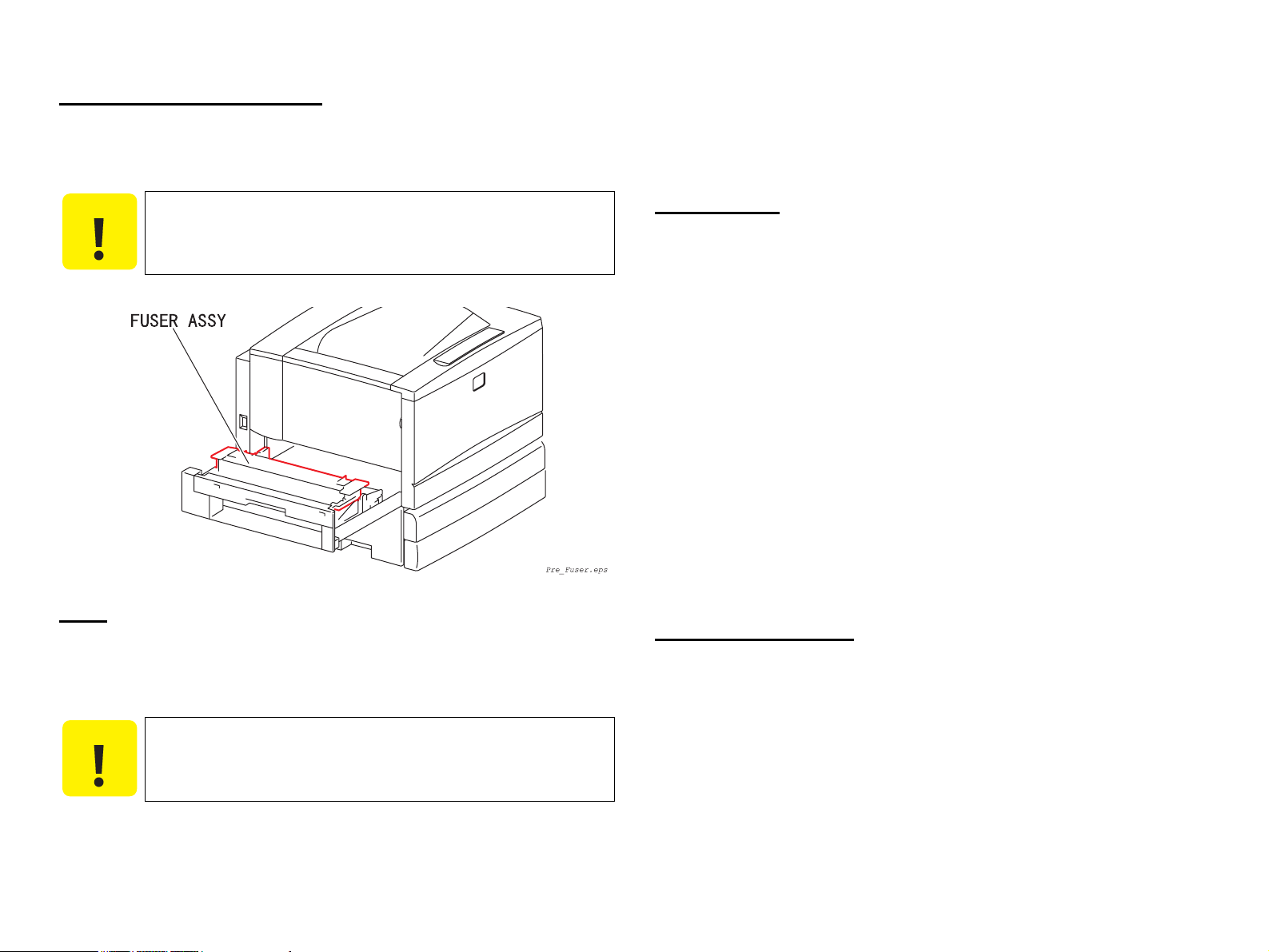

P/J71 (Connector that connects the FUSER CONNECTOR and FUSER

HARNESS ASSY)

This is an interlock connector that cuts off the power supply (24VDC, 5VDC-LD)

to the control circuit and related parts.

This connector is disconnected when the FUSER ASSY (pull-out type unit on the

left side of the printer) is pulled out, cutting off the output (24VDC, 5VDC-LD)

from the power supply and stopping the printer operation without control units.

REGI/MSI INTL SW

This is a safety switch in the control circuit which is turned off to stop all

operations when the right side drawer type unit (MSI/REGI HIGH ASSY) is

drawn out.

EXIT CHUTE SWITCH

This switch is a safety switch. This switch is turned off when the EXIT UPPER

ASSY (the cover on the upper left side of the printer) is opened.

P/J91 (Connector that connects the MAIN HARNESS ASSY and REGI.

HARNESS ASSY)

This is an interlock connector that cuts off the power supply (24VDC, 5VDC-LD)

to the control circuit and related parts.

This connector is disconnected when the MSI/REGI HIGH ASSY (pull-out type

Page 8

Laser Beam

To protect the user or service personnel from exposure to the laser beam from the ROS

Assembly, this printer is equipped with not only a protective control circuit but also an

interlock switch (FRONT COVER SWITCH R) which physically cuts off the power to

the laser beam output circuit. The interlock switch is turned off when the front cover is

opened.

(See “Safety Components” for detailed operation of the interlock switch.)

A laser beam may be emitted during a maintenance operation. Do not turn on these

interlock switches simultaneously under any circumstances except in a normal

operation.

W A R N I N G

Do not expose yourself to the laser beam to prevent injury

(blindness).

Do not open the cover that has the laser beam warning label.

If you disassemble or assemble the printer, turn off the power.

If you need to work on the printer with power applied, strictly

follow the instructions in this manual.

Understand how the laser beam functions and take maximum

precautions not to injure yourself or anyone around you.

C A U T I O N

NOTE: The laser beam in this printer is invisible.

The laser beam has a narrower frequency band and more

coherent phases than any other light (sunlight, electric light). It

has excellent monochromaticity and convergence. A thin laser

beam reaches long distances. Because of its convergence

characteristic, the laser beam converges into one point, causing

high density and high temperature. A laser beam is harmful to the

human body.

Page 9

High Temperature Assembly

To prevent you from becoming injured or burned, do the following: Before working

with a high temperature Assembly (e.g., FUSER ASSY), turn off the power, unplug the

power cord and wait until it cools down.

Do not work with wet or oily hands-you may drop a part or injure yourself. Dry

your hands first.

When pulling out a part (including a harness), do not use too much force. Pull out

the part carefully and slowly step by step.

C A U T I O N

The high temperature Assembly is very hot immediately after any

printer operations. Wait at least 40 minutes before you start

working on the printer.

Parts

To prevent you from becoming injured, keep the following in mind:

When handling heavy parts (including the printer itself), use good posture to

protect your back whenever you lift, move or place parts.

Consumables

Understand the following explanation and handle the consumables carefully.

Some parts may cause a particulate explosion or fire if handled improperly. Do not

handle these parts near fire or throw into a fire.

Some materials (e.g., Developer or Fuser Oil) may cause bodily injury. Do not

swallow or inhale these materials or allow them to come in contact with the eyes.

Help to protect those around you and follow the prohibitions against swallowing

or inhaling those materials. Be careful to protect the eyes at all times.

Place a sheet inside or under the printer so that the floor or workbench is protected.

If the Developer or Fuser Oil gets on your clothing, dry it with a cloth and wash

with clean water.

