Page 1

SERVICE MANUAL

A4 Full Color Laser Printer

EPSON AcuLaser C4200

SEPG05001

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their

respective owners. EPSON disclaims any and all rights in those marks.

Copyright © 2005 SEIKO EPSON CORPORATION.

I&I CS/Quality Management & PL Department

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING

PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO

THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

Page 4

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the

product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by -step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedu res for disassemb ling and assembling

the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Electrical circuit boards schematics

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and always read

NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or condition

that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or condition

that, if not strictly observed, could result in damage to, or destruction of,

equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may also

provide additional information that is related to a specific subject, or

comment on the results achieved through a previous action.

Indicates an operating or maintenance procedure, practice or condition

that, if not strictly observed, could result in injury or loss of life.

Page 5

Abbreviations

A lot of abbreviation s are us ed t h rou gho ut this manual. Some of them are common ones and the oth ers are original ones. The list below includes the mos t o f the majo r ab brev iations

and may include those which are not used in this manual as this is intended to be used in every quarter.

[A]

ADC........................................Auto Density Control

ALM................................................................Alarm

Assy...........................................................Assembly

Aux.............................................................Auxiliary

[B]

B/W.................................................Black and White

BCR............................................... Bias Charge Roll

Bk .....................................................................Black

BCR............................................... Bias Charge Roll

BRKT ............................................................Bracket

BTR ............................................. Bias Transfer Roll

BUR.....................................................Back Up Roll

[C]

C ........................................................................Cyan

CCW...........................................Counter Clockwise

Cl. ...................................................................Clutch

Clk ................................................................... Clock

CHK.................................................................Check

CK....................................................................Check

Conpane...............................................Control Panel

Cont ...........................................................Controller

CR................................. ..........................Charge Roll

CRU...............................Customer Replaceable Unit

CRUM ................................................CRU Memory

CST...............................................................Cassette

CVR.................................................................Cover

CW............................................................Clockwise

[D]

DB...................................................Developing Bias

Deve ..........................................................Developer

Diag..........................................................Diagnostic

dpi..........................................................dots per inch

DTS...................................... ...... ............Detack Saw

Dup.................................................................Duplex

[E]

Elec................................................................Electric

EP.............................................Electro Photography

ESS............................................Electric Sub System

[F]

F ........................................................................Front

FDR................................................................ Feeder

FG......................................... ..............Frame Ground

FIP.....................................Fault Isolation Procedure

FRU...................................... Field Replaceable Unit

FX.............................................................Fuji Xerox

[G]

GG........................................................Guide Gauge

GND..............................................................Ground

[H]

H........................................................................ High

H/R.............................................................Heat Roll

HCF........................................High Capacity Feeder

HCS.......................................High Capacity Stacker

Hex.......................................................Hexadecimal

HVPS ...........................High Voltage Power Supply

[I]

I/F.................................................................Interface

I/L ...............................................................Interlock

ID.......................................................Image Density

[J]

Jxx..................................................................Jack xx

[K]

[L]

L..........................................................................Left

L......................................................................... Low

L/H............................................................ Left Hand

L/P ...........................................................Low Paper

LD................................................ ..........Laser Diode

LEF.................................................Long Edge Feed

LVPS ............................Low Voltage Power Supply

[M]

M..................................................................Magenta

M/N....................................................Multi National

Mag.............................................................Magnetic

MCU...................................... Machine Control Unit

Mech.......................................................Mechanical

MOT ................................................................Motor

MSI............................................Multi Sheet Inserter

[N]

N/F...................................................... Normal Force

N/P.......................................................... ....No Paper

NPS.................................................No Paper Sensor

NV ........................................................Non Volatile

NVM......................................Non Volatile Memory

(to continue to next page)

Page 6

[O]

OHP.............................. ..... .........Overhead Projector

OPC ..................................Organic Photo Conductor

OPT.................................................................Option

[P]

Pyy.................................................................Plug yy

P/J ........................................................Plug and Jack

P/H....................................................Paper Handling

P/R..................................... ...................Pressure Roll

PL ......................................................................Plate

PLT....................................................................Plate

PPM................................................Print Per Minute

PV........................................................Print Volume

PWB .................................. .....Printed Wiring Board

PWBA.............................................. PWB Assembly

[Q]

[R]

R .......................................................................Right

R ........................................................................ Rear

R/H ............................... .......................... Right Hand

RDY.................................................................Ready

Regi........................................................Registration

ROS .......................................Raster Output Scanner

RRP................Removal and Replacement Procedure

RTN................................................................Return

[T]

T ..........................................Tooth (number of Gear)

Temp .....................................................Temperature

TR.................................................................Transfer

TTL ............................... Transistor-Transistor Logic

[U]

[V]

[W]

[X]

Xero.......................................................Xerographic

[Y]

Y.....................................................................Yellow

YMCBk...................... Yellow/Magenta/Cyan/Black

YMCK........................ Yellow/Magenta/Cyan/Black

[Z]

[S]

SEF................................................. Short Edge Feed

SG.......................................................Sign al Ground

SNR ................................................................Sensor

SNS .................................................................Sensor

Sol ................................................................Solenoid

SOS ...................................................... Start Of Scan

SPI .......................................................Scan Per Inch

STD..............................................................Standard

STK................................................................Stacker

STND...........................................................Standard

SW..................................................................Switch

Sync......................................................Synchronous

Page 7

Safety Information

To prevent possible accidents during maintenance work, strictly observe the WARNINGs and CAUTIONs described in this manual.

Never attempt to perform dangerous operations or any other operations which depart from the descriptions and procedures in this manual.

Other than the cautions and warnings stated below, there are many other situations and circumstances that could result in serious bodily injury . Always pay enough attention to

secure safety when working with the printer.

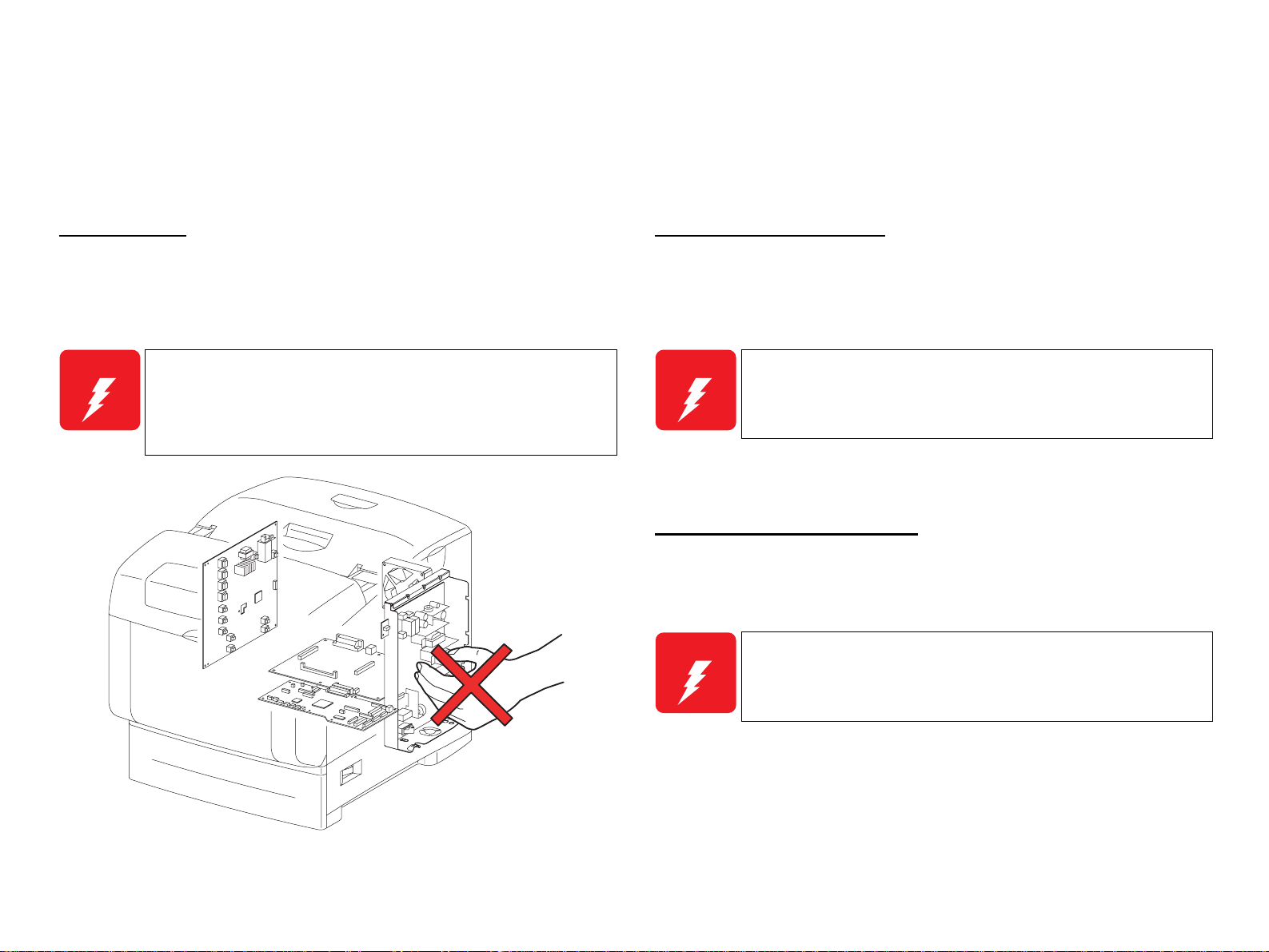

Power Supply

Before starting any service procedure, turn the printer power off and unpl u g the power

cord from the wall outlet.When the power supply cable must b e connected, b e aware of

the potential for electrical shock and do all tasks by following the procedures in this

manual.

W A R N I N G

Do not touch any live parts other than the required parts while

the printer is on.

As the LVPS ASSY (power supply section) is live even when the

power is off, never touch the live parts.

Do not touch any live parts unless instructed to do so.

Mechanical Components

When servicing any driving assembly (e.g., gears), first turn the power off and unplug

the power cord, and then manually rotate the assembly.

W A R N I N G

Do not touch the driving part (e.g., gears) while the as sembly

(printer) is operating.

High Temperature Assembly

When working with hot parts (FUSER etc.) make sure to turn the power off, unplug the

power cable, and leave the printer until it cools down sufficiently to work with to

prevent burn injury.

W A R N I N G

As the inside of the printer is high-temperature state immediately

after the operation, leave it more than 40 minutes before working.

Ida_00_002A

Page 8

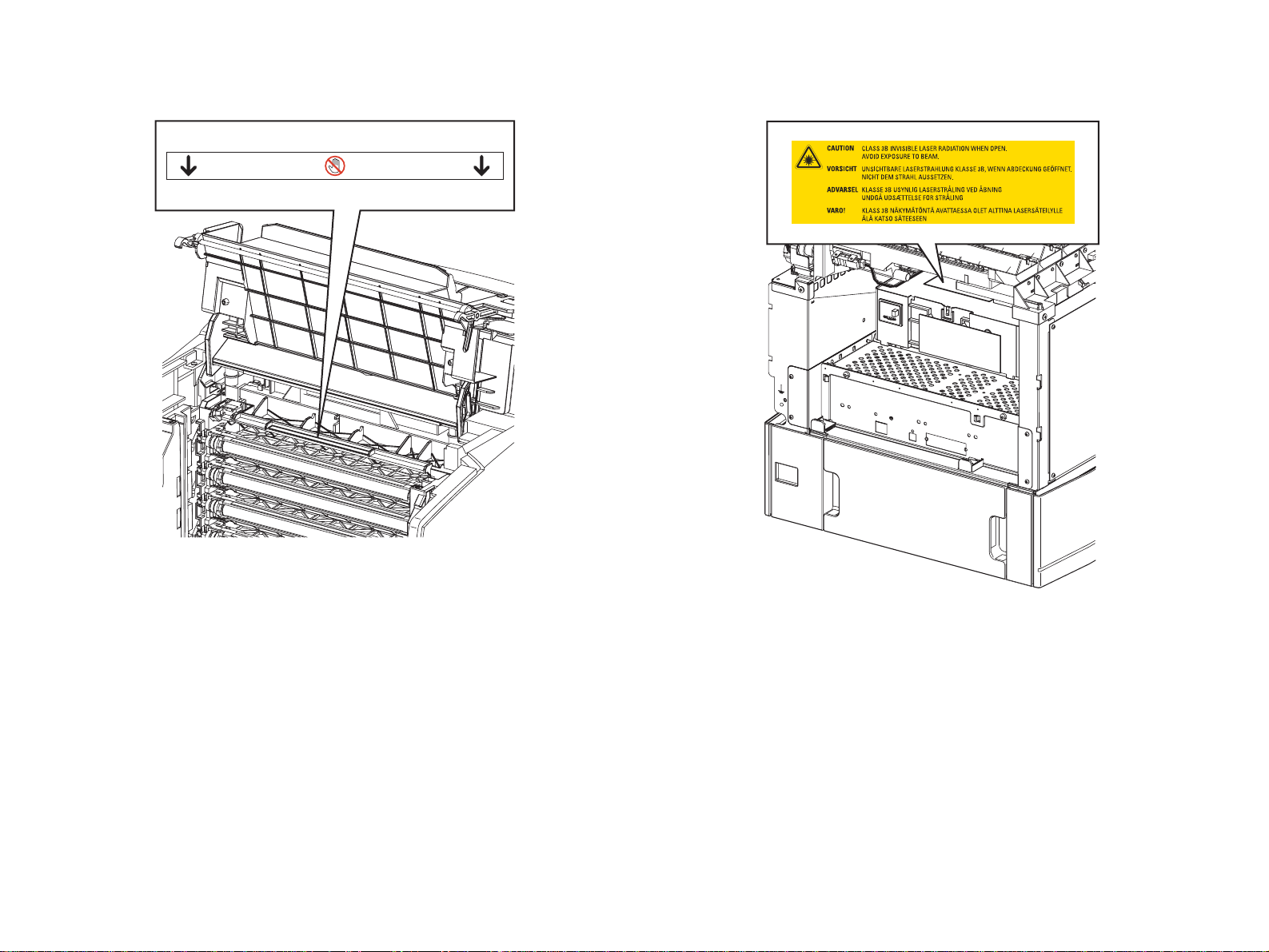

Laser Beam

W A R N I N G

C H E C K

P O I N T

Letting a laser beam get directly into your eyes could result in

loss of vision.

Never open the Cover where the Warning Label about Laser

Beam is affixed.

Before disassembling or assembling, be sure to turn the power

off.

If you need to work on the printer with power applied, strictly

follow the instructions in this manual.

Und erstand hazardous nature of the laser beam, use extreme

caution to avo i d i n jury of yoursel f and anyone around you.

Sin ce the laser beam has a narrower frequency band and more

coherent phases than any other light (sunlight, electric light),

the beam has excellent monochromaticity and convergence,

thus it reaches long distances.

Because of these characteristics, the laser beam converges into

one point, causing high density and high temperature, which is

harmful to the human body.

Reference: The laser beam in this printer is invisible.

ROS ASSY

Ida_00_003A

Page 9

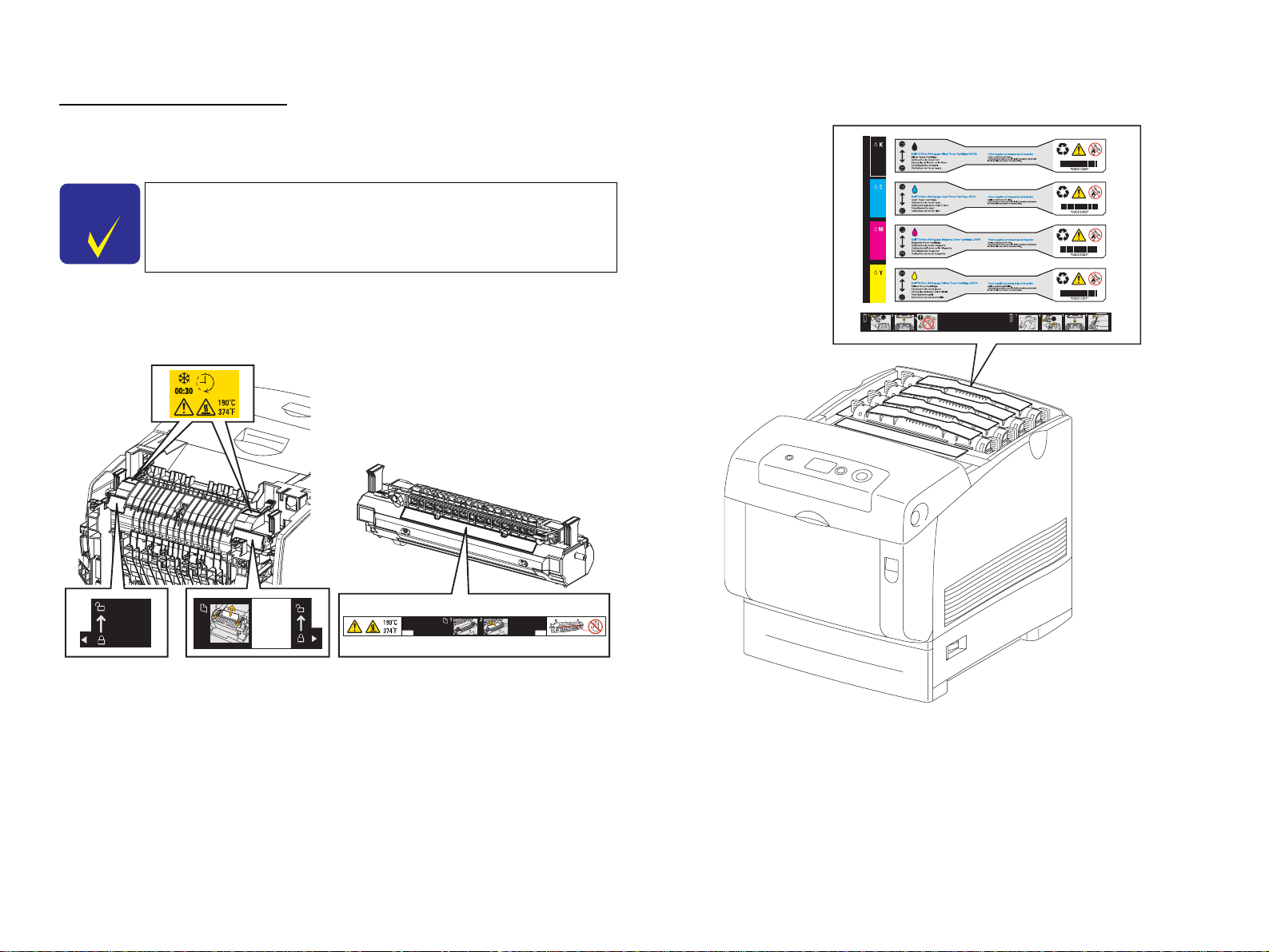

Warning/Caution Labels

Warning labels and caution labels are attached on the corresponding locations on or in

the printer.

Caution Label for Toner Cartridges

C H E C K

P O I N T

In maintenance work, check that the labels are free from peeling

and soiling.

Caution Label for High-temperature Surface

Ida_Sec00_010GA

Ida_00_004A

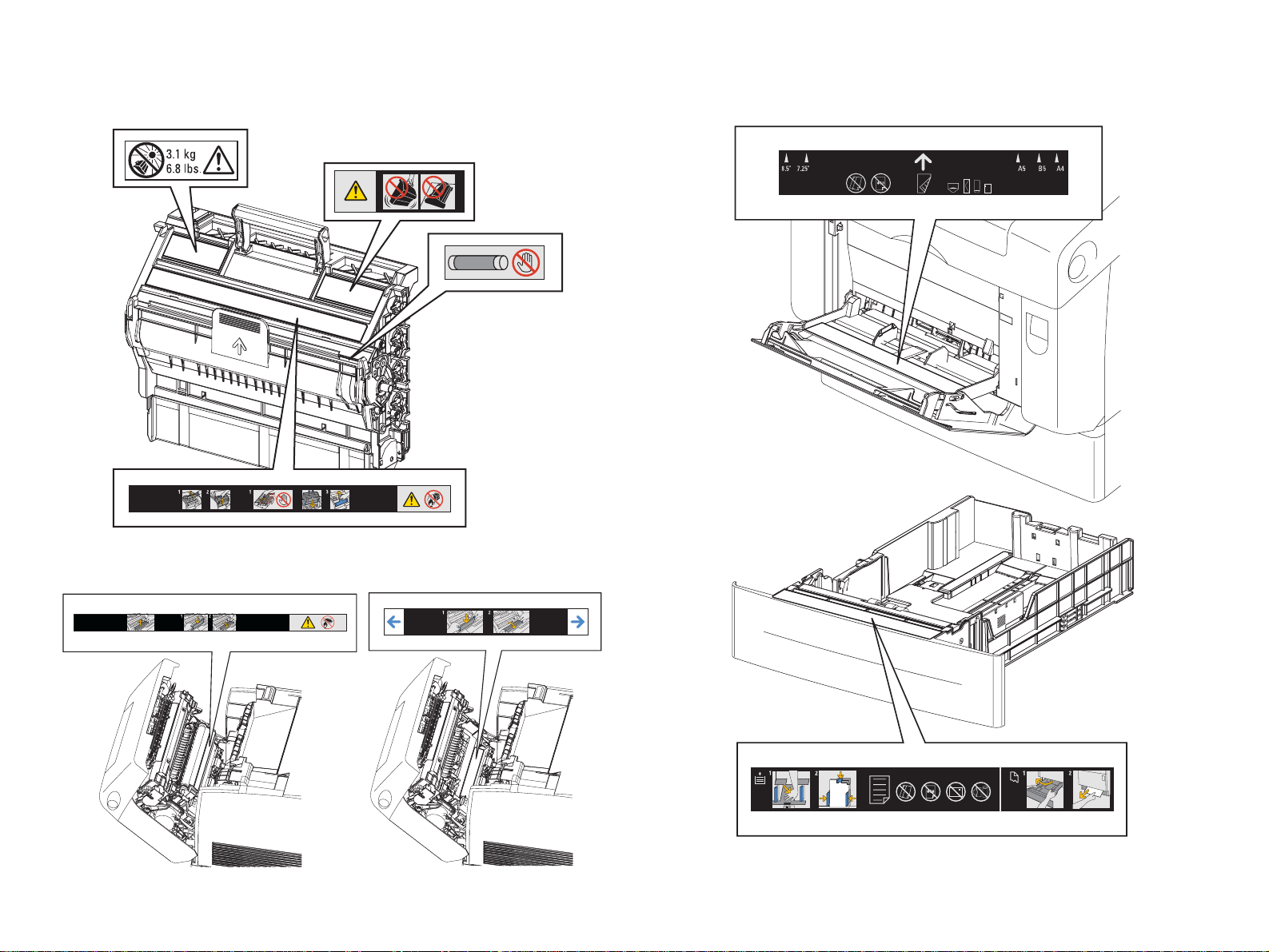

Page 10

Caution Label about PHD ASSY and BTR ASSY Caution Label about MSI and Paper Tray

Ida_Sec00_005FA

Ida_00_009A

Ida_00_006A

Page 11

Caution Label about FRAME ASSY DEVE Caution Label about ROS ASSY

Ida_Sec00_007GA

Ida_Sec00_008GA

Page 12

Cautions relating to Toner cleaning

Storage of Paper

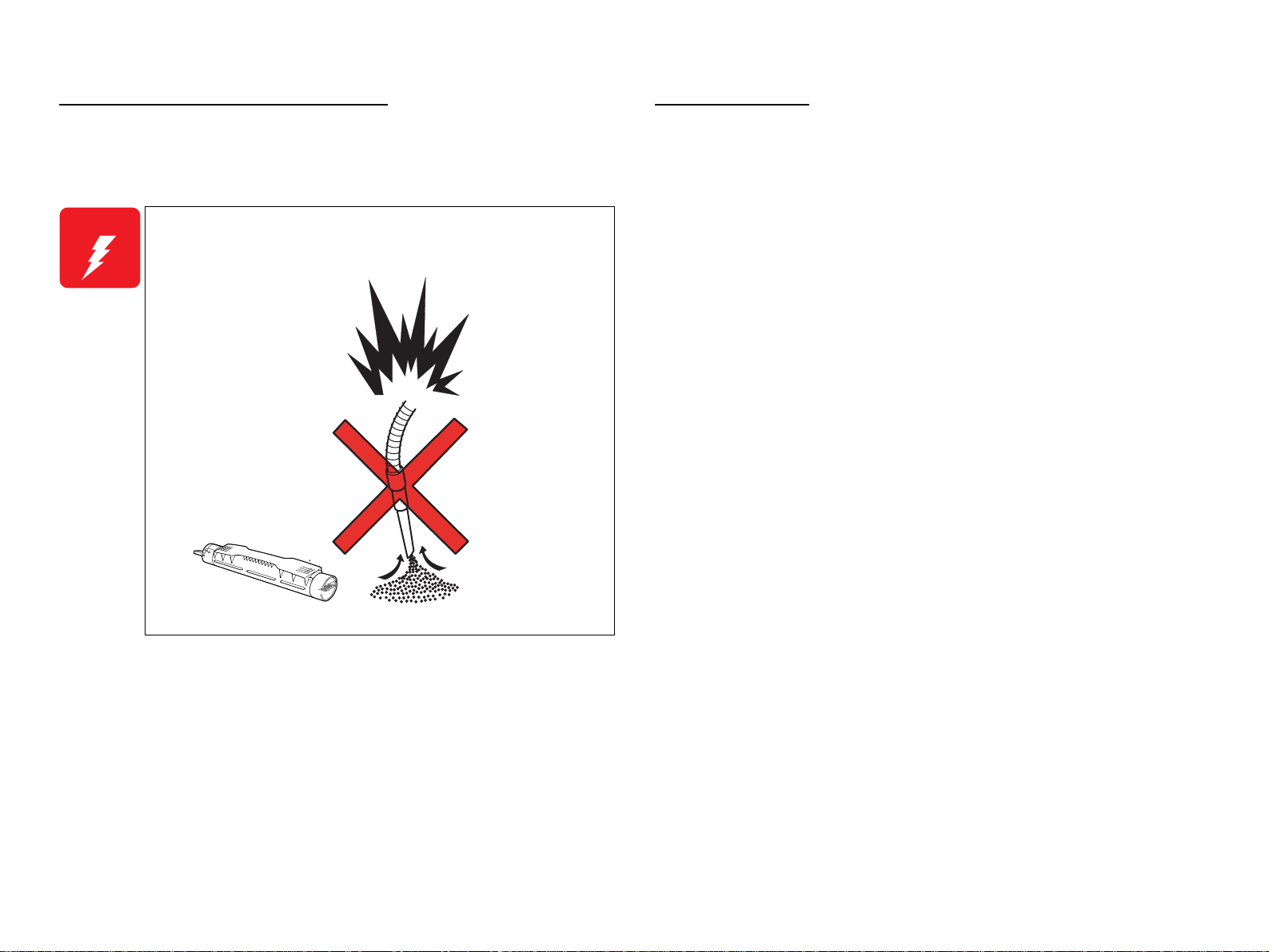

To prevent ignition, explosion, burn, injury, etc., do not use a general vacuum

cleaner for cleaning dropped toner. (To do so may cause the toner to catch fire by

sparks in the vacuum cleaner.)

W A R N I N G

Do not pick up dropped toner with a general vacuum cleaner.

To do so may cause ignition .