The printer has the following consumable parts:

• DRUM CARTRIDGE

(Photoconductor Unit)

• TONER CARTRIDGE Y • TONER CARTRIDGE M

• TONER CARTRIDGE C • TONER CARTRIDGE BK

• WASTE TONER BOX

Improper Printer Use

Modifying, revising, tampering with the printer, especially to the safety mechanism, is

strictly prohibited in all circumstances.

C A U T I O N

Do not lift, move or place heavy parts in a body posture that is

likely to cause injury to yourself or cause the part to drop.

Be careful not to injure yourself with the sharp edges of the parts.

Page 10

Safety System Outline Diagram

The following diagram shows outline of the safety system of this printer.

For names and other details of signal lines, refer to “7.2 Wiring Diagrams and Signal

Information (p. 465)”.

Page 11

Revision Status

Revision Date of Issue Description

A March 14, 2002 Formal First Release

Note: Exploded Diagrams and ASP List for AcuLaser C7000 are not included in this revision.

B April 10, 2002 Revision up:

[Appendix]

7.8 Optional Units (p.562)

(Description for available options are added.)

C June 27, 2002 Revision up:

[Chapter-3]

3.4.2.1 Rolls and Print Quality Defect Intervals (p. 250)

(Interval pitch for "HEAR ROLL", "PRESSURE ROLL" is corrected.)

3.4.2.12 FIP-1.P11 Interval Print Quality Defect (p.256)

(Newly added.)

Page 12

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

Contents

Chapter 1 Product Description

1.1 Features ................................................................................................................. 7

1.1.1 Engine Features ........................................................................................... 7

1.1.2 Controller Features ...................................................................................... 7

1.1.3 Software Features ........................................................................................ 8

1.2 Basic Specifications .............................................................................................. 9

1.2.1 Printer Basic Specifications ......................................................................... 9

1.2.2 Paper Specifications ................................................................................... 15

1.2.3 Reliability, Durability and Maintainability ................................................ 20

1.2.4 Operating Conditions (Including Consumables) ....................................... 21

1.2.5 Storage and Transport of the Printer Body and Optional Products

(Consumables Packaged) .................................................................................... 22

1.2.6 Electrical Features ..................................................................................... 23

1.2.7 Process Specifications ............................................................................... 24

1.2.8 Compliance with Standards and Regulations ............................................ 24

1.2.9 Consumable Components .......................................................................... 25

1.3 External View and Parts Names ......................................................................... 28

1.3.1 External View and Parts Names ................................................................ 28

1.3.2 Dimensional Drawing (in mm) .................................................................. 31

1.4 Controller Specifications .................................................................................... 33

1.4.1 Basic Controller Specifications ................................................................. 33

1.4.2 Controller Configuration ........................................................................... 34

1.4.3 Calibration Function (only with AcuLaser C8600) ................................... 34

1.5 External Interface Specifications ........................................................................ 35

1.5.1 Parallel Interface Specifications ................................................................ 36

1.5.2 USB Interface Specifications ..................................................................... 37

1.5.3 Ethernet Interface ....................................................................................... 37

1.5.4 Type-B Interface Specifications ................................................................ 38

1.6 Control Panel (AcuLaser C8600) ....................................................................... 40

1.6.1 External View and Names ......................................................................... 40

1.6.2 Description of Indicators ........................................................................... 40

1.6.3 Description of Buttons ............................................................................... 41

1.6.4 Operation and Indications on the Control Panel ........................................ 43

1.6.5 Panel Setting Item List .............................................................................. 45

1.6.6 User Setting Items Other Than Setup Menu .............................................. 52

1.6.7 Details of Setting Menus and Setting Items .............................................. 52

1.6.8 Special Operations ..................................................................................... 57

1.7 Control Panel (AcuLaser C7000) ....................................................................... 58

1.7.1 External View and Names ......................................................................... 58

1.7.2 Indications of LEDs ................................................................................... 58

1.7.3 Printer Setting Items .................................................................................. 59

1.8 Engine Restrictions ........................................................................................... 65

1.9 Status Sheet, etc. ................................................................................................. 70

1.9.1 Status Sheet for AcuLaser C8600 .............................................................. 70

1.9.2 Status Sheet for AcuLaser C7000 .............................................................. 72

1.9.3 Reserve Job List (Only with AcuLaser C8600) ......................................... 73

1.9.4 Form Overlay List (Only with AcuLaser C8600) ..................................... 73

1.9.5 Network Status Sheet (Only with AcuLaser C8600) ................................. 74

1.9.6 Engine Status Sheet ................................................................................... 75

1.10 Restrictions (Only for AcuLaser C7000) ......................................................... 79

1.10.1 Network Environment Applicable to AcuLaser C7000 .......................... 79

1.10.2 Restrictions on Network Connections ..................................................... 79

1.10.3 Others ....................................................................................................... 79

1.11 Operating Conditions of Host Computers (Only for AcuLaser C7000) .......... 80

1.12 RAM Expansion ............................................................................................... 81

1.13 Precautions in Handling ................................................................................... 82

1.13.1 Precaution in Turning Off the Power ...................................................... 82

1.13.2 Caution About Hot Parts .......................................................................... 82

1.14 Paper Handling Algorithm (AcuLaser C8600) ................................................ 83

1.15 Differences in Specifications ............................................................................ 86

1.15.1 Differences between AcuLaser C7000 and AcuLaser C8600 ................. 86

1.15.2 Differences in Specifications between Models ....................................... 87

6

Page 13

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

Chapter 2 Operating Principles

2.1 Print Process ....................................................................................................... 91

2.1.1 Print Process Overview .............................................................................. 91

2.1.2 Total Print Process Schematic Diagram .................................................... 91

2.1.3 Print Process Technical Explanation ......................................................... 92

2.1.4 Print Data Flow ........................................................................................ 101

2.1.5 Operation Mode ....................................................................................... 102

2.2 Mechanism Operating Principles ..................................................................... 103

2.2.1 Drive Transmission Route ....................................................................... 103

2.2.2 Gear Layout ............................................................................................. 106

2.2.3 Paper Feed ............................................................................................... 108

2.2.4 Function of Main Working Parts ............................................................. 110

2.3 Control .............................................................................................................. 130

2.3.1 Paper Size Control ................................................................................... 130

2.3.2 Paper Supply Unit Selection Control ....................................................... 131

2.3.3 OHP Front/Back Detection Control ......................................................... 131

2.3.4 ROS Control ............................................................................................ 132

2.3.5 Process Control ........................................................................................ 134

2.3.6 XERO. Control ........................................................................................ 142

2.3.7 DEVE. Control ........................................................................................ 145

2.3.8 IBT Control .............................................................................................. 149

2.3.9 Transfer Layout Control .......................................................................... 153

2.3.10 FUSER Control ...................................................................................... 155

2.4 Operating Principles of Electric Circuitry ........................................................ 157

2.4.1 Features (AcuLaser C8600) ..................................................................... 157

2.4.2 Features (AcuLaser C7000) ..................................................................... 159

3.3 Level 2 FIP ....................................................................................................... 226

3.3.1 Level 2 FIP List ....................................................................................... 226

3.4 Picture Image Trouble ...................................................................................... 249

3.4.1 Picture Image Troubleshooting Entry Chart ............................................ 249

3.4.2 Picture Quality FIP .................................................................................. 249

Chapter 4 Disassembly and Assembly

4.1 Overview ............................................................................................... 258

4.1.1 Precautions ............................................................................................... 258

4.1.2 Tools ........................................................................................................ 260

4.1.3 Items to Check after Assembly ................................................................ 260

4.2 Disassembly and Reassembly Procedure ......................................................... 261

4.2.1 Cover ....................................................................................................... 262

4.2.2 Paper Tray ................................................................................................ 270

4.2.3 Paper Feeder ............................................................................................ 274

4.2.4 MSI/Paper Transportation ....................................................................... 282

4.2.5 (Missing number) .................................................................................... 297

4.2.6 Xerographics ............................................................................................ 298

4.2.7 Development ............................................................................................ 305

4.2.8 IBT ........................................................................................................... 312

4.2.9 Fusing ...................................................................................................... 321

4.2.10 Paper Exit .............................................................................................. 339

4.2.11 Drive ...................................................................................................... 345

4.2.12 Frame ..................................................................................................... 351

4.2.13 Electrical ................................................................................................ 352

4.2.14 Controller ............................................................................................... 358

Chapter 3 Troubleshooting

3.1 Overview .......................................................................................................... 162

3.1.1 Troubleshooting Procedure ...................................................................... 162

3.1.2 Preliminary Checks .................................................................................. 162

3.1.3 Precautions in Performing Work ............................................................. 163

3.1.4 Self-Diagnostic Function by Printer Message (AcuLaser C8600) .......... 164

3.1.5 Self-Diagnostic Function by Printer Message (AcuLaser C7000) .......... 172

3.1.6 Details of the Service Call Error Messages ............................................. 180

3.2 Level 1 FIP (Fault Isolation Procedure) ........................................................... 184

3.2.1 Precautions in Using FIP (Fault Isolation Procedure) ............................. 184

Chapter 5 Adjustment

5.1 Overview .......................................................................................................... 361

5.1.1 Specified Tools ........................................................................................ 361

5.2 USB ID Input .................................................................................................... 362

5.2.1 Installation Procedure for Program .......................................................... 362

5.2.2 Procedure for Program Operation ............................................................ 362

5.2.3 USB ID Confirmation .............................................................................. 363

5.3 Service Utility (for AcuLaser C7000) .............................................................. 364

5.3.1 Overview ................................................................................................. 364

5.3.2 How to Use the Service Utility ................................................................ 365

7

Page 14

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

5.3.3 Operation ................................................................................................. 367

5.4 Diagnostics ....................................................................................................... 369

5.4.1 Diagnostics by Operating the Printer Body Only ................................... 369

5.4.2 Diagnostics Commander .......................................................................... 371

Chapter 6 Maintenance

6.1 Overview .......................................................................................................... 448

6.1.1 Regularly Replaced Parts Replacement ................................................... 449

6.1.2 Main After-Sales Parts Replacement ....................................................... 449

6.1.3 Consumable Replacement ....................................................................... 449

6.2 About On-Site Servicing .................................................................................. 450

6.2.1 On-site Service Flow ............................................................................... 450

6.2.2 Description of the On-site Service ........................................................... 451

6.3 Maintenance Menu (AcuLaser C8600) ............................................................ 453

6.3.1 Entry to the Maintenance Menu (AcuLaser C8600) ................................ 453

6.3.2 Maintenance Menu Items (AcuLaser C8600) .......................................... 454

Chapter 7 APPENDIX

7.1 Connectors ........................................................................................................ 457

7.1.1 P/J Location Drawings ............................................................................. 457

7.2 Wiring Diagrams and Signal Information ........................................................ 465

7.2.1 Overall Wiring Connection Diagram ....................................................... 465

7.2.2 Wiring and Signal Descriptions between Components ........................... 467

7.3 Component Layout ........................................................................................... 489

7.4 Circuit Diagrams .............................................................................................. 491

7.5 Exploded Diagrams .......................................................................................... 503

7.6 Index for Parts .................................................................................................. 550

7.7 ASP List (Parts List) ......................................................................................... 554

7.7.1 ASP List for AcuLaser C8600 ................................................................. 555

7.7.2 ASP List for AcuLaser C7000 ................................................................. 558

7.8 Optional Units .................................................................................................. 562

7.8.1 Duplex Unit ............................................................................................. 563

7.8.2 500-Sheet Paper Cassette Unit ................................................................. 609

7.8.3 Large Capacity Paper Unit ....................................................................... 659

7.8.4 ASP Information ...................................................................................... 716

8

Page 15

PRODUCT DESCRIPTION

CHAPTER

1

Page 16

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

1.1 Features

AcuLaser C8600/AcuLaser C7000 is a non-impact color page printer driven by a laser

and electrophotographic technologies. The resolution is 600/300 dpi and the printing

speed is 8 ppm (A4 color)/35 ppm (A4 monochrome). The printer is equipped with

AcuLaser Color Halftoning as its full color technology.

1.1.1 Engine Features

AcuLaser C8600 has the following features.

High-speed engine that supports A5 to A3W. Printing speed is 8 ppm for color/35

ppm for monochrome (when printing A4 paper).

Full-color printing engine that supports duplex printing and True 600 dpi of high

resolution.

Higher quality printing is possible with high quality plain paper.

Capable of printing on thick paper, extra thick paper, coated paper, and

transparency (dedicated OHP sheets).

Easy maintenance for a color laser printer.

As the standard paper feeders, the printer has two bins, namely, the MP Tray (up to

150 sheets, A3W supported) and the standard universal cassette (up to 250 sheets,

A3 supported).

Adding an optional Large Capacity Paper Unit (two 500-sheet cassettes, A3

supported) allows paper feeding a maximum of 1400 sheets from 4 bins.

Adding an optional 500-Sheet Paper Cassette Unit (one 500-sheet cassette, A3

supported) allows paper feeding a maximum of 900 sheets from 3 bins.

Substituting the standard universal cassette with an A3W paper cassette allows

feeding A3W paper from the Lower Cassette 1.

As paper ejection, a maximum of 250 sheets can be ejected into the Face-down

tray and 150 sheets into the Face-up tray.

1.1.2 Controller Features

1.1.2.1 Controller Features for AcuLaser C8600

Newly developed high-speed controller

New RISC CPU ..............................PowerPC750CX (400MHz)

64-bit high-speed memory .............SDRAM DIMM (PC100 or PC133)

64 MB of standard RAM. By installing additional RAM (2-slot), the memory

can be expanded up to 1 GB (removing the standard RAM and installing 512

MB RAM on both slots). Using the standard RAM as it is expands up to 576

MB.

Color technologies

Enhanced ASIC (VIPS, CDMC) installed

Data compression has been incorporated into the hardware to achieve high-

speed processing.

Equipped with AcuLaser Color Halftoning and CRIT (color RIT)

On-board option of color photocopier (AcuLaser Color Copy Station 8600)

supported

Three types of standard interfaces available

IEEE1284 compatible parallel interface (ECP supported)

USB (Rev. 1.1) interface

Ethernet interface (100Base-TX/10Base-T)

By expanding memory with RAM DIMMs, the following functions can be

enhanced and speeded up.

Drawing area for AcuLaser Color Halftoning

Printing speed

Resolution

Receive buffer capacity

Collate (printing of multiple copies) (with memory expanded to 128 MB or

more)

New control panel (control panel 2001)

HDD can be installed.

Product Description Features 7

Page 17

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

1.1.2.2 Controller Features for AcuLaser C7000

Host-based controller

CPU: TMPR4955AF-200 MHz

Standard RAM: 32 MB, adding RAM DIMM expands to a maximum of 256

MB (Requires to replace the standard 32MB RAM DIMM

with 128MB.)