Damp papers could cause printing quality troubles. To keep papers in their best

condition, store them wrapping tightly with packing material or putting them into a

plastic bag.

Leg_Sec001_014EA

Page 13

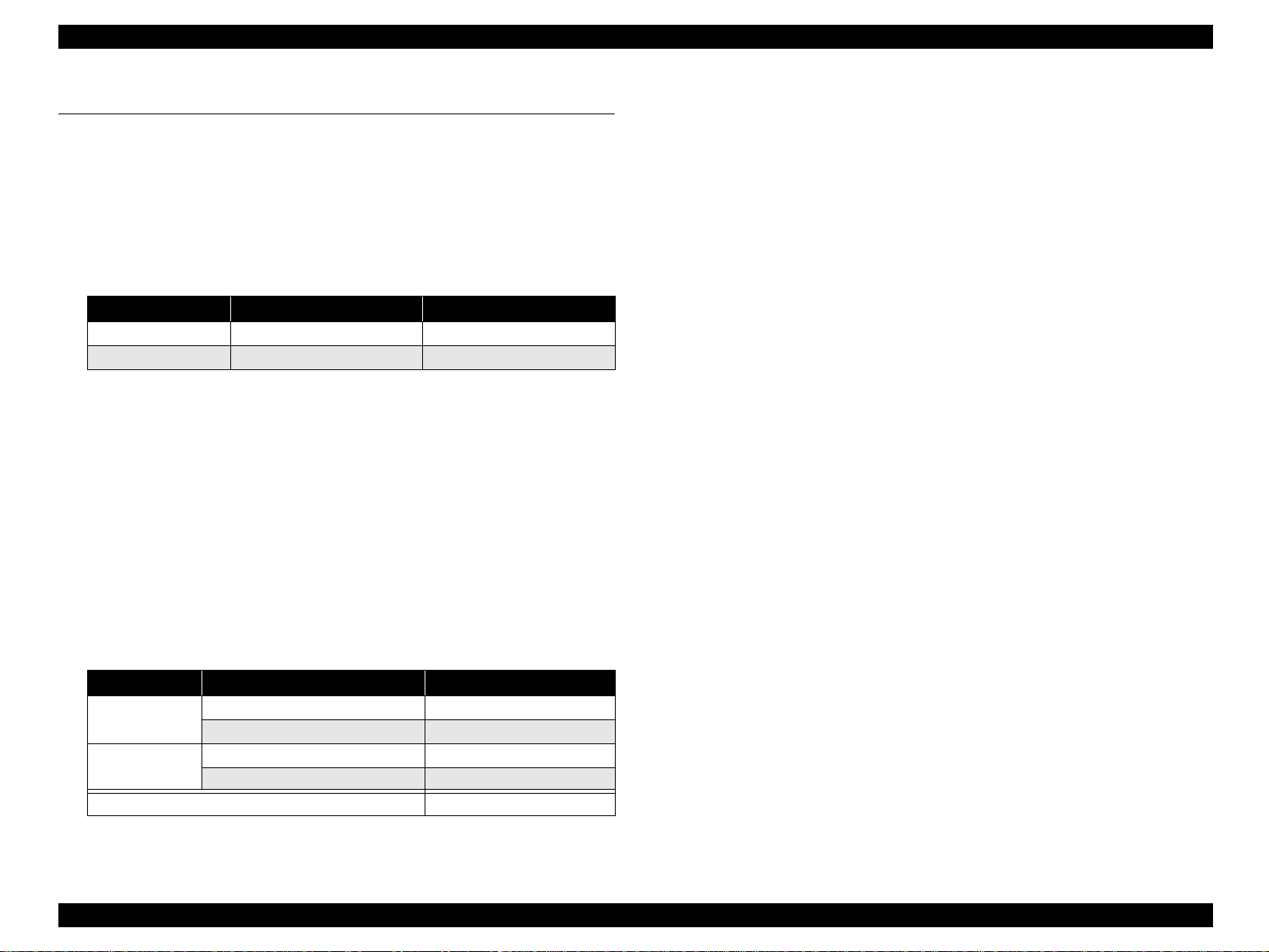

Revision Status

Revision Date of Issue Description

A

JUN 24, 2005

First release

Page 14

EPSON AcuLaser C4200 Revision A

Contents

Chapter 1 PRODUCT DESCRIPTION

1.1 Overview ............................................................................................................... 7

1.1.1 Engine Features ............................................................................................ 7

1.1.2 Controller Features....................................................................................... 7

1.1.3 Software Features ......................................................................................... 8

1.2 Basic Specifications.............................................................................................. 9

1.2.1 Process Specifications & System.................................................................. 9

1.2.2 Printer Basic Specifications .......................................................................... 9

1.3 Paper Specifications ............................................................................................ 19

1.3.1 Paper Type.................................................................................................. 19

1.3.2 Paper that may cause printing defects, paper jams or printer malfunction. 19

1.3.3 Available Paper by Feeder.......................................................................... 20

1.3.4 Printing Area............................................................................................... 20

1.4 Reliability and Serviceability.............................................................................. 21

1.4.1 Reliability ................................................................................................... 21

1.4.2 Durability.................................................................................................... 22

1.4.3 Serviceability.............................................................................................. 22

1.5 Service Conditions............................................................................................... 23

1.6 Conditions for Storage and Transport ................................................................. 24

1.7 Electrical Characteristics..................................................................................... 25

1.8 Compatible Specification .................................................................................... 26

1.9 Consumables/Periodic Replacement Unit........................................................... 27

1.9.1 Specifications.............................................................................................. 27

1.9.2 Conditions for Storage and Transport......................................................... 28

1.10 External Appearance and Unit Names.............................................................. 29

1.10.1 Unit Names............................................................................................... 29

1.11 Engine Restrictions............................................................................................ 31

1.11.1 Controls that Restrict Print Speed............................................................. 31

1.11.2 Controls that Restrict Print Start............................................................... 31

1.11.3 Toner Duty Limiting Value...................................................................... 31

1.12 Notes When Replacing Consumables and Installing Optional Products........... 32

1.12.1 Consumables............................................................................................. 32

1.12.2 Optional Products..................................................................................... 32

1.13 Life Details........................................................................................................ 33

1.14 Engine Control (Appendix)............................................................................... 34

1.15 Controller Specifications................................................................................... 36

1.15.1 Controller Basic Specifications................................................................ 36

1.15.2 Controller Configuration.......................................................................... 37

1.15.3 External Interface Specifications.............................................................. 37

1.16 Control Panel..................................................................................................... 40

1.16.1 External Appearance and Names.............................................................. 40

1.16.2 Panel Settings List.................................................................................... 42

1.16.3 Explanation of Menu and Settings............................................................ 53

1.16.4 Special Operations.................................................................................... 59

1.17 Printer Status..................................................................................................... 60

1.17.1 List of Printer Messages........................................................................... 60

1.17.2 Status Messages and Troubleshooting...................................................... 62

1.17.3 Warning Messages and Troubleshooting ................................................. 63

1.17.4 Error Messages and Troubleshooting...................................................... 65

1.17.5 Service Call Error Messages..................................................................... 68

1.18 Expanding the RAM.......................................................................................... 70

1.19 Handling Precautions ........................................................................................ 71

1.20 Status Sheet....................................................................................................... 72

1.21 Engine Status Sheet/Print Log Report............................................................... 76

1.22 Color Registration Sheet................................................................................... 77

1.23 Form Overlay List............................................................................................. 78

1.24 Paper Handling Algorithm................................................................................ 79

Chapter 2 OPERATING PRINCIPLES

2.1 Print Process........................................................................................................ 82

2.1.1 Print Process Overview .............................................................................. 82

2.1.2 Print Process Diagram................................................................................ 83

2.1.3 Technical Explanation of Print Process...................................................... 84

1

Page 15

EPSON AcuLaser C4200 Revision A

2.2 Flow of Print Data............................................................................................... 92

2.2.1 Data Flow.................................................................................................... 92

2.3 Drive Transmission Path ..................................................................................... 93

2.3.1 DRIVE ASSY MAIN................................................................................. 93

2.3.2 DRIVE ASSY DEVE................................................................................. 94

2.3.3 DISPENSER ASSY (Y, M, C, K).............................................................. 96

2.3.4 DRIVE ASSY FUSER ............................................................................... 97

2.3.5 MOTOR ASSY DUP 17PM....................................................................... 98

2.3.6 DRIVE ASSY (550-sheet Paper Cassette Unit)......................................... 99

2.3.7 DRIVE ASSY 2ND (1,100-sheet Paper Cassette Unit)........................... 100

2.4 Feeding Paper.................................................................................................... 101

2.4.1 Paper Feed Path (When options are not installed).................................... 101

2.4.2 Paper Feed Path (When the 550-sheet Paper Cassette is installed).......... 102

2.4.3 Paper Feed Path (When the 1100-sheet Paper Cassette is installed)........ 103

2.5 Main Structure and Function............................................................................. 104

2.5.1 Paper Cassette........................................................................................... 104

2.5.2 Paper Feeder ............................................................................................. 105

2.5.3 Optional Feeder (550-sheet Paper Cassette)............................................. 106

2.5.4 Optional Feeder (1100-sheet Paper Cassette)........................................... 108

2.5.5 Retard & Regi Assy.................................................................................. 110

2.5.6 Front Assy In............................................................................................ 111

2.5.7 Chute Assy Out......................................................................................... 112

2.5.8 BTR Assy & Fuser Assy........................................................................... 114

2.5.9 Xerographics............................................................................................. 116

2.5.10 Toner Cartridge....................................................................................... 117

2.5.11 Frame & Drive ........................................................................................ 119

2.5.12 Electrical................................................................................................. 120

2.6 Switch and Sensor............................................................................................. 122

2.7 Mode.................................................................................................................. 123

2.7.1 Printing Mode........................................................................................... 123

2.7.2 Operating Modes ...................................................................................... 123

2.8 Control............................................................................................................... 124

2.8.1 Paper Size Control.................................................................................... 124

2.8.2 Paper Feeder Selection Control................................................................ 124

2.8.3 ROS Light Intensity Control..................................................................... 124

2.8.4 Process Control......................................................................................... 125

2.8.5 Color Registration Control....................................................................... 128

2.8.6 BTR ASSY Control.................................................................................. 129

2.8.7 Toner Control............................................................................................ 130

2.8.8 Fuser Control............................................................................................ 131

2.9 Detection Mechanisms..................................... ...... ........................................ ... 132

2.10 Features of the Controller................................................................................ 134

2.10.1 Power Supply.......................................................................................... 136

Chapter 3 TROUBLESHOOTING

3.1 Procedure for Troubleshooting.......................................................................... 138

3.1.1 Procedure for Troubleshooting................................................................. 138

3.1.2 Preliminary Check.................................................................................... 138

3.1.3 Precautions in Performing Troubleshooting Work................................... 139

3.1.4 Notes on Using FIP................................................................................... 140

3.2 Paper Jam .......................................................................................................... 141

3.2.1 Paper Transferring Path and The Main Components ............................... 142

3.2.2 Paper Jam Handling (FIP)........................................................................ 144

3.2.3 Check Points for Frequent Paper Jam....................................................... 151

3.3 Level 1 FIP........................................................................................................ 152

3.3.1 Level 1 FIP............................................................................................... 152

3.3.2 The flow of Level 1 FIP........................................................................... 152

3.4 Level 2 FIP........................................................................................................ 153

3.4.1 List of Warnings and Errors ..................................................................... 153

3.4.2 List of Service Request............................................................................. 158

3.4.3 Engine-related Trouble FIP...................................................................... 163

3.4.4 Controller-related Trouble FIP................................................................. 209

3.4.5 Print Quality Trouble FIP......................................................................... 211

3.4.6 Other FIP.................................................................................................. 225

3.5 Abnormal Noise-related Trouble............................ ...... ..... ................................ 228

3.5.1 Abnormal Noise-related Troubleshooting Entry Chart............................ 228

3.5.2 Abnormal Noise-related FIP..................................................................... 229

3.6 Test Print........................................................................................................... 233

Chapter 4 DISASSEMBLY/REASSEMBLY

4.1 Overview.............................. ...... ...... ................................................................. 236

4.1.1 Precautions................................................................................................ 236

4.1.2 Before starting work................................................................................. 238

4.1.3 Screws....................................................................................................... 239

4.1.4 Tools......................................................................................................... 240

4.1.5 Conventions used in descriptions of procedures...................................... 241

2

Page 16

EPSON AcuLaser C4200 Revision A

4.2 COVERS ........................................................................................................... 242

4.2.1 COVER TOP MAIN................................................................................. 242

4.2.2 CONSOLE PANEL.................................................................................. 243

4.2.3 COVER ASSY FRONT HEAD ............................................................... 244

4.2.4 COVER ASSY TOP PHD........................................................................ 245

4.2.5 COVER REAR ASSY.............................................................................. 246

4.2.6 FAN REAR............................................................................................... 247

4.2.7 COVER SIDE R ASSY............................................................................ 248

4.2.8 COVER FRONT R................................................................................... 249

4.2.9 TRAY ASSY MSI BASE............................................................. ..... ...... . 250

4.2.10 COVER ASSY MSI ............................................................................... 251

4.2.11 COVER FRONT L ASSY...................................................................... 252

4.2.12 COVER SIDE L ASSY.......................................................................... 253

4.2.13 COVER ASSY TOP, COVER TOP STOPPER..................................... 254

4.3 PAPER CASSETTE.......................................................................................... 255

4.3.1 ROLL ASSY RETARD............................................................................ 255

4.3.2 HOLDER ASSY RETARD...................................................................... 256

4.3.3 KIT GUIDE SIDE L, KIT GUIDE SIDE R............................................. 257

4.3.4 KIT GUIDE END..................................................................................... 259

4.4 PAPER FEEDER............................................................................................... 261

4.4.1 CHUTE ASSY FEEDER.......................................................................... 261

4.4.2 COVER CST ............................................................................................ 262

4.4.3 FEEDER ASSY (REFERENCE ONLY) ................................................. 263

4.4.4 SWITCH ASSY SIZE .............................................................................. 266

4.4.5 SWITCH................................................................................................... 267

4.4.6 HARNESS ASSY OPFPLG..................................................................... 268

4.4.7 PICK UP ASSY........................................................................................ 269

4.4.8 ROLL ASSY TURN, BEARING SLEEVE, PLASTIC ........................... 270

4.4.9 SENSOR NO PAPER.............................................................................. . 271

4.4.10 SENSOR LOW PAPER ......................................................................... 272

4.4.11 SOLENOID FEED ................................................................................. 273

4.4.12 ACTUATOR LOW PAPER................................................................... 274

4.4.13 CHUTE UPPER (REFERENCE ONLY)............................................... 275

4.4.14 ROLL ASSY FEED................................................................................ 276

4.4.15 ACTUATOR NO PAPER ...................................................................... 277

4.5 RETARD & REGI ASSY ................................................................................. 278

4.5.1 ACTUATOR REGI.................................................................................. 278

4.5.2 SENSOR REGI......................................................................................... 279

4.5.3 CHUTE ASSY REGI IN.......................................................................... 280

4.5.4 SENSOR OHP.......................................................................................... 281

4.5.5 ROLL ASSY RETARD............................................................................ 282

4.5.6 CHUTE ASSY REGI............................................................................... 283

4.5.7 ROLL REGI METAL............................................................................... 284

4.5.8 ROLL REGI RUBBER ............................................................................ 285

4.5.9 CLUTCH REGI........................................................................................ 286

4.5.10 CLUTCH TURN.................................................................................... 287

4.5.11 ROLL TURN MSI.................................................................................. 288

4.6 CHUTE ASSY IN & OUT................................................................................ 289

4.6.1 FUSER ASSY........................................................................................... 289

4.6.2 BTR ASSY............................................................................................... 290

4.6.3 HOLDER ASSY CTD.............................................................................. 291

4.6.4 SENSOR TNR FULL............................................................................... 292

4.6.5 DRIVE ASSY FUSER............................................................................. 294

4.6.6 SOLENOID FEED MSI........................................................................... 296

4.6.7 SENSOR NO PAPER............................................................................... 299

4.6.8 ACTUATOR NO PAPER MSI................................................................ 300

4.6.9 ROLL ASSY FEED.................................................................................. 302

4.6.10 SENSOR FULL STACK........................................................................ 304

4.6.11 SENSOR DUP JAM............................................................................... 305

4.6.12 ACTUATOR FULL STACK................................................................. 307

4.6.13 MOTOR ASSY DUP 17PM................................................................... 308

4.6.14 ACTUATOR DUP ................................................................................. 309

4.6.15 ROLL DUP............................................................................................. 310

4.6.16 ROLL EXIT............................................................................................ 311

4.6.17 CHUTE ASSY DUP IN ......................................................................... 312

4.6.18 CHUTE ASSY DUP OUT ..................................................................... 315

4.6.19 FAN FRONT.......................................................................................... 319

4.7 XEROGRAPHICS ................................................. ...... ..... ................................ 320

4.7.1 ROS ASSY............................................................................................... 320

4.7.2 HSG ASSY BIAS..................................................................................... 321

4.8 DEVELOPMENT ................................. ...... ...................................................... 322

4.8.1 FRAME ASSY DEVE.............................................................................. 322

4.8.2 CONN_ASSY_CRUM_MC..................................................................... 324

4.8.3 DEVE ASSY (Y), (M), (C), (K)............................................................... 325

4.8.4 DISPENSER ASSY-4 (REFERENCE ONLY)........................................ 326

4.8.5 DISPENSER ASSY (Y)........................................................................... 329

4.8.6 DISPENSER ASSY (M) .......................................................................... 331

4.8.7 DISPENSER ASSY (C) ........................................................................... 333

4.8.8 DISPENSER ASSY (K)........................................................................... 335

4.8.9 SENSOR NO TNR (Y), (M), (C)............................................................. 337

3

Page 17

EPSON AcuLaser C4200 Revision A

4.8.10 SENSOR NO TNR (K)........................................................................... 338

4.8.11 ACTUATOR SENSOR 2....................................................................... 339

4.8.12 BOX ASSY CRUM READER............................................................... 340

4.9 DRIVE............................................................................................................... 342

4.9.1 DRIVE ASSY DEVE............................................................................... 342

4.9.2 DRIVE ASSY MAIN............................................................................... 344

4.10 ELECTRICAL................................................................................................. 345

4.10.1 LVPS ASSY (REFERENCE ONLY)..................................................... 345

4.10.2 LVPS....................................................................................................... 347

4.10.3 HARNESS ASSY AC INLET................................................................ 348

4.10.4 HARNESS ASSY INTERLOCK........................................................... 349

4.10.5 PWBA EEPROM.................................................................................... 350

4.10.6 PWBA MCU IDTN................................................................................ 351

4.10.7 SENSOR HUM....................................................................................... 355

4.10.8 HVPS...................................................................................................... 356

4.10.9 ESS BOX (REFERENCE ONLY) ......................................................... 356

4.10.10 PWBA ESS MAIN............................................................................... 358

4.10.11 PWBA ESS ROM................................................................................. 360

4.10.12 PWBA NIC C533................................................................................. 361

4.11 ONE TRAY OPTION FEEDER..................................................................... 362

4.11.1 1 TRAY OPTION FEEDER ASSY ....................................................... 362

4.11.2 HARNESS ASSY OPFREC................................................................... 363

4.11.3 PWBA OPTFDR 1T............................................................................... 365

4.11.4 COVER RIGHT...................................................................................... 366

4.11.5 HARNESS ASSY OPFPLG2................................................................. 367

4.11.6 CHUTE ASSY FEEDER........................................................................ 369

4.11.7 COVER LEFT........................................................................................ 370

4.11.8 SWITCH ASSY SIZE............................................................................ 371

4.11.9 PICK UP ASSY...................................................................................... 373

4.11.10 ROLL ASSY TURN............................................................................. 376

4.11.11 CLUTCH ELECTRO MAGNETIC..................................................... 377

4.11.12 SENSOR NO PAPER........................................................................... 378

4.11.13 SENSOR LOW PAPER ....................................................................... 379

4.11.14 SOLENOID FEED ............................................................................... 381

4.11.15 DRIVE ASSY....................................................................................... 382

4.11.16 ACTUATOR LOW PAPER................................................................. 383

4.11.17 CHUTE UPPER (REFERENCE ONLY)............................................. 384

4.11.18 ROLL ASSY FEED.............................................................................. 385

4.11.19 ACTUATOR NO PAPER .................................................................... 386

4.11.20 ROLL ASSY RETARD........................................................................ 387

4.11.21 HOLDER ASSY RETARD.................................................................. 388

4.11.22 KIT GUIDE SIDE L, KIT GUIDE SIDE R......................................... 389

4.11.23 KIT GUIDE END................................................................................. 391

4.12 TWO TRAY OPTION FEEDER.................................................................... 393

4.12.1 2 TRAY OPTION FEEDER ASSY....................................................... 393

4.12.2 COVER ASSY LEFT............................................................................. 394

4.12.3 COVER ASSY RIGHT.......................................................................... 395

4.12.4 COVER ASSY FRONT......................................................................... 396

4.12.5 COVER CST.......................................................................................... 397

4.12.6 FEEDER ASSY LEFT........................................................................... 398

4.12.7 FEEDER ASSY RIGHT......................................................................... 399

4.12.8 SWITCH ASSY SIZE............................................................................ 400

4.12.9 CHUTE ASSY FEEDER........................................................................ 401

4.12.10 HARNESS ASSY OPFREC2............................................................... 402

4.12.11 PWBA OPTFDR 2T............................................................................. 403

4.12.12 DRIVE ASSY 2ND.............................................................................. 404

4.12.13 PICK UP ASSY 3RD........................................................................... 405

4.12.14 ROLL ASSY TURN............................................................................. 408

4.12.15 CLUTCH ASSY................................................................................... 409

4.12.16 SENSOR NO PAPER........................................................................... 410

4.12.17 SENSOR LOW PAPER....................................................................... 411

4.12.18 SOLENOID FEED............................................................................... 412

4.12.19 ACTUATOR LOW PAPER....................................... ...... .................... 413

4.12.20 CHUTE UPPER (REFERENCE ONLY)............................................. 414

4.12.21 ROLL ASSY FEED.............................................................................. 415

4.12.22 ACTUATOR NO PAPER.................................................................... 416

4.12.23 PICK UP ASSY 4TH ........................................................................... 418

4.12.24 ROLL ASSY TURN............................................................................. 421

4.12.25 CLUTCH ELECTRO MAGNETIC..................................................... 422

4.12.26 SENSOR NO PAPER........................................................................... 423

4.12.27 SENSOR LOW PAPER....................................................................... 424

4.12.28 SOLENOID FEED............................................................................... 425

4.12.29 ACTUATOR LOW PAPER....................................... ...... .................... 426

4.12.30 CHUTE UPPER (REFERENCE ONLY)............................................. 427

4.12.31 ROLL ASSY FEED.............................................................................. 428

4.12.32 ACTUATOR NO PAPER.................................................................... 429

4.12.33 ROLL ASSY RETARD........................................................................ 431

4.12.34 HOLDER ASSY RETARD.................................................................. 432

4.12.35 KIT GUIDE SIDE L, KIT GUIDE SIDE R......................................... 433

4.12.36 KIT GUIDE END................................................................................. 435

4

Page 18

EPSON AcuLaser C4200 Revision A

4.12.37 FOOT ASSY A, FOOT ASSY B ......................................................... 437

Chapter 5 ADJUSTMENT

5.1 Overview ........................................................................................................... 439

5.1.1 Precautions................................................................................................ 439

5.1.2 Adjustment Execution Timing.................................................................. 440

5.2 Adjustment/Action ............................................................................................ 441

5.2.1 Adjusting Color Registration Alignment.................................................. 441

5.2.2 Writing USB ID........................................................................................ 442

5.2.3 Firmware Update...................................................................................... 444

Chapter 6 MAINTENANCE

6.1 Overview ........................................................................................................... 452

6.2 Cleaning............................................................................................................. 454

6.3 Maintenance Menu............................................................................................ 458

6.3.1 Entry into Maintenance Mode.................................................................. 458

6.3.2 Maintenance Menu Items ......................................................................... 459

6.4 Sheet for Servicing............................................................................................ 460

6.4.1 Engine Status Sheet.................................................................................. 460

6.4.2 Print Log Report....................................................................................... 464

6.5 Consumables and Components That Need Periodic Replacement.................... 466

6.5.1 Consumables............................................................................................. 466

6.5.2 Regular Replacement Parts....................................................................... 468

7.7 Circuit Diagram................................................................................................. 551

Chapter 7 APPENDIX

7.1 Connectors......................................................................................................... 471

7.1.1 The List of Plugs and Jacks...................................................................... 471

7.1.2 P/J Layout Diagram.................................................................................. 474

7.2 Wire Net ............................................................................................................ 479

7.3 Wiring Connection Diagrams.................................................... ...... .................. 482

7.3.1 Marks used in the Diagram....................................................................... 482

7.4 Wiring Connection Diagram between Parts...................................................... 485

7.4.1 Configurations.......................................................................................... 485

7.4.2 Marks used in the Wiring Connection Diagram between Parts................ 488

7.5 Service Parts List ............................................................................................... 516

7.6 Exploded diagram.............................................................................................. 520

5

Page 19

PRODUCT DESCRIPTION

CHAPTER

1

Page 20

EPSON AcuLaser C4200 Revision A

1.1 Overview

This printer is a non-impact color page printer that takes advantage of a laser and

electrophotographic technologies. It provides 1200/600 dpi of resolution, and the

printing speed is 25 pages per minute (ppm) for color single-side printing, or 35 ppm

for monochrome single-side printing.

1.1.1 Engine Features

High-speed A4 tandem engine

Color Monochrome

Simplex printing 25.0 ppm 35.0 ppm

Duplex printing 14.8 ppm 20.4 ppm

Note : When printing on A4-si ze d pape r

Duplex print unit equipped as standard

(Duplex pri nting is not available on extra thic k paper, OHP sheet (transparency),

labels, and envelopes.)

Compatibl e with hig h qual ity plain paper that enables higher quality printing

Printable on thick paper and transparency for laser printer

This product is designed so that users can replace all the consumables.

• Toner cartridges (C, M, Y and K)

• Photoconductor Unit

• Transfer Unit

•Fuser Unit

High-capacity paper supply

Paper Feeder Capacity

Standard

Option

550-sheet paper cassette unit up to 550 sheets

1,100-sheet paper cassette unit up to 1100 shee ts

Maximum 2,350 sheets with 5 bins

MP tray up to 150 sheets

Lower cassette up to 550 sheets

1.1.2 Controller Features

High-speed controller for latest tandem

64-bit RISC CPU: Power PC 750FX 600 MHz

64-bit high-speed memory:DDR333 200 pin SO DIMM

(compatible with the RAM for AcuLaser C9100)

Standard RAM: 128MB

By installing additional RAM, the memory can be expanded up to 640MB

(128MB + 512MB). (The extended RAM must be installed to slot-1.

Changing the initial state of slot-0 is prohibited.)

Enhanced ASIC (FMV-FAIO)

The color management technologies are incorp orated into the hardware to achieve

high-speed processing.