Color technologies

Enhanced ASIC (VIPS) installed

Equipped with AcuLaser Color Halftoning and CRIT (color RIT)

Two types of standard interfaces installed

IEEE1284 compatible parallel interface supporting ECP

USB I/F

Expanding RAM DIMM allows providing enhanced and high-speed performances

on the following functions

Drawing area for AcuLaser Color Halftoning

Printing speed

Resolution

1.1.3 Software Features

1.1.3.1 Software Features for AcuLaser C8600

Installed emulation

Standard ............ ESC/Page-Color mode

Standard ............LJ4, GL2, ESCP2, FX, I239X, and ESC/Page

(monochrome) modes (these have complete compatibility

with AcuLaser C8500)

Optional .............PostScript 3 mode (PostScript 3 module)

Optional ............. Color Copy Unit (AcuLaser Color Copy Station 8600)

HP LaserJet4000, 80 Scalable font and compatible fonts and NLSP font ROM are

installed, and Euro Symbol is supported

Electronic sort, extended interface receive buffer size (for Ethernet interface only,

excluding when emulation is fixed for PS3), font registration when PostScript 3

mode is selected (with an HDD installed)

Calibration function

Form Overlay function (for ESC/Page Color mode of Windows driver only, with

an HDD installed)

Reserve job function (Re-Print Job, Verify Job, Stored Job, Confidential Job, with

an HDD installed)

Color design has been changed (sRGB, gray scale guarantee for graphics, can be

rewritten into the color design of AcuLaser C8500 (for Flash Program DIMM

only))

NOTE: This is not described in manuals.

Specifications of manual feed have been changed (same as EPL-5900).

1.1.3.2 Software Features for AcuLaser C7000

ESC/PageS implemented

Supports color

Supports duplex printing

Supports 2up

Network compatibility

Background job commands establish network connections

Printer status and printer environment monitors by EJL, PJL, and Printer MIB

Remote panel function through HTTP browser by the EpsonNet WebAssist

ROM update function when a flash DIMM is installed (RCC is supported)

Upgrade function of the engine controller ROM (flash)

Engine transfer voltage adjustment function by DIAG mode and control panel

Product Description Features 8

Page 18

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

1.2 Basic Specifications

1.2.1 Printer Basic Specifications

Printing Method

Semi-conductor laser beam scanning and dry two-component toner

electrophotography

Resolution

600 dpi

Print Mode

B/W mode ................. Standard monochrome print mode in which printing is

performed at the fastest speed.

Color mode................ Color mode which uses the color toner of Y, M, C, and

K.

Speed Mode

Standard mode........... Transports paper at the highest speed supported by the

printer.

Middle speed mode ... This mode ensures satisfactory fusing of image on

thick paper exceeding 105 g/m

and monochrome image on transparencies.

This mode also reduces printing speed to enhance the

degree of gloss on the surface of the dedicated coated

paper.

Low speed mode ....... This mode reduces printing speed to ensure satisfactory

fusing of image on thick paper exceeding 220g/m

color image on transparencies.

2

(28 lb) or envelopes,

2

, and

Printing Speed *

3

Both face-up and face-down satisfy the conditions below.

All of the standard tray, the standard universal cassette and the expanded cassette

satisfy the following conditions:

Table 1-1. Printing Speed (Unit: ppm)

Print

Mode

B/W

Color

Note *1: LEF (Long Edge Feed): the long edge of the paper is fed to the printer.

*2: In 2UP mode, the printer creates two print images on the IBT belt and the images are

*3: Not applicable to any operation for which the printing speed is restricted as specified

*4: The printing speed (ppm) for Duplex printing represents the number of pages printed

Speed Mode

Simplex

Standard

Middle

speed

Low speed

Standard

Middle

speed

Low speed

SEF (Short Edge Feed): the short edge of the paper is fed to the printer.

transferred in sequence onto two sheets of paper. This mode is available for LT/A4

(LEF) or smaller.

in 1.8 "Engine Restrictions".

per minute.

The values in parentheses represent the printing speeds when paper is fed from the

optional 500-Sheet Paper Cassette Unit (500 sheets x 1) or the optional Large

Capacity Paper Unit (500 sheets x 2). (The two values given in parentheses indicate

the printing speeds with the optional upper cassette and lower cassette, respectively.)

printing

Duplex

printing *

Simplex

printing

Simplex

printing

Simplex

printing

Duplex

printing *

Simplex

printing

Simplex

printing

A4 LEF

(33.7/27.5)

27.4 (25.5) 27.1 (25.4) 15.7 (15.6) 15.5 (15.4)

4

4

*1

LT LEF

2

2UP *

35.0

(32.9/27.5)

5.3 5.3 2.6 2.6

4.0 4.0 2.0 2.0

8.0 8.0 4.0 4.0

8.0 8.0 4.0 4.0

3.5 3.5 1.8 1.8

2.9 2.9 1.4 1.4

2UP *

34.4

*1

A3 SEF *1B(LD) LEF

2

18.8 (18.3) 18.3 (17.9)

*1

Product Description Basic Specifications 9

Page 19

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

Reference values

B/W, standard mode. With paper sizes other than indicated above when paper

is fed from the standard universal cassette, the printing speeds for your

information are as shown below.

Table 1-2. Reference Values (Unit: ppm)

Paper Size EXE LEF B5 LEF LD14” B4 SEF

Simplex printing 39.2 39.8 21.9 21.5

Duplex printing 40.4 40.7 17.1 16.9

<How to measure continuous printing speed>

The number of sheets printed per minute is measured as follows: Let t seconds be the

time from the ejection of the tail end of the 1st sheet to the ejection of the 11th sheet.

Then the number of sheets printed per minute is calculated as 60/t times the measured

number of pages.

First Printing Time *

Face-up...................... B/W : 8.3 seconds or less

Color : 19.6 seconds or less

Face-down................. B/W : 10.4 seconds or less

Color : 21.7 seconds or less

NOTE 1:

First print is defined as the duration taken after receiving the start command

until completion of outputting the first print. It is applicable when a feeder in

the printer body is selected in the standard mode. (Not applied during the

process control operation.)

2:

The time as indicated above is common to all the feeders including all the

optional feeders.

3:

The values as indicated above are applicable when the paper is A4 LEF.

Warm-up time

Within 330 seconds (at 22°C, 55% Rh, rated voltage: 100V, 115V, 220V)

Paper feed

Table 1-3. Paper Feed

Paper Source Capacity Applicable Paper Size

Standard Standard MSI

(MP tray)

Standard

universal cassette

Optional

Cassette

Unit *

A3W Cassette

2

500-Sheet Paper

Cassette Unit

Large Capacity

Paper Unit

*1

,*4

150 sheets

(16 mm)

75 sheets

20 sheets

250 sheets

(26 mm)

250 sheets

(26 mm)

500 sheets

(53 mm)

500 sheets

(53 mm)

Regular size sheets and custom size

sheets whose dimensions are within the

limits specified below:

• Min.: Width 90 mm (3.5")x

Length 139.7 mm (5.5")

• Max.: Width 330.2 mm (13")x

Length 457.2 mm (18")

A3, A3W, A4, A5, B4, B5, I-B5, LT,

HLT, LG, EXE, GLG, GLT, B(LD),

F4

90x139.7 mm∼330.2x457.2 mm

Postcard, Double postcard, Quadruple

postcard, Transparencies, Labels,

Thick paper

Custom-size envelopes *

Monarch, C10, DL, C6, C5

Yokei #0

B5, LT, A4, B4, A3, LG, B(LD), EXE 64∼105g/m

A3W 64∼105g/m

B5, LT, A4, B4, A3, LG, B(LD), EXE 64∼105g/m

B5, LT, A4, B4, A3, LG, B(LD), EXE 64∼105g/m

*

6

, Yokei #4

3

*

6

, Yokei #6

64∼105g/m

(Recommended

paper, Plain

paper)

105∼250g/m

(Thick paper,

Special paper)

*

6

(Recommended

paper, Plain

paper)

(Recommended

paper, Plain

paper)

(Recommended

paper, Plain

paper)

(Recommended

paper, Plain

paper)

Applicable

Paper

Thickness

2

2

-

2

2

2

2

Note *1: For the paper whose width is more than 304.8 mm (12 inch), the side guide in the

MSI tray must be adjusted.