Three Built-in interfaces

Parallel interface (IEEE 1284 compliant, Supports ECP)

USB interface (Rev. 2.0 HS)

Ethernet interface (100 Base-TX/10 Base-T)

Functions described below can be enhanced and increased in speed by expanding

memory with RAM DIMMs

CPGI drawing area

Image creating speed

Resolution

Receive buffer

Print buffer for collate printing

Updating firmware is available (RCC compatible) when a Flash ROM DIMM is

installed

Large capacity HDD such as 40GB can be installed

Paper eject capacity is 250 sheets, face-down only

PRODUCT DESCRIPTION Overview 7

Page 21

EPSON AcuLaser C4200 Revision A

1.1.3 Software Features

Color technologies

Smooth expanding of color images by ESC/Page-Color

Color/Monochrome auto-detect function

Supports 1200 dpi

Monitors printer status and printer environment by bi-directional EJL and MIB

Adobe PostScript3 is equipped as standard

Supports PCL5c with optional DIMM (1200 dpi not supported)

Engine controller ROM (only for Flash) can be upgraded

Panel display

Supports the new wide panel

Displays remaining amount of C, M, Y, and K toner on the panel

Displays toner cartridge p rese nce, paper size, and remaining amou nt o f papers

Help function

Supports 14 languages: English, French, Italian, German, Spanish,

Portuguese, Dutch, Swedish, Danish, Finnish, Norse, Chinese Simplified,

Chinese Traditional, and Korean

Suppo rts EPSON Status Monitor 3

Employs new user interface suitable for business use

PRODUCT DESCRIPTION Overview 8

Page 22

EPSON AcuLaser C4200 Revision A

1.2 Basic Specifications

1.2.1 Process Specifications & System

Printing method: Semiconductor laser beam scan and electro photography

with dry double component non-electromagnetic toner

Light source: Semiconductor laser

Photoconductor: Negative organic photoconductor

Charging: Roller charger

Development: Exposed area development

Toner: Chemical toner

Primary transfer: Roller transfer method

Fixing: Heated roller method and flexible belt nip method

1.2.2 Printer Basic Specifications

RESOLUTION

600 dpi, 1200 dpi

WARMING UP TIME

35 seconds or less: From turning the power on to ready-to-print status.

(at: 22°C, 55% RH, rated voltage, memory standard)

25 seconds or less: From standby mode to ready-to-print status.

(at 22°C, 55% RH, rated voltage, memory standard)

PRINTING SPEED MODE

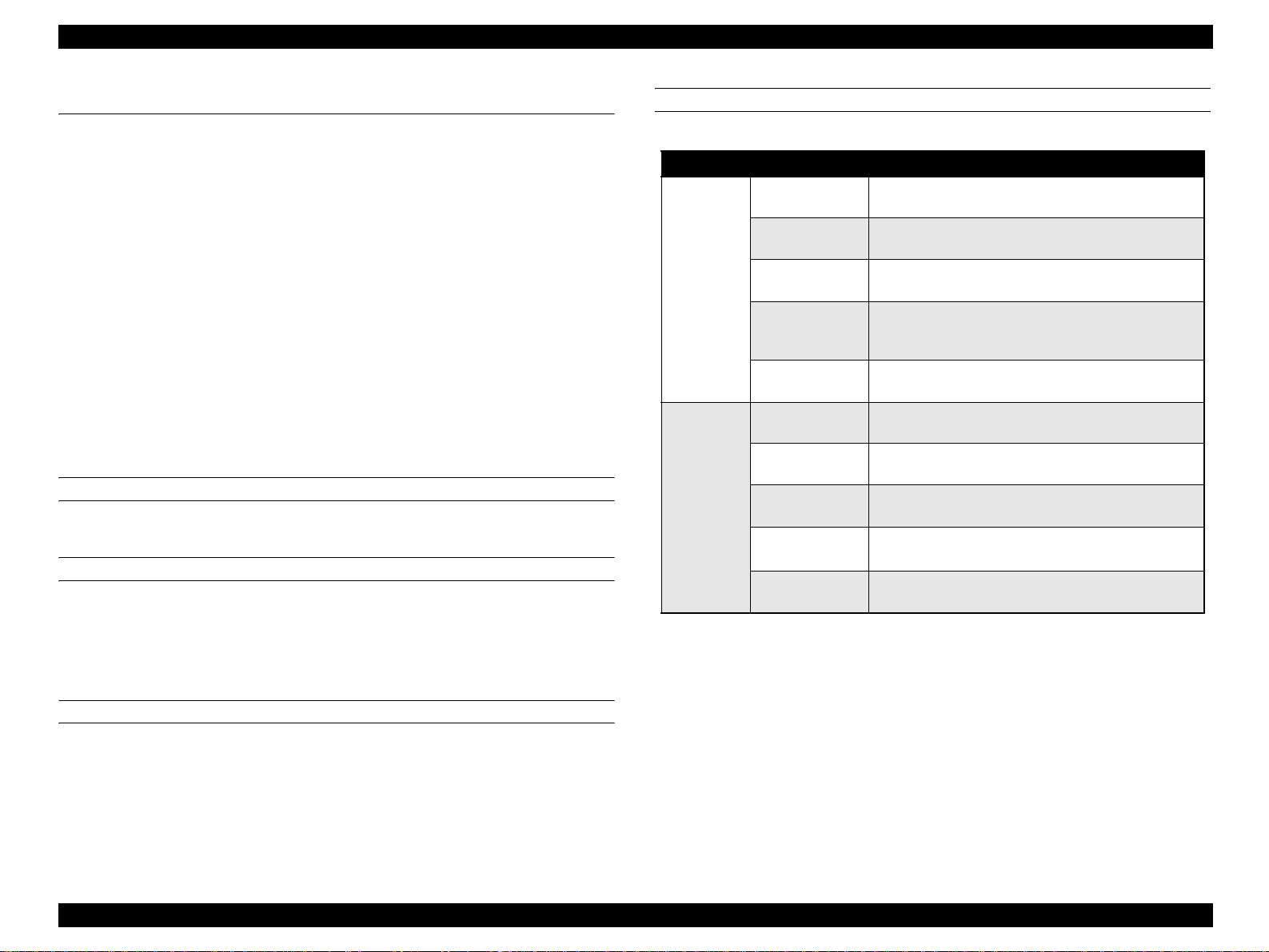

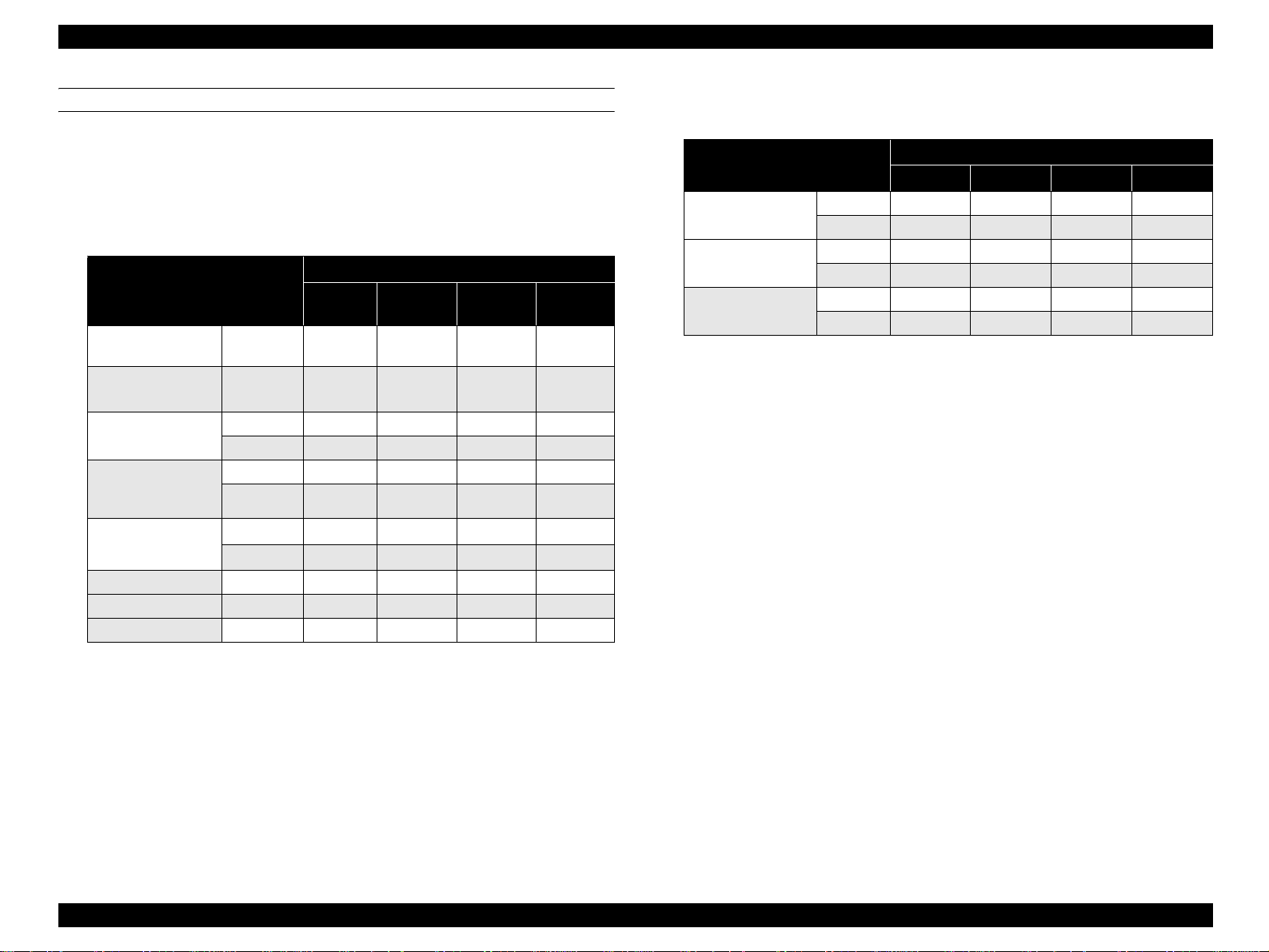

Table 1-1. Printing Speed Mode

Standard 1

Low speed 1

Monochrome

mode (B/W)

Color mode

(F/C)

Note *: 164-216 g/m

Low speed 1

Low speed 2

Low speed 3

Standard 2

Low speed 1

Low speed 1

Low speed 2

Low speed 3

2

Printing Speed Mode

The resolution is set to 600 dpi.

Suitable for plain paper.

The resolution is set to 600 dpi.

Suitable for plain paper, thick paper, an d envelopes.

The resolution is set to 1200 dpi.

Suitable for plain paper, thick paper, an d envelopes.

The resolution is set to 600 dpi.

Suitable for plai n paper, thick paper , extra thick paper

and labels.

The resolution is set to 600 dpi.

Suitable for plain paper (high gross), and tr ansparency.

The resolution is set to 600 dpi.

Suitable for plain paper

The resolution is set to 600 dpi.

Suitable for plain paper, thick paper, an d envelopes.

The resolution is set to 1200 dpi.

Suitable for plain paper, thick paper, an d envelopes.

The resolution is set to 600 dpi.

Suitable for plain paper, extra thick paper*, and labels.

The resolution is set to 600 dpi.

Suitable for plain paper (high gross), and tr ansparency.

*

,

PRINT MODE

Color mode: Use four toners (CMYK) to print in full color.

Monochrome mode: Use only black toner (K) and the highest print speed is

available.

PRODUCT DESCRIPTION Basic Specifications 9

Page 23

EPSON AcuLaser C4200 Revision A

PRINTING MODE BY PAPER TYPE

Table 1-2. Printing Mode by Paper Type

1

Paper Type <Video I/F Name> Gross*

(1) <Plain paper-L> N

Normal

(2) <Plain paper-H> N

(3) <Plain paper-L> H

Normal-HQ

(4) <Plain paper-L> SH

<Plain (PPM-

(5)

Down)>

SH

Thick – <Heavier paper-L> H

Extra Thick – <Heavier paper-H> SH

Extra Thick

Back

Transparency –

<Heavier paper-H>

–

Back Face

<Transparency

(PPM-Down)>

SH

SH –

Envelope – <Envelope> H –

Label – <Label-H> SH –

Note *1: Gross

N: Normal Gross

H: High Gross

SH:Super High Gross

Paper

Weight

105g/m

105g/m

105g/m

105g/m

105g/m

106 to

163g/m

164 to

216g/m

164 to

216g/m

Basic

60 to

60 to

60 to

60 to

60 to

Printing Speed Mode

600 dpi

B/W FC

Standard 1 Standard 2

2

Standard 1 Standard 2

2

2

2

2

2

2

2

Low

speed 1

Low

speed 2

Low

speed 3

Low

speed 1

Low

speed 2

Low

speed 2

Low

speed 3

Low

speed 1

Low

speed 2

Low

speed 1

Low

speed 2

Low

speed 3

Low

speed 1

Low

speed 2

Low

speed 2

Low

speed 3

Low

speed 1

Low

speed 2

1200 dpi

Low

speed 1

Low

speed 1

X

X

X

Low

speed 1

X

X

X

X

X

FIRST PRINT TIM E

The time from receiving the Start command to when trailing edge of the paper leaves

the paper eject roller. Note that the time given in the tables below does not appl y wh en

the printer is in the conditions described in “1.11 Engine Restricti ons” (p31).