*2: Each cassette is equipped with the side guide and end guide (also used to detect

paper size). They can be adjusted by users.

Product Description Basic Specifications 10

Page 20

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

*3: Note the following points when setting envelopes:

Open the flaps and set the envelopes with the flaps positioned at the tail in the paper

feed direction.

Set the envelopes so that the longer edge is fed to the printer, if the length (excluding

the flap) is shorter than the width. (Except for C5)

The minimum length with the flap open must be 143 mm.

The minimum width must be 90 mm.

*4: The MSI tray has the function to detect Paper Empty condition.

*5: Each cassette is equipped with the Paper Out sensor and paper near empty sensor.

Paper Near Empty condition is defined as follows: 40 sheets

paper (64 g/m2)

*6: JIS envelope

± 30 sheets of FX P

Combinations with Optional Cassettes and Resultant Capacity

MSI

Combination

1

2 250 sheets - - 1000 sheets 1400 sheets

3 - 250 sheets 500 sheets - 900 sheets

4 - 250 sheets - 1000 sheets 1400 sheets

NOTE a: The number of sheets is applicable when recommended paper or plain paper is used.

b: Use the A3W cassette by inserting it into the standard universal cassette slot.

c: Either 500-Sheet Paper Cassette Unit or Large Capacity Paper Unit can be installed

(MP

Tray)

150

sheets

only at the bottom.

Standard

Universal

Cassette

250 sheets - 500 sheets - 900 sheets

A3W

Cassette

500-Sheet

Paper

Cassette

Unit

Large

Capacity

Paper Unit

Total

Capacity

Duplex Printing

Minimum size .......... 182 mm/7.16” (W) x 210 mm/8.26” (L)

Maximum size .......... 304.8mm/12” (W) x 457.2mm/18” (L)

Paper wight .............. 64 g/m

2

∼105 g/m2 (17 lb∼28 lb)

Paper Size / Paper Orientation / 2-UP Mode Availability

Table 1-4. Paper Size / Paper Orientation /

2-UP Mode Availability

Paper Orientation

Dimensions

Paper Size

A3W 328x453 SEF - - SEF

A3 297x420 SEF SEF SEF A4 210x297 LEF LEF LEF - { {

A5 148x210 LEF - - - {

B4 257x364 SEF SEF SEF B5 182x257 LEF LEF LEF - { {

I-B5 176x250 LEF - - - {

LT

HLT

Plain paper

LG

EXE

GLG

GLT

B(LD)

F4 210x330 SEF - - -

mm

(inch)

215.9x279.4

(8.5”x11”)

139.7x215.9

(5.5”x8.5”)

215.9x355.6

(8.5”x14”)

184.15x266.7

(7.25”x10.5”)

215.9x330.2

(8.5”x13”)

203.2x266.7

(8”x10.5”)

279.4x431.8

(11”x17”)

MSI

Universal

(MP

Tray)

LEF LEF LEF - { {

LEF - - - {

SEF SEF SEF -

LEF LEF LEF - { {

SEF - - -

LEF - - - { {

SEF SEF SEF -

Casette

500-

Sheet/

LCP

Unit

A3W

Cassette

2UP

mode

*1

X X

X

X

X

X

X

X

Duplex

print

{

X

{

X

X

{

{

{

{

Product Description Basic Specifications 11

Page 21

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

Table 1-4. Paper Size / Paper Orientation /

2-UP Mode Availability (continued)

Paper Orientation

Paper Size

Transparencies

Dimensions

mm

(inch)

210x297

(8.5”x11”)

MSI

Universal

(MP

Tray)

Casette

LEF - - - {

Postcard 100x148 SEF - - - {

Double postcard 148x200 LEF - - - {

Special applications

Quadruple

postcard

MON

C10

DL 110x220 LEF*

200x296 LEF - - - {

98.43x190.54

(37/8”x71/2”)

104.78x241.3

(41/8”x91/2”)

LEF*

LEF*

2

- - - {

2

- - - {

2

- - - {

C5 162x229 SEF - - C6 114x162 LEF*

Yokei #0

Yokei #4

Yokei #6

*3

*3

*3

120x235 LEF*

105x235 LEF*

98x190 LEF*

2

- - - {

2

- - - {

2

- - - {

2

- - - {

500-

Sheet/

LCP

Unit

A3W

Cassette

2UP

mode

*1

X X

Duplex

print

X

X

X

X

X

X

X

X

X

X

X

Paper Feed Reference

Single side aligning (front side) for all sizes (both standard tray (MSI) and each

cassette)

Consumables

Toner Cartridge (Black, Cyan, Magenta, Yellow)

Drum Cartridge (including one Waste Toner Box)

Waste Toner Box

Regularly Replaced Parts

Main Fuser Assembly

Exhaust Filter

Paper Output

Paper output capacity with the recommended paper (EPSON high-quality paper) is

as follows:

Face-down (FD) ......................250 sheets (B5/EXE or larger, up to 105 g/m

(28 lb))

Face-up (FU) ...........................150 sheets (A4 or smaller)

50 sheets (larger than A4)

NOTE: The FD and FU output capacities are applicable to both simplex and

duplex prints. (when recommended paper is used)

See Table 1-5 on page 13 for face-down (FD) output availability.

2

NOTE a: LEF (Long Edge Feed): the long edge of the paper is fed to the printer.

b: SEF (Short Edge Feed): the short edge of the paper is fed to the printer.

c: The envelopes supported vary with intended markets.

Note *1: 2UP is available only for paper size of LT (LEF) or smaller. For custom size paper,

paper length along the transport direction must be 210 mm (8.5 inches) or shorter.

As for envelopes, the length with its flap opened along the transport direction must

be 210 mm (8.5 inches) or shorter.

*2: When setting envelopes, open the flaps and set the envelopes with the flaps

positioned at the tail in the paper feed direction.