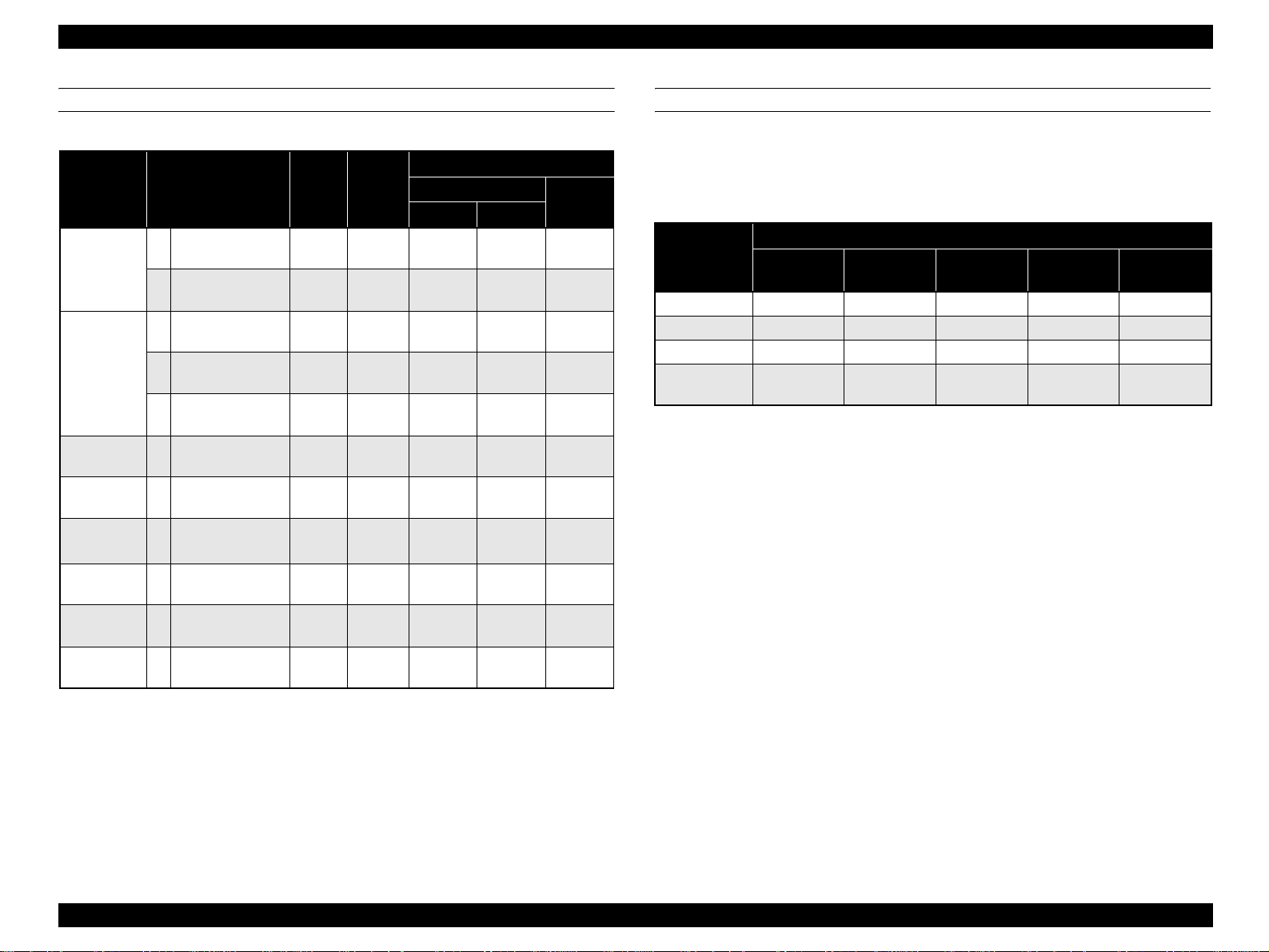

Table 1-3. First Print Time (Unit: seconds or less)

Paper Source

Speed Mode

Standard 1 10.2 10.5 11.1 11.7 11.9

Standard 2 12.0 12.5 13.3 14.1 14.4

Low speed 1 14.3 15.0 16.2 17.3 17.7

Low speed 2/

Low speed 3

Note : Paper size: A 4

MP Tray

(STD)

LC1

(STD)

LC2

(OPT)

LC3

(OPT)

18.4 19.5 21.3 23.0 23.6

LC4

(OPT)

PRODUCT DESCRIPTION Basic Specifications 10

Page 24

EPSON AcuLaser C4200 Revision A

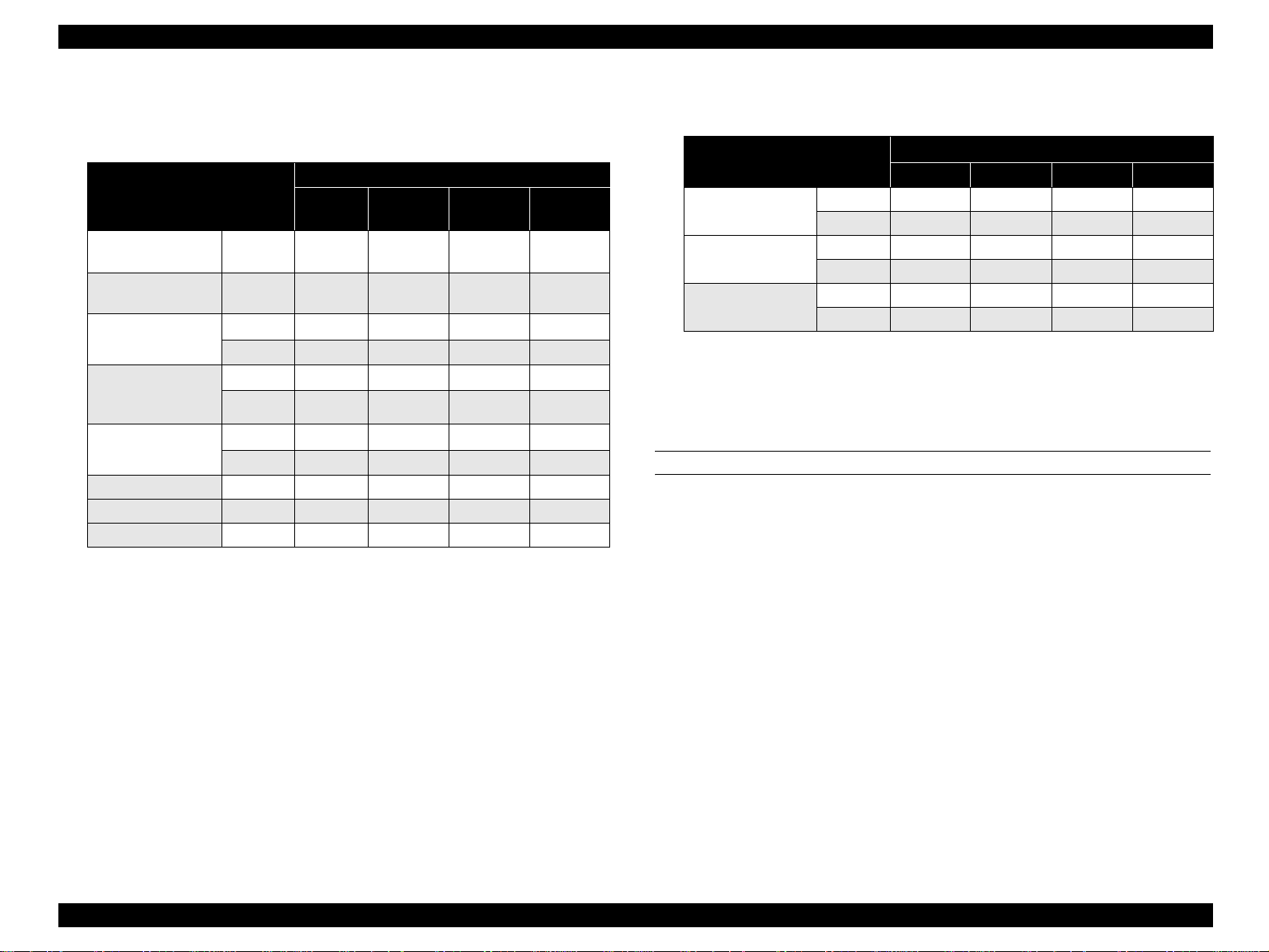

CONTINUOUS PRINTING SPEED

Note that the time given in the tables below does not apply when the printer is in the

conditions described in “1.11 Engine Restrictions” (p31).

Monochrome mode

*1

Simplex printing

Table 1-4. List of Continuous Printing Speed (Unit: ppm)

Printing Speed Mode

Paper Size

LT/Executive JIS-B5/

A5/HL

LT/Executive JIS-B5/

A5

A4

Legal13” (GLG)

Legal14” (LGL)

F4

Envelop/DL/ISO-B5/

GLT

LT and under MP tray 35.2 17.6 11.7 8.2

LT ~ A4 MP tray 33.7 16.8 11.2 8.0

A4 ~ Legal14” (LGL) MP tray 29.4 14.7 9.8 7.2

MP tray 35.2 18.3 12.2 8.2

LC1/2/3/4

MP tray 33.7 17.5 11.7 8.0

LC1/2/3/4 35.0 17.5 11.7 8.0

MP tray 29.4 15.2 10.1 7.2

LC1/2/3/4 30.4 15.2 10.1 7.2

MP tray

LC1/2/3/4

Standard 1Low Speed 1Low Speed 2Low Speed

36.6

35.0

*3

–

18.3 12.2 8.2

17.6

– –

*3

3

– – – –

Duplex printing

Table 1-5. List of Continuous Printing speed (Unit: ppm)

Paper Size

LT/Executive JIS-B5/

A5

A4

Legal13” (GLG)

Legal14” (LGL)

Note *1: See “ Supported paper size, type and orientation” (p14) for details of p a per

orientation.

*2: F eed each of the papers at some intervals.

*3: The speed is 35.0ppm onl y when feeding from LC4 .

MP tray 21.0 11.5 7.8 3.4

LC1/2/3/4 21.0 11.5 7.8 3.4

MP tray 20.4 11.2 7.6 3.3

LC1/2/3/4 20.4 11.2 7.6 3.3

MP tray 18.7 10.2 6.9 3.1

LC1/2/3/4 18.7 10.2 6.9 3.1

Standard 1 Low speed 1 Low speed 2 Low Speed

Printing Speed Mode

PRODUCT DESCRIPTION Basic Specifications 11

Page 25

EPSON AcuLaser C4200 Revision A

Color mode

*1

Simplex printing

Table 1-6. List of Continuous Printing Sp eed (Unit: ppm)

Printing Speed Mode

Paper Size

LT/Executive JIS-B5/

A5/HL

LT/Executive JIS-B5/

A5

A4

MP tray 25.1 18.3 12.2 8.2

LC1/2/3/4

MP tray 24.1 17.5 11.7

LC1/2/3/4

Legal13” (GLG)

Legal14” (LGL)

F4

DL/GLT/ISO-B5

MP tray 21.0 15.2 10.1

LC1/2/3/4

MP tray

LC1/2/3/4 – – – –

LT and under MP tray 35.2 17.6 11.7 8.2

LT ~ A4 MP tray 33.7 16.8 11.2 8.0

A4 ~ Legal14” (LGL) MP tray 29.4 14.7 9.8 7.2

Standard 1Low Speed 1Low Speed 2Low Speed

26.2 18.3 12.2

25.0 17.5 11.7

21.7 15.2 10.1

–

18.3

– –

3

8.2

8.0

8.0

7.2

7.2

Duplex printing

Table 1-7. List of Continuous Printing Speed (Unit: ppm)

Paper Size

*2

LT/Executive JIS-B5/

A5

A4

Legal13” (GLG)

Legal14” (LGL)

Note *1: See “ Supported paper size, type and orientation” (p14) for details of paper

orientation.

*2: Feed each of the papers at some intervals.

MP tray 15.2 11.5 7.8 3.4

LC1/2/3/4 15.2 11.5 7.8 3.4

MP tray 14.8 11.2 7.6 3.3

LC1/2/3/4 14.8 11.2 7.6 3.3

MP tray 13.6 10.2 6.9 3.1

LC1/2/3/4 13.6 10.2 6.9 3.1

Standard 1 Low Speed 1 Low Speed 2 Low S peed 3

PAPER FEED REFERENCE

Reference position to feed paper (in any size) is always center of the feeders.

Printing Speed Mode

PRODUCT DESCRIPTION Basic Specifications 12

Page 26

EPSON AcuLaser C4200 Revision A

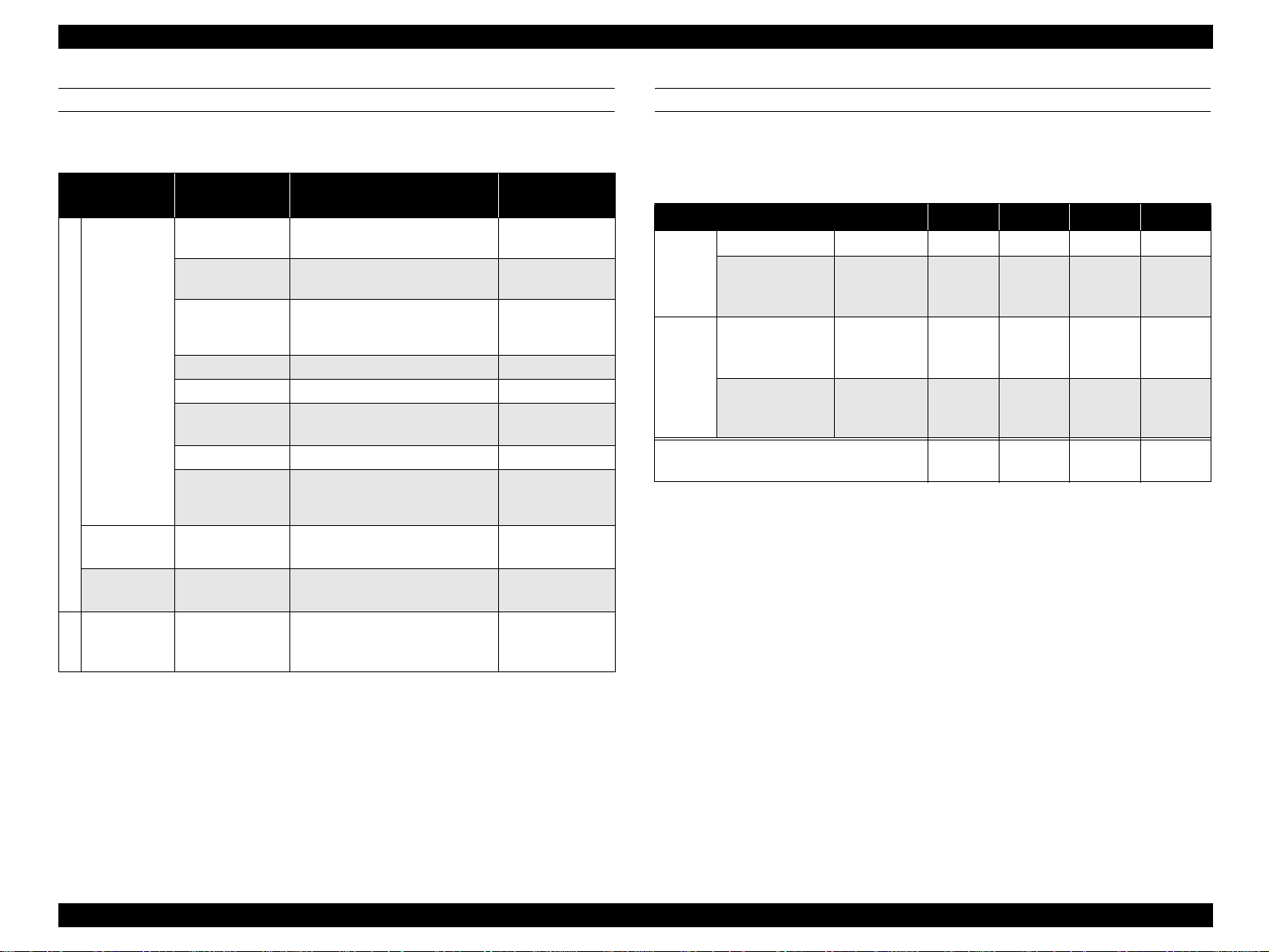

PAPER FEED

Table 1-8. Paper Feed

Feeder

MP tray

Standard

550-sheet

cassette (LC1)

Duplex unit

(built-in)

550-sheet

paper casset te

Option

(LC2, 3, 4)

Note *1: Refer to “1.3 Paper Specifications” (p19).

*2: Environmental condition for the capacity: 22 ºC/55% RH.

Sheet Capacity/

Height Capac ity

150 sheets

150 sheets

15 mm

15 mm Transparencies: A4, LT –

15 mm Labels: A4, LT –

15 mm

15 mm envelopes, DL, ISO-B5 75 to 105 g/m

15 mm

550-sheet

61mm

–

550-sheet

61mm

Paper Type*1/Paper Size

Standard paper:

EPSON High Quality Plain Paper

Standard paper: RX-80

Plain paper/recycled paper:

A4, A5, B5, Letter, GLT, HLT,

Executive, F4 , LGL13”, LGL1 4”

Thick Paper/Extra Th ic k Paper:

A4, A5, B5, LT, GLT, HLT, Ex ecut ive

User defined size

Width 88.90mm to 220.00mm

Length 139.70mm to 355.6 0mm

A4, A5, LT, B5, Executive,

LGL13” (GLG), LGL14”

A4, A5, LT, B5, Executive,

LGL13” (GLG), LGL14”

A4, A5, LT, B5, Executive,

LGL13” (GLG), LGL14”

4024 Paper (20lb)

Available Paper

Basis Weight

2

82 g/m

2

80 g/m

2

75 g/m

60 to 105 g/m

106 to 163 g/m

164 to 216 g/m

60 to 216 g/m

60 to 105 g/m

64 to 163 g/m

60 to 105 g/m

2

2

2

2

2

2

2

2

COMBINATION WITH OPTIONAL CASSETTE

By attaching two types of optional paper feed cassette, the paper supply capacity can

be increased as follows.

*2

MP tray 150 sheets { { { {

Standard

550-sheet paper

cassette

(LC1)

550-sheet paper

cassette

(LC2)

Option

1100-sheet paper

cassette

(LC3/4)

Note : These values are valid with RX-80 paper (80 g/m2) and EPSON high quality plain paper

(82 g/m

Table 1-9. Combination with Optional Cassette

Combination (1) (2) (3) (4)

550 sheets { { { {

550 sheets – { – {

1100 sheets – – { {

Total Capacity

2

).

700

sheets

1250

sheets

1800

sheets

sheets

2350

PRODUCT DESCRIPTION Basic Specifications 13

Page 27

EPSON AcuLaser C4200 Revision A

SUPPORTED PAPER SIZE, TYPE AND ORIENTATION

Table 1-10. List of Supported Paper Size, Type and Orientation

Paper size D imensions in mm (inches)

Paper

Vertical (length) Horizontal (width)

MP Tray

A4 297.00 210.00 { SEF z

A5 148.00 210.00 { SEF z

LT 279.40 (11.00") 215.90 (8.50") { SEF z

HLT 215.90 (8.50") 139.70 (5.50") { – SEF –

GLT 266.70 (10.50") 203.20 (8.00") { – SEF –

EXECUTIVE 266.70 (10.50") 184.15 (7.25") { SEF z

Standard

LGL13” (GLG) 330.20 (13.00") 215.90 (8.50") { SEF z

LGL14” 355.60 (14.00") 215.90 (8.50") { SEF z

F4 330.00 210.00 { – SEF –

User defined paper size 139.70 to 355.60 (5.5" to 14") 88.90 to 220.00 (3.5" to 8.5") { – Discretionary –

Transparency

Labels

*2

DL 110.00 220.00 {*

A4: 297.00 A4: 210.00 { – SEF –

LT: 279.40 LT: 215.90 { – SEF –

A4: 297.00 A4: 210.00 { – SEF –

LT: 279.40 LT: 215.90 { – SEF –

3

Special paper

ISO-B5 250.00 176.00 {*

3

envelopes

Note *1: : Feeding is possible and paper size is automatically detected.

*2: {: Feeding is possible by specifying the size code with the controller.

*3: z: Duplex printing is available.

*4: –: Not available

*5: SEF (Short Edge Feed): Set paper to be loaded from its short side.

*6: LEF (Long Edge Feed): Set paper to be loaded from its long side.

*7: See “Envelope orie ntation” (p.15) for details of details of envelop orientation.

550-sheet Paper

Cassette

Paper Orientation Duplex Printing

(STD/OPT)

– LEF –

– SEF –

PRODUCT DESCRIPTION Basic Specifications 14

Page 28

EPSON AcuLaser C4200 Revision A

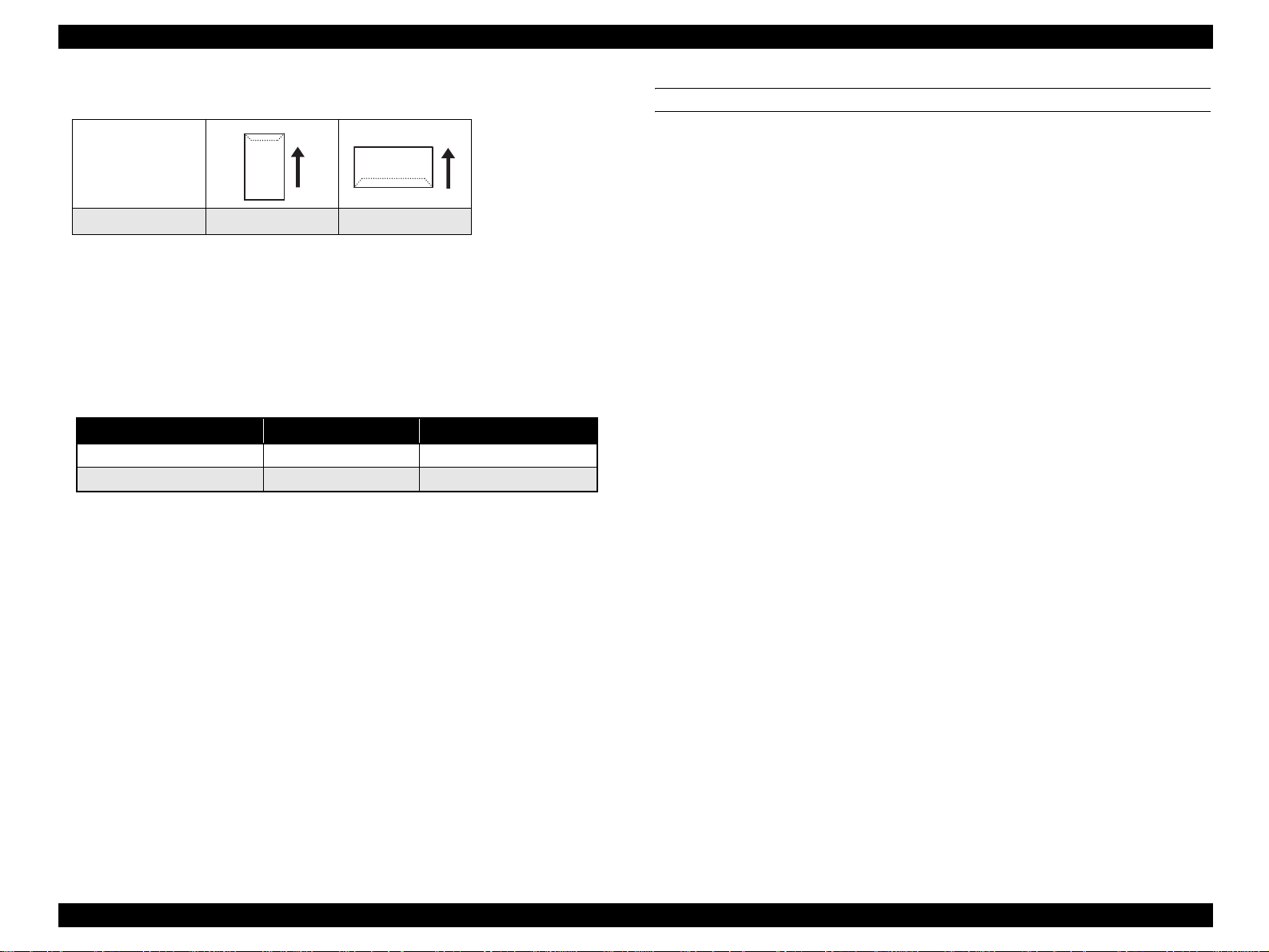

Envelope orientation

Paper feed direction

Envelope type DL ISO-B5

Note *1: Set envelopes with its print surface facing down.

*2: Image quality and feed is not guaranteed when printing on the back side (flap side)

of envelopes.

*3: Envelopes with adhesive or tape are not available.

Printing surface set direction

Table 1-11. Printing Surface Set Direction

MP tray Optional paper cassette

Set direction (Printing surface) Face down Face up

Paper feed direction Top edge first Bottom edge first

PAPER EJECT CAPACITY

Number of sheets: 250 sheets, face down only (A4/LT, Standard paper)

Thickness: 36 mm (Paper ejection automatically stops when the sensor

detected that the ejected papers has built up to a thickness of

36 mm)

Note : Environmental conditions for the capacity: 22 °C/55 % RH, standard paper (simplex/

duplex printing).