*3: JIS envelope

Product Description Basic Specifications 12

Page 22

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

Plain paper

Special

applications

Table 1-5. Face-Down Output Availability

Paper Size Dimensions in mm (inch) FD Availability

A3W 328x453 {

A3 297x420 {

A4 210x297 {

A5 148x210

B4 257x364 {

B5 182x257 {

I-B5 176x250

LT 215.9x279.4 (8.5”x11”) {

HLT 139.7x215.9 (5.5”x8.5”)

LG 215.9x355.6 (8.5”x14”) {

EXE 184.15x266.7 (7.25”x10.5”) {

GLG 215.9x330.2 (8.5”x13”) {

GLT 203.2x266.7 (8”x10.5”) {

B(LD) 279.4x431.8 (11”x17”) {

F4 210x330 {

Transparencies 210x297 (8.5”x11”) FU

Postcard 100x148 FU

Double postcard 148x200 FU

Quadruple postcard 200x296 FU

MON 98.43x190.54 (37/8”x71/2”) FU

C10 104.78241.3 (41/8”x91/2”) FU

DL 110x220 FU

C5 162x229 FU

C6 114x162 FU

Yokei #0

Yokei #4

Yokei #6

*1

*1

*1

120x235 FU

105x235 FU

98x190 FU

X

X

X

*

*

*

*

*

*

*

*

*

*

*

*

NOTE a: FD ejection is not available with sheets larger than 181.9 mm in the paper feeding

direction and 209.9 mm in width.

b: “FU*” in the FD availability columns means face-up ejection for transparencies,

thick paper, and envelope.

c: The FD and FU output capacities are applicable to both simplex and duplex prints

(when recommended paper is used).

Note *1: JIS envelope

Dimensions and Weight

Table 1-6. Dimensions and Weight of Each of

AcuLaser C8600 Printer Body and Optional Units

Dimensions

Printer

body

Width

(mm)

AcuLaser C8600 650

AcuLaser C7000 650

Duplex Unit *

2

Depth

(mm)

*1

647 554 70.0

*1

647 554 69.5

Height

(mm)

- - - 8.2

500-Sheet Paper Cassette Unit (with Feet) 575 602 164 13.3

Option

500-Sheet Paper Cassette Unit (with

Castors)

575 602 206 14.0

Large Capacity Paper Unit 578 602 264 21.2

A3W Cassette 560 547 87.4 ± 1.2 2.7

Note *1: With the MSI (MP Tray) and the paper eject (FU) tray folded

*2: Since the Duplex Unit consists of three separate components, the dimensions of the

Duplex Unit as a single unit are not given.

NOTE a: For printer dimensions with its optional units installed, see Section 1.3.2

"Dimensional Drawing (in mm)".

b: The tolerance of the dimensions is ± 1 mm.

c: The total weight after installing optional units is not the total sum of the weights of

the printer body and the installed optional units, since their installation involves

some part removal.

Weight

(kg

±1%kg)

Power Supply

100/120V version:100/120V±10% (90V∼132V) 50/60Hz±3Hz

220/240V version:220/240V±10% (198V∼264V) 50/60Hz± 3Hz

Product Description Basic Specifications 13

Page 23

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

Power Consumption

Power consumption with the rated voltage (100, 115 or 240 VAC) input is as

follows:

Table 1-7. Power Consumption

Power Consumption Remarks

Average 550 Wh or less

Operating (color)

Operating (B/W)

Standby mode

Low power mode *

Note *1: Including the optional cassette unit and duplex printing unit.

*2: Full pause status. Conforms to the Energy Star program.

*1

Maximum

Average 750 Wh or less

*1

Maximum

Average 240 Wh or less

Maximum

2

Average

1100 W or less 100V/120V version (Fuser is on)

1200 W or less 220V/240V version (Fuser is on)

1100 W or less 100V/120V version (Fuser is on)

1200 W or less 220V/240V version (Fuser is on)

1000 W or less (Fuser is on)

100 W or less (Fuser is off)

20 Wh or less Only with Japanese models

15 Wh or less

AcuLaser C8600/AcuLaser C7000)

(Not applicable to

Current Consumption

100 V ..............................................11 A or less (at rated voltage)

115 V ..............................................10 A or less (at rated voltage)

240 V ..............................................5 A or less (at rated voltage)

Product Life

Printer body (including the standard tray):

Approximately 180,000

years, whichever comes first.

*1

printed pages (450,000 images) on A4 LEF or five

Option

• 500-Sheet Paper Cassette Unit .............. 180,000 sheets

• Large Capacity Paper Unit .................... 180,000 sheets

• A3W Cassette ........................................ 180,000 sheets

• Duplex Unit ...........................................180,000 sheets*

Note *1: Note one full color print is formed with four images. So the printer can prints 180,

000 sheets (= 450,000 images) if its job ratio of monochrome printing to color

printing is 1:1. (450,000 images = 90,000 x 4 + 90,000).

If the printer is used only for monochrome print, it can prints 450,000 sheets

*2: In duplex printing, each side of paper is counted as one sheet.

2

Noise

Table 1-8. Noise

Status Printer Body Only Printer Body + Optional Units

Operating 54.8dB(A) or less 59.4dB(A) or less

Standby mode 38.3dB(A) or less 38.3dB(A) or less

Low power mode 35.0 dB(A) or less 35.0 dB(A) or less

Note *1: Duplex Unit + Large Capacity Paper Unit

*1

Ozone Concentration

The saturated concentration of ozone emission does not exceed 0.02 mg/m

Measurement is based on the BAM standard. The volume subjected to

measurement is 29.3 m

3

.

3

.

Dust Emission

Dust concentration is not more than 0.075 mg/m

BAM standard.

3

. Measurement is based on the

Toxicity

Photoconductor unit (OPC), toner, carrier, and plastic materials are all non-toxic.

Product Description Basic Specifications 14

Page 24

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

1.2.2 Paper Specifications

1.2.2.1 Paper Type

Recommended Paper

4200 paper (B/W), X-Pressions paper (color), EPSON high-quality plain paper

(for color single-side only), EPSON coated paper

Plain Paper

Generally applied copier paper, Recycled paper,

2

64 g/m

Special Applications

Exclusive OHP film (Type: LPCOHPS1)

Postcard

Labels

Color paper

Thick paper (105 g/m

Envelope

NOTE 1:

~ 105 g/m2 (17 lb ~ 28 lb)

2

~ 250 g/m2)

lb: Ream Weight =lb/500 sheets/17”

2

1g/m

=0.2659763 lb

2:

Before purchasing a large amount of paper, try it out and check that it is

×

22"

properly fed.

3:

The following types of paper should not be used with this printer. They could

cause printing defects, paper jams or printer malfunctions.

• Carbon paper, non-carbon paper, thermal paper, impact paper, acid-based

paper

• Paper that was previously used in a thermal or ink jet printer

• Paper that is too thin or too thick

• Paper that is wet or damp

• Paper with special coatings or colored paper with processed surfaces

• Paper that is too smooth or slippery on the surface

• Paper with significantly different roughness on each surface

• Paper with punch holes or perforations

• Irregularly shaped paper or paper with non-perpendicular corners

• Labels that peel off easily

• Paper with glue, staples or paper clips attached to it

• Ink jet paper for special applications (super-fine, glossy, glossy film, etc.)

• OHP sheets manufactured for other color laser printers, monochrome

printers, and photocopiers

• Sheets already printed on other color/monochrome laser printers or

photocopiers

• Sheets of paper stuck together

1.2.2.2 Paper Feedings

Table 1-9. Paper Feedings

Special Applications

Postcard

Double

postcard

Quadruple

postcard

2

Labels

∆ ∆ ∆ ∆

X X X X X

X X X X X

X X X X X

X X X X X

Paper Source

Standard tray

(MSI)

Standard

Universal

Cassette

A3W Cassette

500-sheet

*1

Cassette

Duplex Unit

Recommended

*1

*1

Paper

{

{

{

{

{

Plain

Paper

∆

∆

∆

∆

∆

OHP

{ *

Note *1: Option

*2: Exclusive OHP sheet only

{: Paper feed reliability and image quality are ensured.