PRODUCT DESCRIPTION Basic Specifications 15

Page 29

EPSON AcuLaser C4200 Revision A

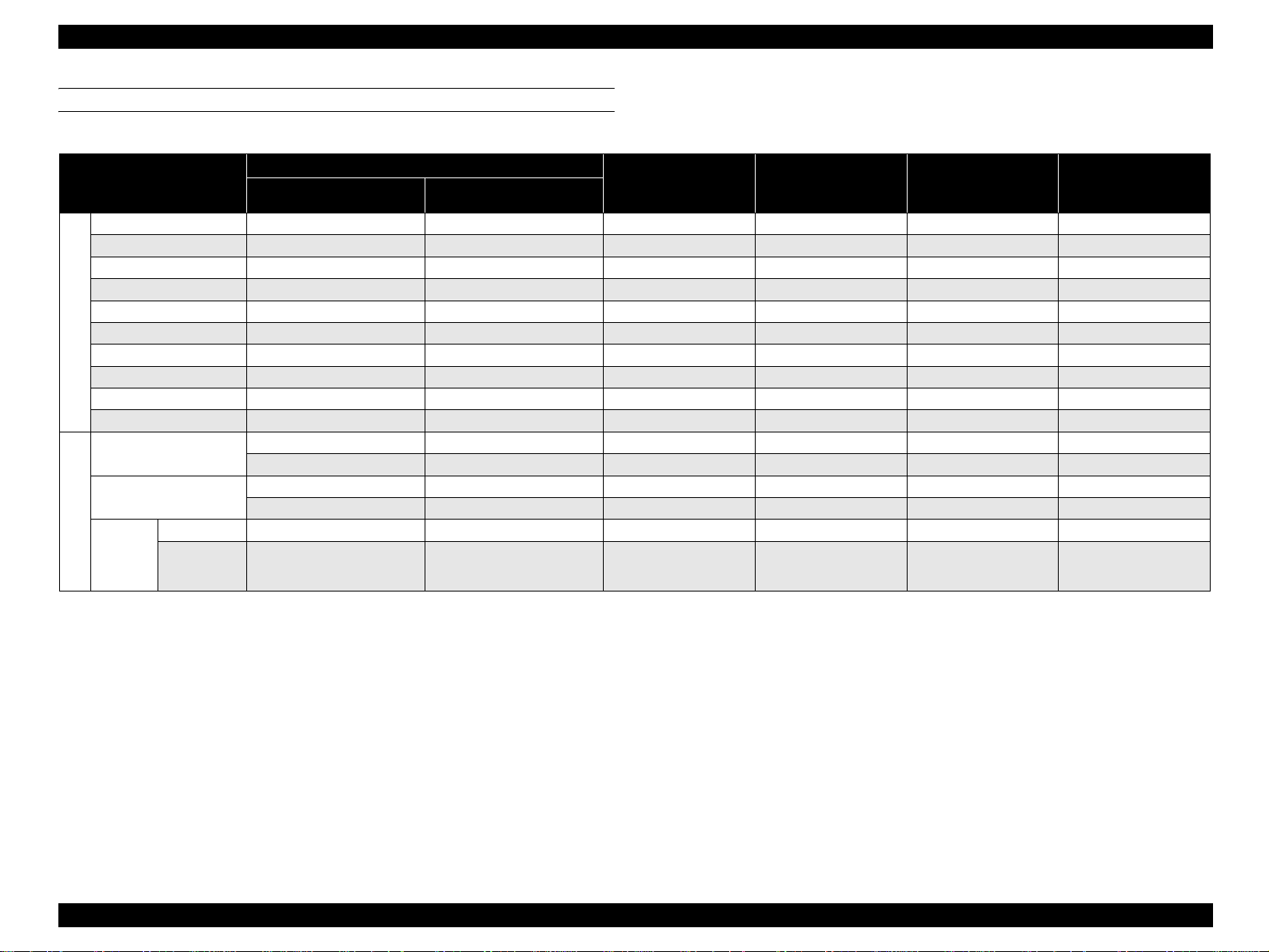

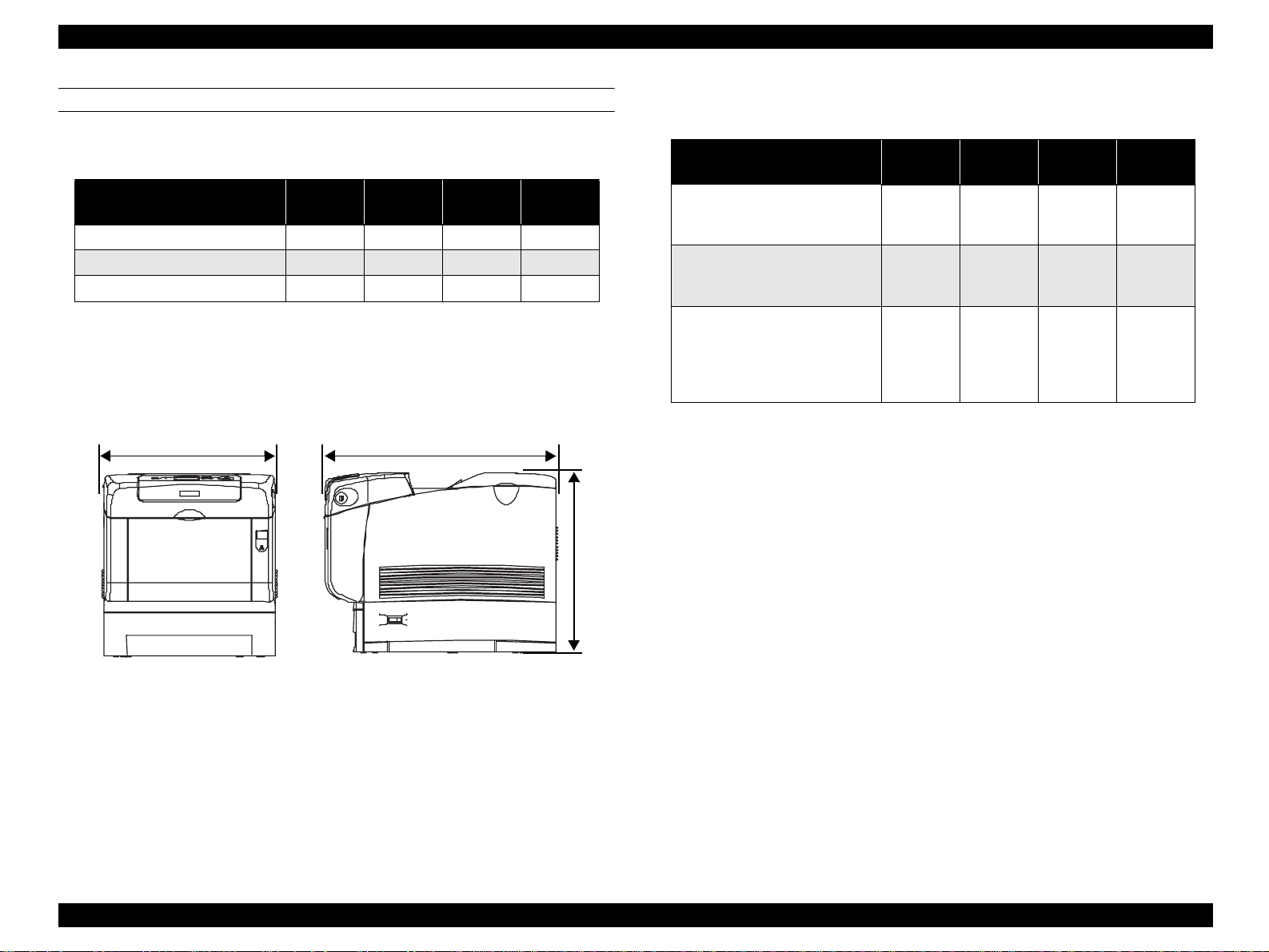

DIMENSIONS AND WEIGHT

Dimensions and weight of each unit

Table 1-12. Dimensions and Weight

Width

(mm)

Main unit 437 588 457 31.5

550-sheet paper cassette 429 509 154 7

1100-sheet paper casset te 584 695 364 21

Note 1: Manufactu rin g tole r ance is ± 5 mm in dimensions and ± 0.5 kg in wei gh t.

2: Consumables (Toner cartridges and Photoconduc to r unit) are not included in the main

unit weight (controller is included).

437mm 588mm

Depth

(mm)

Height

(mm)

Weight

(kg)

Dimensions and weig ht wi th options installed

Table 1-13. Dimensions and Weights with Options In stalled

Width

(mm)

Main unit

+

550-sheet paper cassette

Main unit

+

1100-sheet paper cassette

Main unit

+

550-sheet paper cassette

+

1100-sheet paper ca sette

Note 1: Manufacturing tolerance is ± 5 mm i n dimensions and ± 0.5 kg in weight.

2: Consumabl e s (Toner cartridges and Photoconductor unit) are not included in the main

unit weight (controller is included).

457mm

437 588 584 39

584 695 796 53

584 695 923 60

Depth

(mm)

Height

(mm)

Weight

(k)

Figure 1-1. Dimensions (Main Unit)

PRODUCT DESCRIPTION Basic Specifications 16

Page 30

EPSON AcuLaser C4200 Revision A

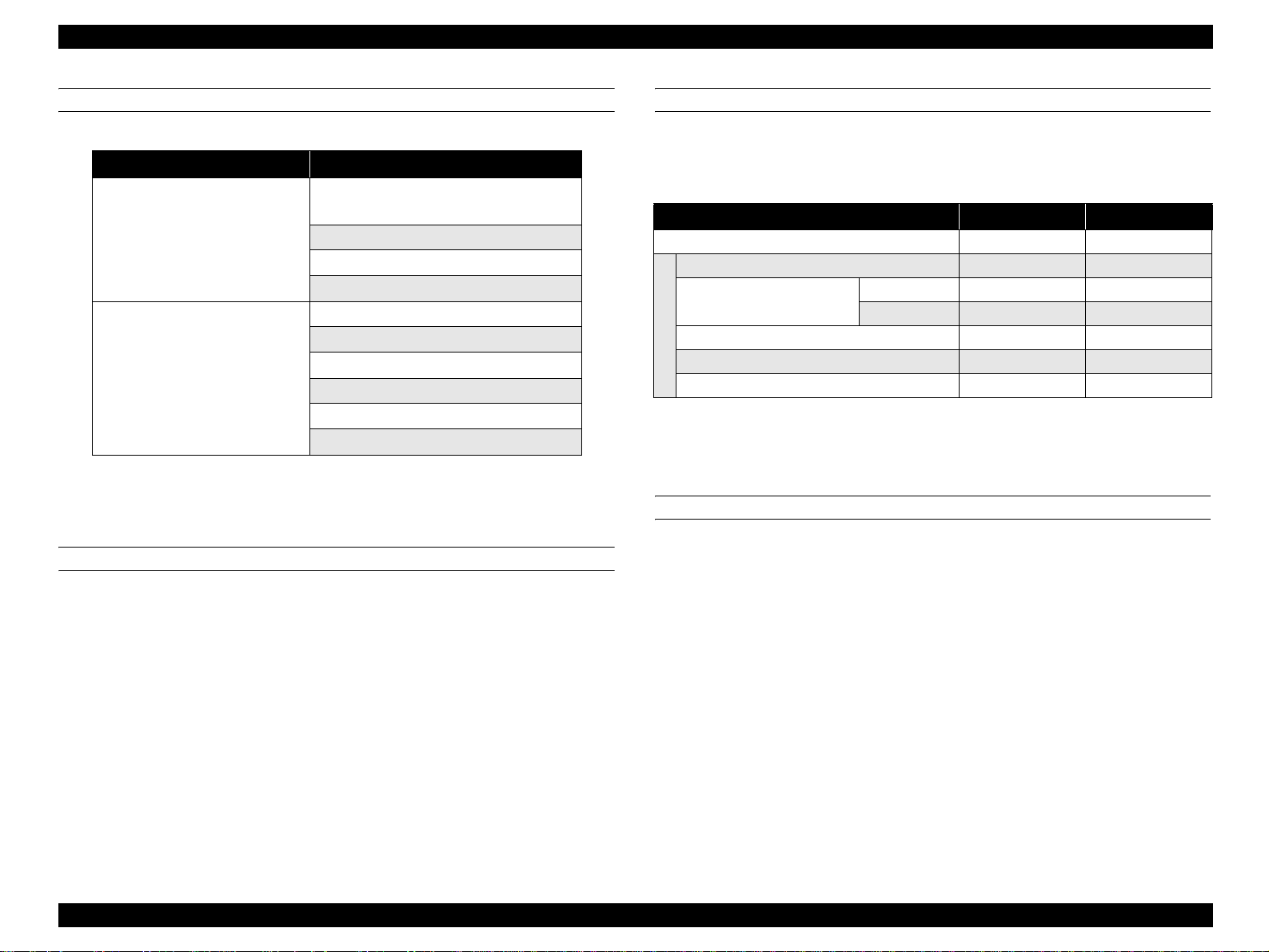

CONSUMABLES AND PERIODIC REPLACEMENT UNIT

Table 1-14. List of Consumables and Periodic Replacement Unit

Classification Replacement Unit

Toner cartridge

(Black, Cyan, Yellow, Magenta)

Consumables

Periodic replacement units

Note : For detailed specifications, refer to “1.9 Consumables/Periodic Replacement Unit”

(p27).

Photoconductor unit

Transfer unit

Fuser unit

Retard Roll

Developer Unit Assy.

Feed Roll Assy. MP

Retard Roll Assy. MP

Regi Roll Assy.

Feed Roll Assy. CST

POWER SUPPLY

Power supply operating voltage/frequency

AC 120 V ± 10 % 50 Hz /60 Hz ± 3 Hz

AC 220 V/240 V ± 10 % 50 Hz /60 Hz ± 3 Hz

Power supply for the controller

DC 5.0 V± 5%, 1 A or less

DC 3.3 V± 5%, 3 A or less

POWER CONSUMPTI ON

The maximum rated current and power consumption are measured with all engine

options and controller options installed.

Table 1-15. List of Power Consumption

110 V 240 V

Maximum rated current 10 A 5 A

Maximum 900 W 960 W

Continuous printing average

Average during standby with the heater on 70 W 71 W

Average in low power mode wit h th e heater off

Power consumption

Power supply off 0 W 0 W

Note : International Energy Star Standards: Color printer with 20 ppm print speed or higher:

45W or less

Color 357 W 354 W

Monochrome 437 W 426 W

21 W 25 W

CONSUMPTION CURRENT

550-sheet paper cassette (option)

5 V/ 0.1 A or less

24 V/ 0.5 A or less

1100-sheet paper casette (option)

5 V/ 0.1 A or less

24 V/ 0.3 A or less

PRODUCT DESCRIPTION Basic Specifications 17

Page 31

EPSON AcuLaser C4200 Revision A

NOISE

Main unit

Item Printing Mode Standby M ode Sleep Mode

Sound pressure 55 dB 35 dB Background noise

Sound power 6.65 B 5.0 B Background noise

Note 1: The method of measuring and calculation conforms to ISO-7779 and ISO-9296.

2: Values mentioned above are actual measurement value.

EXHAUST GAS

Ozone density: 0.02 mg/m

Styrene density: TBD mg/m

Dust density: 0.075 mg/m

TVOC: TBD mg/m

3

or less (the measuring method conforms to BAM)

3

or less

3

or less (the measuring method conforms to BAM)

3

or less

PRODUCT DESCRIPTION Basic Specifications 18

Page 32

EPSON AcuLaser C4200 Revision A

1.3 Paper Specifications

1.3.1 Paper Type

Standard paper

Monochrome: RX-80 paper, 4024 paper (20 lb)

Color: EPSON Color Laser Paper

Plain paper

64 g/m

2

to 105 g/m

(Commonly used copy paper, recycled paper, high quality plain paper)

Recommended recycled paper: Steinbeis Recycling Copy classic

Special Media

EPSON transparency sheets (A4)

Labels

Thick paper (106 g/m

Envelope

C H E C K

P O I N T

lb: Ream weight = Total weight of 500 sheets of 17" x 22"

g/m

Before purchasing a large amount of paper, test the paper if it

can be printed normally.

2

2

to 216 g/m2)

sized paper

2

:1g/m2 = 0.2659763 lb

1.3.2 Paper that may cause printing defects, paper jams or printer malfunction

Transfer paper (carbon paper, non-carbon paper), thermal paper, impact paper,

acid paper

Paper that is too thin or too thick

Paper that is wet or damp

Paper with special coatings or color printer paper with processed surfaces

Glossy (too slick) paper, or paper with too rough surface

Paper that the roughness is significantly different by side