∆: Paper feed and printing are possible for only generally applied types of paper.

X

: Sheets cannot be fed.

Thick

paper

(105∼250

2

g/m

)

Envelope

(MON,

C10, DL,

C6, C5,

Yokei #0

*3

#4

, #6*3)

*3

,

Product Description Basic Specifications 15

Page 25

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

1.2.2.3 Printing Area

PRODUCT SPECIFICATIONS

There are two types of printing areas, namely, the guaranteed print area and the

printable area.

Guaranteed Print Area:

Print quality is guaranteed all over the guaranteed print area.

Printable Area:

Printing is always possible all over the printable area. (Print quality is not

guaranteed out of the guaranteed print area, even within the printable area.)

Printing is not always possible out of the available printing area. (Printing out of

the printable area sometimes may be achieved successfully, but can not always be

achieved.)

The guaranteed print area and printable area are all the area of the sheet except vertical

and horizontal margins of 5 mm. (See illustration below)

However, with the A3W sheet or custom-size sheets with a large size, the guaranteed

print area is different from the printable area.

Guaranteed Print

Area or

Printable Area

Guaranteed Print Area List

Table 1-10. Guaranteed Print Area List (Unit: dots) (600dpi)

Paper Size a

*1

A3W

A3 120 6776 120 120 9680 120

A4 120 4720 120 120 6776 120

A5 120 3256 120 120 4720 120

B4 120 5832 120 120 8360 120

B5 120 4060 120 120 5832 120

LT 120 4860 120 120 6360 120

HLT 120 3060 120 120 4860 120

LG 120 4860 120 120 8160 120

EXE 120 4110 120 120 6060 120

Regular

size paper

Custom

size paper

Note *1: With the A3W sheet or custom-size sheets with a large size, the guaranteed print area

GLG 120 4860 120 120 7560 120

GLT 120 4560 120 120 6060 120

B(LD) 120 6360 120 120 9960 120

F4 120 4720 120 120 7556 120

Postcard 120 2122 120 120 3256 120

Double postcard 120 4484 120 120 3256 120

Quadruple postcard 120 4484 120 120 6752 120

Envelope

(Yokei #0)

Envelope

(Yokei #4)

Envelope

(Yokei #6)

Minimum size 120 1886 120 120 3060 120

Maximum size

is different from the printable area.

*2: JIS envelope

*2

*2

*2

*1

1

390 7016 342 120 10174 406

120 2594 120 120 5310 120

120 2240 120 120 5310 120

120 2074 120 120 4248 120

390 7016 342 120 10174 406

b a

2

c

1

d c

2

print_area01.eps

Figure 1-1. Guaranteed Print Area

Product Description Basic Specifications 16

Page 26

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

Printable Area List

Table 1-11. Printable Area List (Unit: dots) (600dpi)

Paper Size a

*1

A3W

1

120 7508 120 120 10460 120

A3 120 6776 120 120 9680 120

A4 120 4720 120 120 6776 120

A5 120 3256 120 120 4720 120

B4 120 5832 120 120 8360 120

B5 120 4060 120 120 5832 120

LT 120 4860 120 120 6360 120

HLT 120 3060 120 120 4860 120

LG 120 4860 120 120 8160 120

EXE 120 4110 120 120 6060 120

Regular

size paper

GLG 120 4860 120 120 7560 120

GLT 120 4560 120 120 6060 120

B(LD) 120 6360 120 120 9960 120

F4 120 4720 120 120 7556 120

Postcard 120 2122 120 120 3256 120

Double postcard 120 4484 120 120 3256 120

Quadruple postcard 120 4484 120 120 6752 120

Custom

size paper

Envelope

(Yokei #0)

*2

Envelope

(Yokei #4)

*2

Envelope

(Yokei #6)

*2

Minimum size 120 1886 120 120 060 120

Maximum size

*1

120 2594 120 120 5310 120

120 2240 120 120 5310 120

120 2074 120 120 4248 120

120 7508 120 120 10460 120

Note *1: With the A3W sheet or custom-size sheets with a large size, the printable area is

different from the guaranteed print area.

*2: JIS envelope

b a

2

c

1

d c

2

Product Description Basic Specifications 17

Page 27

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

ENGINE SPECIFICATIONS

Maximum Printable Area

320 mm (12.6") (W) / 457.2 mm (18") (L)

Guaranteed Print Area

All area of the sheet except vertical and horizontal margins of 4 mm.

However, the guaranteed print area is limited to within the maximum guaranteed

print area: 297 mm (11.7") (W) /444.5 mm (17.5") (L)

Printable Area

Paper whose width is 304.8 mm (12") or less:

Printing is possible up to each edge of the sheet.

Paper whose width exceeds 304.8mm (12")*:

Printing is possible all over the area of the sheet except the vertical and

horizontal margins of 5 mm.

(See Figure 1-2)

Note "*": For paper whose width is more than 304.8 mm (12"), the side guide in the MSI must

be moved. So print start position changes to 5 mm from the paper edge (a). This

change also applies to A3W cassette.

When Standard Tray (MSI) or A3W Cassette is used

• Maximum paper size: 330.2 mm (13") (W) / 457.2 mm (18") (L)

• Printable area: 320 mm (12.6") (W) / 449.2 mm (17.7") (L)

• Guaranteed print area: 297 mm (11.7") (W) / 431.8 mm (17") (L)

Paper Feed Direction

Guaranteed Print

Area

Side guide is here for paper whose width is 304.8 mm (12") or

less

Side guide is moved to this position for paper whose width is

more than 304.8 mm (12"). (12.6 mm outward)

Figure 1-2. Maximum Printable Area

(Standard Tray (MSI) / A3W Cassette)

Product Description Basic Specifications 18

Page 28

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

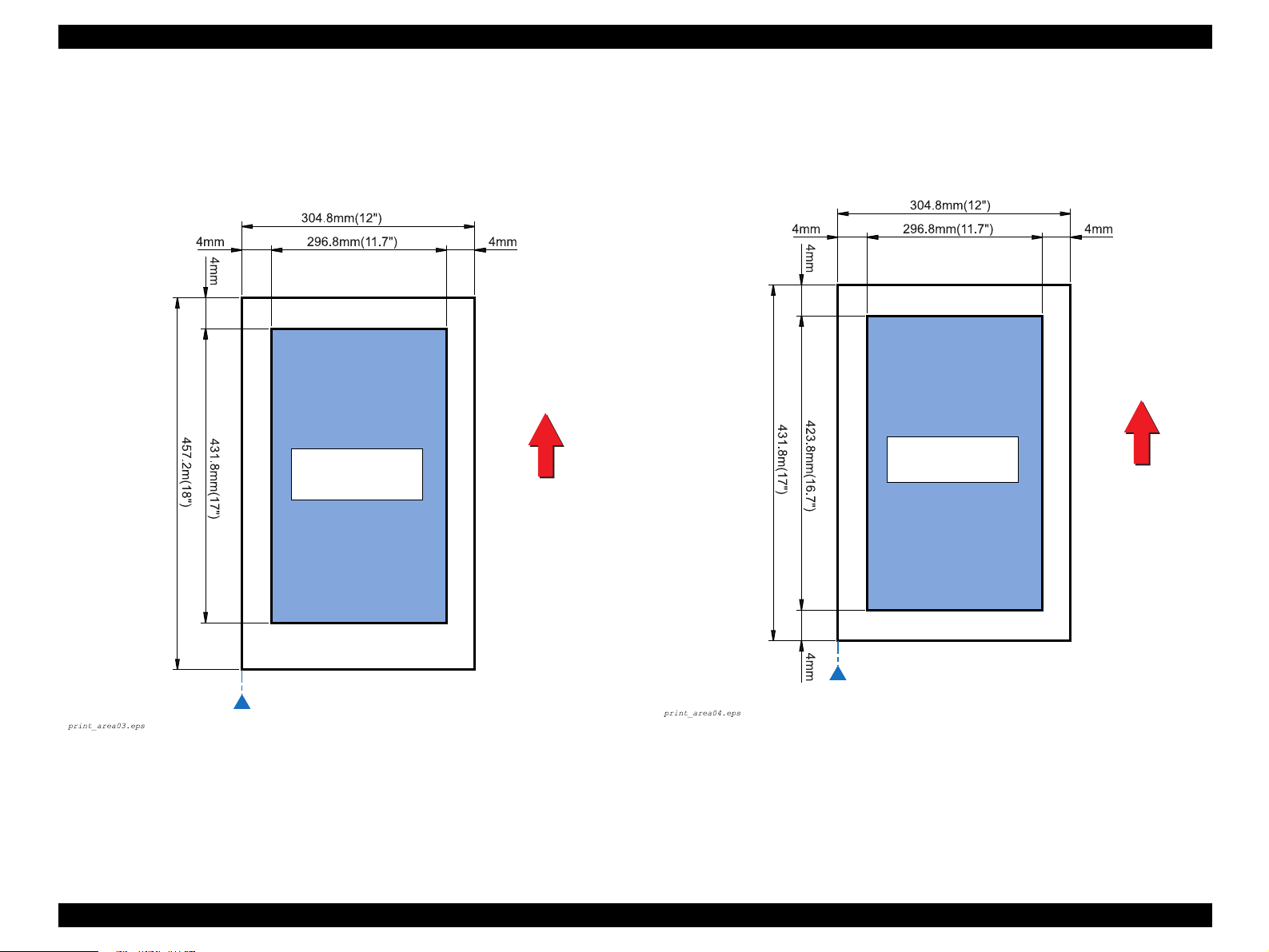

When Standard Universal Cassette is used

• Maximum paper size: 304.8 mm (12") (W) / 457.2 mm (18") (L)

• Printable area: 296.8 mm (11.7") (W) / 449.2 mm (17.7") (L)

• Guaranteed print area: 296.8 mm (11.7") (W) / 431.8 mm (17") (L)

Guaranteed Print

Area

When 500-Sheet Paper Cassette Unit / Large Capacity Paper Unit is used

• Maximum paper size: 304.8 mm (12") (W) / 431.8 mm (17") (L)

• Printable area: 296.8 mm (11.7") (W) / 423.8 mm (16.7") (L)

• Guaranteed print area: 296.8 mm (11.7") (W) / 423.8 mm (16.7") (L)

Paper Feed Direction

Paper Feed Direction

Guaranteed Print

Area

Side guide is here for paper whose width is 304.8 mm (12") or

Side guide is here for paper whose width is 304.8 mm (12") or

less

less

Figure 1-4. Maximum Printable Area

Figure 1-3. Maximum Printable Area (Standard Universal Cassette)

(500-Sheet Paper Cassette Unit / Large Capacity Paper Unit)

Product Description Basic Specifications 19

Page 29

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

1.2.3 Reliability, Durability and Maintainability

MPBF

Printer body (including the standard tray (MSI)):

40,000 pages or more (100,000 images or more*)

Printer body (including the standard tray (MSI) and Duplex Unit):

40,000 pages or more (100,000 images or more*)

Printer body + 500-Sheet Paper Cassette Unit:

40,000 pages or more (100,000 images or more*)

Printer body + Large Capacity Paper Unit:

40,000 pages or more (100,000 images or more*)

Note "*": Since one page of color print is formed with 4 images, the value “100,000 images” is

calculated from the MPBF on the assumption that the job ratio of color printing to

monochrome printing is 1:1.

100,000 = 40,000/2 + (40,000/ 2 x 4)

PAPER FEED RELIABILITY

Standard Paper Tray

Recommended

Paper

Paper jam rate (simplex print)

Paper jam rate (duplex print)

Multiple-sheet feed rate

Note "*": Feeding reliability for envelopes is defined when printed on the front side at normal

temperature only. Envelopes that are adherent due to high temperature are excluded.

(Print on a back side is not guaranteed.)

1/1000 or less 1/500 or less 1/100

1/600 or less 1/300 or less -

1/1000 or less 1/1000 or less 1/50

Plain Paper

Standard Universal Cassette

Special

Applications*

500-Sheet Paper Cassette Unit / Large Capacity Paper Unit

Paper jam rate (simplex print)

Paper jam rate (duplex print)

Multiple-sheet feed rate

Recommended

Paper

1/5000 or less 1/3000 or less 1/100 or less

1/3000 or less 1/1800 or less 1/5000 or less 1/3000 or less 1/50 or less

Plain Paper

Special

Applications*

A3W Cassette

A3W Paper

Paper jam rate

Multiple-sheet feed rate

NOTE: The paper jam rate and multiple-sheet feed rate do not include those at

the sheets boundary between original paper and replenished paper,

occurring after paper is replenished.

1/2000 or less

1/500 or less

Paper jam rate (simplex print)

Paper jam rate (duplex print)

Multiple-sheet feed rate

Recommended

Paper

1/3000 or less 1/2000 or less 1/100 or less

1/1800 or less 1/1200 or less -

1/800 or less 1/500 or less 1/50 or less

Plain Paper

Special

Applications*

Product Description Basic Specifications 20

Page 30

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

PRINTING START POSITION ACCURACY

Reference point of Main scanning direction (c) ±2.5 mm

Reference point of Sub scanning direction (a) ± 2.0 mm

Guaranteed Print

Area

Figure 1-5. Printing Start Position Accuracy

1.2.4 Operating Conditions (Including Consumables)

Temperature and Humidity Conditions

Temperature: 10 ∼ 32°C

Humidity: 15 ∼ 85%RH (no condensation, however)

Altitude

3,100 m or less

Level

Front-rear direction on the table: 5 mm or less (within 646 mm)

Paper Feed Direction

Right-left direction on the table: 10 mm or less (within 560 mm)

Lighting

3,000 lx or less (not to be exposed to direct sunlight)

Space Requirements

In order to ensure that the printer operates properly, provide at least as much space as

shown in Figure 1-6.

SKEW

Direction A4 (Landscape) A3

Main scanning direction (|c-d|)

Sub scanning direction (|a-b|)

SERVICEABILITY

MTTR: Averages within 30 minutes. 95% is completed within 50 minutes.

HEIGHT OF CURL OF PRINTED PAGES

±15 mm or less (for color printing with the image ratio of 5% in non- aligned

condition). (This value varies with the image ratio and aligning pattern.)

±1.5 mm (f=196 mm)

±2.0 mm (e=271 mm)

±3.0 mm (f=406 mm)

±2.0 mm (e=271 mm)

Product Description Basic Specifications 21

Page 31

EPSON AcuLaser C8600/AcuLaser C7000 Revision C

1.2.5 Storage and Transport of the Printer Body and Optional Products (Consumables Packaged)

150 mm

Ventilation

*1

728 mm

*2

633 mm

*1

825 mm

*2

730 mm